Patents

Literature

480 results about "Stress–strain curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The relationship between the stress and strain that a particular material displays is known as that particular material's stress–strain curve. It is unique for each material and is found by recording the amount of deformation (strain) at distinct intervals of a variety of loadings (stress). These curves reveal many of the properties of a material (including data to establish the Modulus of Elasticity, E).

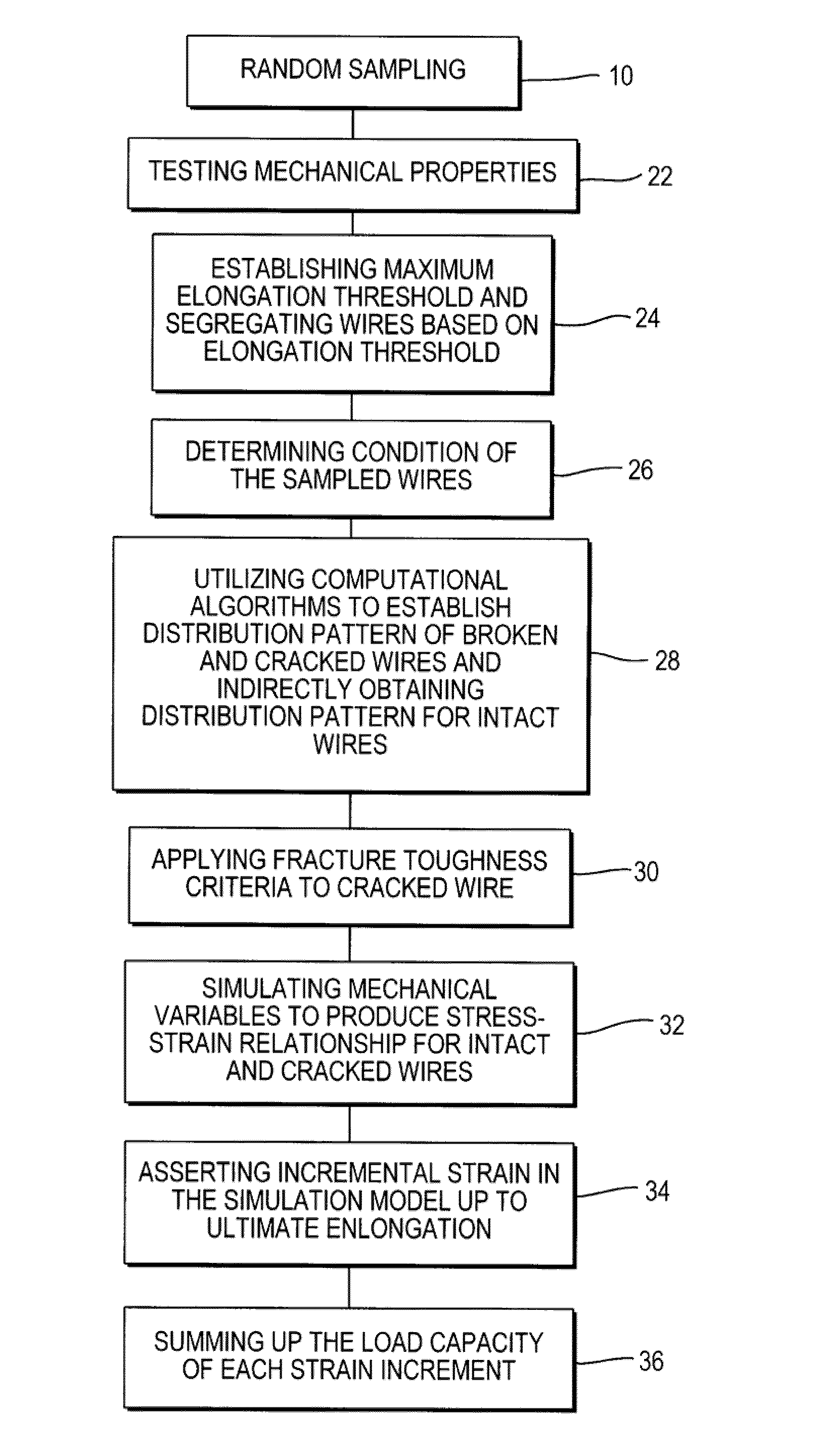

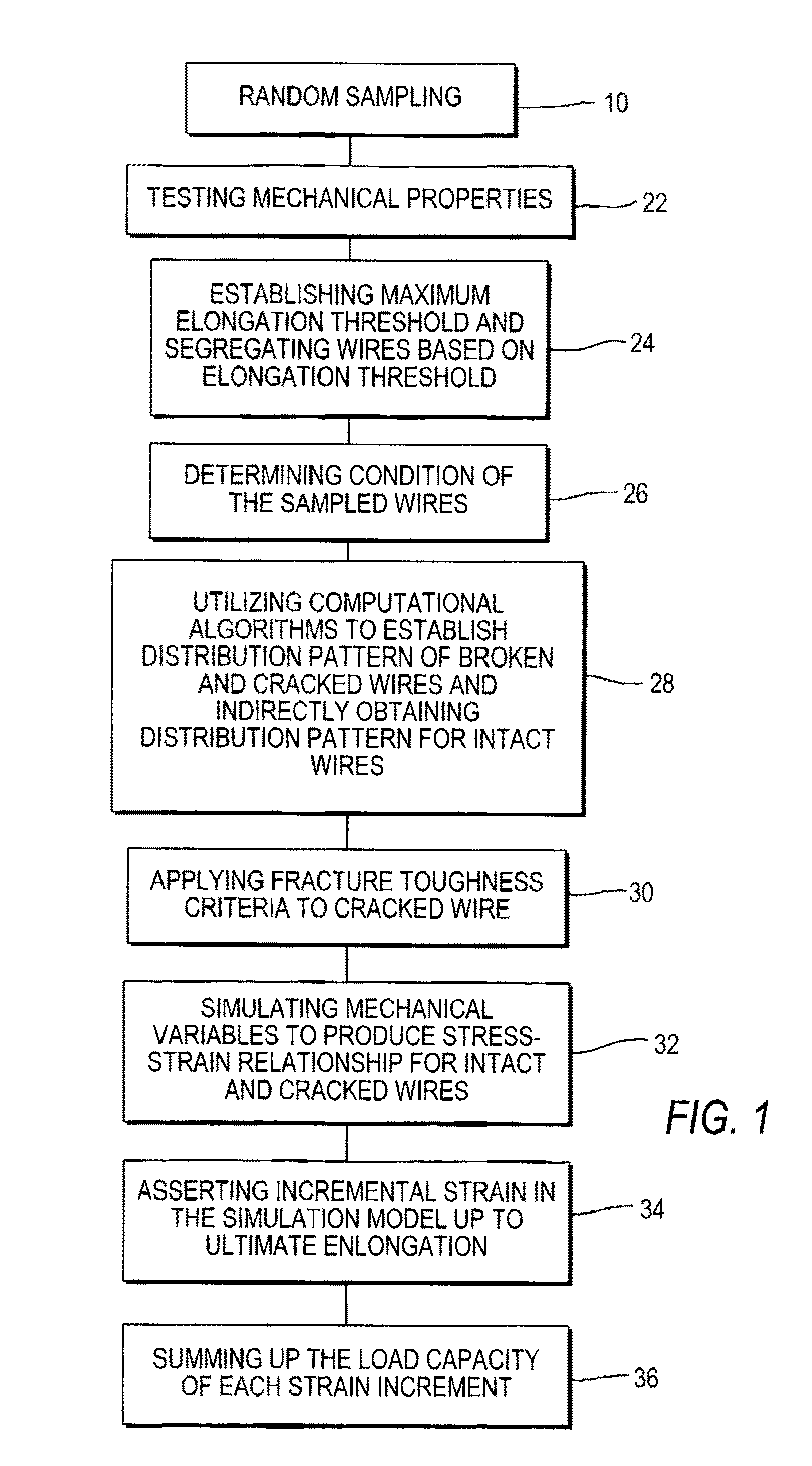

Method for assessment of cable strength and residual life

ActiveUS7992449B1Minimizes vulnerabilityMaterial strength using tensile/compressive forcesStress–strain curveEngineering

A method for determining the condition assessment and residual life span of bridge cables based on a parametric statistical model. The method includes random sampling of individual cable wires, mechanically testing the sampled wires, determining the probability of broken and cracked wires and the ultimate strength of cracked wires using fracture toughness and imputing the above data to simulate stress-strain curves for each wire in the cable, applying strain increments until reaching ultimate elongation. Assessing remaining service life of the cable by determining the rate of change of broken wires detected over a time frame, measuring the rate of change of fracture toughness over said time frame, and applying the rates of change to a time-dependent degradation prediction model.

Owner:MAHMOUD KHALED M

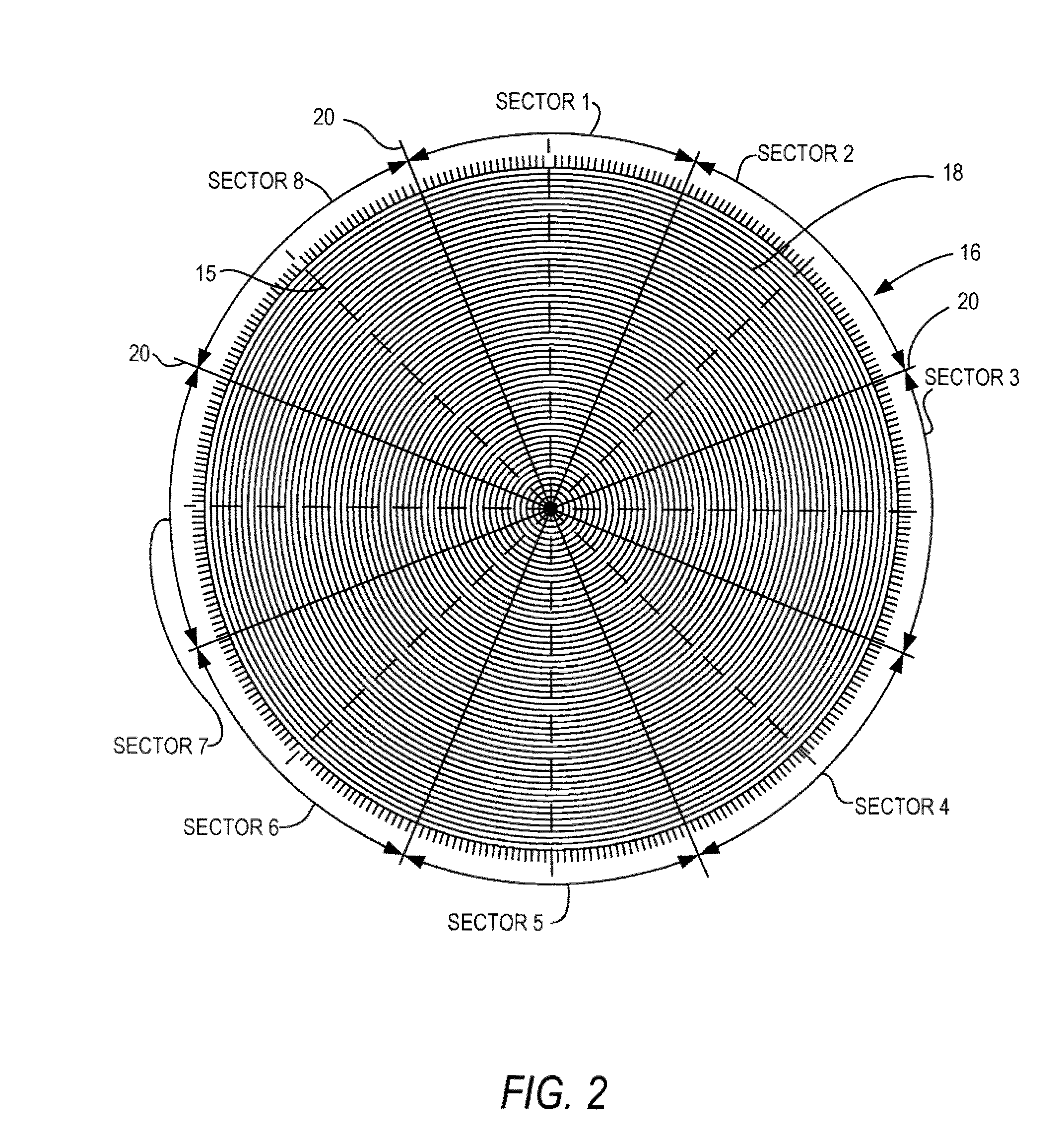

Processes for removing cells and cell debris from tissue and tissue constructs used in transplantation and tissue reconstruction

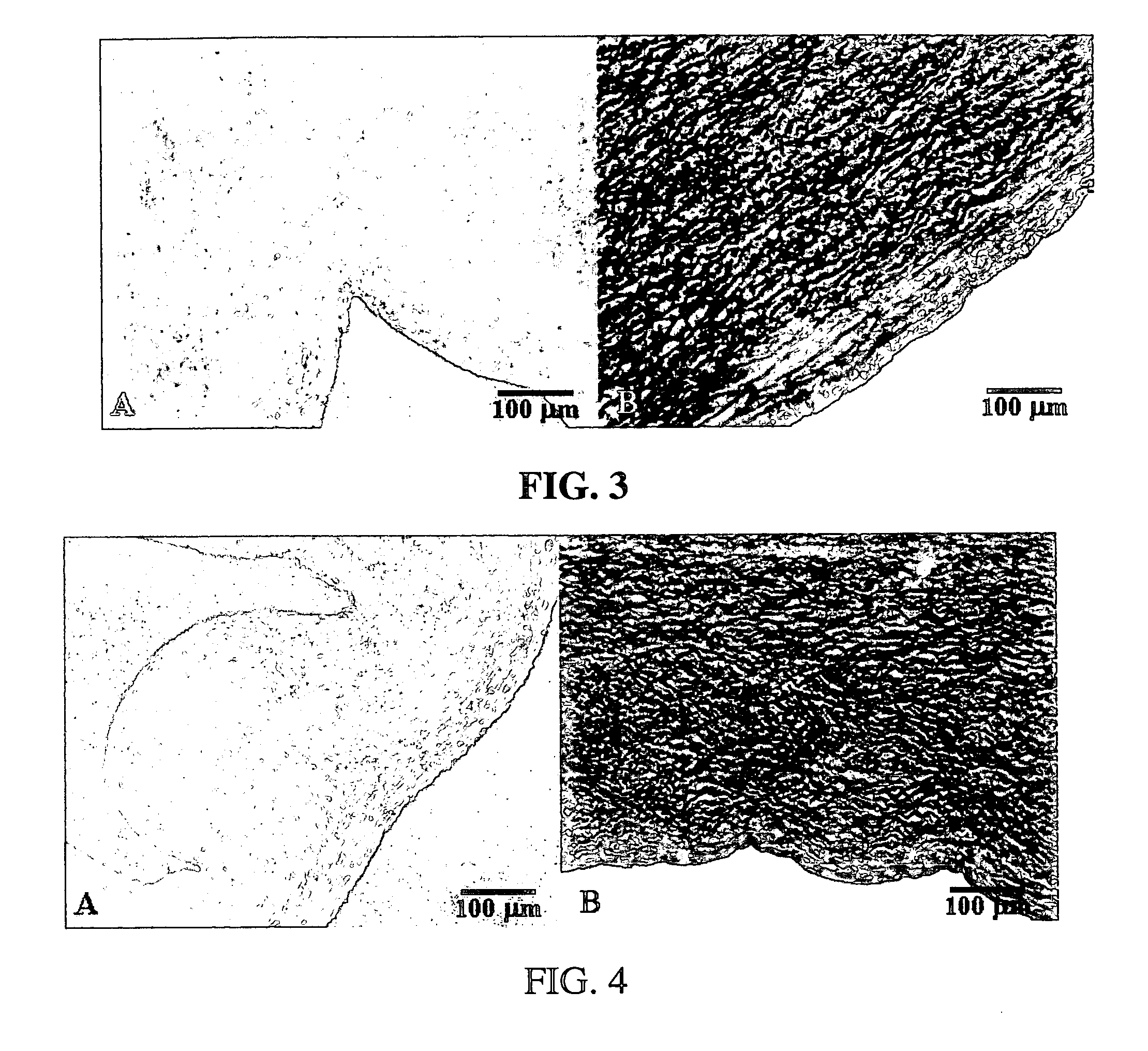

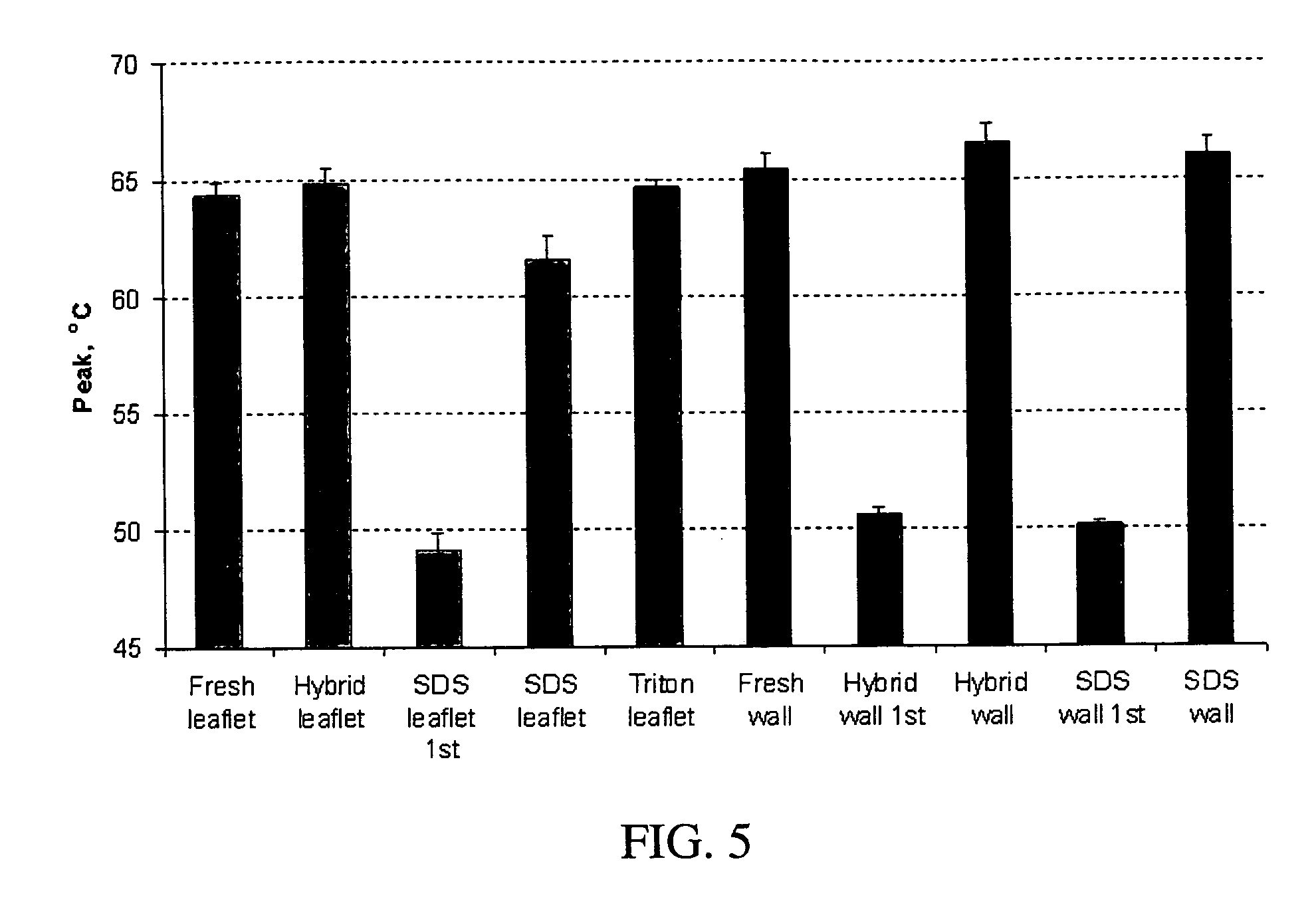

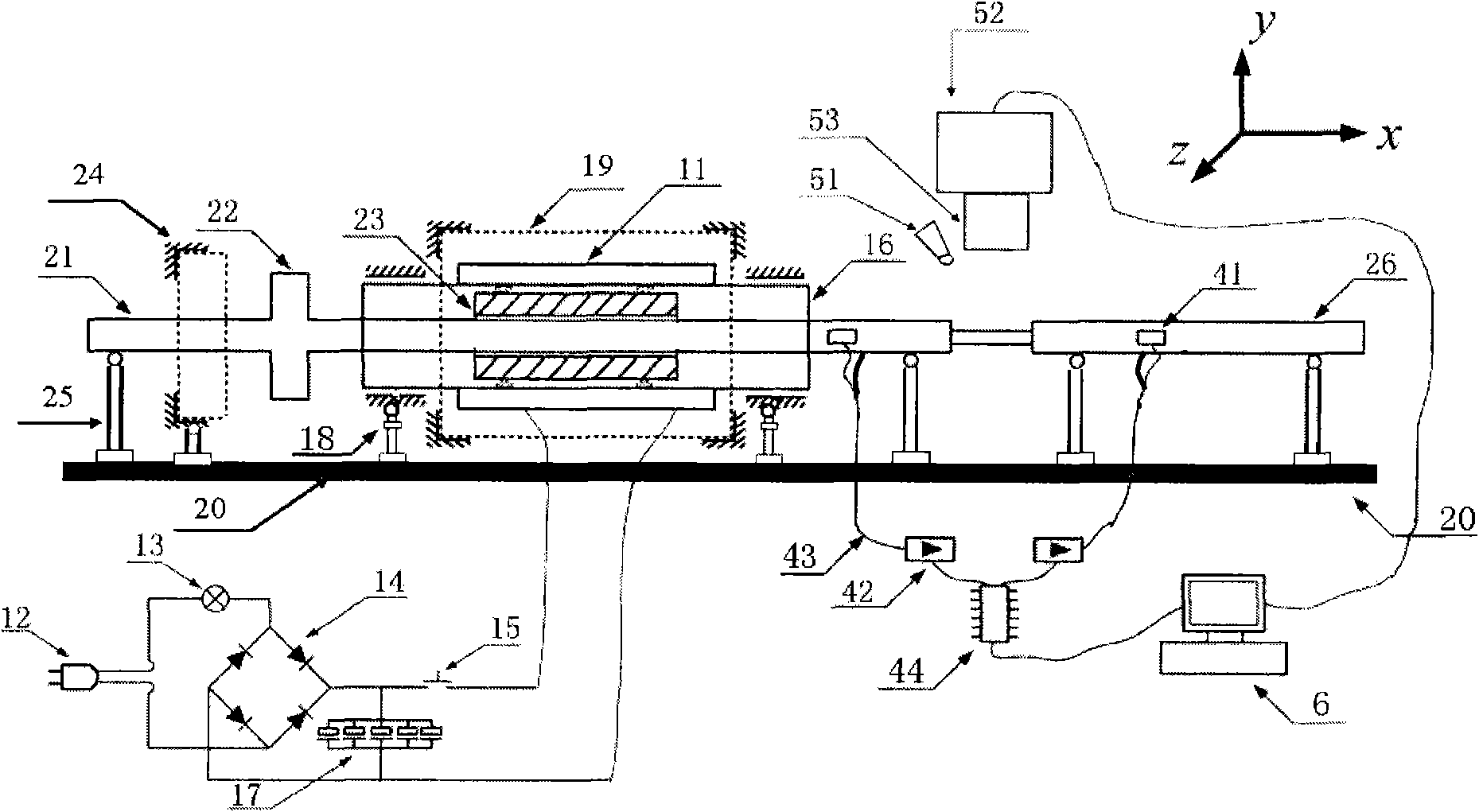

InactiveUS20070123700A1Improve inflammatory responseImprove responseHeart valvesDead animal preservationPresent methodFresh Tissue

Methods for decellularizing mammalian tissue for use in transplantation and tissue engineering. The invention includes methods for simultaneous application of an ionic detergent and a nonionic detergent for a long time period, which may exceed five days. One method utilizes SDS as the ionic detergent and Triton-X 100 as the nonionic detergent. A long rinse step follows, which may also exceed five days in length. This long duration, simultaneous extraction with two detergents produced tissue showing stress-strain curves and DSC data similar to that of fresh, unprocessed tissue. The processed tissue is largely devoid of cells, has the underlying structure essentially intact, and also shows a significantly improved inflammatory response relative to fresh tissue, even without glutaraldehyde fixation. Significantly reduced in situ calcification has also been demonstrated relative to glutaraldehyde fixed tissue. Applicants believe the ionic and non-ionic detergents may act synergistically to bind protein to the ionic detergent and may remove an ionic detergent-protein complex from the tissue using the non-ionic detergent. The present methods find one exemplary use in decellularizing porcine heart valve leaflet and wall tissue for use in transplantation.

Owner:UEDA YUICHIRO +1

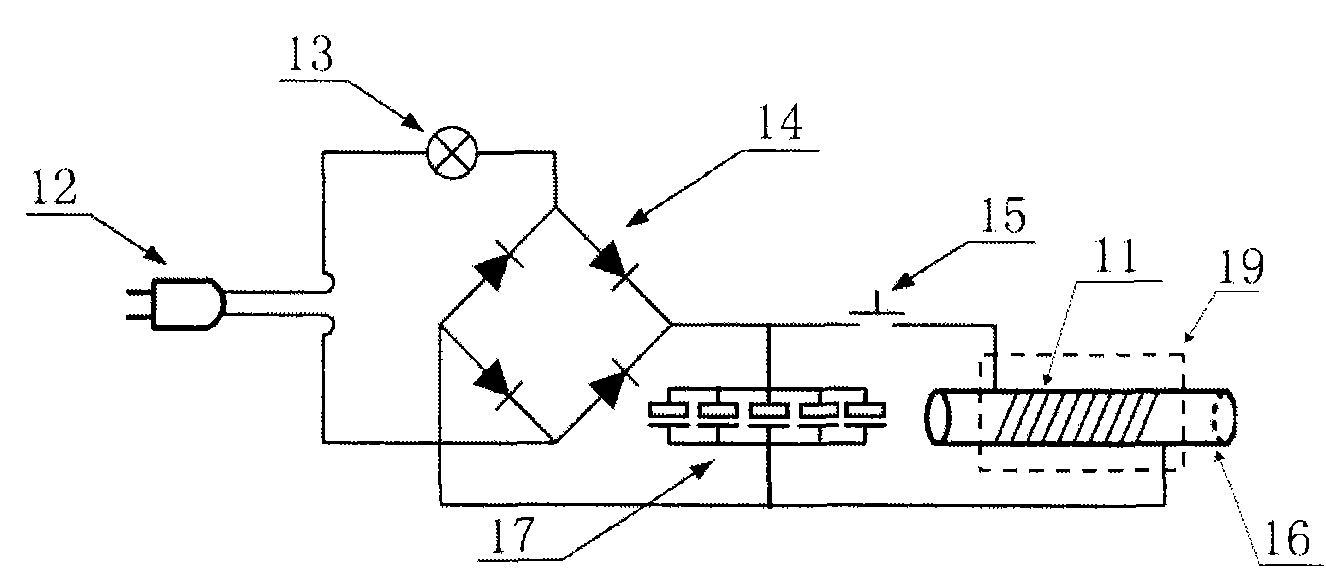

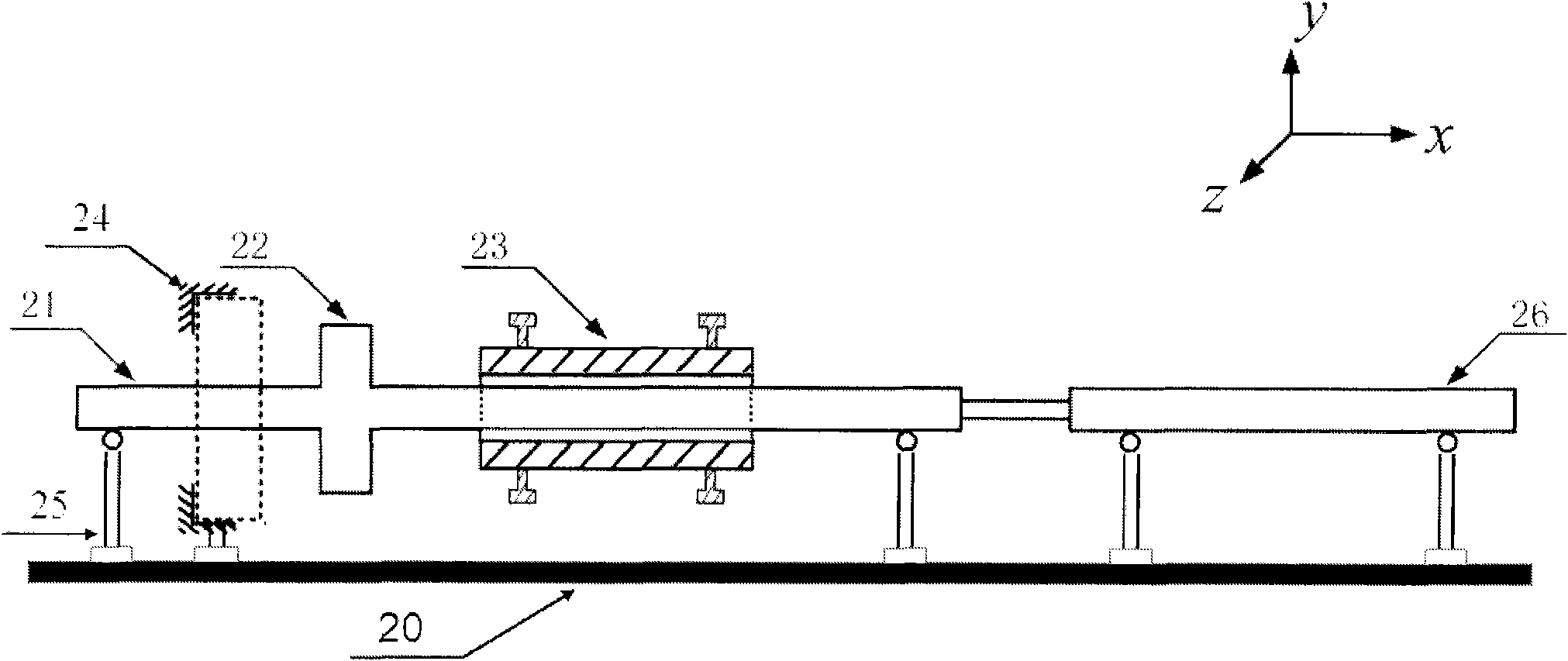

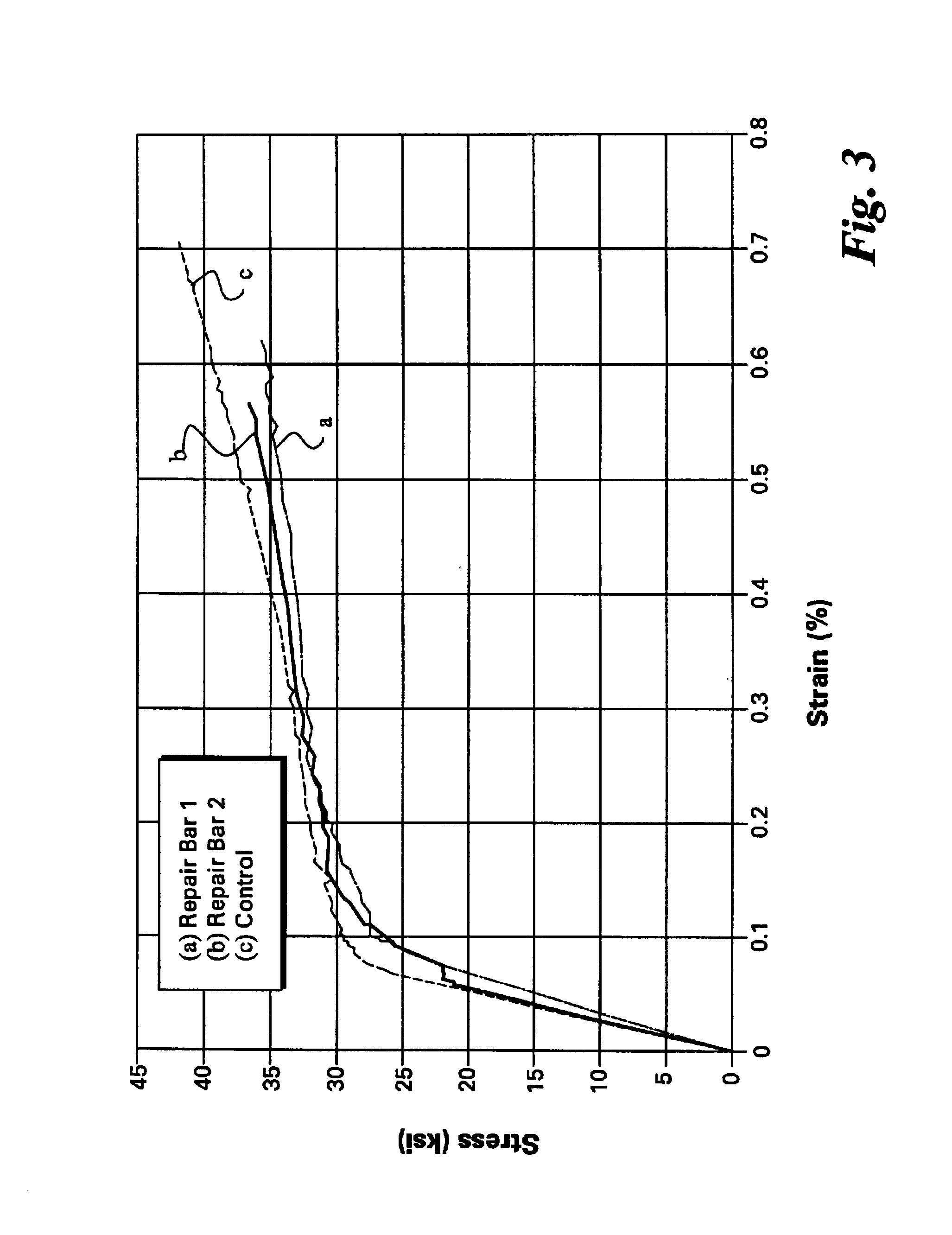

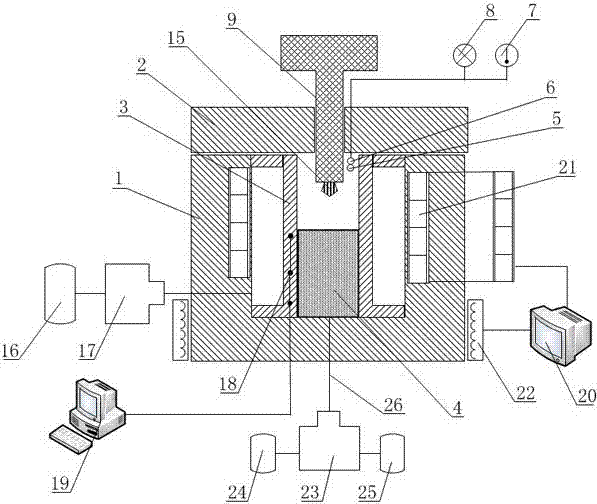

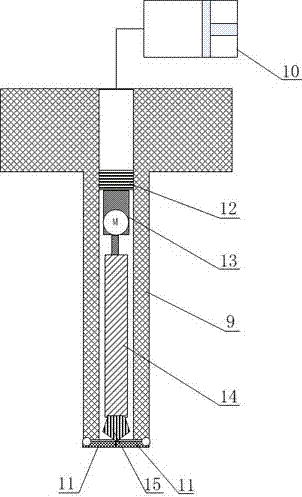

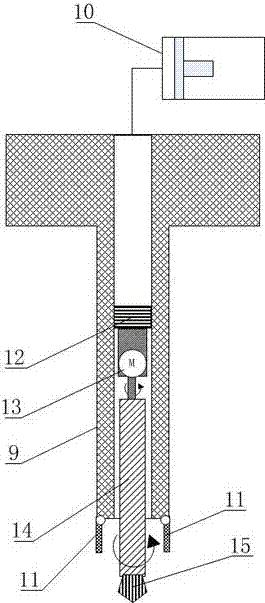

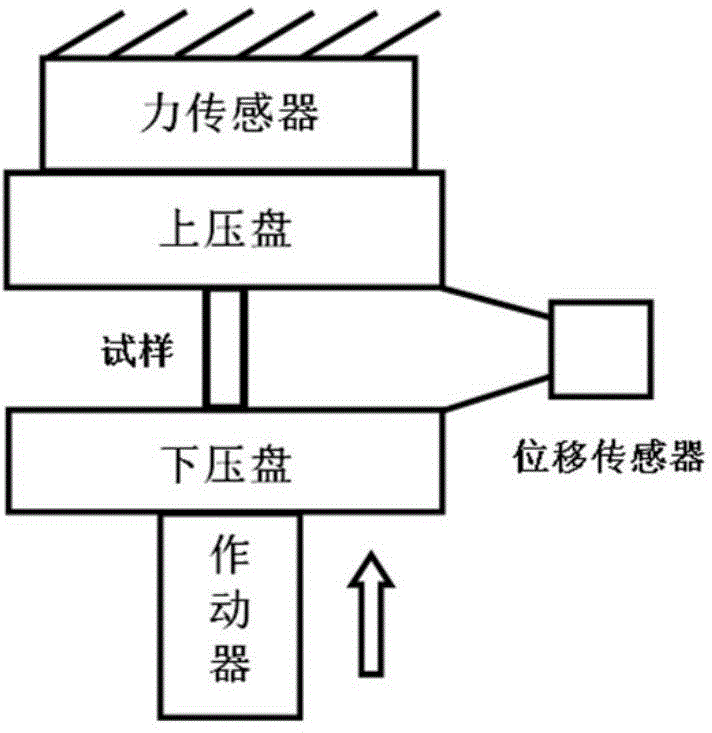

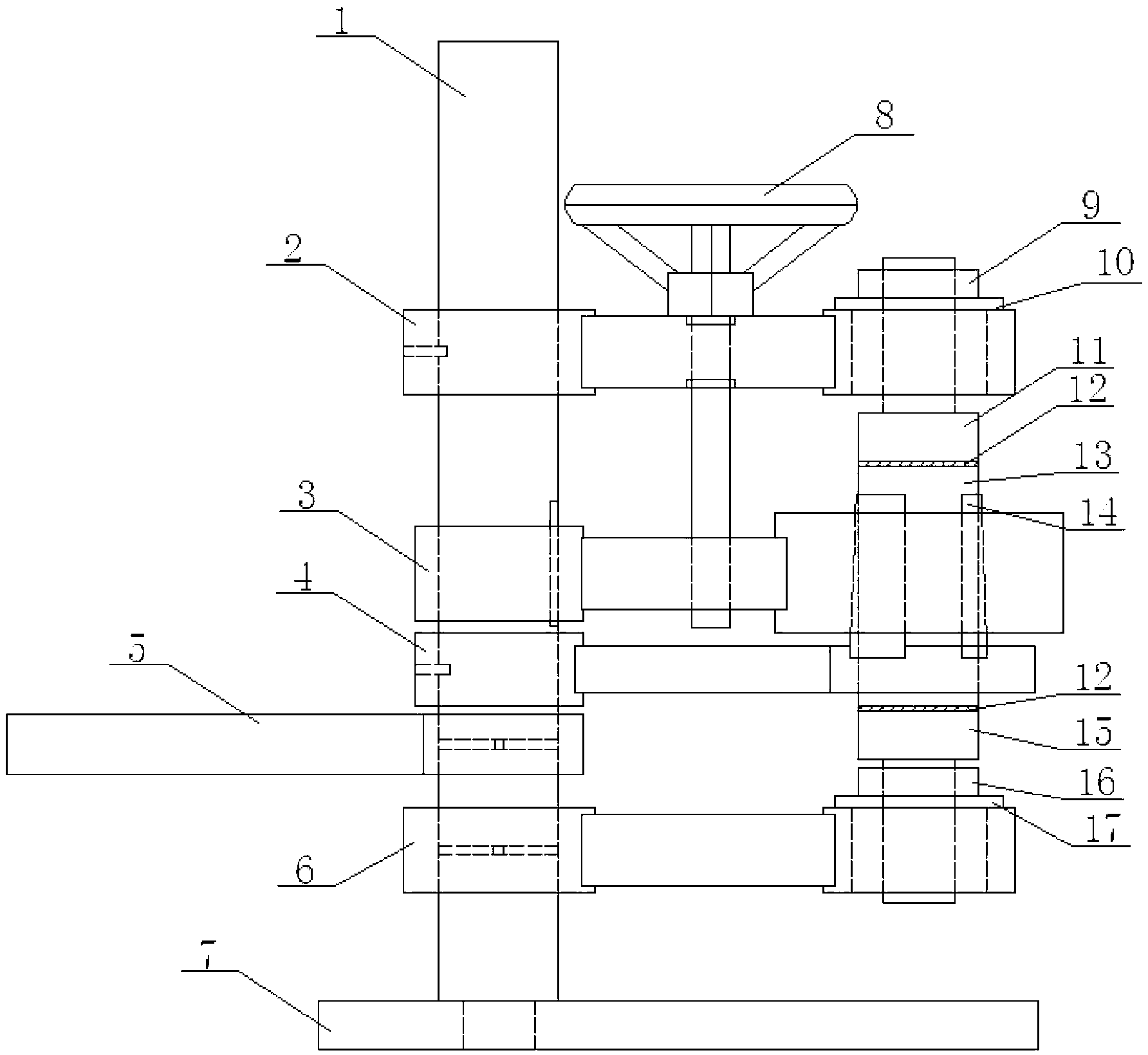

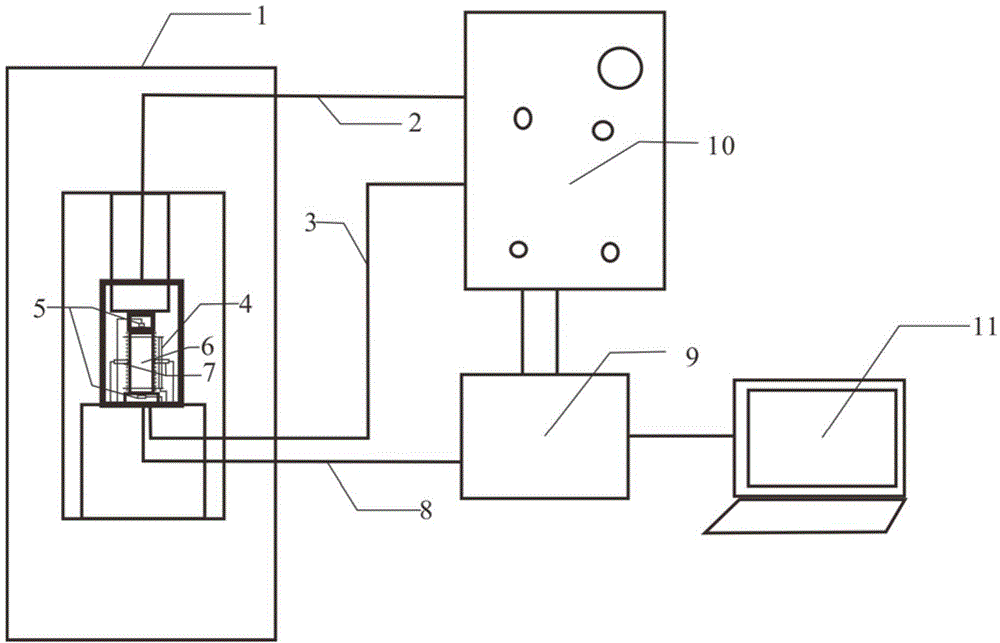

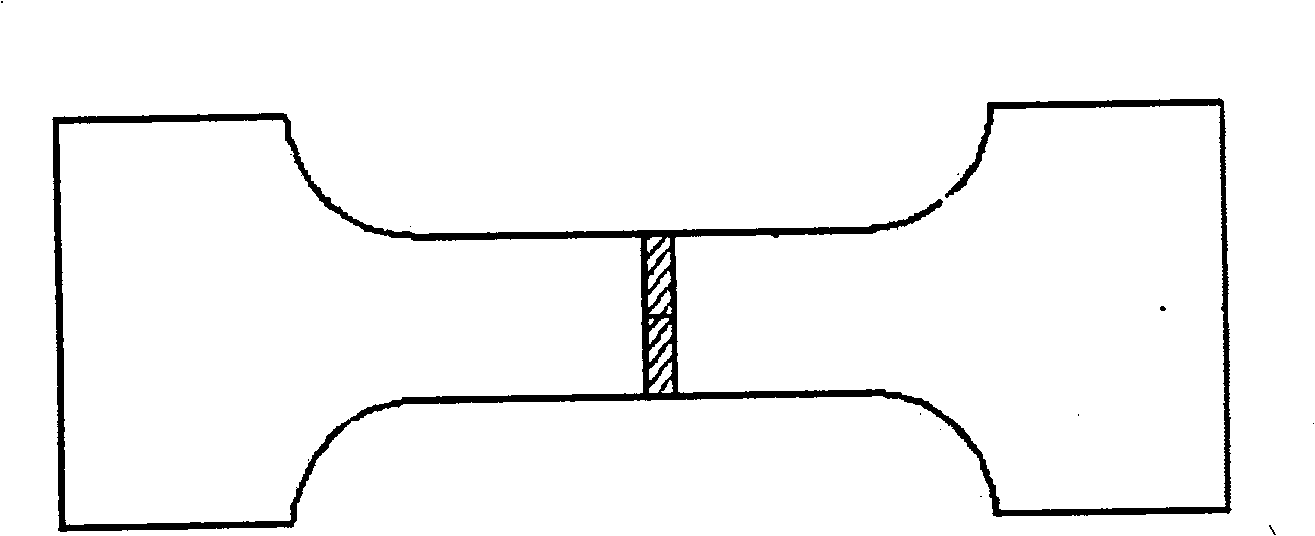

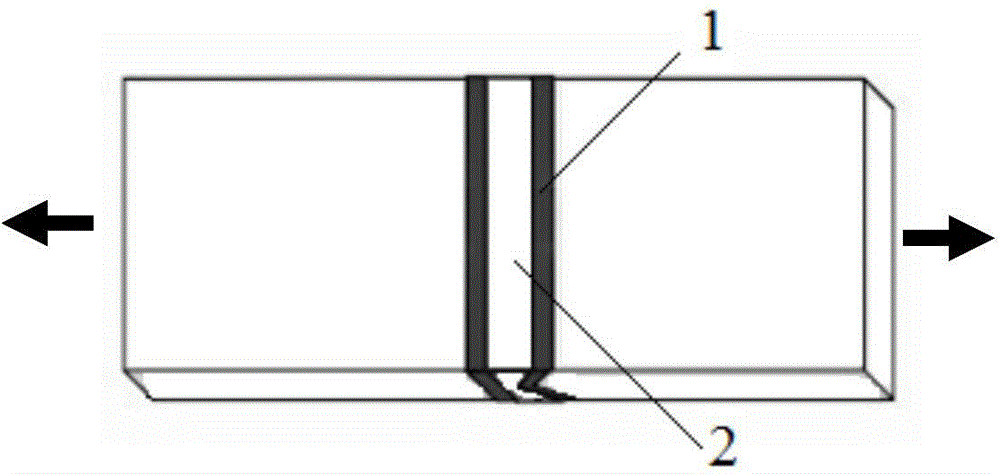

System and method for performing impact loading on micro test piece and measuring dynamic mechanical property

InactiveCN102135480ASolve the study of dynamic mechanical properties at high strain ratesLaunch fastStrength propertiesFerroelectric thin filmsStress–strain curve

The invention relates to a system and a method for performing impact loading on a micro test piece and measuring dynamic mechanical property. The method comprises the following steps of: instantly accelerating a bullet by using an electromagnetic pulse launch technology and launching the bullet at high speed; transmitting a stretching stress wave generated by collision of the bullet to the micro test piece by using a separated Hopkinson bar technology so as to generate the impact loading on the micro test piece; recording strain data of an input bar and an output bar, and acquiring an enlarged surface dynamic deformation image of the micro test piece; analyzing and obtaining a stress strain curve of the micro test piece subjected to the impact loading having different strain rates; and analyzing the surface dynamic deformation image of the micro test piece and obtaining a distribution of a bidimensional displacement field and a strain field during dynamic impact loading of the micro test piece. By the system and the method, the problem of research on the dynamic mechanical property of a micro electro mechanical system (MEMS), and membrane materials such as piezoelectric thin films, ferroelectric thin films and the like is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

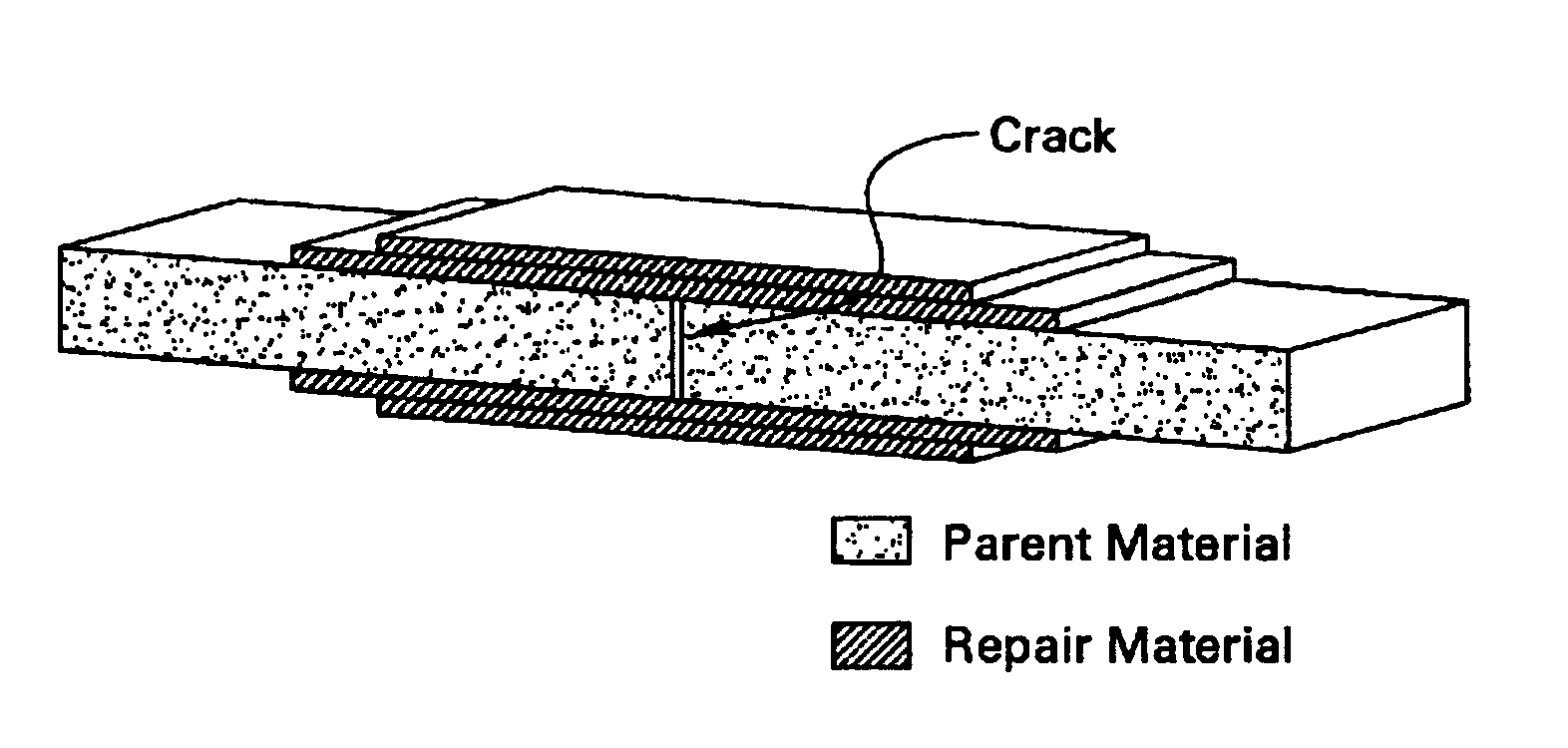

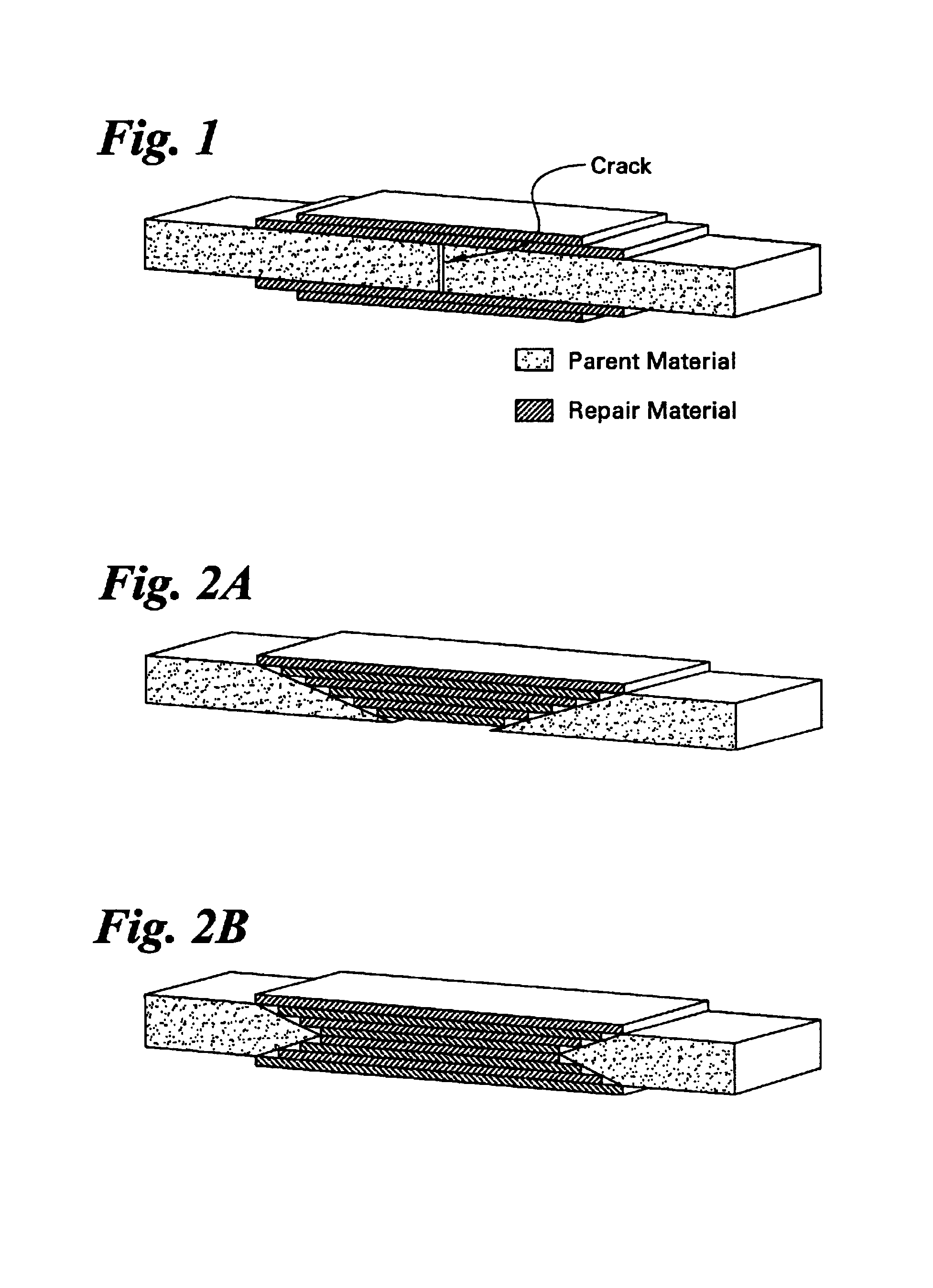

Method for repairing articles of ceramic composites

InactiveUS6820334B2Prolong lifeReduce in quantityBlade accessoriesEfficient propulsion technologiesCeramic compositeMetallurgy

Owner:GENERAL ELECTRIC CO

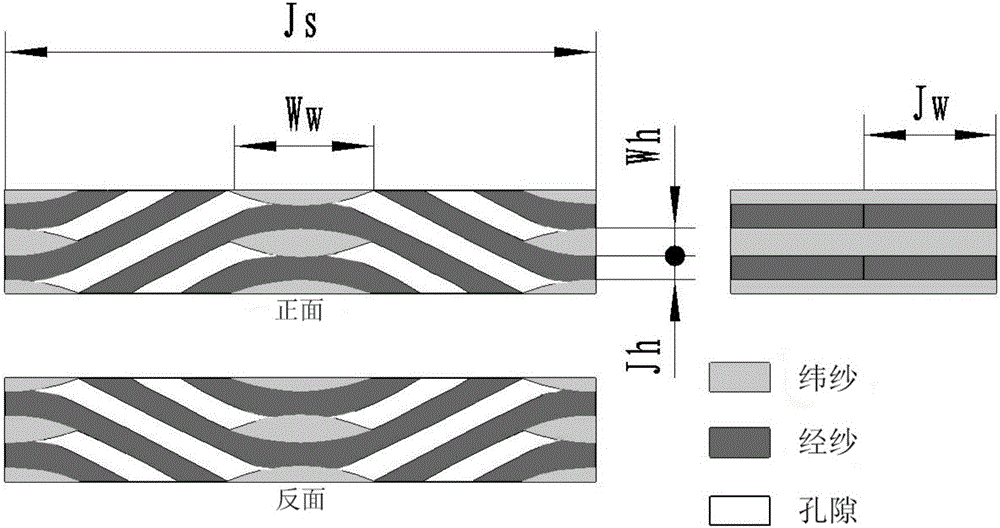

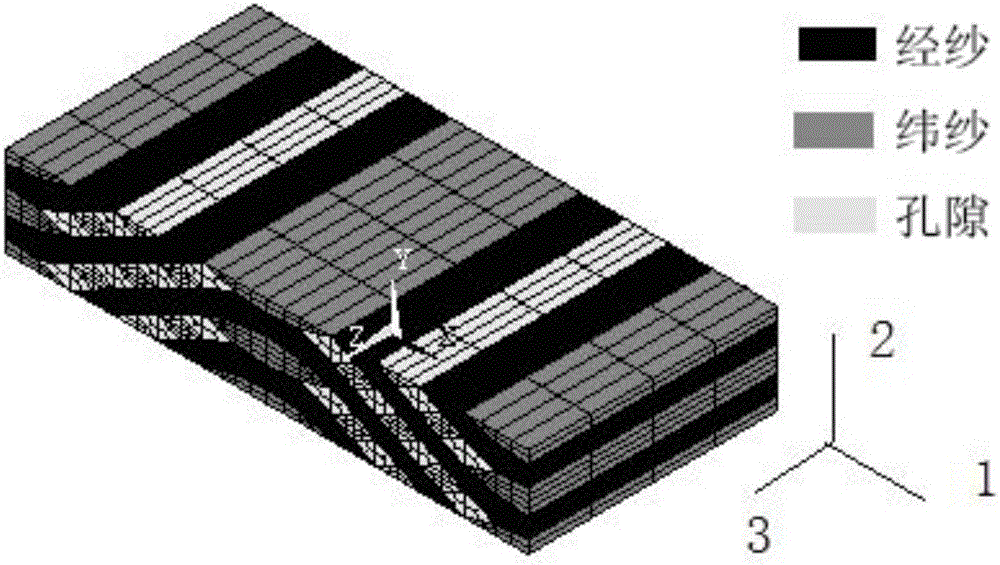

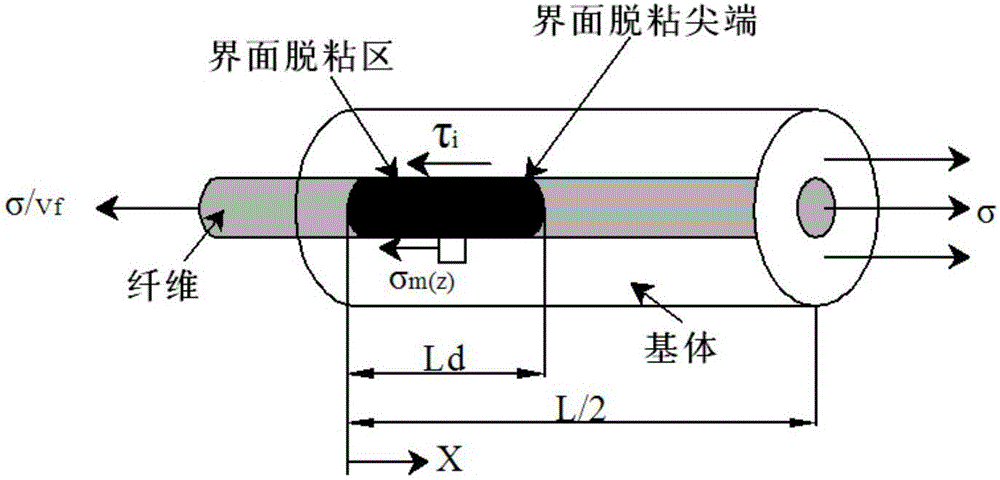

Complex braided structure ceramic matrix composite fatigue retardation behavior prediction method

InactiveCN105701312AFatigue Hysteresis Behavior PredictionDesign optimisation/simulationSpecial data processing applicationsStress–strain curveMaterials science

The invention discloses a complex braided structure ceramic matrix composite fatigue retardation behavior prediction method. The method comprises the steps of calculating a fatigue stress-strain curve under circulation with a microscale model to obtain the unit constitutive relation, substituting the unit constitutive relation into a unit cell model to conduct corresponding stiffness reduction on the unit cell model under different boundary conditions, and conducting statistics on the average stress and average strain of the unit cell model to obtain a unit cell scale fatigue retardation loop under the cycle number. By means of the multiscale model, the micro stress-strain field of a complex braided structure can be given, and therefore the fatigue retardation behavior of the material can be predicted precisely.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

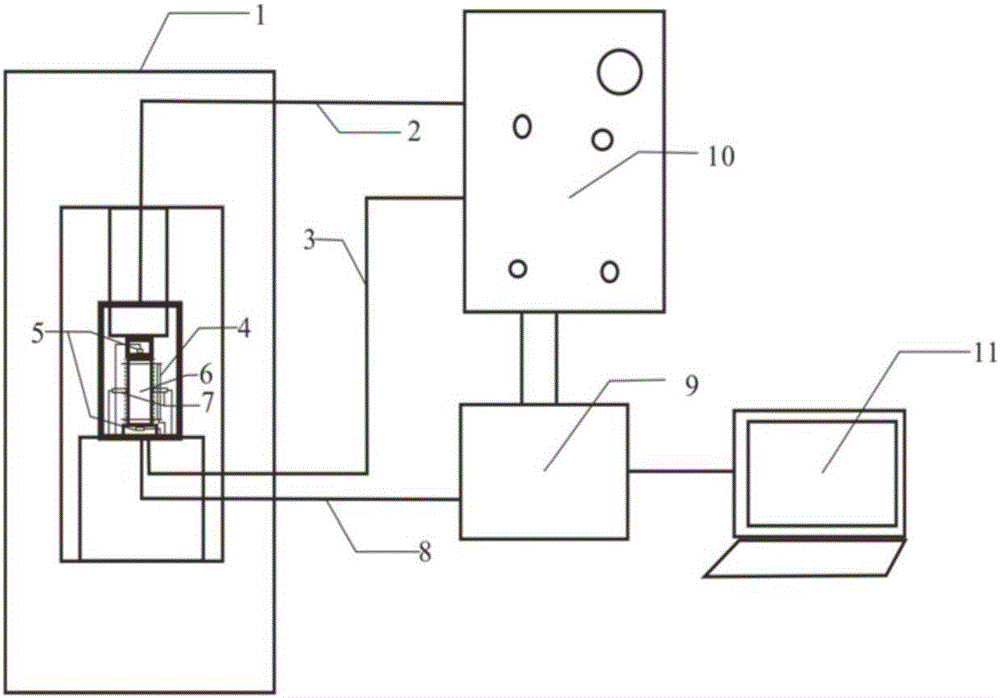

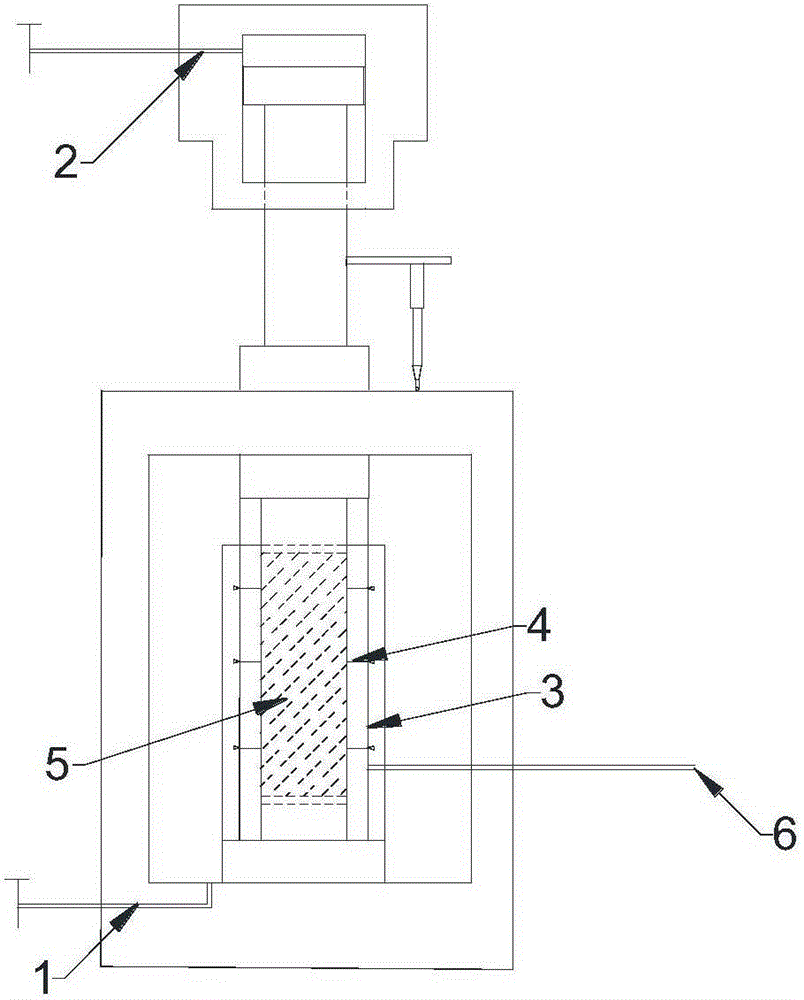

Multifunctional drill bit rock breaking experiment device and method capable of testing triaxial strength parameter of rock

ActiveCN107505207AIncrease profitShort timeMaterial strength using tensile/compressive forcesStress–strain curveRock sample

The invention discloses a multifunctional drill bit rock breaking experiment device capable of testing the triaxial strength parameter of rock. The device comprises a main body device, a pressure head structure, a confining pressure system, an acoustic emission system, a temperature control system and a pore material injection system. The device has the benefits as follows: the real temperature, crustal stress and pore pressure of a stratum can be simulated in a closed environment, a triaxial mechanical test and a drill bit rock breaking test can be completed simultaneously, a stress-strain curve of a rock sample, dynamic vibration of a drill bit and a drill column, bit pressure and influences of footage on the rock sample can be determined, an experiment basis is provided for research of mechanical properties of complex oil and gas reservoirs and drill bit rock breakage under multiple conditions, a rock breaking experiment can be conducted while conventional mechanical properties of the rock are tested, two experiments can be completed once after the designed temperature and pressure conditions are met, the total time consumption is reduced, and the utilization rate of underground rock cores can be effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV

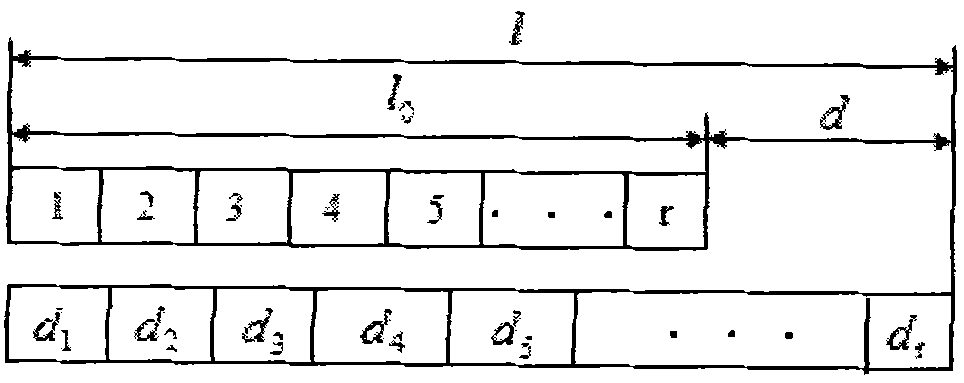

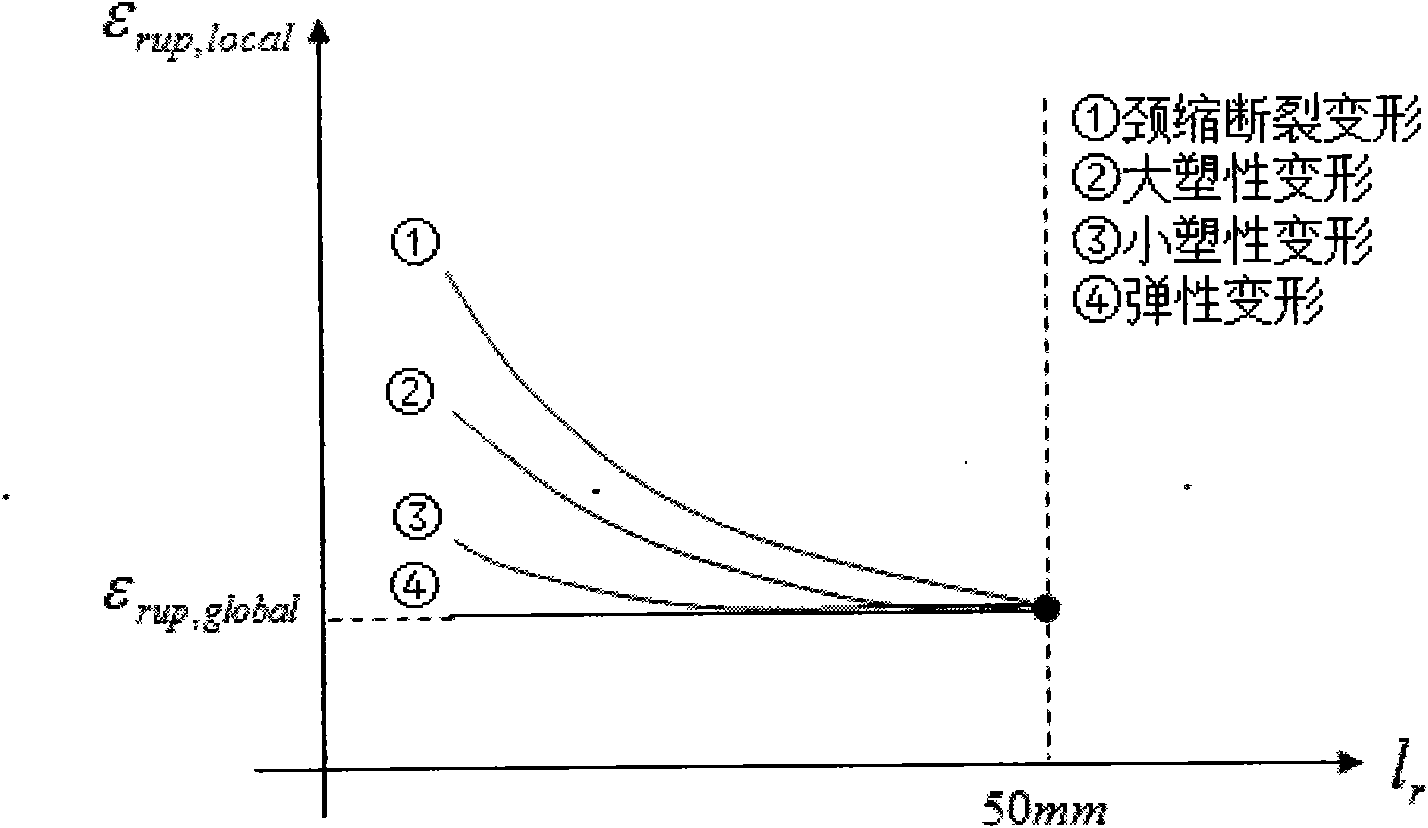

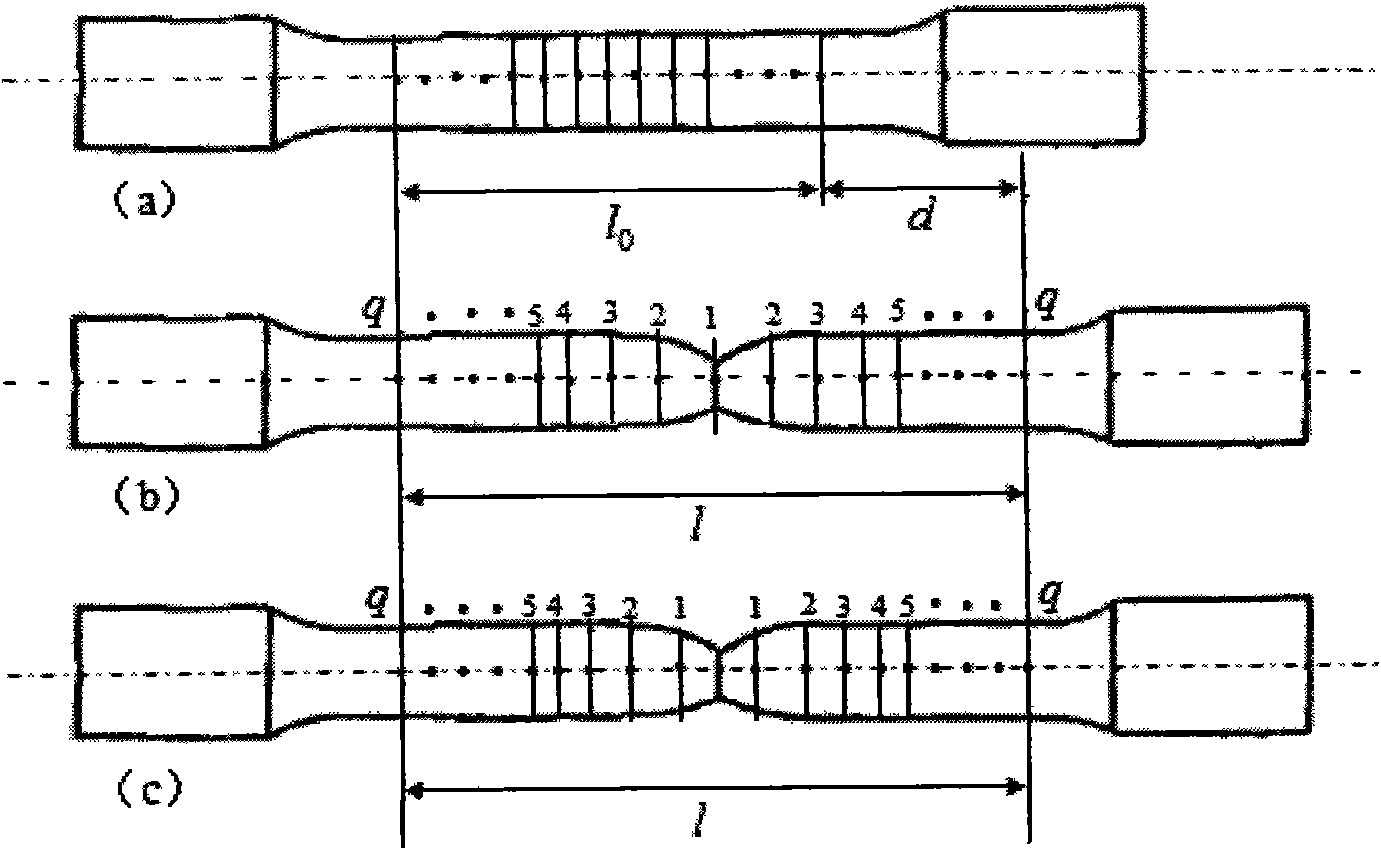

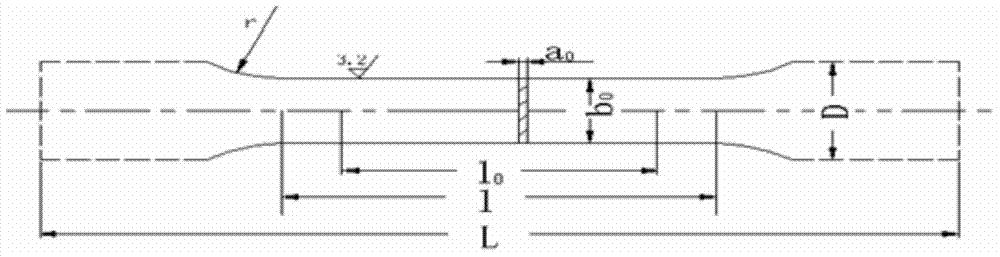

Data measuring and calculating method for uniaxial tensile test

InactiveCN101975693AReduce calculation precisionDiscovery of the intensity effectMaterial strength using tensile/compressive forcesLength effectEnergy absorption

The invention discloses a data measuring and calculating method for a uniaxial tensile test, which comprises the following steps of: marking a measuring point; measuring test data; calculating real breaking strain stress; and drawing an engineering and real stress strain curve. The method of the invention can obtain engineering and real stress strain curves in different reference lengths in the same uniaxial tensile test, establishes a corresponding relationship between the reference length effect and the mesh size effect and provides a thorough solution for the mesh size effect problem in a finite element method, i.e. a real stress strain curve in the equal reference lengths is defined for the same material with different mesh sizes. Meanwhile, theoretical explanation is provided for the practical problems, such as mesh size effect, energy absorption, material strain invalidation, and the like according to a uniaxial tensile basic theory provided by the invention, therefore, the invention has important theory and engineering practical significance.

Owner:肖锋

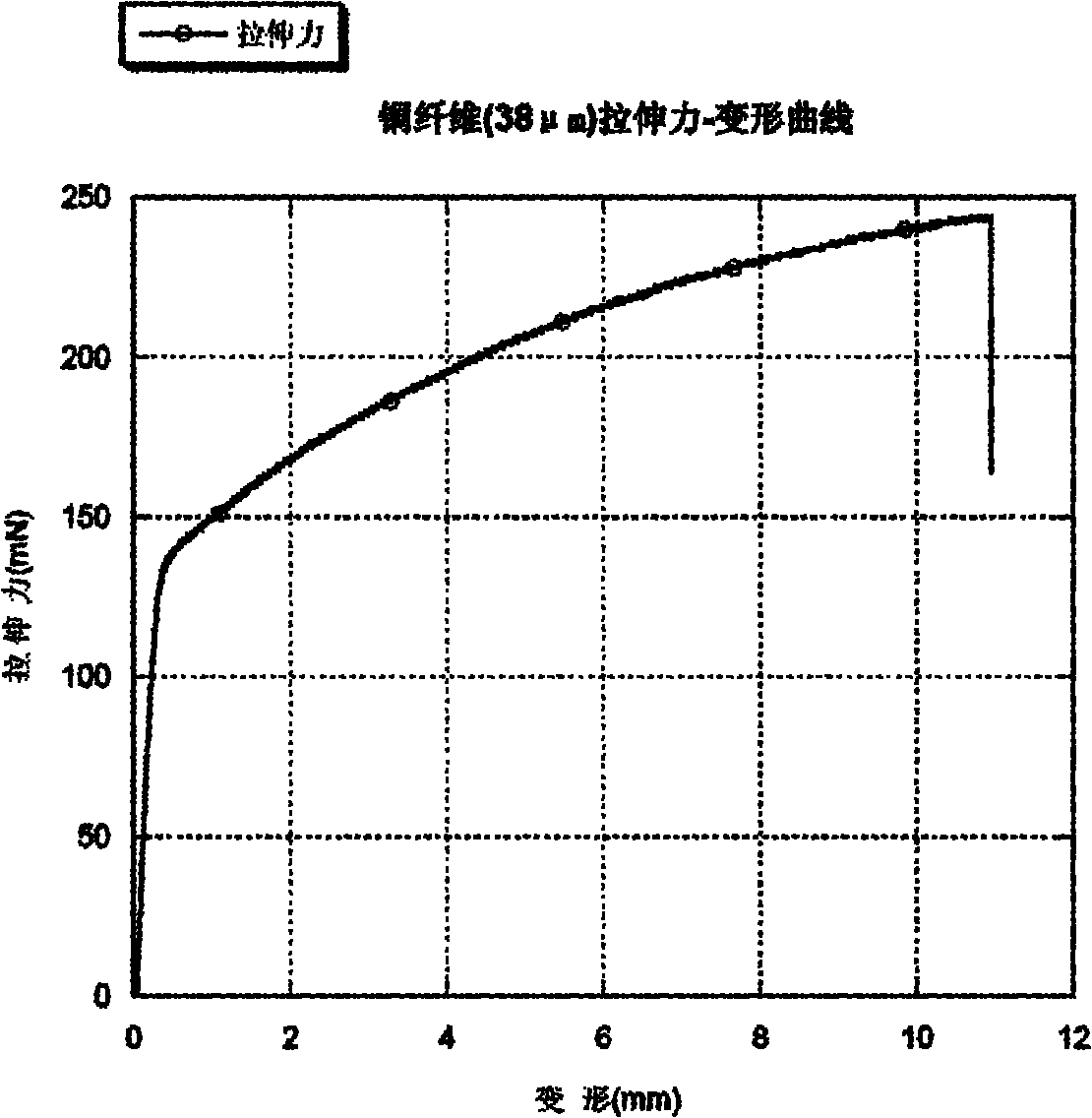

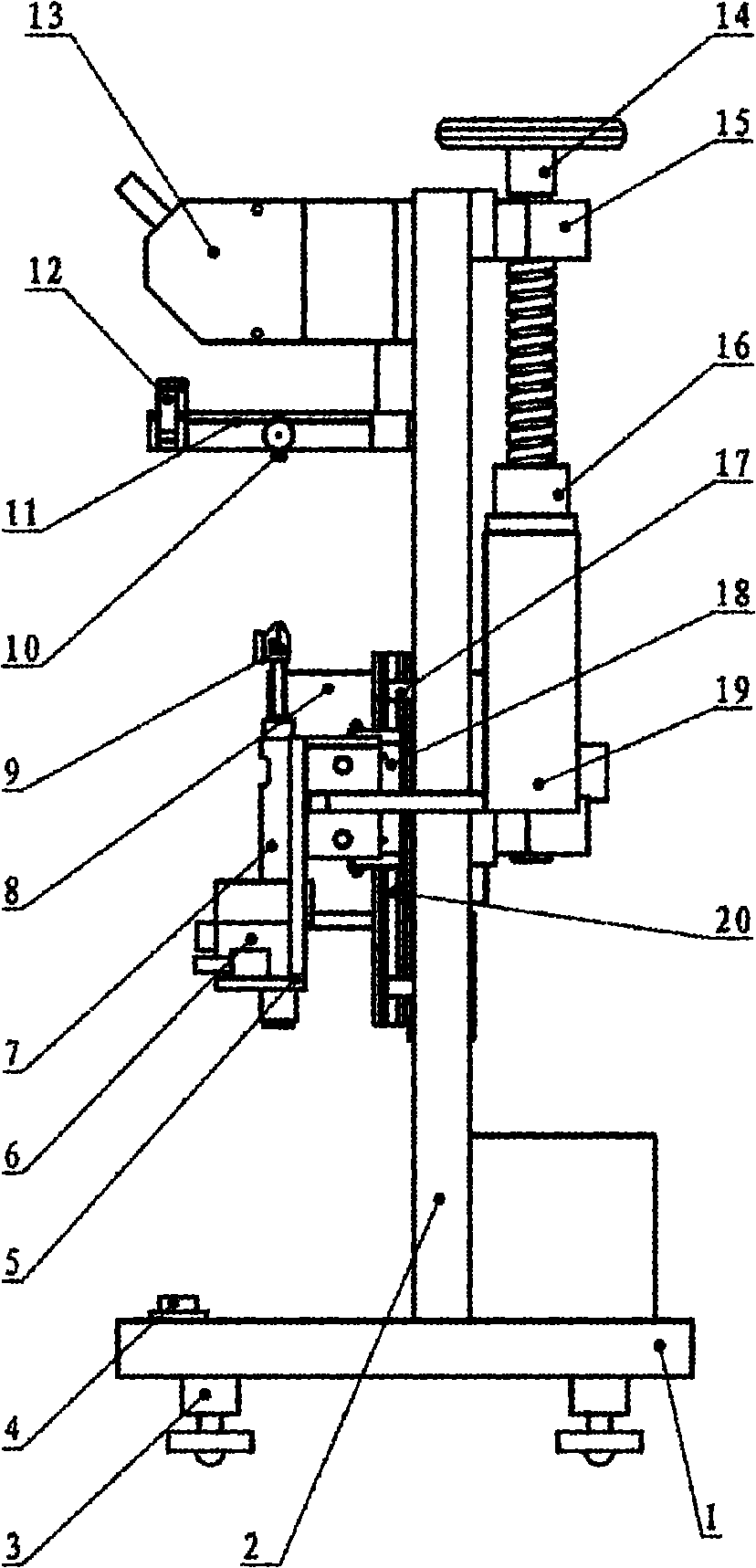

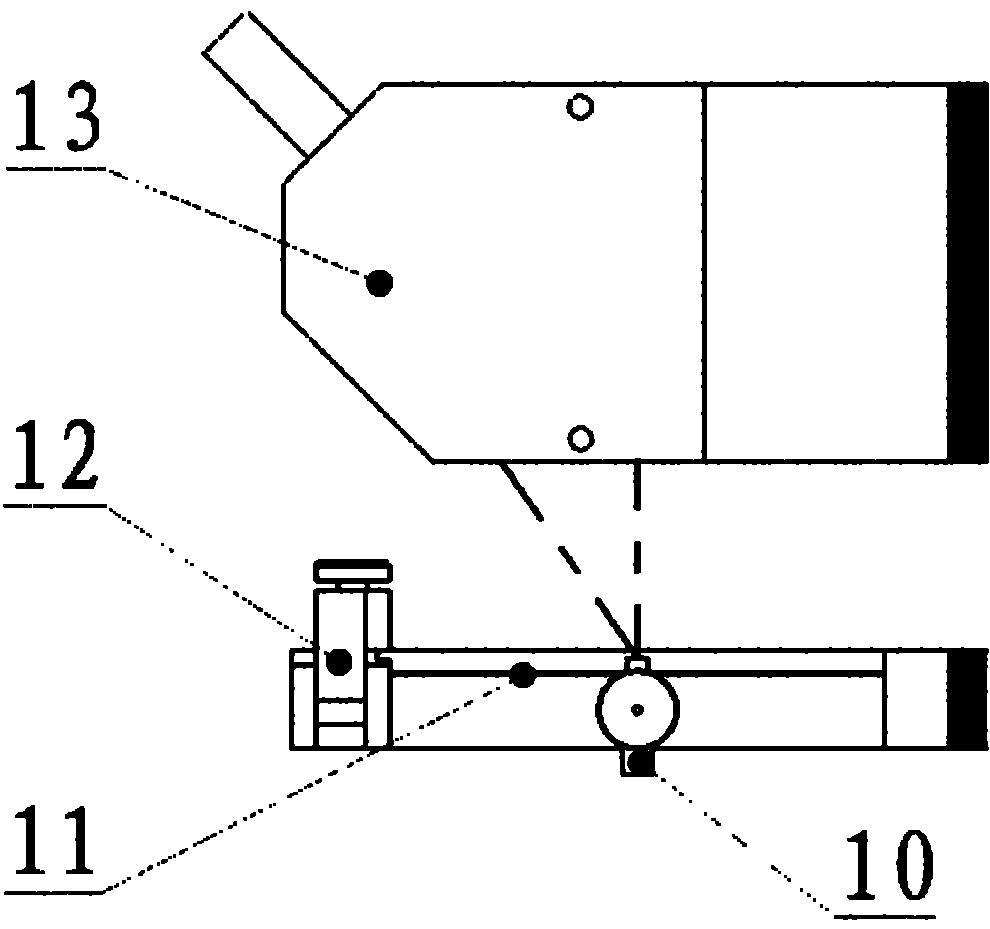

Method and device for testing micro-tensile mechanical properties of metal fiber

ActiveCN101949797AAdjust the measuring rangeAdjust measurement sensitivityMaterial strength using tensile/compressive forcesUsing optical meansTest sampleStress–strain curve

The invention discloses a method and a device for testing micro-tensile mechanical properties of a metal fiber. Being different from the existing tensile tester, the invention is characterized in that a force transducer is composed of a non-contact photoelectric displacement transducer and an elastic element, the force transducer can be used for measuring both the tensile force of a fiber and the displacement of the gripped end of the fiber and helping automatically and accurately obtain the tensile force-deformation curve of a test sample in real time so as to obtain the stress-strain curve of the test sample, and parameter values characterizing the micro-tensile mechanical properties of the metal fiber can be obtained by analyzing the stress-strain curve. By using the optical non-contact measurement method, the invention avoids the interference generated by the traditional contact measurement, and enables the measuring system to be more stable. Besides, the whole device has the advantages of ingenious structure, simple and convenient operation and stable performance, thereby being applicable to testing the micro-tensile mechanical properties of various single fibers (especially metal fibers).

Owner:HUAZHONG UNIV OF SCI & TECH

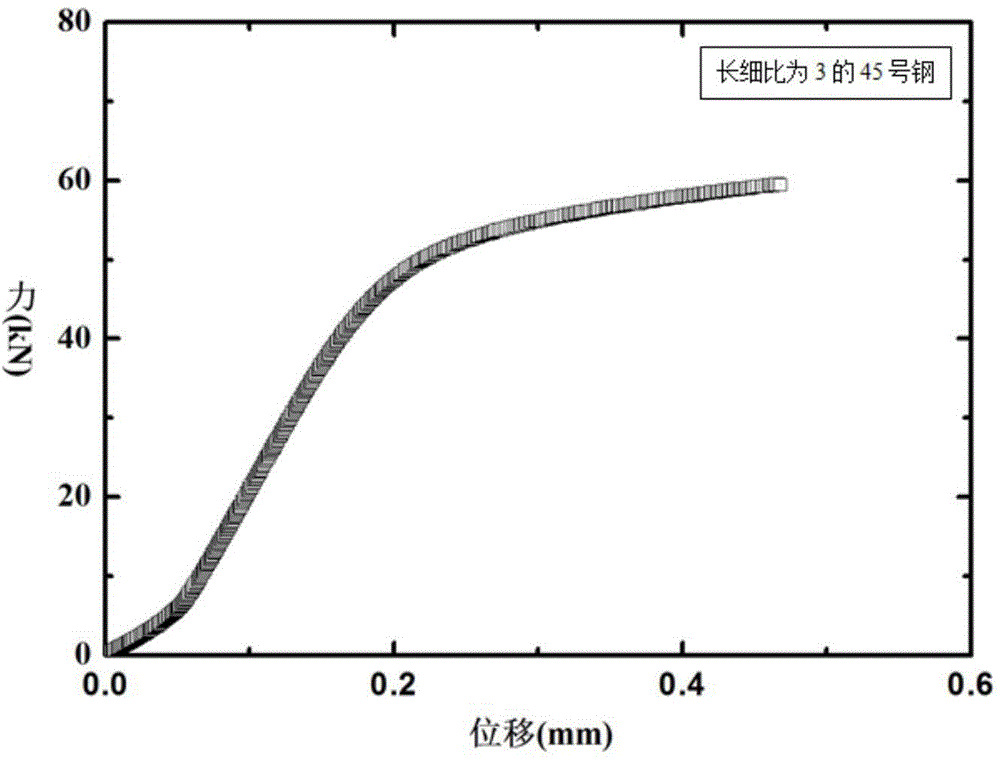

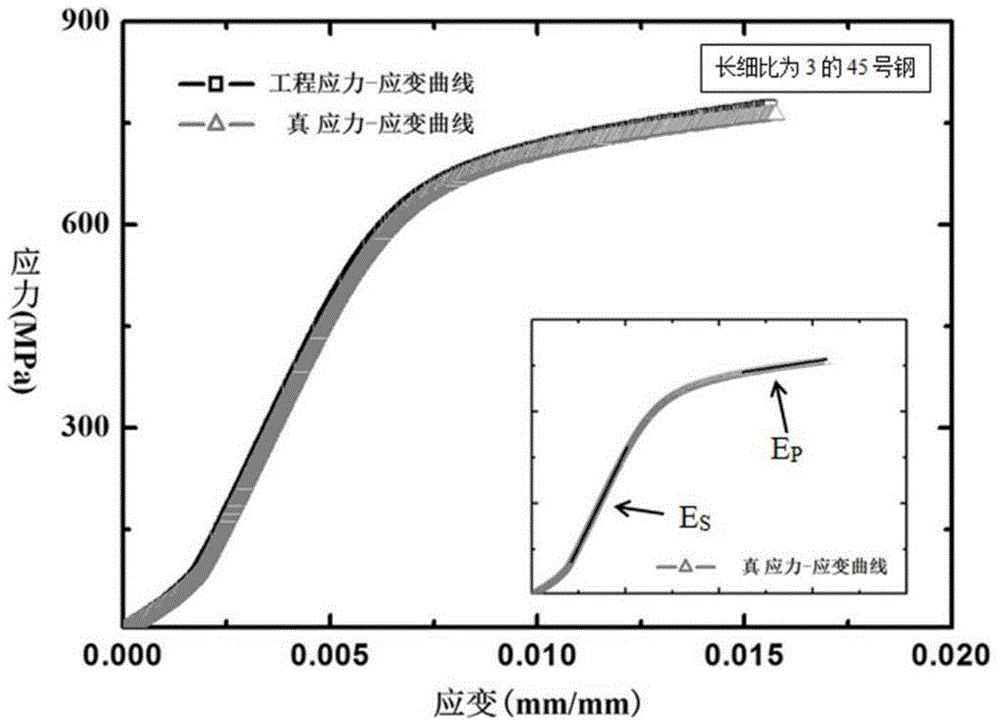

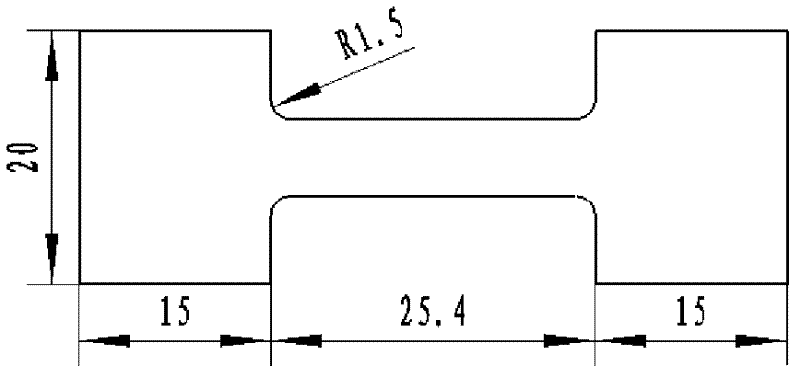

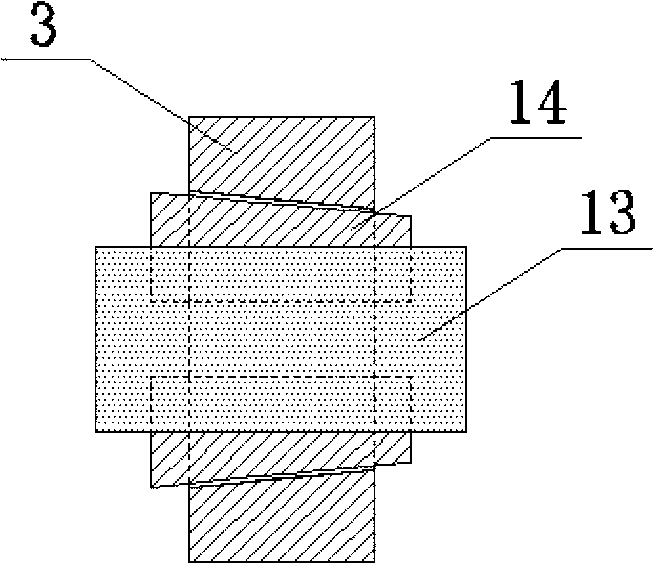

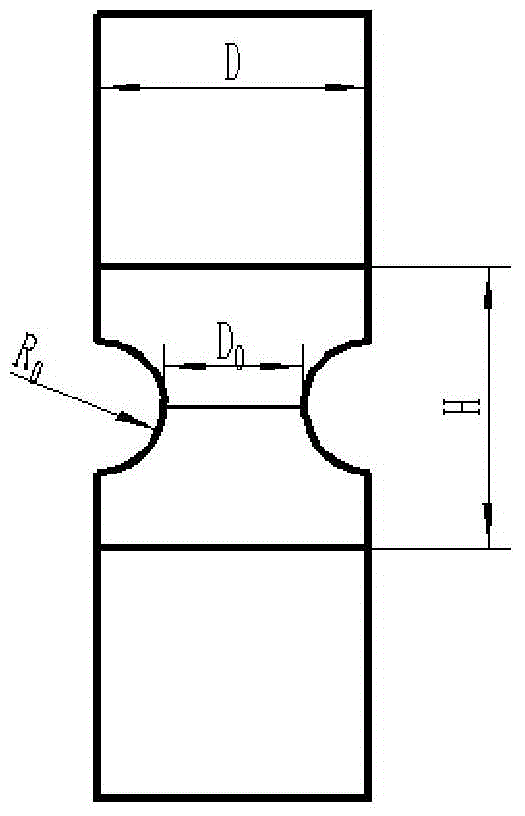

Method for correcting elasticity modulus and stress-strain curve in metal material compression test

ActiveCN104596846ASimplified operational requirementsImprove reliabilityMaterial strength using tensile/compressive forcesStress–strain curveMetallic materials

The invention relates to a method for correcting an elasticity modulus and stress-strain curve in a metal material compression test and a related model. The model is a sandwiched model. According to the method for correcting a metal material compression elasticity modulus and stress-strain curve obtained by the model, most of national standard or non-national standard samples of metal materials with linear strengthening behaviors, particularly metal samples in which L is equal to (2.5-3.5) d or L is equal to (2.5-3.5) b or L is equal to 2d or L is equal to 2b can be corrected, so that the real compression elasticity modulus can be measured on samples which are unsuitable for measuring the compression elasticity modulus in the national standard stipulation; particularly, the method can be used for correcting the elasticity modulus and stress-strain curve of small-size non-national standard samples. According to the method, the construction of a mechanical constitutive equation is greatly convenient, and for research and development of novel materials, the requirements of the test technology on the sizes and shapes of the samples can be lowered, the measured mechanical parameters are reliable, and the research and development period is shortened.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

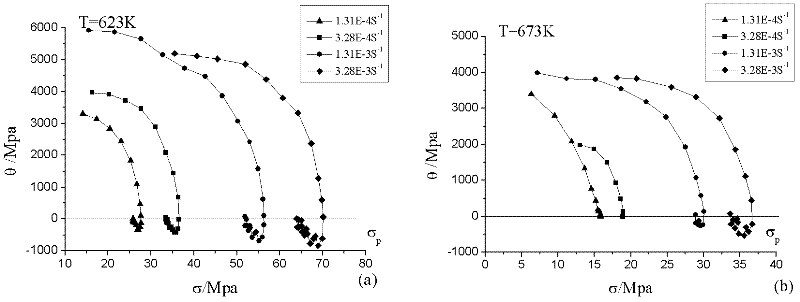

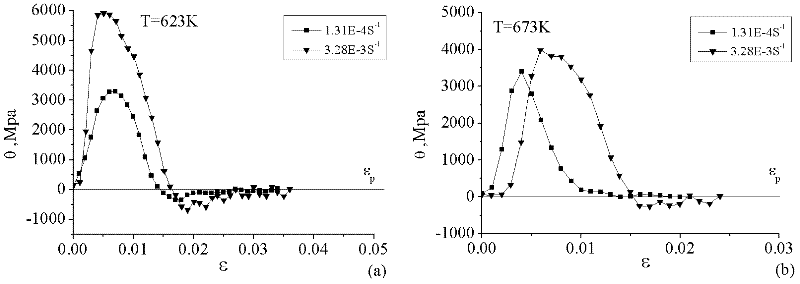

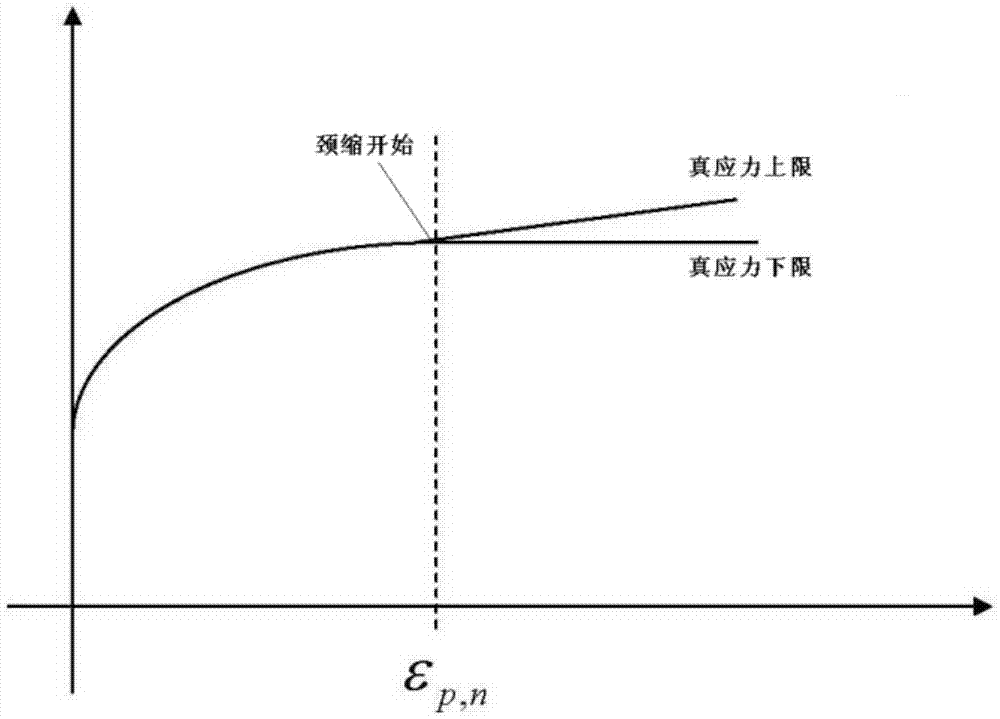

Method for establishing aluminium alloy dynamic recrystallization model by using true stress-true strain curve

InactiveCN102519801AMaterial strength using tensile/compressive forcesMathematical modelStress–strain curve

The invention discloses a method for establishing an aluminium alloy dynamic recrystallization model by using a true stress-true strain curve, belonging to the field of analyzing of material microstructures. The method comprises the following steps of: obtaining a hardening rate of a material by adopting the true stress-true strain curve obtained through a high-temperature tensile test, determining peak value strain, peak value stress and steady-state stress under different conditions by analyzing the change of the hardening rate, and establishing a peak value strain and critical strain mathematical model and a dynamic recrystallization volume fraction according to an empirical formula. The method disclosed by the invention overcomes the disadvantages of being lagging, time-consuming, incomplete and imprecise by using a metallographic method to research the recrystallization behaviour of the material. After being combined with finite element software, the method is capable of quantitatively analyzing the change condition of the dynamic recrystallization volume fraction of aluminium alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

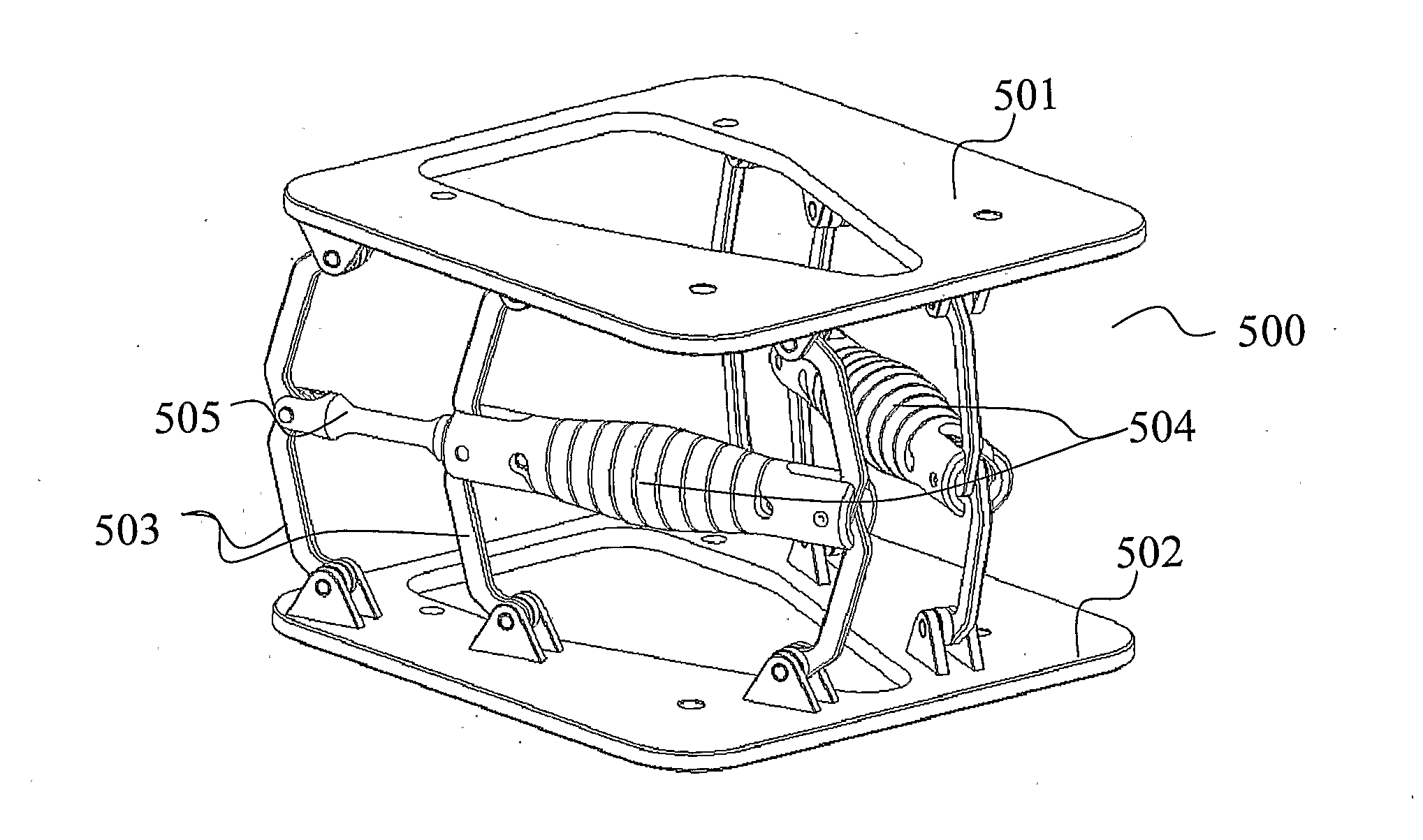

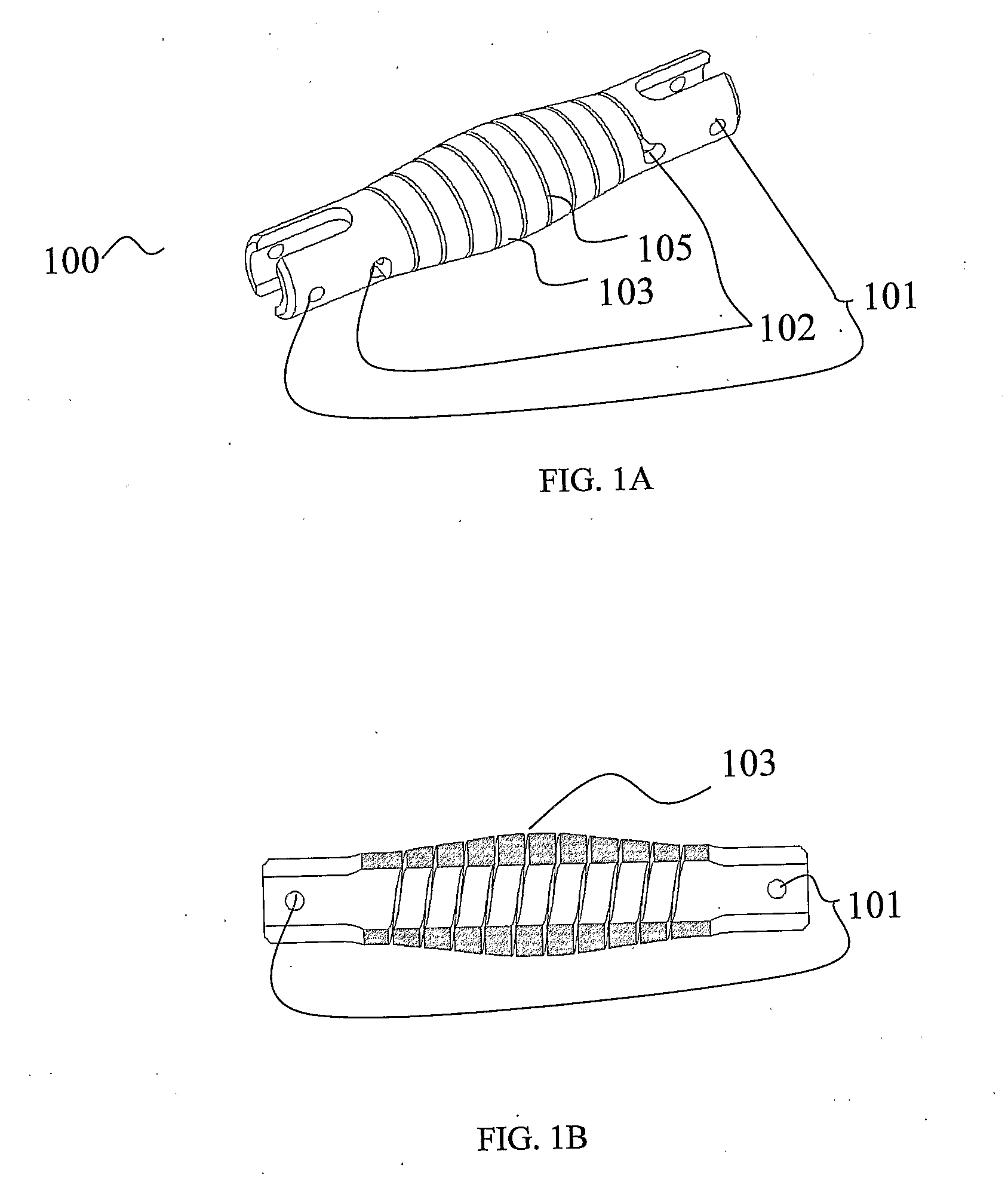

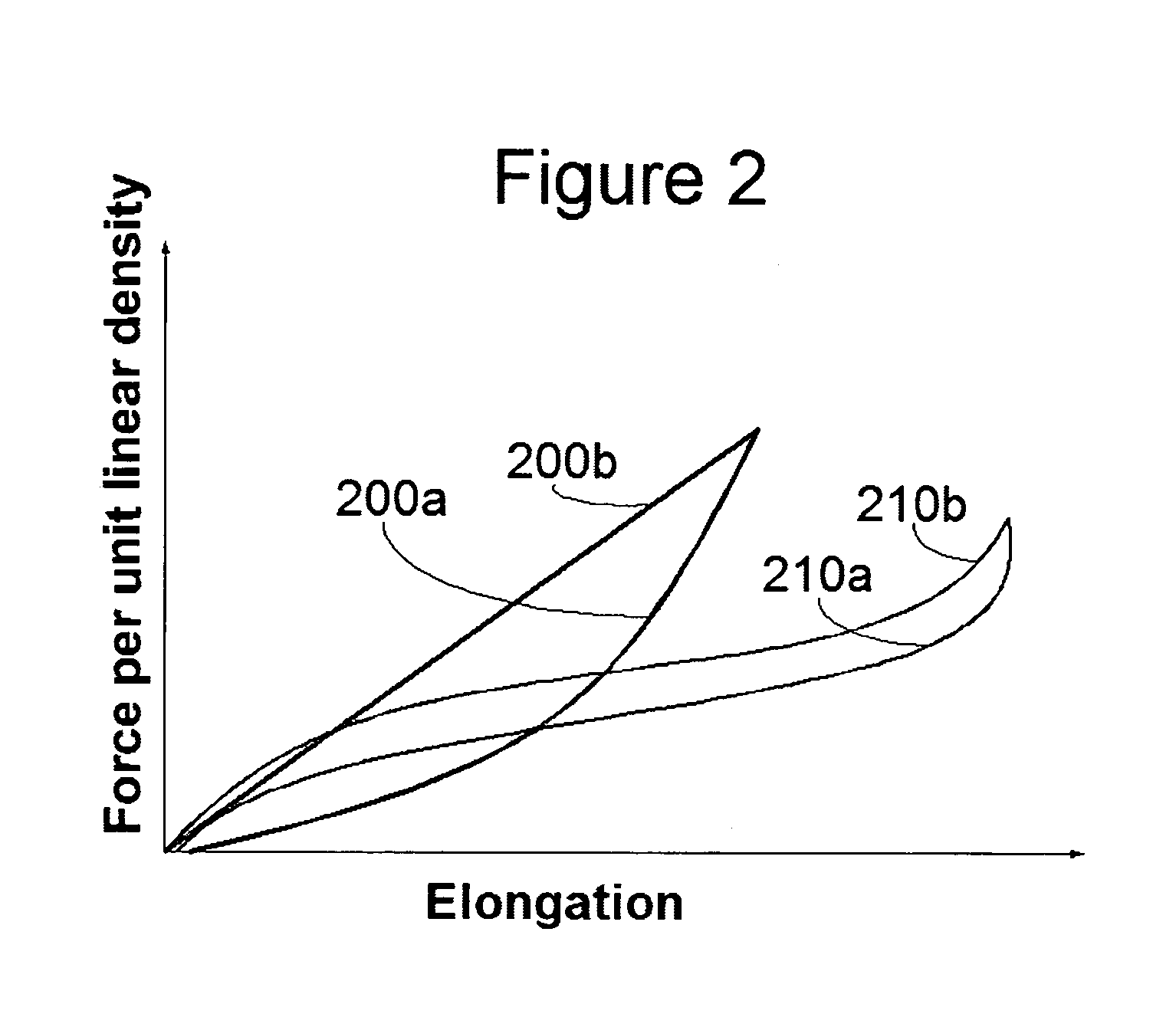

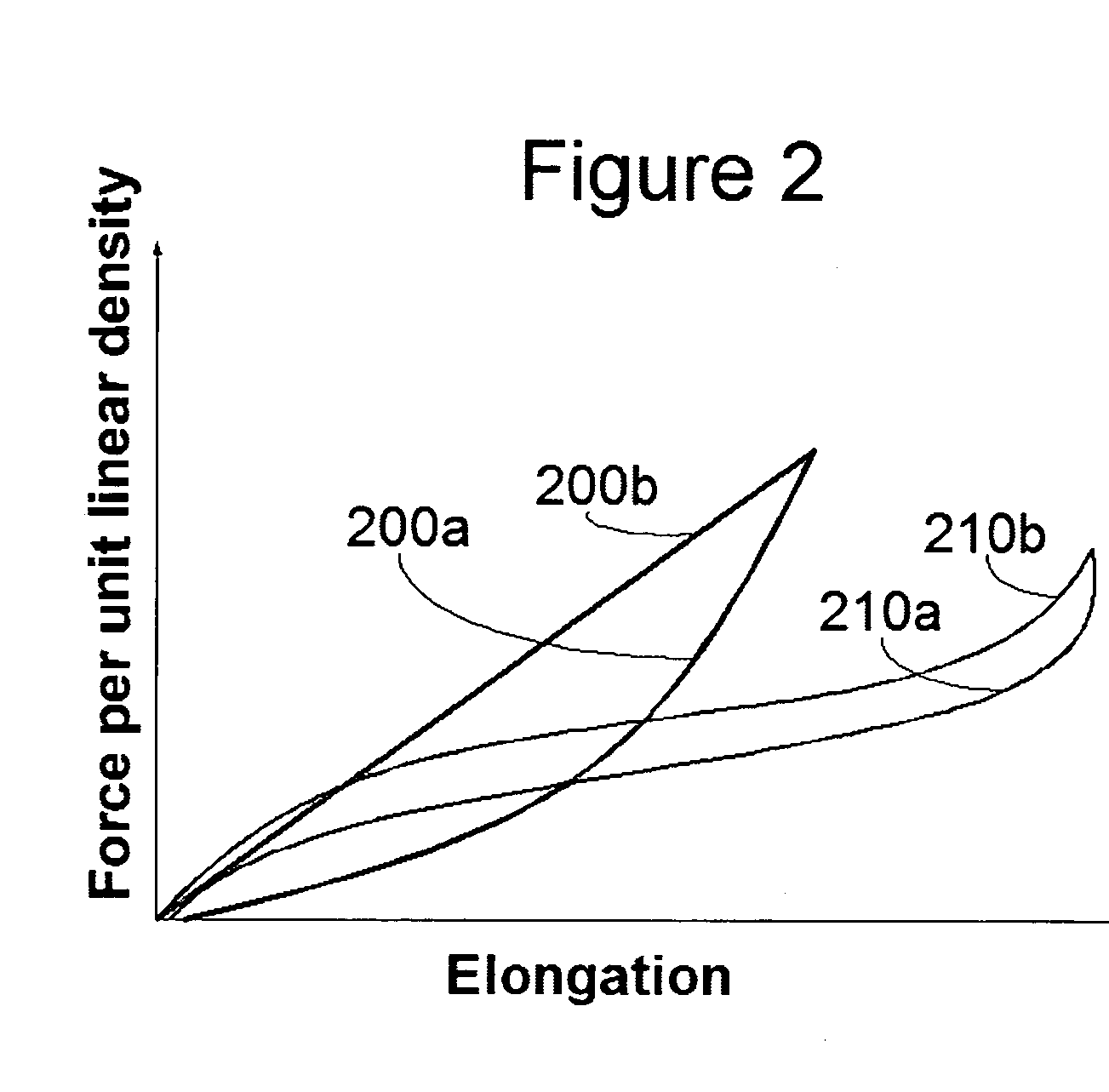

Shock absorbing mechanism with feet protection for vehicle and aircraft seats

ActiveUS20110233975A1Increase stiffnessMinimizing accelerationPedestrian/occupant safety arrangementWire springsJet aeroplaneStress–strain curve

The present invention discloses a method and apparatus for minimizing accelerations during impacts such as those encountered in motor vehicle accidents, helicopter and airplane crashes, explosions, and the like. The preferred embodiment takes the form of a helical spring-like member (100), designed to experience plastic deformation over a desired deformation length, under a given impact load threshold. The spring-like member is preferably installed in a mechanical linkage that is flattened under impact, straining the spring-like member in a predictable fashion. The operating characteristics of this system [namely the stress-strain curve, and thus the deformation length, impact load threshold, and acceptable load range for the system to be protected] can be easily controlled by varying the device dimensions and installation configuration.

Owner:MOBIUS PROTECTION SYST

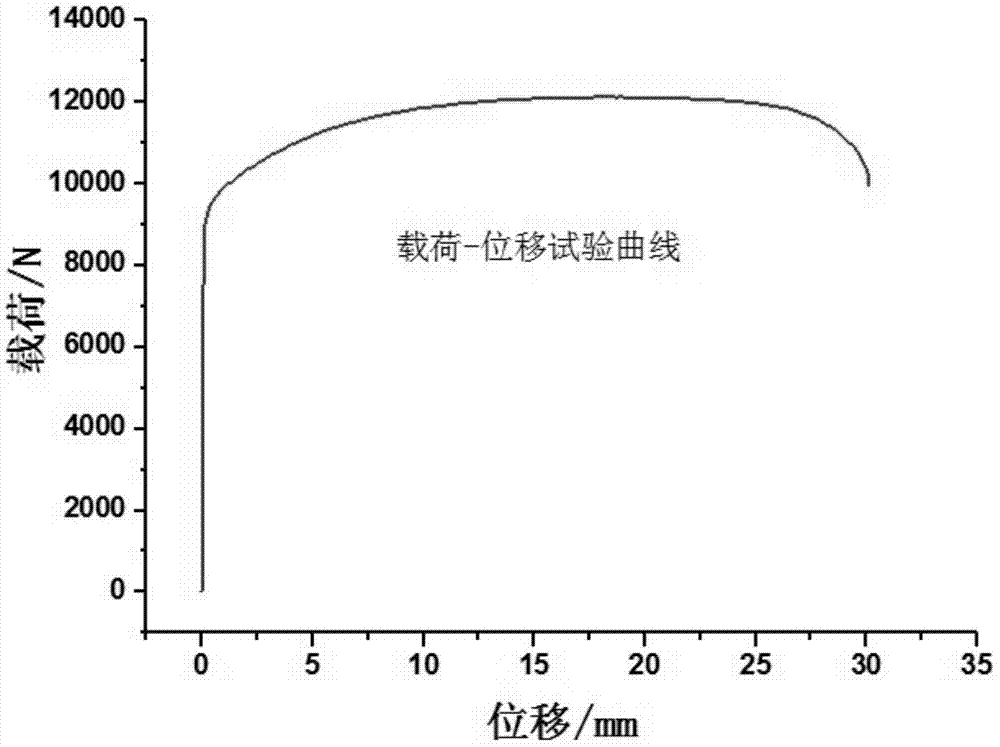

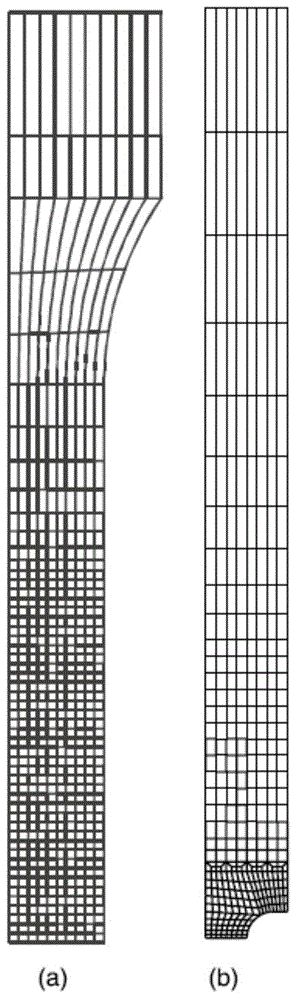

Quick acquisition method of true stress strain curve in whole process of uniaxial drawing

ActiveCN103792143AEffects that impair analytical accuracySimple and fast operationMaterial strength using tensile/compressive forcesStress–strain curveComputer science

The invention relates to a quick acquisition method of a true stress strain curve in whole process of uniaxial drawing. The method comprises the steps of verifying the accuracy of a CAE (computer aided engineering) simulation model by a true stress-true strain curve at an even plastic deformation stage based on the static uniaxial drawing data, and indirectly predicting the true stress-true strain curve at a necking section through the CAE model to obtain the equivalent true stress-true strain curve in whole process of uniaxial drawing. The simple acquisition method of the true stress strain curve of the material in whole process of uniaxial drawing is easy and simple to operate, thus meeting the need of the CAE simulation in the engineering design. Furthermore, the quick acquisition method is in combination with a CAE technology, the influence of the grid effect to the CAE analysis accuracy can be weakened as much as possible.

Owner:CHERY AUTOMOBILE CO LTD

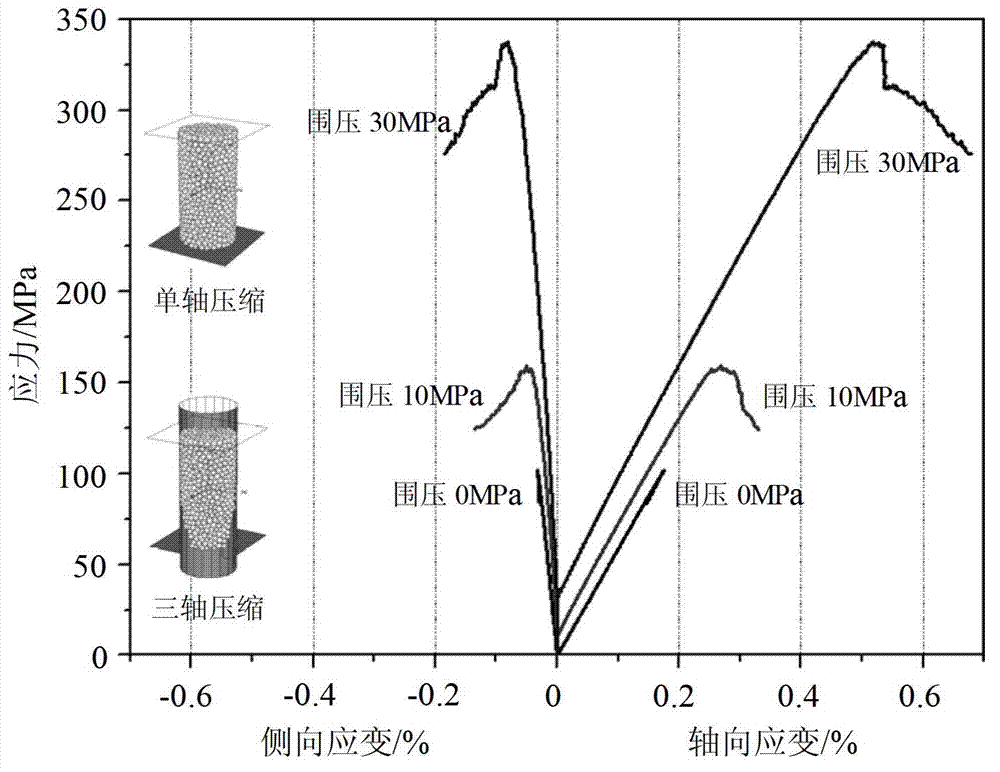

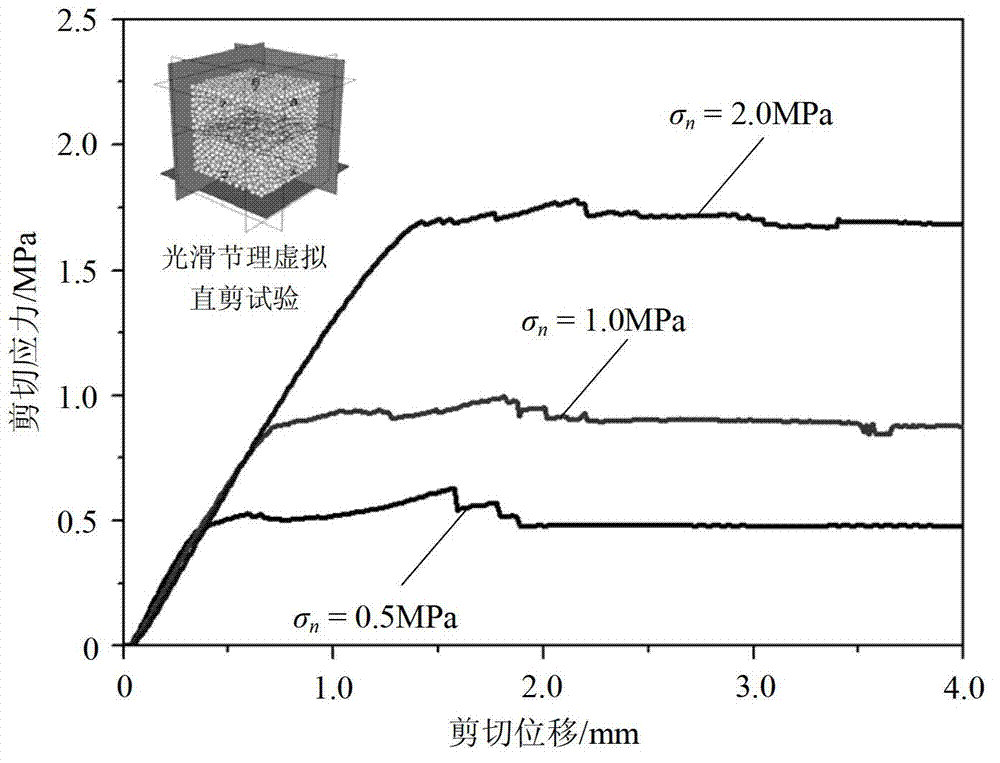

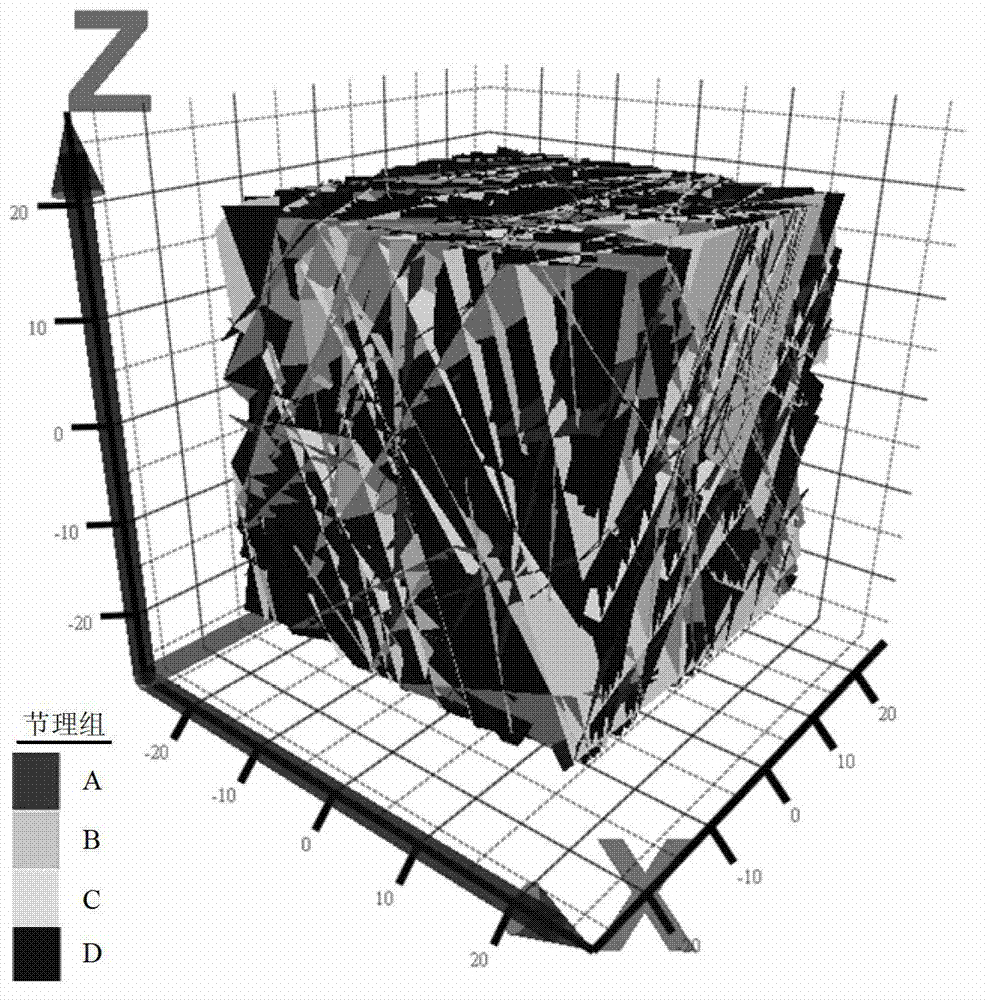

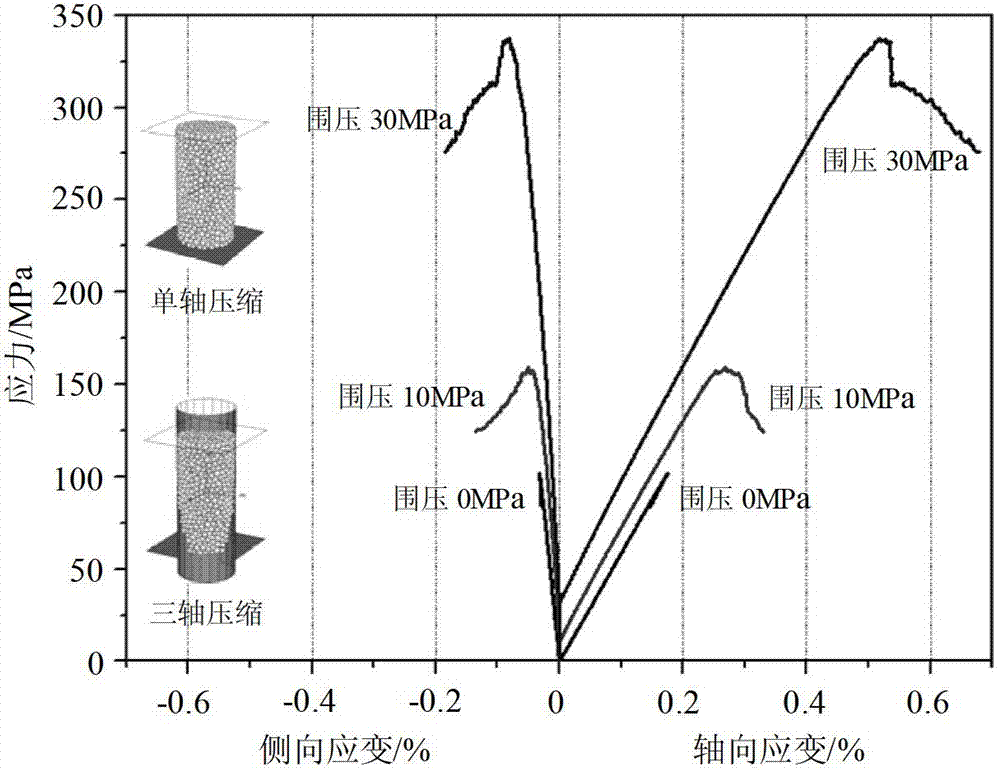

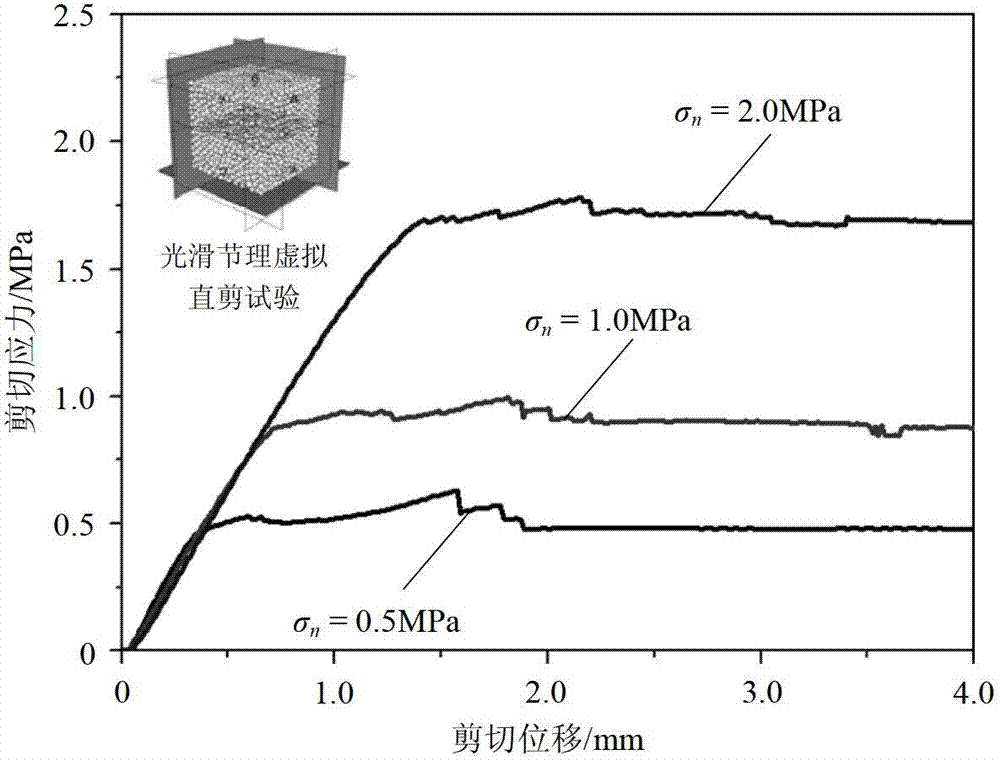

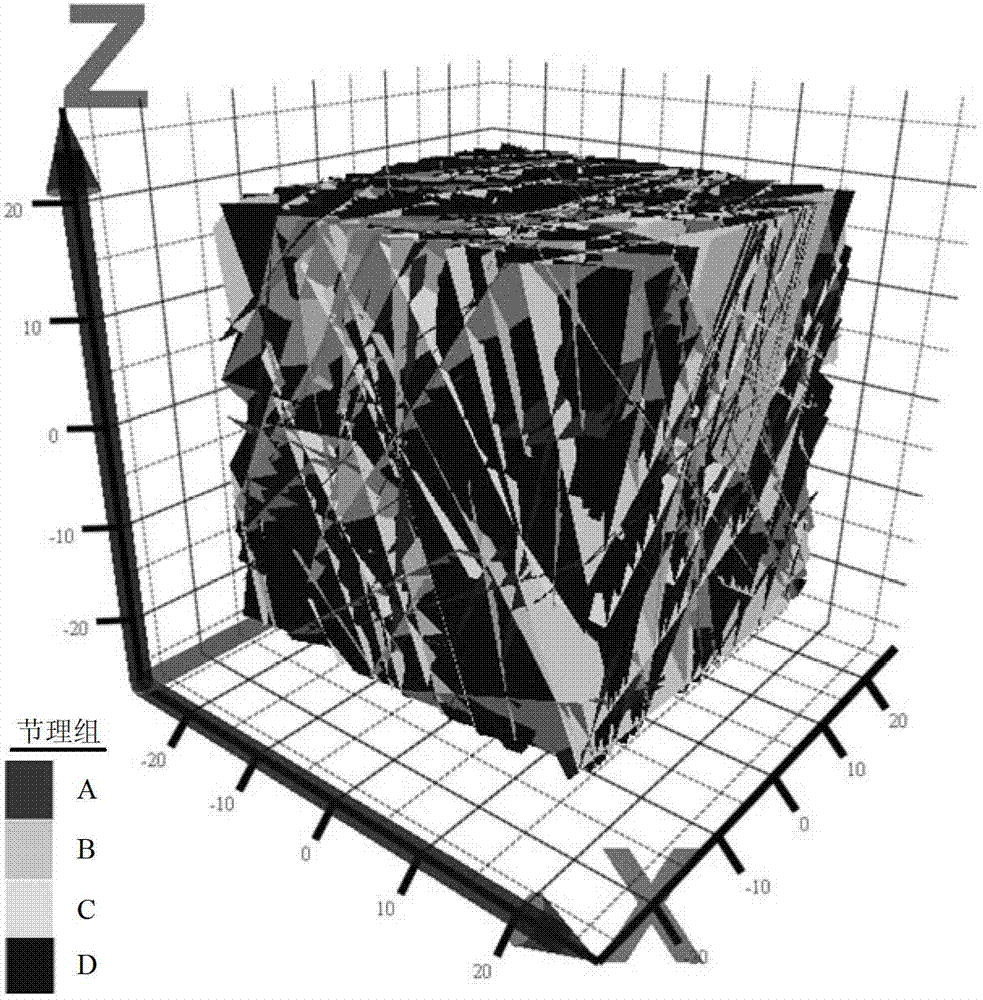

Method for confirming anisotropism of jointed rock mass

InactiveCN103115820AMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesUniaxial compressionStress–strain curve

The invention provides a method for confirming the anisotropism of jointed rock mass. The method comprises the following steps of: firstly building the multi-scale jointed rock mass capable of sufficiently reflecting the rock mechanical property, the joint mechanical property and the joint spatial distribution characteristic, wherein the jointed rock mass with different scales comprises three groups of samples, and the long axial directions of the samples are respectively along the X-direction, the Y-direction and the Z-direction; carrying out virtual uniaxial compression loading along the long axial directions of various kinds of jointed rock mass to obtain a stress-strain curve, and extracting the mechanical parameters of the jointed rock mass along the X-direction, the Y-direction and the Z-direction, i.e. the uniaxial compressive strength, the elasticity modulus and the like; and building an anisotropism index Ksi, and confirming the anisotropism of the mechanical parameters of the jointed rock mass along the different axial directions, i.e. the uniaxial compressive strength, the elasticity modulus and the like under different scales, so that the anisotropic characteristics of the jointed rock mass can be quantitatively researched. The invention provides a method which is simple in principle, convenient to operate, low in cost and good in use effect, so that the anisotropic characteristics of the jointed rock mass can be confirmed.

Owner:UNIV OF SCI & TECH BEIJING

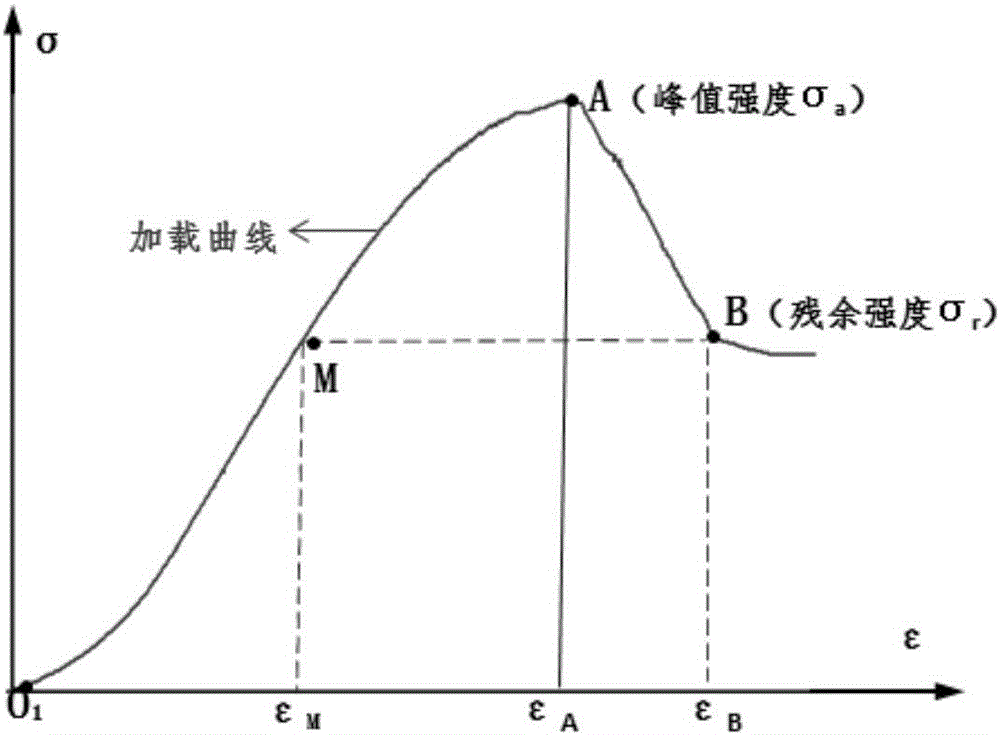

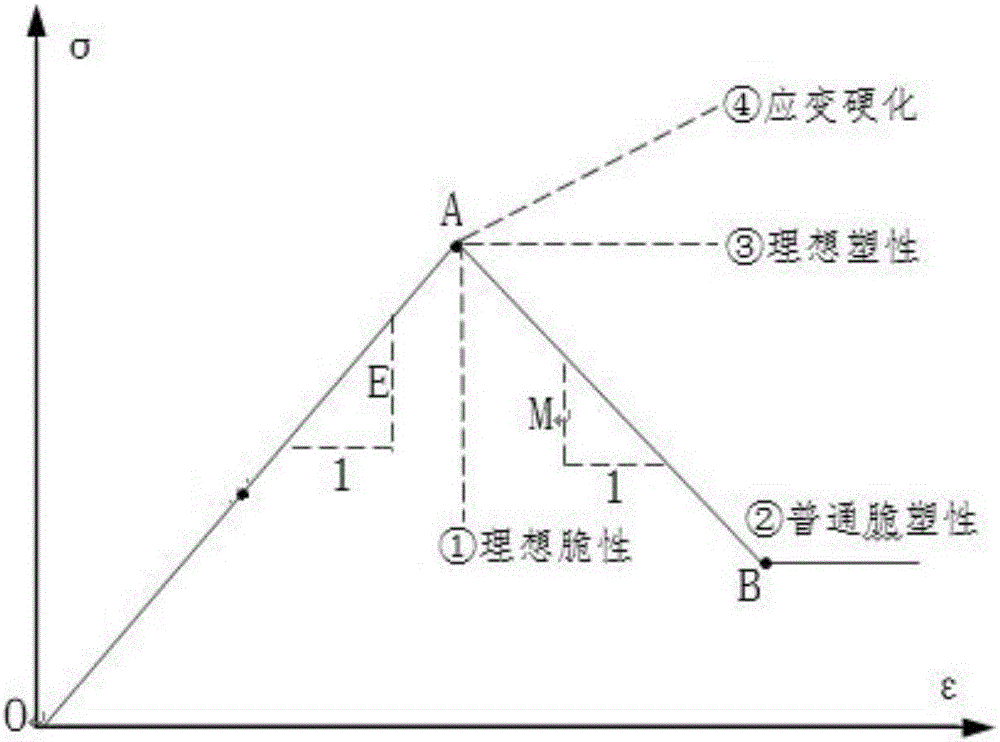

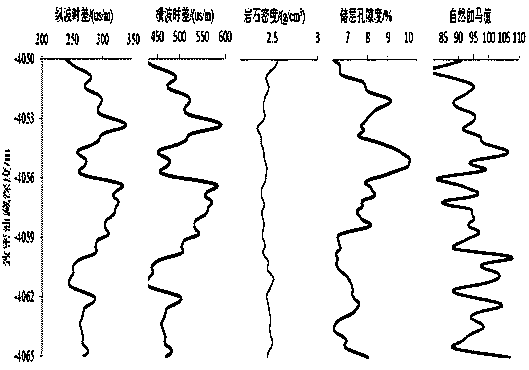

Method for shale-gas-well storing-layer brittleness comprehensive evaluation

ActiveCN106248494AAchieve mutual integrationComprehensiveMaterial strength using tensile/compressive forcesGeological measurementsShale gasStress–strain curve

The invention discloses a method for shale-gas-well storing-layer brittleness comprehensive evaluation. The method includes the following steps that to-be-measured shale samples are subjected a triaxial compression testing experiment, and a complete stress-strain curve is obtained; a brittleness drop coefficient R, a stress depreciation coefficient P and a softening modulus M are calculated, the brittleness indexes corresponding to the brittleness drop coefficient R, the stress depreciation coefficient P and the softening module M are subjected to normalization processing respectively, and a comprehensive brittleness index Bd is obtained; correction is carried out according to a Bd calculation model, the corrected brittleness index Bd<3> serves as an objective function, parameters such as a shale dynamic elastic modulus E in well logging data serve as independent variables, function regression is carried out, a multi-regression function Y of the Bd<3> is obtained and substituted into different-layer-section storing-layer well logging parameters, and the comprehensive brittleness indexes of different well-section storing layers are obtained. According to the method, the whole condition of shale damaging is considered, and the brittleness characteristics of shale can be comprehensively responded; meanwhile, the brittleness of different-depth, different-confining-pressure and different-well-section storing layers is analyzed by combining shale-gas-well logging information, and the adaptability is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

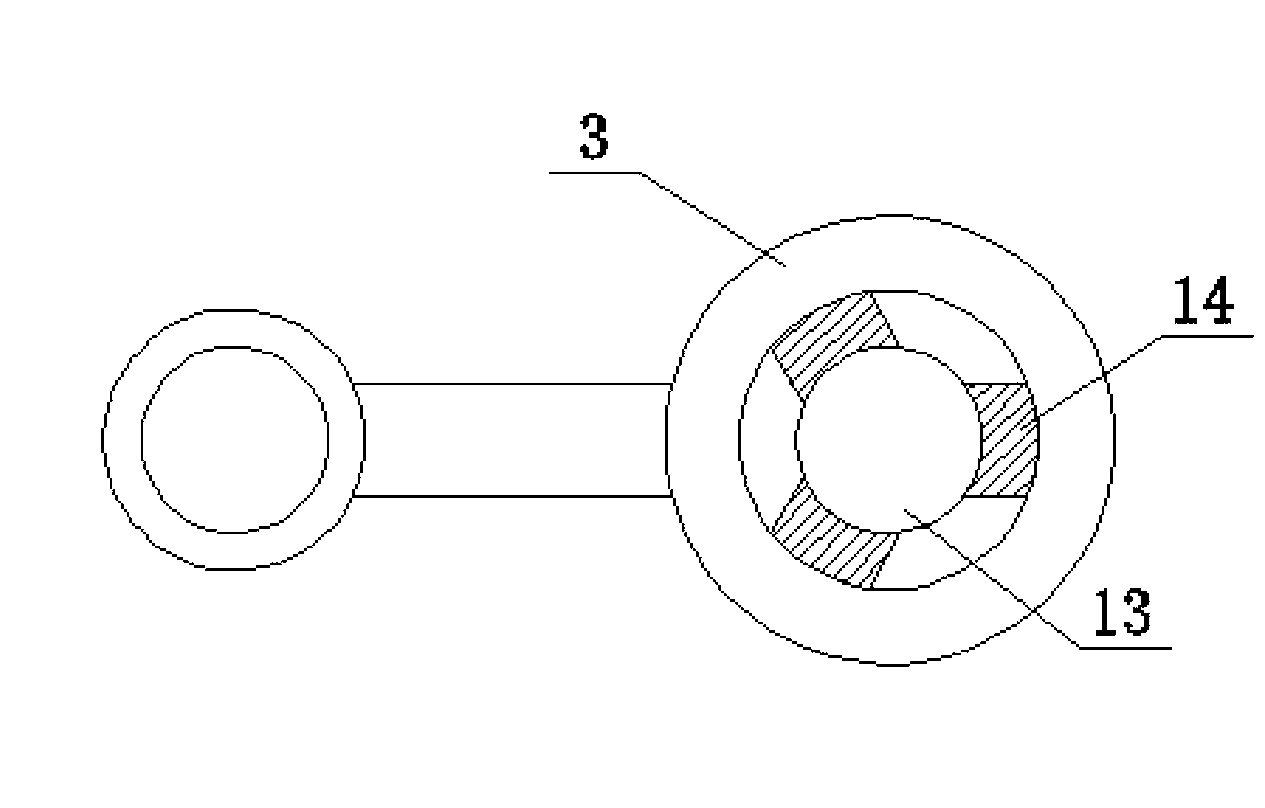

Test method for performing rock direct stretching by using axial centering positioning device

ActiveCN103323329AObvious technical advantagesAccurate testing of tensile strengthMaterial strength using tensile/compressive forcesTensile strainStress–strain curve

The invention discloses a test method for performing rock direct stretching by using an axial centering positioning device. The positioning device comprises an adhesion centering positioning device and a stretching centering positioning device which are matched with each other. The adhesion centering positioning device is used for eliminating the eccentricity caused by the adhesion of a test piece; the stretching centering positioning device is used for eliminating the eccentricity generated in the test piece stretching process; the tensile strength and the ultimate tensile strain and a tensile stress-strain curve of a rock can be accurately tested by using a direct stretching test method. The device is simple in structure, convenient to operate and easy to assemble and disassemble; the problem about the eccentricity when the rock test piece is adhered and stretched is solved; the test method can accurately test the tensile strength of the rock and also can effectively test the ultimate tensile strain and the tensile stress-strain curve of the rock.

Owner:SHANDONG UNIV

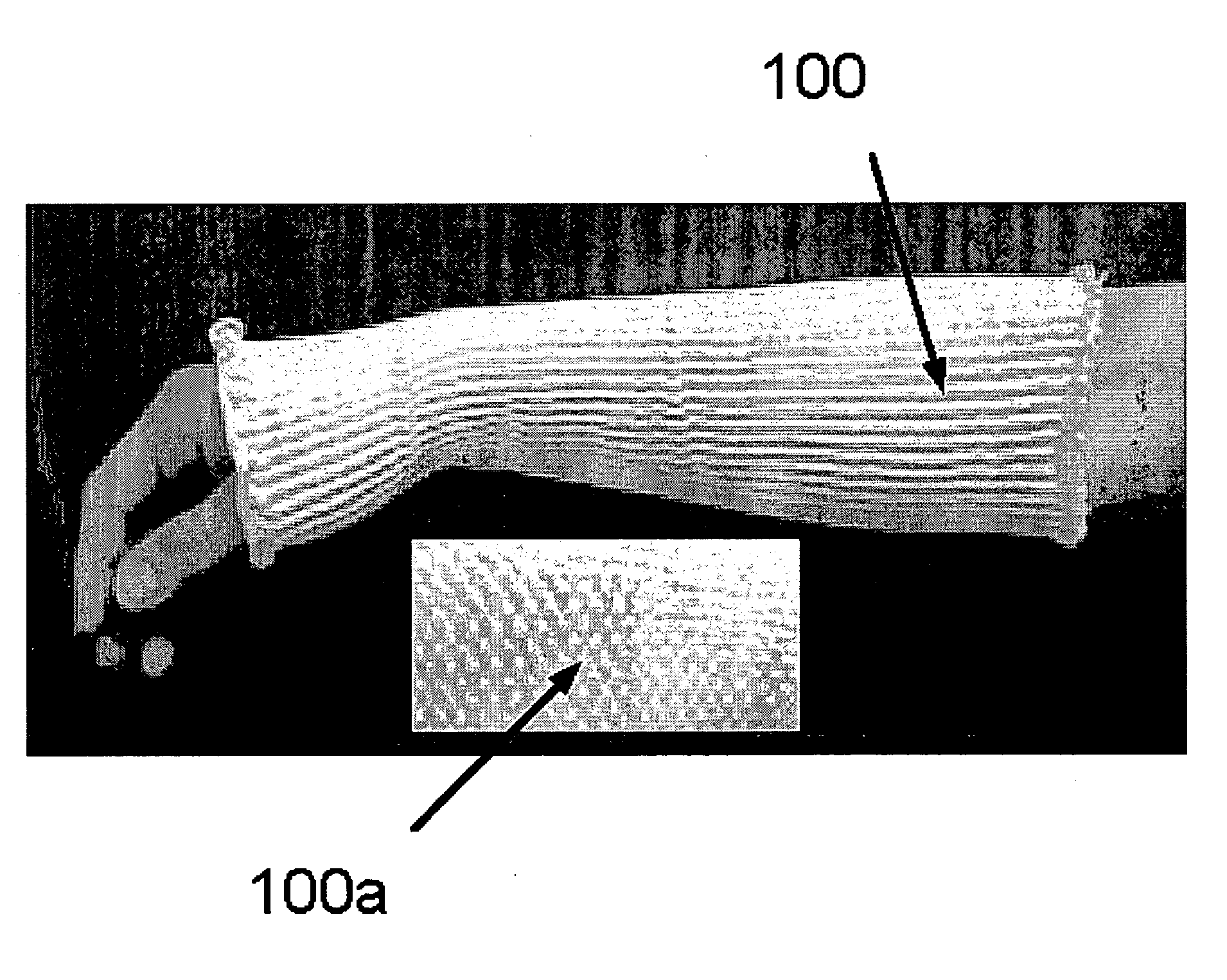

Sleeve-like knitted structure for use as a castliner

ActiveUS6981955B2Improve buffering effectComfortable conformanceFinger bandagesFeet bandagesYarnCushioning

A castliner in the form of a three-dimensionally knitted sleeve comprises a microdenier yarn, and / or a spandex yarn, in particular, a spandex yarn having a flatter stress-strain curve than traditional spandex yarns. The use of the microdenier yarn contributes to the superior cushioning effect. The stretch and recovery properties of the particular spandex yarn contribute to superior fit and reduction of pressure points on the limb or body part to which the castliner is applied. Furthermore, the castliner is rendered water resistant and has significantly improved antimicrobial properties, both of which reduce incidents of skin irritation and unpleasant smell. As a result, the patient wearing the castliner of the invention is able to bathe and get wet without otherwise replacing the hard casting and castliner after such events.

Owner:THE LYCRA CO LLC

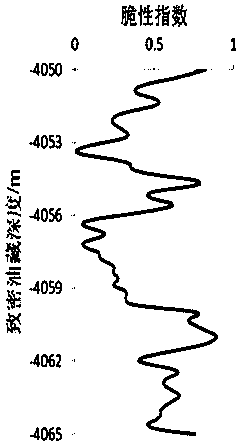

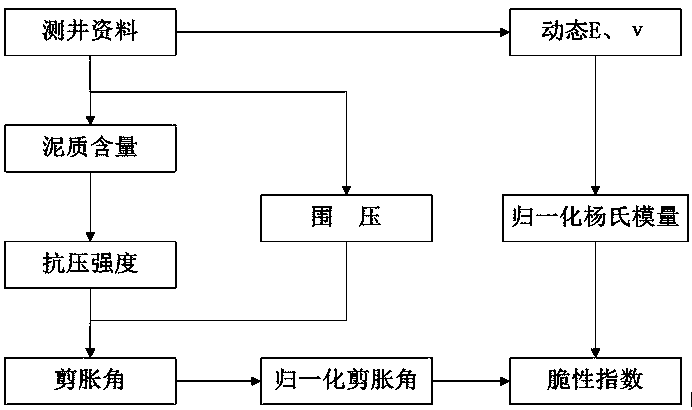

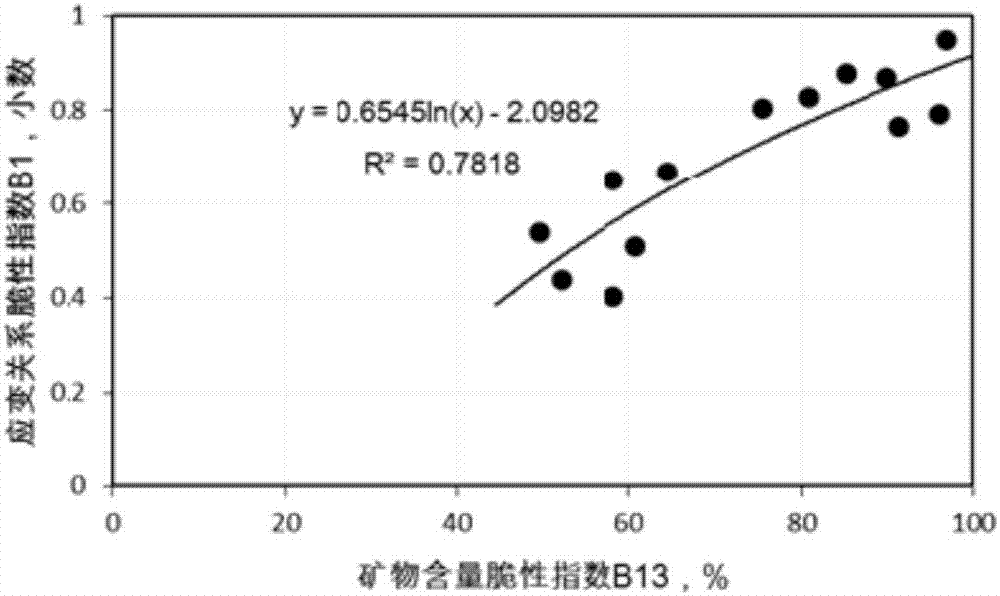

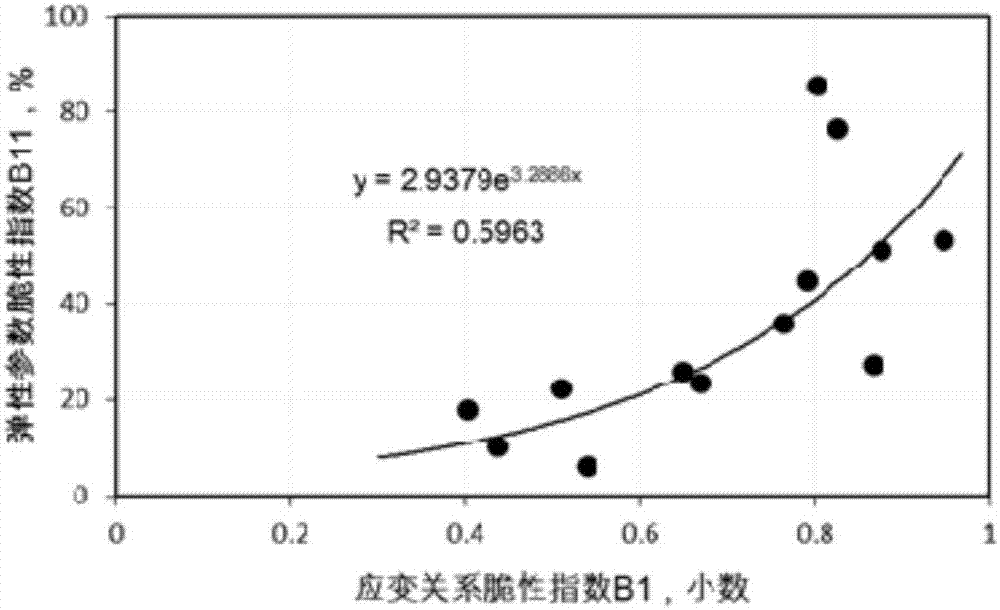

Calculation method for rock brittleness index of compact reservoir

ActiveCN106547034AImprove fracturing effectEarth material testingGeological measurementsWeight coefficientStress–strain curve

The invention provides a method for calculating the rock brittleness rapidly based on logging data, and aims at realizing rapid calculation for the rock brittleness of a compact reservoir under a stratum condition and facilitating high-efficiency exploitation of compact hydrocarbon reservoir. From the aspects of rock rupture form and rupture breaking energy, the method mainly uses the principle that the more complex the rock rupture form is, the lower the rupture breaking energy is and the greater the rock brittleness index is. A young modulus and a dilatancy angle are used to reflect the deformation resistance and the deformation speed of the rocks respectively, the rock brittleness feature can be described effectively, and the young modulus and the dilatancy angle can also reflect characteristics of a rock stress-strain curve in different stages. A grey relation theory is used to calculate weight coefficients of the young modulus and the dilatancy angle, and a new method to calculate the rock brittleness index is established. The method predicts the brittleness index rapidly on the basis of the logging data, evaluation of the rock brittleness is more reasonable, and high-efficiency exploitation of the compact hydrocarbon reservoir is facilitated.

Owner:SOUTHWEST PETROLEUM UNIV

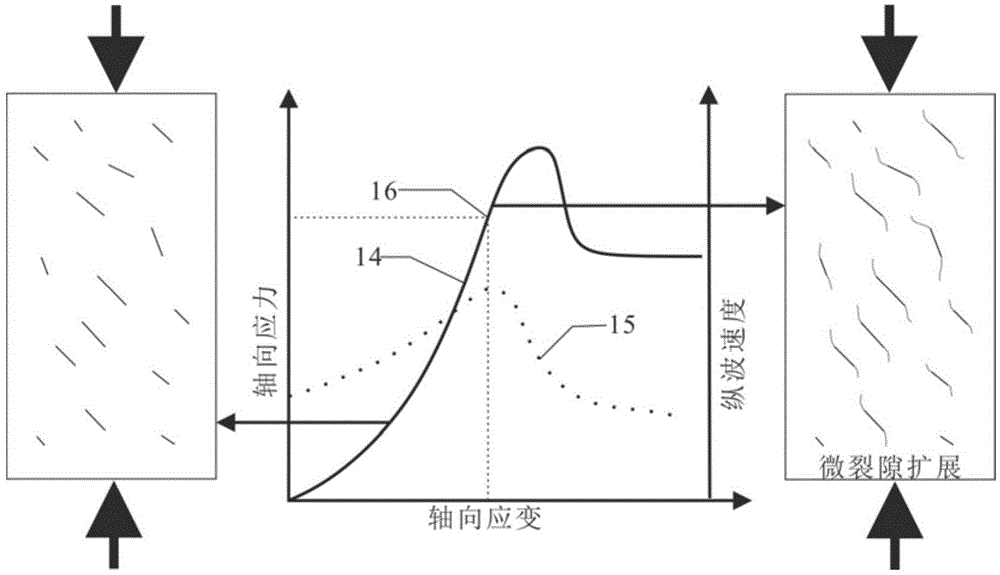

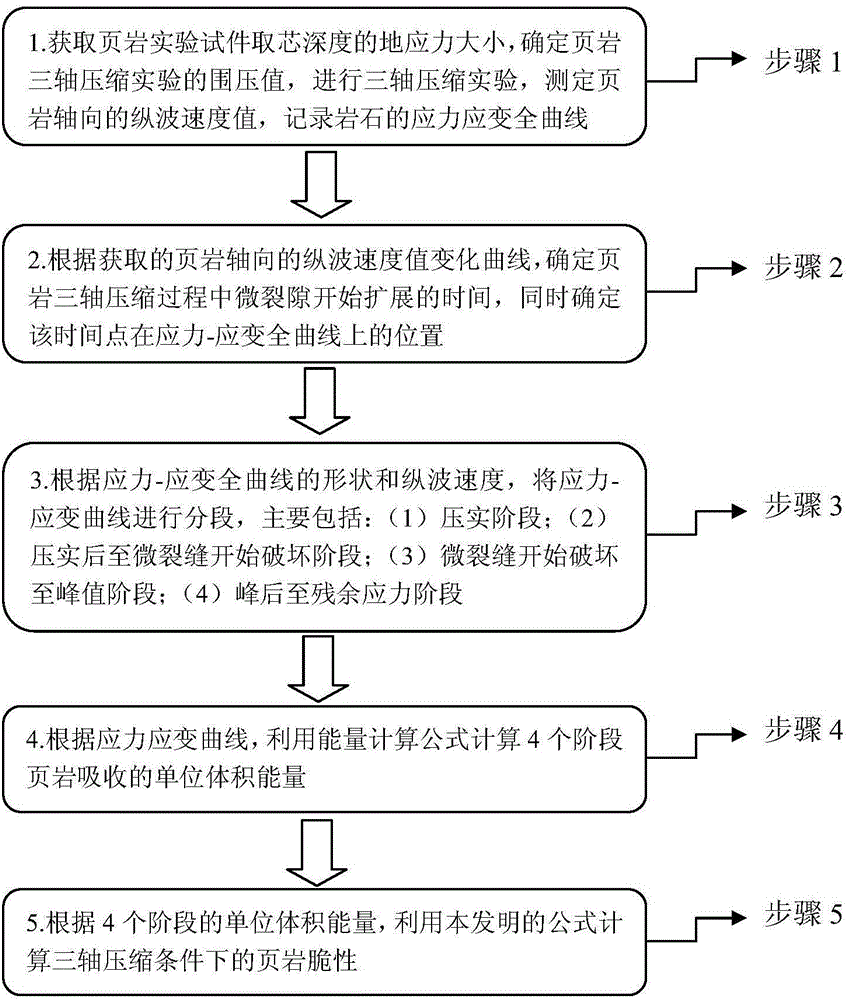

Method for measuring shale brittleness index based on rock stress-strain curves and ultrasonic longitudinal wave speed

ActiveCN104865124AImprove accuracyImprove rationalityAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesLongitudinal waveStress–strain curve

The invention provides a method for measuring a shale brittleness index based on triaxial compression complete stress-strain curves and ultrasonic longitudinal wave speed. The method comprises the following steps: obtaining a triaxial compression complete stress-strain curve and the ultrasonic longitudinal wave speed of each time point in an experimental process by adopting dynamic and static combined triaxial compression experiment; determining a time point when a shale microcrack starts to be damaged by utilizing a change curve of the longitudinal wave speed; according to the change of the longitudinal wave speed and the shape of the complete stress-strain curve, dividing the complete stress-strain curve into four stages, namely, a stage of microcrack closure, a stage from compaction to starting of microcrack damage, a stage from microcrack extension to damage instability and a stage after rock damage instability; by utilizing the complete stress-strain curve, calculating the unit volume energy absorbed by a shale test piece in the corresponding stage; calculating the shale brittleness index by utilizing the ratio of the unit volume energy absorbed in the elastic stage to the absorbed total unit volume energy. The method is a comprehensive calculation method considering mechanical properties of shale in each stage and improves the accuracy and reasonability of rock brittleness evaluation.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

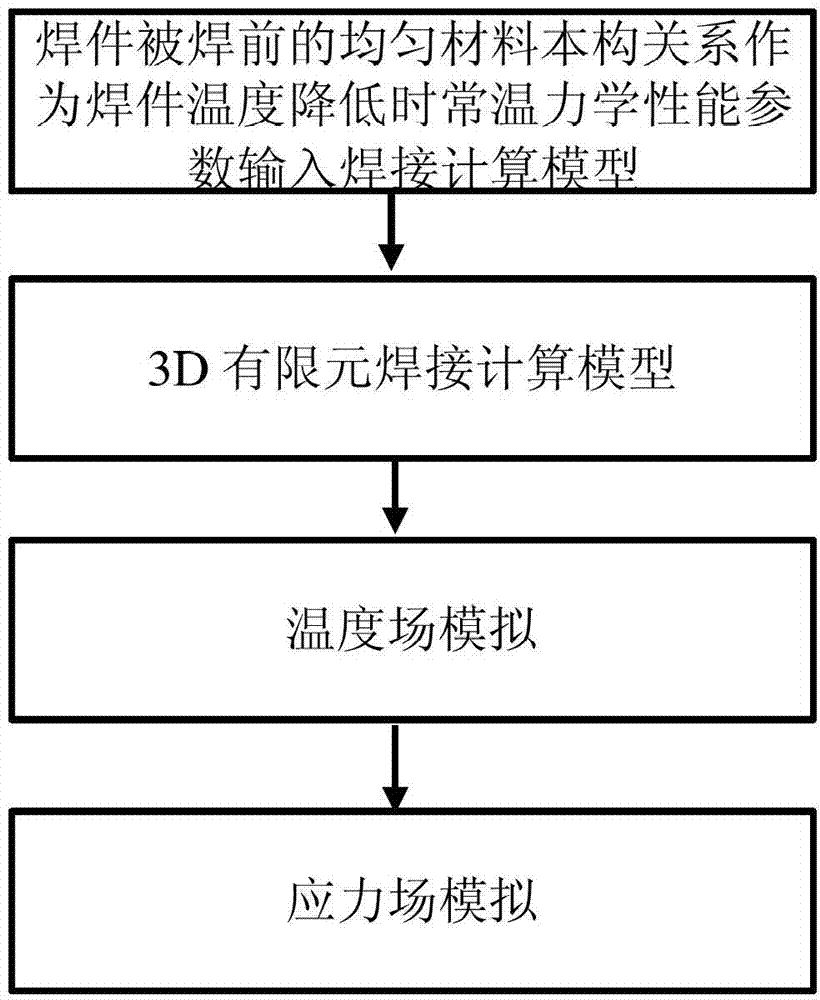

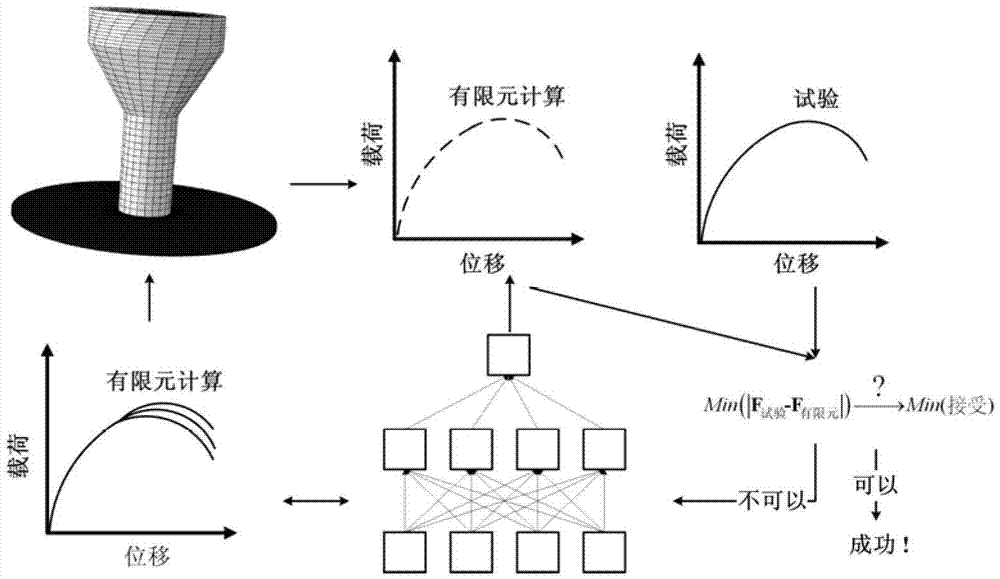

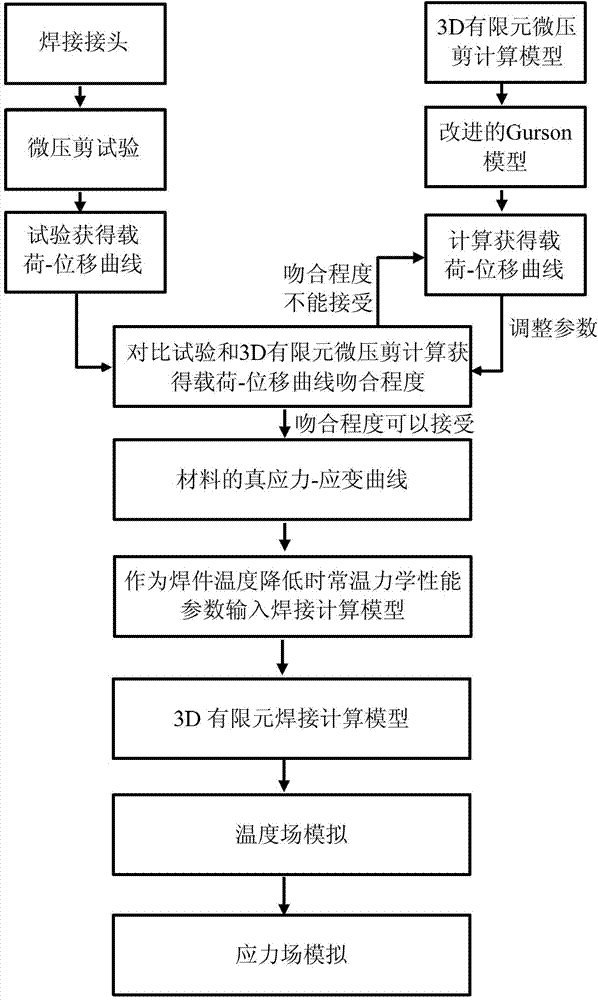

Welding microcell performance test based residual stress computing method

InactiveCN102759504AReduce mistakesAccurate calculationUsing mechanical meansMaterial analysisBacksteppingElement model

The invention provides a welding microcell performance test based residual stress detection method, which comprises the following steps of: carrying out a micro-compression-shear test on a welding microcell so as to obtain a load-displacement curve of the welding microcell, establishing a 3D (three-dimensional) finite element model of a micro-compression-shear test process, and carrying out a finite element reverse backstepping method based on an improved Gurson model so as to obtain a true stress-strain relation of the welding microcell; computing the welding residual stress, wherein in the process of carrying out computing on a welding temperature field, the influence of the mechanical property of the welding microcell on the change of the temperature field is not considered; and after the welding temperature field is obtained, in the process of carrying out computing on a welding stress field, taking normal-temperature mechanical property parameters (when the temperature of a weldment is reduced according to the true stress-strain relation of the welding microcell) into a welding computing model, and then obtaining the welding residual stress through computing. The accuracy of the method disclosed by the invention is higher than that of a result obtained by using a residual stress computing method which is implemented through not considering the mechanical property of the welding microcell.

Owner:XI AN JIAOTONG UNIV

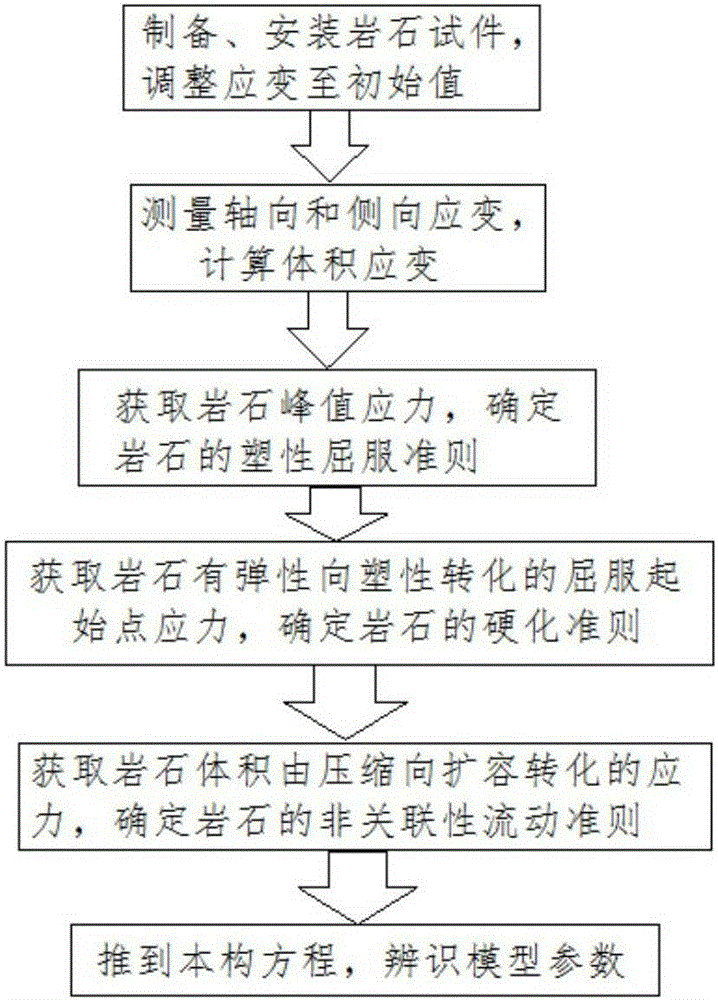

Method of establishing elastic-plastic mechanical constitutive model made of rock material

InactiveCN105181435AImprove accuracyWide applicabilityMaterial strength using tensile/compressive forcesStress–strain curveElastic plastic

The invention discloses a method of establishing an elastic-plastic mechanical constitutive model made of a rock material. The method comprises the following steps: measuring and recording variation values of axial and lateral strains of a rock specimen along with the stress, and calculating a volumetric strain of the rock specimen; drawing a stress-axial / lateral strain relation curve according to recorded full-course axial and lateral strain changes of the rock specimen, and respectively determining a yield failure rule and a hardening rule of the rock material of the specimen; drawing a stress-volumetric strain relation curve according to the calculated volumetric strain of the rock specimen to determine a non-relevant flow rule of the rock material of the specimen; determining the constitutive model by using a thermodynamic elastic-plastic theory in combination with the stress-strain curve, peak stress, yield initial stress and boundary strength of rock. The method disclosed by the invention comprehensively considers the yield rule, the non-relevant flow rule and the hardening rule of the rock material, favorably reflects the elastic-plastic mechanical behavior of the rock material and ensures the uniqueness and the accuracy of the constitutive model.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

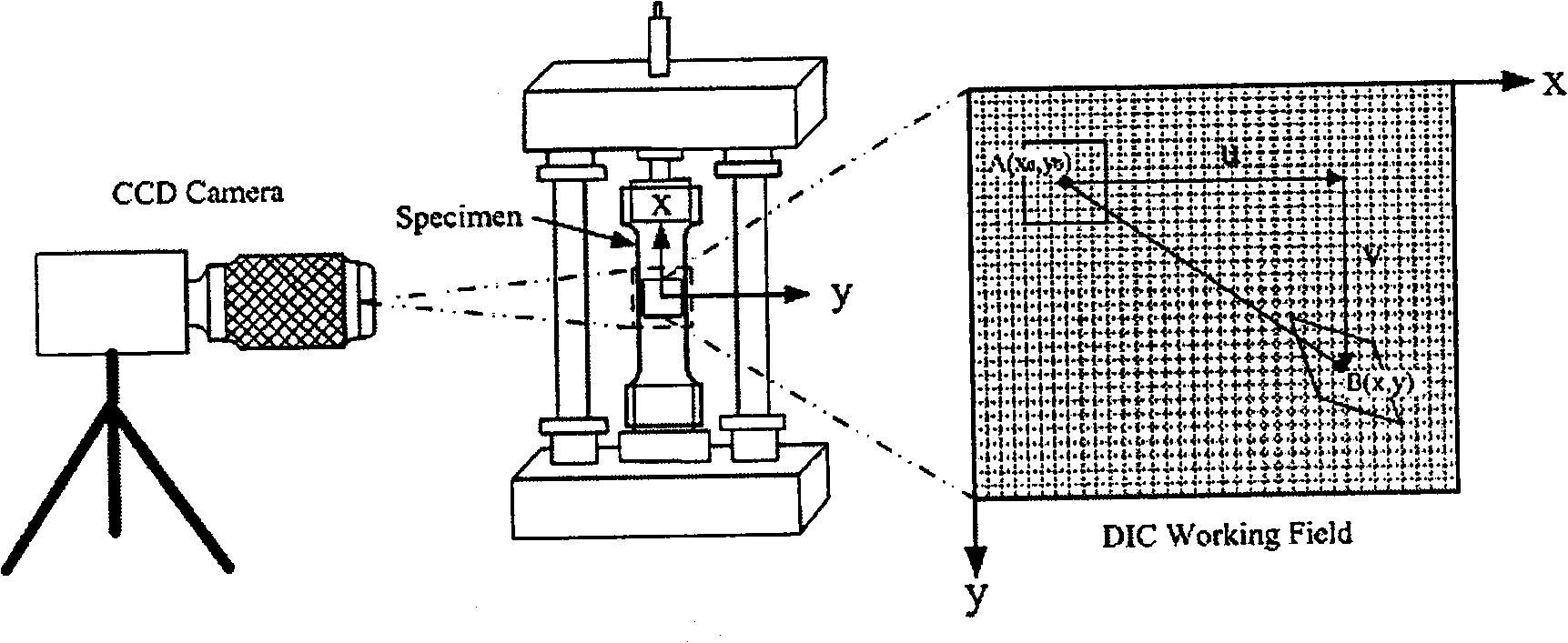

Method for quantitatively measuring inhomogeneous deformation of nano-crystal material

InactiveCN101526453ALow costMaterial strength using tensile/compressive forcesUsing optical meansStress–strain curveEngineering

The invention relates to a method for quantitatively measuring the inhomogeneous deformation of a nano-crystal material. The method comprises the following steps: firstly processing the measured nano-crystal material into a stretching sample, selecting a marking area on the stretching sample and marking the stretching sample; secondly, putting the stretching sample into a mechanics testing machine, and loading the stretching sample under the condition that the quasistatic strain rate of a displacement control mode at room temperature is 10<-4>s<-1>; obtaining data and displaying a stress strain curve by a material testing system of the mechanics testing machine, adopting a digital camera to acquire the image on the surface of the sample at the same time of loading, and recording the image by connecting the digital camera with a computer; and finally, carrying out digital image processing on the image acquired by the digital camera in the process of stretching to obtain the surface displacement and a stain field image of the tested image in the process of stretching. The method measures the cause of formation of a shear zone in a simple mode with low cost, so the method can have wide application prospect in the fields of modern mechanics, microelectronic technology, ultraprecise processing technology, nanometer technology, and the like.

Owner:NANJING UNIV OF TECH

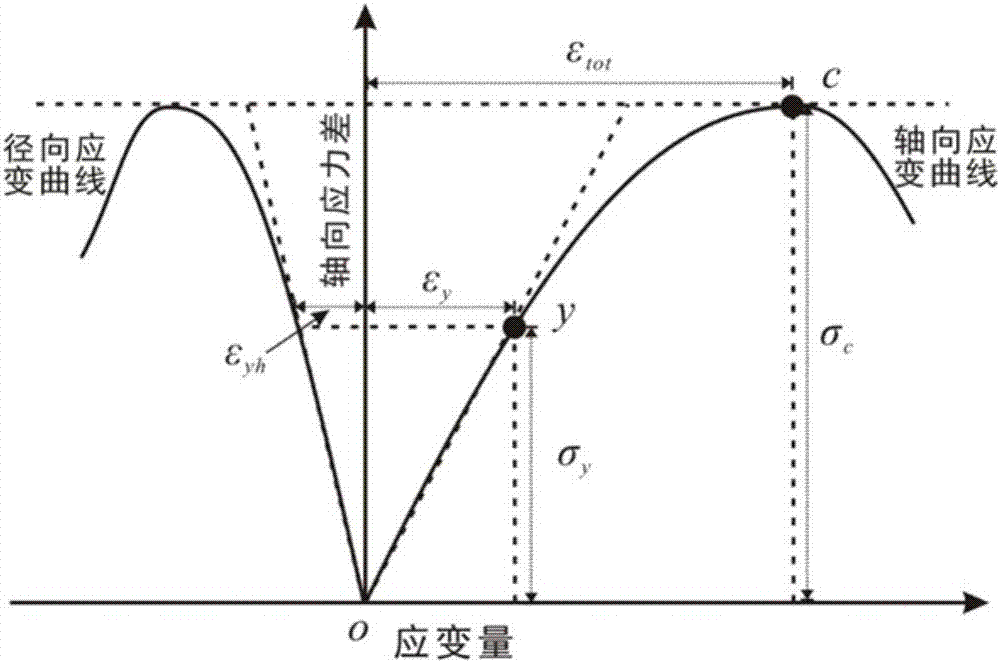

Acquisition method of brittleness index of rock and rock brittleness evaluation method

ActiveCN106872260AFragility Index CharacterizationEasy to readStrength propertiesStress–strain curveYoung's modulus

The invention discloses an acquisition method of a brittleness index of a rock and a rock brittleness evaluation method and relates to the field of brittleness evaluation of the rock. The acquisition method of the brittleness index comprises the following steps: calculating a normalized ratio of yield strain and total strain, a normalized ratio of yield strain and compressive strength, a normalized poisson ratio and a normalized Young modulus according to a resultant stress strain curve of the rock; and determining the brittleness index of the rock according to the normalized ratio of yield strain and total strain, the normalized ratio of yield strain and compressive strength, the normalized poisson ratio and the normalized Young modulus. The brittleness index comprehensively considers elastic and plastic characteristics of the rock and relatively comprehensively considers the whole process of peak-front stage stress-stain of the rock, and the required parameters are easily tested through a mechanical test. The rock brittleness evaluation method disclosed by the invention comprises the step of evaluating the brittleness of the rock by adopting the brittleness index of the rock. The evaluation method of the rock can relatively comprehensively represent the brittleness characteristic of the rock.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

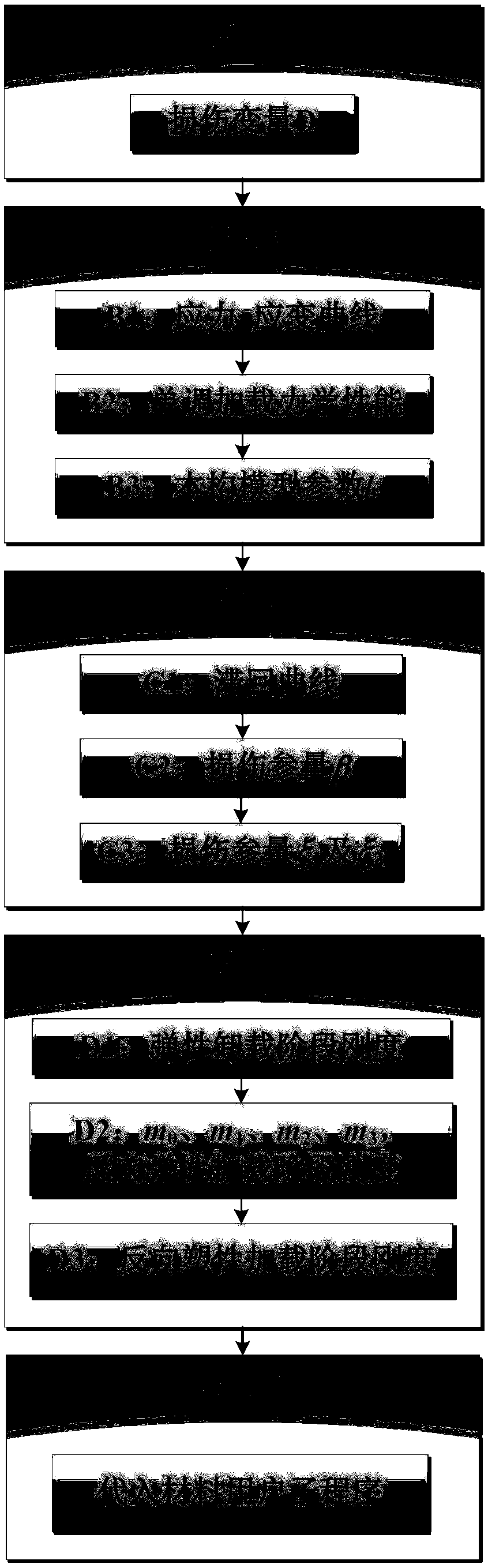

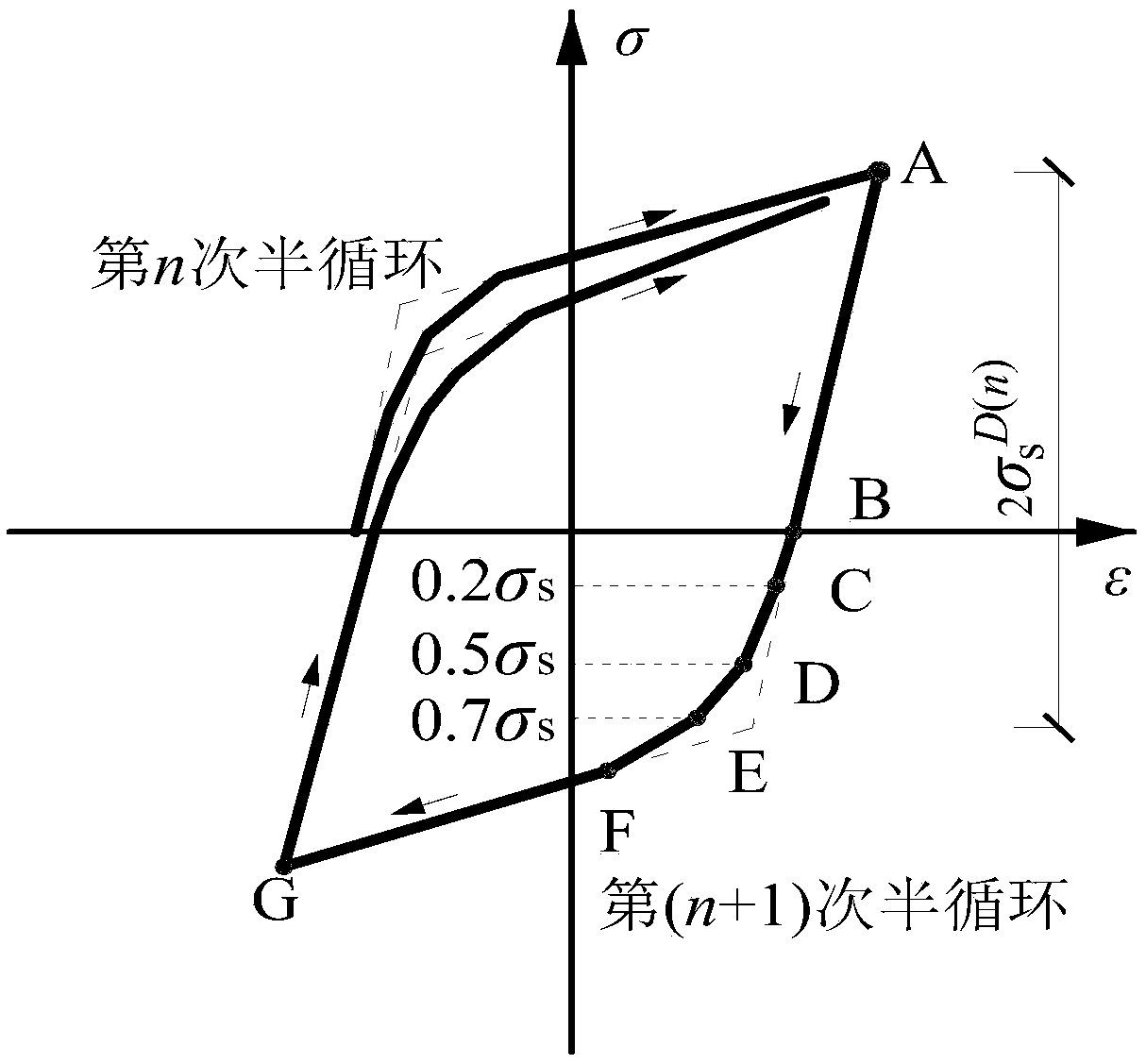

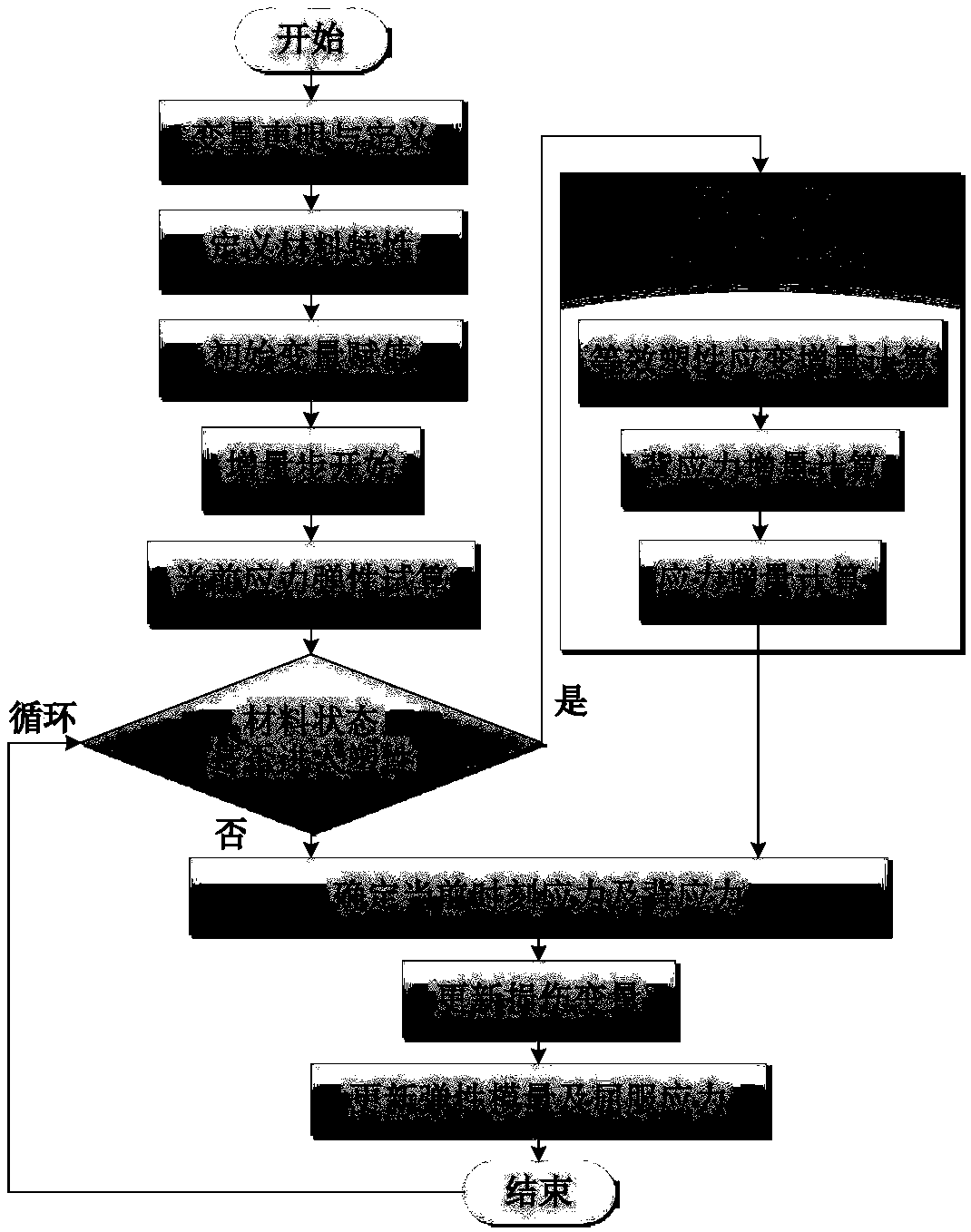

Material constitutive model numerical analysis method taking damage accumulation effect into consideration

ActiveCN108920739AImprove usabilityImprove versatilityGeometric CADDesign optimisation/simulationStress–strain curveEngineering

The invention discloses a material constitutive model numerical analysis method taking damage accumulation effect into consideration. The method includes: step A, defining damage variable D; step B, acquiring material monotonic loading mechanical performance according to a stress-strain curve of a material; step C, calculating damage parameters beta, zeta 1 and zeta 2 according to a hysteretic curve of a material different in strain amplitude; step D, acquiring undetermined parameters m0, m1, m2 and m3 according to the hysteretic curve of the material, and building a material circulation constitutive model taking damage accumulation effect into consideration; step E, through ABAQUS finite element software, substituting related parameters of the material into a material user subprogram VUMAT to accurately simulate damage of the material under circulation load action. By the method, difficulty of accumulation damage model application at the present stage can be solved effectively, damageparameters can be specified, calculation accuracy can be improved, application of the material constitutive model taking damage accumulation effect in the finite element software is realized, and damage to the material under the circulation load action can be simulated accurately.

Owner:TIANJIN UNIV

Method for establishing damaged rock constitutive relation by utilizing residual strength

InactiveCN102998180AEasy to implementDescribe the full stress-strain relationshipMaterial strength using tensile/compressive forcesResidual strengthStress–strain curve

The invention relates to a method for establishing damaged rock constitutive relation by utilizing residual strength. The method comprises the following steps of: carrying out a rock indoor triaxial compression experiment, measuring the axle load sigma1, the confining pressure sigma 3, the peak value intensity strain Epsilon 1c and the residual intensity sigma r of a rock sample, calculating the rock elastic modulus E and poisson ratio Mu, carrying out data regression according to triaxial compression test results, and calculating the uniaxial compressive strength sigma ci and an experience intensity parameter mi of a rock block; then establishing a three-dimensional damage statistic constitutive relation capable of reflecting a rock post-peak softening characteristic; and finally, solving constitutive relation parameters n and F0 according to four boundary conditions of a rock full-stress-strain curve geometric characteristic, and drawing a constitutive relation curve by utilizing Matlab software. The constitutive relation can fully reflect rock post-peak softening and residual intensity characteristics, and can describe the full-stress-strain relation of the rock damage process well, so that a theory formula well corresponds to the actual condition of a rock material; and the method can be realized simply, is widely applied to the theory analysis of the rock material, and has an actual value.

Owner:BEIJING JIAOTONG UNIV +1

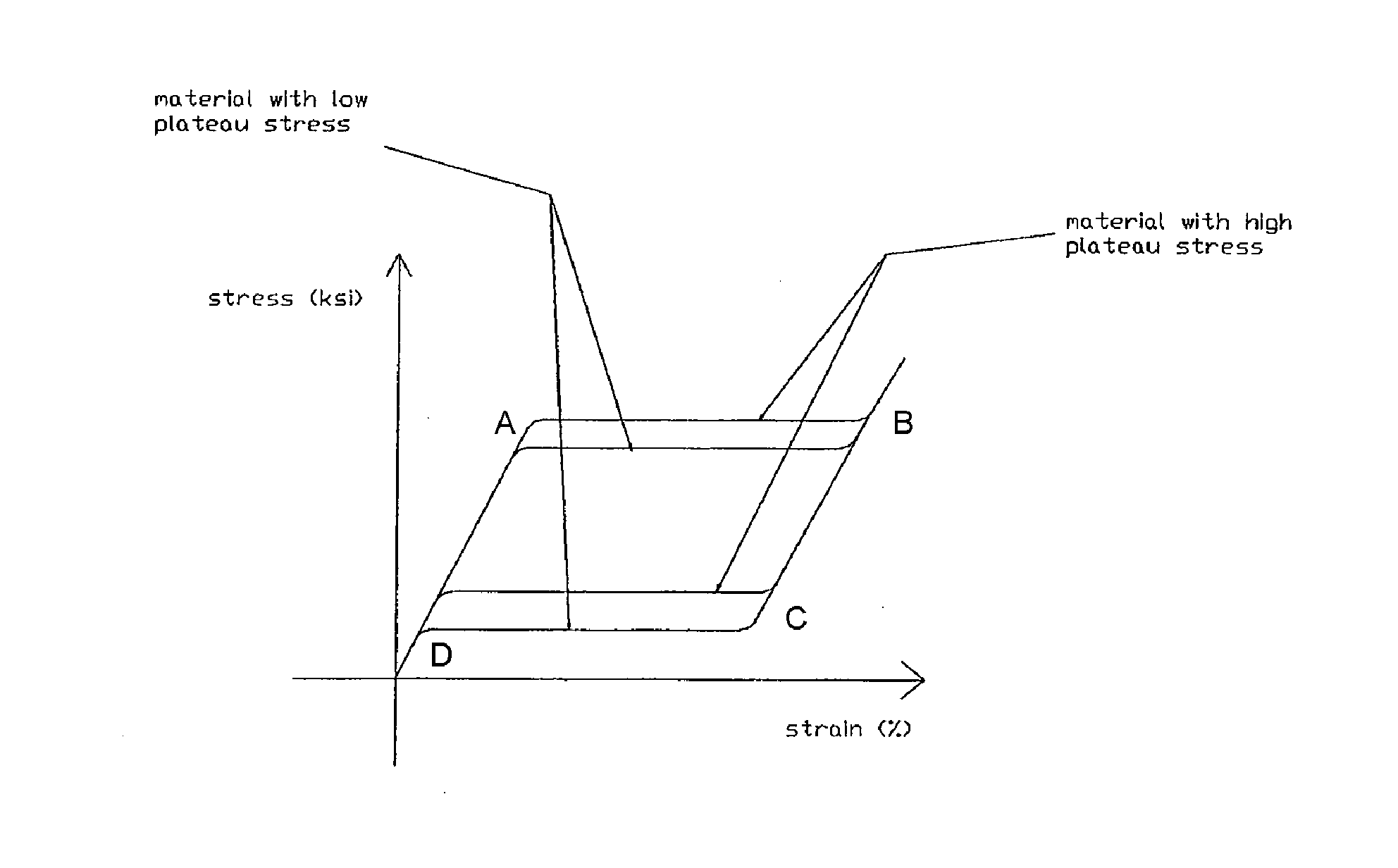

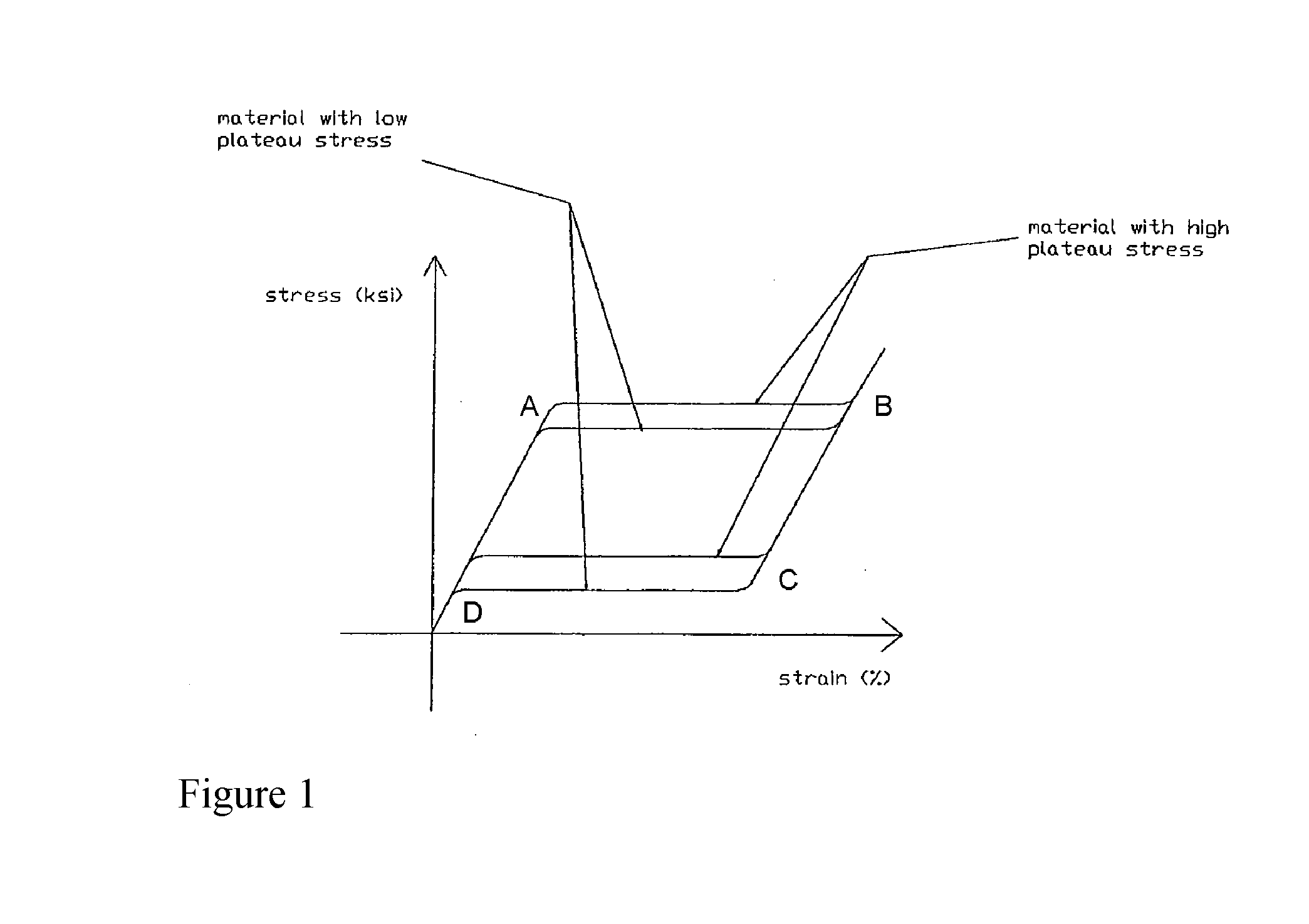

Fatigue resistant endoprostheses

InactiveUS20070293939A1Improve fatigue resistanceImprove the immunityStentsSurgeryCelsius DegreeMetallurgy

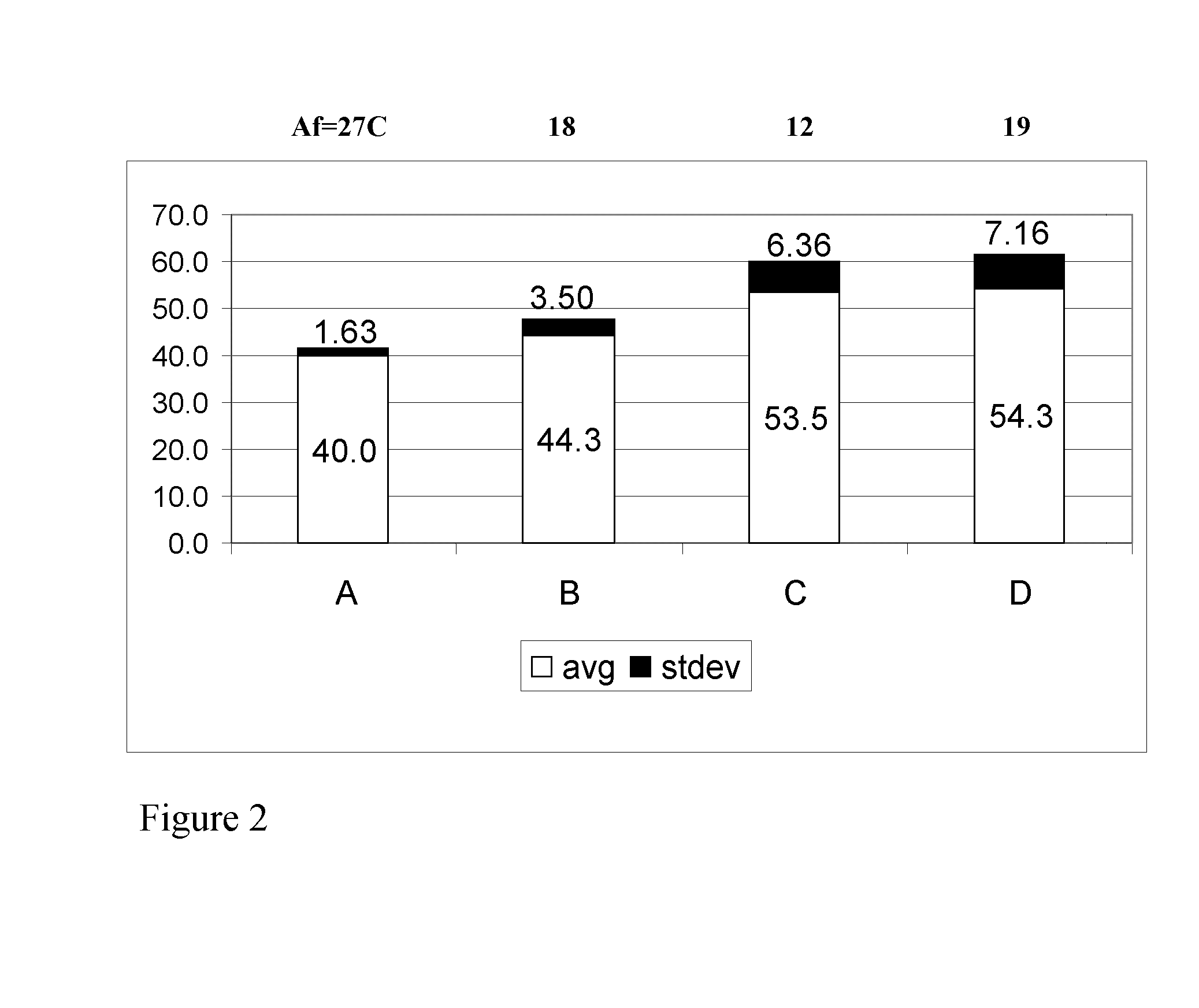

A superelastic endoprosthesis can have improved fatigue resistance, and improved resistance to crack formation by being configuring to have an austenitic finish temperature from about 5 degrees Celsius to about 35 degrees Celsius, a stress-strain curve having an upper plateau stress from about 40 ksi to about 80 ksi, and a lower plateau stress from about 5 ksi to about 50 ksi. Such an endoprosthesis may be fabricated by heating at least a portion of the endoprosthetic body in a fluid, such as air, salt bath, or fluidized sand, having a temperature from about 400 degrees Celsius to about 600 degrees Celsius for at least about 30 seconds. Additionally, only portions of an endoprosthesis may selectively be subjected to the heating parameters of the present invention such that the endoprosthesis exhibits an increased radial stiffness and an increased flexibility in the longitudinal direction.

Owner:ABBOTT LAB INC

Computing method for representative elementary volume of jointed rock

InactiveCN103197042AEasy to determineThe principle is simpleEarth material testingStress–strain curveKnowledge Field

The invention provides a computing method for the representative elementary volume of a jointed rock, which belongs to field of geotechnical engineering calculation parameters. According to the invention, a multi-scale jointed rock sample with an indoor test scale, an on-site in-situ test scale, an engineering scale and the like capable of fully reflecting joint spatial distribution characteristics and rock and joint mechanical characteristics is constructed based on indoor rock and joint mechanical tests and on-site joint geological survey, and virtual uniaxial compression loading is carried out on the sample to obtain a stress-strain curve; a relational graph of uniaxial compressive strength of a variety of jointed rocks and loading-direction sample dimension is drafted, and a relation curve is fitted; in the fitted relation curve, if a ratio of reduction amount of the uniaxial compressive strength to uniaxial compressive strength of an indoor rock sample is less than 0.2% when the loading-direction sample dimension of the jointed rocks is increased by 1 m each time, it is believed that uniaxial compressive strength of the jointed rocks does not change with increase of dimension, and the representative elementary volume of the jointed rocks is obtained. The method provided by the invention has the advantages of simple principles, convenient operation, low cost and a good usage effect and facilitates determination of the representative elementary volume of the jointed rock.

Owner:UNIV OF SCI & TECH BEIJING

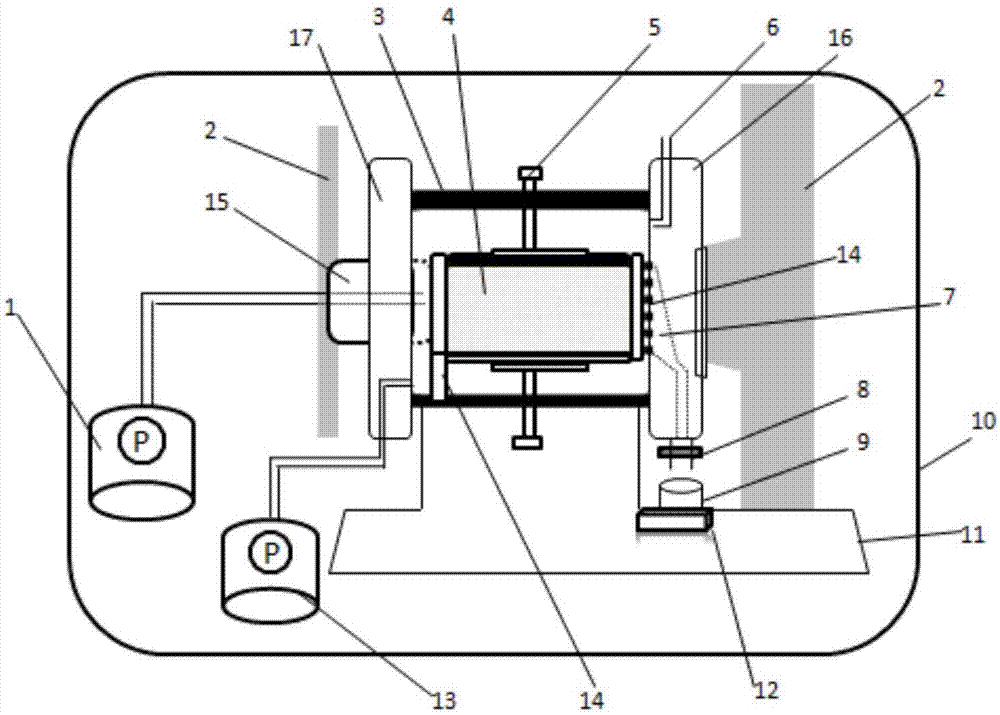

Measuring method for real stress-strain curve of metal welding structure

ActiveCN104596845AAccurate measurementOvercoming the difficulty of distinguishing different regions of material propertiesMaterial strength using tensile/compressive forcesGeometric factorStress–strain curve

A measuring method for a real stress-strain curve of a metal welding structure comprises the steps: firstly, measuring a real stress-strain curve of a notch tensile test, wherein a real fracture strain at a maximum load is a strain hardening index of a metal of a to-be-measured position; calculating real stress-strain curves of notch tensile samples by finite element calculating software, to obtain the real stress-strain curves of the notch tensile samples with different notch sizes, fitting and establishing the relationship between the notch size and a geometric factor, and establishing a geometric factor expression containing the notch size and the real fracture strain at the maximum load and other influence factors; according to a load separation theory and the obtained relational expression and expression, the real stress-strain curve of the metal of the to-be-measured region of the metal welding structure is obtained. Through the small-size notch tensile test and a series of established relationships, the locality of the to-be-measured material region is accurately transmitted to a whole single-region material.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

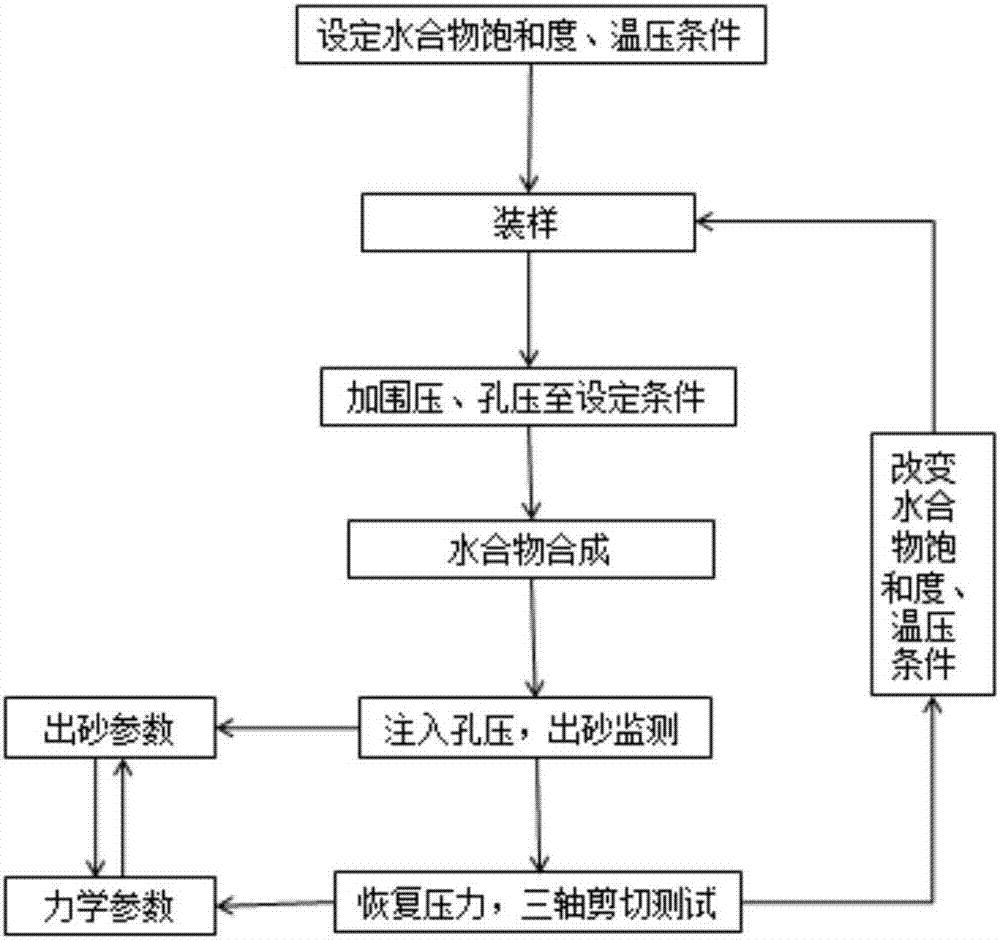

Hydrate-containing sediment shakeout-mechanical parameter coupling process simulation device and method

ActiveCN107121359AEnhance the meaning of engineering guidanceFlow propertiesMaterial strength using tensile/compressive forcesResource developmentStress–strain curve

The invention relates to the technical field of marine gas hydrate resource development engineering, in particular to an indoor experimental device and method for evaluating the mutual coupling relationship between the shakeout process and mechanical parameters of hydrate-containing loose sediments. The device comprises a high-pressure reaction kettle, a thermostatic control system, a triaxial pressurizing system, a confining pressure control system, a pore pressure injection system and a shakeout parameter test system, wherein the confining pressure control system, the pore pressure injection system and the triaxial pressurizing system are connected with the high-pressure reaction kettle; and the shakeout parameter test system is connected with the outlet end of the high-pressure reaction kettle. Through measurement of the mutual coupling relationship between shakeout parameters, such as the shakeout amount, the shakeout grain size and the shakeout speed of the hydrate sediments, under the actual temperature, pressure and stress conditions, and triaxial mechanical parameters, such as the stress-strain curve, the shear strength, the Yong modulus and the cohesion, a support is provided for forecasting the related relationship between the shakeout parameters and the mechanical parameters of a hydrate-containing reservoir, and a new concept is provided for probing into the shakeout mechanism of the natural gas hydrate reservoir.

Owner:QINGDAO INST OF MARINE GEOLOGY

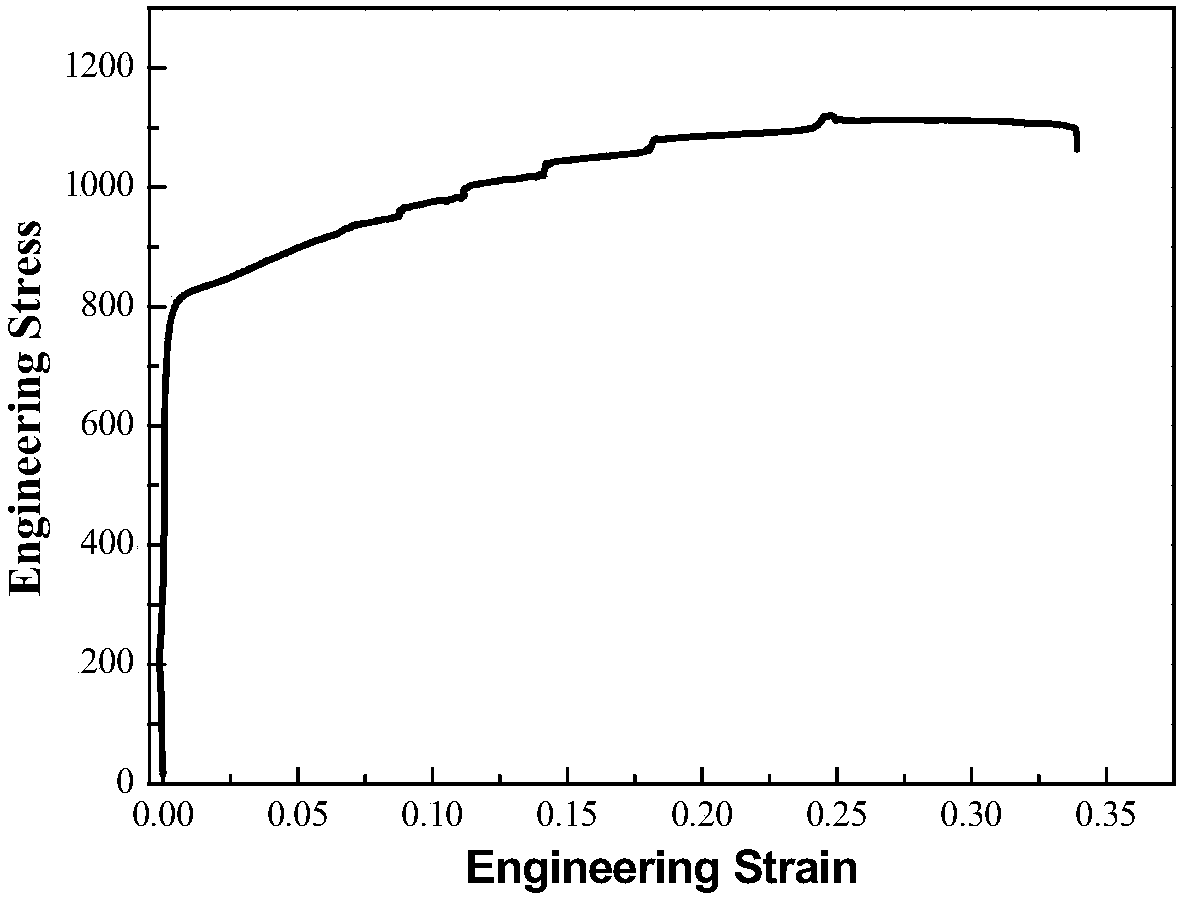

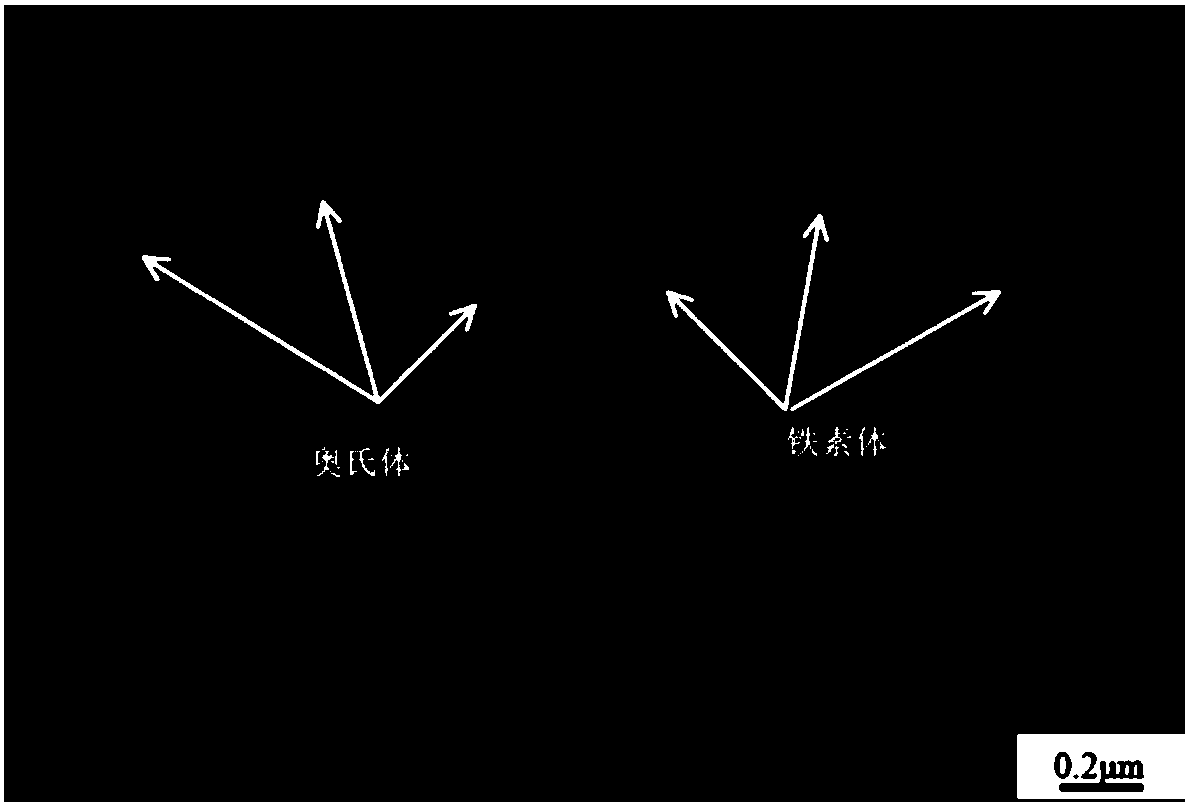

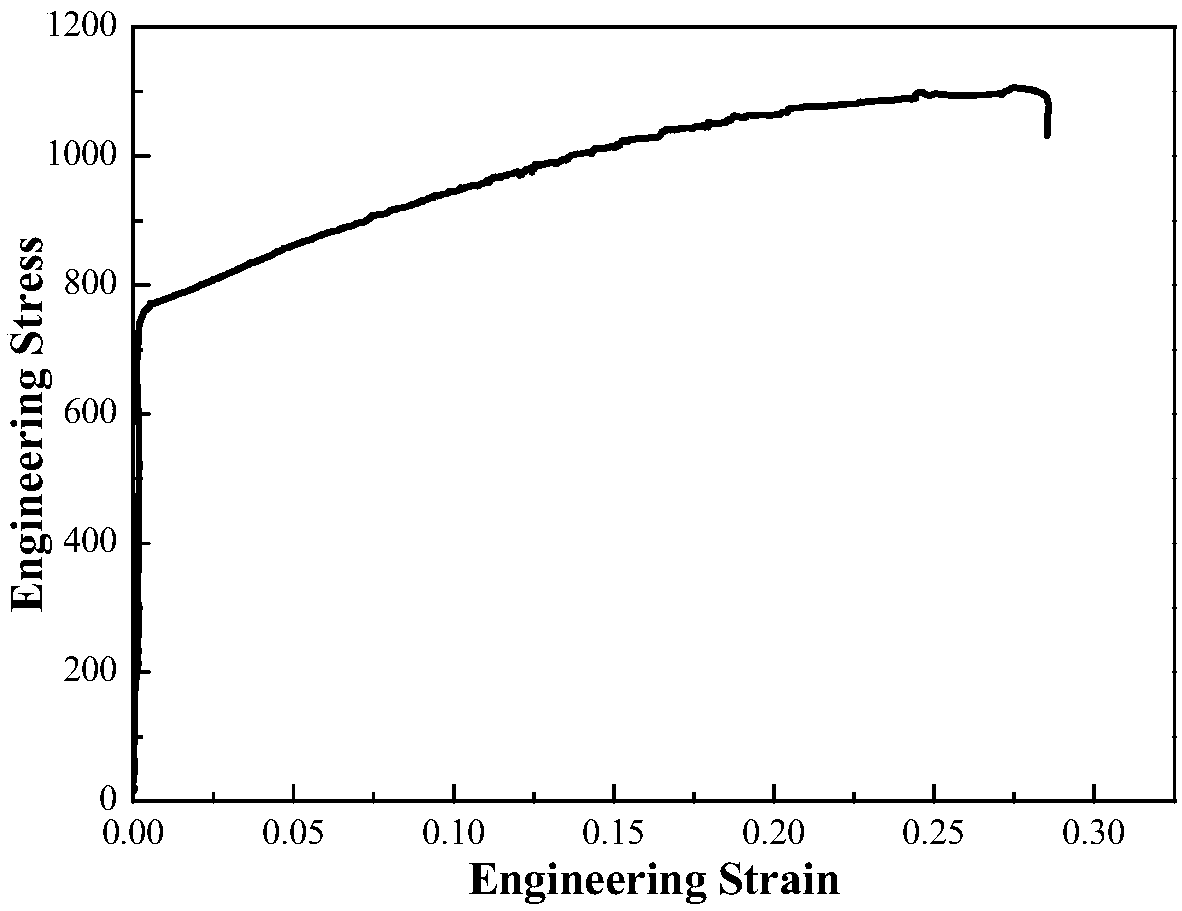

Method for manufacturing cold-rolled medium manganese steel plate with high strength and plasticity and free of yield platform

The invention relates to the technical field of automobile steel, in particular to a method for manufacturing a cold-rolled medium manganese steel plate with high strength and plasticity and free of yield platform. The manufacturing method mainly comprises the following steps of (1) smelting and forging; (2) full-austenitizing rolling, wherein a steel blank is heated to 1100-1200 DEG C, heat preservation is carried out for 2-3 hours, then full-austenitizing rolling is carried out, the steel blank is rolled to 4-5mm thick, and the steel blank is naturally cooled to room temperature; (3) pre-annealing before cold rolling, wherein the steel plate subjected to hot rolling is heated to 640-650 DEG C in a two-phase-region along with a furnace, heat preservation is carried out for 6-8 hours, thenthe steel plate is cooled to 200-300 DEG C along with the furnace, and then the steel plate is air cooled to the room temperature; (4) cold rolling, wherein the steel plate subjected to hot rolling and annealing is rolled to 1-2mm thick by a cold rolling machine; and (5) two-step heat treatment after cold rolling, wherein the purpose is to change the structure and the shape of the steel plate, the shape of the steel plate is changed into a strip shape from an isometric shape, and the structure of the steel plate is composed of ferrite and austenite. According to the manufacturing method, thesteel plate with high strength and plasticity is obtained, meanwhile, the stress-strain curve is continuously yield, and the common yield platform phenomenon in cold-rolled manganese steel is eliminated.

Owner:NORTHEASTERN UNIV

Sleeve-like knitted structure for use as a castliner

ActiveUS20050027219A1Improve buffering effectComfortable conformanceFinger bandagesFeet bandagesYarnCushioning

A castliner in the form of a three-dimensionally knitted sleeve comprises a microdenier yarn, and / or a spandex yarn, in particular, a spandex yarn having a flatter stress-strain curve than traditional spandex yarns. The use of the microdenier yarn contributes to the superior cushioning effect. The stretch and recovery properties of the particular spandex yarn contribute to superior fit and reduction of pressure points on the limb or body part to which the castliner is applied. Furthermore, the castliner is rendered water resistant and has significantly improved antimicrobial properties, both of which reduce incidents of skin irritation and unpleasant smell. As a result, the patient wearing the castliner of the invention is able to bathe and get wet without otherwise replacing the hard casting and castliner after such events.

Owner:THE LYCRA CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com