Composite object and method for the production thereof

A technology of composite materials and oxidized materials, which is applied in the field of manufacturing composite materials, can solve the problems of not being able to implement, not expecting heat conduction, and not being able to achieve glass contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

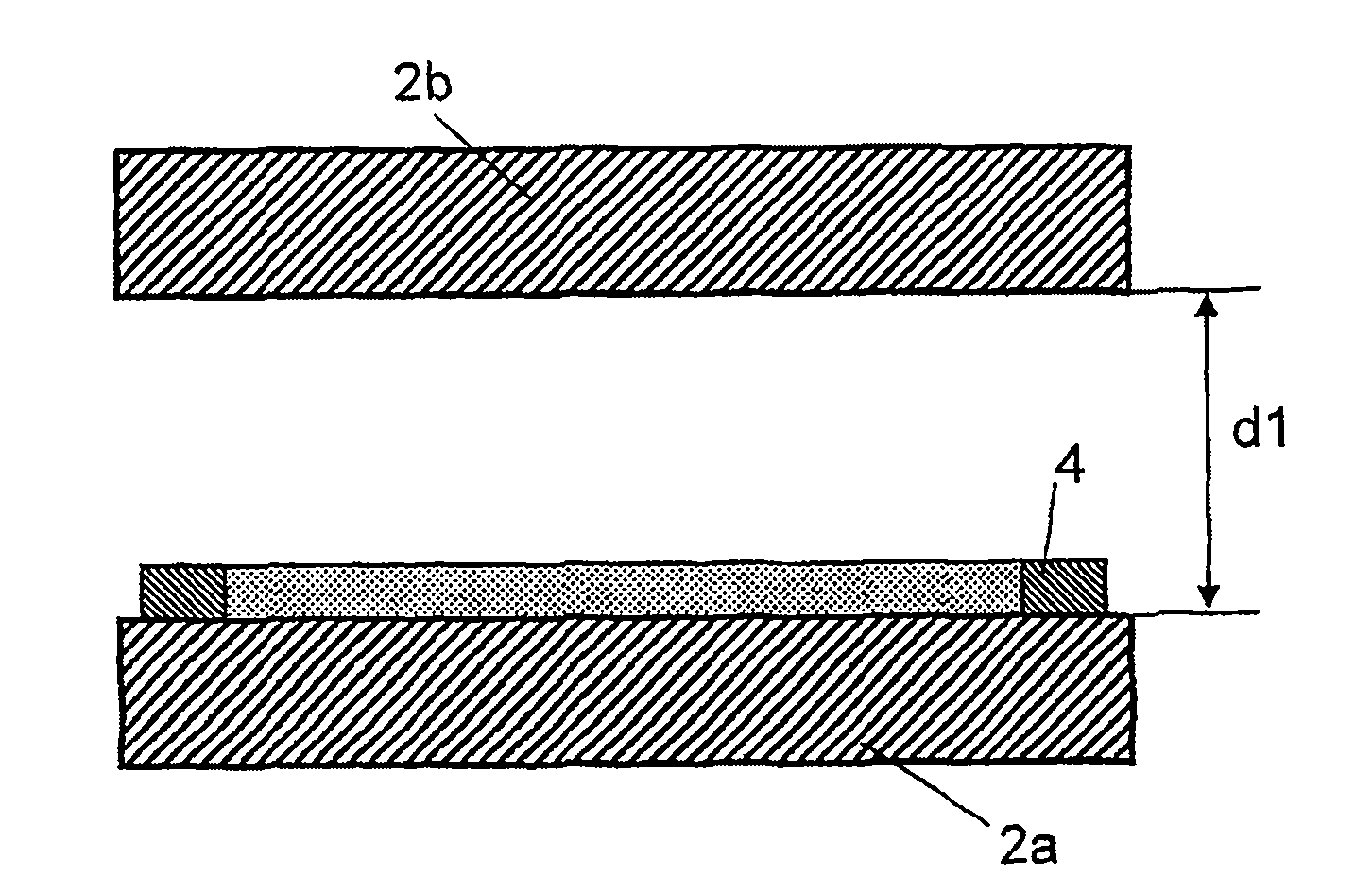

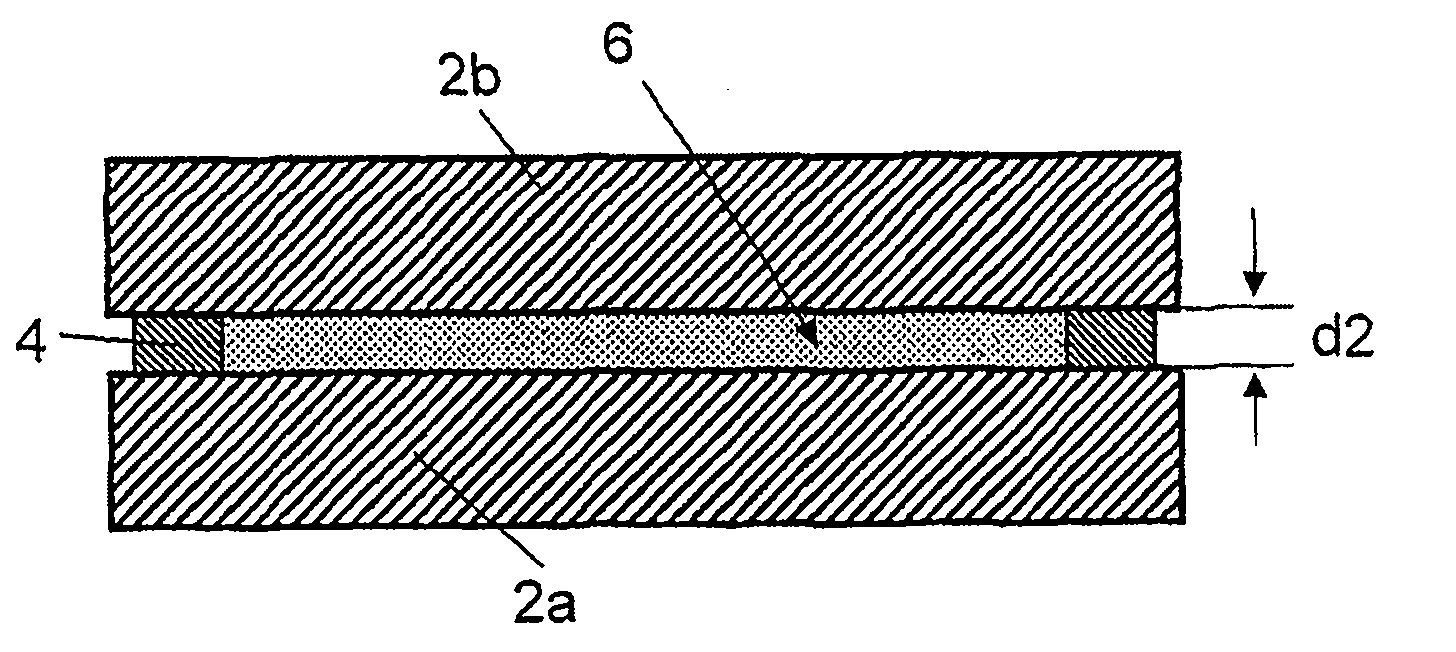

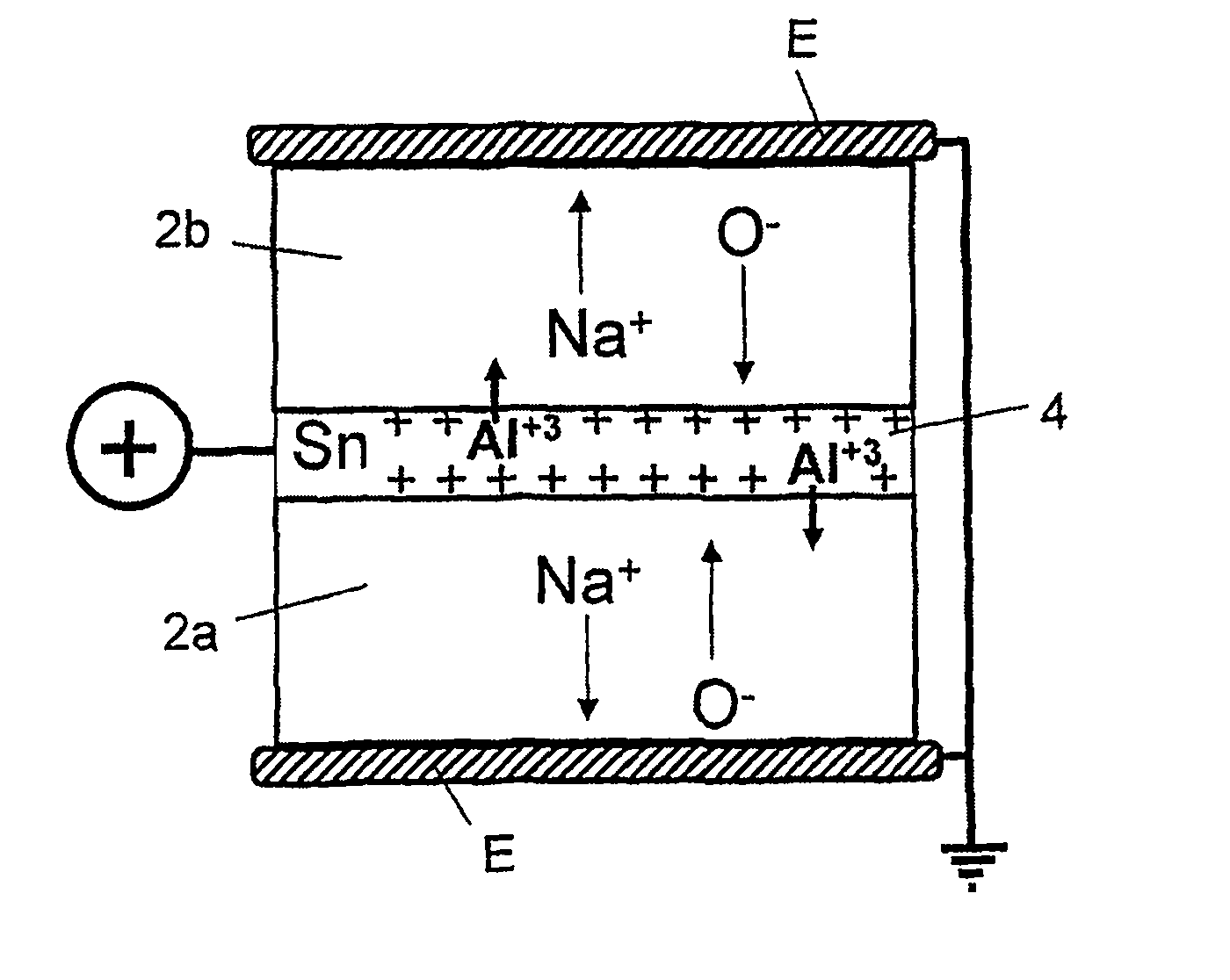

[0060] exist Figure 1a with 1b The embodiment shown in first provides two plate-shaped glass elements 2a and 2b, which have previously been subjected to a cleaning step. The two glass elements are basically aligned horizontally and are initially set at a distance d1 above and below, as in Figure 1a shown. The distance d1 is chosen such that a problem-free venting is then possible, correspondingly eg 5 cm. The lower glass element 2 a is covered with a layer 4 of a tin alloy. As will be explained in more detail below, this is a low-melting tin alloy with a melting point of up to 350° C., which contains at least one reactive metal as an alloy constituent. The geometry of the cut layer 4 corresponds to the bonding region to be bonded in a media-tight manner. For example, to form a media-tightly closed interior 6 between the two glass elements 2a and 2b, a frame-shaped layer 4 is used that surrounds the glass elements in the vicinity of their edges.

[0061] The two glass e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com