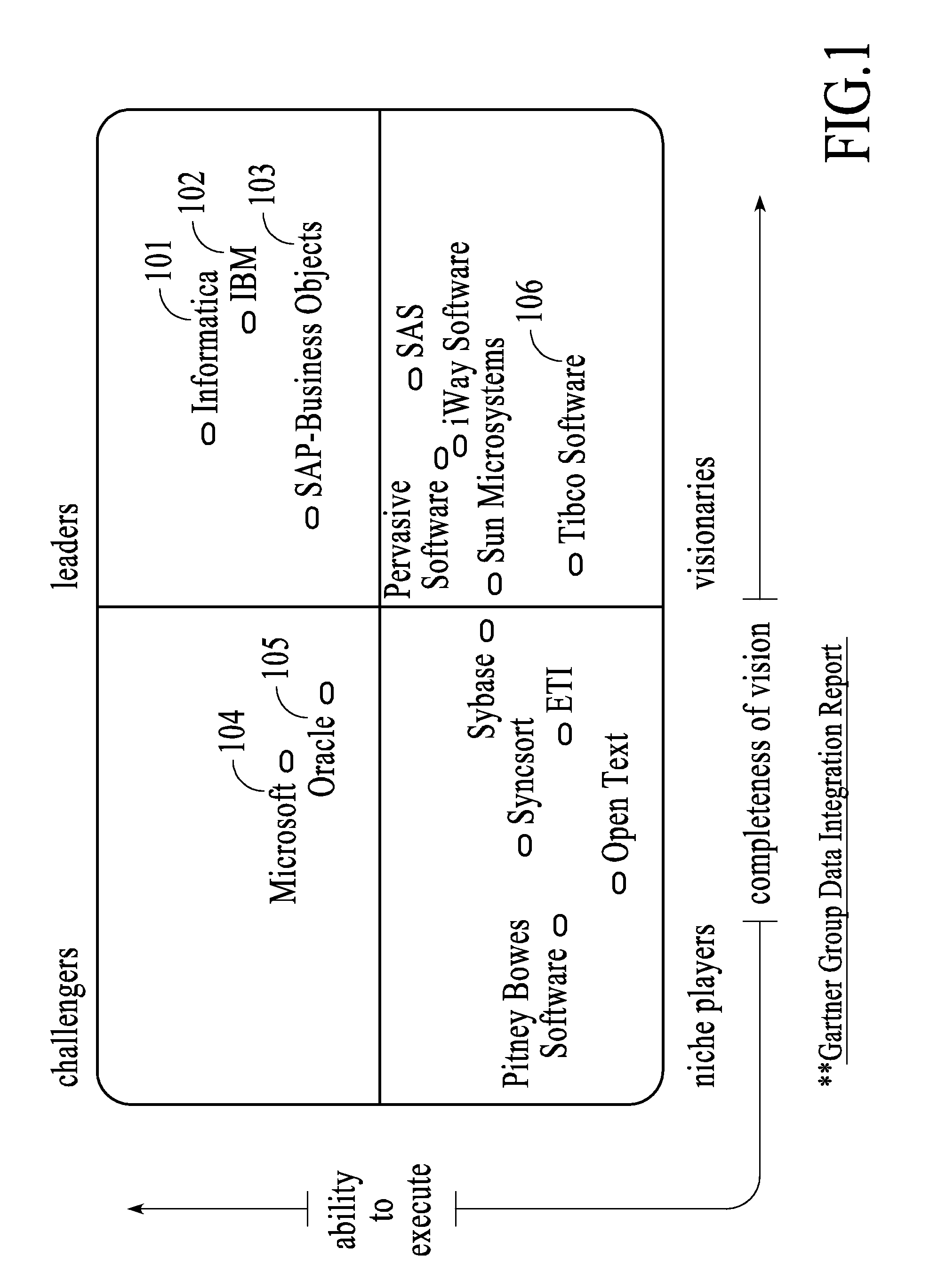

Patents

Literature

130 results about "Composite object" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high-level object made of tightly bound parts. A composite object is an instance of a composite class, which implies the composition aggregation between the class and its parts.

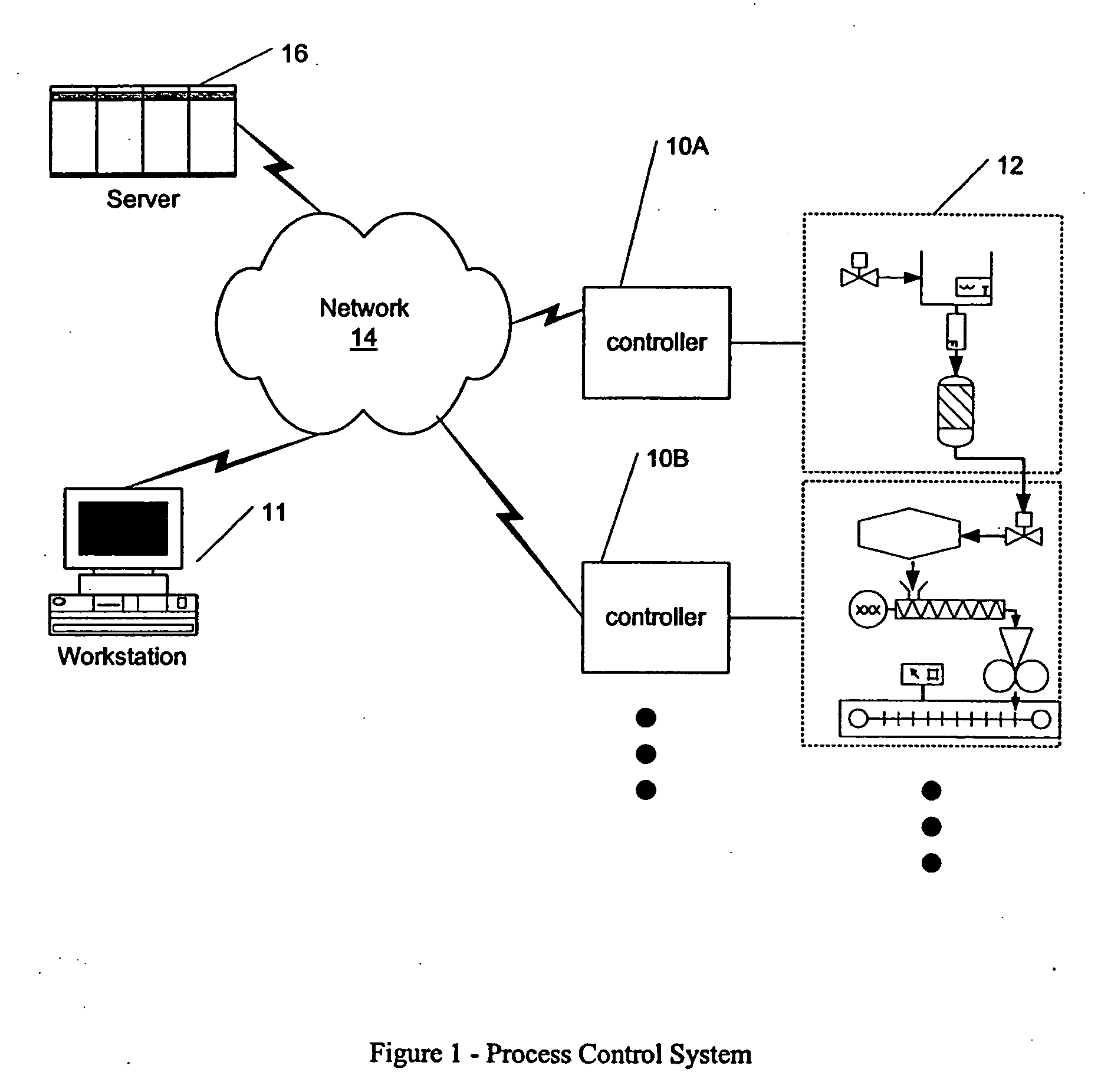

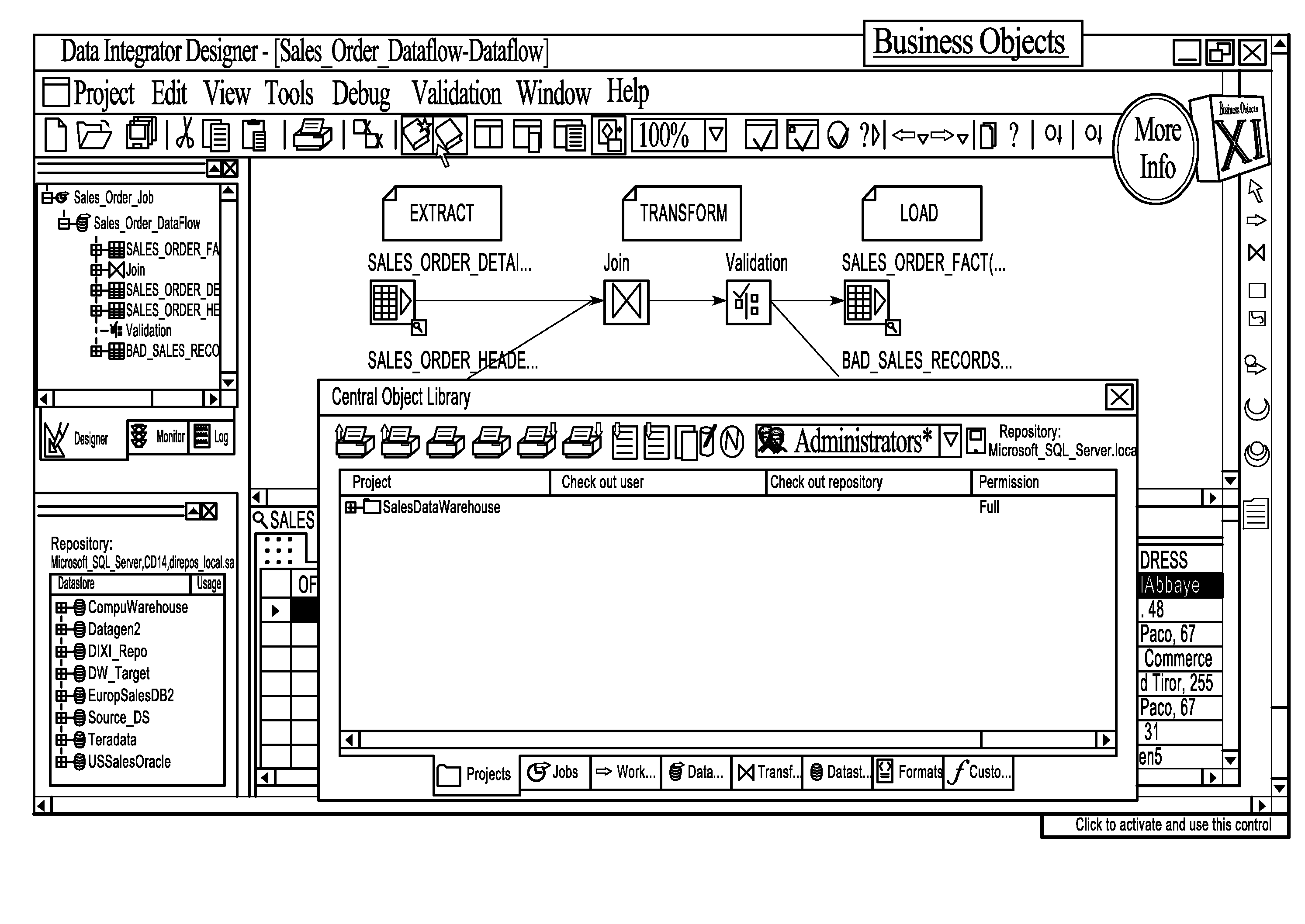

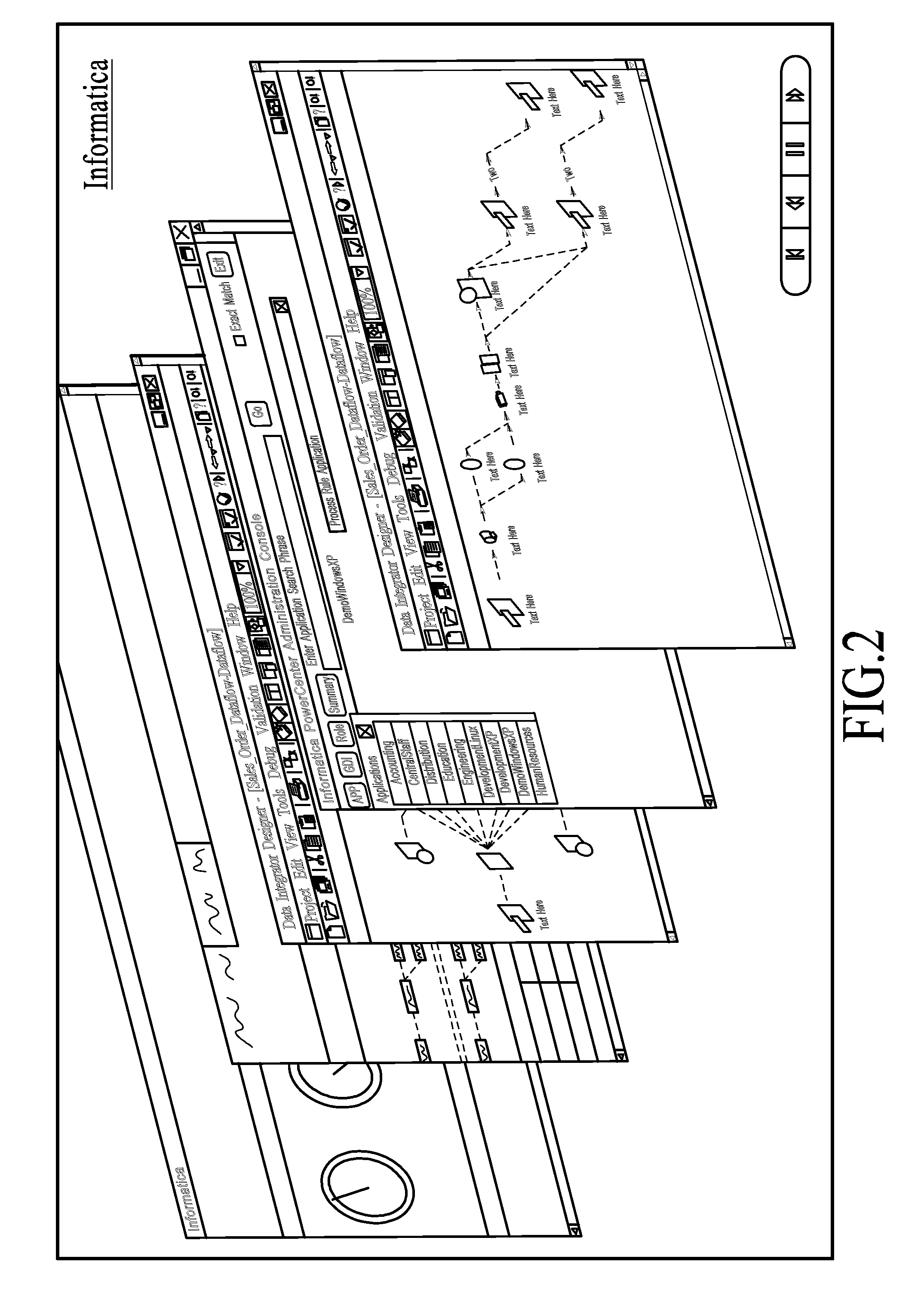

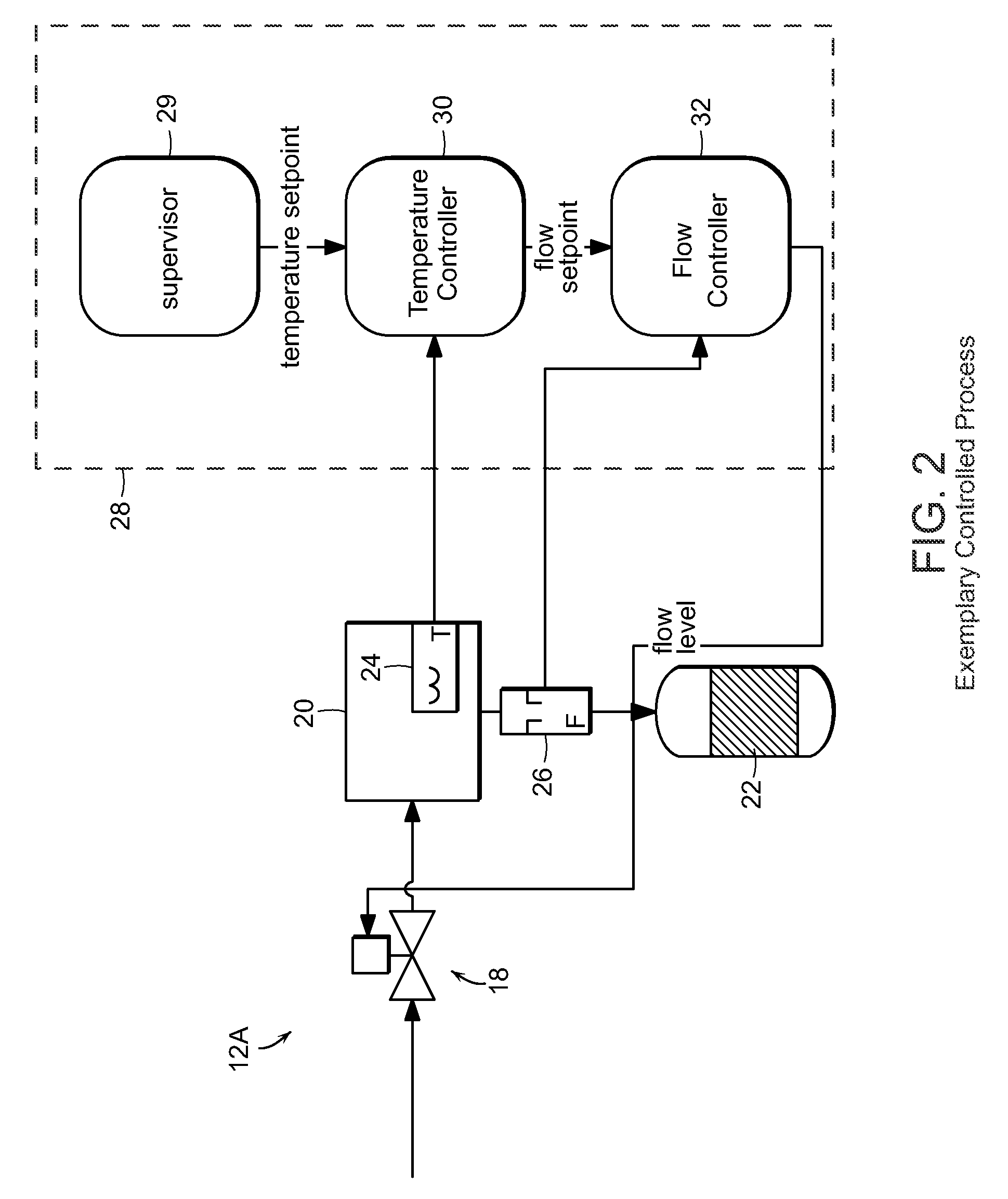

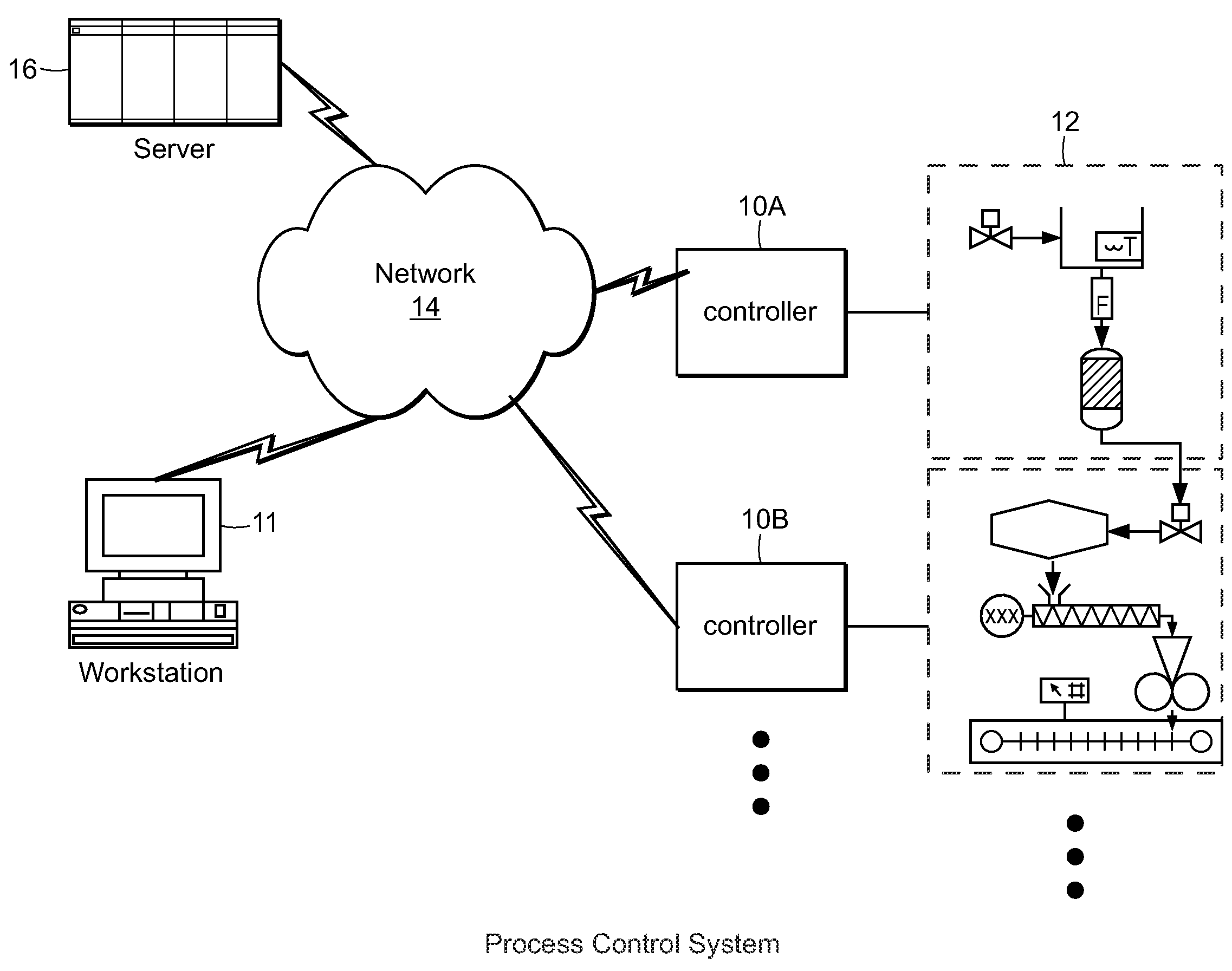

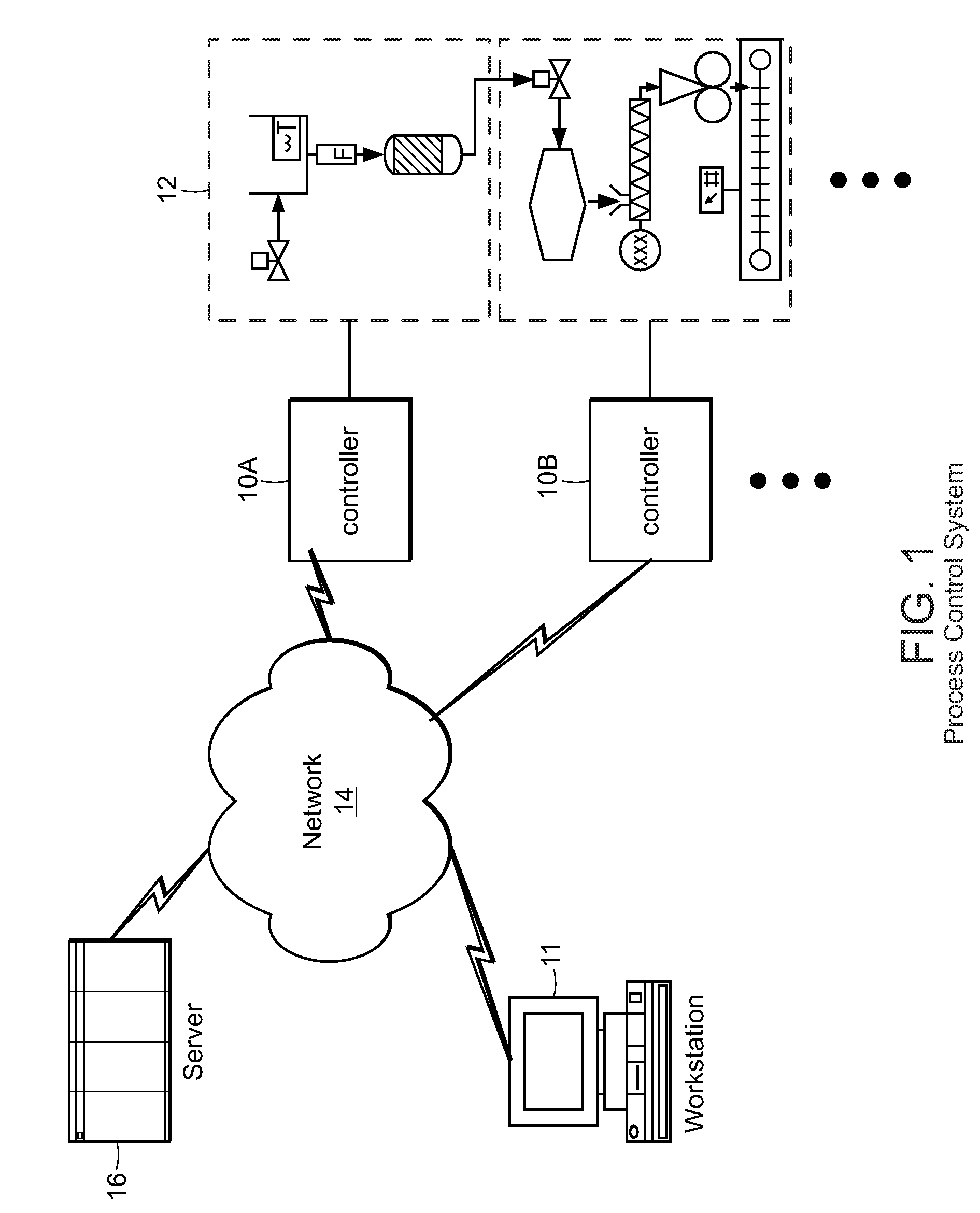

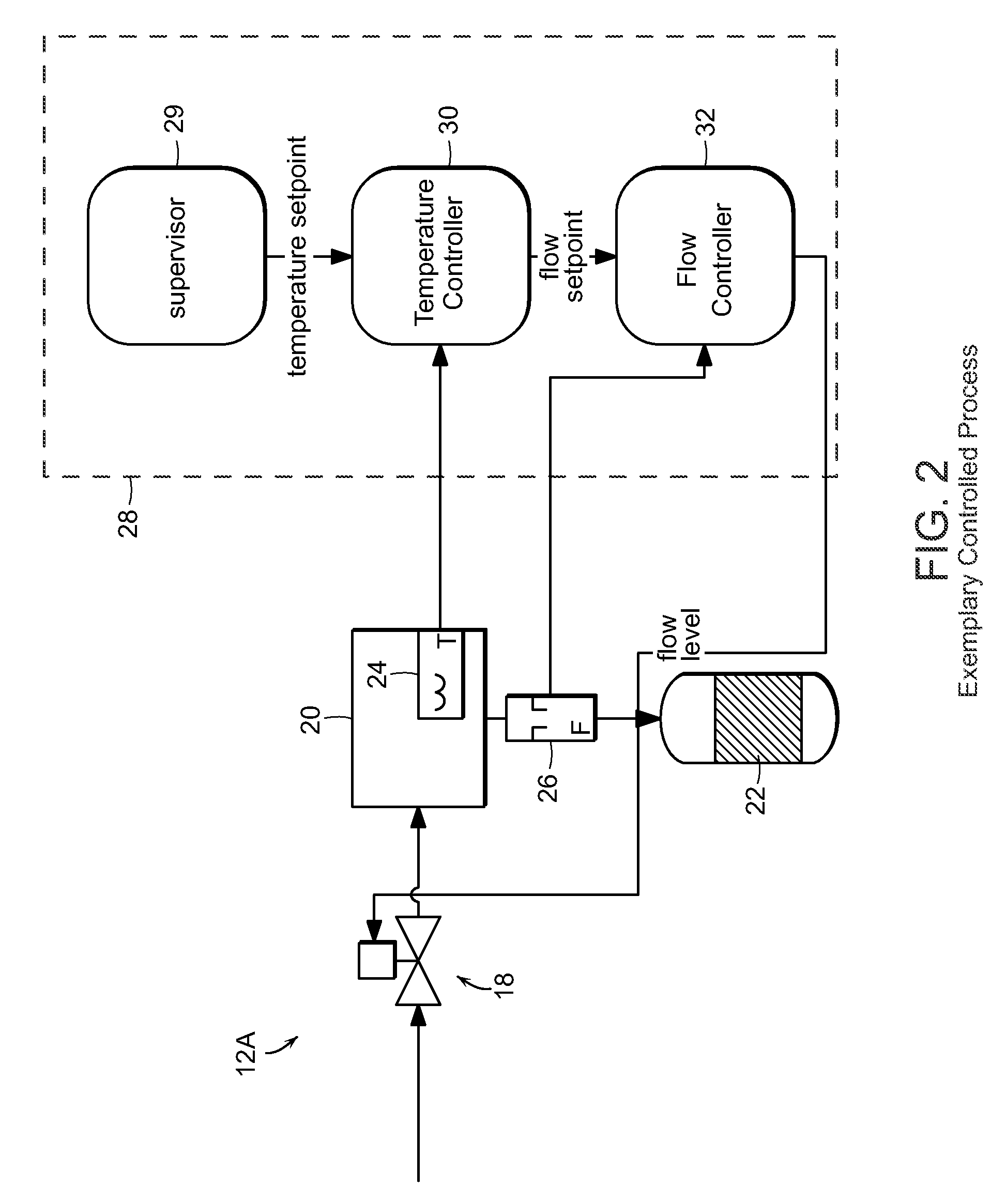

Methods and apparatus for control configuration with versioning, security, composite blocks, edit selection, object swapping, formulaic values and other aspects

InactiveUS7272815B1OptimizationOptimize system configurationData processing applicationsDigital data processing detailsGraphical user interfaceComposite object

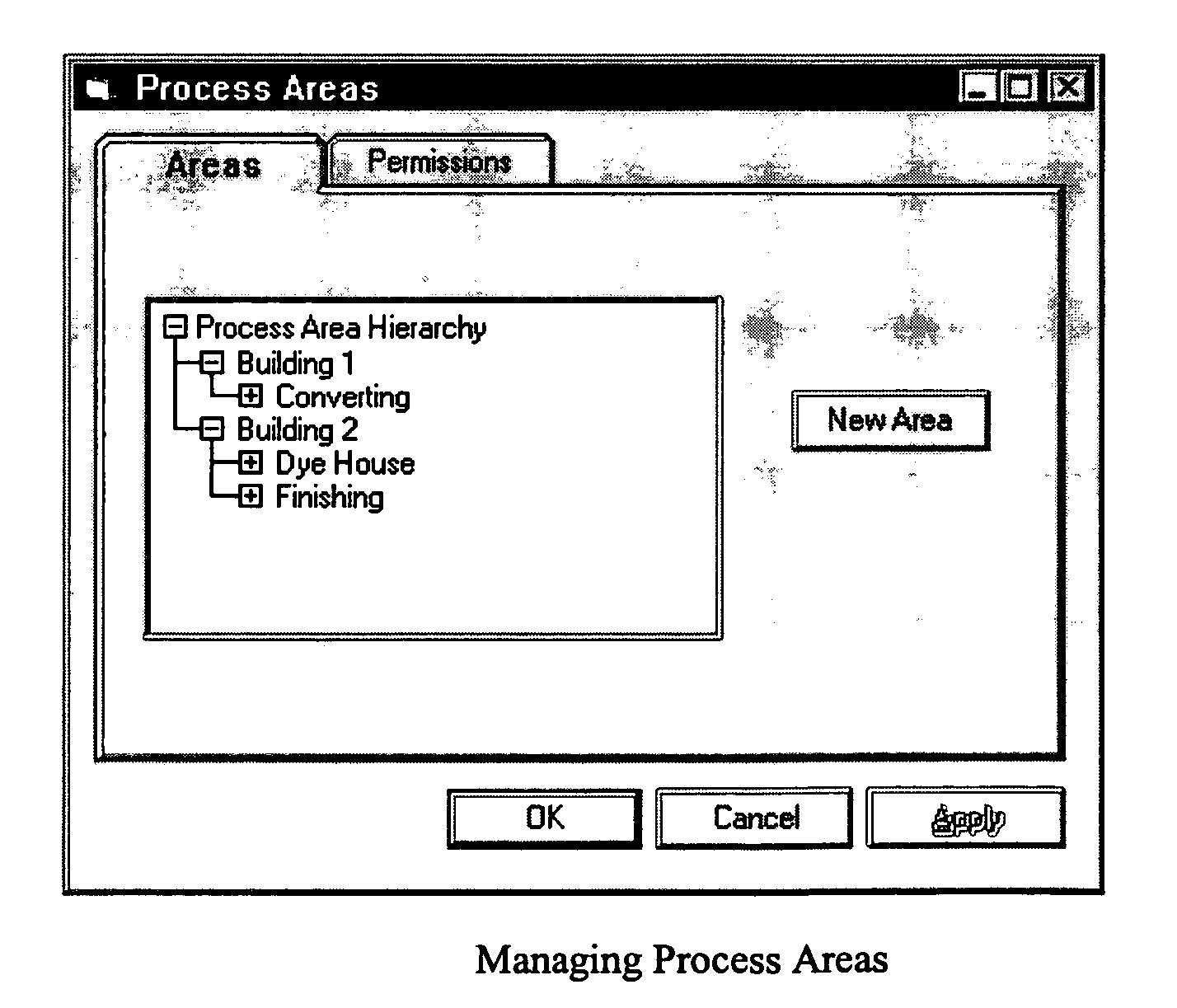

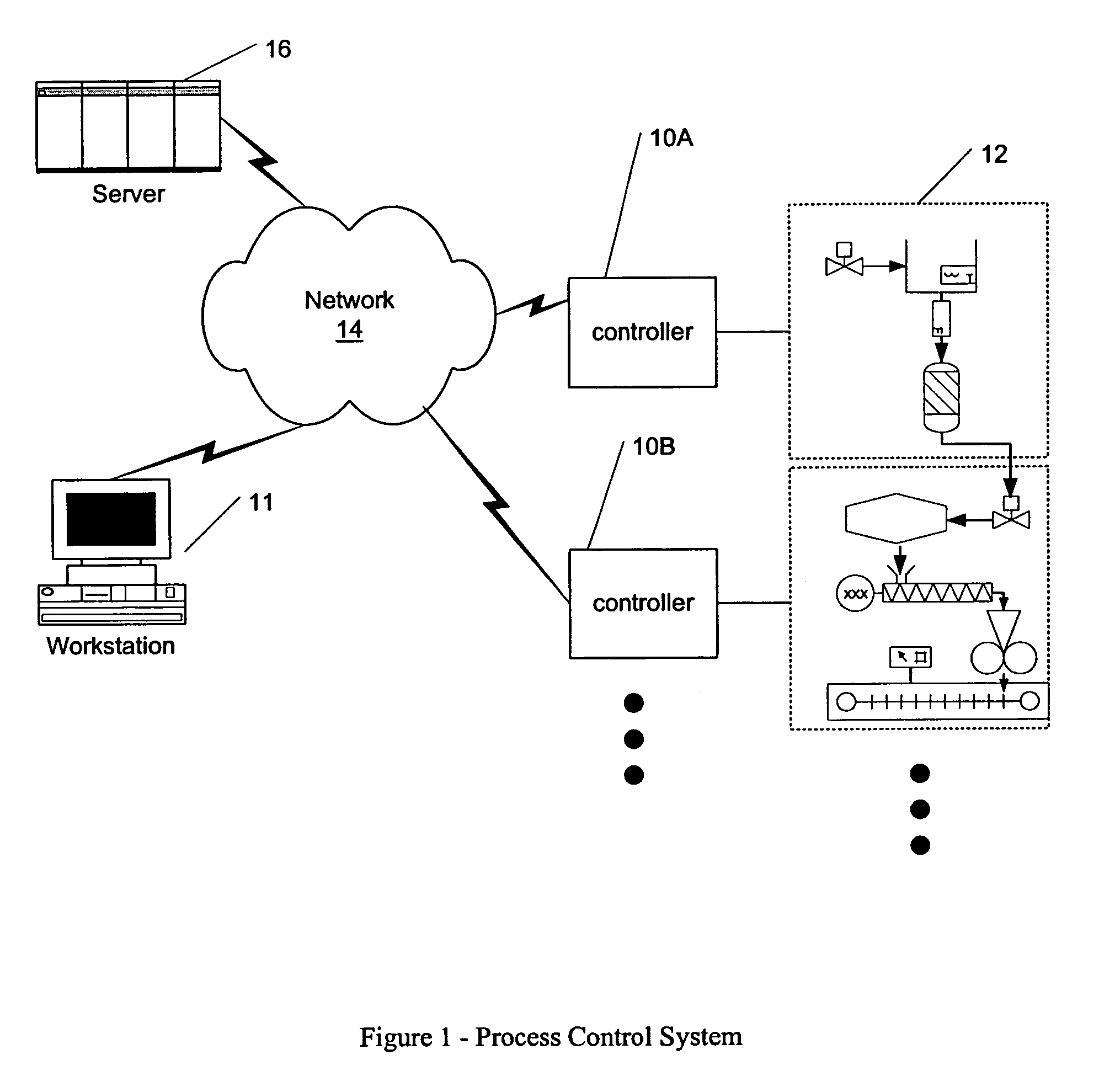

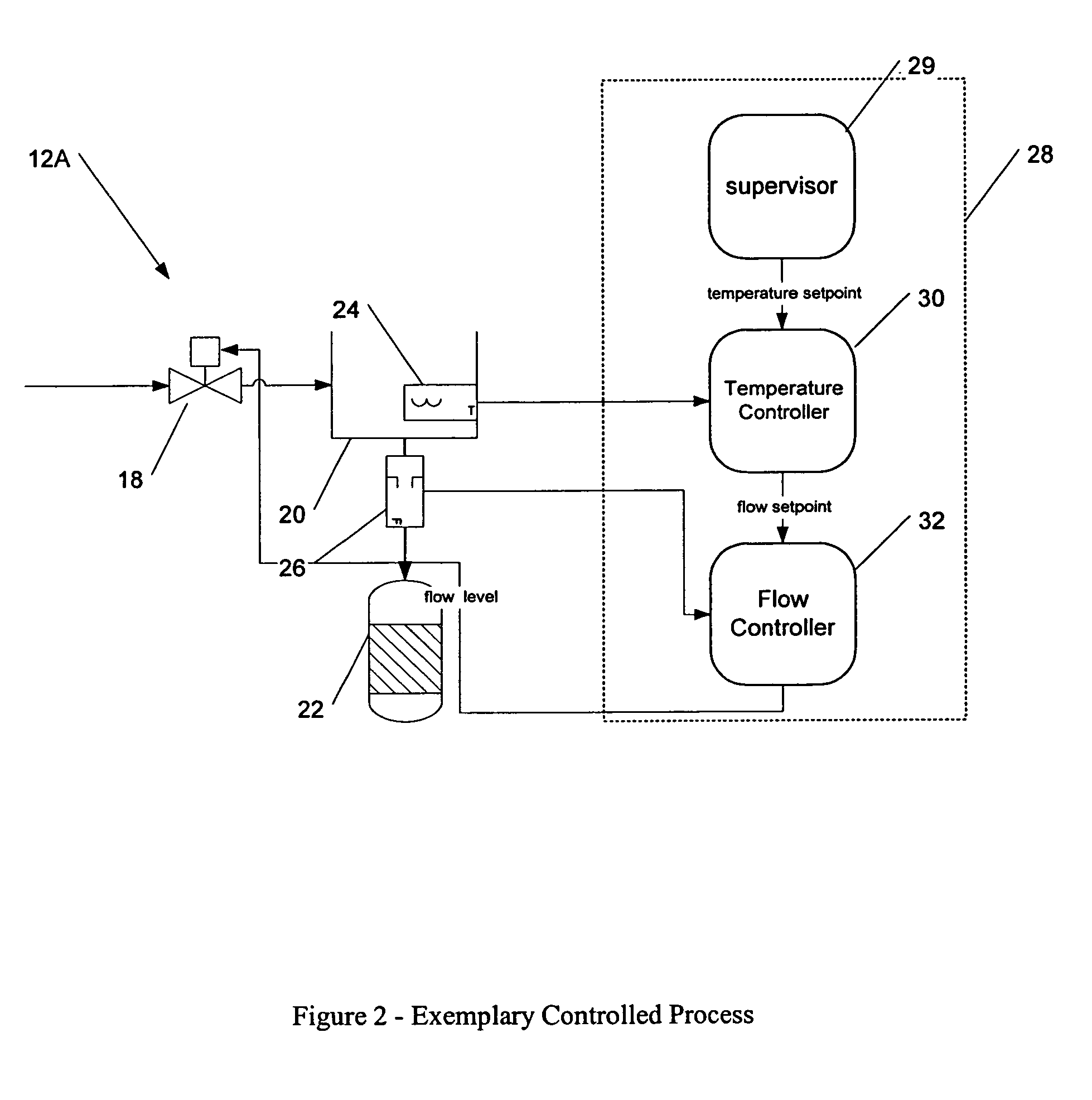

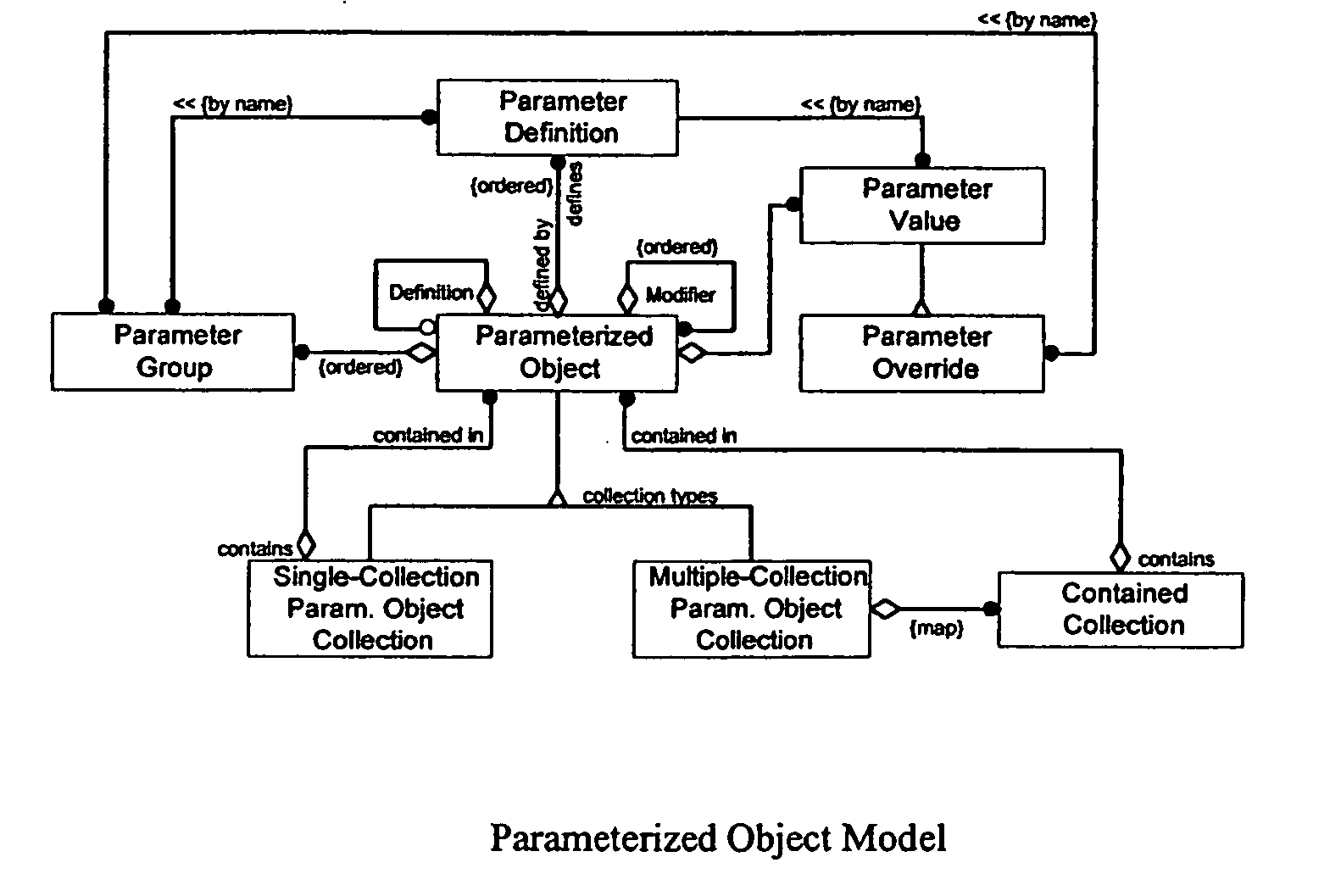

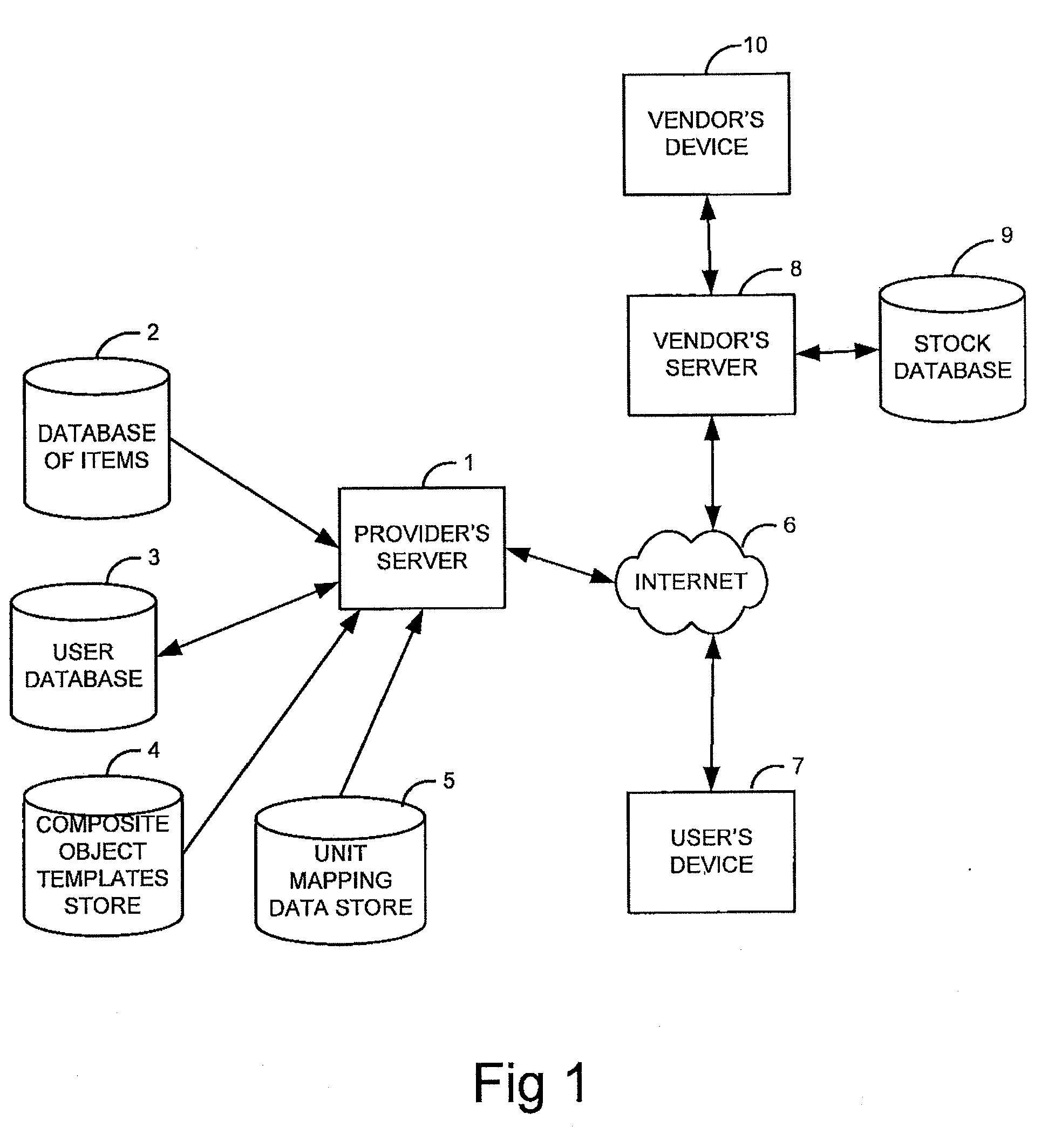

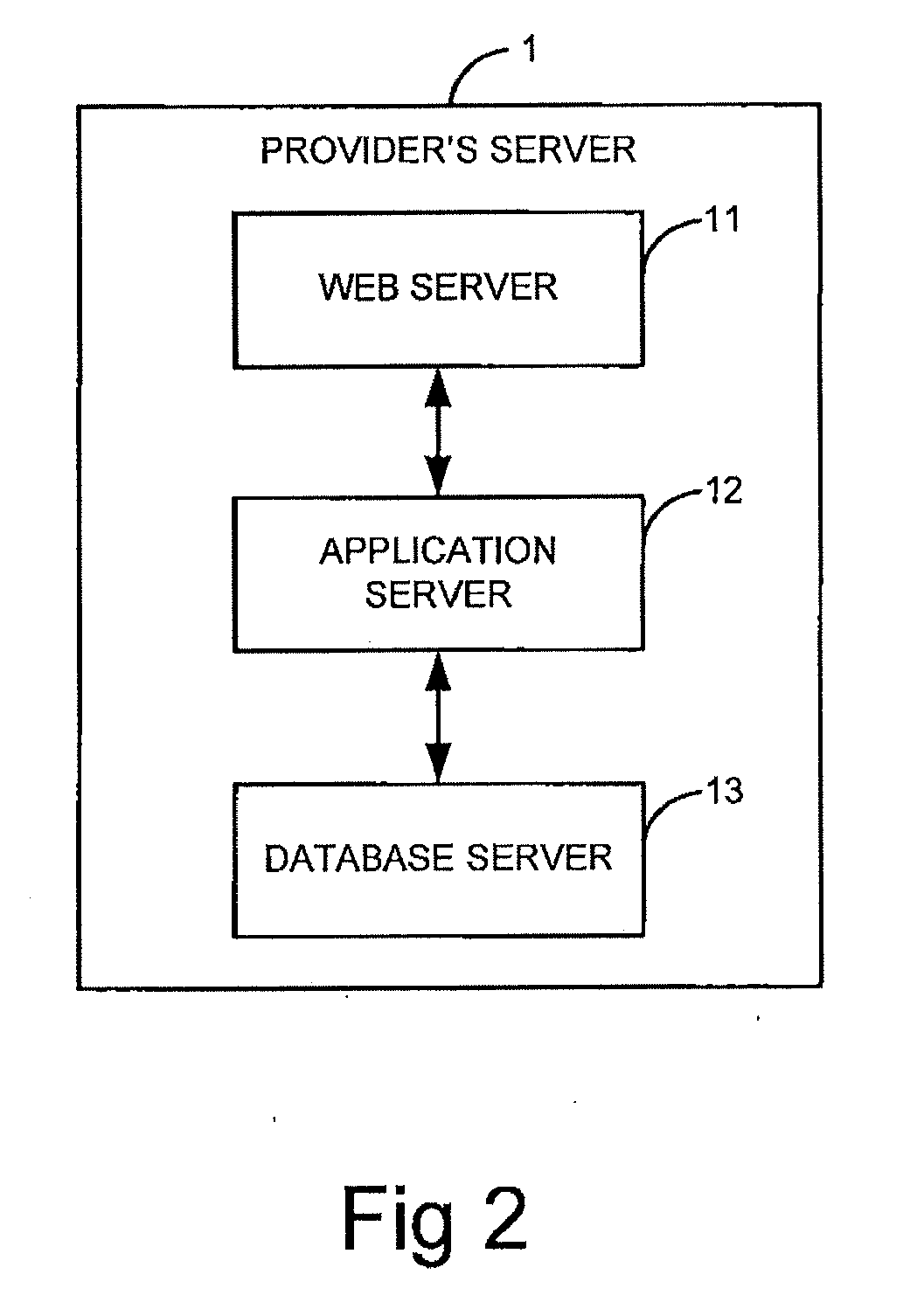

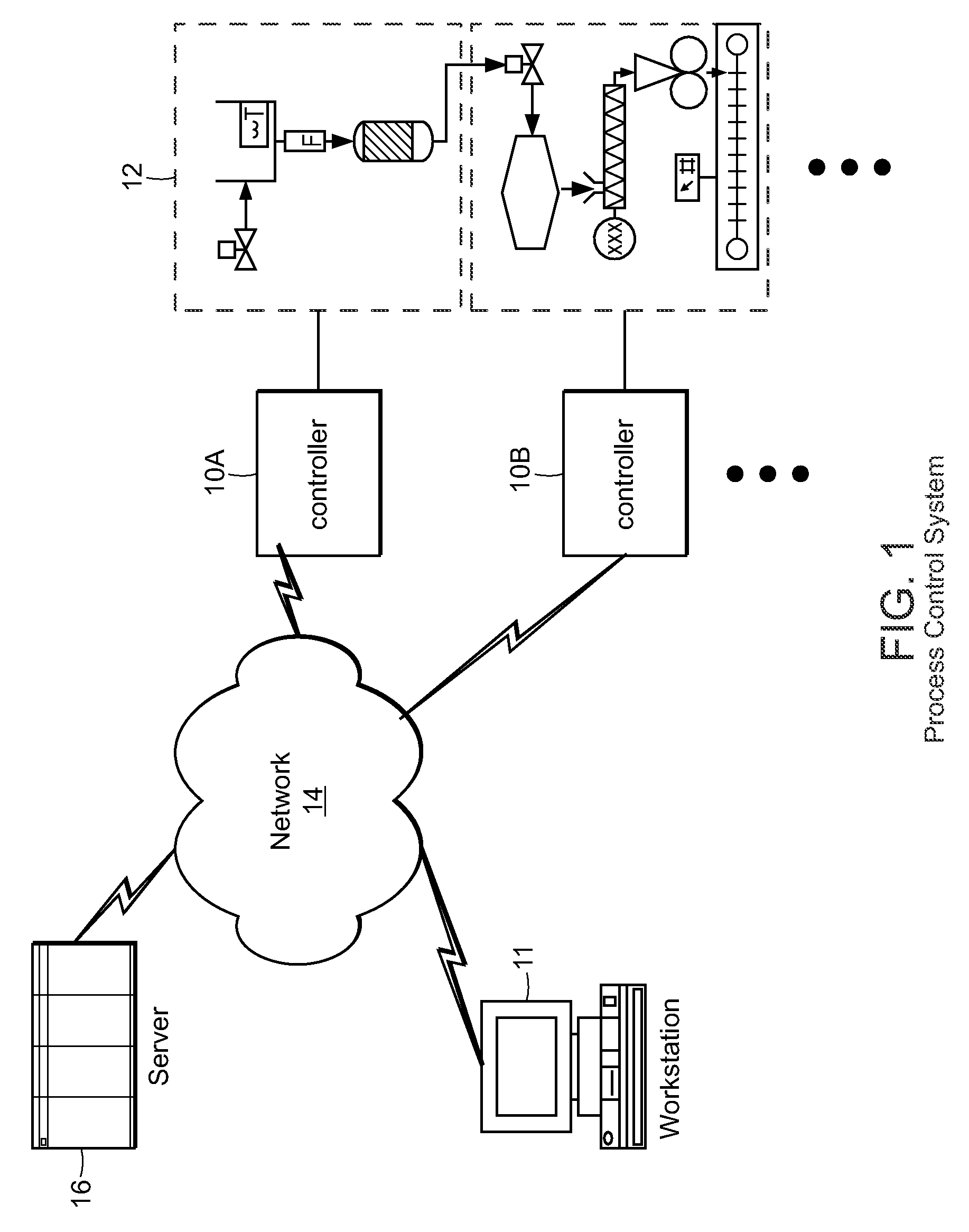

Methods and apparatus for configuring process, environmental, industrial and other control systems generate and / or utilize models representing configurations of control systems and / or the systems controlled by them. Records of changes to the models or the configurations represented by them are maintained, thereby, for example, providing bases for determining current states, prior states and histories of changes. Objects in the model have characteristics, such as an object type characteristic and an area characteristic. Users can have corresponding permissions. A security mechanism apparatus controls access by users to the objects. Composite objects are defined by definition objects and are displayed in encapsulated or expanded formats. Objects can include an edit control type identifier that determines how they are presented for editing. Functionality responds to user commands by transferring characteristics of a first object depicted by the graphical user interface to a second object. Configuration-time formulas contained objects are evaluated to constants prior to downloading to the control system.

Owner:SCHNEIDER ELECTRIC SYST USA INC

Methods and apparatus for control configuration using live data

InactiveUS20060206866A1OptimizationOptimize system configurationData processing applicationsComputer controlGraphicsReal-time data

Methods and apparatus for configuring process, environmental, industrial and other control systems generate and / or utilize models representing configurations of control systems and / or the systems controlled by them. Records of changes to the models or the configurations represented by them are maintained, thereby, for example, providing bases for determining current states, prior states and histories of changes. Objects in the model have characteristics, such as an object type characteristic and an area characteristic. Users can have corresponding permissions. A security mechanism apparatus controls access by users to the objects. Composite objects are defined by definition objects and are displayed in encapsulated or expanded formats. Objects can include an edit control type identifier that determines how they are presented for editing. Functionality responds to user commands by transferring characteristics of a first object depicted by the graphical user interface to a second object. Configuration-time formulas contained objects are evaluated to constants prior to downloading to the control system.

Owner:INVENSYS SYST INC

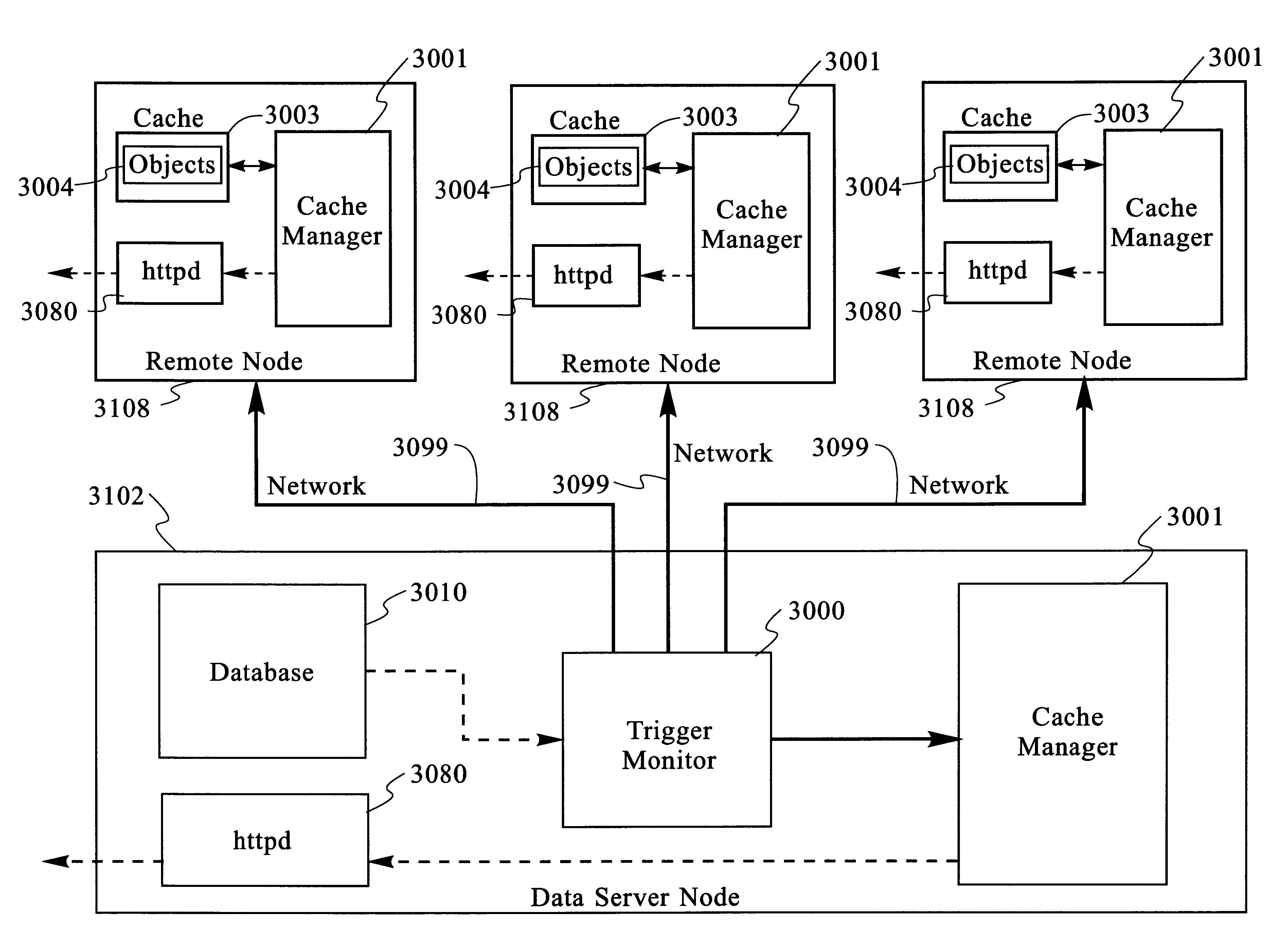

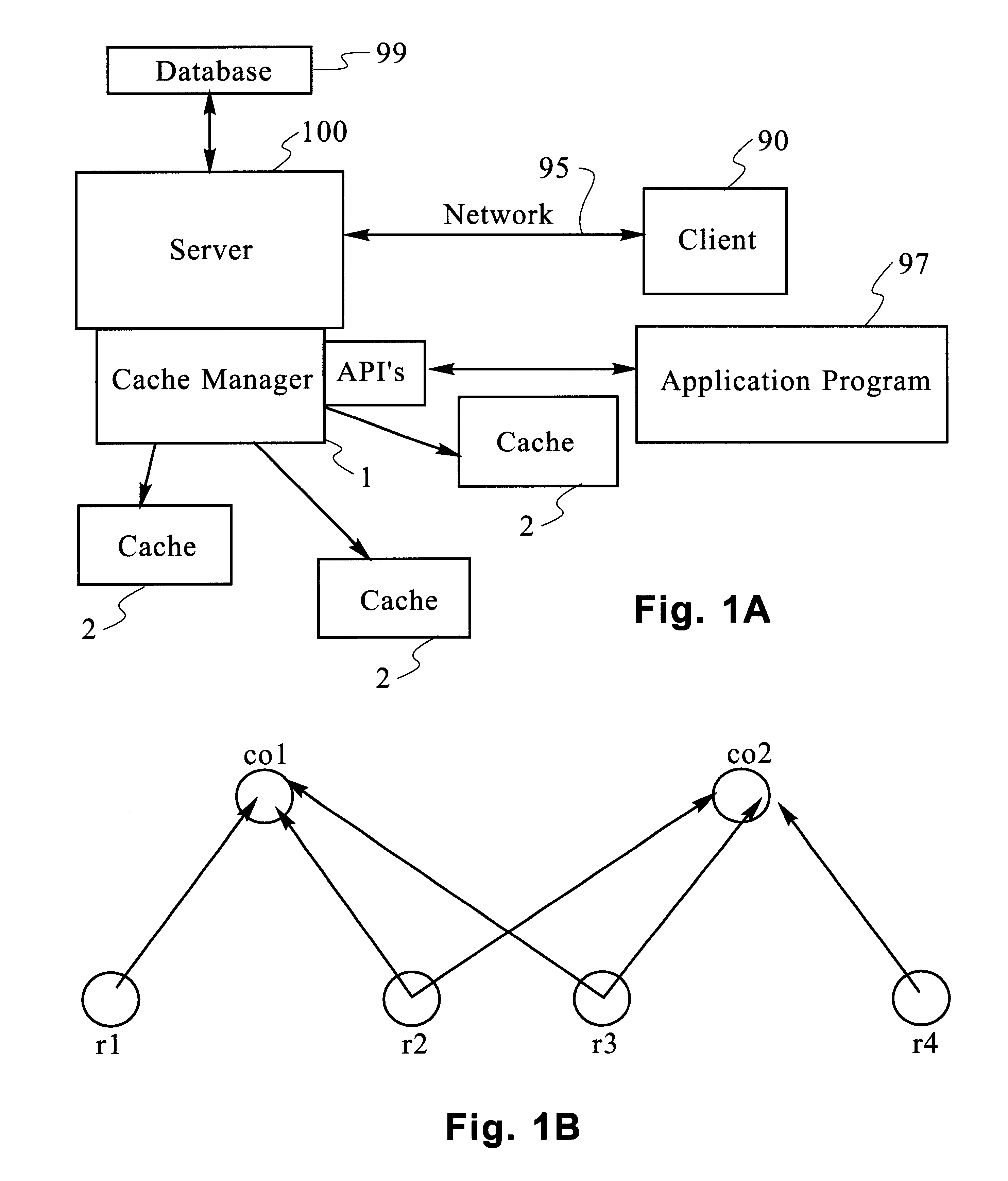

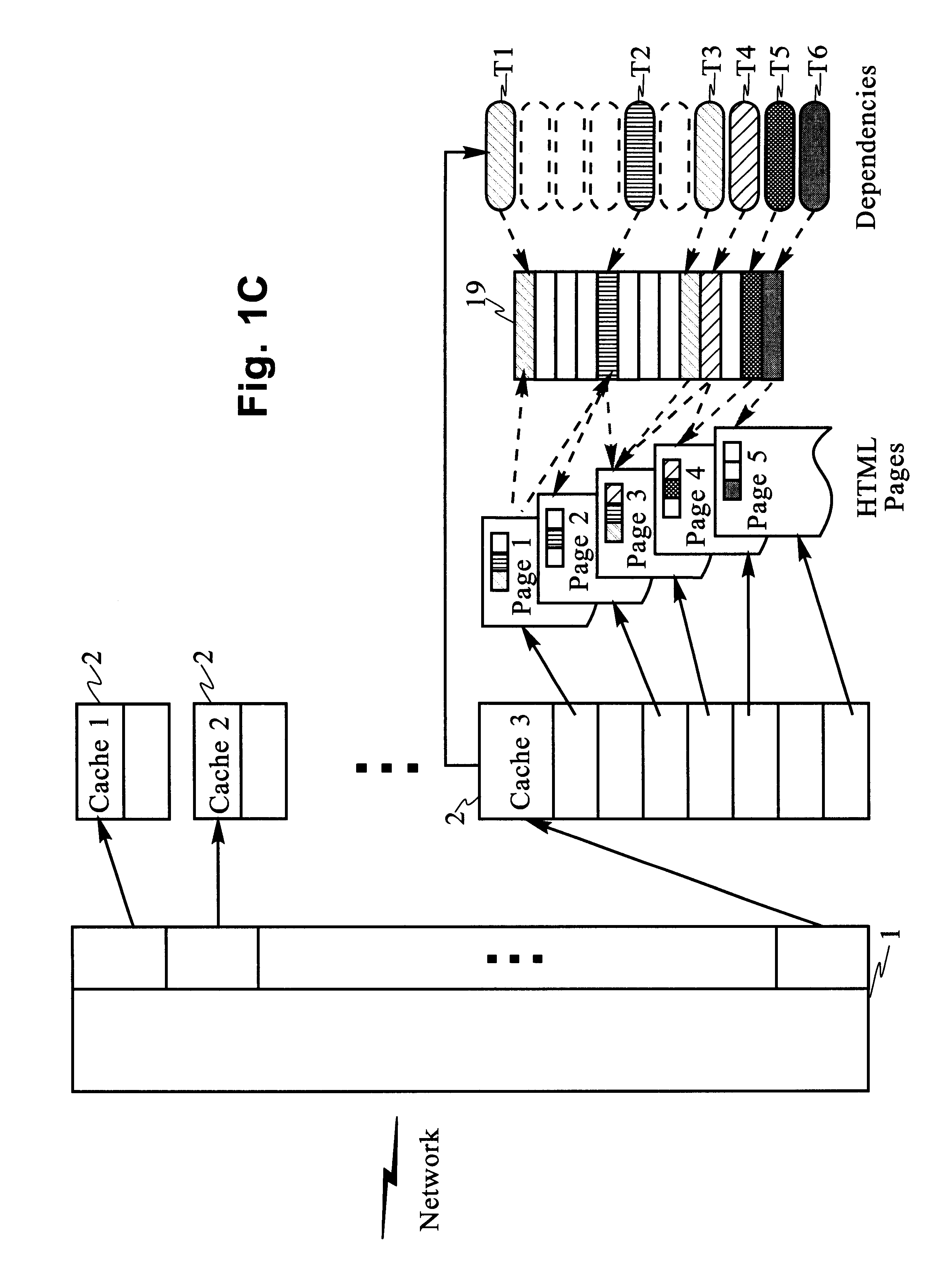

Scaleable method for maintaining and making consistent updates to caches

InactiveUS6256712B1High degreeData processing applicationsDigital data information retrievalData synchronizationExtensibility

A determination can be made of how changes to underlying data affect the value of objects. Examples of applications are: caching dynamic Web pages; client-server applications whereby a server sending objects (which are changing all the time) to multiple clients can track which versions are sent to which clients and how obsolete the versions are; and any situation where it is necessary to maintain and uniquely identify several versions of objects, update obsolete objects, quantitatively assess how different two versions of the same object are, and / or maintain consistency among a set of objects. A directed graph called an object dependence graph, may be used to represent the data dependencies between objects. Another aspect is constructing and maintaining objects to associate changes in remote data with cached objects. If data in a remote data source changes, database change notifications are used to "trigger" a dynamic rebuild of associated objects. Thus, obsolete objects can be dynamically replaced with fresh objects. The objects can be complex objects, such as dynamic Web pages or compound-complex objects, and the data can be underlying data in a database. The update can include either: storing a new version of the object in the cache; or deleting an object from the cache. Caches on multiple servers can also be synchronized with the data in a single common database. Updated information, whether new pages or delete orders, can be broadcast to a set of server nodes, permitting many systems to simultaneously benefit from the advantages of prefetching and providing a high degree of scaleability.

Owner:IBM CORP

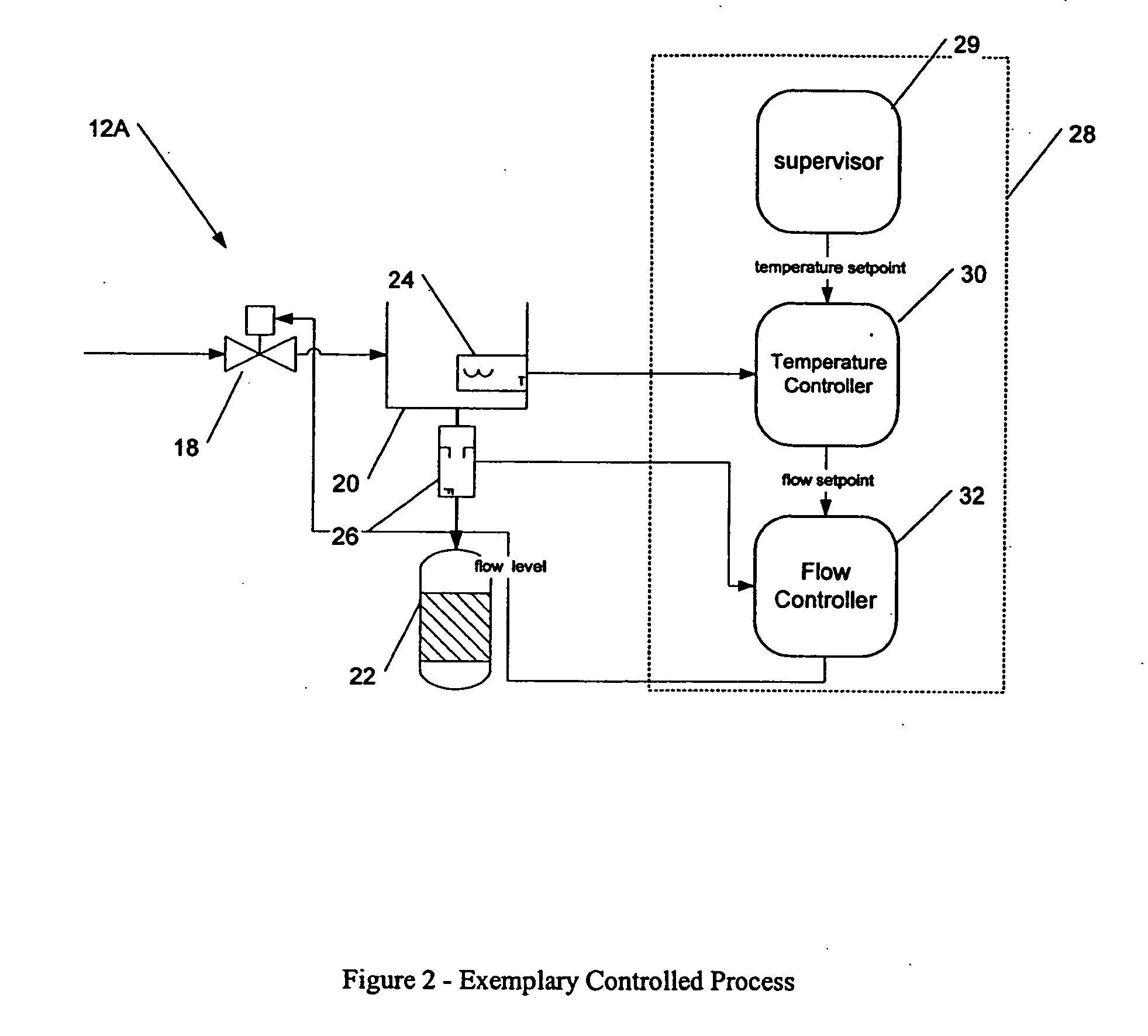

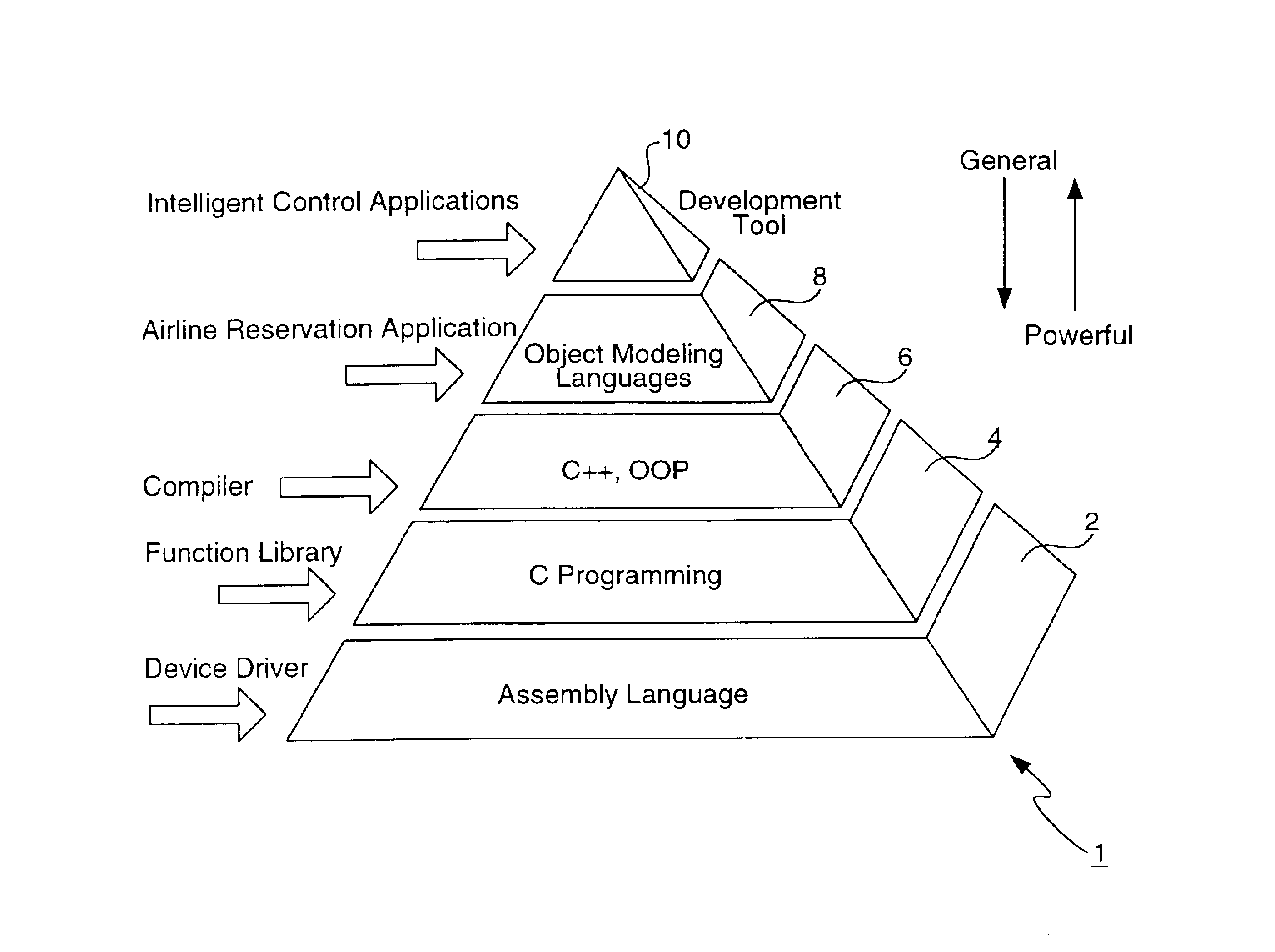

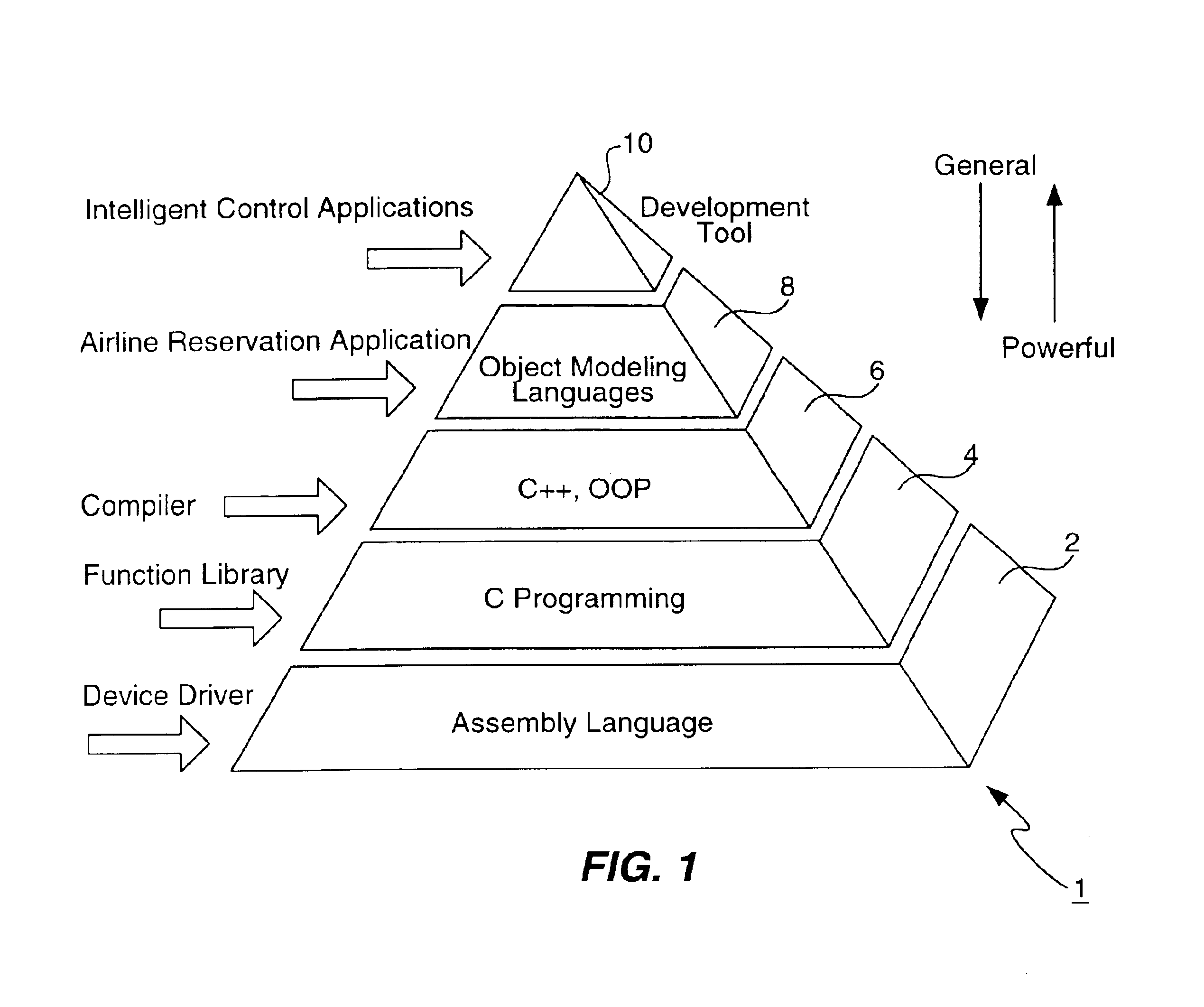

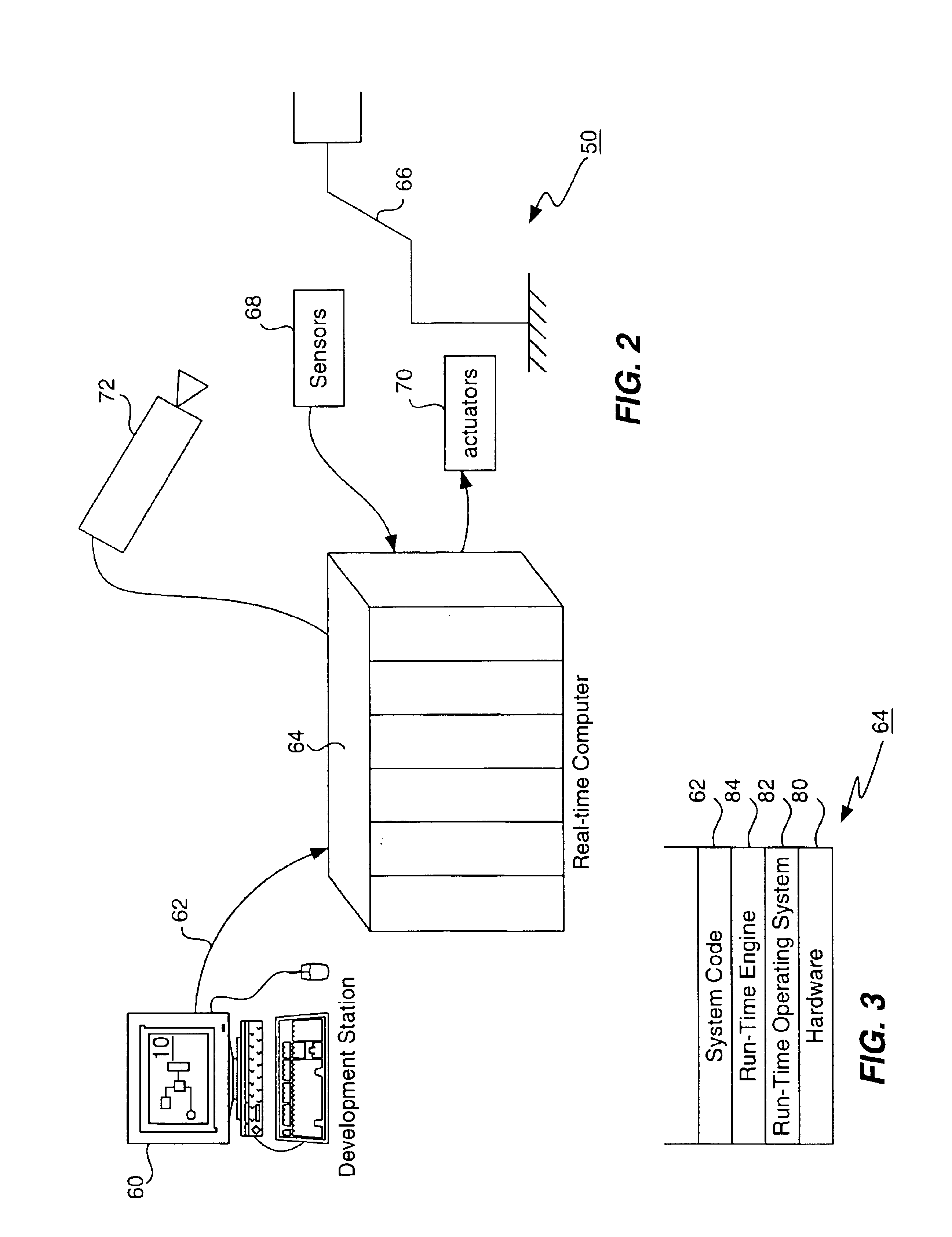

Real-time control system development tool

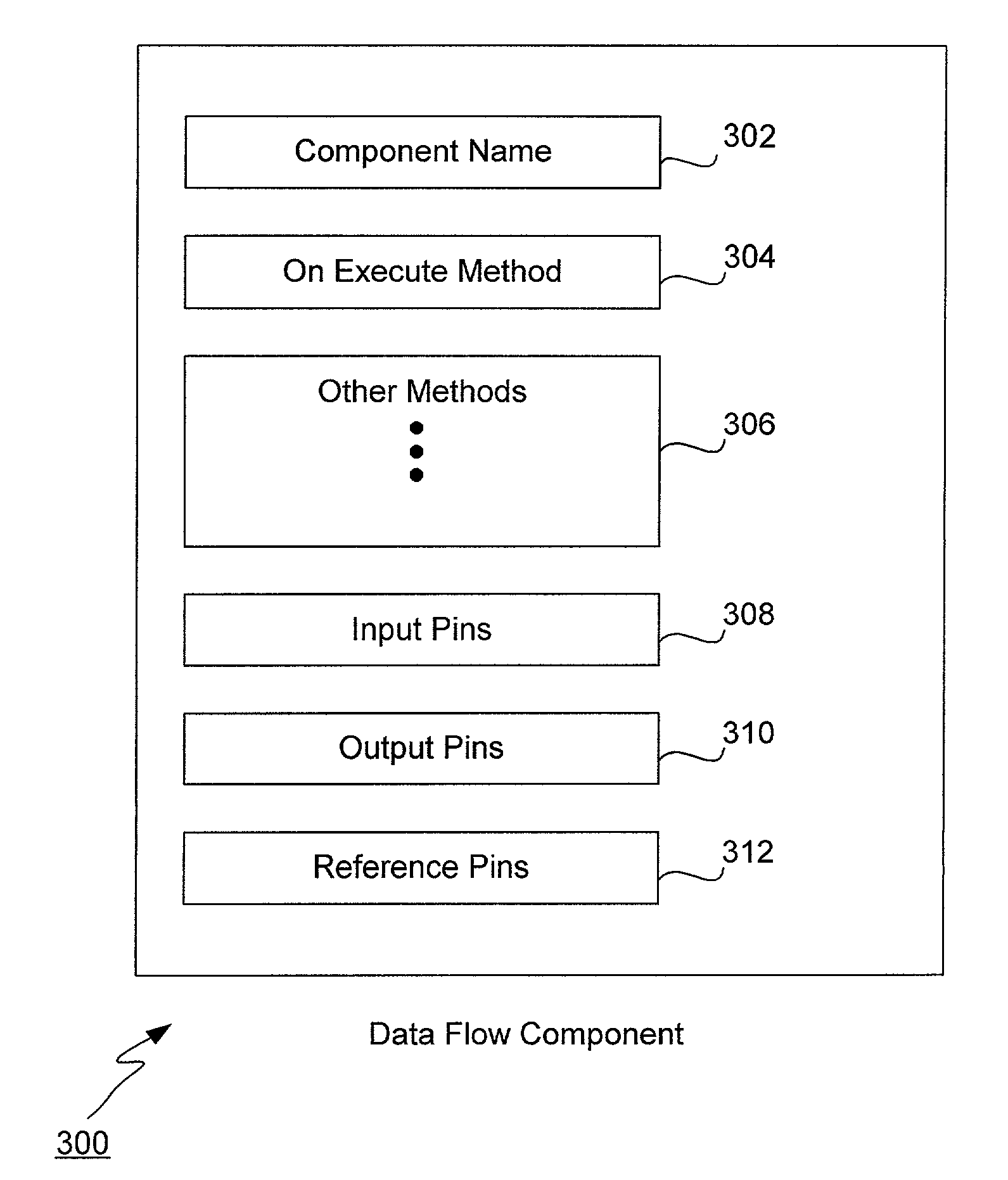

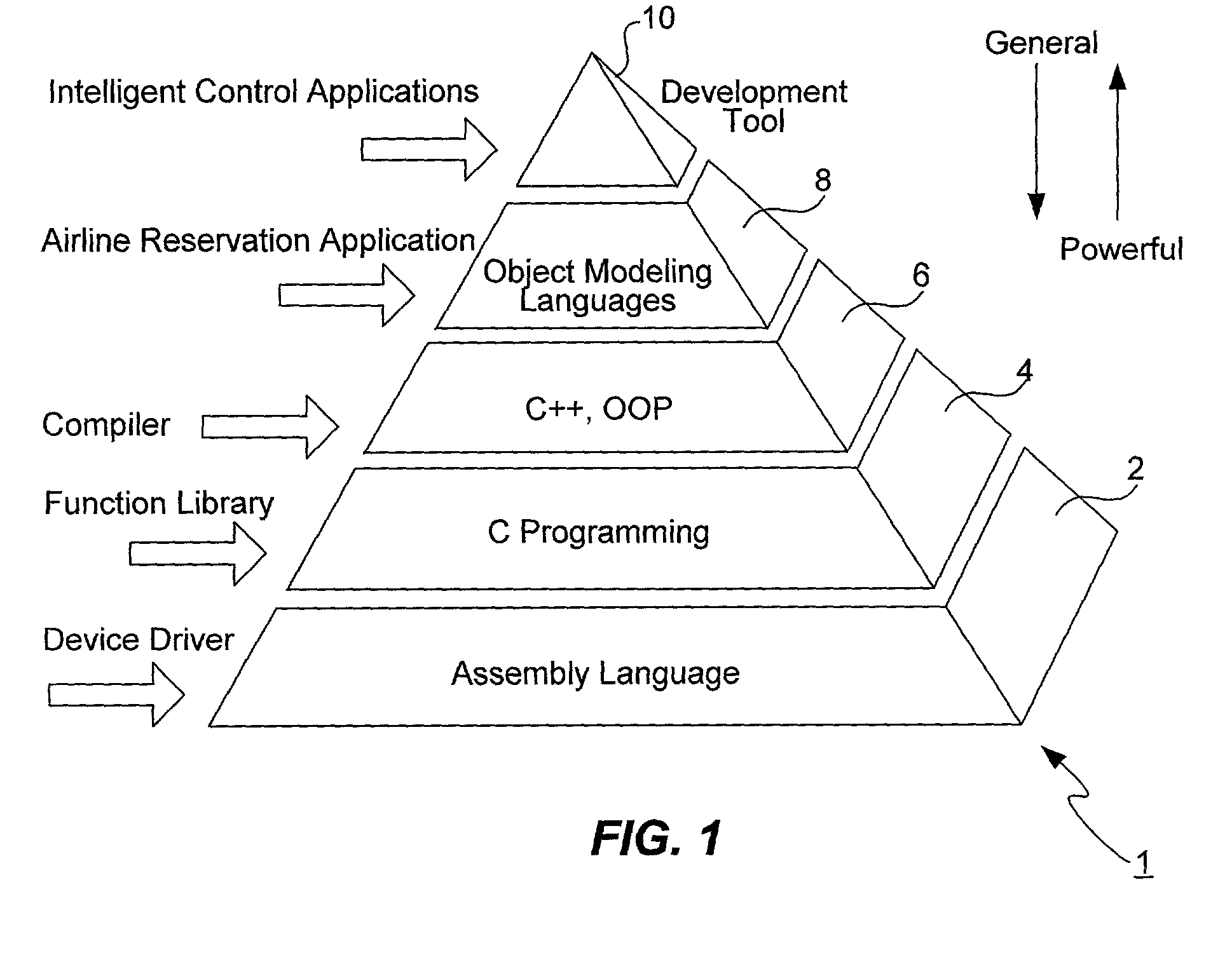

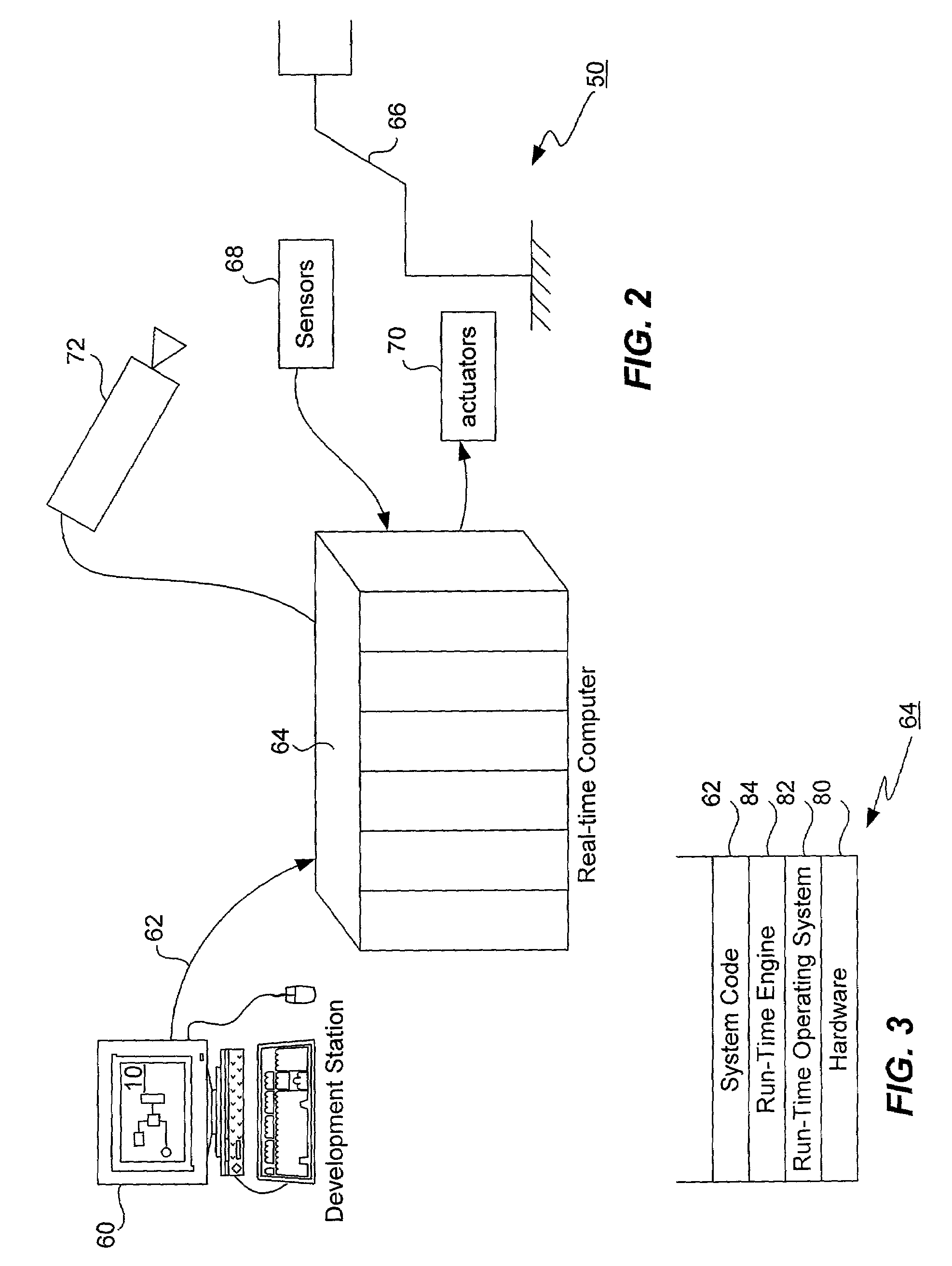

InactiveUS6865429B1Work fasterRapid modelingComputer controlSimulator controlComposite objectData processing

A composite object group (COG) data structure embodied in a computer-readable medium for building a control system that has both a clock cycle and event processing is provided. An interface for passing information to and from the COG data structure is provided. One or more data flow objects are provided in the COG to accept input data and to produce output data on the clock cycle. The data flow object is connected to the interface and provides sampled-data processing for the control system. One or more state machine objects are provided in the COG; each includes a plurality of states and a plurality of transitions between the states that are each triggered by an event. The state machine object provides event-driven processing for the control system, whereby the COG data structure provides both sampled-data and event-driven processing for the control system.

Owner:REAL TIME INNOVATIONS

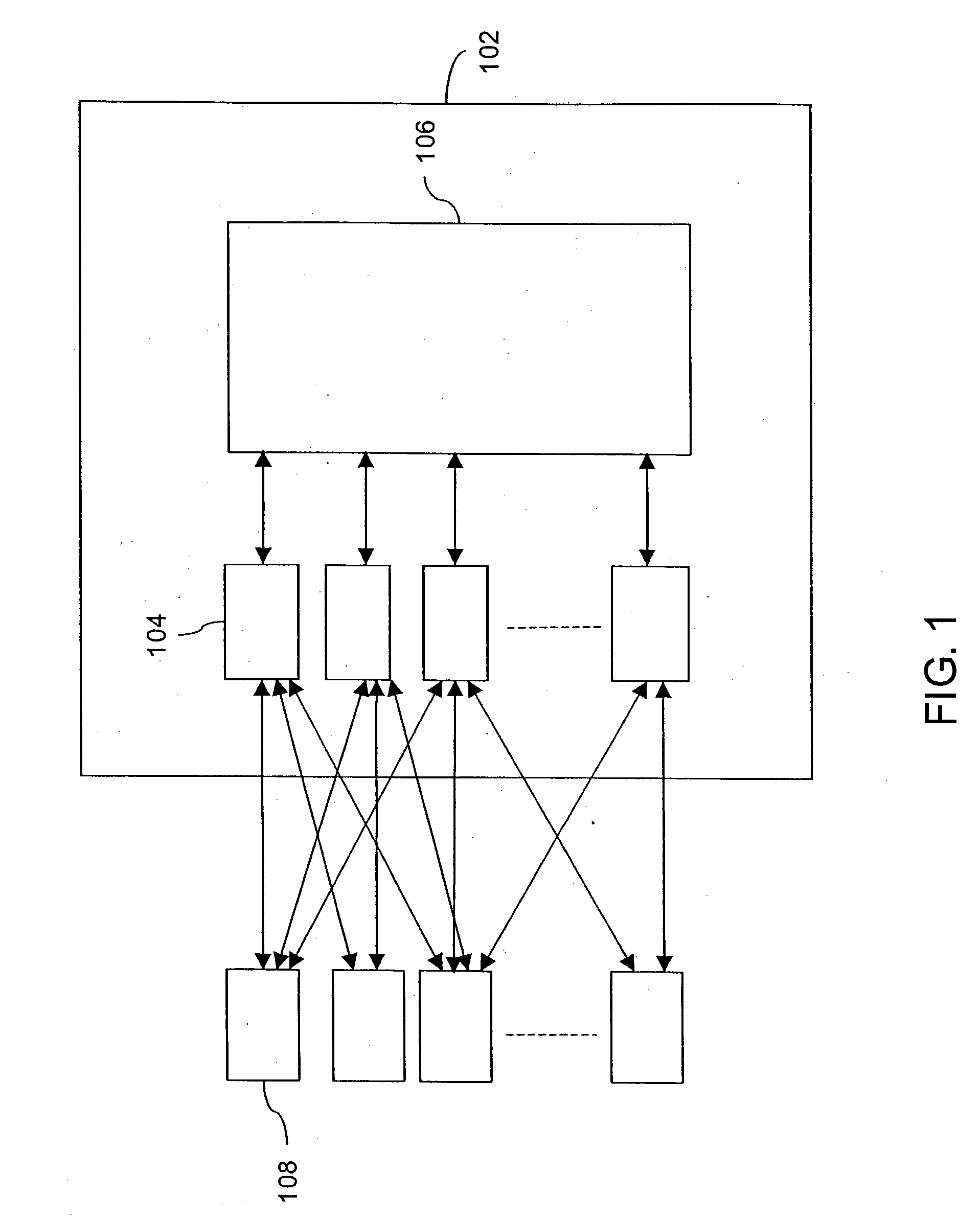

System, multi-tier interface and methods for management of operational structured data

ActiveUS20090125796A1Reduce the impactEasy to moveExecution for user interfacesInput/output processes for data processingSubject-matter expertObject based

Owner:AVRO COMPUTING

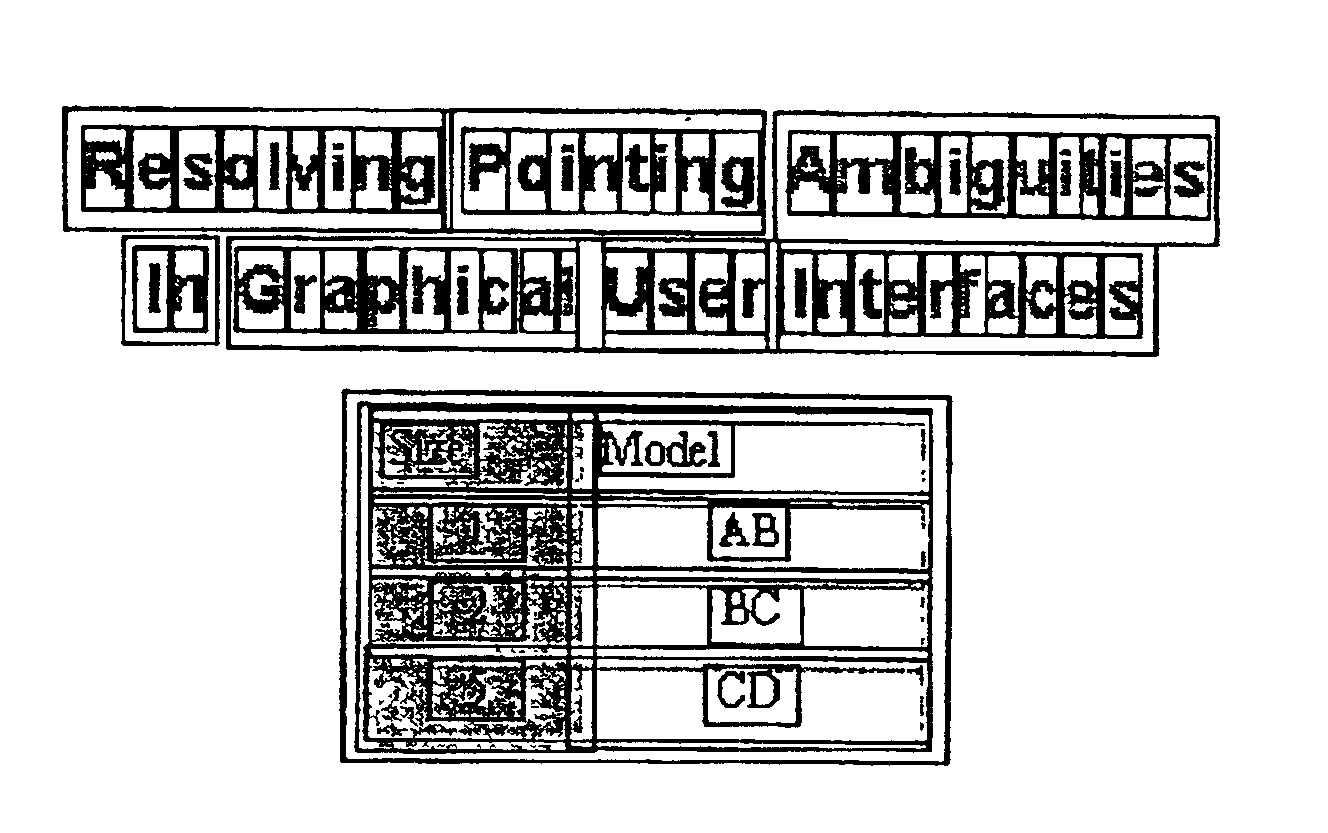

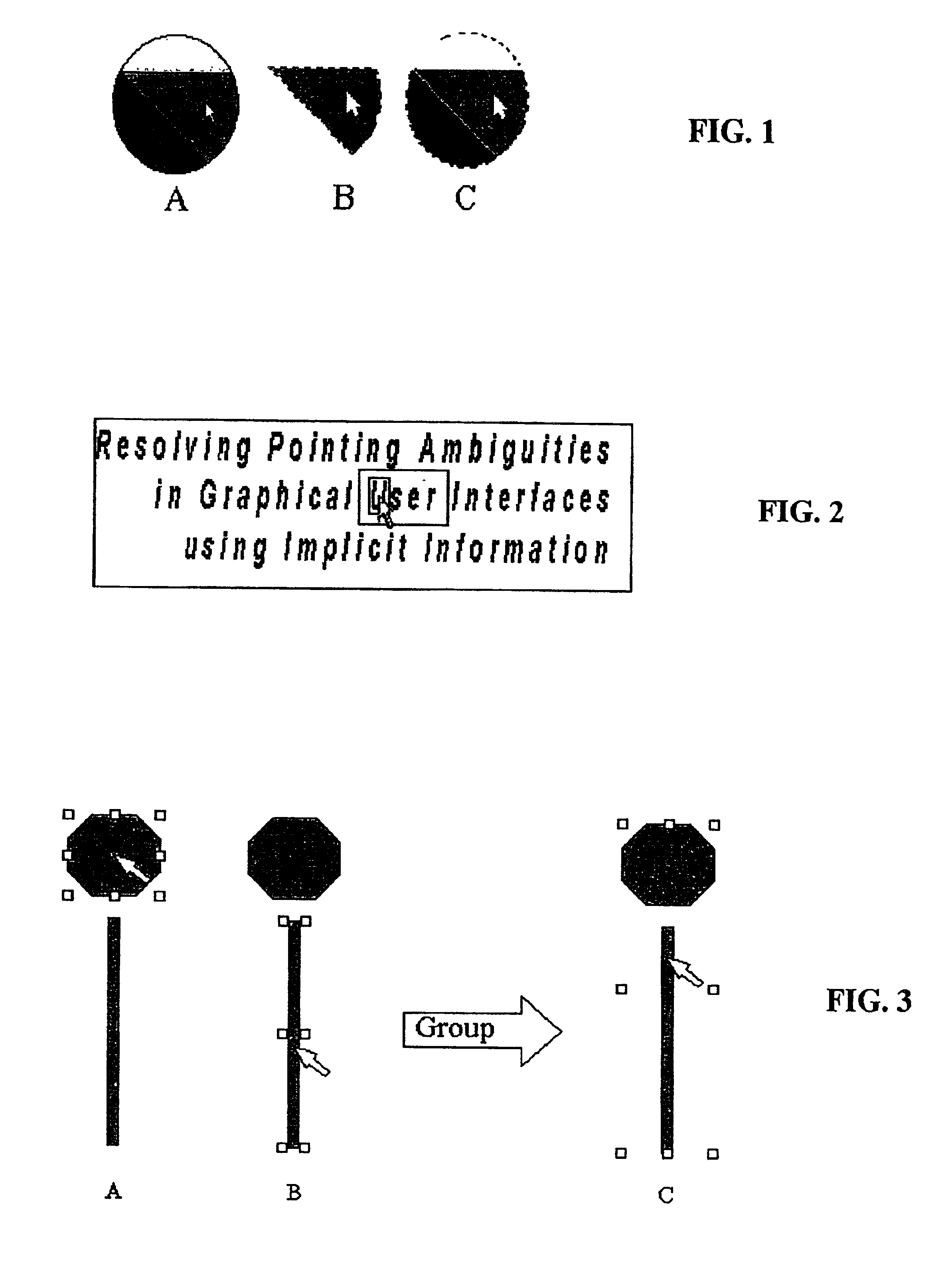

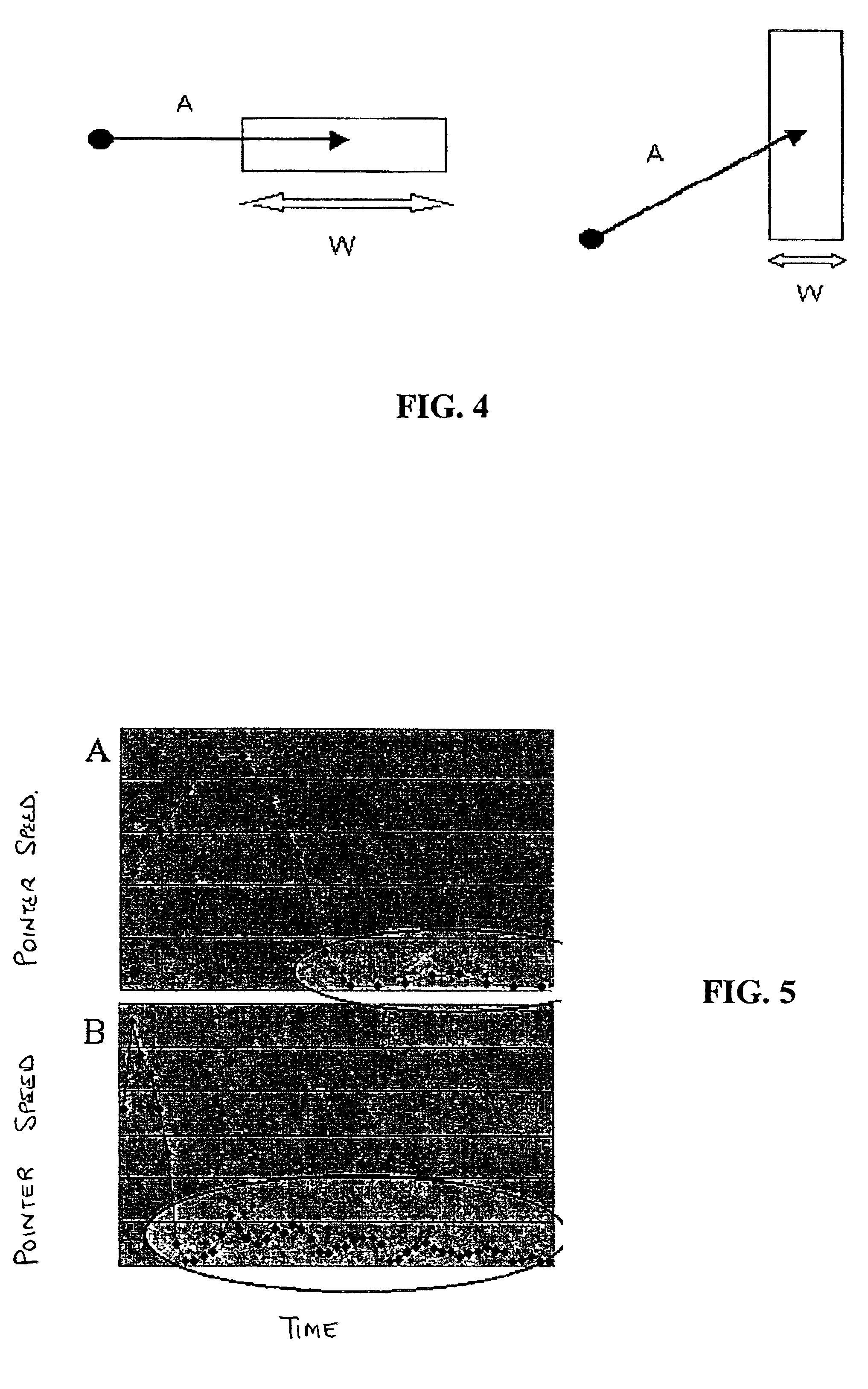

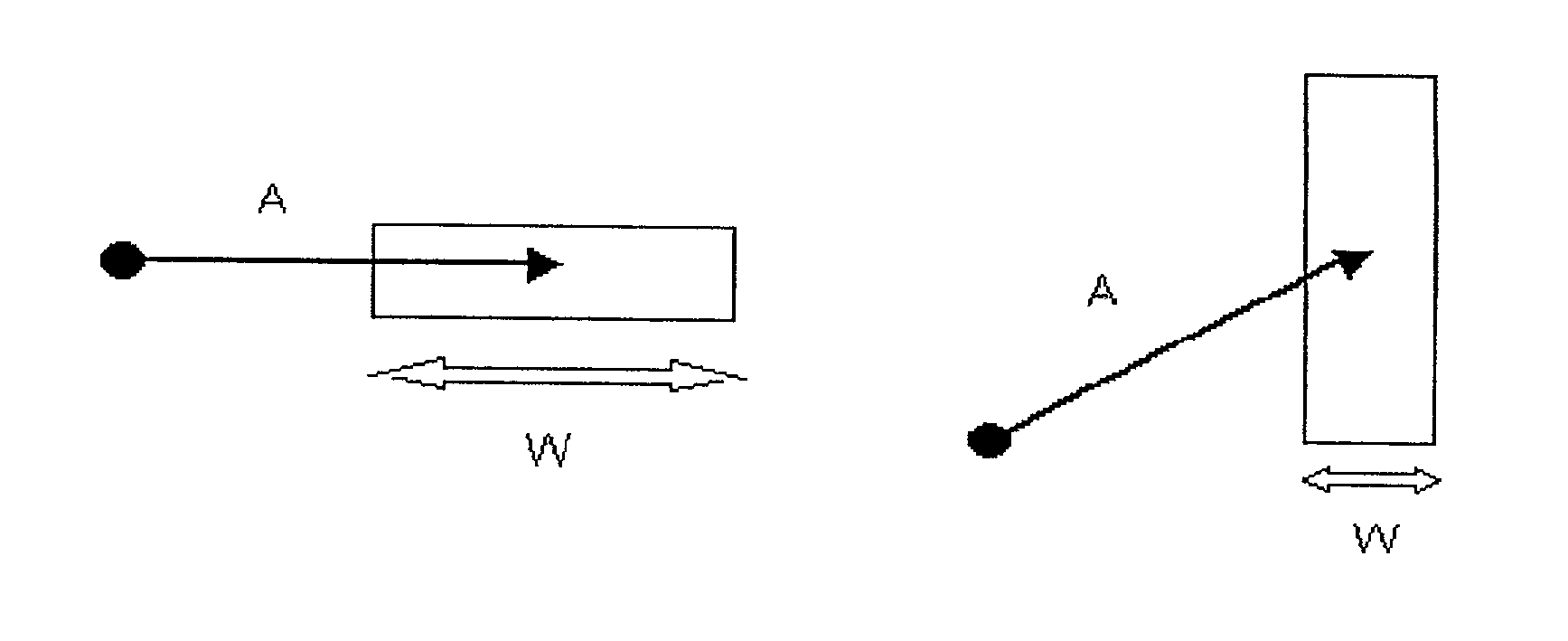

Method and system for implicitly resolving pointing ambiguities in human-computer interaction (HCI)

InactiveUS6907581B2Simple design and implementationEasy accessInput/output processes for data processingObject basedAmbiguity

Owner:RAMOT AT TEL AVIV UNIV LTD

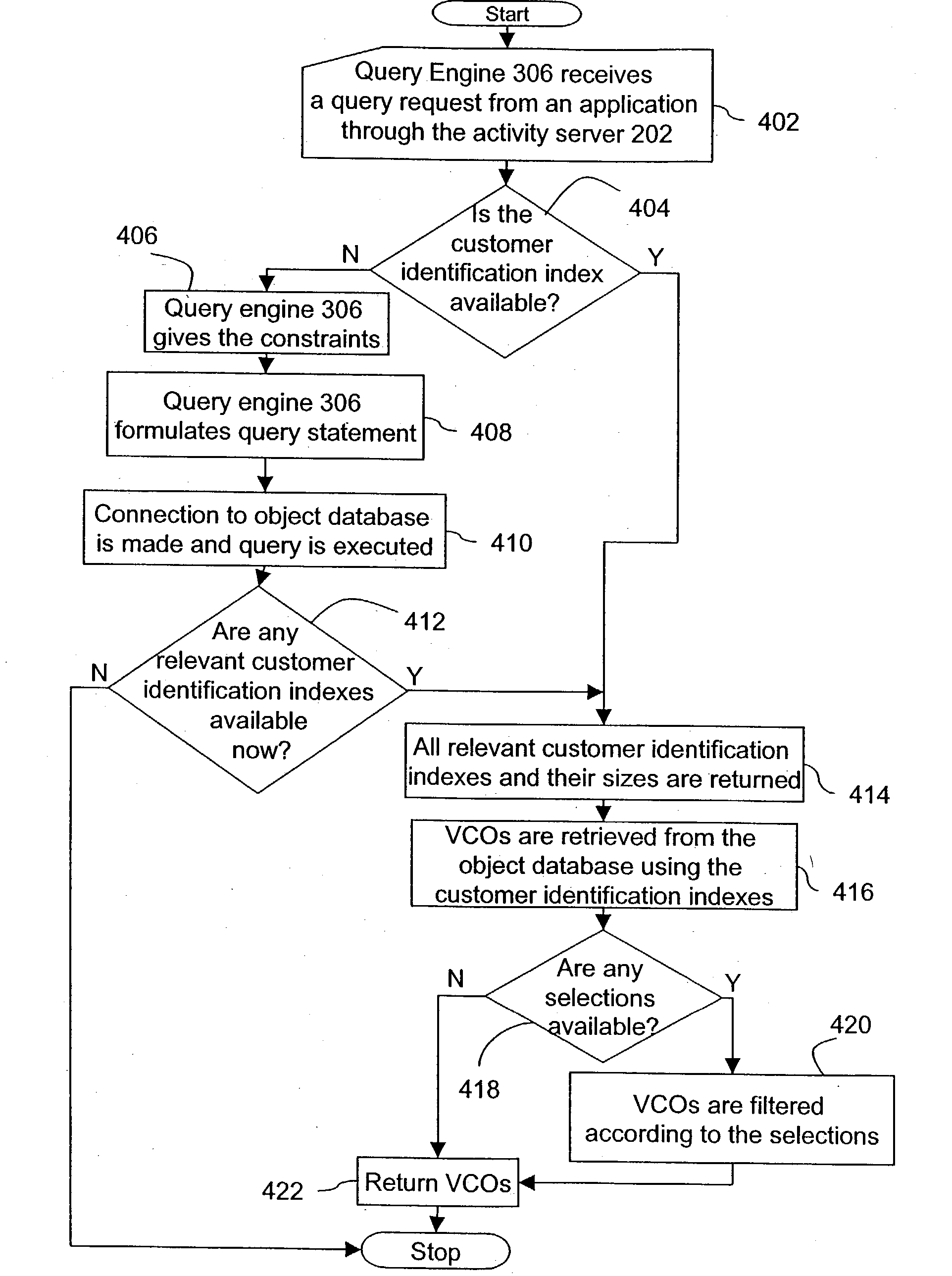

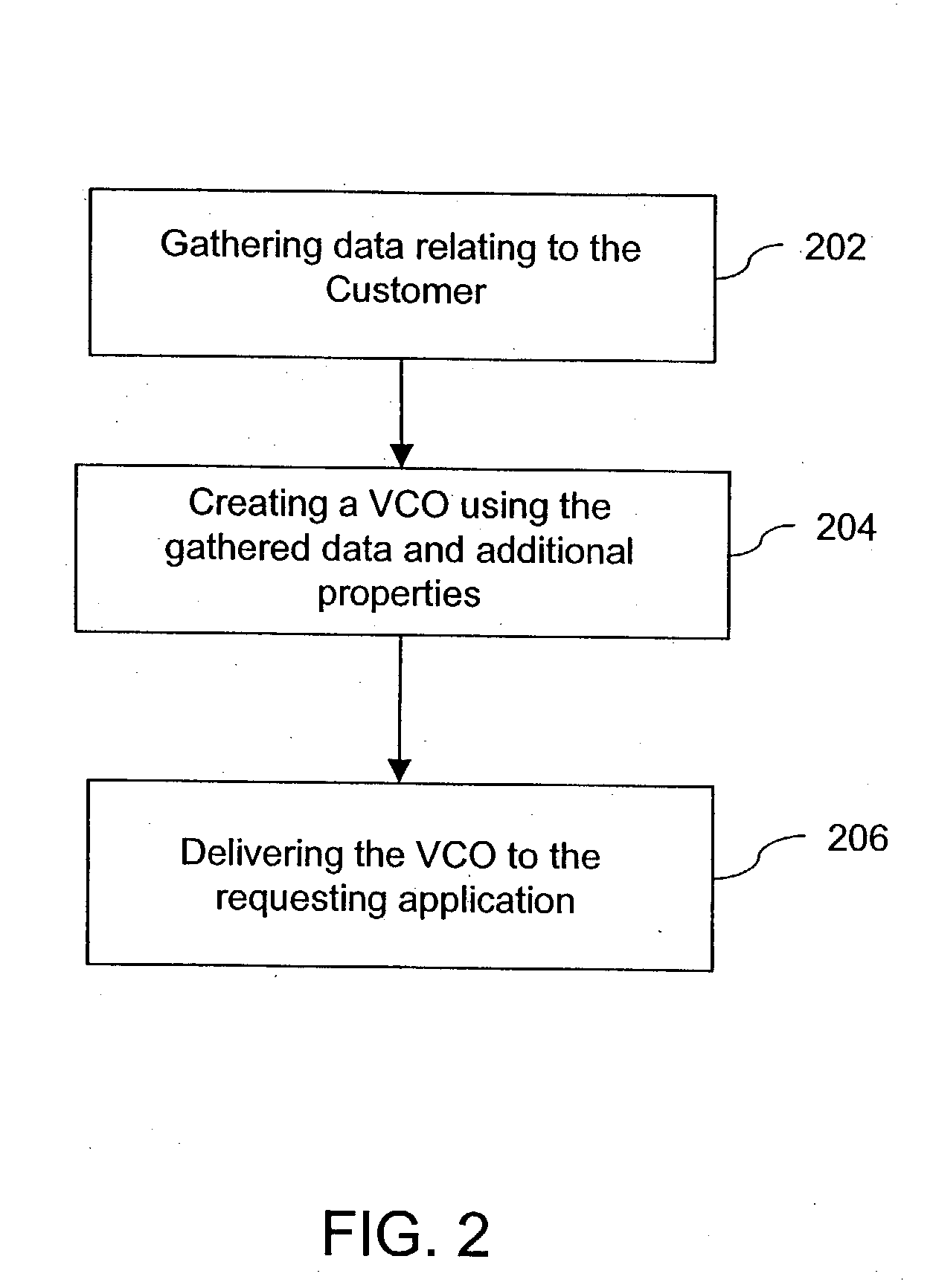

System and method for integrating, managing and coordinating customer activities

ActiveUS20040006506A1Faster and efficient transferDigital data processing detailsOffice automationComposite objectApplication software

A system, method and computer program product for integrating, managing and coordinating activities of customers in an enterprise, across a plurality of applications, resources and touch-points. Customer data is obtained during interactions between a customer and an application, a resource or a touch-point. This data is stored in the form of virtual composite objects in cache memory, on a cluster of servers. The virtual composite objects contain customer data, policies and behaviors of the enterprise. The applications query for the virtual composite objects through the server. The server hosting the queried virtual composite object delivers the queried virtual composite object in real time to the querying application. Any updates to the virtual composite object on account of events at the applications, resources or touch-points, is carried out in real time.

Owner:INFORMATICA CORP

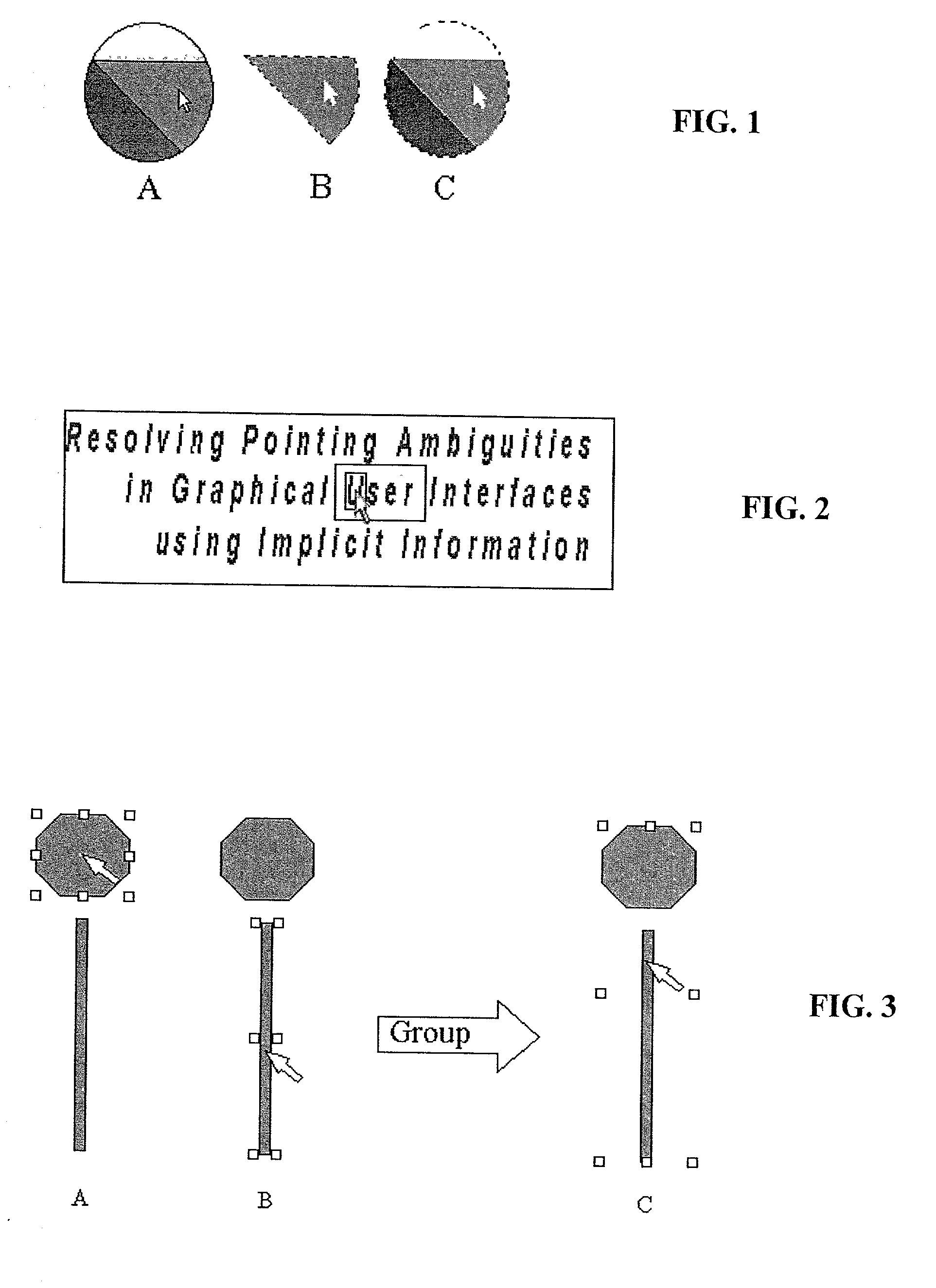

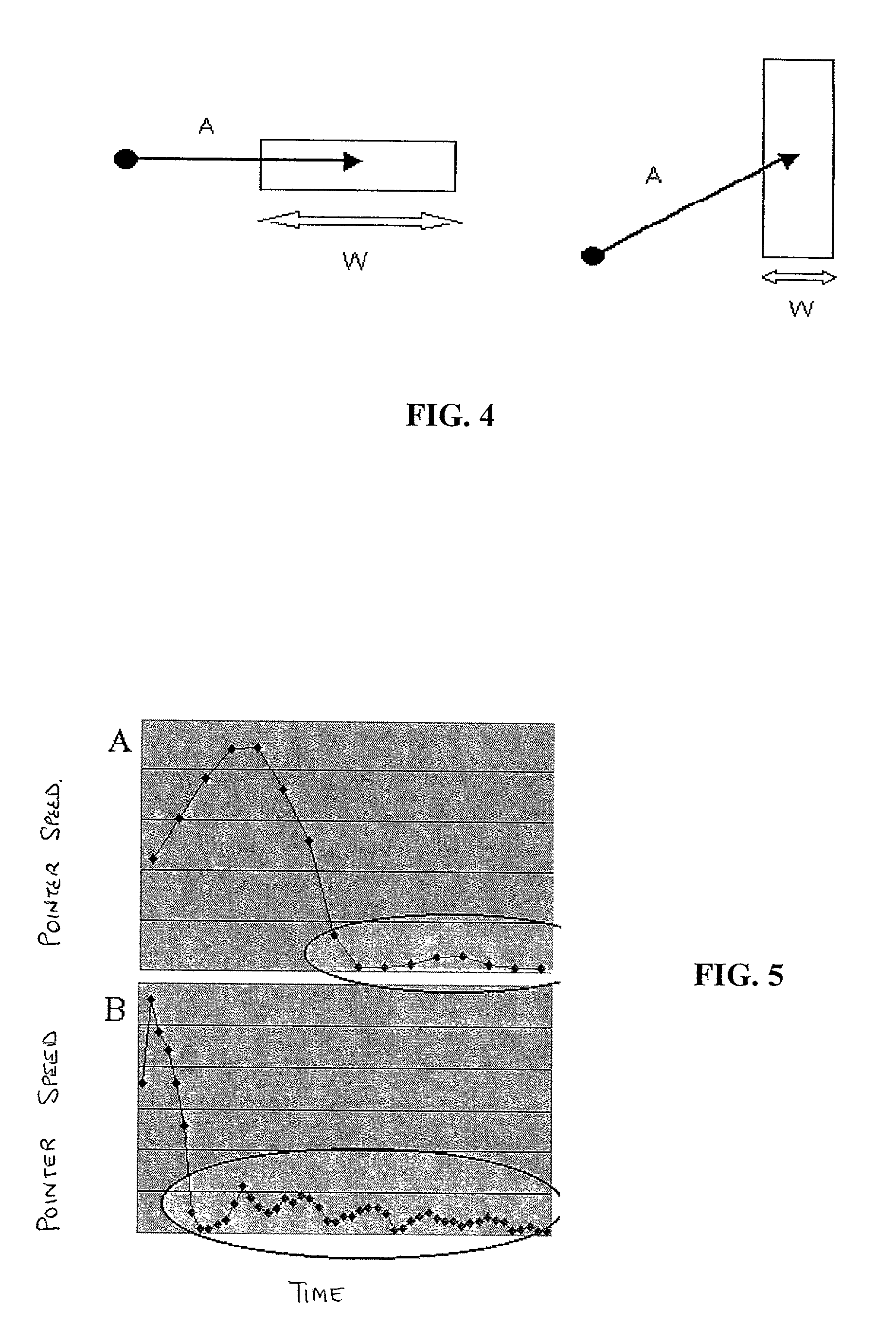

Method and system for implicitly resolving pointing ambiguities in human-computer interaction (HCI)

InactiveUS20030016252A1Accurate understandingStatic indicating devicesInput/output processes for data processingObject basedAmbiguity

A method and system for implicitly resolving pointing ambiguities in human-computer interaction by implicitly analyzing user movements of a pointer toward a user targeted object located in an ambiguous multiple object domain and predicting the user targeted object, using different categories of heuristic (statically and / or dynamically learned) measures, such as (i) implicit user pointing gesture measures, (ii) application context, and (iii) number of computer suggestions of each predicted user targeted object. Featured are user pointing gesture measures of (1) speed-accuracy tradeoff, referred to as total movement time (TMT), and, amount of fine tuning (AFT) or tail-length (TL), and, (2) exact pointer position. A particular application context heuristic measure used is referred to as containment hierarchy. The invention is widely applicable to resolving a variety of different types of pointing ambiguities such as composite object types of pointing ambiguities, involving different types of pointing devices, and which are widely applicable to essentially any type of software and / or hardware methodology involving using a pointer, such as in computer aided design (CAD), object based graphical editing, and text editing.

Owner:RAMOT AT TEL AVIV UNIV LTD

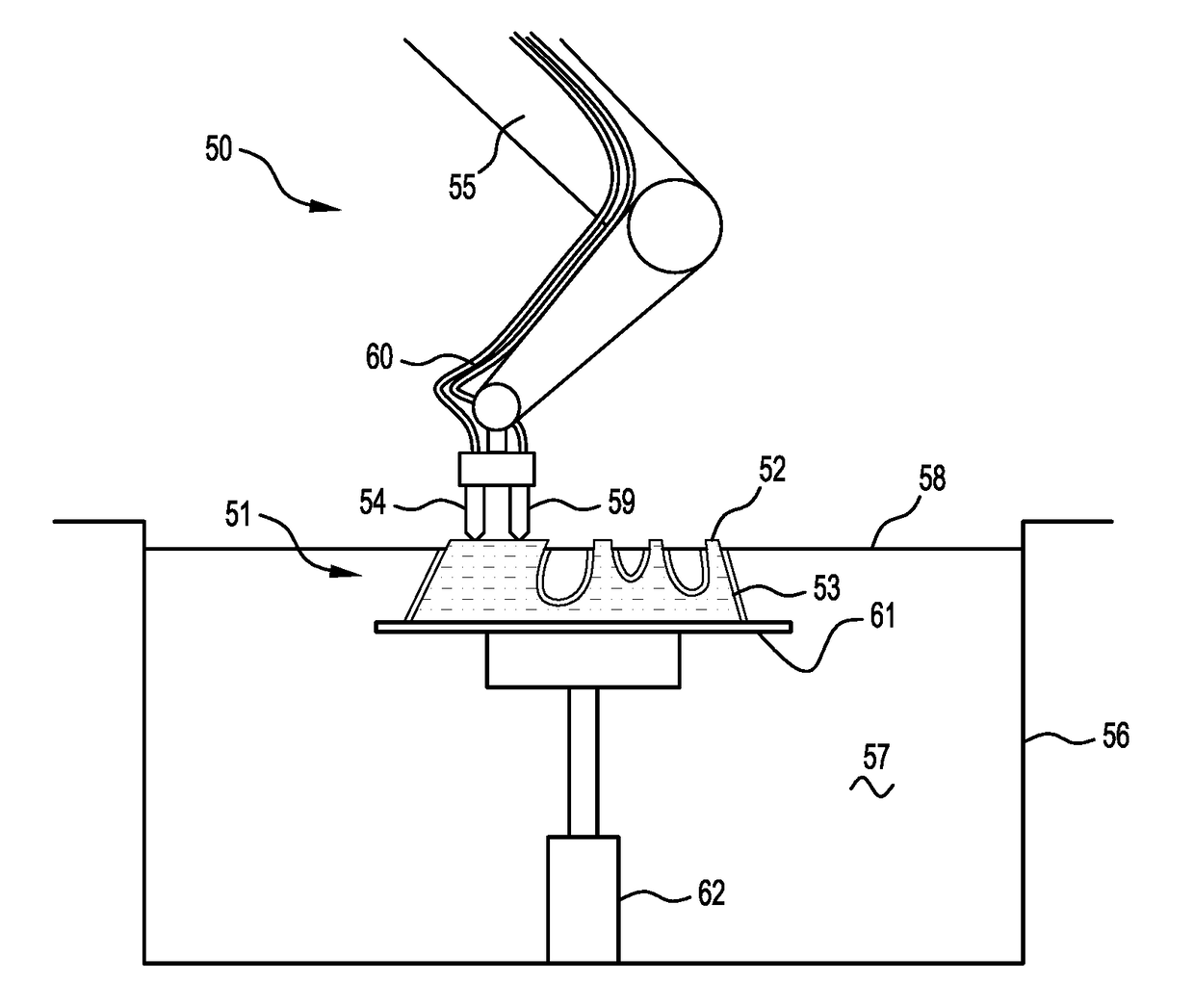

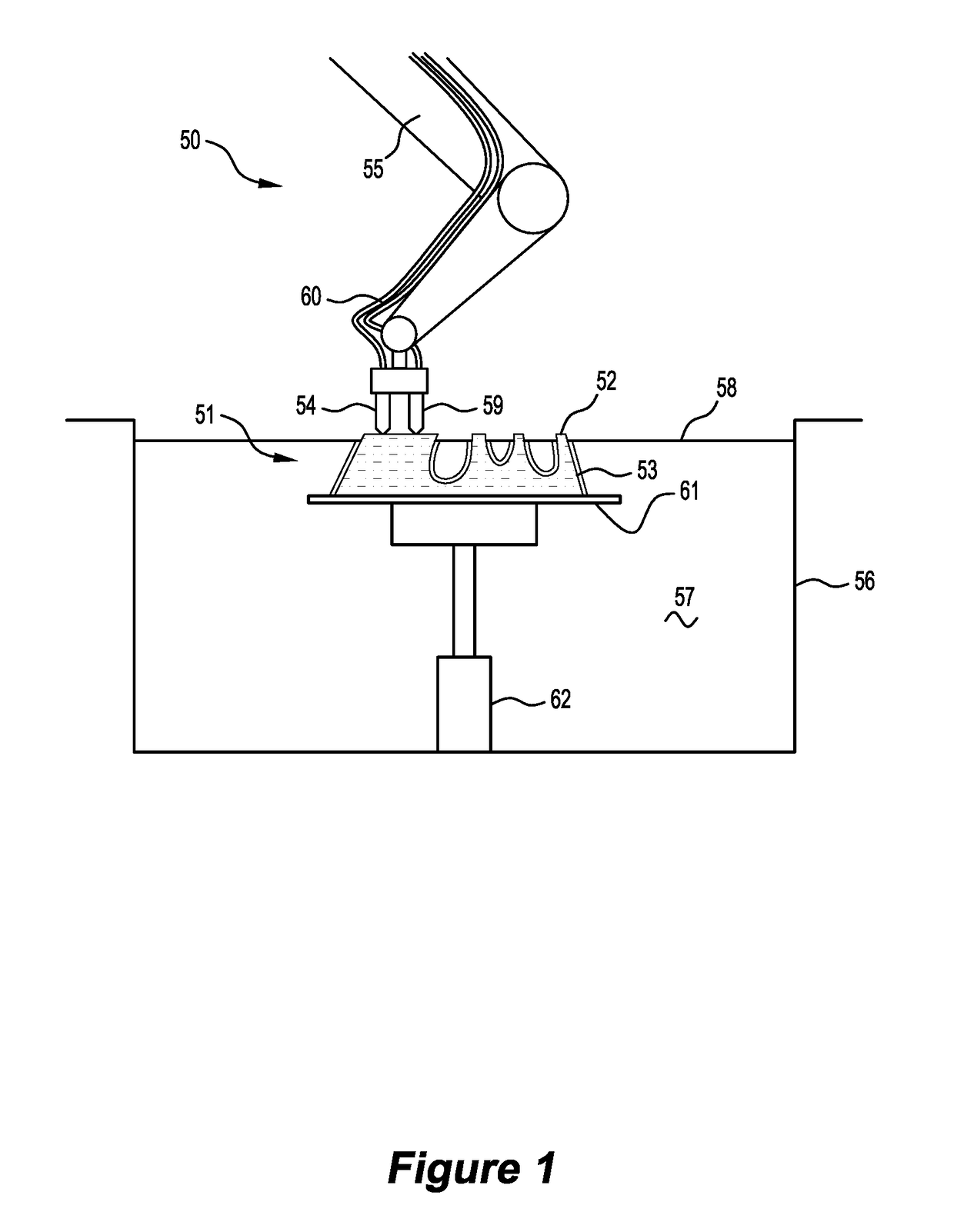

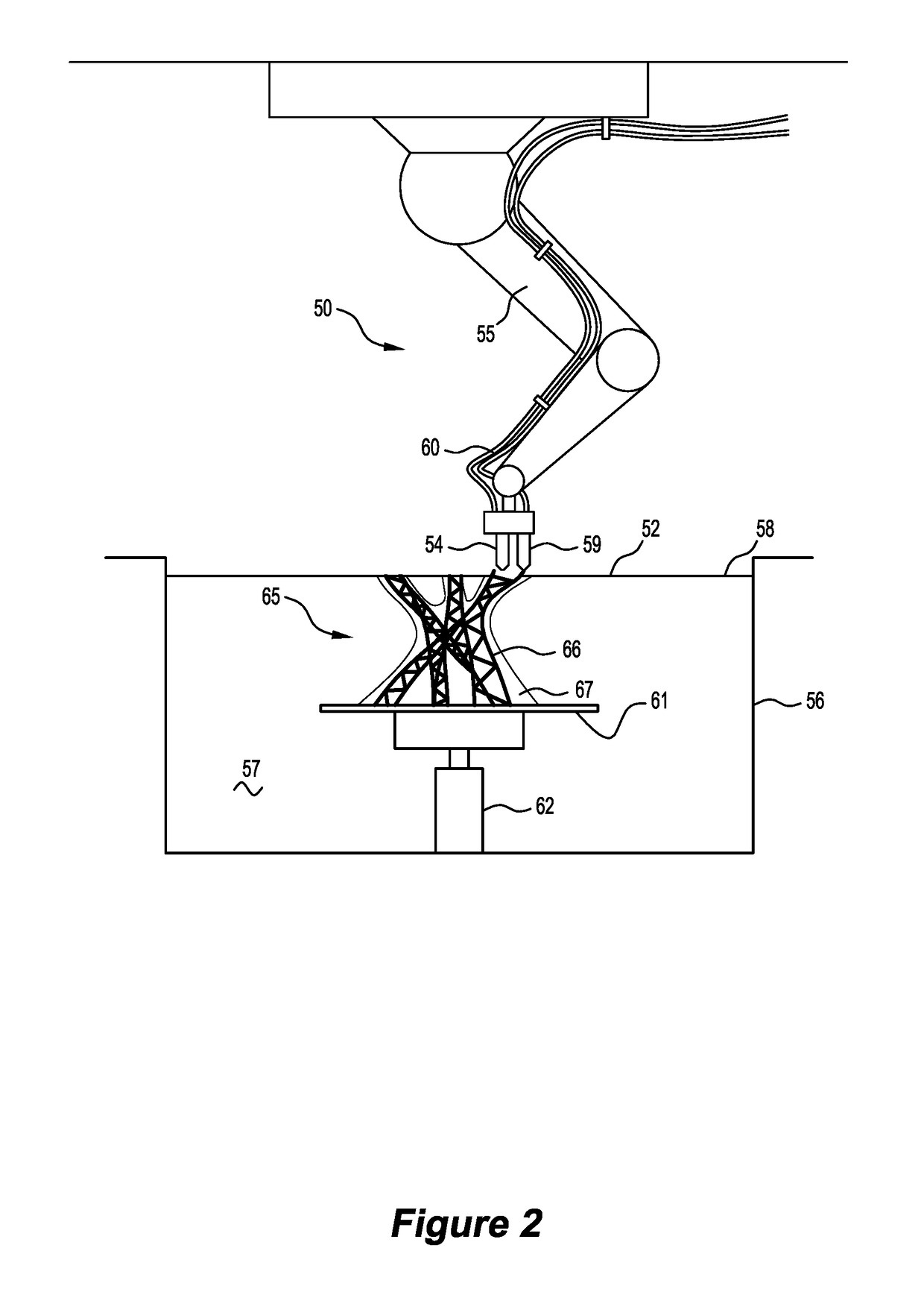

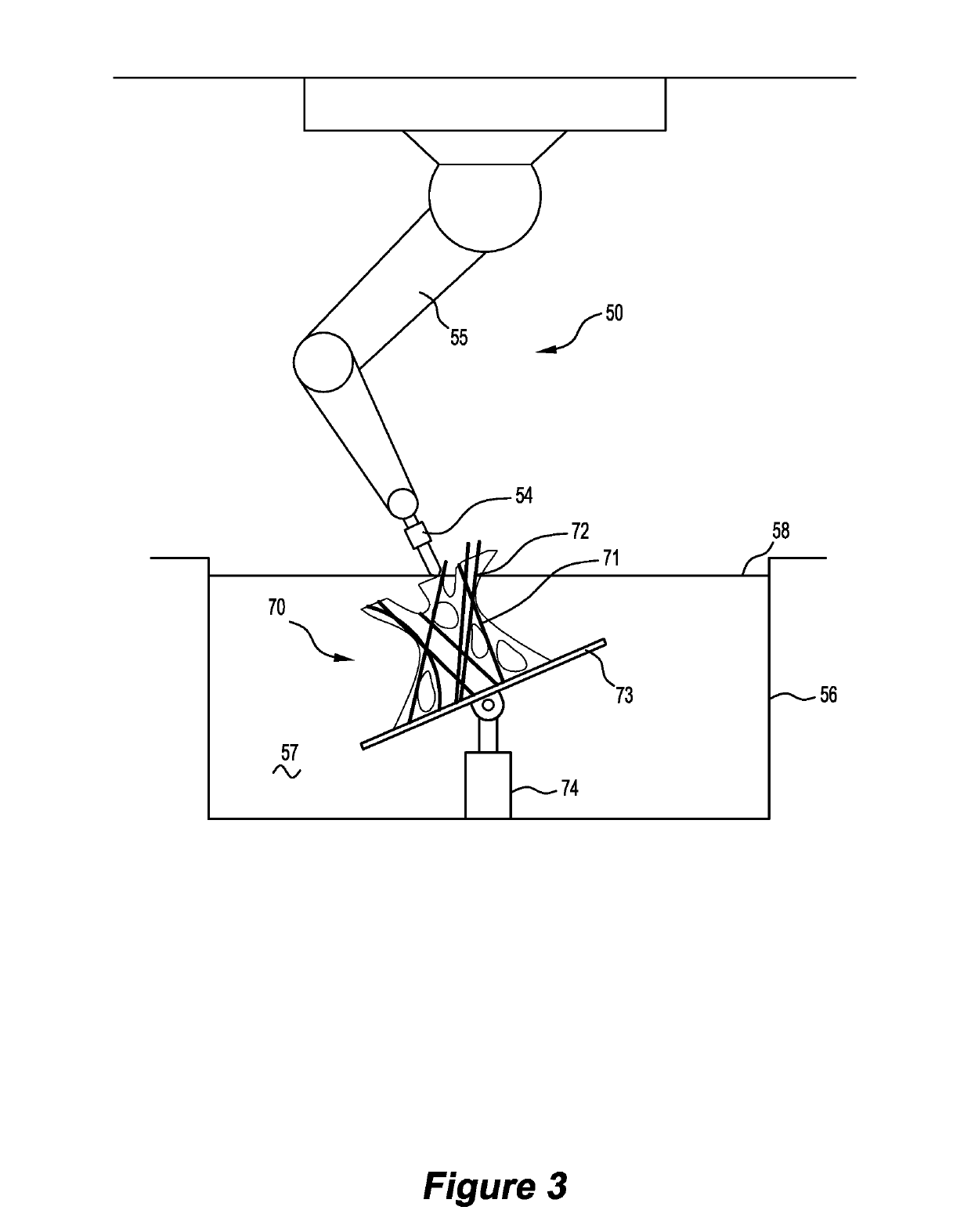

Method and Apparatus for Fabricating a Composite Object

ActiveUS20170106594A1Manufacturing platforms/substratesManufacturing driving meansComposite objectMaterials science

A method for fabricating a composite object with a computer-controlled apparatus, and the apparatus therefor. The comprises a reservoir containing liquid, curable first material, means to selectively solidify the first material and means to selectively deposit a second material. The method involves the steps of selectively depositing portions of the second material, and selectively solidifying portions of the first material, such that the solidified portions of the first material and the deposited portions of the second material form the composite object.

Owner:LAING OROURKE AUSTRALIA PTY LTD

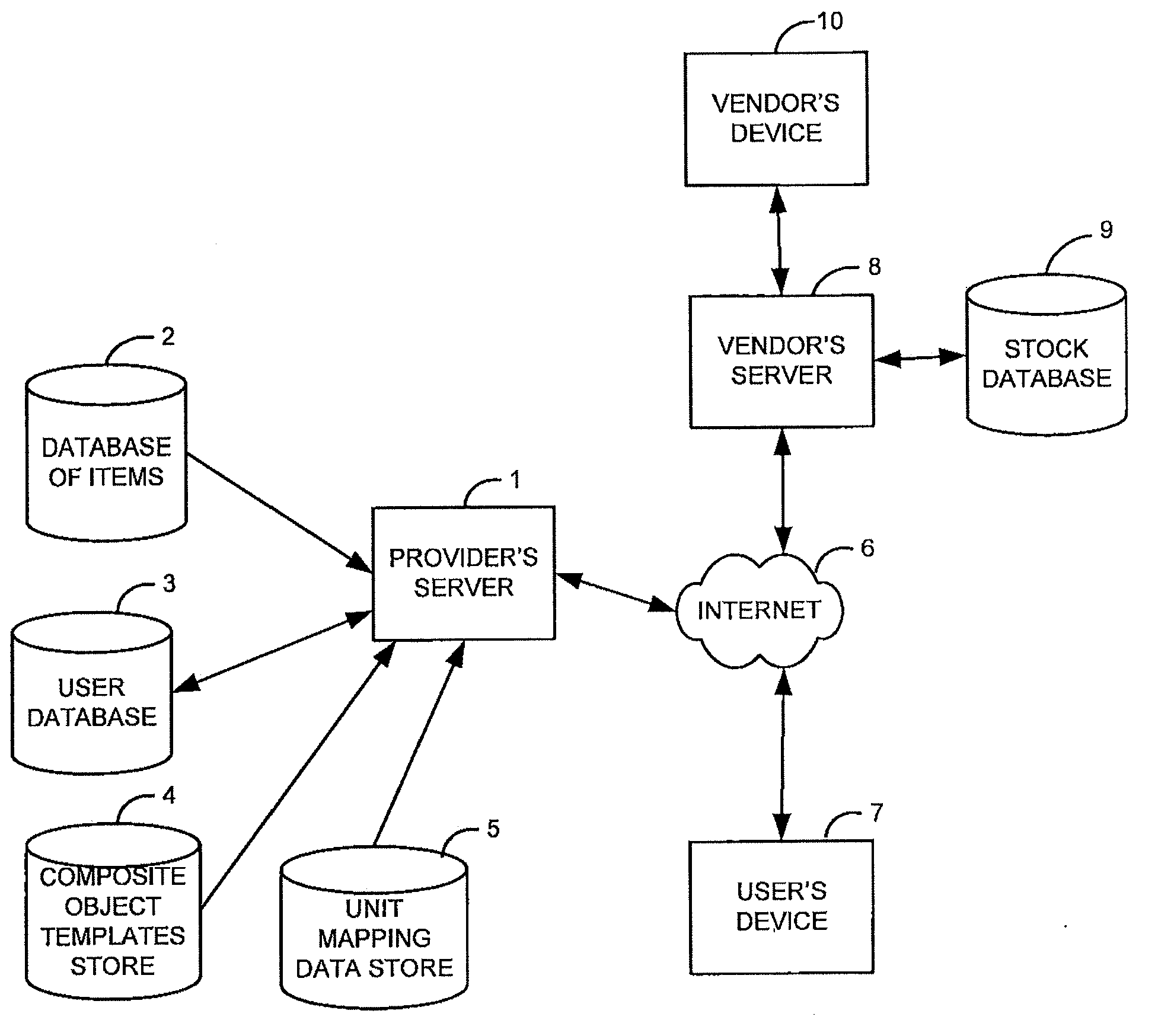

Method and system for managing component objects used in a plurality of composite objects

InactiveUS20110055289A1Avoids wasteful orderingAvoid wastingDigital data processing detailsResourcesComponent Object ModelComposite object

A composite physical object is formed of a plurality of component physical objects, which component physical objects can be used in a multiplicity of composite physical objects and a data management system and method is provided to manage the relationships. A user interface is provided to enable selection of component or composite objects for the addition or removal of component physical objects from the list. Because the relationship between component objects and composite objects is maintained, if a user selects to remove a component physical object from the list, its related component physical objects to be used in a composite object can be identified and also automatically removed. Similarly, operating the other way around, a user can select a composite object to be removed and this will result in the removal of all component physical objects in the list which are used in the composite object.

Owner:ENNIS RUSSEL

Control system configuration and methods with object characteristic swapping

InactiveUS20090118845A1OptimizationOptimize system configurationVersion controlElectric testing/monitoringGraphicsComposite object

Methods and apparatus for configuring process, environmental, industrial and other control systems generate and / or utilize models representing configurations of control systems and / or the systems controlled by them. Records of changes to the models or the configurations represented by them are maintained, thereby, for example, providing bases for determining current states, prior states and histories of changes. Objects in the model have characteristics, such as an object type characteristic and an area characteristic. Users can have corresponding permissions. A security mechanism apparatus controls access by users to the objects. Composite objects are defined by definition objects and are displayed in encapsulated or expanded formats. Objects can include an edit control type identifier that determines how they are presented for editing. Functionality responds to user commands by transferring characteristics of a first object depicted by the graphical user interface to a second object. Configuration-time formulas contained objects are evaluated to constants prior to downloading to the control system.

Owner:SCHNEIDER ELECTRIC SYST USA INC

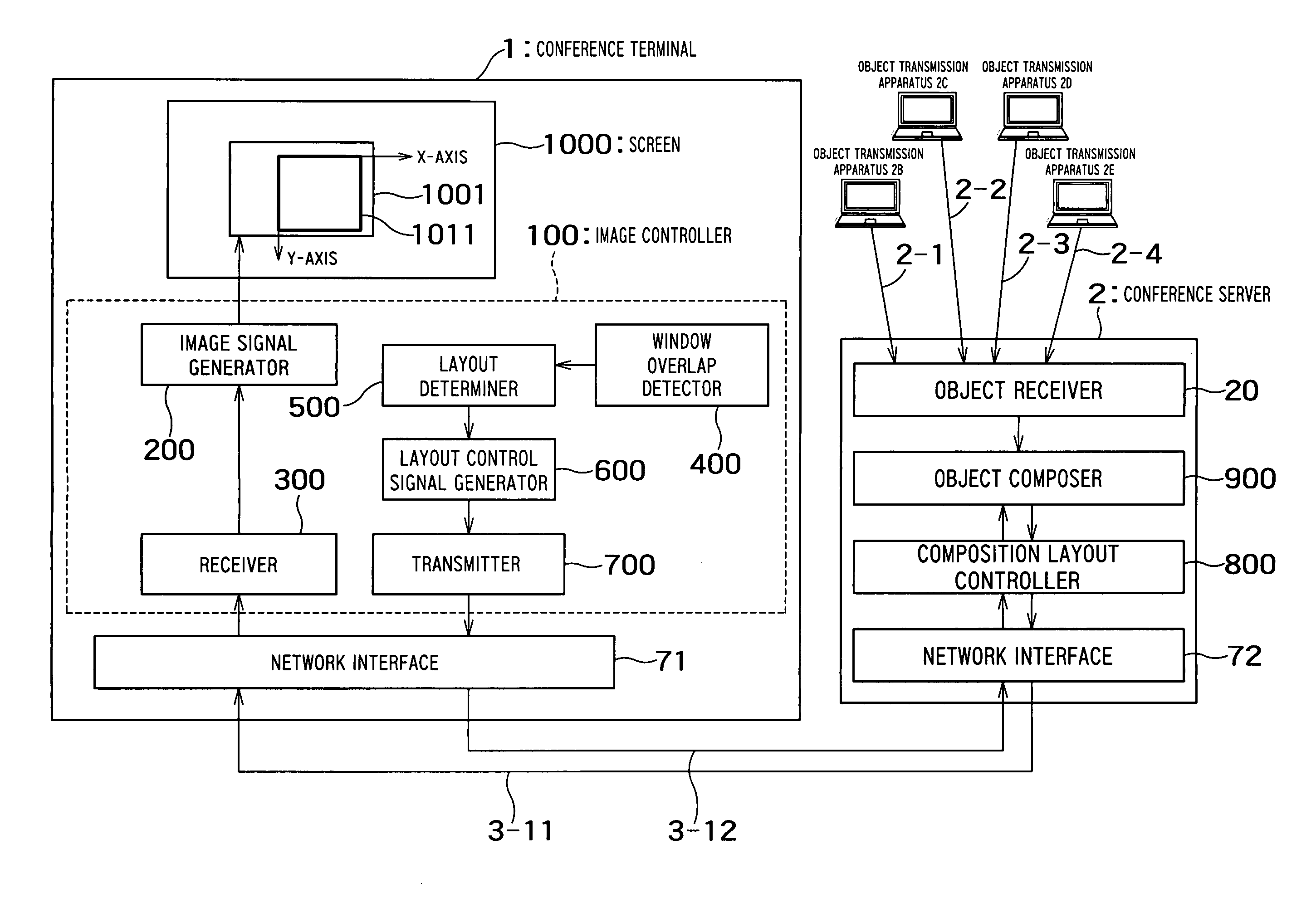

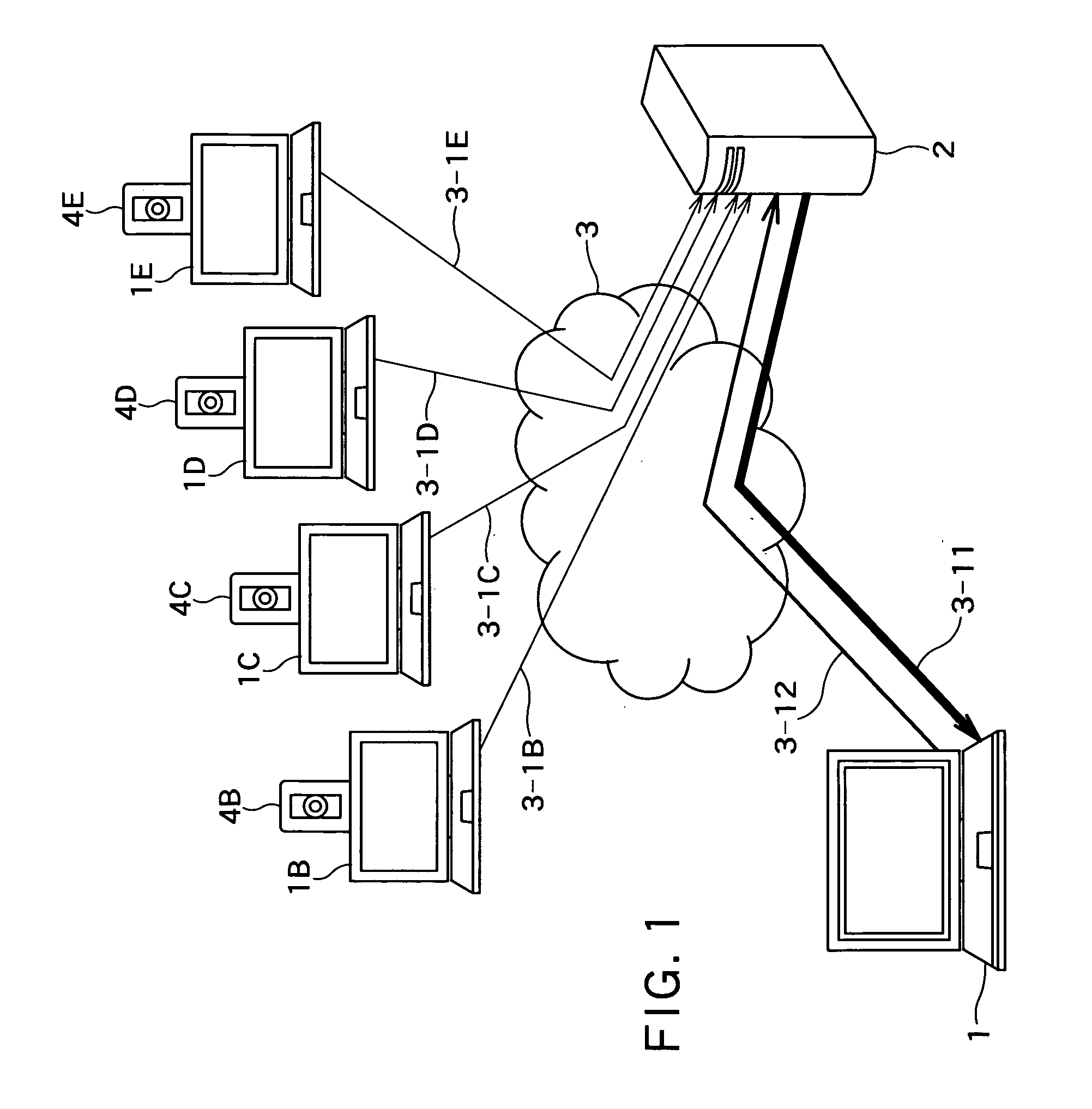

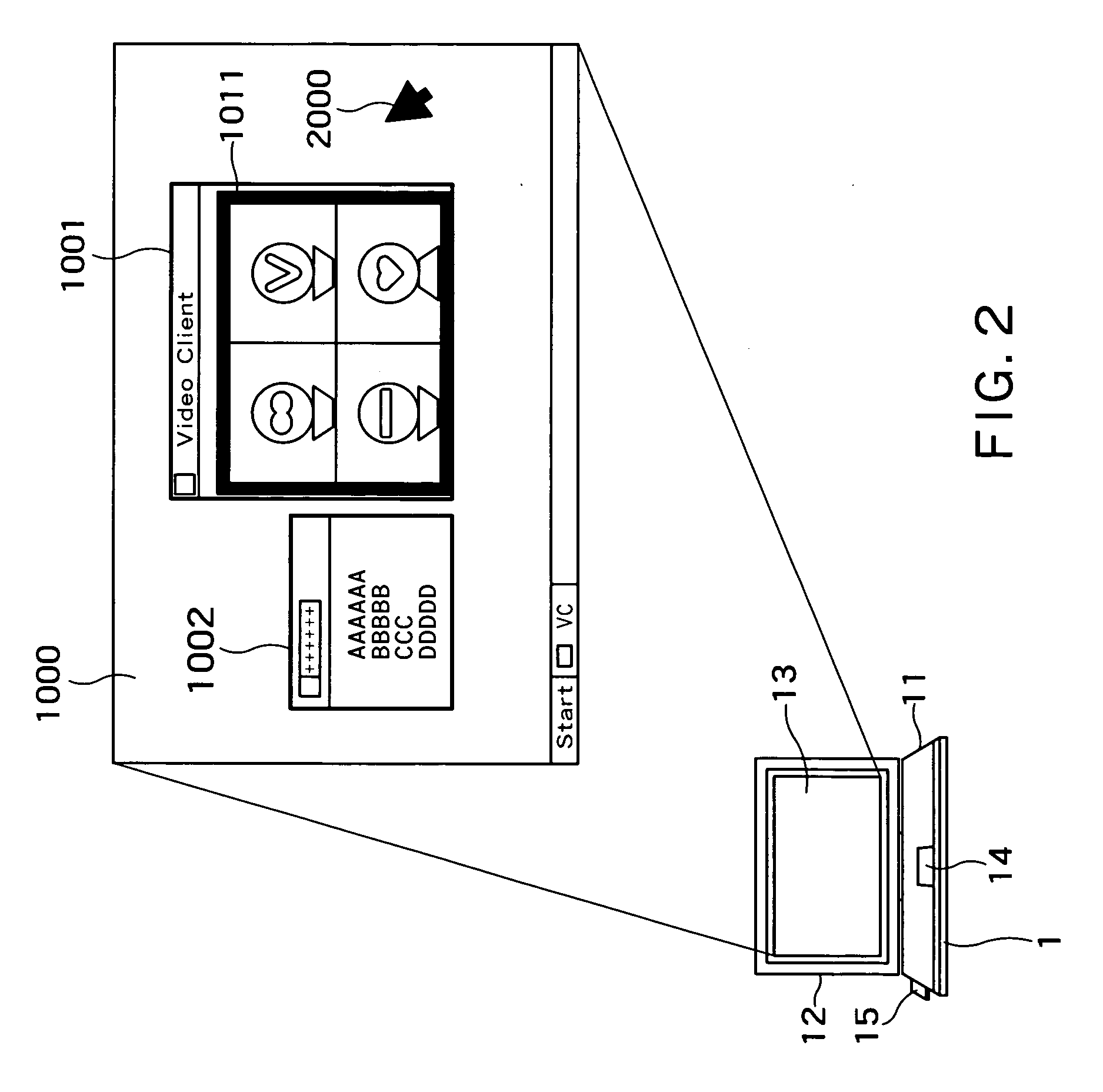

Display apparatus, method, and program

InactiveUS20070050729A1Television systemsExecution for user interfacesComposite objectArtificial intelligence

There is provided with a display apparatus including: a display apparatus which displays a first window and a second window, comprising: a receiver configured to receive a composite object obtained by composing a first object and a second object, from a server; a display unit configured to display the composite object in the first window; a window overlap detector configured to detect an overlap between the second window and the composite object in the first window, and to obtain a position of the overlap in the first window; a layout determiner configured to determine layouts of the objects in the composite object according to the position of the overlap so as not to place the first object and the second object on the position of the overlap; and a transmitter configured to transmit information of the layouts of the objects determined by the layout determiner, to the server.

Owner:KK TOSHIBA

Real-time control system development tool with input pins providing values used by component during execution

InactiveUS7275237B1Work fasterRapid modelingDigital computer detailsRequirement analysisReal-time Control SystemData stream

Owner:REAL TIME INNOVATIONS

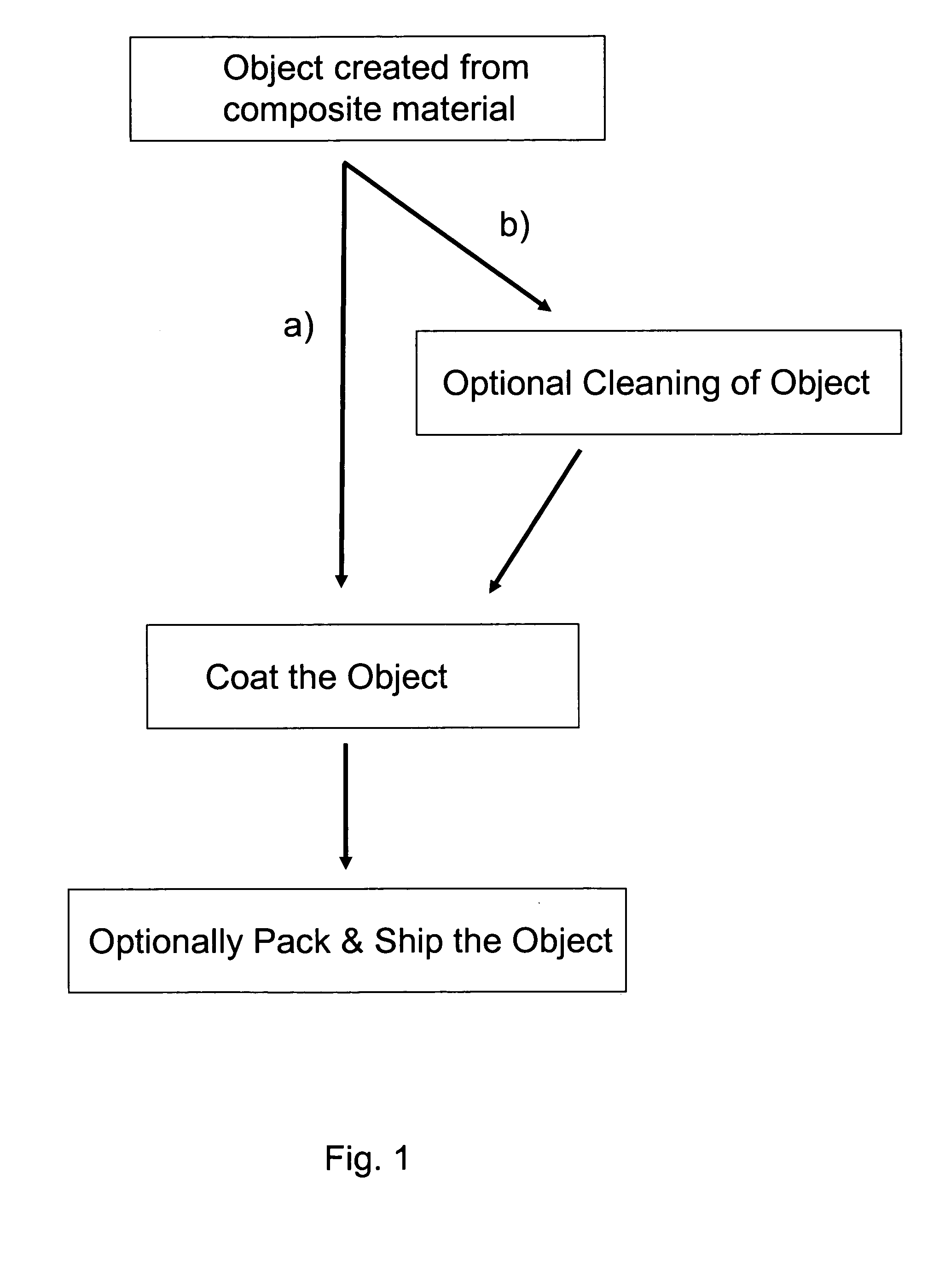

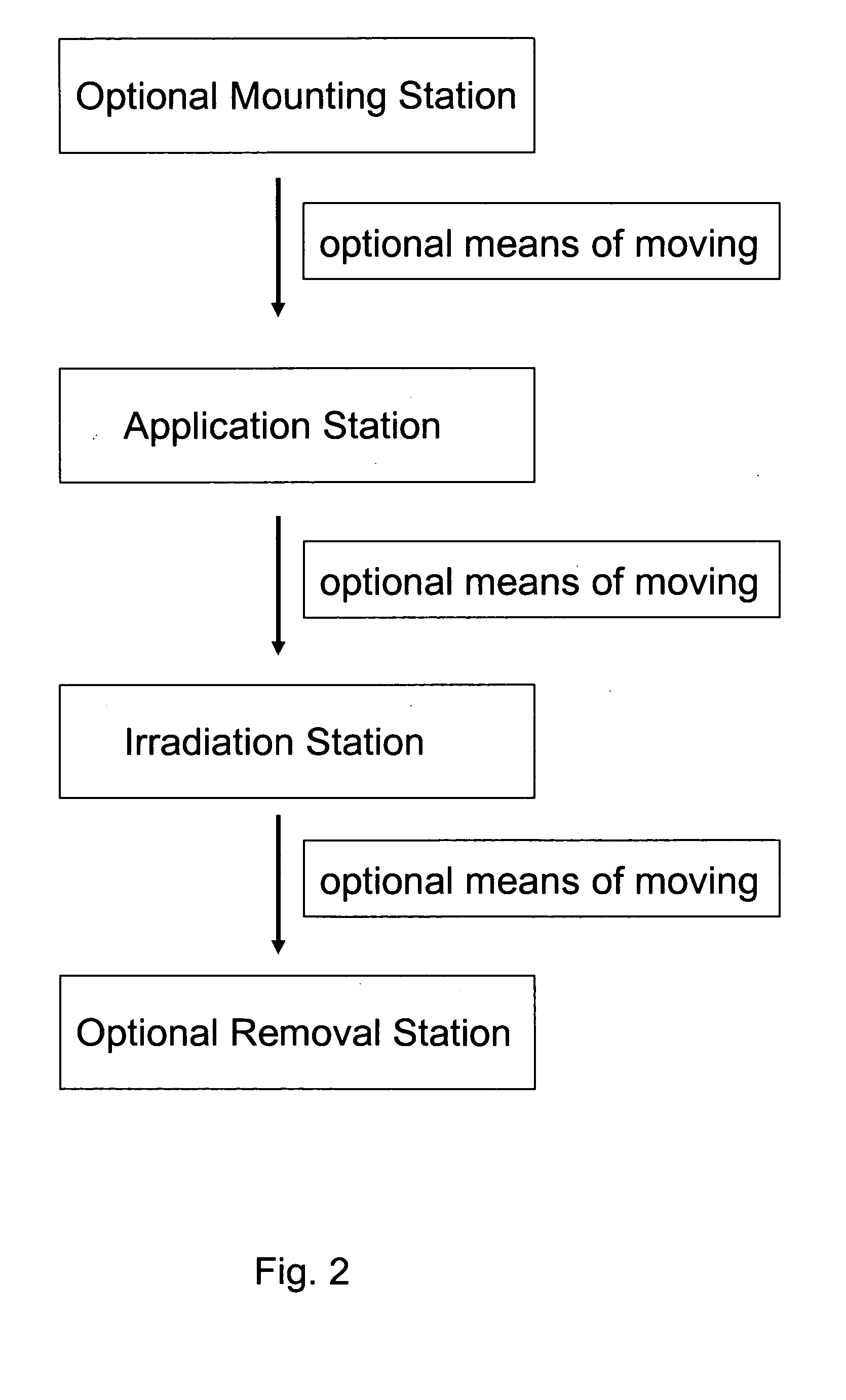

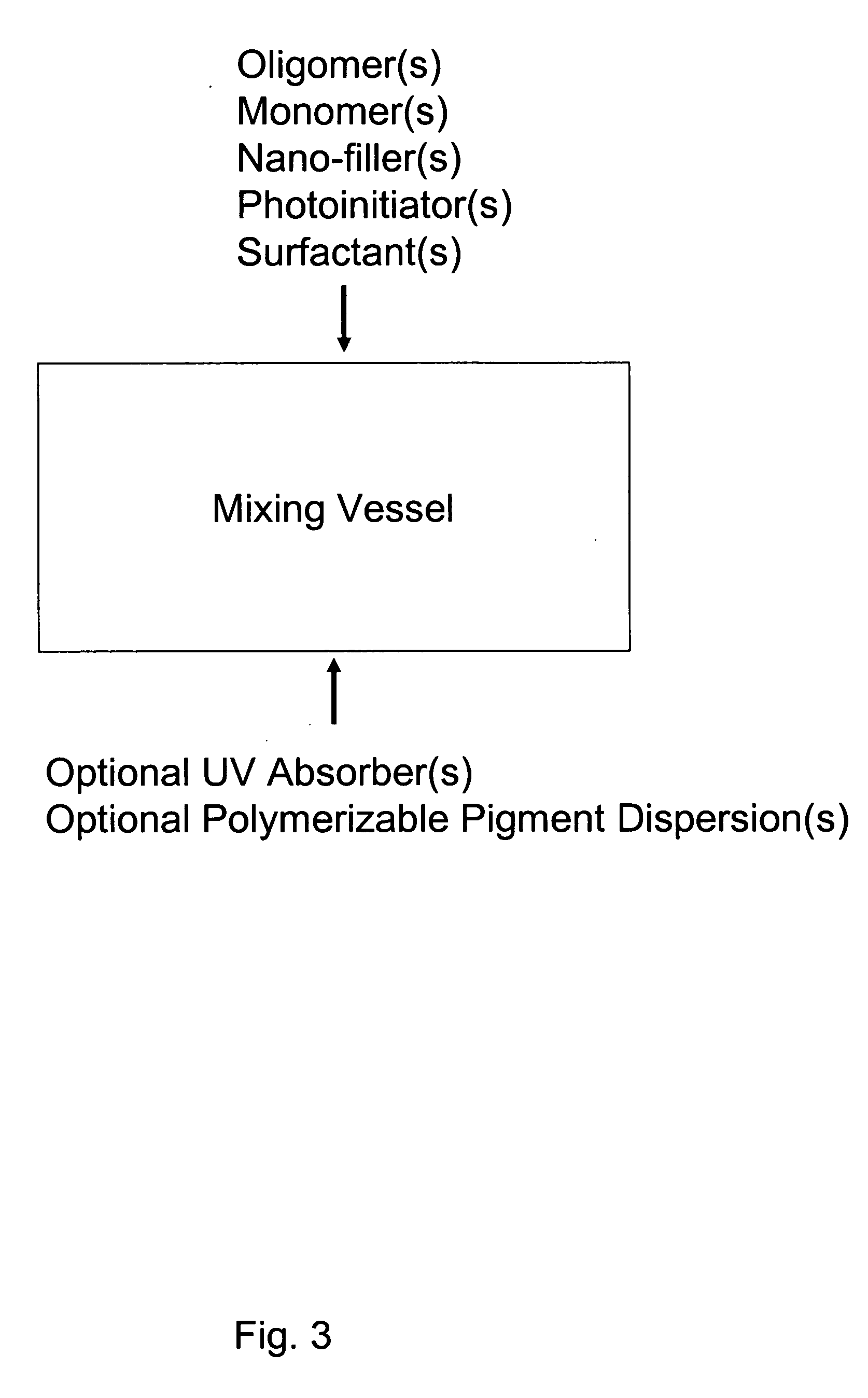

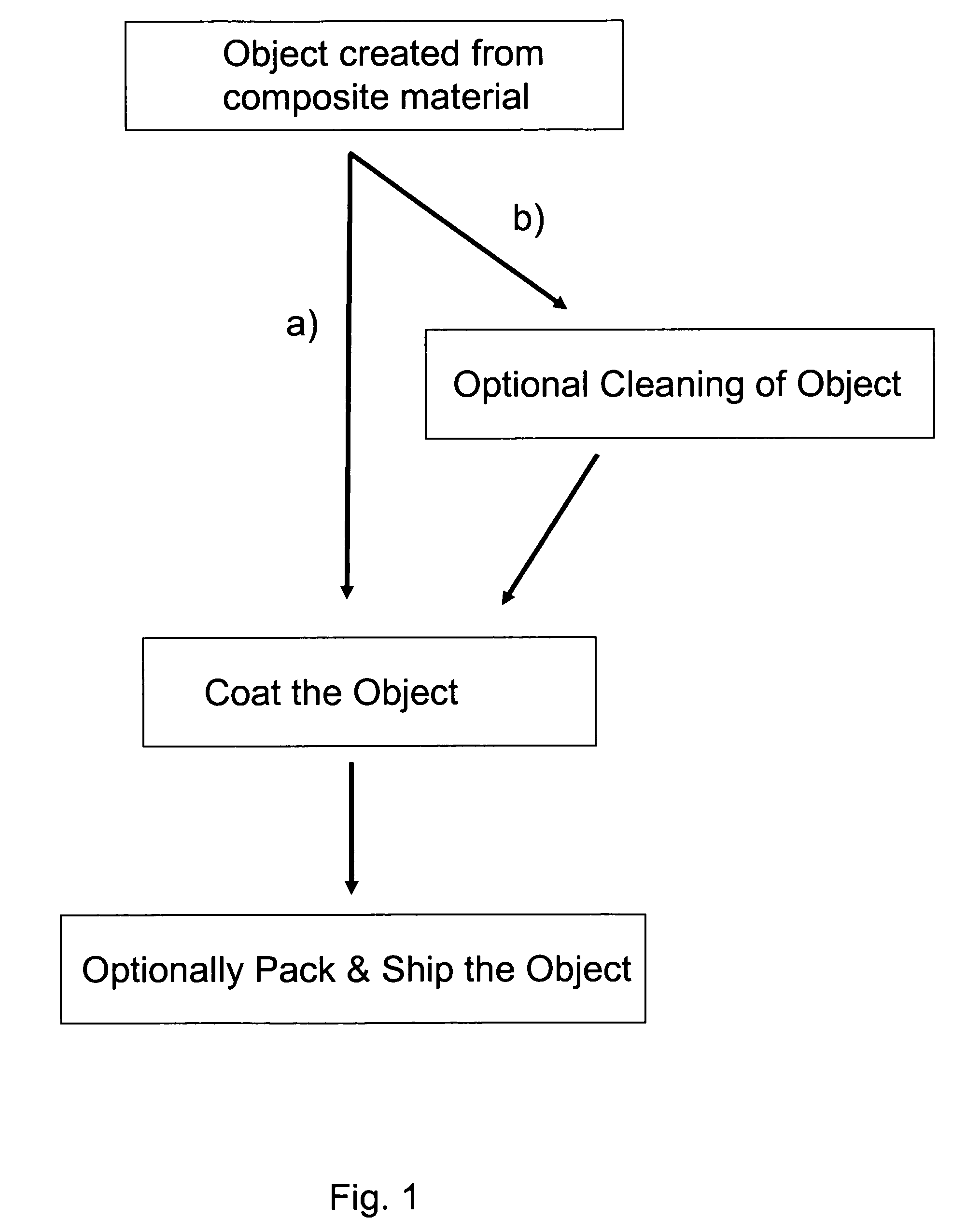

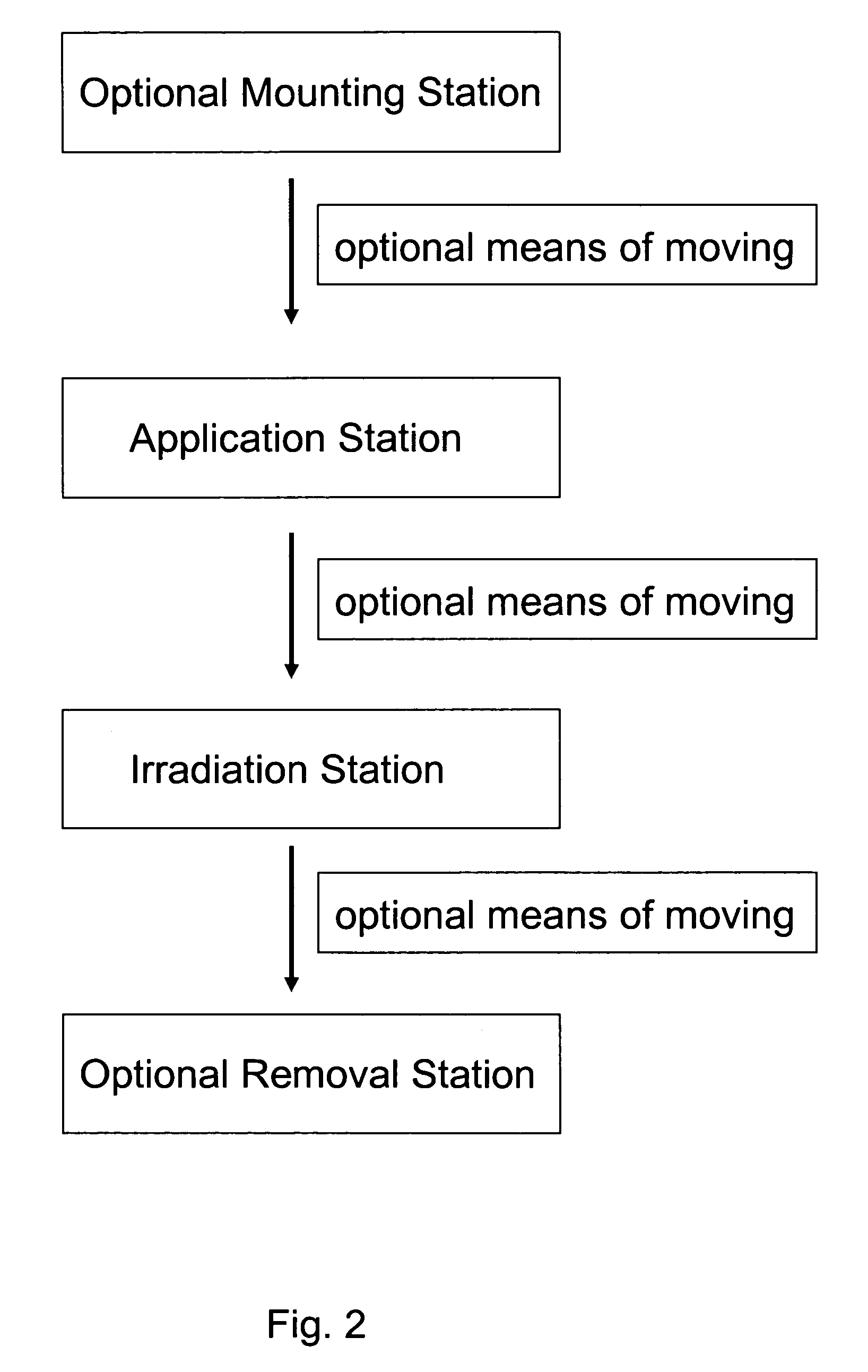

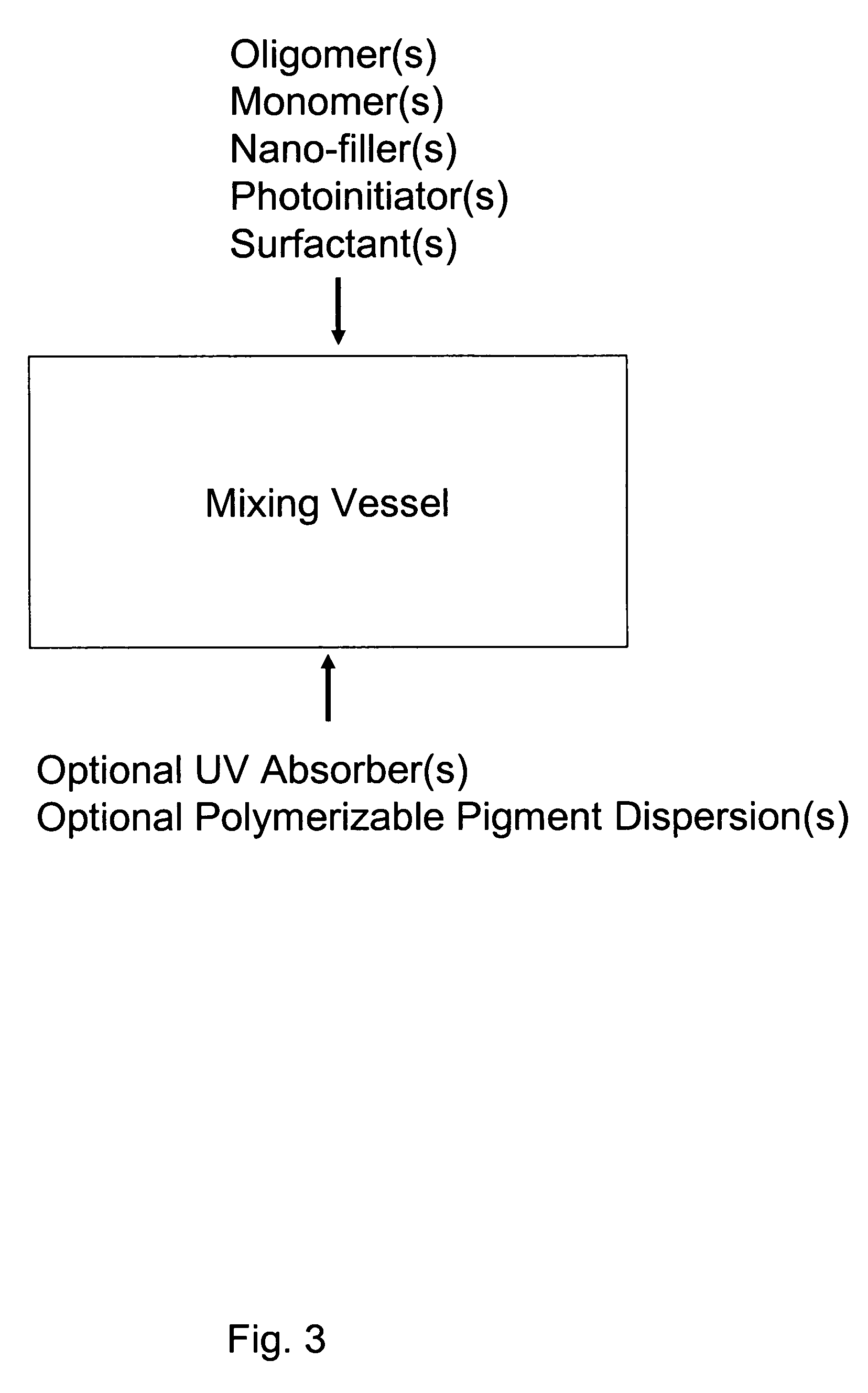

Environmentally friendly coating compositions for coating composites, coated composites therefrom, and methods, processes and assemblages for coating thereof

InactiveUS20050203202A1Exposure was also limitedSynthetic resin layered productsPolyurea/polyurethane coatingsGlass fiberCoated surface

Disclosed are environmentally friendly, substantially all solids coating compositions which are curable using ultraviolet and visible radiation. In addition, the disclosed coating compositions are suitable for coating composite objects and / or objects comprising composite materials, such as, but not limited to, fiberglass, fire retardant fiberglass, carbon fiber, fire retardant carbon fiber, Kevlar®, and fire retardant Kevlar®. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example composite architectural panels. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly, substantially all solids coating compositions curable using ultraviolet and visible radiation.

Owner:ECOLOGY COATING

Control systems and methods with smart blocks

InactiveUS20090118846A1OptimizationOptimize system configurationData processing applicationsComputer controlGraphicsGraphical user interface

Methods and apparatus for configuring process, environmental, industrial and other control systems generate and / or utilize models representing configurations of control systems and / or the systems controlled by them. Records of changes to the models or the configurations represented by them are maintained, thereby, for example, providing bases for determining current states, prior states and histories of changes. Objects in the model have characteristics, such as an object type characteristic and an area characteristic. Users can have corresponding permissions. A security mechanism apparatus controls access by users to the objects. Composite objects are defined by definition objects and are displayed in encapsulated or expanded formats. Objects can include an edit control type identifier that determines how they are presented for editing. Functionality responds to user commands by transferring characteristics of a first object depicted by the graphical user interface to a second object. Configuration-time formulas contained objects are evaluated to constants prior to downloading to the control system.

Owner:SCHNEIDER ELECTRIC SYST USA INC

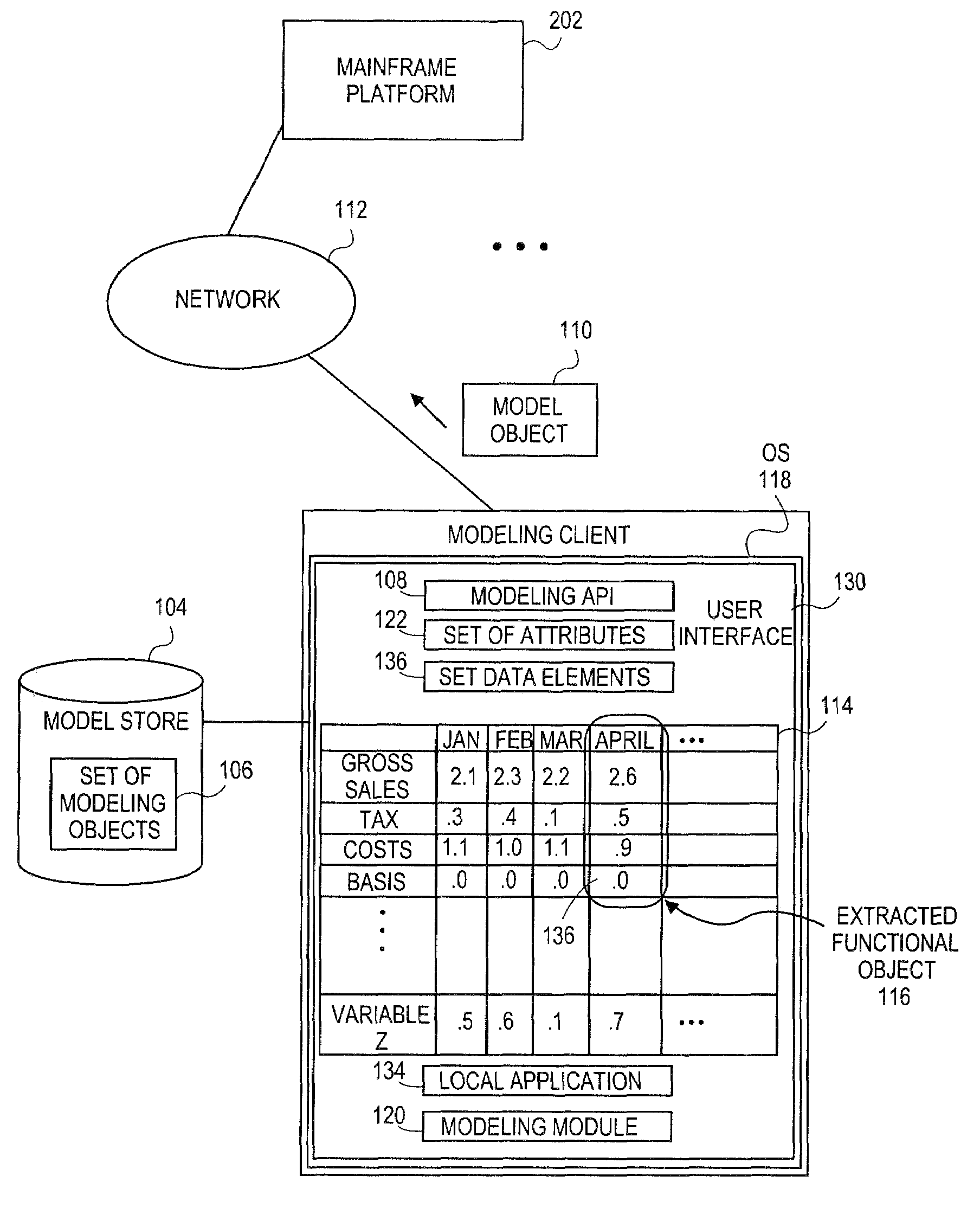

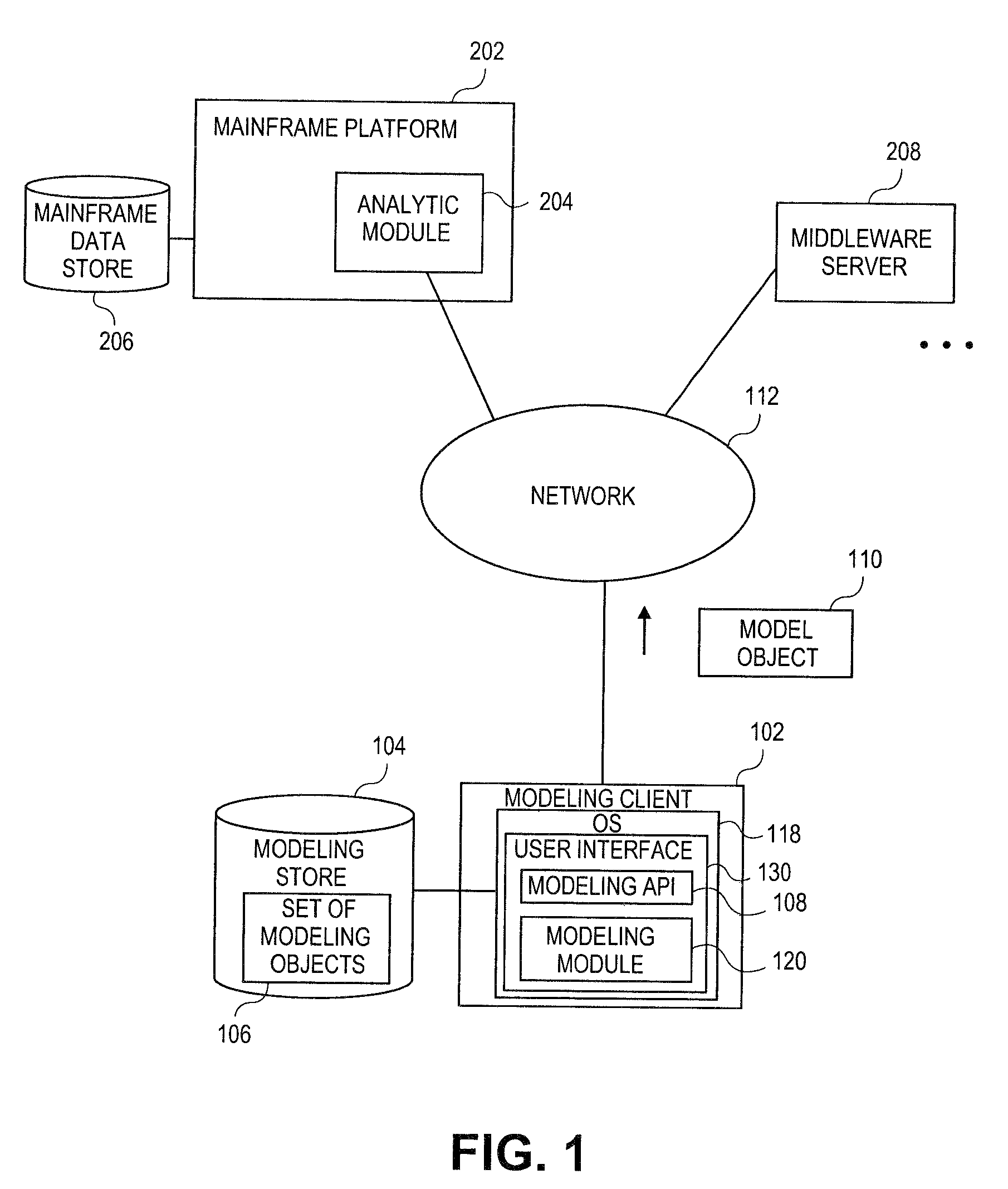

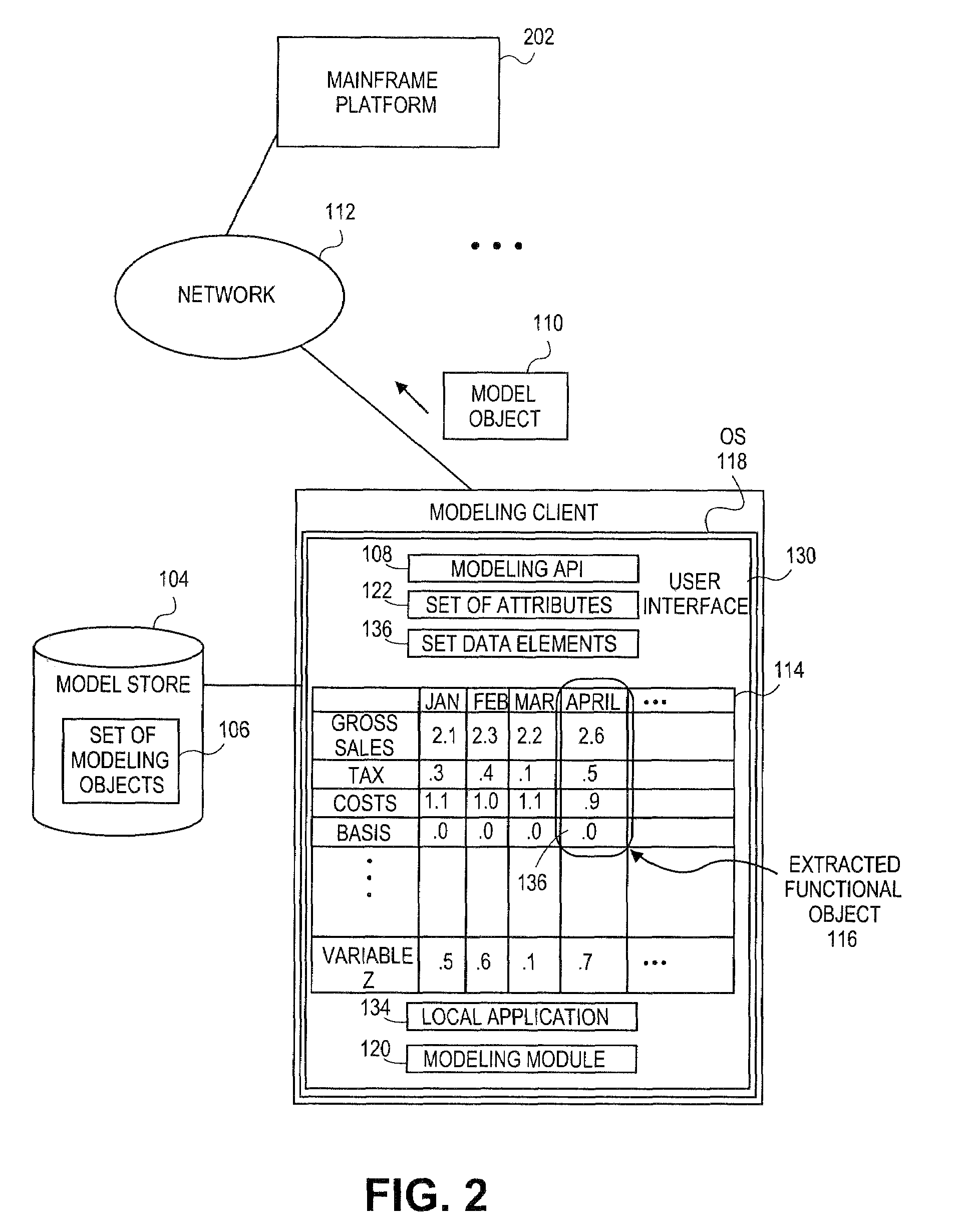

Systems and methods for object-based modeling using composite model object having independently updatable component objects

Embodiments relate to systems and methods for object-based modeling using a composite model object having independently updatable component objects. A modeling client can host modeling logic and an application programming interface (API) to create, access, manipulate, and import / export modeling objects used in modeling applications, such as engineering, medical, financial, and other modeling platforms. In aspects, the source data accepted into the modeling client can include consumer or business-level applications, whose spreadsheet, database or other content can be extracted and encapsulated in extensible markup language (XML) or other object-oriented format. Various model objects can be extracted from source data, and aggregated into a composite model object encapsulating the underlying set of component model objects. In aspects, each of the component model objects can be accessed, updated, and stored independently of the other constituent objects. The modeling client can exchange composite or other modeling objects with external platforms on a programmatic basis.

Owner:RED HAT

Dynamic embedding of literal object data in supplied instance of information object

InactiveUS7340499B1Improve performanceMultiple digital computer combinationsGenerating/distributing signalsComposite objectInformation object

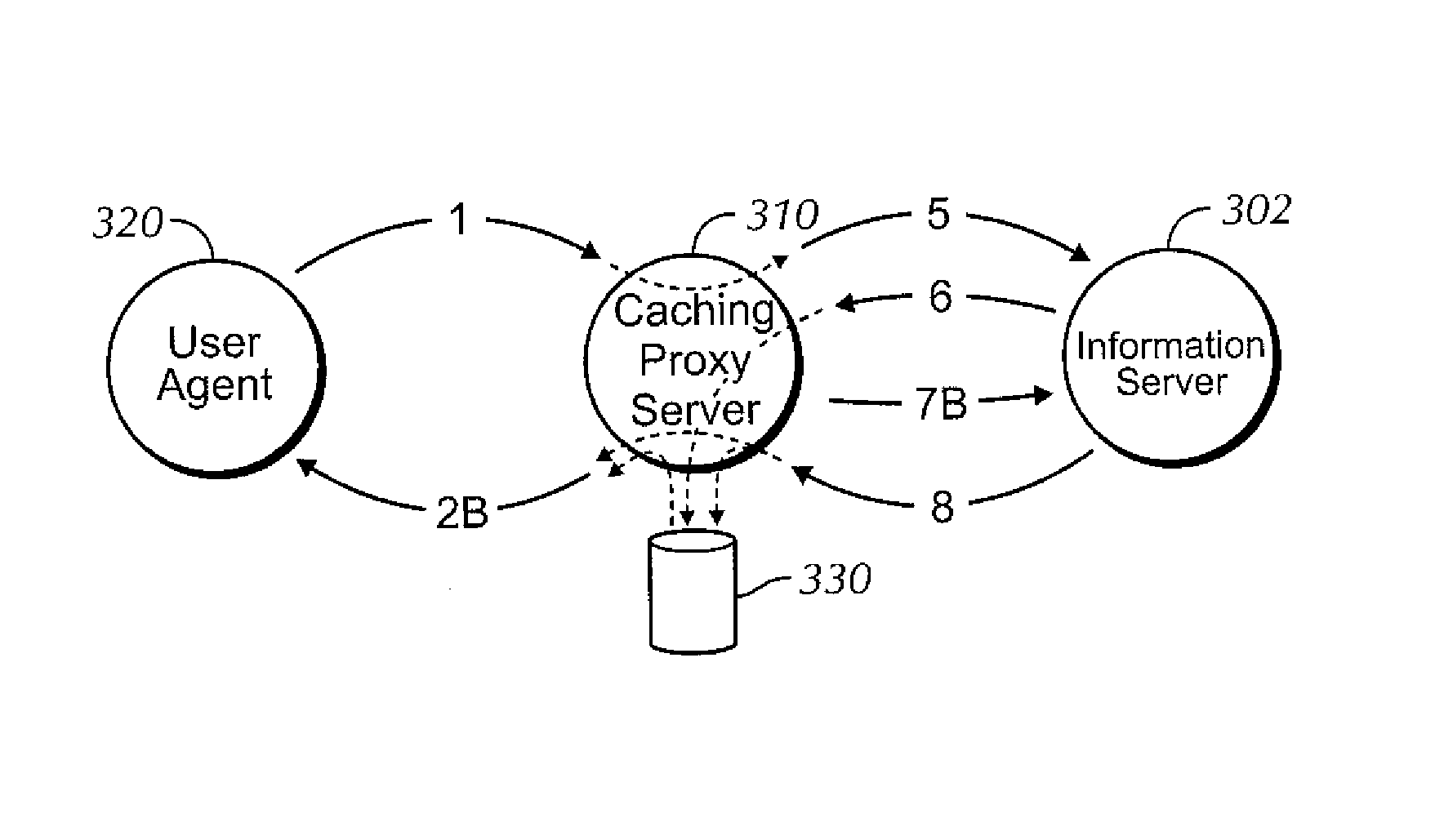

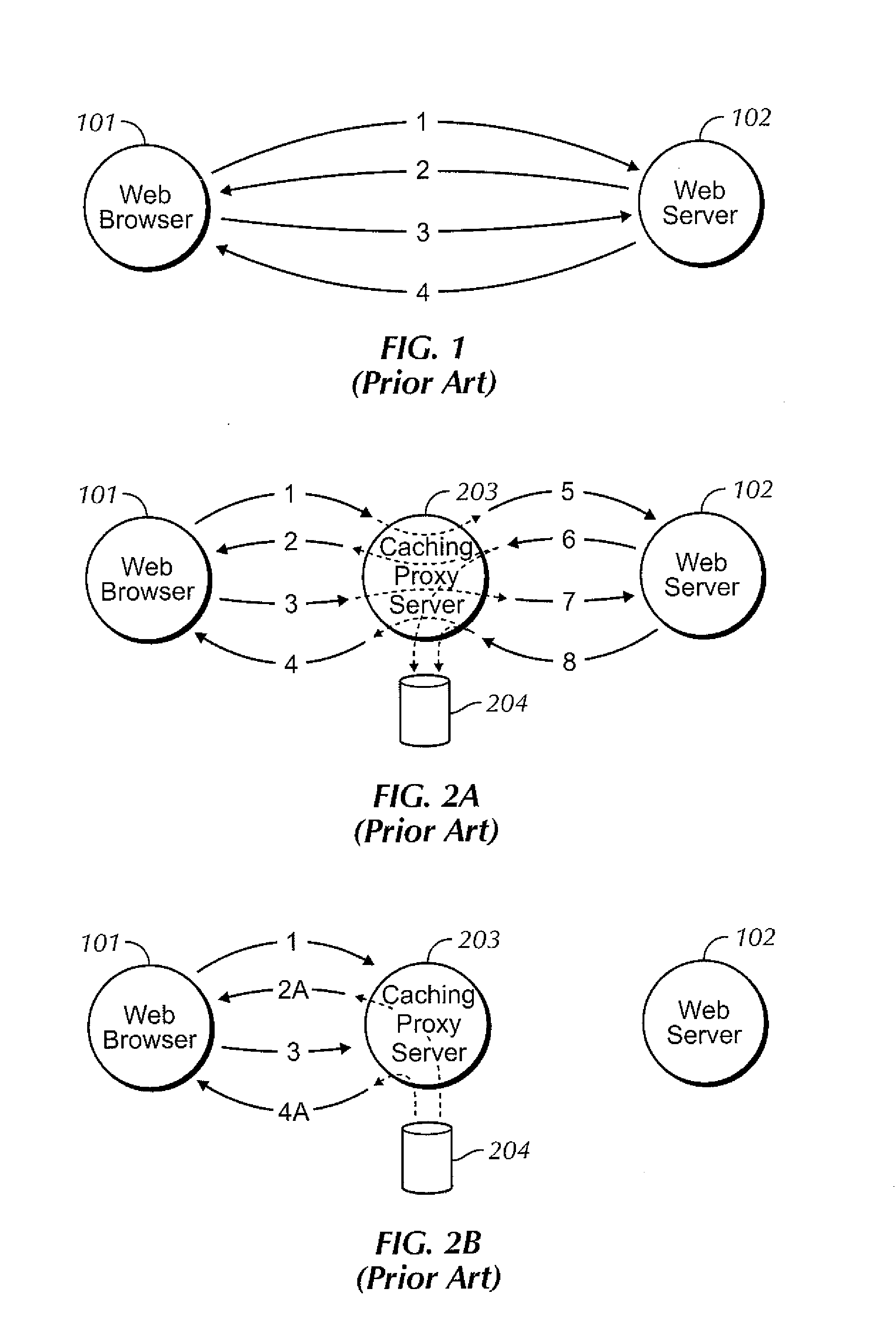

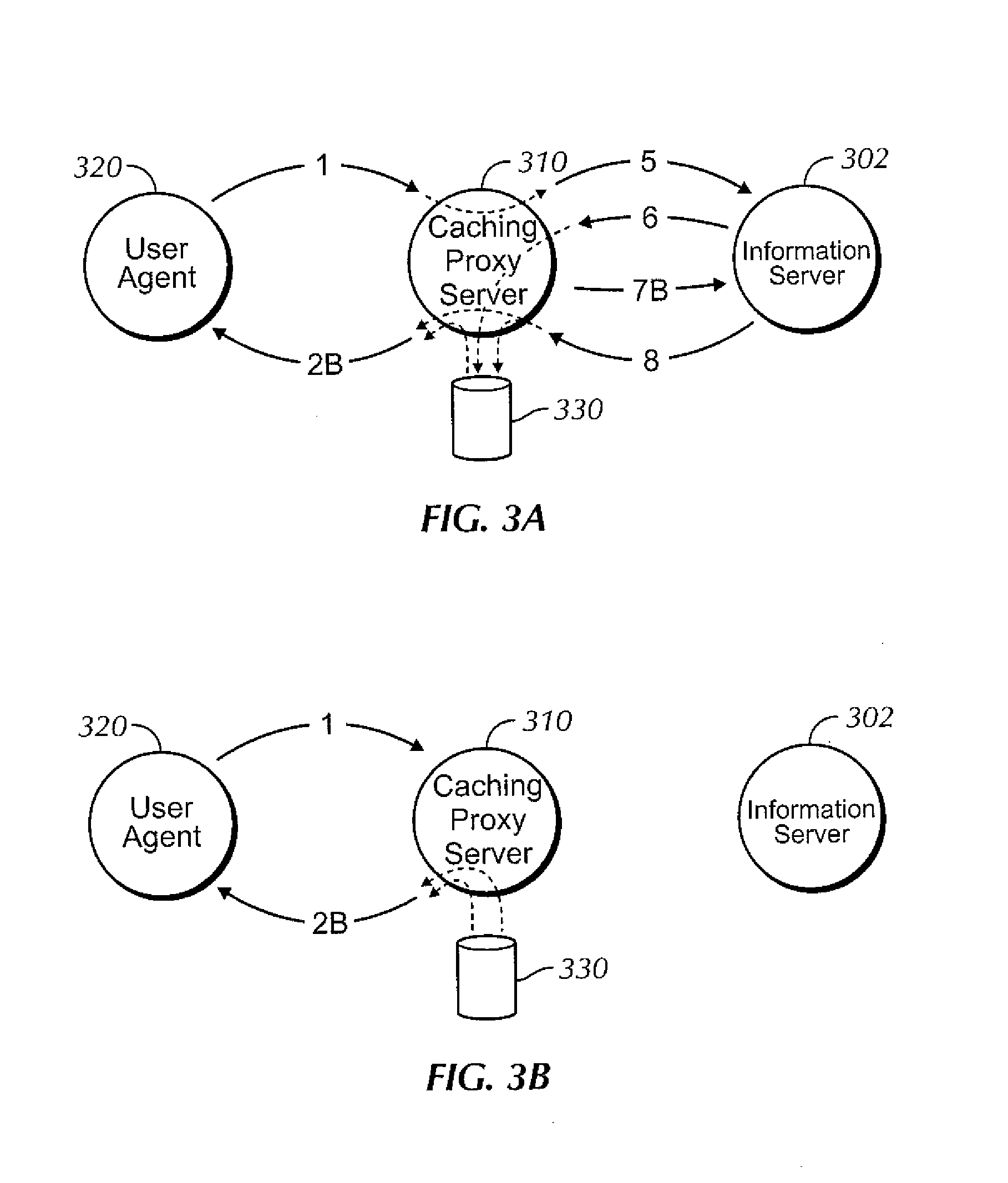

Techniques have been developed whereby information objects referenced in a requested information object (e.g., image, audio, video, application, and / or text objects referenced in an HTML document) are embedded in a composite object and supplied in as literal data therein in response to an object identifier (e.g., an URL request). Referenced information objects may be retrieved from cache or obtained from authoritative information servers and dynamically embedded in a composite information object. In some realizations, composite objects with embedded references are retrieved from cache. In some realizations, individual information objects (including those referenced) are cached and a composite object is dynamically prepared. In some realizations, though not all realizations, the caching techniques are employed in a proxy server implementation.

Owner:ORACLE INT CORP

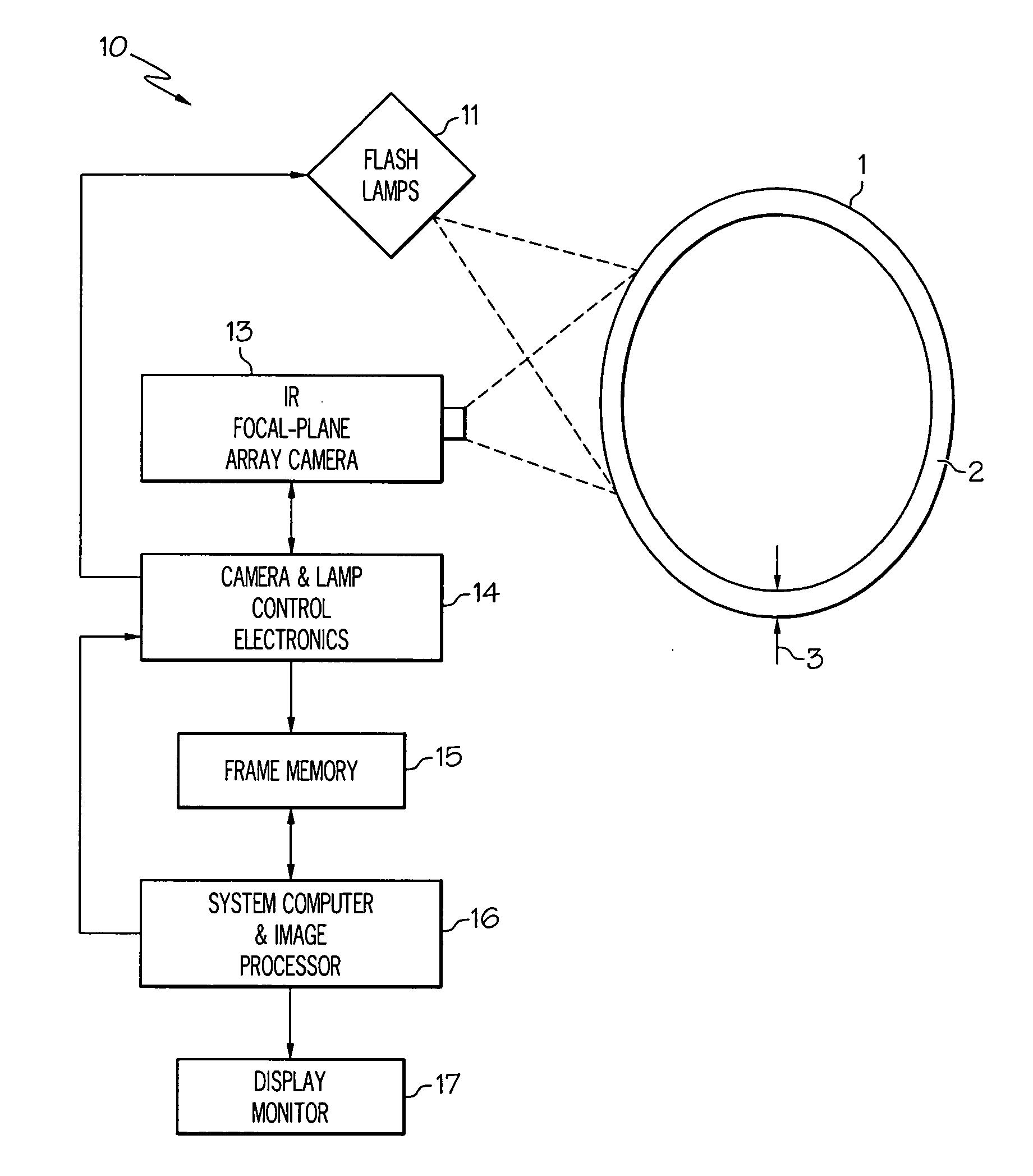

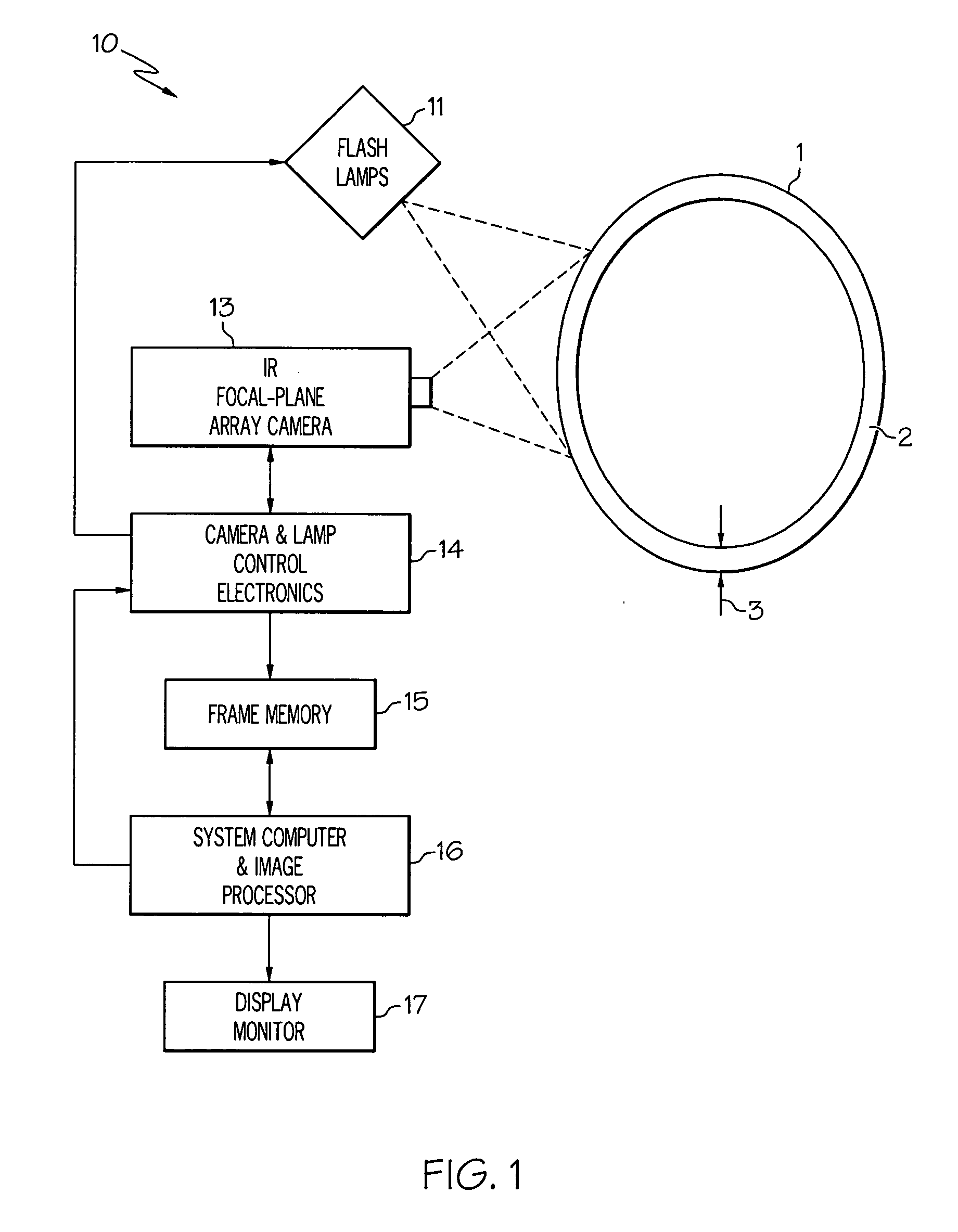

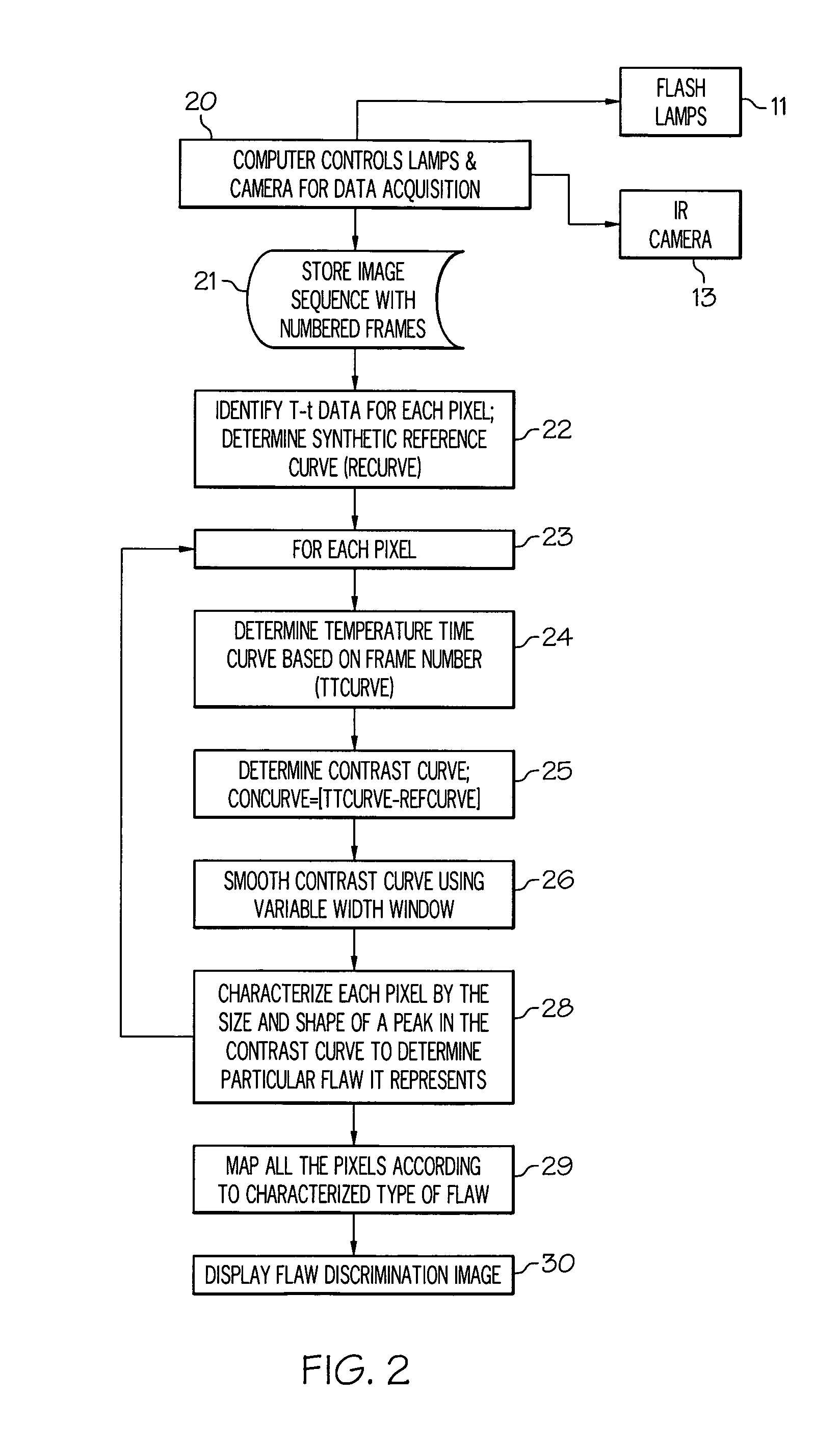

Characterization of flaws in composites identified by thermography

A method for identifying types of flaws in a composite object includes: a) rapidly heating the surface of the object; b) recording pixel intensities in a sequence of IR images; c) determining temperature-versus-time data for each of the pixels from the IR images; and d) determining what type of flaw if any corresponds to each of the pixels using the temperature-versus-time data determined in step (c). A contrast curve derived from the temperature-versus-time data may be used in determining what type of flaws if any corresponds to each of the pixels. The contrast curve may be determined by subtracting a synthetic reference curve from a temperature time curve from the temperature-versus-time data. The types of flaws may be determined from size and / or shapes of peaks in the contrast curves. Some flaws are delaminations, layers of porosity, and uniformly distributed porosity.

Owner:GENERAL ELECTRIC CO

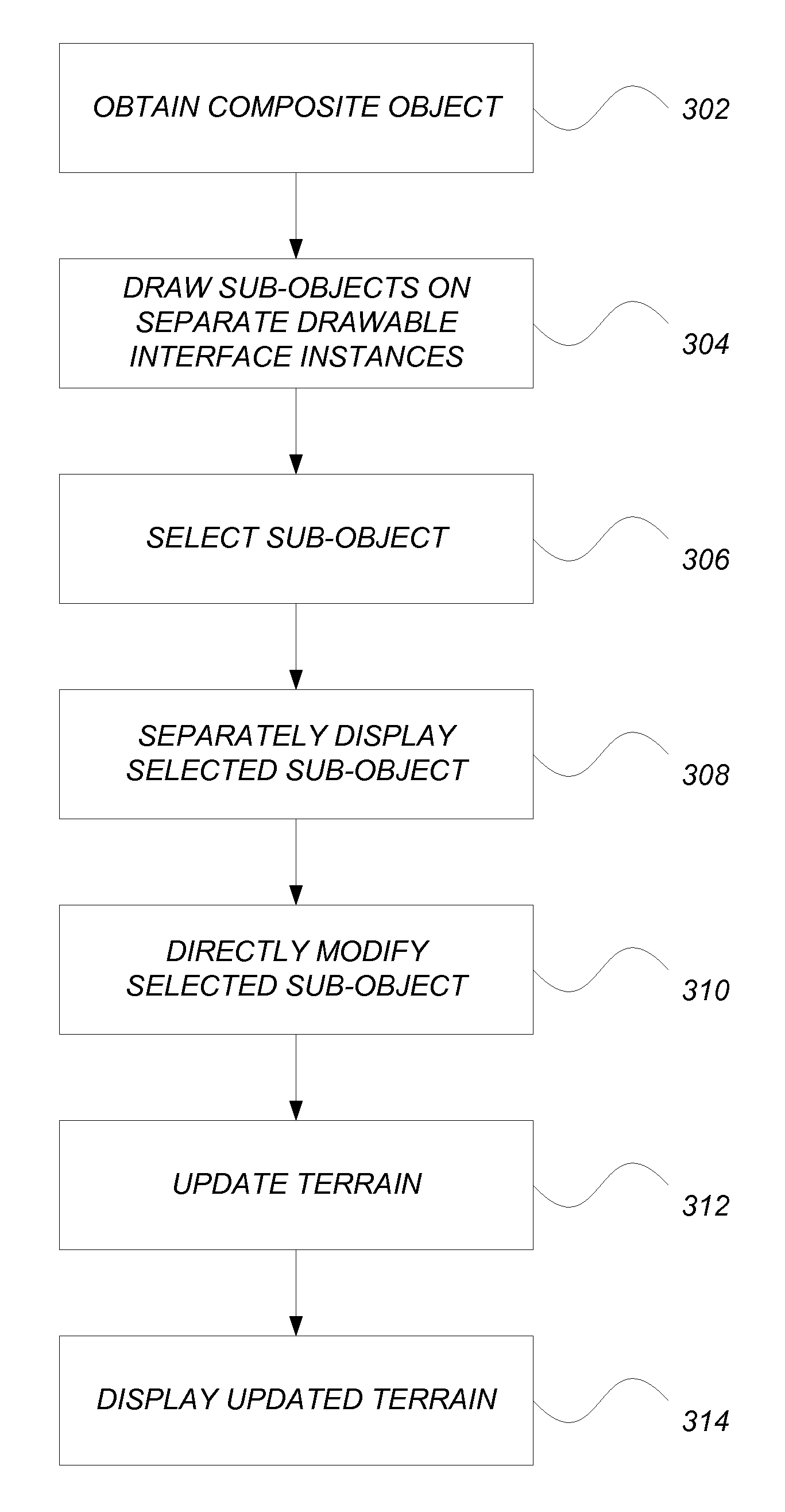

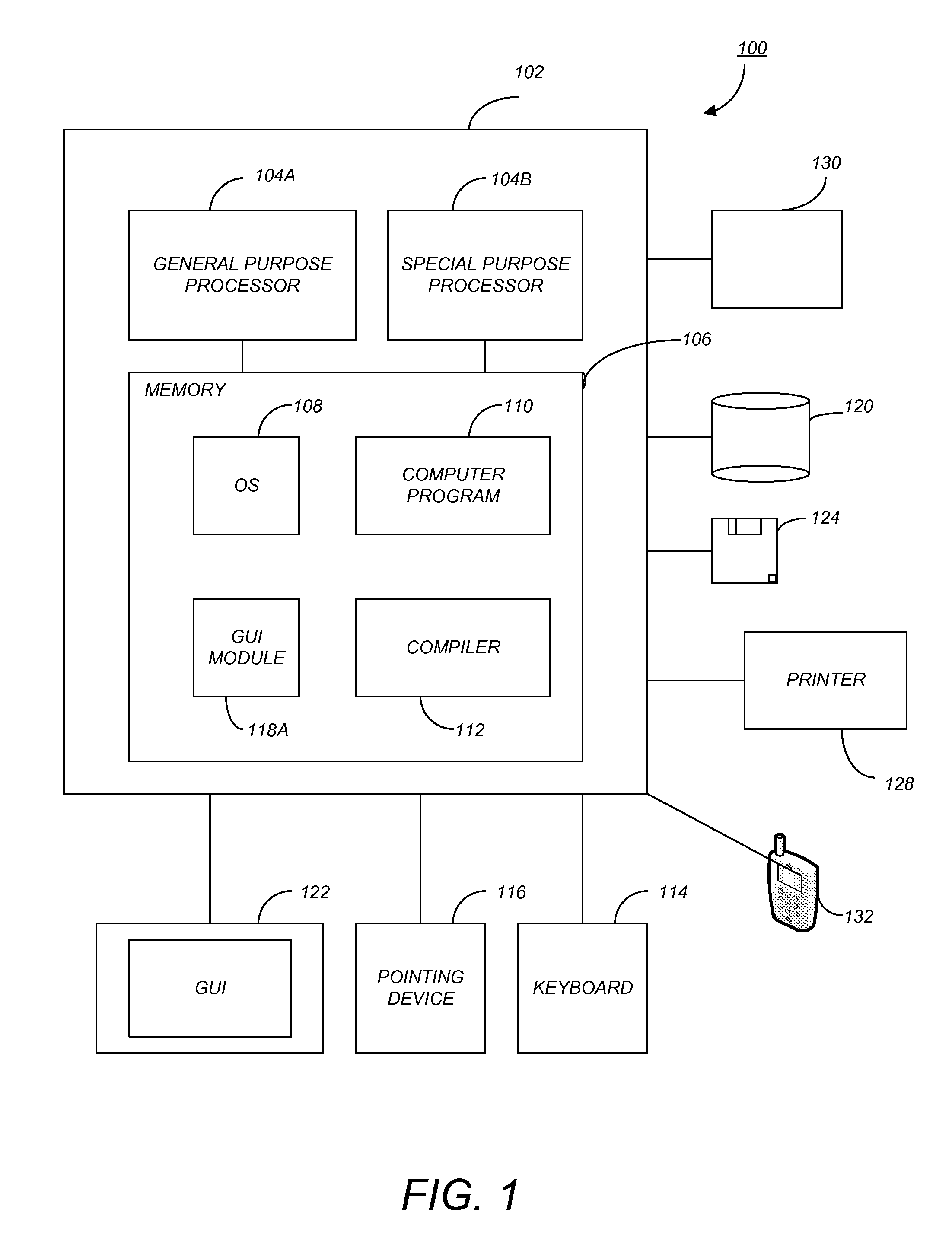

Direct manipulation of composite terrain objects with intuitive user interaction

ActiveUS20130013265A1Minimize earthworkImprove balanceDesign optimisation/simulationGeographical information databasesTerrainComposite object

A method, apparatus, system, and computer readable medium provide the ability to manipulate a terrain in a drawing. A composite object of the terrain is obtained in a CAD BIM application. The composite object is a combination of sub-objects that each define a geometry that is part of the terrain. Each of the sub-objects is drawn on a separate corresponding drawable interface instance. A sub-object is selected and in response, the selected sub-object is displayed in its corresponding drawable interface instance. The selected sub-object is directly modified, in canvas, using the drawable interface instance. In response to the modification, the terrain is dynamically updated and displayed.

Owner:AUTODESK INC

Environmentally friendly coating compositions for coating composites, coated composites therefrom, and methods, processes and assemblages for coating thereof

InactiveUS7323248B2Synthetic resin layered productsPolyurea/polyurethane coatingsCoated surfaceGlass fiber

Disclosed are environmentally friendly, substantially all solids coating compositions which are curable using ultraviolet and visible radiation. In addition, the disclosed coating compositions are suitable for coating composite objects and / or objects comprising composite materials, such as, but not limited to, fiberglass, fire retardant fiberglass, carbon fiber, fire retardant carbon fiber, Kevlar®, and fire retardant Kevlar®. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example composite architectural panels. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly, substantially all solids coating compositions curable using ultraviolet and visible radiation.

Owner:ECOLOGY COATING

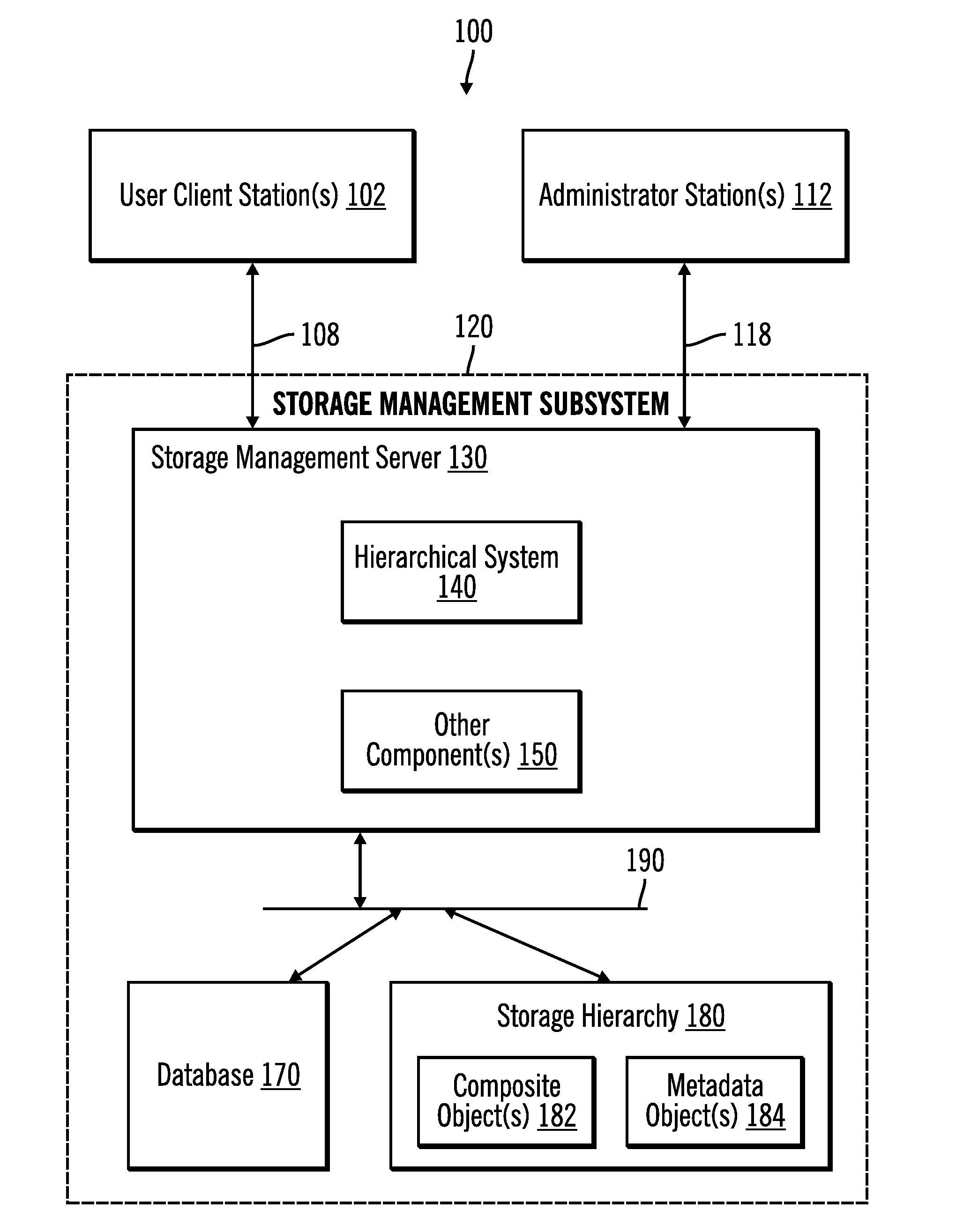

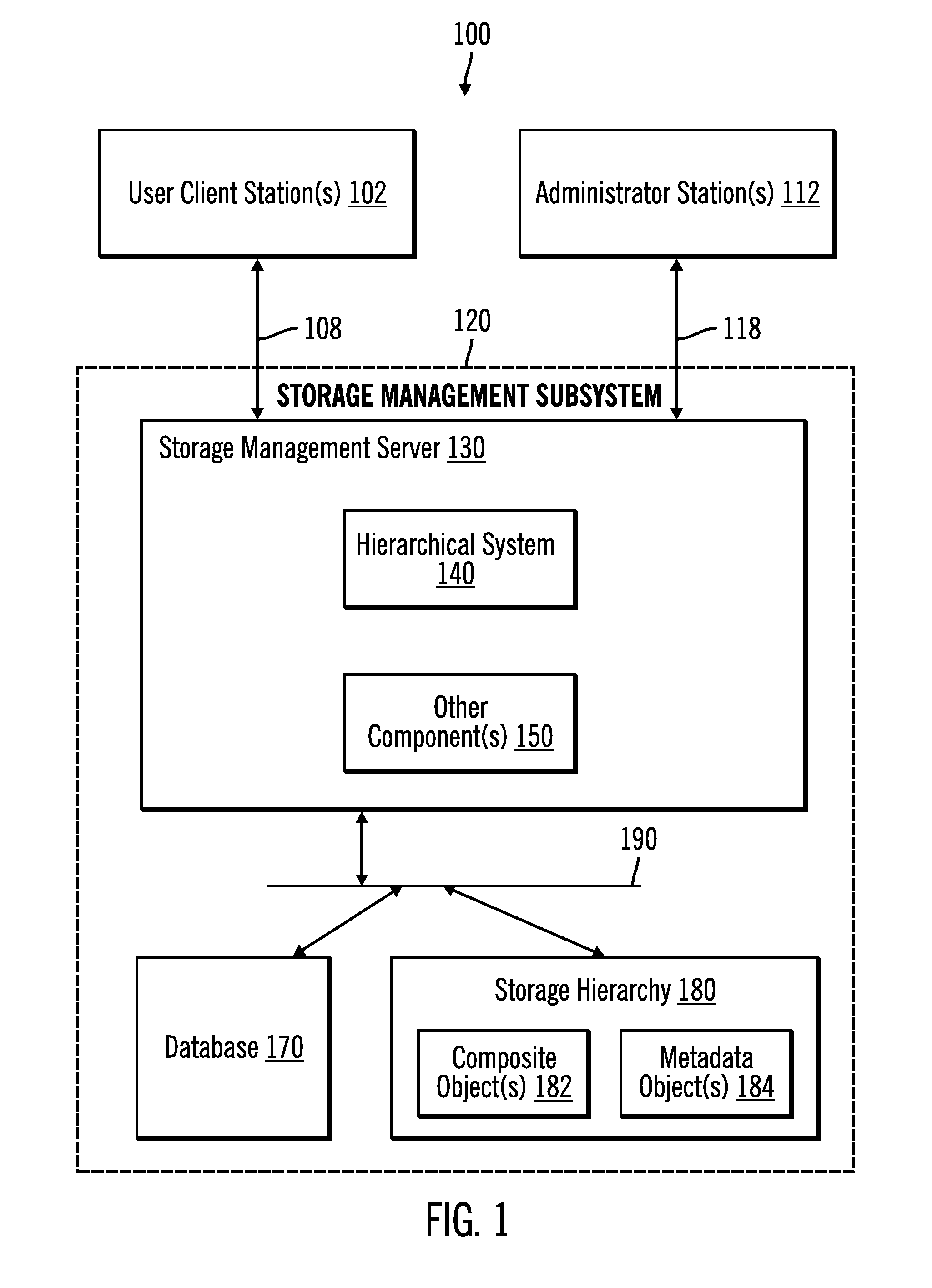

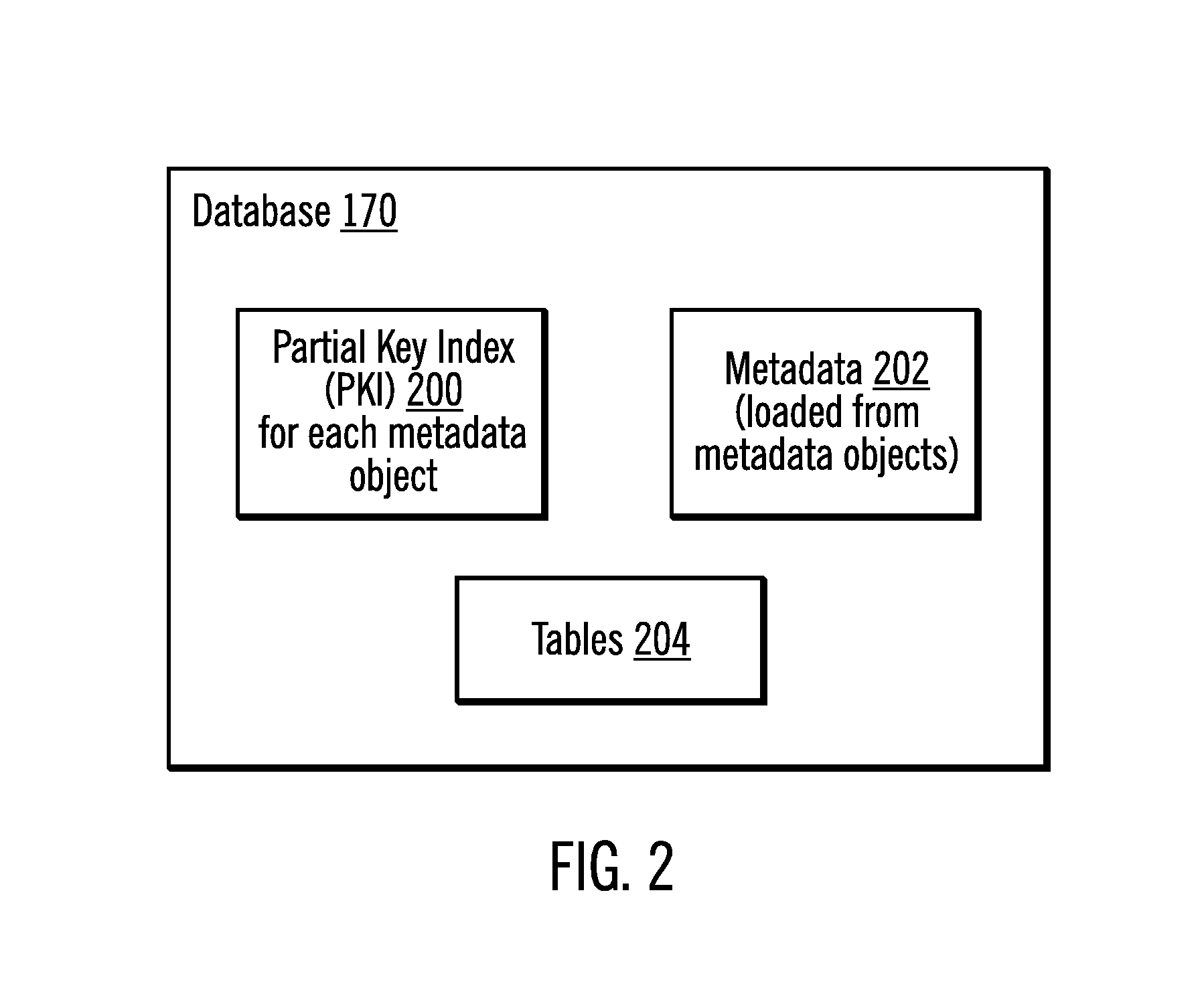

Hierarchical storage management of metadata

InactiveUS20070260592A1Data processing applicationsSpecial data processing applicationsComposite objectComputer science

Provided are techniques for accessing information. A partial key index is created, wherein the partial key index includes one or more partial key index (PKI) entries, wherein each PKI entry identifies a portion of a metadata object, wherein the metadata object includes metadata entries, each of which corresponds to an associated data object. The partial key index is used to locate one or more PKI entries, wherein each of the one or more PKI entries corresponds to one or more data objects in one of the one or more composite objects. Each of the one or more PKI entries is used to retrieve location information of metadata in a metadata object for each of the one or more composite objects. The metadata from each metadata object is loaded into a database using the location information.

Owner:IBM CORP

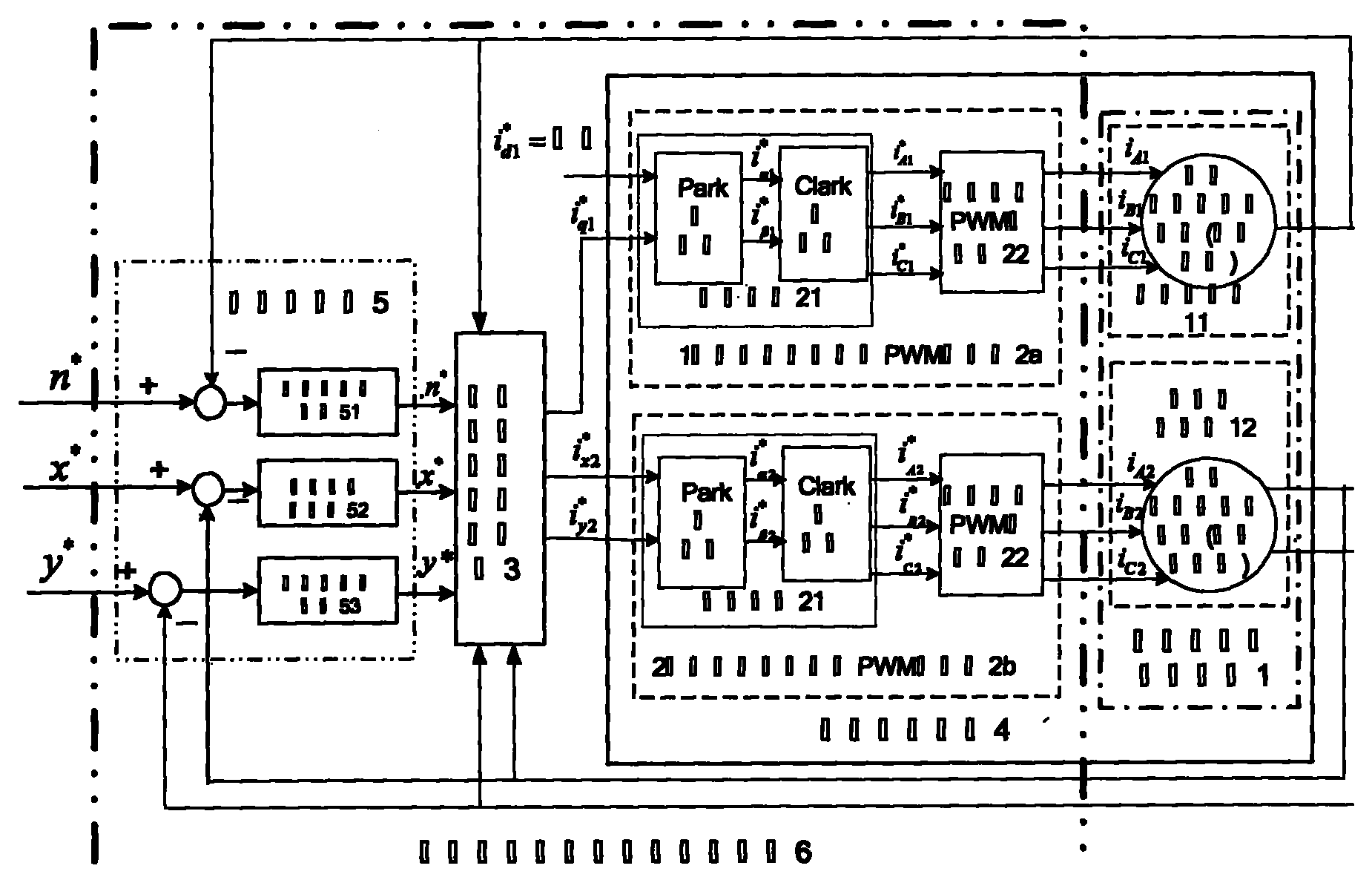

Support vector machine inverse system composite controller based on bearingless synchronous reluctance motor

InactiveCN101814892AAchieve independent controlSimple structureAC motor controlVector control systemsHysteresisSynchronous reluctance motor

The invention relates to a support vector machine inverse system composite controller based on a bearingless synchronous reluctance motor. Two expandable current hysteresis loop PWM (Pulse-Width Modulation) inverters and a bearingless synchronous reluctance motor to be controlled are used as a whole to form a composite object to be controlled; a support vector machine inverse system controller is constructed according to a mathematical model of the object to be controlled and is connected in series before the composite object to be controlled of the bearingless synchronous reluctance motor so as to realize the decoupling control between the electromagnetic torque and the radial levitation force of the motor as well as the radial levitation force in two vertical directions; on the basis, a rotating speed closed loop linear controller and two rotor position closed loop linear controllers are respectively designed for the rotating speed of the motor and the rotor positions to form a linear closed loop controller; an finally the linear closed loop controller, the support vector machine inverse system controller and two expandable current hysteresis loop PWM inverters commonly form the support vector machine inverse system composite controller for dynamically decoupling control on the bearingless synchronous reluctance motor. The control speed, the control precision and the dynamic and static performances of the system can pass parameters for adjusting the linear closed loop controller.

Owner:JIANGSU UNIV

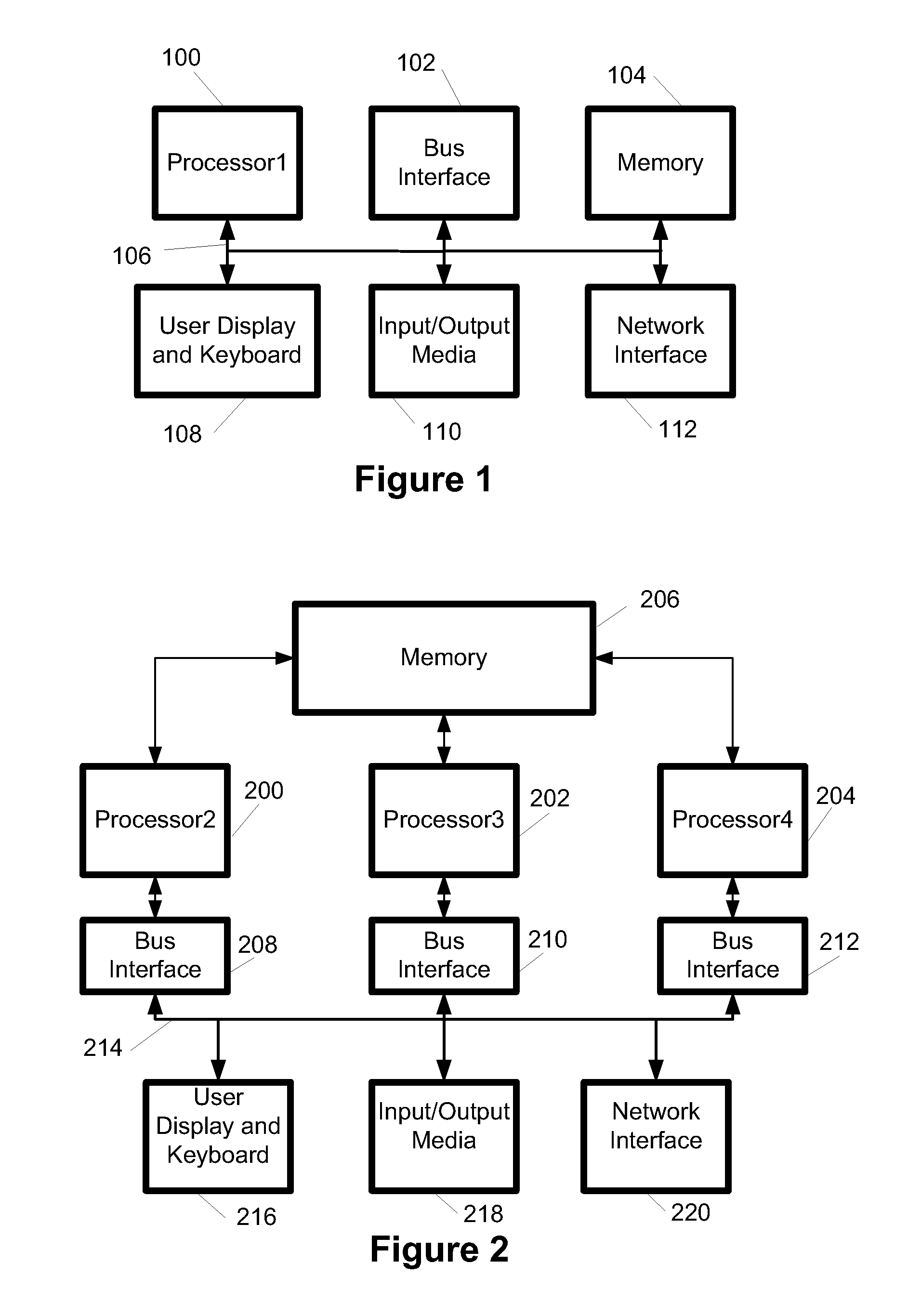

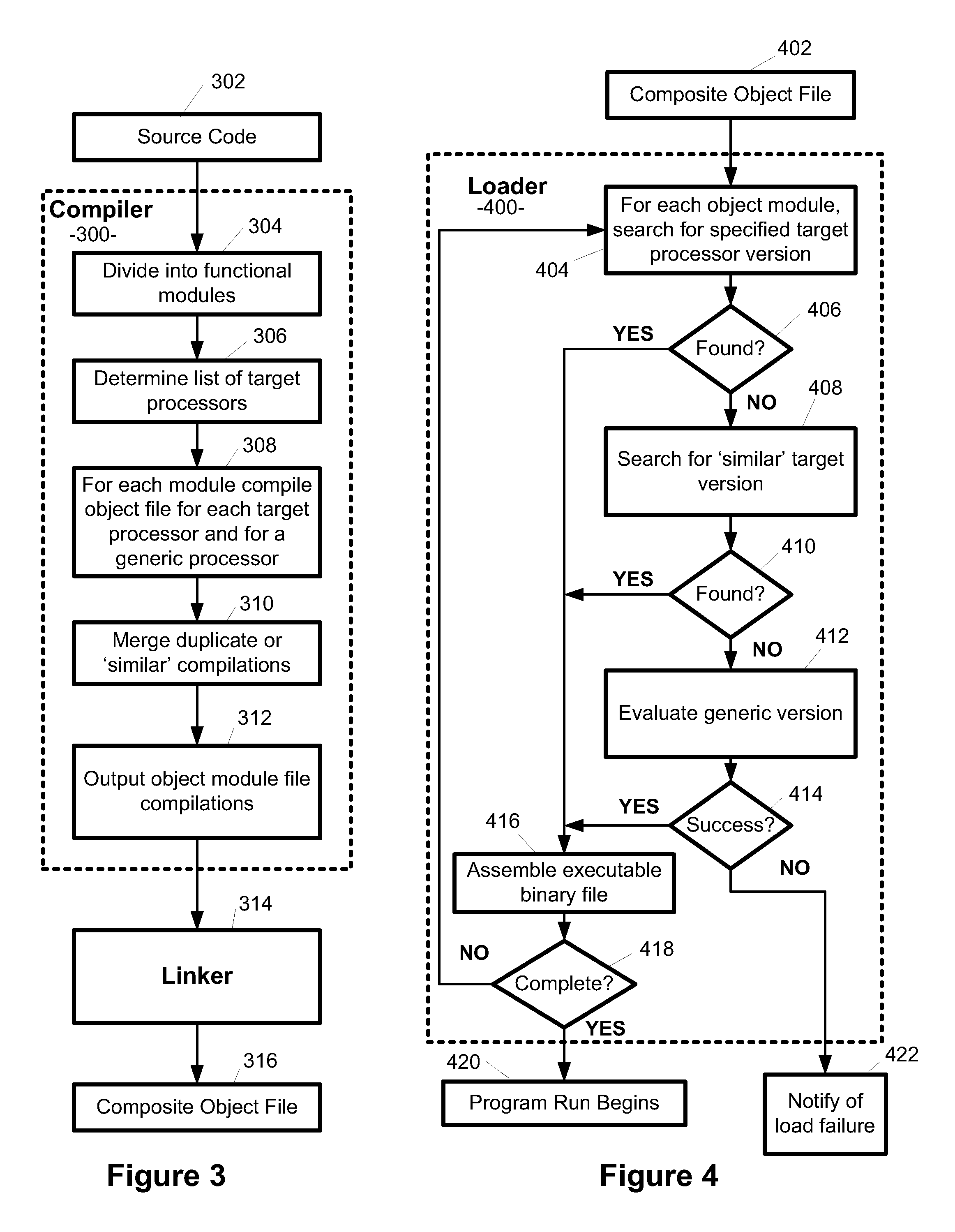

Simultaneous compiler binary optimizations

InactiveUS20110276954A1Specific program execution arrangementsMemory systemsComposite objectObject code

The present invention provides a method to optimize object code files produced by a compiler for several different types of target processors. The compiler divides the source code to be compiled into several functional modules. Given a specified set of target processors, each functional module is compiled resulting in a target object version for each target processor. Then, for each functional module, a merging process is performed wherein identical target object versions or target object versions with similar contents are merged by deleting the identical or similar versions. After this merging process, a composite object code file is formed containing all of the non-deleted target object versions of the function modules.

Owner:IBM CORP

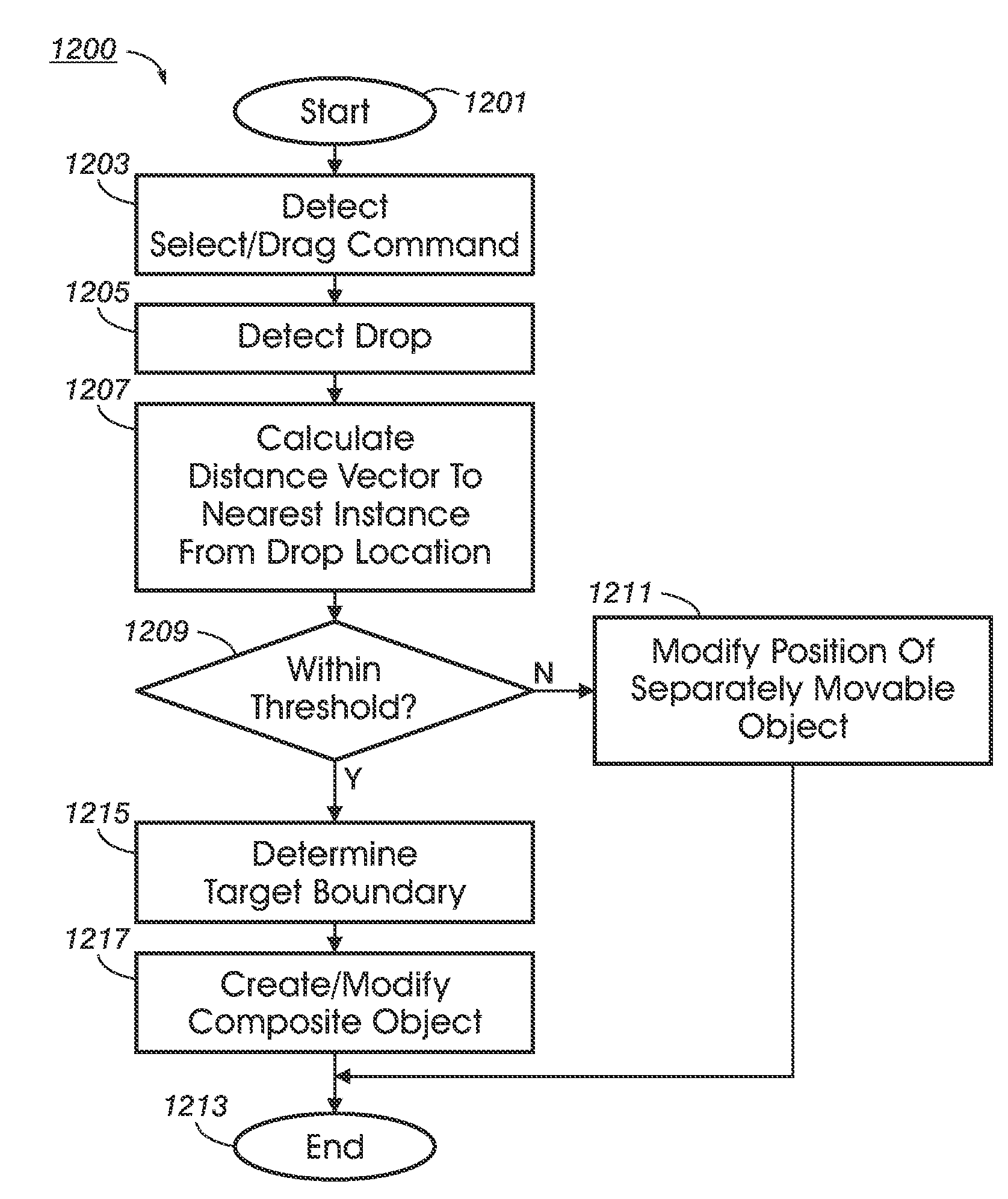

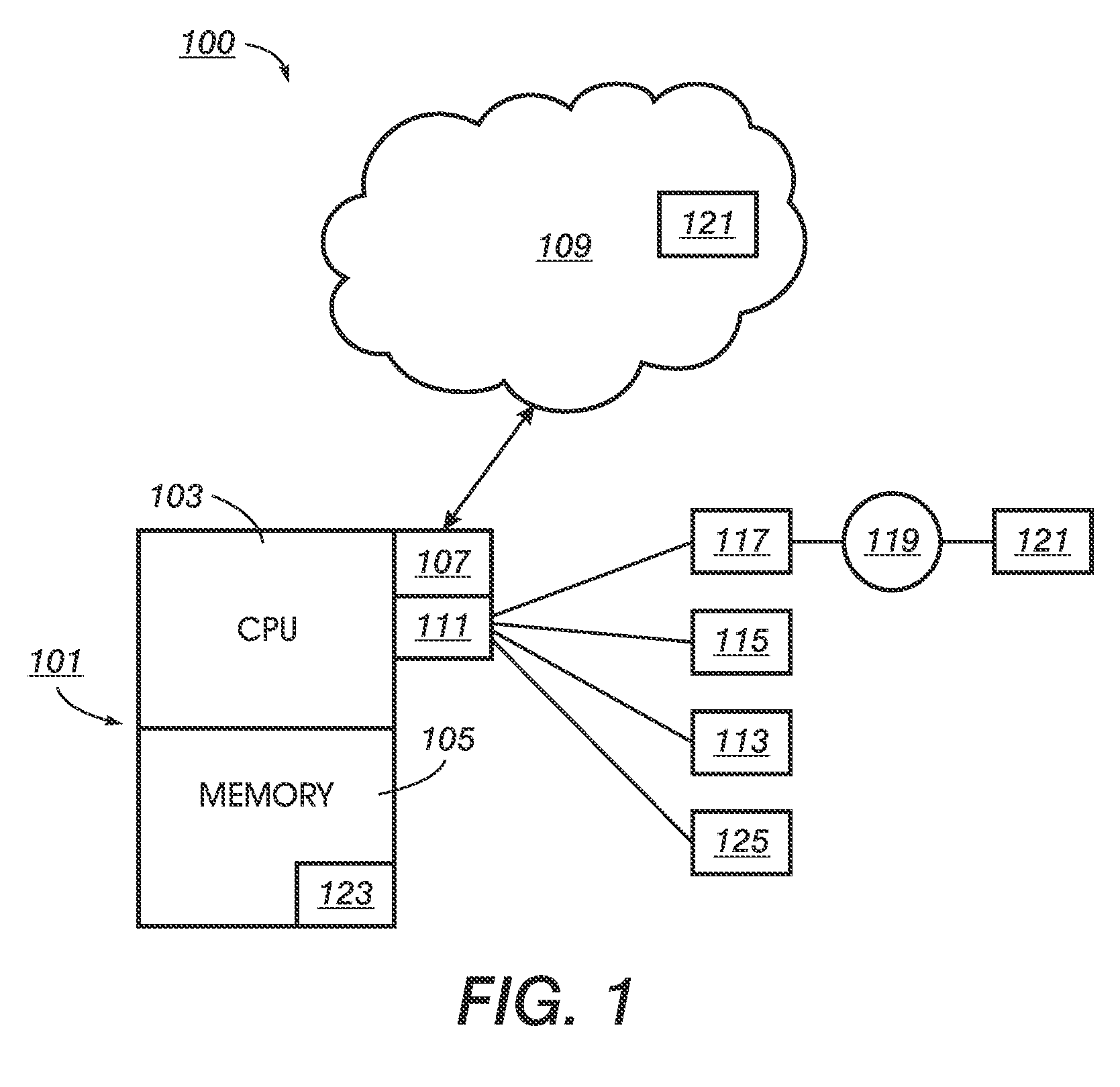

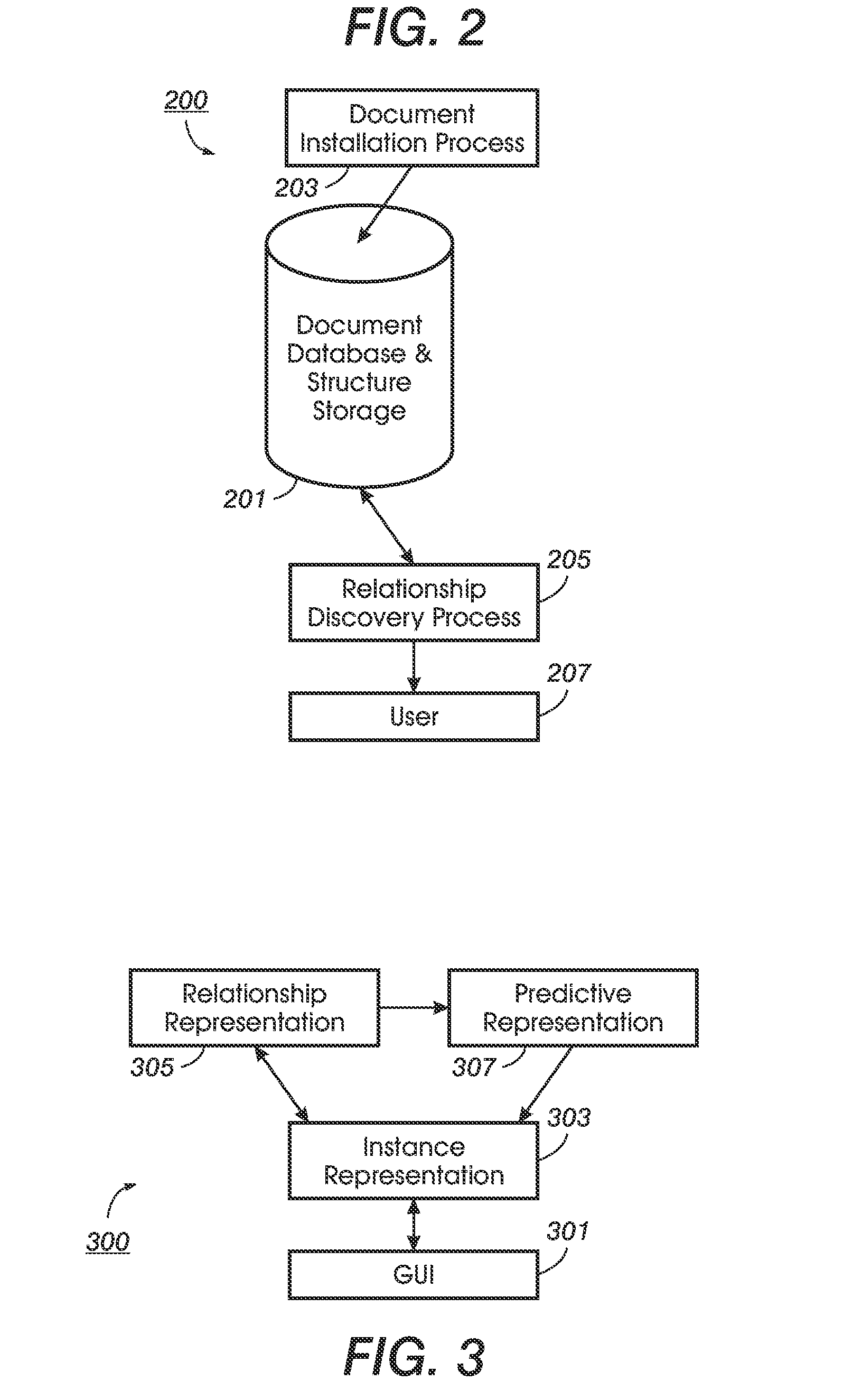

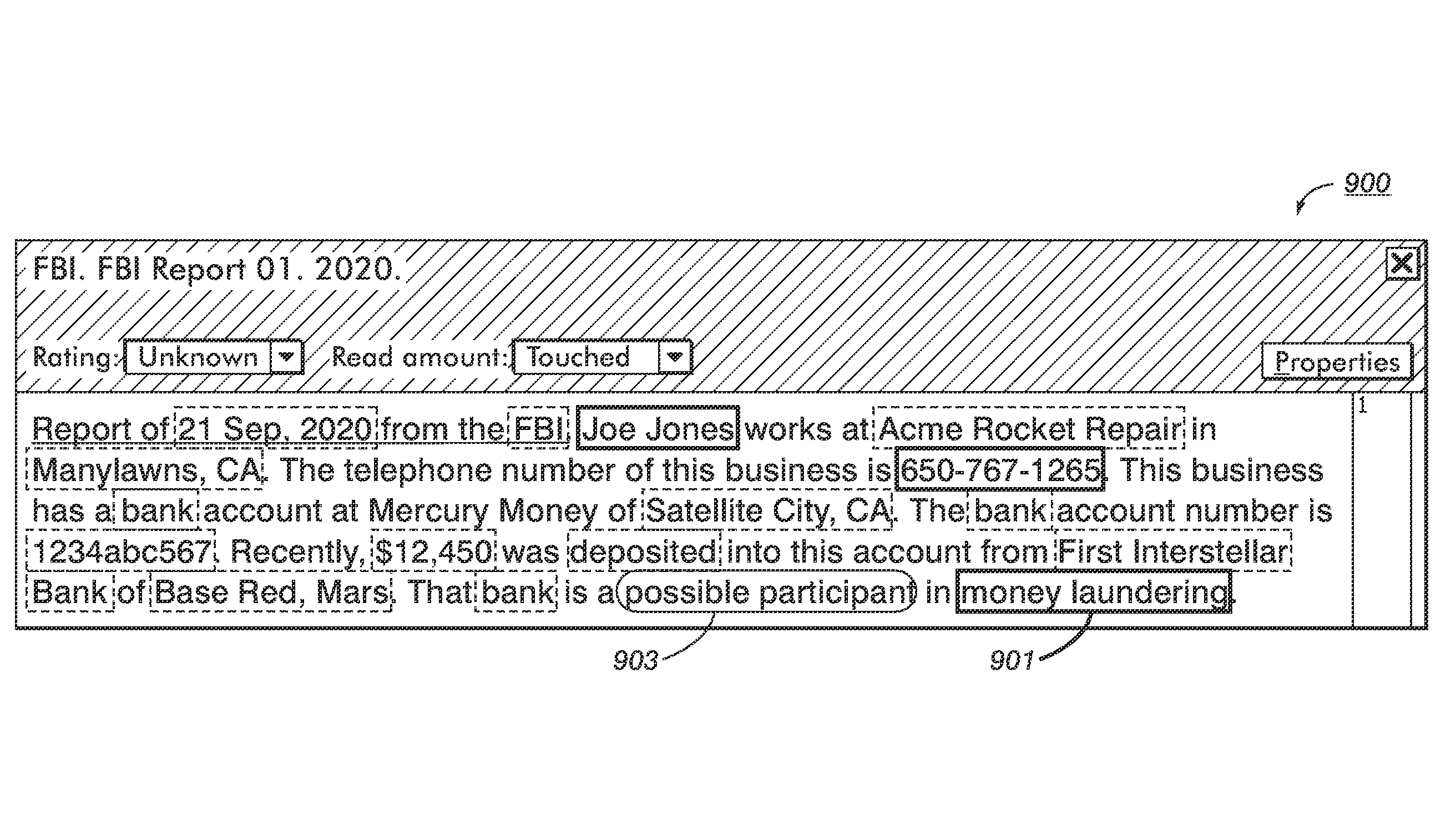

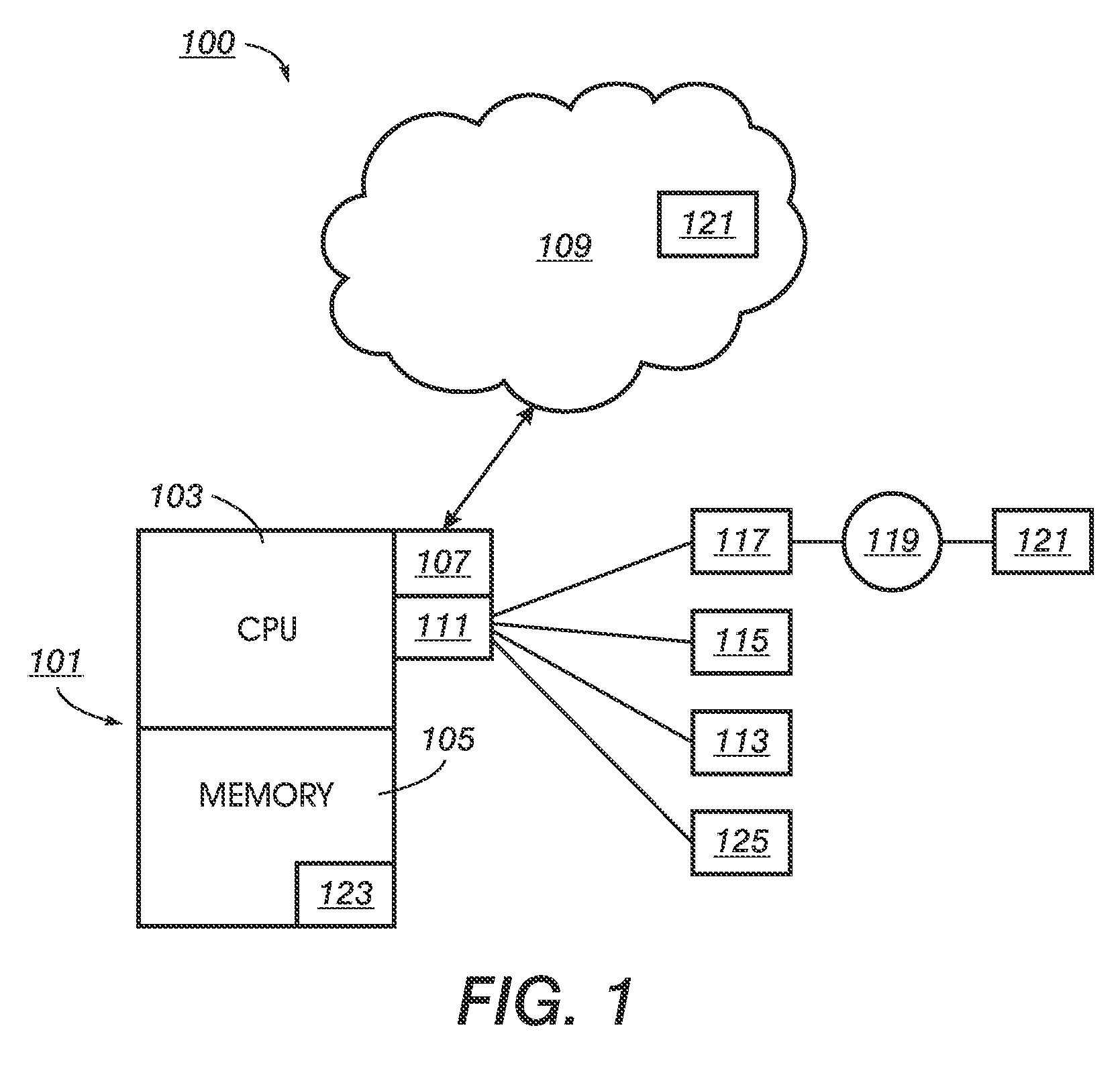

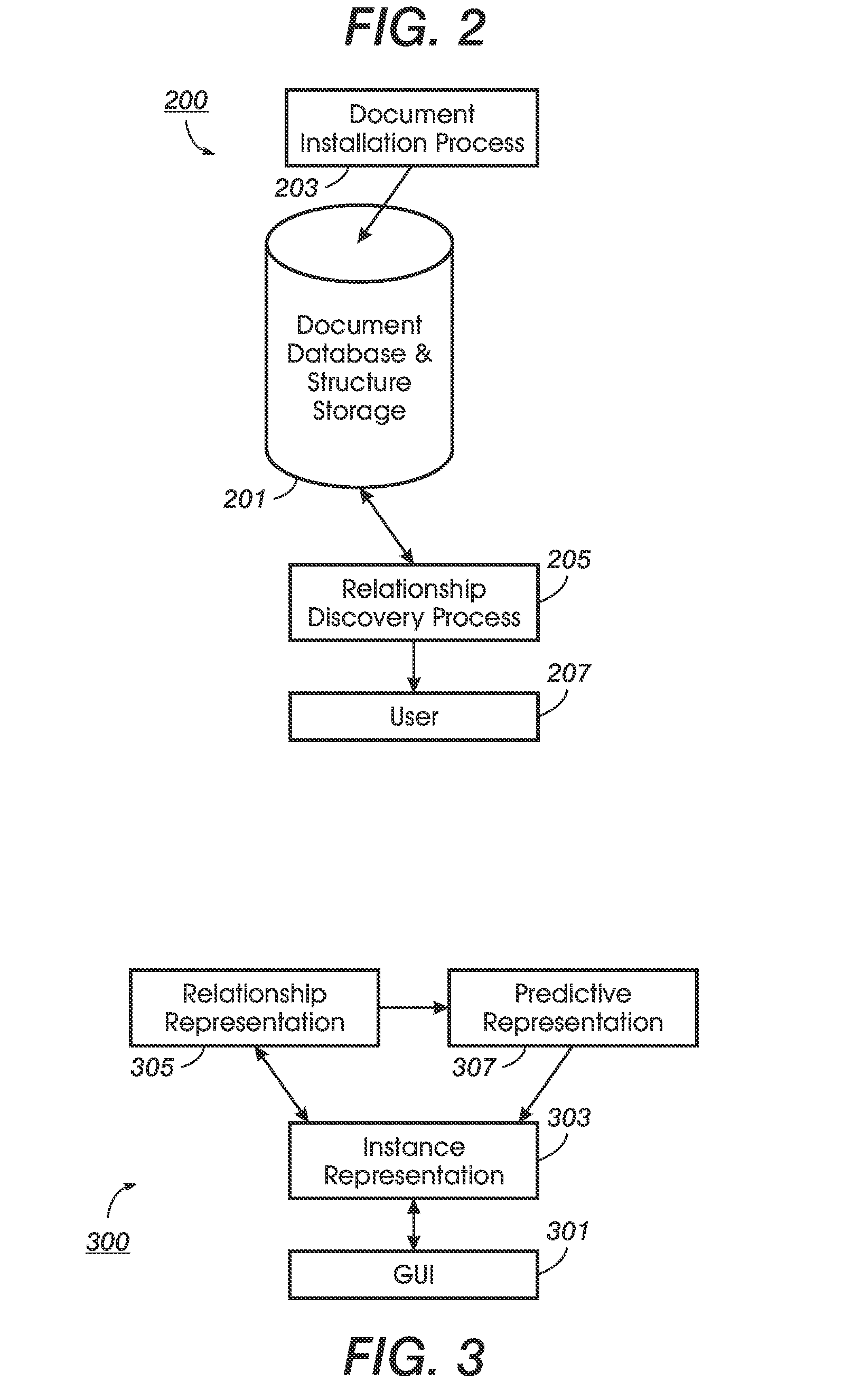

Method, Apparatus, And Program Product For Efficiently Defining Relationships In A Comprehension State Of A Collection Of Information

InactiveUS20070300190A1Digital computer detailsNatural language data processingComposite objectAlgorithm

Aspects of the disclosed technology present a workspace window responsive to a relationship data structure that represents a comprehension state including a presentation of a first instance-representation that represents a first separately-movable instance object and a second instance-representation that represents a second separately-movable instance object. This aspect enables the first instance-representation and detects when the first instance-representation is dropped within a threshold distance of the second instance-representation. When the first instance-representation is dropped, the technology identifies, responsive to the step of detecting, one of a plurality of spatial relationships between the first instance-representation and the second instance-representation. Responsive to the identified spatial relationship, the technology selects an operation, and responsive to the operation modifies a composite object in the relationship data structure. The composite object incorporates an entity / relationship object that is represented by the first separately-movable instance object and an entity / relationship object represented by the second separately-movable instance object. After the composite object as modified, an instance-representation that represents the composite object is presented in the workspace window.

Owner:MAJANDRO LLC

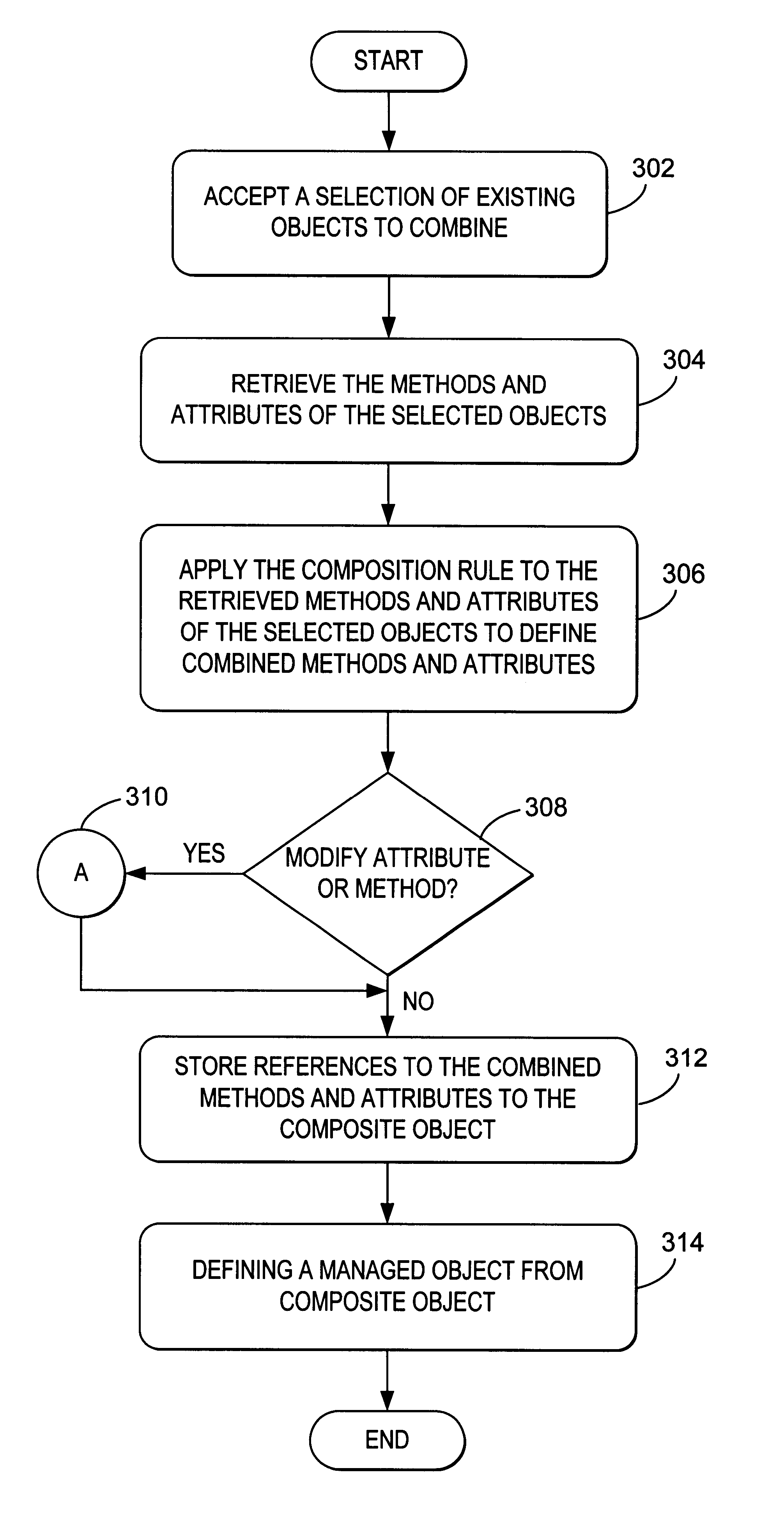

Dynamic expression editor

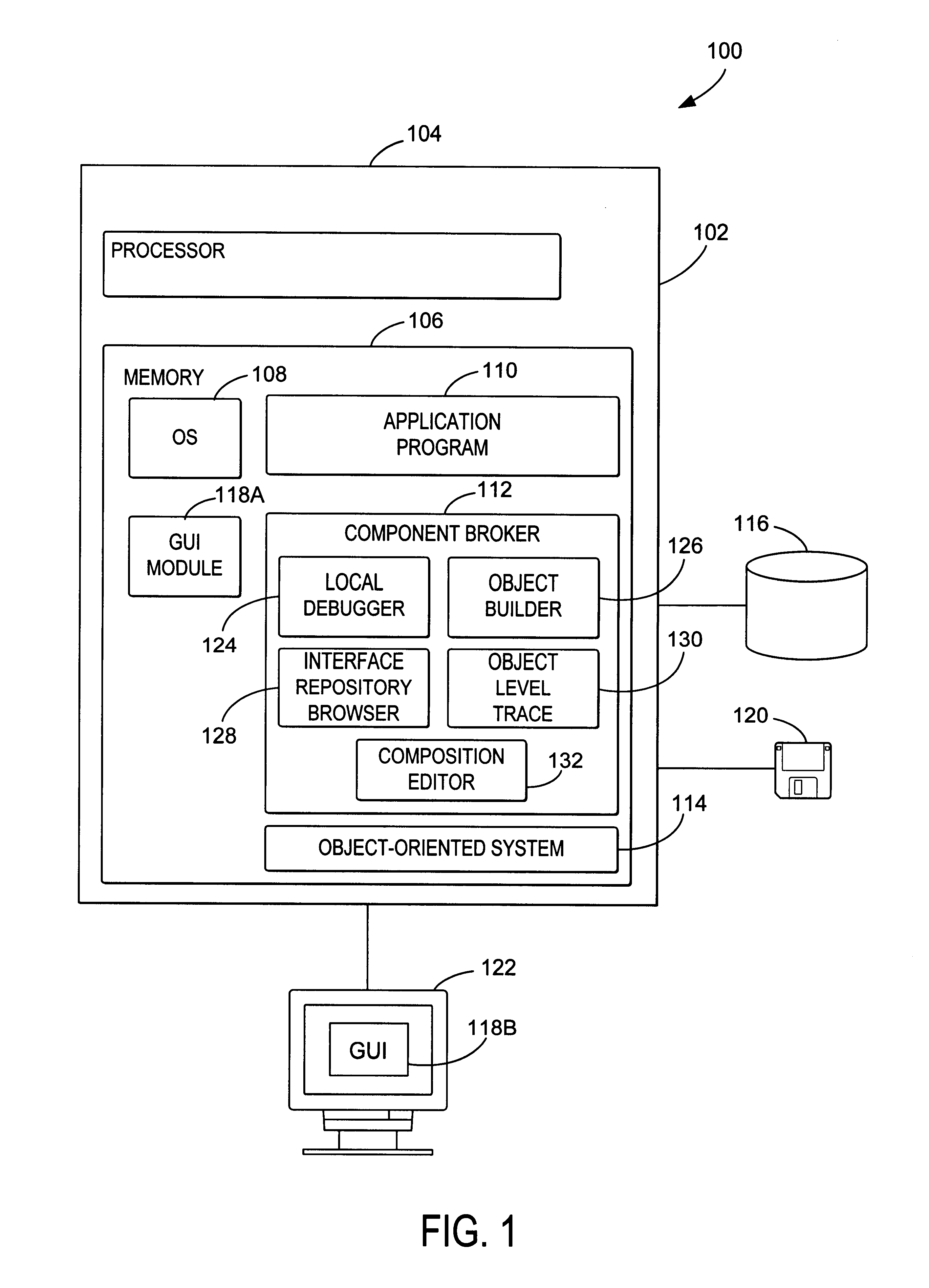

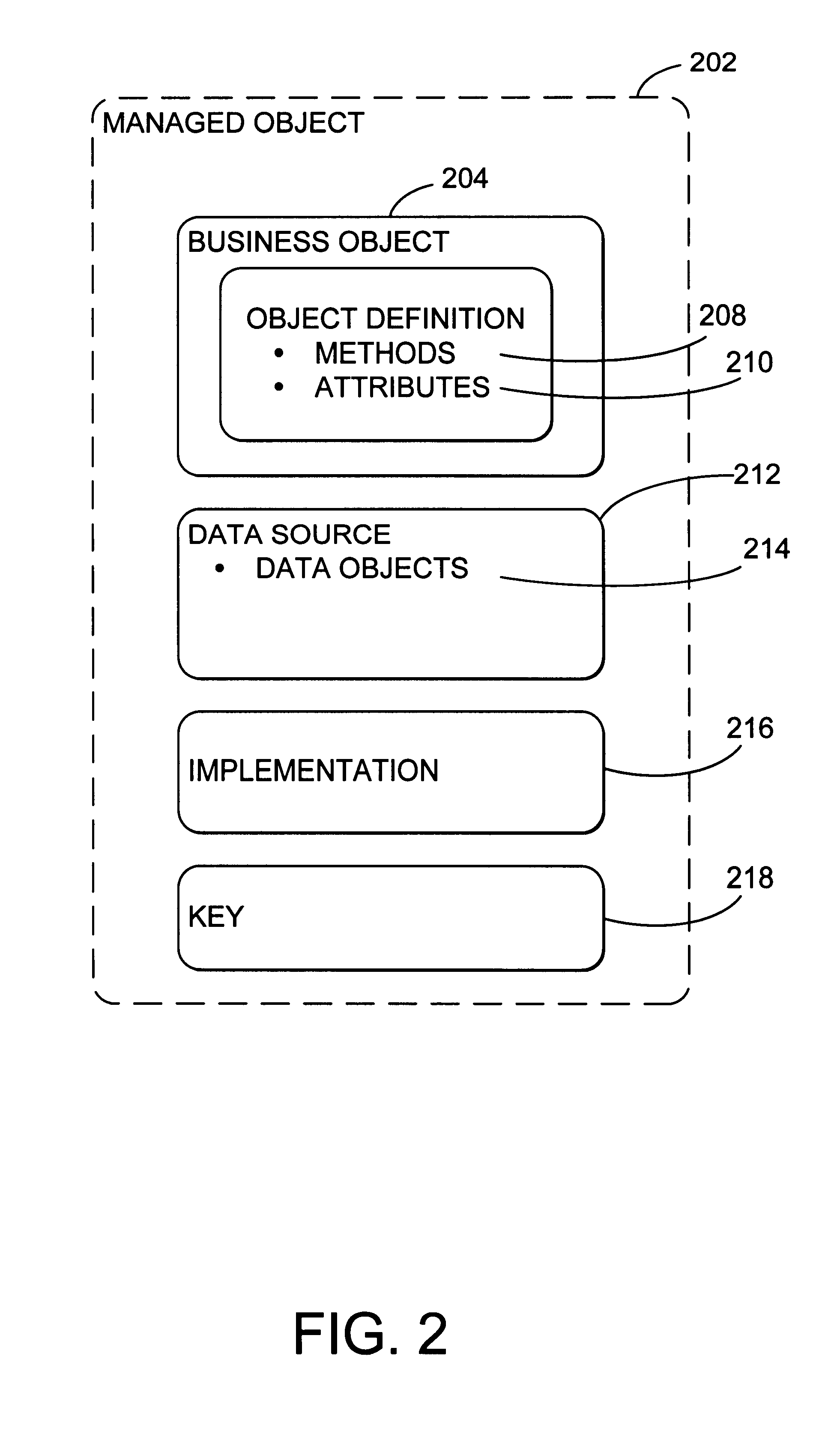

A system, method, and article of manufacture for intuitively defining new attributes and methods as a function of existing attributes and methods is described. The method comprises the steps of creating a composite object having object elements including methods and attributes combined according to a composition rule, displaying a view of expression elements comprising the attributes and methods of the composite object, defining an object element expression combining at least two of the expression elements, and forming the hybrid object element from the selected expression elements. In one embodiment, a drop-down list is used to select a series of attributes, methods and operators that comprise the expression defining the hybrid element. The apparatus comprises means for performing the operations above, including a computer with a processor and memory coupled to a data storage device and a display. The article of manufacture comprises a tangible embodiment of instructions for performing the foregoing operations.

Owner:IBM CORP

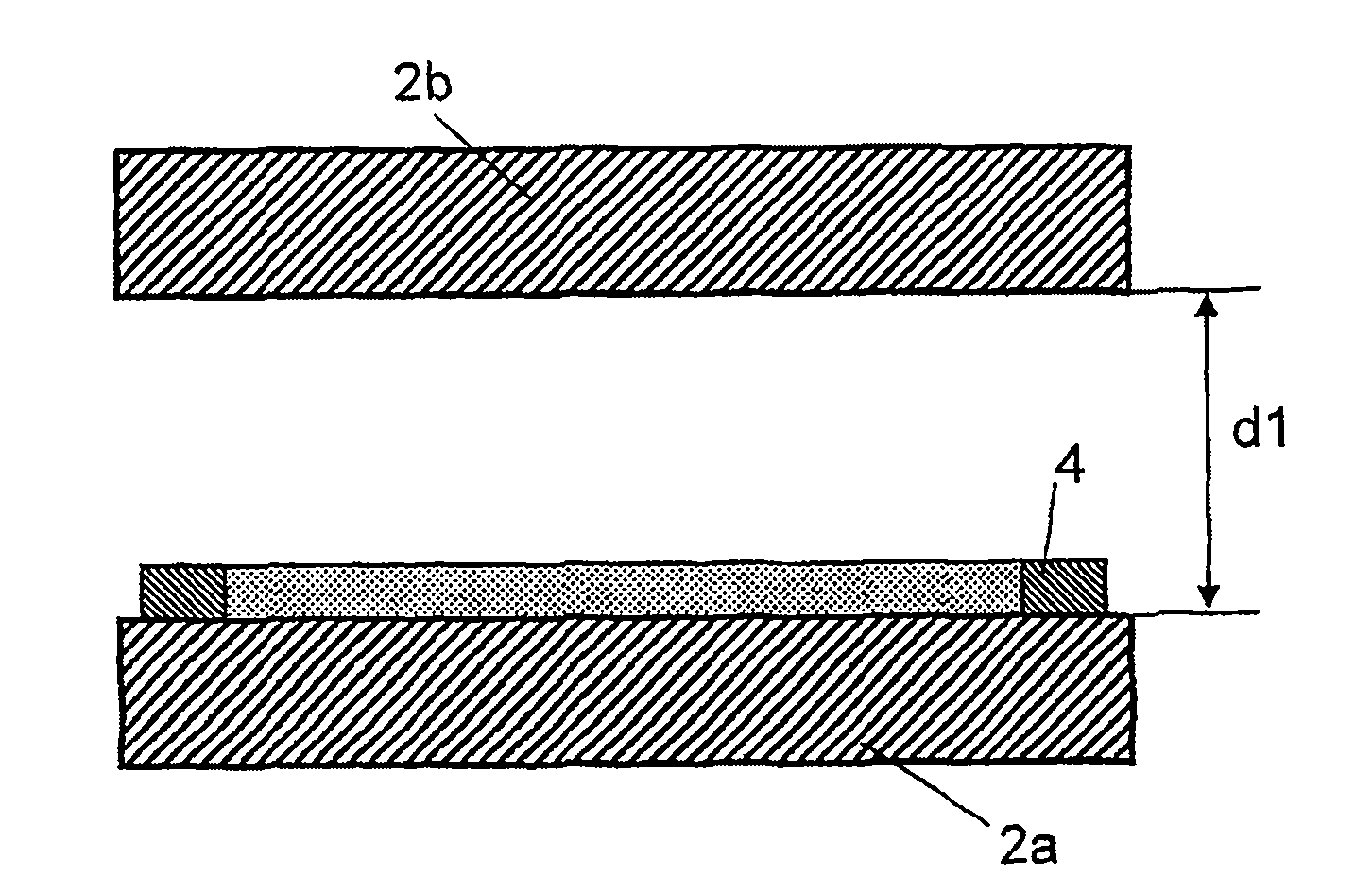

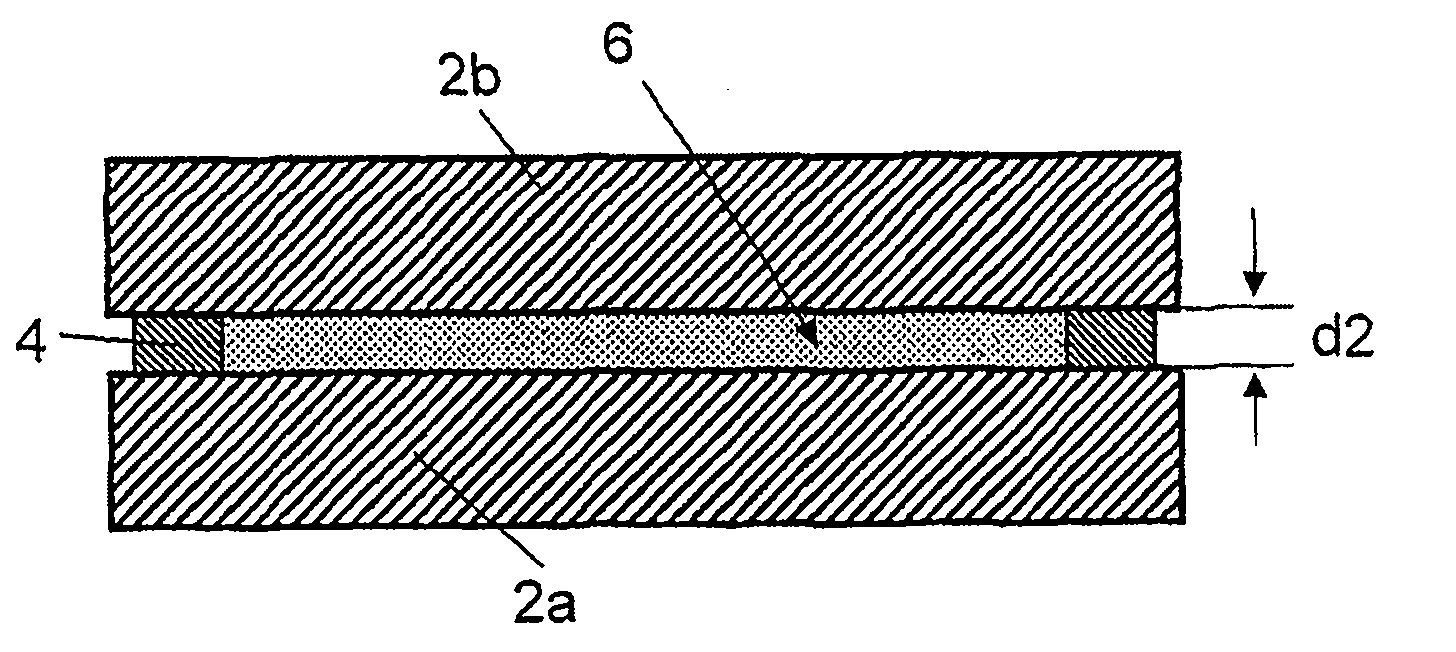

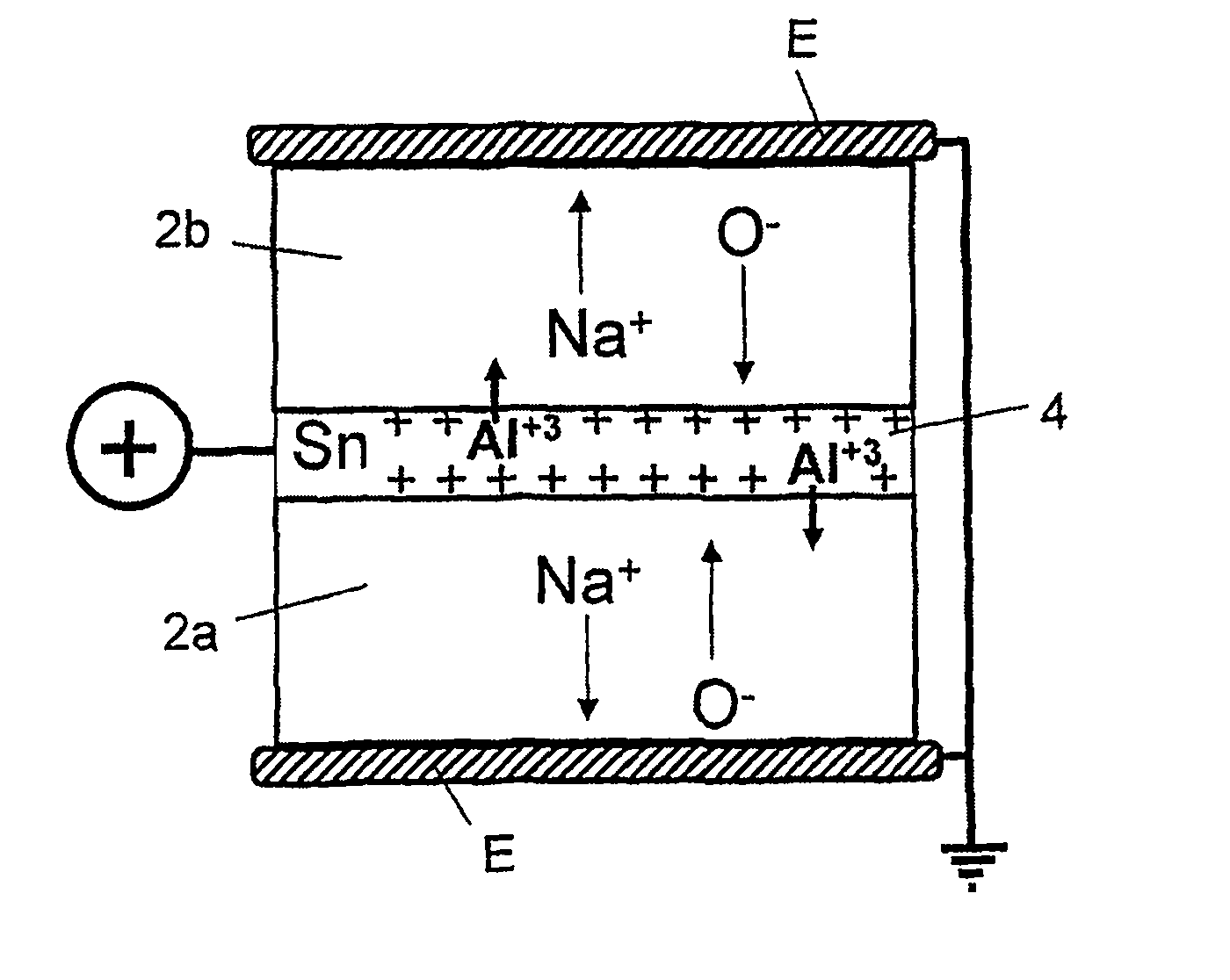

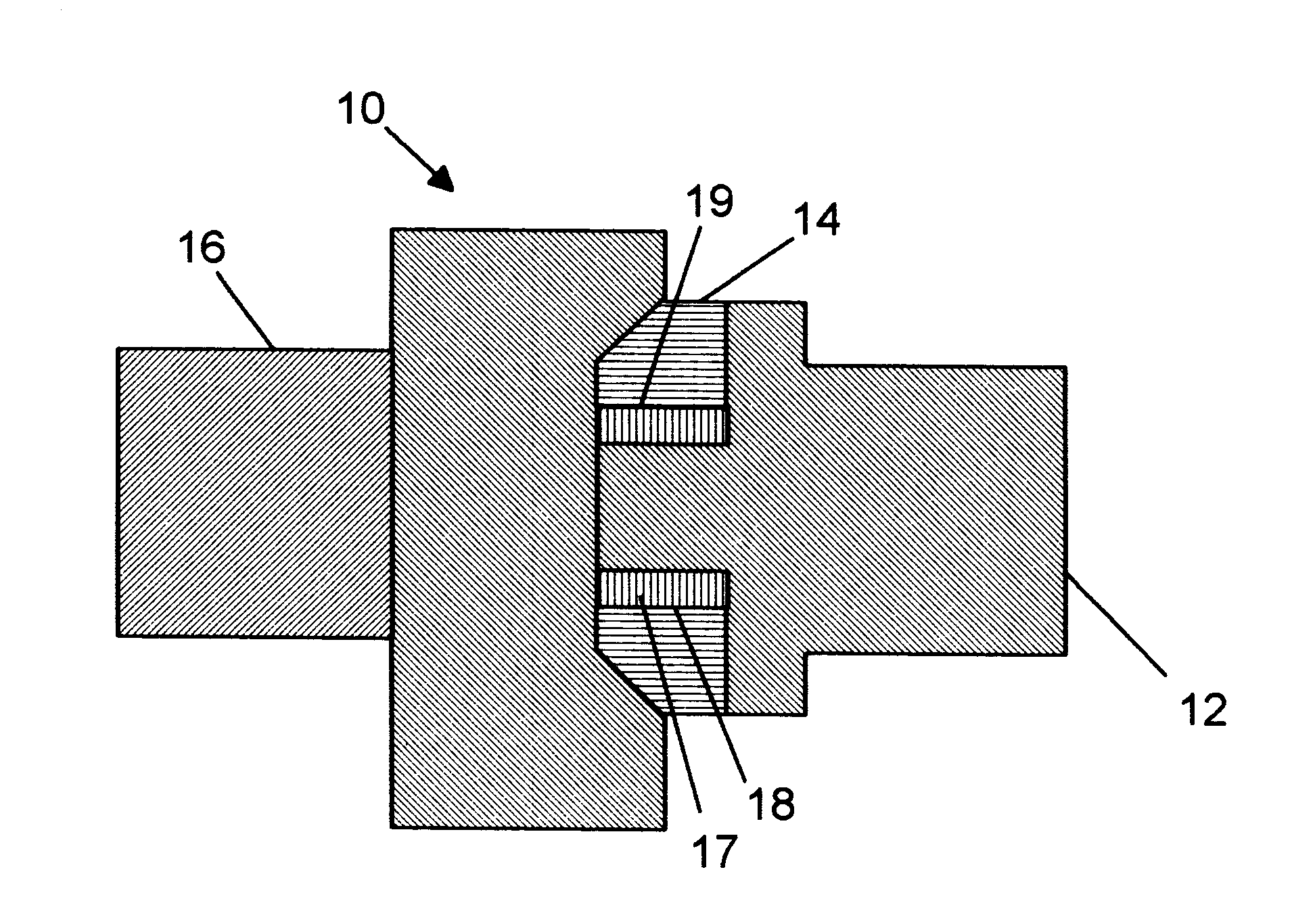

Composite object and method for the production thereof

A composite object comprises two components (2a, 2b) made of an oxidic material, which at an elevated temperature conducts ions, said components being connected to each other in a medium-tight manner by way of a solder bridge (4) in a connecting region (6) located in between. In order to form a reliable connection, it is proposed that the solder bridge is formed by a low-melting tin alloy that has a weight proportion of at least 65% tin and a melting point of no more than 350 C and comprises at least one activating metal as an alloying constituent.

Owner:瑞士材料试验研究所

Method, apparatus, and program product for efficiently defining relationships in a comprehension state of a collection of information

InactiveUS8010646B2Digital computer detailsNatural language data processingComposite objectTheoretical computer science

Aspects of the disclosed technology present a workspace window responsive to a relationship data structure that represents a comprehension state including a presentation of a first instance-representation that represents a first separately-movable instance object and a second instance-representation that represents a second separately-movable instance object. This aspect enables the first instance-representation and detects when the first instance-representation is dropped within a threshold distance of the second instance-representation. When the first instance-representation is dropped, the technology identifies, responsive to the step of detecting, one of a plurality of spatial relationships between the first instance-representation and the second instance-representation. Responsive to the identified spatial relationship, the technology selects an operation, and responsive to the operation modifies a composite object in the relationship data structure. The composite object incorporates an entity / relationship object that is represented by the first separately-movable instance object and an entity / relationship object represented by the second separately-movable instance object. After the composite object as modified, an instance-representation that represents the composite object is presented in the workspace window.

Owner:MAJANDRO LLC

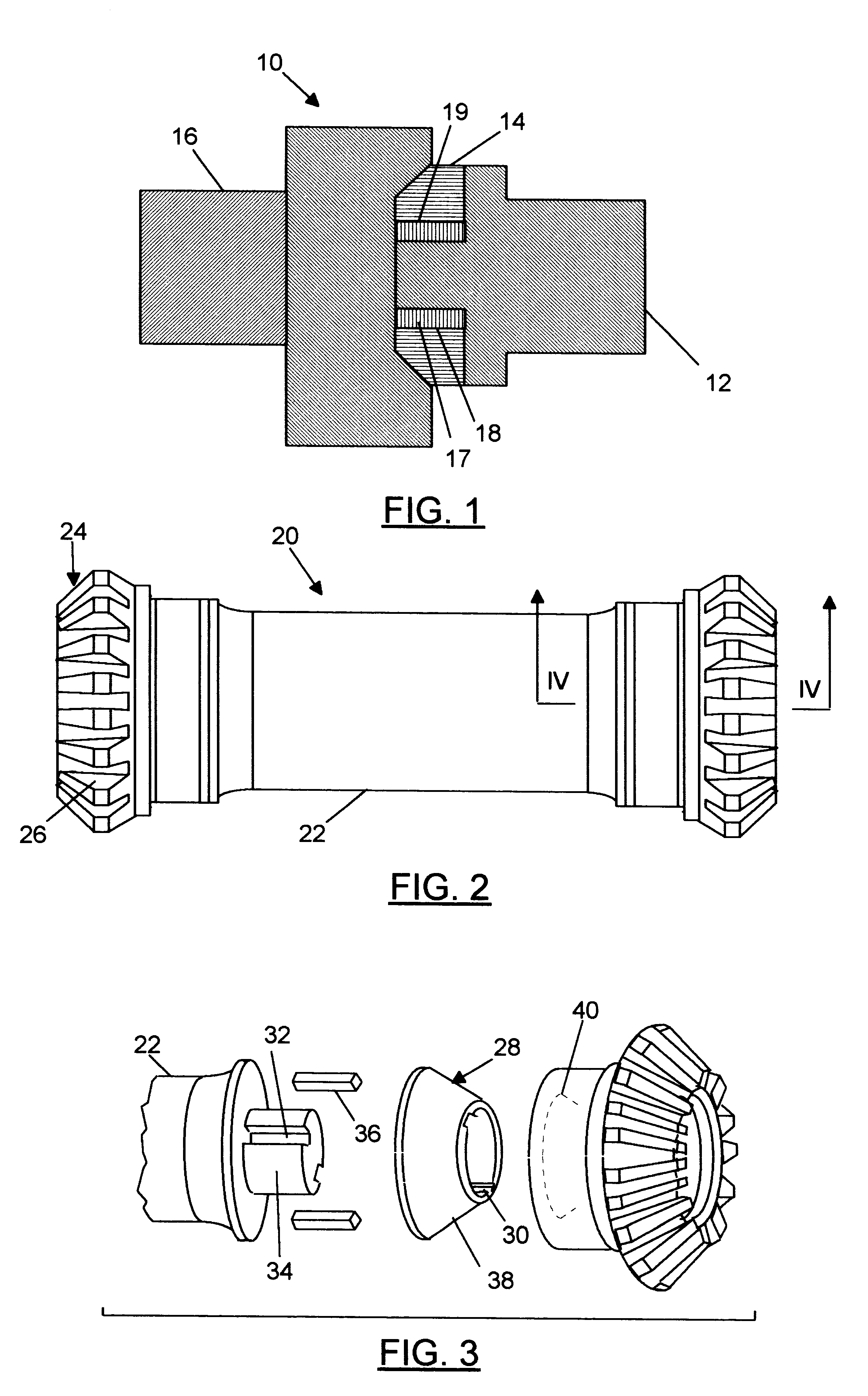

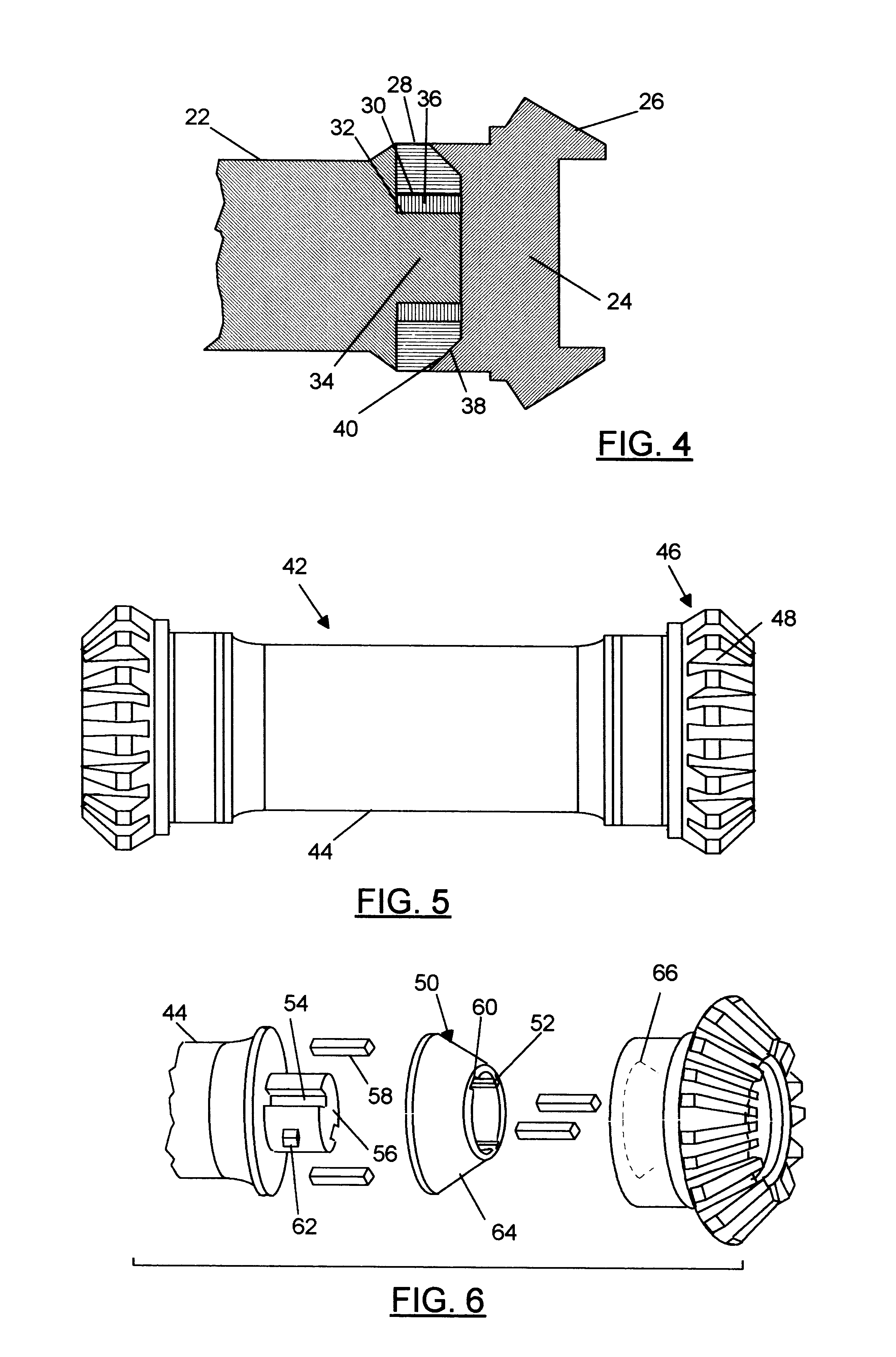

Multi-element composite object

A multi-element composite object composed from first, second, and third metal components is provided, wherein the first metal and the third metal are weld incompatible. The multi-element composite object includes a first component fabricated from a first metal. A second component, fabricated from a second metal, is brazed to the first component A third component, fabricated from a third metal, is inertia welded to the second component . The first metal may be provided as a titanium alloy, e.g. a TiNi alloy. The second metal may be provided as low-carbon mild or alloy steel. The third metal may be provided as alloy steel, e.g., 9310 nickel alloy steel. In an embodiment, the multi-element composite object is a gear assembly, with the first element of the gear assembly object being a shaft and the third element of the gear assembly being a gear member with hardened teeth surfaces. The first and second components can be mechanically keyed together via an anti-rotational element. The anti-rotational element can be provided as a pin-in-groove arrangement or a twist-fit arrangement A method of making a multi-metal composite object including a first component fabricated from a first metal, a second component fabricated from a second metal, and a third component fabricated from a third metal, wherein the first metal and the third metal are weld incompatible, is also disclosed. The first step of the method includes mechanically keying the first component to the second component. Net, the first component is brazed to the second component. Finally, the third component is welded to the second component. Where the first metal is a Ti alloy and the second metal is low-carbon steel, the step of brazing the first component to the second component can include brazing using a brazing material such as Ag and Cu. Where the third component is heat-treated steel, the assembly can be stress-relieved after inertia welding at a temperature sufficiently low so as not to degrade the heat-treated properties of the third component.

Owner:CLAXTON RAYMOND J

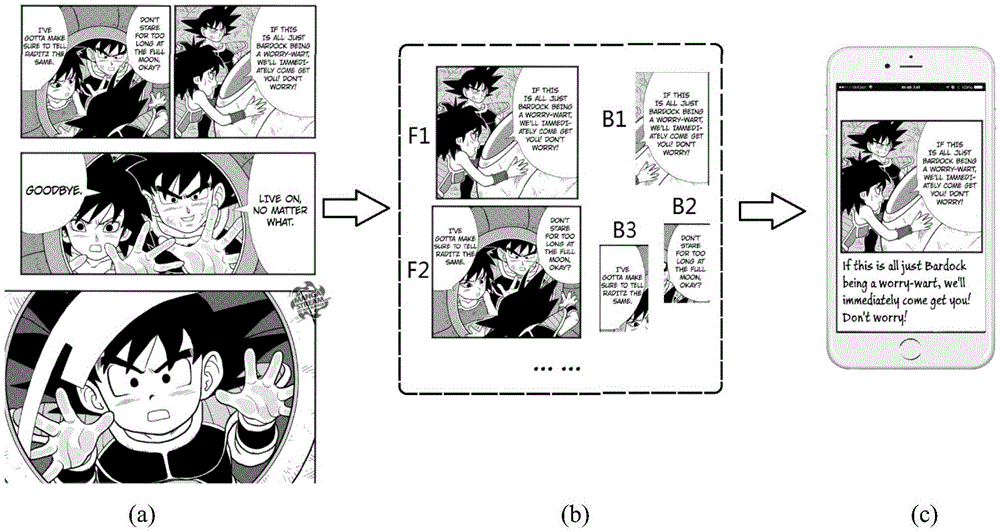

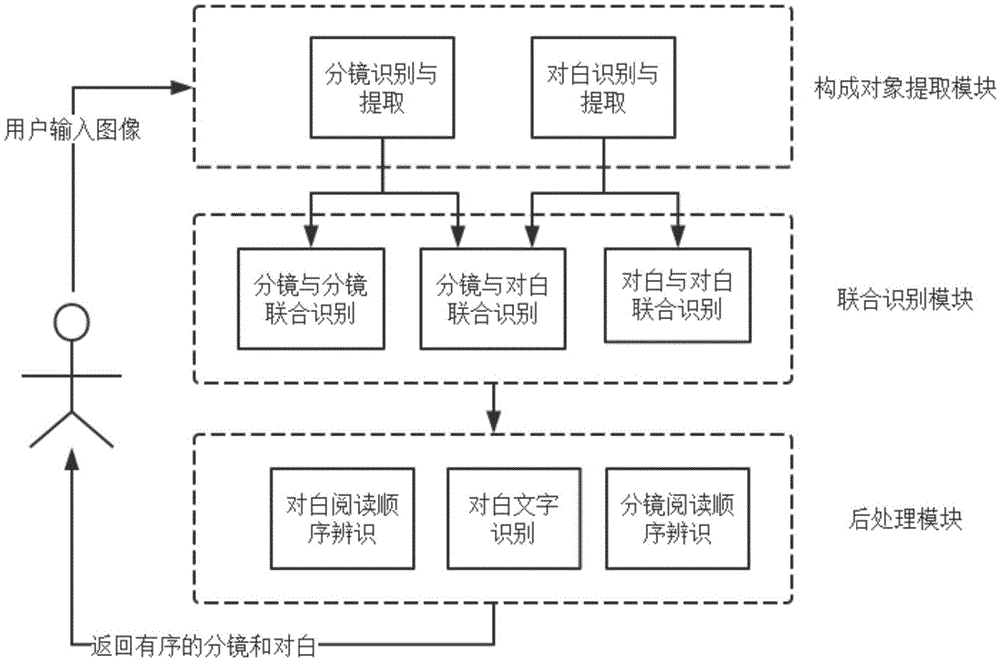

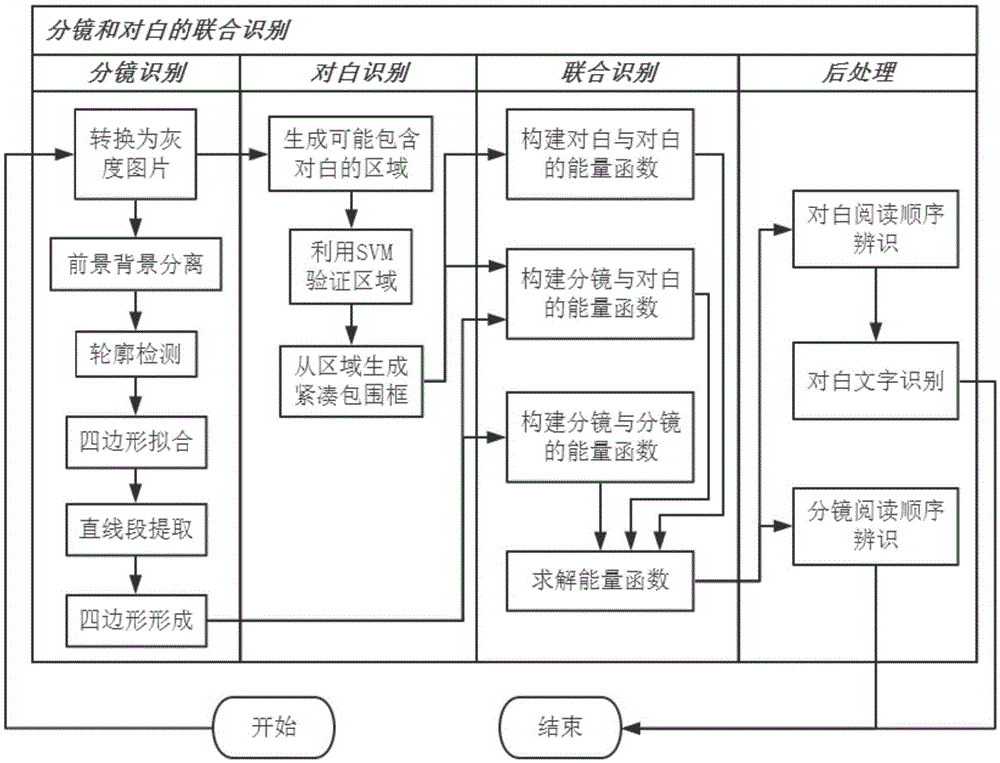

Cartoon image page identification method and system based on dialogue and storyboard united identification

ActiveCN105574524AImprove accuracyBreak through limitationsCharacter and pattern recognitionEnergy minimizationComposite object

The invention discloses a cartoon image page identification method and system based on dialogue and storyboard united identification. A carton image is divided into a storyboard layer and a dialogue layer. The method comprises following steps: extracting to obtain storyboards in a carton image page; extracting to obtain dialogues in the carton image page; carrying out storyboards, dialogues, and storyboard and dialogue united identification; building an energy minimized function, obtaining marking results of a storyboard polygon and a dialogue surrounding fence through optimally solving the energy minimized function; identifying a reading sequence according to the geometric position relation of the polygon, thus finishing the carton image identification. According to the method and the system of the invention, the limitations of an identification method which only pays attention to independent extraction of composite objects and ignores the relation among the objects are broken through; the storyboard identification accuracy is improved; and the method and the system have relatively strong universality.

Owner:PEKING UNIV

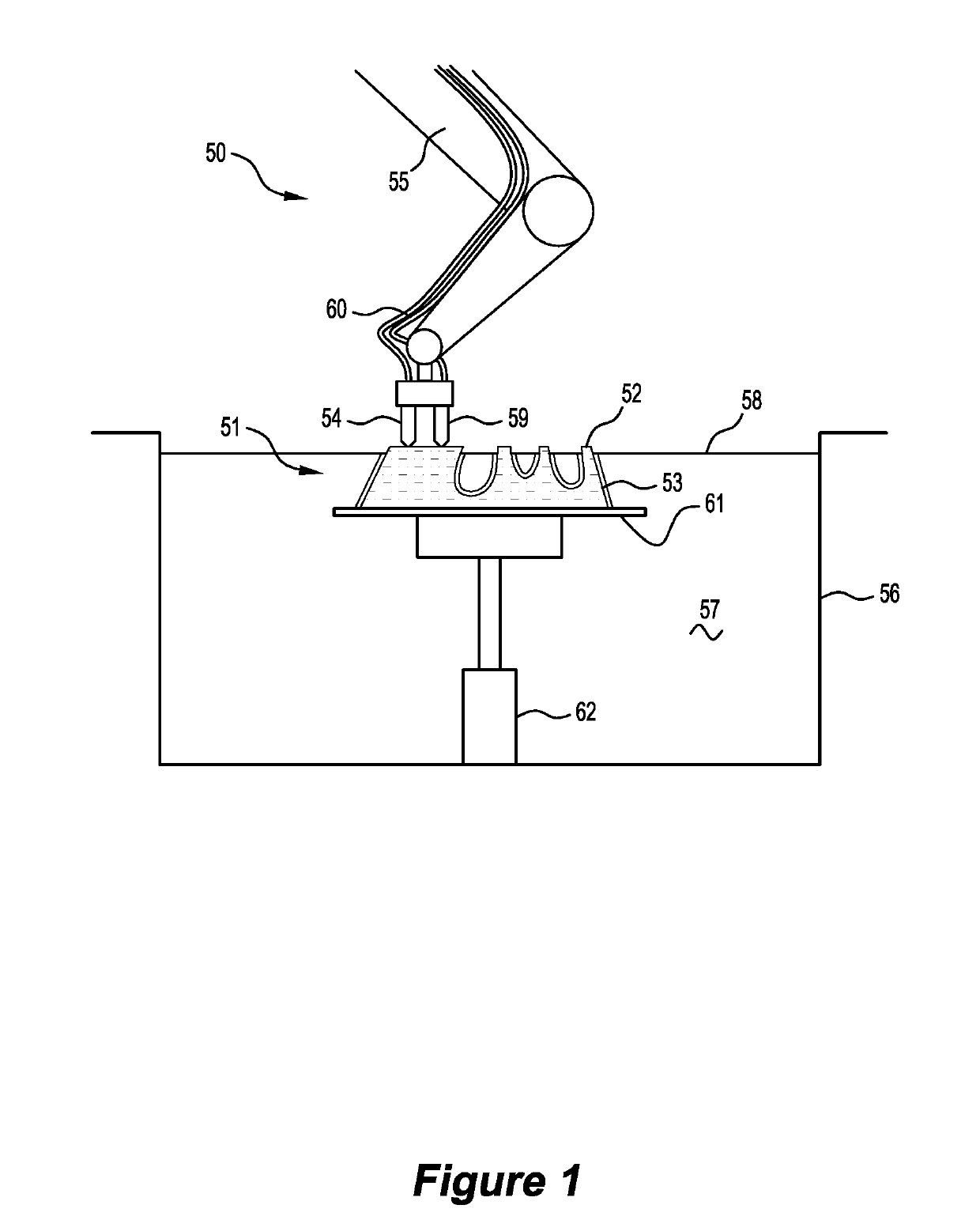

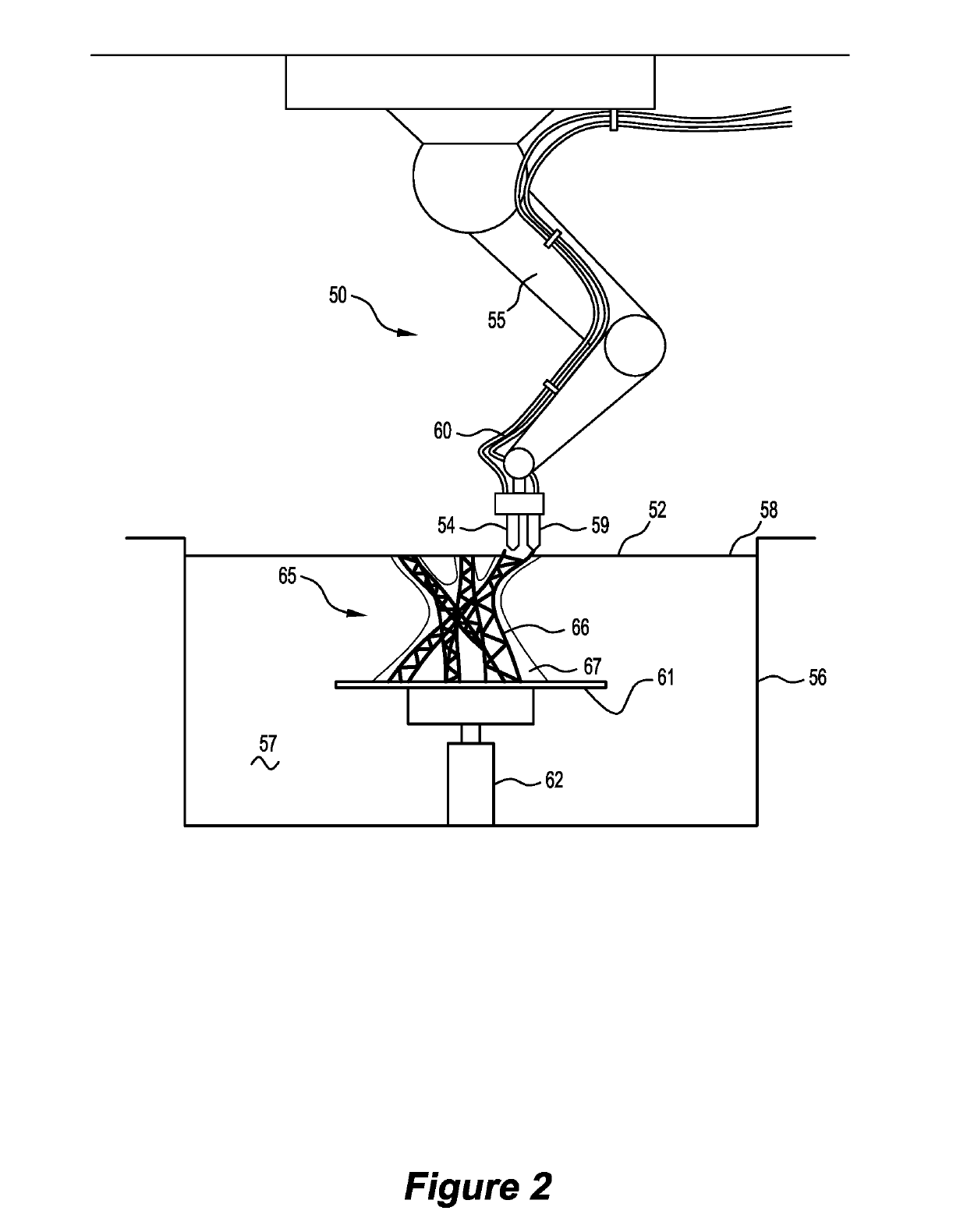

Method and apparatus for fabricating a composite object

InactiveUS10293594B2Manufacturing platforms/substratesManufacturing driving meansComposite objectMaterials science

A method for fabricating a composite object with a computer-controlled apparatus, and the apparatus therefor. The comprises a reservoir containing liquid, curable first material, means to selectively solidify the first material and means to selectively deposit a second material. The method involves the steps of selectively depositing portions of the second material, and selectively solidifying portions of the first material, such that the solidified portions of the first material and the deposited portions of the second material form the composite object.

Owner:LAING OROURKE AUSTRALIA PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com