Small self-adapting wire drawing machine with variable disk diameter

A self-adaptive, wire-drawing machine technology, applied in the field of small wire-drawing machines with adaptive disc diameter changes, can solve the problems of unclear tension counterweight system, inability to adapt to changes in disc diameter, weak dynamic response capability of frequency converters, etc. volume, overcome the effect of slow response of large coil diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

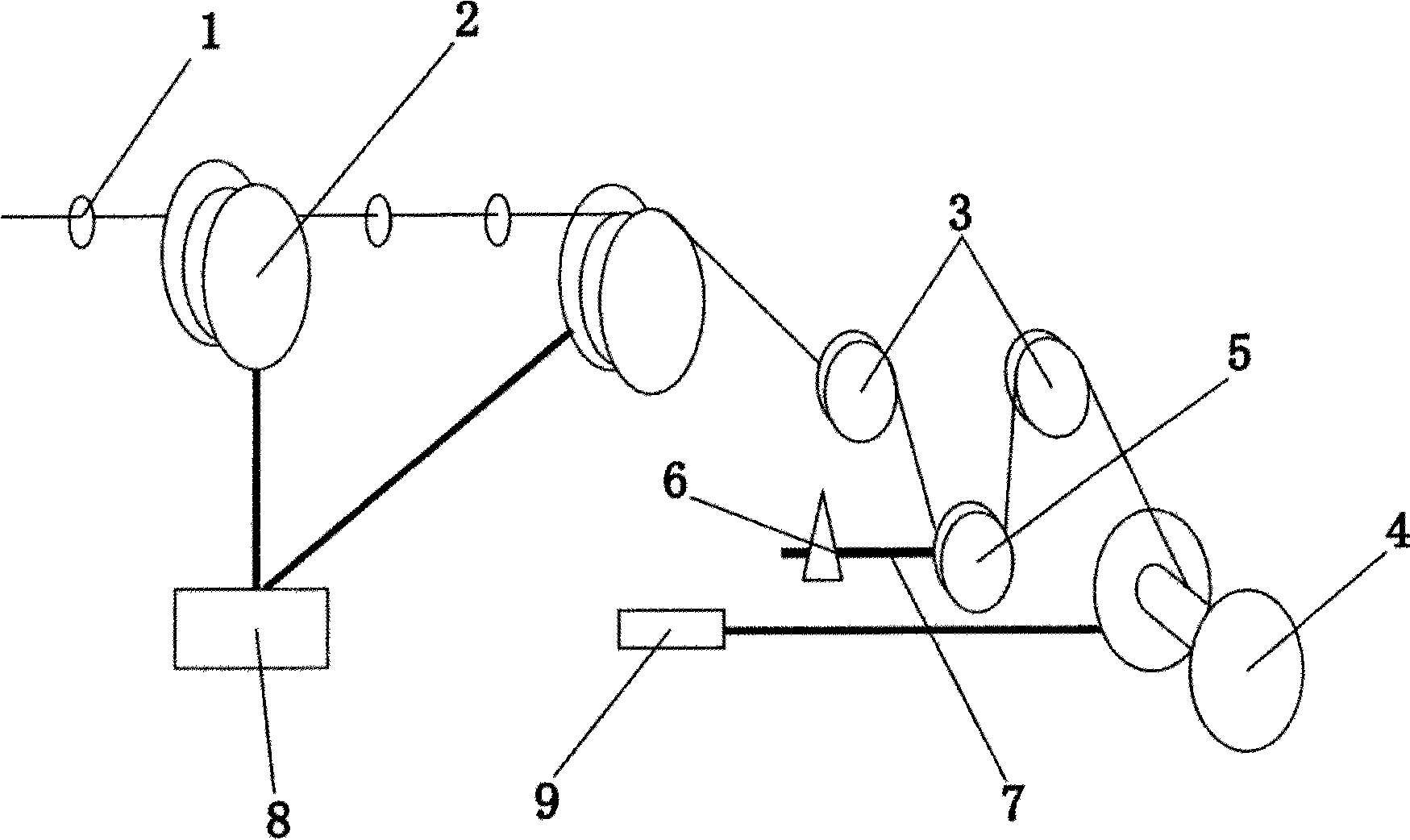

[0021] see figure 1 , a small-sized wire drawing machine adaptive to disc diameter change, including a multi-stage diameter-reducing wire drawing die 1, a multi-stage traction wheel 2, the traction wheel 2 is arranged between the two diameter-reduction dies 1, and the outer edge of the traction wheel 2 is an annular concave Groove; a plurality of pulleys 3 and take-up pulleys 4 are provided behind the traction wheel of the last stage, two supports are arranged between the two pulleys, there is a gap in the middle of the two supports, bar-shaped chute is arranged on each support, and there is a line passing The wheel 5 is located in the gap between the two brackets, the central axis of the thread passing wheel 5 slides up and down in the bar chute, there is an annular groove on the outer edge of the thread passing wheel 5, and a swing rod is installed on one side of the support Seat 6, on the swing rod seat 6, a tension swing rod 7 is installed through a rotating shaft with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com