Method for manufacturing cold-rolled medium manganese steel plate with high strength and plasticity and free of yield platform

A high-strength plastic product, non-yielding technology, applied in the field of automotive steel, can solve the problems of yield plateau, high energy consumption, complex production process and technology, achieve high plastic mechanical properties, eliminate yield plateau phenomenon, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

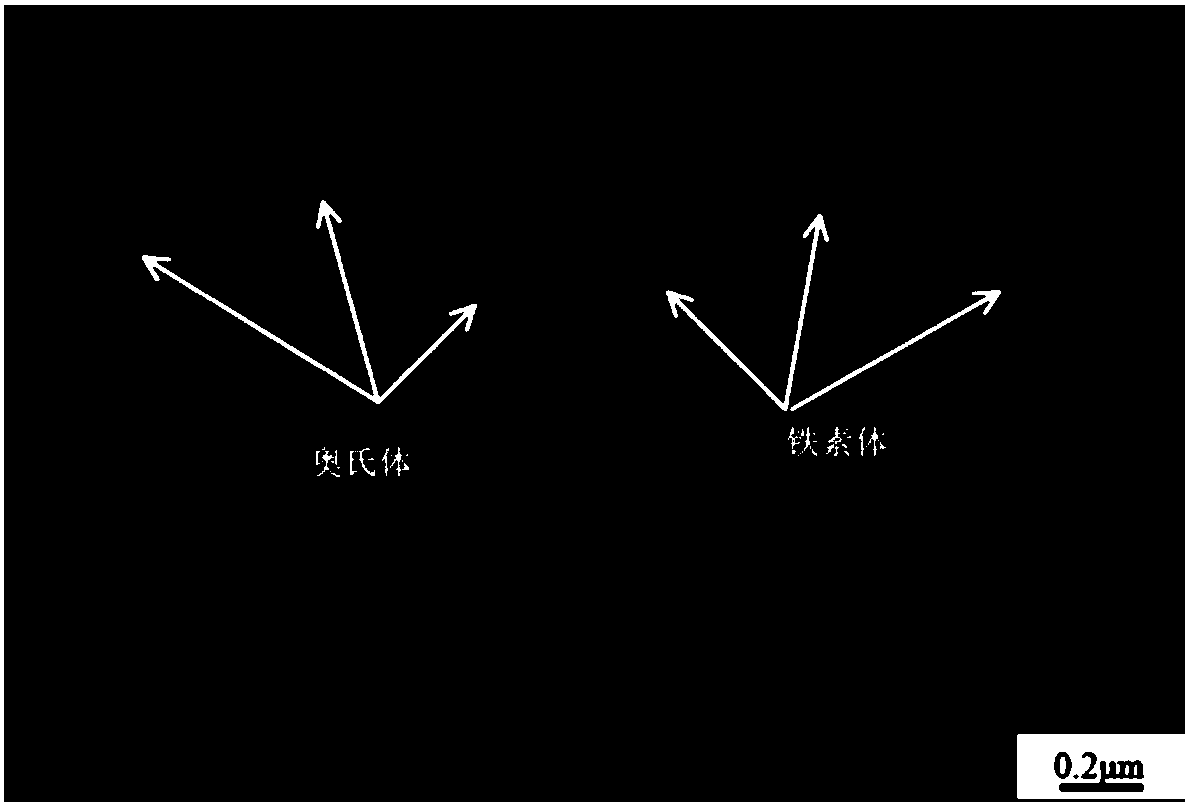

[0034] In the specific implementation process, the high-strength plastic product and non-yield platform cold-rolled medium manganese steel plate and its preparation method described in the present invention specifically include the following steps:

[0035] (1) Smelting medium manganese steel into steel ingots, the specific alloy composition is based on mass percentage C=0.1-0.15%, Mn=6.9-7.2%, Si=1-1.2%, P<0.005%, S<0.003%, Al =0.05~1%, the balance is Fe and unavoidable impurities, heat the ingot to 1650°C, keep it warm for 2~3h, and forge it into a billet;

[0036] (2) Put the billet into a high-temperature furnace at 1100-1200°C, keep it warm for 2-3 hours, and hot-roll it into a thin plate with a thickness of 4-5mm after 9 passes. The initial rolling temperature is 1100-1150°C, and the final rolling temperature is not low. at 900°C, then air cooled to room temperature.

[0037] (3) Heat treatment before cold rolling: Put the hot-rolled steel plate into the RX-36-10 box-ty...

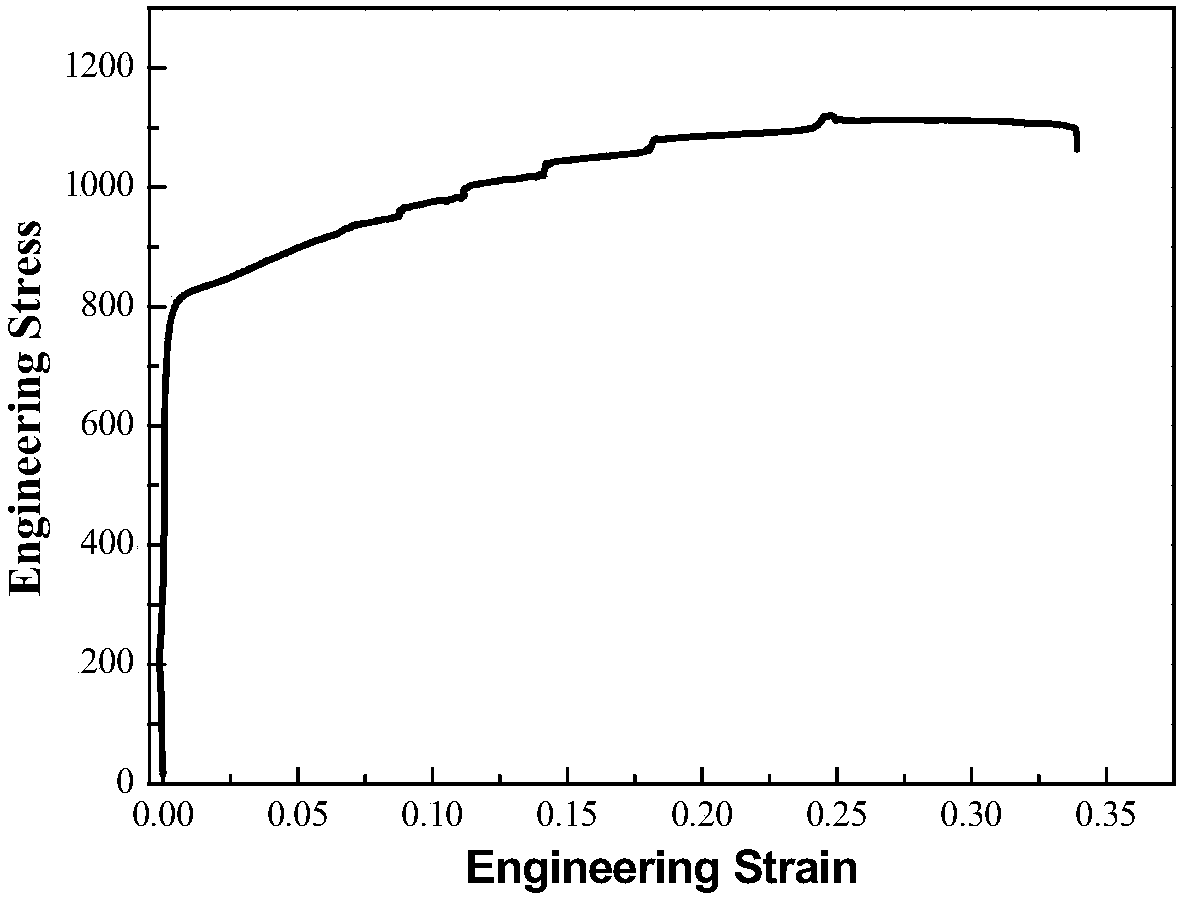

Embodiment 1

[0046] In this example, the preparation method of cold-rolled medium-manganese steel plate with high-strength plastic product and no-yield platform, its alloy composition and weight percentage are respectively: C=0.1%, Mn=6.9%, Si=1%, P=0.0042% , S=0.0025%, Al=0.052%, and the balance is Fe and unavoidable impurities.

[0047] In this embodiment, the high-strength plastic product non-yielding platform cold-rolled medium manganese steel plate and its preparation method, the specific steps are as follows:

[0048] Step 1, smelting and forging:

[0049] According to the alloy composition ratio of cold-rolled medium-manganese steel with high-strength plastic product and no-yield platform, smelting is carried out at 1650°C, and steel ingots with a thickness of 100-110mm are forged afterward;

[0050] Step 2, hot rolling:

[0051] Heat the billet to 1100°C and keep it warm for 2 hours;

[0052] The starting rolling temperature is 1100°C, the final rolling temperature is 930°C, the...

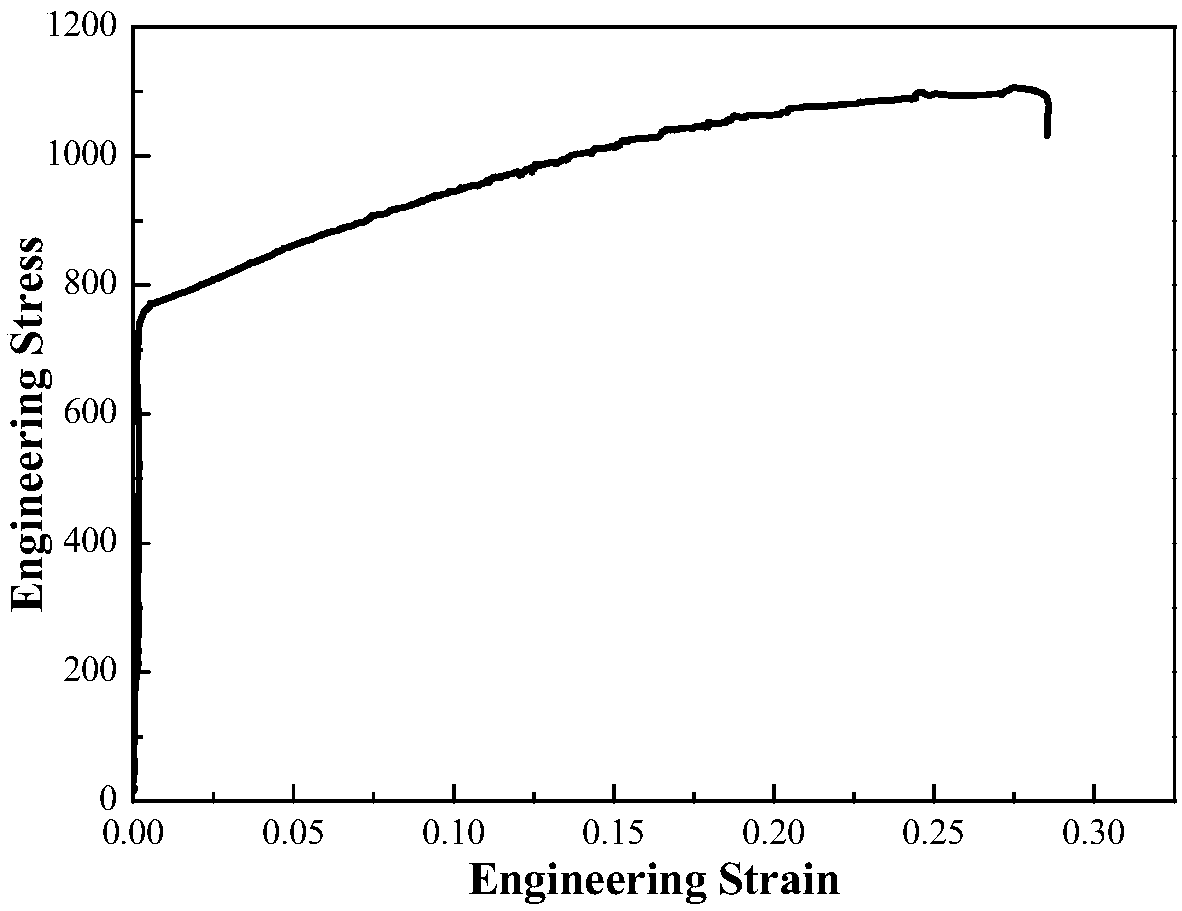

Embodiment 2

[0064] In this example, the preparation method of cold-rolled medium-manganese steel plate with high-strength plastic product without yield platform, its alloy composition and weight percentage are: C 0.1%, Si 1.3%, Mn 7.13%, P=0.0035%, S 0.0028 %, Al0.052%, O 0.0026%, N 0.0031%, and the rest are Fe and unavoidable impurities.

[0065] In this embodiment, the preparation method of the cold-rolled medium-manganese steel plate with high-strength plastic product without yield platform, the specific steps are as follows:

[0066] Step 1, smelting and forging:

[0067] According to the alloy composition ratio of cold-rolled medium-manganese steel with high-strength plastic product and no-yield platform, it is melted at 1650°C, and then forged into a steel ingot with a thickness of 100mm;

[0068] Step 2, hot rolling:

[0069] Heat the billet to 1150°C and keep it warm for 3h;

[0070] The starting rolling temperature is 1150°C, the final rolling temperature is 930°C, the rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com