Method for eliminating low carbon steel cover annealing yield point elongation

A bell-type annealing and yielding platform technology, applied in bell-type furnaces, process efficiency improvement, elongation control and other directions, can solve problems such as affecting the quality qualification rate of cold rolling mills, easily generating slip lines, and increasing production costs. , to ensure the performance, avoid slippage, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

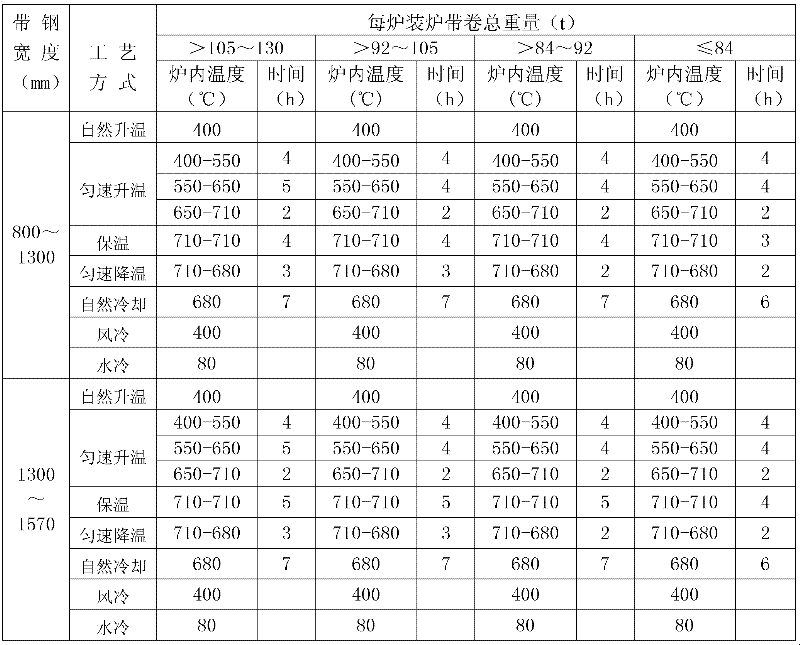

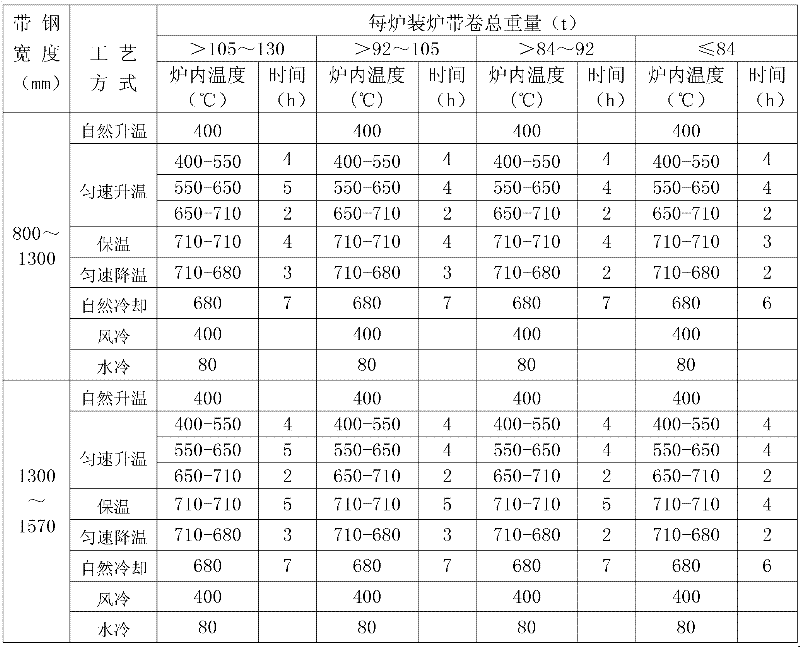

[0015] Steel type Low carbon steel, grade St13. Strip thickness 0.5mm, width 900mm. The bell furnace annealing process is adopted, and the total weight of the coils loaded in each furnace is 85t.

[0016] After the winding furnace is installed, the temperature in the furnace is naturally raised to 400°C;

[0017] Raise the temperature at a constant speed for 4 hours, and raise the temperature in the furnace from 400°C to 550°C;

[0018] Raise the temperature at a constant speed for 4 hours, and raise the temperature in the furnace from 550°C to 650°C;

[0019] Raise the temperature at a constant speed for 2 hours, and raise the temperature in the furnace from 650°C to 710°C;

[0020] Insulate at 710°C for 4h;

[0021] Cool down for 2 hours at a constant speed, and reduce the temperature in the furnace from 710°C to 680°C at a constant speed;

[0022] After cooling at 680°C for 7 hours, remove the heating cover and put on the cooling cover;

[0023] Air cooling until the ...

Embodiment 2

[0027] Steel type Low carbon steel, grade DC03. Strip thickness 1.5mm, width 1350mm. The bell furnace annealing process is adopted, and the total weight of the coils loaded in each furnace is 100t.

[0028] After the winding furnace is installed, the temperature in the furnace is naturally raised to 400°C;

[0029] Raise the temperature at a constant speed for 4 hours, and raise the temperature in the furnace from 400°C to 550°C;

[0030] Raise the temperature at a constant speed for 4 hours, and raise the temperature in the furnace from 550°C to 650°C;

[0031] Raise the temperature at a constant speed for 2 hours, and raise the temperature in the furnace from 650°C to 710°C;

[0032] Insulate at 710°C for 5h;

[0033] Cool down for 3 hours at a constant speed, and reduce the temperature in the furnace from 710°C to 680°C at a constant speed;

[0034] After cooling at 680°C for 7 hours, remove the heating cover and put on the cooling cover;

[0035] Air cooling until th...

Embodiment 3

[0039] Steel type low carbon steel, grade SPCD. Strip thickness 3.0mm, width 1550mm. The bell furnace annealing process is adopted, and the total weight of each furnace is 130t.

[0040] After the coiling furnace is installed, the temperature in the furnace is rapidly raised to 400°C;

[0041] Raise the temperature at a constant speed for 4 hours, and raise the temperature in the furnace from 400°C to 550°C;

[0042] Raise the temperature at a constant speed for 5 hours, and raise the temperature in the furnace from 550°C to 650°C;

[0043] Raise the temperature at a constant speed for 2 hours, and raise the temperature in the furnace from 650°C to 710°C;

[0044] Insulate at 710°C for 5h;

[0045] Cool down at a constant speed for 3 hours, reducing the temperature in the furnace from 710°C to 680°C;

[0046] After cooling at 680°C for 7 hours, remove the heating cover and put on the cooling cover;

[0047] Air cooling until the temperature in the furnace drops to 400°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com