Patents

Literature

18430 results about "Air cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air cooling is a method of dissipating heat. It works by expanding the surface area or increasing the flow of air over the object to be cooled, or both. An example of the former is to add cooling fins to the surface of the object, either by making them integral or by attaching them tightly to the object's surface (to ensure efficient heat transfer). In the case of the latter, it is done by using a fan blowing air into or onto the object one wants to cool. The addition of fins to a heat sink increases its total surface area, resulting in greater cooling effectiveness.

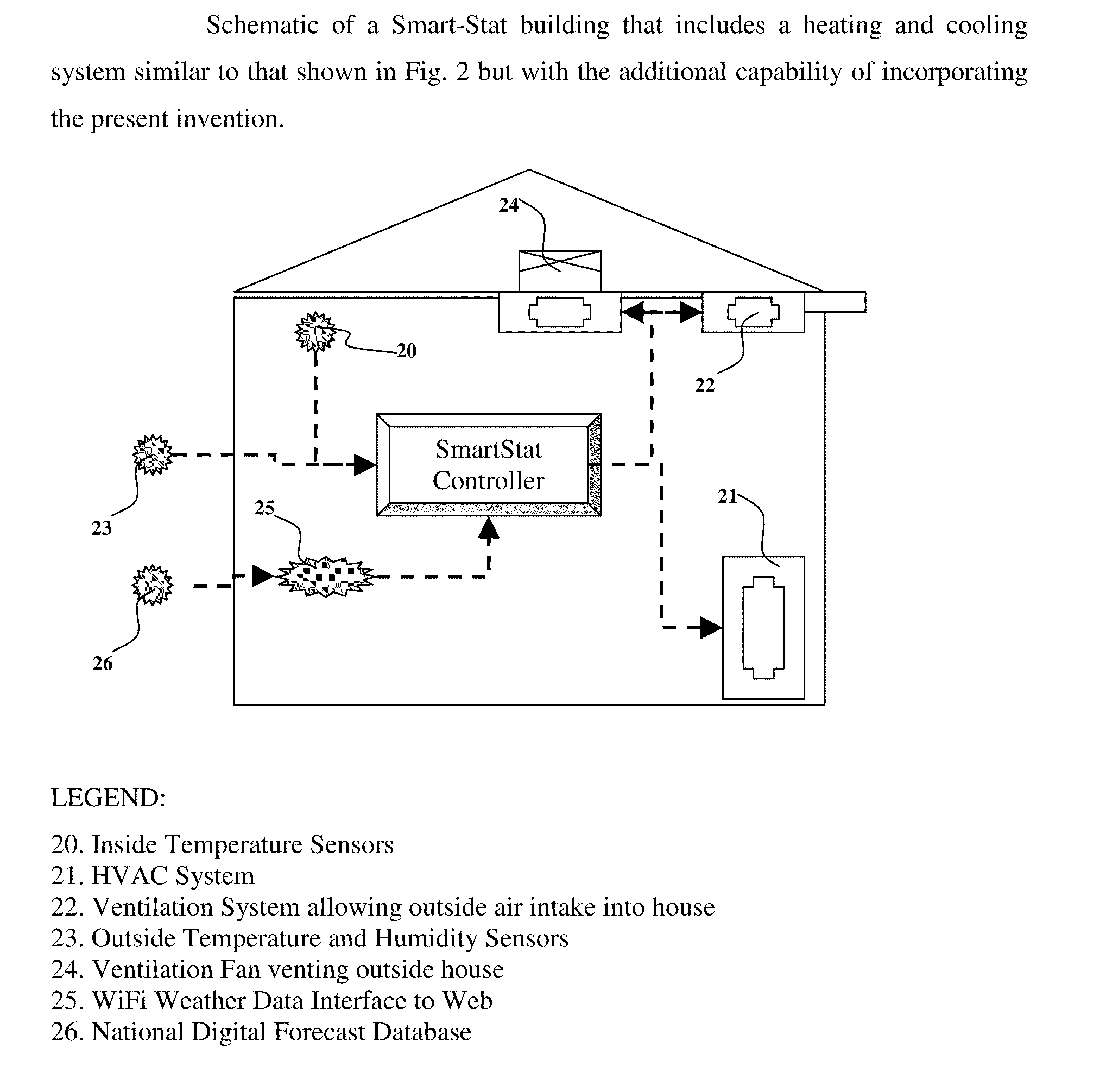

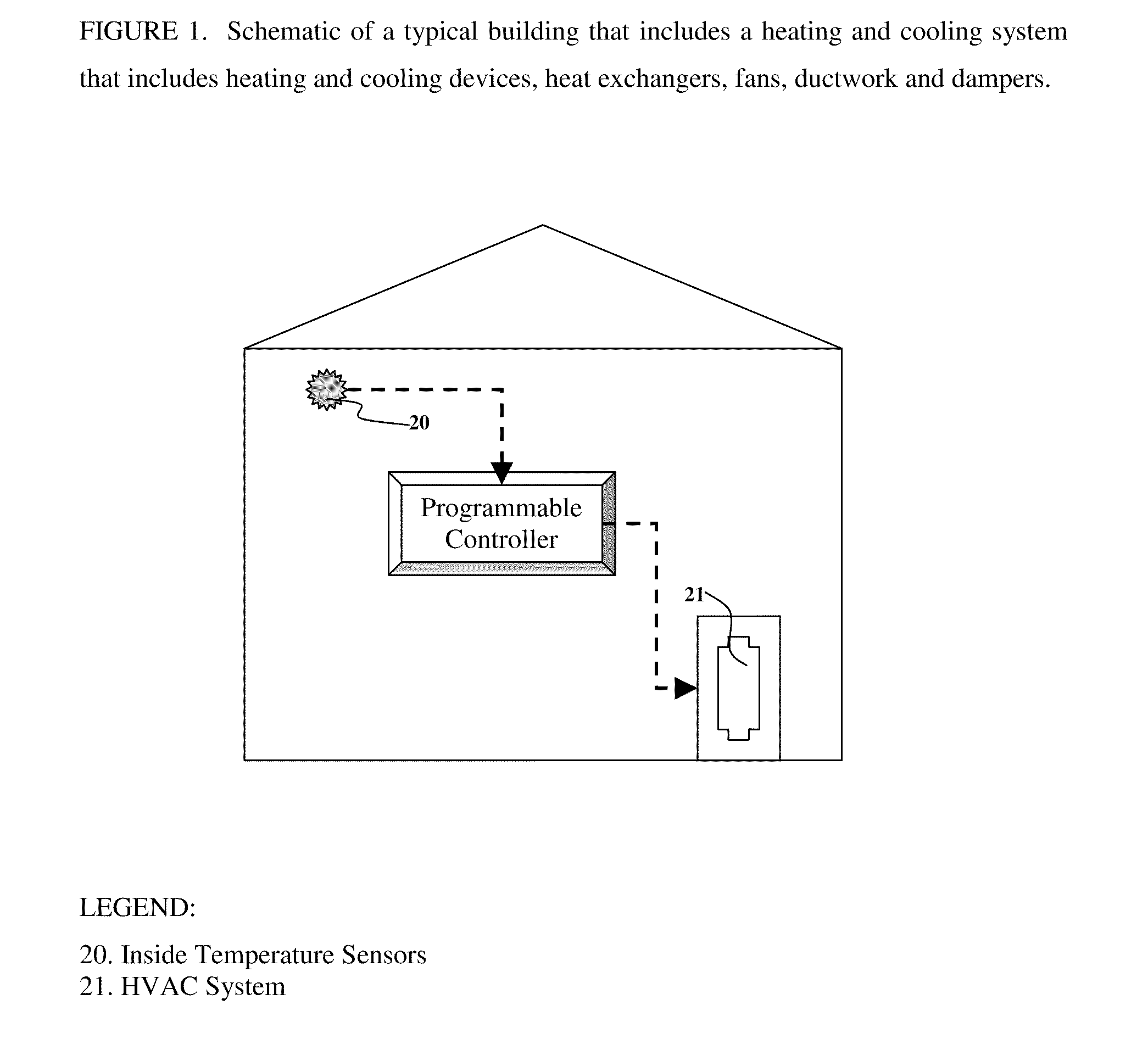

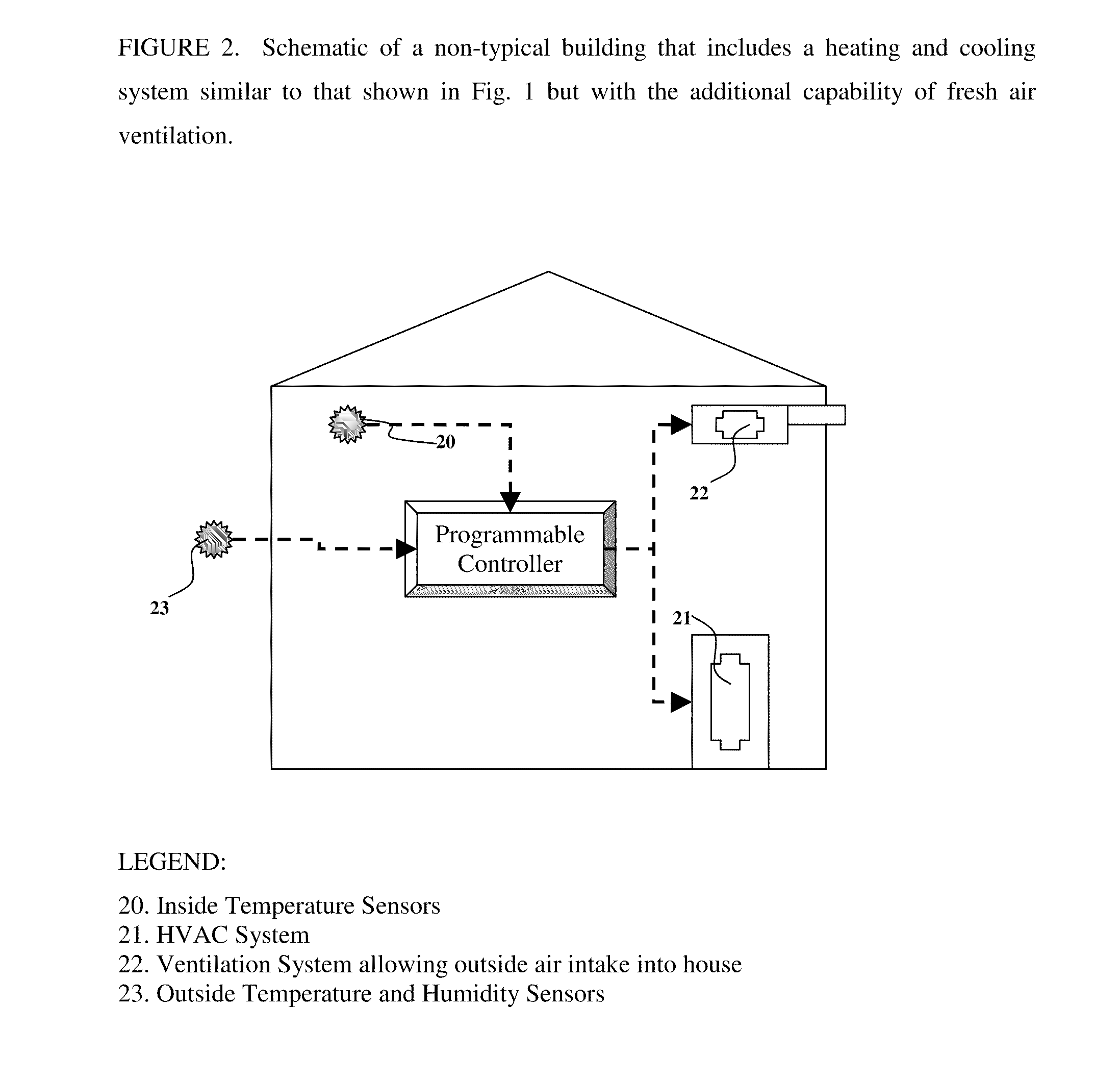

Heating and cooling control methods and systems

InactiveUS20100211224A1Improve energy efficiencySampled-variable control systemsMechanical apparatusCarbon footprintOperating energy

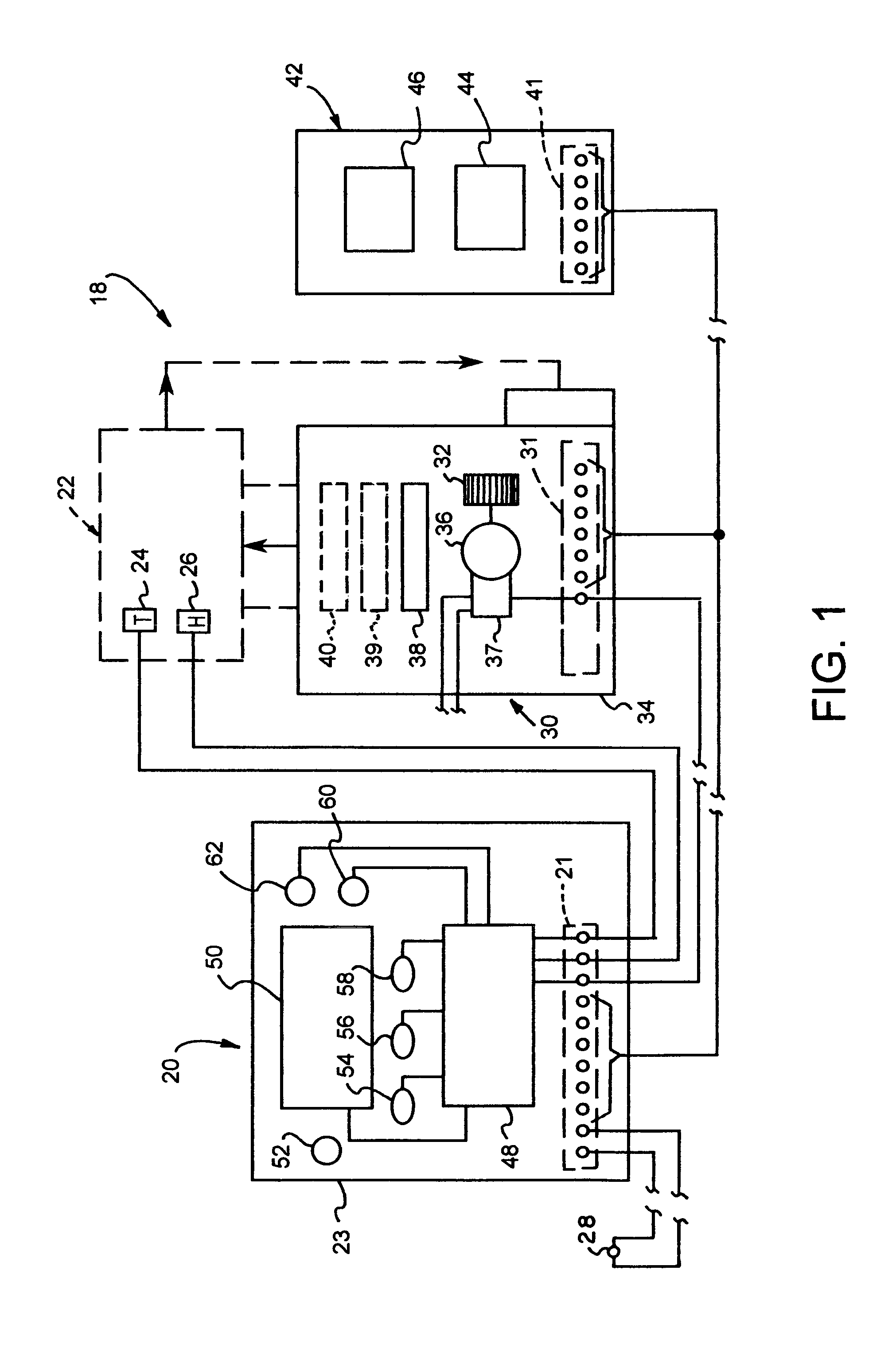

The present invention is related to the field of heating, ventilation and air conditioning (HVAC). More particularly, the present invention is related to methods and systems for controlled heating and cooling in order to reduce costs and the carbon footprint of said heating and cooling by optimizing the use of fresh air ventilation. The present invention is directed to mathematical algorithms incorporated into a controller and a method of determining control signals that are dependent on said mathematical algorithms and user programming that integrates information from multiple sensors, thermostats as well as weather information. Used in any home or building, the controller controls heating, cooling and ventilation systems in order to reduce costs and the carbon footprint of said heating and cooling by optimizing the use of fresh air ventilation. The controller works with typical HVAC systems generally in buildings and homes. The Smart-Stat algorithms are programmed into the controller and enable the controller to identify user-determined set-points alongside data from one or multiple internal temperature sensors. The user-determined set-points are also linked to time of day and day of week in a manner typical for typical thermostat devices available today. In such typical thermostat devices the controller will call for cooling or heating depending on the set points and conditions determined by the sensors in the building. The present invention is capable of interrupting the call for cooling or heating depending on whether the mathematical algorithms identify suitable outside weather conditions that permit the use of outside air cooling or outside air heating. Thus the call for heating or cooling can be redirected to call for ventilation instead of heating or cooling.

Owner:KEELING OLIVER JOE +1

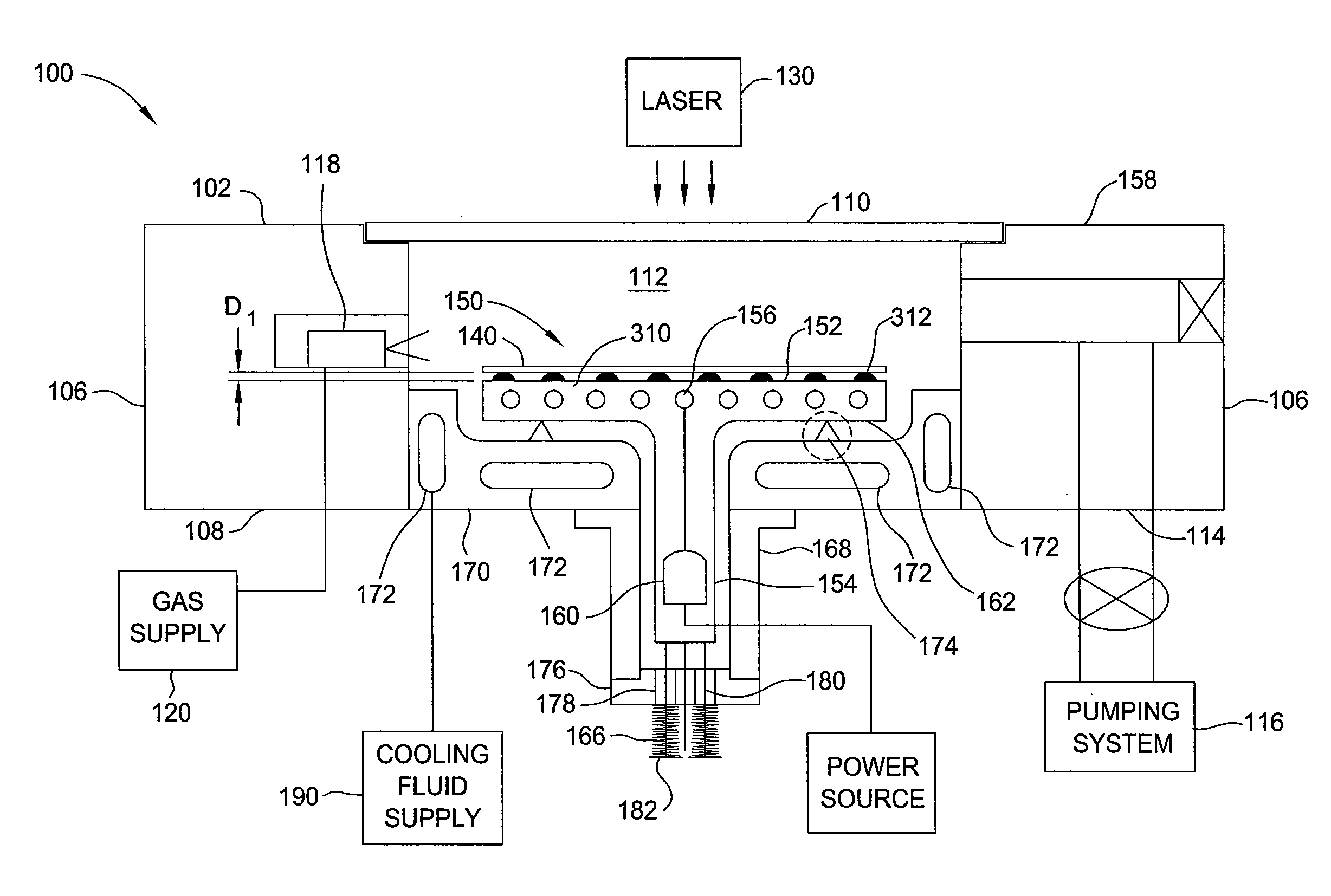

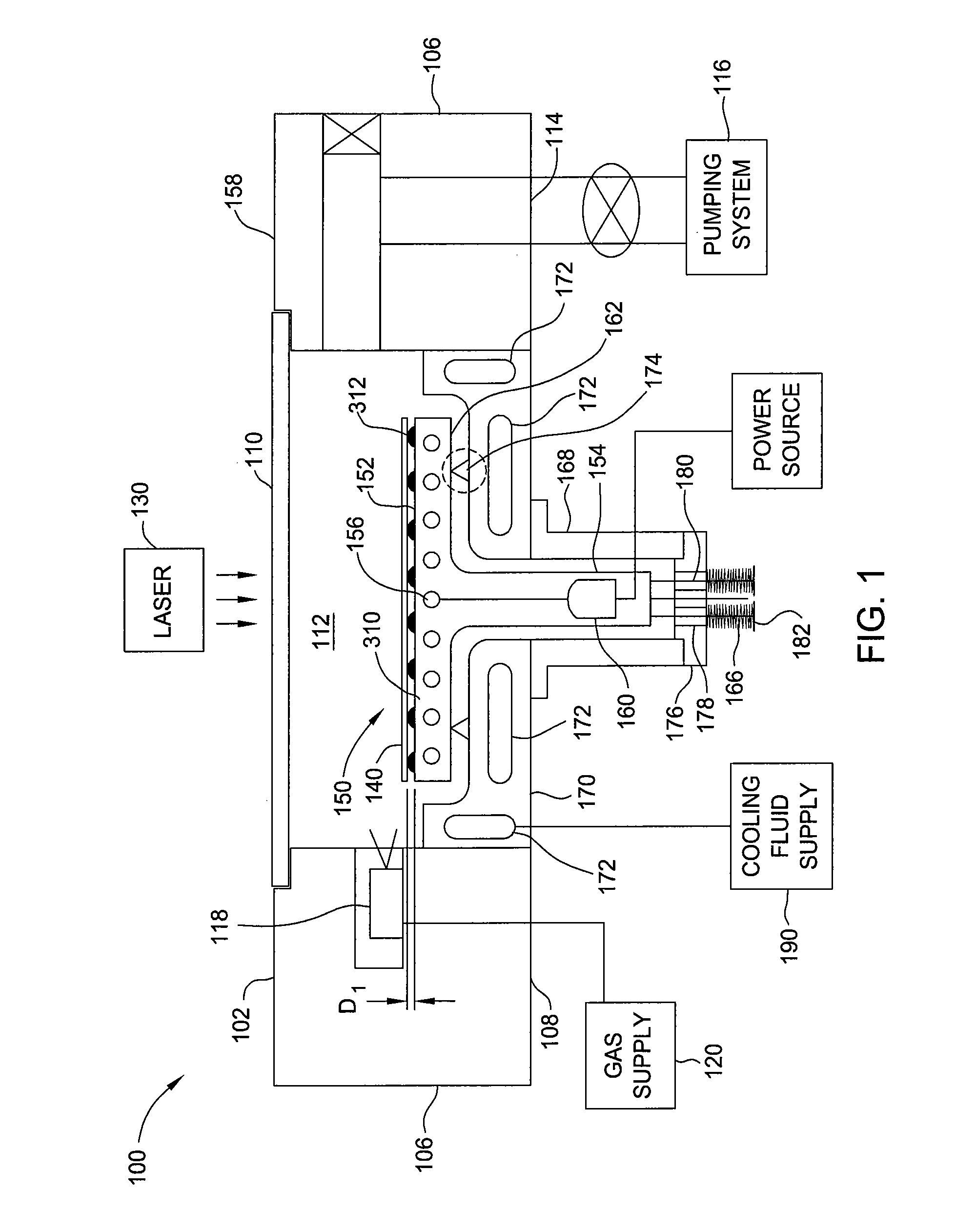

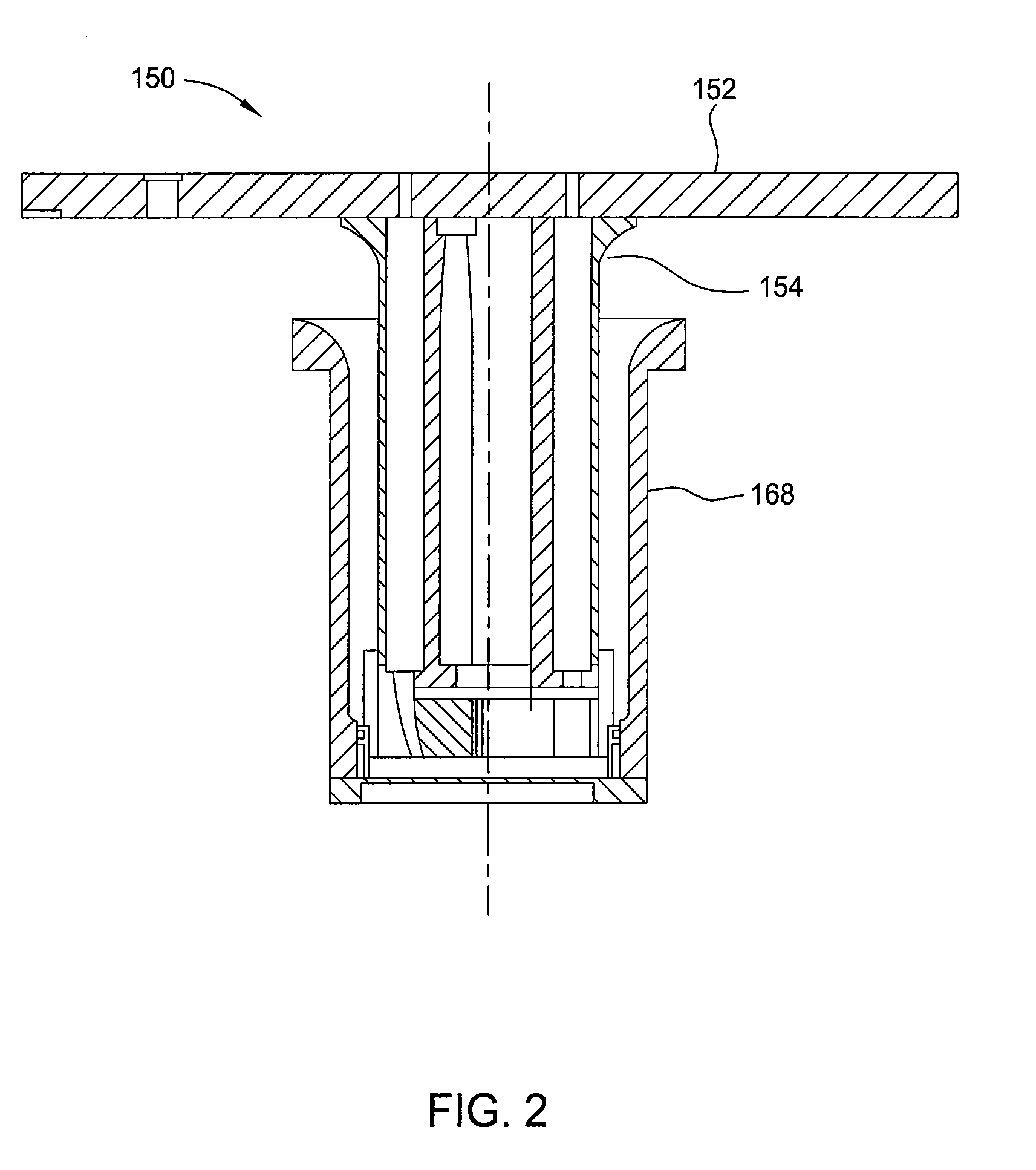

High temperature vacuum chuck assembly

ActiveUS20090179365A1Avoid overall overheatingSleeve/socket jointsMuffle furnacesEngineeringElectrical connector

A vacuum chuck and a process chamber equipped with the same are provided. The vacuum chuck assembly comprises a support body, a plurality of protrusions, a plurality of channels, at least one support member supporting the support body, at least one resilient member coupled with the support member, a hollow shaft supporting the support body, at least one electrical connector disposed through the hollow shaft, and an air-cooling apparatus. The support body has a support surface for holding a substrate (such as a wafer) thereon. The protrusions are formed on and project from the support surface for creating a gap between the substrate and the support surface. The channels are formed on the support surface for generating reduced pressure in the gap. The air-cooling apparatus is used for providing air cooling in the vicinity of the electrical connector.

Owner:APPLIED MATERIALS INC

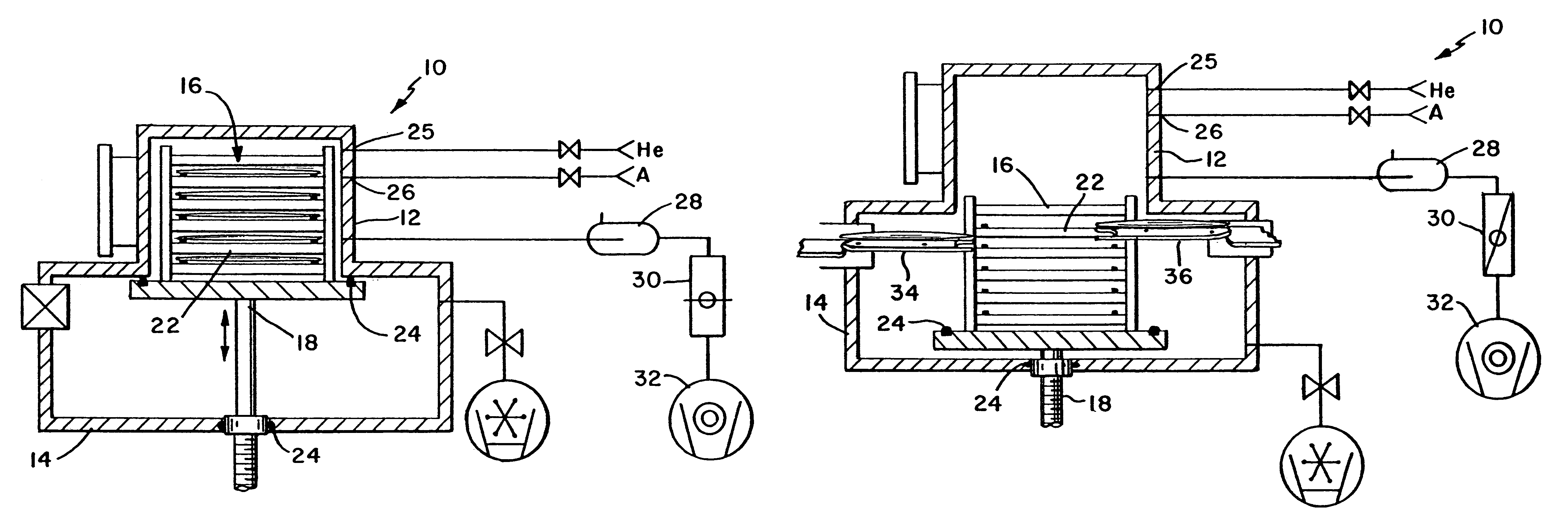

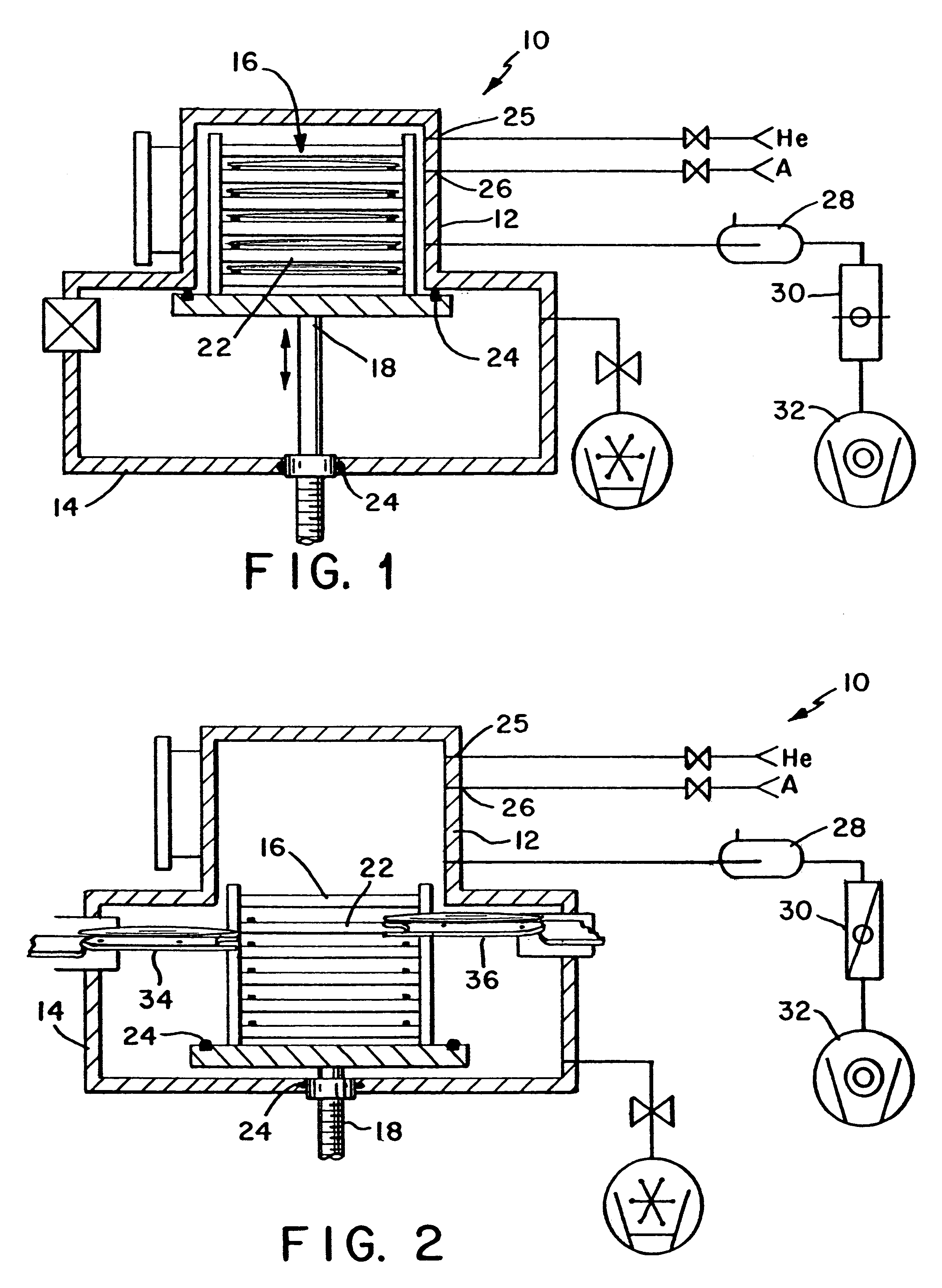

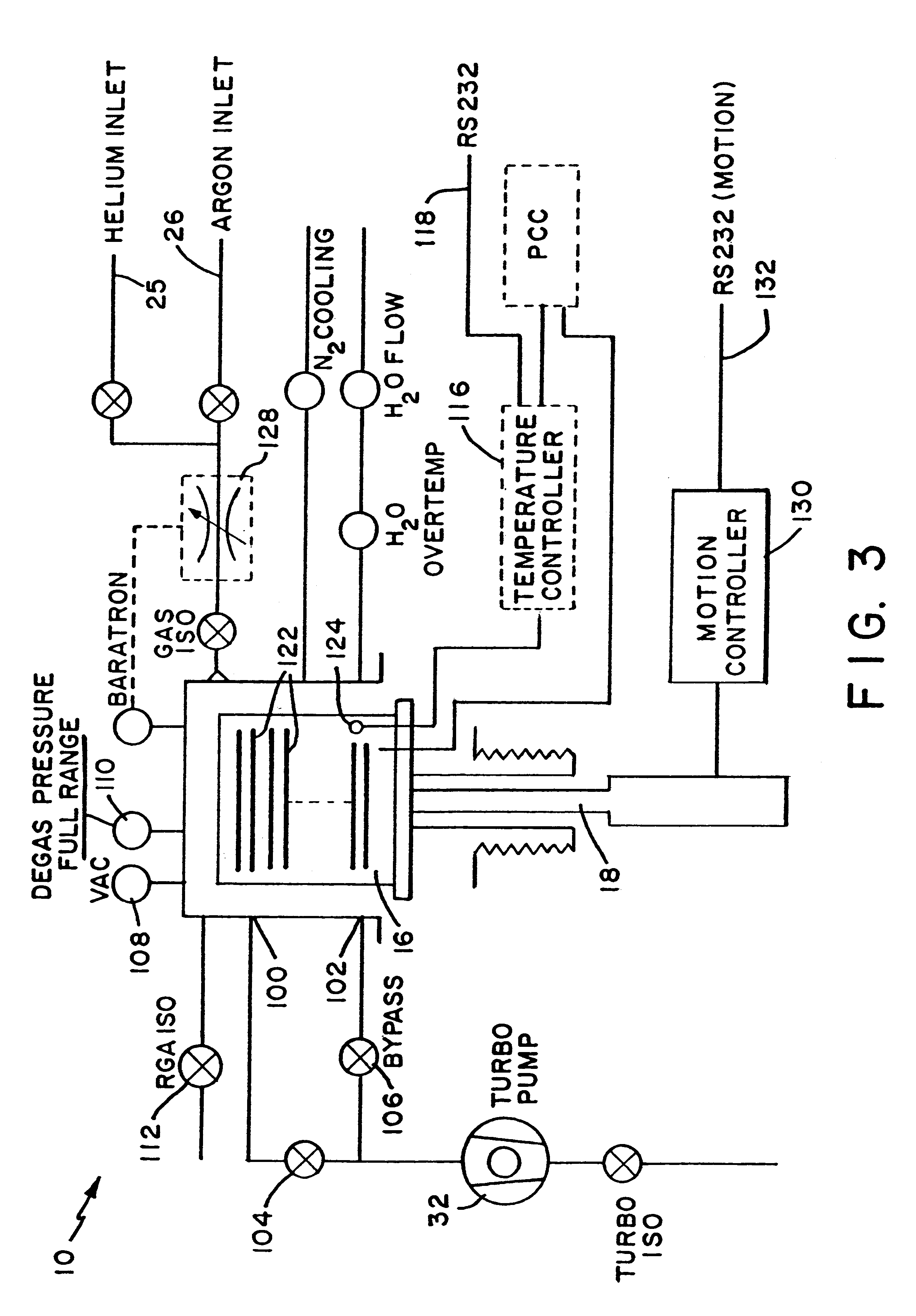

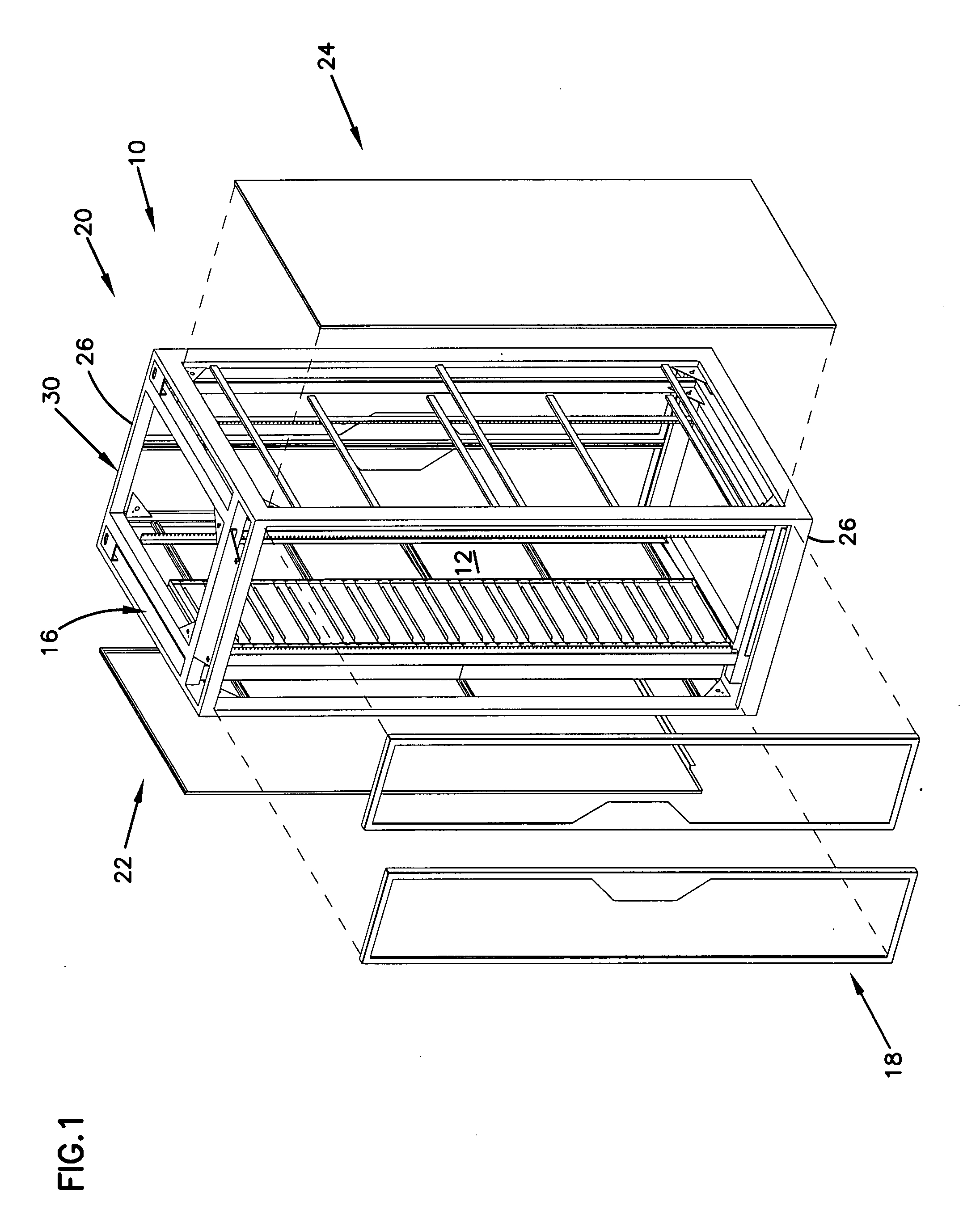

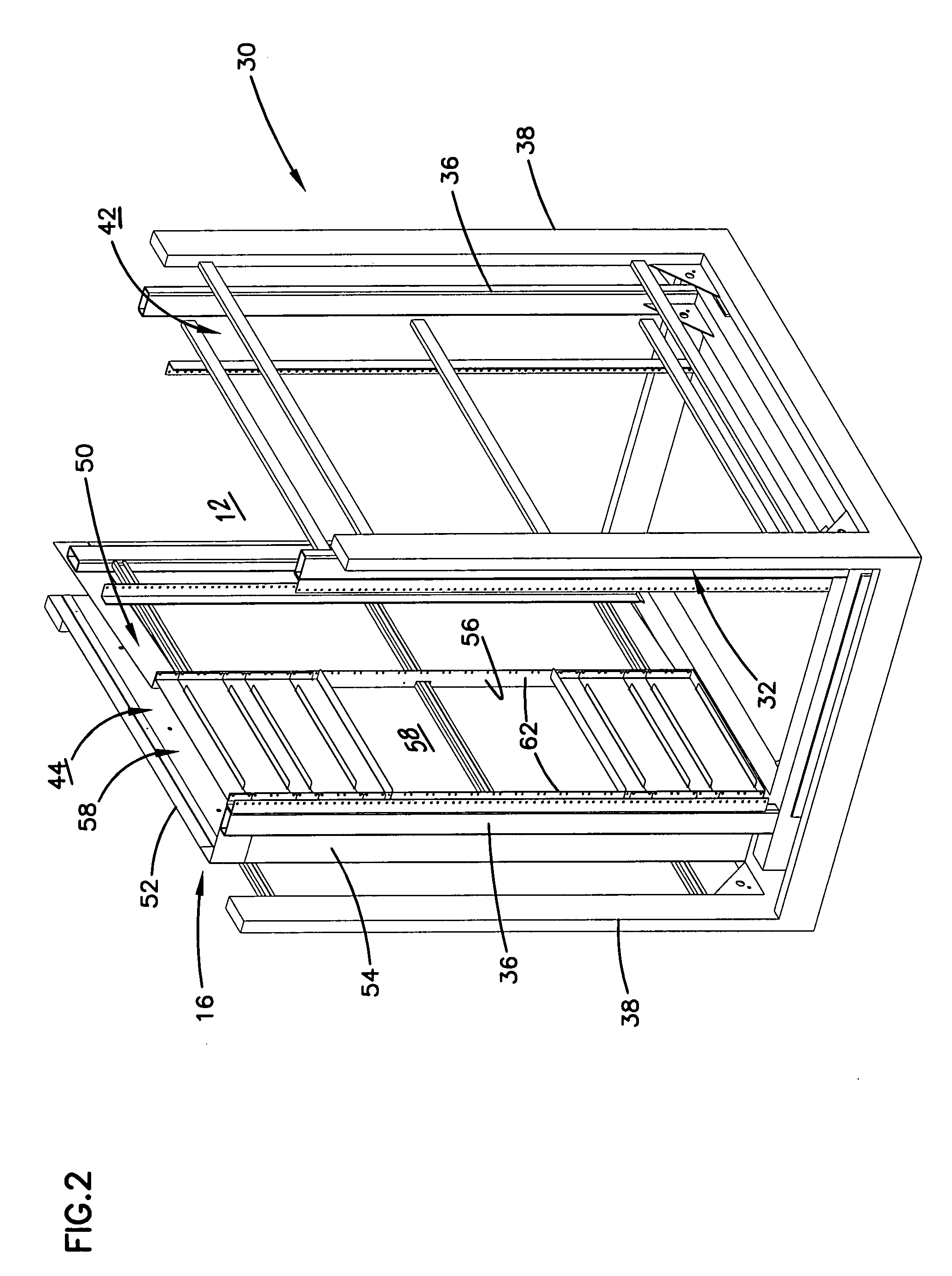

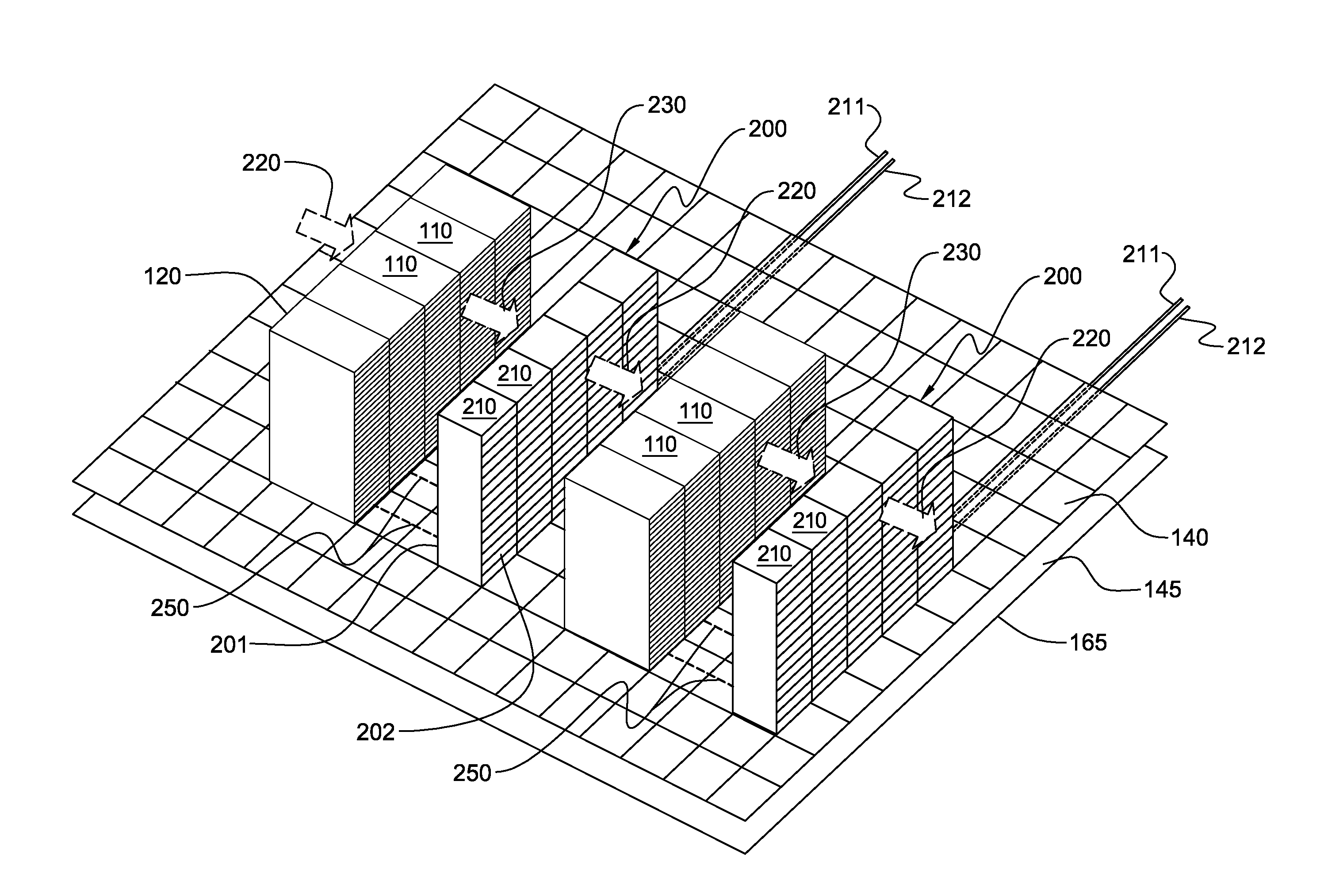

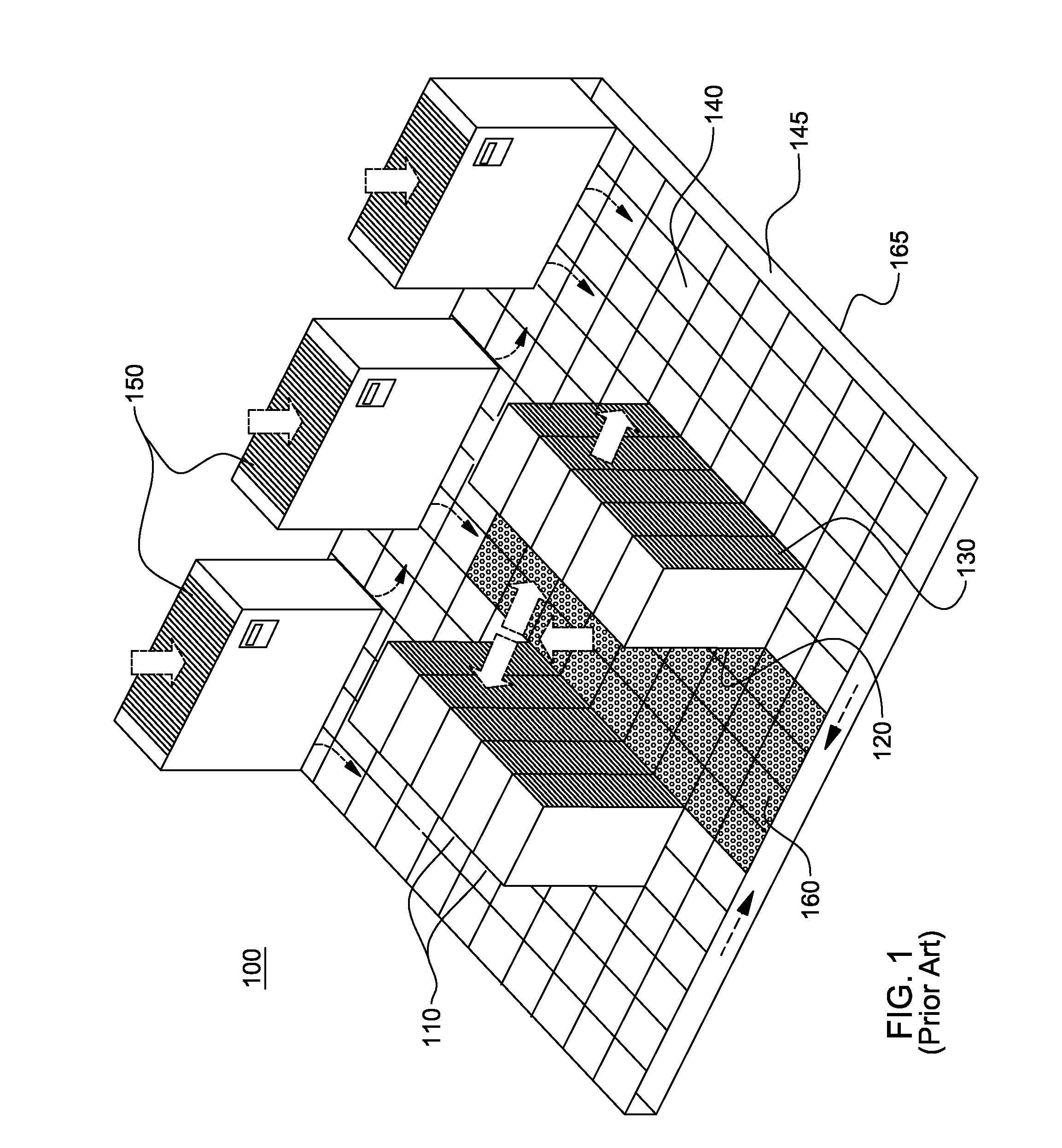

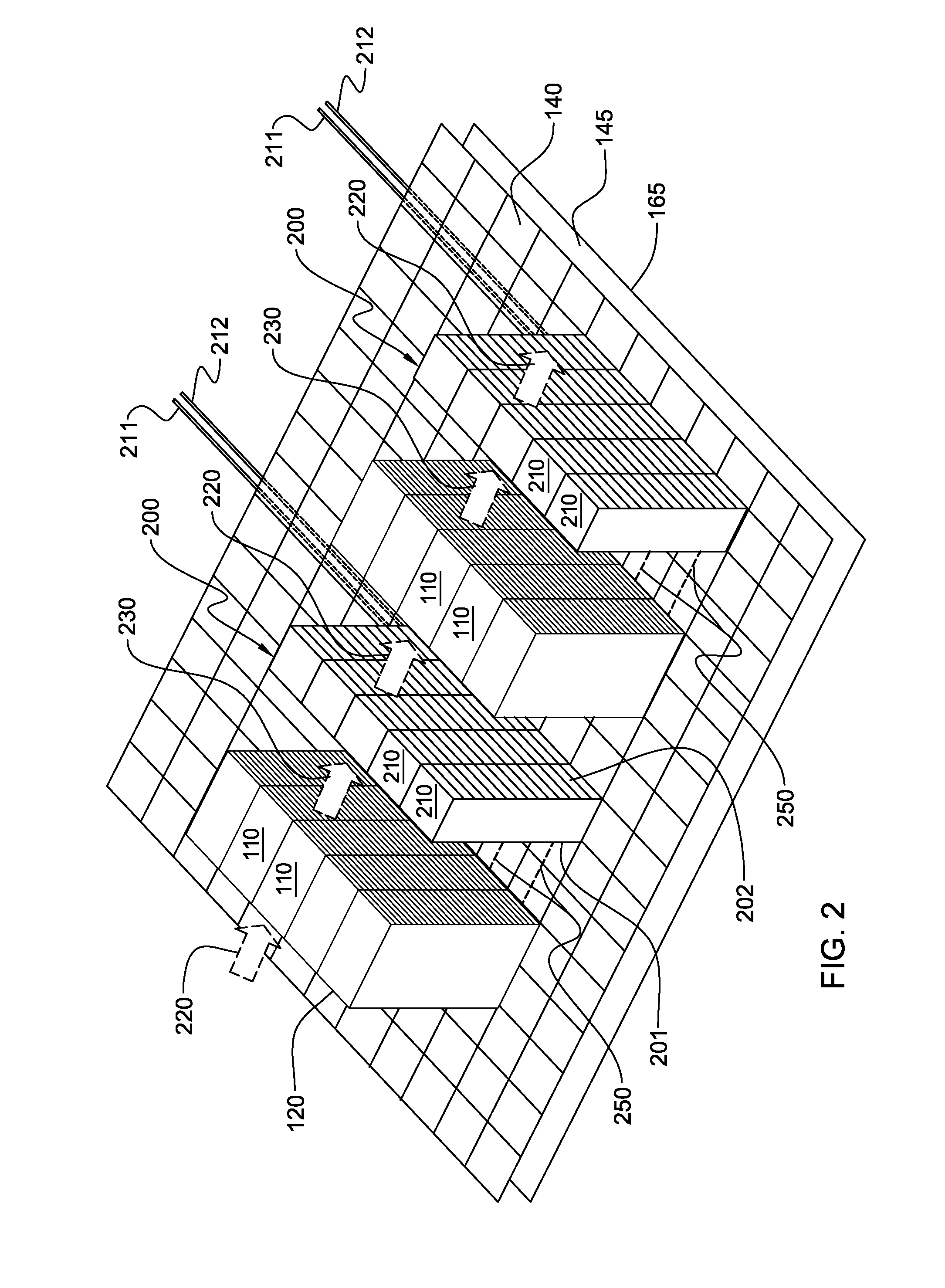

Apparatus and method for enhanced degassing of semiconductor wafers for increased throughput

InactiveUS6497734B1Semiconductor/solid-state device manufacturingConveyor partsEngineeringSemiconductor

A multi-level shelf degas station relying on at least two heaters integrated within wafer holding shelves or slots, where the semiconductor wafers do not have direct contact with the heater shelves. The heaters provide conduction heating. In order to degas a wafer, the heater and wafer holder assembly is positioned in a sequential manner through each wafer slot to the next available slot. If a degassed wafer exists in the slot, a transfer chamber arm removes it. A loader arm then places a wafer in the available, empty slot and the stage is moved upwards to receive the wafer from the loader arm. The transfer chamber arm removes an individual wafer from the heater and wafer holder assembly allowing the removed wafer to be individually processed while the other wafers remain in the heater and wafer holder assembly. In some instances, a loader arm may also remove wafers. The remaining wafers in the heater and wafer holder assembly are subjected to further degas treatment while the wafer(s) removed by the transfer chamber arm are exposed to other process steps. Air-cooling chambers are employed to facilitate cooling the wafer slots for ease of removal and maintenance.

Owner:NOVELLUS SYSTEMS

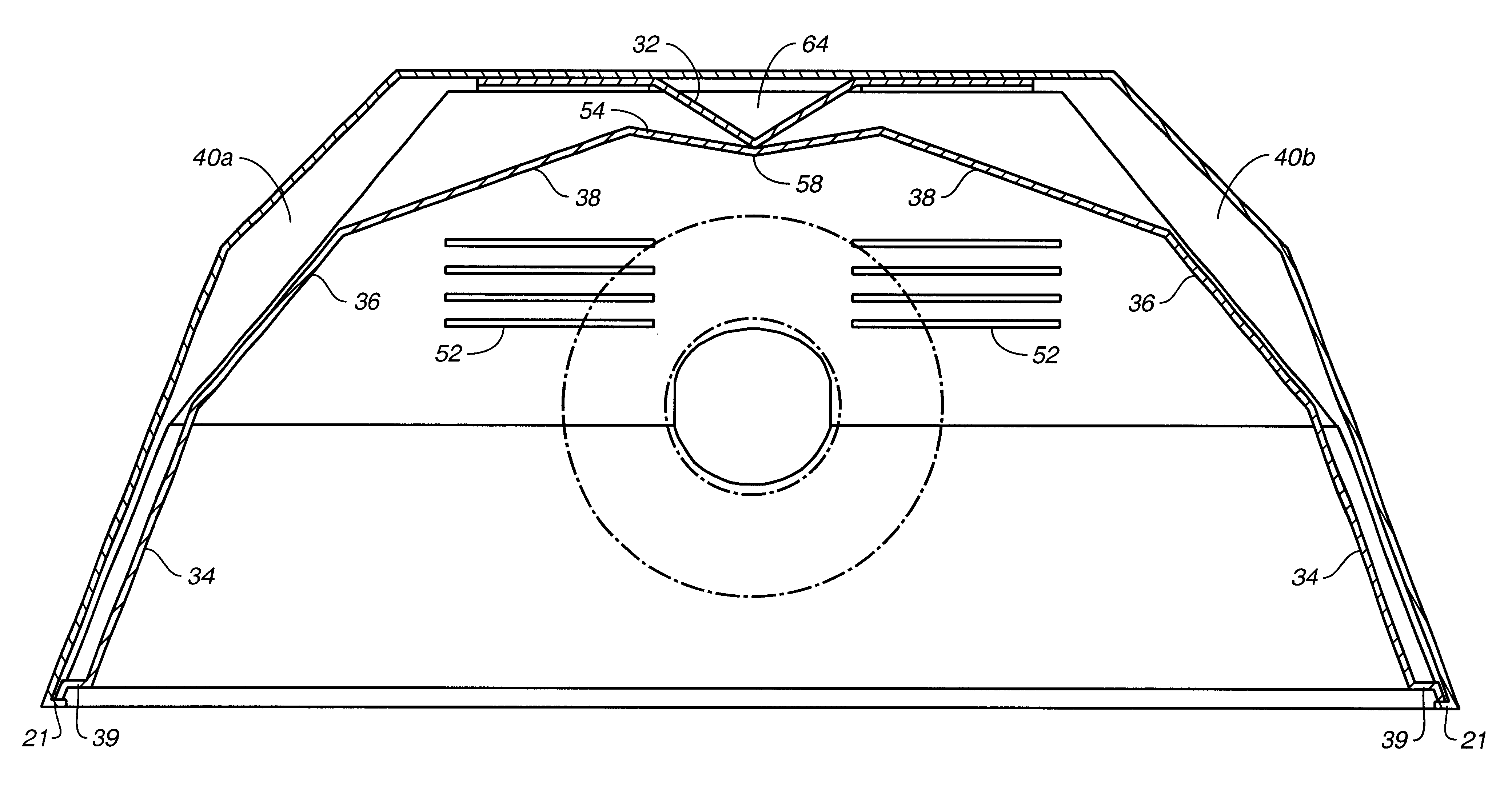

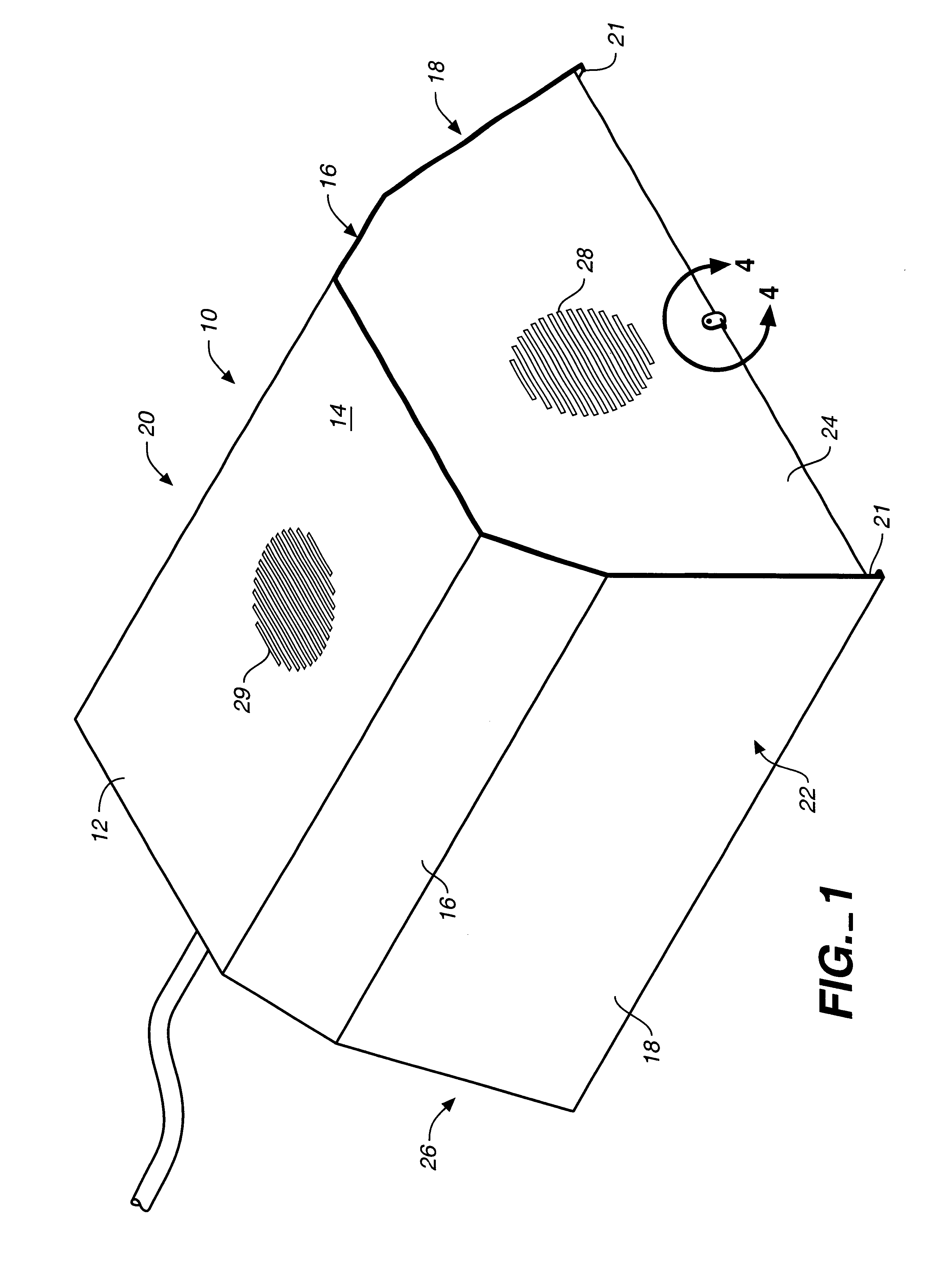

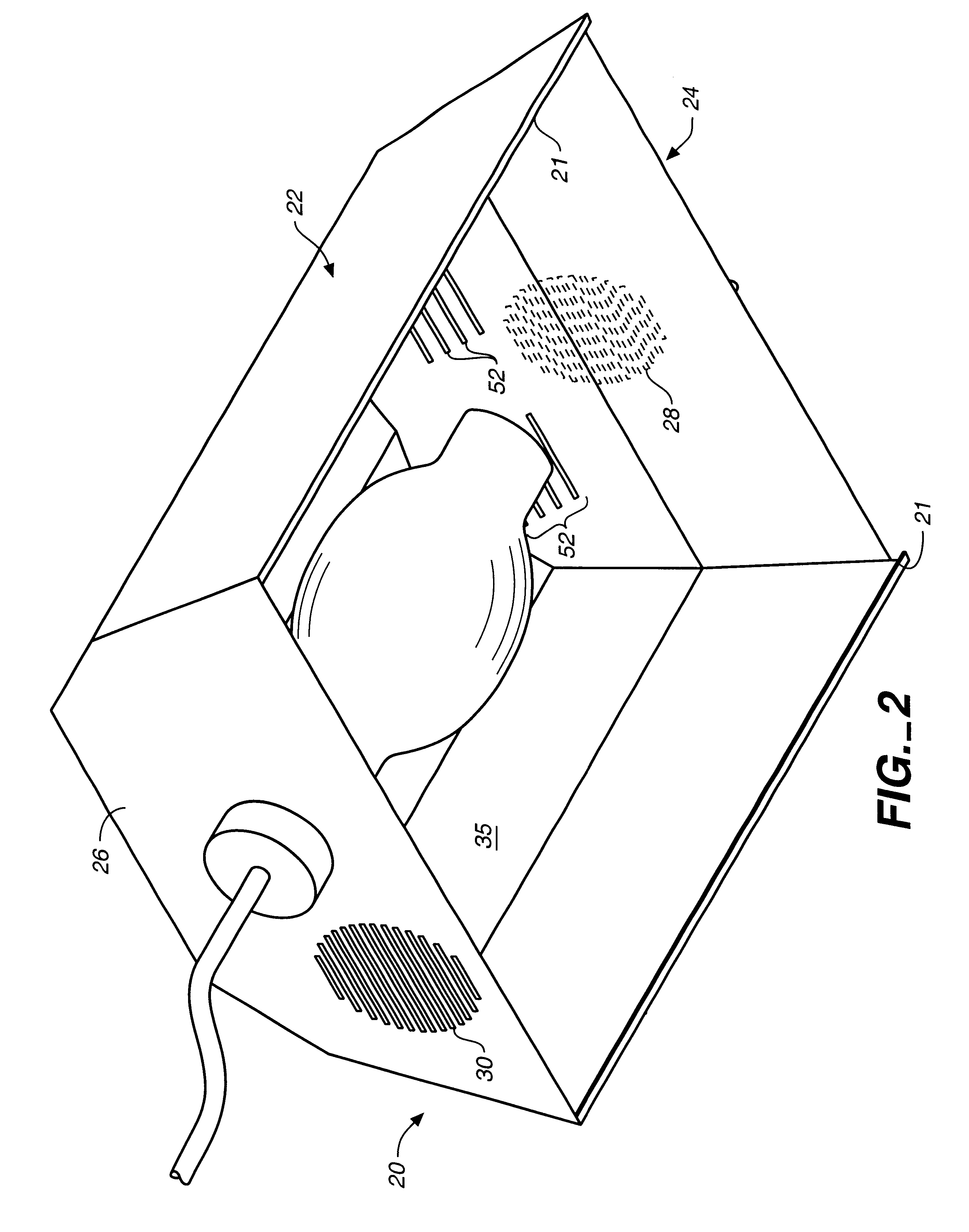

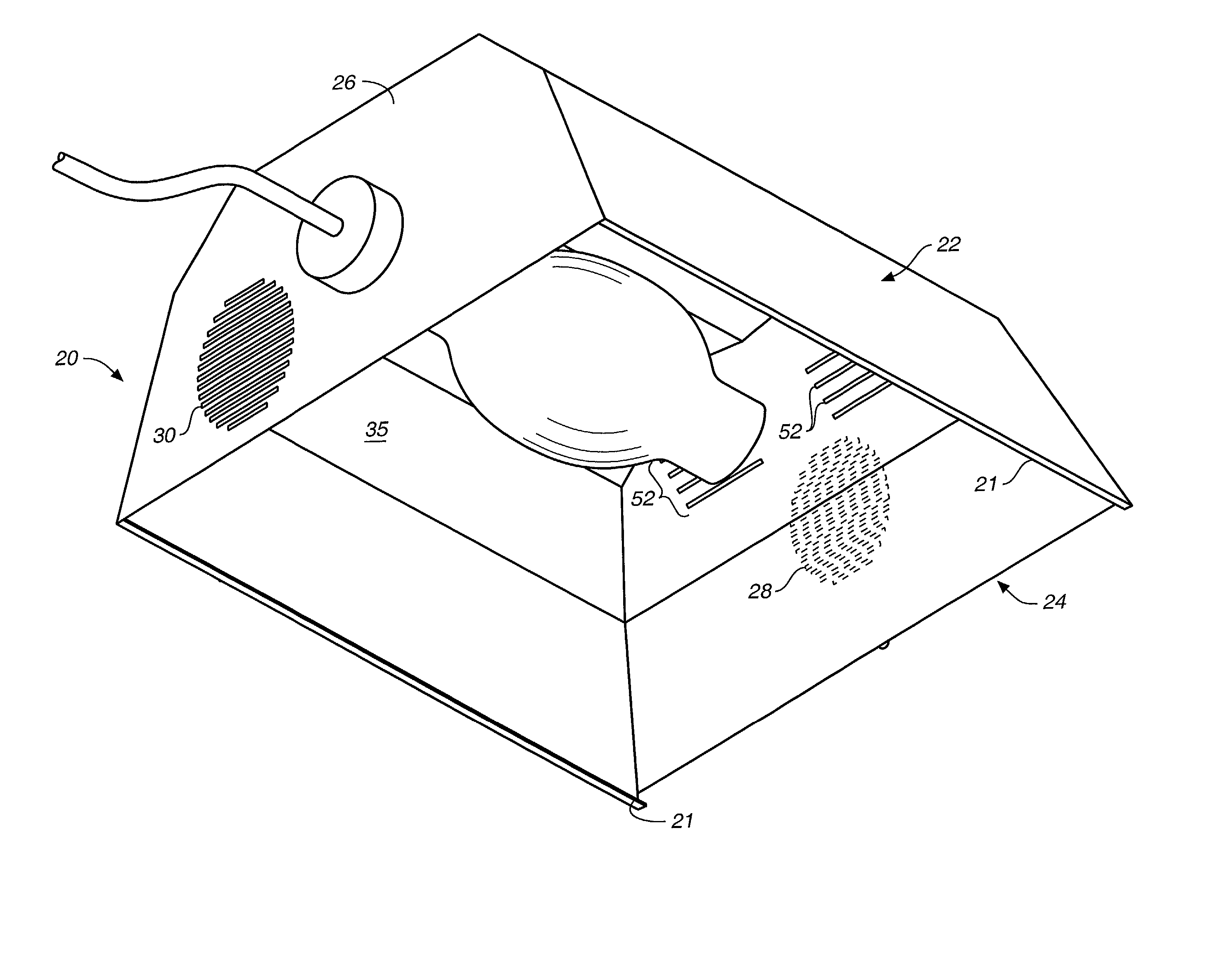

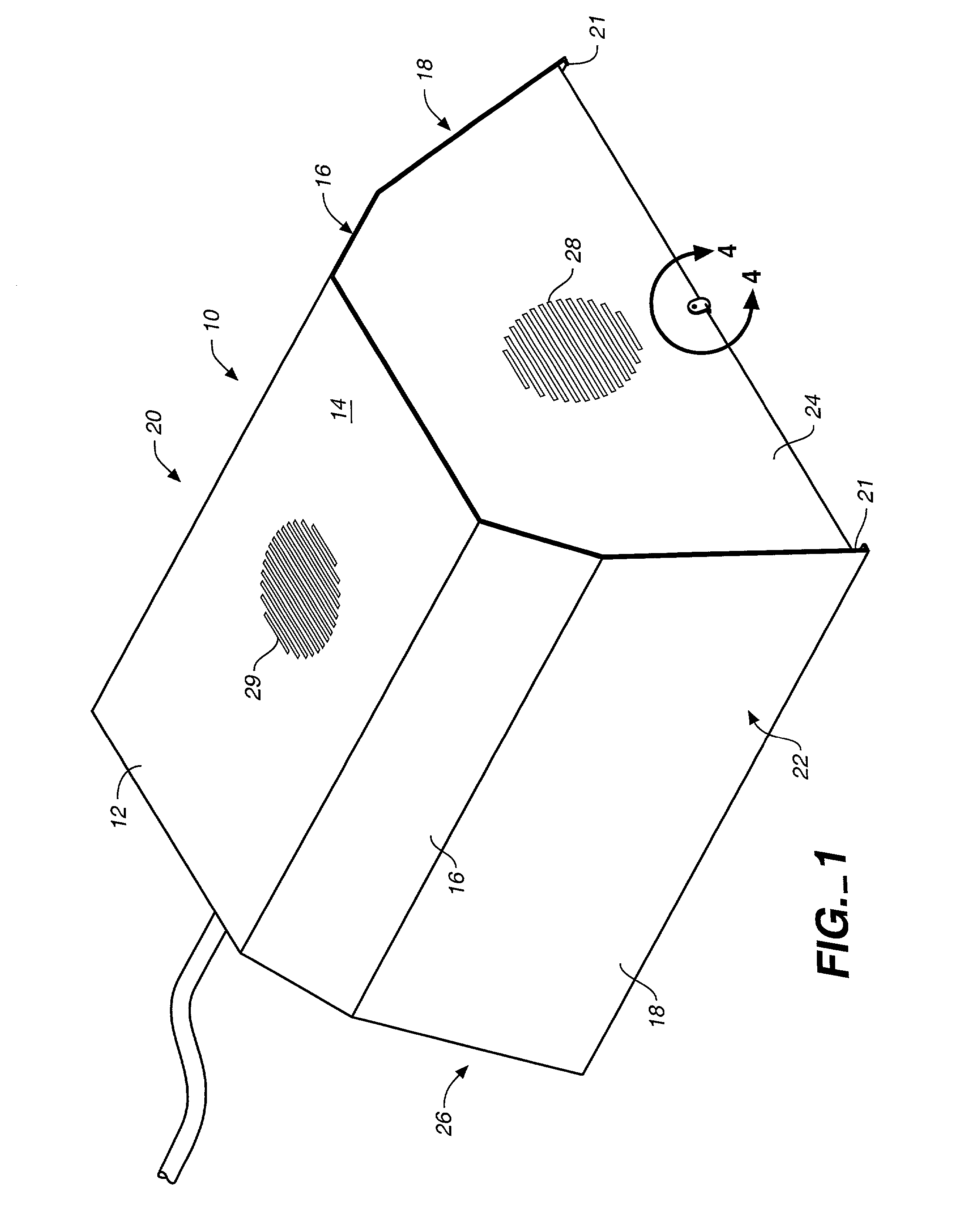

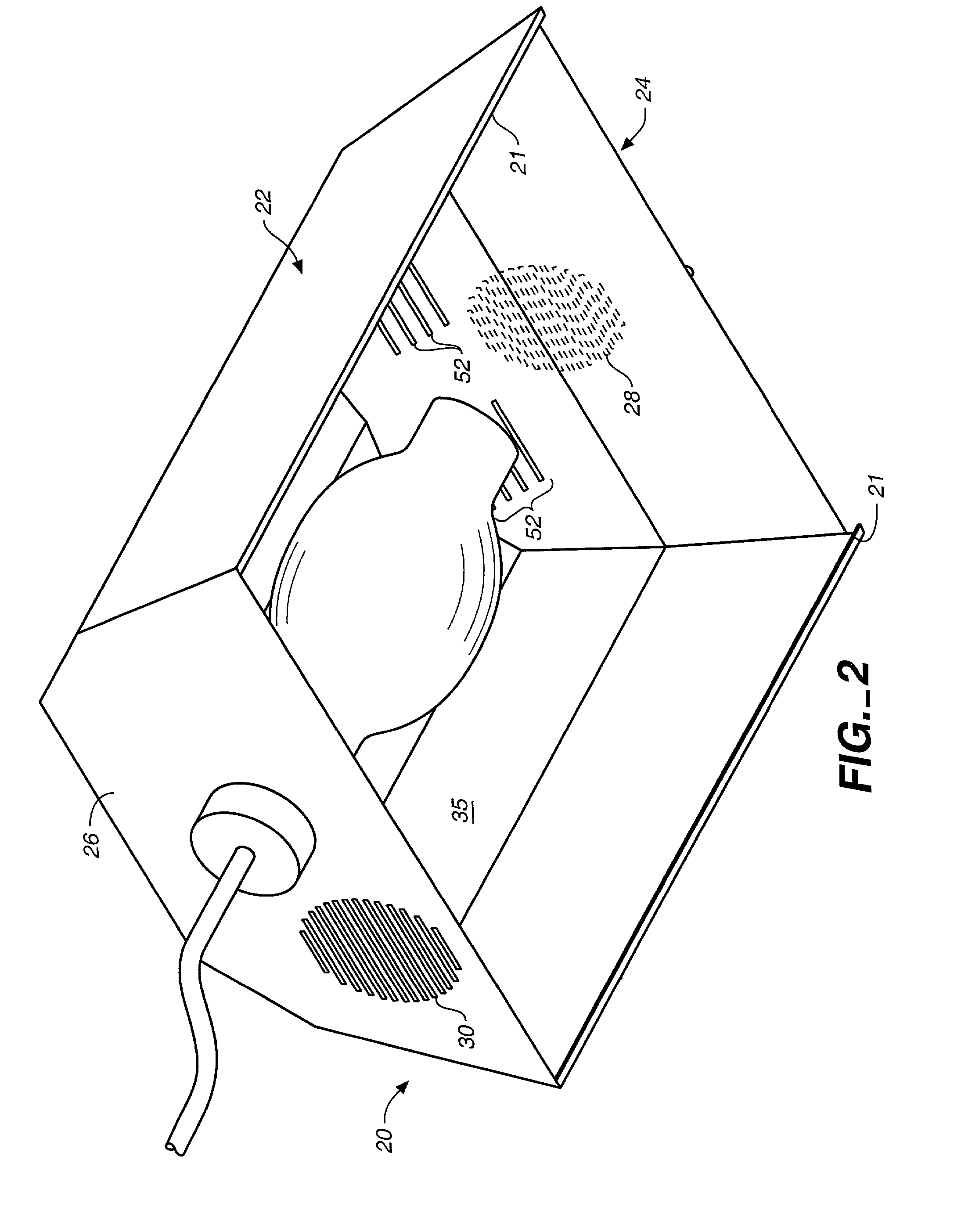

Double-walled grow light housing with air flow cooling system

A grow light having an exterior shell with an air inlet and a hot air exhaust outlet, and a specular interior insertable into the shell. The sides of the specular insert are spaced apart from the walls of the shell so as to form a double-walled housing having air cooling chambers and vents which facilitate the movement and exhaust of air heated by high intensity light bulbs.

Owner:HYDROFARM LLC

Humidity control for air conditioning system

ActiveUS8091375B2Increase humiditySimple methodMechanical apparatusSpace heating and ventilation safety systemsMicrocontrollerAir cycle

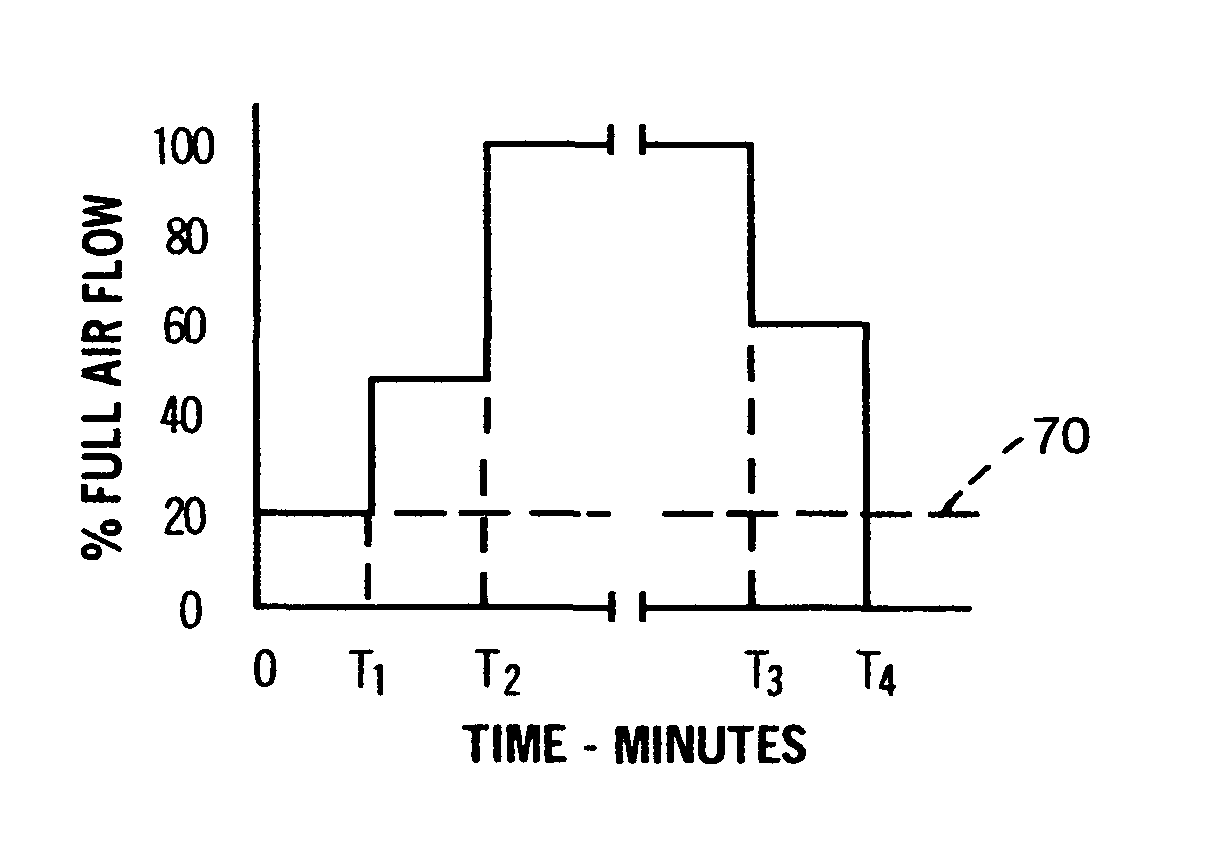

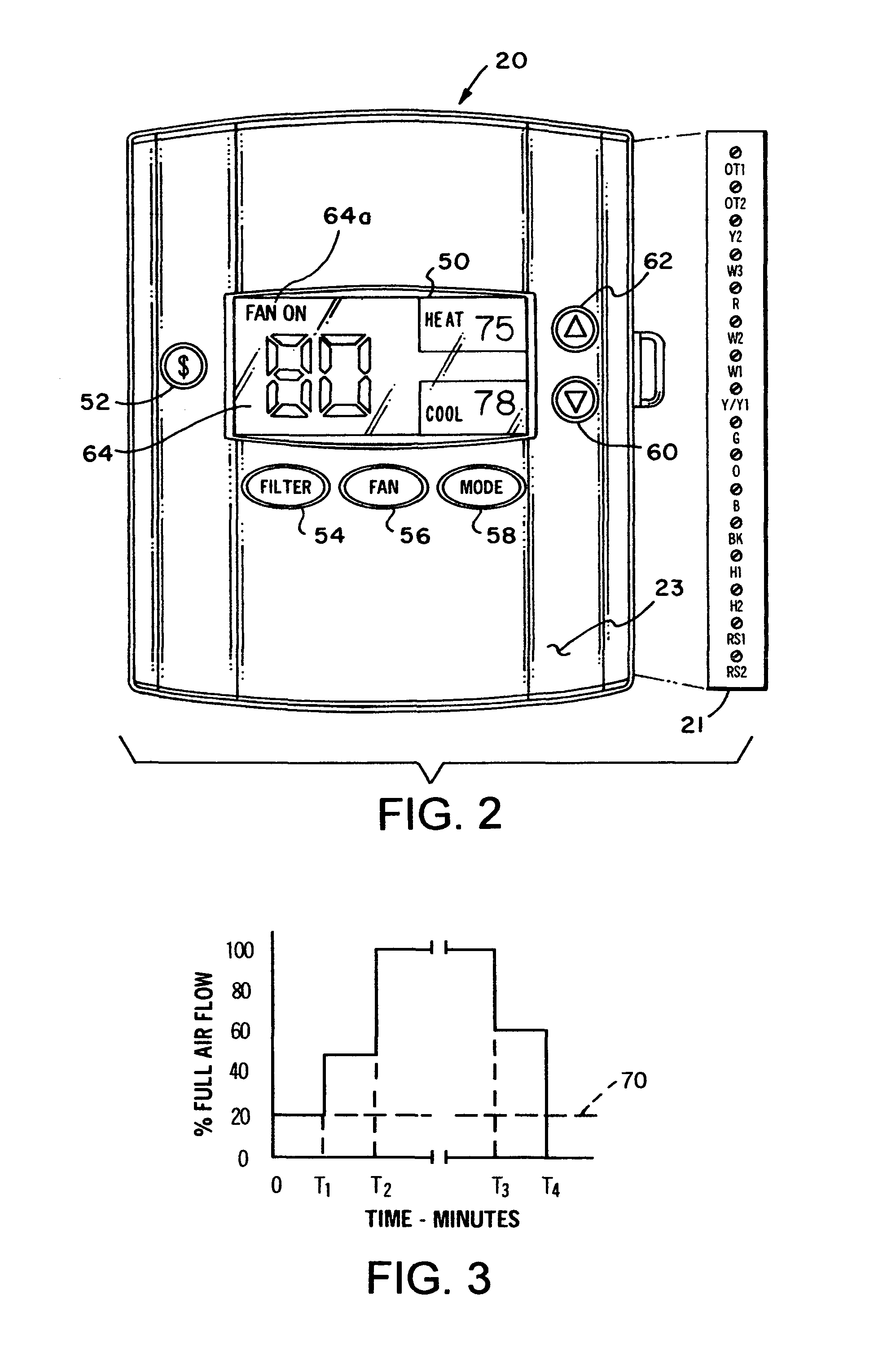

In an air conditioning system for circulating cooled air to an enclosed space, a controller including a temperature sensor, a humidity sensor and a microcontroller for controlling the indoor fan or blower to prevent operation of same if a fan run-on mode is selected or continuous fan operation is selected and the humidity sensed in the enclosed space is greater than a predetermined amount. Continuous fan operation is allowed unless the humidity exceeds a user defined setpoint during an air cooling operating mode. If the humidity sensed is greater than the predetermined amount, the fan is operated only when the system is providing cooled air, such as when the system compressor is energized.

Owner:TRANE INT INC

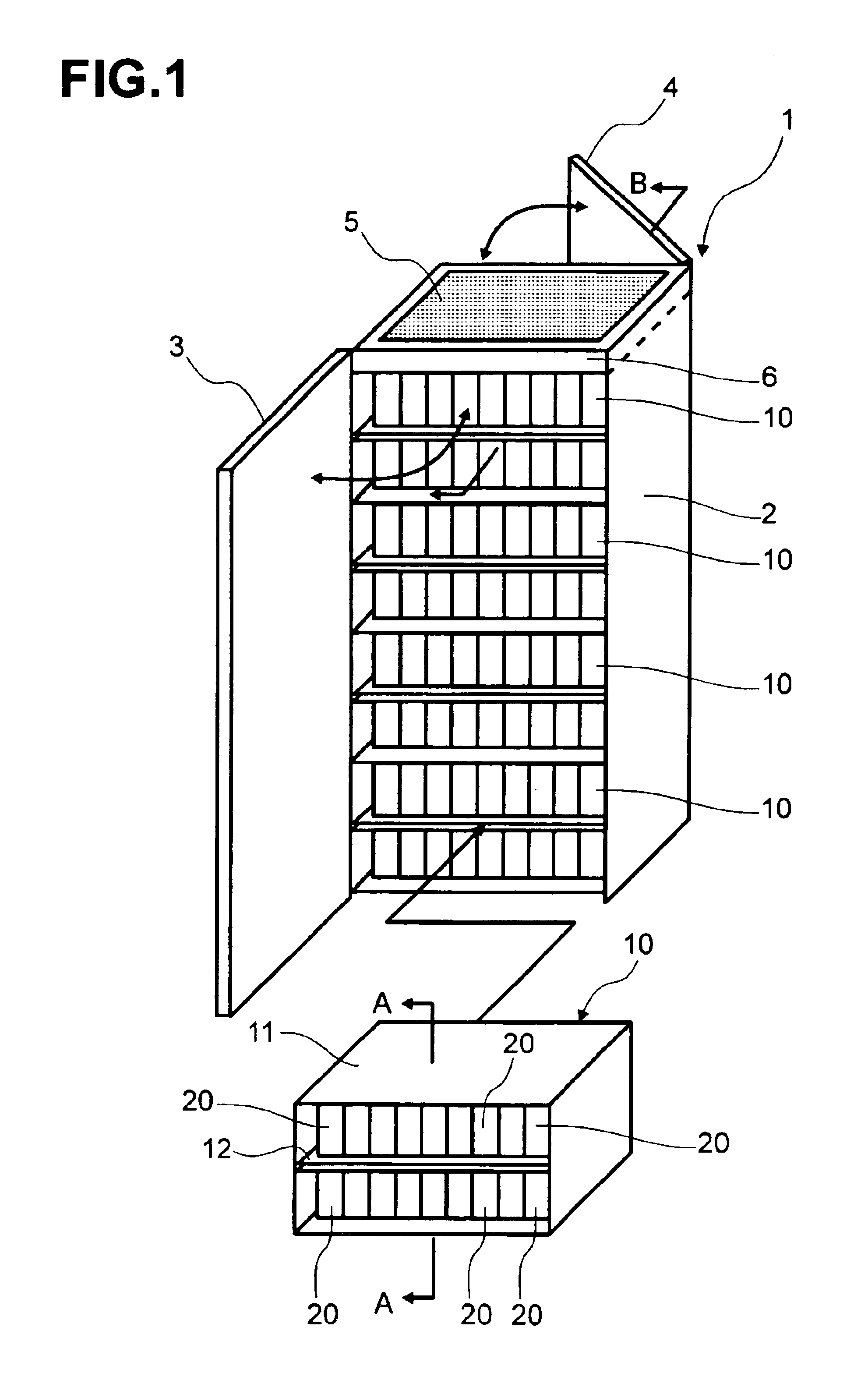

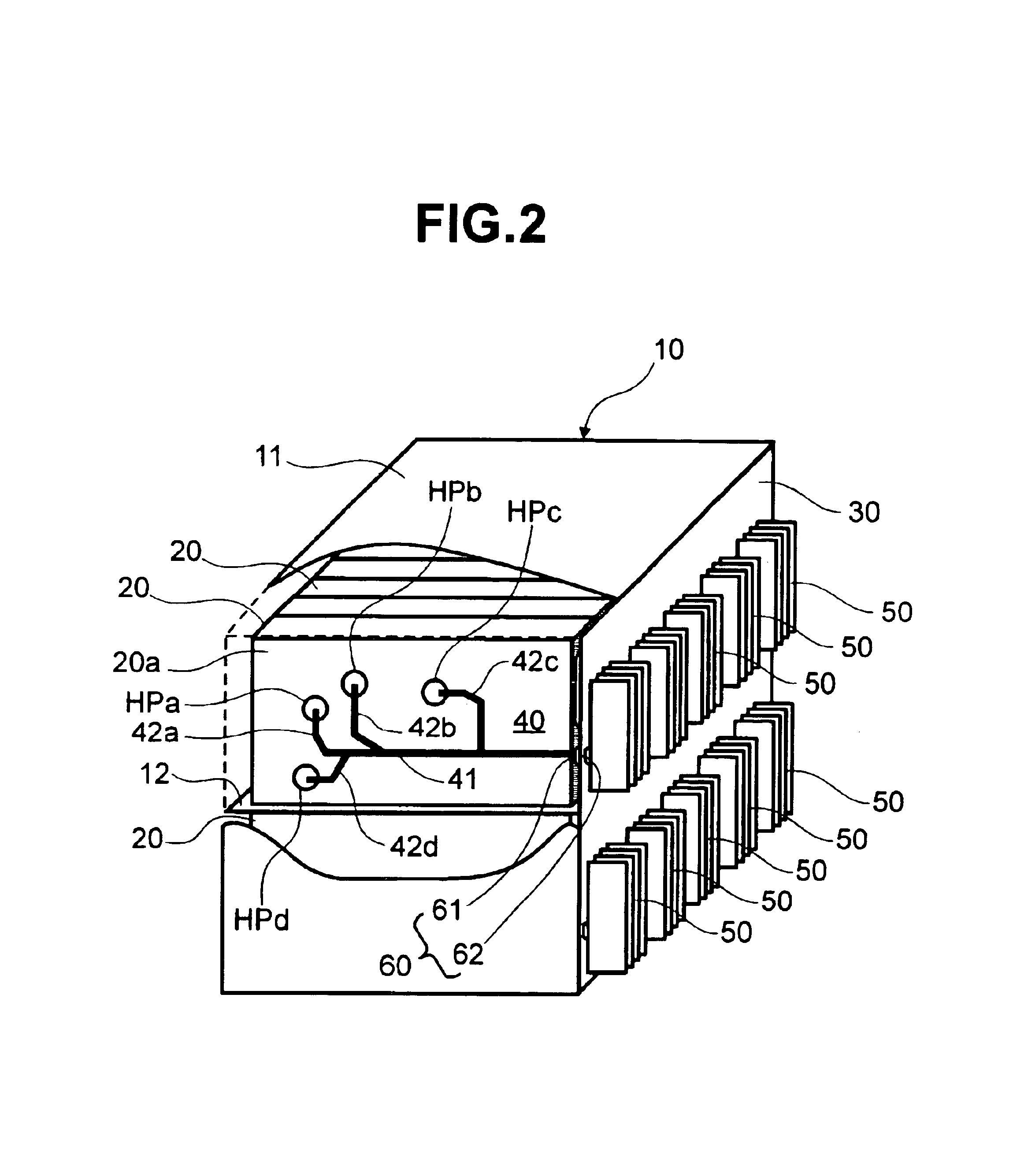

Cooling structure for disk storage device

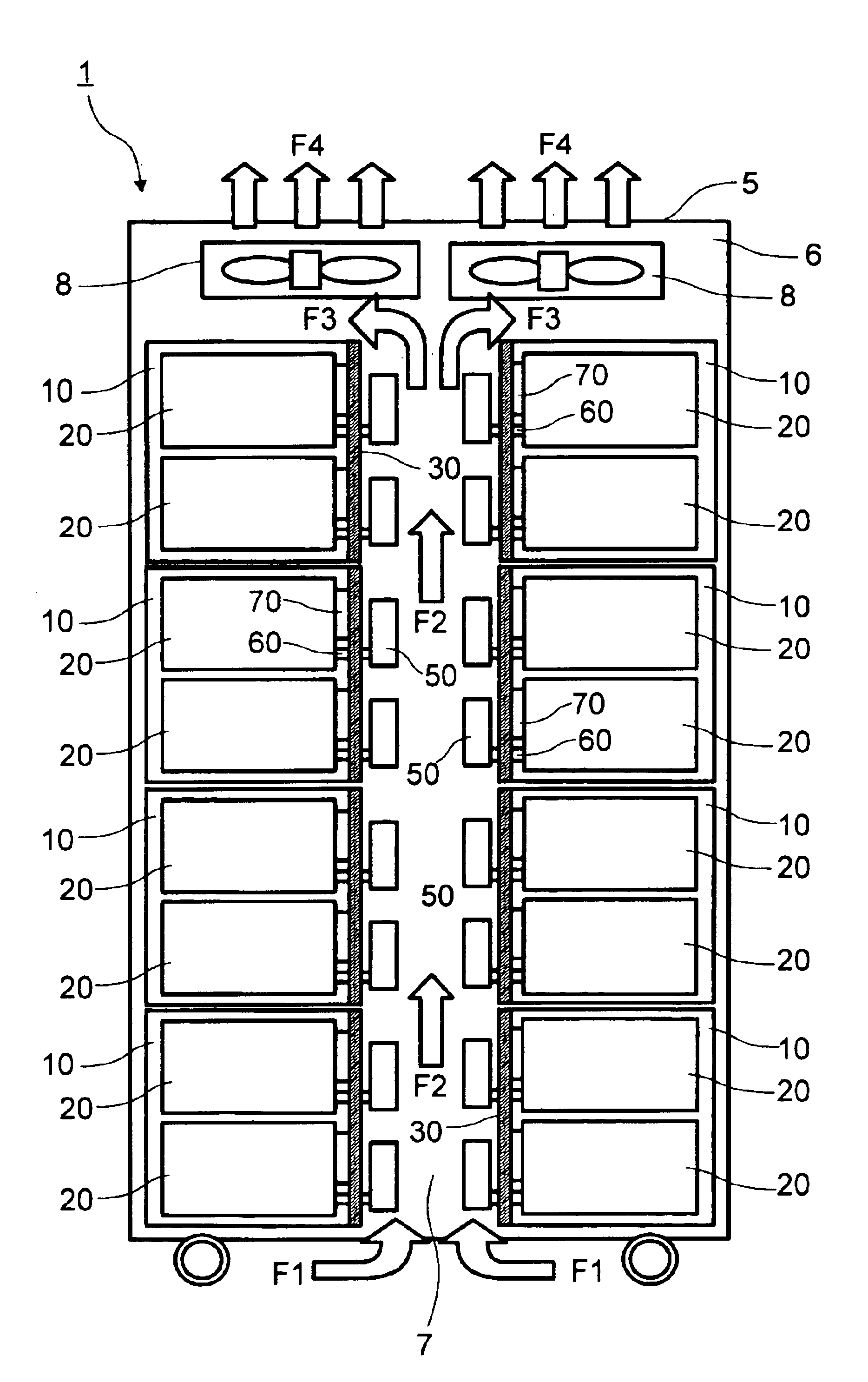

ActiveUS6927980B2Increase freedomImprove cooling effectReducing temperature influence on carrierDomestic cooling apparatusEngineeringSize reduction

A disk drive box 10 accommodates a plurality of disk drives 20 within a case 11. A side face of each of the drives 20 is provided with a heat-absorbing part 40 including a heat pipe, corresponding to heat producing area HP. The heat taken away by the heat-absorbing part 40 is transmitted to a heat sink 50 of the rear of a backboard 30 via a heat connector 60. The heat sink 50 is cooled by cooling air flowing through an air duct 7. By cooling the drive 20 with the heat pipe, clearances between the drives 20 can be substantially eliminated, and it is made unnecessary to form an opening for air cooling in the backboard 30. Thus, size reduction is possible, and it is possible to increase the degree of freedom for a wiring pattern formed on the backboard 30.

Owner:GOOGLE LLC

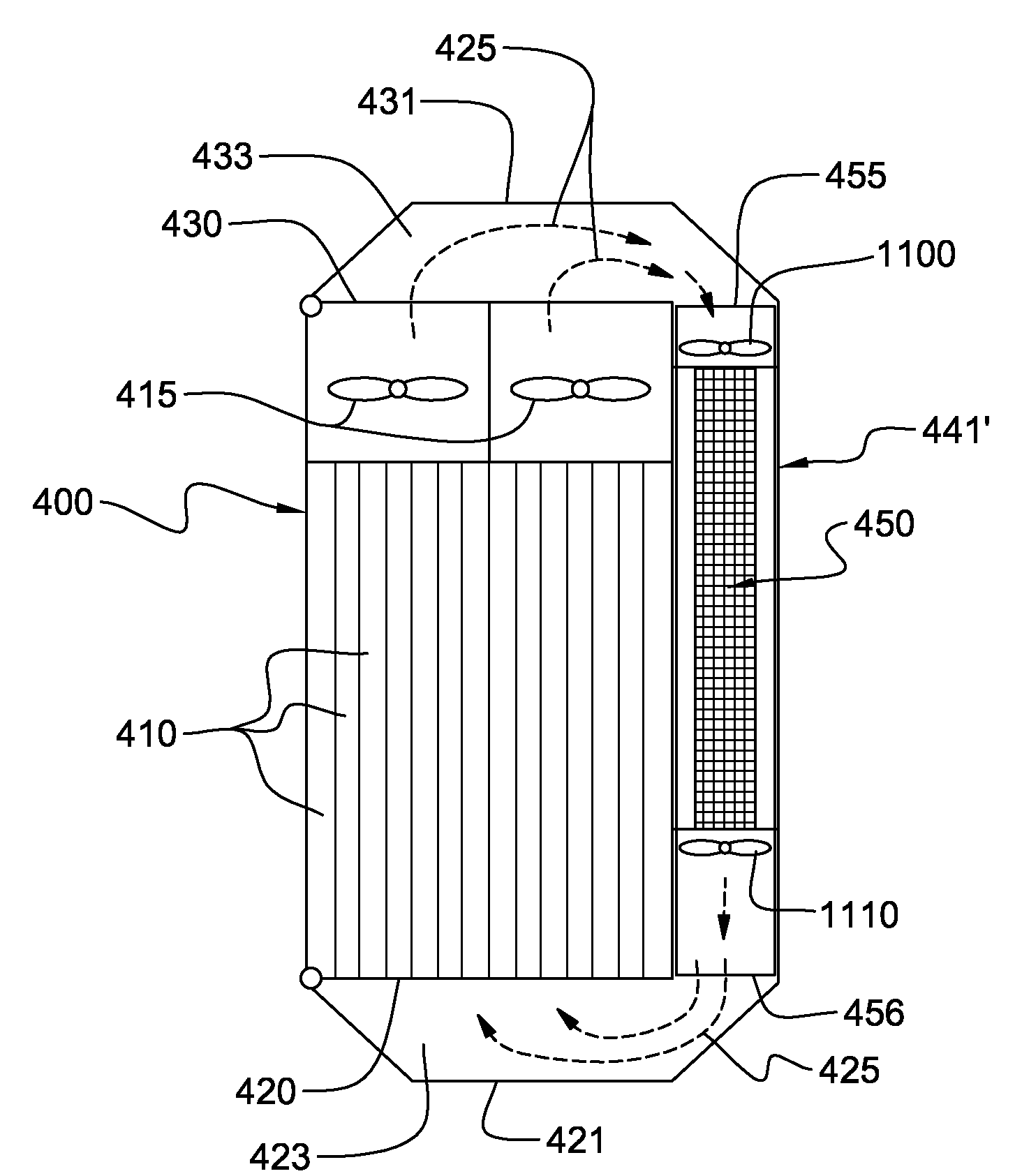

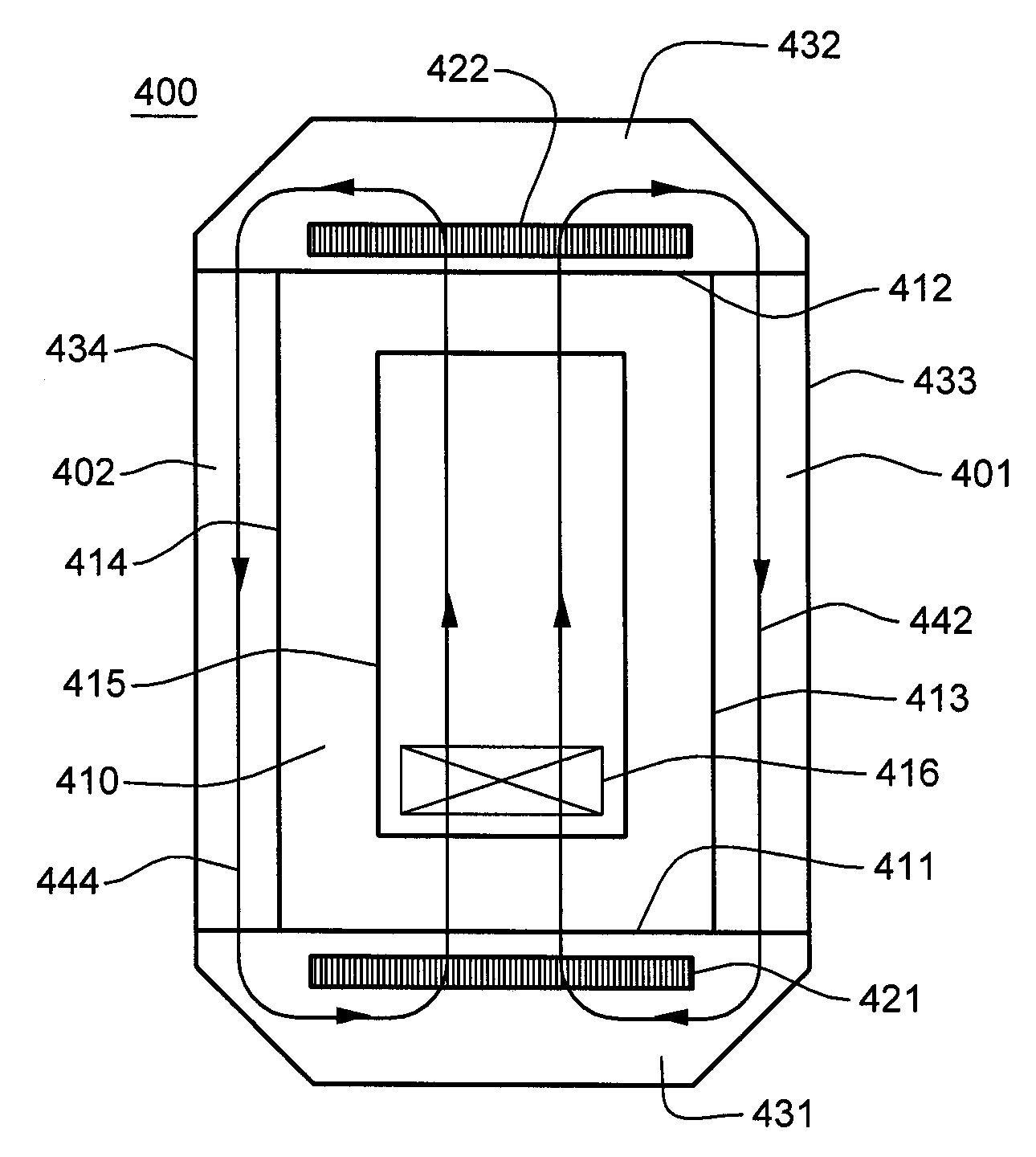

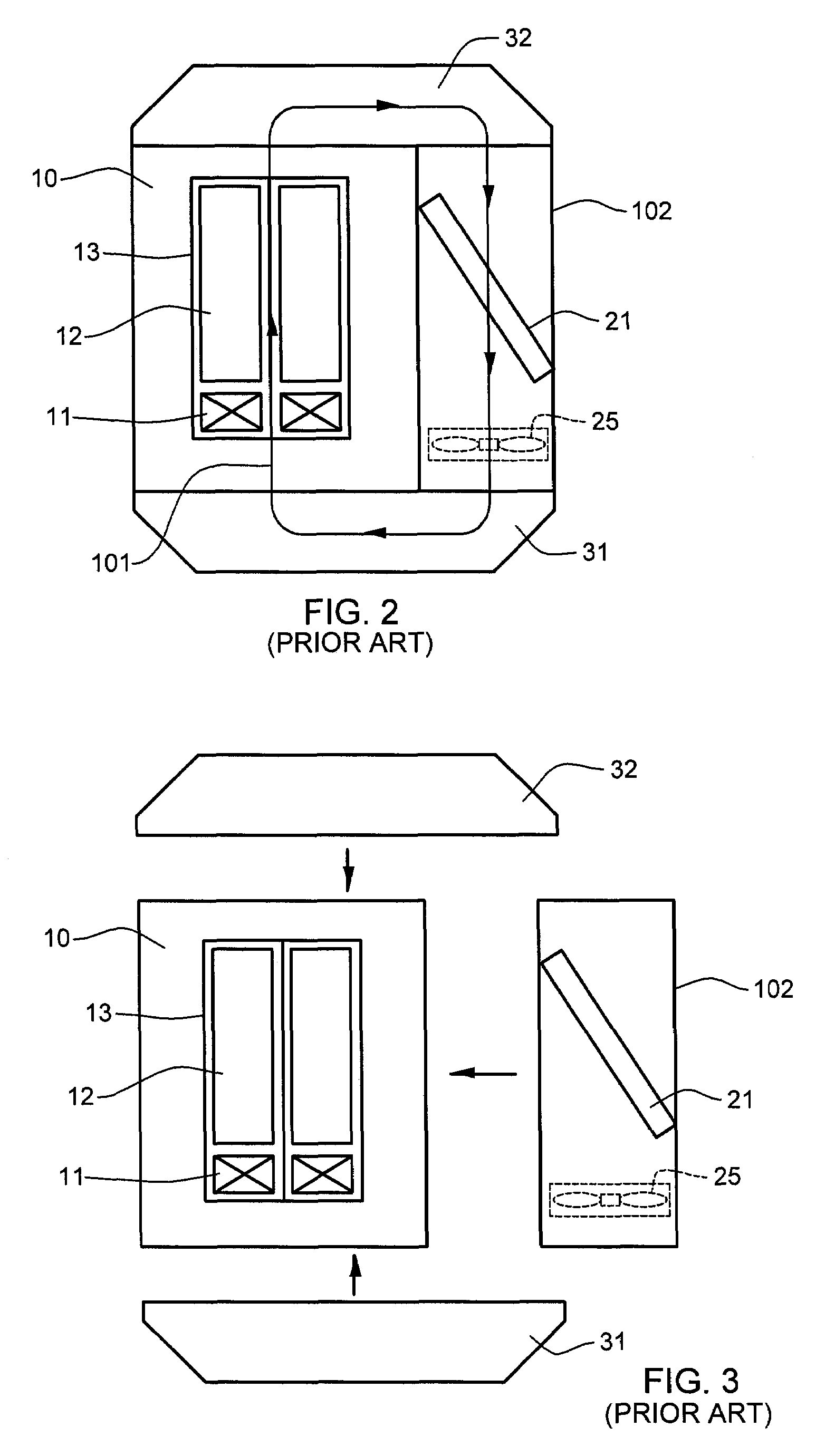

Apparatus and method for facilitating cooling of an electronics system

ActiveUS20090154096A1Overcomes shortcomingEnhanced advantageDigital data processing detailsCompression machines with non-reversible cycleElectronic systemsClosed loop

Apparatus and method are provided for facilitating air-cooling of an electronics system employing a vapor-compression heat exchange system, and front and back covers. An evaporator housing of the heat exchange system is mounted to a system housing of the electronics system and extends at least partially between air inlet and outlet sides of the system housing. The evaporator housing includes air inlet and outlet openings, and an evaporator. The front cover is mounted to the system or evaporator housing adjacent to the air inlet side or air outlet opening, and the back cover is mounted to the system or evaporator housing adjacent to the air outlet side or air inlet opening. Together, the system housing, back cover, evaporator housing and front cover define a closed loop airflow path passing through the system housing and evaporator housing, with the vapor-compression heat exchange system cooling air circulating therethrough.

Owner:IBM CORP

Double-walled grow light housing with air flow cooling system

A grow light having an exterior shell with an air inlet and a hot air exhaust outlet, and a specular interior insertable into the shell. The sides of the specular insert are spaced apart from the walls of the shell so as to form a double-walled housing having air cooling chambers and vents which facilitate the movement and exhaust of air heated by high intensity light bulbs.

Owner:HYDROFARM LLC

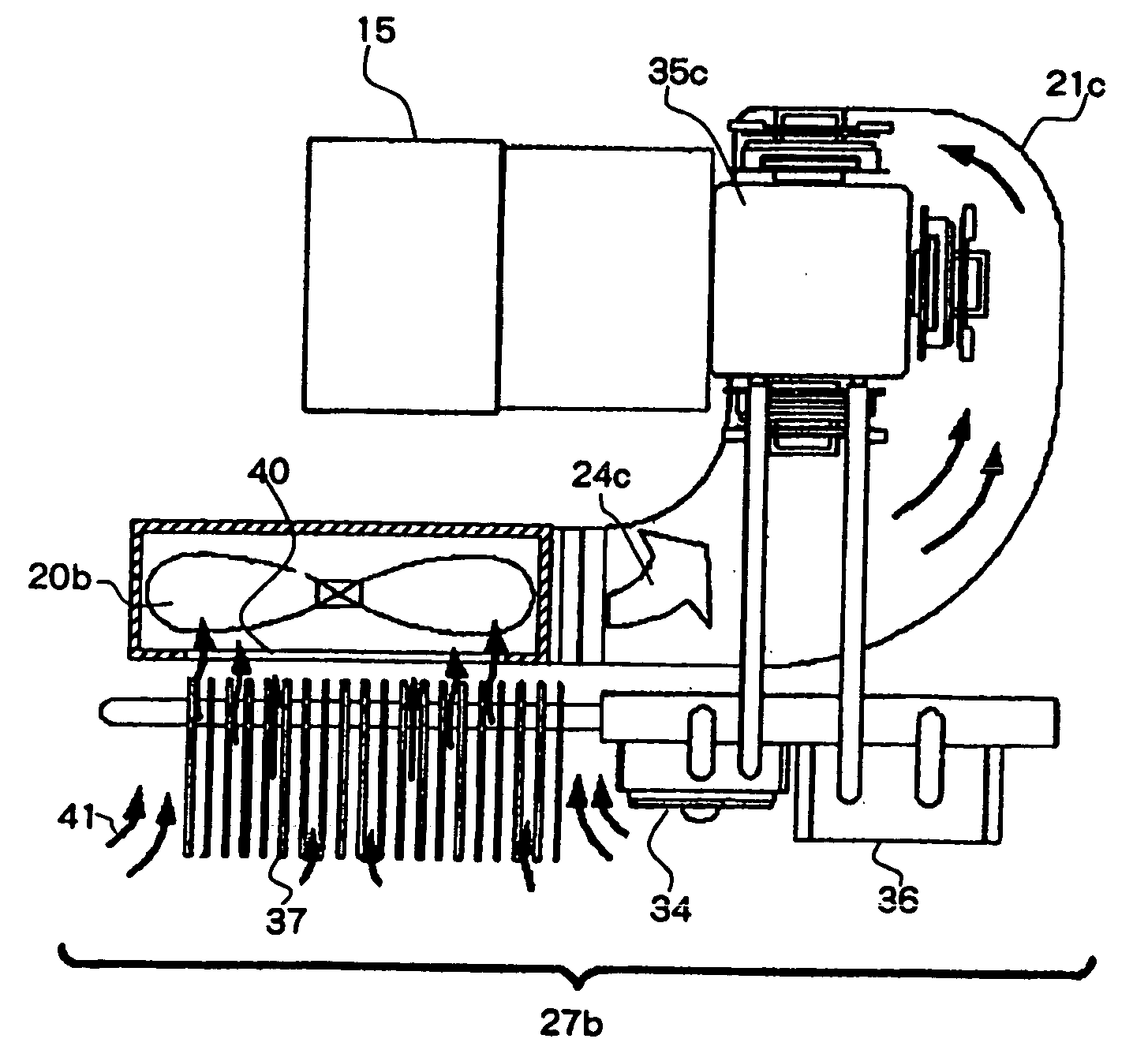

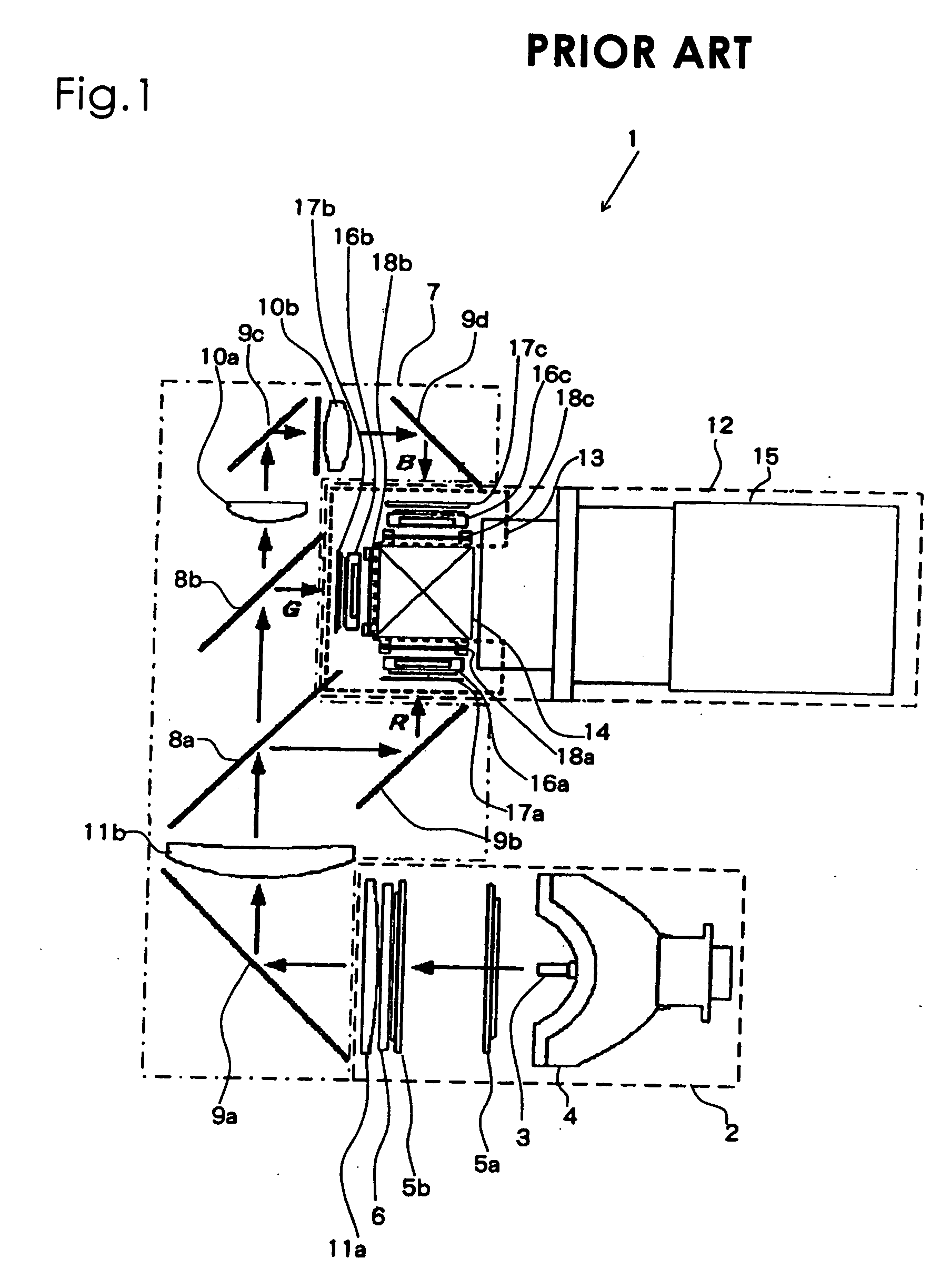

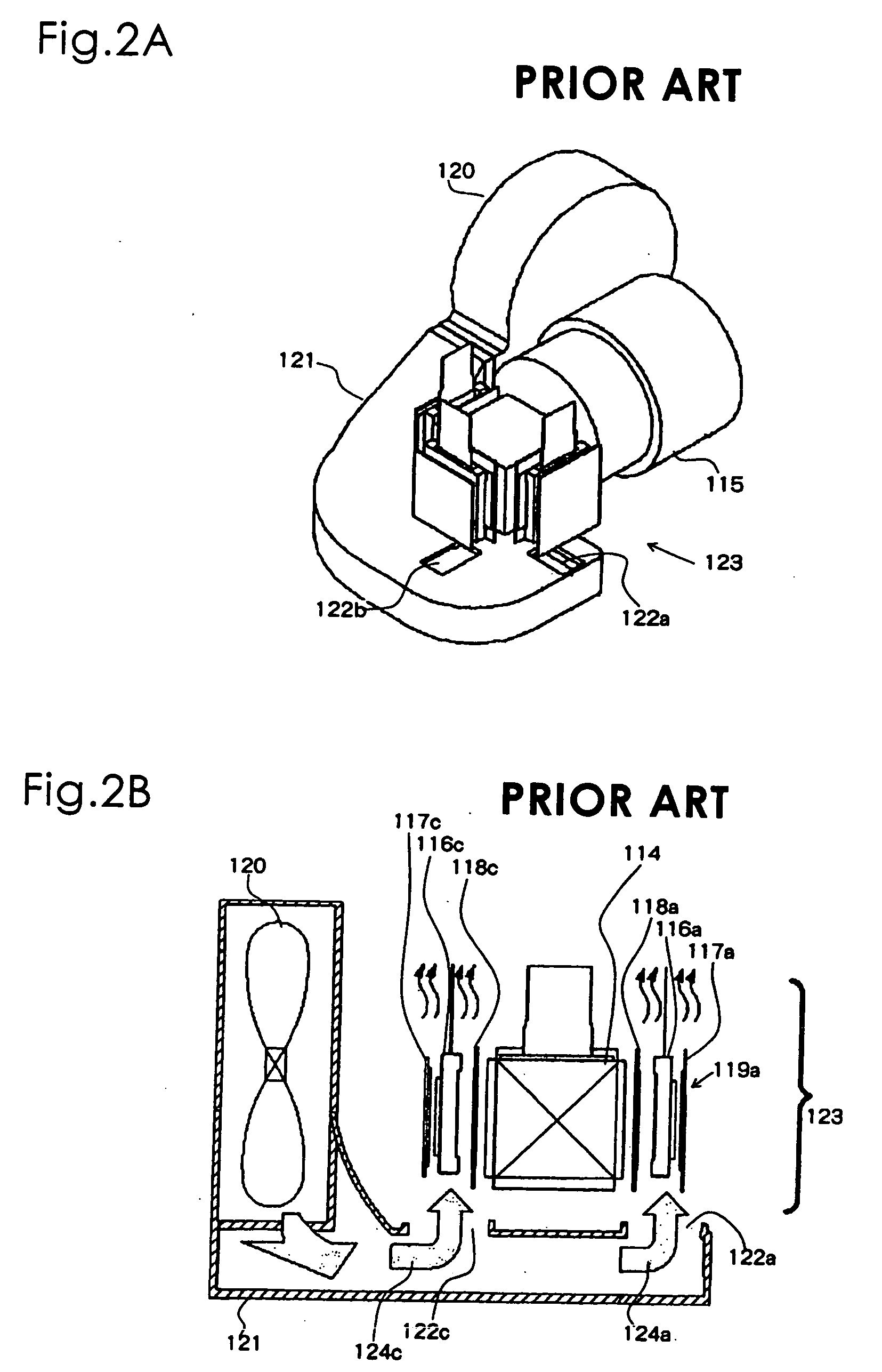

Projection display apparatus using liquid cooling and air cooling

A projection display apparatus comprises a liquid crystal unit assembly which includes a liquid crystal panel, an incident side polarizing plate and an emitting side polarizing plate which are arranged on an incident side and on an emitting side of the liquid crystal panel, respectively, and a color combining prism. The apparatus further comprises a fan; a duct which is connected to the fan and which is provided with an opening for supplying cooling air, wherein the opening is arranged near the liquid crystal panel and the incident side polarizing plate; a holder for holding the emitting side polarizing plate and the color combining prism; and a heat exchanger which is connected to the holder, wherein the heat exchanger uses liquid coolant.

Owner:NEC DISPLAY SOLUTIONS LTD

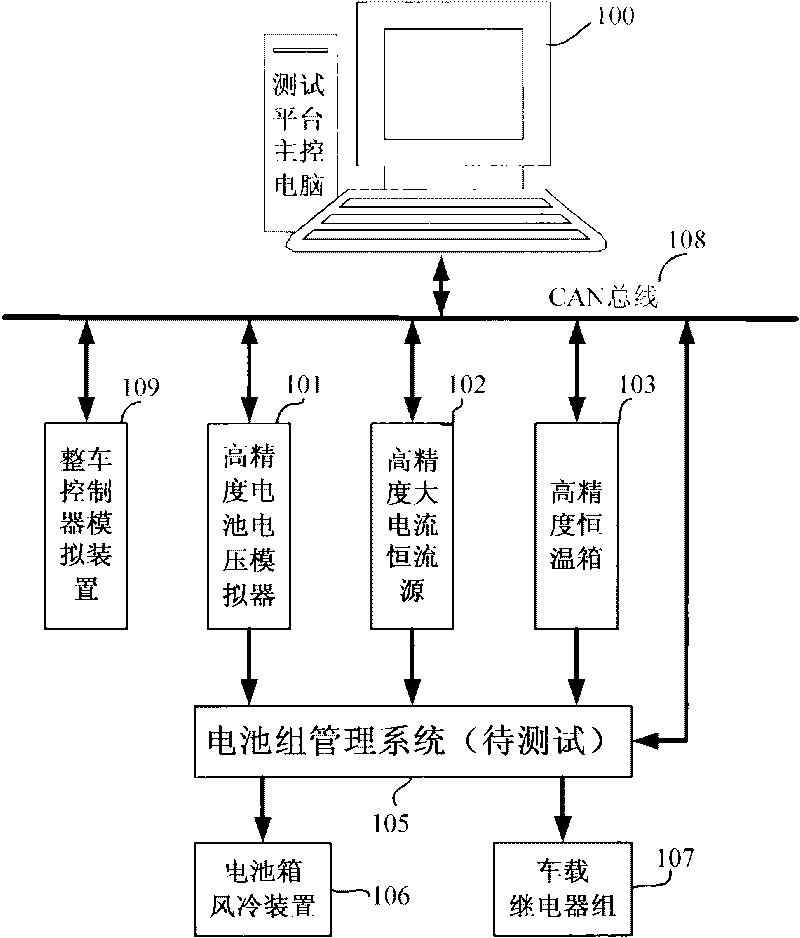

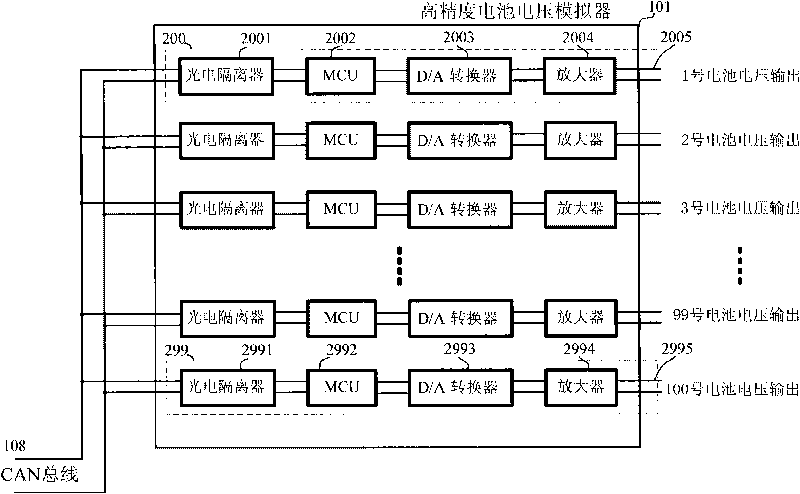

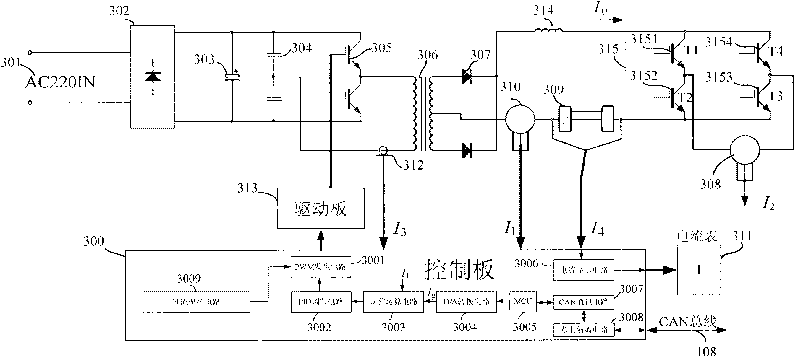

Battery managing system testing platform

InactiveCN101762800AHigh precisionSimple structureElectrical testingElectrical batteryData acquisition

The invention discloses a battery managing system (BMS) testing platform comprising a testing platform main control computer, a high-precision cell voltage simulator, a high-precision large-current constant-current source, a high-precision thermotank, a battery managing system to be tested, a whole vehicle controller simulator and the like which are connected by CAN buses. The battery managing system is connected with a cell box air cooling device, a vehicle relay assembly and the like. The battery managing system testing platform can truly simulate the output state of a battery, comprising single cell voltage, total voltage, charging and discharging current, temperature and the like of the battery, can complete various communication and command functions, protection functions, battery heavy current applying process between the battery managing system and the whole vehicle, and the test and the verification on the functions of overhead protection and the like of the battery. The invention can carry out testing evaluation on the data collection precision of the battery managing system, the evaluation precision of the charge state of the battery and the like.

Owner:BEIHANG UNIV

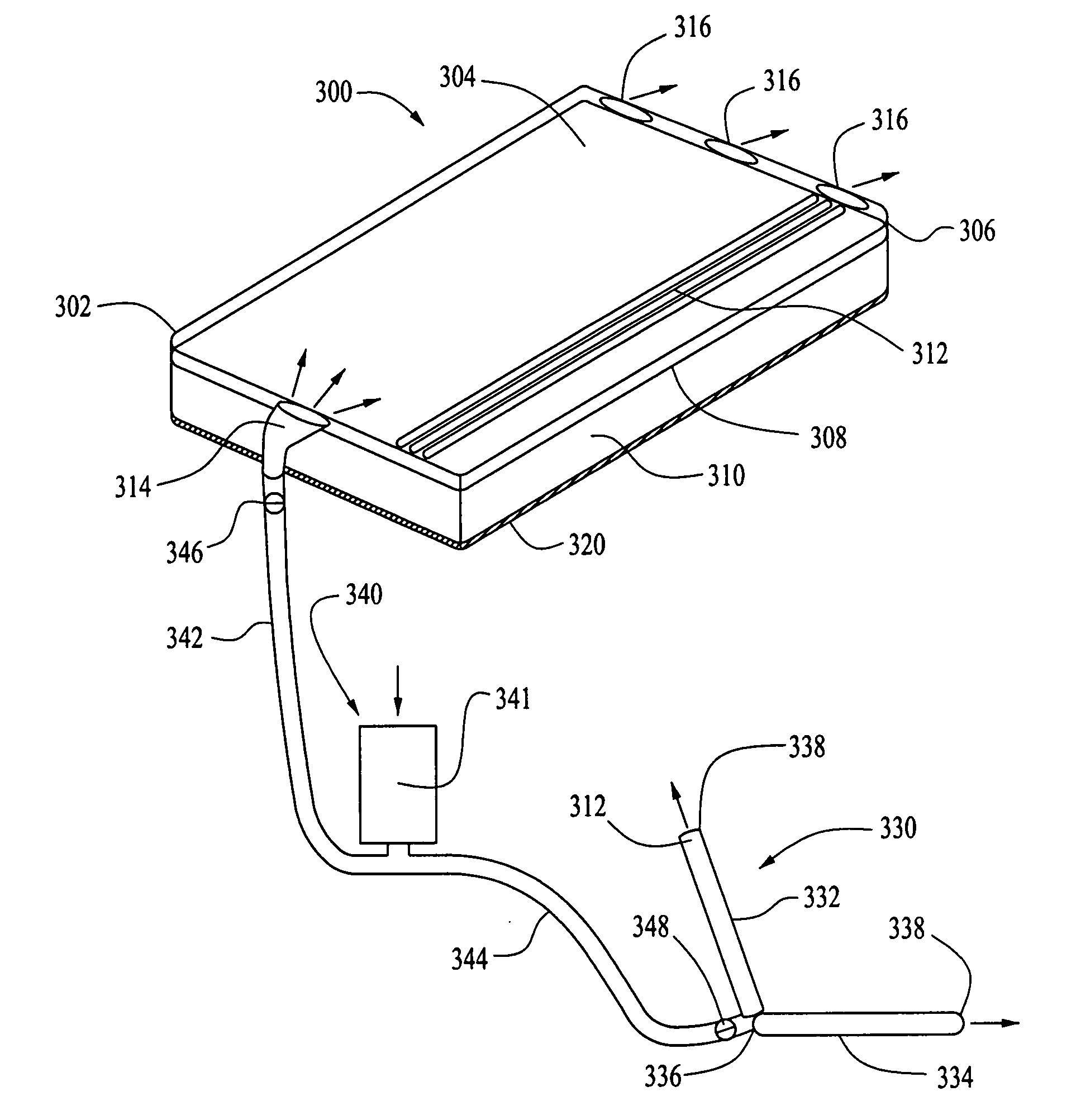

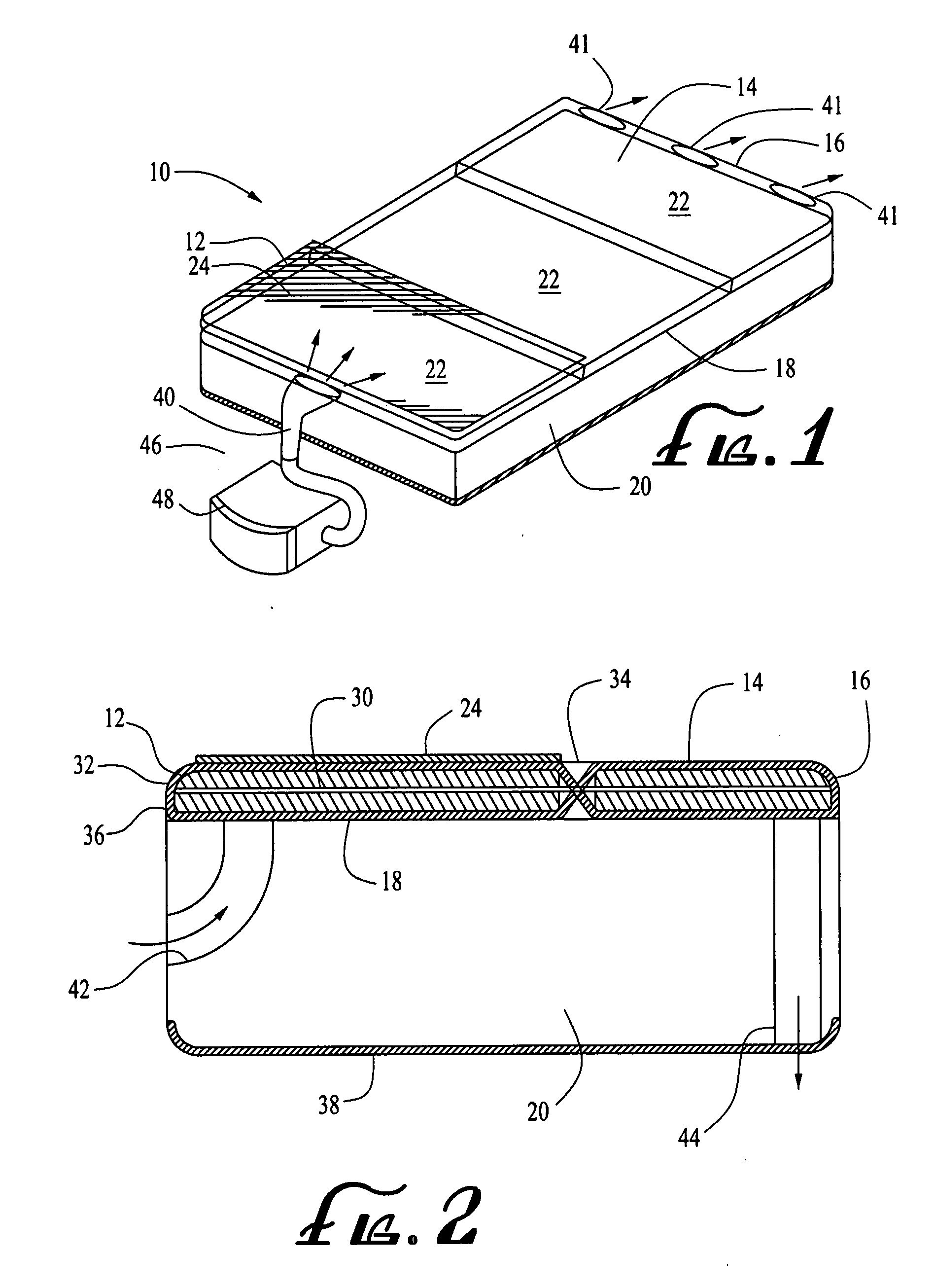

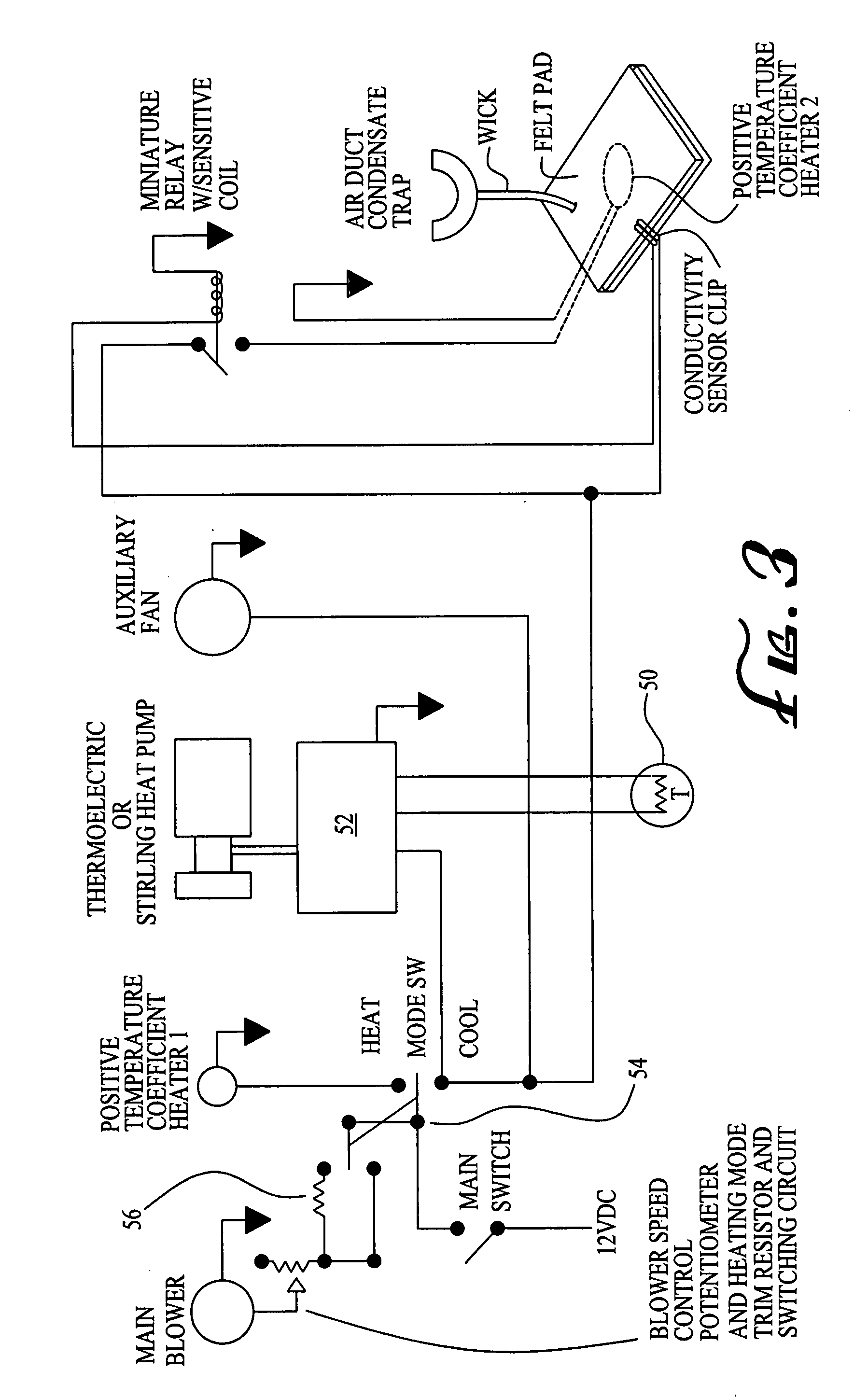

Multiple convective cushion seating and sleeping systems and methods

A multiple convective cushion seating and sleeping system for providing temperature modified air to multiple surfaces, such as a seating surface and a sleeping surface, with the same air cooling or heating source. The invention includes the use of tubular spacer material including tubular spacer fabric. A power unit including a heat pump and blower is in fluid communication with a first convective cushion by a first duct and with a second convective cushion by a second duct to provide the temperature modified air to both convective cushions for controllably heating or cooling multiple users. A thermoelectric heat pump, a Stirling cycle heat pump or other type of heat pump can be used. The invention includes the use or one or more valves to control the air flow to one or more of the convective cushions and provides for manual operation, electronic control and operation by a remote telecommunications unit. The invention can be utilized in vehicles, such as tractor trailers and recreational vehicles, and in buildings such as apartments, dorm rooms and houses.

Owner:FEHER STEVE

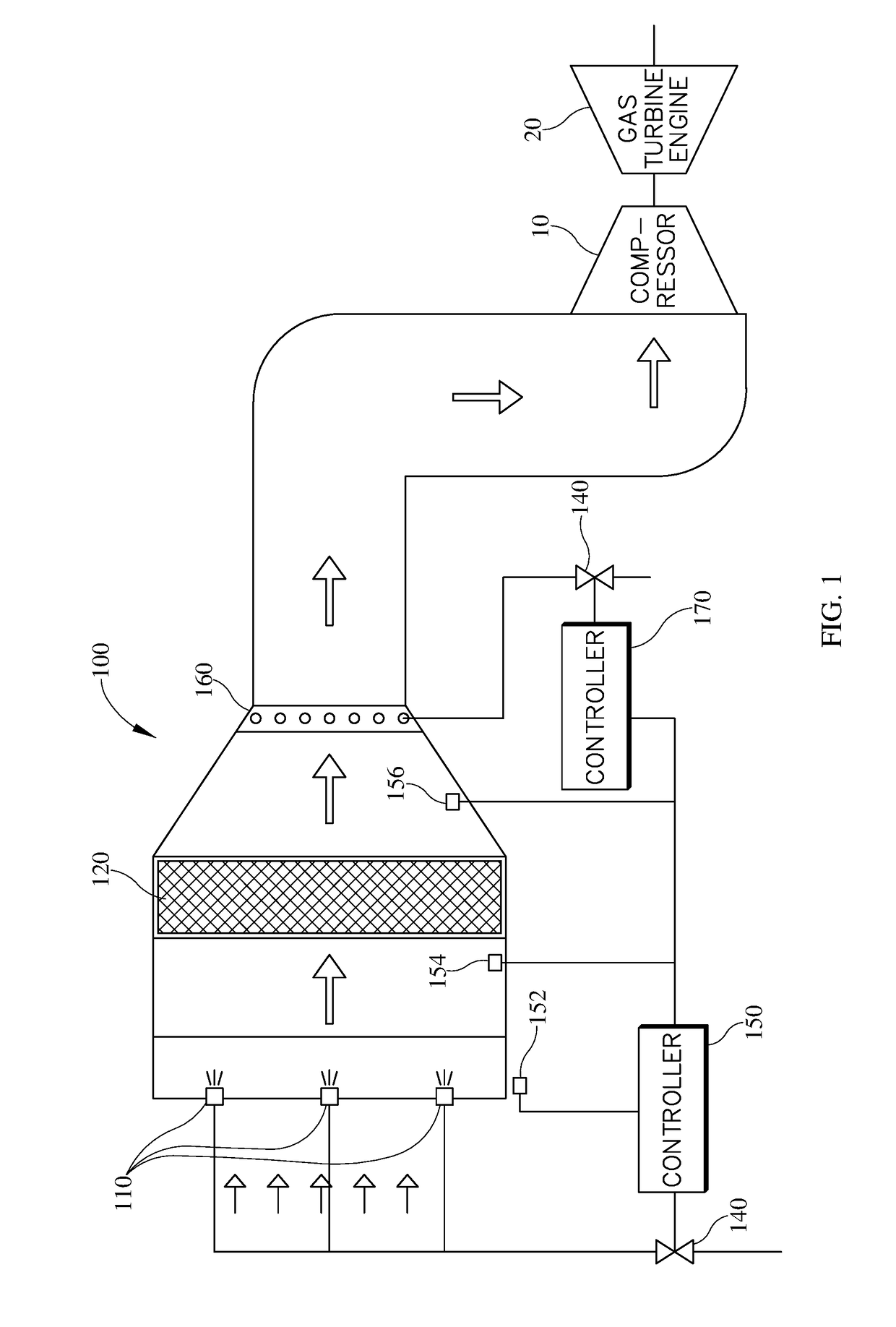

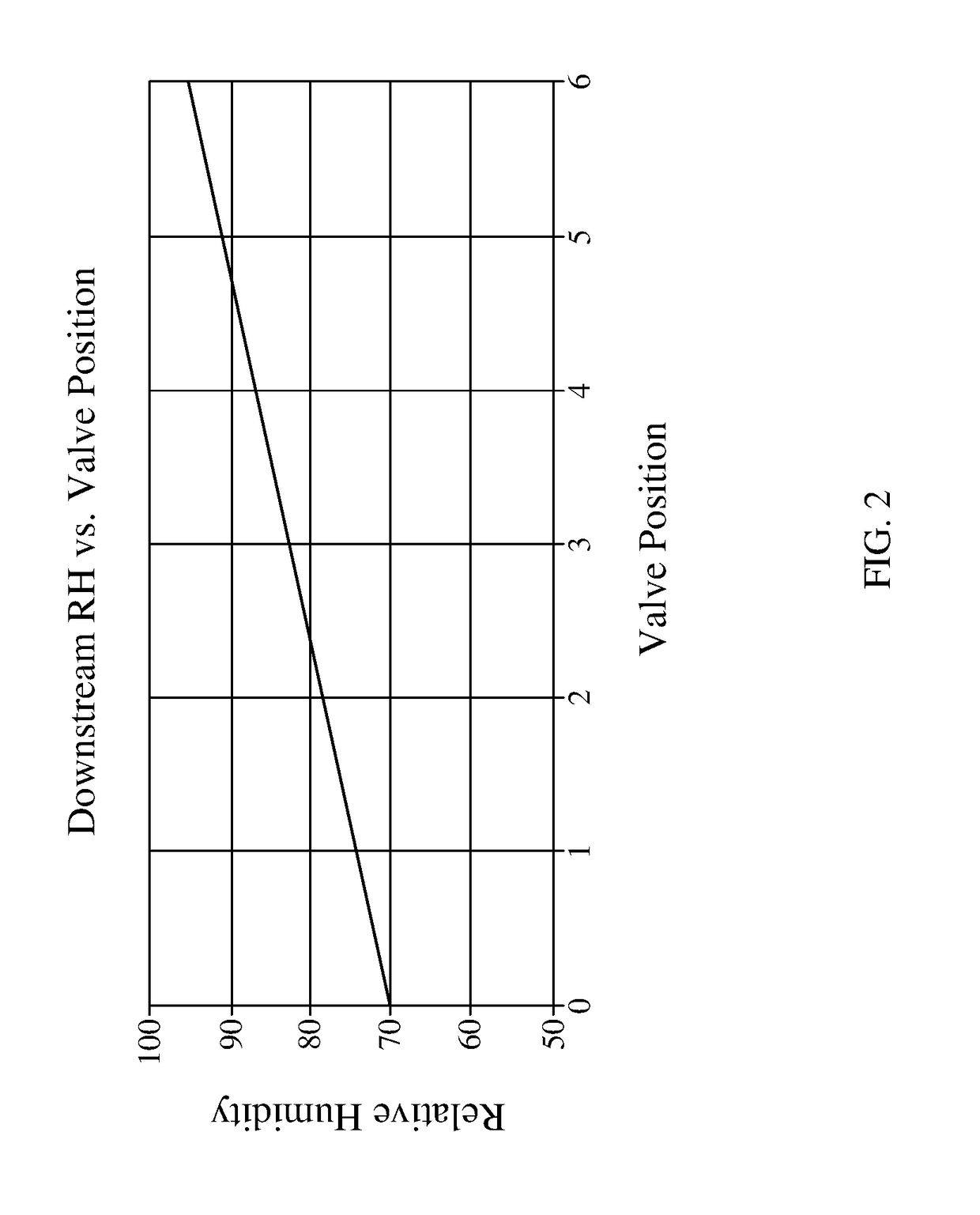

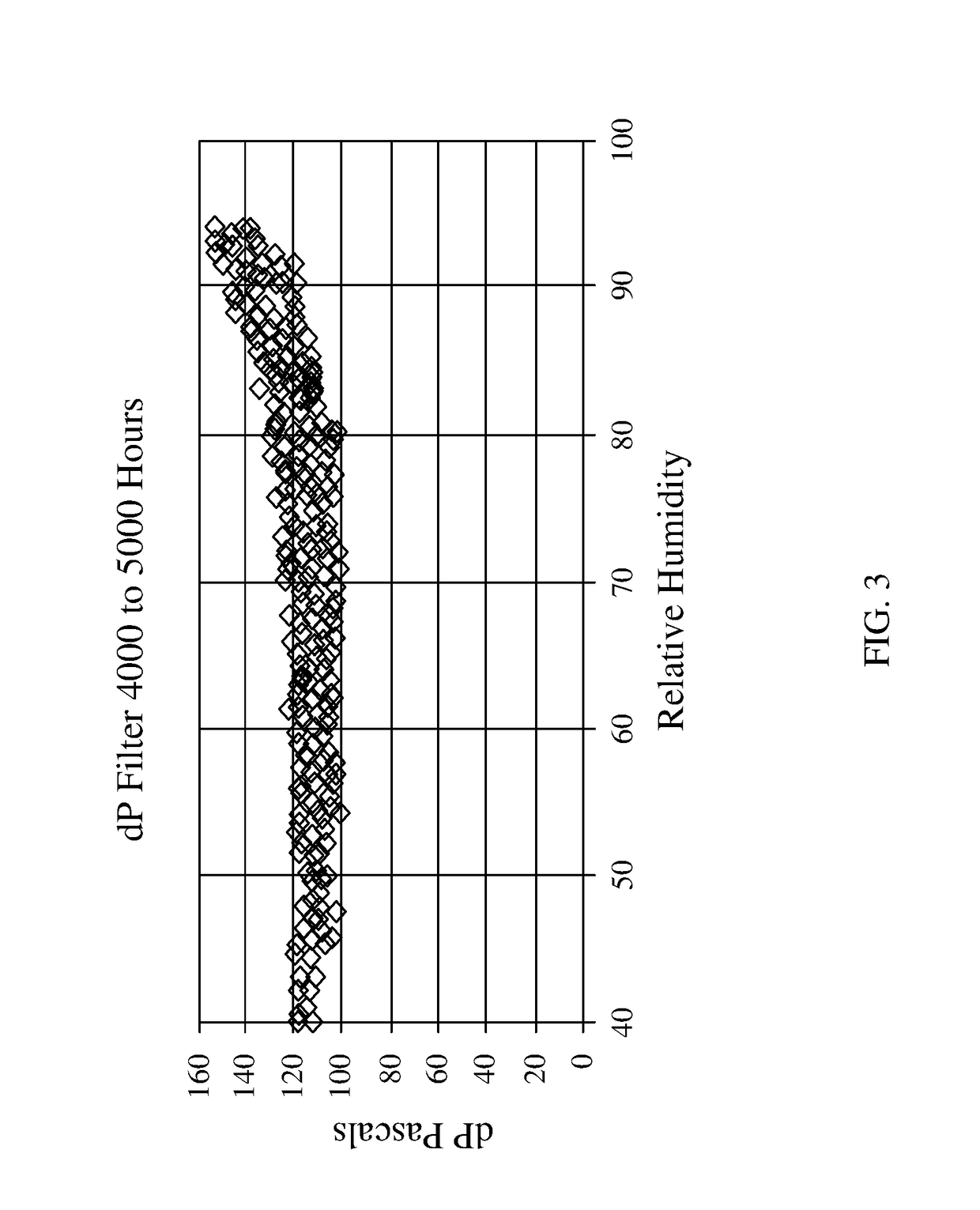

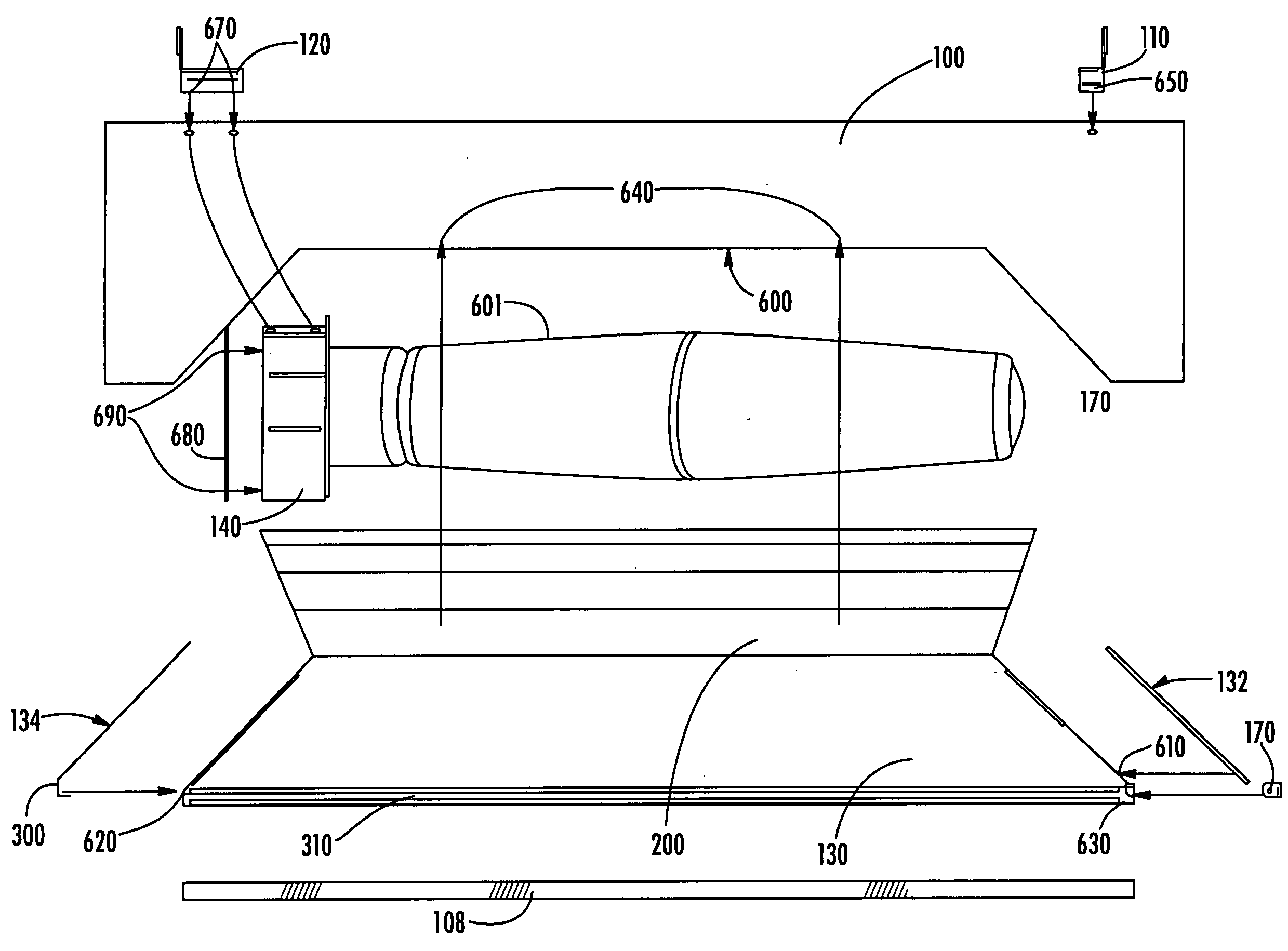

System for reducing inlet air temperature of a device

ActiveUS20180172294A1Reduce device temperatureSimple nozzle designCoolant flow controlLighting and heating apparatusBiomedical engineeringAir temperature

The present embodiments disclose a system (100) for reducing inlet air temperature of a device, comprising: a fogging system that provides air cooling, wherein the fogging system comprises at least one low pressure atomiser (110).

Owner:AAF LTD

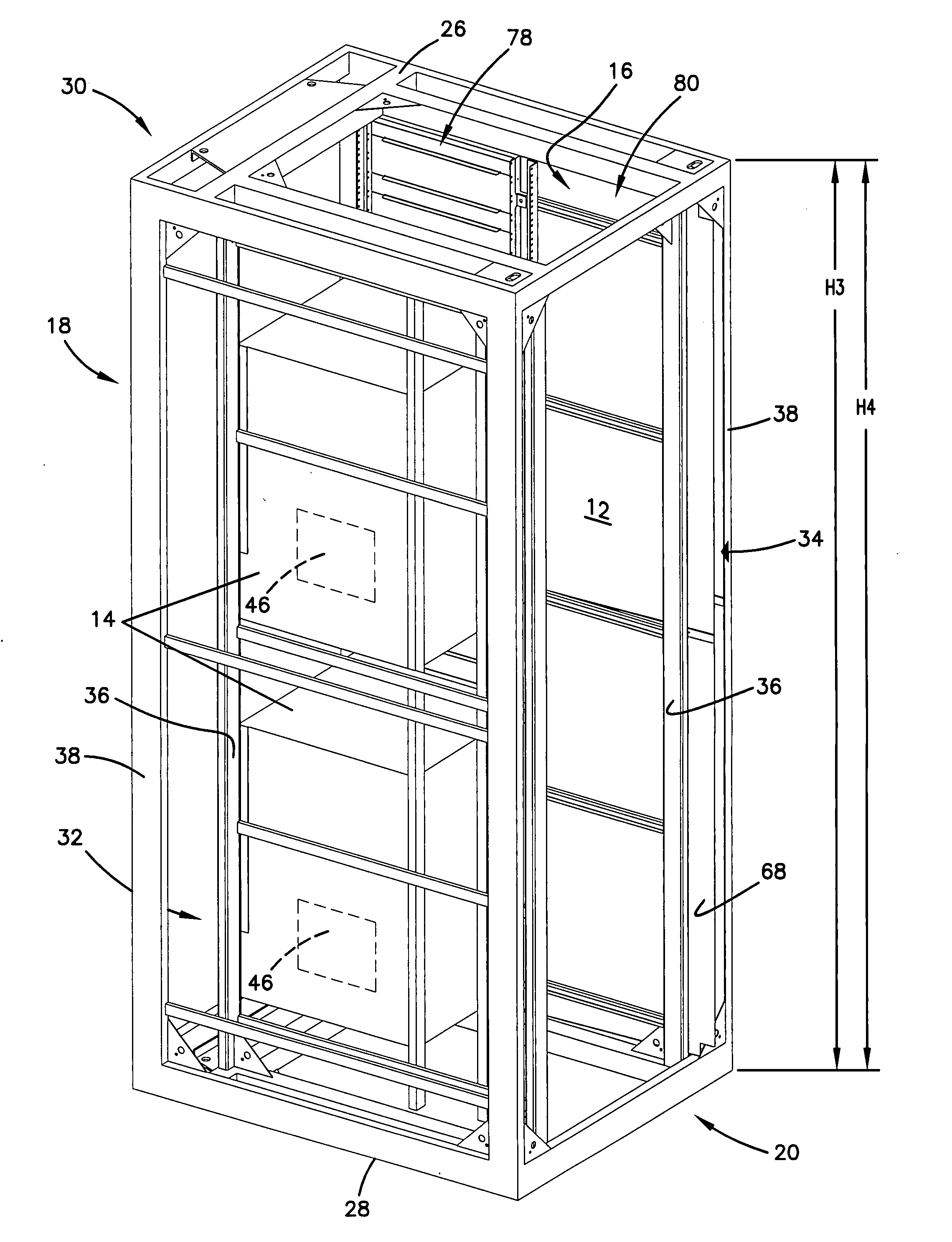

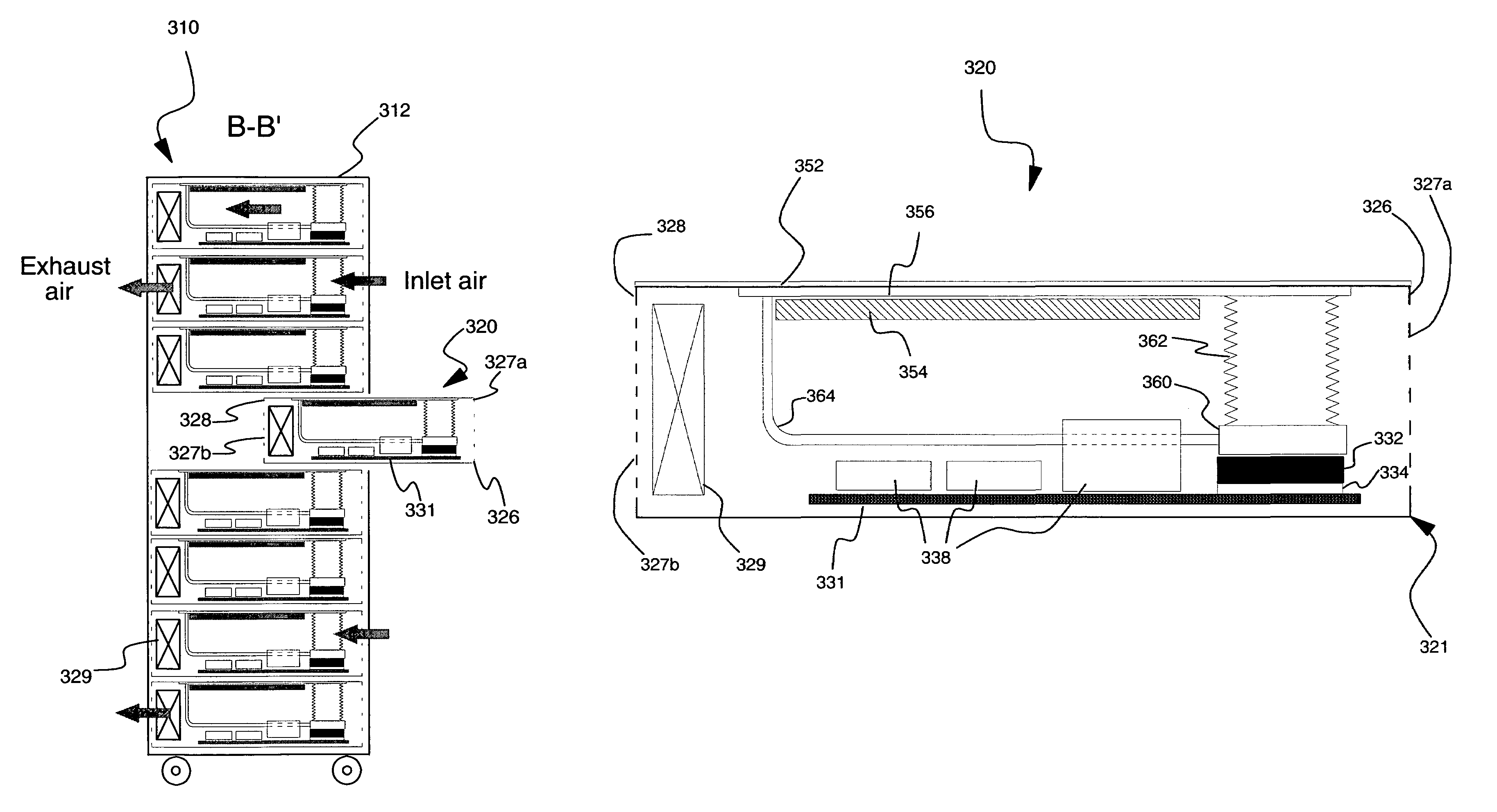

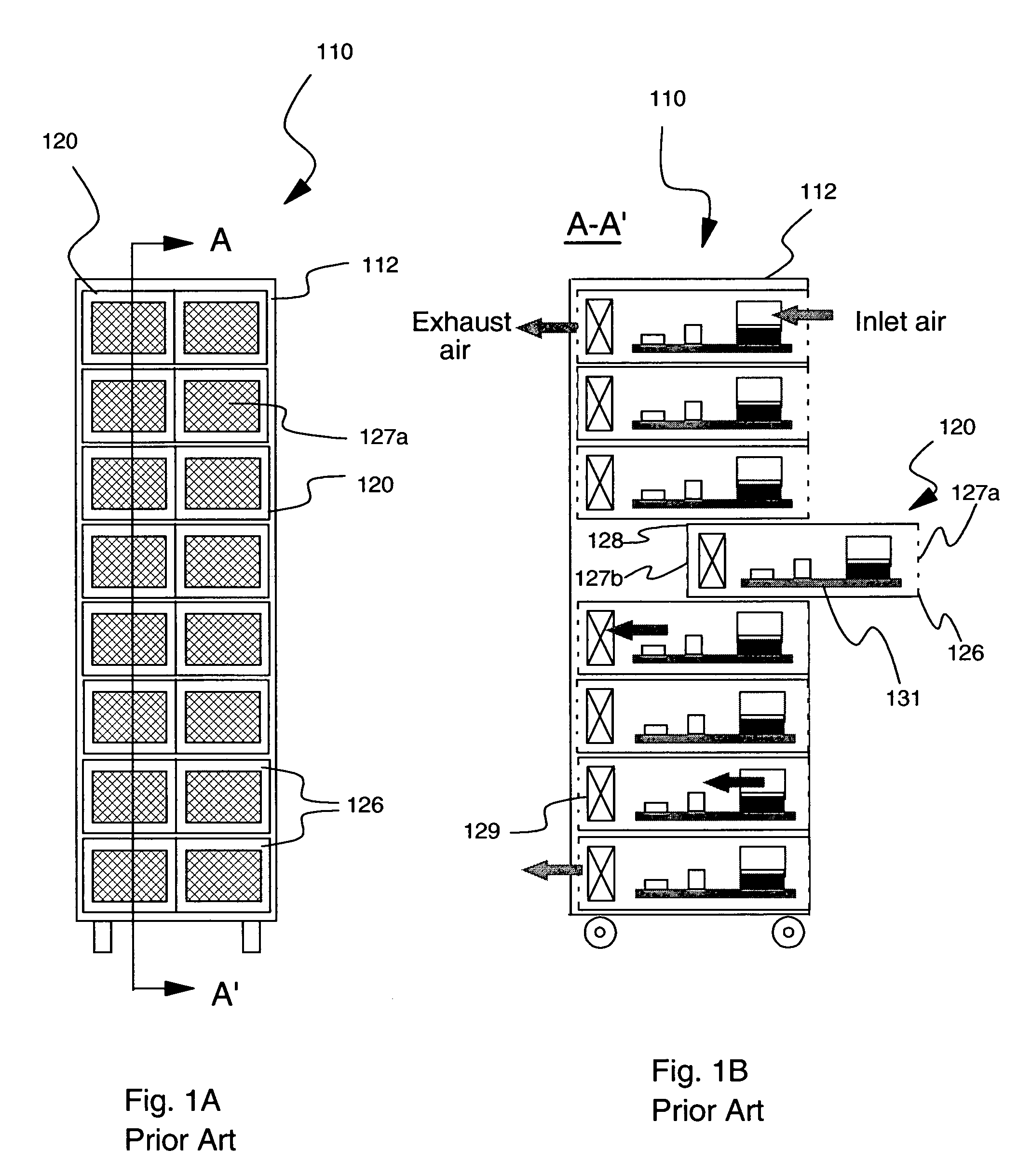

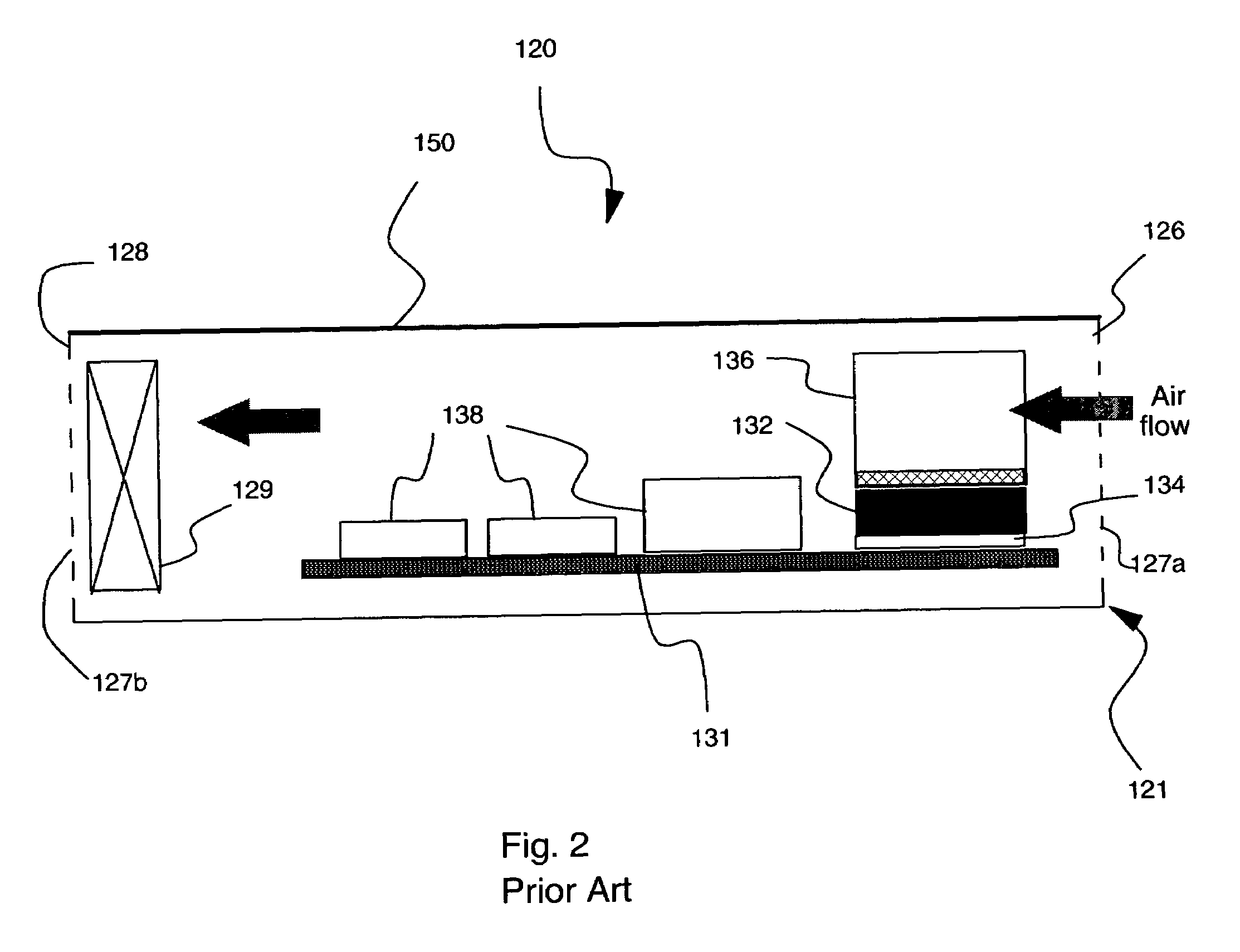

Telecommunication cabinet with airflow ducting

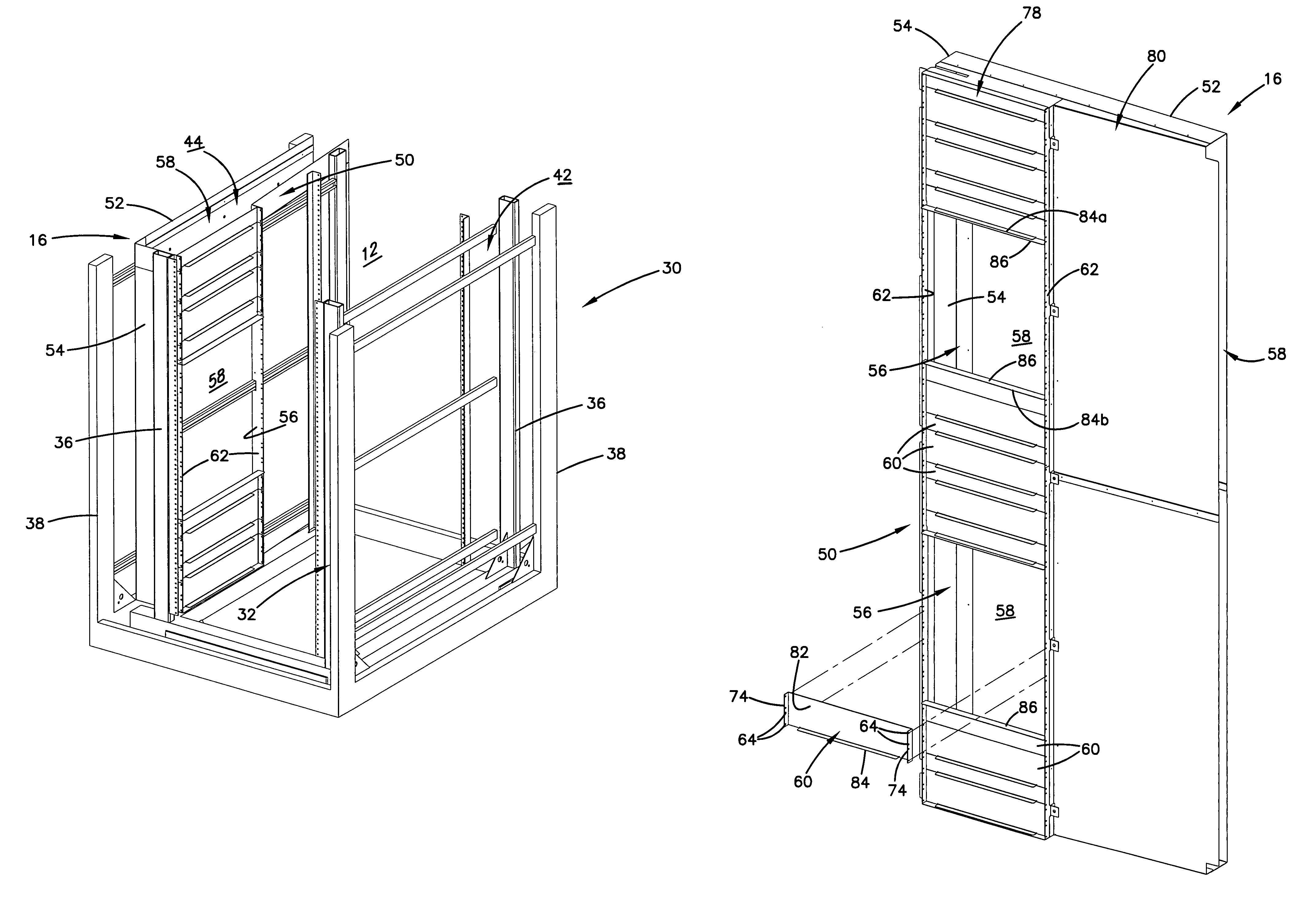

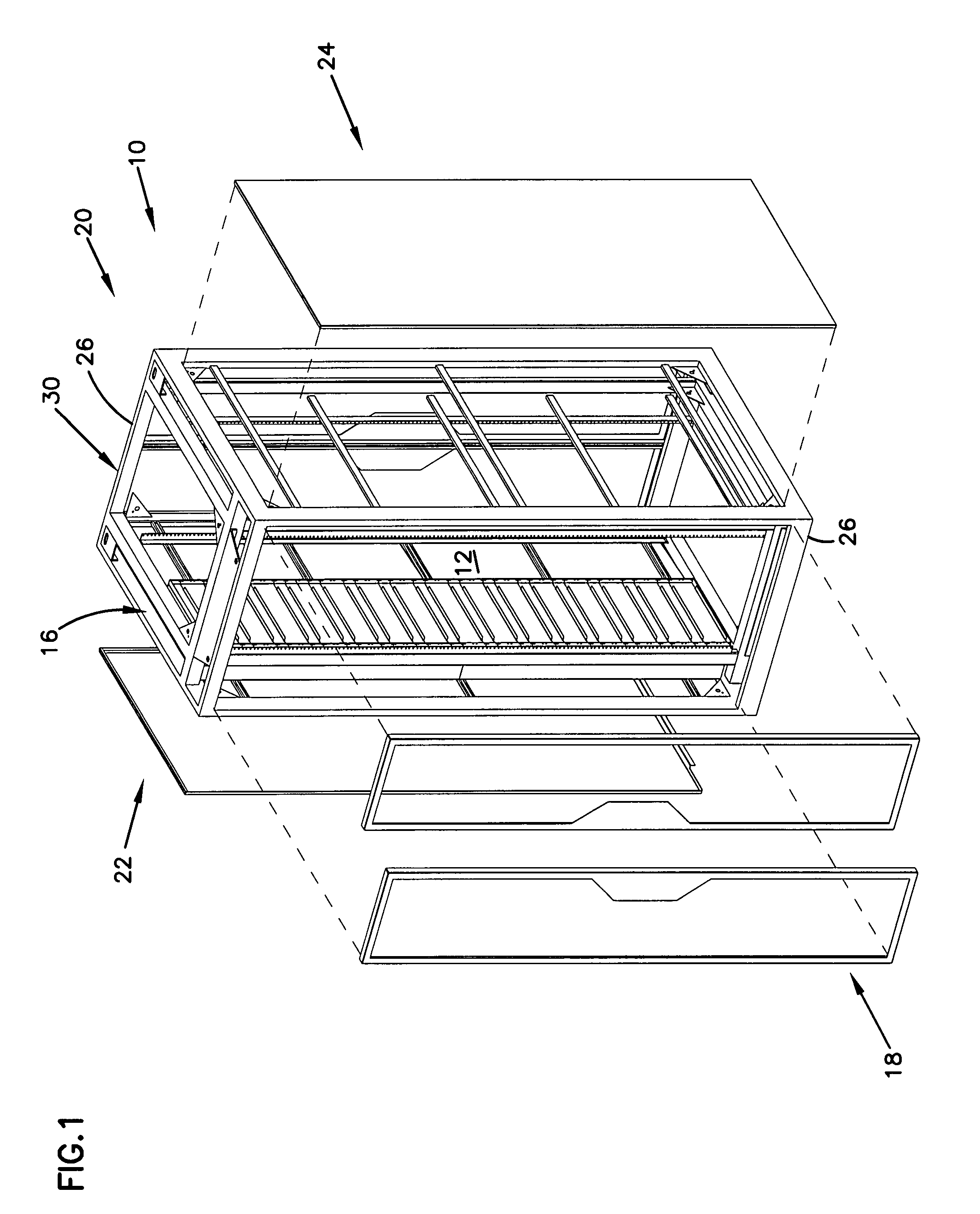

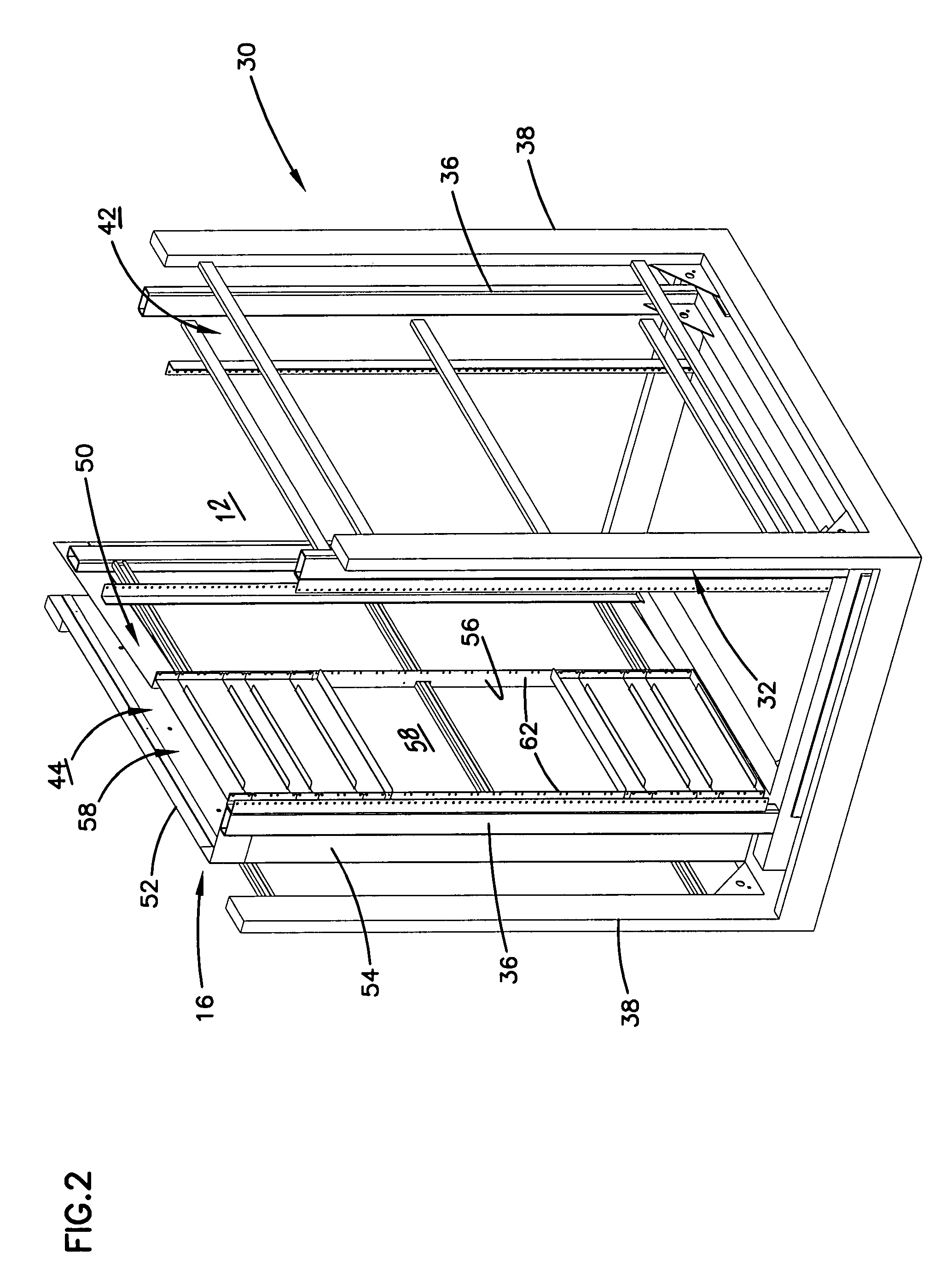

InactiveUS20080266789A1Metal working apparatusShow shelvesElectrical and Electronics engineeringAirflow

A telecommunications cabinet in which active equipment can be mounted. The cabinet including an airflow ducting arrangement located in the interior region of the cabinet. The airflow ducting arrangement accommodating thermal cooling of active equipment having internal side-to-side air cooling arrangements.

Owner:COMMSCOPE TECH LLC

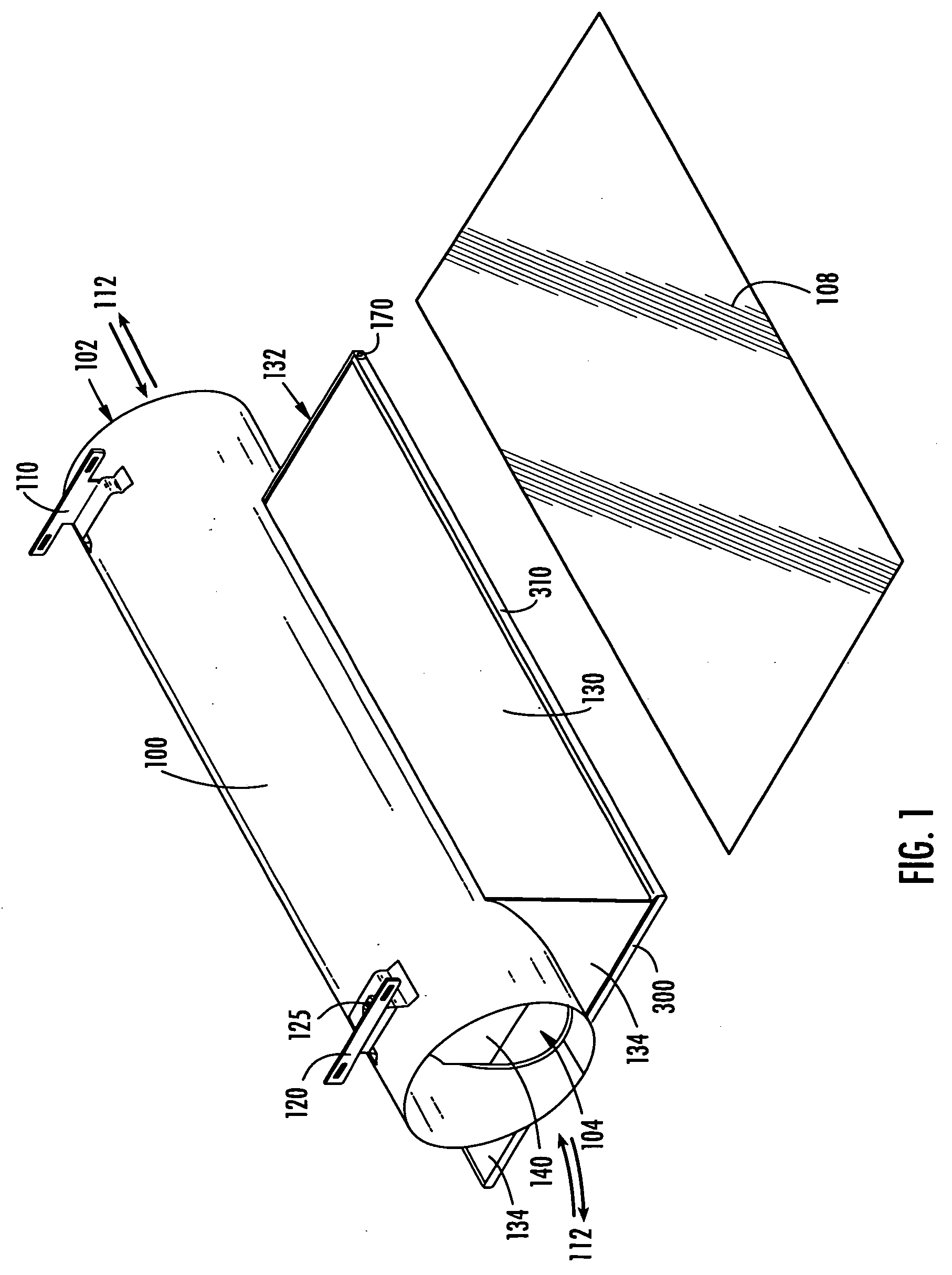

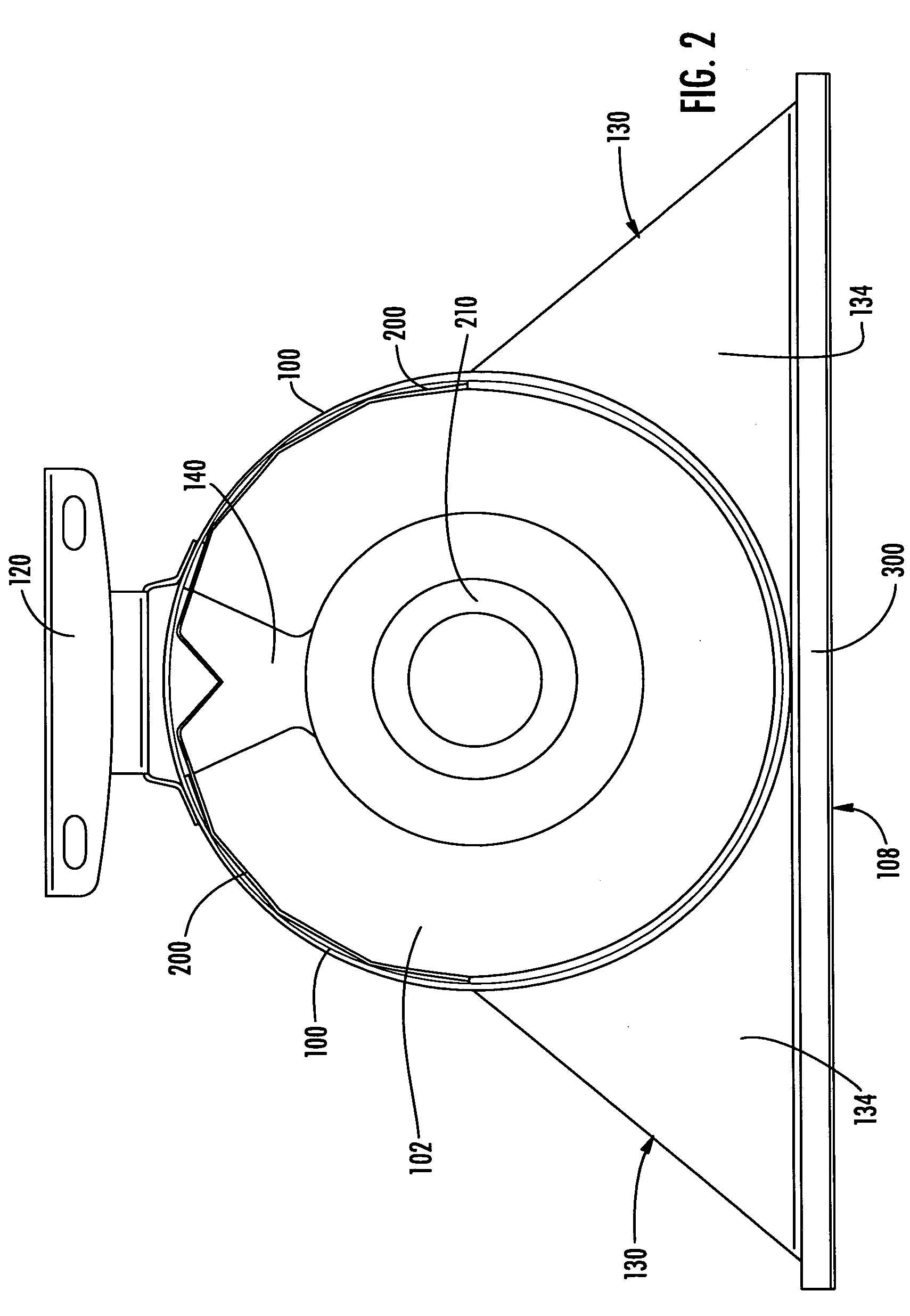

Forced air cooled metallic tubular horticulture light fixture

InactiveUS20080117617A1Sufficient forced air flowAvoid insufficient lengthElectrical apparatusClimate change adaptationForced-airEngineering

A horticultural light fixture for reducing the temperature impact of the light source on growing plants, including a hollow sheet metal tube, having first and second round hollow ends and a cutaway portion on the underside open towards the plants with at least one lamp socket mounted within said metallic tube, locating the lamp over the cutaway portion, further including a reflector mounted within the metallic tube and extending out through the cutaway portion, constructed and arranged to deflect light from the lamp toward the plants, having a transparent portion fittingly attached to the reflector between the lamp and the plants being impermeable to the heated atmosphere while allowing light to pass through.

Owner:IP HLDG LLC

Cooled electronics system and method employing air-to-liquid heat exchange and bifurcated air flow

Owner:INT BUSINESS MASCH CORP

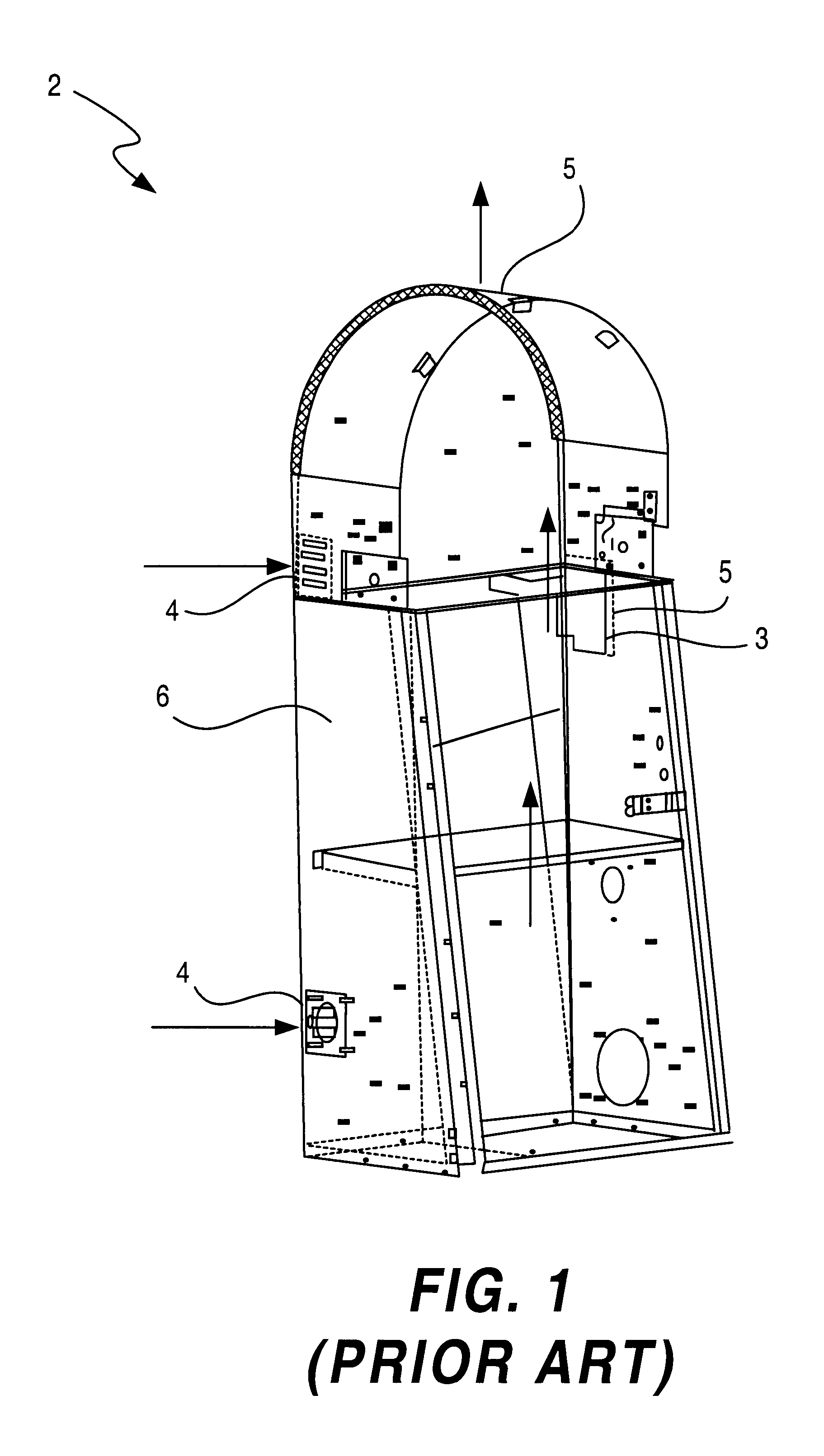

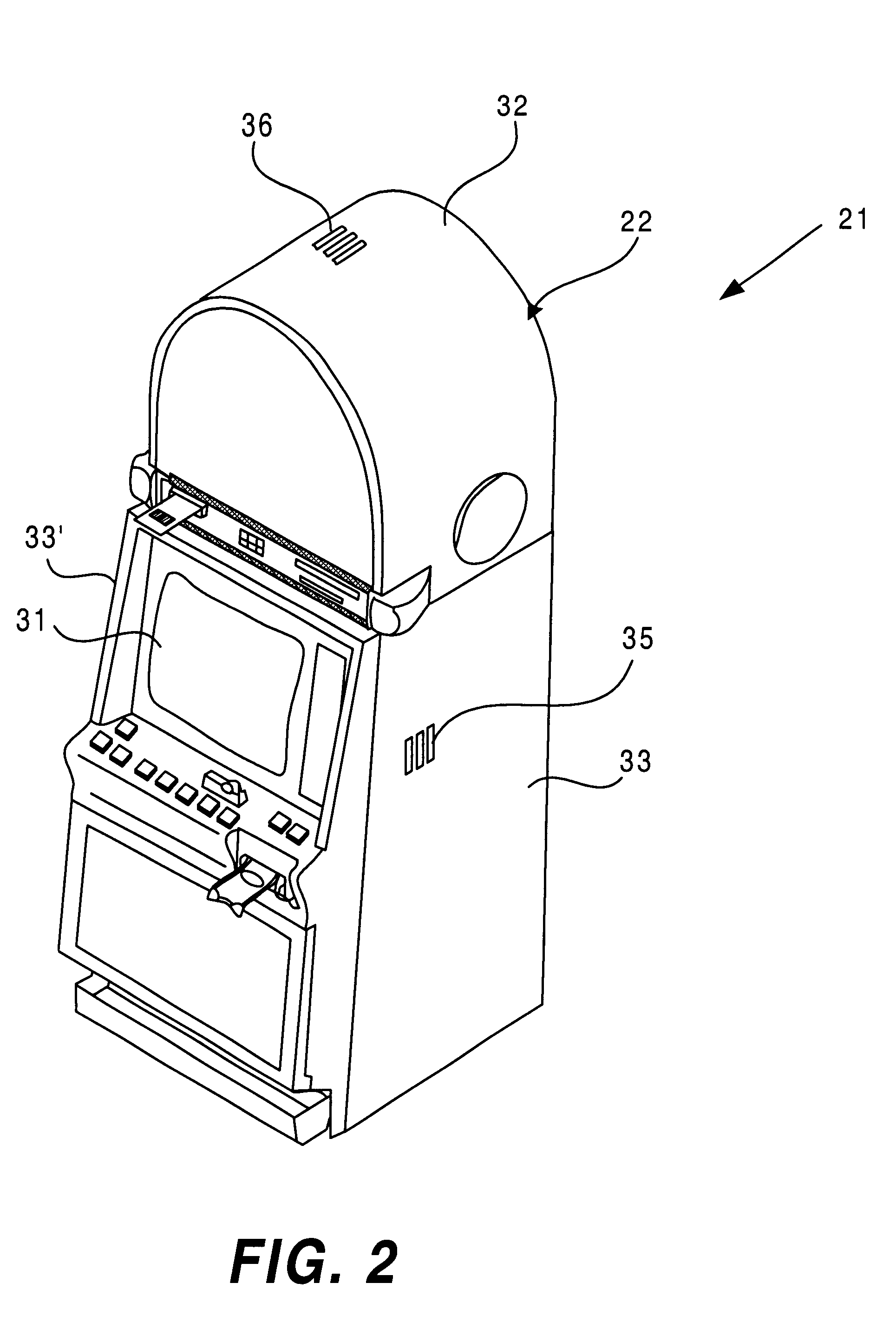

Central forced air cooling of a gaming machine

InactiveUS6280318B1Reduce exposureImprove cooling effectApparatus for meter-controlled dispensingCooling/ventilation/heating modificationsFresh airCentral force

A system and method is provided for cooling a gaming machine. The cooling system includes an air flow assembly which draws fresh air from outside the gaming machine. The air flow assembly provides the fresh air to a set of ducts. The set of ducts channel the fresh air to one or more internal components of the gaming machine. The cooling system may also include an inlet duct to channel air from outside the machine to the air flow assembly and filters for cleaning the air entering the gaming machine.

Owner:IGT

Water management in bipolar electrochemical cell stacks

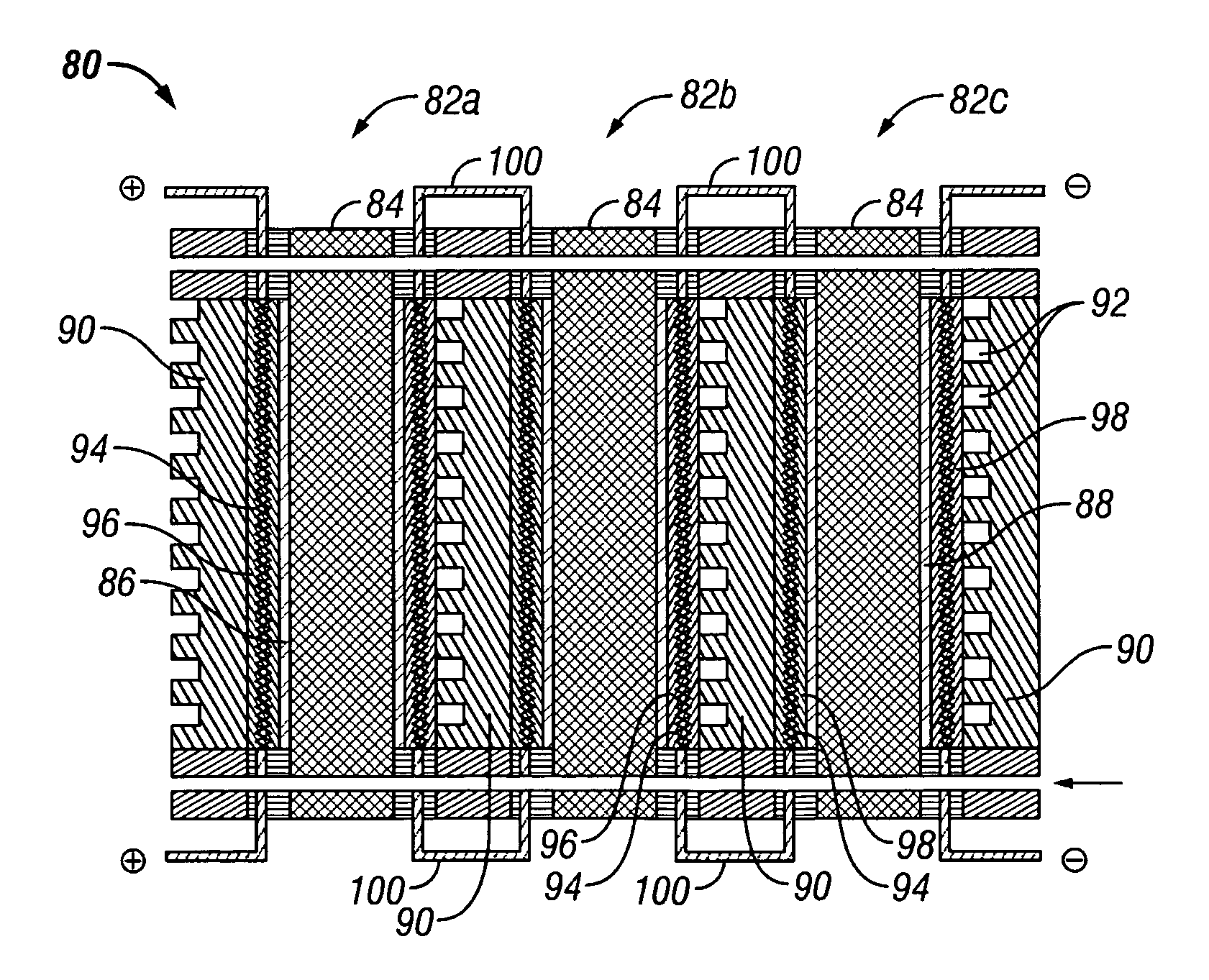

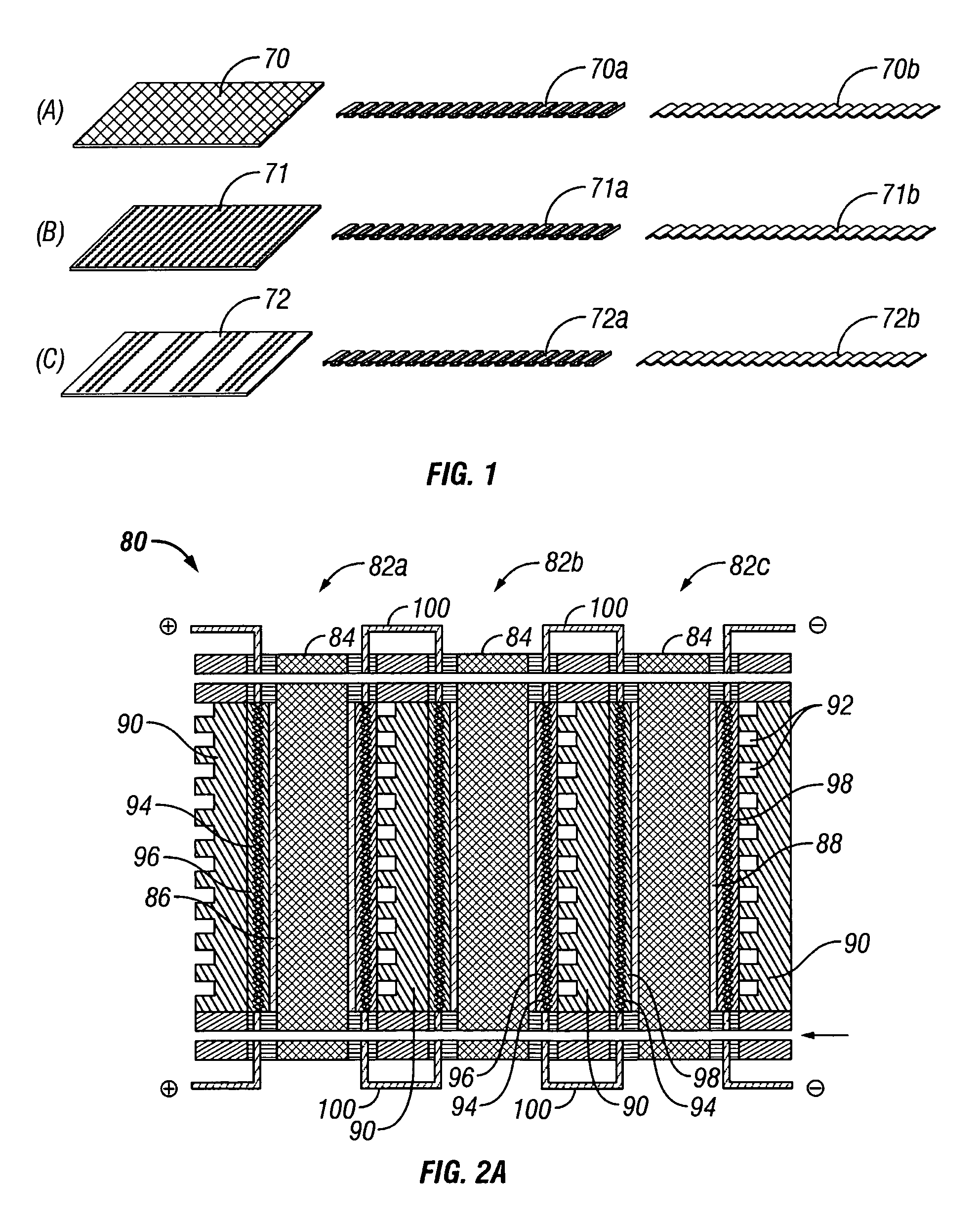

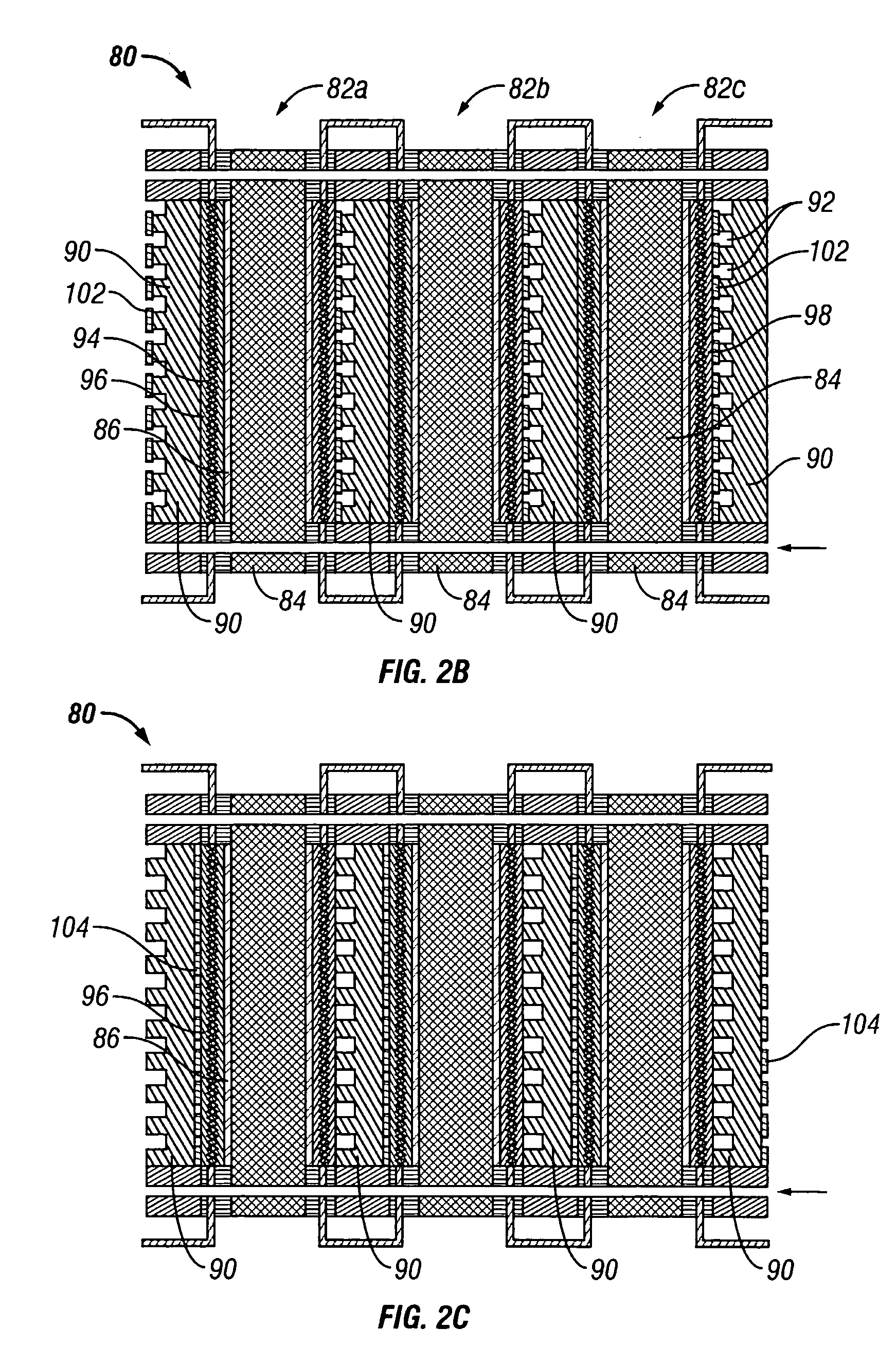

InactiveUS20060199061A1Reduce probabilityPromote loss of waterFuel cells groupingWater management in fuel cellsPolymer electrolytesLiquid water

A bipolar, filter press-like electrochemical cell stack comprising a plurality of electrochemical cells, where each electrochemical cell is supplied with a gaseous anodic reactant and either supplied with a gaseous cathodic reactant or produces a gaseous cathodic product, and where each electrochemical cell avoids drying out the ion exchange membrane polymer electrolyte, avoids flooding at the cathode, facilitates recovery of liquid water at the anode, and reduces water losses from at least one of the electrodes. A water retention barrier is variously positioned, such as between a gas diffusion electrode and a fluid flow field. The barrier may be either: (i) a thin, gas permeable, liquid water impermeable membrane; (ii) a thin, porous sheet of material; or (iii) a thin, substantially solid sheet of material except for a plurality of small through-holes that penetrate from one side of the sheet to an opposing side of the same sheet. The barrier is advantageously used at the cathode and facilitates air cooling of the cell.

Owner:LYNNTECH

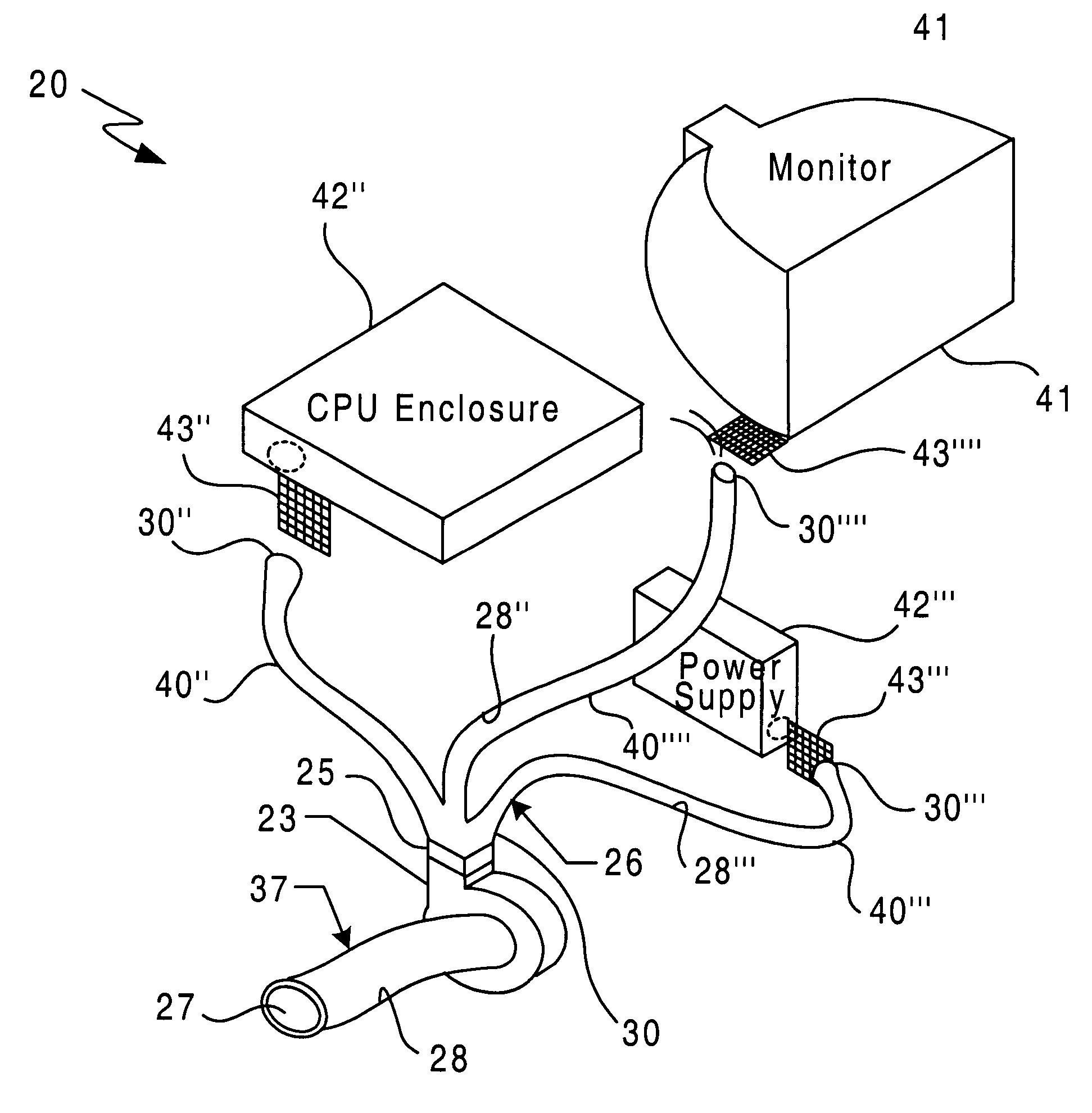

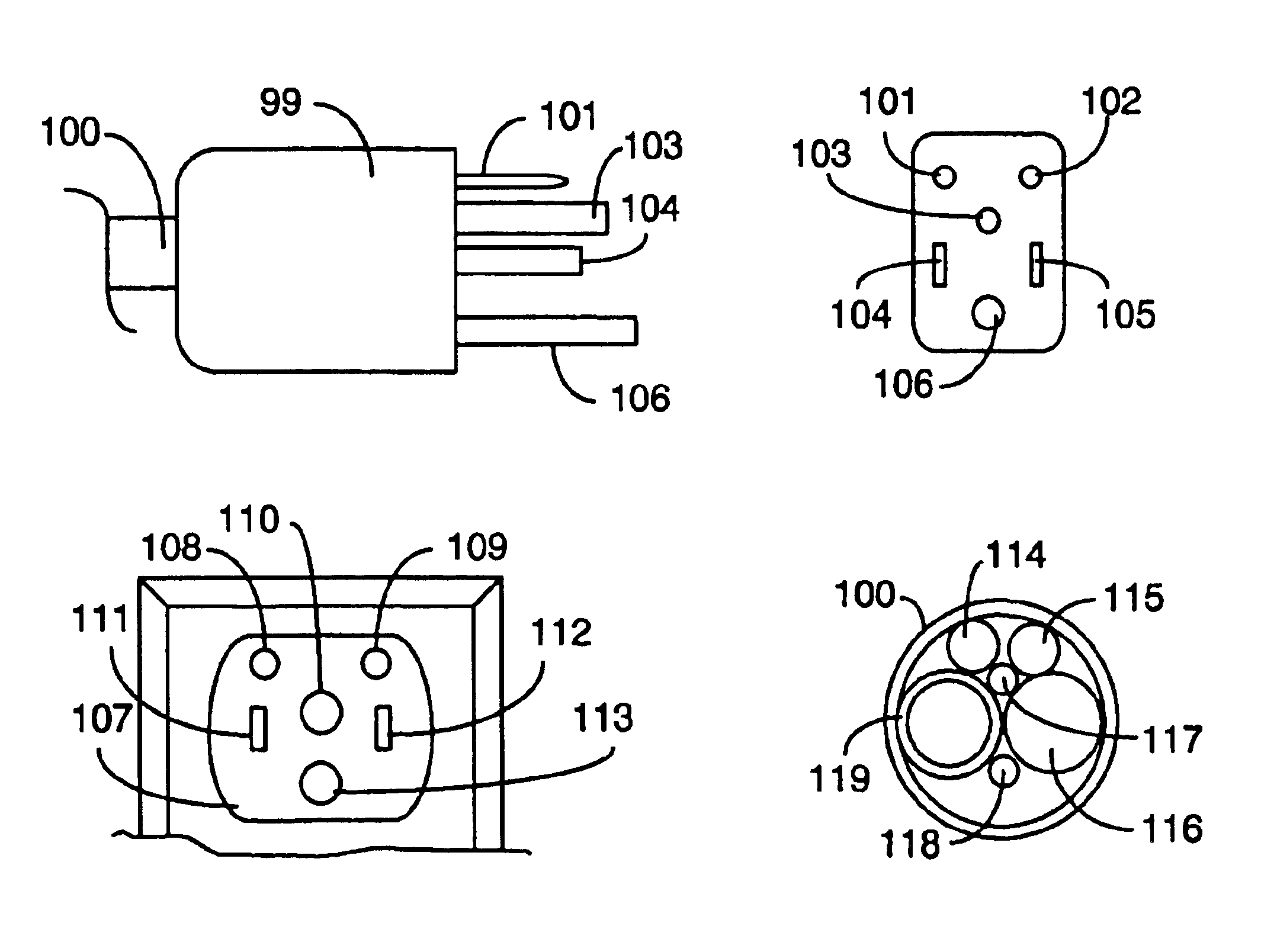

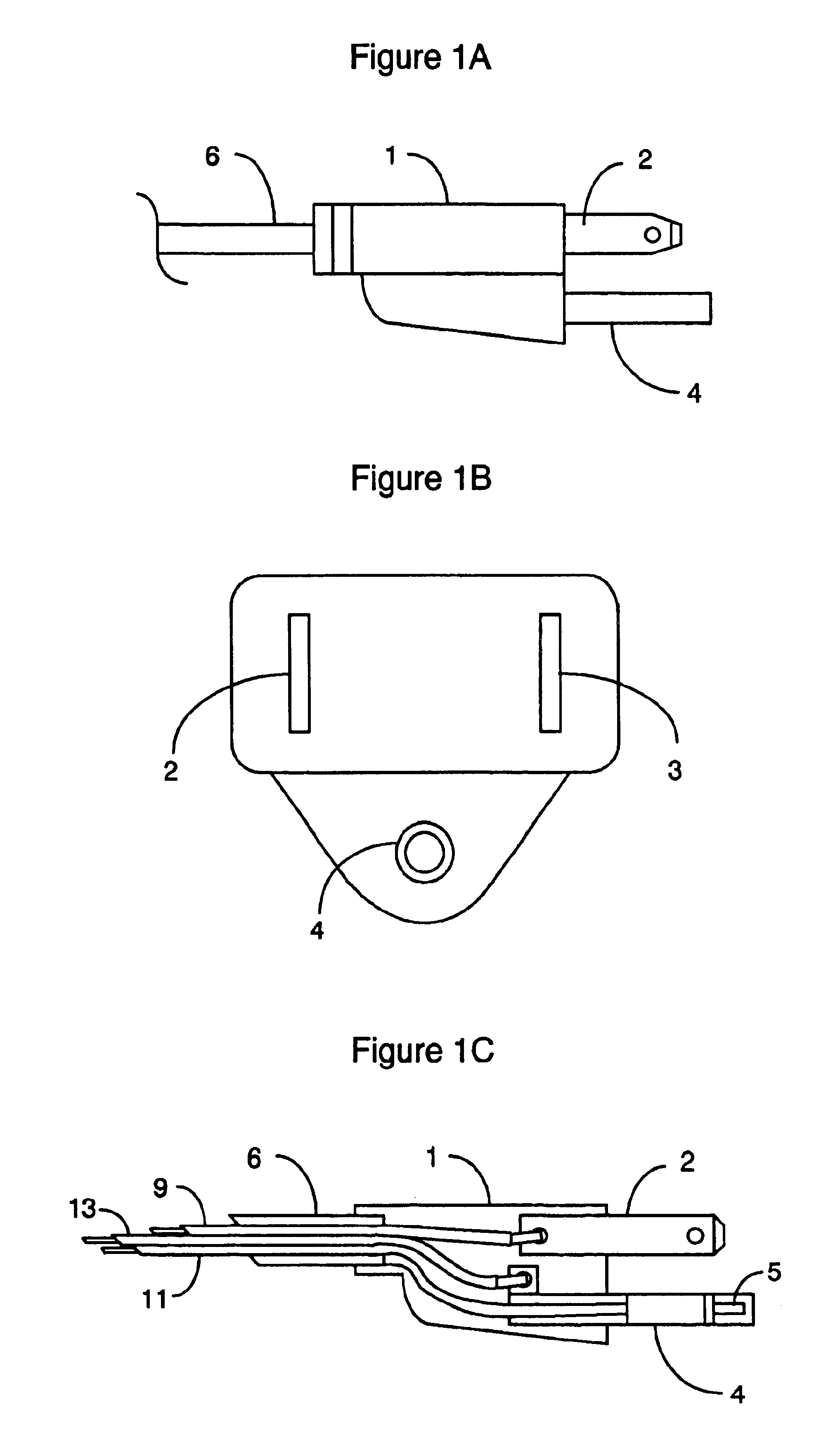

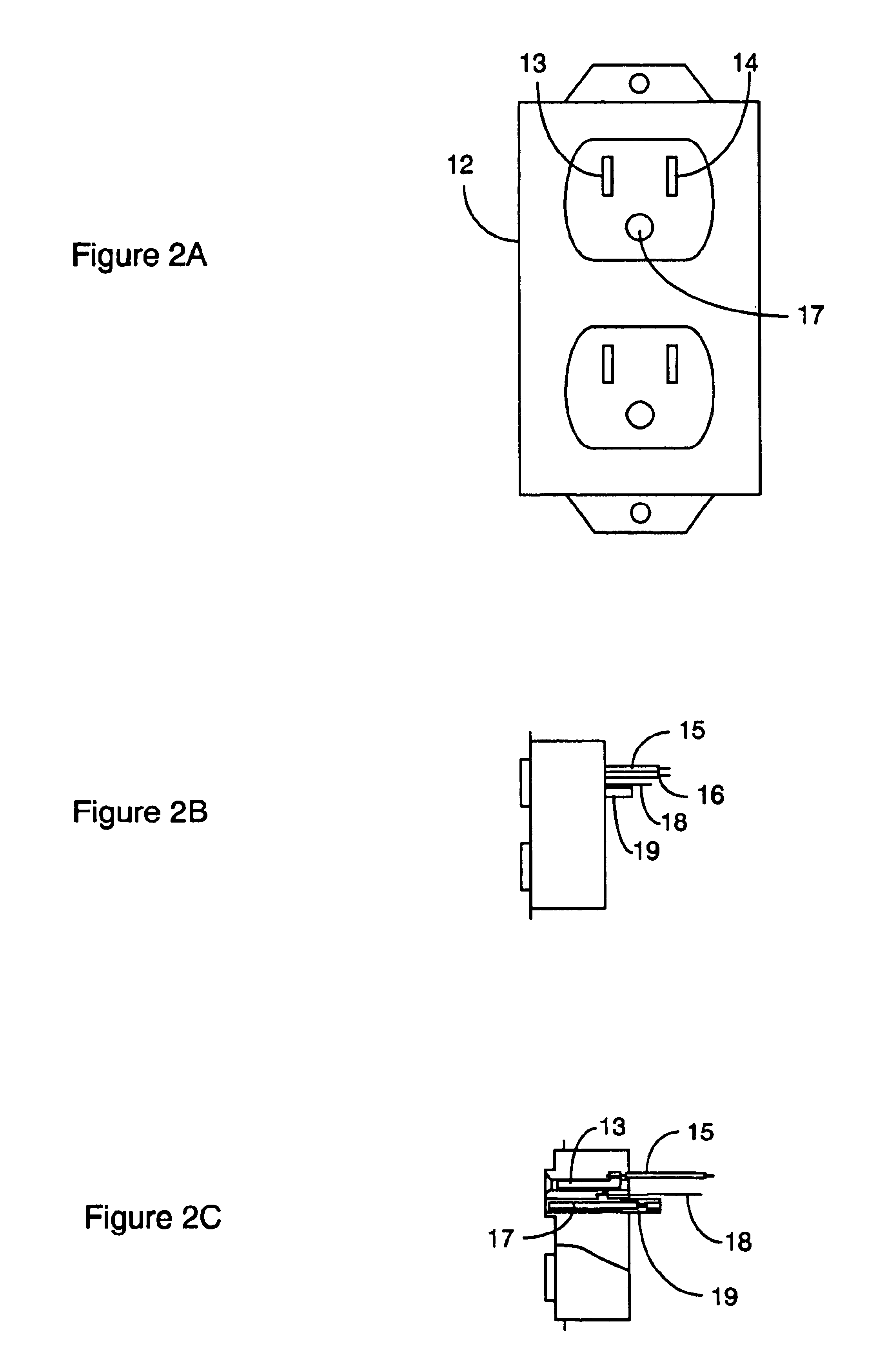

Combined communication and power cable with air cooling for network systems

InactiveUS6855881B2Guaranteed ease of connectionSimple interconnectTwo pole connectionsBase element modificationsFiberNetworked system

A multifunction power / data distribution system which consists of a cable system that provides power, data, and air cooling from a single wall outlet. Each device, has a single cable which brings power, data, and / or cooled air to that device. The system includes an appliance coupler assembly which may incorporate a fiber optics signal line, a coax cable, a cooled air supply line, and / or a telephone line. The data lines may be combined into a single high bandwidth line. Only a single cable is required to be run between the appliance coupler socket on the wall and an appliance, such as a PC, telephone, etc., to connect the appliance to an external power source, to a data network, to telephone network, or to a source of air cooling. The system provides for, and describes several types of, mating wall sockets and appliance end plugs.

Owner:KHOSHNOOD BAHMAN

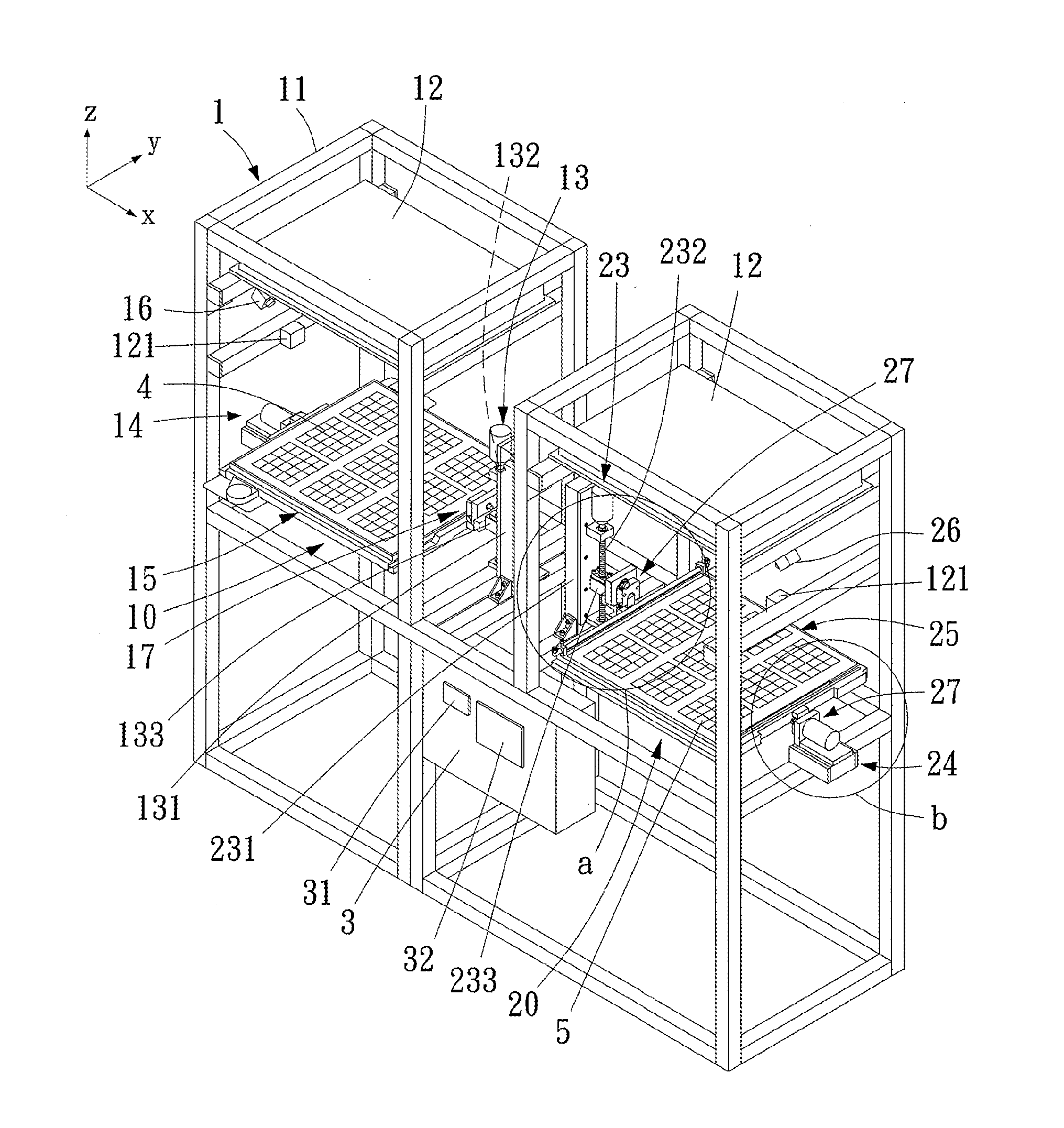

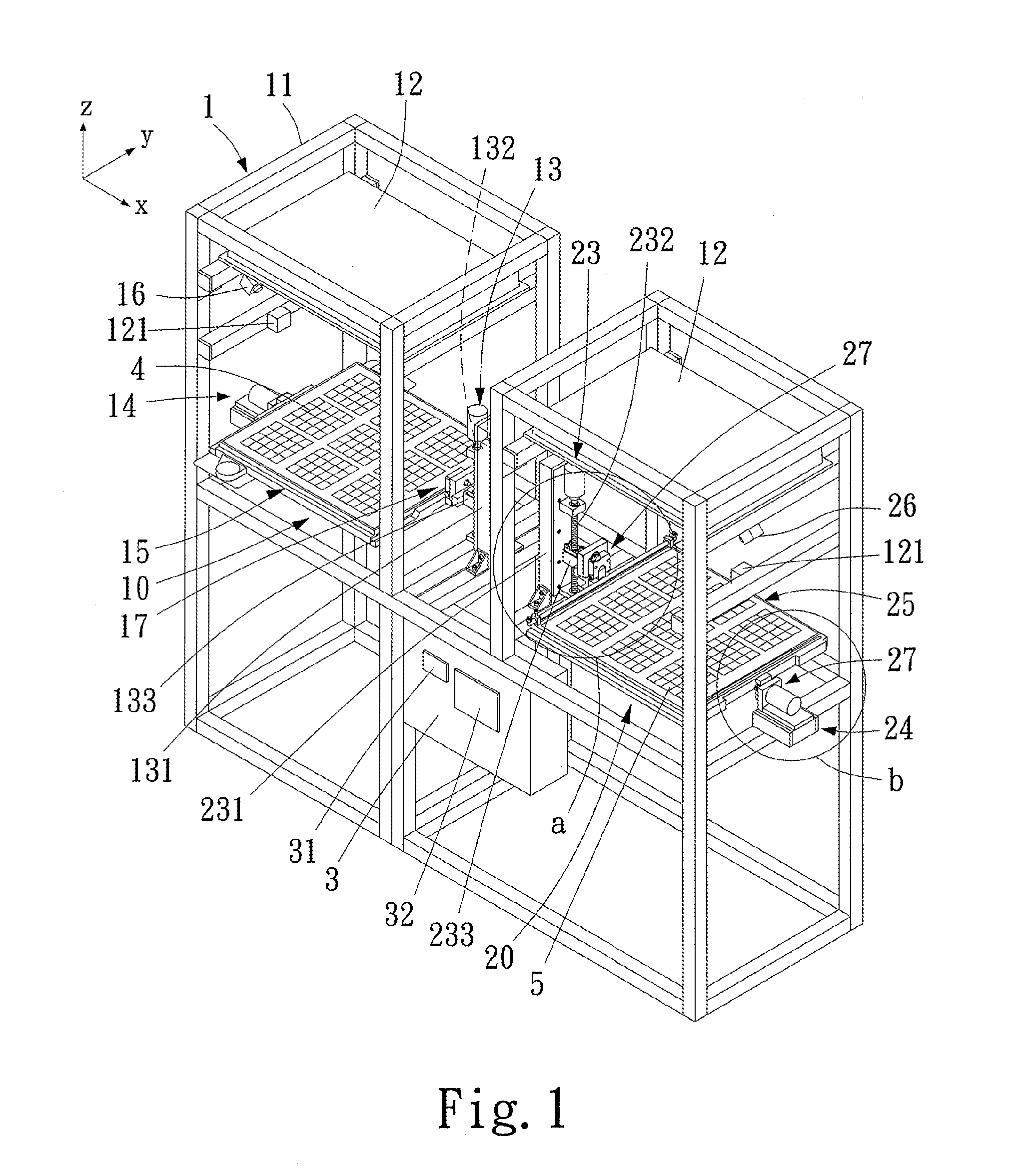

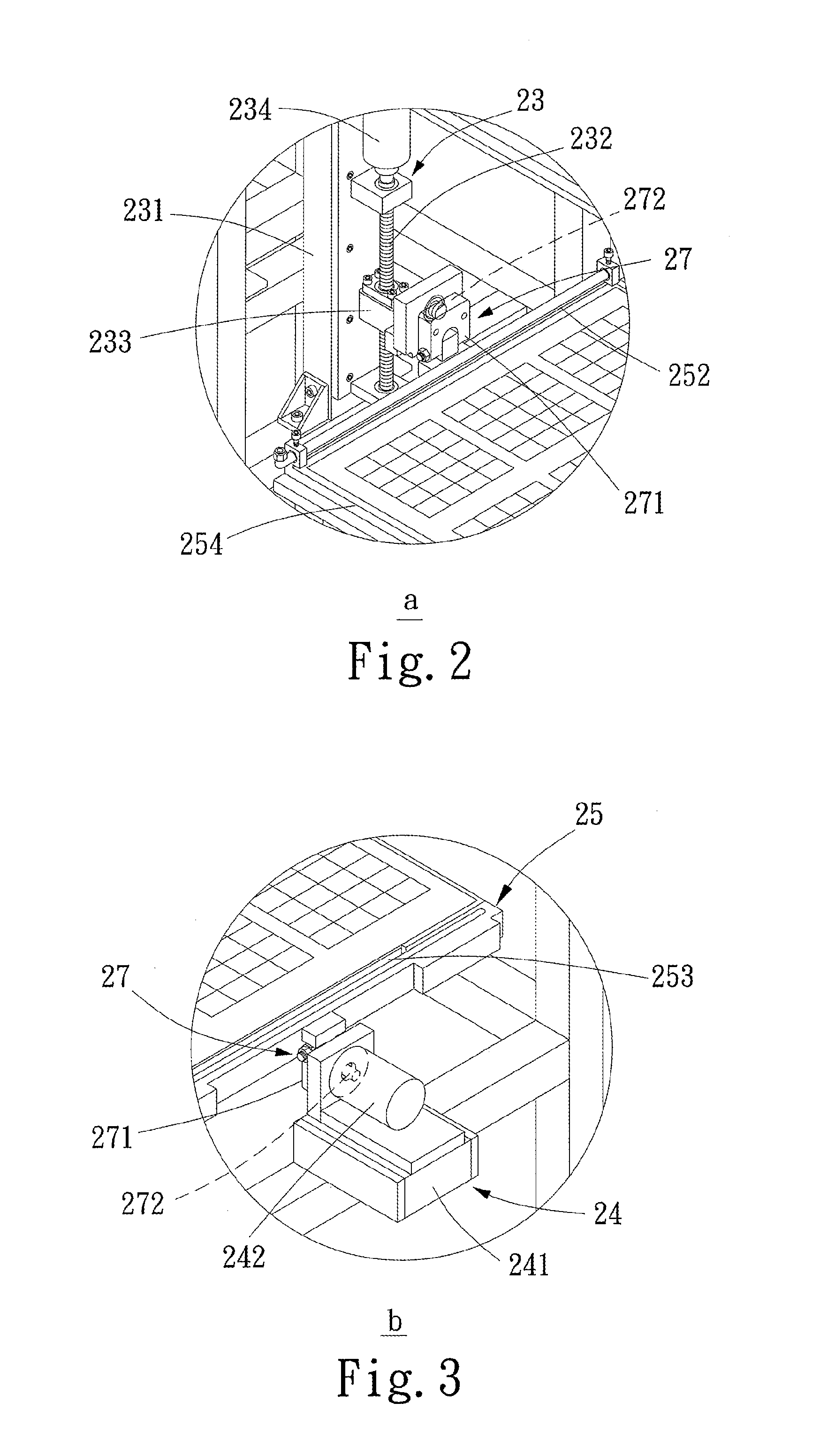

Solar Photovoltaic Panel Test Platform

InactiveUS20120133372A1Photovoltaic monitoringPhotovoltaic energy generationAngle of incidenceControl signal

A solar photovoltaic panel test platform includes a test section and a signal processing section. The test section has a frame, a light-emitting unit disposed on the frame, a first angle adjustment unit and a second angle adjustment unit arranged on the frame, an air-cooling unit mounted on the first angle adjustment unit for connecting with a first solar photovoltaic panel, and a water-cooling unit mounted on the second angle adjustment unit for connecting with a second solar photovoltaic panel. The signal processing section is connected to the first and second angle adjustment units, the light-emitting unit, the air-cooling unit, the water-cooling unit, and the first and second solar photovoltaic panels. The signal processing section serves to receive sensing signals and transmit control signals. The solar photovoltaic panel test platform can provide different illuminations, angles of incidence and heat dissipation modes to test the efficiency of the solar photovoltaic panels.

Owner:TUNGNAN UNIV

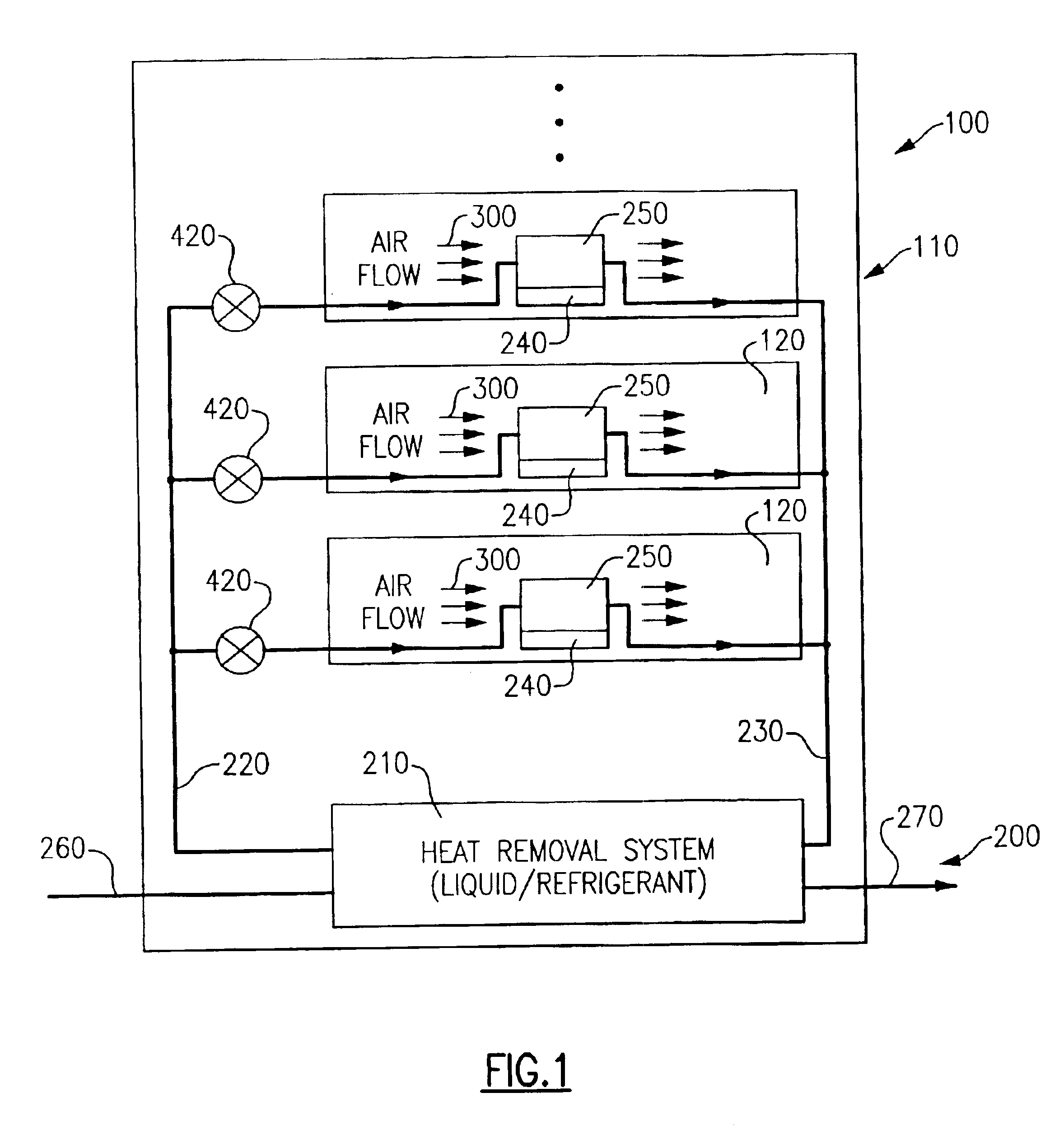

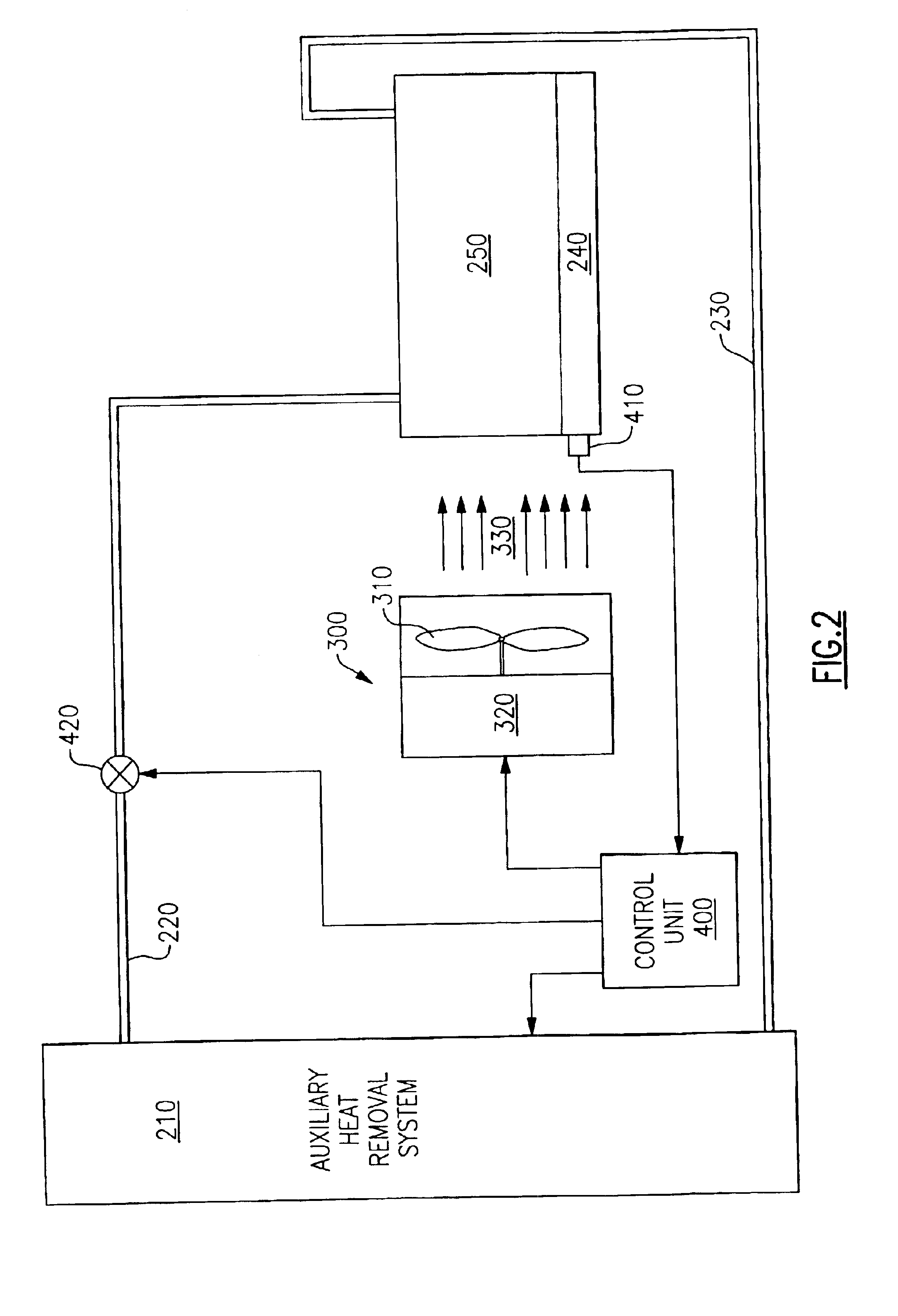

Method and air-cooling unit with dynamic airflow and heat removal adjustability

Method and air-cooling unit are provided for dynamically adjusting airflow rate through and heat removal rate of the air-cooling unit to facilitate cooling of one or more electronics racks of a data center. The air-cooling unit includes a housing, an air-moving device, and an air-to-liquid heat exchanger. The air-moving device moves air through the housing from the air inlet side to the air outlet side thereof, and the heat exchanger cools the air passing through the housing. A control unit controls the air-moving device and the flow of liquid coolant through the heat exchanger to automatically, dynamically adjust airflow rate and heat removal rate of the air-cooling unit to achieve a current airflow rate target and current heat removal rate target therefore. The current targets are based on airflow rate through and heat load generated by one or more associated electronics racks of the data center.

Owner:DAEDALUS BLUE LLC

Cooling assembly for electronics drawer using passive fluid loop and air-cooled cover

InactiveUS6967841B1Increase surface areaOvercomes shortcomingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronics

A cooling apparatus for electronic drawers utilizing a passive fluid cooling loop in conjunction with an air cooled drawer cover. The air cooled cover provides an increased surface area from which to transfer heat to cooling air flowing through the drawer. The increased cooling surface uses available space within the drawer, which may be other than immediately adjacent to a high power device within the drawer. The passive fluid cooling loop provides heat transfer from the high power device to the air cooled cover assembly, allowing placement of the air cooled cover assembly other than immediately adjacent to the high power device. The cooling apparatus is easily disengaged from the electronics drawer, providing access to devices within the drawer.

Owner:INT BUSINESS MASCH CORP

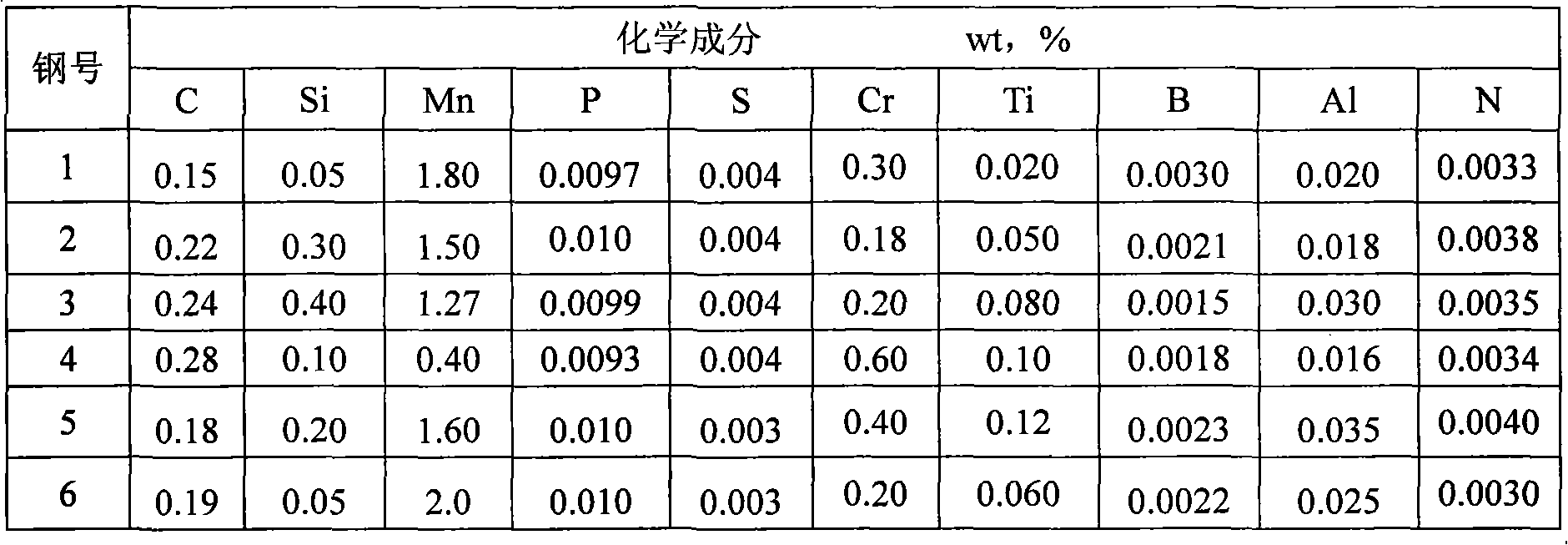

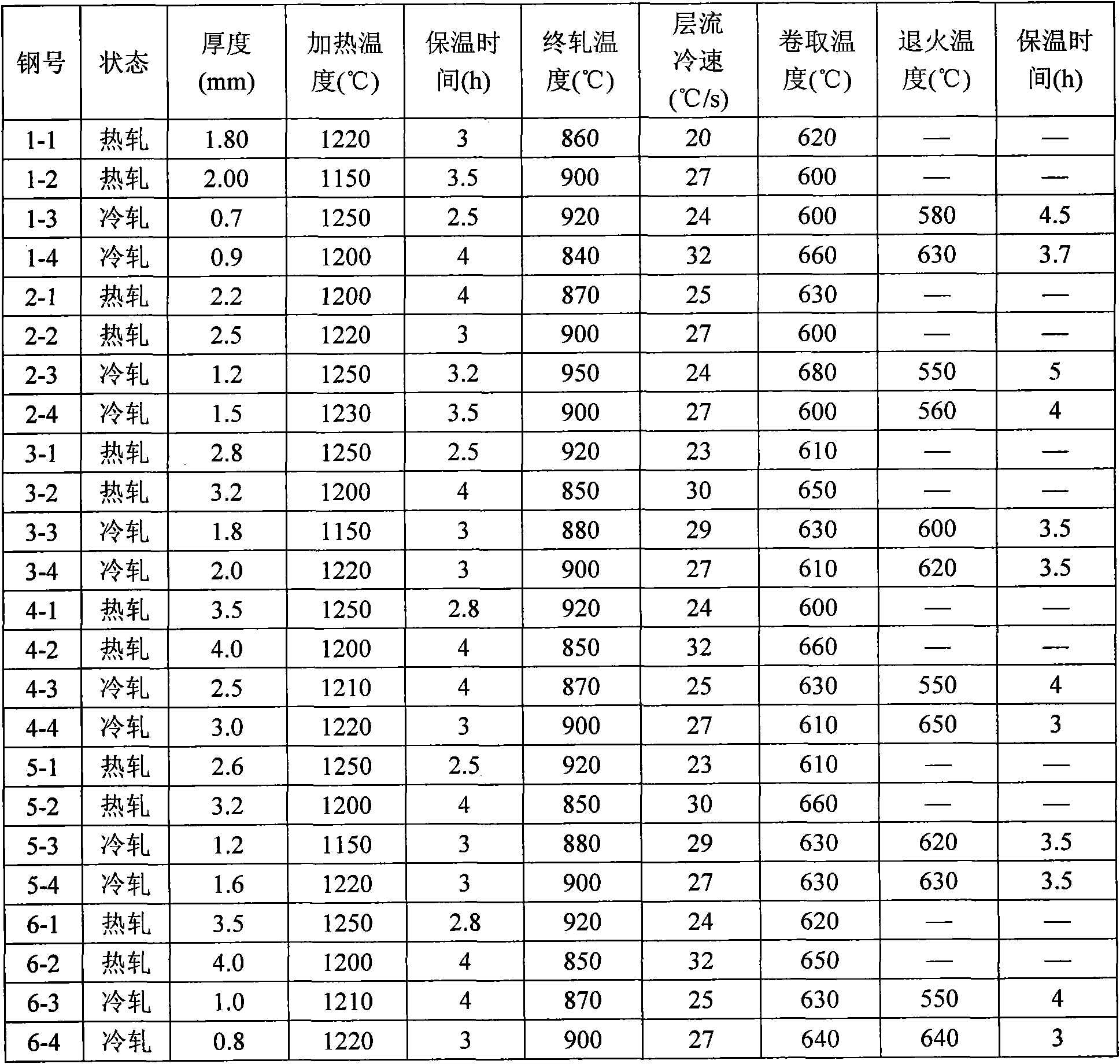

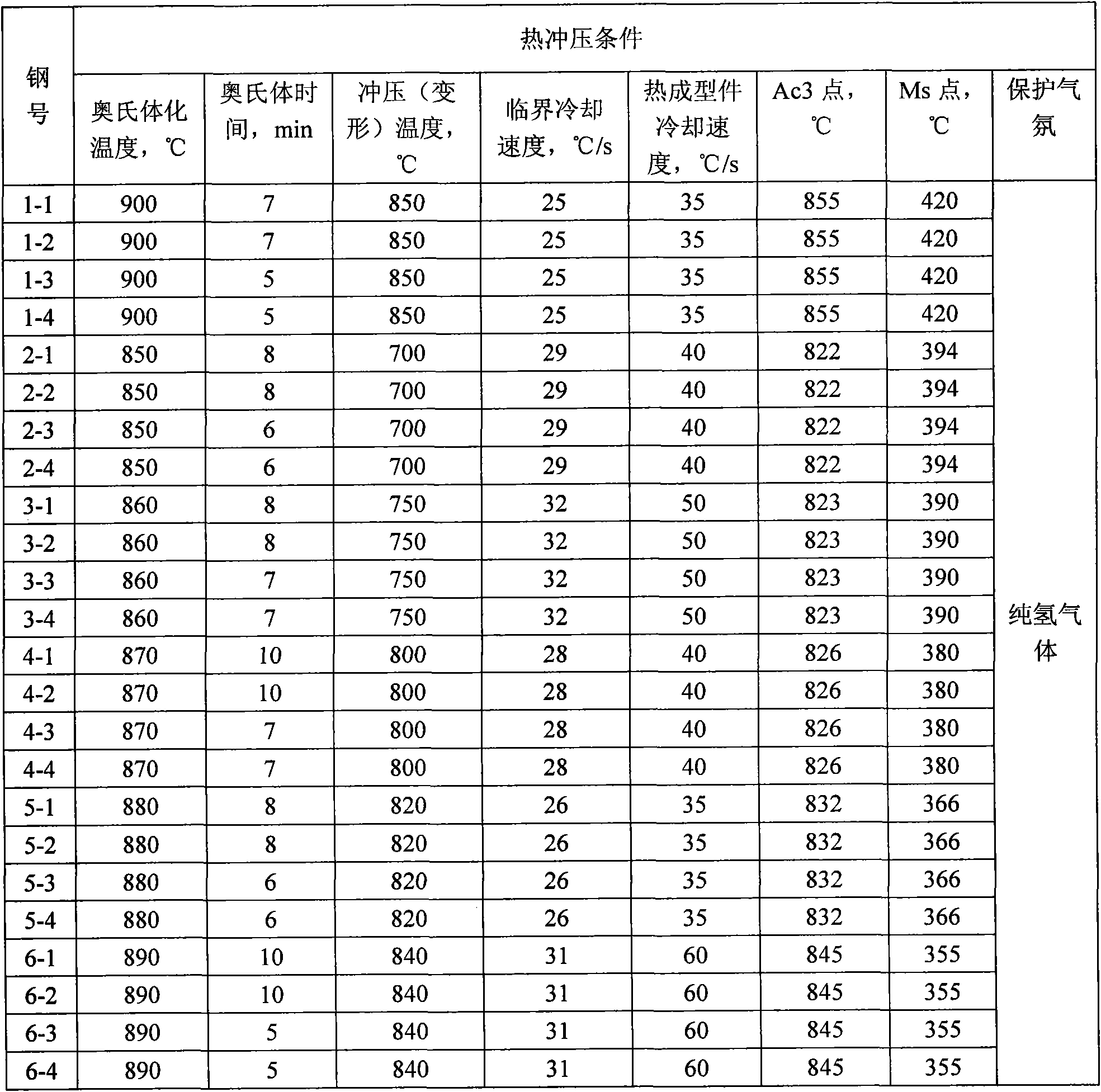

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

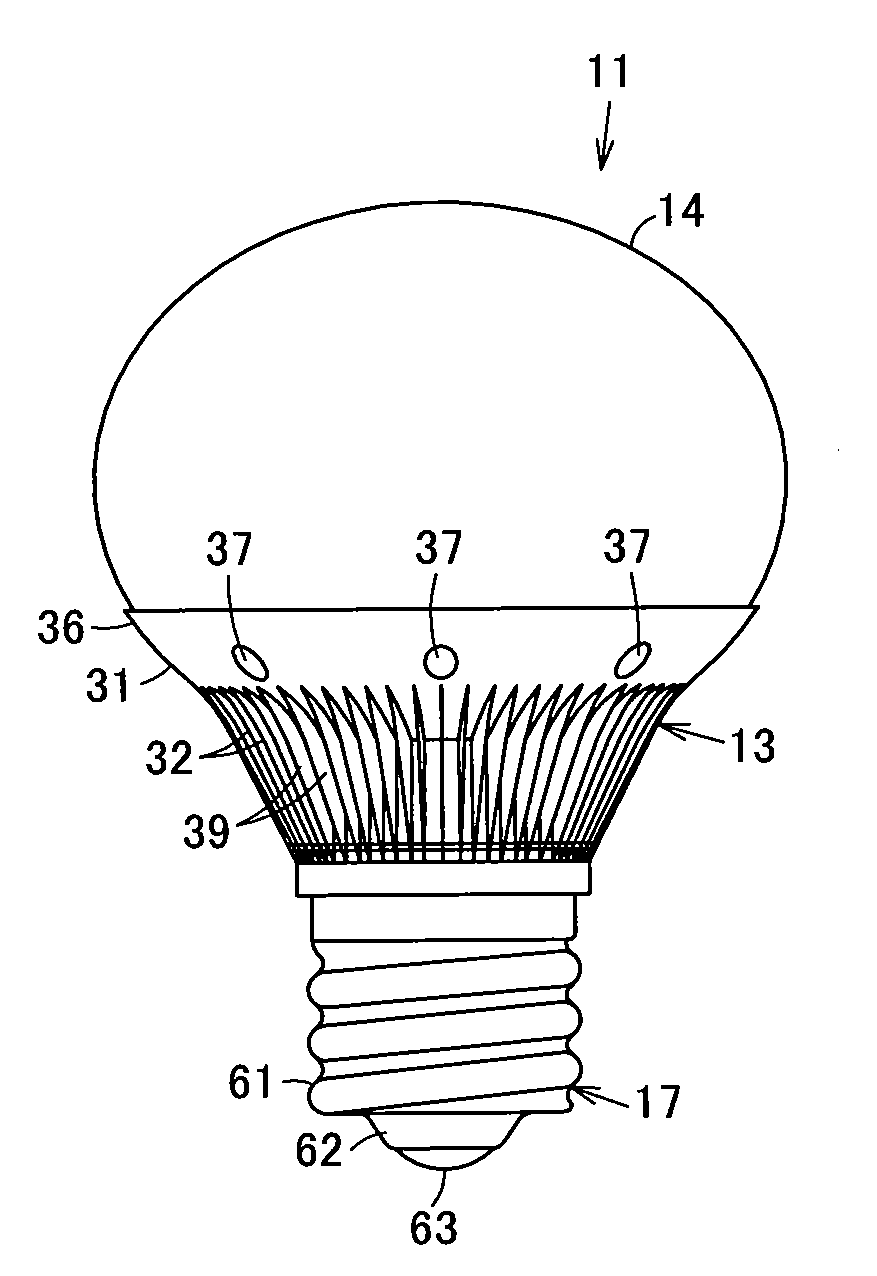

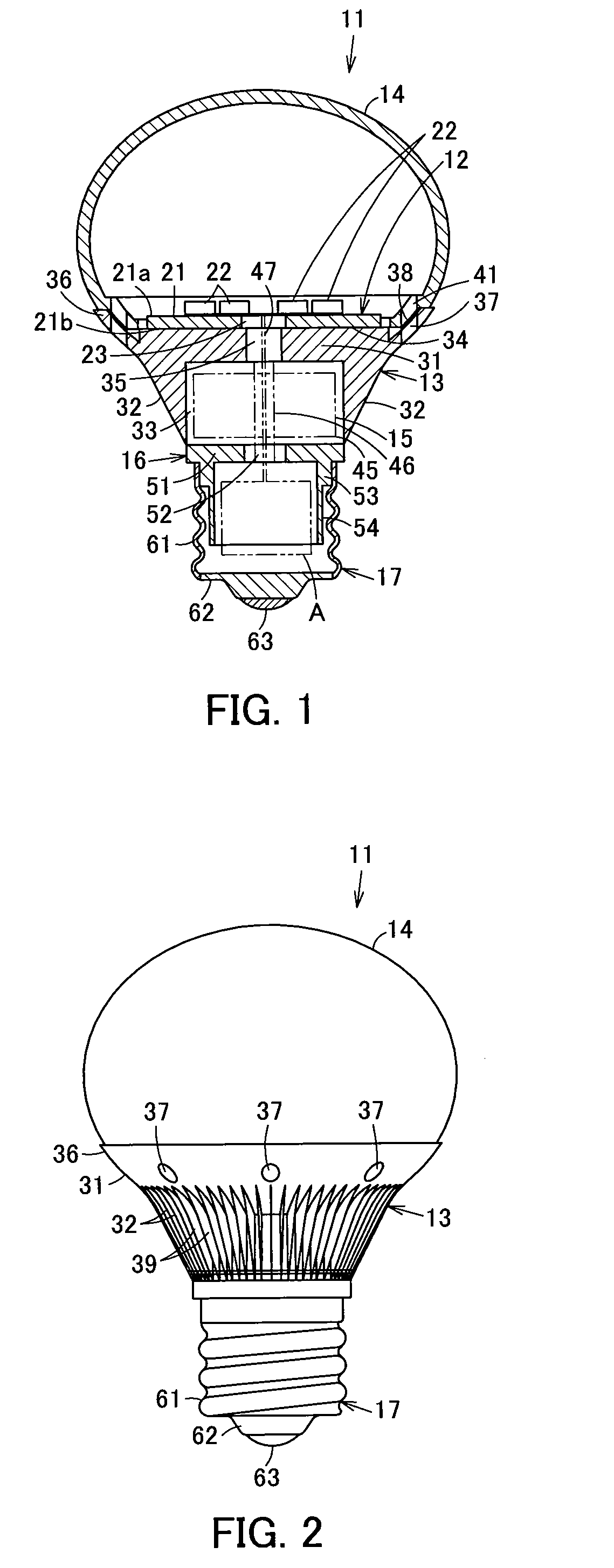

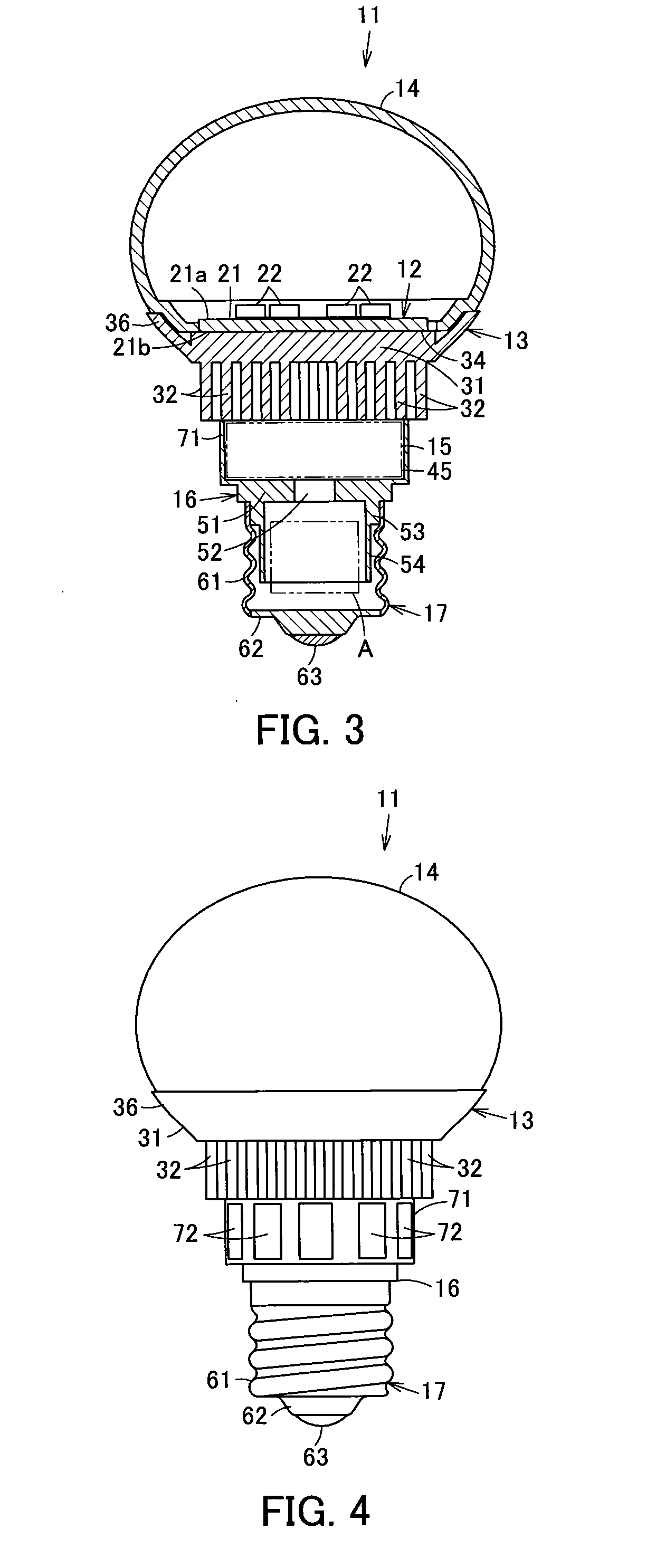

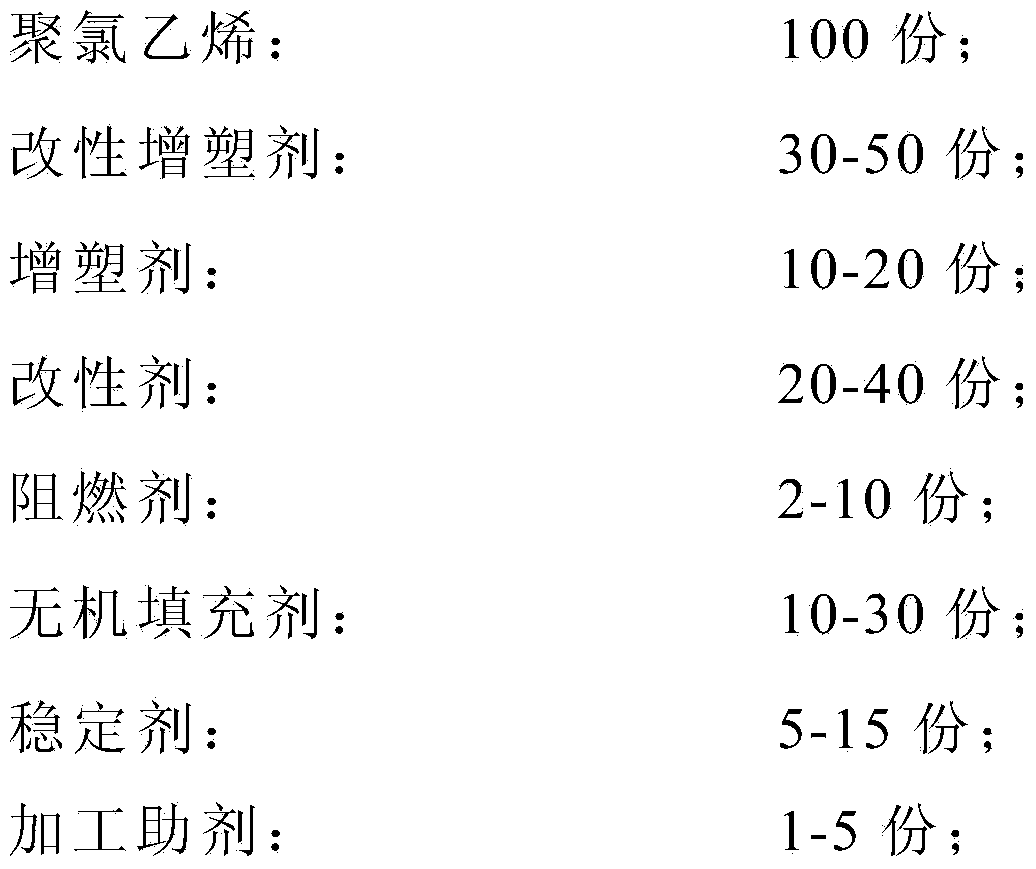

Self-ballasted lamp

InactiveUS20100026185A1Improve radiation efficiencyAvoid heatPoint-like light sourceElectric circuit arrangementsFree rotationEngineering

Owner:TOSHIBA LIGHTING & TECH CORP

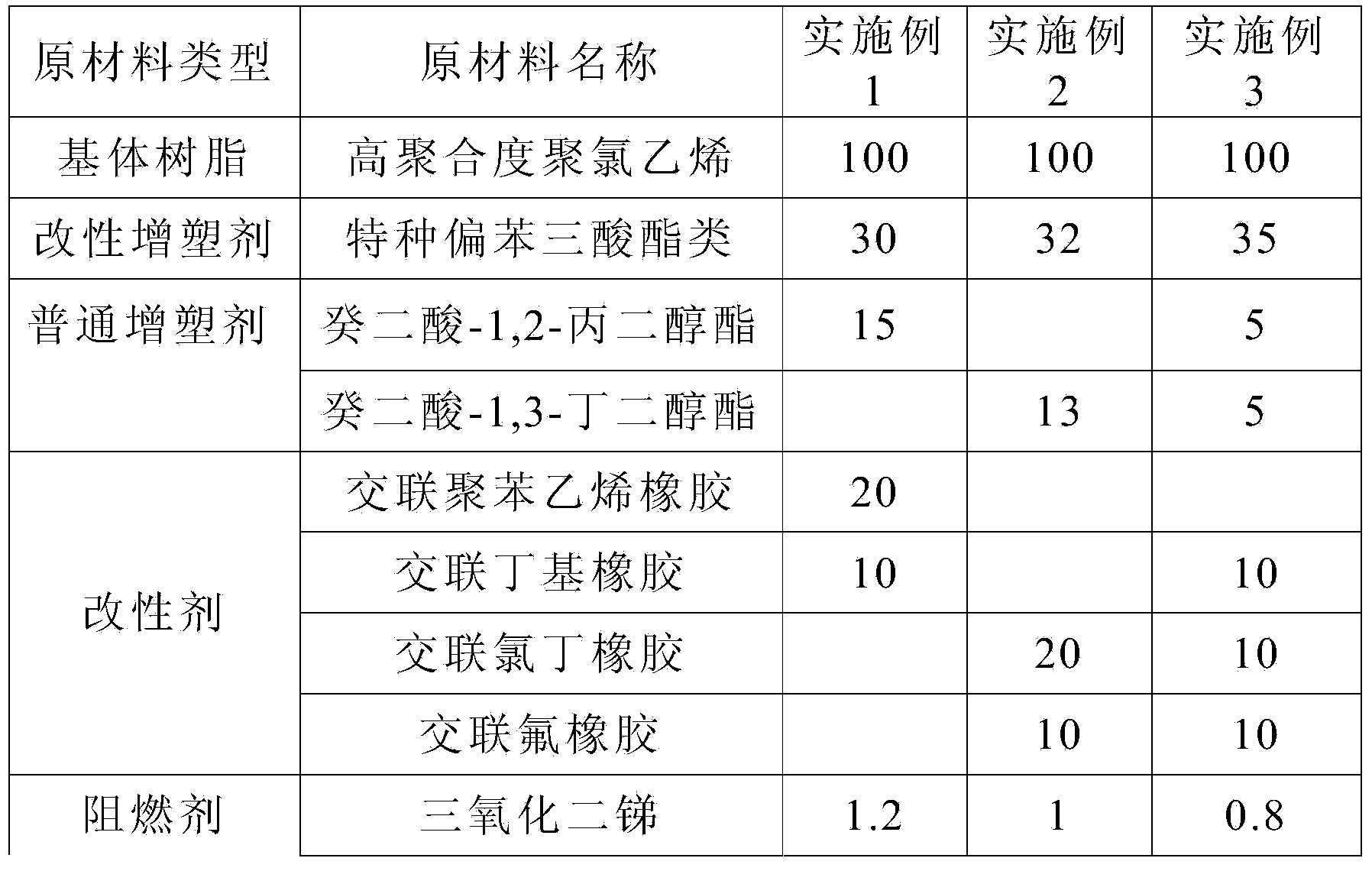

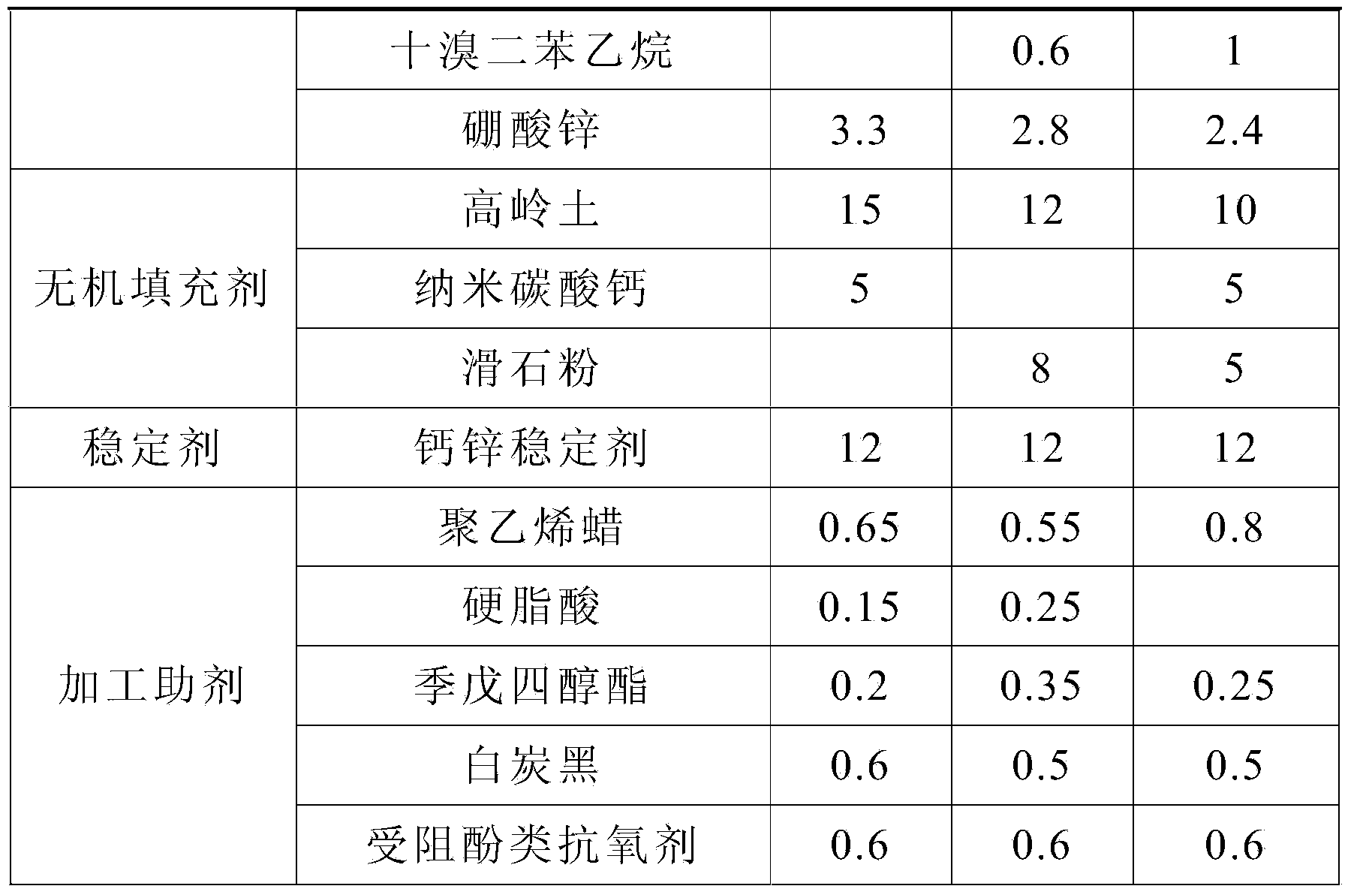

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

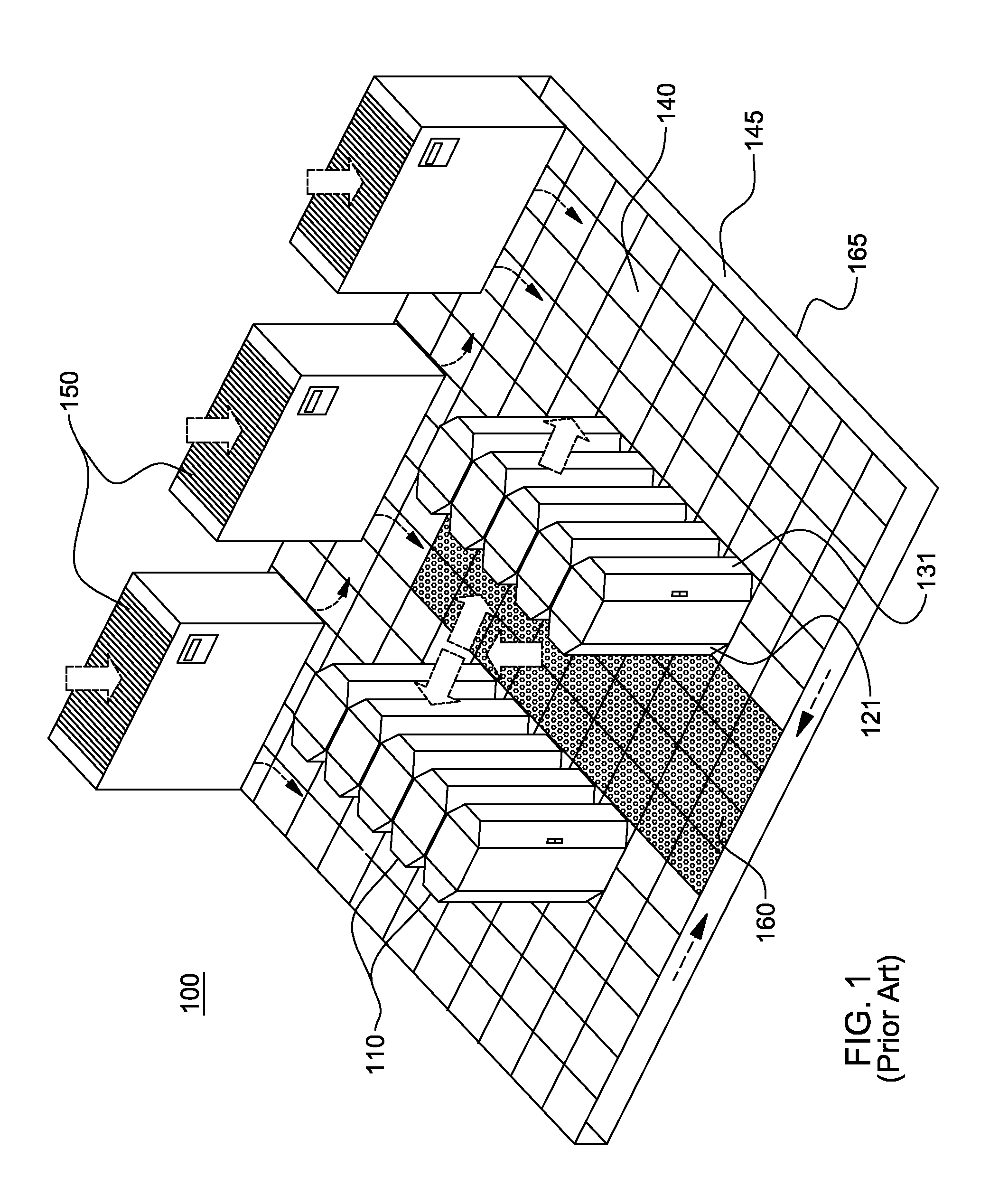

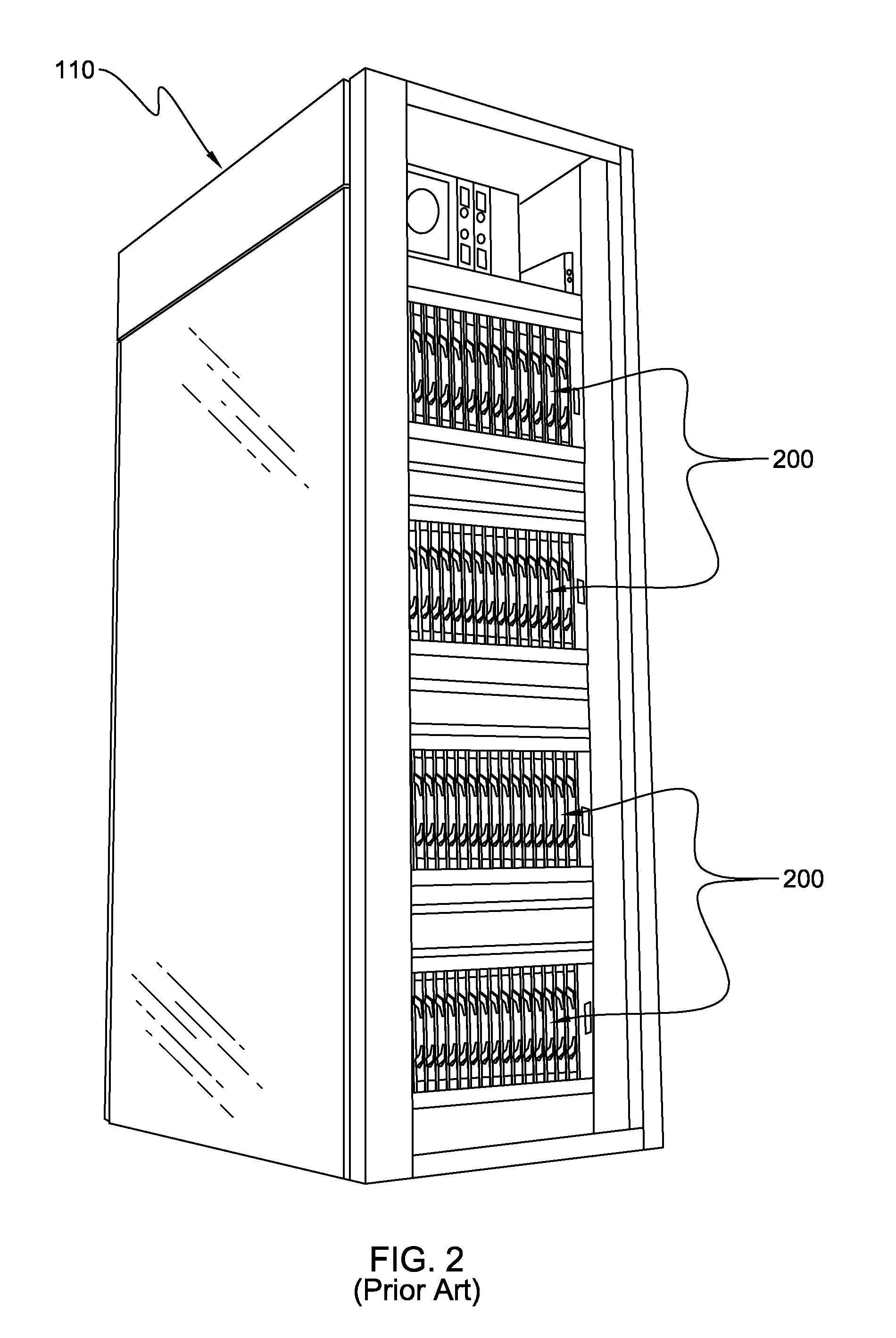

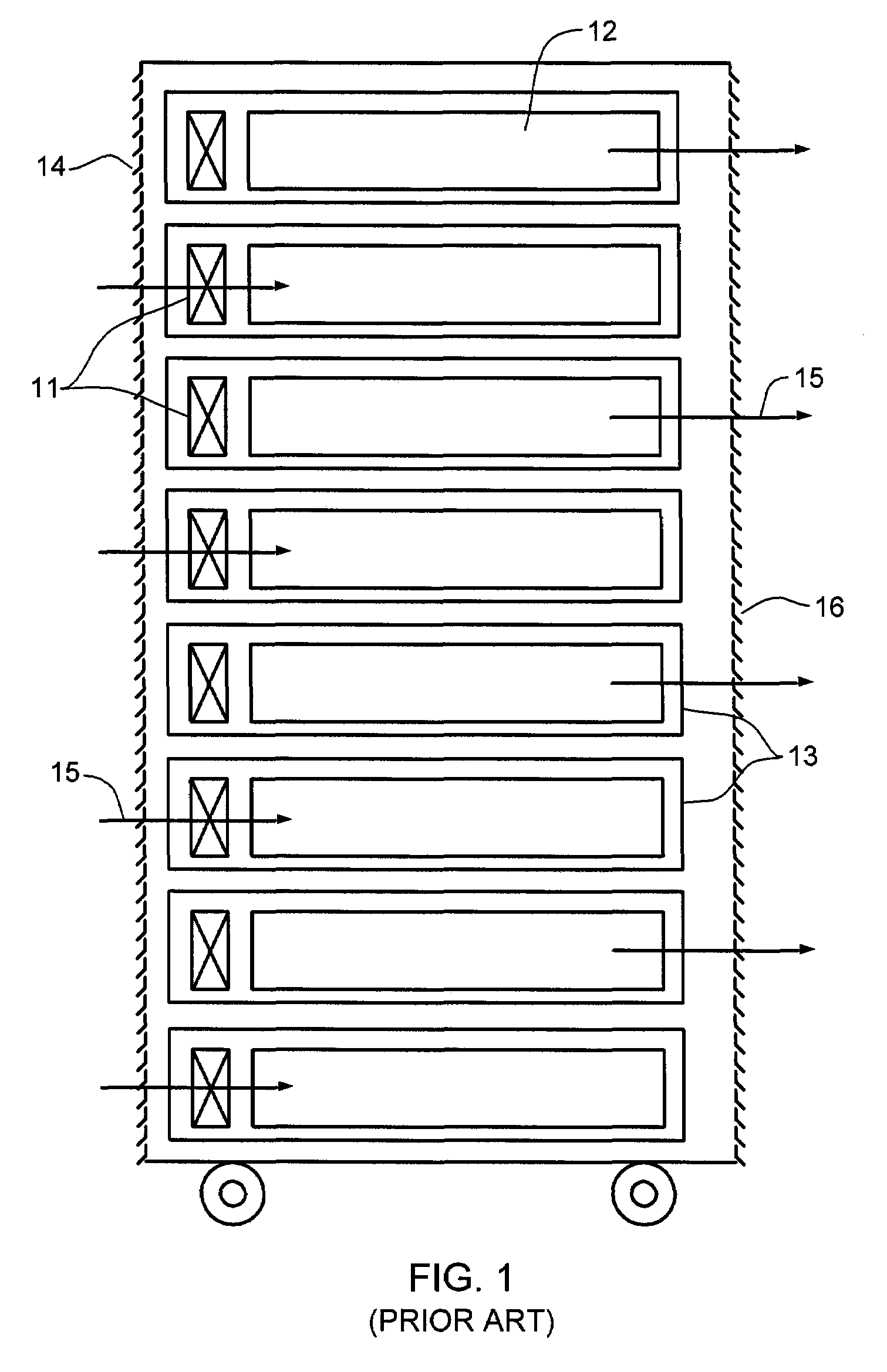

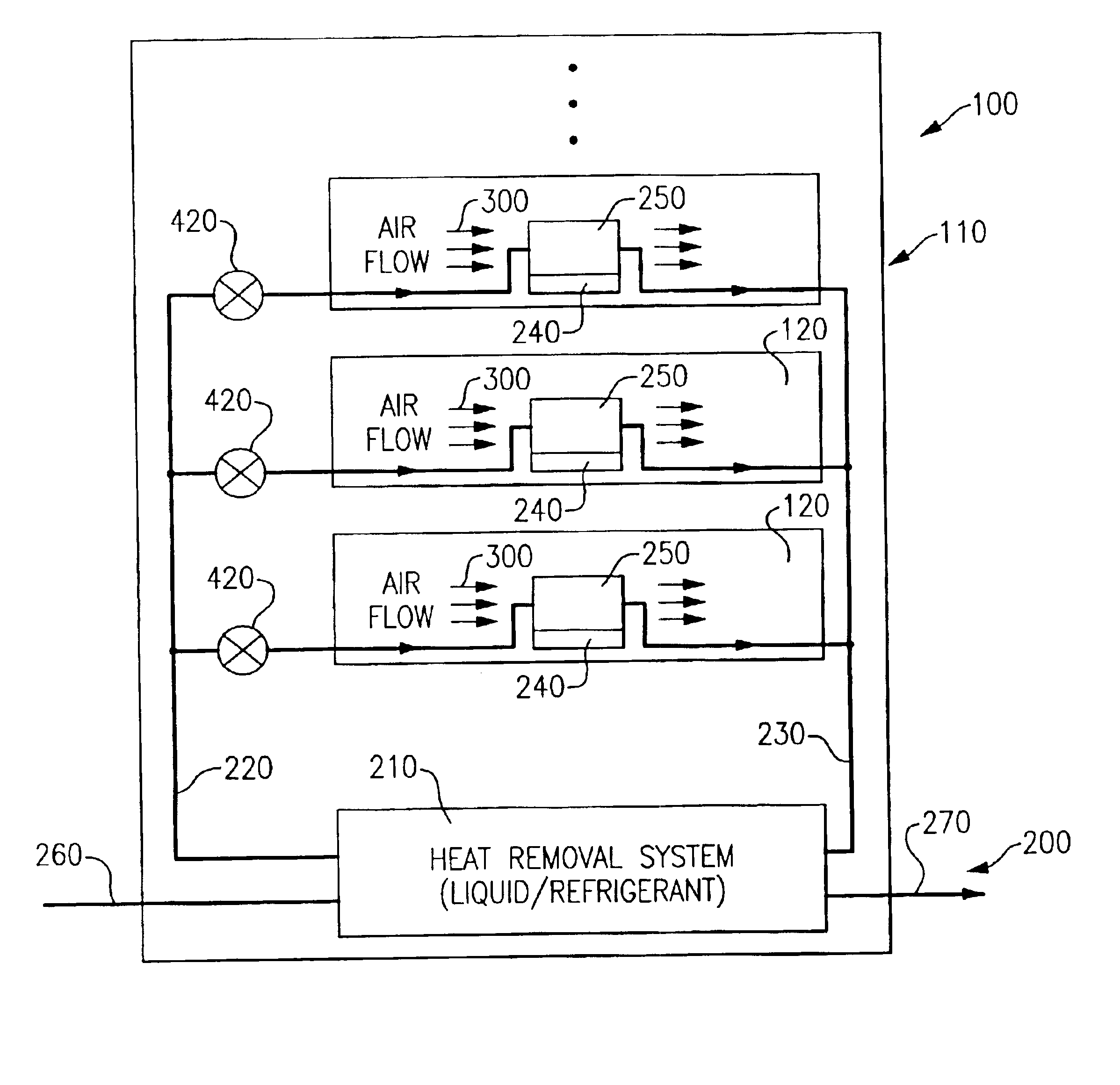

Frame level partial cooling boost for drawer and/or node level processors

InactiveUS6970355B2Small dimensionAvoid the needDomestic cooling apparatusSemiconductor/solid-state device detailsSystems designEngineering

A hybrid cooling system is provided which is particularly useful for cooling electronic circuit components disposed on circuit boards arranged in a plurality of drawers within a cabinet or frame. Air cooling is provided locally with a supplementary, auxiliary, or secondary cooling system being provided at more distant frame level locations. This configuration permits optimal sizing of the respective hybrid cooling system components without negatively impacting the coefficient of performance (COP). Hybrid heat sinks are employed to accommodate the hybrid cooling system design.

Owner:IBM CORP

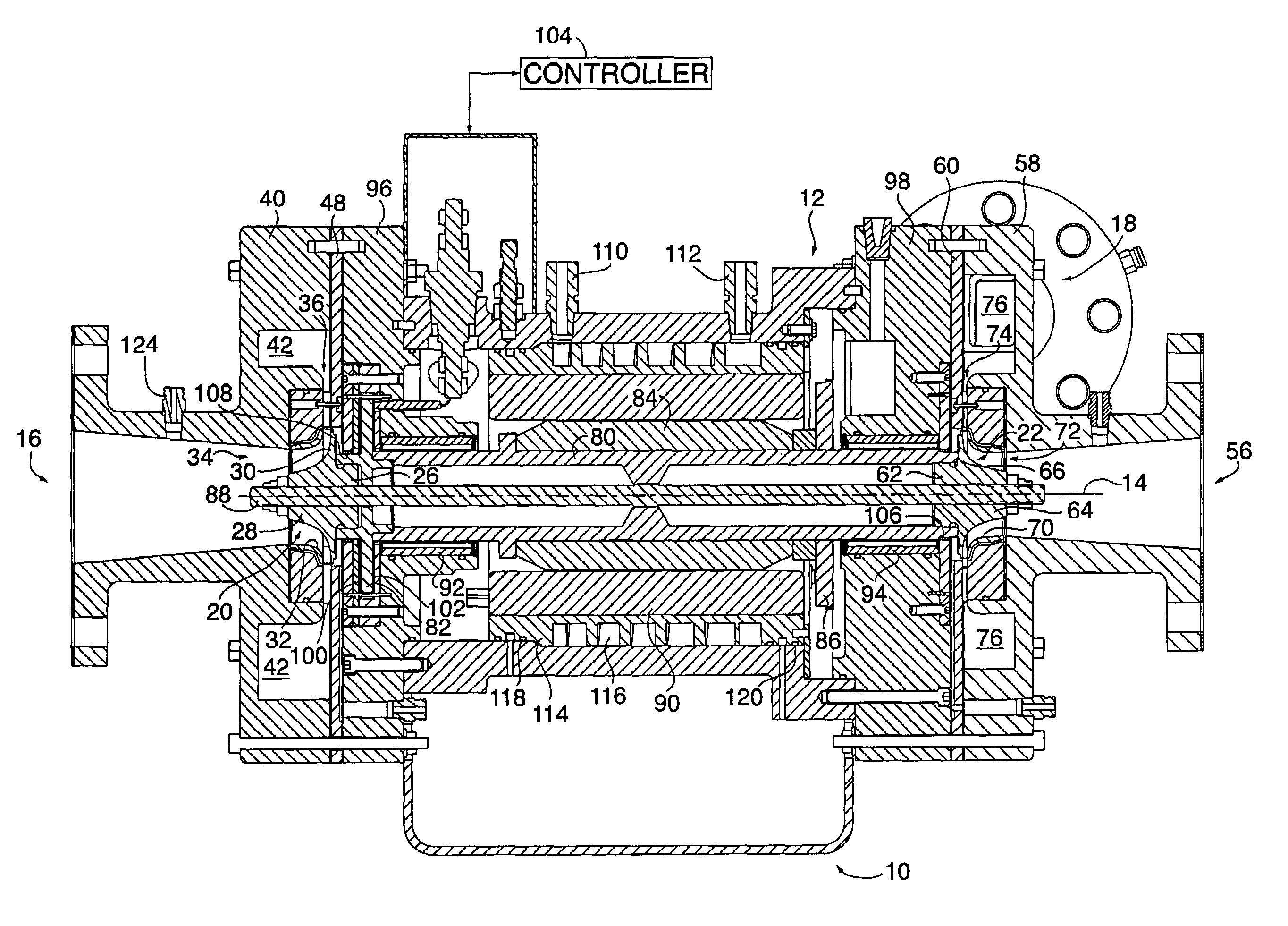

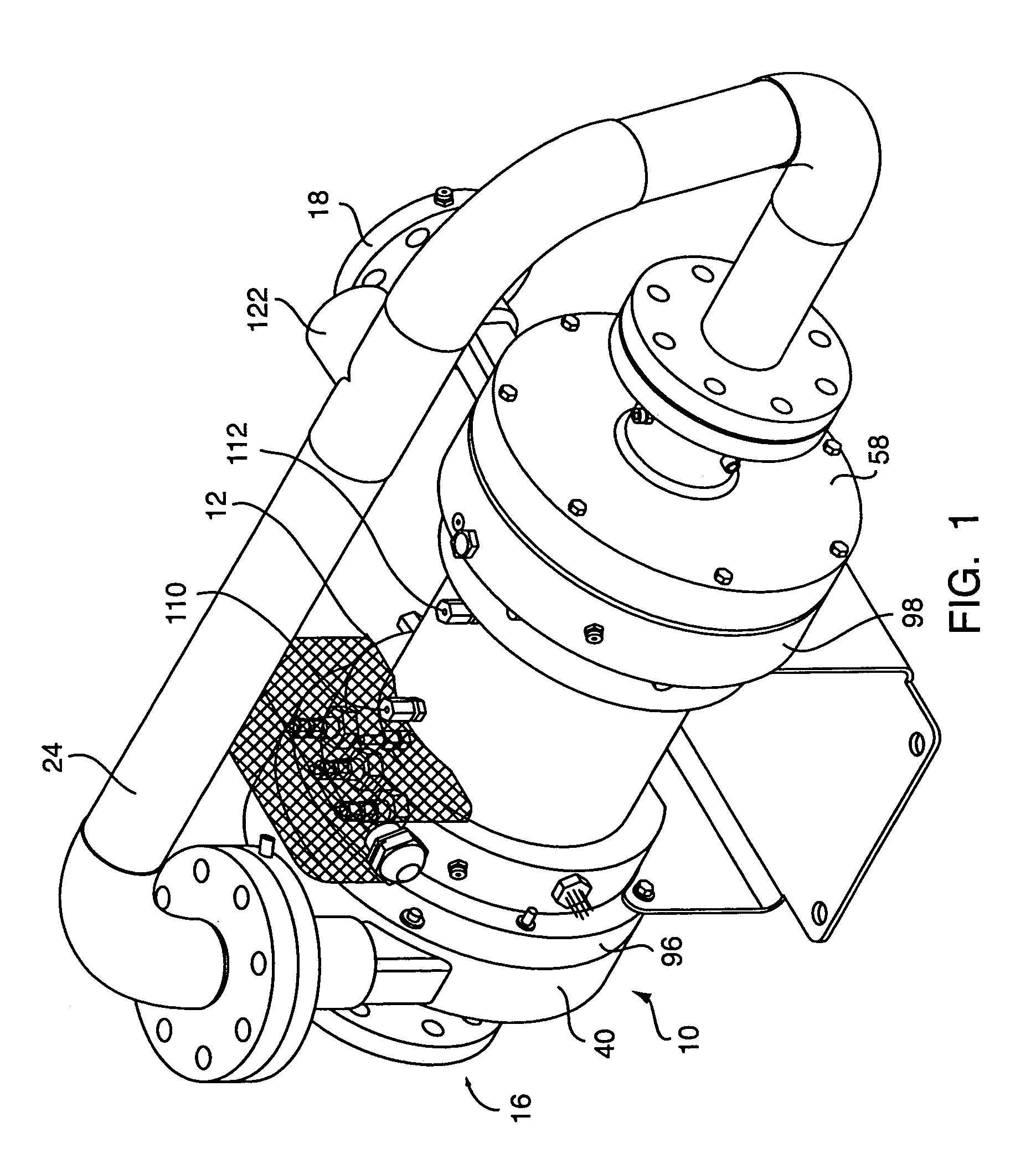

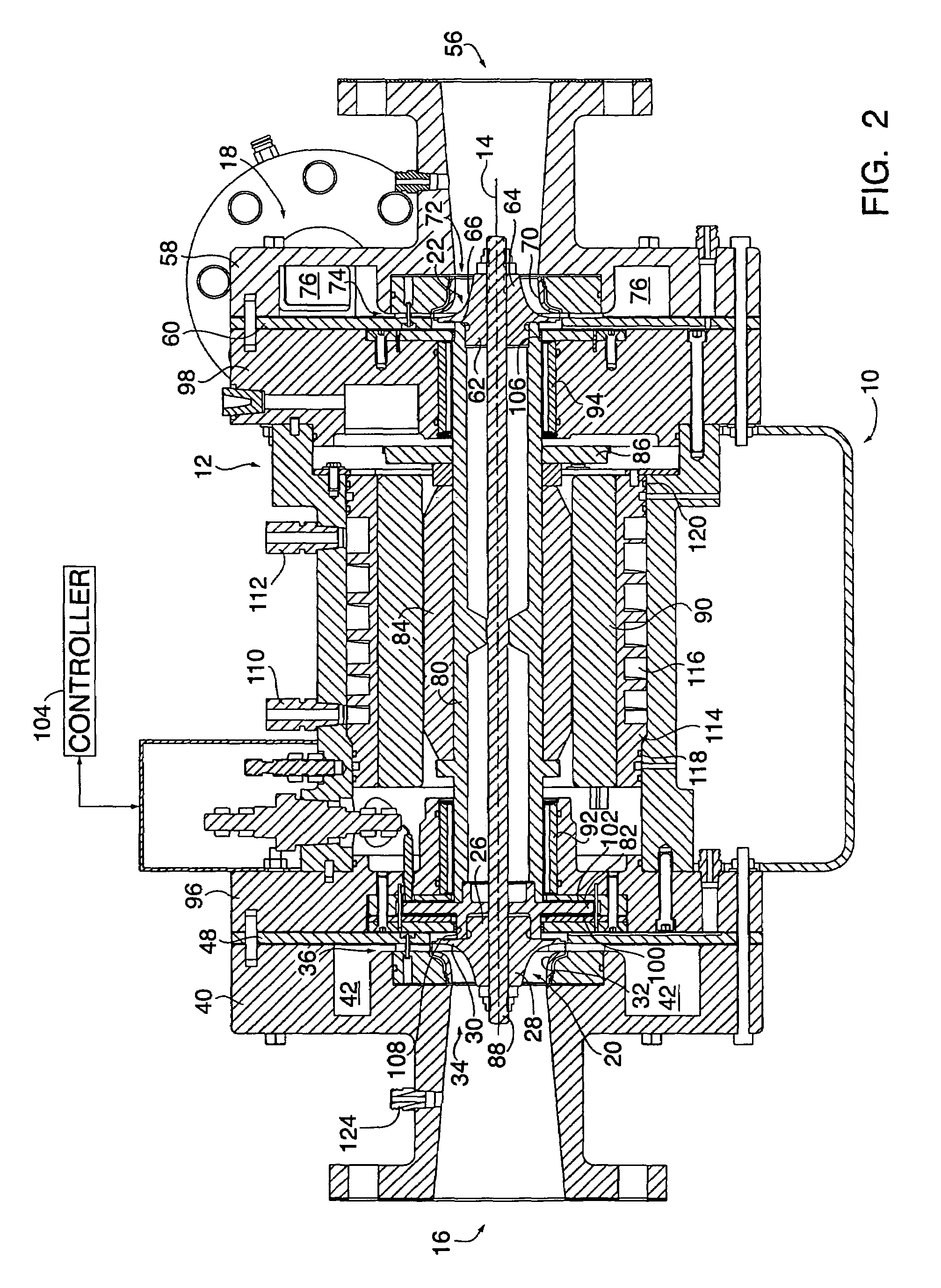

Motor driven two-stage centrifugal air-conditioning compressor

ActiveUS6997686B2Improve cooling effectEnhanced compressor energy efficiencyPositive displacement pump componentsPump controlImpellerMotor drive

A two-stage compressor for generating necessary pressure differential for air-conditioning applications with air-cooled, water-cooled and evaporative-cooled condensing systems using low-pressure refrigerant, such as R134a, is provided. A rotating assembly is mounted for rotation in a compressor housing and includes a shaft, a thrust bearing disk associated with the shaft to maintain an axial position of the rotating assembly, a motor rotor mounted on the shaft, and first and second impellers mounted for rotation with the shaft. First and second journal bearings are mounted in the compressor housing to support the shaft and maintain radial positioning of the rotating assembly. Volute housings including a spiral-shaped volute are associated with each of the impellers to collect and further discharge gas compressed by the impellers. Diffusers having air-foil shaped vanes are locate in the volute channels adjacent the discharge outlets of the impellers to aide in the discharge of gas from the impellers.

Owner:R & D DYNAMICS

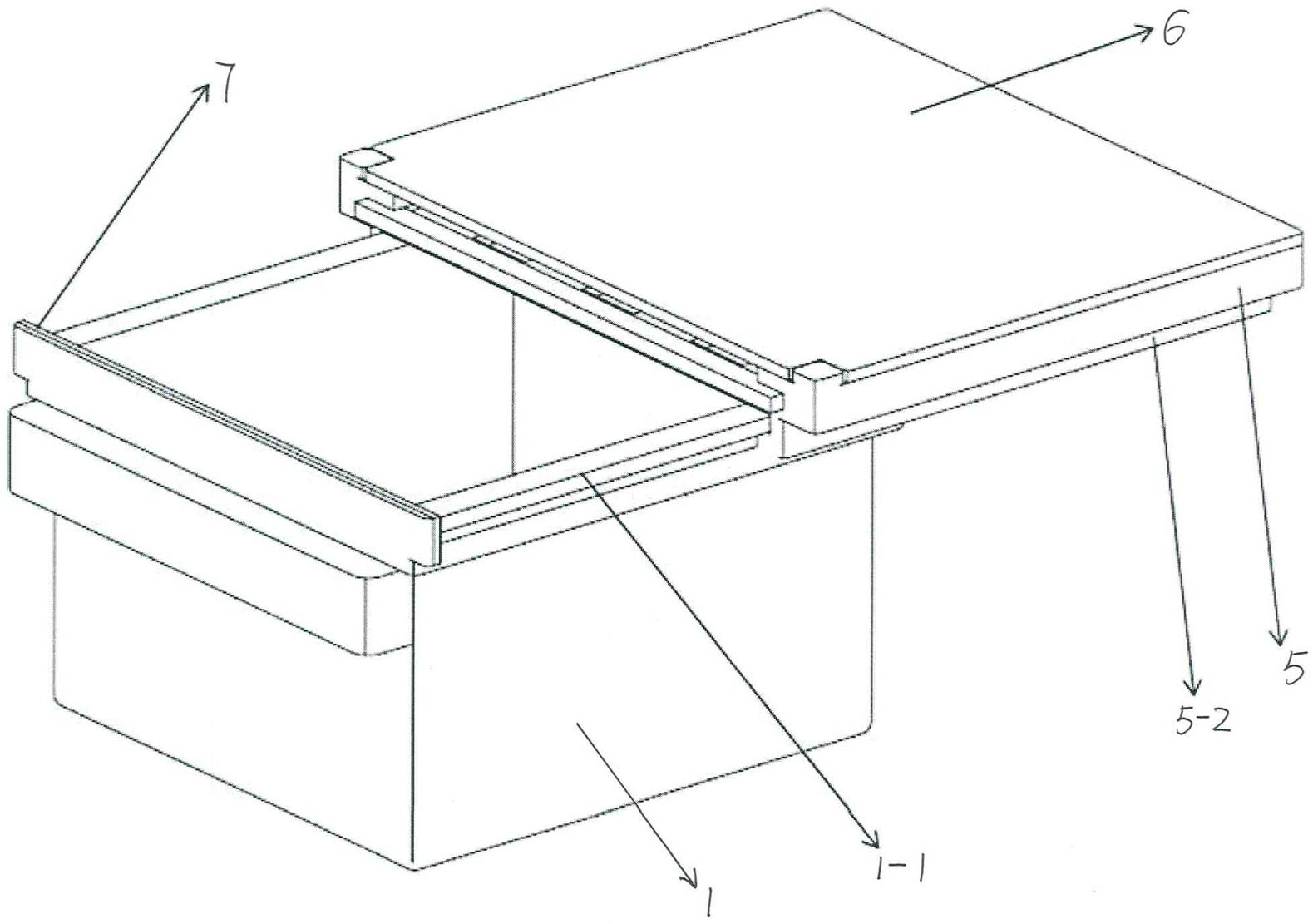

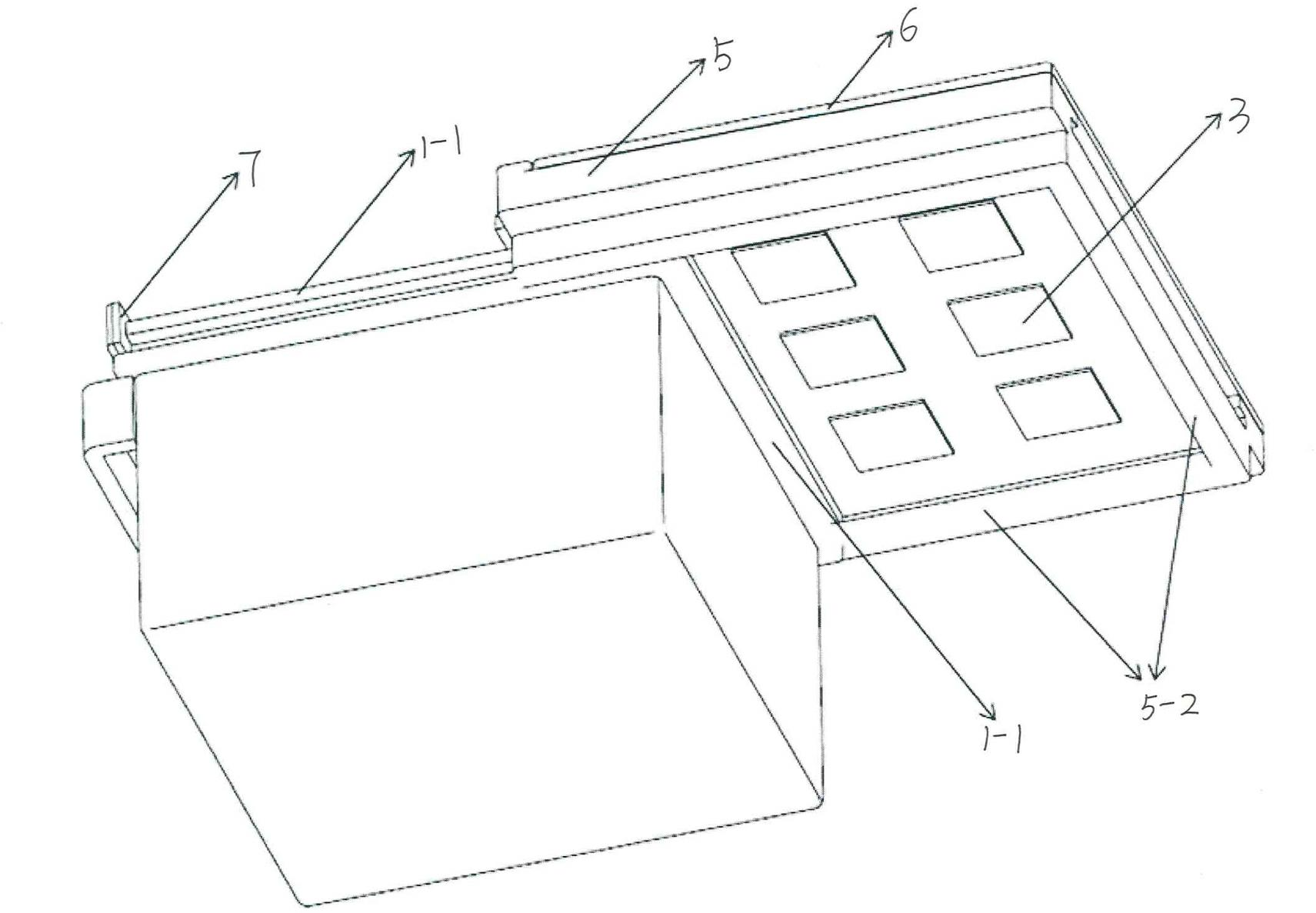

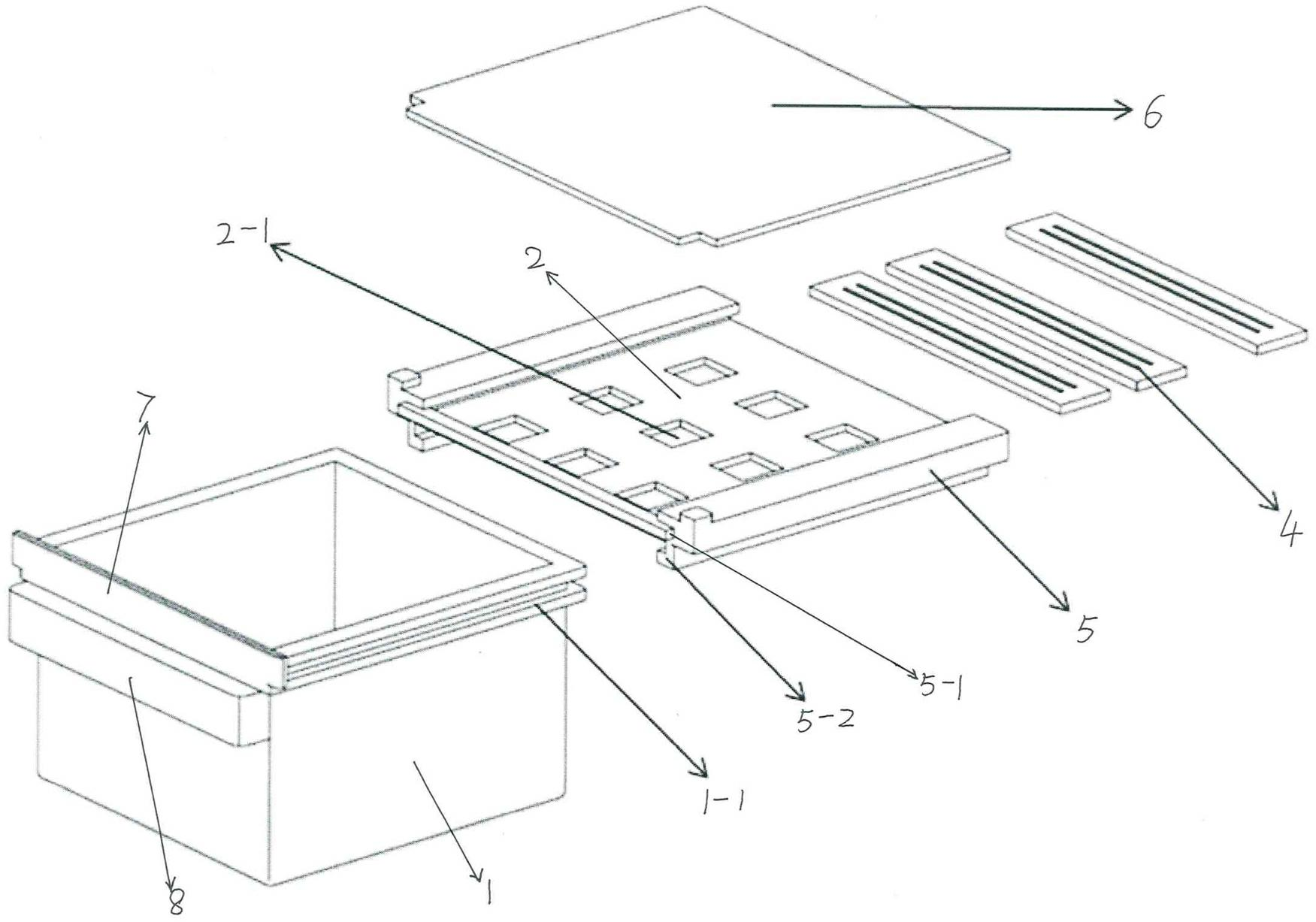

Fruit/vegetable preservation box and refrigerator adopting fruit/vegetable preservation box

ActiveCN102679679AGuaranteed tightnessGuaranteed windproof performanceLighting and heating apparatusCooling fluid circulationEngineeringMoisture

The invention provides a fruit / vegetable preservation box and a refrigerator adopting the fruit / vegetable preservation box, and can solve the problem in the prior art that the fruit / vegetable box in the air-cooled refrigerator fails to integrate tightness, air resistance and vapor permeability. The invention adopts the technical scheme as follows: the fruit / vegetable preservation box comprises a box body and a box cover, wherein the box body and the box cover form a closable cavity; and a plurality of air holes are formed in the box cover and an air-permeable moisture-adjusting film is coated on the lower side of the air holes to form an air passage inside and outside the preservation box. The invention also provides a refrigerator adopting the fruit / vegetable preservation box. The fruit / vegetable preservation box provided by the invention achieves the purpose of increasing the shelf life of fruits and vegetables in the air-cooled refrigerator with simpler structure and lower cost.

Owner:HAIER GRP CORP +1

Wear-resisting alloy steel with high boron, high chrome and low carbon and preparation method thereof

ActiveCN101660097AReduce manufacturing costElectric furnaceProcess efficiency improvementSilicon alloyCerium

The invention discloses a wear-resisting alloy steel with high boron, high chrome and low carbon and a preparation method thereof, which comprises the following chemical constituents in weight percent: 0.1-0.5% of C, 3-26% of Cr, 0.5-1.2% of Si, 0.5-1.5% of Mn, 0.3-2.8% of B, 0.3-2.6% of Cu, 0.2-0.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.02-0.15% of Mg, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. The method comprises the following steps: melting steel scrap and chromium iron in an electric furnace; adding copper plates, ferrosilicon, ferromanganese into the melted steel scrap and chromium iron, heating the melt to 1560-1620 DEG C after the constituents are adjusted to be qualified in stokehold; adding calcium-silicon alloy and aluminium deoxidation into the melt; and then adding ferrotitanium and ferroboron in sequence, melting and discharging; roasting the compound inoculant composed of granular rare earth magnesium alloy with the diameter being less than 12mm and cerium metal, Si3N4, VN, Nb and K; placing the roasted compound inoculant at the bottom ofa steel ladle; carrying out modification and inoculation processes on the smelted liquid steel by pour-over method in the steel ladle, wherein, the pouring temperature of the liquid steel is 1400-1450DEG C; heating castings to 920-1150 DEG C and preserving heat for 2-4 hours; and air cooling the castings to room temperature to obtain the alloy steel in the invention. The alloy steel of the invention has the advantages of high strength, rigidity and toughness, good thermal fatigue resistance property, wear resistance, and low manufacture cost.

Owner:泰州海天机械配件有限公司

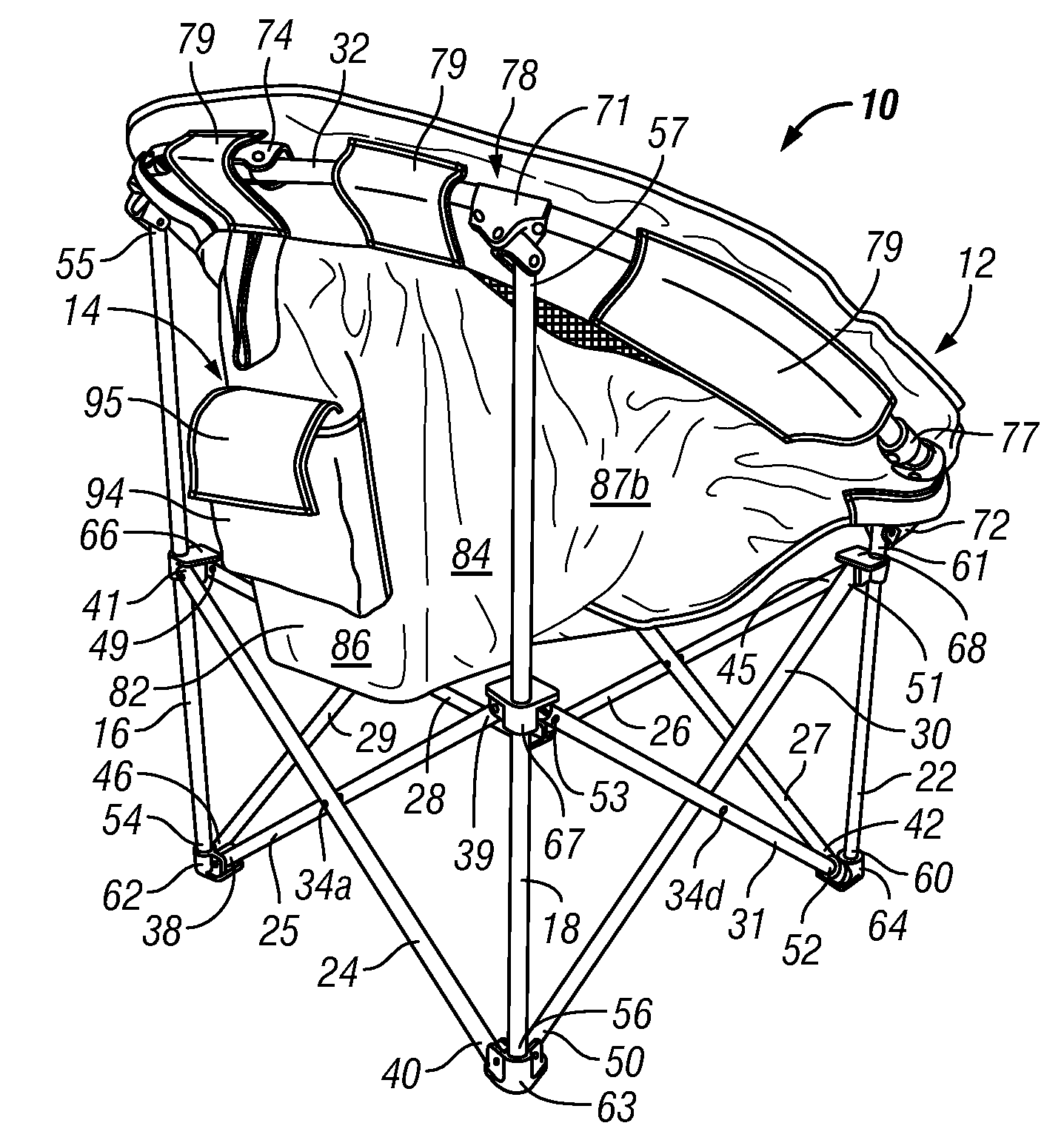

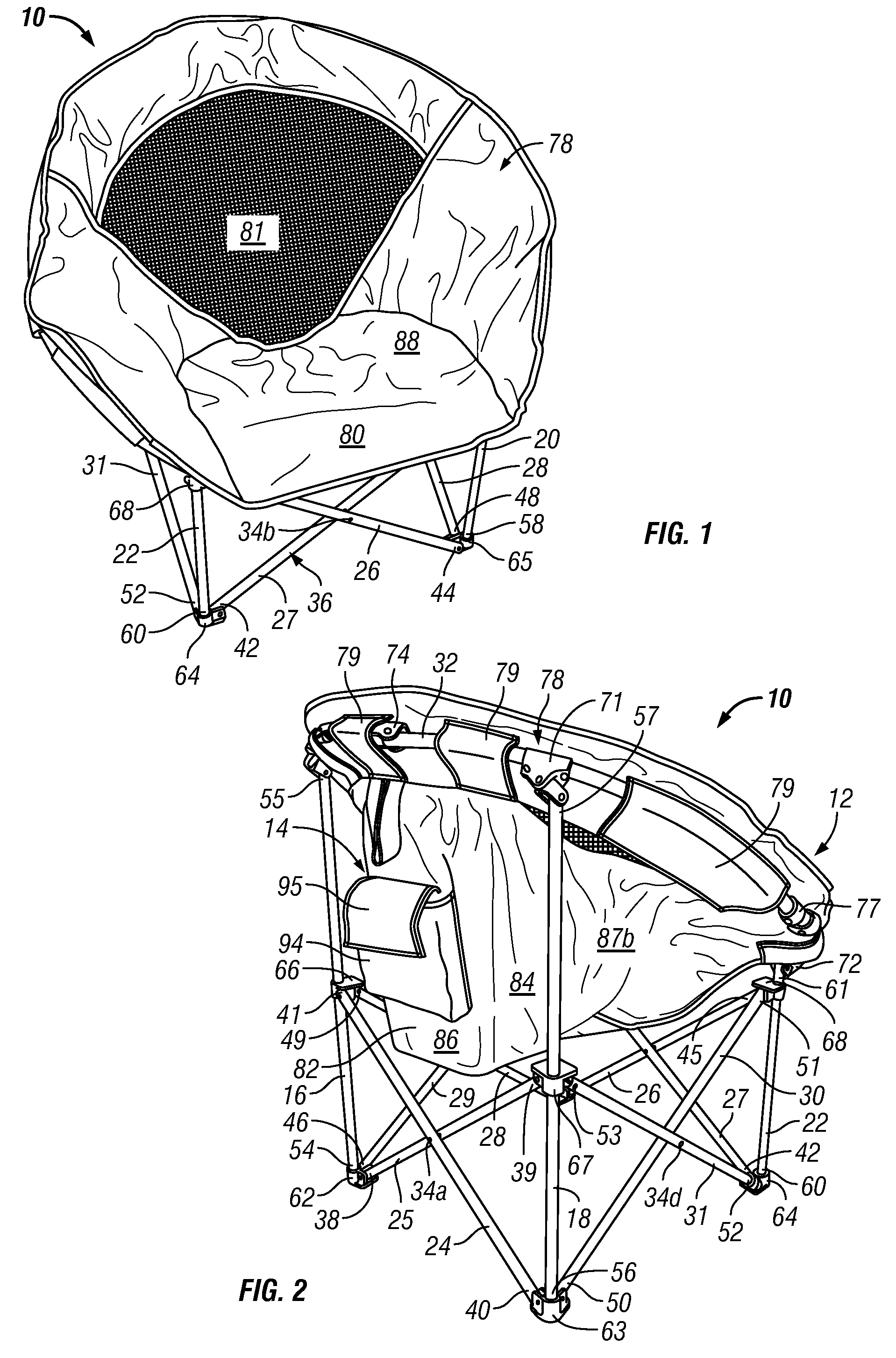

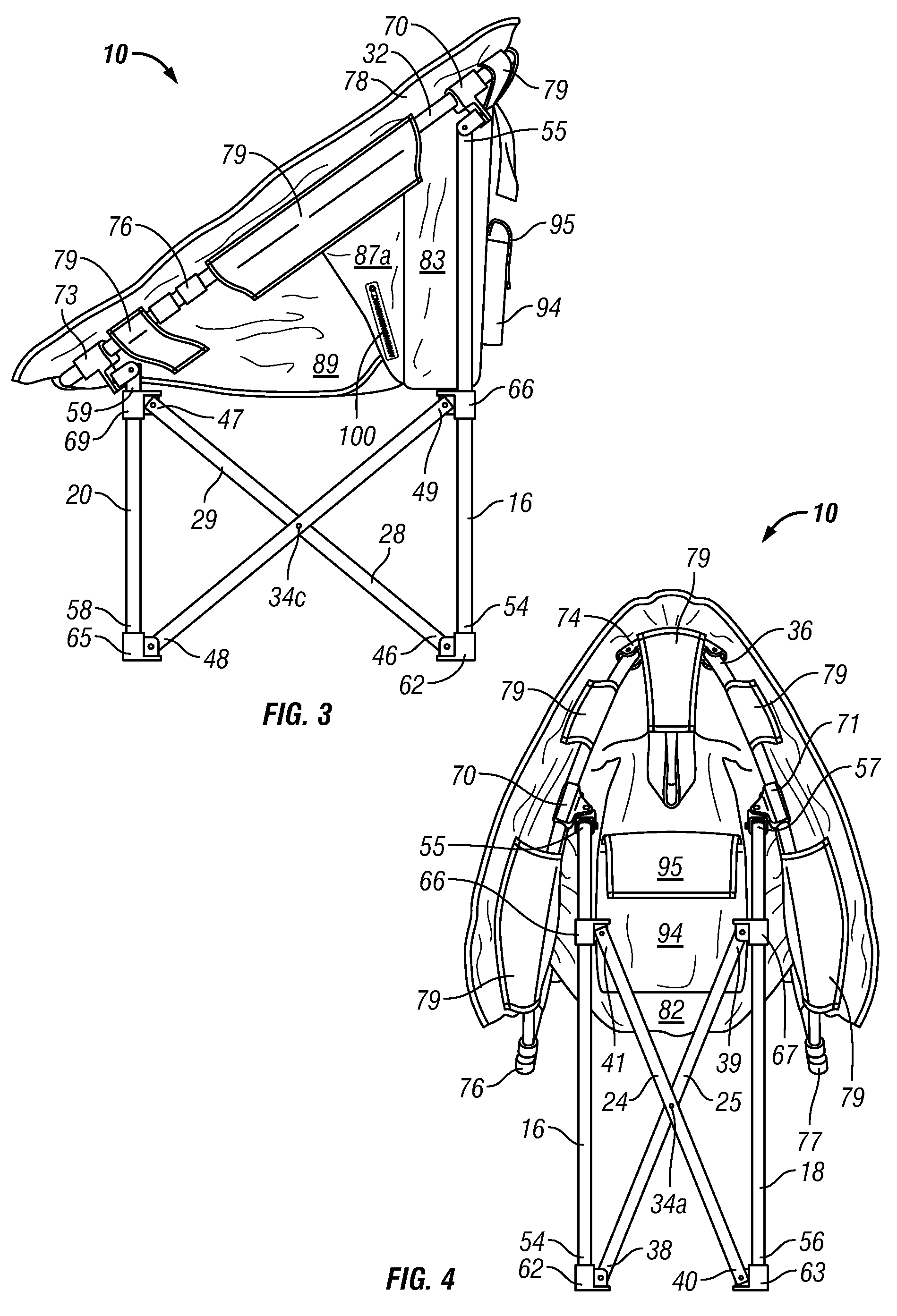

Foldable chair with forced air cooling system

InactiveUS20100164256A1Simple and economical to manufactureSimple and economical to and assembleFoldable chairDismountable chairsToggle switchEngineering

A foldable chair, which includes a forced air cooling system. The foldable chair includes a frame member. A flexible seat, which includes a meshed back rest suspends from the frame member. A fan bag, which has a pocket, is attached to the meshed back rest of the flexible seat. A fan is located at the bottom of the fan bag and is electrically disconnectable to a re-chargeable power source that is housed in a housing, which has an ON / OFF toggle switch so as to supply power to the fan.

Owner:SALISBURY KEITH B

Telecommunication cabinet with airflow ducting

A telecommunications cabinet in which active equipment can be mounted. The cabinet including an airflow ducting arrangement located in the interior region of the cabinet. The airflow ducting arrangement accommodating thermal cooling of active equipment having internal side-to-side air cooling arrangements.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com