Three-dimensional printer with replaceable nozzle

A three-dimensional printer and nozzle technology, which is applied to tool replacement devices, coating devices, manufacturing tools, etc., can solve the problems of unguaranteed printing quality, complex printer structure, mixing materials, etc., and achieves strong practicability and various improvements Sex, the effect of increasing variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and implementation process.

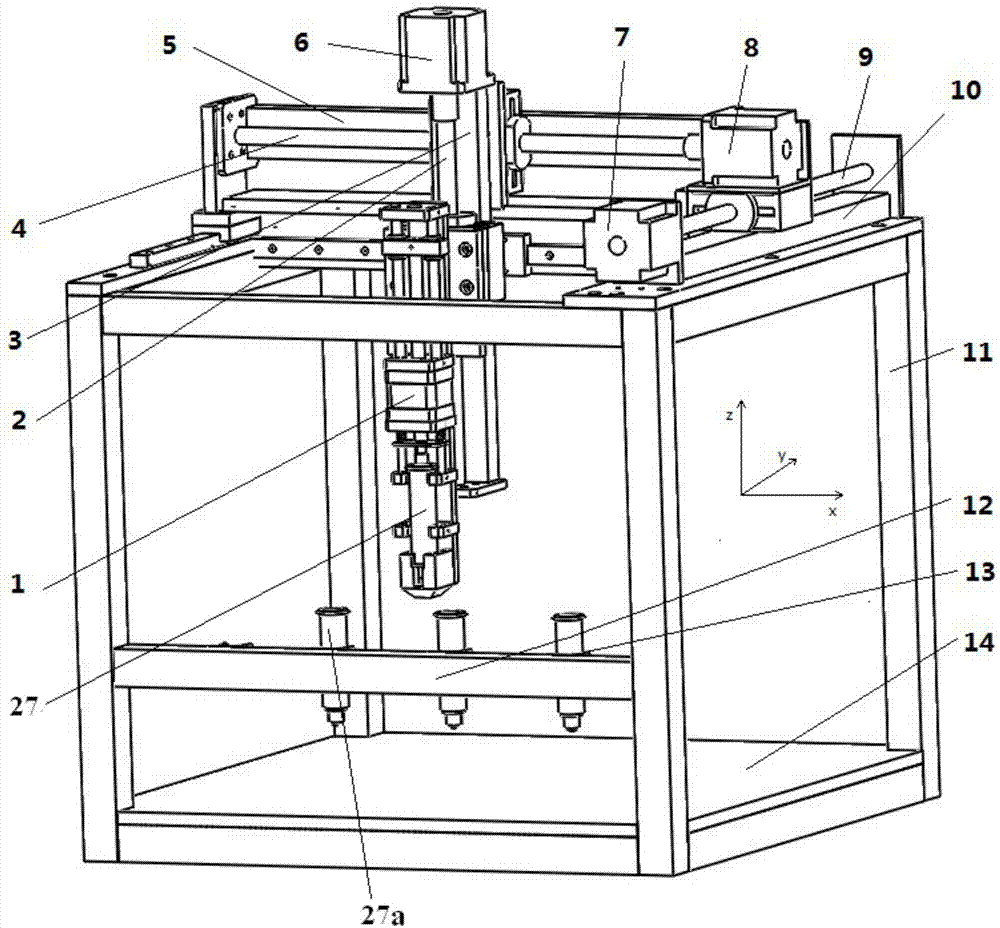

[0037] Such as figure 1 As shown, a three-dimensional printer with replaceable nozzles includes a chassis frame 11, and an X-axis adjustment mechanism, a Y-axis adjustment mechanism, and a Z-axis adjustment mechanism installed on the chassis frame 11 .

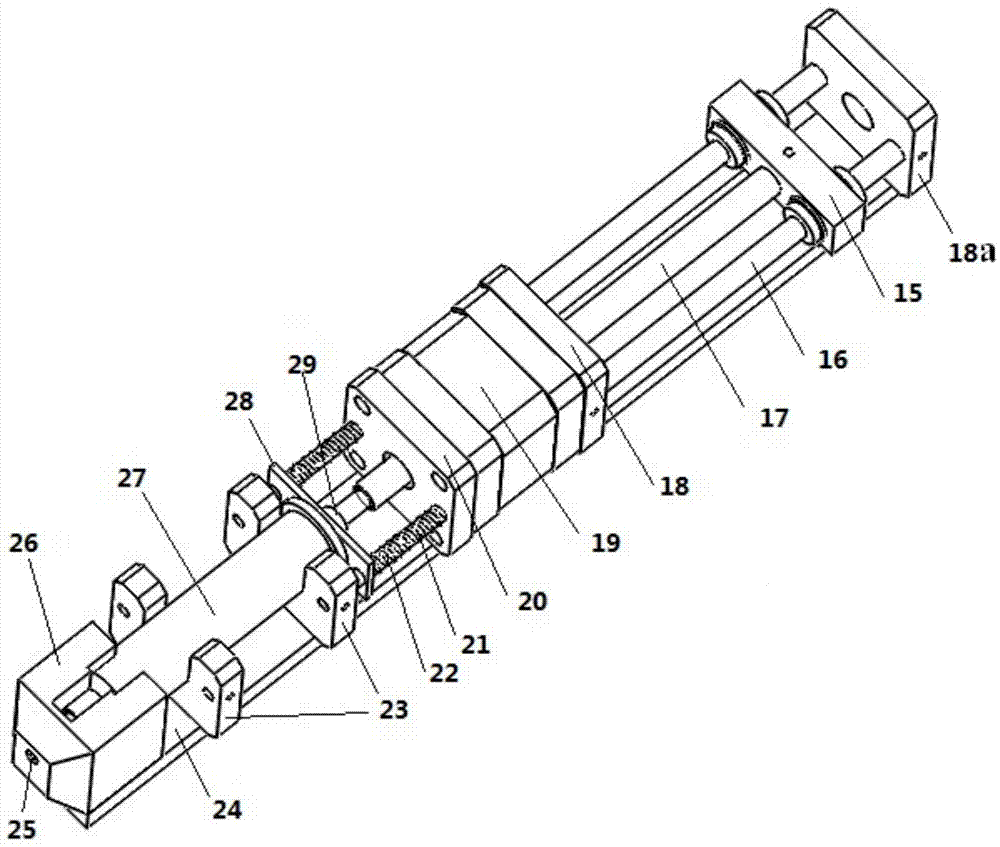

[0038]The Y-axis adjustment structure includes a Y-axis stepping motor 7 fixed in the longitudinal direction of the chassis frame 11 , a Y-axis guide rail 10 , and a Y-axis lead screw 9 installed above the Y-axis guide rail 10 . The X-axis adjustment mechanism includes an X-axis guide rail 5, an X-axis stepping motor 8 and an X-axis screw 4, and the Y-axis screw 9 drives the X-axis guide rail 5 to move in the Y direction through thread engagement. An X-axis stepper motor 8 and an X-axis lead screw 4 are installed on the X-axis guide rail 5 . The Z-axis adjustment mechanism includes a Z-axis guide rail 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com