Patents

Literature

1621 results about "Liquid food" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

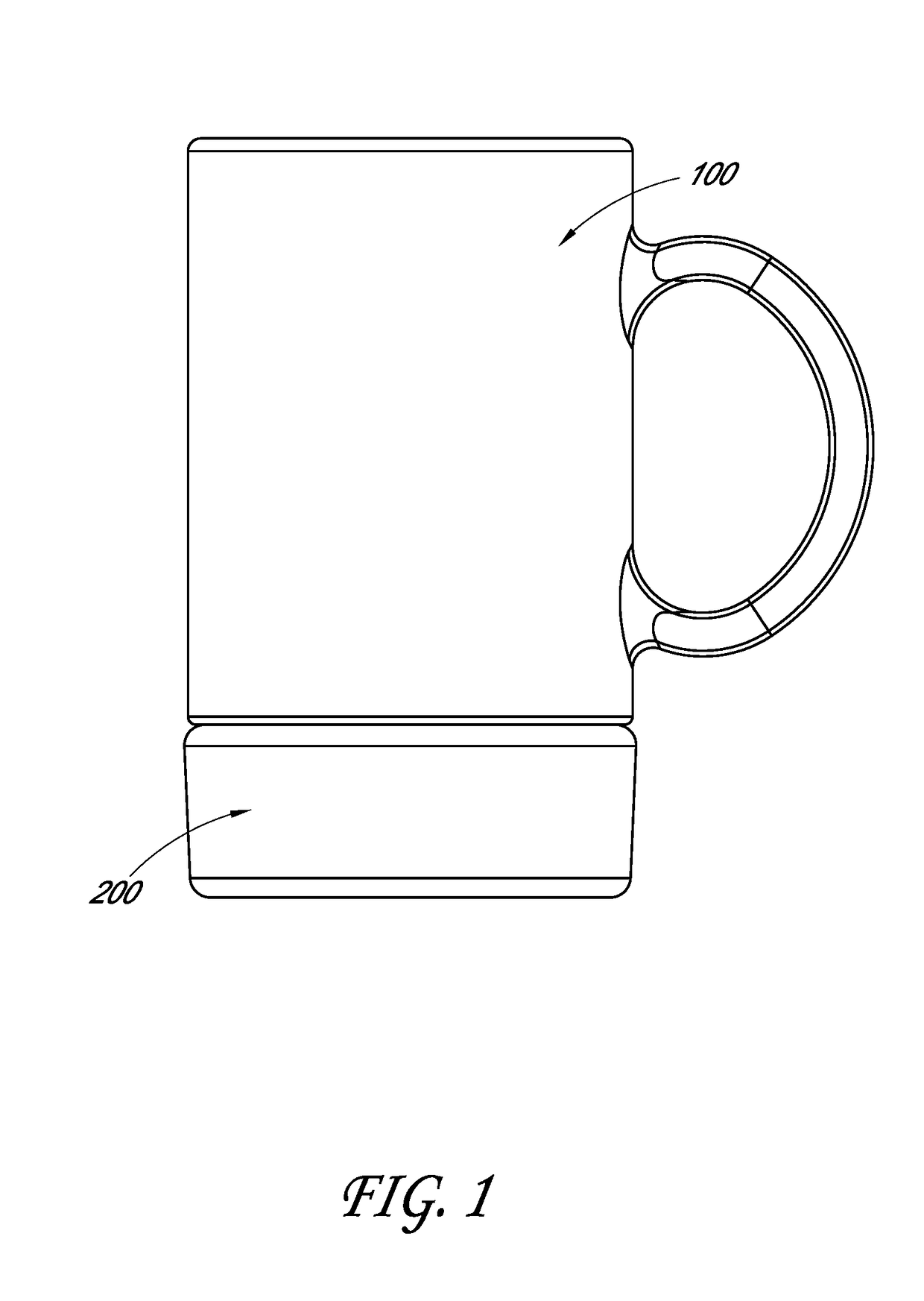

Heated or cooled dishwasher safe dishware and drinkware

InactiveUS20120103562A1Cooking vesselsMachines using electric/magnetic effectsTransmitted powerElectric power

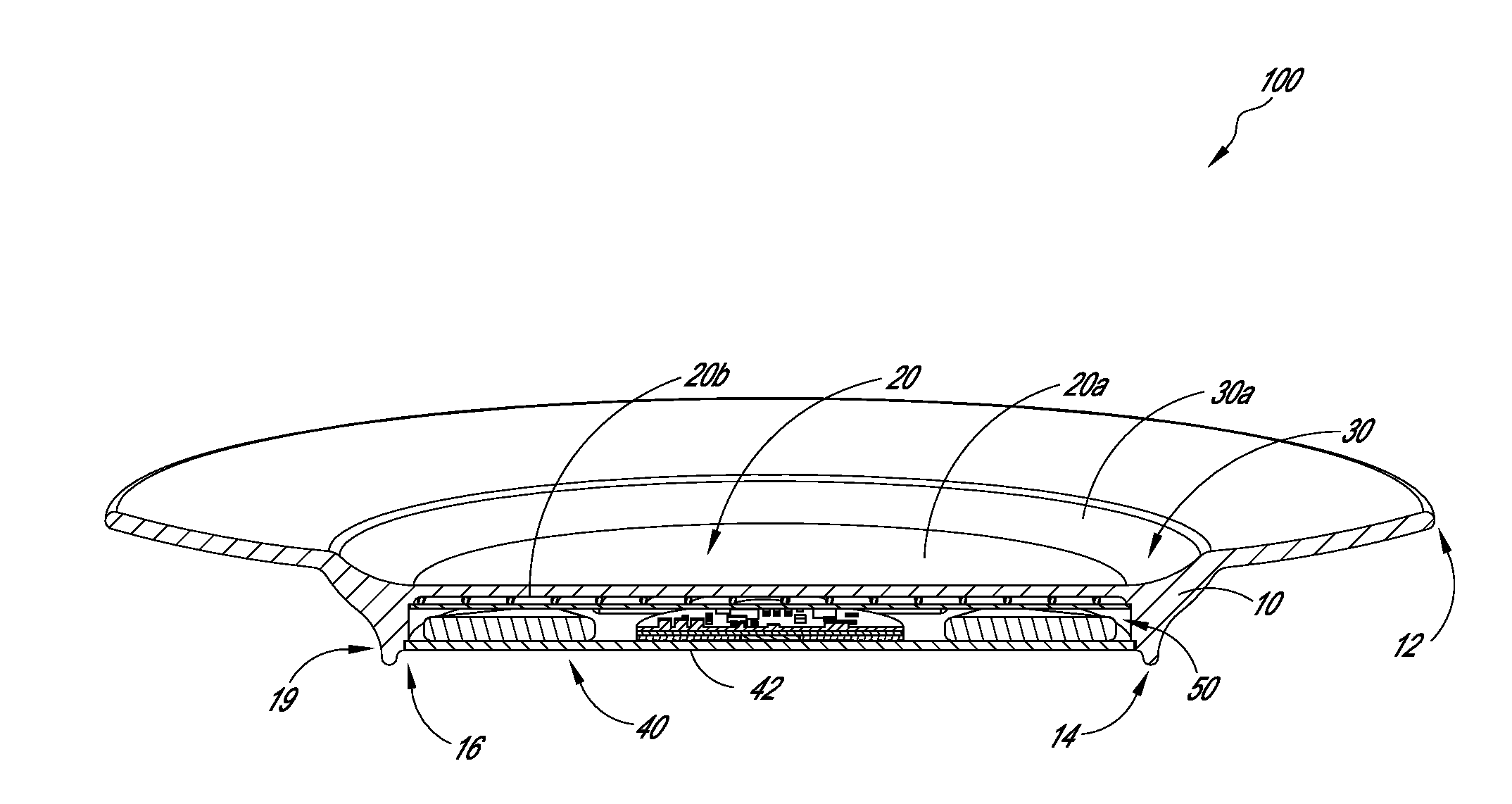

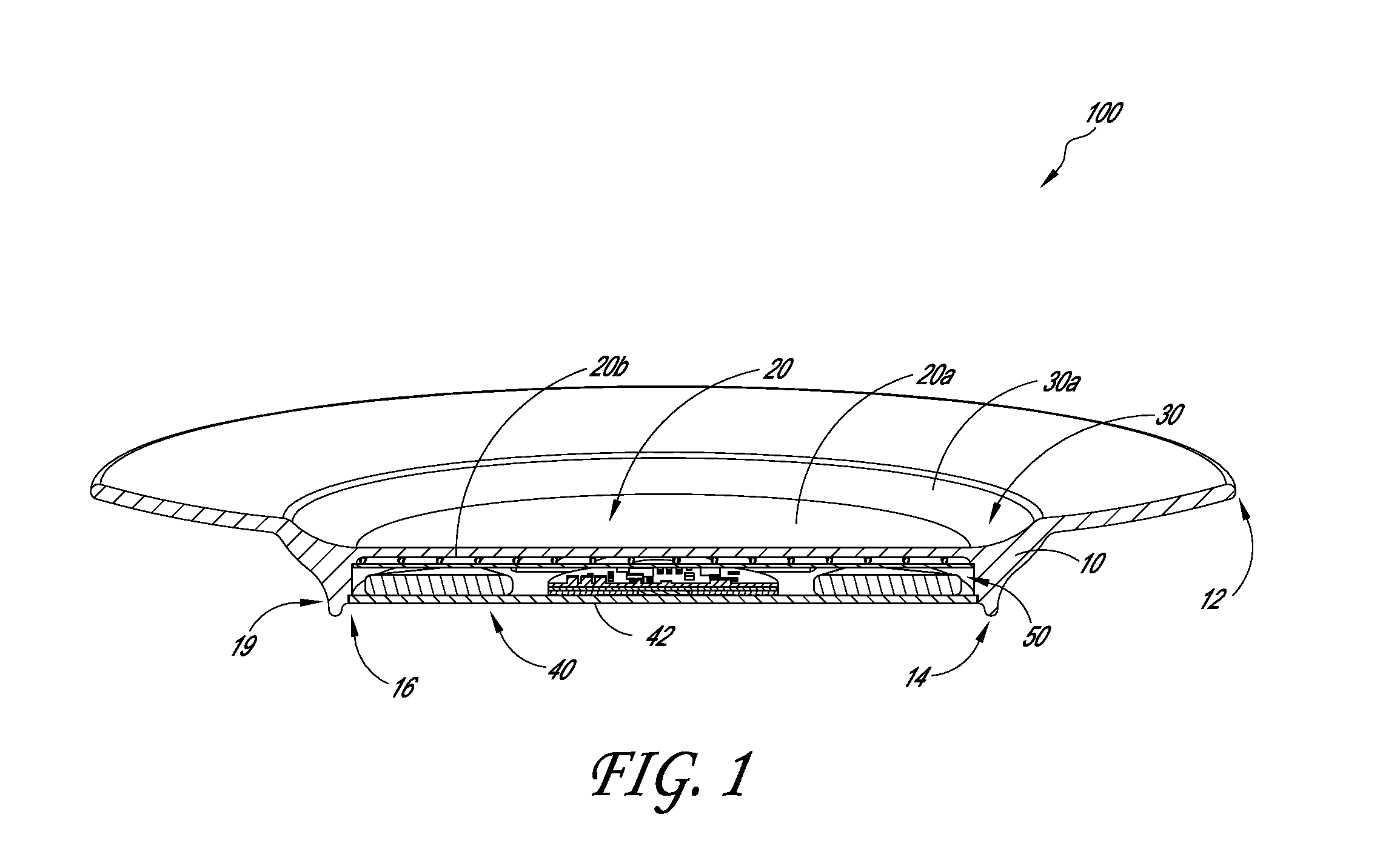

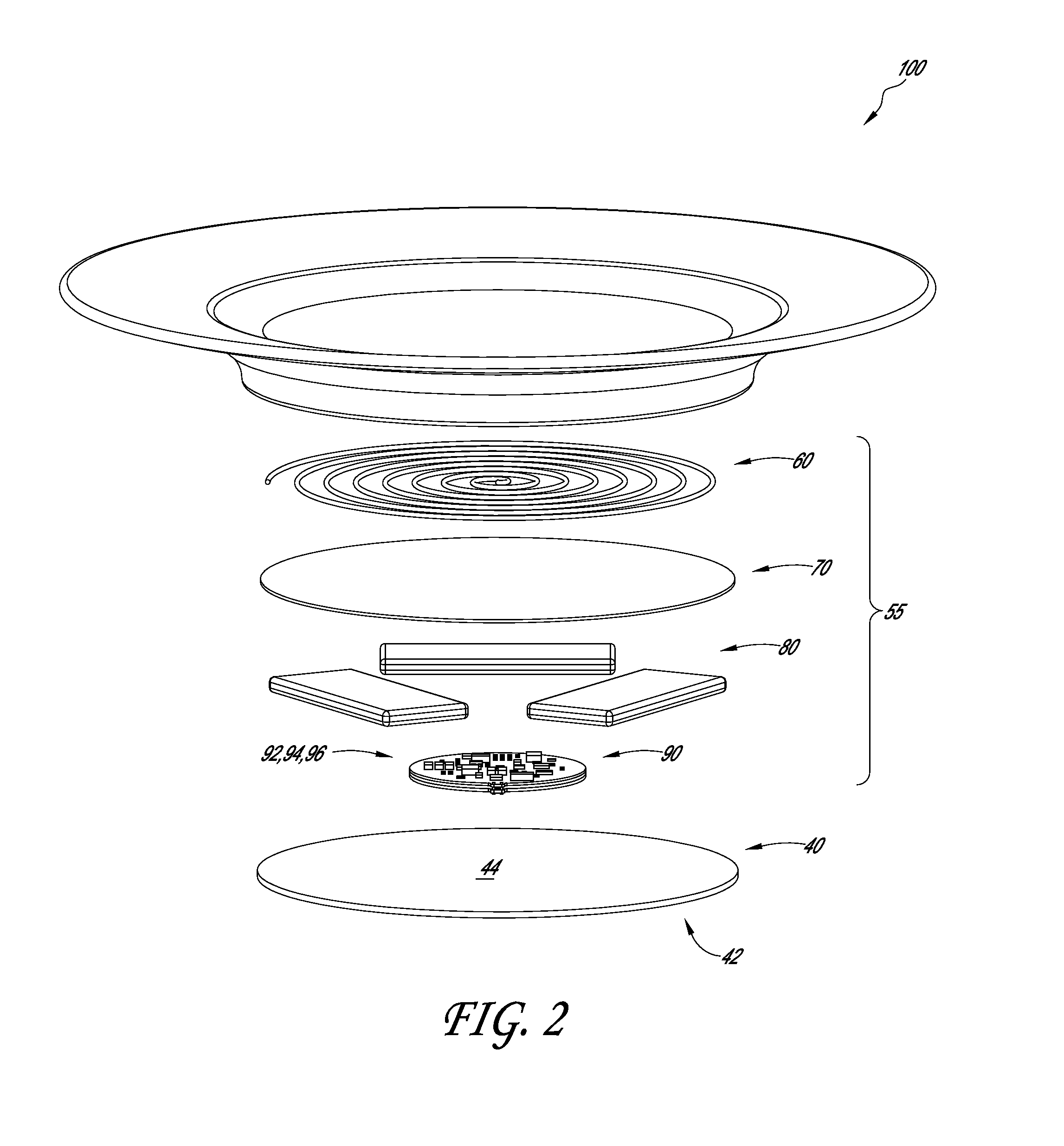

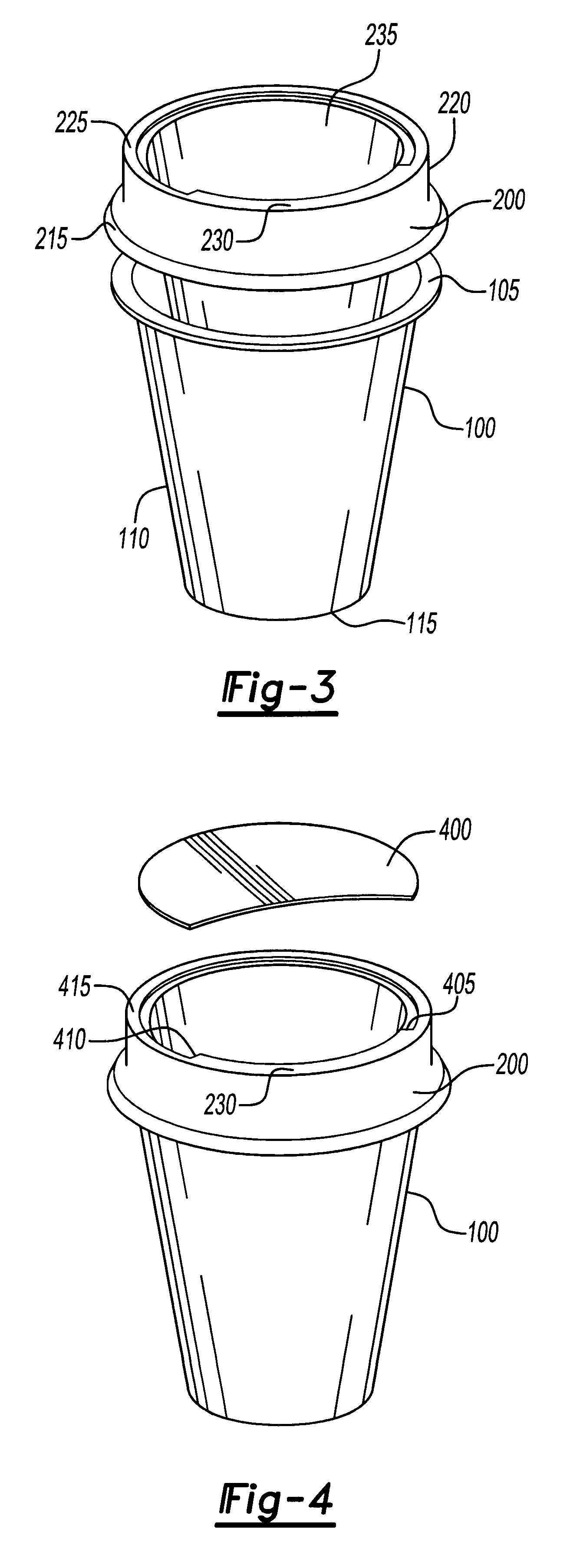

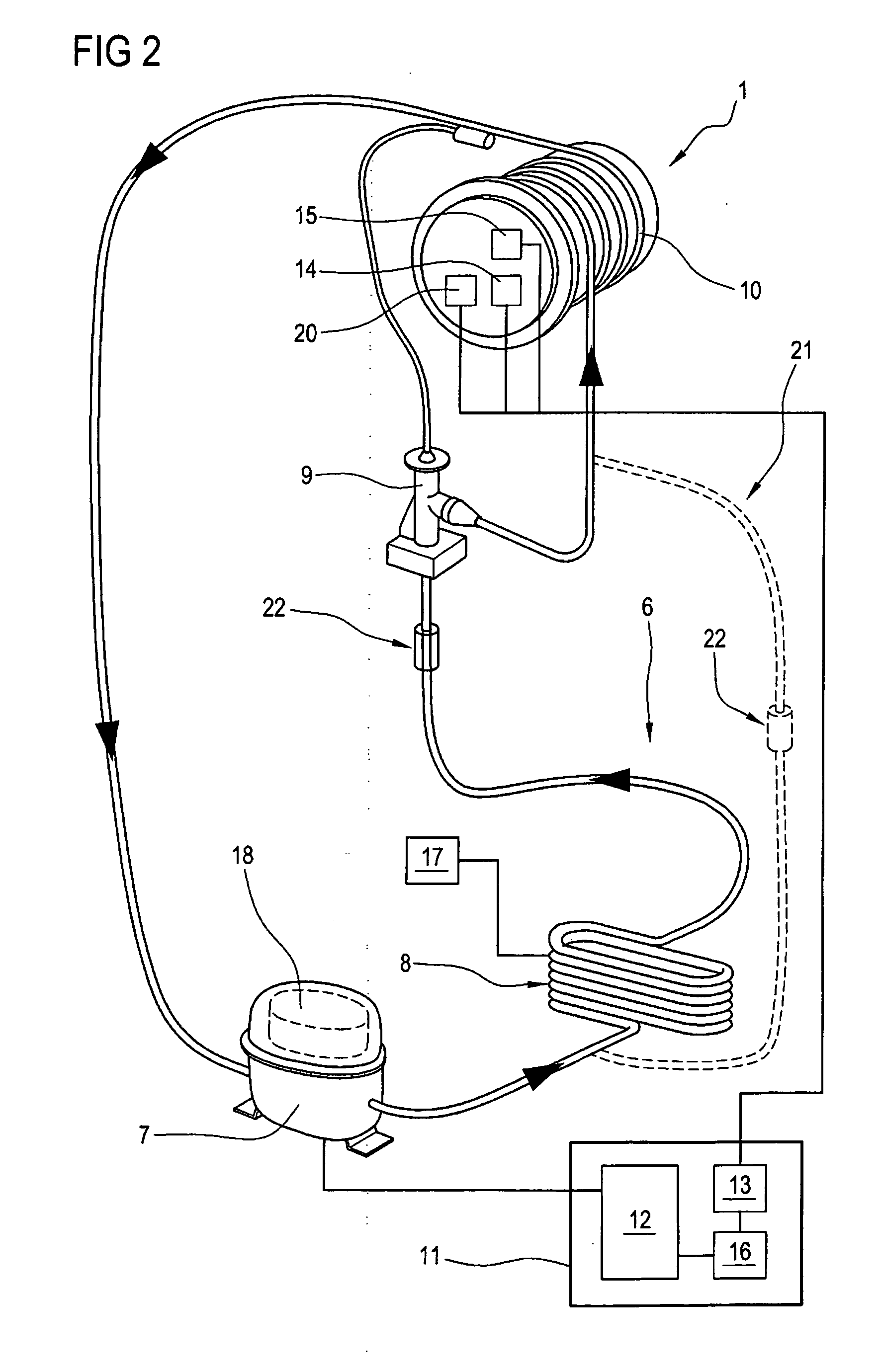

Heated or cooled dishwasher safe dishware and drinkware are provided. The dishware and drinkware can be a plate or mug with a dishwasher safe body having a food or beverage receiving portion and a heating or cooling system. The heating or cooling system can have a heating or cooling element that heats or cools the receiving portion of the body. The heating or cooling system can optionally have a power storage element connected to the heating or cooling element, a charging module operatively connected to the power storage element, and / or a wireless power receiver operatively connected to the charging module and configured to transmit power thereto to charge the power storage device. The heating or cooling system is operable to actively heat or cool at least a portion of the body to maintain the solid or liquid food in a heated or cooled state for an extended period of time.

Owner:EMBER TECH INC

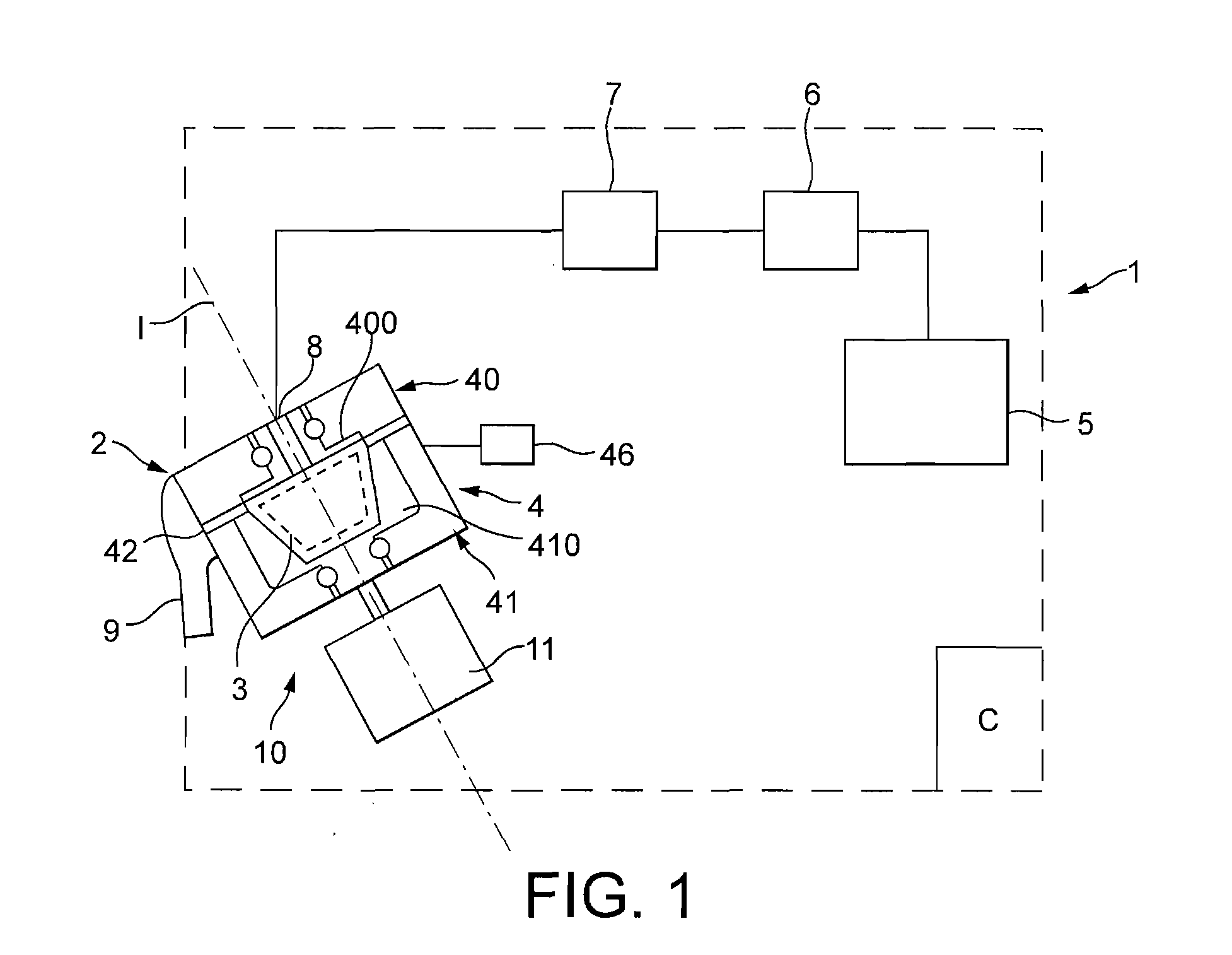

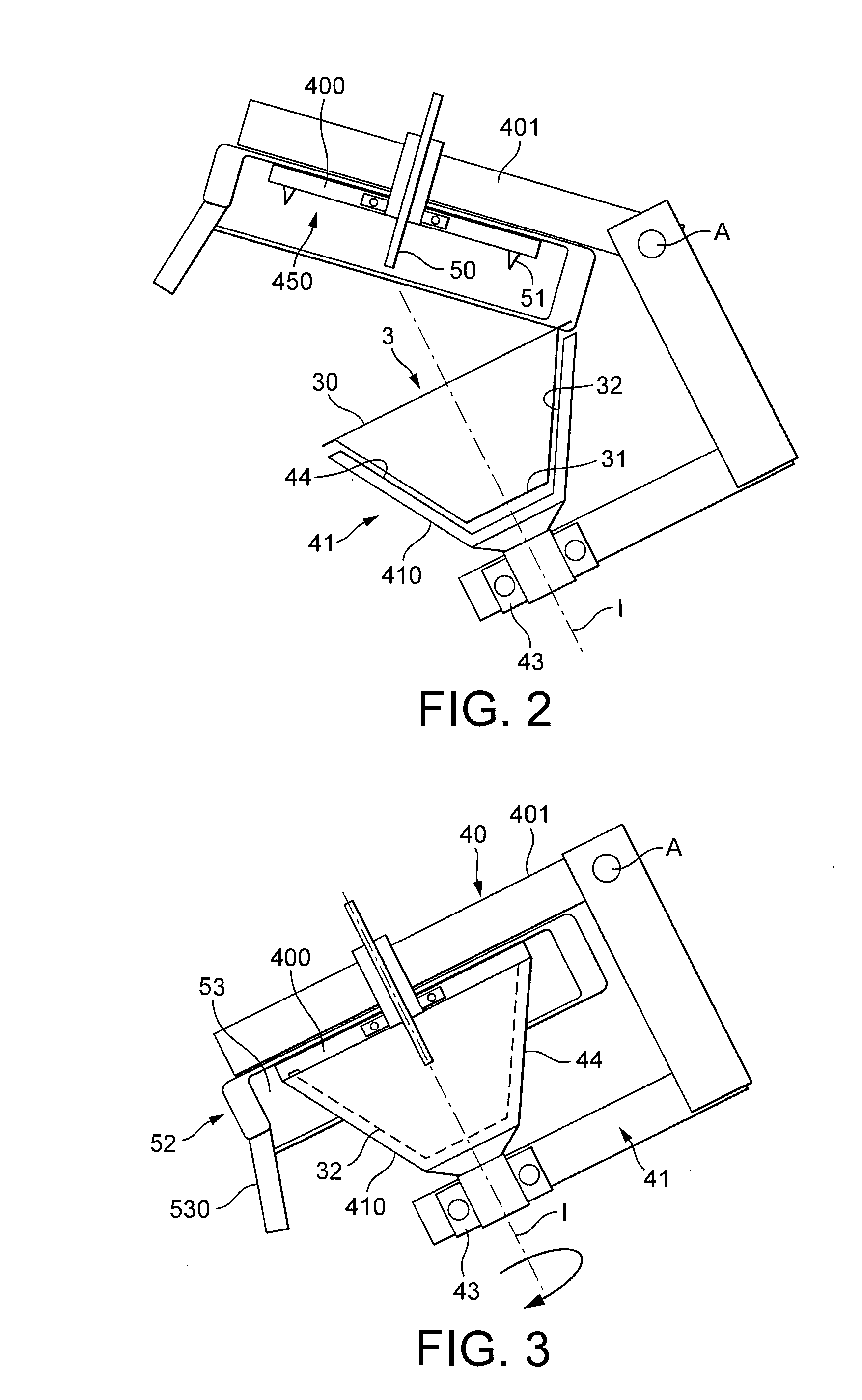

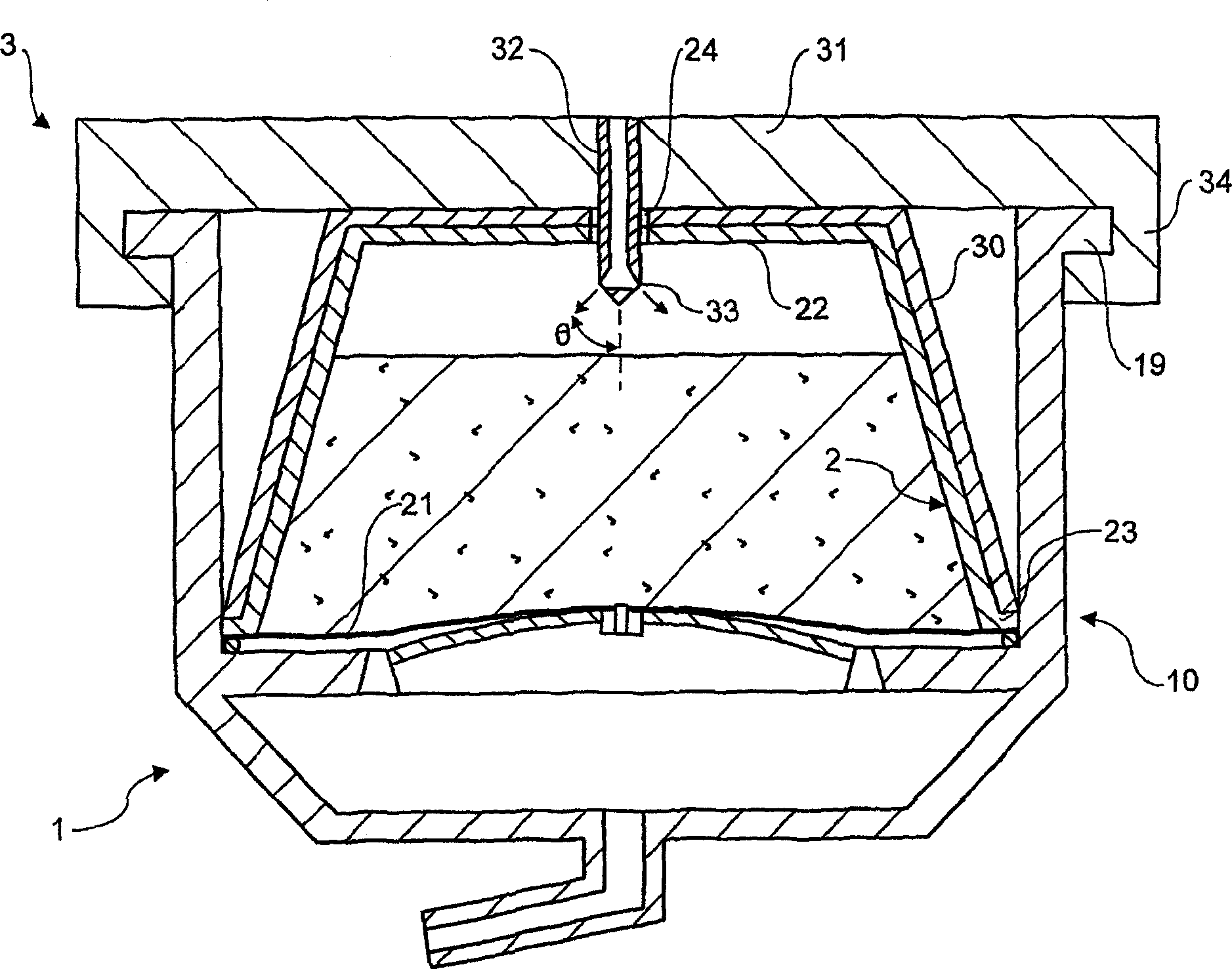

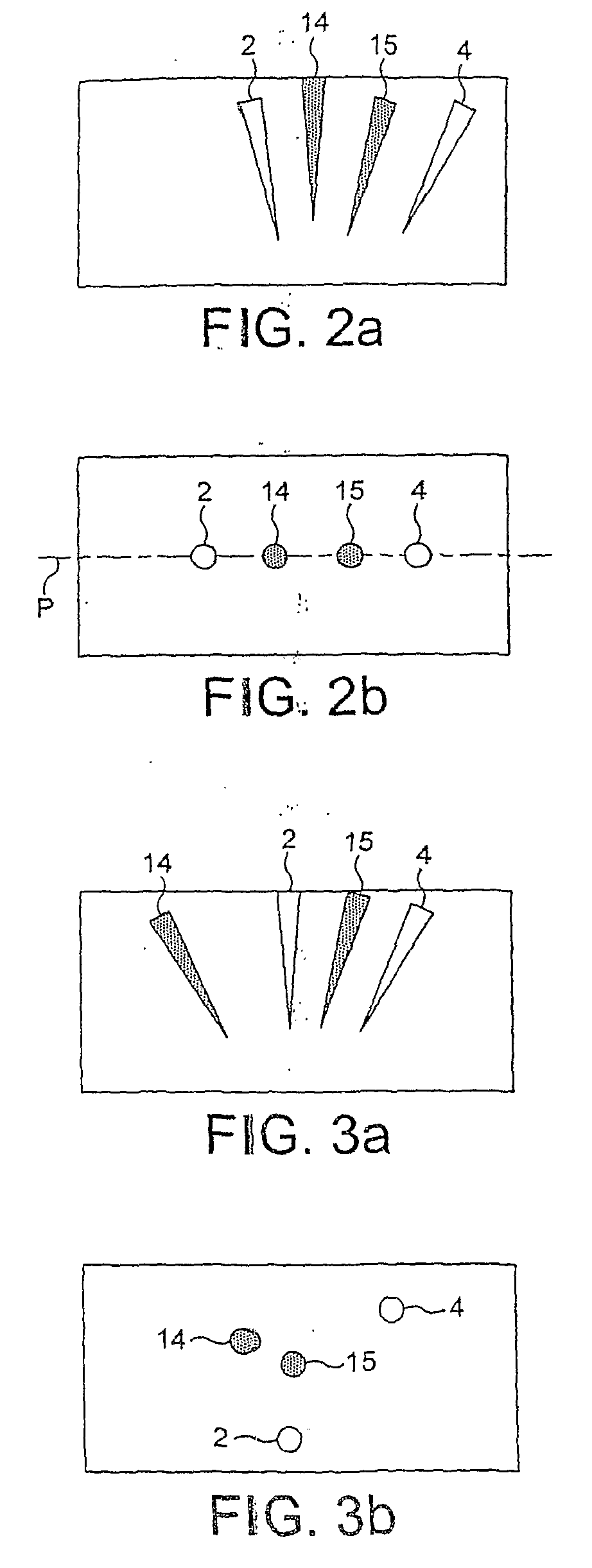

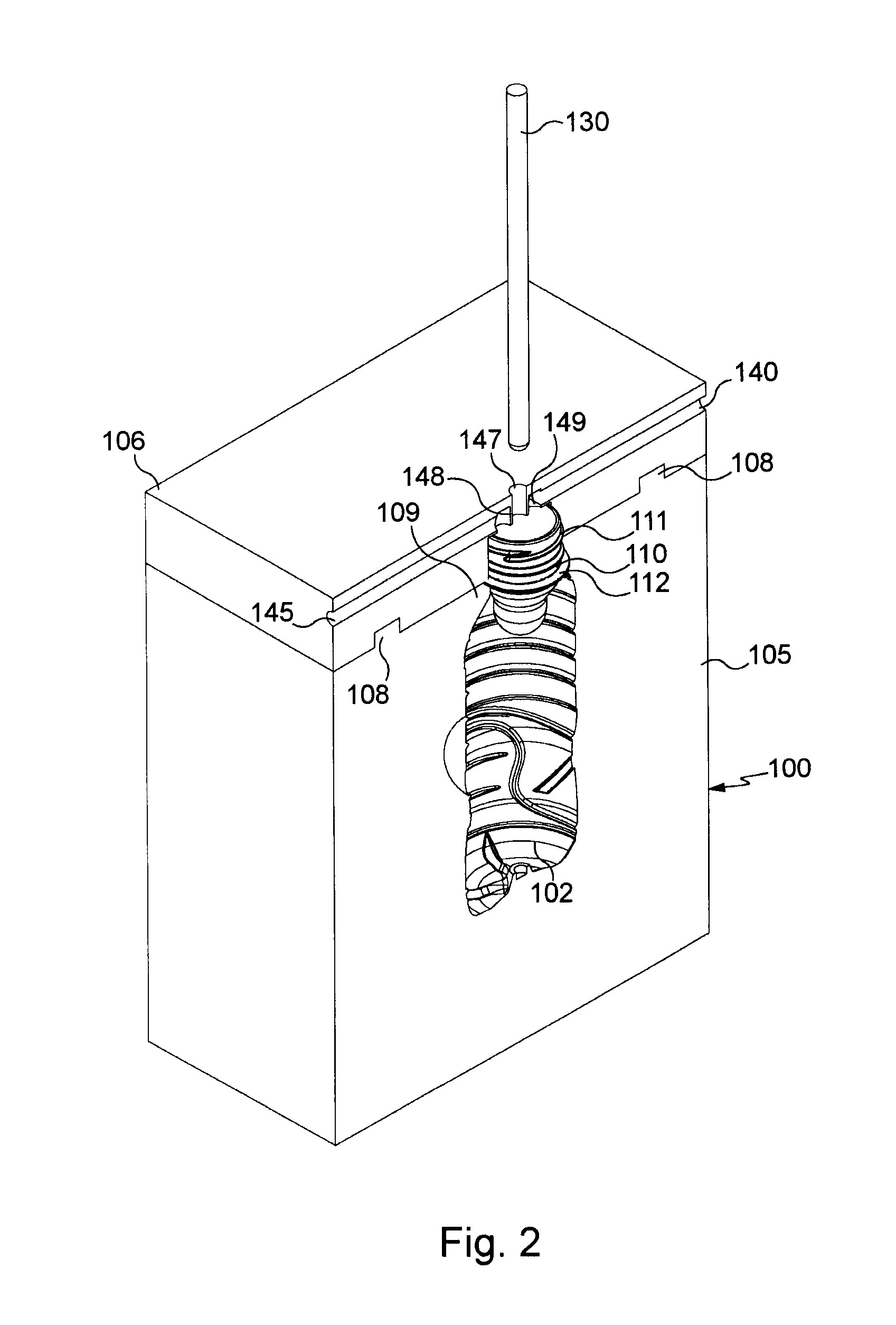

Method for preparing a beverage or food liquid and system using brewing centrifugal force

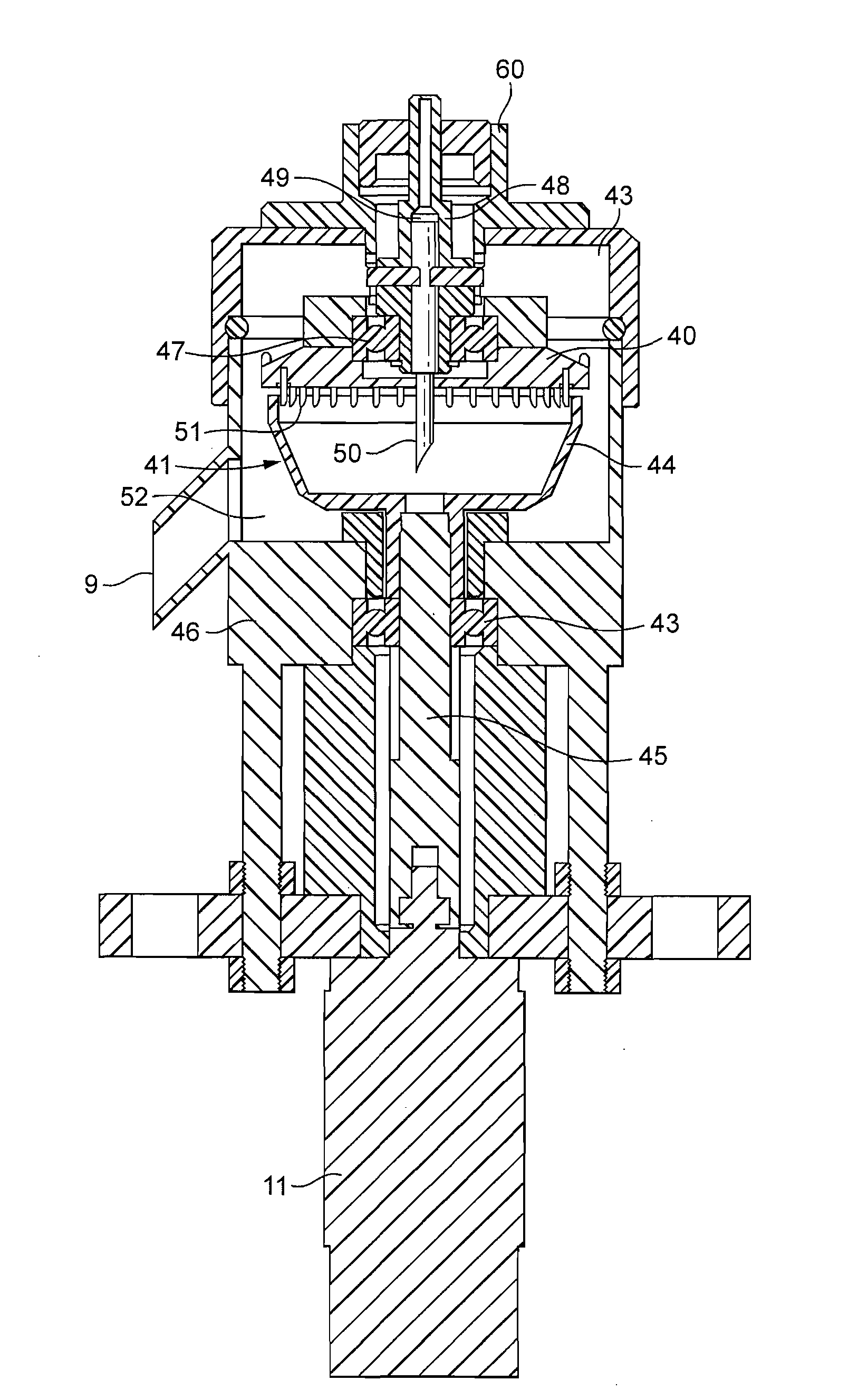

A capsule, device, system and method for preparing a liquid food or beverage. The capsule comprises an enclosure containing one or more extractable or infusible ingredients and configured and dimensioned to have a perimeter and be radially symmetrical about a central axis to facilitate rotation; and an opening arrangement that allows liquid food to leave the capsule after passing through the ingredient(s), wherein the opening arrangement is configured and positioned near or upon the perimeter of the enclosure to allow the liquid food to leave the capsule radially due to the application of the centrifugal forces. The method and device introduce liquid into the capsule to form the liquid food while applying centrifugal forces to the capsule to urge the liquid to pass through the ingredient(s).

Owner:SOC DES PROD NESTLE SA

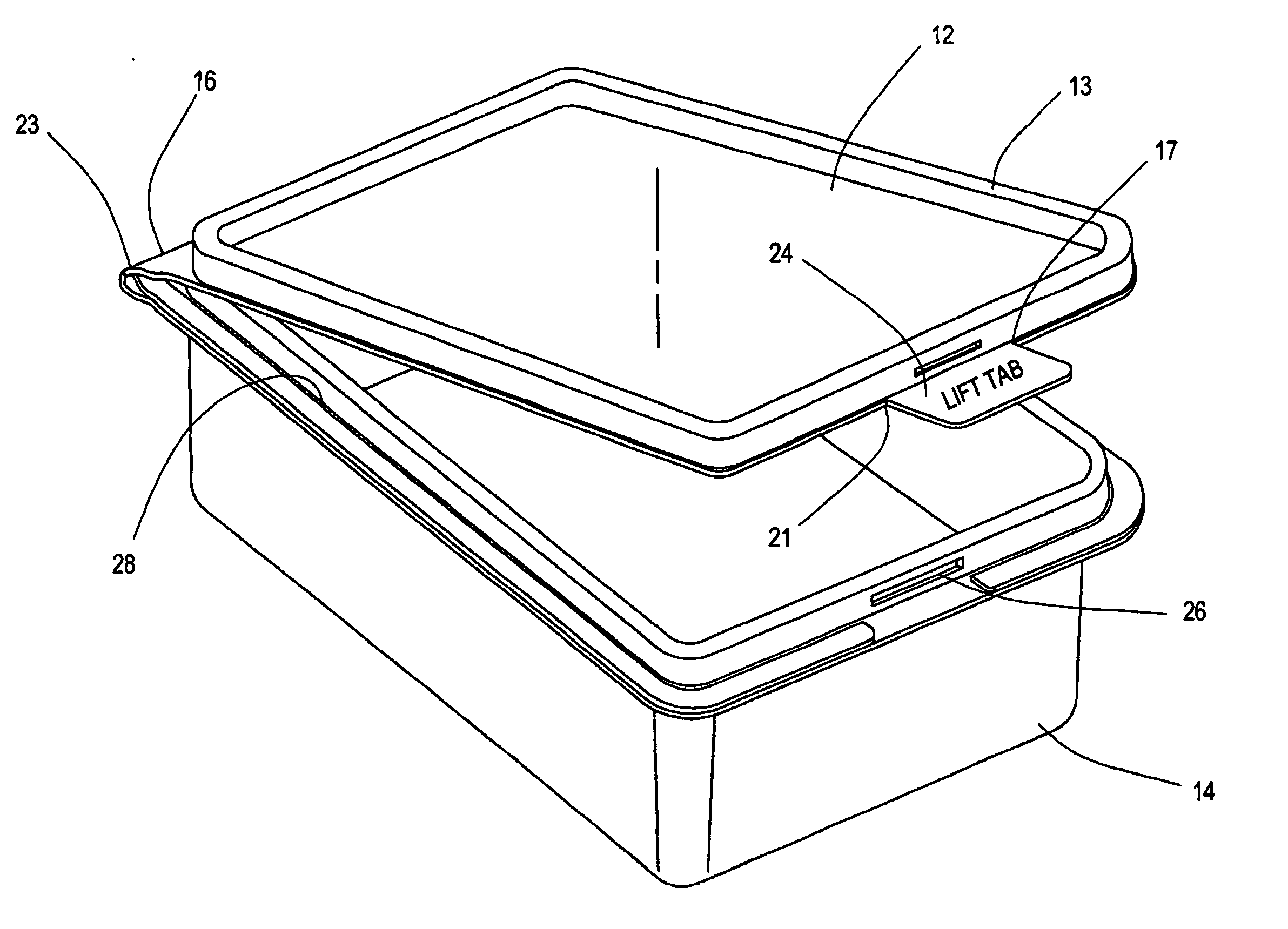

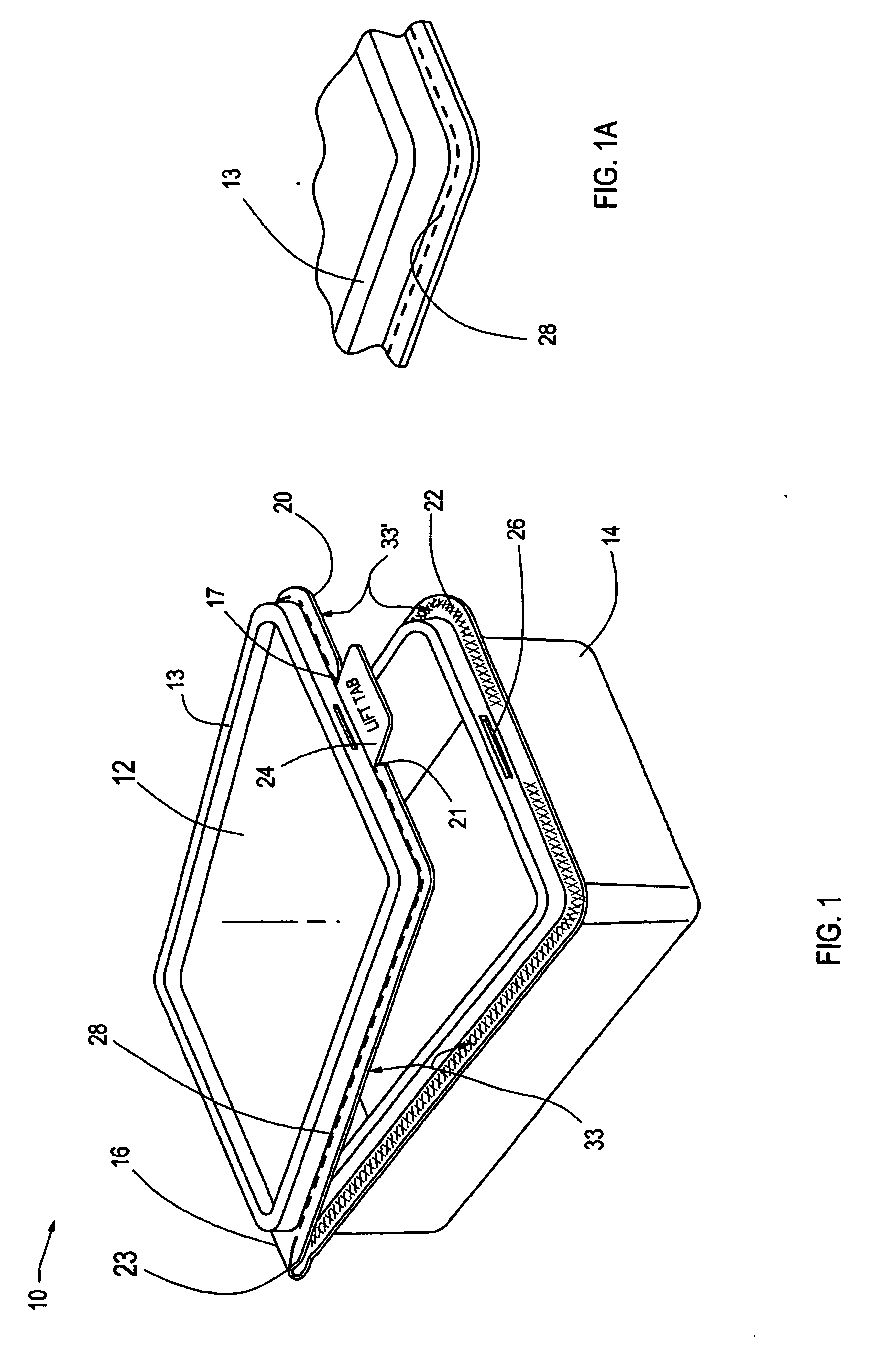

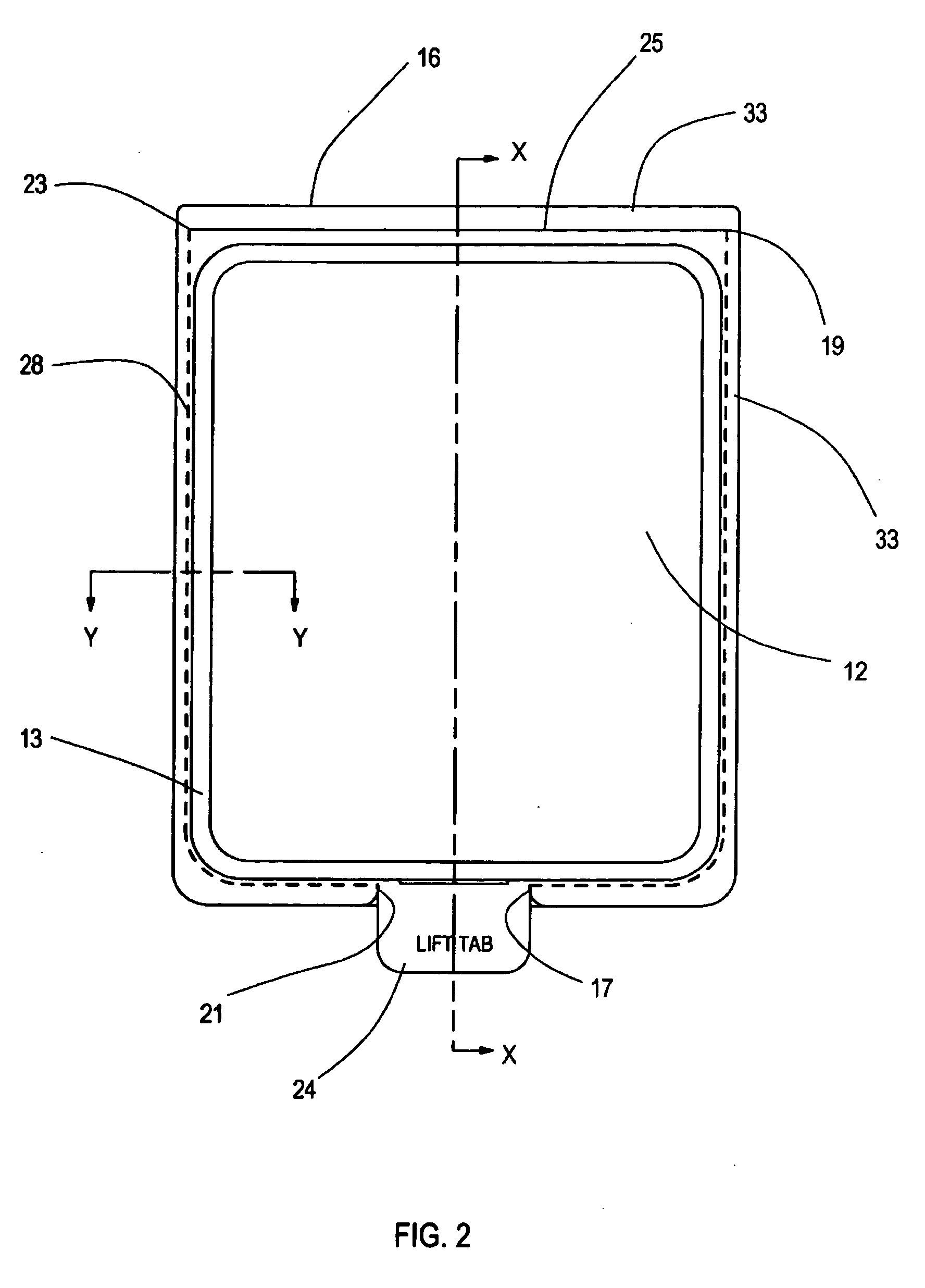

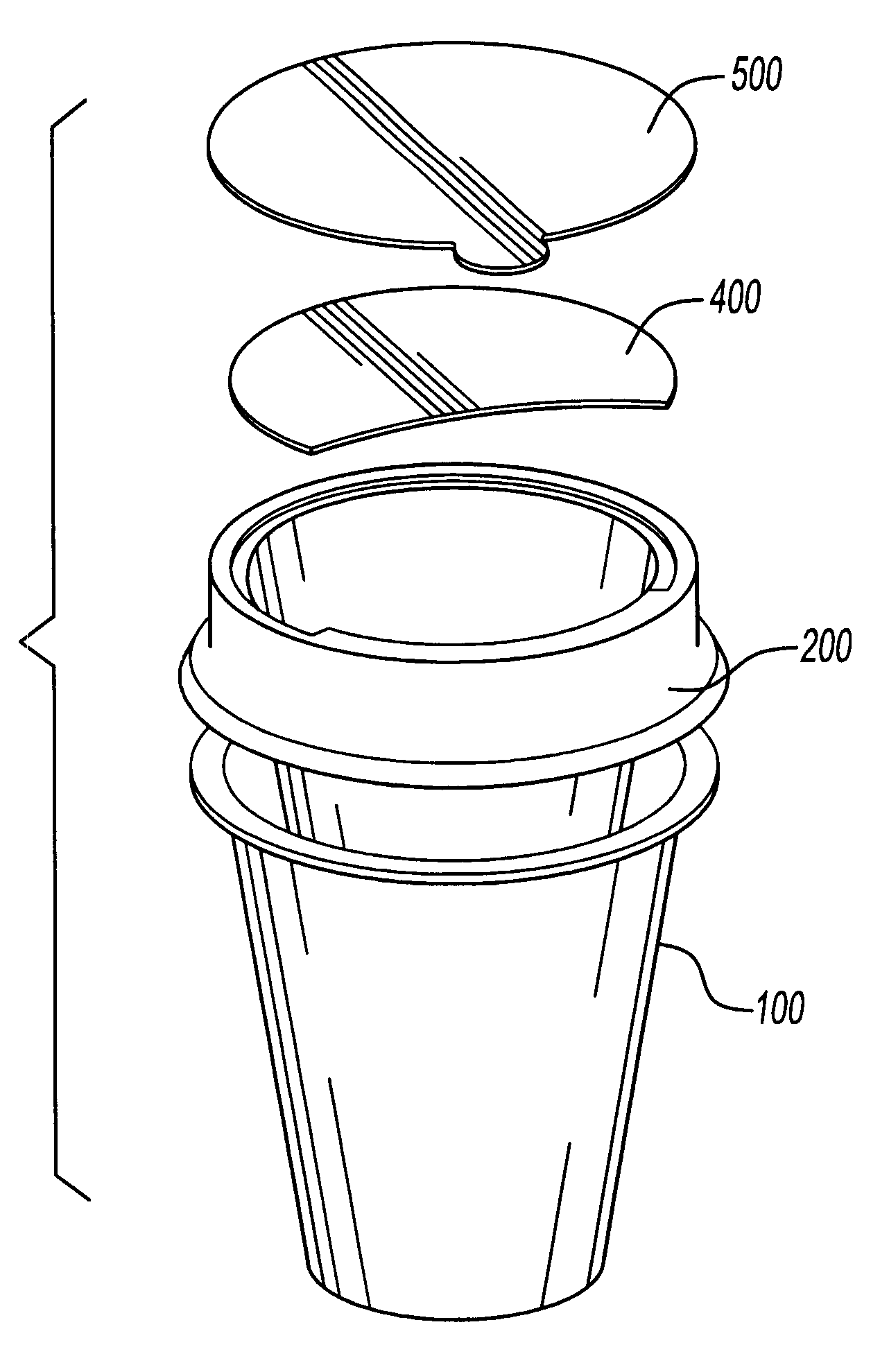

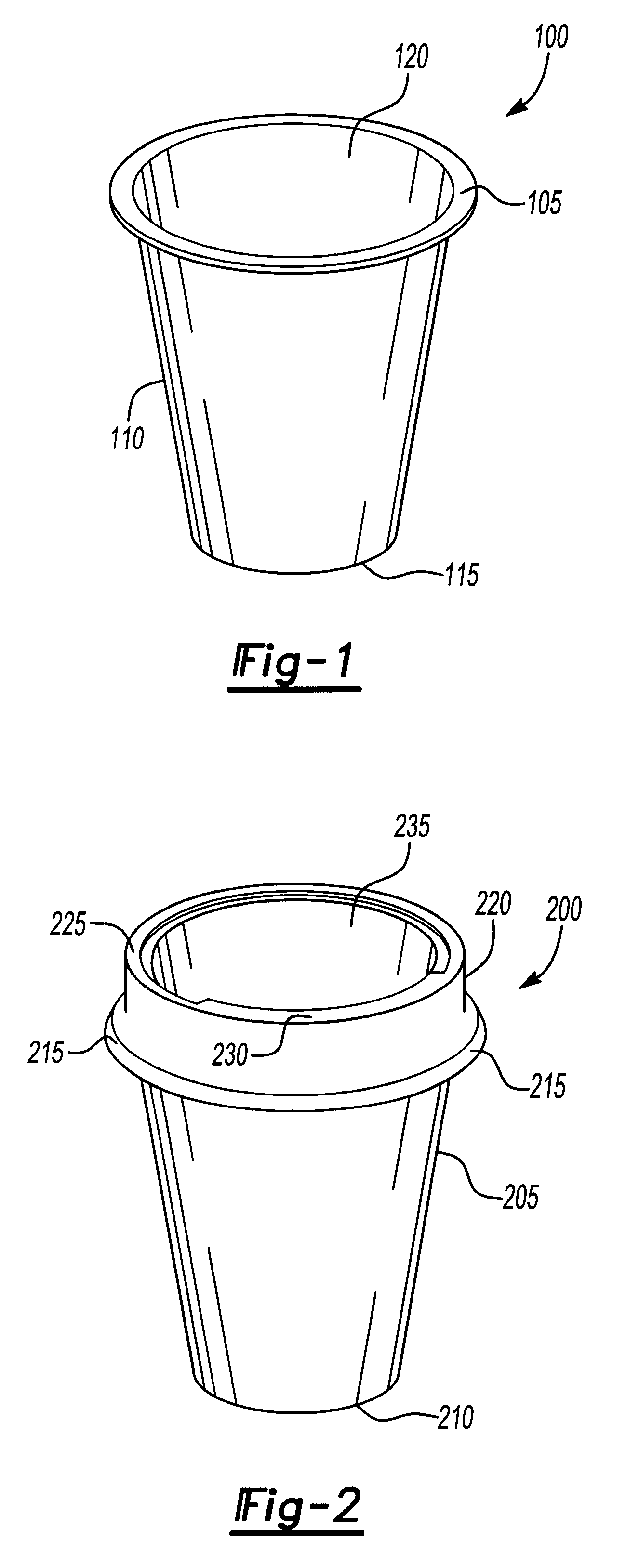

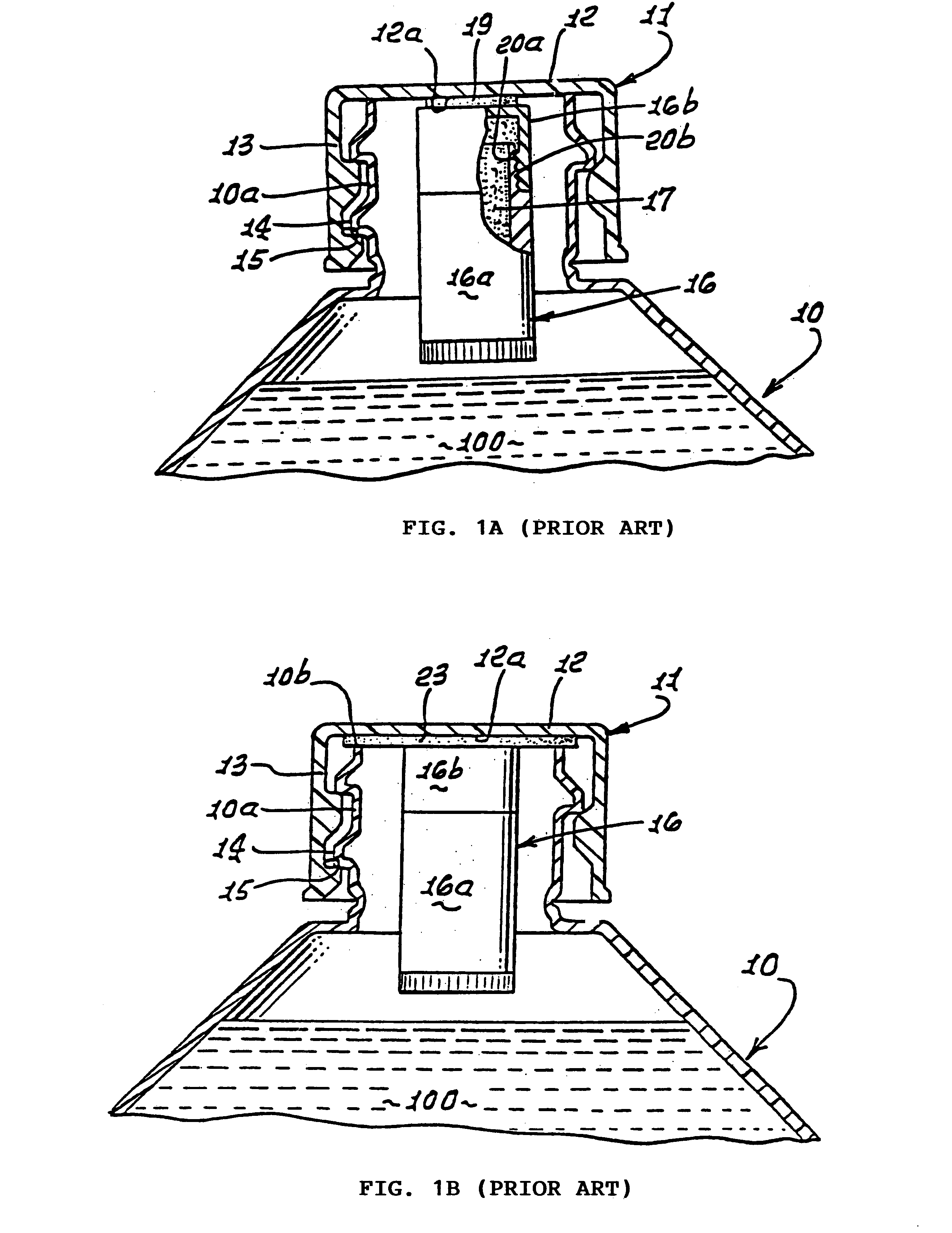

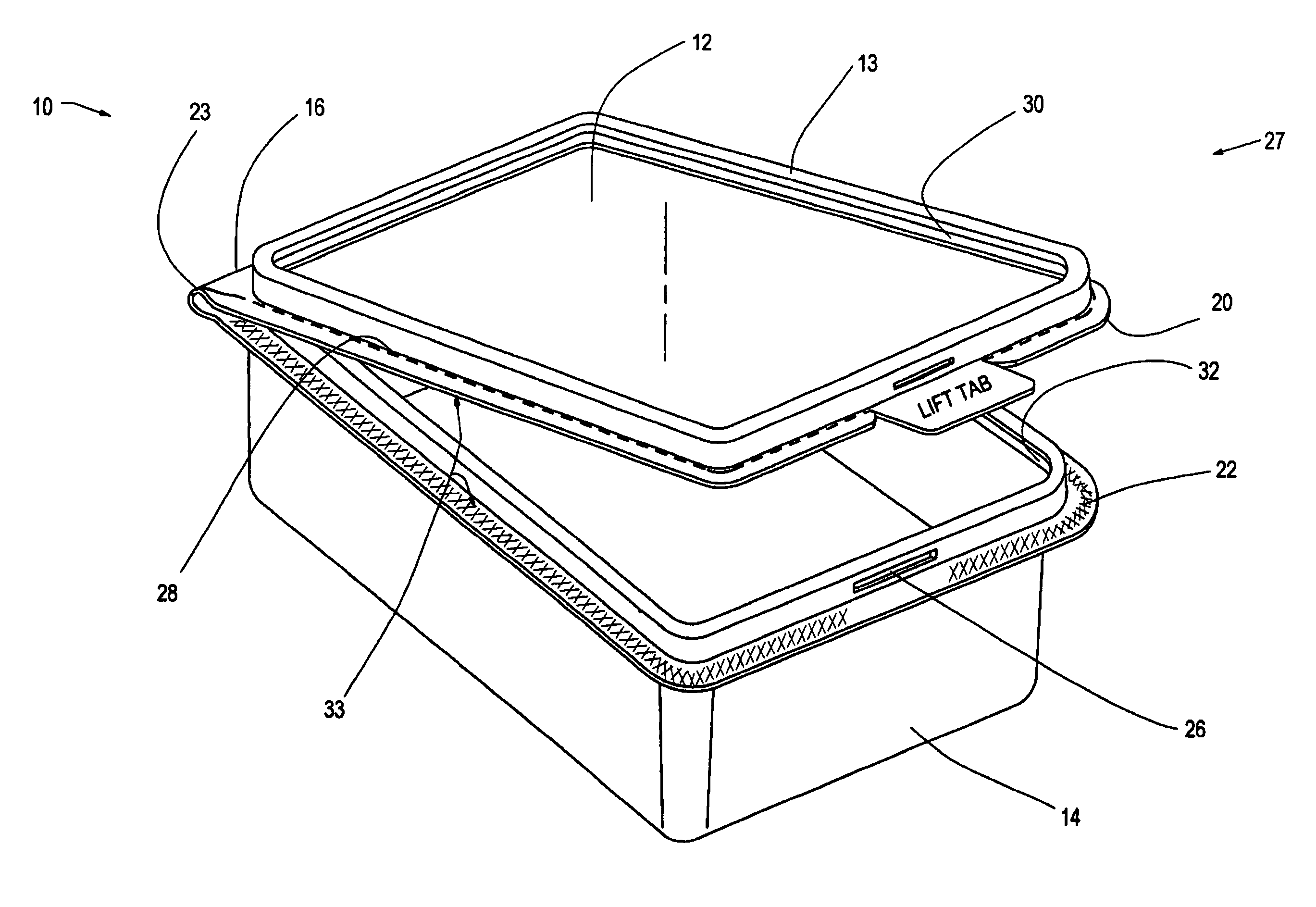

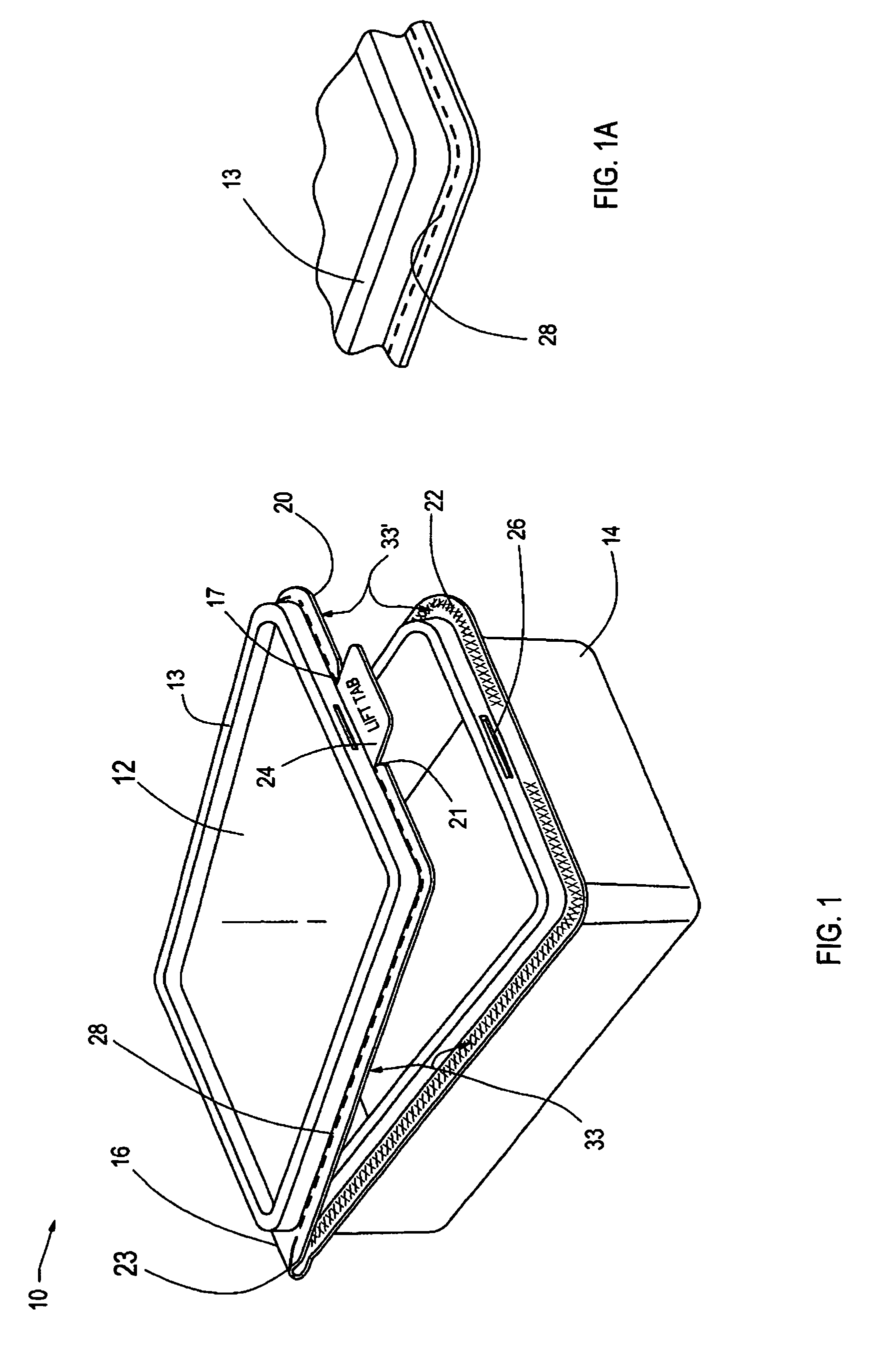

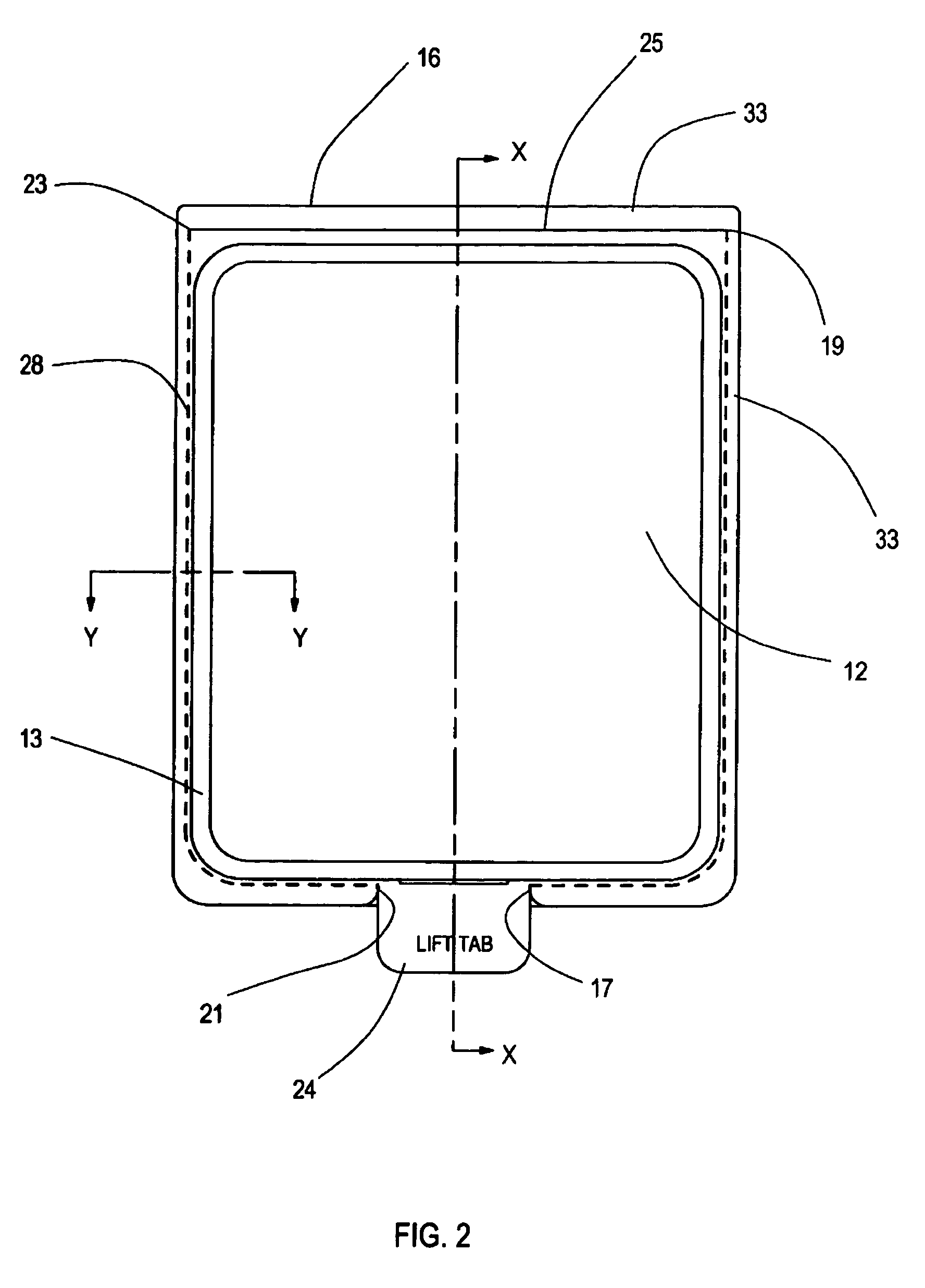

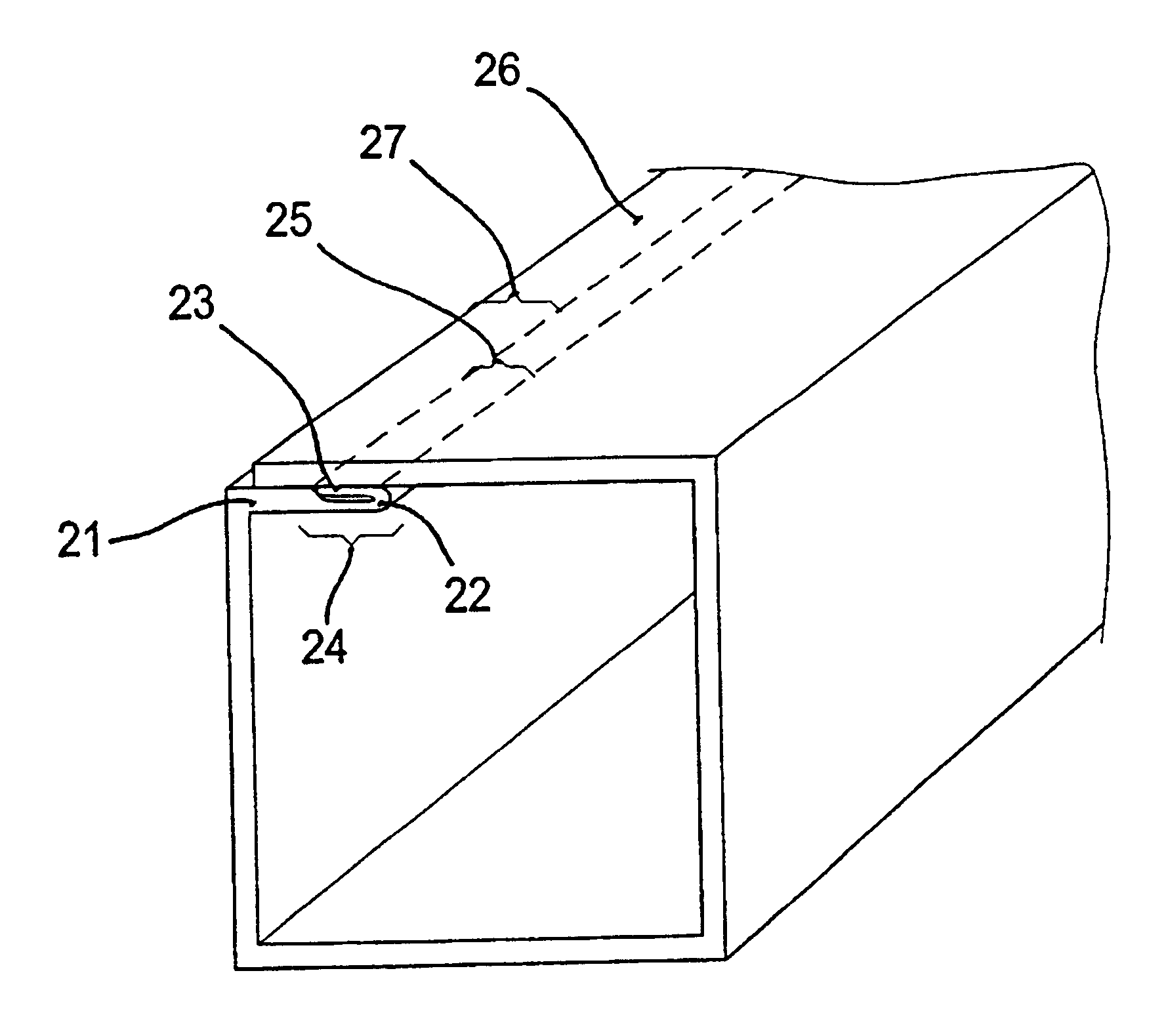

Versatile tamper-evident food container

ActiveUS20070012710A1Improved tamper-evident product packagingWithout riskCapsClosure capsInterference fitMaterial Perforation

A tamper-evident rigid plastic food container system wherein the outer periphery of the mating surfaces of the lid and tray are permanently bonded together after the food product has been placed in the tray, a set of perforated rows at an inner periphery, the interconnect of which needs to be torn into order to open the lid. Intentional, inadvertent or malicious ingress into the container can only be made by tearing at the perforations thereby evidencing the potential tampering and contamination of the packaging contents. The lid and tray edges may further include mechanical interference fits, including snap-fit grips that may be of the releaseably lockable kind to permit sealing, release and re-sealing multiple times without deterioration in reliability, and which can further prevent or minimize leakage of liquid food product.

Owner:PACTIV PACKAGING

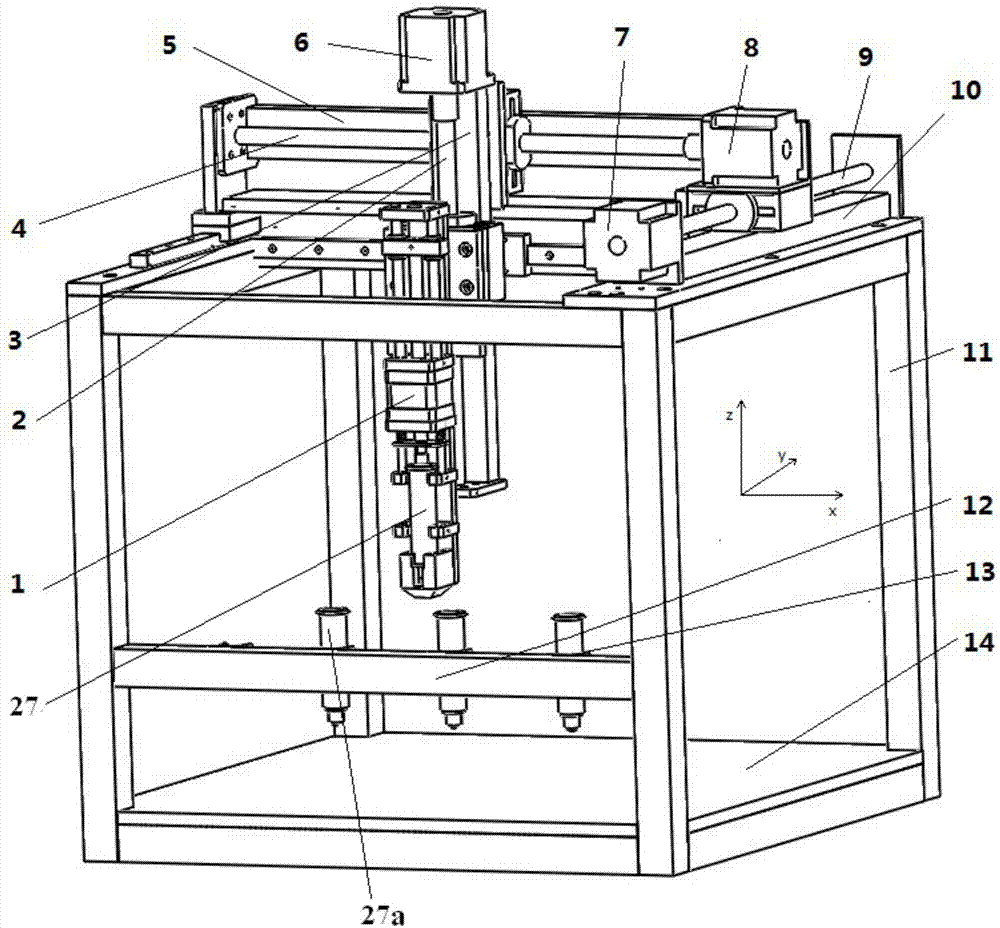

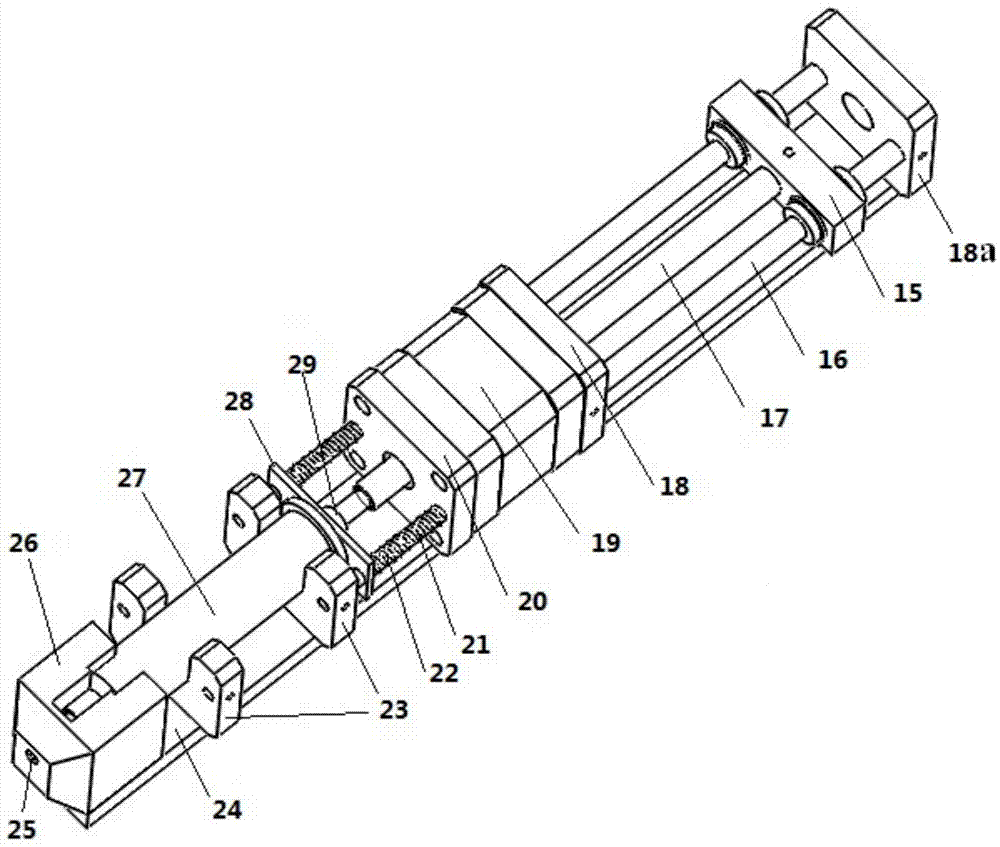

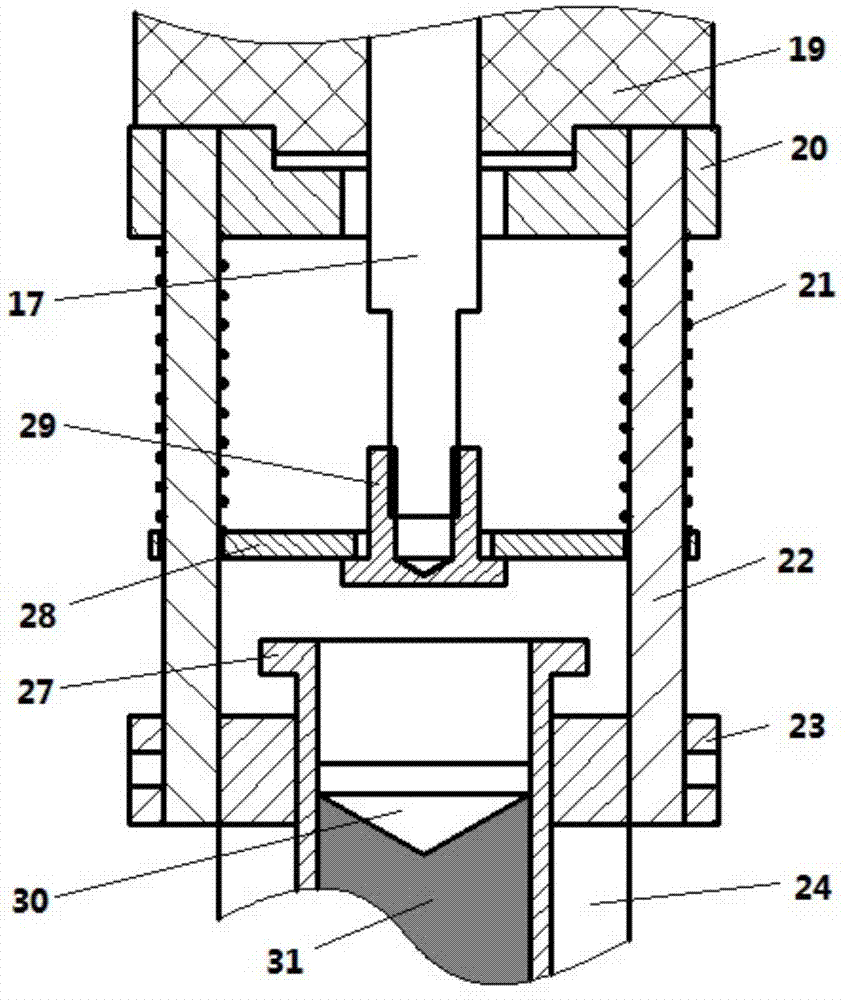

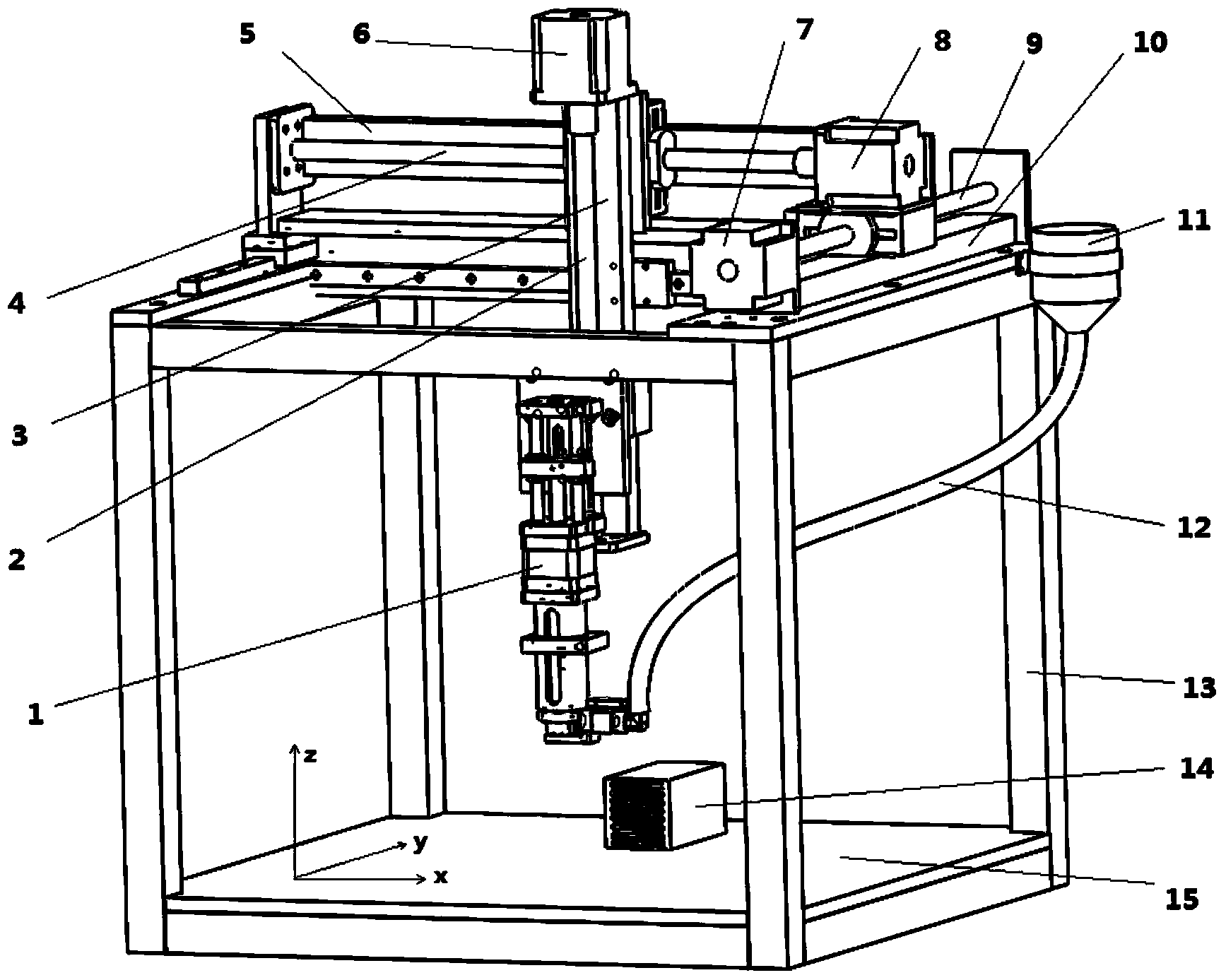

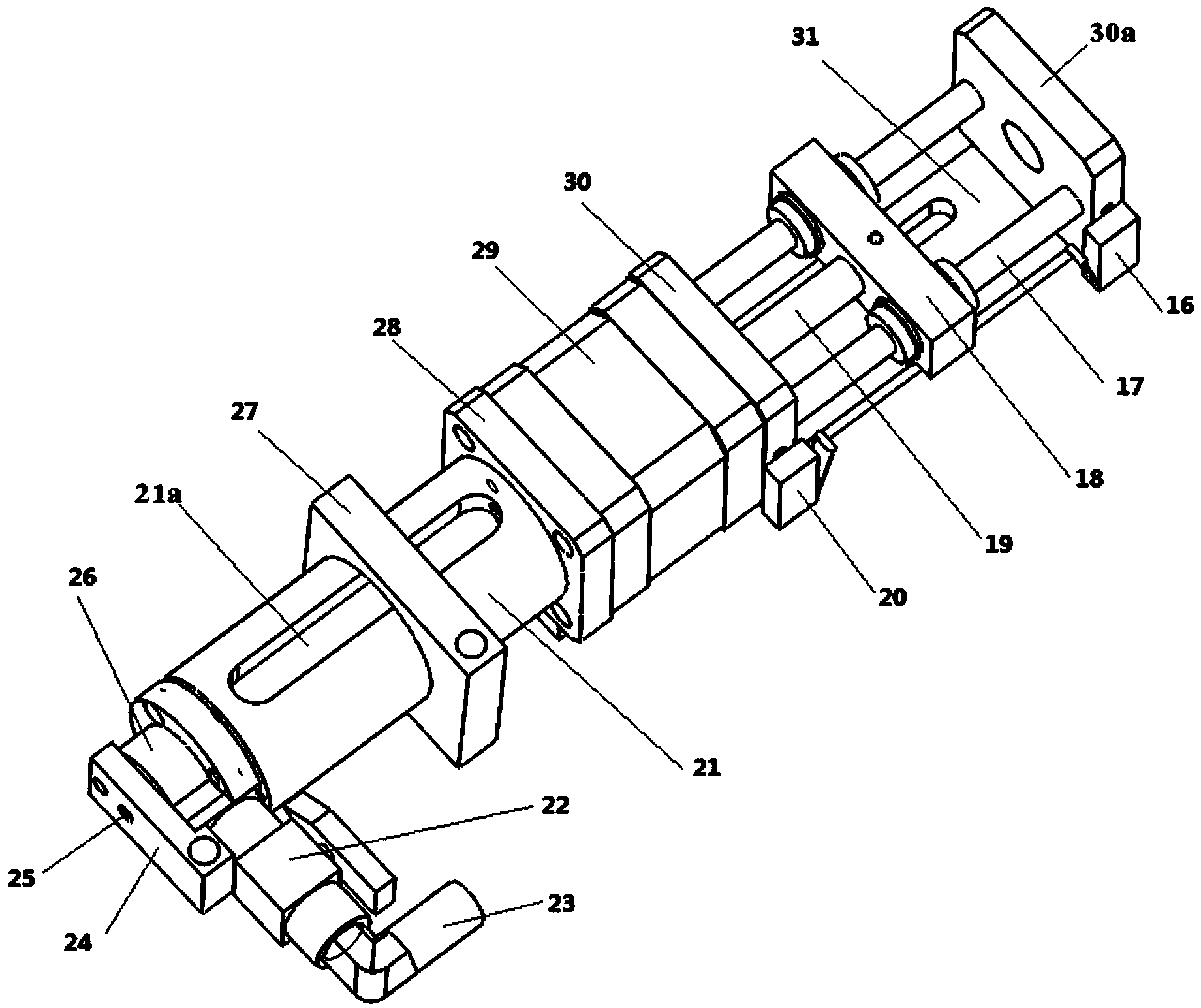

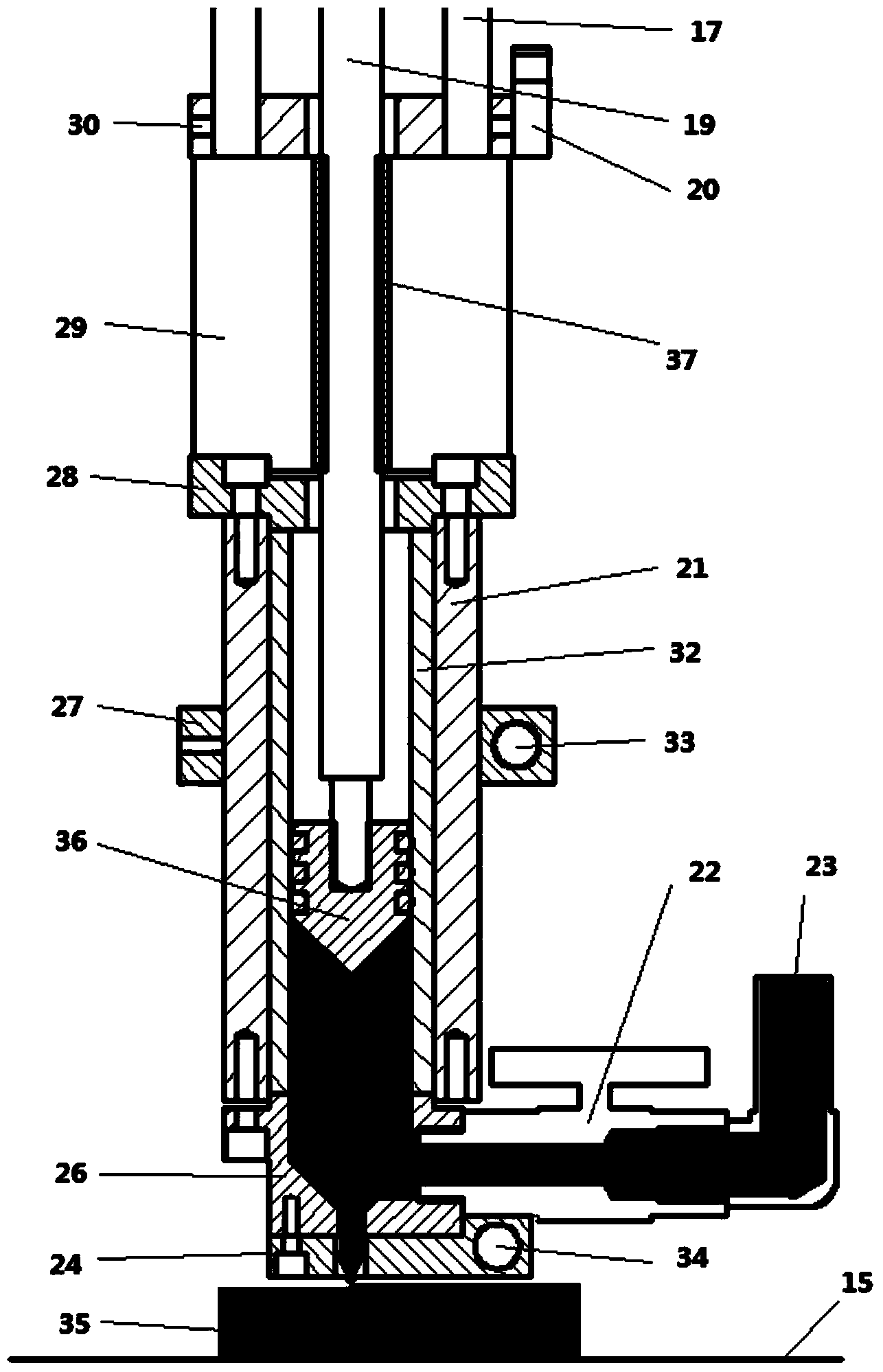

Three-dimensional printer with replaceable nozzle

ActiveCN103878980AAchieve relatively fixedPracticalTool changing apparatusApplying layer meansLiquid foodPiston

The invention discloses a three-dimensional printer with a replaceable nozzle. The three-dimensional printer comprises a three-dimensional adjusting mechanism, and the printing nozzle which performs three-dimensional printing under the adjustment of the three-dimensional adjusting mechanism, wherein the printing nozzle comprises a nozzle bottom plate, a nozzle thermal preservation sleeve which is fixed on the nozzle bottom plate and is provided with a printing through hole and a positioning notch, a material tube which is radially clamped on the nozzle bottom plate, and a linear stepping motor; the material tube is axially clamped in the positioning notch through a material tube pressing plate which is in sliding fit with the nozzle bottom plate; a piston presser used for pushing a piston in a first material tube is fixed at the output end of a lead screw of the motor. When materials in the material tube are used up or the materials are needed to be replaced, the printing nozzle is controlled to automatically replace the material tube, and a three-dimensional object consisting of multiple materials can be printed. The piston is driven to be extruded by adopting the linear stepping motor, thrust is high and can be accurately controlled, and the blockage of the nozzle is avoided. According to the printer, liquid foods and multiple liquid materials such as gel and ceramic powder can be printed.

Owner:ZHEJIANG UNIV

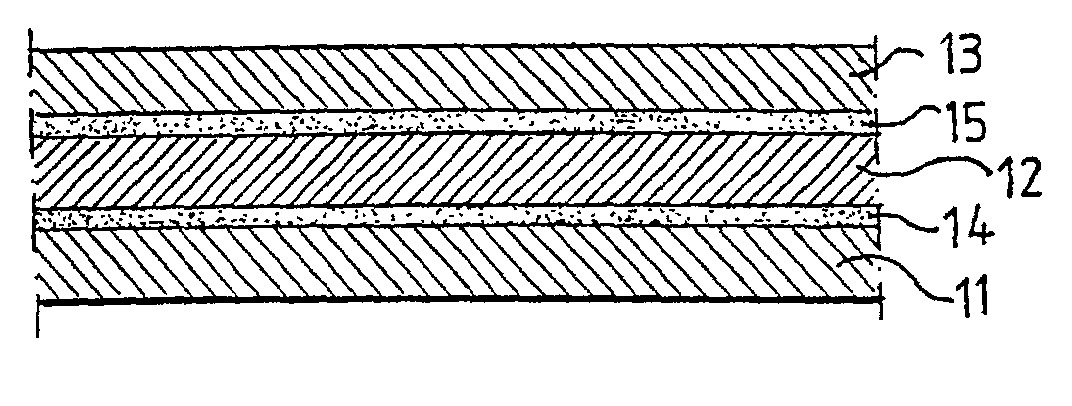

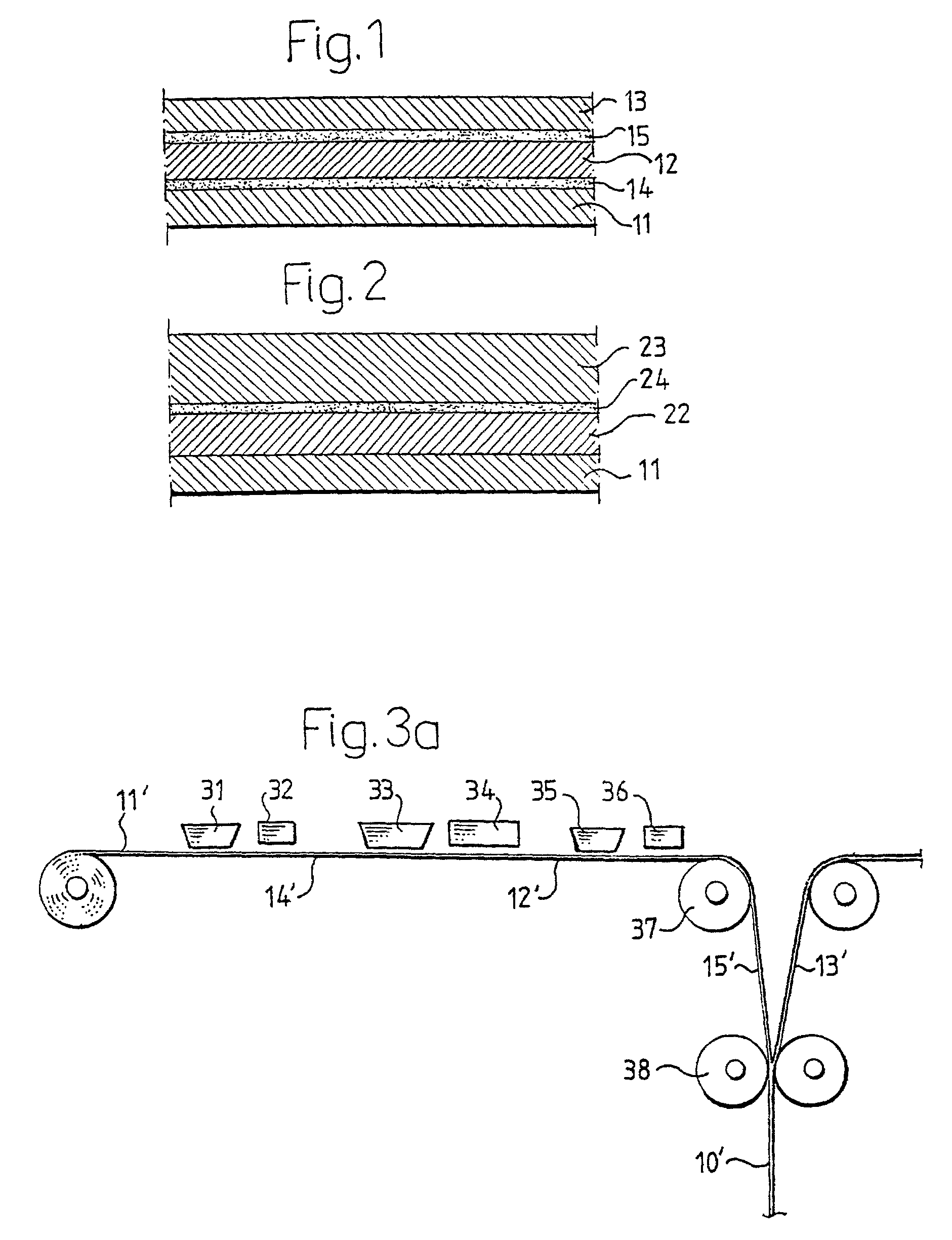

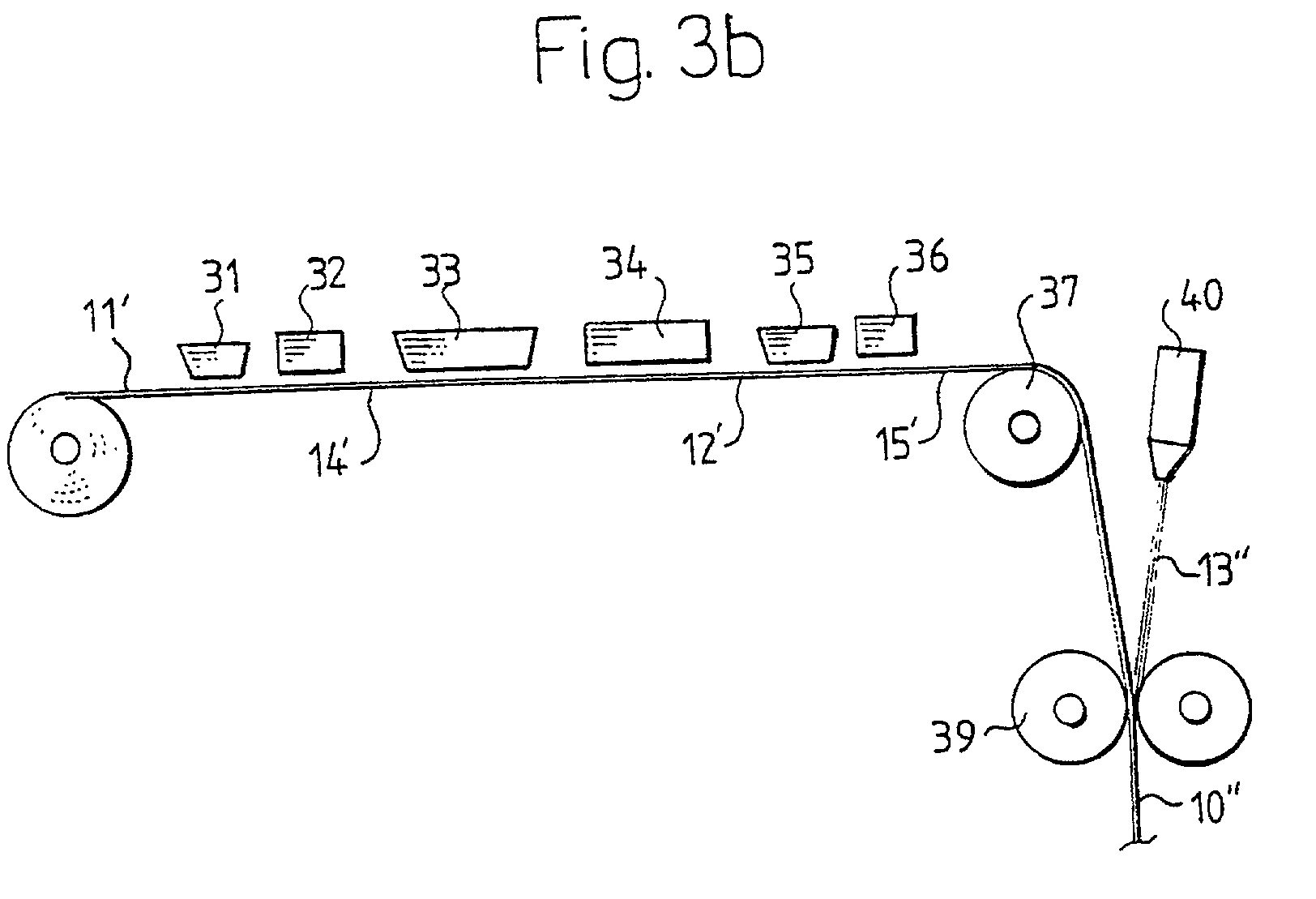

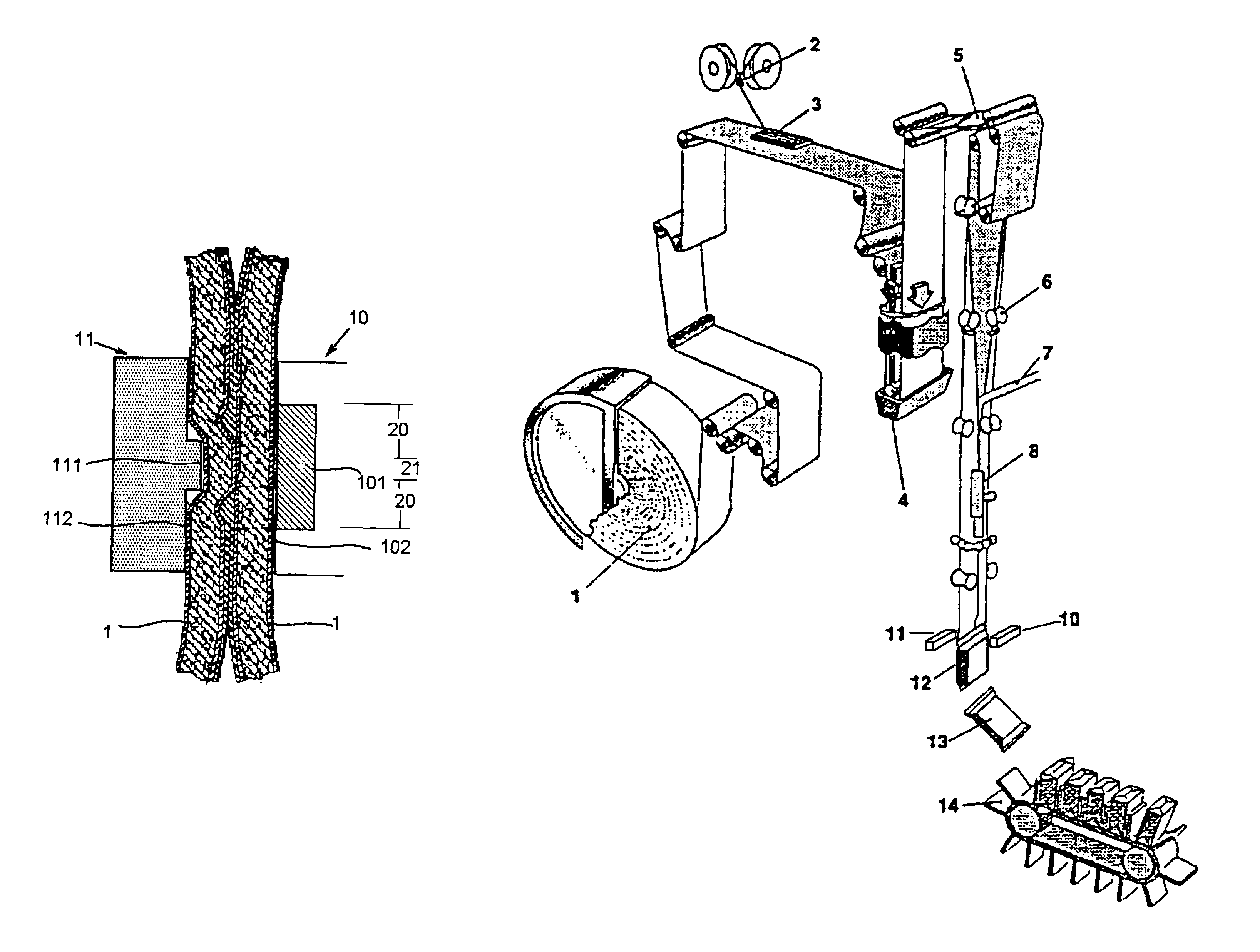

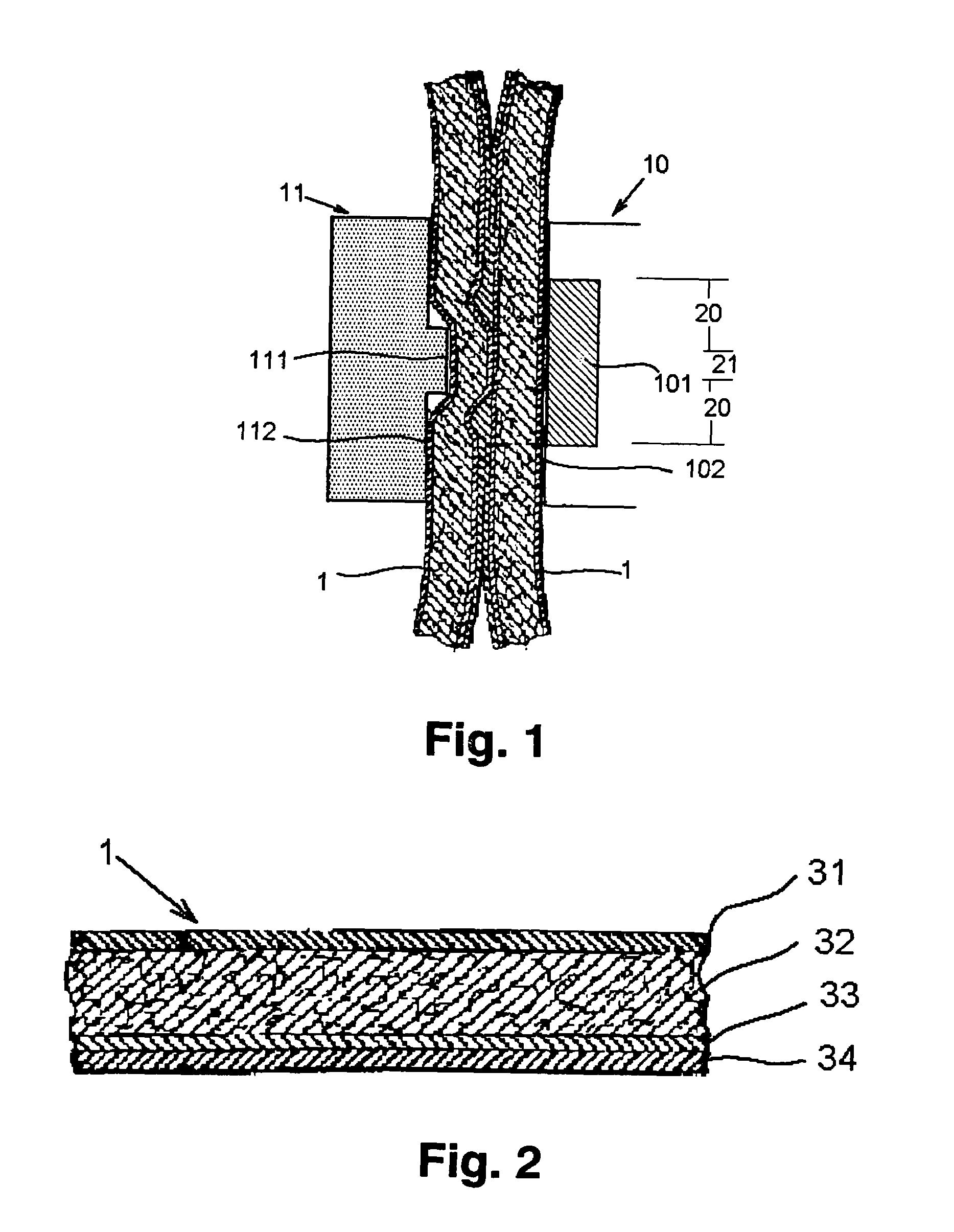

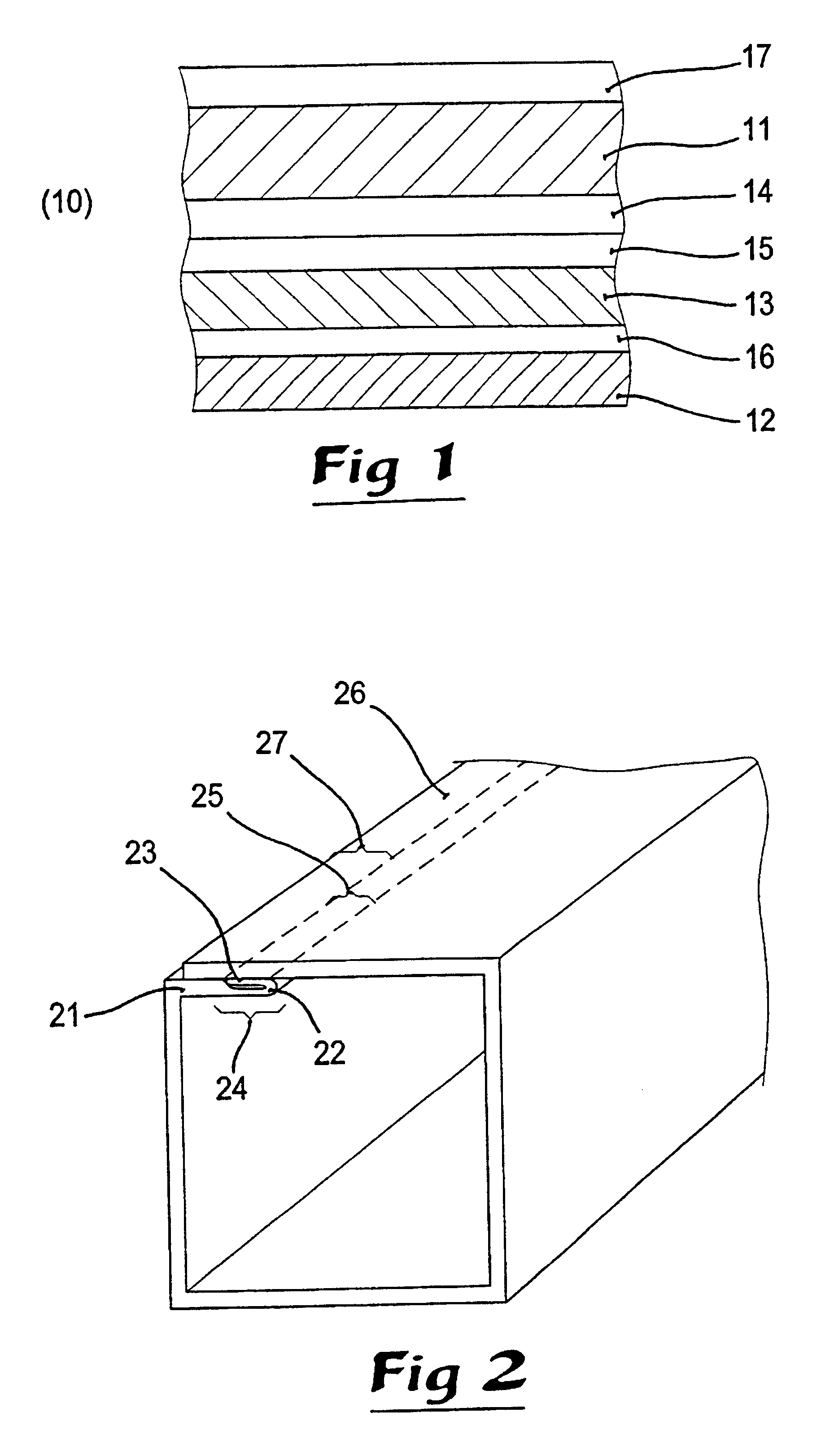

Biodegradable packaging laminate, a method of producing the packaging laminate, and packaging containers produced from the packaging laminate

InactiveUS20020127358A1Improve adhesionExcellent gas barrier performanceAdhesive processesLiquid surface applicatorsLactideBiopolymer

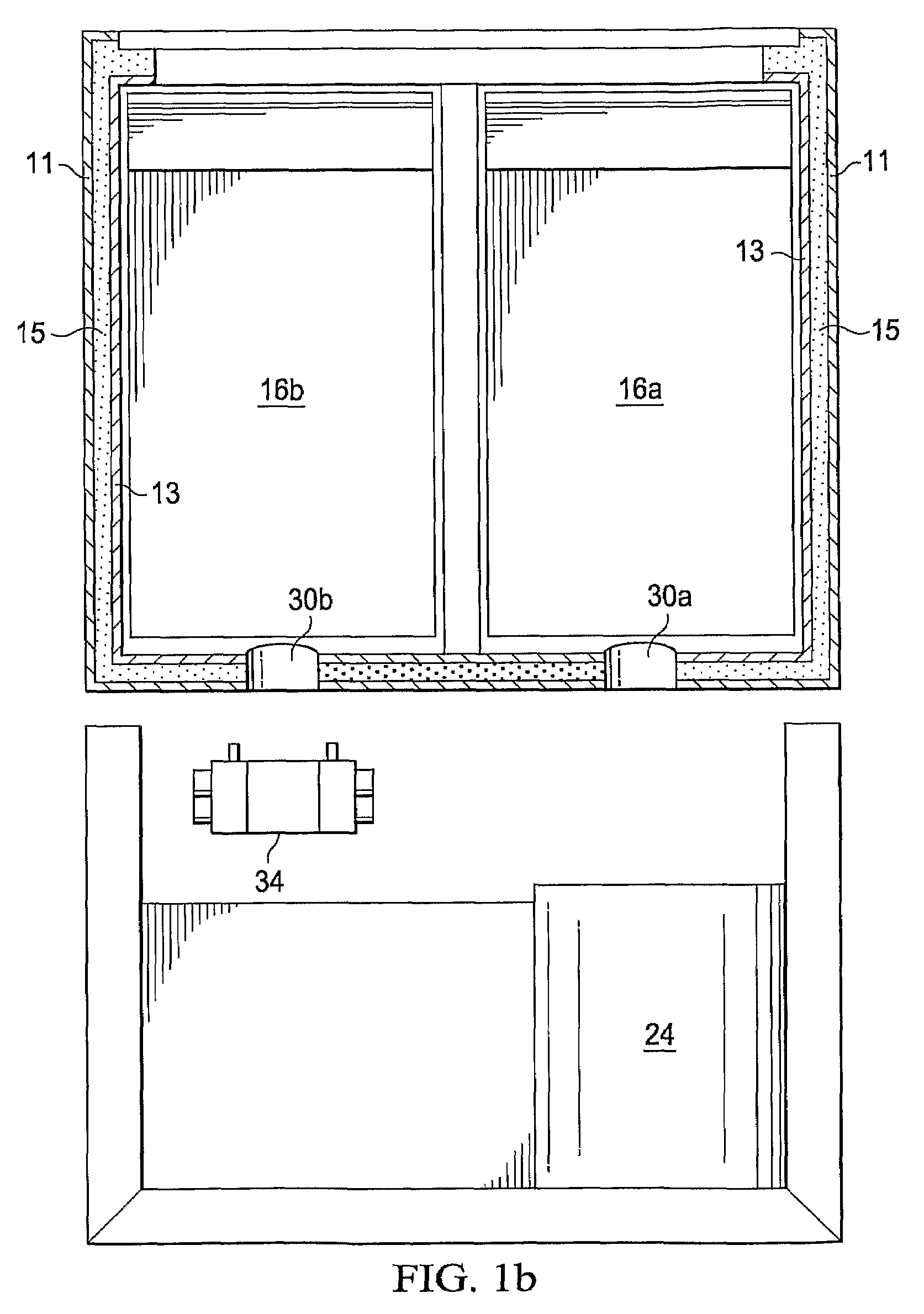

Packaging laminate for packages for liquid foods having excellent liquid and oxygen gas barrier properties in which all included layers are biodegradable. The packaging laminate includes at least one liquidtight layer (11, 13) of homo or copolymers of monomers selected from a group consisting of lactic acid, glycol acid, lactide, glycolide, hydroxy butyric acid, hydroxy valeric acid, hydroxy caproic acid, valerolactone, butyrolactone and caprolactone, as well as an oxygen gas barrier layer (12) of ethylene vinyl alcohol, polyvinyl alcohol, starch or starch derivatives. The oxygen gas barrier layer is preferably applied by a dispersion coating process. The layers may be laminated directly to one another or indirectly by means of interjacent adhesive layers. The packaging laminate may also include a core layer of, for example, paper or paperboard, or a biopolymer. The invention also realises a method of producing the biodegradable packaging laminate according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

Three-dimensional printer for printing liquid materials

ActiveCN103876263AAvoid the hassle of frequent cleaning of equipmentAdditive manufacturing apparatusConfectionerySprayerSpray nozzle

Owner:苏州智能制造研究院有限公司

Non-thermal sterilization method for apple cloudy juice

InactiveCN101214081AEffective sterilizationExtended processing timeFood scienceEscherichia coliEngineering

The invention discloses a liquid food novel non-thermal sterilization method, in particular a non-thermal sterilization method of cloudy apple juice which belongs to the food processing technology field. The technical scheme includes adopting the aseptic operation to send the cloudy apple juice into a reaction vessel and adopting pulse type carbon dioxide with high density for the sterilization. The concrete operation step is: firstly, pumping carbon dioxide with high density into the reaction vessel; secondly, treating for a certain period at the set temperature and pressure condition; thirdly, releasing the carbon dioxide after the treatment to lower the pressure in the reaction vessel to the normal pressure; fourthly, operating the steps from the first to the third repeatedly for more than two times for the pulse type carbon dioxide with high density treatment. The killing effect of Escherichia coli in the cloudy apple juice which is processed in the invention can achieve the result of lowering at least five logarithms to satisfy the commercial aseptic requirement. Compared with the present non-thermal sterilization method, the invention has more obvious sterilization effect and can shorten the treatment time and save energy. The invention has the advantages of low processing temperature, energy saving and environmental protection and can maintain the good flavor of the cloudy apple juice.

Owner:CHINA AGRI UNIV

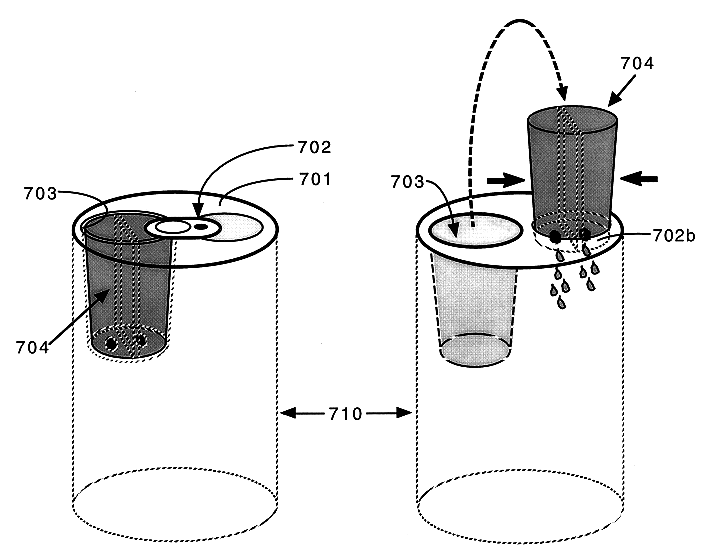

Single handed container for mixing foods

InactiveUS6528105B1Well mixedReady-for-oven doughsBottlesFood contact materialsMechanical engineering

The invention discloses a method and an apparatus for a food container which includes an inner member (which can be a cup or a bottle) for holding a particulate food; an outer member (which can be a second cup or a second bottle) adapted to receive the inner member, with a space between the inner and the outer members, for a liquid food; where the inner member interlocks with the outer member and openings are provided for the discharge of the liquid food; and the particulate food and the liquid food can be consumed simultaneously by tilting the container towards the mouth of the user to discharge or withdraw particulate food from the inner member and liquid food from the outer member through the aperture.

Owner:KELLOGG CO

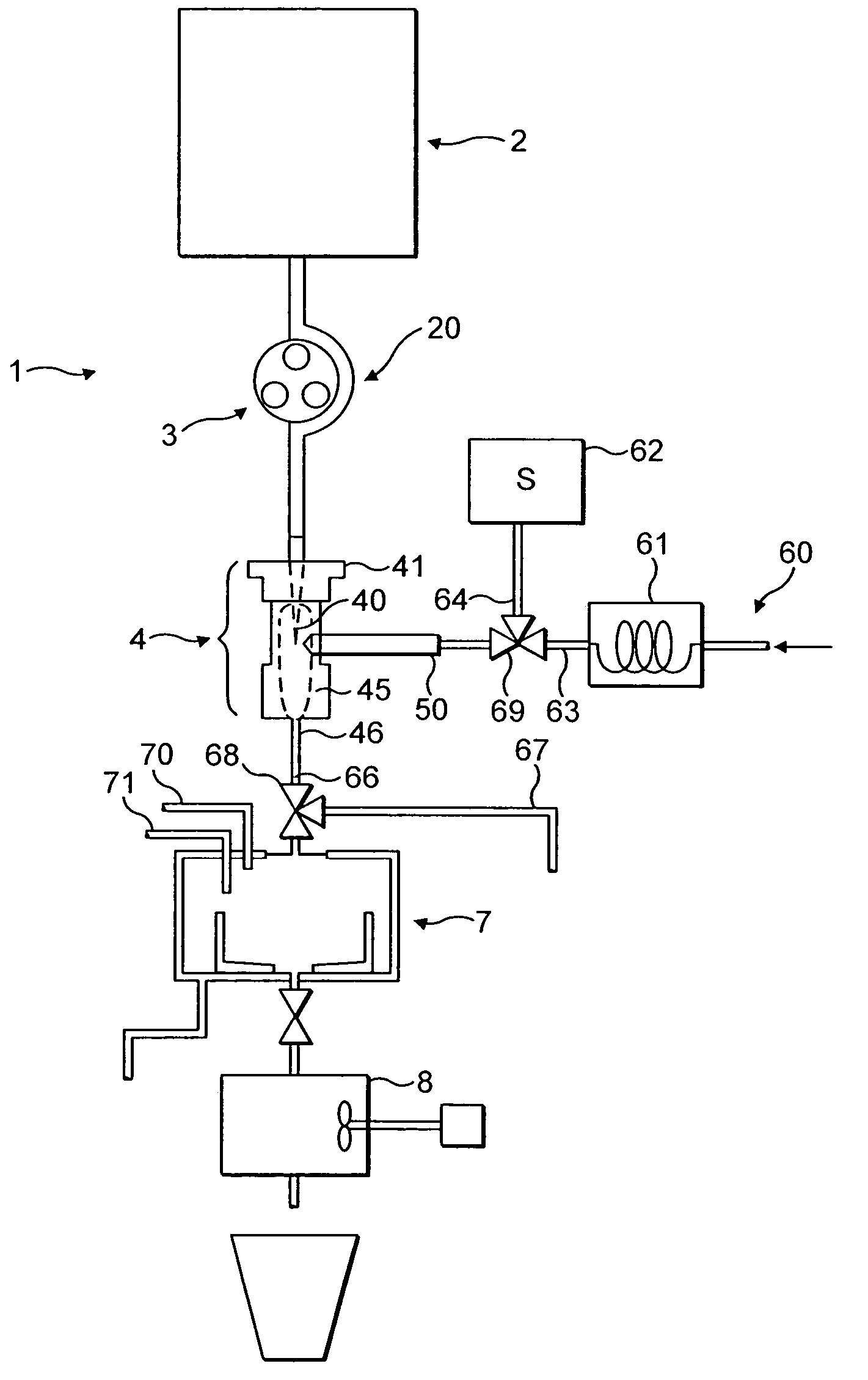

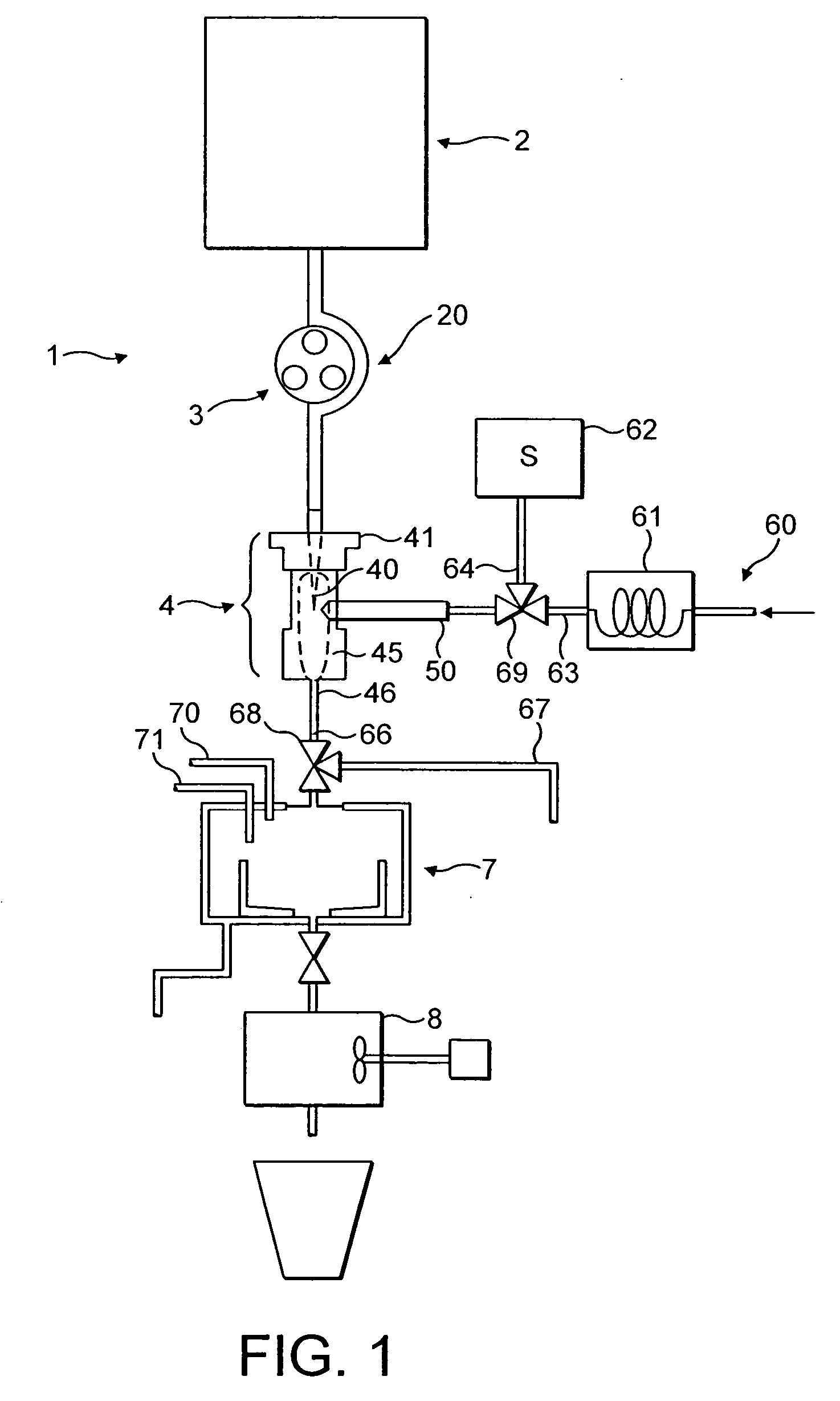

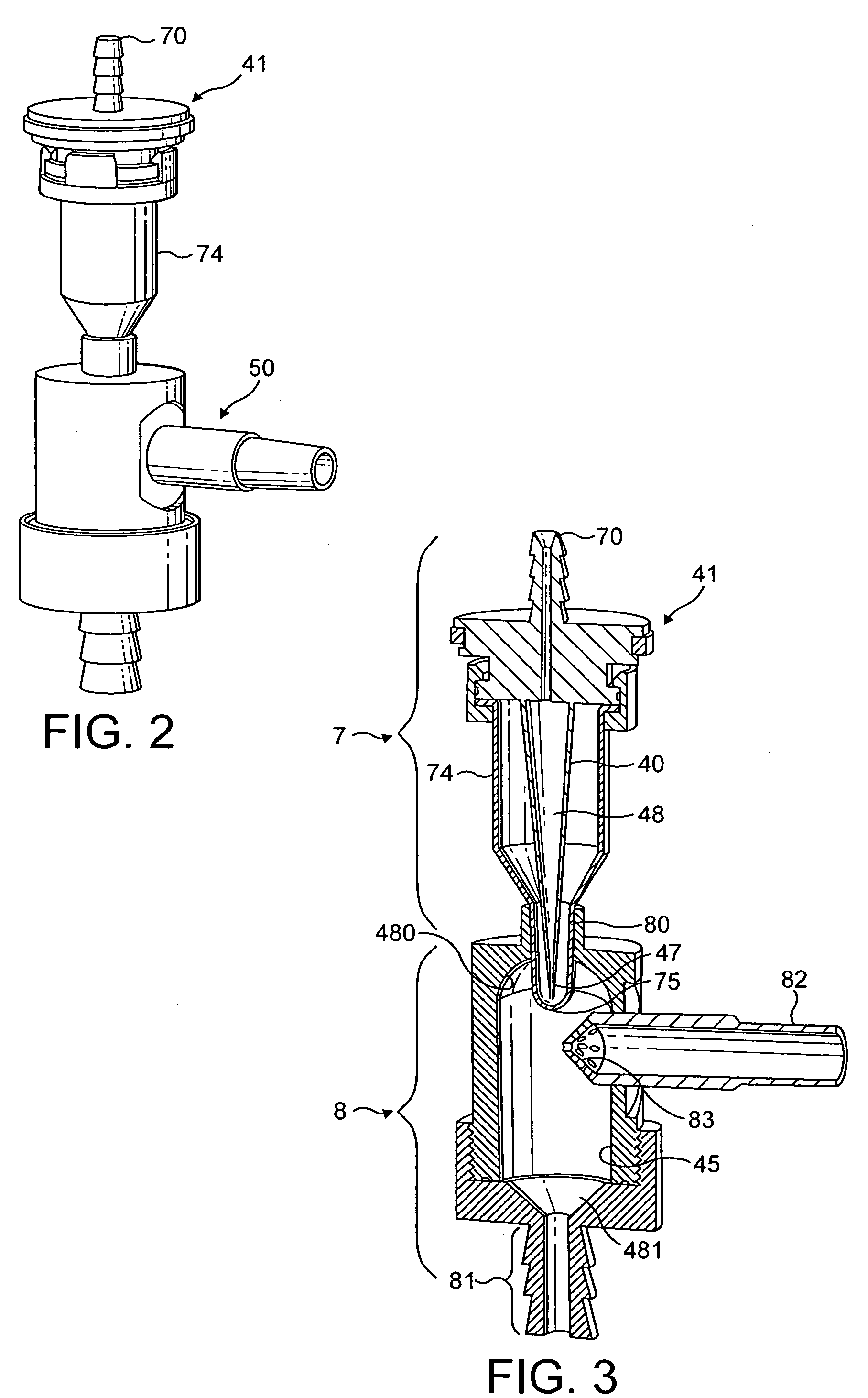

Method for preparing a beverage or food liquid and system using brewing centrifugal force

Owner:SOC DES PROD NESTLE SA

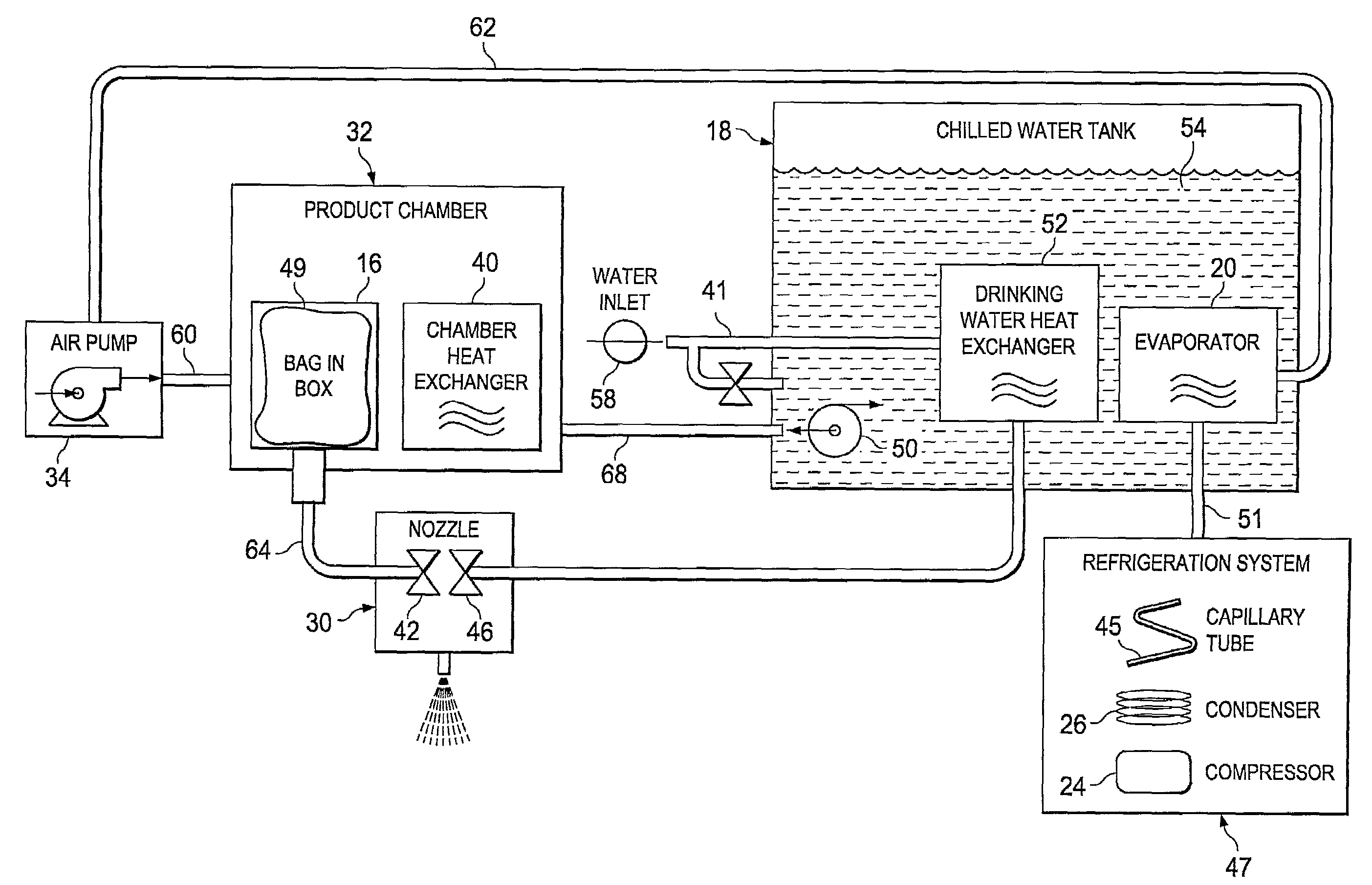

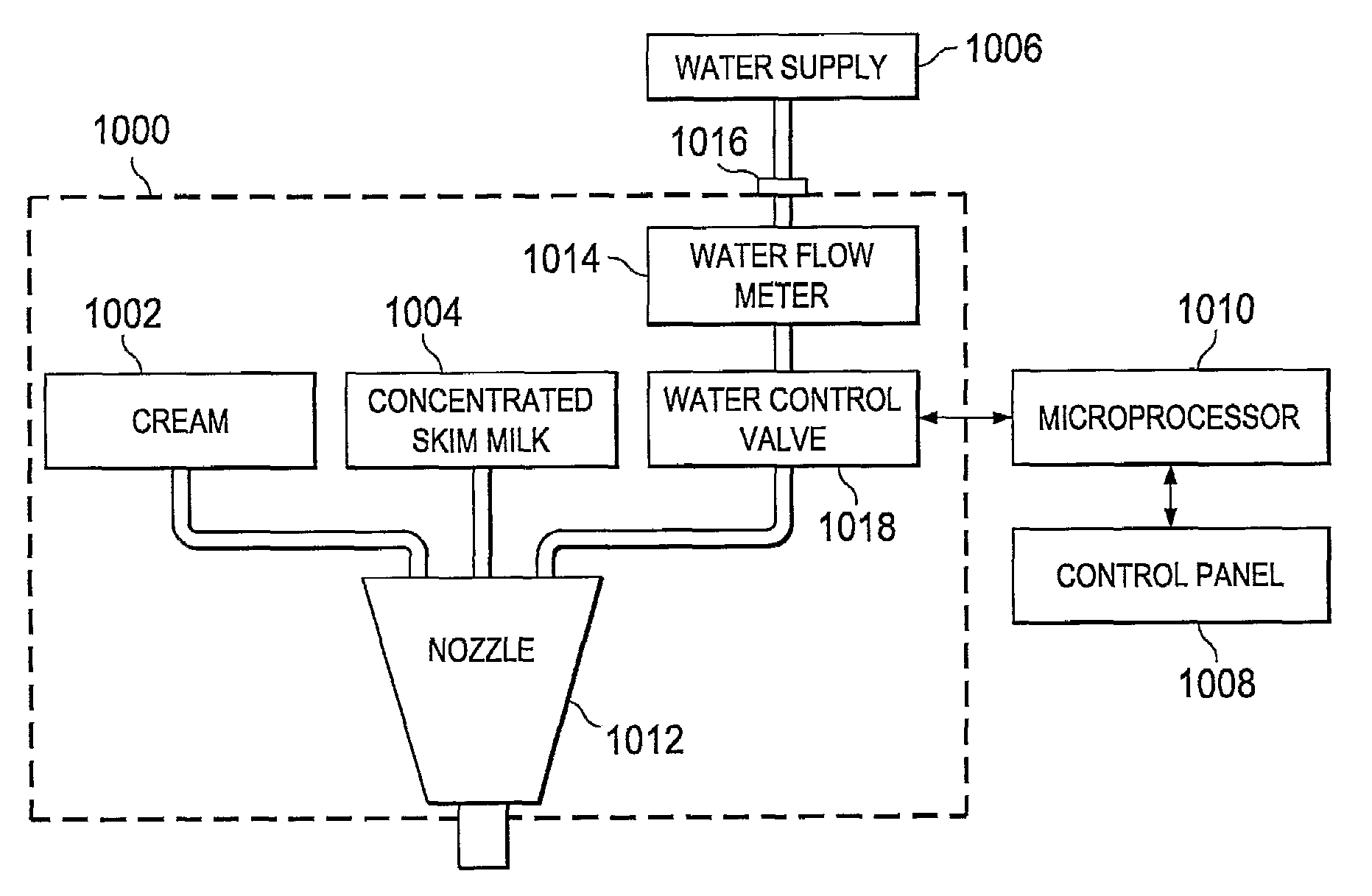

Liquid Food Dispenser System and Method

ActiveUS20090236361A1Accurate volumeArea minimizationPower operated devicesLarge containersBiomedical engineeringLiquid food

A system and method for dispensing fluids is introduced. A preferred embodiment comprises a sealed tank, a bag containing fluid inside the sealed tank, an outlet for dispensing the liquid in the bag, and a pressure generating device to create pressure in the sealed tank.

Owner:FAIRLIFE LLC

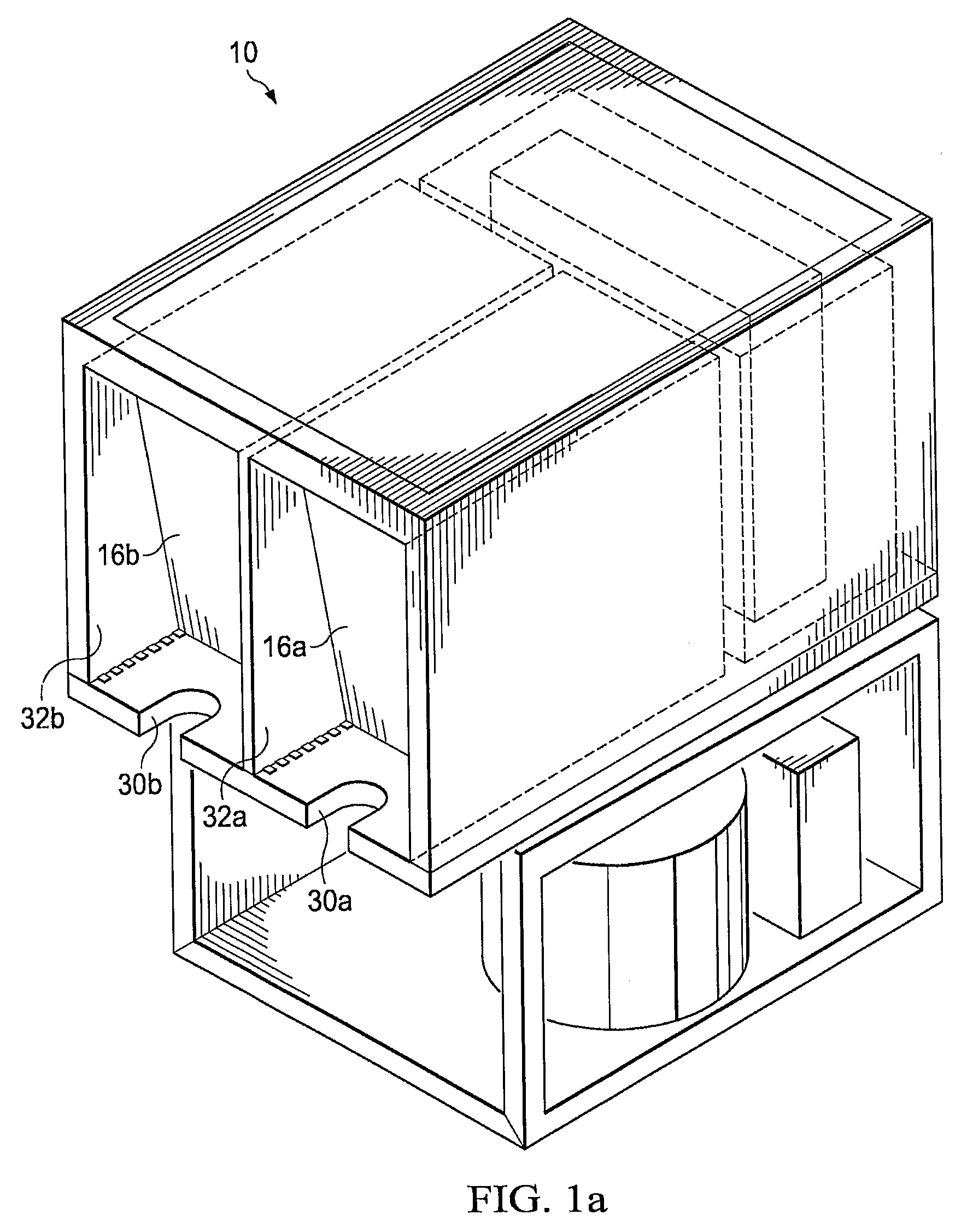

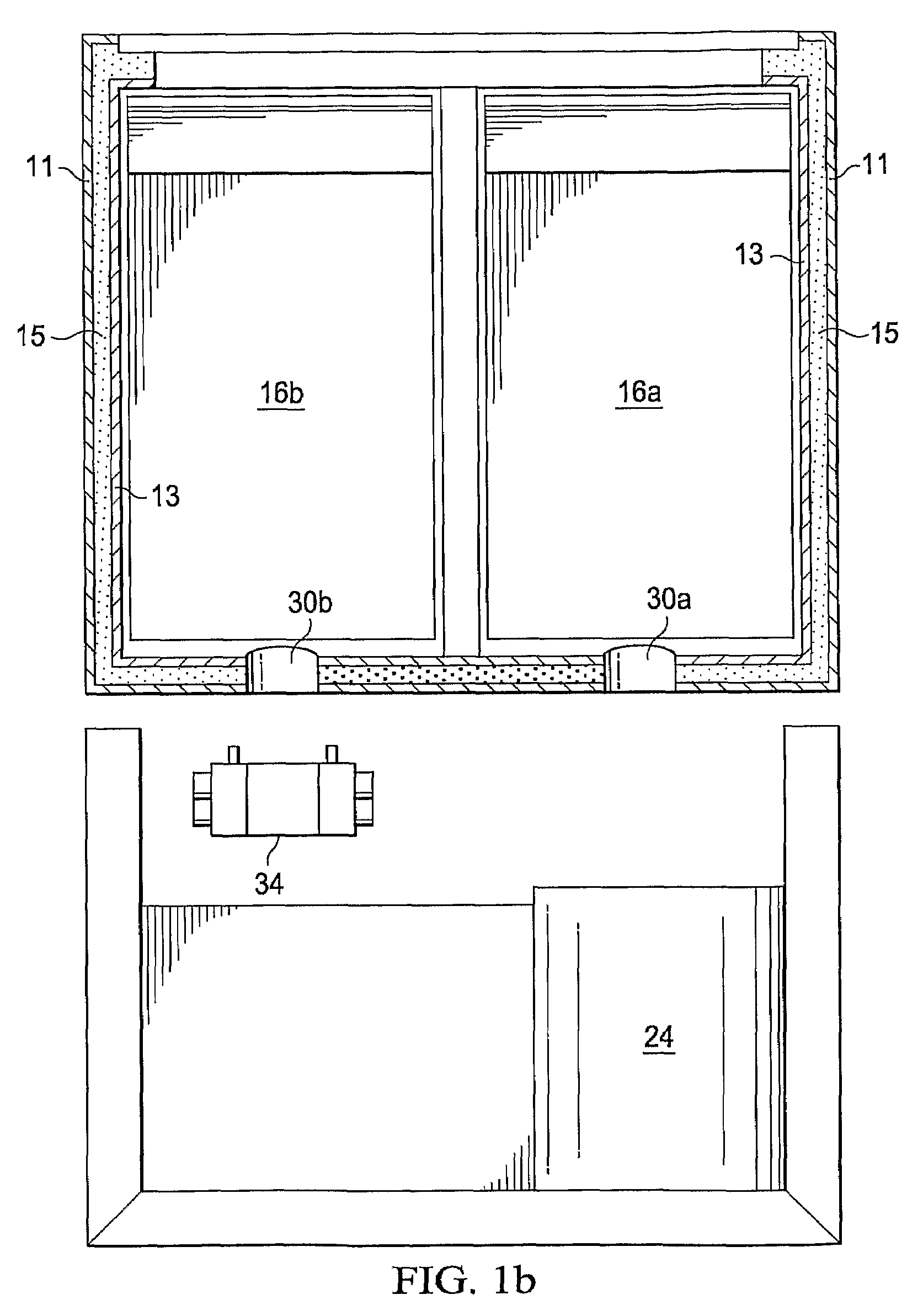

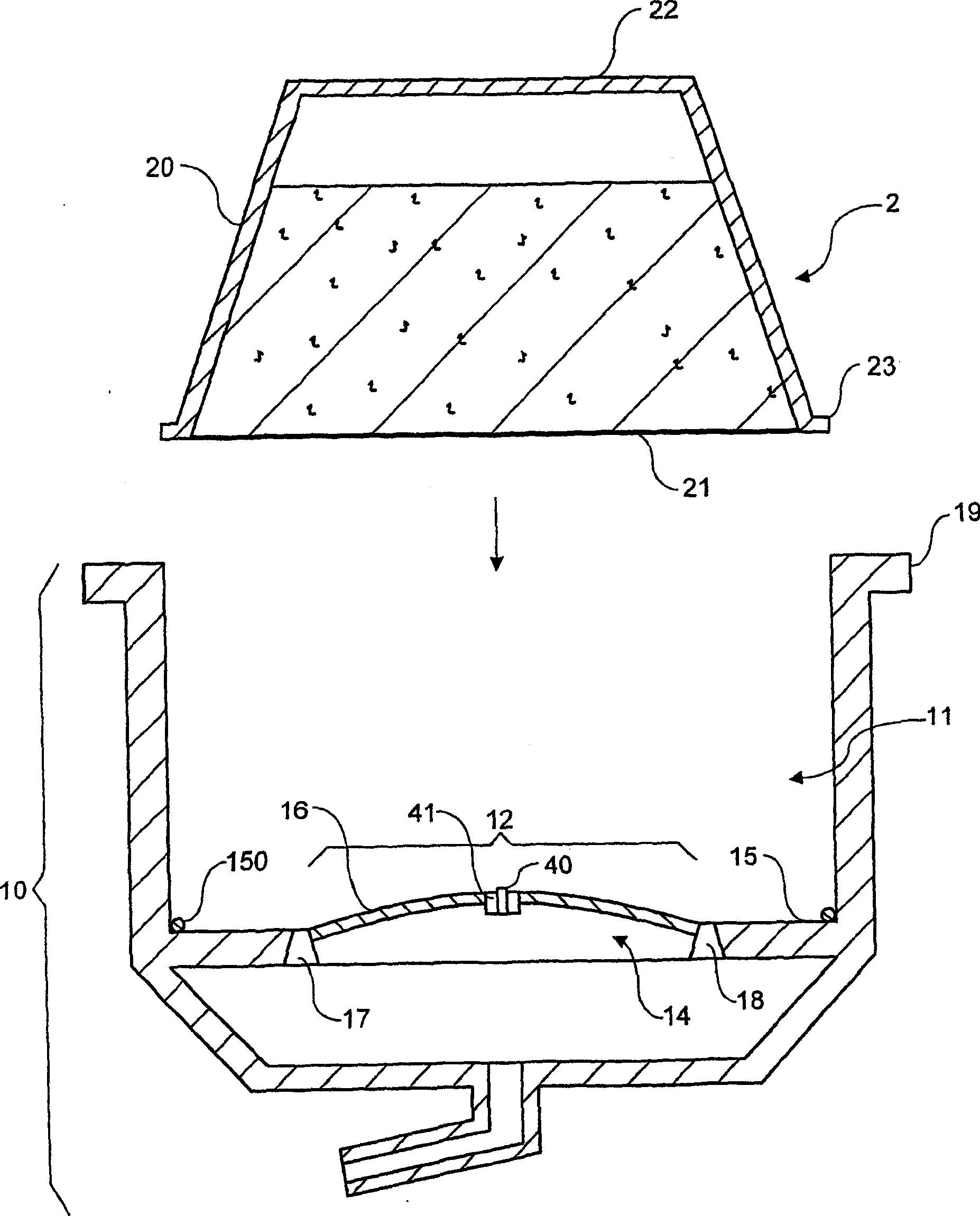

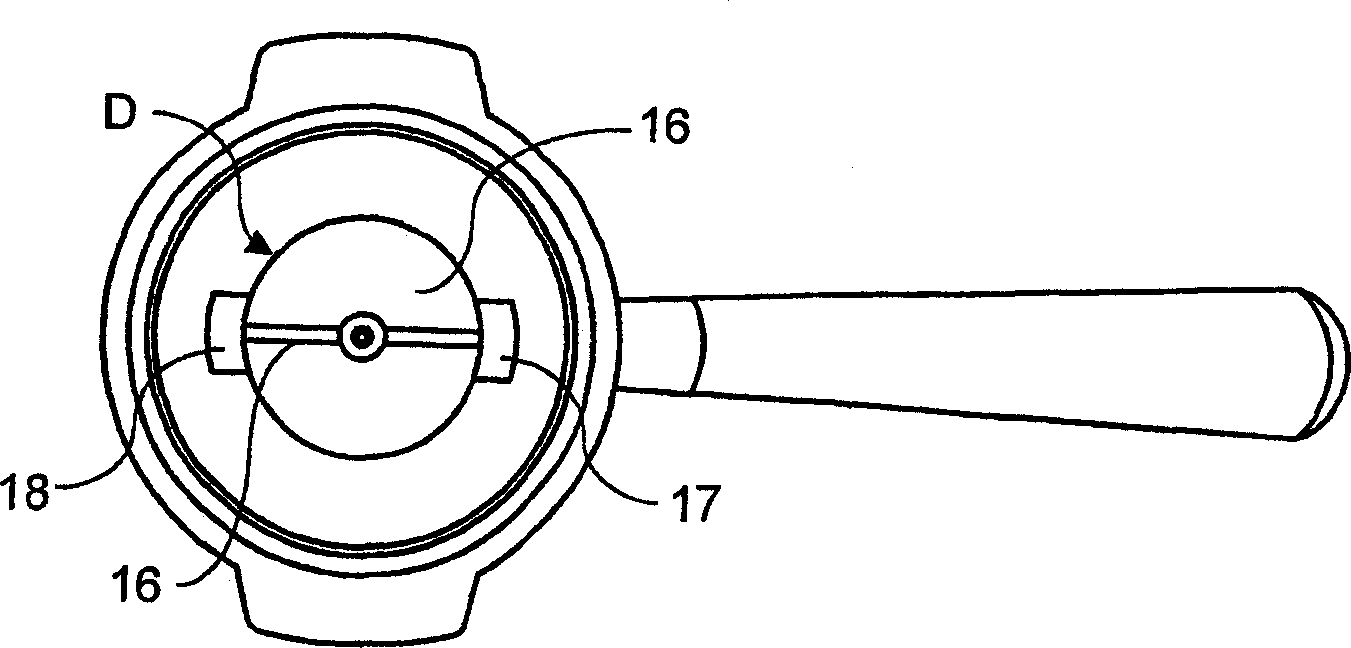

Method, device, and capsule for preparing a foamy liquid food

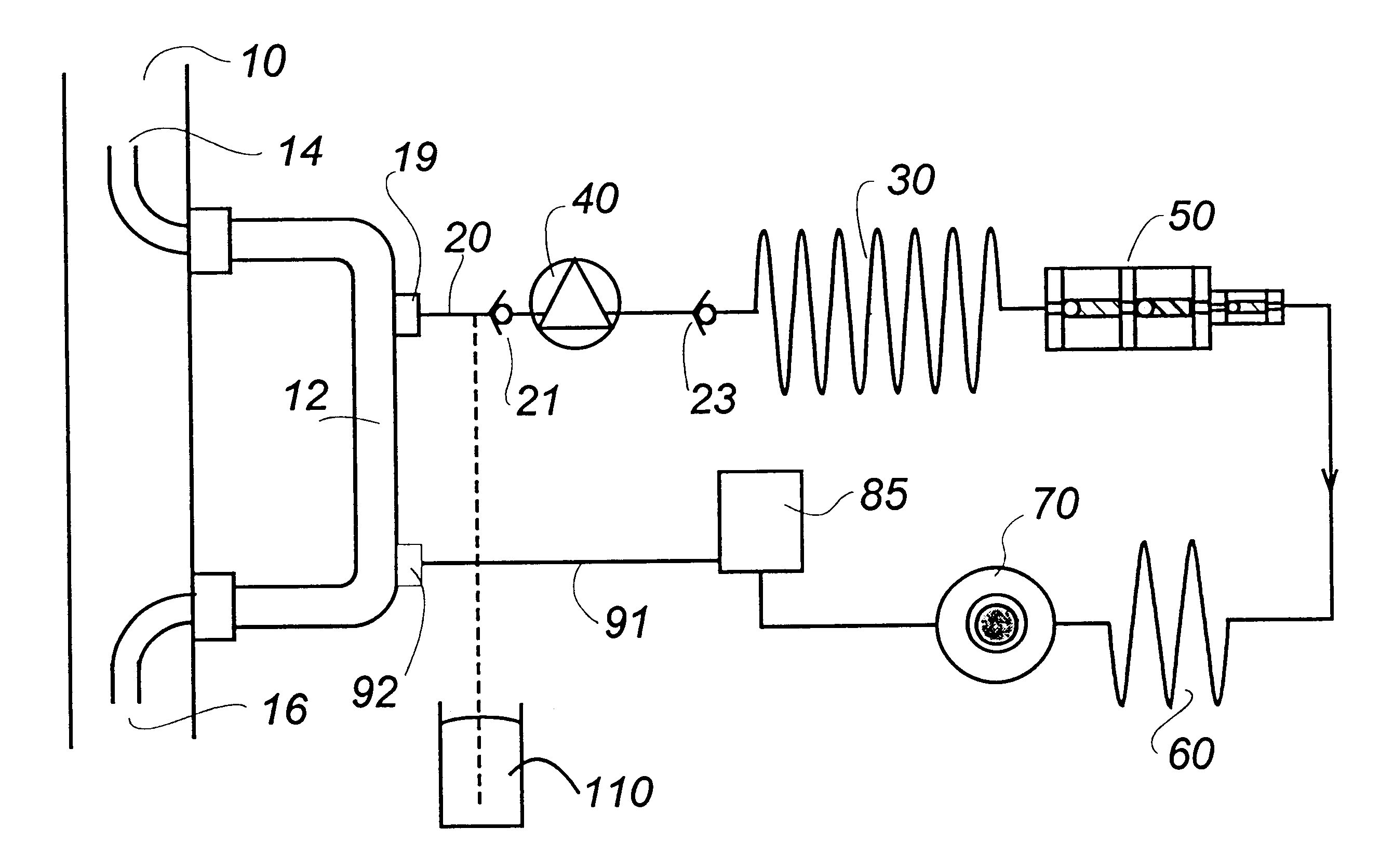

The invention relates to a device (1) for preparing a foamy liquid food from a capsule (2) containing a dose of food soluble substance, an entry side (22) adapted to be traversed by a flow of water entering the capsule, a discharge side (21) adapted to be traversed by a flow of beverage exiting the capsule, wherein it comprises water supply means (32) to provide water within the capsule and beverage and foam conditioning means (12) adapted to engage against the discharge side to hold pressure within the capsule so that the soluble substance can thoroughly mix with water and entrap gas within the capsule to dispense a foamy beverage. The invention also relates to a capsule for preparing the liquid food.

Owner:NESTEC SA

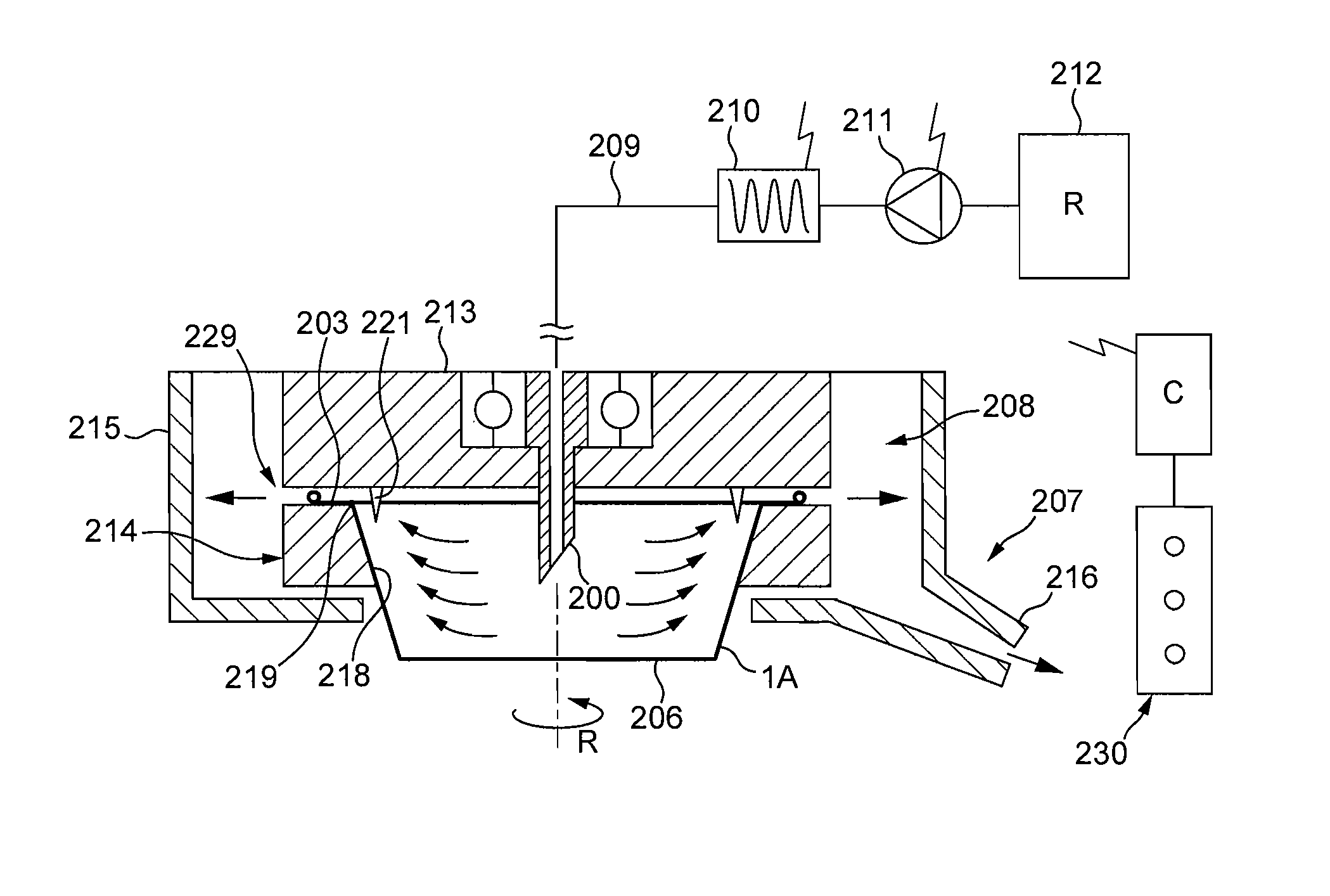

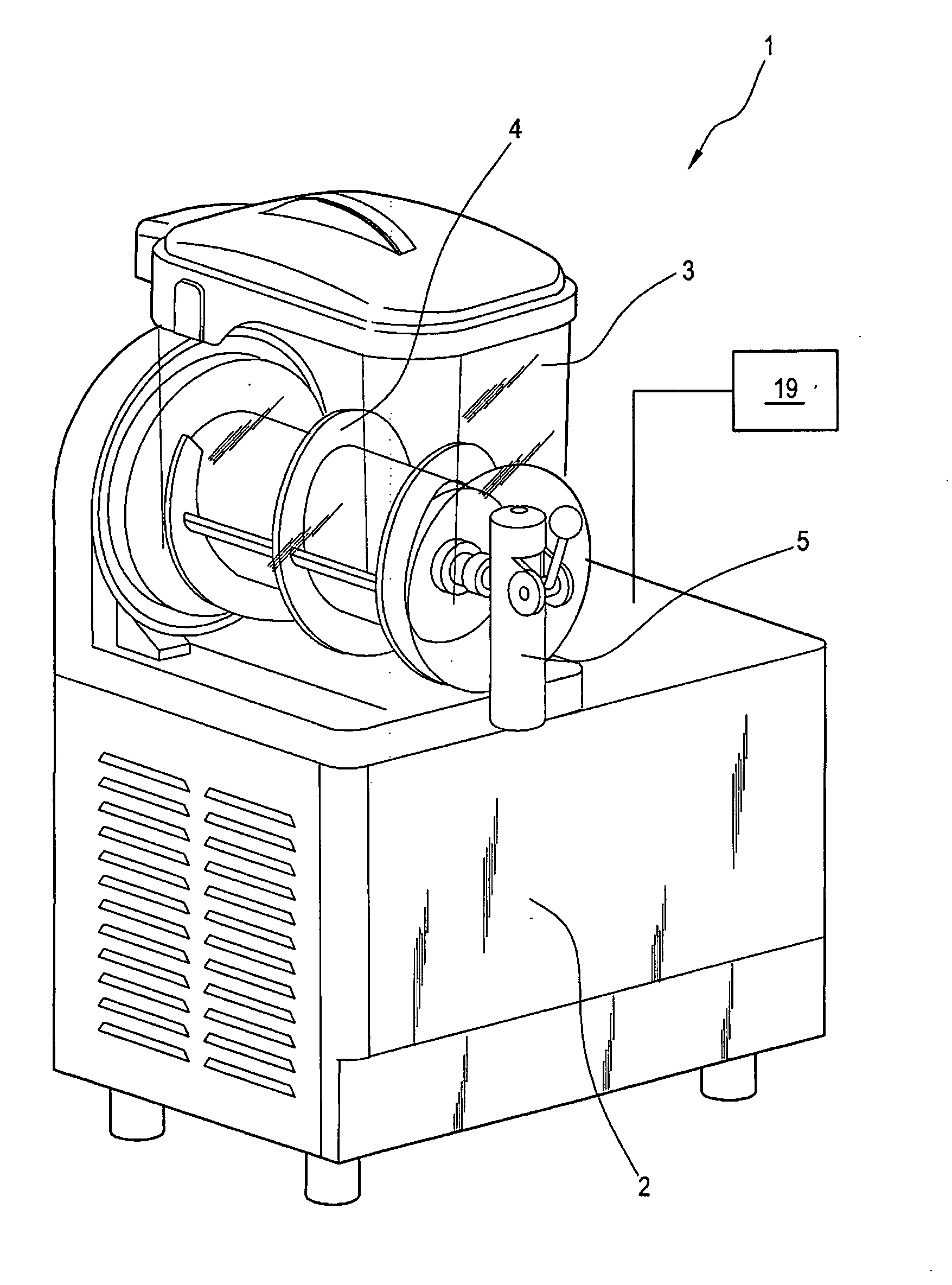

Machine and method for the treatment of liquid or semi-liquid food mixtures

ActiveUS20090191318A1Frozen sweetsCompression machines with non-reversible cycleHeat powerOperating speed

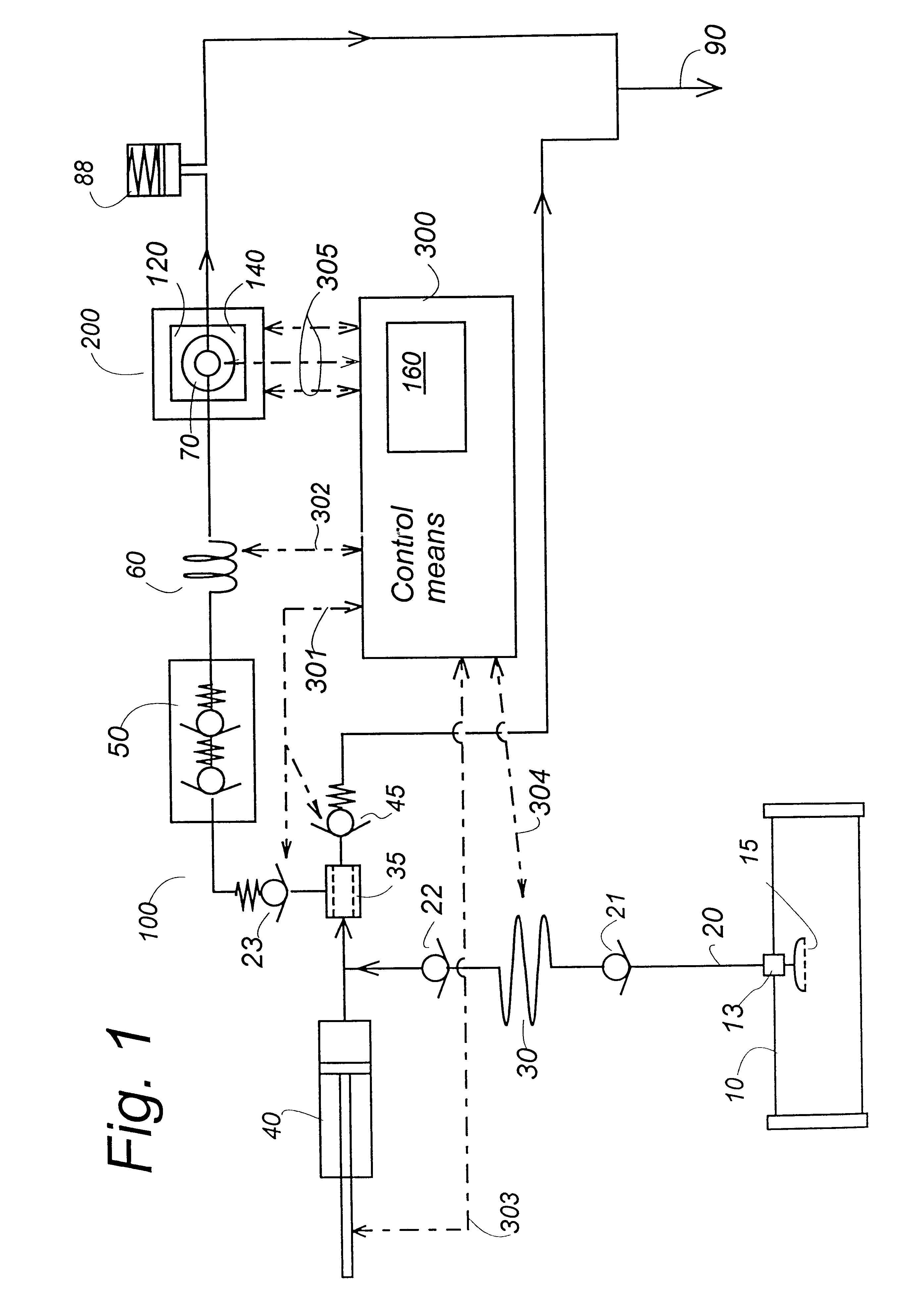

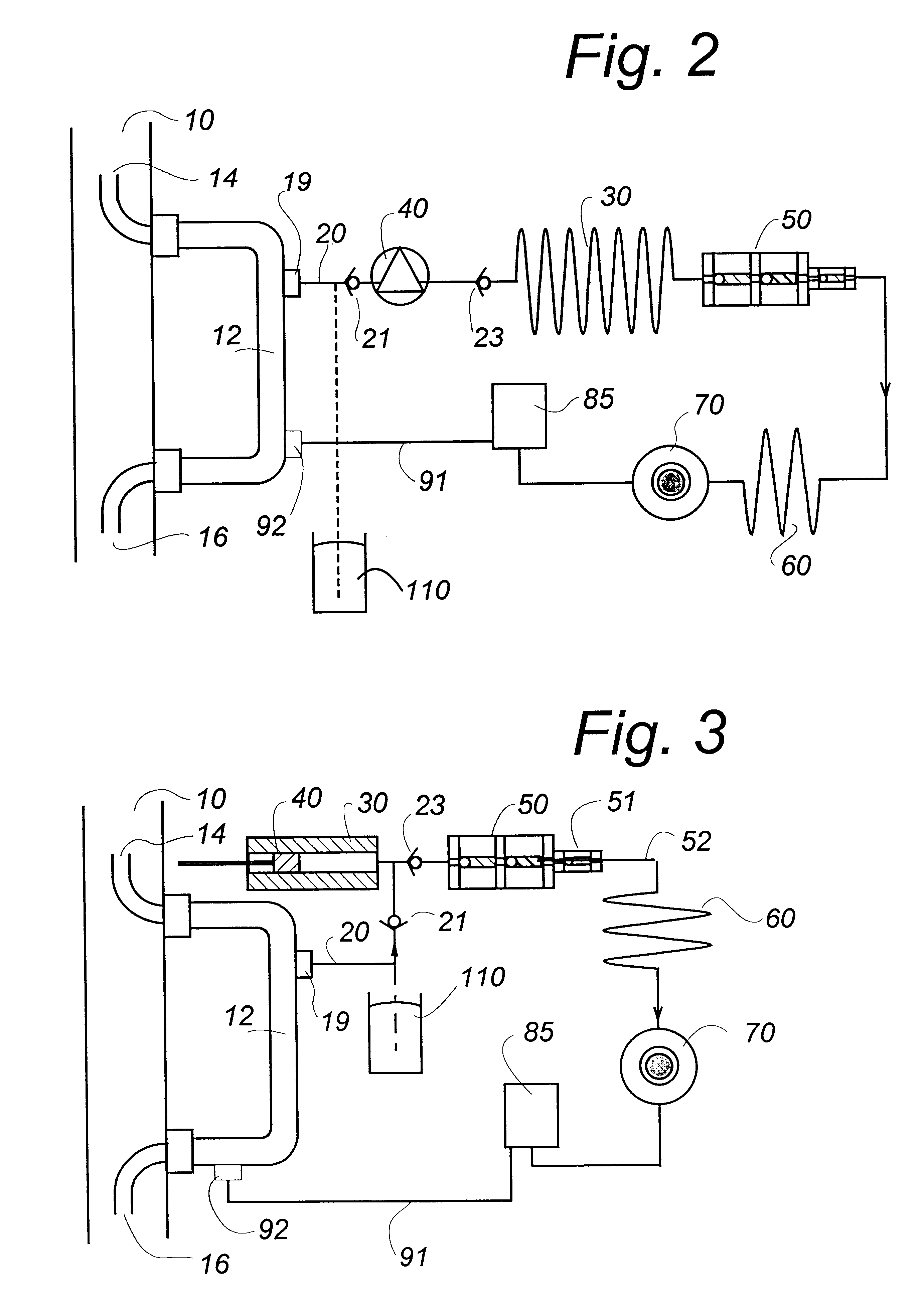

A machine for the treatment of liquid and semi-liquid food mixtures comprises a mixture whipping and freezing / heating tank (3), a circuit (6) for cooling and / or heating basic products of which the mixture consists, comprising a compressor (7) driven by an electric motor (18), and a mixer (4) rotating inside the tank (3) to mix the basic products. The machine also comprises a control unit (11) for the speed of rotation of the compressor (7) electric motor (18), for regulating the compressor operating speed and varying the thermal power supplied by the compressor (7) according to at least the quantity of mixture treated.

Owner:ALI - CARPIGIANI GROUP

Method and flow system for spectrometry and a cuvette for the flow system

InactiveUS6297505B1Easy to produceRadiation pyrometryScattering properties measurementsCuvetteHigh pressure

The present invention relates to an on-line method and a flow system as well as a cuvette for carrying out IR spectrometry for analysis of liquid food products, possibly containing dissolved gases, in a process line in a liquid food product processing plant, especially a dairy processing milk and milk products. A liquid sample is extracted from the process line to a measuring branch, the sample is thermostated and passed to a measurement cuvette. The IR-absorbance spectrum is measured, e.g. in the MID-IR or NIR-range. In order to obtain an on-line monitoring of the process line the liquid food sample is extracted directly from the process line into the measurement branch, in which the pressure is maintaining at least as high as in the adjacent process line. The high pressure ensures that dissolved air will stay dissolved in the liquid food. Before each new sample the measurement branch and cuvette are flushed by high flow rates with a part of the new sample to clean the cuvette. The measurement cuvette has strong windows, preferably diamond windows to stand a high pressure and high flow rates. The on-line system is arranged to carry out eg. 120 measurements per hour.

Owner:FOSS ELECTRIC

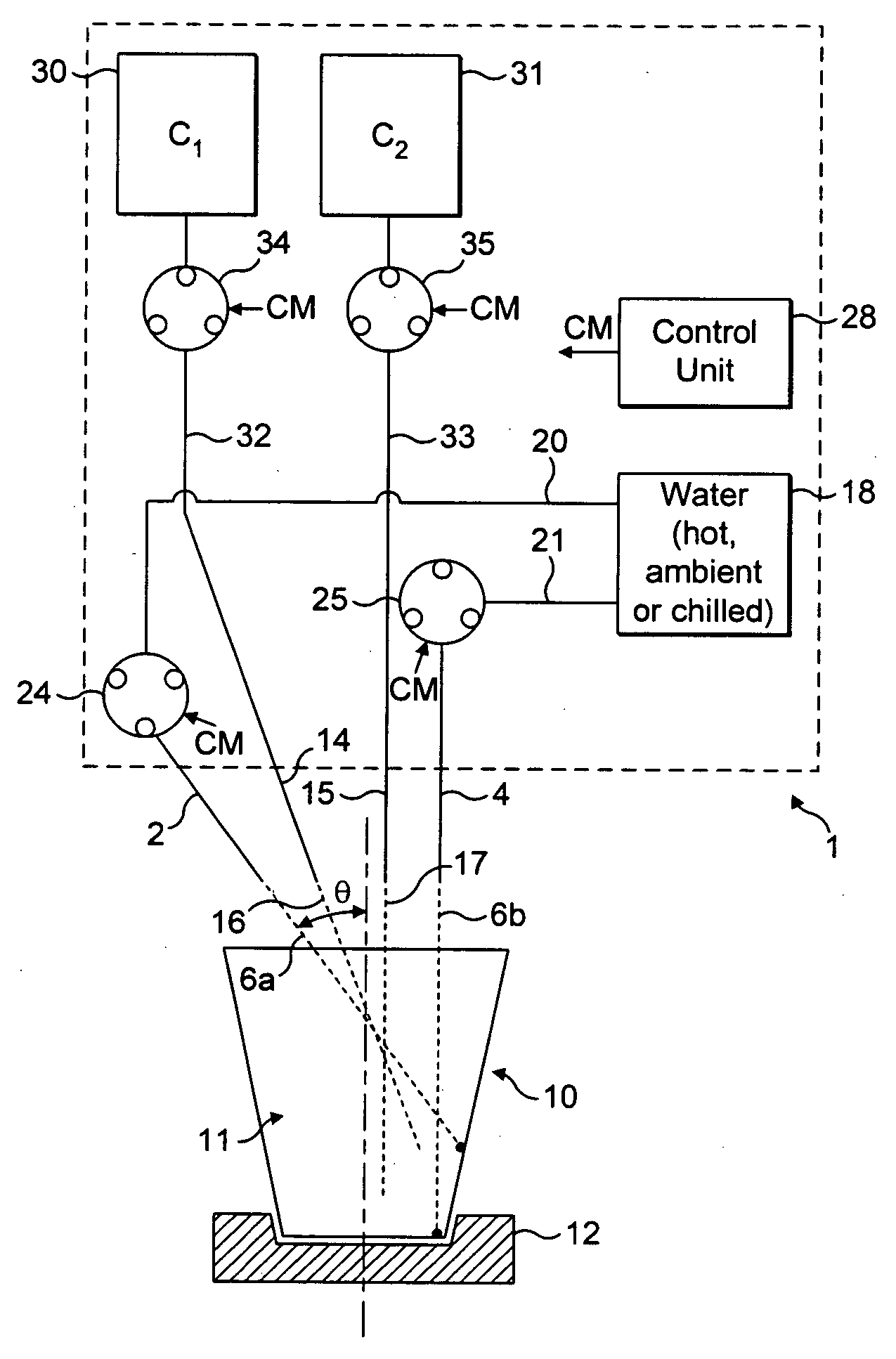

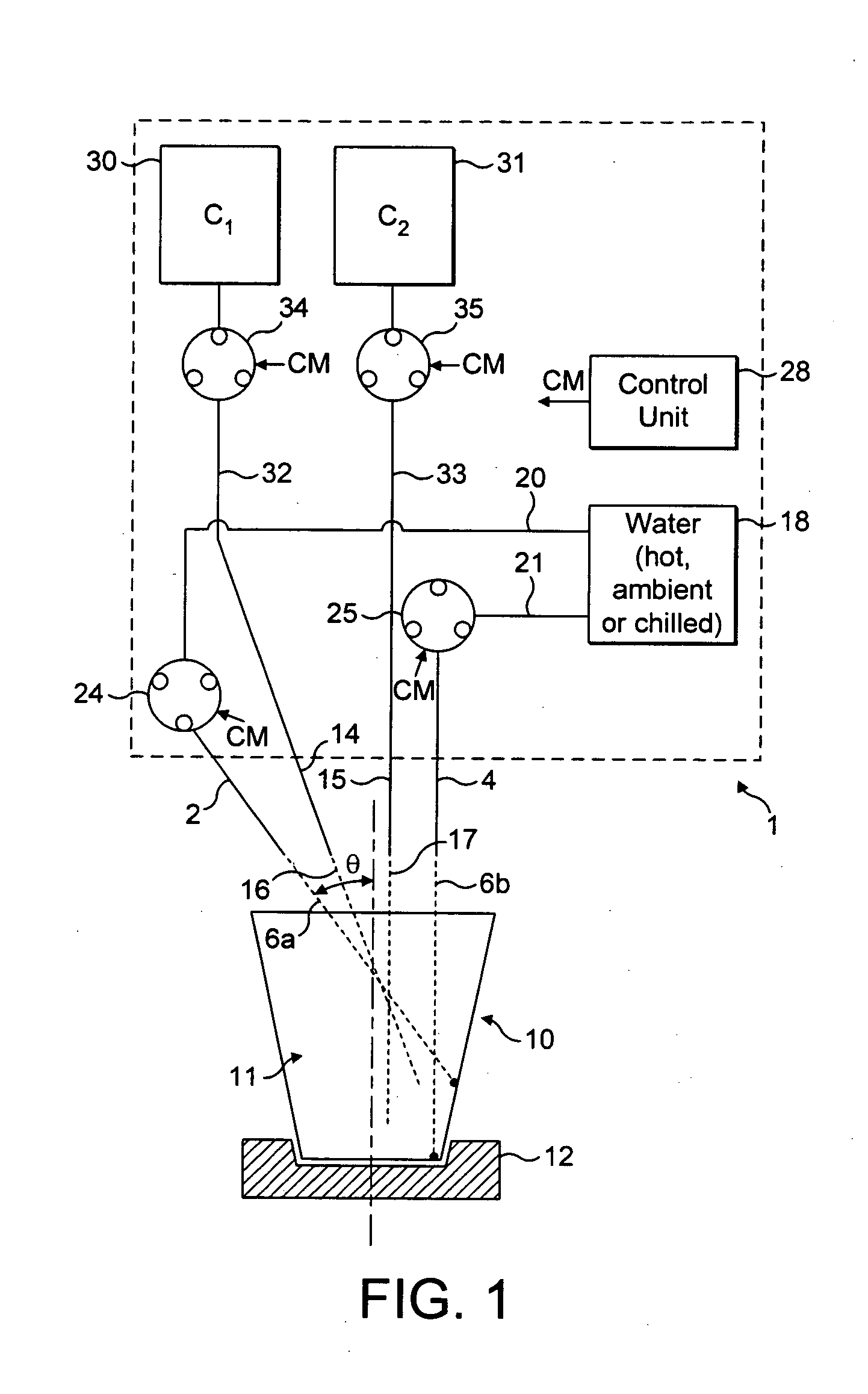

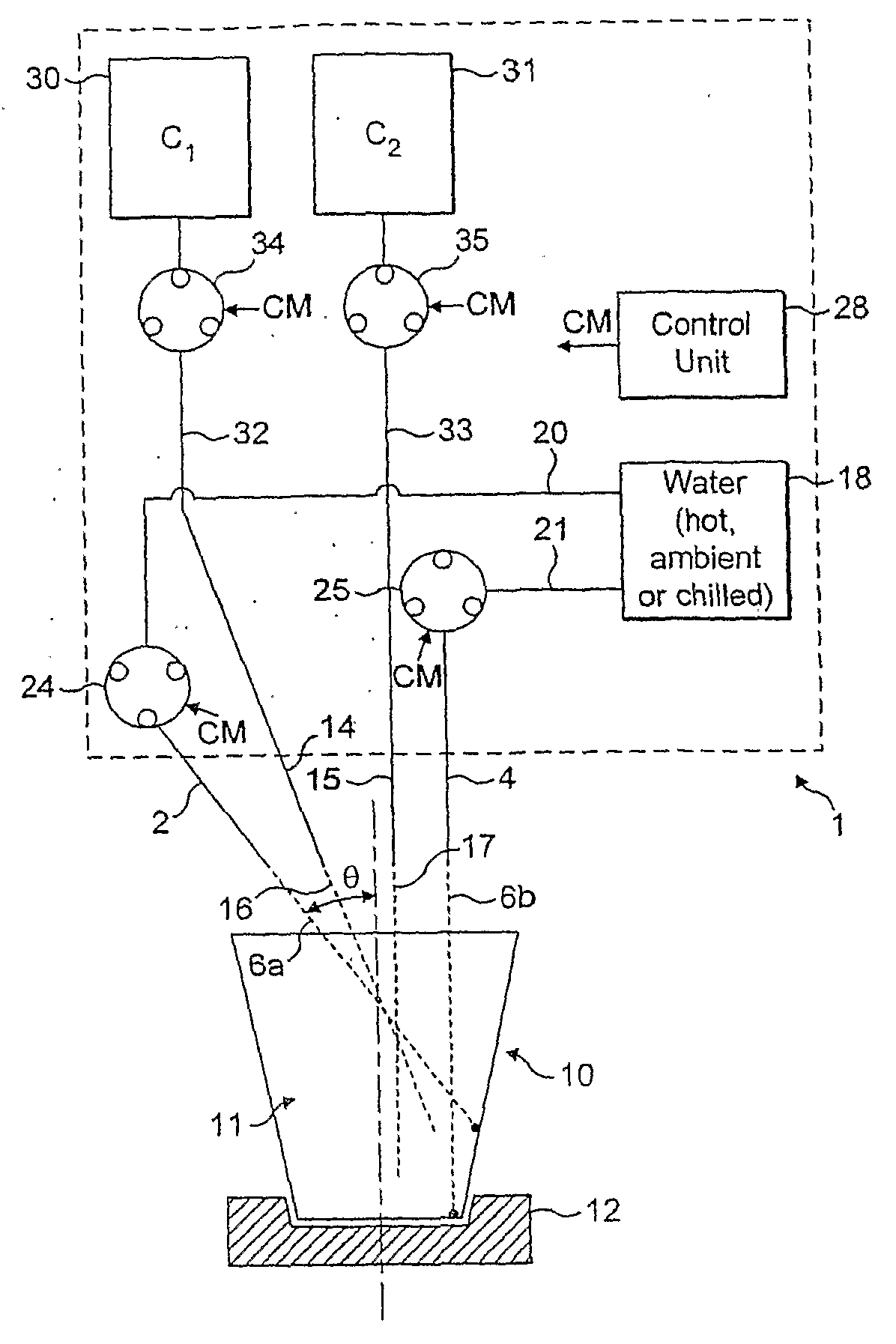

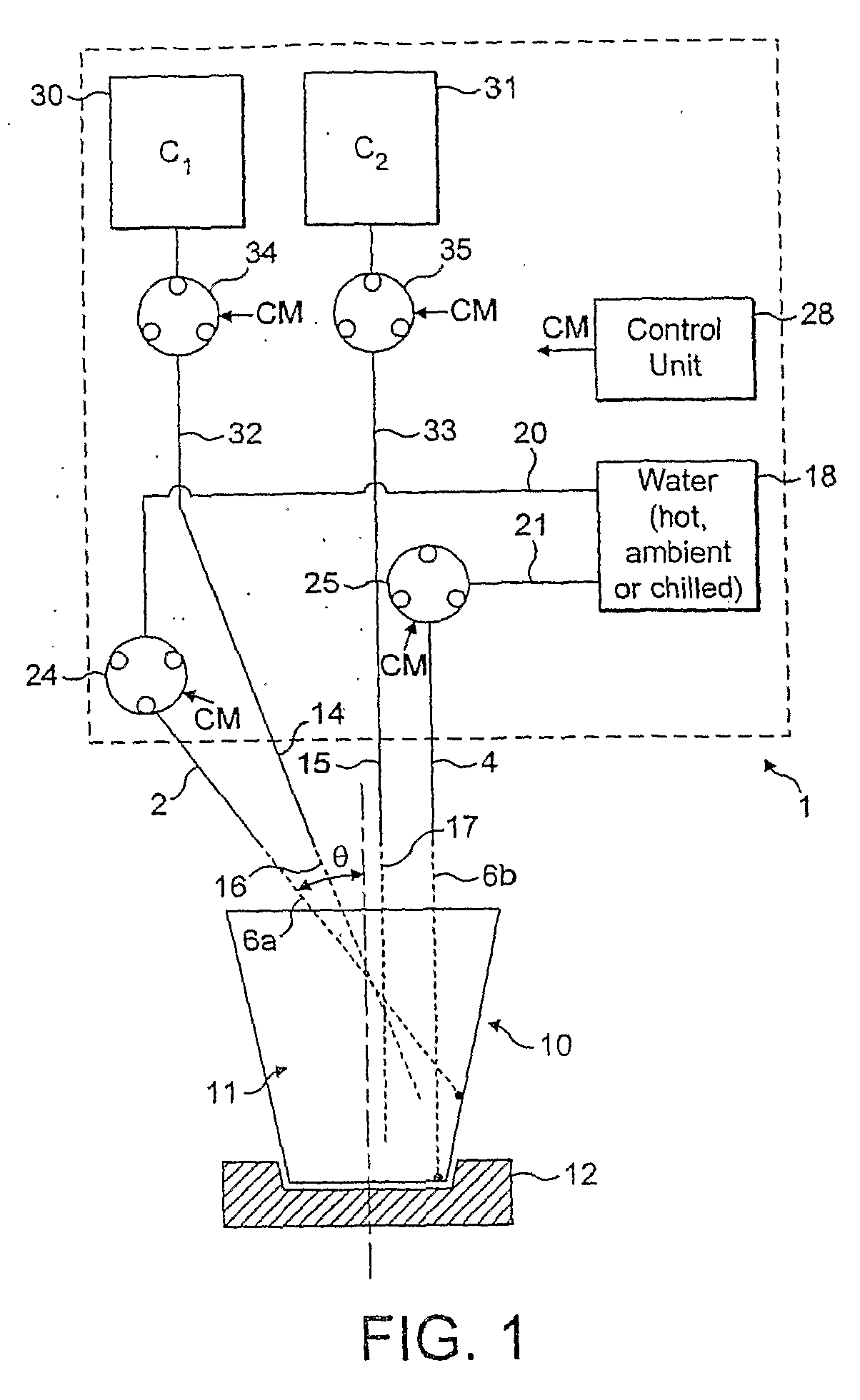

Method and system for in-cup dispensing, mixing and foaming hot and cold beverages from liquid concentrates

InactiveUS20060045942A1Remove cleanGuaranteed mixReady-for-oven doughsMixing methodsLiquid stateDiluent

Liquid food dispensing device (1) for dispensing hot or cold beverages or other liquid foods without using any mixing or whipping chambers comprising at least one liquid component source (30, 31) and a diluent source (18), a delivery device and at least one diluent nozzle and one food component nozzle wherein the delivery device and diluent and food component nozzles are configured for ejecting at least one stream (6a, 6b) of diluent at a predetermined spatial configuration inside a container (10) and within a velocity range effective to create turbulence and mix the food component so to produce the food product such as the hot or cold beverage.

Owner:NESTEC SA

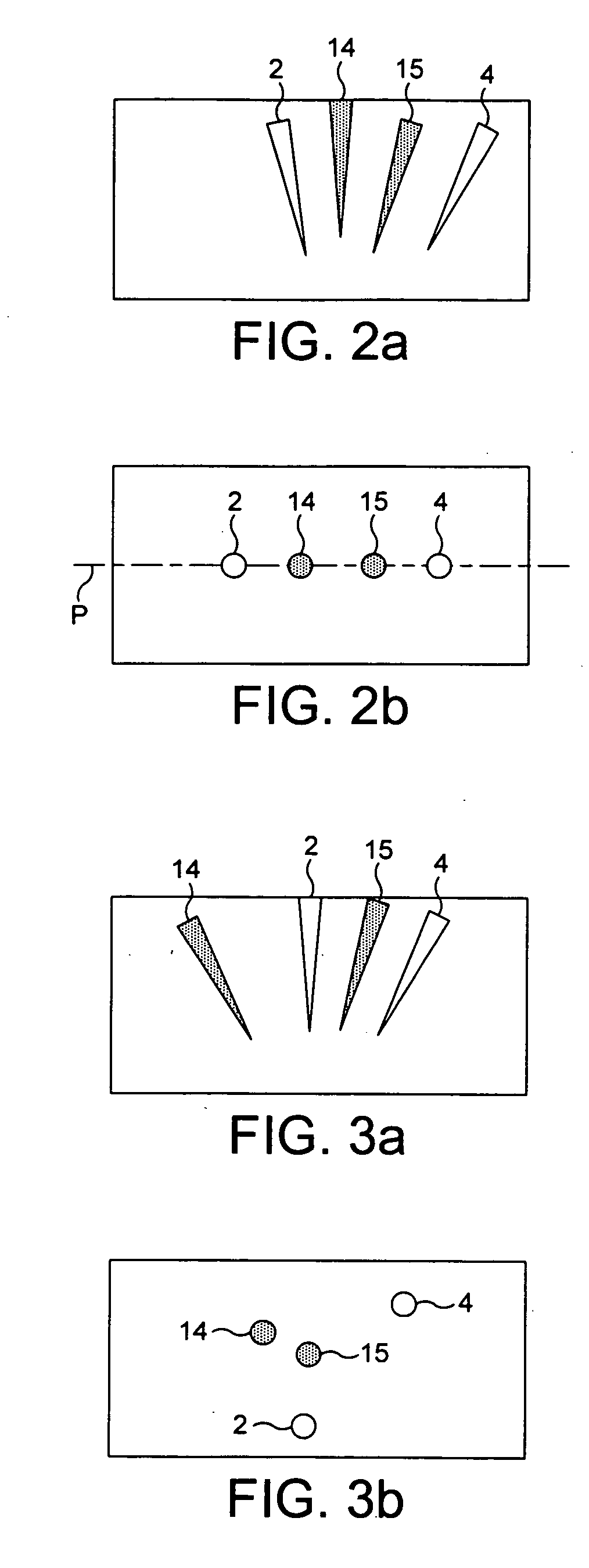

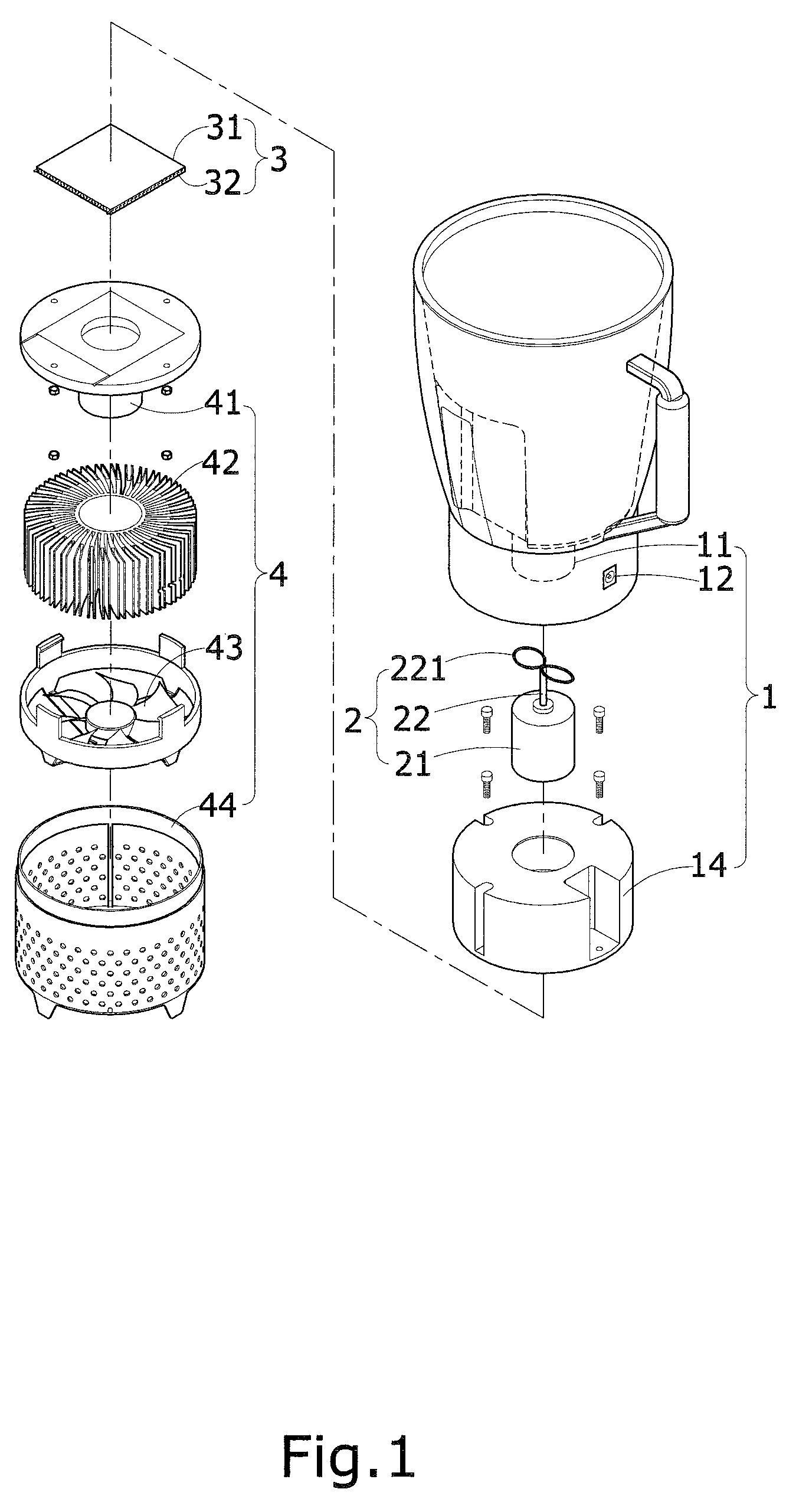

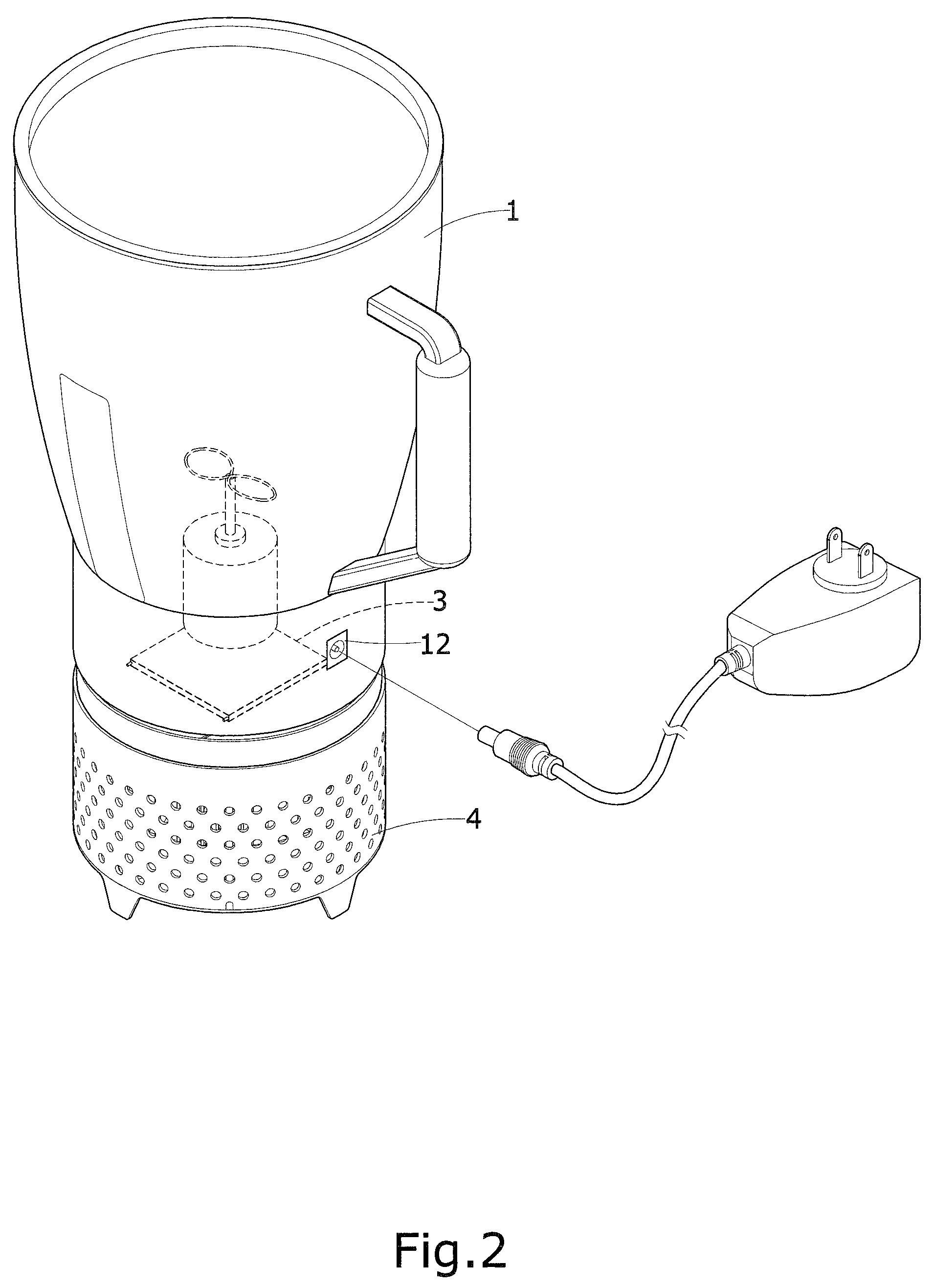

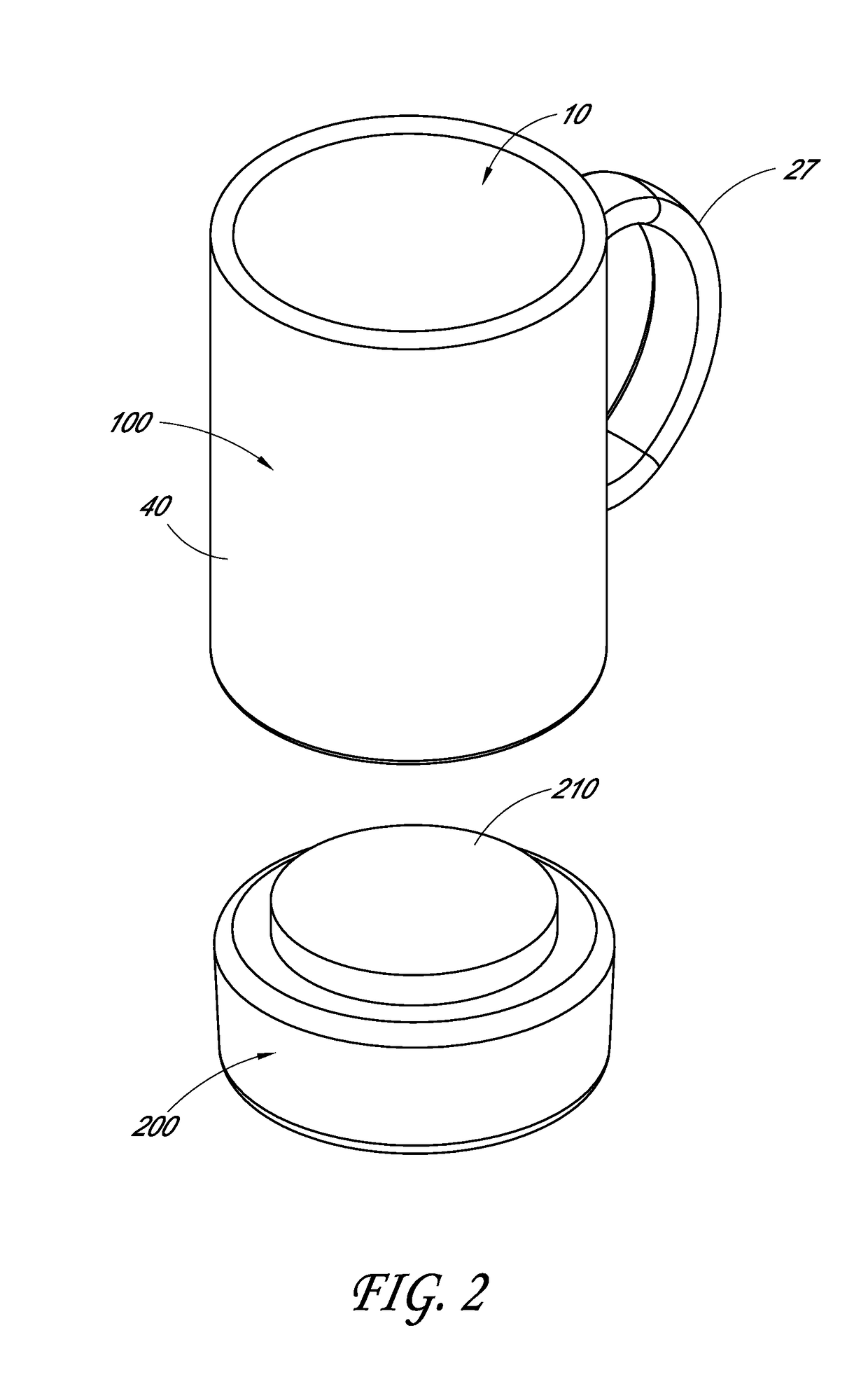

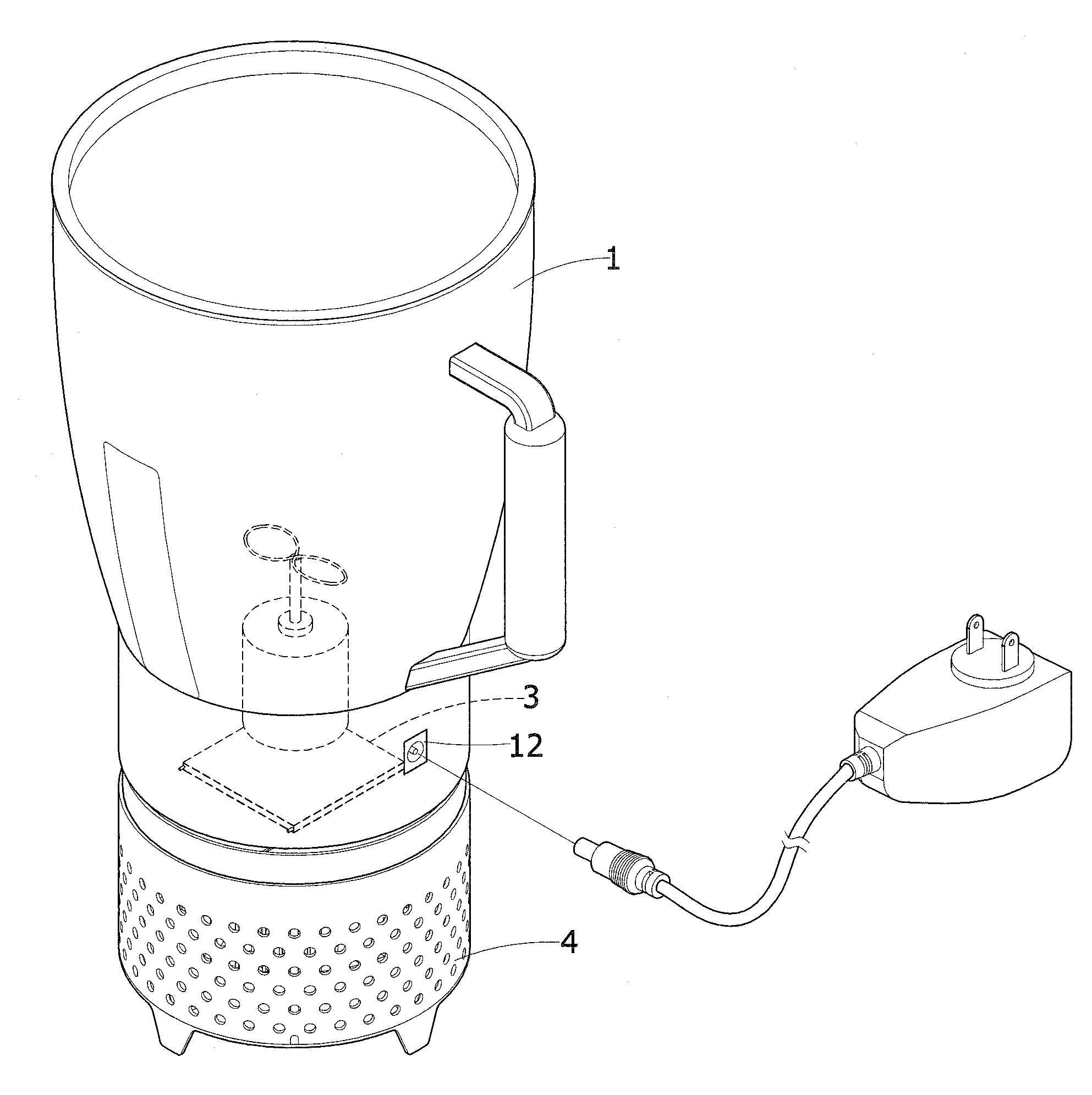

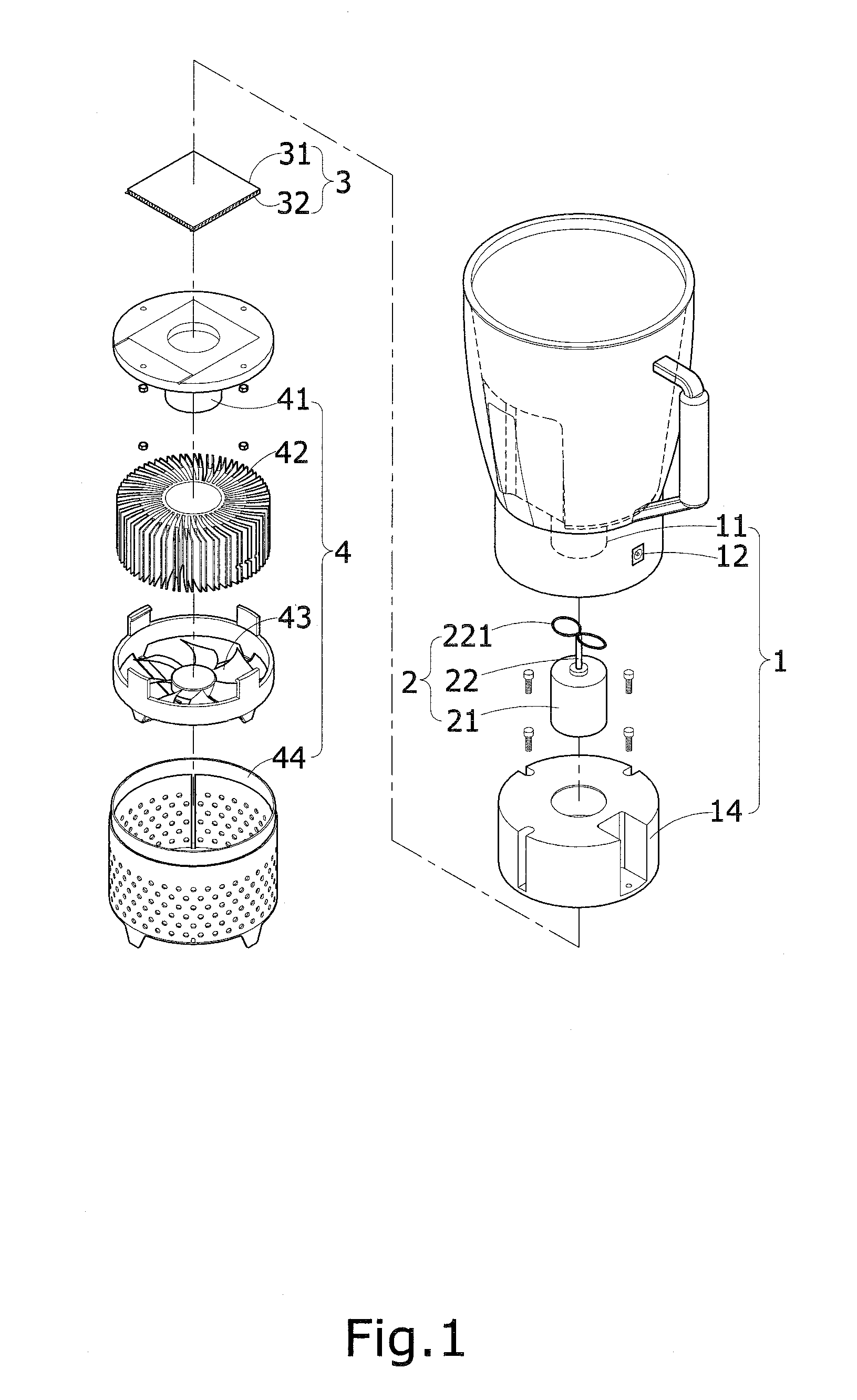

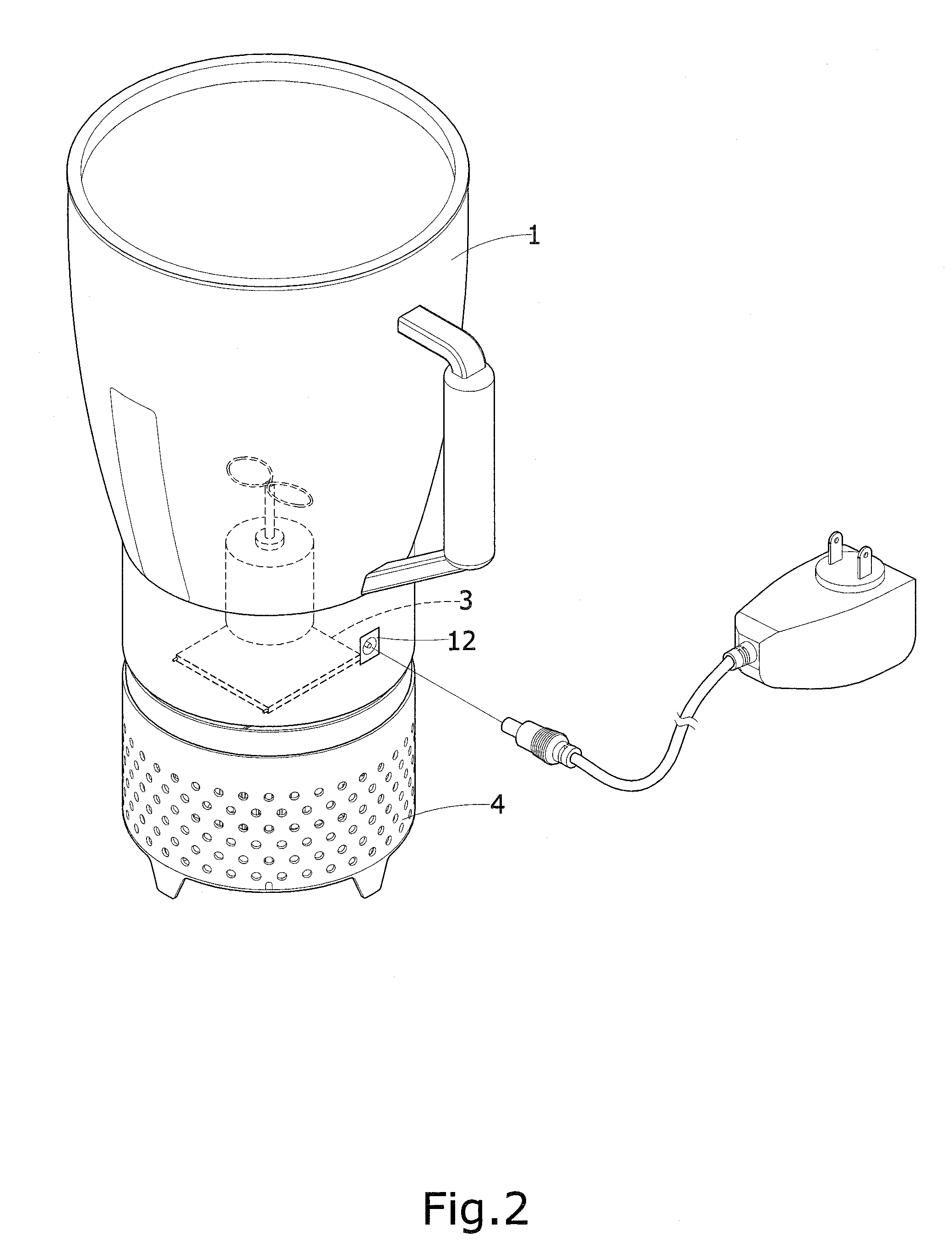

Heating and cooling cup

A heating and cooling cup includes a cup body, a stirring device, a heating and cooling chip, and a heat sink module. A heat conductive block is disposed under the cup body, the heat conductive block abuts against the heating and cooling chip, the stirring device has a stirring rod disposed in the cup body, and a bottom surface of the heating and cooling chip abuts against a heat conductive block of the heat sink module. A temperature of the cup body is changed through the heating and cooling chip, for cooling or heating liquid food in the cup body, and the liquid food is forced to generate convection through the stirring rod for accelerating a temperature variation process.

Owner:LIU PEI CHUAN +1

Method and System for in-Cup Dispensing, Mixing and Foaming Hot and Cold Beverages From Liquid Concentrate

Liquid food dispensing device (1) for dispensing hot or cold beverages or other liquid foods without using any mixing or whipping chambers comprising at least one liquid component source (30, 31) and a diluent source (18), a delivery device and at least one diluent nozzle and one food component nozzle wherein the delivery device and diluent and food component nozzles are configured for ejecting at least one stream (6a, 6b) of diluent at a predetermined spatial configuration inside a container (10) and within a velocity range effective to create turbulence and mix the food component so to produce the food product such as the hot or cold beverage.

Owner:NESTEC SA

Composite food additive and preparation method thereof

The invention relates to a complex food additive. The complex food additive is compounded with various raw materials which are compounded together by adopting a spray drying process so that the food additives with various physical forms can be used to the utmost extent, and the use limitation of liquid food additives in the process of compounding the food additive is avoided; simultaneously, the complex food additive can compound the food additives with various functions together as much as possible to meet the requirements of customers on various performances of the food additives. The complex food additive can be customized according to specific requirements of the customers, can be applied to various foods such as dairy foods, beverages, repasts, and the like, and endow products with perfect states, mouthfeels and functional characteristics.

Owner:BEIJING ALCHEMIST TECH

Device for maintaining separate ingredients in liquid food products

InactiveUS6263923B1Reduce manufacturing costEasy to useCapsLiquid fillingAdditive ingredientScrew thread

A device for maintaining ingredients separately within a container, of the type having a removable container cap applied on a neck with a central opening, has a sub-container body mounted in the container neck which is formed with a proximate end having screw threads which can be engaged with internal screw threads in the container neck for holding them securely together to allow the ingredients to be shaken out of the sub-container body and mixed with fluid in the container. The sub-container body can have inner divider walls forming multiple compartments with respective orifices for dispensing ingredients selectively from the compartments. The sub-container body may be sealed to the underside of the cap with a sealing film, or seated on the neck rim and held by the cap. In one version, the proximate end of the sub-container body has a protruding shape with inclined walls for guiding it into the neck opening. In other versions, the sub-container body is formed integrally with the container cap, or is formed as an annular ring shape carried between inner and outer flanges of the cap. These improved devices allow viscous or powdered ingredients to be mixed by shaking with fluid in the container without risk of spilling or splashing outside the container.

Owner:CASTILLO JAMES A

Versatile tamper-evident food container

ActiveUS8083089B2Improved tamper-evident product packagingWithout riskCapsClosure capsInterference fitEngineering

A tamper-evident rigid plastic food container system wherein the outer periphery of the mating surfaces of the lid and tray are permanently bonded together after the food product has been placed in the tray, a set of perforated rows at an inner periphery, the interconnect of which needs to be torn into order to open the lid. Intentional, inadvertent or malicious ingress into the container can only be made by tearing at the perforations thereby evidencing the potential tampering and contamination of the packaging contents. The lid and tray edges may further include mechanical interference fits, including snap-fit grips that may be of the releasably lockable kind to permit sealing, release and re-sealing multiple times without deterioration in reliability, and which can further prevent or minimize leakage of liquid food product.

Owner:PACTIV PACKAGING

Liquid food dispenser system and method

ActiveUS8181822B2Area minimizationAvoid flowPower operated devicesCream preparationBiomedical engineeringLiquid food

A system and method for dispensing fluids is introduced. A preferred embodiment comprises a sealed tank, a bag containing fluid inside the sealed tank, an outlet for dispensing the liquid in the bag, and a pressure generating device to create pressure in the sealed tank.

Owner:FAIRLIFE LLC

High pressure pasteurization of liquid food product

InactiveUS20080311259A1Reduce moistureProvide securityDough treatmentMilk preservationLiquid productMicroorganism

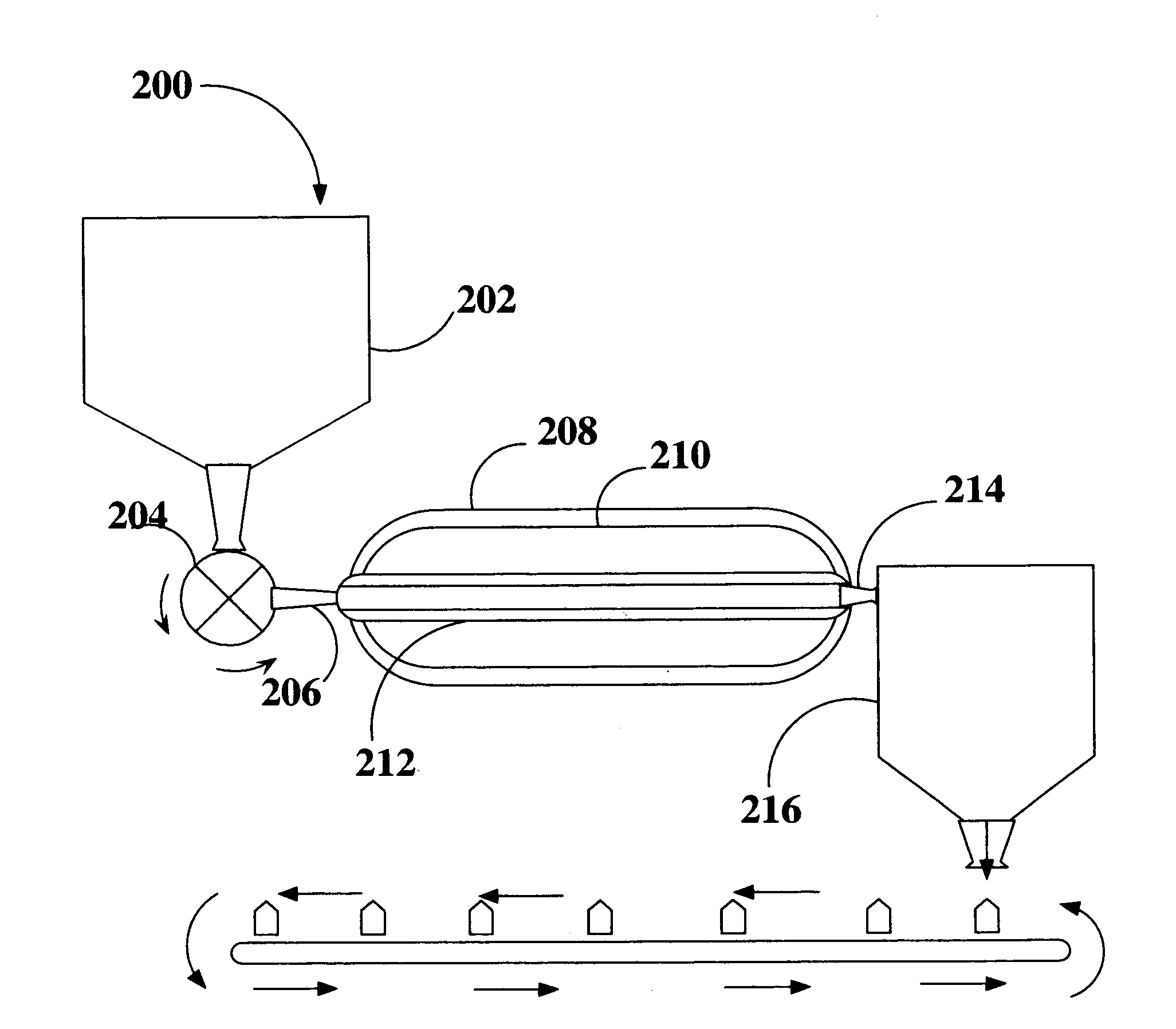

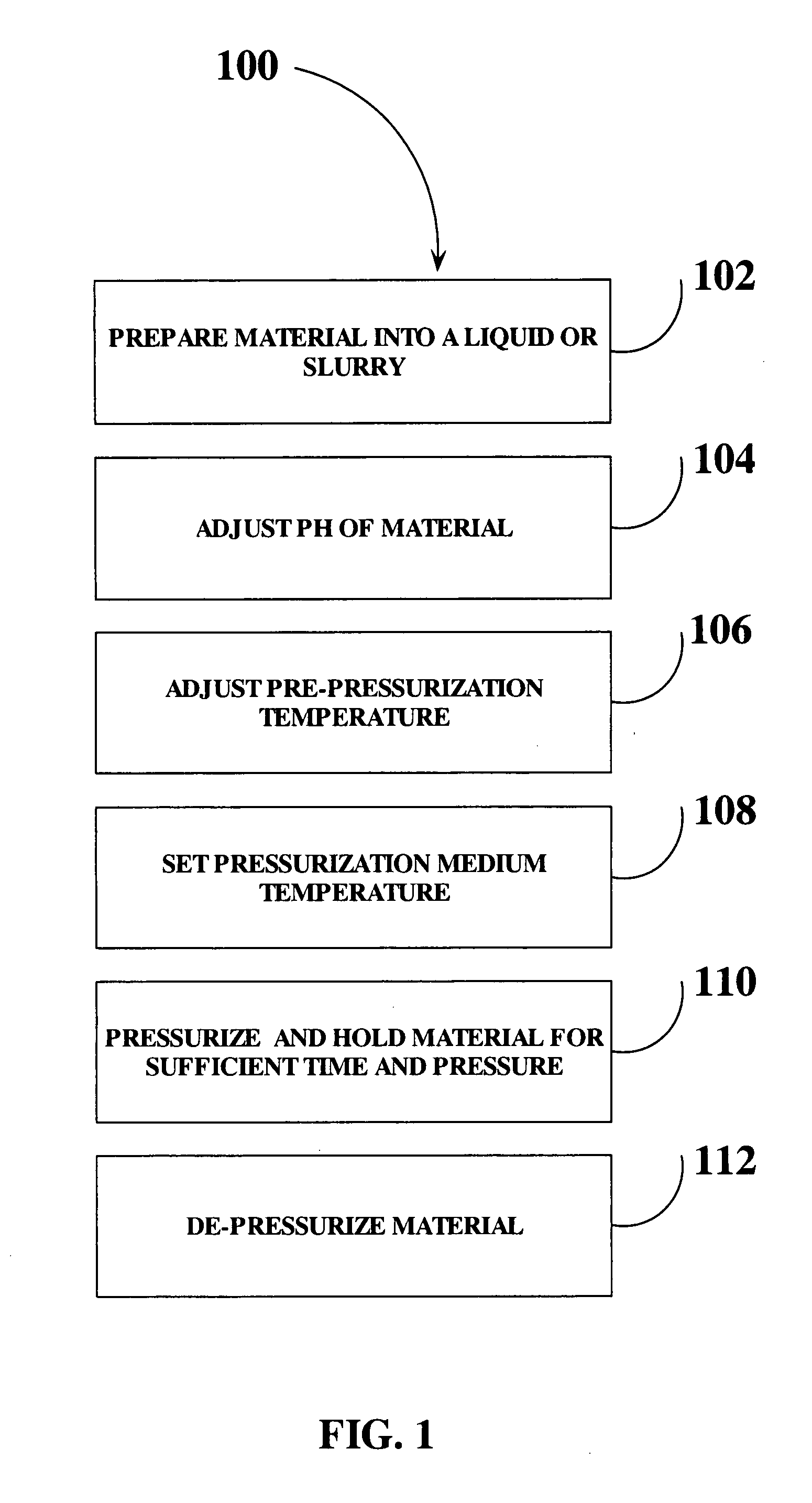

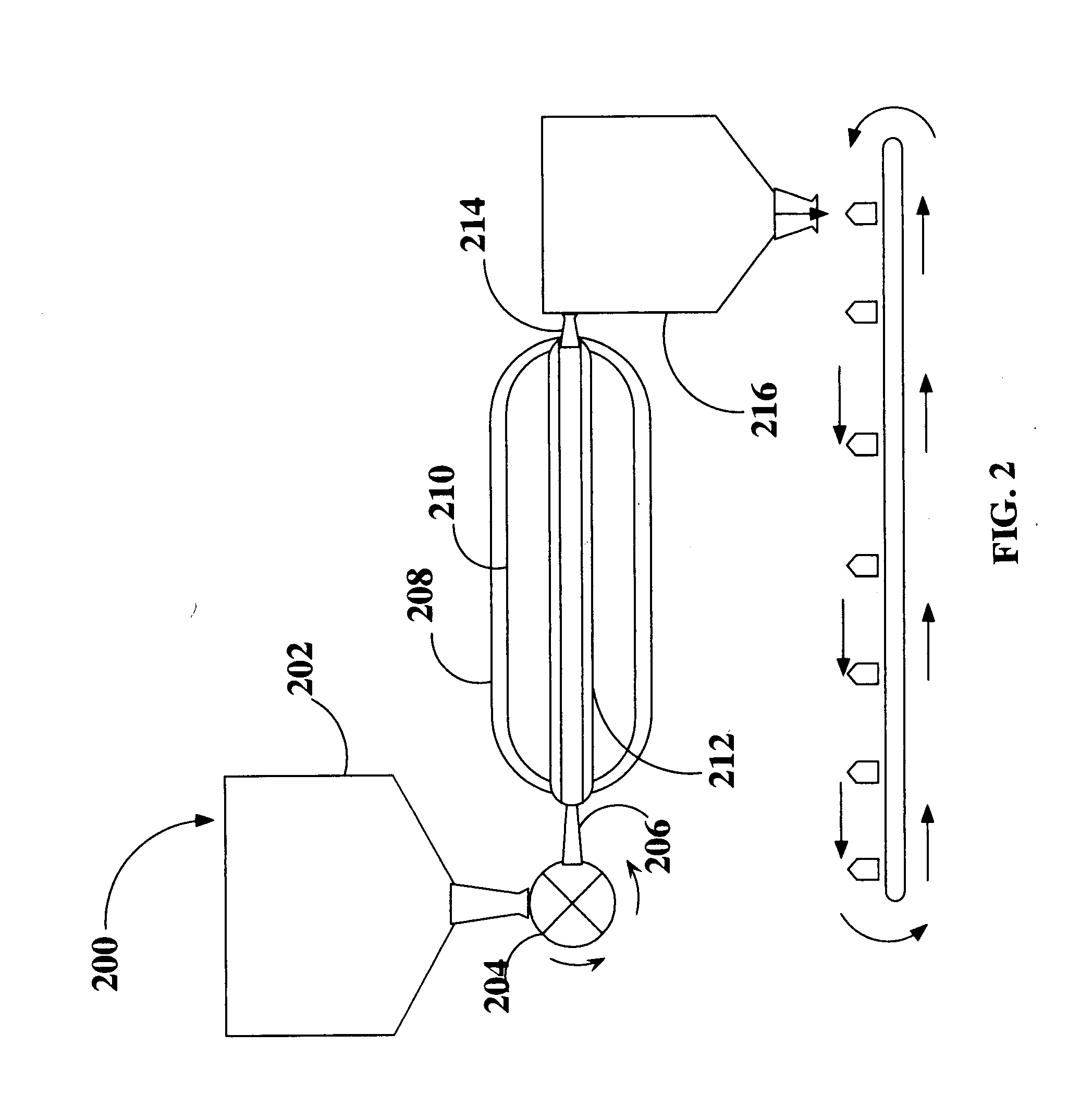

The present invention is a method for pasteurization or sterilization of liquid food products using high pressure in a continuous or semi-continuous flow. The invention involves pressurizing and depressurizing the liquid product for a sufficient duration of time to achieve a 2.5 log cycle reduction in microorganisms. The uniform application of high pressure to the liquid food product coupled with a controlled pH and temperature of the liquid food product, the setting and maintaining the pressurizing media temperature, and the rapid depressurization resulting in cellular disruption of the microorganisms within the liquid product inactivating or destroying the microorganisms, such as vegetative microorganisms, while preserving the functionality of the liquid product.

Owner:LUCENT TECH INC +1

Heat seal device

InactiveUS7003934B1Improve sealingReduce adverse effectsWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringImpurity

A heat-sealing device moves a tube-shaped packaging material through operation of a seal jaw and counter jaw under the liquid surface of liquid food, and heat-seals a seal zone containing a cutting predetermined zone in the tube transverse direction. The tube-shaped packaging material is formed from the packaging material web, and is filled up with liquid food. The operation surface of the seal jaw facing the seal zone has a substantially flat surface. The heat-sealing device has a removal / mixture mechanism on the operation surface of the counter jaw. The removal / mixture mechanism removes seal prevention impurity from this seal zone and / or mixes the impurity with the melting / softening packaging material in this seal zone. Thus, even if the packaging laminated material is covered with an oxide, residual substances, or impurities, the heat-sealing device reduces the bad influence of the seal prevention impurity.

Owner:TETRA LAVAL HLDG & FINANCE SA

Packaging container for the cold storage of liquid foods and a method of producing the packaging container

InactiveUS6554182B1Superior gas and aroma barrier propertyCost effectiveFlexible coversMechanical working/deformationCardboardFlavor

The disclosure relates to a packaging container for long-term cold storage of liquid foods for retaining superior flavor and aroma properties in the packed product, and produced from a packaging laminate including a core layer of paper or paper-board, an inside aroma barrier layer of PET and a gas barrier layer, by fold formation and sealing of a planar packaging blank so that all contact surfaces vis-a-vis the packed product consist of the PET layer. The disclosure also relates to a method of fold forming and sealing the packaging laminate into a packaging container according to the invention. Good shelf-life after cold storage for at least six weeks at 8° C., or at least 10 weeks at 4° C. will be attained using the packaging container according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

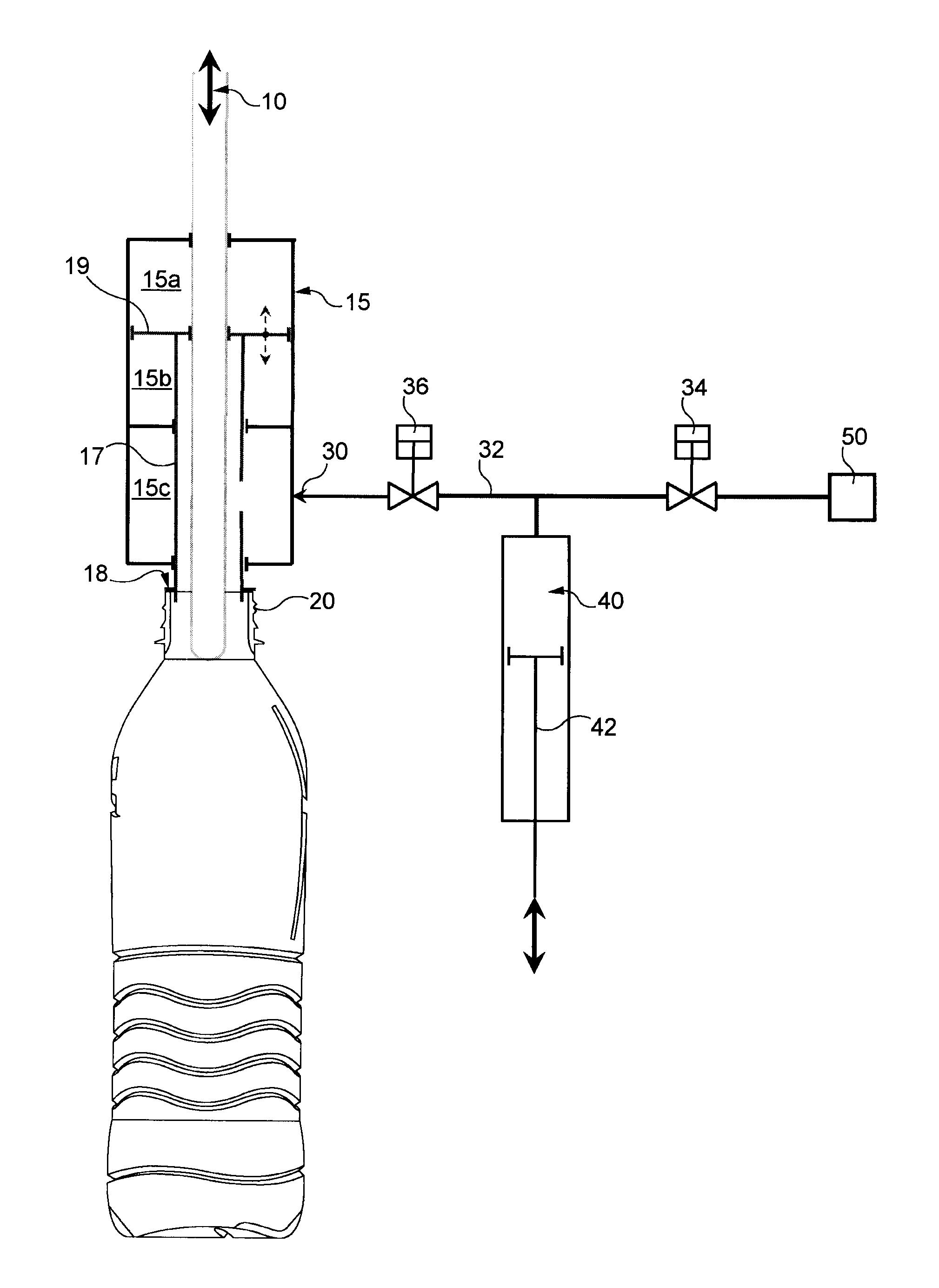

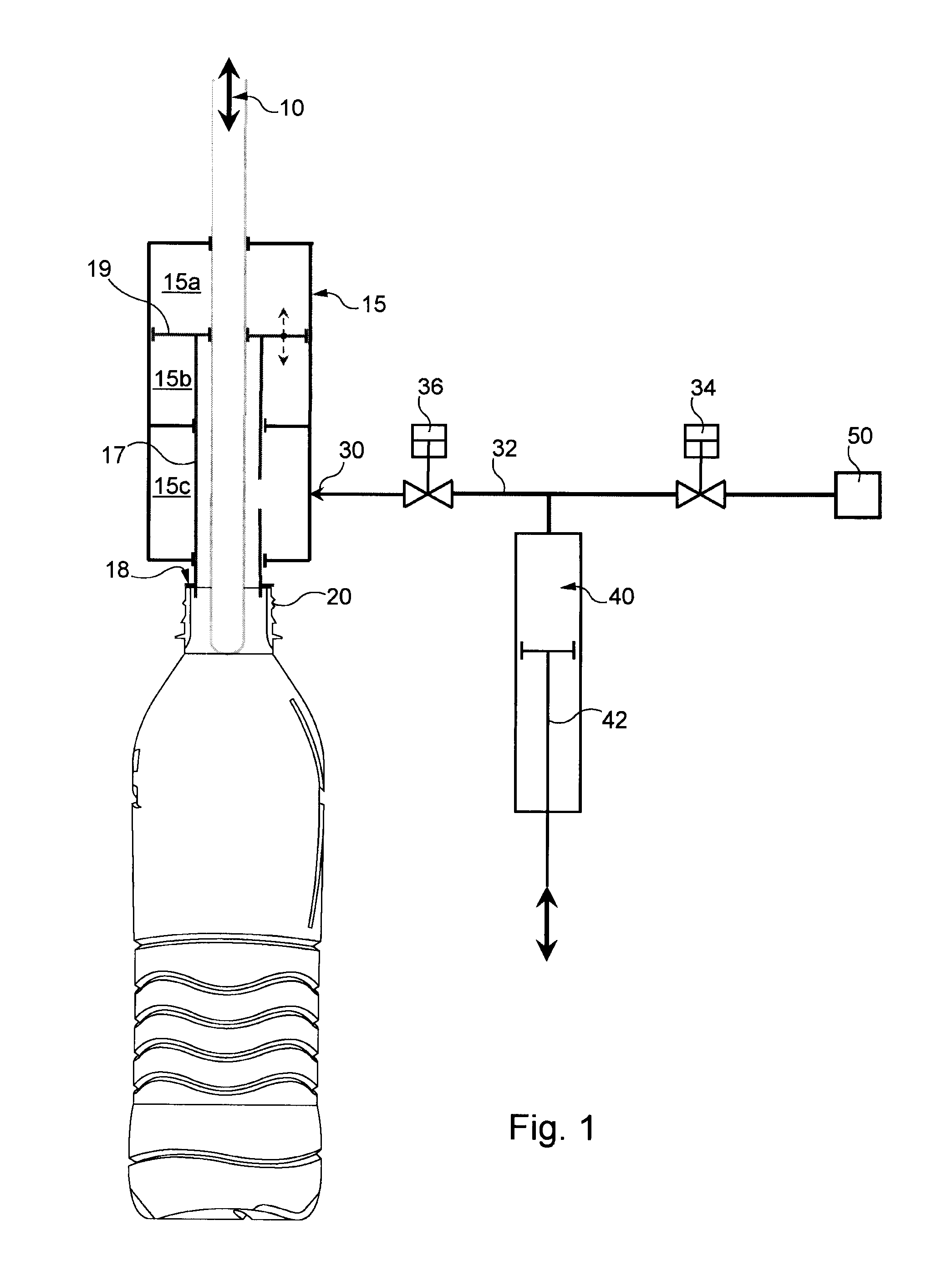

Device for packaging a liquid food product

ActiveUS20110265433A1Process stabilityIntegrated/avoids the splashing of the beverageSolid materialLiquid materialEngineeringBiomedical engineering

The invention relates to a device for delivering a beverage into a thermoplastic container formed from a heated preform (110), the preform being approximately cylindrical and positioned in a mould, characterized in that it includes injection means for injecting at least one beverage into a recess in the preform so as to promote expansion of the preform inside the mould, the mould defining the shape of the container, said injection means comprising an injection head (18) designed to inject at least one beverage through a mouth of the recess, said injection head being integrated into the mould.

Owner:DISCMA

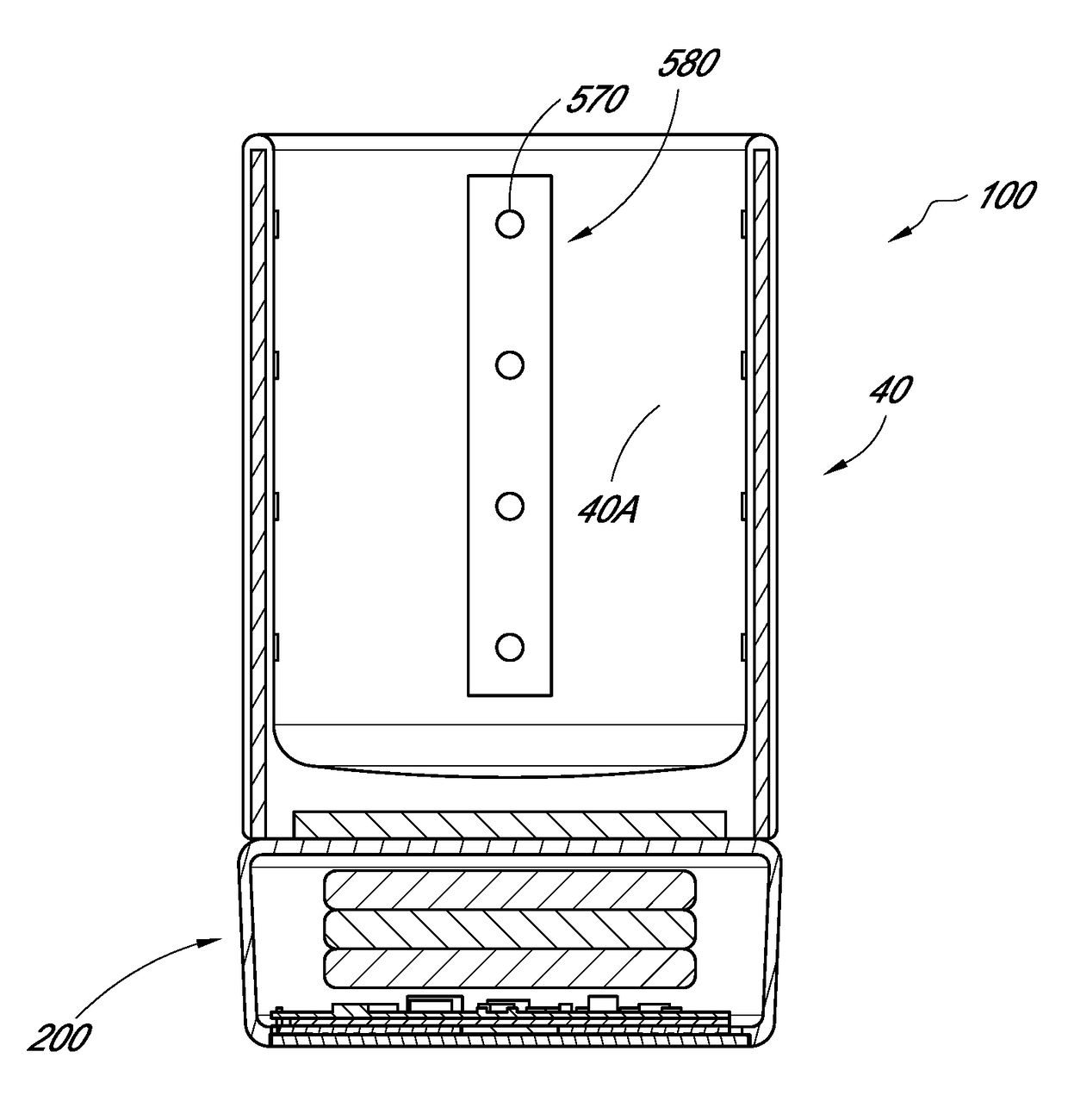

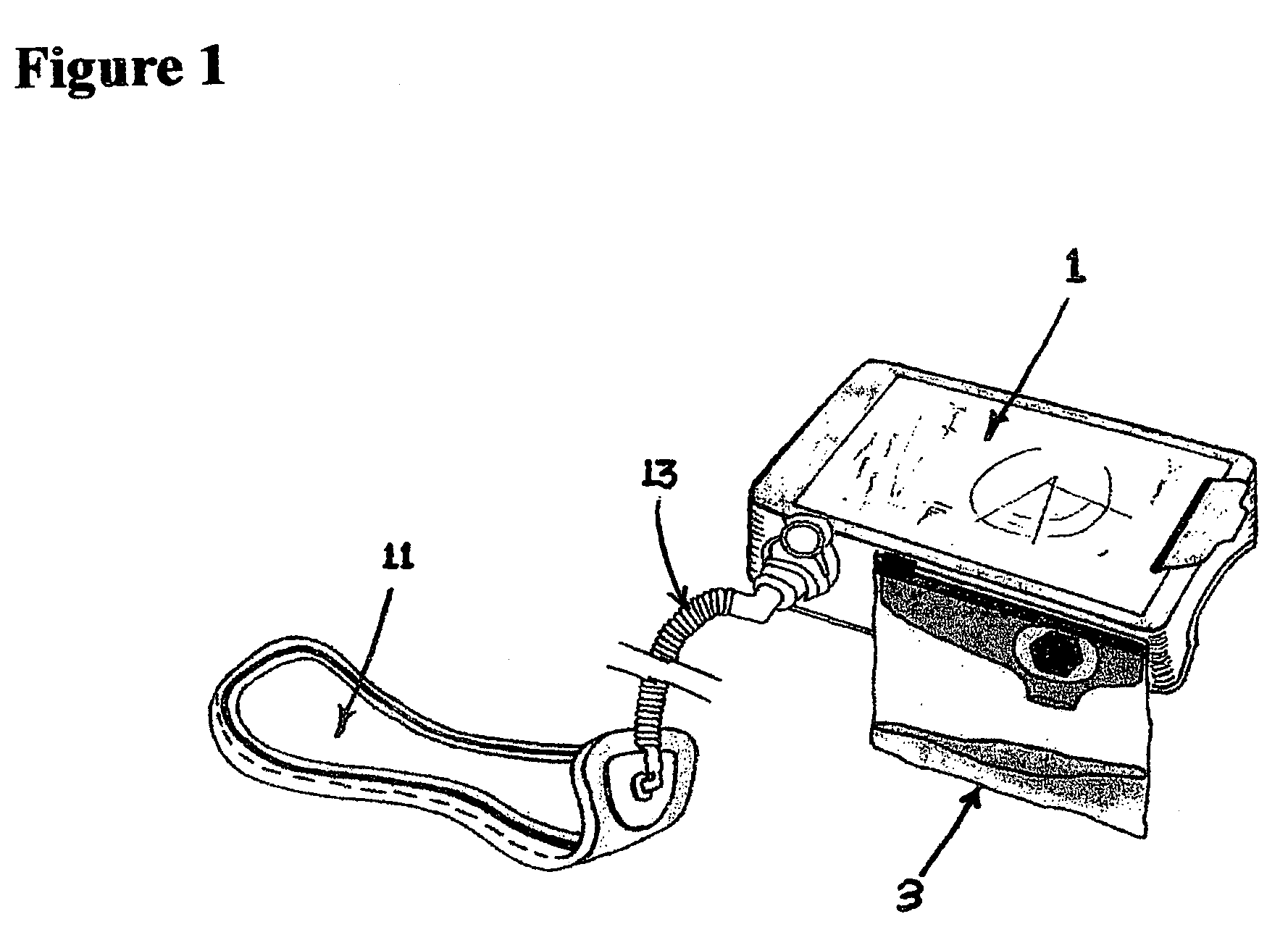

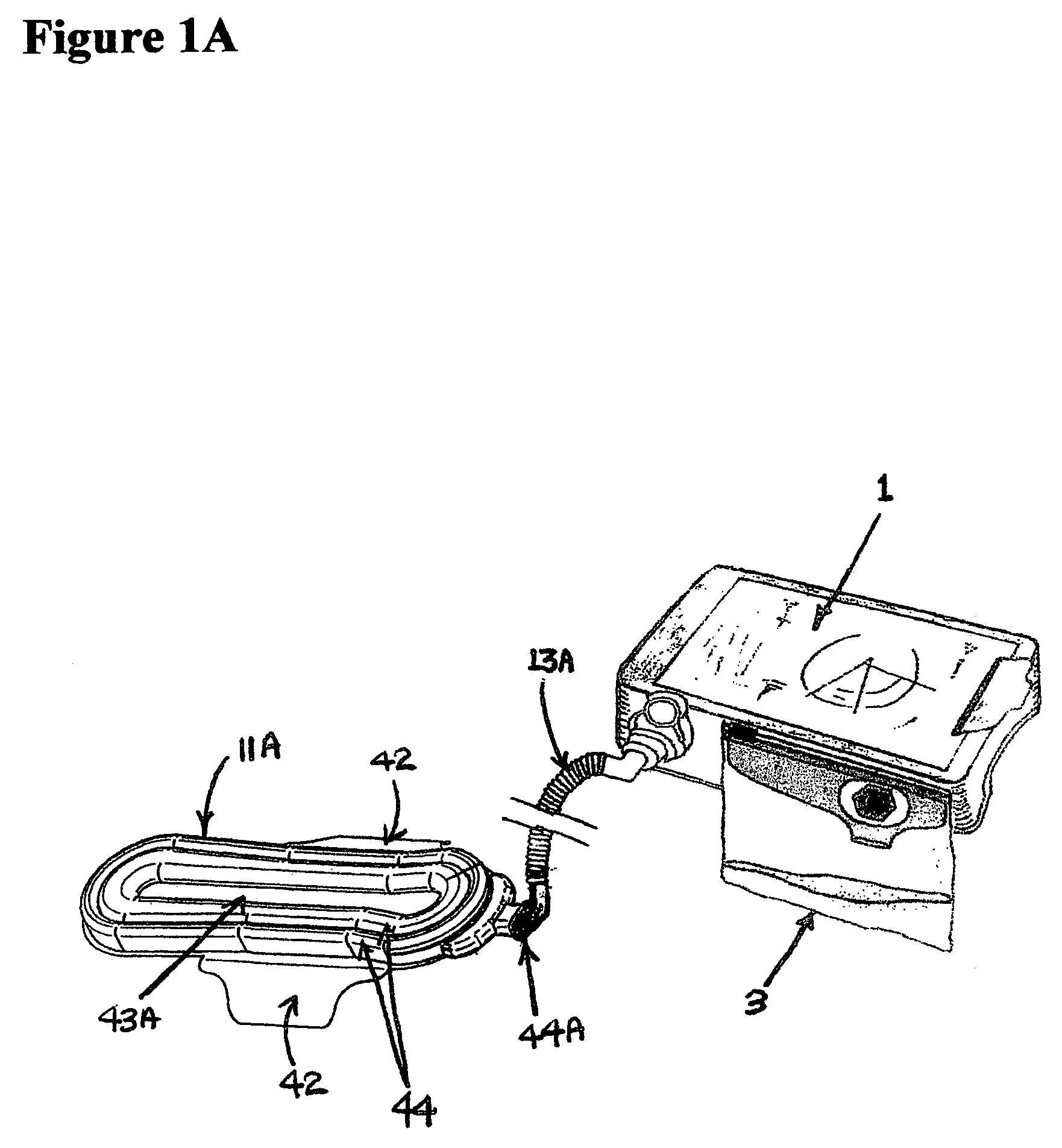

Drinkware and plateware and active temperature control module for same

ActiveUS9801482B1Easy to useGood adhesionWater-boiling vesselsMachines using electric/magnetic effectsOperating instructionTransceiver

An active temperature control module can be used with drinkware and plateware devices. The drinkware can be a mug made of metal, and optionally coated with a ceramic material. The active thermal control module can optionally be removably coupleable to a surface of the drinkware or plateware device. The module can include at least one heating element that can thermally communicate with a surface of the drinkware or plateware device to thereby effect heat transfer through the base to food stuff (e.g., a solid food, a liquid food) in the drinkware or plateware device. The module can include at least one sensor configured to sense a parameter of the foodstuff, and at least one power storage element configured to provide power to the at least one heating element. The module can include control circuitry configured to control operation of the one or more heating elements, and a transceiver configured to transmit operating information of the module to a remote electronic device and to receive operating instructions from the remote electronic device. Optionally, the module can include a heat transfer pack that can thermally communicate with the at least one heating element, and which can be interposed between the at least one heating element and a surface of the drinkware or plateware device.

Owner:EMBER TECH INC

Device and method for hygienically delivering a liquid food

InactiveUS20050269362A1Easy to produceSimplify cleaningOpening closed containersBottle/container closureFood deliveryEngineering

A method and device for hygienically delivering a liquid food to or from a food or beverage dispenser by delivering a flow of liquid food through an outlet positioned at a distance of all surfaces of the dispenser and by frequently cleaning the outlet with a flow of cleaning liquid directed onto the external surfaces demarcating the outlet to eliminate the liquid and solid food residue. The device may include a connection fitment with an elongated food delivery member which is configured to connect to a cleaning chamber of the dispenser. The device can be easier and more conveniently cleaned and / or sanitized enabling the dispensing of microbial sensitive food products such as milk concentrate and the like.

Owner:NESTEC SA

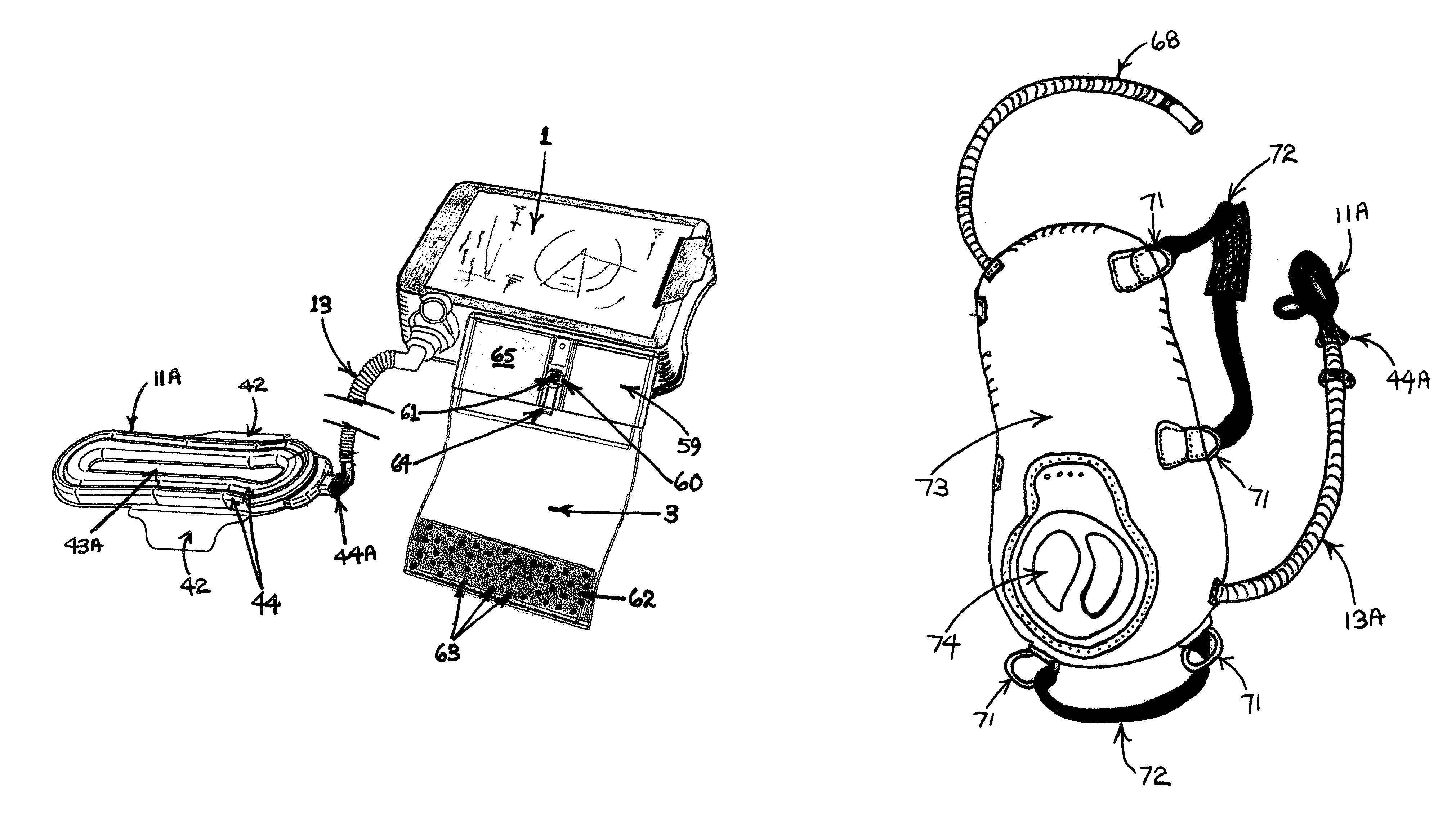

Automatic self cleaning bladder relief and hydration system

InactiveUS7141043B2Minimizing bulkMinimize discomfortNon-surgical orthopedic devicesSuction devicesSemi automaticUrine Collections

Owner:HARVIE MARK R

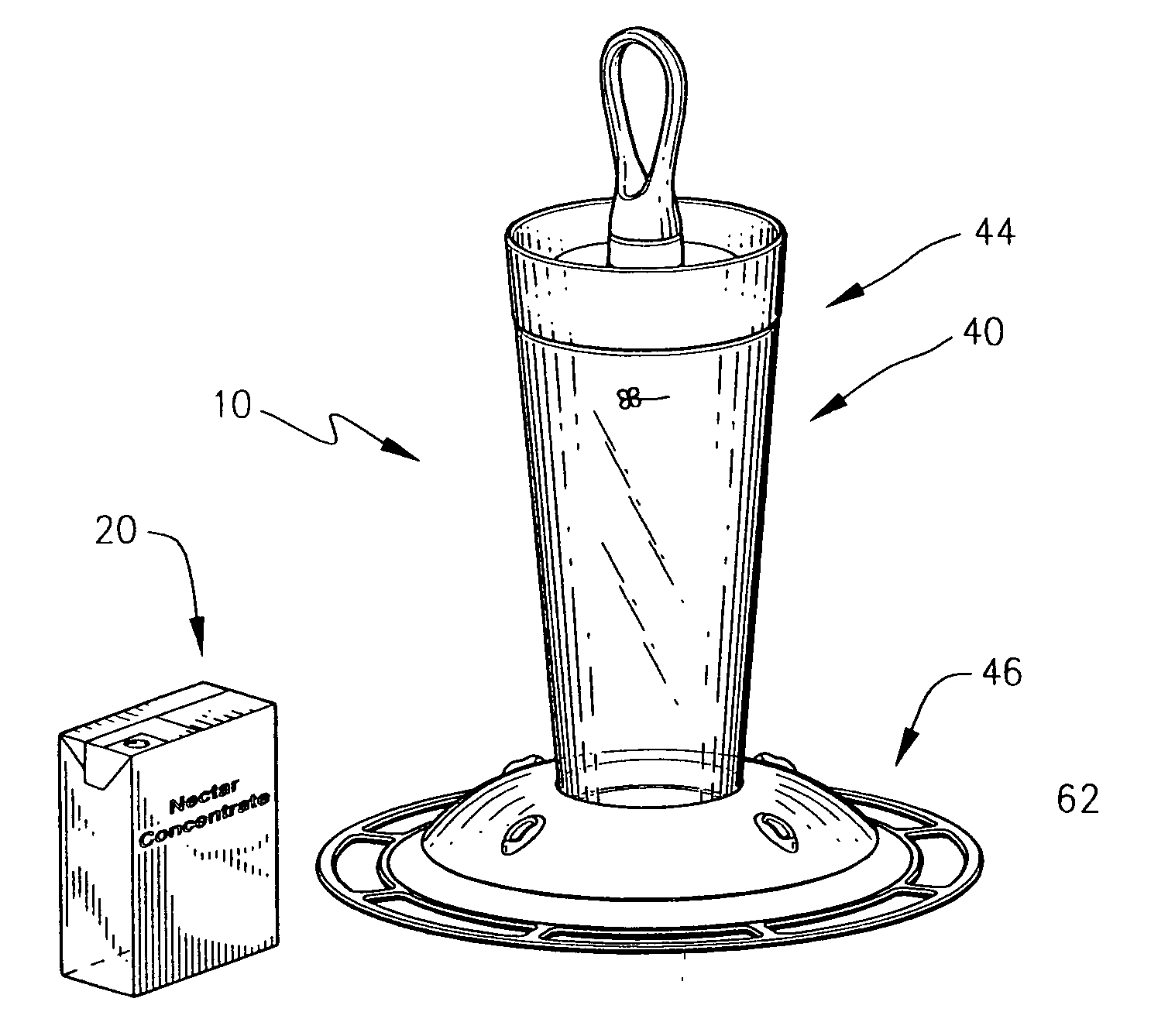

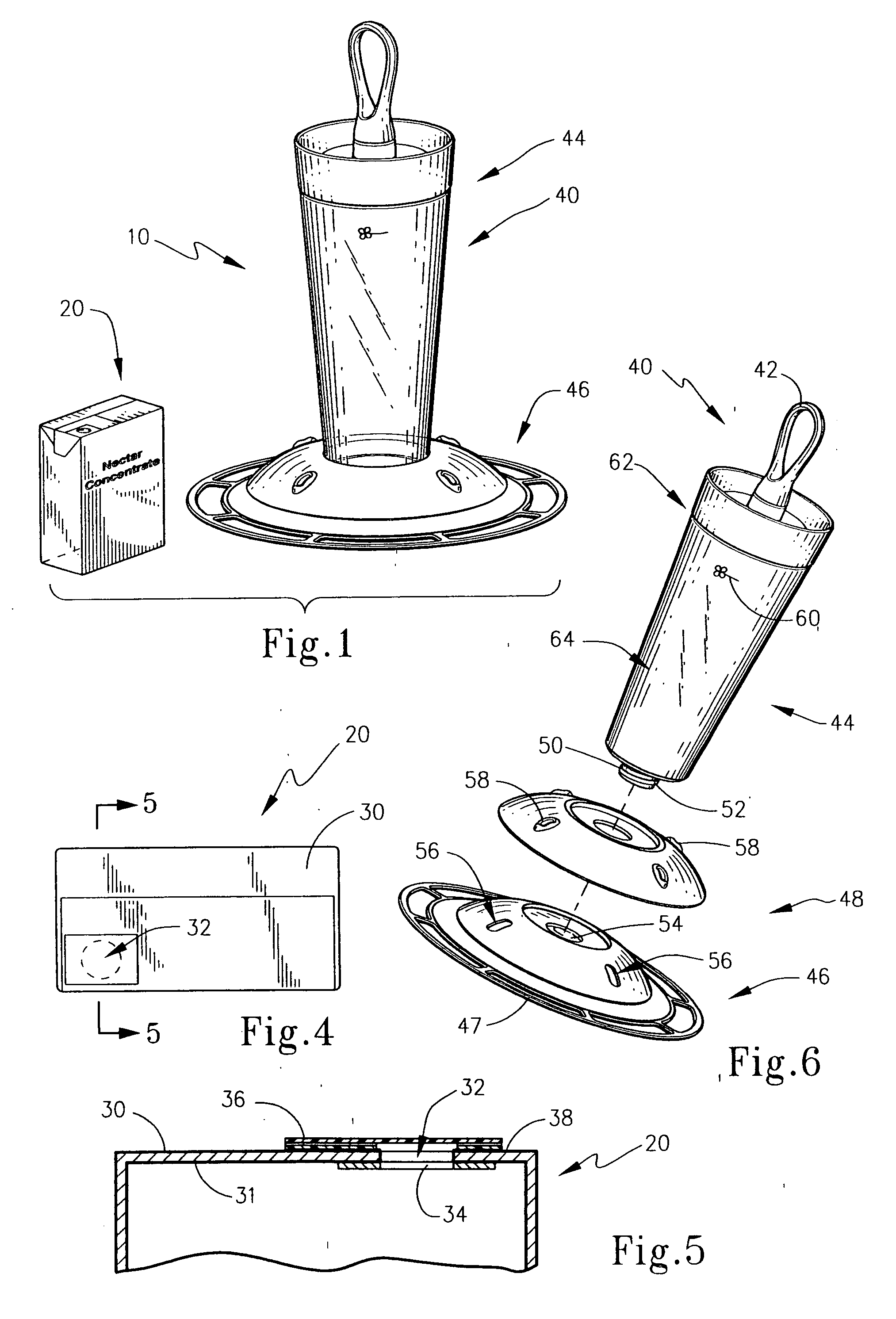

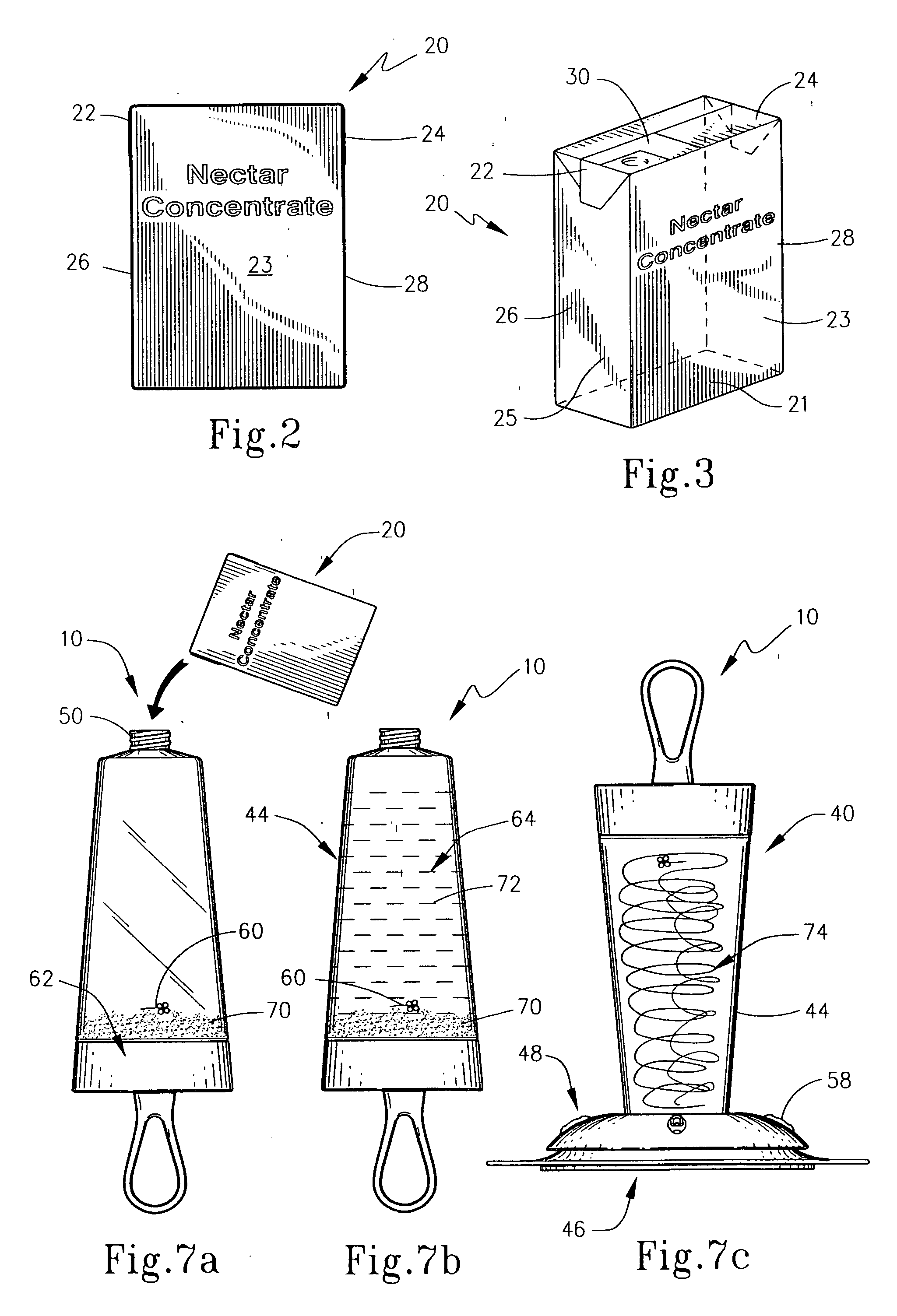

Nectar feeding system

The present invention provides a feeding system for dispensing liquid food to a bird. The system includes a container of concentrated sugar solution that is dilutable with water at a selected dilution ratio of concentrate to water and a feeder to be supported by a support structure. The feeder includes a reservoir having a selected volume and an index marking correlating to a selected partial volume whereby the ratio of the partial volume to the difference between the selected volume and the partial volume is equal to the dilution ratio for the concentrate. The base of the feeder mounts to the reservoir and has at least one feed outlet to make the liquid in the reservoir available to the bird. The present invention is also directed to a method of providing nectar solution to hummingbirds.

Owner:WOODSTREAM CORP

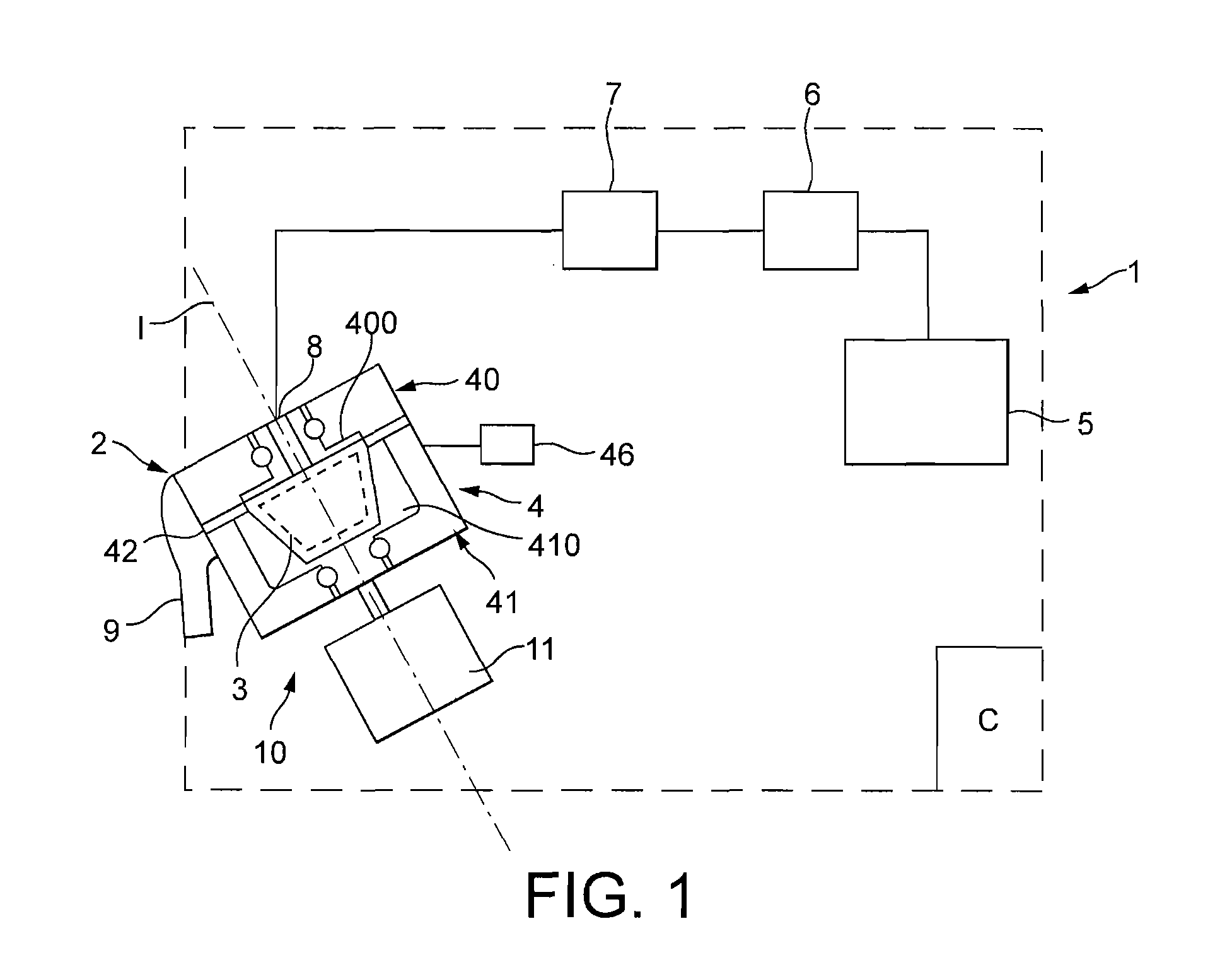

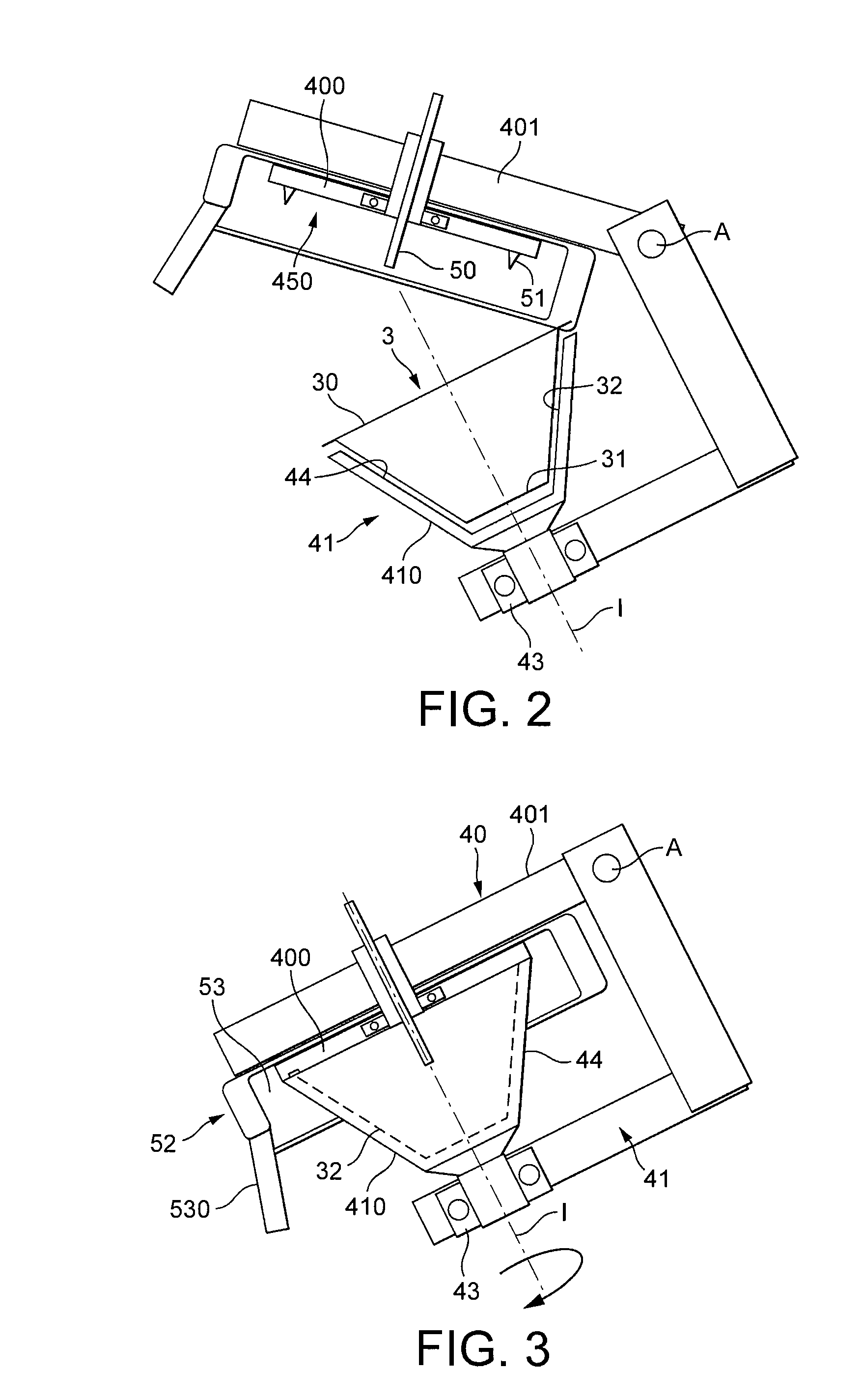

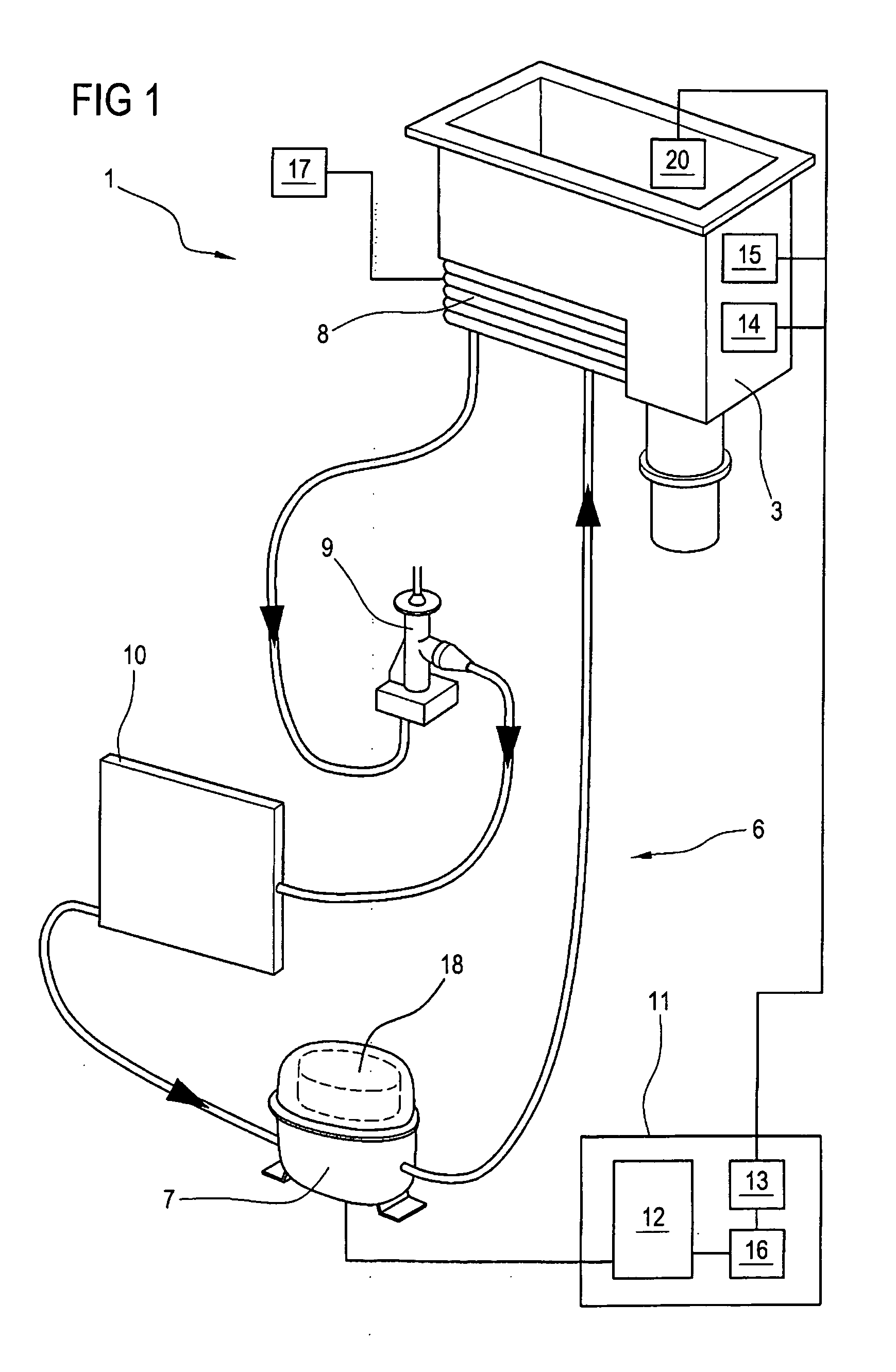

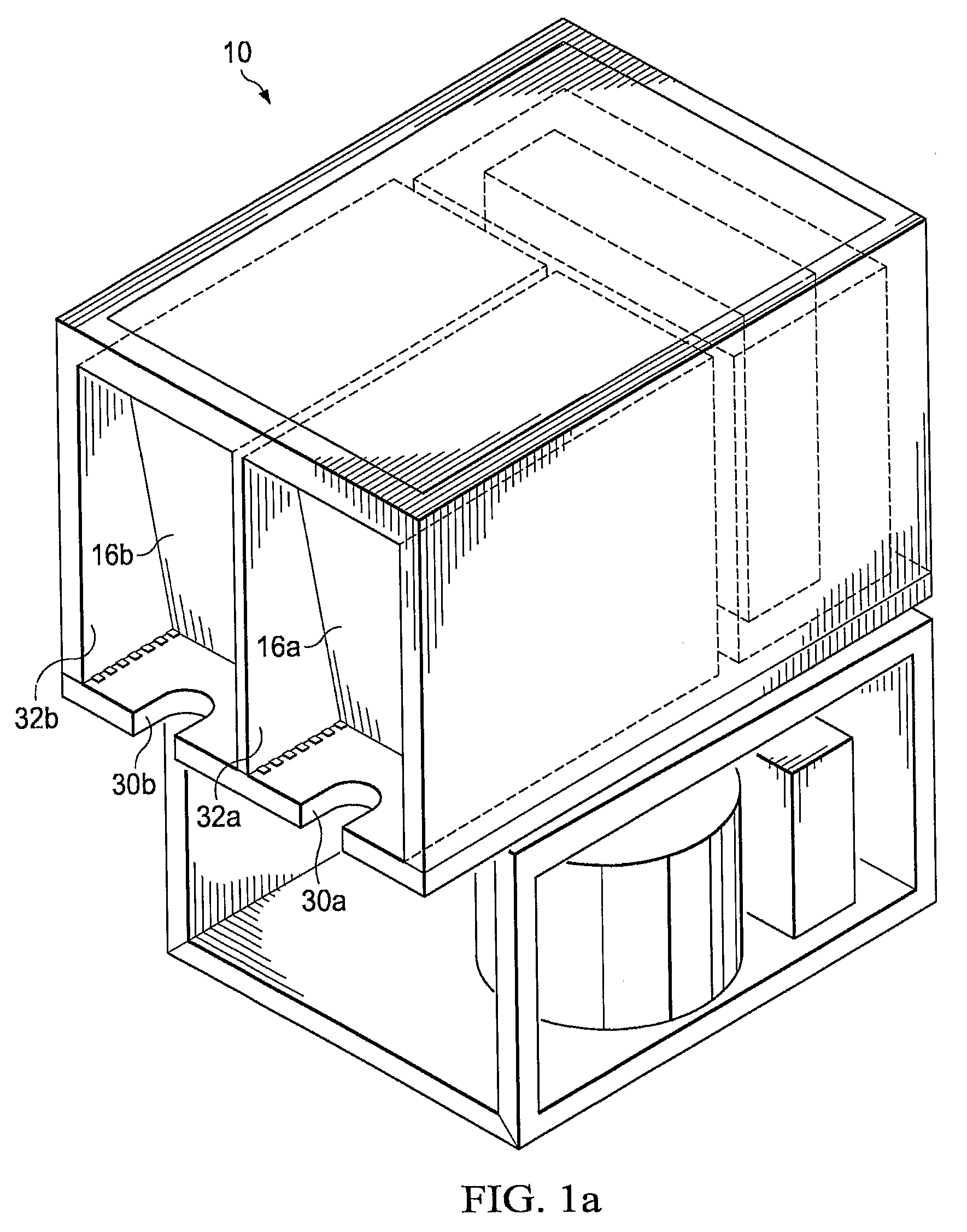

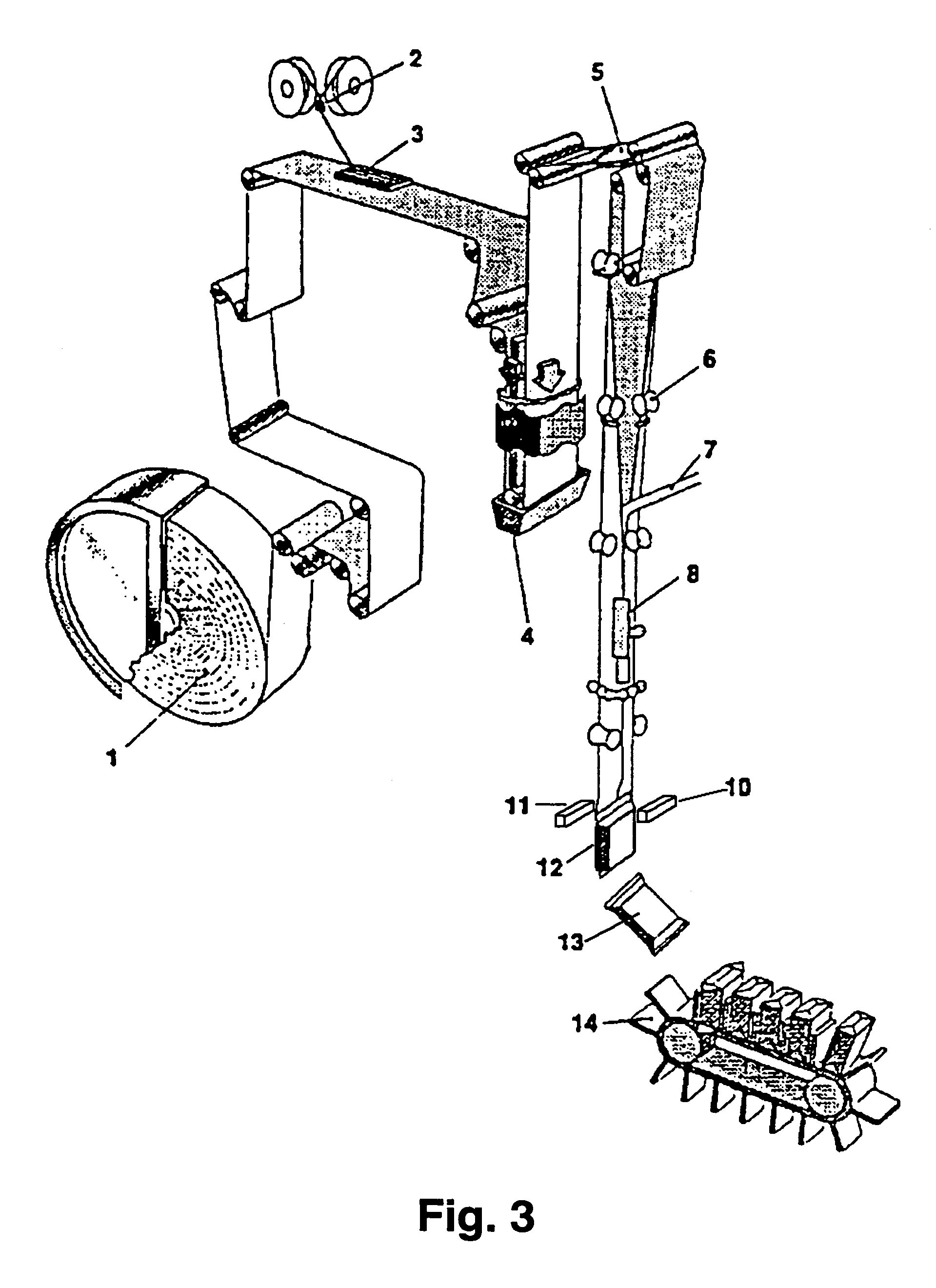

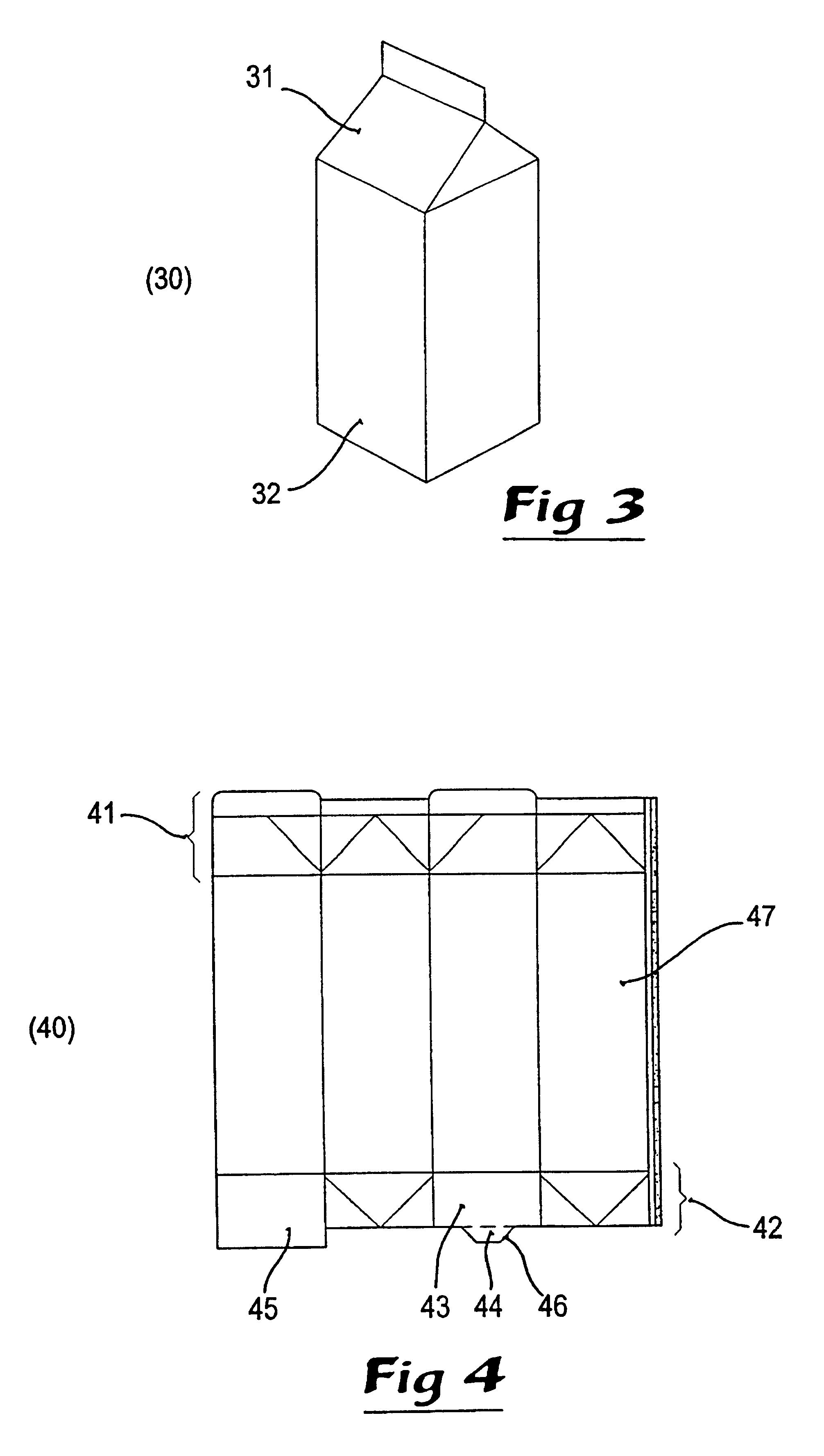

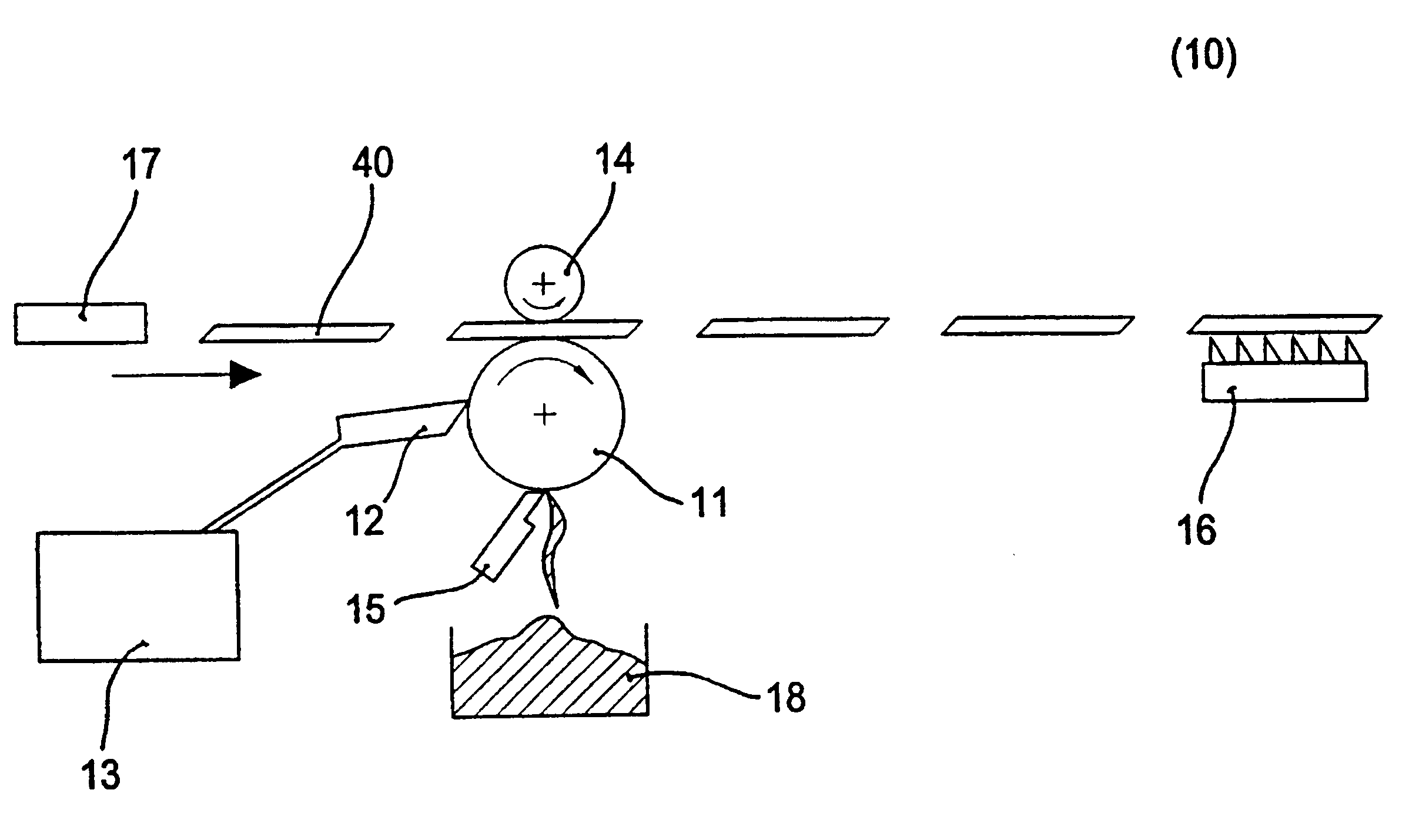

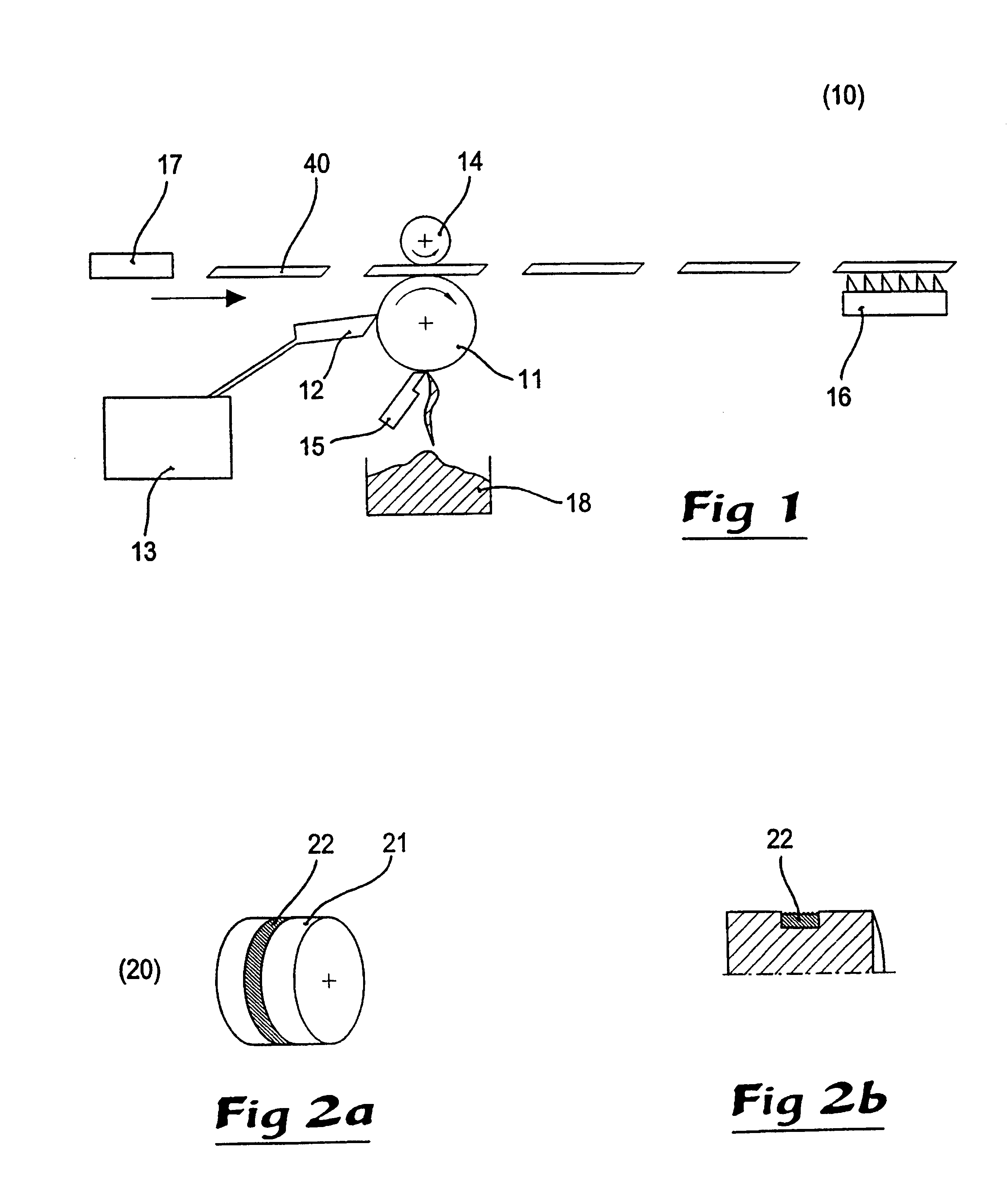

Method and an apparatus for producing packaging containers for liquid foods, as well as packaging containers

The disclosure relates to a method and an apparatus (10) for producing a packaging container for liquid foods from a packaging container blank (40) by permanently uniting and sealing at least two of its edges (61, 65) with the aid of a hot melt glue, the hot melt glue being applied along one of the two edges with the aid of a heated applicator roller (11). The circumferential surface (21) of the hot roller is preferably made of hardened steel with a coating (22) countersunk in a groove int he surface along the circumference of the circumferential surface, the coating possessing good slippage properties in relation to the hot melt glue and the coating being of a width which corresponds to the region intended for application. A counter roller (14) acts on the opposite side of the packaging laminate blank against the applicator roller for controlling the outflow of the applied hot melt glue strand. How melt glue is applied to the applicator roller by means of a heated nozzle (12) and the surplus which is not transferred to the packaging laminate blank is scrapped off from the applicator roller by means of a doctor blade (15). The hot melt glue is preferably an ethylene vinyl acetate based composition with a high melting point and high viscosity which is applied at least approx. 180° C.

Owner:TETRA LAVAL HLDG & FINANCE SA

Heating and cooling cup

A heating and cooling cup includes a cup body, a stirring device, a heating and cooling chip, and a heat sink module. A heat conductive block is disposed under the cup body, the heat conductive block abuts against the heating and cooling chip, the stirring device has a stirring rod disposed in the cup body, and a bottom surface of the heating and cooling chip abuts against a heat conductive block of the heat sink module. A temperature of the cup body is changed through the heating and cooling chip, for cooling or heating liquid food in the cup body, and the liquid food is forced to generate convection through the stirring rod for accelerating a temperature variation process.

Owner:LIU PEI CHUAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com