Double-spray-nozzle 3D printing system and method of thermoplastic resin base continuous fiber prepreg material

A thermoplastic resin, continuous fiber technology, applied in the field of dual-jet 3D printing systems, can solve the problems of continuous fiber 3D printing methods with low mechanical properties and the failure to give full play to the reinforcement performance of continuous fibers, so as to save raw materials, reduce quality, and improve printing. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the advantages of the invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

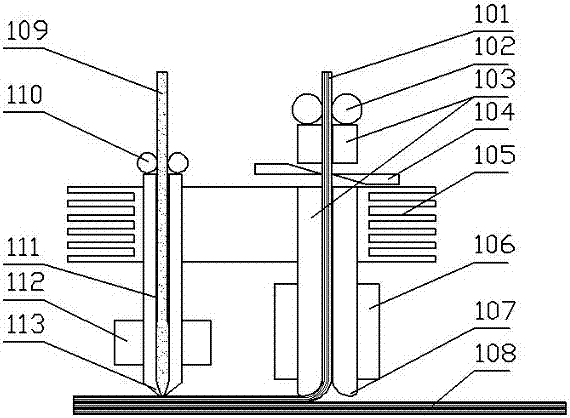

[0034] Such as figure 1 As shown, a dual-nozzle 3D printing system for thermoplastic resin-based continuous fiber prepreg, the printing nozzle is a dual-nozzle design, and the dual-nozzle is installed on an ordinary FDM 3D printer to achieve x, y, z three-axis Movement; including a thermoplastic resin-based continuous fiber prepreg 3D printing nozzle 401 and a thermoplastic pure resin 3D printing nozzle 402; the thermoplastic resin-based continuous fiber prepreg 3D printing nozzle 401 includes a thermoplastic resin-based continuous fiber prepreg 101, for It provides the continuous fiber prepreg supply roll 102 of the downward driving force, the metal guide tube 103 arranged below the continuous fiber prepreg supply roll 102, the centering shearing mechanism 104 arranged between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com