Patents

Literature

1346results about How to "Guaranteed tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

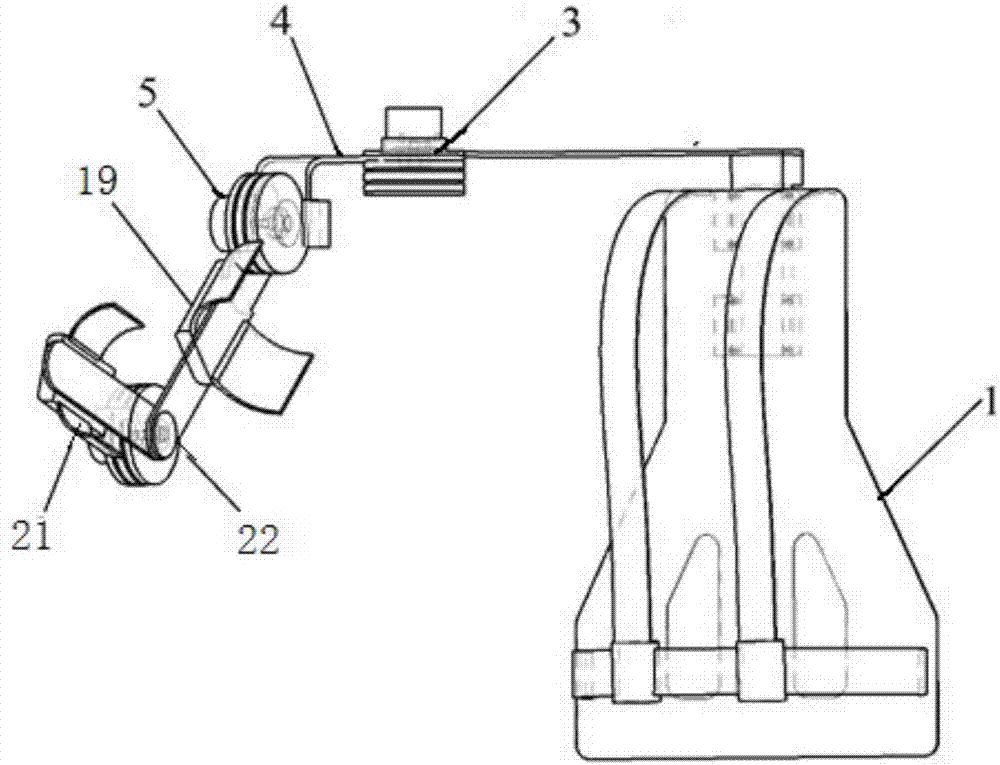

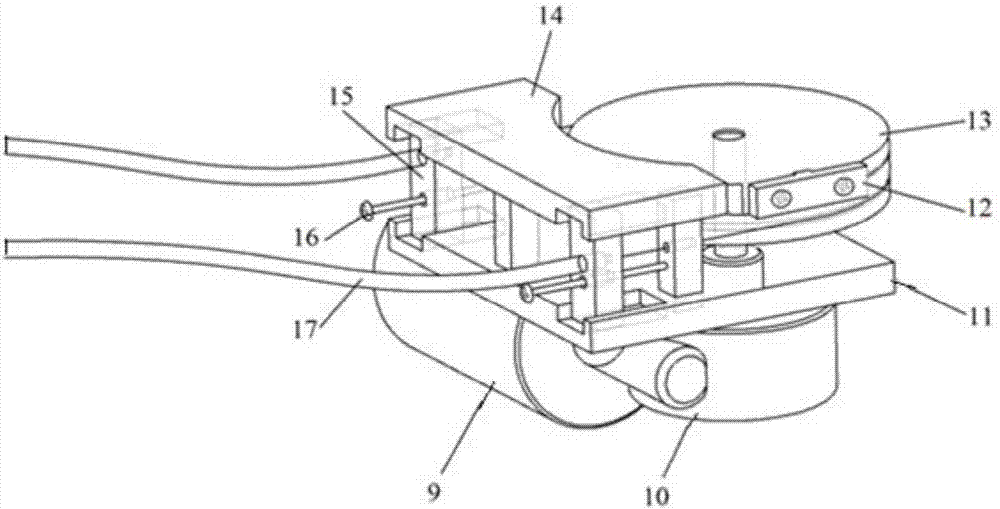

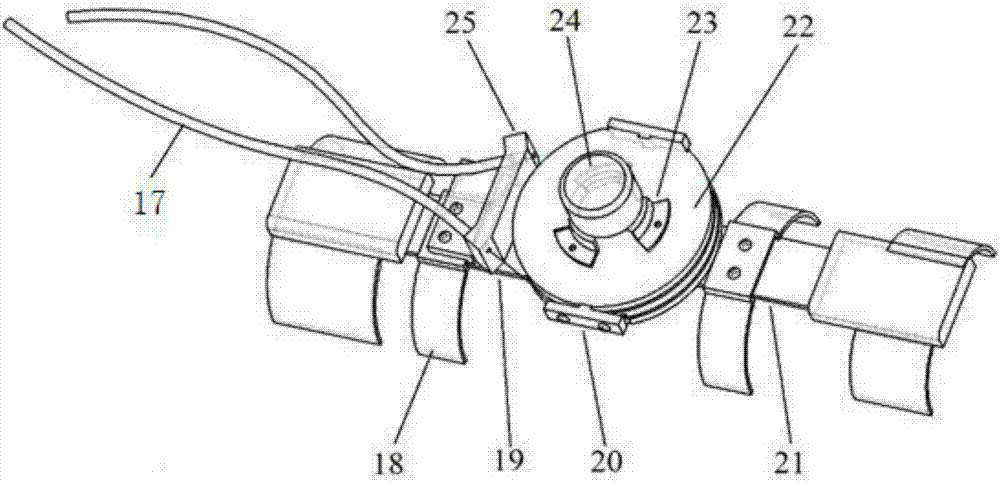

Wearable upper limb exoskeleton rehabilitation device

ActiveCN107374907AWith synergistic rehabilitationIt has the following beneficial effects: the present invention utilizes a wearable structure to realize collaborative rehabilitationChiropractic devicesEngineeringWinch

The invention provides a wearable upper limb exoskeleton rehabilitation device, which includes a fixed backboard served as a base; a driver module can make torque force transfer to each joint by Bowden cable; an exoskeleton module of elbow join is used for coupled rehabilitation movement. rehabilitative training of the elbow, coupled rehabilitation of forearm and exoskeleton of the upper arm and the exoskeleton; a mechanical hard limit device for joint, can achieve mechanical hard limit protection for a forearm connecting rod and a upper arm connecting rod; a three direction adjustable adaptive module, the position of joint winch in the shoulder adduction is adjusted to adopt different somatotype of the patients; a shoulder joint module, the shoulder joint module can achieve rehabilitation training for abduction degree of freedom in the shoulder and rehabilitation training of shoulder flexion and extension degree. The Wearable upper limb exoskeleton rehabilitation device makes use of the wearable structure to realize the free movement of patients during rehabilitation training.

Owner:SHANGHAI JIAO TONG UNIV

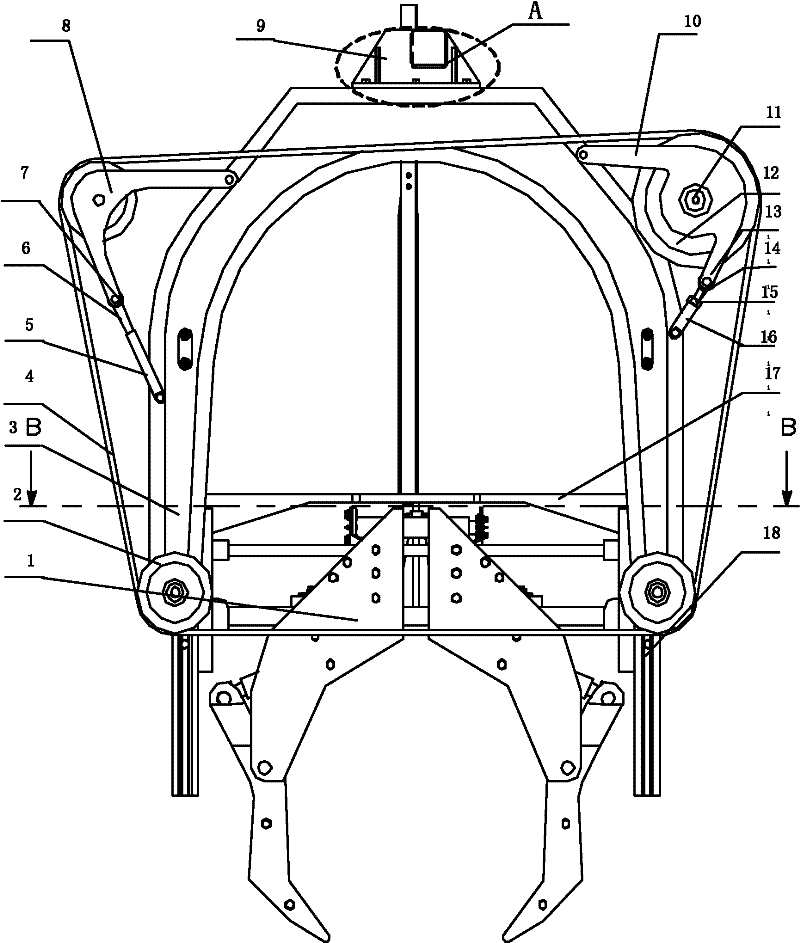

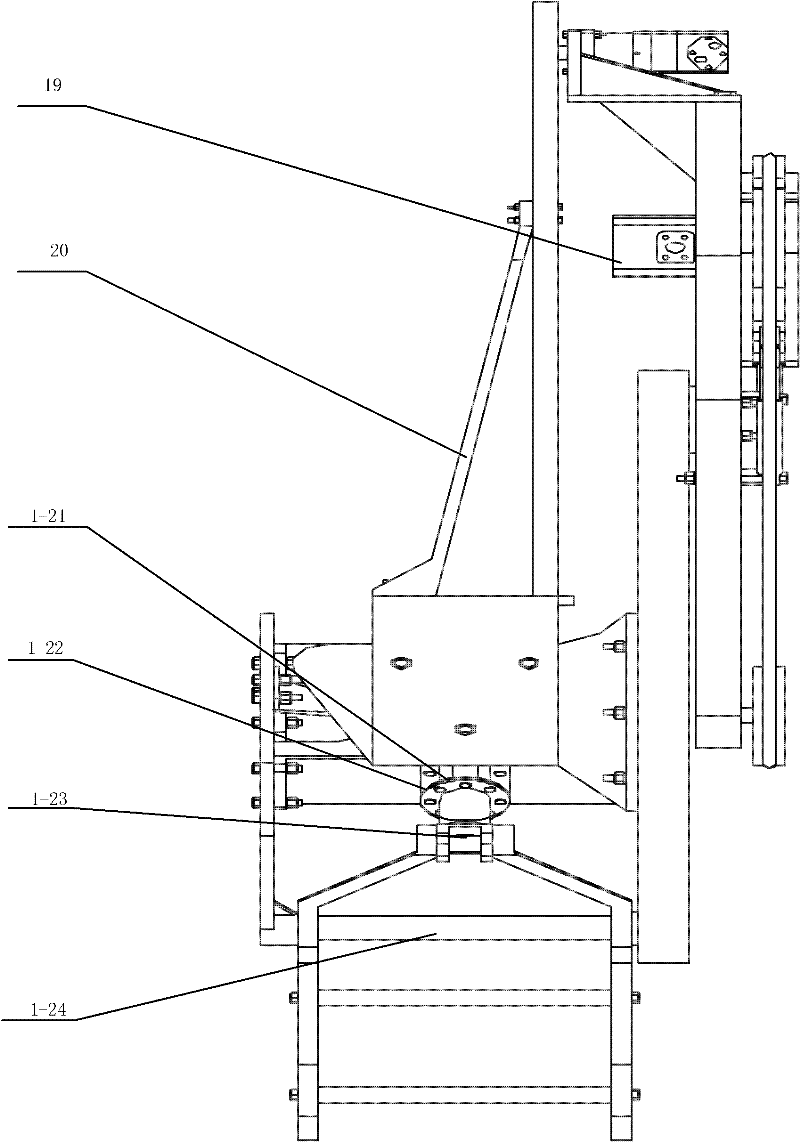

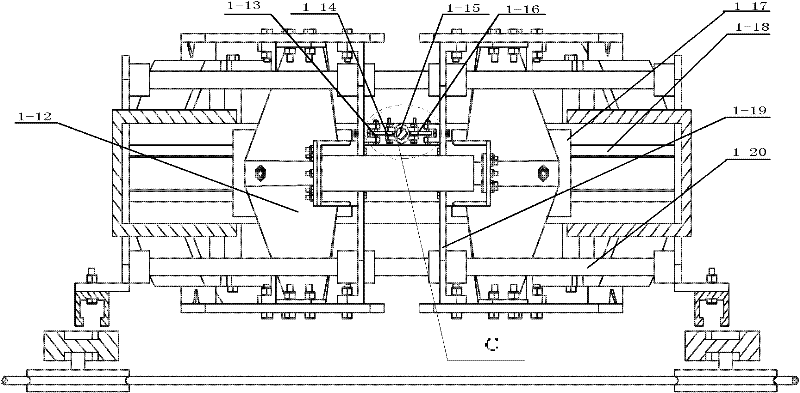

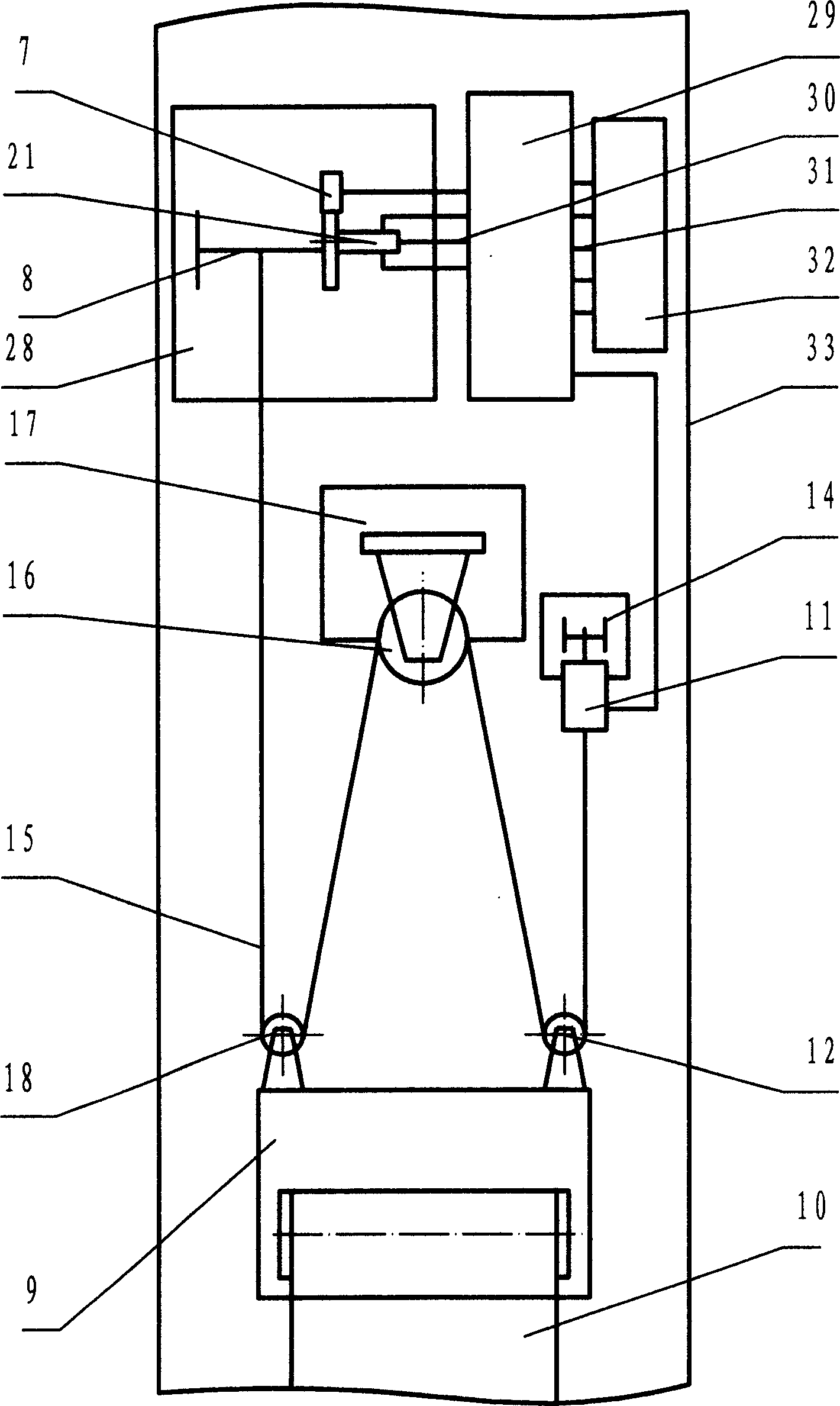

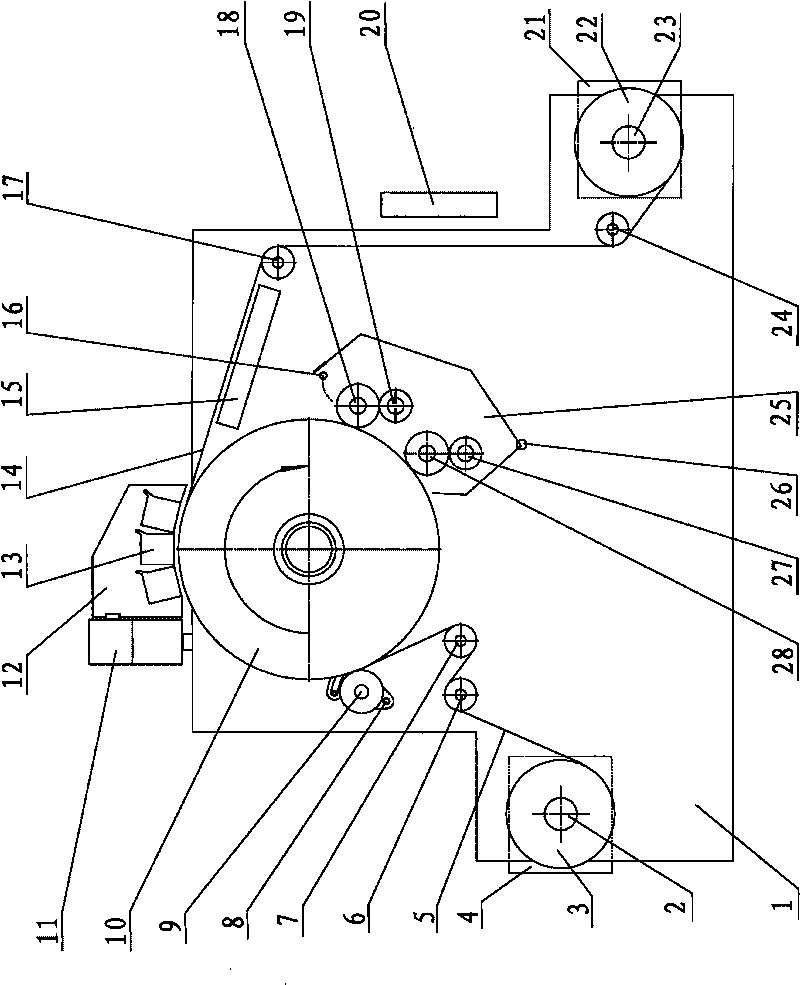

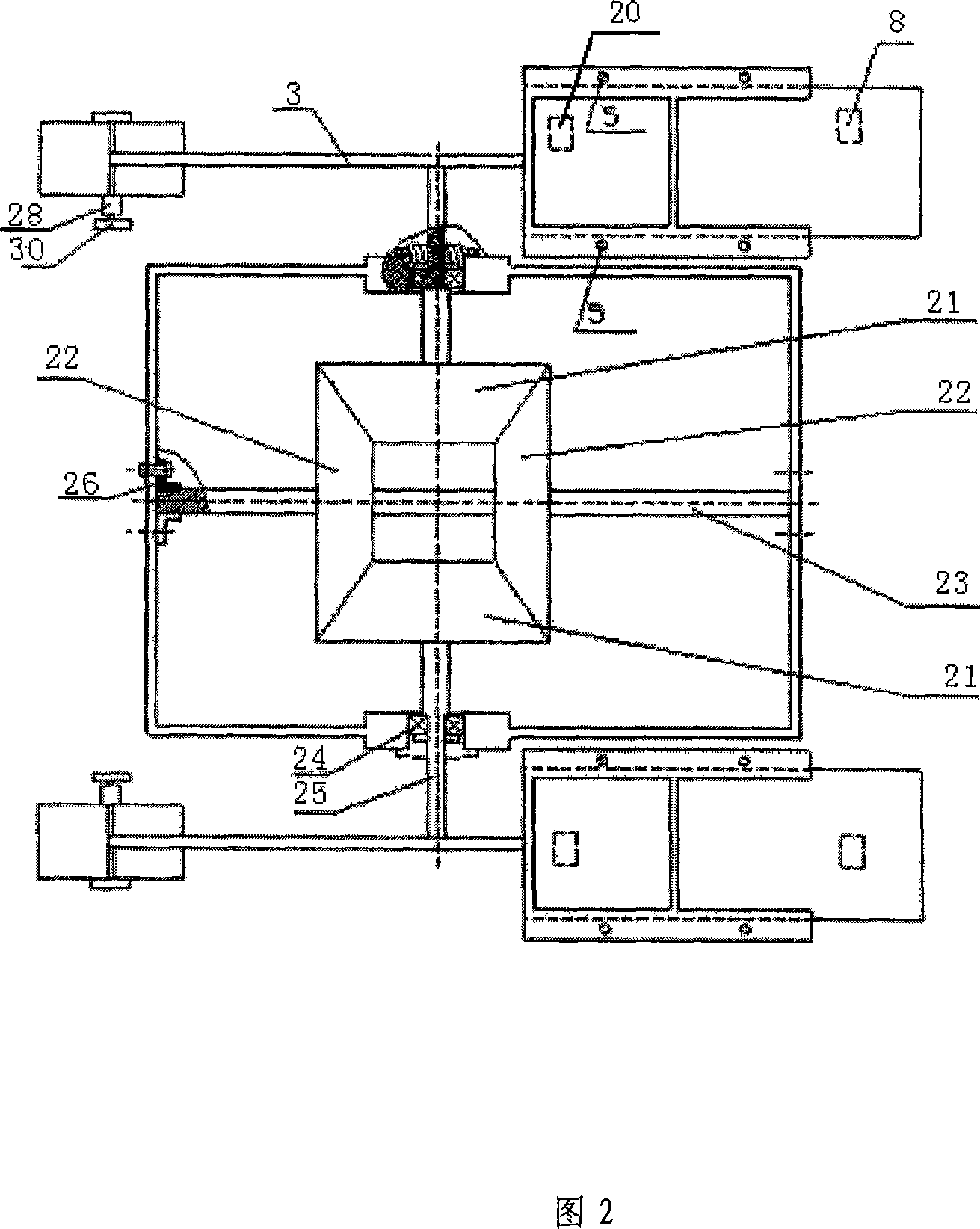

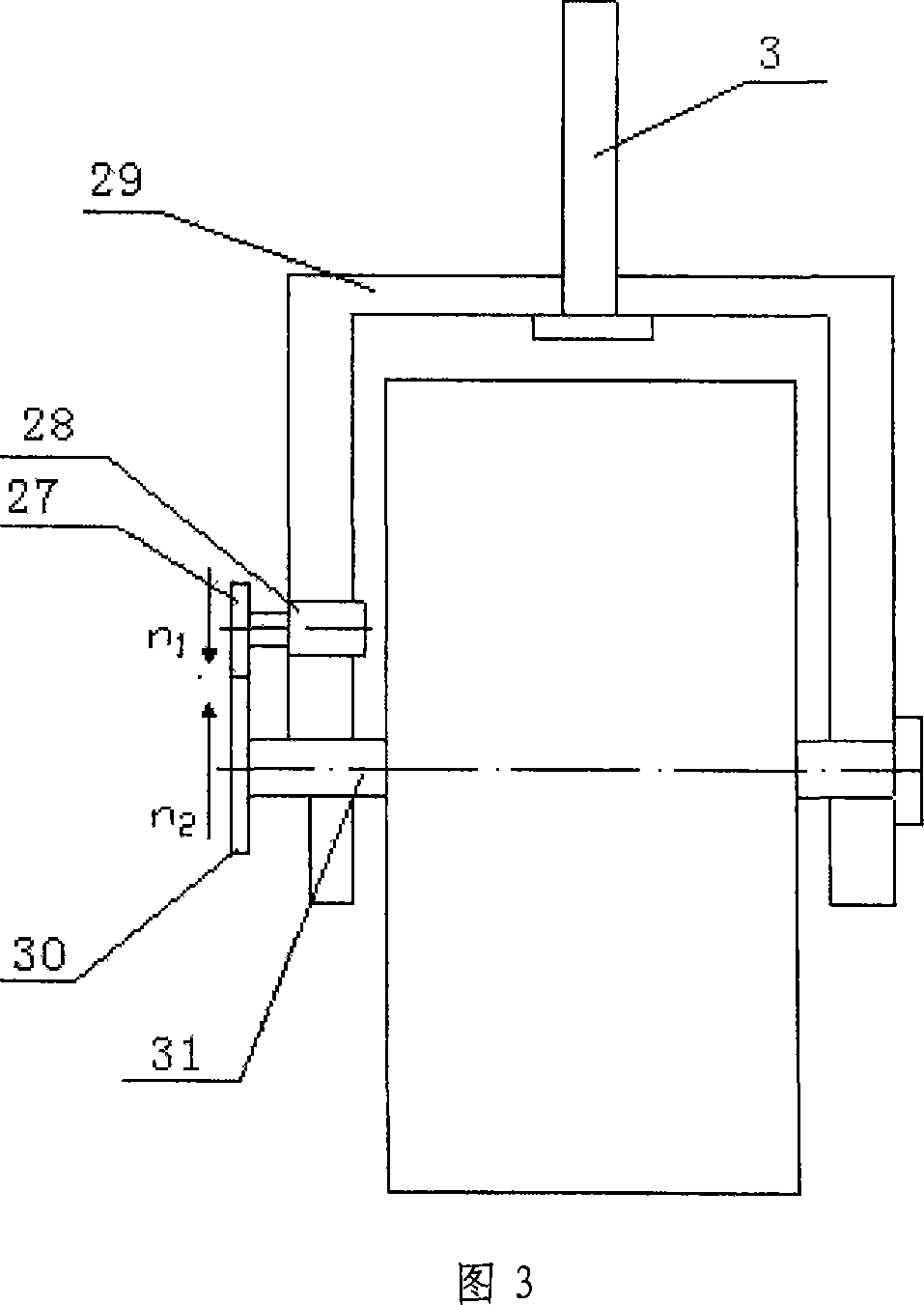

Variable structure adaptive feed type rope saw

InactiveCN102229009ALarge diameter rangeGuaranteed tensionMetal sawing devicesHydraulic cylinderControl system

The invention mainly aims to provide a variable structure adaptive feed type rope saw for cutting composite pipes with different diameters amphibiously. The rope saw consists of a clamping mechanism, a cutting mechanism, a feeding mechanism and a tensioning mechanism; the clamping mechanism comprises a V-shaped plate, the V-shaped plate is formed by folding two mutually independent half plates, each half plate is connected with respective sliding block, and the sliding block and a guide rail I form a sliding pair; the two half plates fixed on respective sliding blocks can move relatively in the radial direction along the guide rail I; the half plates are connected with a hydraulic cylinder respectively, and the hydraulic cylinder is connected with a control system; and the lower ends of the half plates are connected with clamping claws through fixing pins, and the rear ends of the clamping claws are connected with the hydraulic cylinder. The rope saw is suitable for the pipes with diameters of phi 300 to phi 1,500 millimeters, so the diameter range of the cut pipes is greatly expanded; and meanwhile, different cutting speeds can be automatically adjusted according to different cutting states to adapt the rope saw, and the cutting efficiency is improved.

Owner:HARBIN ENG UNIV

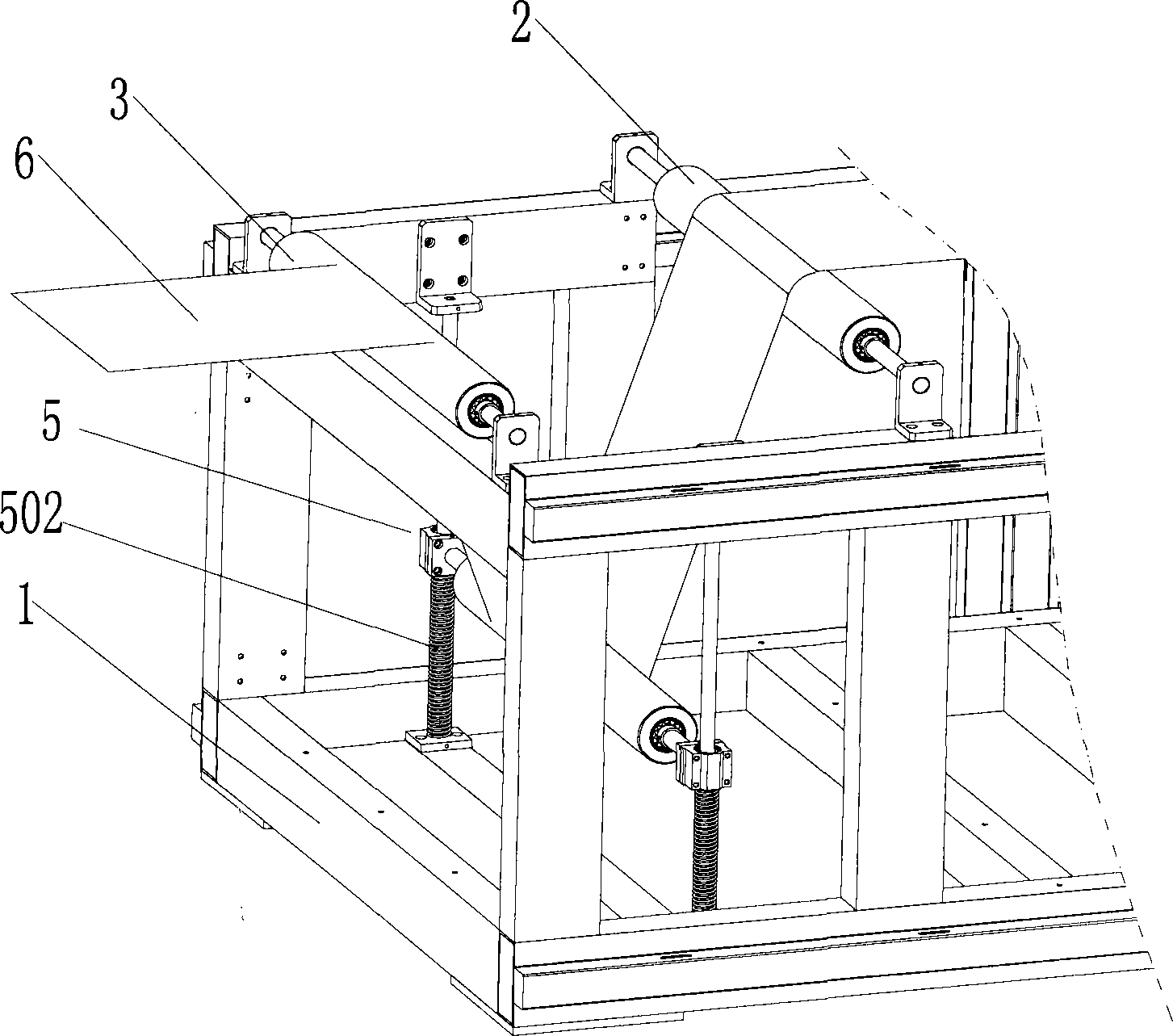

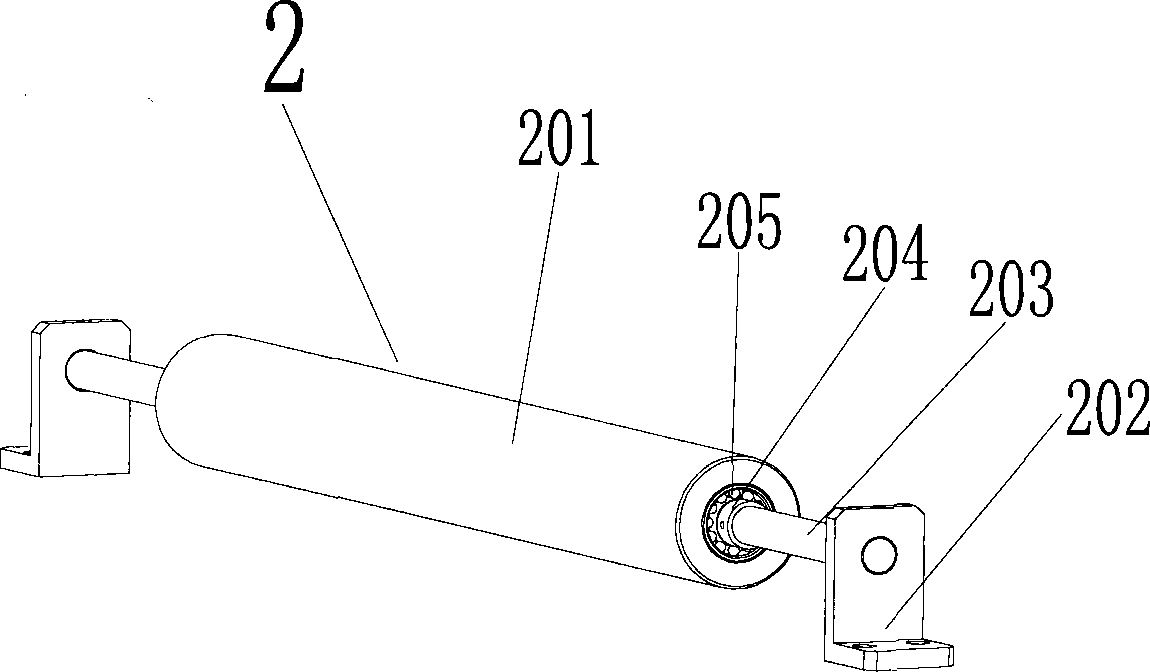

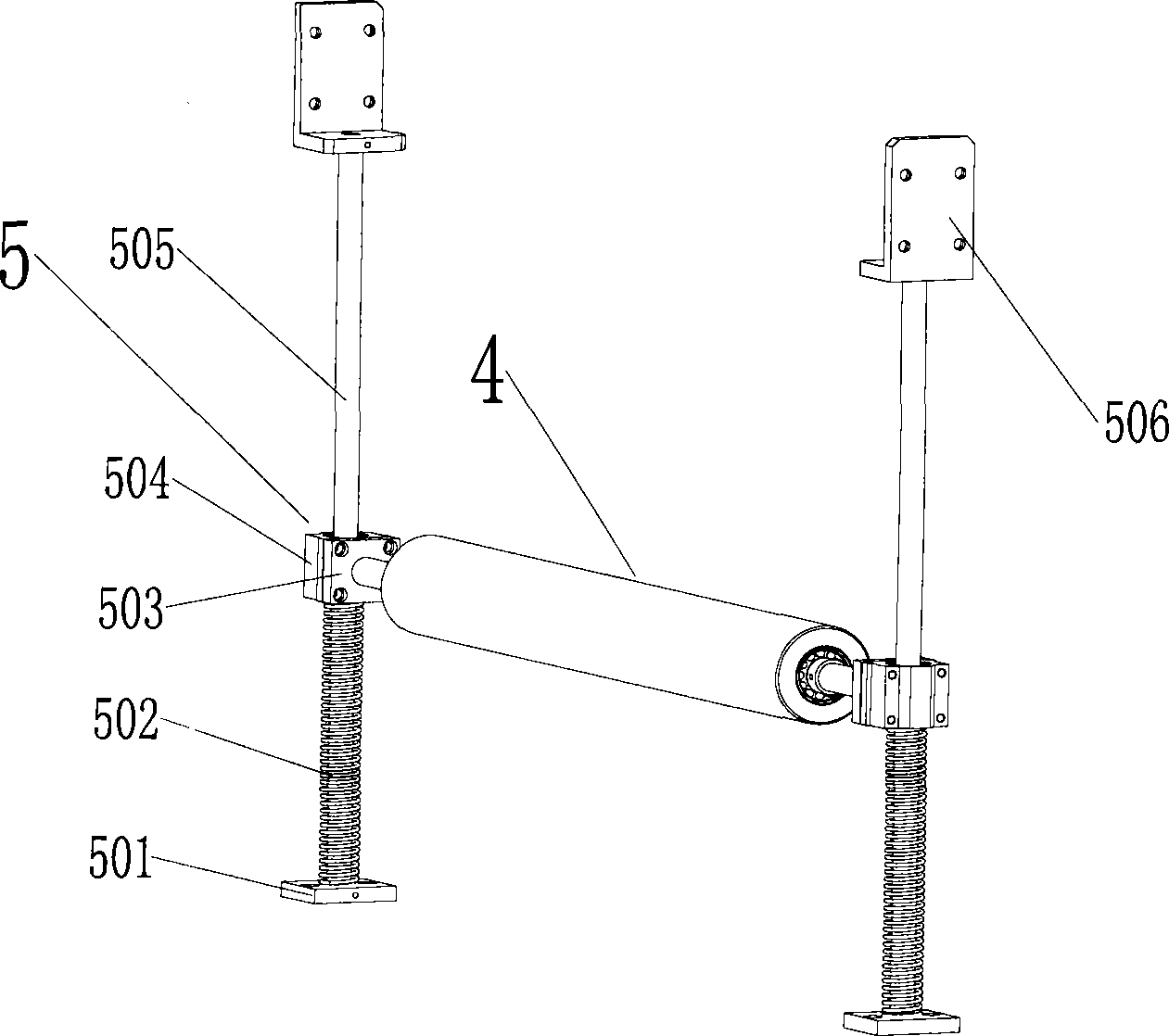

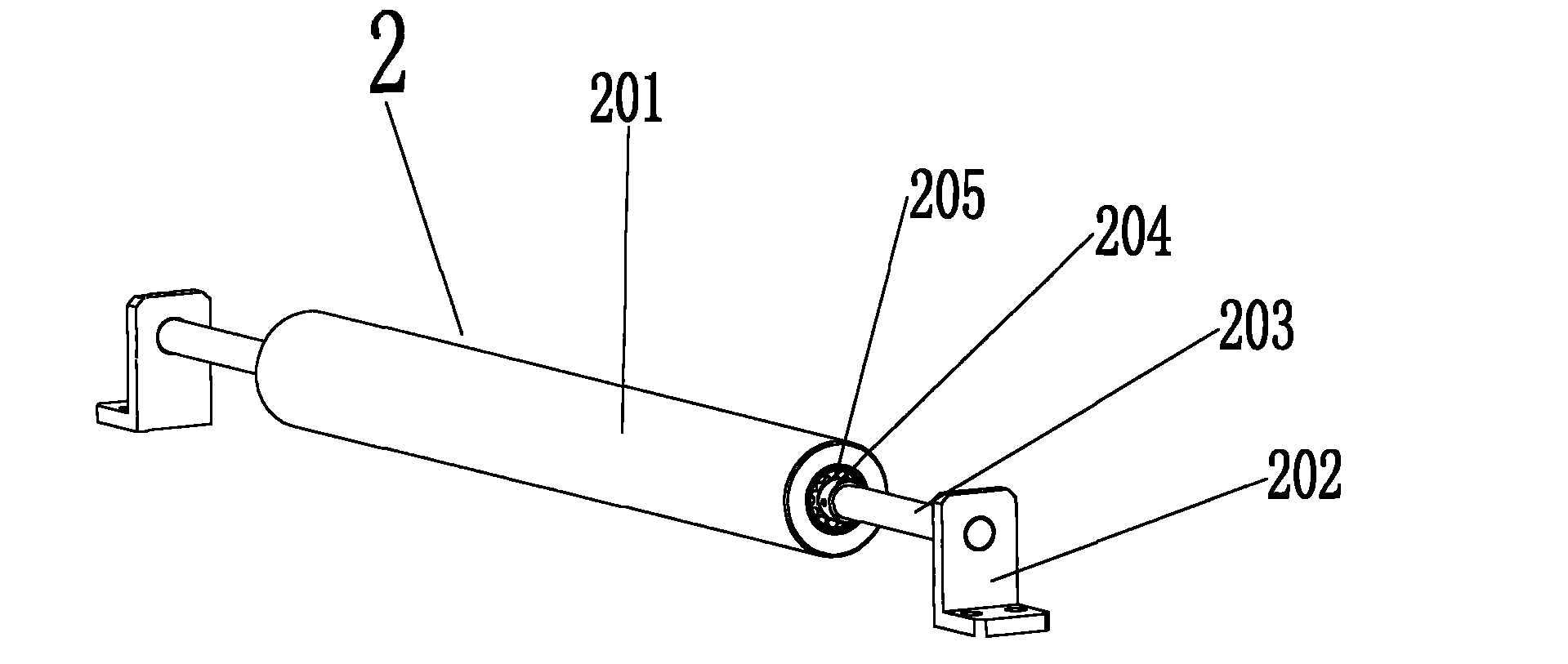

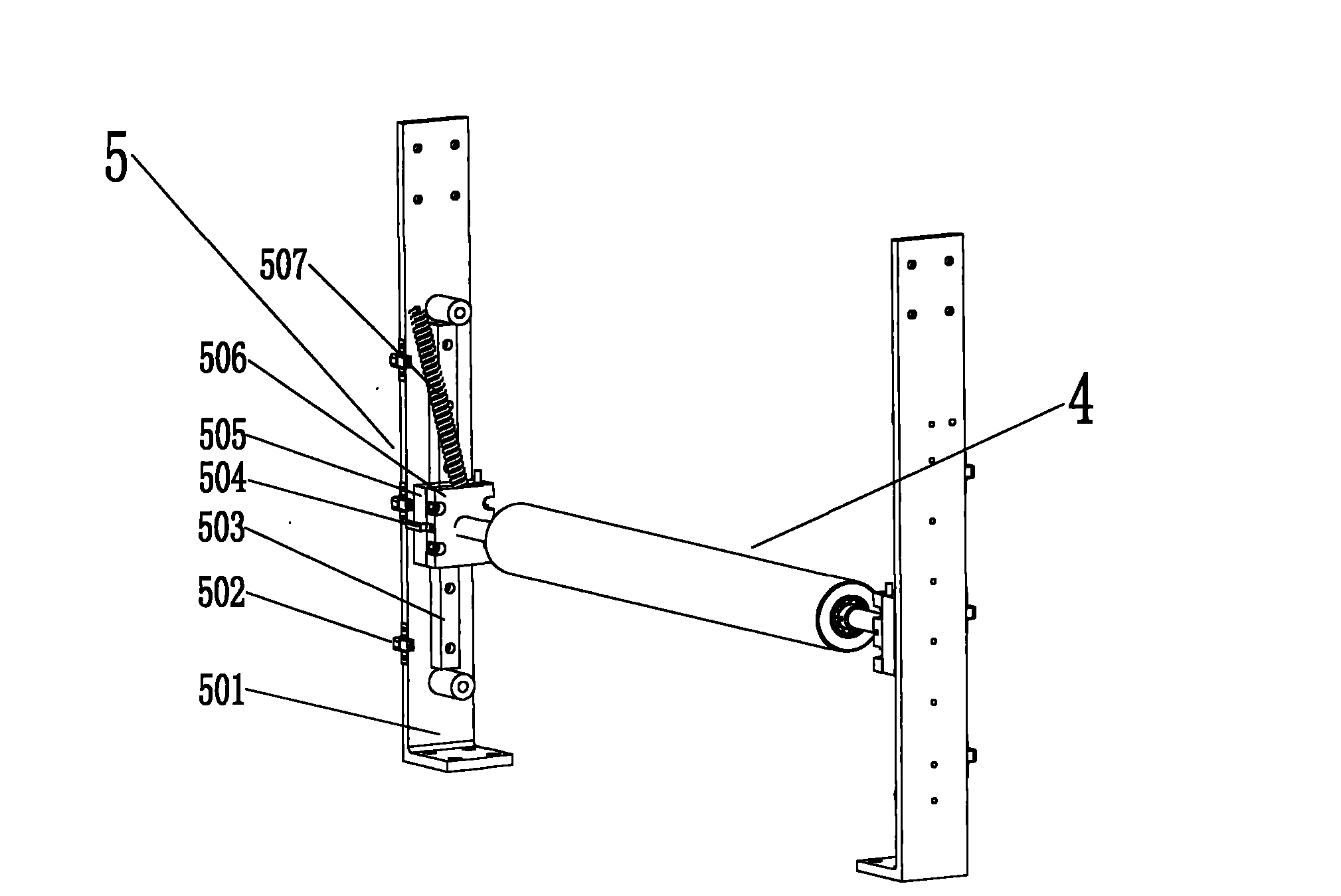

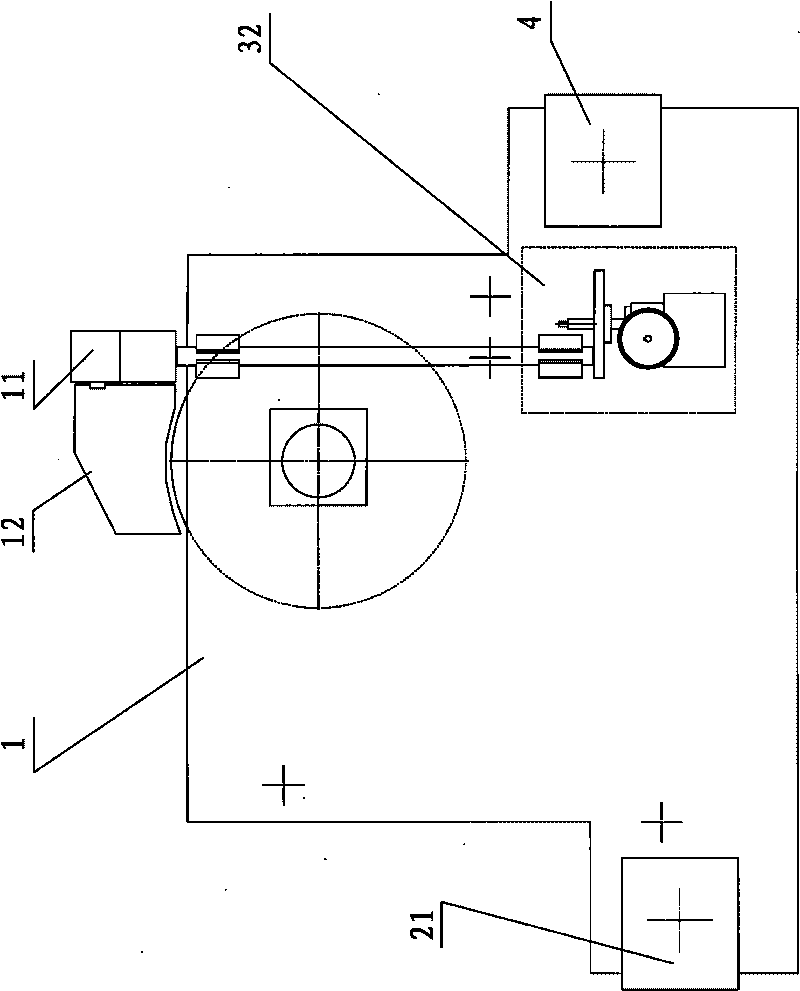

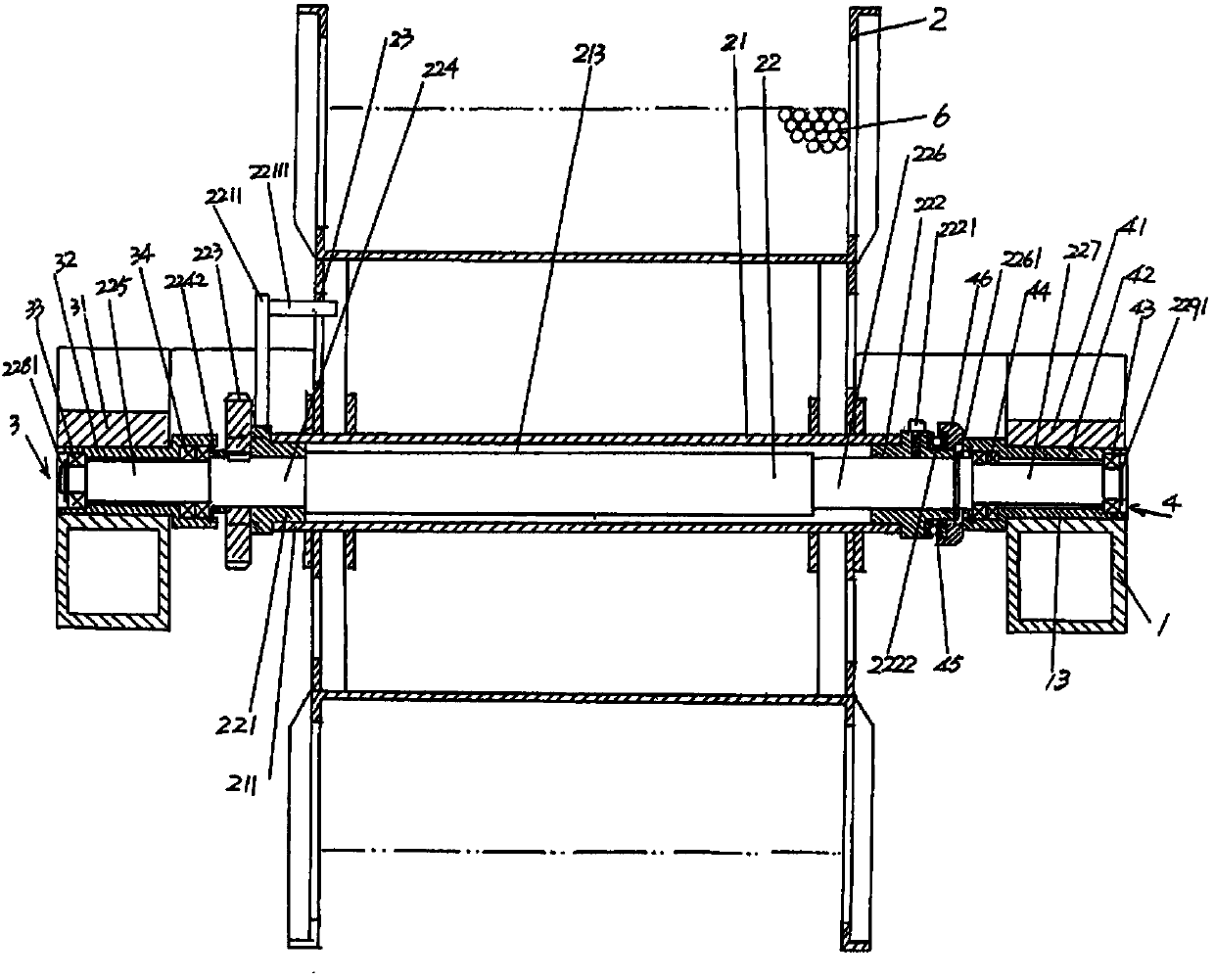

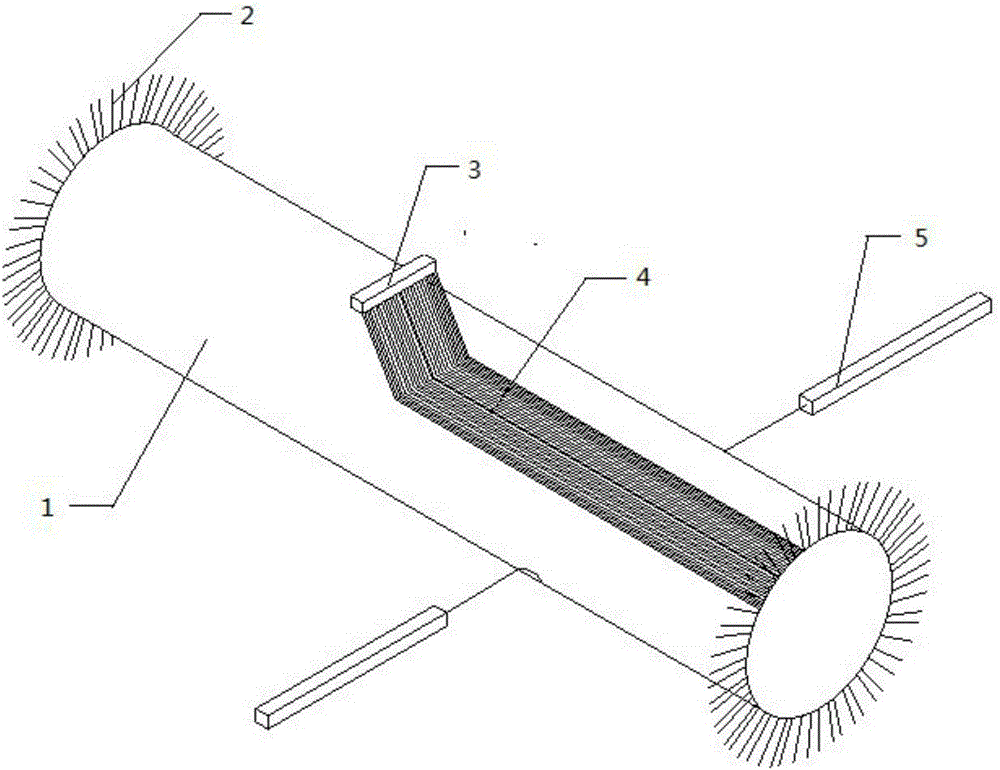

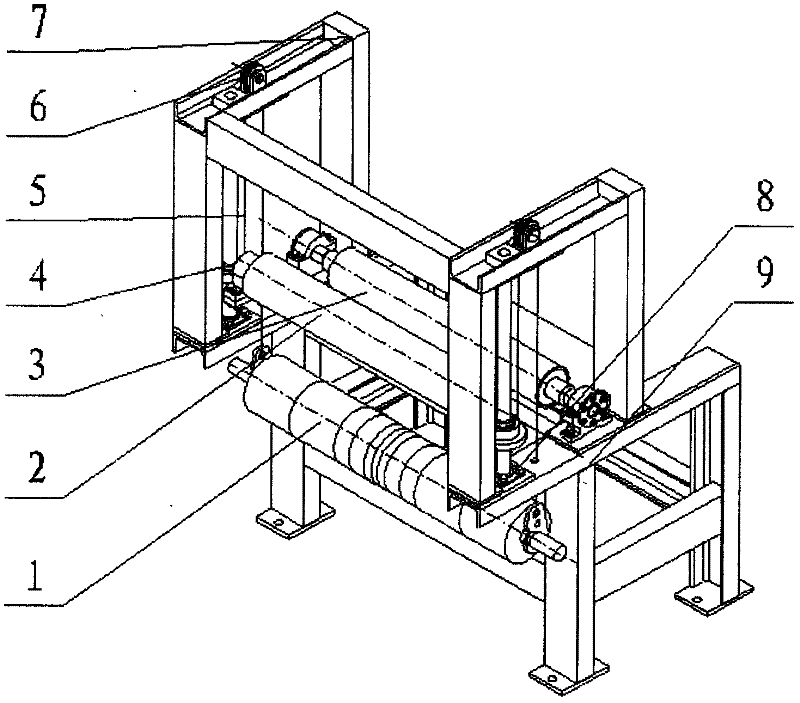

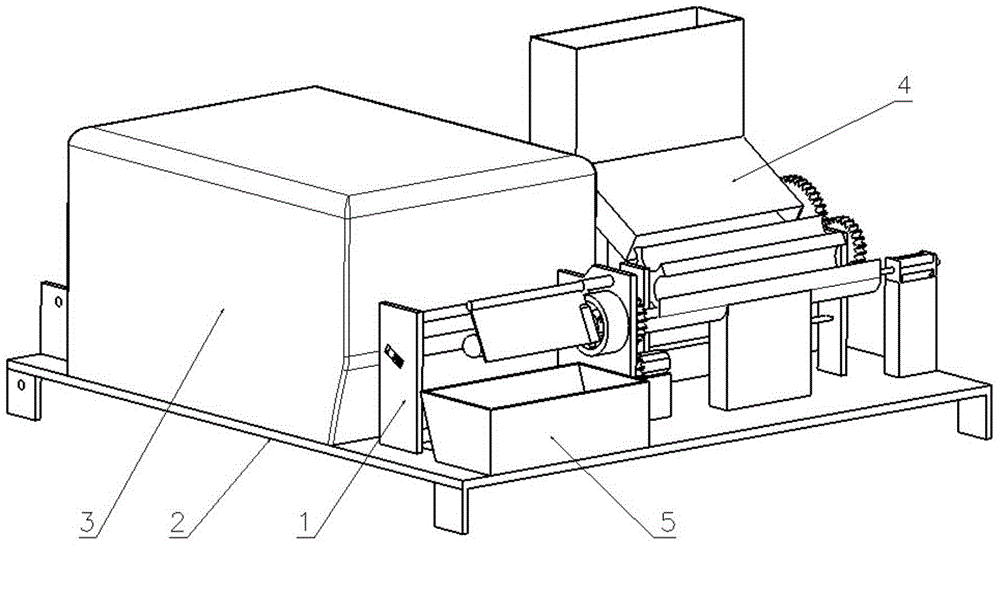

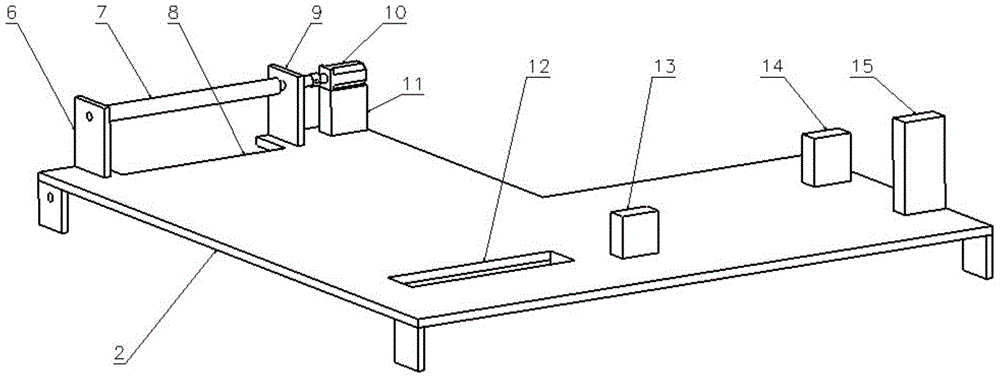

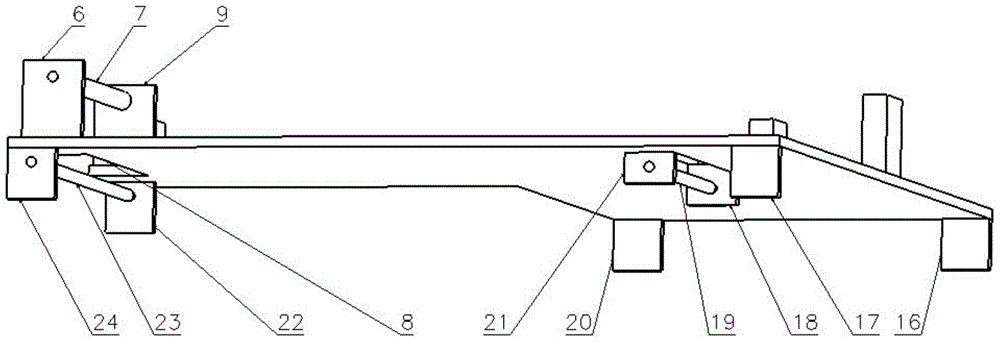

Coiled material conveying tensioning device

ActiveCN102491118AAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

The invention provides a coiled material conveying tensioning device, which comprises a working platform support (1), and a first guide roller assembly (2), a second guide roller assembly (3), a tensioning guide roller assembly (4) and a tensioning guide roller support assembly (5), which are arranged on the working platform support, wherein the tensioning guide roller support assembly (5) is arranged between the first guide roller assembly and the second guide roller assembly, and the tensioning guide roller assembly is supported on the tensioning guide roller support assembly and below the first guide roller assembly and the second guide roller assembly; the tensioning guide roller support assembly can regulate the height of the tensioning guide roller assembly to allow a coiled material to be tensioned after the coiled material passes through a first guide roller, a tensioning guide roller and the second guide roller. The coiled material conveying tensioning device with a simple structure has the advantages of quick response and automatic regulation of the tension of the coiled material at a feeding end.

Owner:CHERY AUTOMOBILE CO LTD

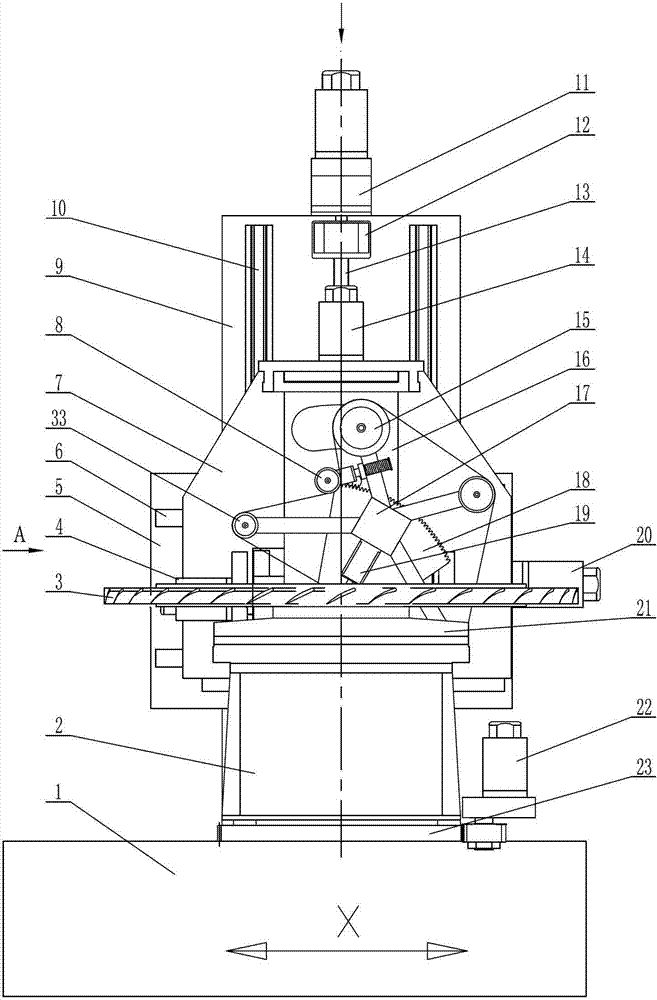

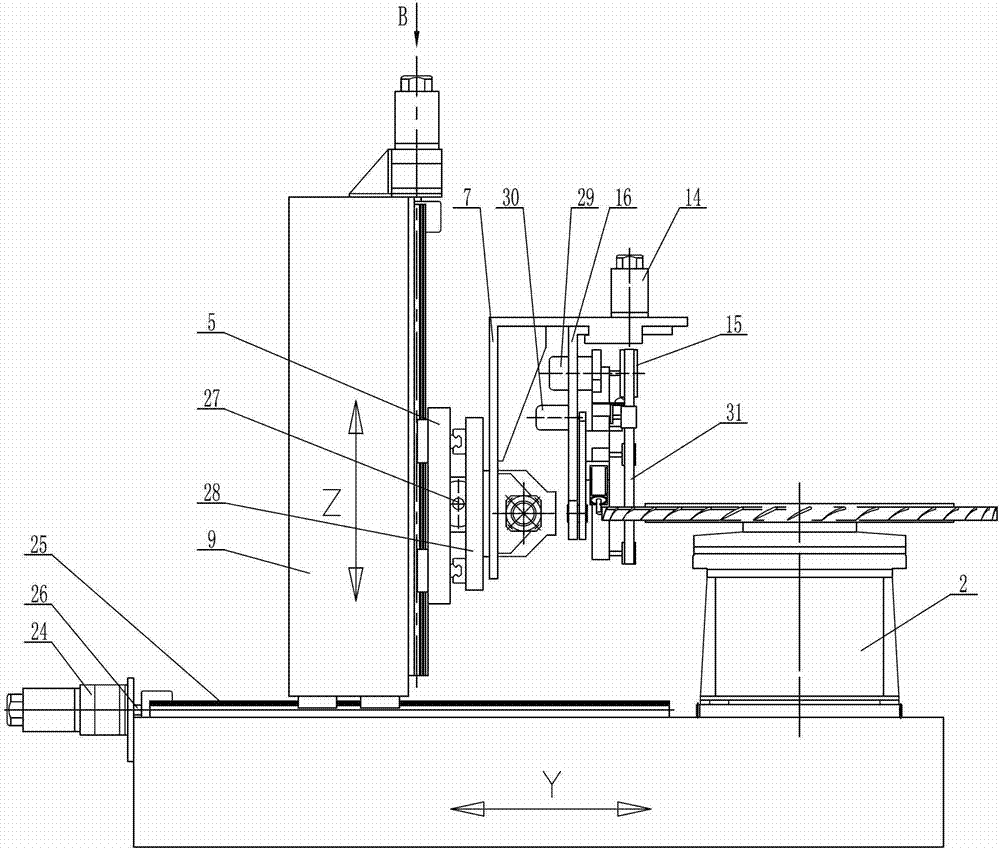

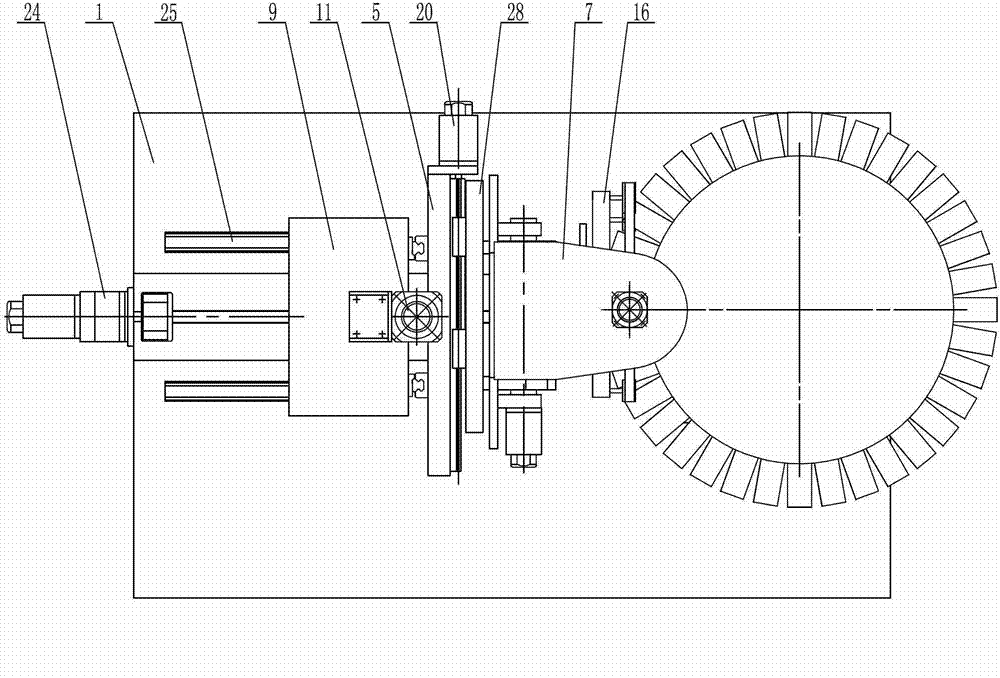

Abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk

InactiveCN102729124AImprove work efficiencyGuaranteed accuracyBelt grinding machinesSix degrees of freedomBelt grinding

The invention discloses an abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk. An X axis transverse feed mechanism, a Y axis transverse feed mechanism and a Z axis longitudinal feed mechanism form a grinding head feed mechanism; an A axis deflection motor, an A axis deflection bracket, a B axis motor, a gear train bracket, a C axis motor, a C axis revolving bracket and the like form a position adjusting mechanism of the grinding head. The abrasive belt grinding device provided by the invention guarantees rigidity of a grinding head mechanism and a work piece clamping mechanism through rational distribution of the grinding head feeding, the position adjustment of the grinding head and the position and angle adjustment of the work piece and through combination of space in six degrees of freedom by a short transmission chain; a contact wheel and an abrasive belt can cut into a narrow gap between two blades of the blisk, so as to ensure the contact between the contact wheel and the work piece to be stable when the contact wheel rotates at a high speed; so that the abrasive belt grinding device can improve the work efficiency, and meanwhile, dimensional accuracy of complex cambered surface of the work piece in processing can be guaranteed, the quality of the molded surface is ensured, the rate of qualified products is improved, the labor intensity of workers is reduced and the management and production costs are lowered.

Owner:CHONGQING UNIV +1

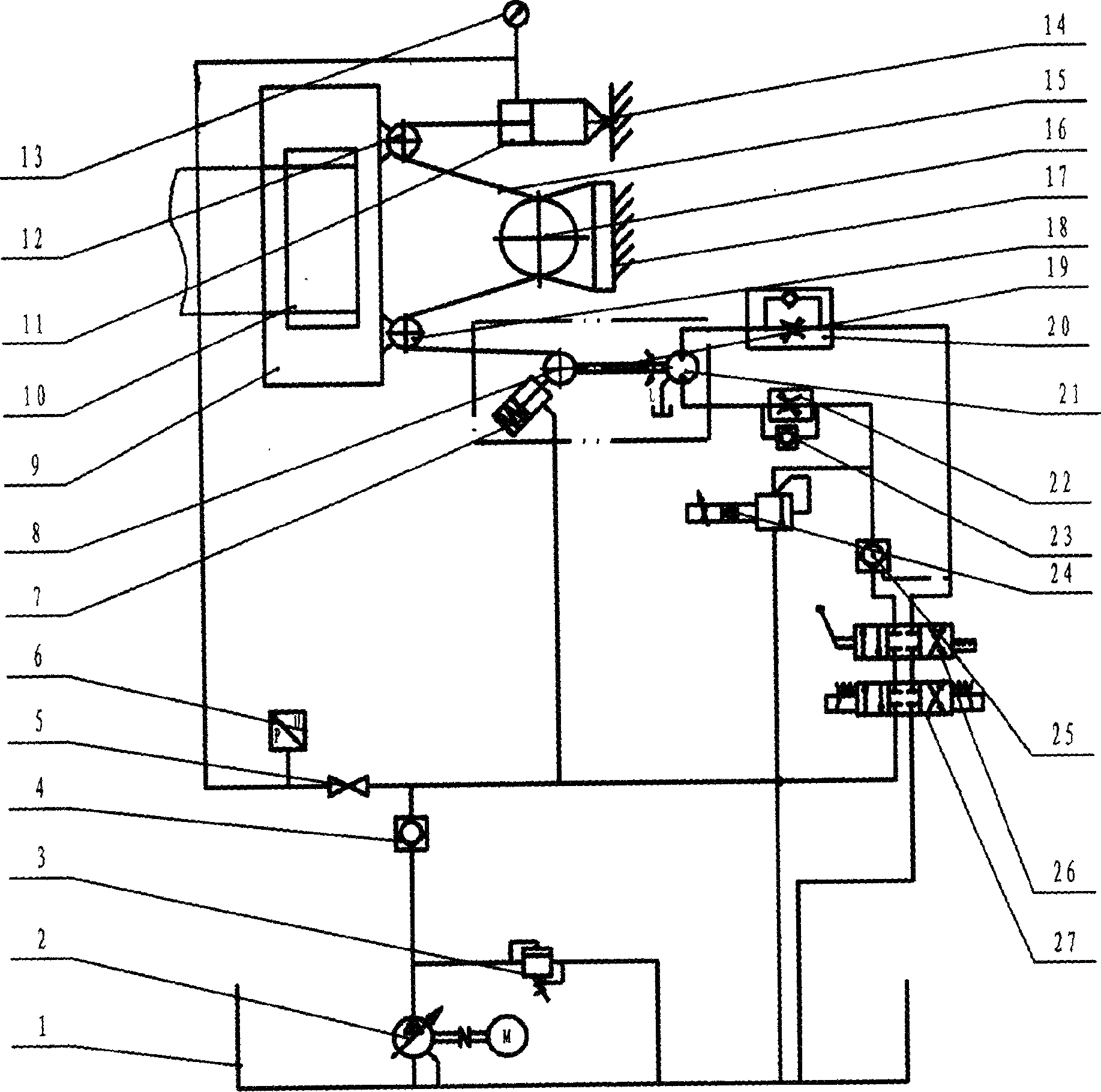

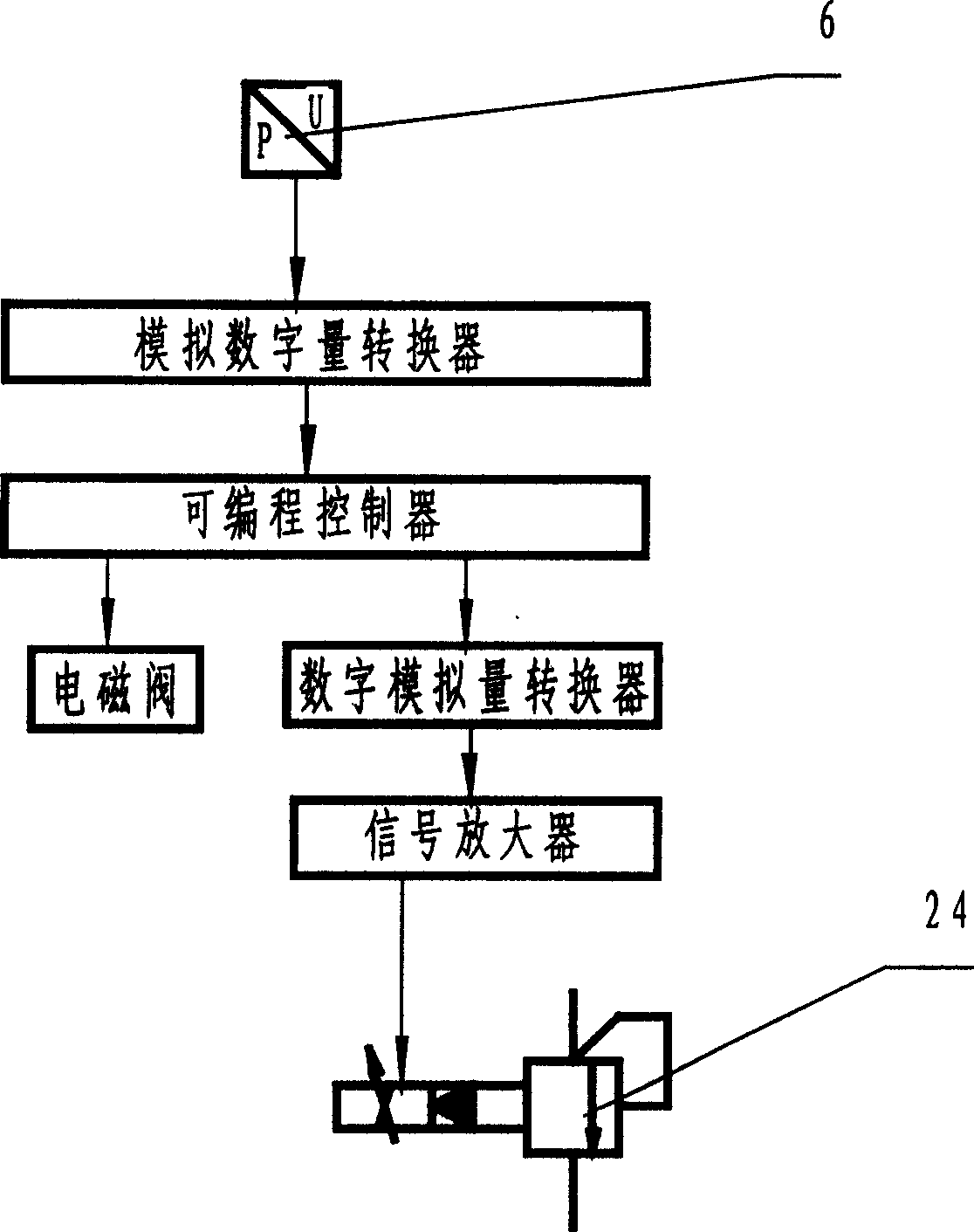

Automatic tightening device of belt conveyor

An automatic tensioning device for belt conveyor is suitable for long-range covneyor or a rubber belt conveyer, of which belt has a large extension rate. It achieves a large regulative range, an accurate control of tension force, and stable adjustment. The system consists of a tension monitor, a hydraulic device and a hydraulic hoist. The tension monitor comprises a detecting cylinder, a pressure sensor, a shutoff valve and a pressure meter. The hydraulic device comprises a pump, a reversing solenoid valve, a overflow valve, a manual valve, a hydraulic one-way valve, a proportional reversing valve, a one-way throttle valve, a one-way valve, a throttle valve, a tank, and oil-way. The outlet of the pump is respectively connected with the tension monitor, the cylinder and the driving circuit of the hydraulic hoist via the one-way valve.

Owner:TAIYUAN UNIV OF TECH

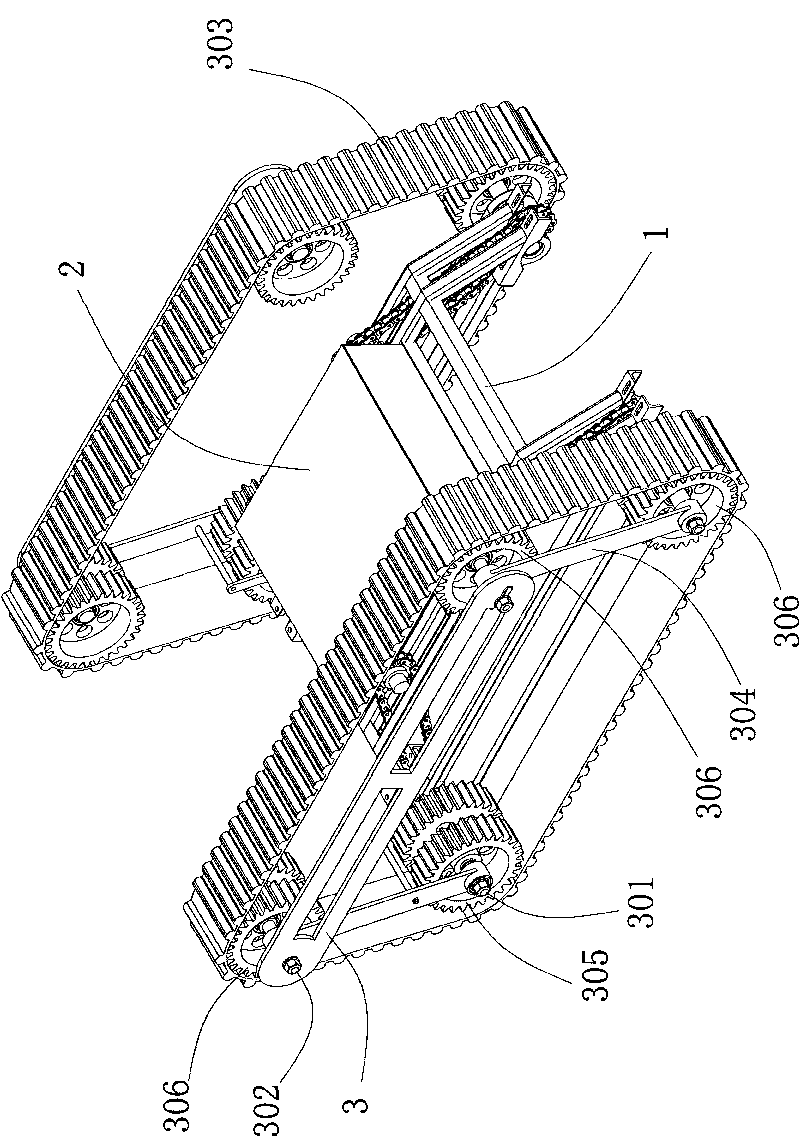

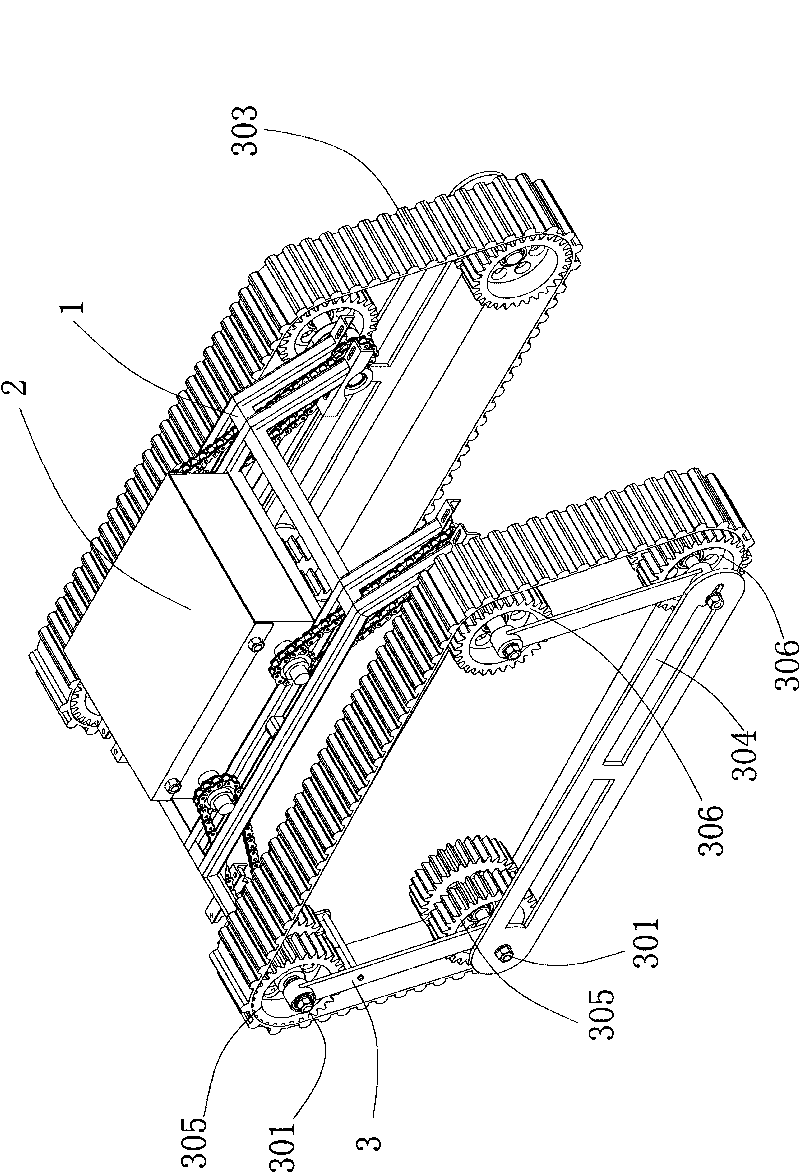

Deformed caterpillar robot

ActiveCN101734295AImprove obstacle-surpassing ability and smoothness of motionGood shock absorptionEndless track vehiclesFuselageDrive shaft

The invention discloses a deformed caterpillar robot which comprises a robot stand and a robot body, wherein robot body is installed on the robot stand; both sides of the robot stand are respectively provided with a set of deformed caterpillar running mechanism; each deformed caterpillar running mechanism comprises a traveling drive shaft, a caterpillar deformed drive shaft, a caterpillar and a deformed oscillating bar mechanism; each traveling drive shaft and each caterpillar deformed drive shaft are arranged on the robot stand in parallel; one end of each deformed oscillating bar mechanism is fixedly connected with each caterpillar deformed drive shaft, and the other end is supported on each traveling drive shaft by a bearing; a drive caterpillar wheel is installed on each traveling drive shaft; driven caterpillar wheels are both arranged on each caterpillar deformed drive shaft and each deformed oscillating bar mechanisms; and each drive caterpillar wheel and all driven caterpillar wheels are meshed with each caterpillar. The deformed caterpillar robot has steady running, high obstacle crossing and climbing capability, simple structure, stable working and reliable control.

Owner:NAT UNIV OF DEFENSE TECH

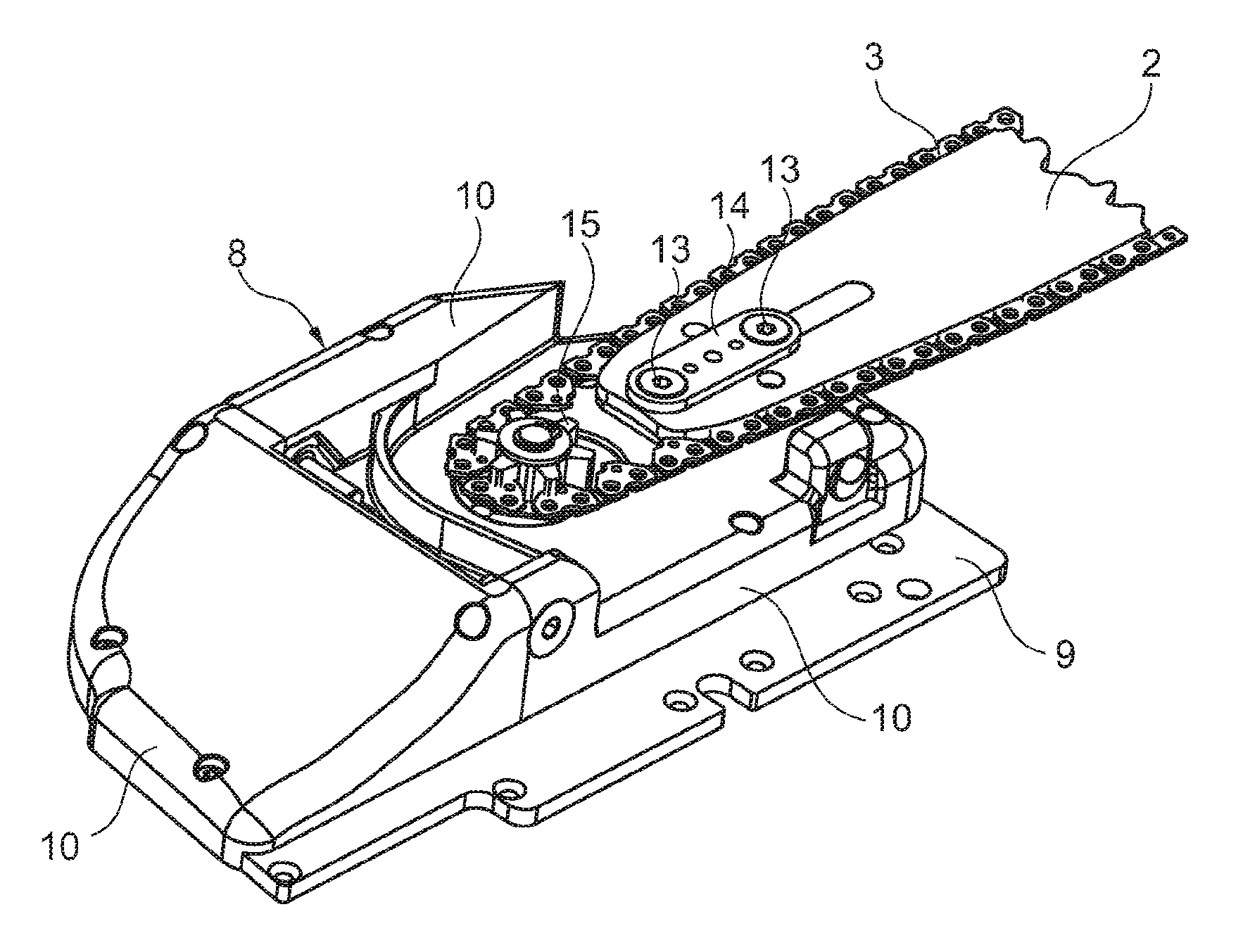

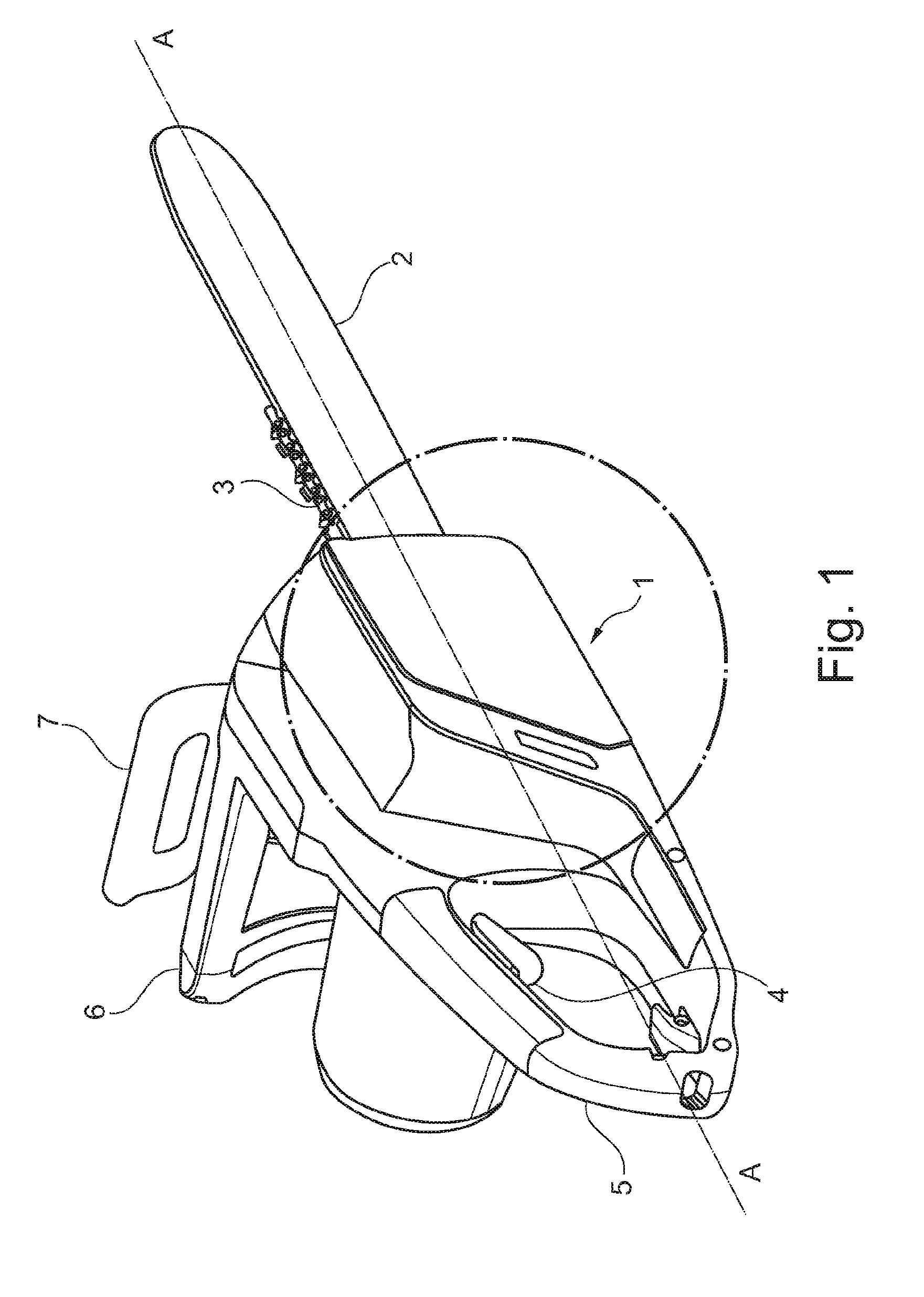

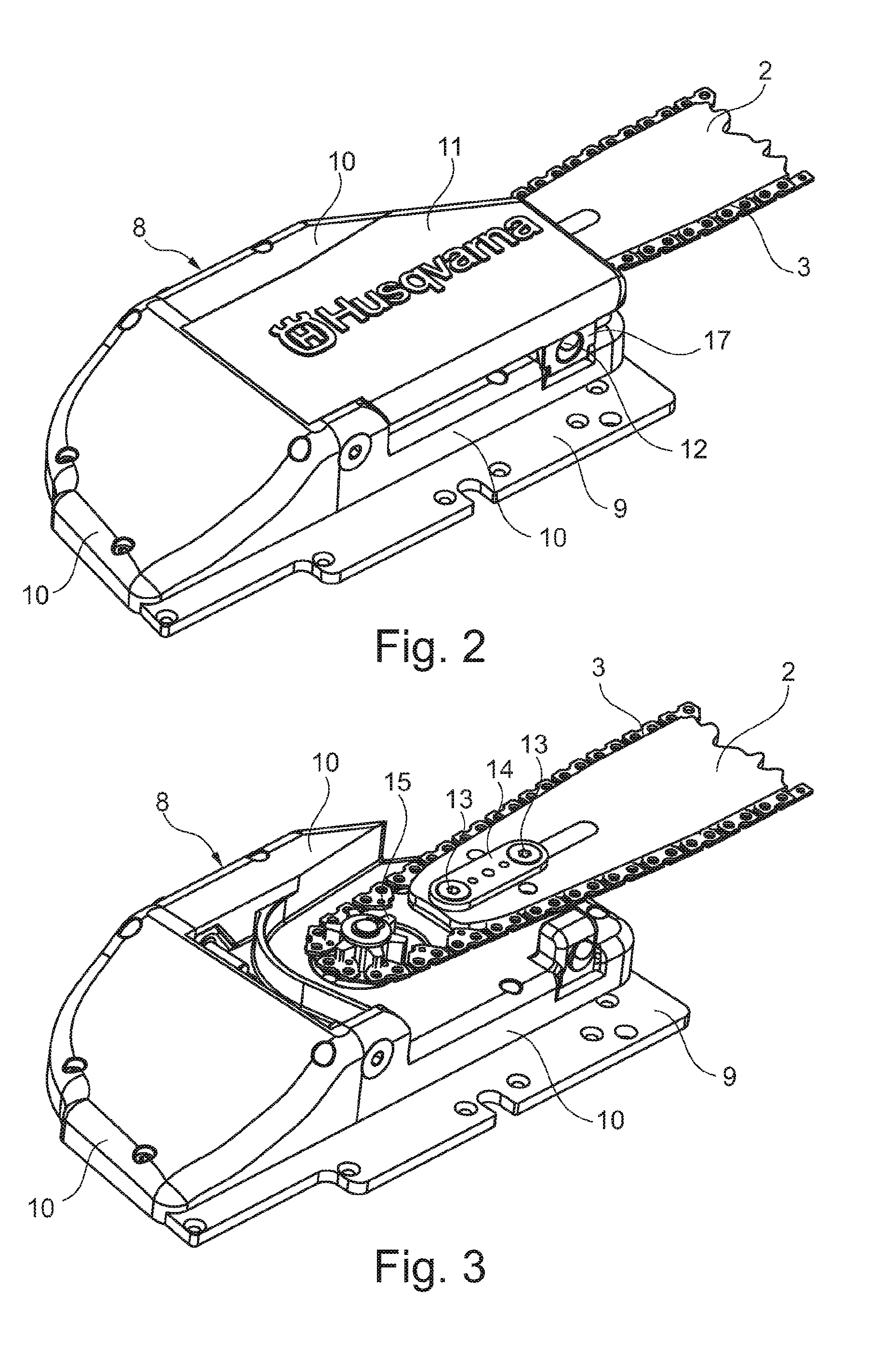

Quick-action chain tensioning device for a chainsaw, and such mechanism and method

InactiveUS20140106915A1Easy to disassembleFacilitate attachment/detachmentGearingChain sawsRatchetGear drive

To facilitate the demounting of a chain (3) from a chainsaw, the saw has a lever arm preferably in the form of hinged cover (11) arranged to displace the sprocket (15) towards the guide bar (2) the other upon opening of the cover (11). Upon closing the cover (11), the sprocket (15) is displaced in the opposite direction to pre-tension the chain (3). The sprocket (15, 115) may be driven over a gear transmission (27, 127), which when the chain (3, 103) is running at ordinary cutting speed uses resulting forces to automatically tension the chain (3, 103) by displacing the sprocket (15, 115) away from the guide bar (2, 102). A ratchet mechanism (34) may be provided to maintain the chain tension upon reduction of the chain speed by preventing the sprocket (15) from moving toward the guide bar (2).Alternatively, a mechanism for automatically tensioning the chain (3, 238) of a chainsaw includes a driving inner sprocket (76, 201), and an outer ring member (77, 204) surrounding the inner sprocket (76, 201). A spring (64, 87, 228) may be provided for assisting the ratchet mechanism or as a substitute therefore.

Owner:HUSQVARNA AB

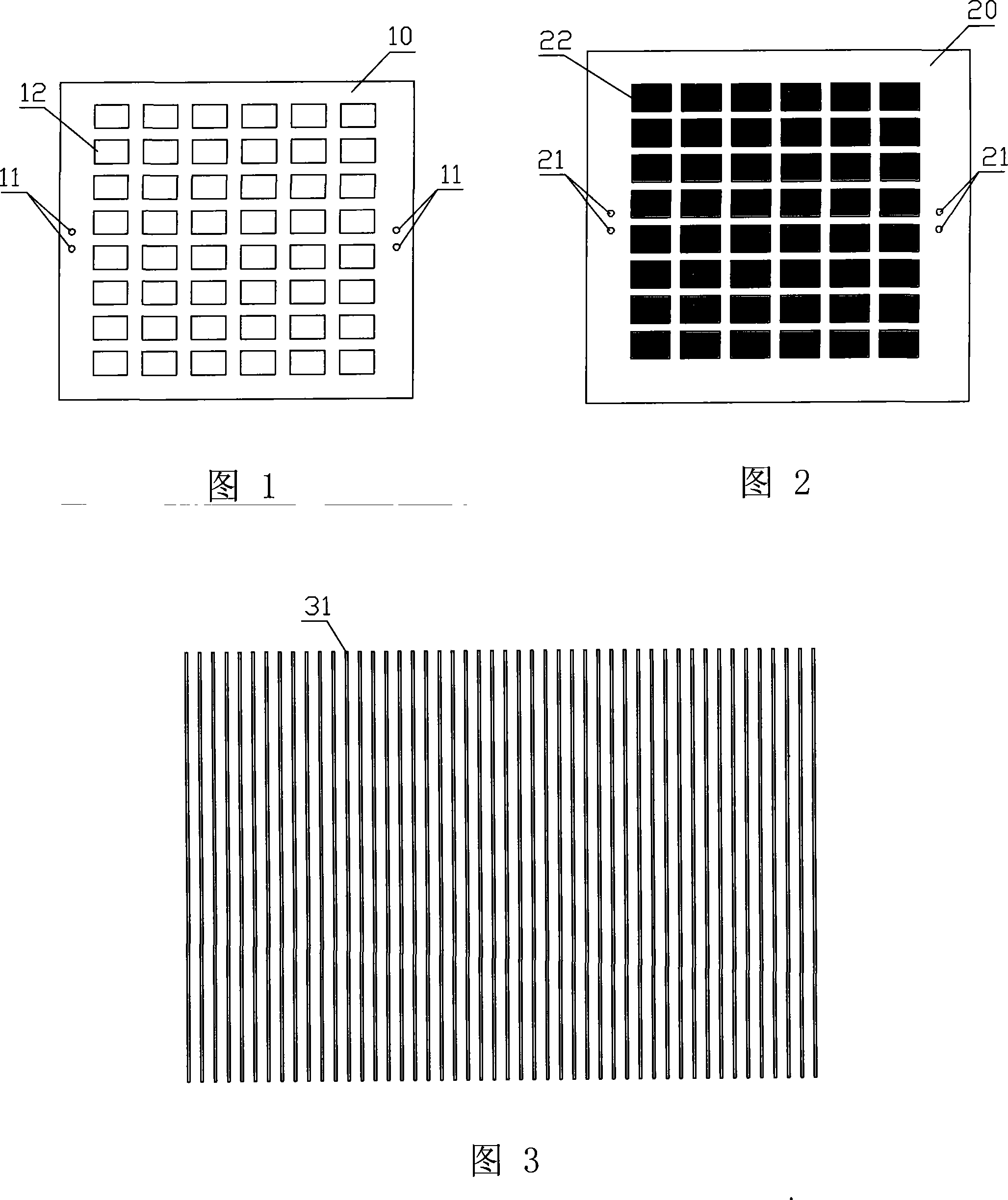

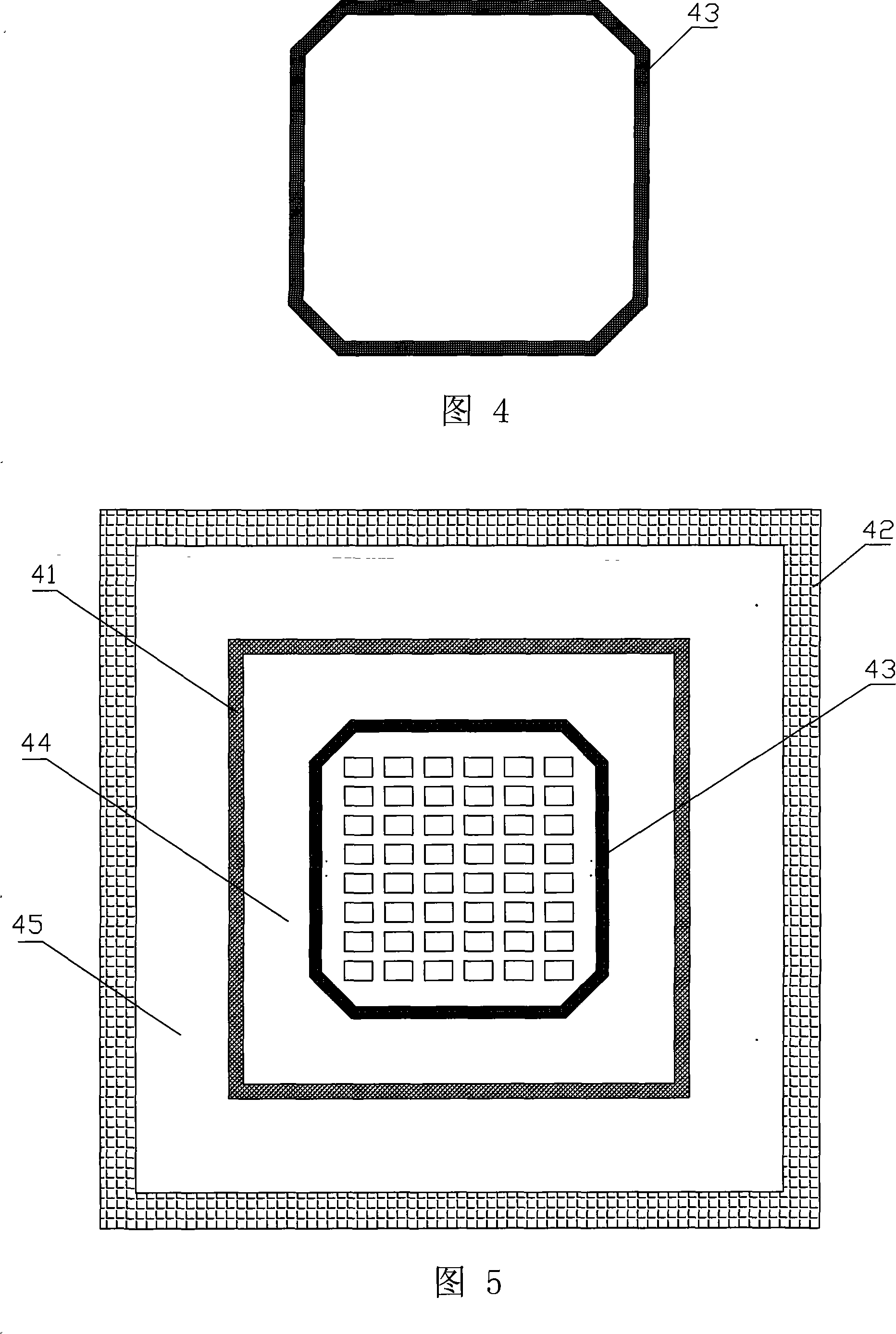

Method for preparing organic electroluminescent display mask plate

InactiveCN101250685AGuaranteed tensionReduce tensionVacuum evaporation coatingSputtering coatingWire gauzeSheet steel

The invention discloses a method for producing mask plates of organic electroluminescent displays, which comprises following steps: taking a sheet of magnetic conductive thin sheet steel, utilizing stainless steel etching or laser cutting to open holes on the thin sheet steel to form patterns, flatly spreading a silk screen on the thin sheet steel with the patterns, coating mucilage which is used to stretch the silk screen on the edge of the thin sheet steel, then, removing the silk screen on the region of thin sheet steel patterns, then, stretching the silk screen, taking a frame body, clinging the frame body on the stretched silk screen to form a net frame, tailoring along the outer margin of the net frame after bonding stably, cutting another magnetic conductive sheet steel into an outer frame of the mask plate which is needed, then, connecting the outer frame of the mask plate and the magnetic conductive thin sheet steel in the net frame, then, cutting off the silk screen, shedding the net frame, lastly, cutting off excess sheet steel along the outer margin of the outer frame of the mask plate, and finishing producing the mask plate. The method of the invention utilizes the silk screen to stretch the thin sheet steel, which lowers the production cost and simplifies the technological process, the net frame is more stably connected with the outer frame, the operation is comparatively simpler, and the precision is greatly increased.

Owner:TRULY SEMICON

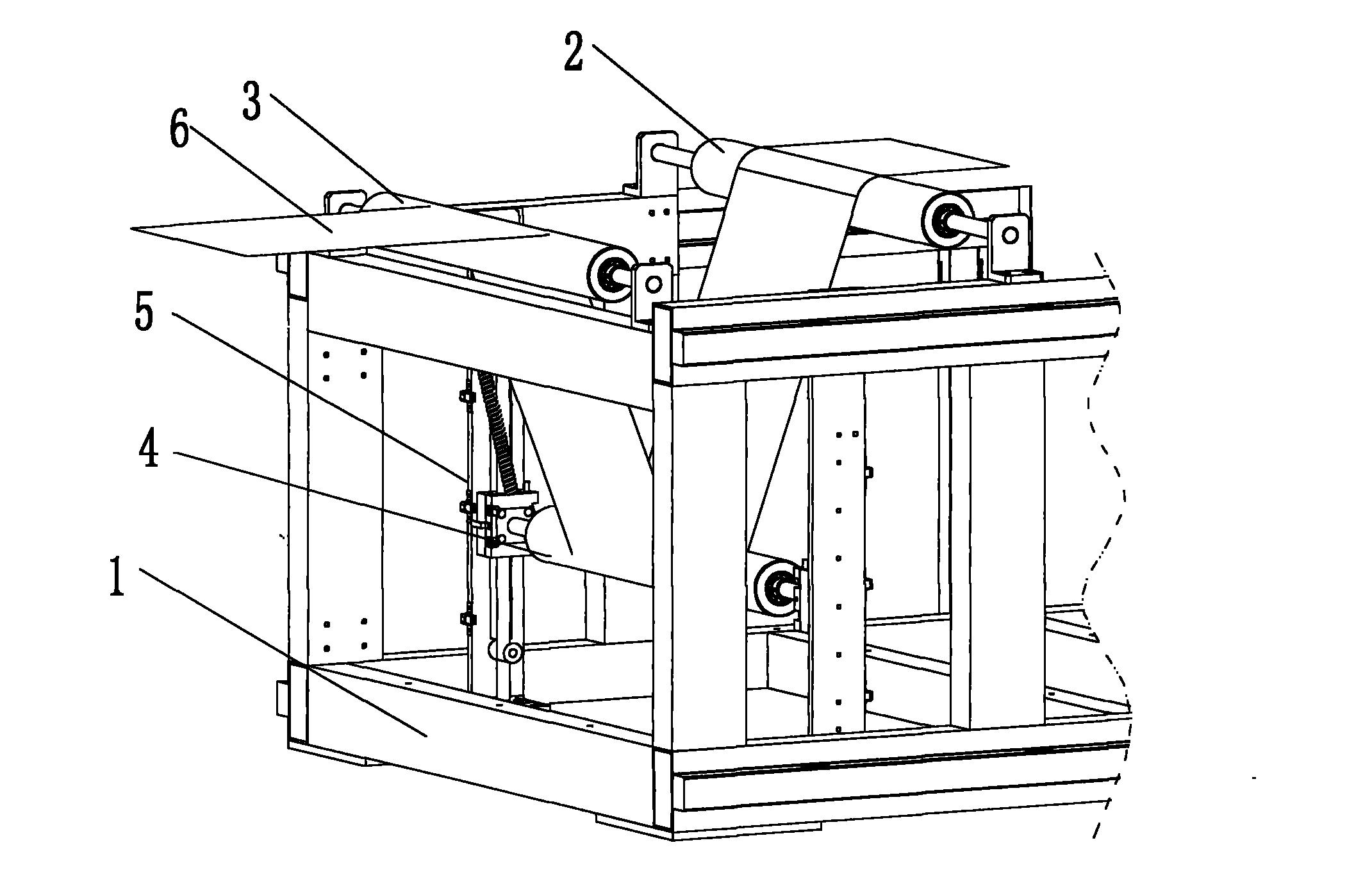

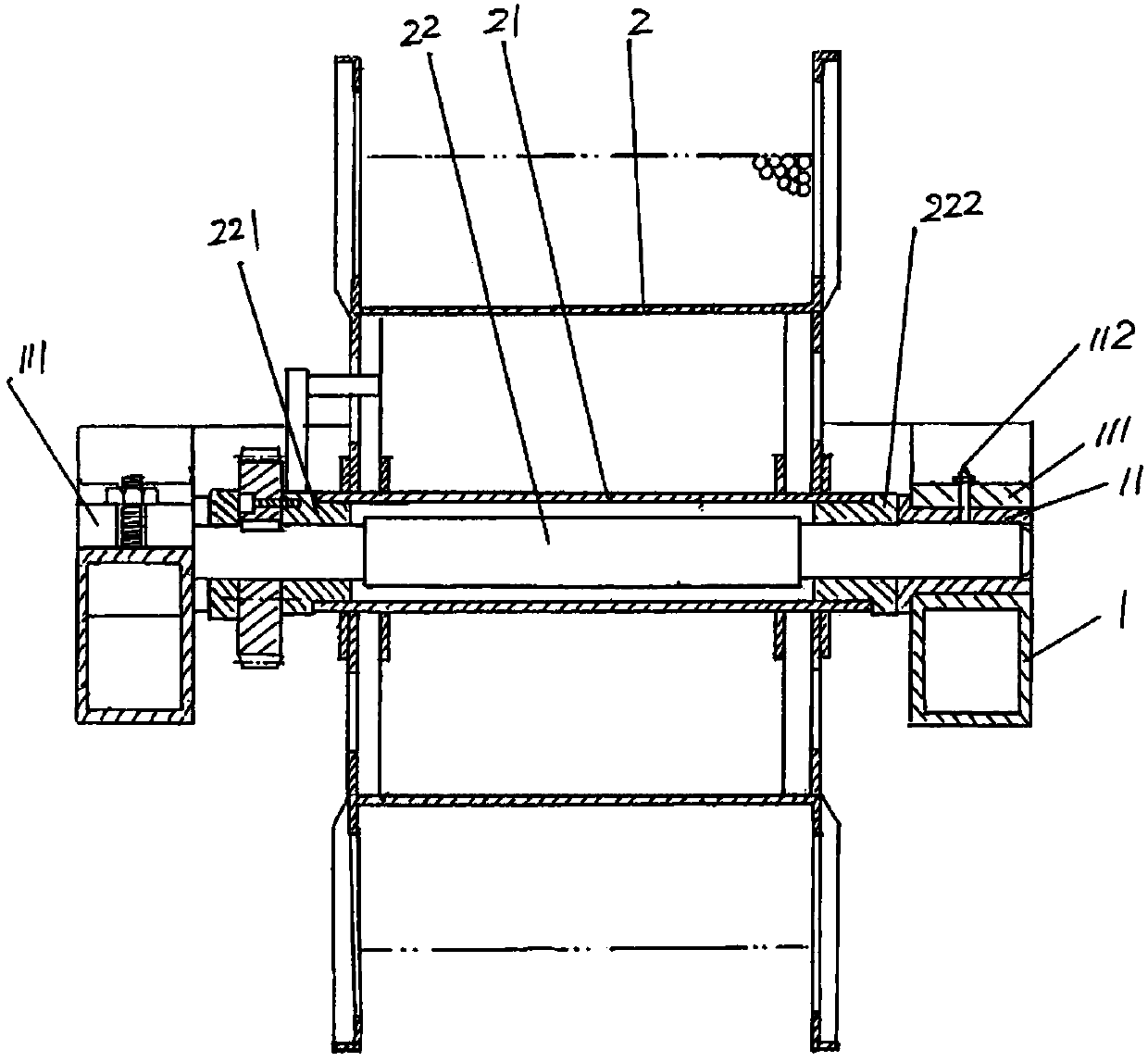

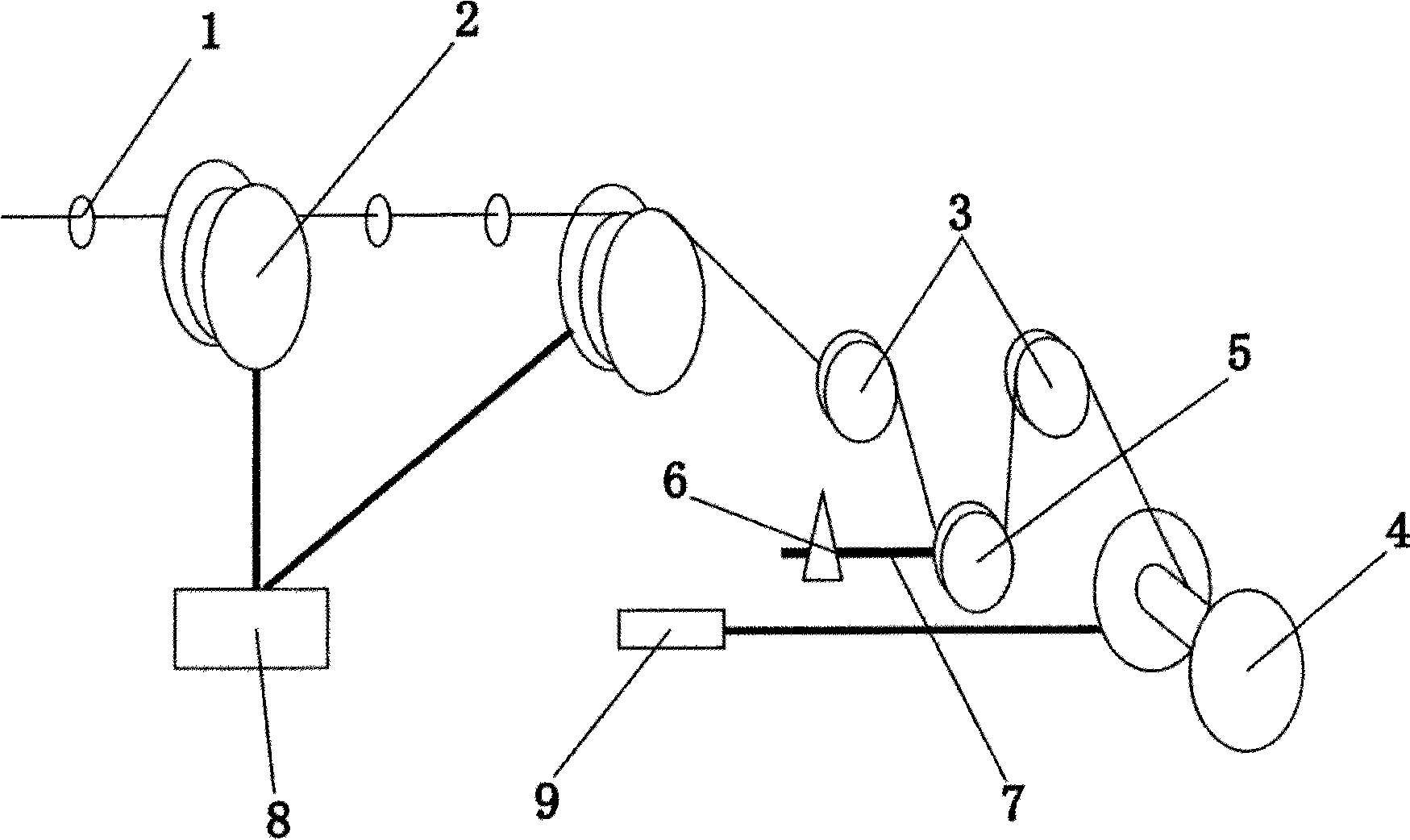

Coiled material conveying and tensioning device

ActiveCN102514968AAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

The invention discloses a coiled material conveying and tensioning device, which comprises a workbench support (1), and a first guide roller assembly (2), a second guide roller assembly (3), a tensioning guide roller assembly (4) and a tensioning guide roller support assembly (5) which are arranged on the workbench support, wherein the tensioning guide roller support assembly is arranged between the first guide roller assembly and the second guide roller assembly; the tensioning guide roller assembly is erected on the tensioning guide roller support assembly; the tensioning guide roller assembly is positioned below the first guide roller assembly and the second guide roller assembly; the first guide roller assembly comprises a first guide roller; the second guide roller assembly comprises a second guide roller; the tensioning guide roller assembly comprises a tensioning guide roller; and a coiled material passes through the first guide roller, the tensioning guide roller and the second guide roller in turn to reach a tension state. The coiled material conveying and tensioning device has a simple structure and has the advantages of high response speed and capacity of automatically adjusting the tension of the coiled material at a feed end.

Owner:CHERY AUTOMOBILE CO LTD

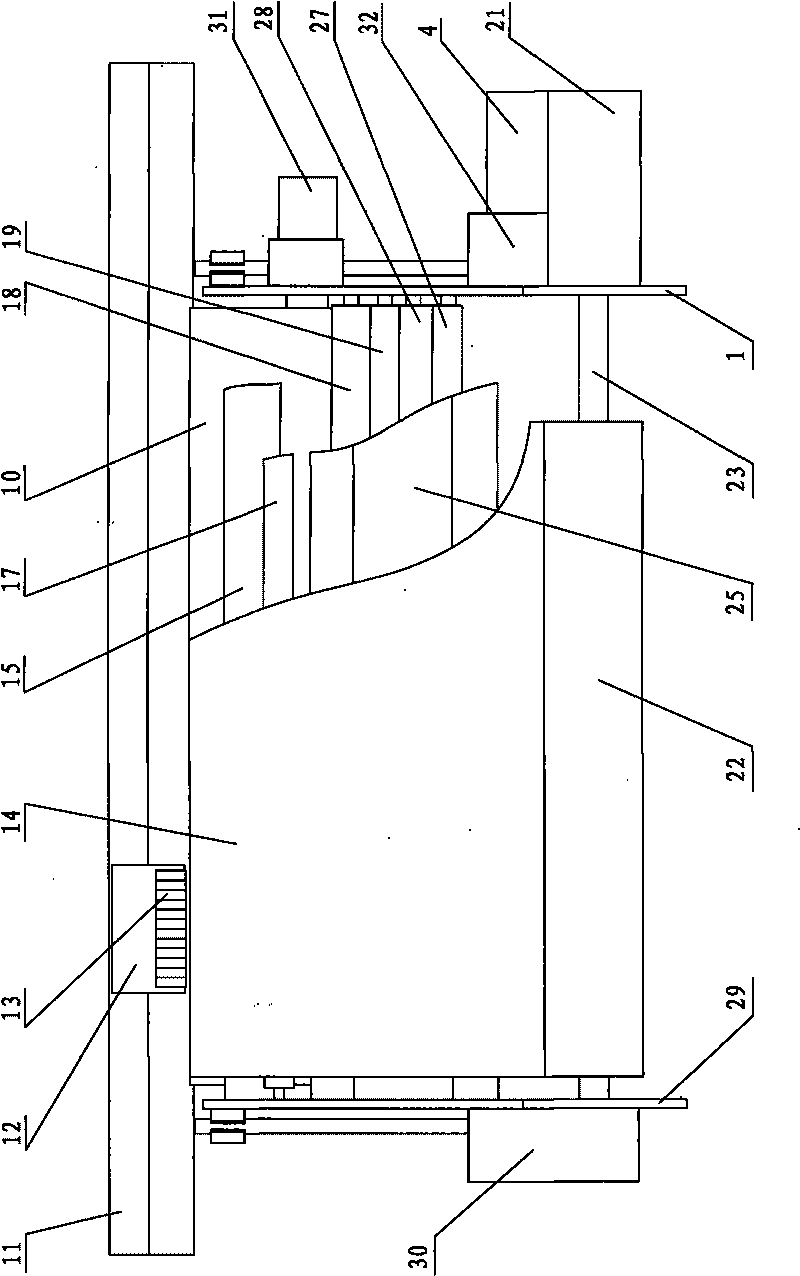

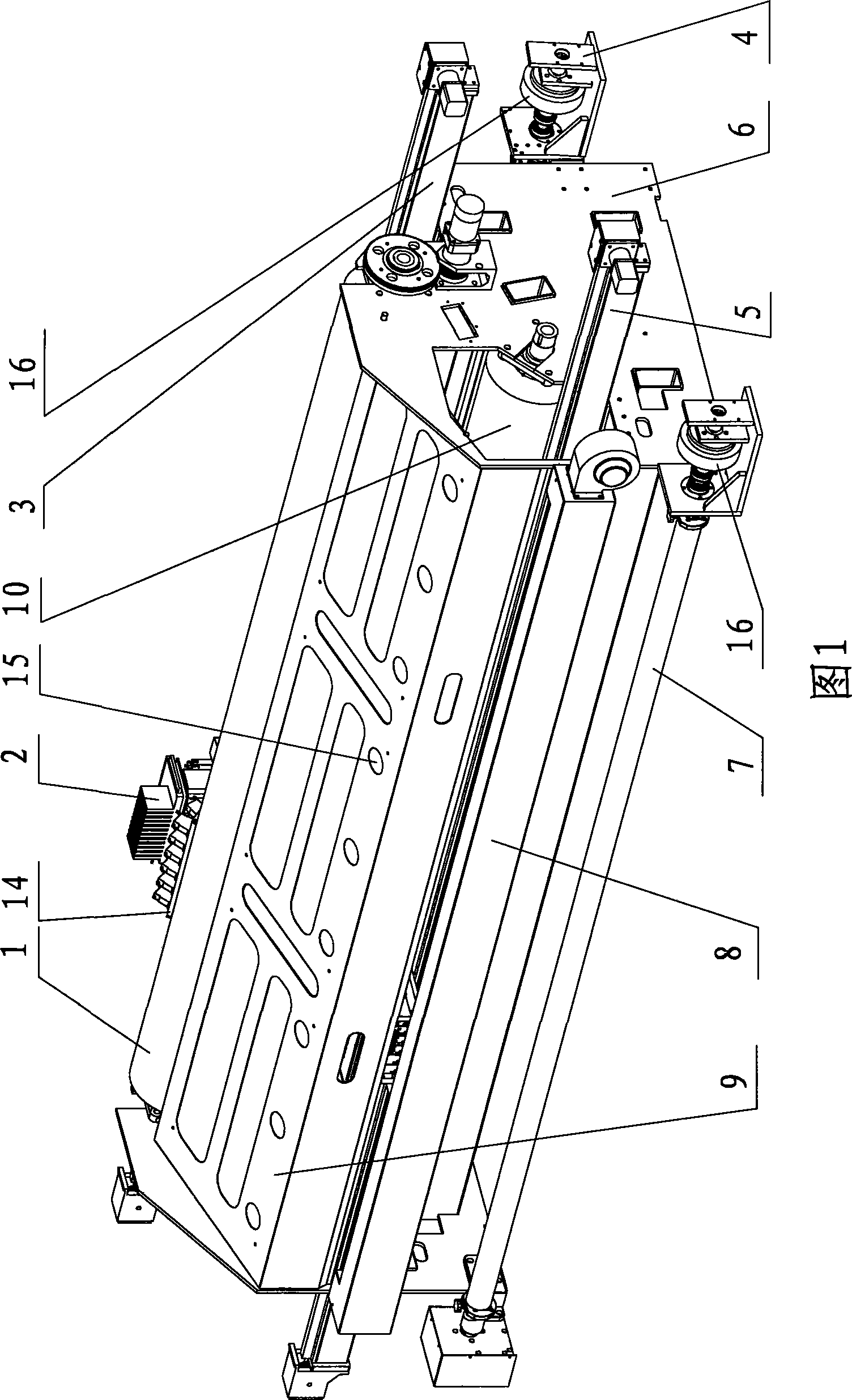

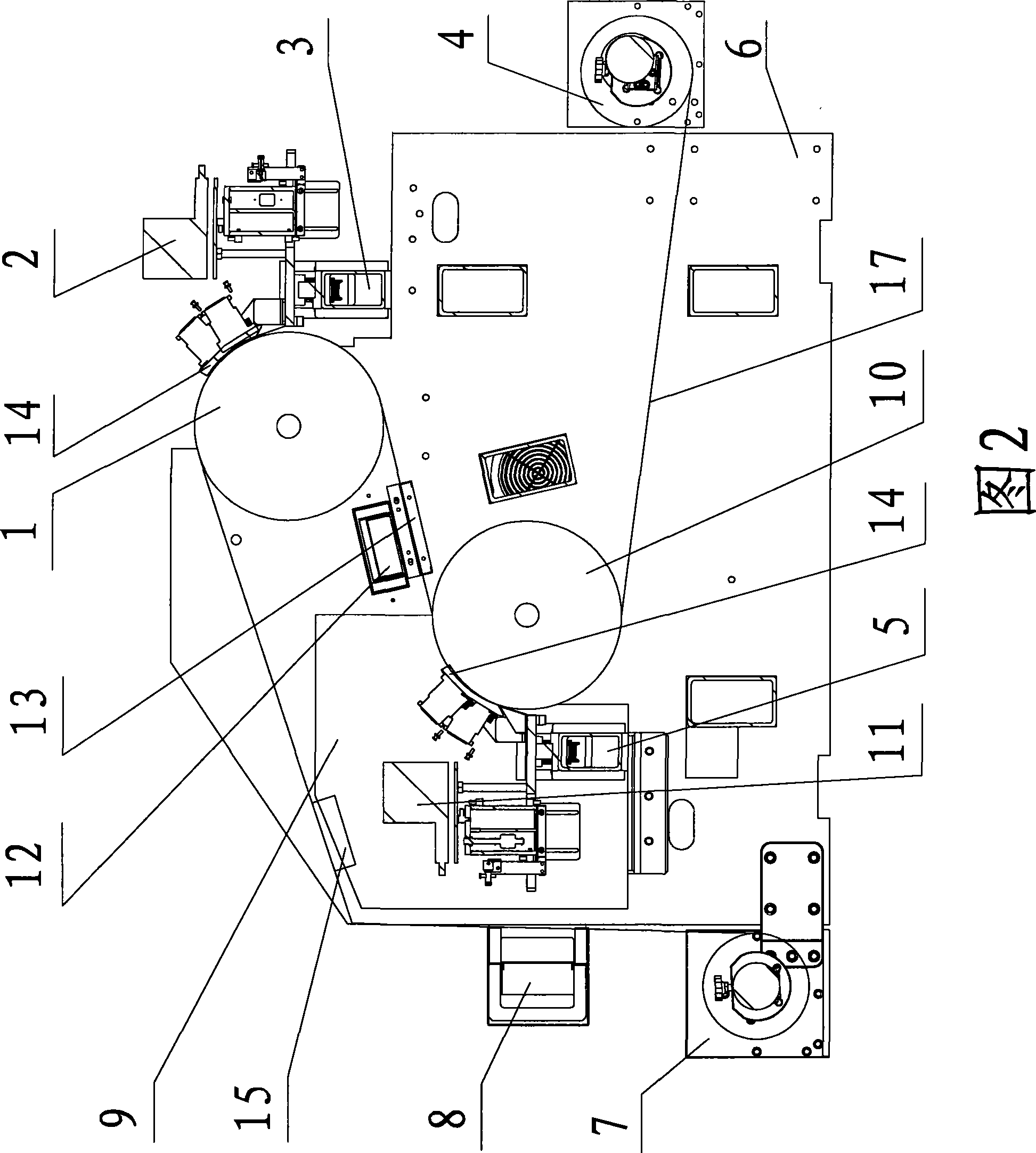

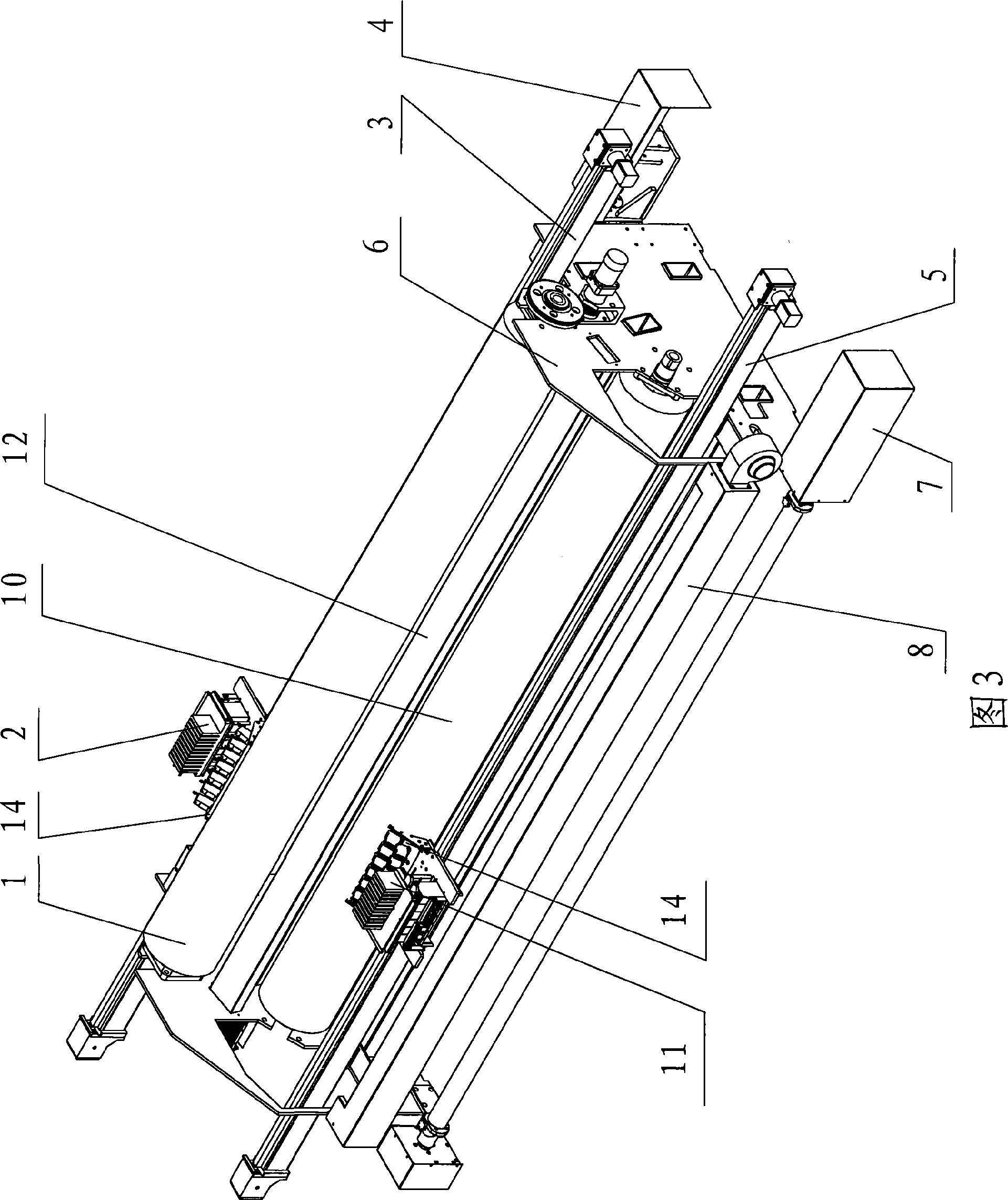

Digital ink-jet textile printing machine

InactiveCN101722723AEasy to processRealize printingTypewritersPower drive mechanismsTextile printerEngineering

The invention relates to textile printing equipment, in particular to a digital ink-jet textile printing machine capable of personalized jet printing. The digital ink-jet textile printing machine comprises a main driving roller used as a driving roll, a material feeding device, a material receiving device, a guide rail unit and a nozzle set unit, wherein the main driving roller, the material feeding device and the material receiving device are rotatably arranged between two parallel wall plates; the material receiving device and the material feeding device are respectively arranged at both sides of the main driving roller and parallel to the main driving roll; the guide rail unit is arranged on the wall plates at both sides with synchronous lifting; and the nozzle set unit is arranged above the main driving roller and can be arranged on the guide rail unit in a reciprocating way. The digital ink-jet textile printing machine has the advantages of good synchronism, high jet printing precision, wide jet printing material breadth, no pollution of jet printing materials and devices, long service life, wide application range, and the like.

Owner:梁健

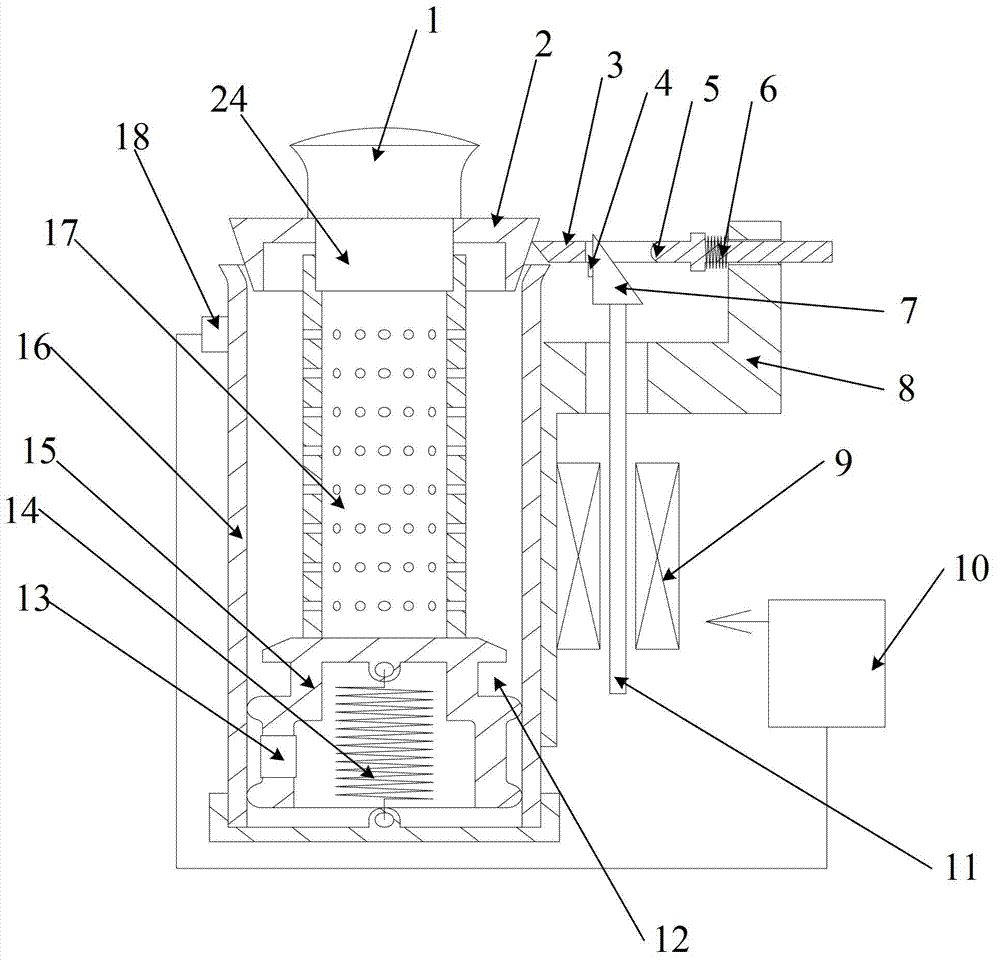

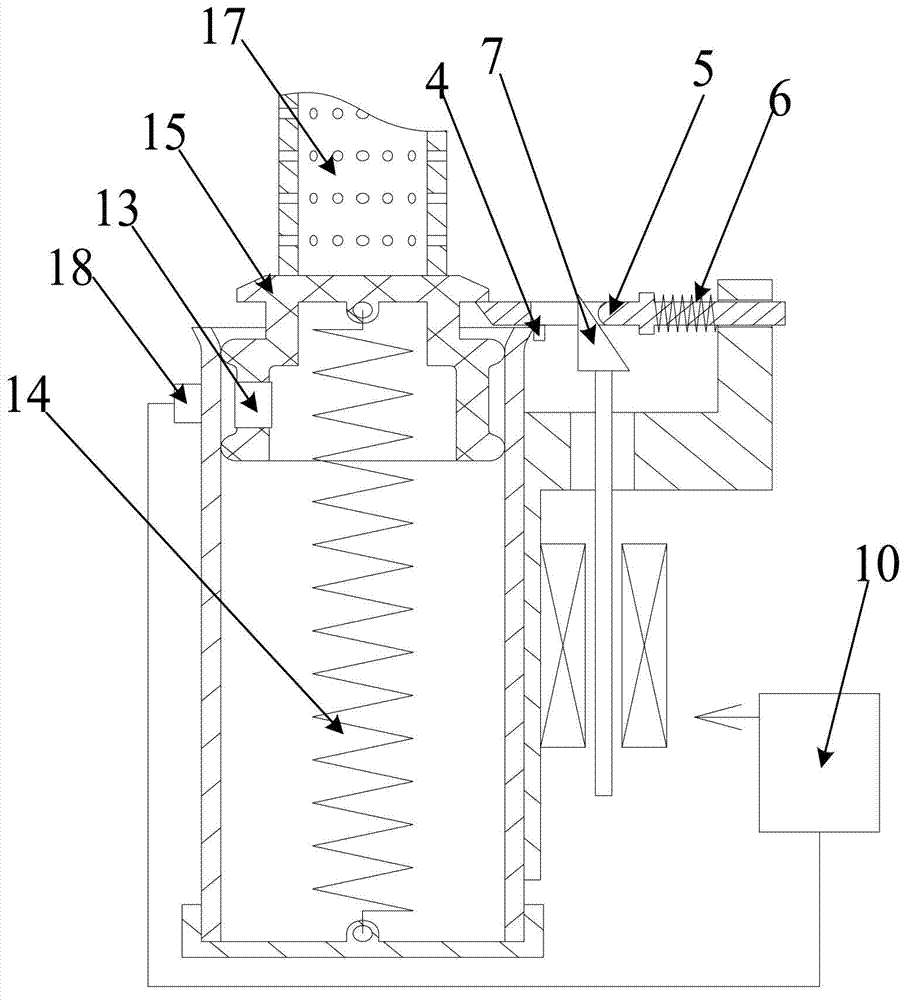

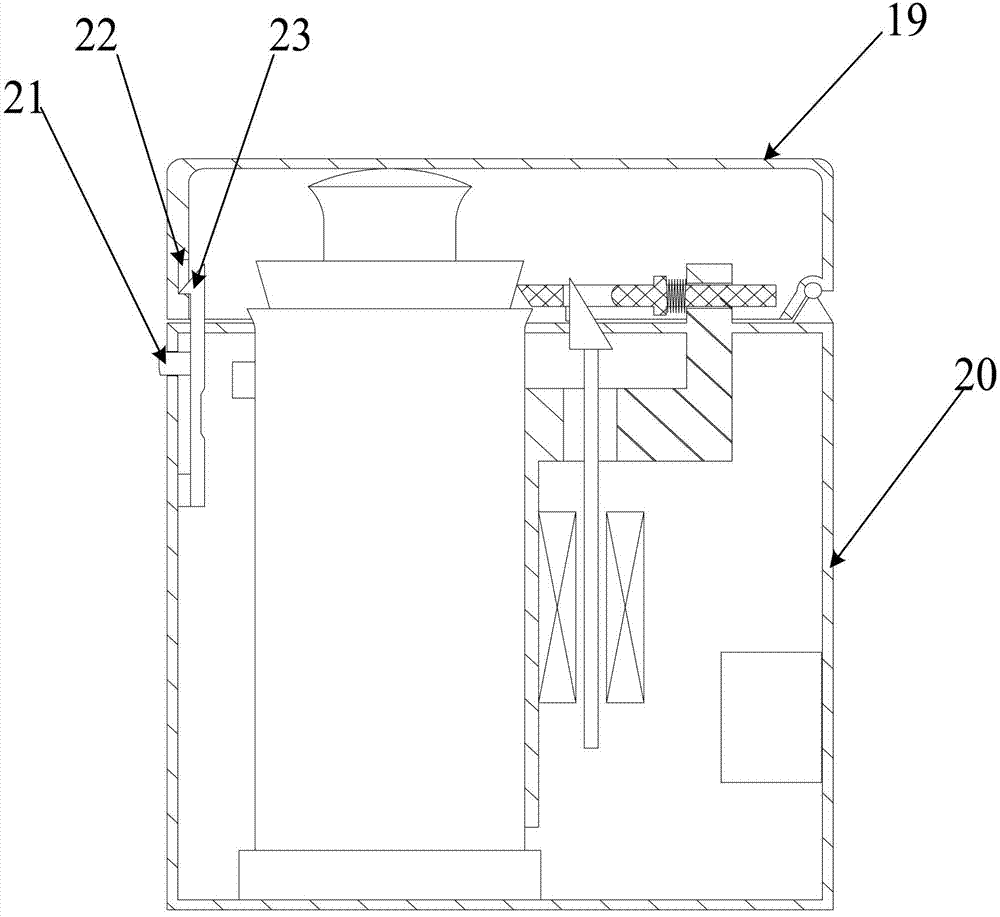

Timed passive air sampler

ActiveCN103033398AGuaranteed tensionAvoid contactWithdrawing sample devicesAutomatic controlEngineering

The invention discloses a timed passive air sampler, which comprises an air sampler main body, wherein the air sampler main body comprises a packaging barrel with an opening at the top, an adsorbent cage which is sheathed in the packaging barrel, a blocking pillar, an electromagnet and a timing driving circuit; a timing beginning sensor and a mounting bracket are arranged on the side wall of the packaging barrel; a rubber plug matched with the top of the packaging barrel is arranged at the top end of the adsorbent cage; a return spring is arranged between the bottom of the adsorbent cage and the bottom of the packaging barrel; a bayonet which can be pulled out to expose the packaging barrel and a sensing body corresponding to the timing beginning sensor are arranged on the adsorbent barrel; the blocking pillar is arranged on the mounting bracket and can move in the radial direction of the packaging barrel and be matched with the bayonet; the electromagnet is arranged on the outer wall of the bracket of the packaging barrel and can control the blocking pillar to be departed from the bayonet; and the timing driving circuit is connected with the timing beginning sensor and the electromagnet. The timed passive air sampler can implement the accurate automatic control of the sampling time, automatic packaging, and effectively improve the sampling accuracy of the passive air sampler.

Owner:SHENZHEN INST OF BUILDING RES

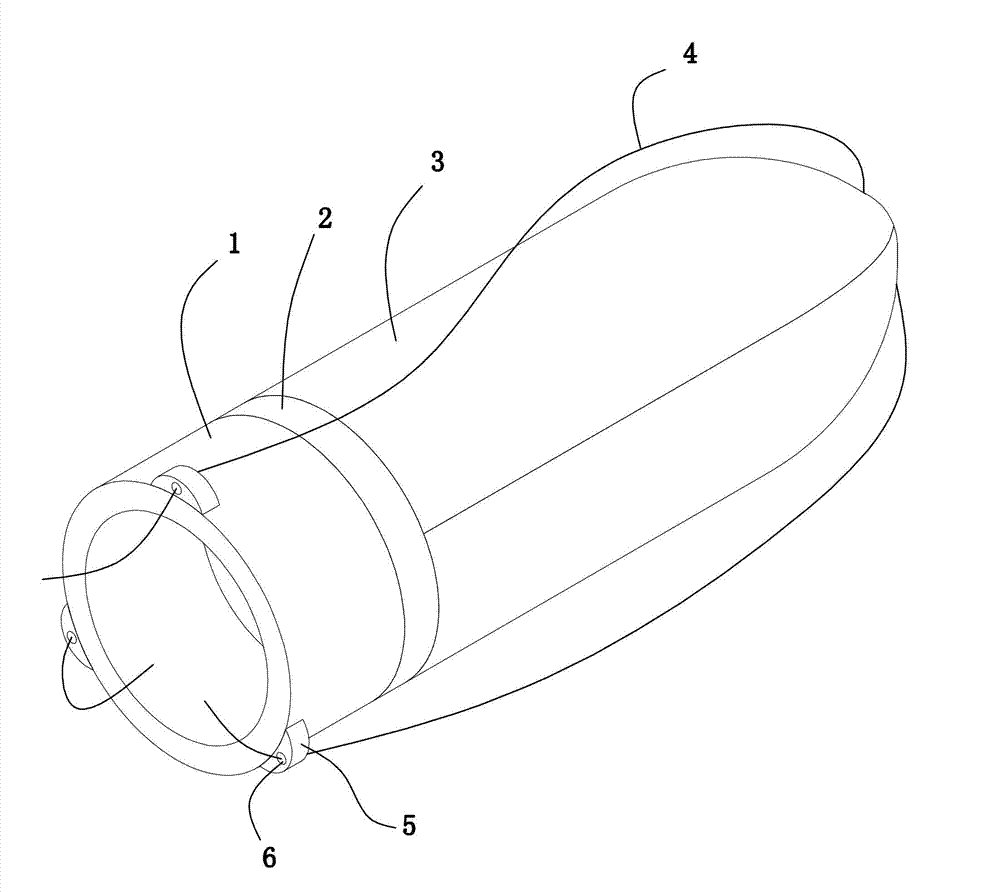

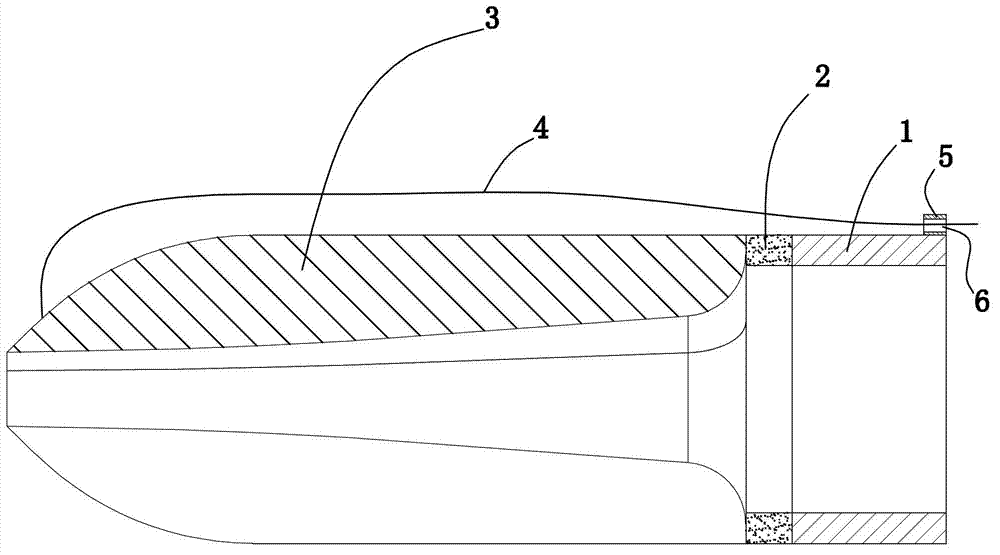

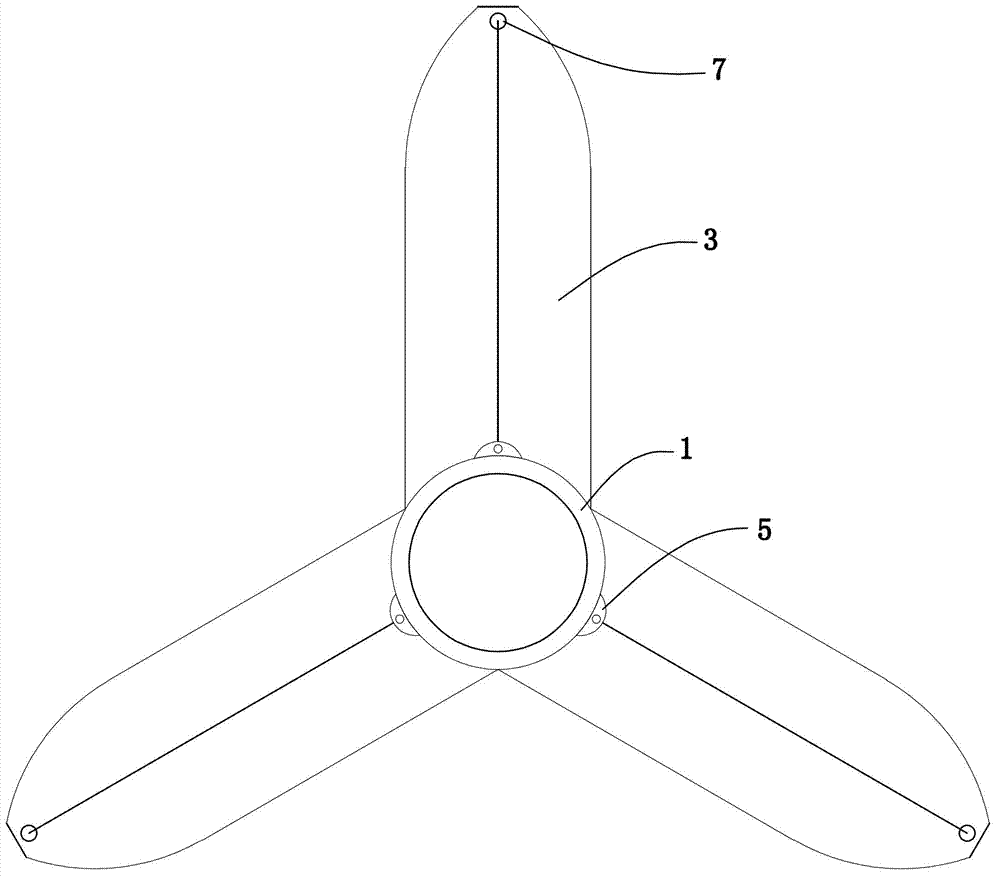

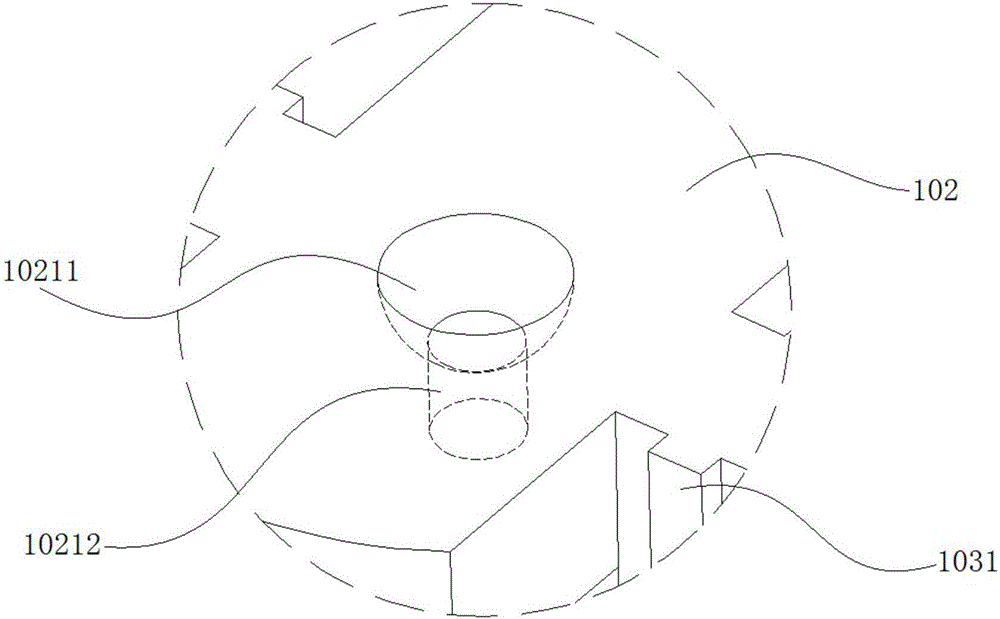

Pneumoperitoneum-free peritoneoscope suspending type abdominal wall puncture device

InactiveCN102846343AAvoid obstructionPain reliefCannulasSurgical needlesPERITONEOSCOPEAbdominal wall

The invention relates to a pneumoperitoneum-free peritoneoscope suspending type abdominal wall puncture device, and overcomes the defect that secondary trauma occurs easily to patients by using a kirschner pin to puncture into abdominal walls to suspend the abdominal walls. The puncture device comprises a sleeve and a plurality of supporting arms arranged on the sleeve in a central radial shape, wherein a deformation portion is connected to the end portion of the sleeve and connected with the supporting arms; and one ends of pull ropes are fixed on the end portion of the supporting arms, lugs with rope holes are arranged on the sleeve away from the deformation portion, and the other ends of the pull ropes penetrate through the rope holes in the lugs to be fixed on the outer portion of the abdominal wall. A supporting surface is arranged after the supporting arm is opened, and a barrel-shaped space is formed after the supporting arm is suspended, so that enough surgical fields are provided during the surgery; and the supporting arm of the puncture device is inserted from a cut of the abdominal wall and is opened gradually, so that the kirschner pin is not needed to perform puncture and suspension, the secondary trauma is prevented, and the puncture device is helpful for alleviating traumatic pains of patients.

Owner:王小军

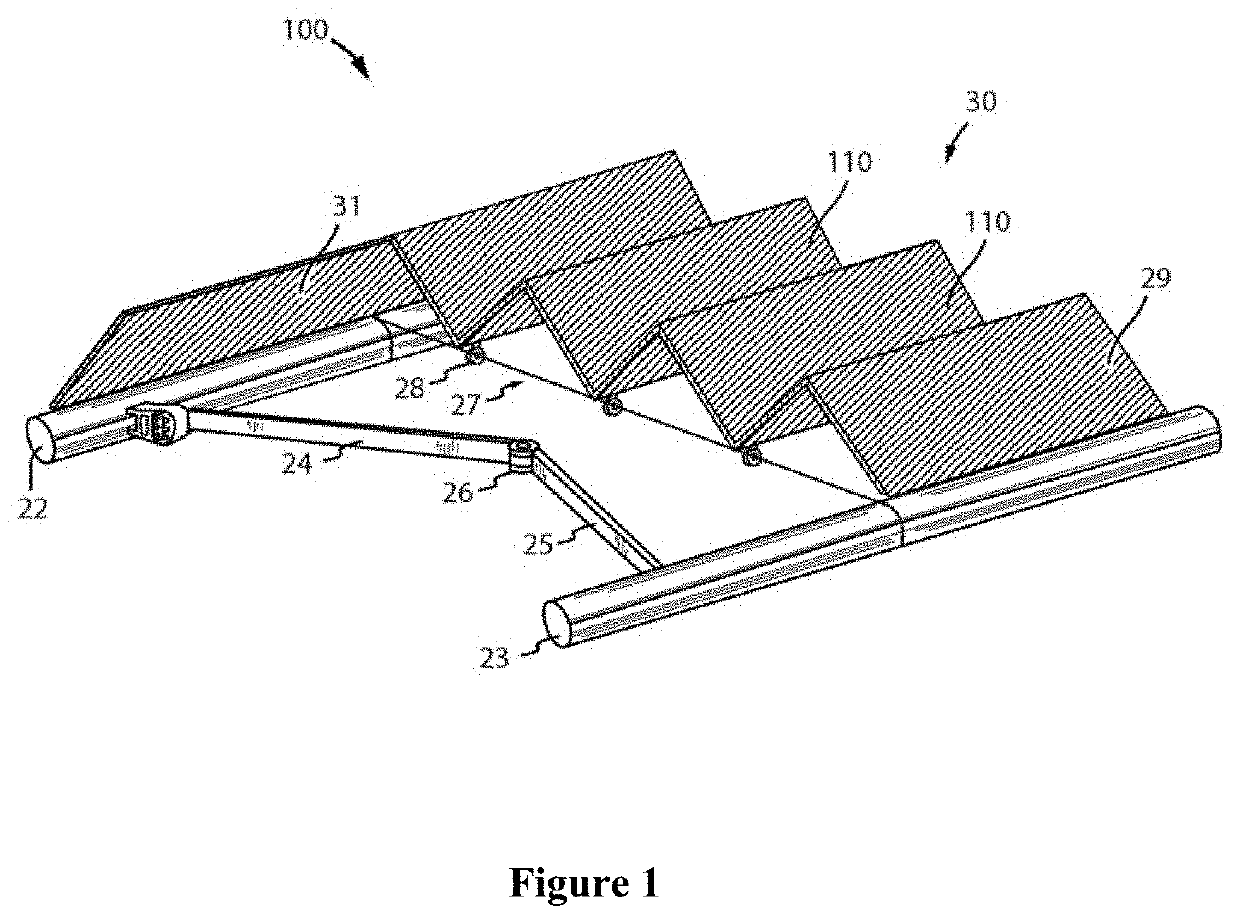

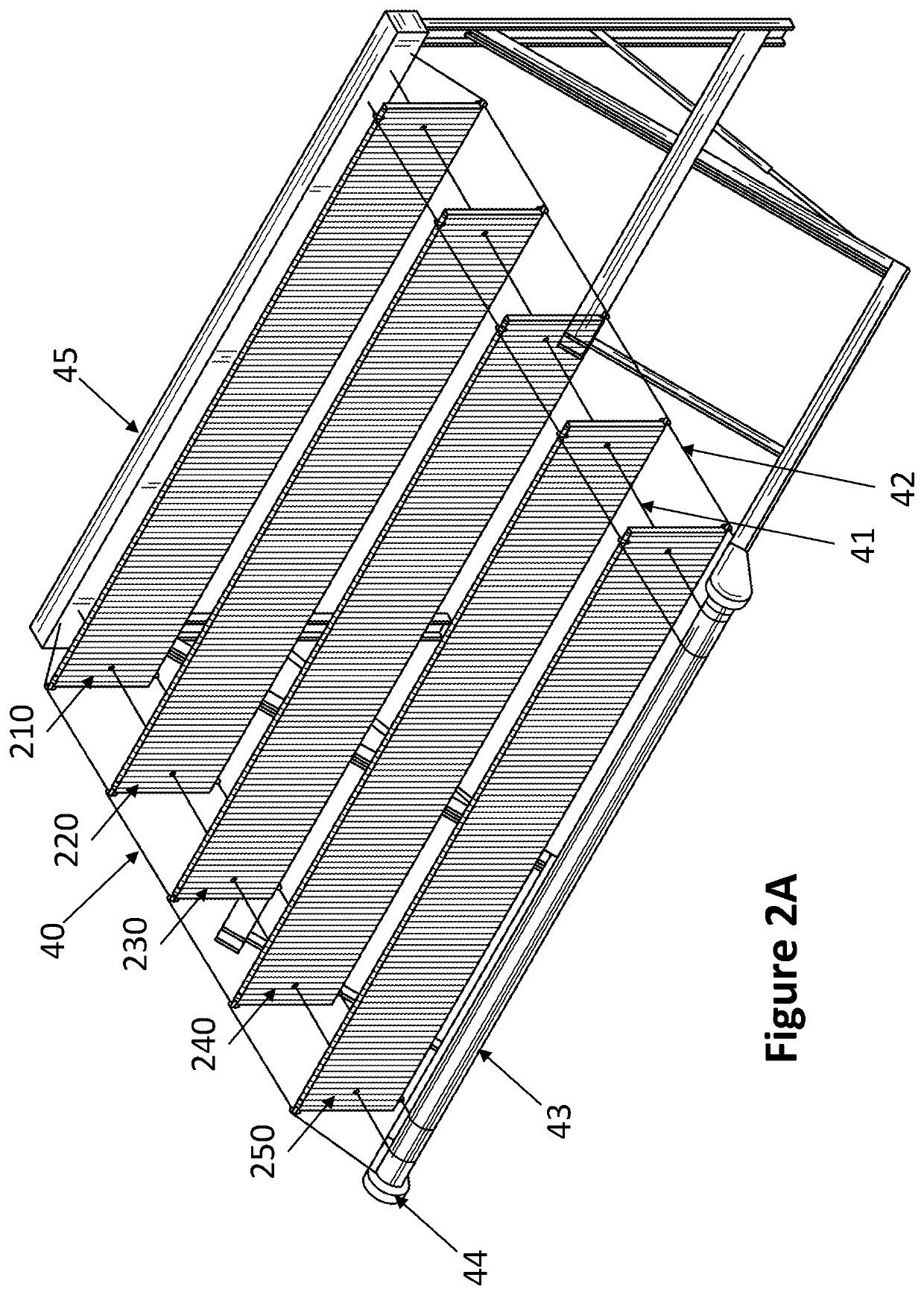

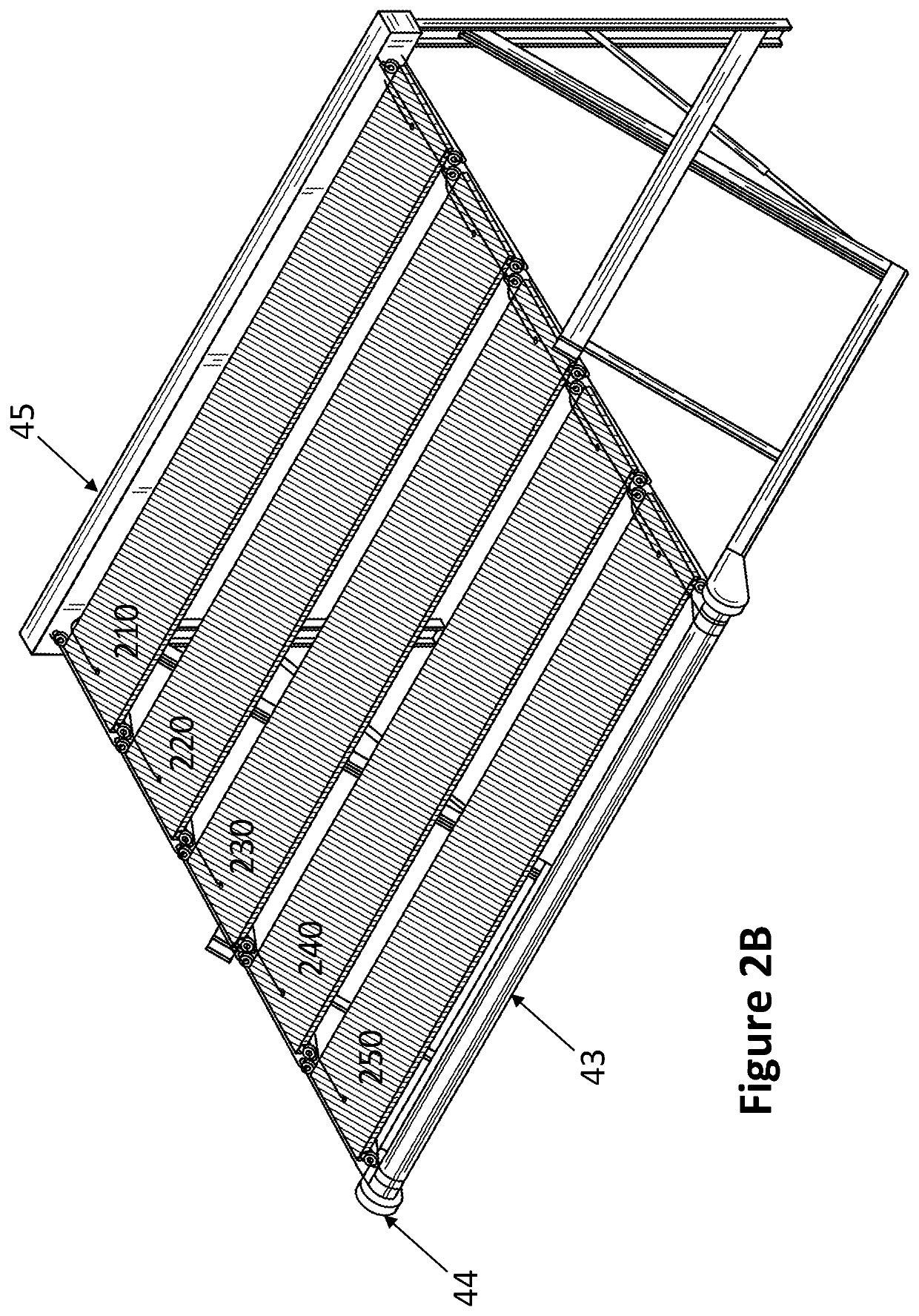

Innovative Energy Generating Photovoltaic Awning

ActiveUS20190386606A1Tension on the wire is constantGuaranteed tensionPhotovoltaic supportsSunshadesAwningArm moving

Apparatus, systems and methods are provided for solar awnings or canopies that include rigid solar modules, for example photovoltaic cells or panels. The awnings have solar modules or panels stacked together substantially vertically (e.g., each module is oriented vertically with respect to the next module). The solar modules in the stack are interconnected to each other, such that each solar module is connected electrically and mechanically to adjacent solar modules. The first solar module in the stack of modules is fixed to one end of the base of the awning. The base of the awning is typically mounted to a building, vehicle, mobile home, or other appropriate structure. The last solar module in the stack is attached to a lead arm of the awning. The lead arm moves back and forth (e.g., away and toward) from the base of the awning to enable the expansion or retraction of the awning.

Owner:EVOLUSUN INC

Synchronous two-sided digital ink-jet machine

InactiveCN101439620AWidth limitEnsure printing accuracyTypewritersOther printing apparatusEngineeringMechanical engineering

The invention relates to an inkjet printing device, in particular to a synchronous double-face digital inkjet printing machine which can realize individual inkjet printing without printing width limitation. The device comprises a wall plate, a cloth takeup and placing device which is arranged on the wall plate, an auxiliary inkjet printing roll with the same diameter as a main inkjet printing roll is alternately arranged with the main inkjet printing roll between the wall plates, and the auxiliary inkjet printing roll is driven by the main inkjet printing roll through a material to be printed; the printing material winds the main inkjet printing roll and the auxiliary inkjet printing roll with the front face and the rear face contacting the main inkjet printing roll and the auxiliary inkjet printing roll respectively, and a bearing plate is arranged below the material to be printed between the inkjet printing rolls; one sides of the main inkjet printing roll and the auxiliary inkjet printing roll are equipped with an upper jet head set and a lower jet head set which can reciprocate and an ink supply larry. The jet head sets can horizontally reciprocate for inkjet printing, can print wide printing materials without limitation by the width of the jet head sets; the material to be printed always wind the inkjet printing rolls at the front printing point and the rear printing point without warping and buckling, and the jet heads get close to the material to be printed; the main inkjet printing roll drives the auxiliary inkjet printing roll, which ensures the inkjet printing precision of the two faces.

Owner:沈阳飞图印花科技有限公司

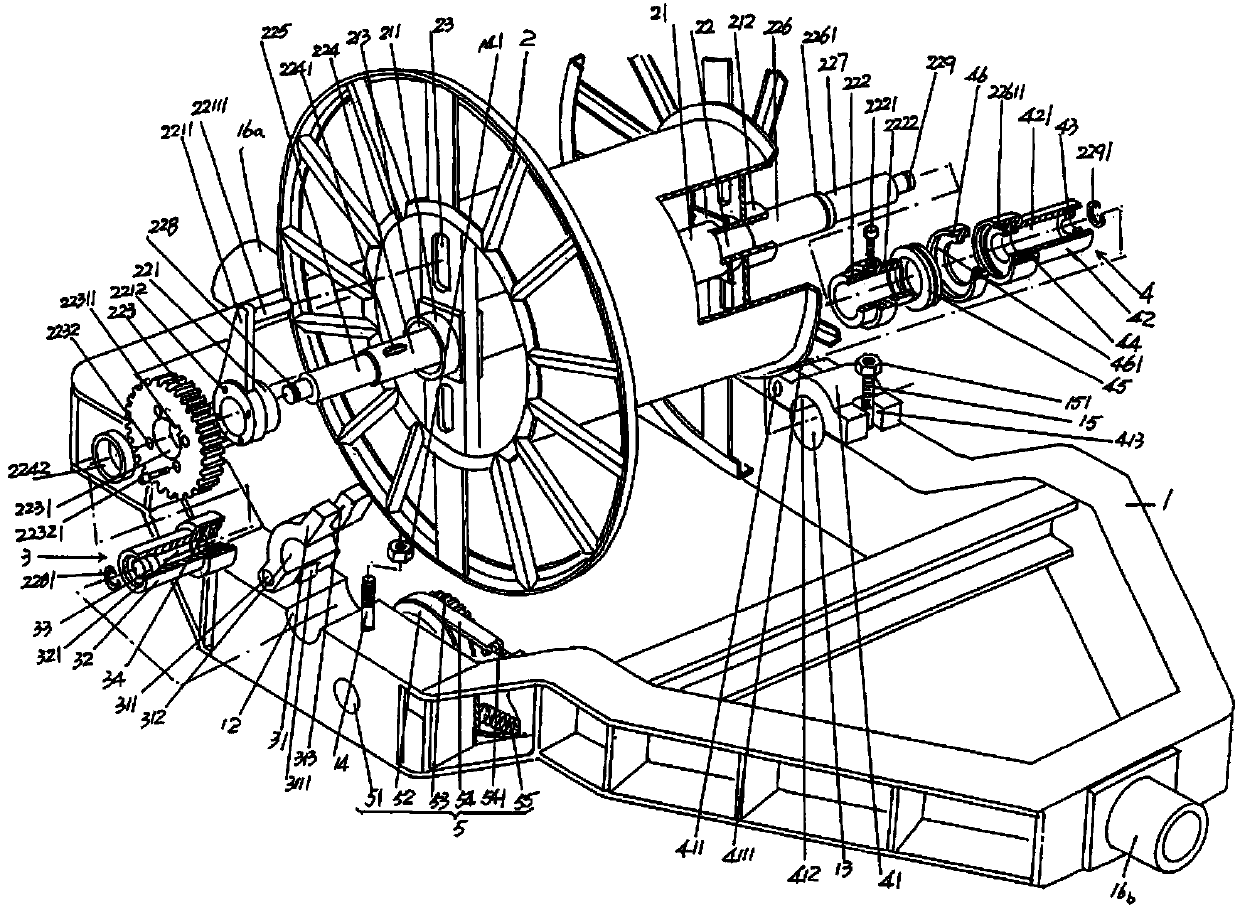

Cradle and pay-off reel structure of cable-former stranding cage device

The invention discloses a cradle and pay-off reel structure of a cable-former stranding cage device and belongs to the technical field of electric wire and cable processing facilities. The cradle and pay-off reel structure of the cable-former stranding cage device comprises a cradle and a pay-off reel. The center of the pay-off reel is provided with a pay-off reel center shaft sleeve; one end of the pay-off reel center shaft sleeve forms an outer centring sleeve matching end; the other end of the pay-off reel center shaft sleeve forms an inner centring sleeve matching end; a pay-off reel center shaft outer centring sleeve is provided with a damping arm; the damping arm is fixedly provided with a deflector rod; a pay-off reel center shaft is fixedly provided with a damping gear. The cradle and pay-off reel structure of the cable-former stranding cage device is characterized in that one side of the cradle is provided with a pay-off reel center shaft outer pivotal bearing mechanism; the other side of the cradle is provided with a pay-off reel center shaft inner pivotal bearing mechanism; one end of the pay-off reel center shaft is supported to the pay-off reel center shaft outer pivotal bearing mechanism; the other end of the pay-off reel center shaft is supported to the pay-off reel center shaft inner pivotal bearing mechanism; one side of the cradle is provided with a damping gear regulating mechanism; the damping gear is matched with the damping gear regulating mechanism. The cost of spare parts is reduced, the working strength is reduced, the cabling efficiency is improved, and the tension of a lead released from the pay-off reel is ensured.

Owner:CHANGSHU CABLE WORKS

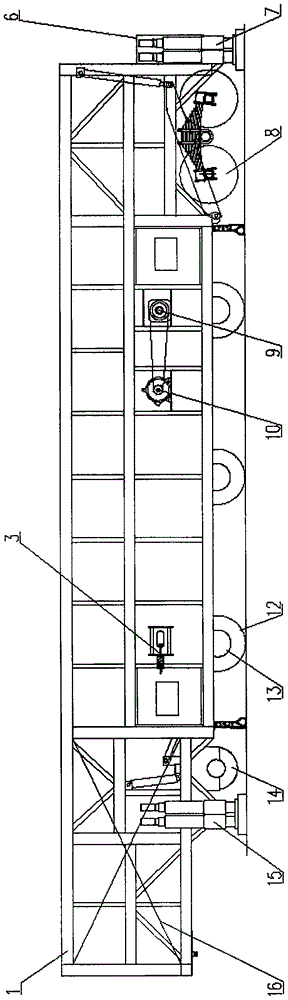

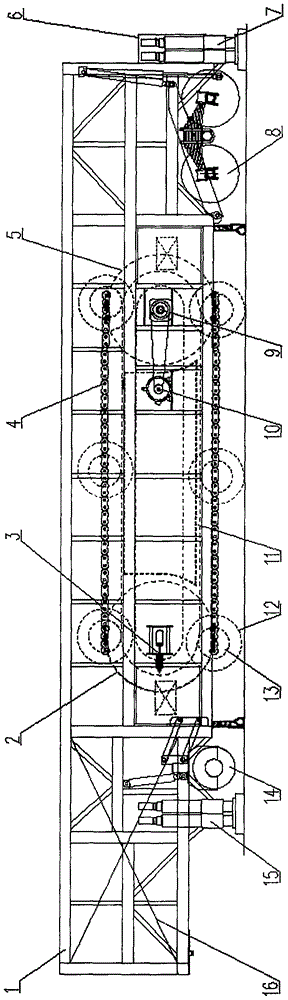

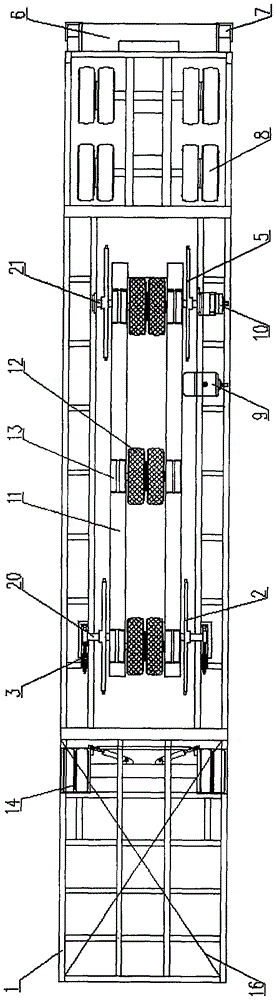

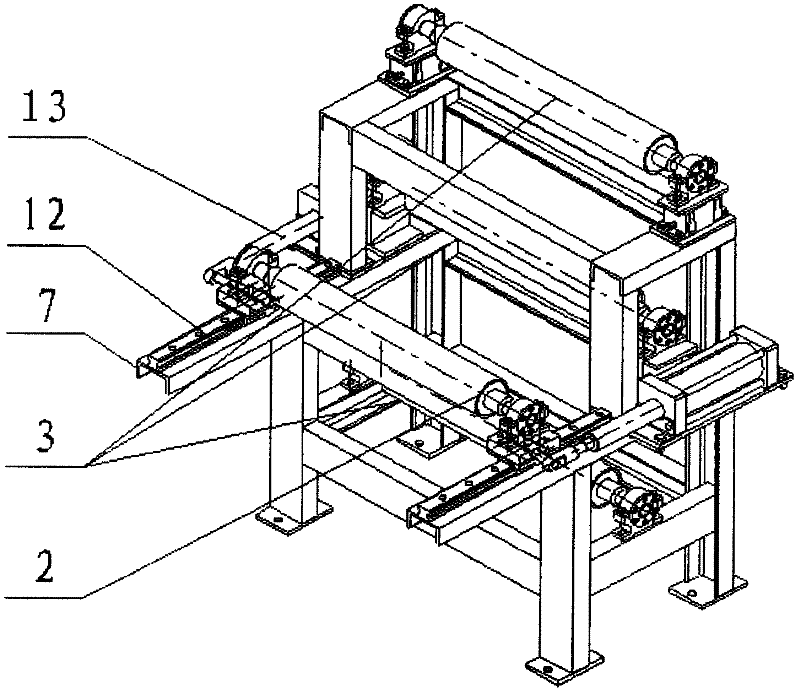

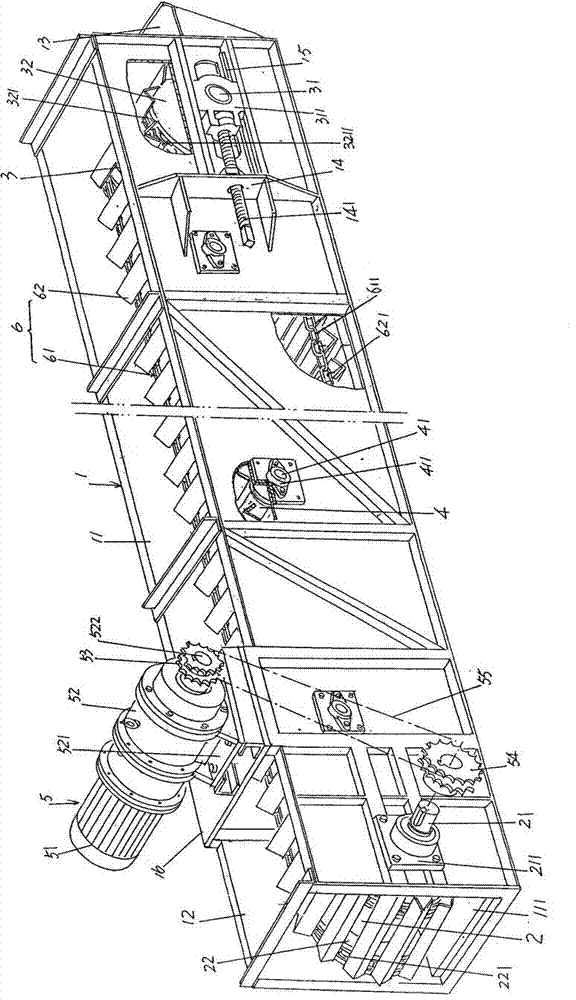

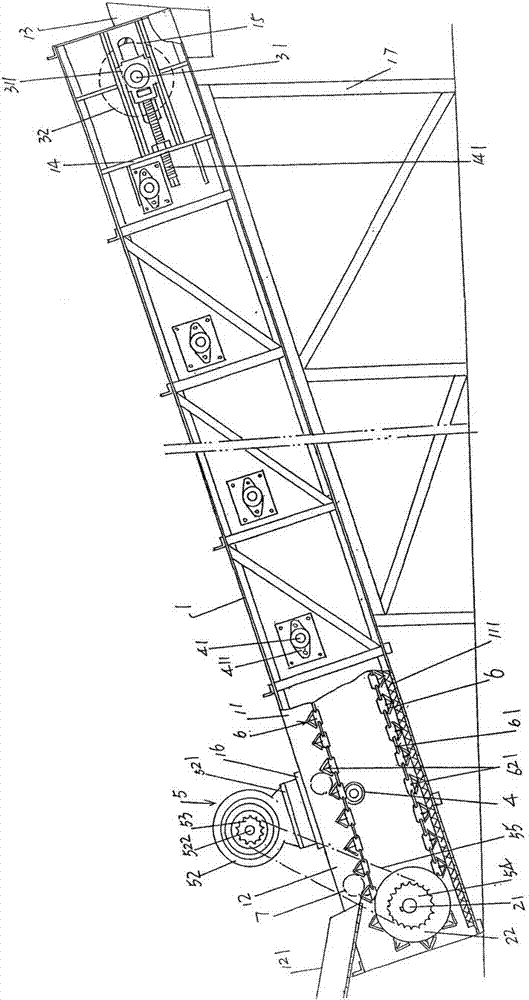

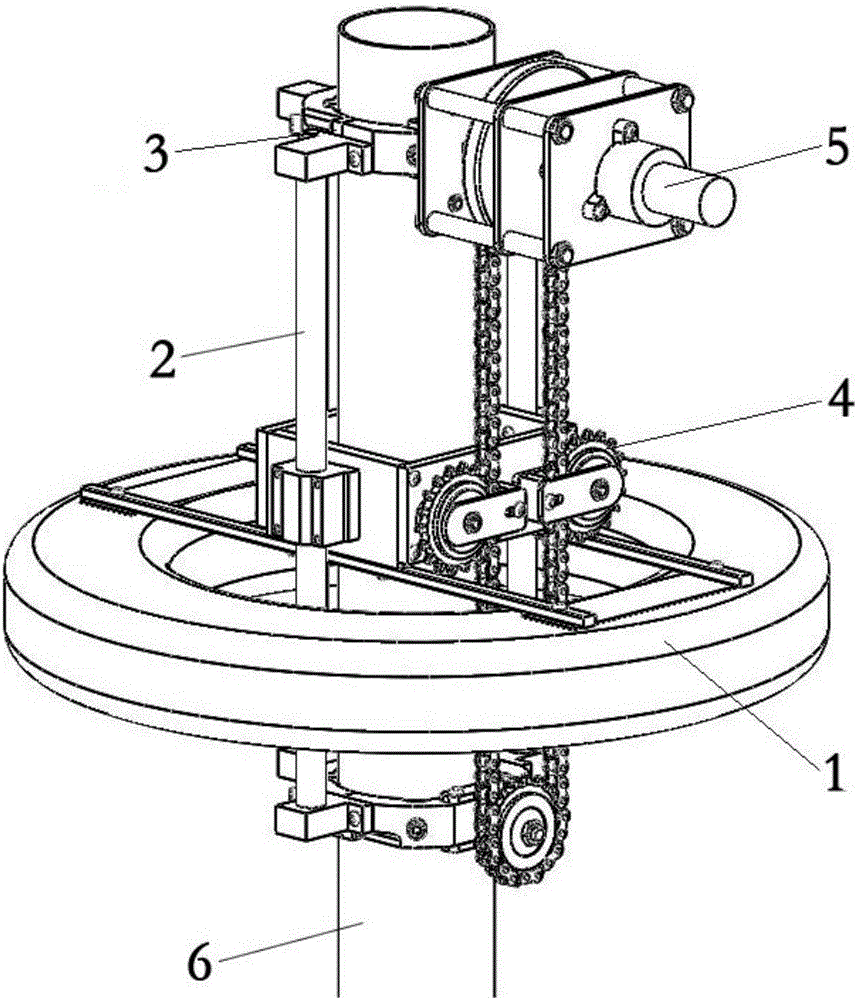

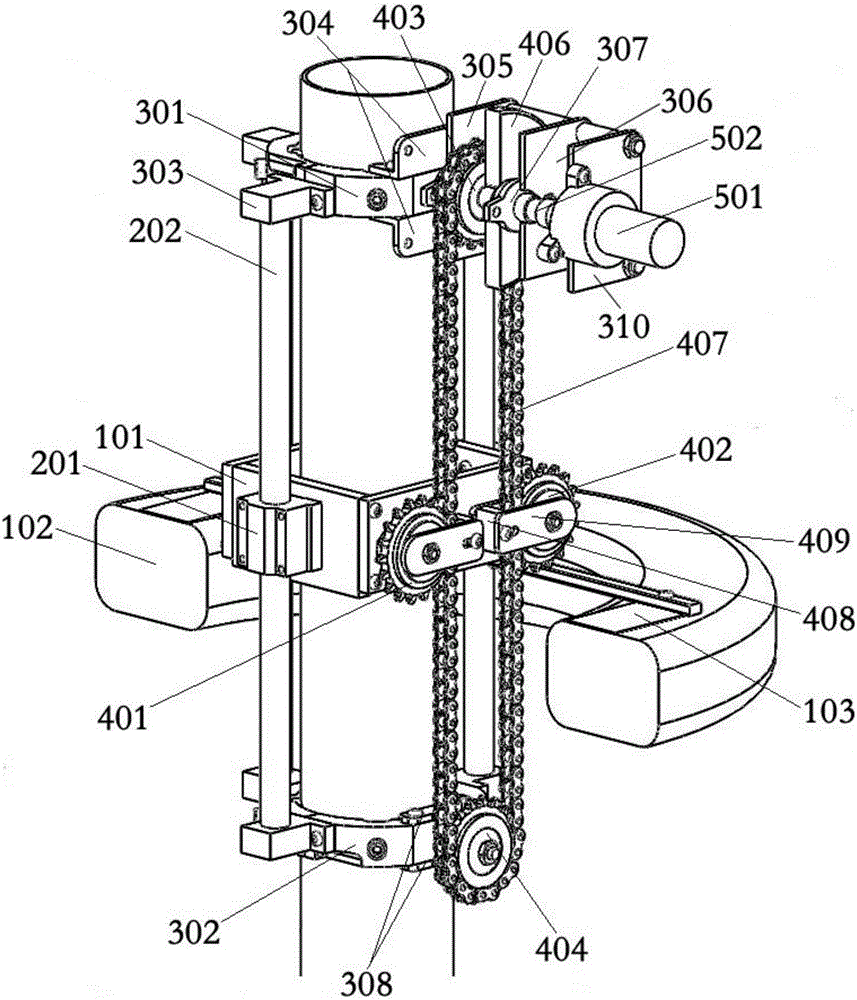

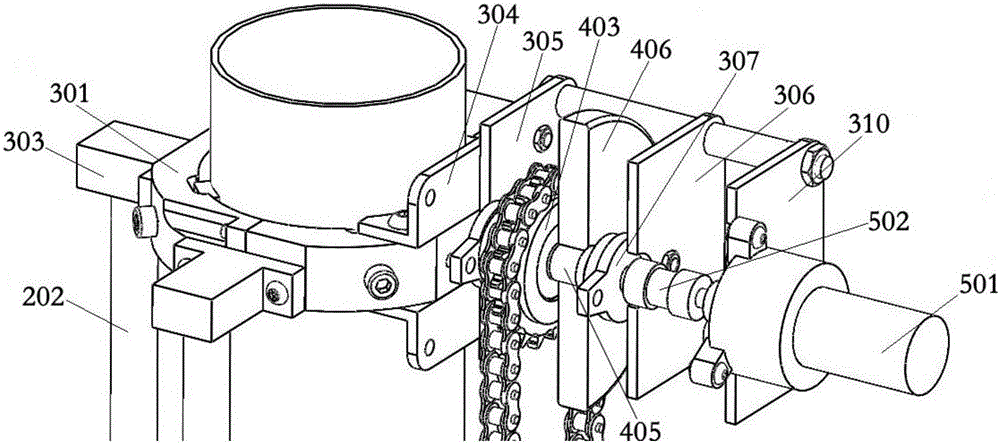

Full-scale-movement linear circulating accelerated loading test system

PendingCN106769558AImprove efficiencyReduce distanceMaterial strength using repeated/pulsating forcesShock testingStress conditionsFull scale

The invention provides a full-scale-movement linear circulating accelerated loading test system. The full-scale-movement linear circulating accelerated loading test system comprises a machine frame, a guide rail, two or more rolling wheel sets and two chain transmission pairs, wherein a front walking and guiding wheel and a back walking wheel are fixed to the lower part of the machine frame through a lifting mechanism; the guide rail is arranged on the machine frame; the upper loading surface of the guide rail is a linear section; the lower loading surface of the guide rail is shaped like a boat bottom; the two ends of the upper loading surface and the lower loading surface are connected in smooth transition through curved sections; the guide rail adopts a box-type structure and is internally filled with a shock-absorbing material; each rolling wheel set comprises two loading wheels and a rolling wheel; the rolling wheel is positioned between the two loading wheels and is coaxial with the loading wheels. The full-scale-movement linear circulating accelerated loading test system adopts a design scheme that the chain transmission pairs drive the rolling wheel sets, a chain and the rolling wheel sets are assembled together through chain pin shafts and connecting components, and the axes of wheel axles of the rolling wheel sets are vertical to and intersected with the longitudinal centerline of the chain; the full-scale-movement linear circulating accelerated loading test system is simple in structure, high in reliability and low in using cost and maintenance cost; the distance from the loading wheel to the rolling wheel is small, the stress condition is good, noise is low, and the efficiency is high.

Owner:SHANDONG JIAOTONG UNIV

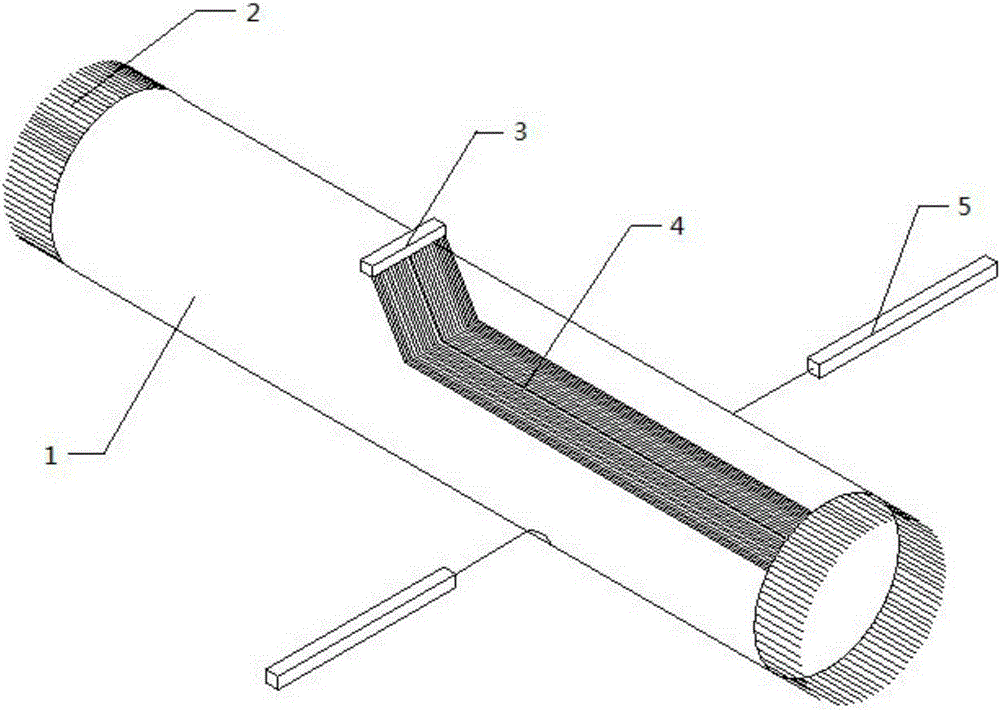

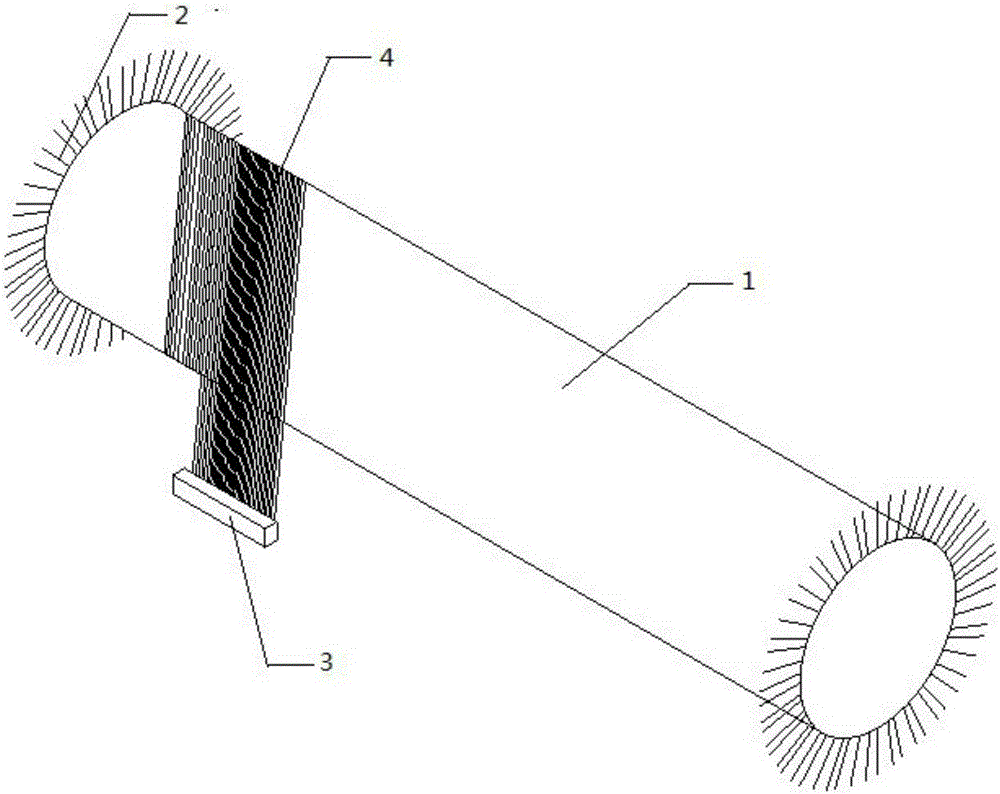

Manufacturing method for glass steel pipeline in zero-degree winding manner

The invention discloses a manufacturing method for a glass steel pipeline in a zero-degree winding manner. The method sequentially comprises the steps that winding yarn immersed in resin is used for hoop winding, then, a wire guiding head drives the winding yarn to pass multi-tooth comb rings buckled at the two ends of a core die to be axially wound, finally, winding yarn immersed in resin is in hoop winding again to stabilize an axial winding layer, hoop and axial winding is repeated, and pipeline winding with different strength requirements is achieved. Continuous winding of the axial zero degree of the winding yarn and pipelines is achieved, the axial mechanical performance of the pipelines is optimal, and then the high requirement of industrial fields for the axial performance can be met. The required axial strength is achieved, the production cost is reduced to the maximum degree, meanwhile, the pipeline thickness is reduced, and the pipelines are convenient to transport and use.

Owner:HEBEI HAOZHENG NON METALLIC MATERIALS TESTING SERVICES CO LTD

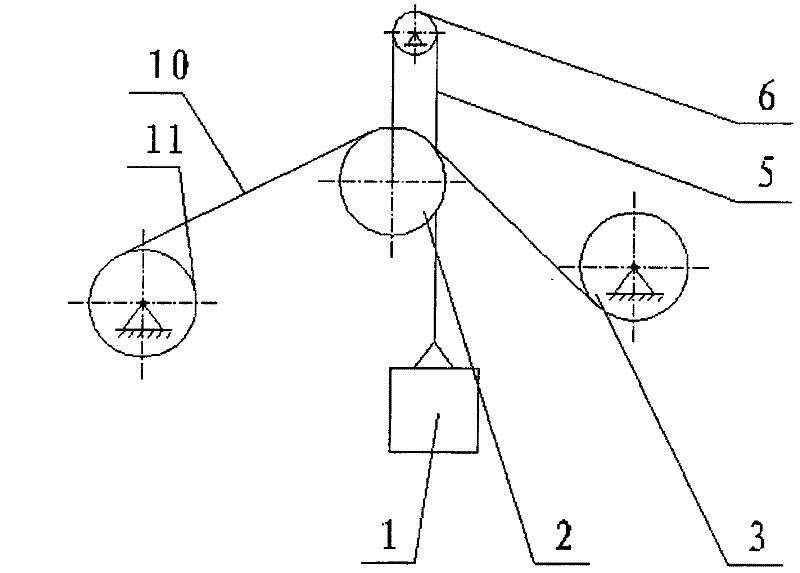

Tension adjusting mechanism for copper foil surface treating machine

The invention relates to a tension adjusting mechanism for a copper foil surface treating machine; an upper bracket is fixed on the upper surface of a lower bracket; a guide roller is arranged in the middle of the upper surface of the lower bracket; a counterweight roller is positioned at one side of a tension adjusting roller and below the longitudinal beam of the lower bracket; the counterweight roller is hung at one end of a steel wire rope by virtue of fixed pulleys; the tension adjusting roller is positioned at the other side of the counterweight roller and above the longitudinal beam of the lower bracket; the tension adjusting roller is arranged on guide rod fixing seats positioned on the upper surface of the lower bracket; the pair of fixed pulleys are respectively arranged on the upper surface of a longitudinal beam of the upper bracket; the pair of guide rod fixing seats are respectively positioned on the upper surface of the lower bracket and the lower surface of the longitudinal beam of the upper bracket; and the positions of the two guide rod fixing seats correspond to each other. The tensile force generated by the gravity of a counterweight block is direct, and a copper foil is ensured to be tensioned since the change of the tensile force generated by the instant relaxation and tension of the copper foil can be made up by the movement of the tension adjusting roller at any time, so that the tensile force of the rolled copper foil is guaranteed to be constant. The tension adjusting mechanism has the characteristics of being simple in processing and installing as well as simple and convenient to operate, control and use.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

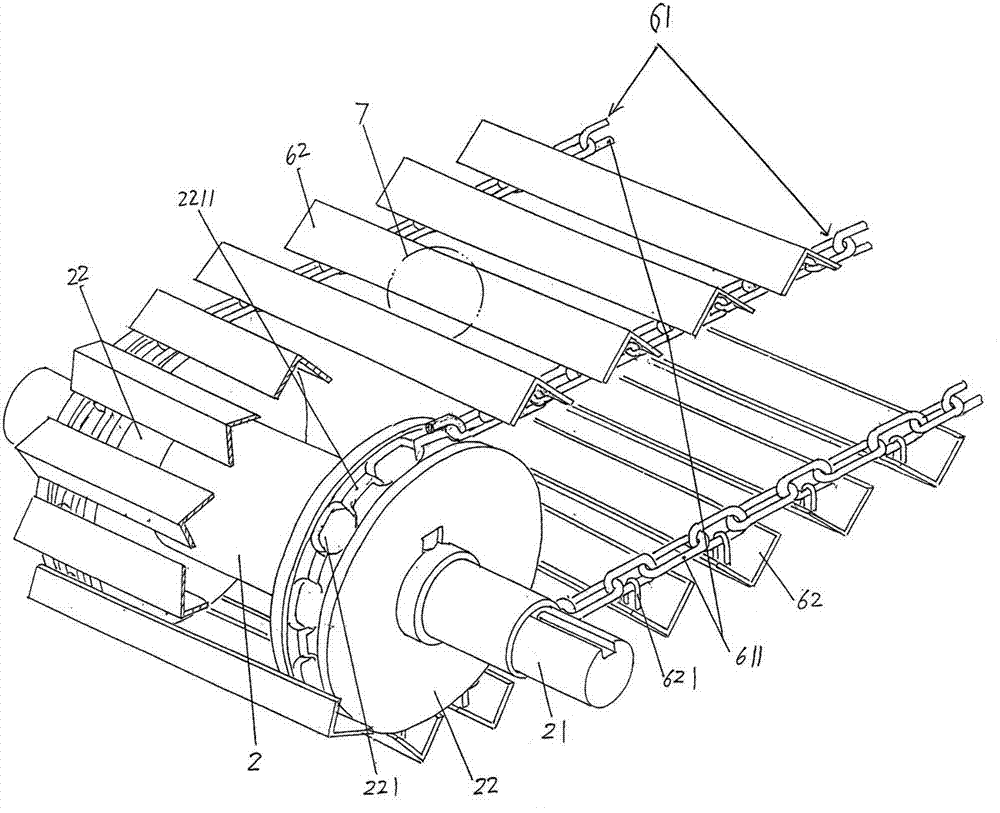

Steel ball conveyor device

ActiveCN103205554AGuaranteed traction effectImprove load effectFurnace typesHeat treatment furnacesSprocketSteel ball

The invention discloses a steel ball conveyor device belonging to the field of conveying machinery. The steel ball conveyor device comprises a conveying box, a main driving roller, a direction-changing driving roller, a group of carrier rollers, a power transmission mechanism and a steel ball carrying mechanism, wherein a wear-resisting plate is arranged in a conveying cavity of the conveying box; the main driving roller is supported on the wall of the conveying box; chain traction chain sprockets are respectively formed at the two ends of the main driving roller; the direction-changing driving roller is supported on the wall of the conveying box; chain direction-changing traction chain sprockets are respectively formed at the two ends of the direction-changing driving roller; the group of carrier rollers are supported in the middle of the conveying box; the power transmission mechanism is arranged on the top of the conveying box; the steel ball carrying mechanism comprises a pair of curtain rail plate traction chains and a group of curtain rail plates; the direction-changing driving roller is supported on a direction-changing driving roller shaft head support bearing seat; the direction-changing driving roller shaft head support bearing seat is arranged a guide rail; the guide rail is arranged on the wall of the conveying box; the wall of the conveying box is provided with an adjusting screw rod seat which is provided with an adjusting screw rod; and the pair of curtain rail plate traction chains are respectively formed by chain links which are connected in a circulating way. The steel ball conveyor device is beneficial to unloading a steel ball, reliable in transmission and matching, good in firmness and long in service life, can guarantee the traction effect for the curtain rail plates, and is simple and convenient to operate, examine and maintain.

Owner:CHANGSHU FEIFAN METALWORK

Test tube labeling machine with capabilities of automatic feeding and blanking

InactiveCN104691880ARealize automatic feeding processRealize blankingLabelling machinesLabelling elongated objectsDrive motorEngineering

The invention belongs to the field of labeling, relates to a test tube labeling machine with the capabilities of automatic feeding and blanking and aims at solving the problem of low efficiency of a labeling machine in the prior art. The test tube labeling machine mainly comprises a labeling mechanism, a bottom plate, a feeding mechanism and a blanking cabin, wherein the labeling mechanism consists of a turntable mechanism, a label pressing mechanism, a rotation mechanism and a rack assembly; the turntable mechanism consists of a turntable, a gear ring, a turntable driving gear, a turntable driving motor and a driving motor support seat; the feeding mechanism consists of a plate pushing mechanism, a rotary wheel mechanism and a feeding cabin mechanism which are fixed to the bottom plate sequentially. According to the test tube labeling machine, automatic feeding and blanking of a test tube can be realized, the labeling efficiency can be improved, test tubes with different diameters can be clamped, the test tubes stored in a feeding cabin can successfully enter the rotary wheel mechanism without the blockage phenomenon by adopting a cam mechanism, and the test tubes in a feeding cabin can singly and orderly enter a U-shaped groove for labeling by adopting the rotary wheel mechanism, the structure is simple, the debugging is convenient, the cost is low and the operation is convenient.

Owner:JILIN UNIV

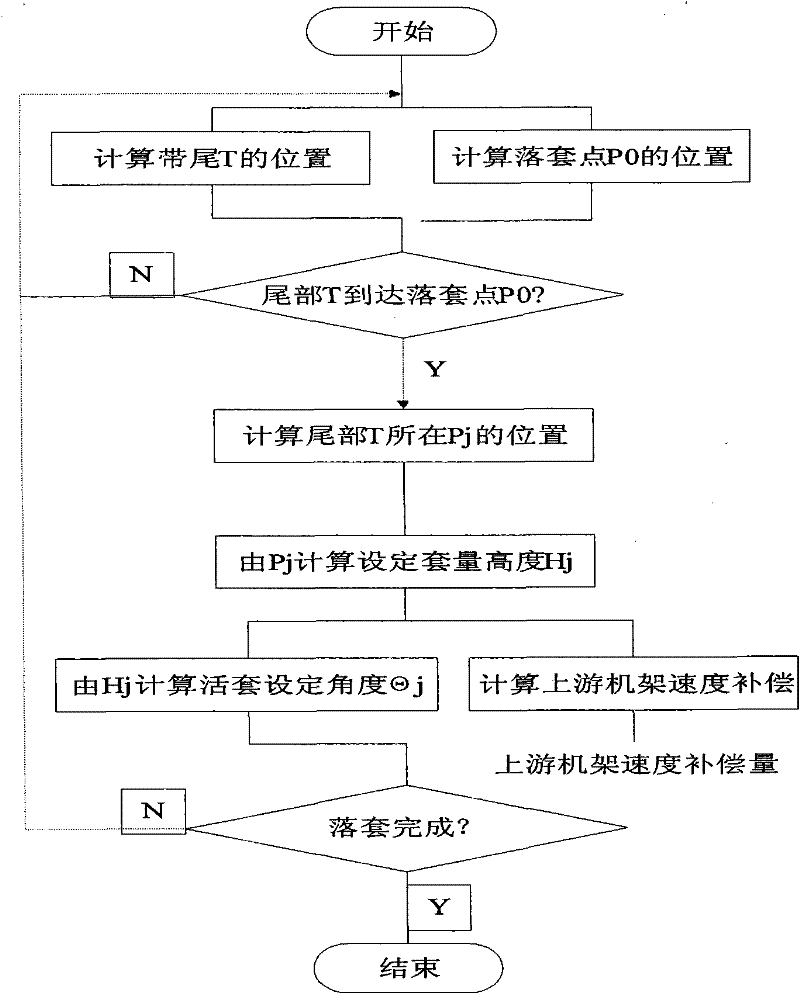

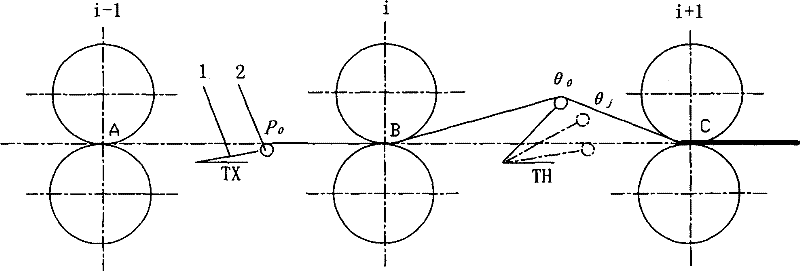

Stable sleeve-dropping method for moveable sleeve of hot milling machine

InactiveCN102205349AClear logical relationshipAvoid flickFlexible work arrangmentsMetal rolling arrangementsControl functionMovement control

The invention relates to a stable sleeve-dropping method for a moveable sleeve of a hot milling machine and belongs to the technical field of steel rolling. According to the method, a sleeve-dropping controller controls a sleeve-dropping process of a rear moveable sleeve according to the following steps: tracking the position of a strip steel tail; confirming a sleeve-dropping position; establishing a sleeve-dropping angle control function; and lastly, after detecting and confirming that the strip steel tail reaches the confirmed sleeve-dropping position, starting a moveable sleeve rod and simultaneously controlling a sleeve-dropping angle of the moveable sleeve rod according to the sleeve-dropping angle control function till the moveable sleeve drops to the position as high as a rolling level. According to the method, by organically considering a frame driving transmission speed together with the moveable sleeve motion control, in the process of slowly digesting the sleeve quantity, a moveable sleeve roller keeps a tensile force on the strip steel till the moveable sleeve completely drops off, and the drifting phenomenon in a throwing process is prevented while a hollow sleeve isprevented from being formed, thereby achieving the purpose of stably dropping the sleeve.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

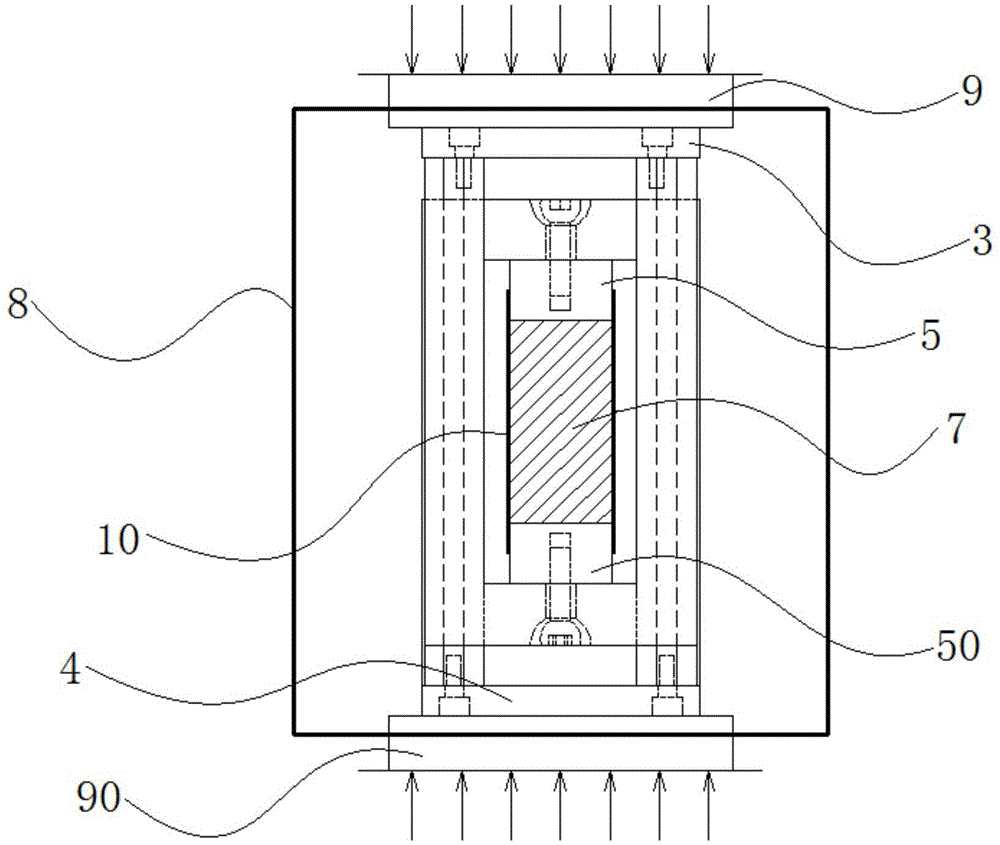

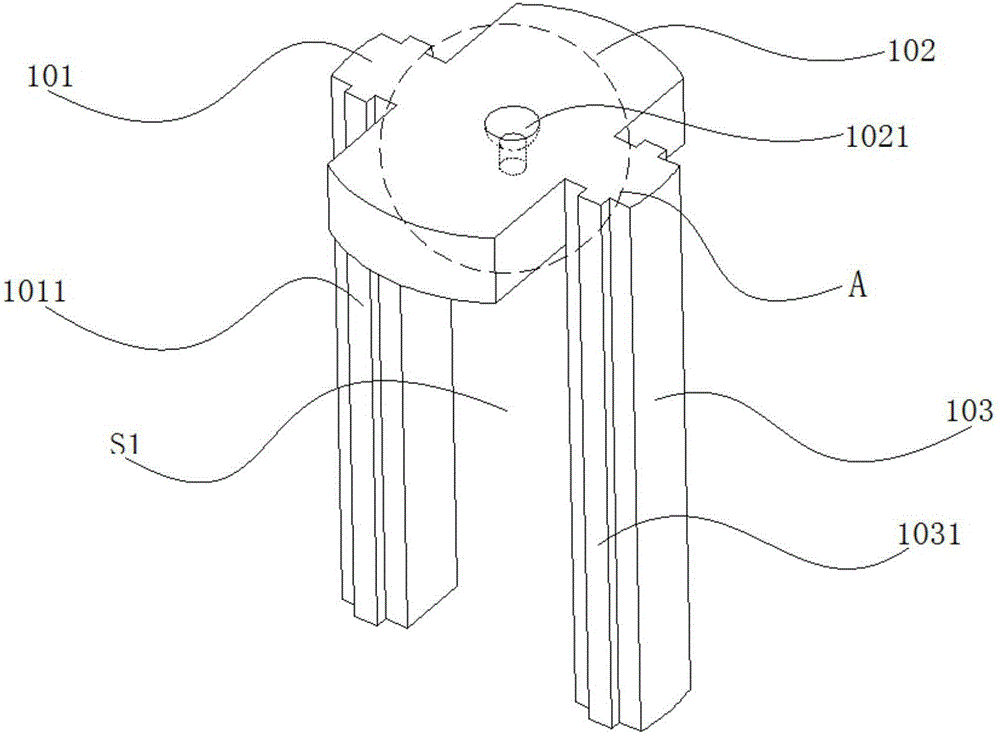

Rock tensile test device under confining pressure effect and test method thereof

ActiveCN106546488AThe test results are accurate and reliableEasy to operateMaterial strength using tensile/compressive forcesCOMPONENT IIPull force

The invention provides a rock tensile test device under a confining pressure effect and a test method thereof. The device comprises a component I, a component II, a connecting plate and a base plate, wherein the component I is equipped with a slide rail; the component II is equipped with a slide slot; under the restricting effect of the slide rail and the slide slot, the component II only can move along the vertical direction, and meanwhile, the pressure on a test machine is converted into a pull force for a sample; and the ball twisting form connection of a pull head and a cross beam can guarantee the stress acting on the center of the sample. The rock tensile test device provided by the invention has a simple structure, is reliable in test result, is capable of performing a rock tensile test under the confining pressure effect on a present tri-axial test machine, and is capable of greatly saving the test cost.

Owner:HEBEI UNIV OF TECH

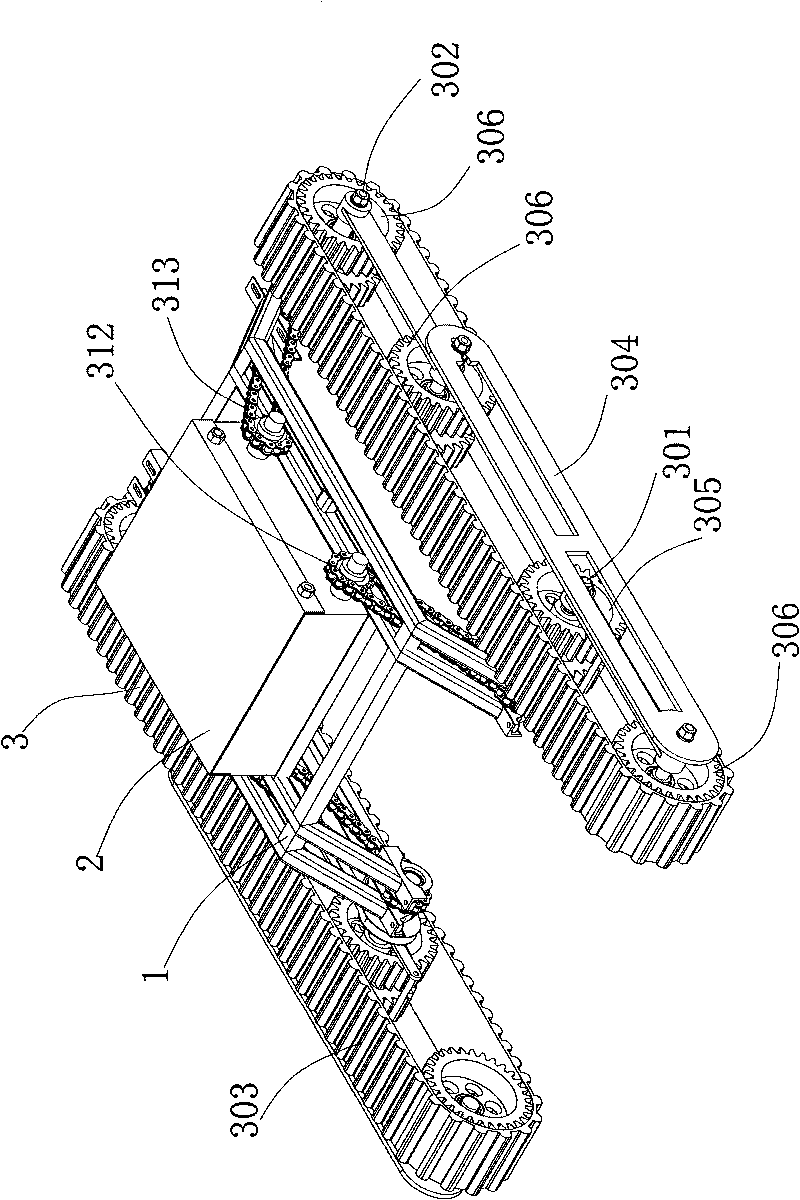

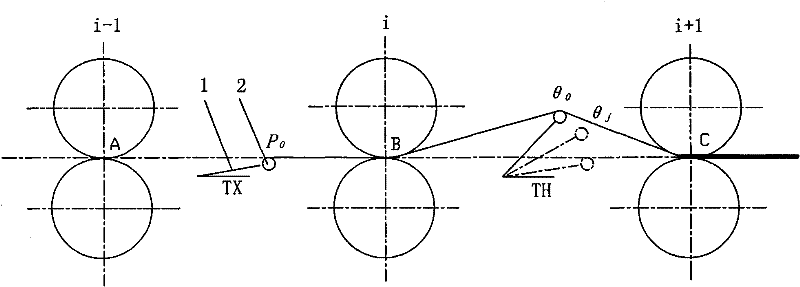

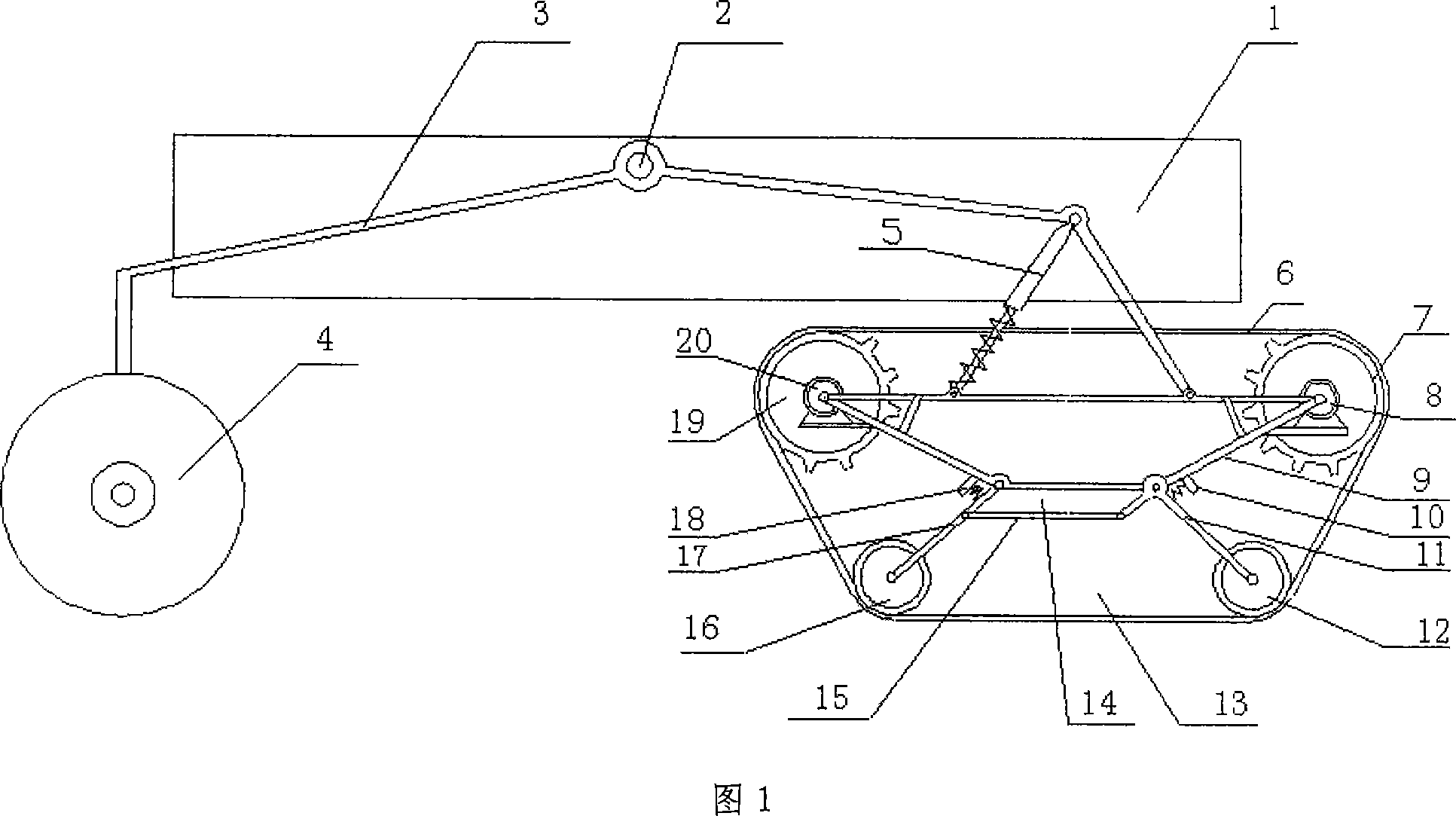

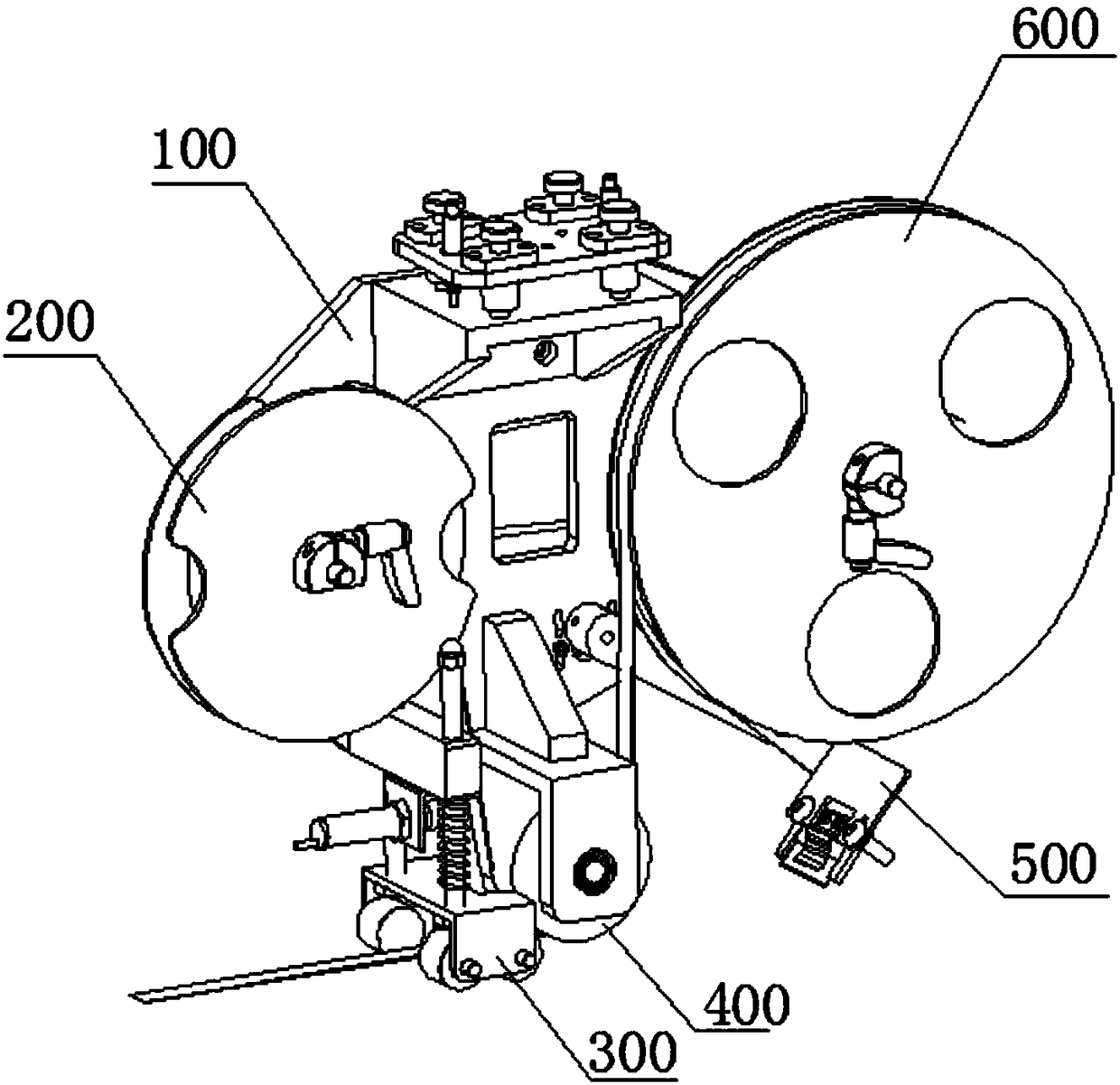

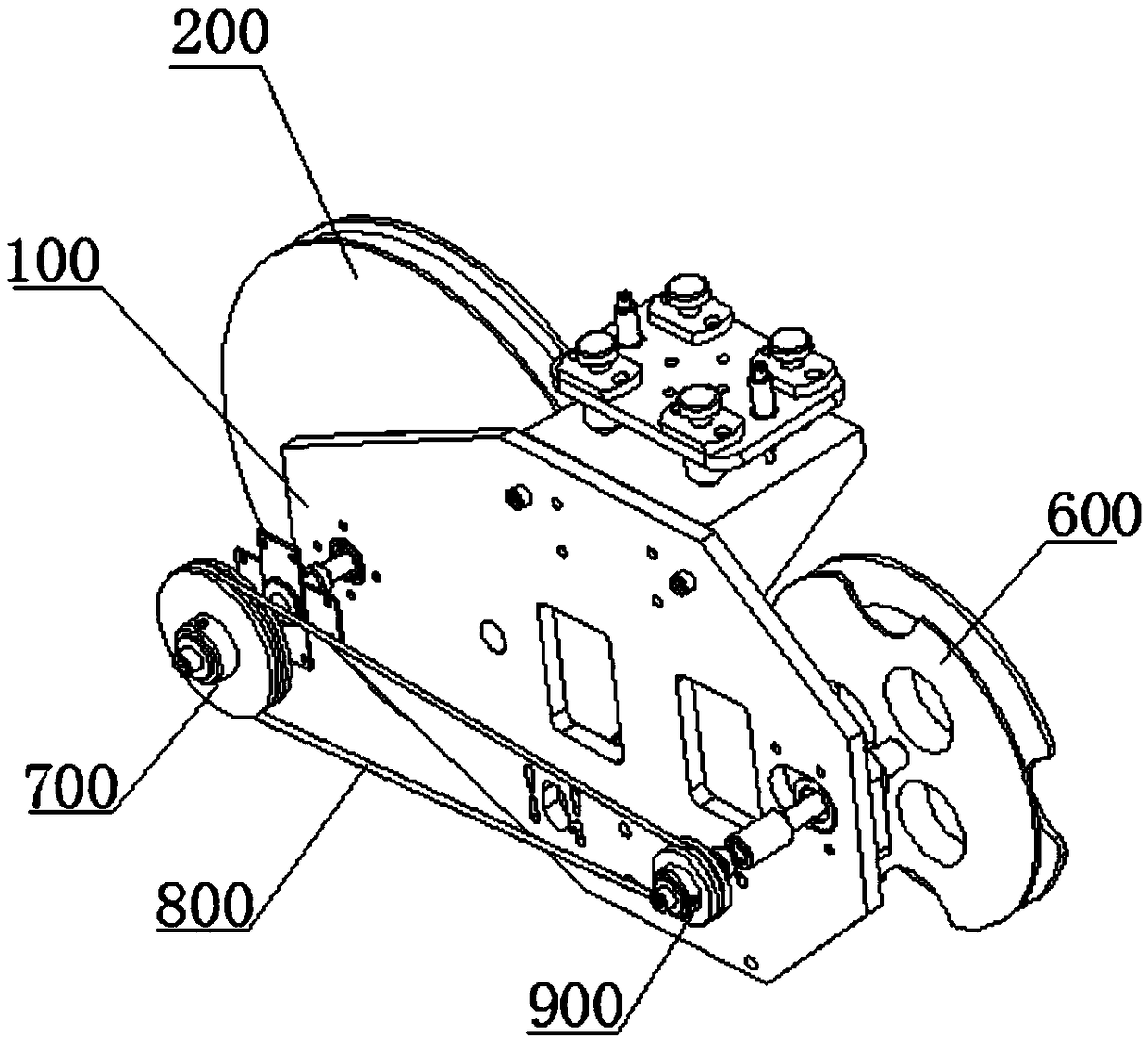

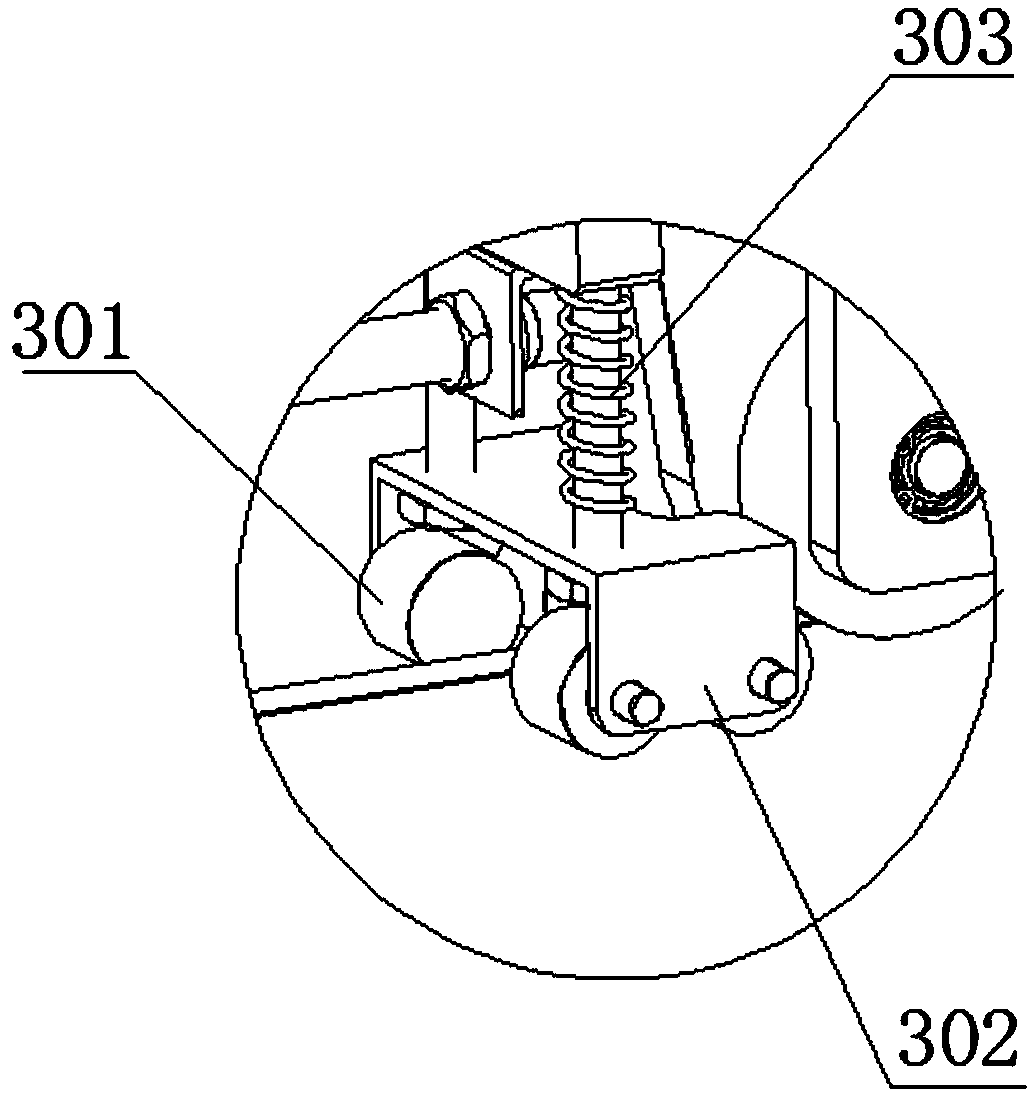

Combined type obstacle crossing walking system

InactiveCN101181911AGuaranteed to be under tensionGuaranteed tensionEndless track vehiclesBogieDrive wheel

The invention discloses a composite obstacle-surmounting walking system, which belongs to an obstacle-overriding walking mechanism. It is characterized in that it consists of a rocker suspension (3), a differential balance mechanism (2), a rear wheel (4), and a front track wheel (13), wherein the front track wheel (13) and the rocker suspension (3) Hinged and damping spring (5) is installed between the two, front crawler wheel (13) is made of track (6), internal support (9), drive motor (8,20), two driving wheels ( 7, 19), and two load-bearing wheels (12, 16) located below that are connected to the internal bracket (9) through a parallelogram mechanism (14), the side bars on both sides of the parallelogram mechanism (14) are connected to the interior Elastic stoppers (10, 18) are respectively installed between the supports (9). The composite obstacle-crossing walking mechanism has good obstacle-crossing performance, strong ground adaptability, easy control and light weight, and can be used for various special detection vehicles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

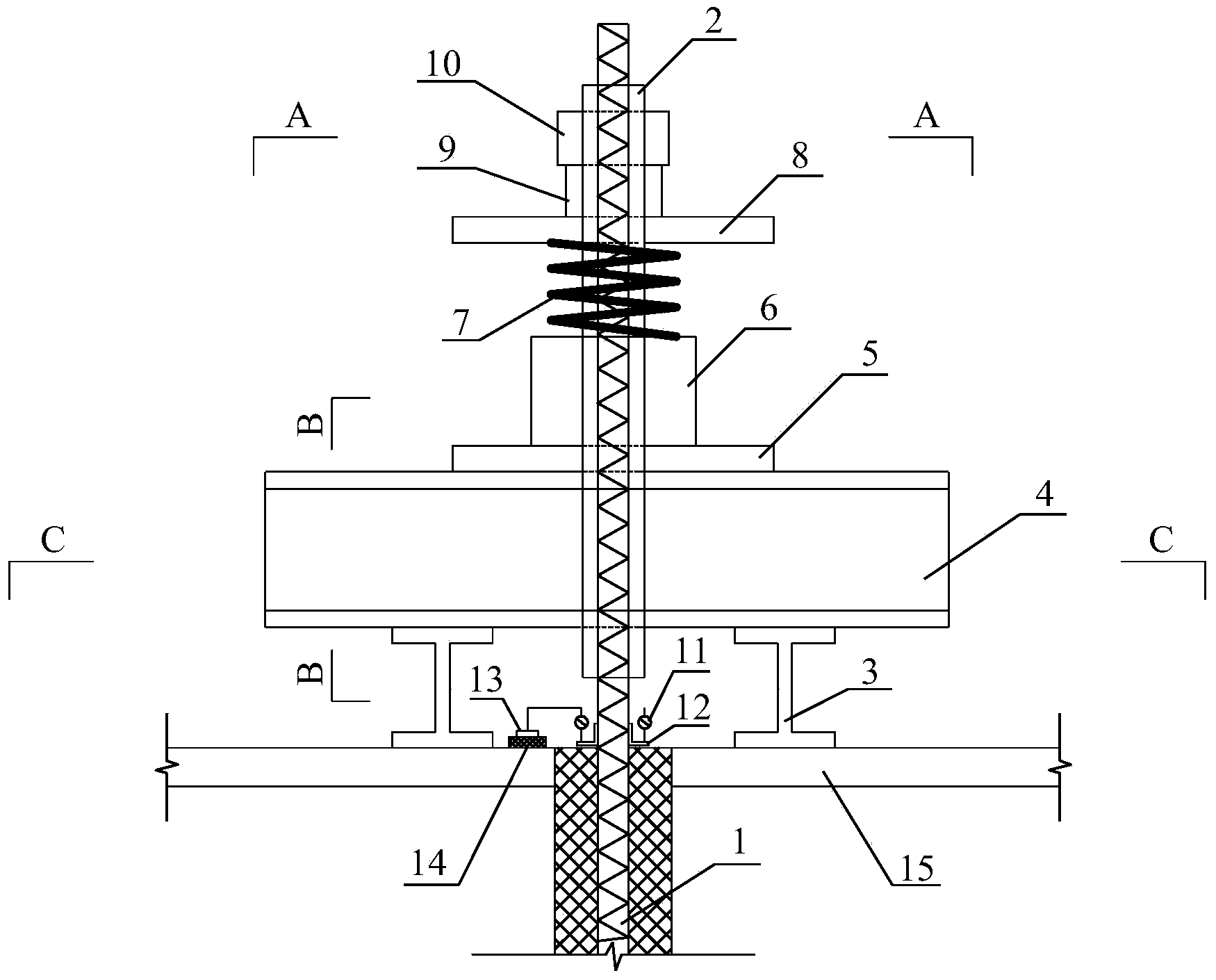

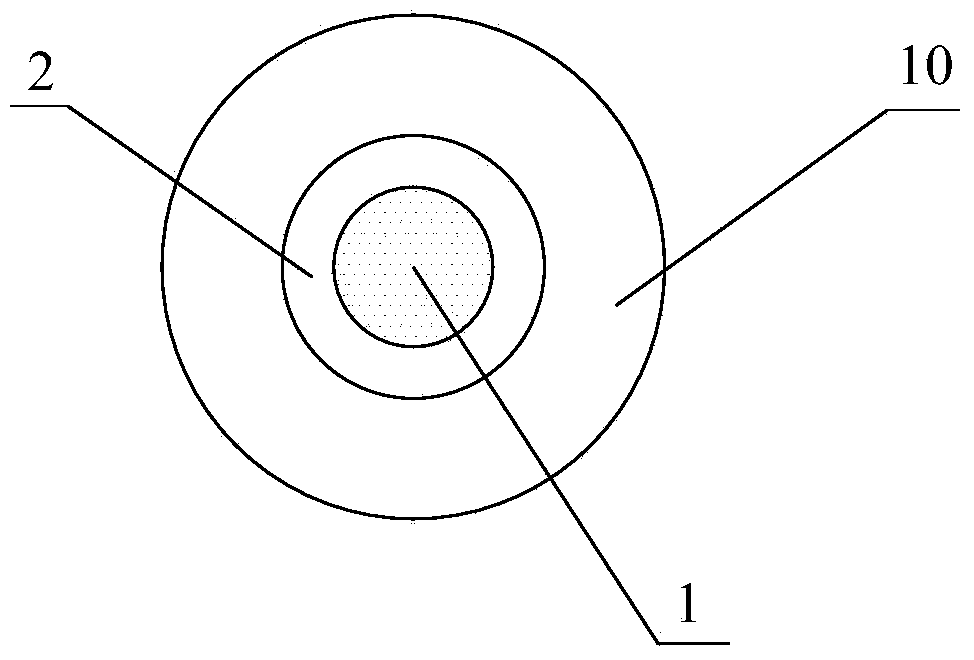

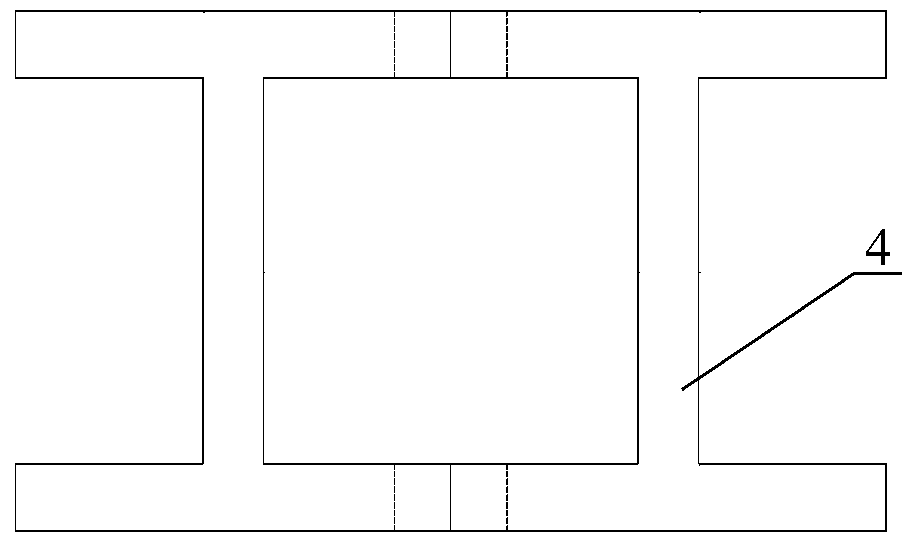

Creep test loading device for non-metal anti-floating anchor

The invention belongs to the technical field of in-situ test equipment and relates to a creep test loading device for a non-metal anti-floating anchor. An anchor body is of a solid rod-shaped structure and is bonded with a steel casing pipe. H-shaped steel is perpendicular to a concrete cushion layer and is symmetrically arranged on the two sides of the anchor body. A counterforce beam is a box-type section formed by welding two pieces of H-shaped steel. The counterforce beam is provided with a steel base plate. The steel base plate, a penetrating jack, a spring, a steel plate, an anchor cable axial force meter and an anchorage device are stacked on the counterforce beam and arranged outside the steel casing pipe in a sleeved mode. The anchorage device is welded to the outside of the steel casing pipe. A dial indicator is arranged on L-shaped organic glass in an erecting mode. The L-shaped organic glass is arranged on the interface of the concrete cushion layer and the anchor body. A magnetic indicator base of the dial indicator is arranged on a standard beam arranged on a concrete buttress. The concrete buttress is arranged on the concrete cushion layer. The creep test loading device is simple in overall structure, convenient to install, high in testing precision and high in operability.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

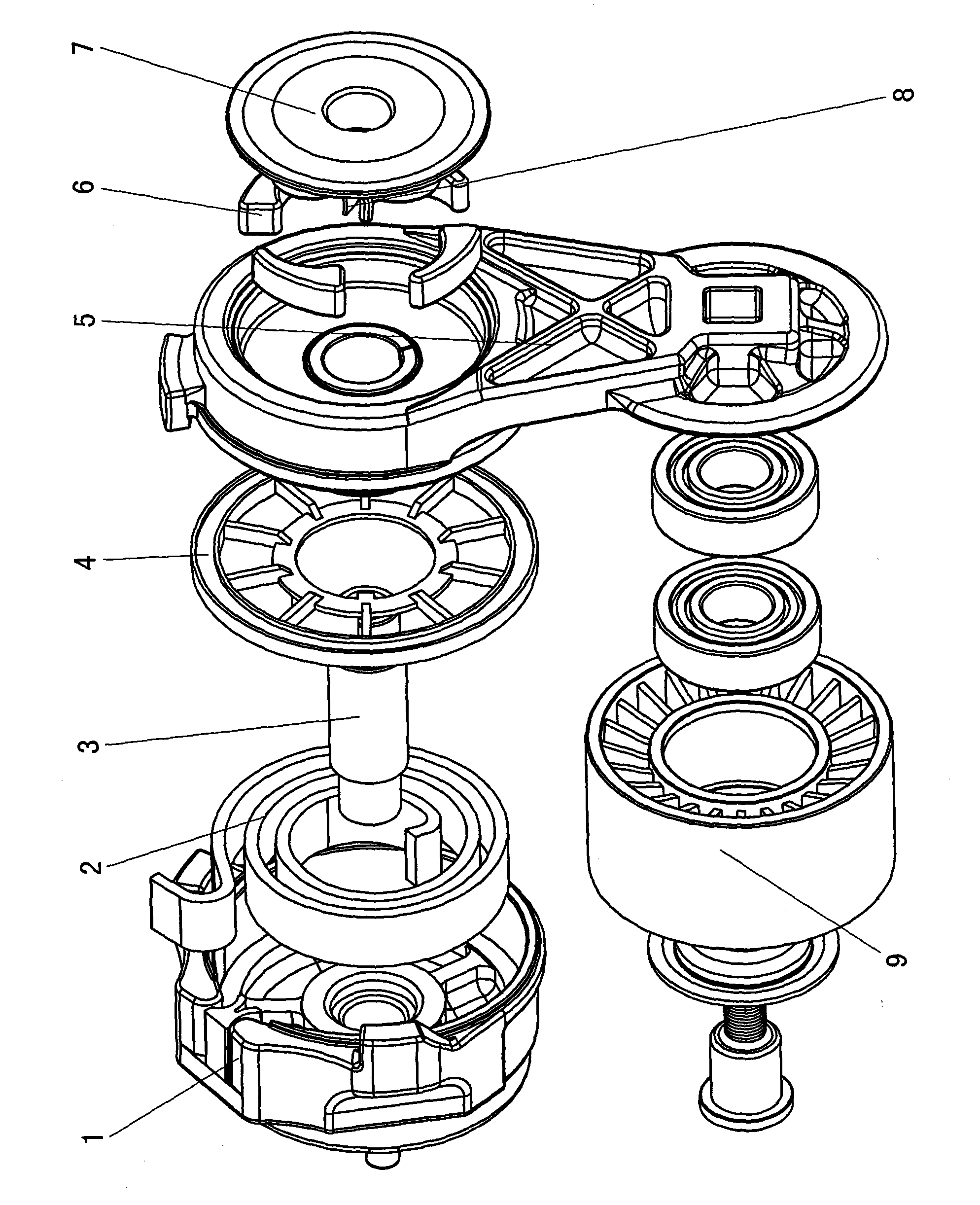

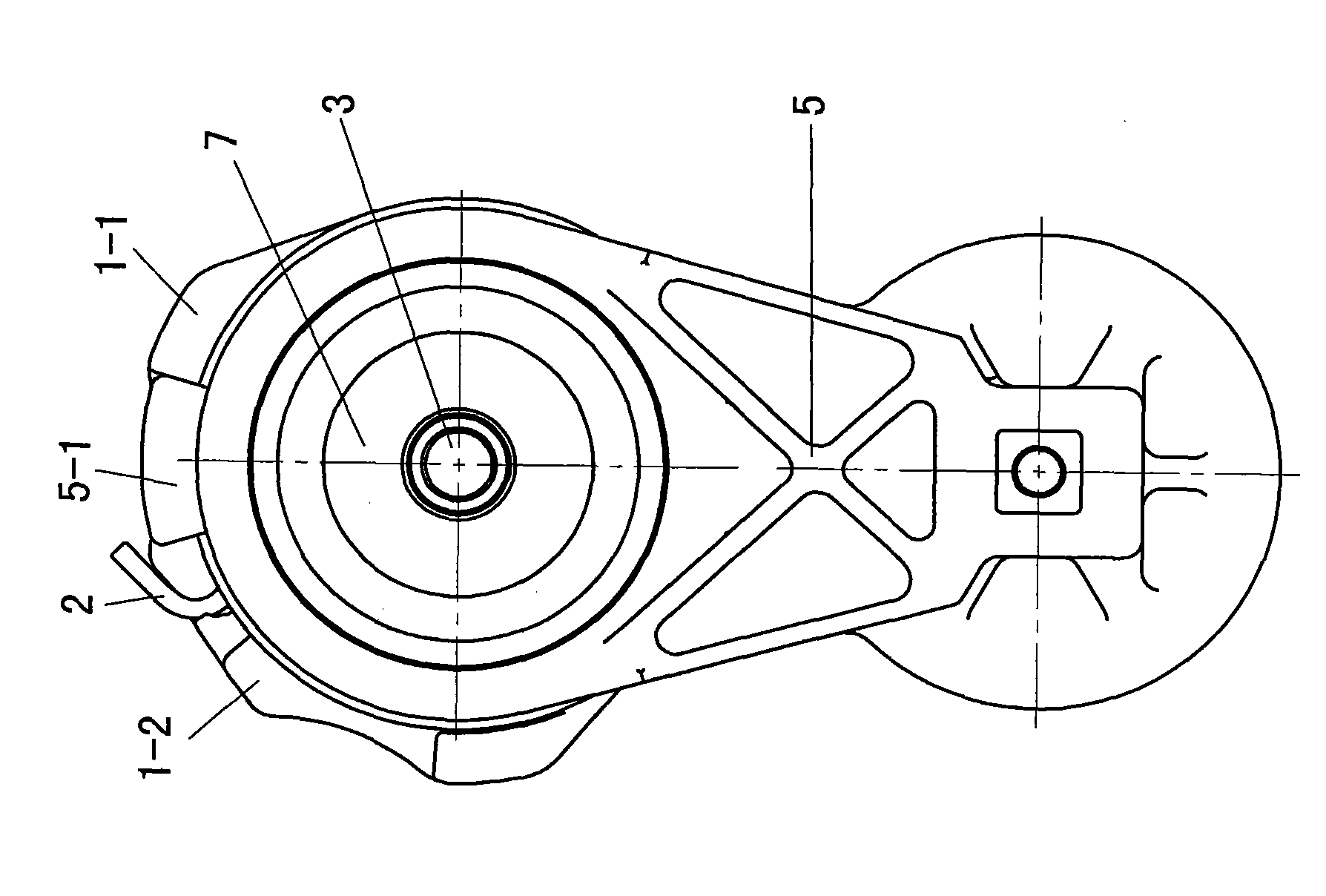

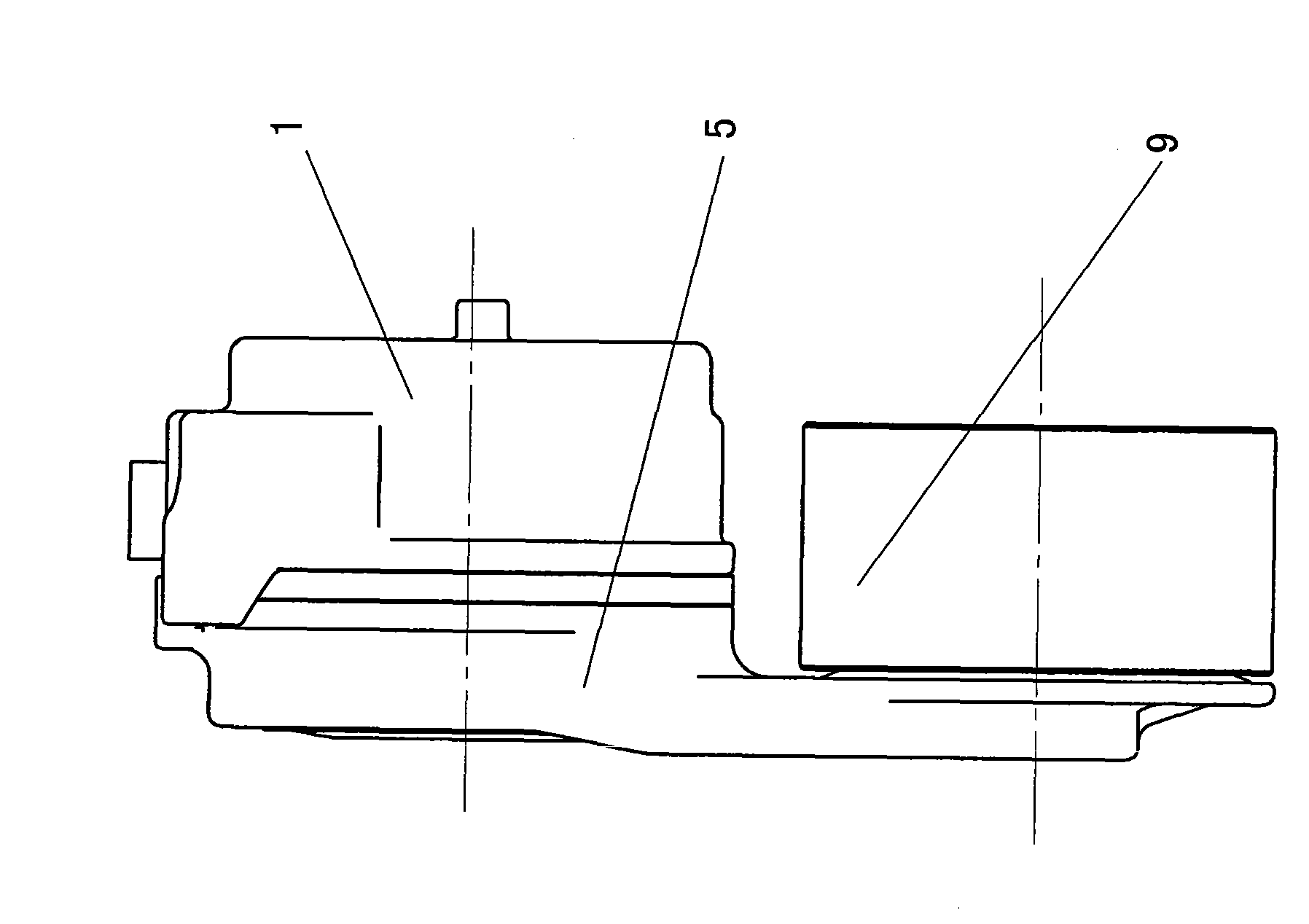

Belt tensioning device of vehicle engine

ActiveCN101666369AGuaranteed tensionReduce vibrationGearingMachines/enginesVibration amplitudeEngineering

The invention discloses a belt tensioning device of a vehicle engine. In order to eliminate or reduce the problems of belt creep and the like, the belt tensioning device comprises a base (1) and the like and is characterized by comprising a close cover (7), an elastic part and an asymmetric damping block (6), wherein one side of the close cover (7) facing to a cavity is provided with a convex pushing structure (12), the asymmetric damping block (6) is elastically connected with a pushing branch structure through the elastic part and is positioned between a circular wall (13-1) and the pushingbranch structure, the outward side of the asymmetric damping block (6) is in an arc shape which coincides with the shape of the circular wall (13-1); and when the inward side of the asymmetric dampingblock (6) moves opposite to the side of the pushing branch structure adjacent to the asymmetric damping block (6), the distance between the inward side and the side is closer and closer or farther and farther. The invention has different positive damping and negative damping, and can eliminate or reduce the problems of belt creep and shake, large rocker vibration amplitude, engine vibration and noise, and the like.

Owner:SHANGHAI BEIXU AUTOMOBILE TECH CO LTD

Oscillating buoy type ocean wave power generating device

InactiveCN105888952ASimple and compact structureReasonable layoutEngine fuctionsMachines/enginesWave powerElectric generator

The invention relates to an oscillating buoy type ocean wave power generating device. The oscillating buoy type ocean wave power generating device comprises a wave power absorbing device which floats on the sea, a supporting device which is connected with the wave power absorbing device by a sliding device, a conversion device and an output device which is connected with the conversion device. The supporting device comprises an upper supporting frame and a lower supporting frame which are arranged in parallel and with same axle center. The upper supporting frame and the lower supporting frame are both mounted on an ocean column in a sleeving manner. A main shaft of the conversion device is connected with a generator rotary shaft of an input device. According to the device, the up-and-down reciprocating motion of wave can be converted into the rotation of the main shaft through sprocket chain transmission. The main shaft is connected with a energy storage flywheel, so that an electric generator can run stably during the conversion of the ascending and descending of the wave power absorbing device under the action of the wave. The continuity of power generating can be guaranteed, so that the stability of power generating can be guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

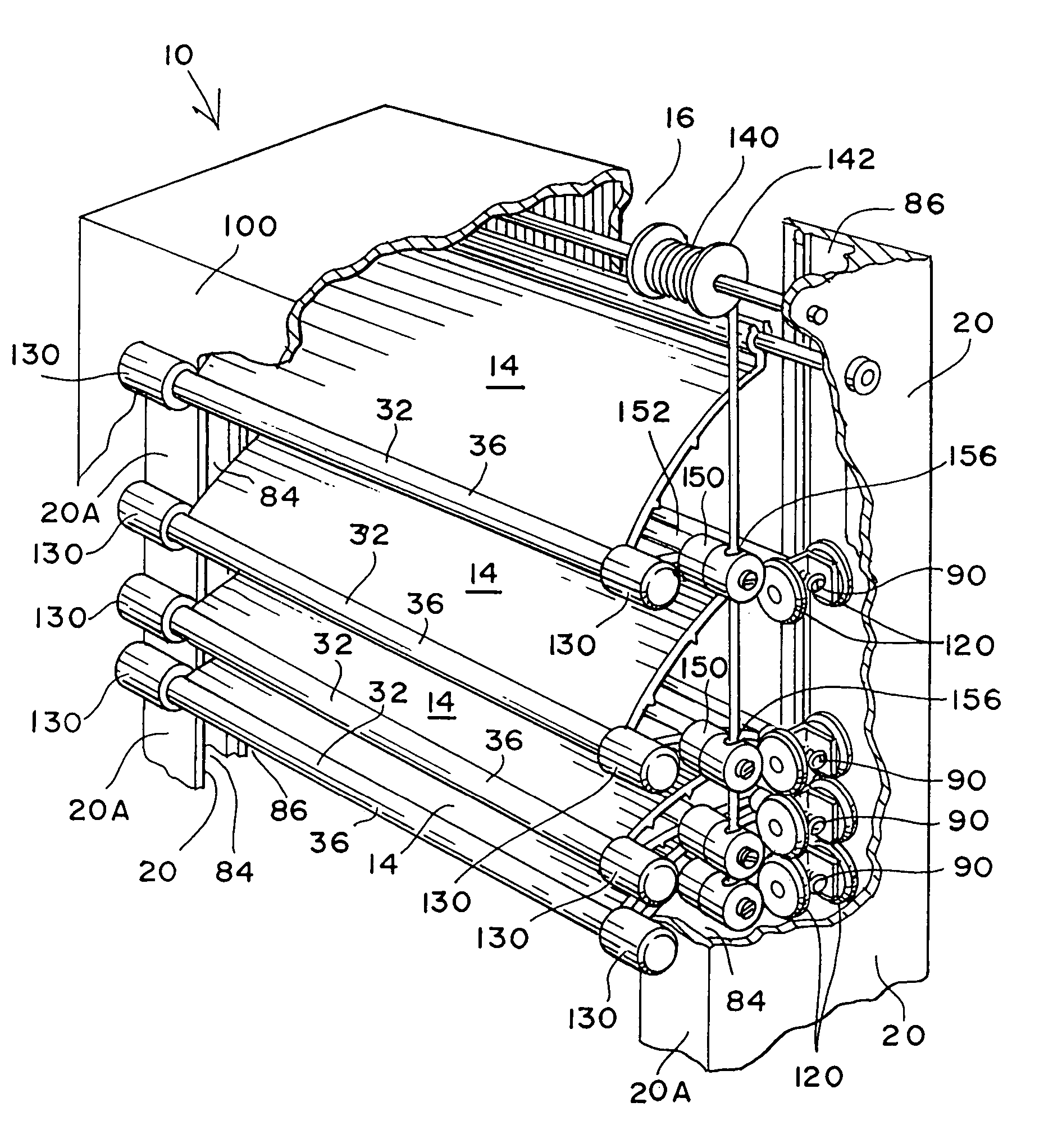

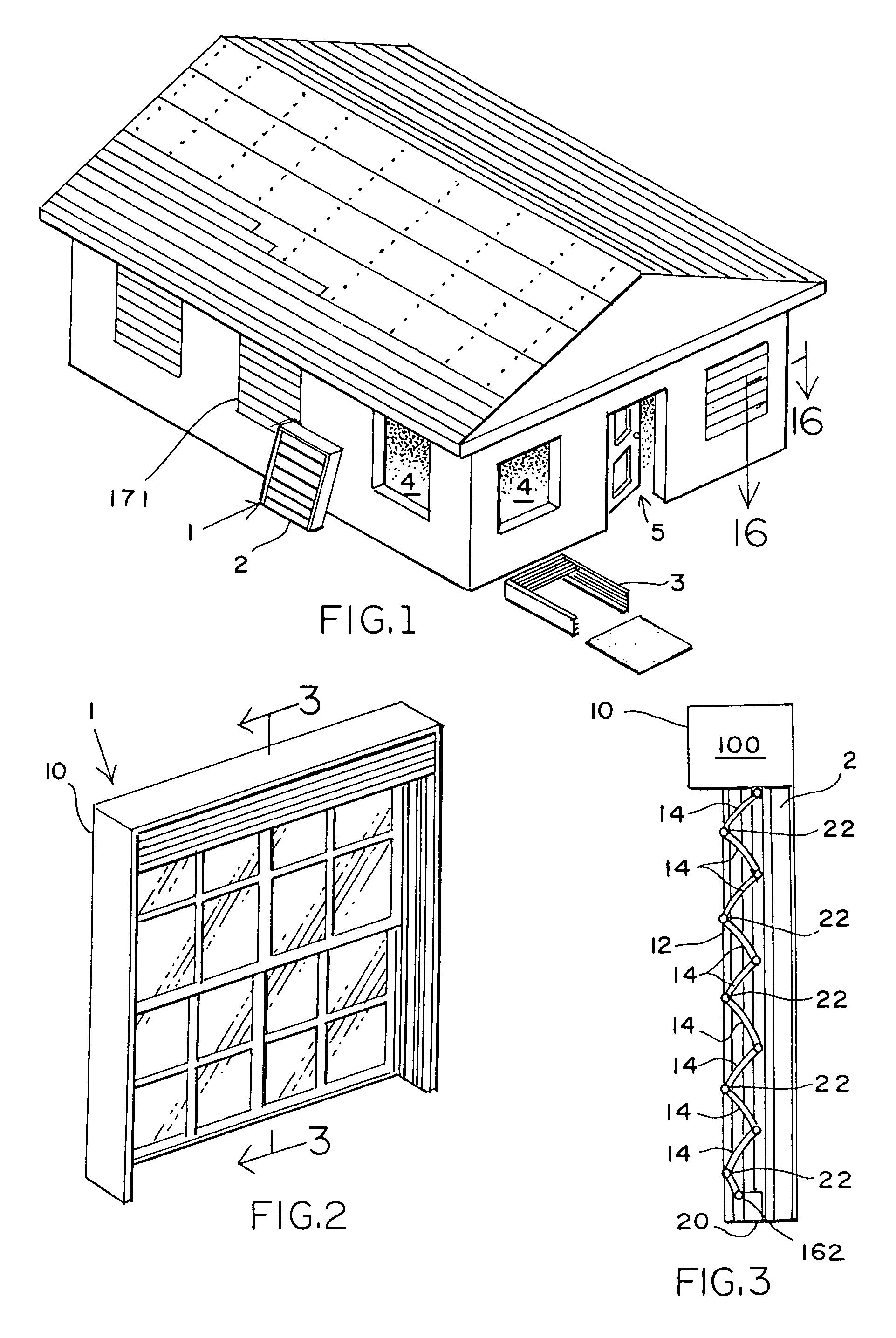

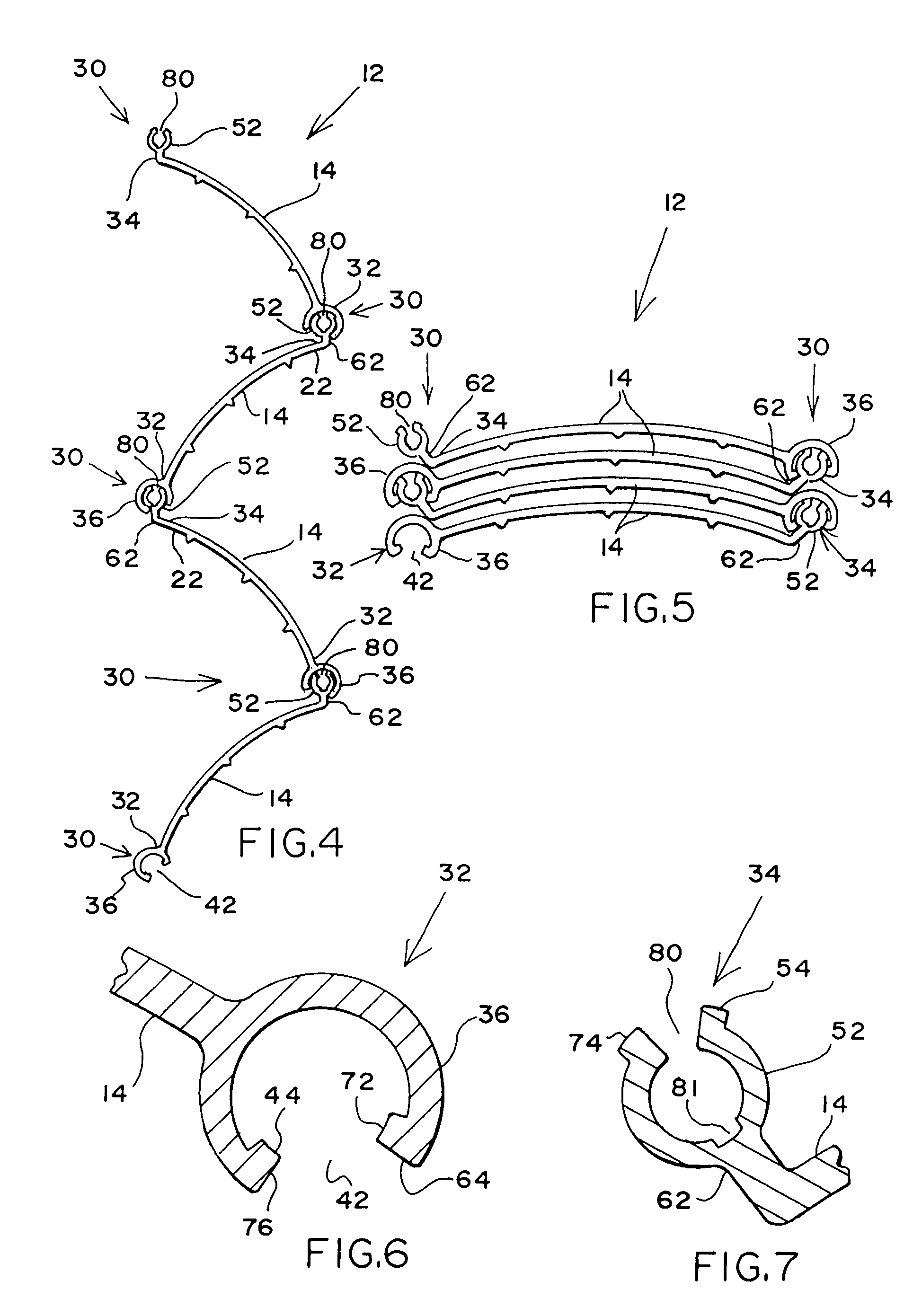

Shutter window/door and method

InactiveUS7121316B2Accomplished inexpensively and non-destructivelyGuaranteed tensionShutters/ movable grillesCorner/edge jointsWindow shutterHinge joint

A shutter system is disclosed which is unitized in a single rectangular frame or bracket with a window or door for use in a building opening that includes a plurality of shutter plates that can be folded and unfolded, each of the shutter plates having a hinged joint with adjoining shutter plates. The rectangular bracket has guide members with tracks for guiding the shutter plates using extensions with rollers from each of the hinged joints to cooperate with the guide members. There are also further extensions at the ends of the shutter plates on no less than every other plate, each of these securing wheel carriers at the end of the shutter plate and within a track in the rectangular bracket. The wheel carriers are equipped with a spring to put the secured shutter plate in tension because this adds additional strength to the shutter plates to resist bending and impact of the shutter system when in a fully deployed configuration.

Owner:BIGGERS DOUGLAS W

Double faced adhesive tape attaching mechanism and double faced adhesive tape attaching equipment

The invention relates to the technical field of automatic adhesive tape attaching, in particular to a double faced adhesive tape attaching mechanism and double faced adhesive tape attaching equipment.The double faced adhesive tape attaching mechanism comprises a rack. The rack is provided with an adhesive tape putting wheel for loading double faced adhesive tape, an adhesive tape pressing wheel for keeping the double faced adhesive tape to be attached to a workpiece, a storage wheel for rolling release paper and a pressure maintaining mechanism for exerting pressure on the workpiece. The adhesive tape pressing wheel presses the adhesive tape to the workpiece, the movement of the workpiece drives the adhesive tape pressing wheel to rotate, and the adhesive tape pressing wheel drives the adhesive tape putting wheel to rotate through the double faced adhesive tape; and the adhesive tape putting wheel is connected with an adhesive tape putting belt wheel, the storage wheel is connected with a storage belt wheel, the adhesive tape putting belt wheel is connected with the storage belt wheel through a conveyor belt, and the adhesive tape putting wheel drives the storage wheel to rotate through the adhesive tape putting wheel and the storage belt wheel. The double faced adhesive tape attaching equipment comprises the double faced adhesive tape attaching mechanism. By means of the double faced adhesive tape attaching mechanism and the double faced adhesive attaching equipment, the technical problems that in the prior art, debugging is difficult and the cost is high are solved.

Owner:国机智能科技有限公司 +1

Small self-adapting wire drawing machine with variable disk diameter

The invention discloses a small self-adapting wire drawing machine with a variable disk diameter, which comprises multi-stage diameter-reducing wire drawing dies and multi-stage traction wheels, wherein each traction wheel is arranged between every two diameter-reducing dies; an annular groove is formed at the outer edge of each traction wheel; a plurality of pulleys and take-up pulleys are arranged behind the last-stage traction wheel; two brackets are arranged between two pulleys; a gap is formed between two brackets; each bracket is provided with a strip-shaped sliding groove; a wire passing wheel is positioned in the gap between two brackets; the central axis of each wire passing wheel slides up and down in each strip-shaped sliding groove; an annular groove is formed at the outer edgeof each wire passing wheel; a swinging rod seat is installed at one side of each bracket; a tension swinging rod is installed on each swinging rod seat through a rotation axis with a torsion spring;a rolling wheel is installed at the front end of each tension swinging rod; each rolling wheel is butted below the outer edge of each wire passing wheel; and an angle sensor is installed at the rotating connection point of each tension swinging rod and each rotation axis to sense the rotation angle of each tension swinging rod. The small self-adapting wire drawing machine with variable disk diameters overcomes the defects of prior wire drawing machines, ensures the consistency of the winding diameter of real-time computation and the practical winding diameter, completely solves the problems ofslow response of the large winding diameter and oscillation of the small winding diameter, shortens the production cycle and saves the cost.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

Rayon and polyester filament blended spinning technology

InactiveCN103526418AGuaranteed tensionAvoid breakingAuxillary apparatusWoven fabricsNatural stateEngineering

The invention relates to rayon and polyester filament blended spinning technology. The technology is characterized by including the following steps: 1) placing polyester filaments in a water steaming box for steaming at the water temperature of 85-100 DEG C for 80 minutes; 2) disposing the polyester filaments treated in the step 1) under the natural state for presetting for 10-20 hours; 3) measuring high limit in stretchability of rayon, namely a value of the maximum appliable pressure to the rayon; 4) adopting a water-jet loom for performing blended spinning on the rayon and the polyester filaments with the maximum pressure value. The high limit in stretchability of the rayon, namely the value of the maximum appliable pressure to the rayon, is measured firstly, and stretching resistance capability of the rayon is lower than that of the polyester filaments, so that tension of the rayon and the polyester filaments can be guaranteed within a bearable range by blending with the value of the maximum appliable pressure to the rayon, and both the rayon and the polyester filaments are less prone to breakage.

Owner:HUZHOU JINTADI TEXTILE MILL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com