Patents

Literature

200results about How to "Achieve relatively fixed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

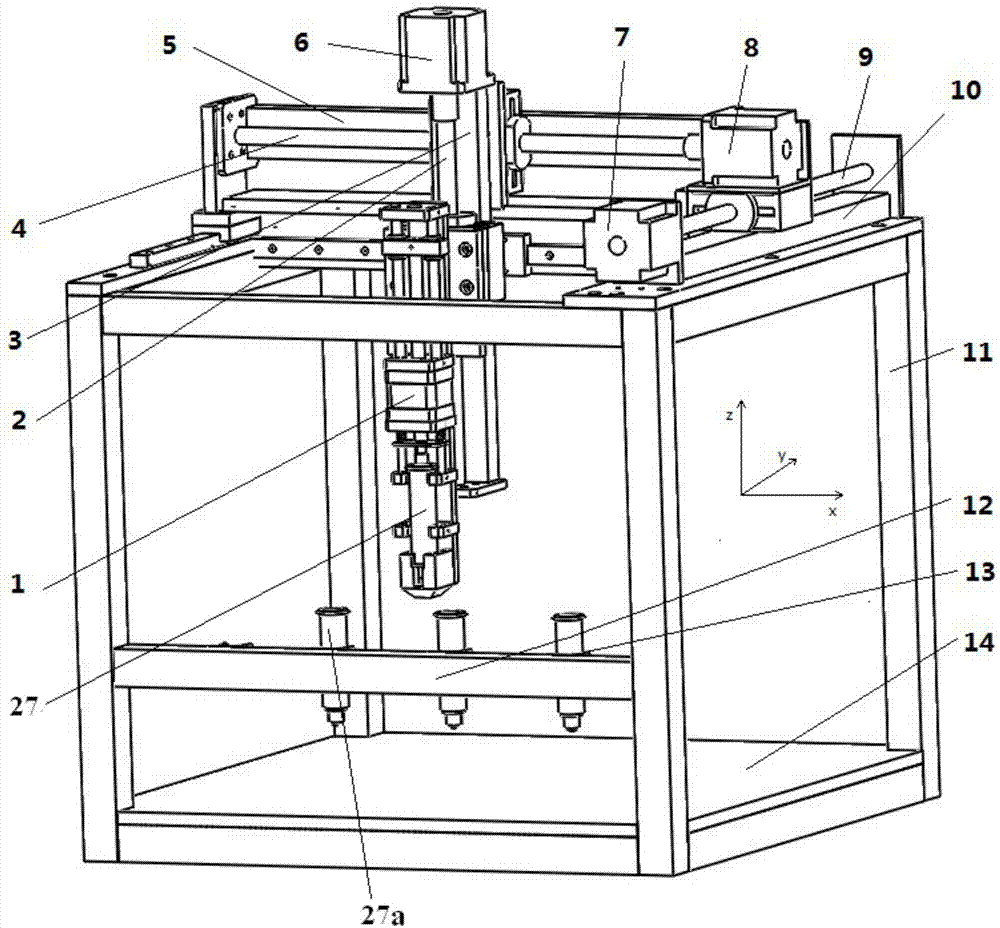

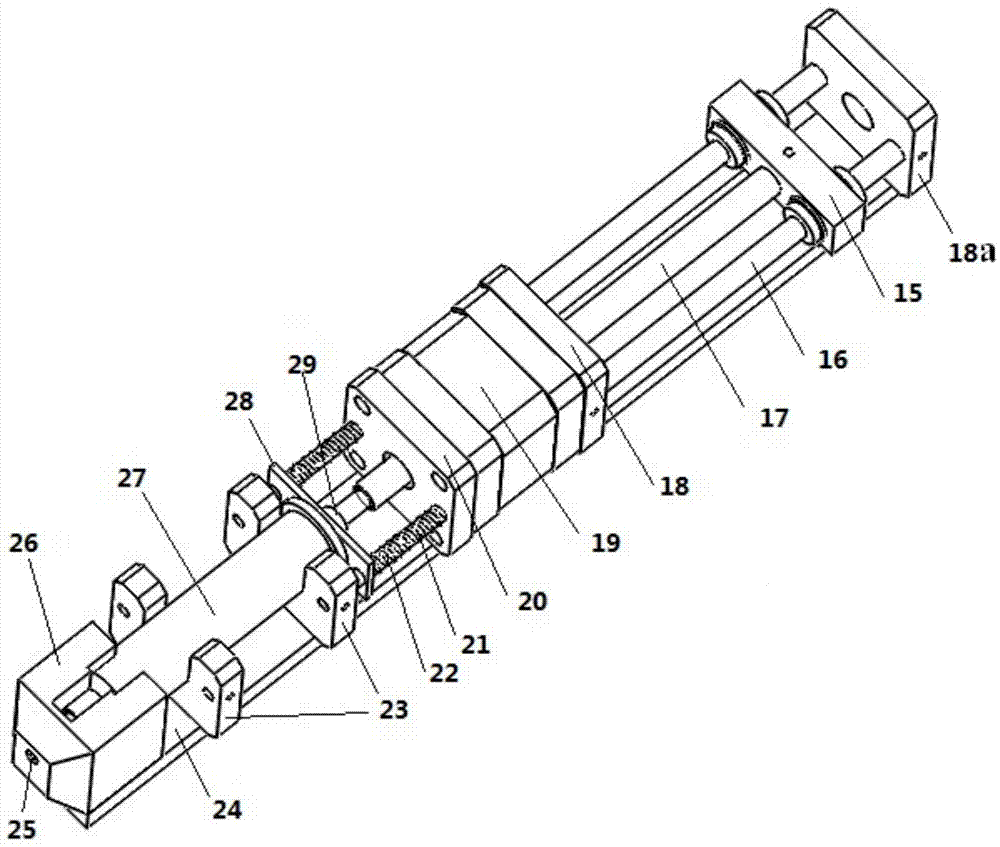

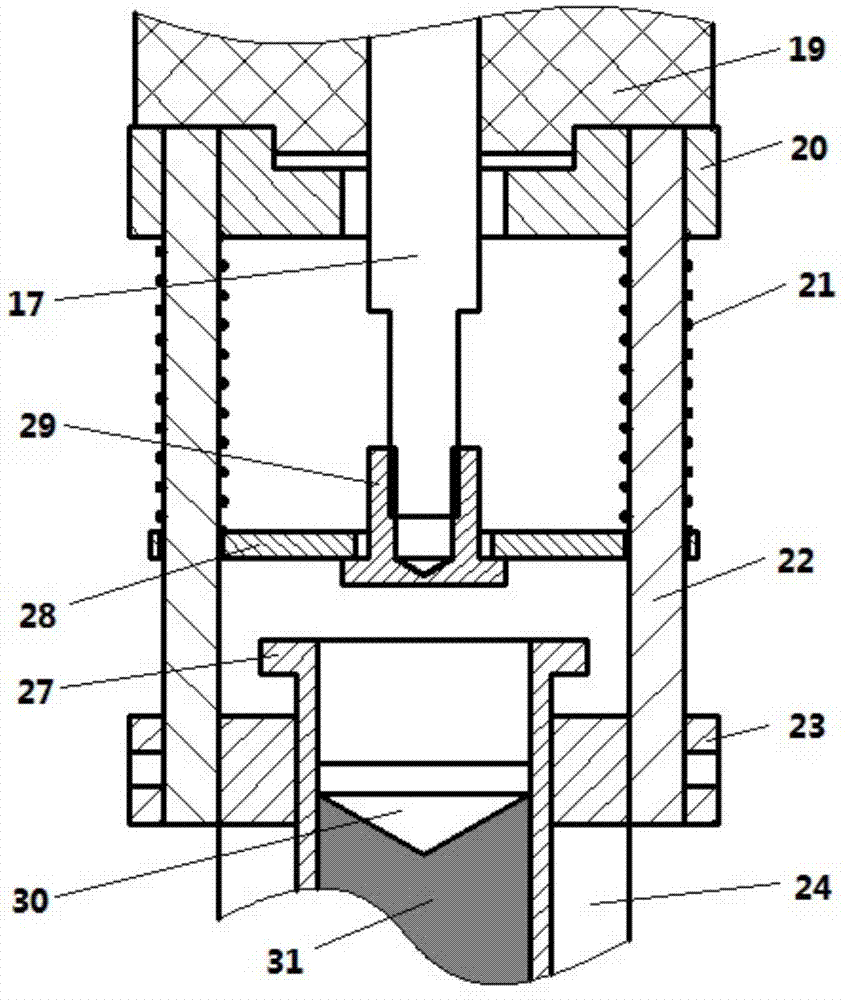

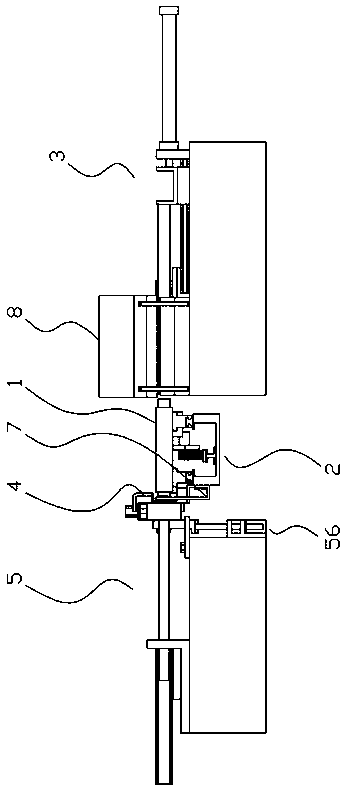

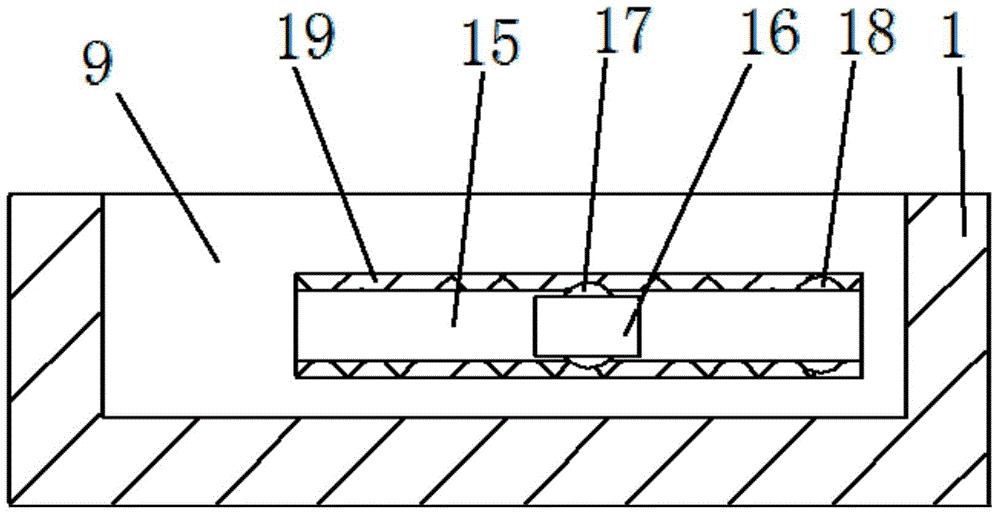

Three-dimensional printer with replaceable nozzle

ActiveCN103878980AAchieve relatively fixedPracticalTool changing apparatusApplying layer meansLiquid foodPiston

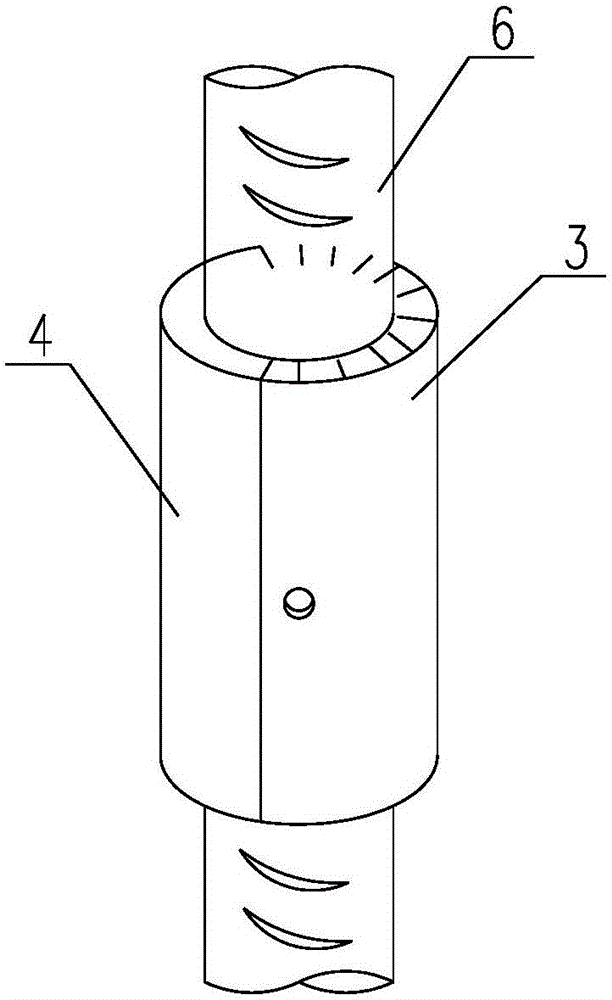

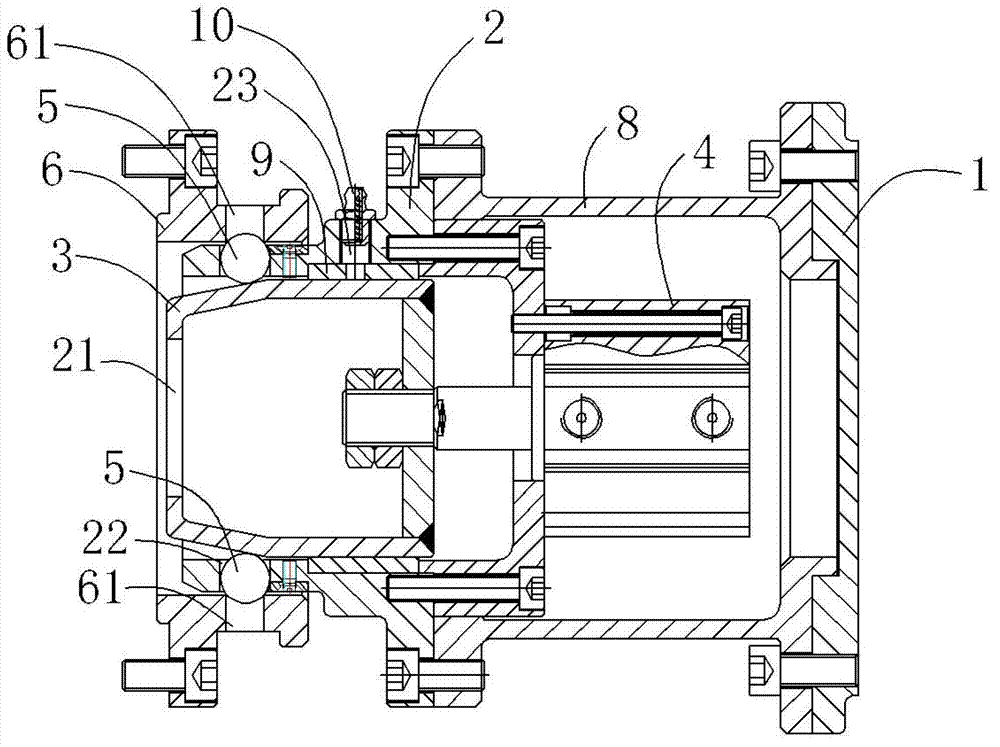

The invention discloses a three-dimensional printer with a replaceable nozzle. The three-dimensional printer comprises a three-dimensional adjusting mechanism, and the printing nozzle which performs three-dimensional printing under the adjustment of the three-dimensional adjusting mechanism, wherein the printing nozzle comprises a nozzle bottom plate, a nozzle thermal preservation sleeve which is fixed on the nozzle bottom plate and is provided with a printing through hole and a positioning notch, a material tube which is radially clamped on the nozzle bottom plate, and a linear stepping motor; the material tube is axially clamped in the positioning notch through a material tube pressing plate which is in sliding fit with the nozzle bottom plate; a piston presser used for pushing a piston in a first material tube is fixed at the output end of a lead screw of the motor. When materials in the material tube are used up or the materials are needed to be replaced, the printing nozzle is controlled to automatically replace the material tube, and a three-dimensional object consisting of multiple materials can be printed. The piston is driven to be extruded by adopting the linear stepping motor, thrust is high and can be accurately controlled, and the blockage of the nozzle is avoided. According to the printer, liquid foods and multiple liquid materials such as gel and ceramic powder can be printed.

Owner:ZHEJIANG UNIV

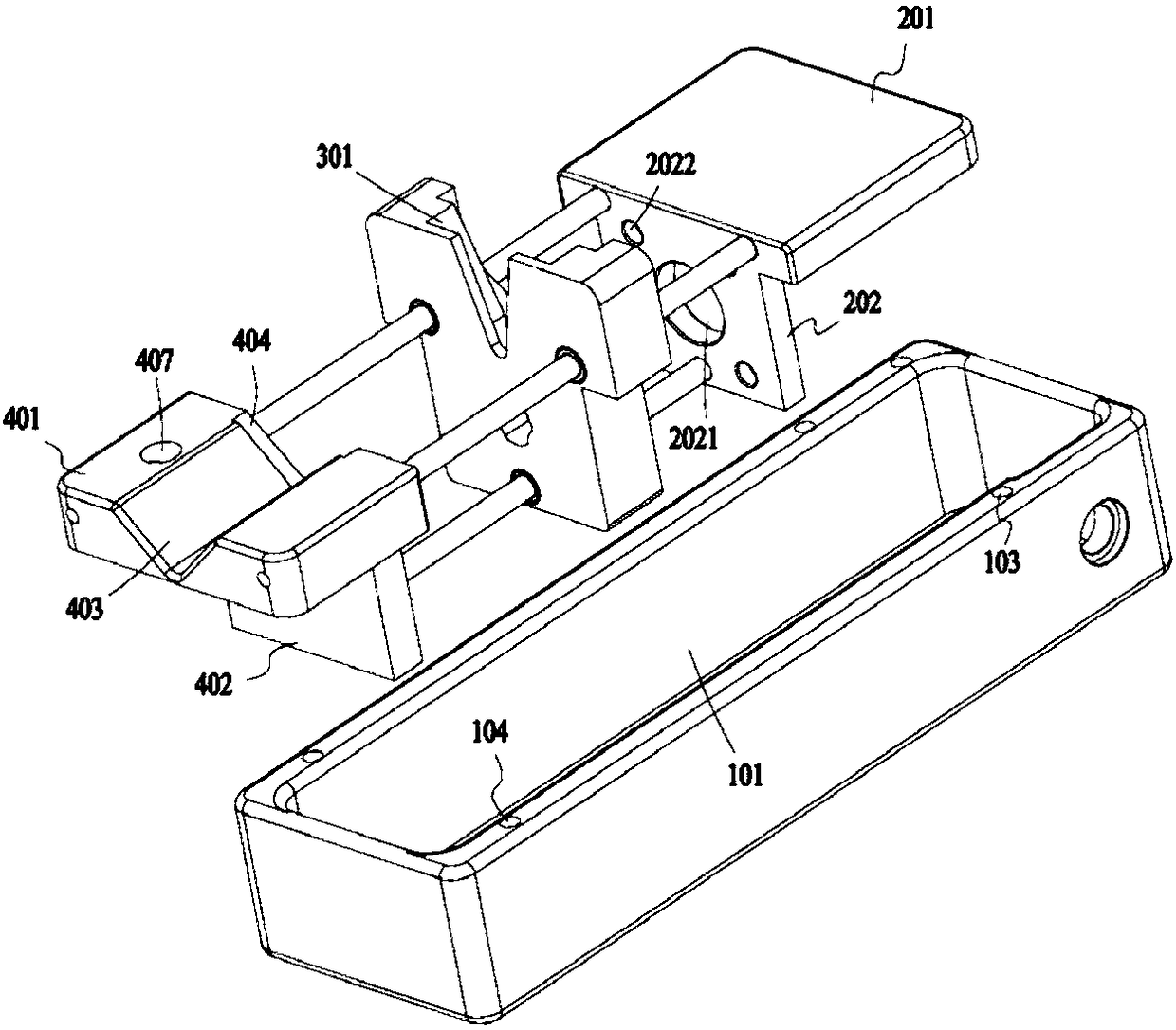

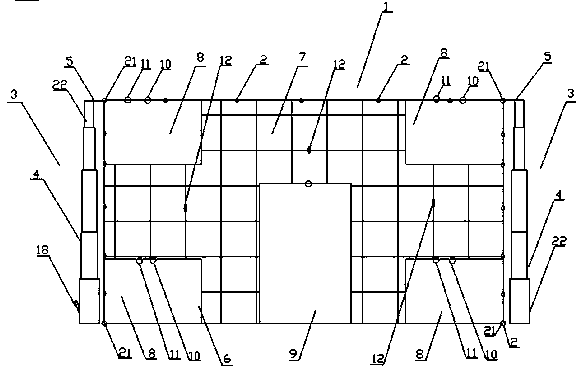

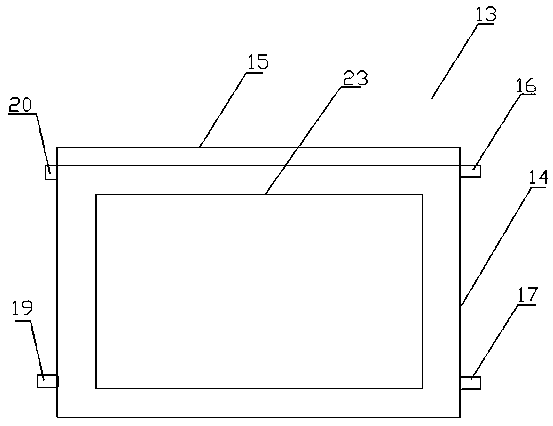

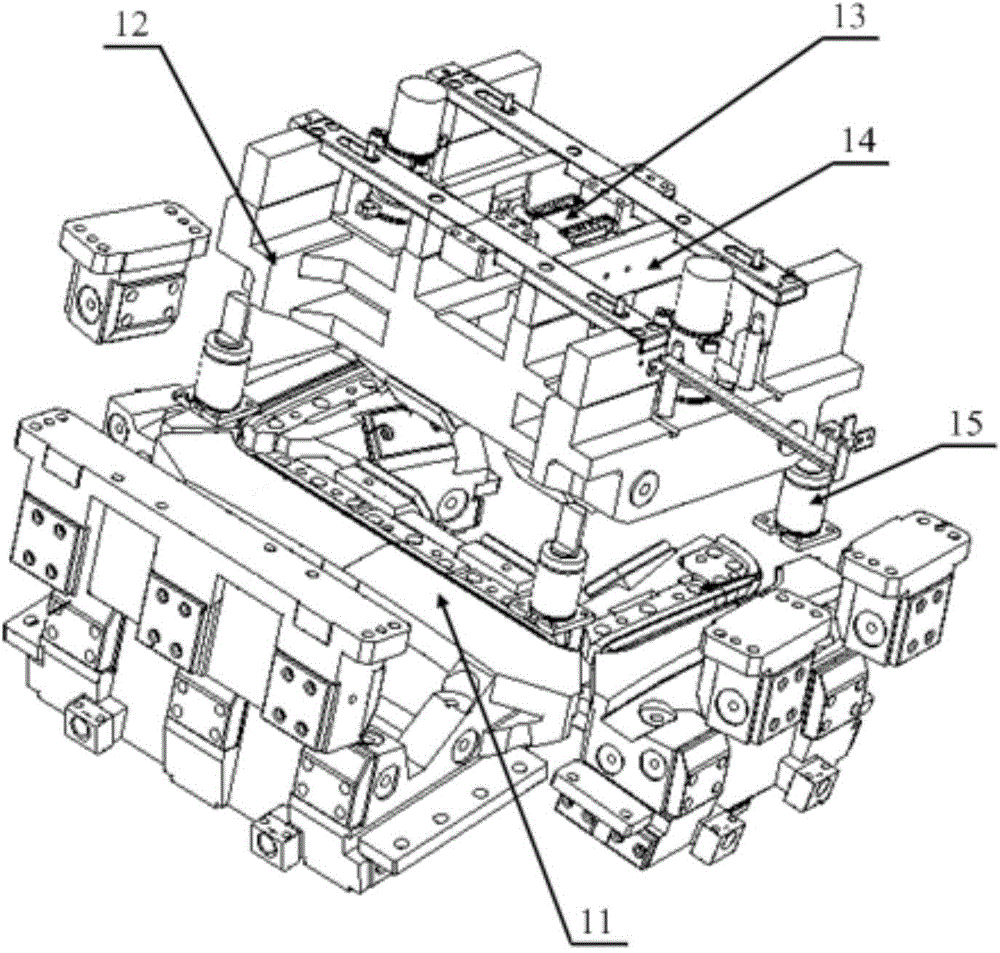

Packaging box automatic box sleeving device and electric appliance packaging production line

ActiveCN104210705AImprove nesting efficiencyAlleviates the need to adjust boxes to keep nesting operations running smoothlyPackagingProduction lineStandard plane

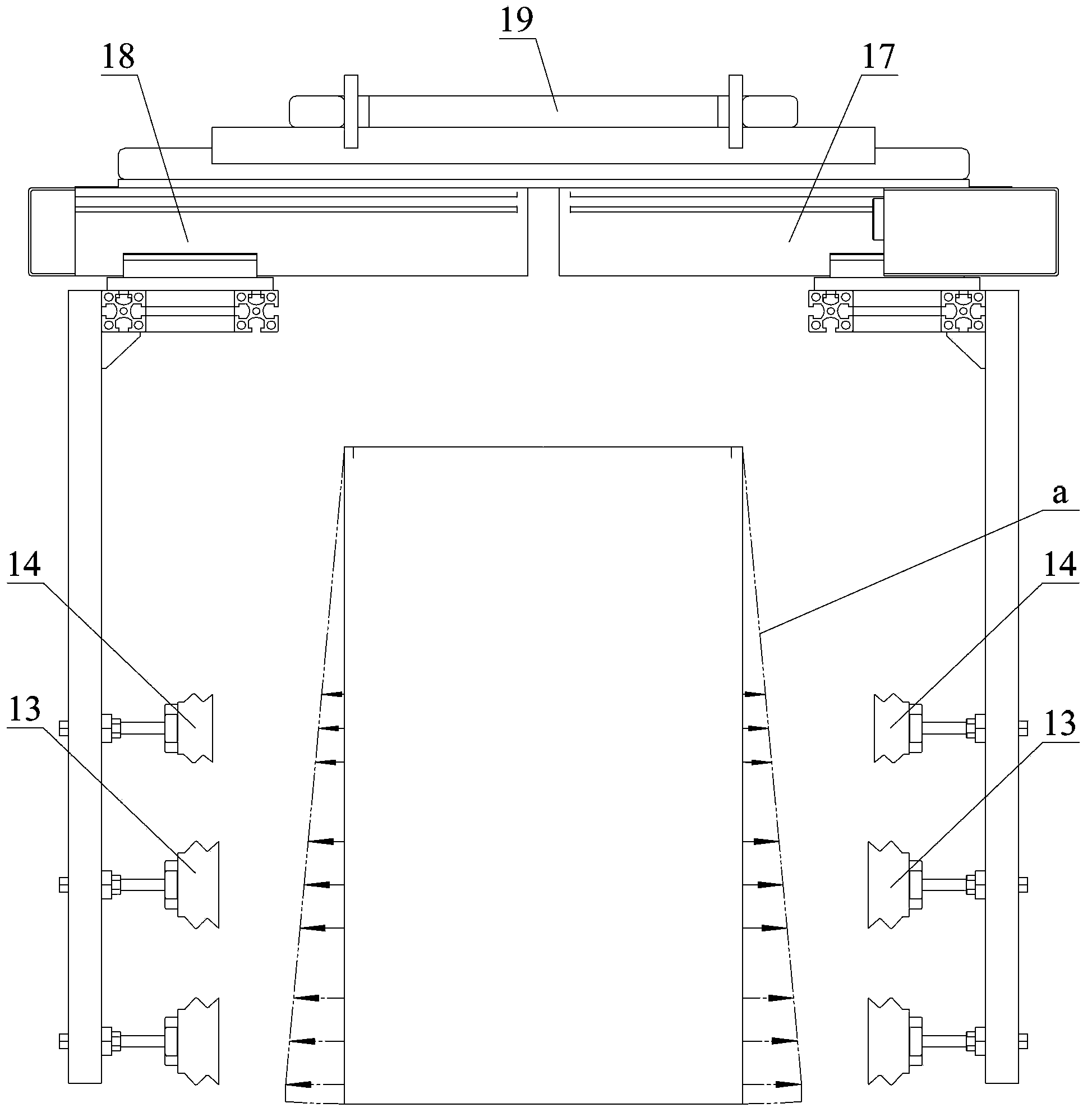

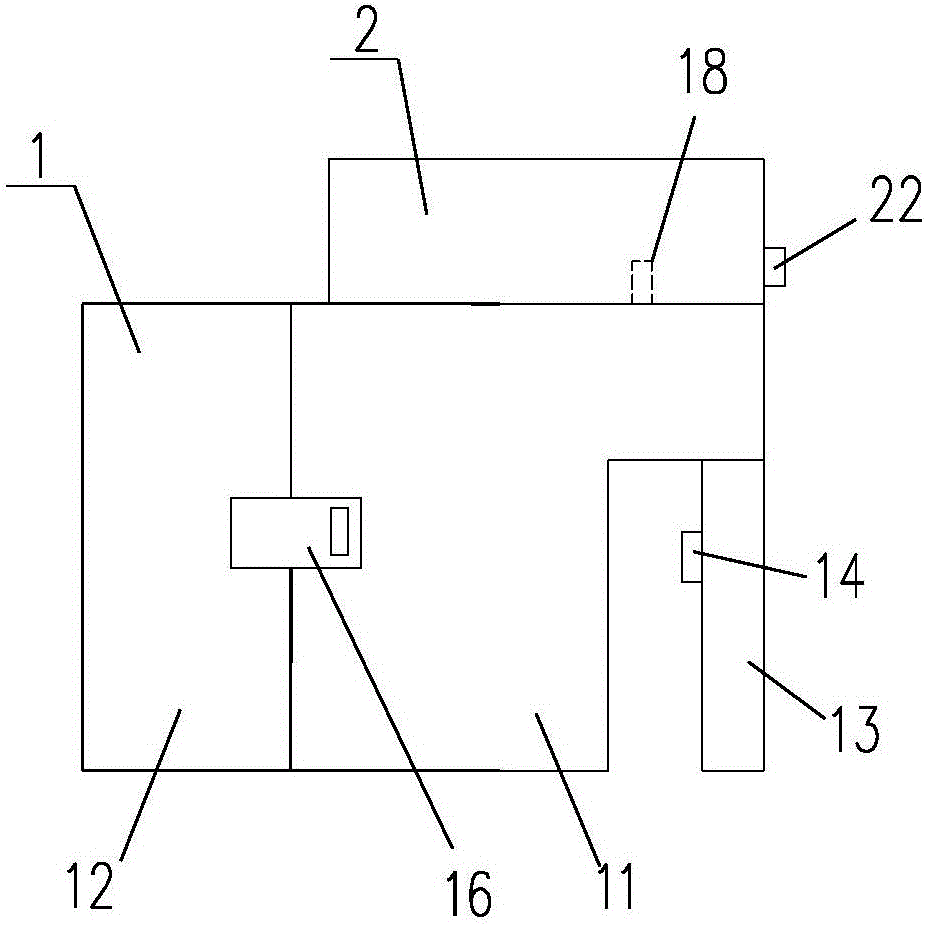

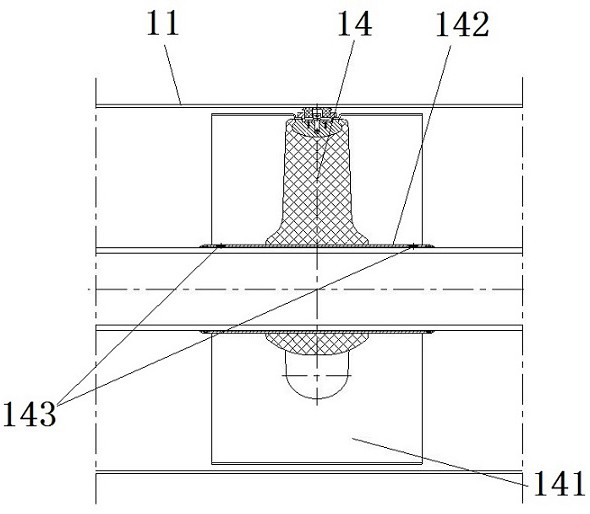

The invention discloses a packaging box automatic box sleeving device which comprises an imbibition box mechanism. The imbibition box mechanism comprises a sucking jaw group formed by at least two sucking jaws placed on the same side. The sucking jaw group comprises a packaging box end sucking jaw (11) provided with an end sucking disc (13) and a packaging box middle sucking jaw (12) provided with a middle sucking disc (14). The distance between the working face of the end sucking disc (13) and the standard plane of a surface to be adsorbed of a packaging box is smaller than the distance between the working face of the middle sucking disc (14) and the standard plane. The sucking jaw group has a box expanding stroke far away from the standard plane. When the packaging box has an effect on an electric appliance under the effect of the packaging box automatic box sleeving box, the packaging box cannot interfere with the electric appliance easily, then the situation that an operator needs to adjust the packaging box to guarantee the fact that box sleeving operation is carried out smoothly is relieved, and accordingly the box sleeving efficiency of the electric appliance is improved.

Owner:GREE ELECTRIC APPLIANCES INC

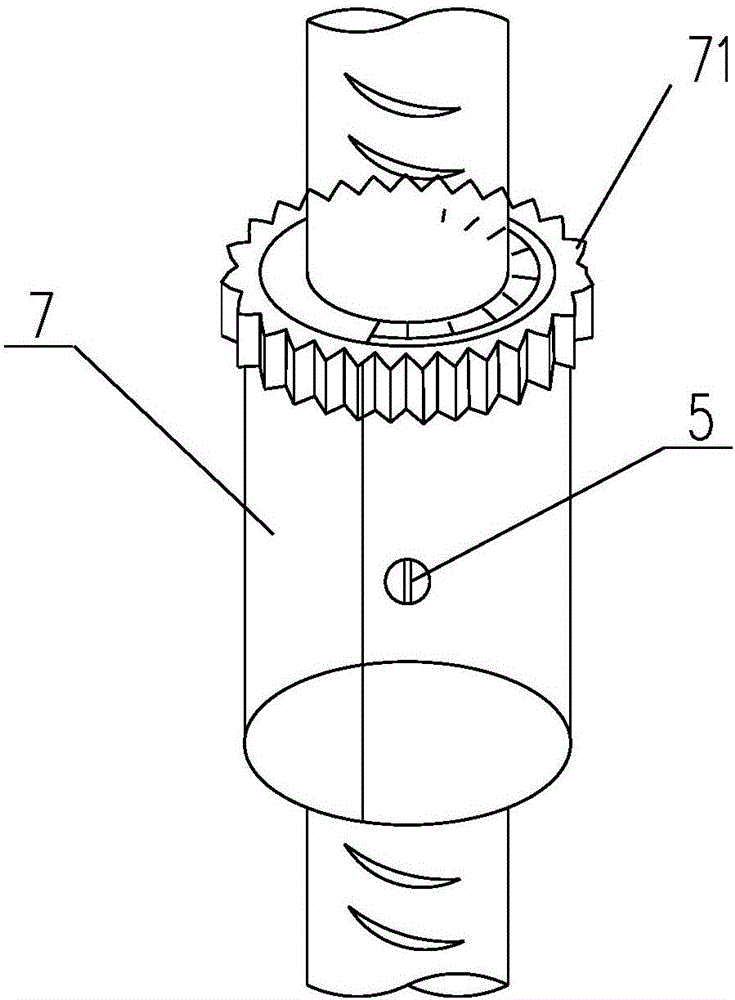

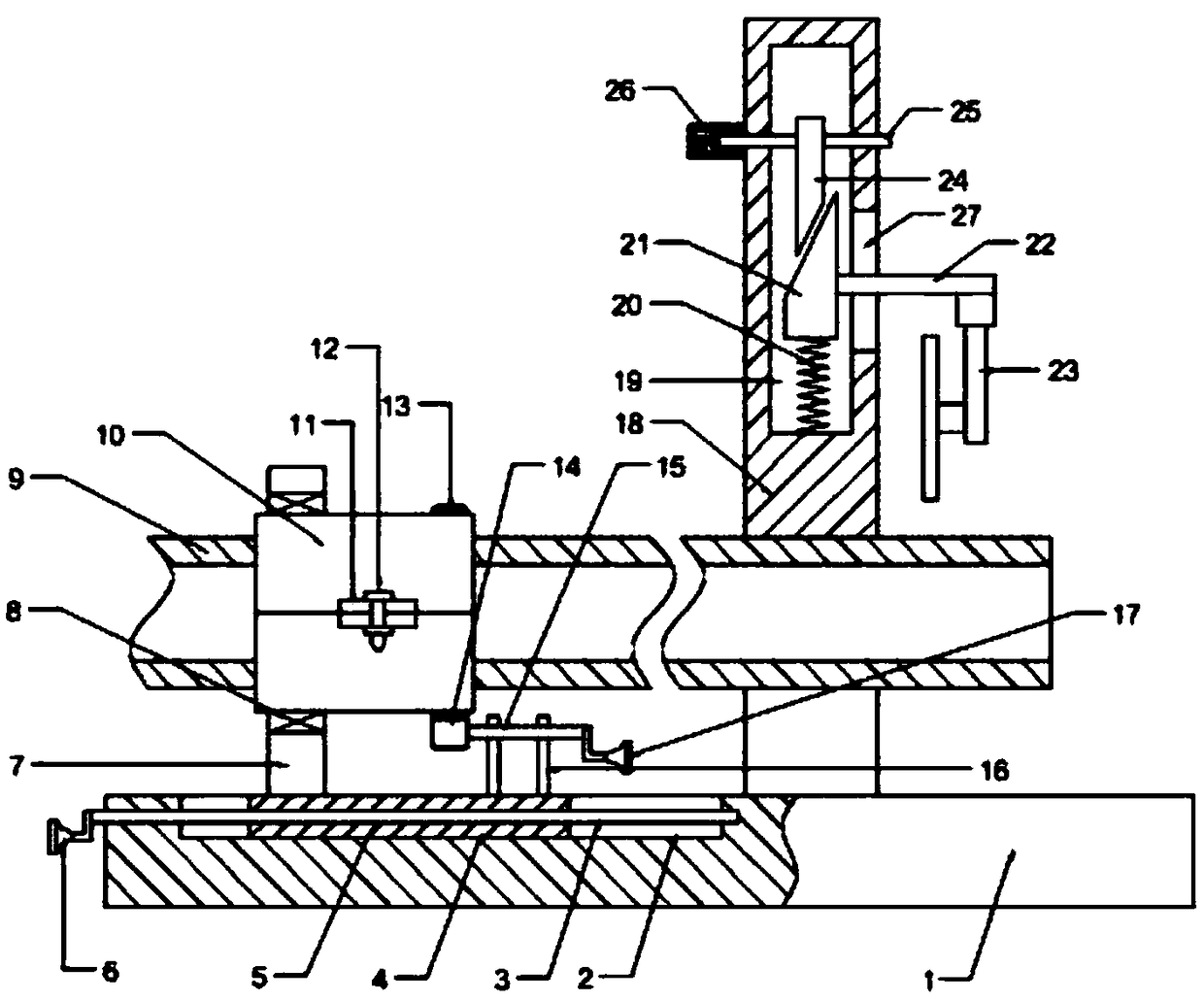

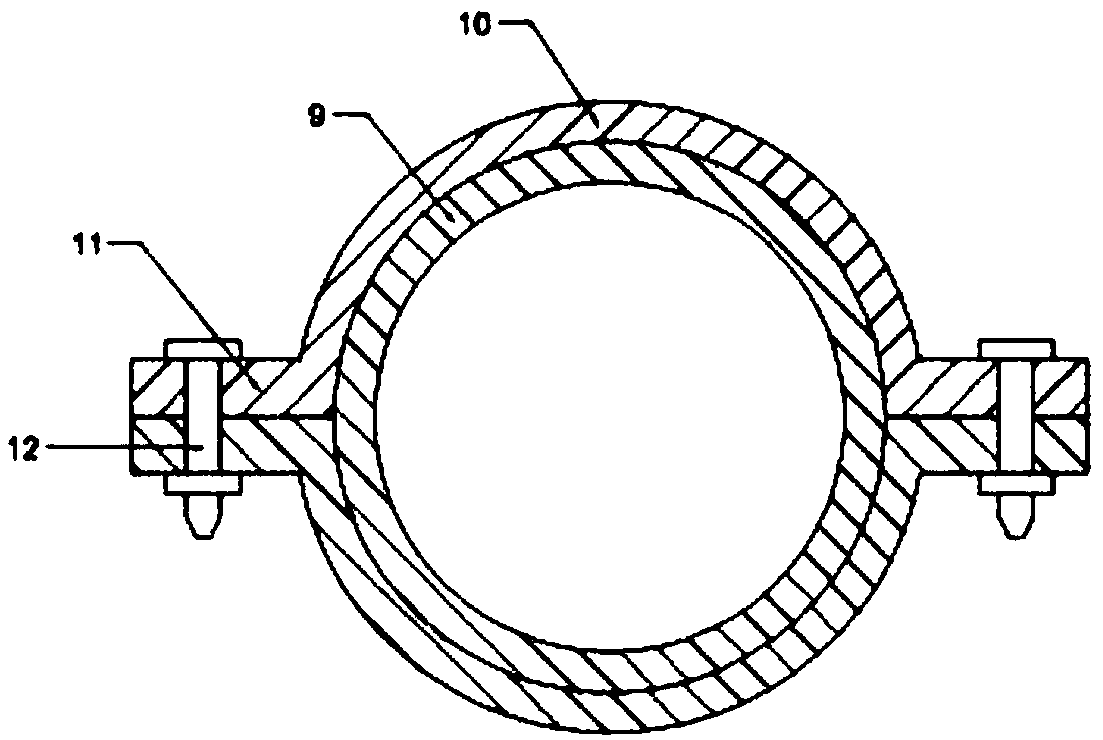

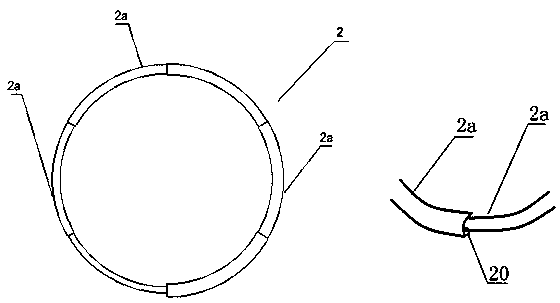

Handheld diameter-variable reinforcing steel bar electric derusting device and using method thereof

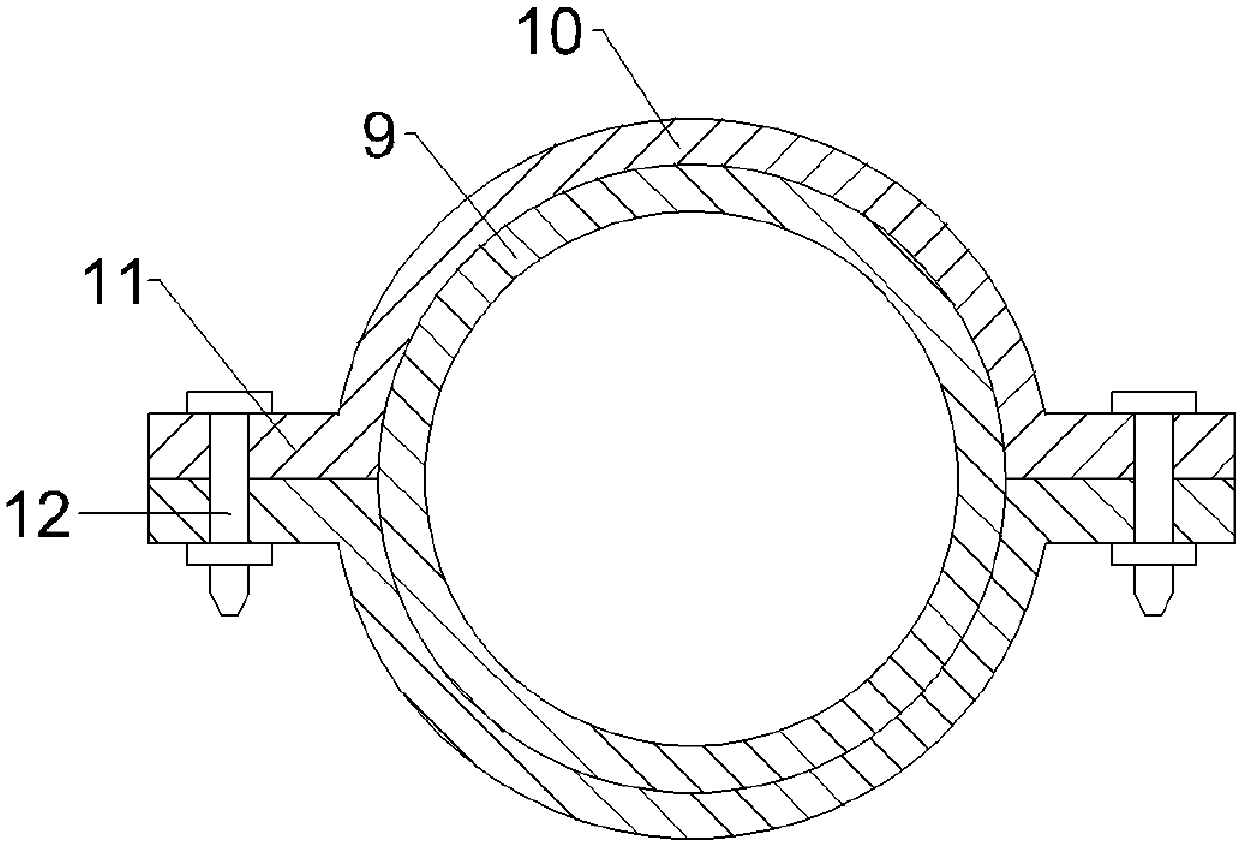

The invention relates to a handheld diameter-variable reinforcing steel bar electric derusting device and a using method thereof. The device comprises a machine body, a cylinder body, a steel wire brushing plate, an elastic fixing piece, a gear-carried motor and a derusting agent liquid-injection box. The machine body is of a rotating retractable structure; the cylinder body is composed of two oppositely combined half cylinder bodies; the steel wire brushing plate made of steel wires is of a circular arc structure, and the steel wire brushing plate is fixed in the cylinder body through the elastic fixing piece; a gear ring is arranged on the outer side of the cylinder body and engaged with a gear of the gear-carried motor mounted in the machine body in a transmission mode so as to enable the cylinder body and the machine body to rotate relatively and drive the steel wire brushing plate to rotate around a reinforcing steel bar to conduct derusting; a handle is arranged on the outer side of the machine body; an electric motor start button is arranged on the handle; and the derusting agent liquid-injection box is fixed on the top of the machine body. According to the handheld diameter-variable reinforcing steel bar electric derusting device and the using method thereof, rapid derusting is conducted on the reinforcing steel bar by adopting an electric derusting mode, the structure is simple and light, handheld operation is convenient, labor intensity of a worker is reduced greatly, derusting efficiency is improved, and the derusting effect is strengthened.

Owner:CHINA THIRD METALLURGICAL GRP

Pipe cutting equipment based on electromagnetic driving principle

InactiveCN108453304ASame magneticSame pole magnetismLarge fixed membersTube shearing machinesBall bearingArchitectural engineering

The invention provides pipe cutting equipment based on the electromagnetic driving principle. The pipe cutting equipment comprises a base. The base is provided with a groove. A moving plate is arranged in the groove and provided with a horizontal threaded through hole. A threaded rod is in threaded connection into the horizontal threaded through hole. The left end of the threaded rod extends to the left side of the base. A first handle is fixedly connected to the left end of the threaded rod. A first support plate is fixedly connected to the upper side of the moving plate and internally provided with a ball bearing. A pipe clamping device is arranged inside the ball bearing and comprises two half-round sleeves. Flanges are fixedly arranged at the rims of the sleeves correspondingly. The flanges of the two sleeves are connected through a locking bolt. Pipes are arranged inside the two sleeves. The pipe cutting equipment has the beneficial effects that the threaded rod is driven by the first handle to rotate; the moving plate matched with the threaded rod moves toward the right side, and thus the pipe clamping device is driven to move; and the pipes can be propelled toward the rightside conveniently.

Owner:韩银兰

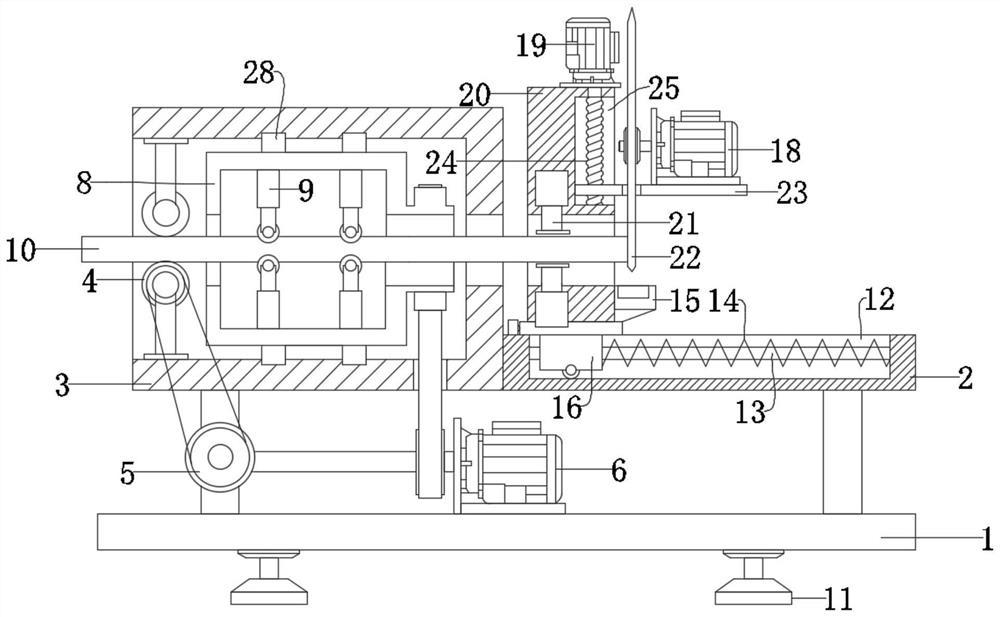

Building reinforcing steel bar cutting device

The invention discloses a building reinforcing steel bar cutting device. The device comprises a bottom plate, a reinforcing steel bar, a box body and a carrier plate, the box body is fixedly connectedwith the carrier plate, the box body and the carrier plate are fixedly connected to the bottom plate through stand columns, a cutting assembly is arranged on the carrier plate, a straightening assembly is arranged in the box body, and a driving assembly is installed at the inlet position of the box body and drives the reinforcing steel bar to move. According to the reinforcing steel bar cutting device, the reinforcing steel bar is clamped through clamping blocks, relative fixation between the reinforcing steel bar and a fixing frame is effectively achieved, the reinforcing steel bar and the fixing frame move synchronously, at the moment, the reinforcing steel bar is effectively cut through a cutting motor, and the cutting efficiency of the reinforcing steel bars is greatly improved; and before the reinforcing steel bar is cut, the actual straightening effect of the reinforcing steel bar is effectively improved under the action of straightening wheels, and therefore, good application prospects are realized.

Owner:钟玲

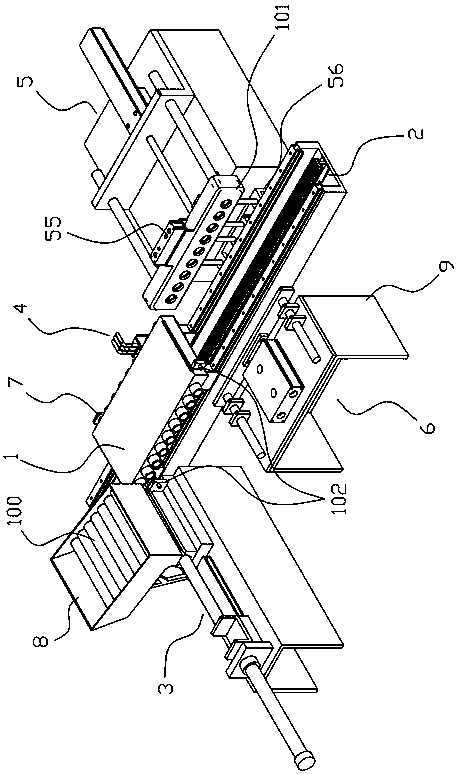

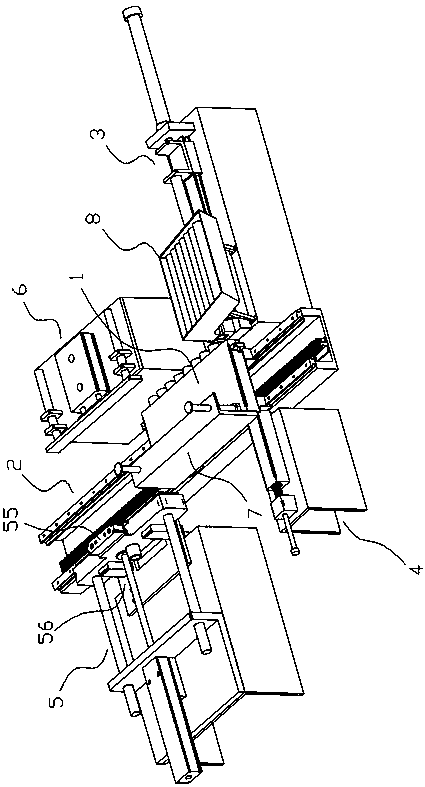

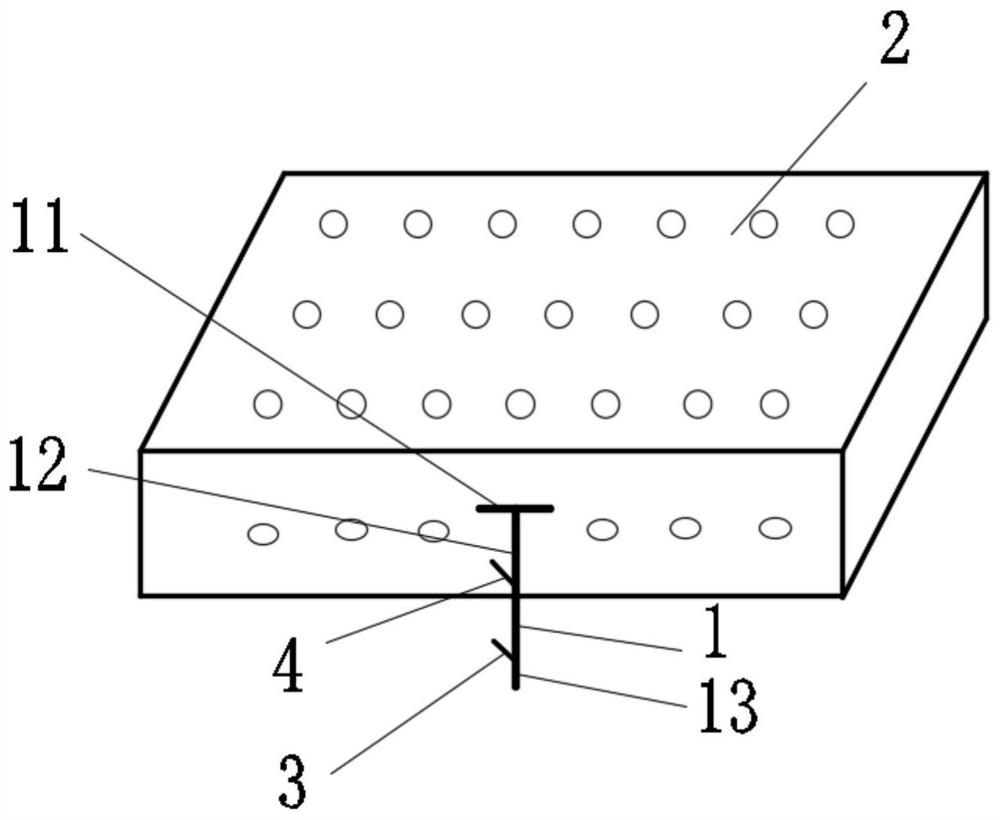

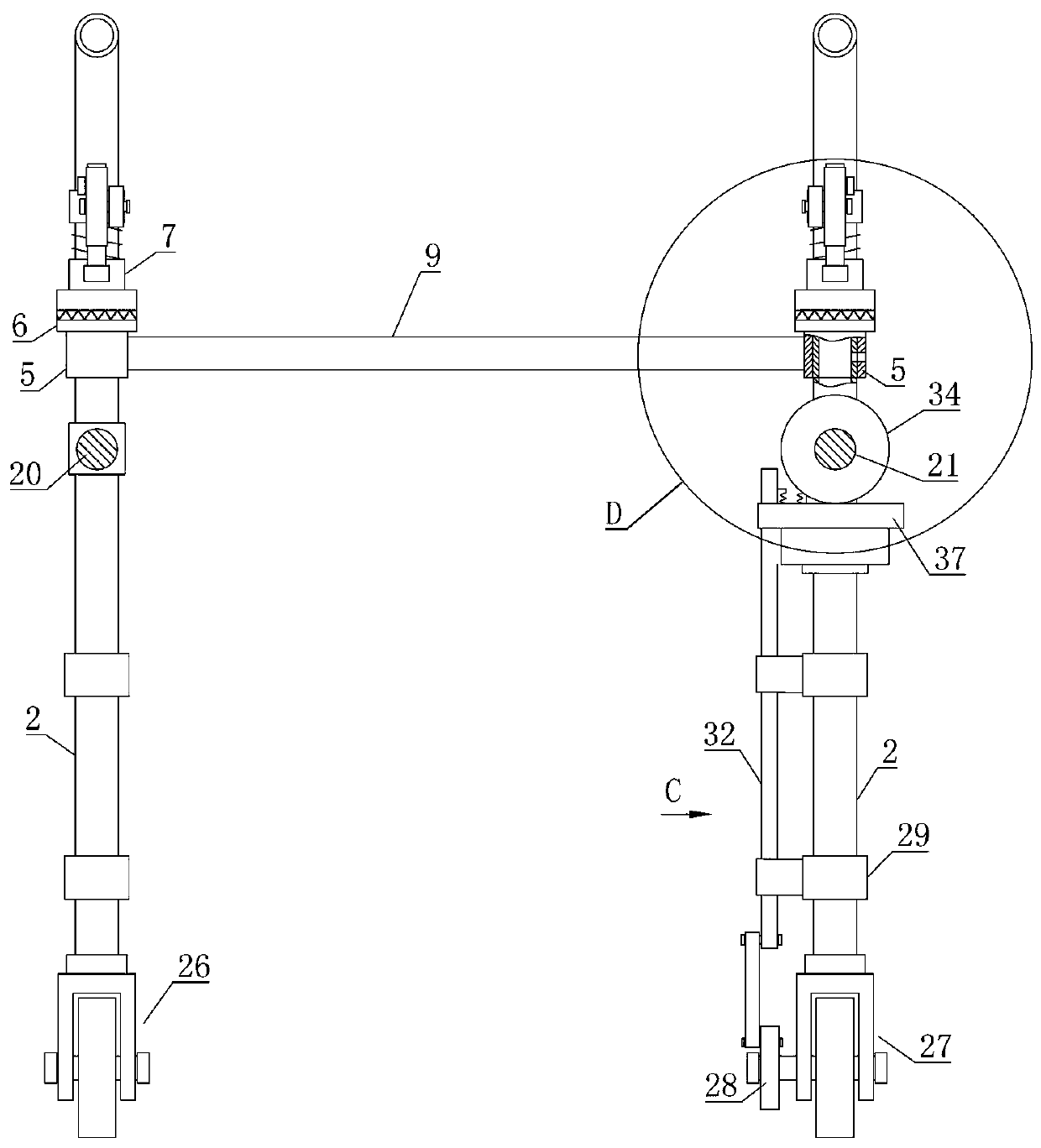

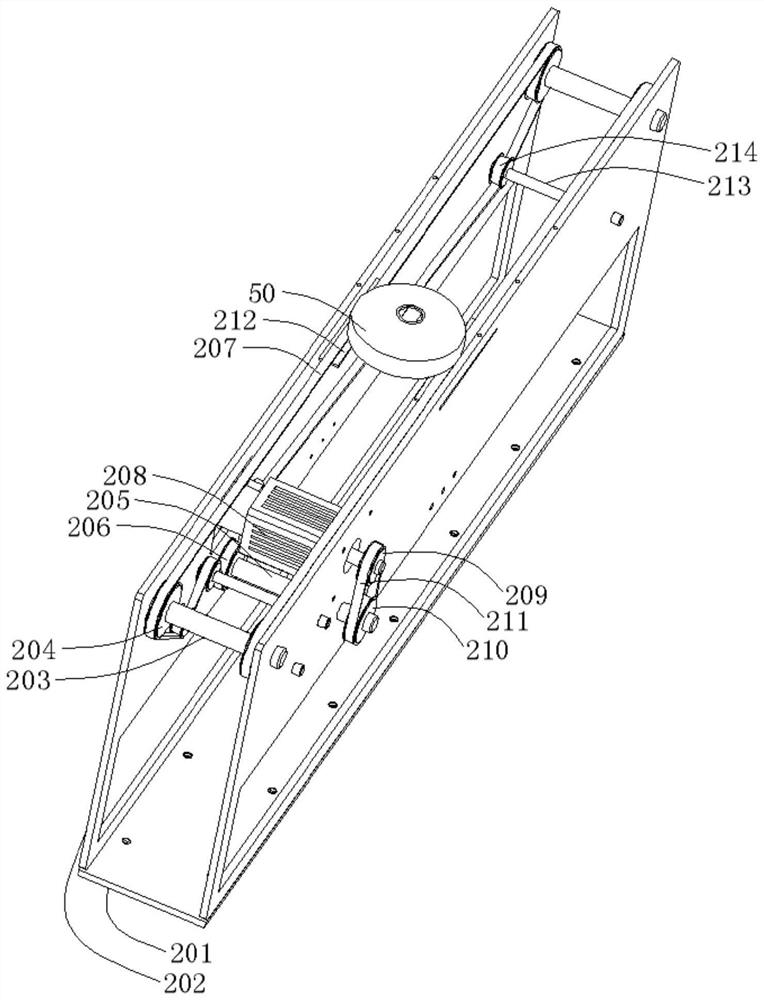

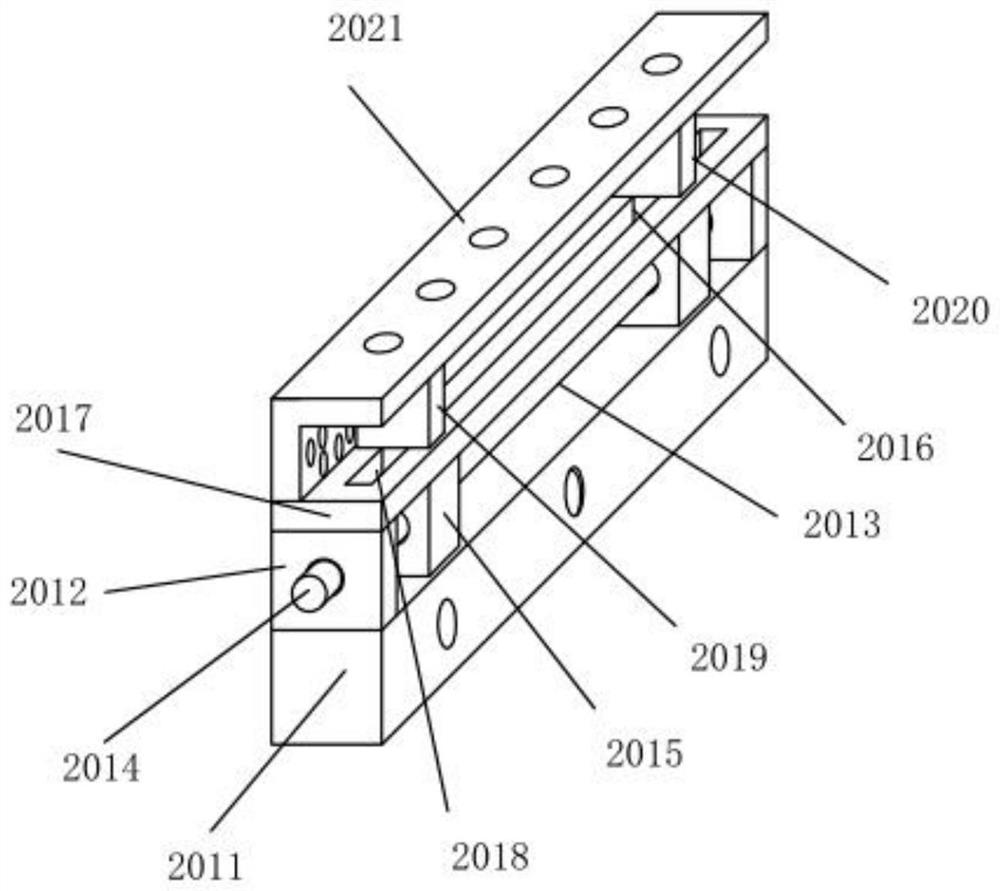

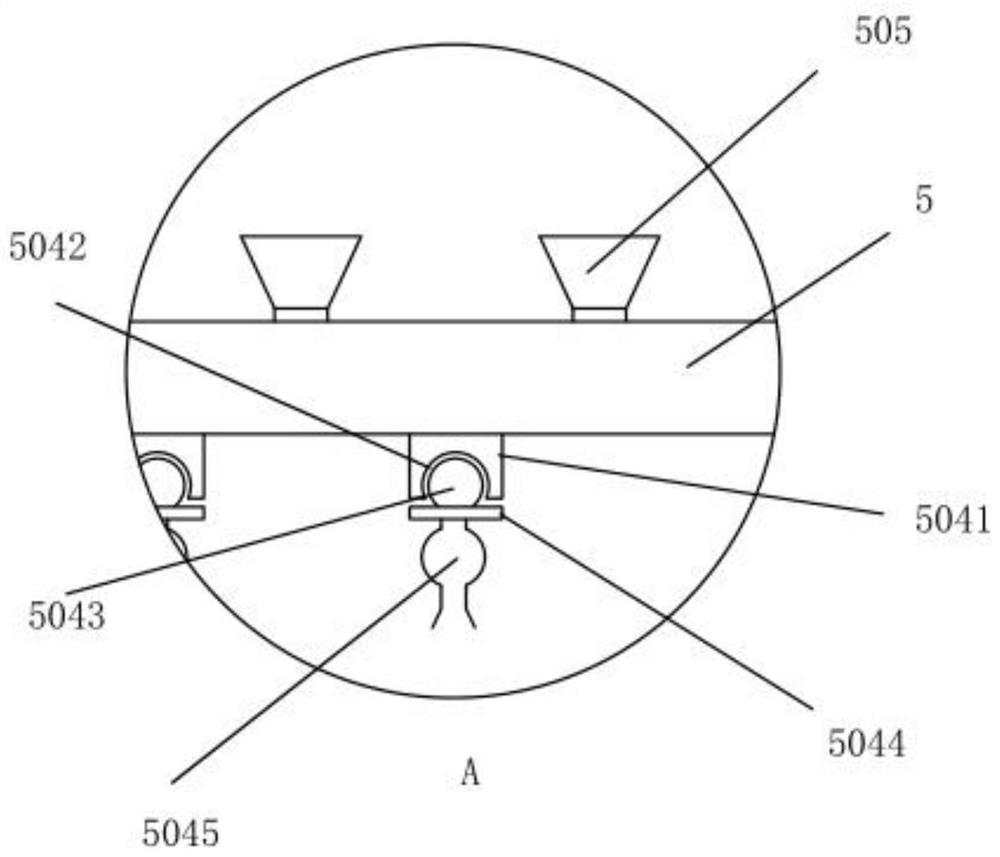

Automatic assembling production line of heat pipe radiator for 5G communication base station

ActiveCN111390457ARealize assembly line productionHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineThermodynamics

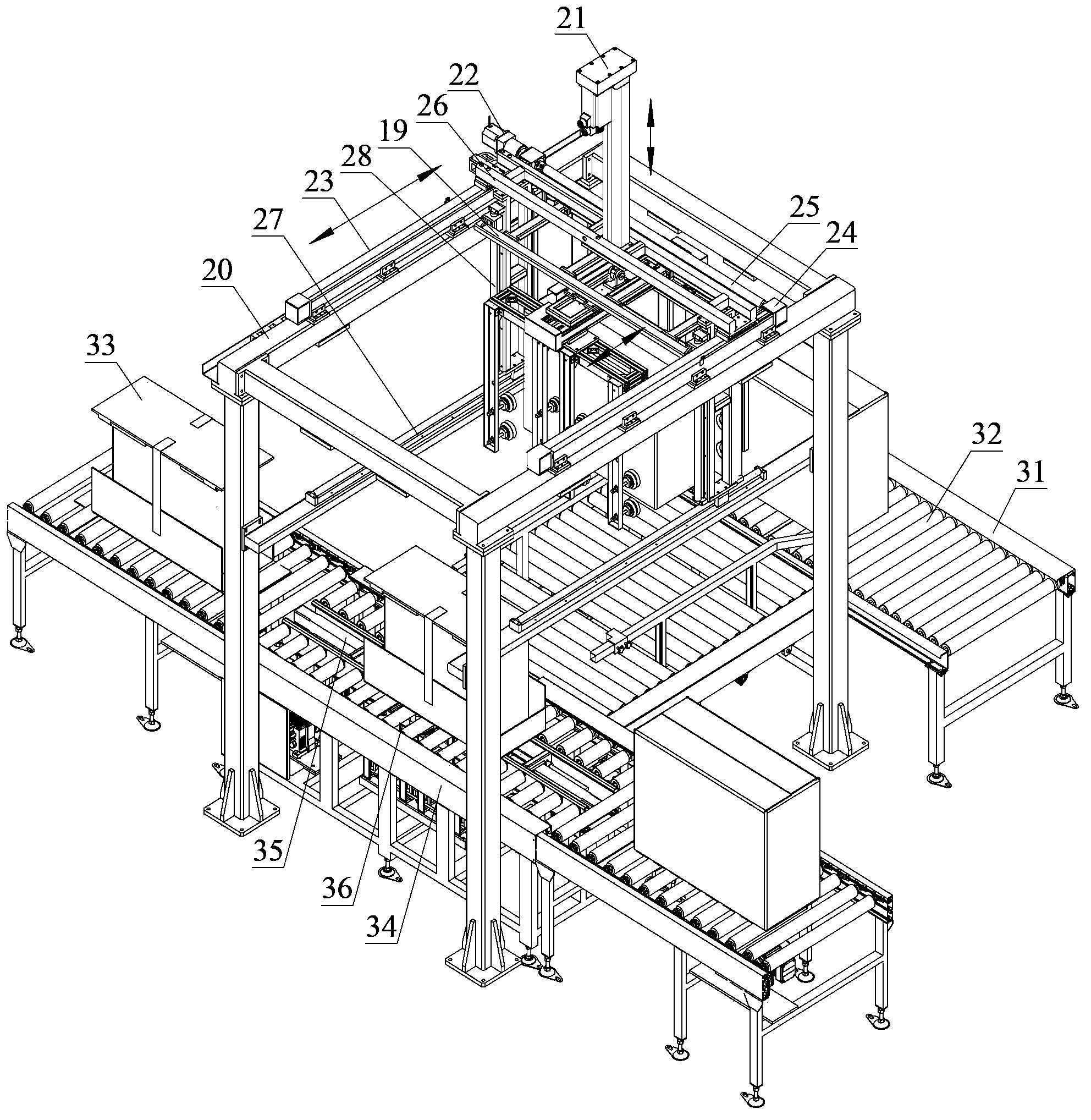

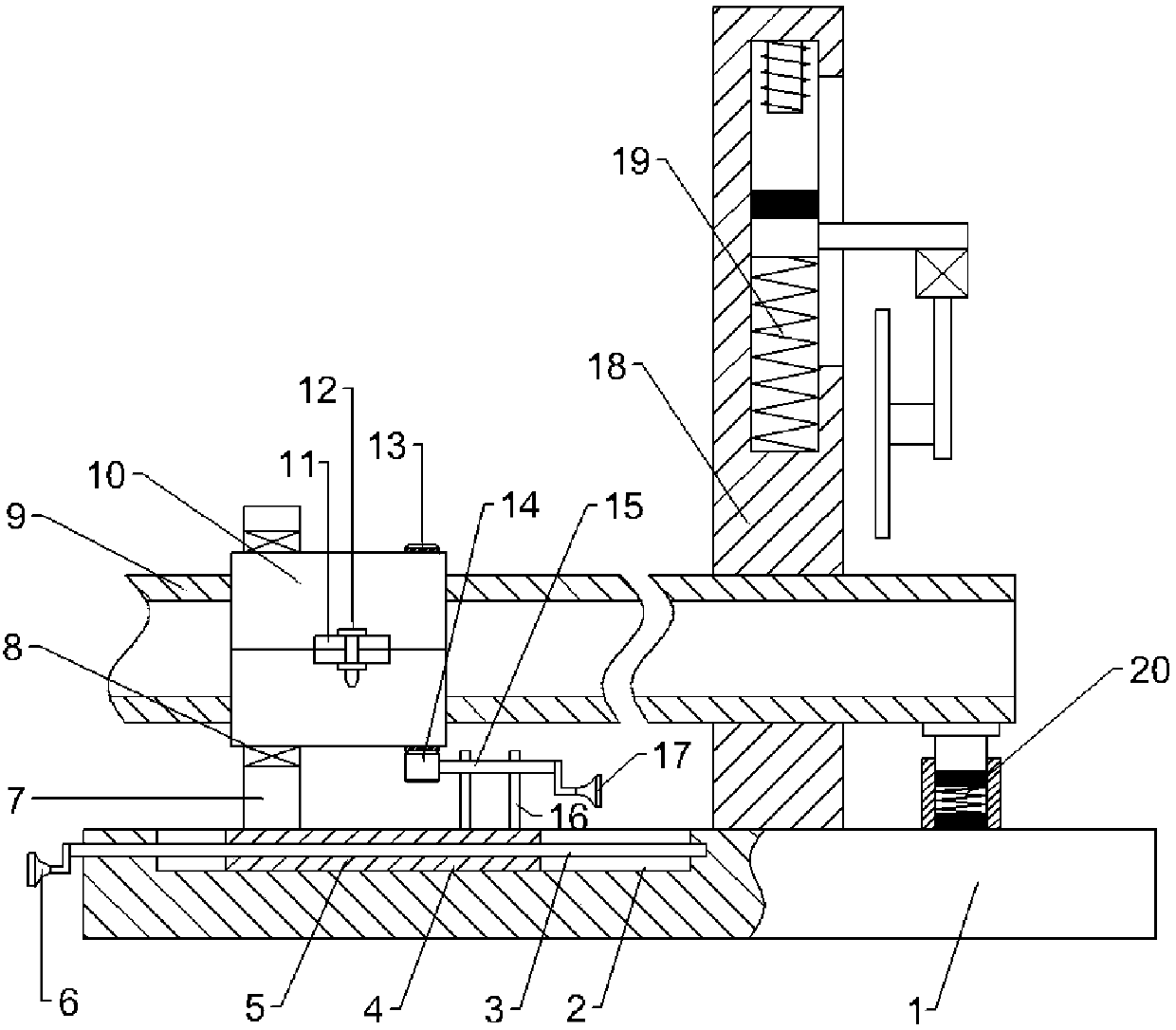

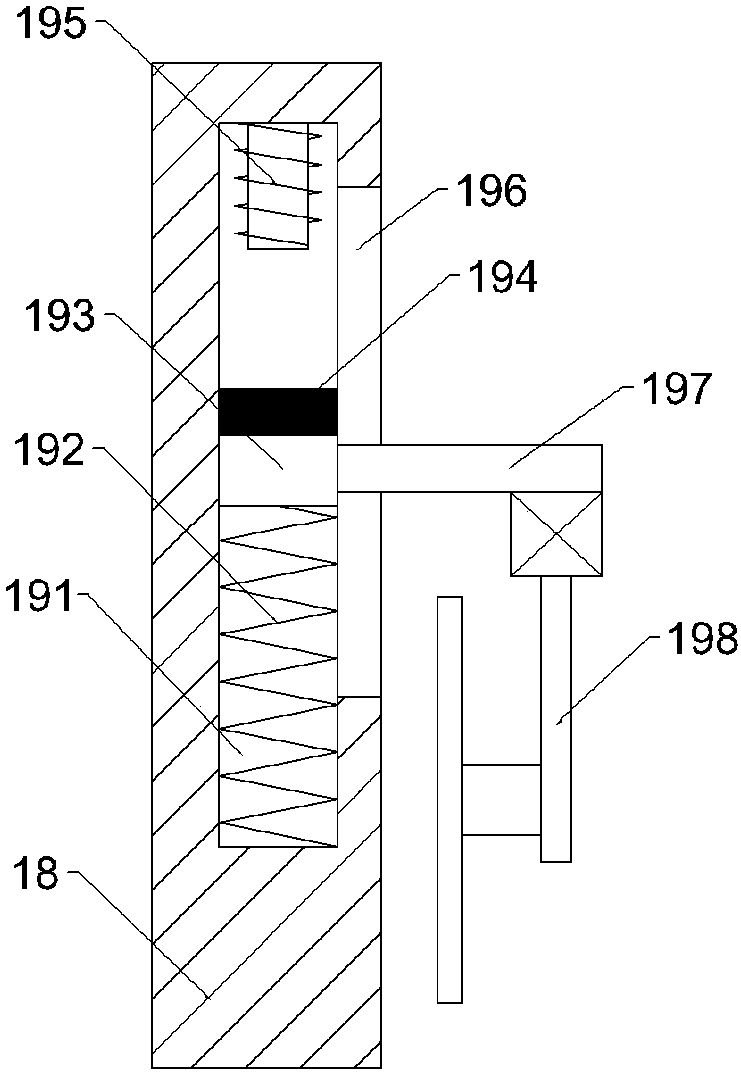

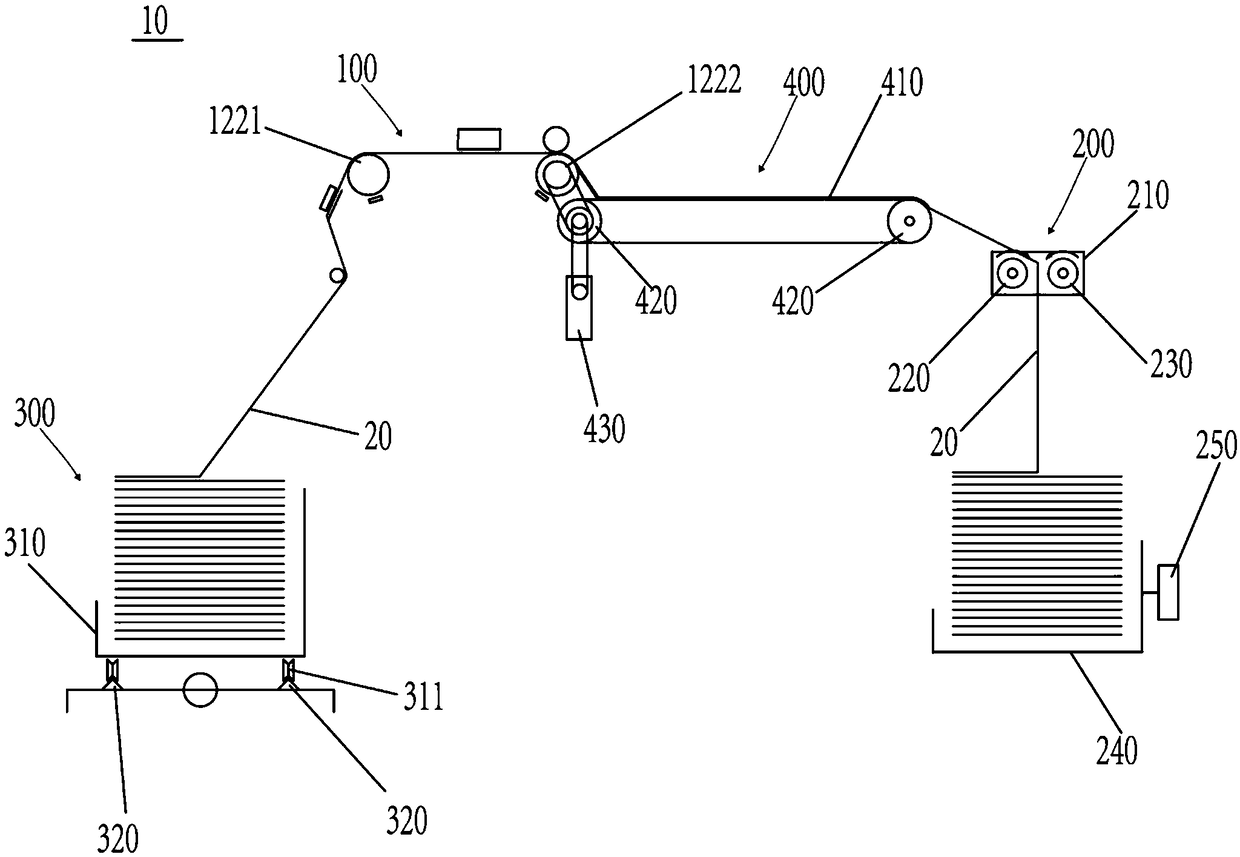

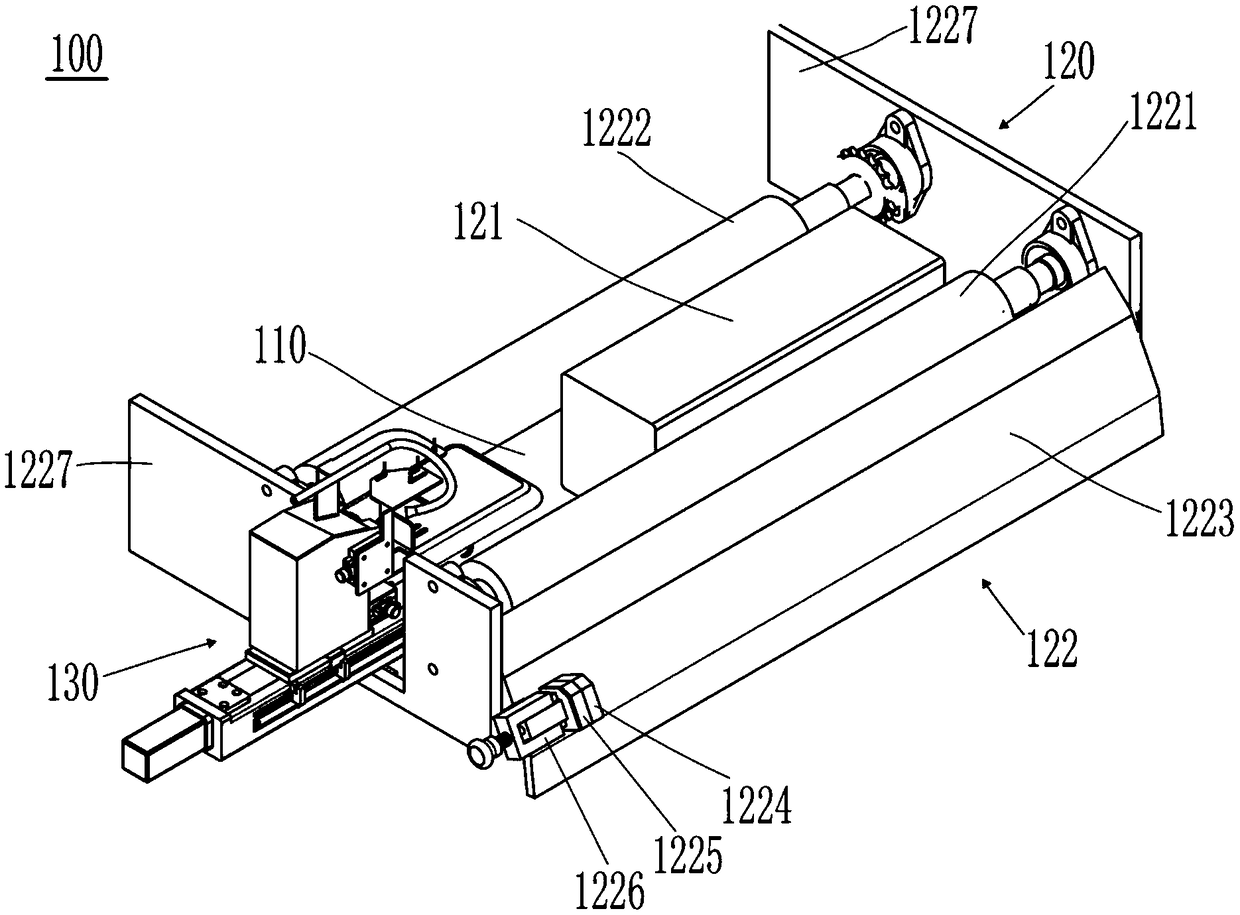

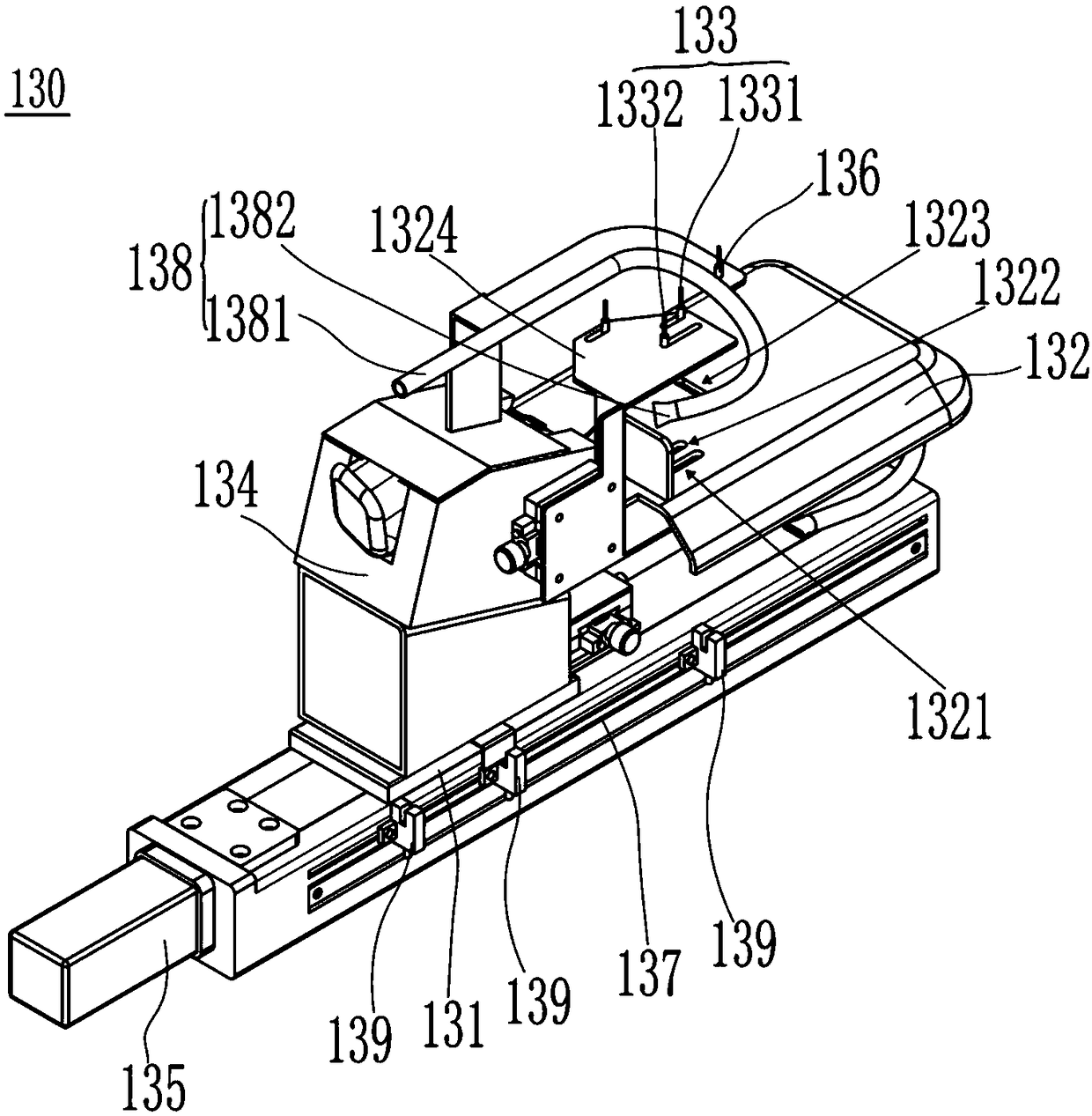

The invention discloses an automatic assembly production line of a heat pipe radiator for a 5G communication base station, and relates to the technical field of communication equipment processing. Theautomatic assembly production line comprises a fixing tool, a conveying platform, a heat pipe feeding mechanism, a solder spraying mechanism, a substrate feeding mechanism, and a pressing mechanism.The fixing tool is used for horizontally positioning and intensively collecting heat pipes together. The fixing tool is installed on the conveying platform and used for achieving horizontal conveyingof the fixing tool. The heat pipe feeding mechanism is located on the left side of the conveying platform and used for conveying the heat pipes into the fixing tool. The solder spraying mechanism is located on the right side of the conveying platform and used for spraying solder to the assembling ends of the heat pipes. The substrate feeding mechanism is located on the right side of the conveyingplatform and used for clamping a substrate and then conveying the substrate to an assembling station. The pressing mechanism is located on the left side of the conveying platform and used for pressingthe heat pipes on the fixing tool into the substrate. According to the automatic assembly production line, the feeding of the heat pipes, the spraying of the solder, the feeding of the substrate andthe overall pressing are completed on one conveying platform, assembly line type production is achieved, the overall automation degree is high, and the assembly efficiency is obviously improved.

Owner:CHAOHU POWER SUPPLY CO STATE GRID ANHUI PROVINCE ELECTRIC POWER CO LTD +1

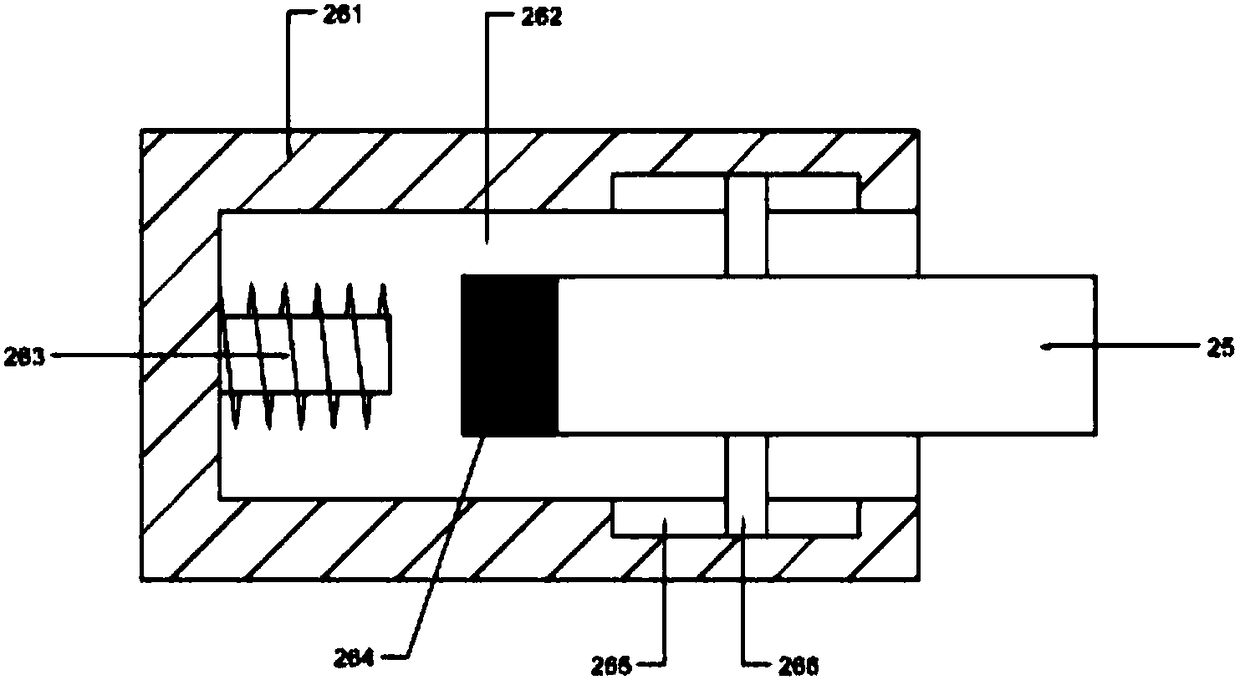

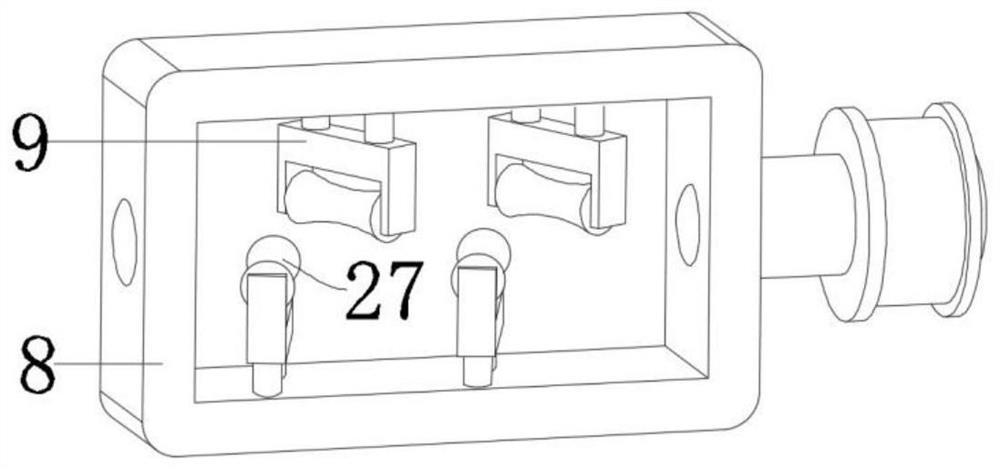

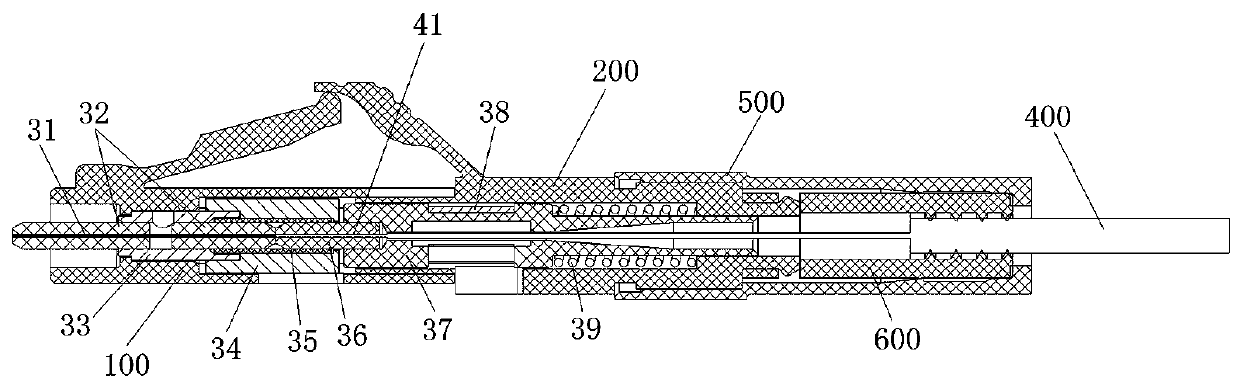

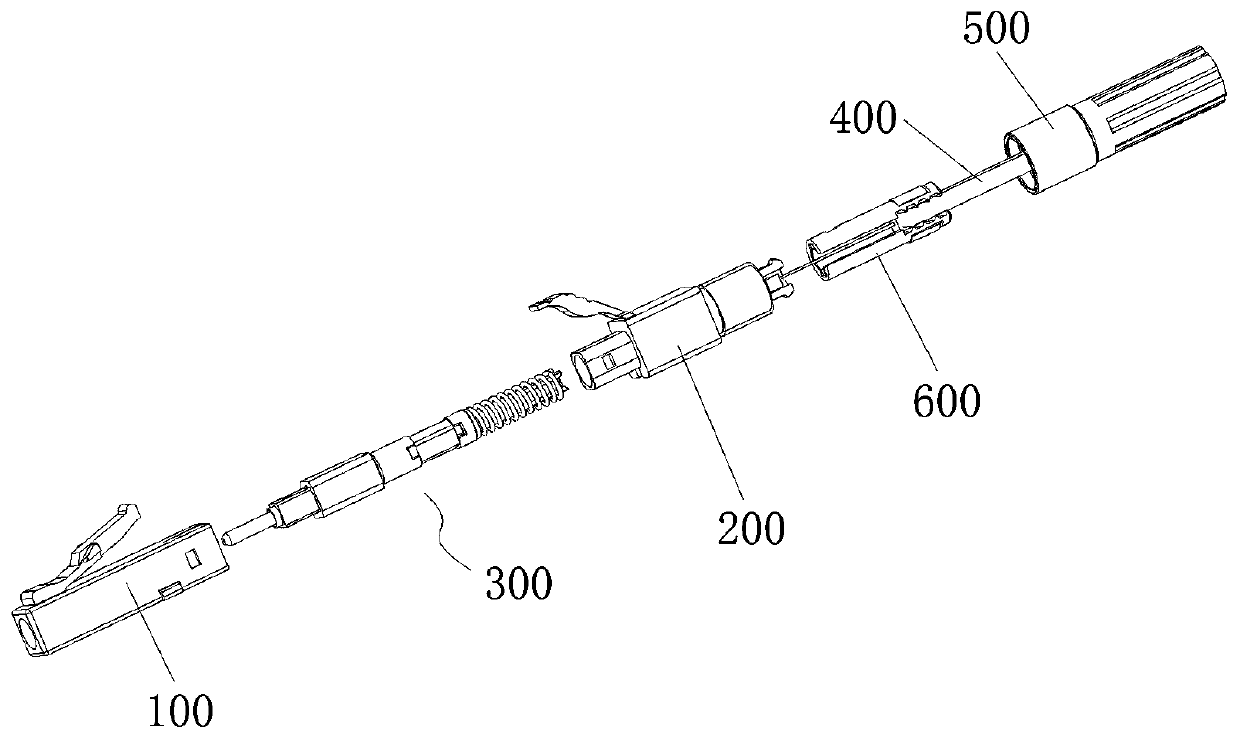

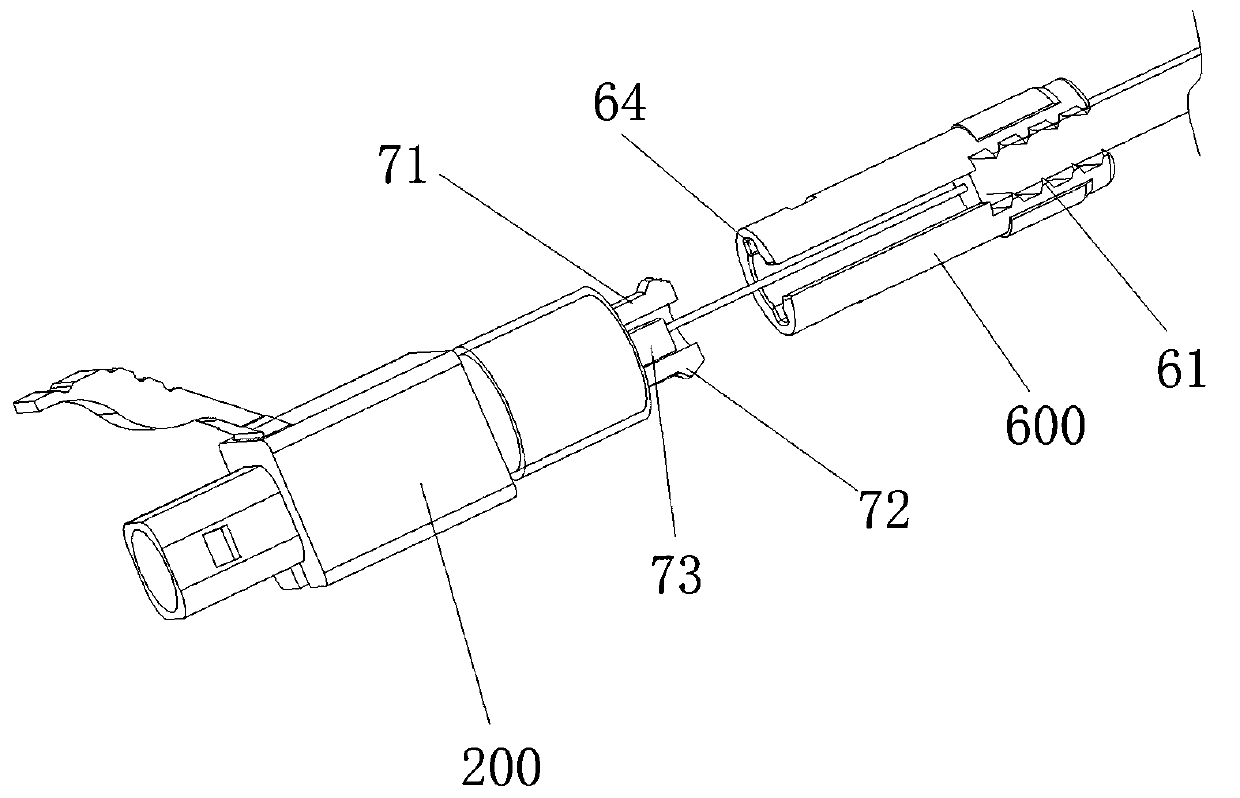

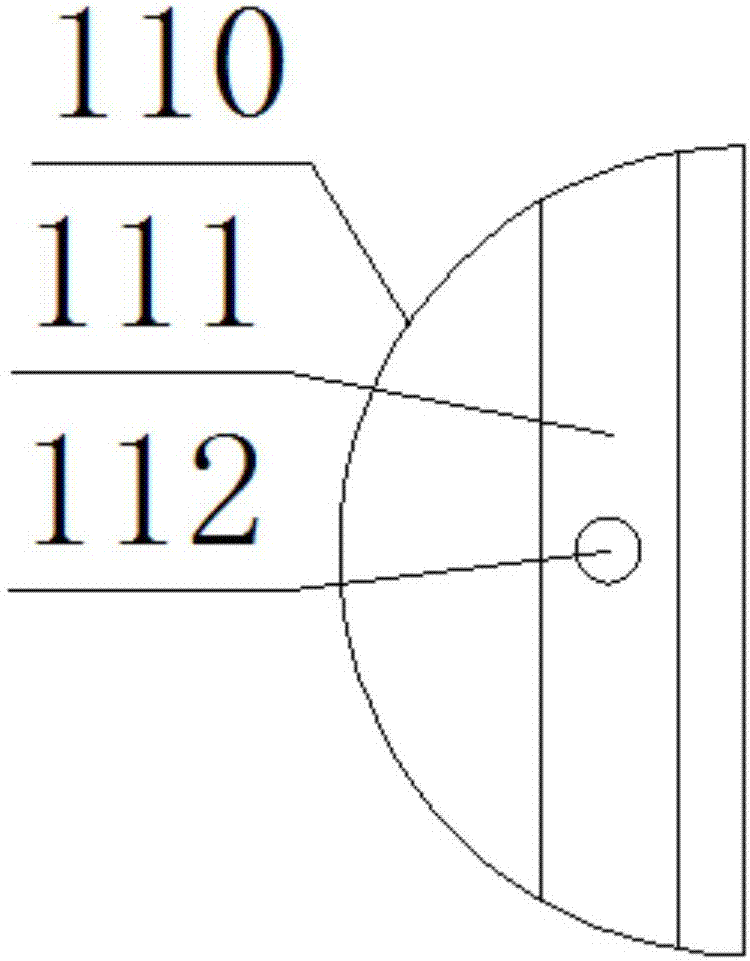

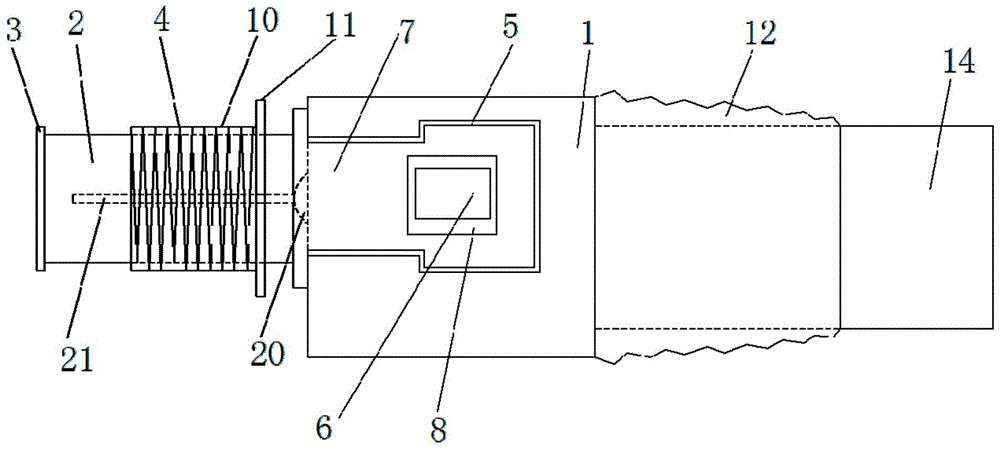

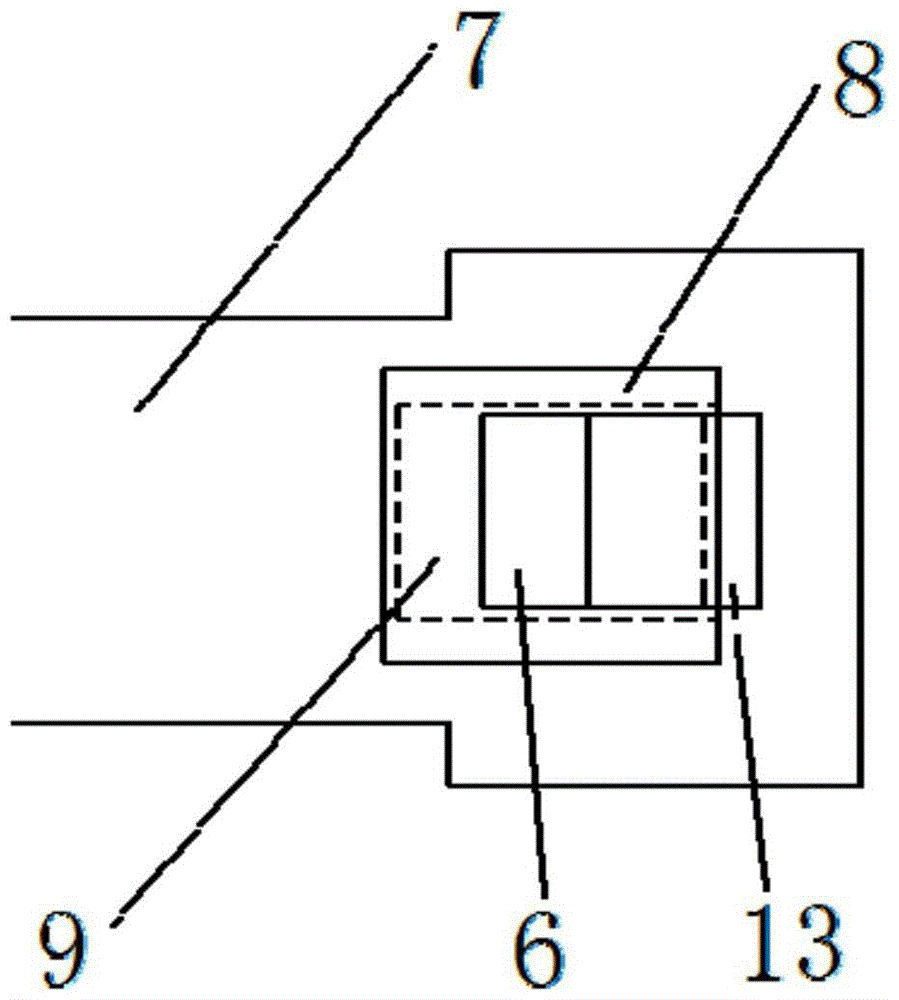

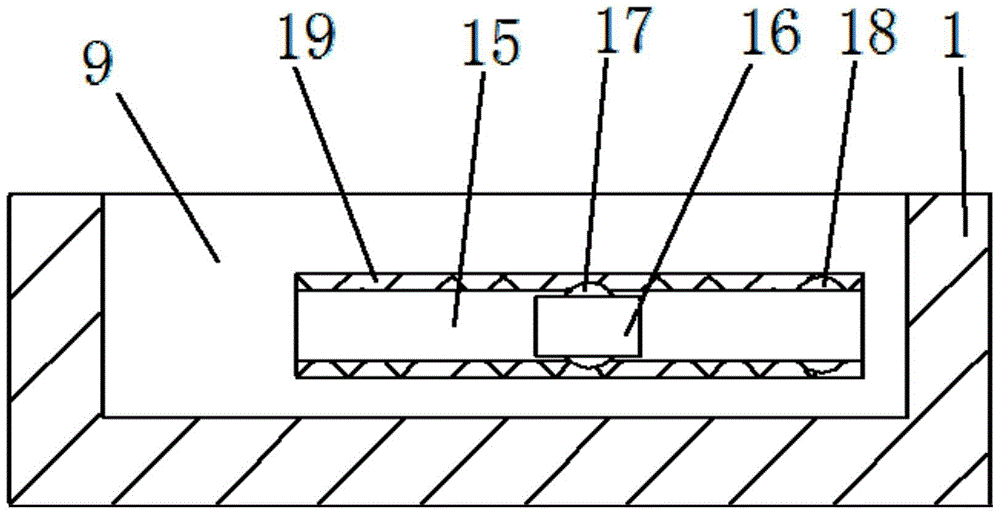

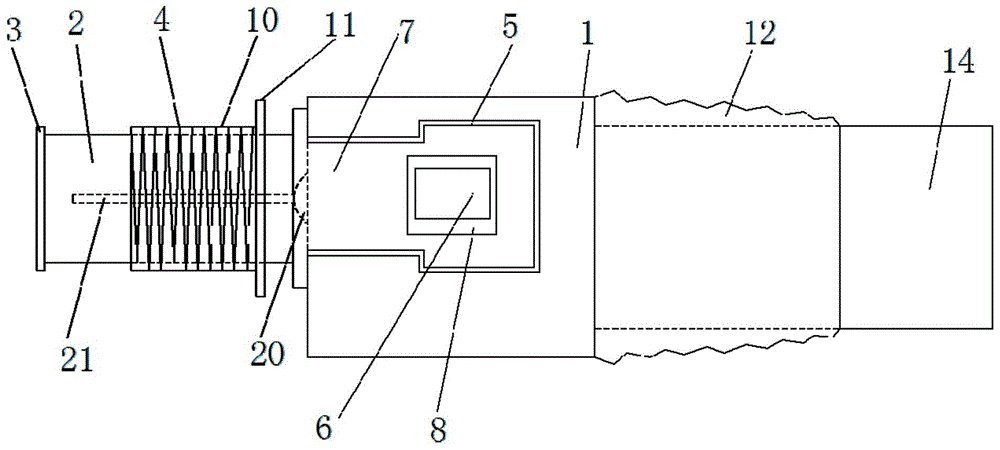

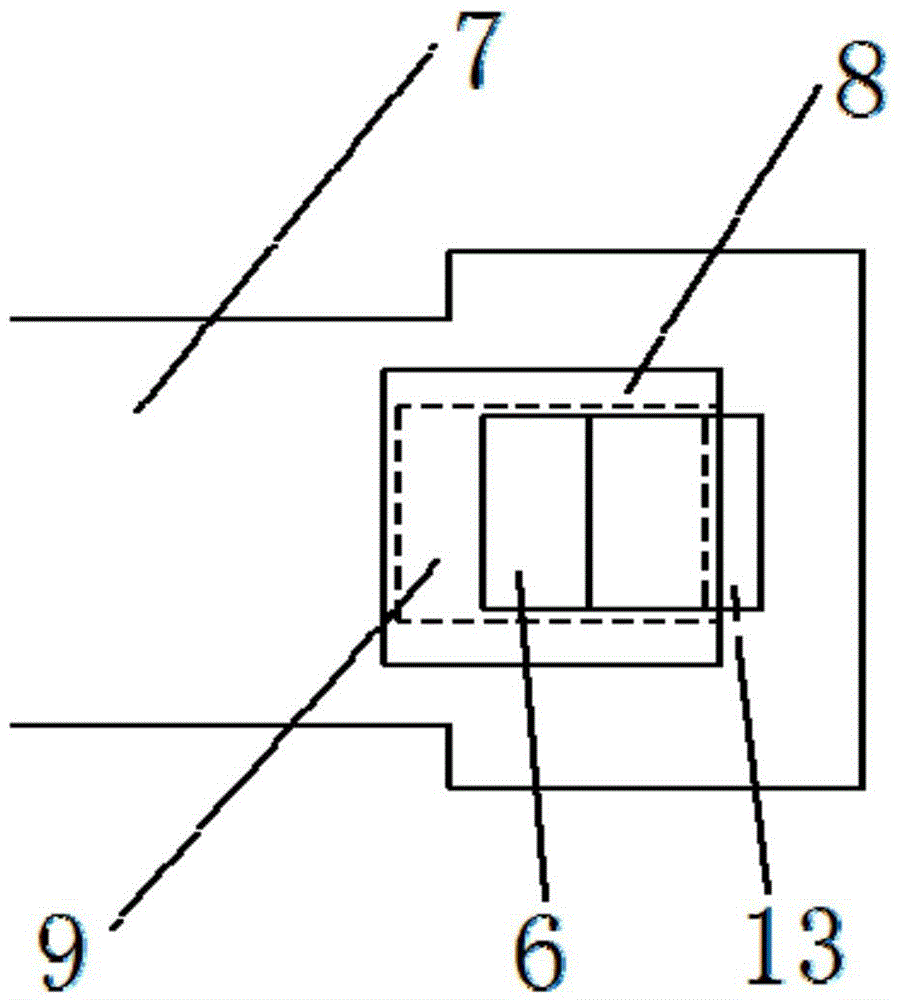

Optical fiber connector for field construction

ActiveCN110208913ANo torsionCoupling accuracy influenceCoupling light guidesEngineeringOptical fiber connector

The invention provides an optical fiber connector for field construction. The optical fiber connector comprises a connector shell, wherein the front end of the connector shell is a plug-in end, and the rear end of the connector shell is a wiring end; an embedded optical fiber and a mounting sleeve are arranged in the connector shell; an optical cable press-fitting structure is also arranged on theconnector shell and comprises a tail clamp; the tail clamp and the connector shell are assembled together in a circumferential rotation-stopping manner through a circumferential rotation-stopping structure; an elastic arm is arranged on one of the tail clamp and the connector shell; a bulge is arranged on the outer side of the elastic arm; a plug-in part which is in plug-in fit with the bulge toform front and back axial stop fit is arranged on the other of the tail clamp and the connector shell; and the optical cable press-fitting structure also comprises a connecting nut which is spirally assembled at the rear part of the connector shell and is sleeved outside the tail clamp. The tail clamp is fixed relative to the connector shell, so that the connecting optical fiber in the optical cable cannot be twisted during assembly, and the influence on the coupling accuracy of the embedded optical fiber and the connecting optical fiber is avoided.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

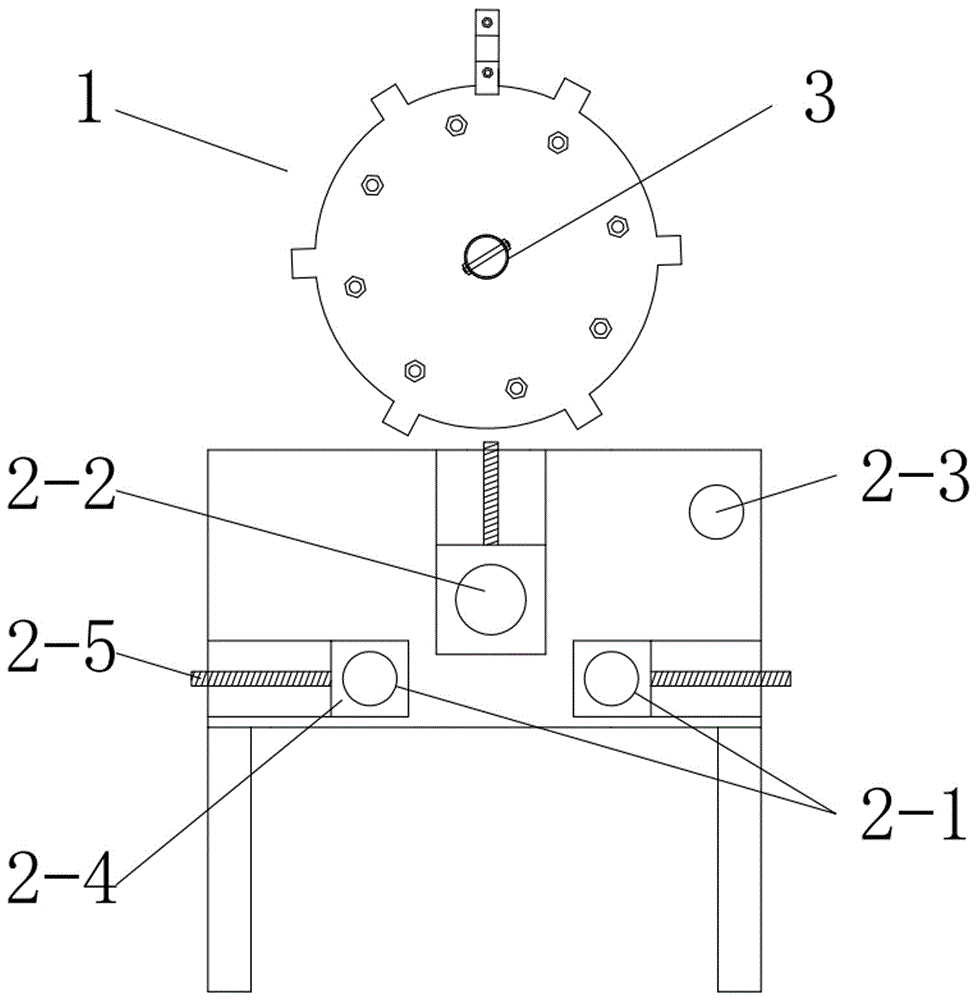

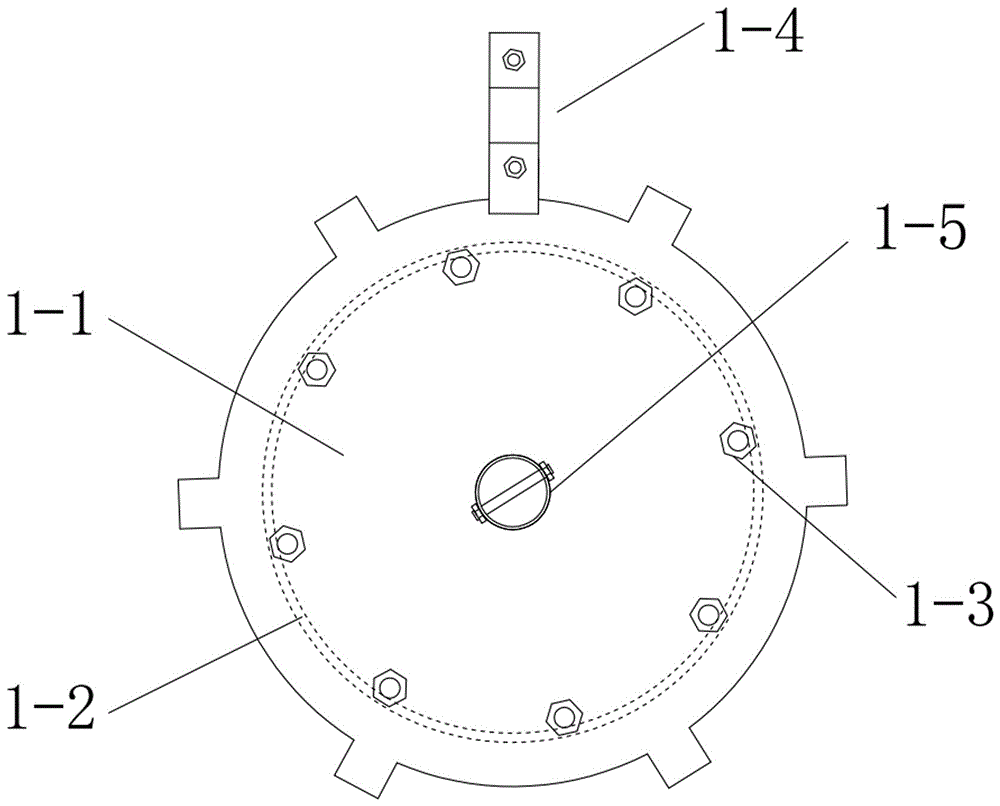

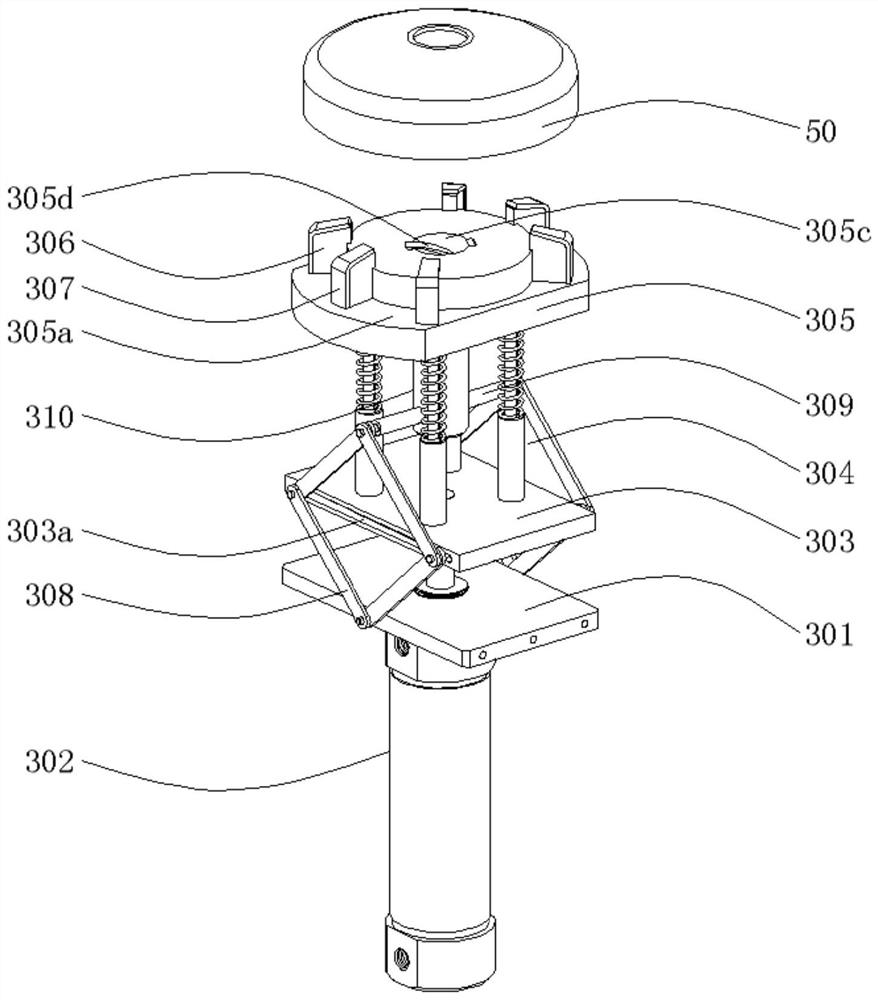

Fast replacing mechanism for robot fixture

The invention discloses a fast replacing mechanism for a robot fixture. The fast replacing mechanism comprises a fixed connection member, a sliding sleeve, a driving mechanism, positioning members and a flange sleeve, wherein the right end of the fixed connection member is fixedly connected with a robot flange, the outer wall of the left end of the fixed connection member is sleeved by the right end of the flange sleeve, a cavity is formed in the middle of the fixed connection member, the sliding sleeve is sleeved in the cavity, the driving mechanism is fixedly connected with the fixed connection member, a plurality of inner positioning holes which are communicated with the cavity are formed on the side wall of the fixed connection member, outer positioning holes which are communicated with the inner positioning holes are formed at the positions on the side wall of the flange sleeve, the positions correspond to positions of the inner positioning holes, the positioning members are sleeved in the inner positioning holes respectively, the sliding sleeve can move rightwards or leftwards along the cavity under the actions of the driving mechanism, the sliding sleeve can abut against the inner ends of the positioning members during sliding, and simultaneously, the other ends of the positioning members are forced to be snapped in the corresponding outer positioning holes. By means of matching of the positioning members, the inner positioning holes, the outer positioning holes and the sliding sleeve, fixed connection of the fixed connection member and the flange sleeve is achieved, so that connection of a robot and the fixture is achieved.

Owner:湖南创研智能装备有限公司

Pipe cutting equipment with supporting function

InactiveCN107900724AAchieve relatively fixedAchieve reductionFeeding apparatusPositioning apparatusBall bearingArchitectural engineering

Pipe cutting equipment with a supporting function comprises a base. A groove is formed in the base. A movable plate is arranged in the groove. A horizontal threaded through hole is formed in the movable plate. A threaded rod is connected into the horizontal threaded through hole in a threaded mode. The left end of the threaded rod extends to the left side of the base. A first handle is fixedly connected with the left end of the threaded rod. A first supporting plate is fixedly connected with the upper side of the movable plate. A ball bearing is arranged in the first supporting plate. A pipe clamping device is arranged in the ball bearing and comprises two semicircular sleeves. Flanges are fixedly arranged on the edges of the sleeves correspondingly. The flanges of the two sleeves are connected through locking bolts. A pipe is arranged in the two sleeves. The pipe cutting equipment has the beneficial effects that the two sleeves are fixed together through the locking bolts, relative fixing of the pipe and the sleeves is achieved, and then the left portions of the sleeves are fed into the ball bearing in the first supporting plate.

Owner:丁文海

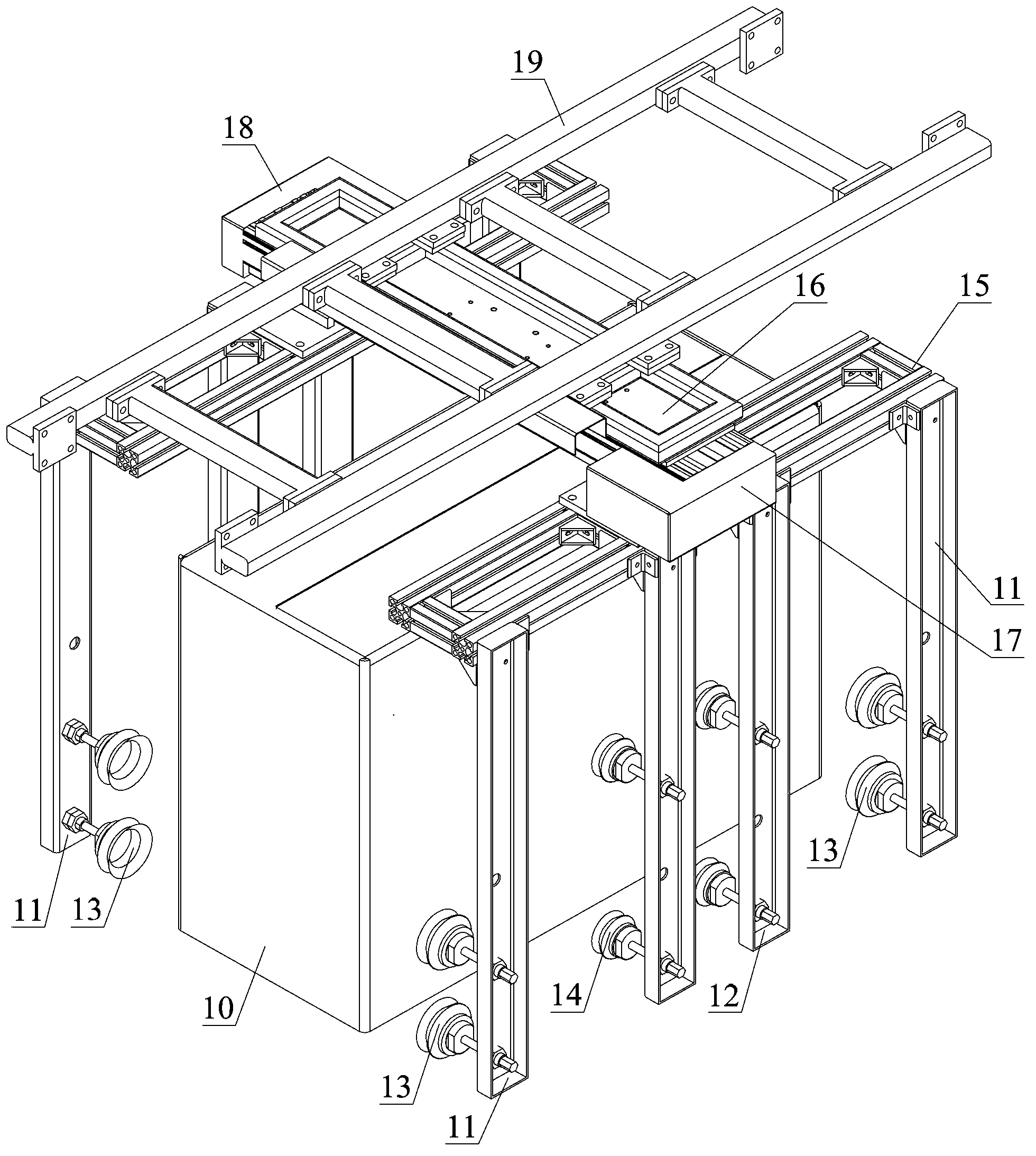

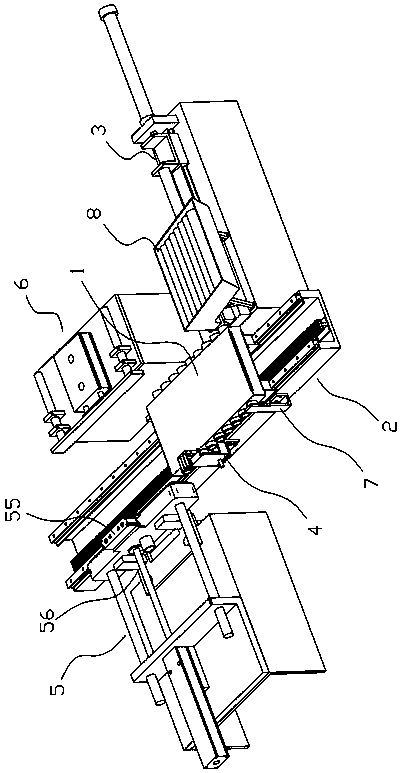

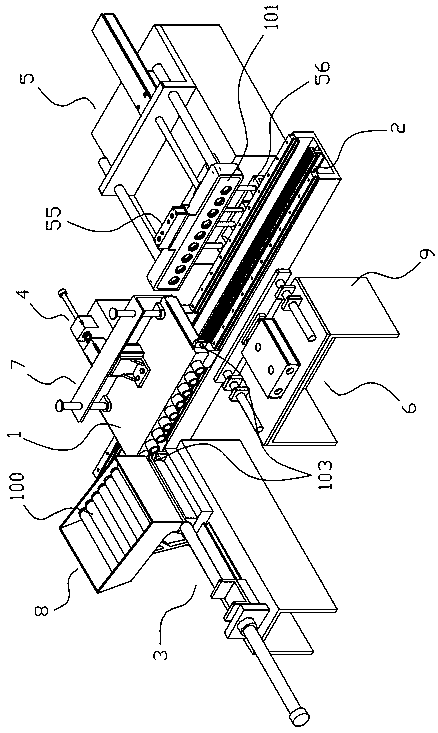

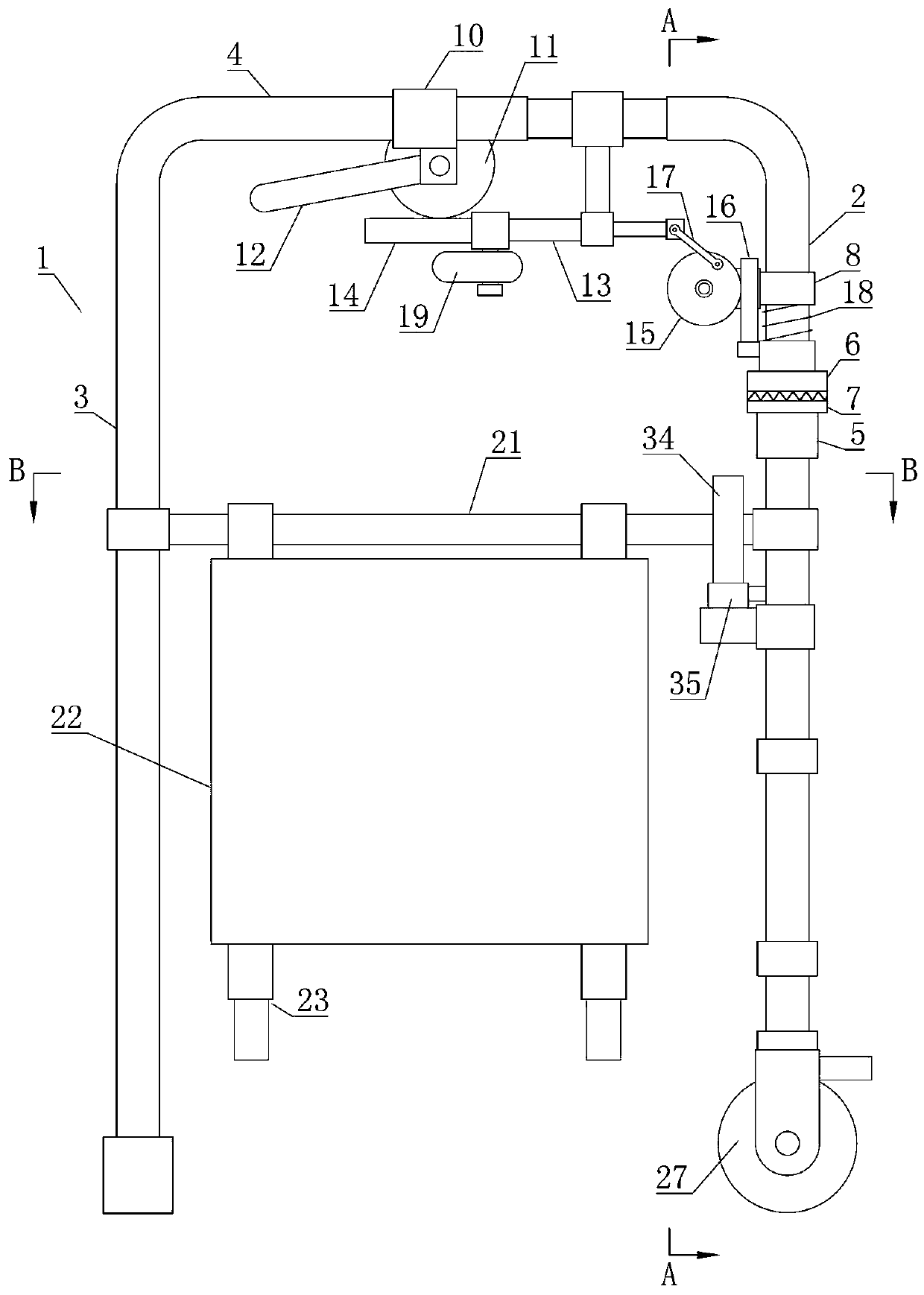

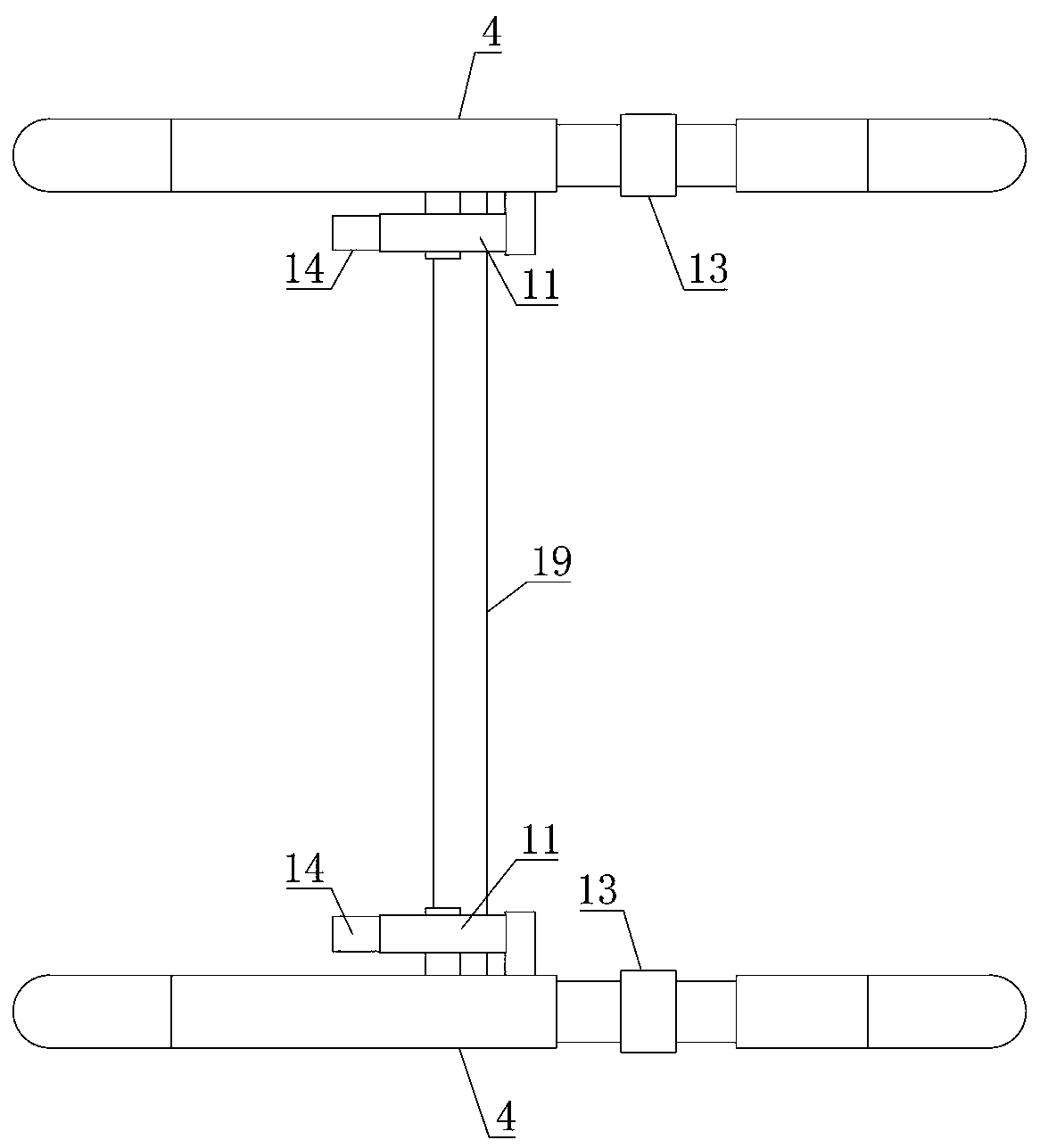

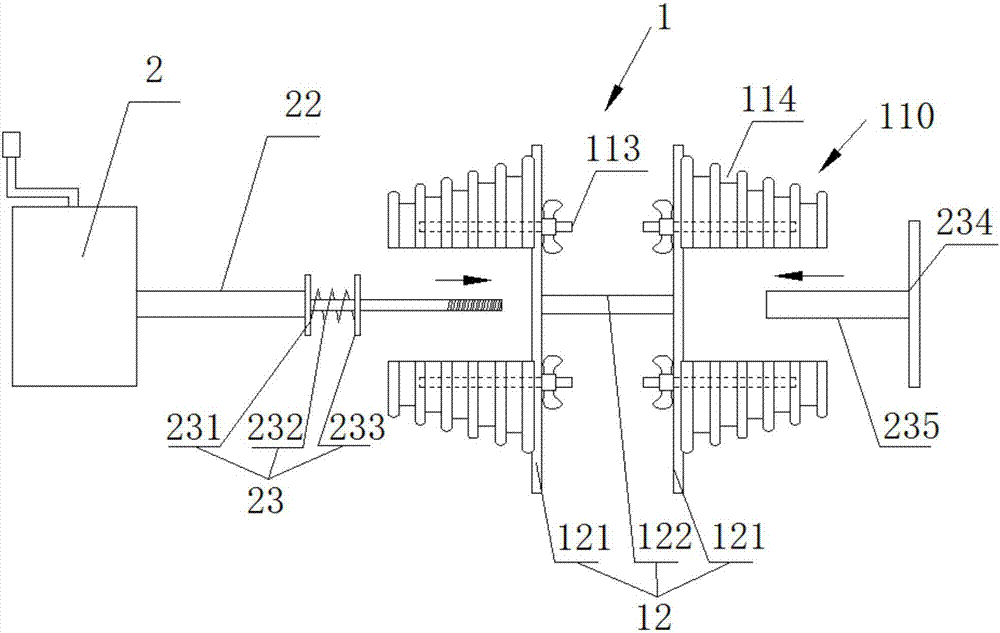

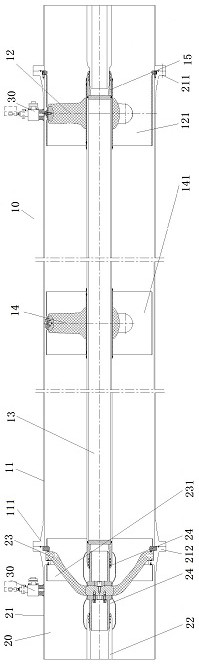

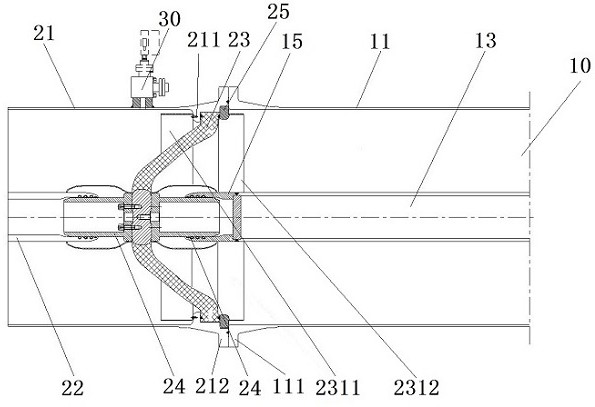

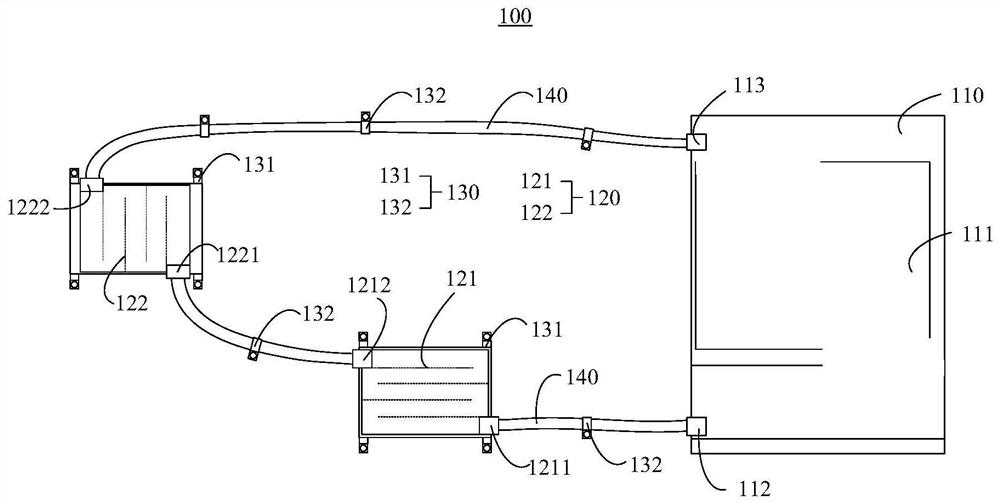

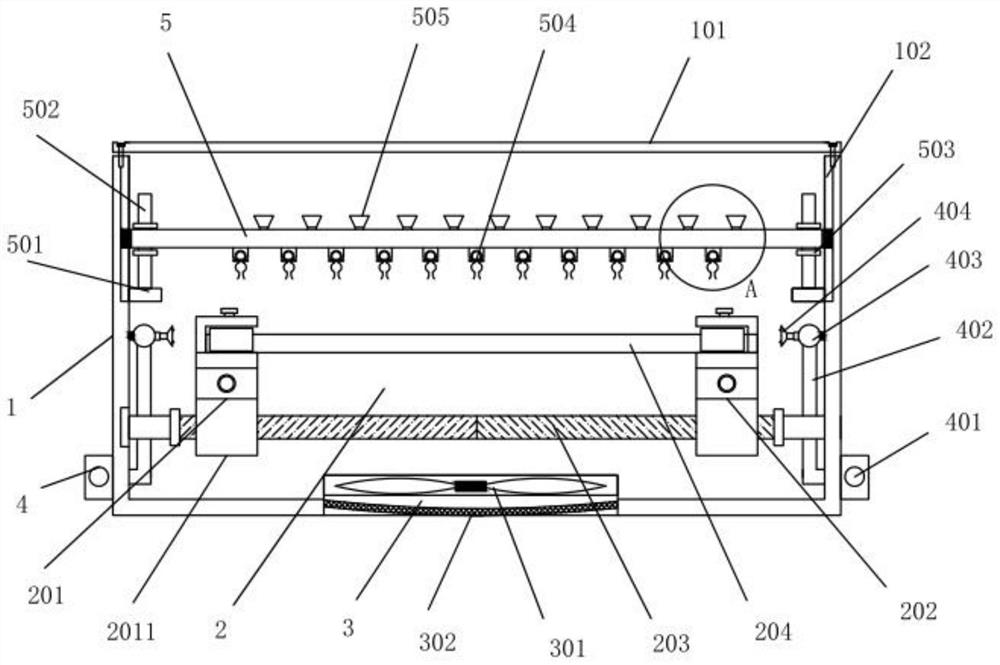

Automatic assembly line for heat pipe radiator for communication base station

ActiveCN111283429ARealize assembly line productionHigh degree of automationAssembly machinesMetal working apparatusProduction lineThermodynamics

The invention discloses an automatic assembly line for a heat pipe radiator for a communication base station, and relates to the technical field of communication equipment processing. The line comprises a fixing tool, a conveying platform, a heat pipe feeding mechanism, a welding ring feeding mechanism, a substrate feeding mechanism and a pressing mechanism, wherein the fixing tool is used for horizontally positioning and centralizedly collecting heat pipes together, the conveying platform is provided with the fixing tool, and is used for achieving horizontal conveying of the fixing tool, theheat pipe feeding mechanism is located on the left side of the conveying platform and is used for conveying the heat pipes in the fixing tool, the welding ring feeding mechanism is located on the right side of the conveying platform and is used for assembling welding rings to assembling ends of the heat pipes, the substrate feeding mechanism is located on the right side of the conveying platform and is used for clamping and then conveying a substrate to an assembly station, and the pressing mechanism is located on the left side of the conveying platform and is used for pressing the heat pipeson the fixing tool into the substrate. In the line, feeding of the heat pipes, feeding of the welding rings, feeding of the substrate and overall pressing are all completed on one conveying platform,assembly line type production is realized, the overall automation degree is high, and the assembly efficiency is remarkably improved.

Owner:WUHU YIZE SMALL & MEDIUM ENTERPRISE PUBLIC SERVICE CO LTD

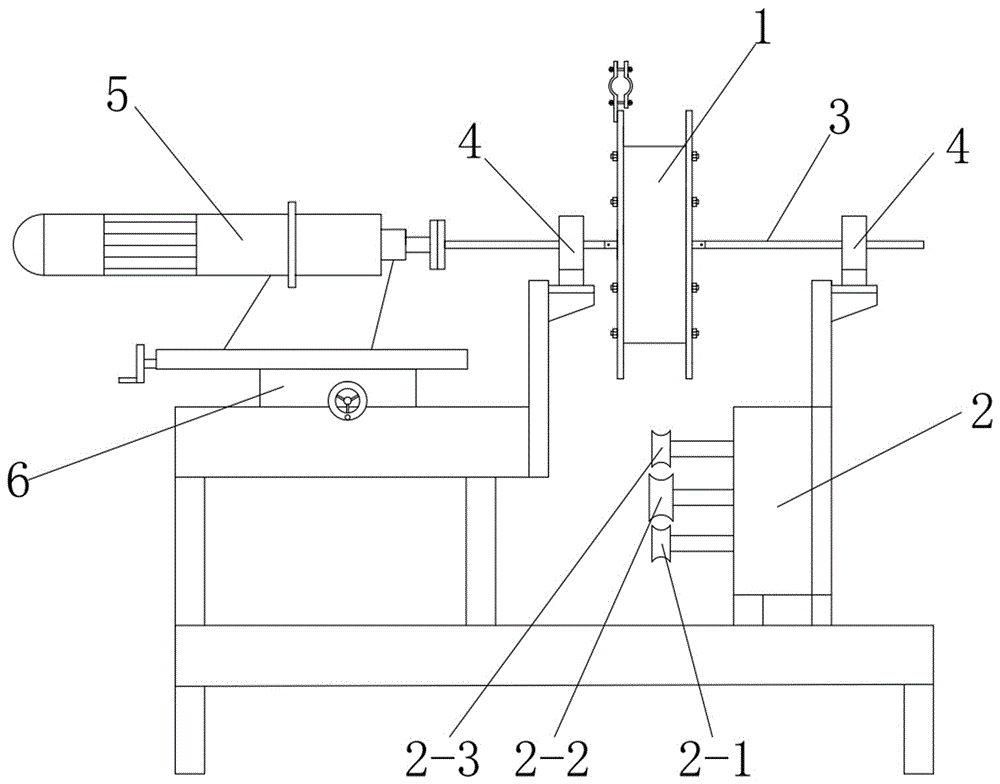

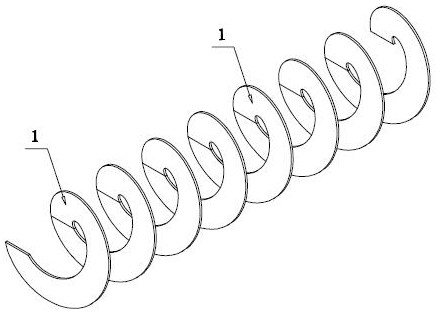

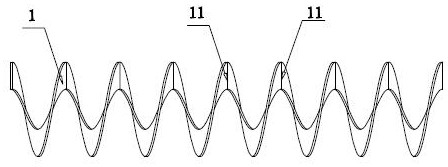

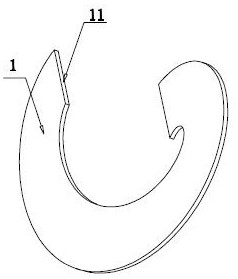

Copper casing pipe coiler

The invention relates to the field of a bending forming processing technology of casing pipe materials, in particular to the field of a preparing technology of a multi-layer spiral-structure copper casing pipe for a heat exchanger. The invention particularly discloses a copper casing pipe coiler. The copper casing pipe coiler comprises a rack, and a bending mechanism and a pipe coiling disc which are arranged on the rack, wherein the pipe coiling disc is driven by a speed reducer with a motor to rotate through a rotating shaft, the rotating shaft penetrates through a bearing and is supported by bearing pedestals arranged on the rack, and the speed reducer is fixed to a sliding table of the rack and can move on the surface of the rack in the axial direction of the rotating shaft through the sliding table; the bending mechanism comprises a dynamic pipe conveying wheel group arranged below the pipe coiling disc, a bending wheel arranged among the dynamic pipe conveying wheel group and a guide wheel which is positioned between the dynamic pipe conveying wheel group and the pipe coiling disc and is close to the periphery of the pipe coiling disc; and a pipe head positioning clamp is arranged on the pipe coiling disc. The copper casing pipe coiler can process the copper casing pipe and make a multi-layer spiral coiled pipe for the heat exchanger and has the advantages of being high in processing efficiency, neat and even in coiled pipe appearance and low in worker labor intensity.

Owner:常熟在路上创业孵化器有限公司

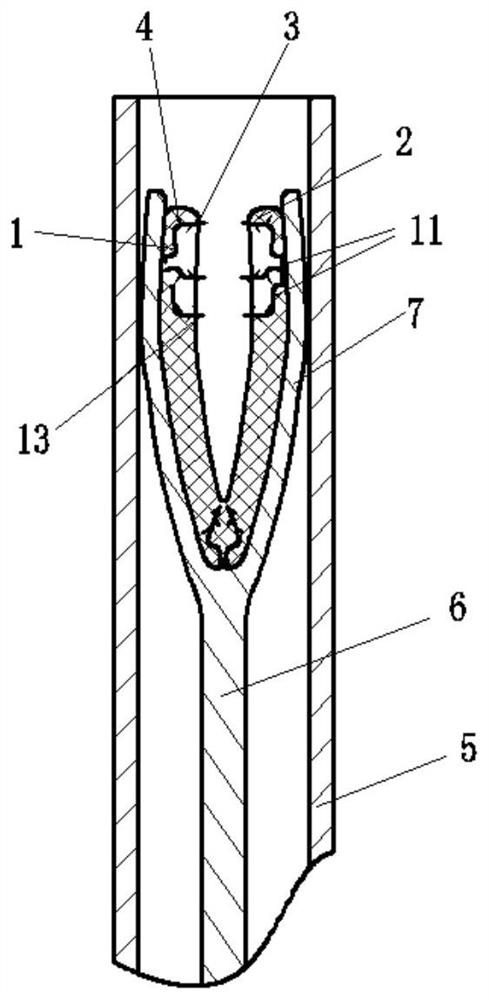

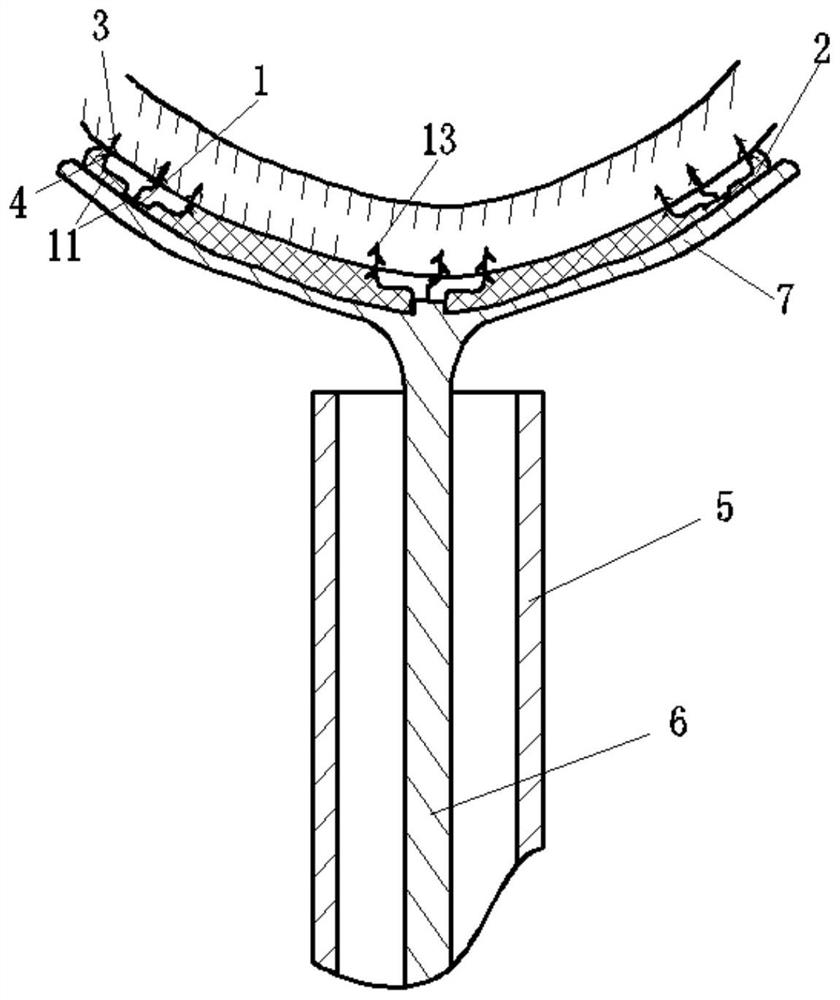

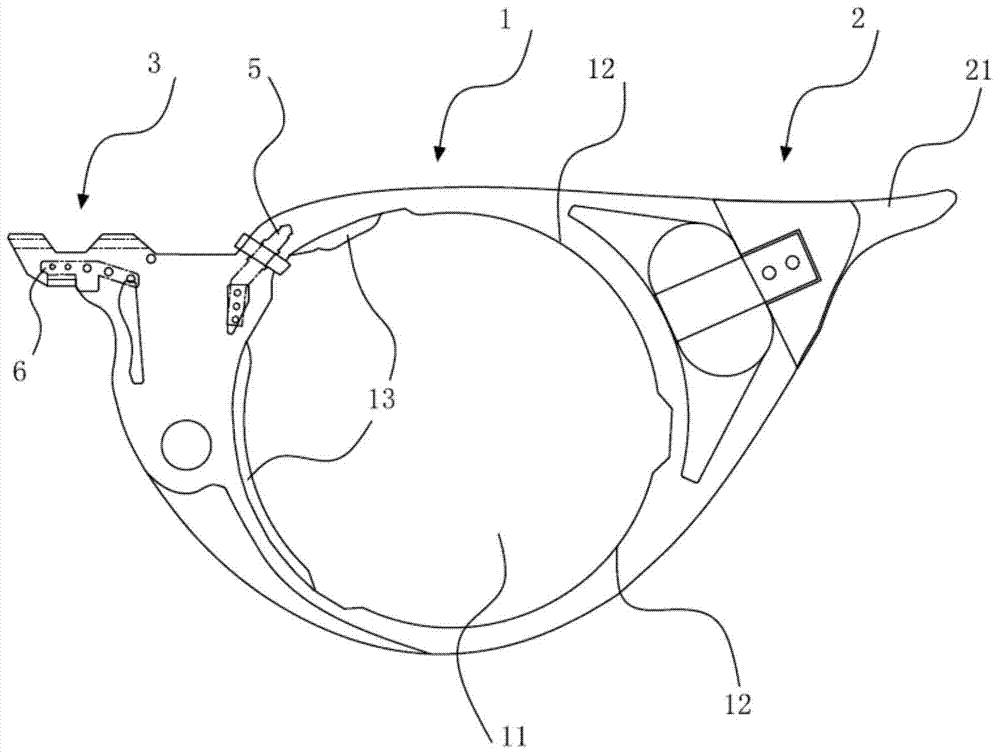

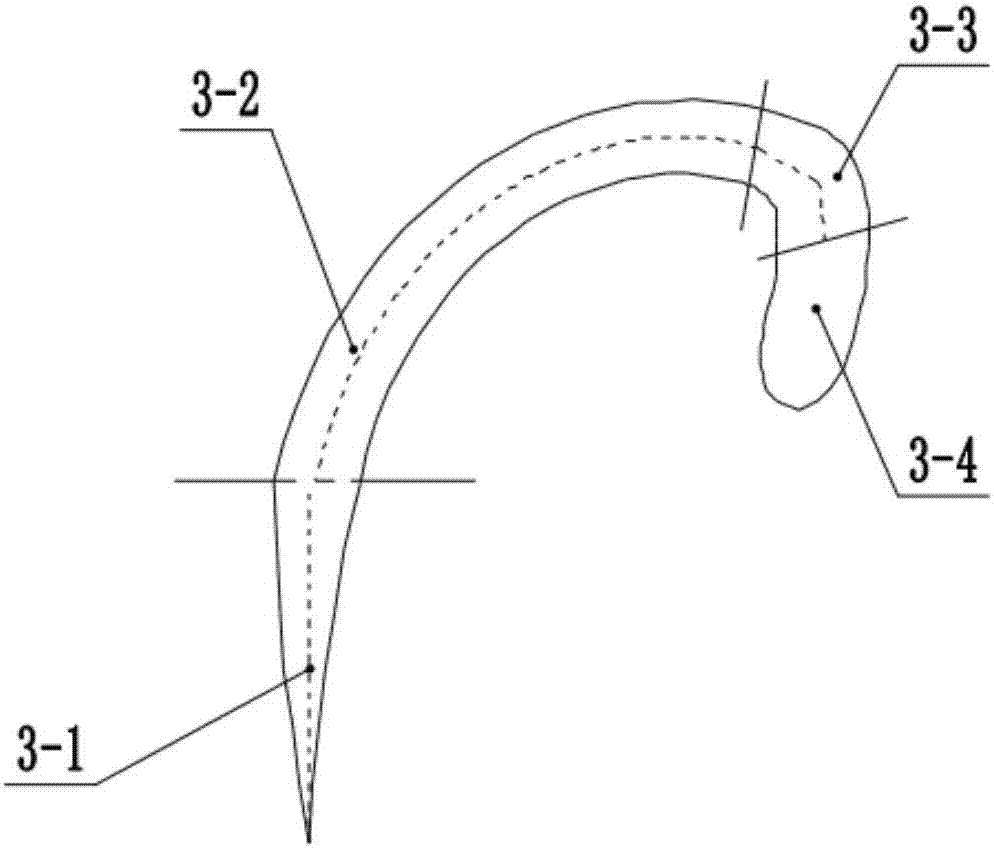

Myocardial patch with microneedle

PendingCN113069241AEffectively fixedAvoid slipping or even slipping outProsthesisCardiac muscleRat heart

The invention provides a myocardial patch with a microneedle. The myocardial patch comprises a myocardial patch body and the microneedle; the myocardial patch body is of a porous structure; the myocardial patch body has anatomical morphology adaptability; the microneedle sequentially comprises a needle root, a needle body and a needle tip from the near end to the far end, wherein the needle body is located between the needle root and the needle tip; the needle root is provided with a stop structure; an anchoring structure is arranged on the needle body and / or the needle tip; when the myocardial patch makes contact with target tissue of a heart, part or all of the needle body and the anchoring structure on the microneedle pierce into the target tissue along with the needle tip to implement minimally invasive or damage-free anchoring; the myocardial patch body, the stop structure and the anchoring structure cooperate with each other, so that the myocardial patch body and the target tissue are attached and relatively fixed; and the myocardial patch body can be implanted into a target position through a blood vessel or an endoscope by means of a delivery system, thus implementing a minimally invasive implantation operation.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

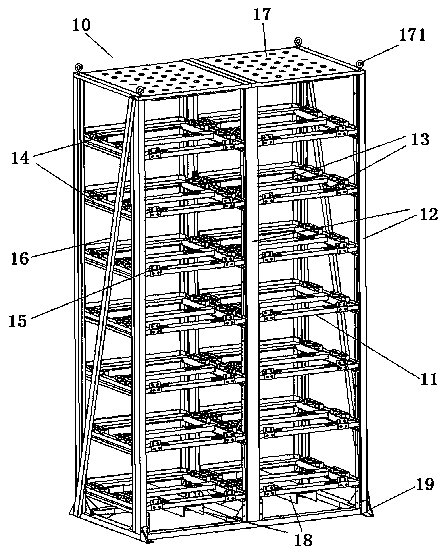

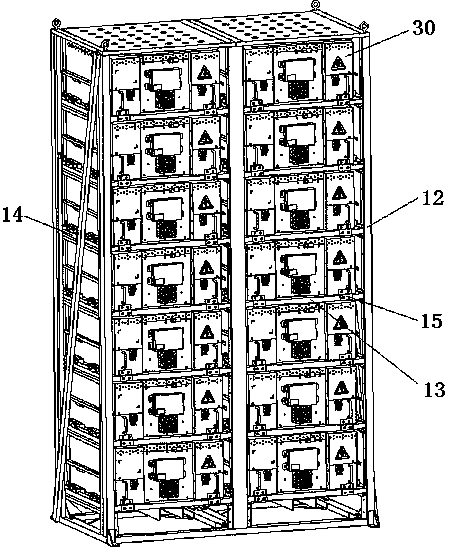

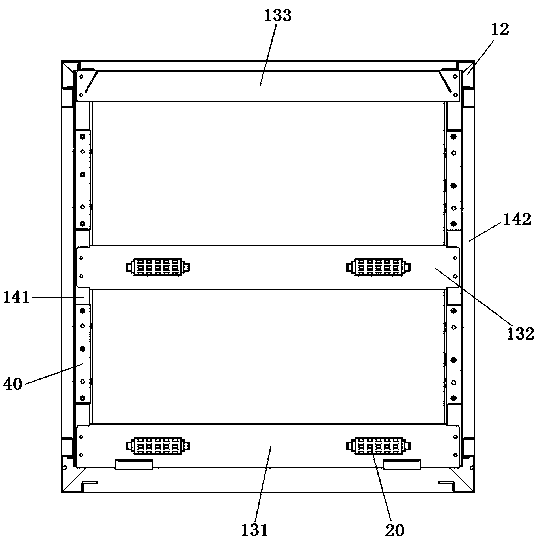

Battery transferring frame

InactiveCN111196446AAvoid colliding with each otherPlay a protective effectLarge containersElectrical batteryControl theory

The invention relates to a battery transferring frame to solve the problems in the prior art that both time and labor are wasted and the battery is likely to be damaged when the battery is placed on the transferring frame. The battery transferring frame comprises a bearing frame, battery placing cabins, a bottom support mechanism, lateral guiding structures and limiting pieces, wherein at least one row of battery placing cabins are arranged on the bearing frame in the up-down direction; each of the battery placing cabins is provided with a cabin opening allowing the battery to enter and exit the battery placing cabin, and the cabin opening is towards the horizontal direction; the bottom support mechanism is mounted at the bottoms of the battery placing cabins and comprises a ball or an idler wheel; the ball or the idler wheel is used for being in rolling contact with the bottom of the battery; the lateral guiding structures are mounted on the two sides of the battery placing cabins; each of the lateral guiding structures comprises balls or idler wheels distributed in the depth direction of the battery placing cabins; the balls or idler wheels are used for being in rolling contact with the side walls of the batteries and directing the batteries to enter the battery placing cabins; and the limiting pieces are detachably or movably mounted at all battery placing cabins and are used for being in stop fit with the batteries in the directions entering and / or exiting the battery placing cabins.

Owner:STATE GRID TIANJIN ELECTRIC POWER +3

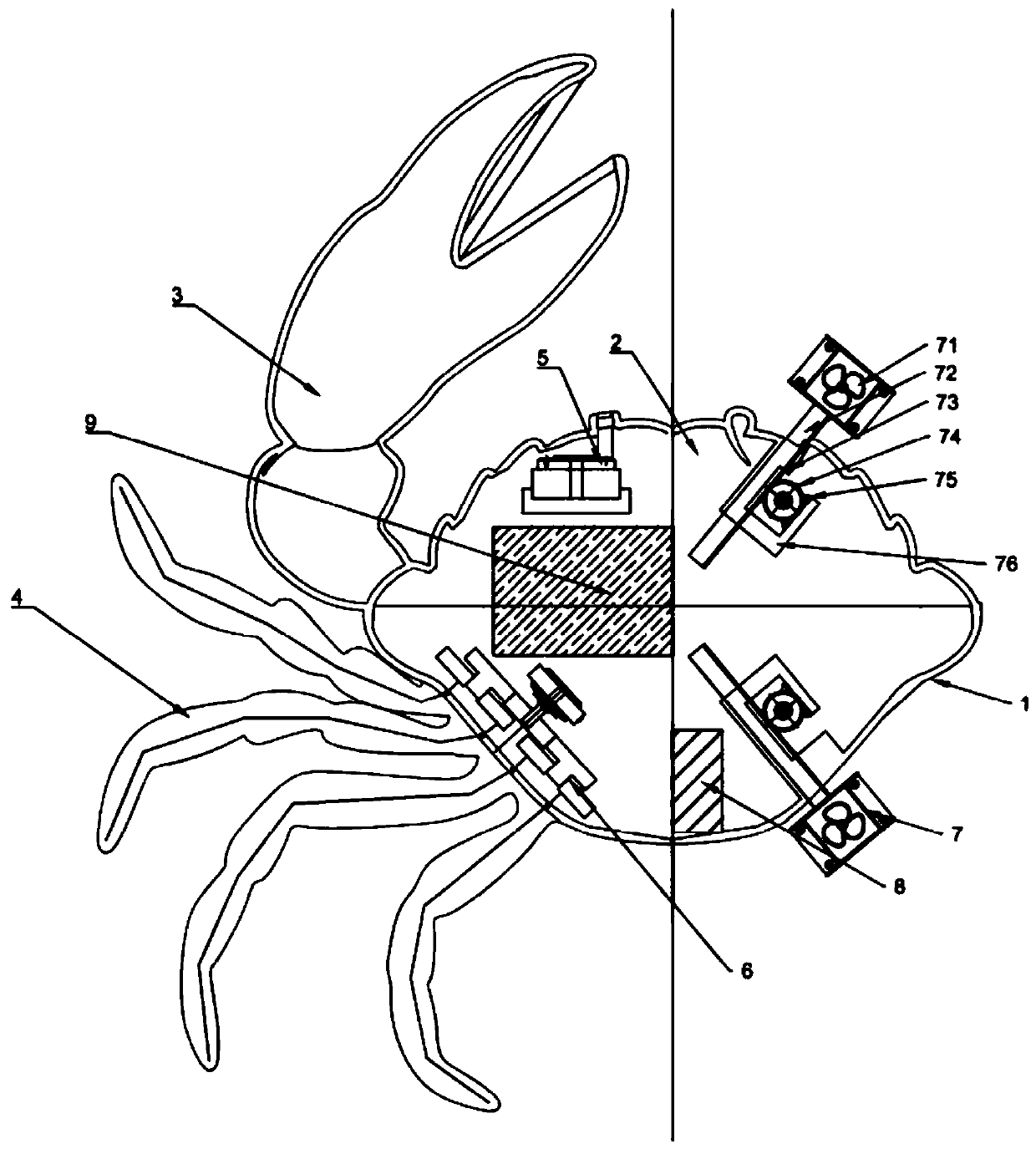

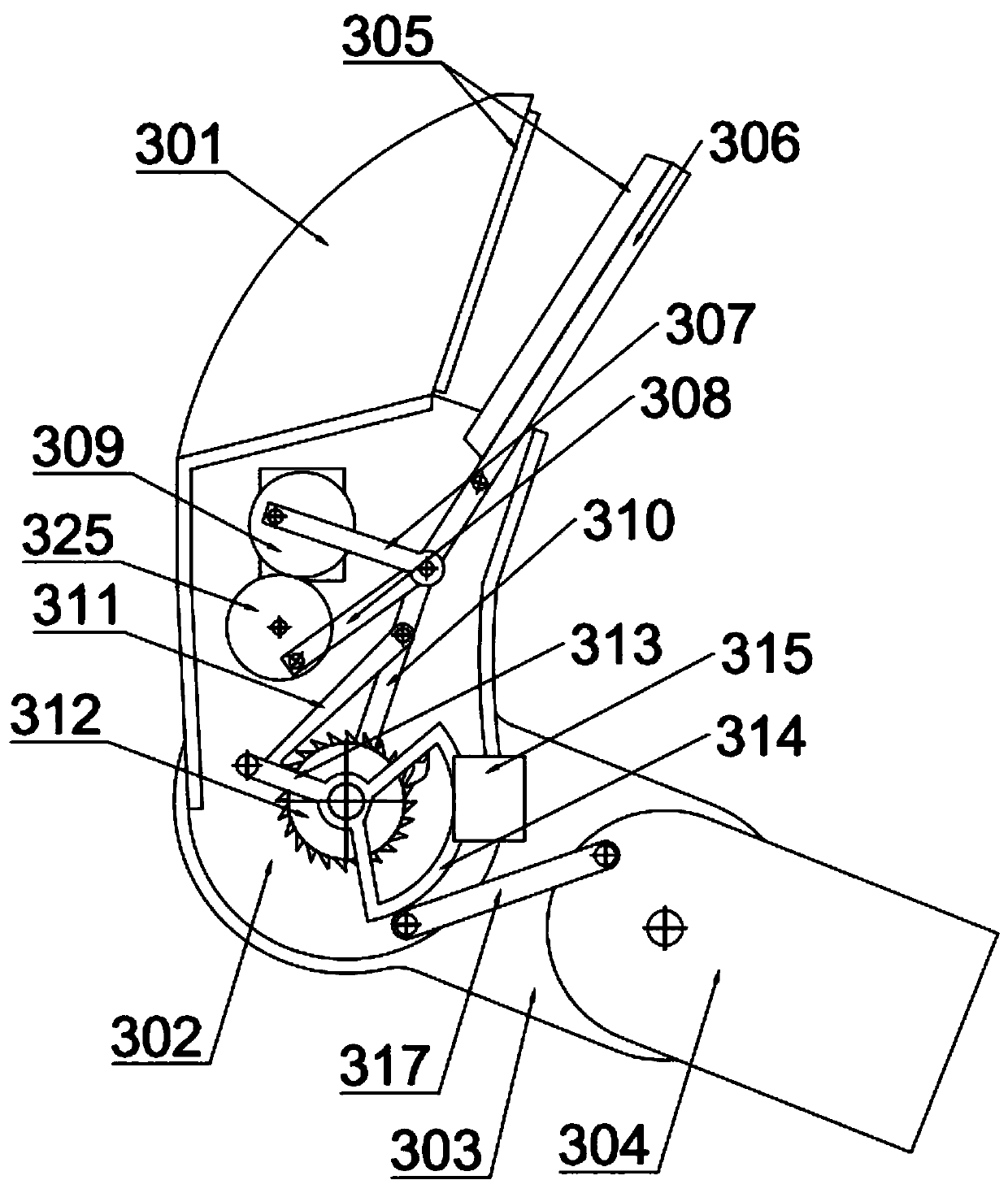

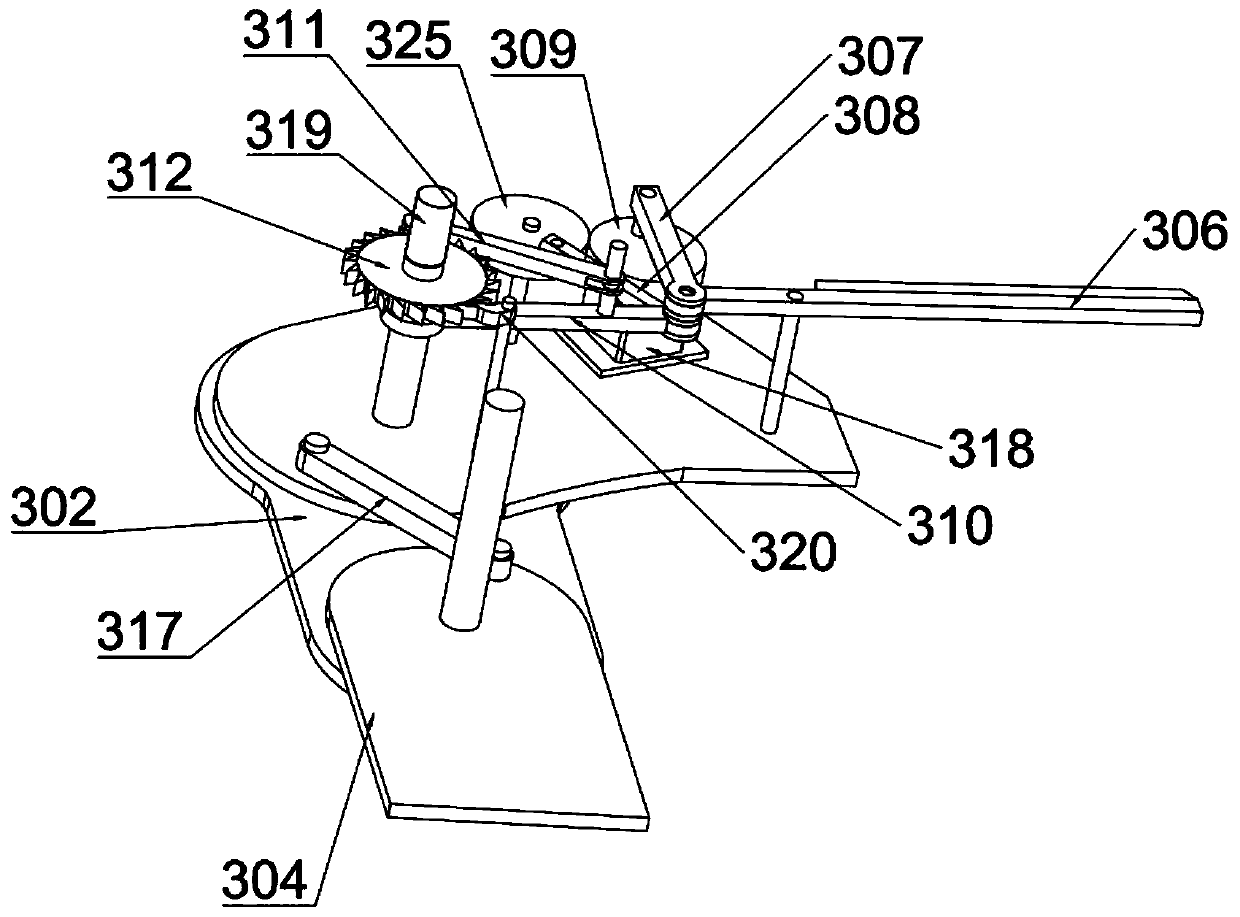

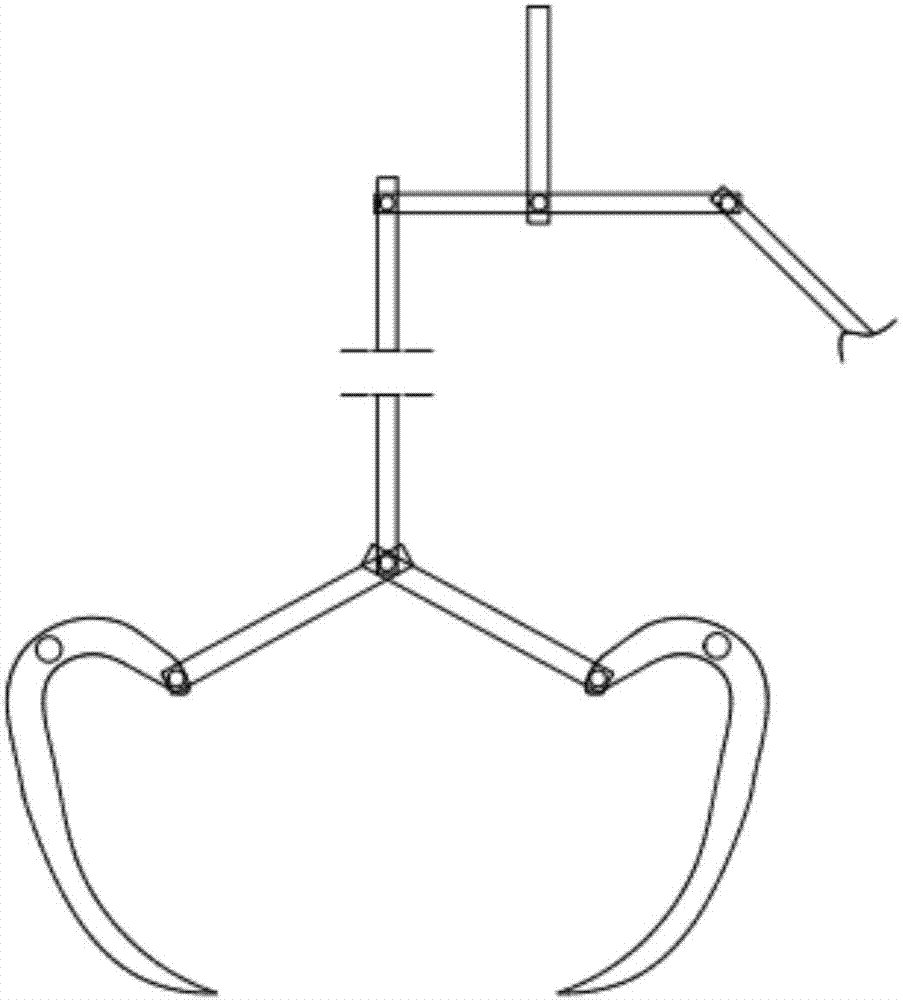

Solar-power diving crab-simulating robot with functions of bionic observation and weeding

ActiveCN110959374ALess disturbingEffect on growth and reproductionHarvestersRenewable energy machinesFisheryEngineering

The invention discloses a solar-power diving crab-simulating robot with the functions of bionic observation and weeding. The robot comprises a main body, crab claws, crab legs and a mimic waterproof shell, wherein the crab legs and the crab claws are arranged on both sides of the main body separately, the crab claws include third claw arms which are fixed on both sides of the front part of the main body, second claw arms which are hinged to the end parts of the third claw arms and first claw arms which are hinged to the end parts of the second claw arms, and crab claw weeding shears are arranged at the tail ends of the first claw arms; and shear extension mechanisms and reset mechanisms are arranged inside the crab claws, the shear extension mechanism are used for driving the crab claw weeding shears to open and close and driving the crab claws to extend inwards at the same time, and the reset mechanisms are used for returning the crab claws to original positions. The disturbance to crabs is minimized, the influences on the growth and reproduction of the crabs are avoided, overgrowing aquatic weeds can be removed in time through the crab claw weeding shears, and it is ensured thatthe breeding environment is suitable for growth and reproduction of the crabs.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

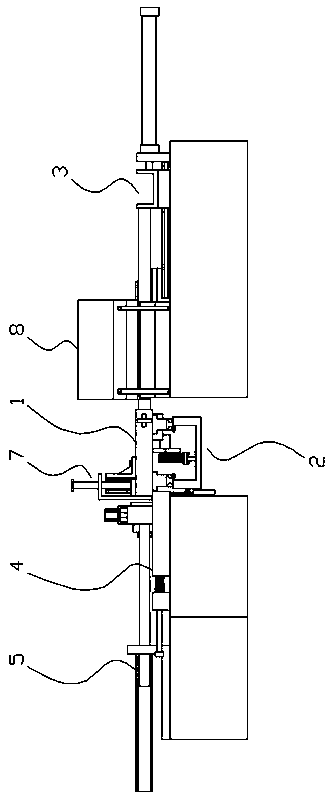

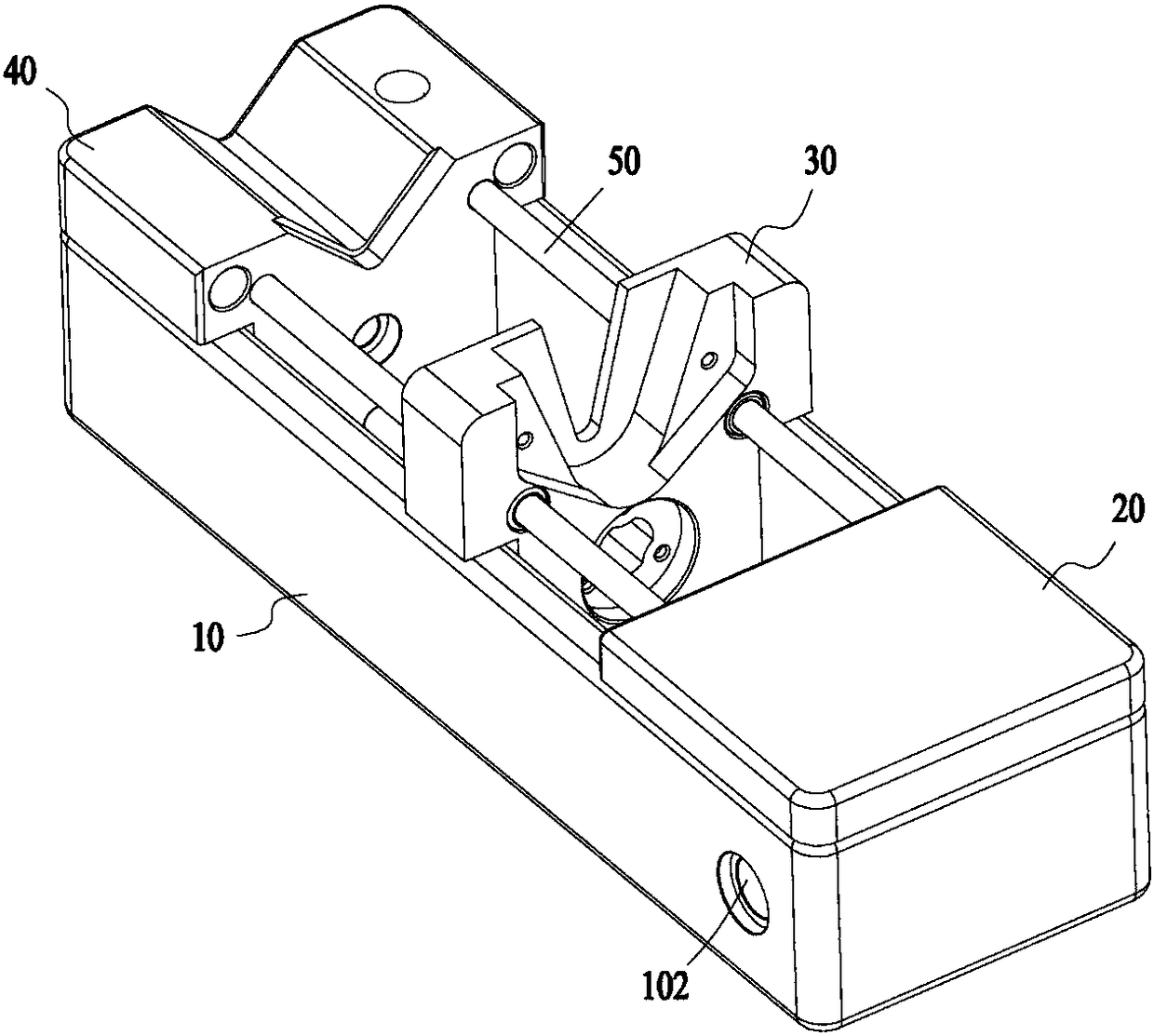

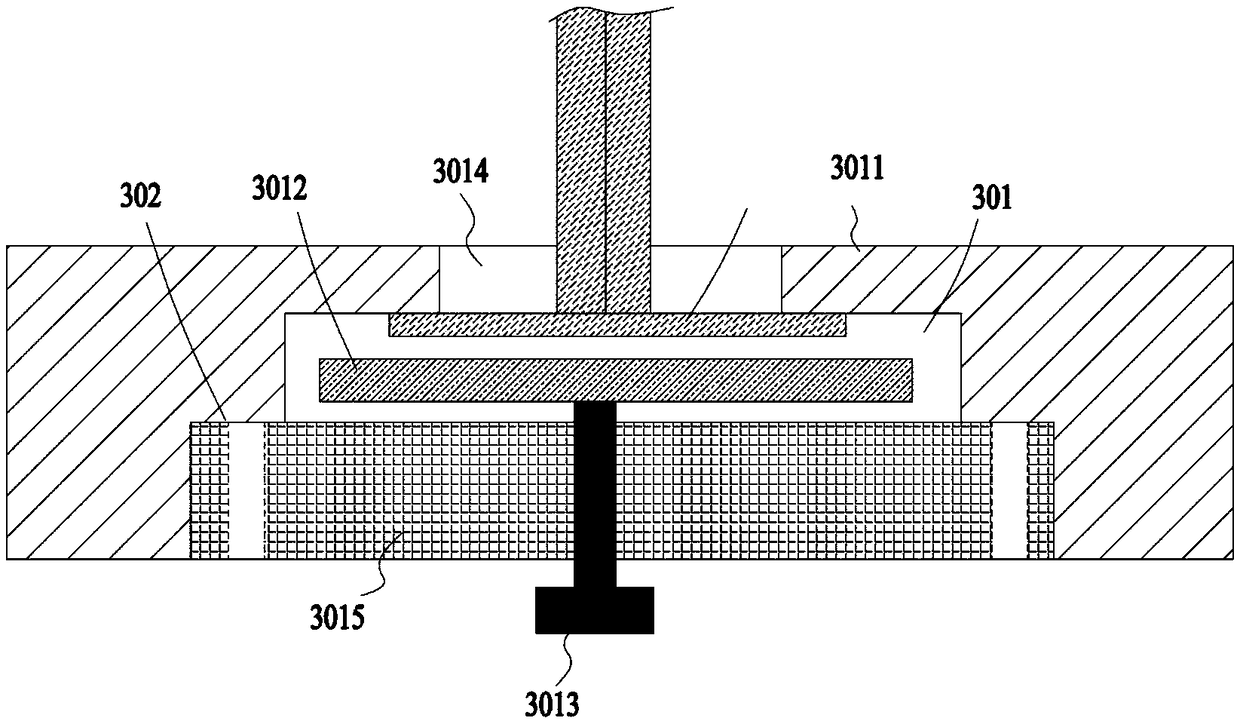

Injection pump

InactiveCN108311178AAchieve relatively fixedImprove stabilityLaboratory glasswaresFluid controllersEngineeringInjection pump

The invention discloses an injection pump. The injection pump comprises a motor, a sliding block and a cylinder base; the motor acts on the sliding block to drive the sliding block to be close to or far away from the cylinder base; a first clamping groove for limiting an injector pull rod cap is formed in the sliding block; a second clamping groove for limiting an injector needle cylinder cap is formed in the cylinder base; the first clamping groove comprises a baffle and a driving plate which are arranged opposite; the driving plate is connected with a driving piece; and the driving piece acts on the driving plate and can drive the driving plate to be close to or far away from the baffle. The pull rod cap of the injector is limited between the baffle and the driving plate and the pull rodcap can be extruded in the first clamping groove through motion of the driving plate, so that relative fixation of the pull rod cap and the sliding block is realized and the stability in the injection process is improved.

Owner:SUZHOU XUNFEI SCI INSTR CO LTD

Novel walking aid for bone and joint patient

Provided is a novel walking aid for a bone and joint patient. Rotating sleeves rotationally sleeve the upper portion of a foreleg, a lower separation and reunion plate sleeving the foreleg is coaxially fixed to the rotating sleeves, an upper separation and reunion plate located above a lower separation and reunion device vertically slidingly sleeves the foreleg, a first connecting rod is fixed between the two rotating sleeves, a control rod located below a transverse rod and downwards inclining towards a rear leg is fixedly installed on a control shaft, a sliding frame is slidingly connected with the transverse rod, a control rack fixedly connected with the sliding frame is meshed with a control gear, a connecting gear is rotationally connected with a gear rack, a connecting rack fixedly connected with the upper separation and reunion plate is meshed with the connecting gear, and a middle rod is arranged between the connecting gear and the sliding frame. When the walking aid interactively walks and a patient feels uncoordinated in walking with the walking aid on the body, by loosening the control rod, the positions of two supports can be relatively fixed, and the use safety and reliability of the patient are ensured; when a seat plate is unfolded, the locking of a walking wheel can be realized, and the safety of the patient is ensured.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

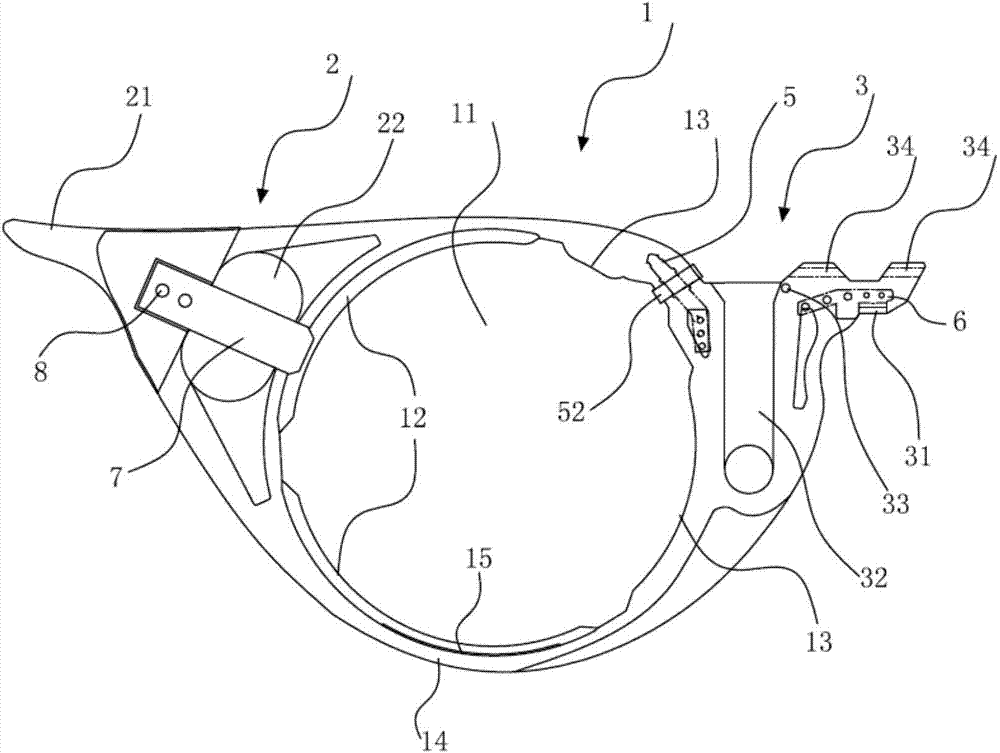

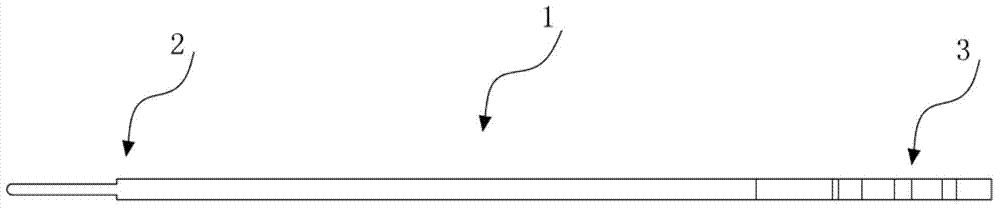

Netting machine plastic shuttle

The invention discloses a netting machine plastic shuttle. The netting machine plastic shuttle comprises an annular body, a head portion and a tail portion, wherein the head portion and the tail portion are located at the two ends of the annular body, a circular opening used for containing a shuttle core is formed in the annular body, the annular body, the head portion and the tail portion are all made of plastic materials, the connecting part of the annular body and the tail portion is provided with a first strengthening rib, and the tail portion is internally provided with a second strengthening rib. The netting machine plastic shuttle has the advantages that since traditional fish-shaped shuttles are all made of copper, the netting machine plastic shuttle adopts the shuttle of which the most part is made of plastic materials, more shuttles can be installed on a netting machine under the condition of the same supporting capacity, and therefore a netting machine with larger width can be fabricated, and finally the efficiency of the netting machine is improved. The service life of the shuttle is improved and is 4-5 times the length of an original copper shuttle. Due to the fact that the copper shuttle is replaced by the plastic shuttle, the mechanical strength of the whole shuttle is weakened, the fracturing problem is prone to occur, but the fracturing problem of the shuttle is not prone to occur any more by the arrangement of the first strengthening rib and the second strengthening rib.

Owner:张家港市新盈模具塑化有限公司

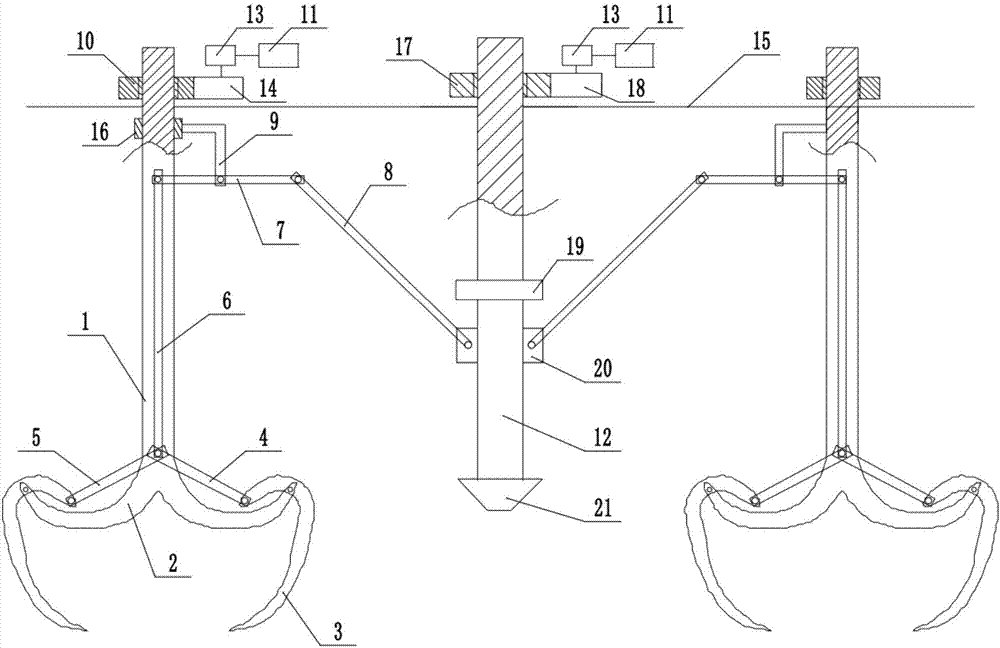

Position fixed device for engineering vehicle in construction process

PendingCN107380142APrevent compromising security operationsAchieve relatively fixedBraking element arrangementsArchitectural engineeringBuilding construction

A position fixed device for an engineering vehicle in a construction process is used for fixing the position of the large construction vehicle in a stopping state of the vehicle. The structure of the position fixed device comprises anchoring mechanisms and pressing mechanisms, wherein each anchoring mechanism comprises fixing anchor jaws, a first connecting rod, a second connecting rod and a vertical connecting rod, and the bottom of the vertical rod is hinged to the first connecting rod and the second connecting rod; and the other ends of the first connecting rod and the second connecting rod are hinged to the fixing anchor jaws correspondingly, the anchoring mechanisms firmly grab the ground through grabbing actions, the pressing mechanisms are used for enabling the anchoring mechanisms to be inserted the ground, and thus the vehicle body is fixed. In a word, the position fixed device for the engineering vehicle in the construction process is simple in structure, high in practicability, and suitable for industrial production.

Owner:HEBEI ROAD & BRIDGE GROUP

System for training precise shooting of football based on sports management

ActiveCN109821208AImprove dead corner scoring rateAchieve relatively fixedBall sportsWireless transmissionControl system

The invention provides a system for training precise shooting of football based on sports management. The system comprises a hanging net, a lifting mechanism and a control system, wherein the liftingmechanism is connected with the two top corners at the upper end of the hanging net; the control system is in wireless transmission connection with the lifting mechanism. Annular expansion latch fasteners are arranged at the four corners of the hanging net, after the lifting mechanism lifts the hanging net to a height equal to the height of a football door, the annular expansion latch fasteners are connected with the football door, and fixing of the hanging net is achieved. The surface of the hanging net is divided into four bonus point areas, one deduction area and a non-scoring area. The system can be used for training a player to shoot a football into the bonus point areas, and the football training level is improved; when the collected relevant data is used in training statistics and academic research, the football teaching level and the sports management level are easily improved.

Owner:CHONGQING UNIV

Winding tool of stator coil

InactiveCN107546933ASimple structureImprove winding efficiencyManufacturing dynamo-electric machinesCopper wireStator coil

The invention provides a winding tool of a stator coil. The winding tool comprises a winding mechanism, a driving mechanism and a counter. The driving mechanism drives the winding mechanism to rotate.The winding mechanism comprises a winding portion and a fixing seat. The winding portion comprises two winding sub-portions. The two winding sub-portions are oppositely arranged and are fixed to thefixing seat in a sliding mode, so that the two winding sub-portions perform relative motions to achieve the coil diameter adjusting purpose. The winding portion is provided with multiple notches for limiting copper wires. The counter is used for calculating the turn number of the winding portion. Compared with the prior art, the winding tool is simple in structure and high in winding efficiency. By arranging the winding portion into the two winding sub-portions capable of performing relative motions, the same winding portion can be used for winding different diameters of coils, and the complicated work of dismounting and replacing the winding portion is avoided.

Owner:ANHUI JINWAN PUMP TECH CO LTD

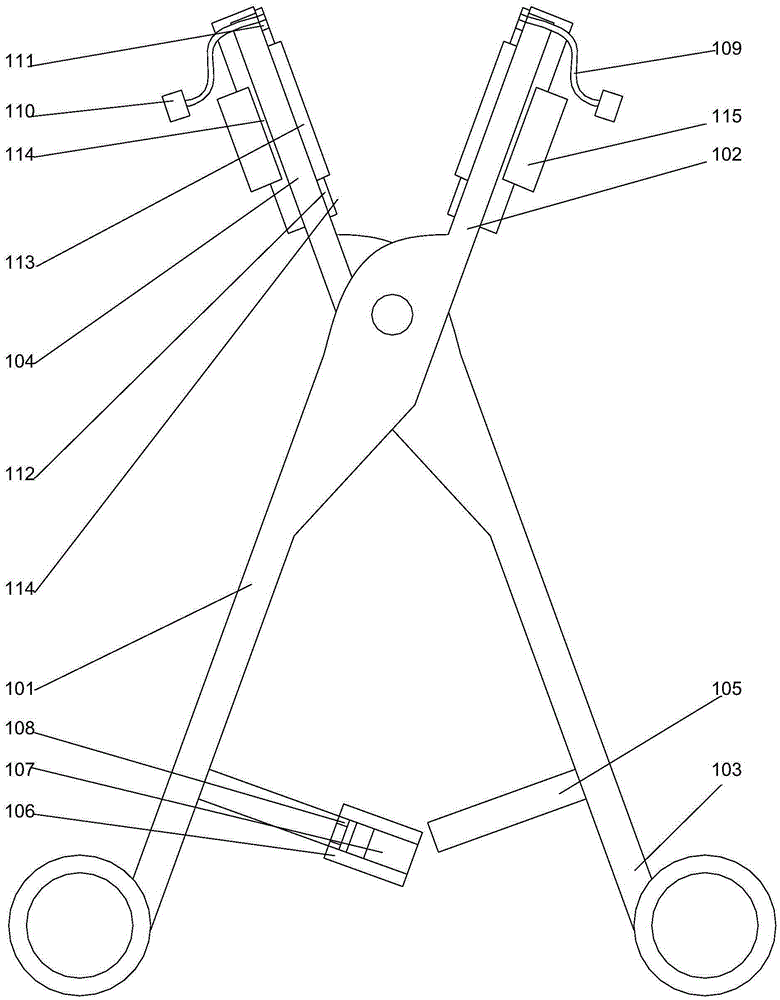

Flushing device for general surgery department

The invention discloses a flushing device for general surgery department. The flushing device comprises a left tong arm, a right tong head connected to the left tong arm, a right tong arm and a left tong head connected to the right tong arm, wherein the left tong arm and the right tong arm are mutually hinged by virtue of a pin shaft; locking strips are respectively arranged on opposite surfaces of the left tong arm and the right tong arm; the end, away from the pin shaft, of the left tong head and the end, away from the pin shaft, of the right tong head are provided with through holes; stream guidance tubes are arranged inside the through holes; the stream guidance tubes are made from medical silica gel; the end, away from the corresponding through hole, of each of the stream guidance tubes is provided with a seal cover; and suction ports are arranged on the seal covers. The flushing device disclosed by the invention, by virtue of the locking devices, is conducive to the fixation of the integral structure; meanwhile, by adopting two stream guidance tubes, flushing for an operative site and suction for liquid are conveniently implemented; and the flushing device is simple to operate, and operation steps are effectively simplified, and operation efficiency is improved.

Owner:李林浩

Bus bar unit and pipe bus bar

InactiveCN112152174AAvoid the problem that the length of the plug is too short or even falls offPrecise positioningTotally enclosed bus-bar installationsStructural engineeringMechanical engineering

The invention relates to the technical field of GIL and provides a bus unit and a pipeline bus. The bus unit comprises a bus cylinder and a conducting rod, wherein one end of the bus cylinder is provided with a fixed insulator which is fixedly arranged relative to the bus cylinder, two axial ends of the fixed insulator are provided with a fixed connecting seat and a plug-in connecting seat respectively, the fixed connecting seat is used for fixing and conductively connecting the corresponding conducting rod in the bus unit or in the adjacent bus unit, and the plug-in connecting seat is used for plug-in matching and conductively connecting the corresponding conducting rod in the bus unit or in the adjacent bus unit. The fixed connecting seat and the plug-in connecting seat arranged on the two sides of the insulator in the bus unit change a conductive rod in the prior art into a mode that one end is fixed and the other end is telescopic, the telescopic movement of only one end of the conductive rod is limited, and the whole conductive rod can still adapt to temperature change through self telescopic deformation; a problem that the insertion length of the conducting rod is too short and even falls off when the conducting rod expands with heat and contracts with cold can be effectively avoided.

Owner:PINGGAO GRP +1

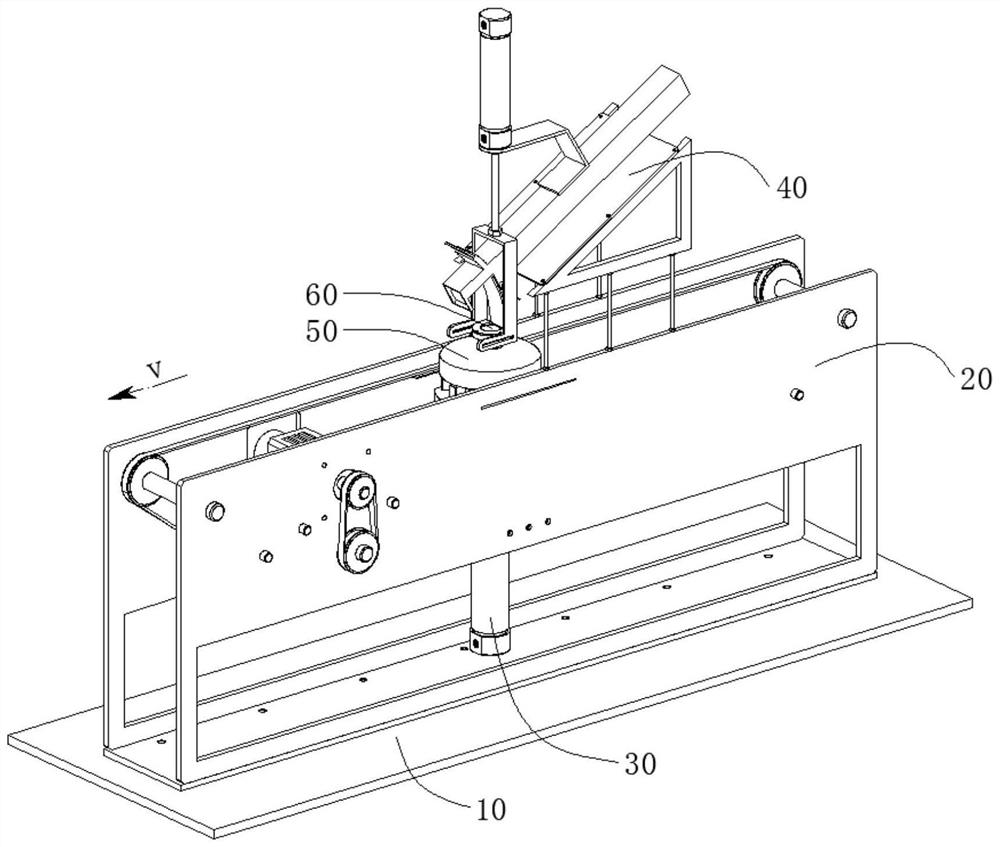

Thread shearing mechanism and method

PendingCN108842427AHigh degree of automationImprove dismantling efficiencySevering textilesWaste management

The invention discloses a thread shearing mechanism and method. The thread shearing mechanism comprises a working table, a feeding device and a thread shearing device. The feeding device comprises a feeding platform and a feeding assembly, wherein the feeding platform and the feeding assembly are arranged on the working table, and the feeding assembly is used for driving cut-parts to move along the feeding platform; the thread shearing device comprises a thread shearing base, a thread shearing platform, a thread shearing detection component, a thread shearing device body and a thread shearingdriving component; the thread shearing base is arranged on the working table, the thread shearing platform is movably connected to the thread shearing base, the thread shearing driving component is used for driving the thread shearing platform to move, a thread shearing support is connected to the thread shearing platform, the thread shearing detection component comprises a first detection elementand second detection elements which are arranged on the thread shearing support, detection intervals are formed between the first detection element and the second detection elements, the thread shearing device body is arranged on the thread shearing platform and located between the detection intervals in the vertical direction, and the thread shearing device body is used for shearing fishing threads on the cloth pieces. The thread shearing mechanism is high in thread shearing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

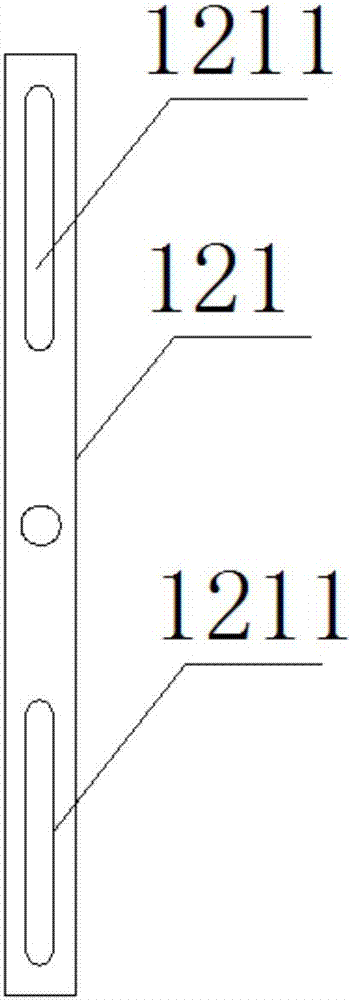

Blade assembling device of spiral conveying equipment

InactiveCN114029679ASimple structureEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesPhysicsMechanical engineering

A blade assembling device for spiral conveying equipment is used for solving the problem that machining of spiral blades of large spiral conveying equipment is time-consuming and labor-consuming. The device comprises brackets, wherein the brackets are of U-shaped structures, a pair of supporting rods are arranged at the bottoms of the brackets, the supporting rods are arranged left and right, the two supporting rods are fixedly connected through a connecting plate, and a main shaft provided with spiral blades is arranged between the two brackets; a clamping adjusting unit used for clamping the single blades to be installed and enabling every two adjacent single blades to be kept in a contact state; a moving unit arranged on the connecting plate and used for driving the clamping adjusting unit so that the clamping adjusting unit can move in a reciprocating mode in the direction of the main shaft. The blade assembling device of the spiral conveying equipment is simple in structure, relative fixation between the single blade and the main shaft can be achieved, contact between every two adjacent single blades is kept, and then welding is facilitated.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

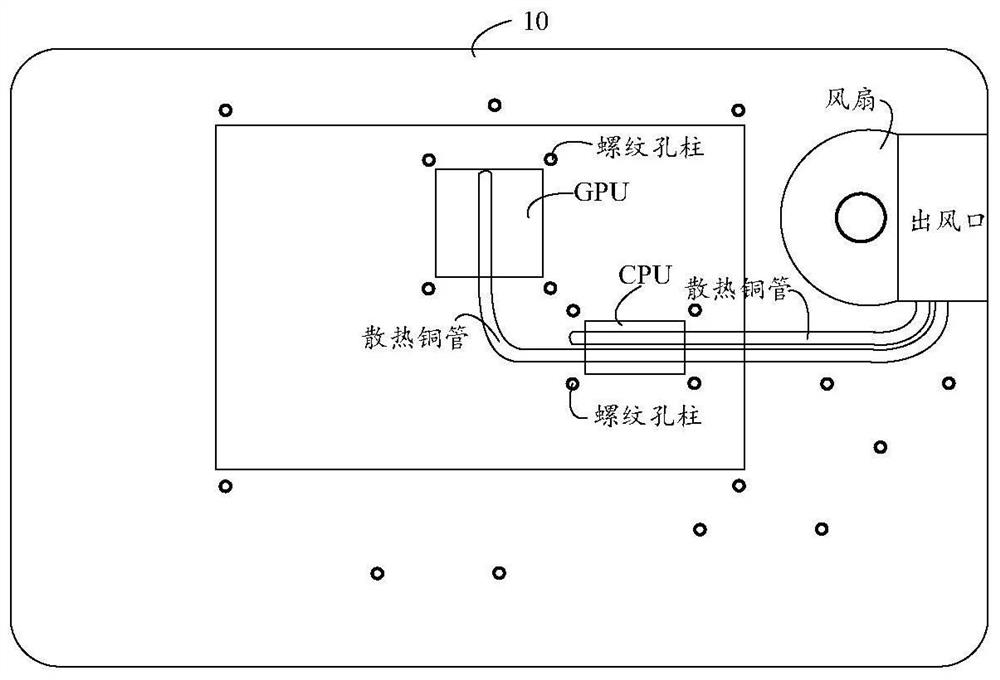

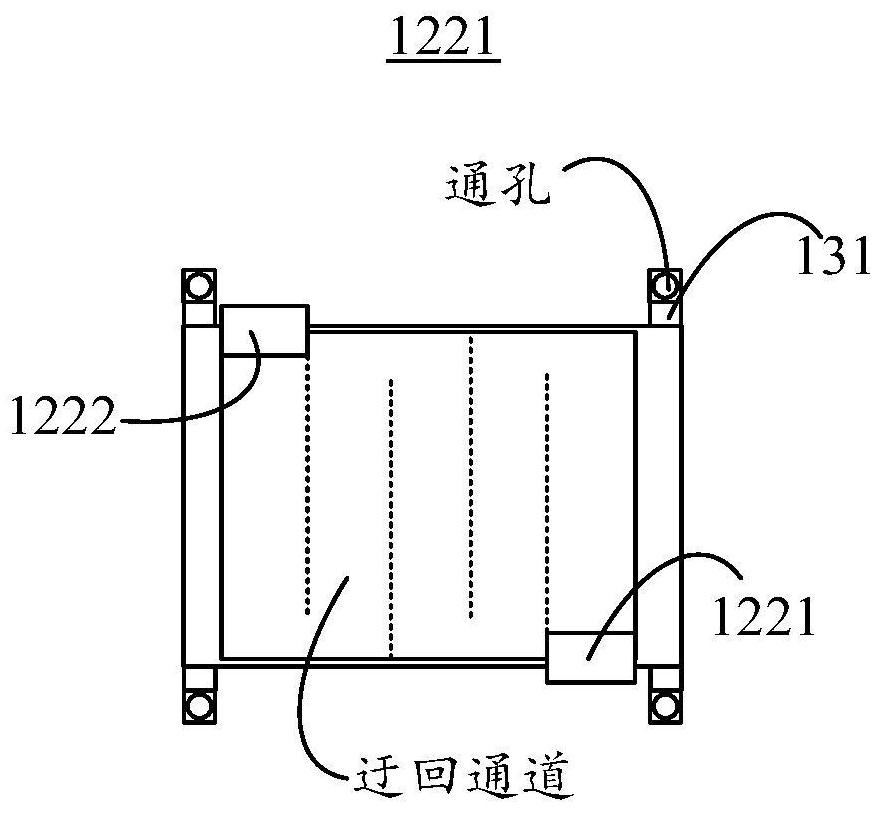

Auxiliary heat dissipation device for computer hardware

InactiveCN113268128AFix fixExtension of timeDetails for portable computersCooling fluidHot Temperature

The invention provides an auxiliary heat dissipation device for computer hardware. The auxiliary heat dissipation device comprises a liquid cooling heat dissipation part, a liquid cooling pipeline, a copper cold head and an auxiliary fixing part. Relatively low-temperature cooling liquid is input into the copper cold head from the first liquid inlet through the heat dissipation liquid outlet of the liquid cooling heat dissipation part via the liquid cooling pipeline, so that the relatively low-temperature cooling liquid passes through a circuitous channel, takes away part of heat of a target part ( and becomes relatively high-temperature cooling liquid), flows out from the first liquid outlet, and returns to the heat dissipation structure of the liquid cooling heat dissipation part from the heat dissipation liquid inlet through the other section of liquid cooling pipeline for heat dissipation (and becomes cooling liquid with relatively low temperature). The circuitous channel communicating the first liquid inlet and the first liquid outlet in the copper cold head can prolong the time for the cooling liquid to flow through the copper cold head, so that more heat of a target part is taken away, and a better heat dissipation effect is achieved. Moreover, the air-cooled heat dissipation system of a notebook computer cannot be influenced, the air-cooled heat dissipation system can operate simultaneously, and the heat dissipation efficiency is ensured.

Owner:陕西工业职业技术学院

Auxiliary welding device for valve seat and bottle cap in fire extinguisher bottle body

InactiveCN113102928AIngenious designReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftElectric machinery

The invention discloses an auxiliary welding device for a valve seat and a bottle cap in a fire extinguisher bottle body, and relates to the technical field of fire extinguisher production. The auxiliary welding device for the valve seat and the bottle cap in the fire extinguisher bottle body comprises a working platform, a conveying mechanism, a jacking mechanism and a lowering mechanism, wherein the conveying mechanism is arranged on the upper side of the working platform and intermittently conveys the bottle cap with the valve seat not welded or welded; the conveying device comprises a transverse plate I, a vertical plate I, a conveying shaft, a driving shaft, a conveying motor and a lifting strip; the jacking mechanism is arranged on the inner side of the conveying mechanism and used for jacking the bottle cap, so that the bottle cap can abut against and be welded to the descending valve seat conveniently; the jacking mechanism comprises a fixing plate I, a telescopic air cylinder I, a lifting plate, a positioning plate and a telescopic frame; the lowering mechanism is arranged above the jacking mechanism and used for lowering the valve seat, so that the valve seat can abut against and be welded to the rising bottle cap conveniently; and the lowering mechanism comprises a discharging pipe, a lifting plate, a material blocking strip, a material taking block, a fixing plate II and a telescopic air cylinder II. In conclusion, the auxiliary welding device for the valve seat and the bottle cap in the fire extinguisher bottle body provided by the invention is ingenious in design and reasonable in structure, manual participation is reduced, and the welding efficiency is improved.

Owner:来安县誉强消防科技有限公司

A power connection plug

ActiveCN104953318BEasy to replaceEasy to operateCoupling contact membersEngineeringMechanical engineering

Owner:深圳市鑫冠辉电子有限公司

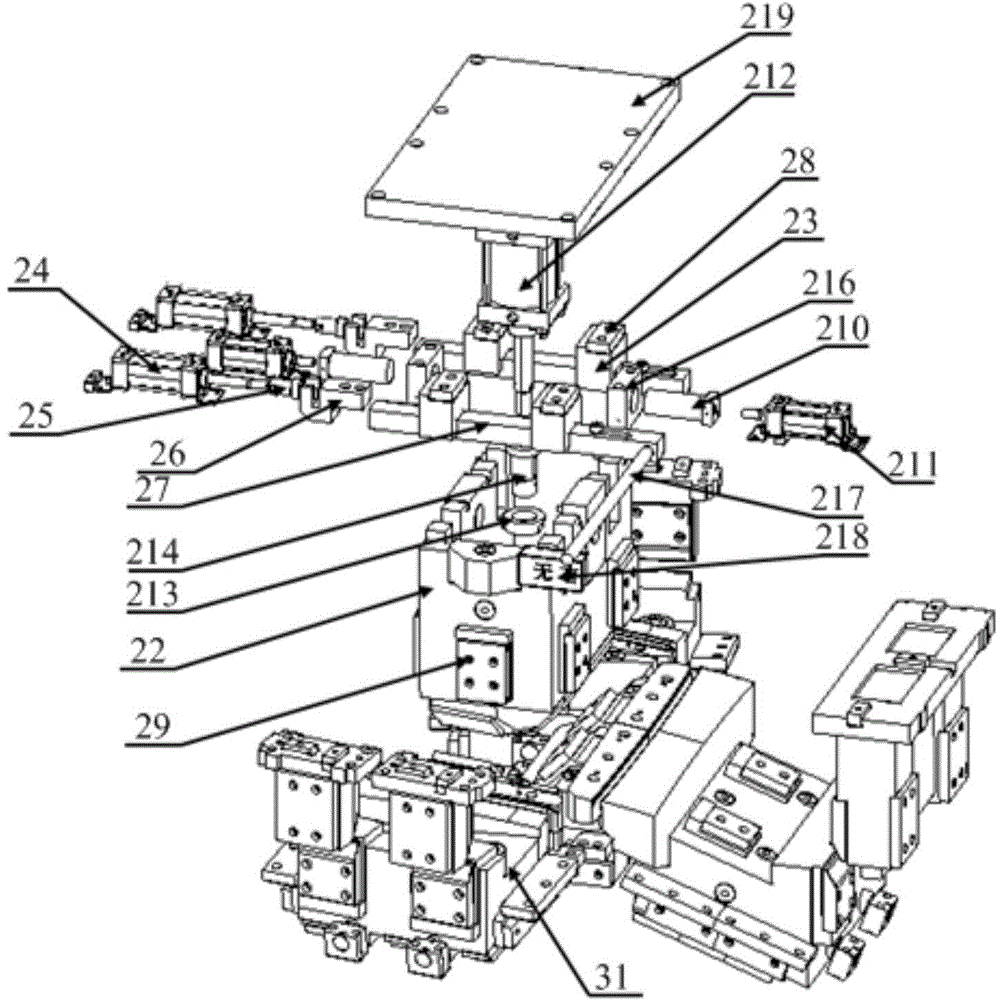

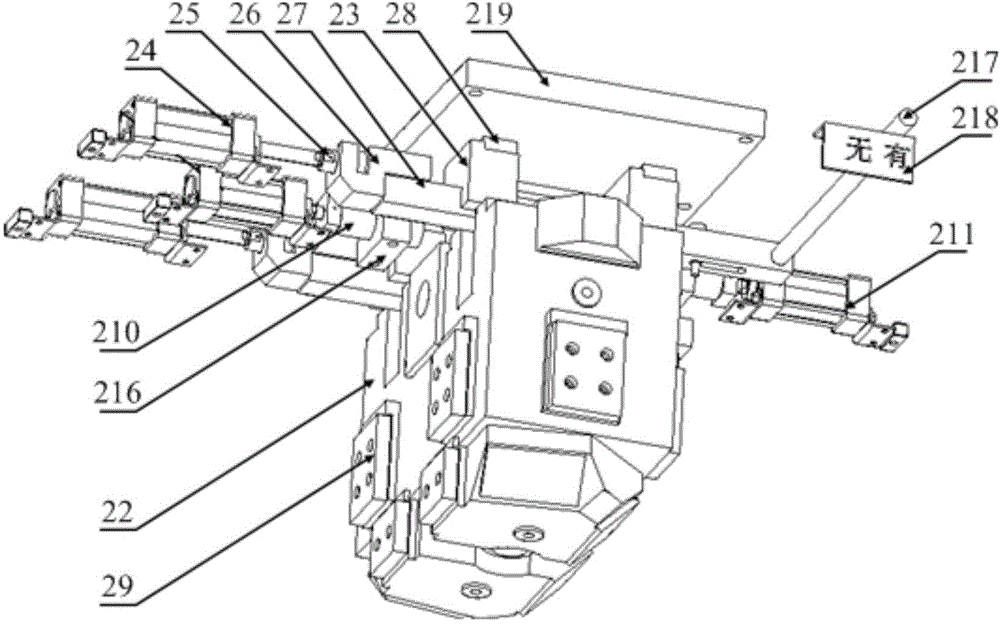

Lateral edge folding die for automobile top cover

The invention discloses a lateral edge folding die for an automobile top cover. The lateral edge folding die comprises an upper die holder (21), an oblique device driving body (22) and a skylight opening and closing switching device. The oblique device driving body (22) is installed on the upper die holder (21). The skylight opening and closing switching device comprises a supporting block driving mechanism and further comprises a lateral locking piece (210) arranged on the upper die holder (21) and a driving piece (211) exerting lateral acting face to the lateral locking piece (210). A locking hole is formed in the oblique device driving body (22). The lateral locking piece (210) is provided with a locking end capable of extending into the locking hole. The lateral locking piece is additionally arranged on the lateral edge folding die so that the oblique device driving body can be fixed relative to the upper die holder when a top cover skylight does not need to be machined; when the upper die holder moves, vibration of the oblique device driving body is weakened obviously, connection failure of parts in the lateral edge folding die is not likely to happen, and therefore reliability of the die in the process of work is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Circuit board with safety protection function

InactiveCN111800981APracticalImprove securityCircuit arrangements on support structuresPrinted circuit board receptaclesStructural engineeringControl theory

Owner:东莞权利得工业设计有限公司

Electric connection plug

The invention discloses an electric connection plug which comprises a base body and a plug, wherein the base body is connected with a cable; the plug is detachably connected with the base body, two sides of the base body are provided with shallow slots, and the shallow slots are internally provided with positioning blocks; corresponding parts at two sides of the plug are provided with positioning clips, clip holes are formed in the corresponding parts of the positioning clips, and the clip holes are buckled on the positioning blocks; the plug is internally provided with an insert needle, the base body is provided with a bulge which is connected with the cable, aand the insert needle is in contact with the bulge; the plug is a cylindrical plug, the end part of the plug is provided with a convex ring, and the plug is sleeved by a drivepipe; the outer side wall of the drivepipe is provided with outer threads, the end part of the drivepipe is provided with a hexagonal rotary block. The electric connection plug is convenient in assembly, low in cost, safe and reliable, and capable of ensuring the relative fixation of the plug and an insert hole.

Owner:深圳市鑫冠辉电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com