Patents

Literature

1497results about "Manufacturing driving means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

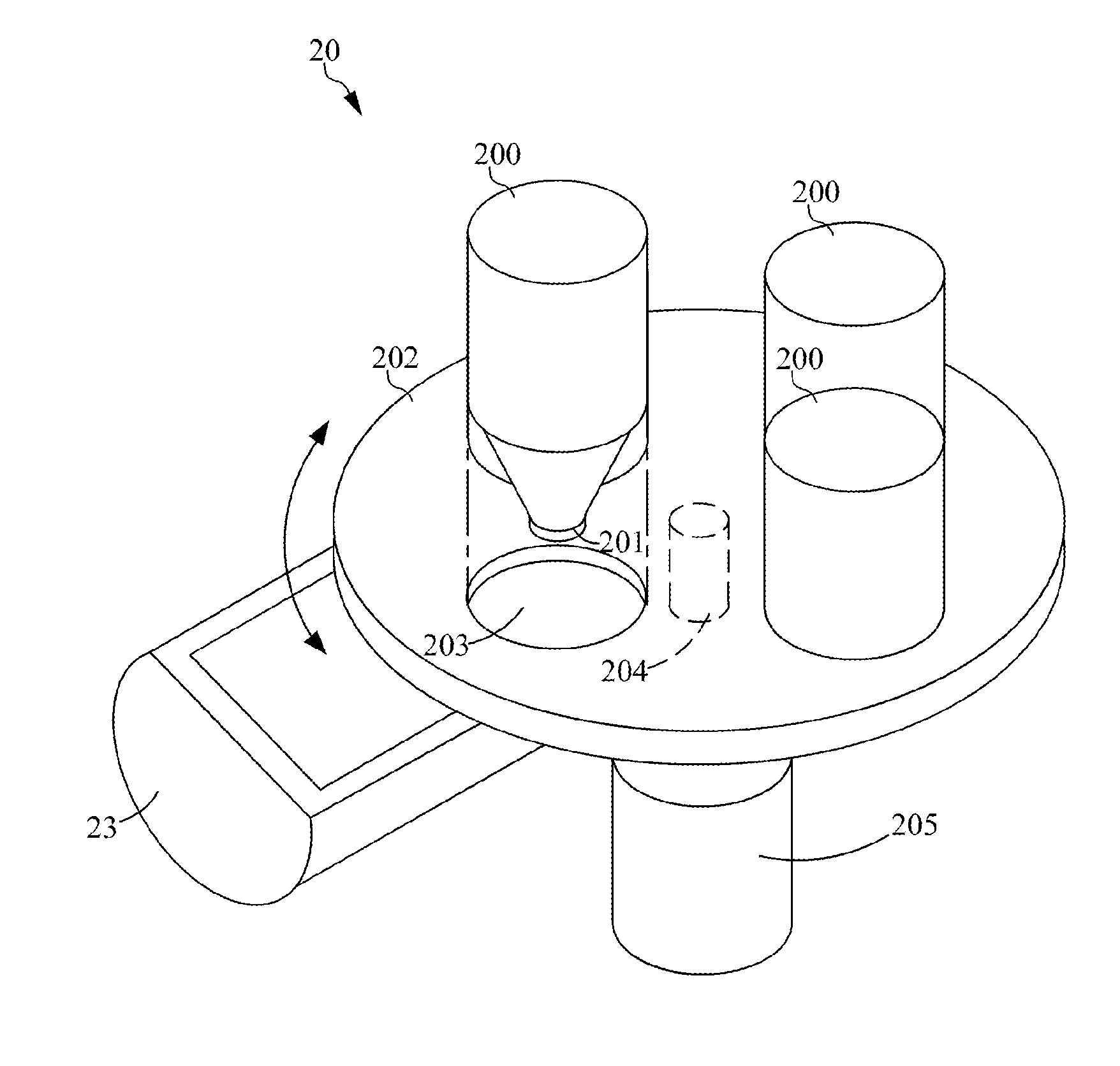

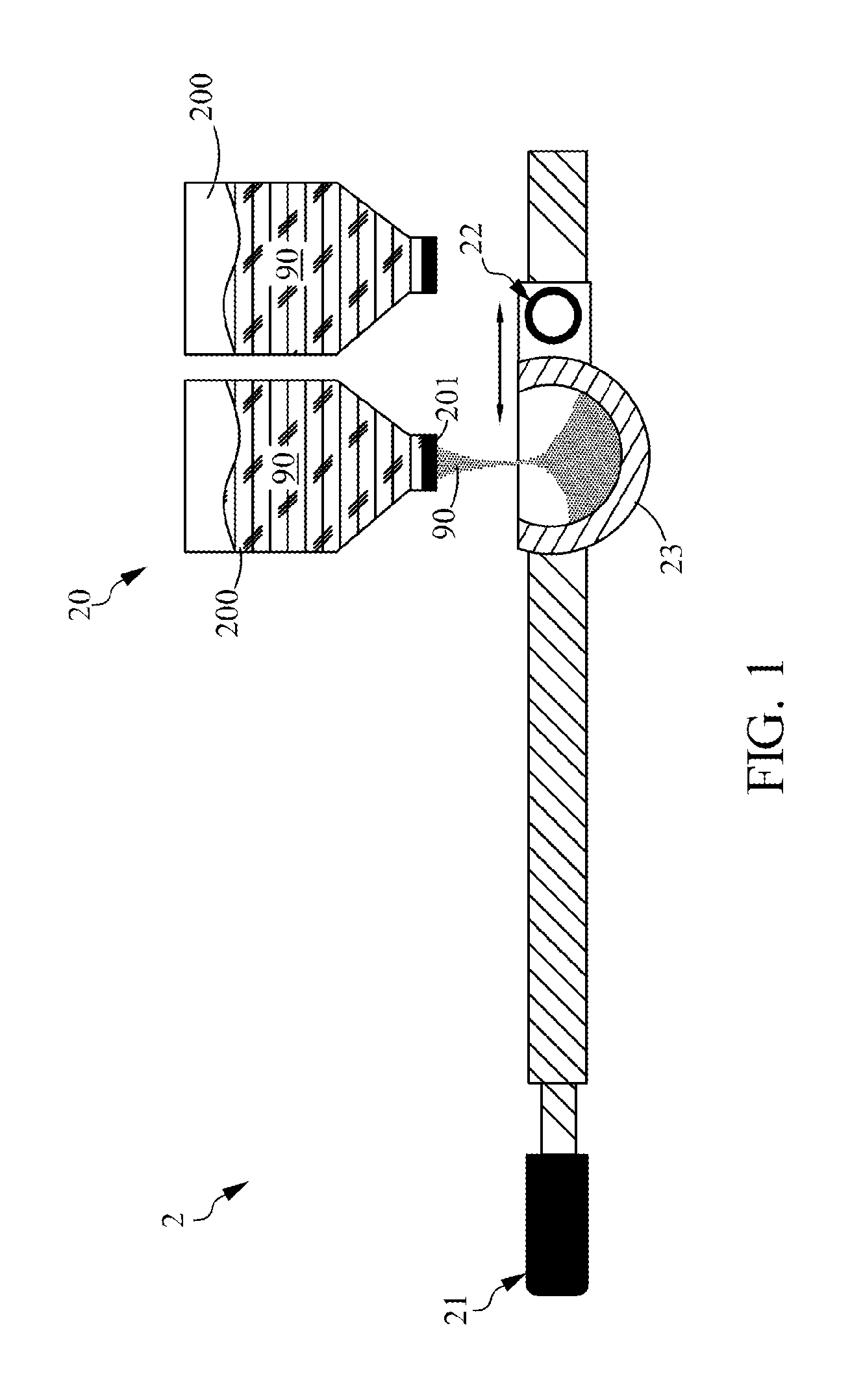

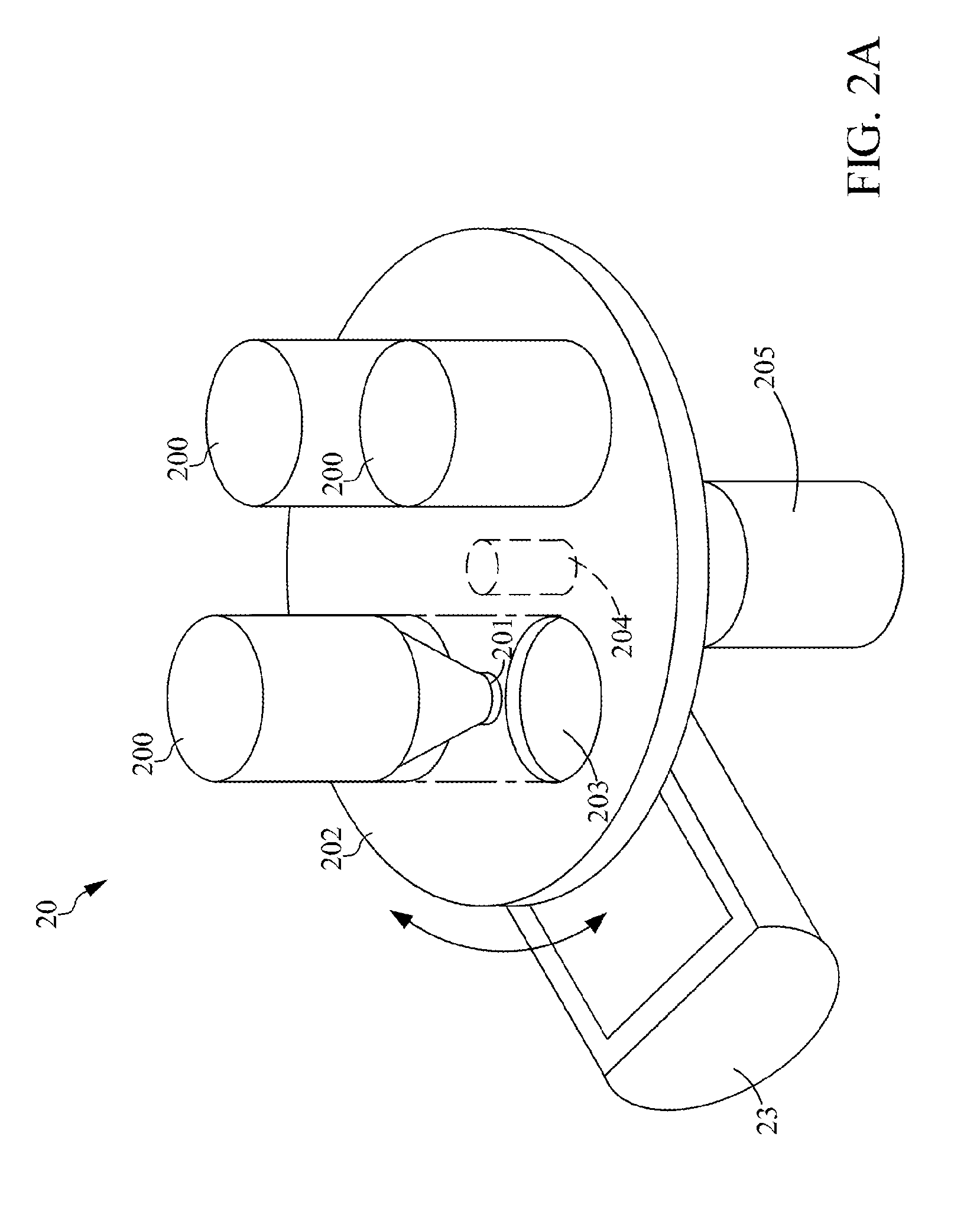

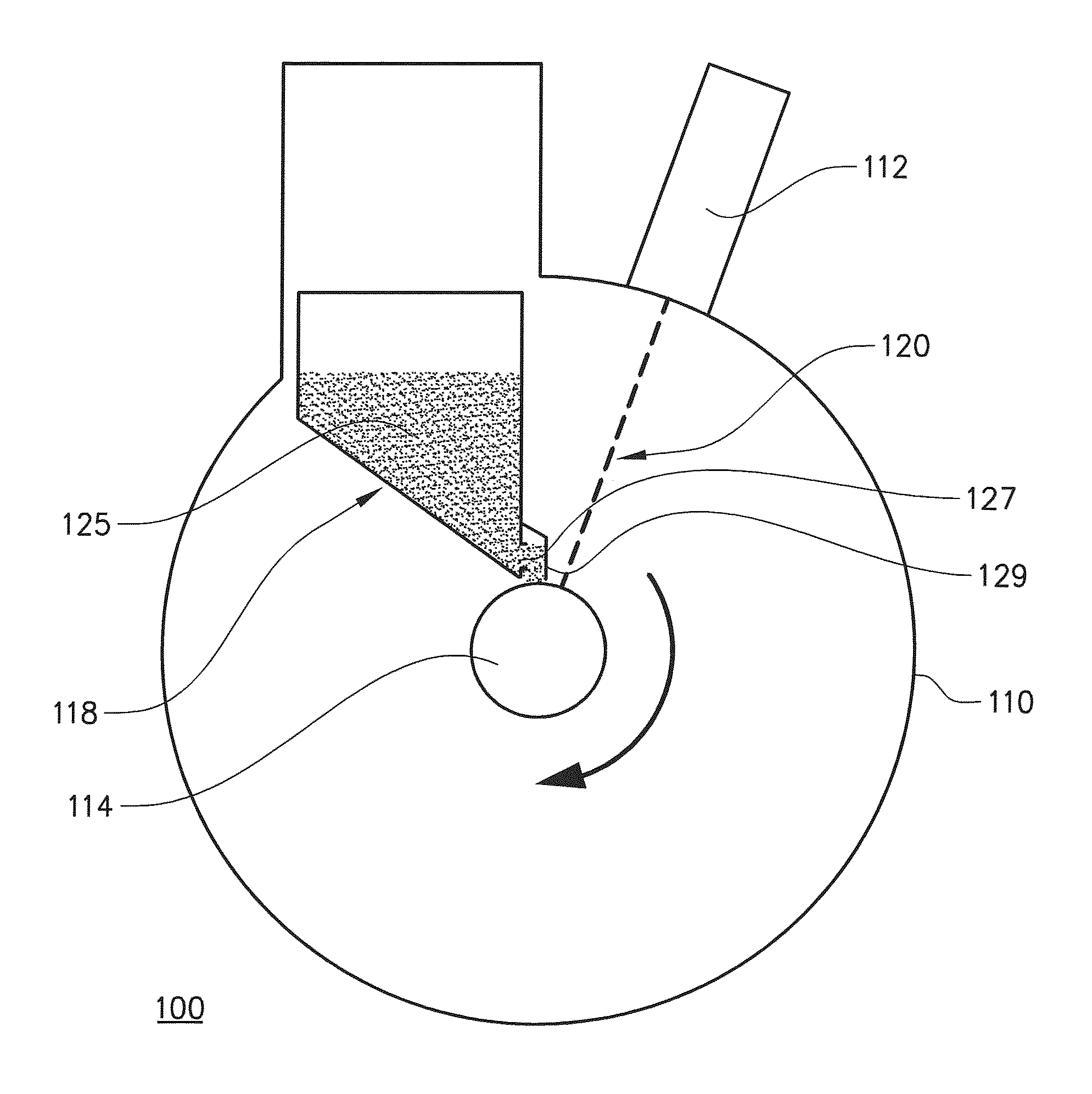

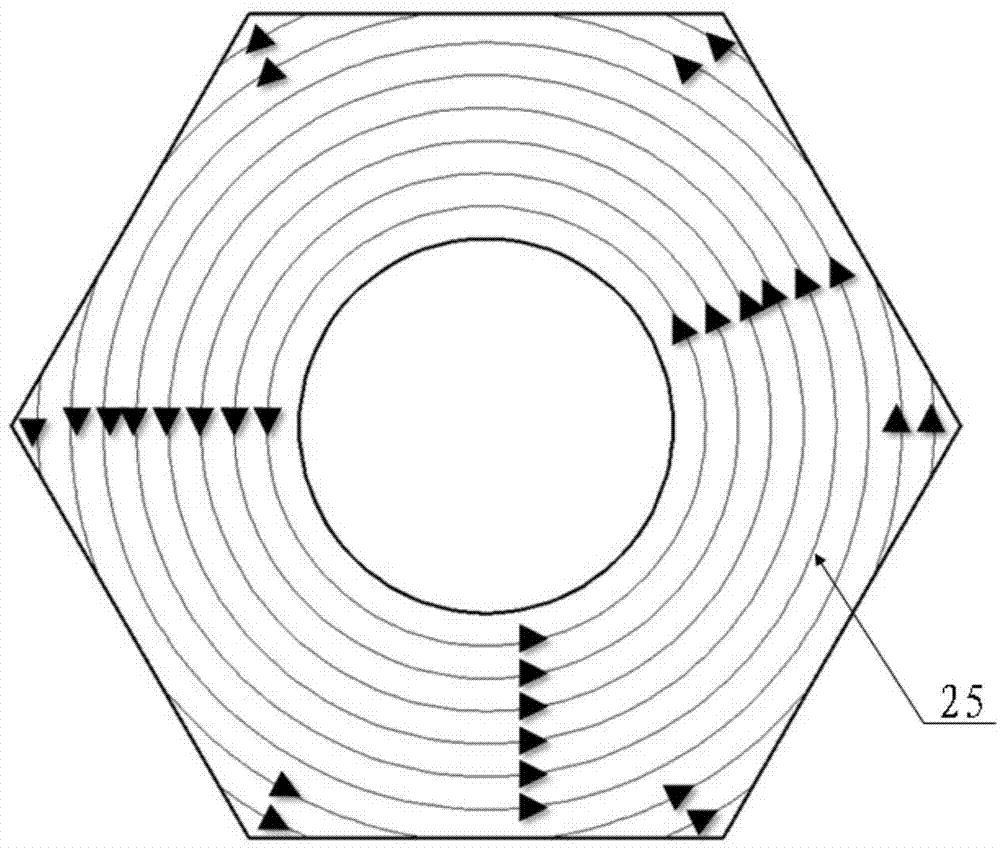

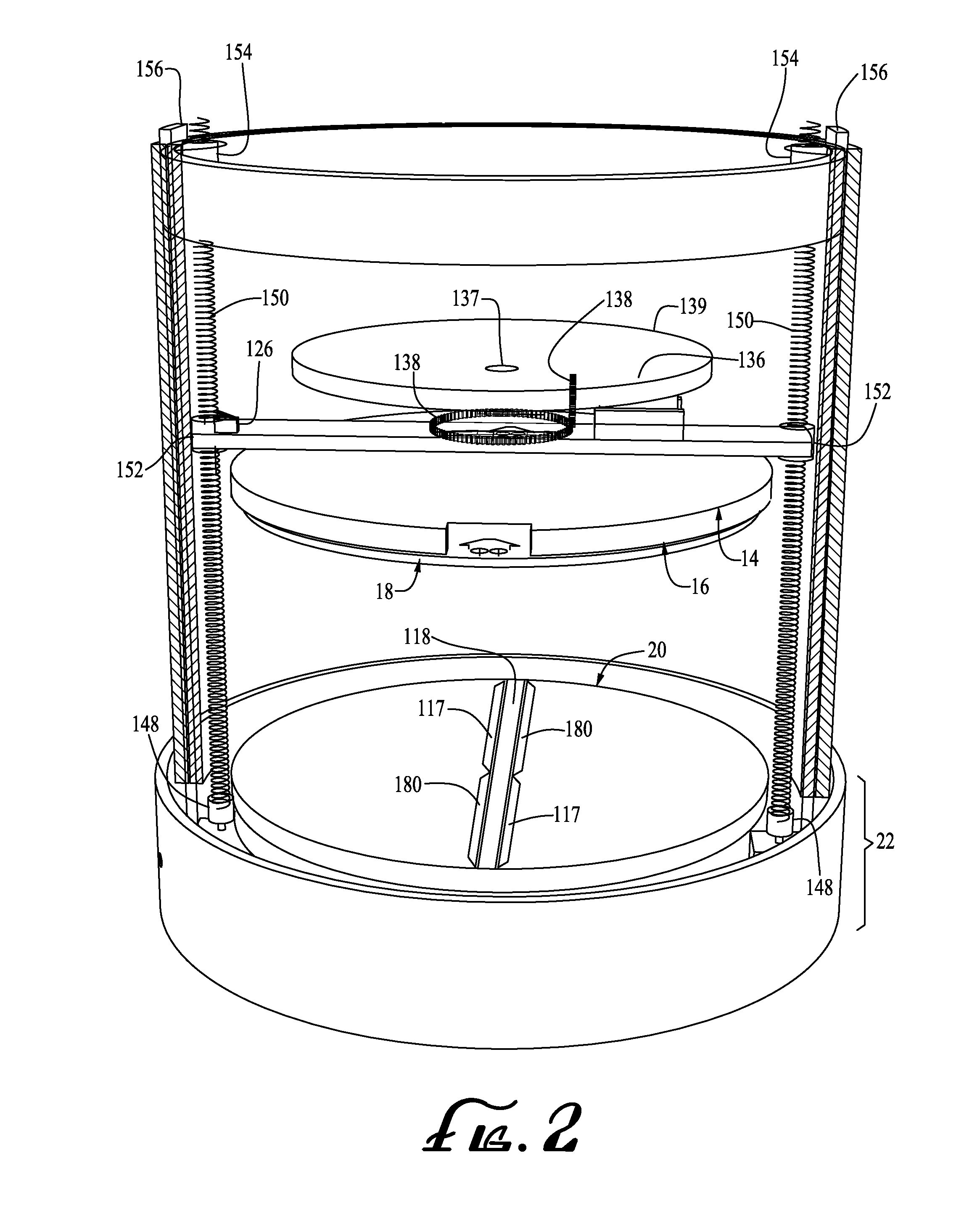

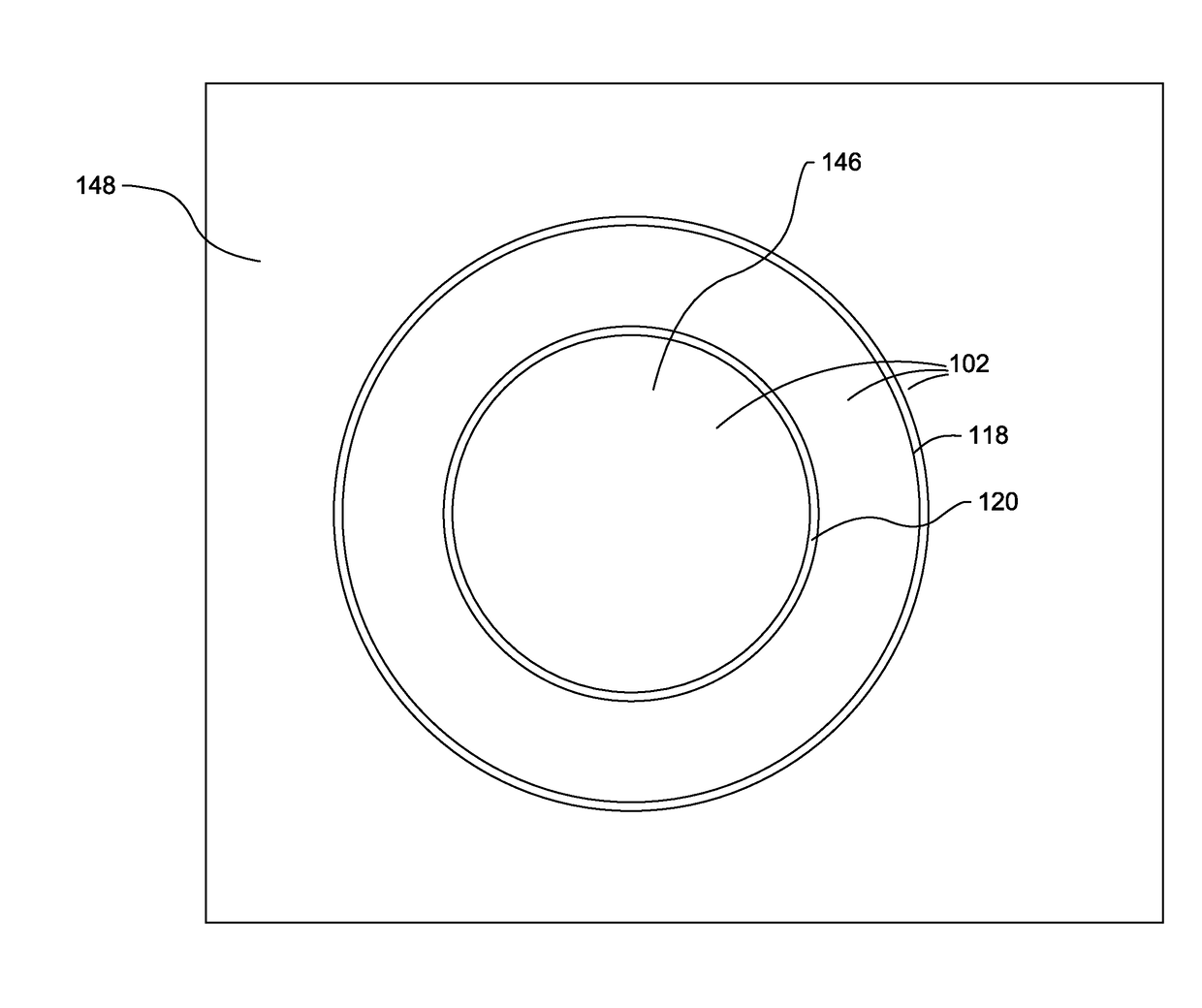

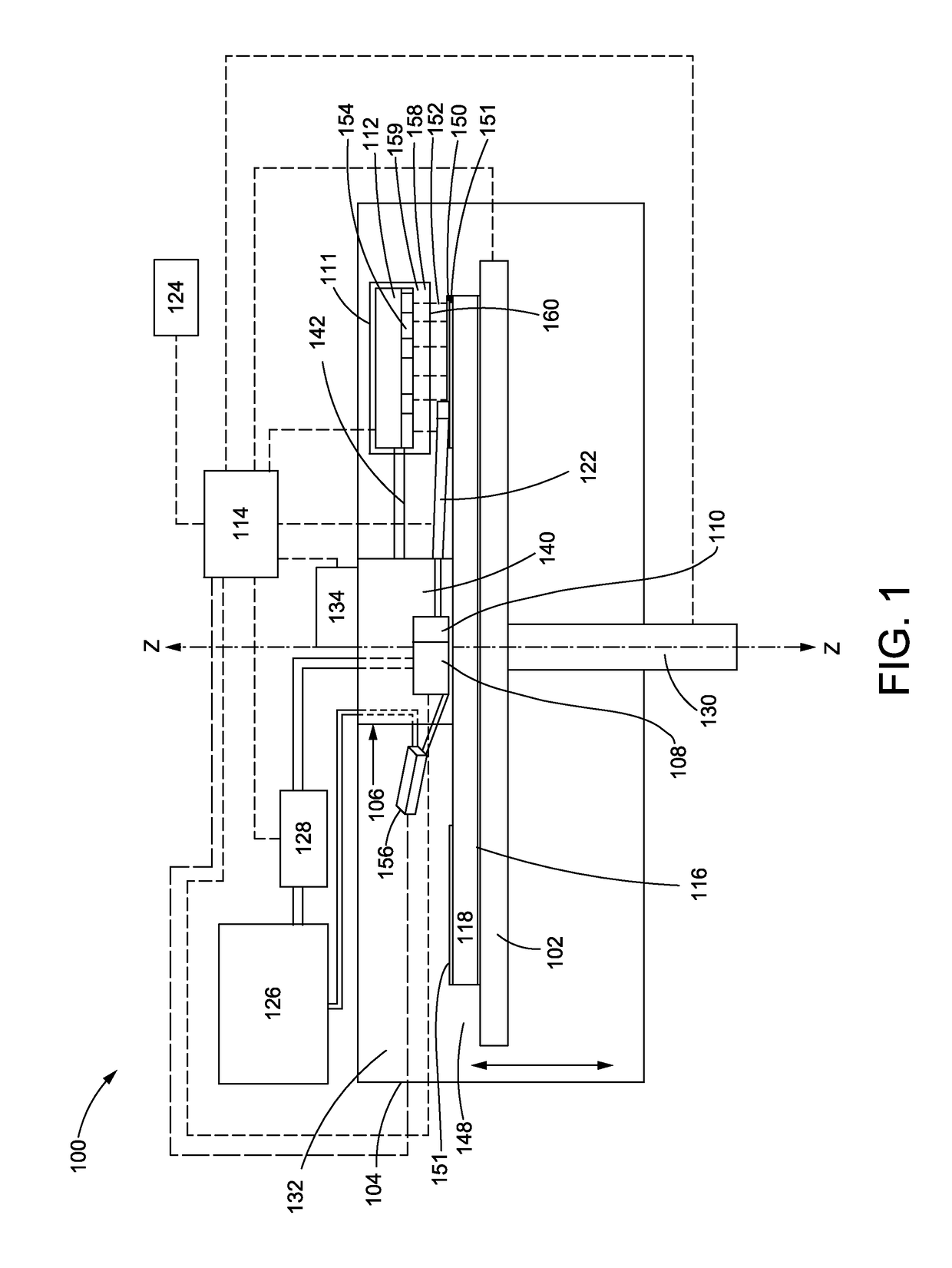

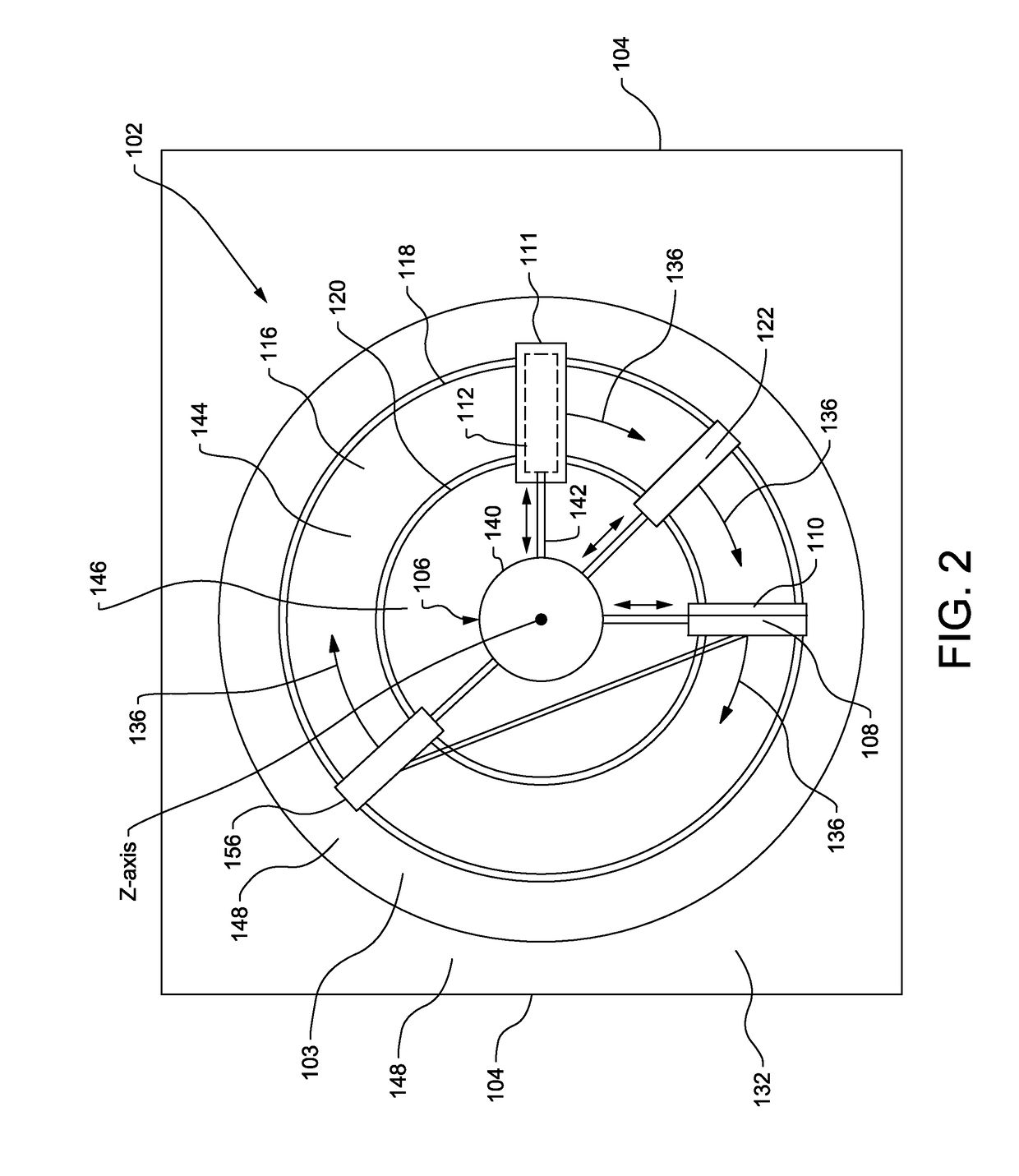

3D printing using spiral buildup

ActiveUS20140265034A1High and accurate level of detailShort timeManufacturing platforms/substratesManufacturing driving meansSingle CenterPhotopolymer

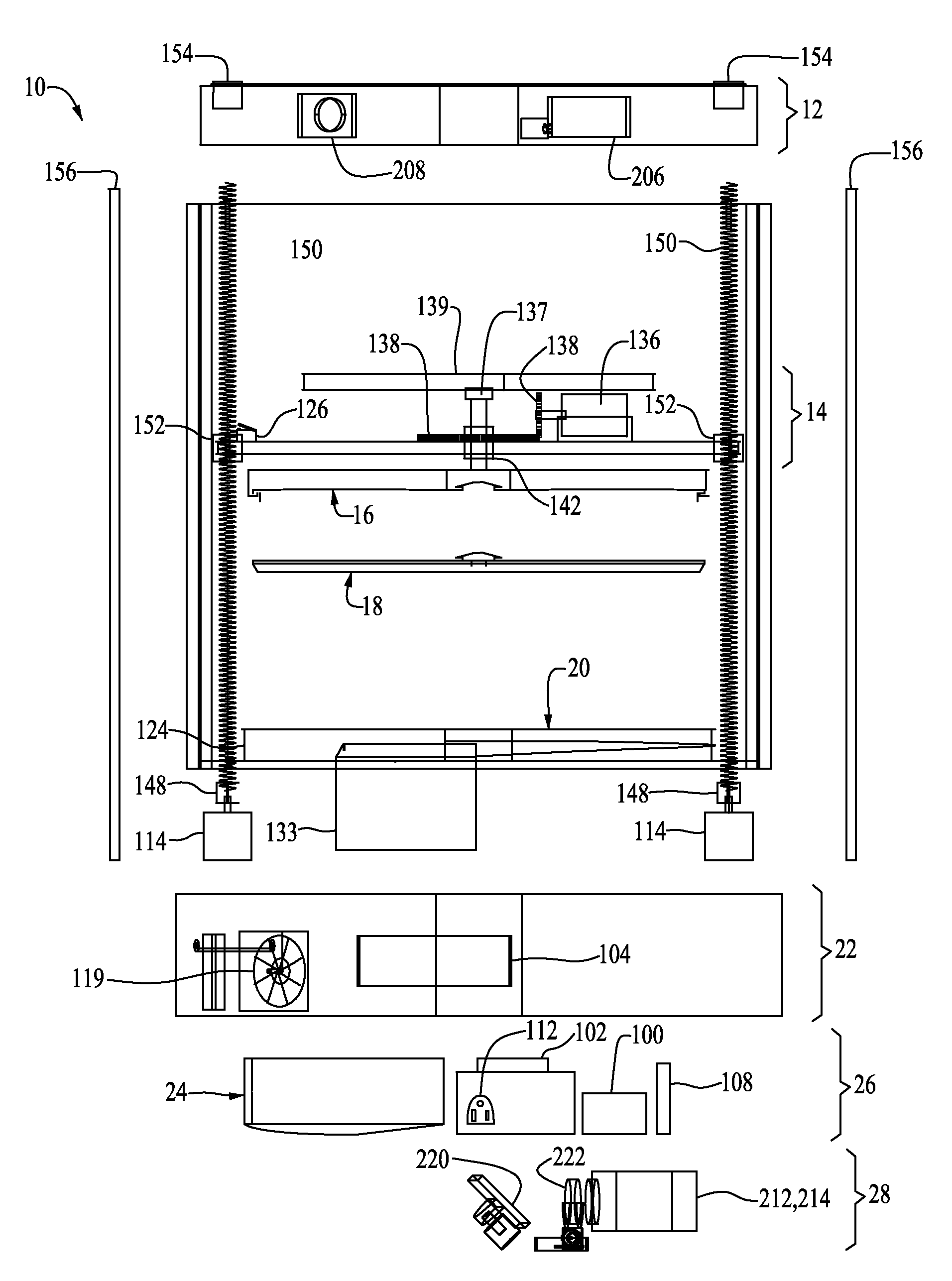

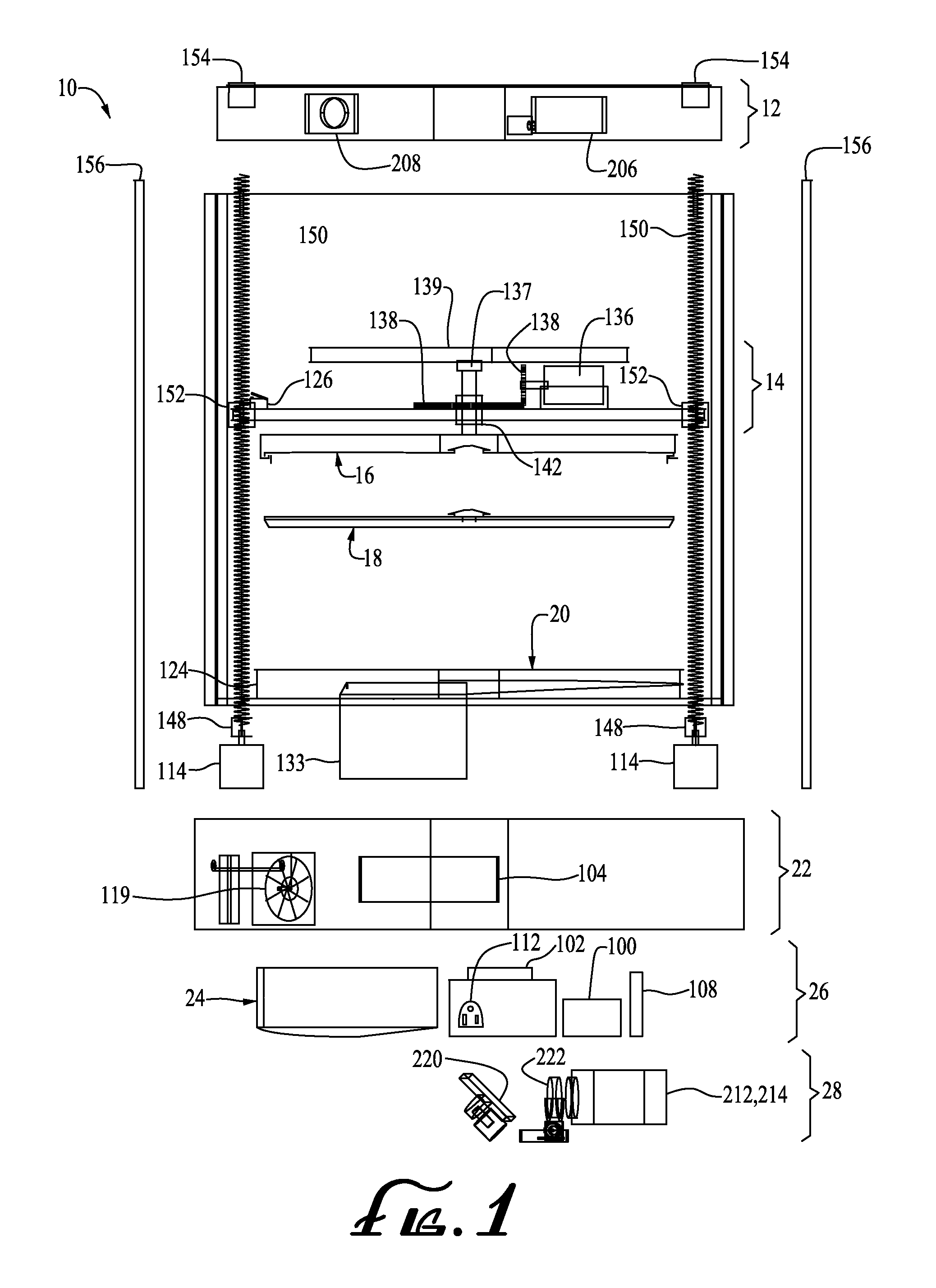

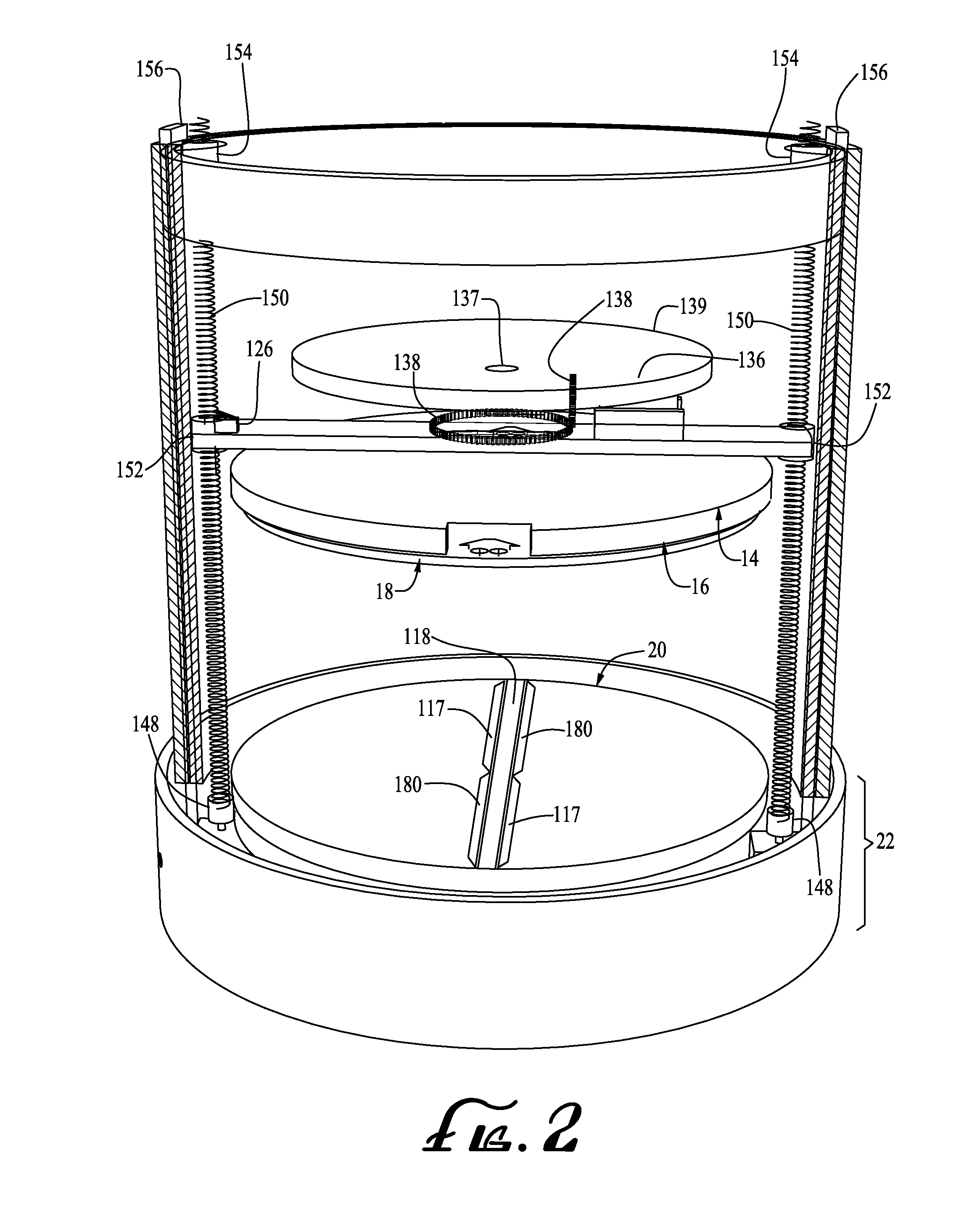

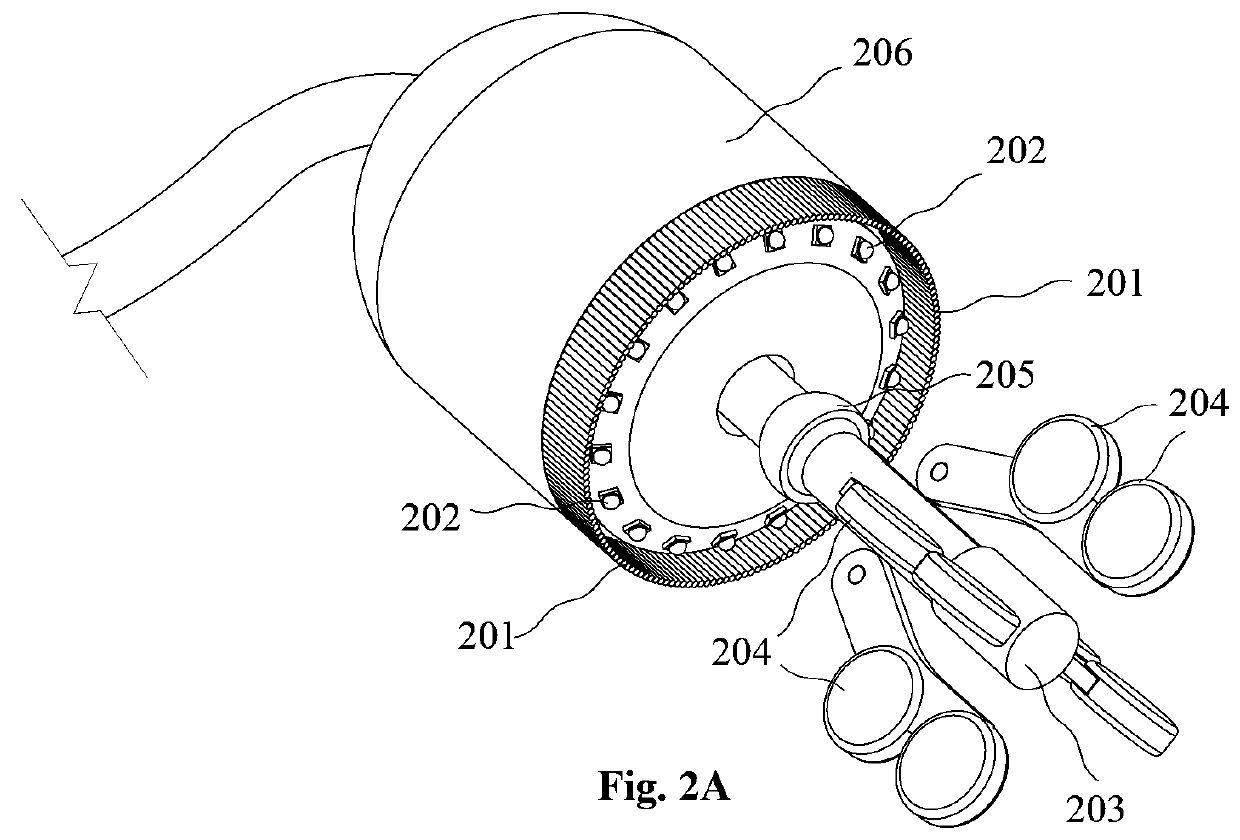

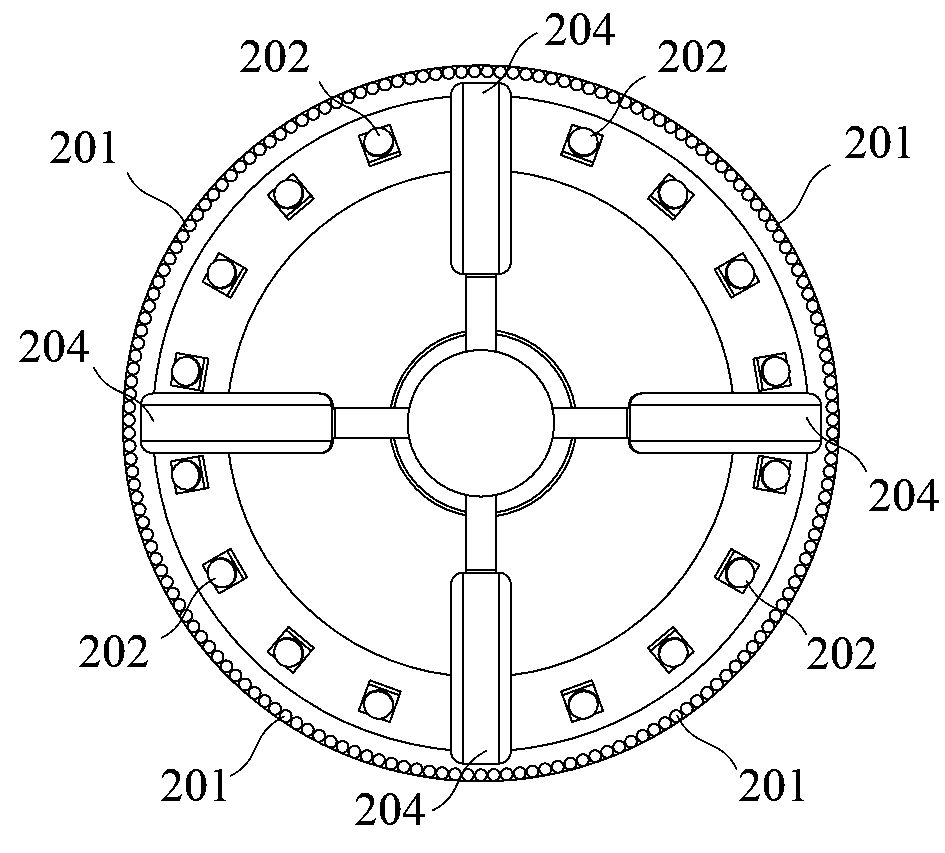

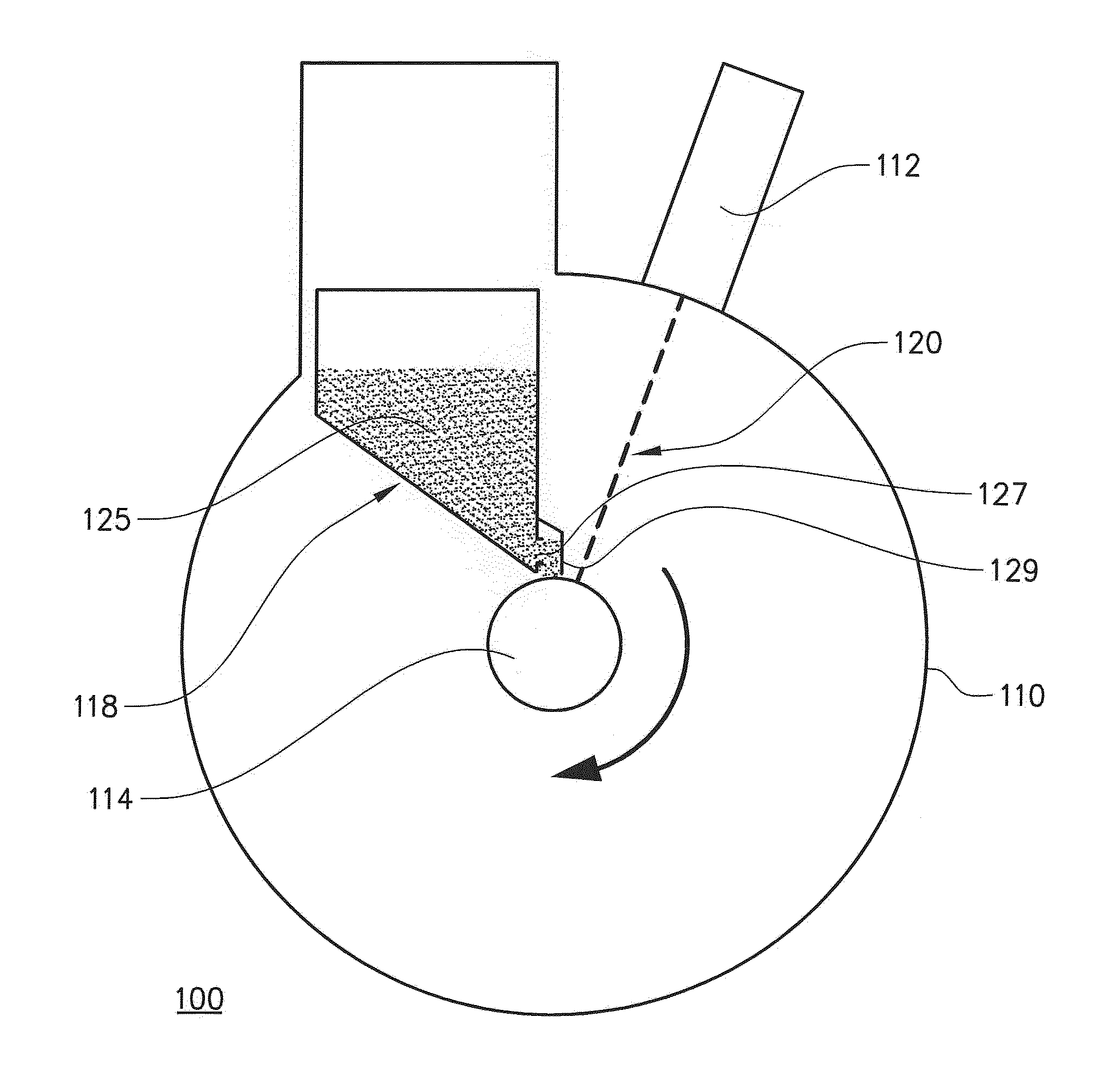

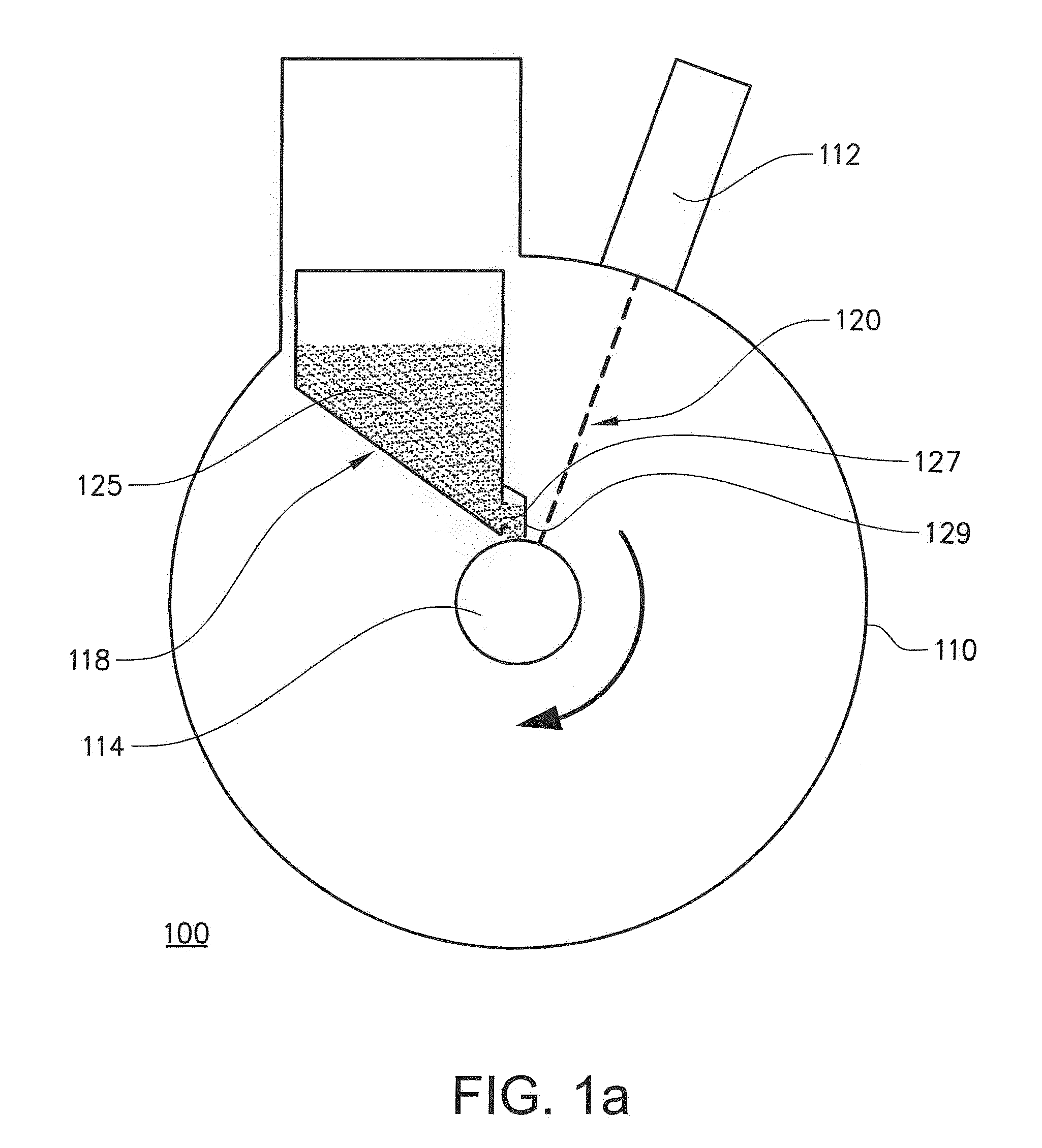

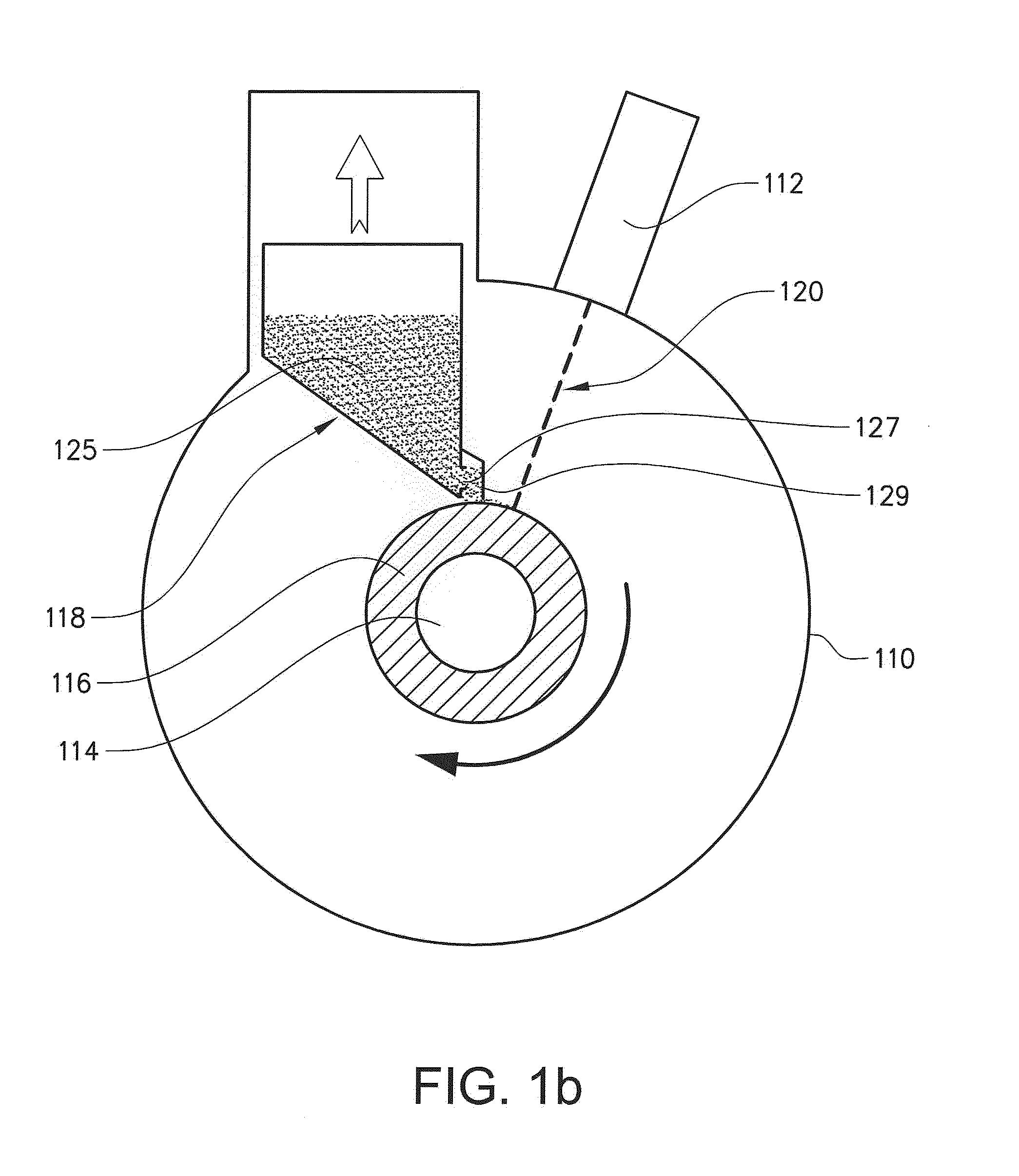

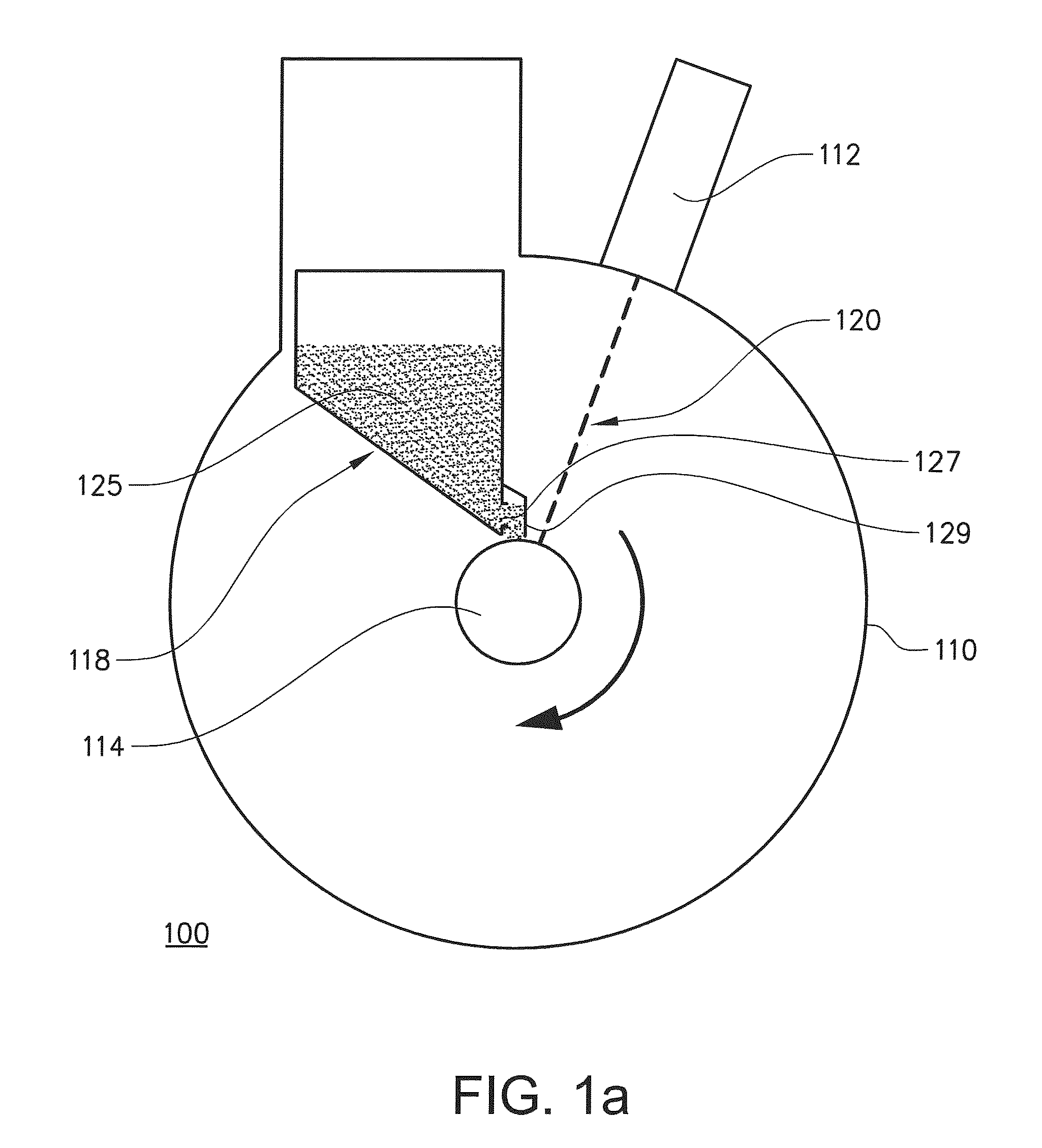

Methods, devices and systems for efficient 3D printing that address conventional inefficiencies while utilizing a single compact device are set forth. Some embodiments utilize a circular-shaped build area revolving symmetrically around a single center point utilizing a continuous helical printing process. In one embodiment a liquid photopolymer for solidification is deposited on a build platform to form the physical object The Build platform is continuously rotated and simultaneously raised in a gradual programmed manner. Focused from below the platform produces a single continuous “layer” of material deposited and bonded in a helical fashion.

Owner:ORANGE MAKER

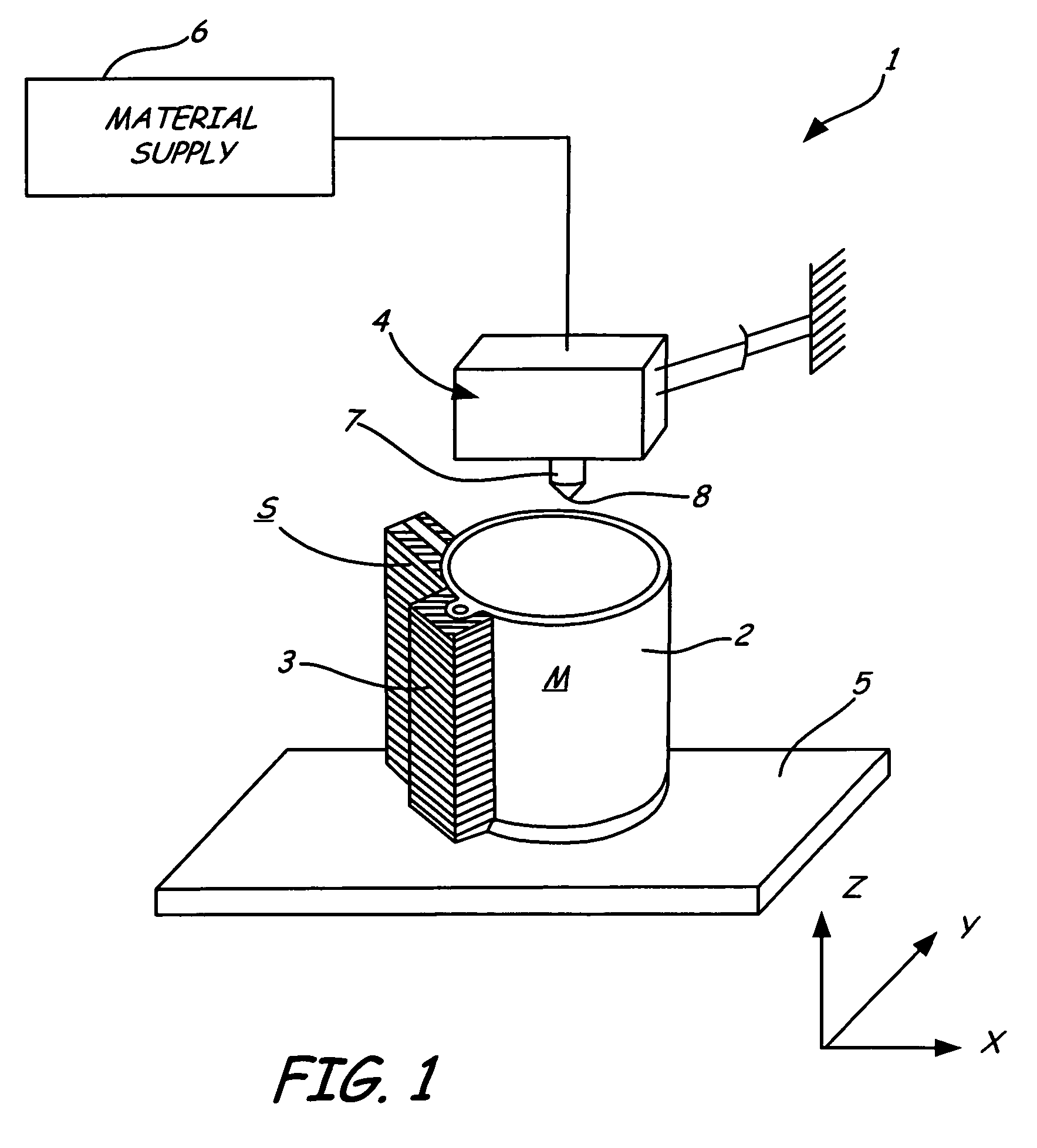

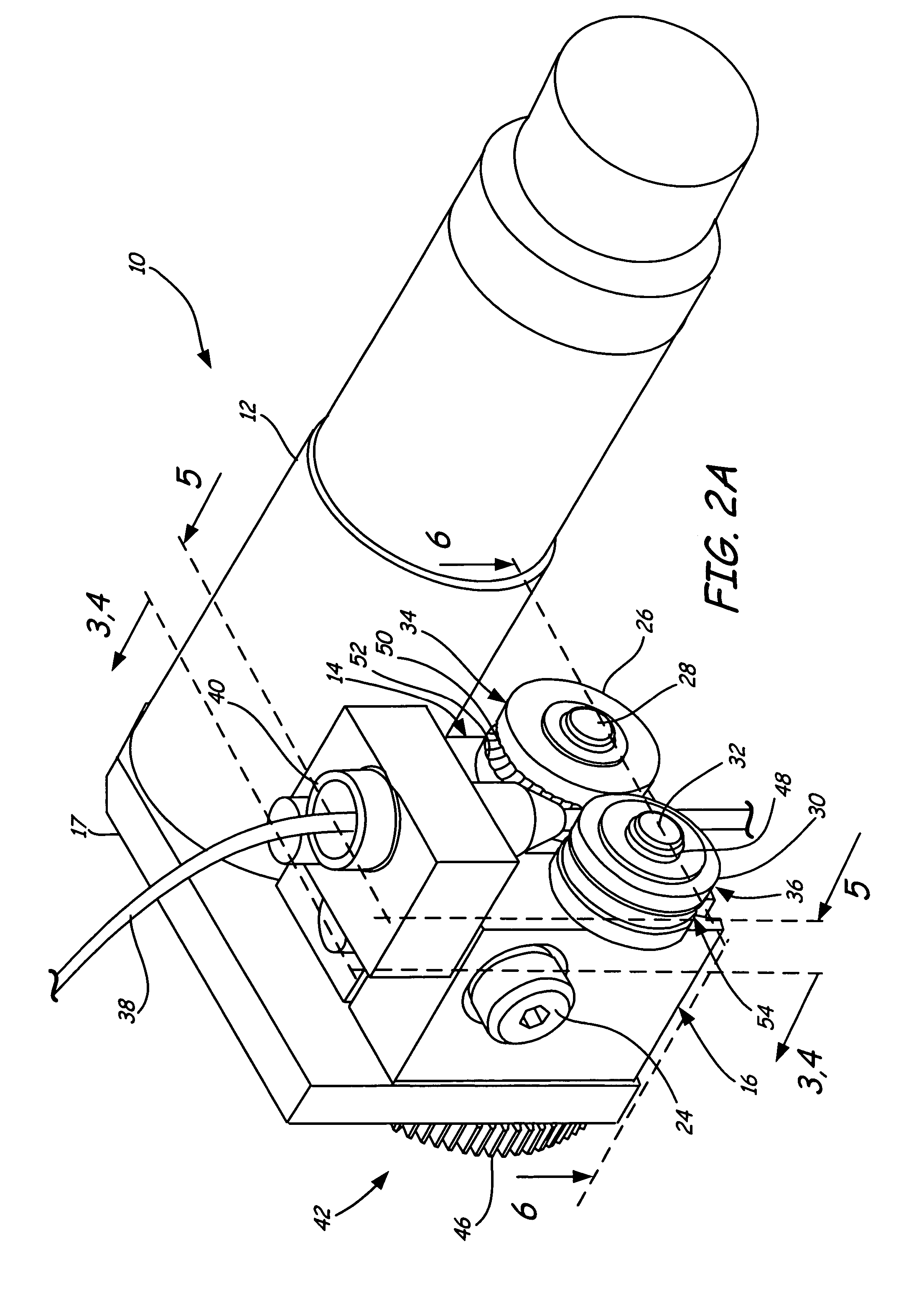

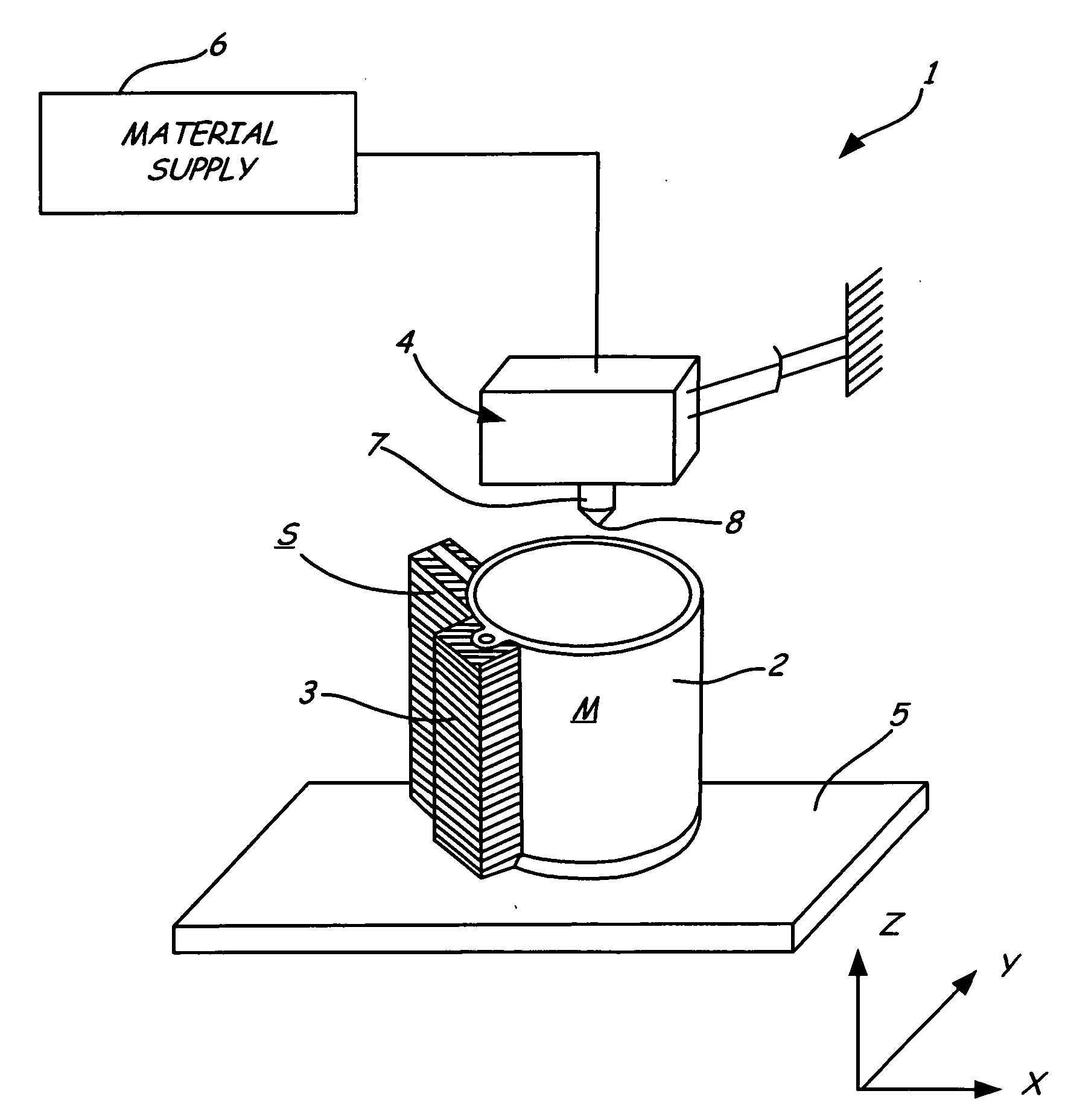

Rapid prototyping system with controlled material feedstock

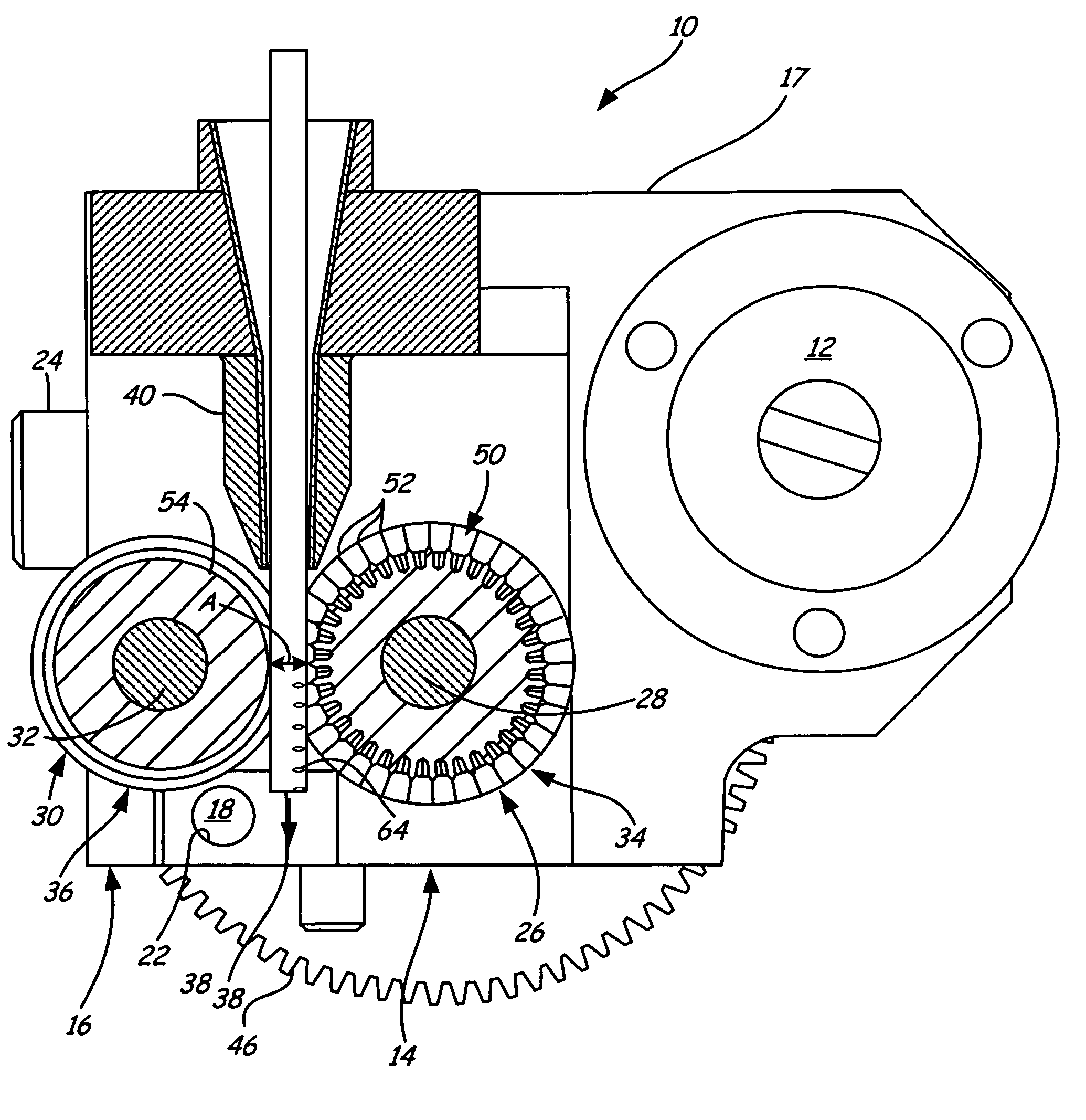

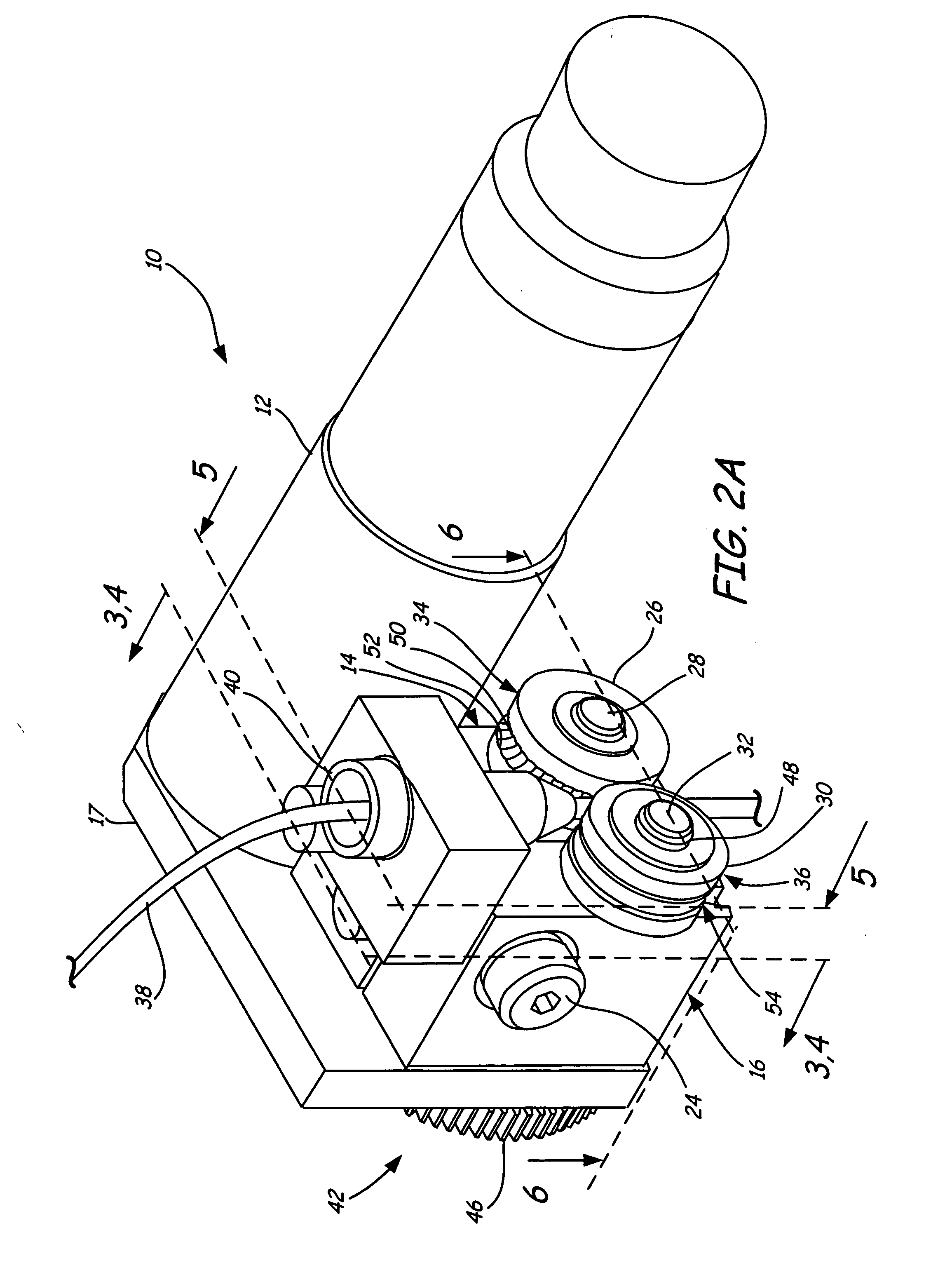

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Additive manufacturing of composite materials

ActiveUS20170259502A1Manufacturing driving means3D object support structuresEngineeringMovement system

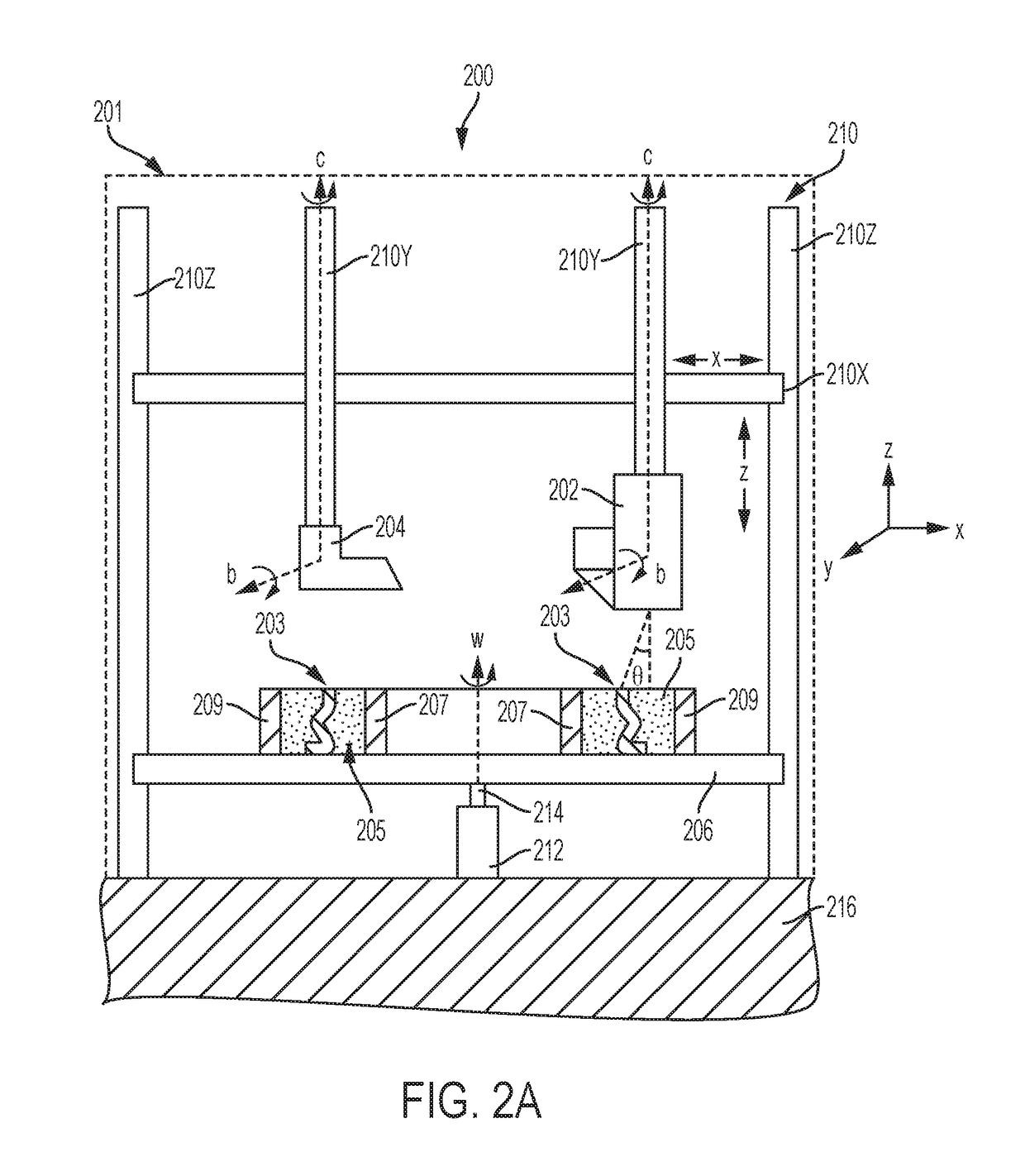

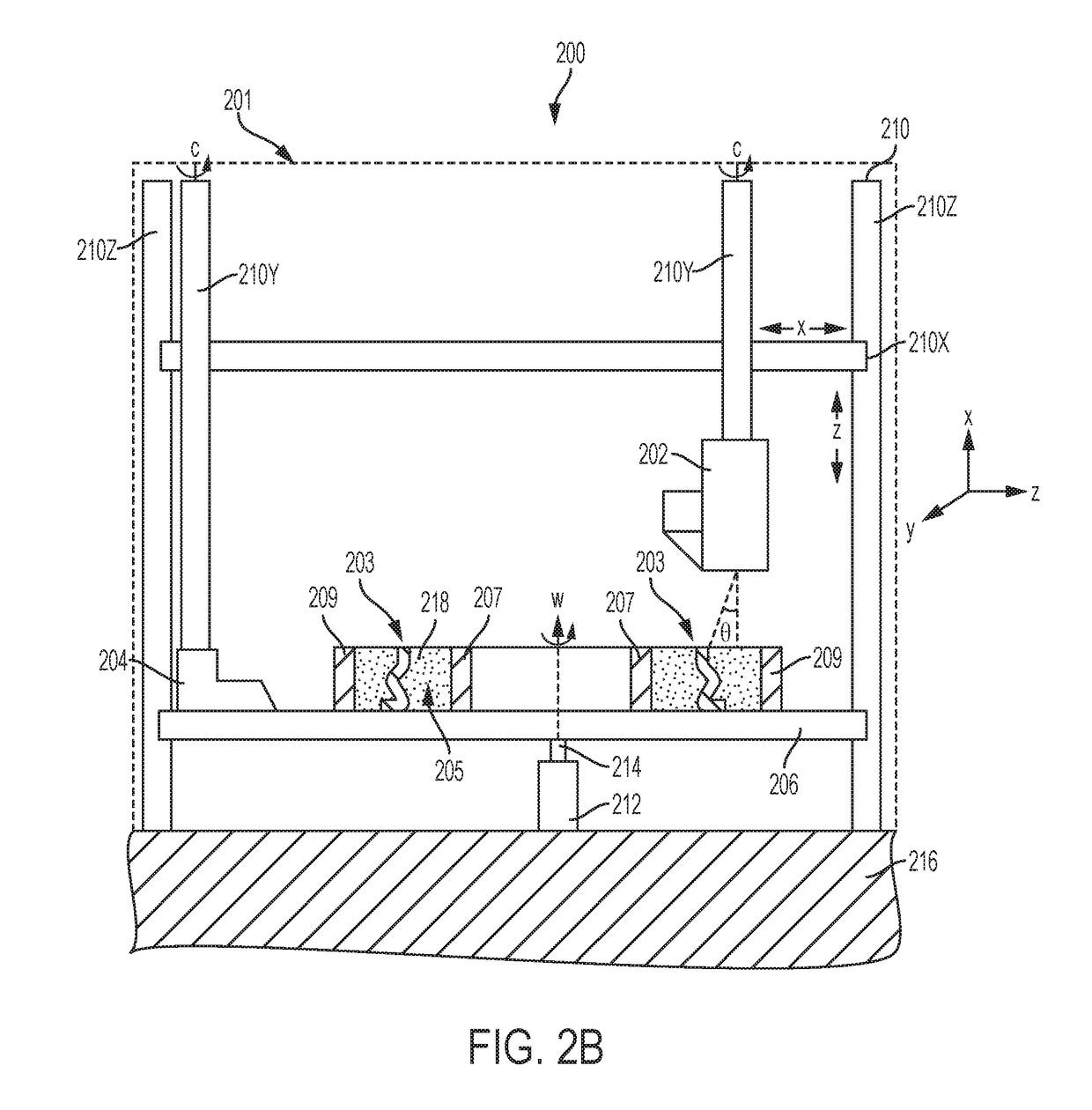

An additive manufacturing apparatus having a three-dimensional movement system comprising a first part; a second part coupled to the first part and movable relative to the first part; a third part coupled to the first part and the second part and movable relative to the first part and movable relative to the second part wherein the three-dimensional movement system moves an assembly in three dimensions relative to a base; a rotatable build table coupled to the base, and rotatable in a first plane parallel to the base; and a nozzle, wherein the assembly comprises the nozzle, wherein the nozzle is rotatable in a second plane not parallel to the base, wherein the nozzle comprises an opening for passing a printer filament through the nozzle, and for depositing the printer filament onto the build plate.

Owner:MANTIS COMPOSITES INC

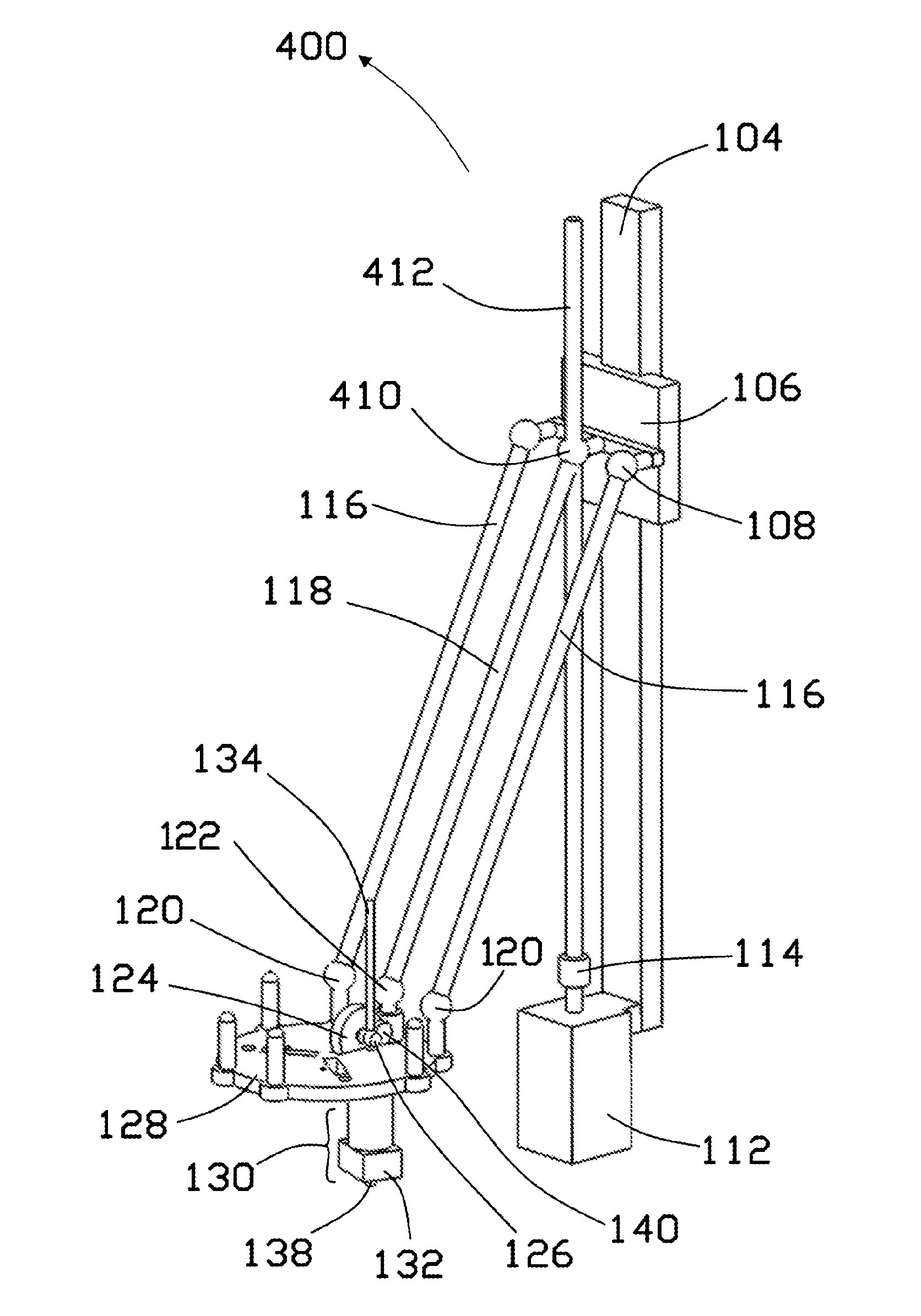

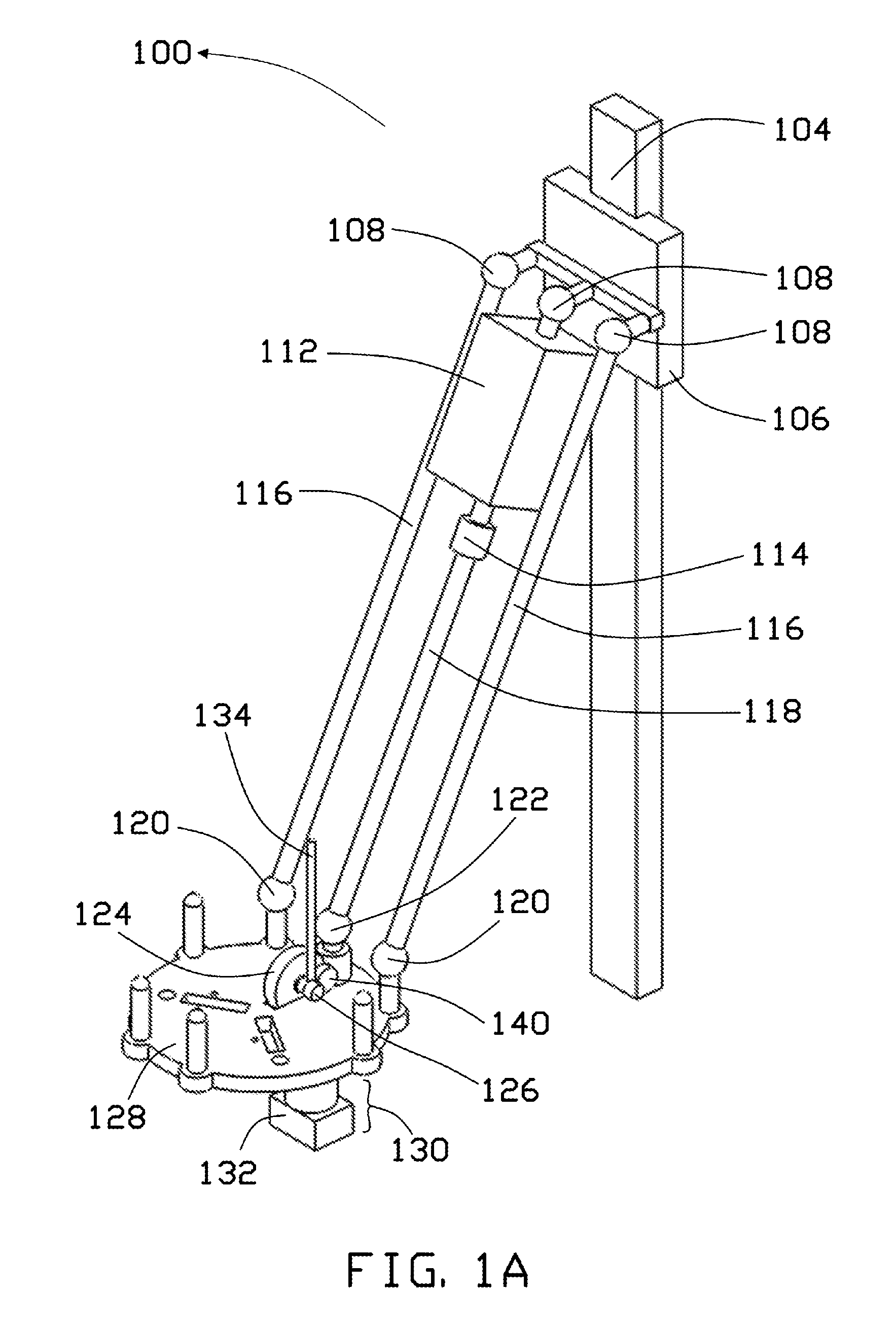

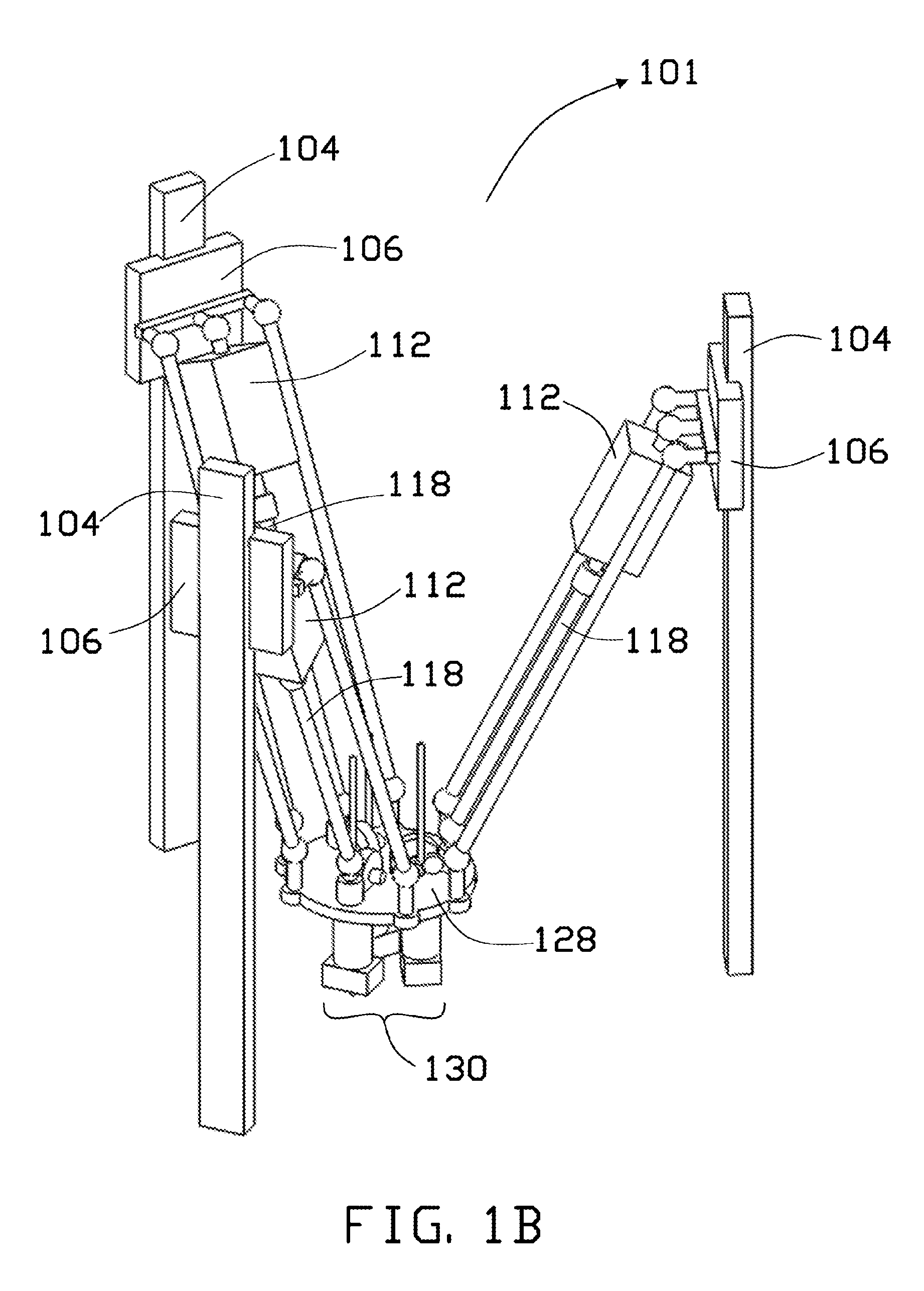

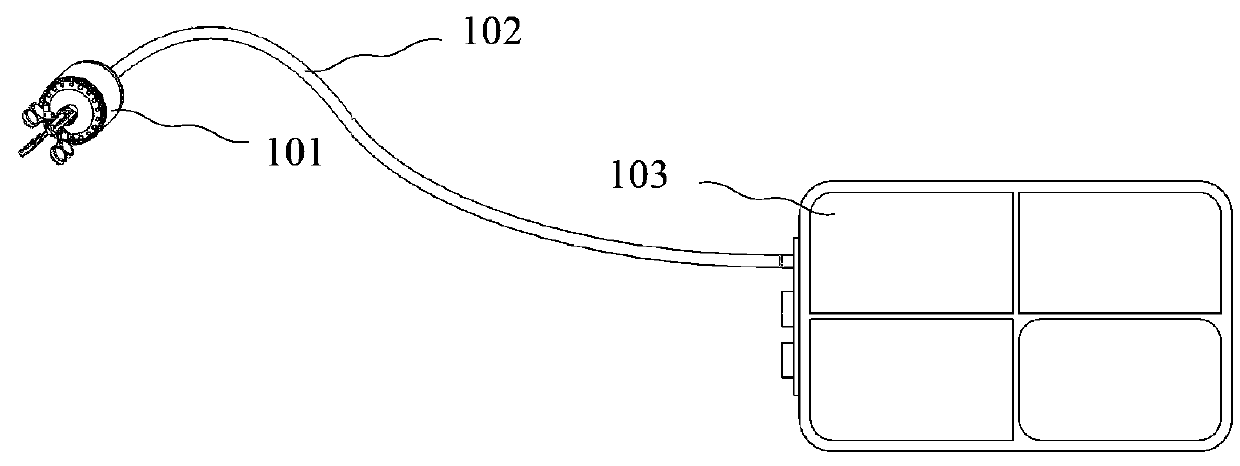

Control mechanism for end-effector maneuver

A control mechanism for maneuvering an end effector is provided. The control mechanism comprises multiple actuator assemblies, multiple arm assemblies, and the end effector. Each of the multiple arm assemblies connect the end effector and the multiple actuator assemblies respectively. Each multiple actuator assemblies controls the movement of the multiple arm assemblies independently. One of the arm is rotated by a tool actuator where the rotating motion of the rotating arm drives a tool attached at the end effector. The control mechanism positions the tool actuator away from the end effector, thereby operating the tool at a remote location away from the end effector.

Owner:KURNIANTO DANIEL

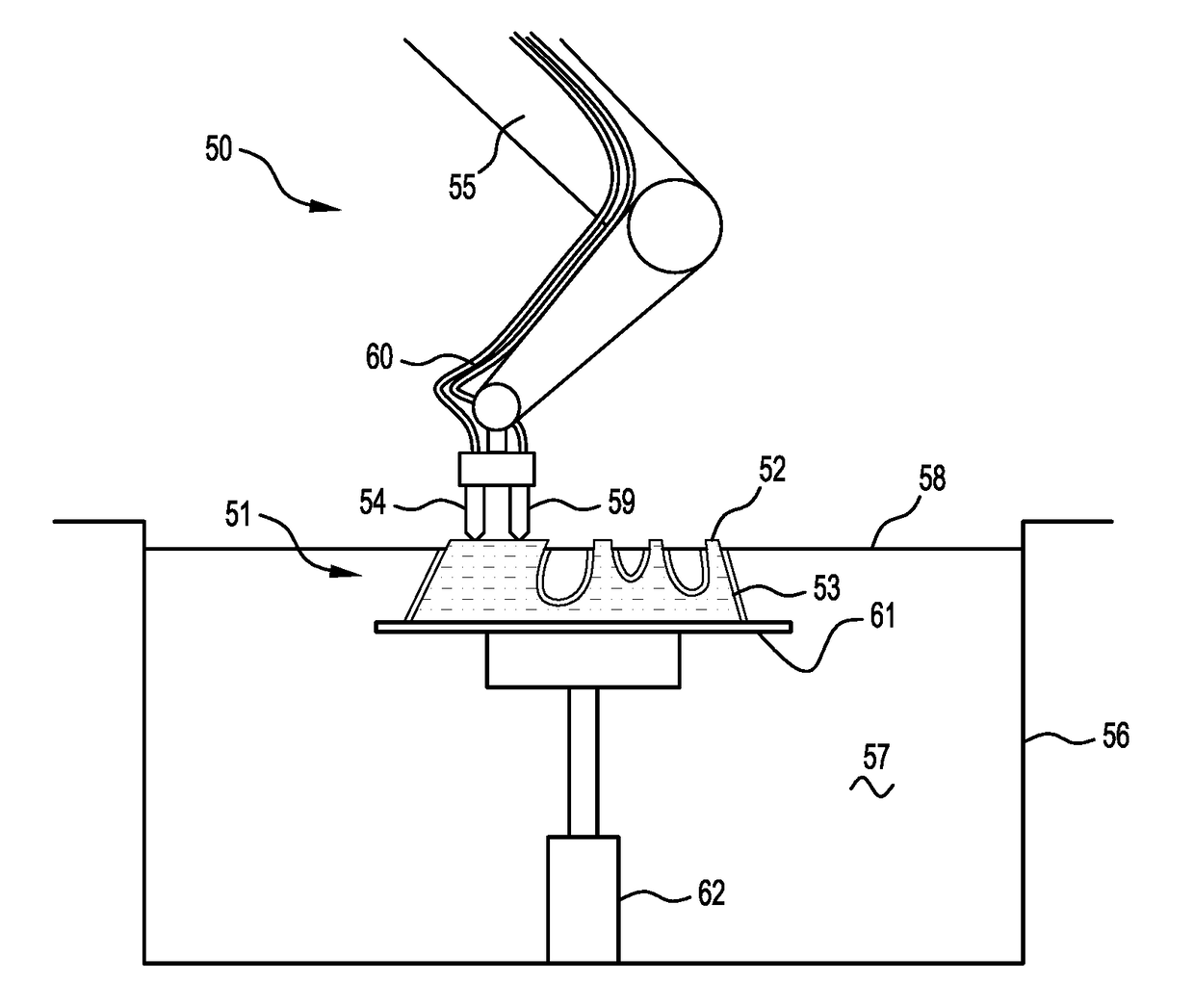

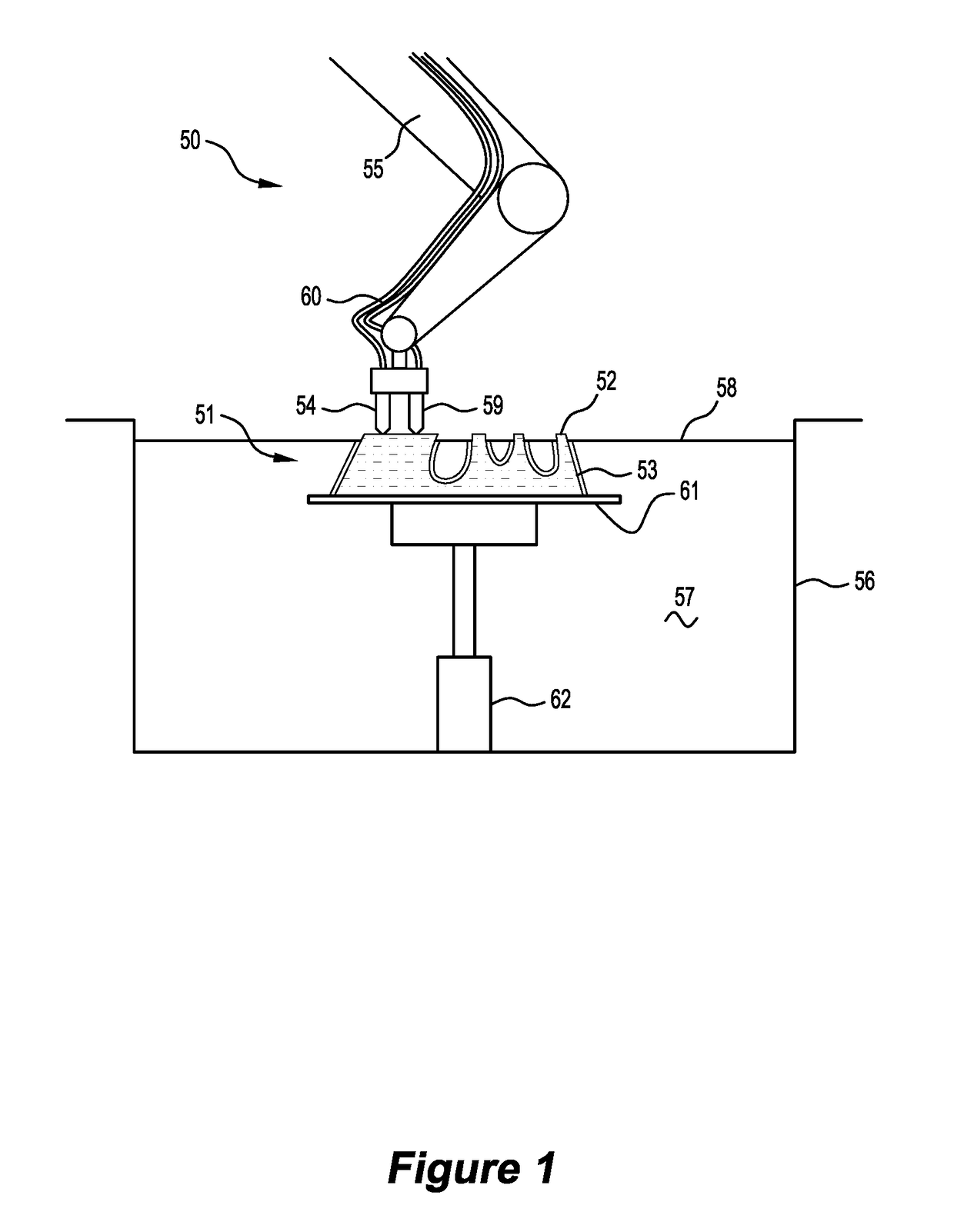

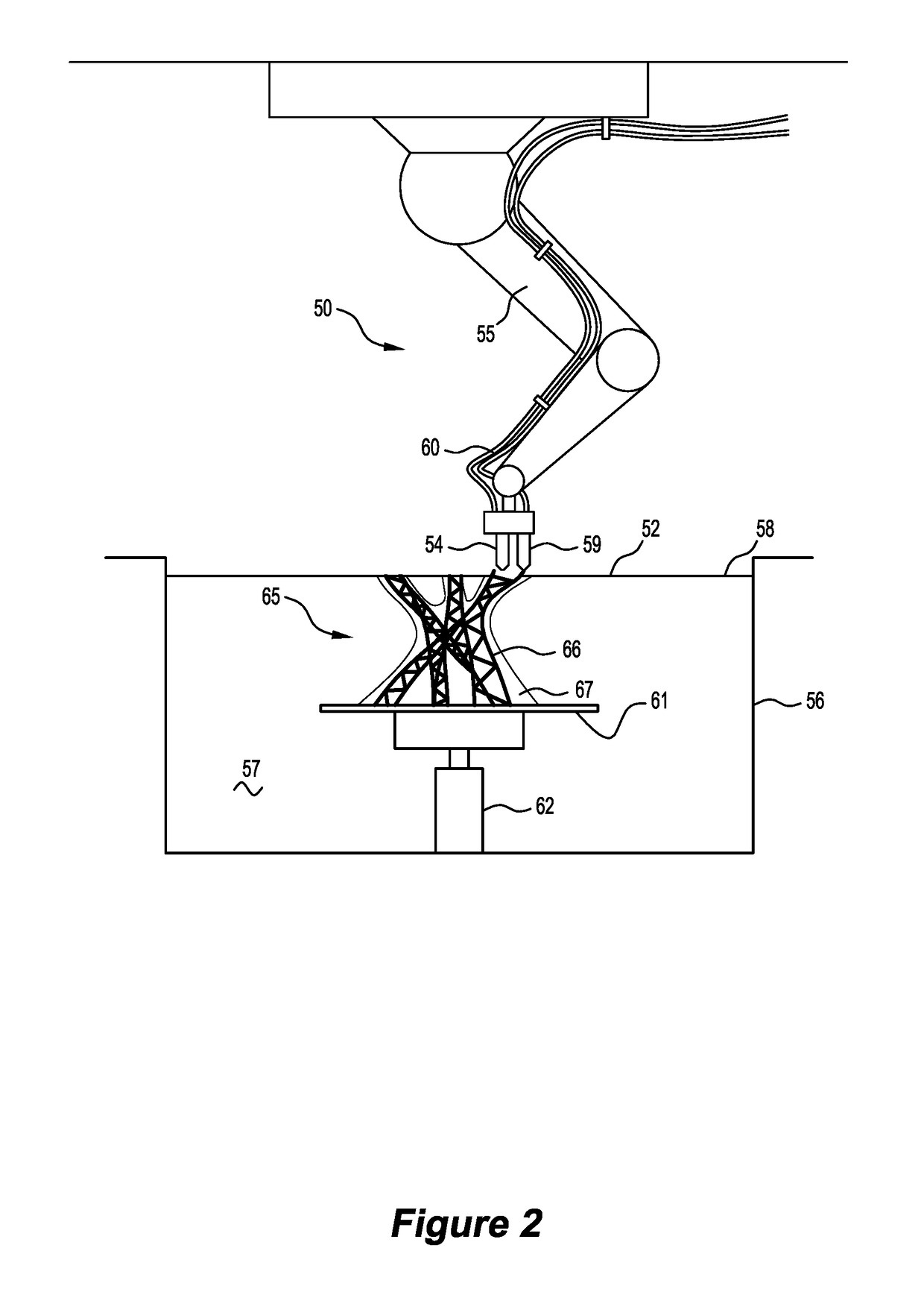

Method and Apparatus for Additive Mechanical Growth of Tubular Structures

InactiveUS20160031155A1High strengthEliminate needLiquid surface applicatorsManufacturing driving meansAdditive layer manufacturing3D printing

Owner:CONTINUOUS COMPOSITES INC

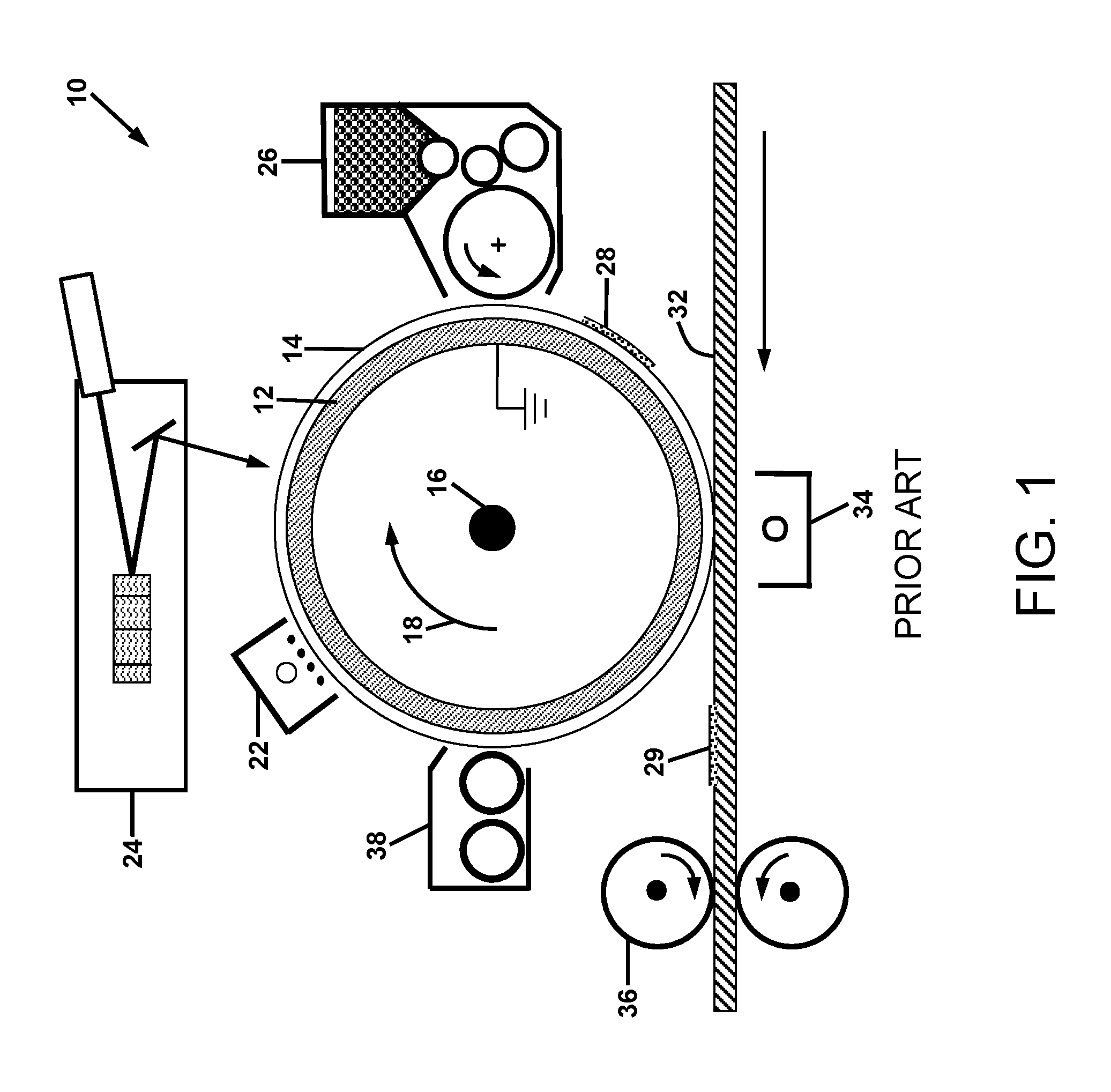

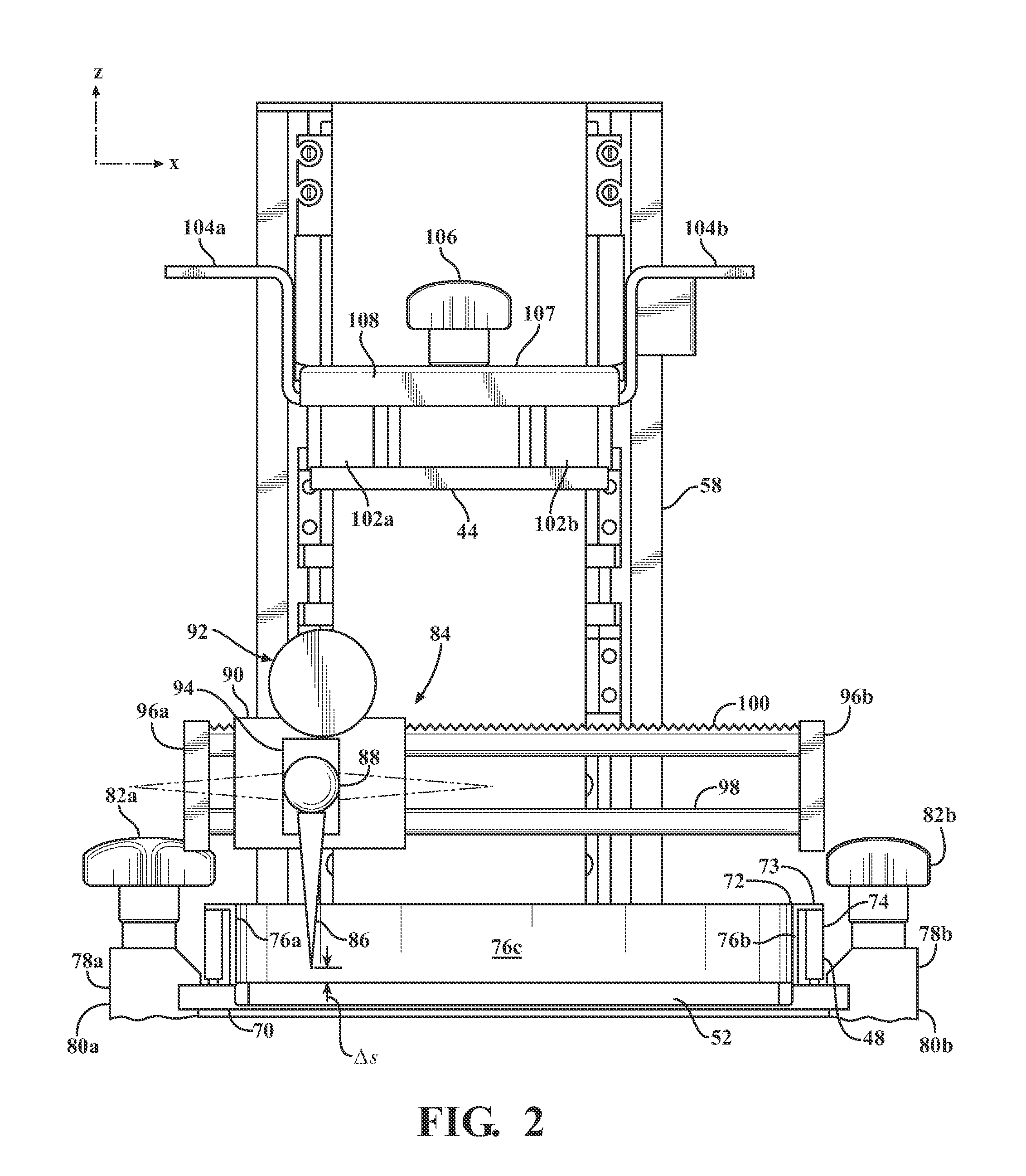

Apparatus and method for forming three-dimensional objects using linear solidification

ActiveUS20130001834A1Manufacturing platforms/substratesManufacturing driving meansLight-emitting diodeLaser diode

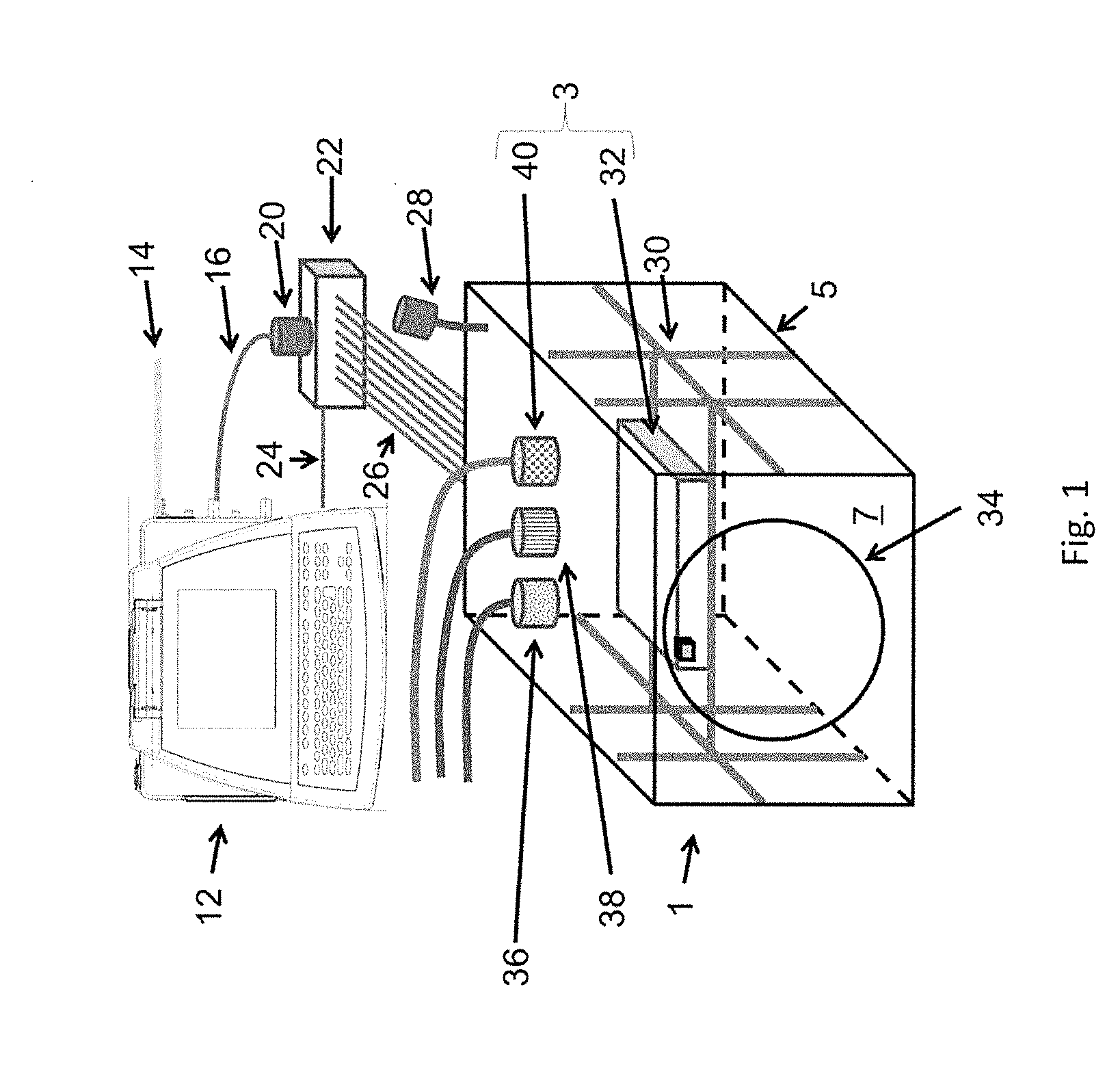

An apparatus and method for making a three-dimensional object from a solidifiable material using a linear solidification device is shown and described. In certain examples, the linear solidification device includes a laser diode that projects light onto a scanning device, such as a rotating polygonal mirror or a linear scanning micromirror, which then deflects the light onto a photohardenable resin. As a result, the linear solidification device scans a line of solidification energy in a direction that is substantially orthogonal to the direction of travel of the laser diode. In other examples, the linear solidification device is a laser device array or light emitting diode array that extends in a direction substantially orthogonal to the direction of travel of the array.

Owner:GLOBAL FILTRATION SYST

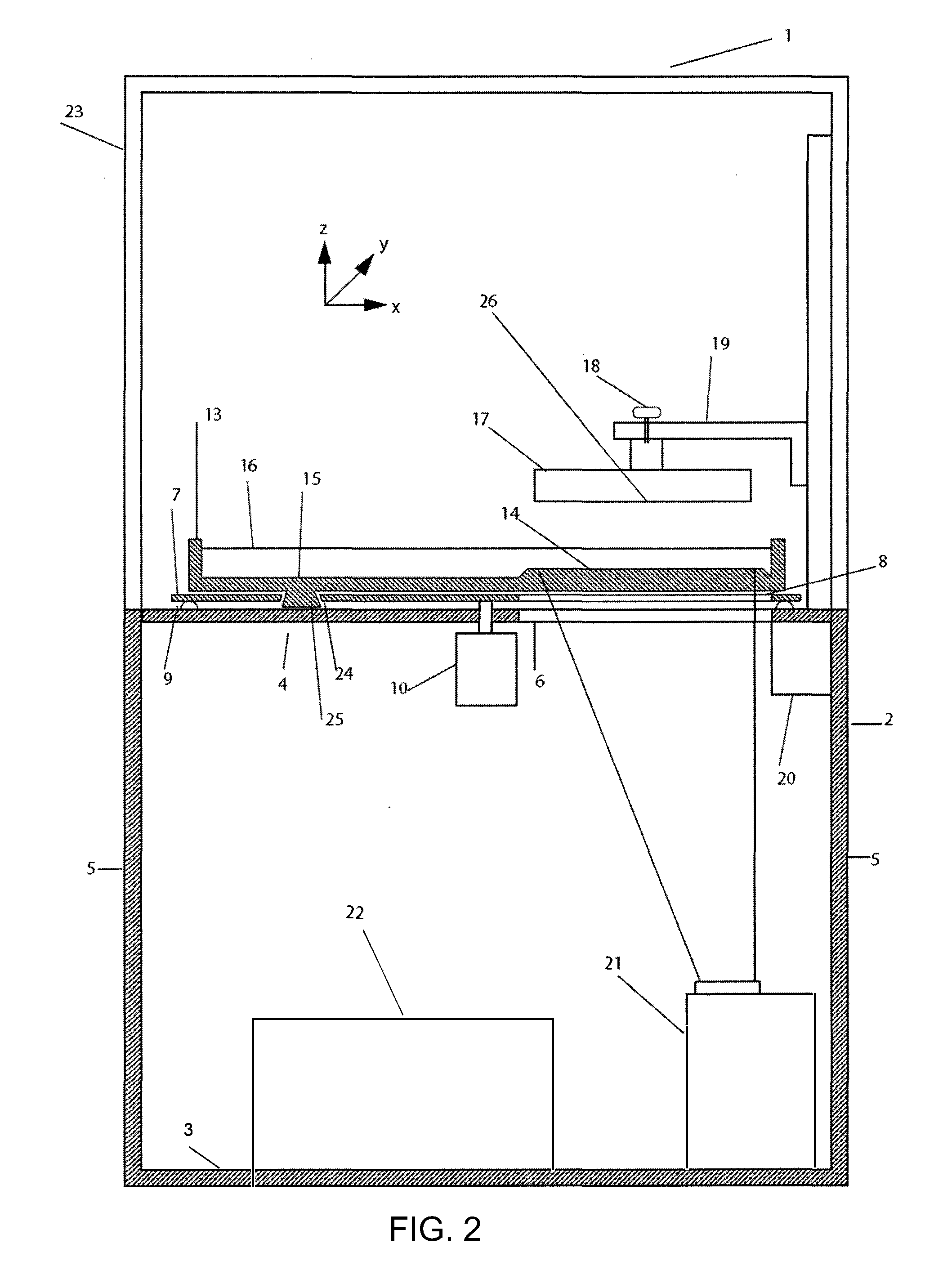

Device and method for powder distribution and additive manufacturing method using the same

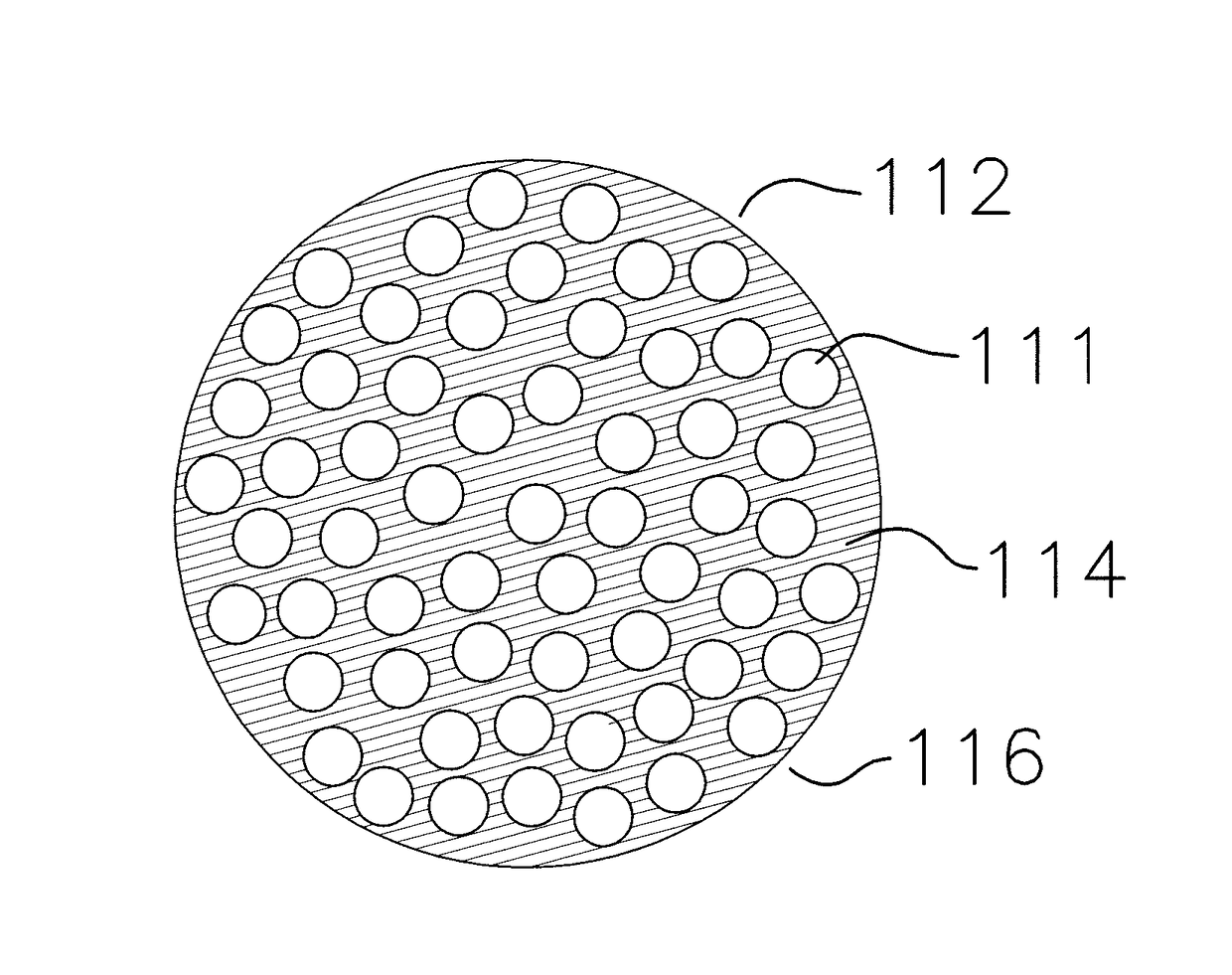

ActiveUS20130186514A1Improve compactnessWell mixedLiquid surface applicatorsManufacturing driving meansMetallurgyThermal deformation

The present disclosure provides a device and method for powder distribution and an additive manufacturing method, wherein different size or kind of powders could be chosen to be accommodated within a receptacle. The receptacle can uniformly mix the powder by a rotation movement, pour out the powders by the rotation movement and distribute the powders for forming a layer by a translation movement. In another embodiment, the receptacle further comprises a heating element for preheating the powders. Not only can the present disclosure uniformly mix the powders so as to reduce the thermal deformation and distribute the powder layer compactly, but also can the present disclosure distribute different kinds of powder in different layer so as to increase the diversity in additive manufacturing.

Owner:IND TECH RES INST

Method and apparatus for additive manufacturing

ActiveUS20150306819A1Easy to manufactureSuitable for manufactureManufacturing driving meansElectric discharge tubesAdditive layer manufacturingMaterials science

The present invention relates to a method for forming a three-dimensional article through successive fusion of applied powder. Said method comprising the steps of: providing at least one powder hopper comprising powder to be used for forming said three-dimensional article, providing a predetermined amount of powder at a build support, directing an energy beam over said build support causing at least a portion of said powder to sinter and causing at least a portion of said powder to bond to said build support, directing an energy beam over said build support causing said powder to fuse in selected locations according to a model to form a first portion of said three-dimensional article, rotating said build support around an axis of rotation for creating said three-dimensional article, which three-dimensional article is build up layer by layer in a radial direction with respect to said axis of rotation.

Owner:ARCAM AB

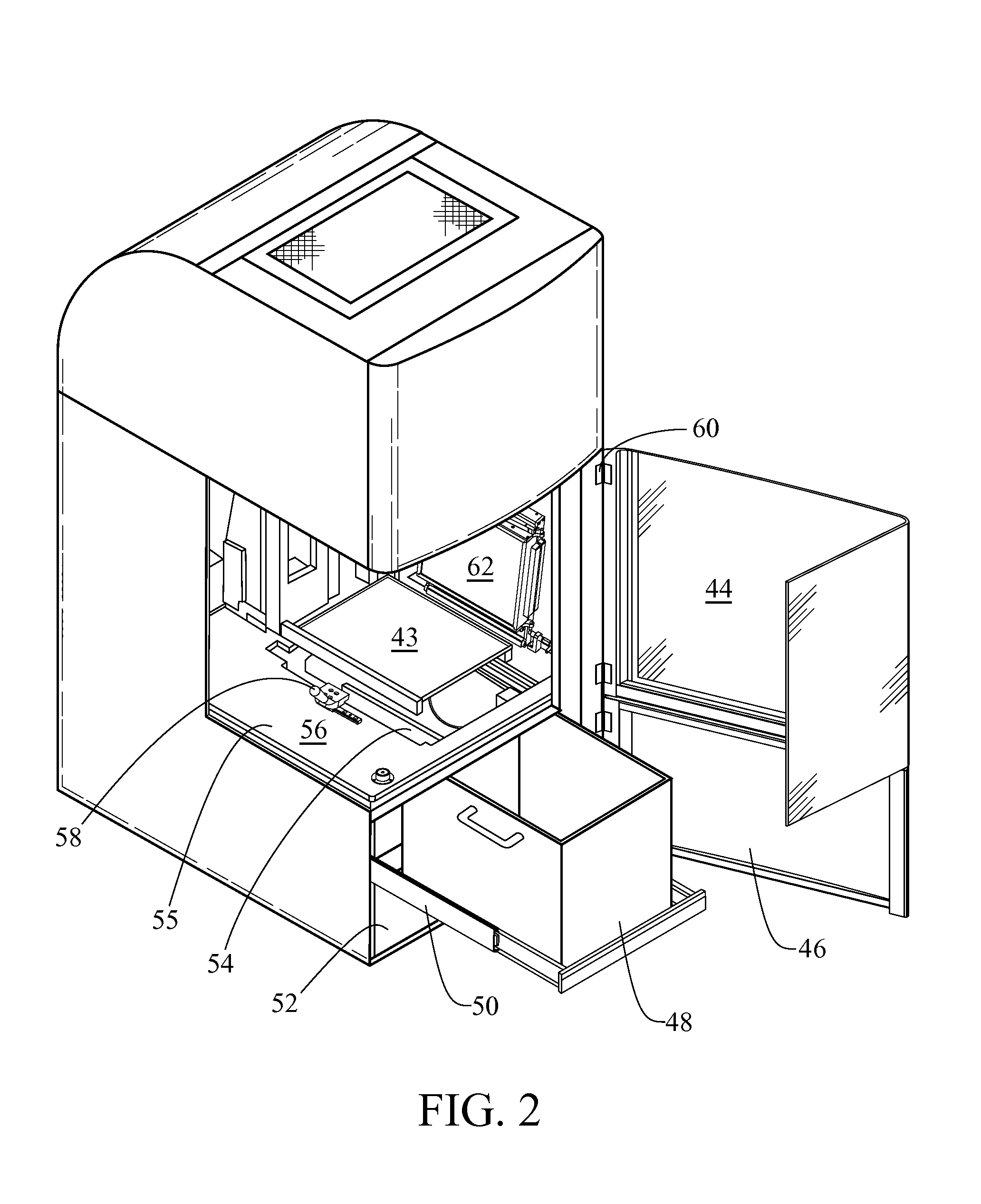

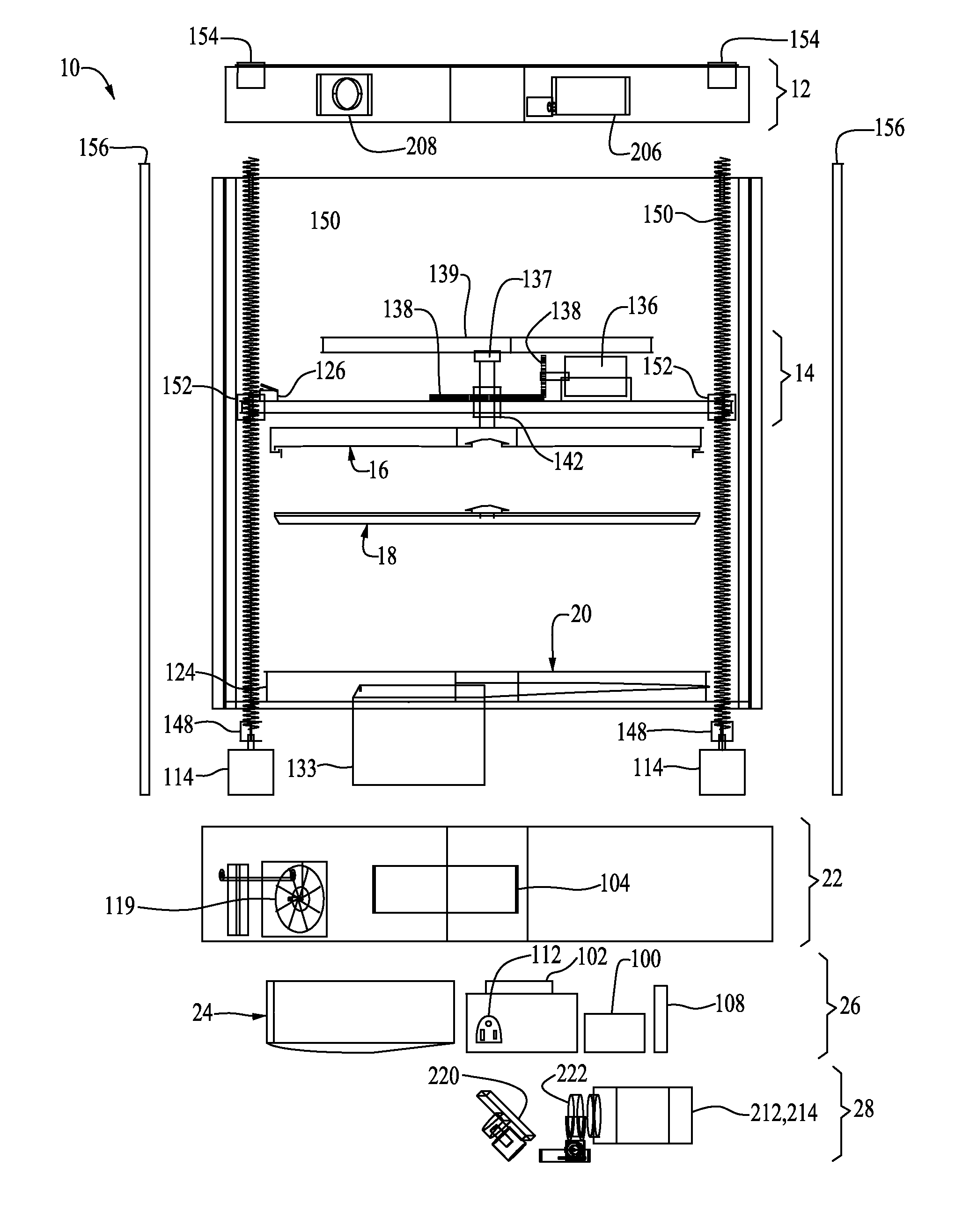

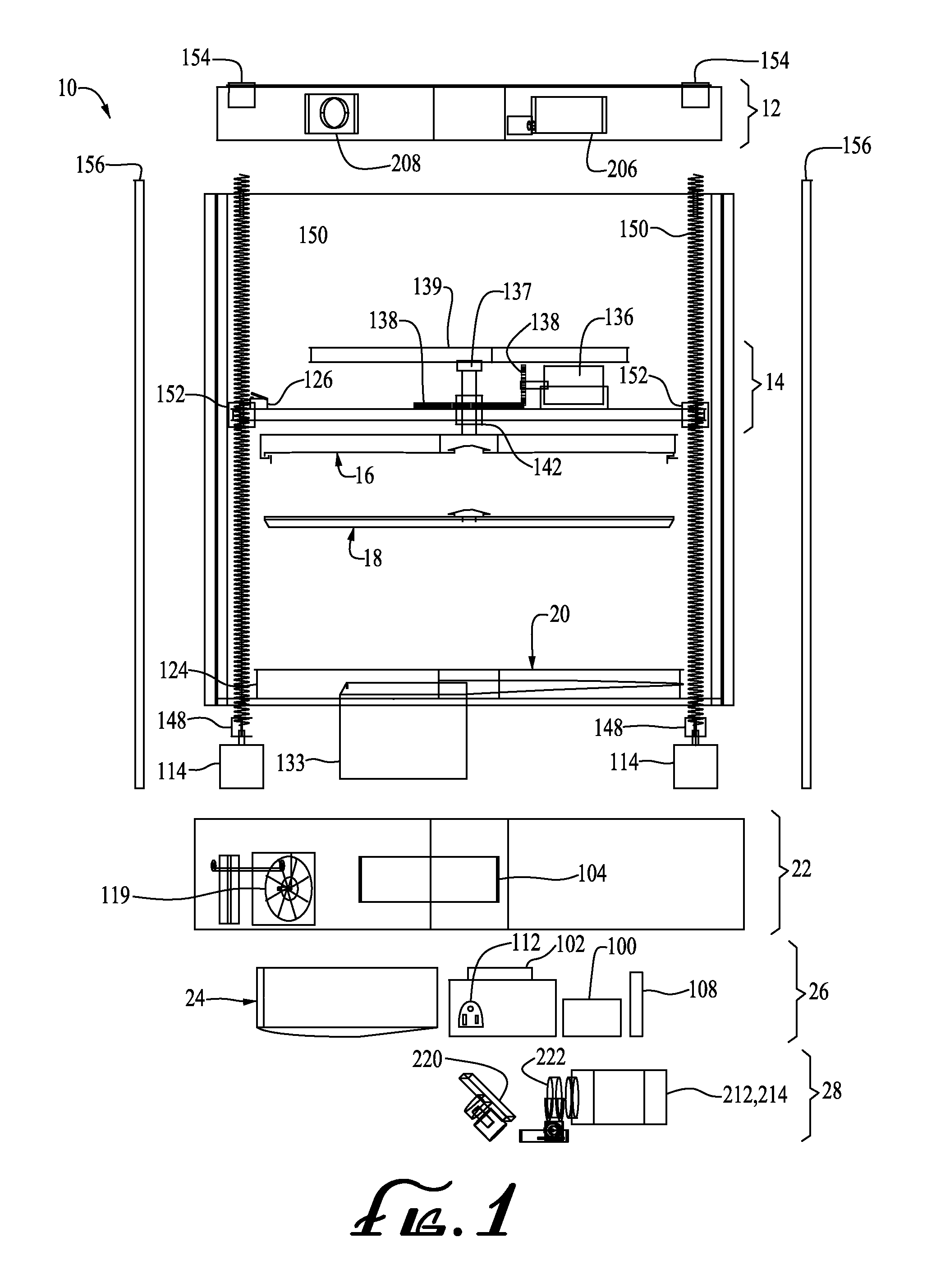

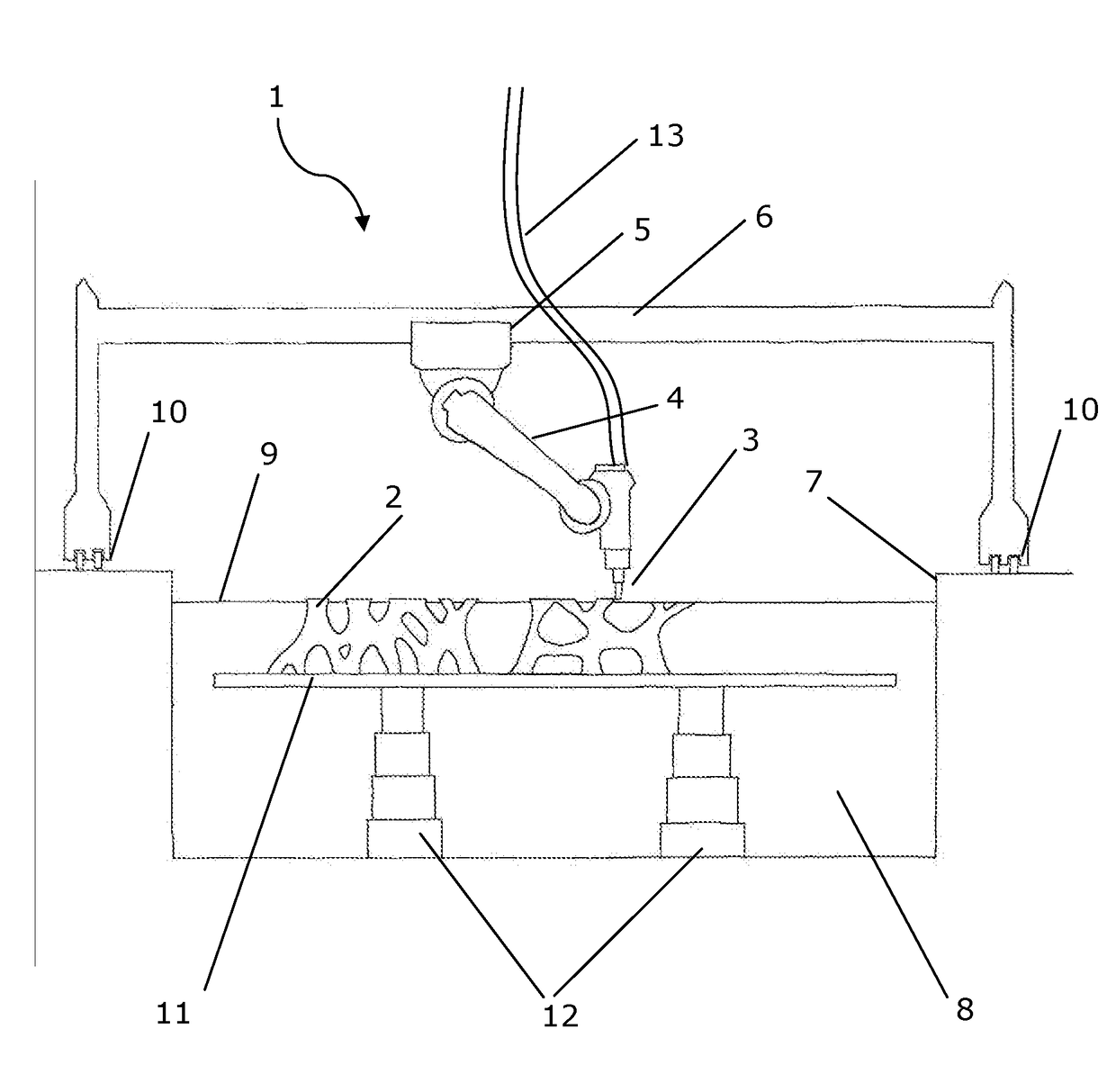

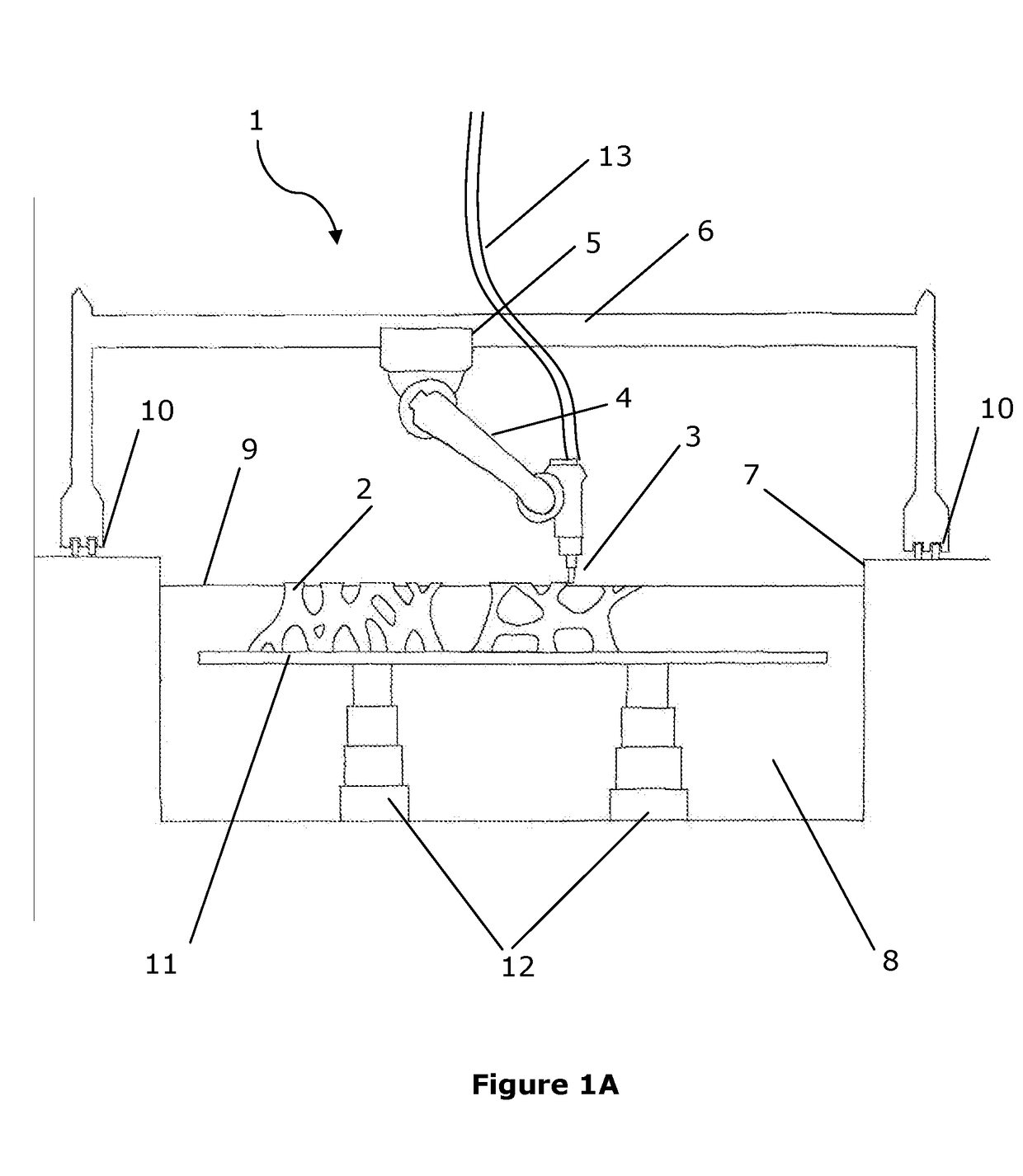

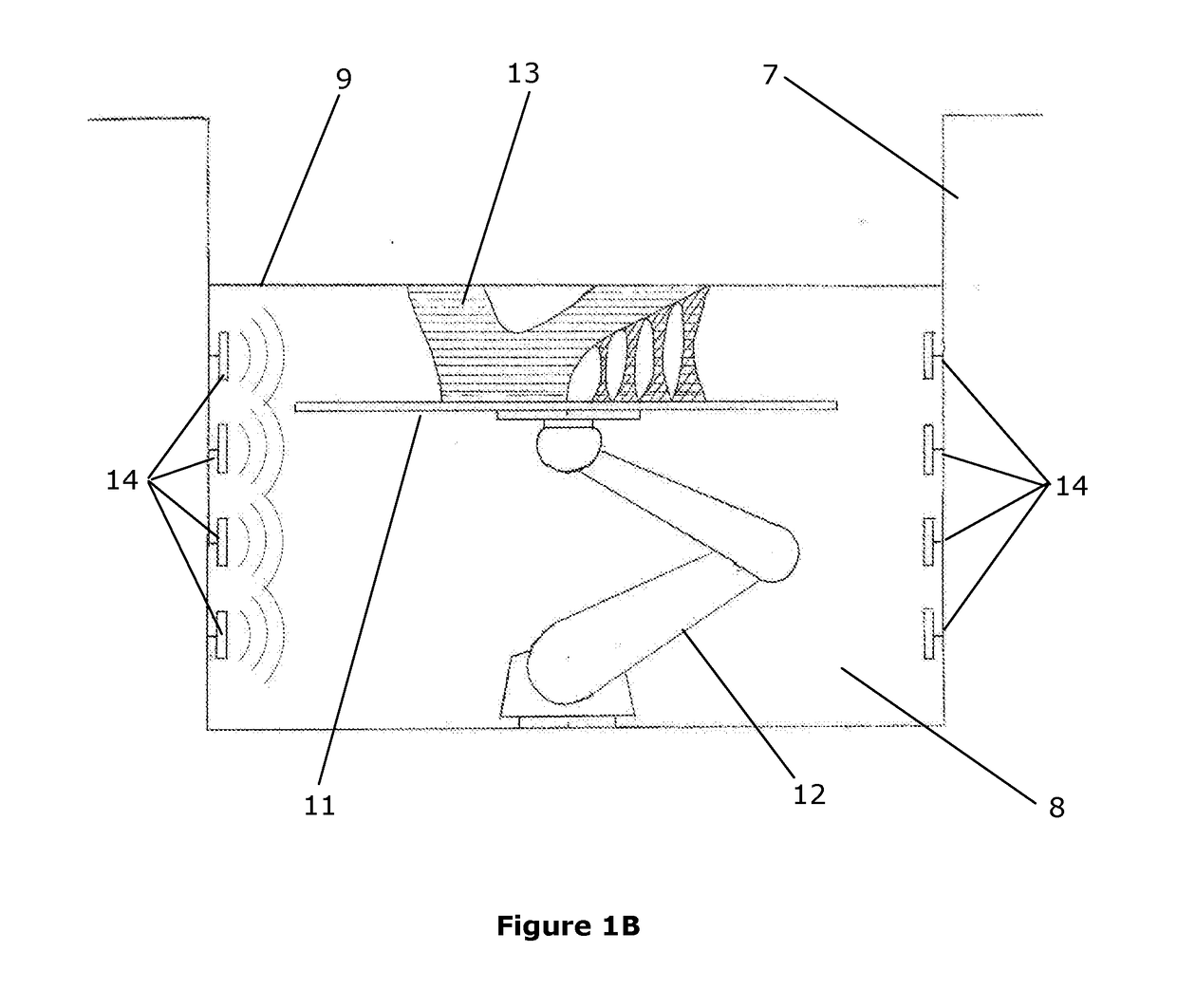

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

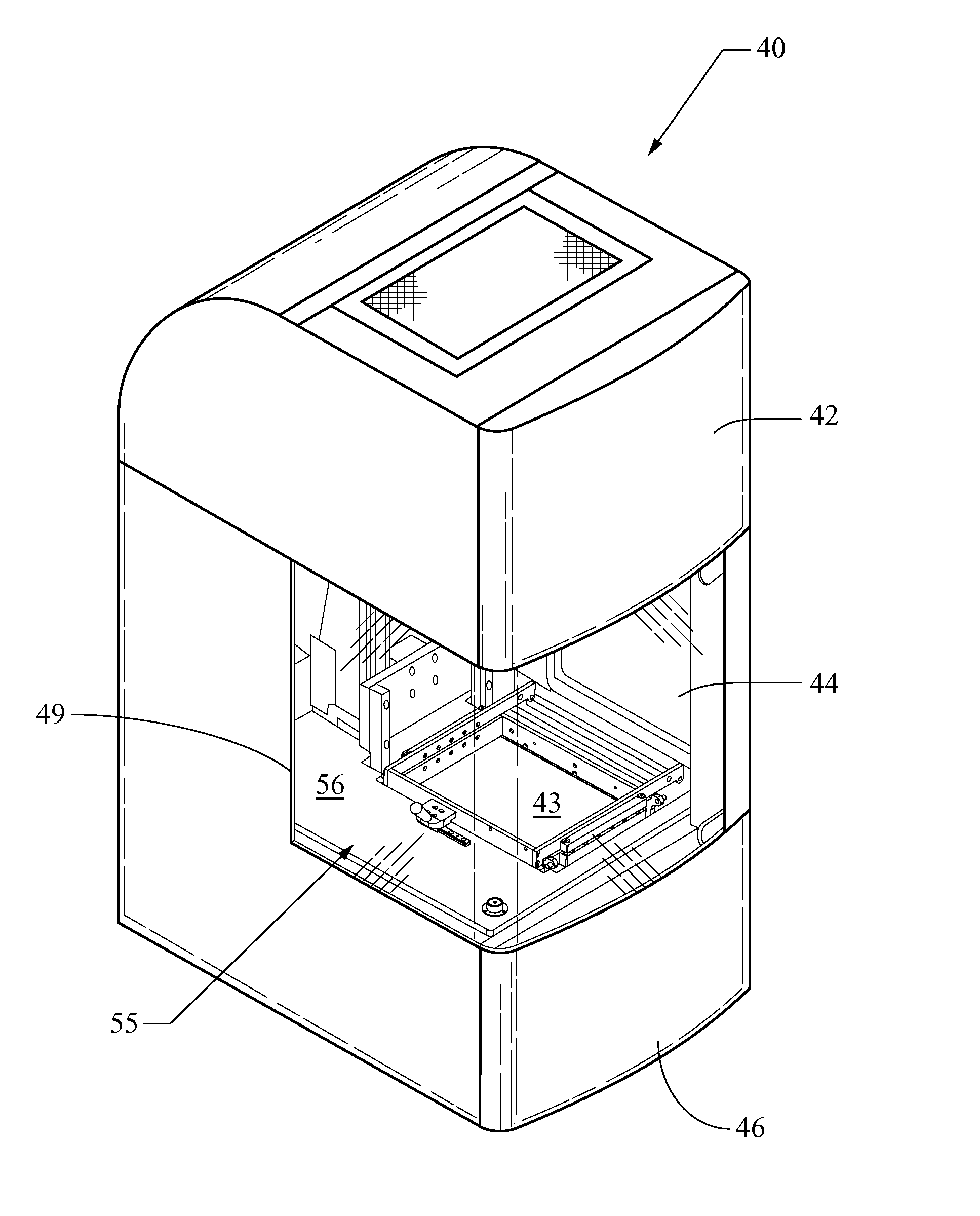

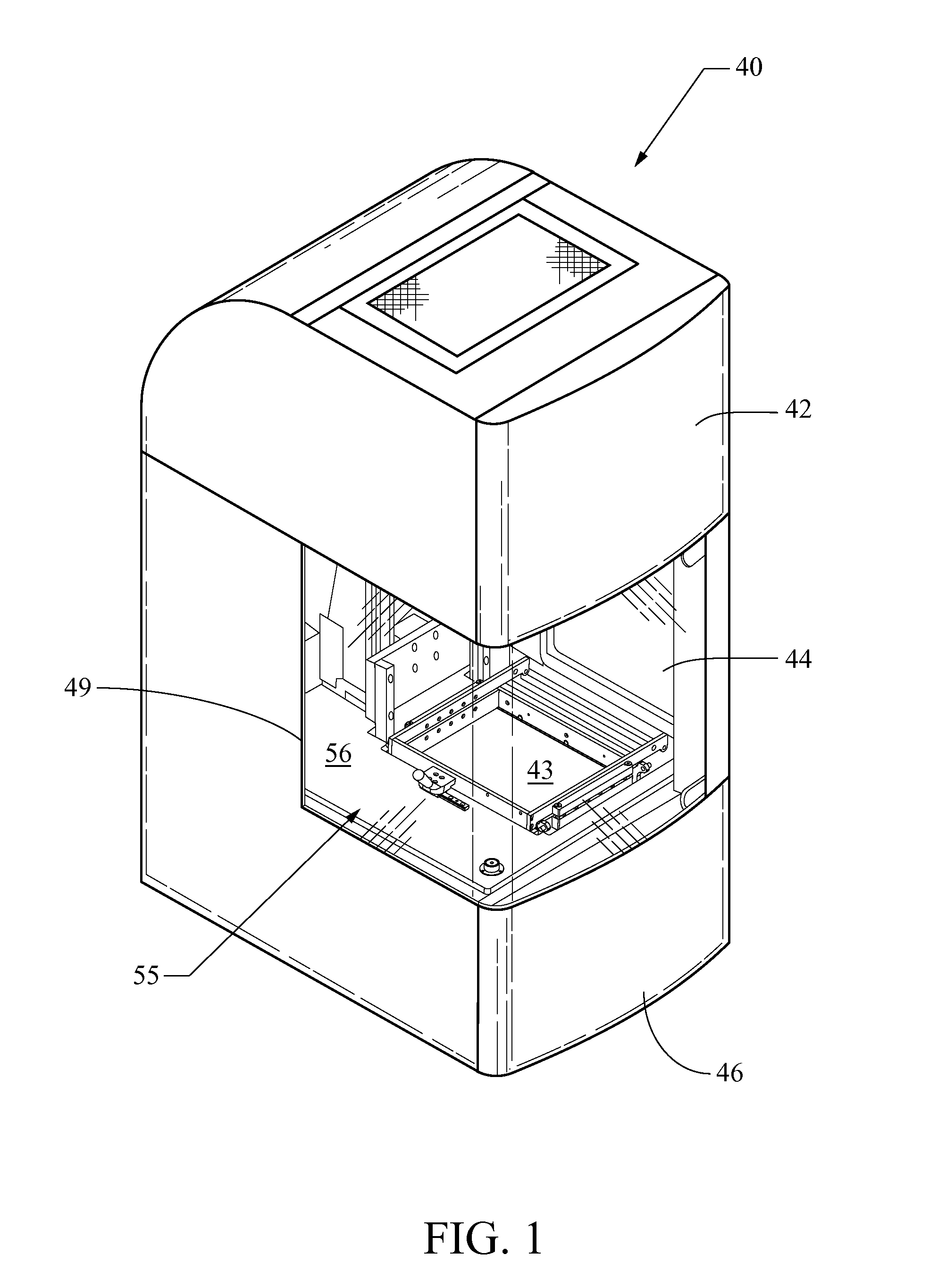

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

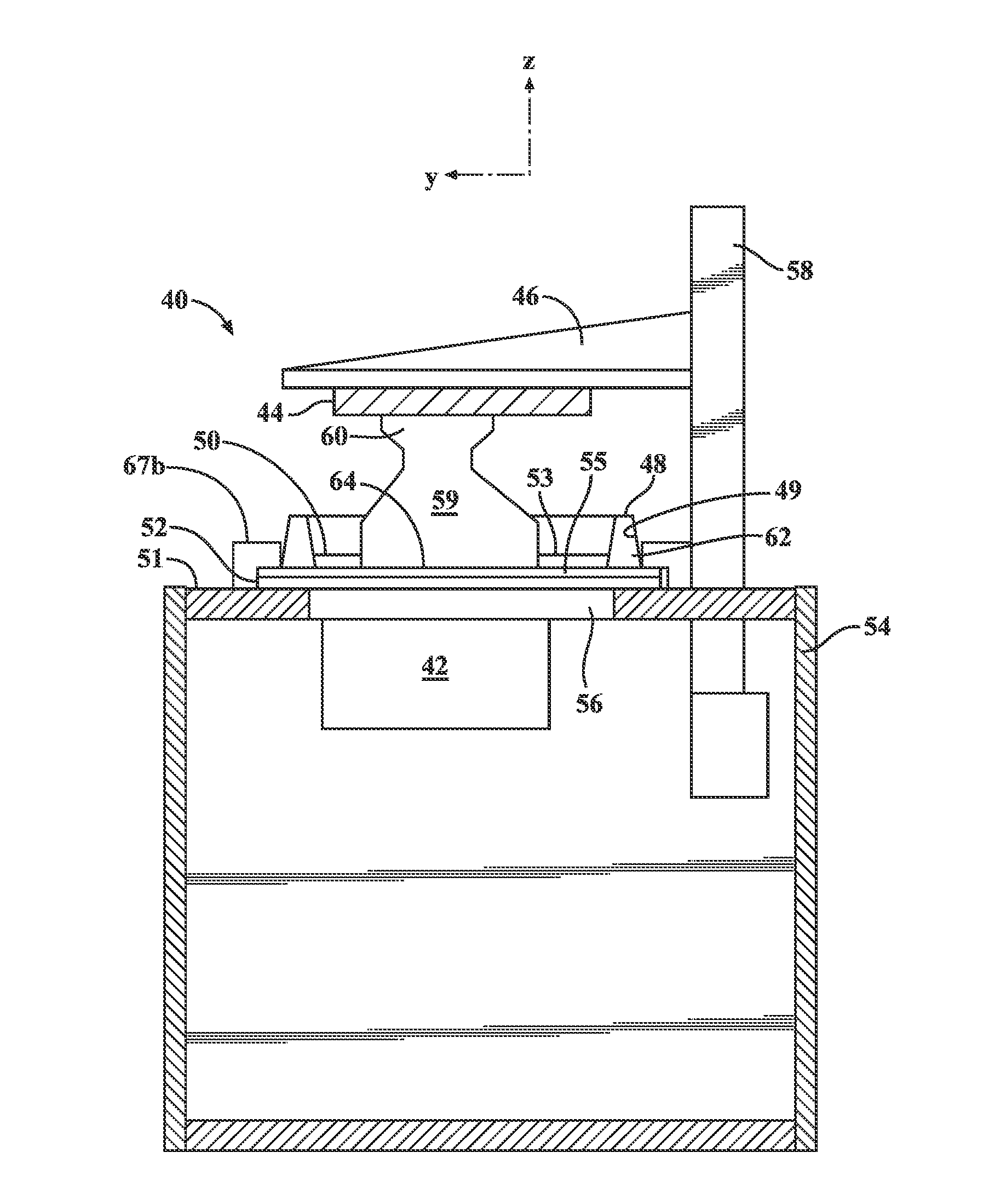

Apparatus for fabrication of three dimensional objects

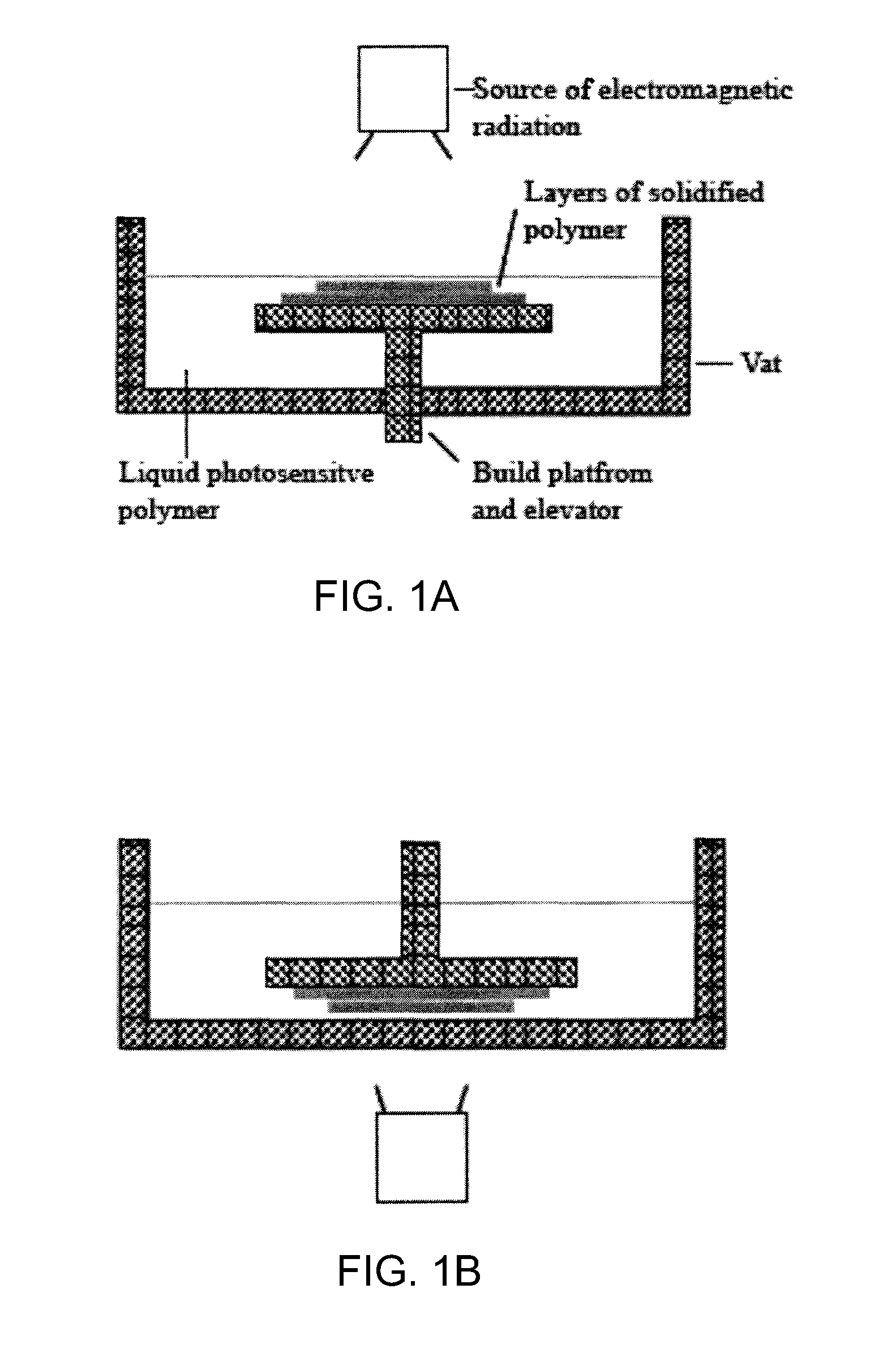

ActiveUS20140339741A1Reduce power outputIncrease exposure timeManufacturing driving meansManufacturing enclosuresPhotosensitive polymerEngineering

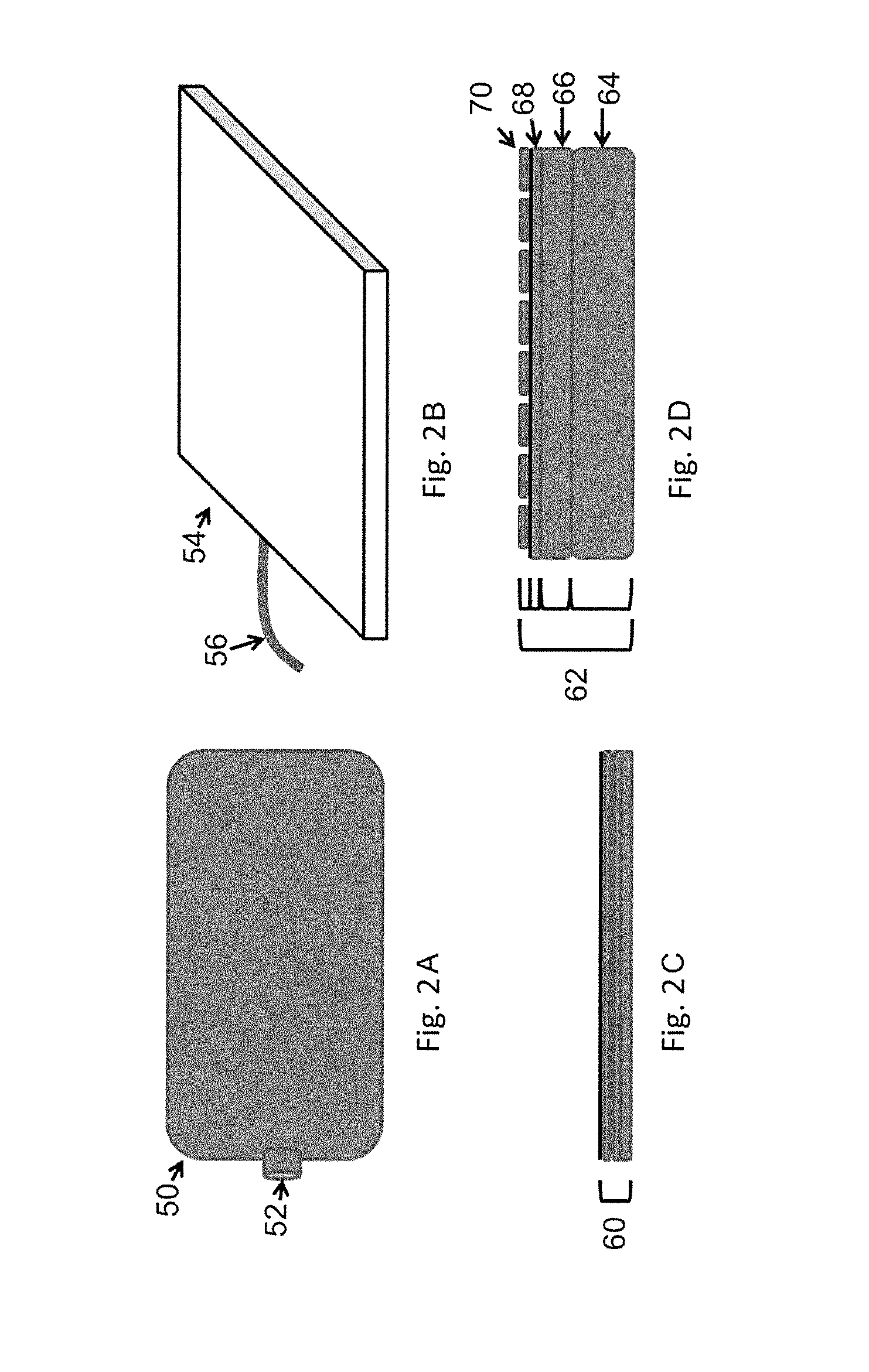

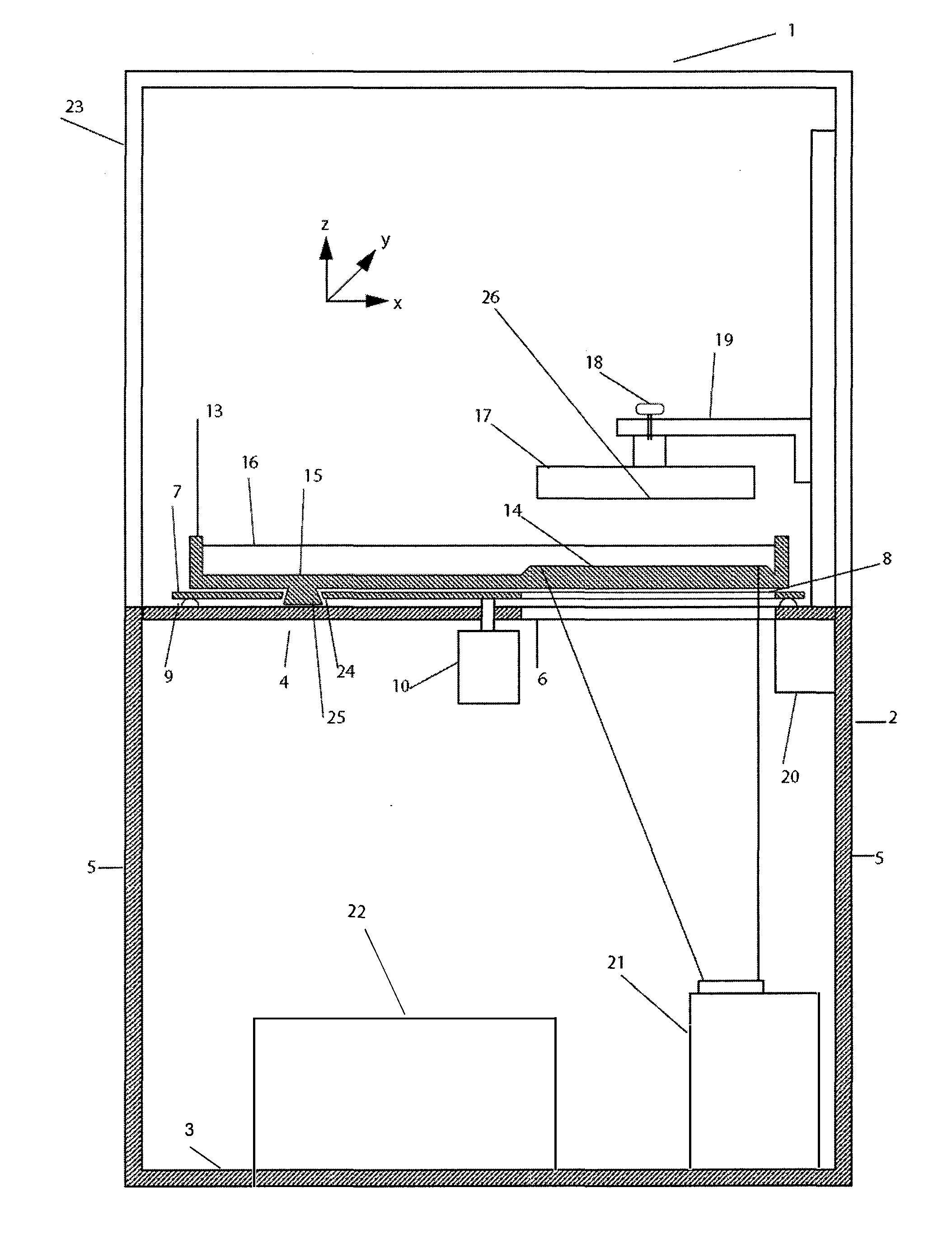

An apparatus for bottom-up fabrication of three dimensional objects, the apparatus comprising: a vat for a photosensitive polymer, the floor of the vat including a working surface arranged such that, in use, light incident on the working surface interacts with the photosensitive polymer at the working surface to fabricate a portion of the three dimensional object; a build platform capable of being inserted into the vat, the build platform having a planar surface; an elevator mechanism capable of adjusting the separation between the working surface of the vat and the planar surface of the build platform; and a rotation mechanism capable of varying the relative rotational position of the vat relative to the build platform, the relative rotation being about an axis which is normal to the working surface of the vat.

Owner:HOLO INC

Apparatus and method for forming three-dimensional objects from solidifiable paste

ActiveUS20150224710A1Manufacturing driving meansAuxillary shaping apparatusEngineeringMechanical engineering

An apparatus and method for making a three-dimensional object from a solidifiable paste is shown and described. The apparatus includes a pastes spreader, at least a portion of which extends into the solidifiable paste. The container holding the solidifiable paste and the spreader are movable relative to one another. In one system, the spreader vibrates as the container and the spreader move relative to one another. In another system, the spreader is part of a spreader assembly in which a first spreader and second spreader are angled with respect to one another, and the assembly is rotatable and lockable into multiple rotational positions. The apparatus and method allow three-dimensional objects to be progressively built upside down by ensuring that the previously solidified object section has a substantially homogeneous layer of solidifiable material available for forming a new layer of the solidified object prior to exposure to solidification energy.

Owner:GLOBAL FILTRATION SYST

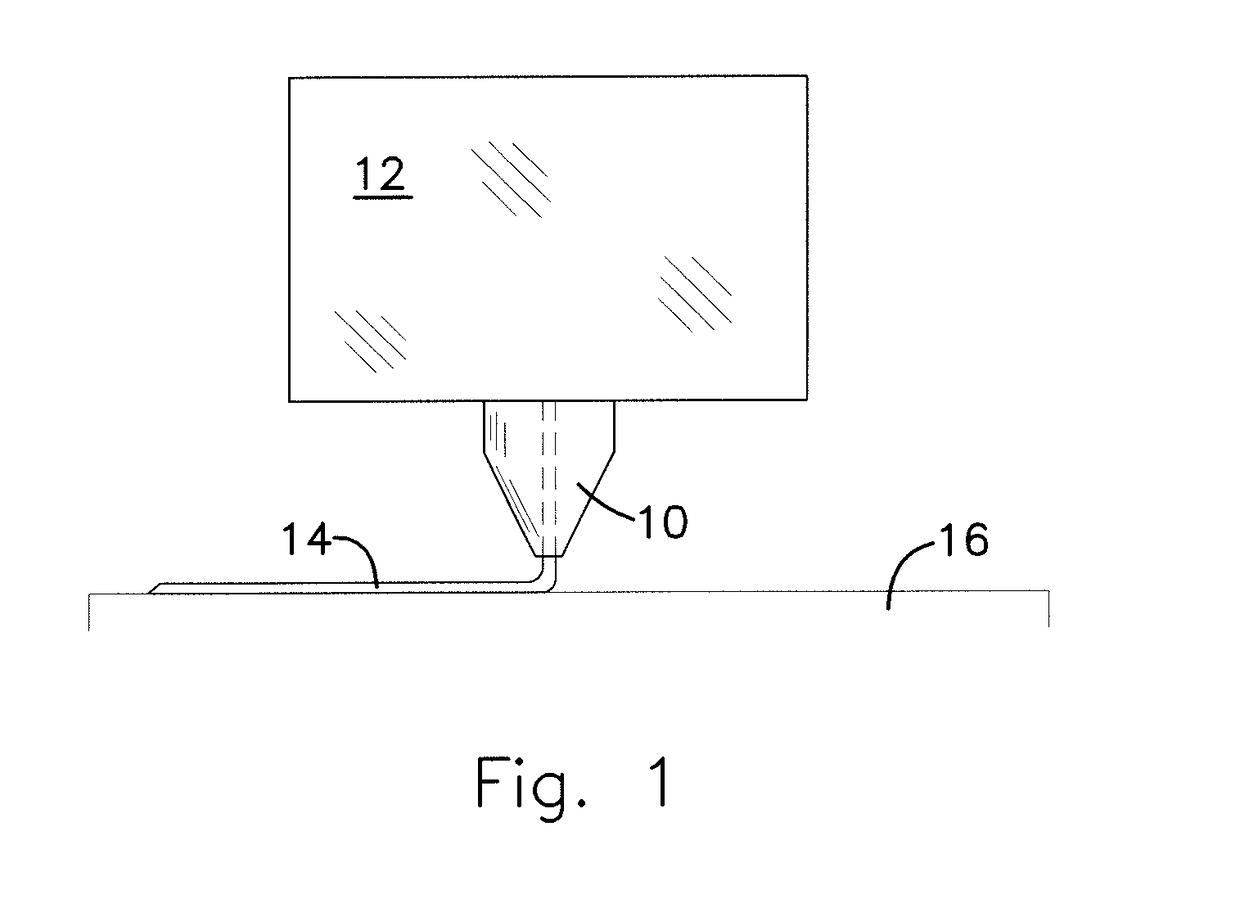

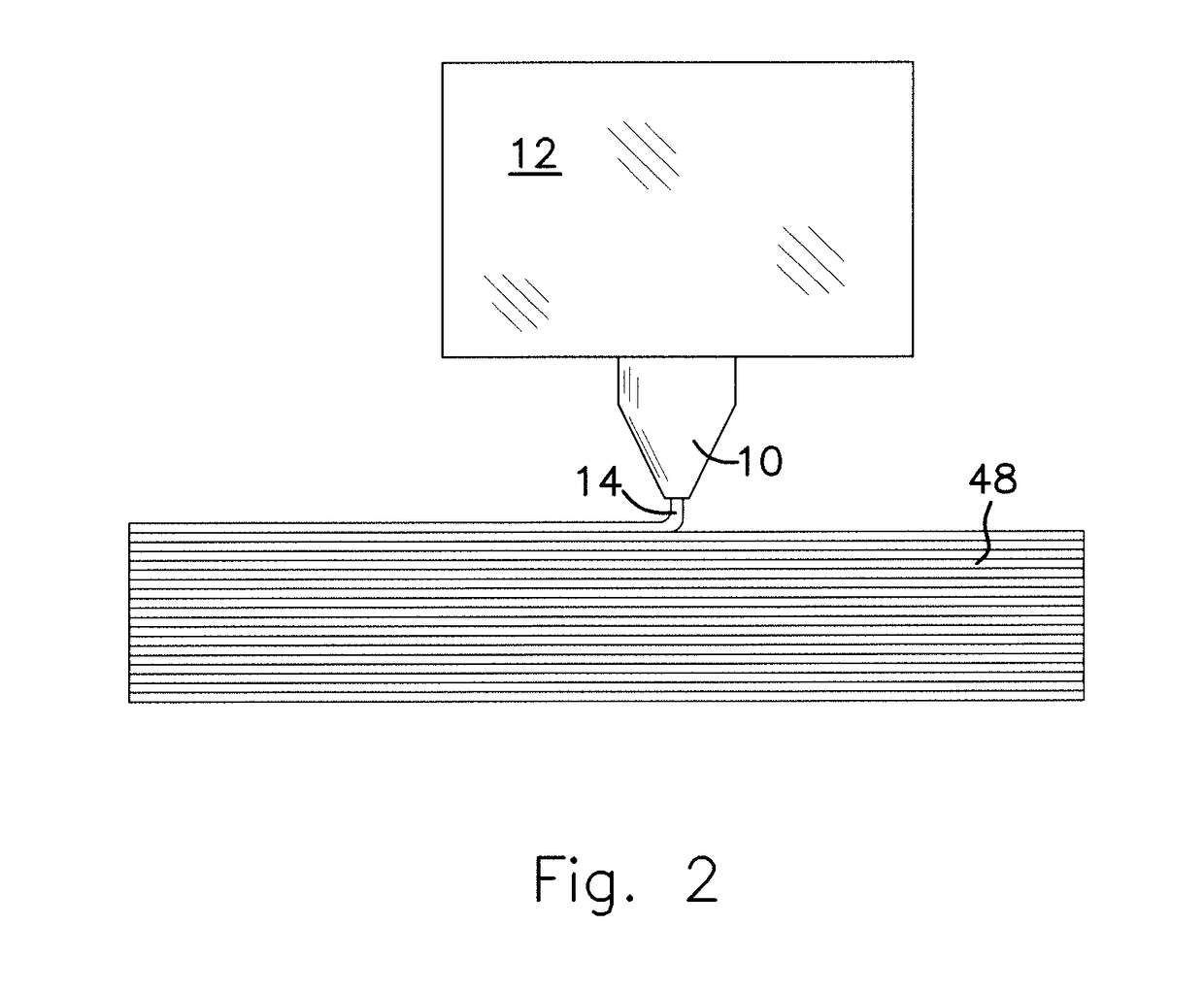

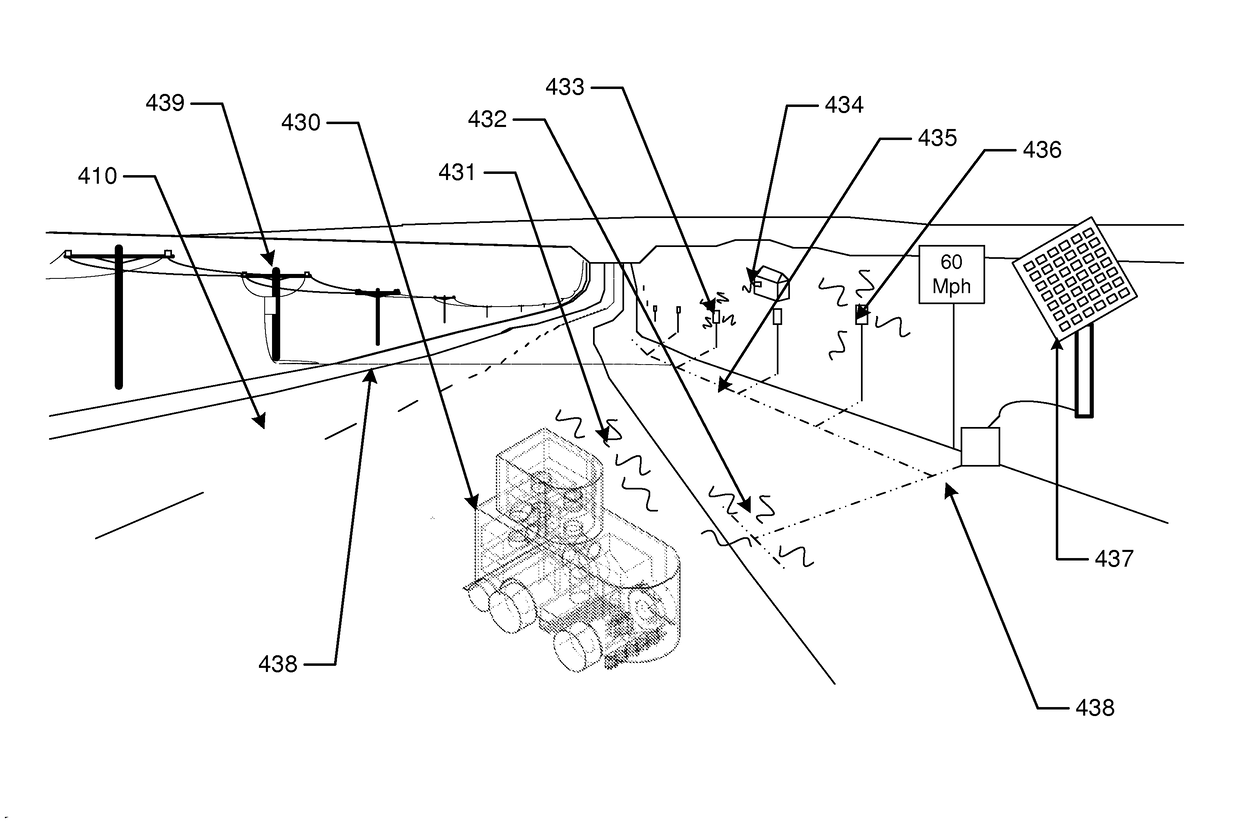

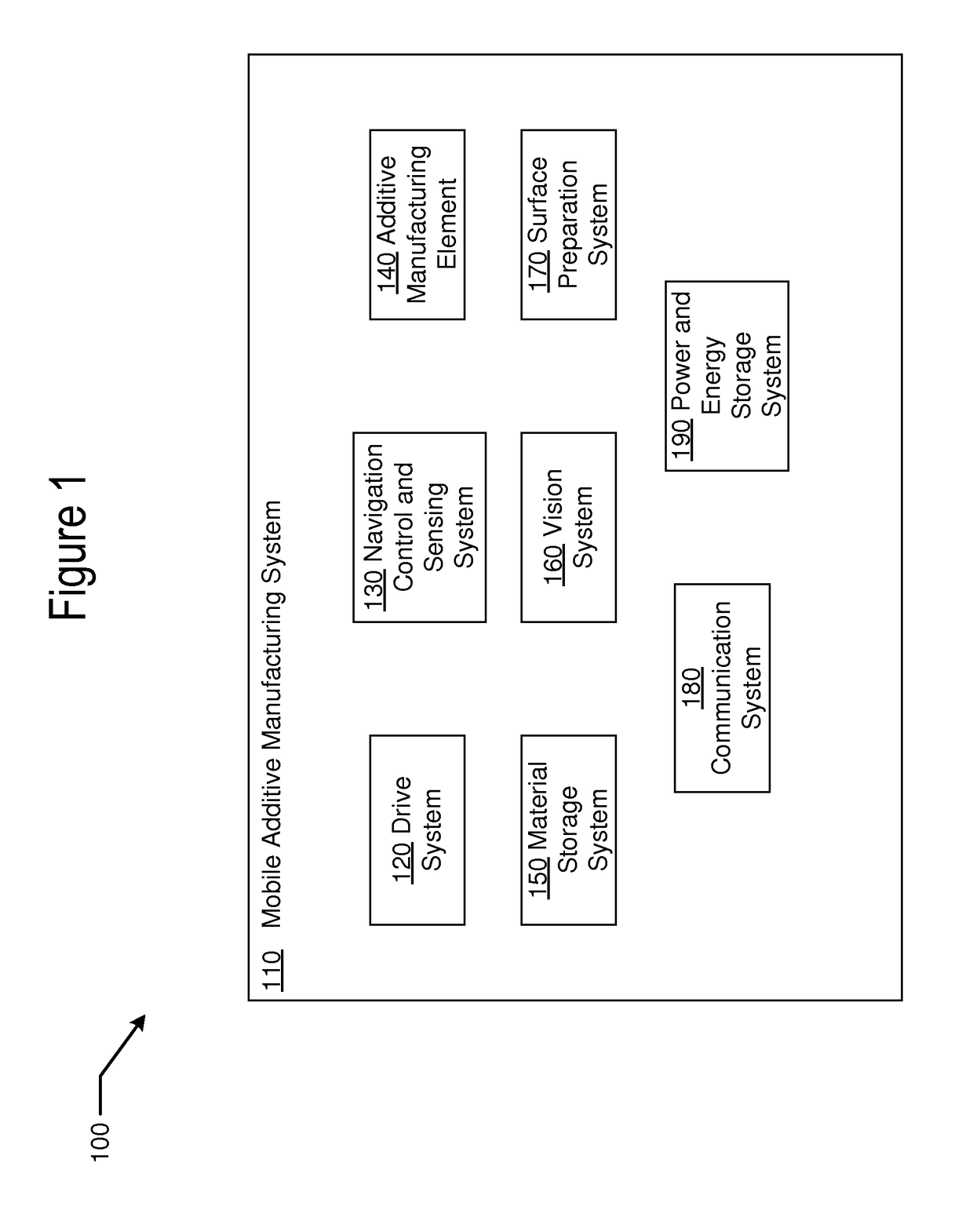

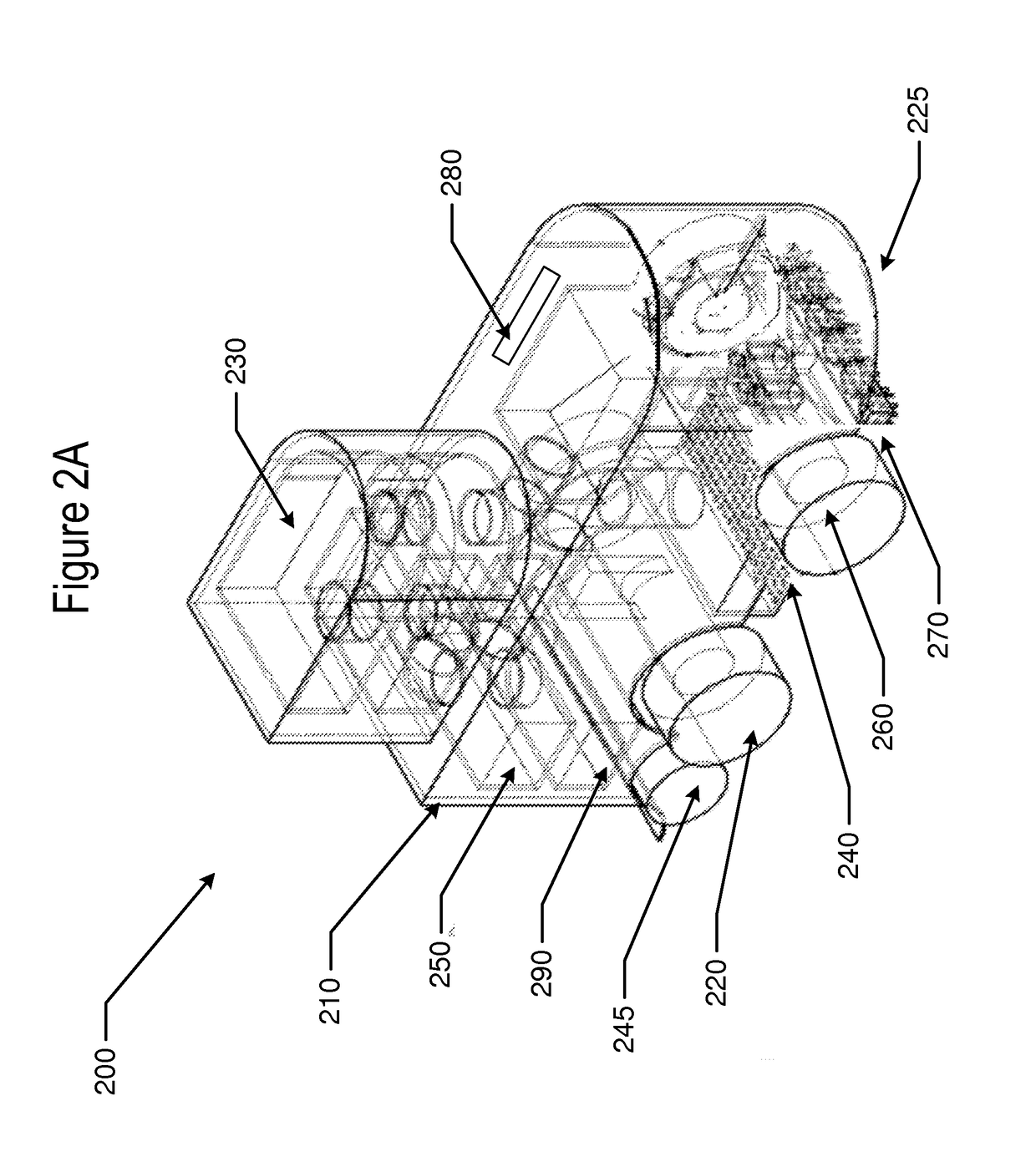

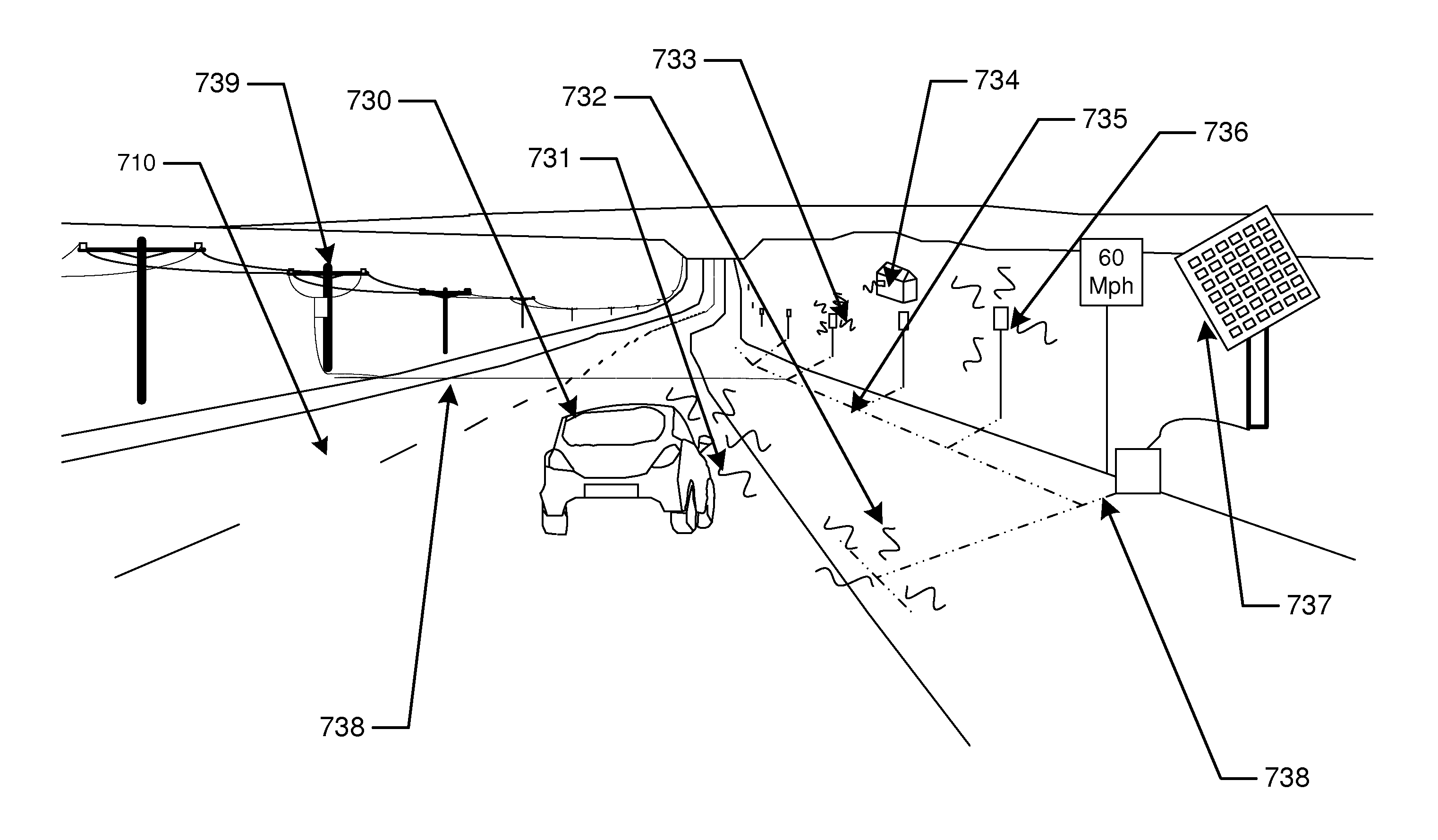

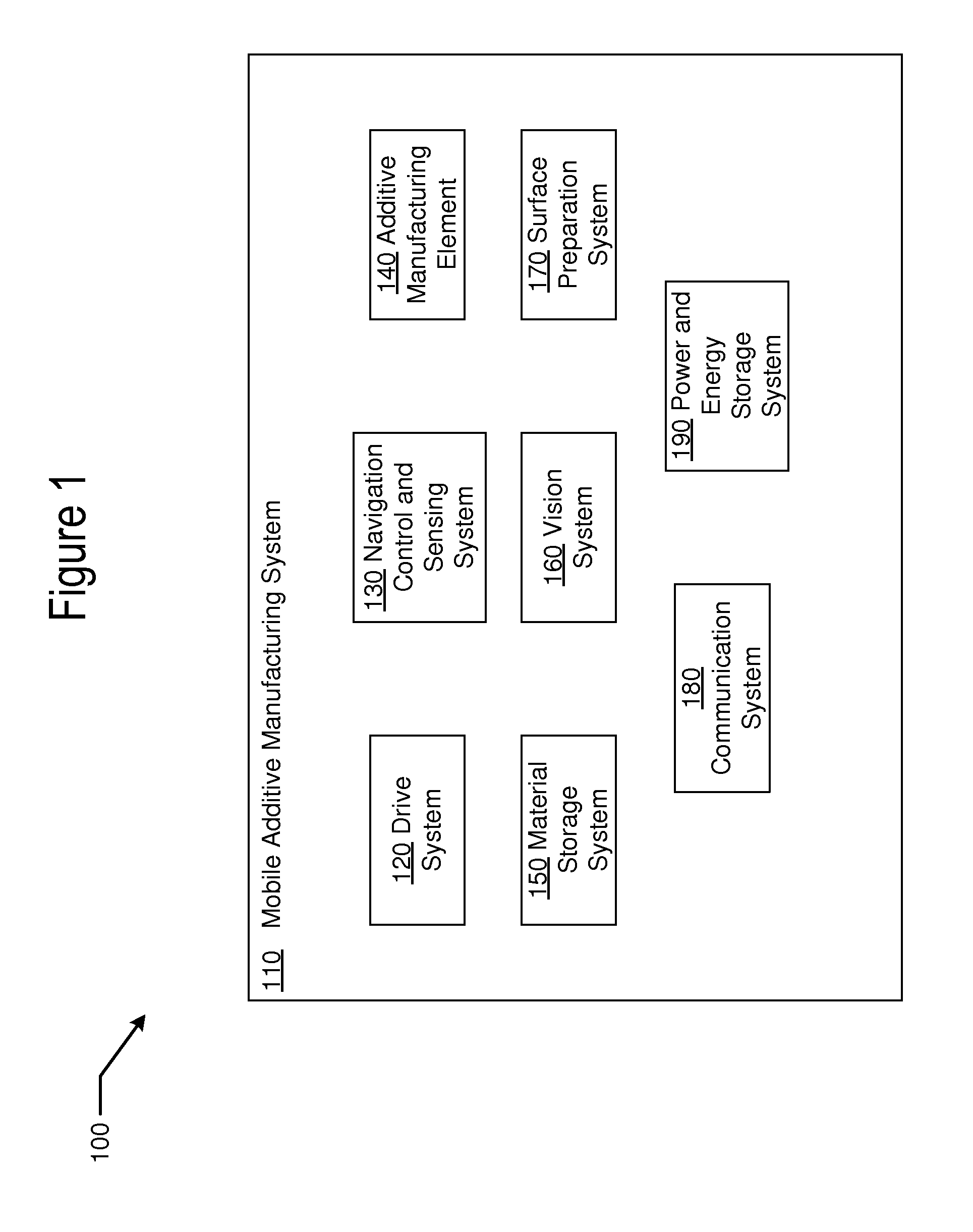

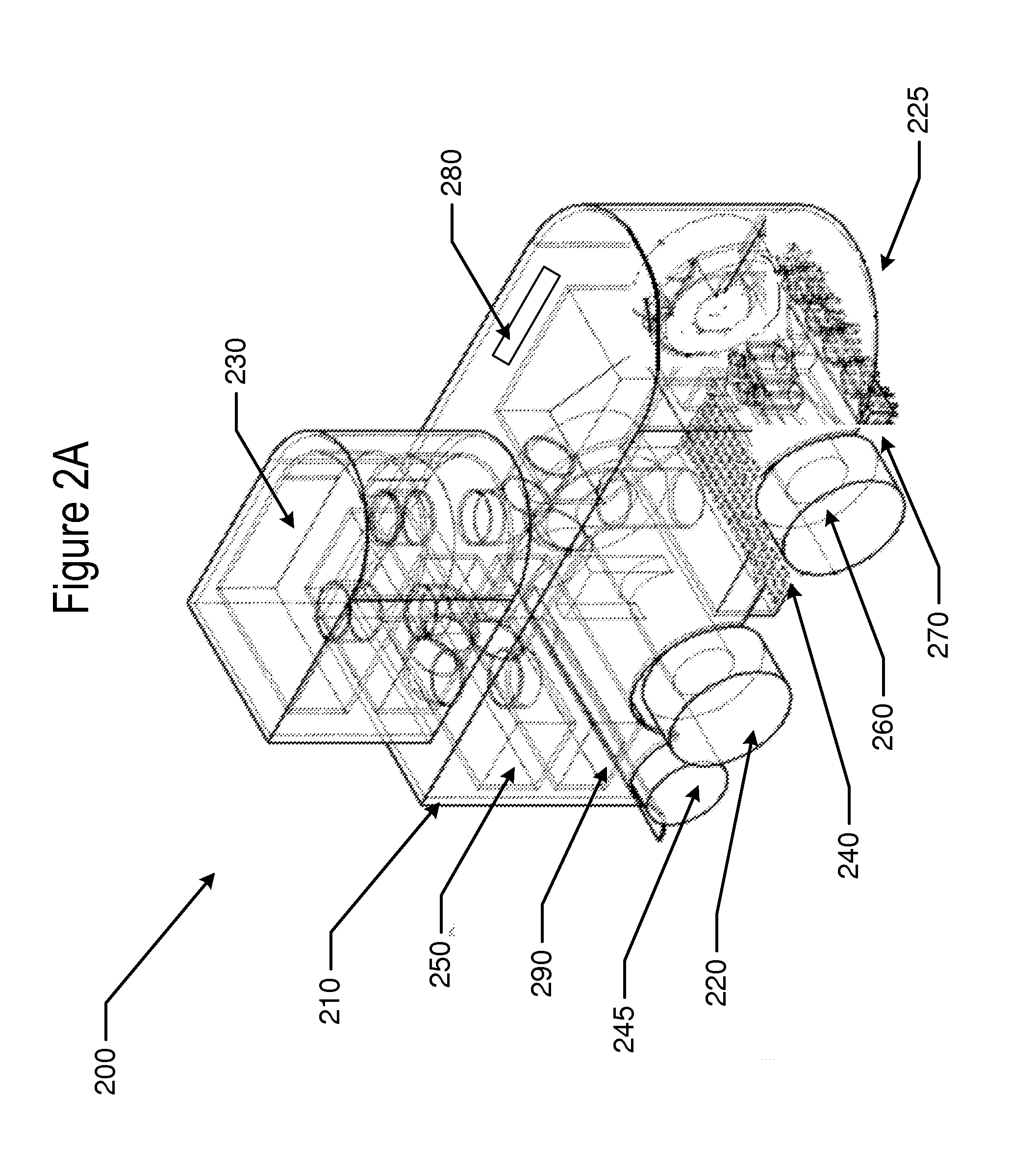

Methods and apparatus for mobile additive manufacturing of advanced structures and roadways

ActiveUS9724877B2Manufacturing platforms/substratesManufacturing driving meansAdditive layer manufacturingManufacturing engineering

The present disclosure provides various aspects for mobile and automated processing utilizing additive manufacturing and the methods for their utilization. In some examples, the mobile additive manufacturing apparatus may perform surface treatments that support the building of walls. Other examples may involve the support of creating and repairing advanced roadways.

Owner:ADDIBOTS

Method and apparatus for additive manufacturing

ActiveUS9505172B2Easy to manufactureBuilding time is minimumManufacturing driving meansManufacturing heating elementsRotational axisAdditive layer manufacturing

The present invention relates to a method for forming a three-dimensional article through successive fusion of applied powder. Said method comprising the steps of: providing at least one powder hopper comprising powder to be used for forming said three-dimensional article, providing a predetermined amount of powder at a build support, directing an energy beam over said build support causing at least a portion of said powder to sinter and causing at least a portion of said powder to bond to said build support, directing an energy beam over said build support causing said powder to fuse in selected locations according to a model to form a first portion of said three-dimensional article, rotating said build support around an axis of rotation for creating said three-dimensional article, which three-dimensional article is build up layer by layer in a radial direction with respect to said axis of rotation.

Owner:ARCAM AB

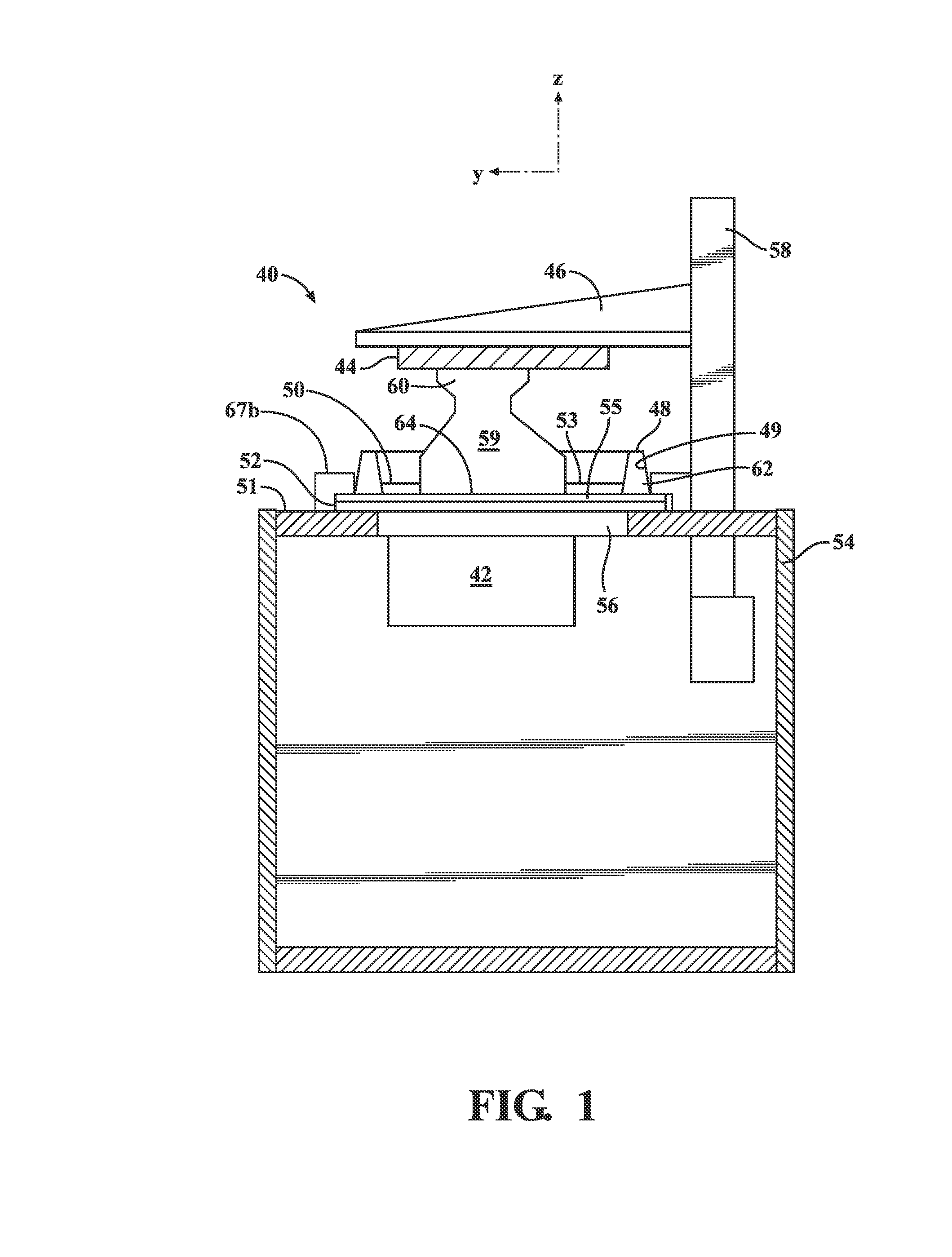

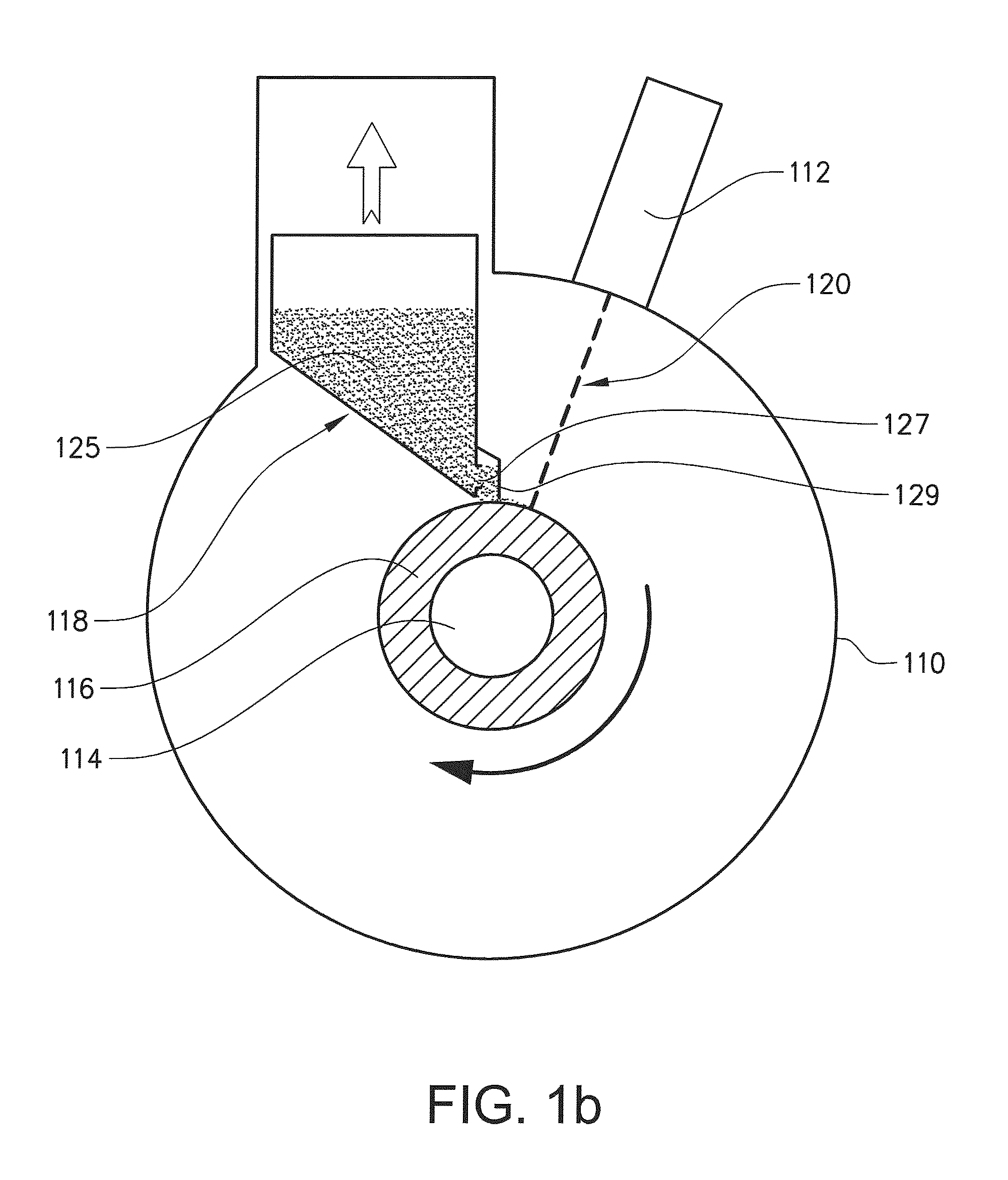

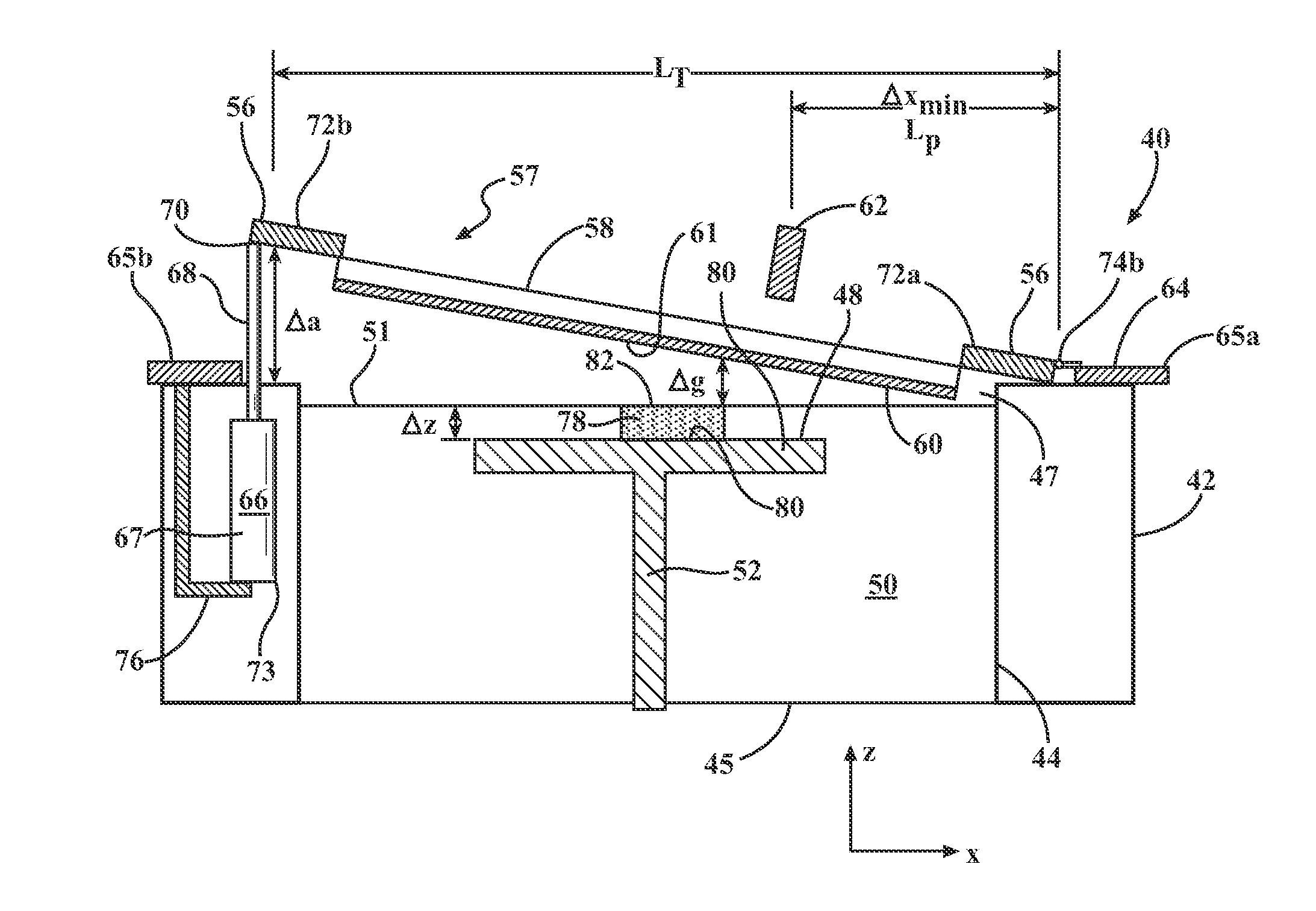

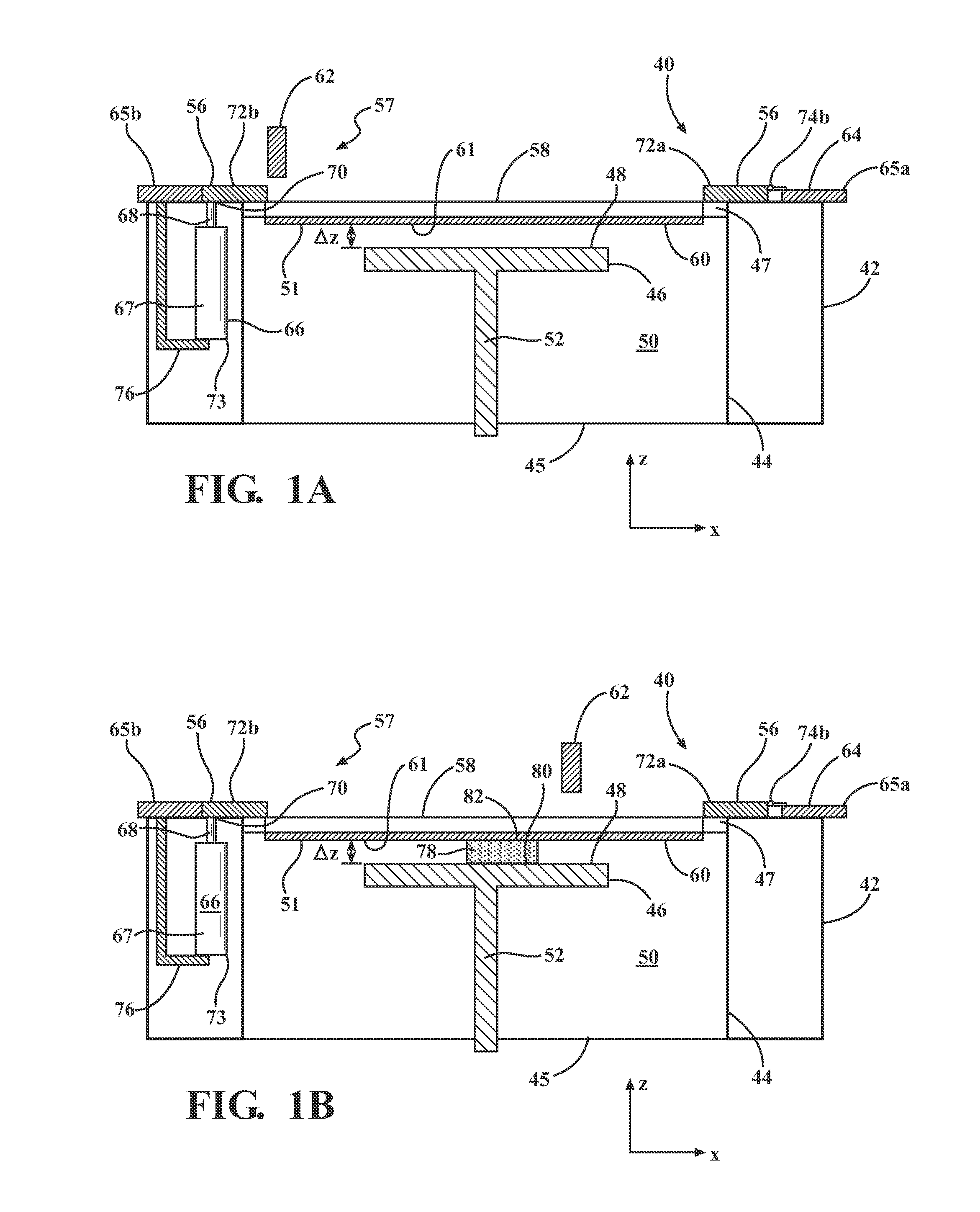

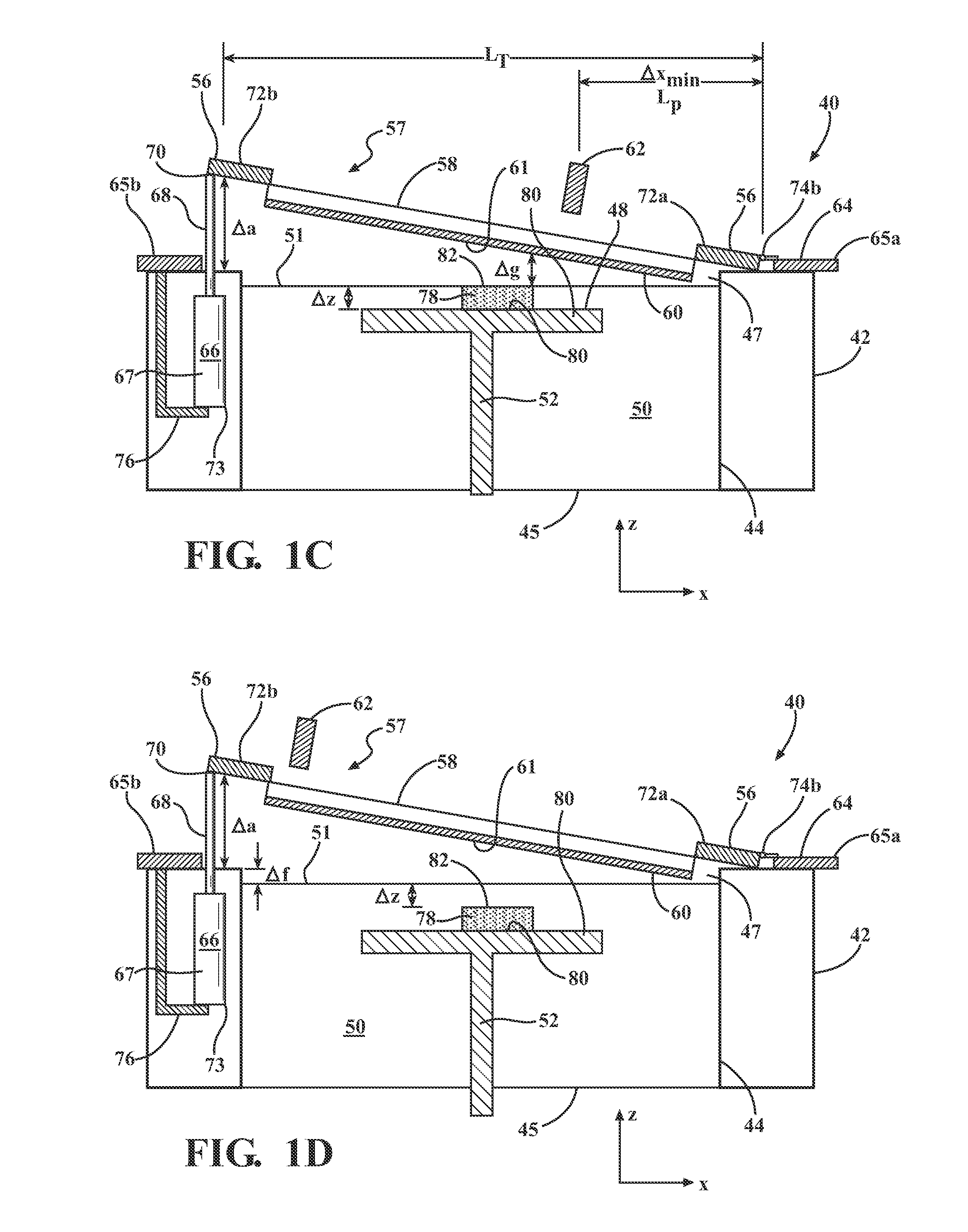

Apparatus and method for forming three-dimensional objects using a tilting solidification substrate

An apparatus and method for making a three-dimensional object from a solidifiable material using a linear solidification device is shown and described. The apparatus includes a solidification substrate that is tiltable relative to a film about a tilting axis. Layers of the solidifiable material solidify in contact with a film located between the most recently solidified object layer and a solidification substrate that comprises the solidification substrate assembly. The tilting of the solidification substrate relative to the film allows the substrate to be used to squeeze excess solidifiable material from between the film and the most recently solidified object surface while minimizing or eliminating the formation of bubbles in the solidifiable material which can prolong object build times. In addition, tilting the solidification substrate before separating an adhered object surface from the film breaks any vacuum formed between the substrate and the film which reduces the forces involved in separating the object form the film.

Owner:GLOBAL FILTRATION SYST

Method and Apparatus for Fabricating a Composite Object

ActiveUS20170106594A1Manufacturing platforms/substratesManufacturing driving meansComposite objectMaterials science

A method for fabricating a composite object with a computer-controlled apparatus, and the apparatus therefor. The comprises a reservoir containing liquid, curable first material, means to selectively solidify the first material and means to selectively deposit a second material. The method involves the steps of selectively depositing portions of the second material, and selectively solidifying portions of the first material, such that the solidified portions of the first material and the deposited portions of the second material form the composite object.

Owner:LAING OROURKE AUSTRALIA PTY LTD

Two-motor multi-head 3D printer extrusion system

InactiveUS20150140147A1Save valuable spaceLow costManufacturing driving meansConfectioneryEngineeringDrive motor

A 3D printing system having a rotating plate wherein at least two printing components are selectively attached to said rotating plate, and wherein said rotating plate is capable or rotating to selectively engage each said printing component to a drive motor which is capable of driving the printing component when engaged.

Owner:KONSTANTINOS JOSHUA FROST +1

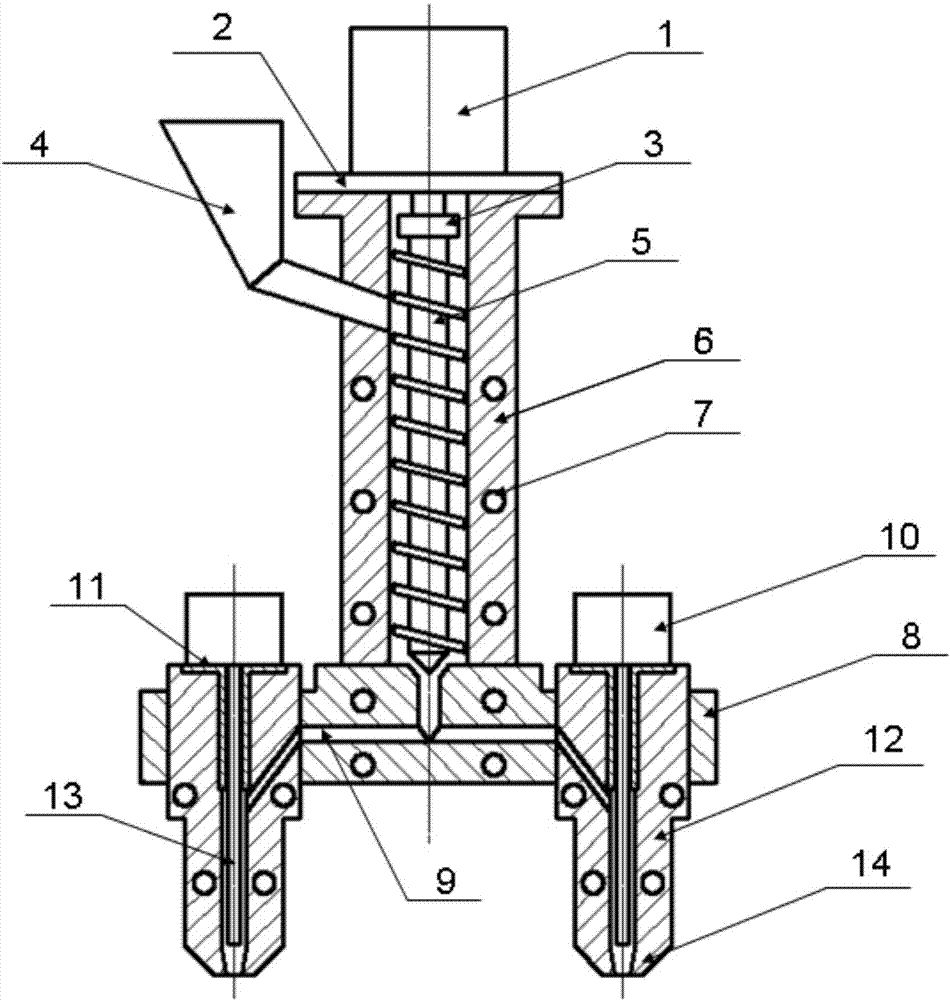

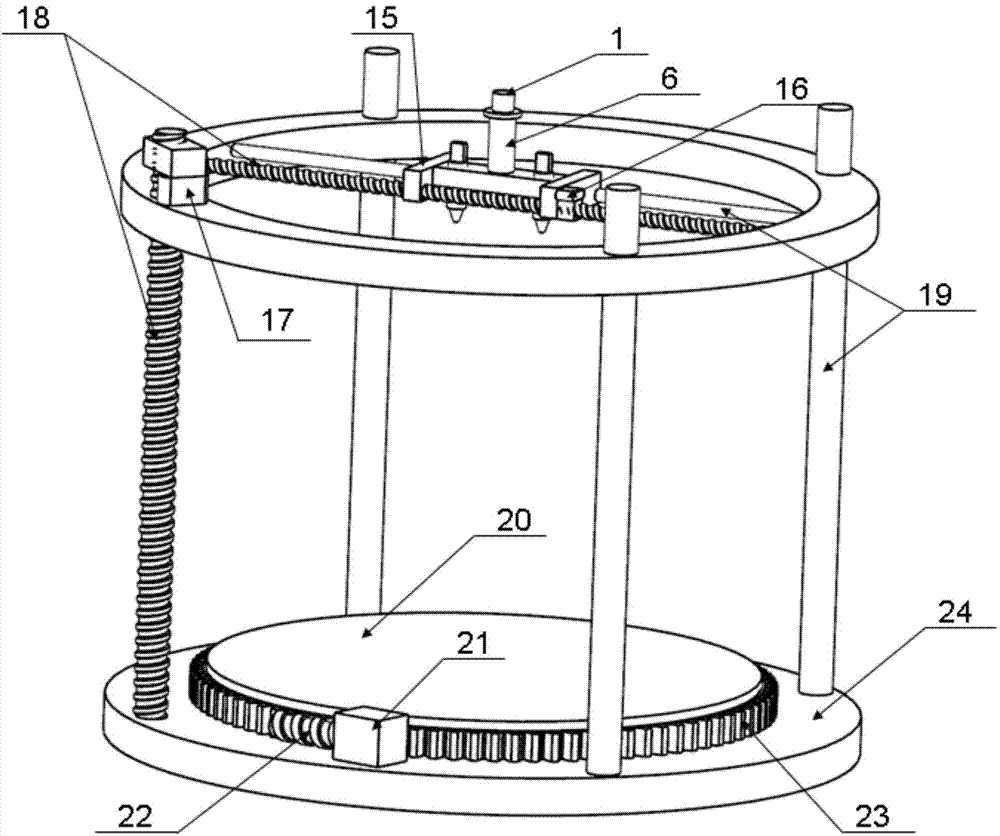

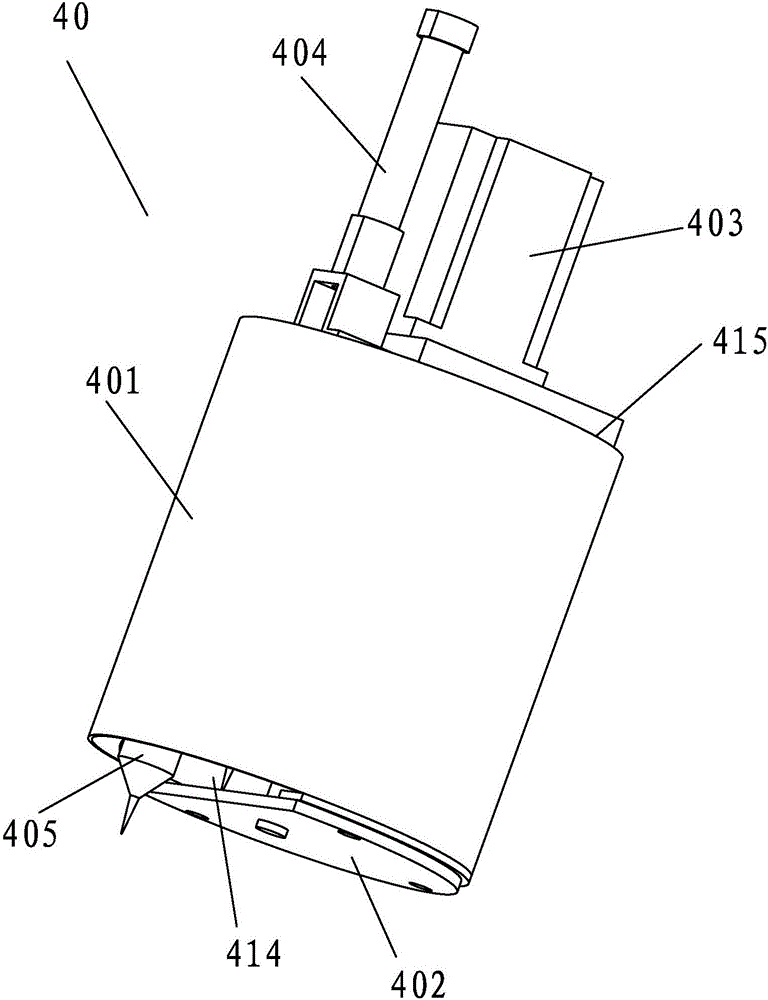

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

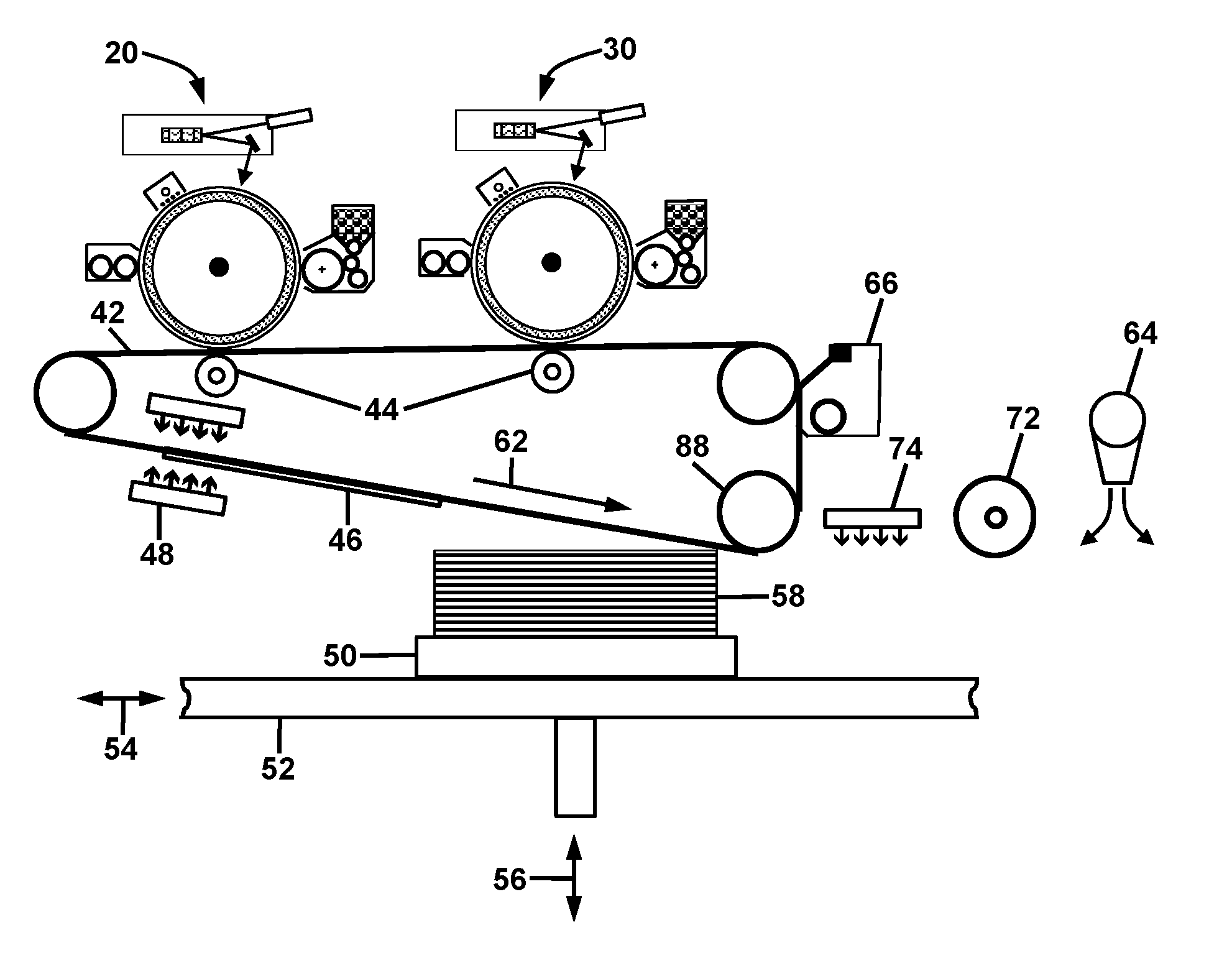

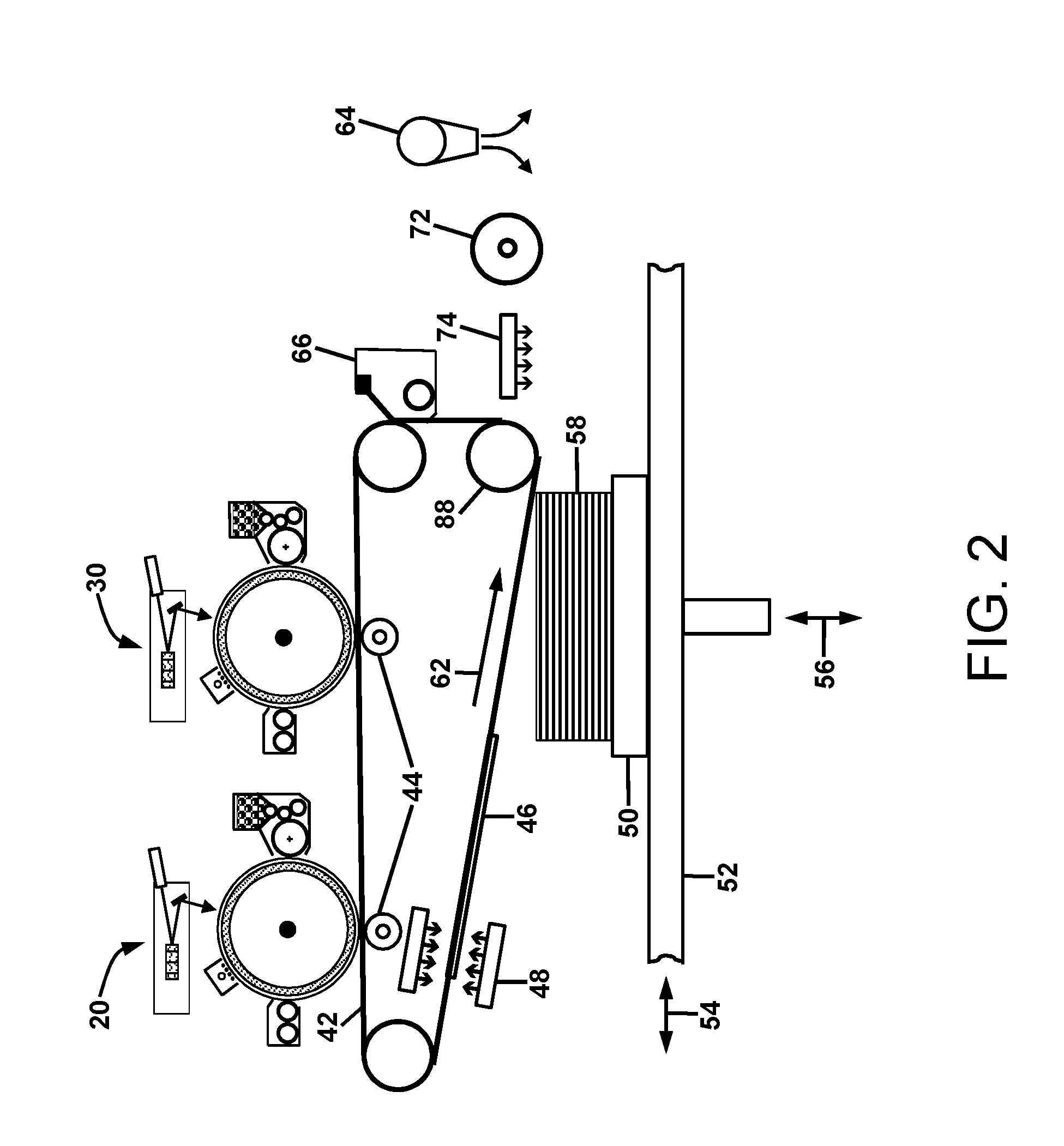

Fabrication of 3D objects via multiple build platforms

ActiveUS20160200084A1Shorten cycle timeImprove productivityMechanical working/deformationManufacturing driving meansProduction rateMultiple platform

A method is disclosed for improving the productivity of digitally fabricated 3D objects with the same or different shape and material composition. The improved productivity is enabled by the incorporation of multiple build platforms and multiple objects per build platform within a 3D object fabrication apparatus. Some 3D manufacturing processes such as those based on electrophotography require a wait time to condition the build object before the next layer of build and support material can be applied. Under these fabrication conditions, the utilization of multiple build platforms in the 3D object manufacturing process effectively minimizes the wait time between layer deposition so that the productivity for fabricating 3D objects is improved. Furthermore, the incorporation of an additional adjacent set of multiple platforms enables rapid changeover when the fabrication of one set of 3D objects is completed on an adjacent set of build platforms.

Owner:XACTIV

3D printing using spiral buildup

ActiveUS9321215B2High and accurate level of detailShort timeManufacturing platforms/substratesManufacturing driving meansSingle CenterPhotopolymer

Methods, devices and systems for efficient 3D printing that address conventional inefficiencies while utilizing a single compact device are set forth. Some embodiments utilize a circular-shaped build area revolving symmetrically around a single center point utilizing a continuous helical printing process. In one embodiment a liquid photopolymer for solidification is deposited on a build platform to form the physical object The Build platform is continuously rotated and simultaneously raised in a gradual programmed manner. Focused from below the platform produces a single continuous “layer” of material deposited and bonded in a helical fashion.

Owner:ORANGE MAKER

Methods and apparatus for mobile additive manufacturing of advanced structures and roadways

ActiveUS20140374933A1Manufacturing platforms/substratesManufacturing driving meansAdditive layer manufacturingManufacturing engineering

The present disclosure provides various aspects for mobile and automated processing utilizing additive manufacturing and the methods for their utilization. In some examples, the mobile additive manufacturing apparatus may perform surface treatments that support the building of walls. Other examples may involve the support of creating and repairing advanced roadways.

Owner:ADDIBOTS

3D Printing

ActiveUS20170190112A1Manufacturing driving meansAdditive manufacturing with solidsPositive pressureLaser beams

A system and method for Selective Laser Fusing of a 3D part is disclosed. The system may comprise a platform, a gantry, a dispenser, a first press, a laser configured to emit a laser beam onto powdered material, a positive pressure chamber at least partially surrounding the laser, and a controller. The controller may be configured to: (a) receive data that includes a representation of the 3D part sliced into a plurality of layers; (b) rotate on a path about an axis either the platform or simultaneously each of the dispenser, the first press, the positive pressure chamber and the laser; (c) activate the dispenser to deposit the powdered material during (b); (d) activate the laser to emit during (b) the laser beam onto the powdered material to Fuse the powdered material into a layer of the plurality of layers; and (e) repeat (b)-(d) to make the 3D part.

Owner:CATERPILLAR INC

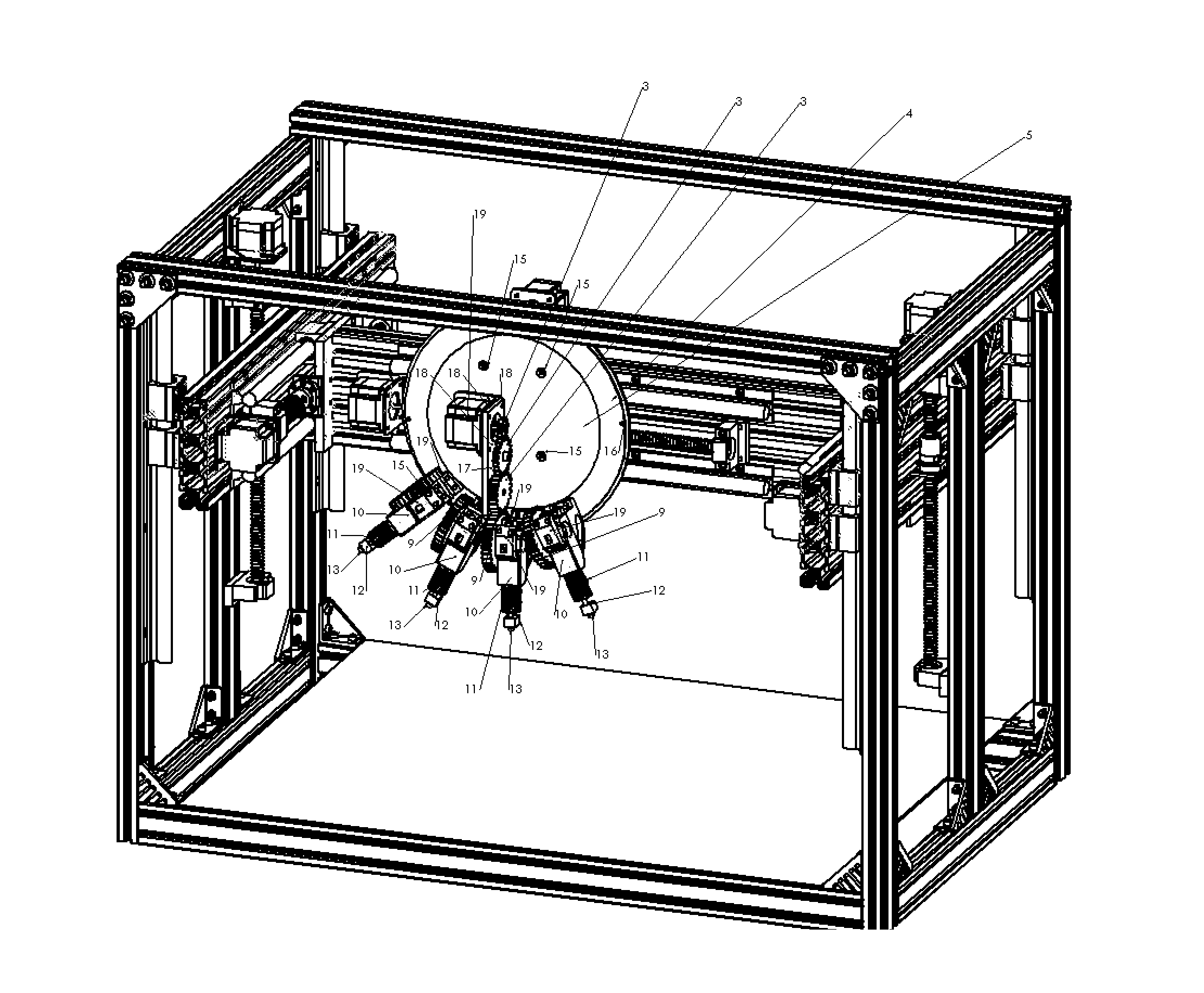

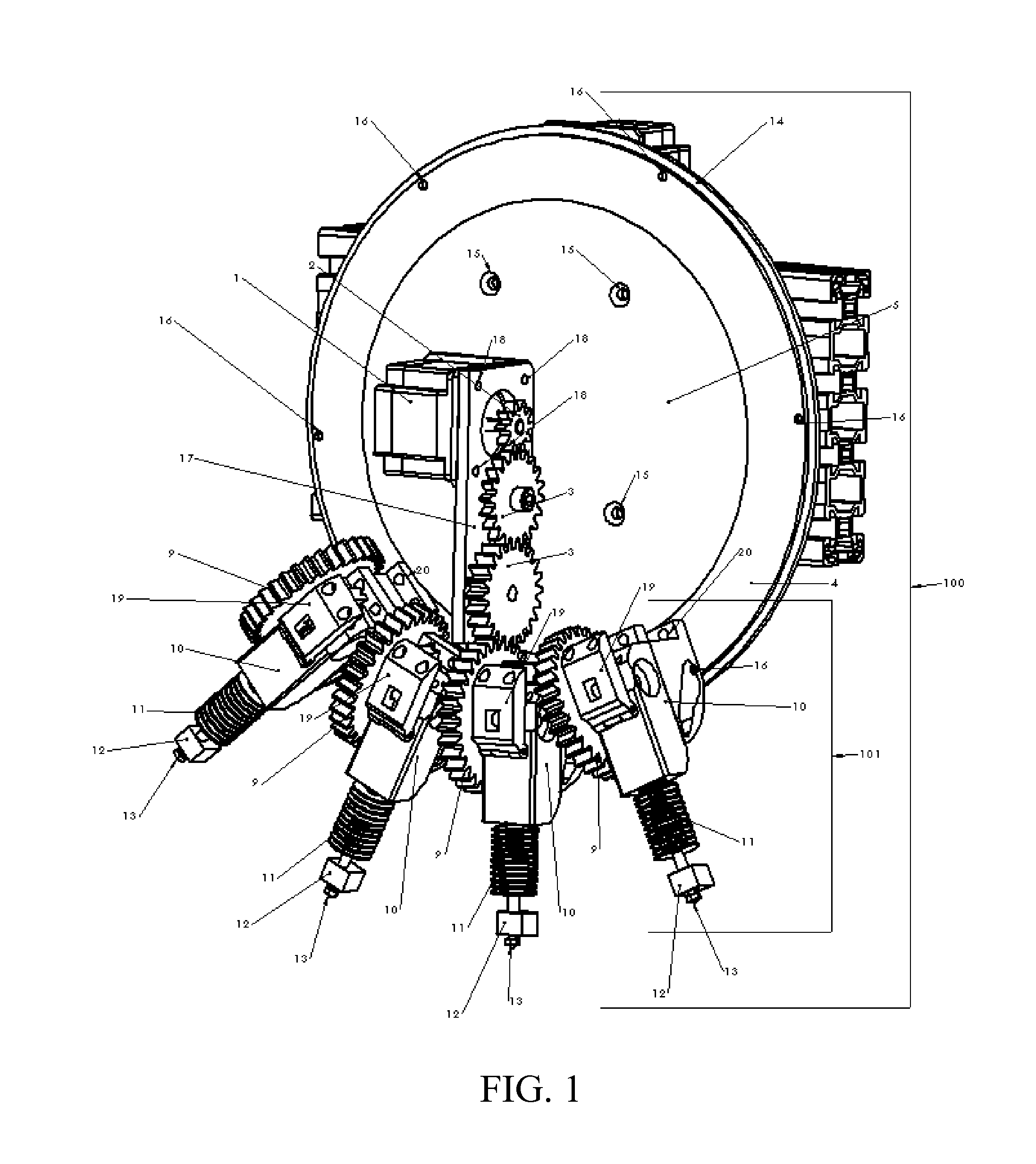

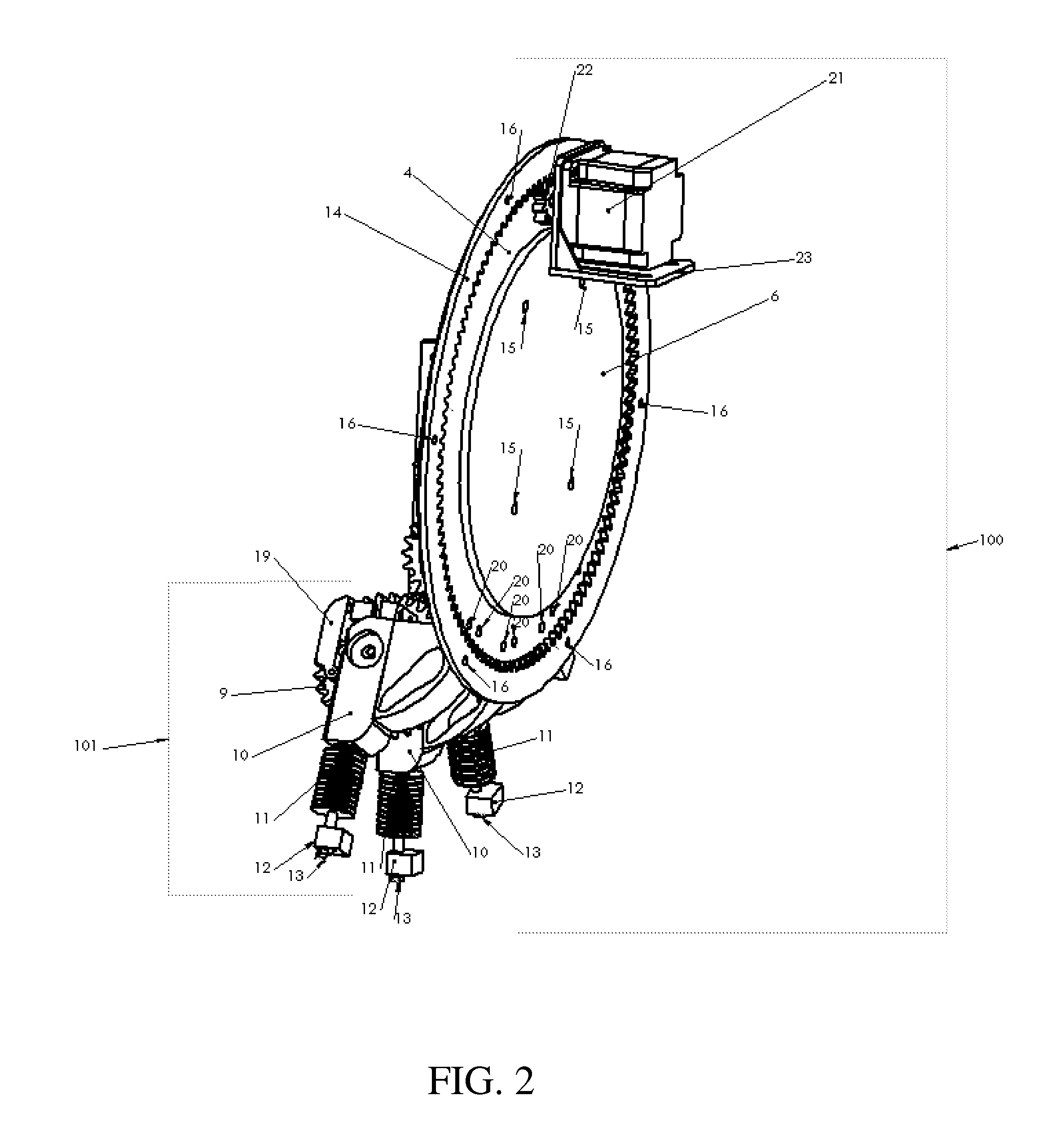

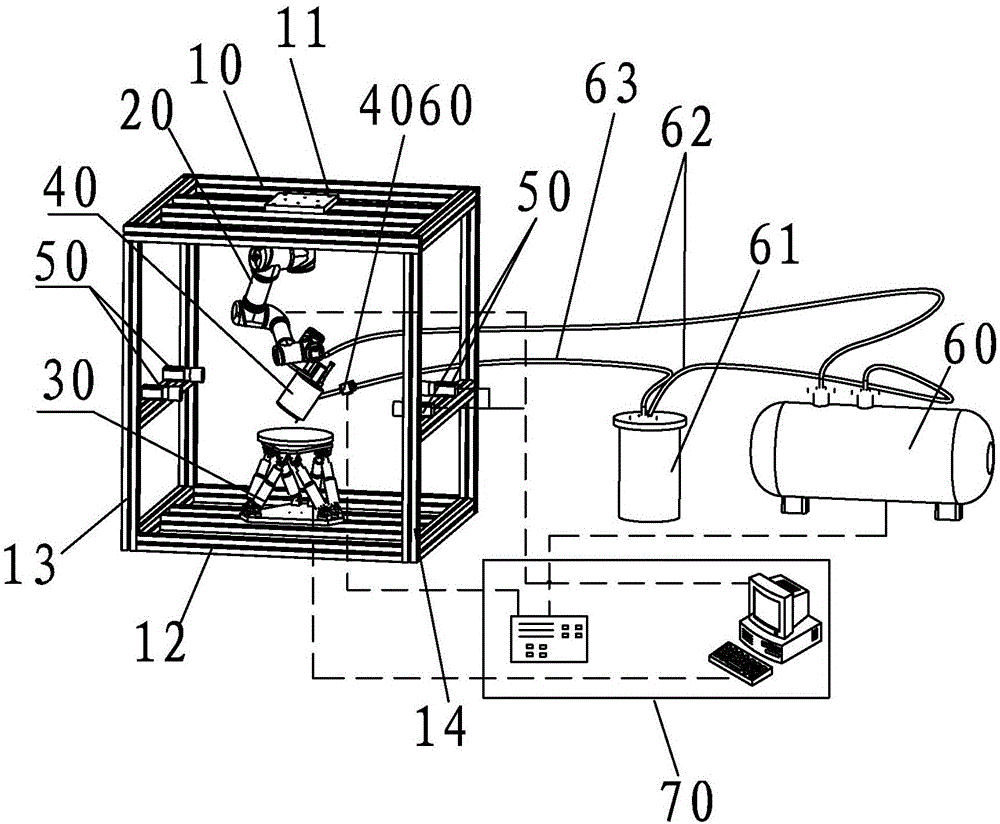

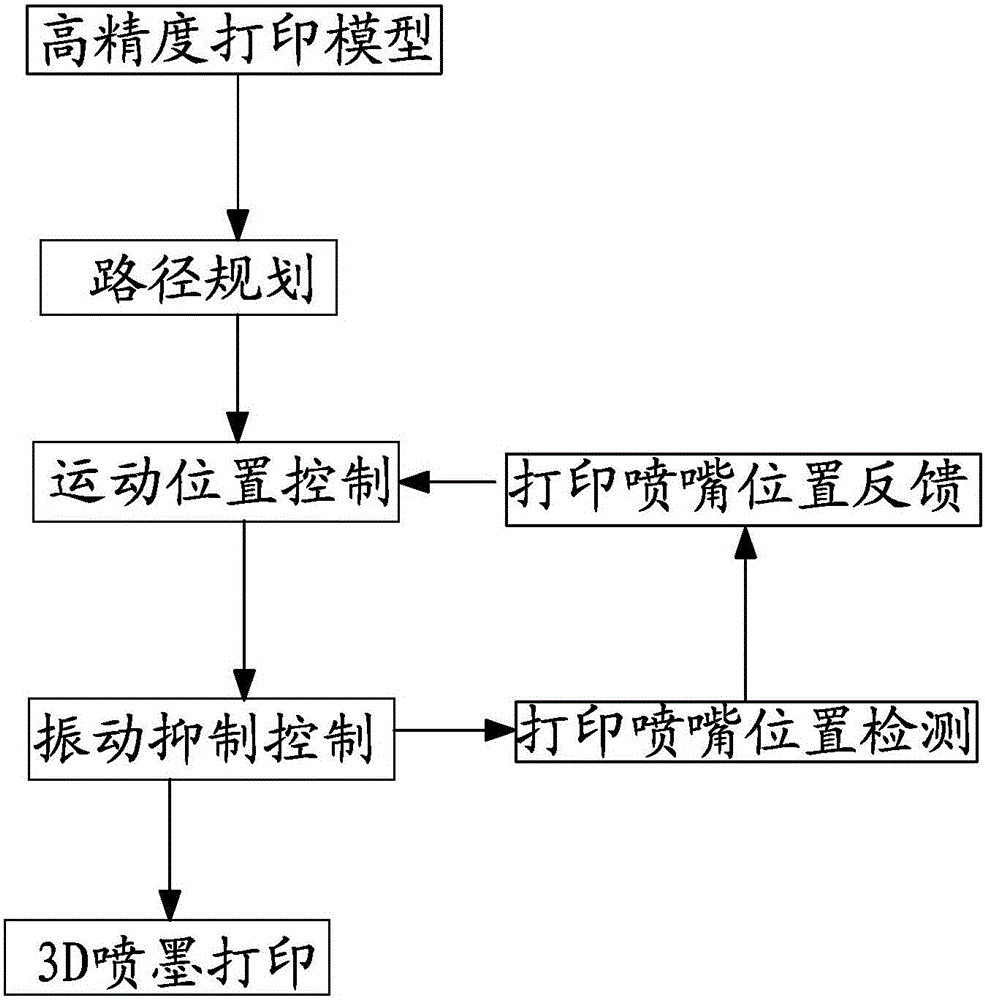

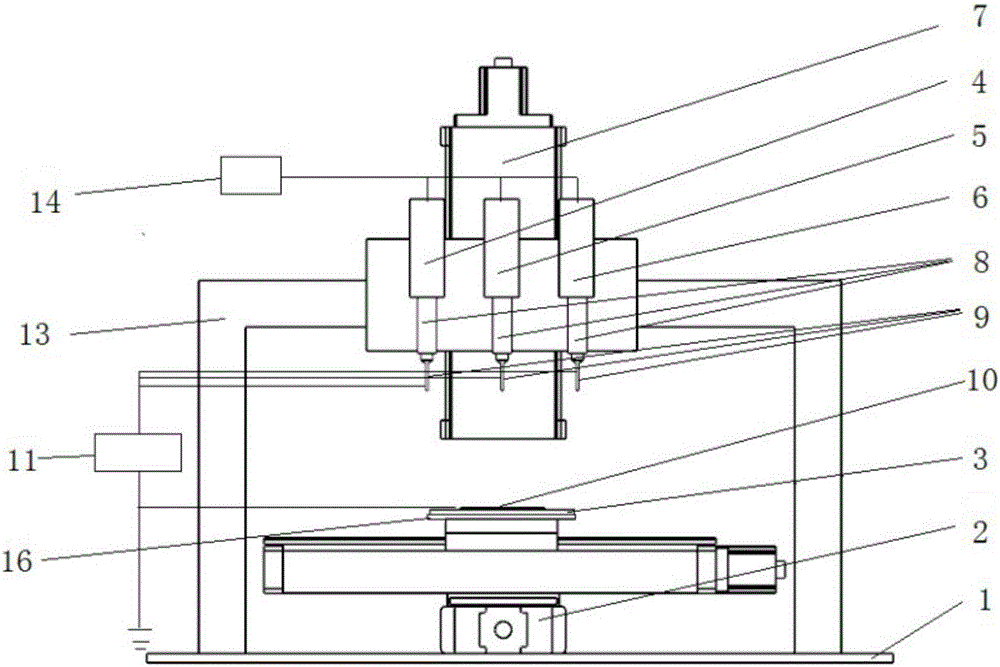

3D printing system based on multi-axis linkage control and machine vision measurement

ActiveCN106264796ARealize 3D patterned printingSimple structureManufacturing driving meansBone implantMachine visionControl system

The invention relates to a 3D printing system based on multi-axis linkage control and machine vision measurement. The 3D printing system comprises a rack, a workbench for placing an artificial bone scaffold, a printing device arranged above the workbench, a material conveying device for conveying a printing material, an image collection camera, a drive mechanism for adjusting the direction of the printing device and a control system, wherein the printing device, the material conveying device, the image collection device and the drive mechanism are all connected with the control system; the workbench is a six-degree-of-freedom parallel platform connected with the rack; the drive mechanism is a six-axis mechanical arm; and the printing device is connected with the six-axis mechanical arm. When in use, the artificial bone scaffold is put on the six-degree-of-freedom parallel platform, and the position of the printing device is controlled by the six-axis mechanical arm; and through the cooperation between the six-degree-of-freedom parallel platform and the six-axis mechanical arm, accurate control on the spatial position of a printing nozzle of the printing device is realized, and three-dimensional pattern printing is realized on a complicated tiny artificial bone surface and the internal surface of a porous structure.

Owner:QUANZHOU INST OF EQUIP MFG

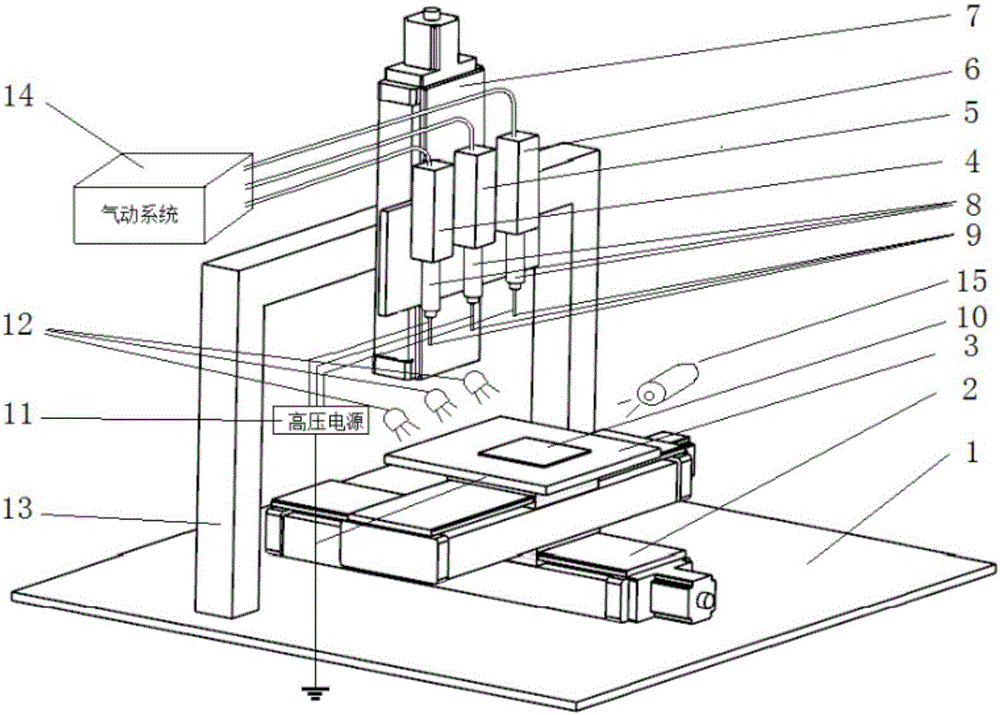

Micro-nano scale 3D printer and method

InactiveCN106738896AHigh resolutionLow costManufacturing driving means3D object support structuresMicro nanoSpray nozzle

The invention discloses a micro-nano scale 3D printer and a method. The 3D printer comprises a spraying head set, a printing tool, a controller and a three-dimensional movement mechanism. The spraying head comprises a plurality of spraying heads, and each spraying head applies a high-voltage pulse power supply between a corresponding electric conductive nozzle and an electric conductive base plate. Fluids are pulled from the nozzles by utilizing strong electric field force formed between the nozzles and the base plate to form Taylor Cones and stable conic jet flows. The controller controls the three-dimensional movement mechanism to drive the spraying head set and the printing tool to move relatively and meanwhile controls the movement of all the spraying heads to conduct micro-droplet spray printing on preset positions of the base material on the printing tool, and a model material, a release material and a supporting material are printed sequentially. Based on electrofluid power spraying printing (namely electric spraying printing), the micro-nano scale 3D printer solves the difficult problems that for micro-nano 3D printing, macro / micro cross-scale manufacturing cannot be achieved, the types of printable materials are few, and support is difficult to remove, and especially overcomes the deficiencies and the limitation, in the aspects of the cost, materials, resolution ratio, macro / micro cross-scale manufacturing, support removing and the like, of the of the current micro-nano scale 3D printing technology.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for real-time simultaneous additive and subtractive manufacturing with a dynamically grown build wall

A method for large-scale, real-time simultaneous additive and subtractive manufacturing is described. The apparatus used in the method includes one or more build units and a machining mechanism that are attached to a positioning mechanism, and a rotating build platform. The method involves at least rotating the build platform; repetitive cycles of moving the build unit(s) to deposit powder and irradiating at least a selected portion of the powder to form at least one fused layer to form at least one object and a build wall that retains unfused powder about the object; and removing the build wall by rotational machining.

Owner:GENERAL ELECTRIC CO

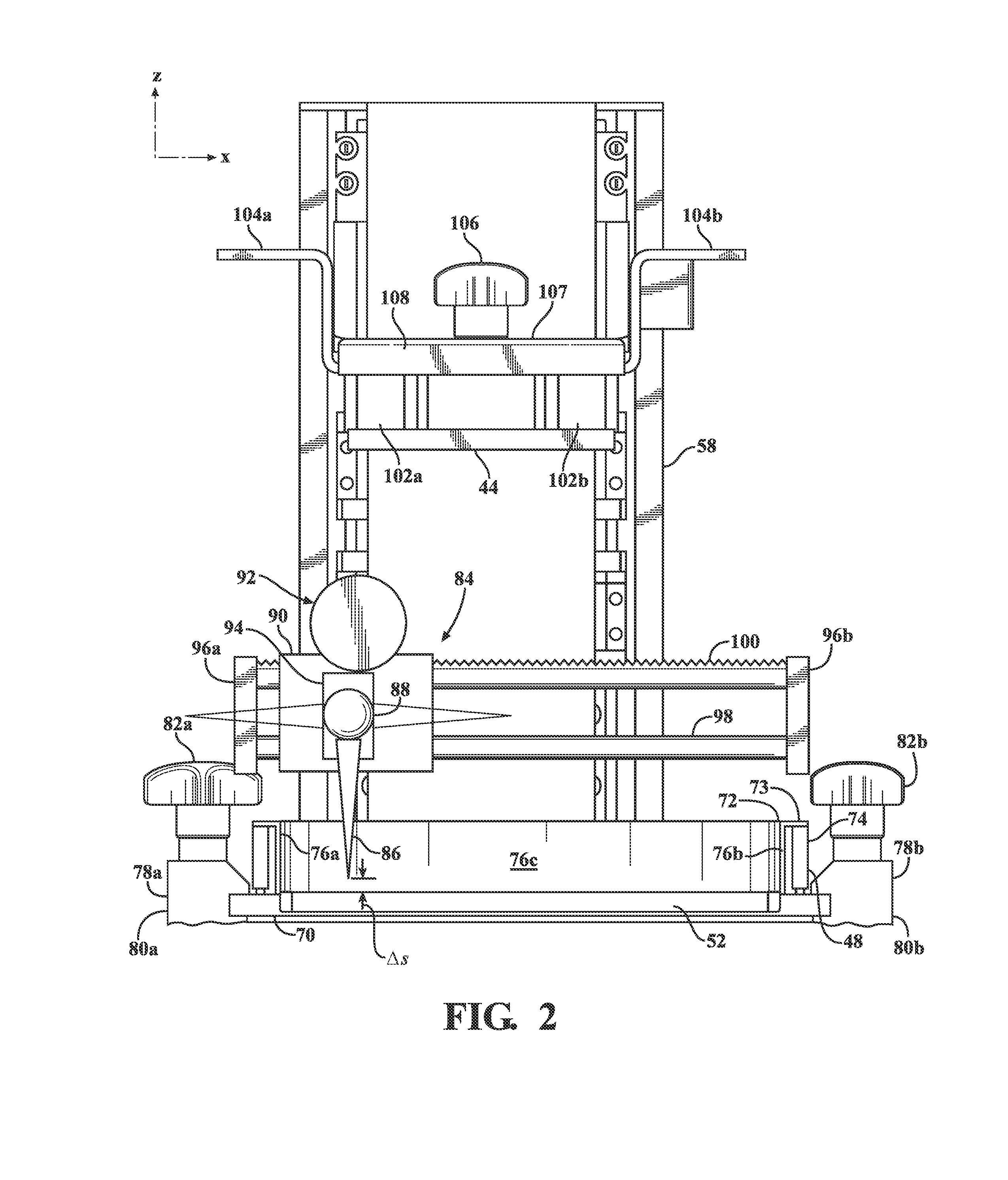

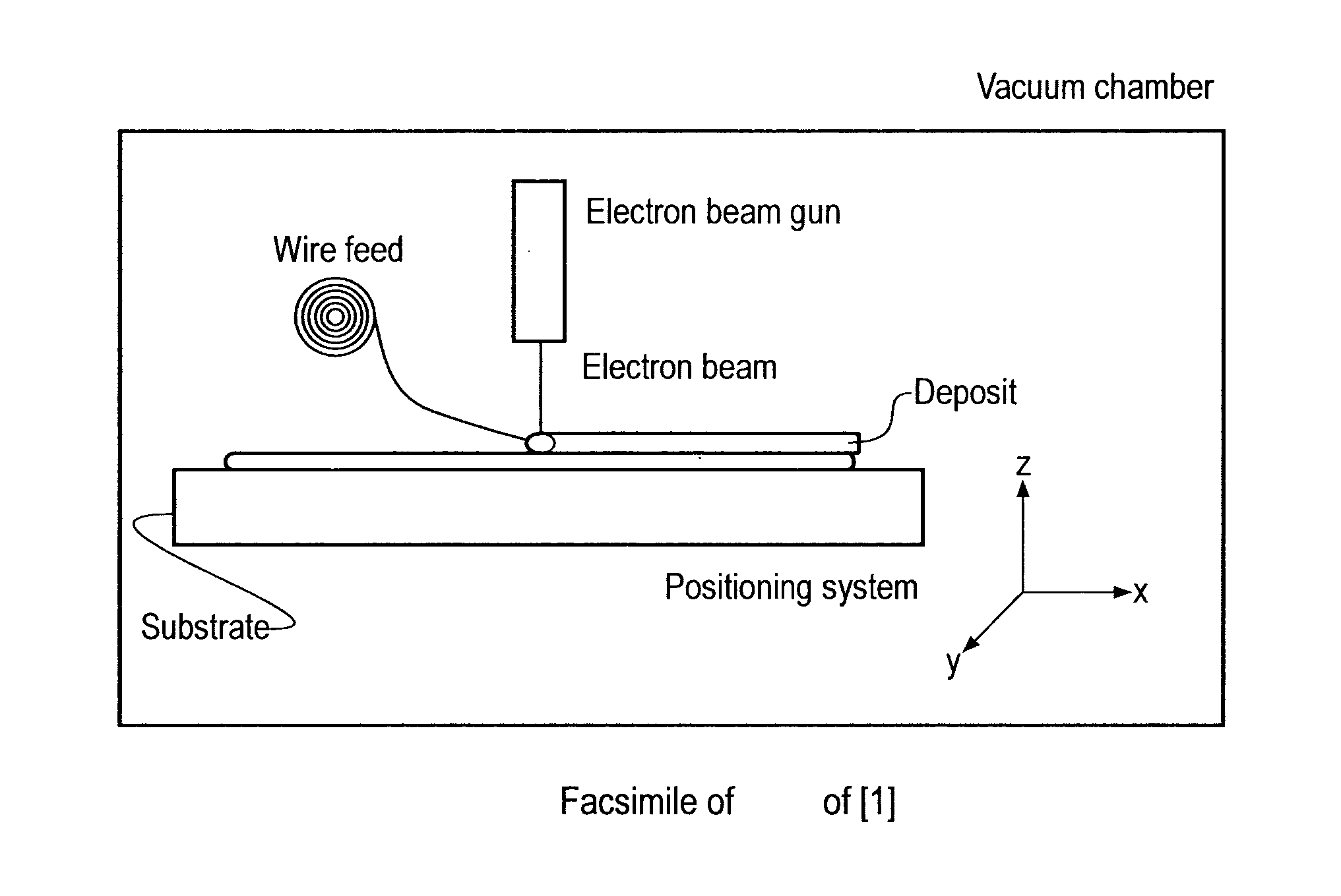

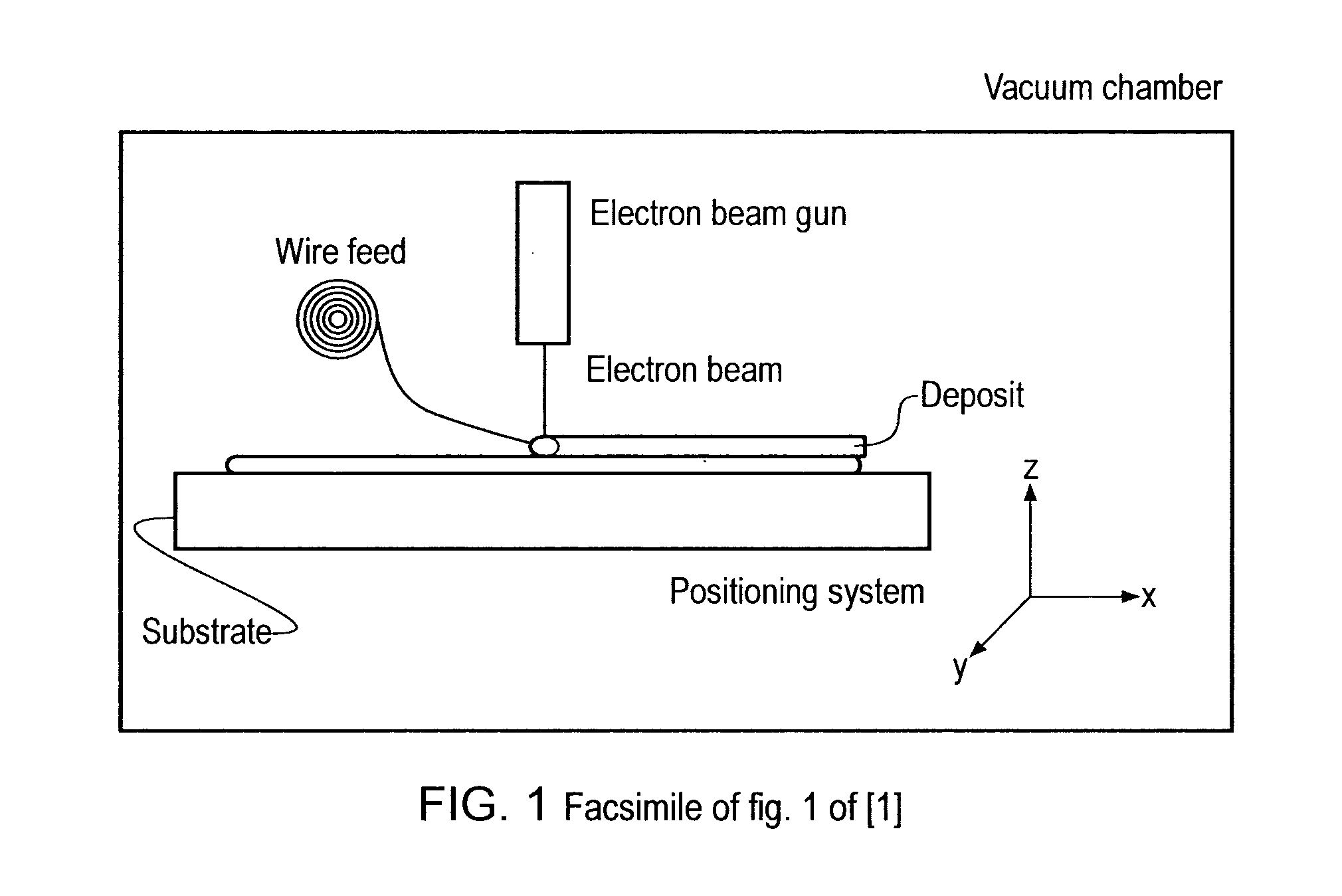

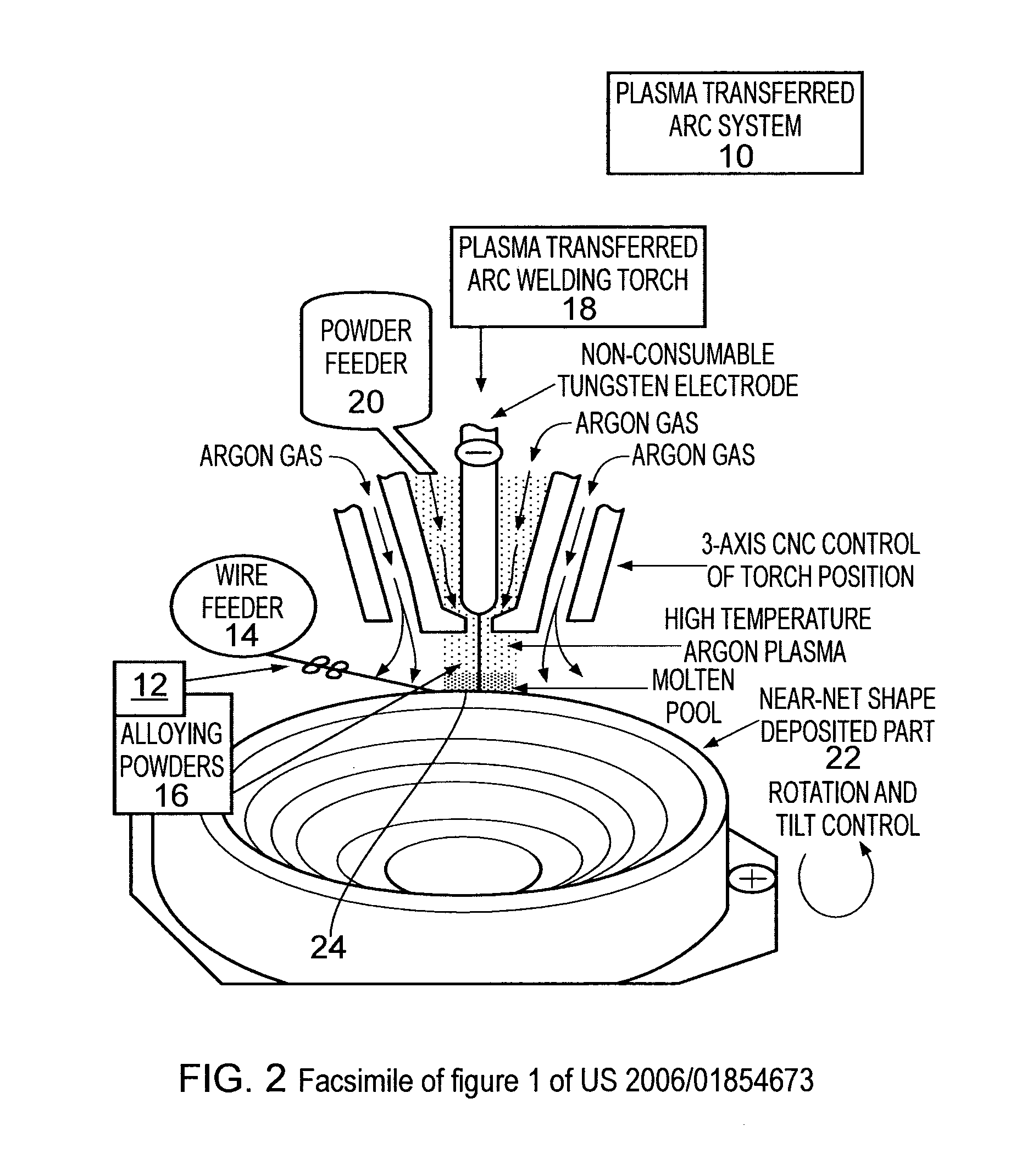

Method and device for manufacturing titanium objects

ActiveUS20120193335A1Rapid layered manufactureManufacturing driving meansWelding/cutting auxillary devicesHigh energyNuclear engineering

This invention relates to a method and reactor of manufacturing an object by solid freeform fabrication, especially an object made of titanium or titanium alloys. The reactor of production of an object of a weldable material by solid freeform fabrication comprises a reactor chamber which is closed to the ambient atmosphere, wherein the reactor is given a design such that all adjacent wall elements forming the reactor chamber are joined with an obtuse angle (larger than 90°), the actuator located below the reactor chamber is given a design such that the actuator protrudes into the reactor chamber through an opening at the bottom of the reactor chamber holding the support substrate inside the reactor chamber, the opening is sealed by at least one elastic gas impermeable membrane which is gas tight attached to the reactor wall at the opening and to the actuator, the actuator located outside the reactor chamber is given a design such that the actuator protrudes into the reactor chamber through an opening at the side of the reactor chamber holding the high energy plasma transferred arc welding torch with wire feeder of the weldable material inside the reactor chamber, the opening is sealed by the at least one elastic gas impermeable membrane which is gas tight attached to the reactor wall at the opening and to the actuator, and the reactor is equipped with at least one closable gas inlet located at the lowest level of the reactor chamber and at least one closable gas outlet located at the highest level of the reactor chamber.

Owner:NORSK TITANIUM

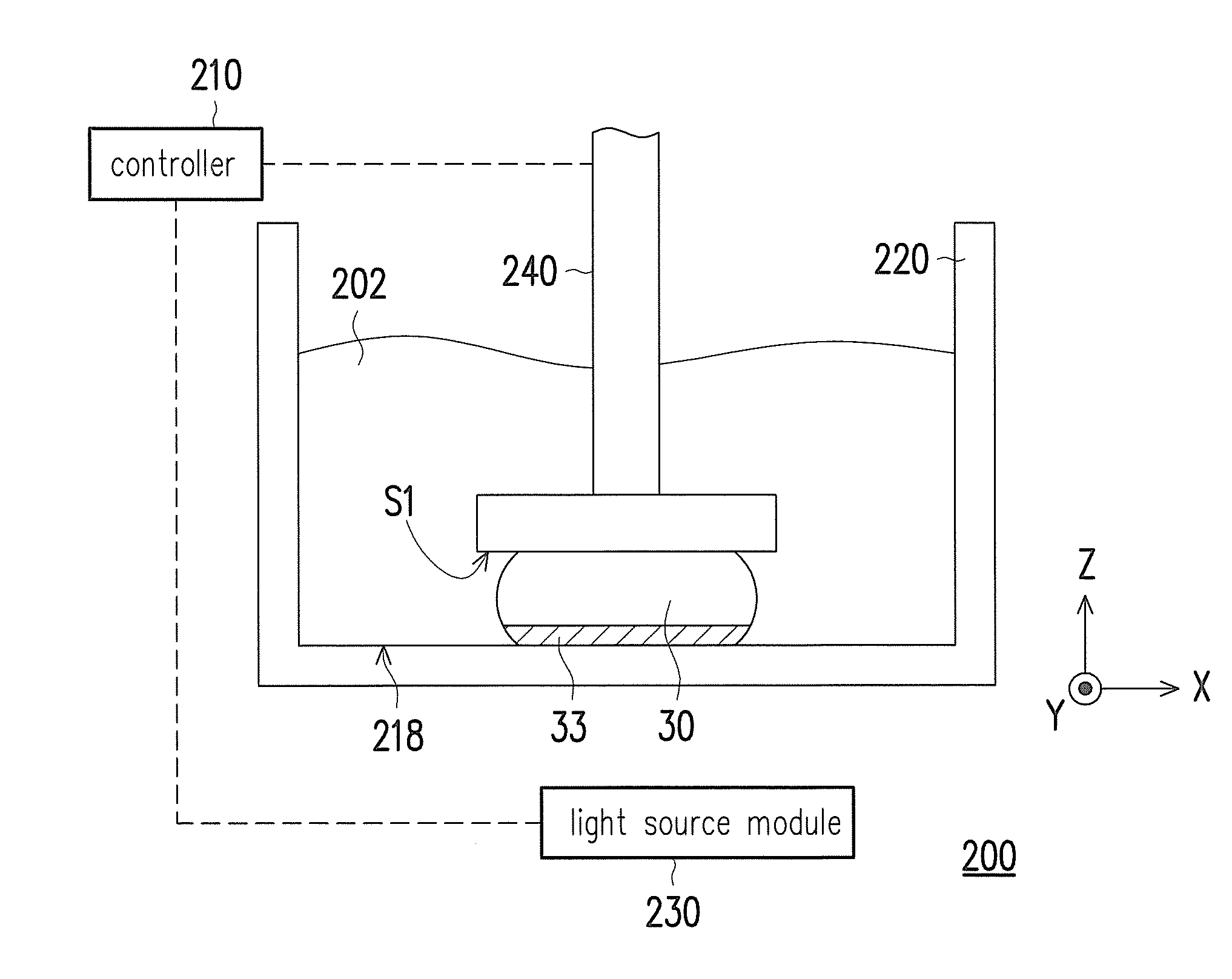

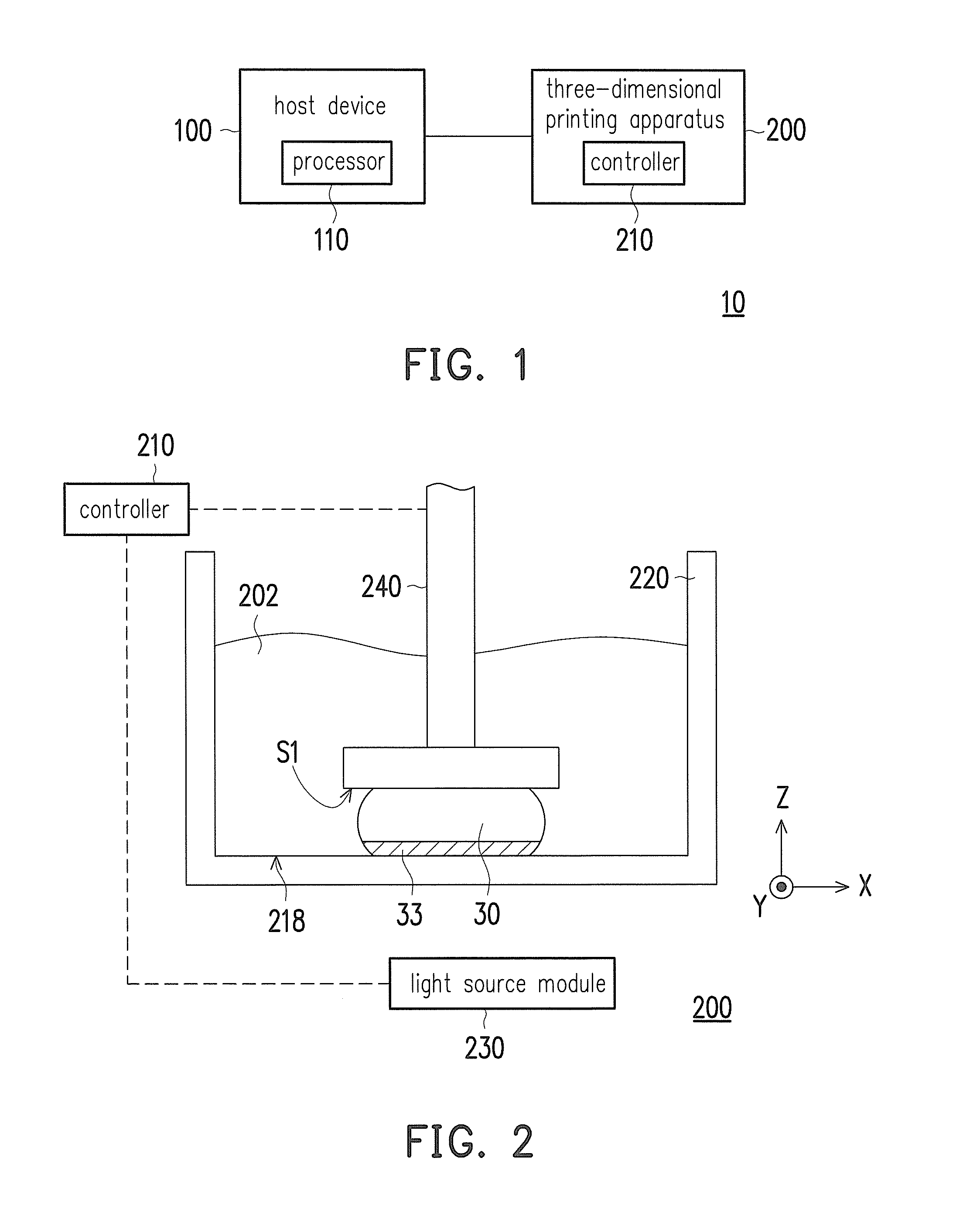

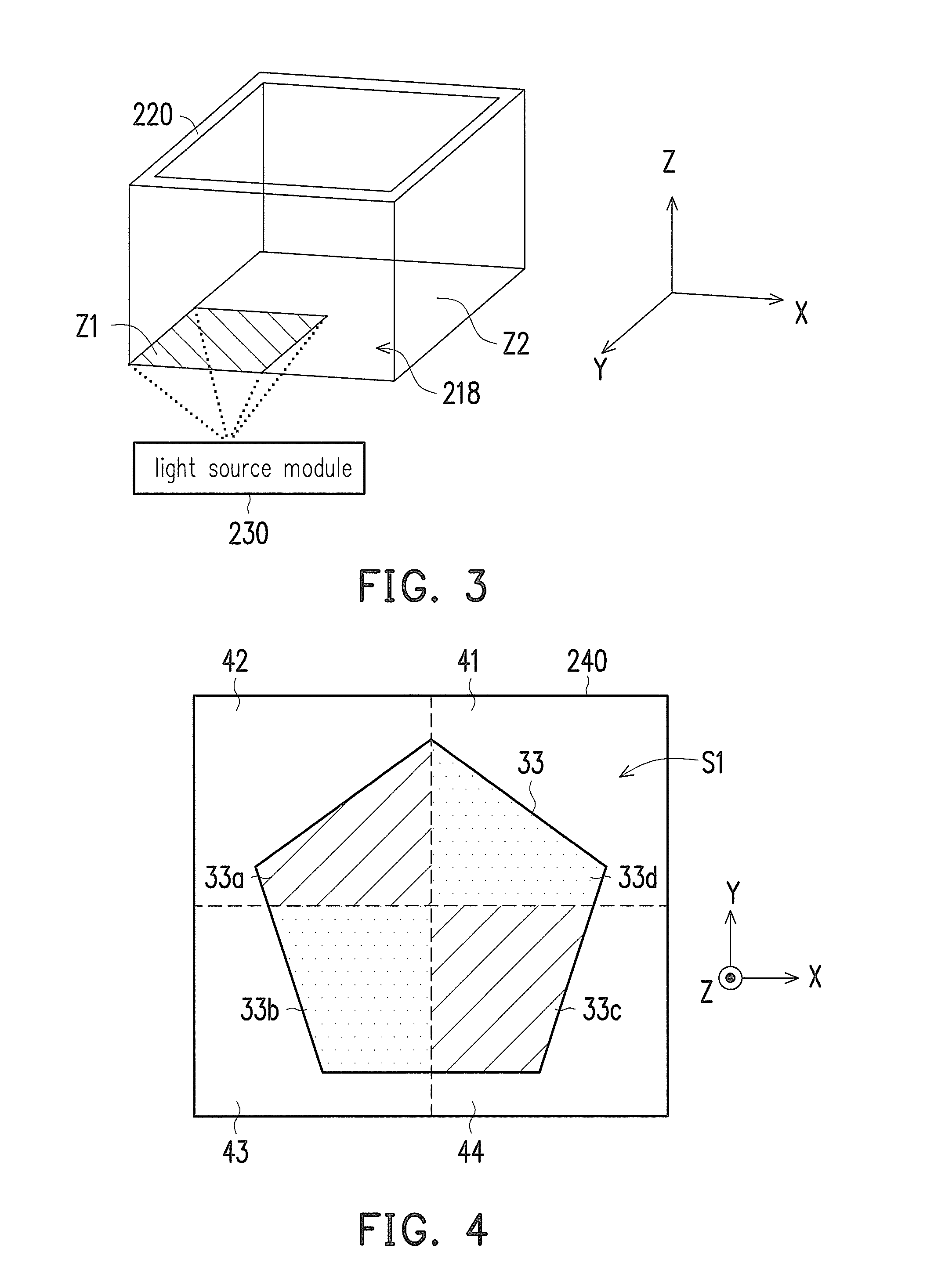

Three dimensional printing apparatus and printing method thereof

InactiveUS20160096332A1Low production costSmall rangeManufacturing driving meansAuxillary shaping apparatusMarine engineeringLight source

A three-dimensional printing apparatus and a printing method thereof are provided. The three-dimensional printing apparatus includes a tank, a movable platform, a light source module, and a controller. The bottom of the tank includes an irradiated area and a non-irradiated area. The movable platform is movably disposed above the tank. The light source module is disposed under the tank and only provides light to the irradiated area to irradiate a liquid-formation material. The controller controls the movable platform to move along a first axis direction, such that at least one layer object of a three-dimensional object is cured on the movable platform layer by layer. The layer object is composed of object sections. During a period of forming one layer object, the controller controls the movable platform to move on a horizontal plane, such that the object sections of the layer object are cured sequentially above the irradiated area.

Owner:XYZPRINTING +2

Apparatus for Fabricating an Object

InactiveUS20170232679A1Manufacturing driving meansAdditive manufacturing with liquidsAdditive layer manufacturingComputer control

Owner:LAING OROURKE AUSTRALIA PTY LTD

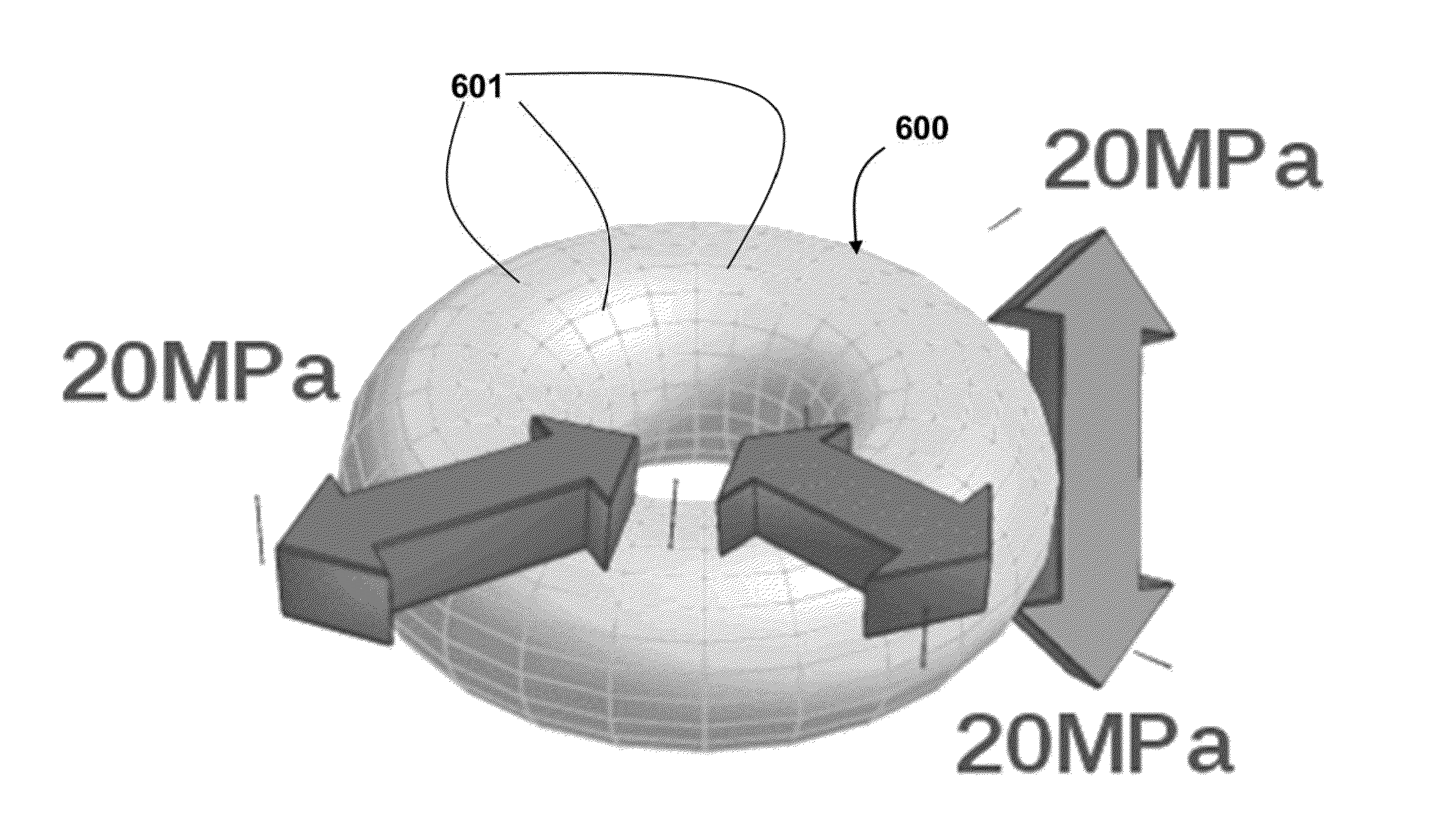

Method and Apparatus for Printing 3D Objects Using Additive Manufacturing and Material Extruder with Translational and Rotational Axes

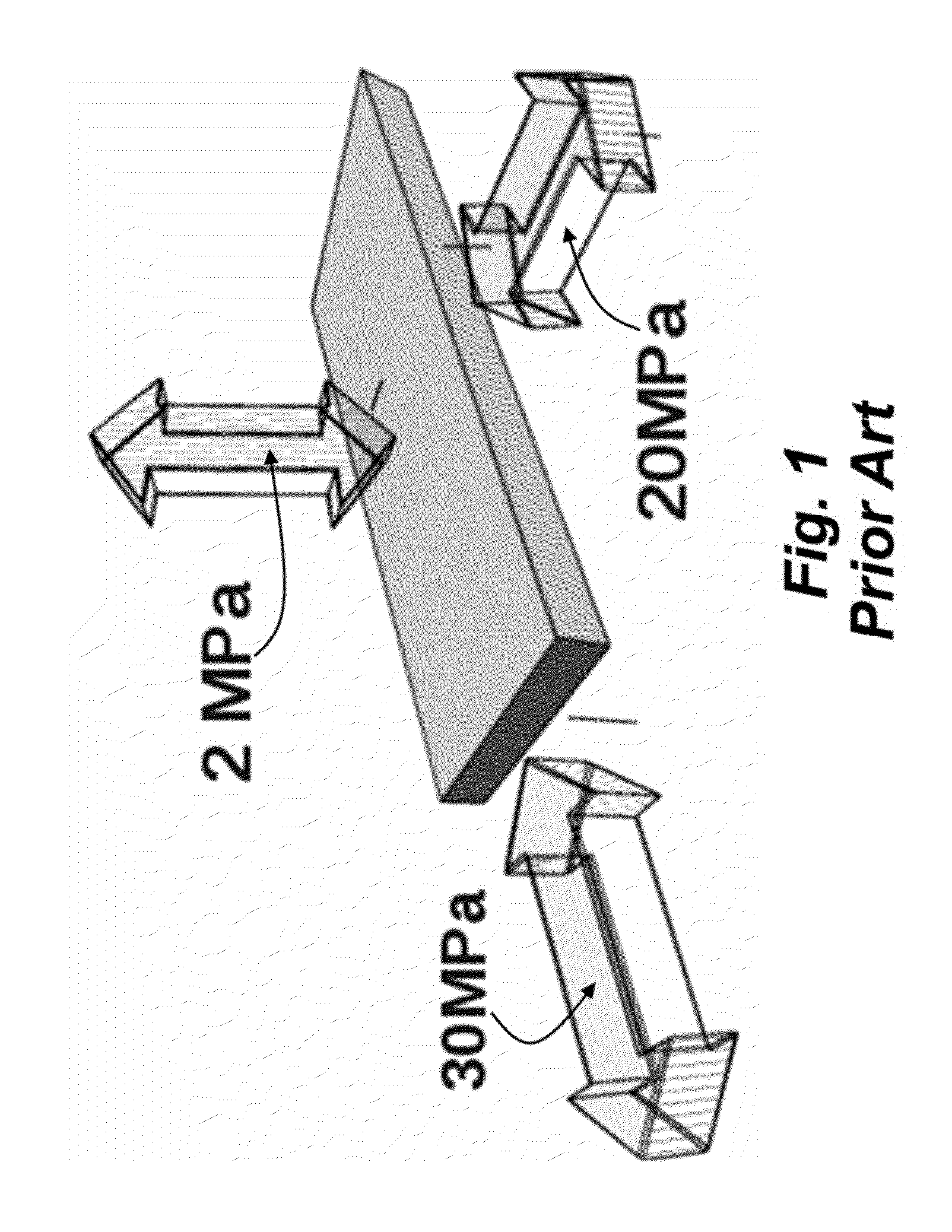

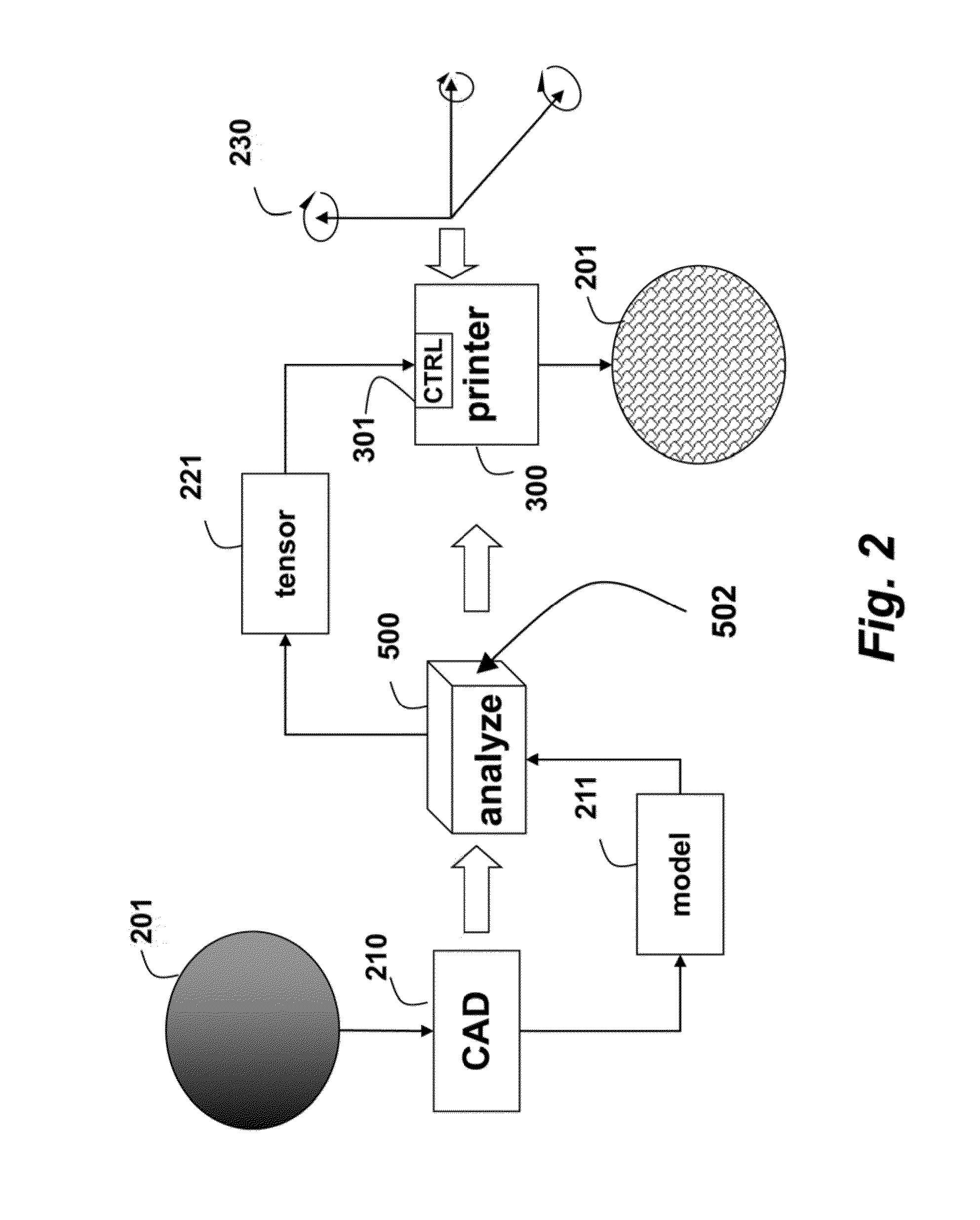

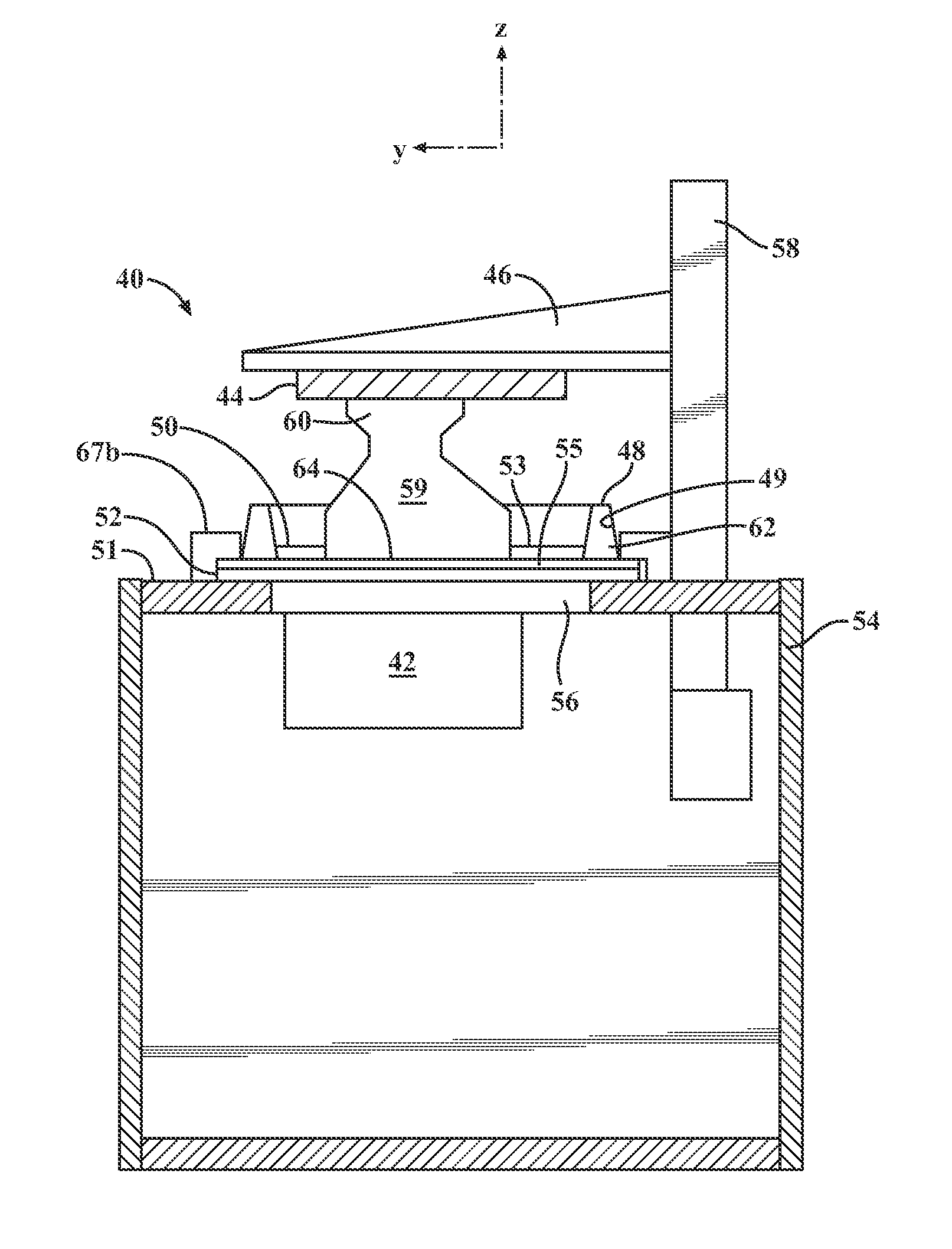

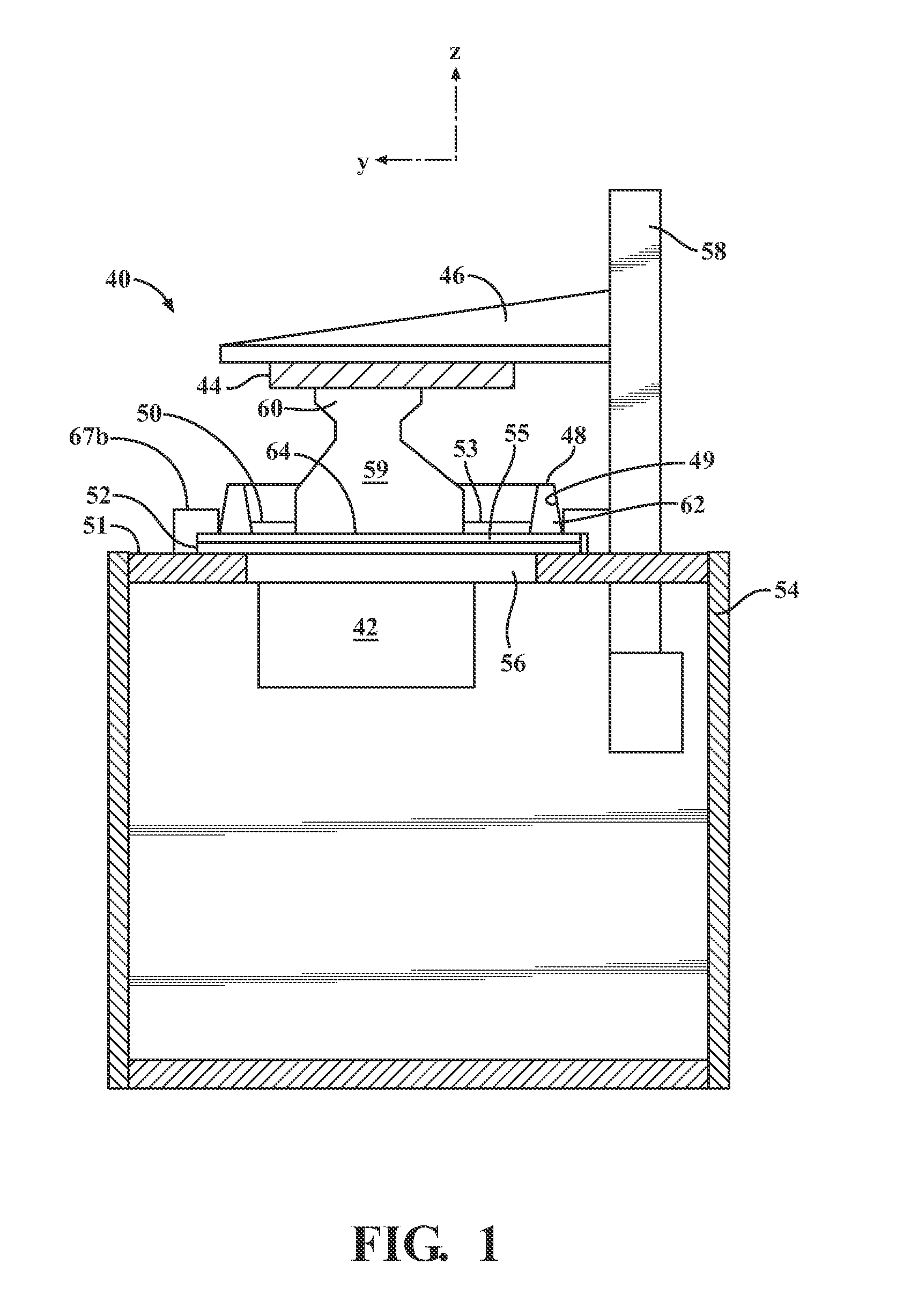

A 5D printer, which additively manufactures an object, includes an extruder that can move linearly along three orthogonal axes and rotationally around at least one of the axes with respect to the object while depositing a material. A gantry is movable along X, Y and Z axes, and a trunnion table movable about A and B axes is mounted on the gantry. A platen is mounted on the trunnion table, and the extruder deposits the material on the platen while moving the gantry and trunnion table. A model of the object is analyzed to produce a stress tensor for the object, and the depositing is according to the stress tensor.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Apparatus and method for forming three-dimensional objects from solidifiable paste

An apparatus and method for making a three-dimensional object from a solidifiable paste is shown and described. The apparatus includes a pastes spreader, at least a portion of which extends into the solidifiable paste. The container holding the solidifiable paste and the spreader are movable relative to one another. In one system, the spreader vibrates as the container and the spreader move relative to one another. In another system, the spreader is part of a spreader assembly in which a first spreader and second spreader are angled with respect to one another, and the assembly is rotatable and lockable into multiple rotational positions. A paste dispenser is also described which is configured to dispense paste while moving along a travel axis. The apparatus and method allow three-dimensional objects to be progressively built upside down by ensuring that the previously solidified object section has a substantially homogeneous layer of solidifiable material available for forming a new layer of the solidified object prior to exposure to solidification energy.

Owner:GLOBAL FILTRATION SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com