Patents

Literature

37425results about "Programme total factory control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

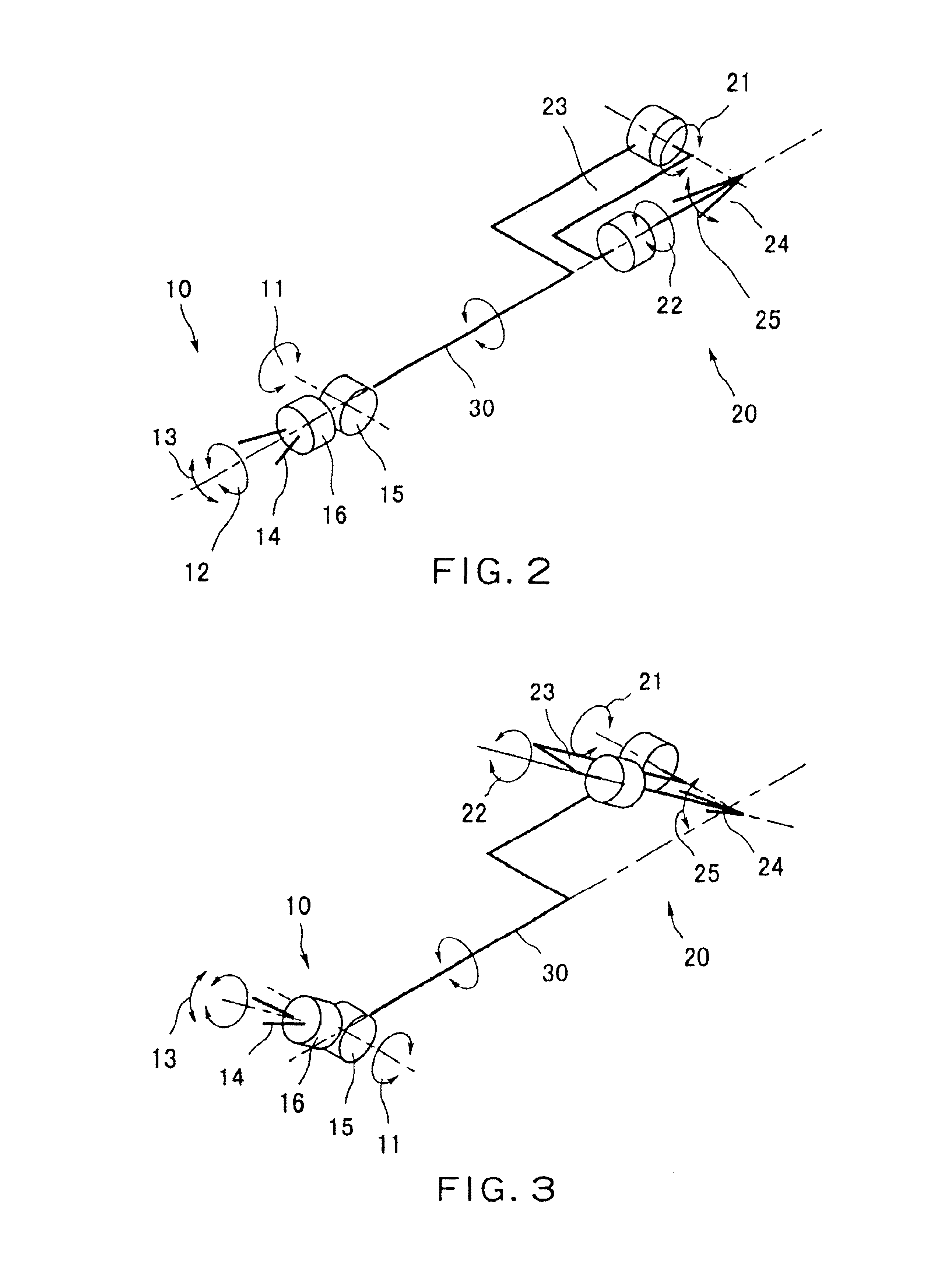

Manipulator

A manipulator comprises an operation command unit provided with an attitude adjusting unit and an end effector control unit, a connecting unit having one end connected to the operation command unit, a working unit connected to the other end of the connecting unit and provided with an end effector and a support unit supporting the end effector for motions, and a control unit that transmits an operation command provided by the attitude adjusting unit to the support unit to adjust the attitude of the end effector and transmits an operation command provided by the end effector control unit to the end effector to operate the end effector. The support unit includes a first joint capable of turning about a first axis perpendicular to the center axis of the connecting unit, and a second joint capable of turning about a second axis perpendicular to the first axis. The end effector can be turned for rolling about an axis substantially parallel to the second axis of the second joint. The attitude adjusting unit has a third joint having a third axis perpendicular to the center line of the connecting unit. The end effector control unit is formed such that the fingers of an operator gripping operating members included in the end effector control unit extend substantially in parallel to the fourth axis.

Owner:KARL STORZ GMBH & CO KG

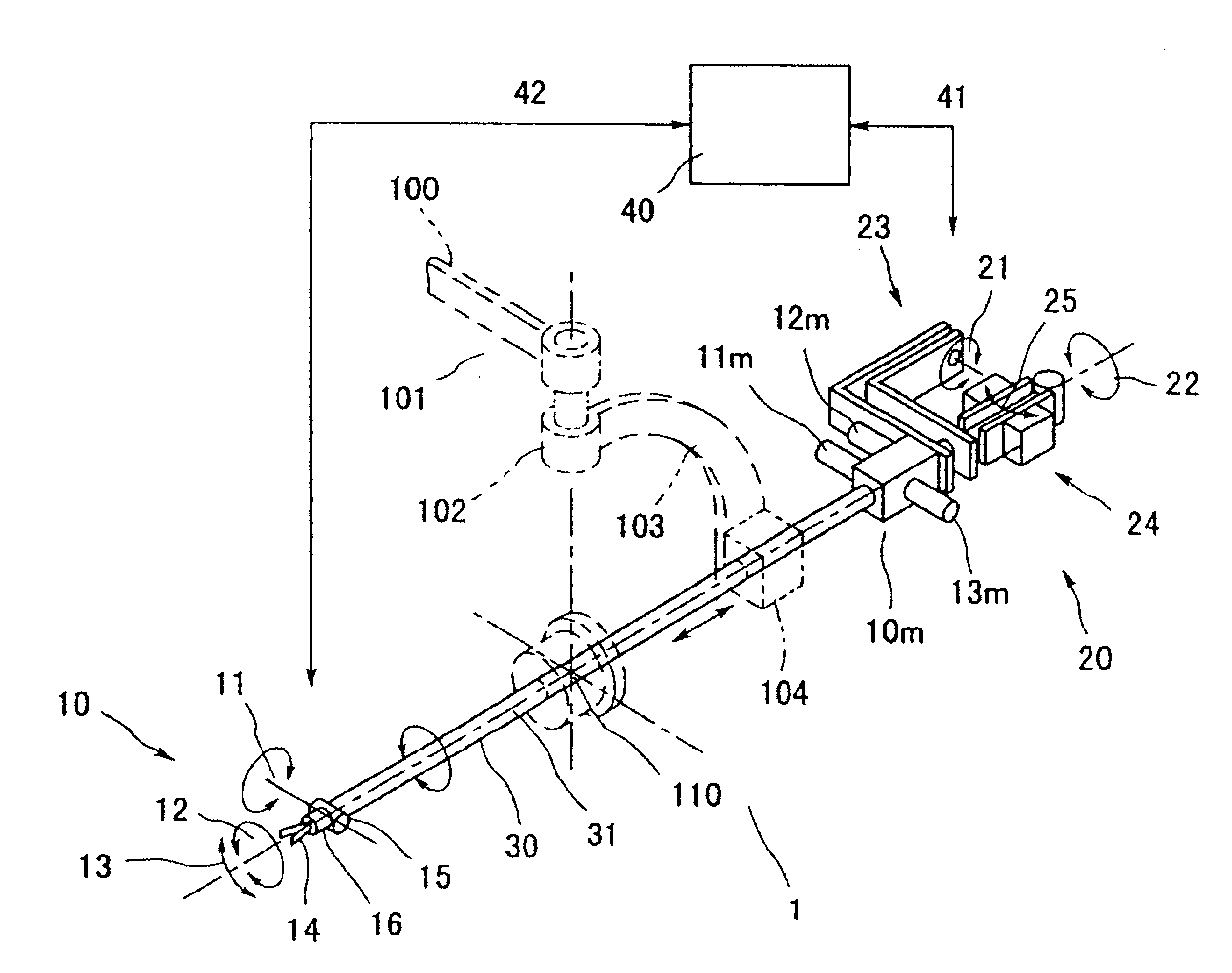

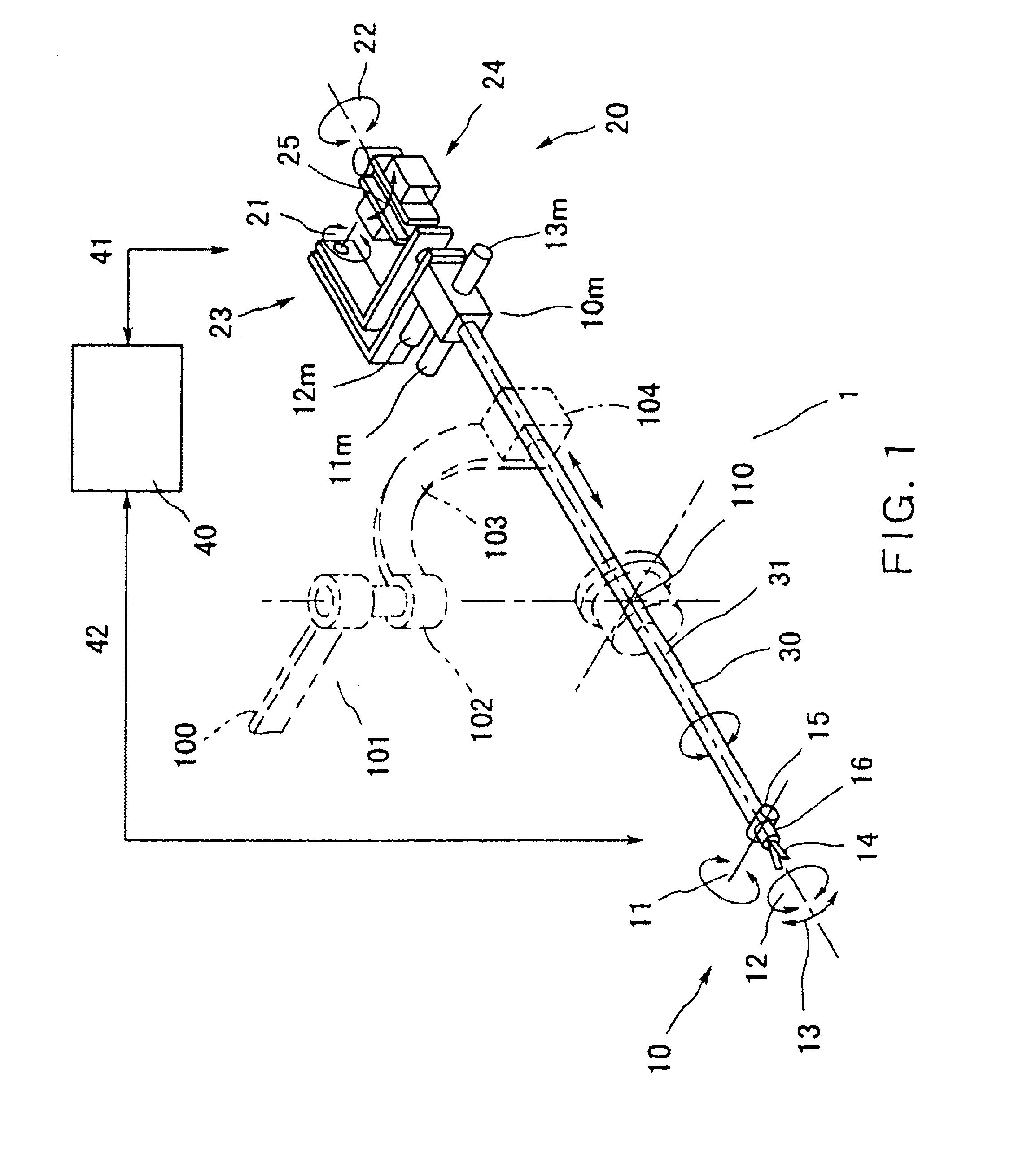

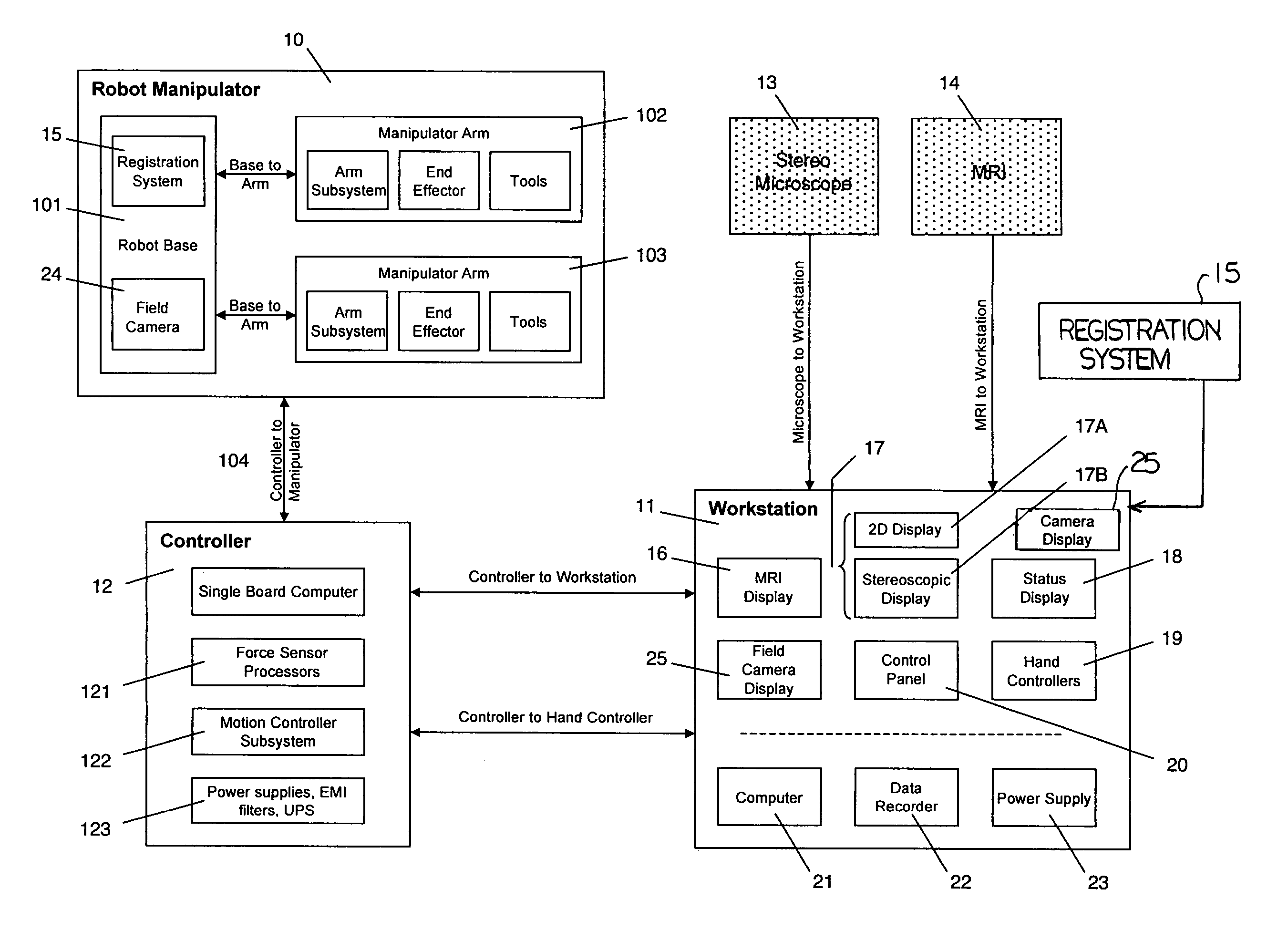

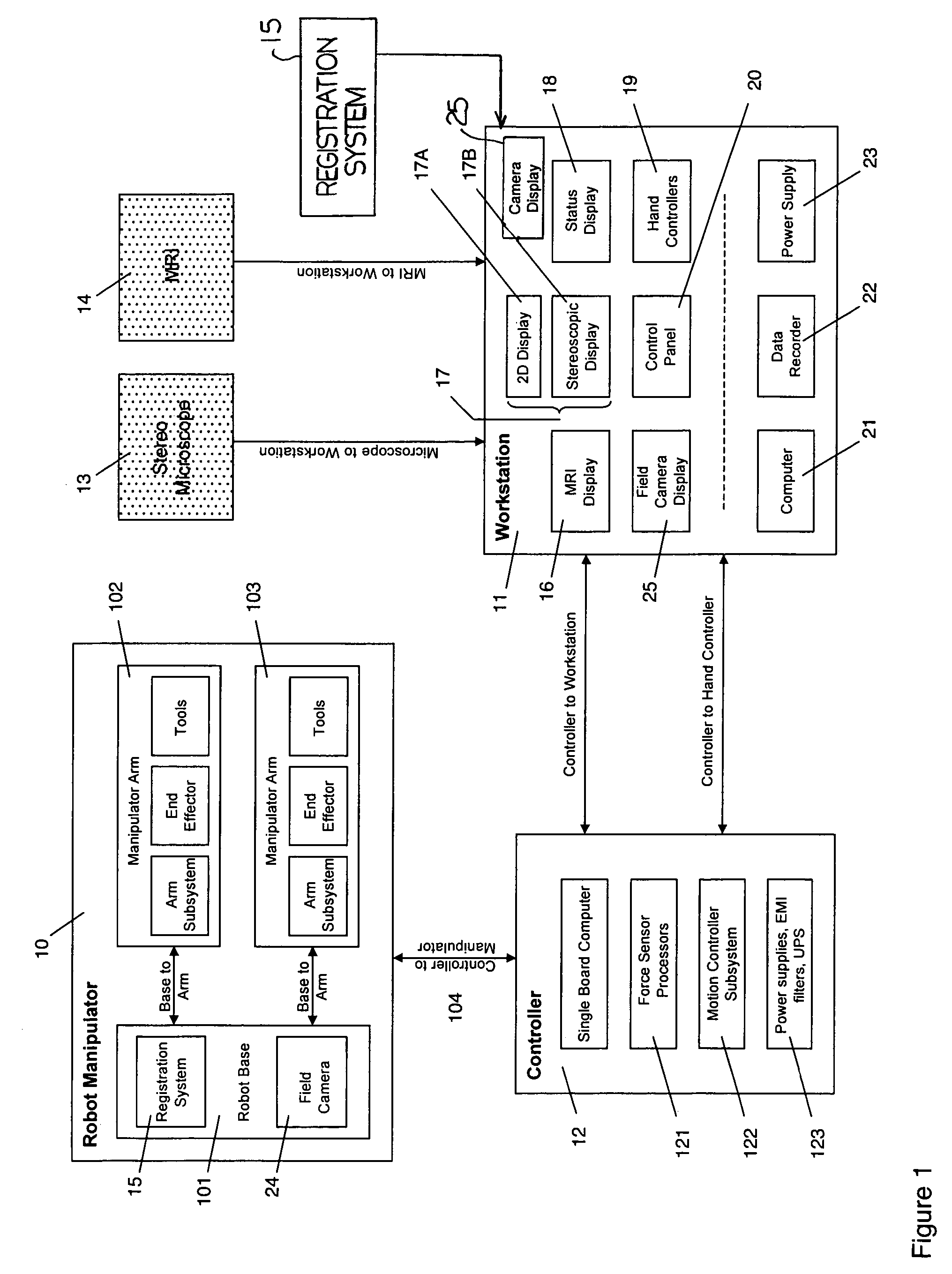

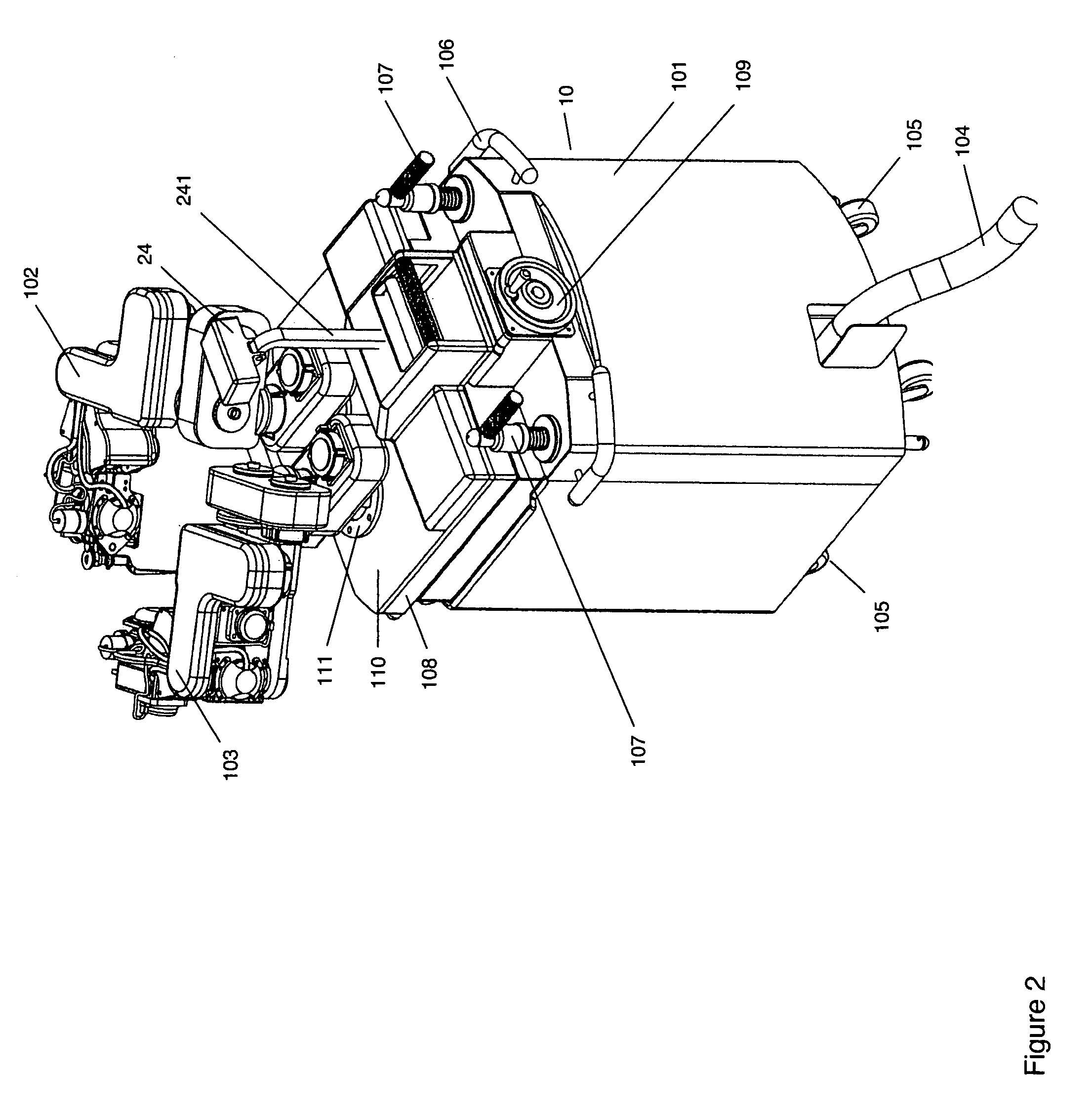

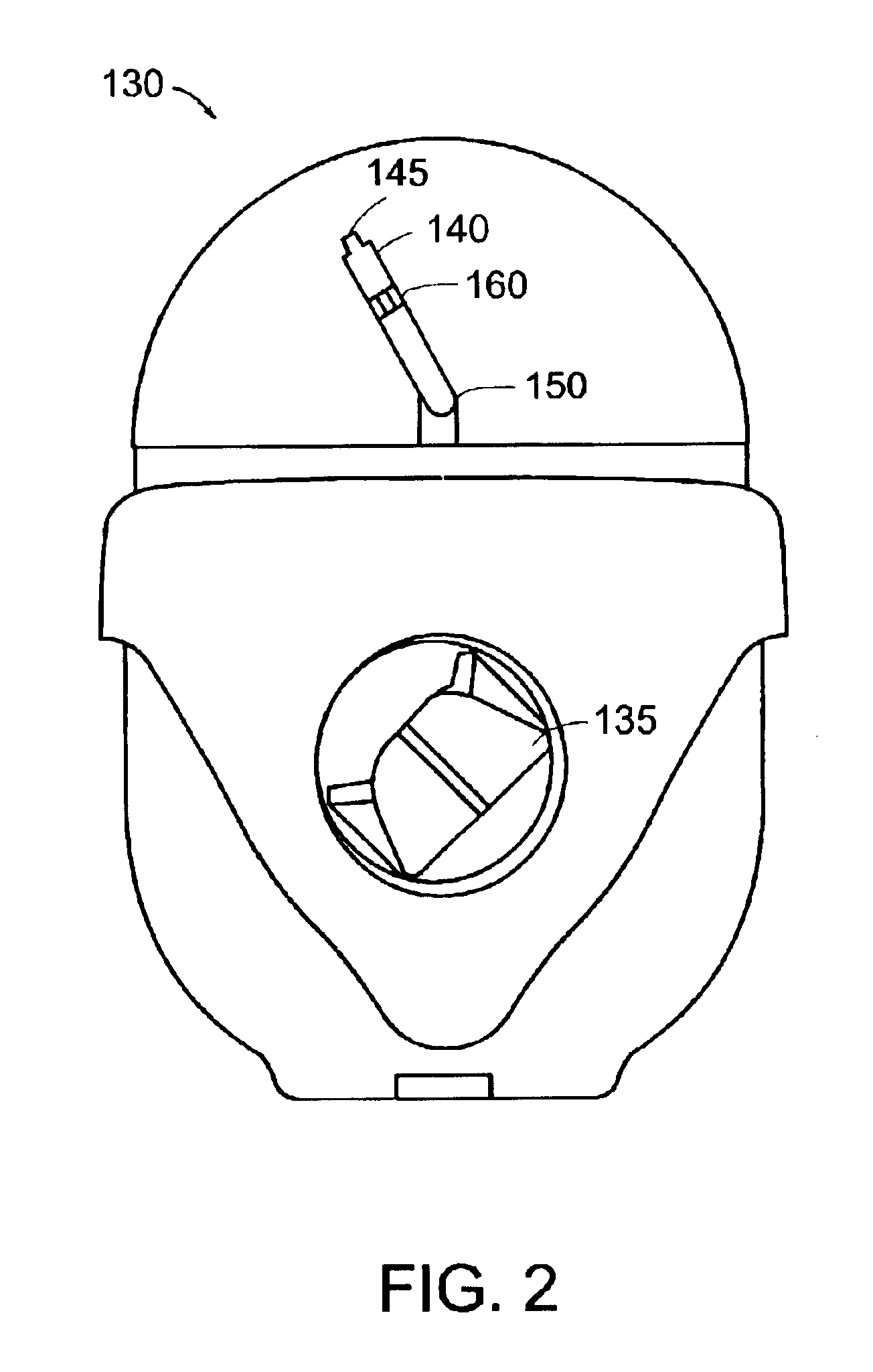

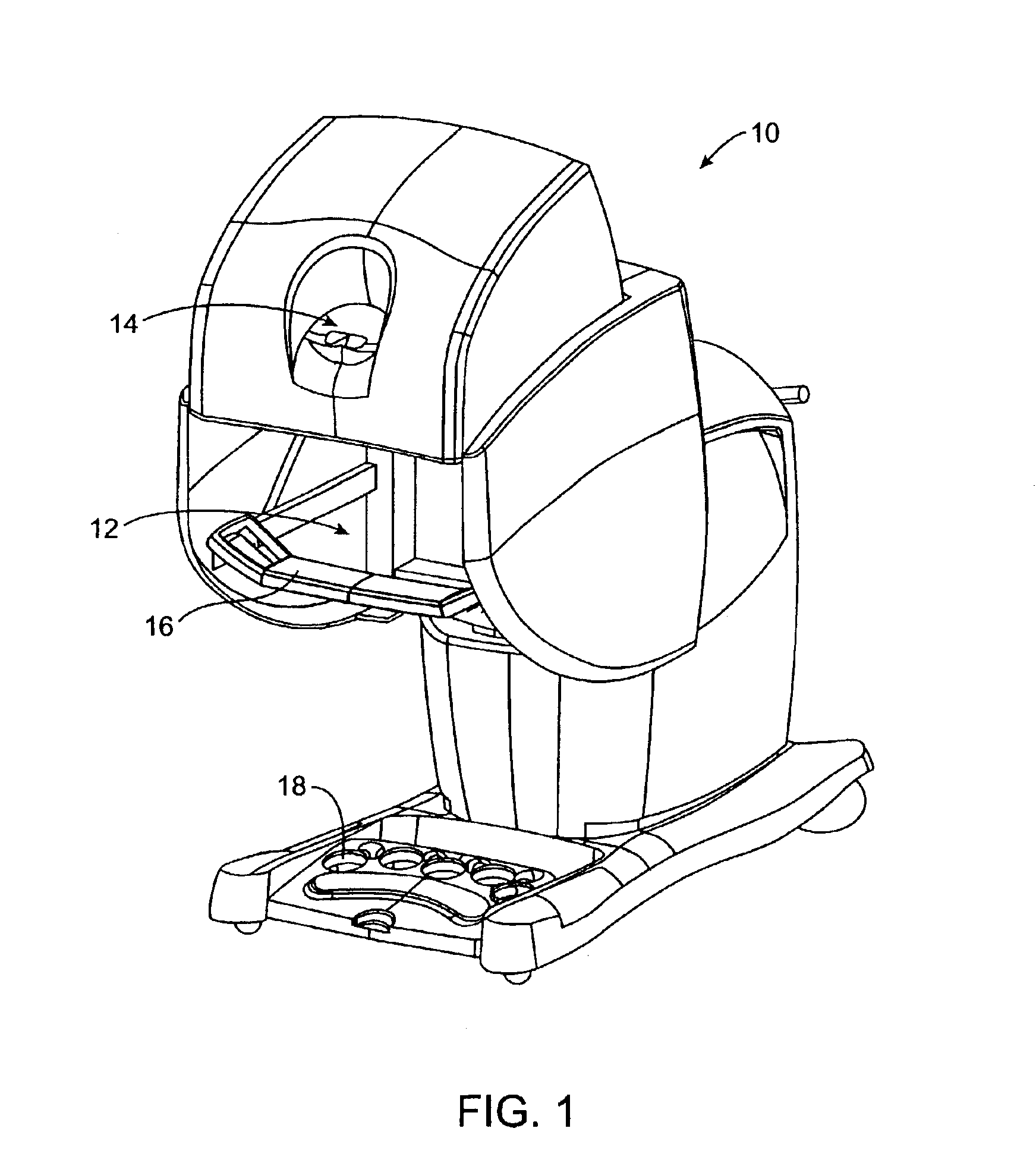

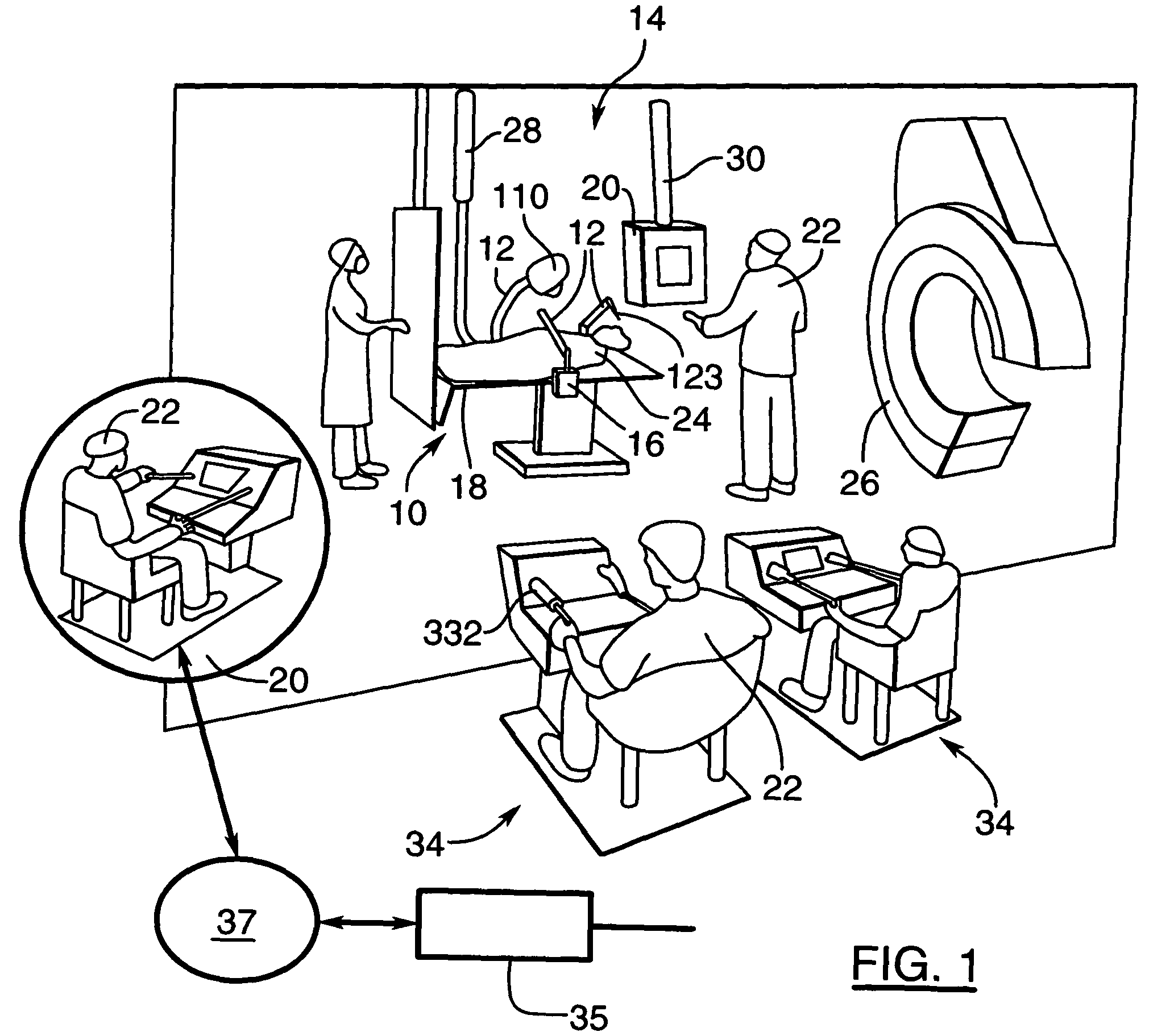

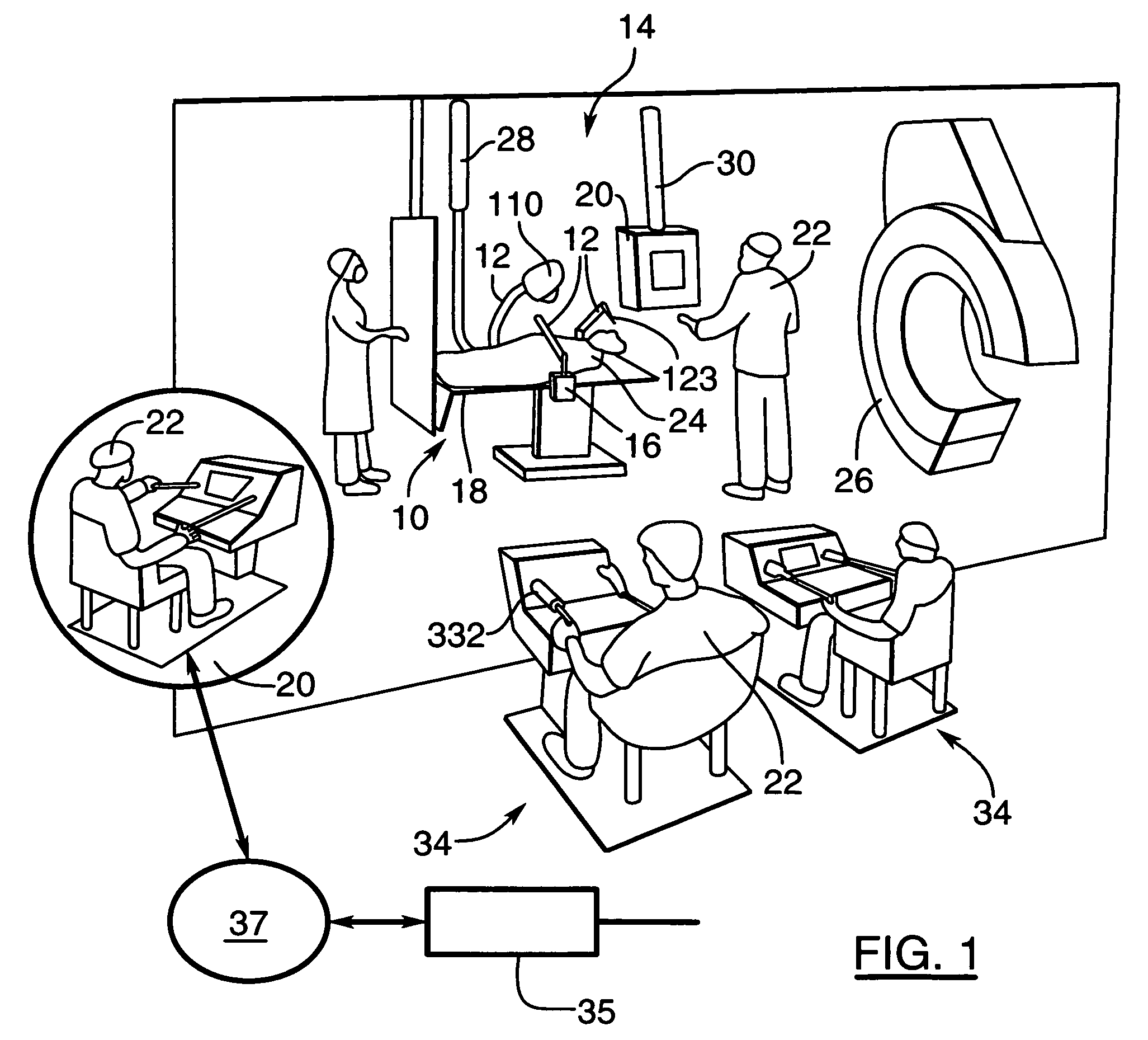

Microsurgical robot system

ActiveUS7155316B2Minimize patient riskComplete efficientlyProgramme-controlled manipulatorEndoscopesMicroscopic observationDisplay device

A robot system for use in surgical procedures has two movable arms each carried on a wheeled base with each arm having a six of degrees of freedom of movement and an end effector which can be rolled about its axis and an actuator which can slide along the axis for operating different tools adapted to be supported by the effector. Each end effector including optical force sensors for detecting forces applied to the tool by engagement with the part of the patient. A microscope is located at a position for viewing the part of the patient. The position of the tool tip can be digitized relative to fiducial markers visible in an MRI experiment. The workstation and control system has a pair of hand-controllers simultaneously manipulated by an operator to control movement of a respective one or both of the arms. The image from the microscope is displayed on a monitor in 2D and stereoscopically on a microscope viewer. A second MRI display shows an image of the part of the patient the real-time location of the tool. The robot is MRI compatible and can be configured to operate within a closed magnet bore. The arms are driven about vertical and horizontal axes by piezoelectric motors.

Owner:DEERFIELD IMAGING INC

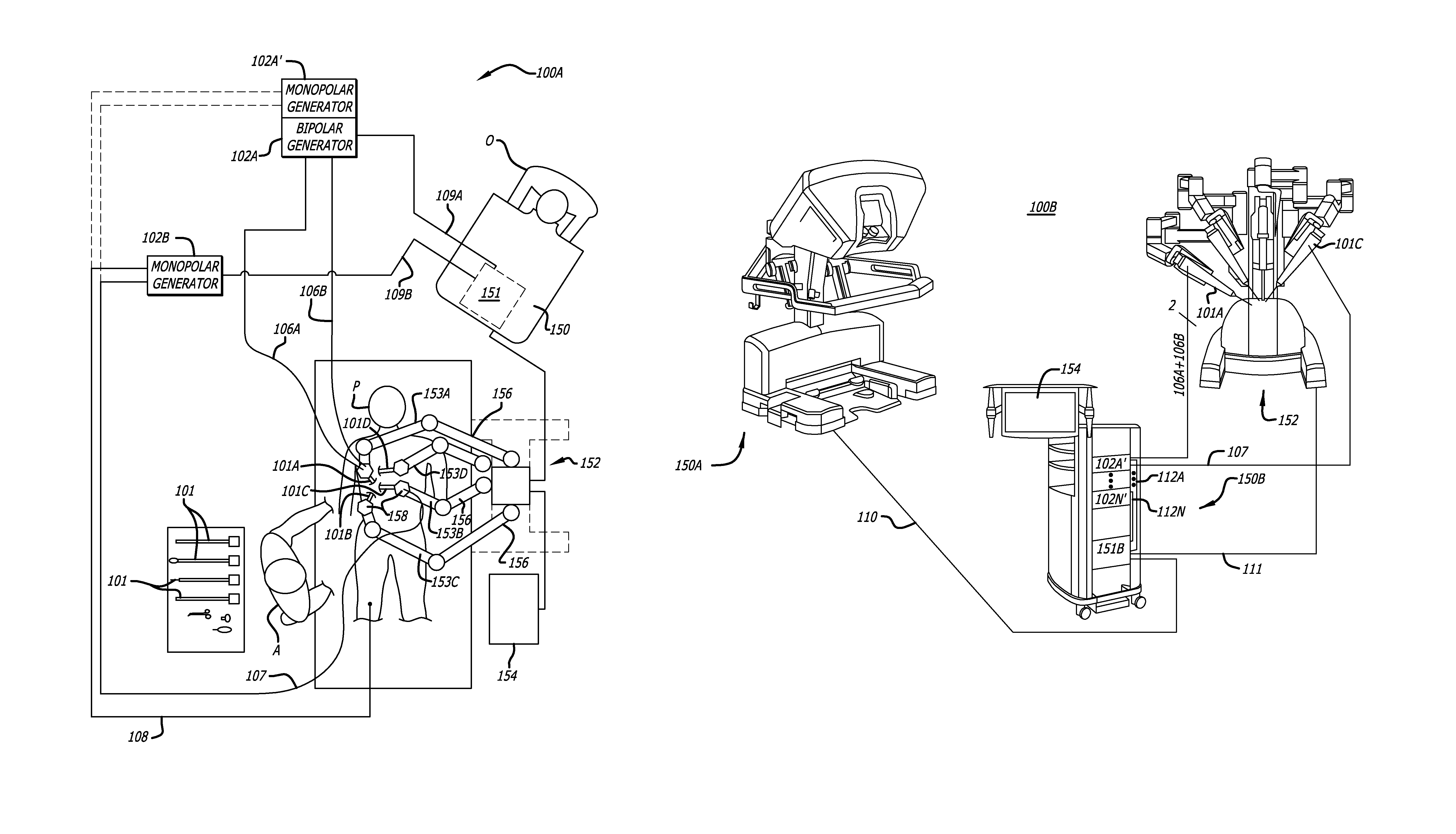

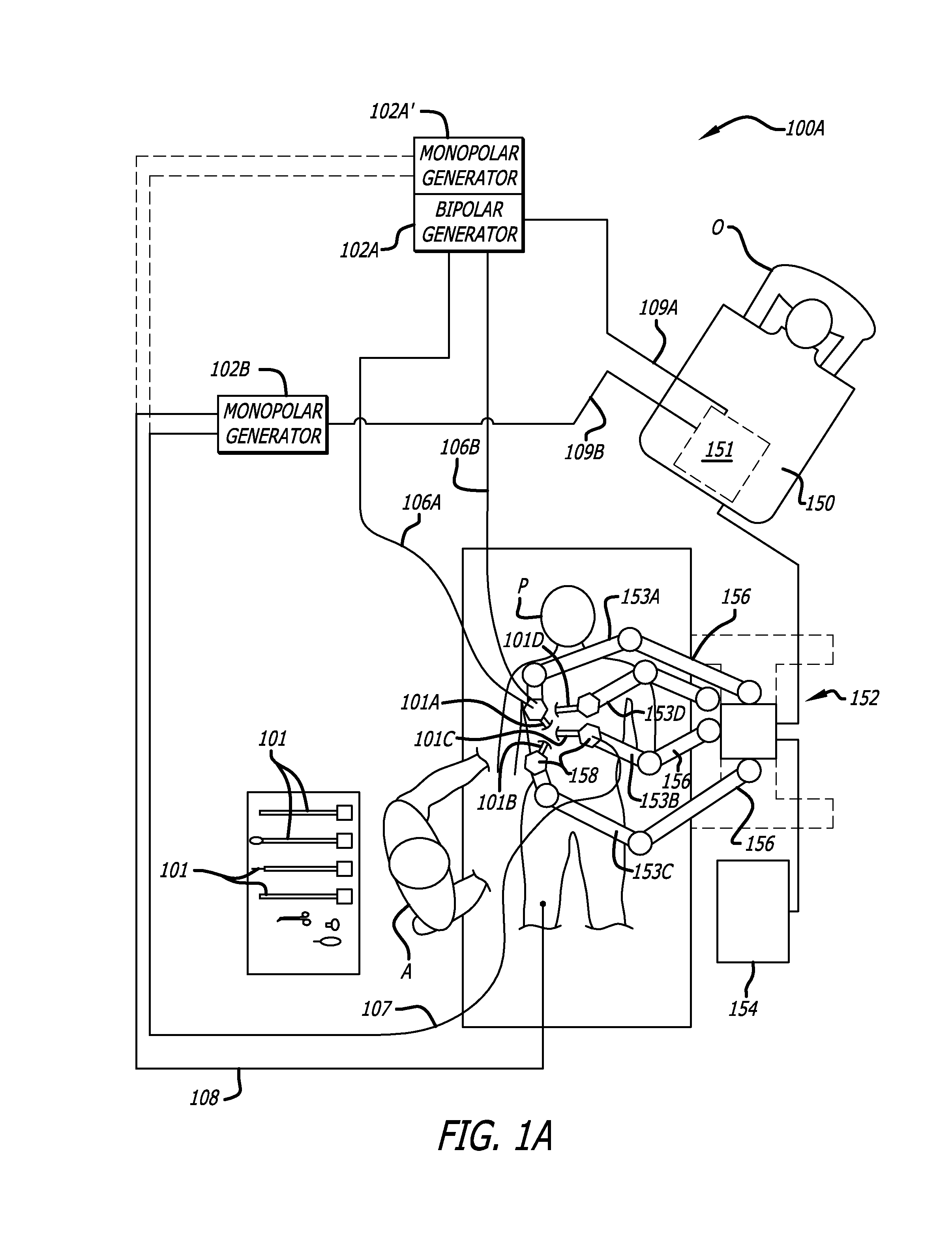

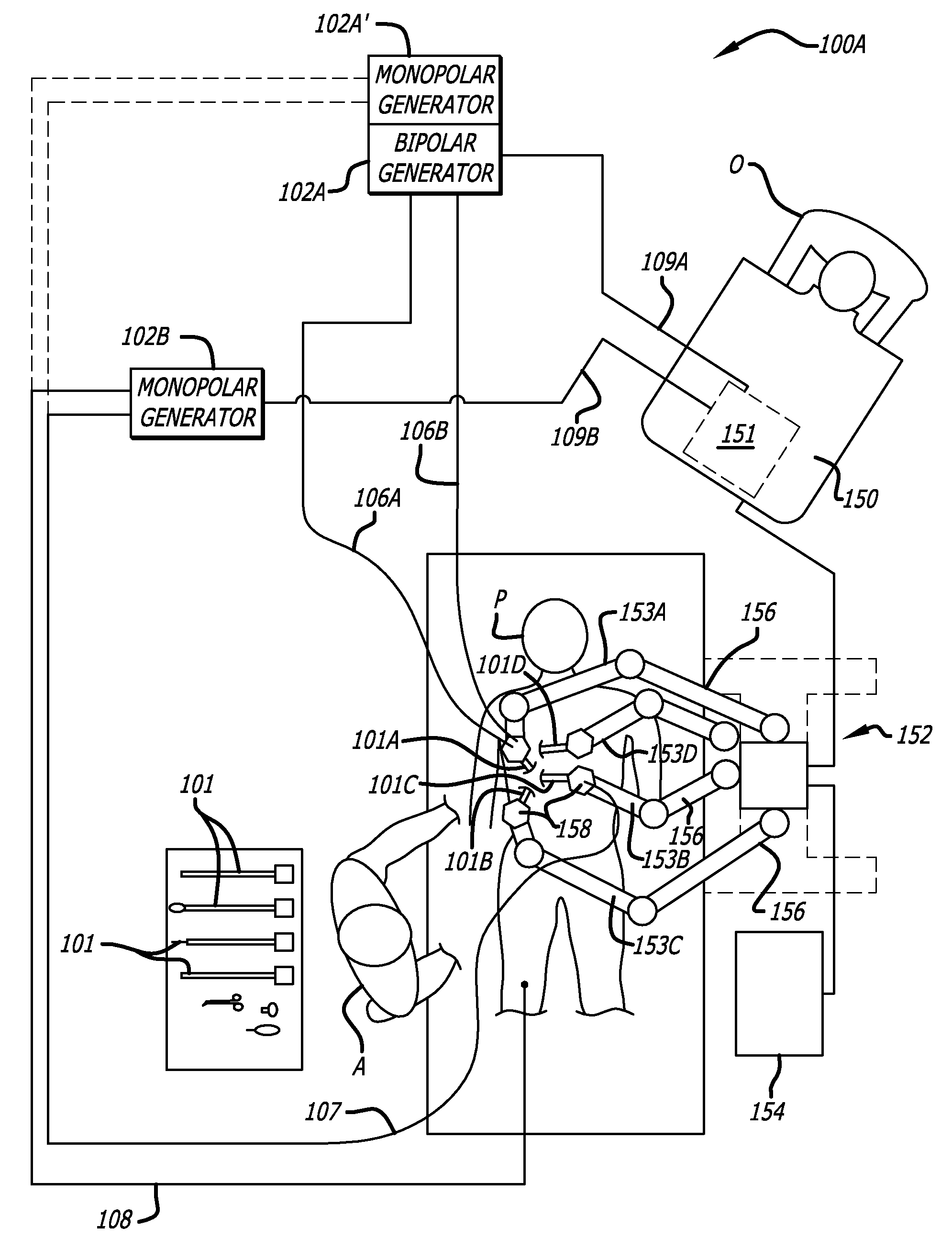

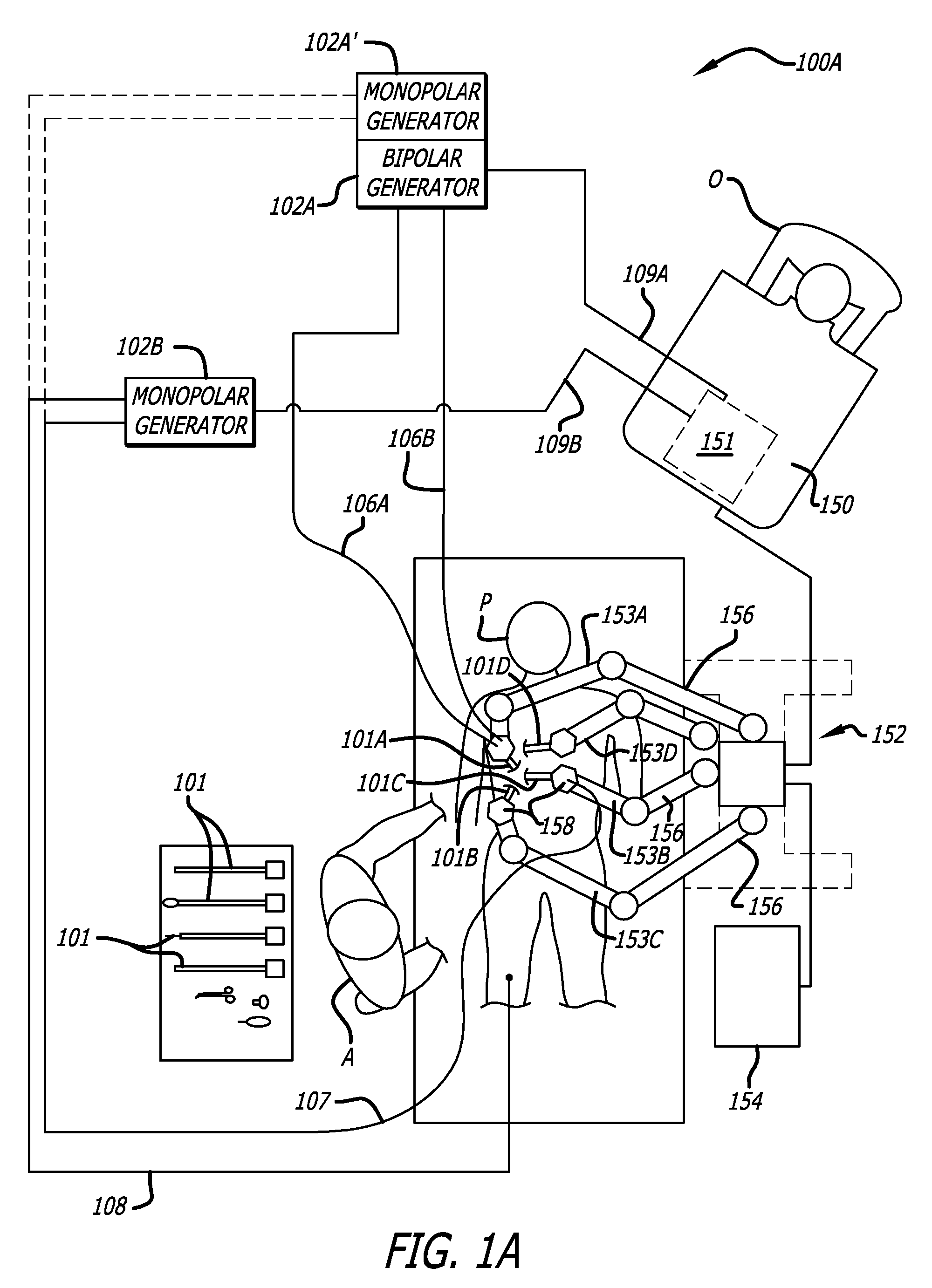

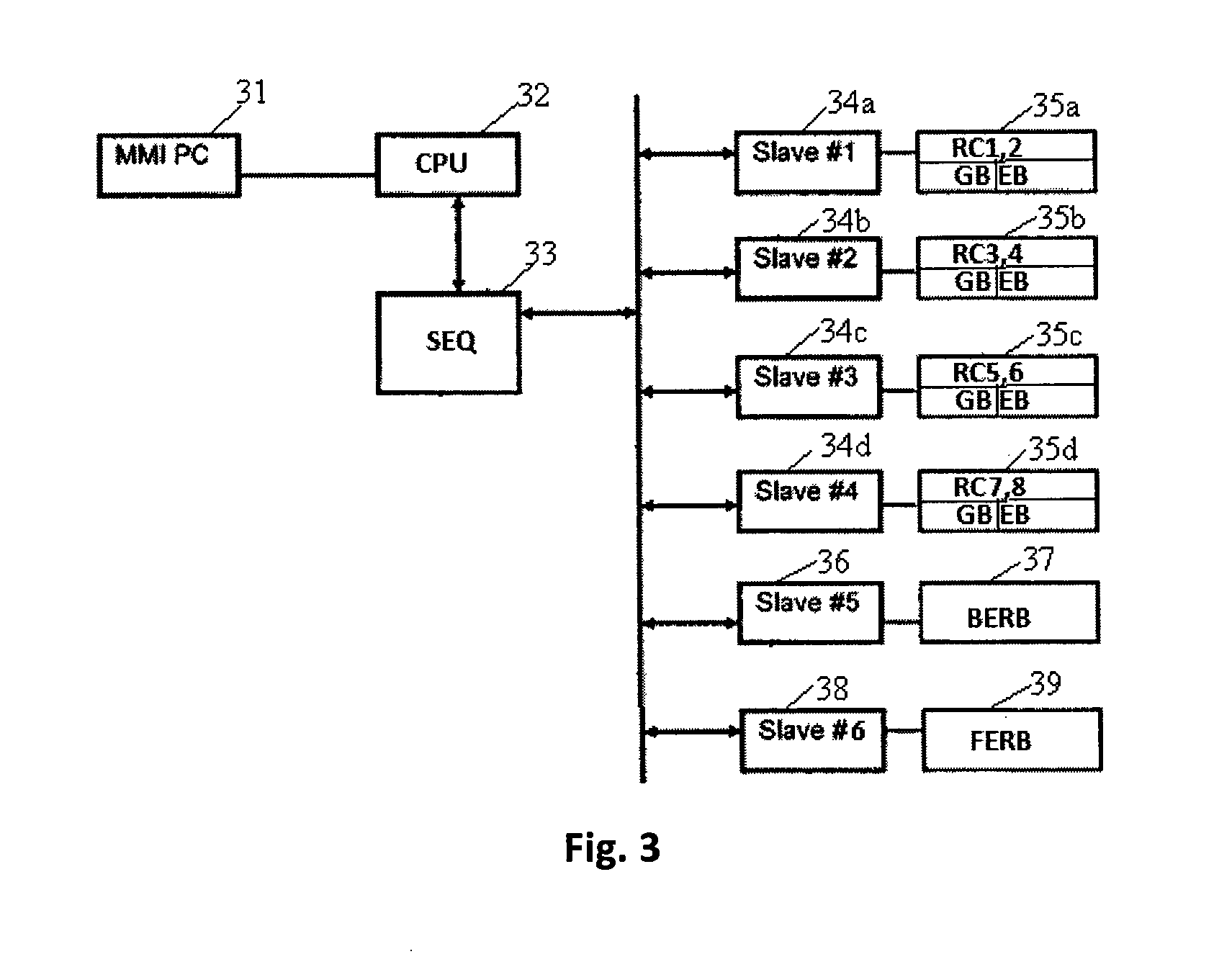

Adaptable integrated energy control system for electrosurgical tools in robotic surgical systems

A method for a minimally invasive surgical system is disclosed including reading first tool information from a storage device in a first robotic surgical tool mounted to a first robotic arm to at least determine a first tool type; reading equipment information about one or more remote controlled equipment for control thereof; comparing the first tool information with the equipment information to appropriately match a first remote controlled equipment of the one or more remote controlled equipment to the first robotic surgical tool; and mapping one or more user interface input devices of a first control console to control the first remote controlled equipment to support a function of the first robotic surgical tool.

Owner:INTUITIVE SURGICAL OPERATIONS INC

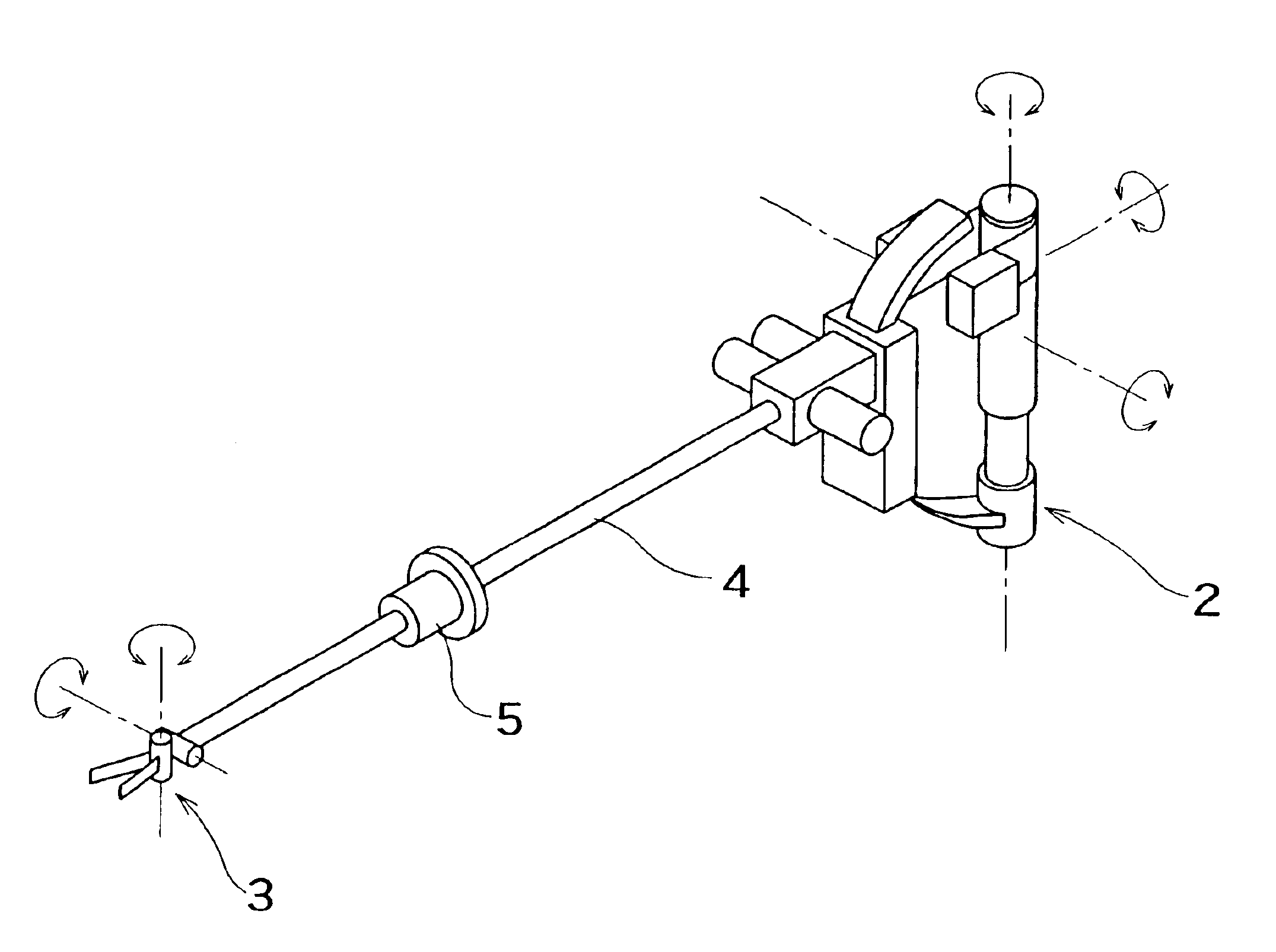

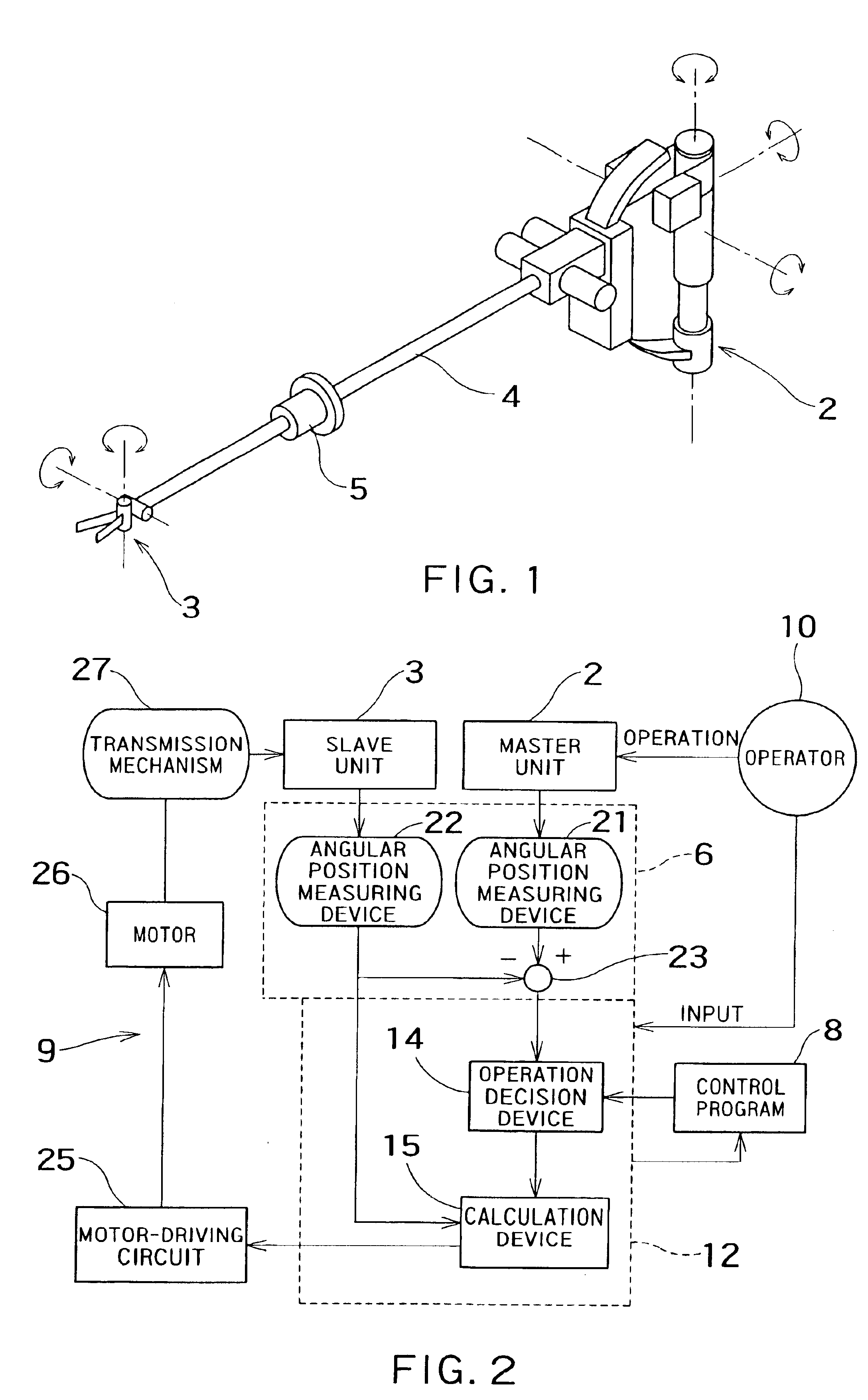

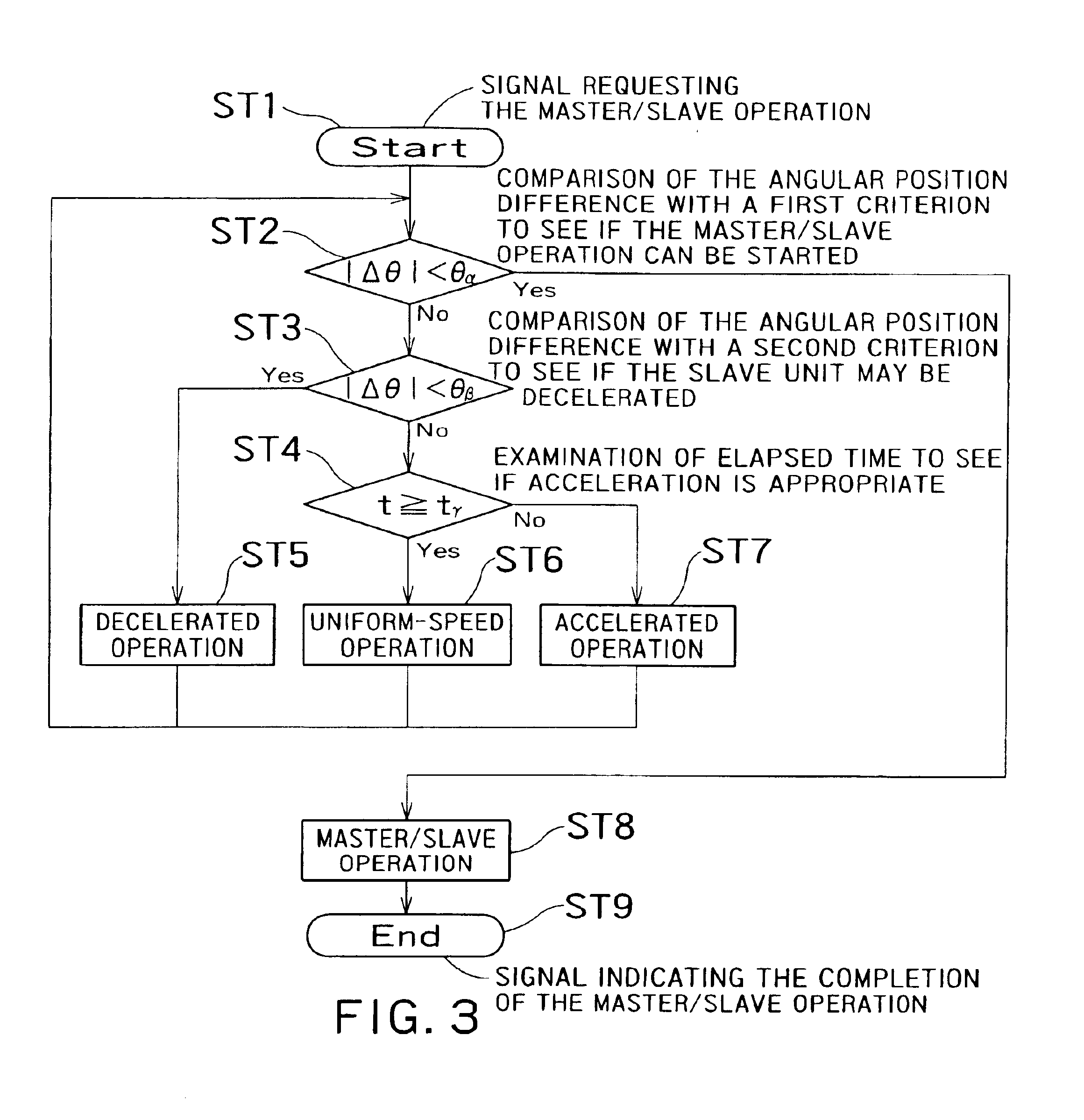

Medical manipulator and method of controlling the same

InactiveUS6853879B2Easy to operateWithout spoiling safetyProgramme-controlled manipulatorDigital data processing detailsOperabilityOperation mode

A medical master / slave manipulator is excellent in operability and capable of reducing burden on the operator. The medical master / slave manipulator includes a master unit provided with an operation control portion, a slave unit provided with a working device, an interlocking mechanism interlocking the slave unit with the master unit, an orientation difference measuring mechanism for measuring the orientation difference between the orientation of the master unit and that of the slave unit, and a control mechanism for controlling the slave unit to adjust the orientation of the slave unit to that of the master unit so that the orientation difference is reduced to zero in a transient master / slave operation mode in which an operation mode changes from an unrestricted operation mode to a master / slave operation mode.

Owner:TERUMO KK

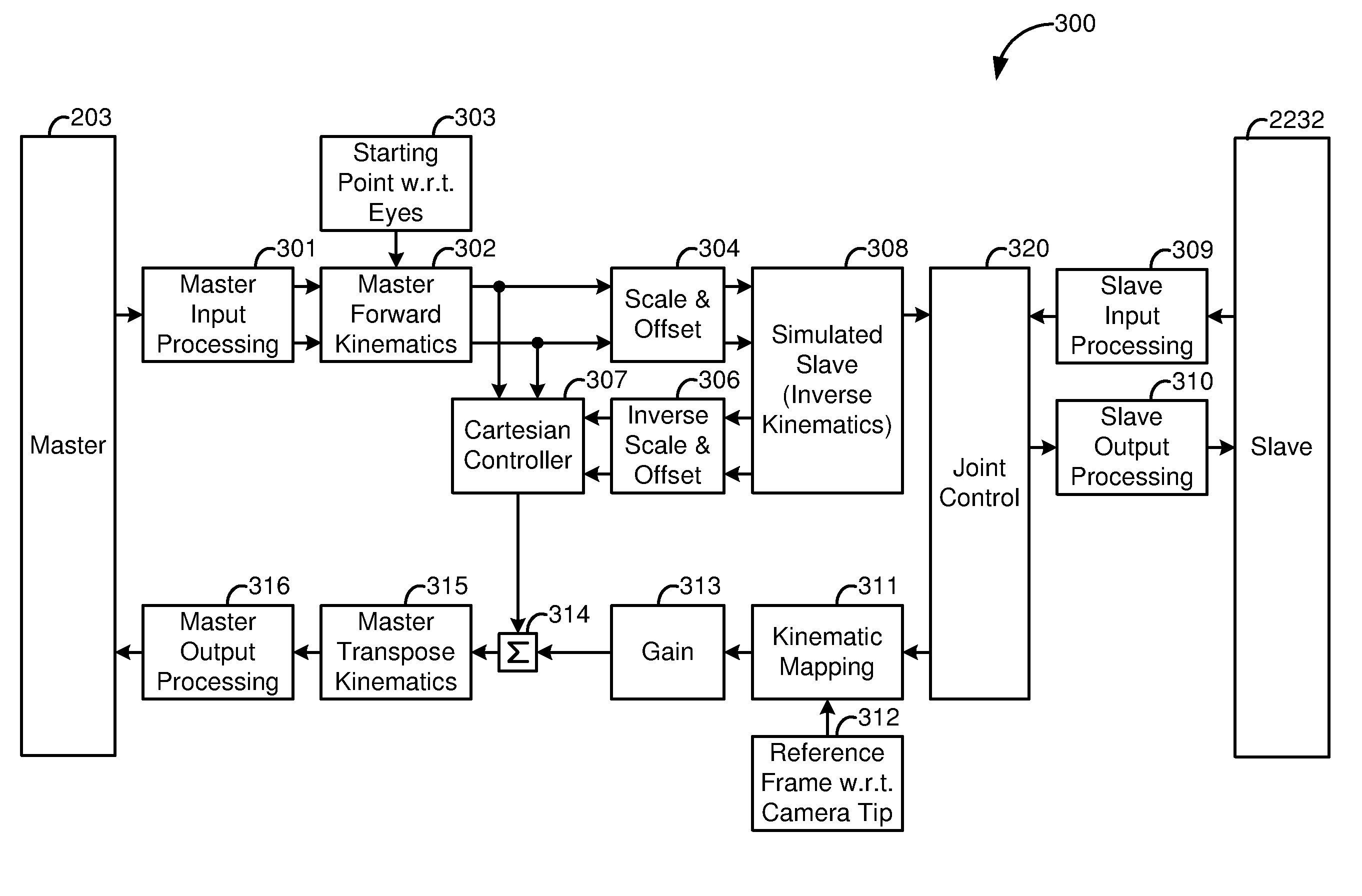

Medical robotic system with coupled control modes

In a coupled control mode, the surgeon directly controls movement of an associated slave manipulator with an input device while indirectly controlling movement of one or more non-associated slave manipulators, in response to commanded motion of the directly controlled slave manipulator, to achieve a secondary objective. By automatically performing secondary tasks through coupled control modes, the system's usability is enhanced by reducing the surgeon's need to switch to another direct mode to manually achieve the desired secondary objective. Thus, coupled control modes allow the surgeon to better focus on performing medical procedures and to pay less attention to managing the system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

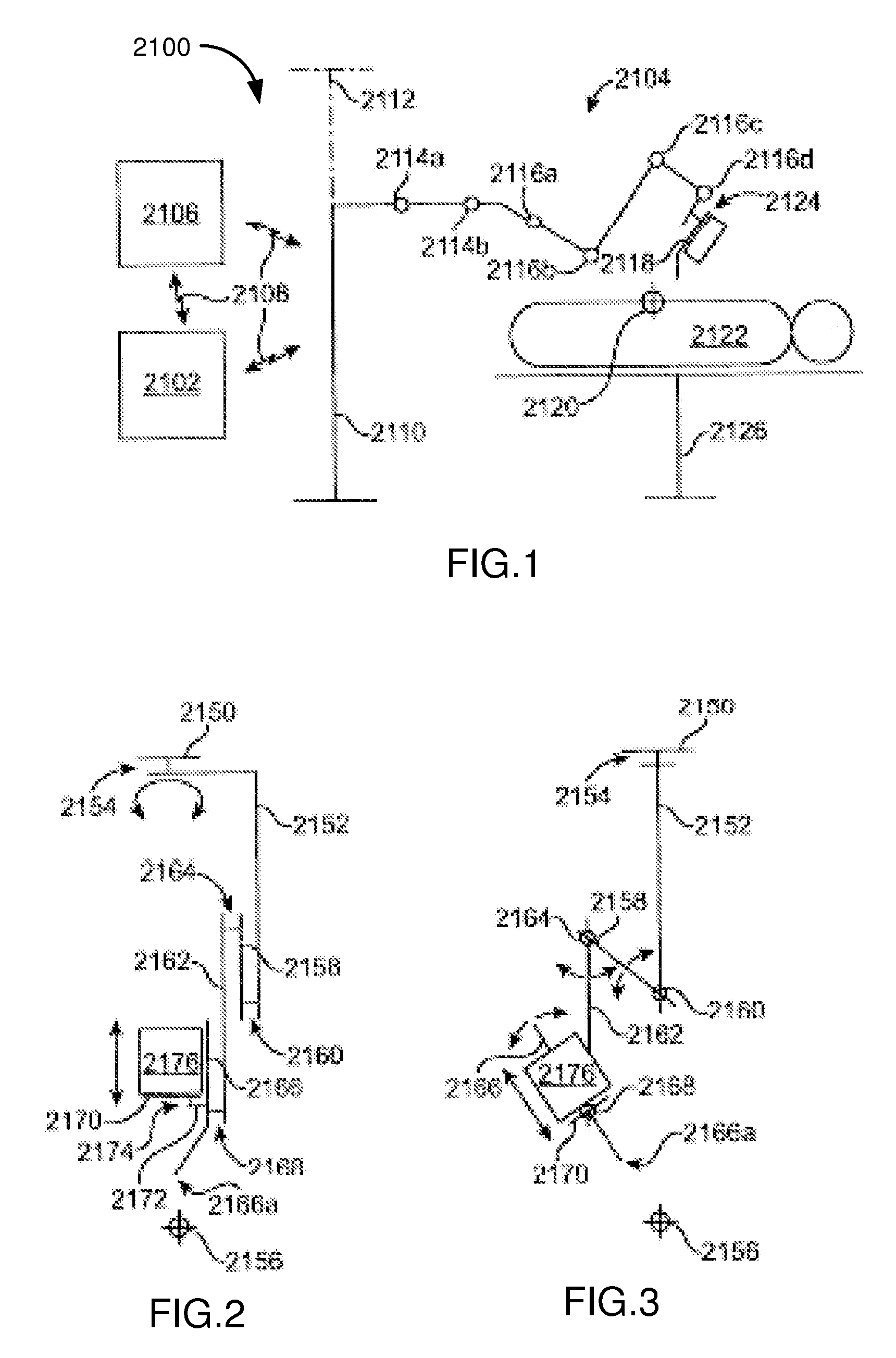

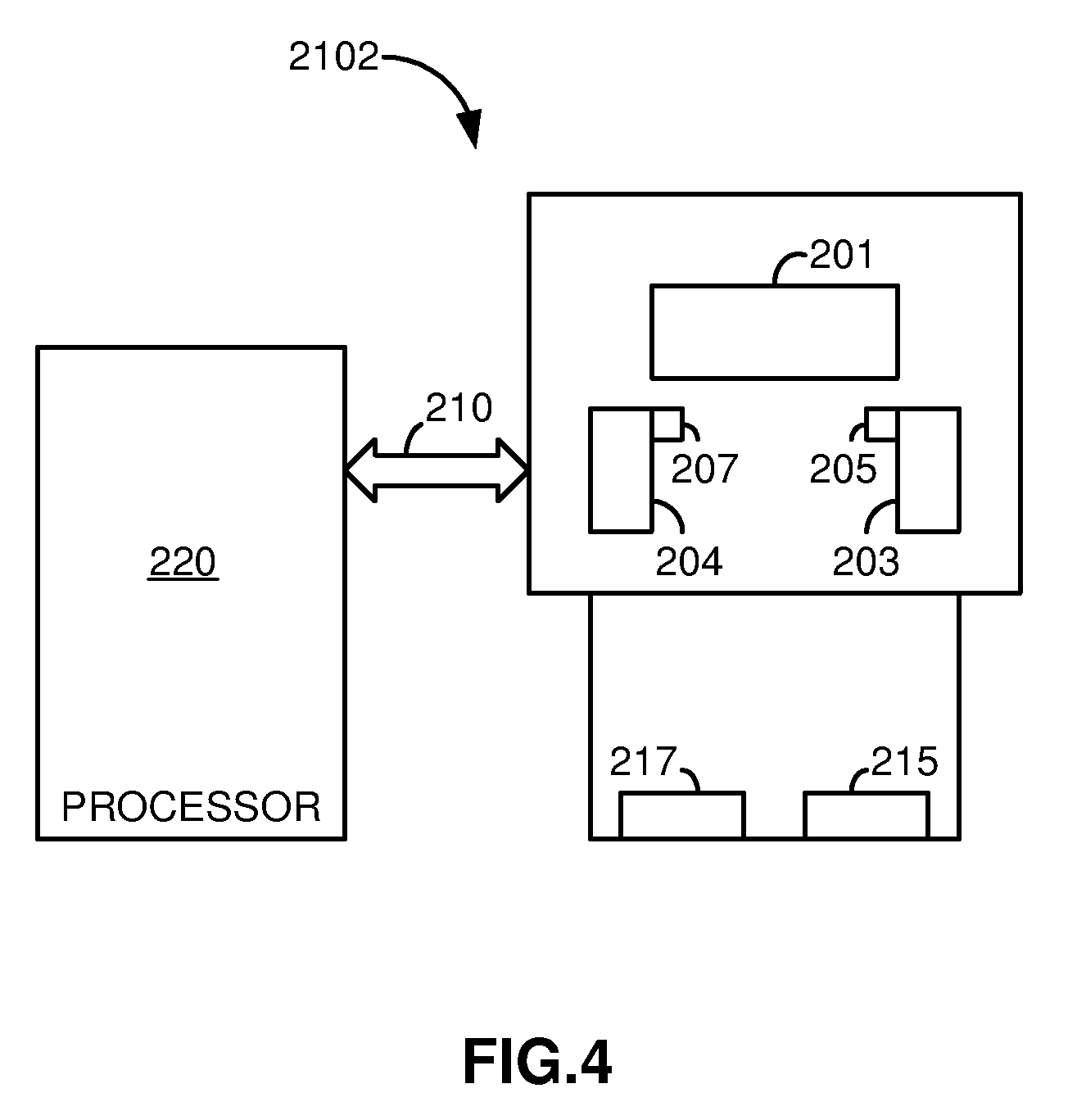

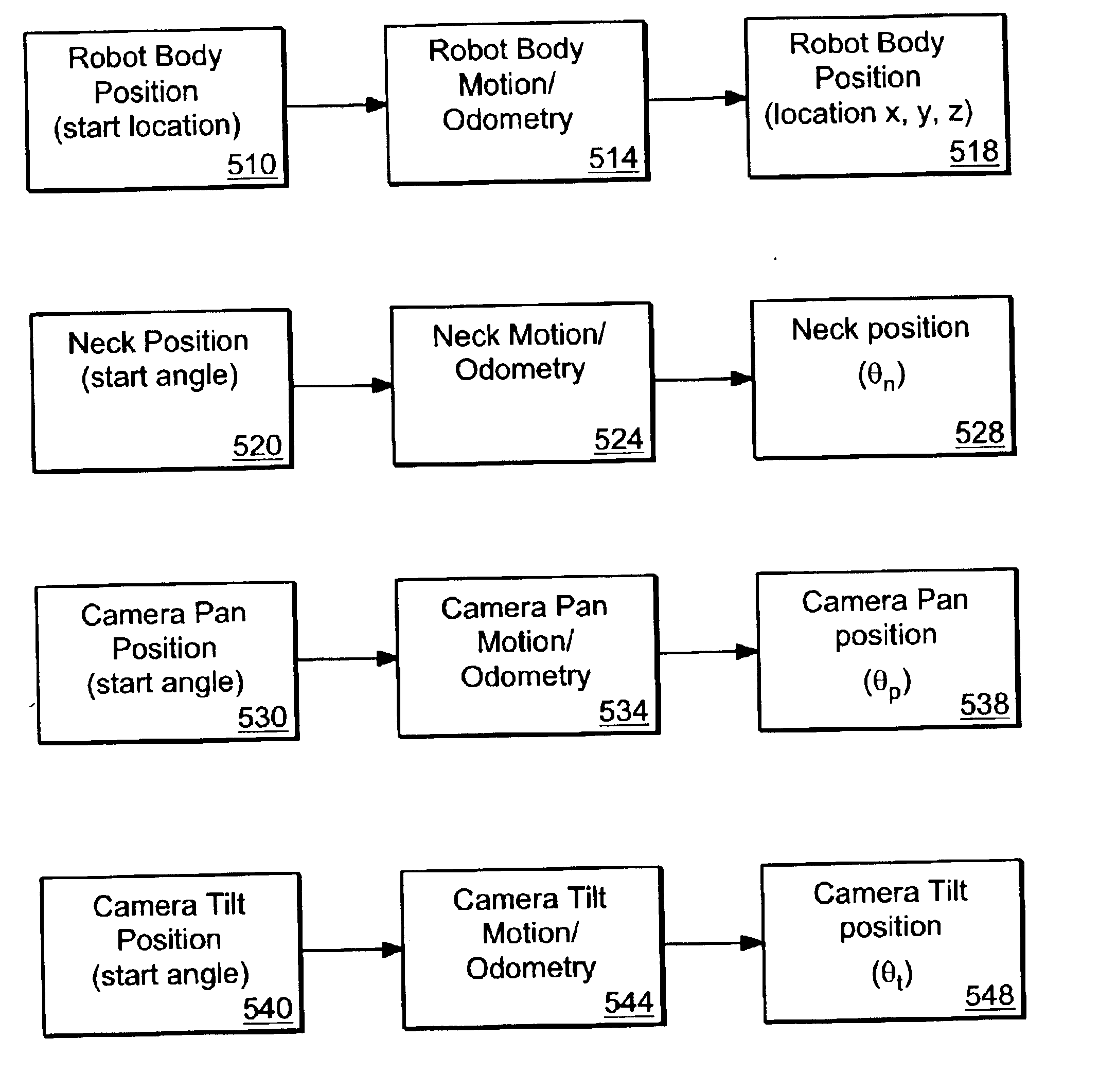

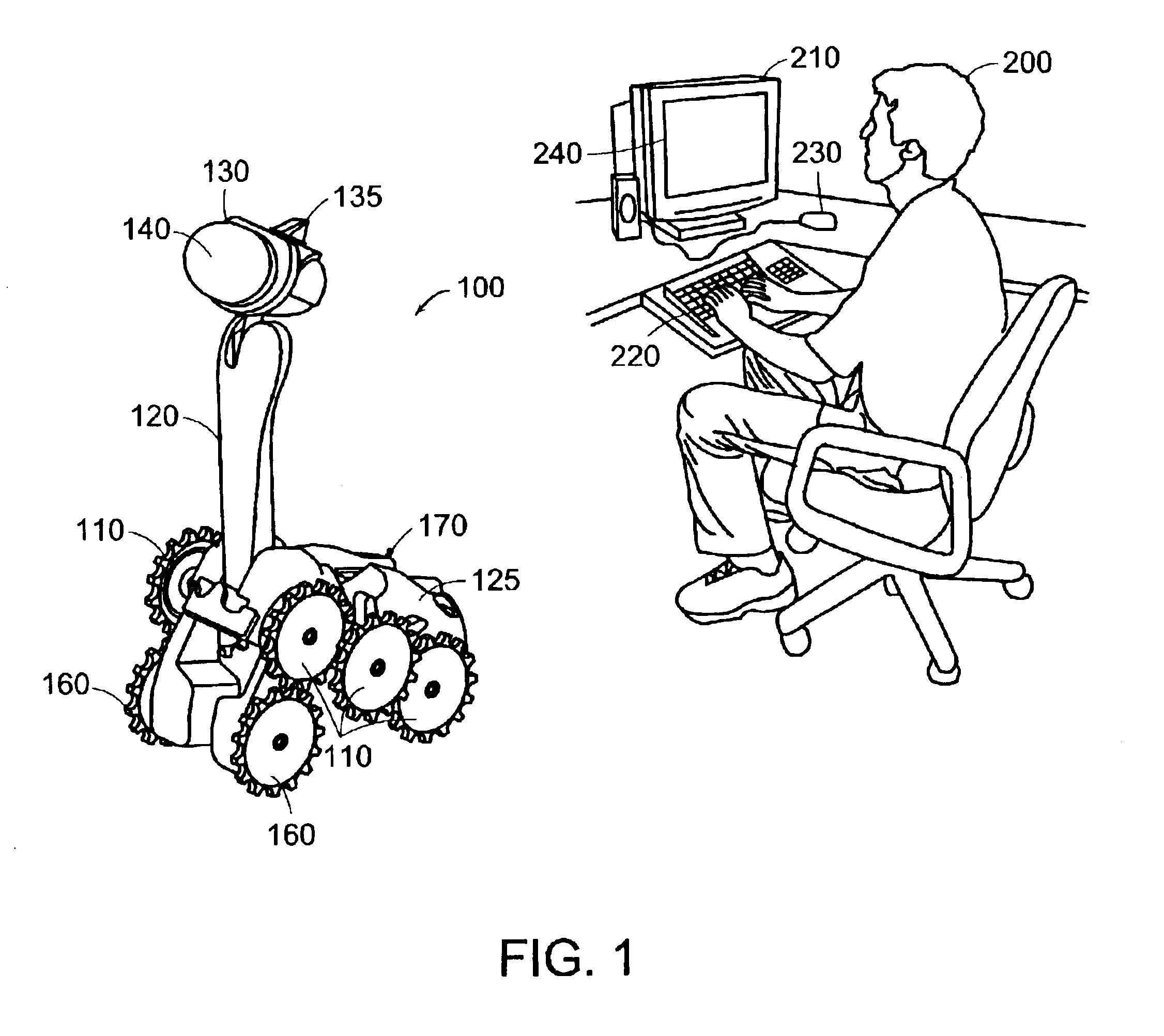

Method and system for remote control of mobile robot

InactiveUS6845297B2Easy to navigateSimplified user interfaceProgramme-controlled manipulatorBronchoscopesRobot environmentTele operation

A system for tele-operating a robot in an environment includes a user interface for controlling the tele-operation of the robot, an imaging device associated with the robot for providing image information representative of the environment around the robot, means for transmitting the image information to the user interface, means for converting the image information to a user-perceptible image at the user interface, means for designating one or more waypoints located anywhere in the user-perceptible image towards which the robot will move, the waypoint in the user-perceptible image towards which the robot will first move being designated as the active waypoint using an icon, means for automatically converting the location of the active waypoint in the user-perceptible image into a target location having x, y, and z coordinates in the environment of the robot, means for providing real-time instructions to the robot from the user interface to move the robot from the robot's current location in the environment to the x, y, and z coordinates of the target location in the environment, and means for moving the icon representing the active waypoint in the user-perceptible image to a new location in the user-perceptible image while the robot is executing the real-time instruction, wherein the location-converting means automatically converts the new location of the icon representing the active waypoint into a new target location having x, y, and z coordinates in the environment of the robot towards which the robot will move.

Owner:IROBOT CORP

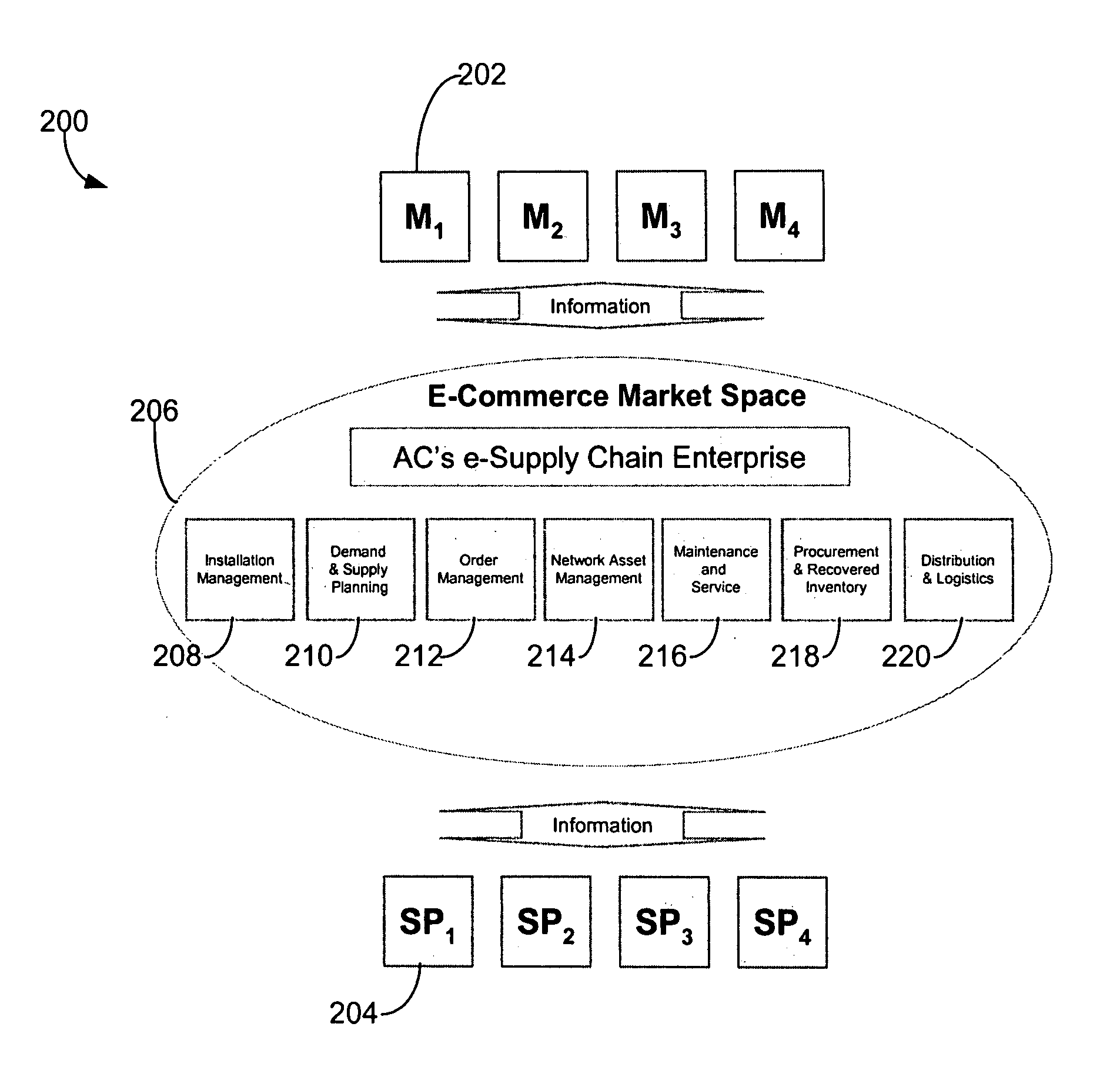

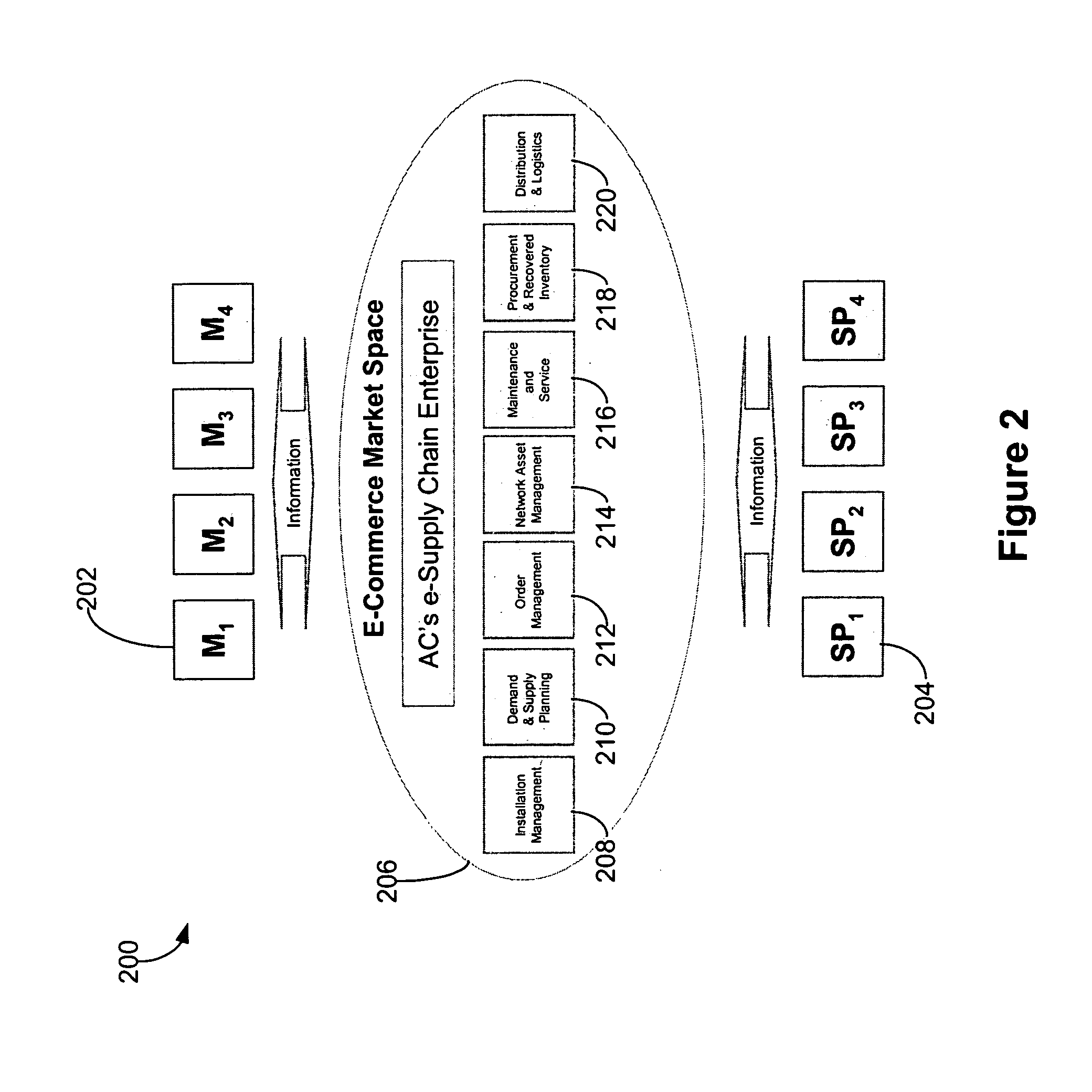

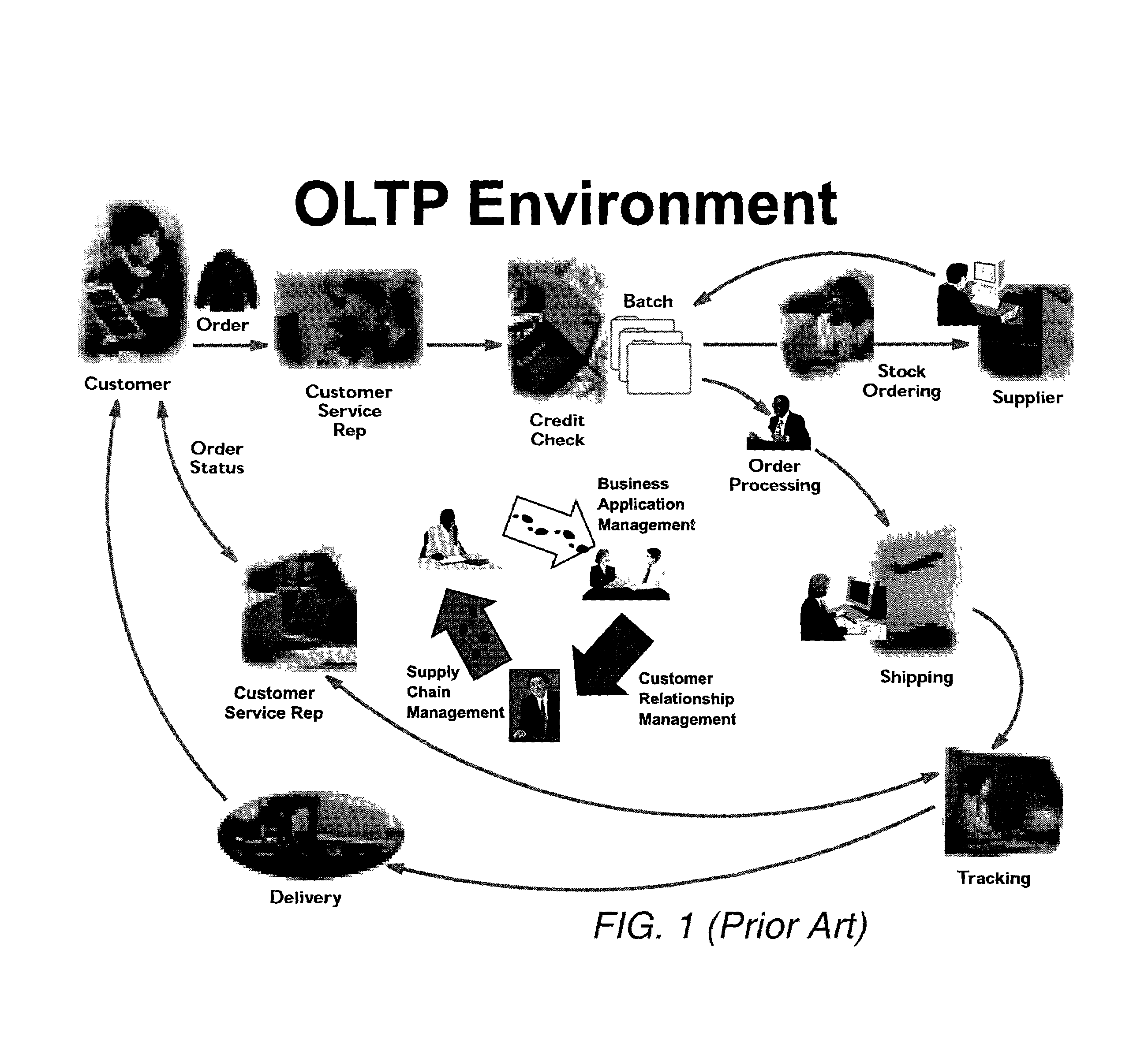

Scheduling and planning maintenance and service in a network-based supply chain environment

InactiveUS7716077B1Simple personalization processTechnology managementResourcesData synchronizationExternal data

A system, method and article of manufacture are provided for administrating a network-based supply chain on a network. Operation of entities is monitored. Entities include server processes, disk space, memory availability, CPU utilization, access time to a server, and / or a number of connections in a network-based supply chain. Items including merchandising content, currency exchange rates, tax rates, and / or pricing in the network-based supply chain are updated at predetermined intervals. In addition, external data stored separately from the network-based supply chain is synchronized with internal data stored on the network-based supply chain. Contact information received from users of the network-based supply chain is also managed. Users include service providers and manufacturer utilizing the network-based supply chain. The items are altered based on profiles of the users of the network-based supply chain.

Owner:ACCENTURE GLOBAL SERVICES LTD

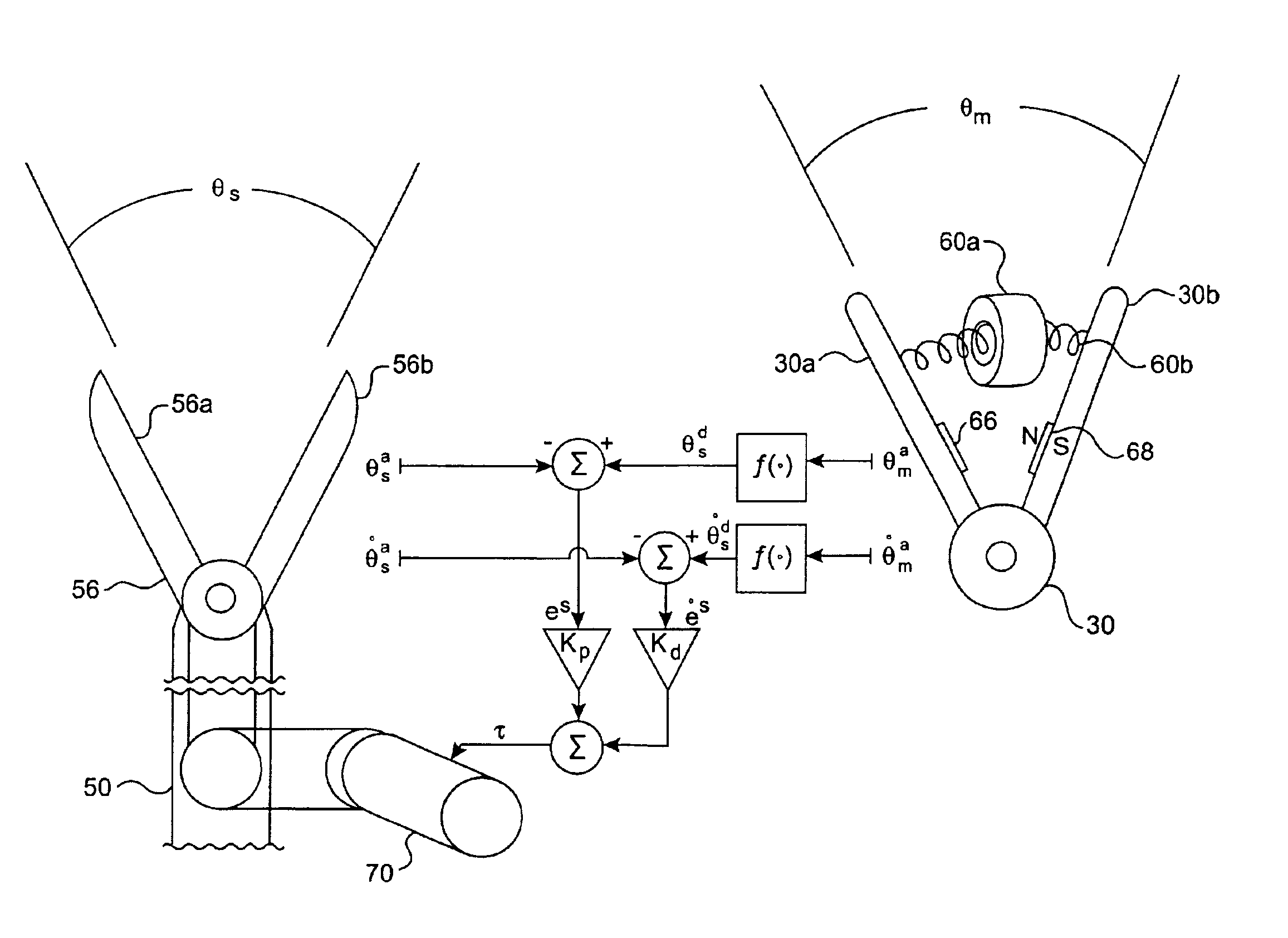

Grip strength with tactile feedback for robotic surgery

InactiveUS6879880B2Enhanced telepresenceImprove grip strengthProgramme-controlled manipulatorDigital data processing detailsSurgical robotEngineering

Surgical robots and other telepresence systems have enhanced grip actuation for manipulating tissues and objects with small sizes. A master / slave system is used in which an error signal or gain is artificially altered when grip members are near a closed configuration.

Owner:INTUITIVE SURGICAL OPERATIONS INC

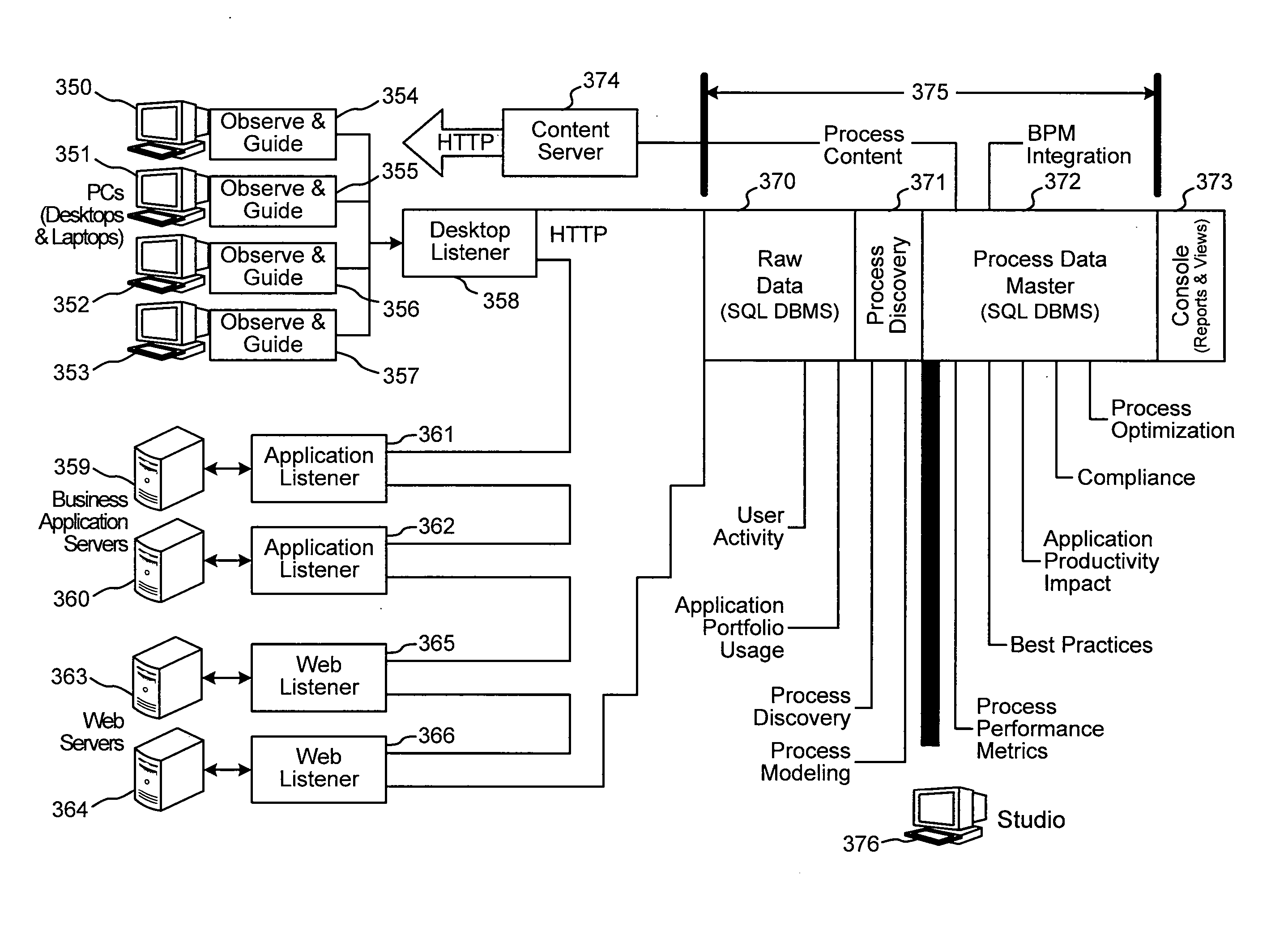

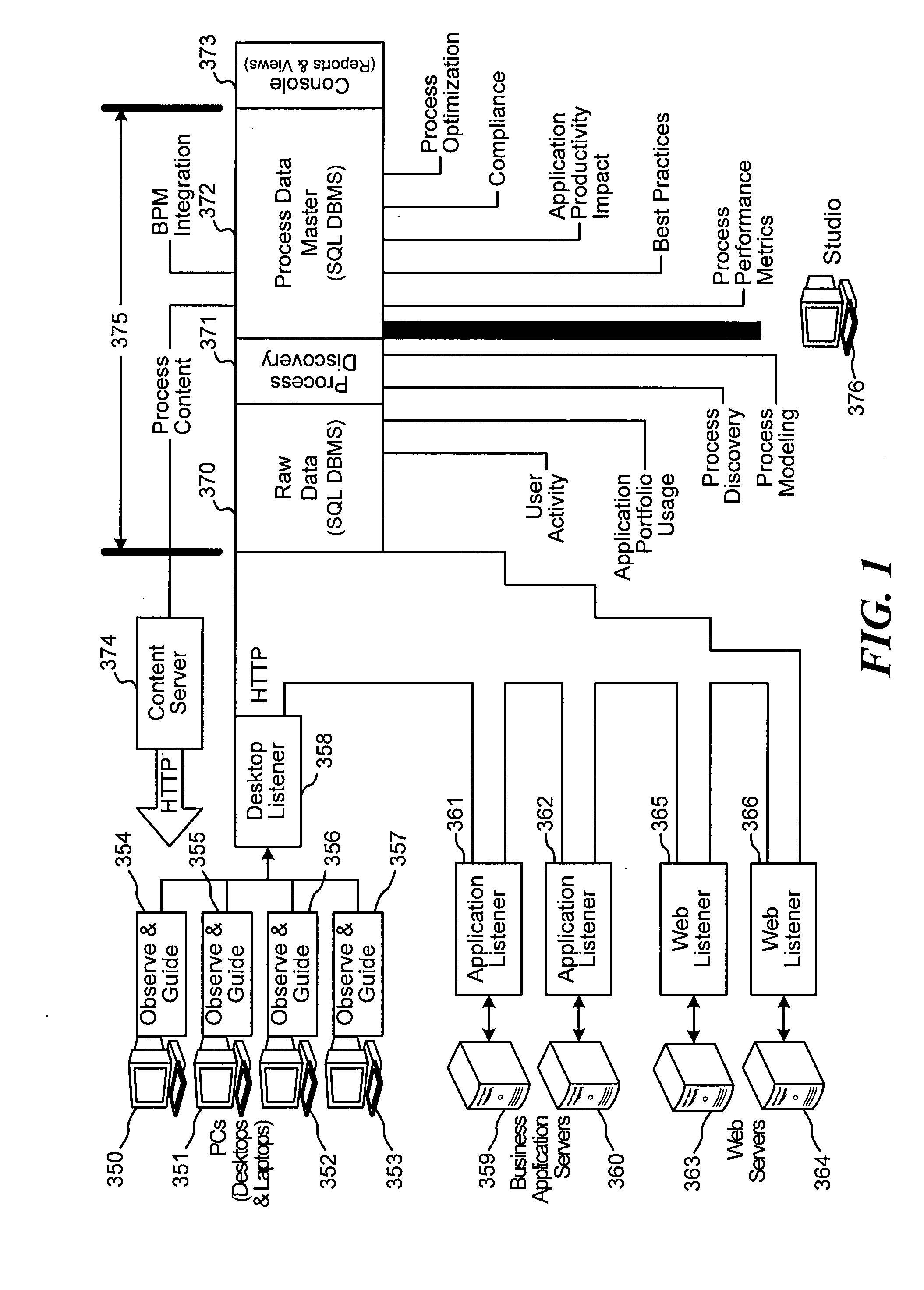

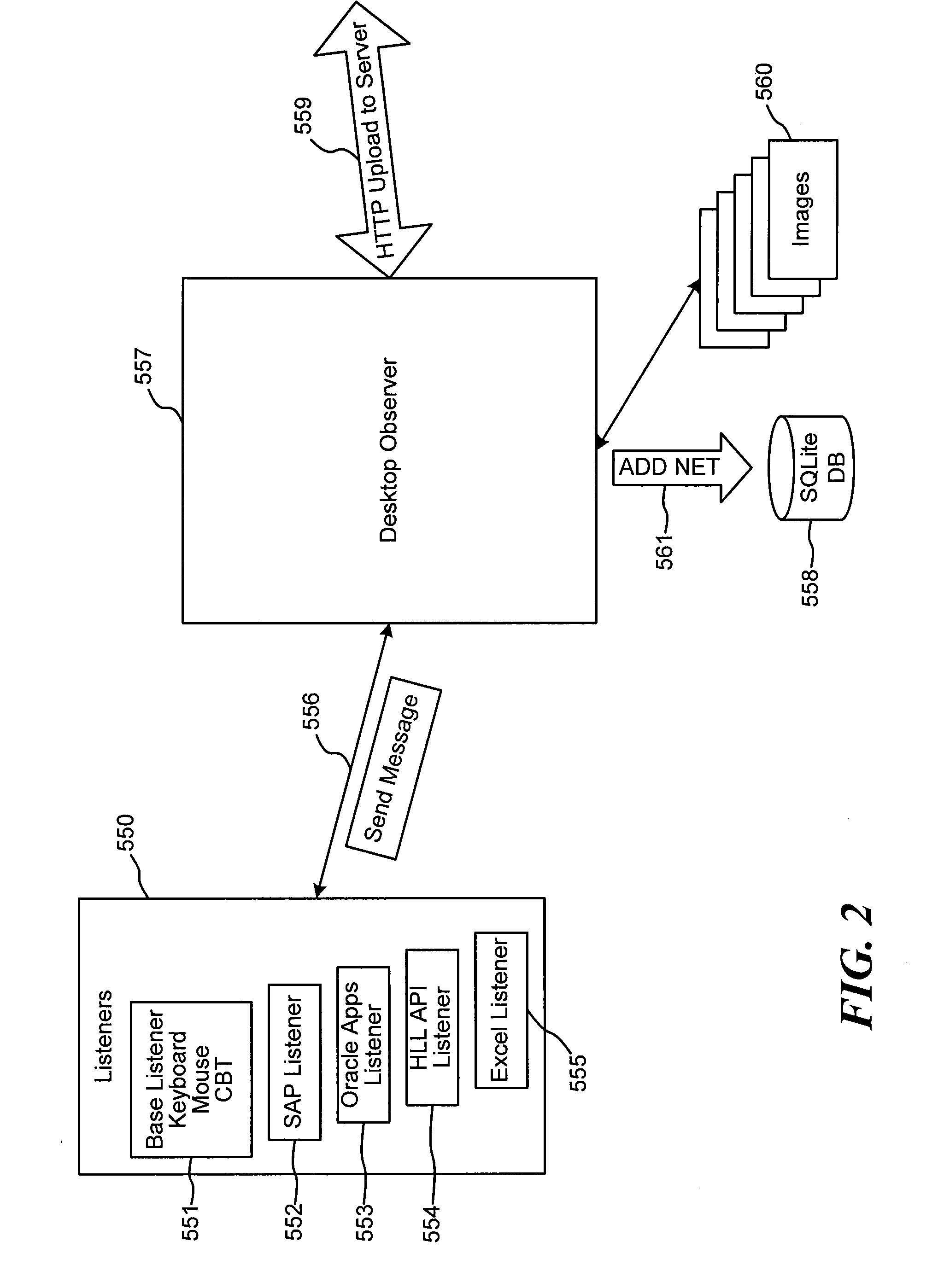

System and method for capture of user actions and use of capture data in business processes

InactiveUS20060184410A1Prevent wrong actionEnsure complianceDigital computer detailsOffice automationGood practiceData storing

Systems and methods are disclosed for capturing data representative of user interactions with a desktop computer, and processing the capture data to identify and analyze business processes performed by the user. The disclosed system comprises listeners that capture key actuations, mouse-clicks, screen information, and other data representative of user interaction with a desktop computer. A desktop observer is provided to accept capture data from listeners, to temporarily store the capture data if necessary, and to pass the capture data to a process intelligence server. The process intelligence server includes a process discovery module the analyzes the capture data and identifies business processes corresponding to the capture data, or models business processes. A process data master storage is provided. A process analysis module is provided to determine performance metrics, best practices, application productivity impacts, compliance, and optimization analysis on the data stored in the process master storage. Methods are disclosed for capture, catalog, combination, correlation, change, compression, and certification.

Owner:QLIP MEDIA

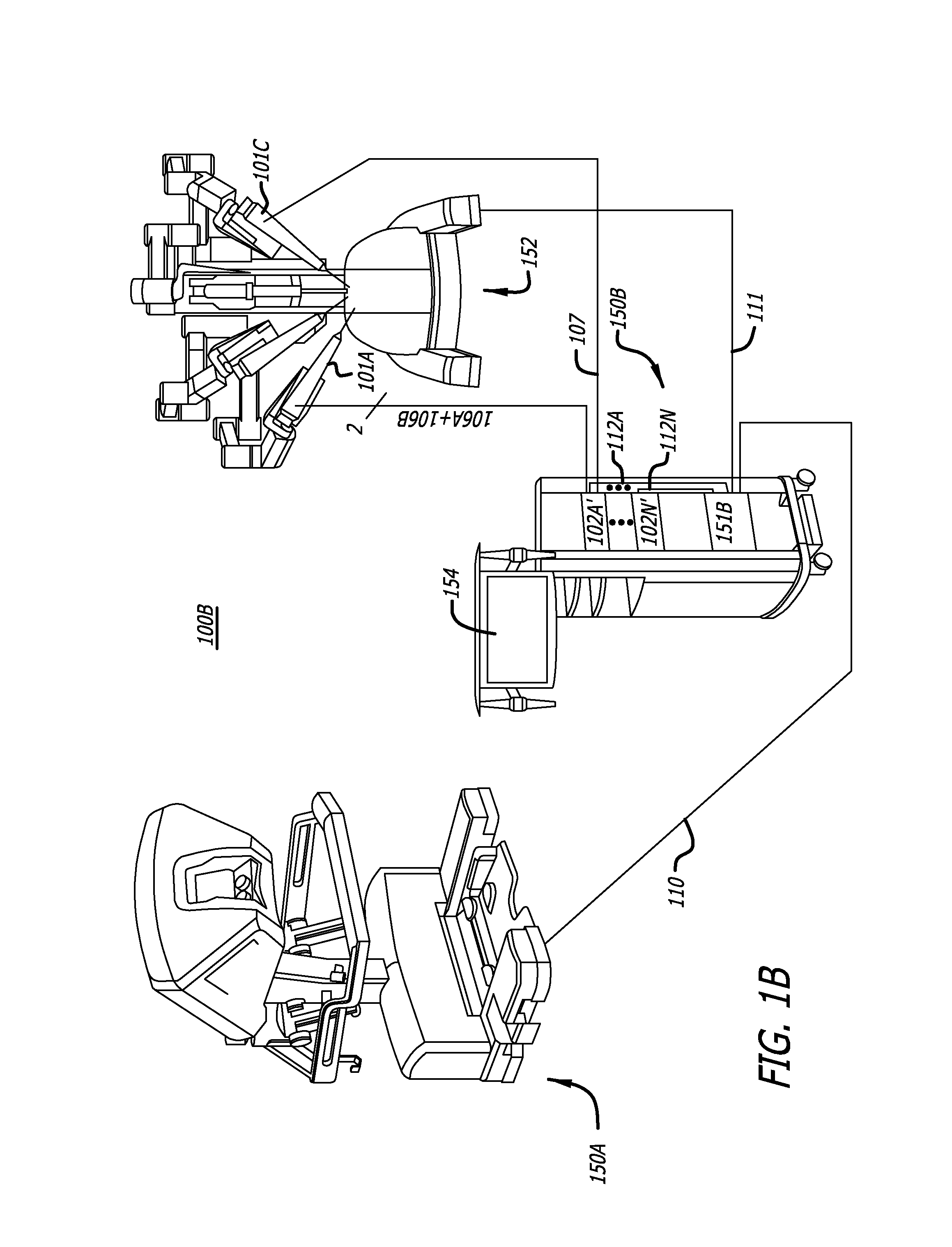

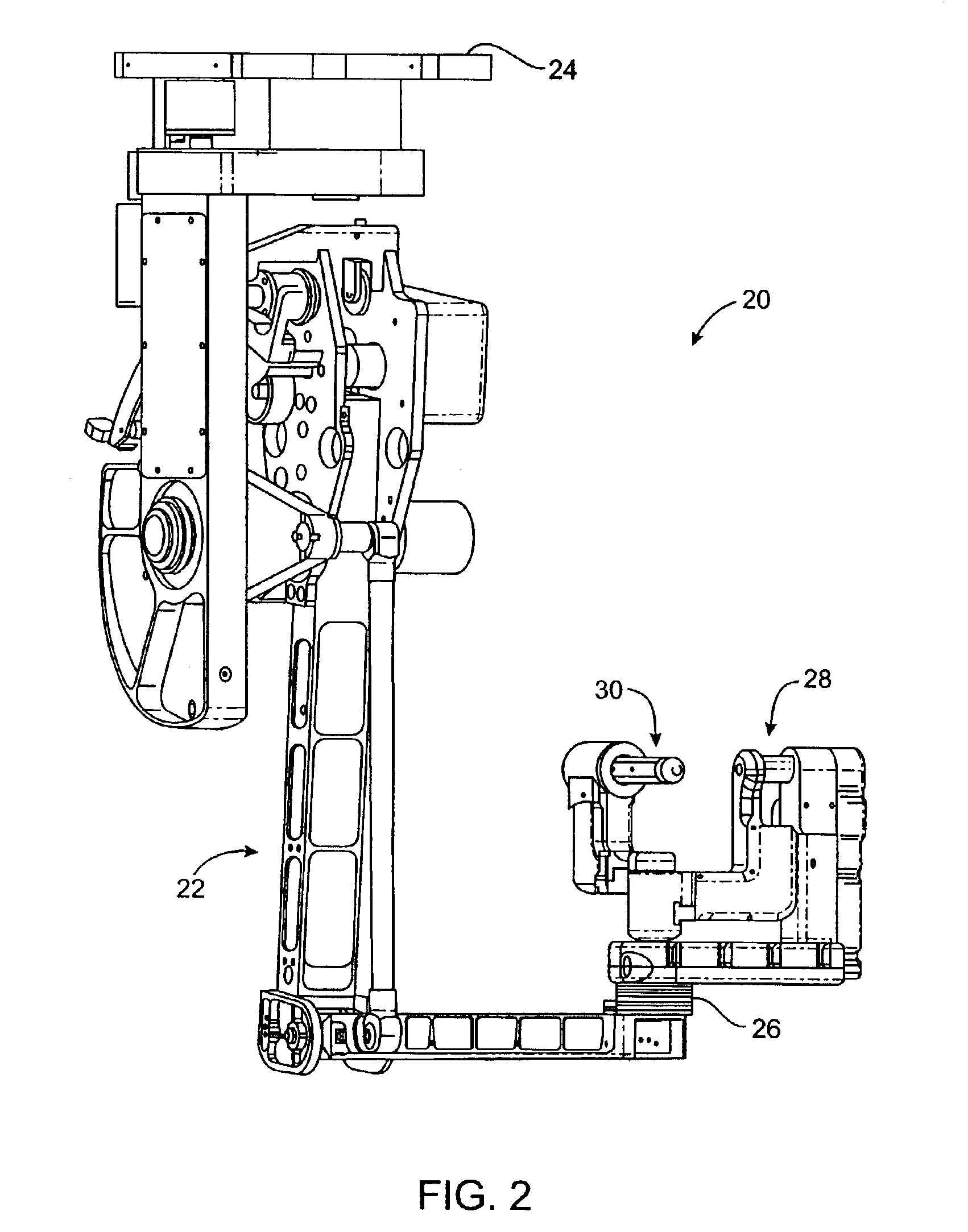

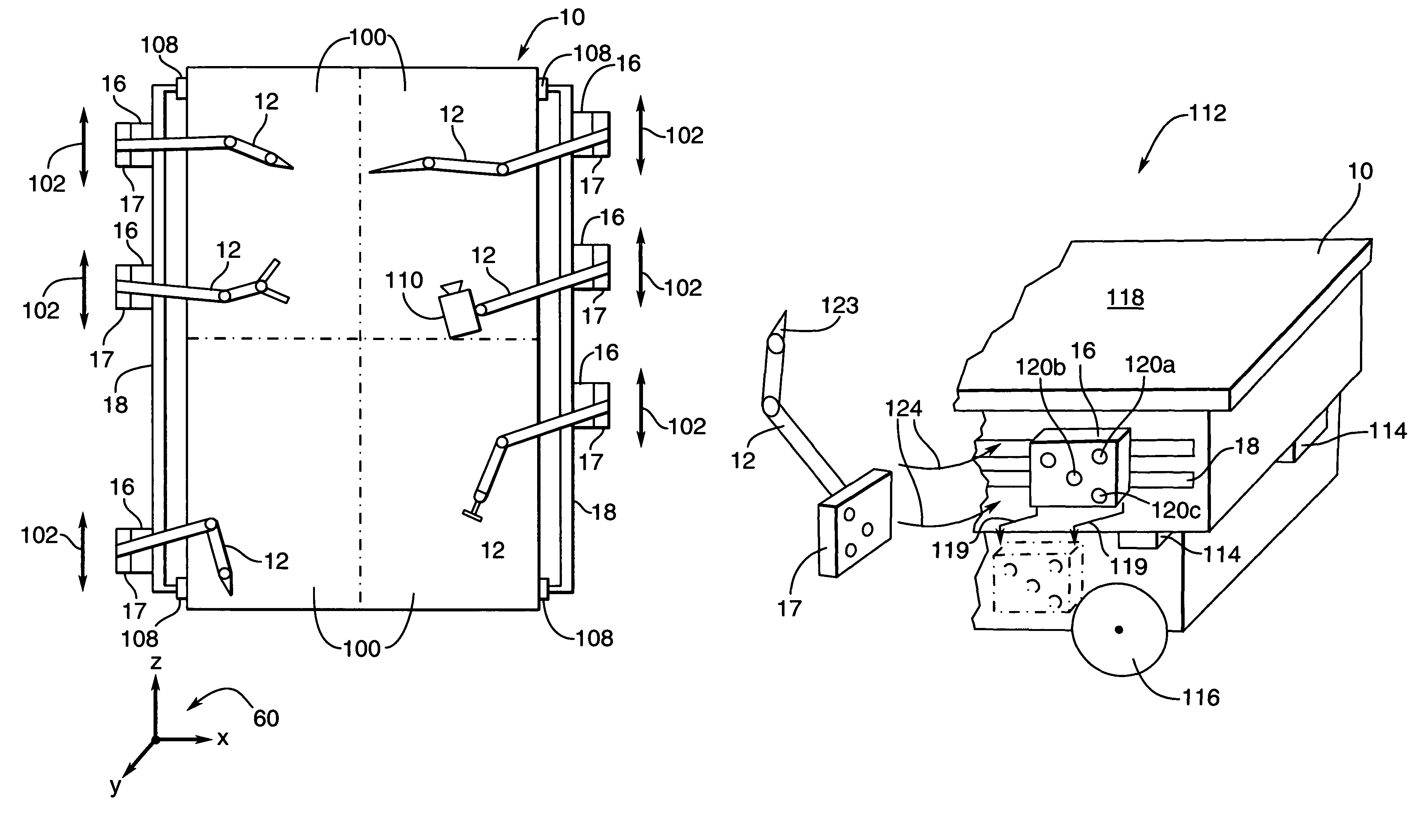

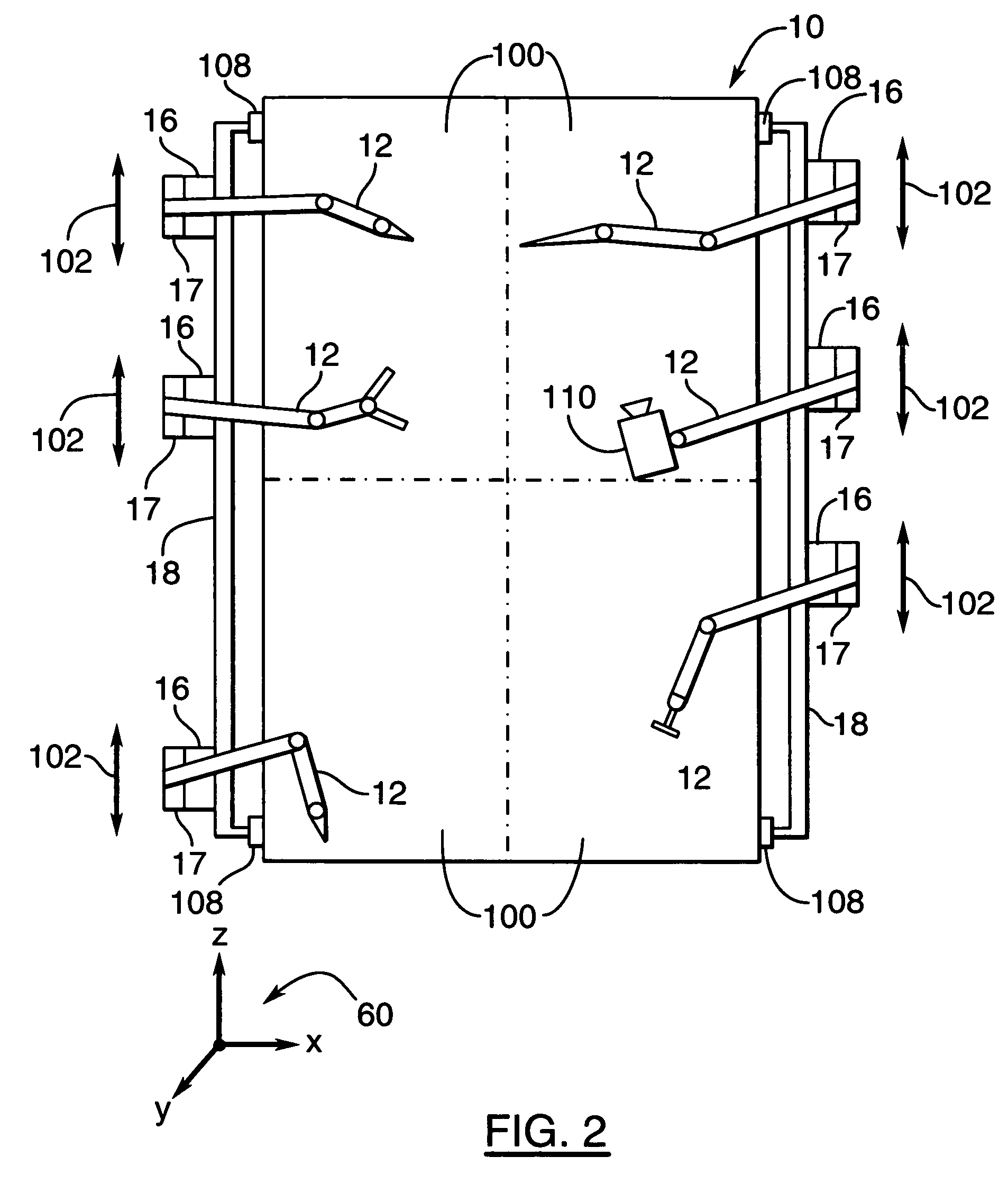

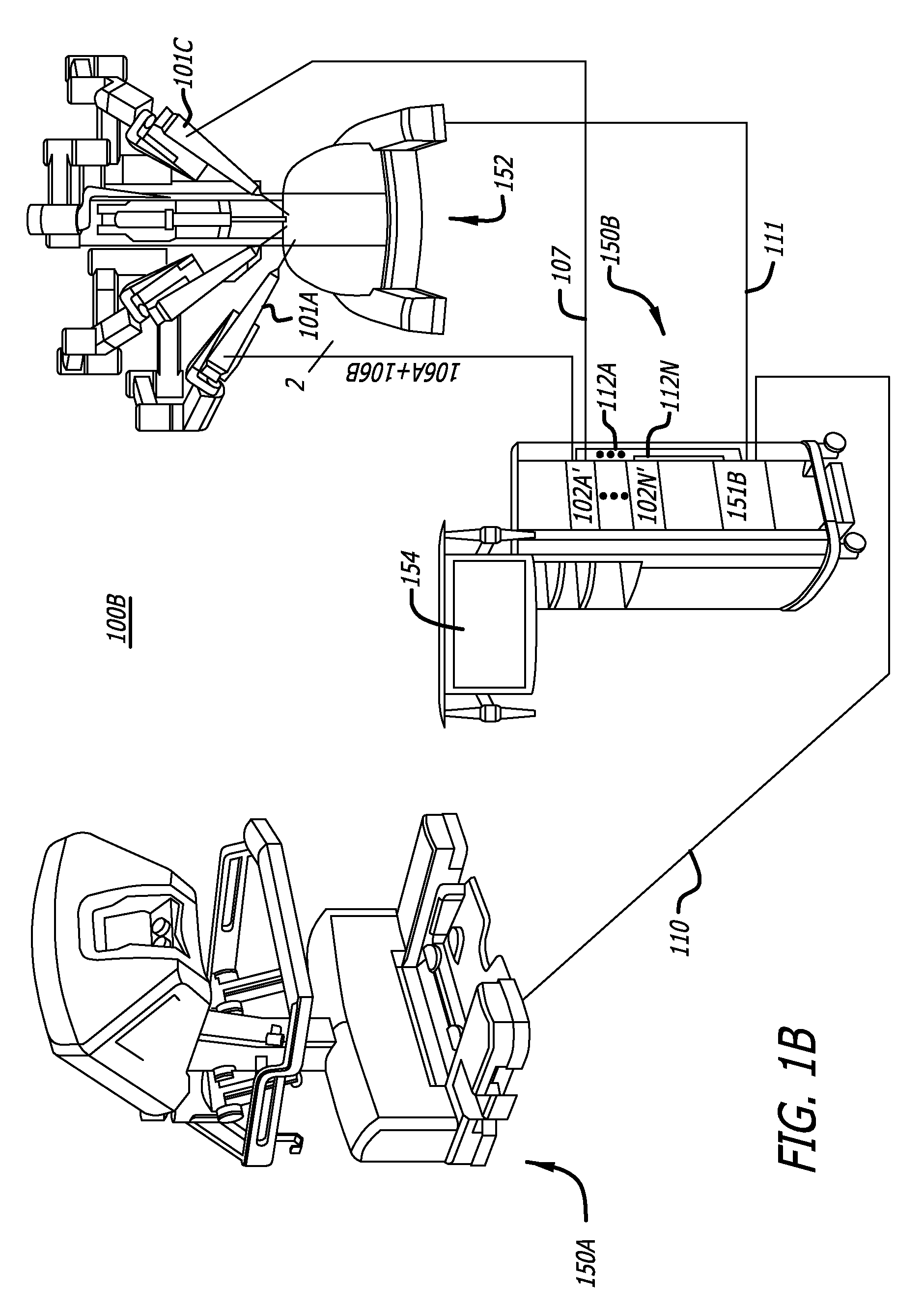

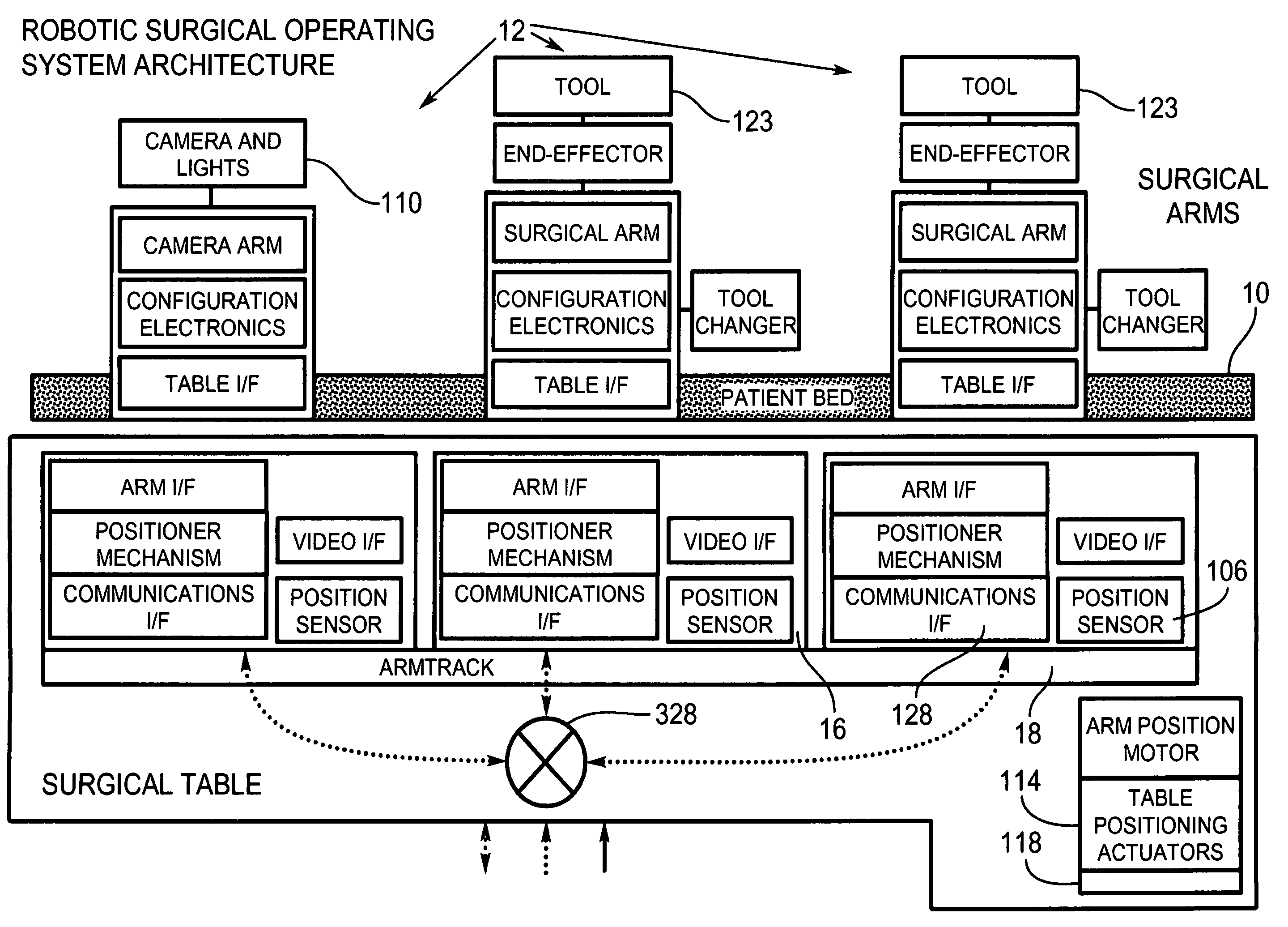

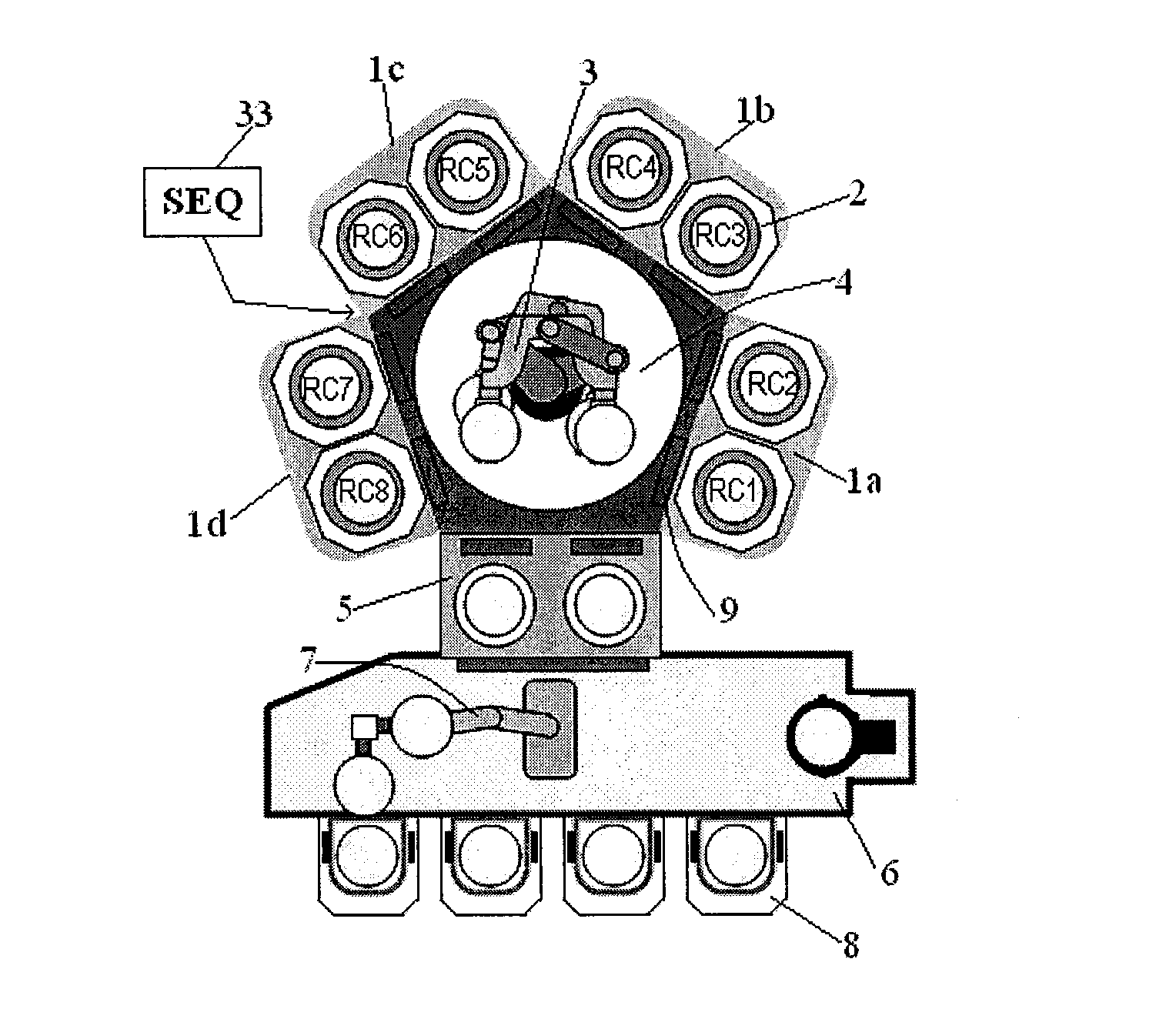

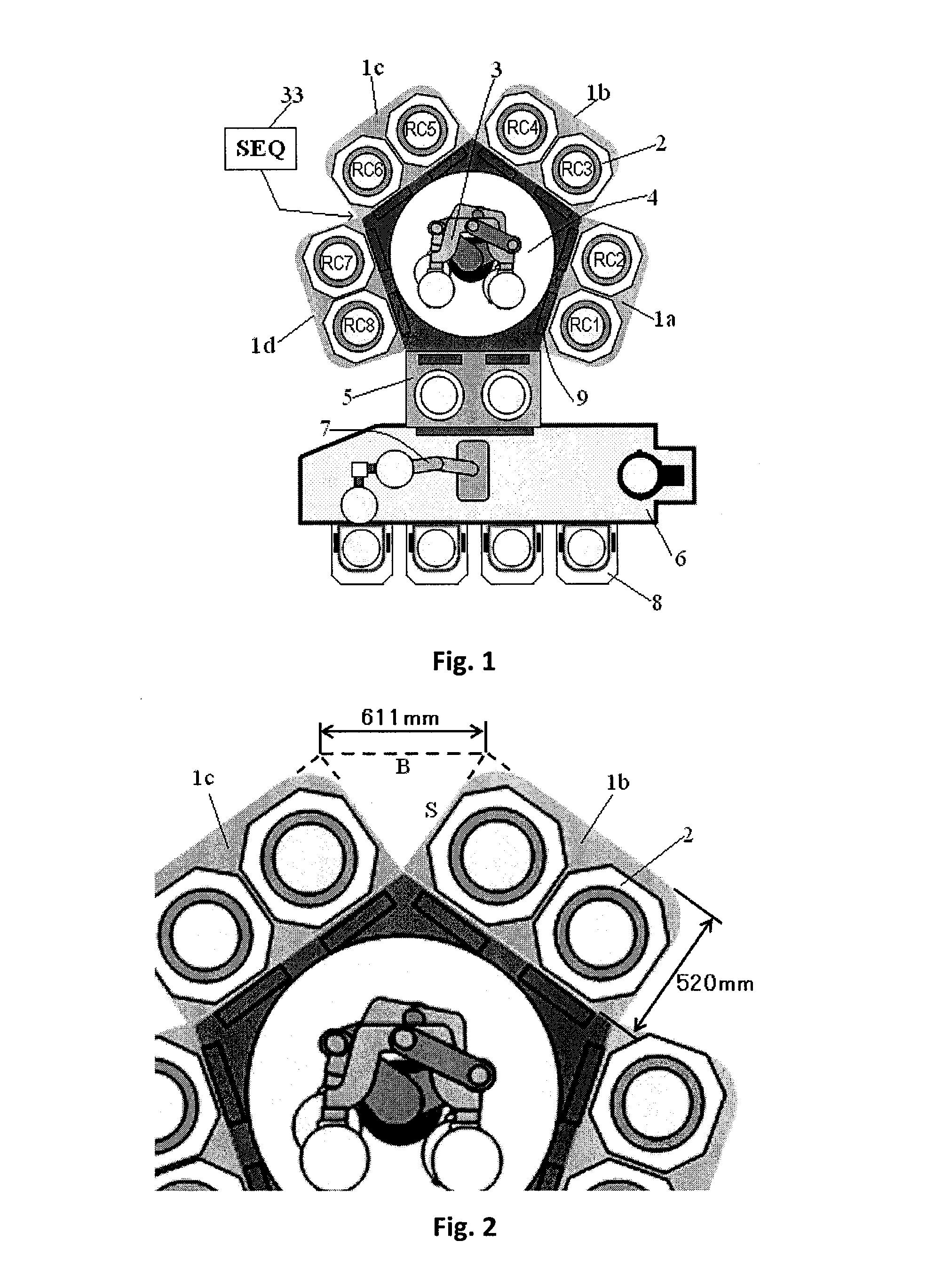

Multi-purpose robotic operating system and method

ActiveUS7979157B2Stable operating platformEasy to installProgramme-controlled manipulatorDiagnosticsSurgical operationRobotic systems

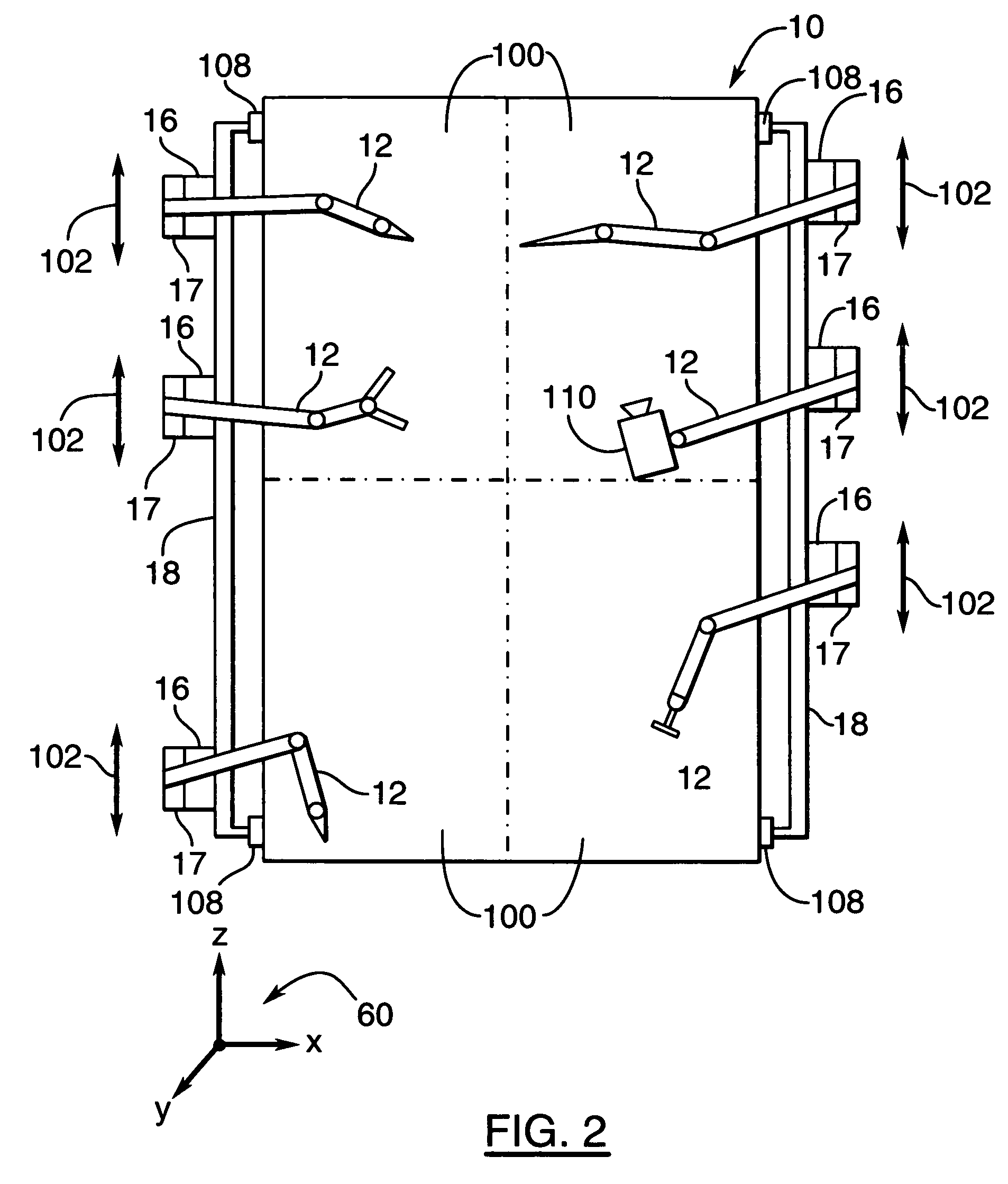

A dynamically configurable robotic system and method for performing surgical operations using a plurality of robotic arms remotely controlled by at least one operator console. The system comprises a track system configured for mounting to a patient support table, such that the track system provides a stable operating platform for the robotic arms and for facilitating placement of a proximal end of each of the arms at a selected position about a periphery of the patient support table. the system and method also have a plurality of base stations for operatively coupling each of the robotic arms to the track system, such that each of the base stations include a housing, a first connector for coupling the housing to the track system, the first connector configured for facilitating movement of the housing along the track system while coupled thereto, and a second connector for coupling the housing to the proximal end of at least one of the robotic arms, the second connector configured for providing at least one of power supply, control signalling, and data communication with respect to the coupled robotic arm. The system and method also have a control unit for coupling to at least two of the base stations and configured for dynamically connecting operative remote control between the coupled base stations and a first operator console of the at least one operator console.

Owner:CENT FOR SURGICAL INVENTION & INNOVATION

Adaptable integrated energy control system for electrosurgical tools in robotic surgical systems

A method for a minimally invasive surgical system is disclosed including reading first tool information from a storage device in a first robotic surgical tool mounted to a first robotic arm to at least determine a first tool type; reading equipment information about one or more remote controlled equipment for control thereof; comparing the first tool information with the equipment information to appropriately match a first remote controlled equipment of the one or more remote controlled equipment to the first robotic surgical tool; and mapping one or more user interface input devices of a first control console to control the first remote controlled equipment to support a function of the first robotic surgical tool.

Owner:INTUITIVE SURGICAL OPERATIONS INC

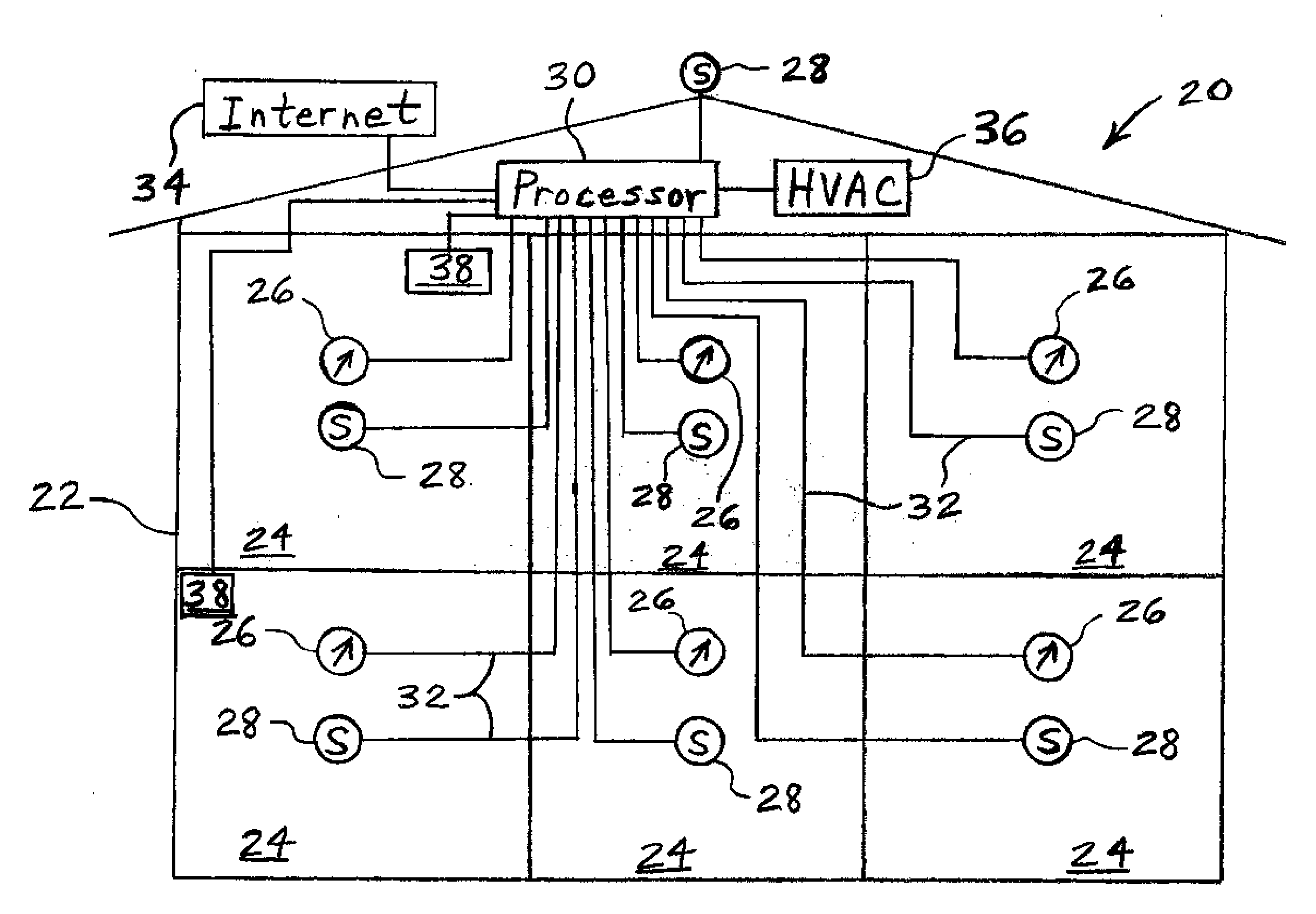

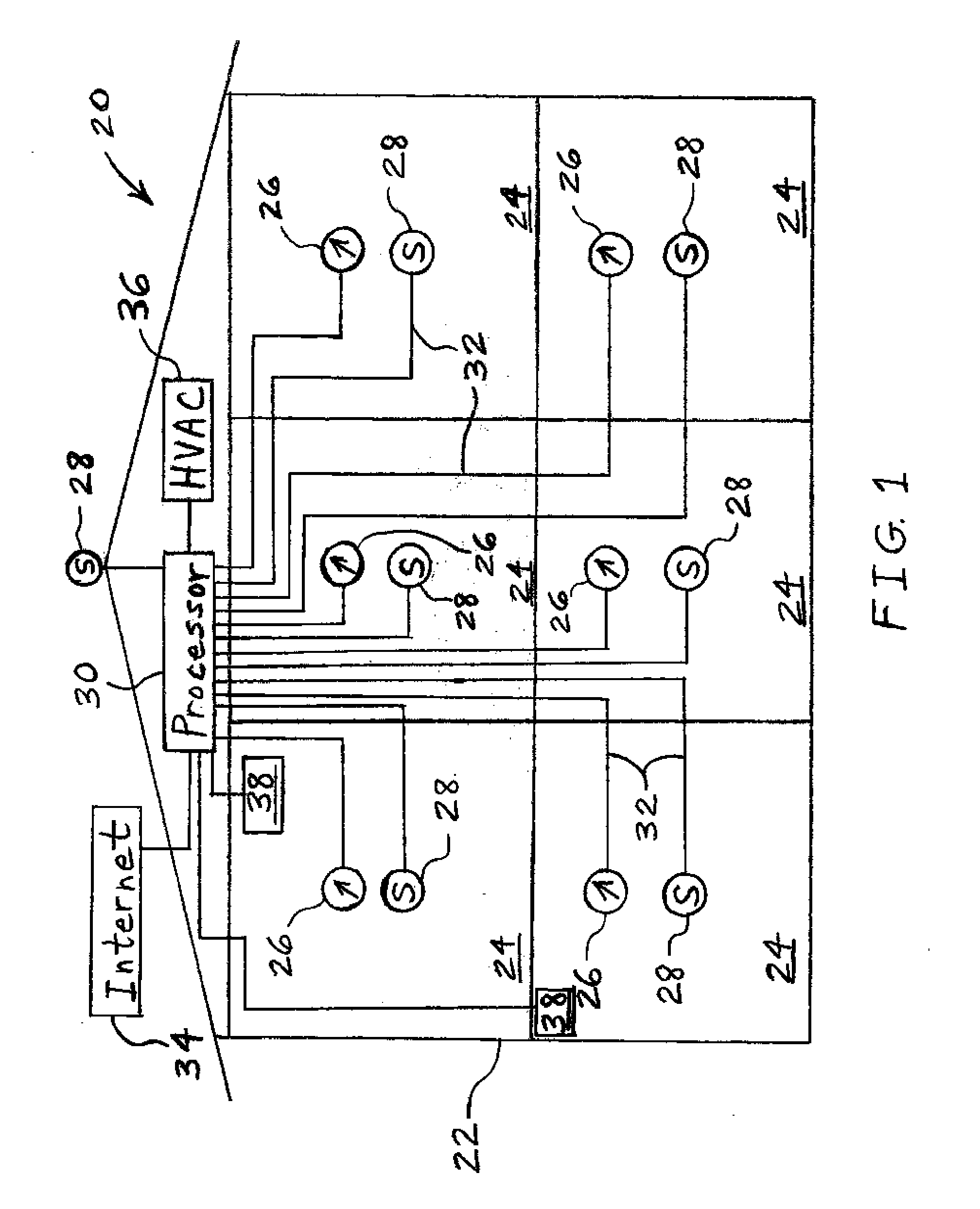

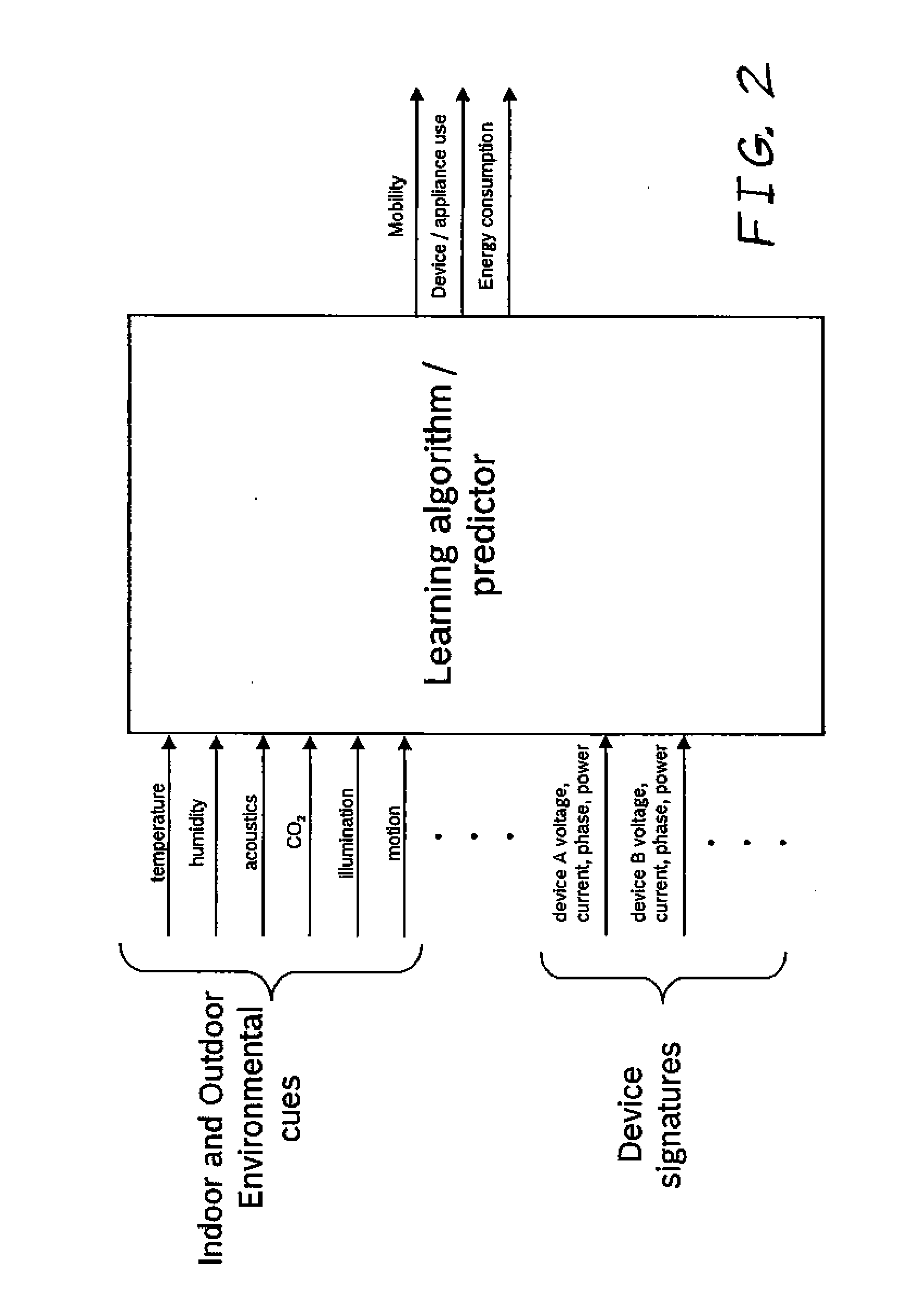

Sensor-Based Occupancy and Behavior Prediction Method for Intelligently Controlling Energy Consumption Within a Building

InactiveUS20100025483A1Sacrificing comfort levelReduce energy costsTemperature control without auxillary powerMechanical apparatusPredictive methodsSimulation

A method for controlling energy consumption within a building includes providing at least one environment sensing device and at least one energy consumption sensing device associated with the building. Current data is collected from the environment sensing device and the energy consumption sensing device along with associated time-of-day data. A value of a future energy consumption parameter is predicted based upon the collected current data, the associated time-of-day data, and historic data collected from the environment sensing device and the energy consumption sensing device. A profile of future costs per unit of energy consumption as a function of time is determined. Energy consumption is controlled dependent upon the predicted future energy consumption parameter value and the determined profile of energy consumption costs.

Owner:ROBERT BOSCH GMBH

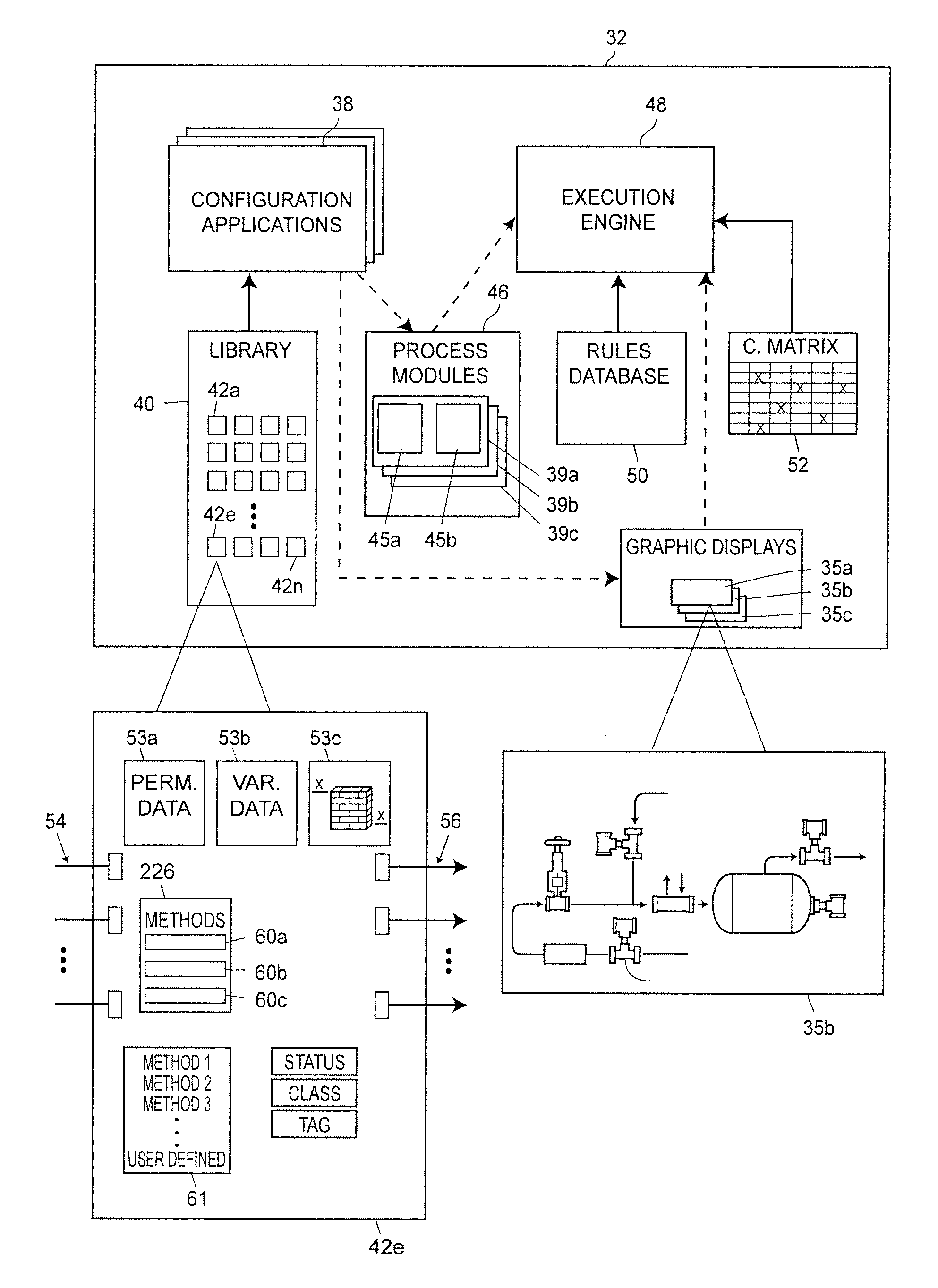

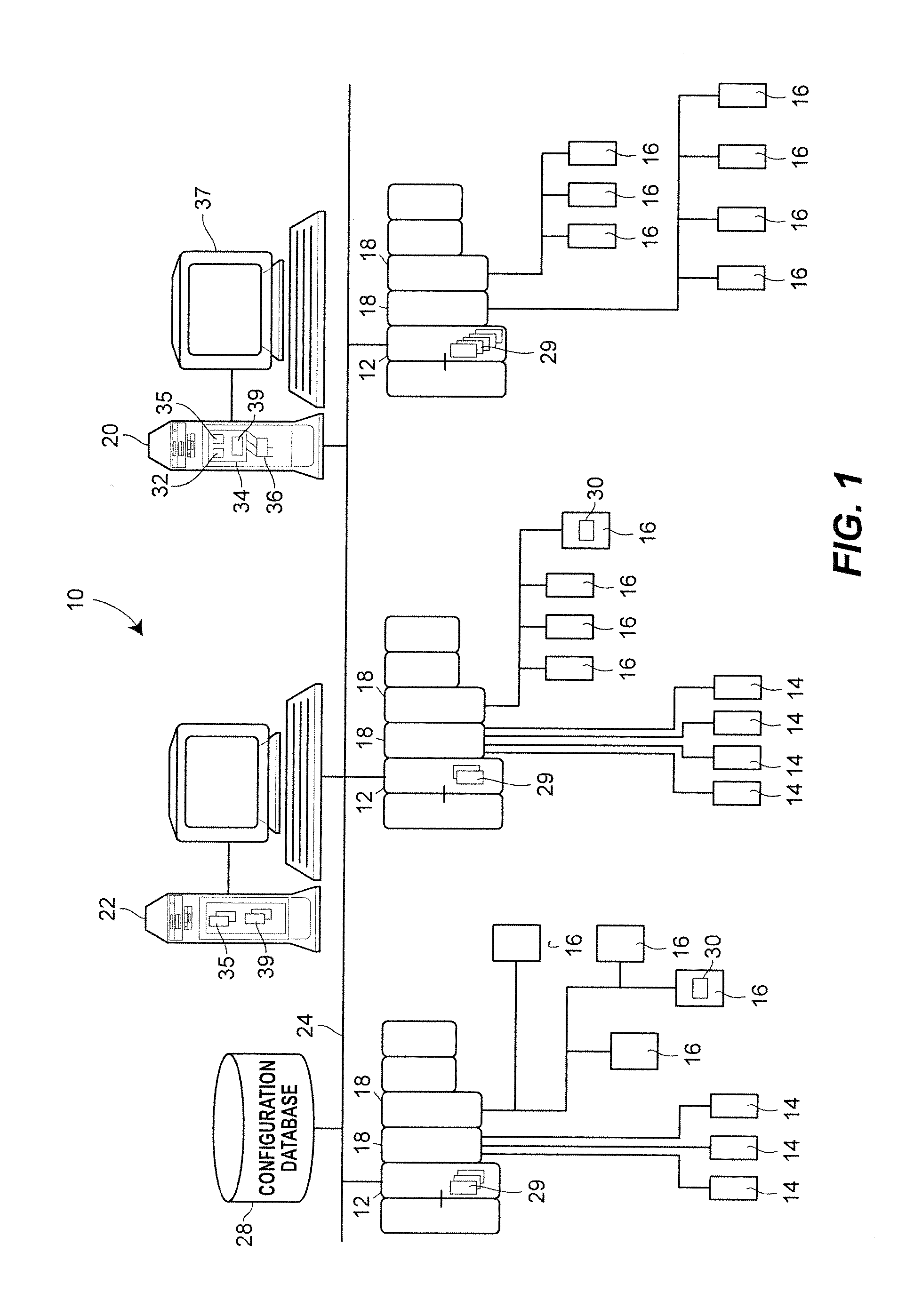

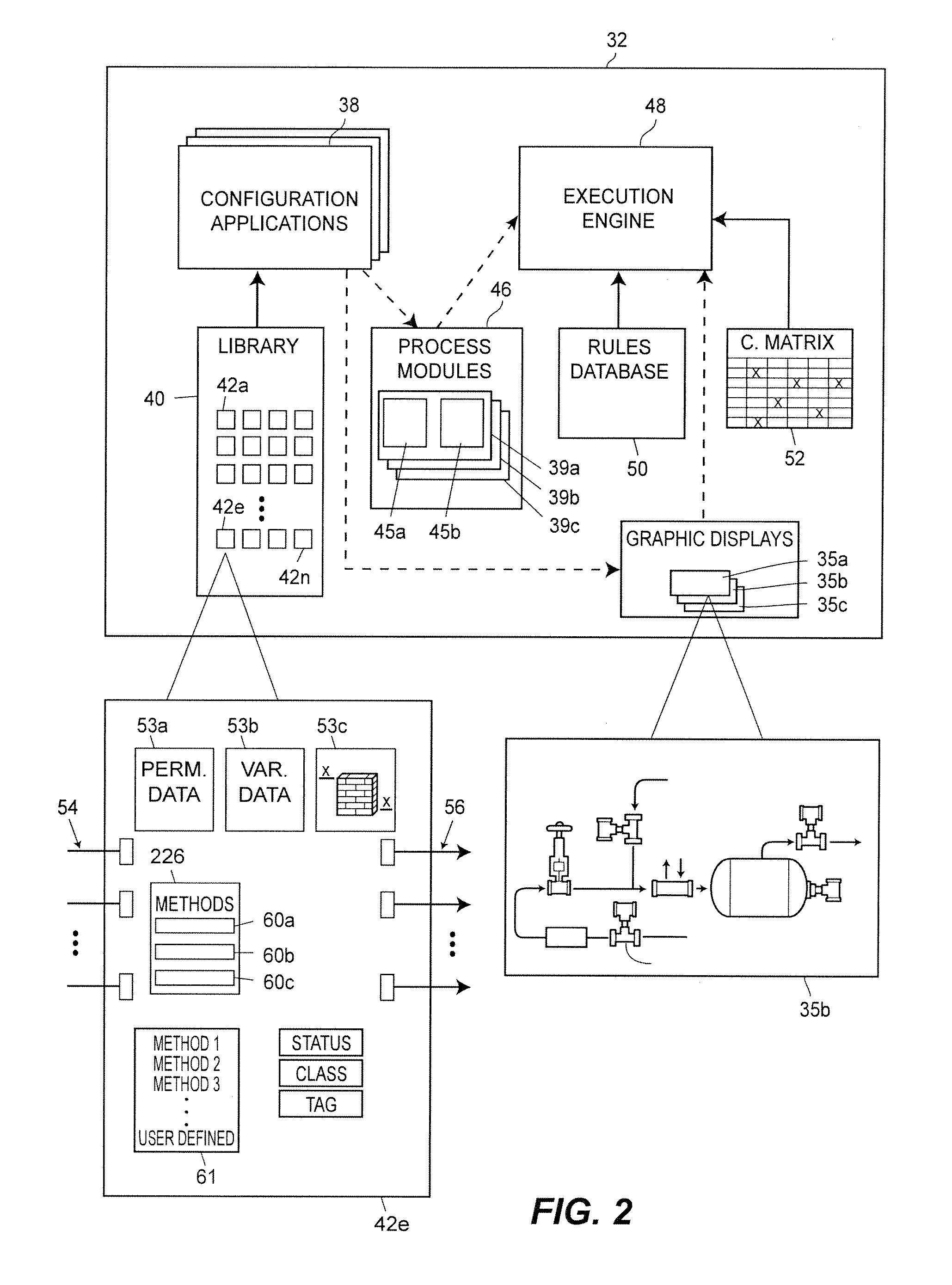

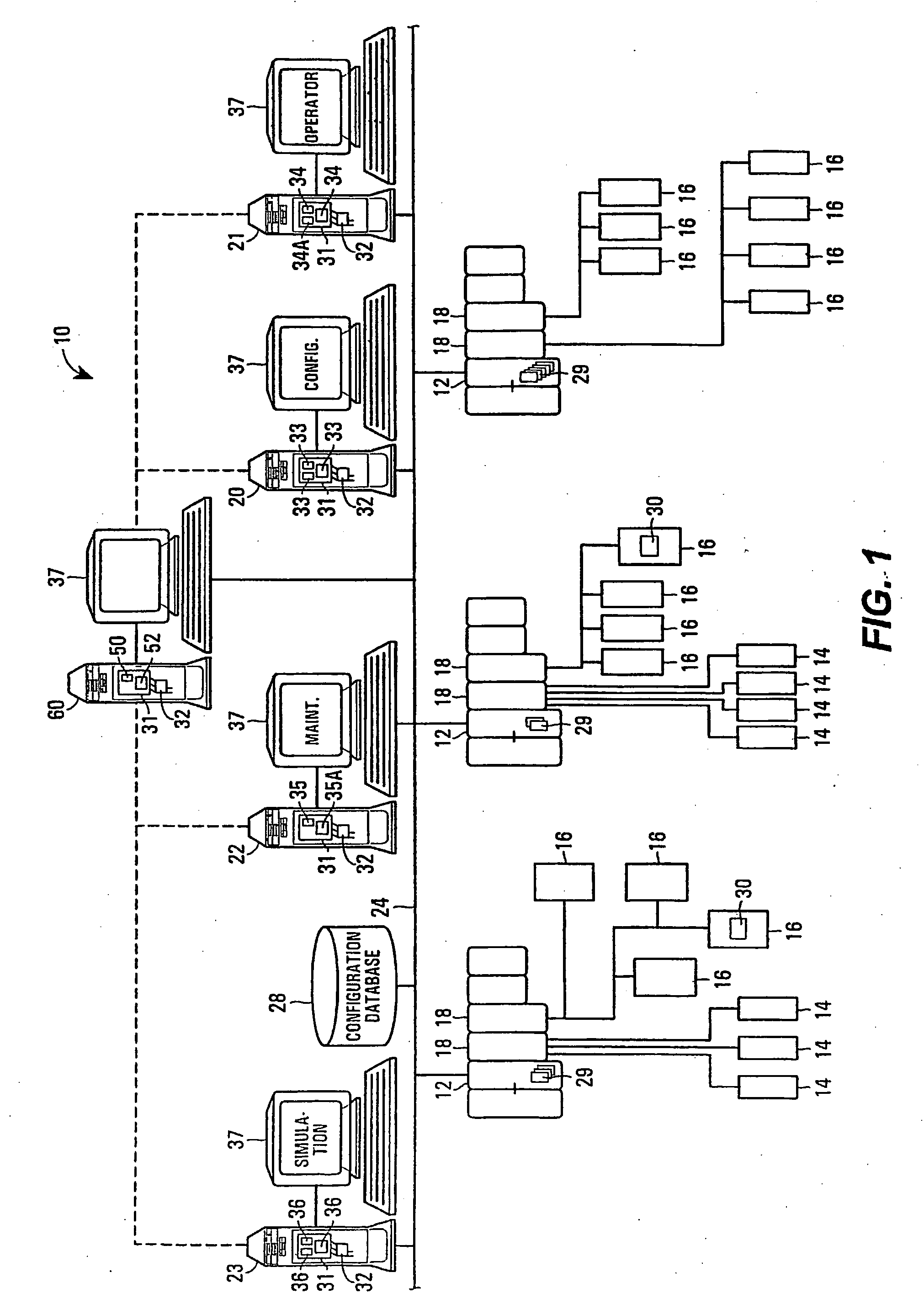

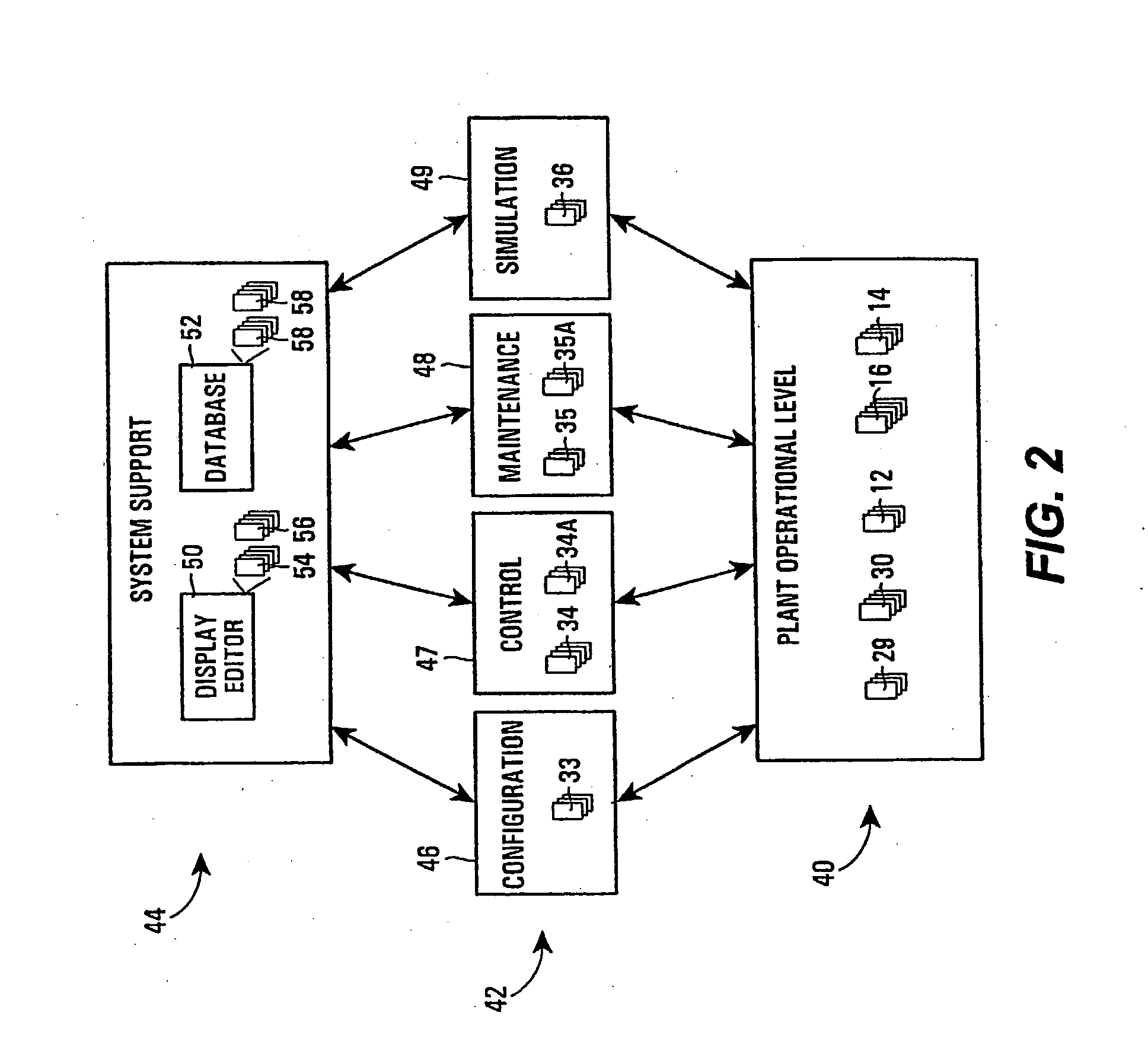

Dynamic User Interface for Configuring and Managing a Process Control System

ActiveUS20120029661A1Reduce the number of timesImprove convenienceElectric controllersIgnition automatic controlControl systemComputerized system

A process control management method in a computer system for configuring and supervising a process plant includes providing an interactive user interface to manage a plurality of objects in the process plant, where each of the plurality of objects corresponds to a physical or logical entity in the process plant, including generating a navigation pane to display a set of selectable items, each in the set of selectable items corresponding to a respective one of the plurality of objects, and generating a command pane to display a set of selectable controls, each in the set of selectable controls corresponding to a task to be performed on at least one of the plurality of objects in the process plant; receiving a selection of one of an item in the set of selectable items via the navigation panel and a control in the set of selectable controls via the command panel; determining an operational context based on the received selection, wherein the operational context corresponds to one of a range of actions applicable to the selection if the selection is an item selection, or a range of items to which the selection is applicable if the selection is a control selection; and adjusting one of the navigation pane or the command pane according to the operational context, including displaying a subset of selectable items in the navigational pane, wherein each in the subset of selectable items is within the range applicable to the selection, if the selection is a control selection, and displaying a subset of selectable controls in the command pane, wherein each in the subset of selectable controls is within the range applicable to the selection, if the selection is an item selection.

Owner:FISHER-ROSEMOUNT SYST INC

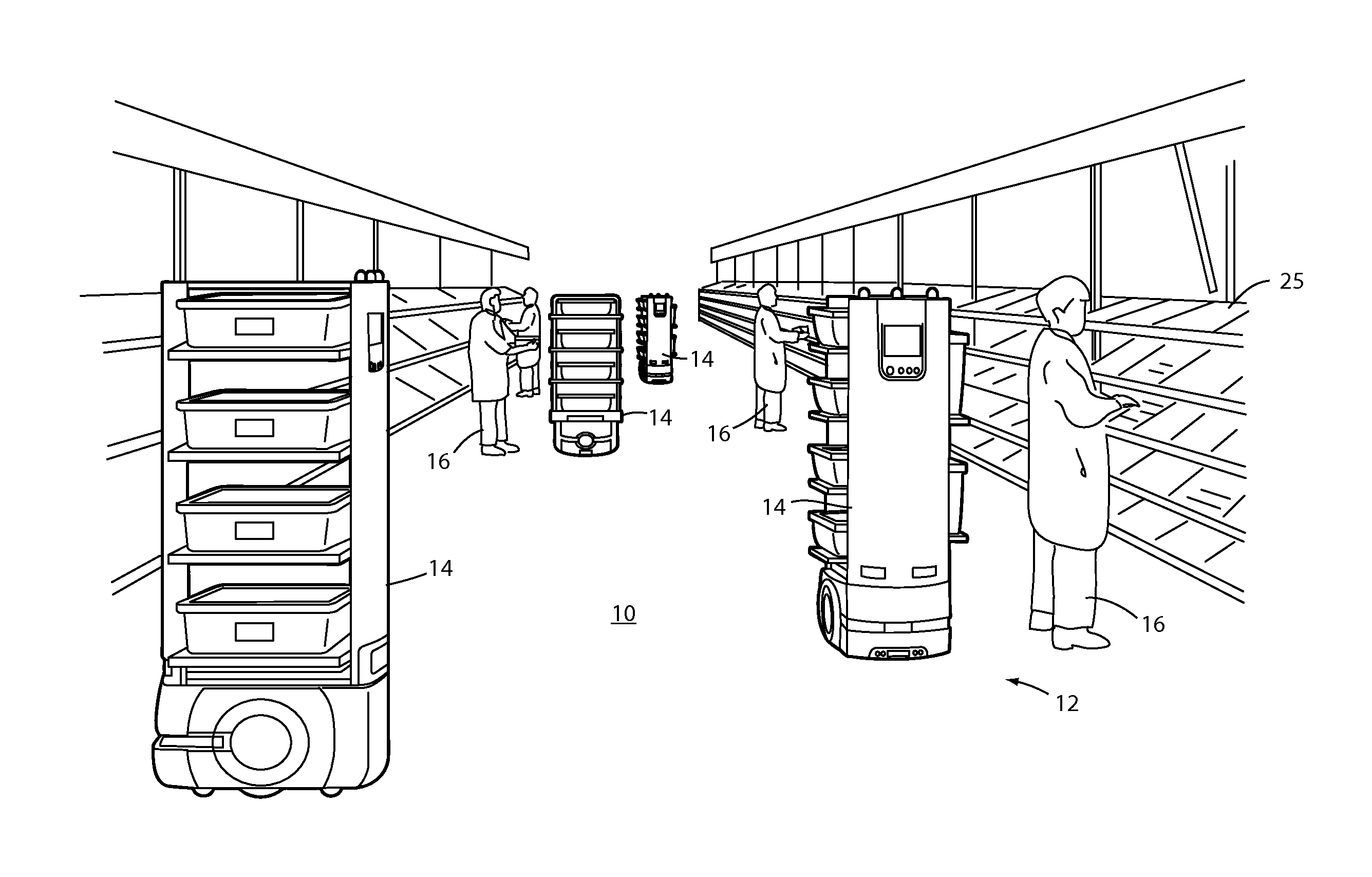

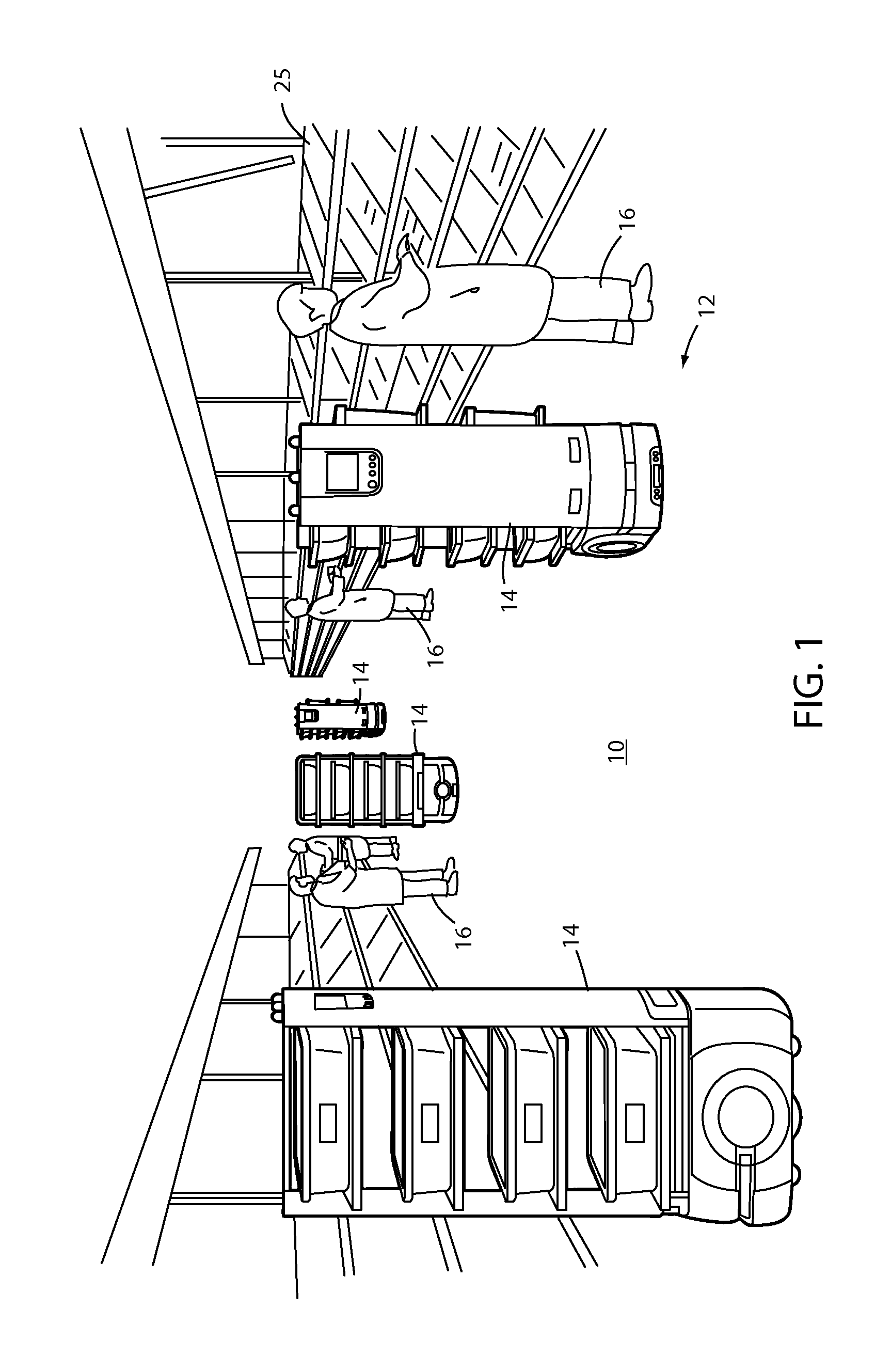

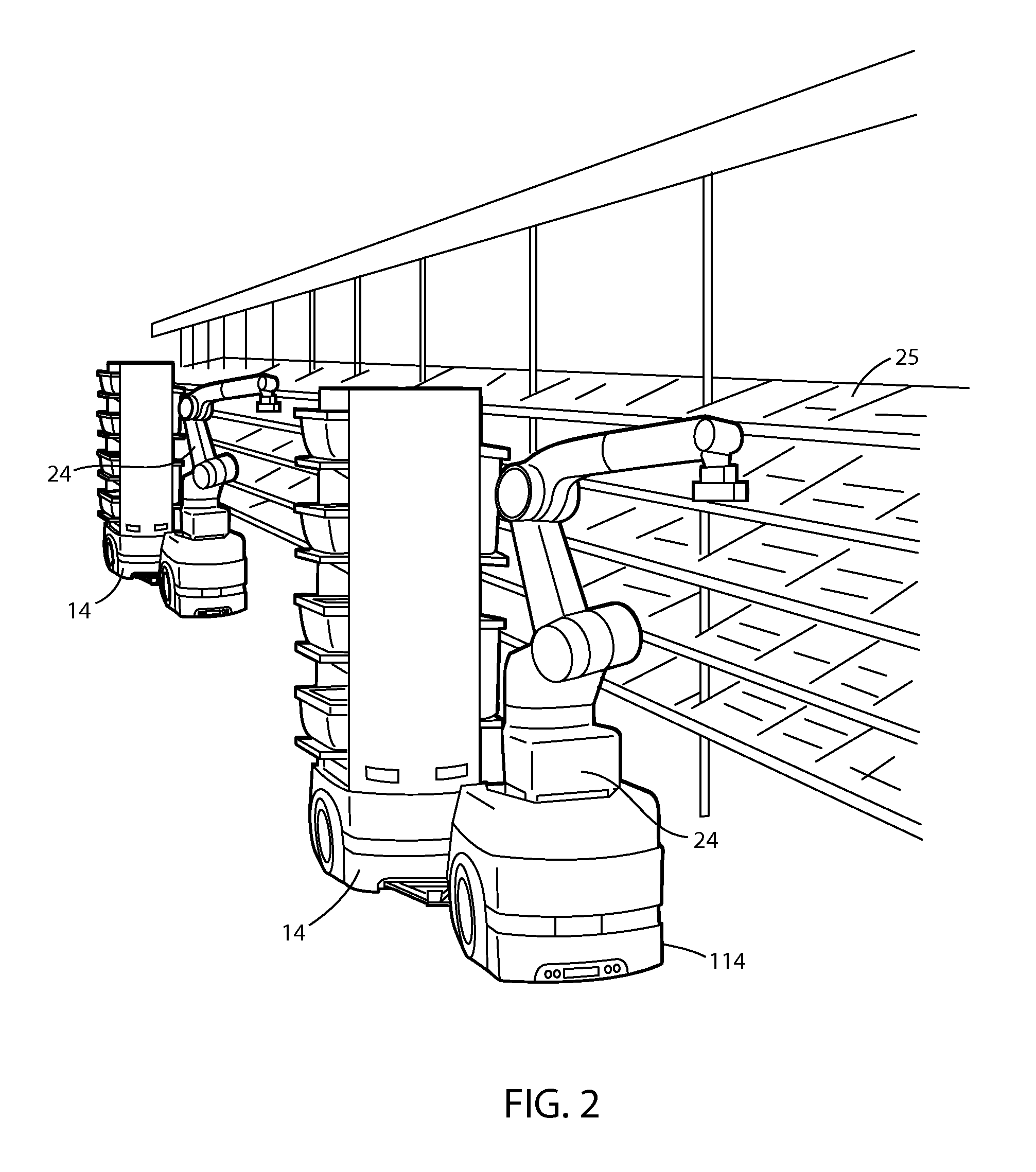

Autonomous mobile picking

ActiveUS20150073589A1Reduce labor costsFacilitates picking articleProgramme-controlled manipulatorData processing applicationsMobile vehicleOrder fulfillment

An order-picking method includes autonomously routing a plurality of mobile robotic units in an order fulfillment facility and picking articles to or putting articles from the robotic units in the order fulfillment facility. A material-handling robotic unit that is adapted for use in an order fulfillment facility includes an autonomous mobile vehicle base and a plurality of article receptacles positioned on the base. A visual indicator associated with the receptacle facilitates picking articles to or putting articles from the robotic unit.

Owner:DEMATIC

Multi-purpose robotic operating system and method

ActiveUS20060149418A1Stable operating platformEasy to installProgramme-controlled manipulatorOperating tablesSurgical operationRobotic systems

A dynamically configurable robotic system and method for performing surgical operations using a plurality of robotic arms remotely controlled by at least one operator console. The system comprises a track system configured for mounting to a patient support table, such that the track system provides a stable operating platform for the robotic arms and for facilitating placement of a proximal end of each of the arms at a selected position about a periphery of the patient support table. the system and method also have a plurality of base stations for operatively coupling each of the robotic arms to the track system, such that each of the base stations include a housing, a first connector for coupling the housing to the track system, the first connector configured for facilitating movement of the housing along the track system while coupled thereto, and a second connector for coupling the housing to the proximal end of at least one of the robotic arms, the second connector configured for providing at least one of power supply, control signalling, and data communication with respect to the coupled robotic arm. The system and method also have a control unit for coupling to at least two of the base stations and configured for dynamically connecting operative remote control between the coupled base stations and a first operator console of the at least one operator console.

Owner:CENT FOR SURGICAL INVENTION & INNOVATION

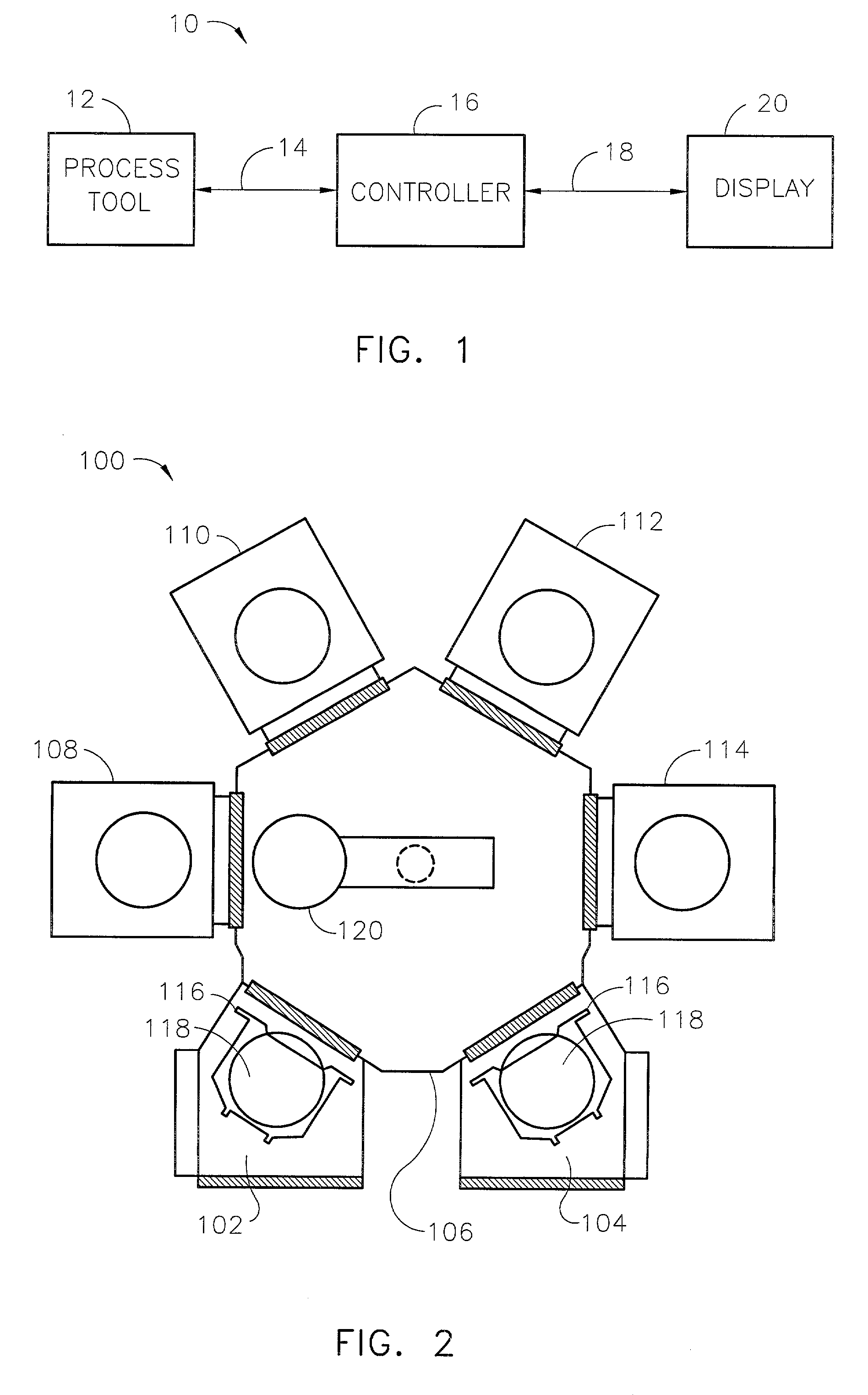

High-throughput semiconductor-processing apparatus equipped with multiple dual-chamber modules

Owner:ASM JAPAN

System and method for visually representing project metrics on 3-dimensional building models

Provided are a system and method for visually representing project metrics on 3-dimensional product models. The system comprises: a user interface unit for receiving an input of color information, including variations in the colors and color tones of objects to be visualized in response to the course of a project, and output conditions, including a time interval at which an output is required, from a user; a database unit for storing the objects and temporal and / or spatial relationships between the objects; and an image formation unit for determining colors and color tones of the objects according to the project course based on the output conditions input by the user, and forming and outputting 3-dimensional images of the objects by the determined colors and color tones.

Owner:KYUMAN SONG

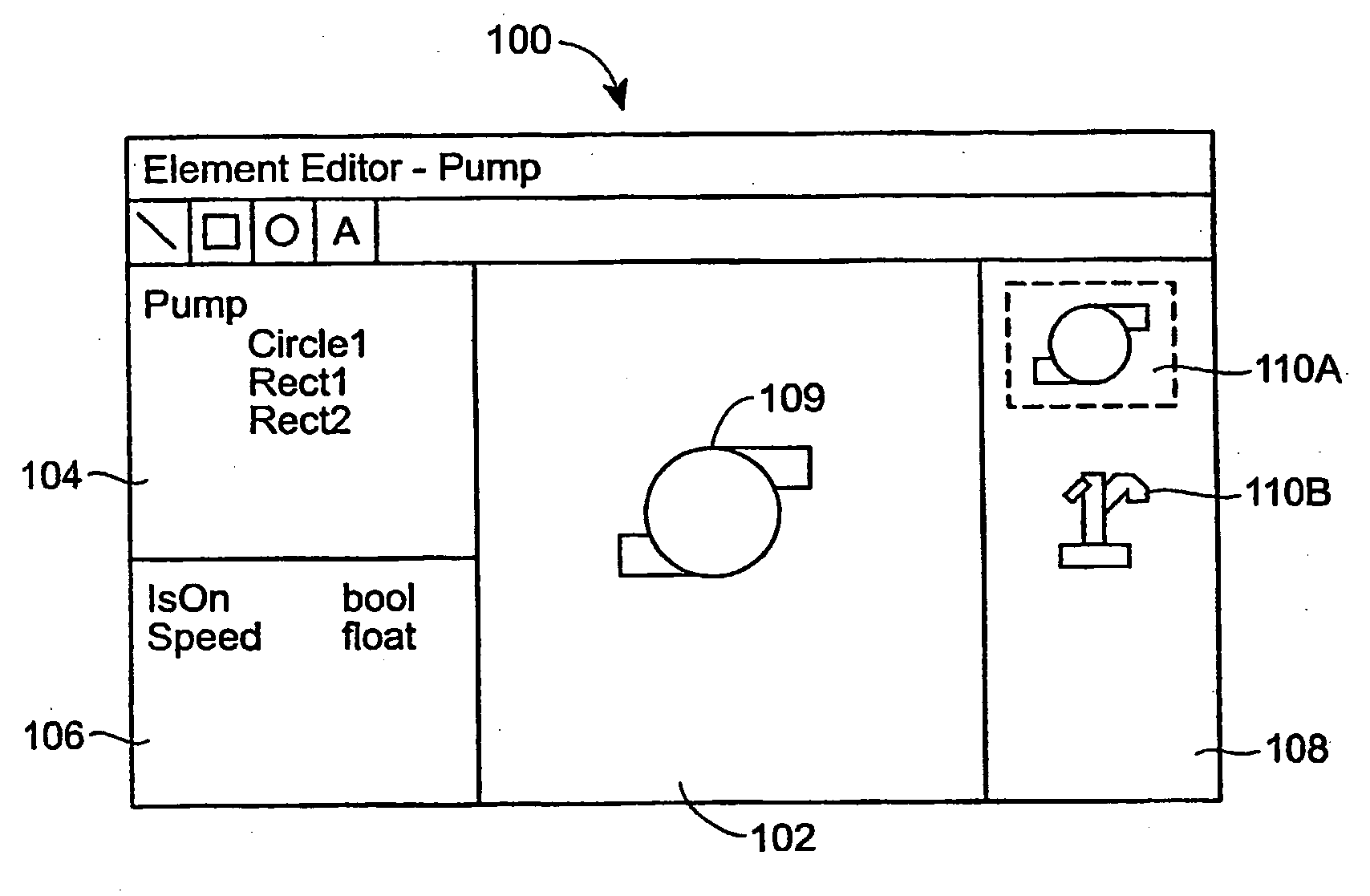

Graphic element with multiple visualizations in a process environment

ActiveUS20070132779A1Graphic element more versatileTechnology managementProgram controlGraphicsDisplay design

Smart graphic elements are provided for use as portions or components of one or more graphic displays, which may be executed in a process plant to display information to users about the process plant environment, such as the current state of devices within the process plant. Each of the graphic elements is an executable object that includes a property or a variable that may be bound to an associated process entity, like a field device, and that includes multiple visualizations, each of which may be used to graphically depict the associated process entity on a user interface when the graphic element is executed as part of the graphic display. Any of the graphic element visualizations may be used in any particular graphic display and the same graphic display may use different ones of the visualizations at different times. The different visualizations associated with a graphic element make the graphic element more versatile, at they allow the same graphic element to be used in different displays using different graphical styles or norms. These visualizations also enable the same graphic element to be used in displays designed for different types of display devices, such as display devices having large display screens, standard computer screens and very small display screens, such as PDA and telephone display screens.

Owner:FISHER-ROSEMOUNT SYST INC

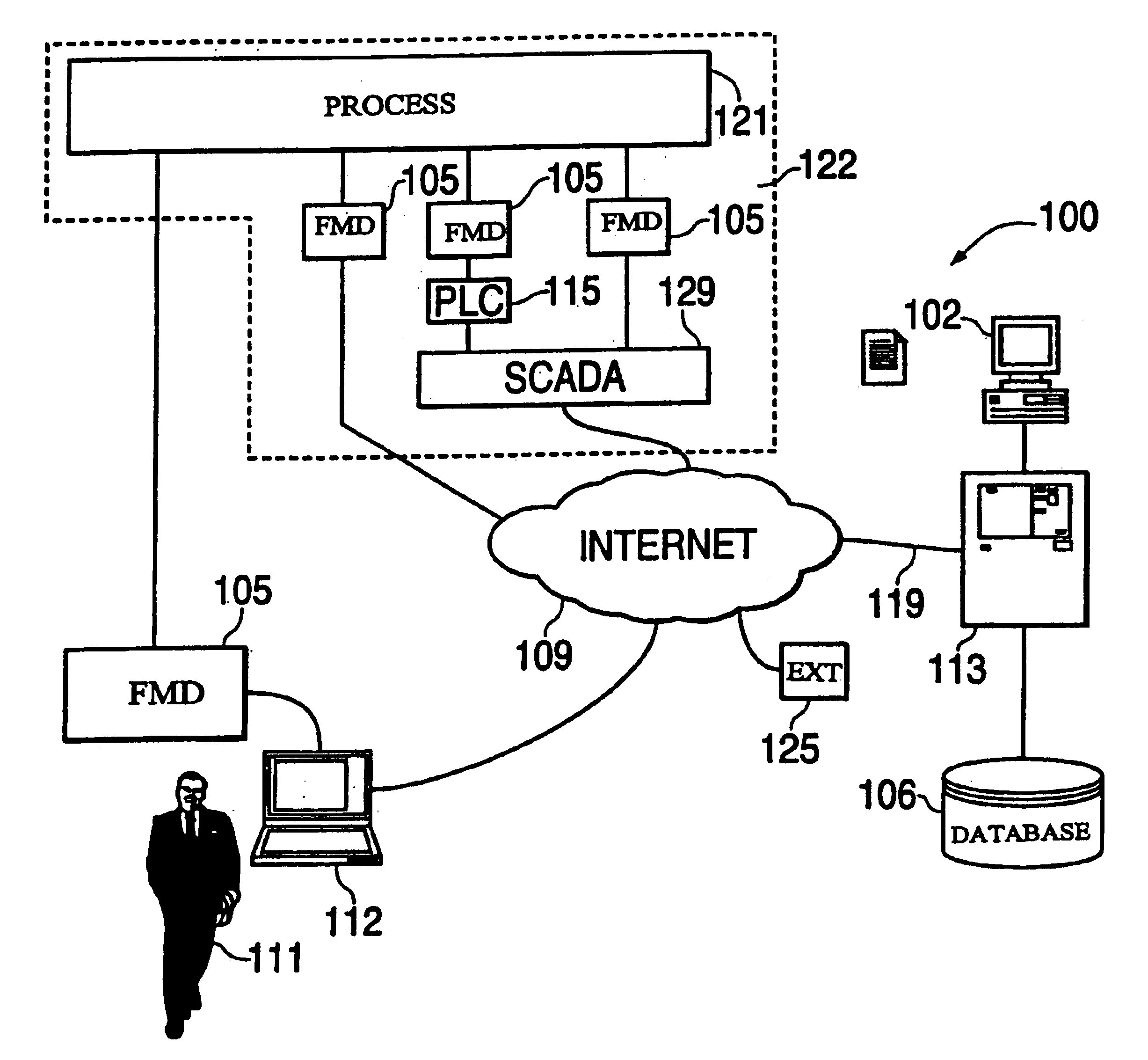

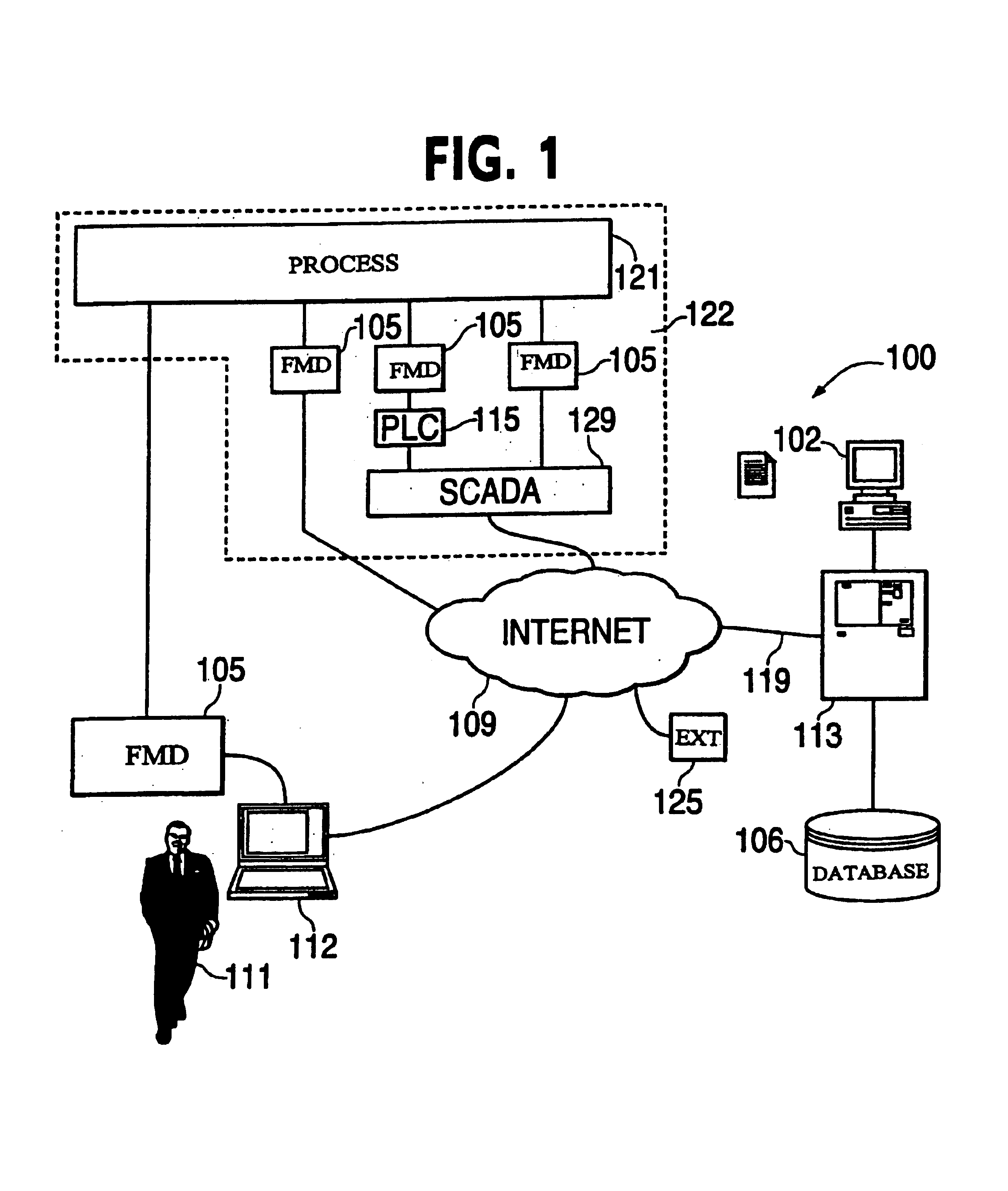

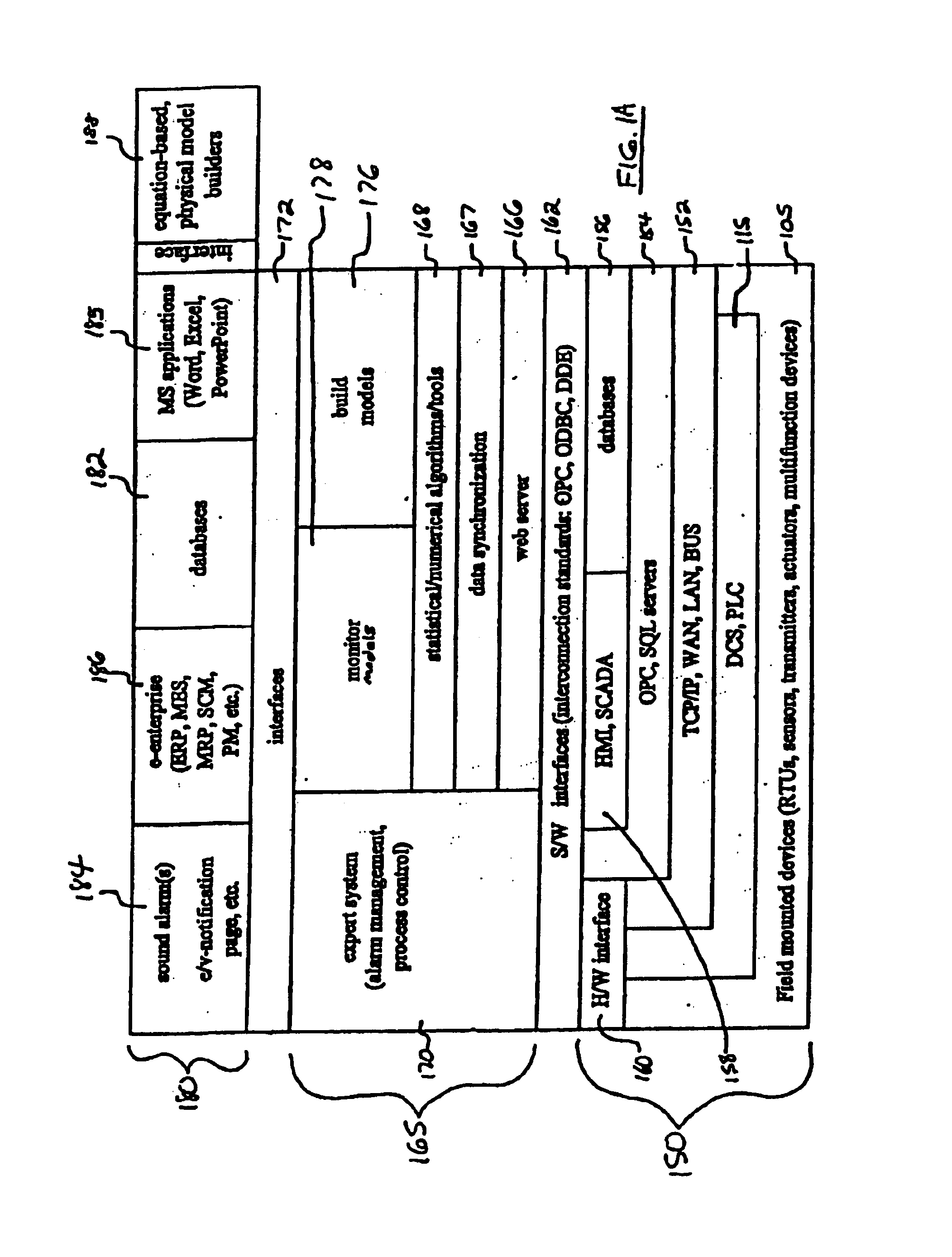

Method and apparatus for the creation of personalized supervisory and control data acquisition systems for the management and integration of real-time enterprise-wide applications and systems

A system and method provide for the creation and operation of real-time enterprise-wide, personalize supervisory and control data acquisition systems. Personalized SCADA applications are constructed from a virtual application service and a personal agent framework using simple drag and drop operations or other high level action. The virtual application service includes a communications gateway that communicates with disparate and non-interoperable systems and external field devices to communicate low level time data collected from such systems into the application environment transforming the collected data in a single common data format. The virtual application service includes application cells that receive the reformatted data and process it to provide high level analysis and context, storing the processed data in an object server. The object server provides a unified, hierarchical object model for all of the data received from the underlying devices and systems. The virtual application service communicates with personal agent frameworks containing presentation cells and service agents. The service agents are representative of the virtual application service, and provide the personal agent framework with access to the object server to receive and send data from the object server to the presentation cells. The presentation cells subscribe to the object server's data objects via the service agent. Presentation cell provide a graphical representation and mapping of data objects and hence underlying devices and systems, to allow a user to manage and control such systems.

Owner:EUTECH CYBERNETICS PTE

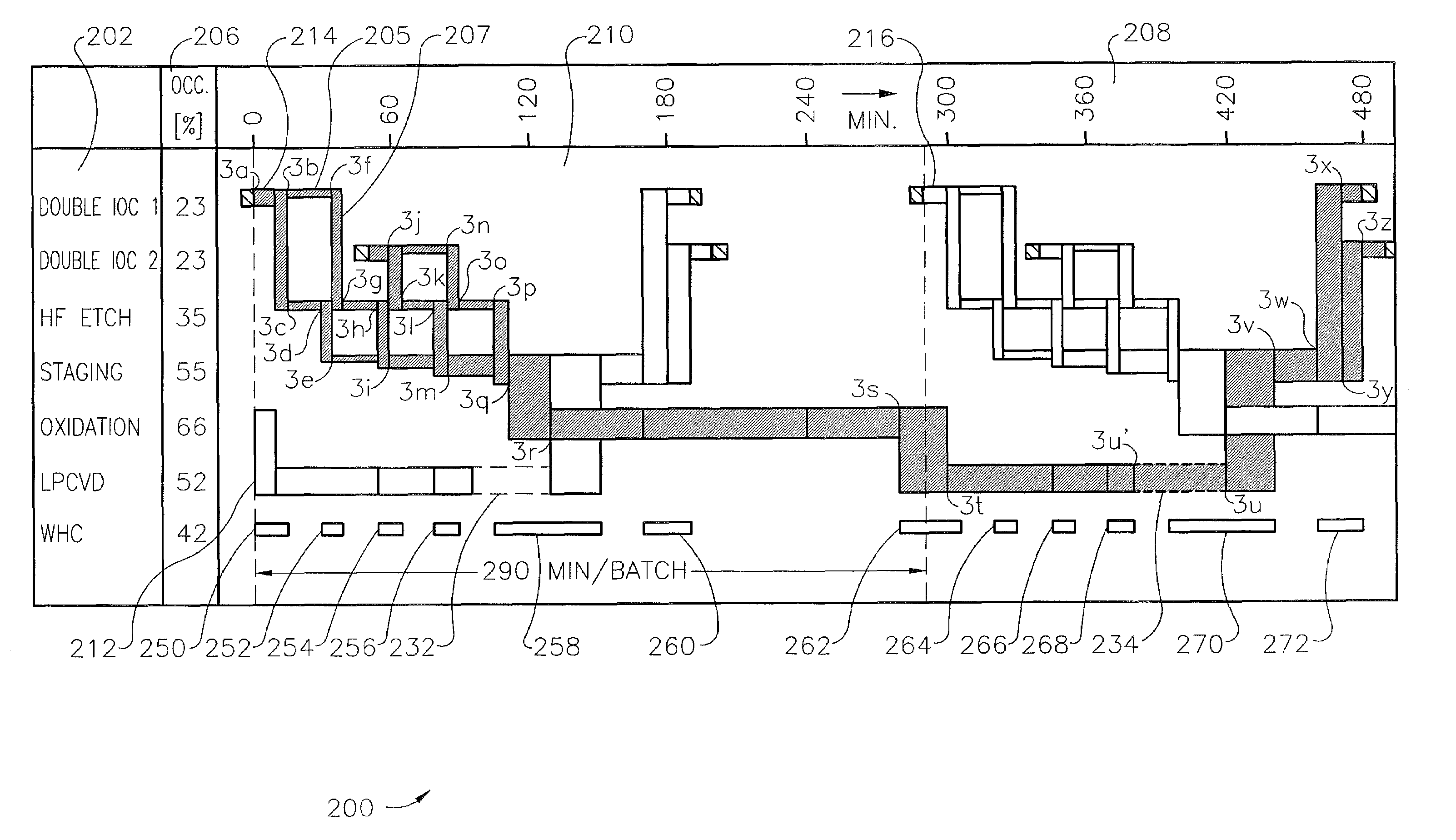

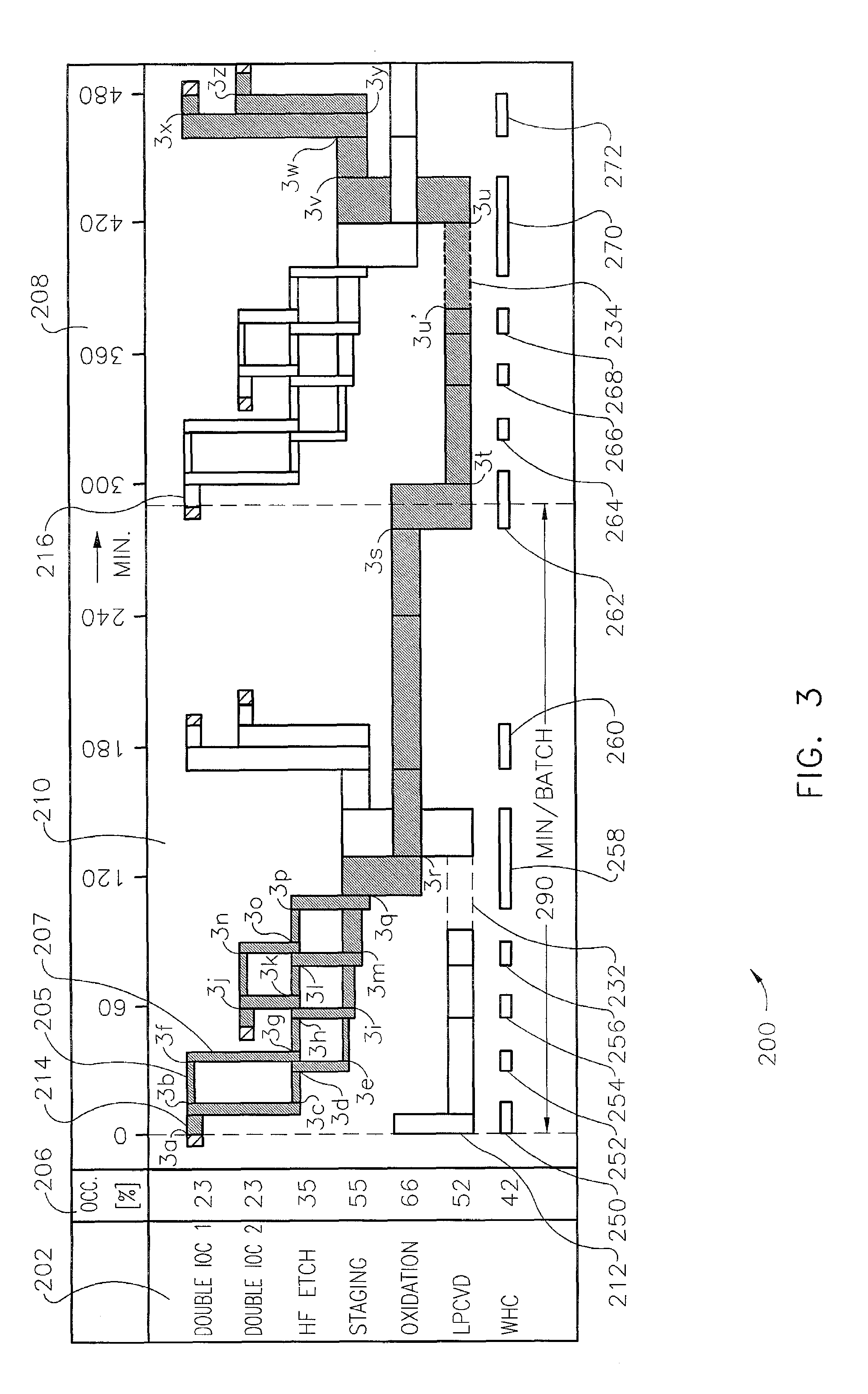

Graphical representation of a wafer processing process

A method for graphically representing the progress of wafers being processed in a plurality of process stations is disclosed. In one step, the start of a process performed on the wafers in one of the plurality of process stations is determined. Then, the generation of a first line segment parallel to a first axis is initiated. Next, the end of the process in one of the plurality of process stations is determined. Then the generation of the first line segment parallel to the first axis is terminated. The start of a transfer of the wafers from one of the plurality of process stations to another one of the plurality of process stations is detected in a next step. Then, the formation of a second line segment connected with the first line segment and substantially perpendicular to the first axis is initiated. The completion of the transfer of the wafers is then determined and the formation of the second line segment perpendicular to the first axis is terminated. The process is then repeated for each process station until the wafers have been processed through all the process stations.

Owner:ASM INTERNATIONAL

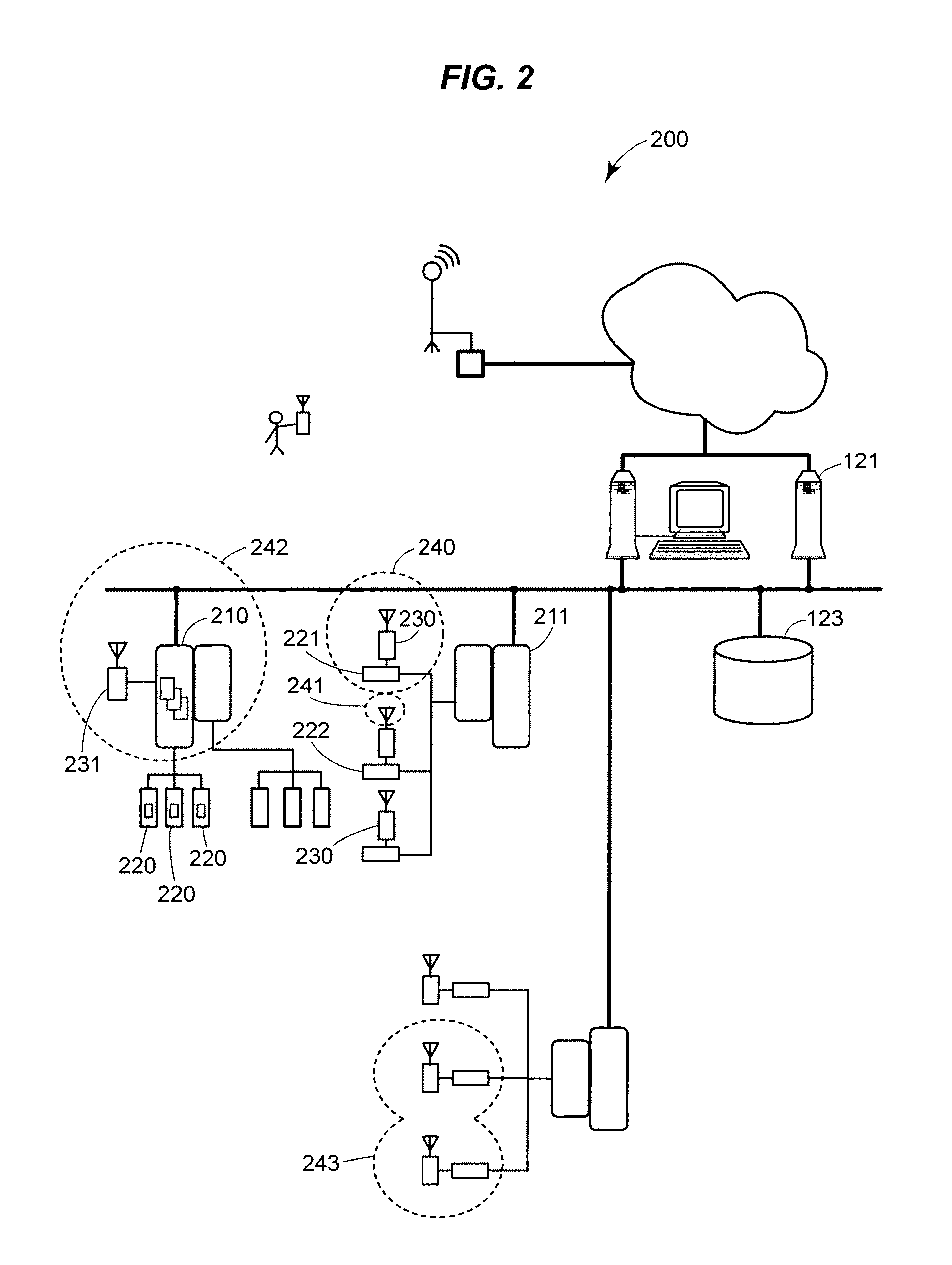

Location Dependent Control Access in a Process Control System

ActiveUS20090065578A1Avoid changeProvide securityIndividual entry/exit registersTotal factory controlControl systemPosition dependent

A method of accessing an element in a process control environment using a portable communicator includes defining a plurality of control areas within the process control environment, determining a position of a user operating a portable communicator with respect to one or more of the control areas, establishing an identity of the user, and selectively allowing the user to access an element within the process control environment via the portable communicator depending on the determined position of the user with respect to the one or more control areas and on the identity of the user.

Owner:FISHER-ROSEMOUNT SYST INC

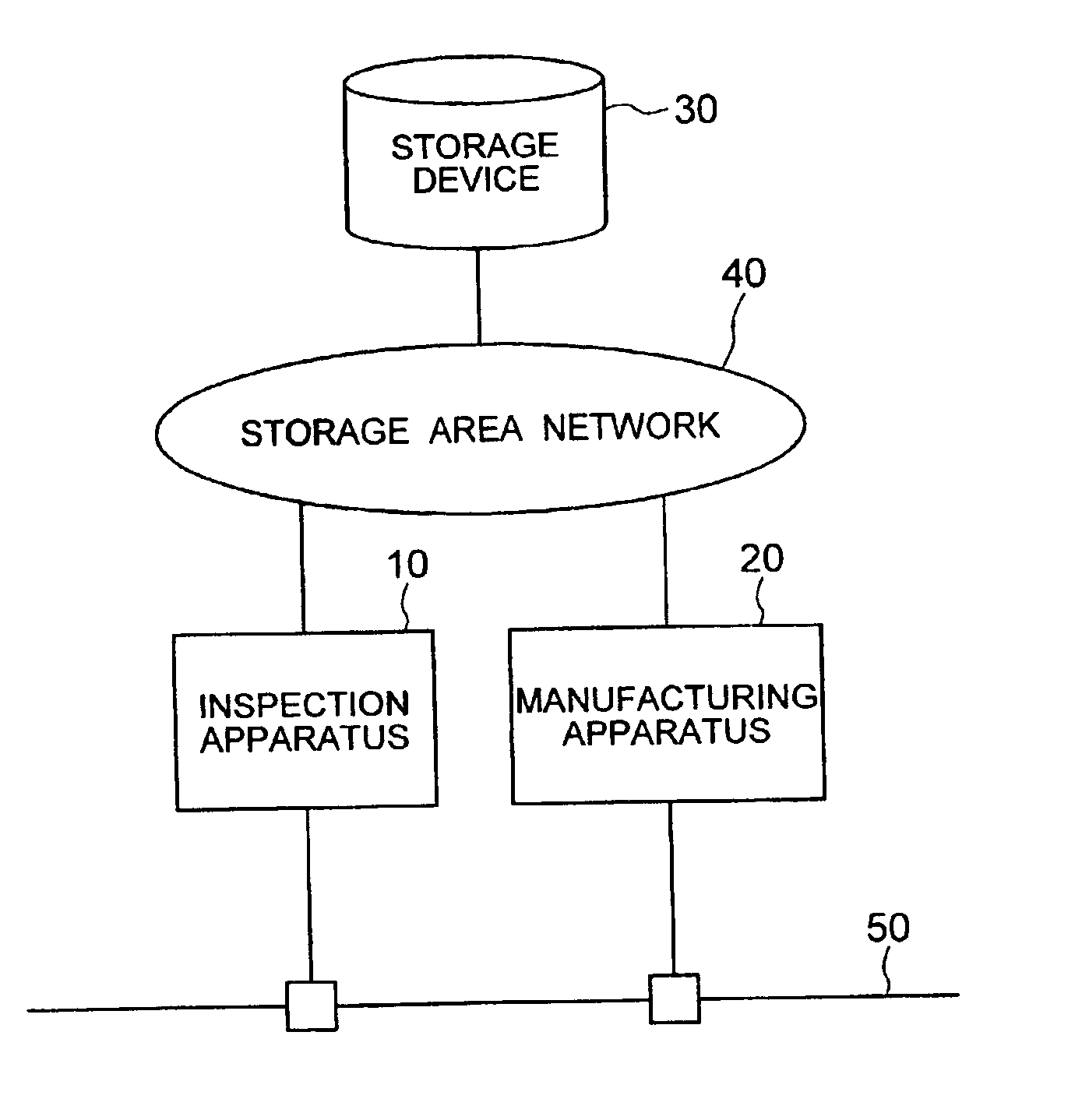

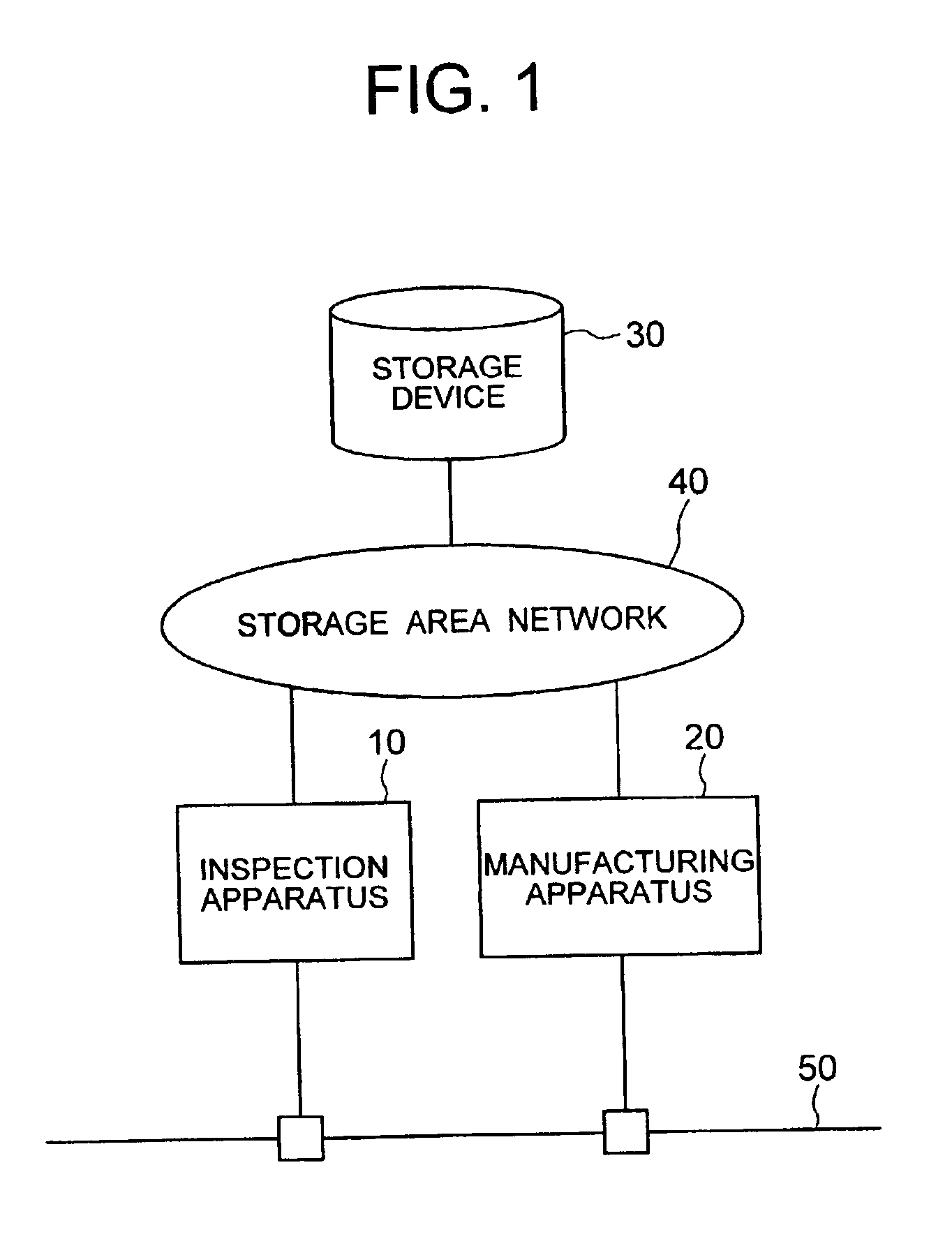

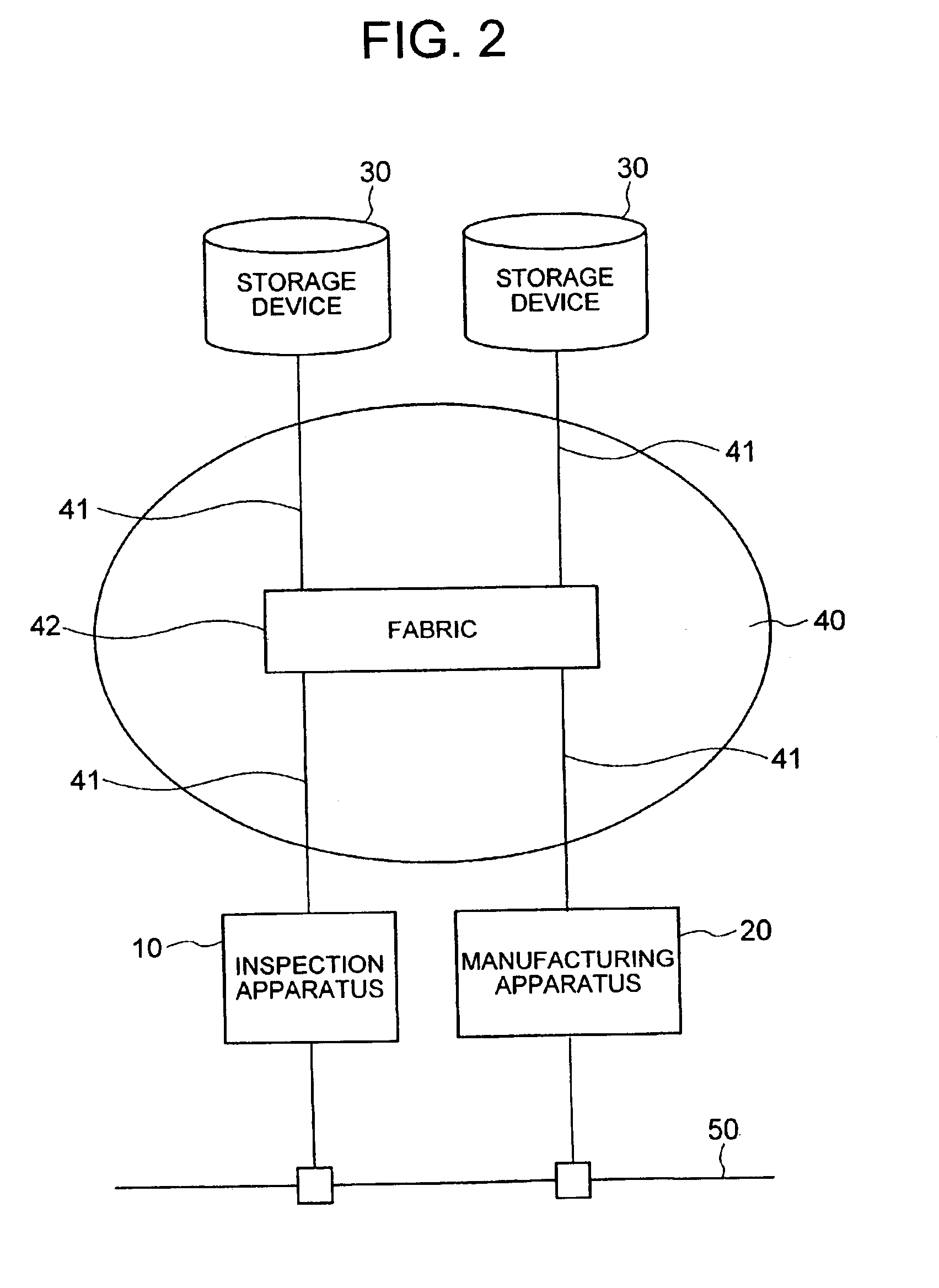

Semiconductor production system

InactiveUS6850854B2Improve system throughputIncrease in sizeSemiconductor/solid-state device testing/measurementElectronic circuit testingStorage area networkObservation unit

A semiconductor production system has a semiconductor manufacturing apparatus having an exposure unit, a control unit for controlling the exposure unit and a storage device; a semiconductor inspection apparatus having an observation unit, a control unit for controlling the observation unit and a storage device; and a storage device commonly used by the semiconductor manufacturing apparatus and the semiconductor inspection apparatus. The manufacturing apparatus, the inspection apparatus and the commonly used storage device are interconnected via a storage area network. With the semiconductor manufacturing apparatus and the storage device linked together via the storage area network, a large volume of image data or design data can be communicated at high speed, thus improving the system throughput.

Owner:HITACHI LTD

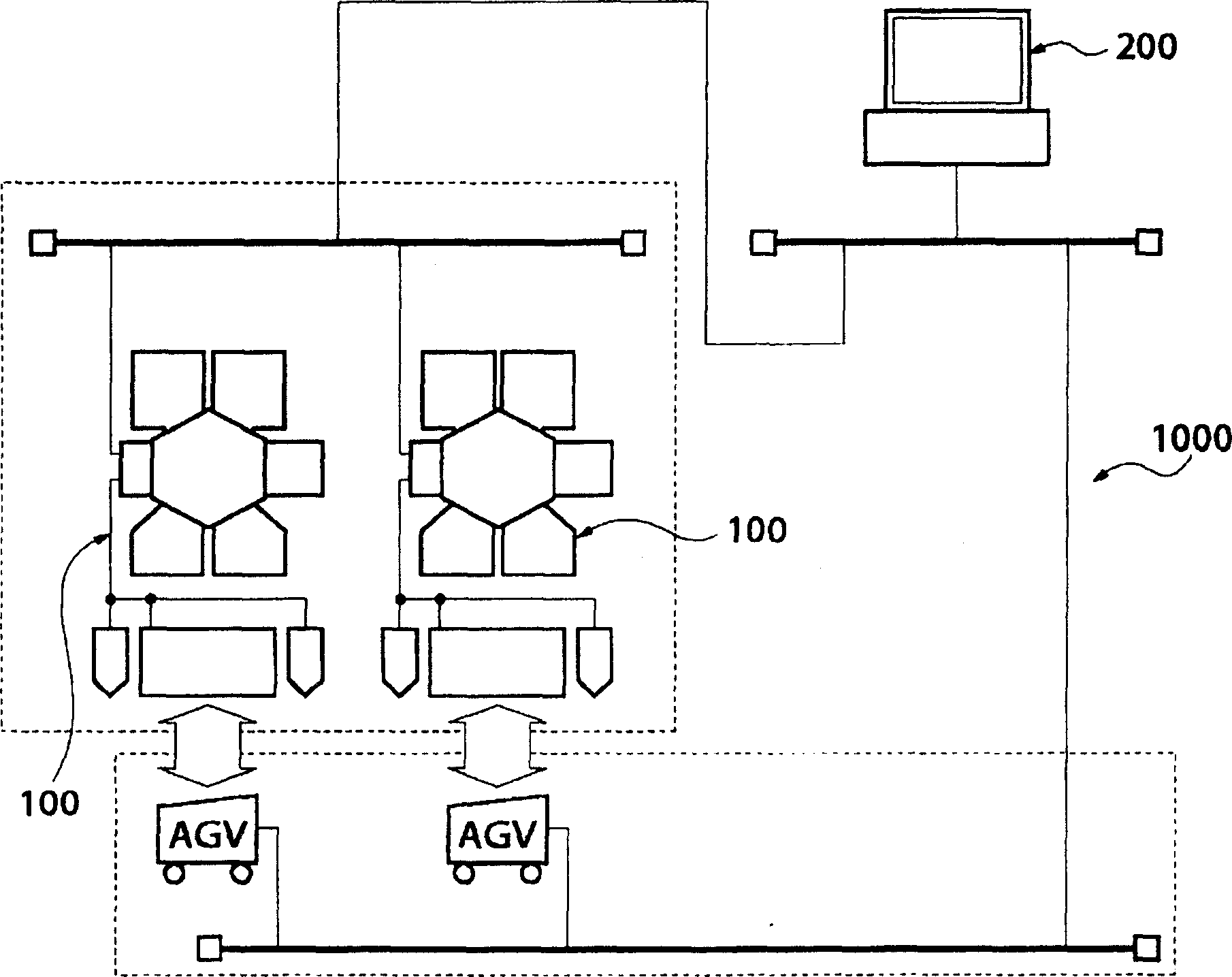

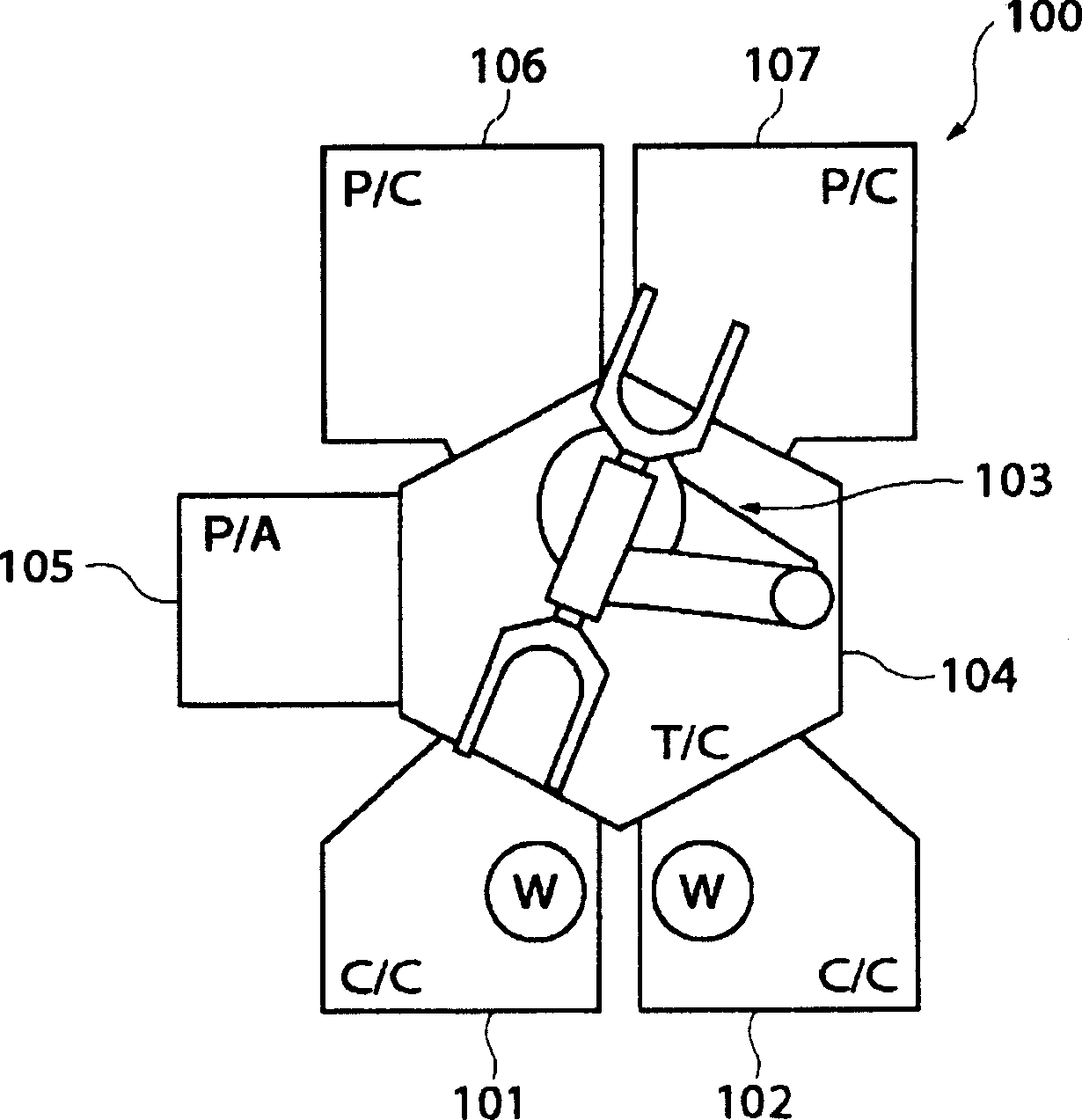

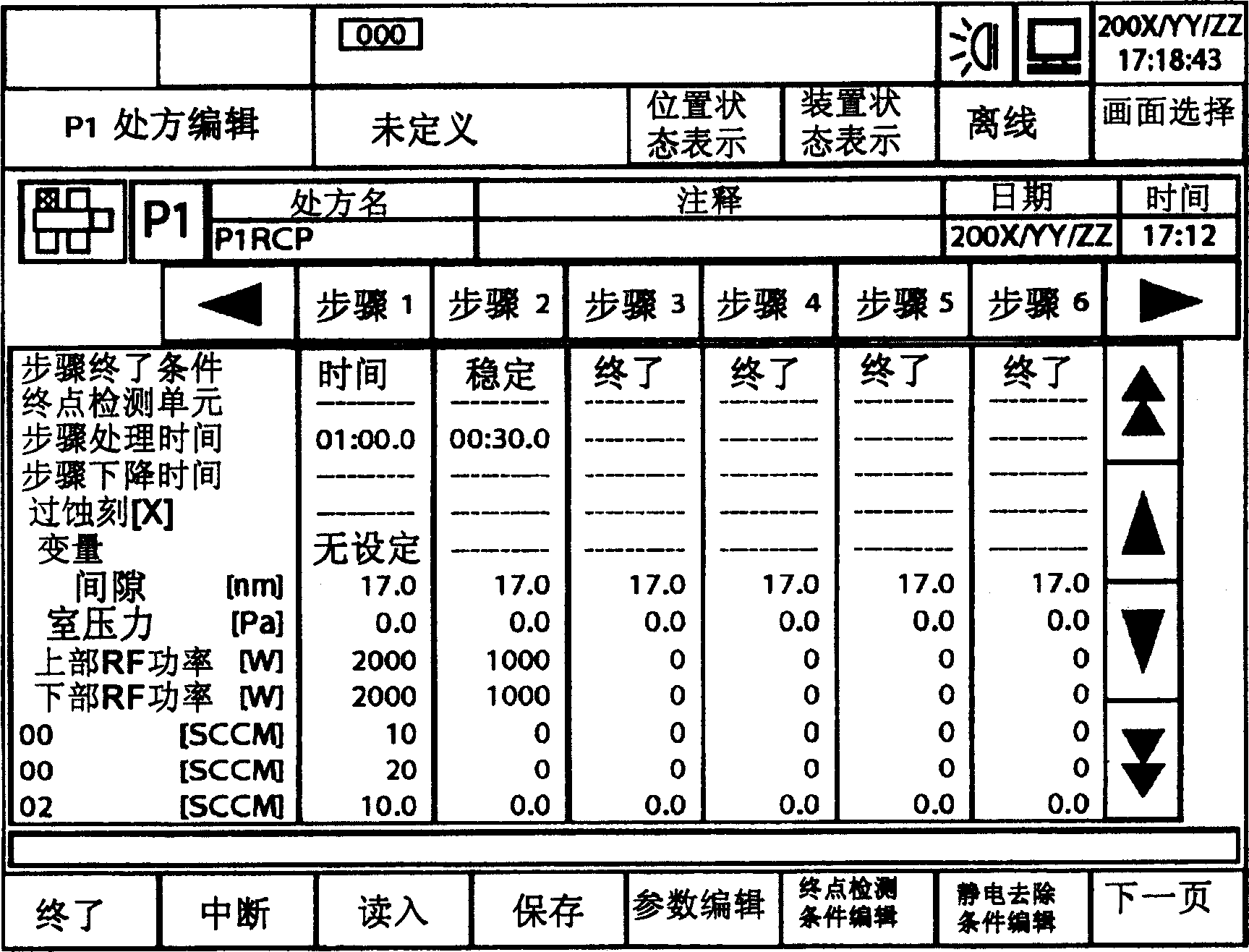

Base plate processing device,base plate processing method and progarm

ActiveCN1664987AIncrease production capacityIndeed implement the requirementsComputer controlSemiconductor/solid-state device manufacturingStable stateProduct processing

An etching apparatus 100 as the substrate processing apparatus is provided with a rotary arm 103 for carrying a substrate included in a lot, and process chambers 106 and 107 for carrying out etching to the substrate as product processing. The etching apparatus 100 is controlled by a host computer 200 in which a transportation recipe, a recipe for product processing and a recipe for dummy processing are registered. When a chamber neglecting time being each neglecting time of the process chambers 106 and 107 does not become time out, the host computer 200 discriminates that processing atmosphere in the process chambers used for etching to the lot is stable, omits the execution of the dummy processing, and executes etching to the substrate of the lot.

Owner:TOKYO ELECTRON LTD

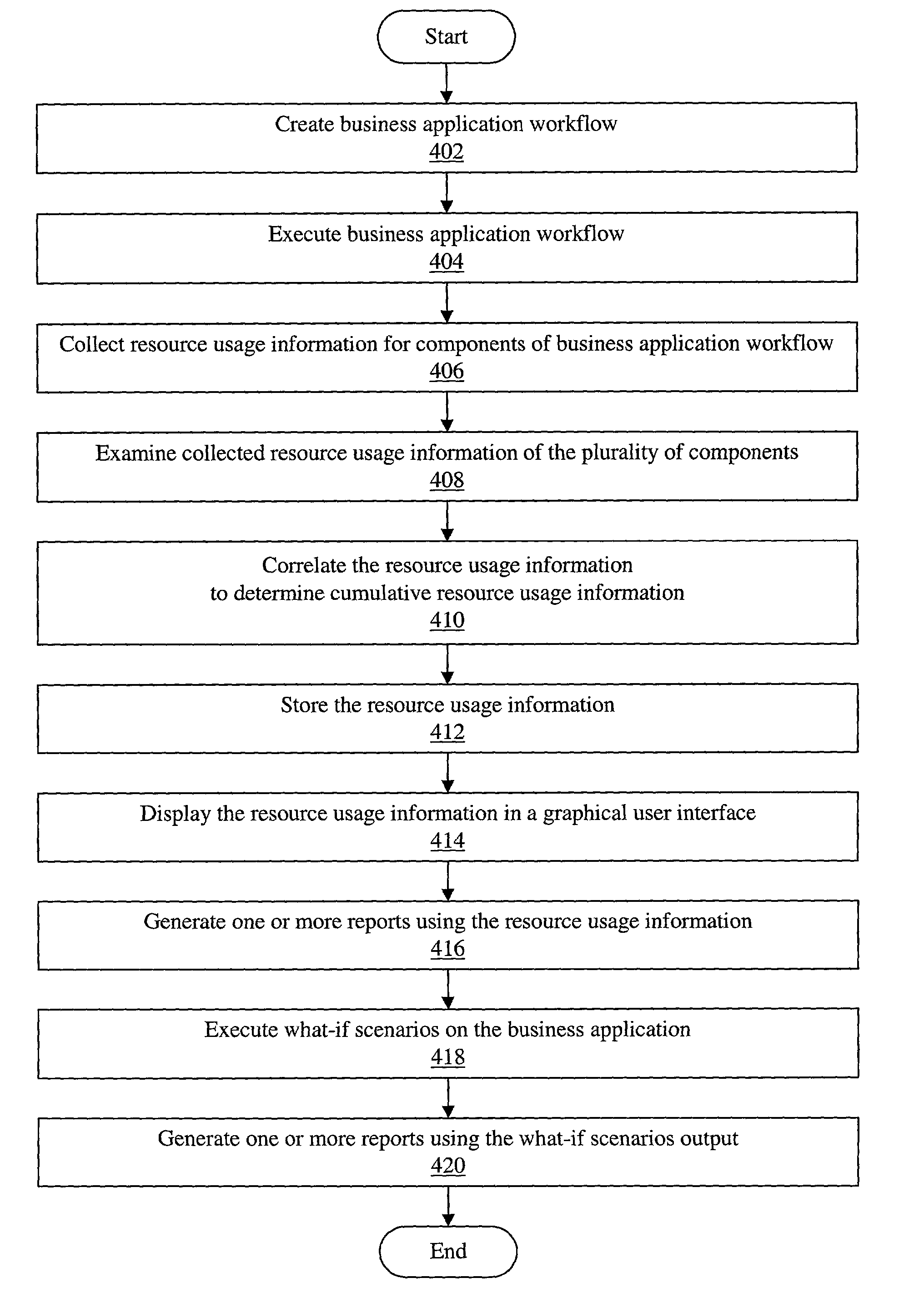

System and method for application performance management

InactiveUS7350209B2General purpose stored program computerHardware monitoringComputer resourcesUser interface

Owner:BMC SOFTWARE

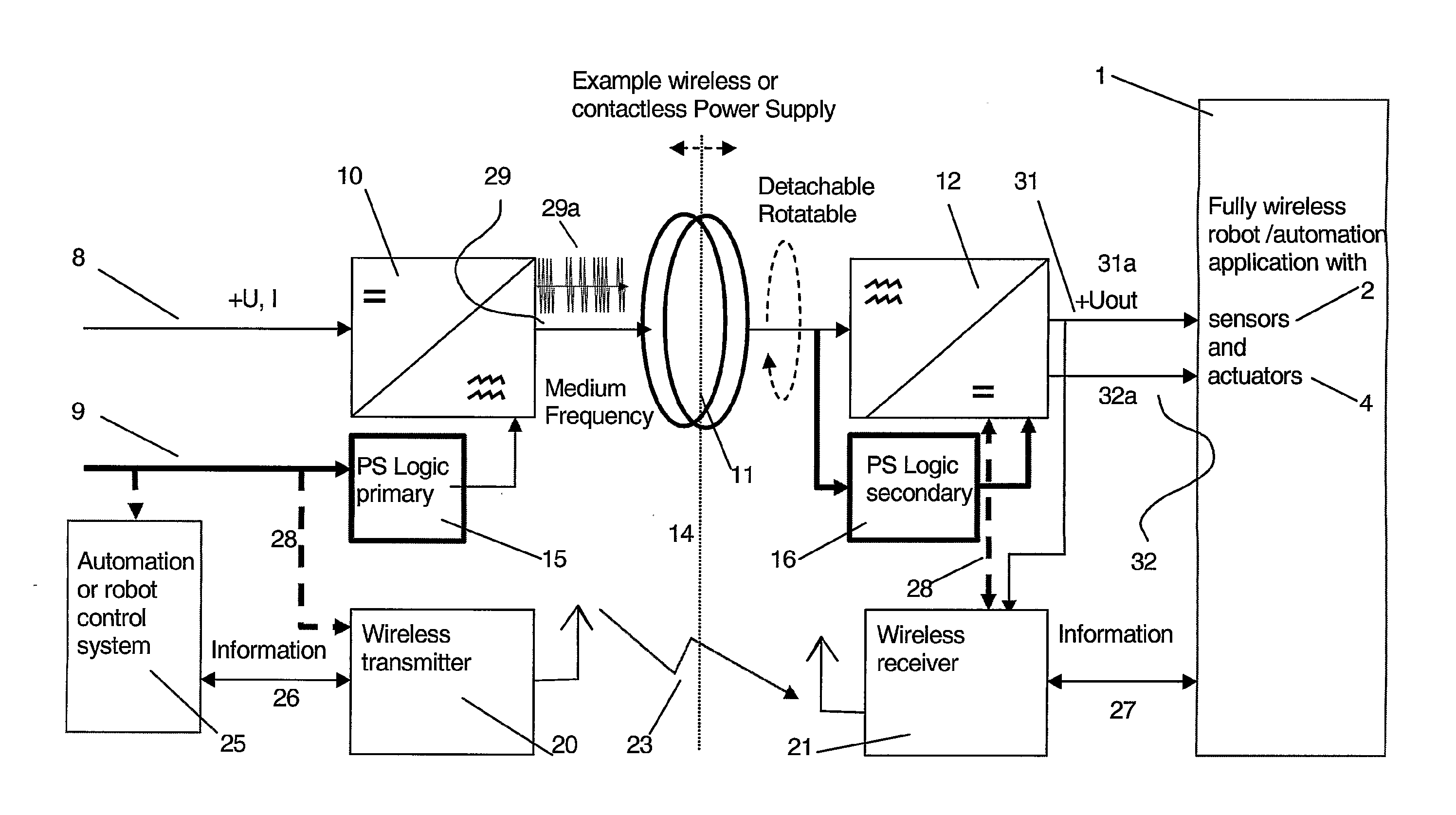

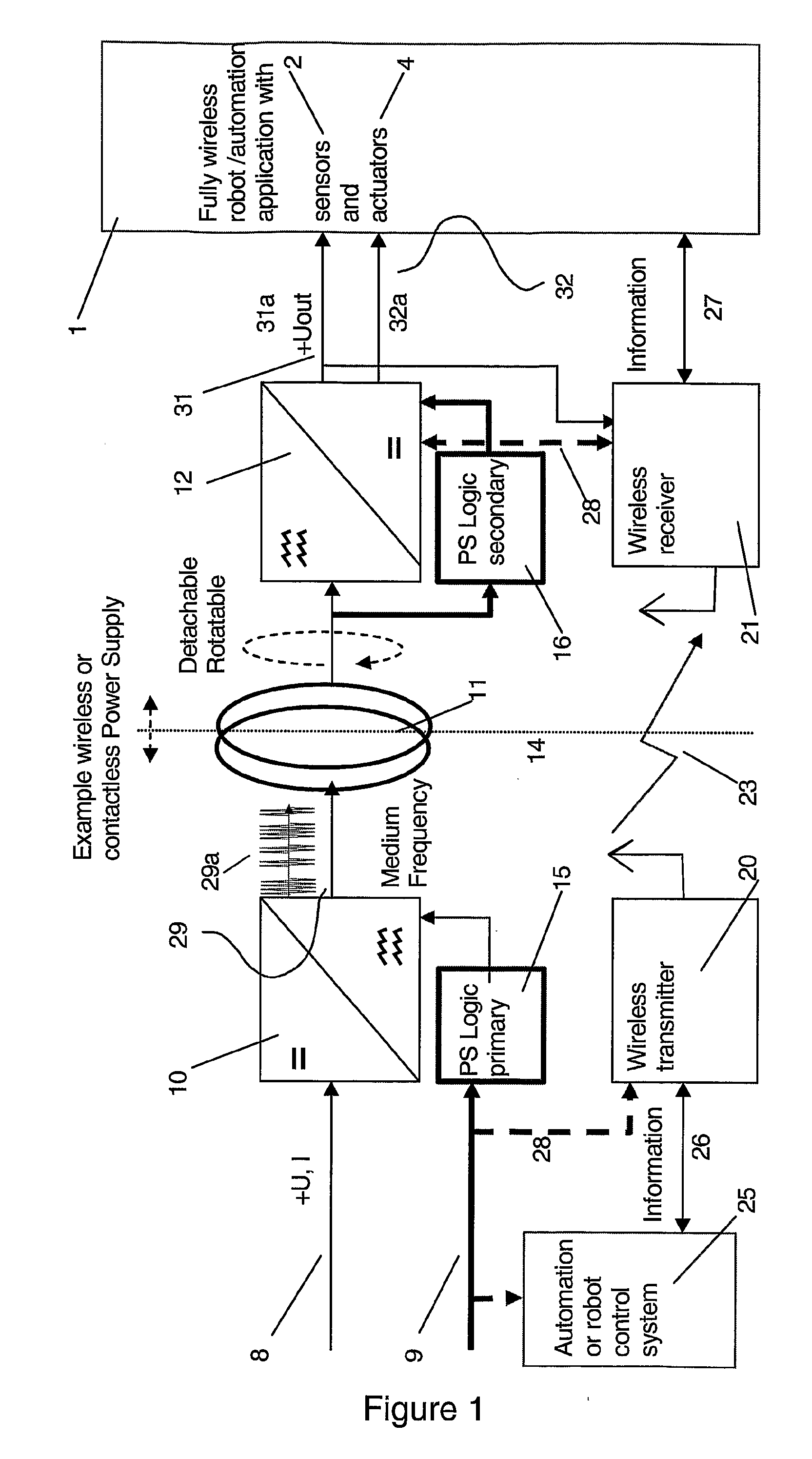

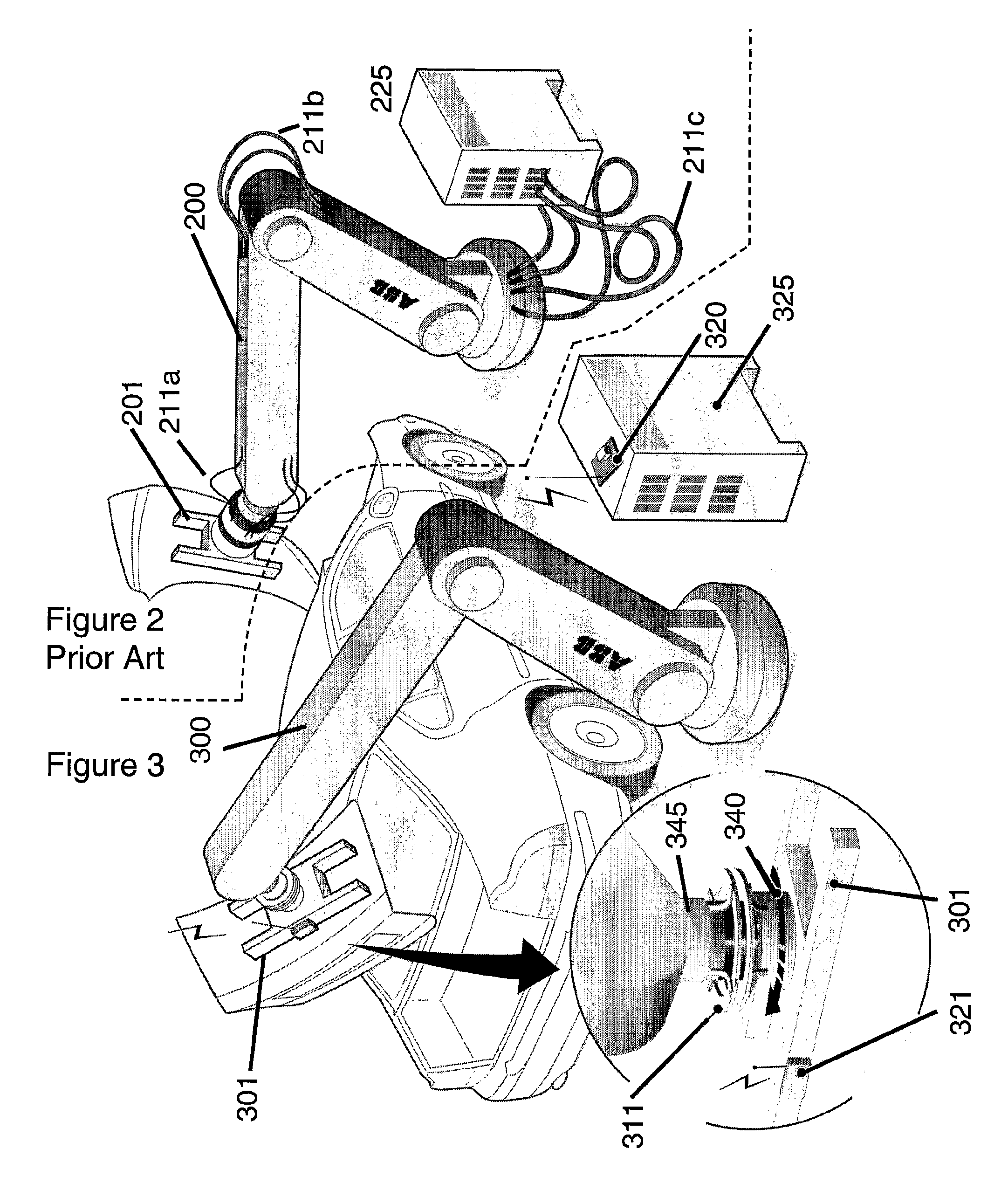

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

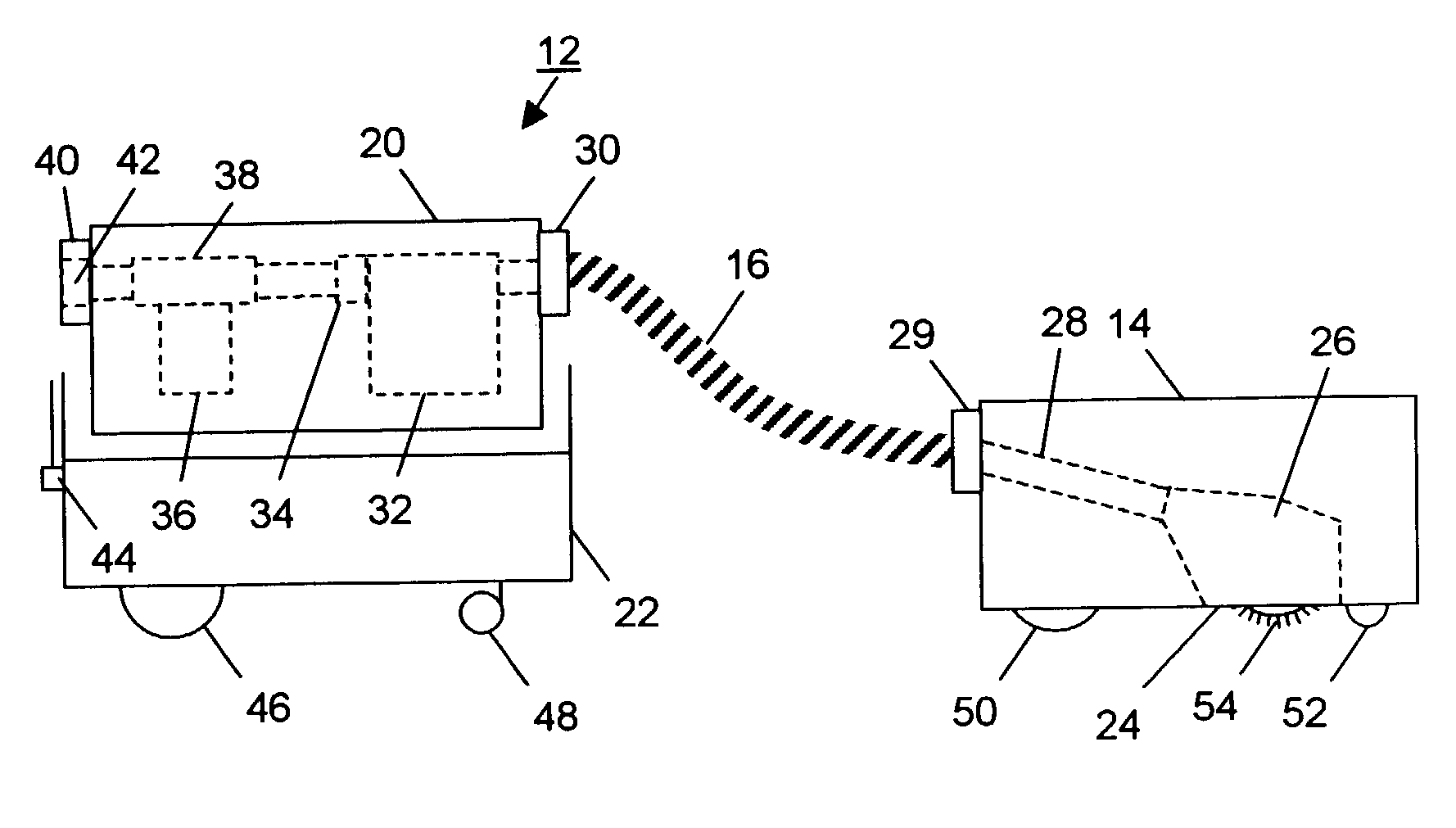

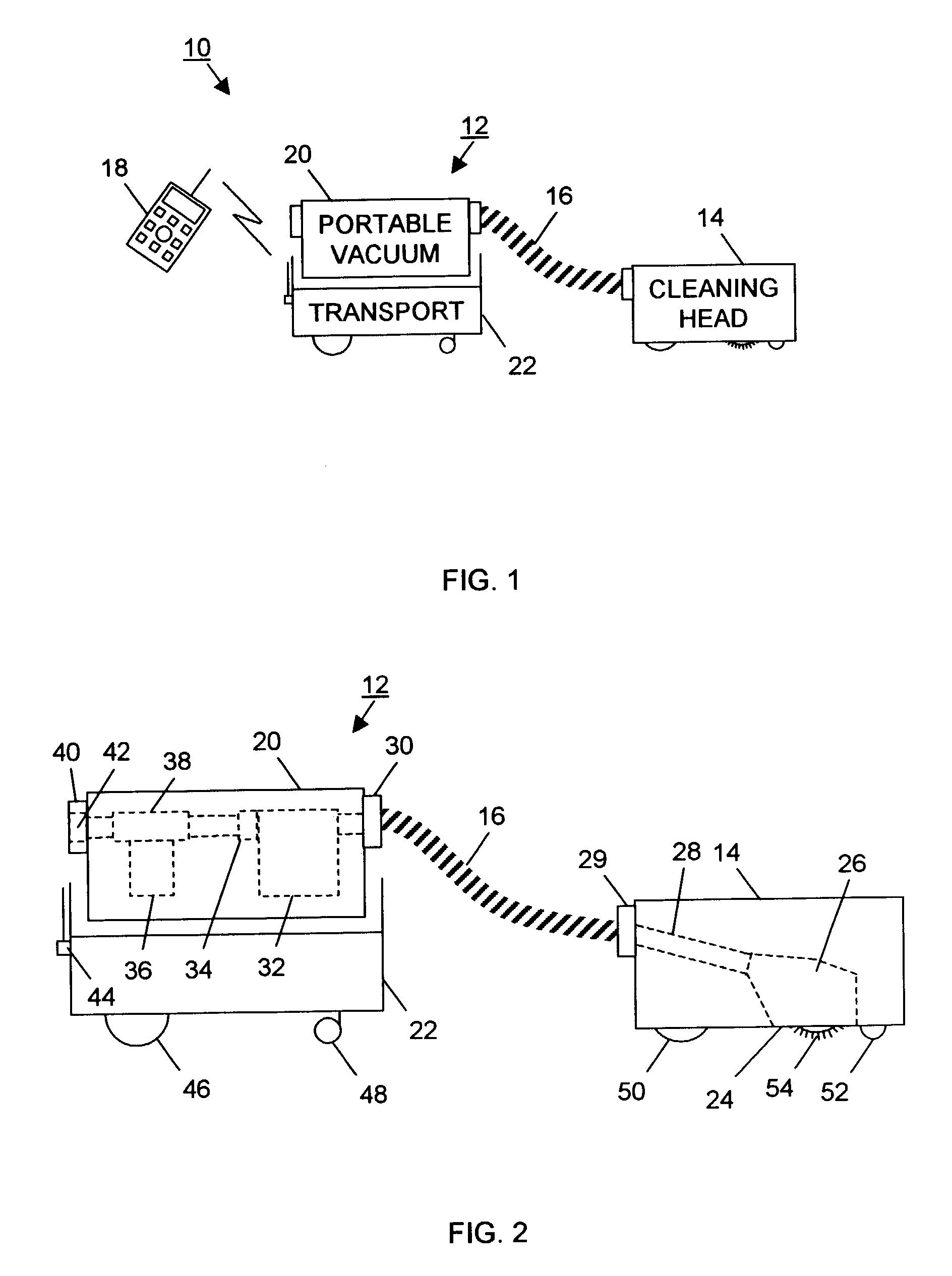

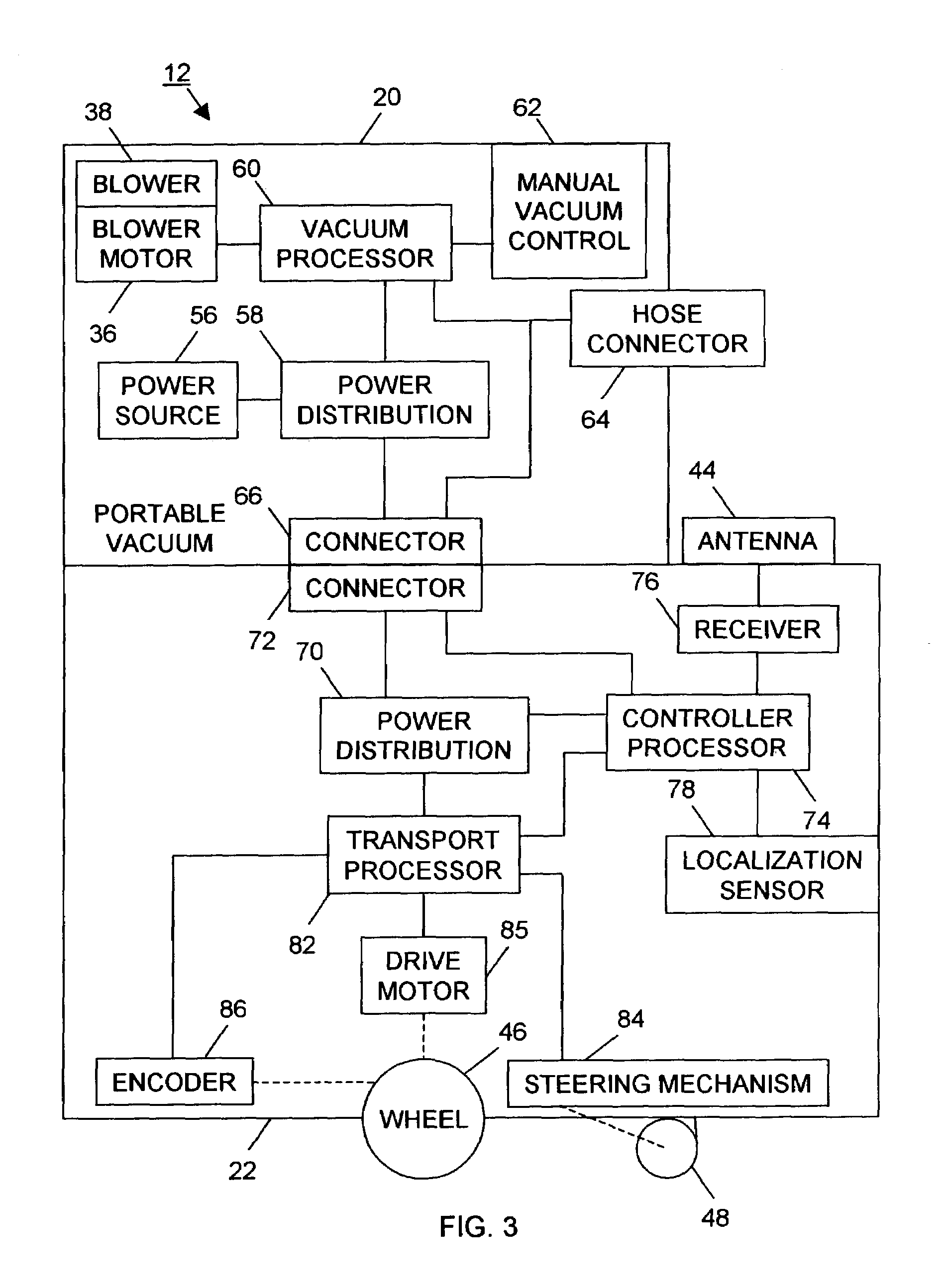

Robotic vacuum with removable portable vacuum and semi-automated environment mapping

ActiveUS7113847B2Programme-controlled manipulatorAutomatic obstacle detectionRemote controlRobotic arm

A robotic vacuum cleaner (10) with a self-propelled controller (12) with a vacuum source (36, 38) and a dirt receptacle (32), a self-propelled cleaning head (14) with a suction inlet (24), and an interconnecting hose (16) is provided. The controller and cleaning head cooperatively traverse a surface area in tandem when the interconnecting hose is connected between the cleaning head and the controller. In one embodiment, the controller includes a power source (56) making the robotic vacuum autonomous. In another embodiment, the controller includes a power cord dispense / retract assembly (168) to provide access to utility power. In another aspect, the controller includes a portable vacuum (20) that is removed for manual operations. In still another aspect, a method of semi-automated environment mapping for a self-propelled robotic vacuum is provided. With respect to the method, the robotic vacuum also includes a remote control (18).

Owner:ROYAL APPLIANCE MFG

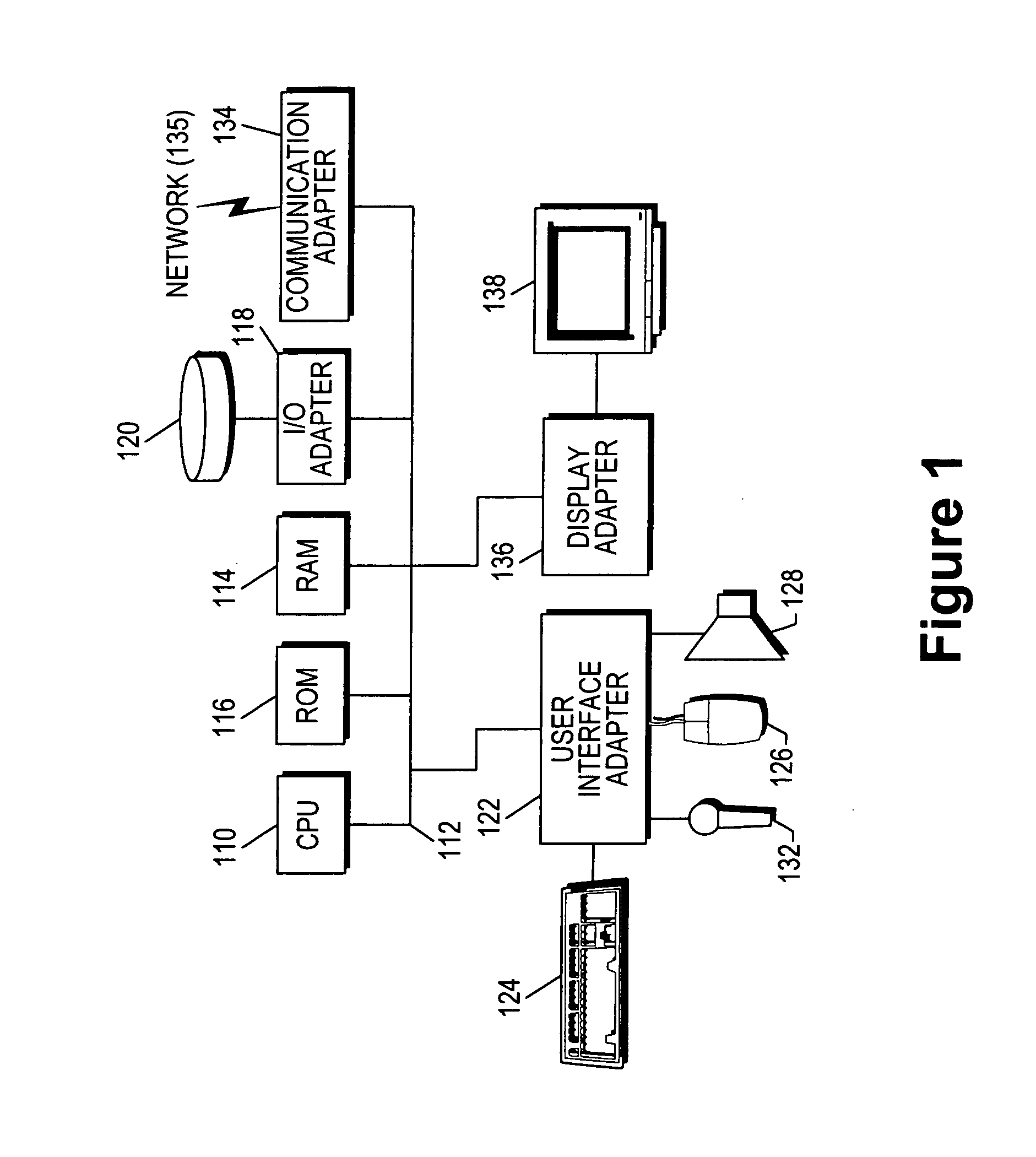

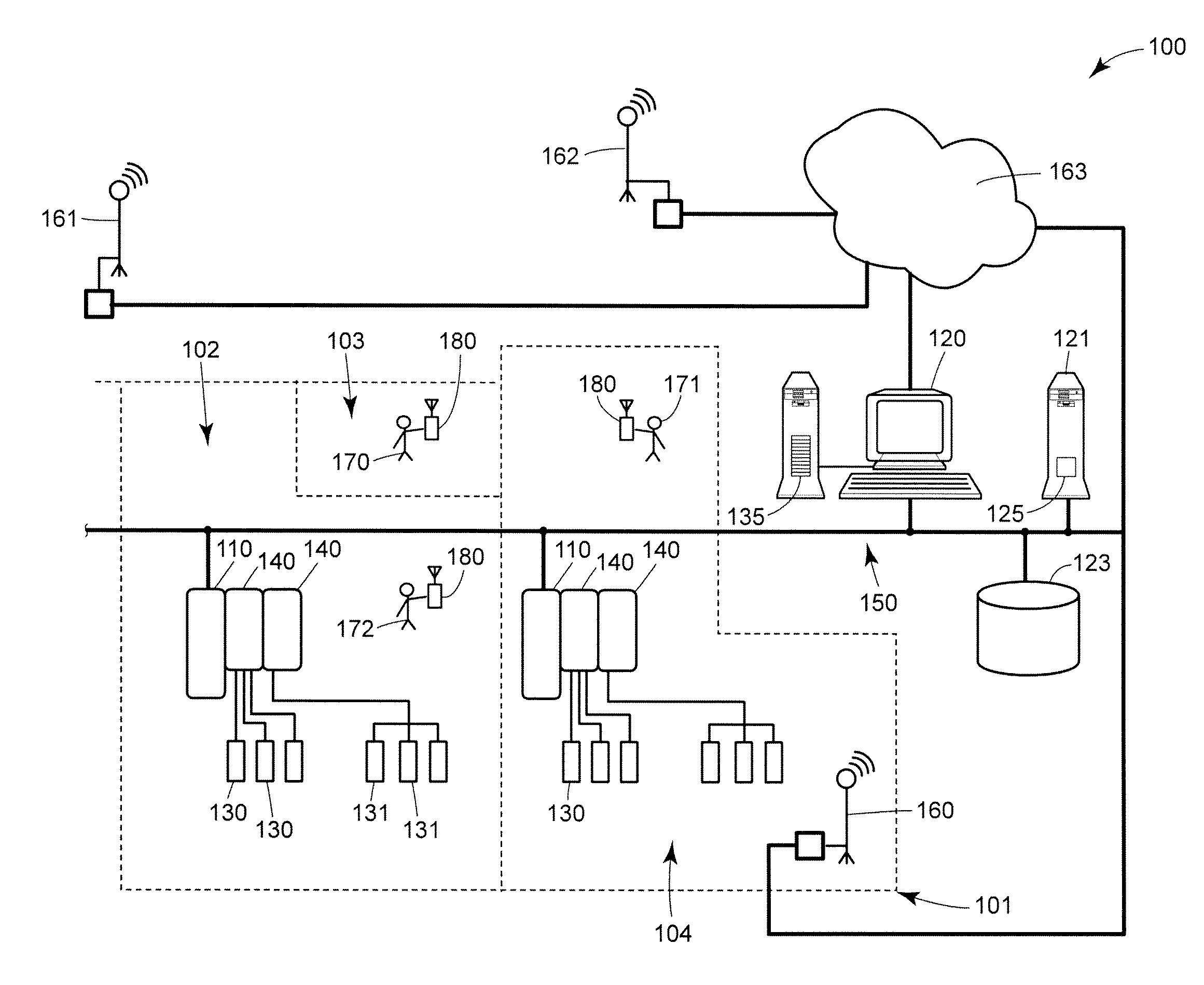

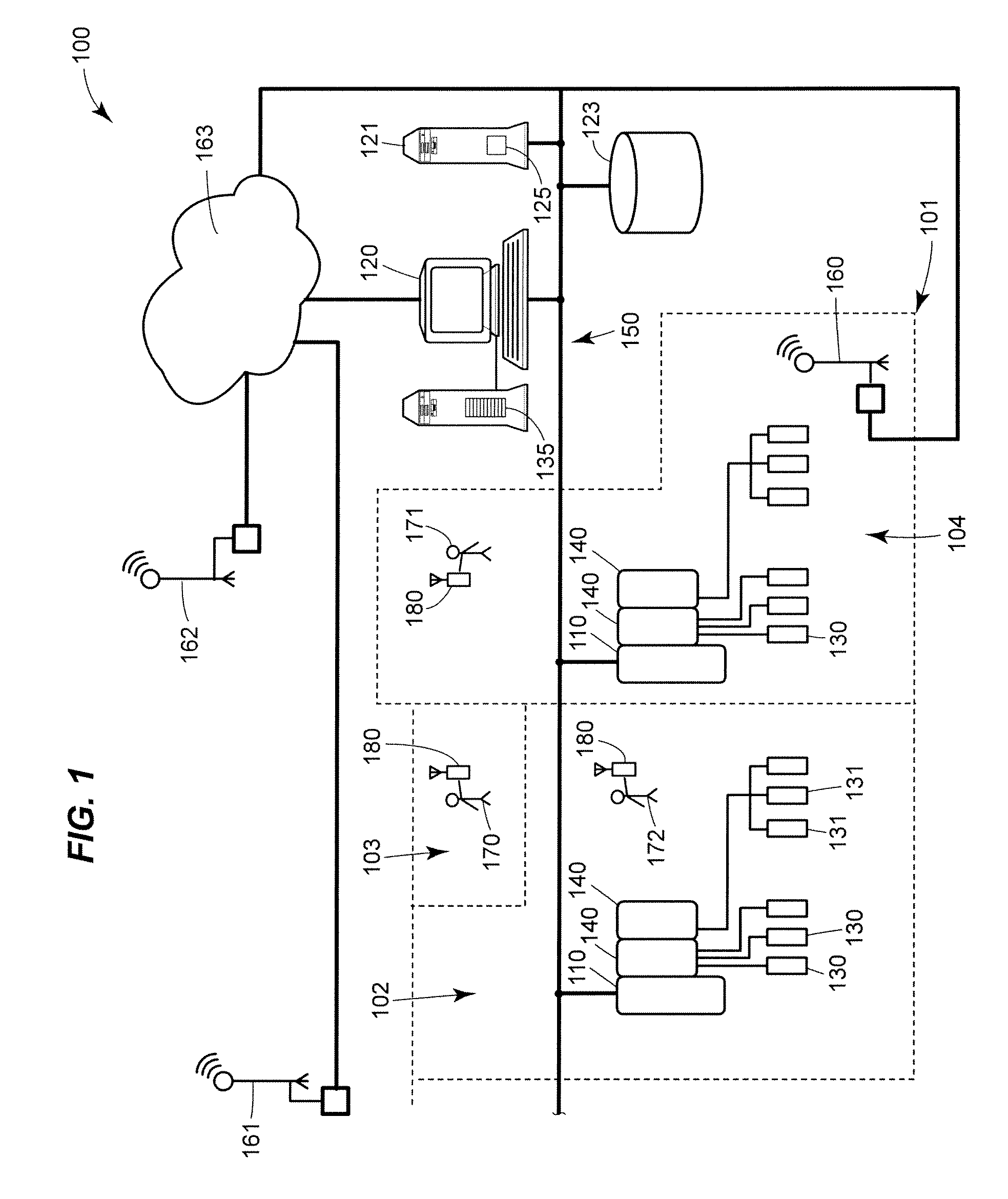

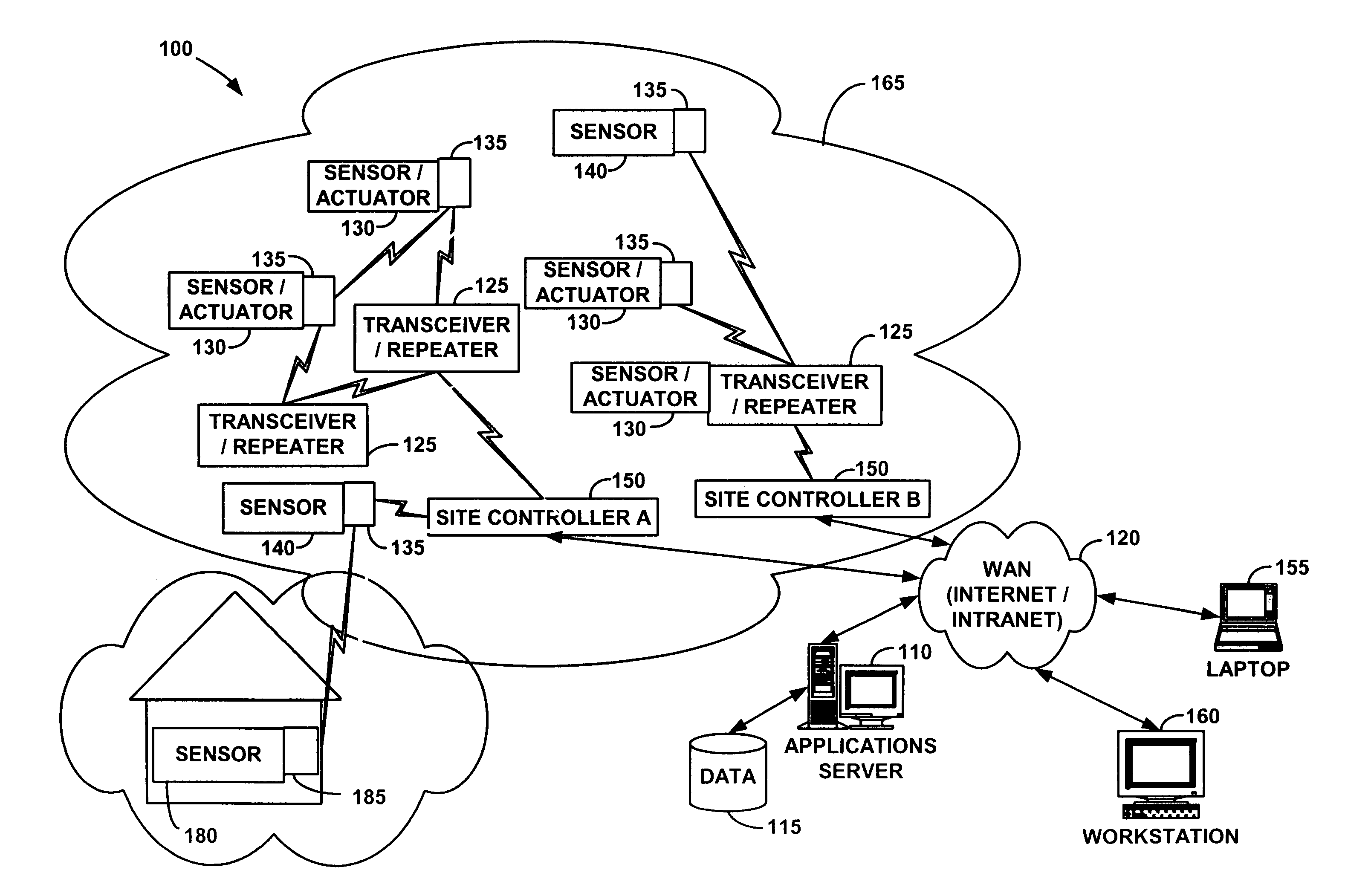

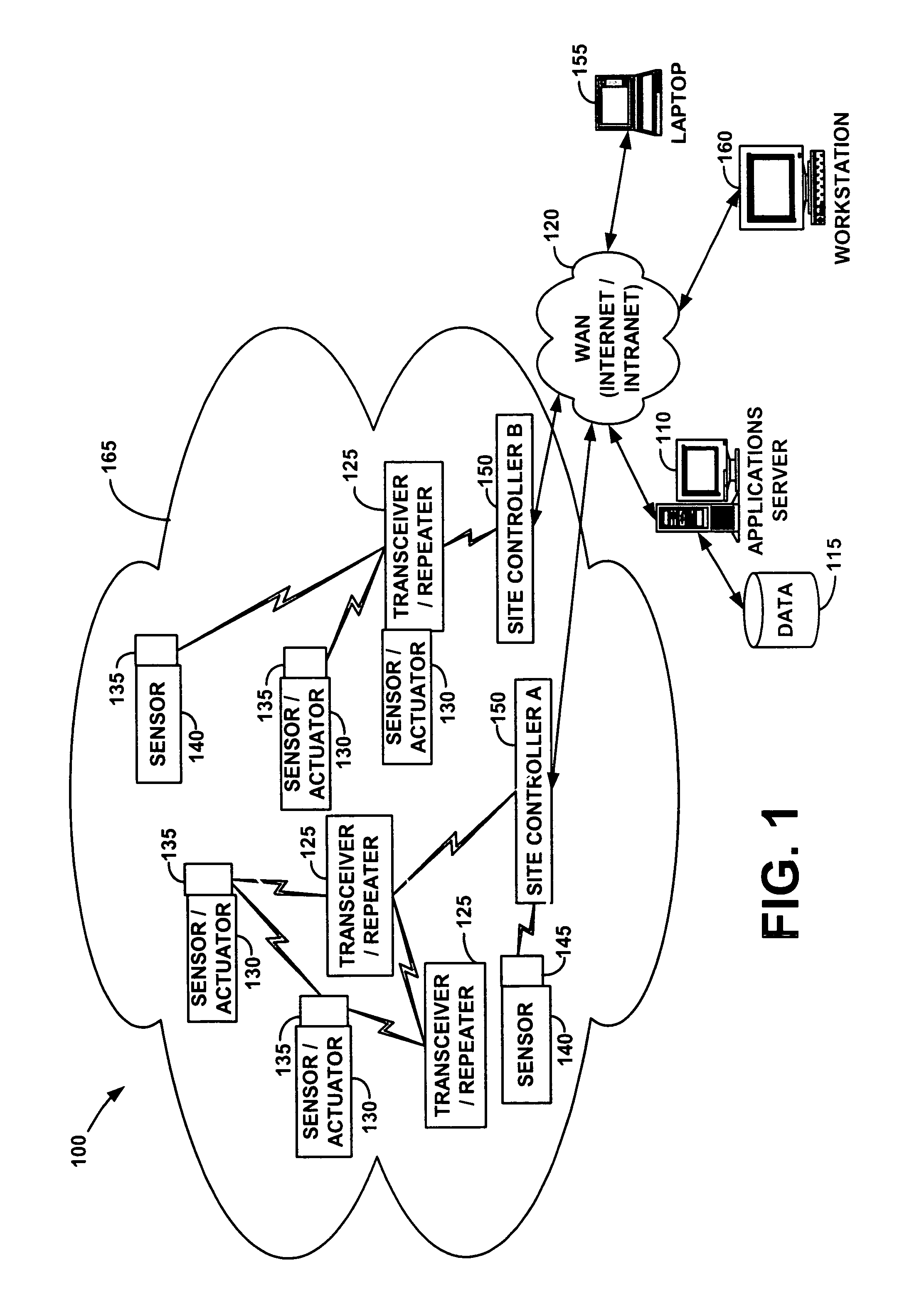

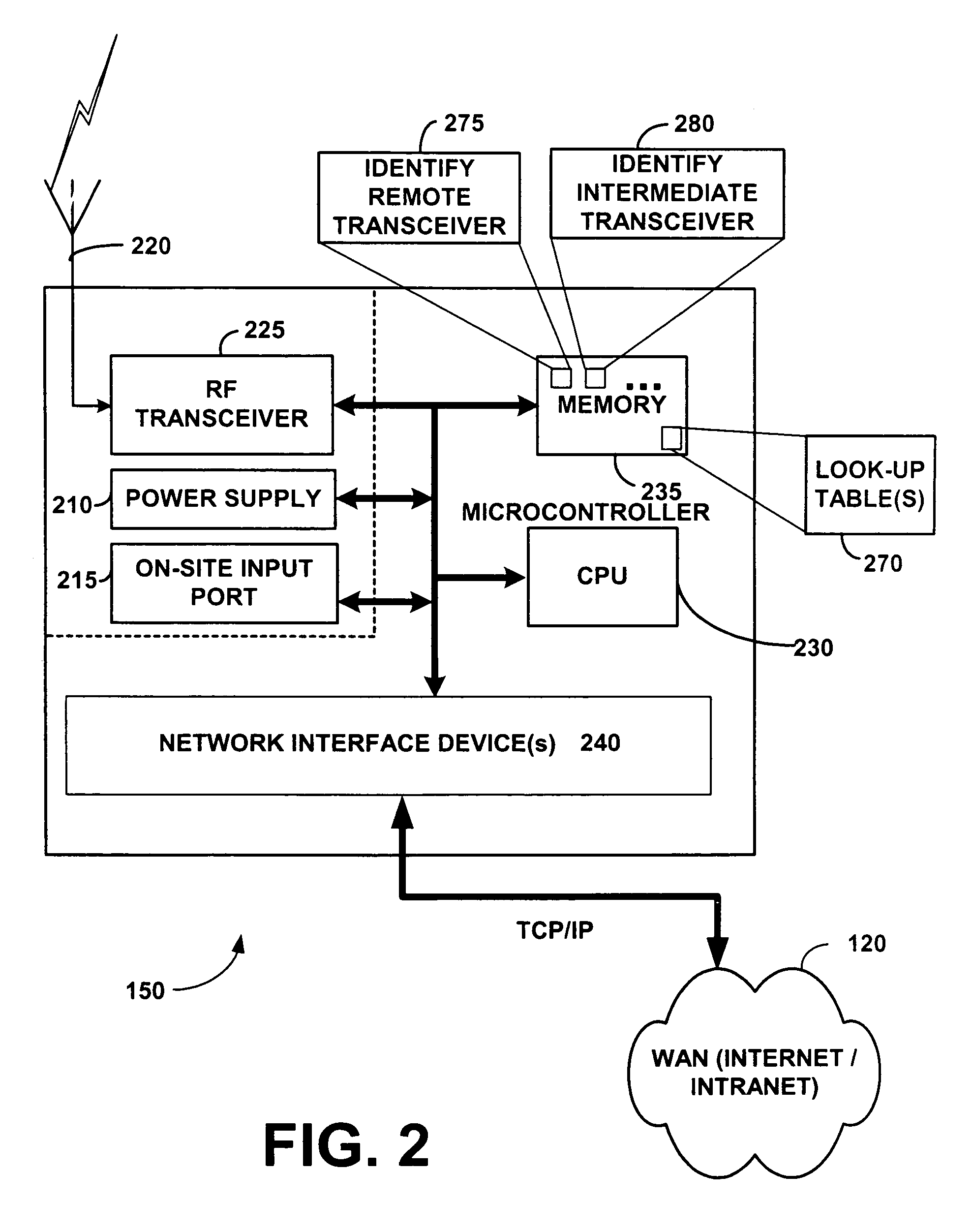

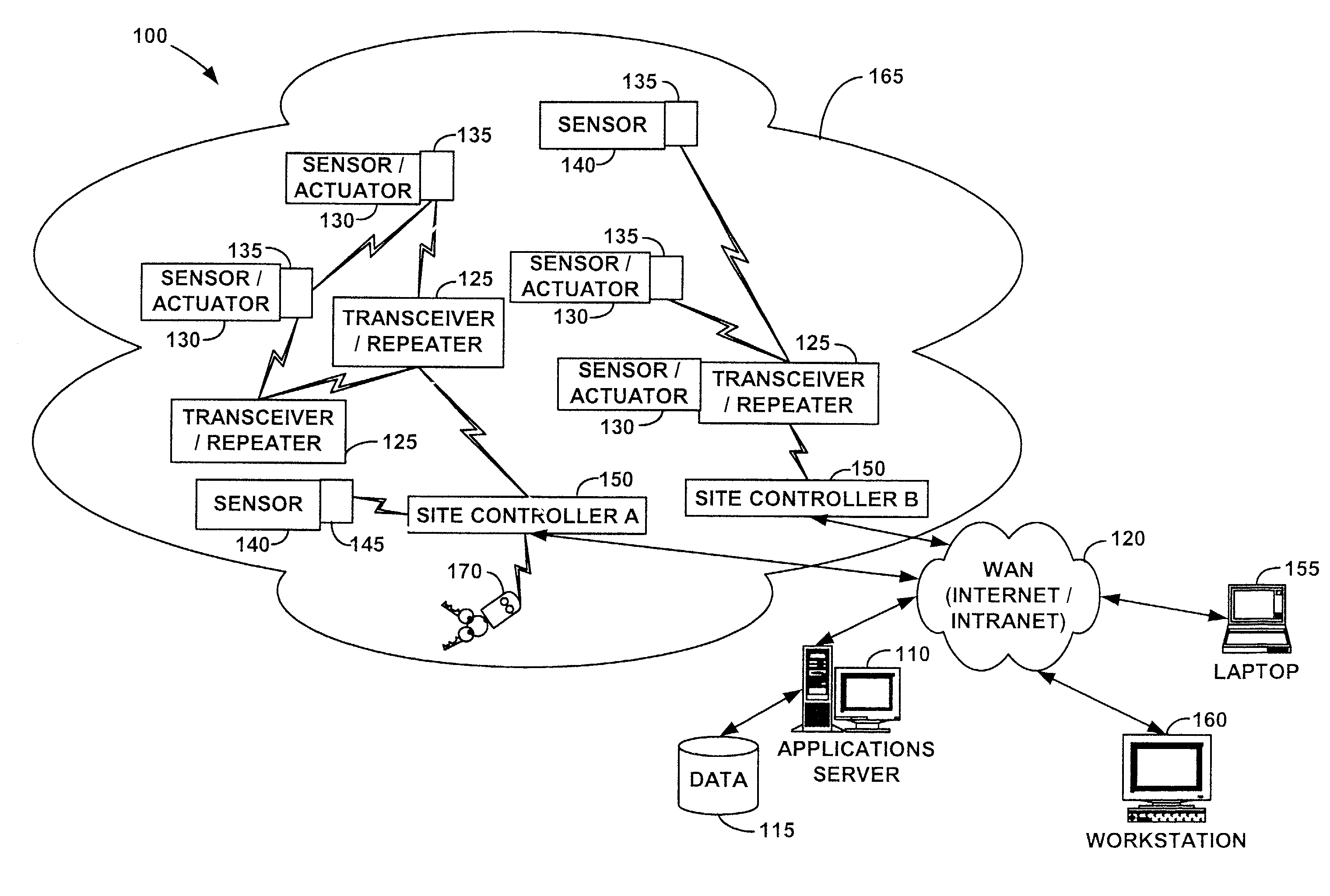

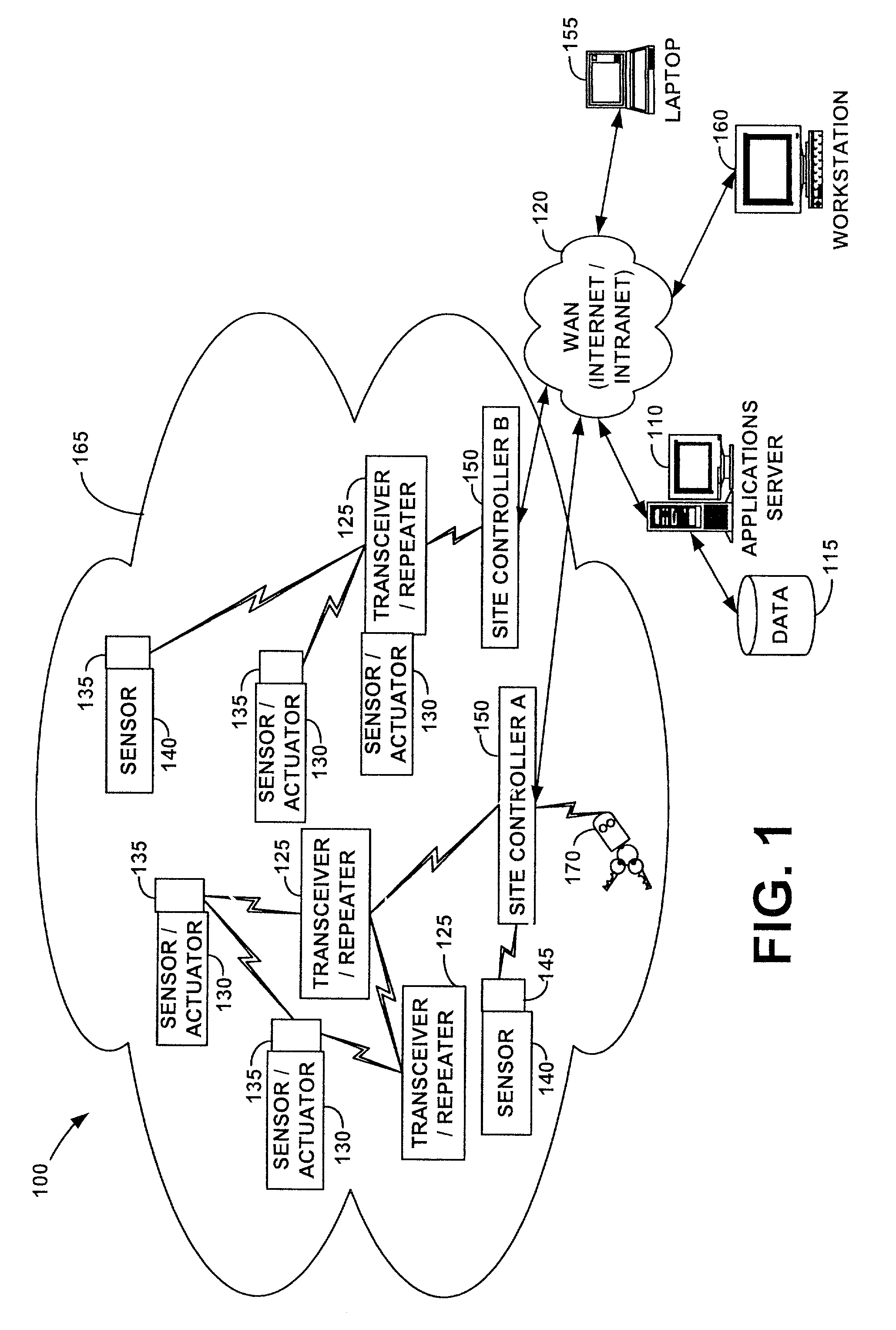

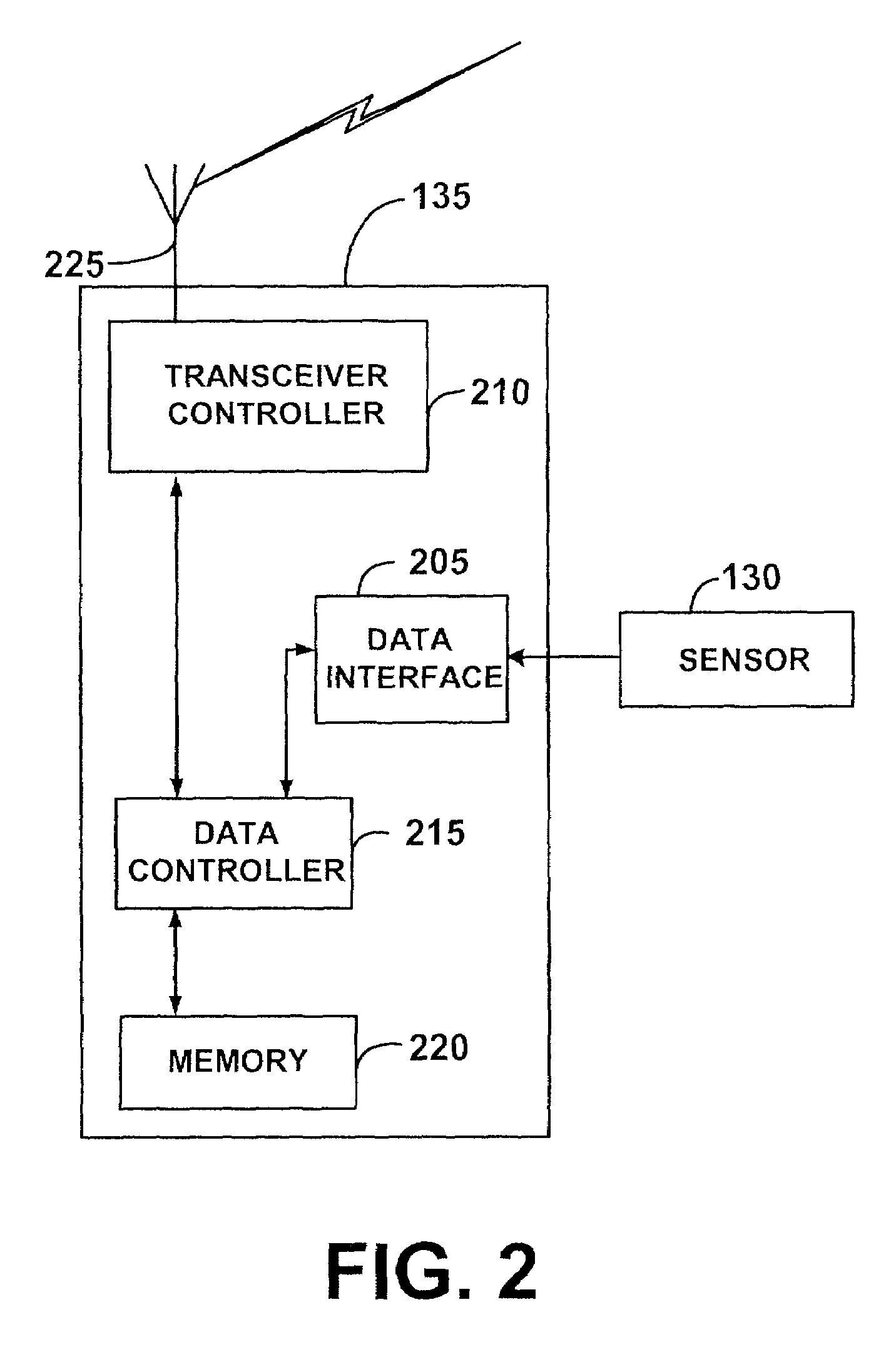

System and method for controlling communication between a host computer and communication devices associated with remote devices in an automated monitoring system

InactiveUS7650425B2Low costMinimize complexityAlarmsProgramme total factory controlTelecommunications linkTransceiver

A site controller adapted to be used in an automated monitoring system for monitoring and controlling a plurality of remote devices via a host computer connected to a first communication network is provided. The site controller is configured for controlling communication with the host computer and a plurality of communication devices that define a second communication network associated with the plurality of remote devices. Briefly described, in one embodiment, the site controller comprises a transceiver configured to communicate with the plurality of communication devices via the second communication network; a network interface device configured to communicate with the host computer via the first communication network; and logic configured to: manage communication with each of the plurality of communication devices, via a first communication protocol, based on one or more communication paths for each of the plurality of communication devices, each communication path comprising one or more communication devices involved in the communication link between the transceiver and each of the plurality of communication devices; and manage communication with the host computer via a second communication protocol.

Owner:SIPCO

Systems and methods for enabling a mobile user to notify an automated monitoring system of an emergency situation

InactiveUS7263073B2Electric signal transmission systemsCircuit arrangementsTransceiverMonitoring system

Systems and methods for enabling a mobile user to notify an automated monitoring system of an emergency situation are provided. The automated monitoring system may be configured for monitoring and controlling a plurality of remote devices and may comprise a site controller in communication with the plurality of remote devices via a plurality of transceivers defining a wireless communication network and in communication with a host computer via a wide area network. Briefly described, one such method comprises the steps of: receiving notification that the mobile user desires to initiate transmission of an emergency message to the site controller; determining the identity of the mobile user; and providing an emergency message over the wireless communication network for delivery to the site controller, the emergency message indicating the identity of the mobile user.

Owner:SIPCO

System for providing control to an industrial process using one or more multidimensional variables

InactiveUS6865509B1Quick analysisHigh reliability and precisionElement comparisonElectric testing/monitoringComputer-aidedComputer aid

Owner:SMITHS DETECTION

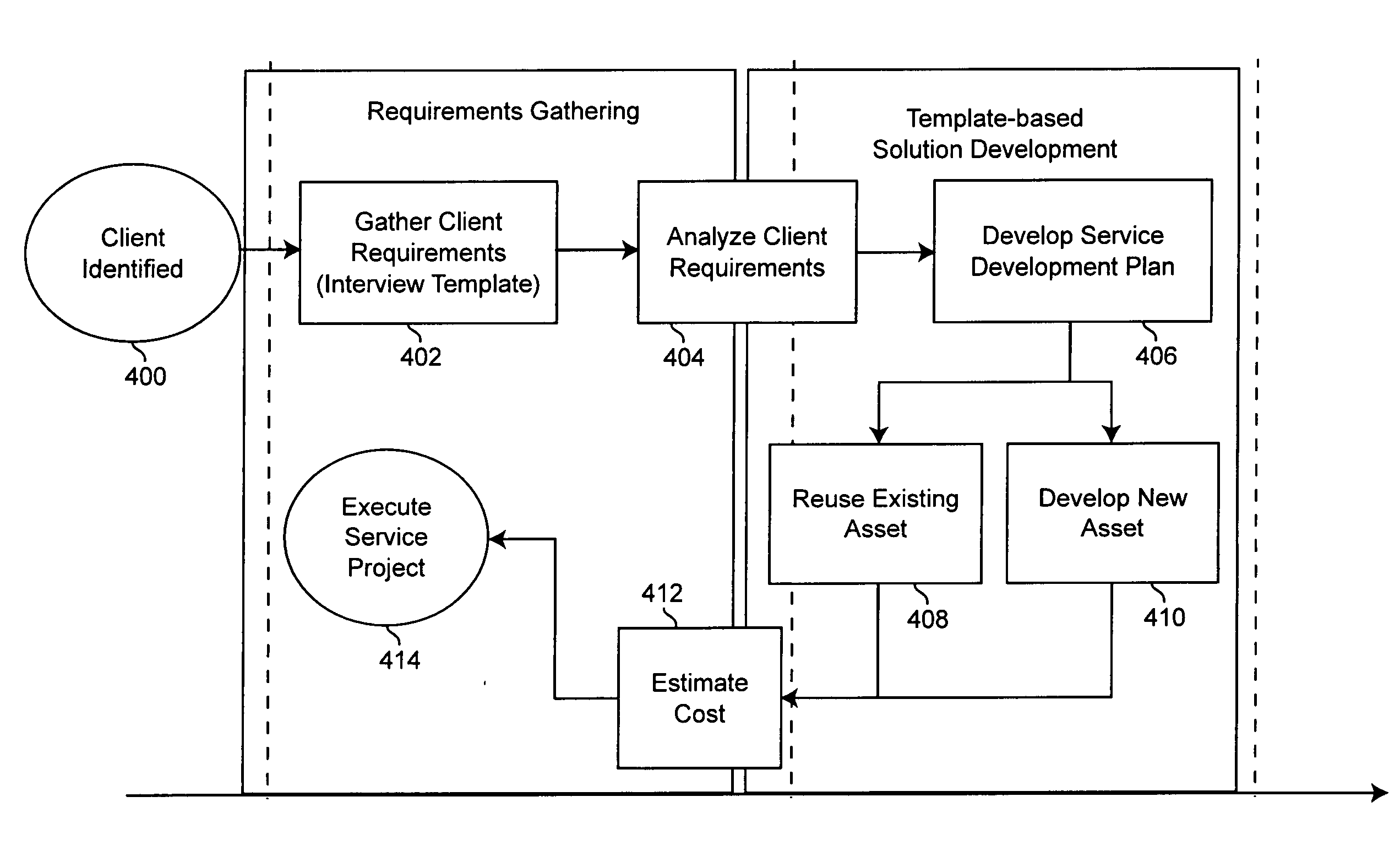

Method and apparatus for model-driven managed business services

InactiveUS20070179793A1Avoid longerAvoid costly service implementationMarket predictionsResourcesSupporting systemTemplate based

A mechanism provides a model-driven solution template-based approach for managed business services. Key assets of the business services are templatized and made configurable. The mechanism implements a metamodel describing standard service offerings that can be configured to meet specific business and operational requirements at a level of business process and system components. A cost and pricing model of service offerings helps assess the service costs and resource requirements based on a client's selection of standard and customized processes and system components. A supporting system solution is developed based upon underlying solution templates and solution artifacts as well as client-specific requirements.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com