Infrared ray shielding glass with front surface and side surface having consistent reflection hues

A technology for shielding glass and infrared rays, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of inconsistent reflection color and tone of glass surface, affecting the visual effect of buildings, serious color cast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

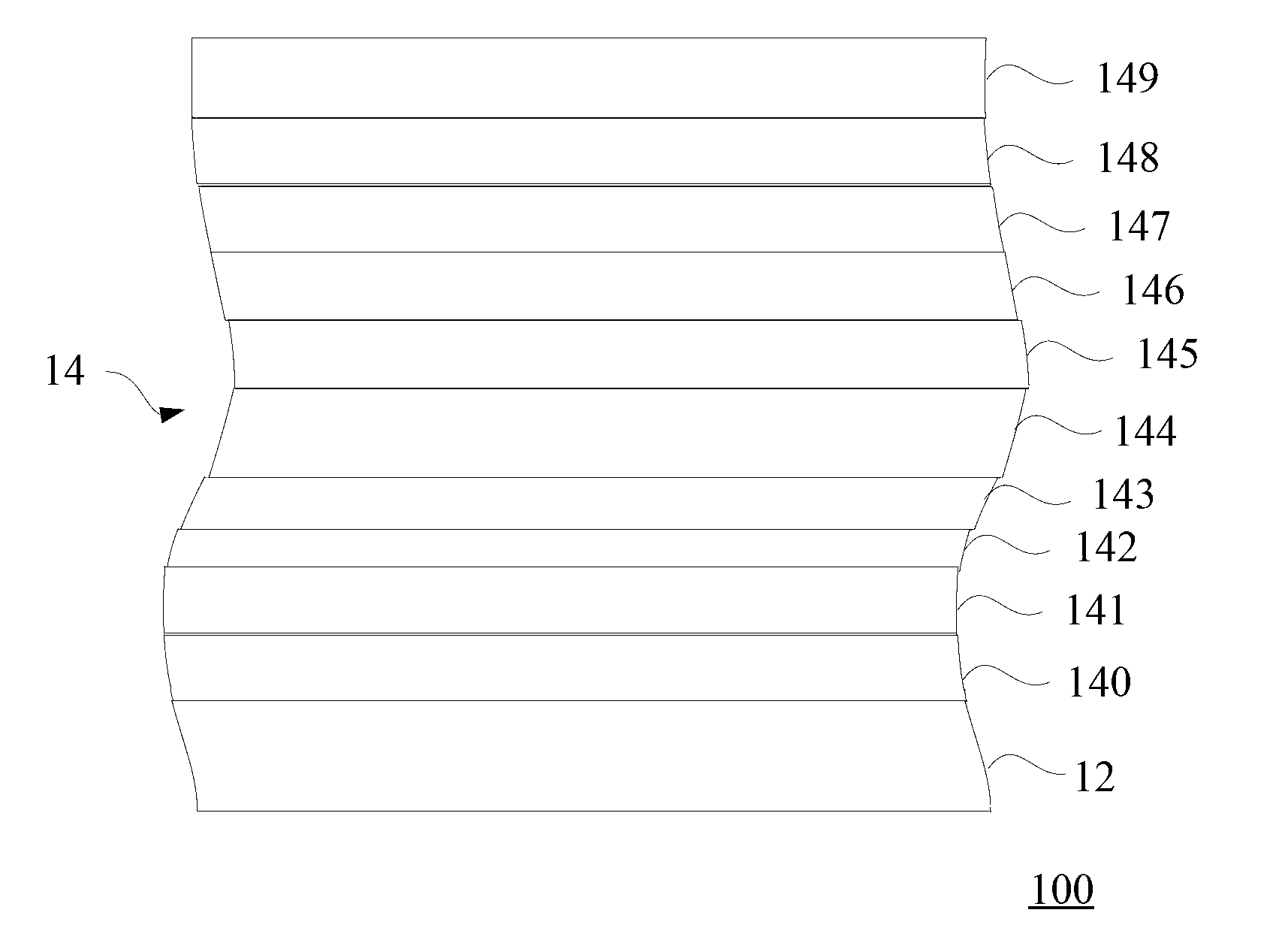

[0026] An infrared shielding glass with the same reflection tone on the front and sides, the structure of the infrared shielding film layer from the glass substrate to the outside is as follows: Si 3 N 4 (12nm) / ZnO(30nm) / Ag(8nm) / AZO(10nm) / ZnO(10nm) / ZnSnO x (35nm) / ZnO(10nm) / Ag(20nm) / Cu(3nm) / NiCr(1nm) / AZO(10nm) / ZnO(10nm) / ZnSnO x (55nm) / ZnO(10nm) / Ag(16nm) / AZO(10nm) / ZnO(10nm) / ZnSnOx (10nm) / Si 3 N 4 (7nm)

[0027] Among them, the first composite dielectric layer is made of Si 3 N 4 Layer and ZnO layer, the thickness is 42nm; the thickness of the bottom infrared shielding layer is 8nm; the first protective layer is composed of AZO, the thickness is 10nm; the second composite dielectric layer is composed of ZnO layer and ZnSnO x Layer composition, the thickness is 55nm; the thickness of the infrared shielding mixed layer is 23nm, and it is made of the silver layer of 20nm and the continuous copper film layer of 3nm formed on the silver layer; The second protective layer is made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com