Patents

Literature

2840 results about "Rapid prototyping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. Construction of the part or assembly is usually done using 3D printing or "additive layer manufacturing" technology.

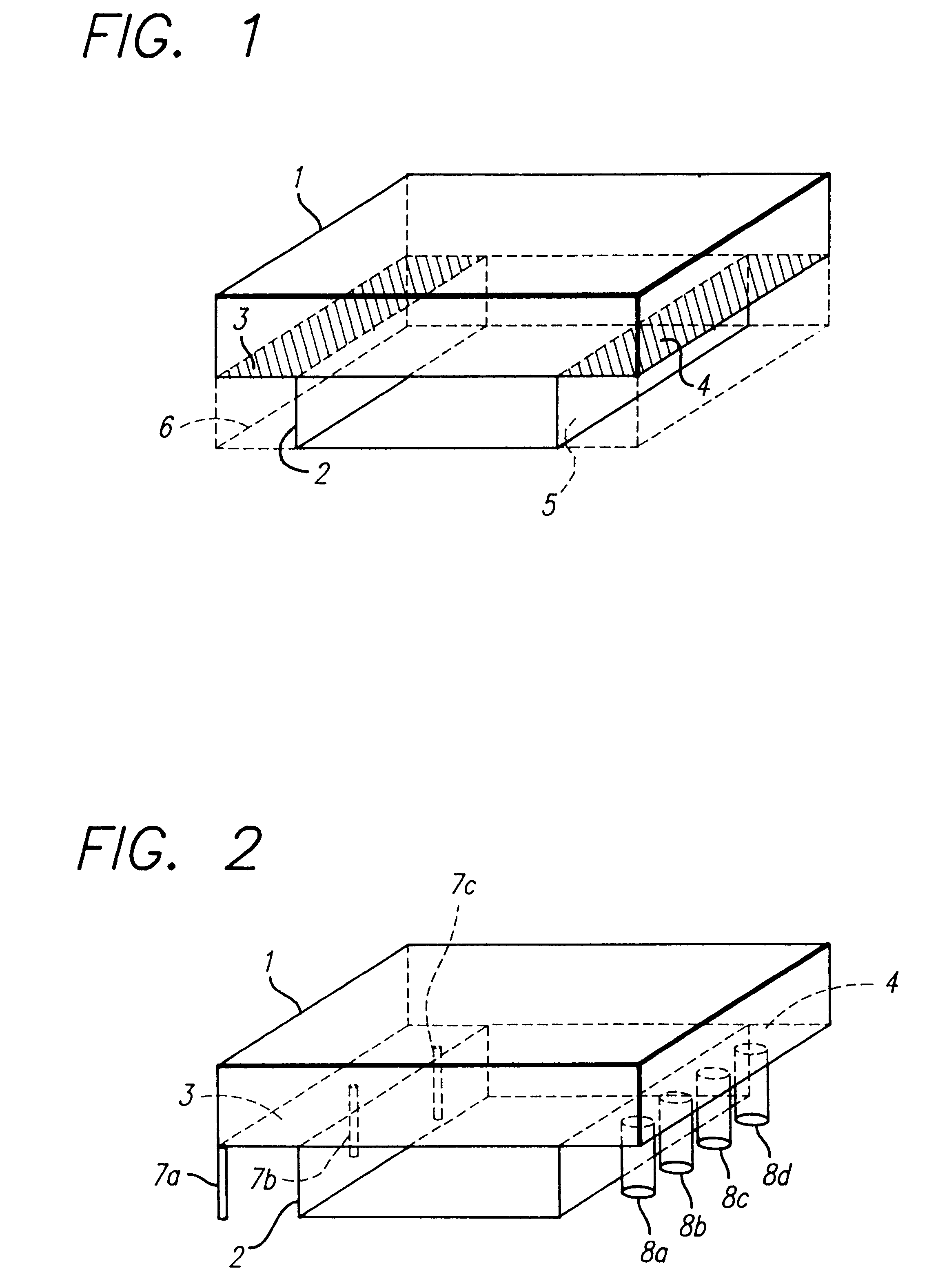

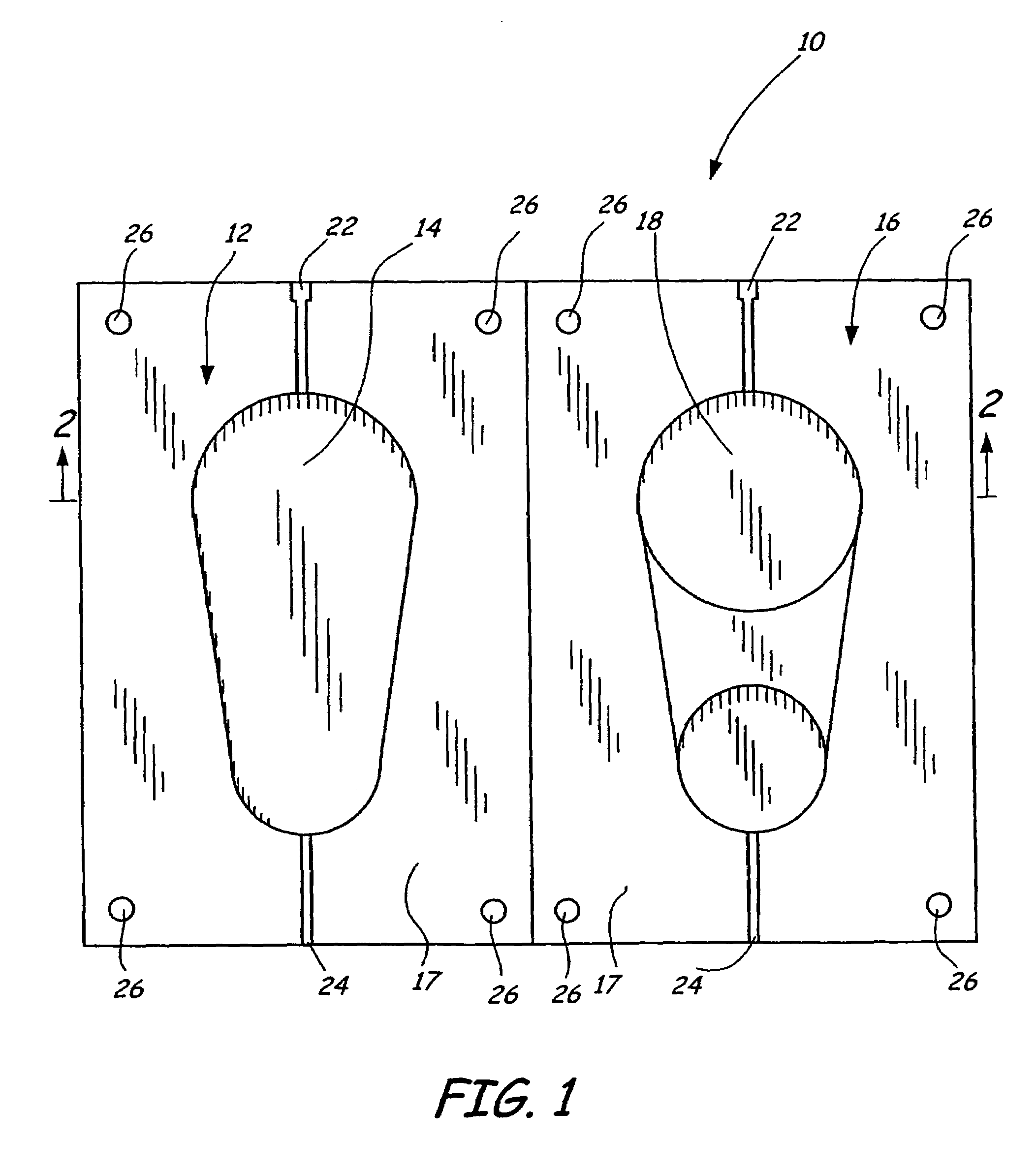

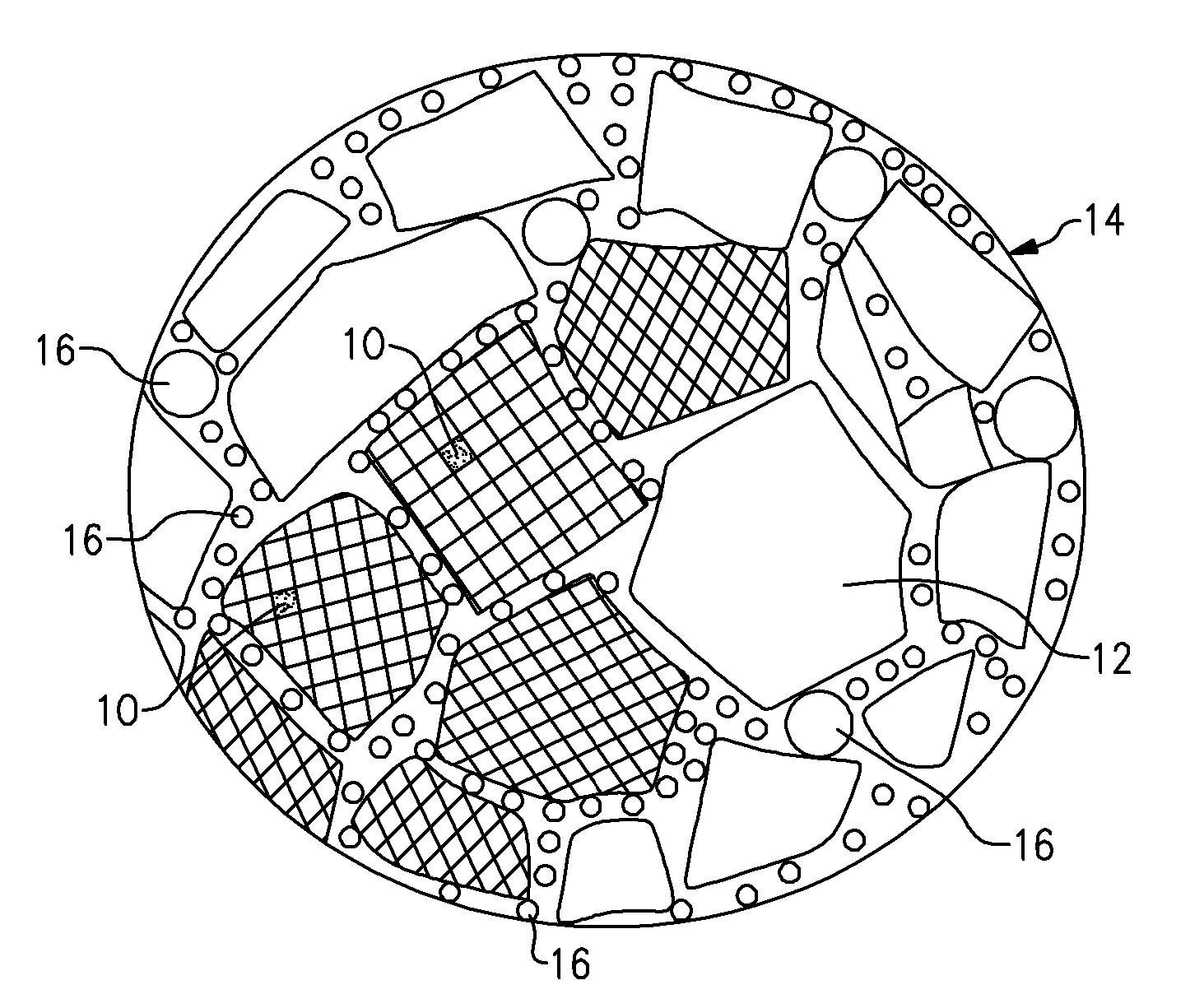

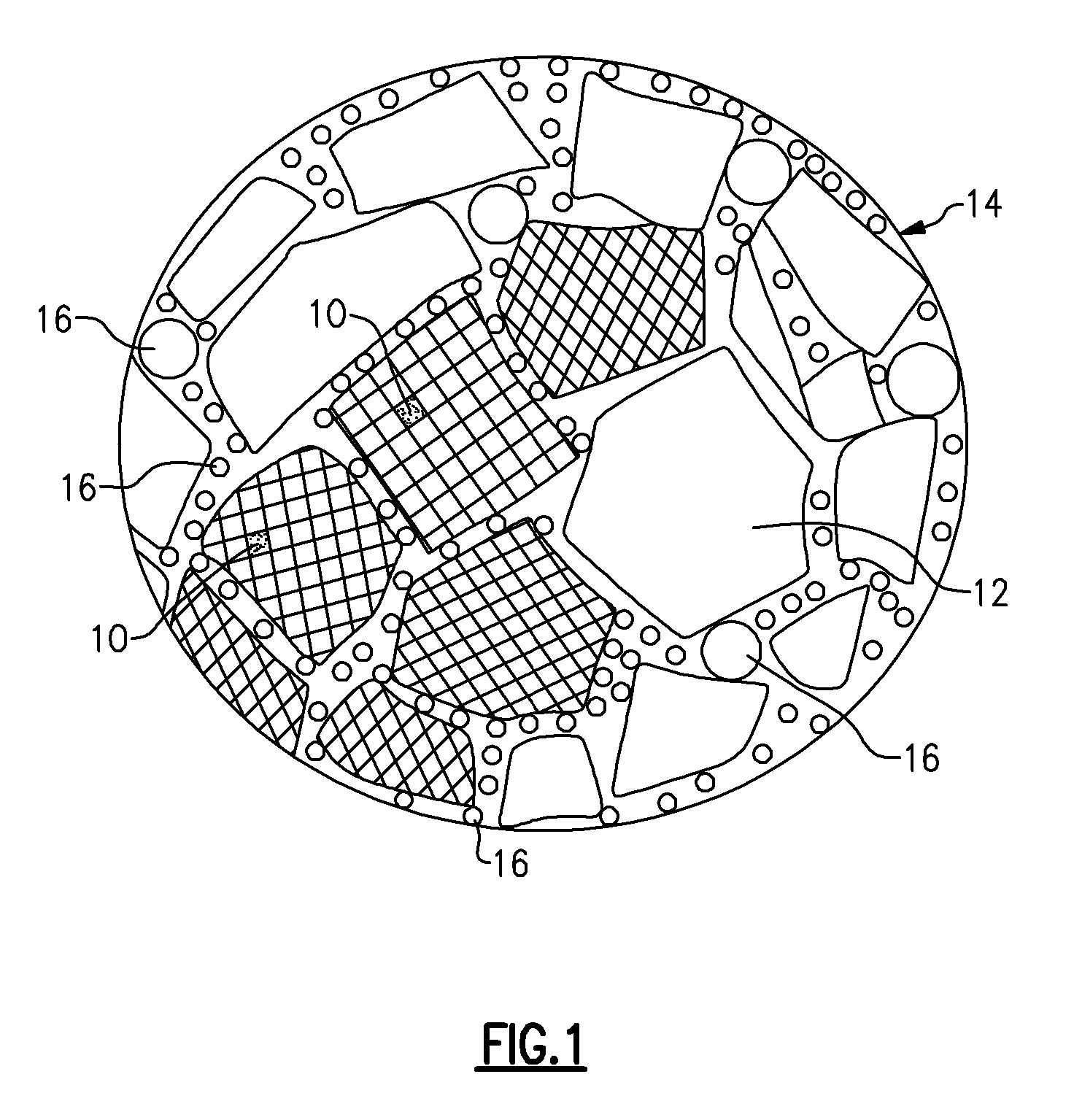

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6193923B1Easy to disassembleMinimal damageAdditive manufacturing apparatusCeramic shaping apparatusEngineeringSelective deposition

A variety of support structures and build styles for use in Rapid Prototyping and Manufacturing systems are described wherein particular emphasis is given to Thermal Stereolithography, Fused Deposition Modeling, and Selective Deposition Modeling systems, and wherein a 3D modeling system is presented which uses multijet dispensing and a single material for both object and support formation.

Owner:3D SYST INC

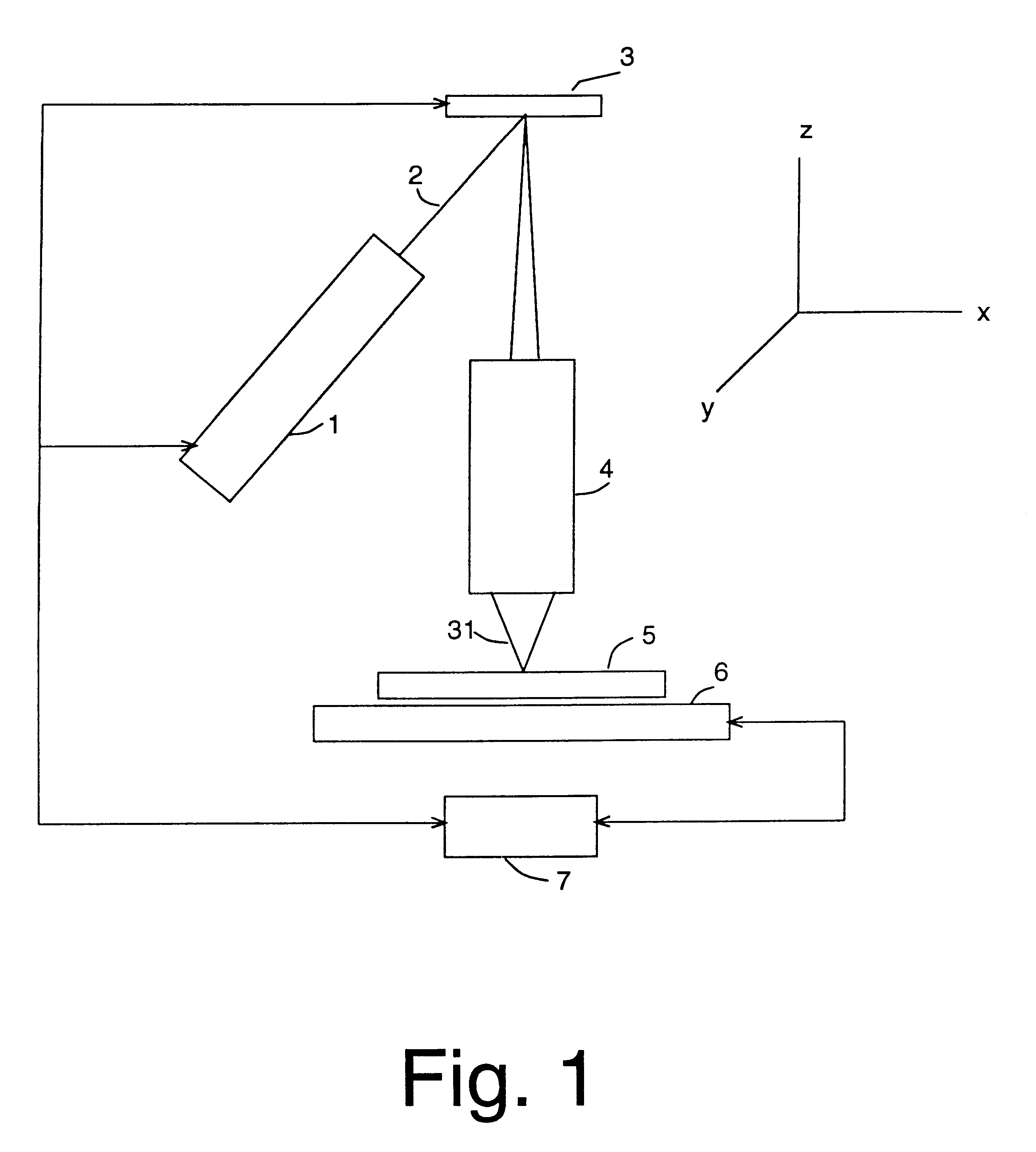

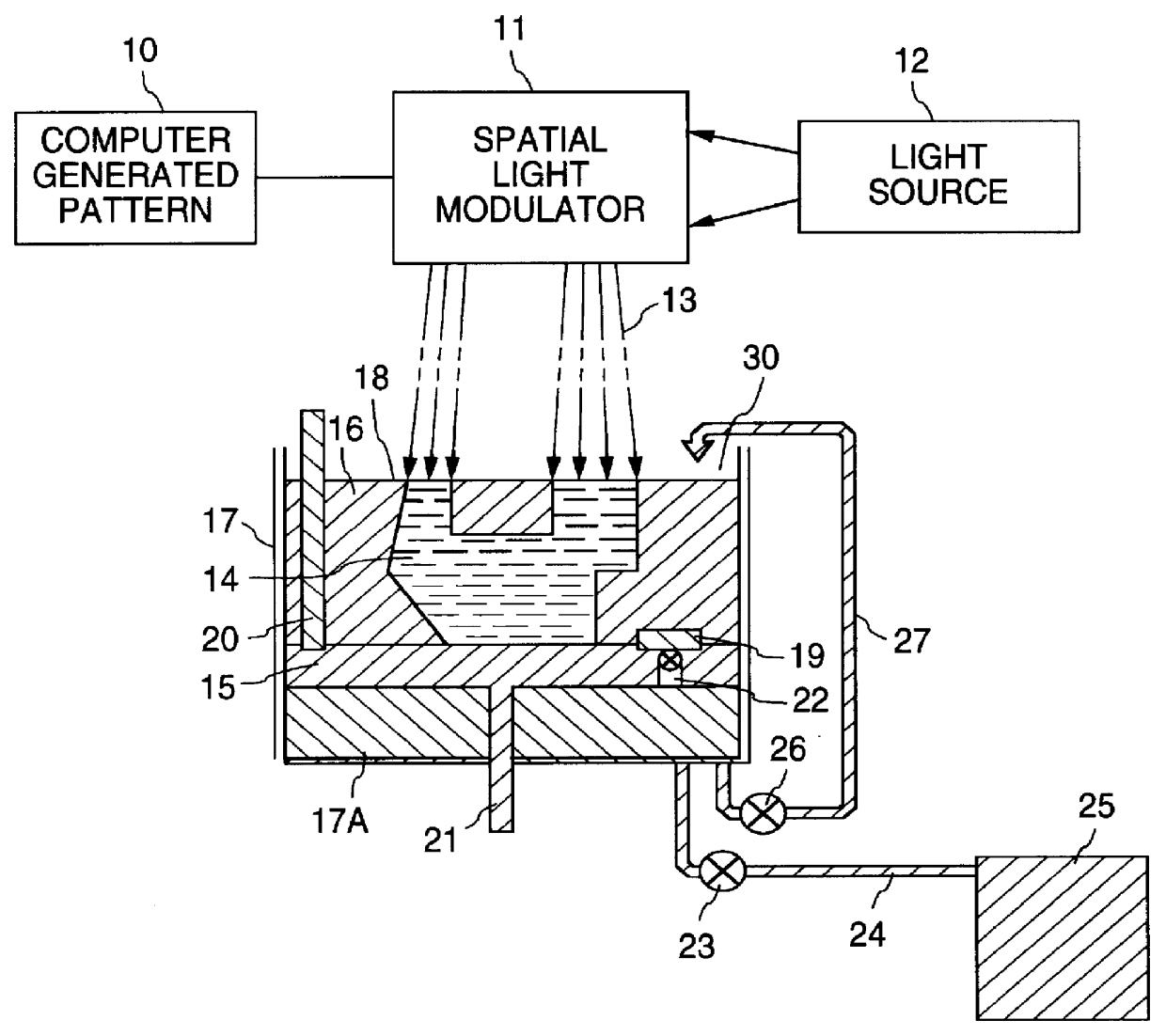

Seamless, maskless lithography system using spatial light modulator

InactiveUS6312134B1Eliminate needImprove processing throughputMirrorsPhotomechanical exposure apparatusRadiation DosagesSpatial light modulator

The invention is a seamless projection lithography system that eliminates the need for masks through the use of a programmable Spatial Light Modulator (SLM) with high parallel processing power. Illuminating the SLM with a radiation source (1), which while preferably a pulsed laser may be a shuttered lamp or multiple lasers with alternating synchronization, provides a patterning image of many pixels via a projection system (4) onto a substrate (5). The preferred SLM is a Deformable Micromirror Device (3) for reflective pixel selection using a synchronized pulse laser. An alternative SLM is a Liquid Crystal Light Valve (LCLV) (45) for pass-through pixel selection. Electronic programming enables pixel selection control for error correction of faulty pixel elements. Pixel selection control also provides for negative and positive imaging and for complementary overlapping polygon development for seamless uniform dosage. The invention provides seamless scanning by complementary overlapping scans to equalize radiation dosage, to expose a pattern on a large area substrate (5). The invention is suitable for rapid prototyping, flexible manufacturing, and even mask making.

Owner:ANVIK CORP

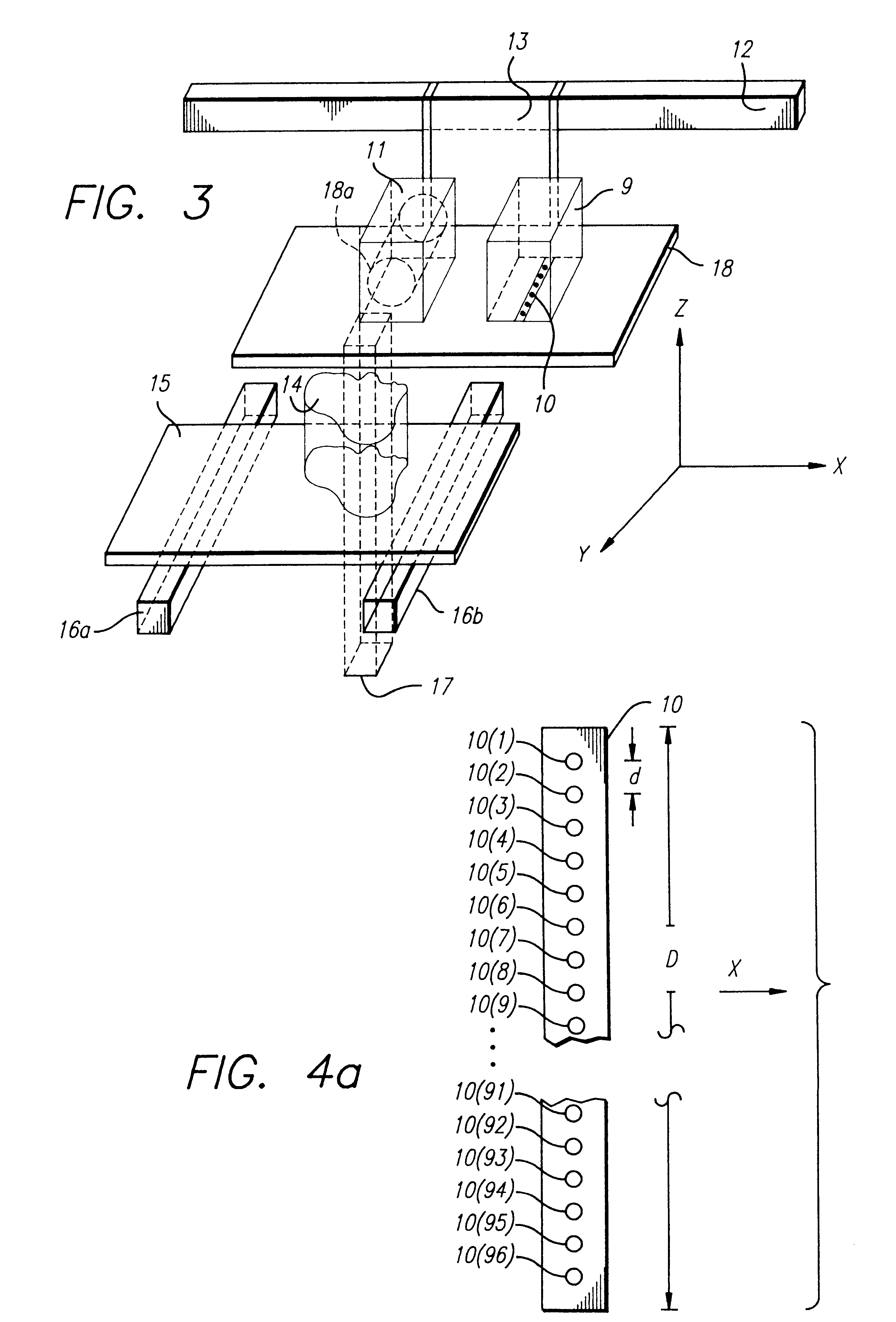

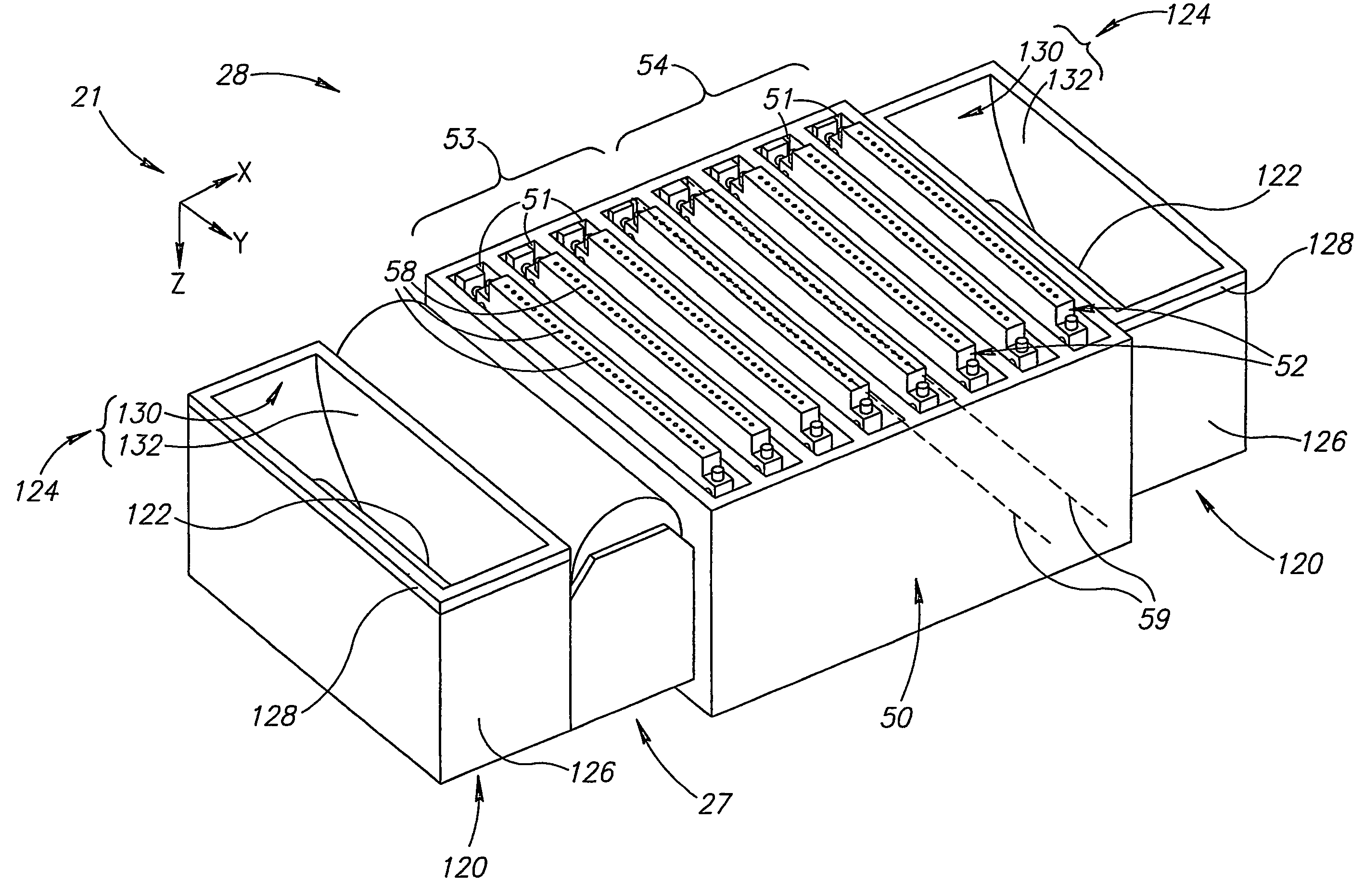

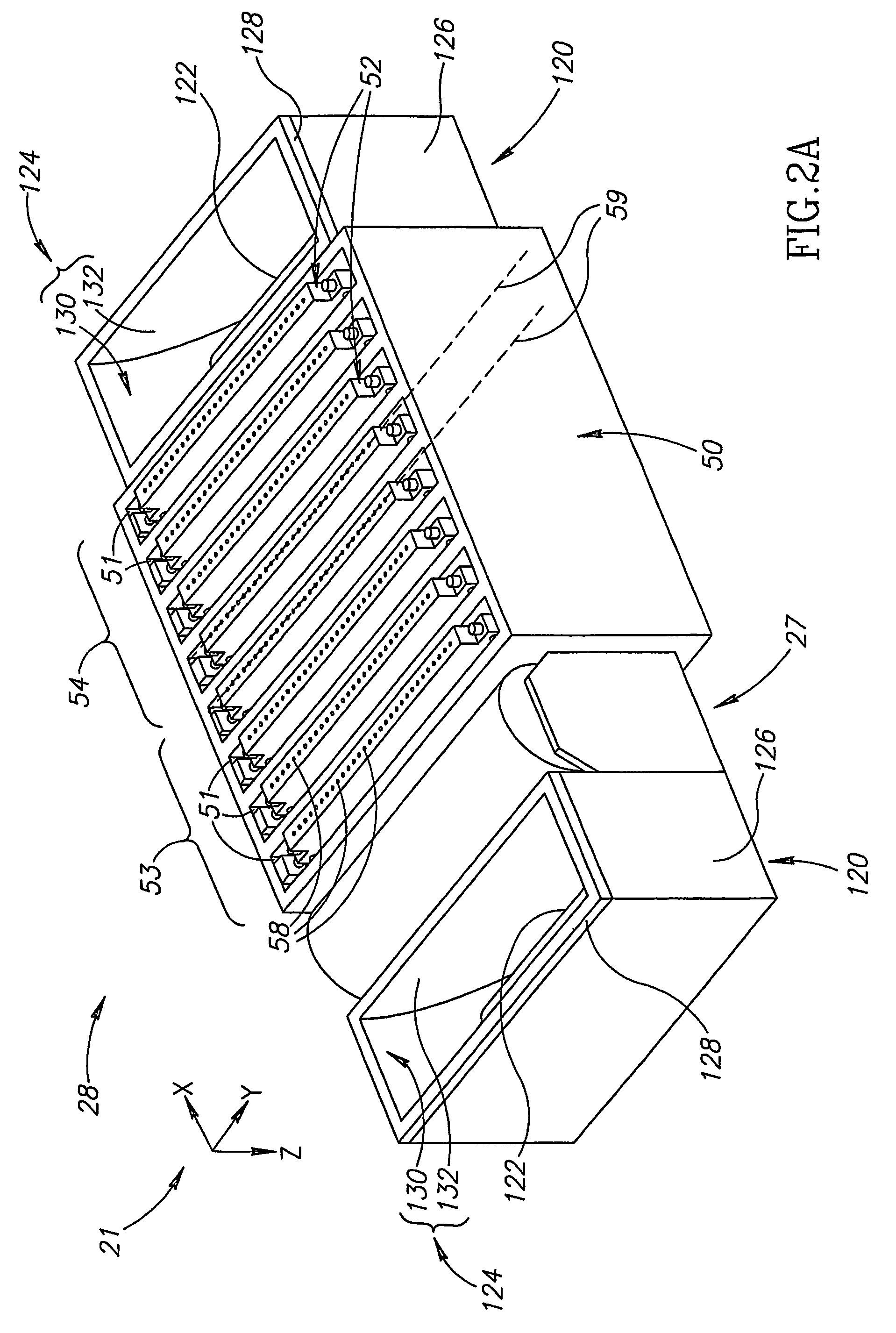

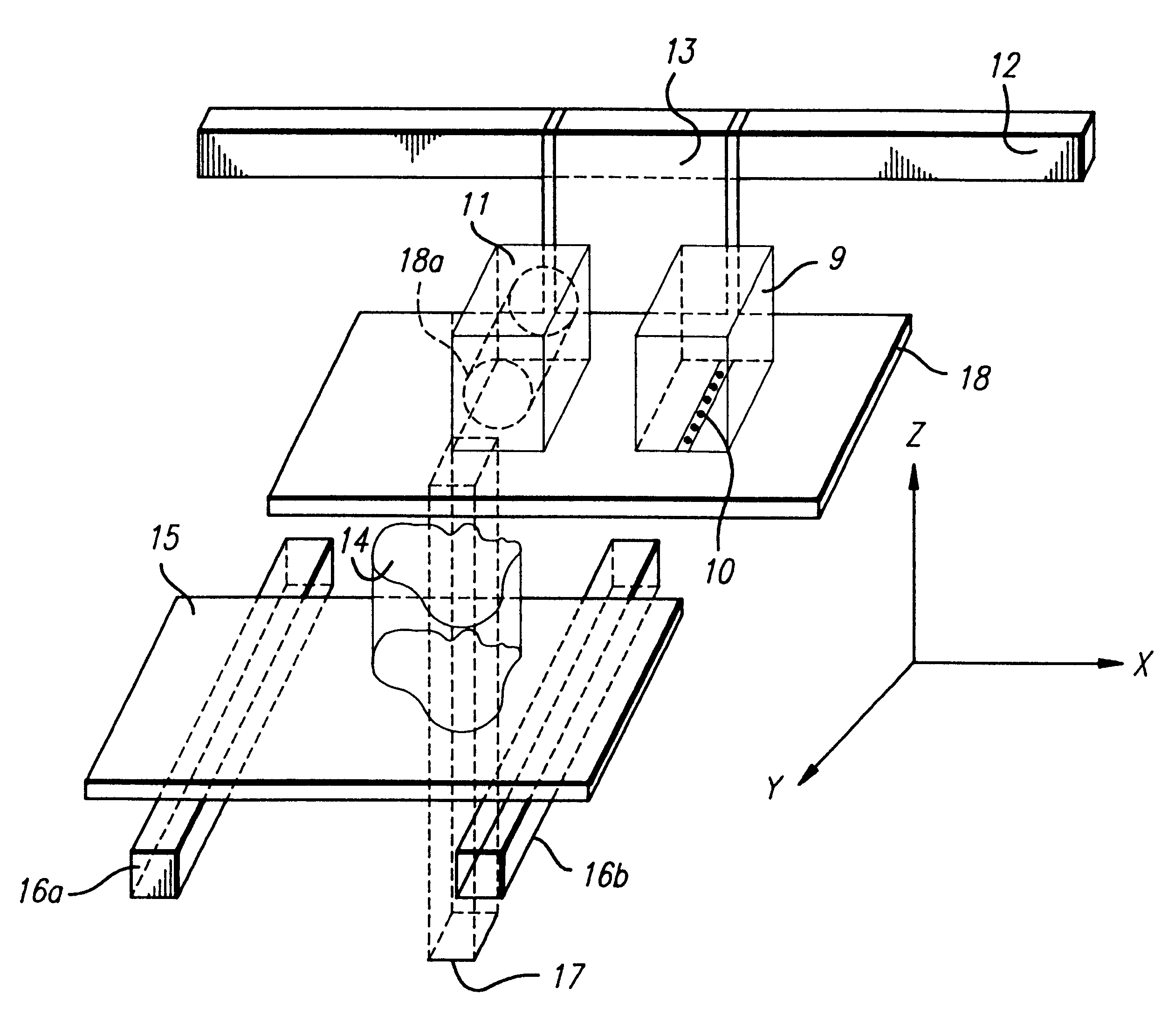

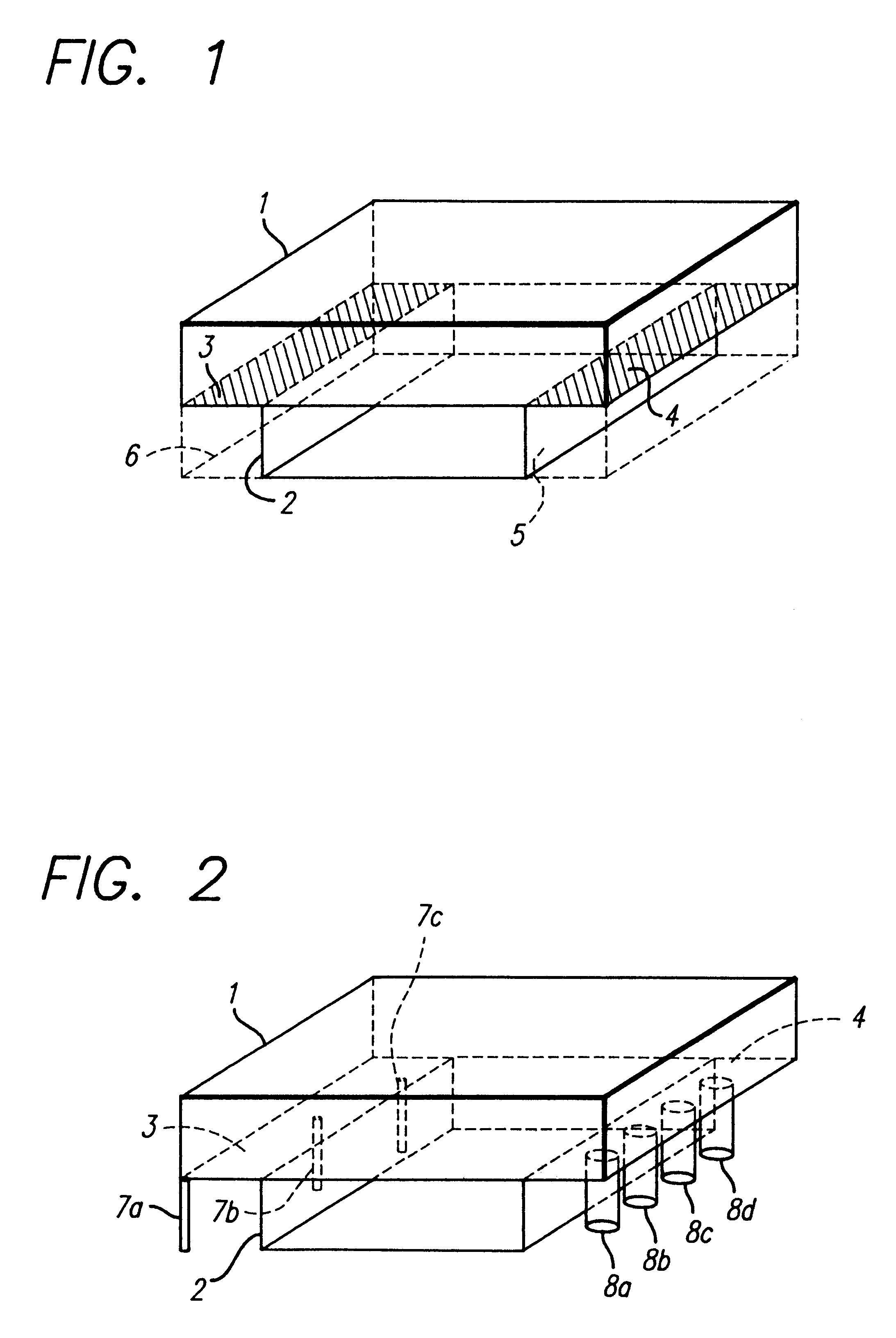

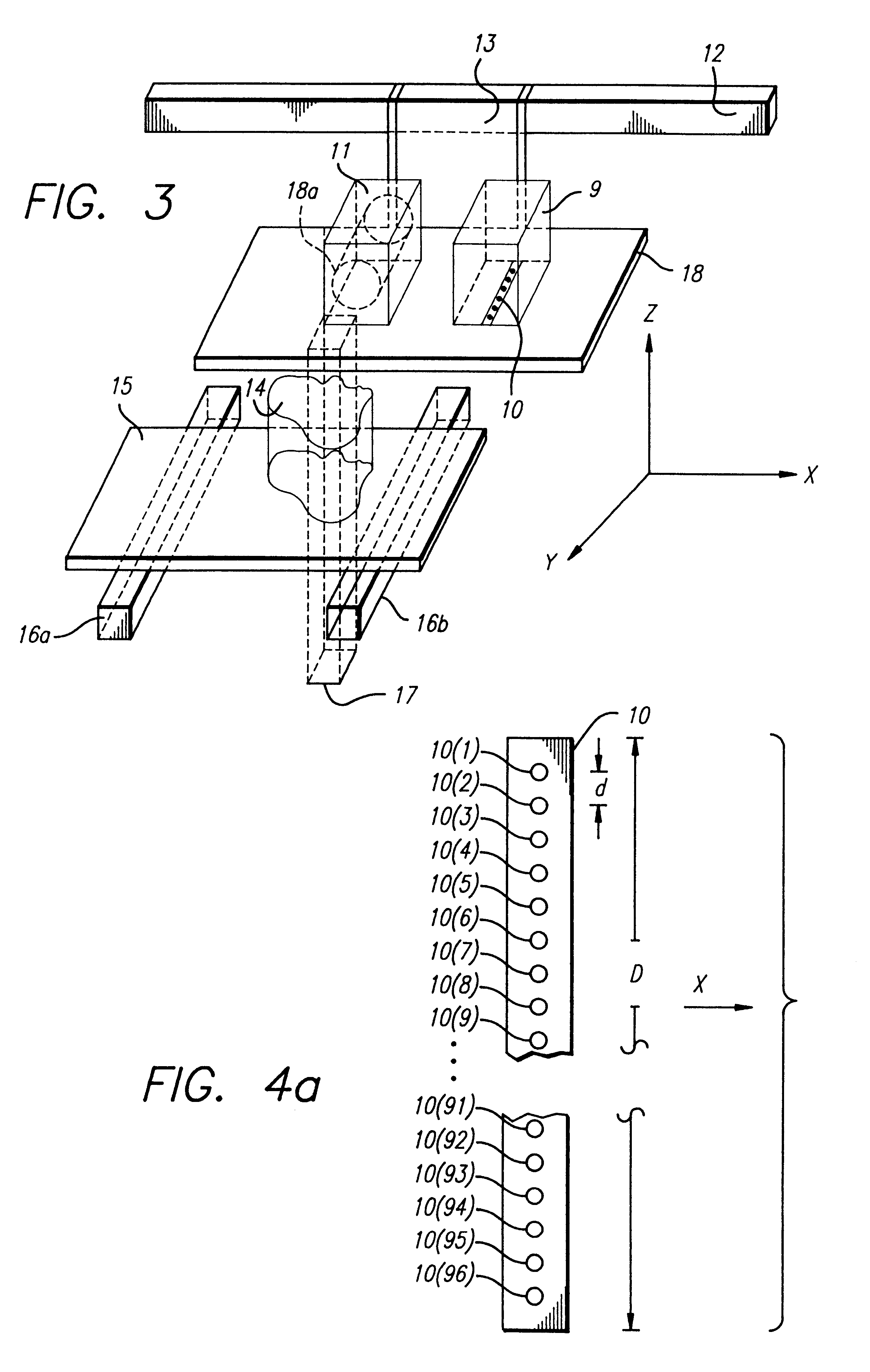

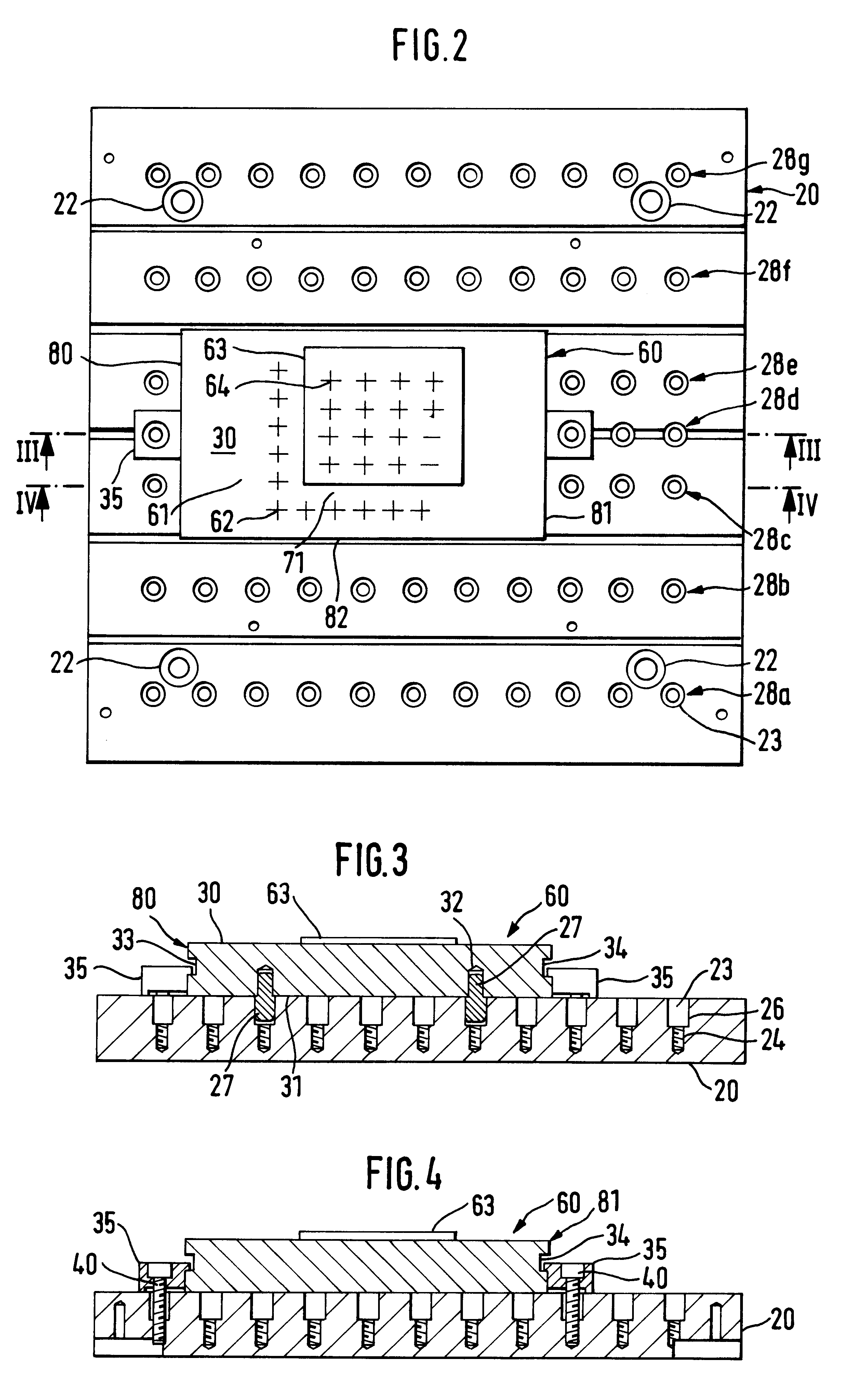

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

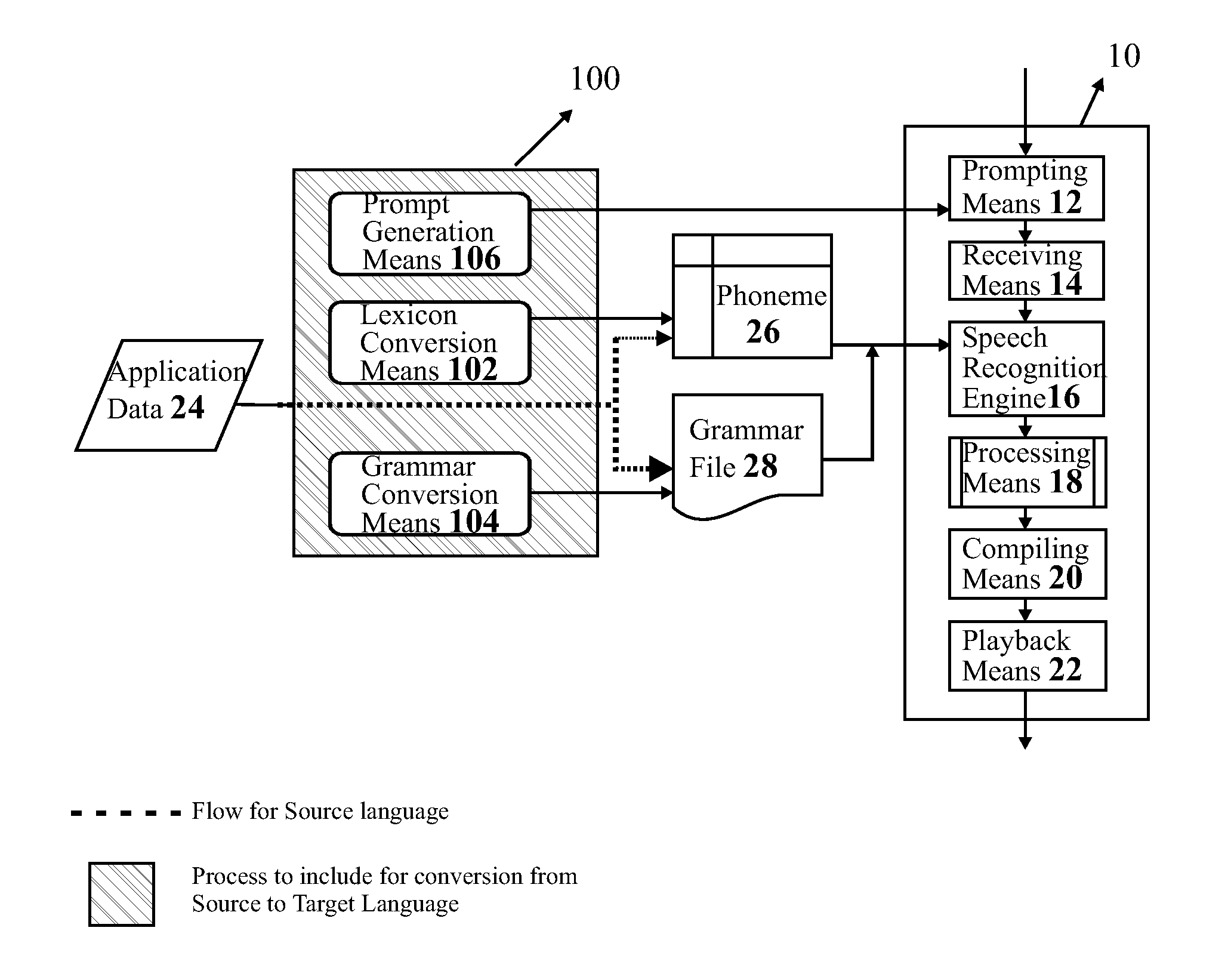

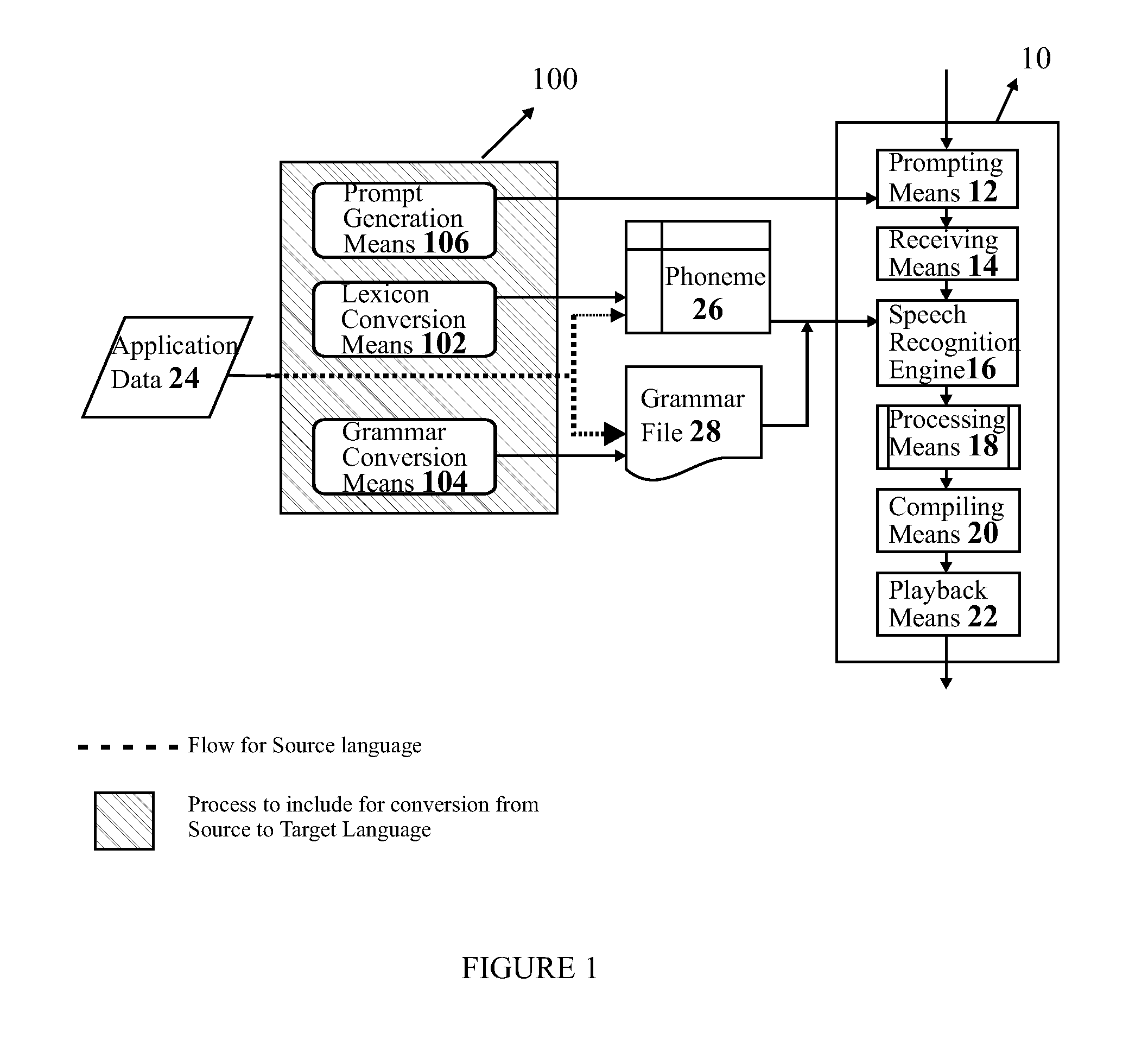

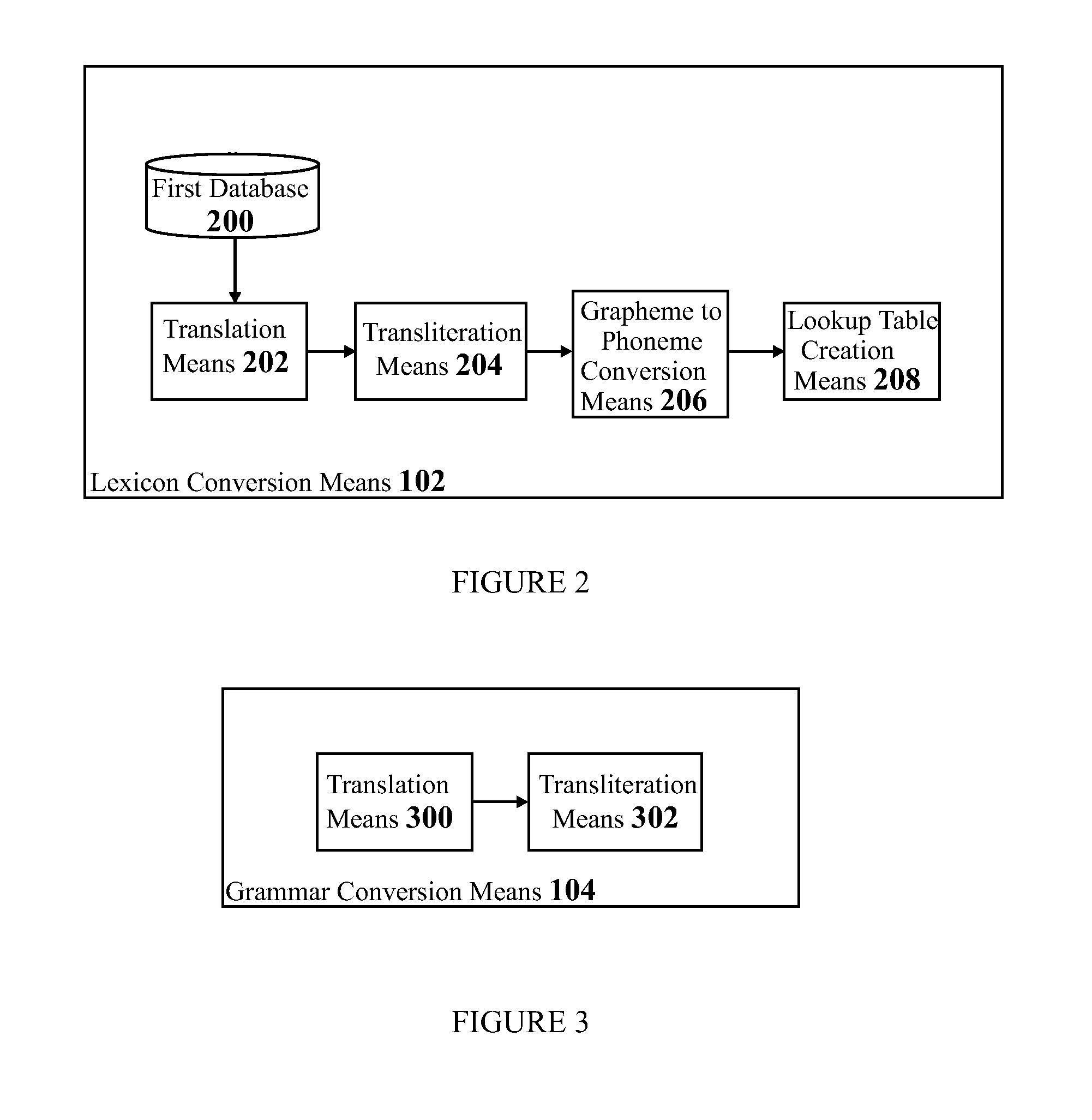

System and method for rapid prototyping of existing speech recognition solutions in different languages

ActiveUS8498857B2Fast transplantNatural language translationSpeech recognitionRapid prototypingPorting

A system and method for porting of existing speech recognition solutions in a source language to a target language has been disclosed. The system envisaged by the present invention enables porting of a working speech recognition solution in the source language to a working system in the target language, thus minimizing the development process and reusing existing speech recognition solution components to recognize multiple languages.

Owner:GENERAL ATOMICS +1

Computerized Planning Tool For Spine Surgery and Method and Device for Creating a Customized Guide for Implantations

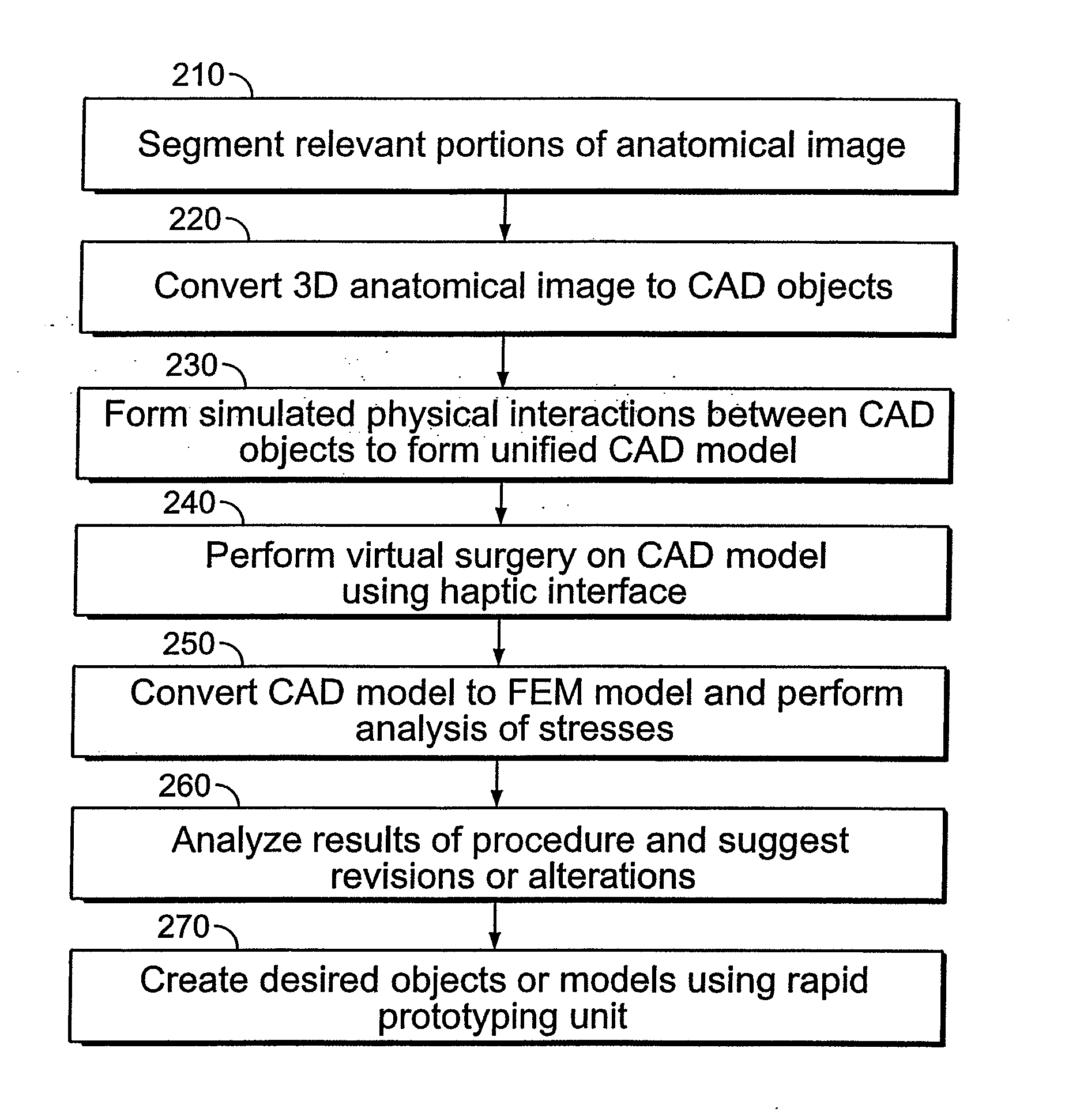

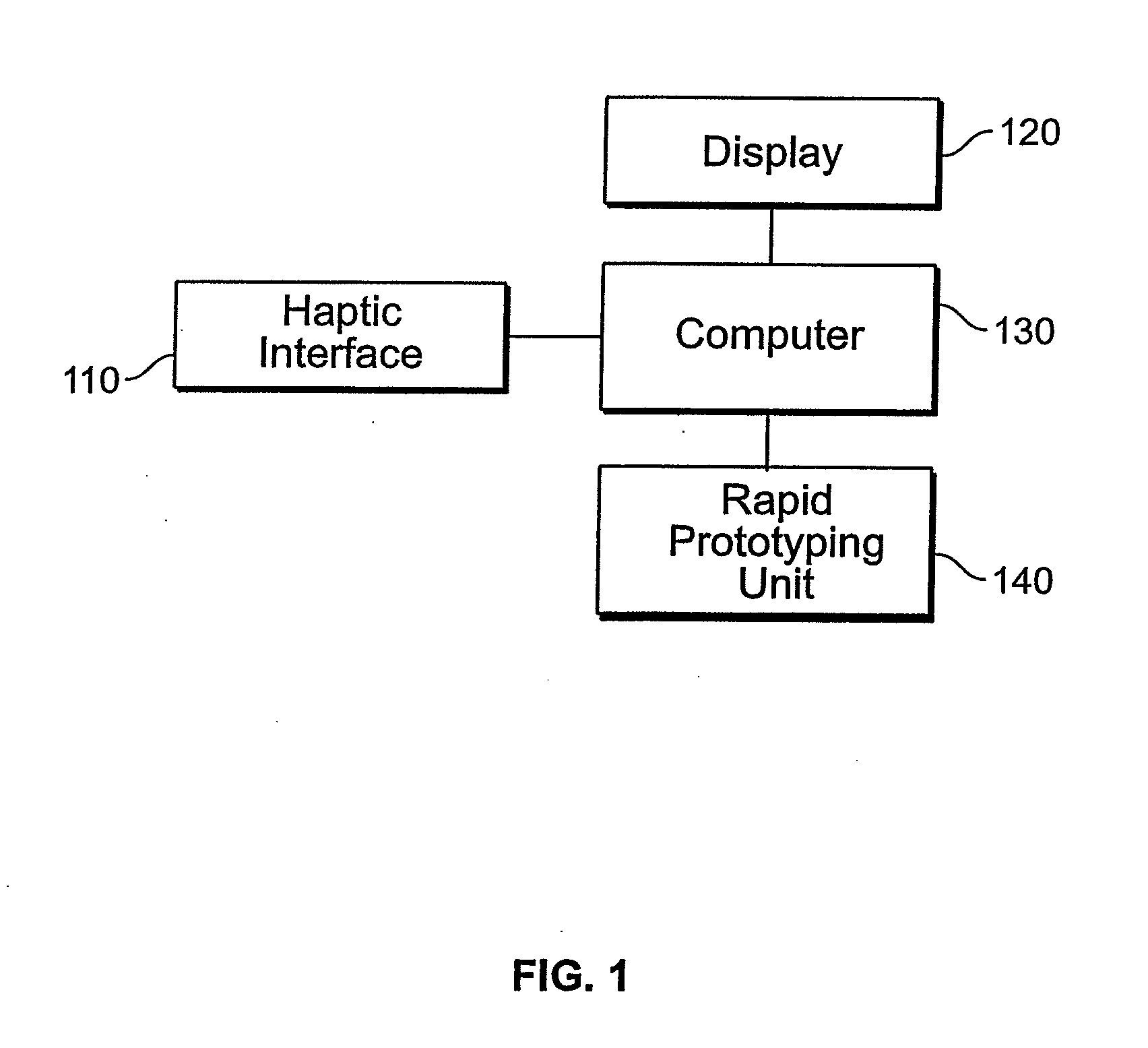

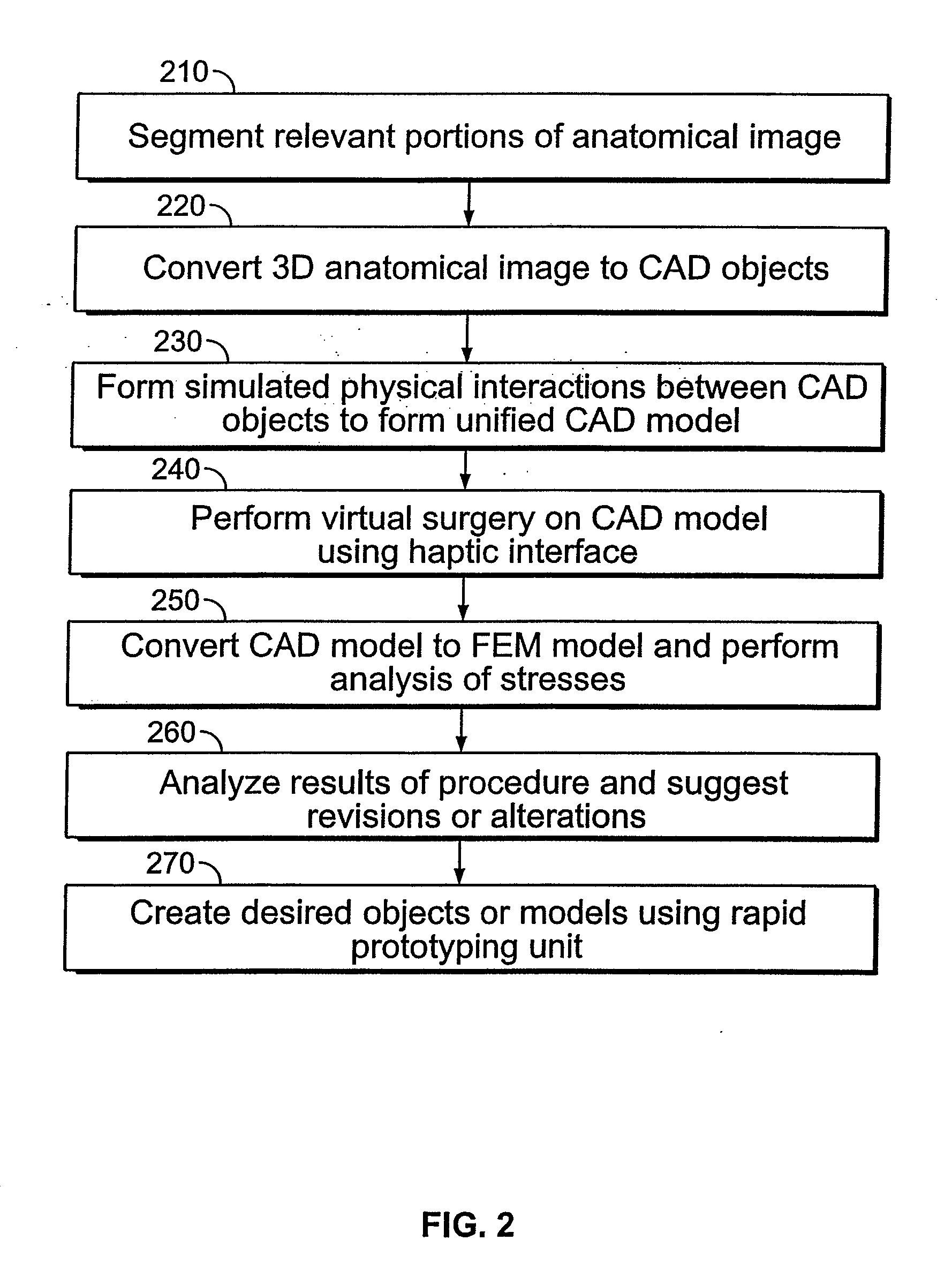

InactiveUS20100217336A1Minimal effortMaximize accuracyMedical simulationAdditive manufacturing apparatusTouch PerceptionFinite element software

A system for planning a spine surgery, comprising a haptic interface capable of providing force feedback to the user and a computer adapted to simulate a surgical procedure by responding to inputs from the haptic interface and outputting haptic feedback to the haptic interface is provided.The system further comprising a rapid prototyping unit including a unit that is adapted to create models of the anatomical region where the surgical procedure will be performed in its current unoperated condition and in the predicted postoperative condition. Further the rapid prototyping unit is adapted to create a three dimensional guide to be used in the surgical procedure as well as suggest revisions to the surgical procedure. The system further comprises a computer that simulates loading of the spine and planned implanted hardware using finite element software.

Owner:DIGNITY HEALTH

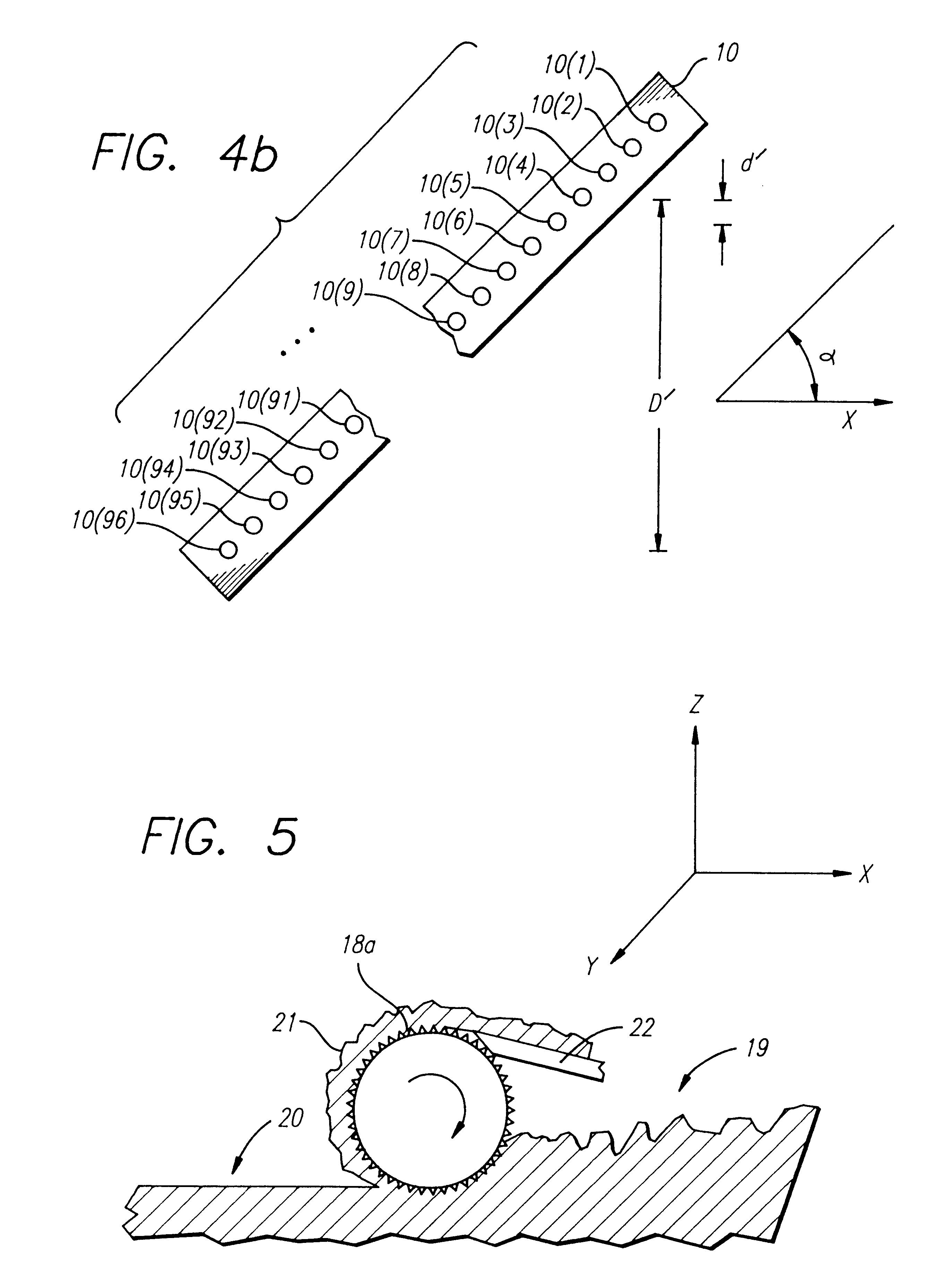

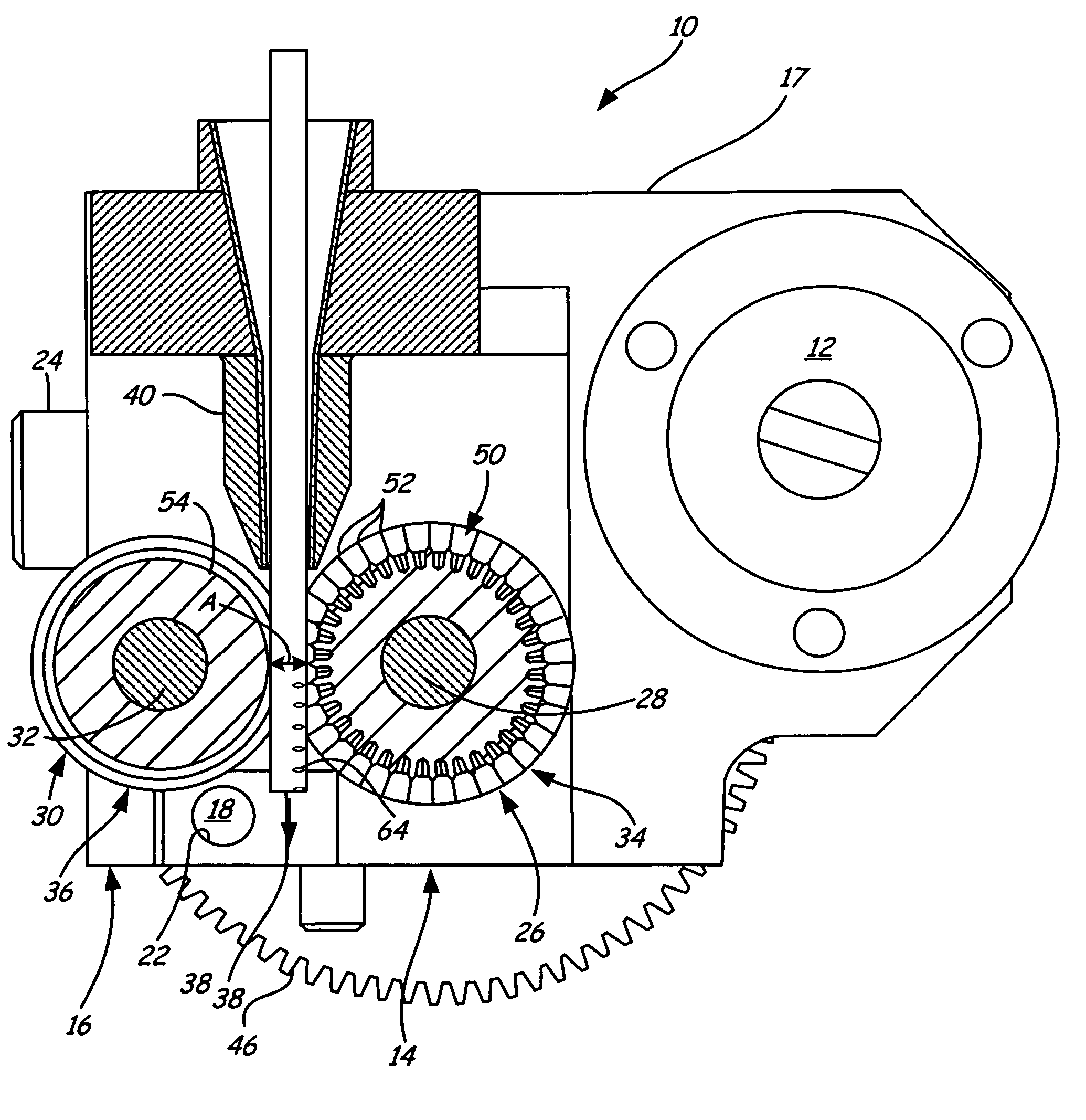

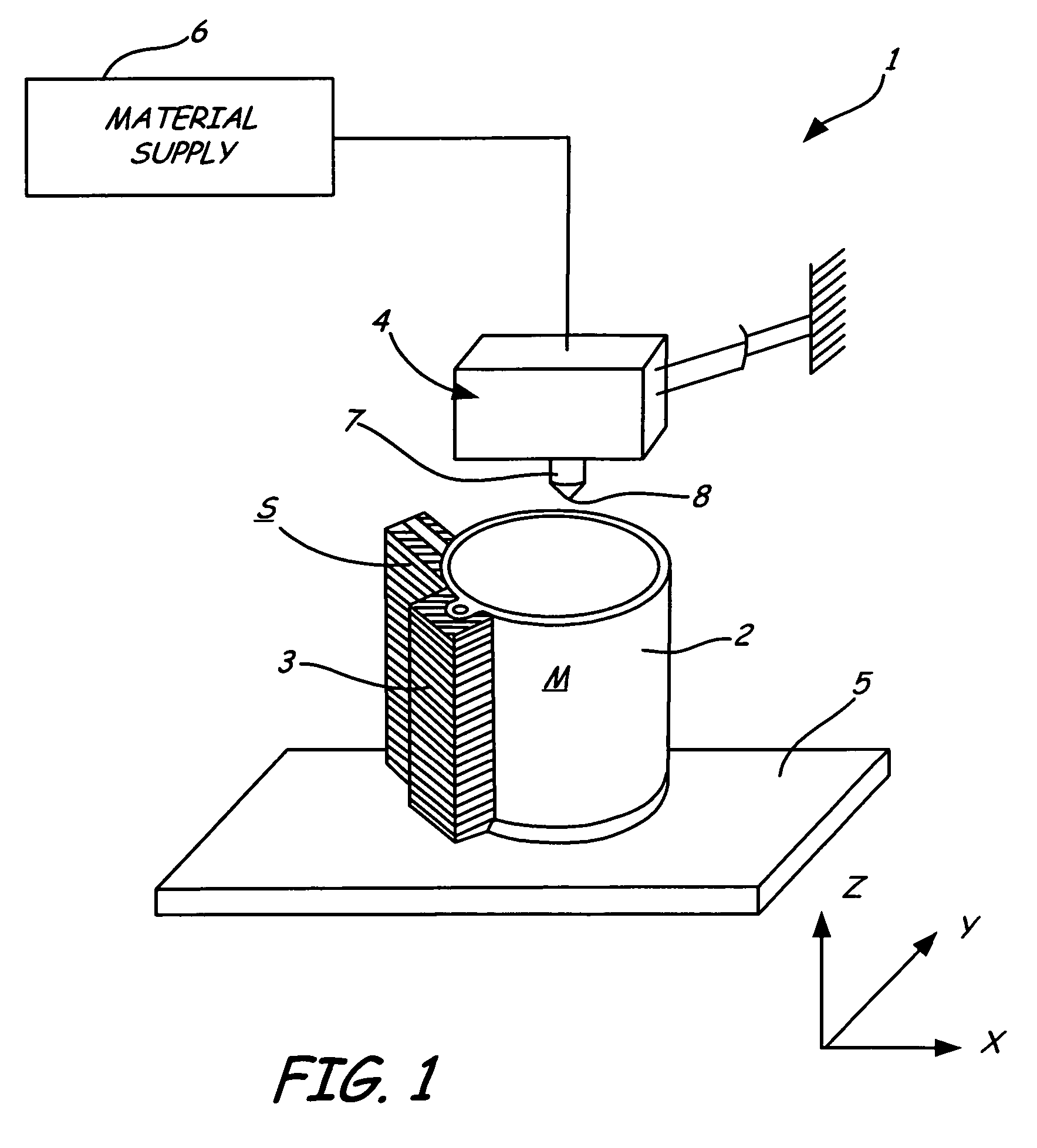

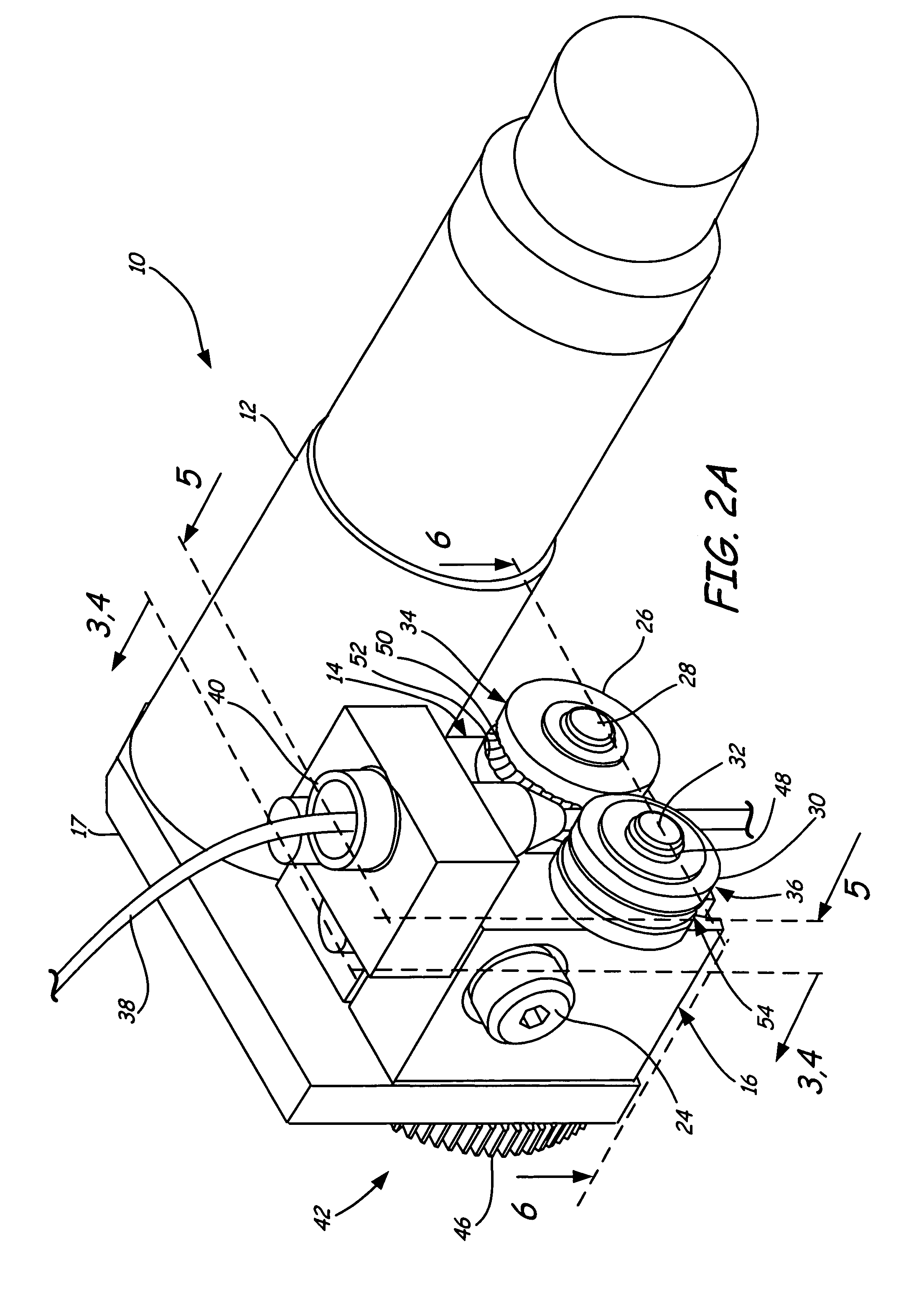

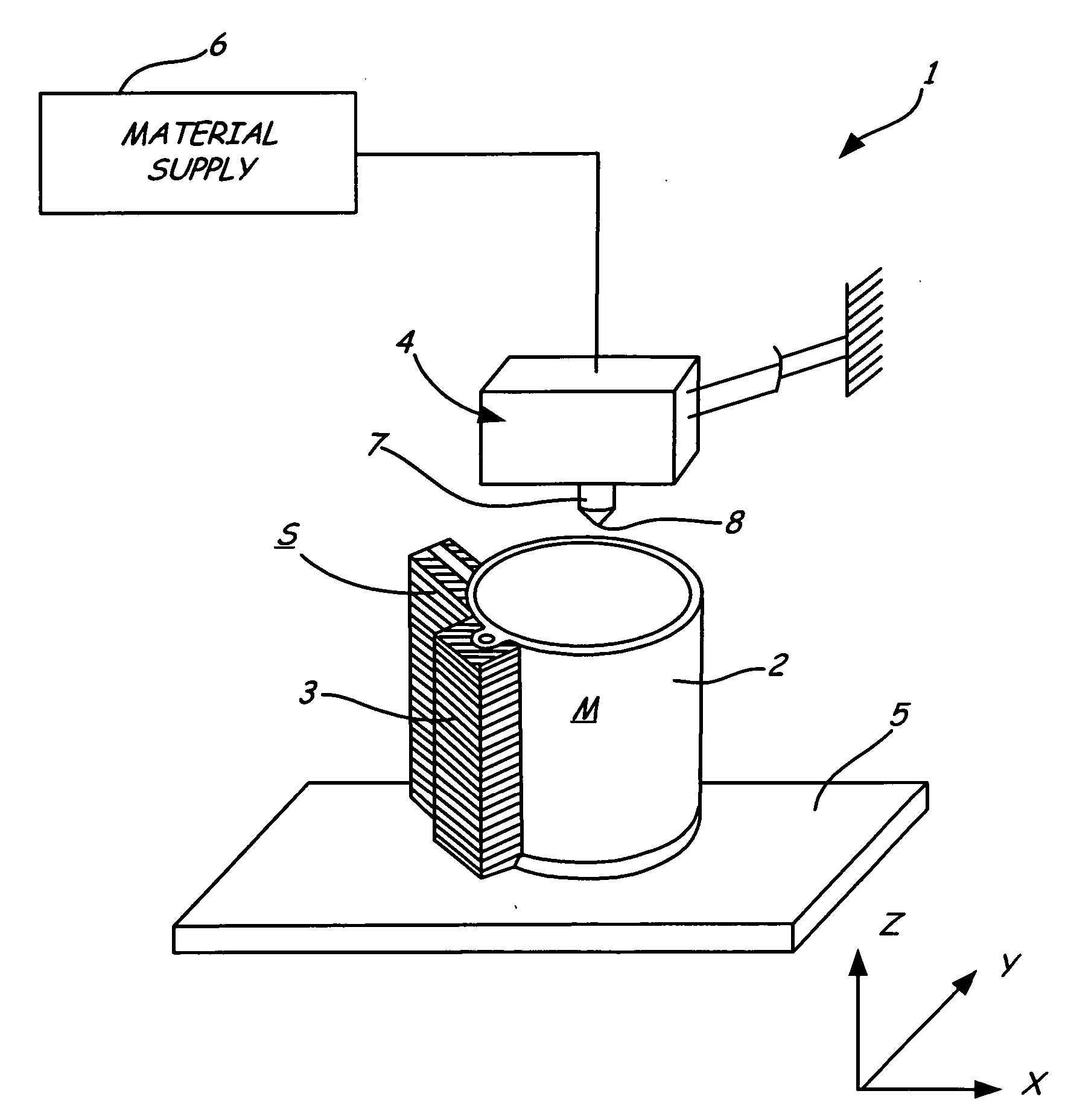

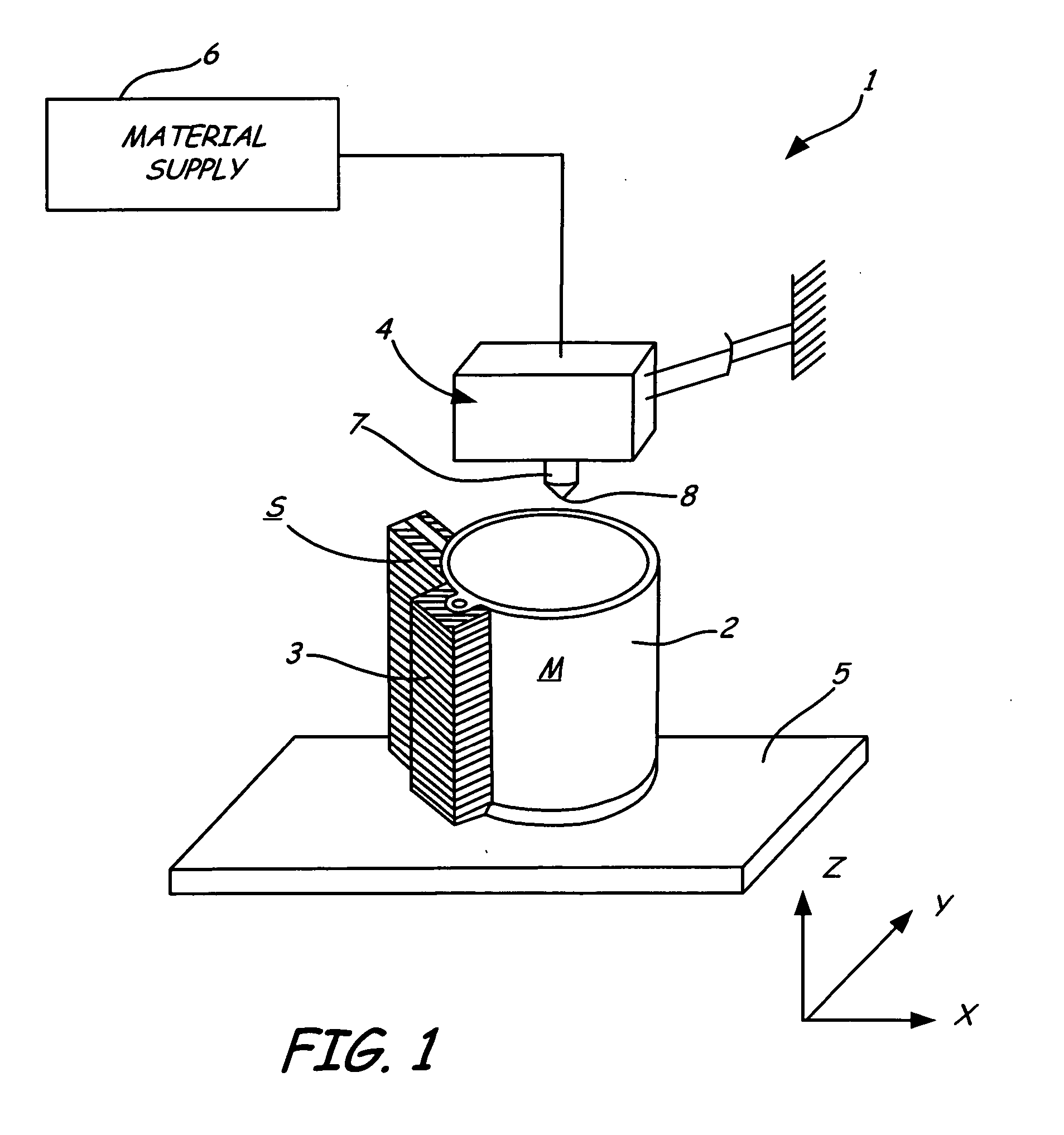

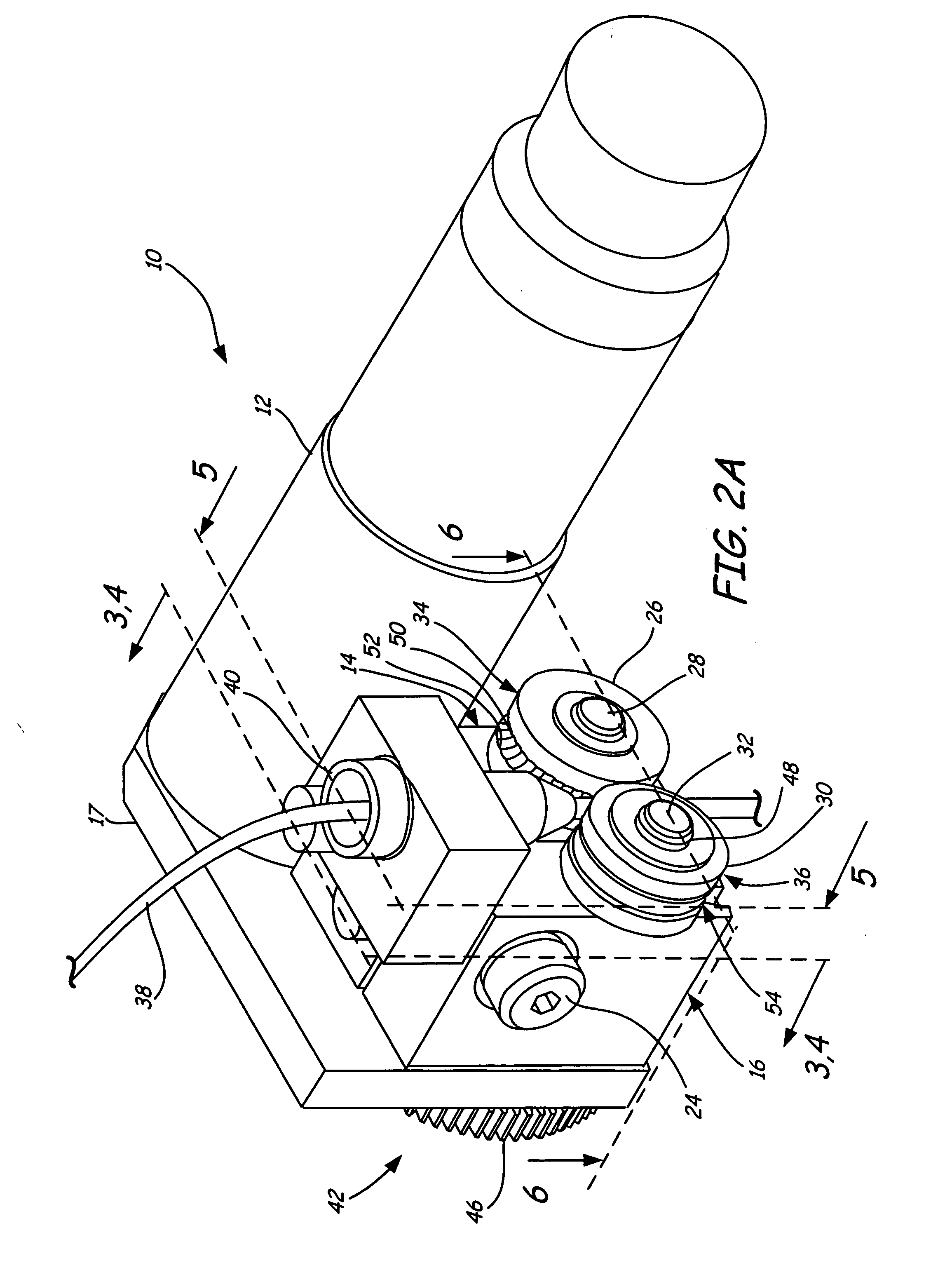

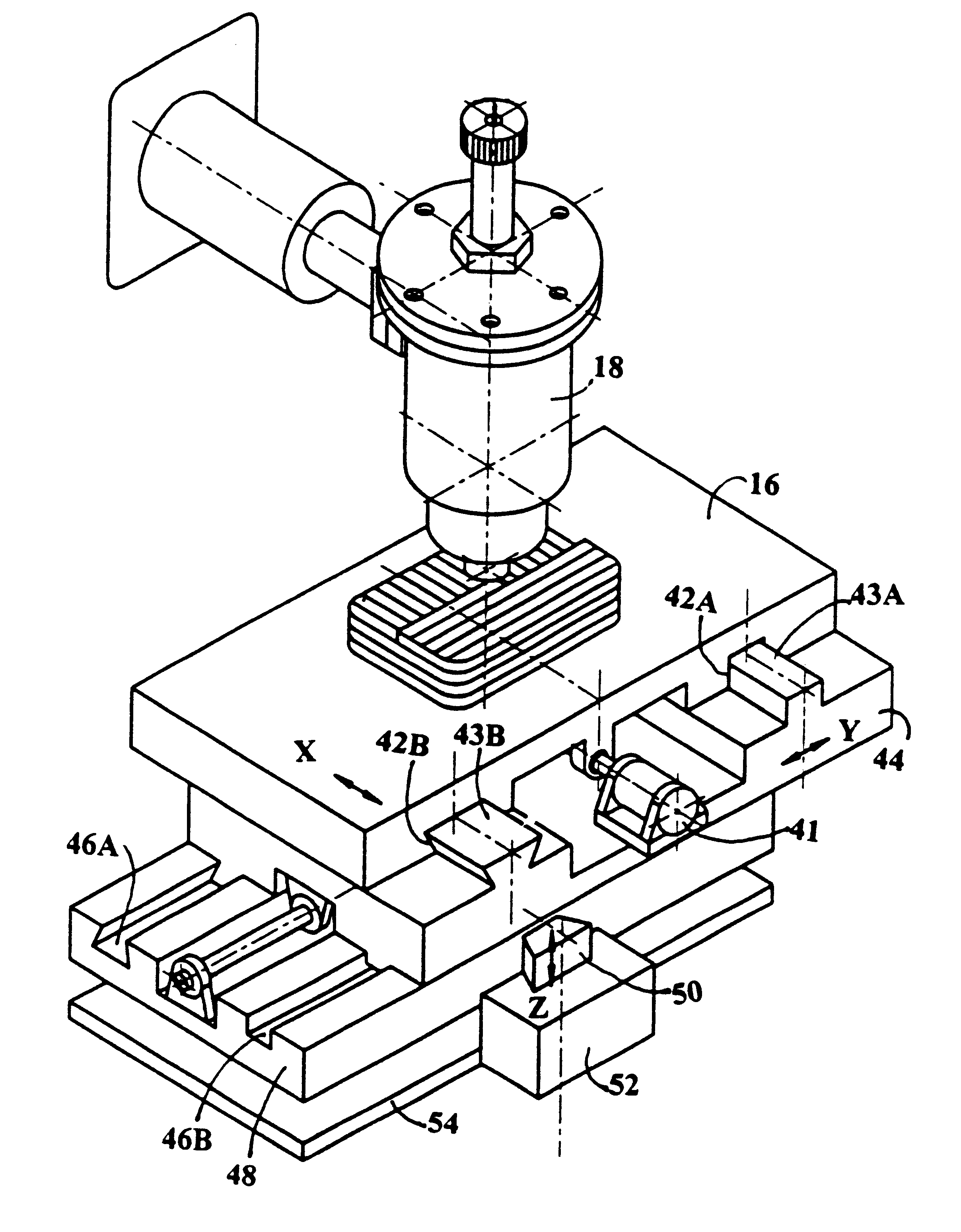

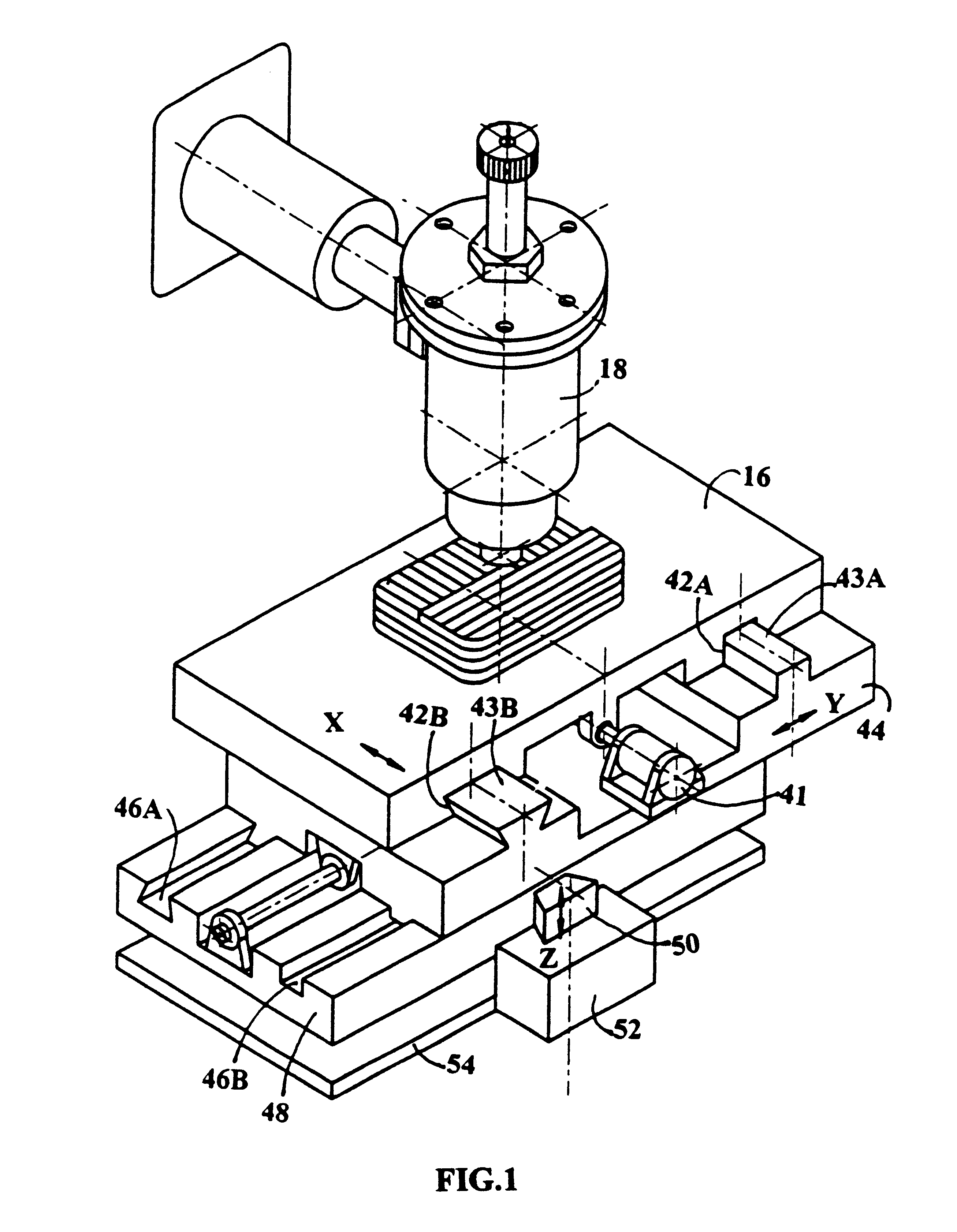

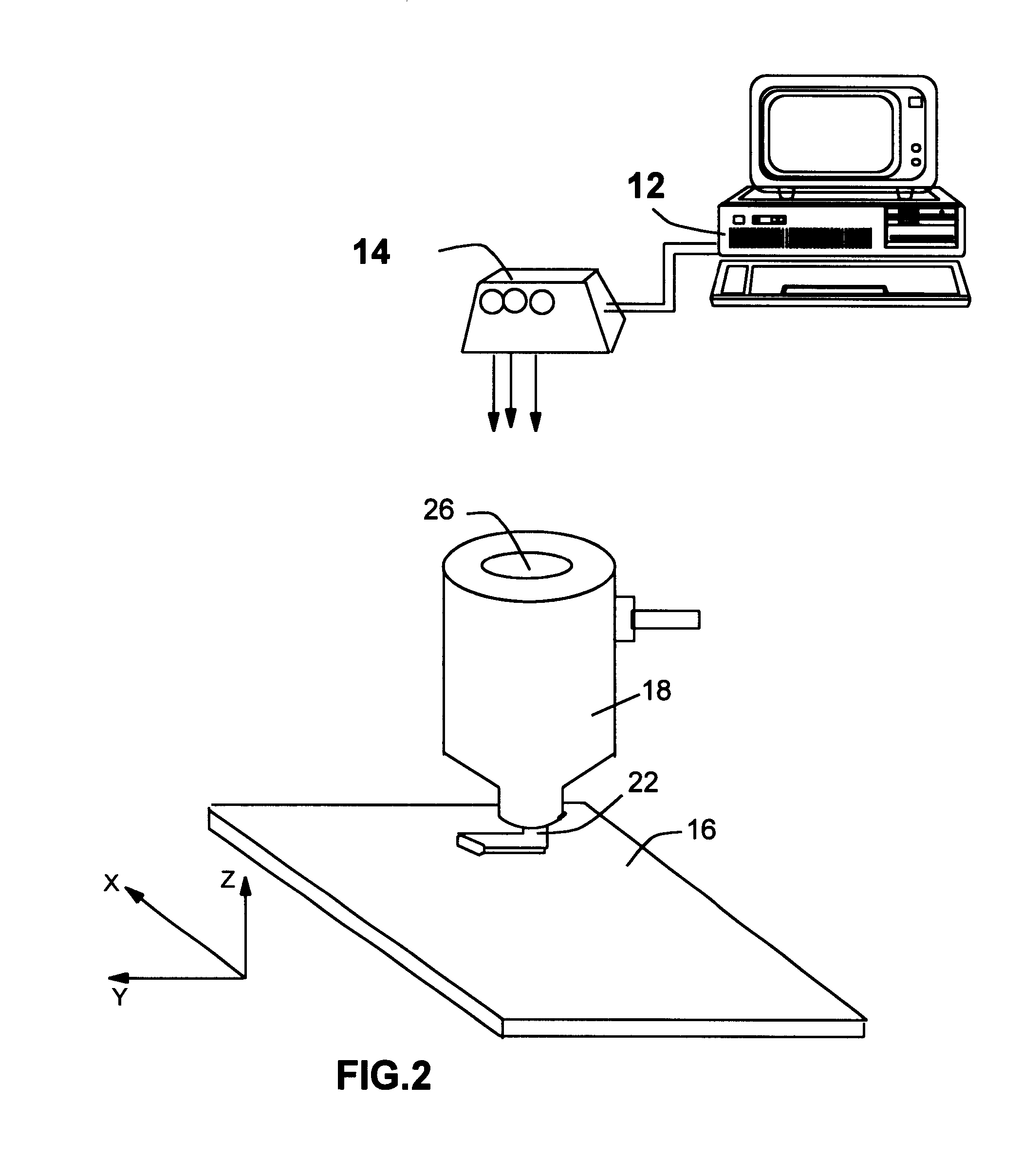

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

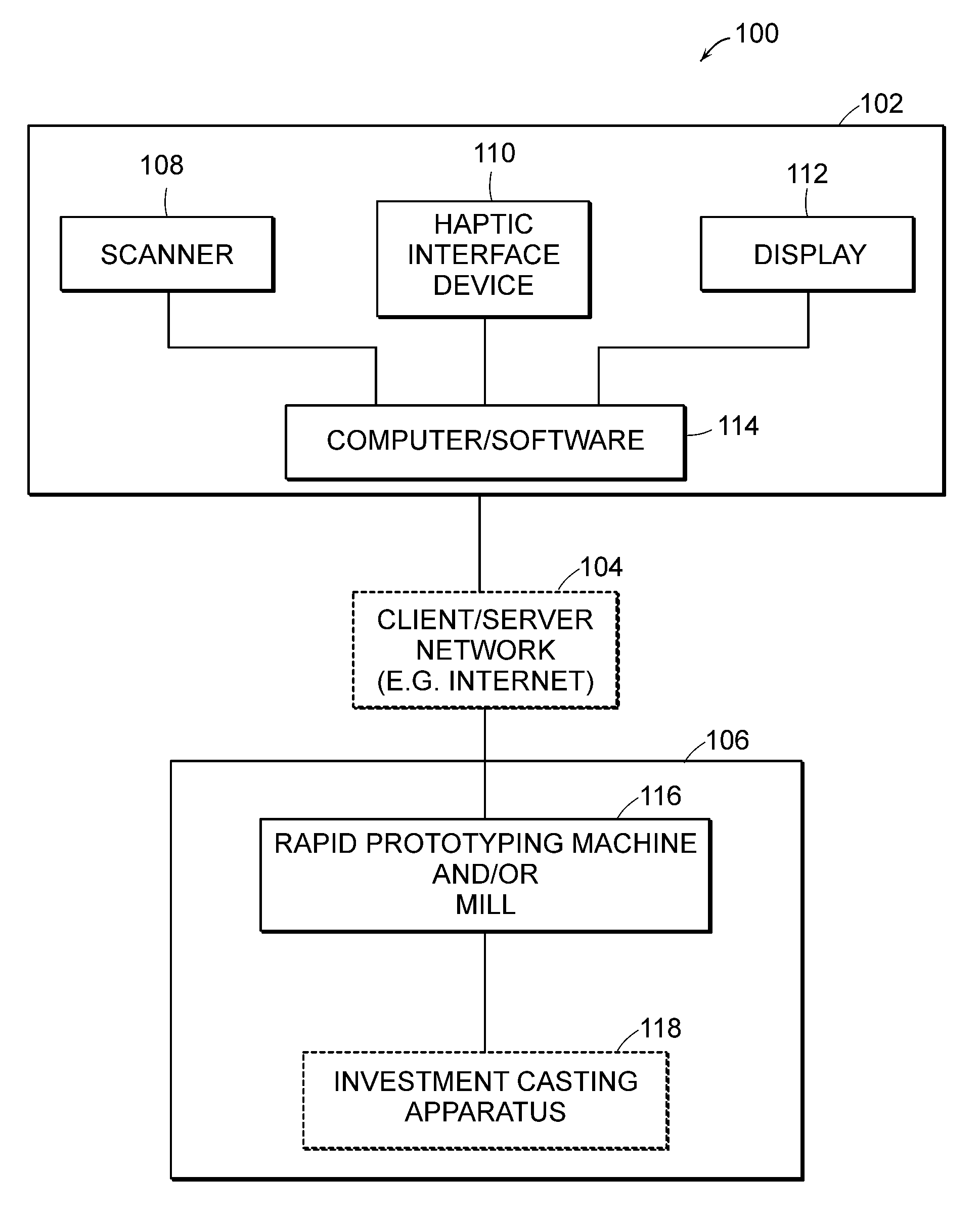

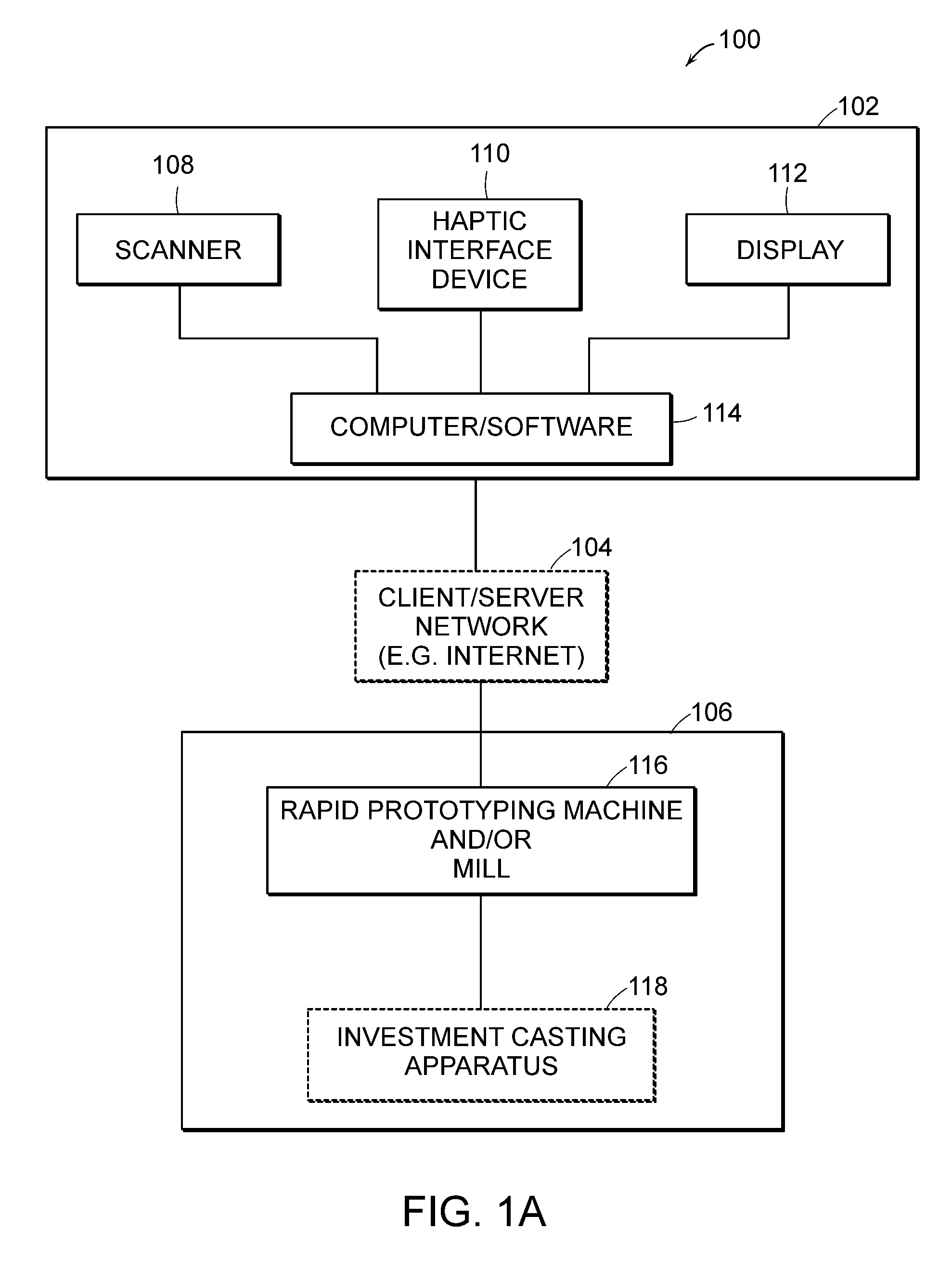

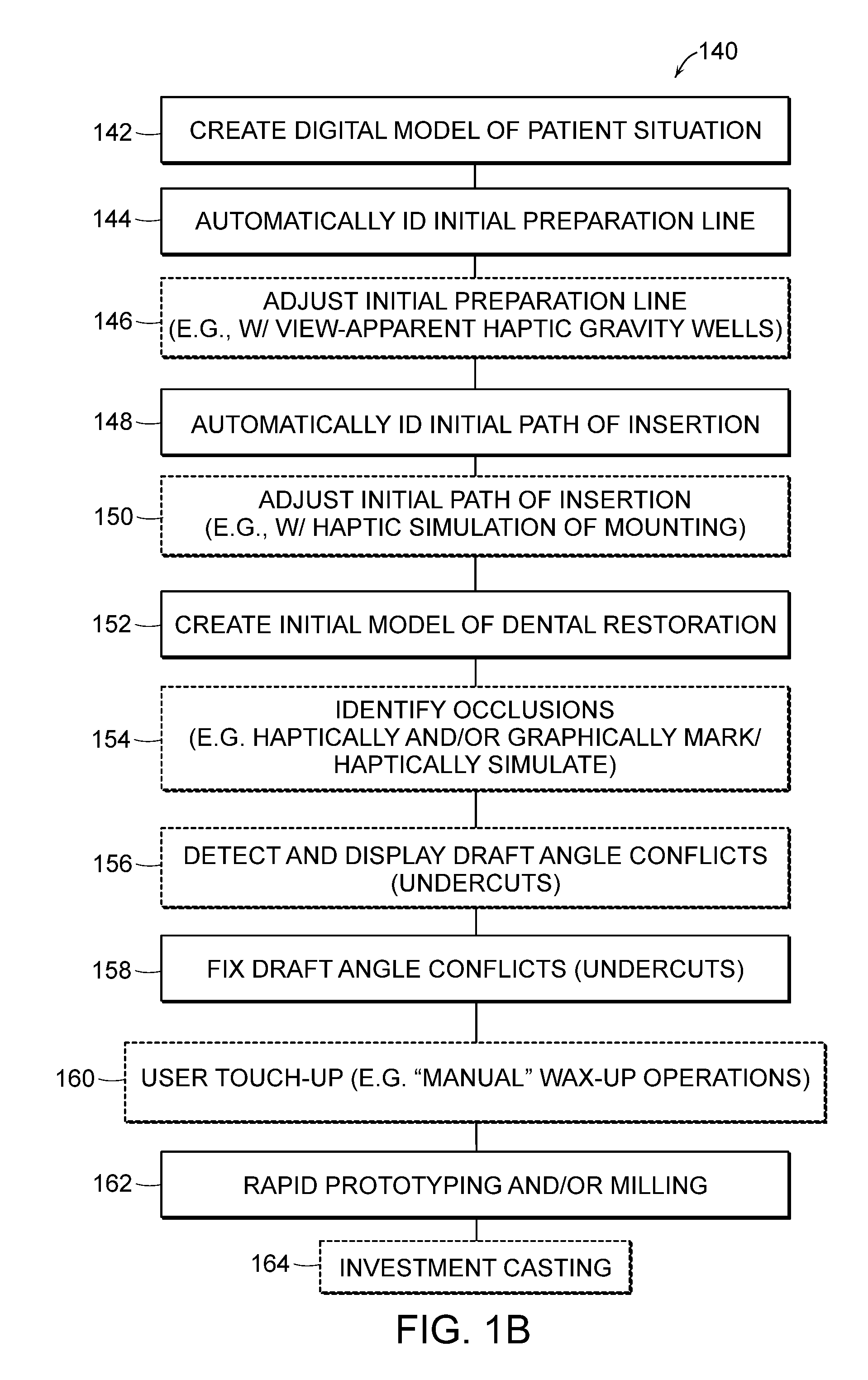

Systems for haptic design of dental restorations

InactiveUS20080261165A1Big advantageEasy to useAdditive manufacturing apparatusOthrodonticsVoxelInvestment casting

The invention provides systems for integrated haptic design and fabrication of dental restorations that provide significant advantages over traditional practice and existing computer-based systems. The systems feature technical advances that result in significantly more streamlined, versatile, and efficient design and fabrication of dental restorations. Among these technical advances are the introduction of voxel-based models; the use of a combination of geometric representations such as voxels and NURBS representations; the automatic identification of an initial preparation (prep) line and an initial path of insertion; the ability of a user to intuitively, haptically adjust the initial prep line and / or the initial path of insertion; the automatic identification of occlusions and draft angle conflicts (e.g., undercuts); the haptic simulation and / or marking of occlusions and draft angle conflicts; and coordination between design output and rapid prototyping / milling and / or investment casting.

Owner:SENSABLE TECH

Rapid prototyping and fabrication method for 3-D food objects

InactiveUS6280785B1Versatile and Realistic Rapid PrototypingRapid productionLayered productsConfectioneryFree formControl signal

A freeform fabrication method for making a three-dimensional food object from a design created on a computer, including: (a) providing a support member by which the object is supported while being constructed; (b) operating a material dispensing head for dispensing a continuous or intermittent strand of food composition in a fluent state; this food composition including a liquid ingredient and a primary body-building food material and the dispensed food composition having a rigidity and strength sufficient for permitting the food composition to be built up layer by layer into a three-dimensional shape in a non-solid state; and (c) operating control devices for generating control signals in response to coordinates of the object design and controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing of the food composition to construct a 3-D shape of this object. The method optionally includes an additional step of applying a heat treatment to the 3-D shape after this 3-D shape is constructed. This method can be used to form an intricate shape of a cake mix, which is then baked in an oven. It can also be used to form a custom-designed decorative shape on the top surface of a pre-made cake.

Owner:NANOTEK INSTR GRP LLC

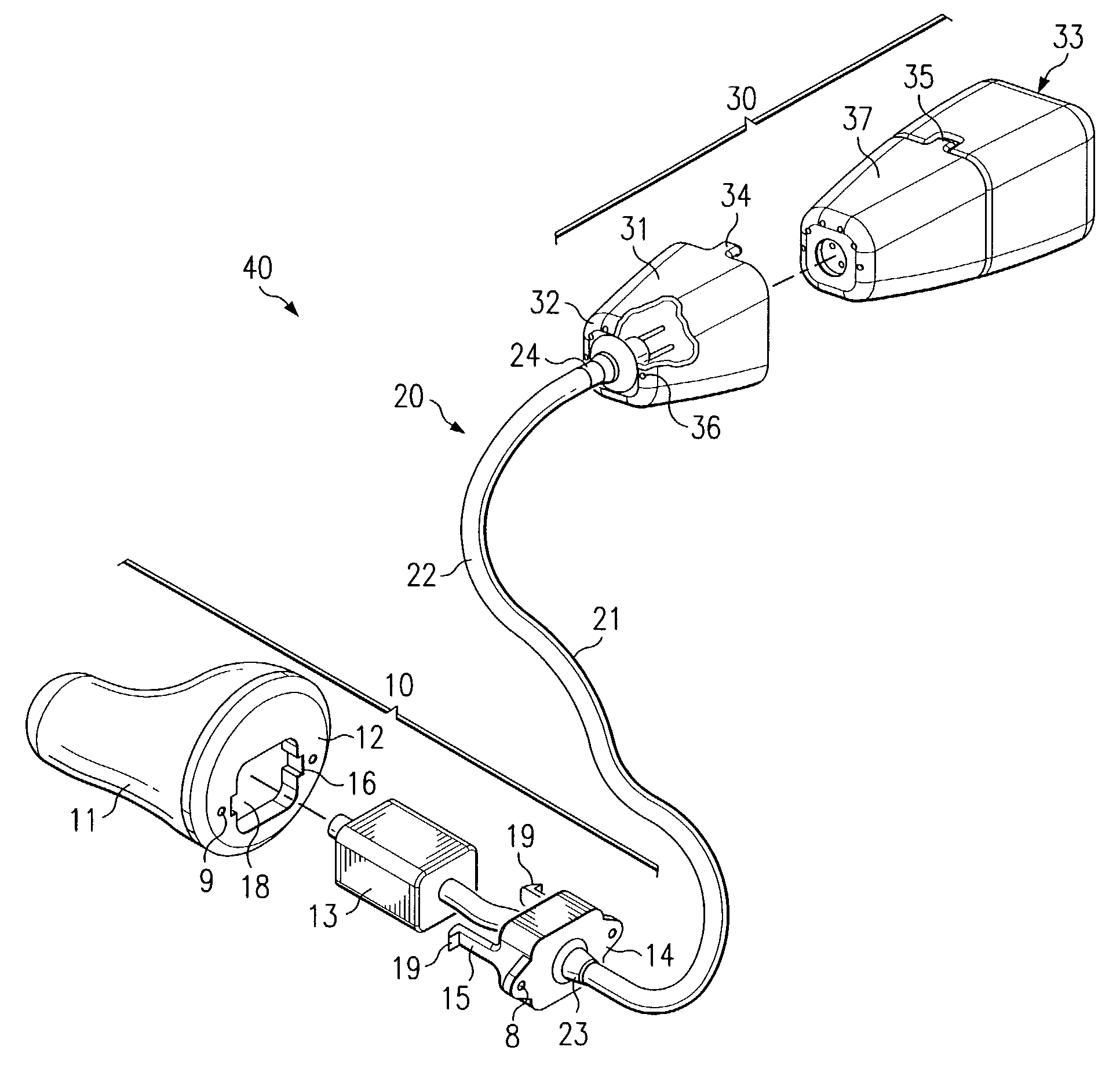

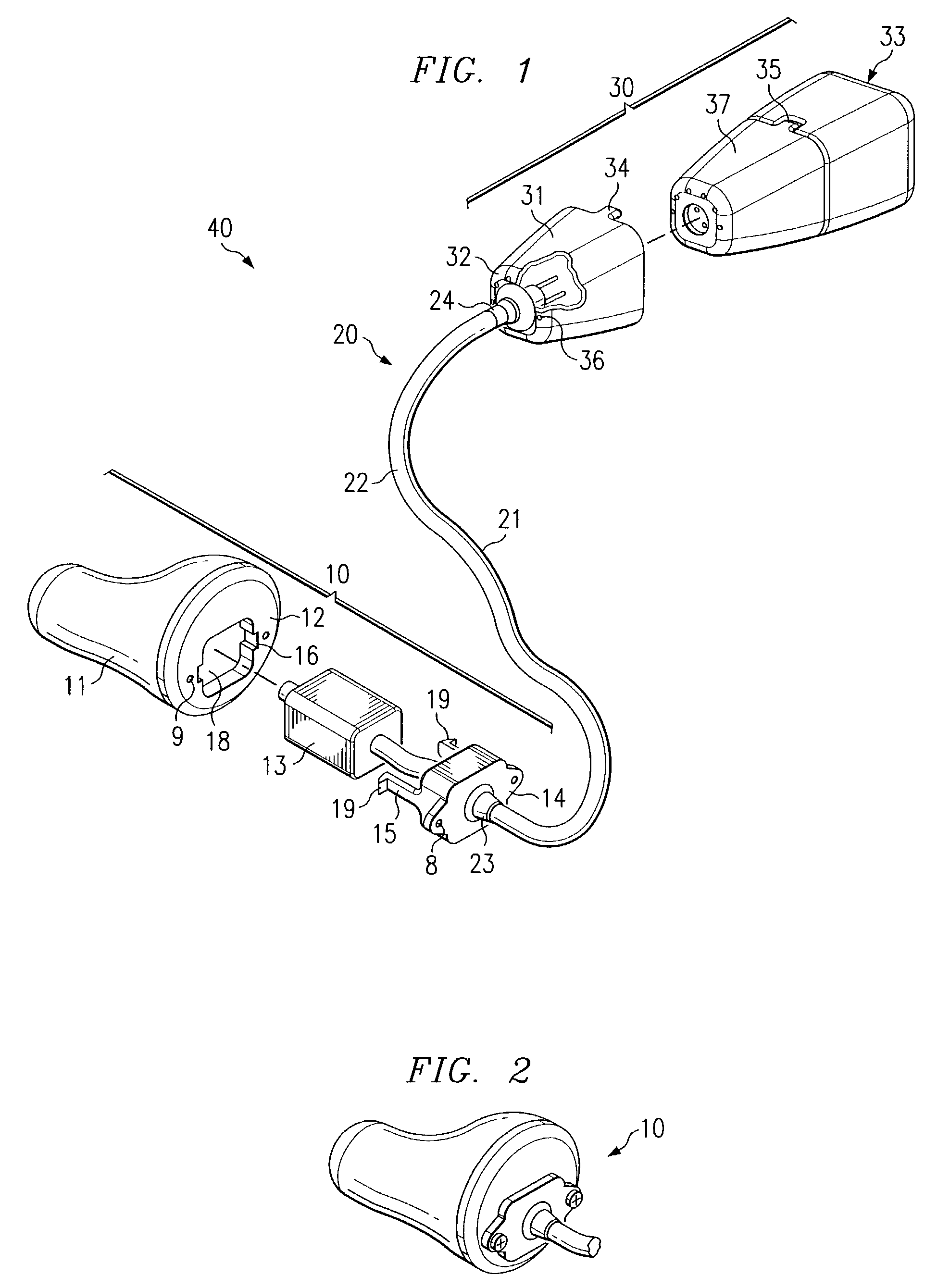

BTE/CIC auditory device and modular connector system therefor

InactiveUS7110562B1Reduce feedbackEasy to assembleAdditive manufacturing apparatusIntra aural earpiecesEngineeringHeadphones

An earpiece auditory device includes a behind-the-ear (BTE) component, which includes processing circuitry. In an embodiment, the device also includes a completely-in-canal (CIC) component, shaped to fit into the ear canal of the user such that it touches the bony portion of the ear canal. In some embodiments, the CIC component includes either a universal fit or a custom fit ear mold. The custom fit ear mold can be fabricated using a rapid prototyping technology, in which the contours of the user's ear canal are scanned, and the scan data is used either directly or indirectly to replicate the ear canal contours of that user into the custom fit ear mold. In some embodiments, the ear mold is detachably interconnected with a speaker module, preferably using either an intermediate sleeve or a detachable locking pin assembly. In another embodiment, the speaker module is permanently encapsulated within the ear mold.

Owner:HEAR WEAR TECH

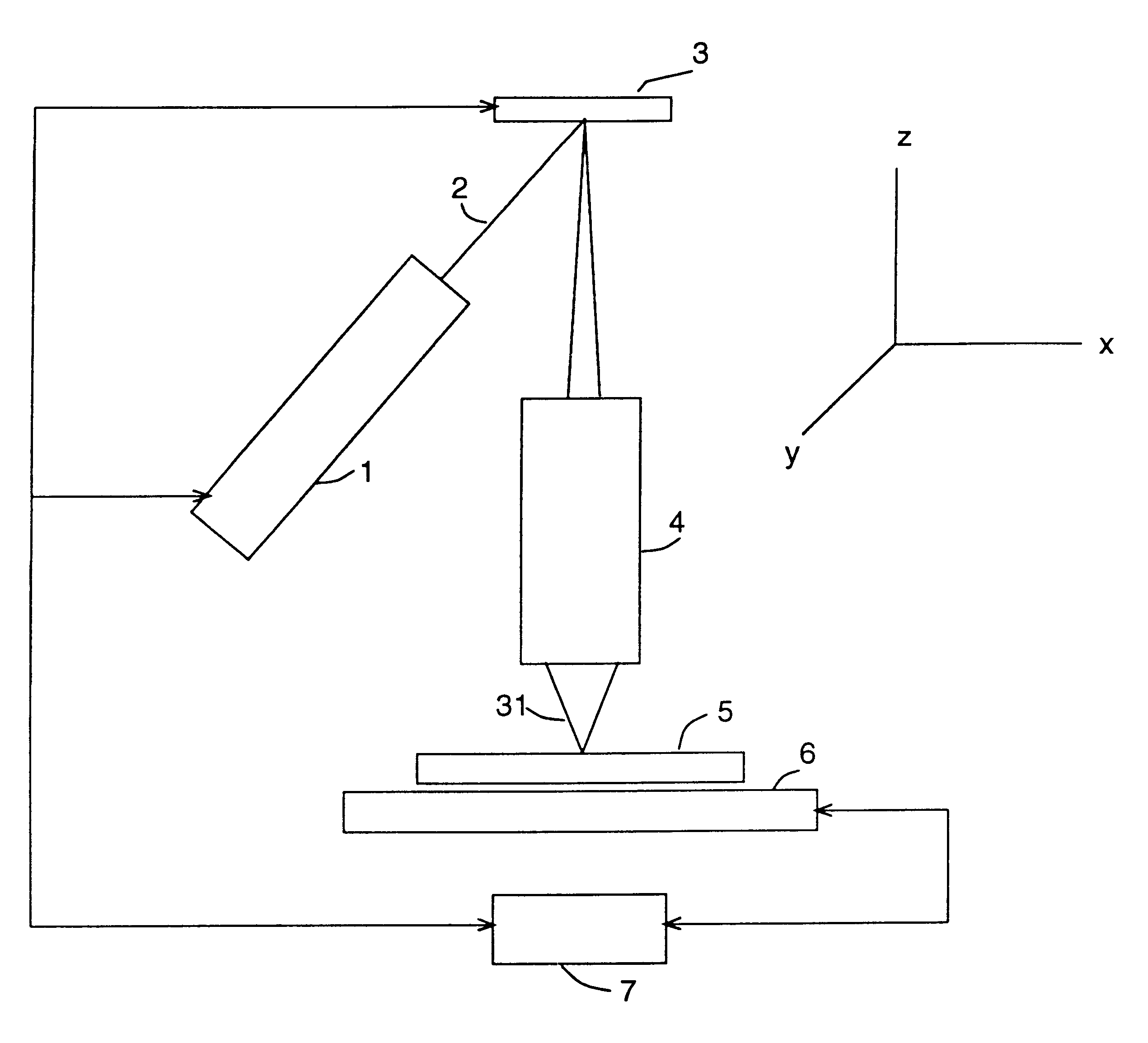

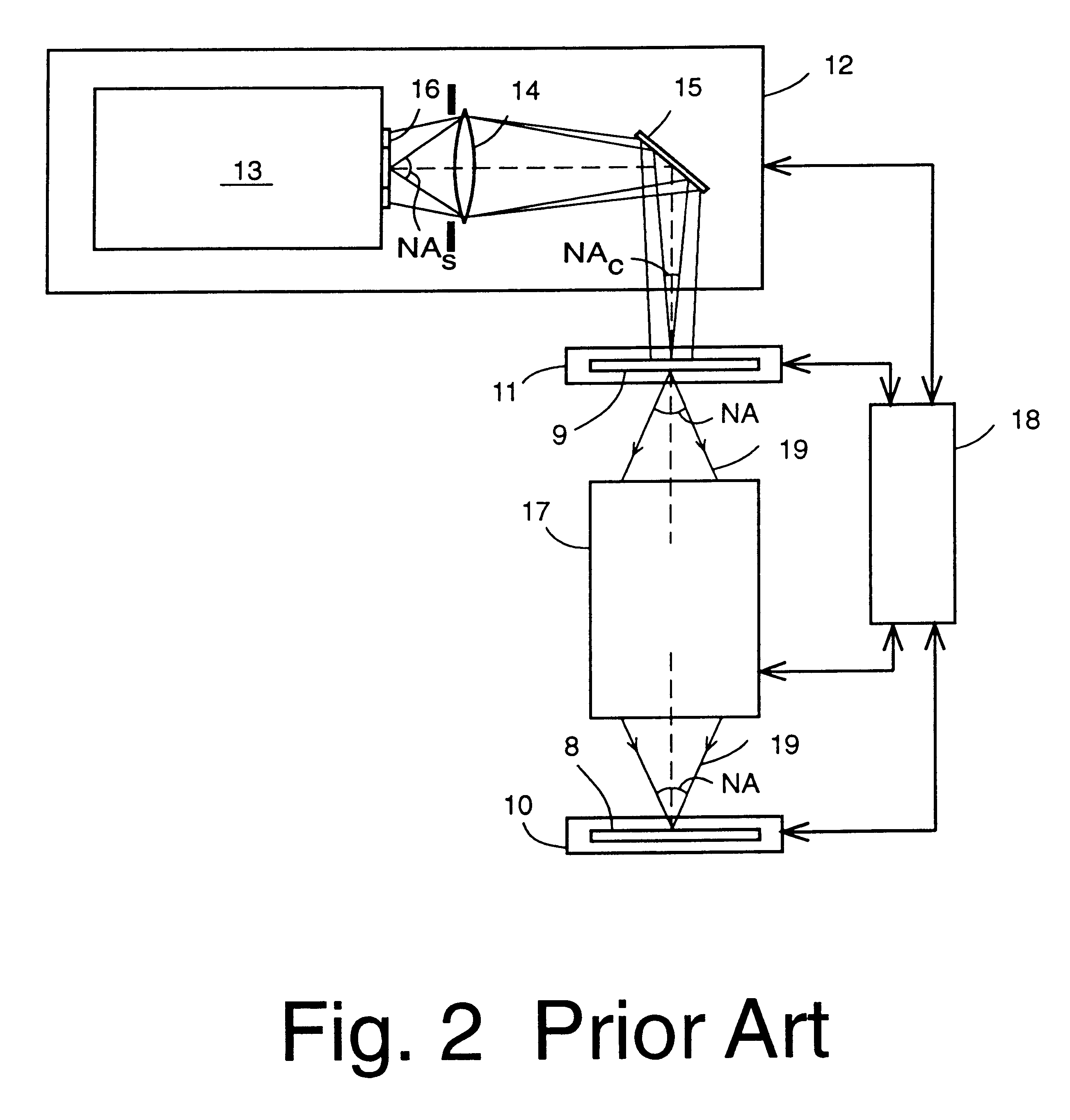

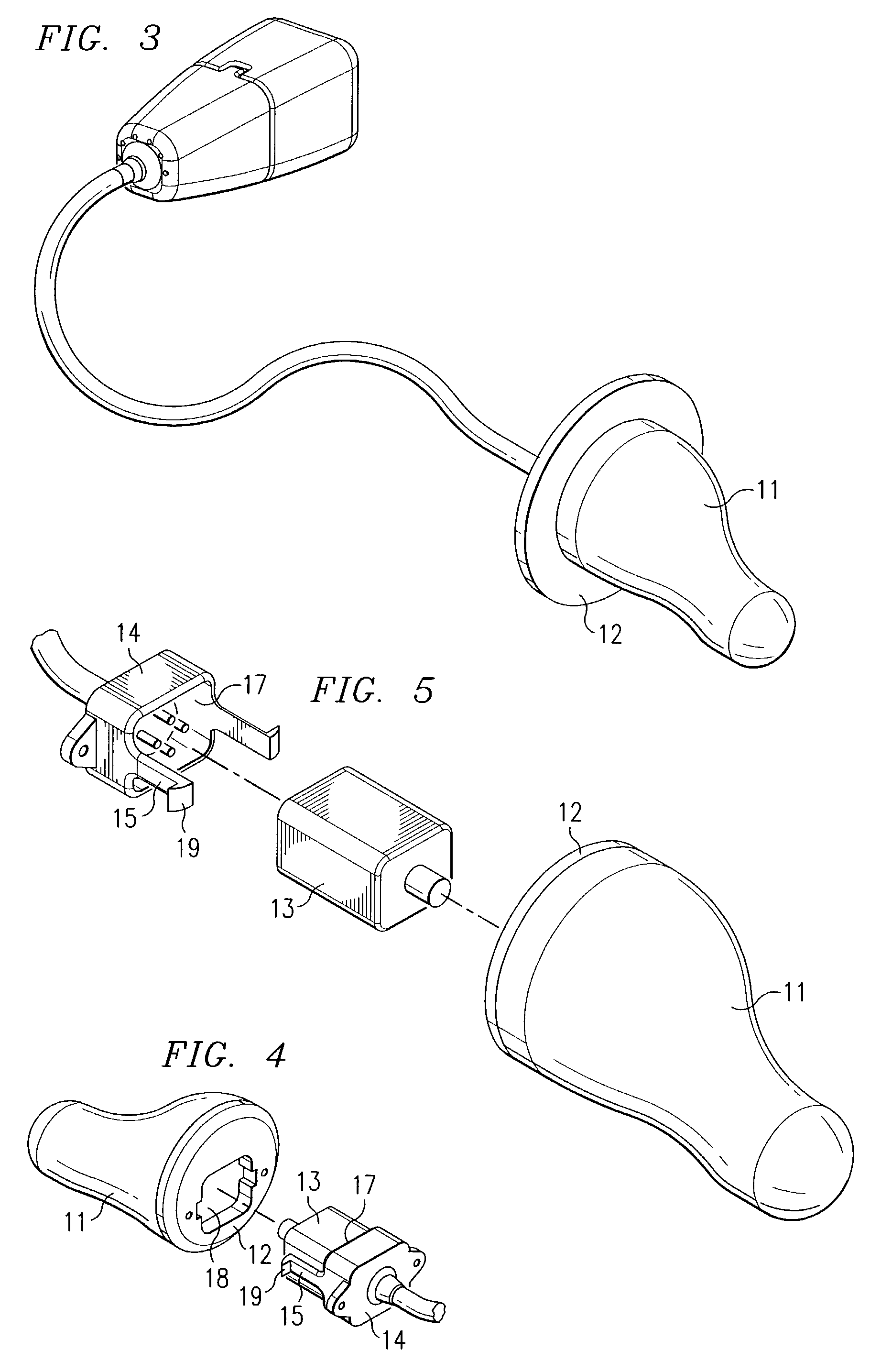

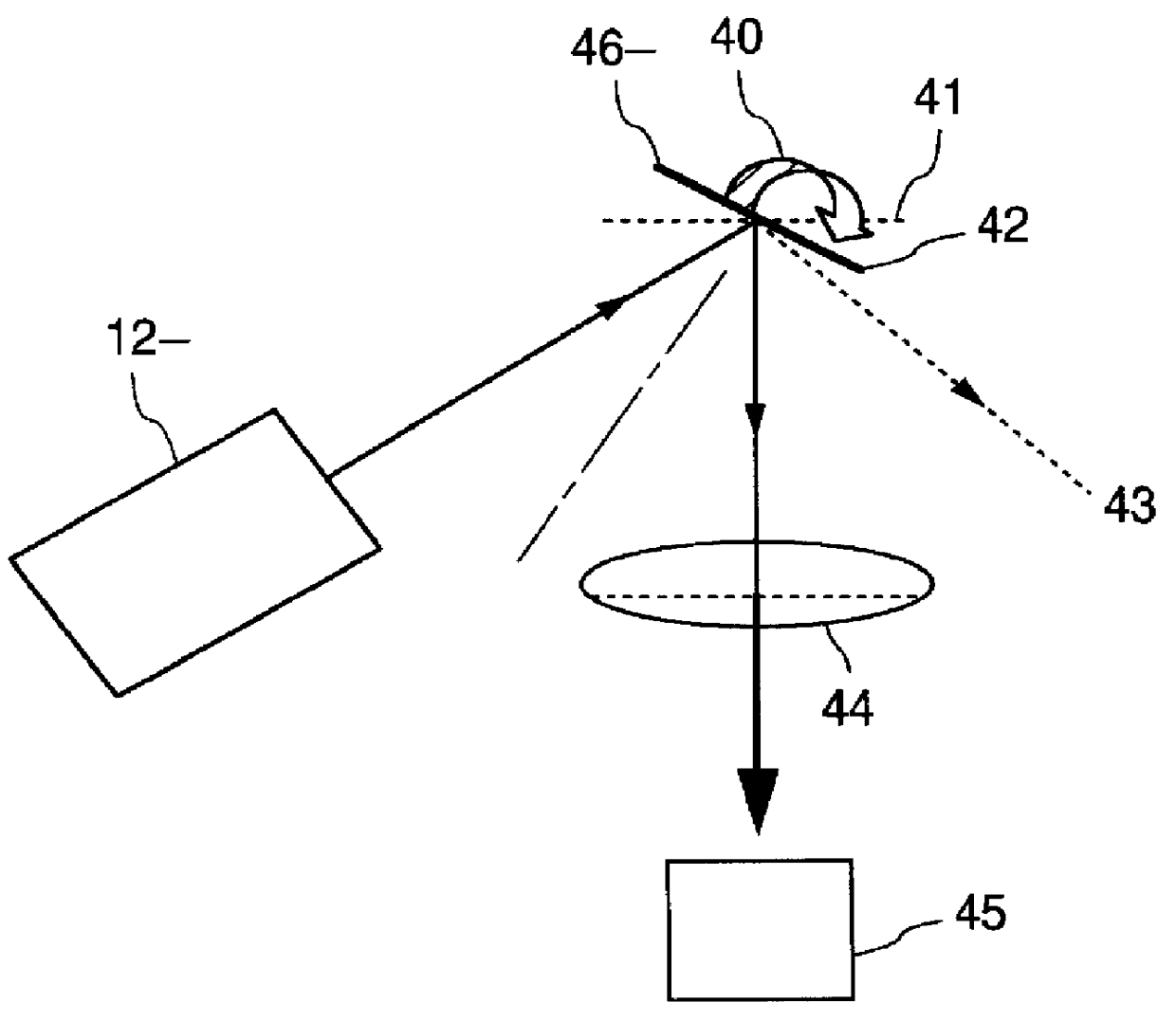

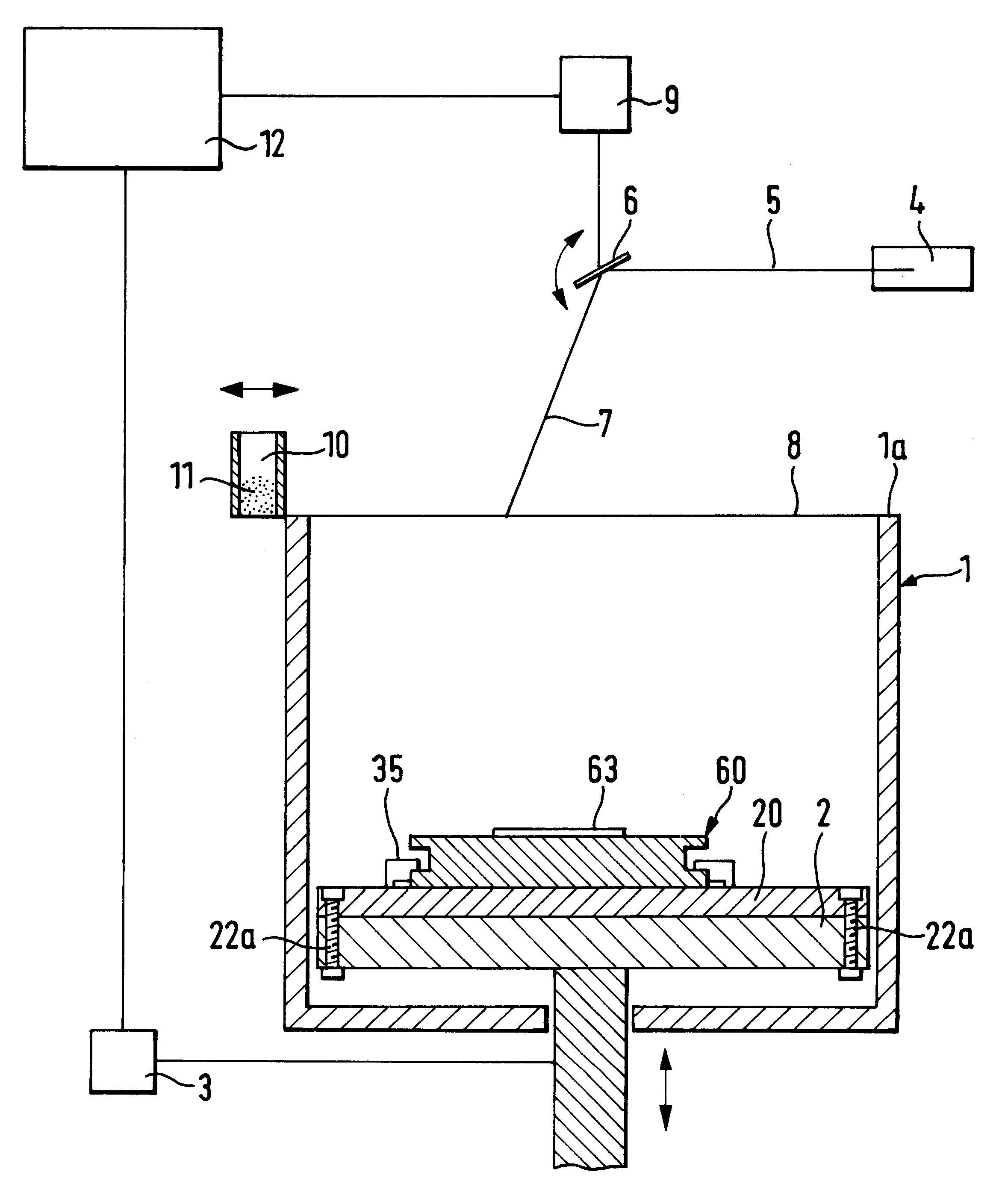

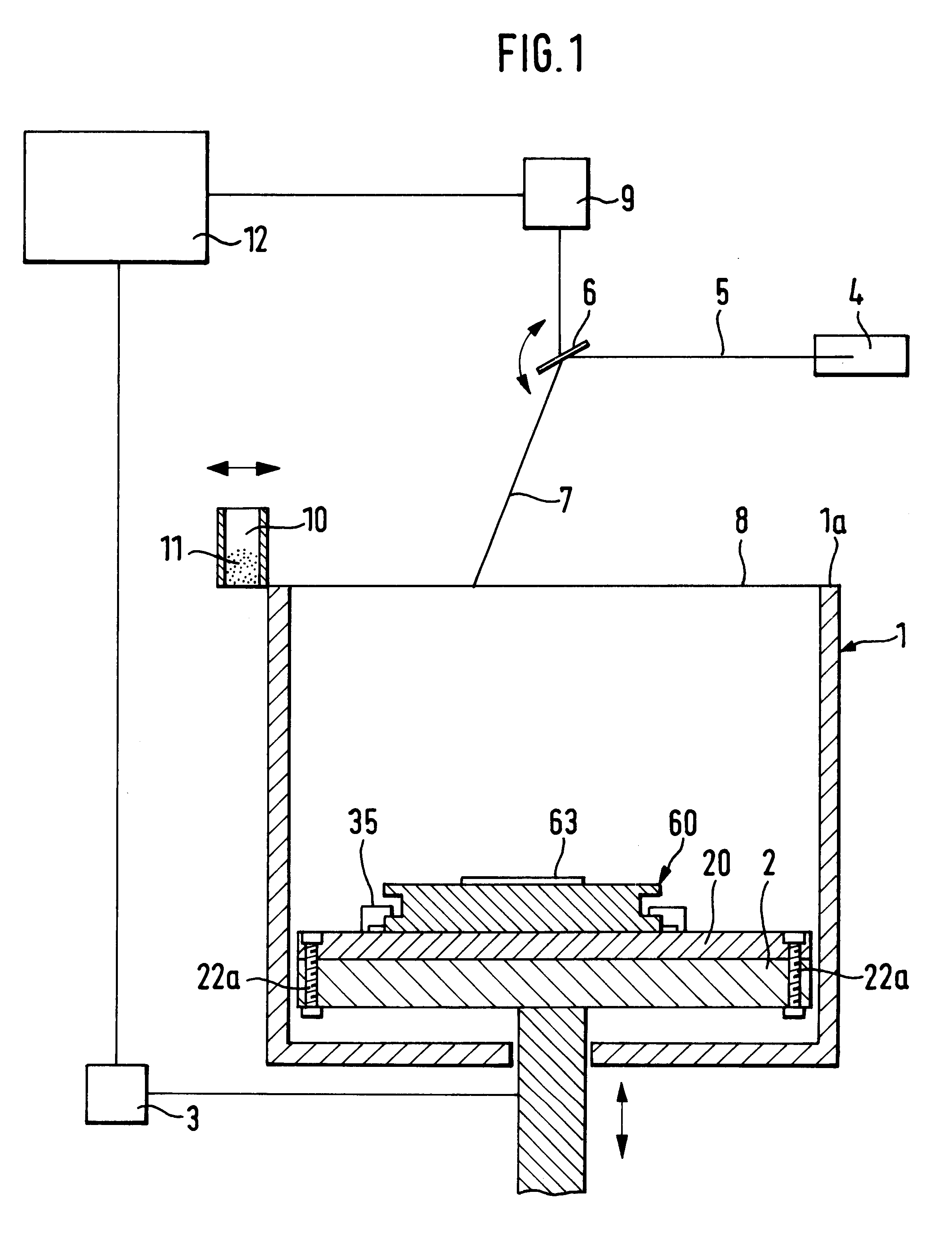

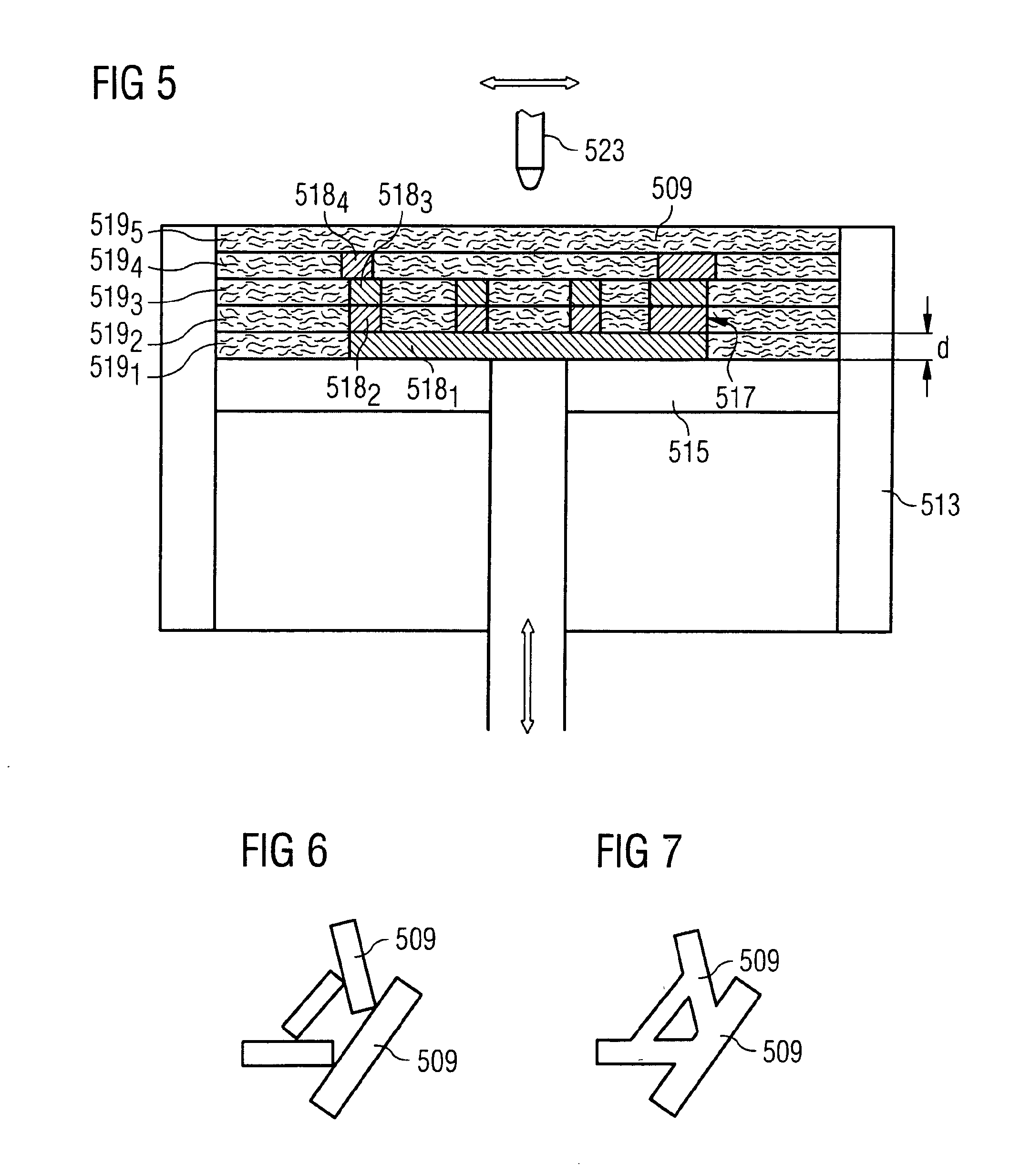

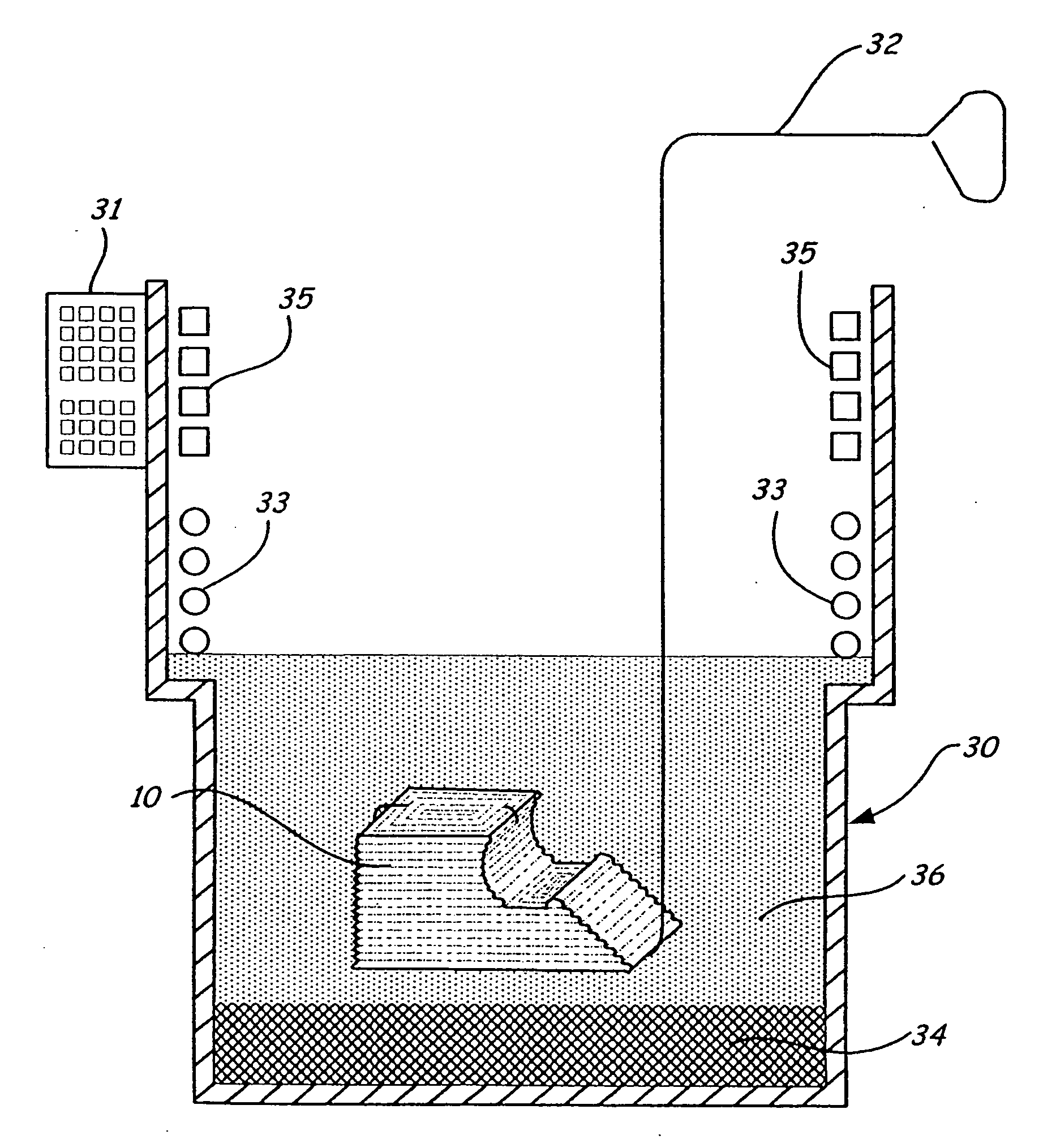

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

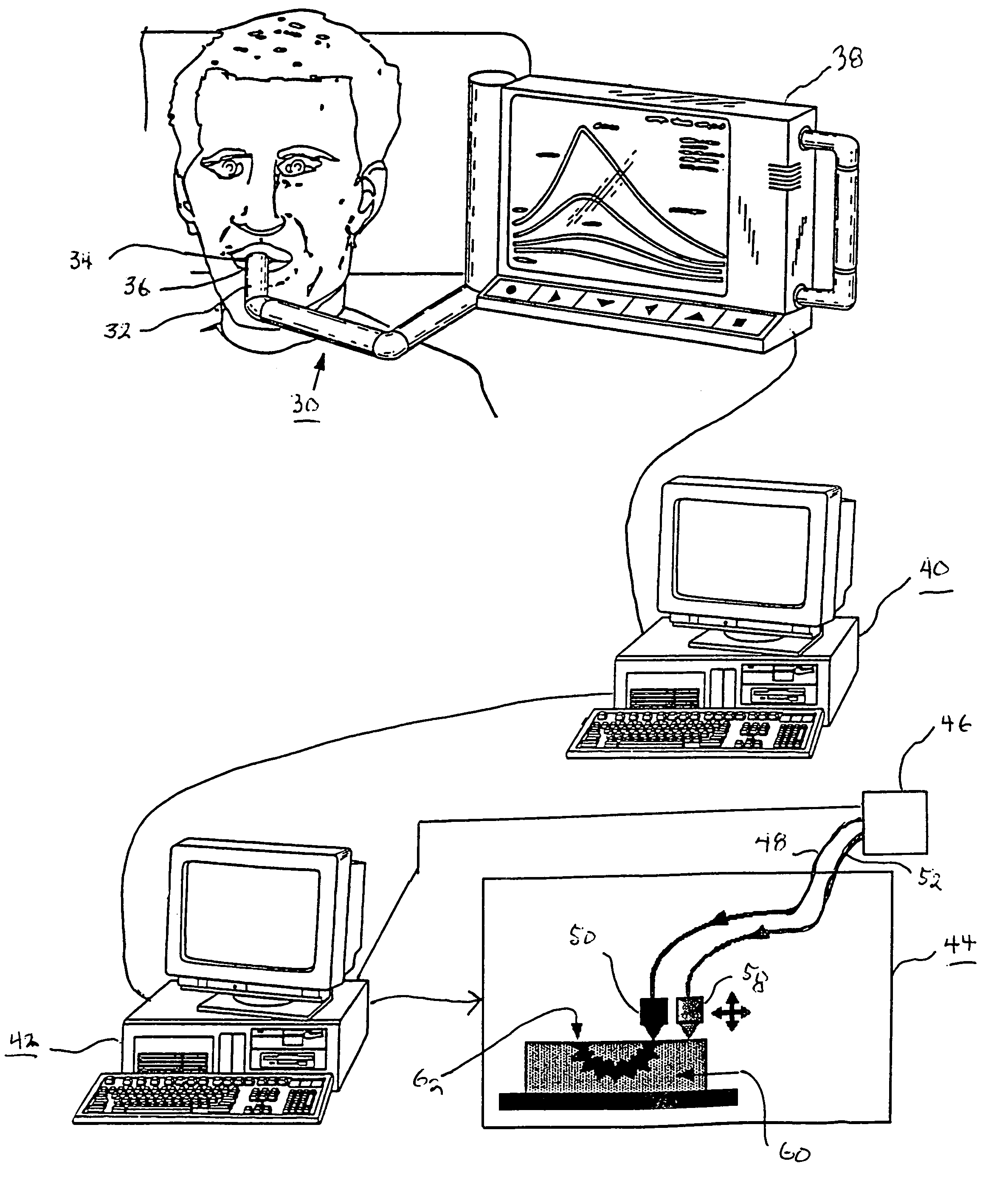

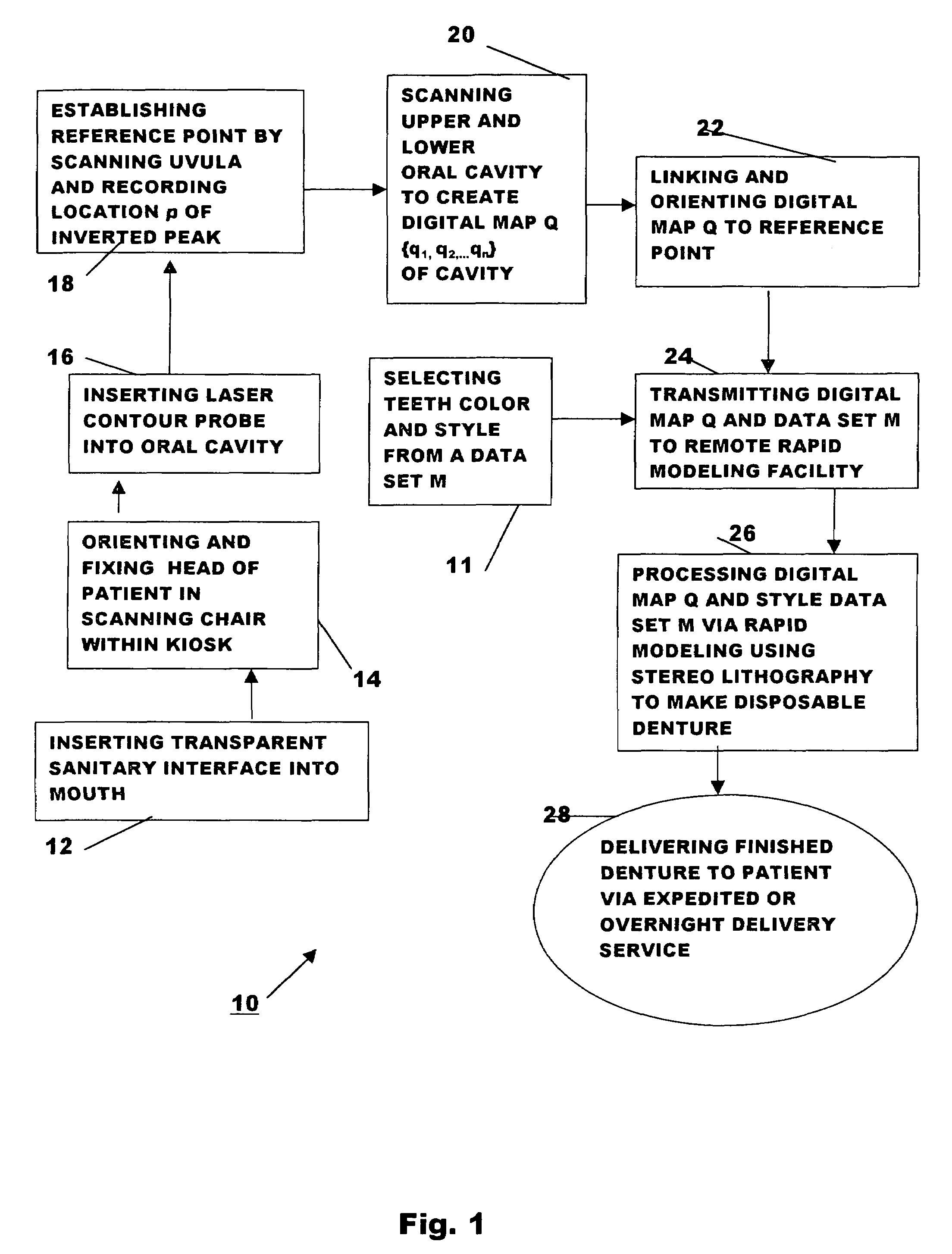

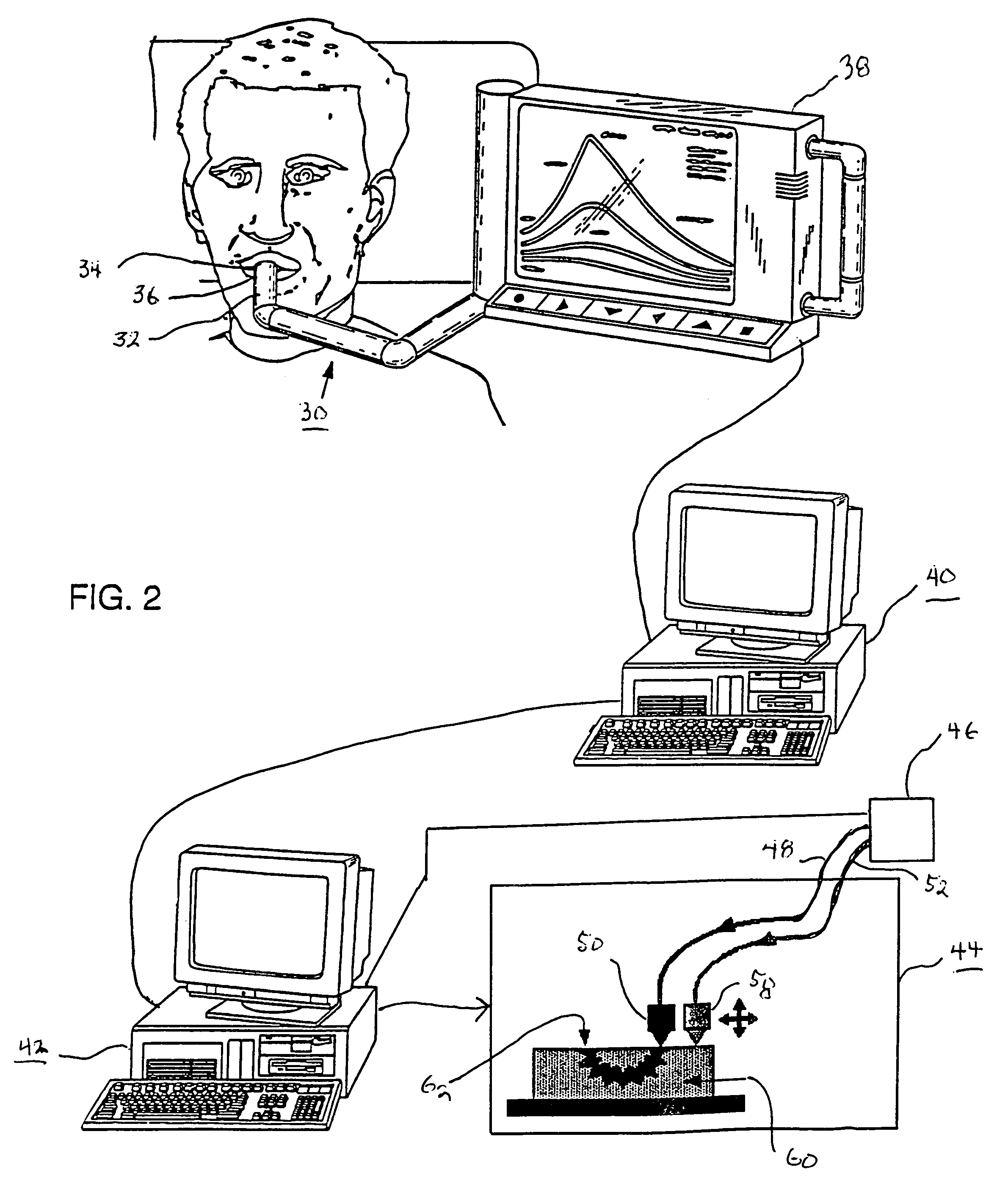

Method for automatically creating a denture using laser altimetry to create a digital 3-D oral cavity model and using a digital internet connection to a rapid stereolithographic modeling machine

InactiveUS7153135B1Low costFit closelyAdditive manufacturing apparatusImpression capsDenturesLaser scanning

A method is presented for rapidly making and delivering directly to a consumer a full upper and / or lower denture on the basis of contemporaneous digital image information laser scanned from the person's oral cavity after all respective upper and / or lower teeth have been removed, the delivery of the denture occurring substantially contemporaneously with the creation of the contemporaneous digital image information and optionally including and based on archived digital image information laser scanned from the person's oral cavity before all respective upper and / or lower teeth have been removed and digitally stored. According to which this contemporaneous digital image information and archival digital image information of the oral cavity is converted, by means of what is called the rapid prototyping technique and thus with a processing step (20) and a combination of an optional laser scanning step (18) solely for archiving the oral cavity when upper and / or lower teeth are present and a repetition of the laser scanning step (18) at a subsequent time when upper and / or lower teeth have been removed, a pre-selected block of plastic is used in a processing step (26) at a remote rapid modeling facility for receiving and processing digital information to form the block of plastic or like material into a denture of which at least a part is formed to substantially perfectly fit in juxtaposed relationship to the corresponding gums of the consumer. At least, pre-selected outer or non-juxtaposing is selected for manufacture of the denture using an arbitrary archived digital image not derived from the consumer's oral cavity image but selected by the consumer for its style, cosmetic characteristics, for example, color of teeth, size and variety of teeth, and / or perceived suitability.

Owner:THOMAS RICHARD J

Three-dimensional fabricating systems for rapidly producing objects

InactiveUS20160288376A1High strengthAdditive manufacturing apparatus3D object support structuresFree Radical SuppressionPolypropylene

This invention relates to rapid prototyping systems, specifically, a composition for a release film comprising one or more base materials selected from the group consisting of silicone, polycarbonate, polyethylene, and polypropylene; and one or more free-radical inhibitors.

Owner:DENTSPLY SIRONA INC

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6270335B2Less distortionReduce the risk of bridgingAdditive manufacturing apparatusConfectioneryEngineeringSelective deposition

Owner:3D SYST INC

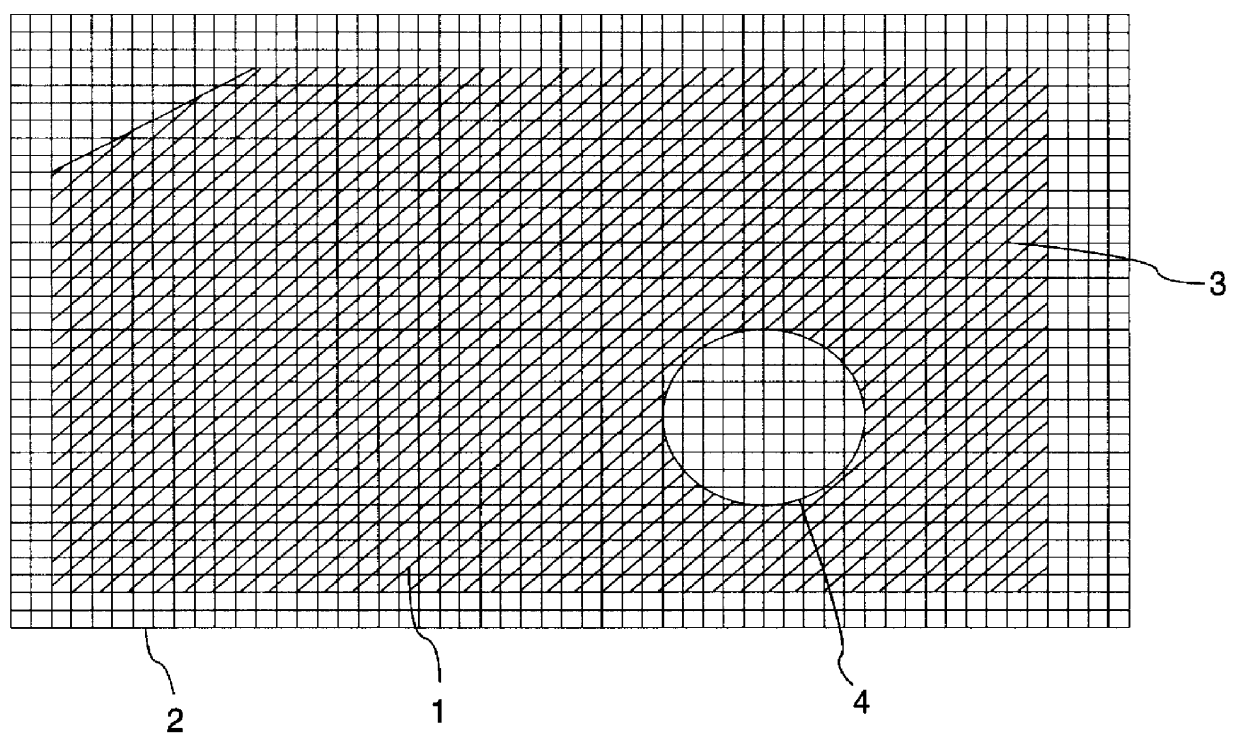

Method of calibrating an apparatus for producing a three-dimensional object, calibration apparatus and method and apparatus for producing a three-dimensional object

InactiveUS6483596B1Simple methodEnhanced radiationPretreated surfacesElectrical measurementsElectromagnetic radiationRapid prototyping

The invention refers to a method for calibrating the control of a radiation device producing electromagnetic radiation or particle radiation in a rapid prototyping system. The method comprises the steps of arranging a calibration plate at a defined position in the rapid prototyping system, the calibration plate having an upper side with a first region and a second region separate from the first region, the first region being provided with optically detectable reference marks and the second region having a medium which is sensitive to the radiation of the radiation device, producing a test pattern by exposing said medium to said radiation at predetermined desired positions defined by position coordinate data, digitizing the first region of the calibration plate with the reference marks thereon and the second region of the calibration plate having the test pattern, comparing the digitized reference marks and the digitized test pattern and calculating and providing correction data for the control of the radiation device on the basis of the comparison.

Owner:EOS ELECTRO OPTICAL SYST

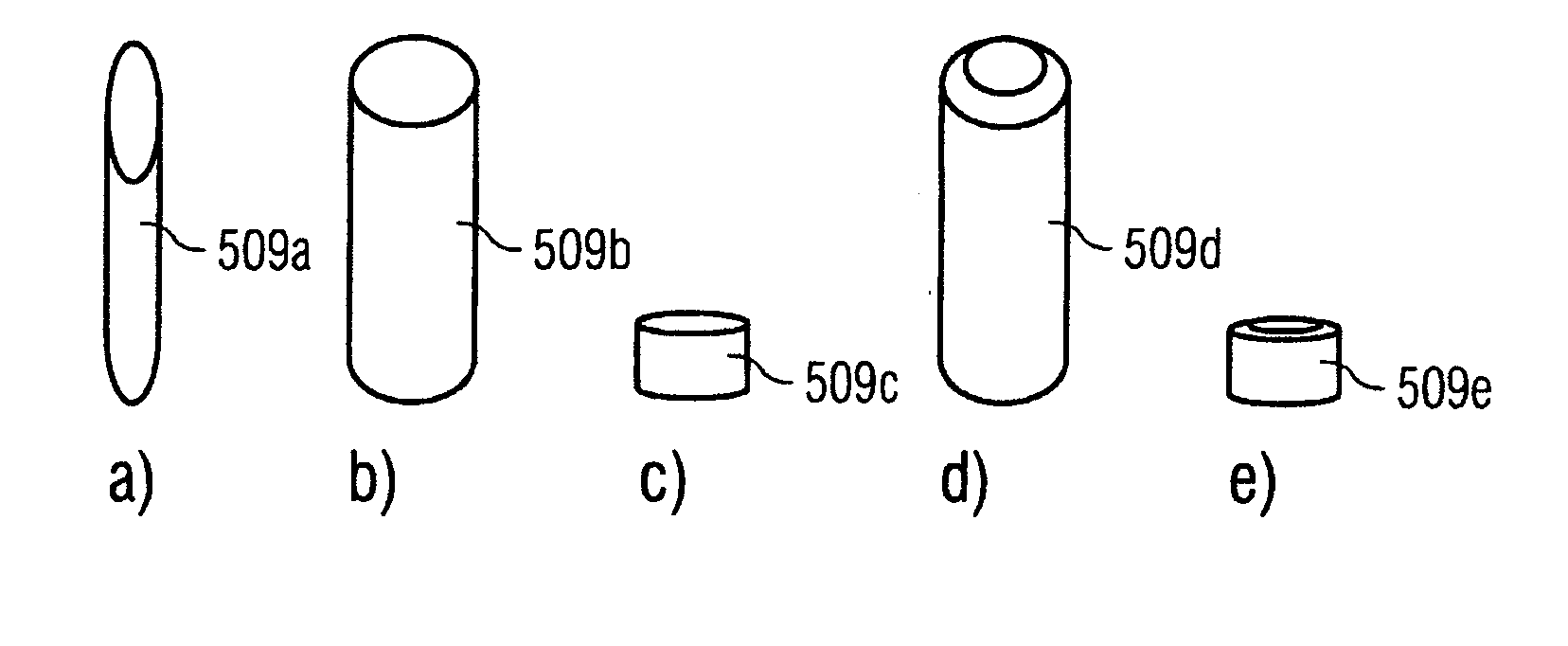

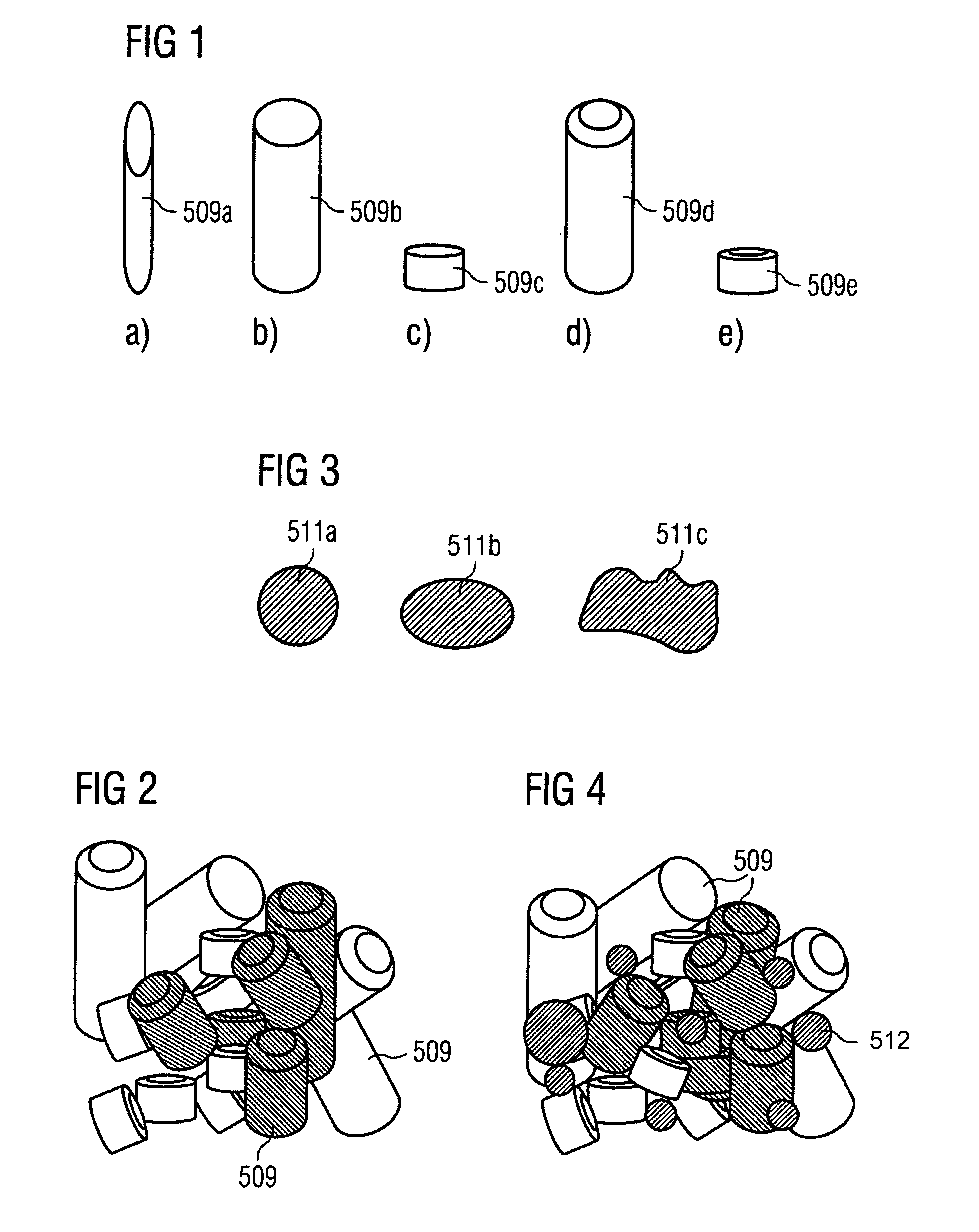

Fibers and methods for use in solid freeform fabrication

ActiveUS20110143108A1Easy to produceSpecific characteristicAdditive manufacturing apparatusSynthetic resin layered productsFiberRapid prototyping

A shaped body comprised of individual, interconnected layers may be produced from fibers in accordance with a solid freeform fabrication or rapid prototyping method. The fibers may be produced by extrusion molding a thermoplastic material.

Owner:EVONIK OPERATIONS GMBH

System and method for manufacturing full and partial dentures

There is provided a system for fabricating at least a portion of a denture. The system includes a three-dimensional scanning device for scanning a surface of a denture template, and a computer-readable medium including a computer program for receiving data from the scanning device, creating a 3-dimensional model of the surface, and optionally modifying the 3-dimensional model and / or adding features to the 3-dimensional model. The system also includes a fabricator for creating the at least the portion of the denture, from a selected material, based on the 3-dimensional model. The fabricator may be a device including a lathe, or a rapid prototyping machine. There is also provided a method for fabricating at least a portion of a denture.

Owner:SMITHKLINE BECKMAN CORP

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS20060045787A1Additive manufacturing apparatusTransportation and packagingCopperRapid prototyping

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

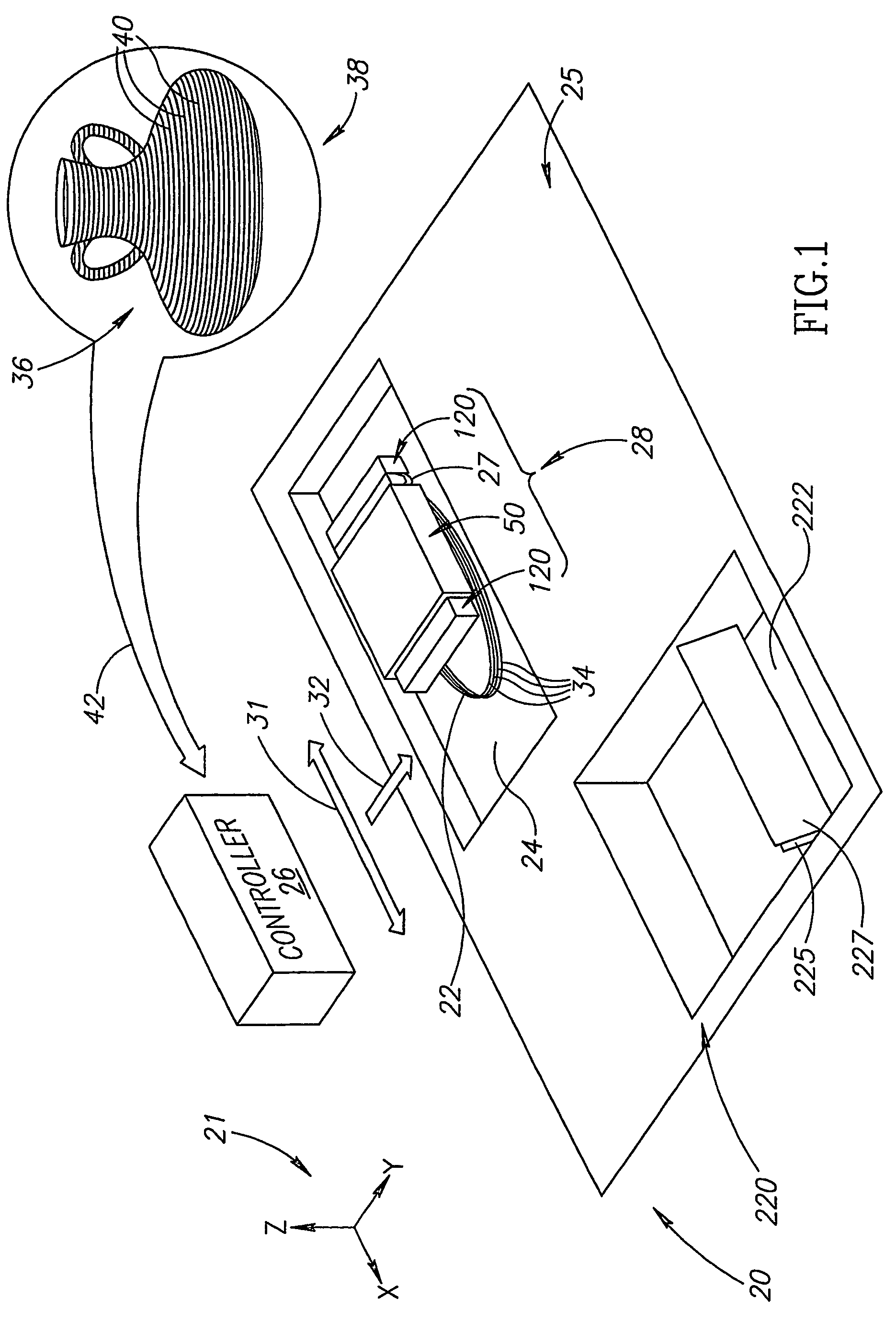

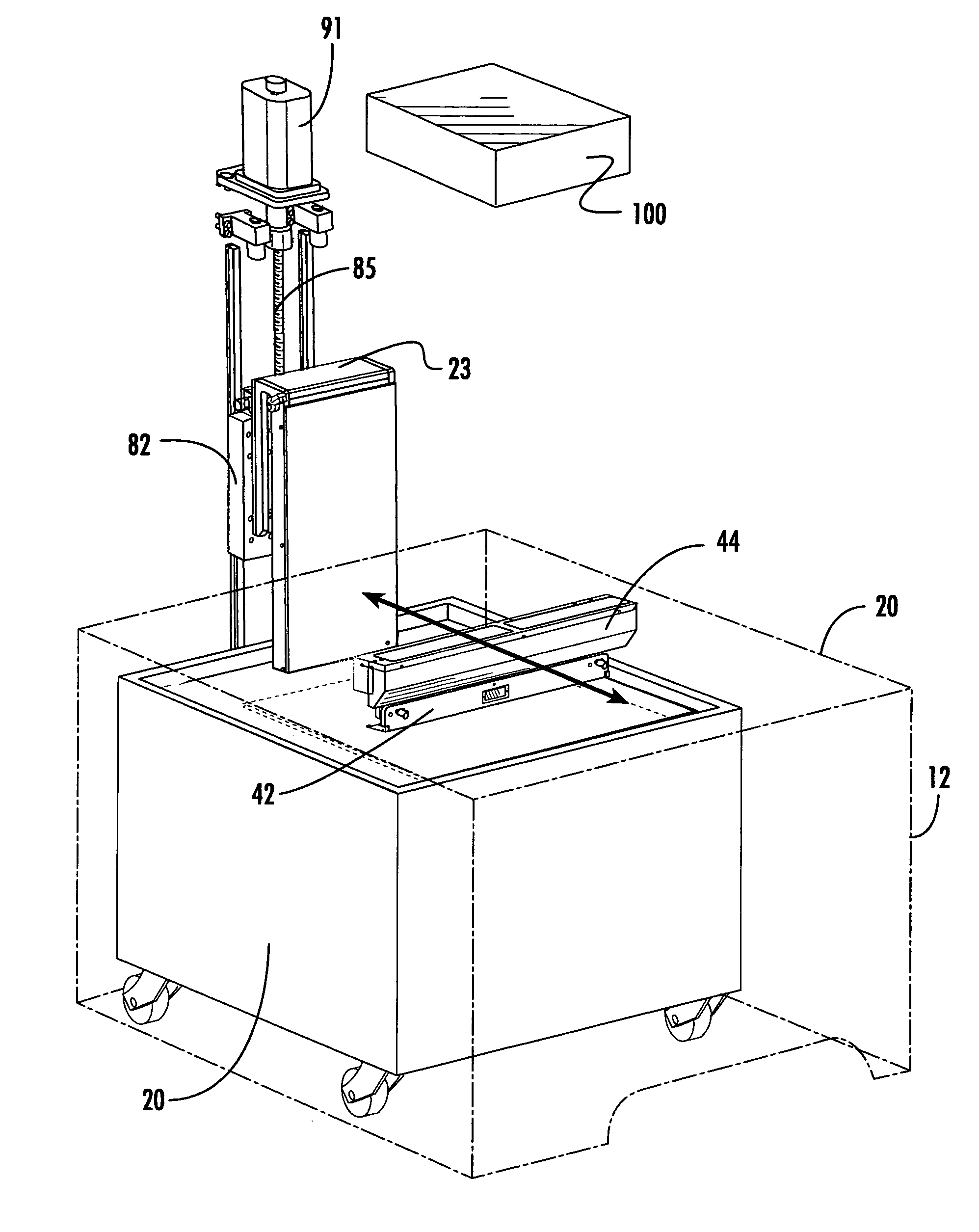

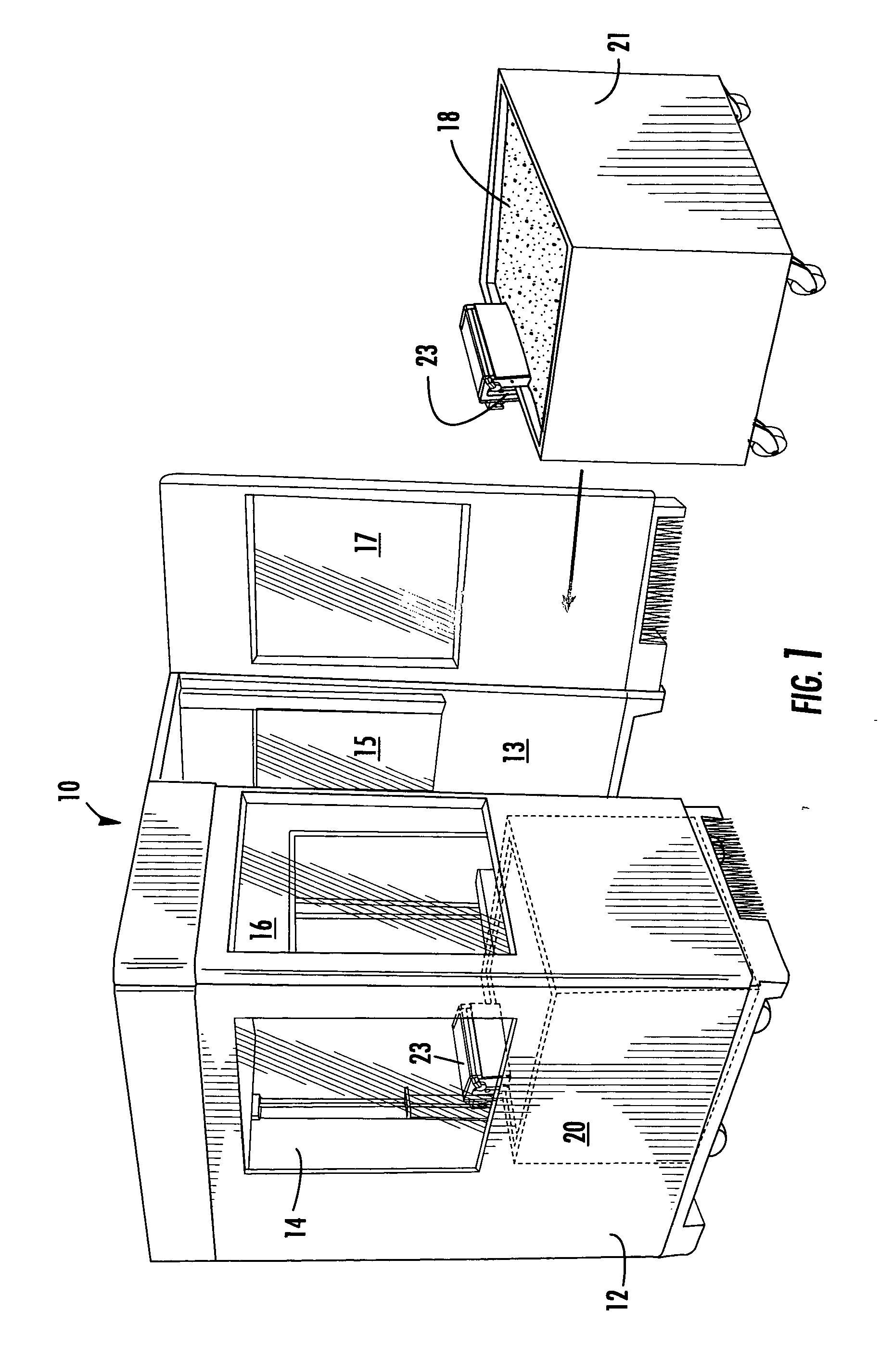

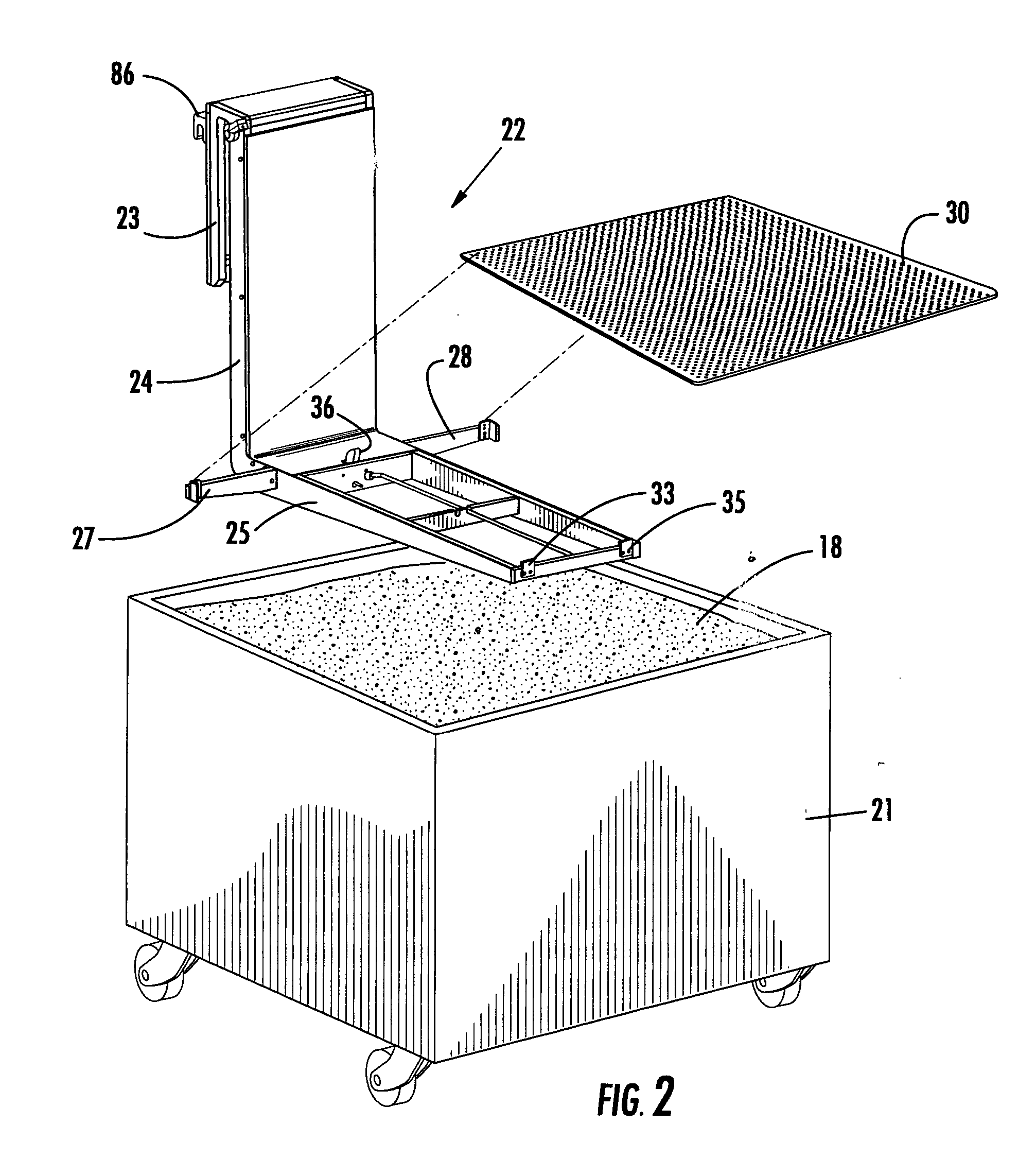

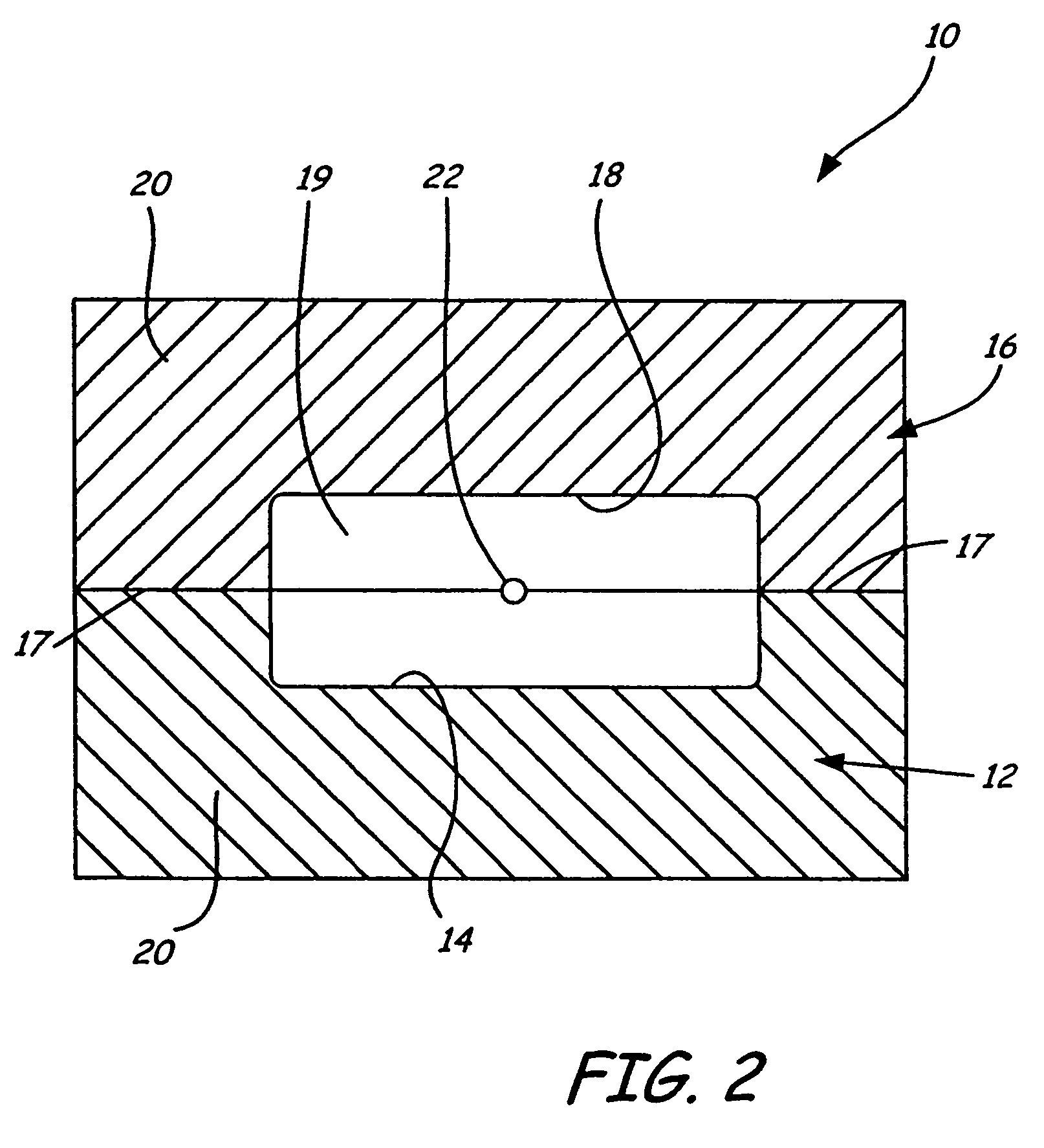

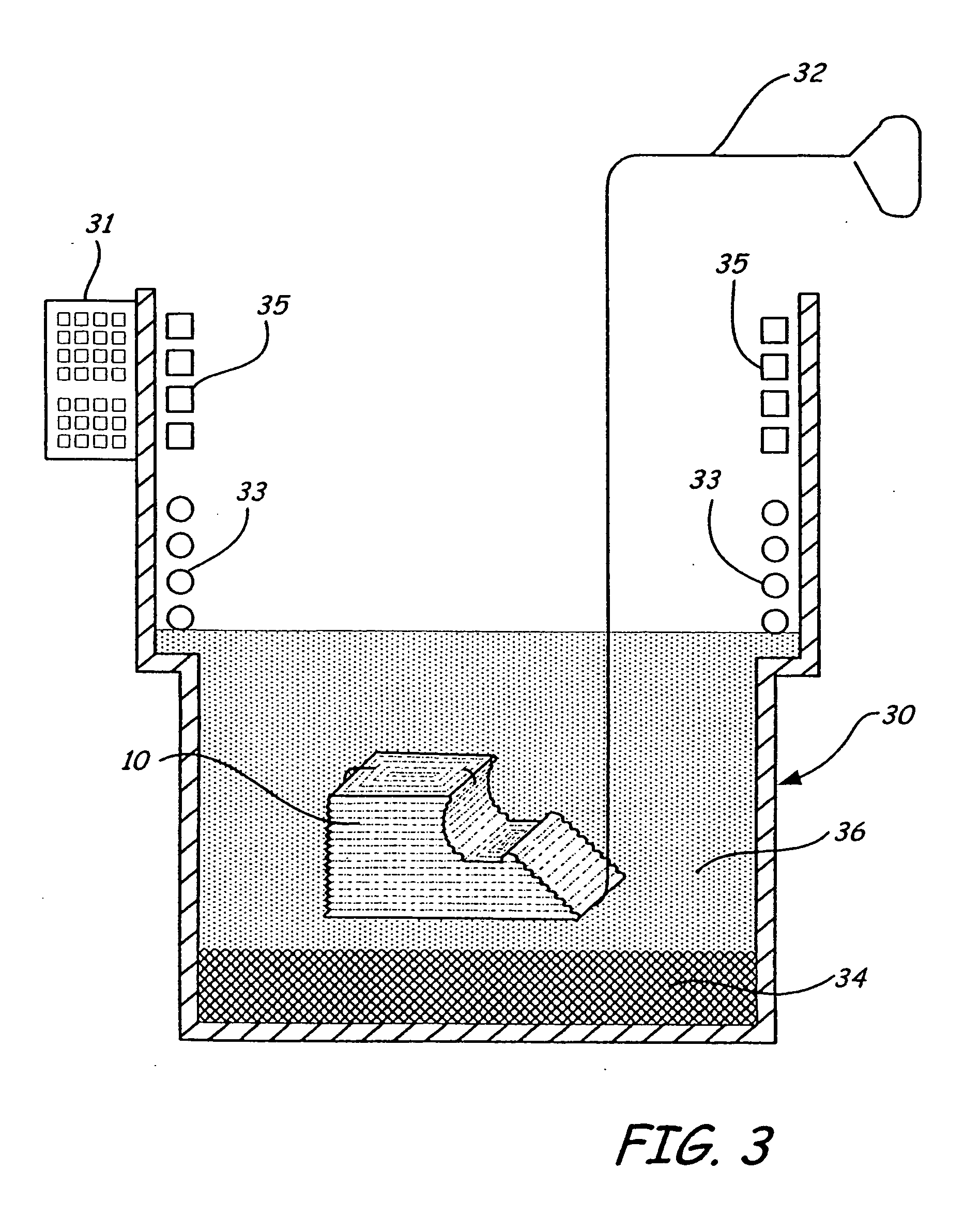

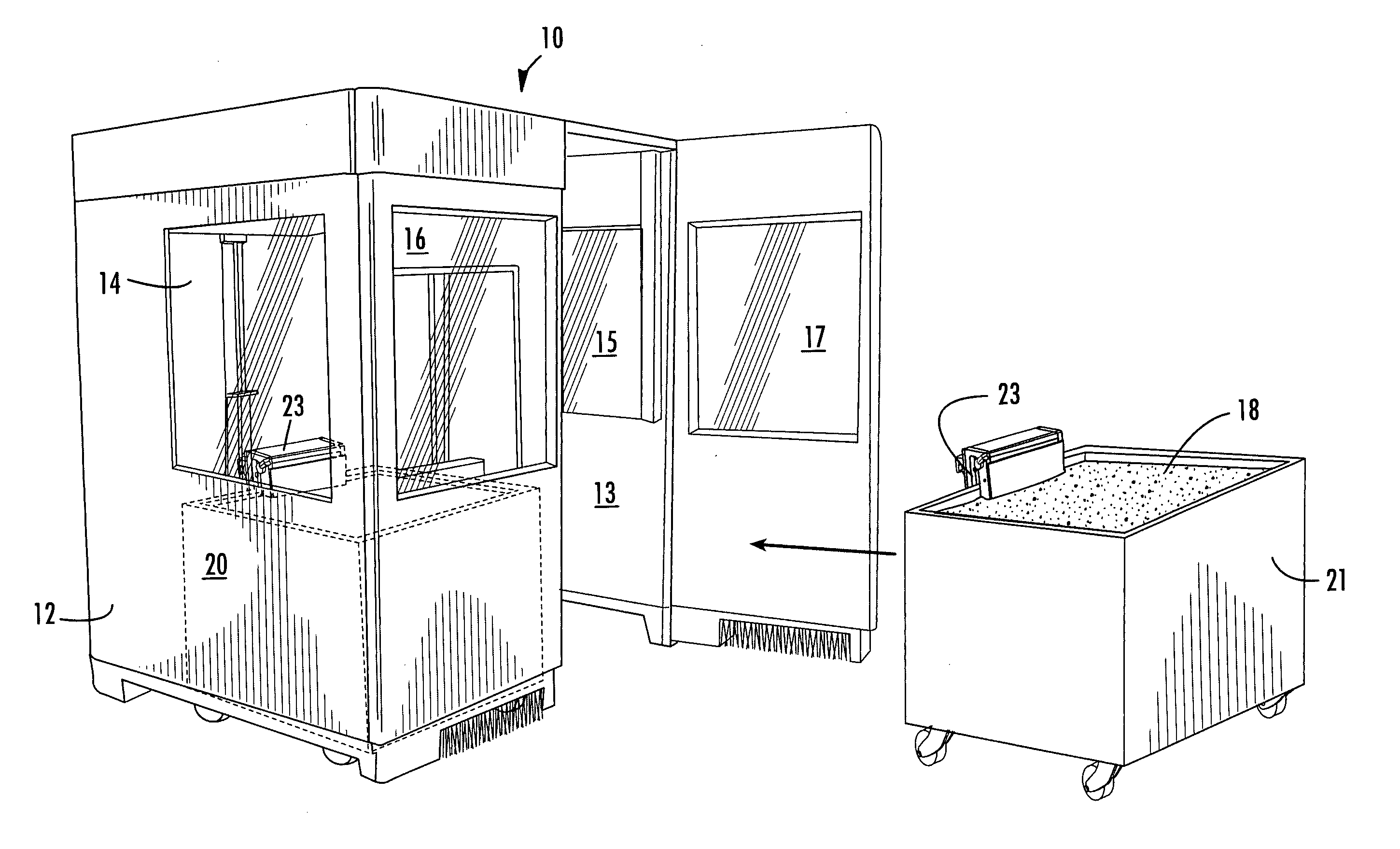

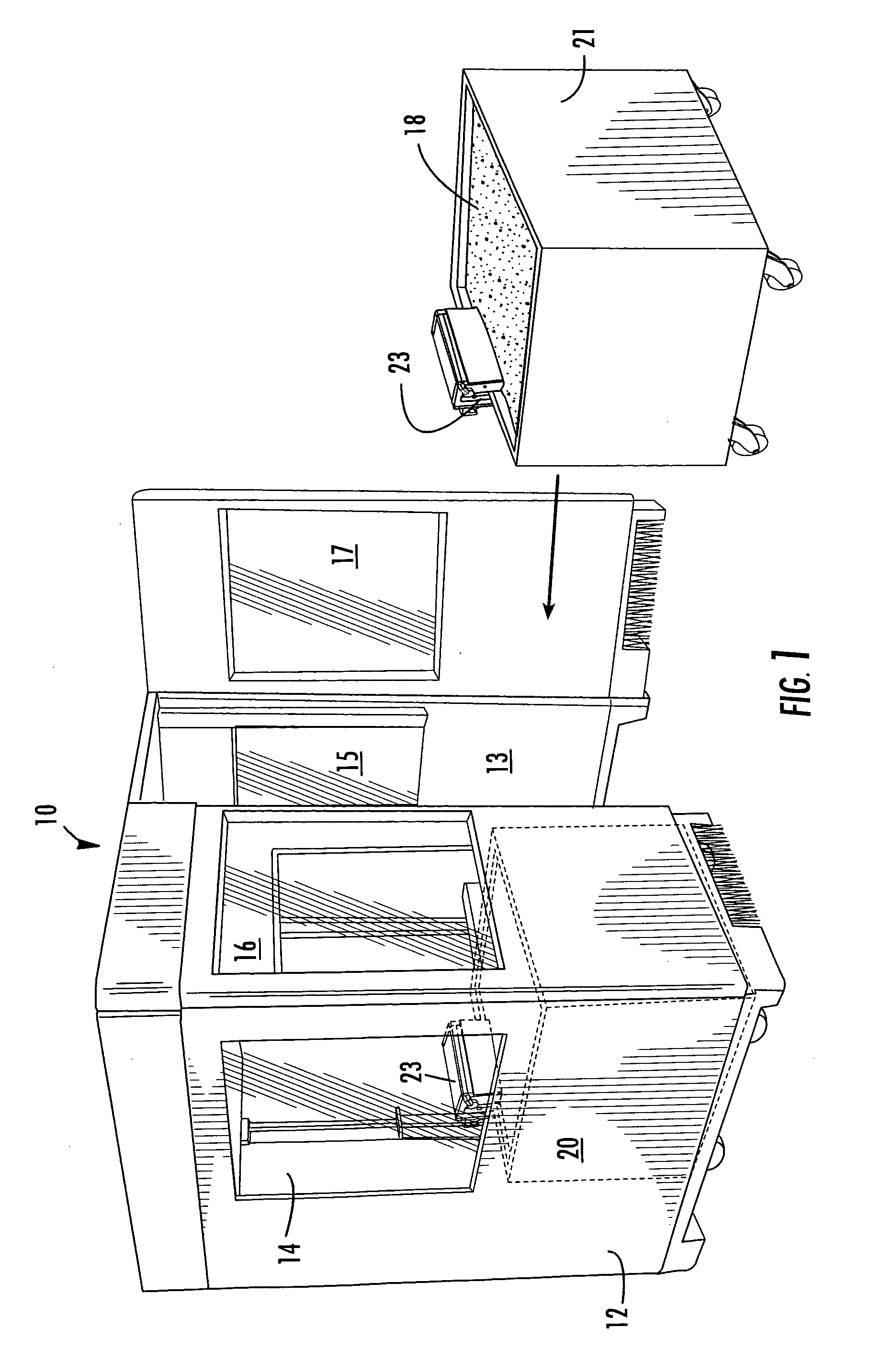

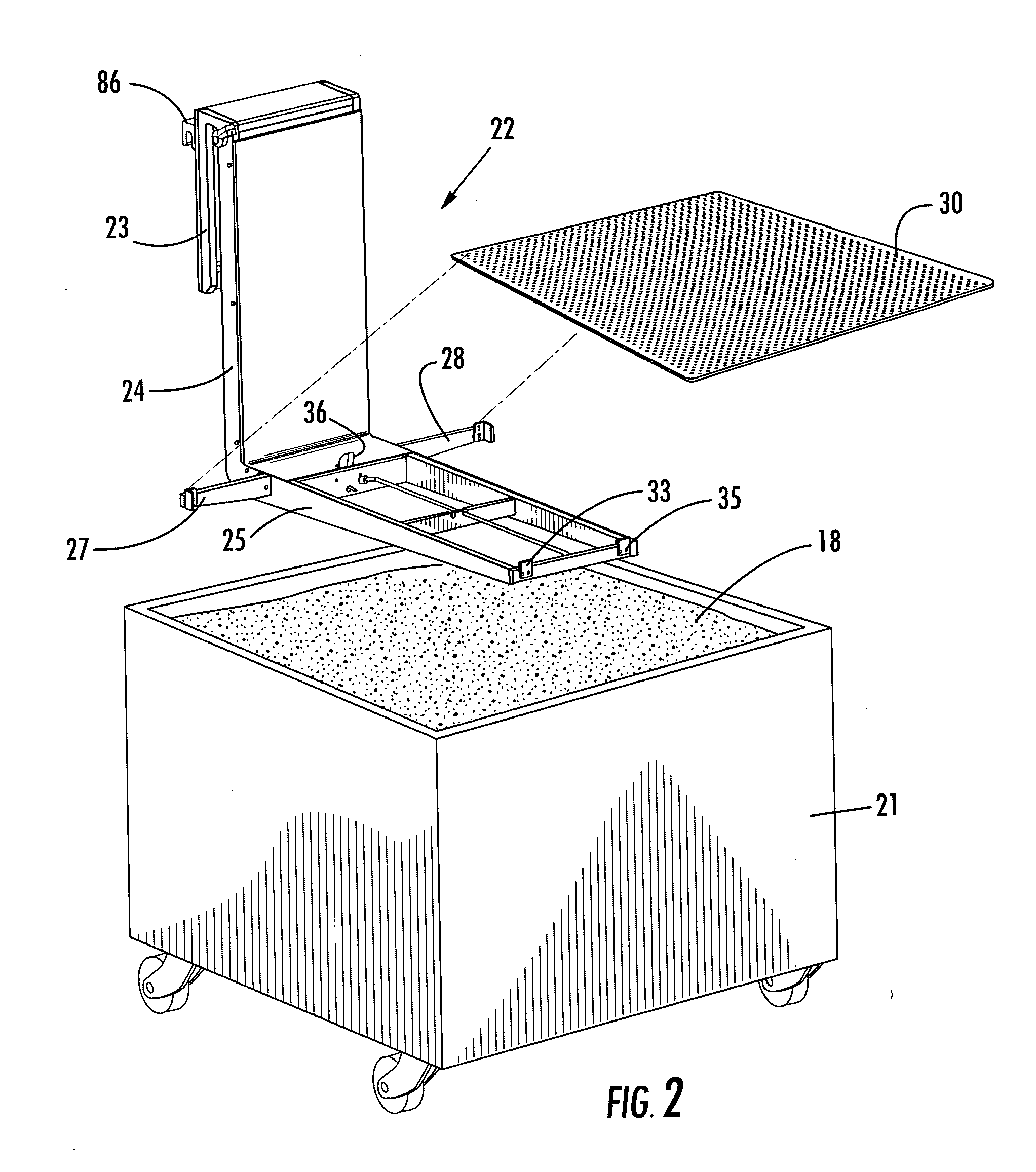

Rapid prototyping and manufacturing system and method

ActiveUS20070074659A1Simplify obtaining precisionFast preparationConfectioneryPretreated surfacesEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

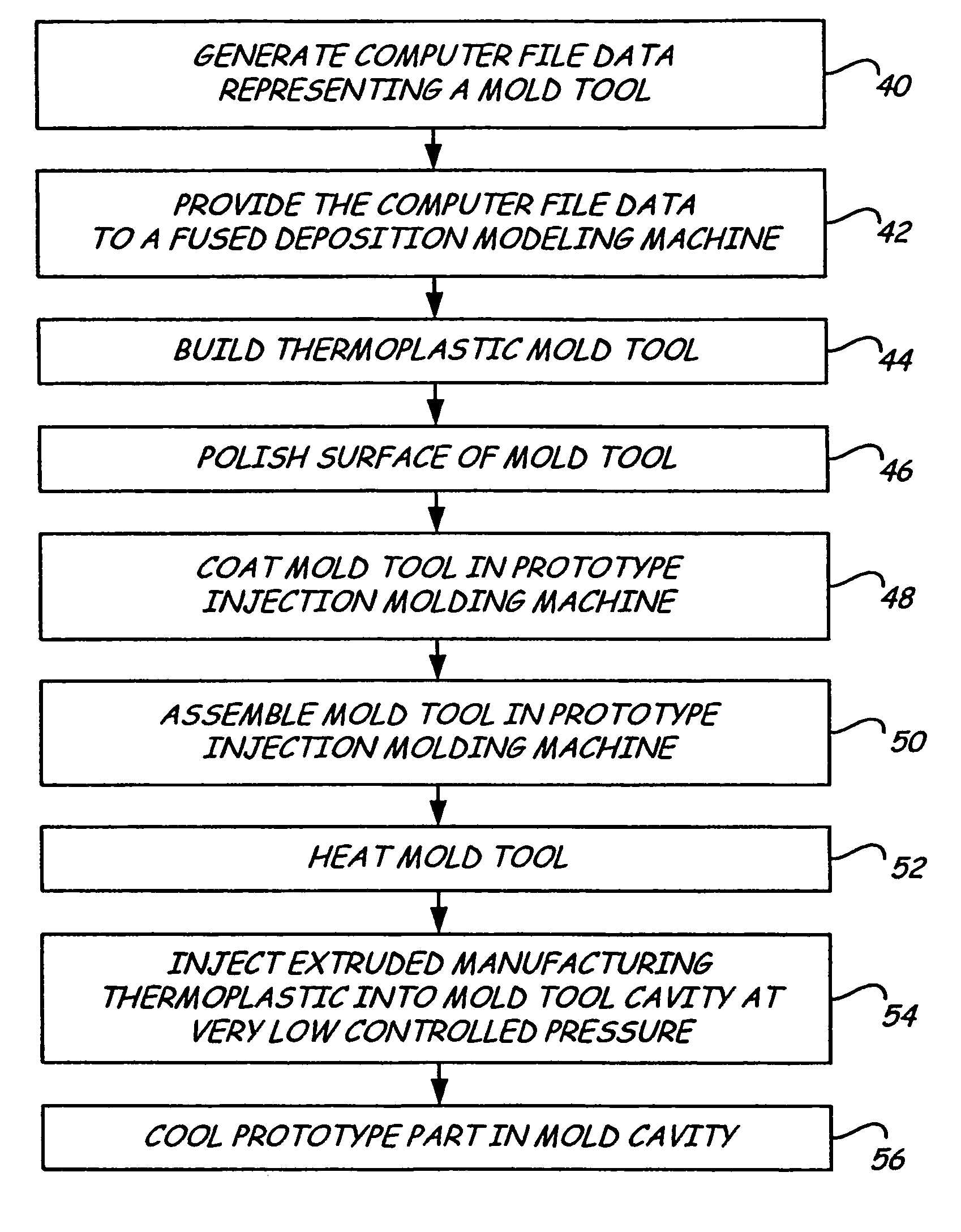

Rapid prototype injection molding

InactiveUS7125512B2Additive manufacturing apparatusMechanical vibrations separationInjection mouldingRapid prototyping

Owner:STRATSYS INC

Smoothing method for layered deposition modeling

Disclosed is a method for smoothing the surface of an object built from a polymeric or wax material using a layered manufacturing rapid prototyping technique. After the object is built it is exposed to a vaporized solvent such as in a vaporizer for an exposure time sufficient to reflow the object surface. A solvent is chosen based on its ability to transiently soften the material which forms the object, and thereafter evaporate off the object. The object is removed from the solvent and allowed to dry, producing a smooth finished part.

Owner:DYEMANSION

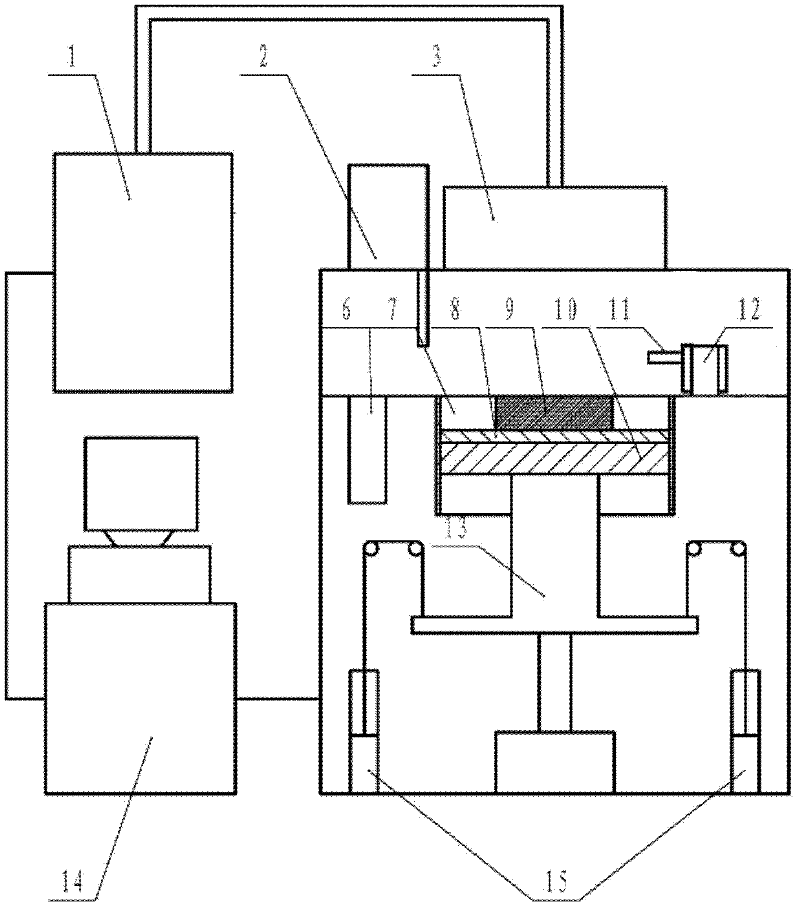

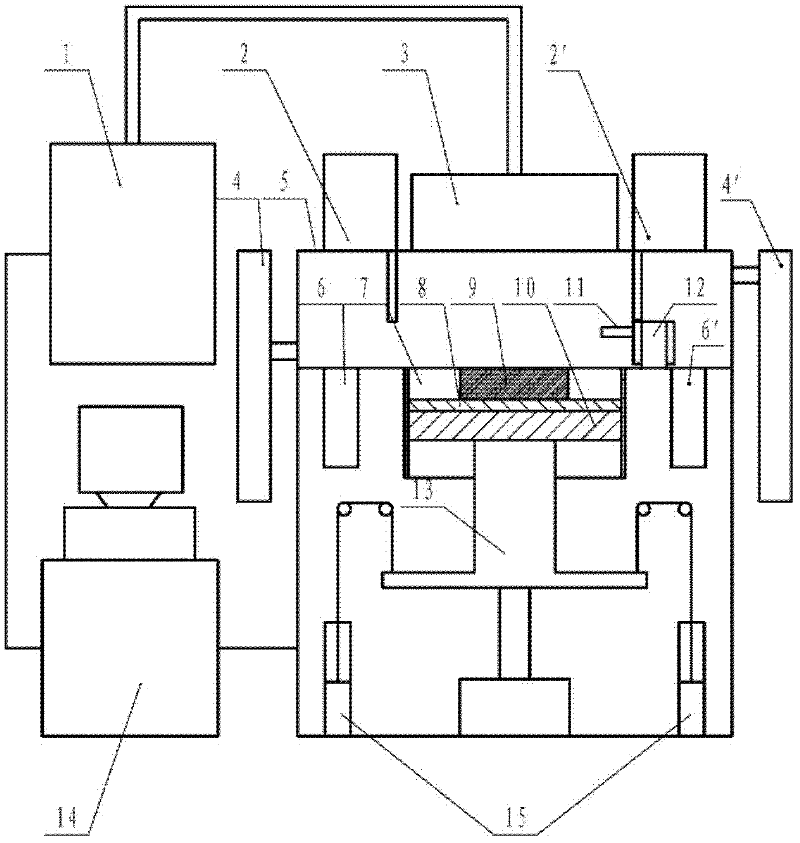

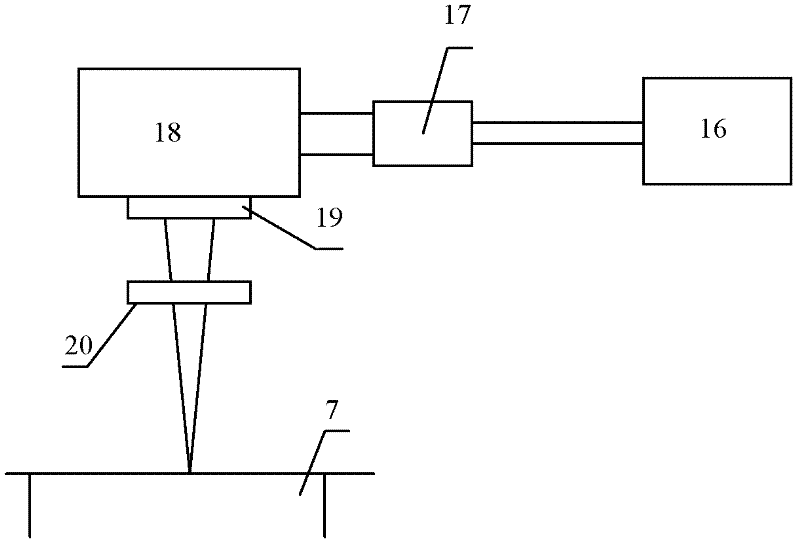

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

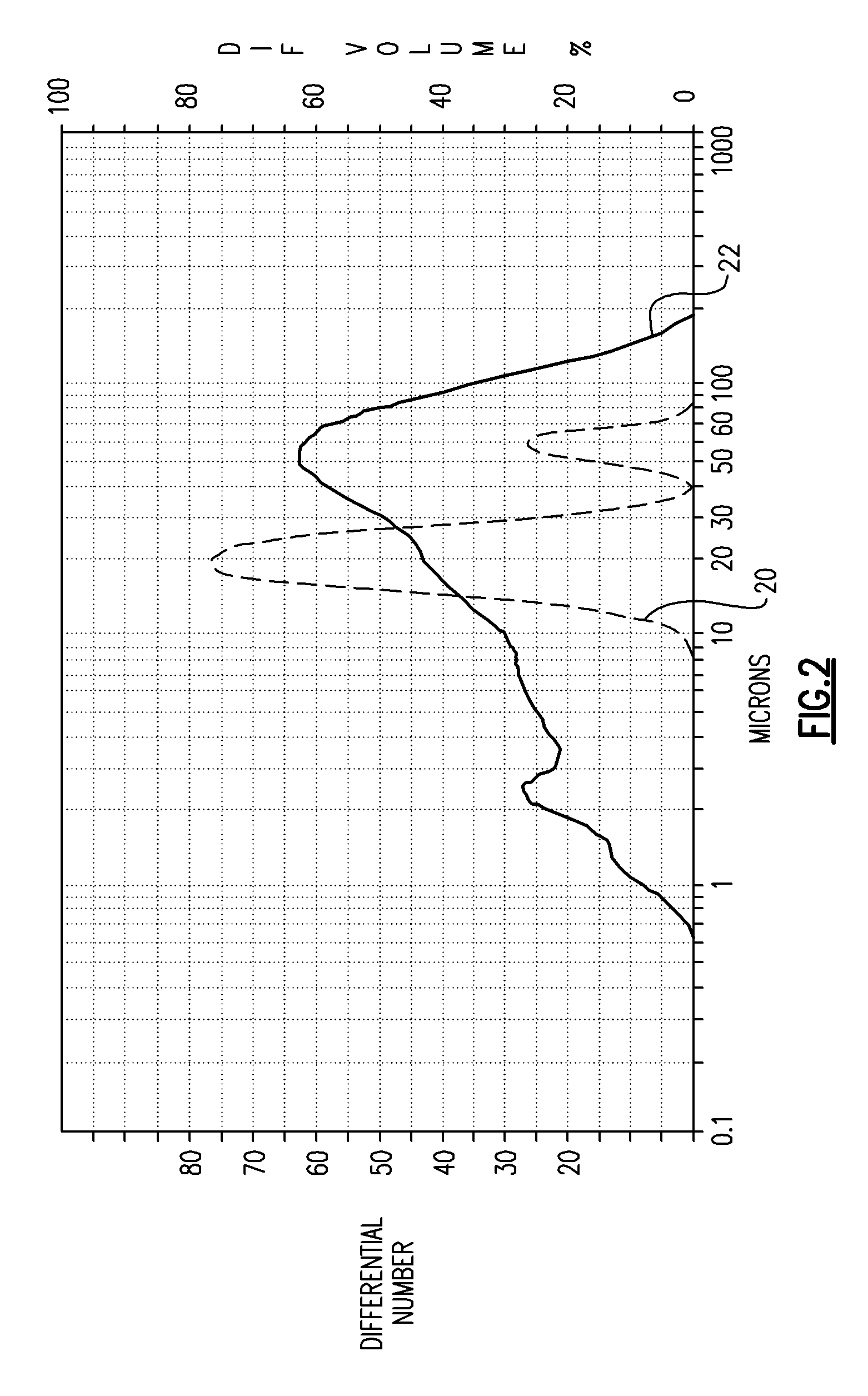

Surface modified particulate and sintered or injection molded products

ActiveUS20150080495A1Simple technologyWeaken energyConductive materialCeramic shaping apparatusParticulatesPolymer science

Disclosed are interfacially modified particulate and polymer composite material for use in injection molding processes, such as metal injection molding and additive process such as 3D printing. The composite material is uniquely adapted for powder metallurgy processes. Improved products are provided under process conditions through surface modified powders that are produced by extrusion, injection molding, additive processes such as 3D printing, Press and Sinter, or rapid prototyping.

Owner:TUNDRA COMPOSITES LLC

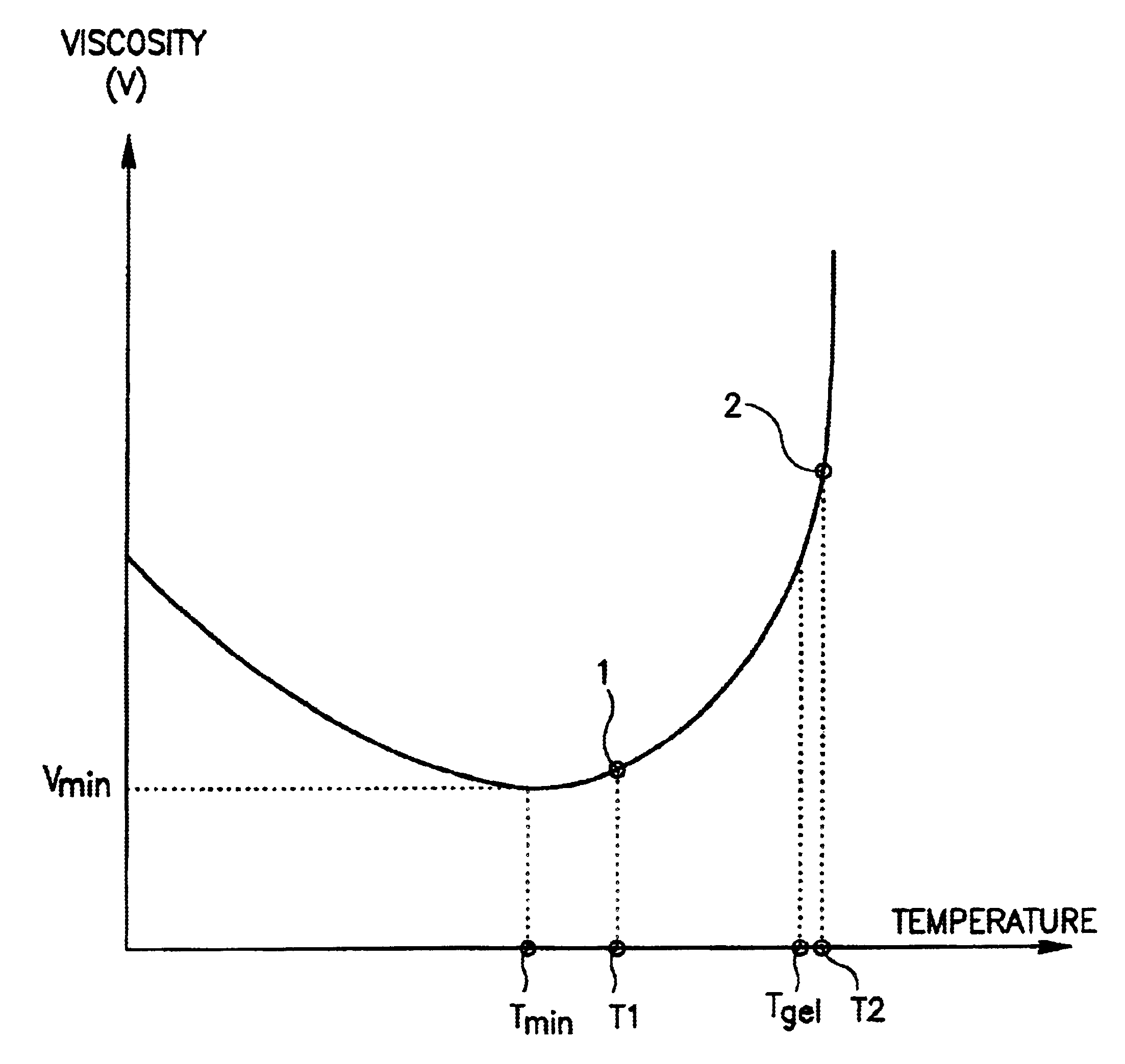

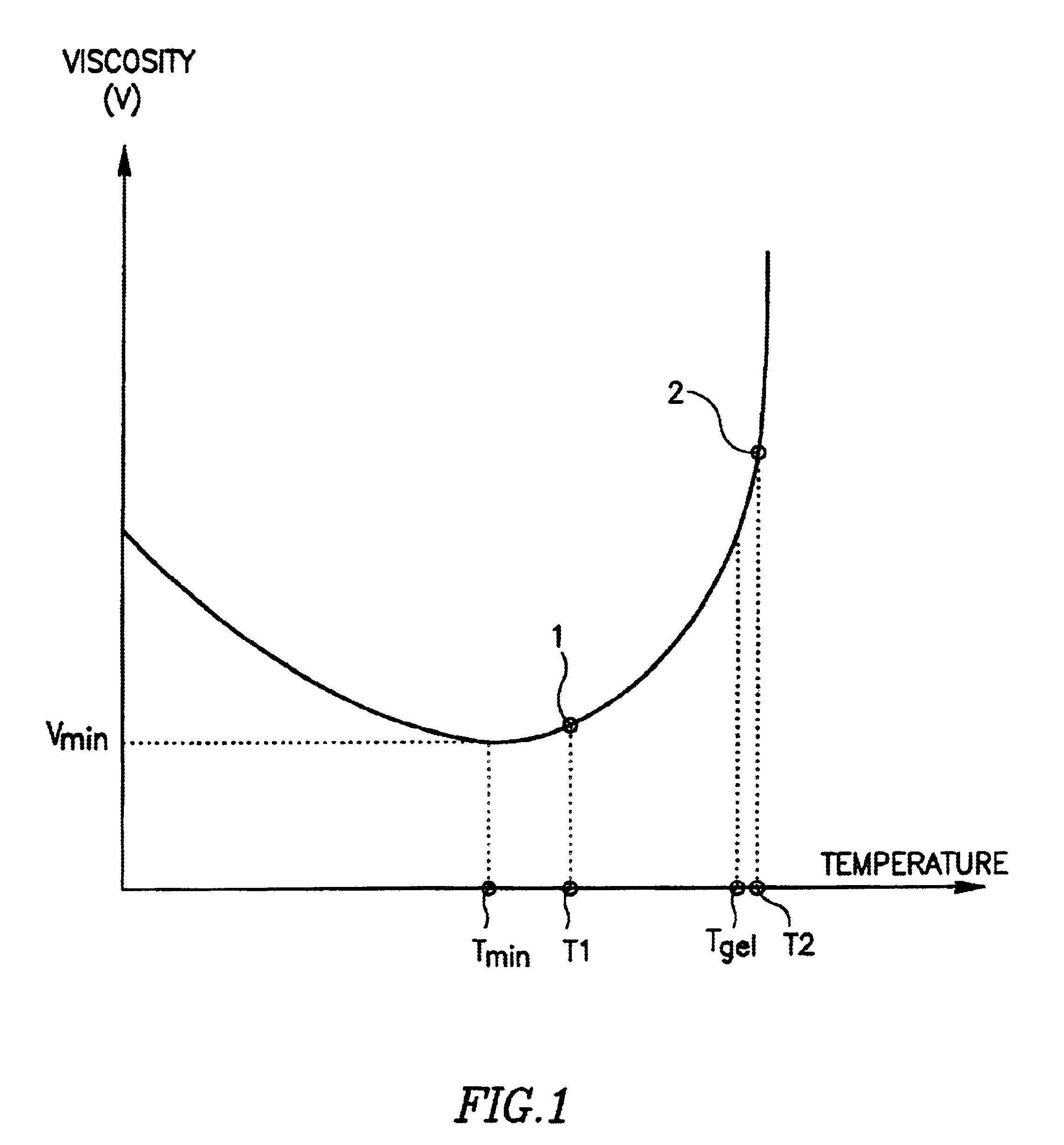

Reverse thermal gels and the use thereof for rapid prototyping

InactiveUS6863859B2Reduce surface tensionHigh strengthAdditive manufacturing apparatusPhotosensitive materialsLower critical solution temperatureWater soluble

The present invention relates to novel polymeric compositions that exhibit Reverse Thermal Gelation (RTG) properties for use as Support Materials (SM) in the manufacture of three-dimensional objects. These polymers are Temperature Sensitive Polymers that respond with a significant change of properties to a small change in temperature. Temperature Sensitive Polymers exhibit cloud point (CP) or lower critical solution temperature (LCST) in aqueous solutions. Water-soluble Temperature Sensitive Polymers are chosen to give low viscosity liquid at low temperature when dissolved in water and by that to permit easy dispensing at low temperature. Raising the temperature above their gelation temperature (Tgel) will result in solidification of the composition. At its gel position the material has favorable characteristics as a support and building material. The gel layers have the appropriate toughness and dimensional stability to support the model layers during the building process. After the building process is completed the gel can be cooled down to a temperature below its Tgel so the gel can liquefy and be removed easily by rinsing with water.

Owner:STRATASYS LTD

Dental restorations using nanocrystalline materials and methods of manufacture

Dental articles are produced using relatively low sintering temperatures to achieve high density dental articles exhibiting strengths equal to and greater than about 700 MPa. Ceramic powders comprised of nanoparticulate crystallites are used to manufacture dental articles. The ceramic powders may include sintering agents, binders and other similar additives to aid in the processing of the ceramic powder into a dental article. The ceramic powders may be processed into dental articles using various methods including, but not limited to, injection molding, gel-casting, slip casting, or electroforming, hand, cad / camming and other various rapid prototyping methods. The ceramic powder may be formed into a suspension, pellet, feedstock material or a pre-sintered blank prior to forming into the dental article.

Owner:IVOCLAR VIVADENT AG

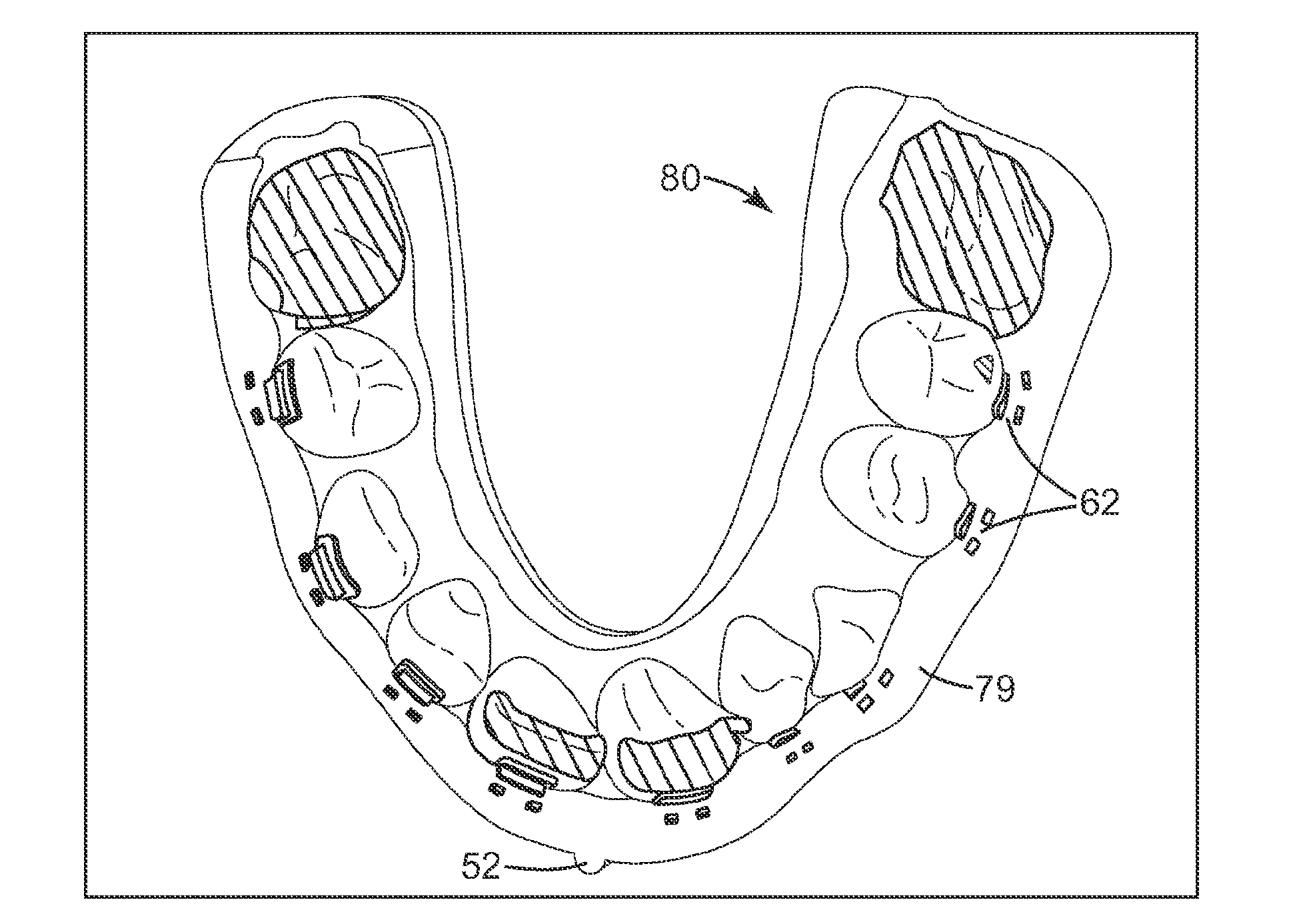

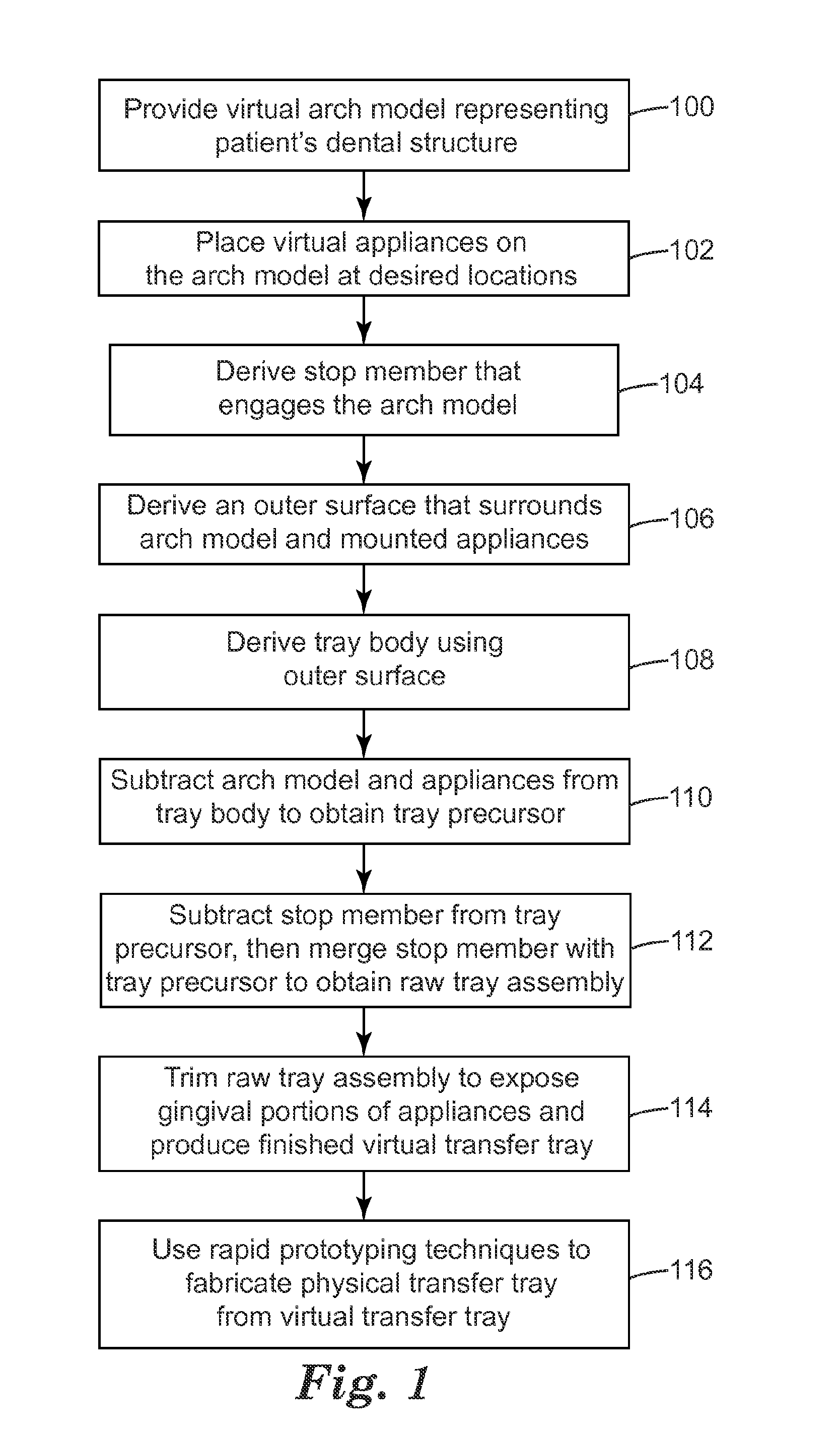

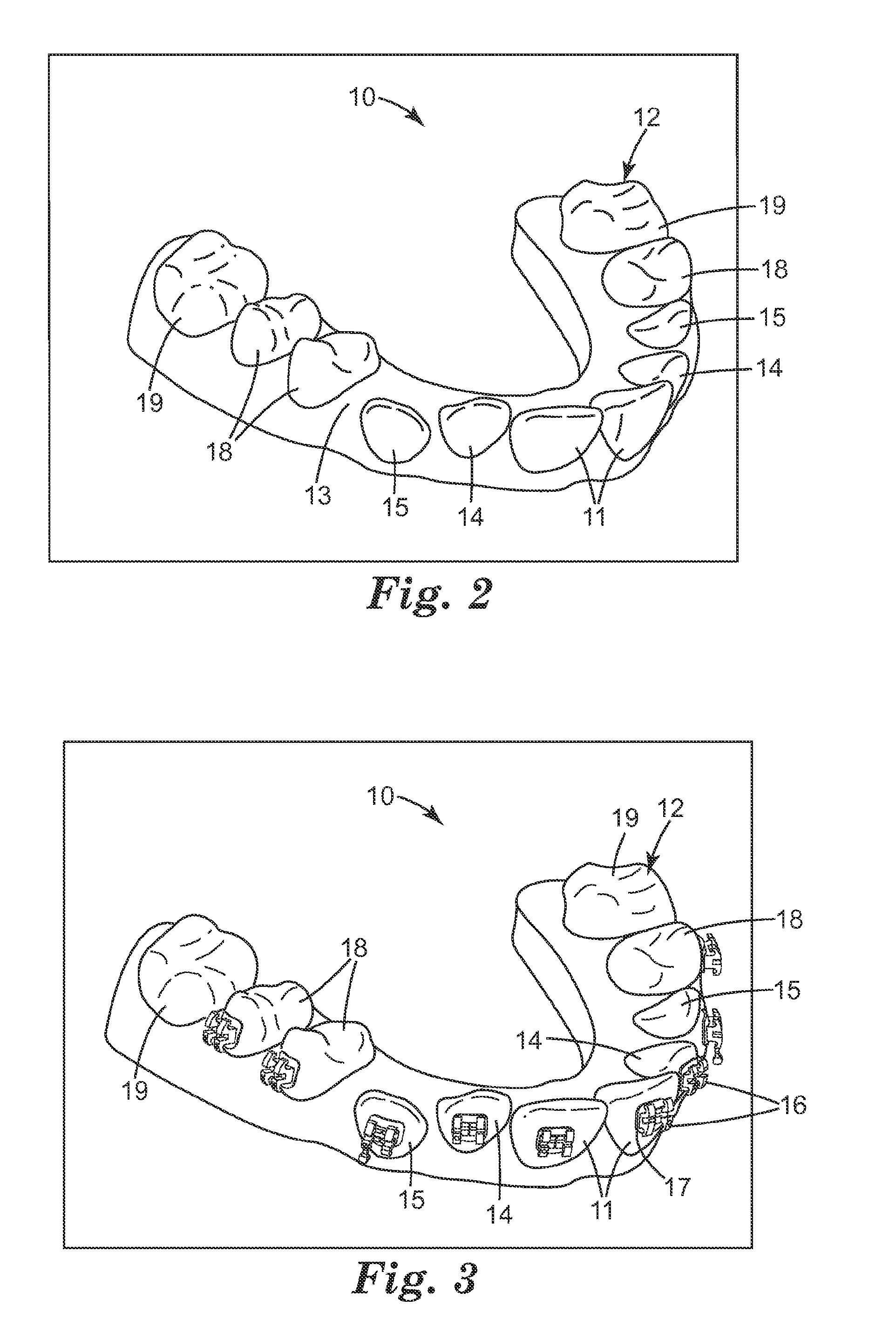

Rapid prototyped transfer tray for orthodontic appliances

InactiveUS20110091832A1Shorten driving distanceMinimizing adhesive smearingProgramme controlBracketsEngineeringRapid prototyping

The present invention is directed to computer-implemented methods of making a transfer tray using rapid prototyping techniques, where the gingival edge of the tray is defined to intersect with at least one receptacle for receiving an orthodontic appliance. This tray configuration helps to minimize the travel distance of the tray when placing the tray over a patient's teeth, while also preserving a high degree of mechanical retention for retaining the appliance until such time that the appliance is bonded to the tooth. Other aspects of the tray and associated methods of bonding are directed to a frangible web that extends over the gingival portion of the receptacle and fractures to facilitate tray removal after bonding.

Owner:3M INNOVATIVE PROPERTIES CO

Rapid prototyping and manufacturing system and method

InactiveUS20070077323A1Simplify obtaining precisionFast preparationAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

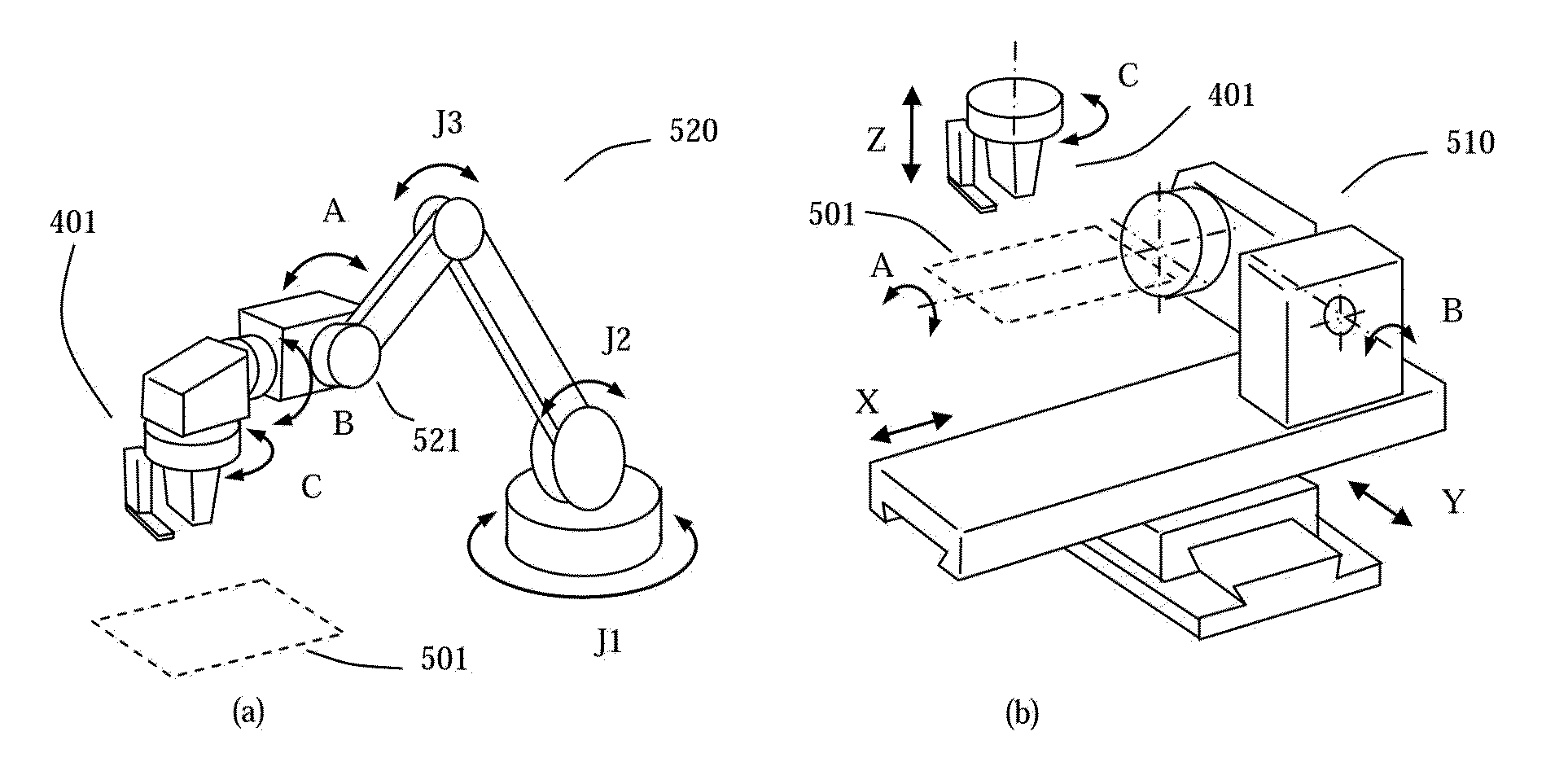

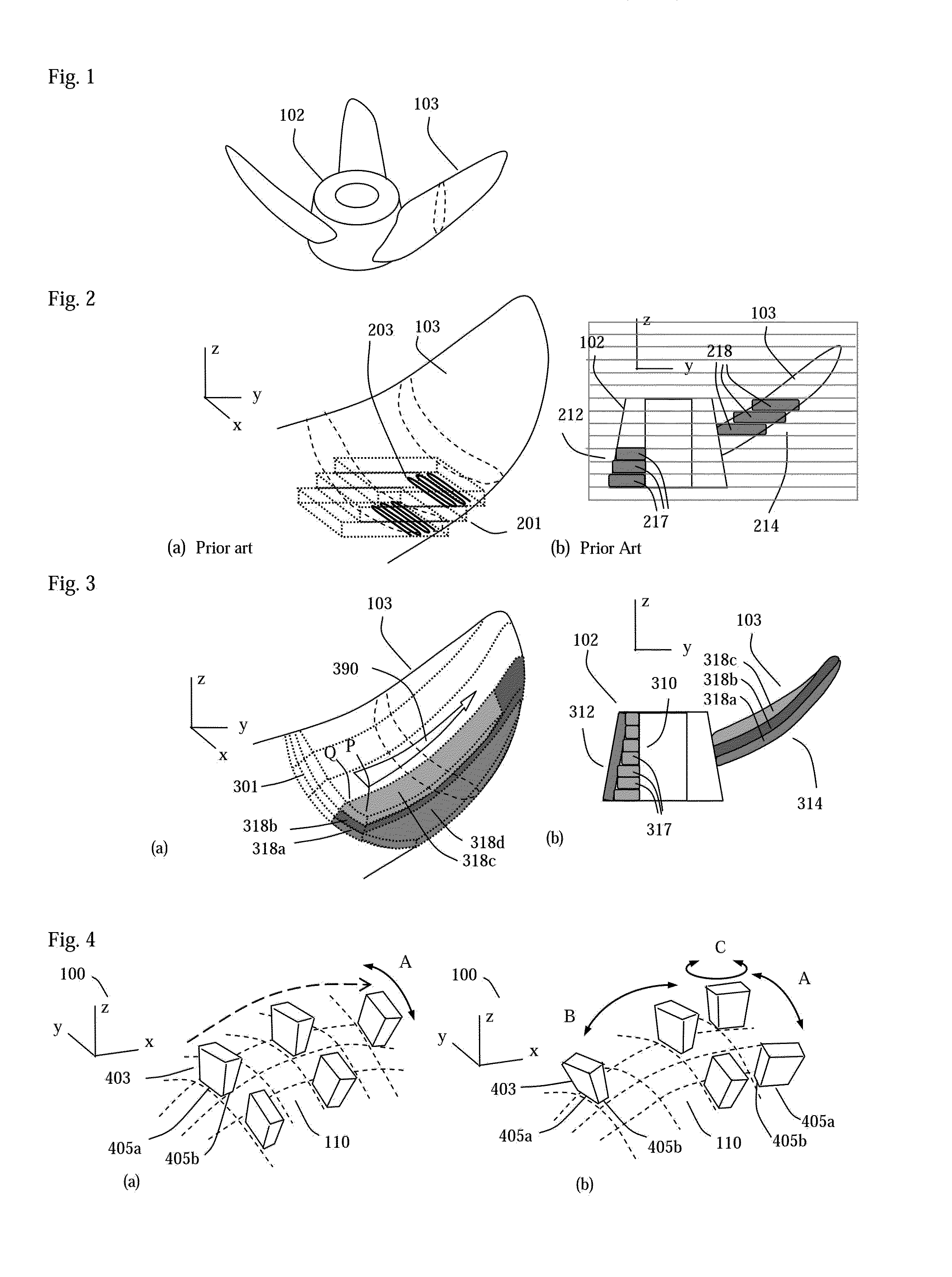

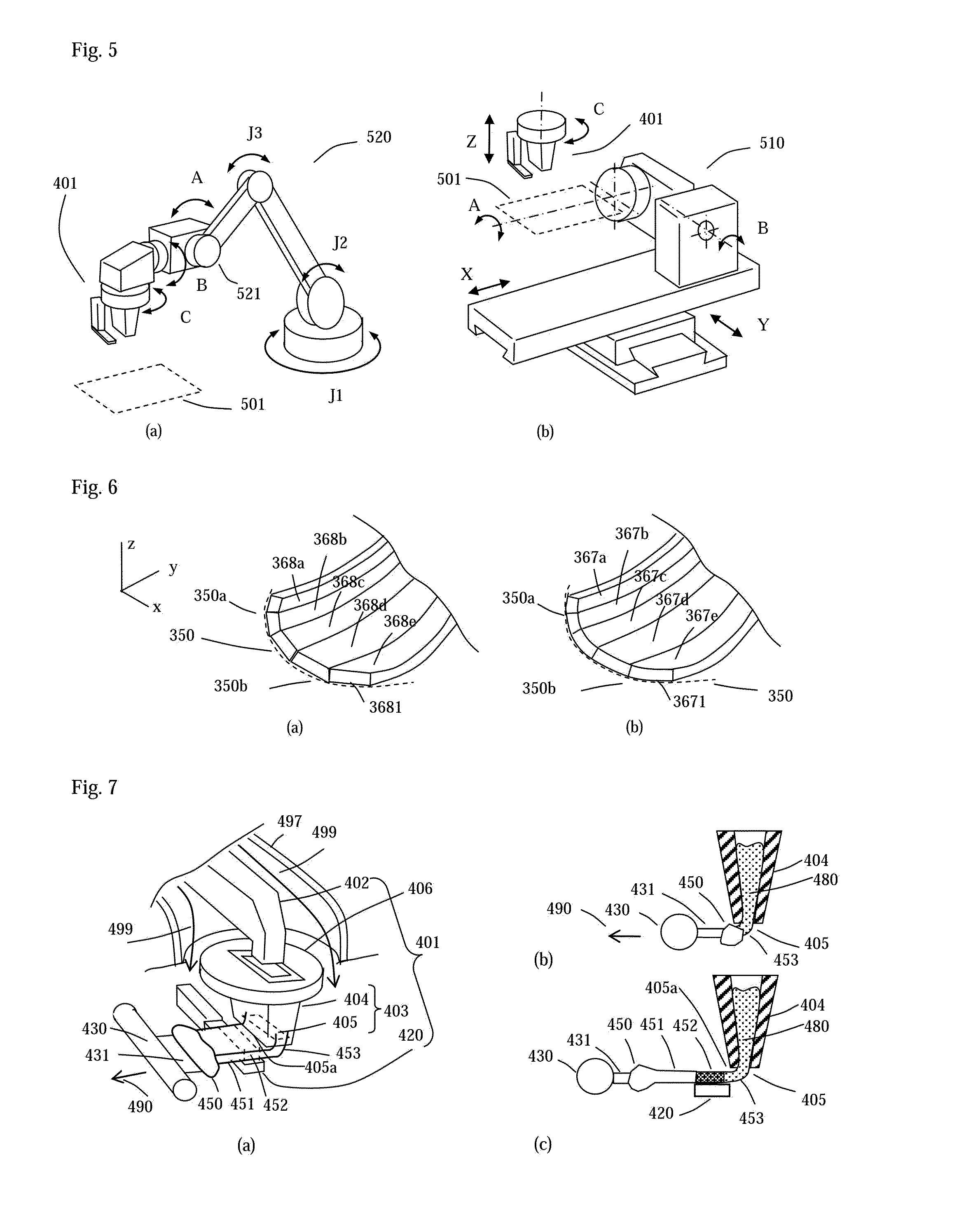

Flexible 3D Freeform Techniques

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

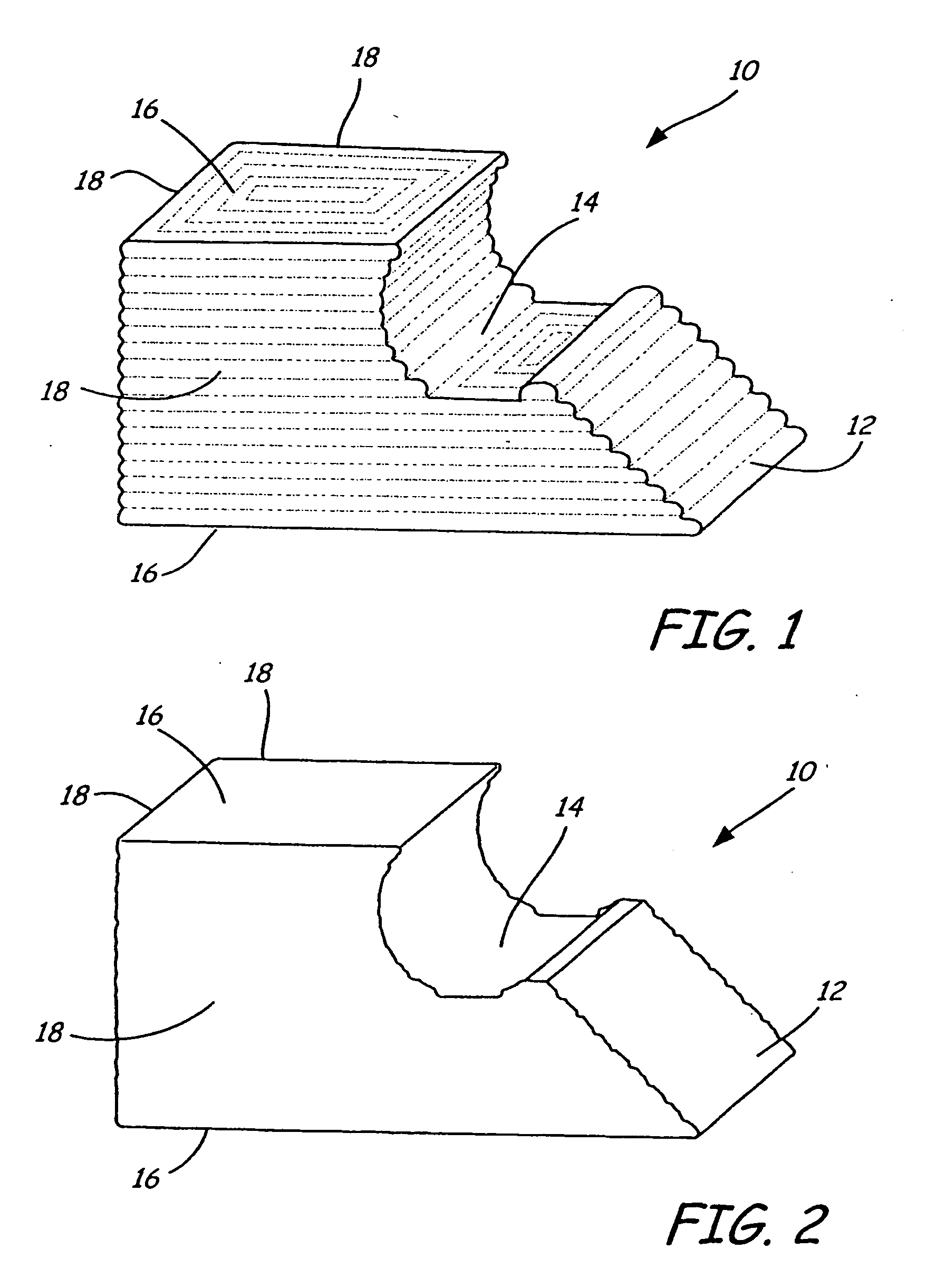

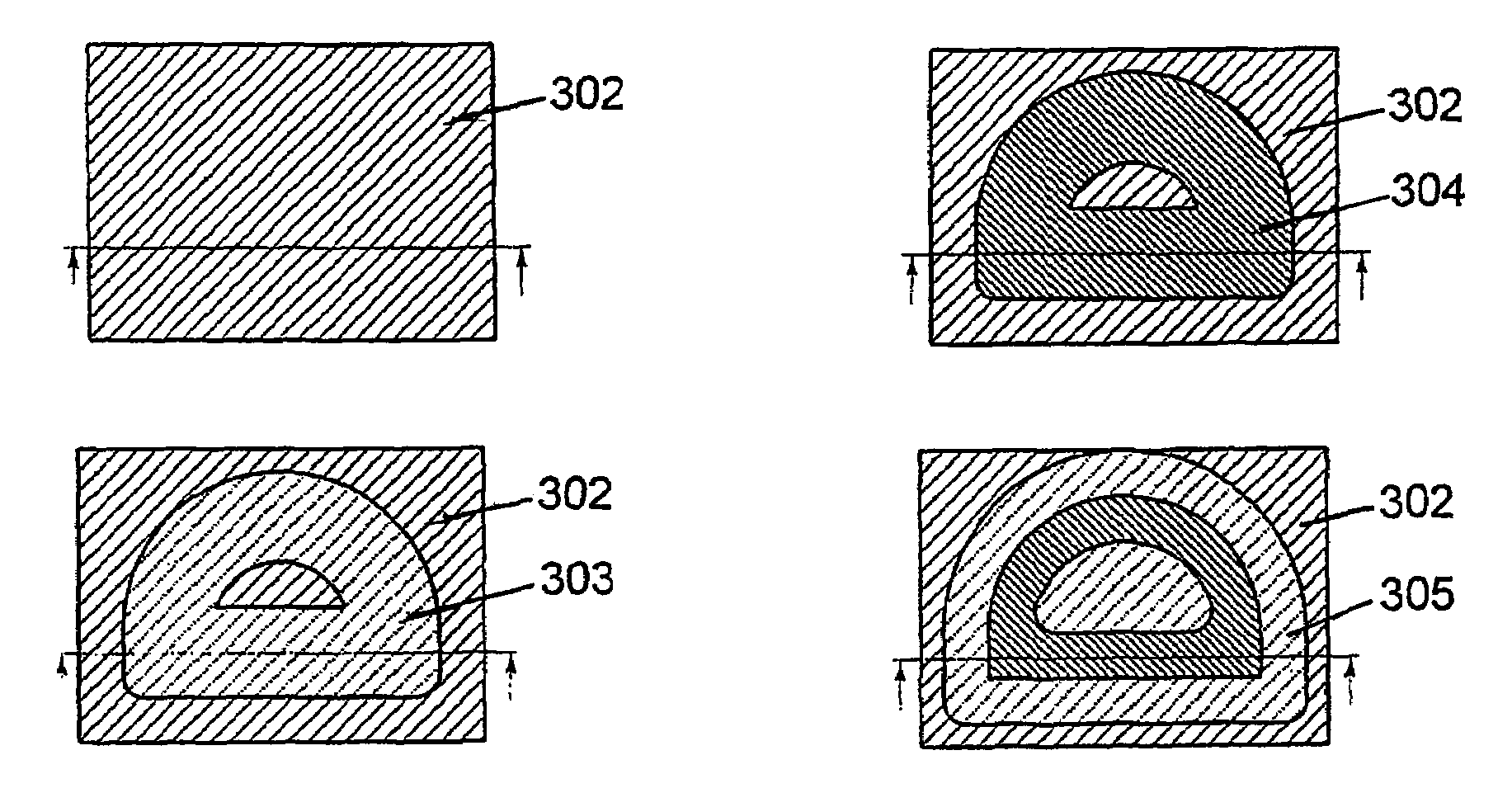

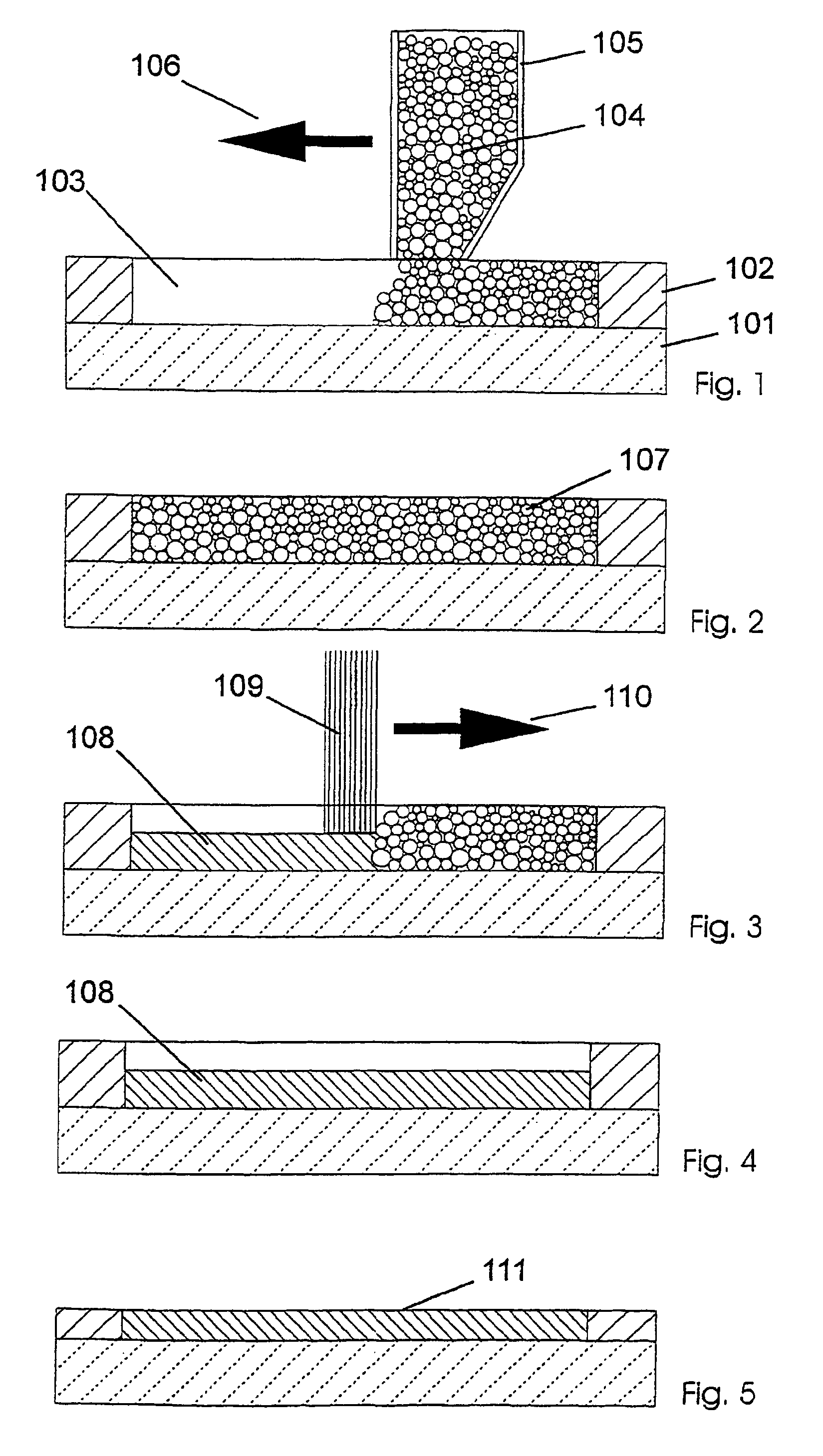

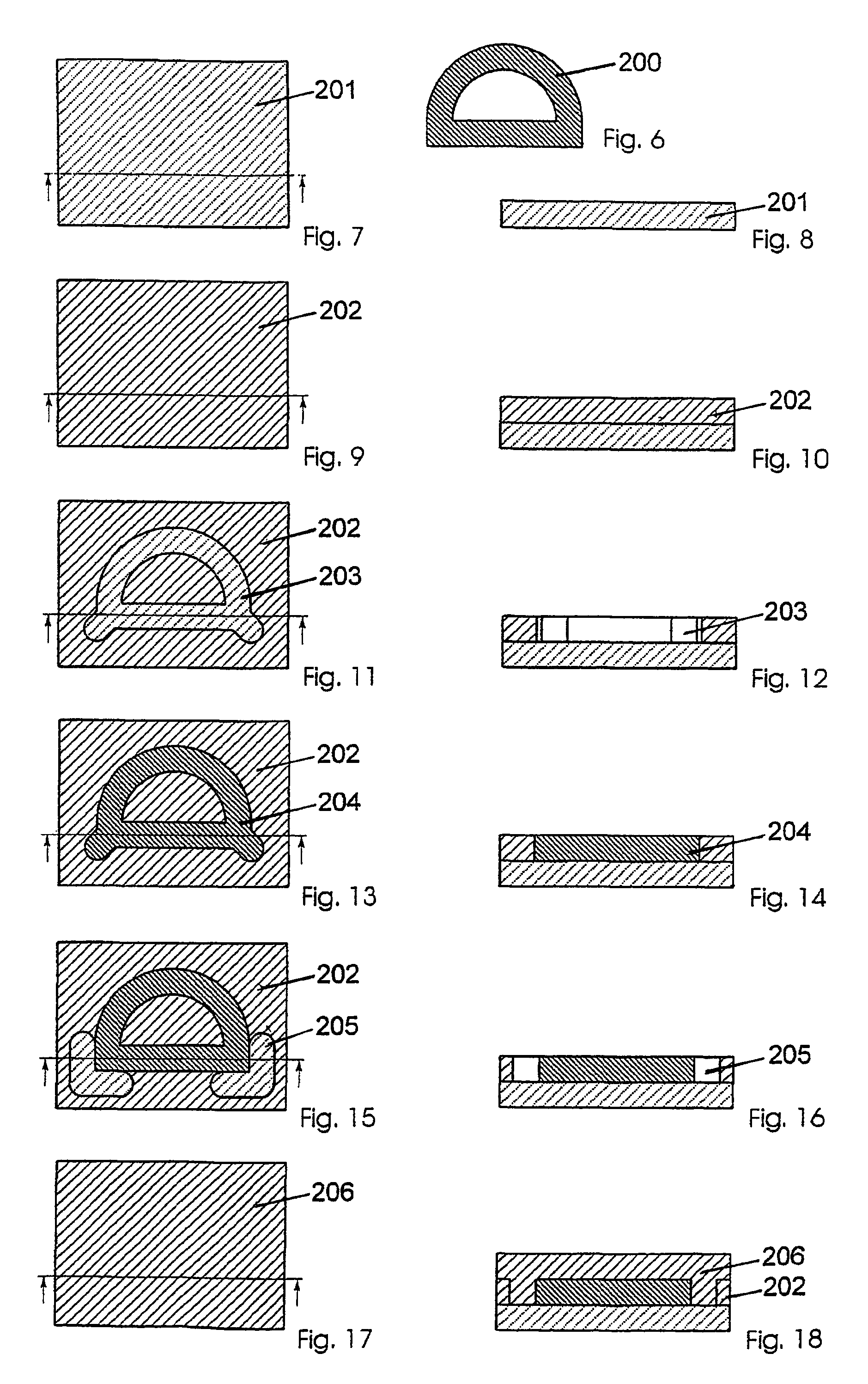

Method for producing a part and device for carrying out this method

InactiveUS7003864B2Faster machinabilityReduced tool wearMouldsWood working apparatusEngineeringRapid prototyping

The present invention relates to a method for producing a part (108, 200, 300), comprising the following steps:a) applying a first flat layer consisting of a support material (102, 202, 302), to a construction platform (101, 201, 301),b) introducing at least one recess (103, 203, 303) into the support material (102, 202, 302),c) filling the recess (103, 203, 303) with a construction material (104, 204, 304),d) applying a further layer of support material (102, 202, 302),e) repeating steps b) through d) until completion of the part (108, 200, 300), andf) removing the support material (102, 202, 302).This method is to provide a manufacturing method and a device that combine the advantages of the layerwise construction (rapid prototyping) with the advantages of machining (e.g. high-speed cutting) and particularly permit the production of sharp-edged contours.Furthermore, the present invention relates to a device for carrying out the method.

Owner:HERMLE MASCHENBAU

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS7141207B2Additive manufacturing apparatusTransportation and packagingRapid prototypingZinc

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com