Patents

Literature

5043 results about "Product processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product by process is an online compilation of processes , material and interesting stories about products. Product by process is an attempt to go beyond the polished products and objects that surround us and take a look at how they are manufactured and recycled.

Base plate processing device,base plate processing method and progarm

ActiveCN1664987AIncrease production capacityIndeed implement the requirementsComputer controlSemiconductor/solid-state device manufacturingStable stateProduct processing

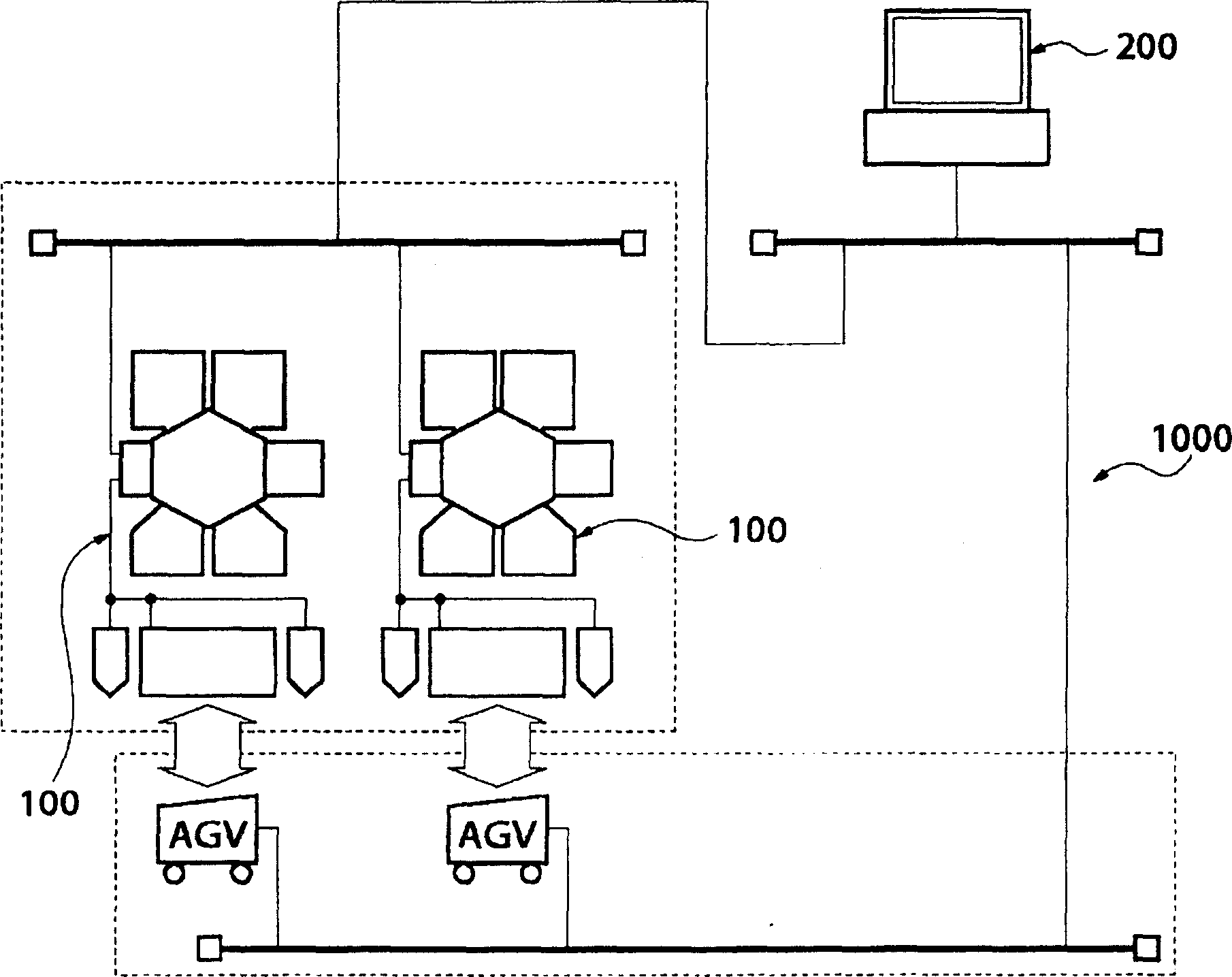

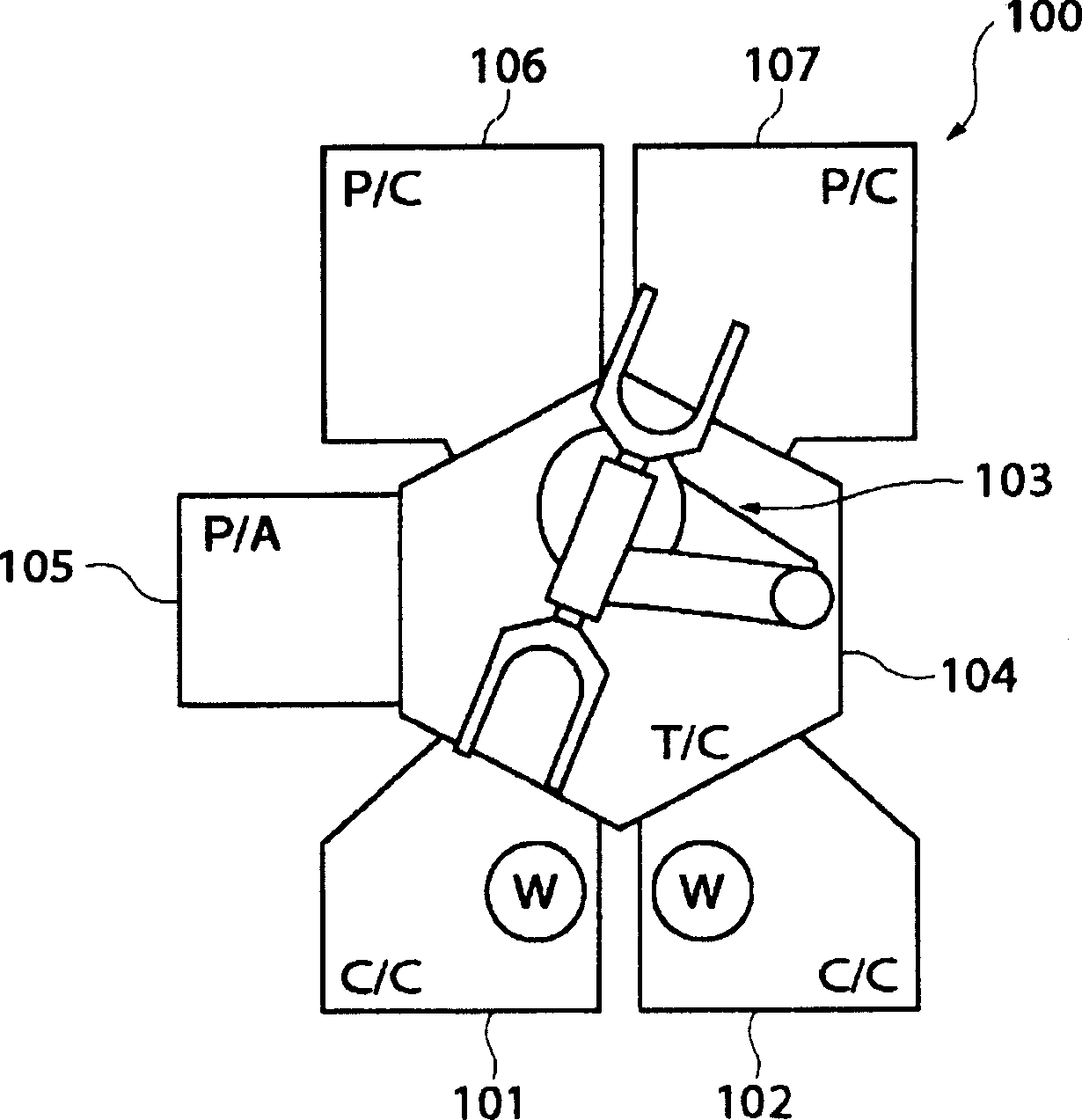

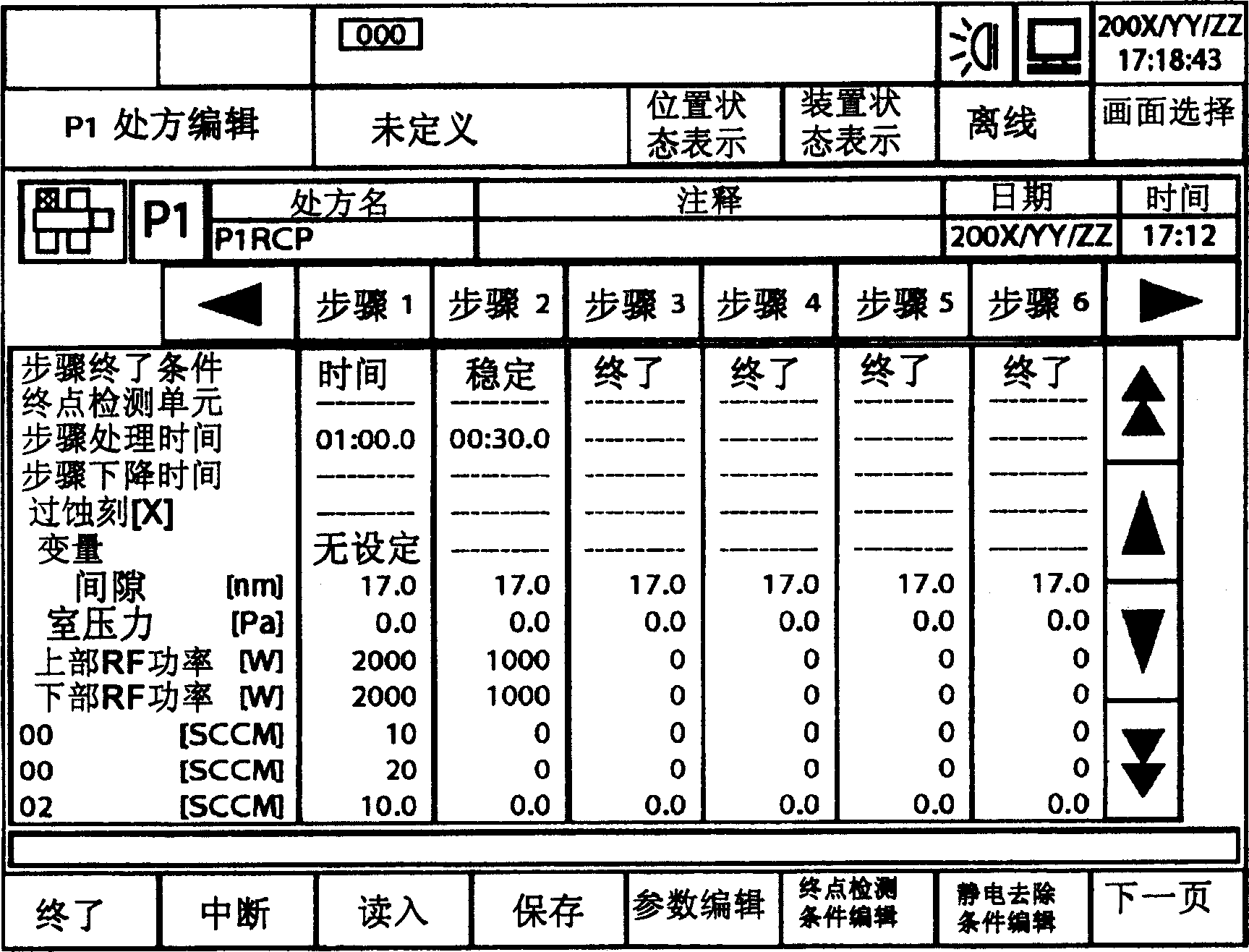

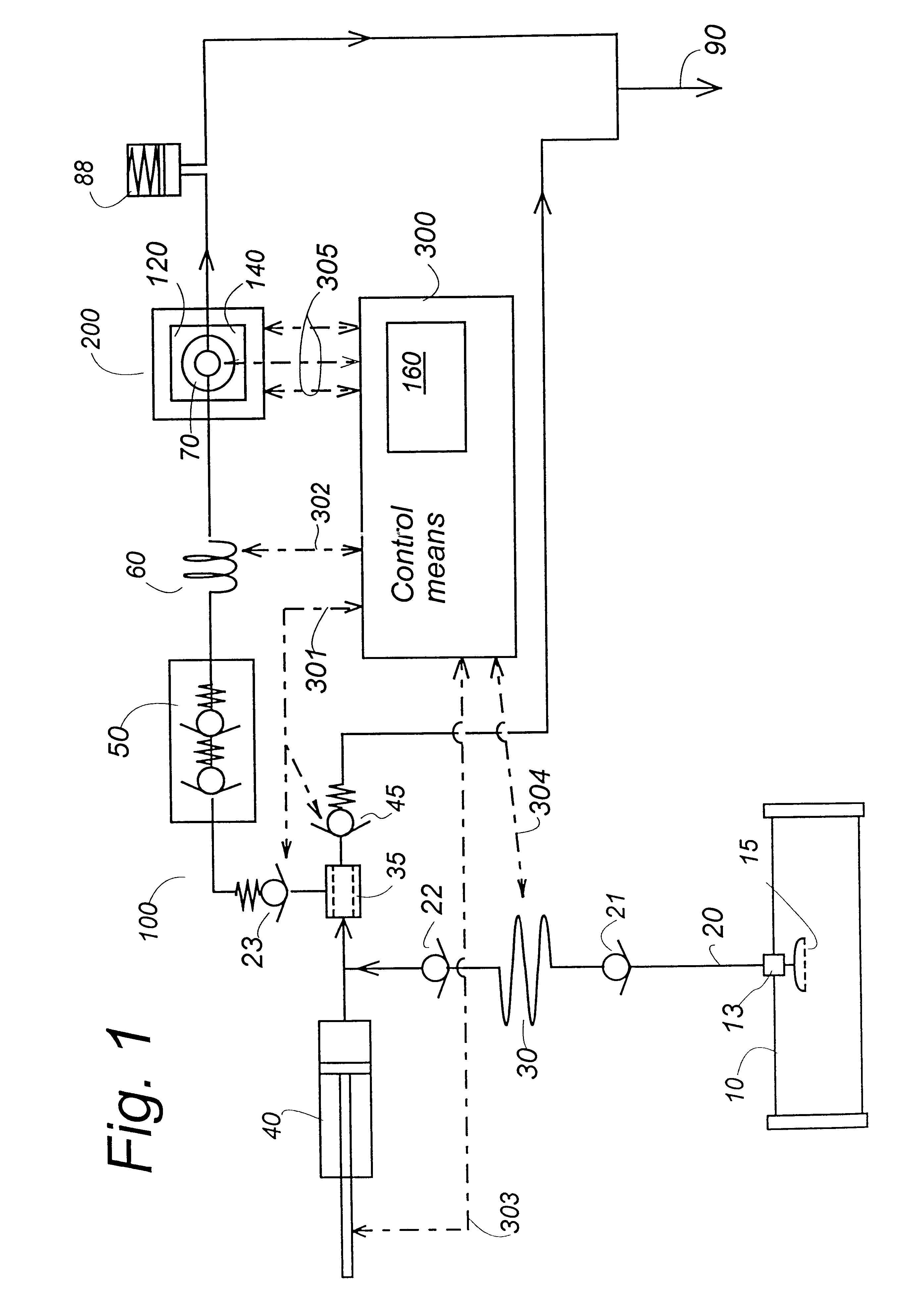

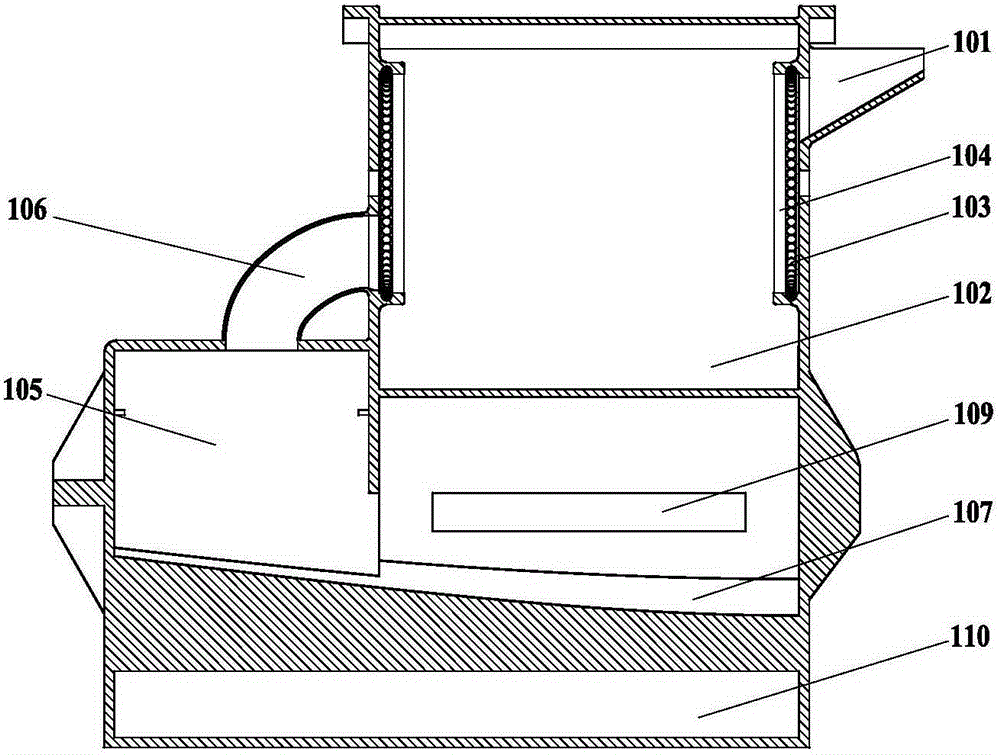

An etching apparatus 100 as the substrate processing apparatus is provided with a rotary arm 103 for carrying a substrate included in a lot, and process chambers 106 and 107 for carrying out etching to the substrate as product processing. The etching apparatus 100 is controlled by a host computer 200 in which a transportation recipe, a recipe for product processing and a recipe for dummy processing are registered. When a chamber neglecting time being each neglecting time of the process chambers 106 and 107 does not become time out, the host computer 200 discriminates that processing atmosphere in the process chambers used for etching to the lot is stable, omits the execution of the dummy processing, and executes etching to the substrate of the lot.

Owner:TOKYO ELECTRON LTD

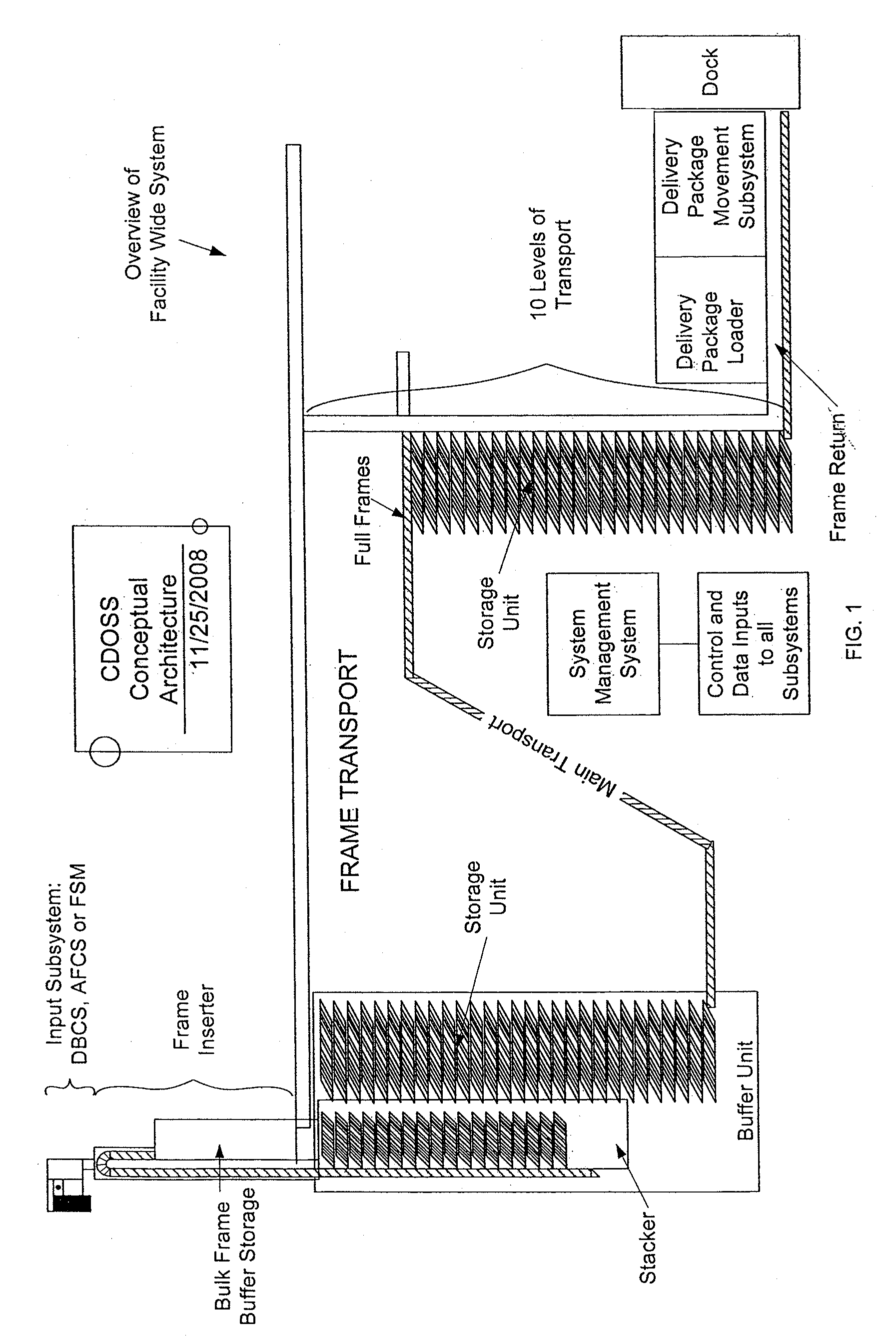

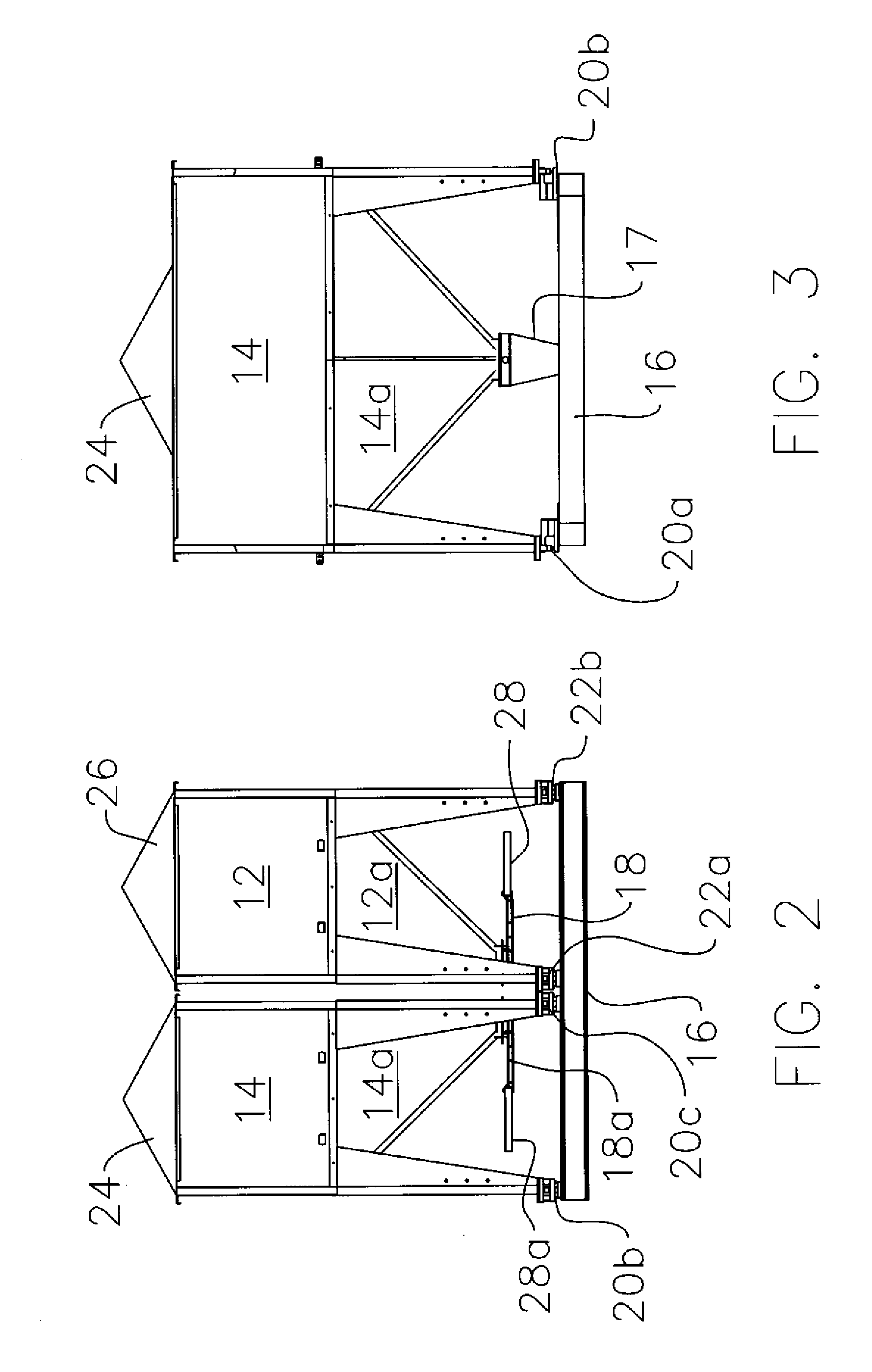

Facility Wide Mixed Mail Sorting and/or Sequencing System and Components and Methods Thereof

ActiveUS20110046775A1Reduce network congestionWidth minimizedConveyorsData processing applicationsEngineeringProduct processing

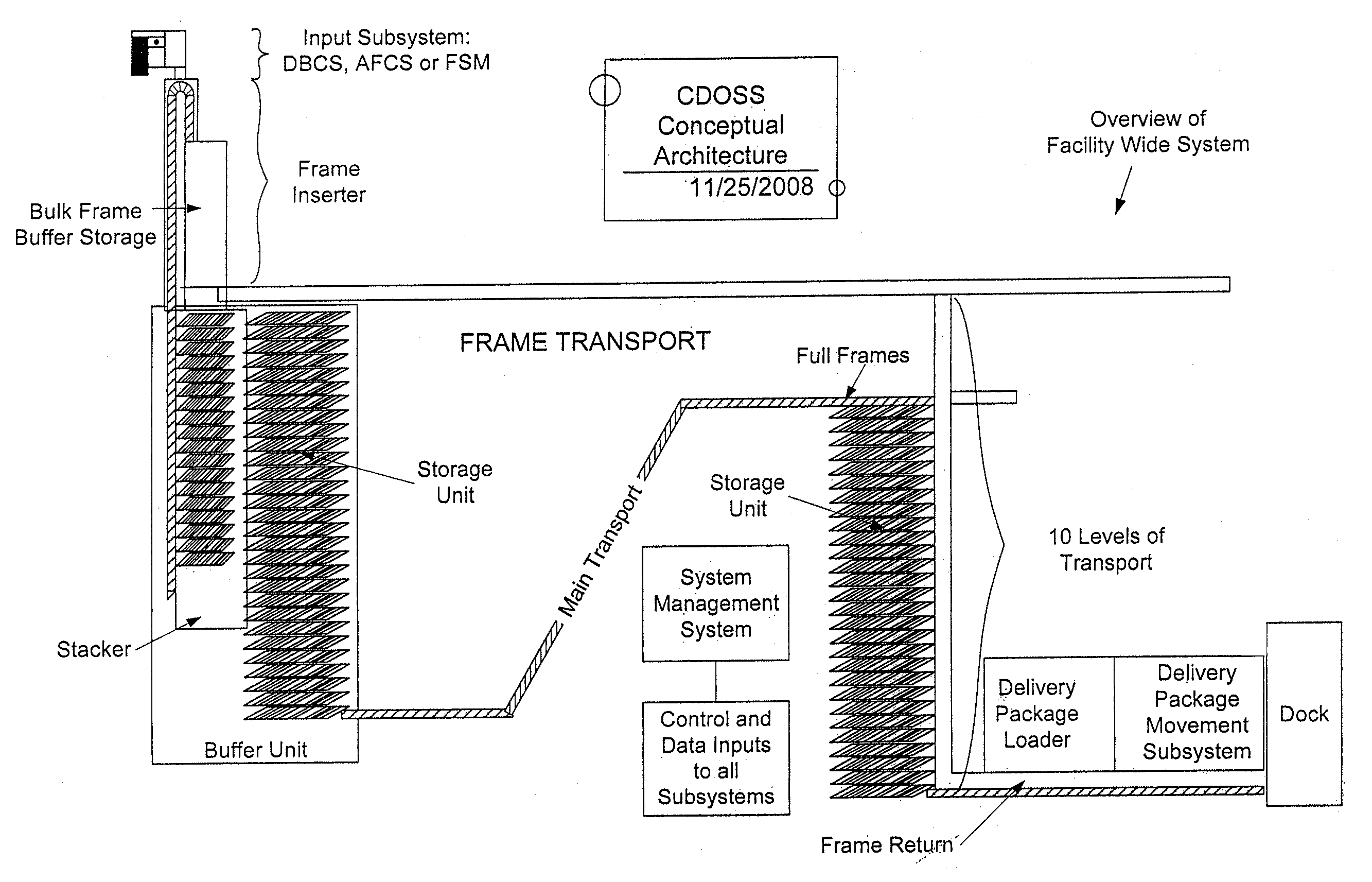

The invention generally relates to a facility wide sorting and / or sequencing system for improving product processing operations and, more particularly, to a facility wide system and related functionality for simultaneously sorting and sequencing mixed mail pieces such as, for example, flats and letter mail pieces. The flats and letter mail pieces are placed in frames so that all types of mail pieces can be sorted and / or sequenced simultaneously through merging and diverting a stream of filled trays into and out of different streams at a full or substantially full transport speed.

Owner:LOCKHEED MARTIN CORP

Process for preparing composite enzyme and product thereof

A compound ferment production process and a product thereof are applicable to the technical field of foods. The formulation of the product comprises fruit vegetable ferment raw juice, plant ferment raw juice, corn ferment, peas ferment and multielement alditol. The production process comprises the following: a step of preparing fruit vegetable ferment liquid, during which, selecting and cutting fresh fruits and vegetables into slices or pieces, blending the slices or pieces, adding apple vinegar on the slices or the pieces, and storing the fruits and vegetables hermetically at room temperature to prepare the fruit vegetable ferment raw juice through natural fermentation; a step of preparing the plant ferment liquid, during which, selecting, chipping and blending herbal plants, adding common salt into the sliced herbal plants, and storing the sliced herbal plants hermetically at room temperature to prepare the plant ferment raw juice through natural fermentation; and a step of fermentation and product processing, during which, taking the fruit vegetable ferment raw juice, the plant ferment raw juice, the corn ferment and the peas ferment, carrying out the second fermentation at room temperature, adding the multielement alditol during the second fermentation, using a sealed jar during the fermentation, preparing the compound ferment product after a postmaturation process, and preparing the liquid, powdery and solid particle ferment through mechanical processing and forming. The process and the product thereof which have a novel and scientific design and long-term maturation through the natural fermentation can increase the vitality of the ferment, facilitate the demand of a human body and improve the health of the human body through frequent edibility.

Owner:沈阳麦金利食品制造有限公司

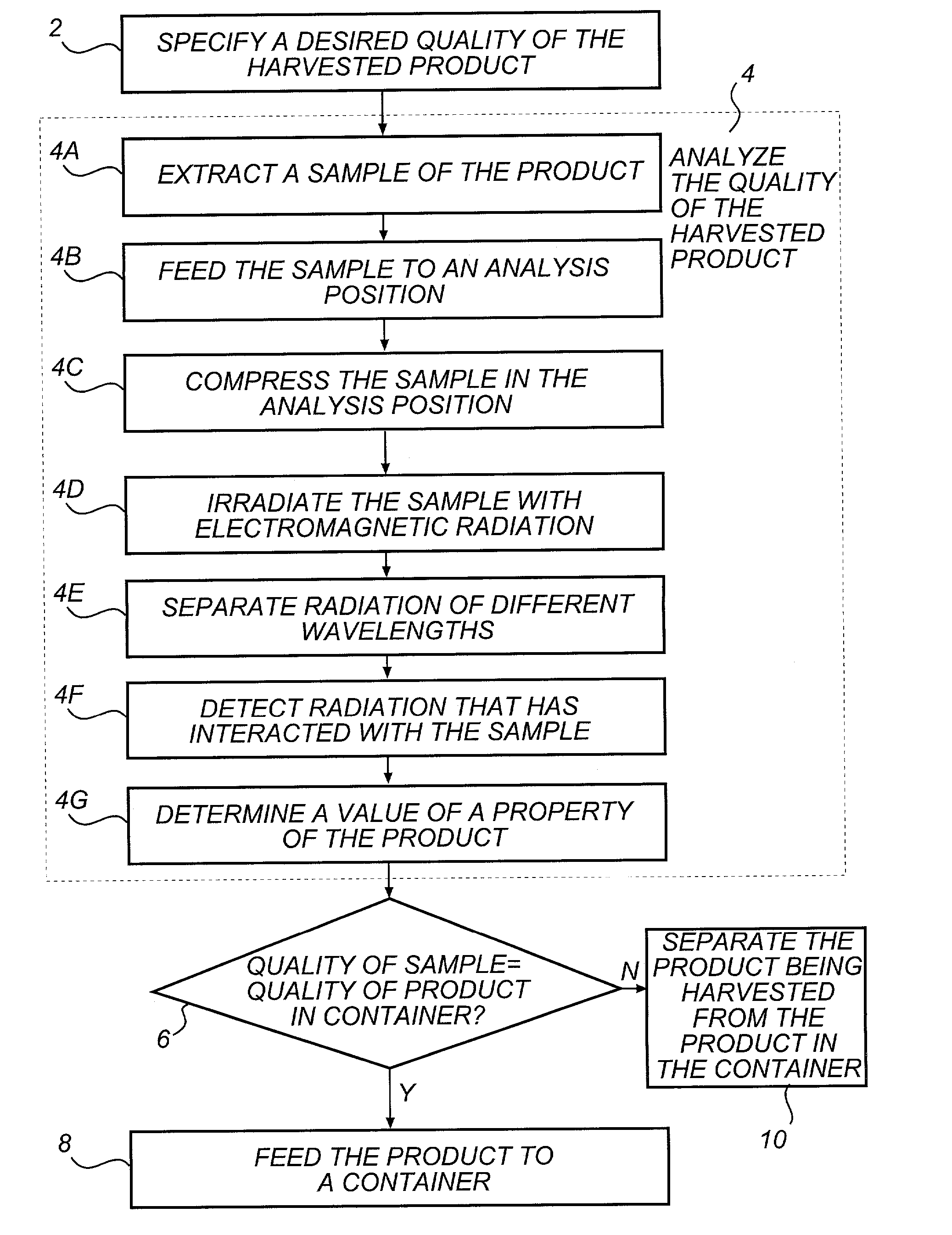

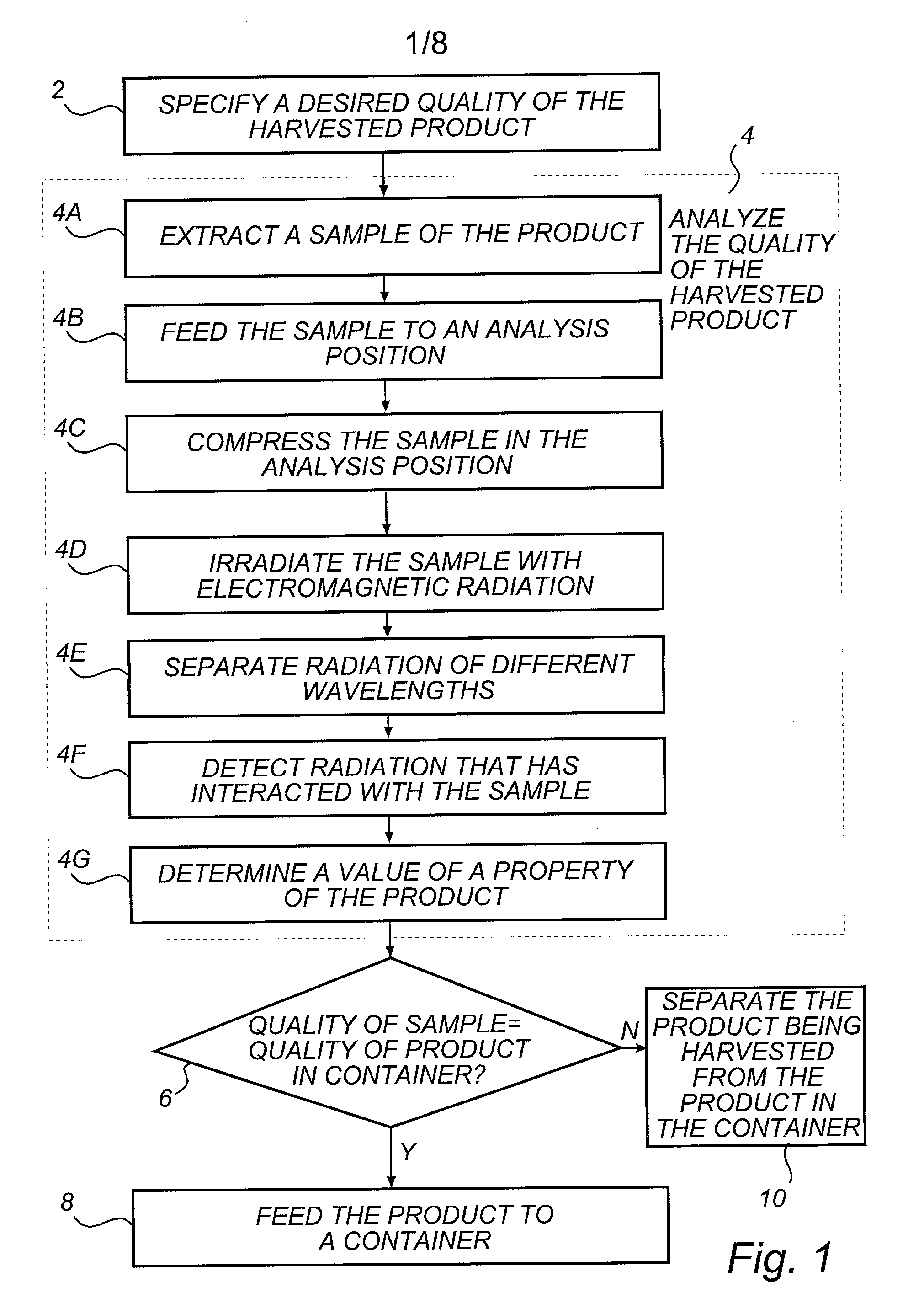

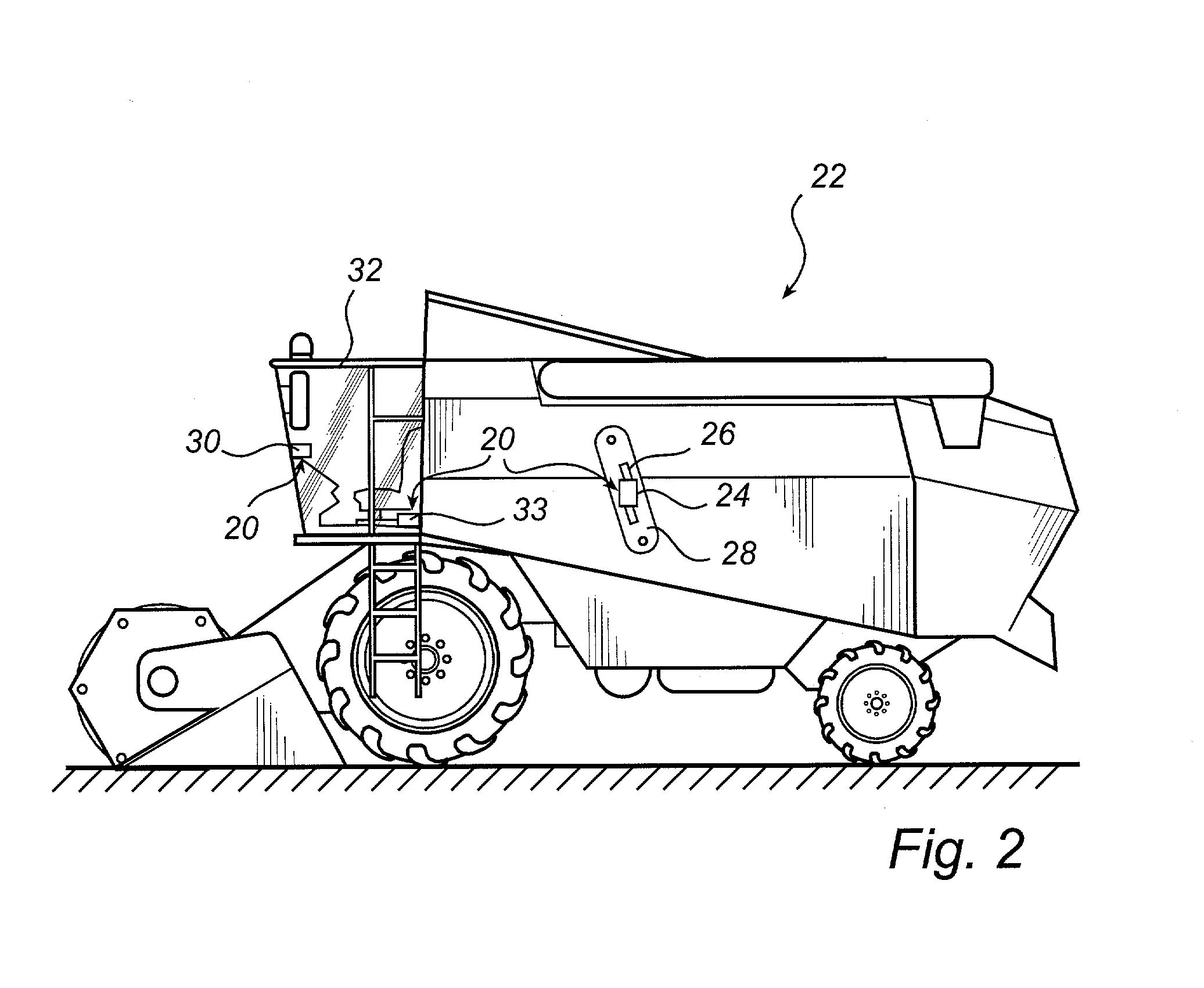

Sorting grain during harvesting

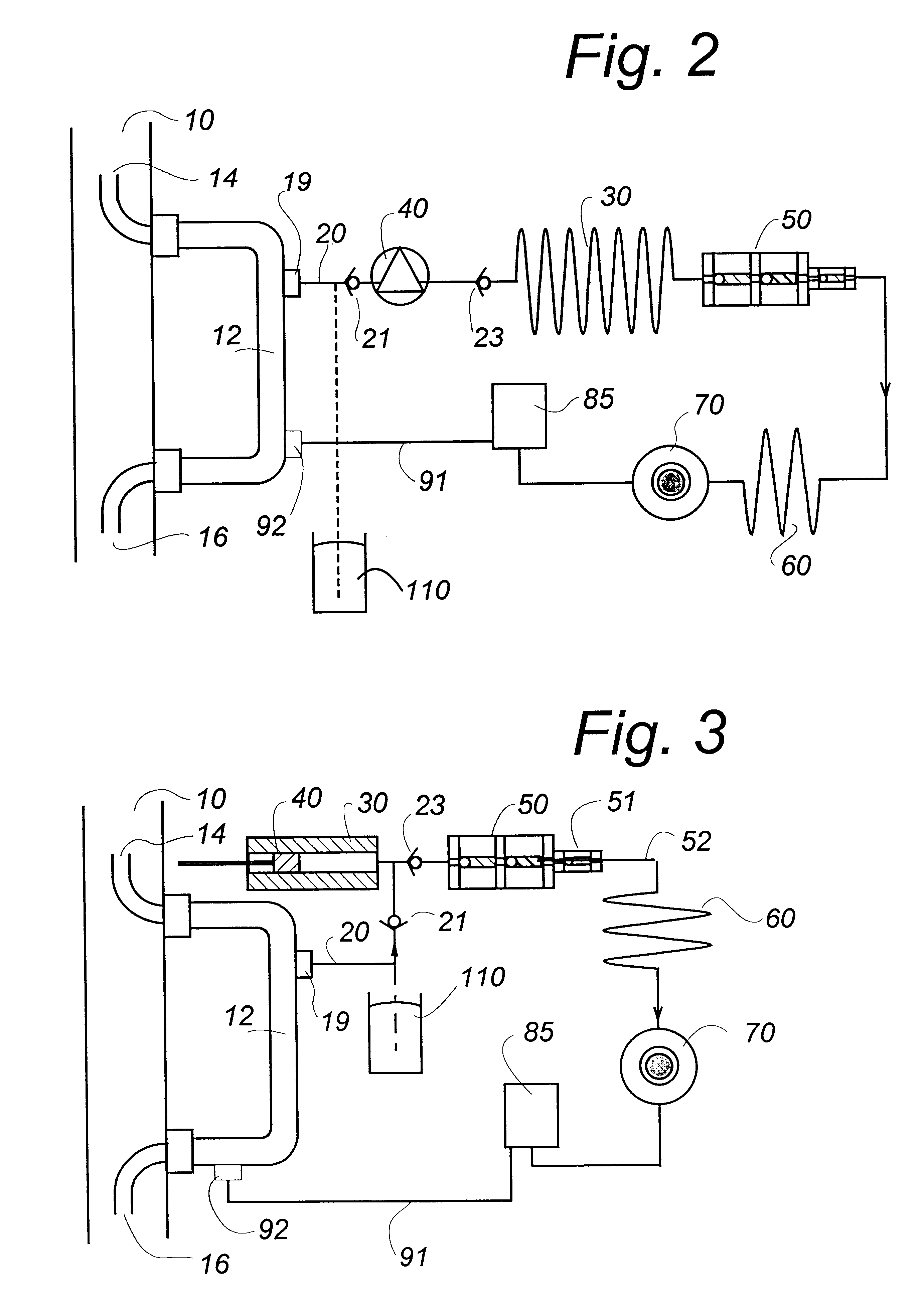

A method for segregating qualities of an agricultural product during processing of the product comprises the step of setting a desired range of a measurement value (2). The measurement value represents a property of the product and defines a first quality of the product for which the measurement value is inside the range and a second quality of the product for which the measurement value is outside the range. The method further comprises the step of analyzing (4) the quality of the product that is being processed. The step of analyzing comprises the steps of continuously extracting samples of the product (4a), irradiating each sample by electromagnetic radiation (4d), spatially separating electromagnetic radiation of different wavelengths (4e), and detecting electromagnetic radiation emitted from the sample (4f). The step of detecting produces intensity signals indicative of detected electromagnetic radiation of different wavelengths. The step of analyzing further comprises the steps of determining a sample value of said property of the product from the intensity signals, and determining a measurement value (4g) from at least one sample value. The method further comprises the step of separating the product of said first quality from the product of said second quality on the combine.

Owner:FOSS ANALYTICAL AB (SE)

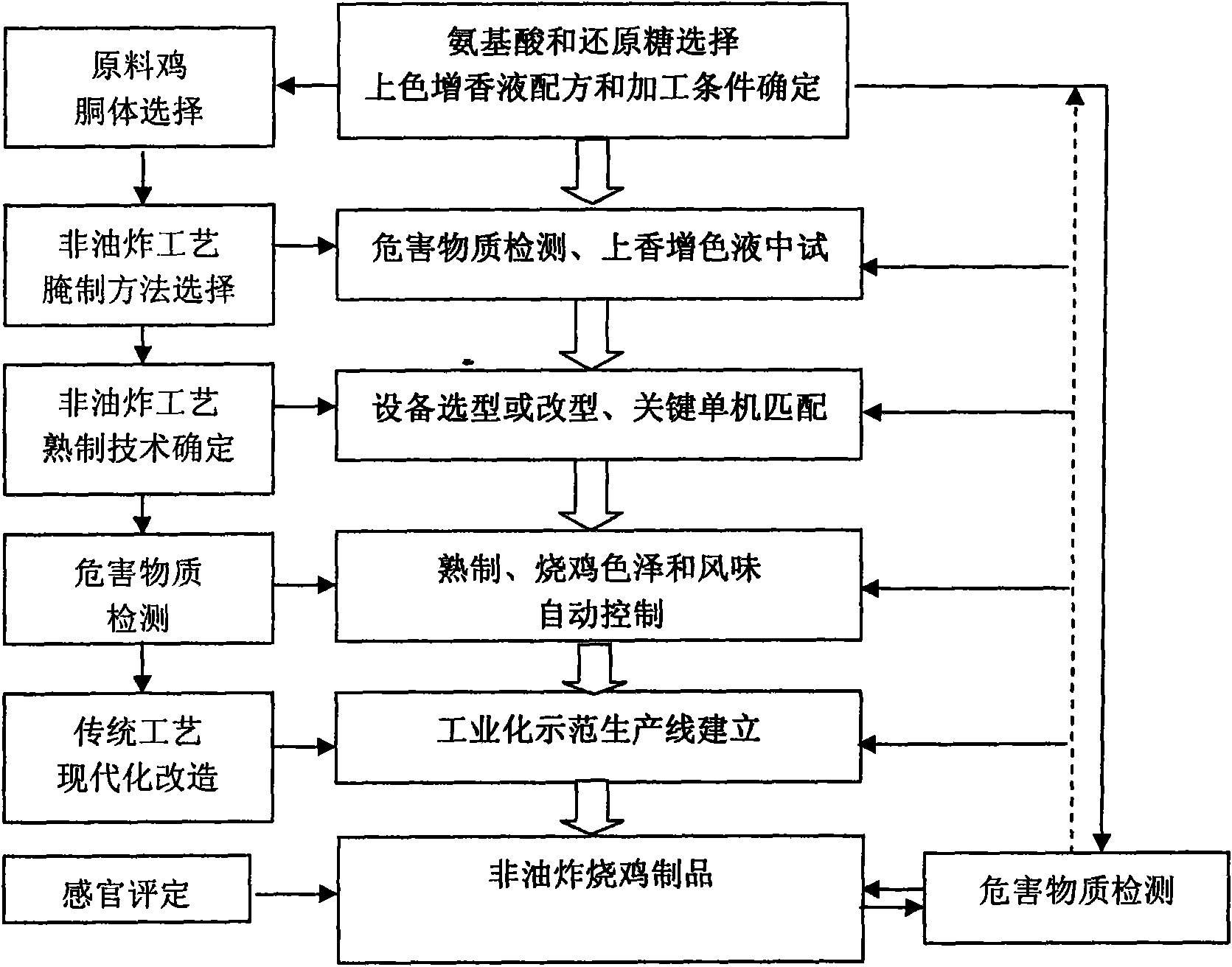

Non-fried production method for grilled chicken

InactiveCN101940273ALow content of hazardous substancesGreat tasteFood preparationFlavorMaillard reaction

The invention relates to a food processing method, in particular to a non-fried production method for grilled chicken. Different heating modes are adopted in the non-fried new process, then fragrant color increasing liquid is applied to the surface of a poultry carcass by selecting a proper method, Maillard reaction is further performed under certain condition, the poultry carcass generates the color similar to that of the traditional grilled chicken, meanwhile, multiple natural flavor substances can be produced, and the fragrance of the product is increased. By adopting the technology, the method realizes modernized technical reformation of the traditional special grilled chicken product processing technique, furthest reduces carcinogenic benzopyrene and heterocyclic amine in the traditional special fried grilled chicken products, avoids illegal colorants, and develops a novel grilled chicken product with good taste, good flavor, good color and high safety.

Owner:赵保雷

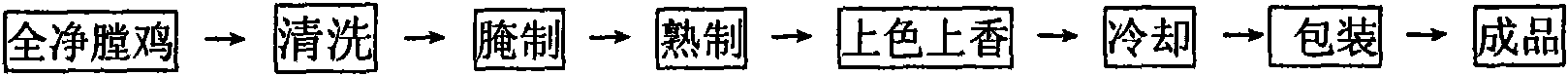

Method and flow system for spectrometry and a cuvette for the flow system

InactiveUS6297505B1Easy to produceRadiation pyrometryScattering properties measurementsCuvetteHigh pressure

The present invention relates to an on-line method and a flow system as well as a cuvette for carrying out IR spectrometry for analysis of liquid food products, possibly containing dissolved gases, in a process line in a liquid food product processing plant, especially a dairy processing milk and milk products. A liquid sample is extracted from the process line to a measuring branch, the sample is thermostated and passed to a measurement cuvette. The IR-absorbance spectrum is measured, e.g. in the MID-IR or NIR-range. In order to obtain an on-line monitoring of the process line the liquid food sample is extracted directly from the process line into the measurement branch, in which the pressure is maintaining at least as high as in the adjacent process line. The high pressure ensures that dissolved air will stay dissolved in the liquid food. Before each new sample the measurement branch and cuvette are flushed by high flow rates with a part of the new sample to clean the cuvette. The measurement cuvette has strong windows, preferably diamond windows to stand a high pressure and high flow rates. The on-line system is arranged to carry out eg. 120 measurements per hour.

Owner:FOSS ELECTRIC

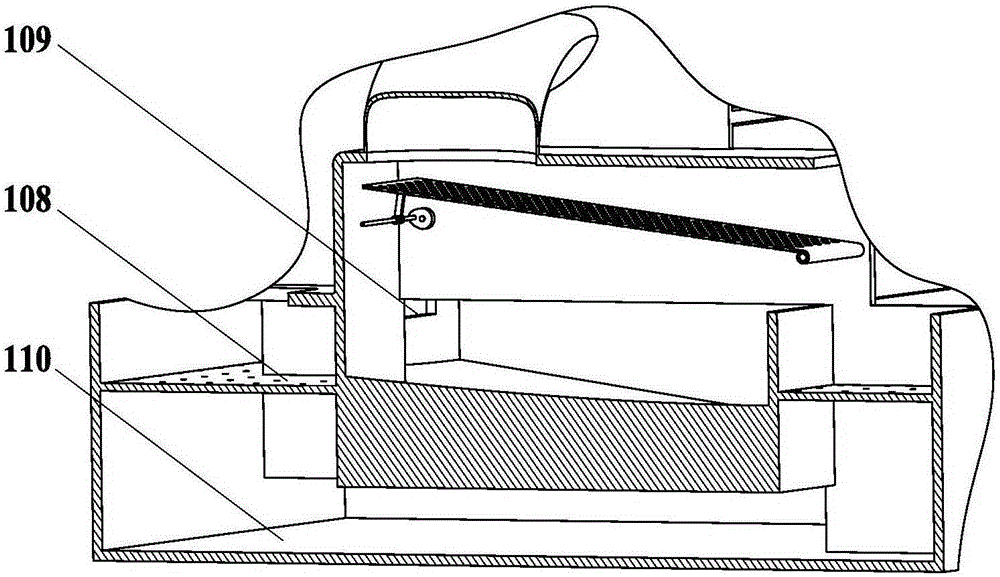

Three-time separating seed extractor for seed melons

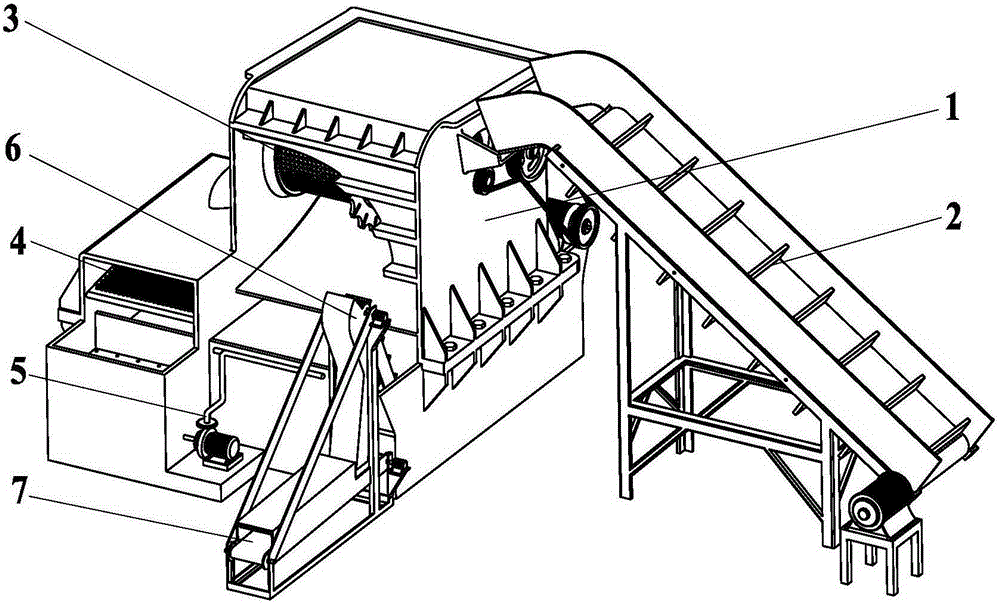

The invention relates to the field of agricultural product processing, particularly a three-time separating seed extractor for seed melons. The seed extractor comprises a machine body, a whole seed melon transfer device, a roller separating device, a vibrating separation device, a washing device, a fishing device and a transferring and drying device, wherein the whole seed melon transfer device is positioned on the right side of the machine body for transferring the whole melon to the machine body; the roller separating device is mounted on the right side in the machine body for primarily separating the seed melon; the vibrating separating device is mounted on the left side of the roller separating device for secondarily separating the seed melon; the washing device is mounted at the front end of the machine body for separating the seed melon for the third time; the fishing device is positioned on the right side of the washing device for fishing out separated seeds; and the transferring and drying device is positioned below the front end of the fishing device for drying and transferring the seeds. The seed extractor provided by the invention can be used for separating seeds from melon pulp and melon peel for seed melons, soaking the seeds by melon juice and drying the seeds.

Owner:威海高新园区运营管理有限公司

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

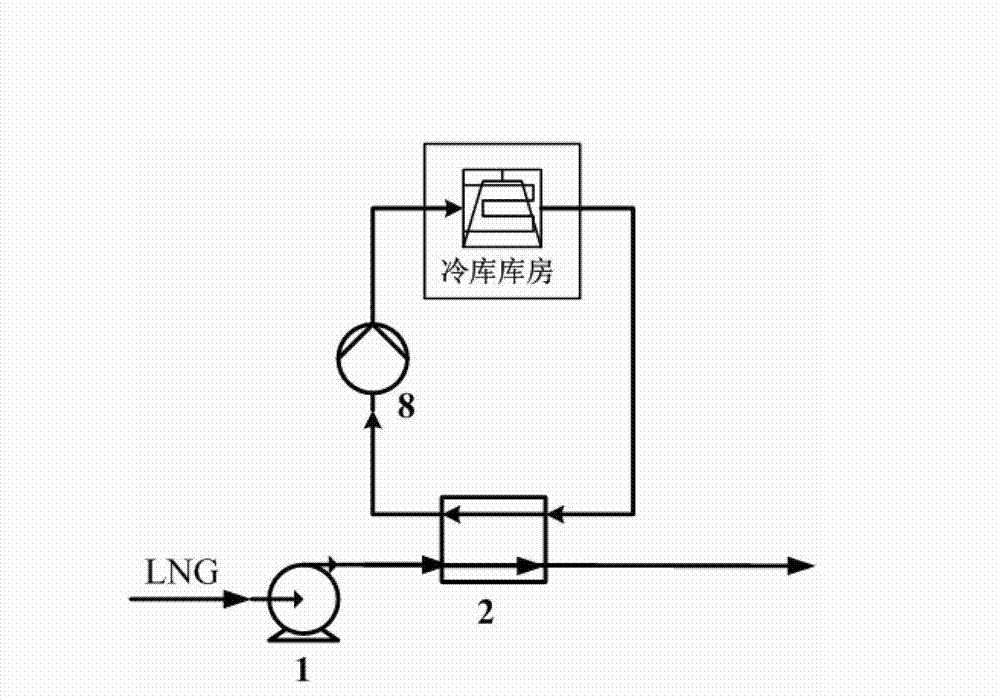

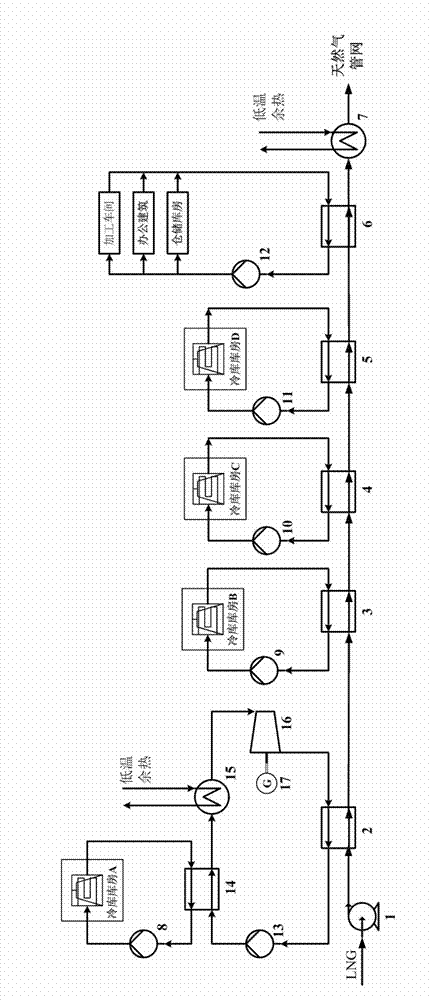

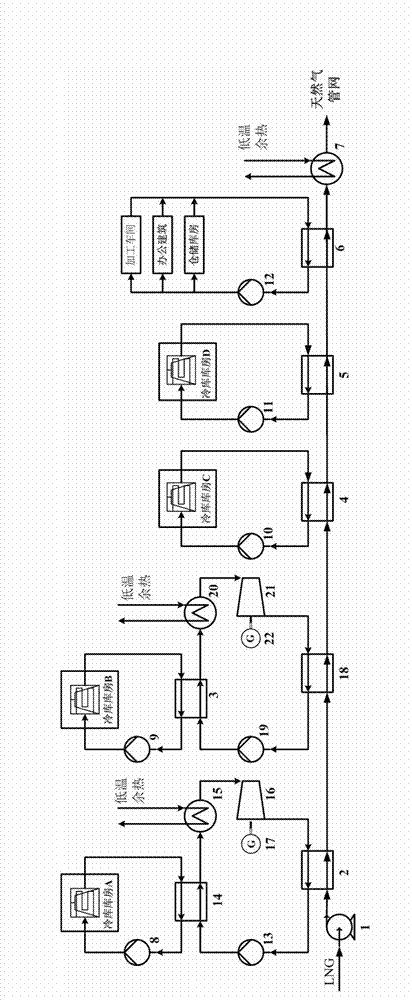

Energy cascade comprehensive utilization method of LNG (liquefied natural gas) cold energy

ActiveCN102967099AEfficient use ofEffective Energy Utilization Efficiency ImprovementDomestic cooling apparatusLighting and heating apparatusSystem integrationGeneration process

The invention discloses an energy cascade comprehensive utilization method of LNG (liquefied natural gas) cold energy. The energy cascade comprehensive utilization method comprises the following steps that firstly, the LNG cold energy of a deep cold part is converted into electric energy by Rankine cycle power generation; then, the LNG cold energy of a middle cold part is recovered by a cooling medium for supplying cold to a cold storage warehouse, meanwhile, the gasifying pressure of a power generation working medium in the Rankine cycle power generation process is controlled, the cold energy released by the gasifying of the liquid power generation working medium is matched with the temperature of the required cold energy of the cold storage warehouse, and the cold energy released by the gasifying of the liquid power generation working medium is used as a cold source for supplying cold to the cold storage warehouse; and the LNG cold energy of a shallow cold part is recovered and used as a cold source for an air conditioner system of a cold storage plant, and is used for supplying cold to product processing workshops of the cold storage, office buildings and storage warehouses. The energy cascade comprehensive utilization method has the advantages that through the system integration, the LNG is gradually used for power generation, cold supply of cold storage warehouses and cold supply of plant air conditioners from lower grade to upper grade according to the temperatures, the cascade utilization of the cold energy is realized, and the cold energy of the LNG is utilized highly efficiently in the low-temperature cold storages.

Owner:JINAN UNIVERSITY

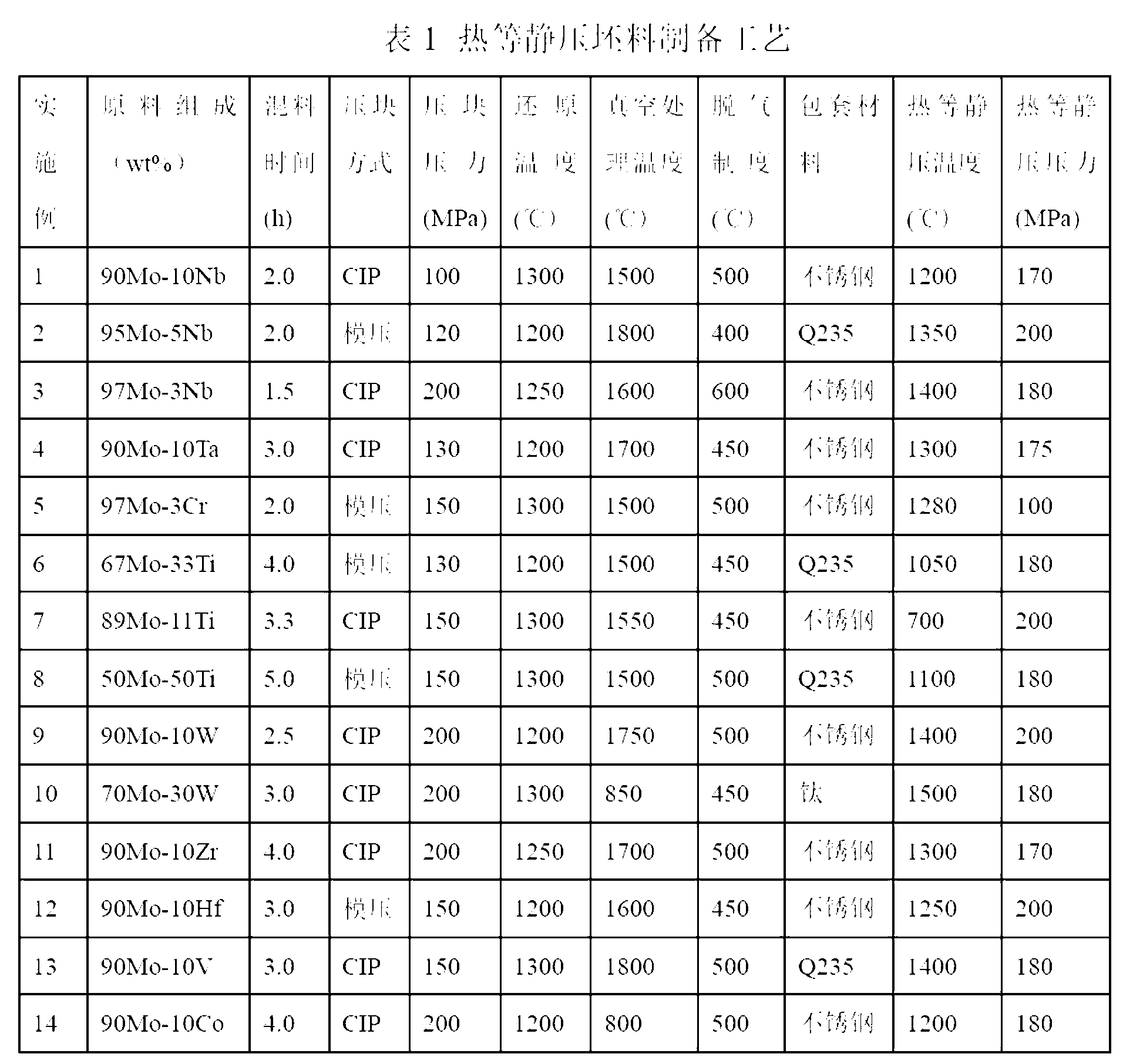

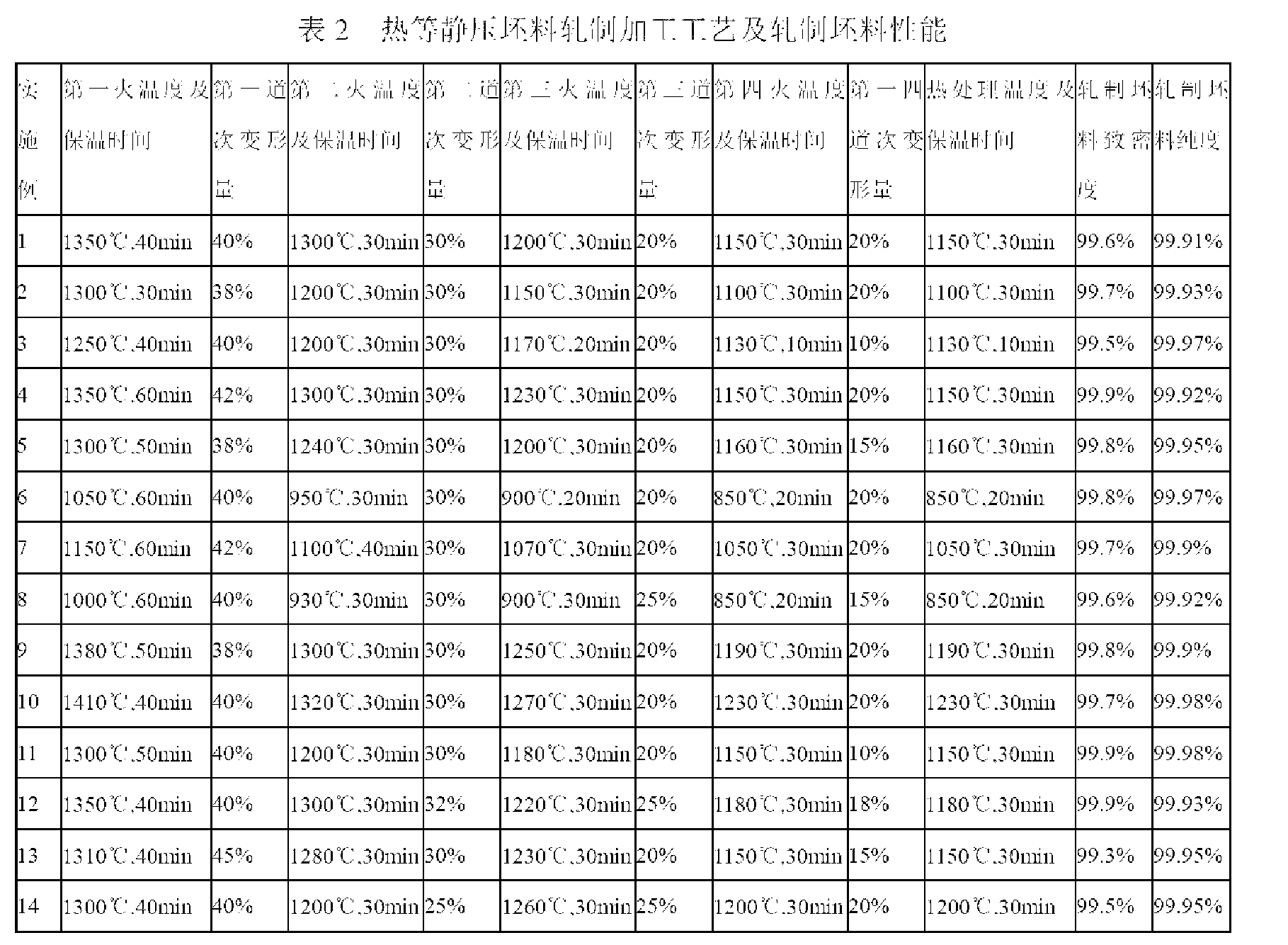

Method for mill processing of high-purity and high-density molybdenum alloy target

ActiveCN103302295AReduce processing costsShorten the processing cycleVacuum evaporation coatingSputtering coatingHigh densityProcessing cost

The invention relates to a method for mill processing of a high-purity and high-density molybdenum alloy target and belongs to the technical field of colored target preparation. The method comprises the technical steps of powder mixing, briquetting, presintering and reduction, vacuum treatment, shaping, hot isostatic pressing jacket processing, jacket charge, jacket degassing, sealing weld, hot isostatic pressing treatment, rolling with a jacket, and finish product processing. Due to the rolling with the jacket, the method solves the problems that active metal components are difficult to reduce after oxidized during deformation processing of a molybdenum alloy containing active metal, so that the deformation processing cannot be performed. Compared with a processing method of cutting into thin blanks with a large-thickness blank line, the processing cost can be lowered greatly, the processing cycle can be shortened greatly, and the production efficiency is improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

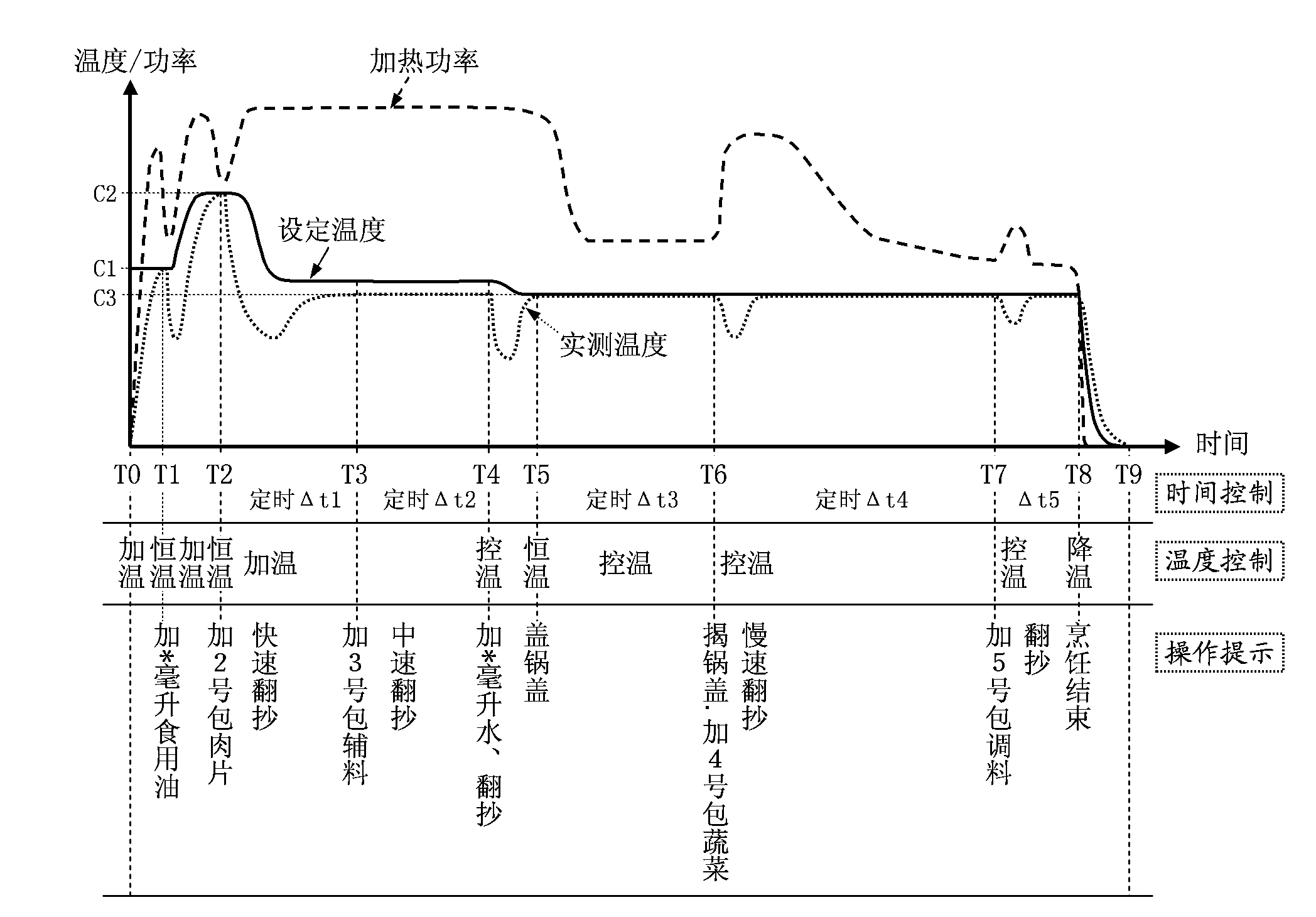

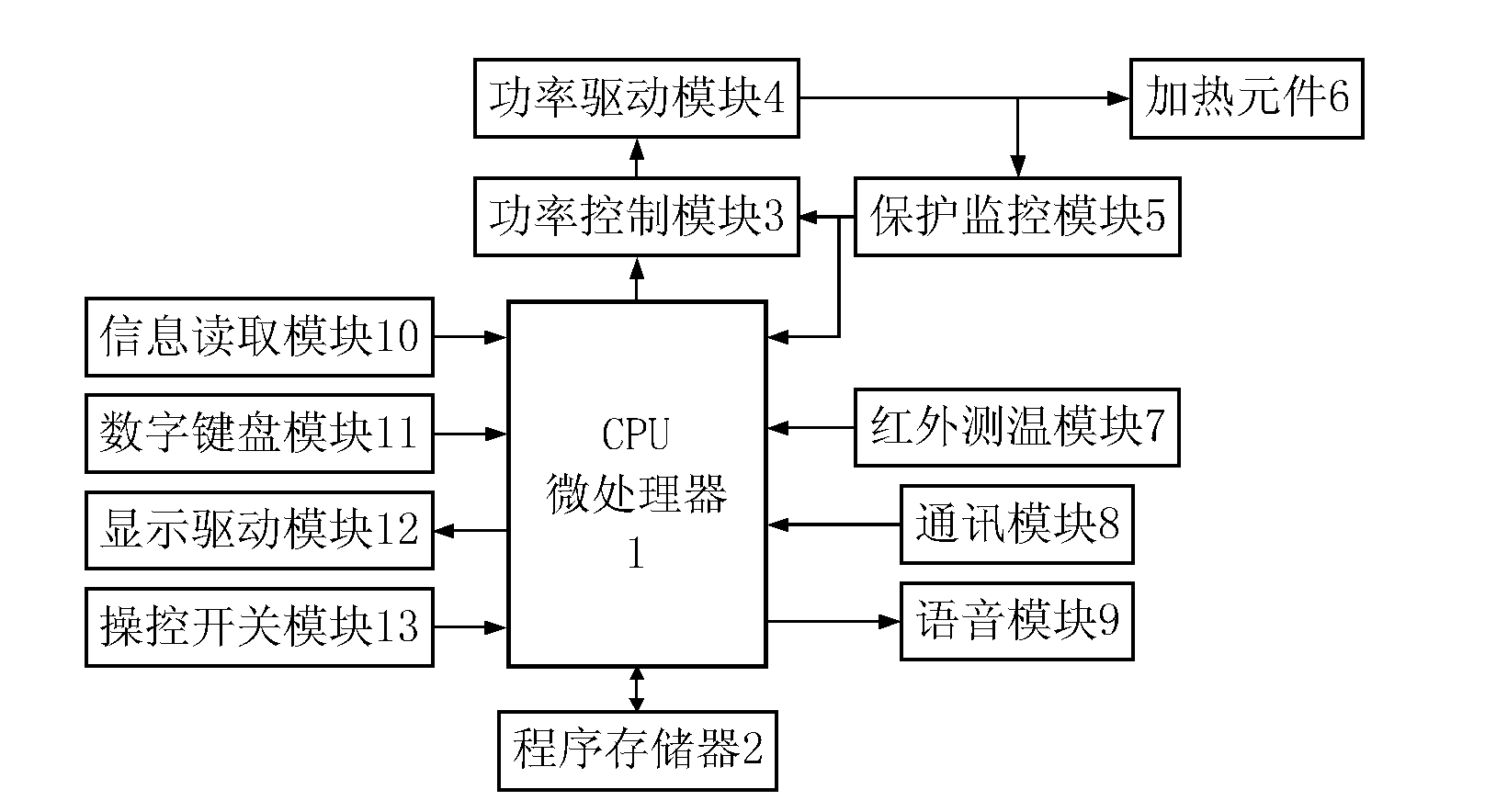

Making method of instant dish

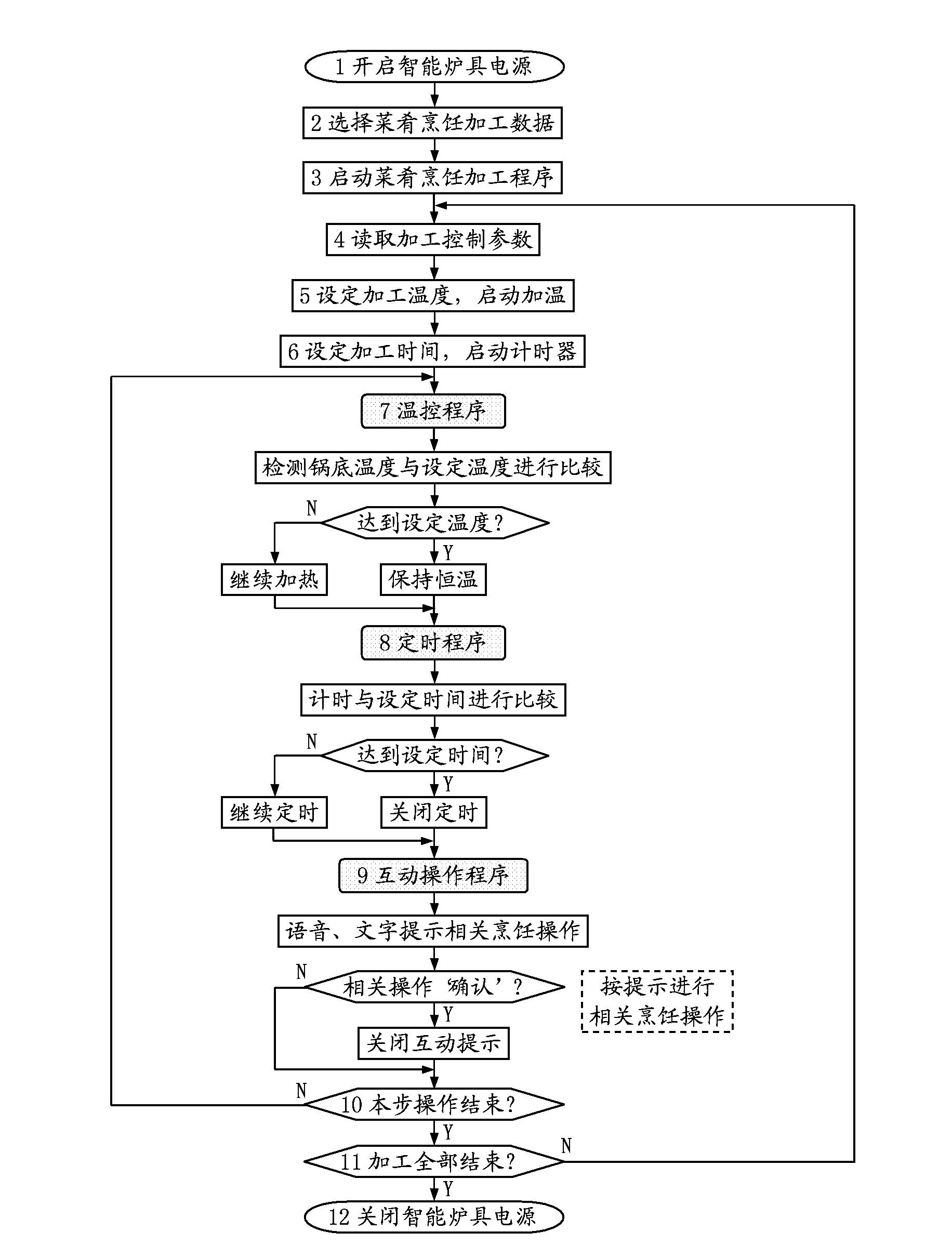

InactiveCN102726782AConvenient cooking and processing dataMeet the requirements of automatic cooking standardizationCooking vesselsFood preparationCooking processComputer science

The invention discloses a making method of an instant dish. The method comprises: packaging fresh raw materials or semi-finished raw materials and seasonings, as well as auxiliary materials in different bags quantitatively so as to obtain instant dish materials, specifying a cooking processing information code in a commodity identifier on the outer package of the instant dish materials; under the control of a CPU microprocessor, downloading food cooking processing data into an intelligent cooker for storage via a wired or wireless communication method by the intelligent cooker; after inputting the dish cooking processing information code, calling corresponding food cooking processing data, and controlling the making process of the instant dish. The method of the invention can make the cooking process of a dish meet the requirements of automatic cooking standardization so as to realize large-scale rapid making of delicious Chinese dishes, drive the rapid development of related industries (such as semi-finished product processing, distribution and the like of dishes), and promote the scientific and technological progress of intelligent cookers. The making method provided in the invention can be applied to a variety of intelligent cookers interactive with people in cooking.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

Simulated fat and method for preparing same

The invention discloses a simulated fat. The base material for preparing the simulated fat comprises konjaku flour and carrageenin of which the compound weight ratio is 1:0.3-0.45, and the auxiliary material comprises egg white protein, a defoamer, alkaline gel and water. The simulated fat is prepared by using compounded vegetable glue as the base material assisted by the egg white protein and vegetable oil through the steps of stirring with the water, molding, precooking, forming, cooling, mould unloading, recooking and secondary cooling under the action of the gel. The simulated fat product has a plurality of physical characteristics similar to natural fat and has no health hazards. The simulated fat can be used as a substitute in meat products processing and is widely applied to the meat products processing. Sausages, hamburger bakemeat and the like processed from the simulated fat are completely same with animal fat from the appearance and the cross section, have quite similar mouthfeel and flavor and low fat, are rich in dietary fiber, and do not contain cholesterol.

Owner:CHINA MEAT RES CENT

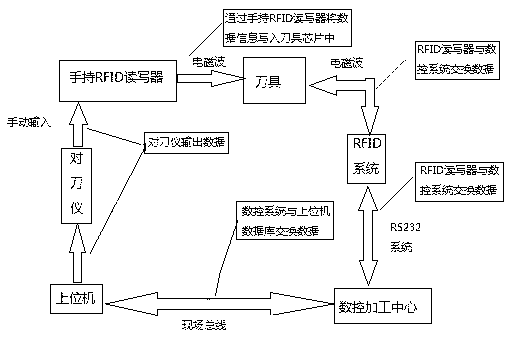

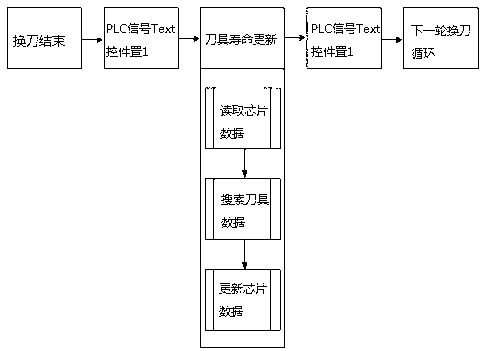

RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of Siemens 840D numerical control system

InactiveCN103076764AImprove entry efficiencyImprove accuracyProgramme controlComputer controlTerra firmaReader writer

The invention belongs to the technical field of machine tools and particularly relates to an RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of a Siemens 840D numerical control system. Through research on an RFID automatic identification technology and integration with a numerical control system, a tool in a machining center is automatically identified. An RFID reader-writer selected by the invention is a BIS-C-600 type reader-writer produced by Germany BALLUFF company, an automatic tool identification technology is integrated in a numerical control system, tool information is automatically identified and tool key data is read and input to the numerical control system of the machining center, and thus the accuracy and efficiency of tool information entry are effectively improved; and life monitoring data in the numerical control system is written an RFID chip, thus a tool which is discarded or approaches the life limit is effectively prevented from being misused, and the risks that the machining quality of products is reduced and even the production safety accidents are caused are avoided. The firm foundation is laid for further realizing the tool network-based management of the whole workshop.

Owner:TONGJI UNIV

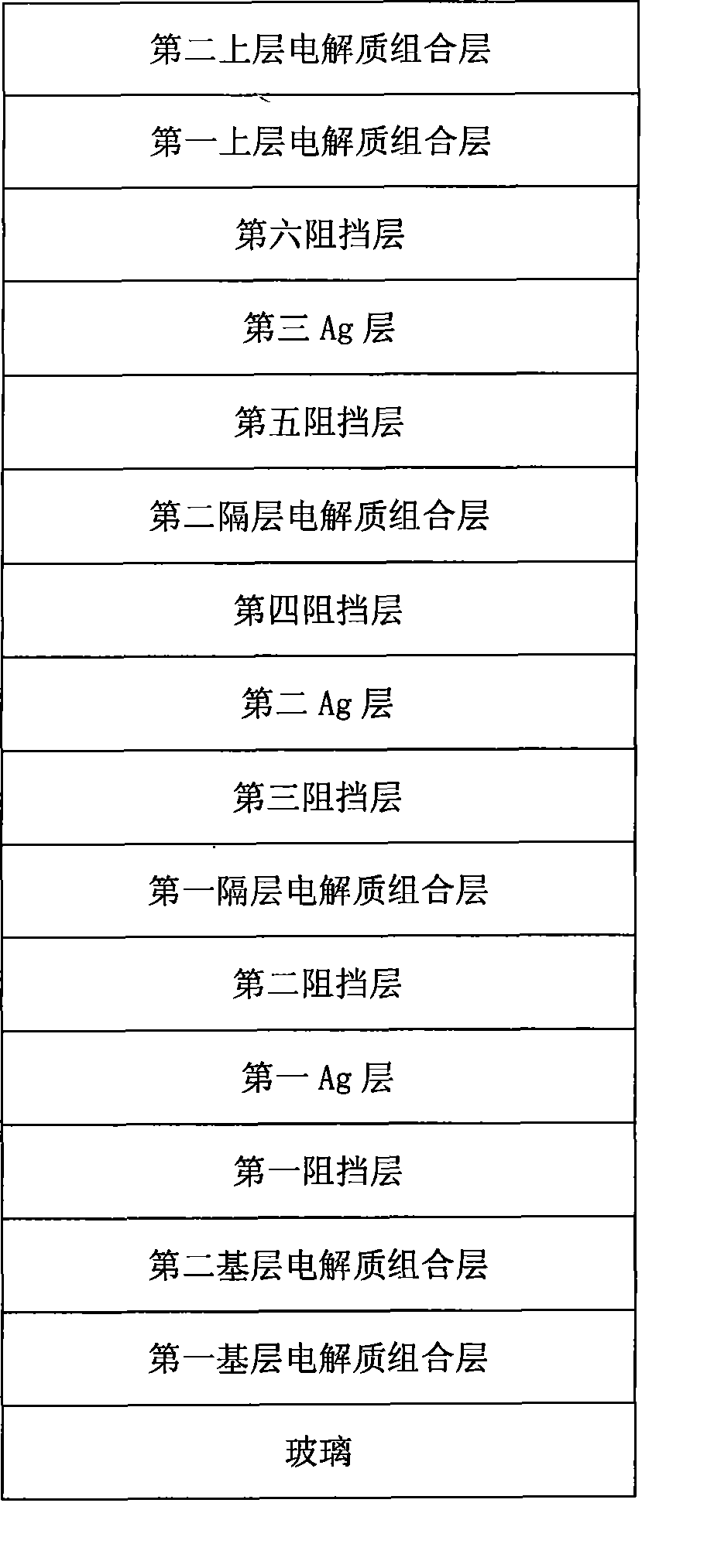

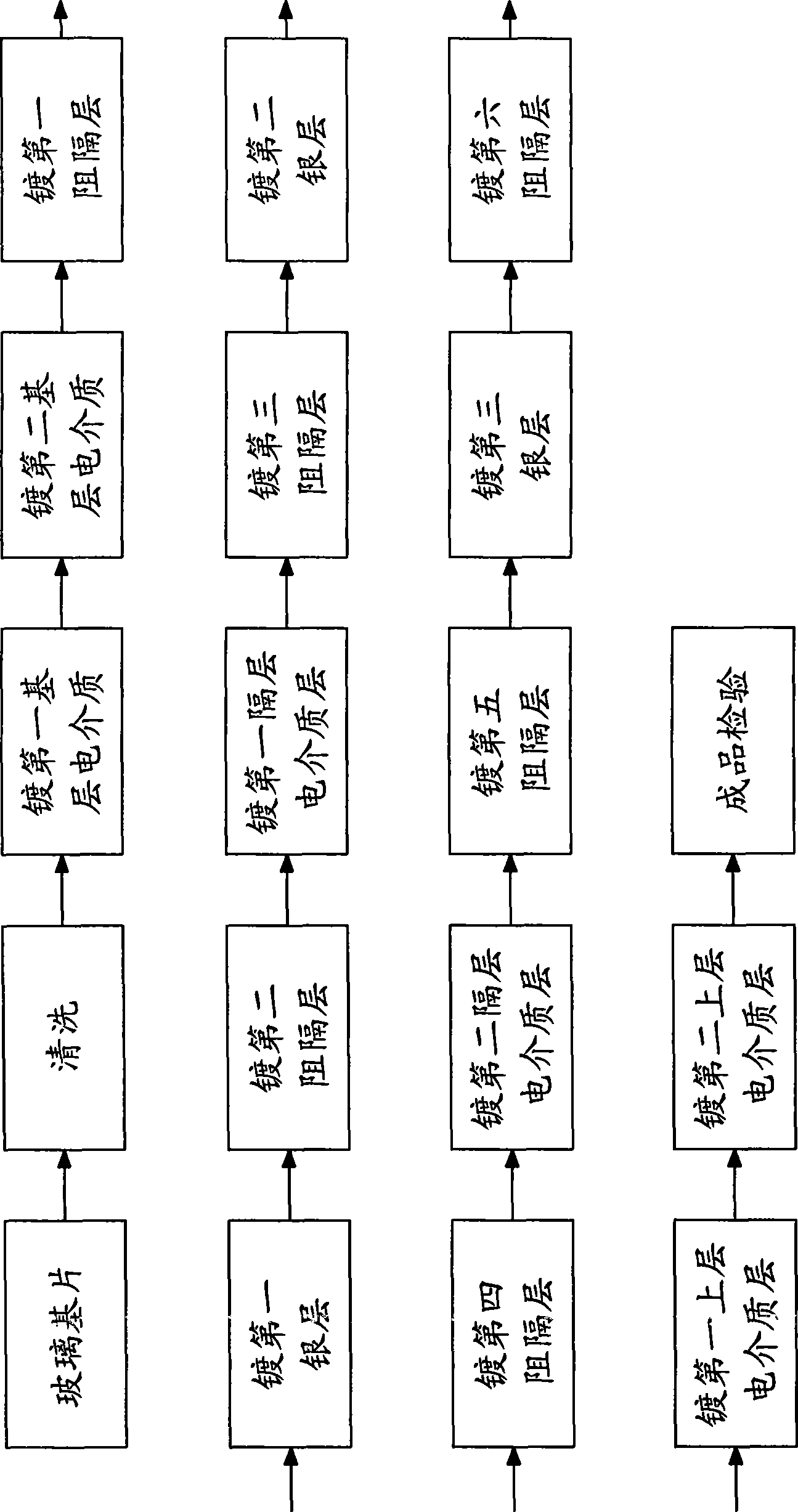

Three-silver low radiation film glass capable of being subsequently processed

The invention provides a three-silver low radiation film glass supporting subsequent processing, which is characterized in that the film layer structure of the glass comprises glass, a first base layer dielectric combination layer, a second base layer dielectric combination layer, a first blocking layer, a first Ag layer, a second blocking layer, a first interlayer dielectric combination layer, a third blocking layer, a second Ag layer, a fourth blocking layer, a second interlayer dielectric combination layer, a fifth blocking layer, a third Ag layer, a sixth blocking layer, a first upper layer dielectric combination layer, and a second upper layer dielectric combination layer. The invention also provides a process for producing the glass. The three-silver low radiation glass supporting the subsequent processing is produced by adopting a unique film layer configuration, has the performances of low radiance (less than 0.2), stable optical performance, various colors, heat resistance and weather resistance, can achieve allopatric processing and satisfy all the requirements in the subsequent processing of joint products, and can be popularized and applied to vehicle glass and civil architecture glass.

Owner:CSG HOLDING

Long fibre nonwoven wallpaper base stock and preparation method thereof, and nonwoven wallpaper prepared by the same

ActiveCN101343846AGood flexibilityNice appearanceWater-repelling agents additionPaper/cardboardPulp and paper industryMachining process

The invention relates to a non-woven wall paper, in particular to a long fiber non-woven wall paper raw paper and the preparation method and the non-woven wall paper prepared in the method. The long fiber non-woven wall paper raw paper comprises fiber pulp material and adhesive agent, wherein the fiber pulp material comprise wood pulp fiber and functional fiber, the weight proportion between the wood pulp fiber and the functional fiber adopts 0 to 95 percent to 5 to 100 percent, and the adhesive agent occupies 1 to 10 percent of the total weight of the raw paper; the functional fiber at least contains a functional fiber which fineness is 0.8 to 25 D, and which length is 15 to 60 mm. The surface of the wall paper in the invention presents natural stripes, the outer appearance is artistic, and further treatment is not required. Simultaneously, during the wall paper product processing, no shrinkage and moist feeling occur, the paper uncover is complete, and the paper flexibility is good. The wall paper product adopting flame-resistant fiber can be burnt on the fire source, the fire is extinguished after leaving the fire source, and the non-woven wall paper has a good flame-resistant performance.

Owner:浙江凯恩新材料有限公司 +1

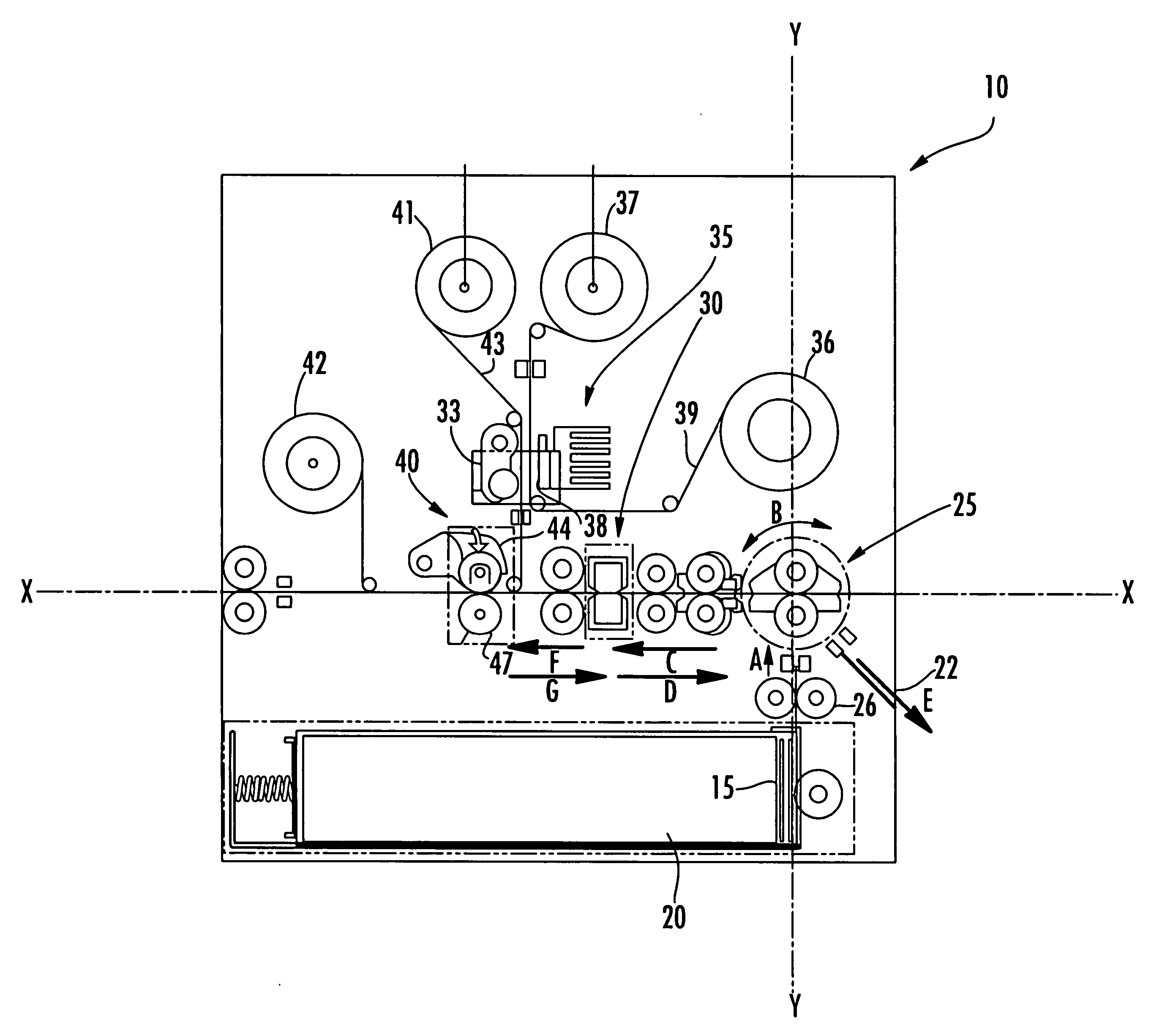

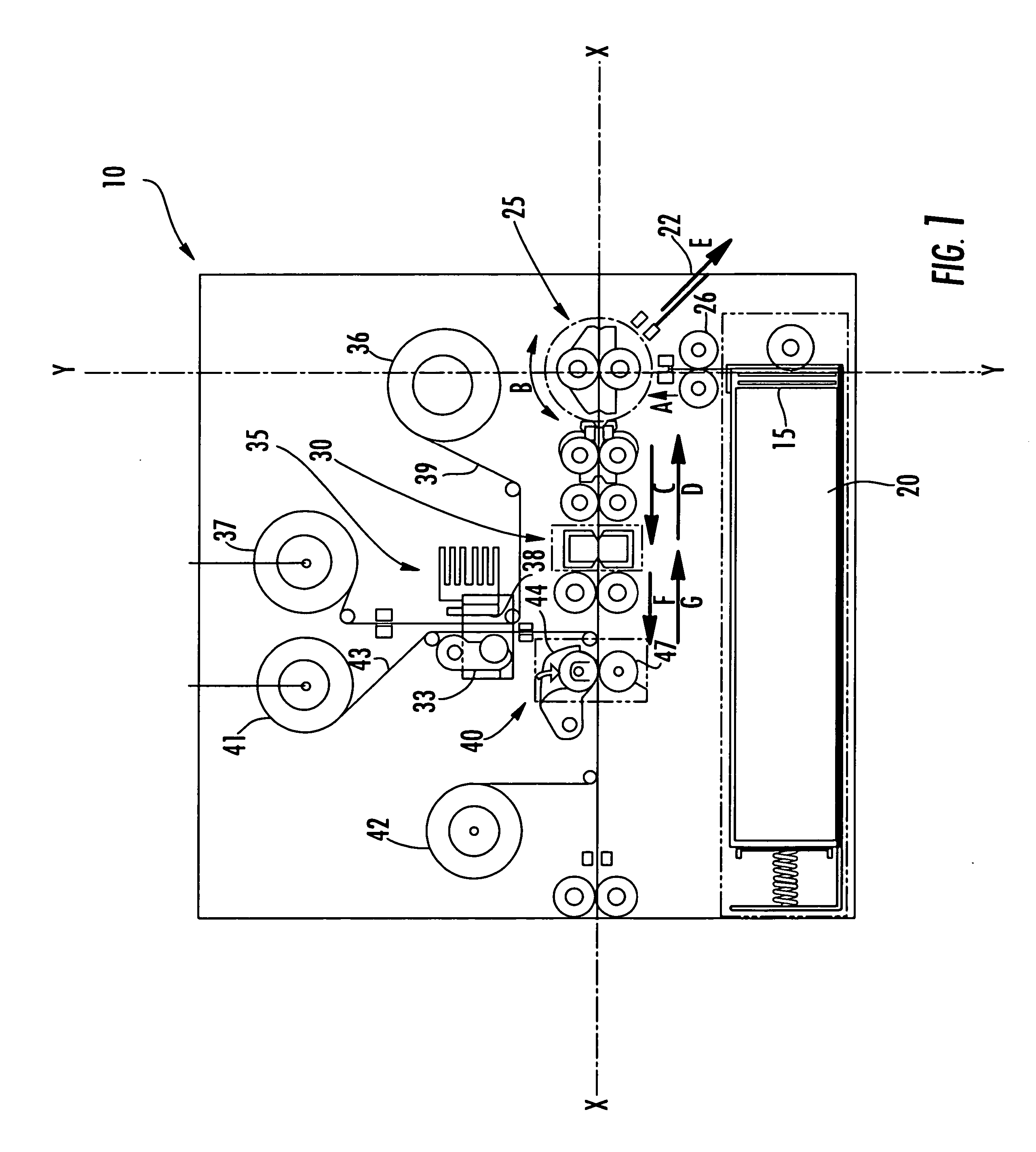

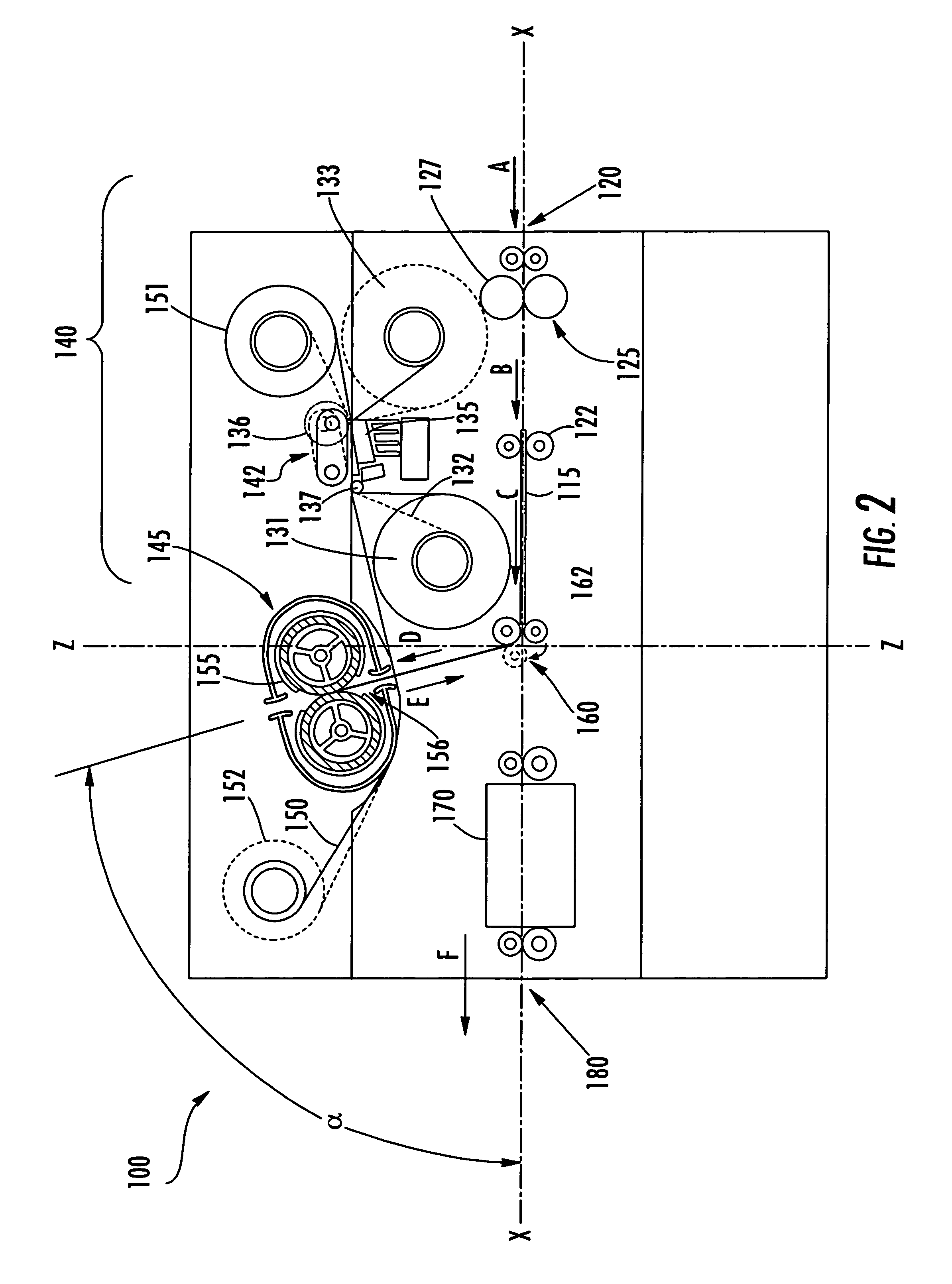

Single-pass double-sided image transfer process and system

ActiveUS20070099462A1Improve precisionEasy to operateEngagement/disengagement of coupling partsRecord carriersState of artImage transfer

The present disclosure is directed to a printing assembly incorporating an improved double-sided image transfer station. The present disclosure also describes a product processing apparatus including a cross feed processing architecture. The single-pass double-sided image transfer station and cross feed processing architectures described herein provide numerous advantages over prior art product processing devices. In particular, the single-pass double-sided image transfer station provides for reduced print times, less shuttling of the product during printing, and a less complex, therefore, more reliable printing operation overall. The cross feed architecture provides an efficient processing path for the product through the device and facilitates processing modularization.

Owner:ZEBRA TECH CORP

Method for preparing low fats fishbone leisure food

InactiveCN101176561AMeet health requirementsImprove processing levelFood preparationSnack foodHuman health

The utility model relates to a preparation method of a fishbone snack food with low fat, which belongs to the technical field of the snack food handling. The utility model uses fishbone, which is the leftovers in the marine product processing as material; after rinsing, fishy smell removal, washing, curing, embrittlement, and flavour treating, the fishbone is made into the fishbone snack food product with low fat. The utility model can cure the fishbone adequately by means of the autoclave steaming; and then removes the moisture content by means of the microwave to embrittle the products. Themethod gets rid of the deep fry, has low fat, can meet the requirements of the human health adequately. The method of preparing the fishbone snack food with low fat for filling calcium is easy and quick, and is very good for improving the processing level of the farm products, the livestock products and the marine products in our country, and can bring along great economic benefits. The utility model uses the castoff as material to reduce the production cost, and prepares new products.

Owner:JIANGNAN UNIV

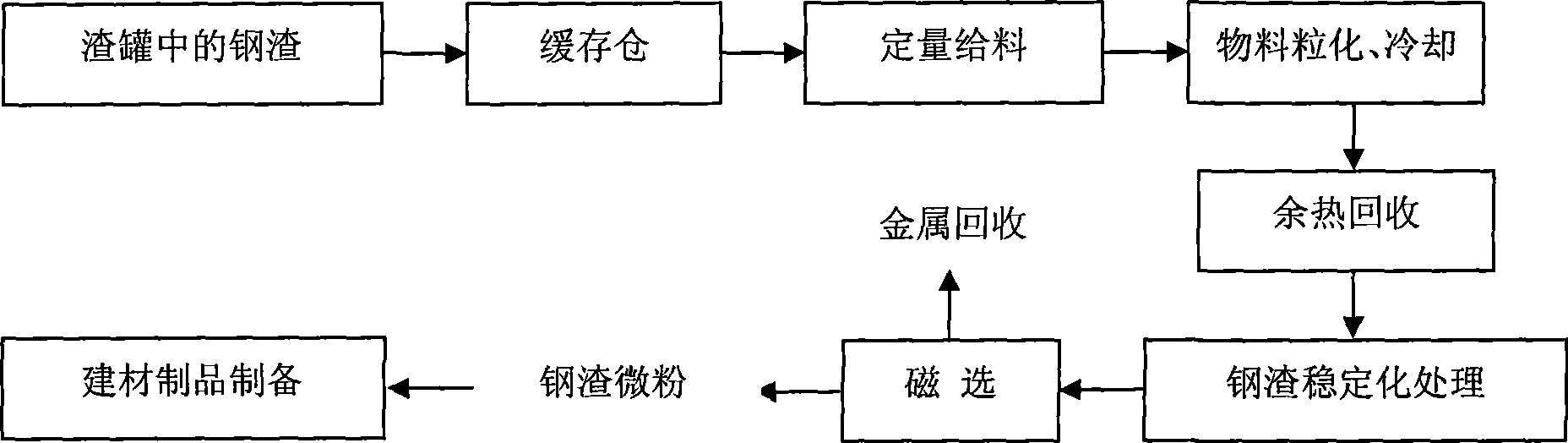

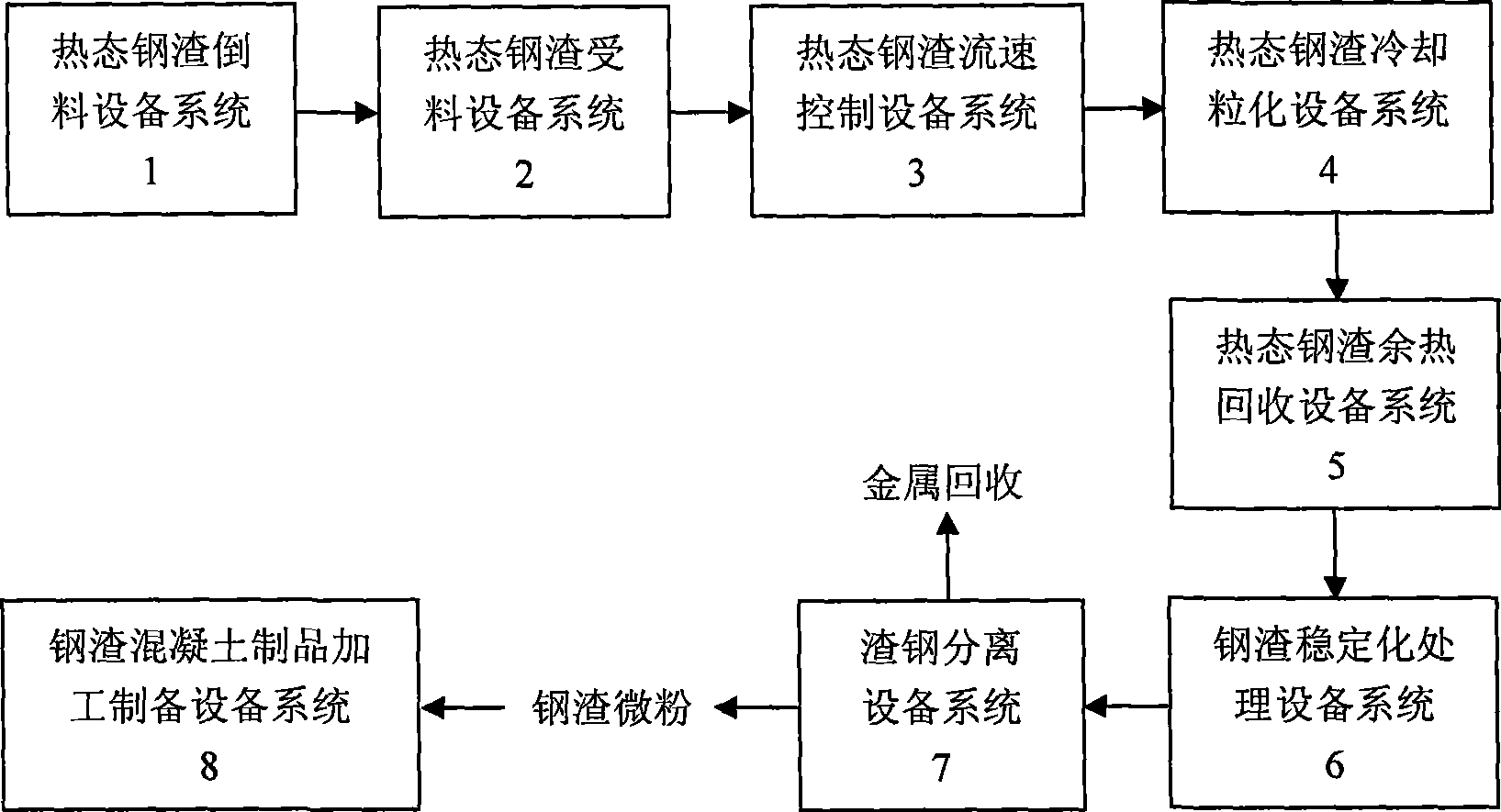

Method for recovery of waste heat of steel slag and comprehensively processing and utilizing steel slag

InactiveCN101413037AAvoid water explosionImprove energy efficiencyIncreasing energy efficiencyRecycling and recovery technologiesThermal stateSlag

The invention provides a mehtod for recovering waste heat of steel slag and comprehensively processing and using the steel slag, and belongs to the technical field of steel slag treatment. The method comprises the following steps: a thermal state steel slag material discharging system discharges steel slag into a thermal state steel slag material receiving system for primary crushing; the crushed steel slag is subjected to secondary crushing by a thermal state steel slag velocity control system and quantificationally fed into a thermal state steel slag cooling granulating system for re-crushing and cooling, high-temperaure hot air generatd in the cooling process is collected by a thermal state steel slag waste heat recovery system and enters a heat exchange system to form vapor for power generation or heat supply; the cooled steel slag enters a steel slag stabilizing treatment system, and the steel slag after the stabilizing treatment is treated by a steel slag separation system to obtain steel slag tailing micropowder and metal slag steel respectively; and, the steel slag micropowder is mixed with other materials and used to prepare concrete products by a steel slag concrete product processing preparation system. The method has the advantages of adaptability to various types of steel slag to be processed, good operational environment and no secondary pollution.

Owner:SHOUGANG CORPORATION

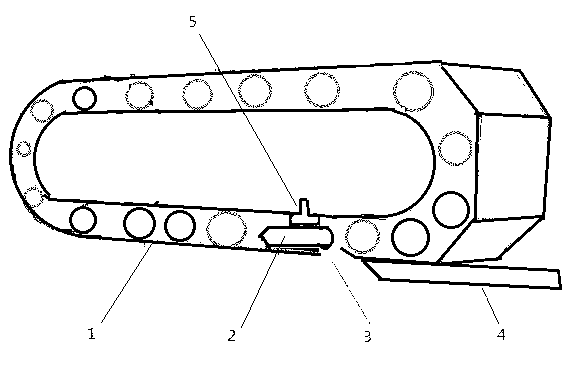

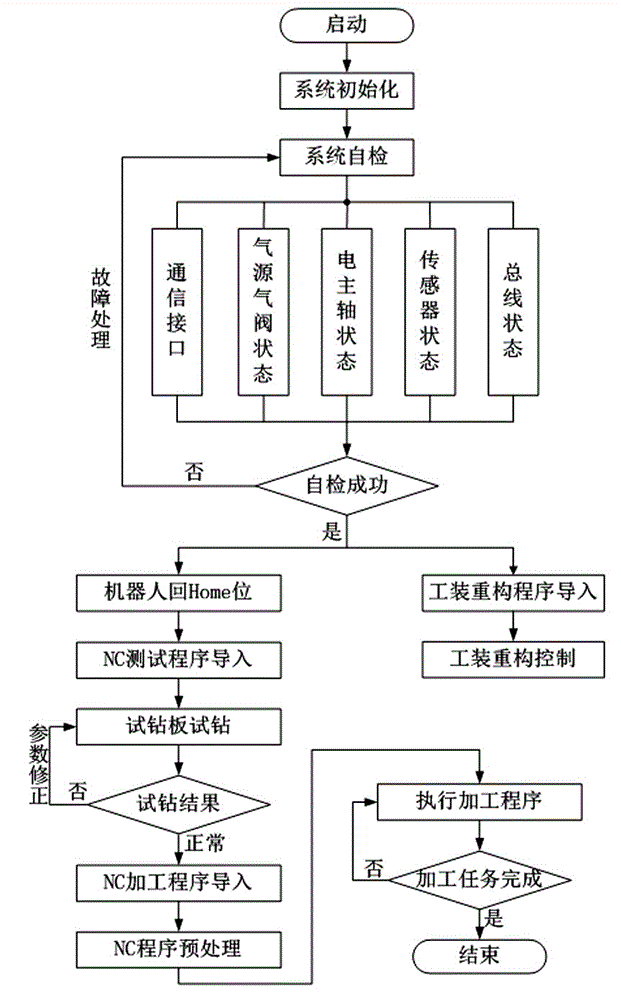

Intelligent flexible production line based on automatic robot assembling and operating method thereof

ActiveCN105033998AAvoid pollutionImprove processing qualityProgramme-controlled manipulatorProduction linePersonal computer

The invention discloses an intelligent flexible production line based on automatic robot assembling and an operating method thereof. The production line consists of an industrial personal computer, a track, a mobile platform, an industrial robot, an industrial robot control cabinet, a rivet feeding system, a vacuum scrap suction device, a main control cabinet, a knife test station, and a flexible tool. The industrial robot, the industrial robot control cabinet, the rivet feeding system, the vacuum scrap suction device, the main control cabinet are installed on the mobile platform; an end effector is carried on the tail end of the industrial robot; and the flexible tool and the knife test station are arranged at one side of the track. According to the invention, the processing process of the high-intelligence control can be realized; the process can be controlled precisely; the product processing quality is high and stability is high; and the production line and the operating method are suitable for various products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

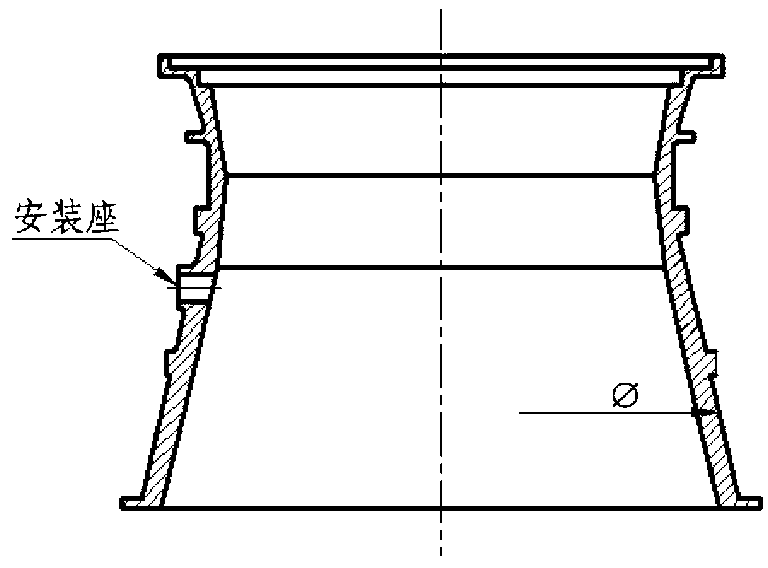

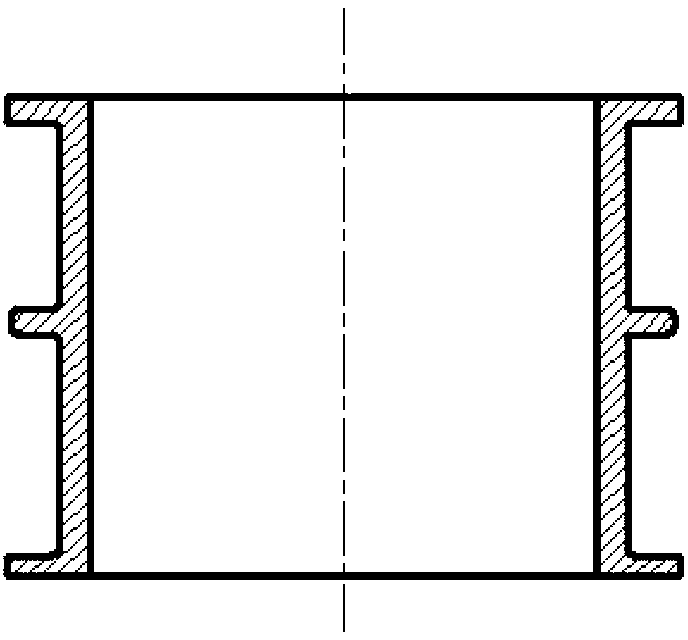

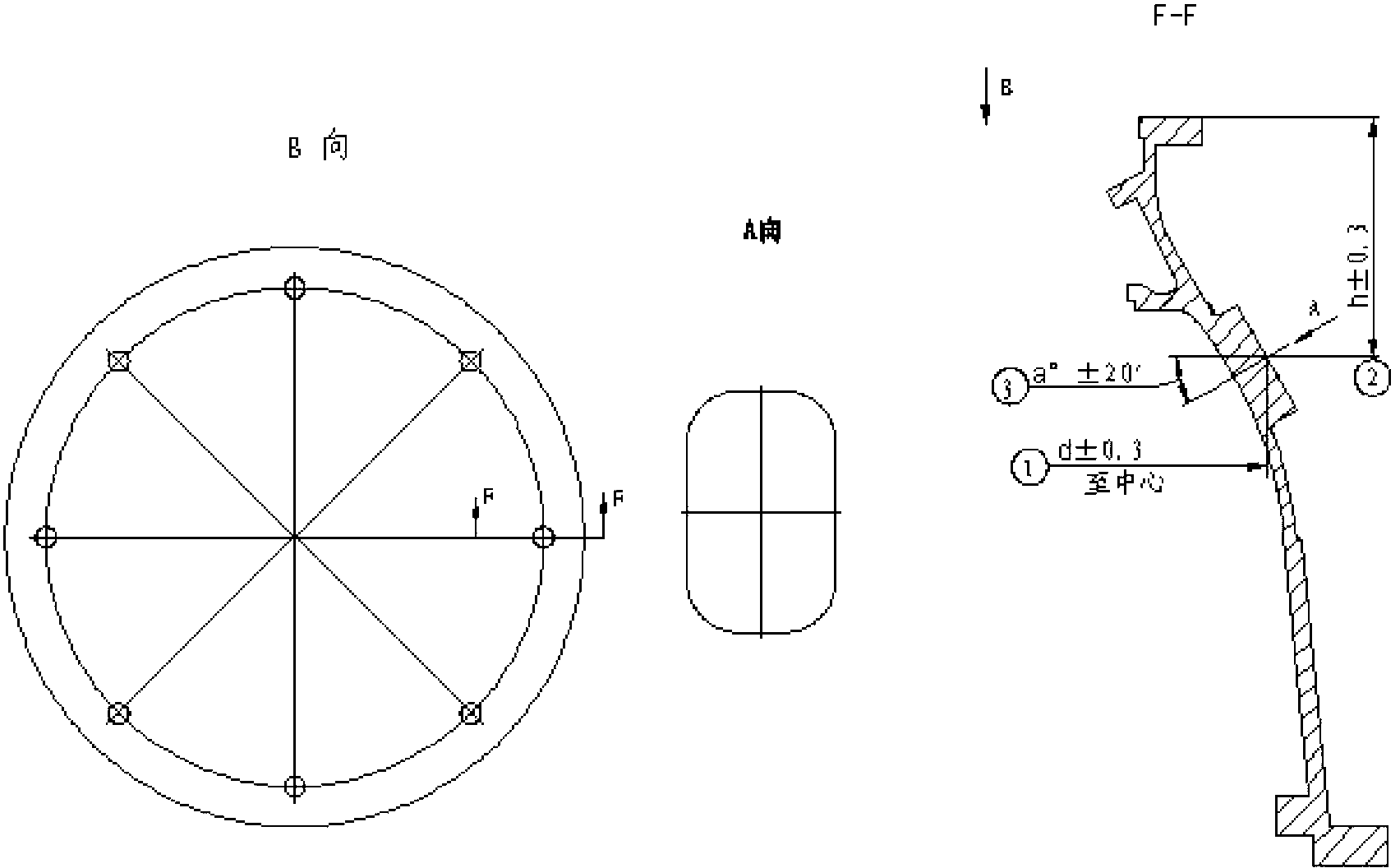

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952AGuaranteed accuracyReduce manufacturing costMeasurement devicesNumerical controlAviation

The invention discloses a method for detecting the diameter of an outer wall of a tapered case of an aviation engine on line. According to the method, a five-coordinate numerical control milling center with a Renishaw MP10 trigger-type measuring head is equipped, tapered case parts and a mounting seat on the surface of a tapered case are equipped; a fine adjustment ring gauge of the used measuring head is measured on line; a point contact-type measurement mode is adopted; a machine tool siemens control system Sinumeric 840 D on-line measurement technology is adopted; and an on-line measurement quick tool path amendment and error compensation generation technology is adopted. The method has a broad application prospect; and by the on-line measurement technology, a numerically-controlled machine tool is impelled to form a machining and detecting integrated numerical control machining unit. By the method, the traditional manufacturing mode that a design characteristic is equipped with a set of measurement tool in the current industry is changed, the manufacturing cost of the tool is saved, repair labor-hour is saved, and first-pass yield of product processing is improved, so that the development period and the production cost of new products are reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

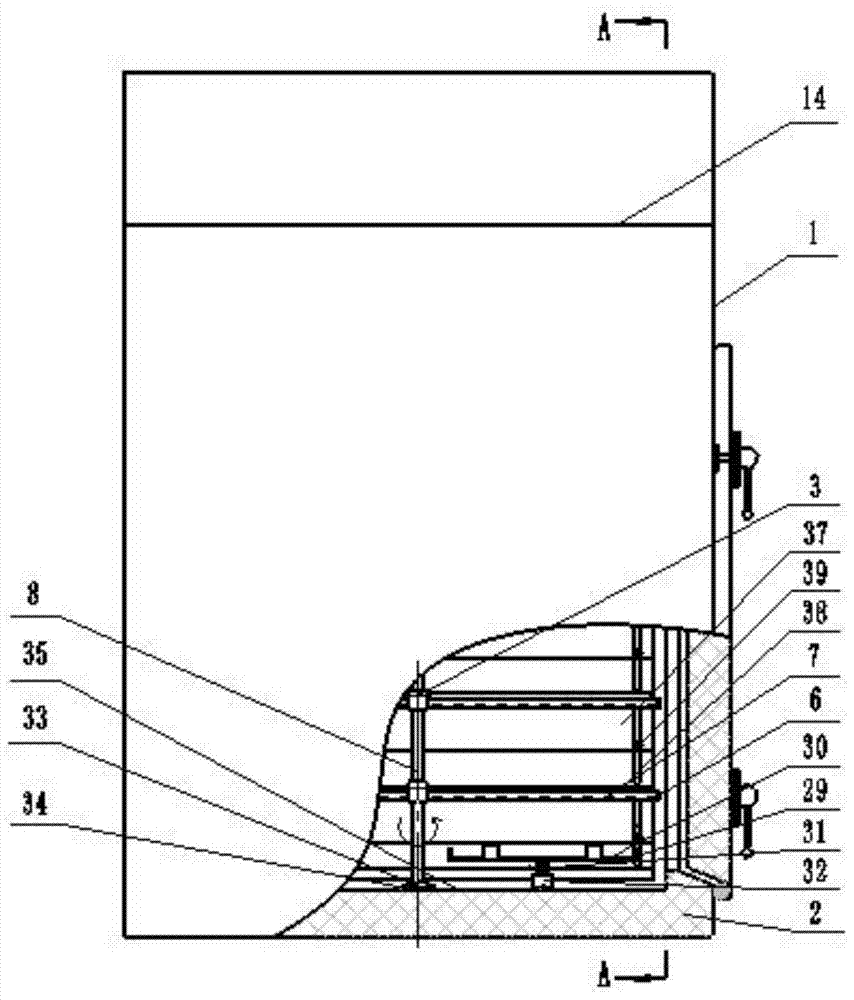

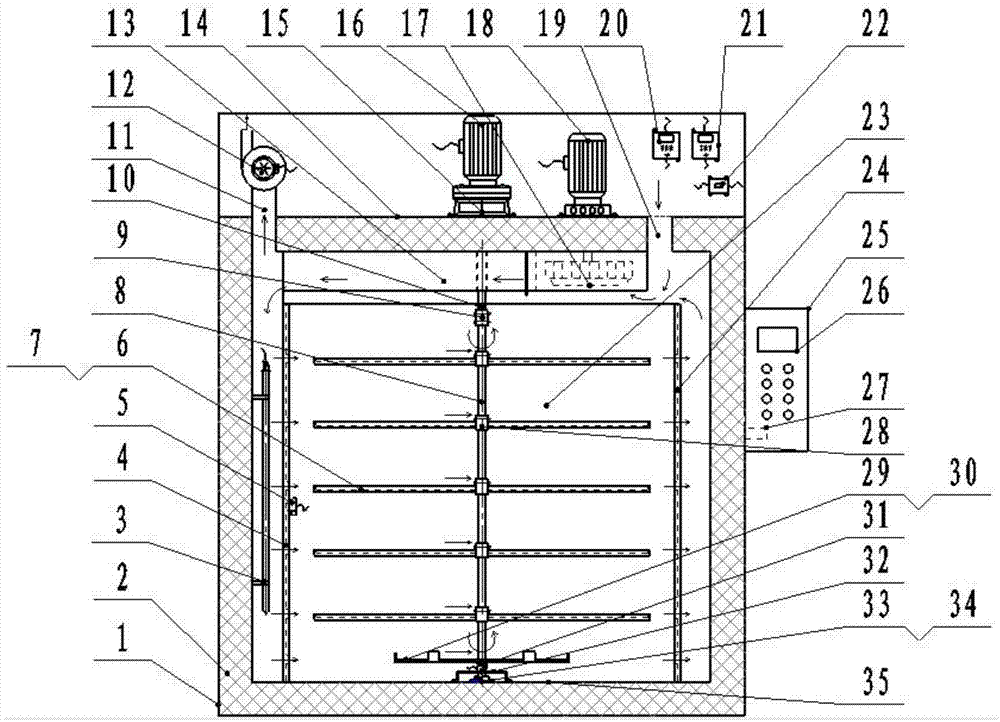

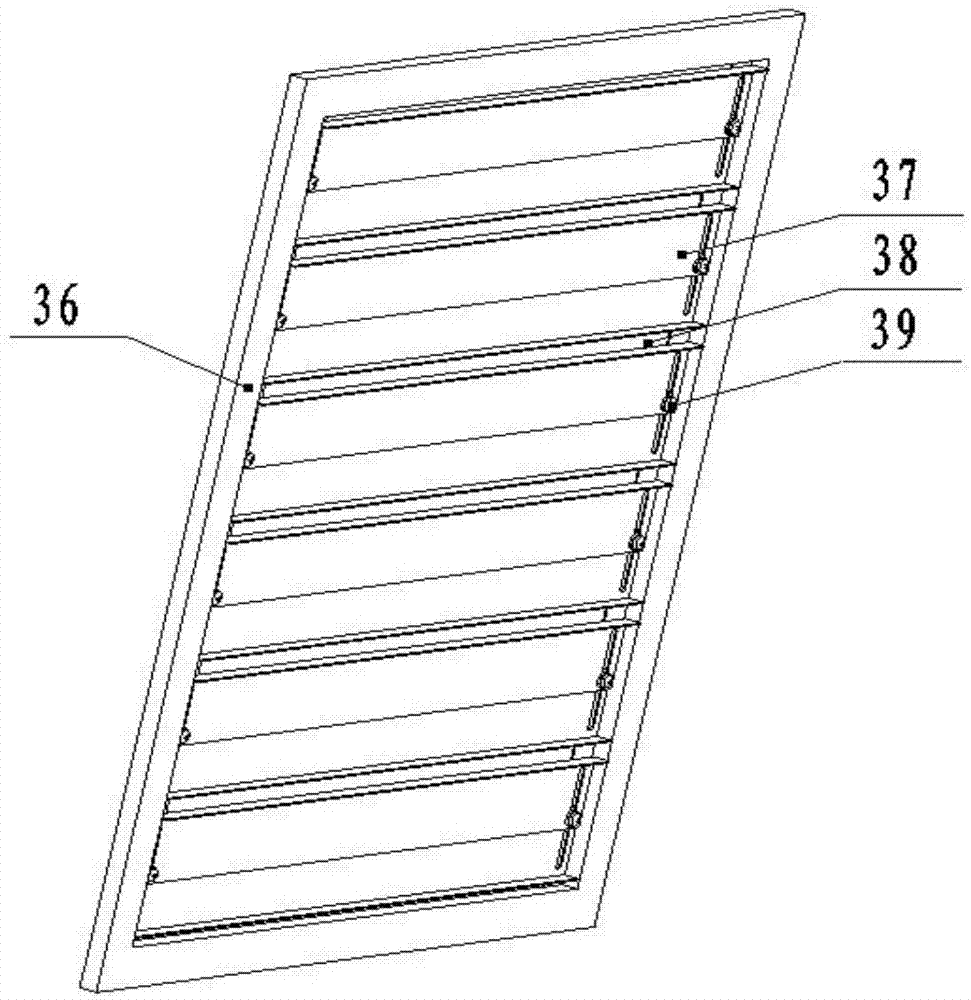

Rotary disk type air jet impact drying machine

InactiveCN103673563AEasy to manufacture and installLow costDrying gas arrangementsDrying solid materialsJet flowAutomatic control

The invention belongs to the technical field of agricultural product processing, and particularly relates to a rotary disk type air jet impact drying machine. The rotary disk type air jet impact drying machine comprises an air flow circulation system, a rotary disk system, a weighing system and an automatic control system. In the drying process, hot air flow with certain pressure is jetted into a drying chamber (23) through an adjustable strip-shaped air flow jet (38), multiple layers of round material racks (6) evenly distributed in the drying chamber (23) in the axial direction of a rotary material shaft (8) carry a material disk (7) to rotate in the horizontal plane, the rotary disk system can conduct drying in a rotation speed changing and rotation mode changing mode and the weighing system can indicate the drying condition of materials. The rotary disk type air jet impact drying machine solves the problems that an existing air jet impact drying machine is limited in carrying capacity, hard to meet the drying requirements of batch agricultural materials and high in manufacturing cost, and air flow adjustment is inconvenient; meanwhile, the rotary disk type air jet impact drying machine can realize the batch-type drying process of drying-tempering-drying-tempering, improve the drying efficiency, and lower the running energy consumption of the rotary disk system, and is high in automation degree and good in material adaptability.

Owner:CHINA AGRI UNIV

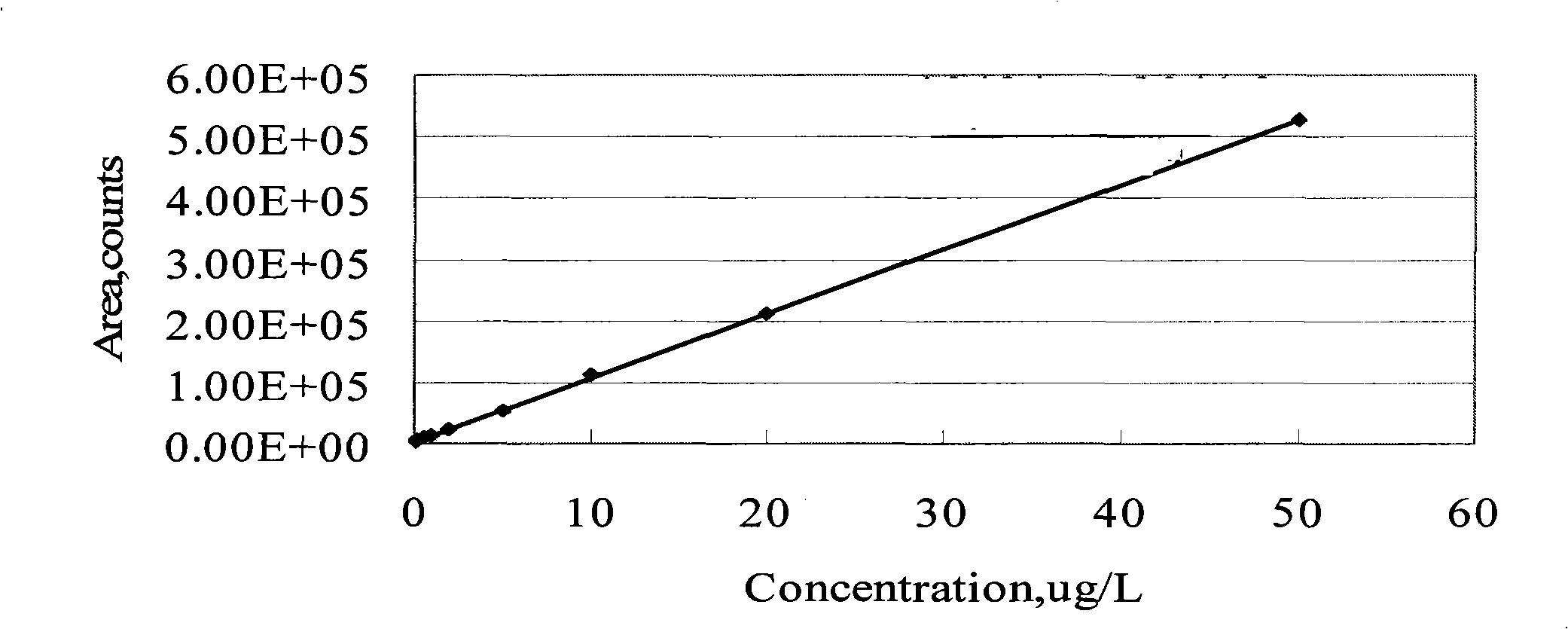

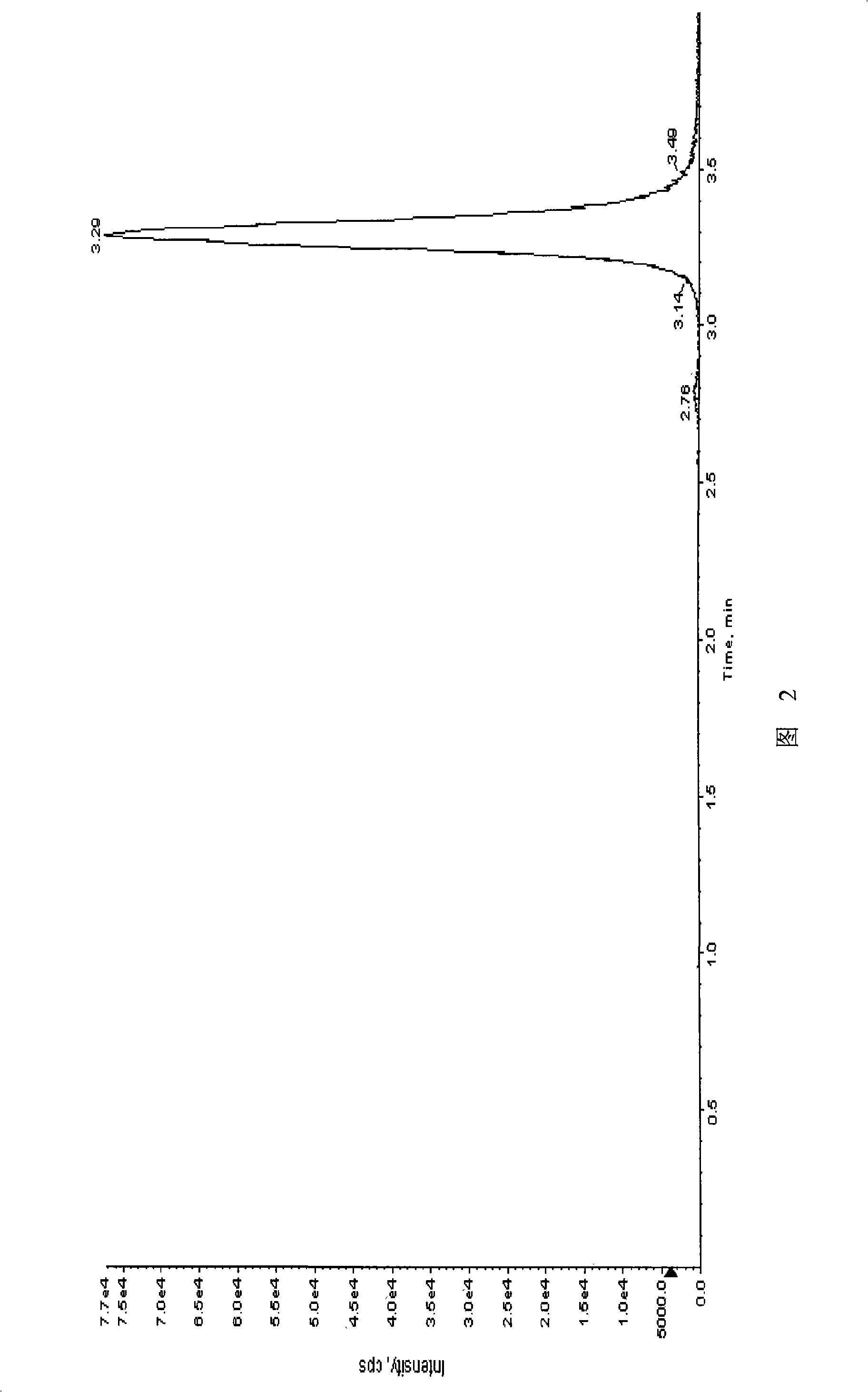

Aflatoxin degradation method

The invention discloses a method for degrading aflatoxin, which makes use of gamma rays to irradiate a sample containing the aflatoxin, wherein the gamma rays are generated by a radioactive substance Co, and the irradiation dose is between 0 and 10 kGy not including 0, preferably between 2 and 10 kGy, more preferably between 4 and 10 kGy, particularly preferably between 6 and 10 kGy, and the most preferably 10 kGy. The sample containing the aflatoxin is a farm product containing the aflatoxin or a product obtained by processing the farm product, such as food, feedstuff, and the like. The method is particularly applicable to degrading the aflatoxin B1, not only can kill pathogenic microorganisms but also can degrade biotoxin therein, and does not generate any industrial pollution.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Technique for producing germinating brown rice vinegar and products thereof

InactiveCN101215517AAdvantages of production processMerit productMicroorganism based processesVinegar preparationHorticultureProduct processing

The invention relates to a process technology of germinated brown rice vinegar and products, belonging to the technical filed of agricultural products processing, which is characterized in that the invention adopts germinated brown rice as the main raw material via saccharifying, alcoholic fermentation and acetic fermentation to obtain the germinated brown rice vinegar which contains abundant health care components such as gamma-aminobutyric acid (GABA) and the like. The method is high in industrialization degree, which reserves the functional components such as GABA and the like when obtaining the vinegar and the end product is clear and transparent, wherein the GABA content is 200-350mg / l, which is a novel health-care rice vinegar product.

Owner:NANJING AGRICULTURAL UNIVERSITY

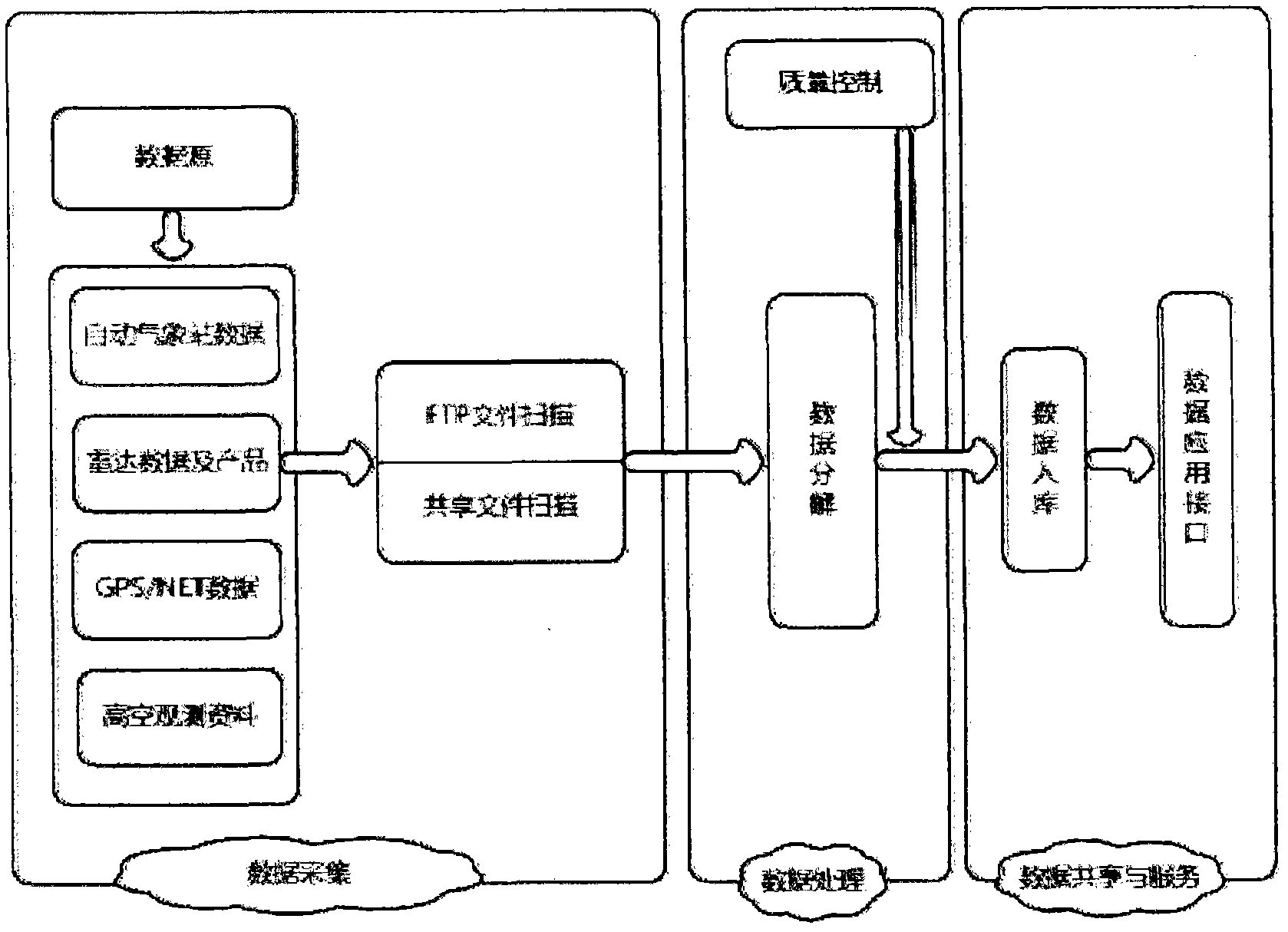

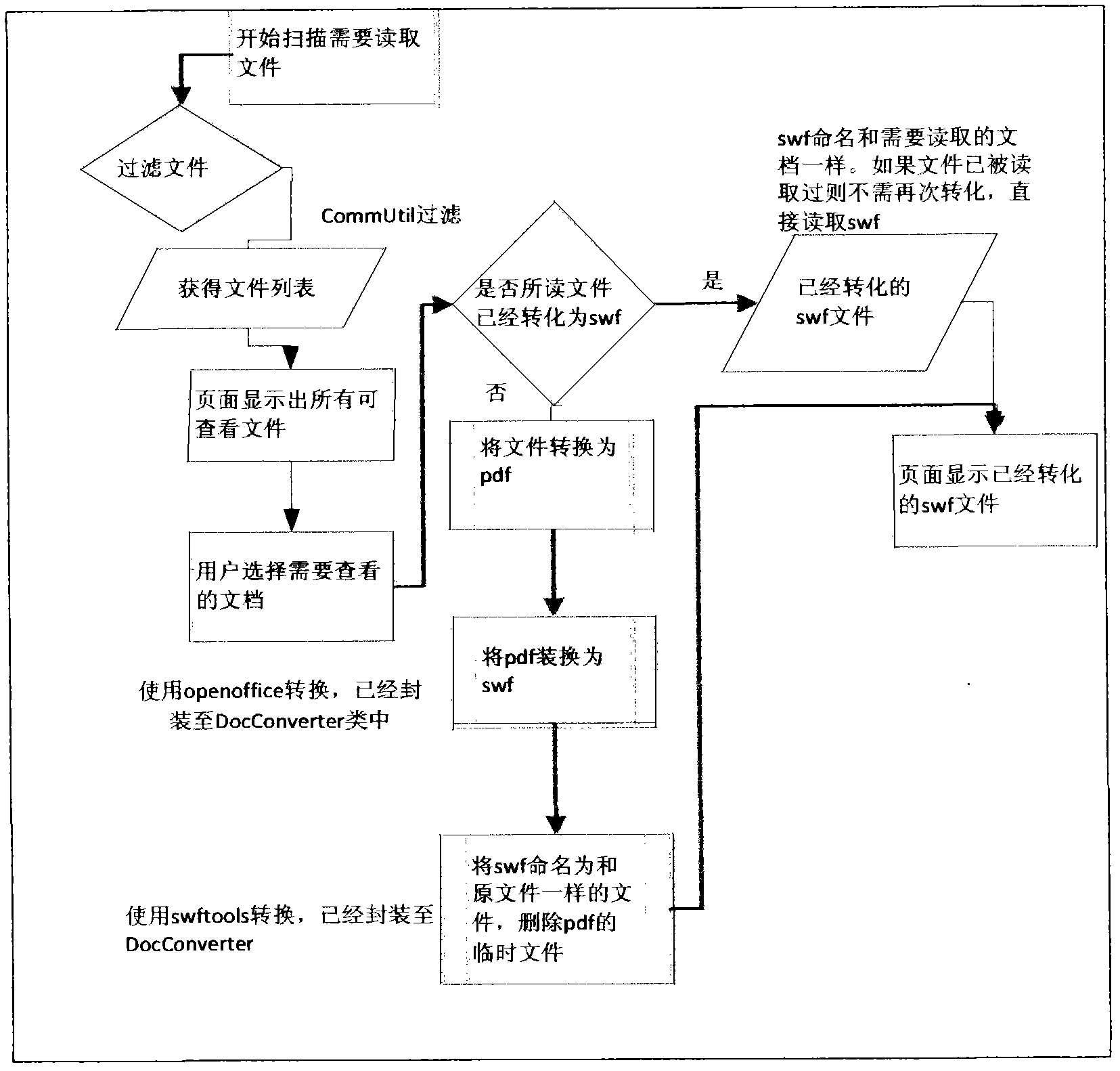

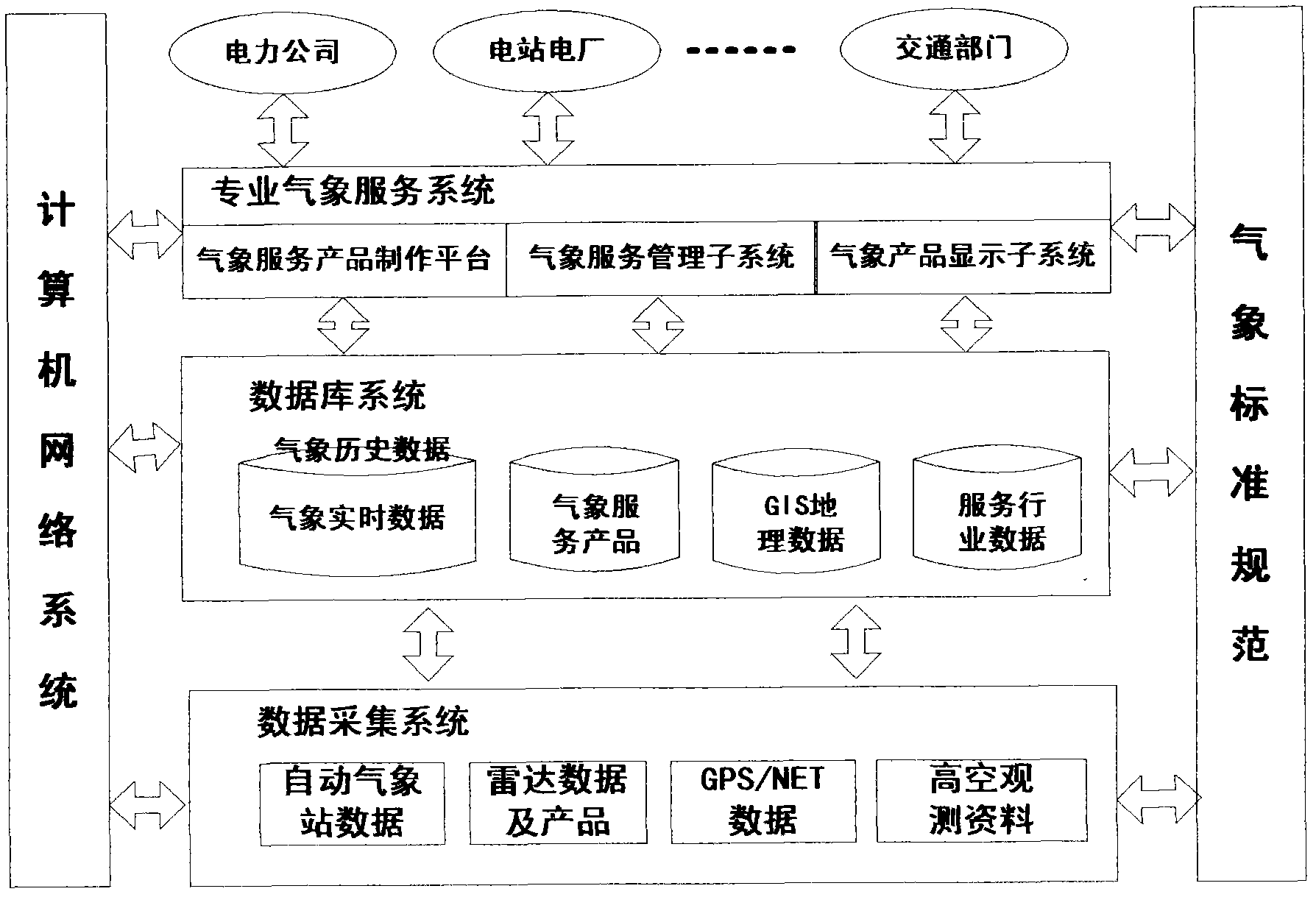

Integrative specialized weather service integrated system

InactiveCN102521716APrepare your dataFully reflect the needsResourcesManagement unitData acquisition

The invention discloses an integrative specialized weather service integrated system which comprises a data acquisition and sharing unit, a product processing unit, a product release and display unit and a service management unit, and integrates weather data acquisition, specialized weather service product manufacturing, processing and release, specialized weather service monitoring and management, and other links. The integrated system remarkably improves the specialized weather service level, facilitates expanding service field, increases service items, improves pertinence and fine level of the service product, and meets the requirements of various users to the maximum extent.

Owner:CHENGDU UNIV OF INFORMATION TECH

Method for producing table vinegar by fermenting yellow serofluid and bean dregs

InactiveCN103710253AReduce pollutionIncrease production capacityMicroorganism based processesVinegar preparationPectinaseAcetic acid

The invention discloses a method for producing table vinegar by fermenting yellow serofluid and bean dregs, which comprises the following steps: dehydrating bean dreg byproducts from bean product processing, and performing puffing pretreatment; sterilizing or boiling yellow serofluid at a high temperature, cooling, adding the treated bean dregs and a cellulase / pectinase composite enzyme preparation, and performing enzymolysis for 24 hours; and adding bean milk and 95% edible alcohol into the enzymolysis solution, inoculating with a Saccharomyces cerevisiae seed solution and an acetic acid bacterium Huniang A.S1.01 seed solution, performing aerobic fermentation at 20-30 DEG C for 5-10 days, centrifuging the matured fermentation solution, filtering, and sterilizing to obtain the finished table vinegar product. The method is low in cost, high in return, short in production cycle, high in equipment utilization rate and huge in market potential, avoids using grain materials, can relieve argument and scruple of all levels in the society about safety of table vinegar (industrial glacial acetic acid blending phenomenon), and saves grains.

Owner:HUNAN AGRICULTURAL UNIV

Preserved meat processing method

InactiveCN103584135AReduce salt contentReduce the content of benzopyreneFood preservationFood preparationPreservativeProduct processing

The invention relates to the field of meat product processing, and particularly relates to a preserved meat processing method. The preserved meat processing method can lower the content of benzopyrene in a preserved meat product by selecting and controlling the smoking temperature, humidity and smoking materials in the smoking step. The processing method provided by the invention can improve the preserved meat pickling temperature properly by using nisin and biological preservatives to shorten the pickling time from 40 days of the conventional art to 15 days, thereby preventing meat deterioration in the pickling process, improving preservation effect of preserved meat, and improving work efficiency.

Owner:HUNAN AGRICULTURAL UNIV +1

Preparation method of soluble fish protein ammonia acid fertilizer

InactiveCN104557339AReduce lossesSimple methodBio-organic fraction processingAnimal corpse fertilisersProduct processingNutrients substances

The invention relates to a preparation method of a soluble fish protein ammonia acid fertilizer, belongs to the field of biological technical processing, and particularly belongs to the field of fertilizer additive preparation. The preparation method comprises the following steps: crushing and pulping leftovers from fishery product processing or deep-sea low-value shrimp into fish pulp, mixing with water, adding lactic acid bacillus and protease, and fermenting for 3-8 days respectively through continuous ventilation and interval ventilation at a temperature of 40-45 DEG C to obtain the soluble fish protein ammonia acid fertilizer. The preparation method disclosed by the invention is simple, and short in heating treatment time, so that the heating cost is saved and the loss of nutrient substances is reduced. The fish protein ammonia acid soluble fertilizer prepared by adopting the preparation method has a good application effect, and particularly has remarkable effect on fruits and vegetables.

Owner:ZHOUSHAN YUANFENG MARINE BIOTECH

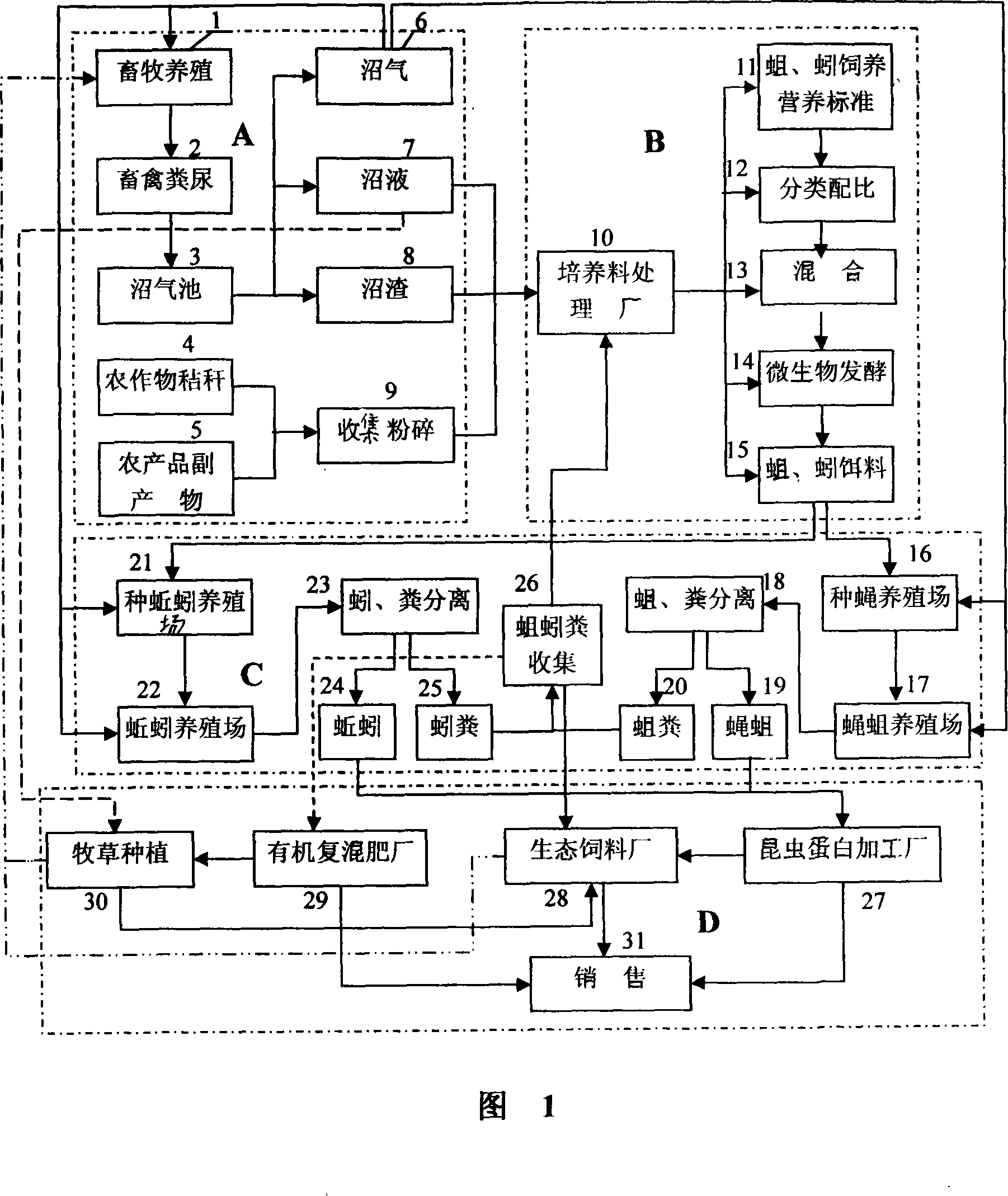

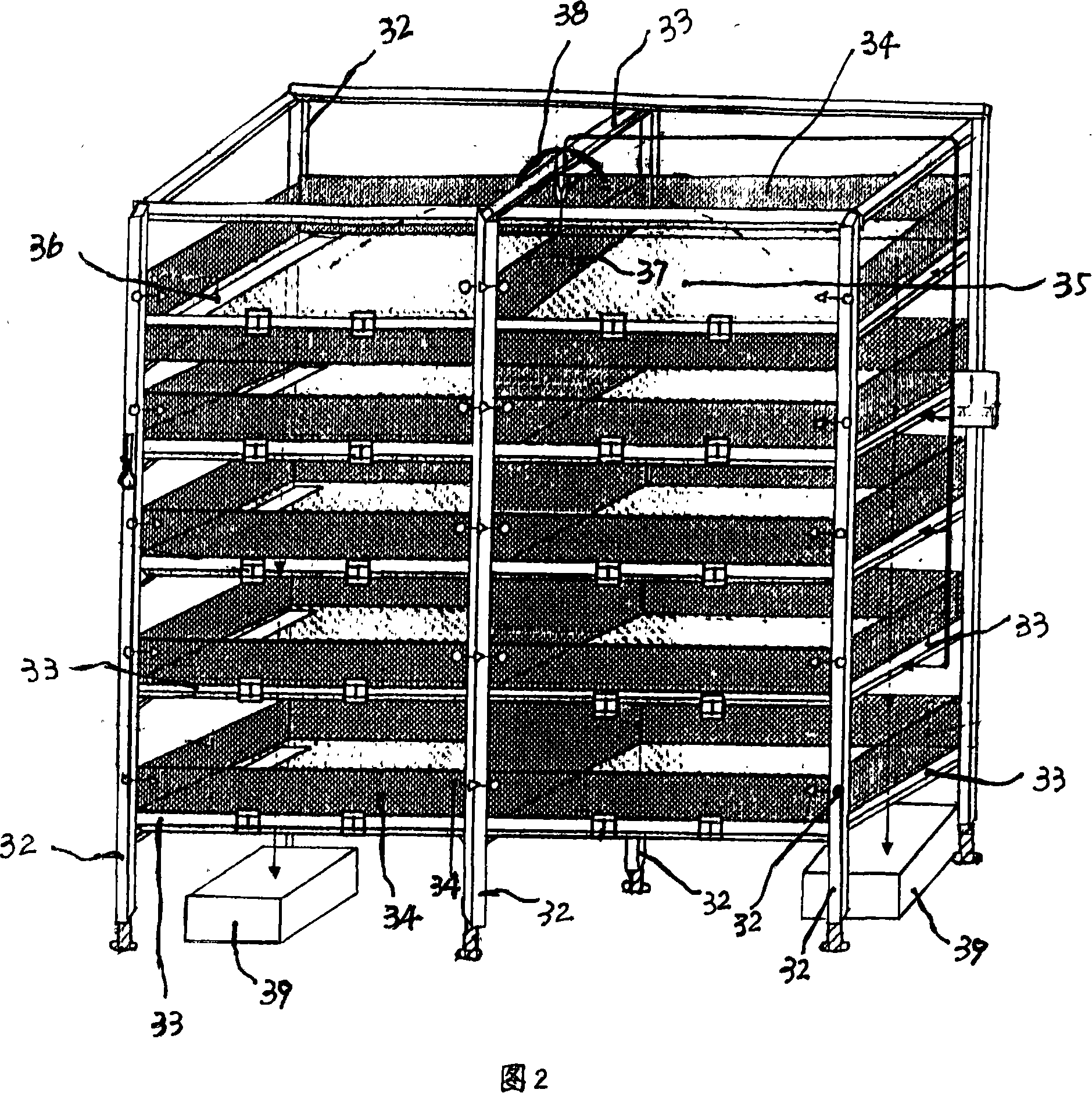

Fly maggot, earthworm ecological efficient circulation culturing method and culturing apparatus therefor

The present invention relates to a maggot and earthworm ecological high-effective circulating cultivation method and cultivation equipment by using said method, belonging to the field of maggot and earthworm cultivation technology. Said cultivation process includes the following several processes: raw material supply process, bait processing process, circulating cultivation process and pasture planting and product processing process. Besides, said invention also provides the concrete steps of above-mentioned every process, and concrete operation method of said cultivation equipment.

Owner:李金穗 +1

Water-in-water multicolor paint and preparation method thereof

The invention provides a water-in-water multicolor paint and a preparation method thereof, belonging to the field of preparation of paints. The paint comprises the following materials by mass: 5-15% of water, 30-35% of silicone-acrylic emulsion, 20-30% of white lacquer, 20-30% of protective colloid system, 0.5-1.5% of film-forming additive, 0.5-1% of defoaming agent, 0.1-0.5% of stabilizing agent and defined amount of thickening agent. The water-in-water multicolor paint is obtained through protective colloid system preparation, granulation and finished product processing. The prepared water-in-water multicolor paint has the advantages of environmental friendliness, stable product, convenience in spraying, brilliant color, lifelike effect and the like. Combination of tap water and the stabilizing agent HG-7 breaks the limitation that the water-in-water paint has to use deionized water, thus lowering the production cost. The paint is convenient for construction and can be sprayed up once by using a spray gun, thus not only saving labor but also shortening the construction period.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

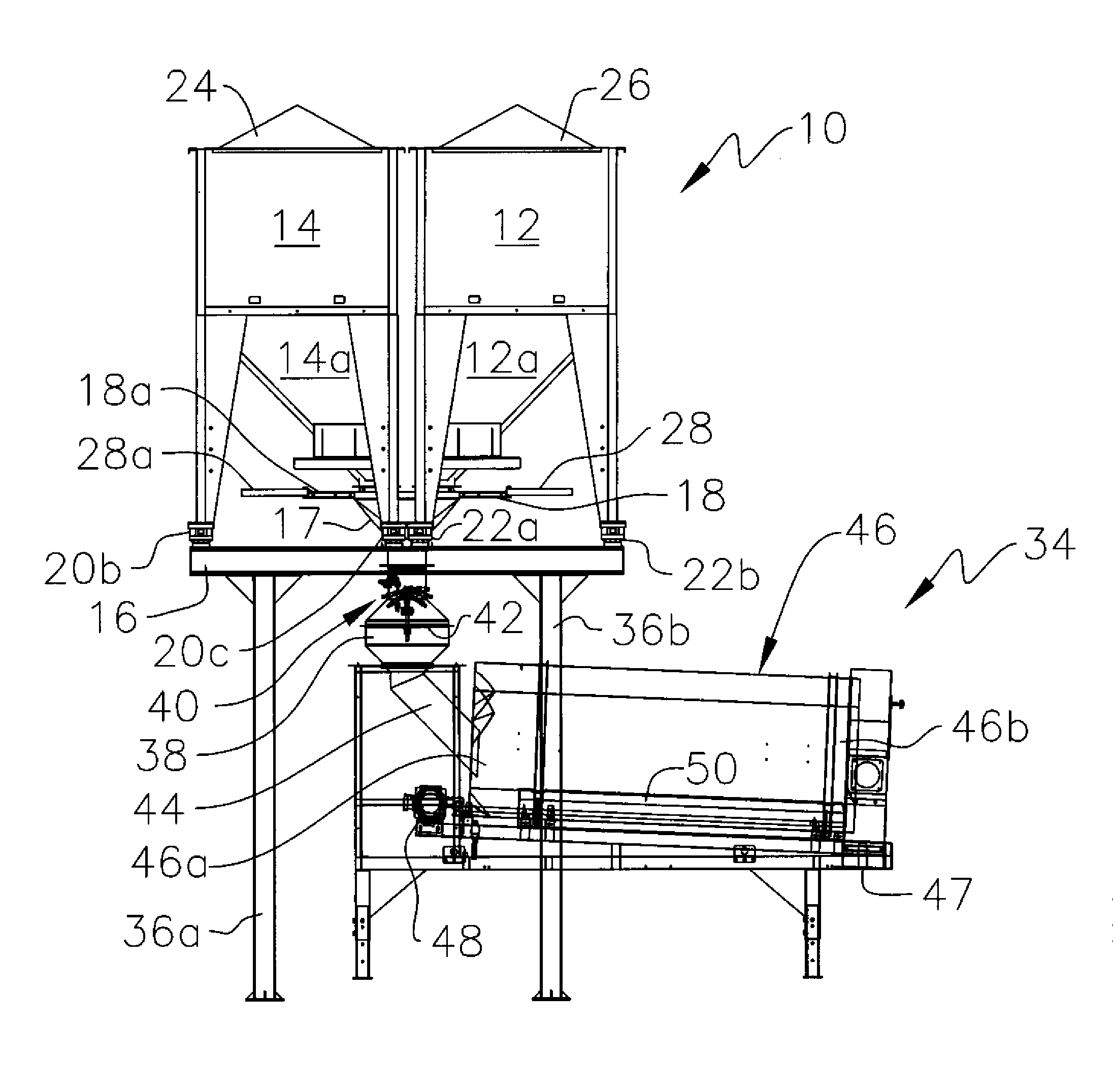

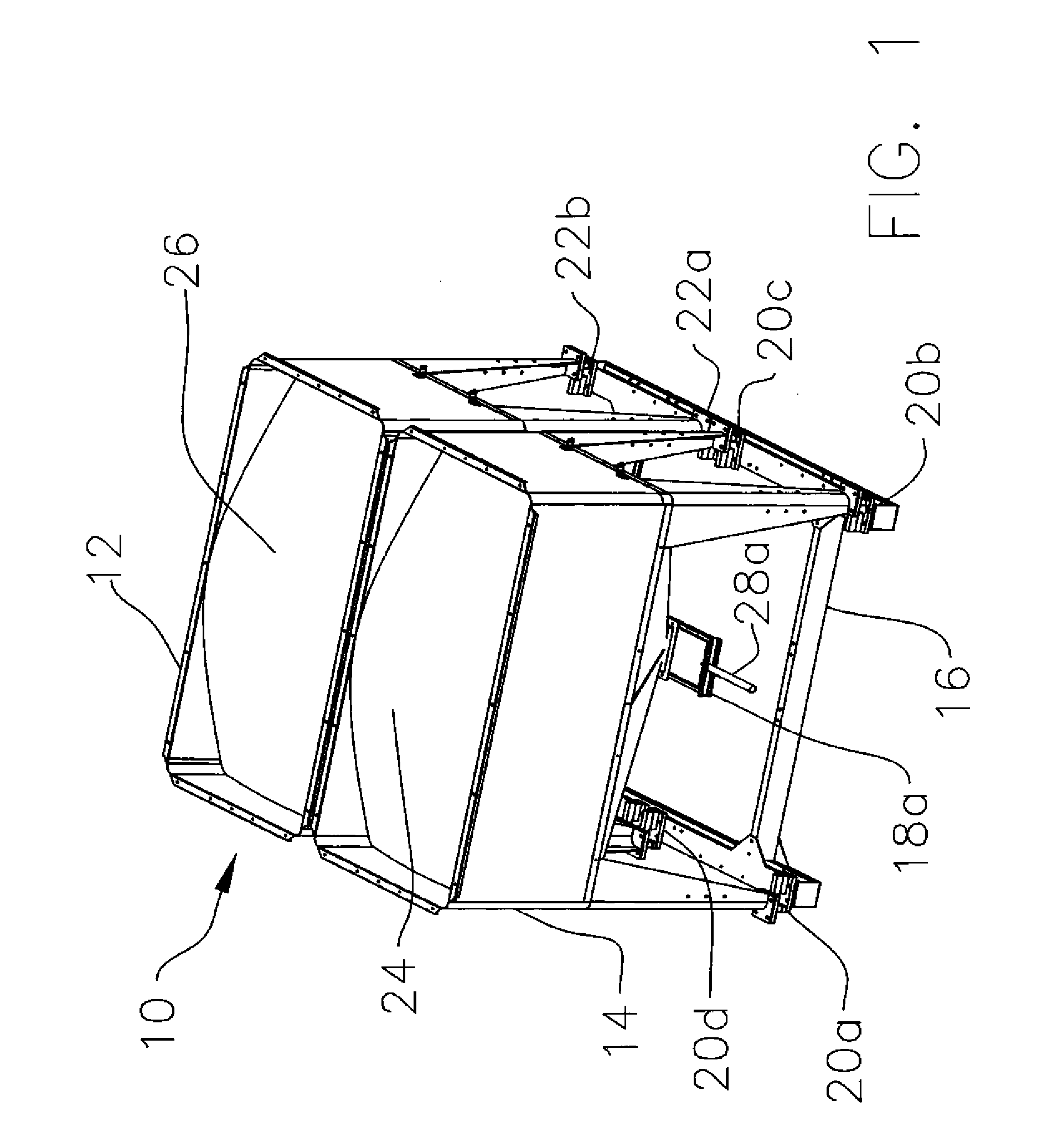

Multi-flow bulk weighing system

InactiveUS20120181093A1Precision therapyEasy to controlWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeDischarge rateProcess engineering

An arrangement for weighing bulk materials includes plural hoppers each having its own weighing system for accurately determining material discharge rate (lbs / minute) and for directing the contents of the hoppers to a product processing stage either sequentially from one hopper at a time while the other hoppers are being re-filled to provide continuous, non-stop operation, or in the alternative, from two or more hoppers simultaneously for blending the materials under the precise control of a programmed controller. Material discharge rate from each hopper is determined by continuous weighing of each hopper and its contents and is controlled in real time by precise computer controlled positioning of each hopper's slide gate. In the blending mode of operation, accurate monitoring of the material discharge rate is coordinated with processing of the material in a subsequent processing stage to allow for variation of the discharge rate to precisely match the subsequent processing parameters.

Owner:KSI CONVEYORS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com