Netting machine plastic shuttle

A net weaving machine and plastic shuttle technology, applied in textile, shuttle, textile and paper making, etc., can solve the problems of heavy weight, high running speed, and the failure of the net weaving machine to work normally, so as to improve efficiency, reduce quality and enhance use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

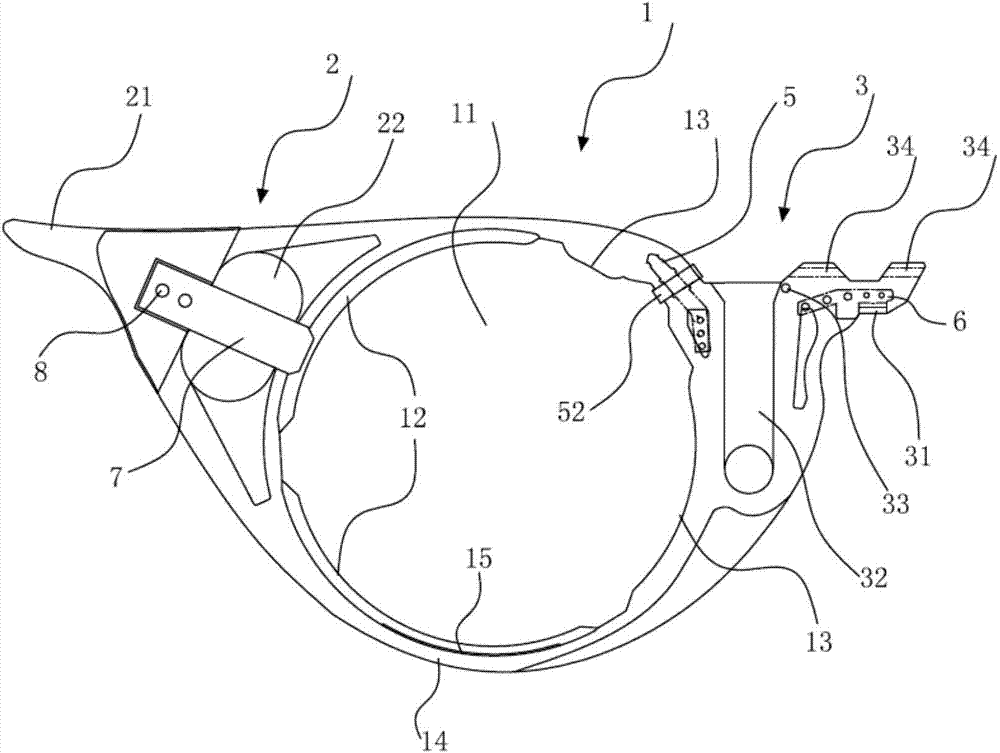

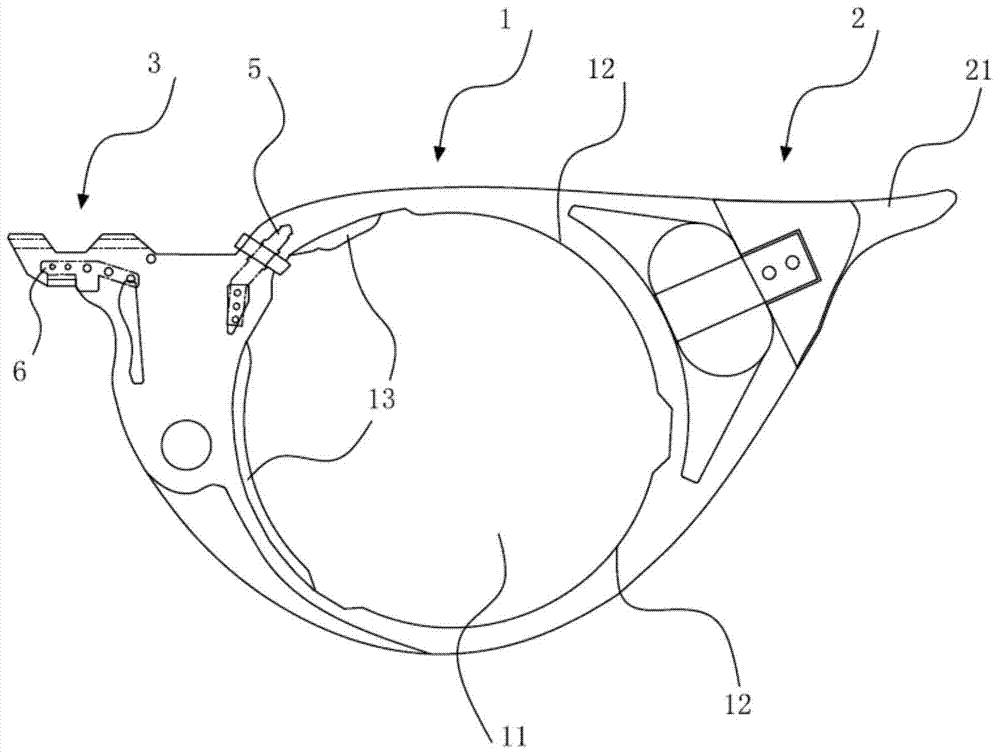

[0029] Attached below Figure 1 to Figure 9 And the specific embodiment will further describe the plastic shuttle of the net weaving machine of the present invention.

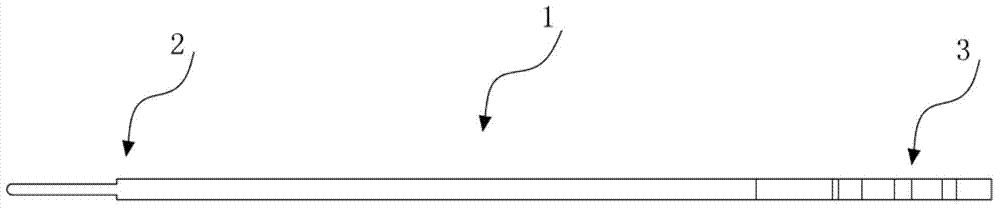

[0030] Such as figure 1 , figure 2 , image 3 with Figure 9 As shown, a plastic shuttle for a net weaving machine is disclosed, comprising an annular body 1, a head 2 and a tail 3, the head 2 and the tail 3 are located at both ends of the annular body 1, and the annular body 1 is provided with a bobbin for accommodating the bobbin. The circular opening 11 of 4, the annular body 1, the head 2 and the tail 3 are all made of plastic, and the three are integrally formed by injection molding.

[0031] The junction of the annular body 1 and the tail 3 is provided with a first rib 5, one end of the first rib 5 is connected with the annular body 1, and the other end of the first rib 5 is connected with the tail 3; the tail 3 is provided with a second The reinforcing rib 6 and the second reinforcing rib 6 are bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com