Patents

Literature

2111 results about "Microelectromechanical systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microelectromechanical systems (MEMS, also written as micro-electro-mechanical, MicroElectroMechanical or microelectronic and microelectromechanical systems and the related micromechatronics and microsystems) is the technology of microscopic devices, particularly those with moving parts. It merges at the nano-scale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines in Japan, or micro systems technology (MST) in Europe.

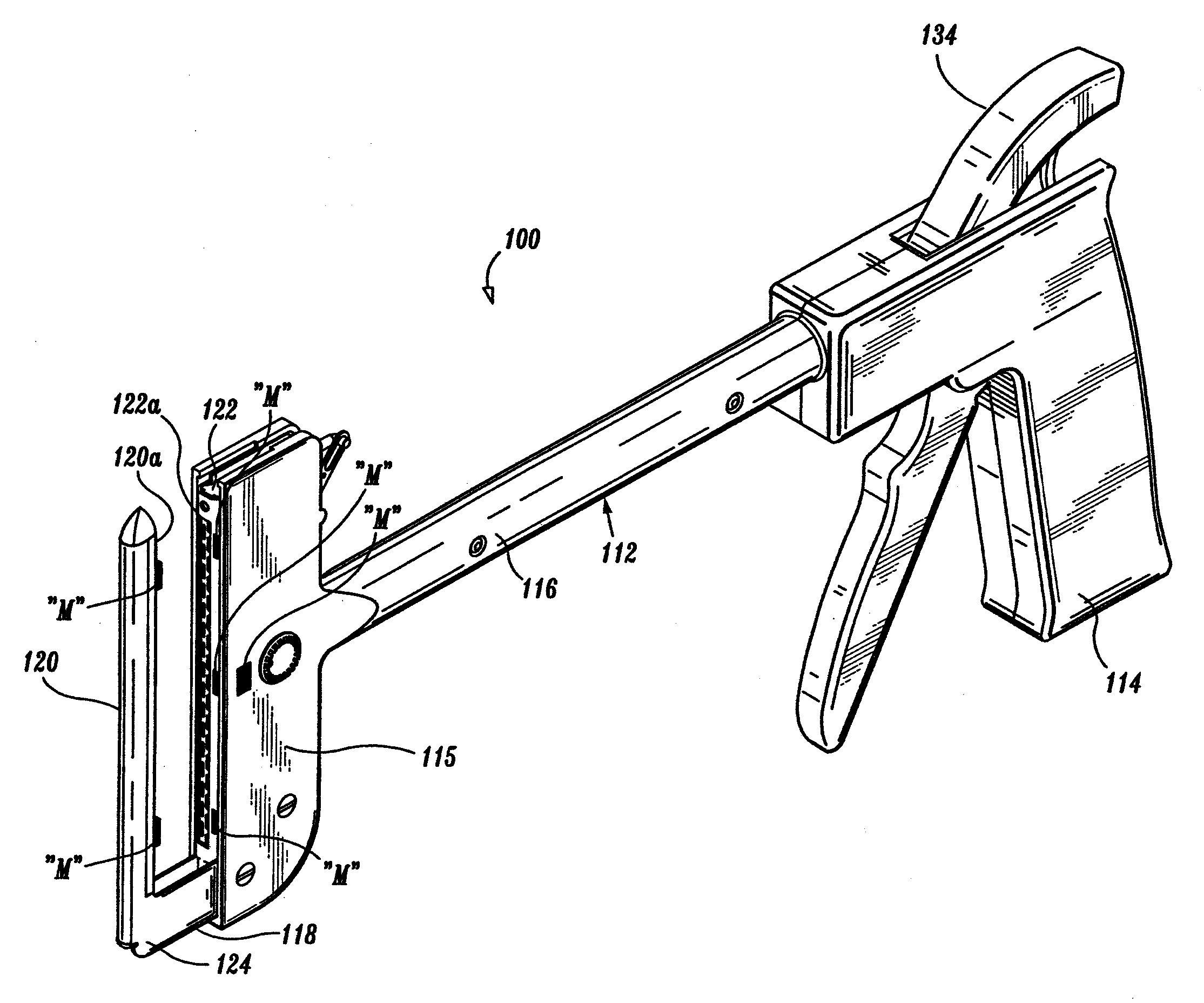

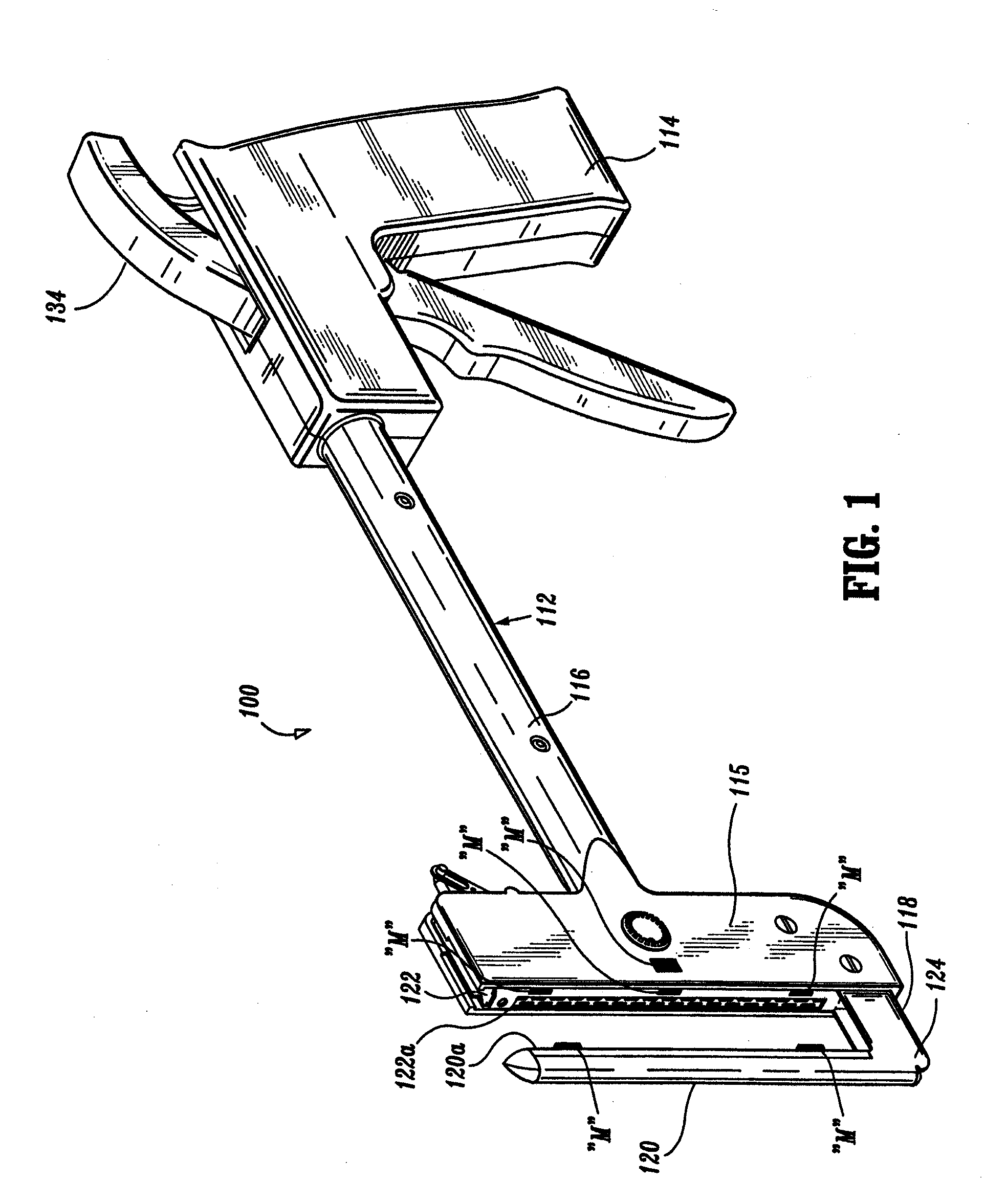

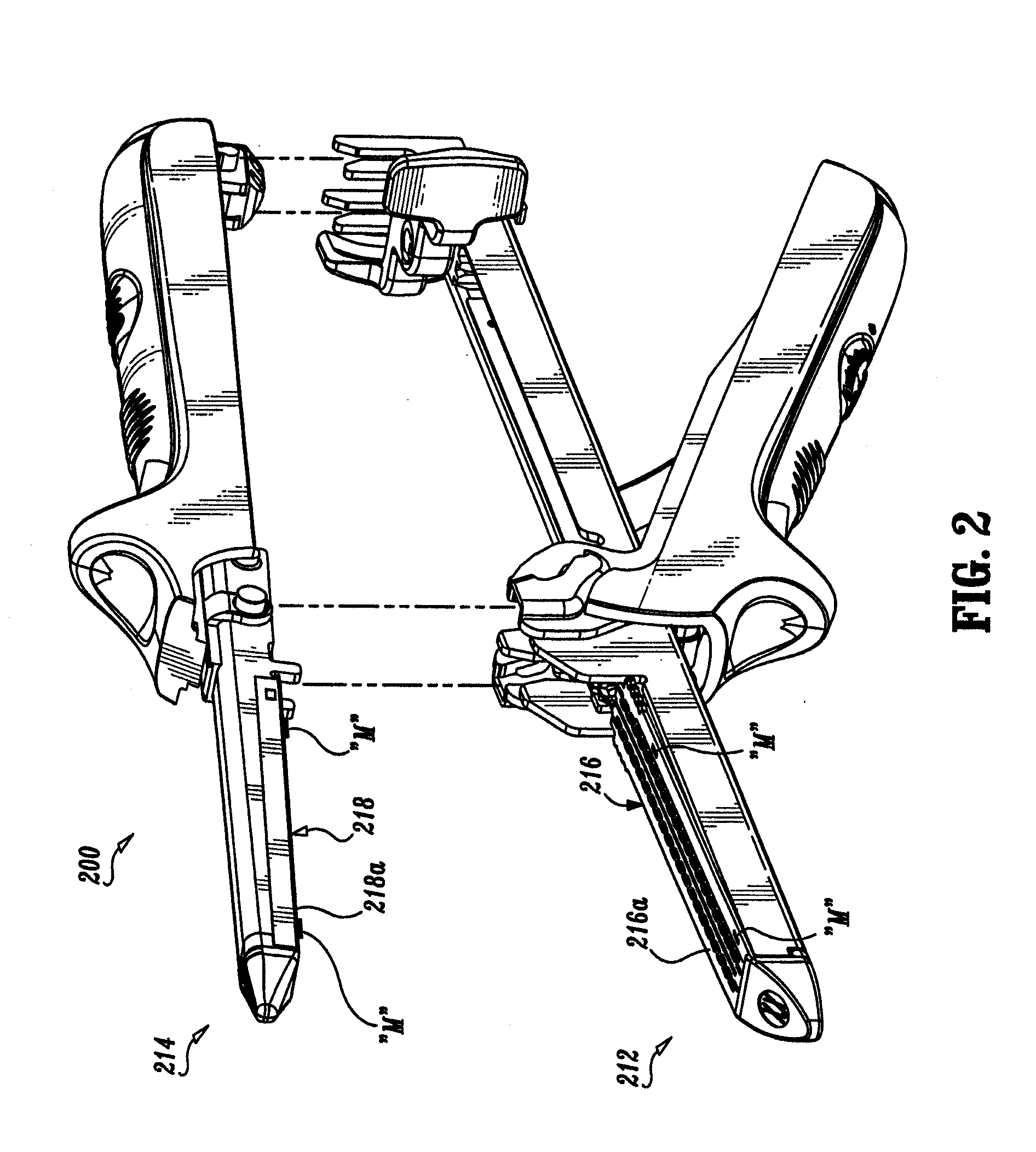

Surgical Instrument Including MEMS Devices

InactiveUS20120016362A1Effective and safer and easy to useControl the effects they have on target tissue and on the patientSuture equipmentsStapling toolsSurgical instrumentationMicroelectromechanical systems

Surgical instruments are disclosed that are couplable to or have an end effector or a disposable loading unit with an end effector, and at least one micro-electromechanical system (MEMS) device operatively connected to the surgical instrument for at least one of sensing a condition, measuring a parameter and controlling the condition and / or parameter.

Owner:COVIDIEN LP

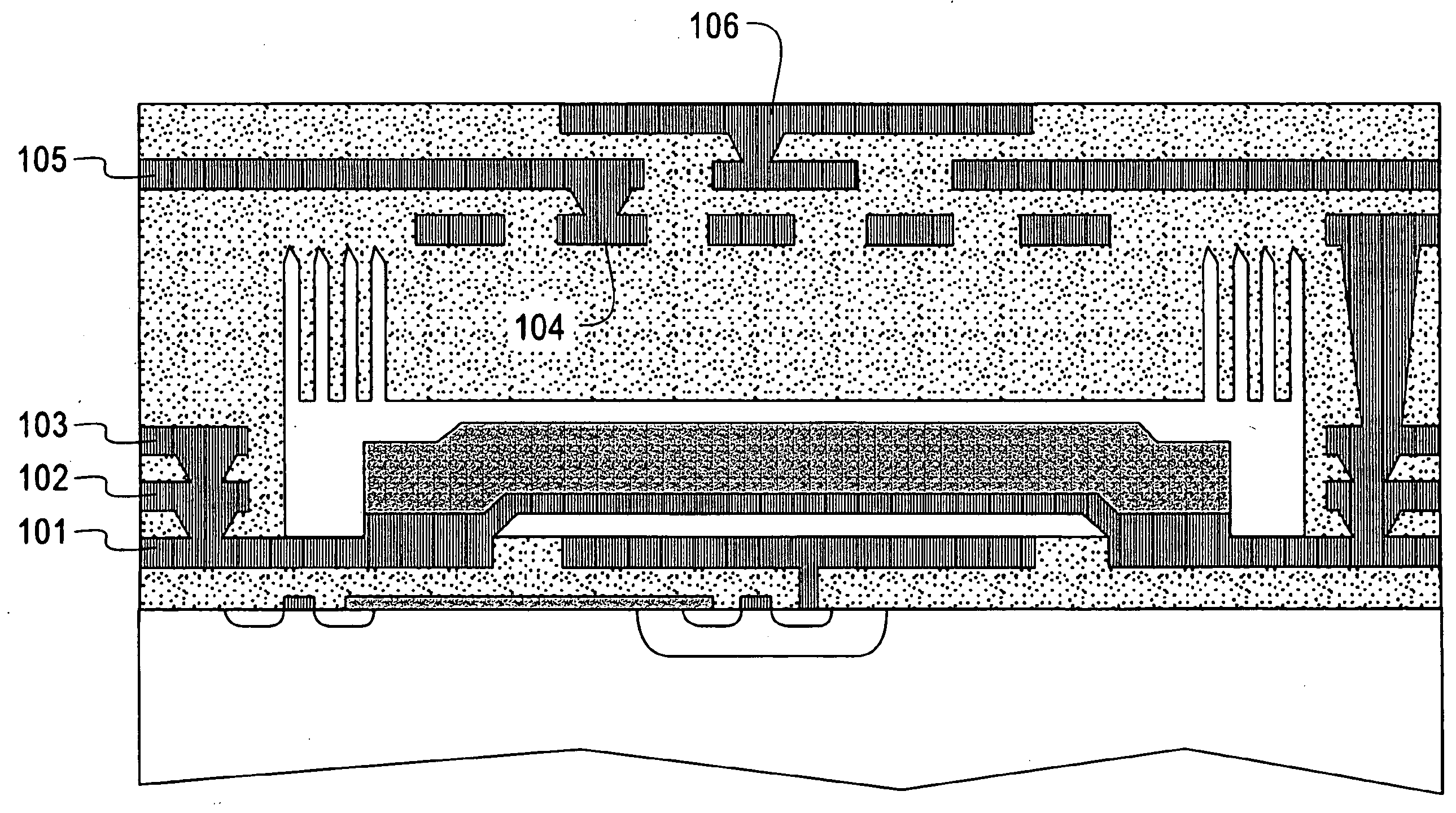

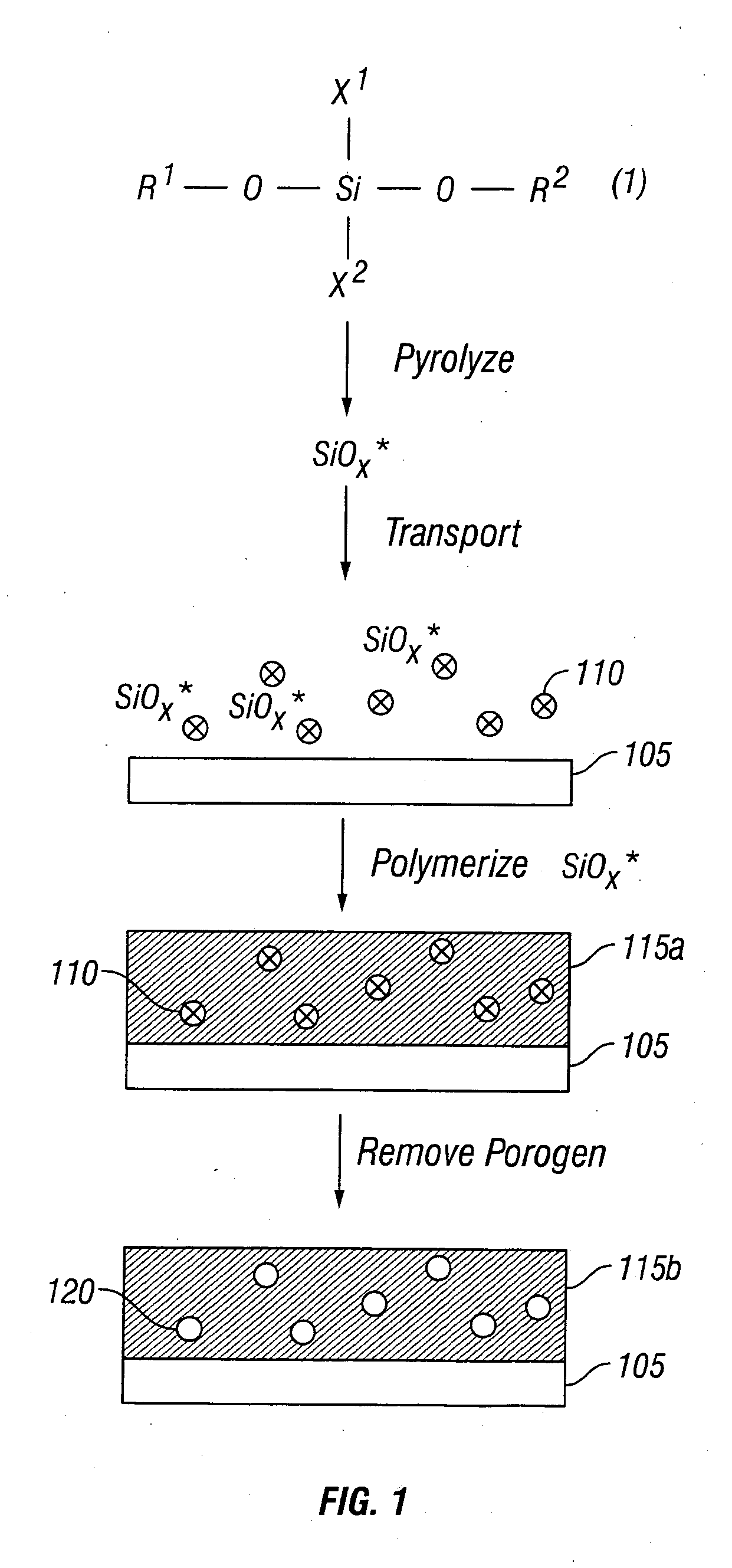

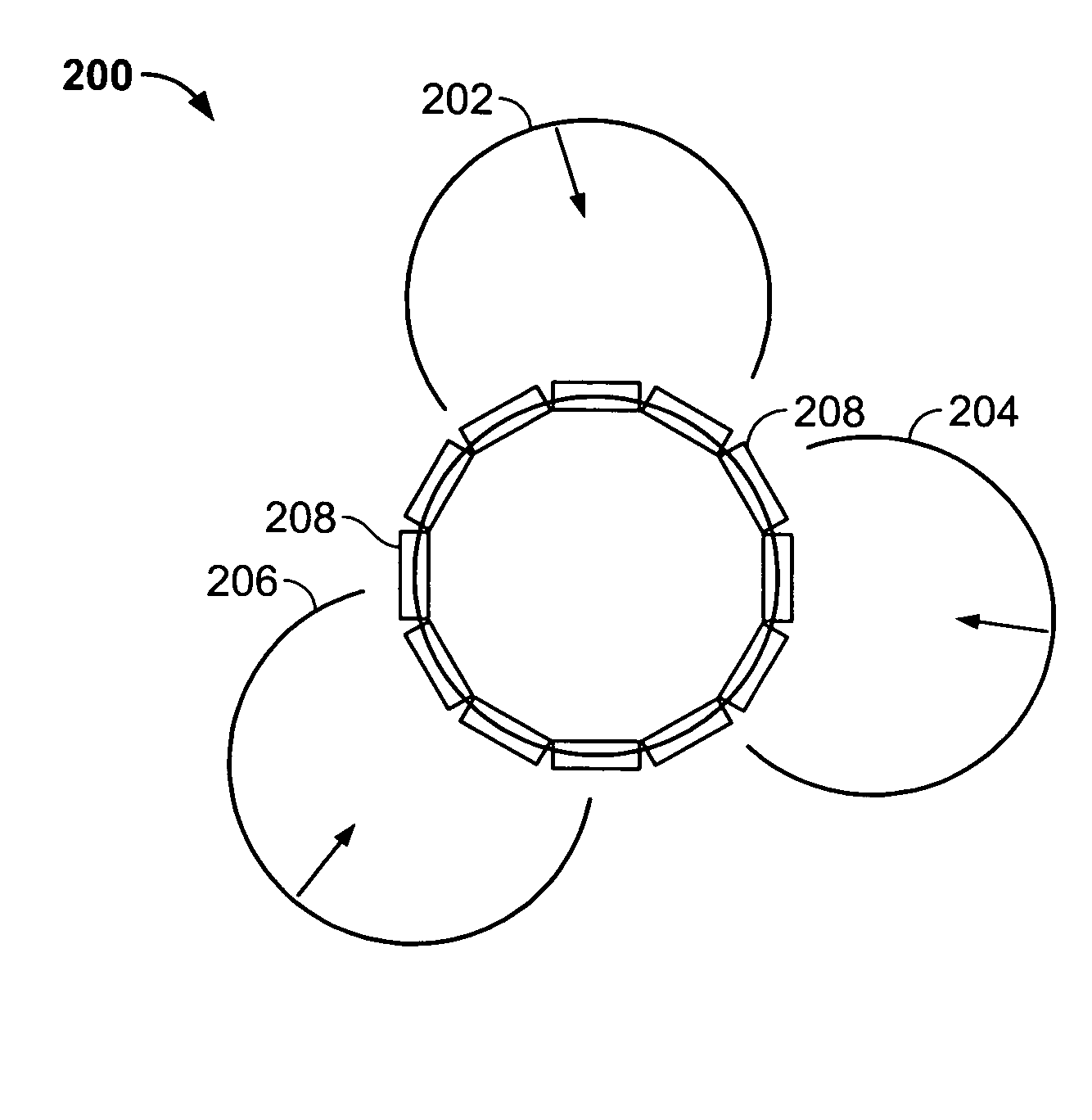

Low temperature bi-CMOS compatible process for MEMS RF resonators and filters

InactiveUS20090108381A1Impedence networksSemiconductor/solid-state device detailsMetal interconnectOxygen plasma

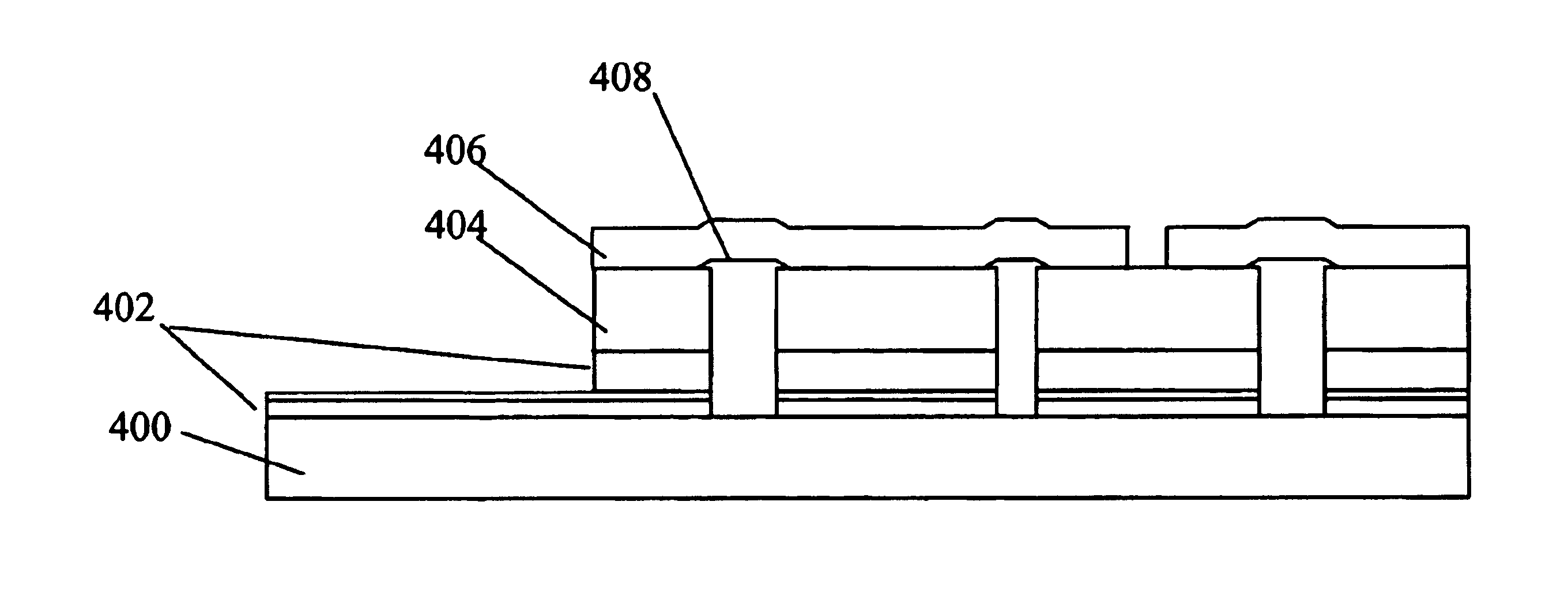

A method of formation of a microelectromechanical system (MEMS) resonator or filter which is compatible with integration with any analog, digital, or mixed-signal integrated circuit (IC) process, after or concurrently with the formation of the metal interconnect layers in those processes, by virtue of its materials of composition, processing steps, and temperature of fabrication is presented. The MEMS resonator or filter incorporates a lower metal level, which forms the electrodes of the MEMS resonator or filter, that may be shared with any or none of the existing metal interconnect levels on the IC. It further incorporates a resonating member that is comprised of at least one metal layer for electrical connection and electrostatic actuation, and at least one dielectric layer for structural purposes. The gap between the electrodes and the resonating member is created by the deposition and subsequent removal of a sacrificial layer comprised of a carbon-based material. The method of removal of the sacrificial material is by an oxygen plasma or an anneal in an oxygen containing ambient. A method of vacuum encapsulation of the MEMS resonator or filter is provided through means of a cavity containing the MEMS device, filled with additional sacrificial material, and sealed. Access vias are created through the membrane sealing the cavity; the sacrificial material is removed as stated previously, and the vias are re-sealed in a vacuum coating process.

Owner:IBM CORP

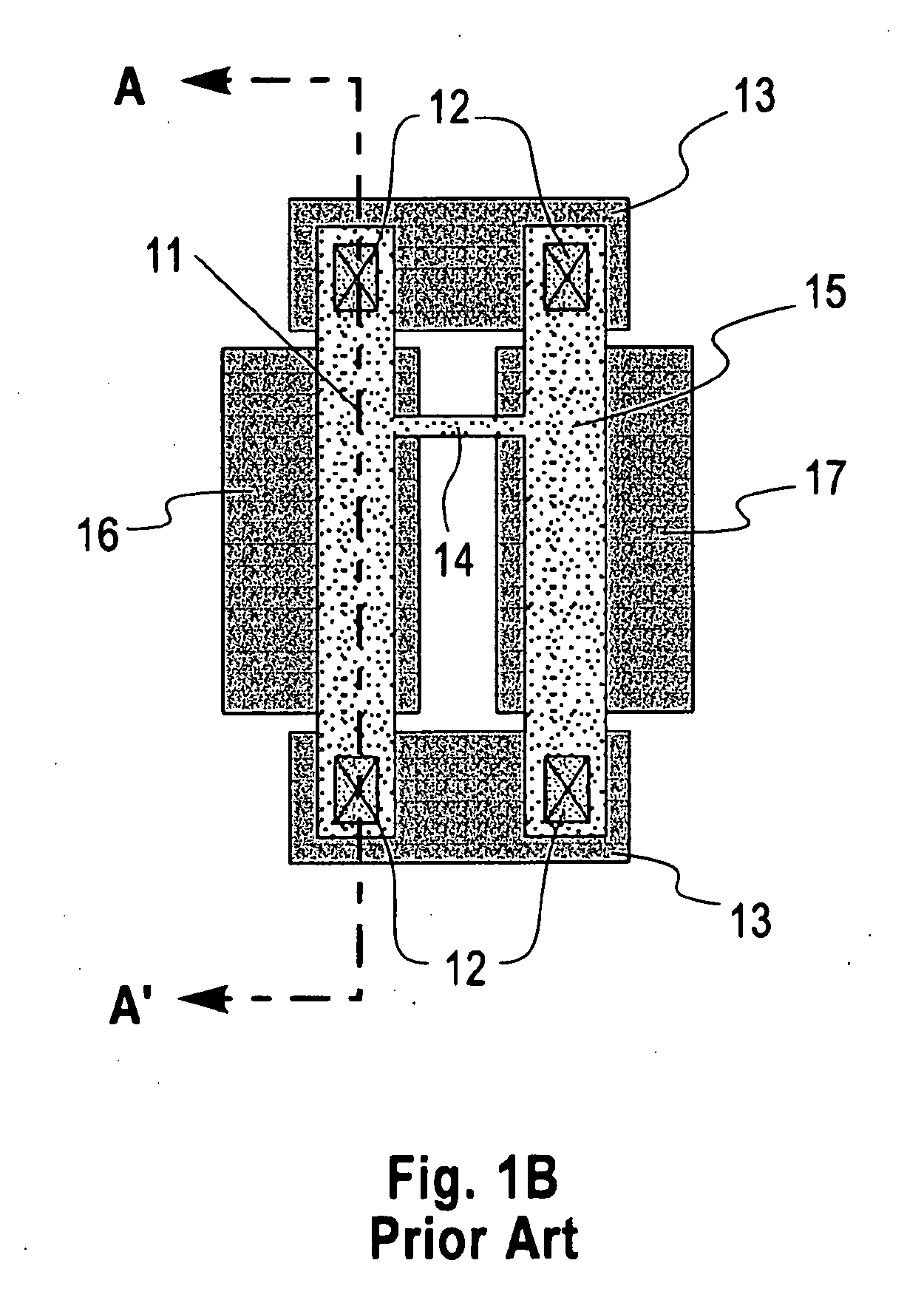

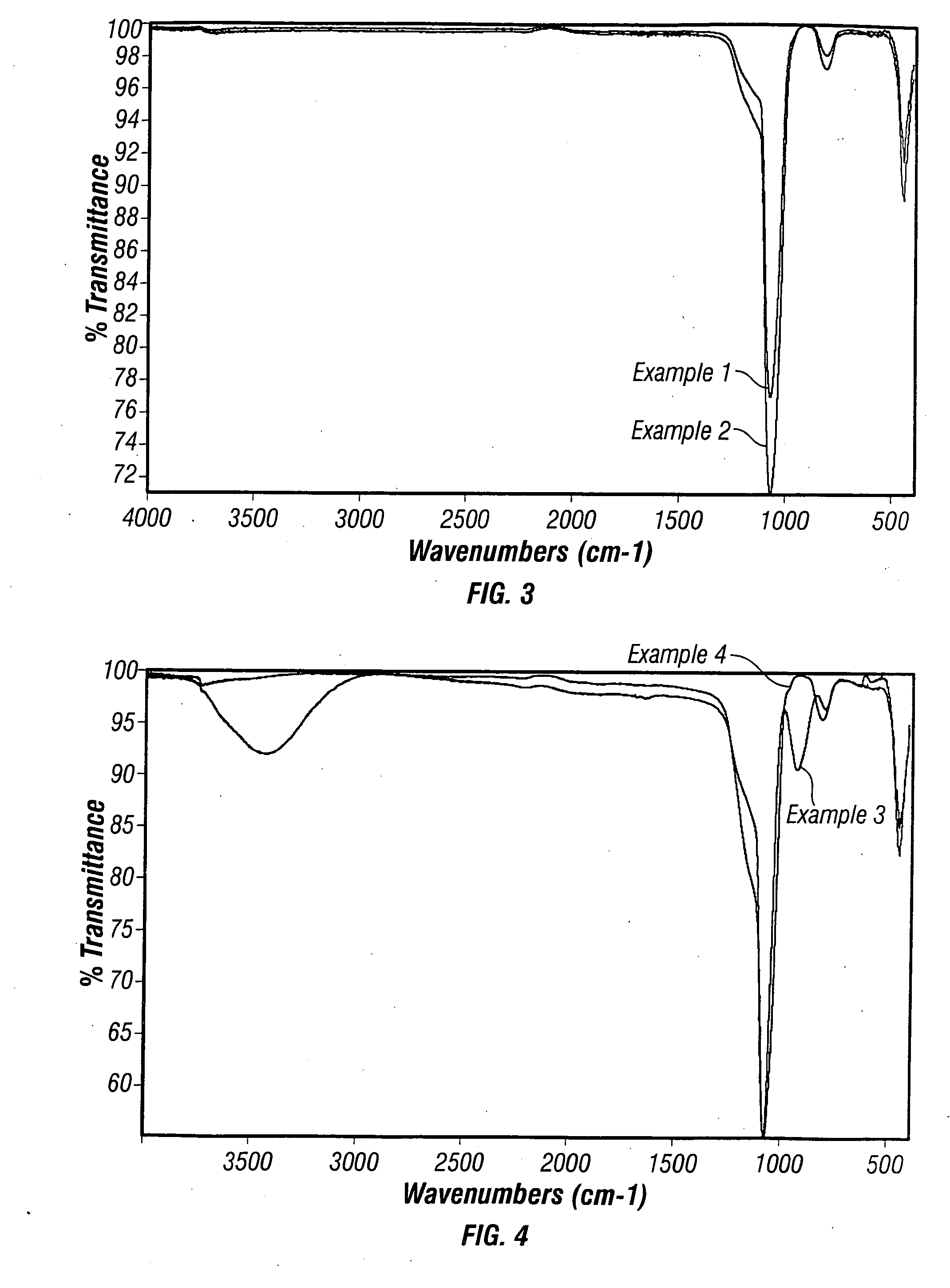

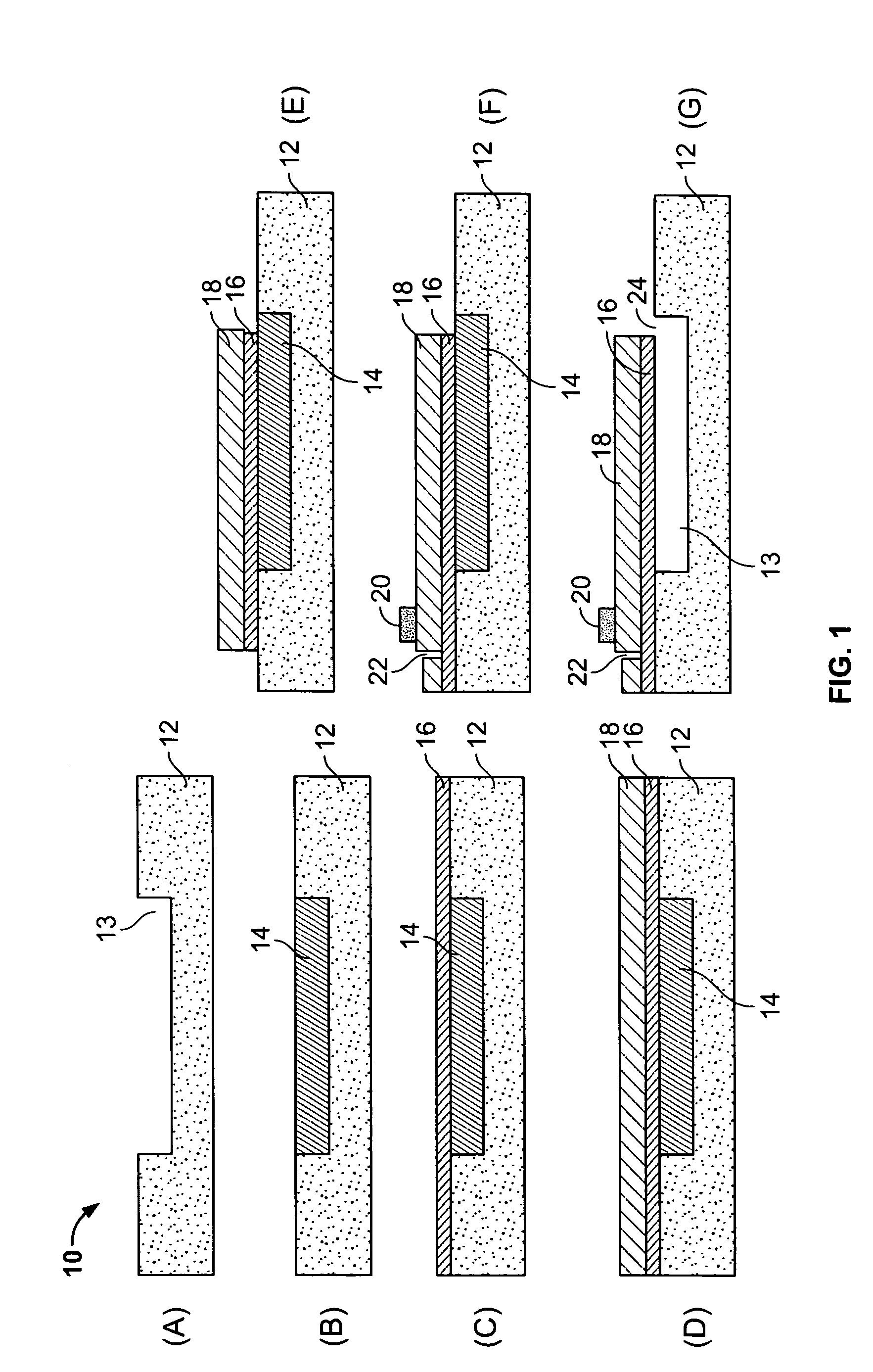

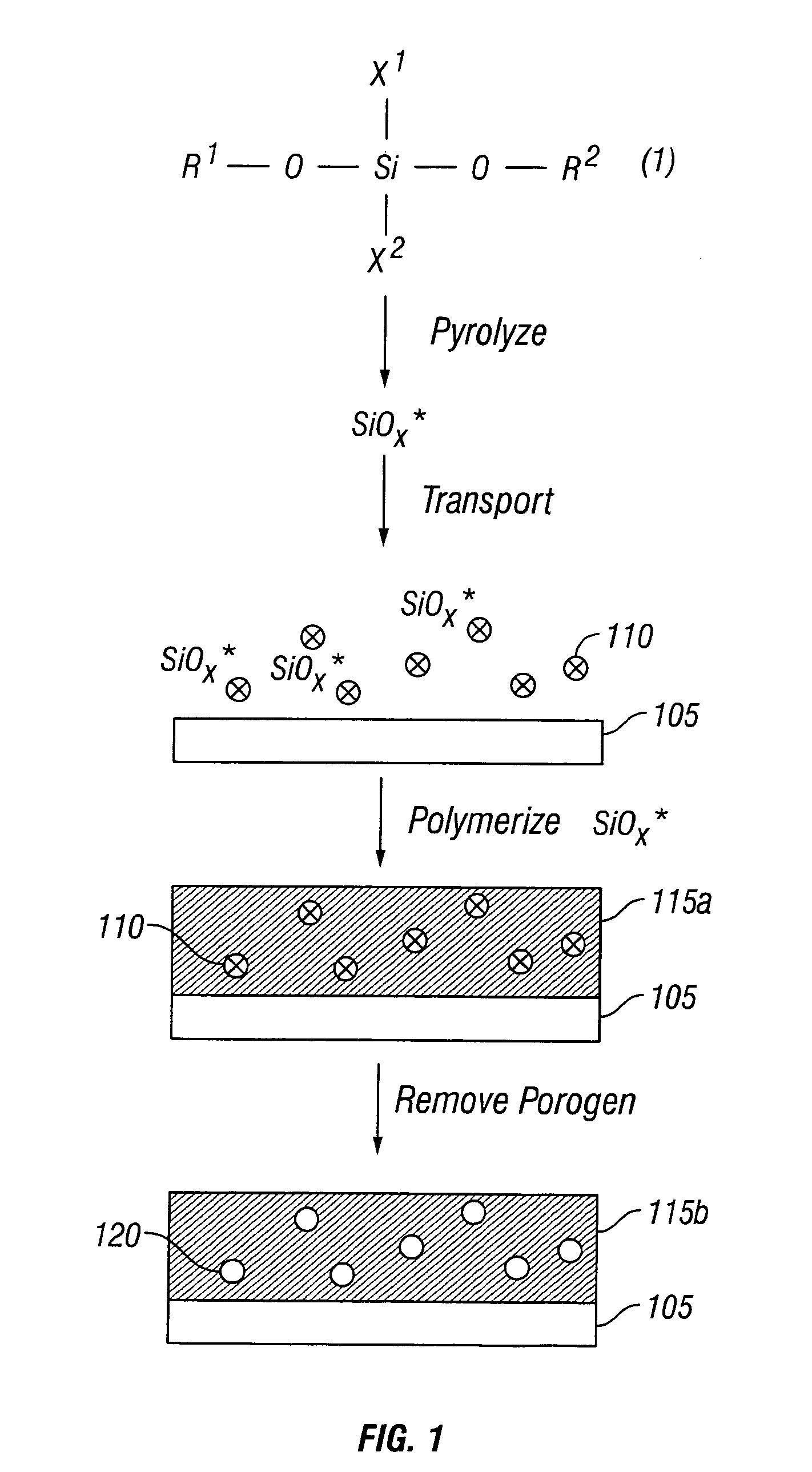

Apparatus, precursors and deposition methods for silicon-containing materials

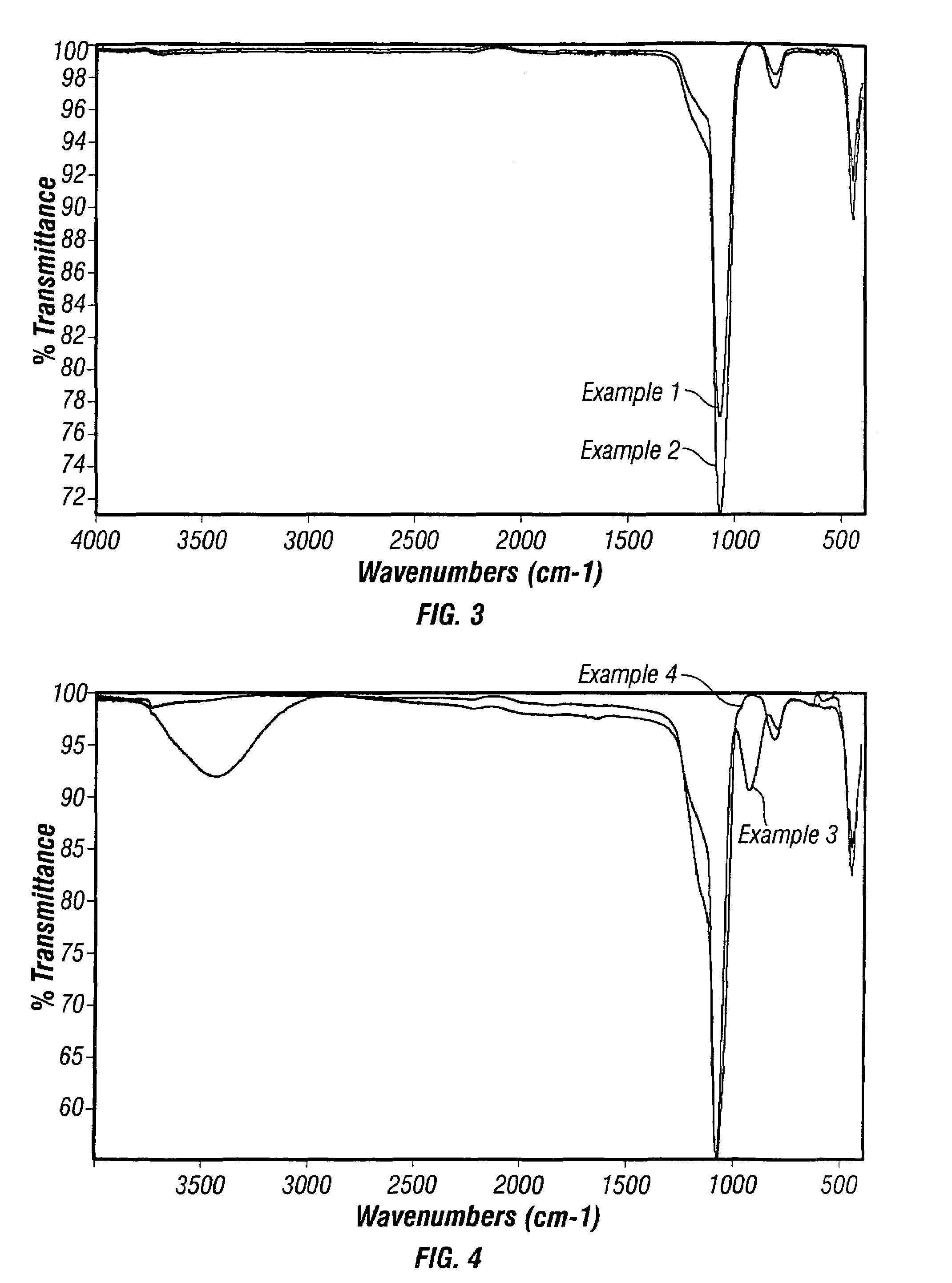

A method for making a Si-containing material comprises transporting a pyrolyzed Si-precursor to a substrate and polymerizing the pyrolyzed Si-precursor on the substrate to form a Si-containing film. Polymerization of the pyrolyzed Si-precursor may be carried out in the presence of a porogen to thereby form a porogen-containing Si-containing film. The porogen may be removed from the porogen-containing Si-containing film to thereby form a porous Si-containing film. Preferred porous Si-containing films have low dielectric constants and thus are suitable for various low-k applications such as in microelectronics and microelectromechanical systems.

Owner:ASM JAPAN

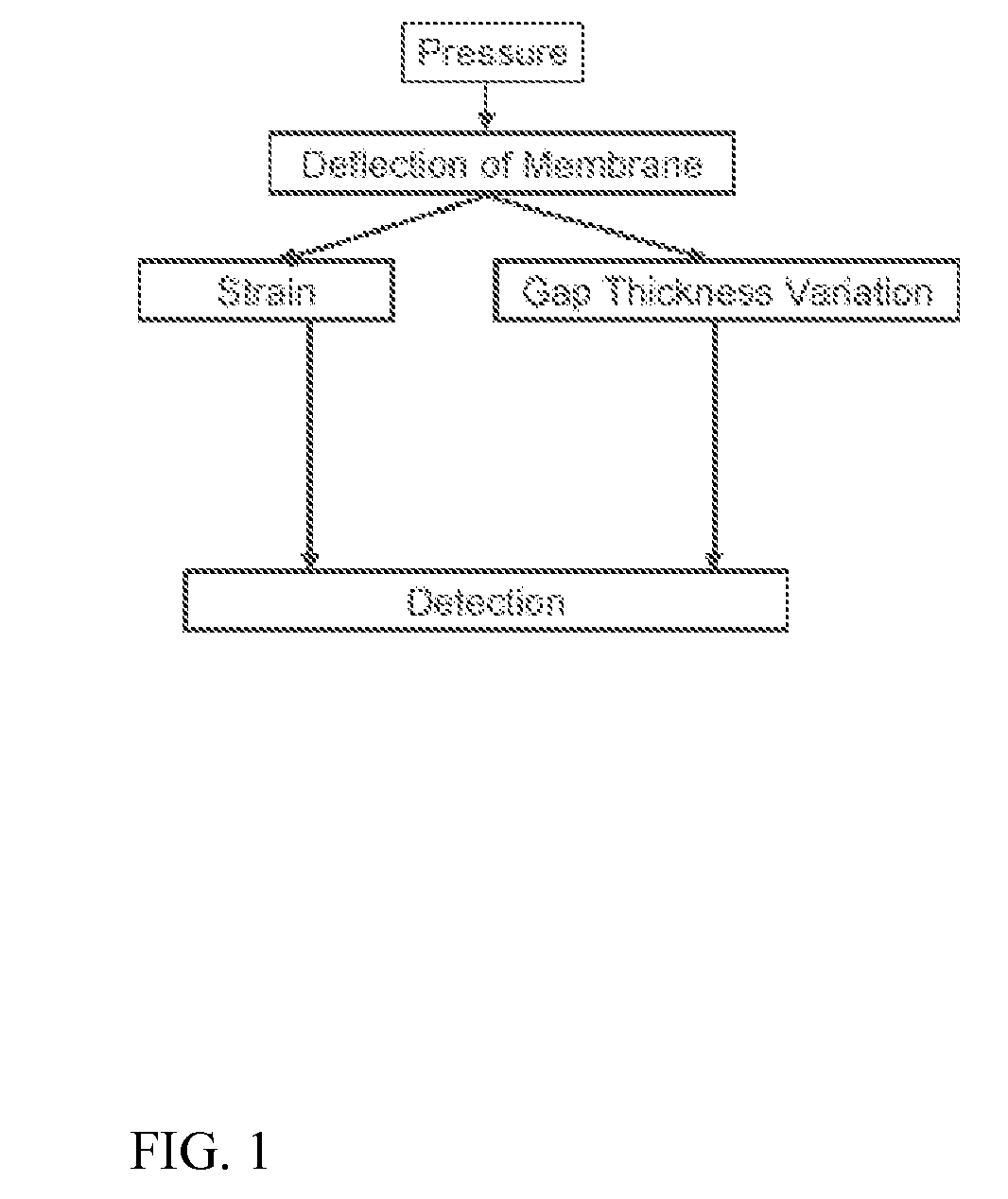

Assembly of a capacitive acoustic transducer of the microelectromechanical type and package thereof

A microelectromechanical-acoustic-transducer assembly has: a first die integrating a MEMS sensing structure having a membrane, which has a first surface in fluid communication with a front chamber and a second surface, opposite to the first surface, in fluid communication with a back chamber of the microelectromechanical acoustic transducer, is able to undergo deformation as a function of incident acoustic-pressure waves, and faces a rigid electrode so as to form a variable-capacitance capacitor; a second die, integrating an electronic reading circuit operatively coupled to the MEMS sensing structure and supplying an electrical output signal as a function of the capacitive variation; and a package, housing the first die and the second die and having a base substrate with external electrical contacts. The first and second dice are stacked in the package and directly connected together mechanically and electrically; the package delimits at least one of the front and back chambers.

Owner:STMICROELECTRONICS SRL

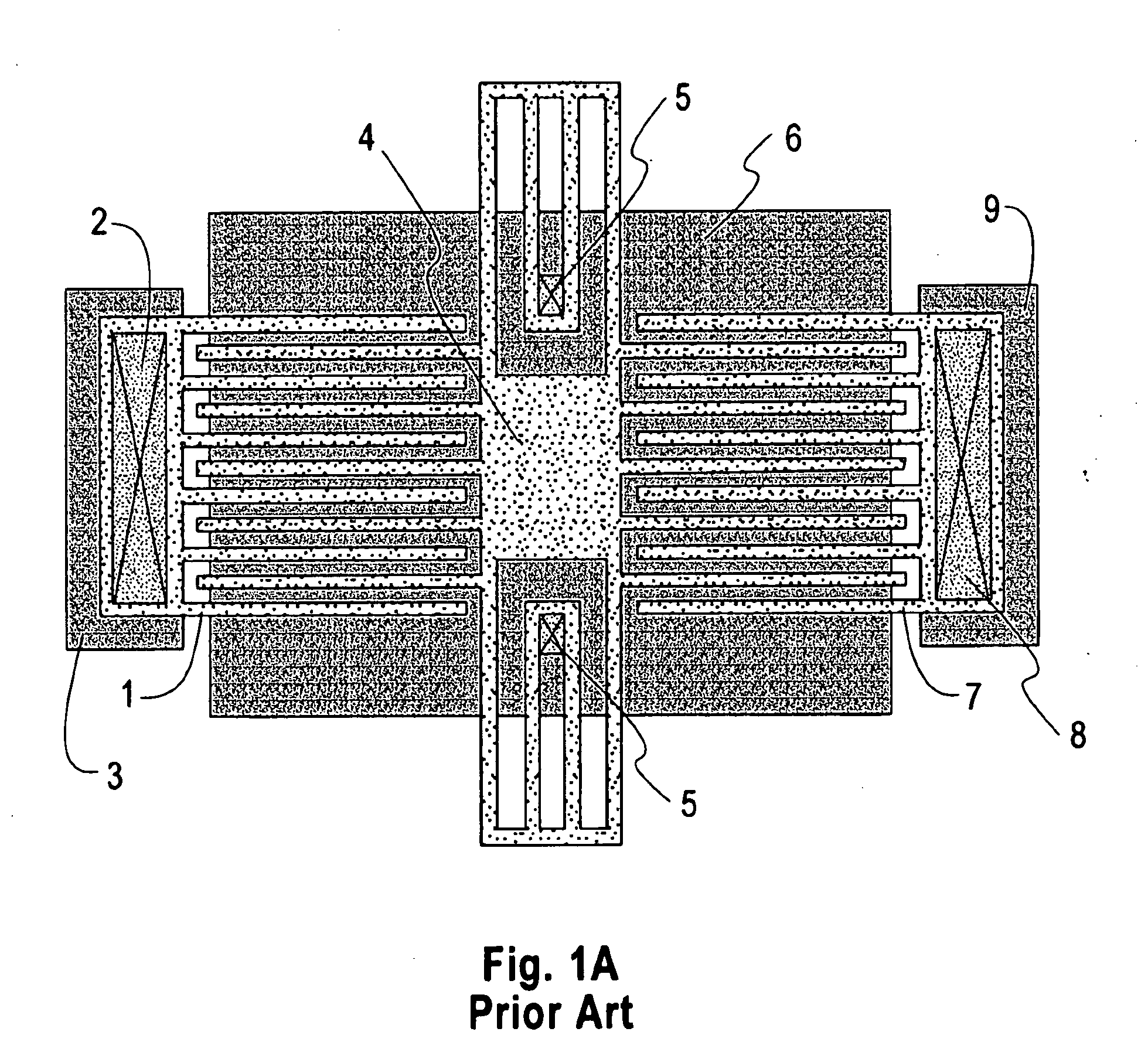

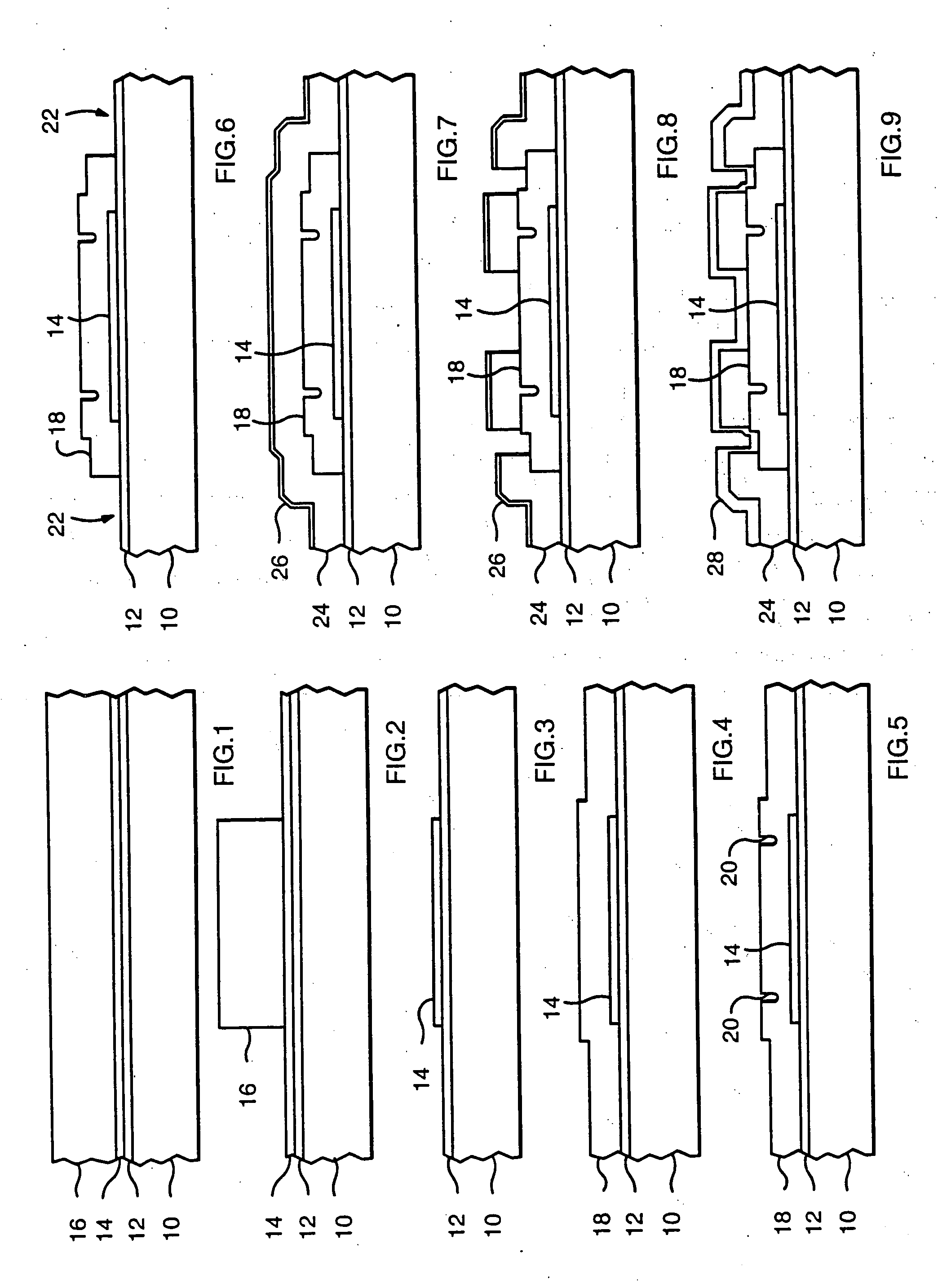

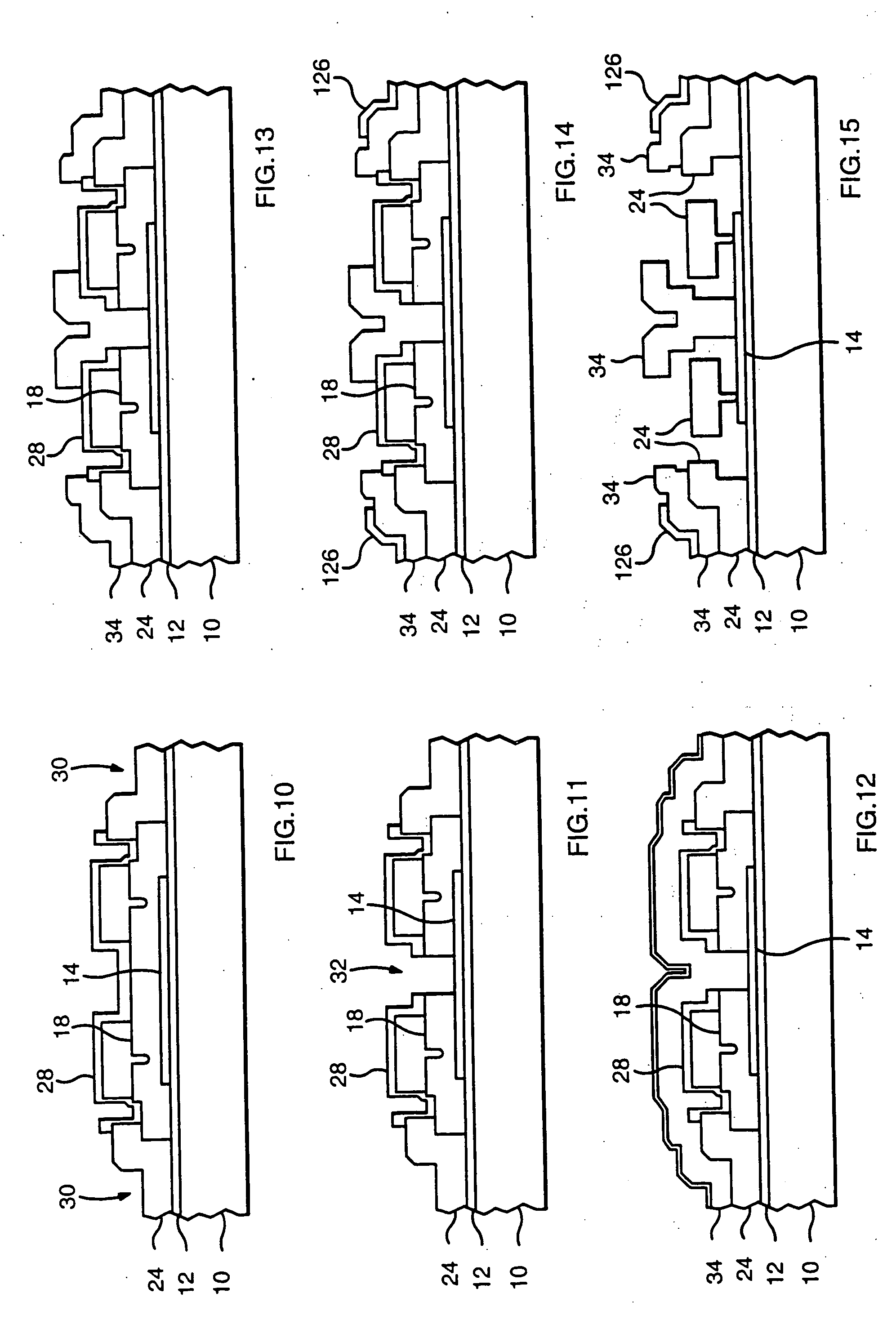

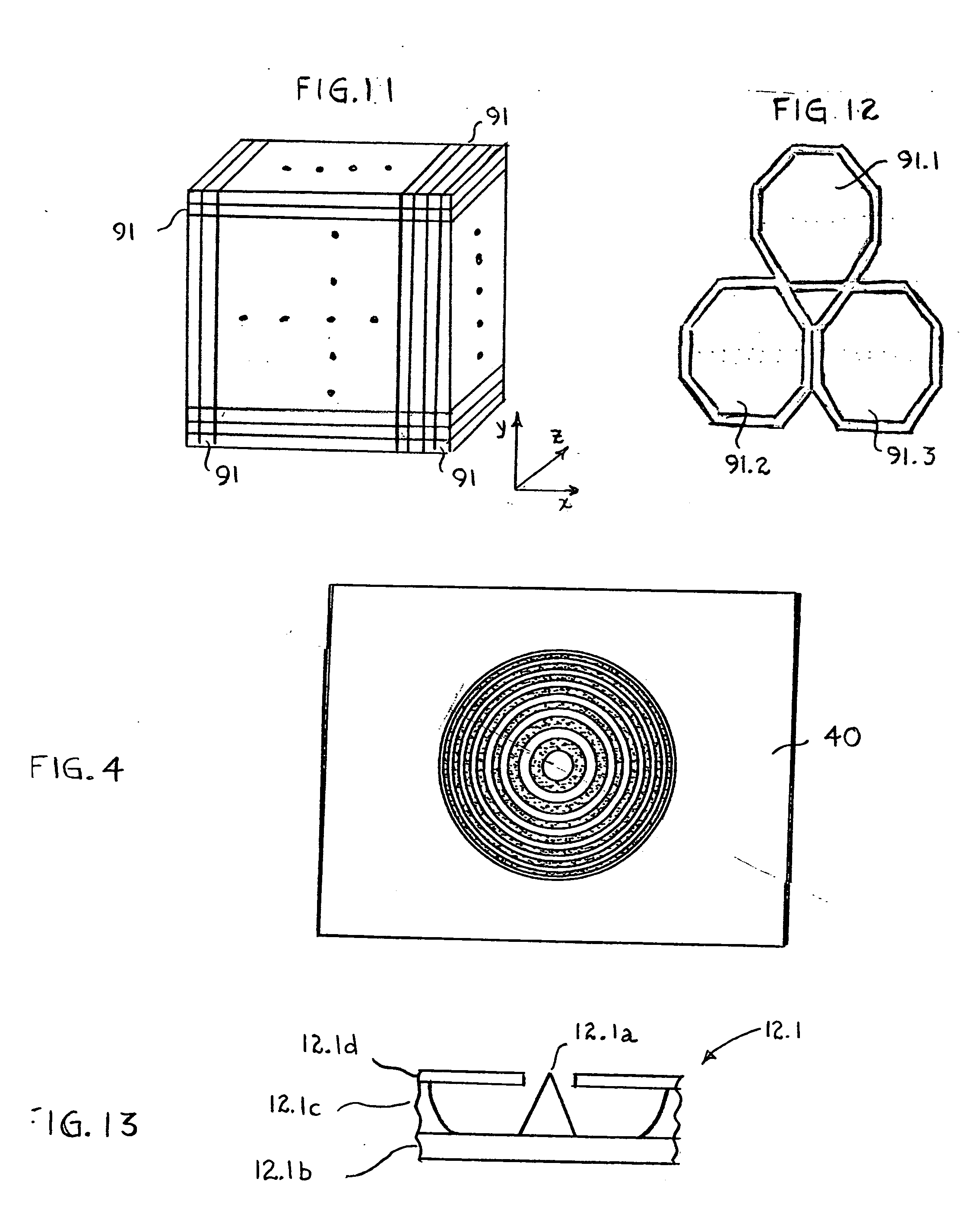

Method of fabricating microelectromechanical systems and devices having trench isolated contacts

InactiveUS6936491B2Acceleration measurement using interia forcesSolid-state devicesEngineeringMicroelectromechanical systems

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a MEMS device, and technique of fabricating or manufacturing a MEMS device, having mechanical structures encapsulated in a chamber prior to final packaging and a contact area disposed at least partially outside the chamber. The contact area is electrically isolated from nearby electrically conducting regions by way of dielectric isolation trench that is disposed around the contact area. The material that encapsulates the mechanical structures, when deposited, includes one or more of the following attributes: low tensile stress, good step coverage, maintains its integrity when subjected to subsequent processing, does not significantly and / or adversely impact the performance characteristics of the mechanical structures in the chamber (if coated with the material during deposition), and / or facilitates integration with high-performance integrated circuits. In one embodiment, the material that encapsulates the mechanical structures is, for example, silicon (polycrystalline, amorphous or porous, whether doped or undoped), silicon carbide, silicon-germanium, germanium, or gallium-arsenide.

Owner:ROBERT BOSCH GMBH

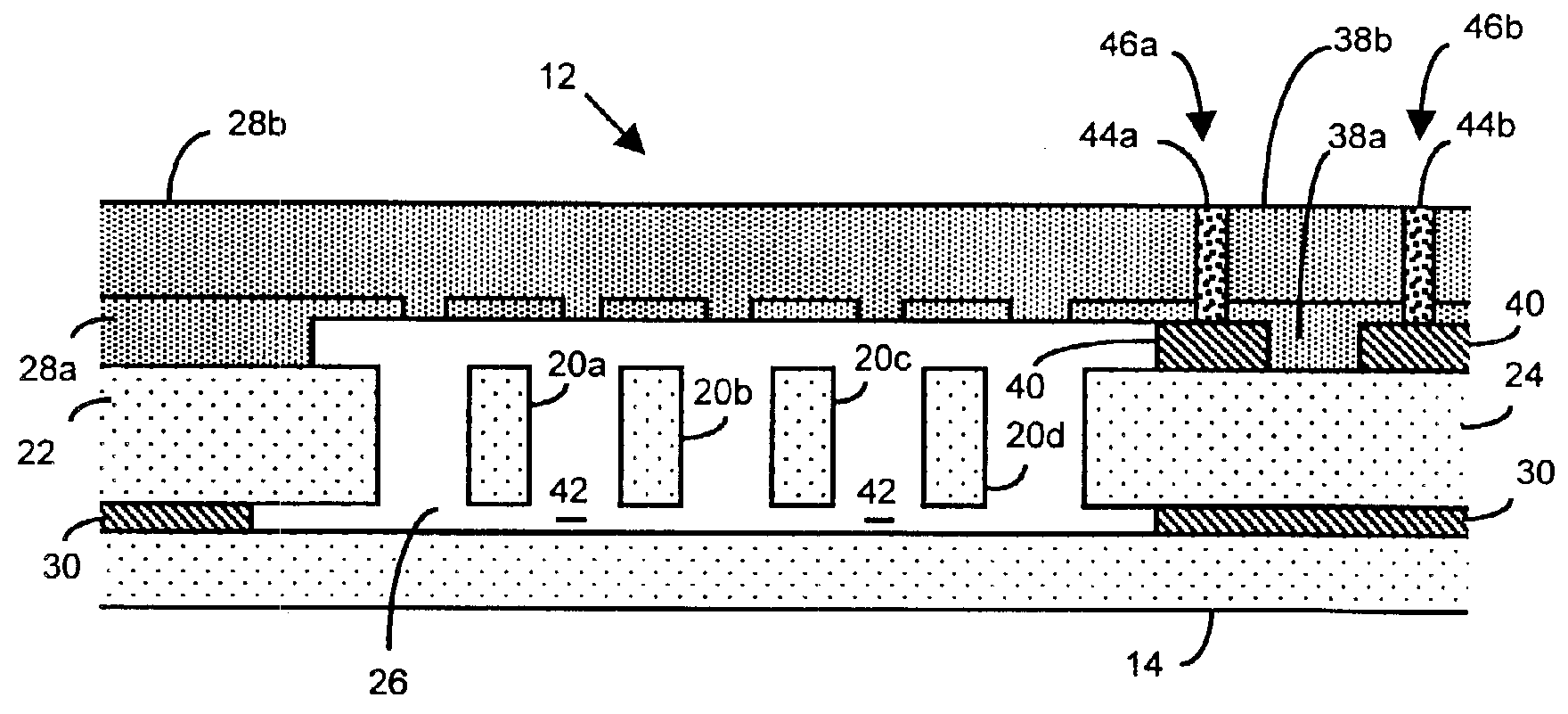

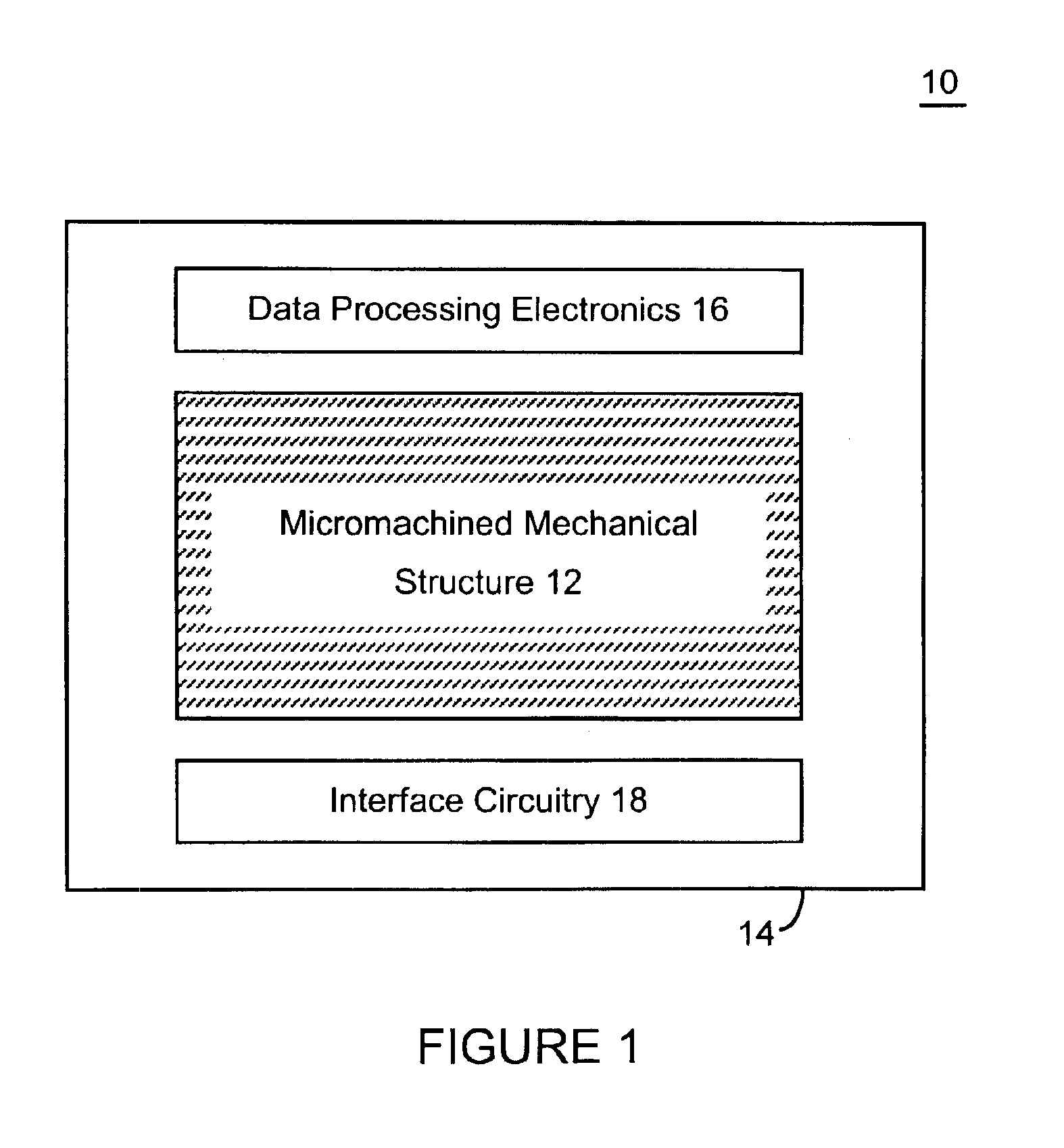

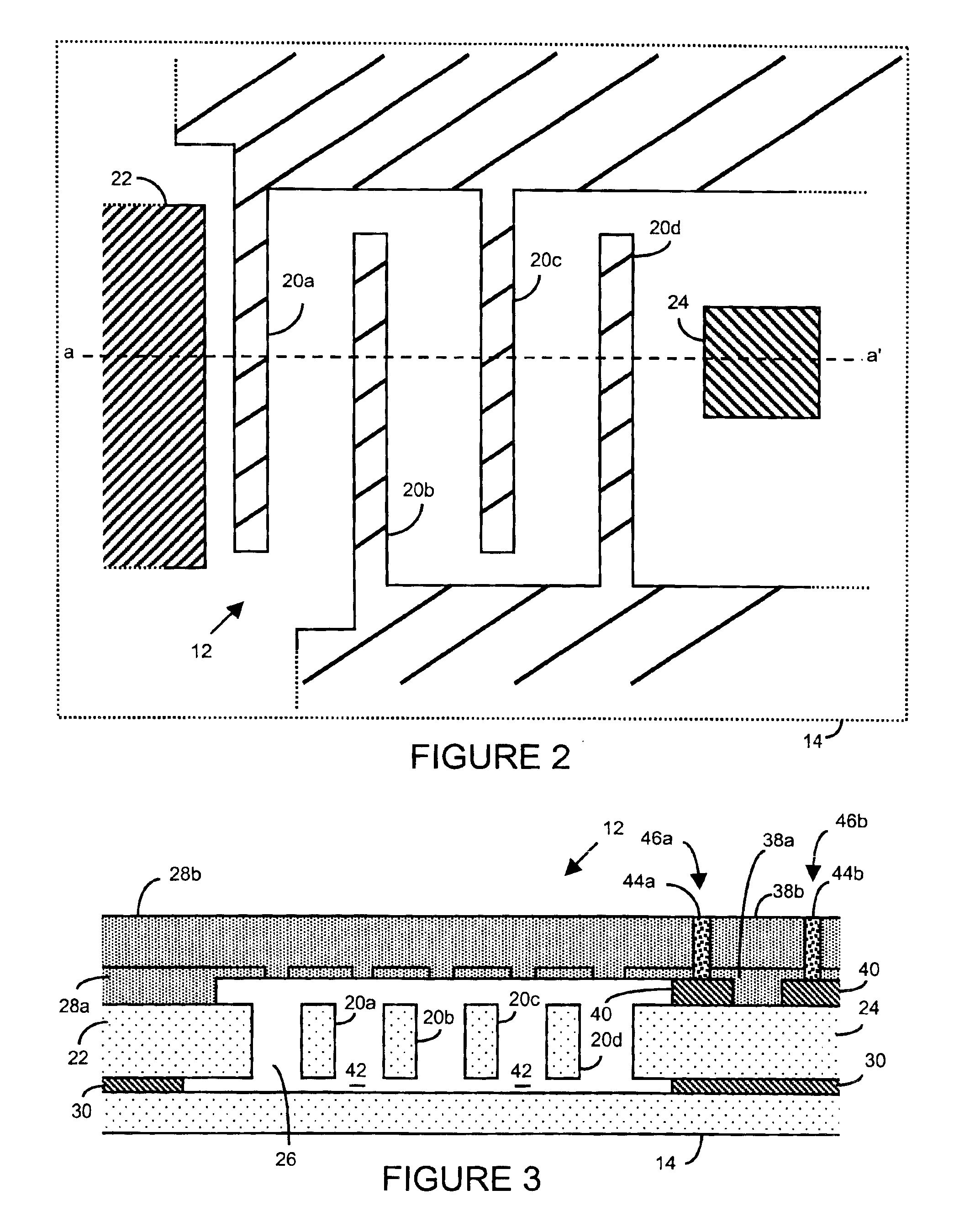

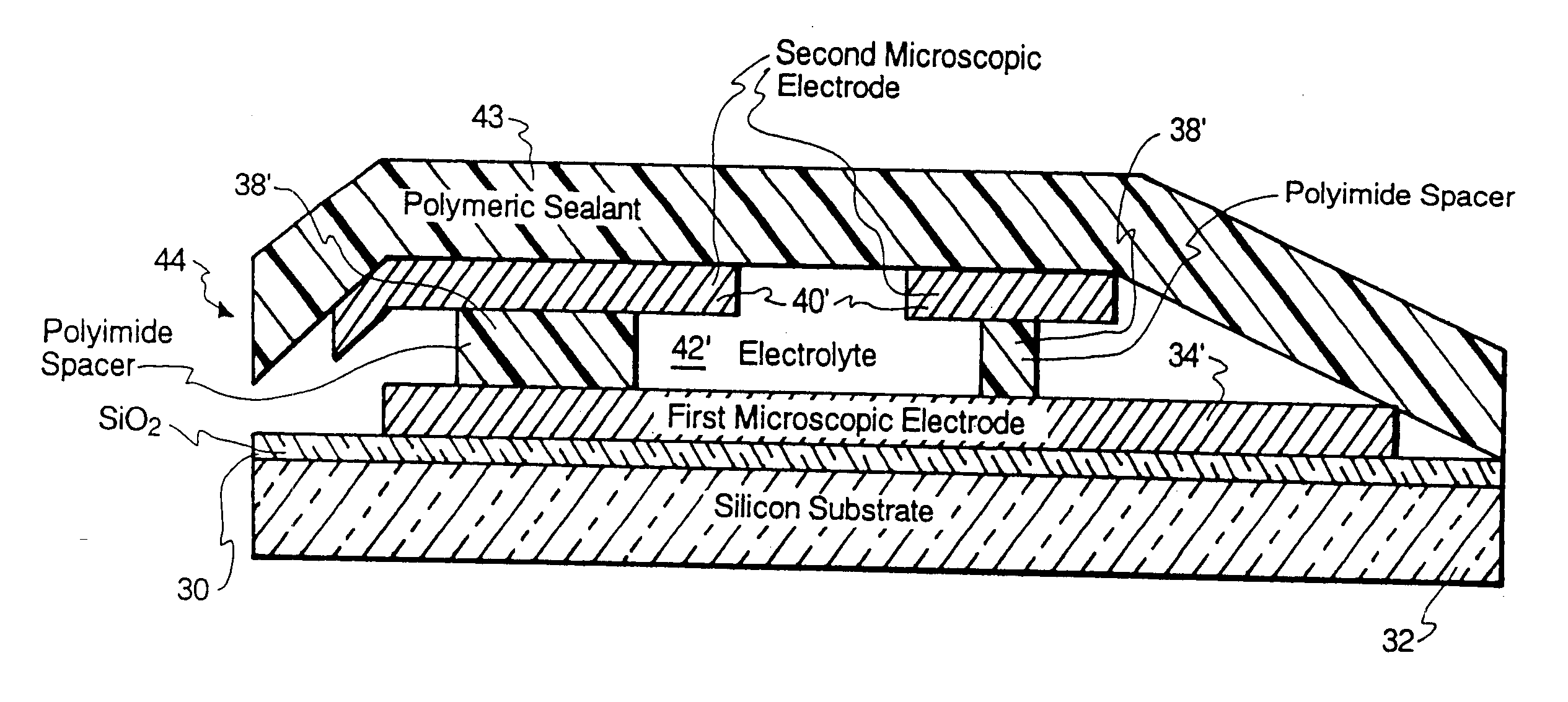

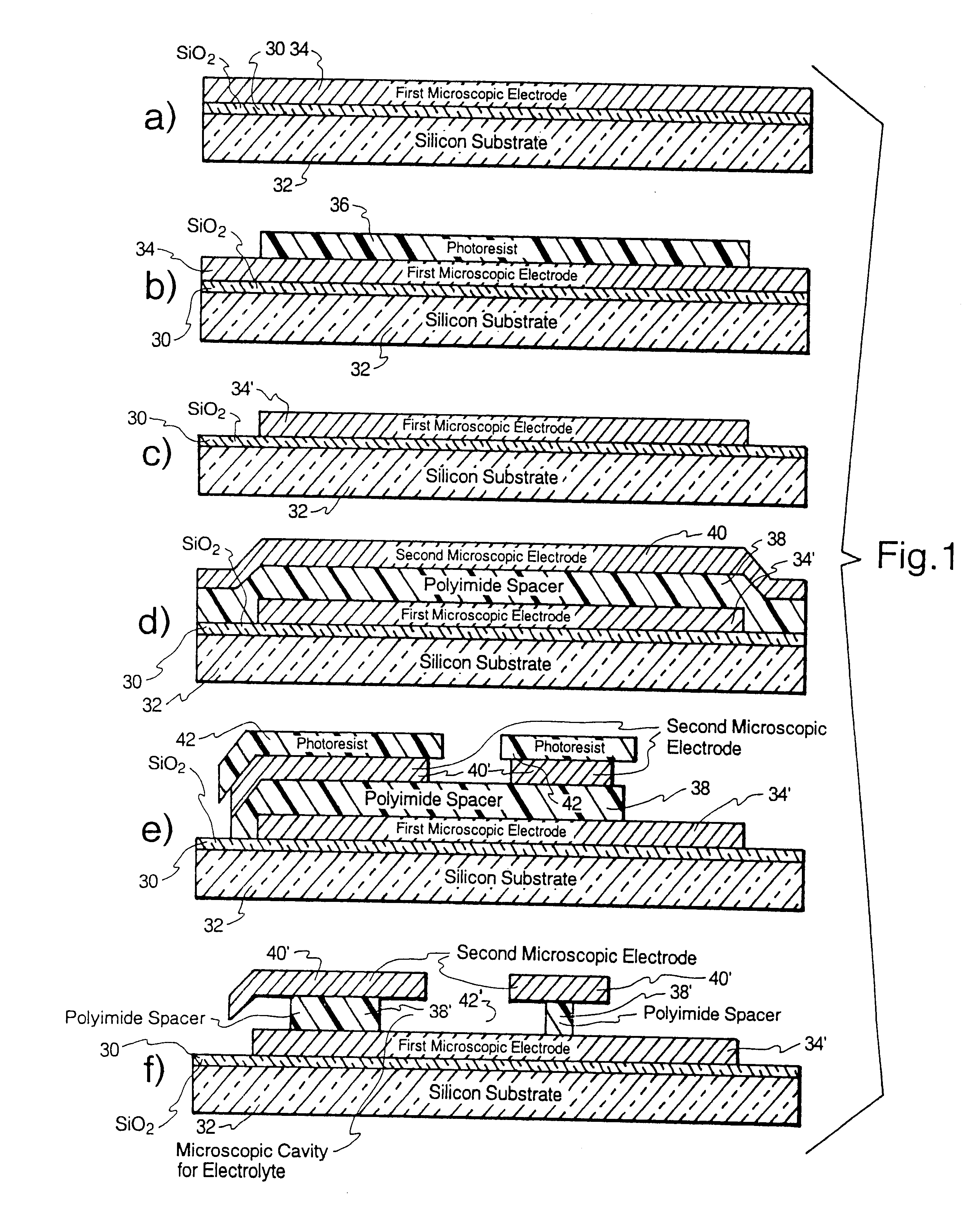

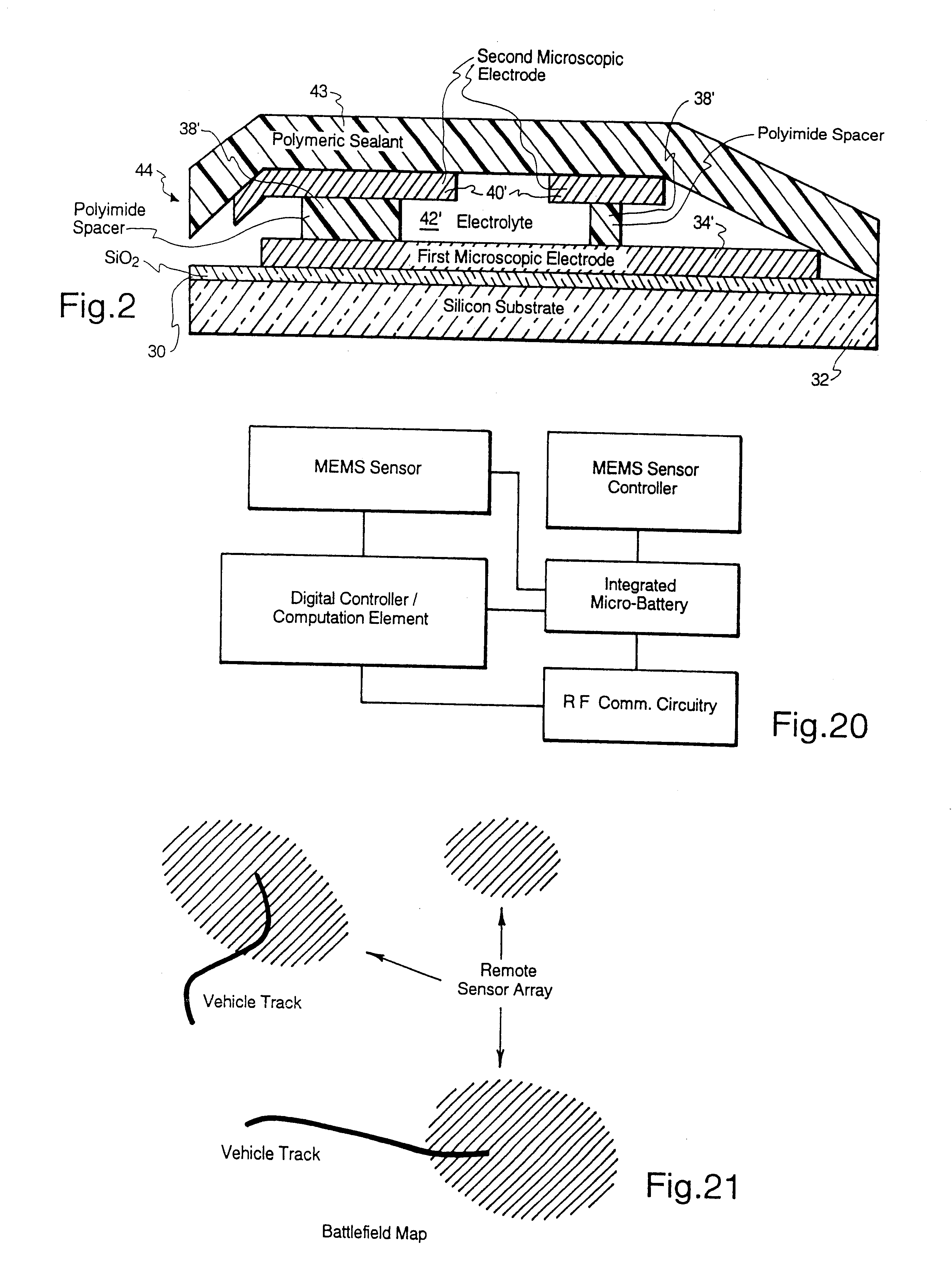

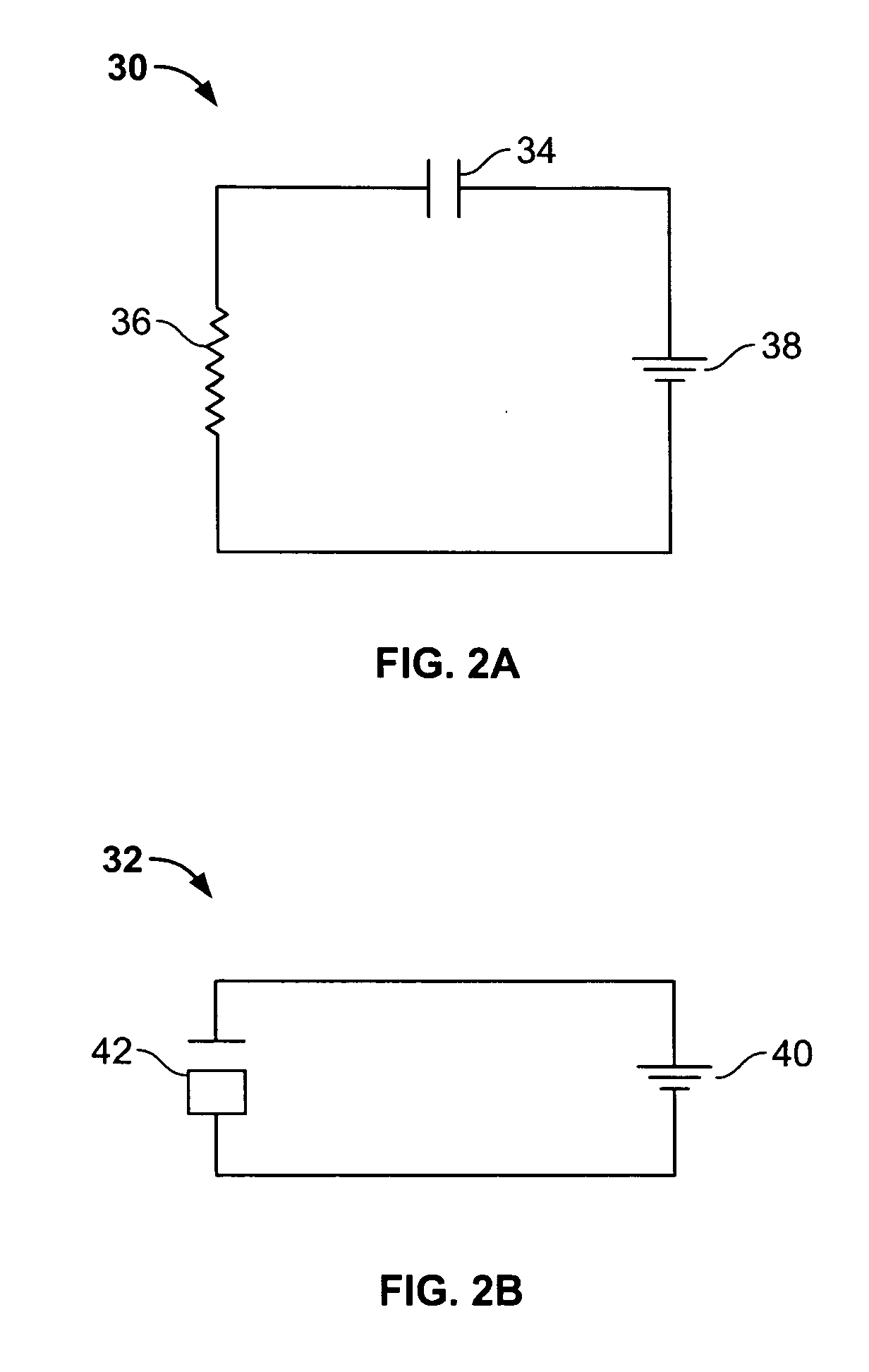

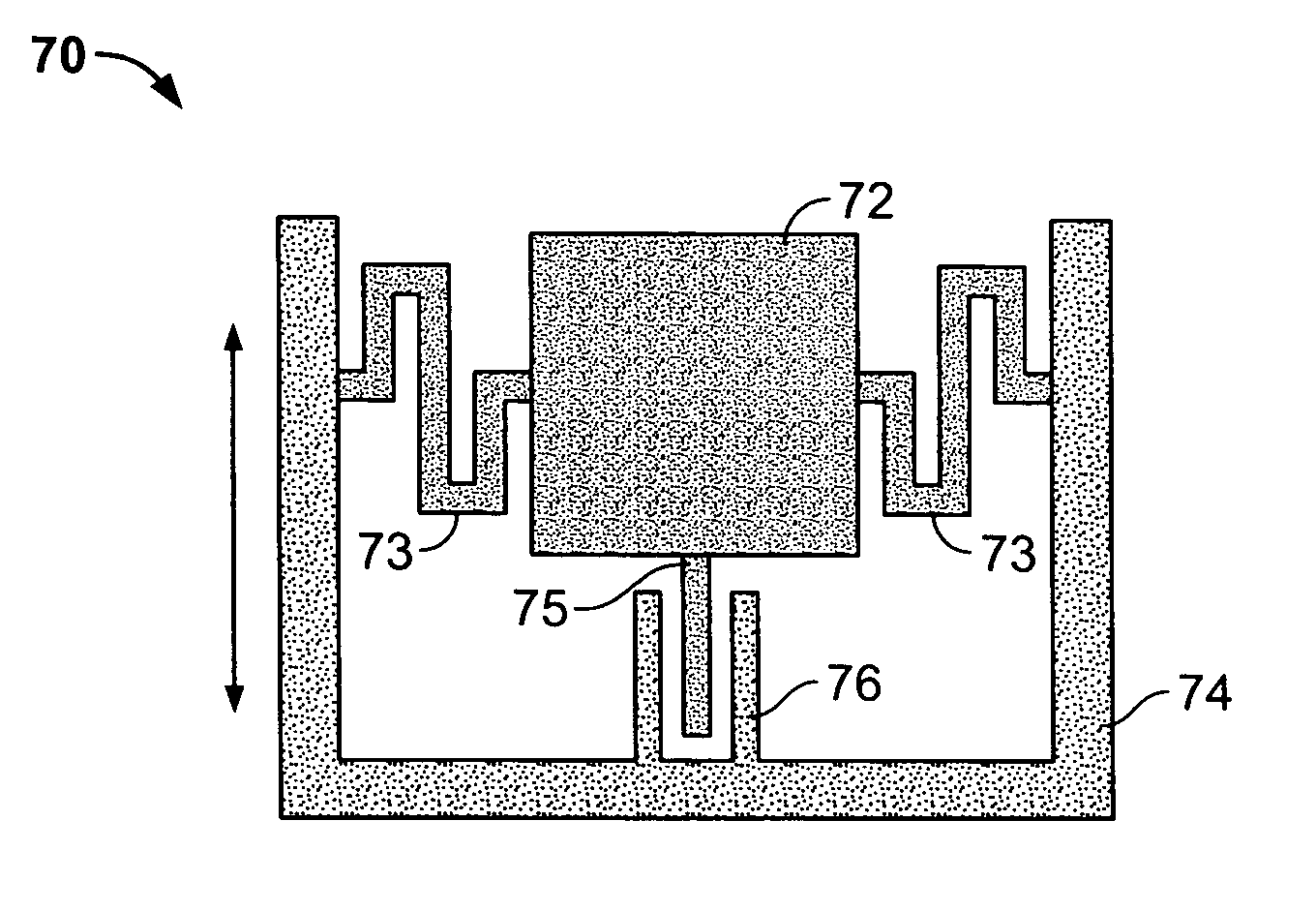

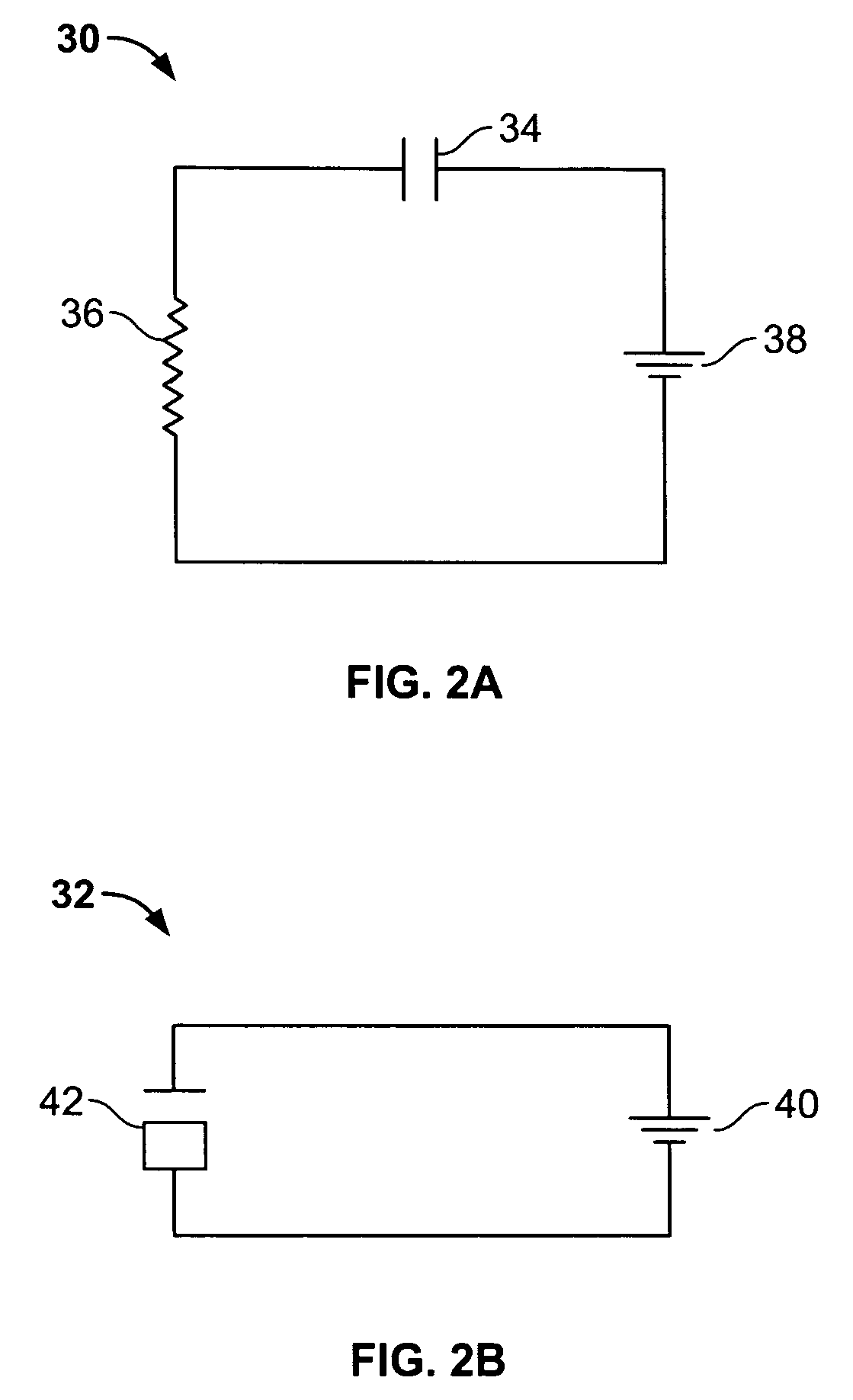

Microscopic batteries for MEMS systems

InactiveUS6610440B1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureElectricityMicrofabrication

Microscopic batteries, integratable or integrated with microelectromechanical systems or other microscopic circuits, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed, among which comprise closed system microscopic batteries for internal storage of electricity using interval reactants only, which comprise microscopic electrodes, electrolyte and reservoir for the electrolyte.

Owner:BIPOLAR TECH

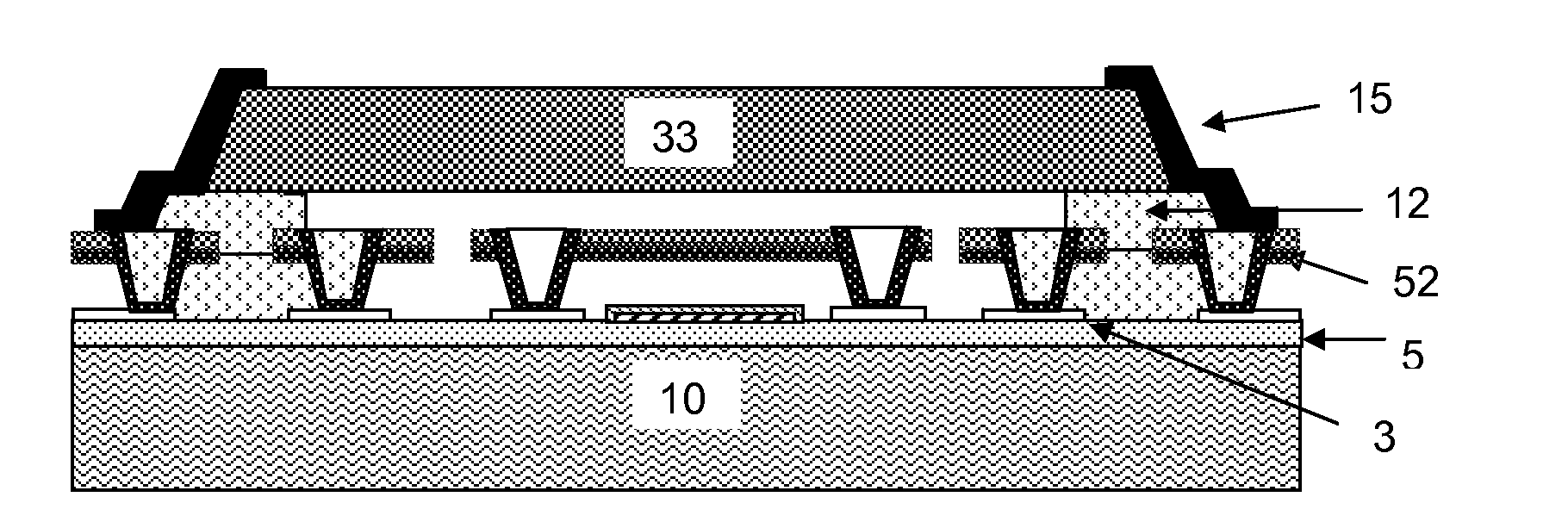

System and method of fabricating micro cavities

InactiveUS20080308920A1Decorative surface effectsSemiconductor/solid-state device detailsEpoxyMicroelectromechanical systems

A system and method for manufacturing micro cavity packaging enclosure at the wafer level using MEMS (MicroElectroMechanical Systems) process, wherein micro cavities are formed from epoxy-bonded single-crystalline silicon wafer as its cap, epoxy and deposited metal or insulator as at least part of its sidewall, on substrate wafers.

Owner:WAN CHANG FENG

Method and system of releasing a MEMS structure

ActiveUS7250353B2Semiconductor/solid-state device detailsSolid-state devicesDevice formMicroelectromechanical systems

A MEMs (microelectromechanical systems) structure is provided. In one implementation, the MEMs structure includes a substrate wafer including a MEMs device formed on a surface of the substrate wafer, and a MEMs cover structure to cover the MEMs device formed on the surface of the substrate wafer. The MEMs cover structure comprises a first wafer bonded to a second wafer, in which only the first wafer of the MEMs cover structure is sawed through and not the second wafer of the MEMs cover structure during dicing of the MEMs structure.

Owner:INVENSENSE

MEMS devices with unreleased thin film components

ActiveUS7012726B1Decorative surface effectsSemiconductor/solid-state device manufacturingMicroelectromechanical systemsEngineering

In one embodiment, the invention provides a MEMS device. The MEMS device comprises a plurality of functional components including at least one moveable component; and a sacrificial component to at least reduce movement of the moveable component during shipping of the microelectromechanical systems device, wherein the sacrificial component can be removed after shipping.

Owner:SNAPTRACK

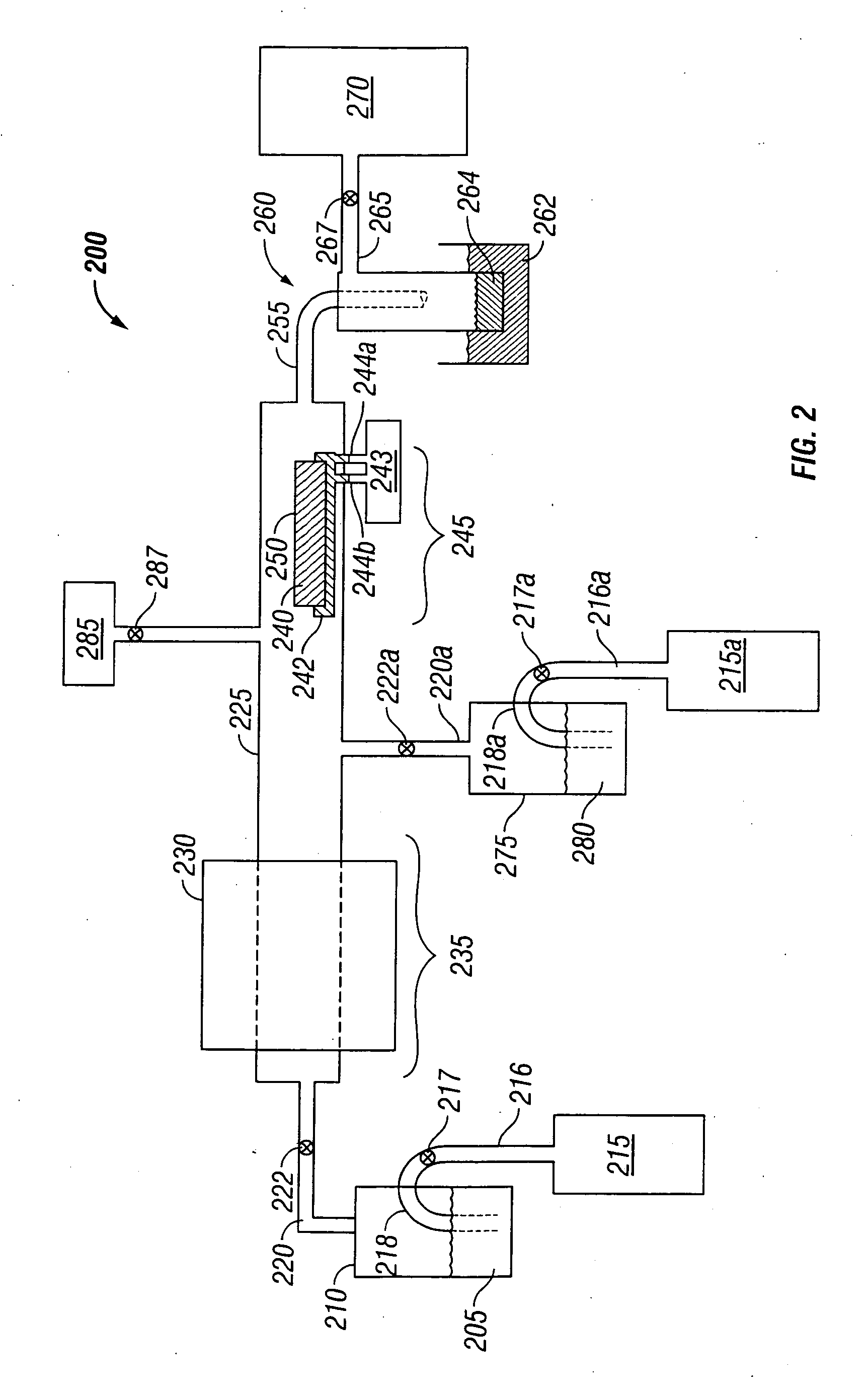

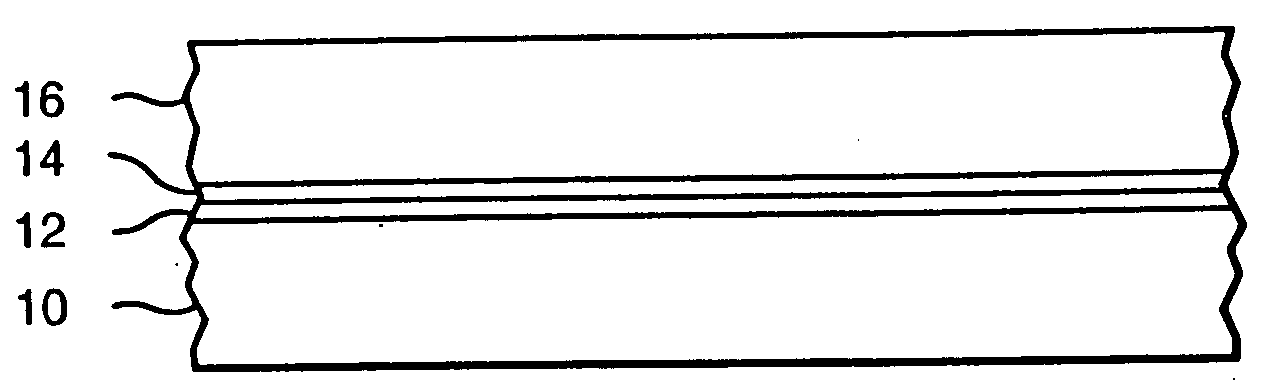

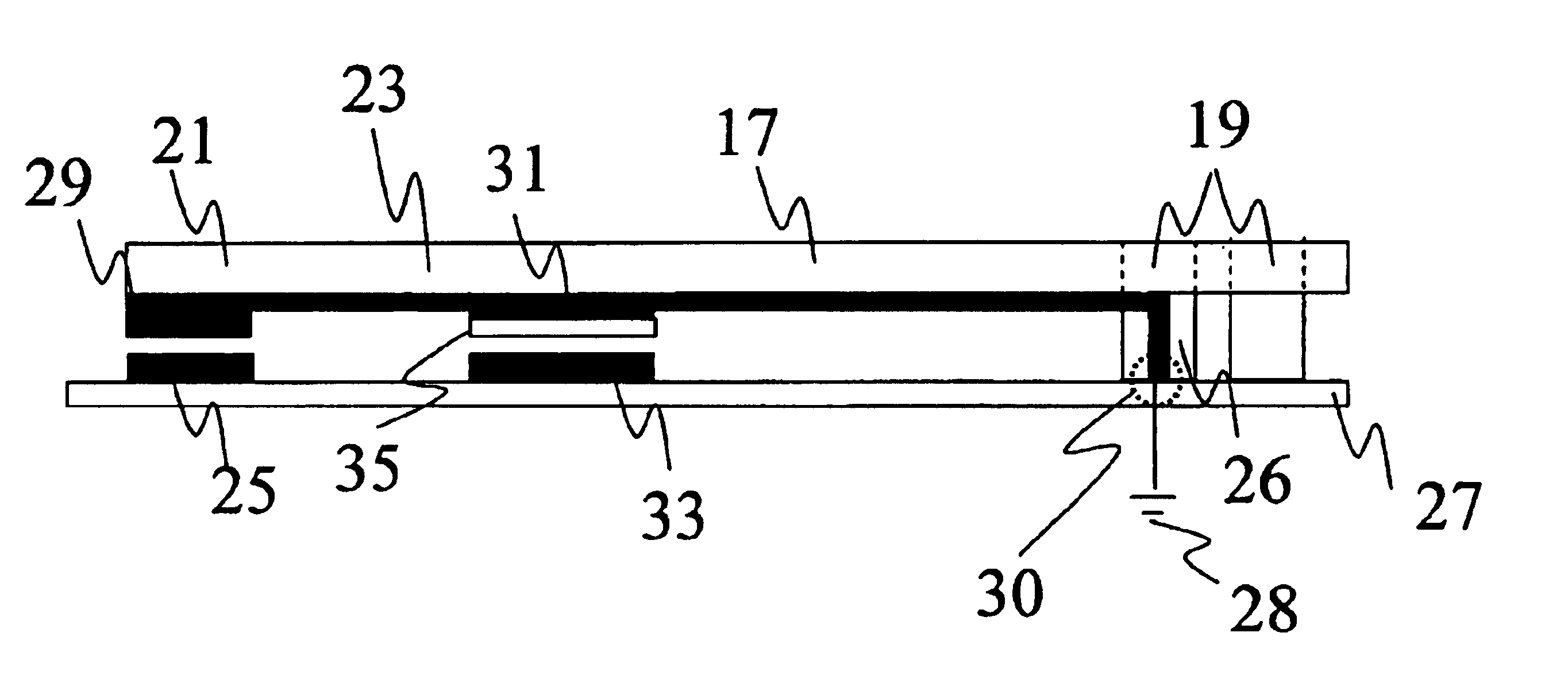

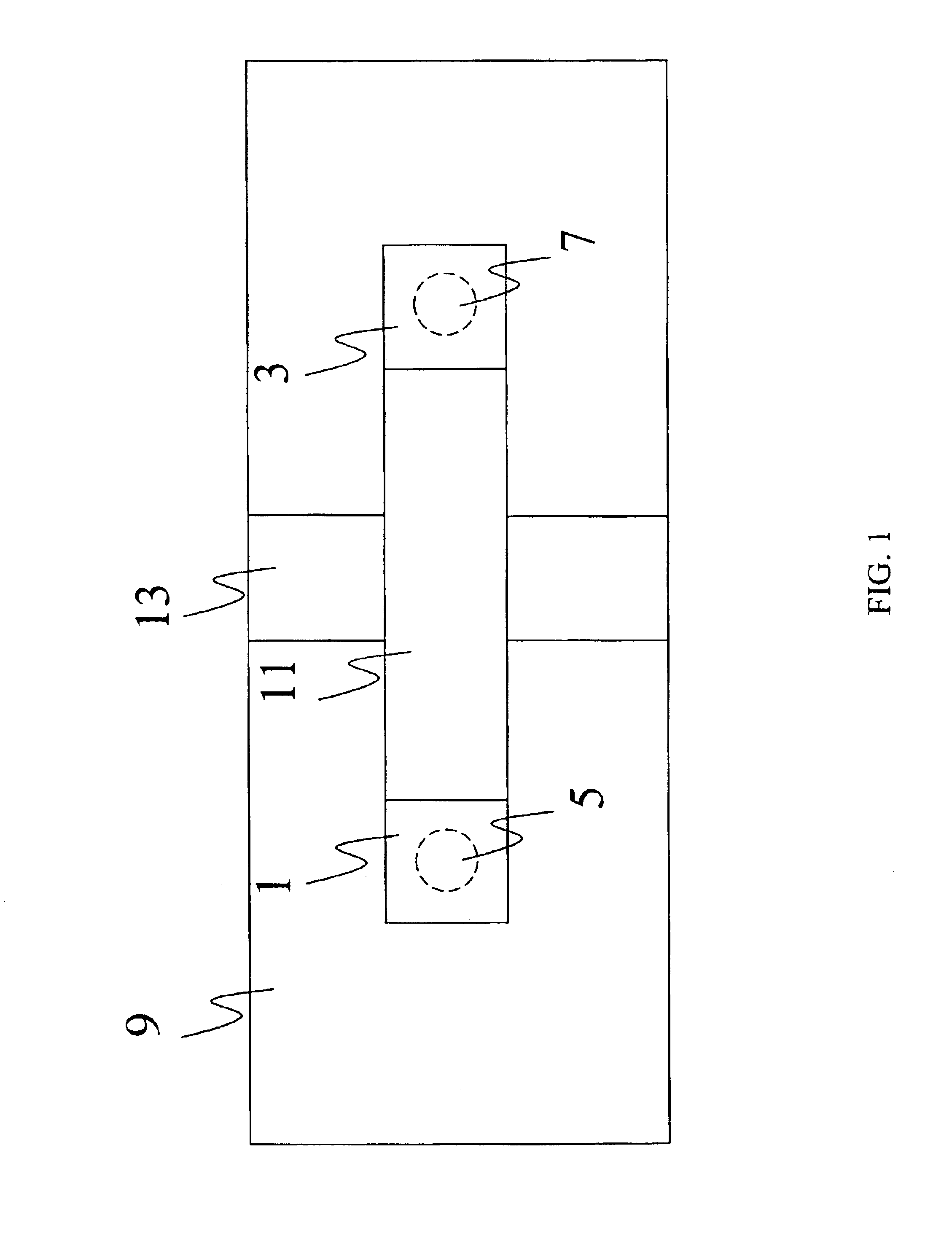

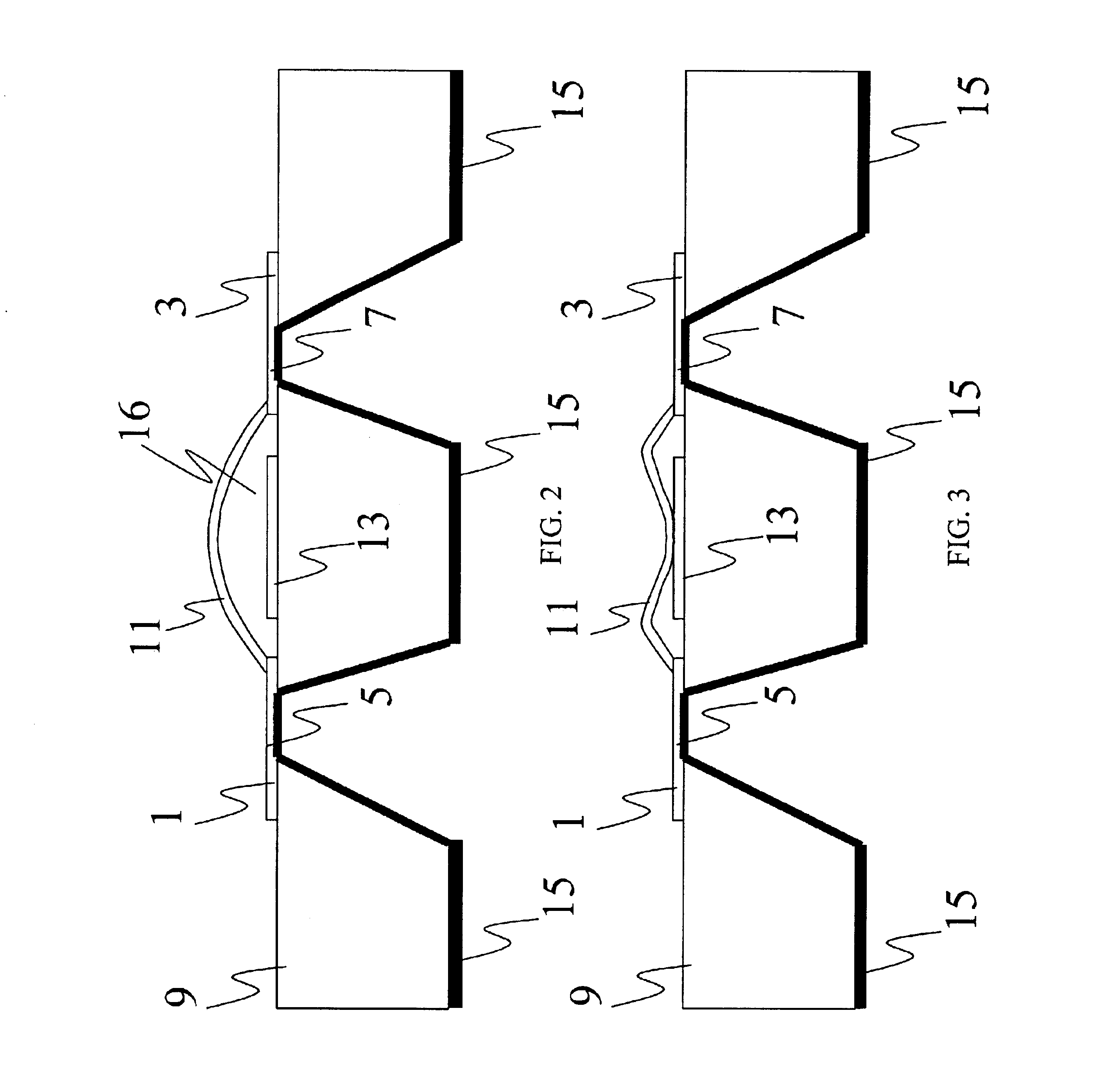

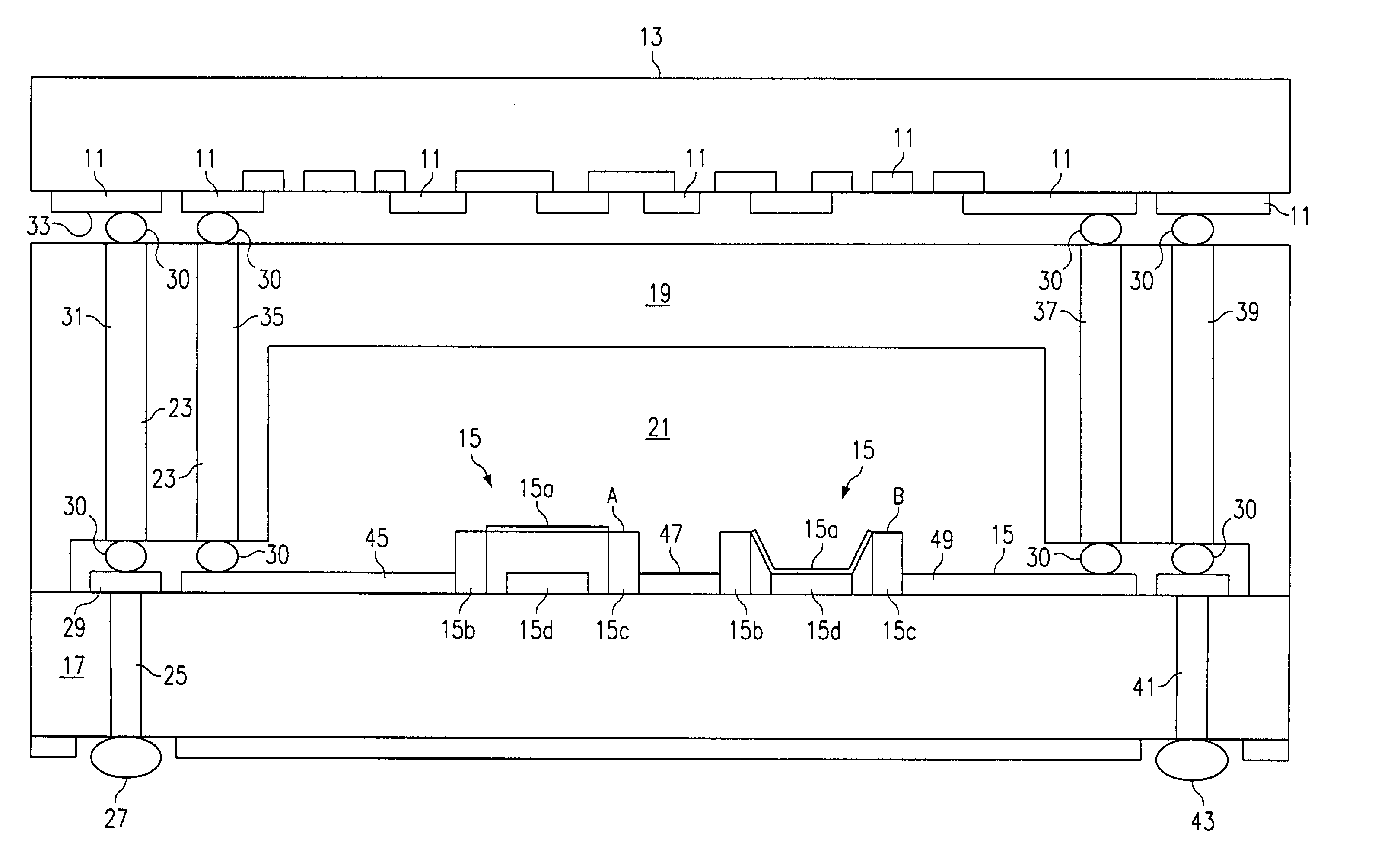

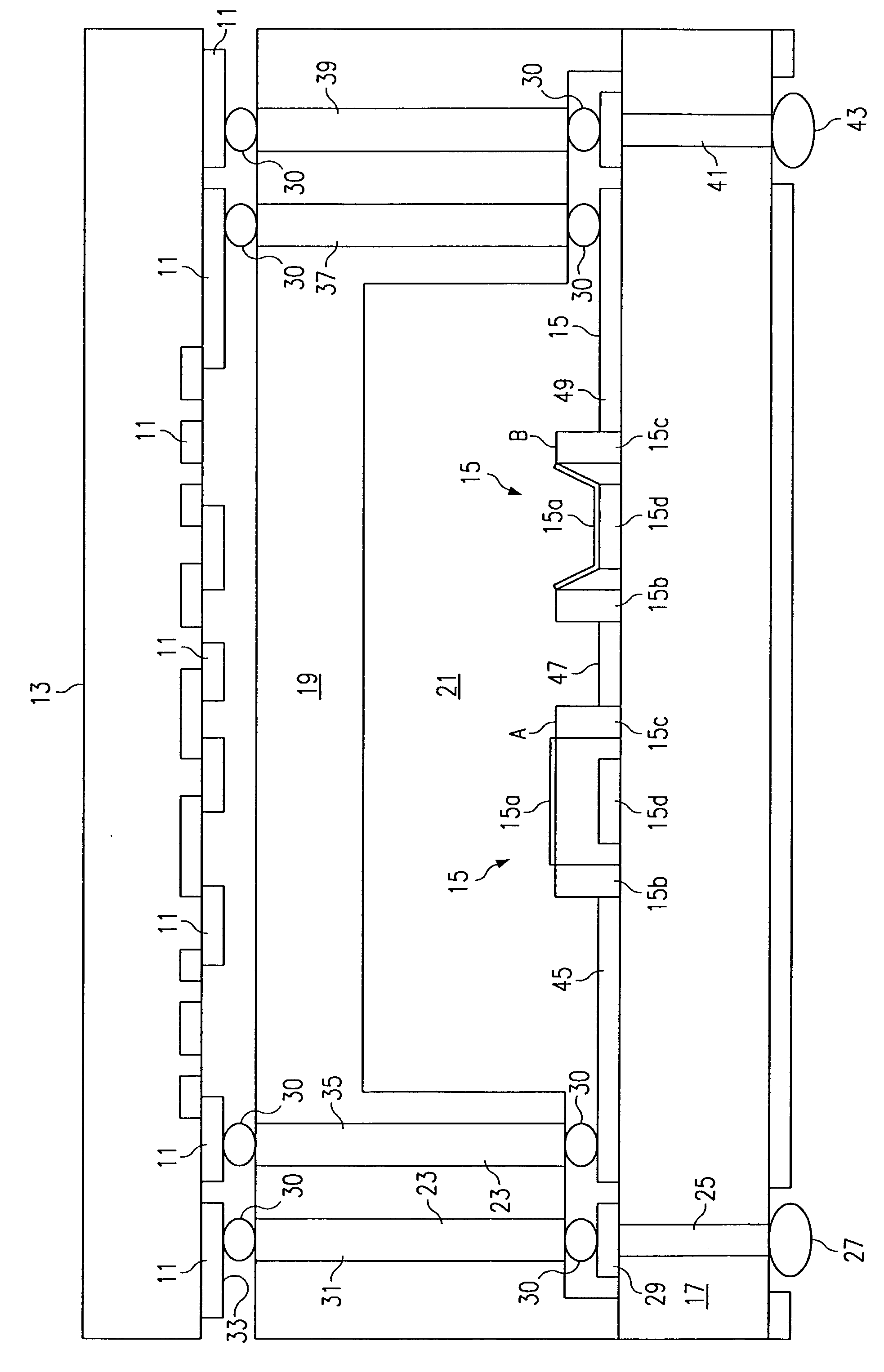

Wafer level interconnection

InactiveUS20030001251A1Television system detailsPiezoelectric/electrostriction/magnetostriction machinesDielectricElectrical conductor

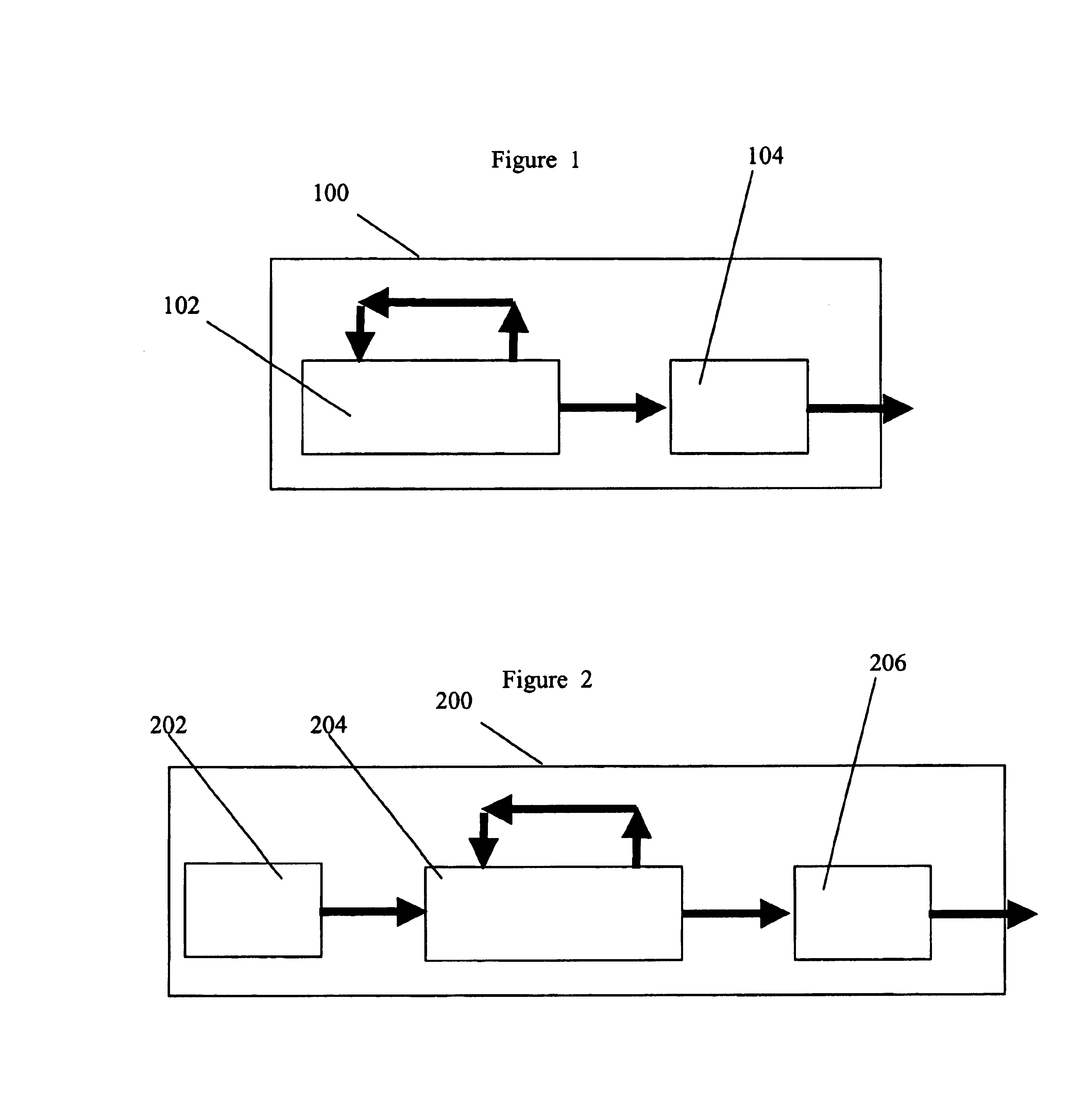

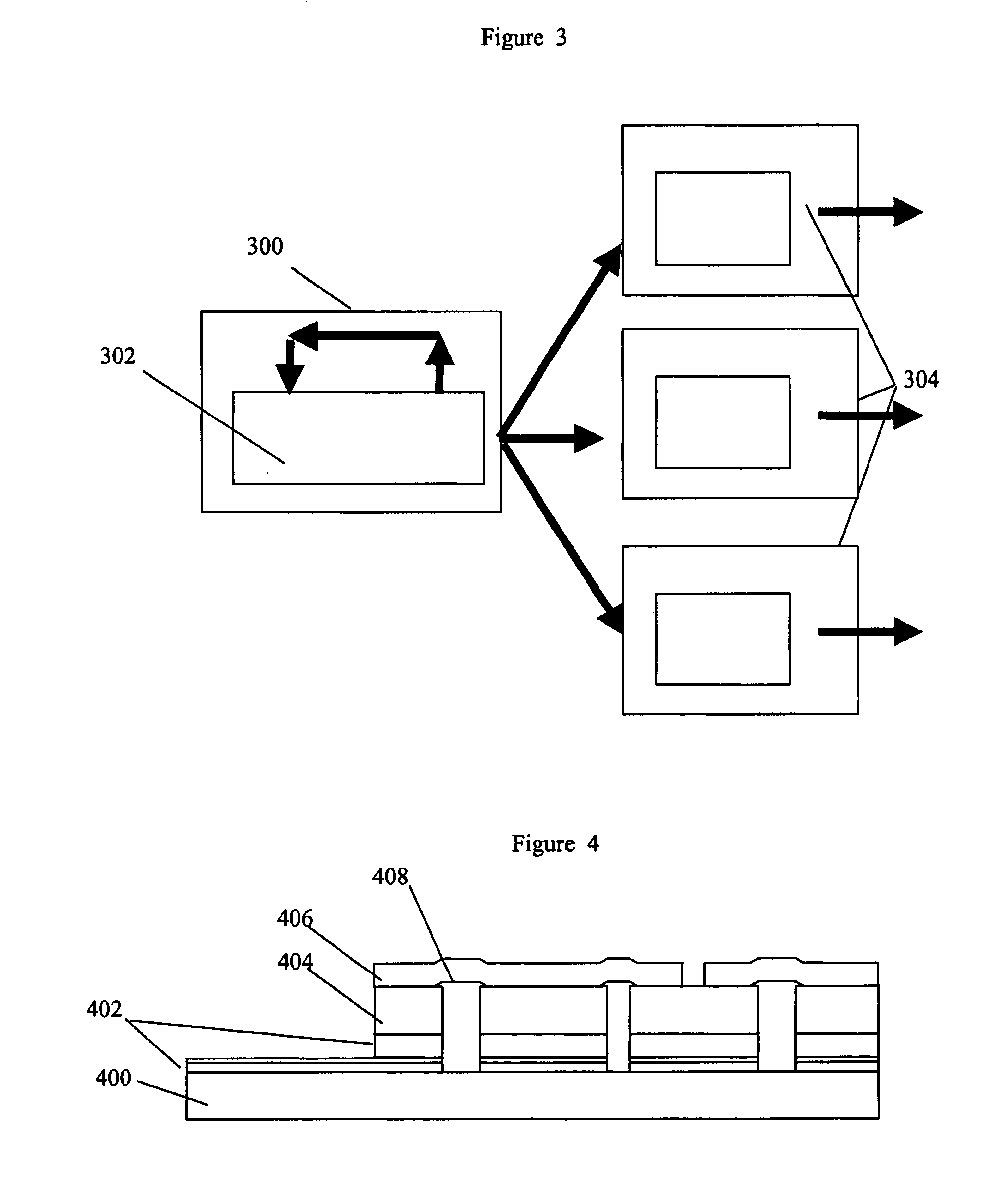

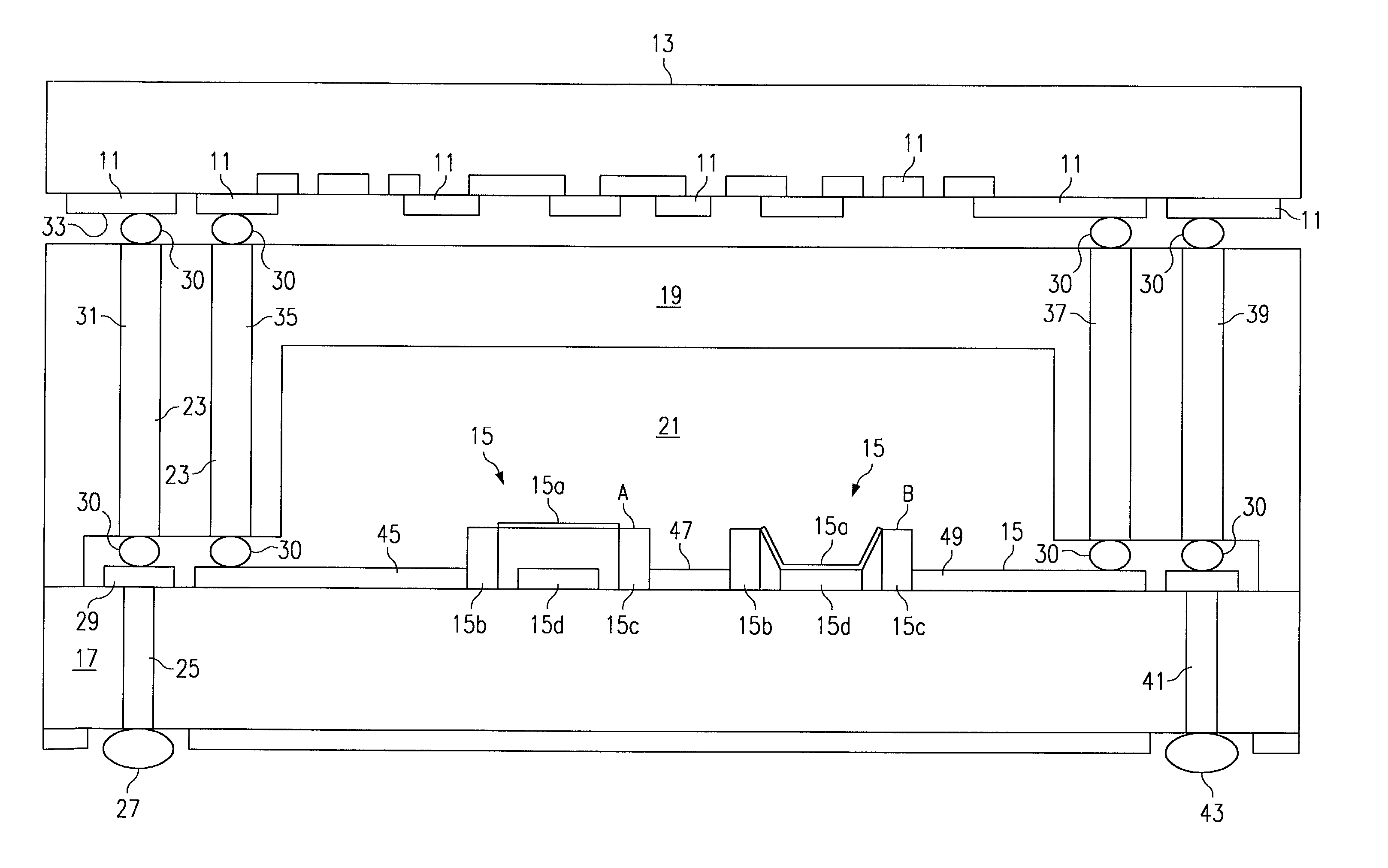

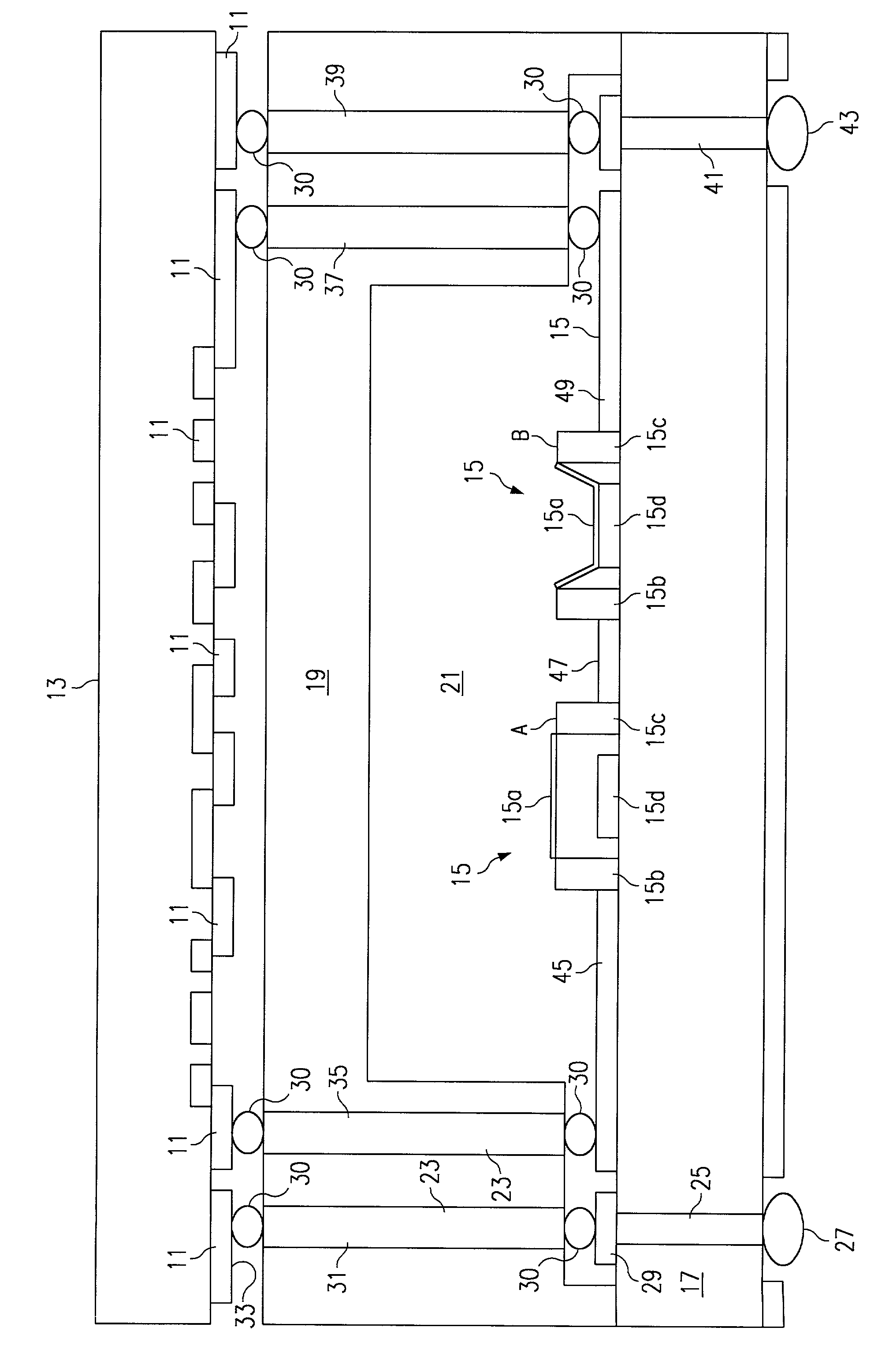

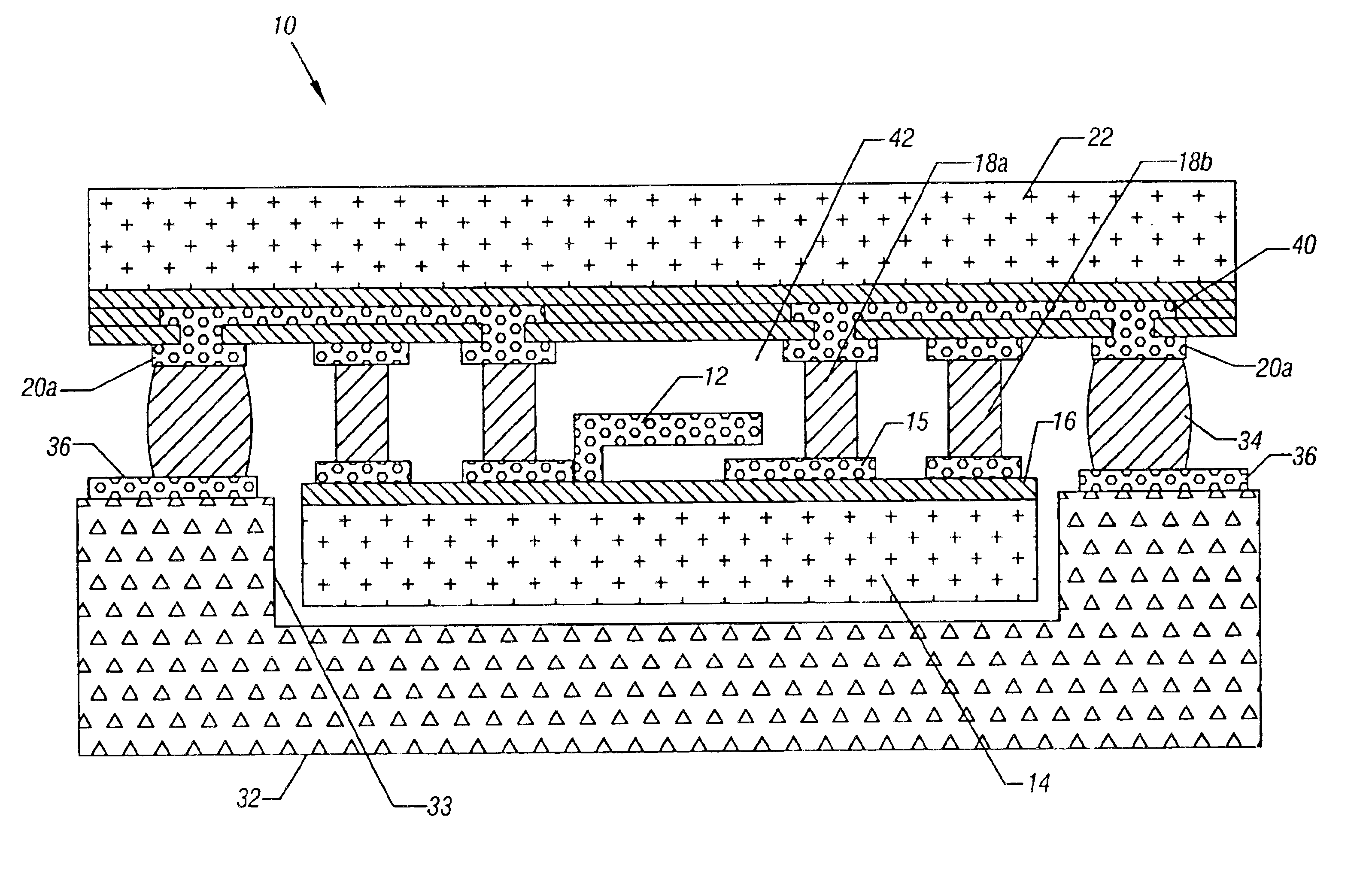

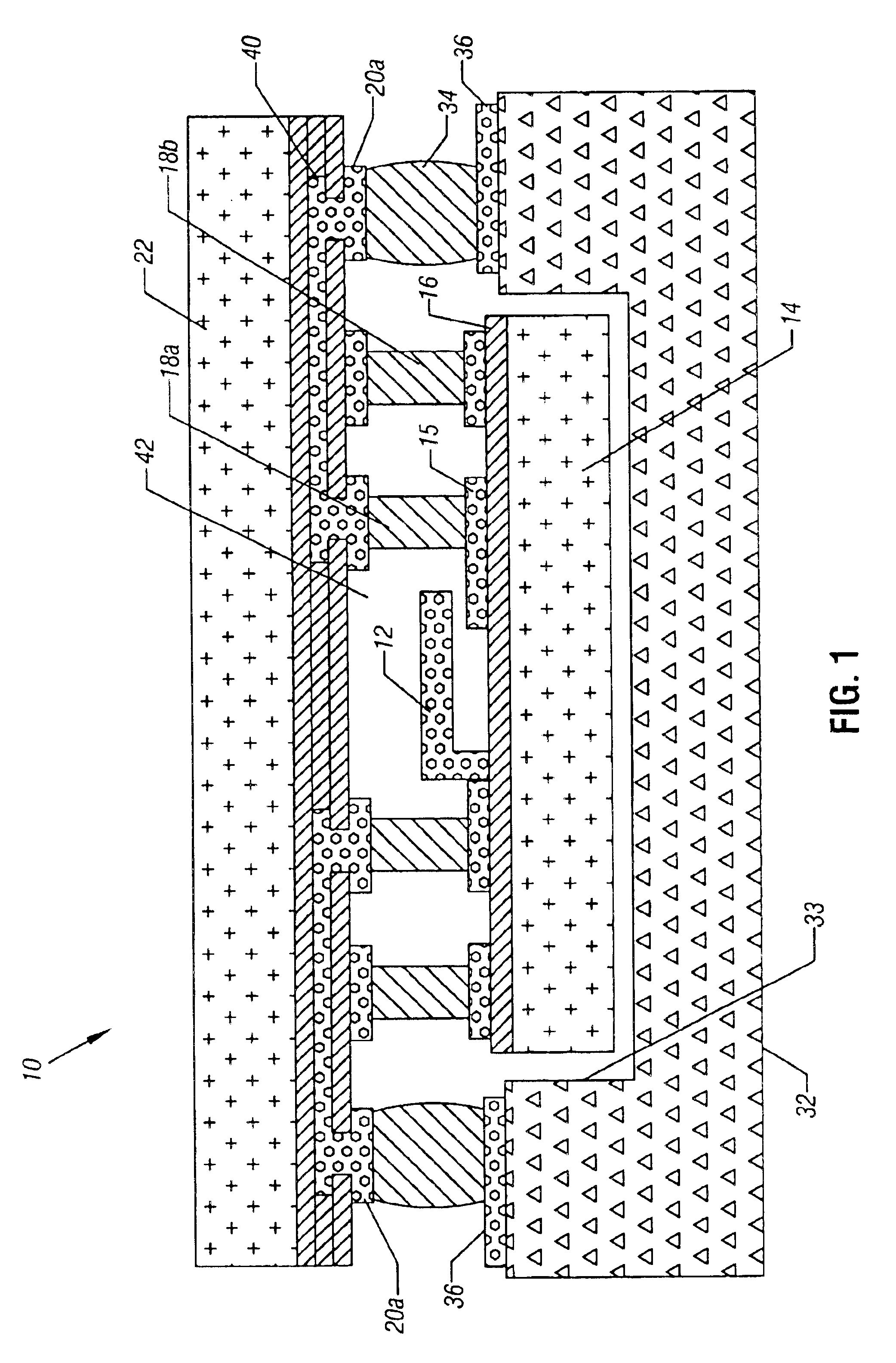

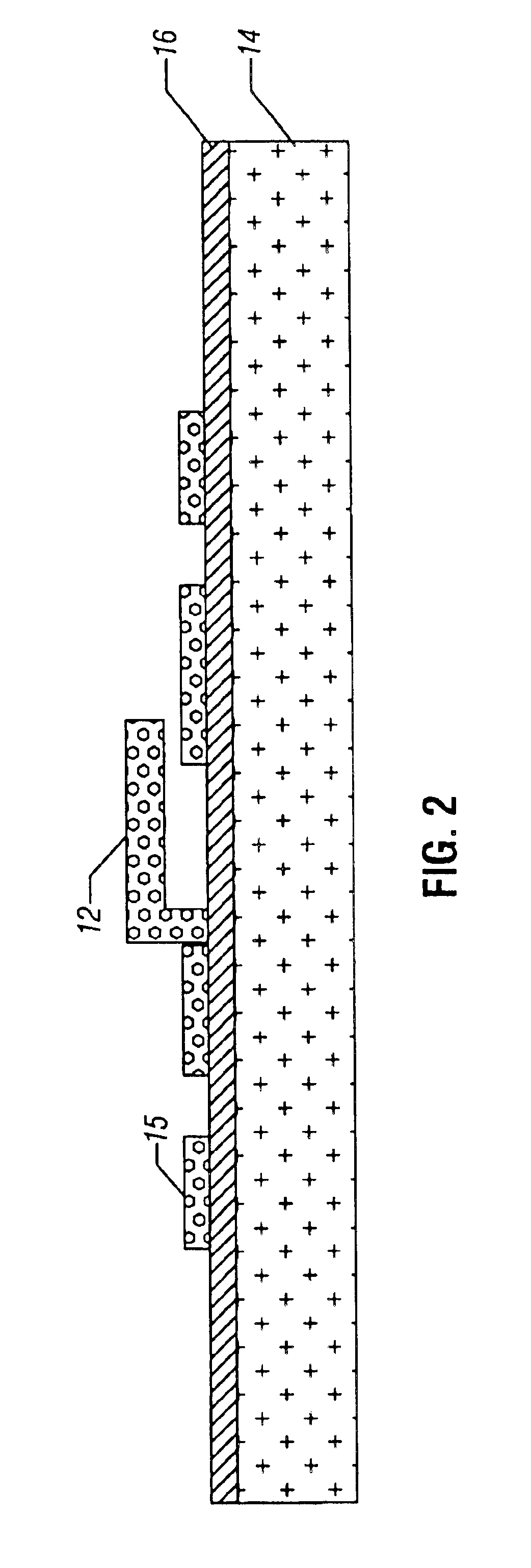

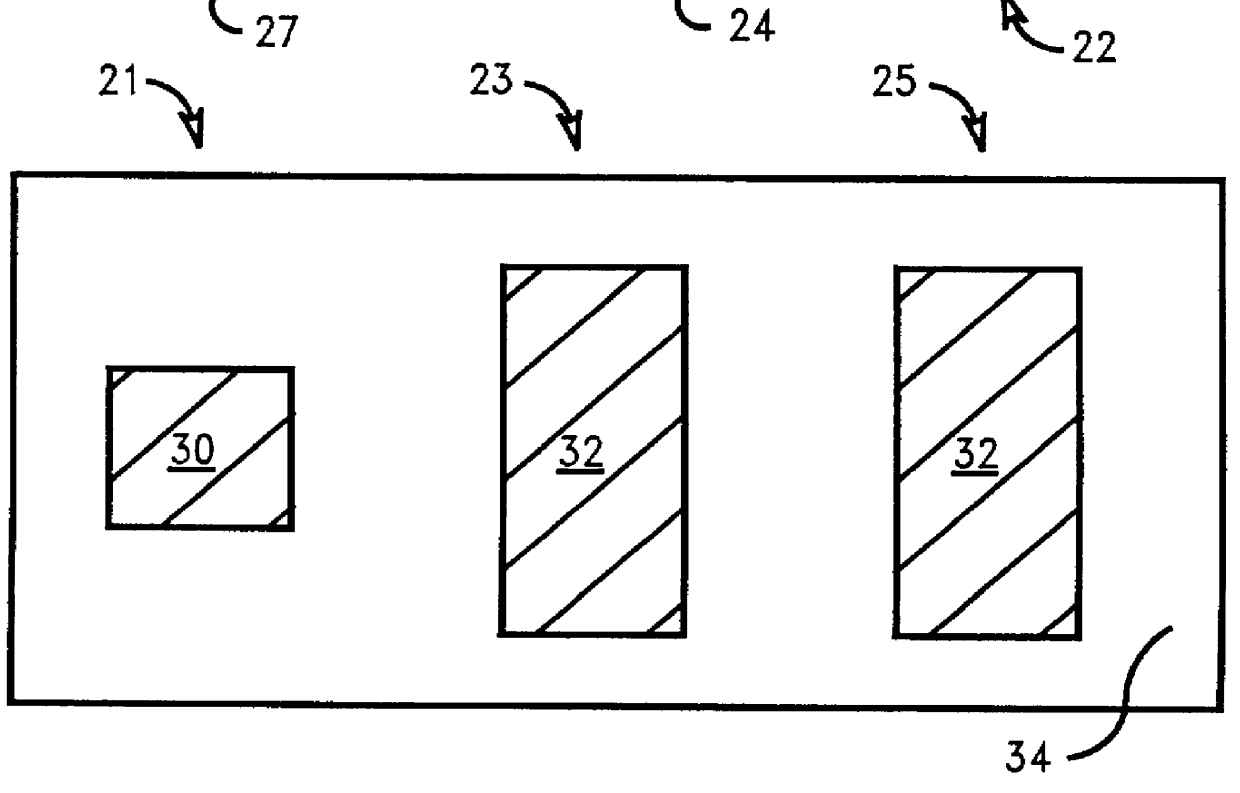

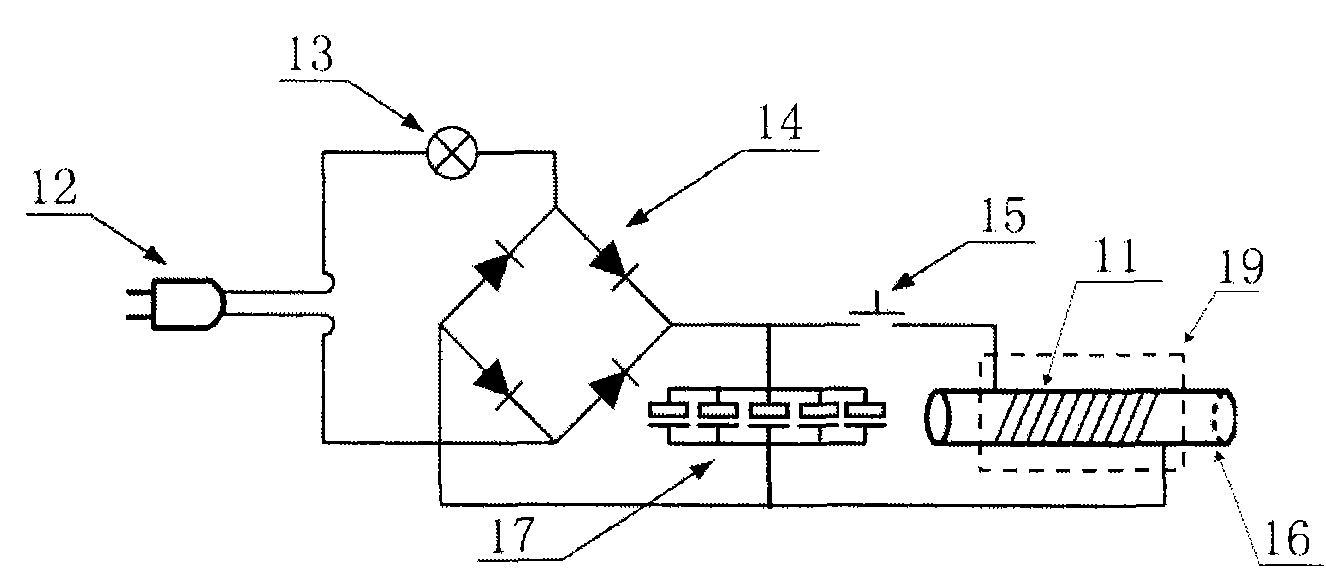

RF MicroElectroMechanical Systems (MEMs) circuitry(15) on a first high resistivity substrate (17)is combined with circuitry (11) onsecond low-resisitivity substrate (13) by overlapping the first high resisitivity substrate (17)and MEMs circuitry (15) with the low resisitivity substrate(13) and circuitry (11) with the MEMs circuitry (15)facing the second circuitry (11). A dielectric lid (19) is placed over the MEMs circuitry (15)and between the first substrate (17)and second substrate (13)with an inert gas in a gap (21)over the MEMs circuitry (15). Interconnecting conductors (25,31,35,37,39,41) extend perpendicular and through the high resistivity substrate (17)and through the dielectric lid (19) to make electrical connection with the low resisitivity substrate (13).

Owner:RAYTHEON CO

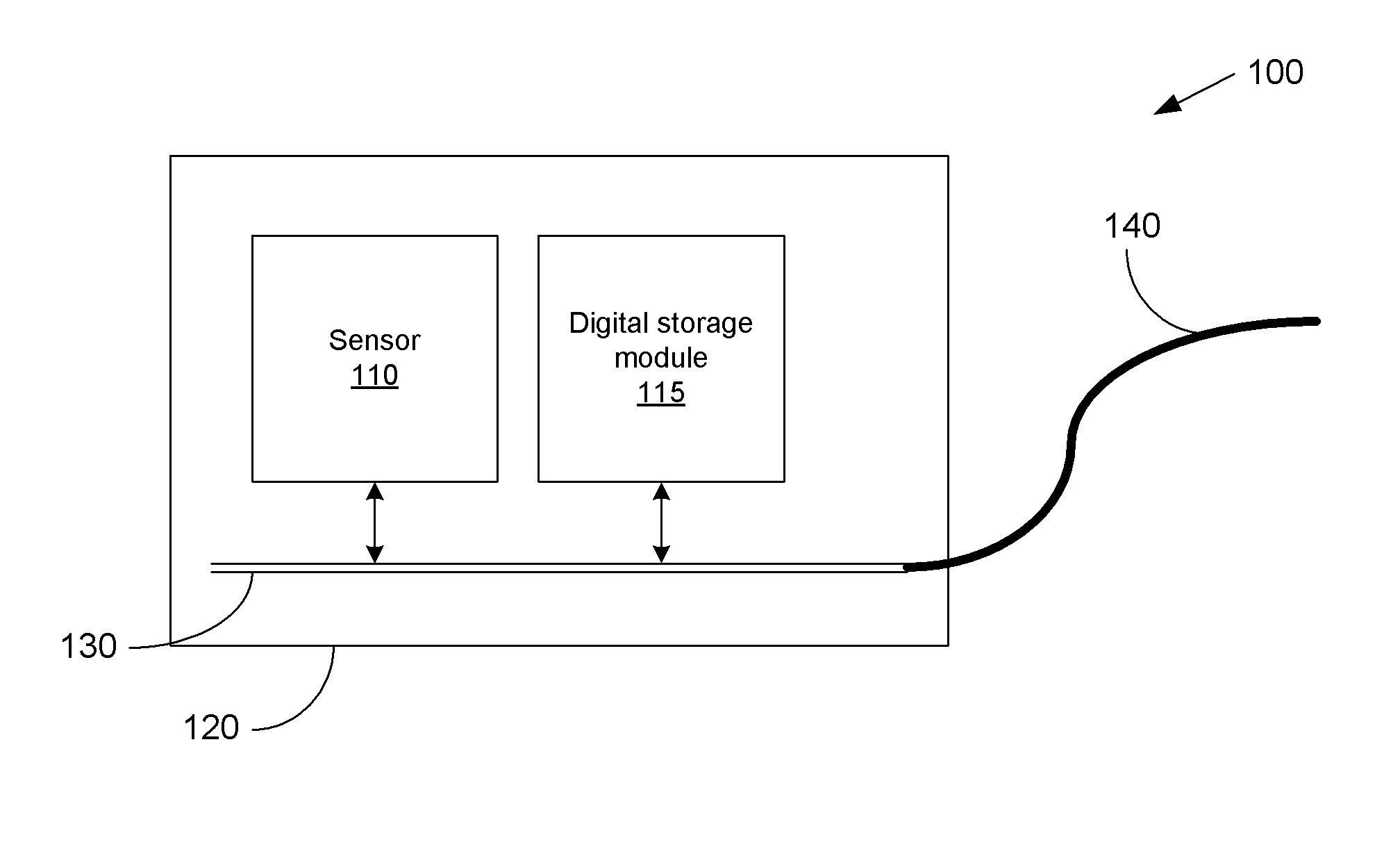

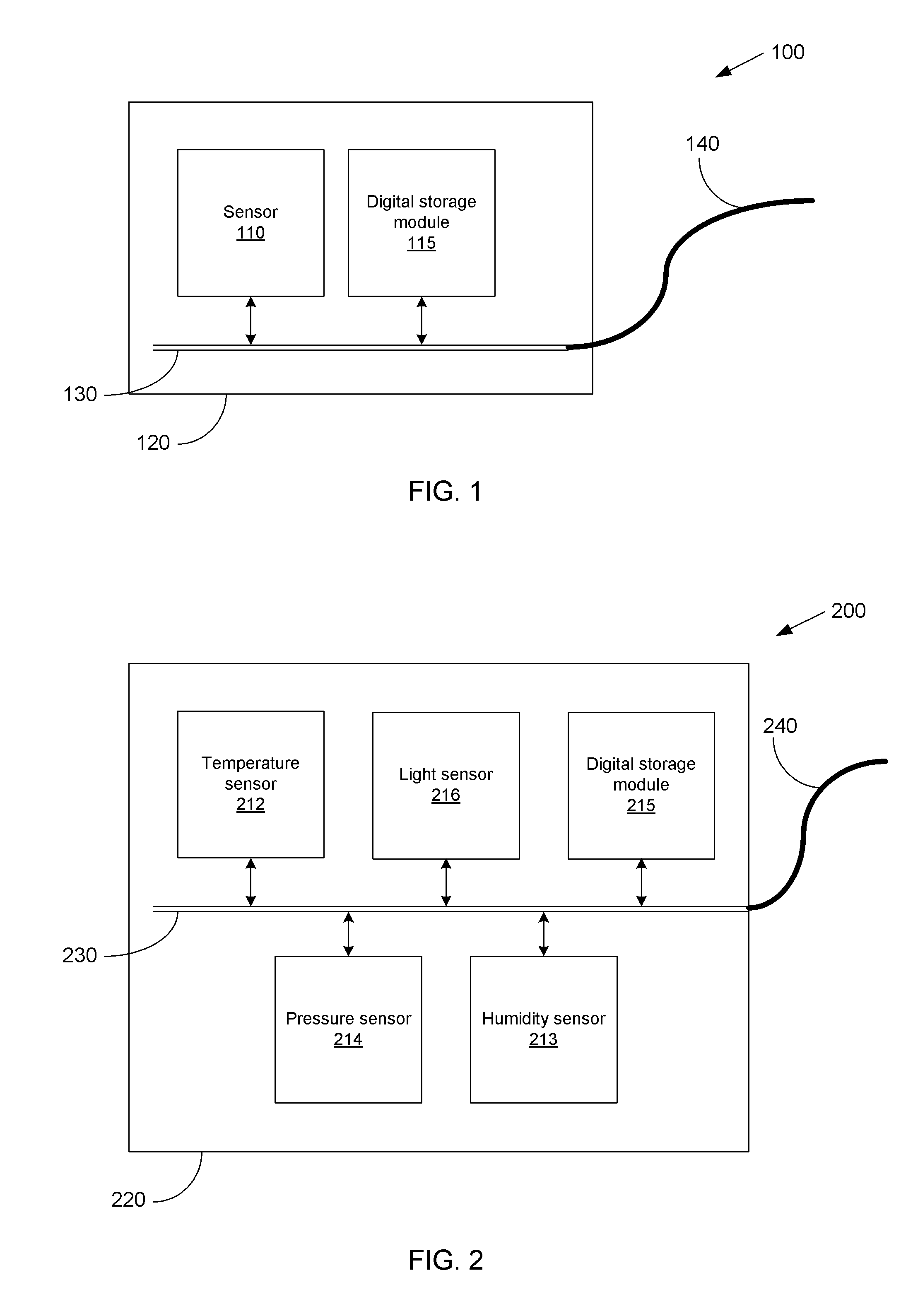

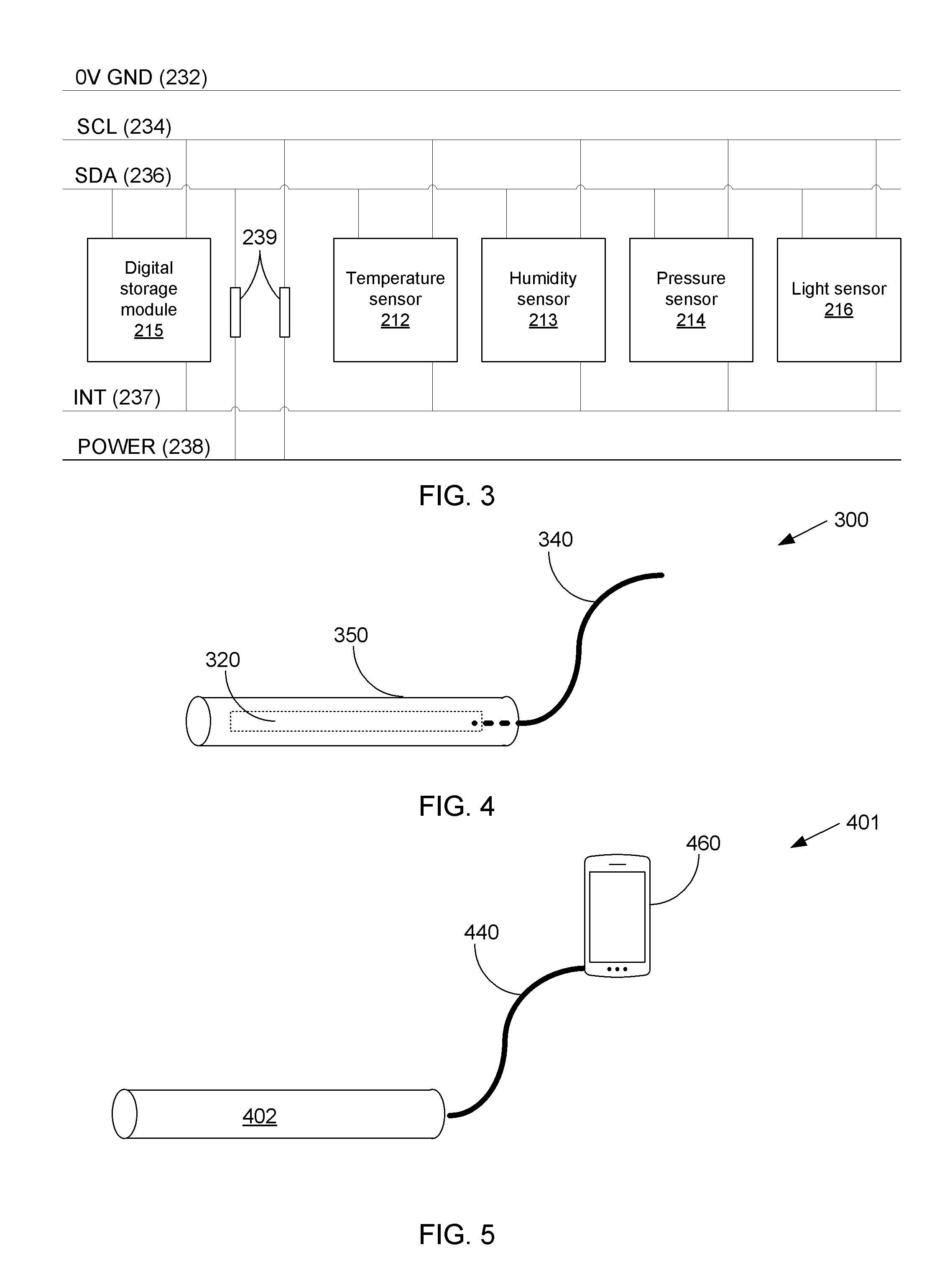

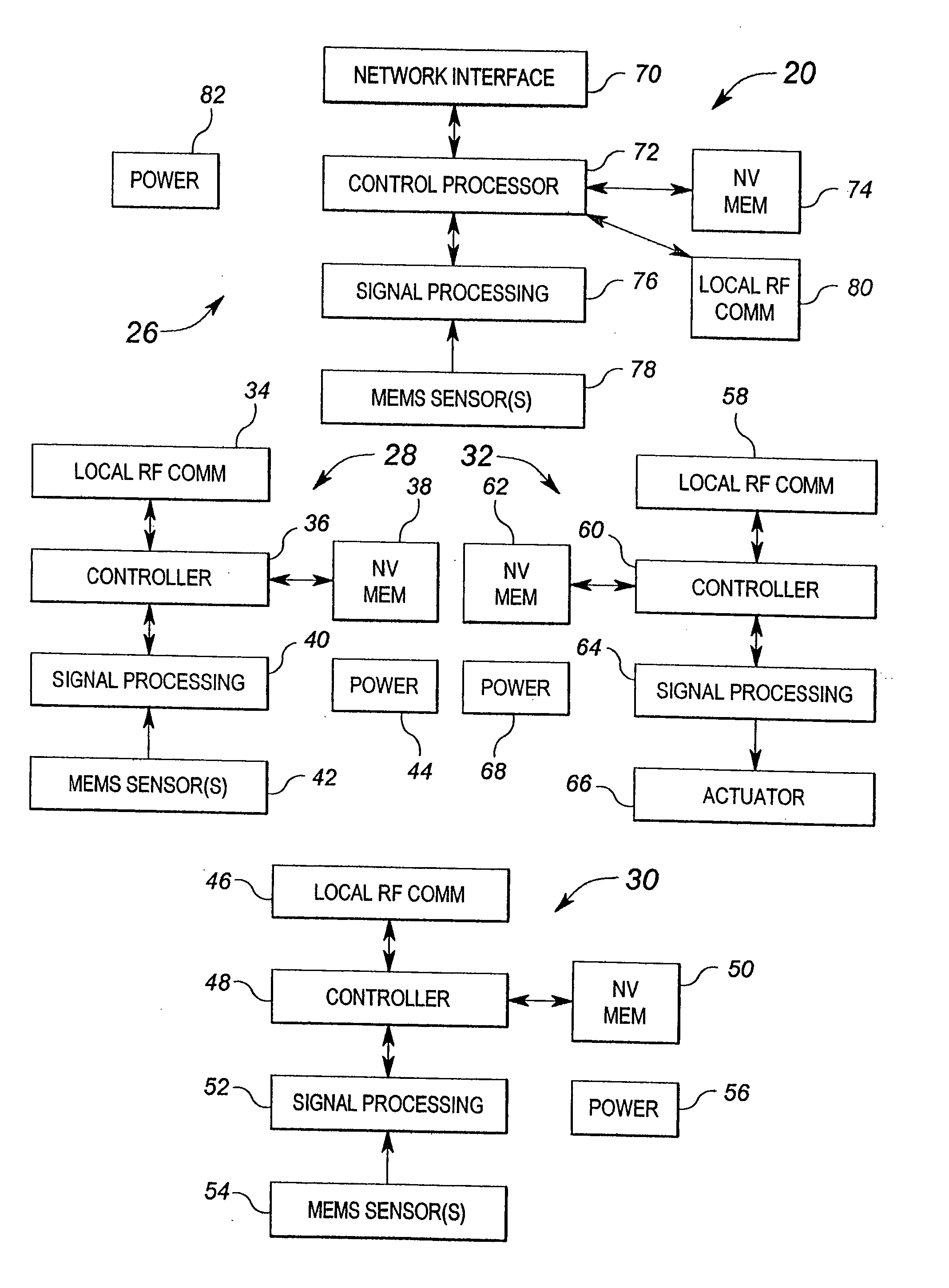

Sensor probe and related systems and methods

ActiveUS20150151960A1Television system detailsTelemetry/telecontrol selection arrangementsTelecommunicationsDigital storage

The invention provides a sensor probe which has: one or more microelectromechanical systems (MEMS) sensors configured to sense one or more parameters and a communication bus in electrical communication therewith. The one or more sensors and communication bus are disposed on a substrate. The sensor probe includes a digital storage module in which a unique probe identifier is stored and which is in electrical communication with the communication bus. The probe includes, a cable, a first end of which is in electrical communication with the communication bus and a second end of which is in electrical communication with a remote monitoring unit. The cable is configured to provide electrical power received from the remote monitoring unit to the one or more sensors, via the communication bus, and to communicate data received from the one or more sensors, via the communication bus, to the remote monitoring unit.

Owner:MCCLELAND BARRY JOHN +1

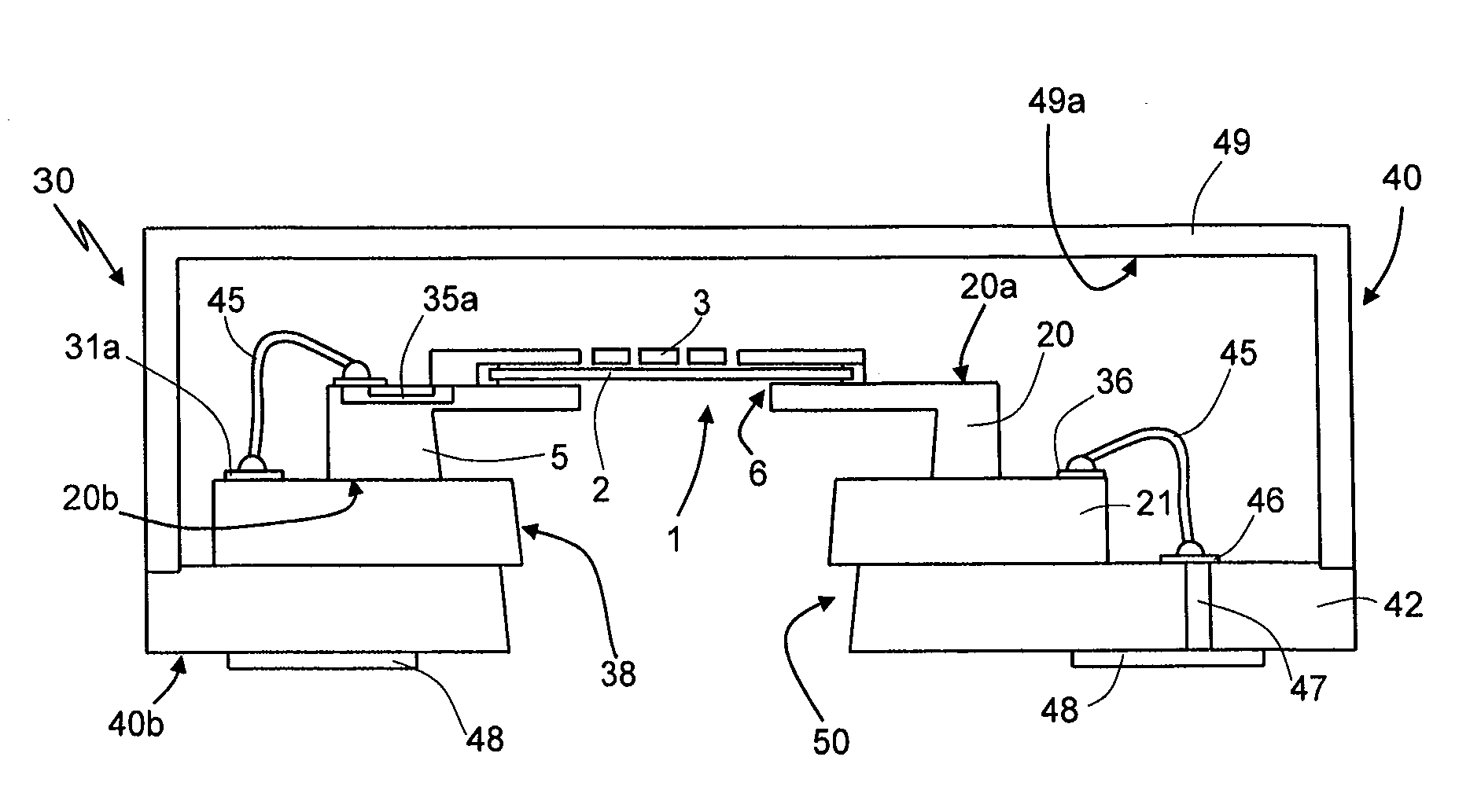

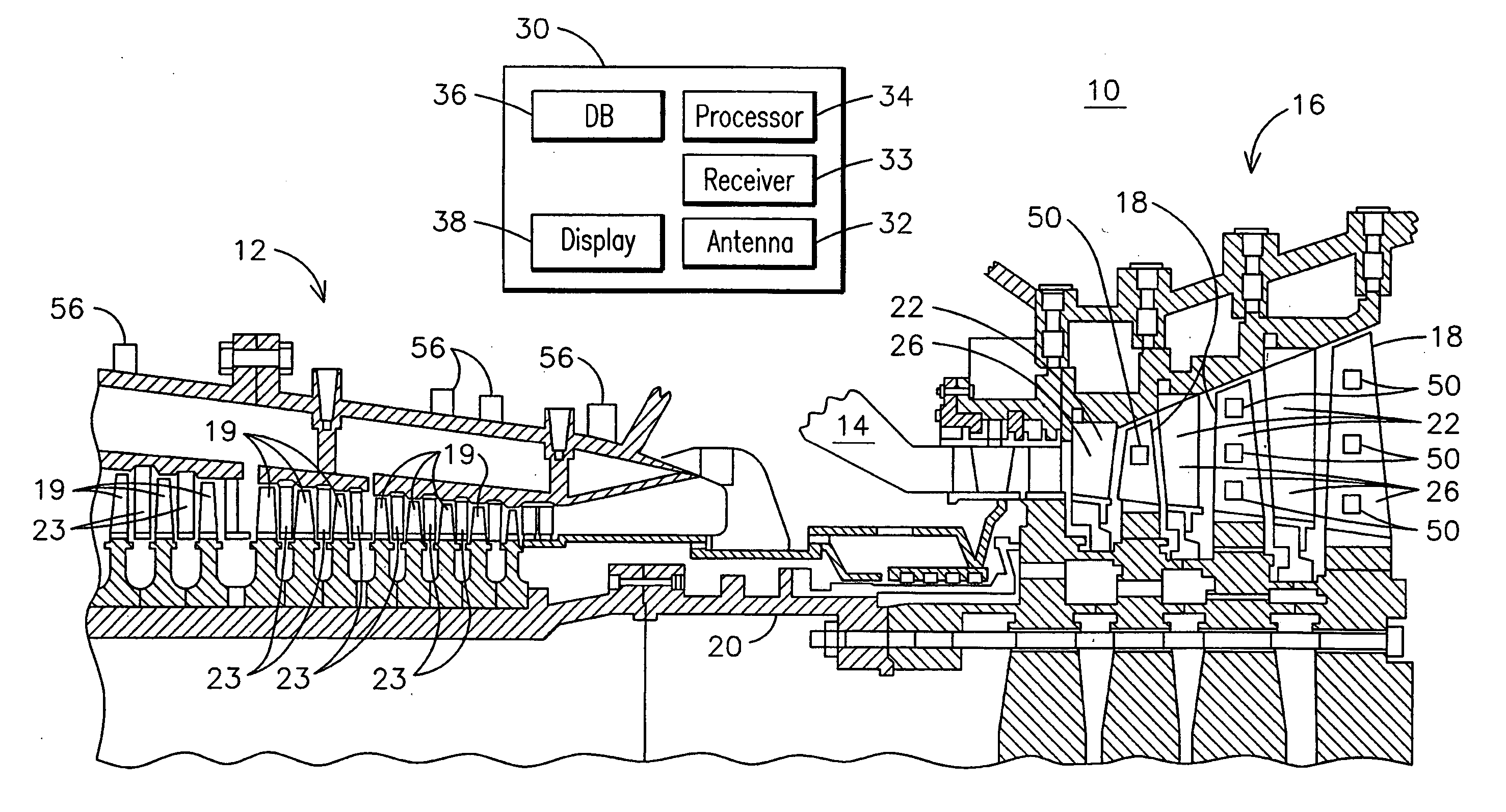

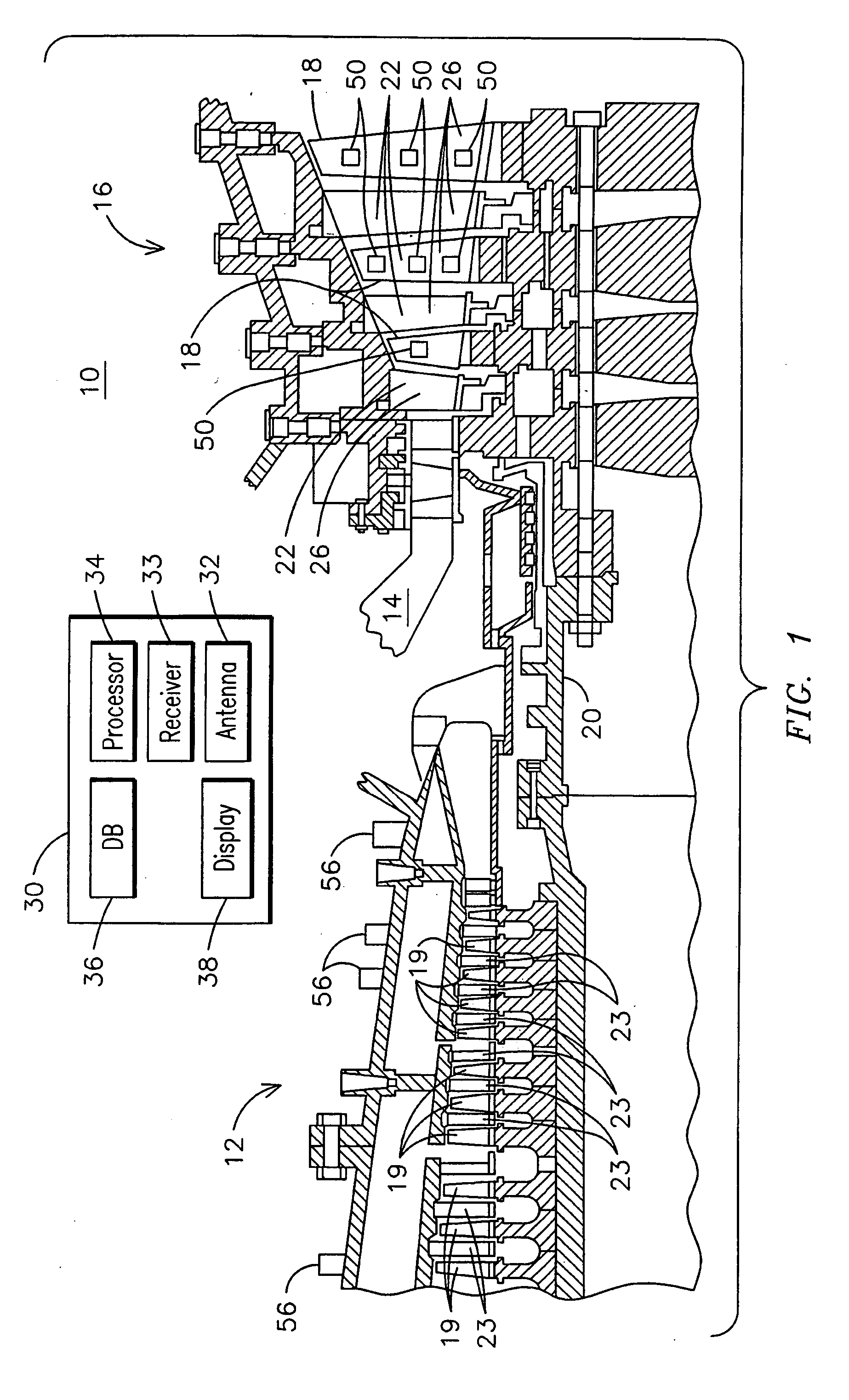

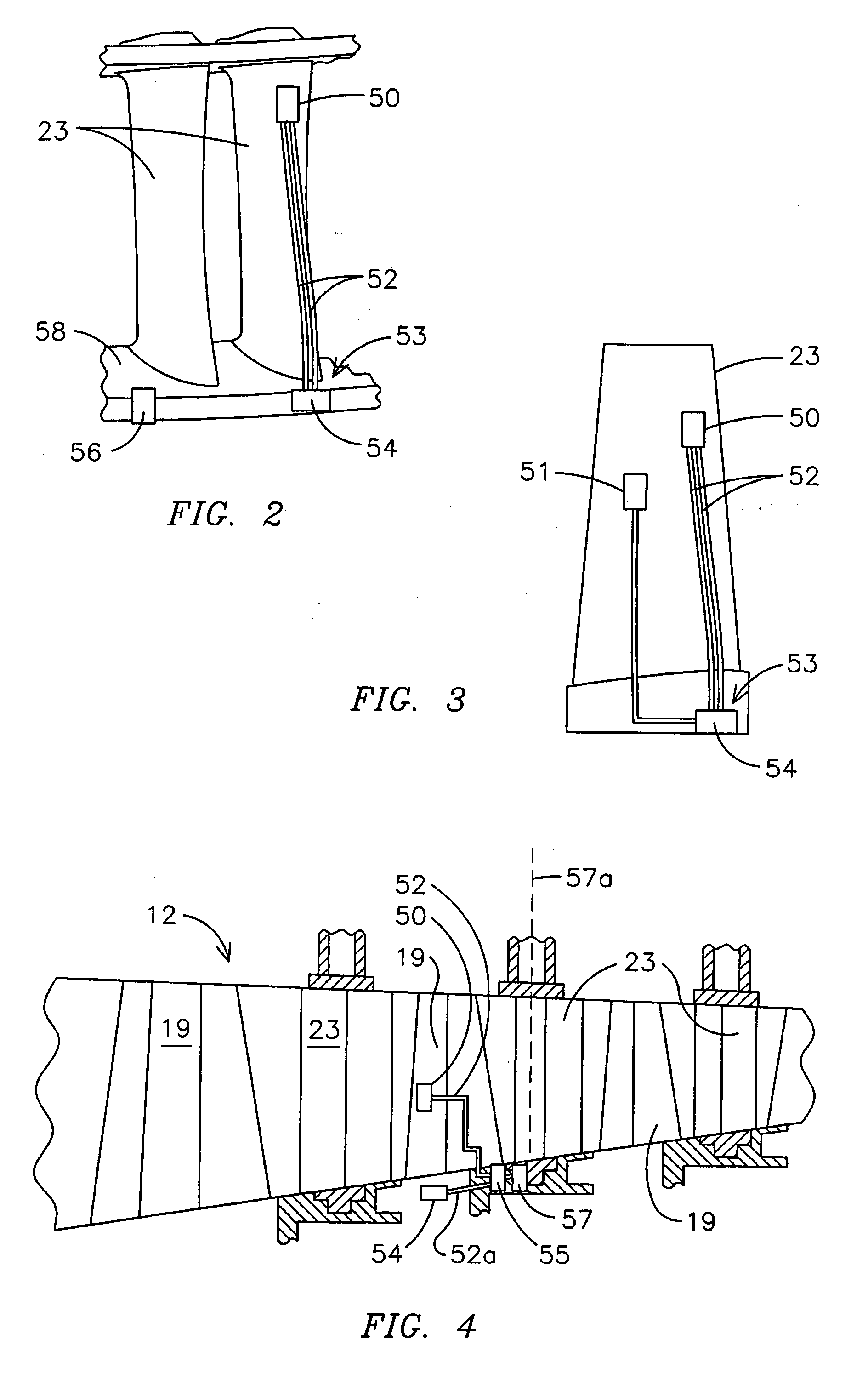

Apparatus and method of monitoring operating parameters of a gas turbine

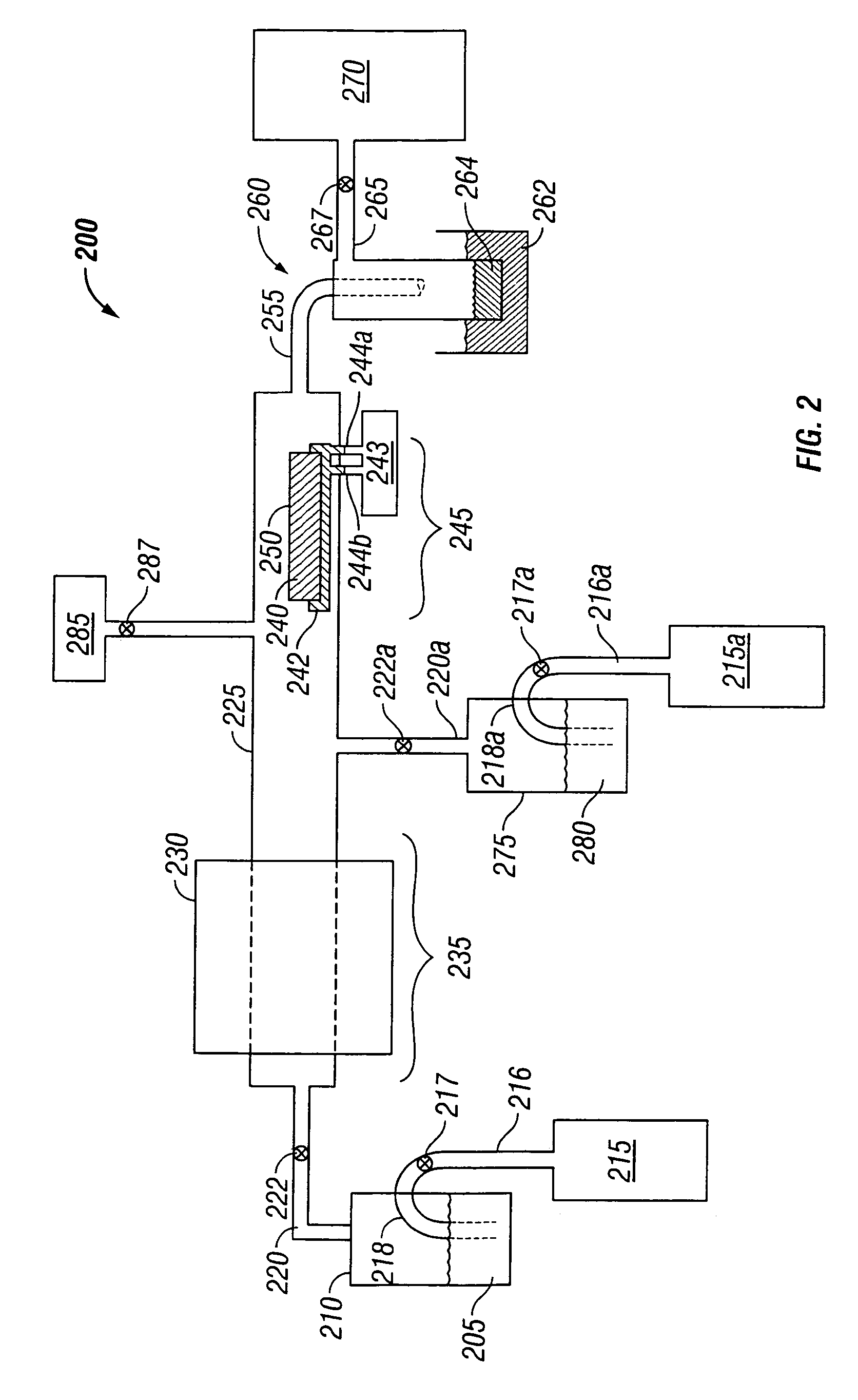

A component for use in a combustion turbine (10) is provided that includes a substrate (212) and a microelectromechanical system (MEMS) device (50, 250) affixed to the substrate (212). At least one connector (52) may be deposited in electrical communication with the MEMS device (50, 250) for routing a data signal from the MEMS device (50, 250) to a termination location (59). A barrier coating (216) may be deposited on the substrate (212) wherein the MEMS device (50, 250) is affixed beneath a surface of the barrier coating (216). A plurality of trenches (142) may be formed in the barrier coating (216) at respective different depths below the surface of the barrier coating (216) and a MEMS device (50, 250) deposited within each of the plurality of trenches (142). A monitoring system (30) is provided that may include a processing module (34) programmed for receiving data from the MEMS device (50, 250).

Owner:SIEMENS ENERGY INC

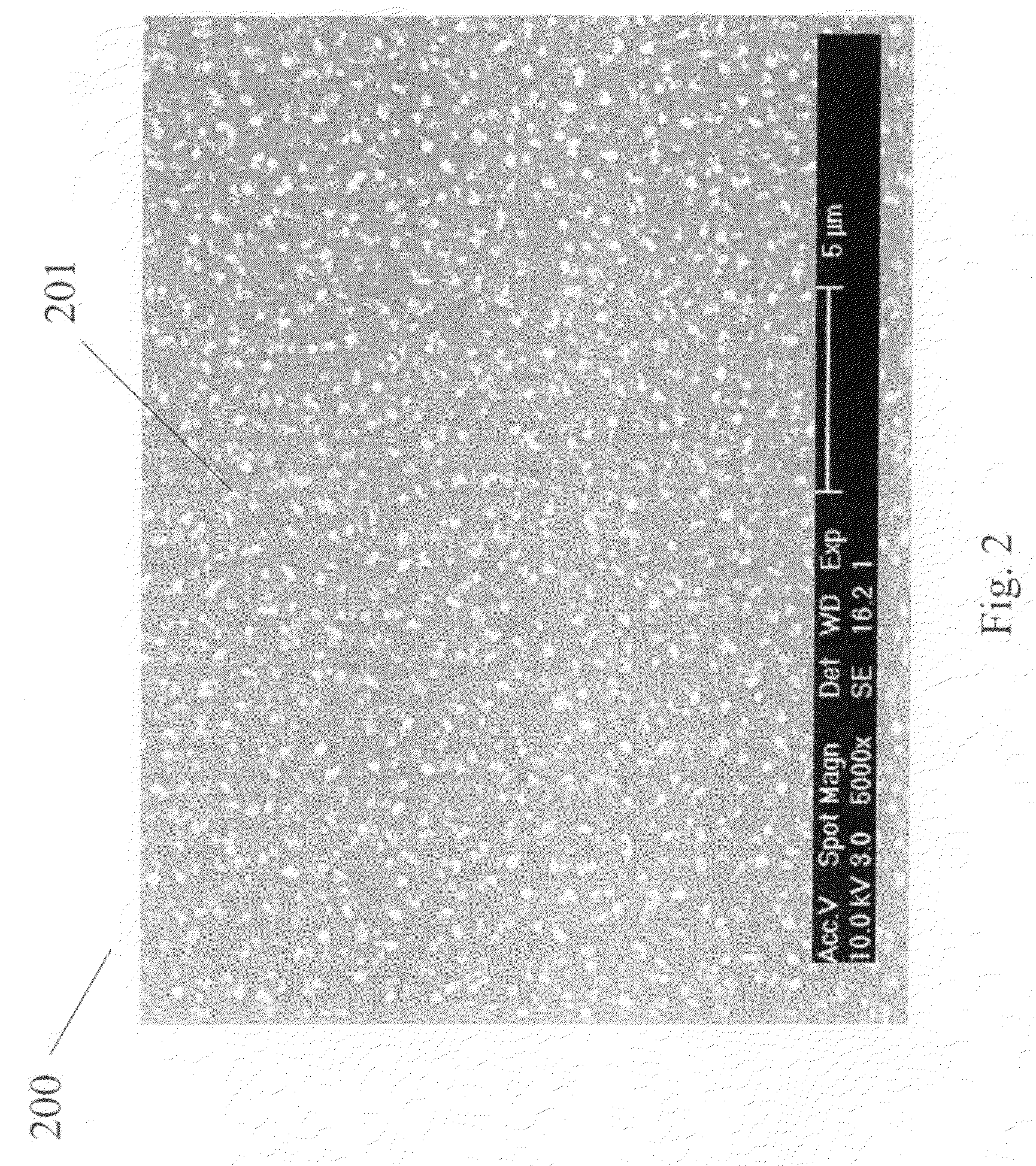

Nano/micro-textured surfaces and methods of making same by aluminum-induced crystallization of amorphous silicon

InactiveUS20090176018A1Enhanced cell attachmentPromote cell growthVacuum evaporation coatingSputtering coatingAmorphous siliconMicroelectromechanical systems

The present invention discloses a method of surface texturing at nano / micro-scale by aluminum-induced rapid crystallization of amorphous silicon for controlling the wettability of a surface, enhancing cell attachment to a surface, and promoting cell growth on a surface. The present invention can be used in a variety of applications, such as producing superhydrophobic or superhydrophilic surfaces for medical devices, microelectromechanical systems, and microfluidic channels.

Owner:ZOU MIN +1

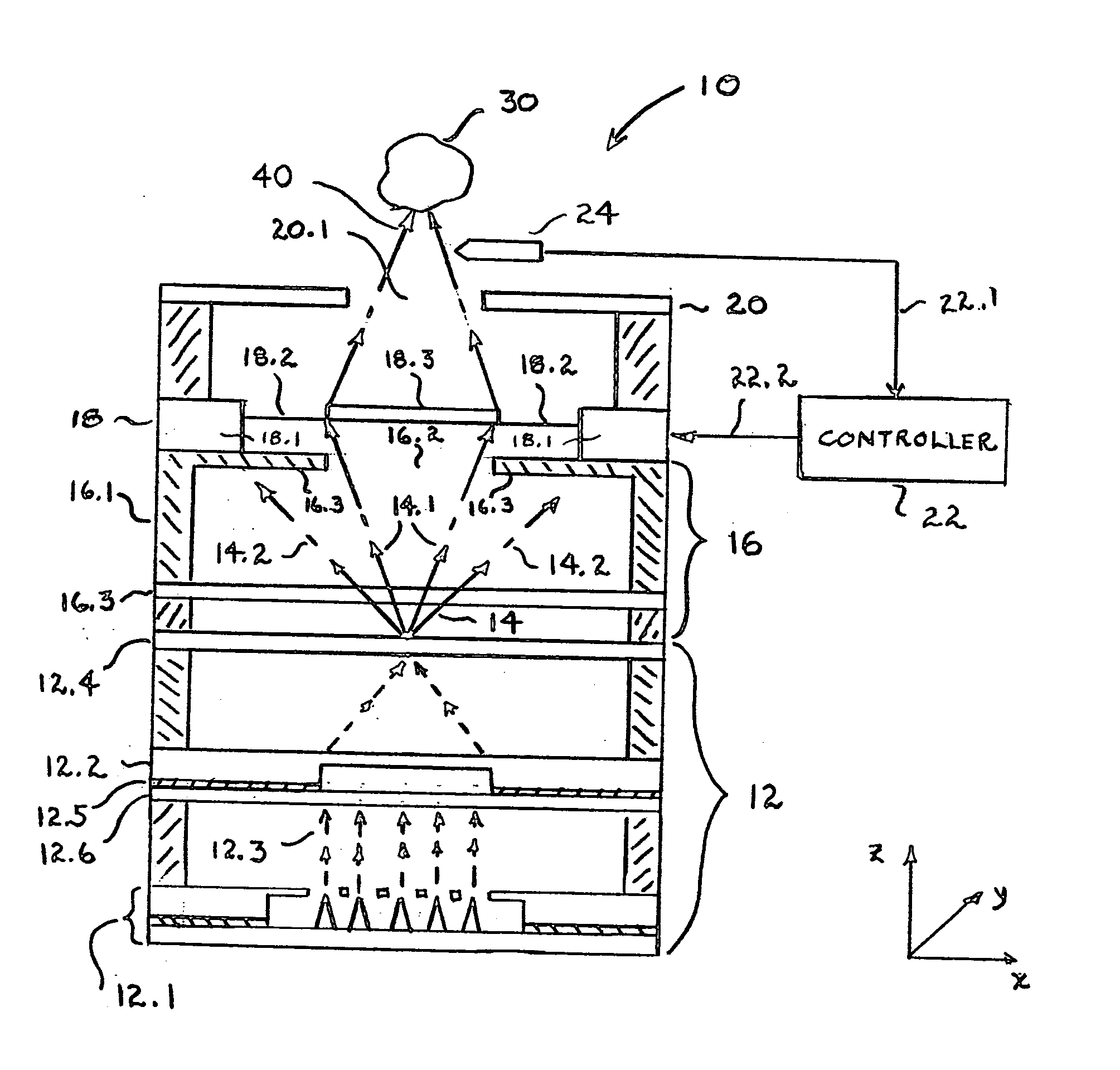

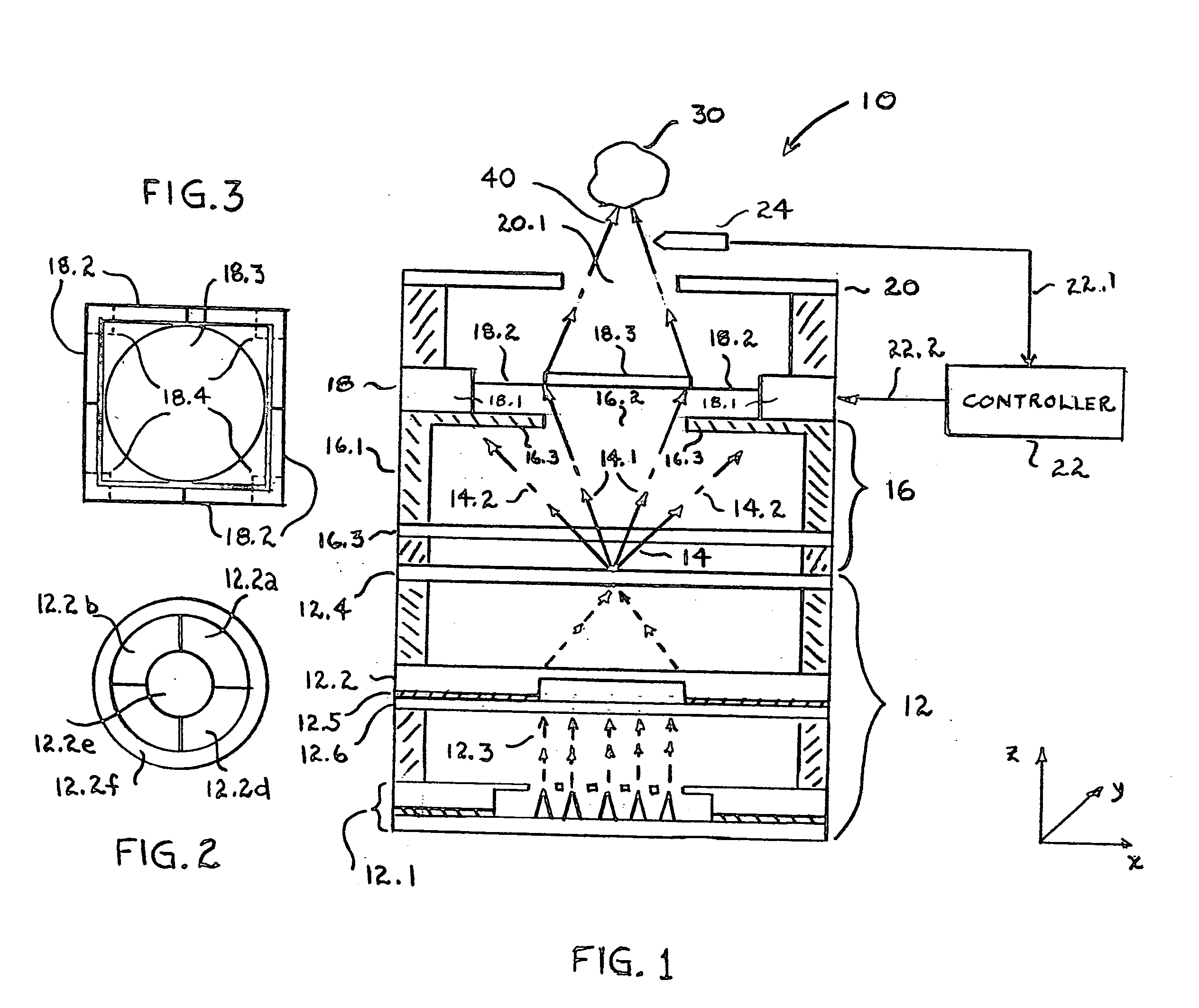

Microelectrical mechanical structure (MEMS) optical modulator and optical display system

InactiveUS20050002086A1Eliminating light attenuation of lightEliminating expenseTelevision system detailsColor television detailsPlanar substrateActuator

A MEMS optical display system includes an illumination source for providing illumination light, a collimating lens for receiving the illumination light and forming from it collimated illumination light, and a converging microlens array having an array of lenslets that converge the collimated illumination light. The converging microlens array directs the illumination light to a microelectrical mechanical system (MEMS) optical modulator. The MEMS optical modulator includes, for example, a planar substrate through which multiple pixel apertures extend and multiple MEMS actuators that support and selectively position MEMS shutters over the apertures. A MEMS actuator and MEMS shutter, together with a corresponding aperture, correspond to pixel. The light from the converging microlens array is focused through the apertures and is selectively modulated according to the positioning of the MEMS shutters by the MEMS actuators, thereby to impart image information on the illumination light. The light is then passed to a diffused transmissive display screen by a projection microlens array.

Owner:MICROSOFT TECH LICENSING LLC

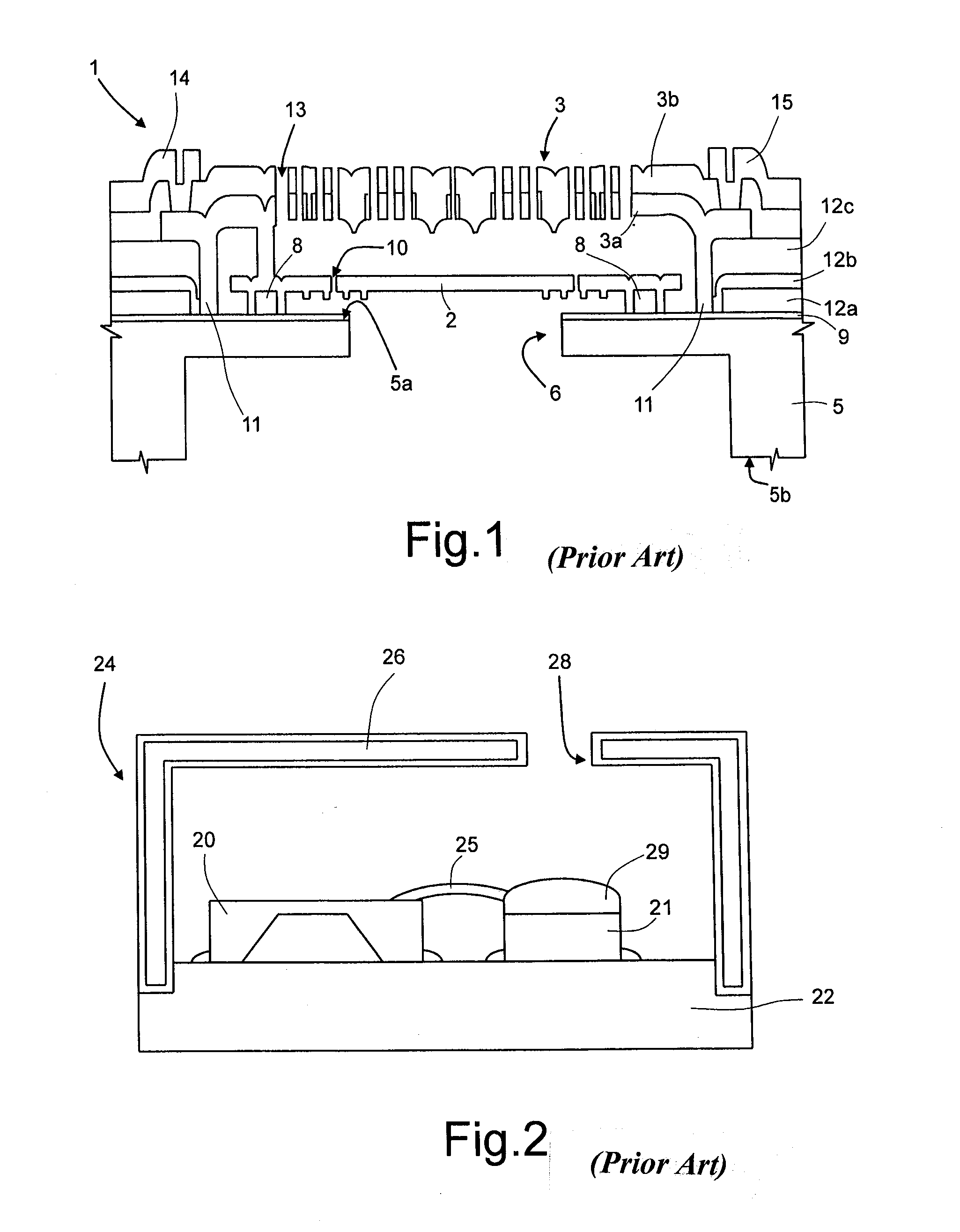

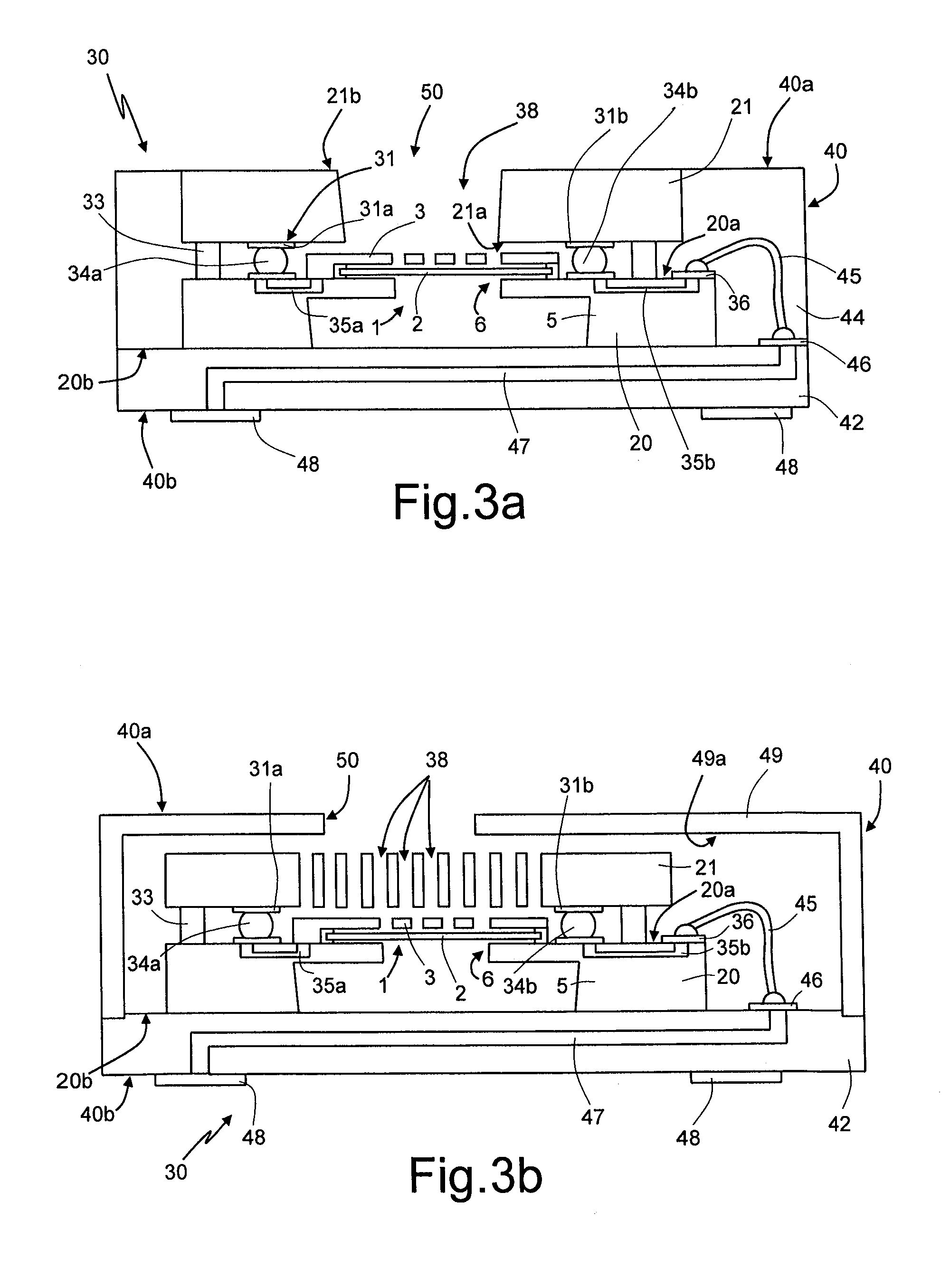

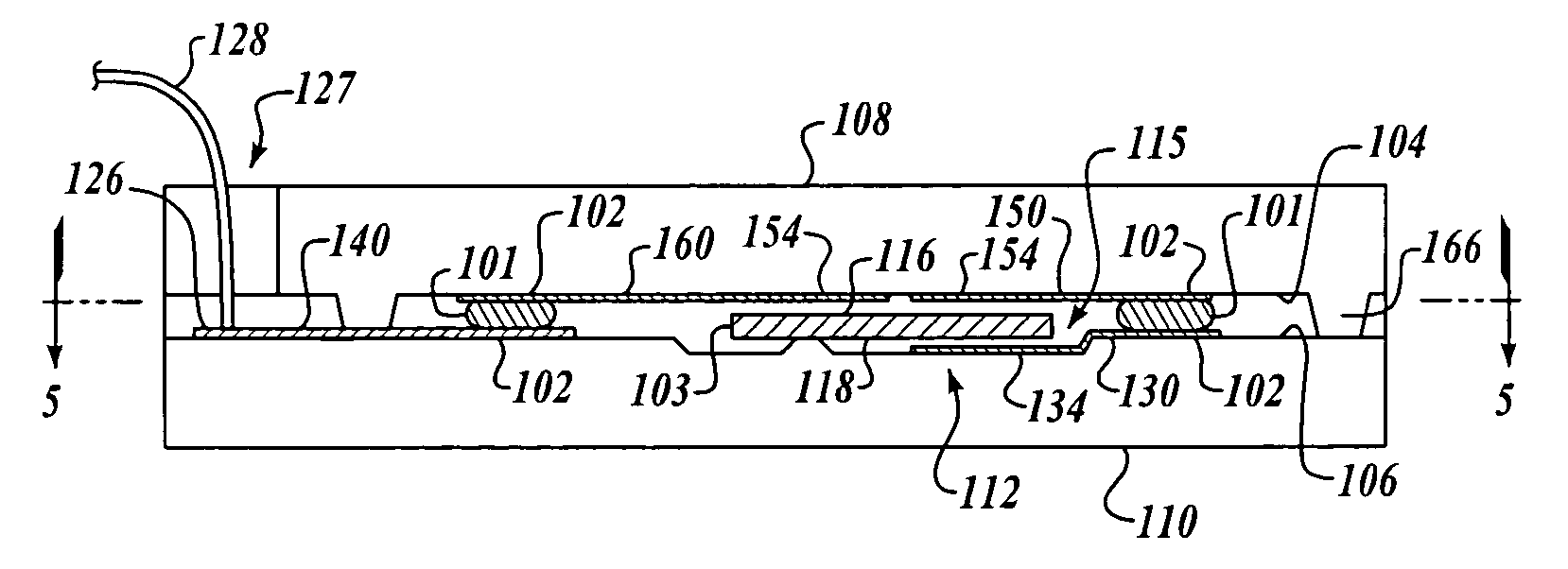

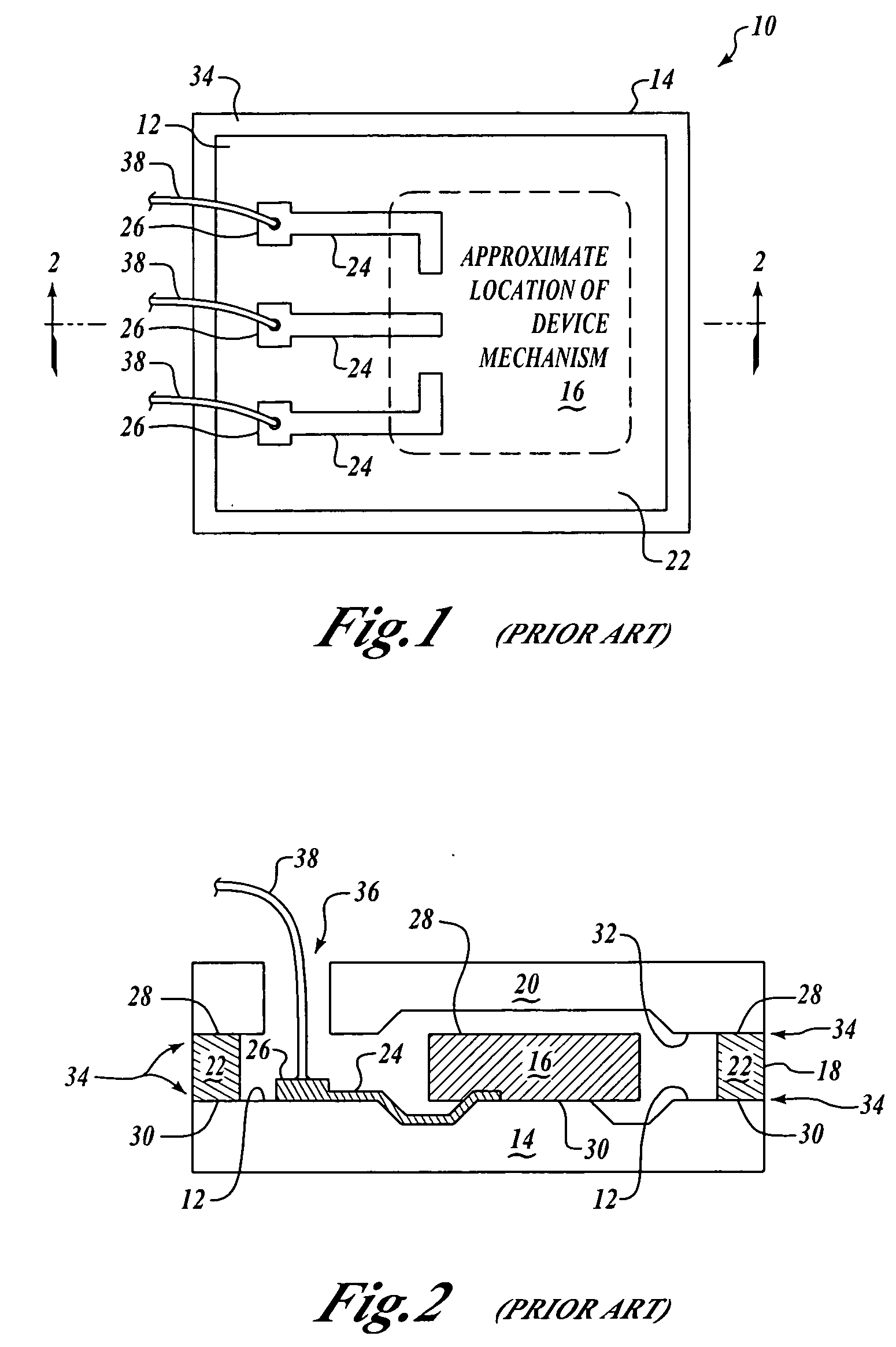

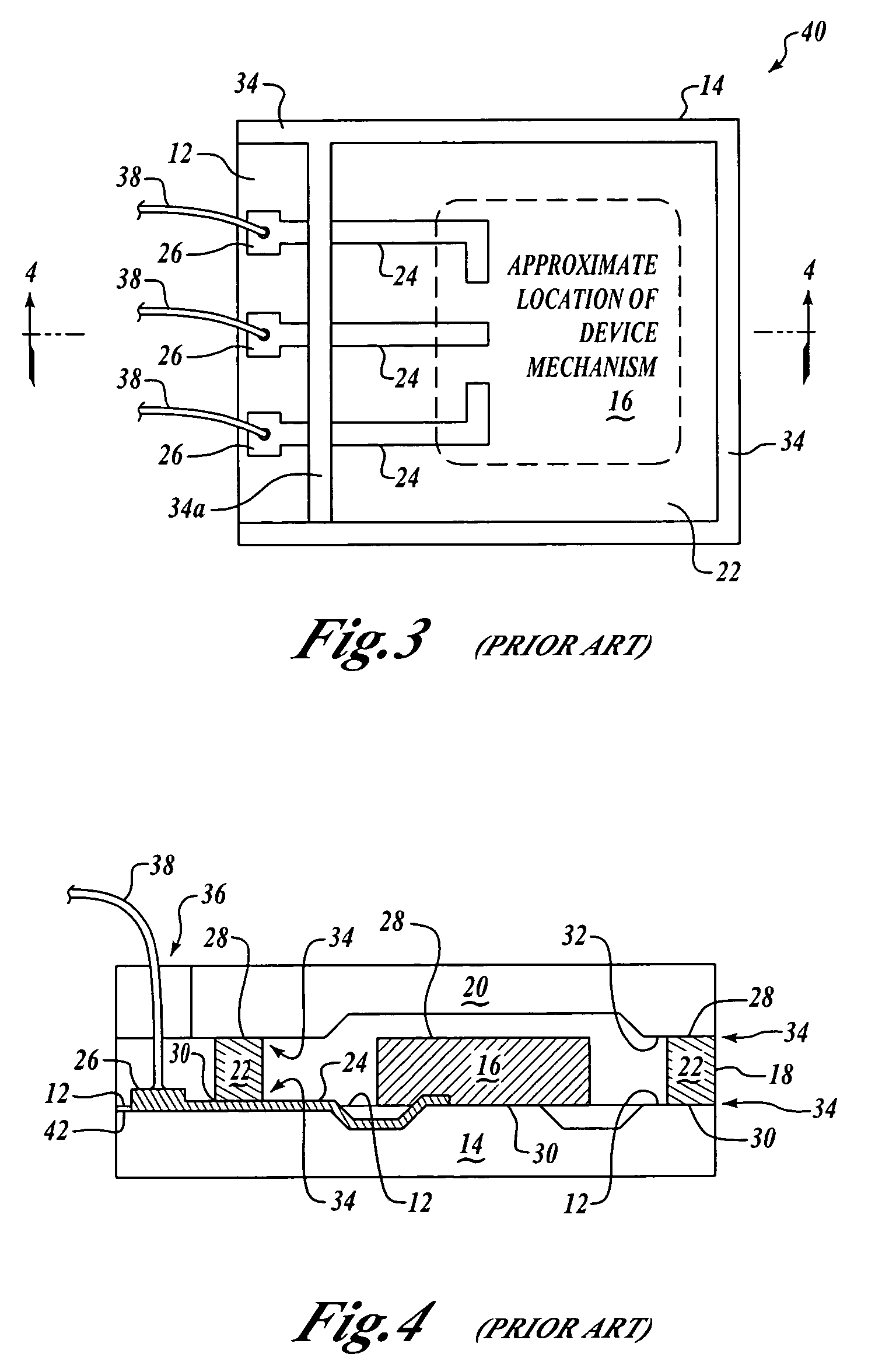

Flip chip bonded micro-electromechanical system (MEMS) device

InactiveUS20050205951A1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsEngineeringMicroelectromechanical systems

A micro-electromechanical system (MEMS) device having a pair of spaced apart top and bottom substrates or cover plates having mutually opposing inner surfaces structured to cooperate with a micro-machined electromechanical device mechanism, such as a micro-machined sensor or actuator mechanism. Such a micro-machined electromechanical device mechanism is coupled to the inner surface of one of the top and bottom substrates. A metal chip bond pad is formed on the inner surface of the bottom substrate and is electrically coupled to an electrical path; another metal chip bond pad formed on the inner surface of the top substrate in a complementary position opposite the chip bond pad on the bottom substrate; and an electrically conductive gold stud bump is mechanically and electrically coupled between the metal chip bond pads on the top and bottom substrates.

Owner:HONEYWELL INT INC

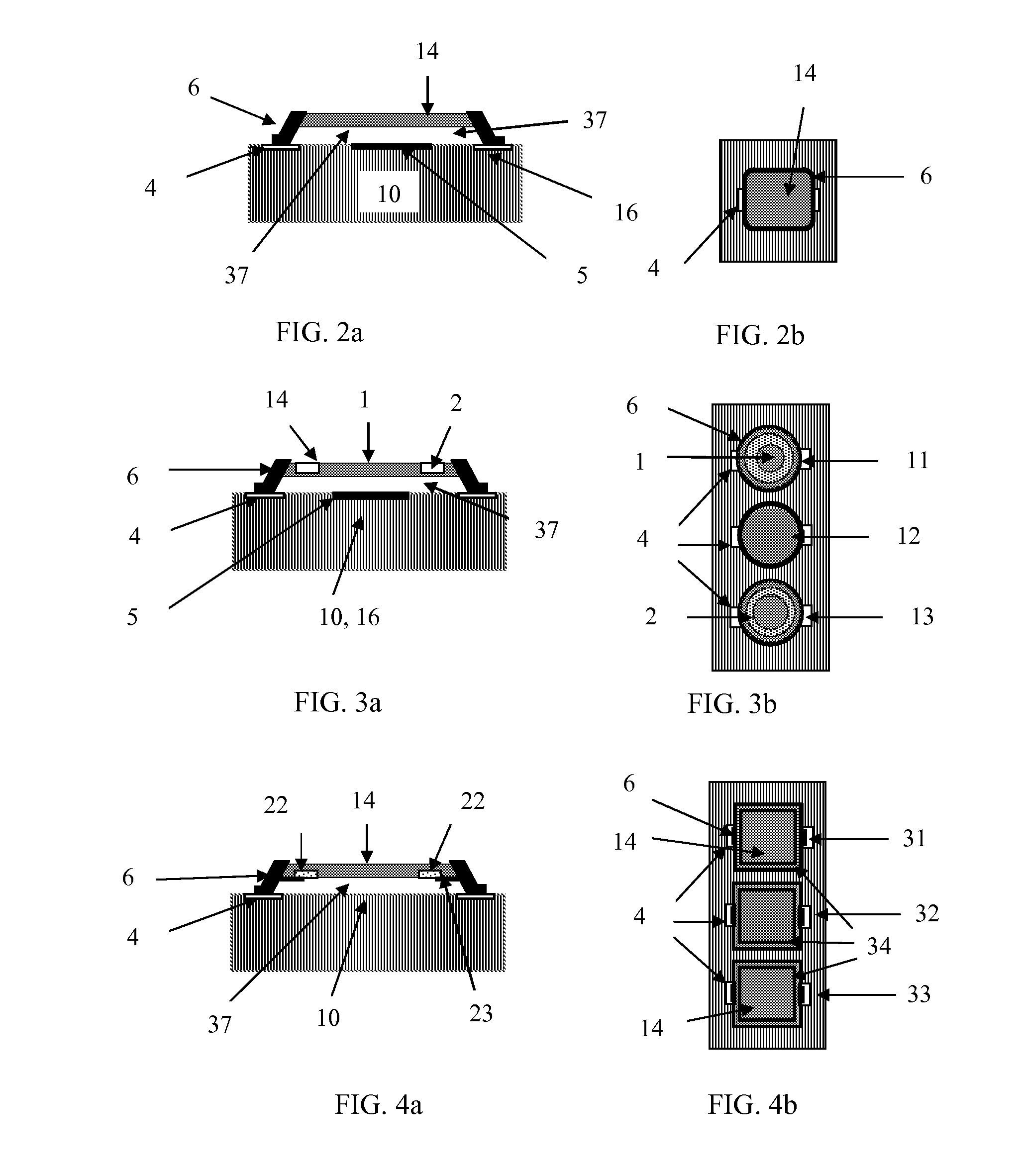

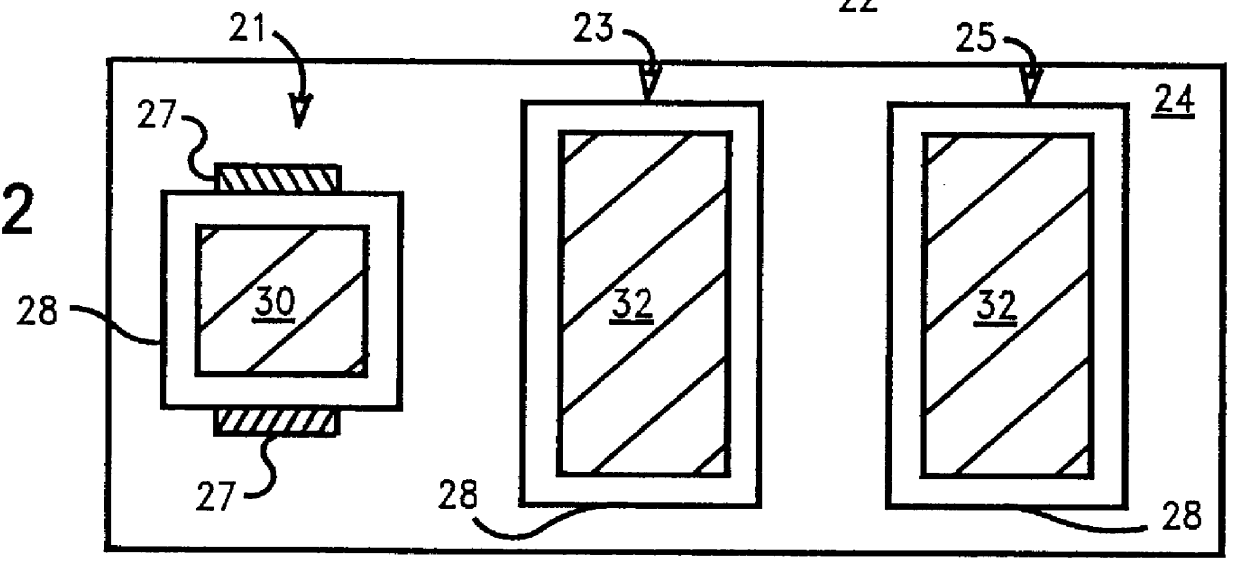

Packaging microelectromechanical structures

InactiveUS6852926B2Semiconductor/solid-state device detailsSolid-state devicesSemiconductor structureSurface mounting

A MEMS device may be formed in a hermetic cavity by sealing a pair of semiconductor structures to one another, enclosing the MEMS device. The two structures may be coupled using surface mount techniques as one example, so that the temperatures utilized may be compatible with many MEMS applications. Electrical interconnection layers in one or the other of these structures may be utilized to allow electrical interconnections from the exterior world to the MEMS components within the cavity.

Owner:INTEL CORP

Nonvolatile memory cell using microelectromechanical device

InactiveUS6054745ATransistorElectrostatic/electro-adhesion relaysControl signalMicroelectromechanical systems

A nonvolatile memory cell comprises a conductive cantilever beam having a free end in a first charge state, a first FET having a conductive gate in a second charge state and a pull-in electrode adapted to bring the cantilever beam into electrical contact with the gate to effect a charge state change in the gate. A pull-in electrode input is connected to the electrode, a cantilever input is connected to the cantilever, a column select input is connected to the first FET and a row select input is connected to the first FET. The nonvolatile memory cell is selected by signals applied to the row select input and the column select input. The cell also includes a second FET connected between the cantilever beam and the cantilever input for controlling the passage of signals from the cantilever input to the cantilever beam and a third FET connected between the pull-in electrode and the pull-in electrode input for controlling the passage of signals from the pull-in electrode input to the electrode. The second FET and third FET have gates connected to the row select input. The row select input turns on the second FET and the third FET to allow the passage of signals from the pull-in electrode input to the pull-in electrode and from the cantilever input to the cantilever beam when the nonvolatile memory cell is selected.

Owner:IBM CORP

Medical devices having MEMs functionality and methods of making same

ActiveUS20050177223A1High data densitySacrificing rangeInertial sensorsMeasuring/recording heart/pulse rateElectromagnetic potentialEngineering

Implantable medical devices, including stents, grafts, covered stents, catheters, patches or the like having regions of the device which are functionalized employing microelectromechanical systems that are capable of acting as electromechanical sensors or biosensors in response to either an endogenous event, such as tissue growth, biochemical binding events, pressure changes, or respond to an externally applied stimulus, such as RF energy, to cause a change in the state of the device, such as to induce an oscillation signal which may be interrogated and interpreted external the body or may generate an induced electrical or electromagnetic potential in the device to activate micromotors to effect a geometric change in the device.

Owner:VACTRONIX SCI LLC

Microelectromechanical RF and microwave frequency power regulator

InactiveUS6847266B2Electrostatic/electro-adhesion relaysCurrent interference reductionContact padEngineering

Microelectromechanical RF and microwave frequency power limiter and electrostatic protection devices for use in high-speed circuits are presented. The devices utilize an airbridge or a cantilever arm including a contact pad positioned operatively adjacent to an electrically conductive and substantially planar transmission line. When the power level in the transmission line exceeds a particular threshold, the airbridge or cantilever arm yields due to force between the contact pad and the transmission line, directing undesired power away from active devices. This characteristic can either serve as a method by which to limit the amount of power passing through the transmission line to a determined value or as a method by which to protect devices along the transmission line from damage due to large electrostatic bursts.

Owner:HRL LAB

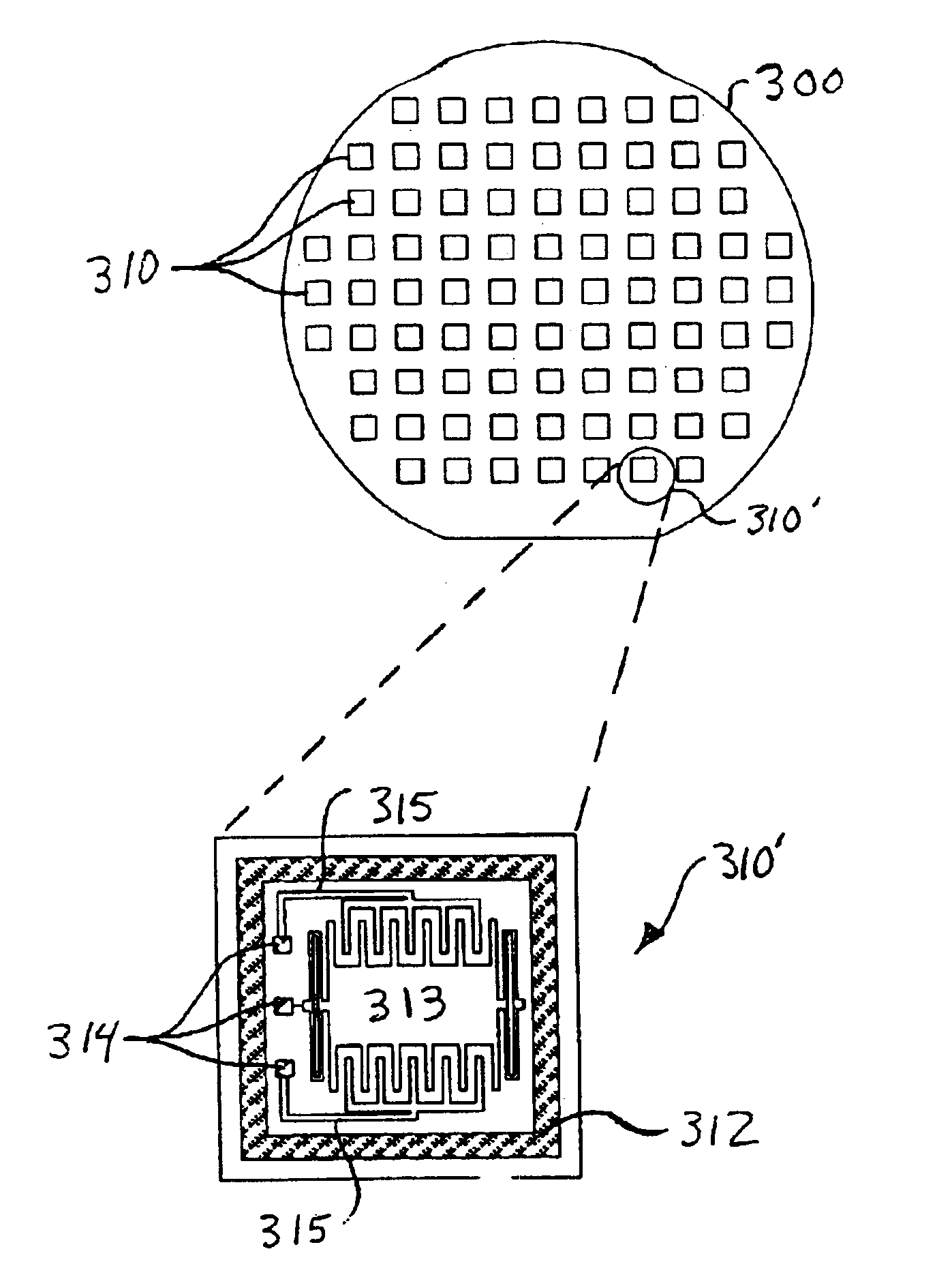

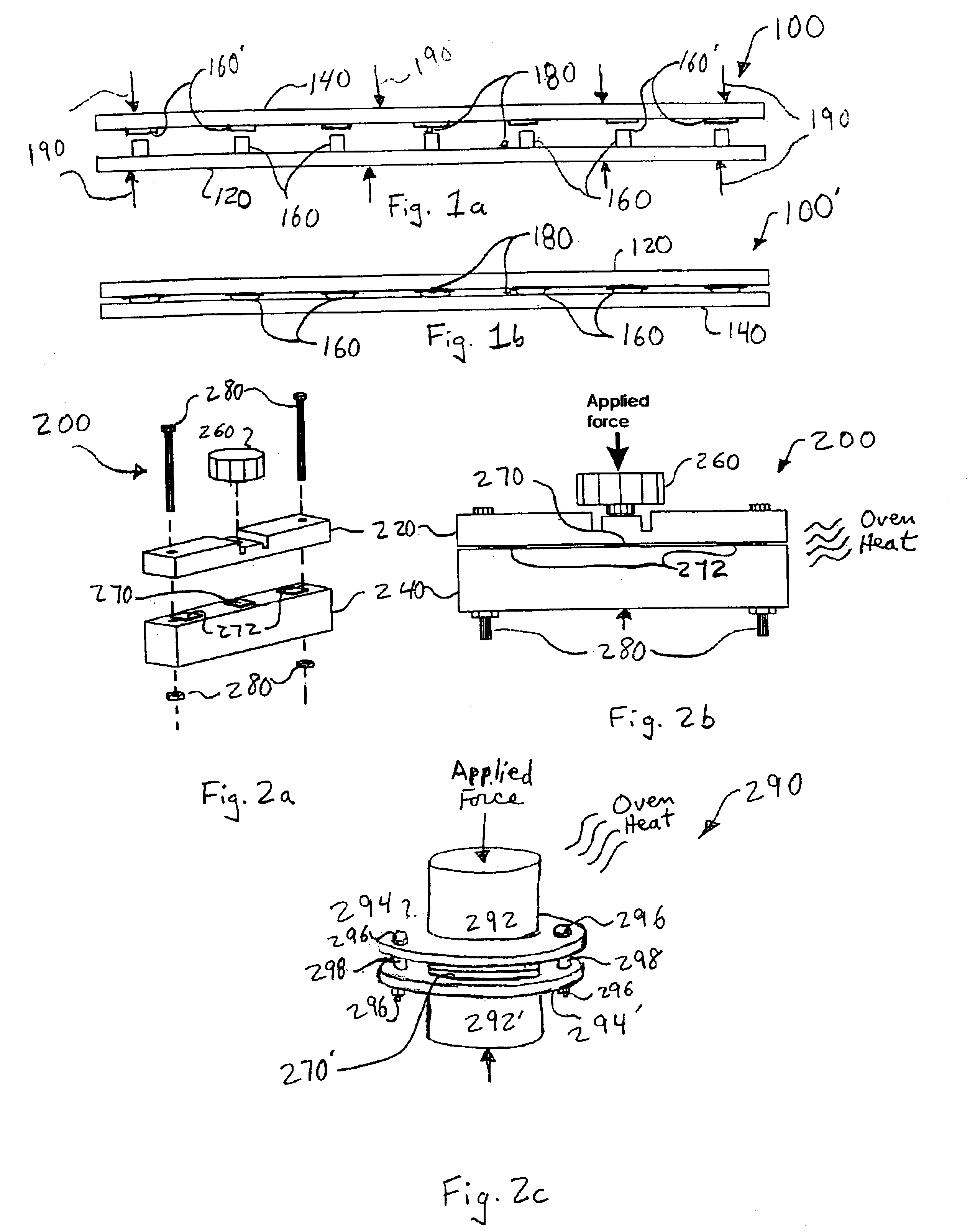

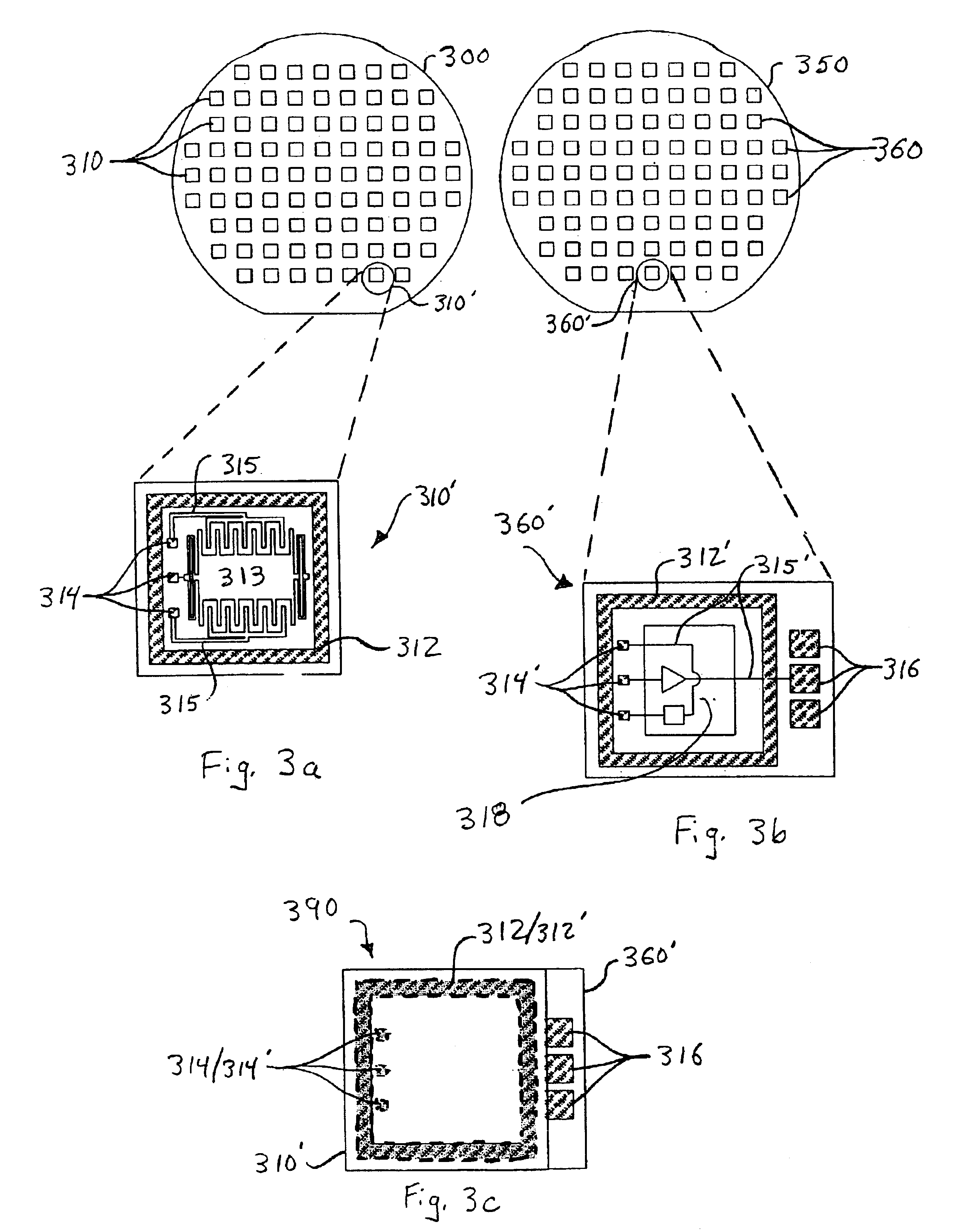

Microelectromechanical systems using thermocompression bonding

InactiveUS6853067B1Reduce parasitic capacitanceReduce parasitismDecorative surface effectsSemiconductor/solid-state device detailsReduced sizeEngineering

Improved microelectromechanical systems (MEMS), processes and apparatus using thermocompression bonding are disclosed. For example, process embodiments are disclosed in which wafer-scale as well as die-scale thermocompression bonding is utilized to encapsulate MEMS and / or to provide electrical interconnections with MEMS. Apparatus embodiments include apparatus for performing thermocompression bonding and bonded hybrid structures manufactured in accordance with the process embodiments. Devices having various substrate bonding and / or sealing configurations variously offer the advantage of reduced size, higher manufacturing yields, reduced costs, improved reliability, improved compatibility with existing semiconductor manufacturing process and / or greater versatility of applications.

Owner:MICROASSEMBLY TECH

Focusable and steerable micro-miniature x-ray apparatus

ActiveUS20050105690A1Inexpensive to fabricateUse disposableX-ray tube windowsHandling using diaphragms/collimetersX-rayEngineering

A micro-miniature x-ray apparatus comprises: a first chip subassembly including a source of x-rays including both Bremsstrahlung photons and characteristic x-rays; a second chip subassembly including a filter for transmitting the characteristic x-rays and blocking the Bremsstrahlung photons; a third chip subassembly including a movable element for focusing or collimating the transmitted characteristic x-rays into a beam and means for controlling the position of the focusing element. In one embodiment, the controlling means include a micro-electromechanical system (MEMS). In another embodiment, the position of the movable element determines how the x-ray beam is steered to the focal area. In still another embodiment, the x-ray source includes a field emitter electron source and a target responsive to the electrons for generating x-rays. In this case, the x-ray beam is also steered by selectively energizing the anode segments. In yet another embodiment, the movable element includes a Fresnel zone plate; in still another embodiment it includes an array of poly-capillaries. Advantageously, our x-ray source, including its focusing, collimating and steering components, can be fabricated small enough to be mounted at the end of a catheter. In addition, in some embodiments it can also fabricated sufficiently inexpensively to be disposable after each use.

Owner:LUCENT TECH INC

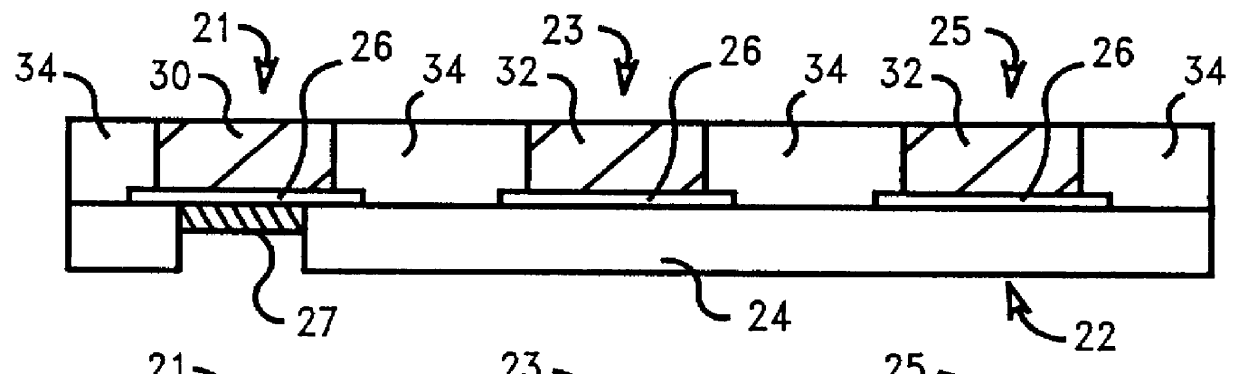

Medical devices having MEMs functionality and methods of making same

ActiveUS7235098B2Accelerate endothelializationPromote formationInertial sensorsMeasuring/recording heart/pulse rateElectricityElectromagnetic potential

Implantable medical devices, including stents, grafts, covered stents, catheters, patches or the like having regions of the device which are functionalized employing microelectromechanical systems that are capable of acting as electromechanical sensors or biosensors in response to either an endogenous event, such as tissue growth, biochemical binding events, pressure changes, or respond to an externally applied stimulus, such as RF energy, to cause a change in the state of the device, such as to induce an oscillation signal which may be interrogated and interpreted external the body or may generate an induced electrical or electromagnetic potential in the device to activate micromotors to effect a geometric change in the device.

Owner:VACTRONIX SCI LLC

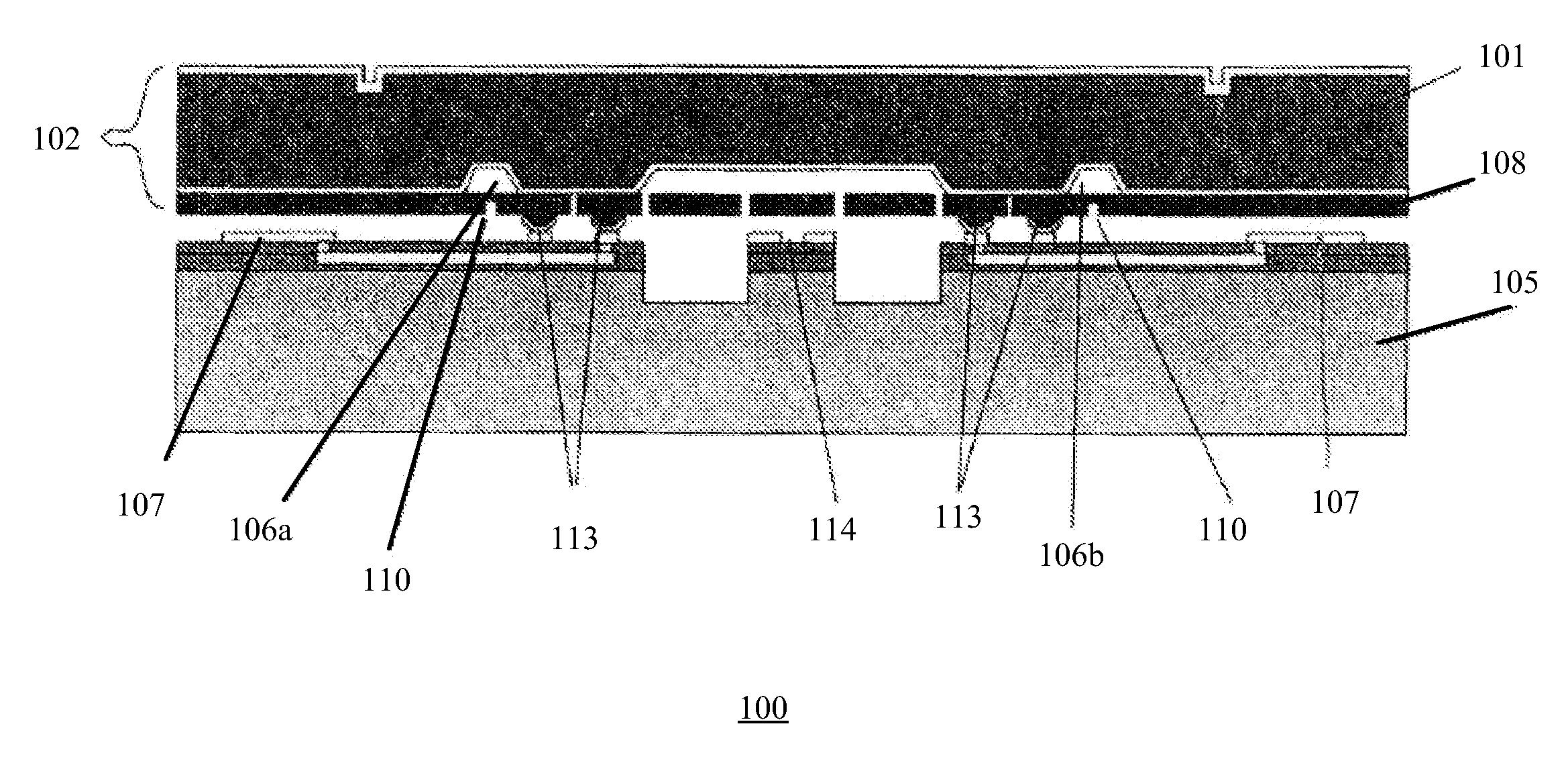

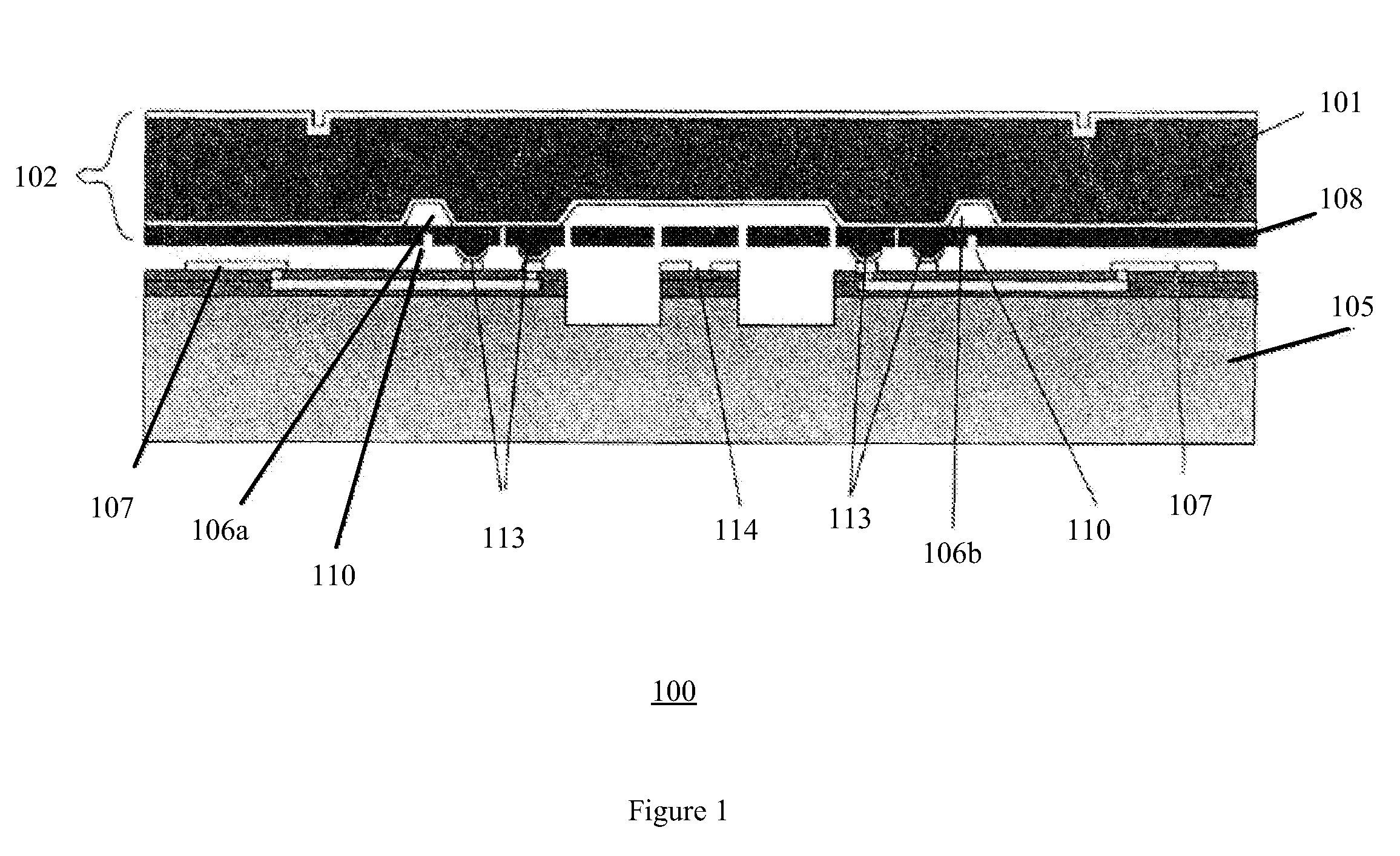

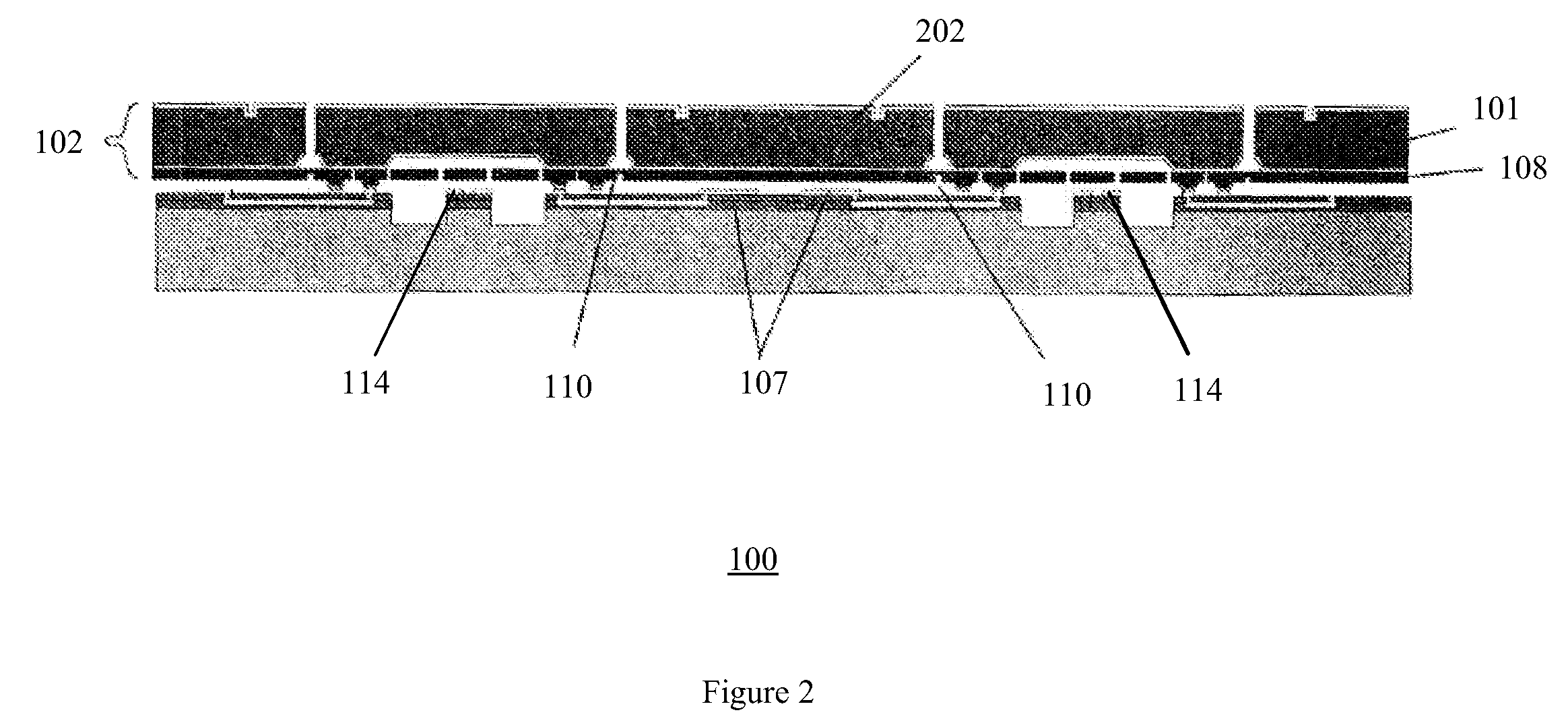

Wafer level interconnection

InactiveUS20030047799A1Television system detailsPiezoelectric/electrostriction/magnetostriction machinesDielectricElectrical conductor

RF MicroElectroMechanical Systems (MEMS) circuitry (15) on a first high resistivity substrate (17) is combined with circuitry (11) on a second low resistivity substrate (13) by overlapping the first high resistivity substrate (17) and MEMS circuitry (15) with the low resistivity substrate (13) and circuitry (11) with the MEMS circuitry (15) facing the second circuitry (11). A dielectric lid (19) is placed over the MEMS circuitry (15) and between the first substrate (17) and second substrate (13) with an inert gas in a gap (21) over the MEMS circuitry (15). Interconnecting conductors (25, 31, 35, 37, 39, 41) extend perpendicular and through the high resistivity substrate (17) and through the dielectric lid (19) to make electrical connection with the low resistivity substrate (13).

Owner:RAYTHEON CO

Apparatus, precursors and deposition methods for silicon-containing materials

A method for making a Si-containing material comprises transporting a pyrolyzed Si-precursor to a substrate and polymerizing the pyrolyzed Si-precursor on the substrate to form a Si-containing film. Polymerization of the pyrolyzed Si-precursor may be carried out in the presence of a porogen to thereby form a porogen-containing Si-containing film. The porogen may be removed from the porogen-containing Si-containing film to thereby form a porous Si-containing film. Preferred porous Si-containing films have low dielectric constants and thus are suitable for various low-k applications such as in microelectronics and microelectromechanical systems.

Owner:ASM JAPAN

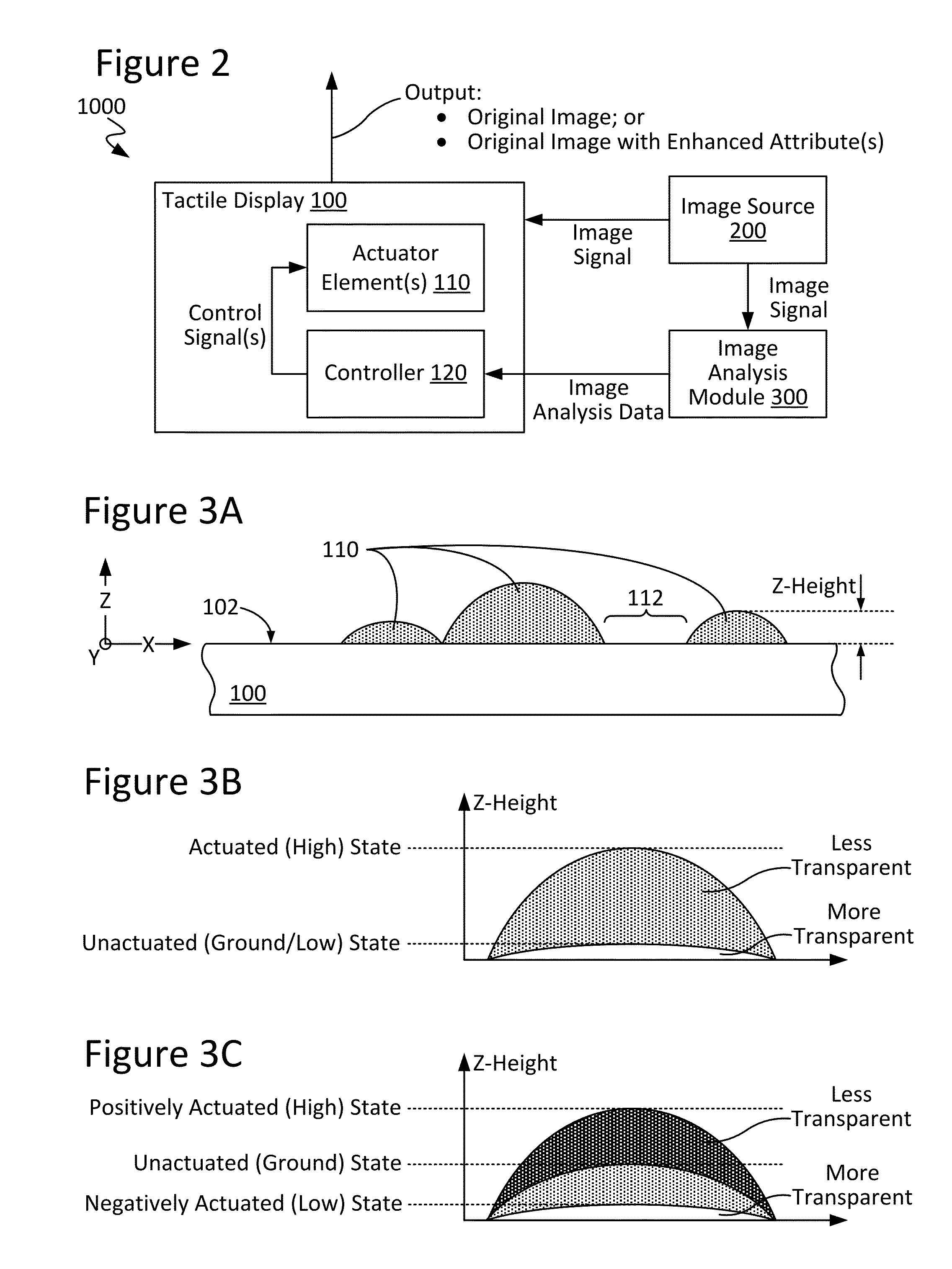

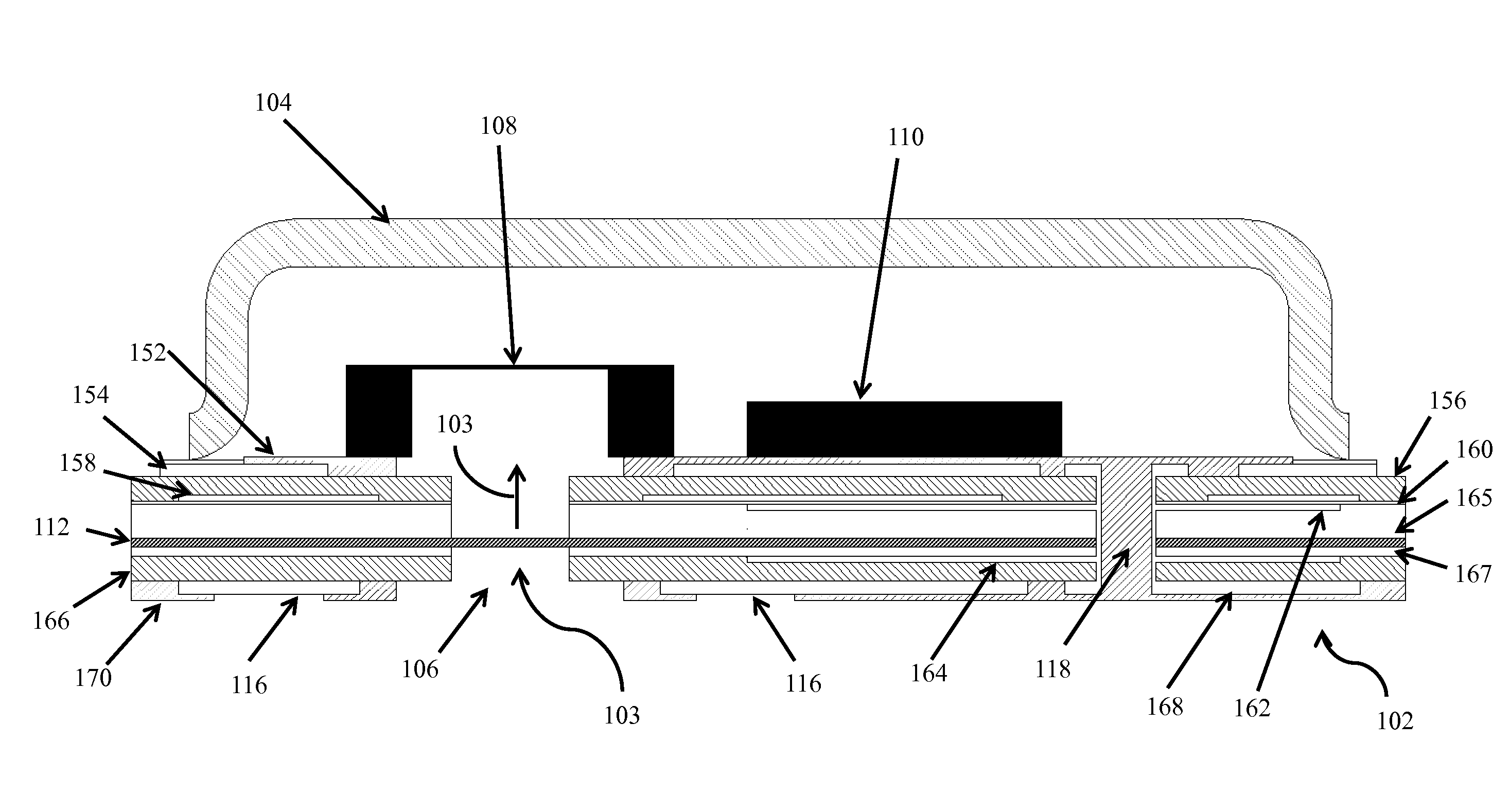

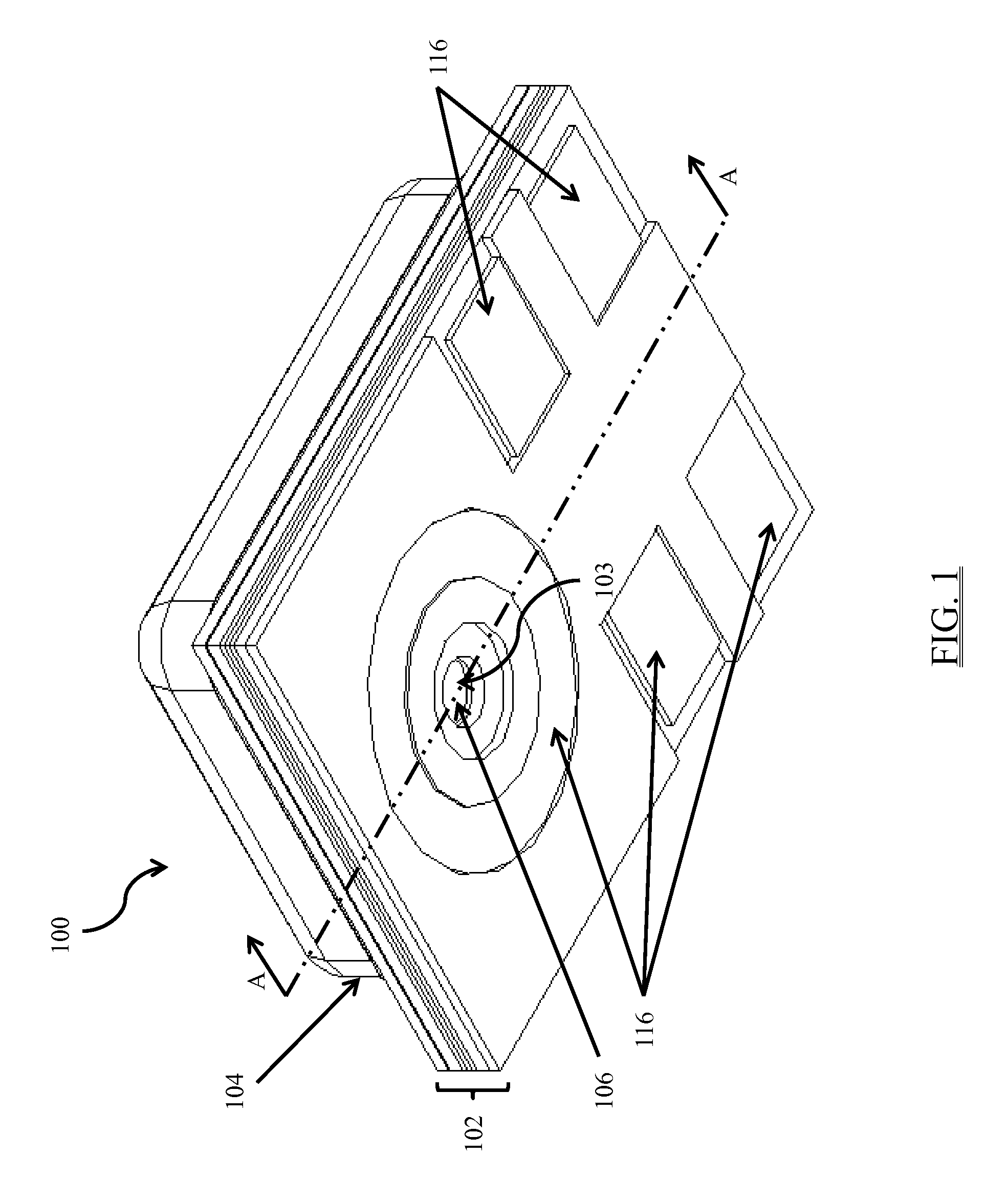

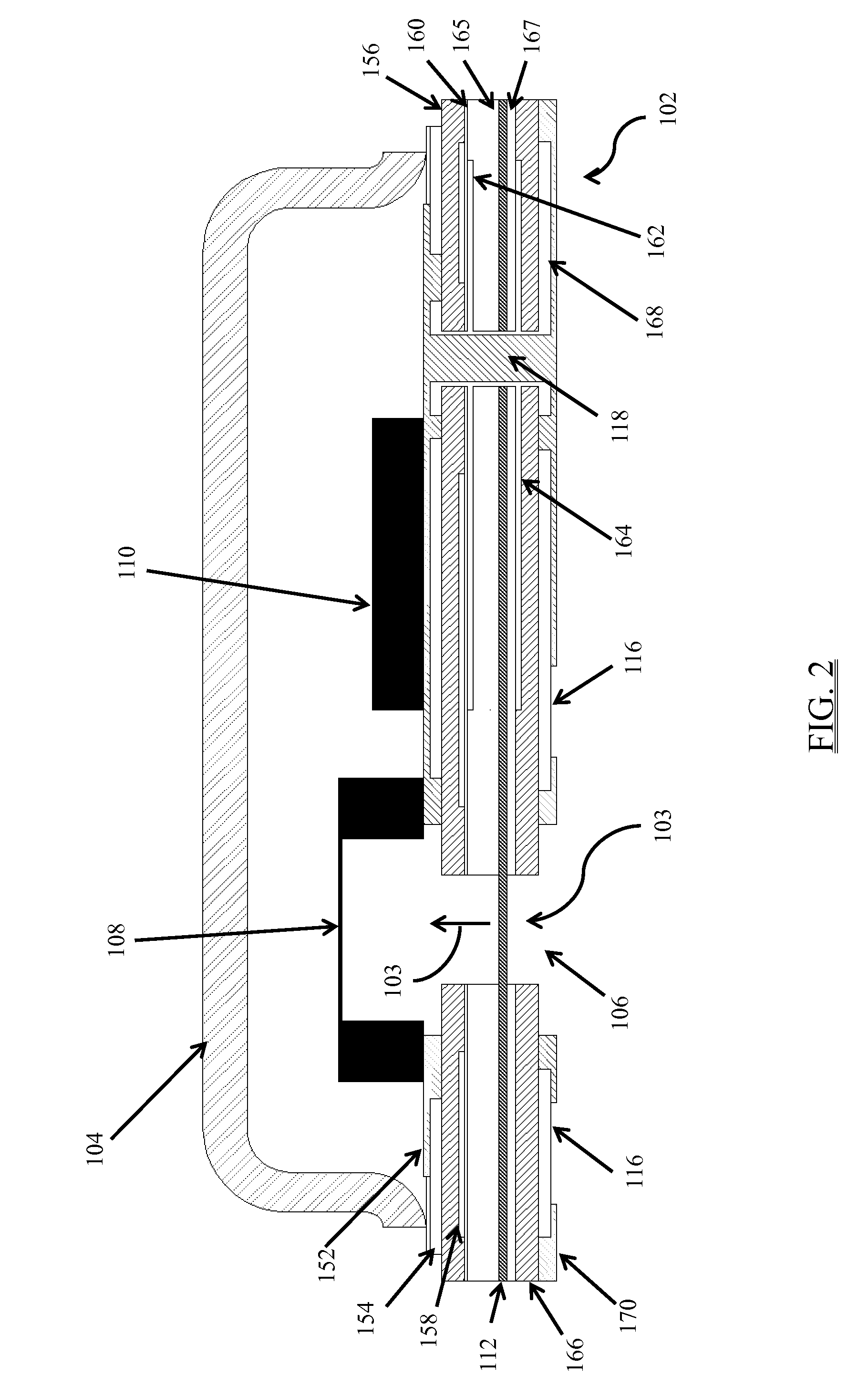

Techniques for image enhancement using a tactile display

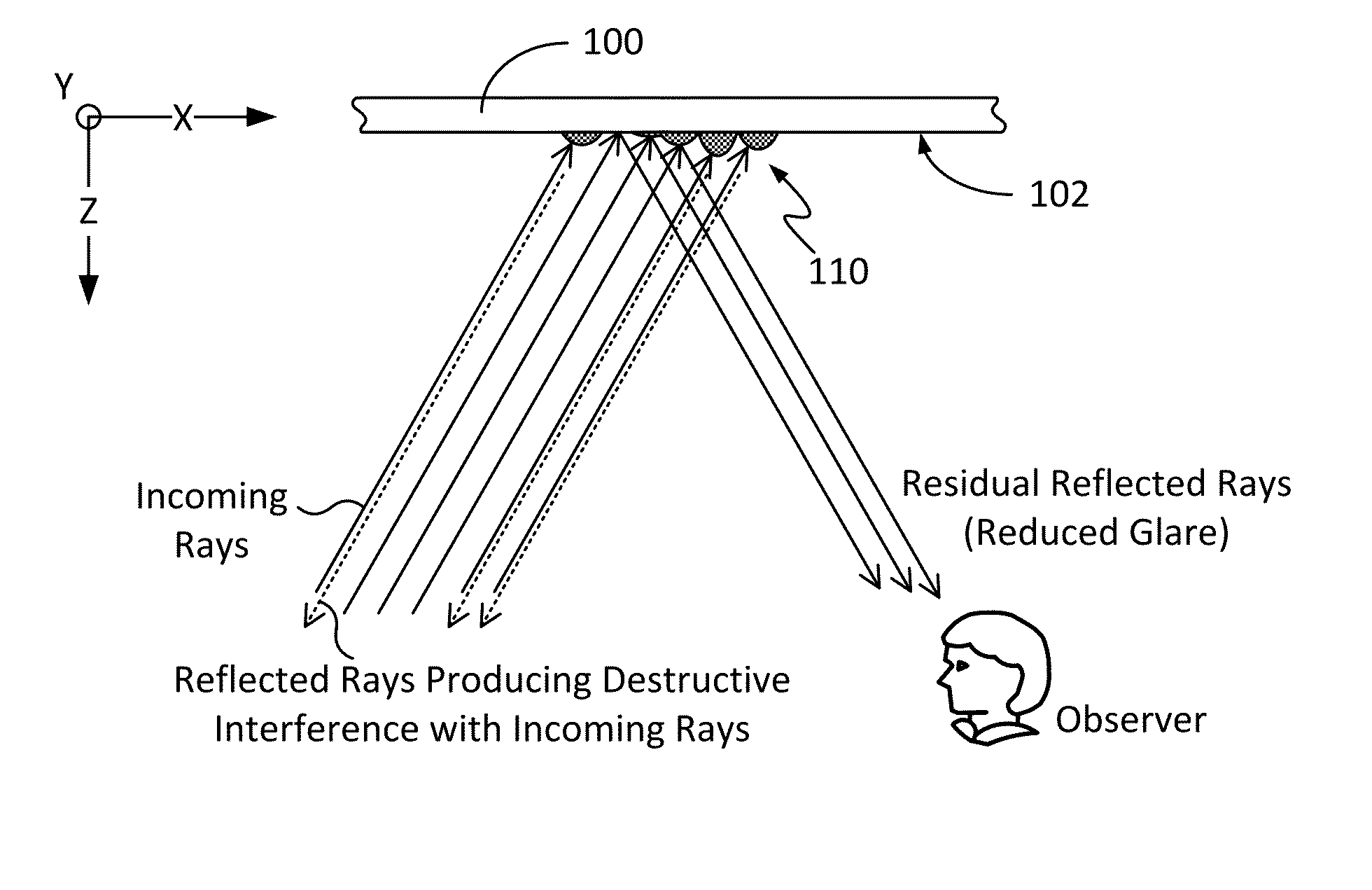

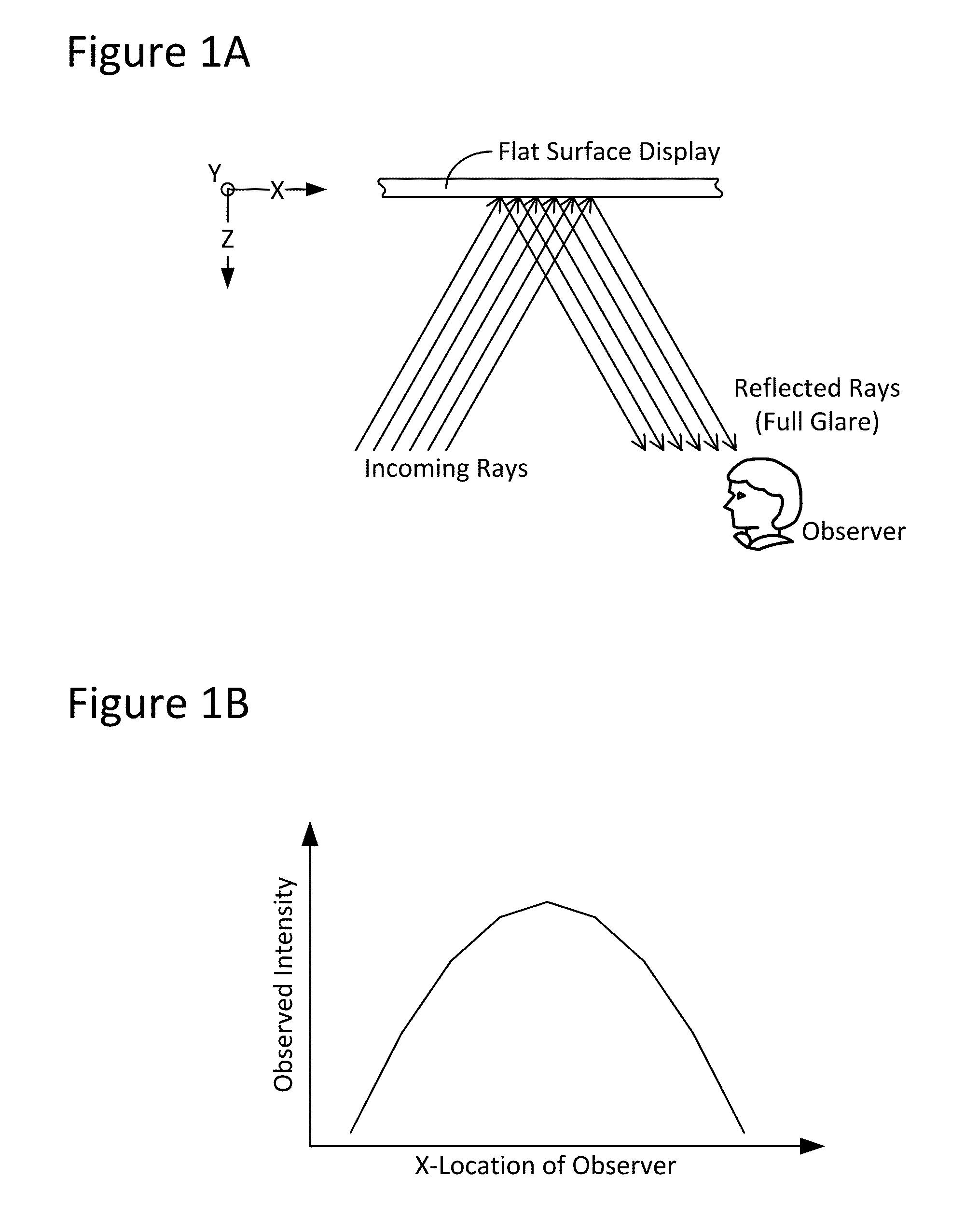

Techniques are disclosed for enhancing the quality of a displayed image using a tactile or other texture display. In particular, the disclosed techniques leverage active-texture display technology to enhance the quality of graphics by providing, for example, outlining and / or shading when presenting a given image, so as to create the effect of increased contrast and image quality and / or to reduce observable glare. These effects can be present even at high viewing angles and in environments of high light reflection. To these ends, one or more graphics processes, such as edge-detection and / or shading, may be applied to an image to be displayed. In turn, an actuator element (e.g., microelectromechanical systems, or MEMS, devices) of the tactile display may be manipulated (e.g., in Z-height) to provide fine-grain adjustment of image attributes such as: pixel brightness / intensity; pixel color; edge highlighting; object outlining; effective shading; image contrast; and / or viewing angle.

Owner:INTEL CORP

Microphone Assembly With Barrier To Prevent Contaminant Infiltration

ActiveUS20140044297A1Piezoelectric/electrostrictive microphonesMicrophonesMicroelectromechanical systemsMechanical engineering

A microphone assembly includes a cover, a base coupled to the cover, a microelectromechanical system (MEMS) device disposed on the base. An opening is formed in the base and the MEMS device is disposed over the opening. The base includes a barrier that extends across the opening and is porous to sound. The remaining portions of the base do not extend across the opening.

Owner:KNOWLES ELECTRONICS INC

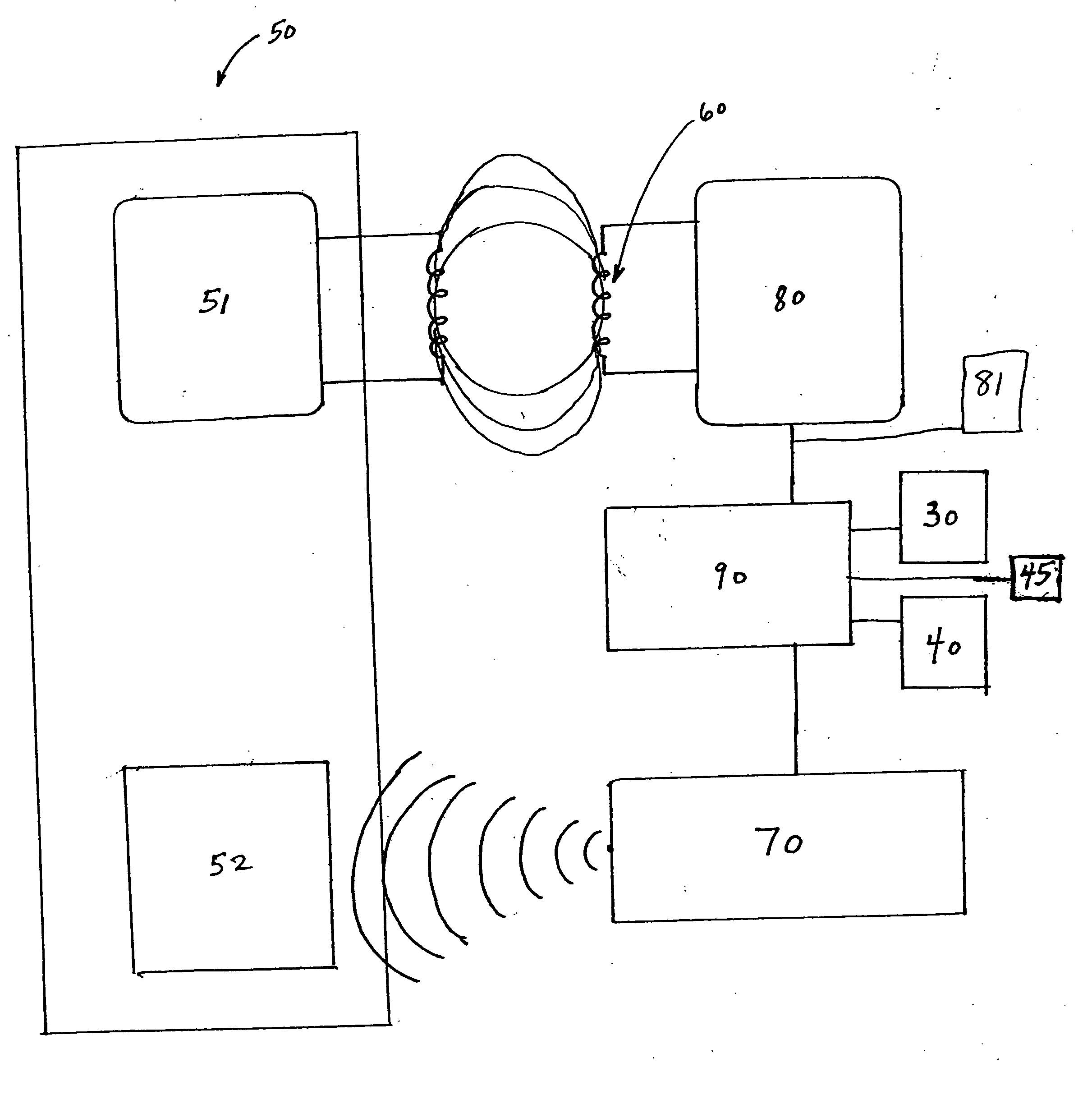

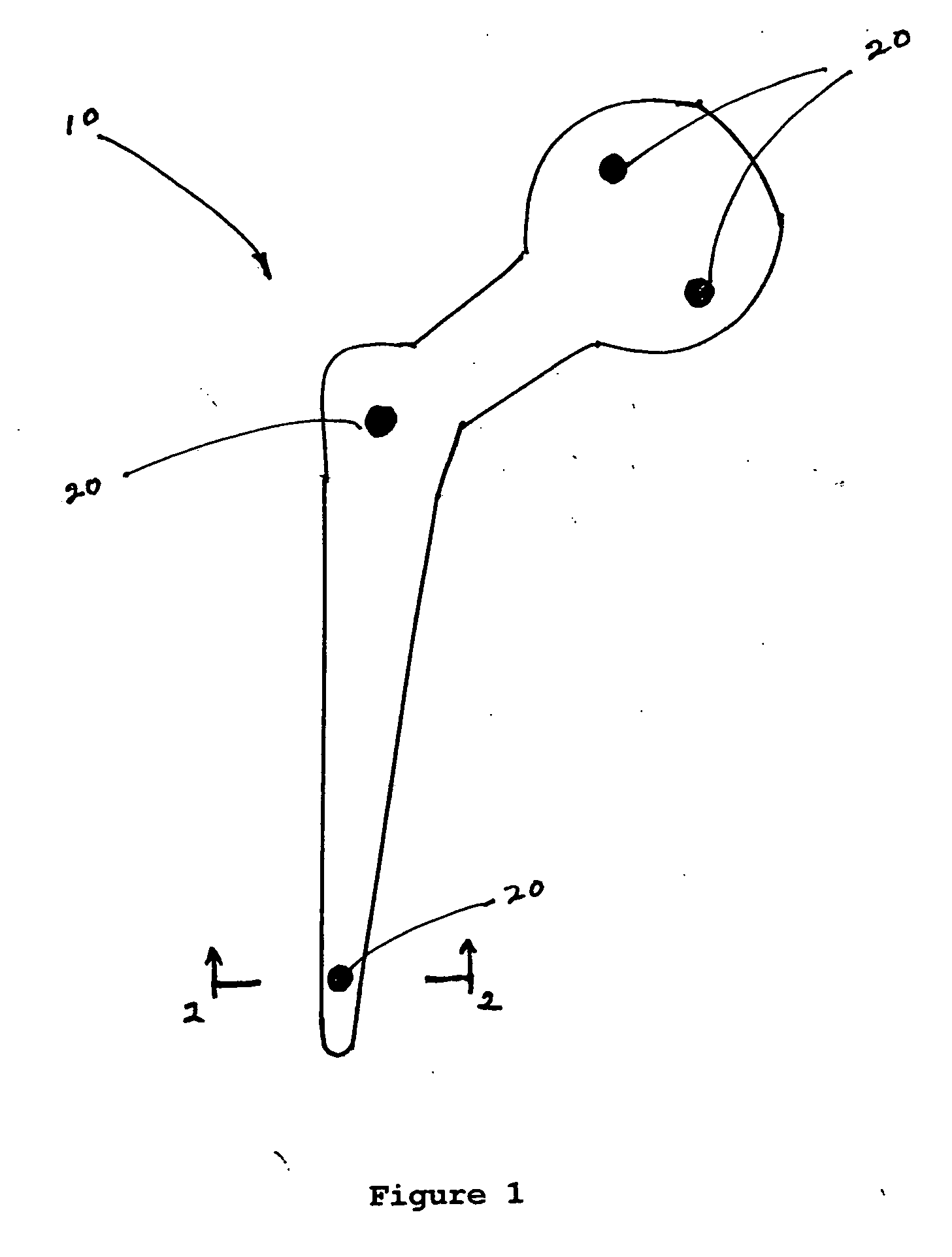

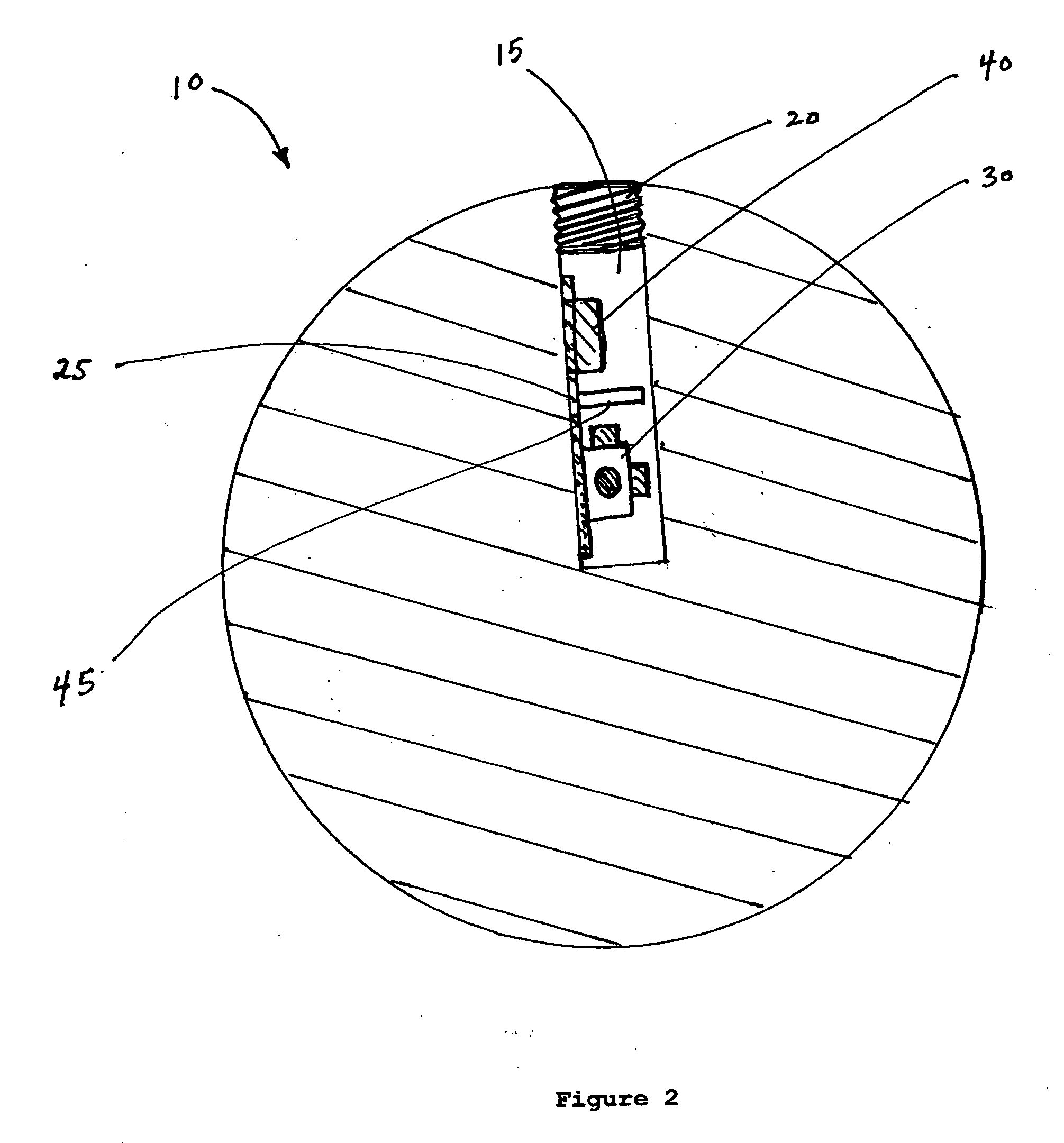

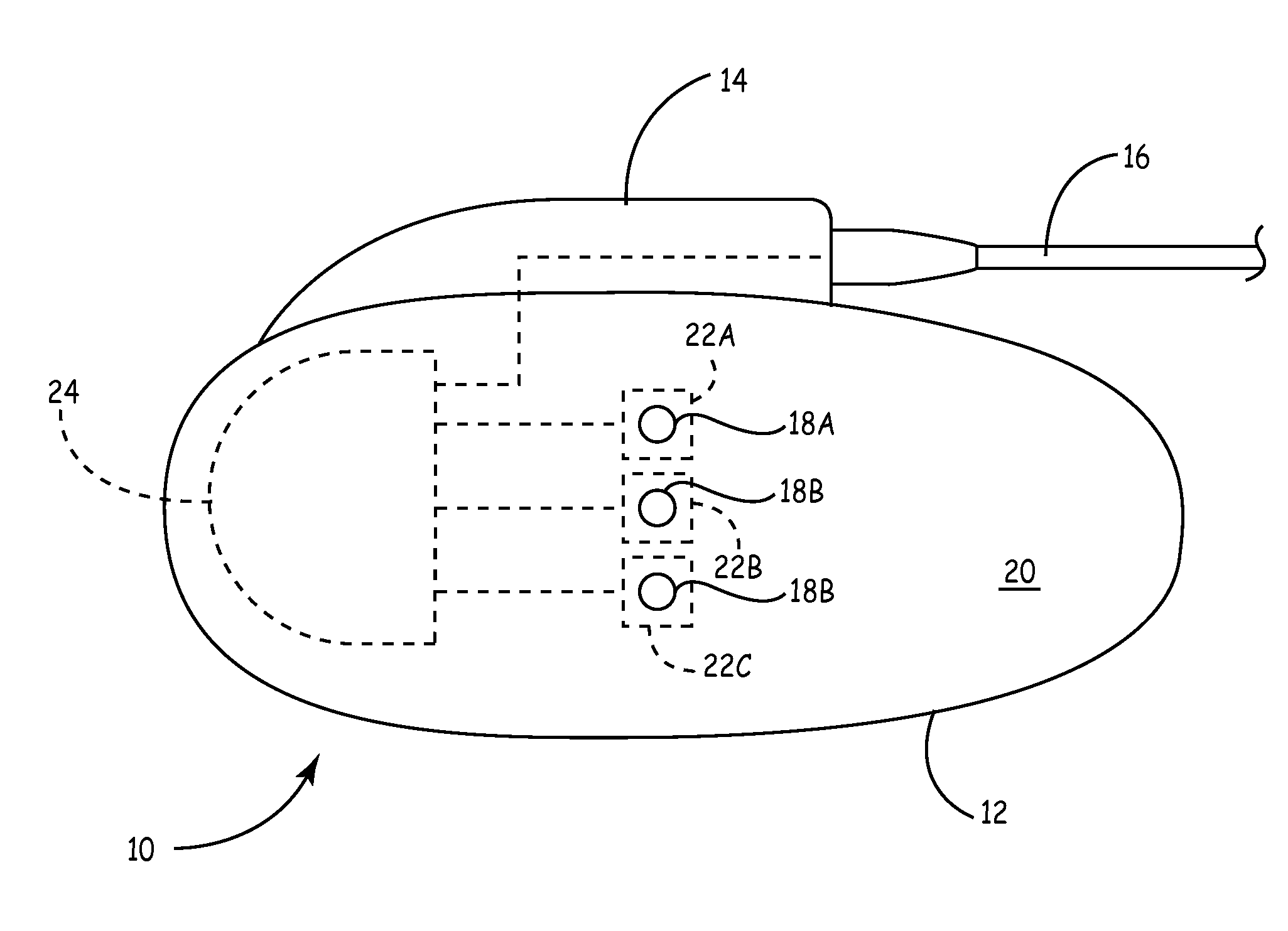

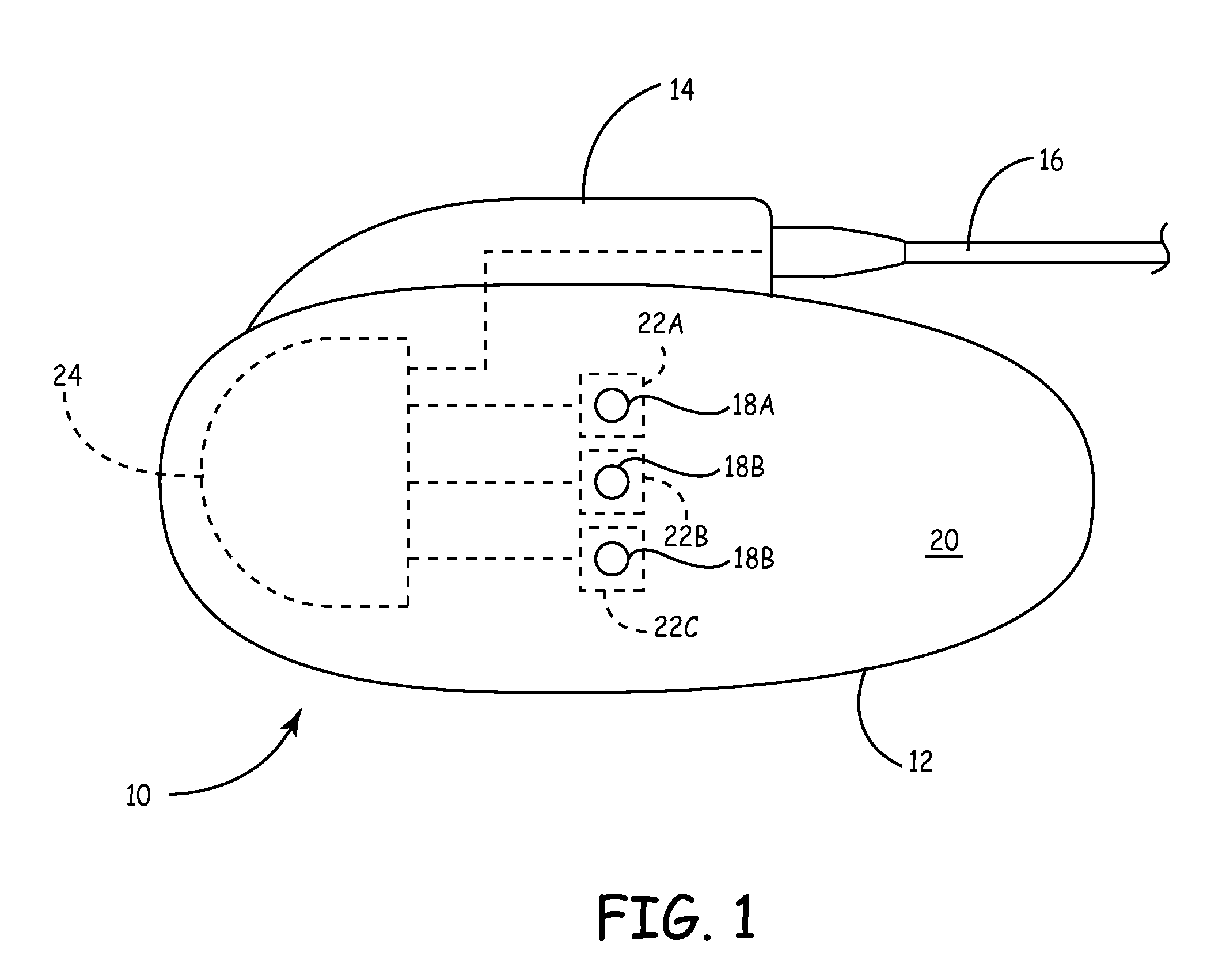

Navigational markers in implants

A prosthetic implant for the body having an associated gyroscope, accelerometer and / or magnetometer as the sensor to detect changes in position of the implant. The device incorporates a miniature gyroscope, accelerometer, and / or magnetometer as a permanent part of the prosthesis for navigational information. Alternatively, the magnetometer can be external to the implant when the implant has magnetic elements associated with it. The sensors can be microelectromechanical system (MEMS) sensors placed within a drilled hole and sealed with a screw or a cap (20). The implant can be responsive to an external interrogation and powering systems. The device provides information so as to help to properly place the prosthetic implant during surgery and to assess proper functioning. The gyroscope, accelerometer, and / or magnetometer are used after implantation to provide diagnostic information in situ based upon the changed positioning or motion of the device in the prosthesis. The device can be a total joint replacement, dental implant or other type of prosthetic implant.

Owner:JOHNSON LANNY L

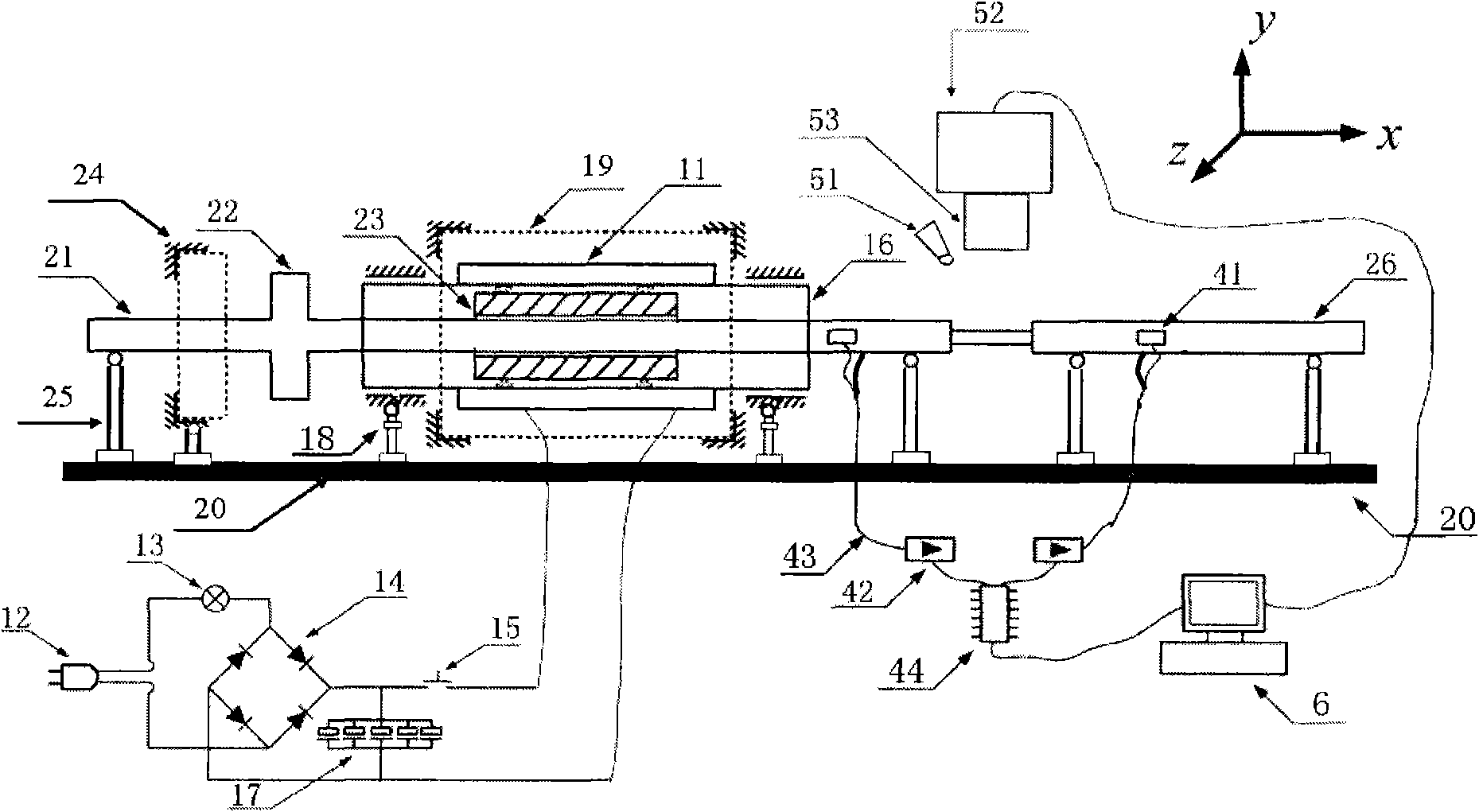

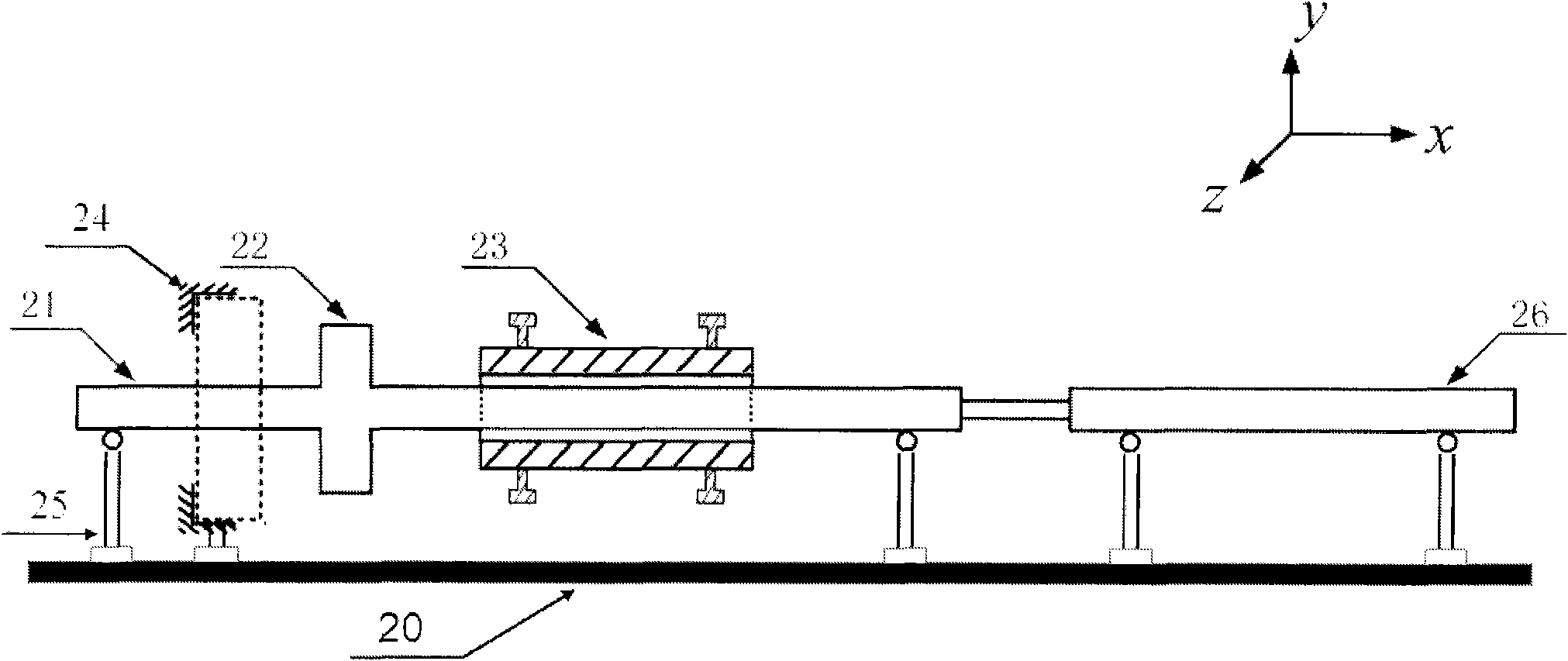

System and method for performing impact loading on micro test piece and measuring dynamic mechanical property

InactiveCN102135480ASolve the study of dynamic mechanical properties at high strain ratesLaunch fastStrength propertiesFerroelectric thin filmsStress–strain curve

The invention relates to a system and a method for performing impact loading on a micro test piece and measuring dynamic mechanical property. The method comprises the following steps of: instantly accelerating a bullet by using an electromagnetic pulse launch technology and launching the bullet at high speed; transmitting a stretching stress wave generated by collision of the bullet to the micro test piece by using a separated Hopkinson bar technology so as to generate the impact loading on the micro test piece; recording strain data of an input bar and an output bar, and acquiring an enlarged surface dynamic deformation image of the micro test piece; analyzing and obtaining a stress strain curve of the micro test piece subjected to the impact loading having different strain rates; and analyzing the surface dynamic deformation image of the micro test piece and obtaining a distribution of a bidimensional displacement field and a strain field during dynamic impact loading of the micro test piece. By the system and the method, the problem of research on the dynamic mechanical property of a micro electro mechanical system (MEMS), and membrane materials such as piezoelectric thin films, ferroelectric thin films and the like is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

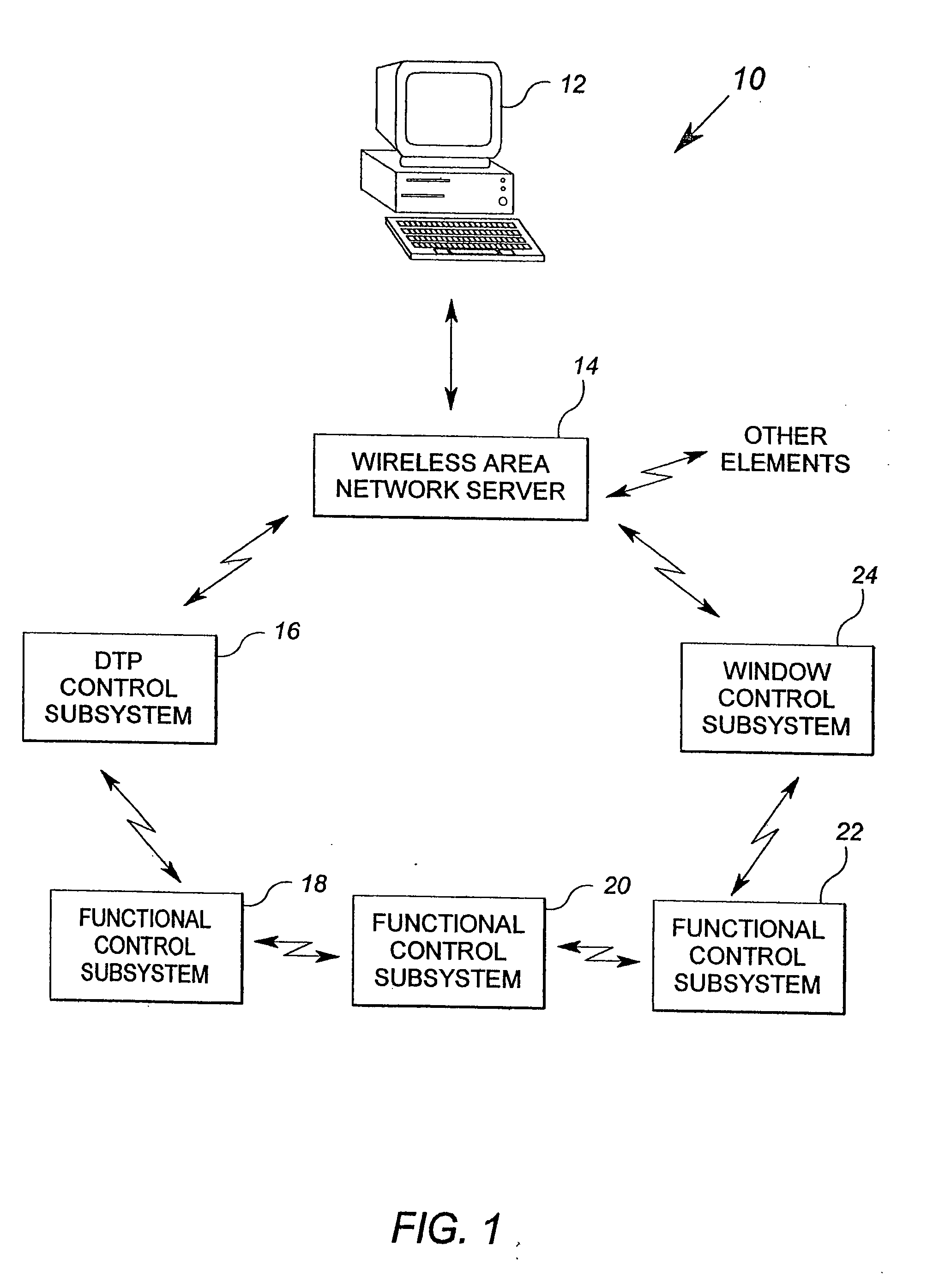

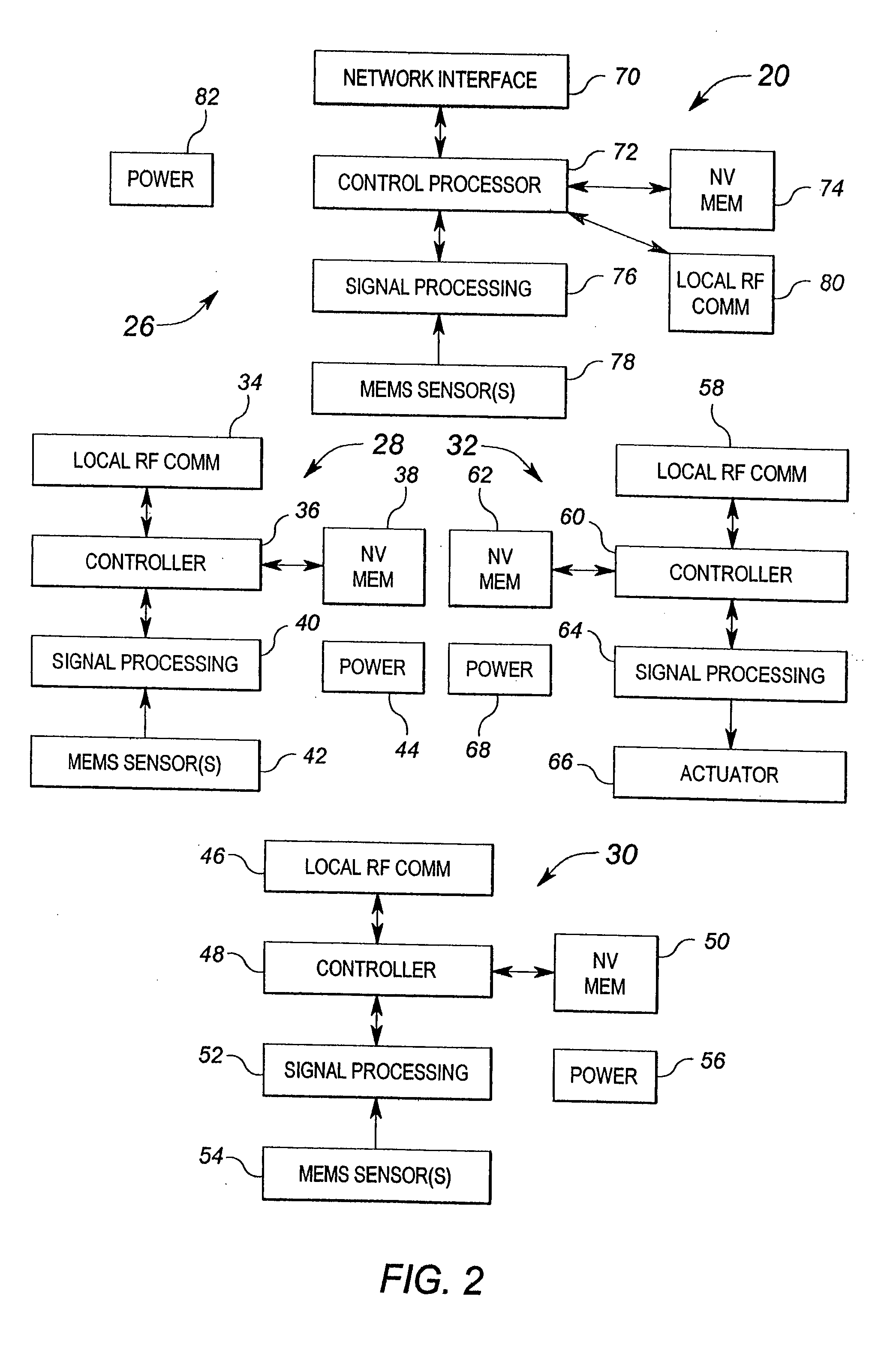

Method and apparatus for controlling building component characteristics

ActiveUS20050268629A1Readily apparentSpace heating and ventilationDoors/windowsEngineeringMicroelectromechanical systems

A building component system includes a building component that is controllable between a first state and a second state in response to a sensed condition. The system may include a sensor on a first side of the building component and a sensor on the second side of the building component. The building component may be a window that is controllable between an opaque state and a clear state by a micro electromechanical system (MEMS) network that senses the conditions on both sides of the window.

Owner:SIEMENS IND INC

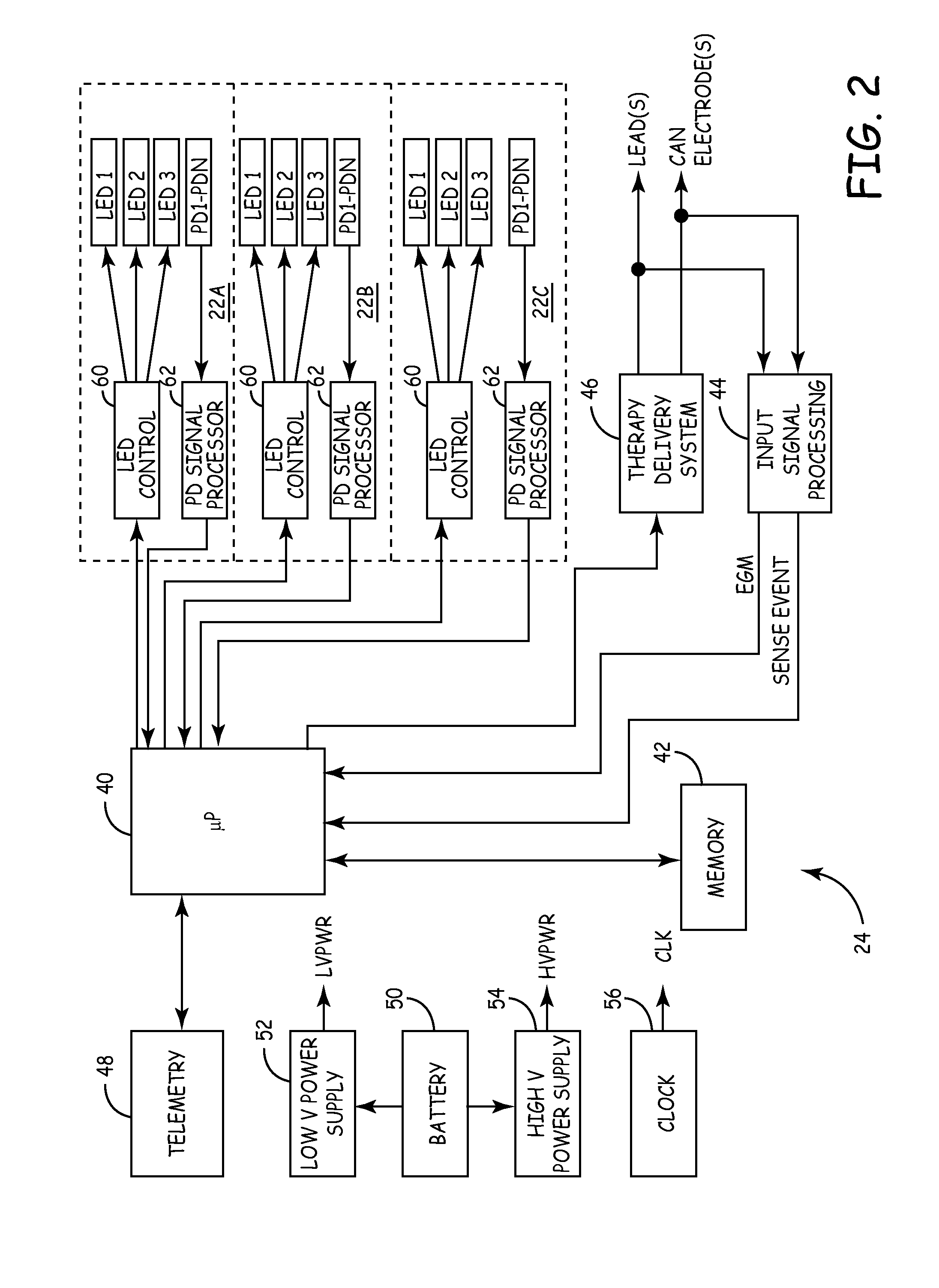

Optical Device

ActiveUS20090270953A1ElectrotherapySolid-state devicesMicroelectromechanical systemsReflective layer

A reflectance-type optical sensor includes one or more photodiodes formed in a semiconductor substrate. A well having sidewalls and a bottom is formed in the top surface of the substrate, and a reflective layer is formed on the sidewalls and bottom. A light-emitting diode (LED) is mounted in the well, so that light emitted laterally and rearwardly from the LED strikes the sidewalls or bottom and is redirected in a direction generally perpendicular to the top surface of the substrate. The optical sensor can be fabricated using microelectromechanical systems (MEMS) fabrication techniques.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com