Patents

Literature

3185 results about "Air cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED light

InactiveUS20050174780A1Increase illuminationLife maximizationPoint-like light sourceElectric circuit arrangementsLeading edgeAir cycle

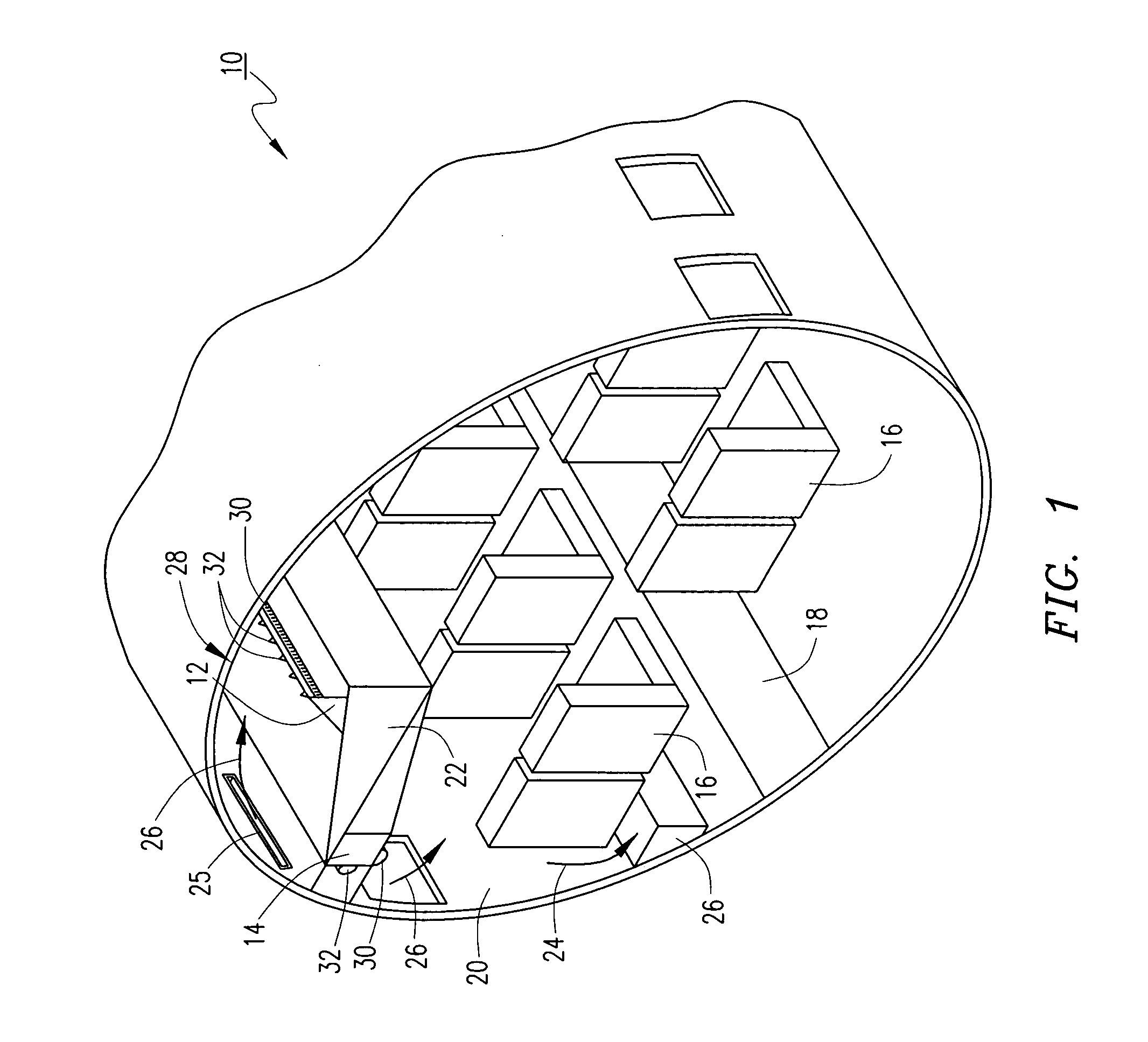

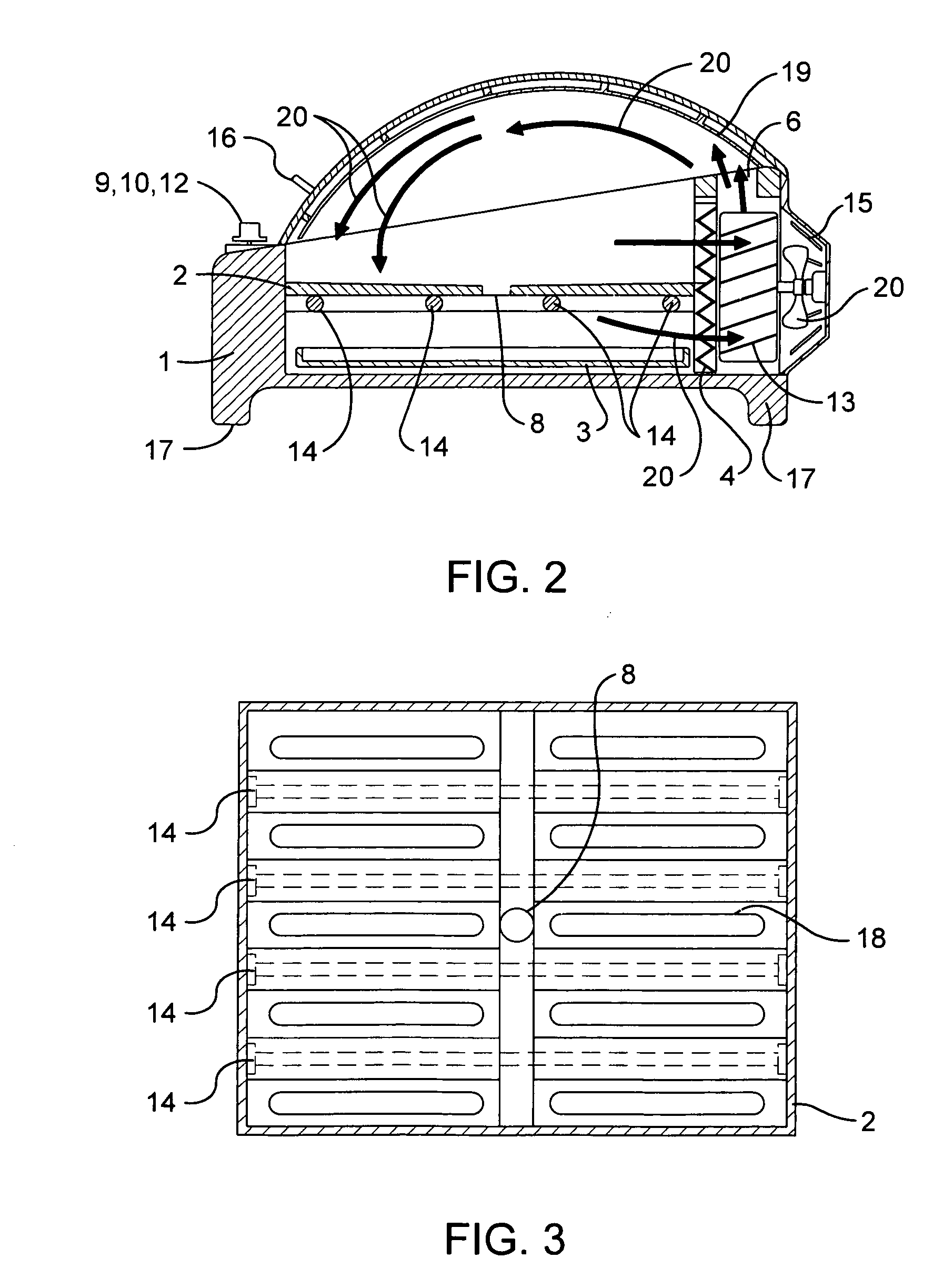

Disclosed herein is an LED light. The LED light comprises a socket electrically connected to a receptacle, and a cooling fan for forcibly circulating air. The cooling fan is received in a main body, which has a plurality of radial partition walls formed on the outer peripheral surface thereof in such a manner as to be spaced apart from one another with a gap having a slit shape for ventilation. A plurality of LEDs is attached to the outer periphery and / or the inner leading edge of the main body. A circuit board is provided to control the light such that an alternating current supplied from the socket is rectified into a direct current, which is supplied to the cooling fan and the LED.

Owner:DAEJIN DMP

LED lighting device

InactiveUS20110156584A1Prevent glareSpread widelyPlanar light sourcesPoint-like light sourceAir cycleUltrasound attenuation

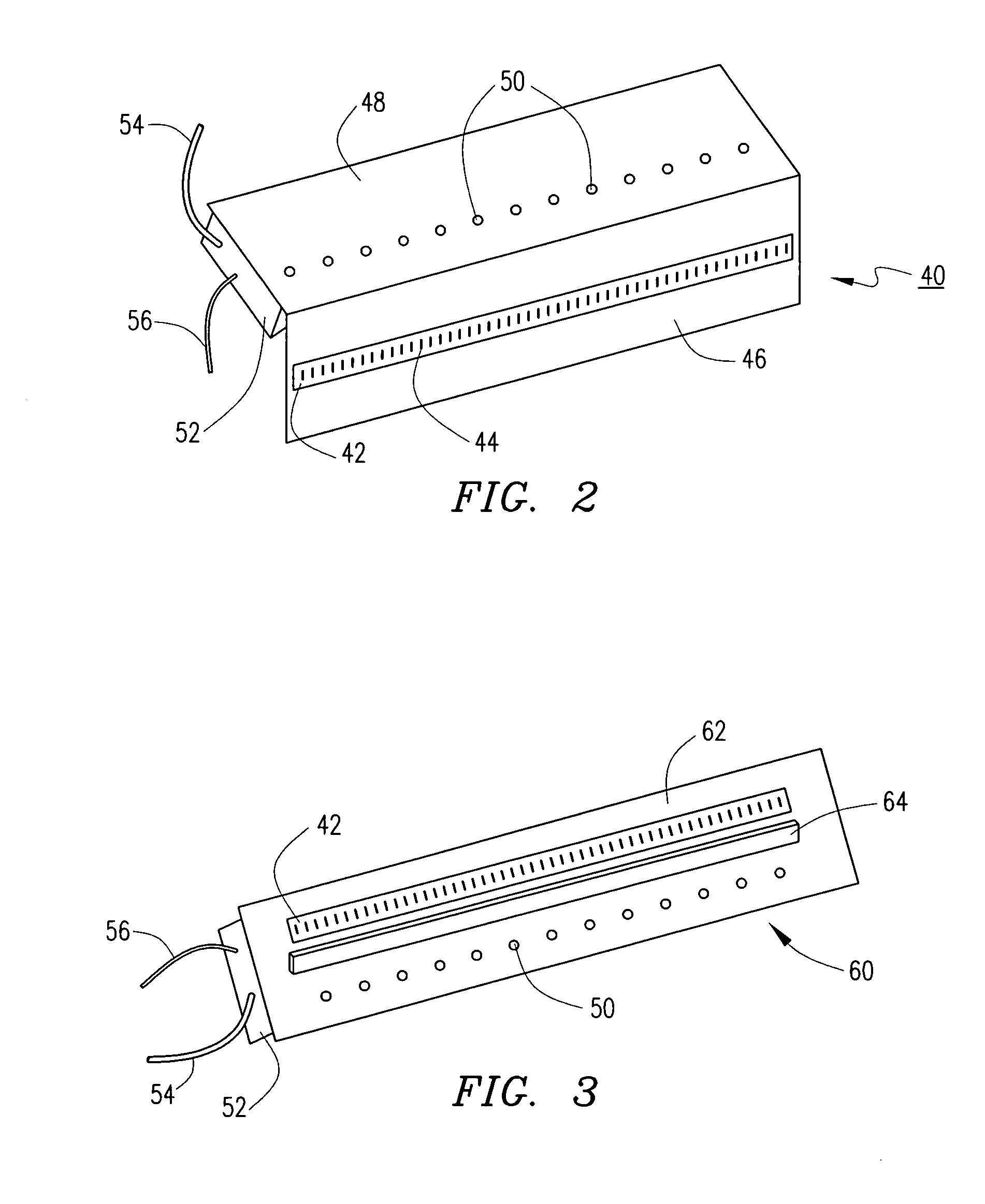

The present invention relates to a lighting device using an LED. One embodiment of the invention provides a lamp-shaped LED lighting device that can replace a known lighting device. The lamp-shaped LED lighting device promptly emits the heat generated by an LED element, which influences the optical output and the lifespan of the LED lighting device, through a lamp-shaped frame with a heat-ventilation structure that facilitates air circulation. In addition, the lamp-shaped LED lighting device prevents glare from an LED light source by using a lateral reflecting member, a diffusion lens and a diffusion cover and diffuses the light from the light source widely without optical attenuation. Another embodiment of the invention provides a tube and panel-shaped LED lighting devices that can be replaced with a previous tube-shaped fluorescent light and a panel-shaped lighting device. The tube and panel-shaped LED lighting devices rapidly emit the heat generated by an LED element, which influences the optical output and the life span of the LED lighting device, through a tube and panel-shaped frame with a heat-sink structure. In addition, the tube and panel-shaped LED lighting devices prevent glare from the LED light source by optically arranging a curved reflecting plate, a diffusion plate and a diffusion window which include a diffusion lens at the upper portion of the LED element. Furthermore the tube and panel-shaped LED lighting devices diffuse the light from the LED light source widely without optical attenuation.

Owner:SOLARKOR

Data Centre

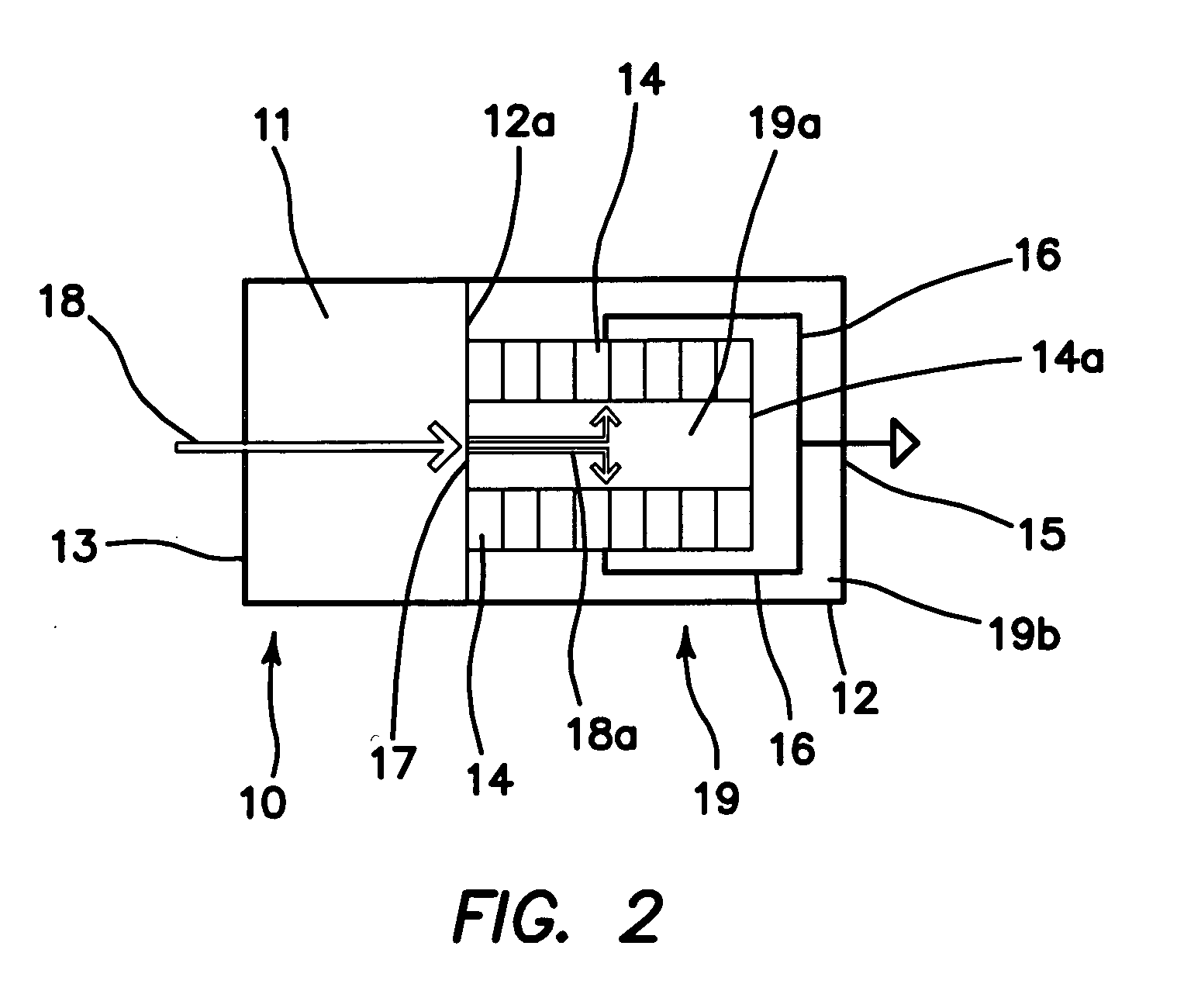

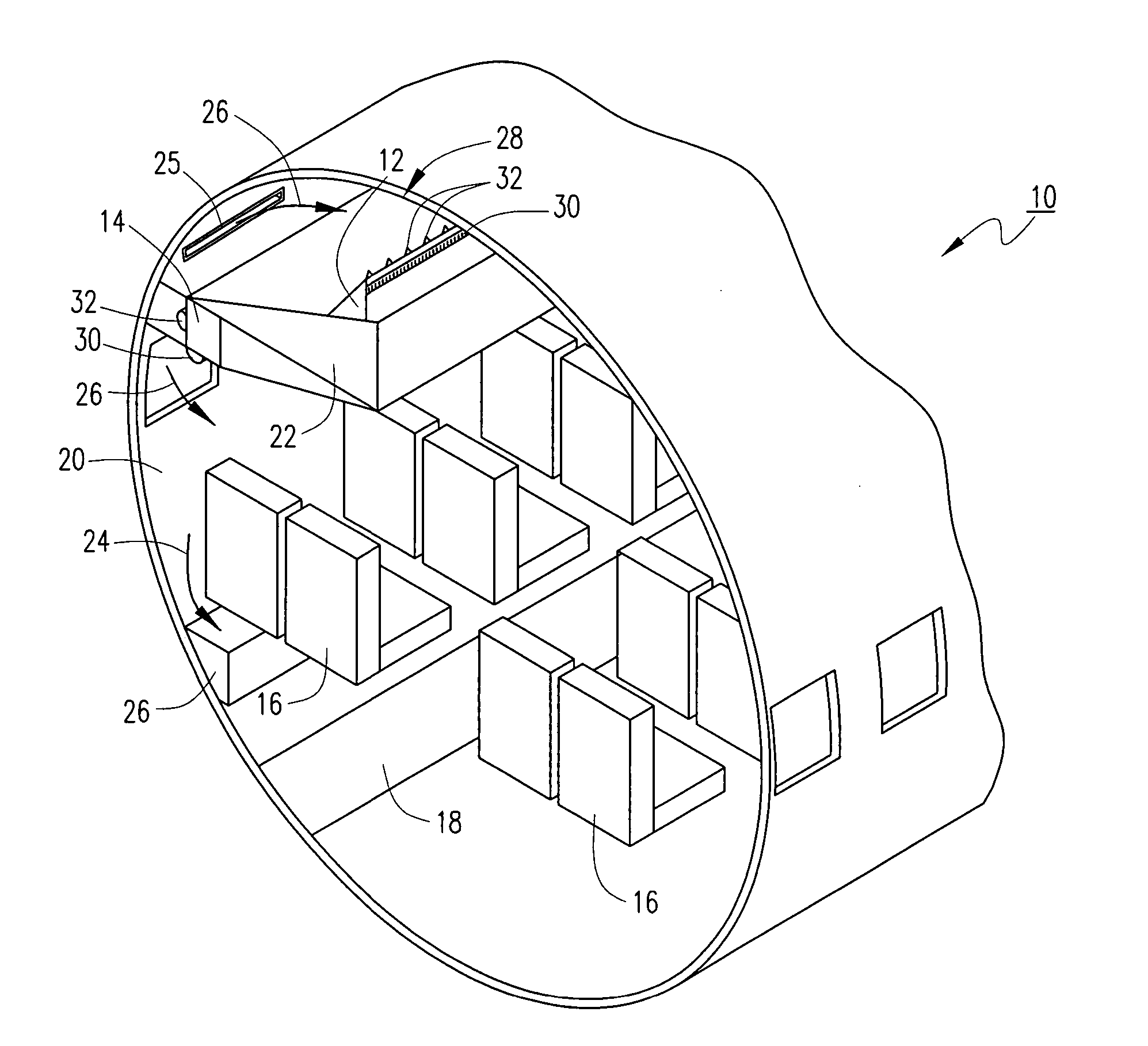

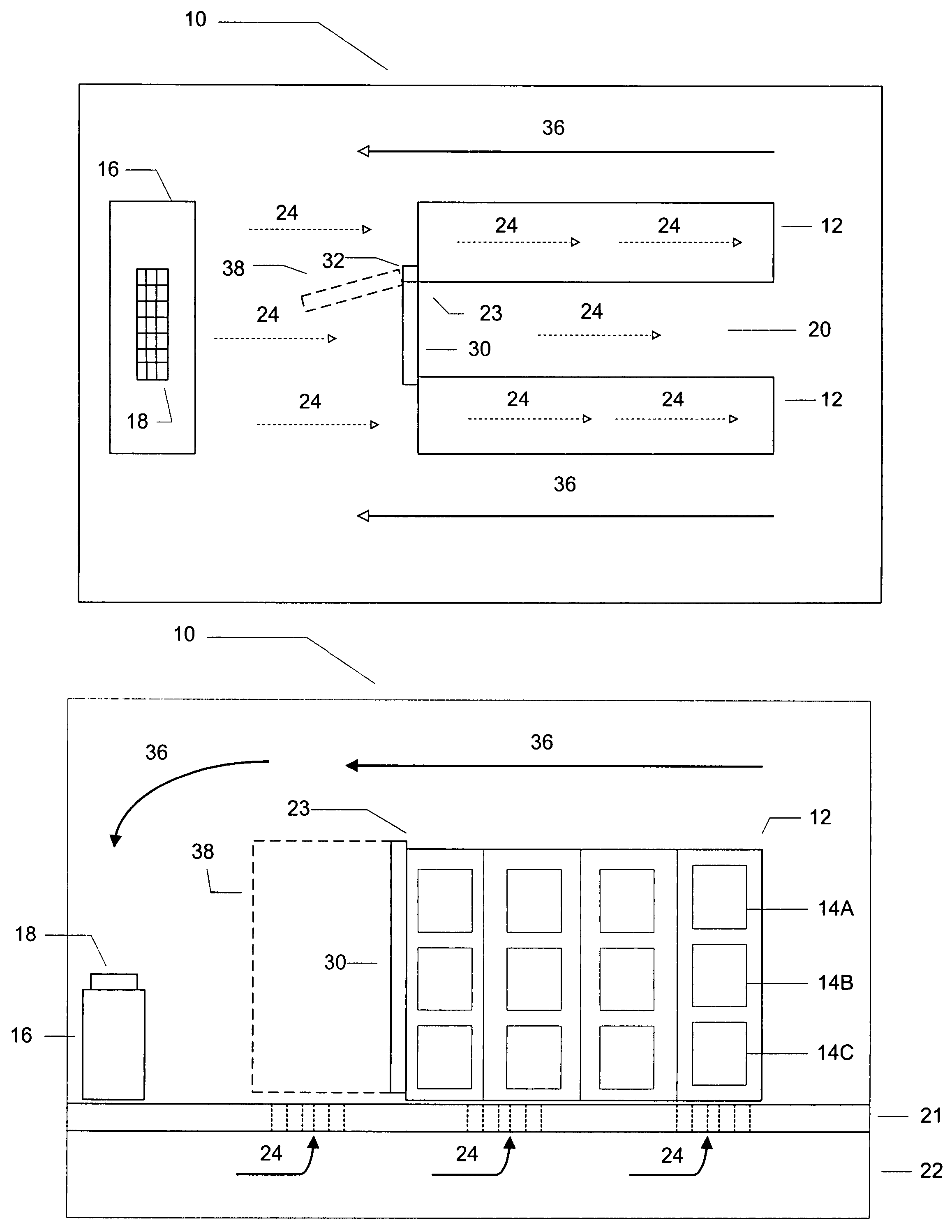

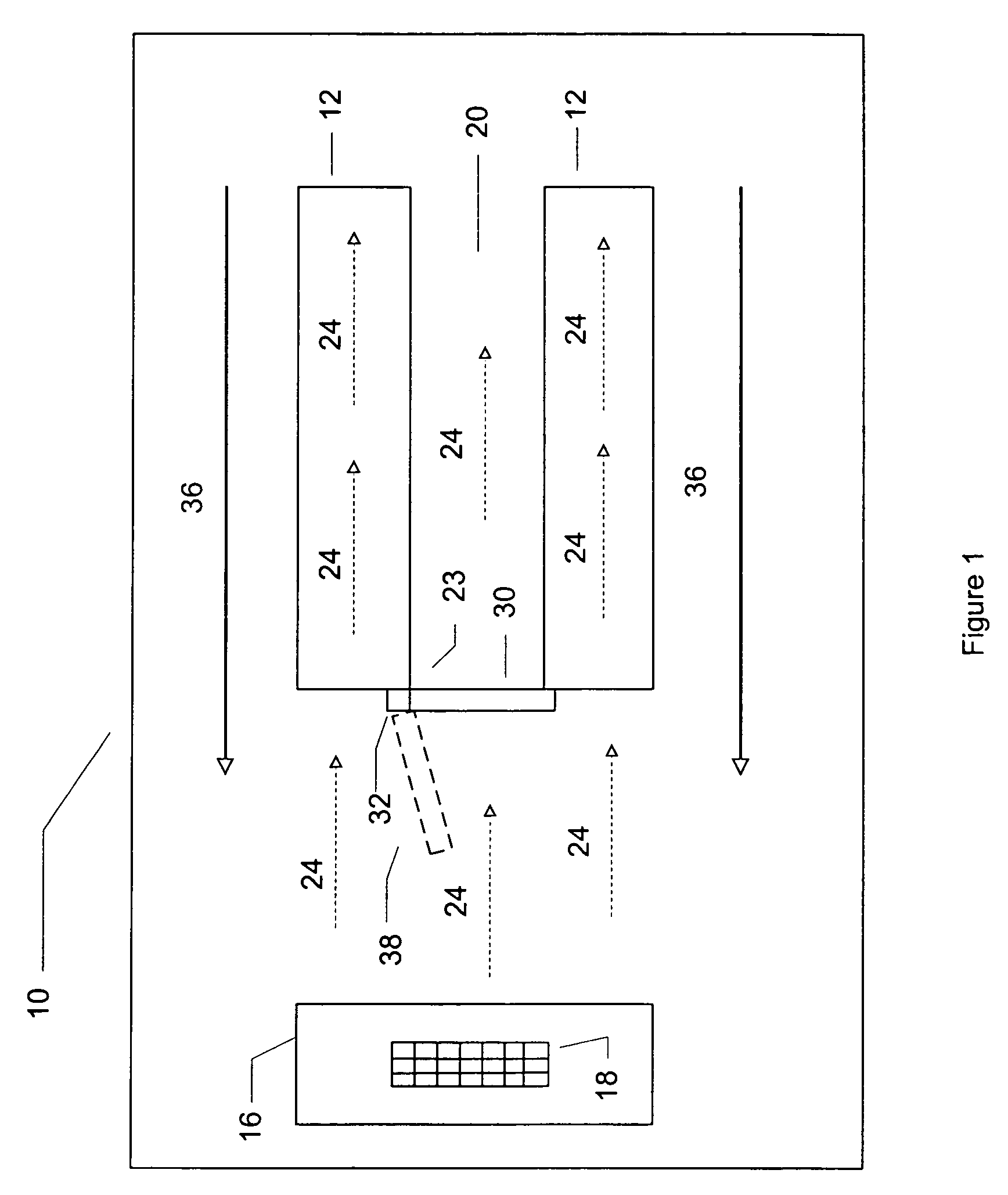

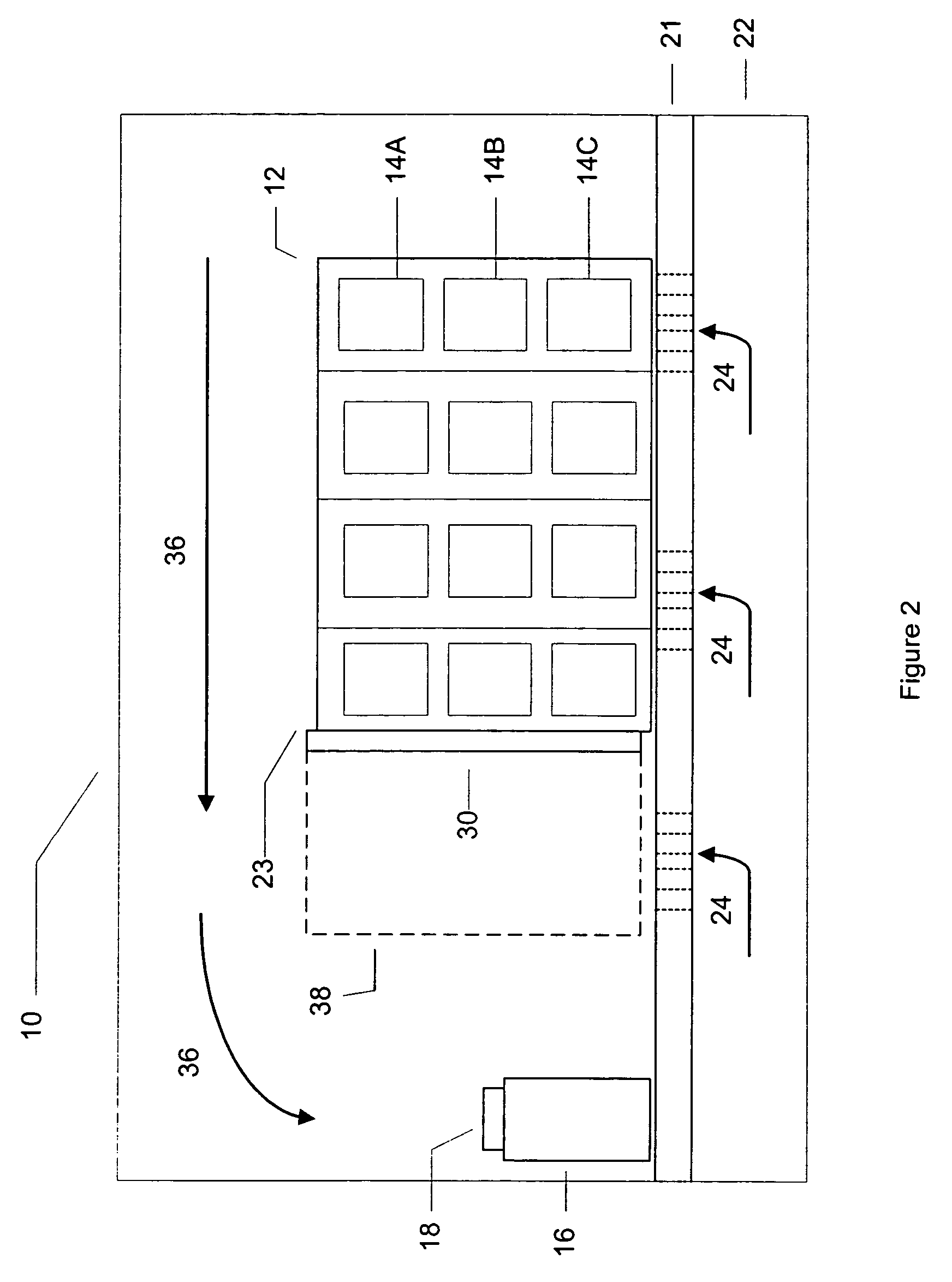

ActiveUS20110083824A1Facilitating correct positioningImprove efficiencyCoupling device connectionsSpace heating and ventilationMaximum dimensionEngineering

A data centre (100) includes at least one rack room (in for example module 140) having a floor and a plurality of rack storage areas on the floor, each rack storage area being arranged to accommodate a plurality of racks (143) in which a plurality of rack-mountable electronic components may be housed, one or more controllable air circulation systems (in for example module 122), one or more cold aisles (144) in the rack room, each cold aisle being adjacent to a rack storage area, and one or more hot aisles (145) in the rack room, each hot aisle being adjacent to a rack storage area. There may be a large air duct, in the form of a personnel corridor (123), for transporting, under the control of the one or more air circulation systems, cooling air, above the floor, to the one or more cold aisles. The air supply corridor / duct (123) may have a height greater than 1.5 m above the floor and a cross-sectional area of at least 2 m2 and a maximum dimension in the plane of the cross-section of less than 3 m.

Owner:BRIPCO

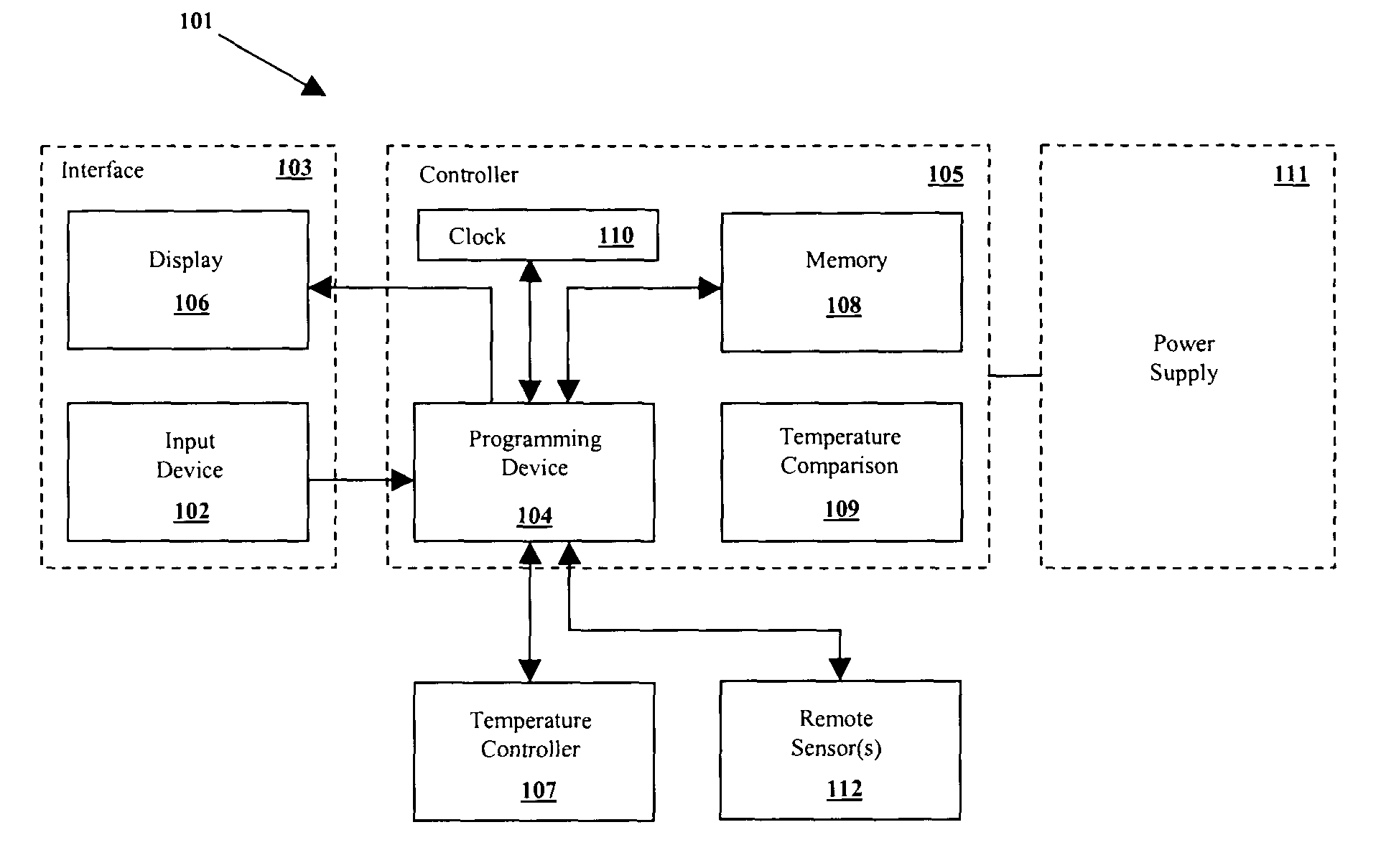

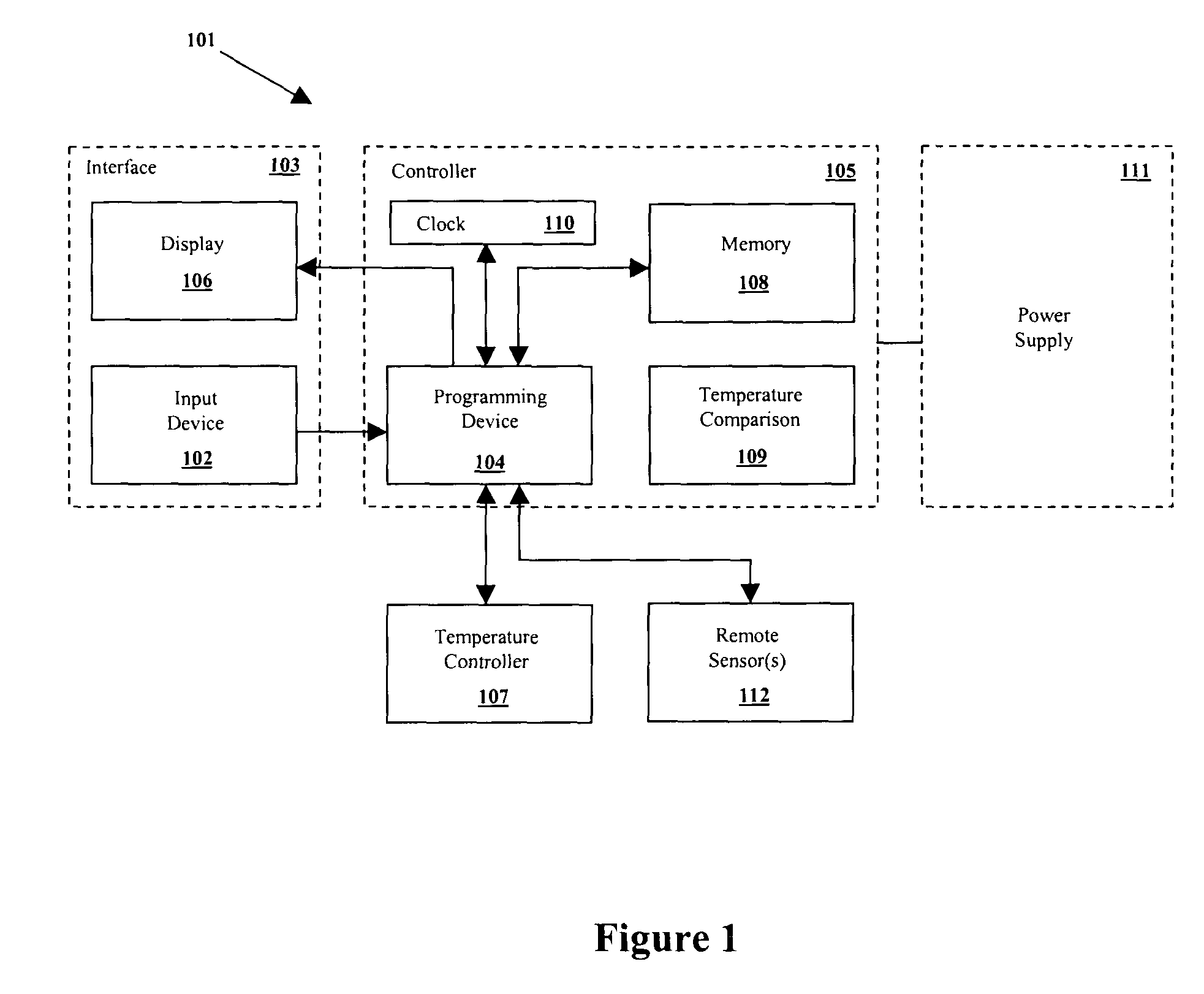

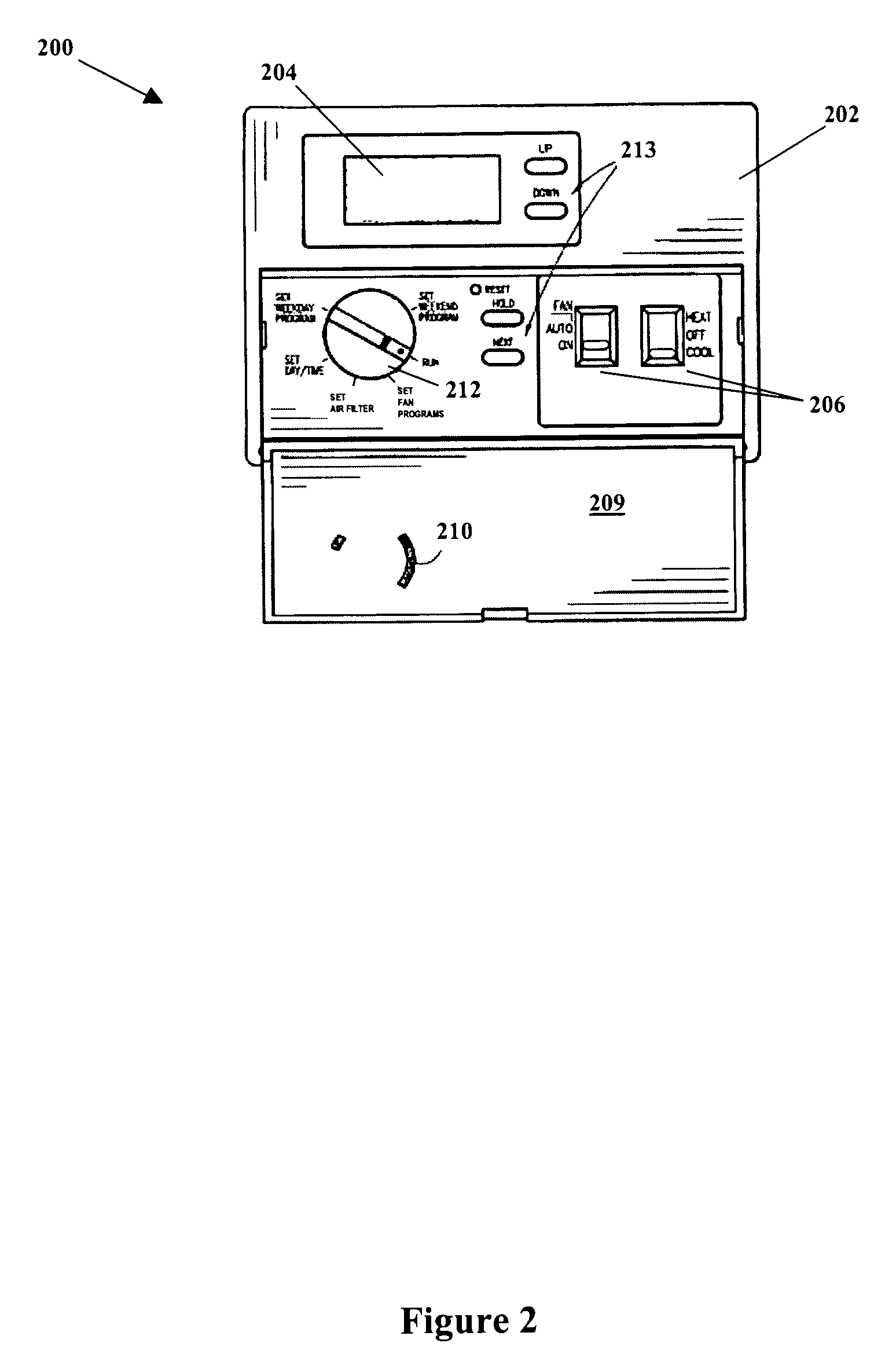

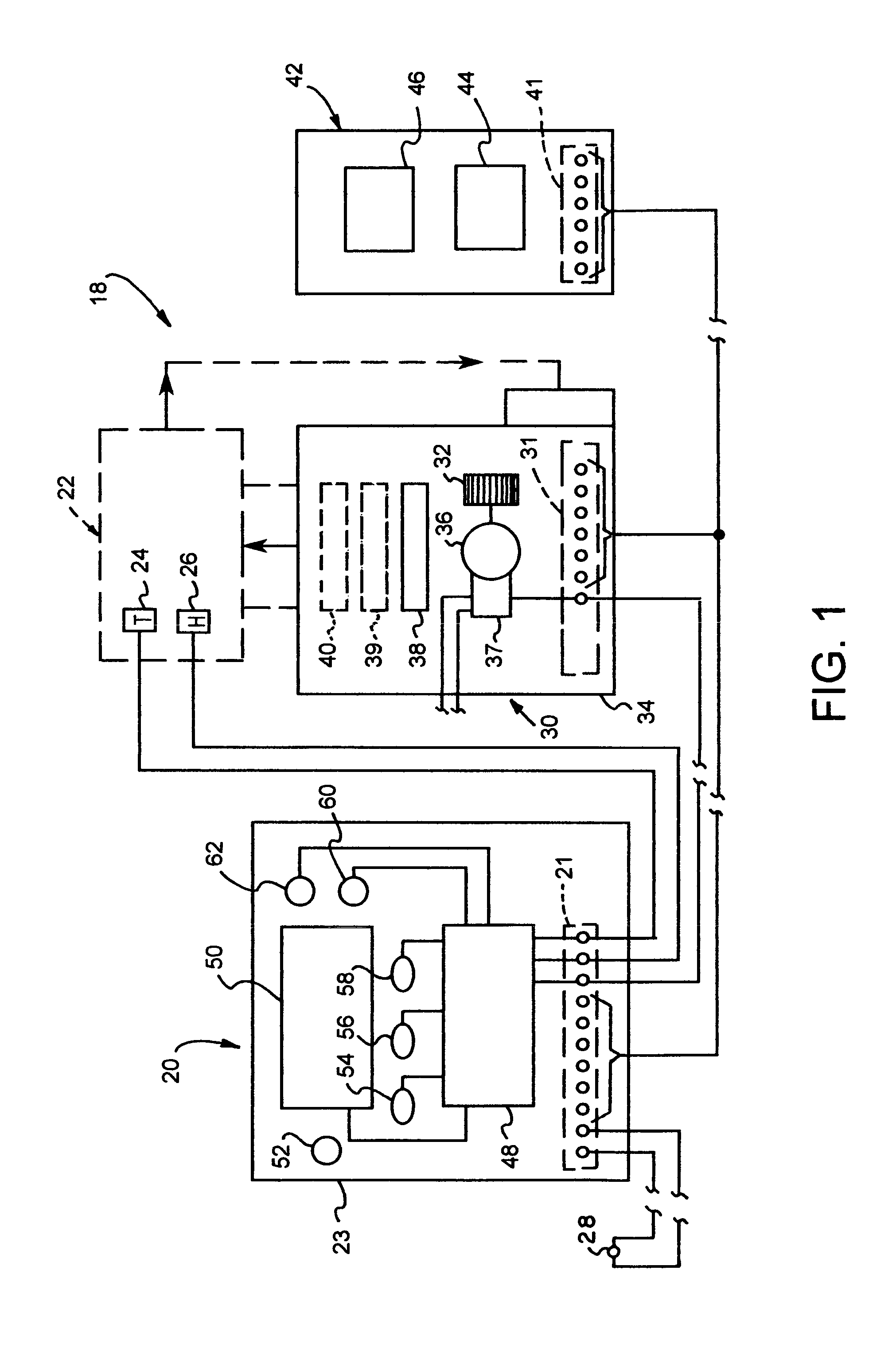

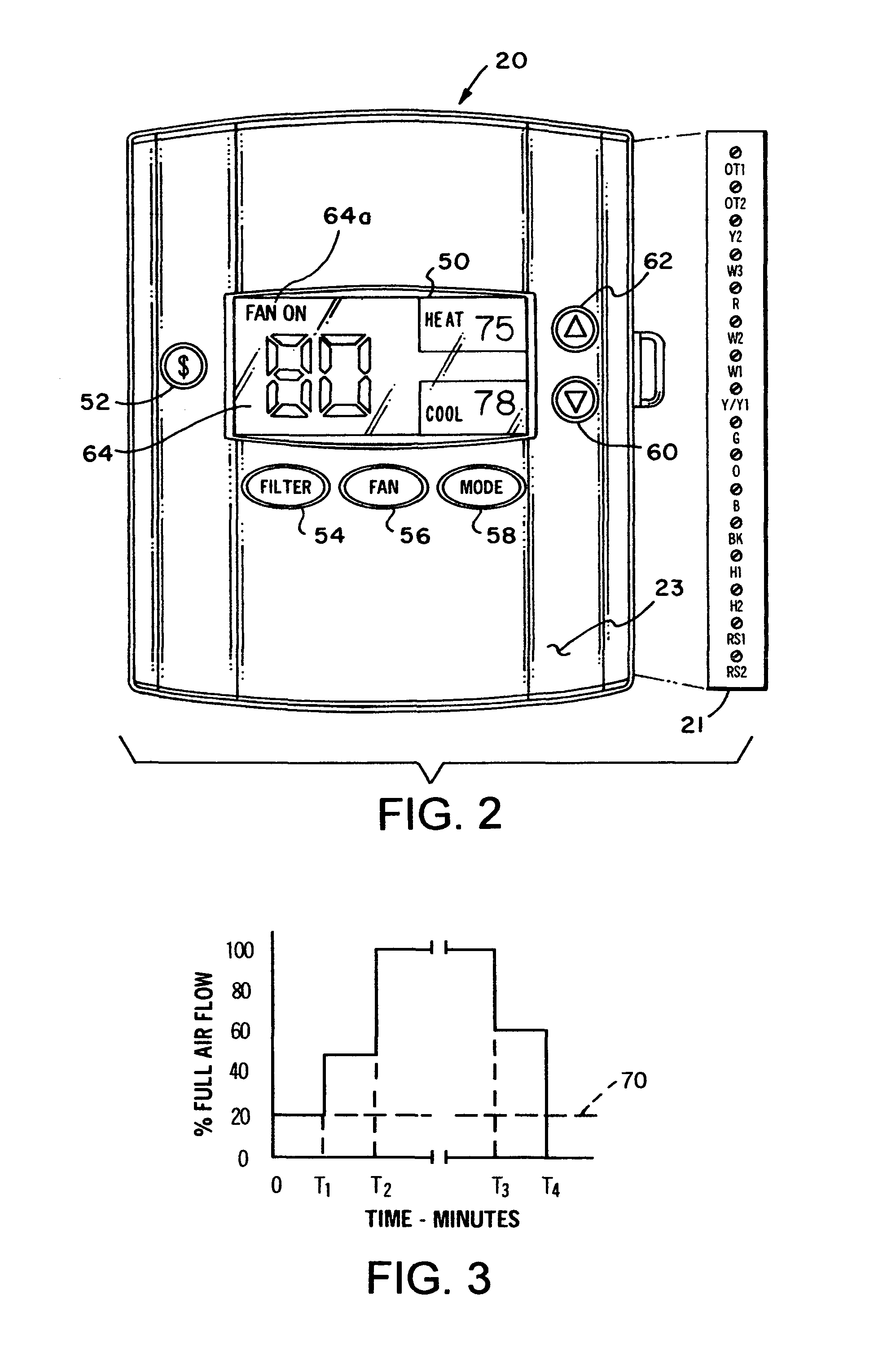

Programmable thermostat incorporating air quality protection

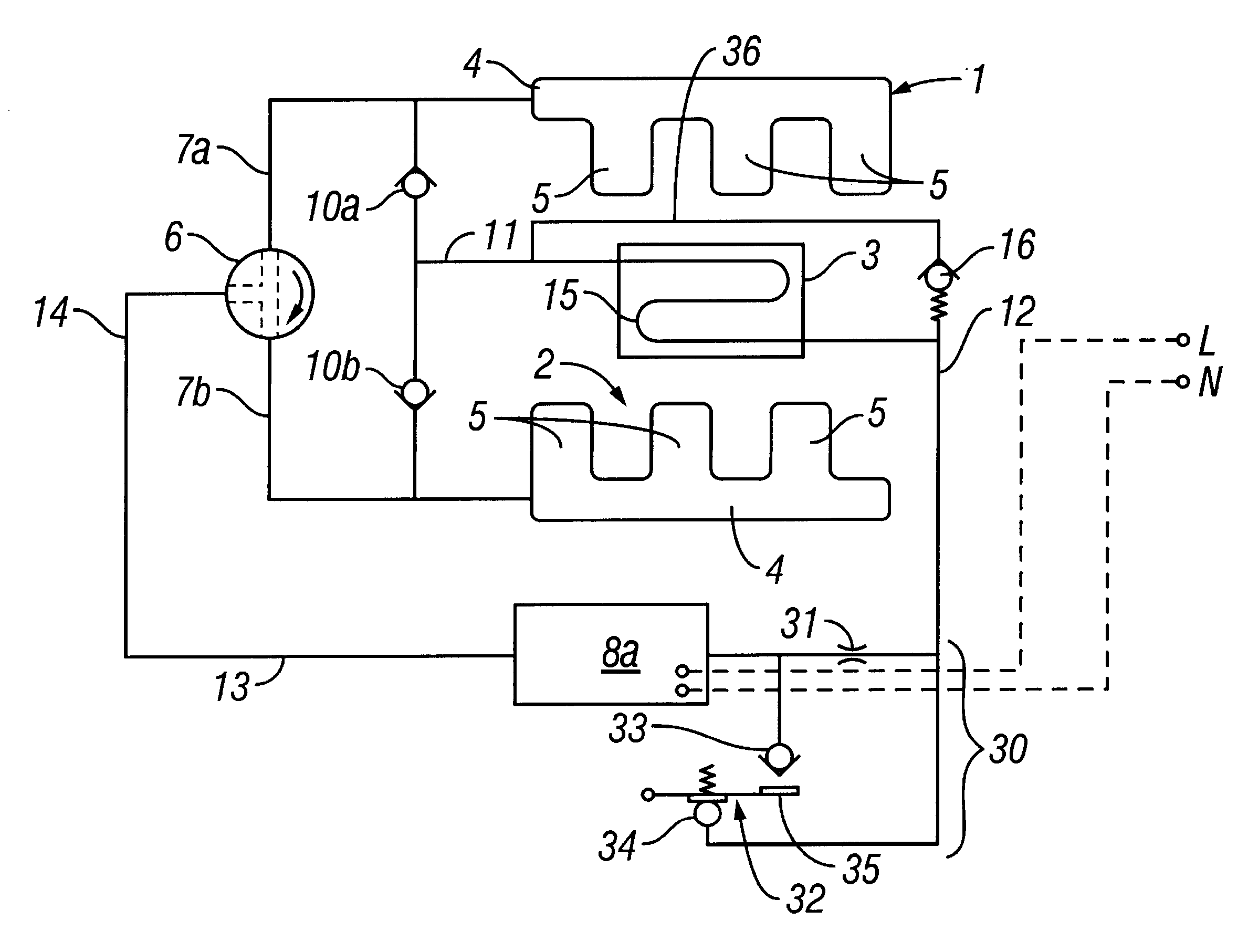

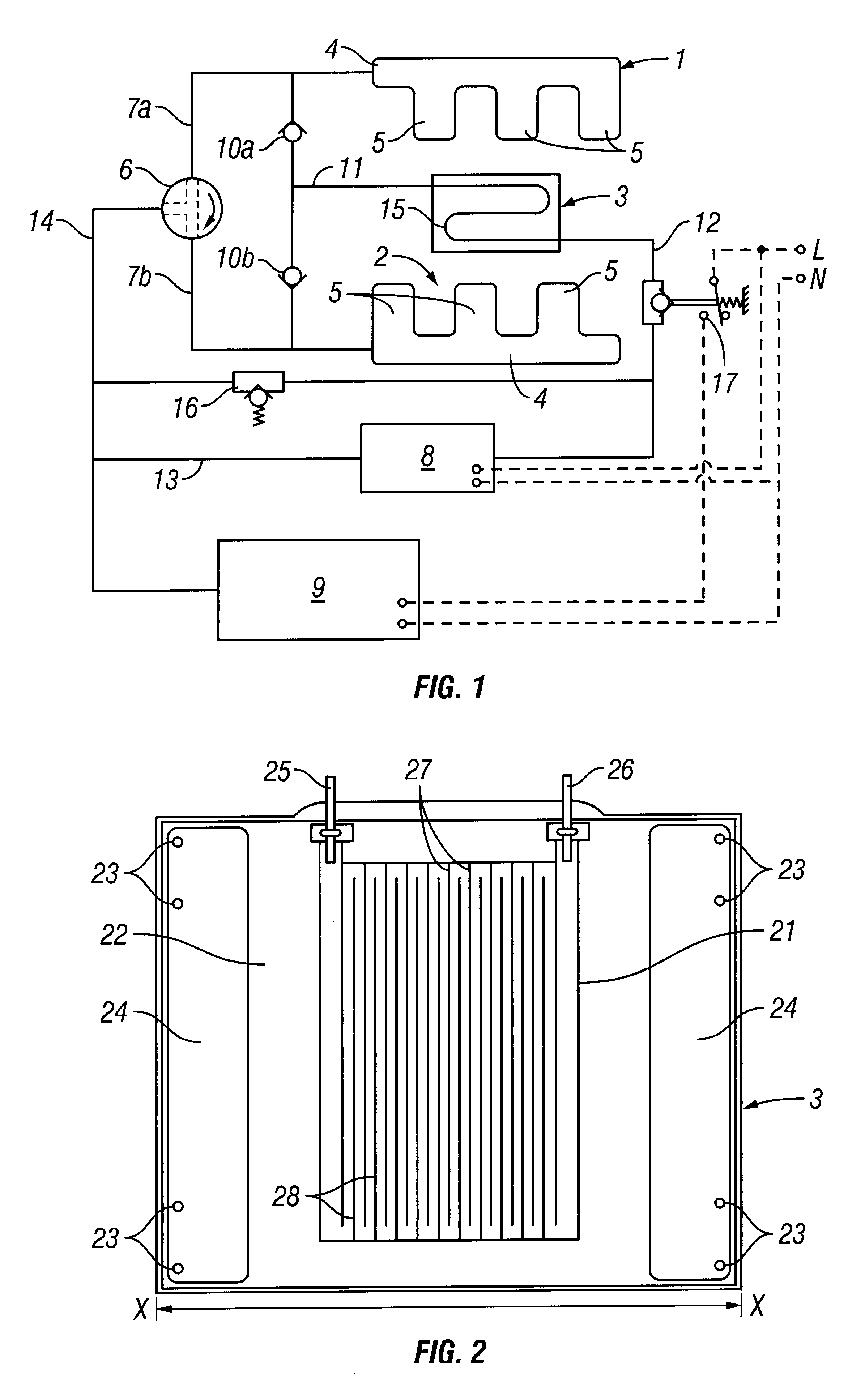

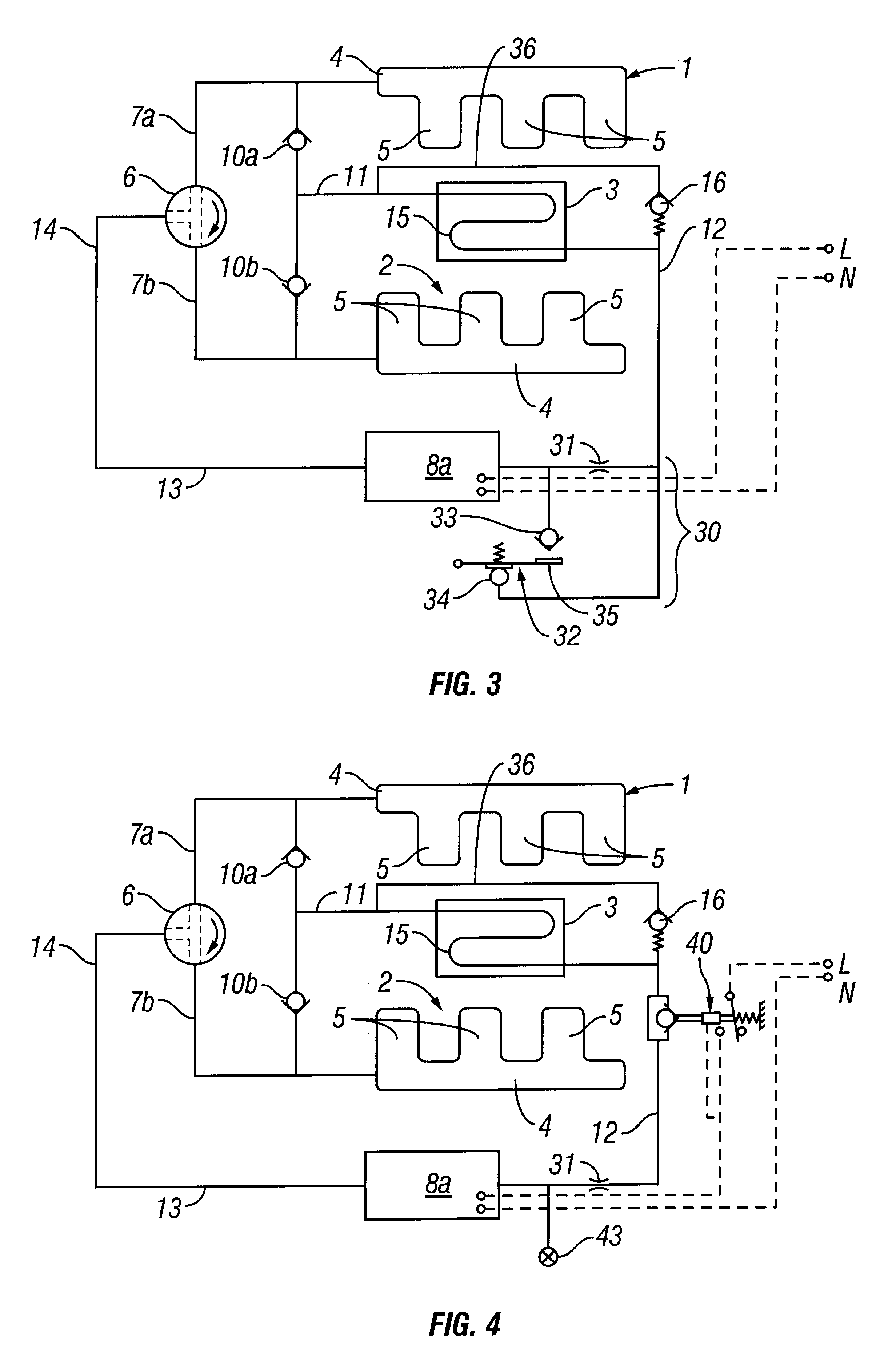

InactiveUS6988671B2Mechanical apparatusSpace heating and ventilation safety systemsAir filtrationTemperature control

The invention is directed to programmable temperature control in which a controller may be programmed to control a thermal output of said temperature-modifying device, and to operate an air circulating system independently of the temperature-modifying device. The apparatus may incorporate a user input for entering air handling information to program the air circulating system to operate at predetermined intervals. The controller may be further programmed to receive air filtration information from the user input and to generate air filtration output information. The system may also be programmed to receive information regarding a characteristic of the air circulating system from an sensor for use in calculating the air filtration output information.

Owner:JOHNSON CONTROLS TECH CO INC

Low volumetric compression ratio integrated turbo-compound rotary engine

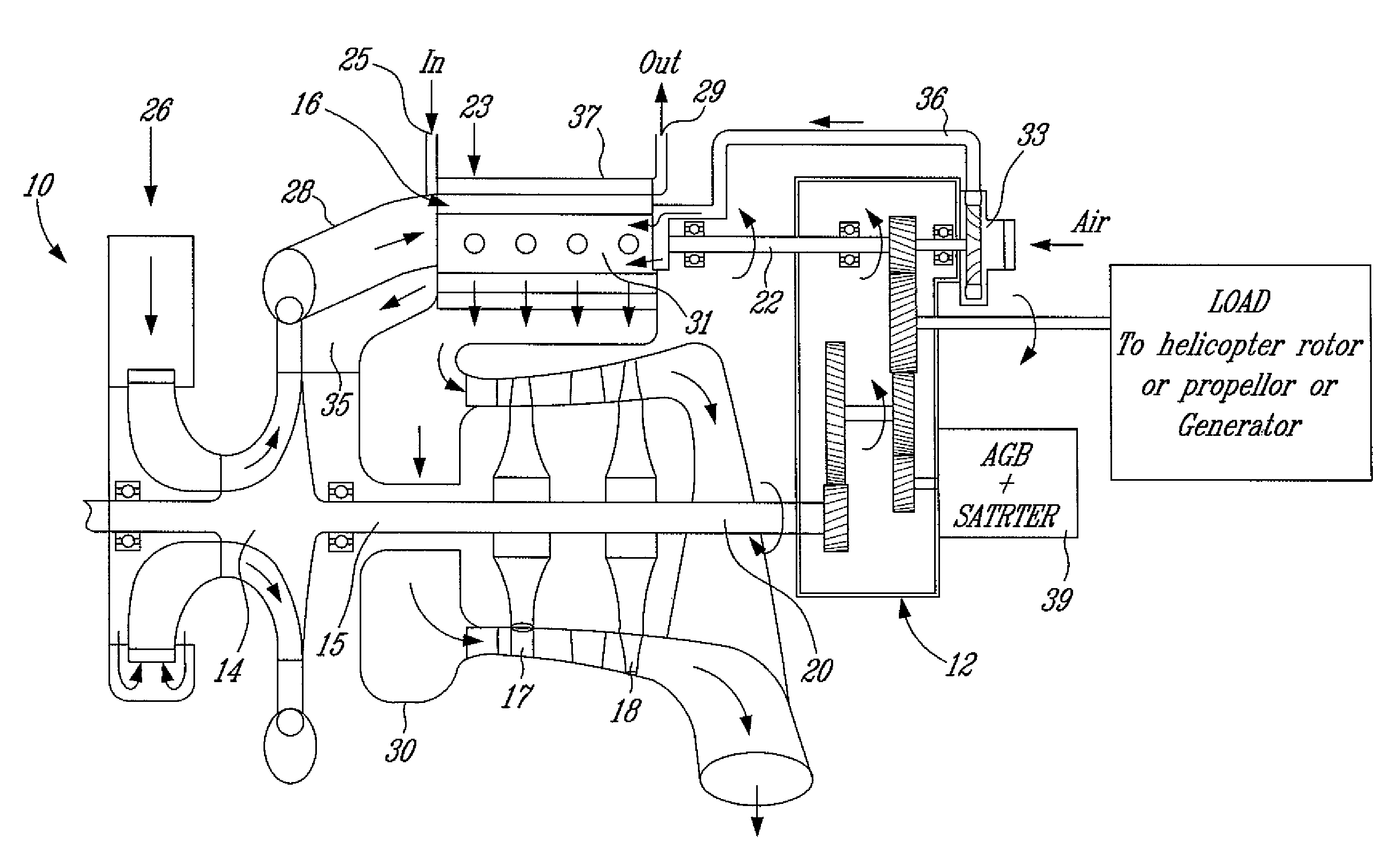

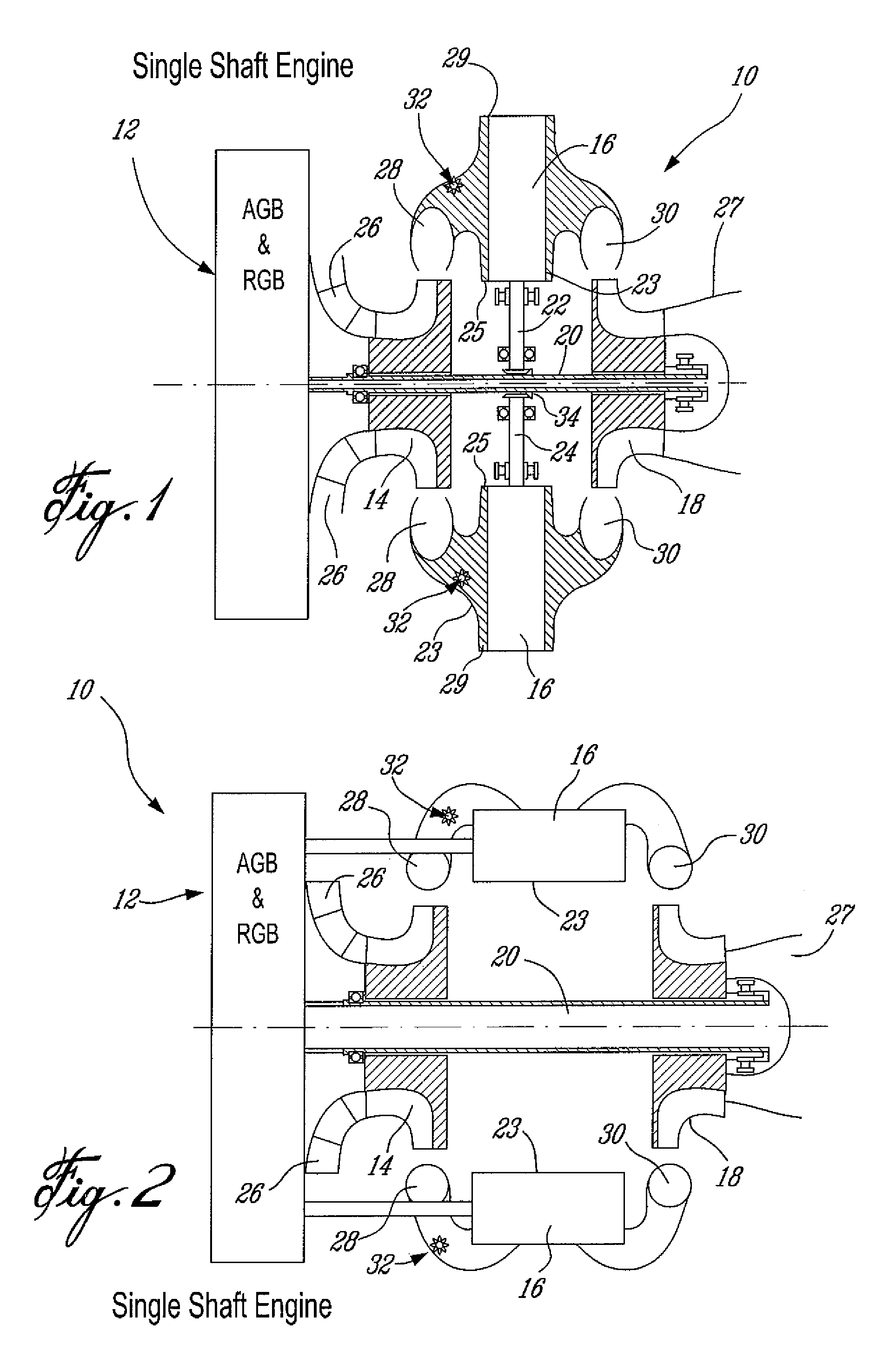

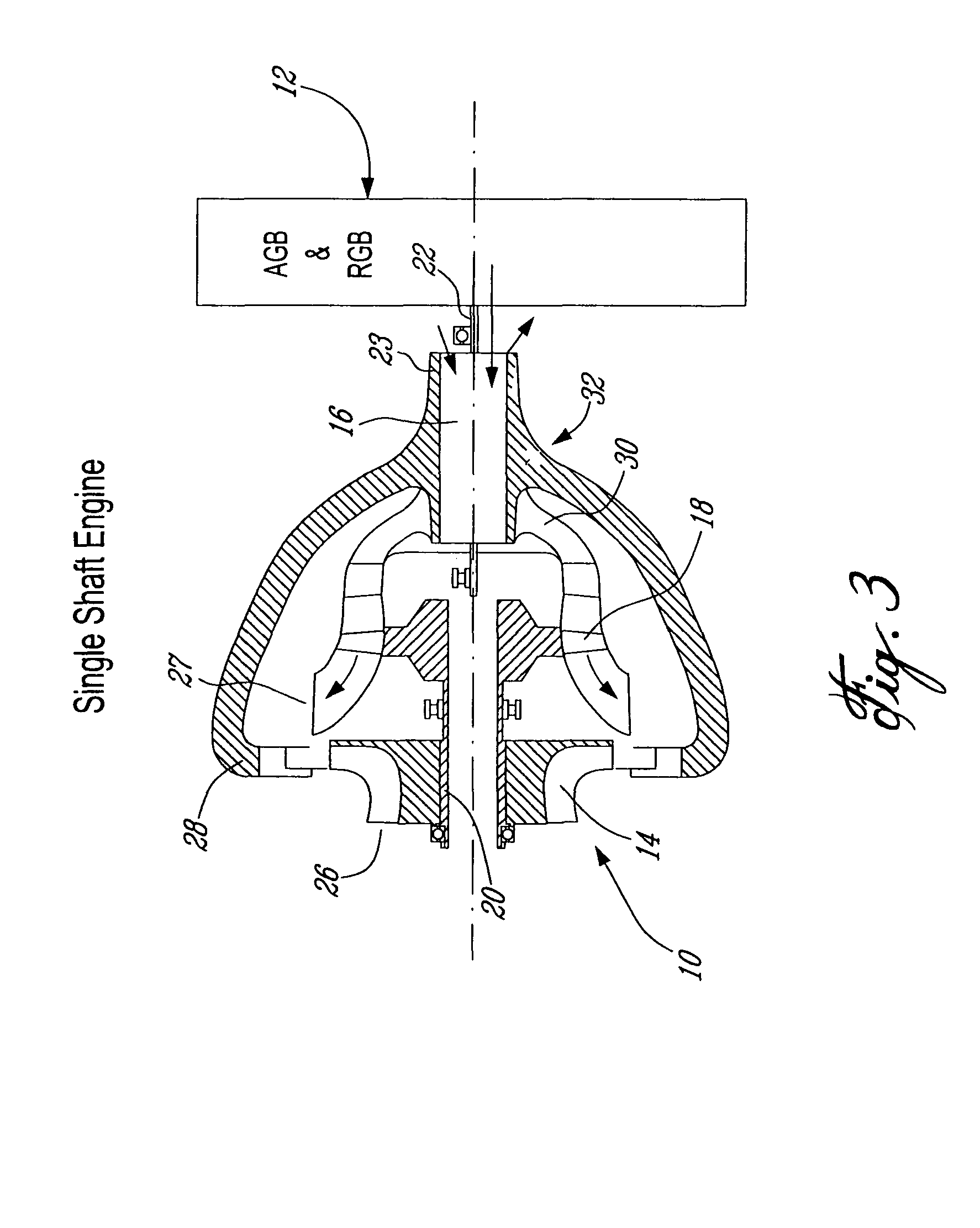

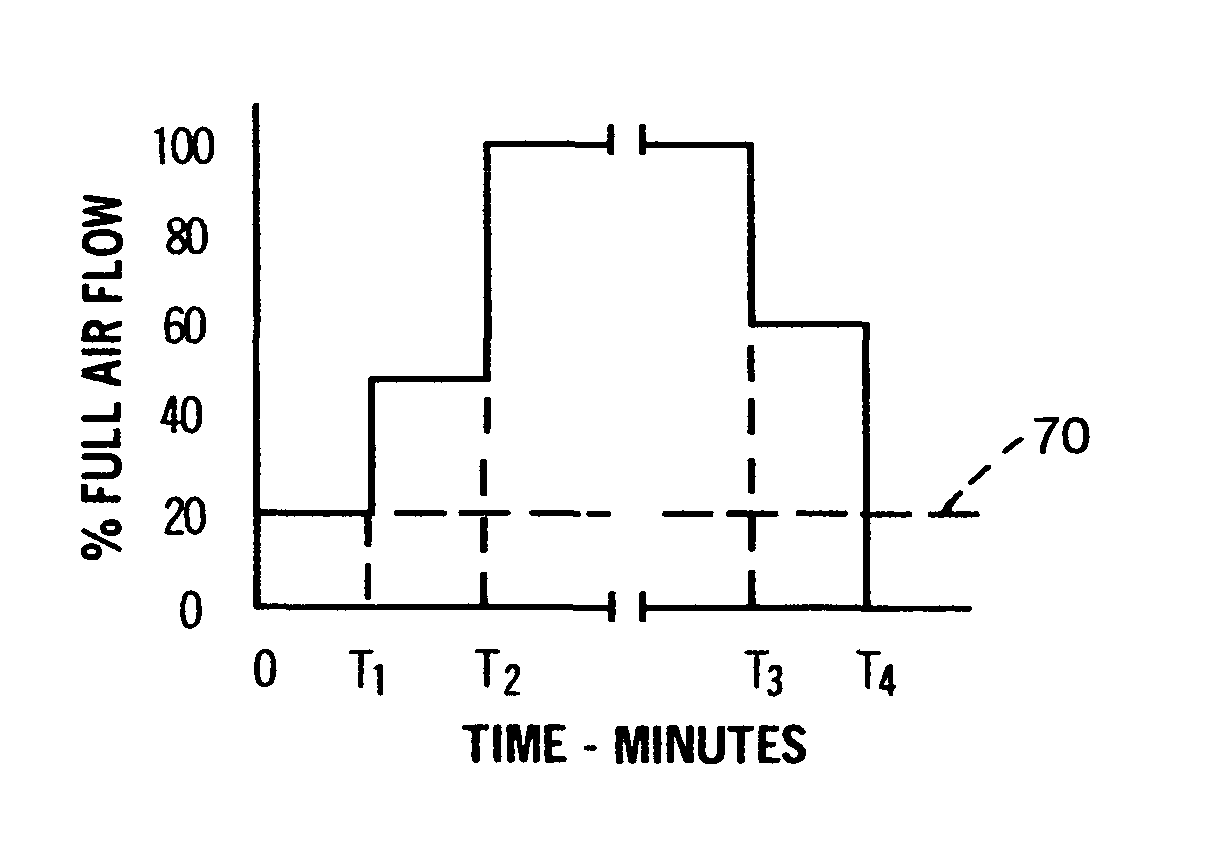

ActiveUS7775044B2Reduce the compression ratioImprove thermal efficiencyGas turbine plantsEfficient propulsion technologiesAir cycleRotary engine

Owner:PRATT & WHITNEY CANADA CORP

Humidity control for air conditioning system

ActiveUS8091375B2Increase humiditySimple methodMechanical apparatusSpace heating and ventilation safety systemsMicrocontrollerAir cycle

In an air conditioning system for circulating cooled air to an enclosed space, a controller including a temperature sensor, a humidity sensor and a microcontroller for controlling the indoor fan or blower to prevent operation of same if a fan run-on mode is selected or continuous fan operation is selected and the humidity sensed in the enclosed space is greater than a predetermined amount. Continuous fan operation is allowed unless the humidity exceeds a user defined setpoint during an air cooling operating mode. If the humidity sensed is greater than the predetermined amount, the fan is operated only when the system is providing cooled air, such as when the system compressor is energized.

Owner:TRANE INT INC

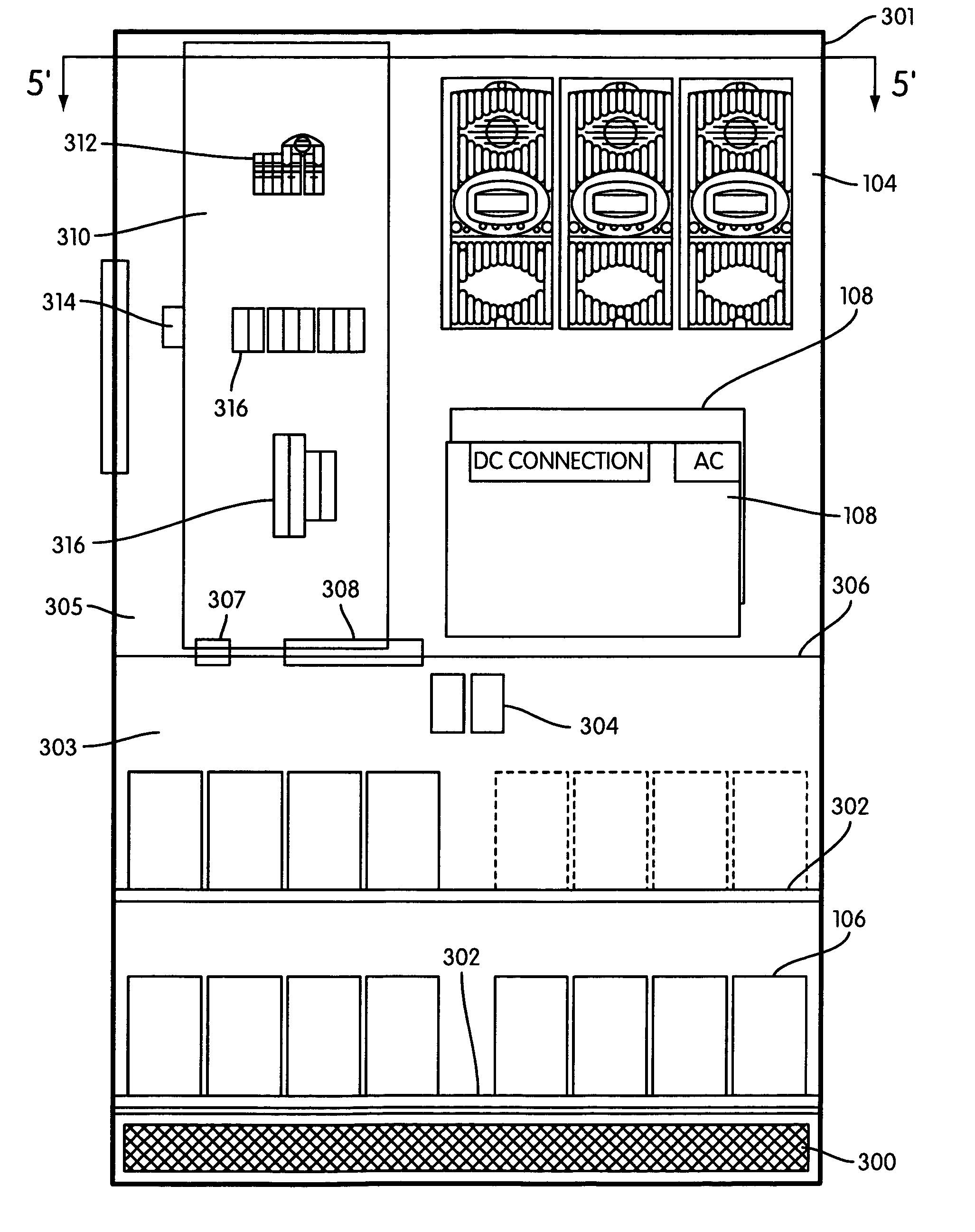

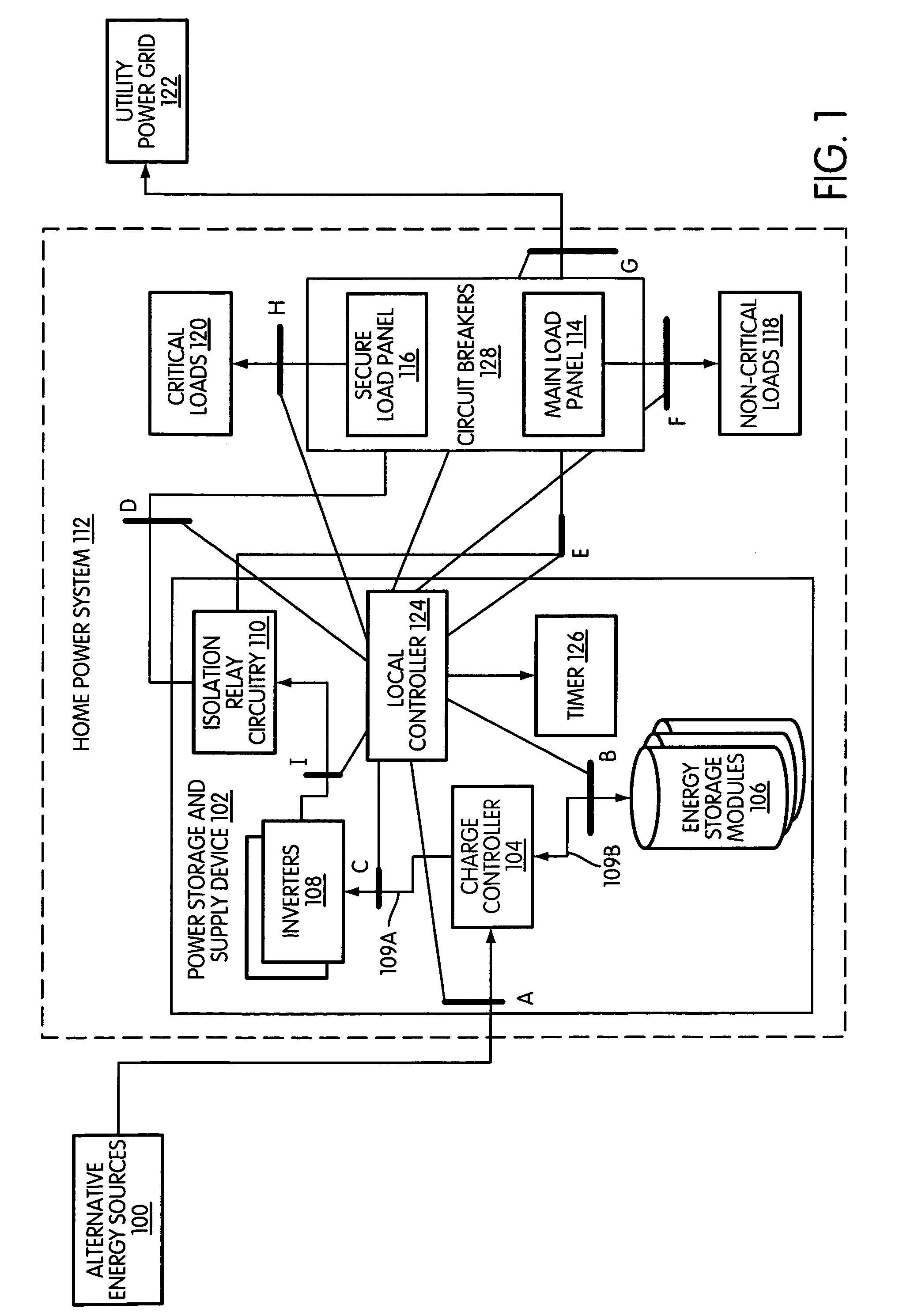

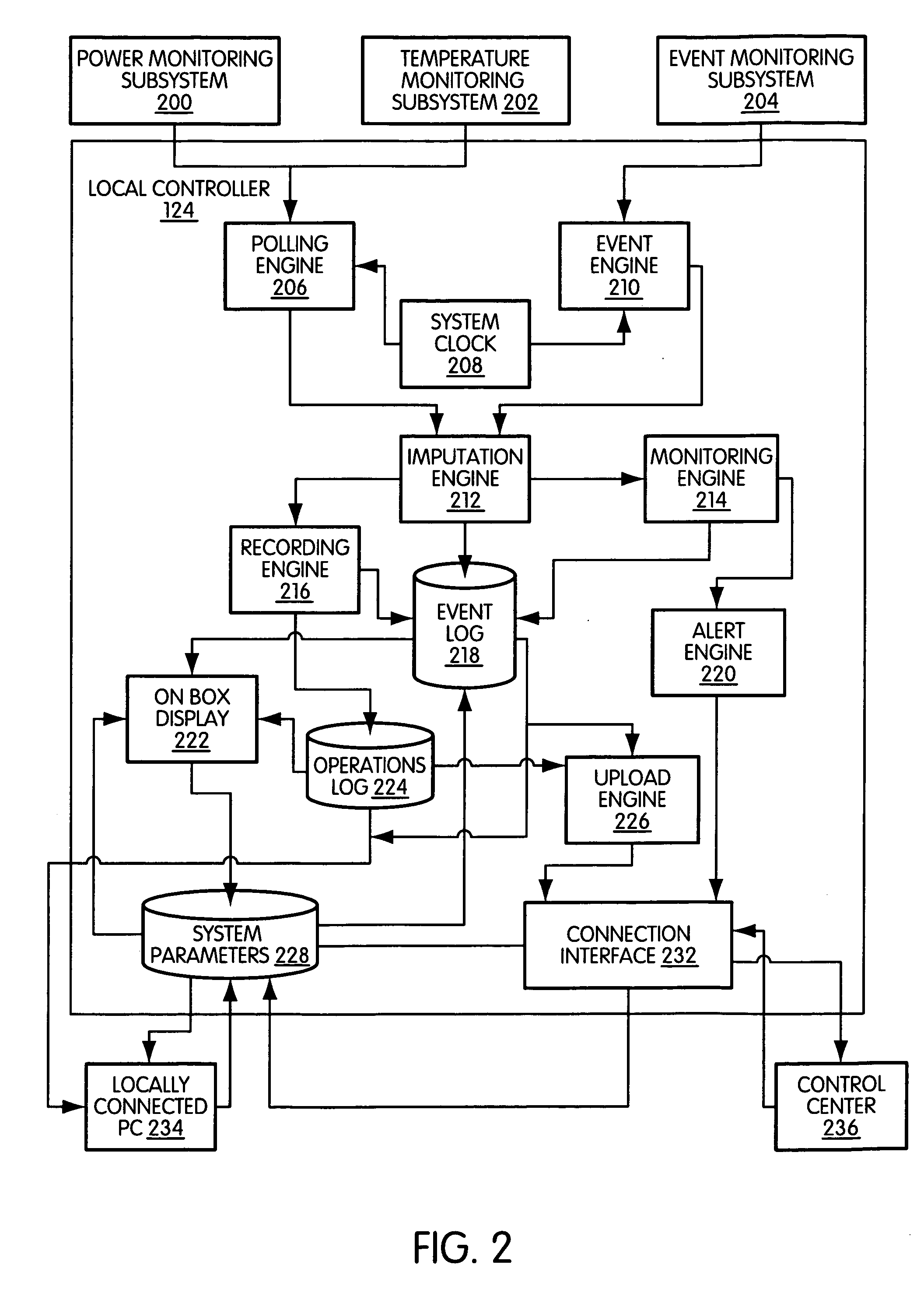

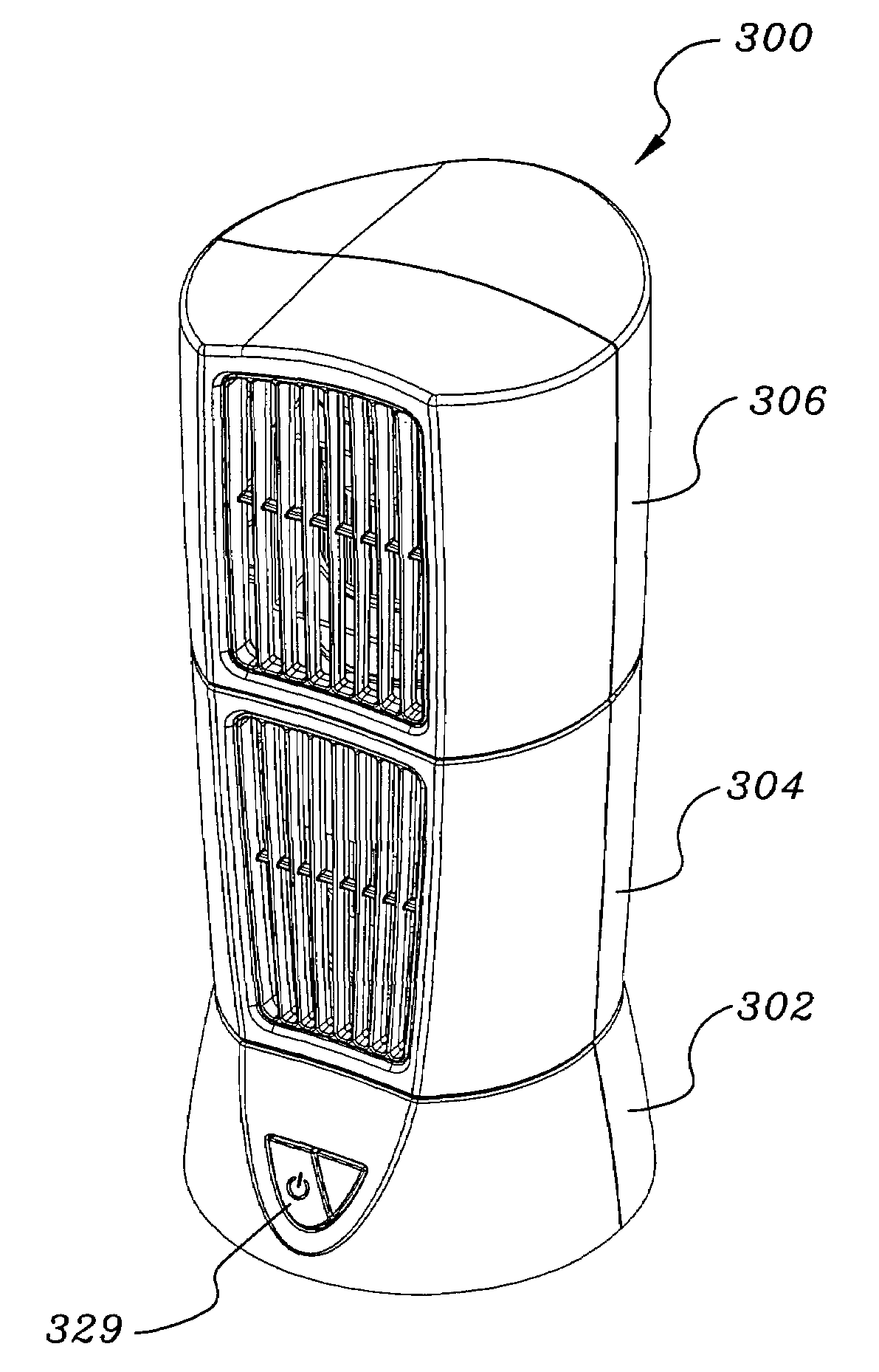

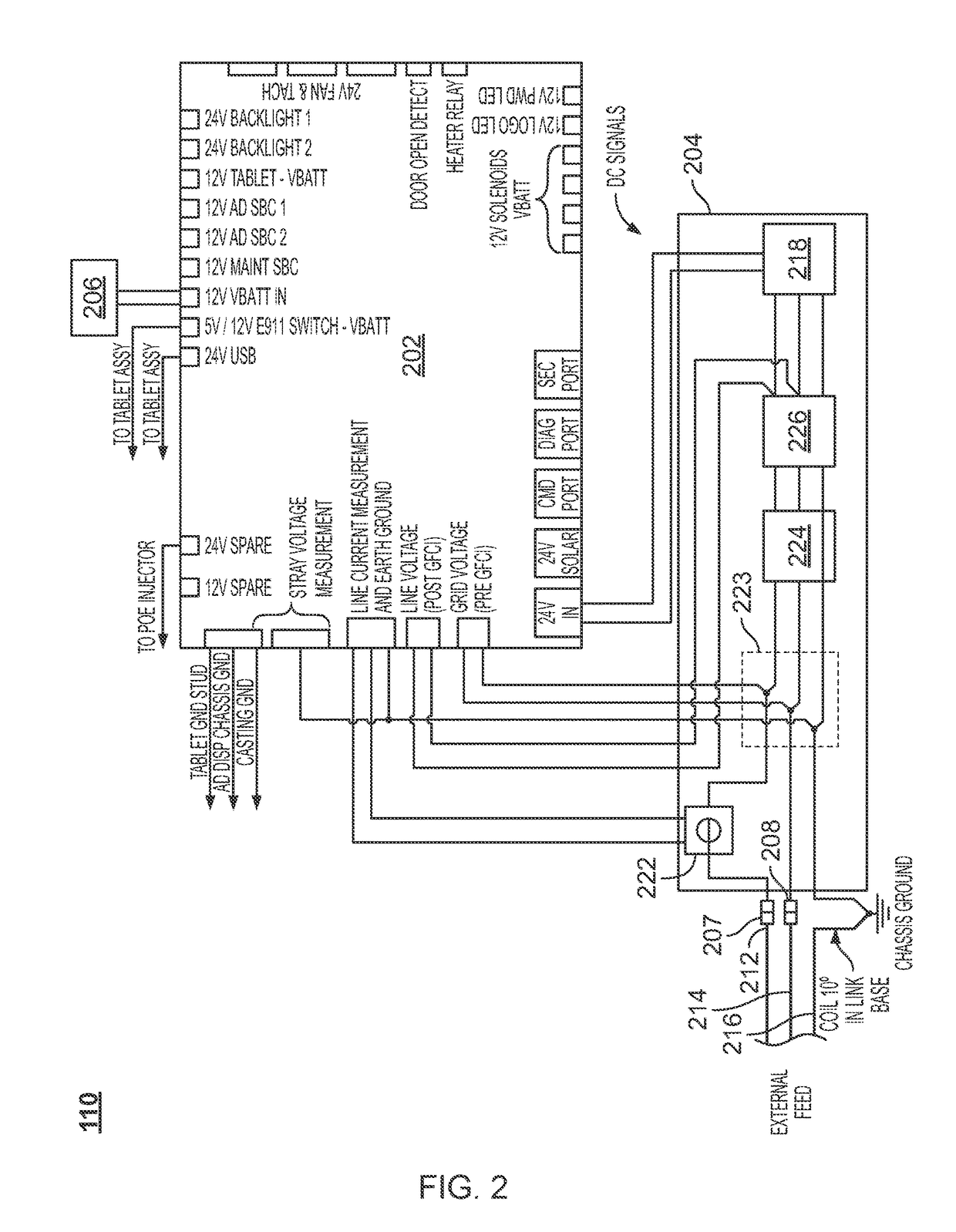

Fully integrated power storage and supply appliance with power uploading capability

Systems, methods and devices for integrating alternative energy sources and energy storage components into a single device with systems for control and safety monitoring to provide for use of the generated power on the premises, resale of power to the utility, and for power supply from storage and / or the alternative energy sources in the event of an interruption of supply from a utility's power grid. The device integrates the necessary components into a cabinet for use as a home appliance. The power storage and supply device cabinet contains essentially all necessary electrical components including charge controllers, inverters, relay circuitry, circuit breakers, and energy storage modules, such as batteries. A local controller device is disposed inside the cabinet and is configured to monitor and control the processes conducted by the power storage and supply device. The cabinet includes a ventilation system which uses an air intake located at the bottom of the cabinet for receiving air that is pulled into the lower section of the cabinet by fans located in the middle of the cabinet. The air is then circulated into the upper section of the cabinet where it is vented out through exhaust ports. Further, the cabinet of the power storage and supply device is compartmentalized by a separator panel that divides access to the compartments of the cabinet according to both levels associated with safety and a user's expertise.

Owner:GRIDPOINT

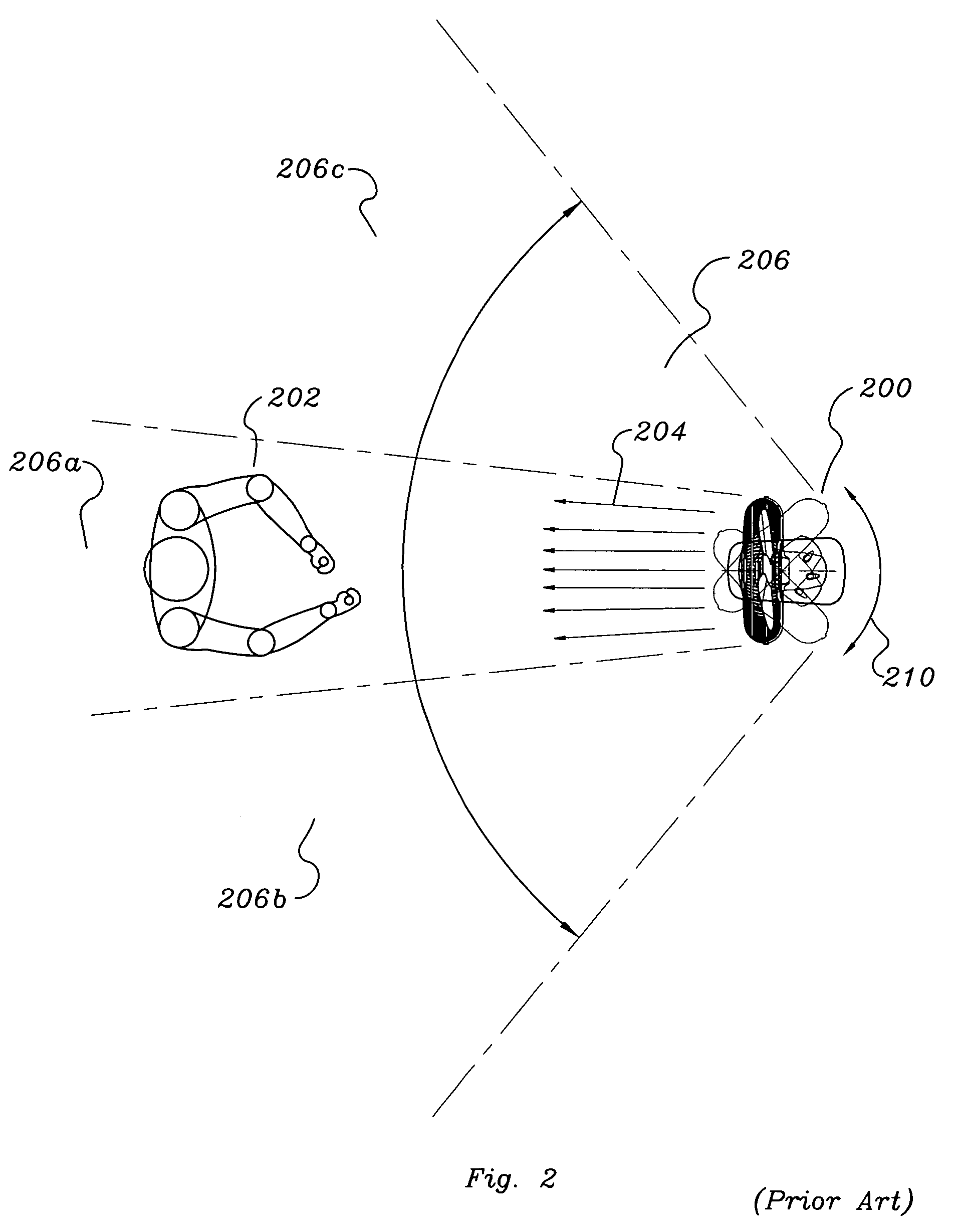

Multi-directional air circulating fan

Owner:LASKO OPERATION HLDG LLC

LED lighting device

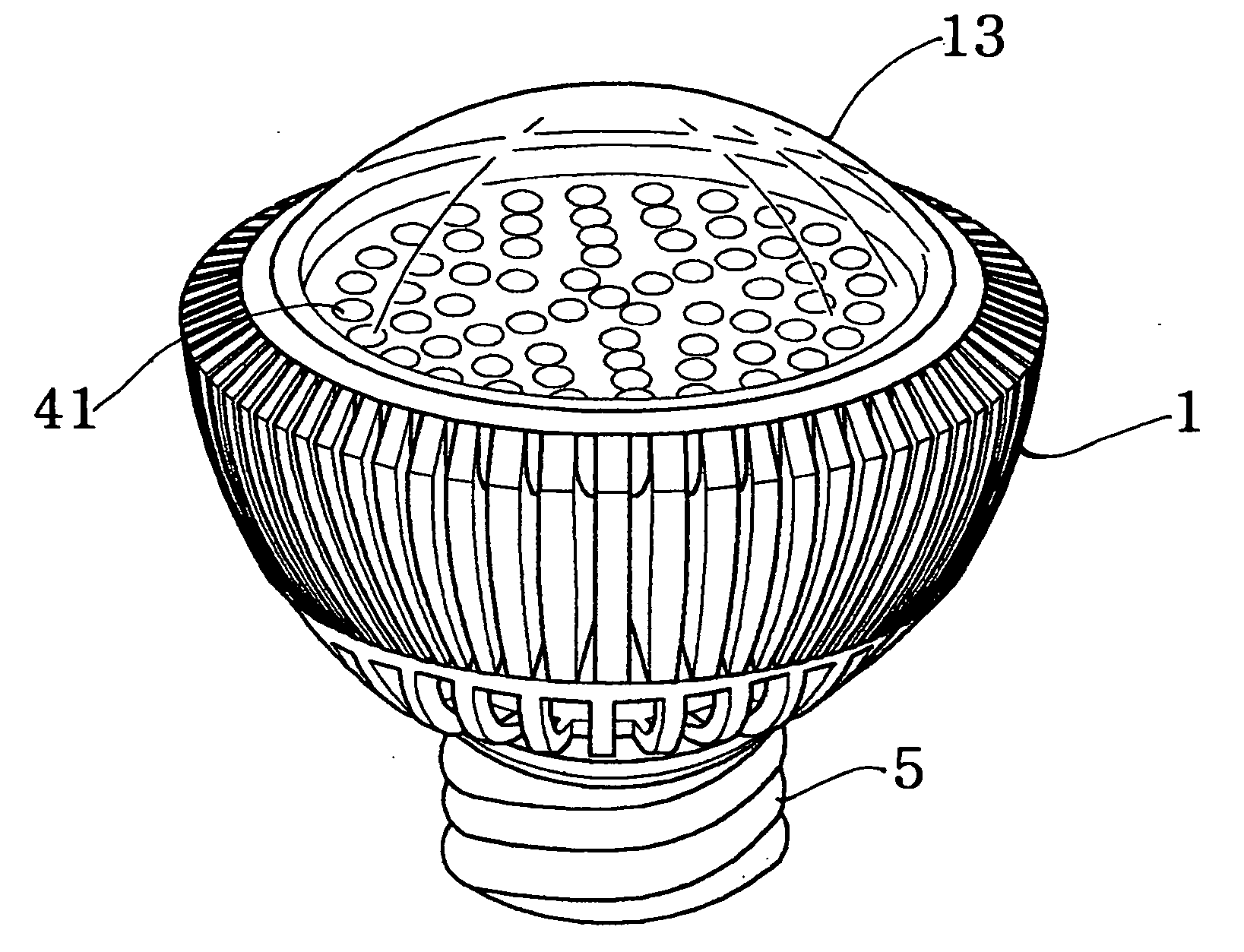

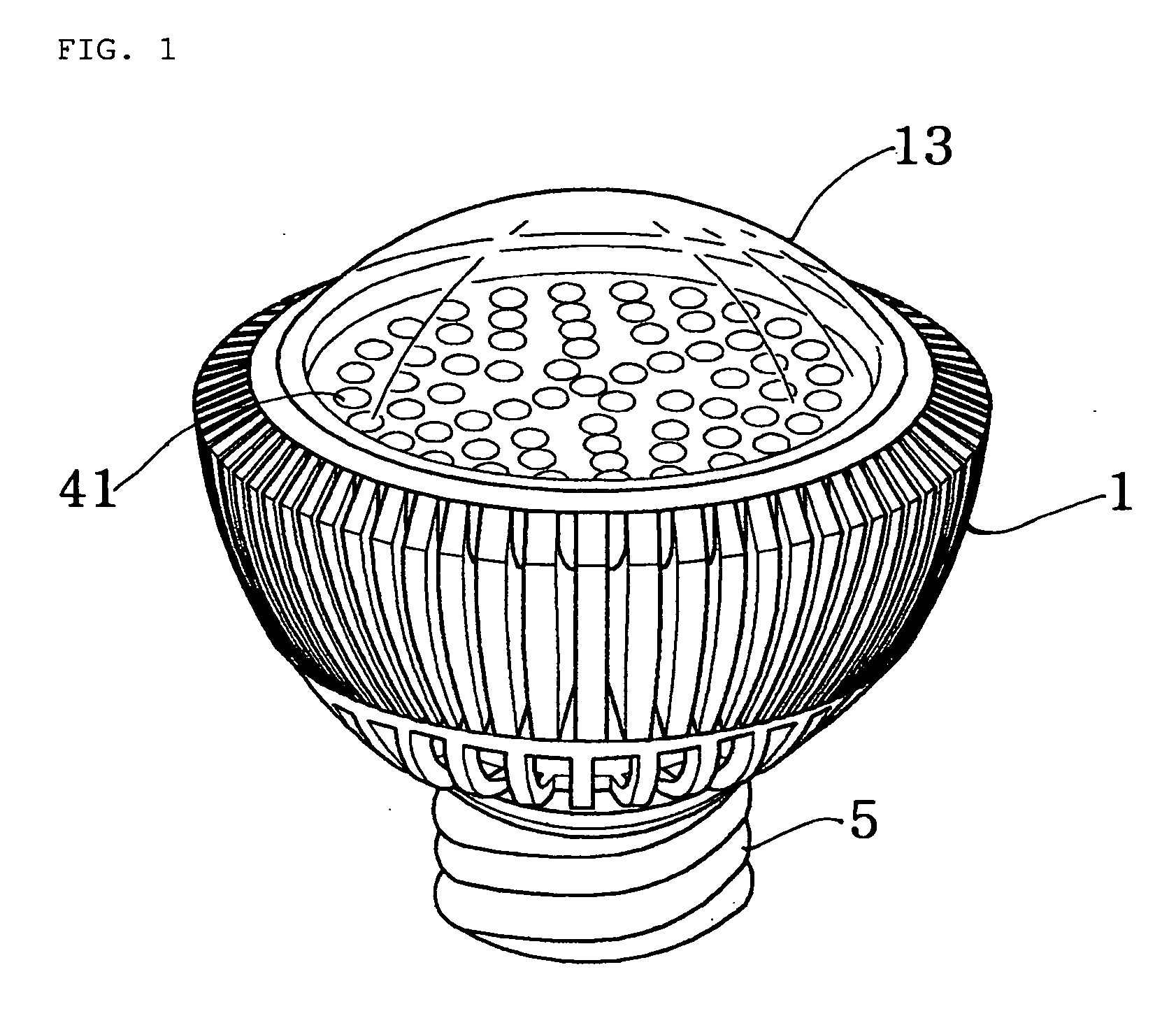

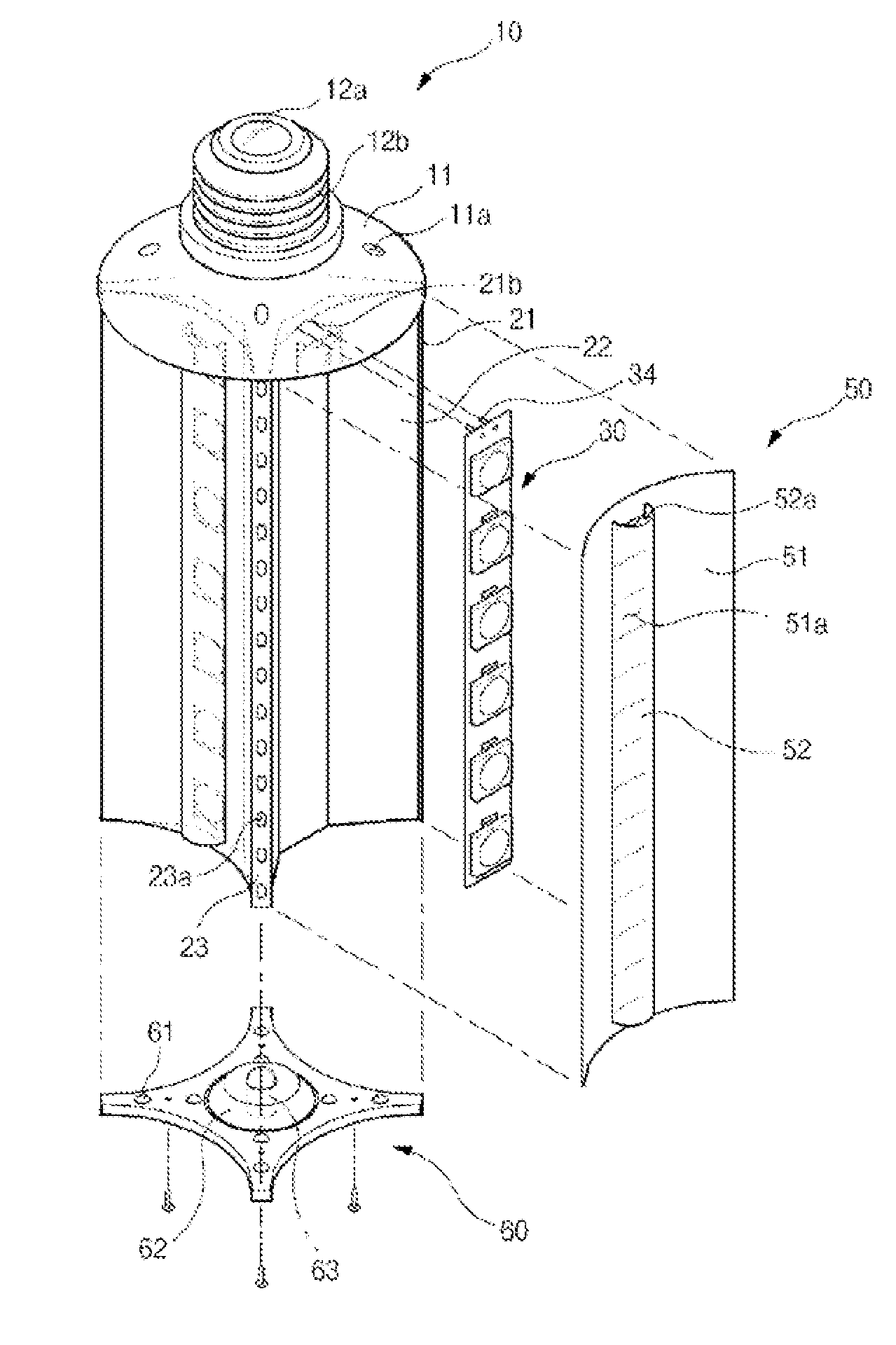

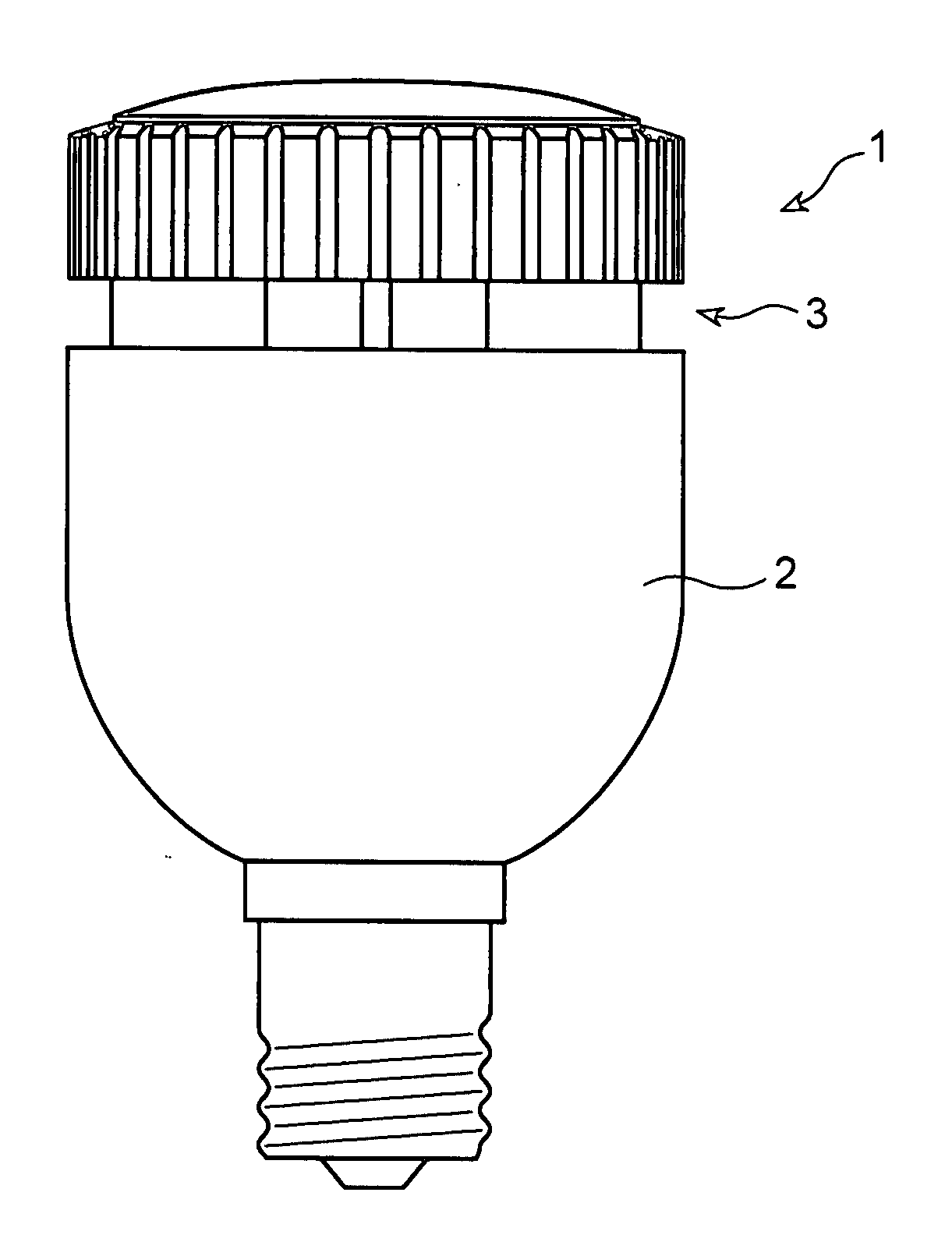

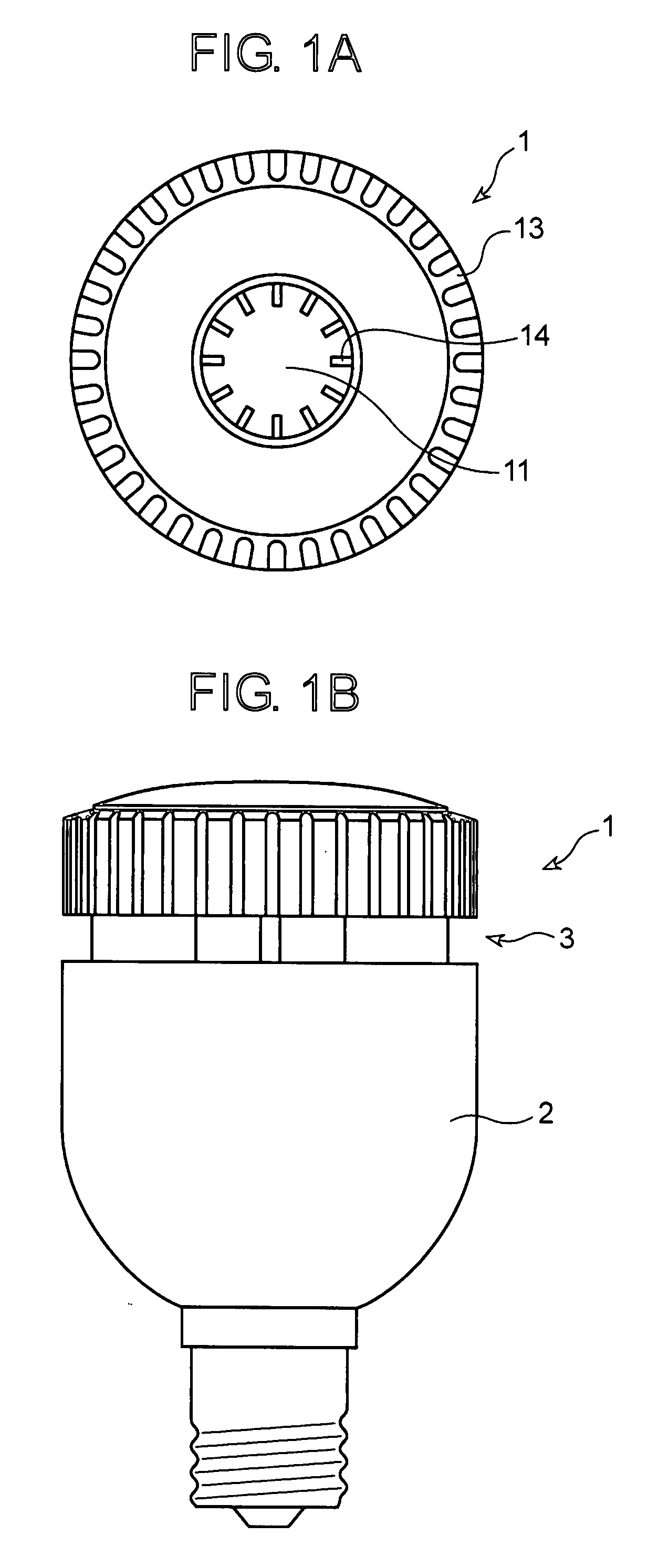

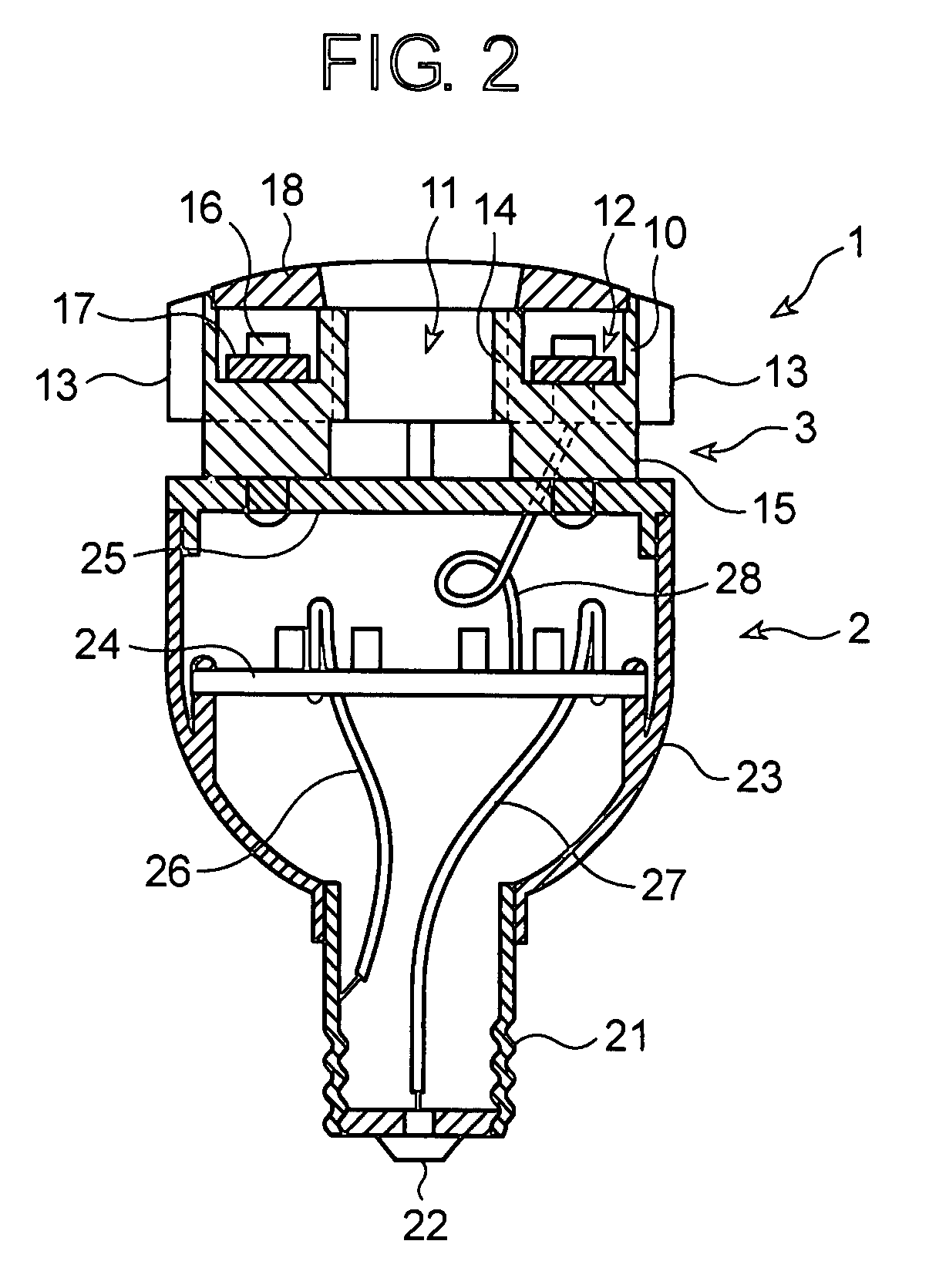

InactiveUS20080024067A1Improve heating efficiencyLimit temperature risePoint-like light sourceElectric circuit arrangementsAir cycleEffect light

An LED lighting device has high cooling efficiency and long life with a plurality of high-intensity LEDs mounted thereto. The LED lighting device is composed of a light emission part provided with a plurality of LEDs and a heat radiator for the LEDs, a power source part generating a current to be supplied to the LEDs from a commercial power source, and an air circulation part for circulating ambient air. The light emission part and the power source part are thermally separated by the air circulation part. The light emission part is provided with an annular heat radiation base having a hole formed at a central portion thereof and a substrate attaching face formed around the hole, and an LED substrate which is attached to the substrate attaching face and on which a plurality of LED chips are mounted. The heat radiation base has heat radiation fins as the heat radiator which are formed on an outer periphery of the heat radiation base and on an inner periphery of the hole. By the presence of the air circulating part, little heat generated from the power source part is transmitted to the light emission part. Therefore, it is possible to accomplish desired designing of heat radiation of the light emission part concerned with intensity and life of an LED, which is critical to performance of an LED lighting device.

Owner:ATEX CO LTD

LED ultraviolet air sanitizer light fixture

A lighting fixture and lighting system for a transportation vehicle is disclosed that provides color variations for lighting the passenger cabin of an airplane, train, bus or other type of transportation vehicle. The lighting fixture and system further provide ultraviolet light that helps to disinfect the circulating air in the passenger cabin. A fixture in an exemplary lighting system provides visible light for lighting up the passenger cabin and germicidal ultraviolet light directed toward or into an output vent(s) of the air circulation system of the passenger vehicle. The ultraviolet light is segregated from the visible light such that ultraviolet light is only directed toward or into the circulation vents of the vehicle's air circulation system.

Owner:LUMINATOR HLDG

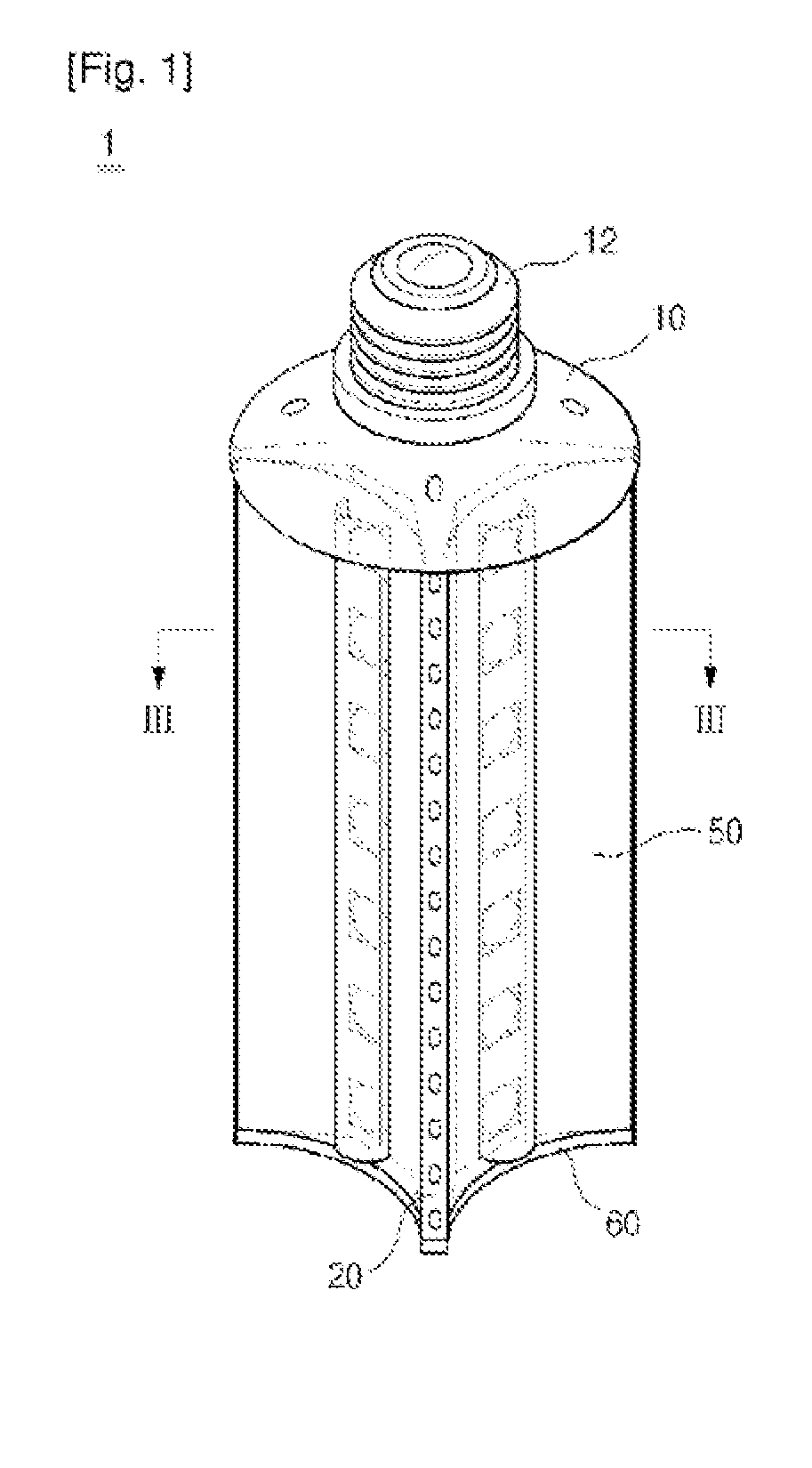

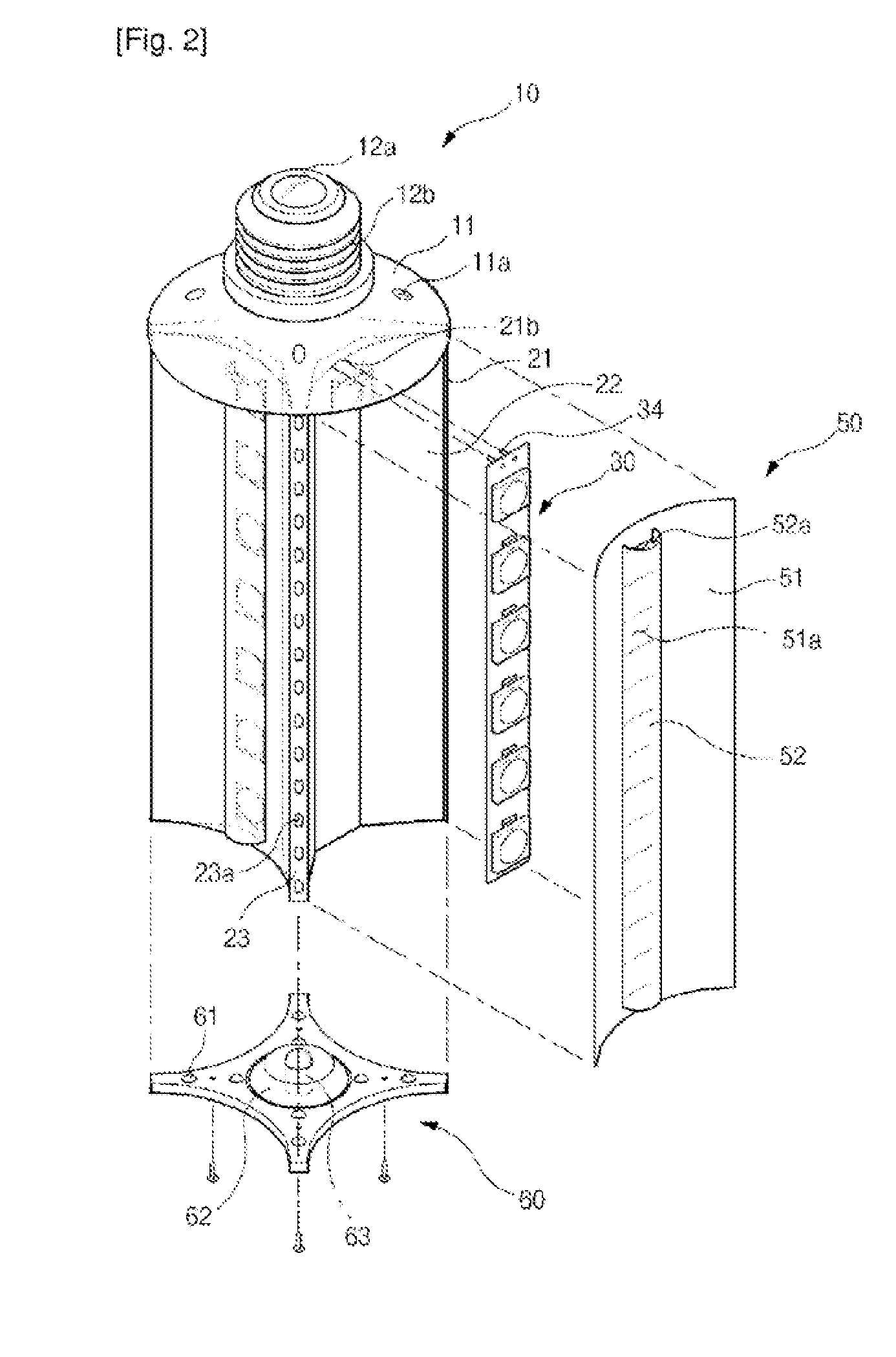

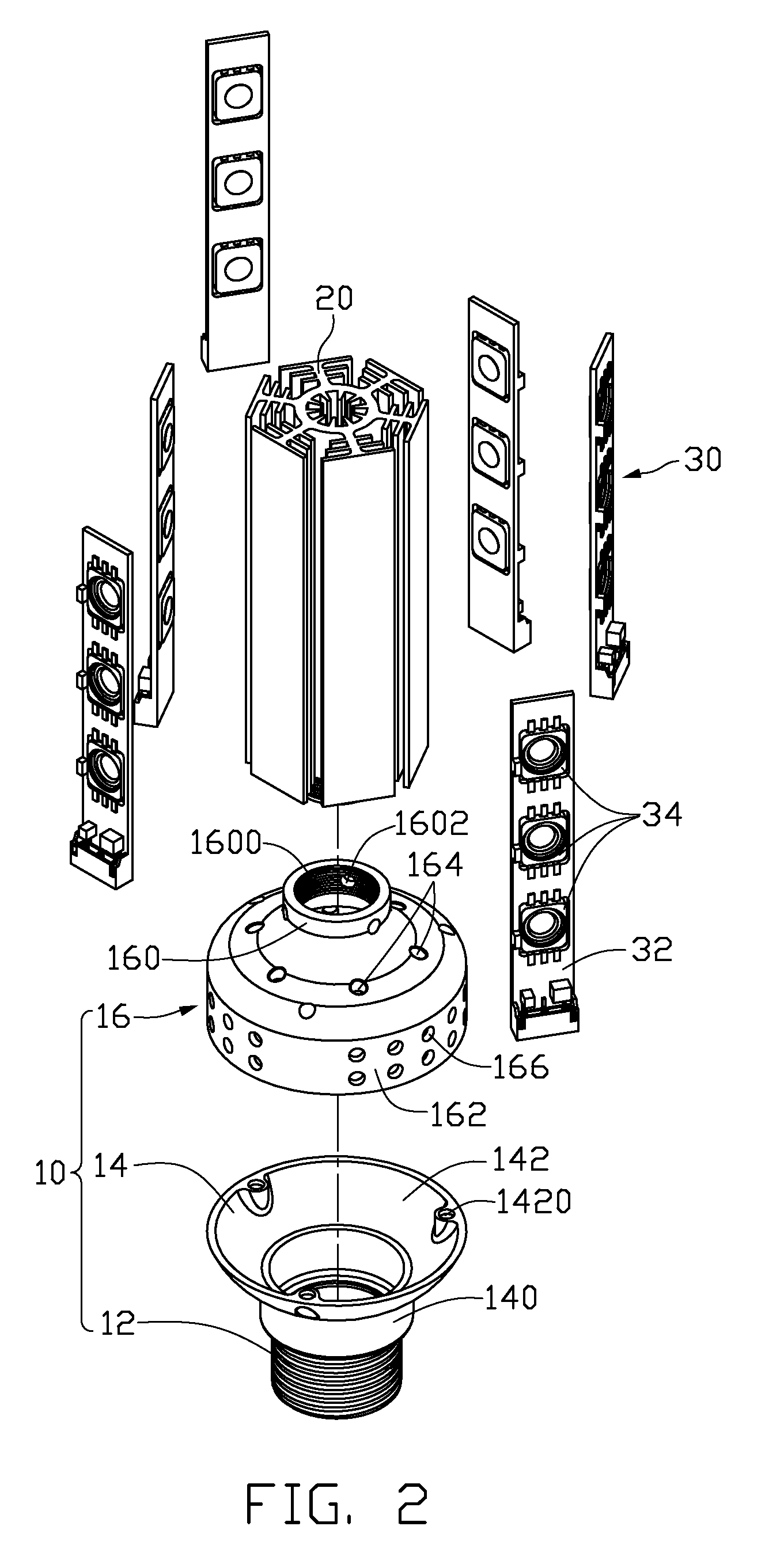

LED lamp having heat dissipation structure

InactiveUS20080316755A1Elongate light sourcesLighting heating/cooling arrangementsAir cycleEngineering

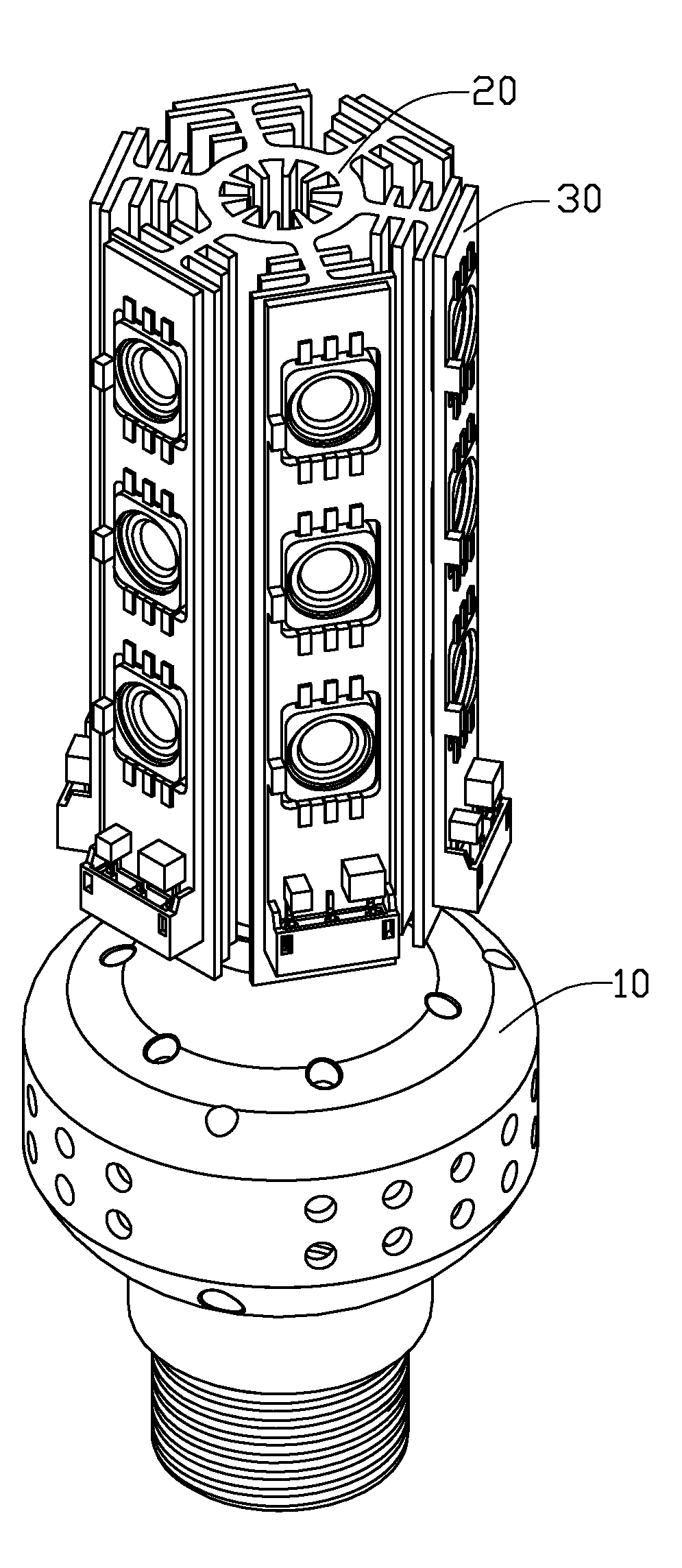

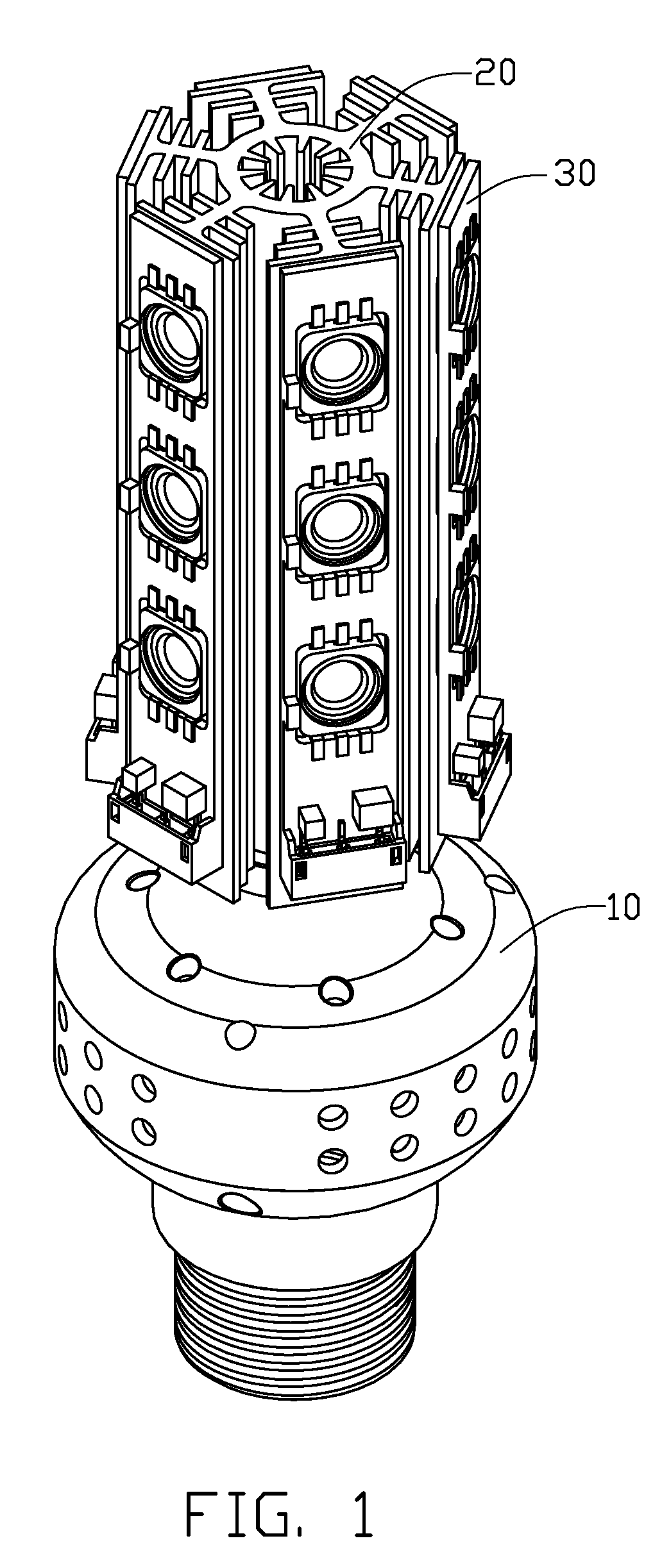

An LED lamp includes a lamp base, a heat sink and a plurality of LED modules. The lamp base includes a lamp holder and an enclosure connecting with the lamp holder. The enclosure defines a plurality of vents therein. The heat sink is mounted on the lamp base and includes a cylinder at a centre thereof and a plurality of fins surrounding the cylinder. The cylinder has a through hole therein, which communicates with the enclosure. The through hole, the enclosure and the vents cooperatively form an air circulation passage communicating with ambient air. The LED modules are mounted on outmost ones of the fins of the heat sink, respectively.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

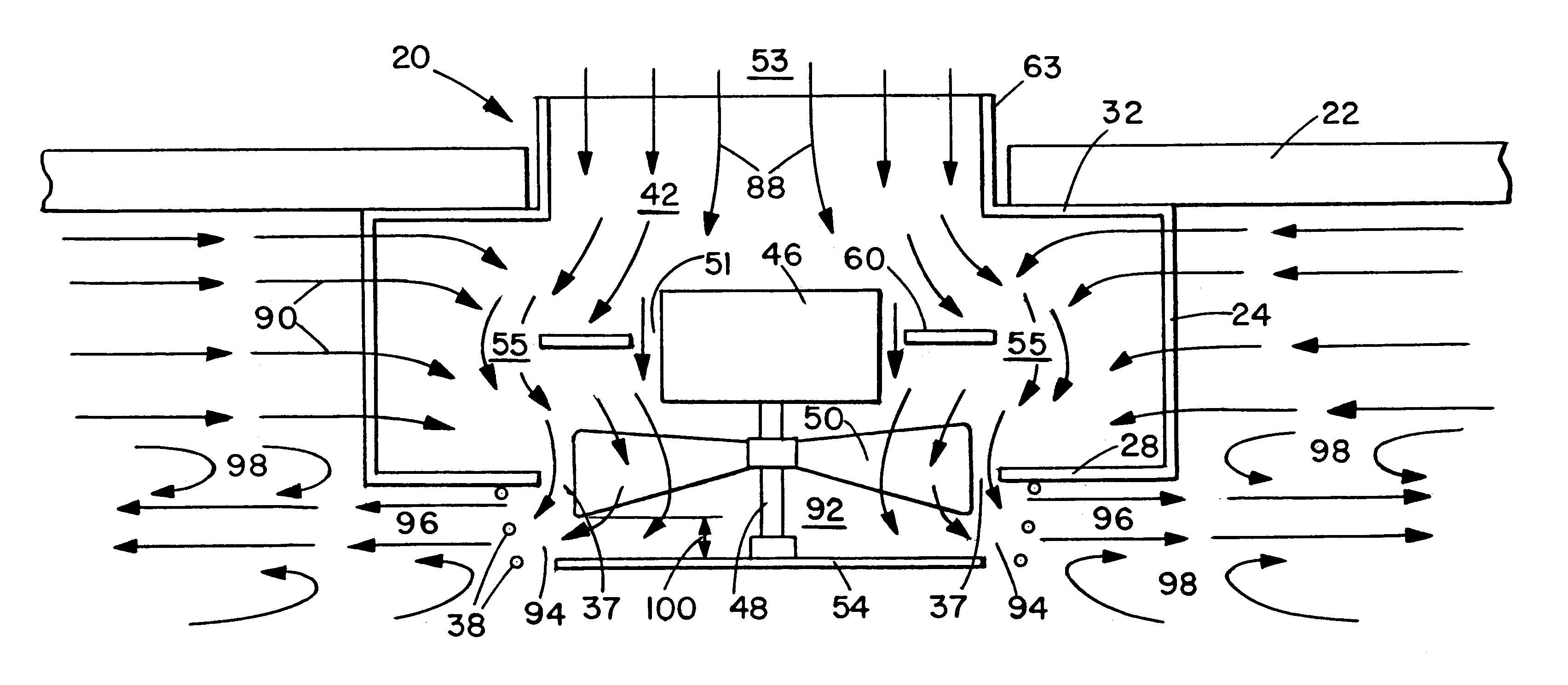

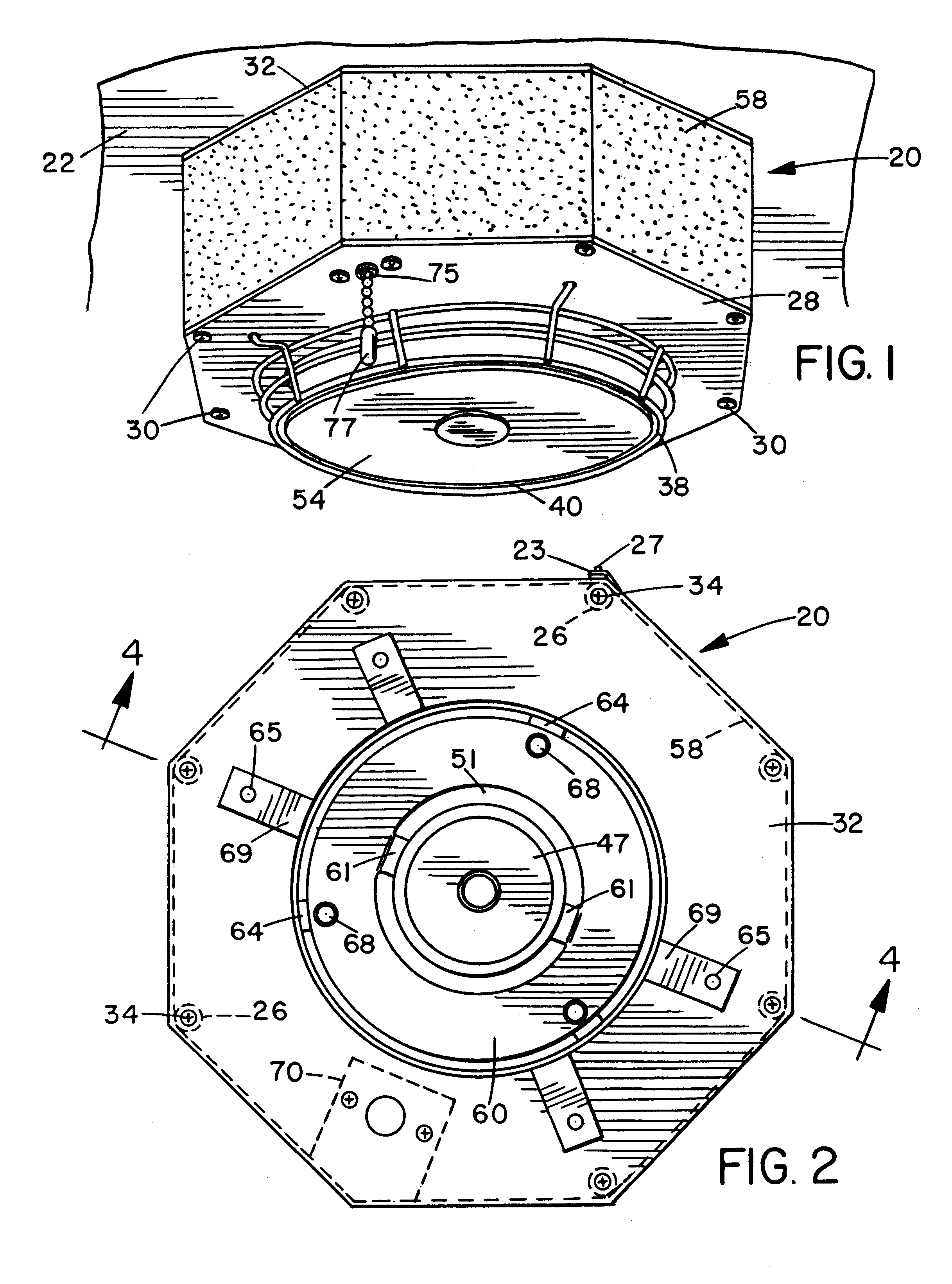

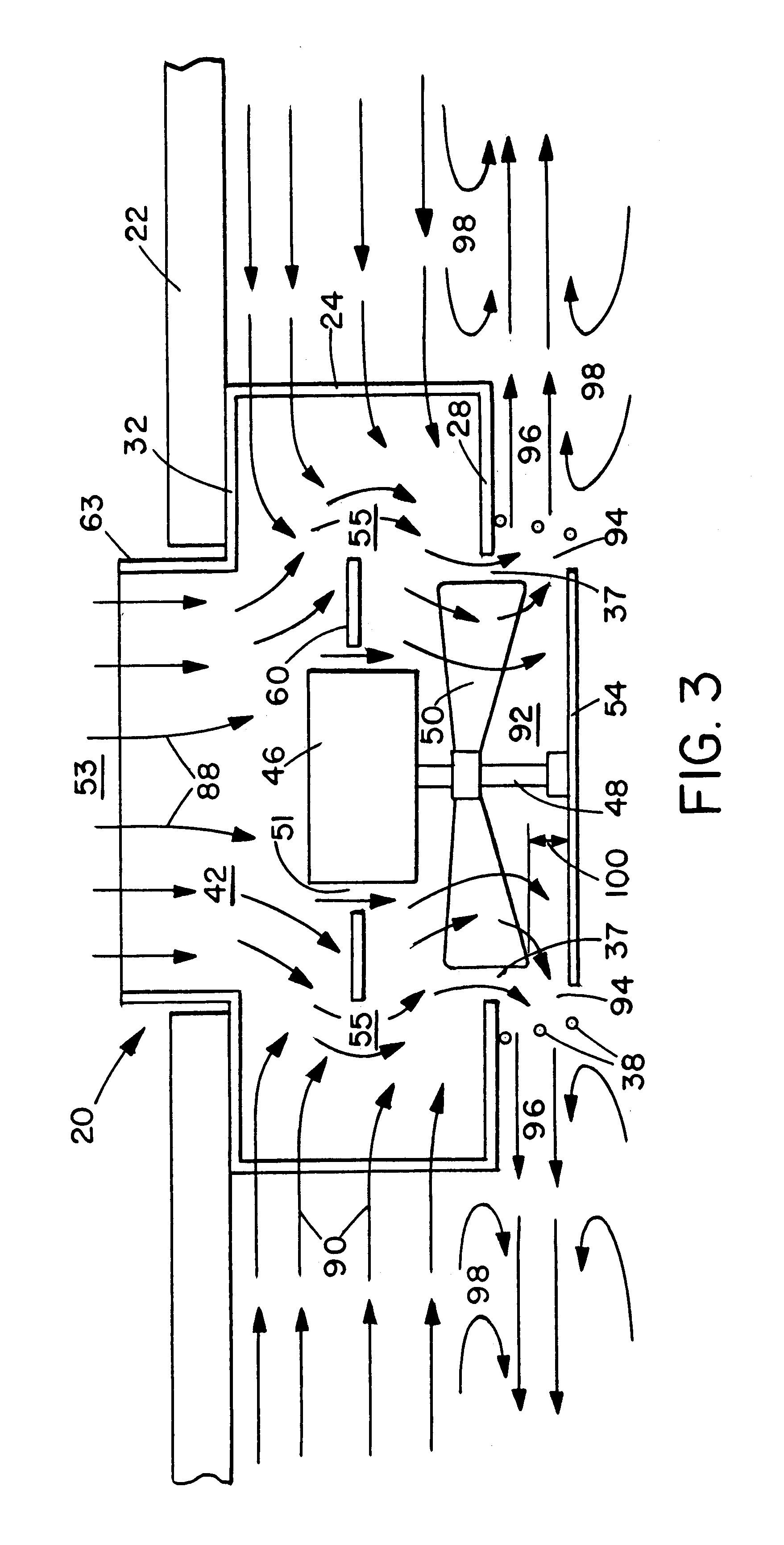

Recirculating air mixer and fan with lateral air flow

An air circulation and mixing device is disclosed which can cover a ceiling air ventilation duct, taking air discharged from the duct and drawing air at the room's ceiling, mixing the two, and redirecting the mixed air so that it is discharged radially and parallel to the ceiling, rather than directly downwardly. The device has an open frame whose sides may be covered with removable air filtration media and which forms a primary interior having a lower aperture and normally an upper aperture. An open-sided grille below the lower aperture forms a secondary space. A fan is mounted within the primary space and turns blades within the lower aperture and a disk at the bottom of the secondary space. An annular plate surrounding the fan housing blocks downward flow of incoming air and forces the air to flow radially outwardly around the edge of the plate, thus also insuring good mixing with the incoming ceiling air. The rotating disk receives air blown downwardly through the lower aperture and redirects it radially outwardly through the openings in the side of the grille, such that airflow becomes horizontal and parallel to the ceiling, so that the air flow slows and the air becomes gradually dispersed throughout the entire room. The device can also be mounted over a through-wall air duct outlet by using a duct extension.

Owner:COOK E F

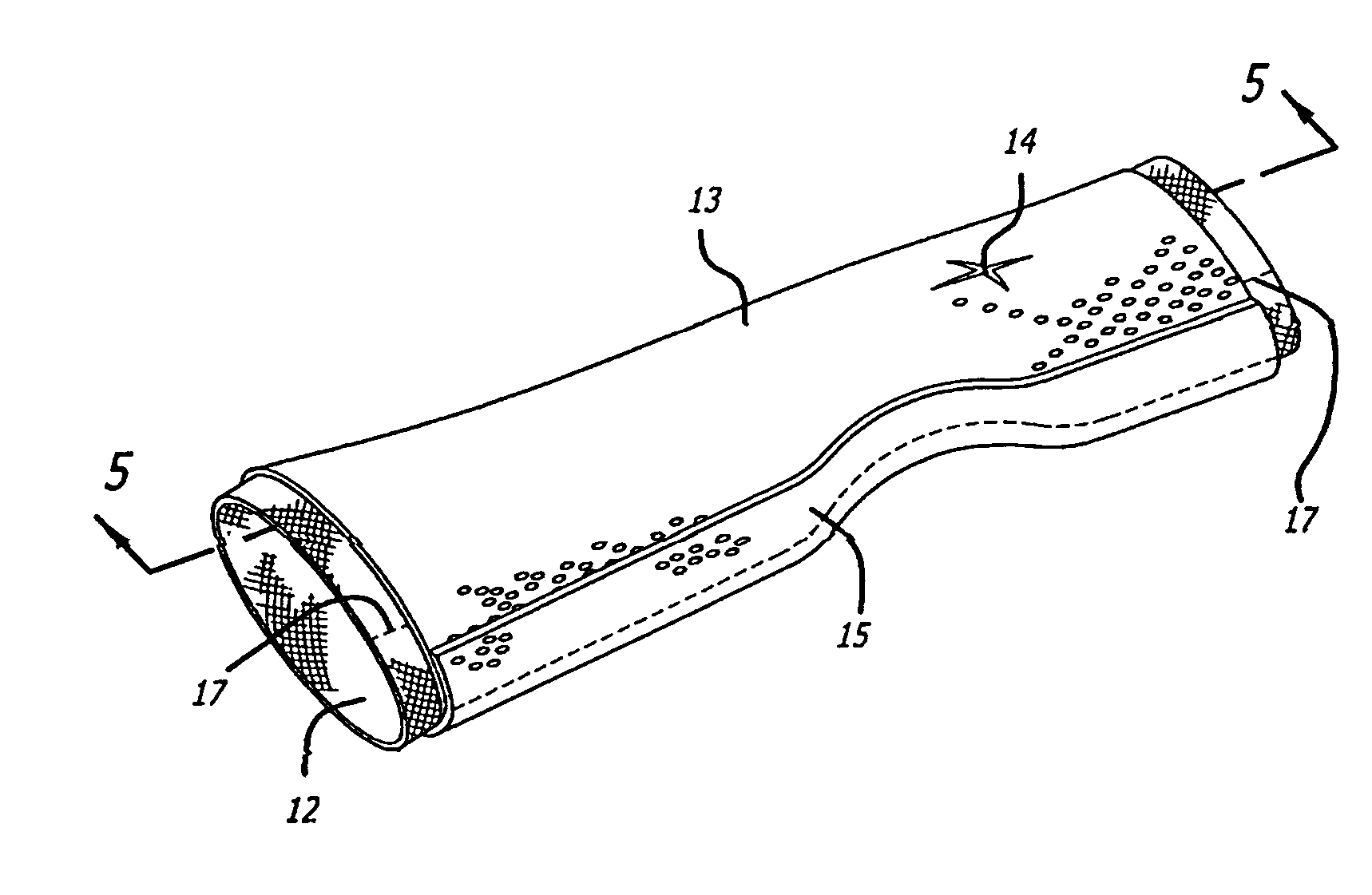

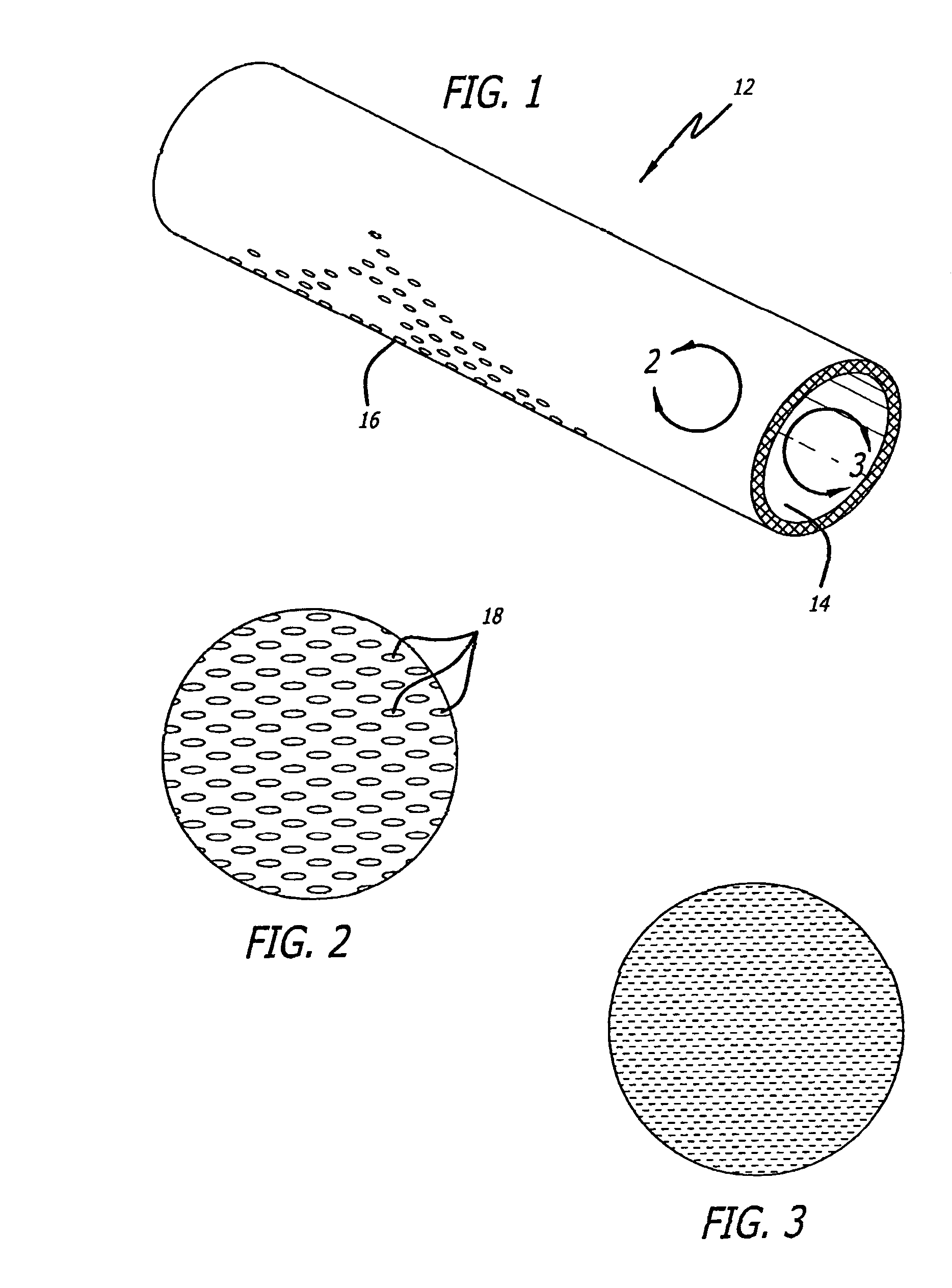

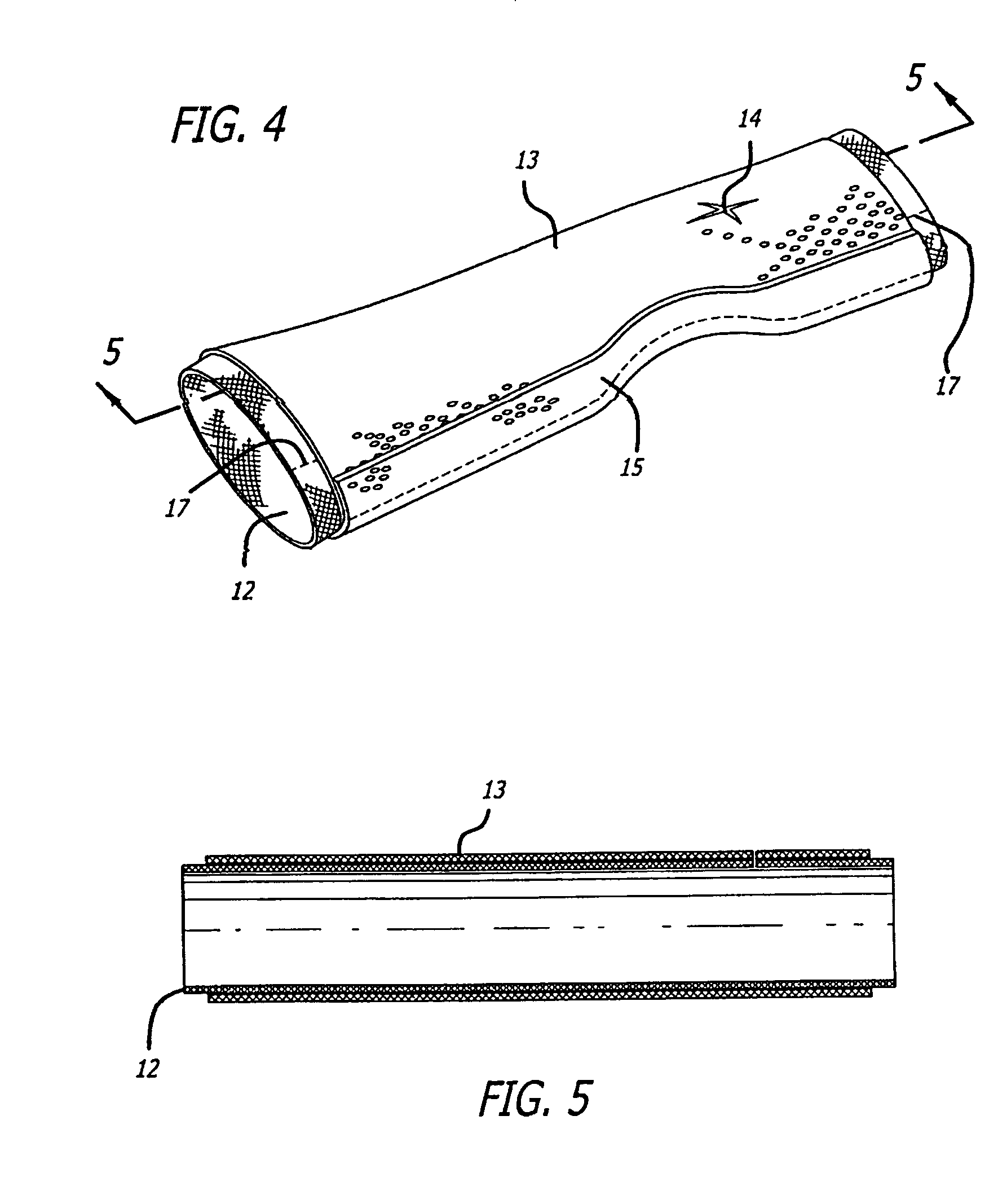

Cast assembly with breathable double knit type padding

ActiveUS7465283B2Quicker and efficient dryingEasy to flow outFeet bandagesPlaster of paris bandagesAir cycleEngineering

A cast or support assembly includes inner double knit padding material in which the outer layer is woven or knit to have substantial size openings, while the inner layer of the double knit material to be located against the skin of the patient is more closely woven or knit. Additional casting fabric is also provided, with this casting fabric being impregnated with water hardenable material. The outer casting fabric may include openings extending through it, so that the entire cast assembly has ventilation openings allowing air circulation to accomplish rapid drying following wetting of the assembly by sweat, rain, or by swimming, for example.

Owner:OSSUR HF

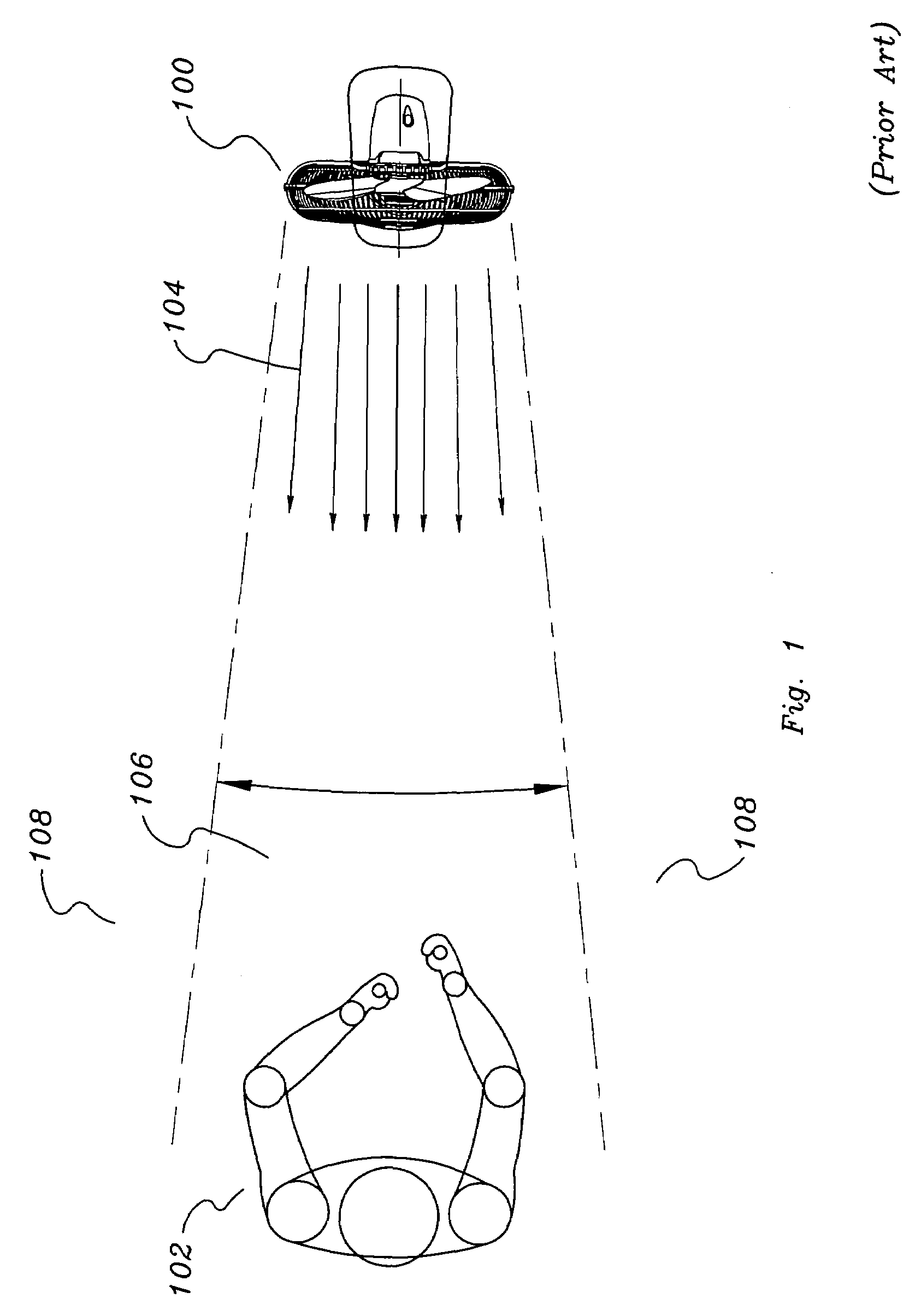

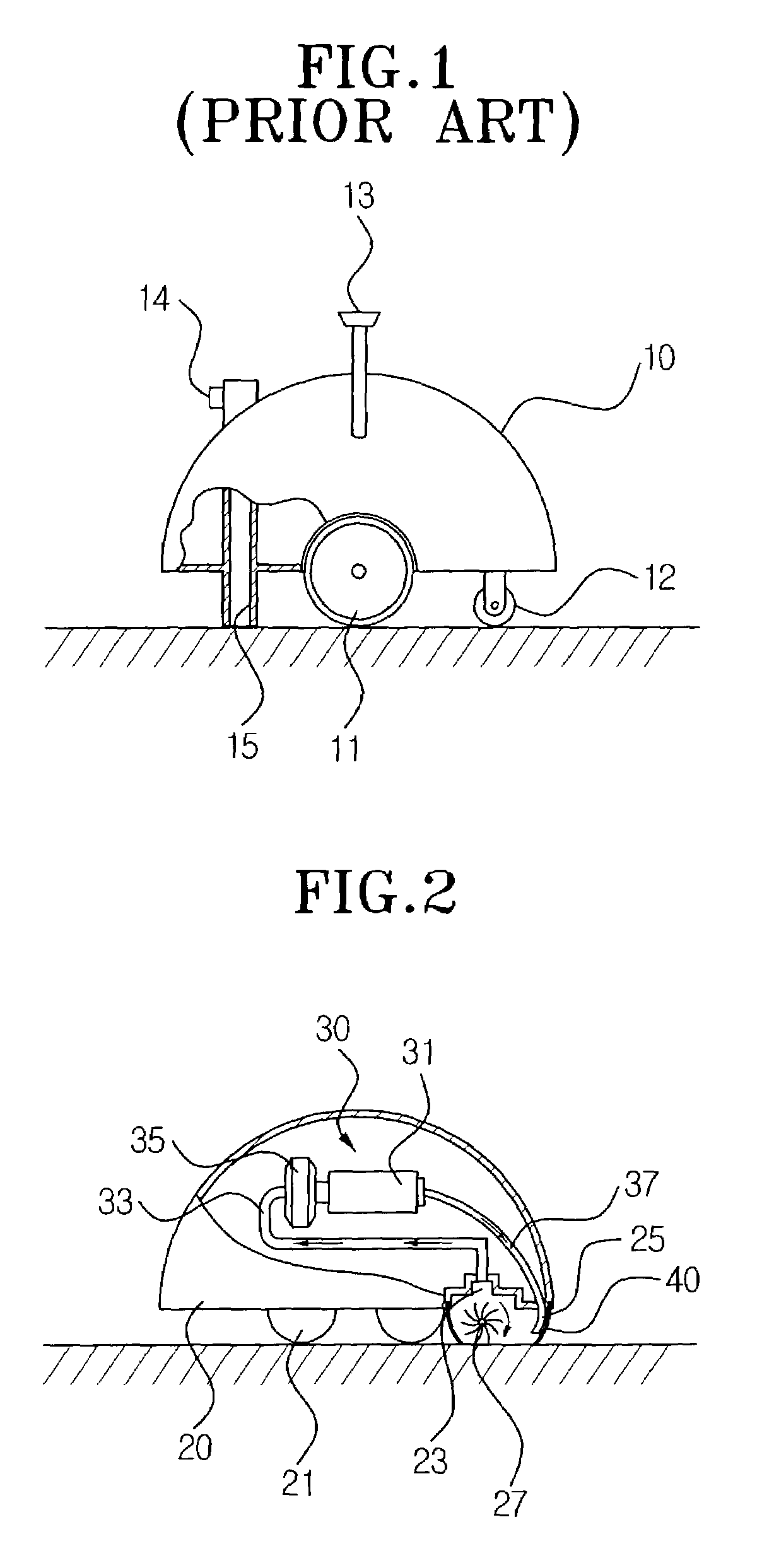

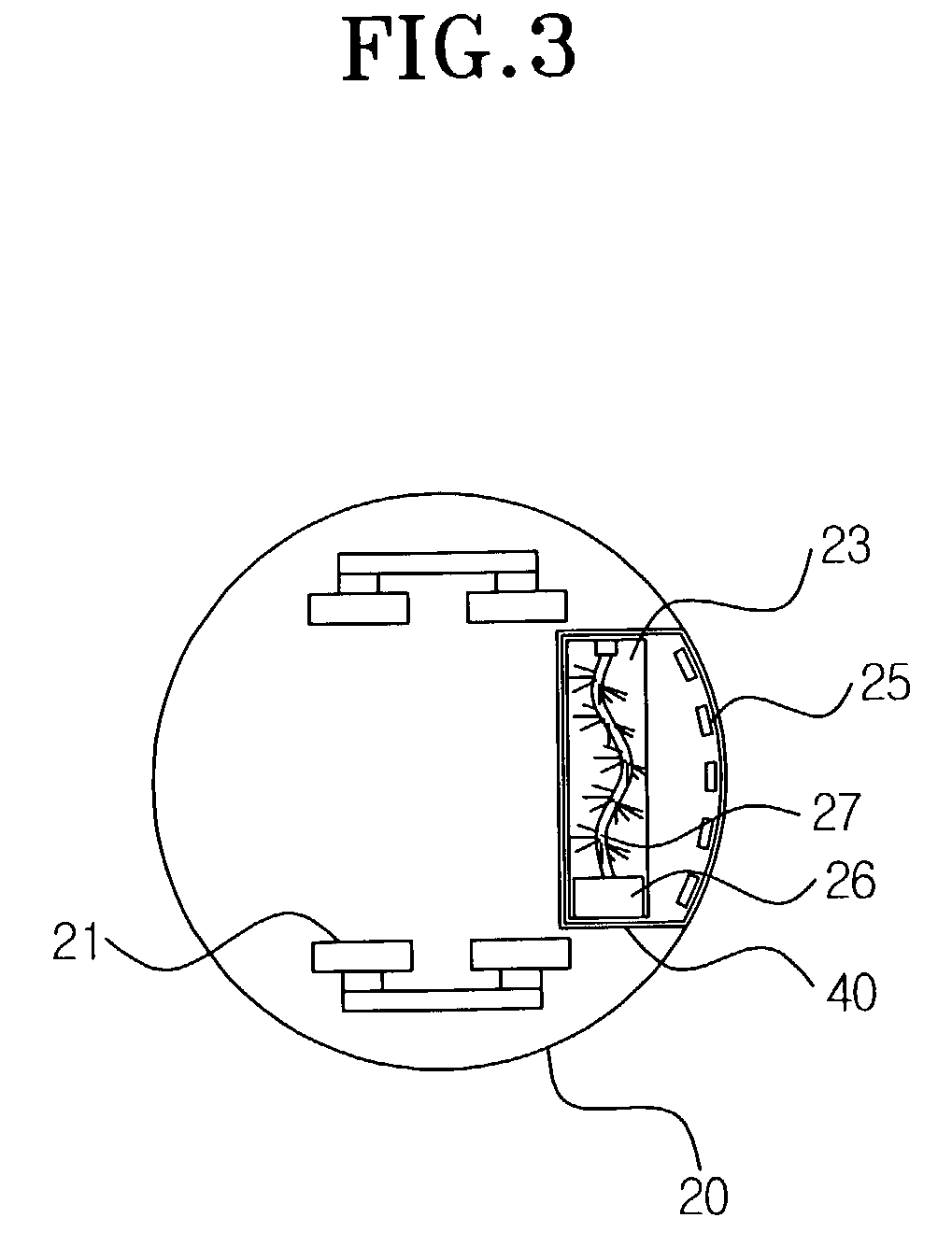

Robot vacuum cleaner with air agitation

InactiveUS7059012B2Efficient removalPromote sheddingCleaning filter meansSuction filtersAir cycleVacuum cleaner

A robot vacuum cleaner comprises a cleaner body having a wheel disposed at a lower portion and a suction port through which contaminants are drawn in from a cleaning surface; and an air circulating mechanism for filtering out contaminants from the contaminant-laden air drawn in through the suction port and then jetting the contaminant-free air to an air jet opening to help dislodge contaminants from the cleaning surface. The air jet opening is adjacent to the suction port; and the two elements are surrounded by a sealing member for sealing off a portion between the cleaning surface and the cleaner body to prevent dislodged contaminants from being dispersed outwardly.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

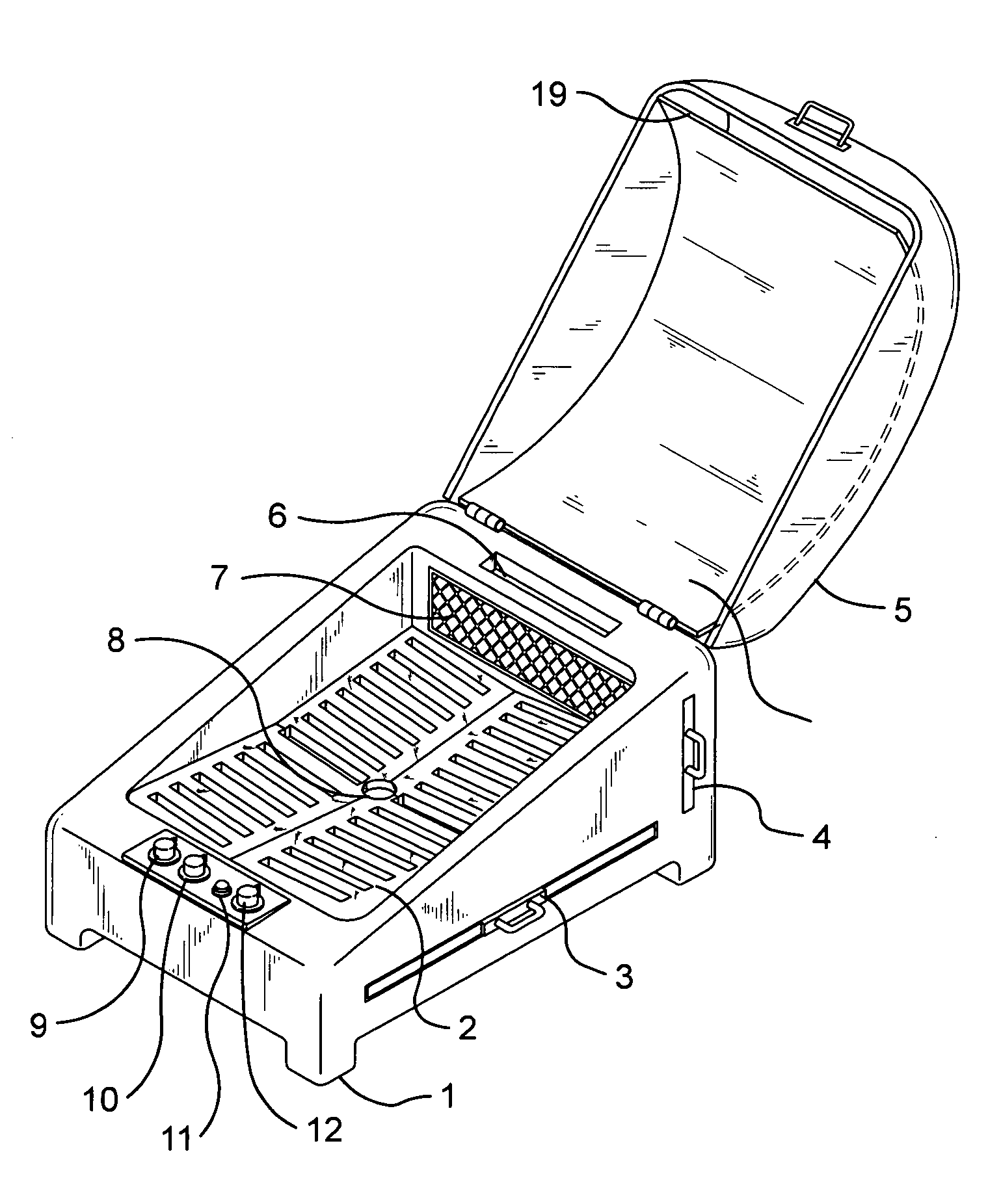

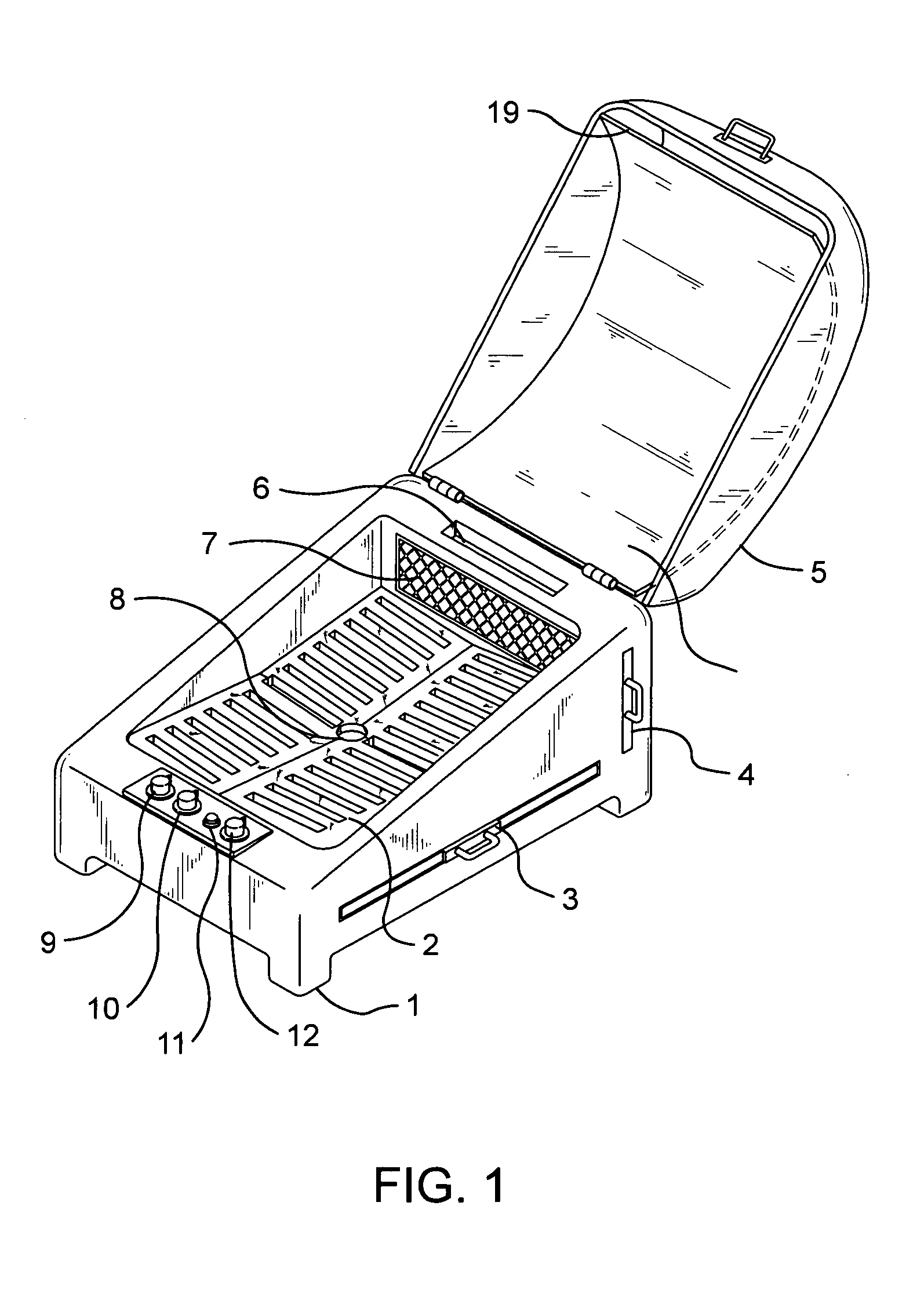

Convection grill

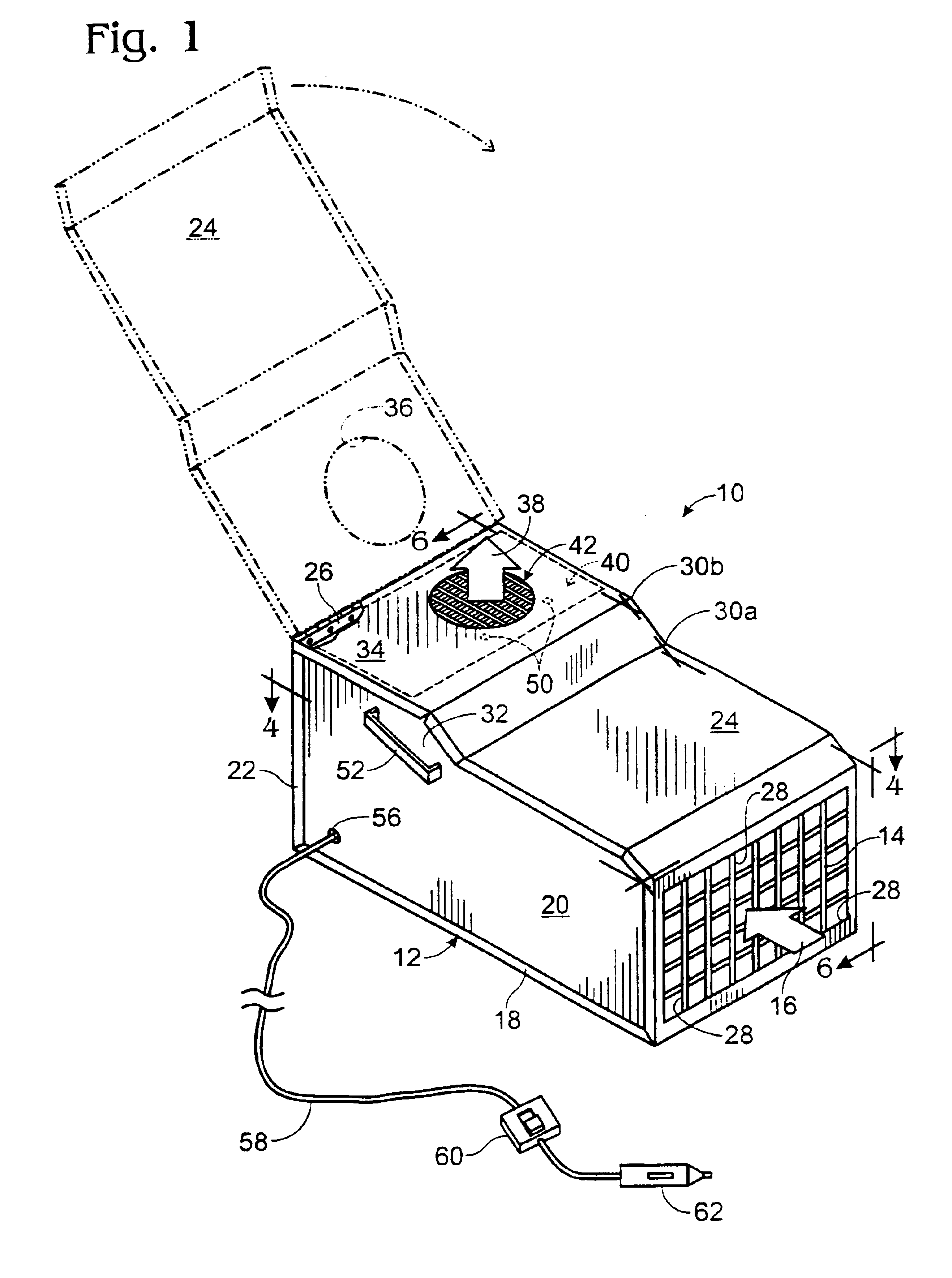

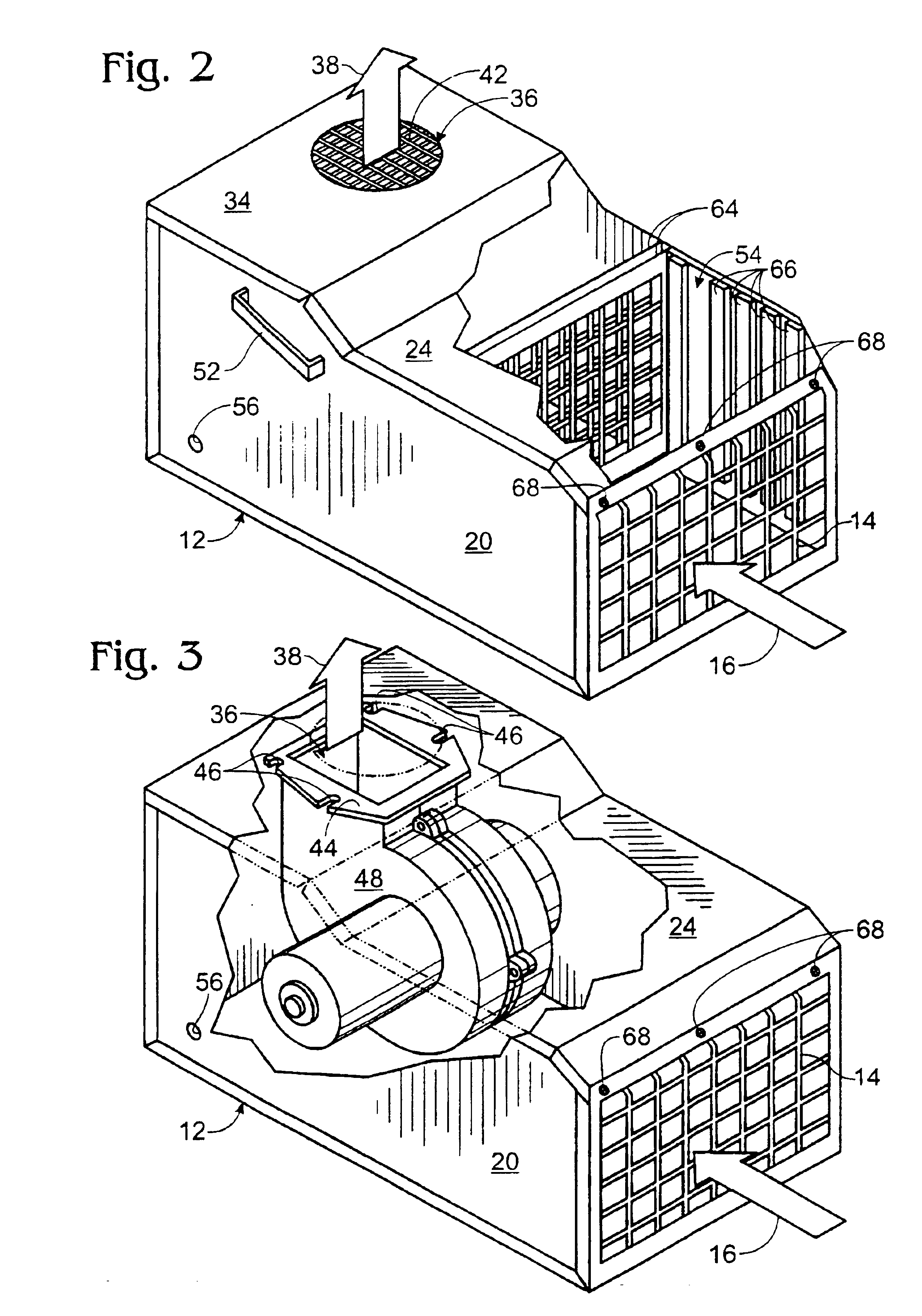

A portable electric grill for that has utilizes an electric fan to draw smoke and cooking odors through a filter then redirects and circulates the cleaner hot air around food to create convection heating thereby improve and making faster the cooking process. The grill can be used for indoor or outdoor use. It has a removable lid that when in the down position it provides the circulation of the hot air throughout the grill. It has a removable grill plate that either sits on top of heating elements or has heating elements imbedded in the grill plate. The grill plate is used for searing various foods and then allowing the convection air to cook the foods throughout. It has controls for regulating temperature, cooking time and fan speed. It has a pull-out grease tray to catch and dispose of drippings from cooking food. The filter is removable for cleaning.

Owner:JONES EDWARD MICHAEL

Alternating pressure pads

InactiveUS6928681B1Easy to cleanEasy to disinfectStuffed mattressesSpring mattressesAir cycleLine tubing

An alternating pressure pad comprises at least two sets of inflatable cells, an air supply line to each set, a pump to circulate pressurized air through a circuit including the sets of cells and to return air from the cells to the pump, valve means for alternately causing inflation and deflation of each set, a sensor pad in the circuit through which pressurized air is passed and detecting means for detecting a reduction in air flow through the sensor pad to a level below a predetermined level and for increasing air pressure in the sets of cells to restore the air flow to a level above the predetermined level.

Owner:HUNTLEIGH TECH LTD

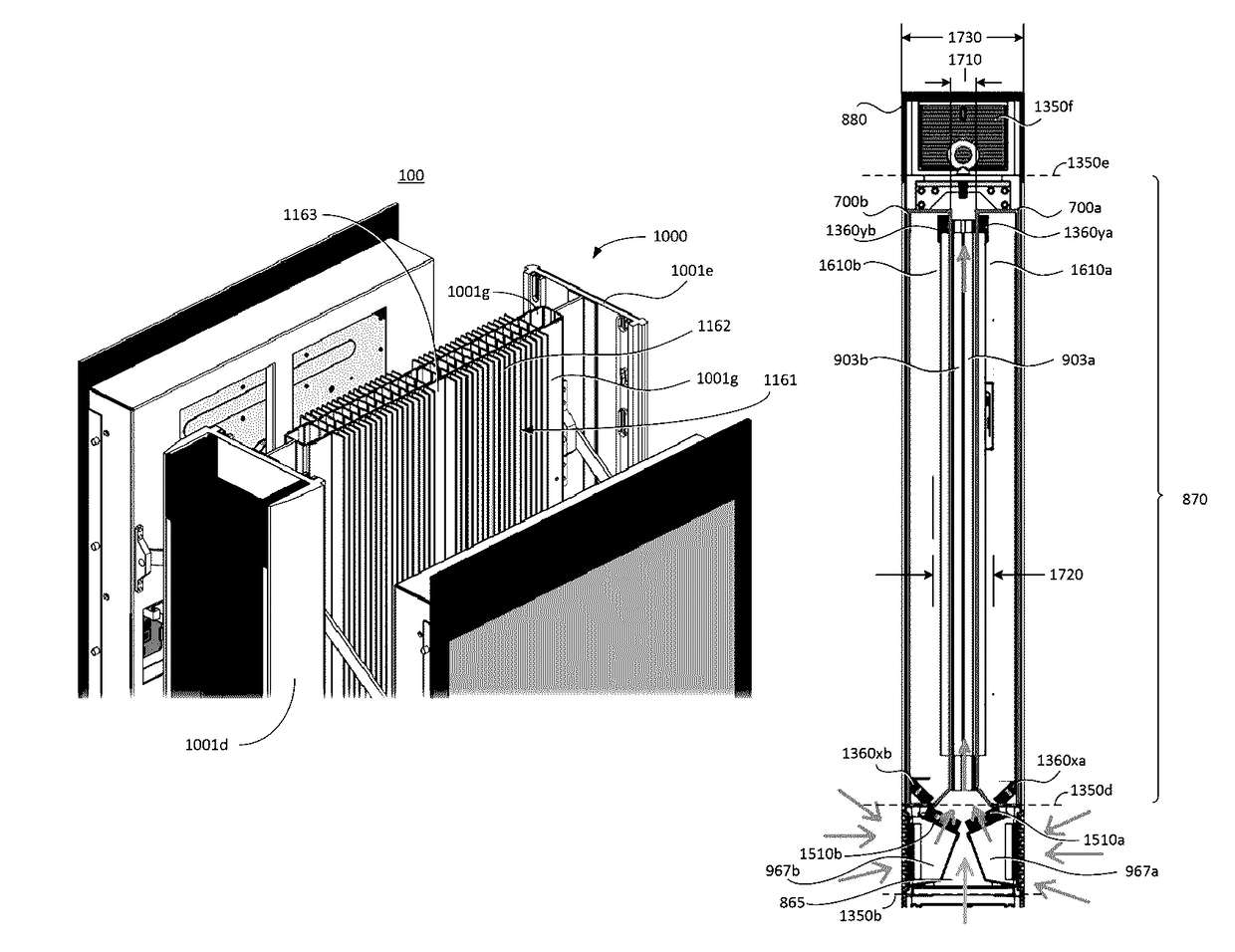

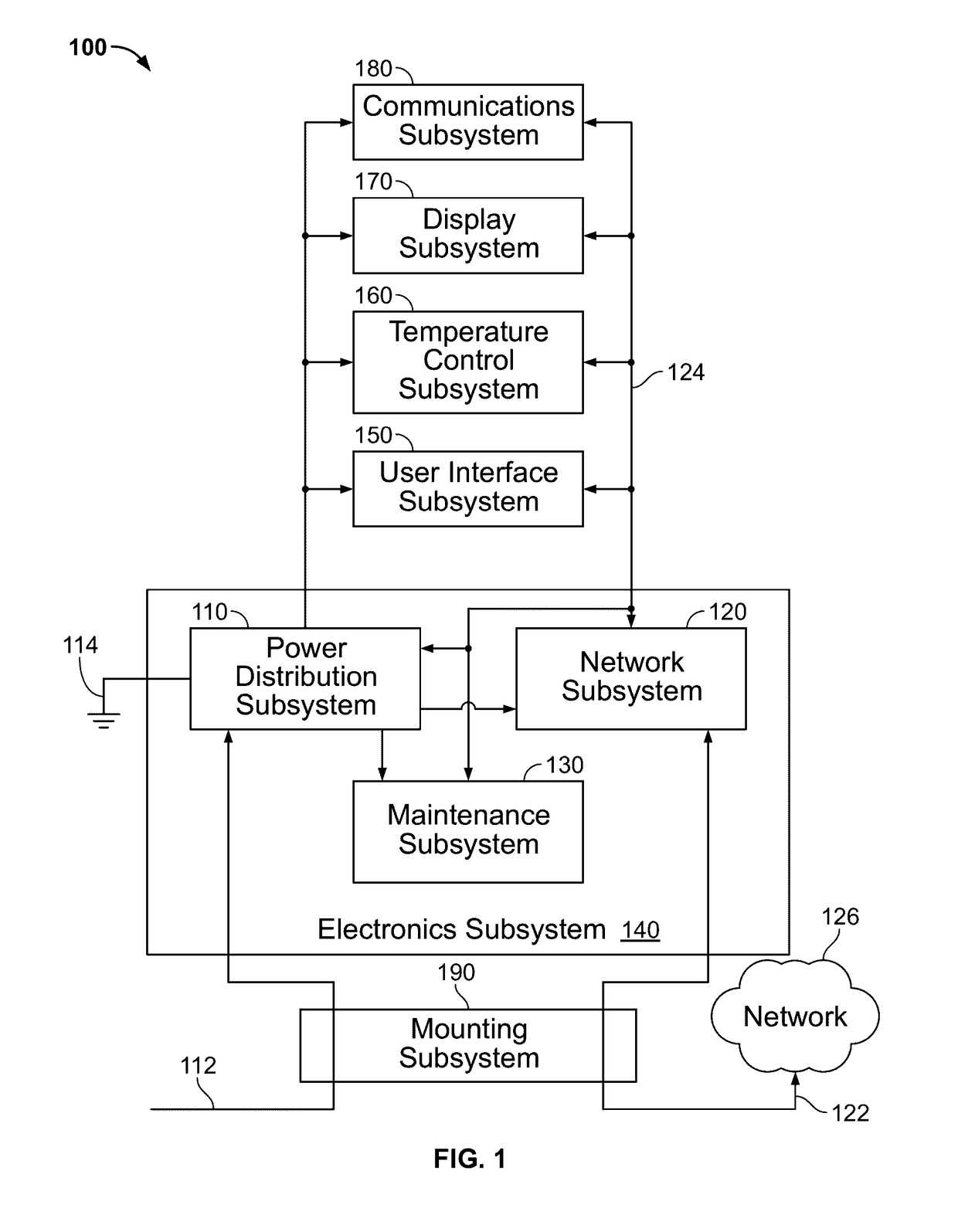

Techniques and apparatus for controlling the temperature of a personal communication structure (PCS)

ActiveUS9622392B1Easy accessExpand accessDigital data processing detailsCooling/ventilation/heating modificationsAir cycleTemperature control

Techniques for operating a personal communication structure (PCS) are described. In particular, a temperature control system for controlling the temperature of a PCS is described. The temperature control system may include a ribbed heat sink and first and second air circulation controllers. The heat sink may be coupled to the PCS's frame, adjacent to the back surface of a housing for a display module. The first air circulation controller may be configured to recirculate air in a cavity within the display module's housing. The second air circulation controller may be configured to move ambient air across the heat sink.

Owner:CITYBRIDGE LLC

Portable motor vehicle cabin air purifier

InactiveUS6773477B2Improve comfortEasy to moveHuman health protectionCombination devicesHEPAAir cycle

A portable air purifier for reducing pollutants in the passenger cabin of a vehicle to concentrations at least as low as the US-EPA National Ambient Air Quality Standards for: carbon monoxide, ozone, nitrogen dioxide, sulfur dioxide, lead, and particulate matter; plus benzene to a European ambient air standard. The purifier includes an air inlet and air outlet in communication with the vehicle cabin, with air circulation provided by a DC electric motor / blower attachable to a vehicle power plug. The filter assembly includes a specified series of filter media packets and a HEPA filter. The machine's preferred location is in the center of a rear seat where it can serve as an armrest / console and be secured by a seat belt.

Owner:ZELLER MARIE DEHARPPORT

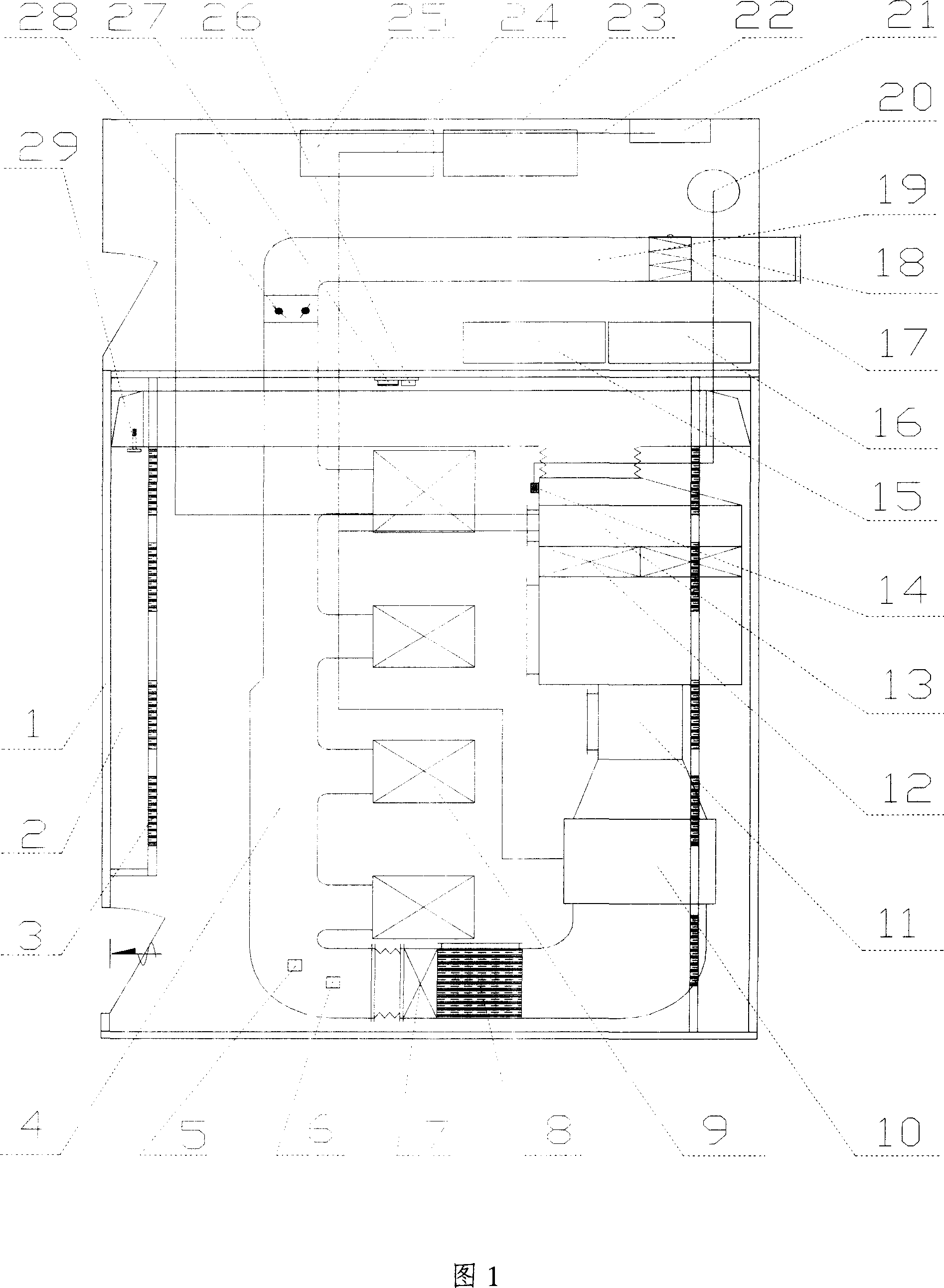

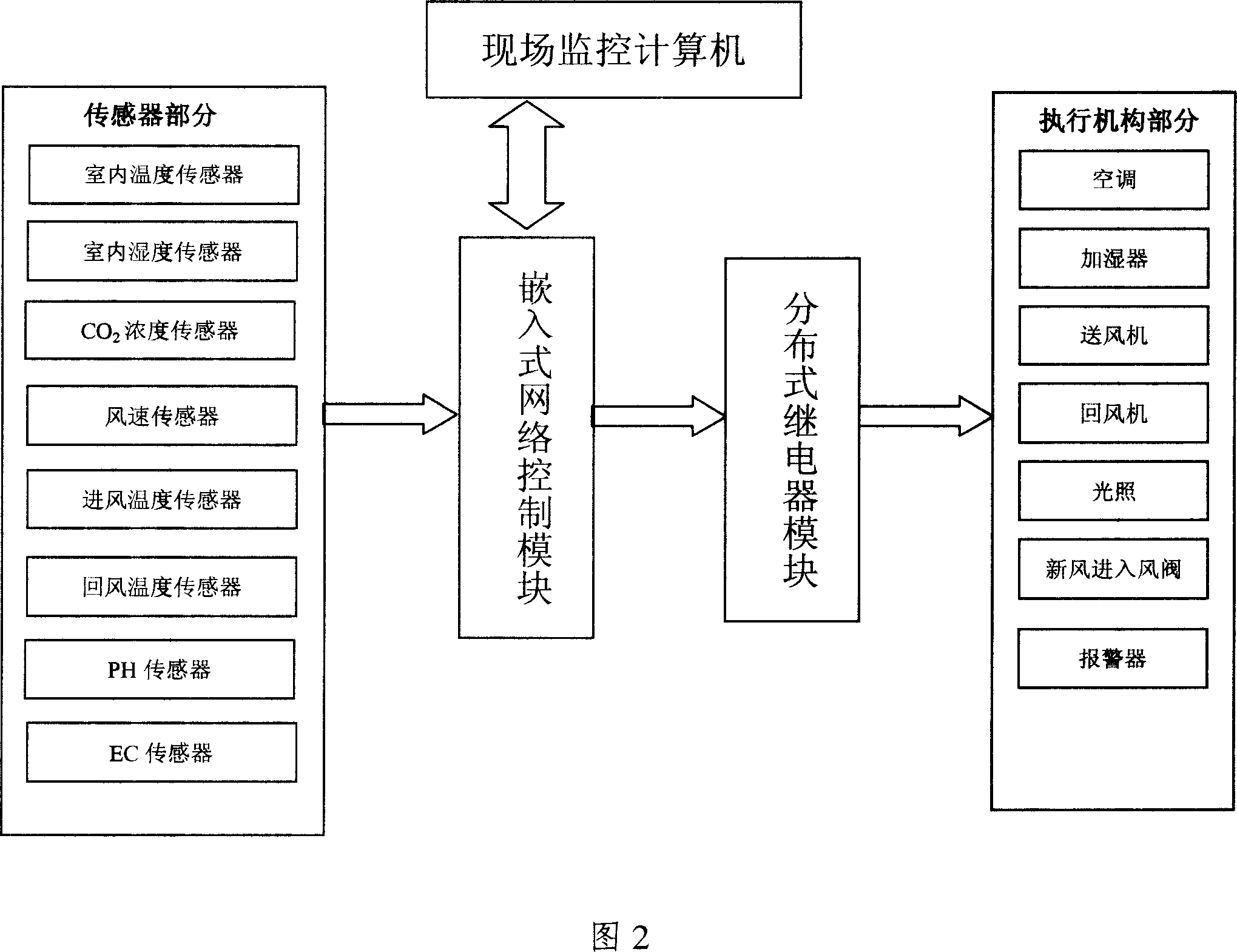

Closed type fully using artificial light environment controlled plant factory

ActiveCN101057550AControl light timeControl light intensityClimate change adaptationSaving energy measuresAir cycleEngineering

The invention discloses an environment control plant factory through seal-typed artificial light, which comprises the following parts: fender structure, air circulating system, temperature adjusting system, moisture adjusting system, CO2 supplying system, light supplying system, control system based on inserted network technique and automatic power-metering system, wherein the systems are seal, heat-proof and light-tight, which provides clean and fitful growing environment for plant. The invention saves cost and energy consumption, which realizes normalized and standardized cultivating management and planning manufacturing.

Owner:CHINA AGRI UNIV

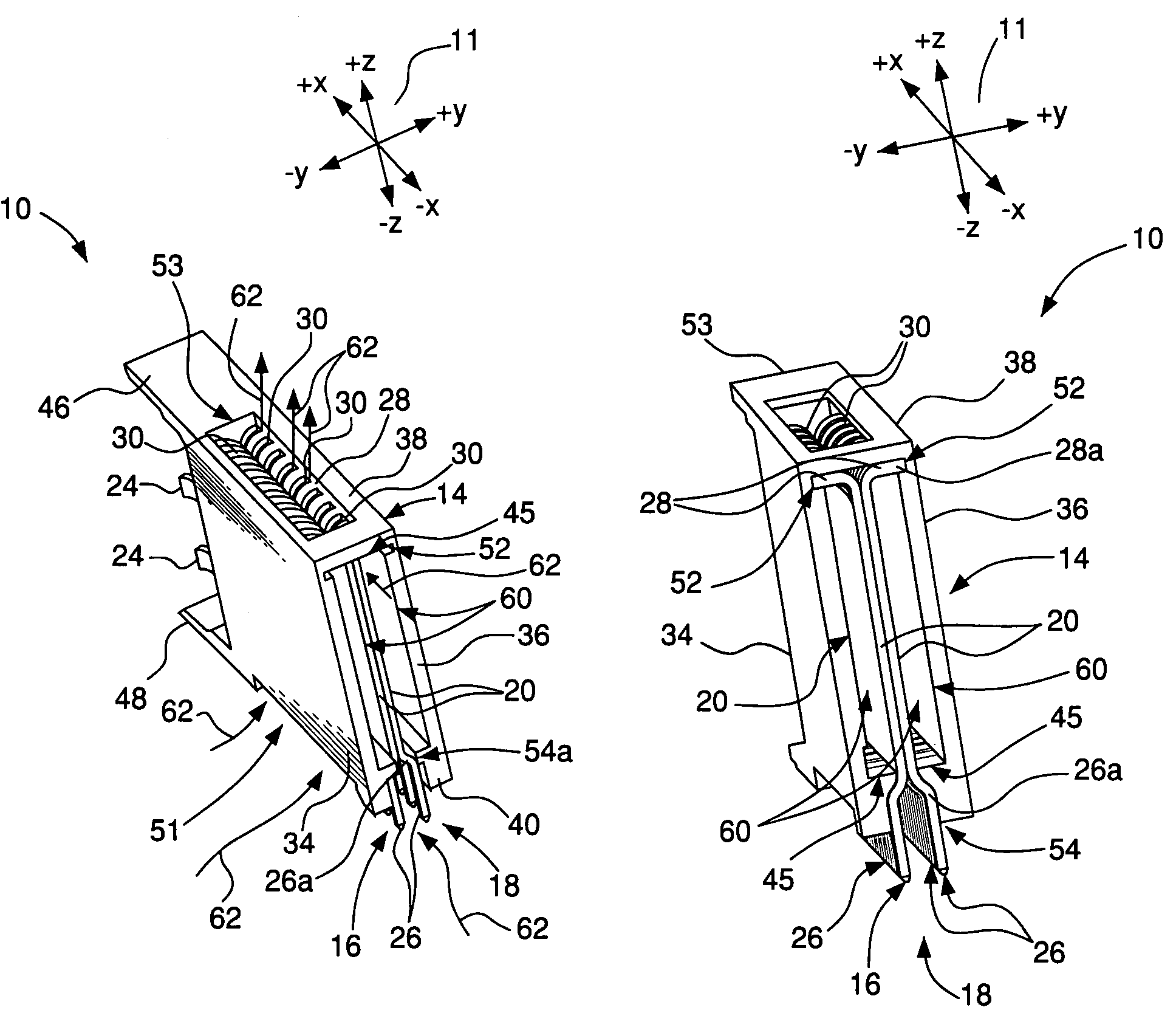

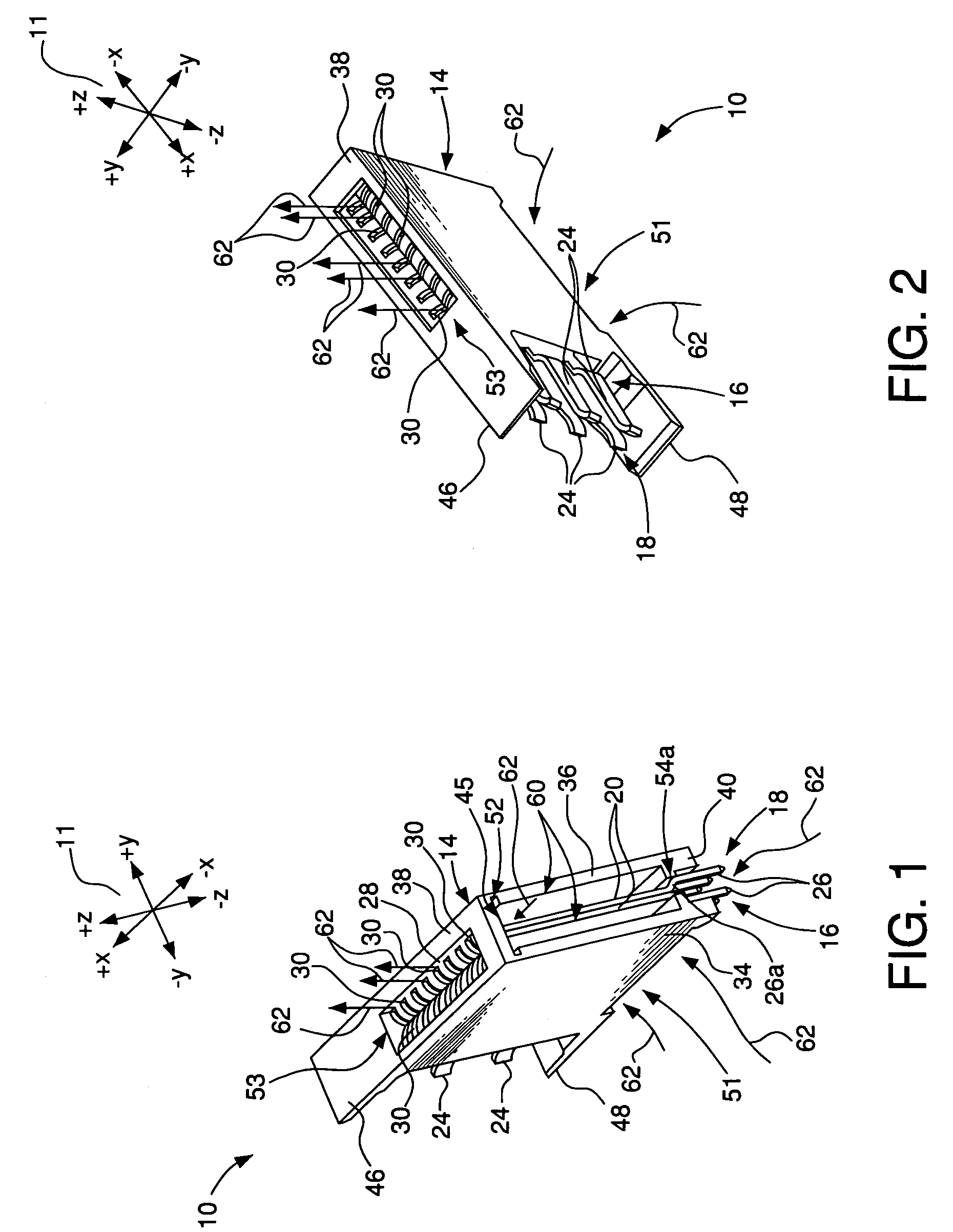

Electrical connector with air-circulation features

ActiveUS7303427B2Coupling device detailsCooling/ventilation/heating modificationsAir cycleElectricity

Owner:FCI AMERICAS TECH LLC

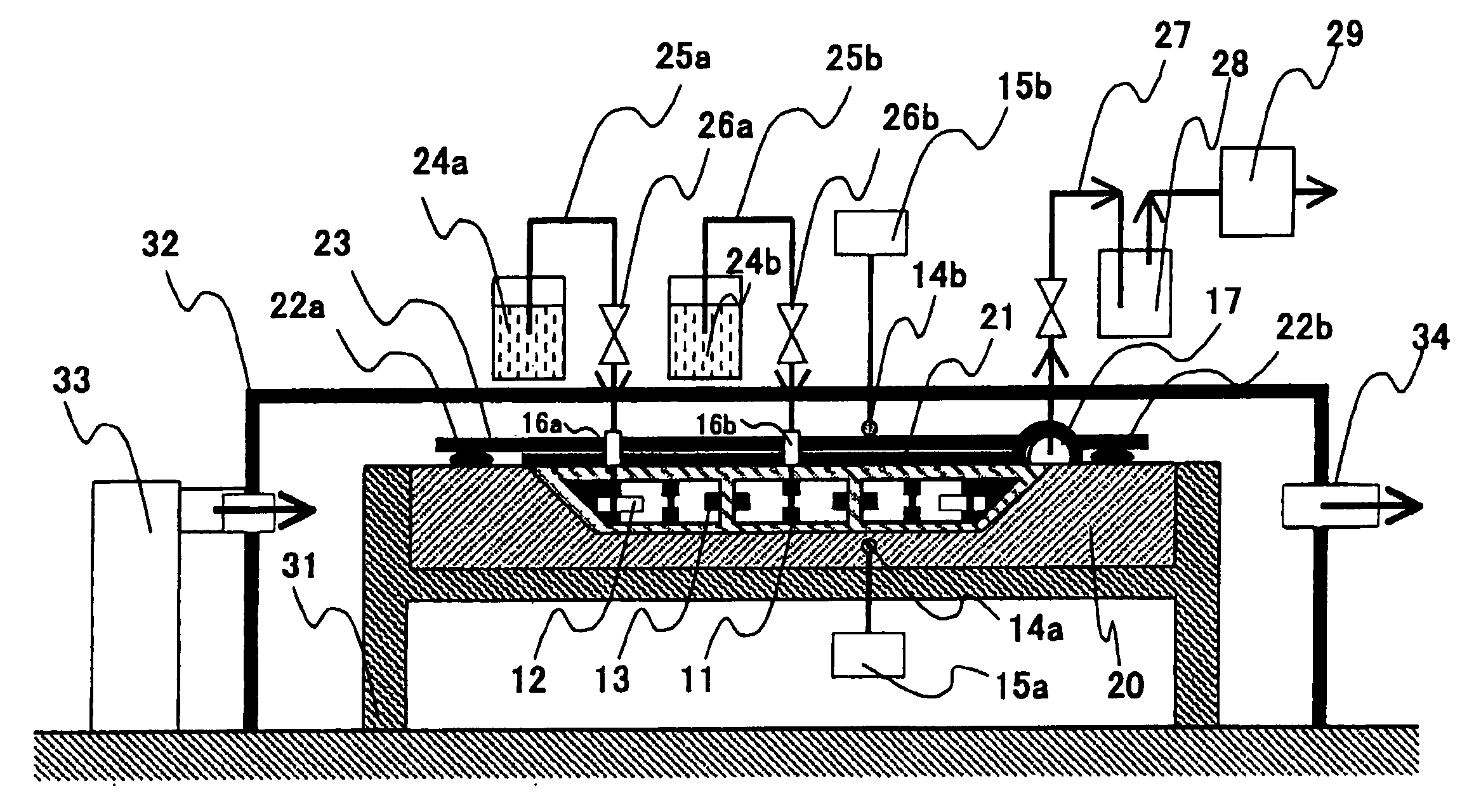

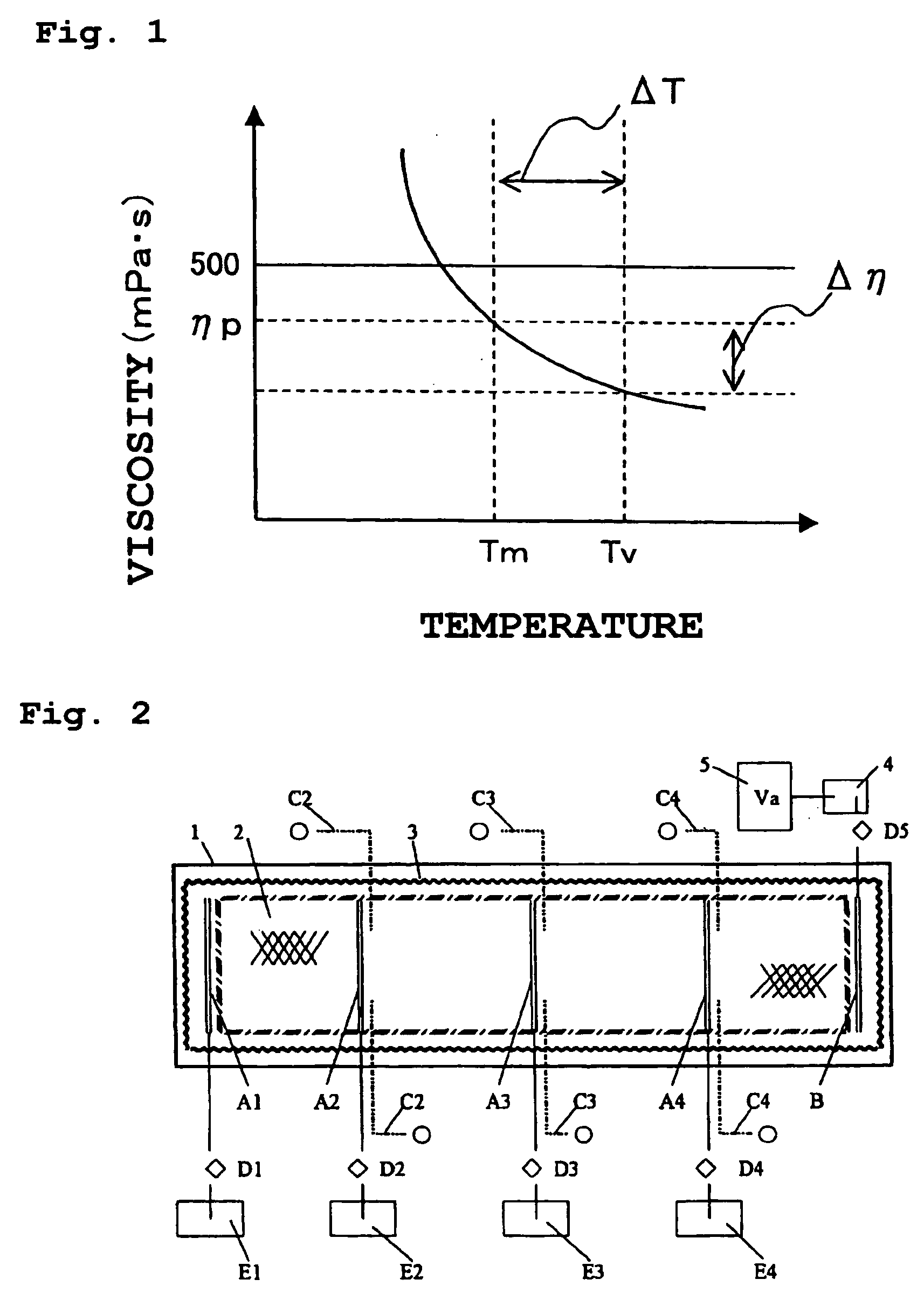

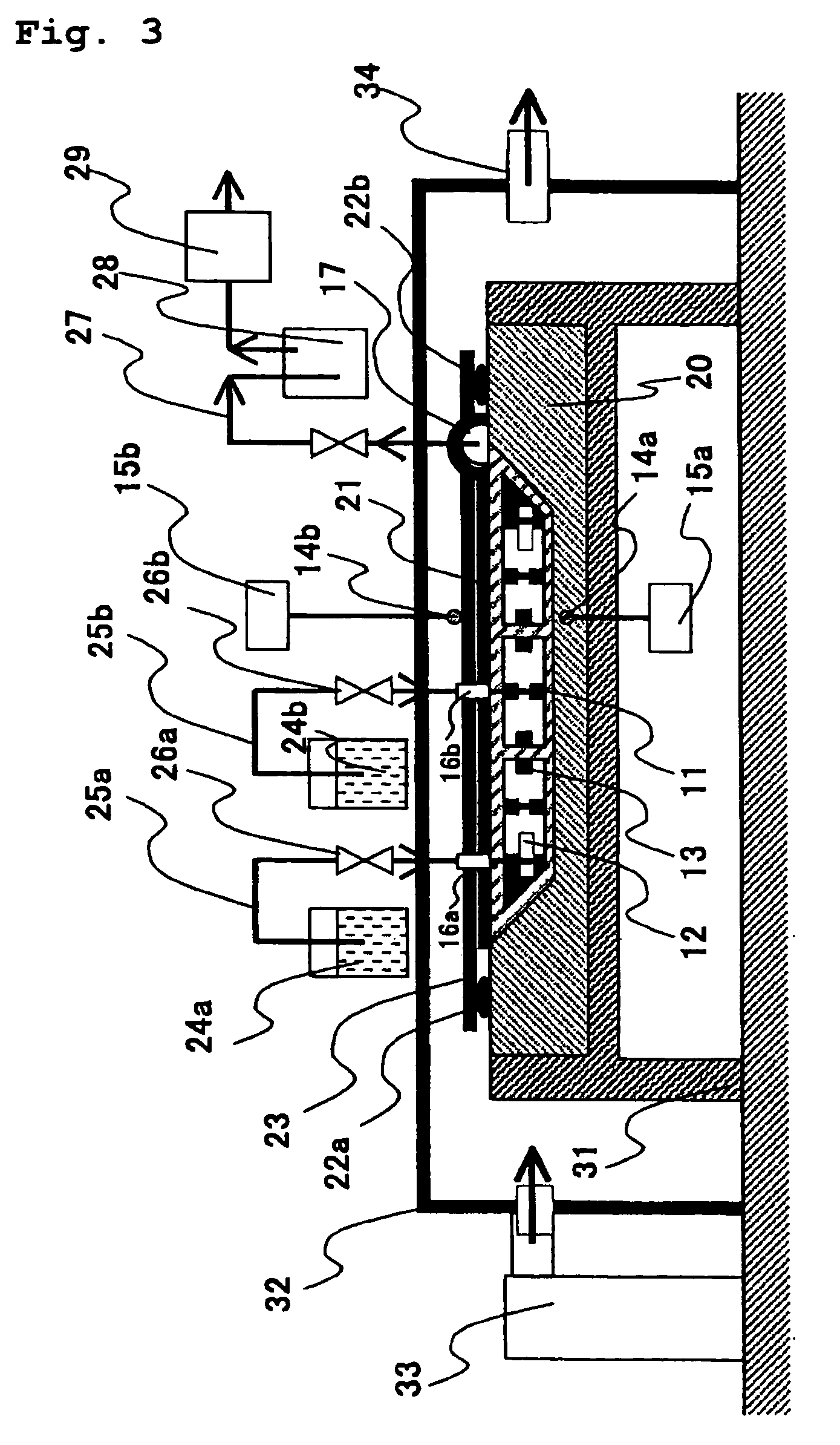

Method for producing upsized frp member

InactiveUS20040130072A1Improve mass productionReduce manufacturing costLamination ancillary operationsLaminationAir cycleFiber

The present invention relates to a method for manufacturing a large FRP member and has the following structure. The method for manufacturing a large FRP member, comprising the following steps (A) to (F). They are: setting step (A) of disposing a preform containing a reinforcing fiber base material on a surface of a molding die; sealing step (B) of covering a molding portion with a bagging material or a mold and providing at least one suction port and at least one resin injection port for sealing; evacuating step (C) of evacuating the molding portion through the suction port; hot-air heating step (D) of heating the molding portion by hot air; resin injection step (E) of injecting a thermosetting resin from the resin injection port for impregnating the reinforcing fiber base material with the resin while a temperature Tm of the molding die and a temperature Tv of the bagging material or the mold are both set to room temperature or more, and a difference DeltaT in temperature between the Tm and the Tv is set to 10° C. or less; and curing step (F) of curing the resin by maintaining the molding portion at a predetermined temperature Tpc which is equal to or more than room temperature. Preferably, the preform described above includes the reinforcing fiber base material and a resin distribution medium. In addition, it is preferable that in the hot-air heating step (D), the molding die be placed in a sealed chamber which is heat insulated with a heat insulating material, the hot air be circulated and supplied, and timing of starting the injection of the resin from a plurality of the resin injection ports be controlled in accordance with signals supplied from resin detection sensors provided in the molding die. The present invention provides a method for manufacturing a large FRP member having superior quality at an inexpensive cost and with high production yield, in which non-impregnated portions and voids are unlikely to be formed.

Owner:TORAY IND INC

Data center room cold aisle deflector

ActiveUS7266964B2Ducting arrangementsSpace heating and ventilation safety systemsAir cycleData center

A method and system of deflecting air circulated in a data center room are disclosed. A method for controlling air circulation within a room having an aisle between racks with computer systems mounted thereon comprises supplying cooling air to computer systems in the racks via holes in a floor of the room and using a deflector to reduce flow of cooling air along the aisle toward an air intake of a cooling unit without passing the computer systems.

Owner:ORACLE INT CORP

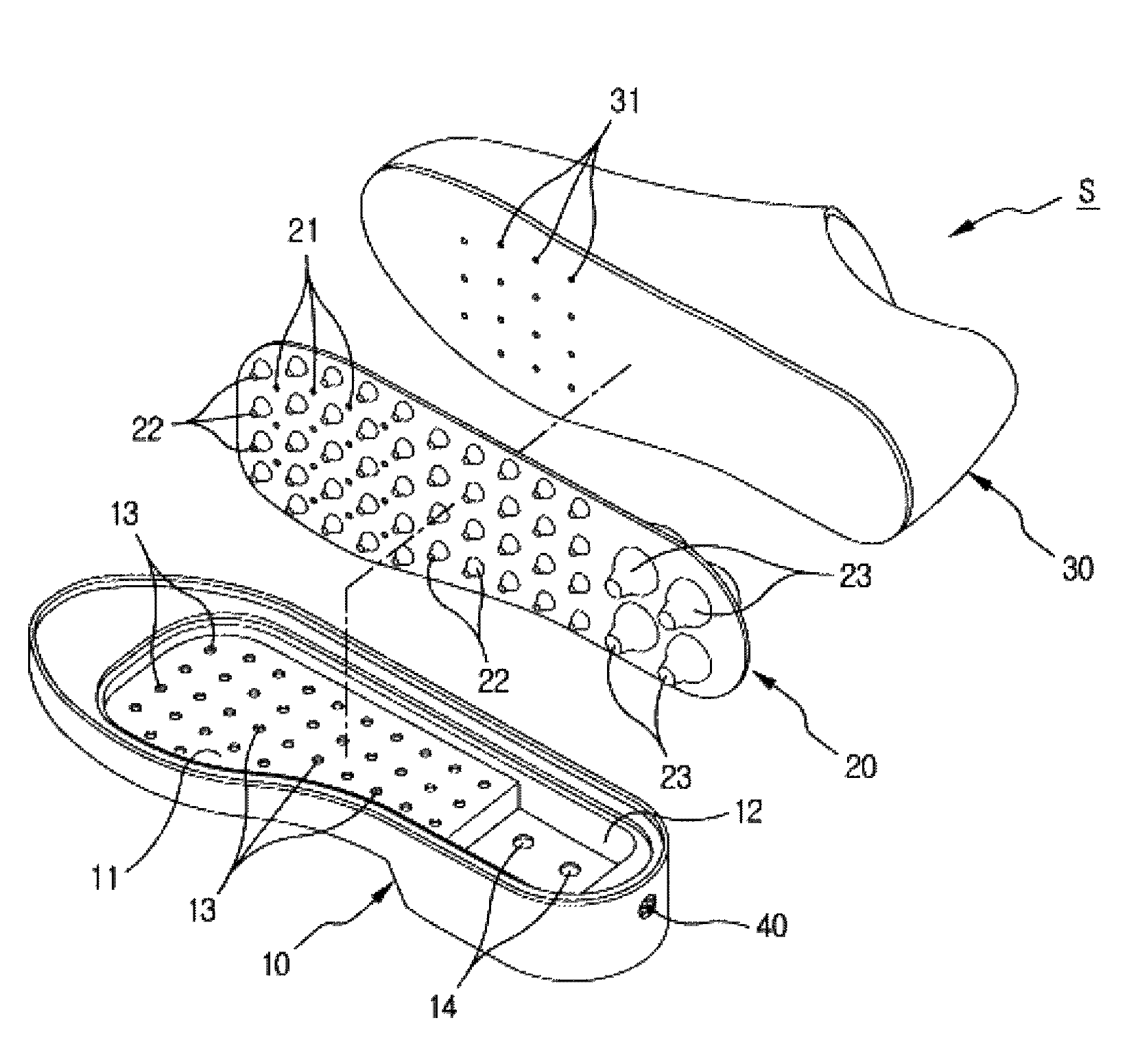

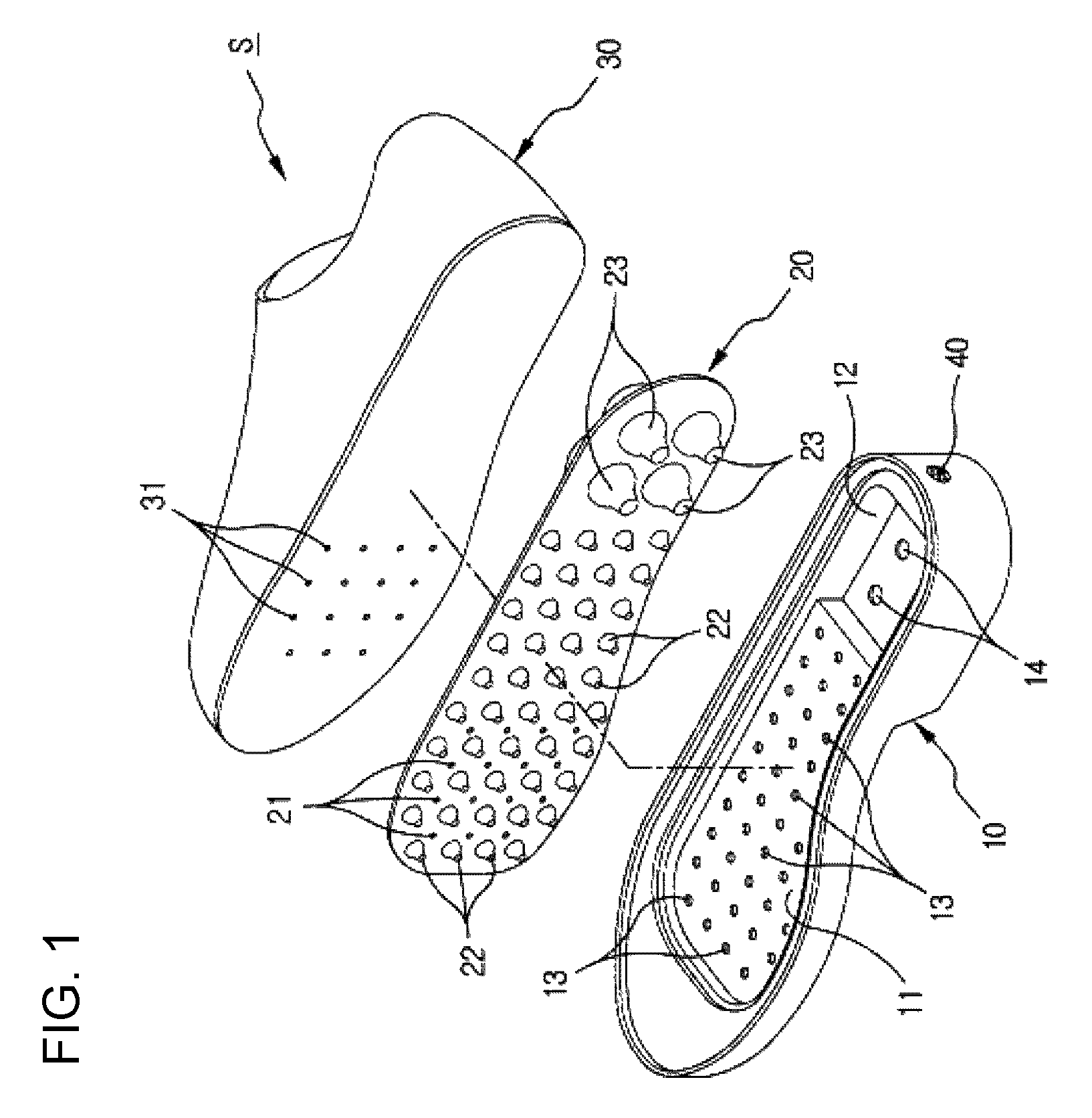

Air-circulating shock absorbing shoes

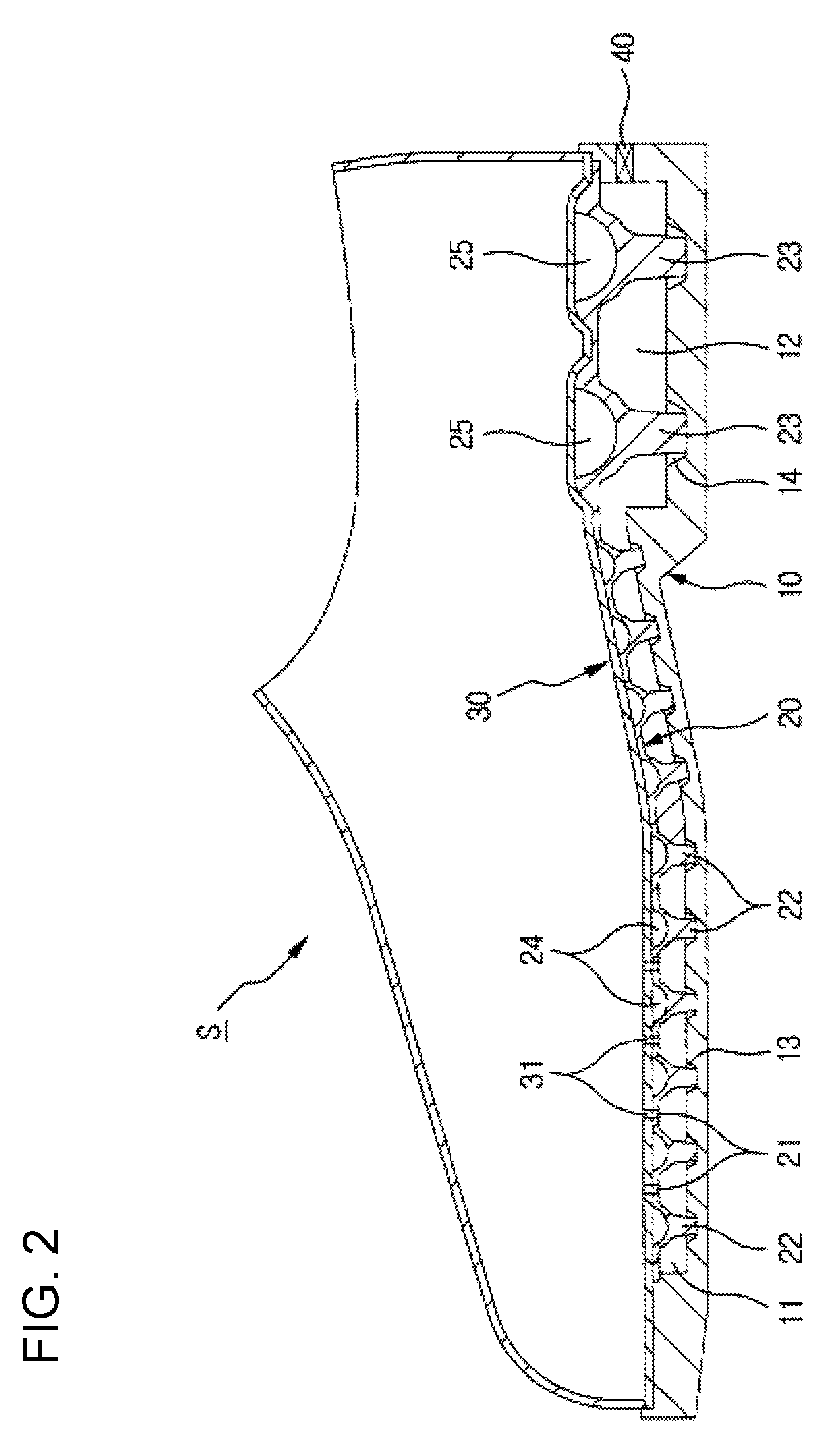

Disclosed is an air-circulating and shock-absorbing shoe that protects the backbone and knee joints and provides smooth air circulation for pleasant wearing of shoes for a long time. The shoe includes an outsole formed with the firstfirst and secondsecond air chambers, a midsole and an insole formed with multiple air suction holes connected with the firstfirst air chamber, and a check valve formed in the secondsecond air chamber of the outsole. The shoe is formed with multiple concaved holes on the bottoms of the firstfirst and secondsecond air chambers, multiple air cushion projections formed on the bottom of the midsole and inserted into the concaved holes, and shock-absorbing holes formed on the top of the air cushion projections.

Owner:YANG HEE WOON

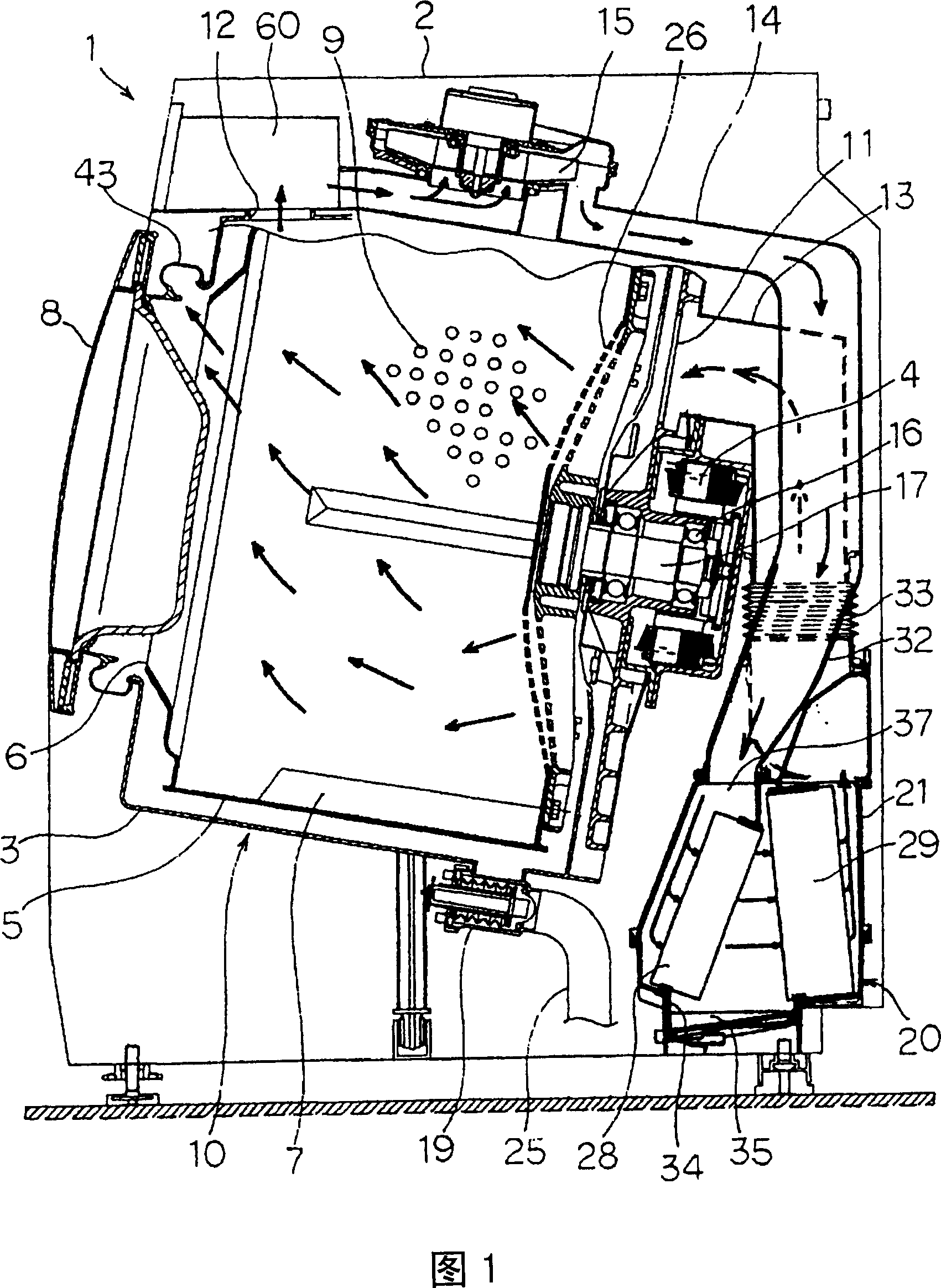

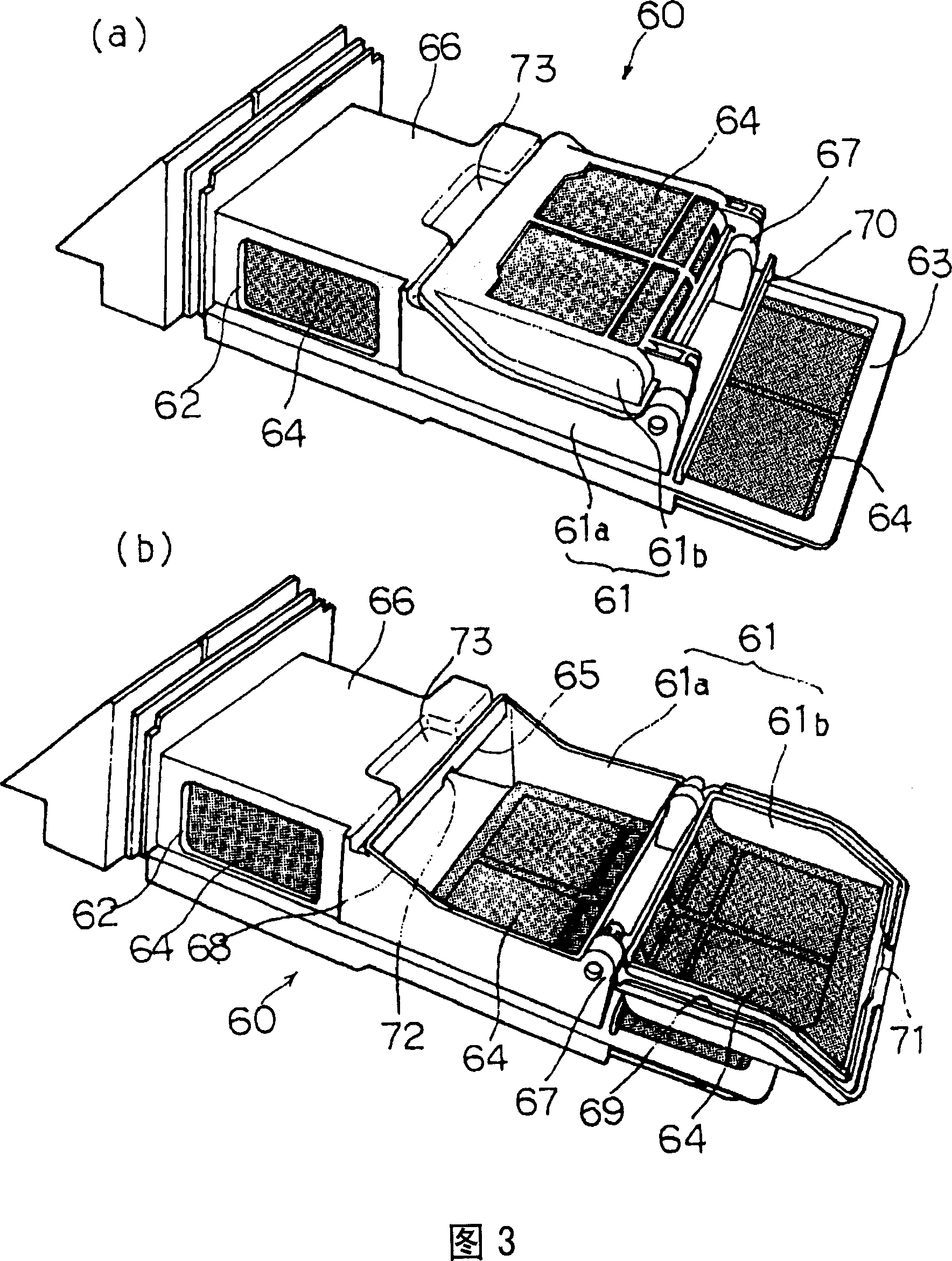

Clothes drying device

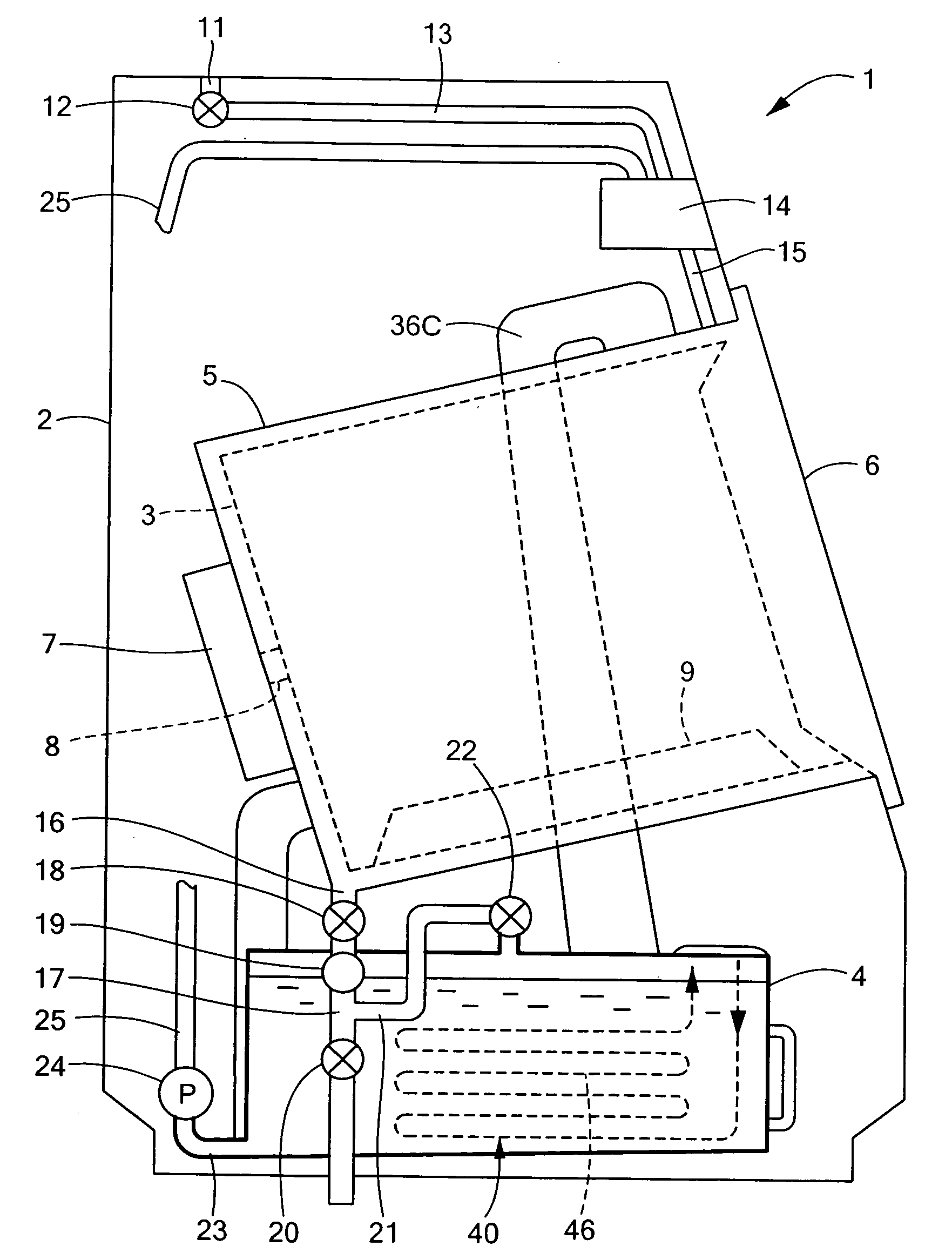

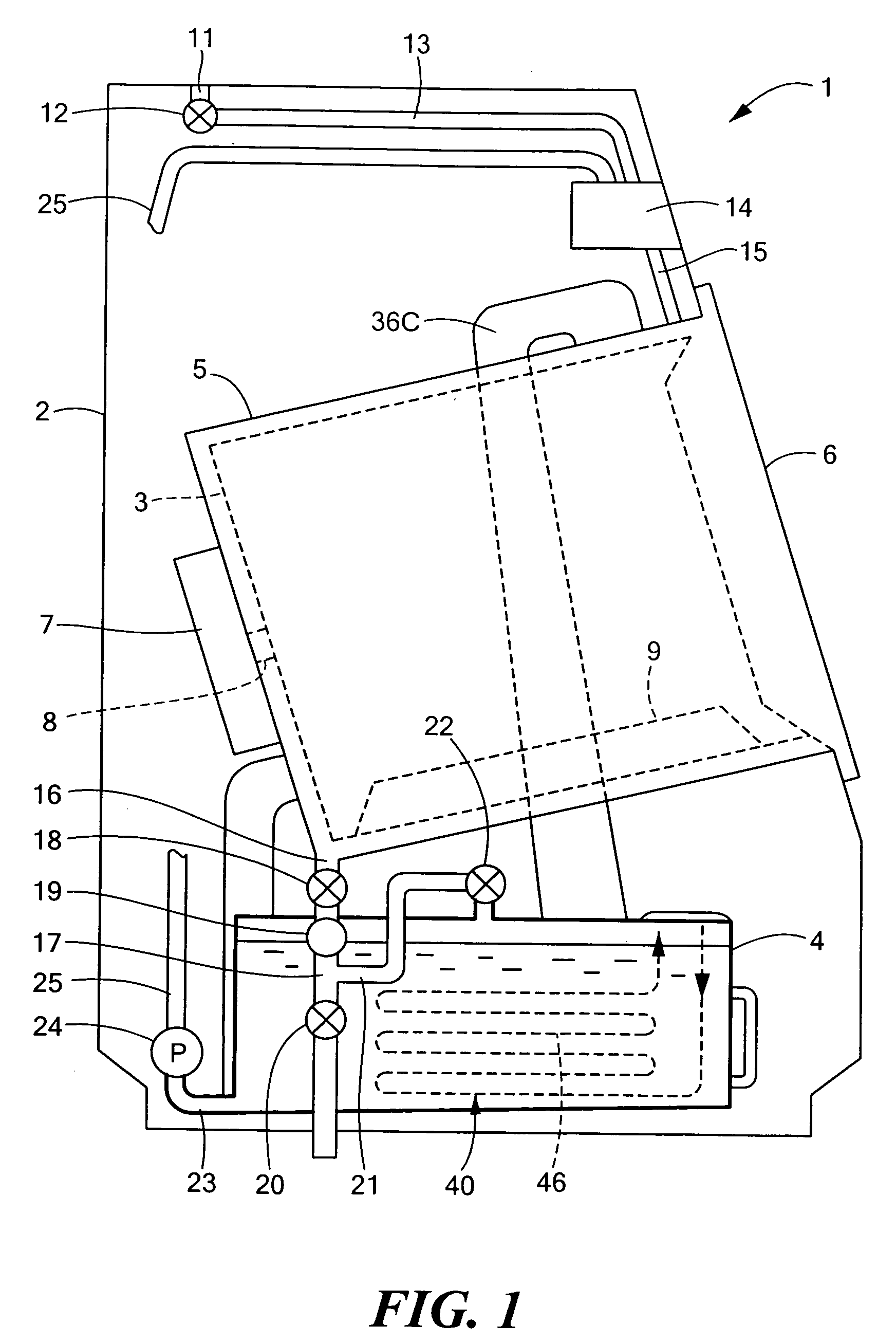

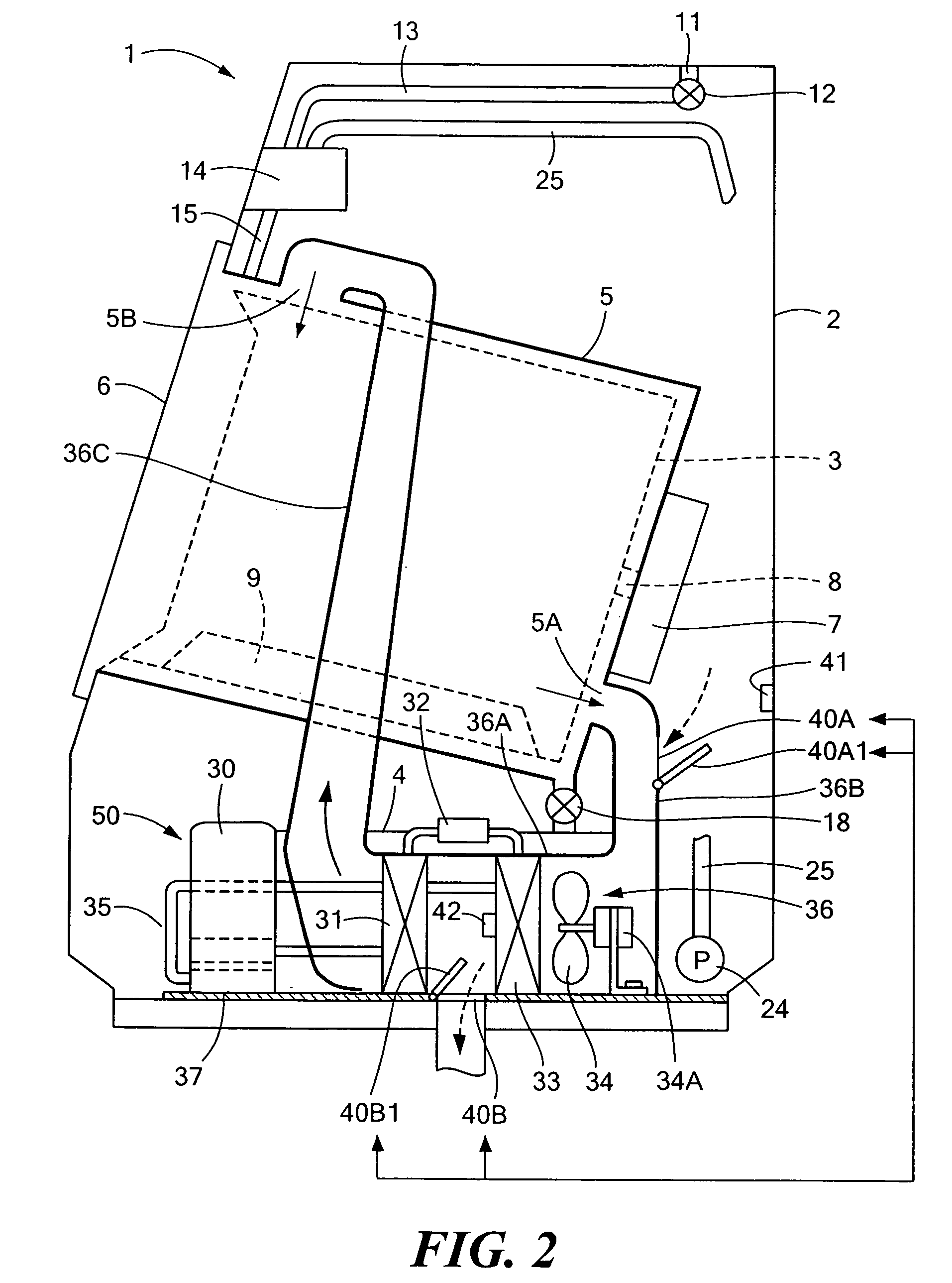

ActiveCN1936160AStable jobSuppression temperatureTextiles and paperHome appliance efficiency improvementAir cycleEngineering

The present invention provides a clothing dryer which permits a stable operation of a heat pump generating drying air to be circulated between a drying chamber and the heat pump. An air circulation route is formed which delivers air heated by a heater 29 of a heat pump unit 20 to a water tank 3 to be a drying chamber, returns the air discharged from the water tank 3 to the heat pump unit 20 through a filter unit 60, dehumidifies in a heat absorber 28 and delivers again to the heater 29. The filter unit 60 is provided with a lint filter 61 and a duct communicating with an air outlet 46 and an air introduction opening 47 is formed. Since the air is discharged from the air outlet 46 and an external air is introduced from the air introduction opening 47 when the amount of heat accumulated in the air in the air circulation route increases, an excessive increase in the temperature and pressure of a refrigerant with an increase in the amount of accumulated heat can be suppressed, and overloading a compressor 27 can be restrained, whereby the heat pump is stably operated.

Owner:PANASONIC CORP

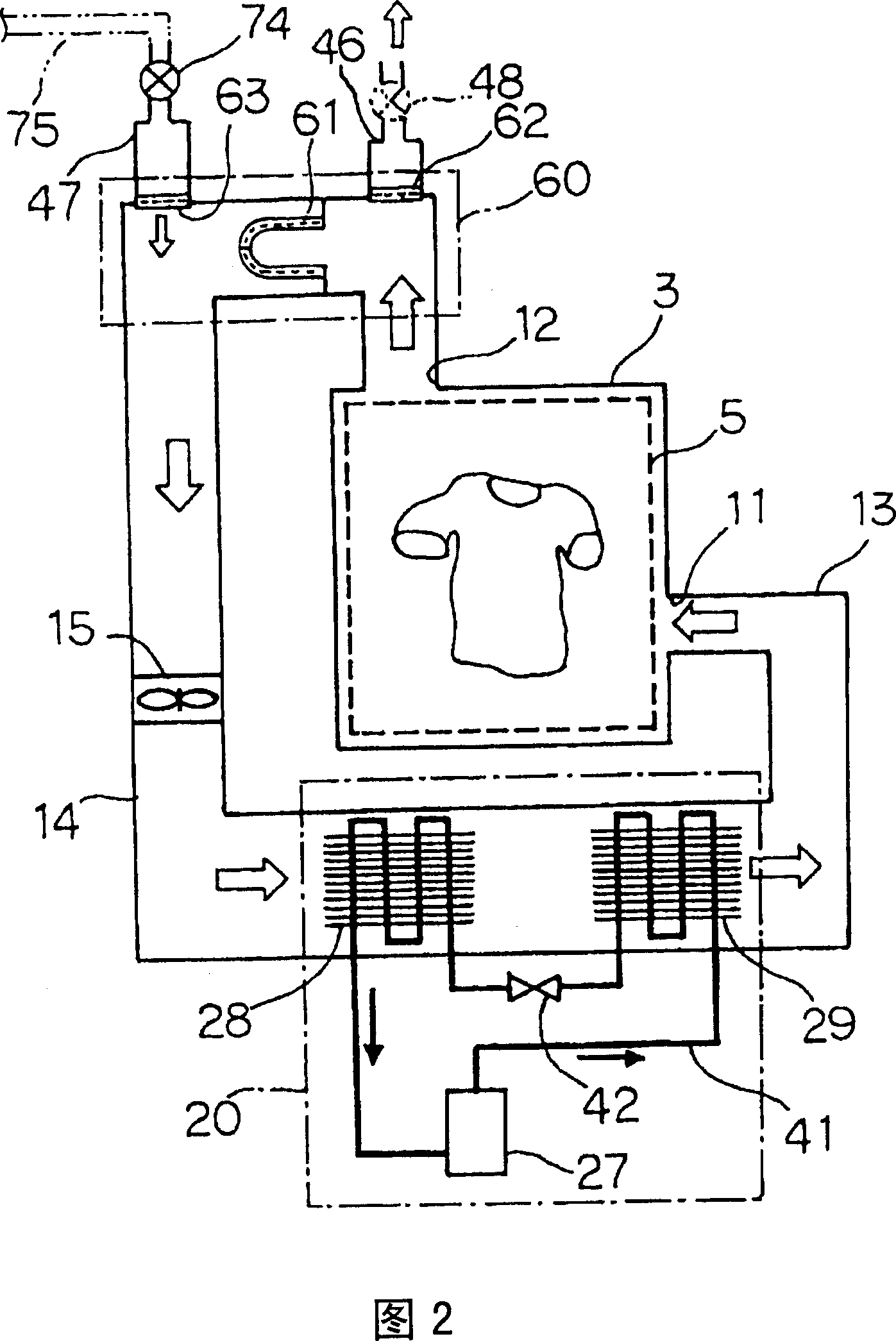

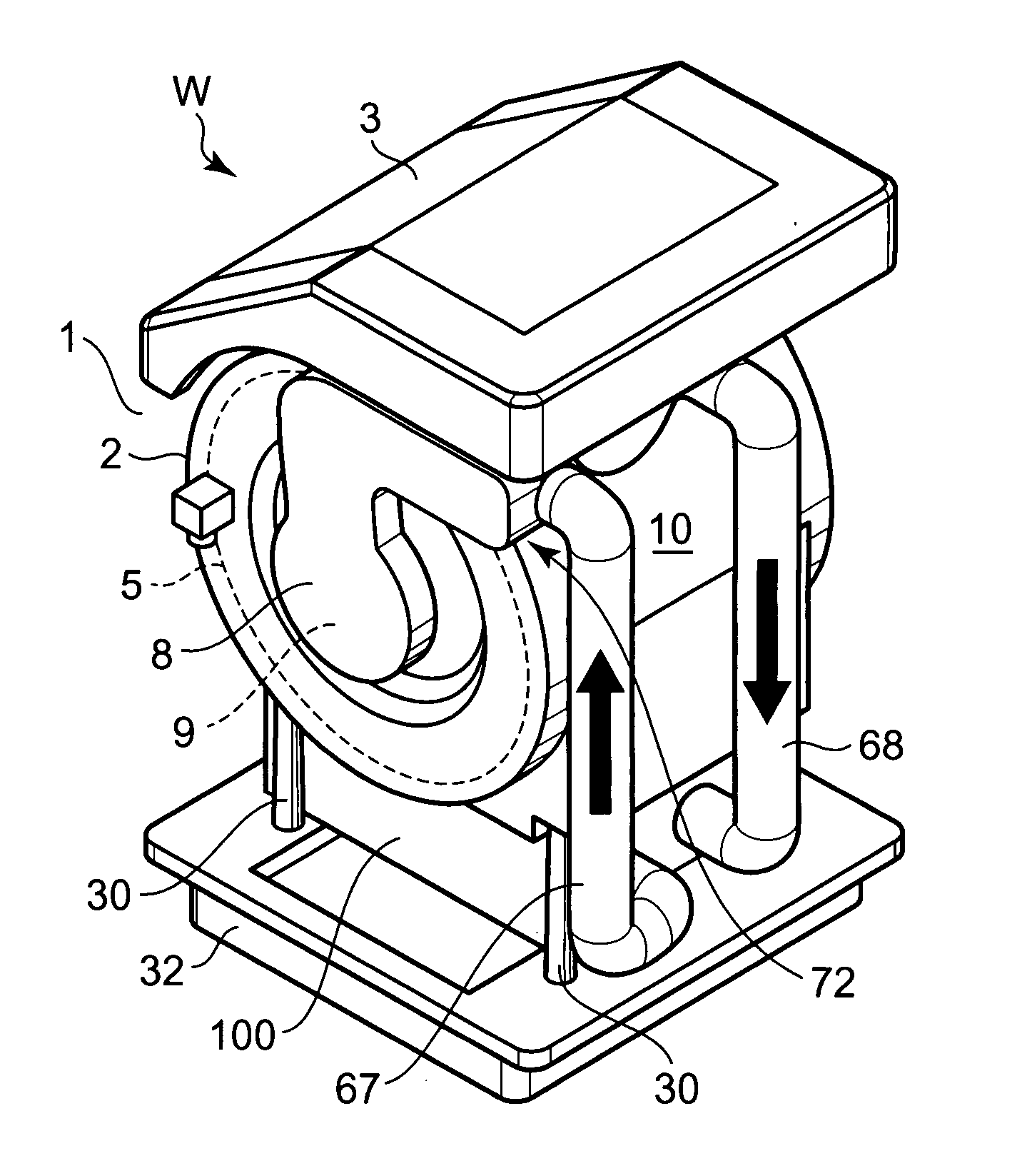

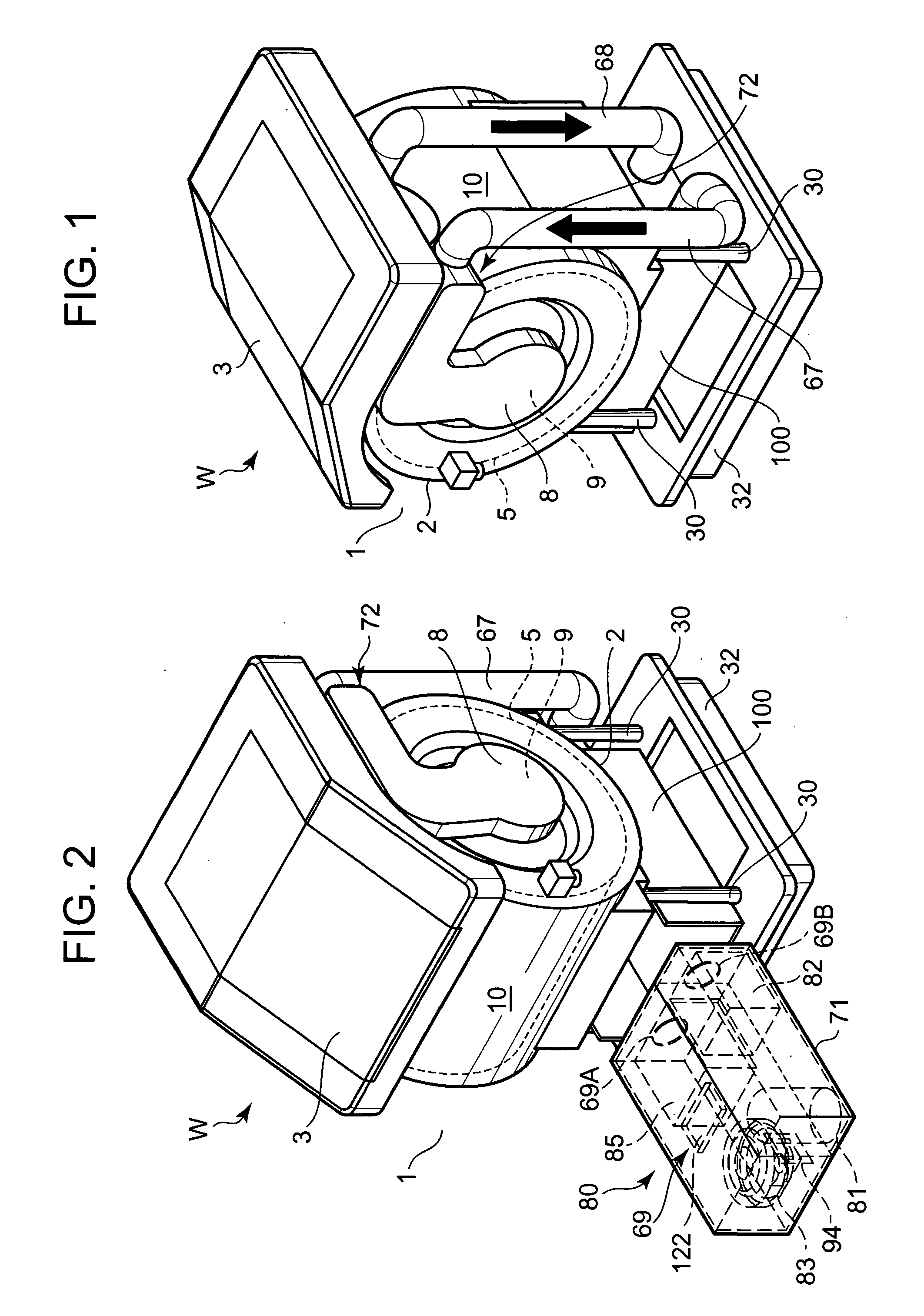

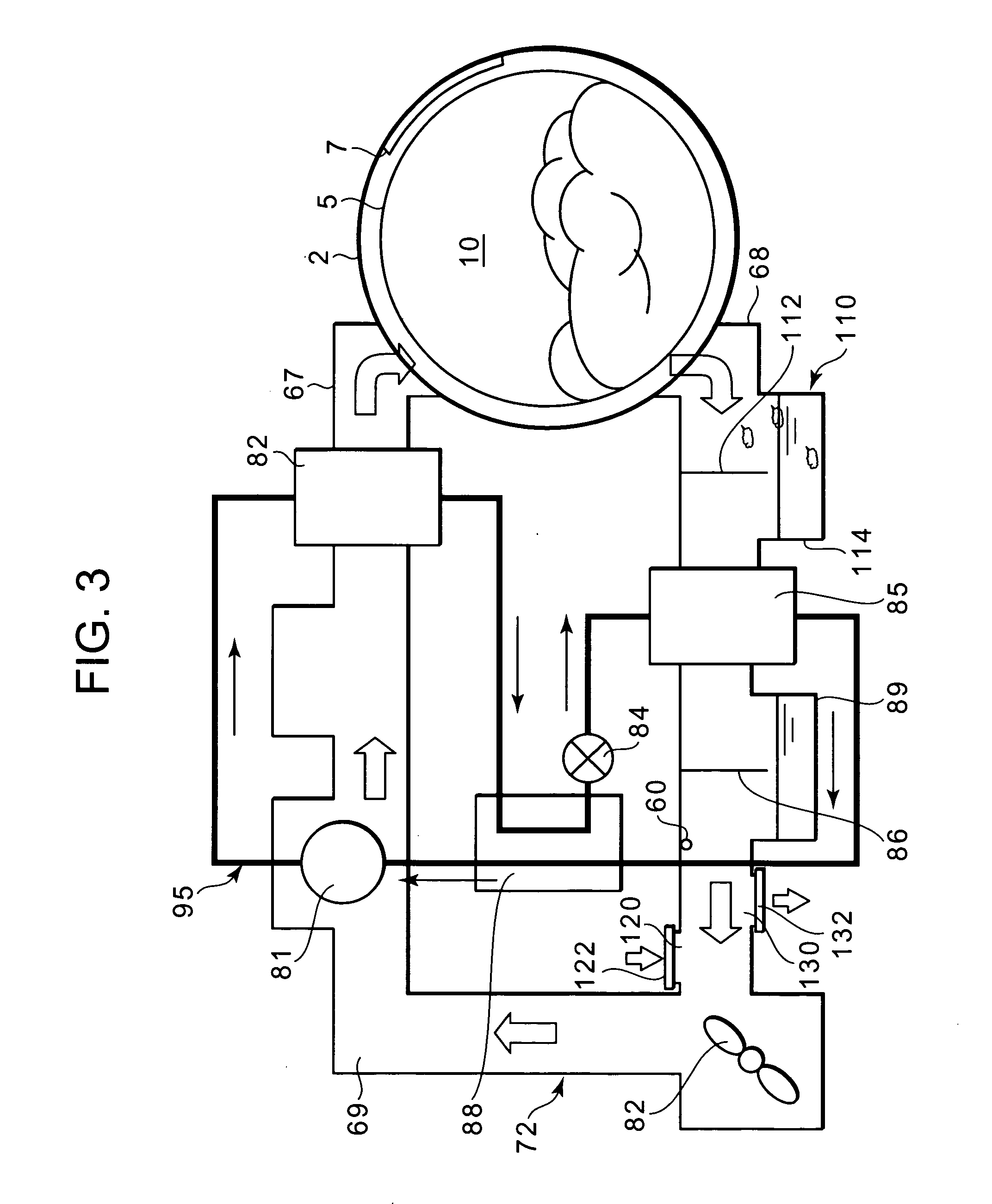

Drying unit and laundry washing/drying machine equipped with the drying unit

ActiveUS20080235977A1Increase the rate of heatingShorten the timeDrying gas arrangementsOther washing machinesAir cycleProcess engineering

In a laundry washing / drying machine involving drying by a heat pump cycle, in an initial stage of the drying operation the heat within an air circulation path is deficient and therefore it is impossible to effect quick heating of air on a drum inlet side up to a sufficiently high temperature. According to the present invention there is provided a drying unit capable of raising the drum inlet air temperature quickly up to a sufficiently high temperature in an initial stage of the drying operation and thereby shortening the drying time. The drying unit includes a heat pump cycle device for performing a cycle of radiating, with use of a radiator, the heat of a refrigerant compressed by a compressor, passing the refrigerant through a pressure reducing / expansion valve, evaporating the refrigerant in an evaporator and compressing the refrigerant again by the compressor, an air circulation path for allowing air to be circulated by a blower in such a manner that air heated by the radiator is introduced into a drying chamber to dry the laundry, exhaust air discharged from the drying chamber is passed through the evaporator, then is heated again by the radiator and the air thus dehumidified is circulated by the blower, and an external heat source applying device for applying the heat of an external heat source to the evaporator to quicken the rise in temperature of the air in an initial stage of the drying operation.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

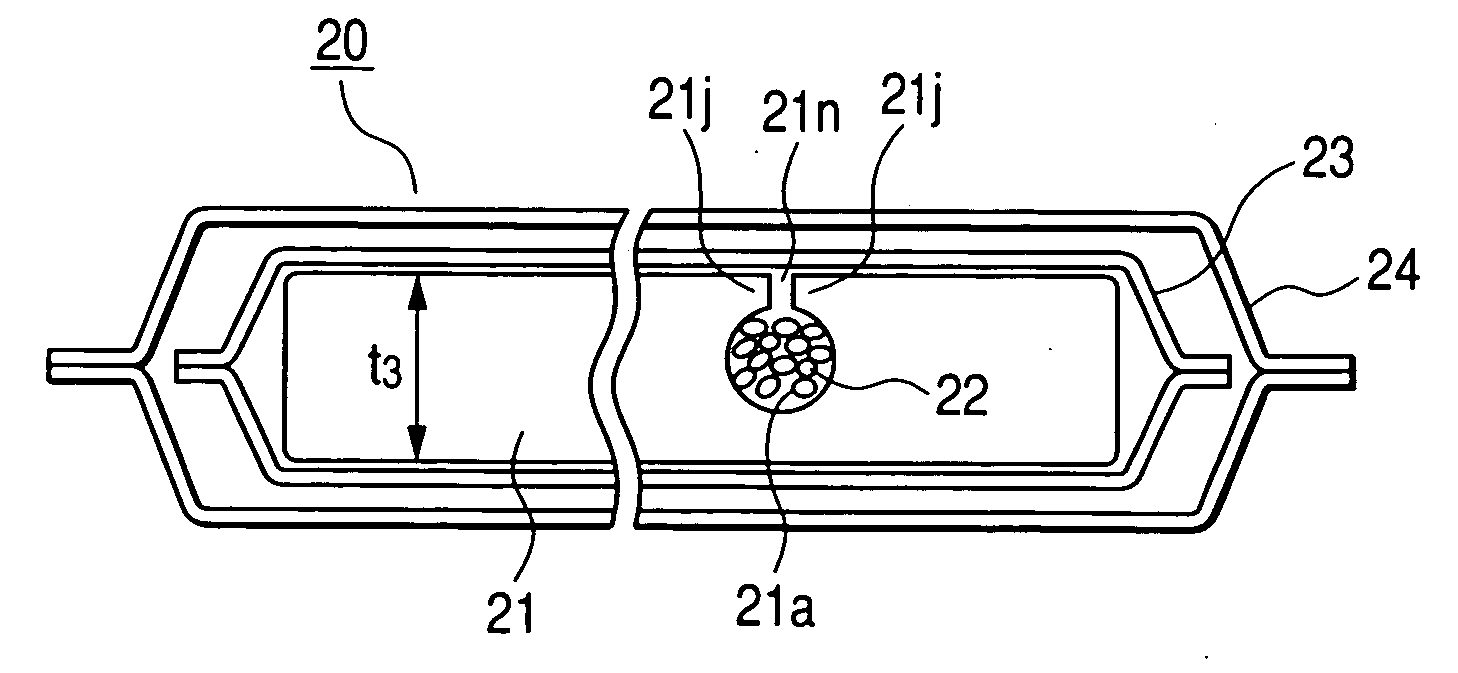

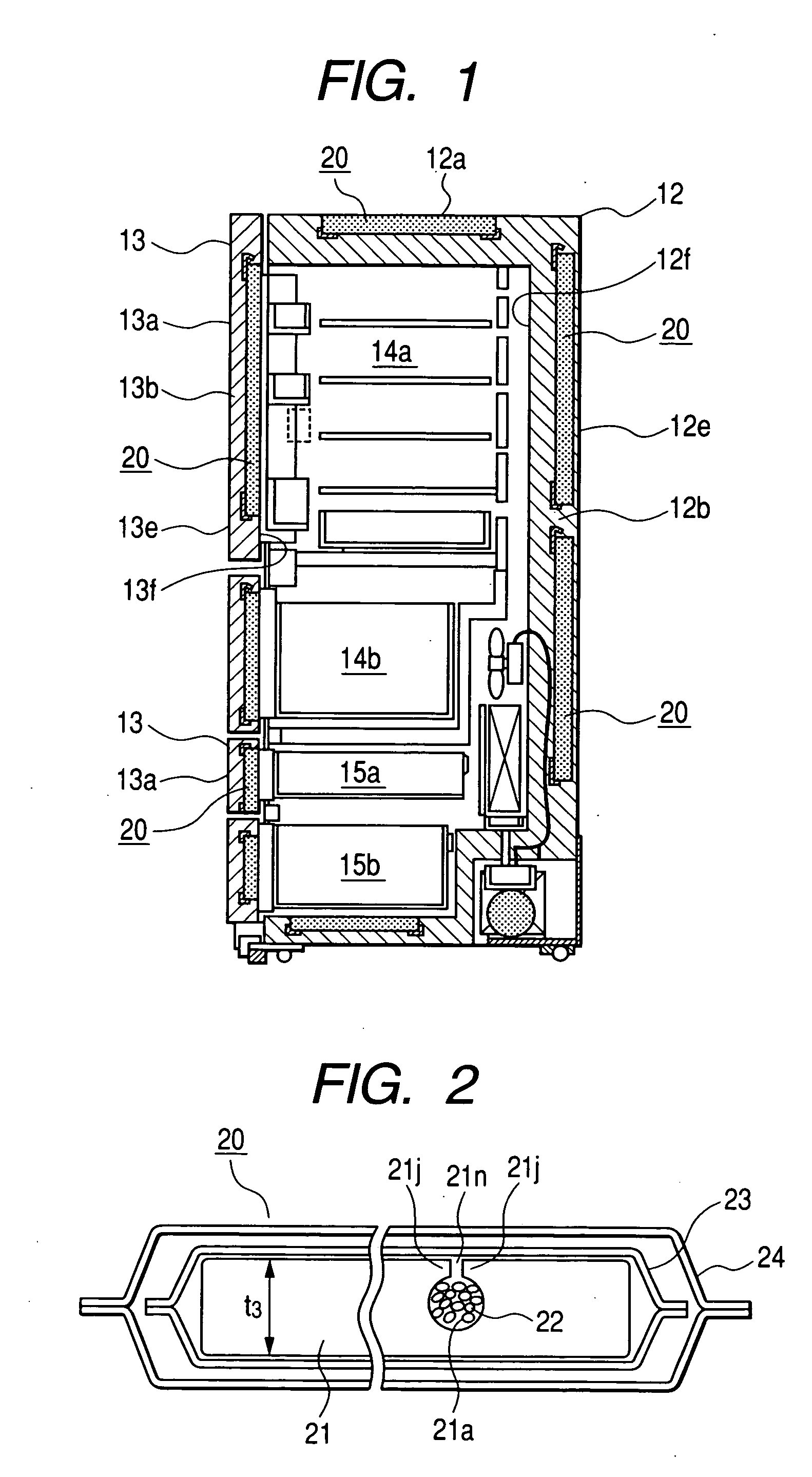

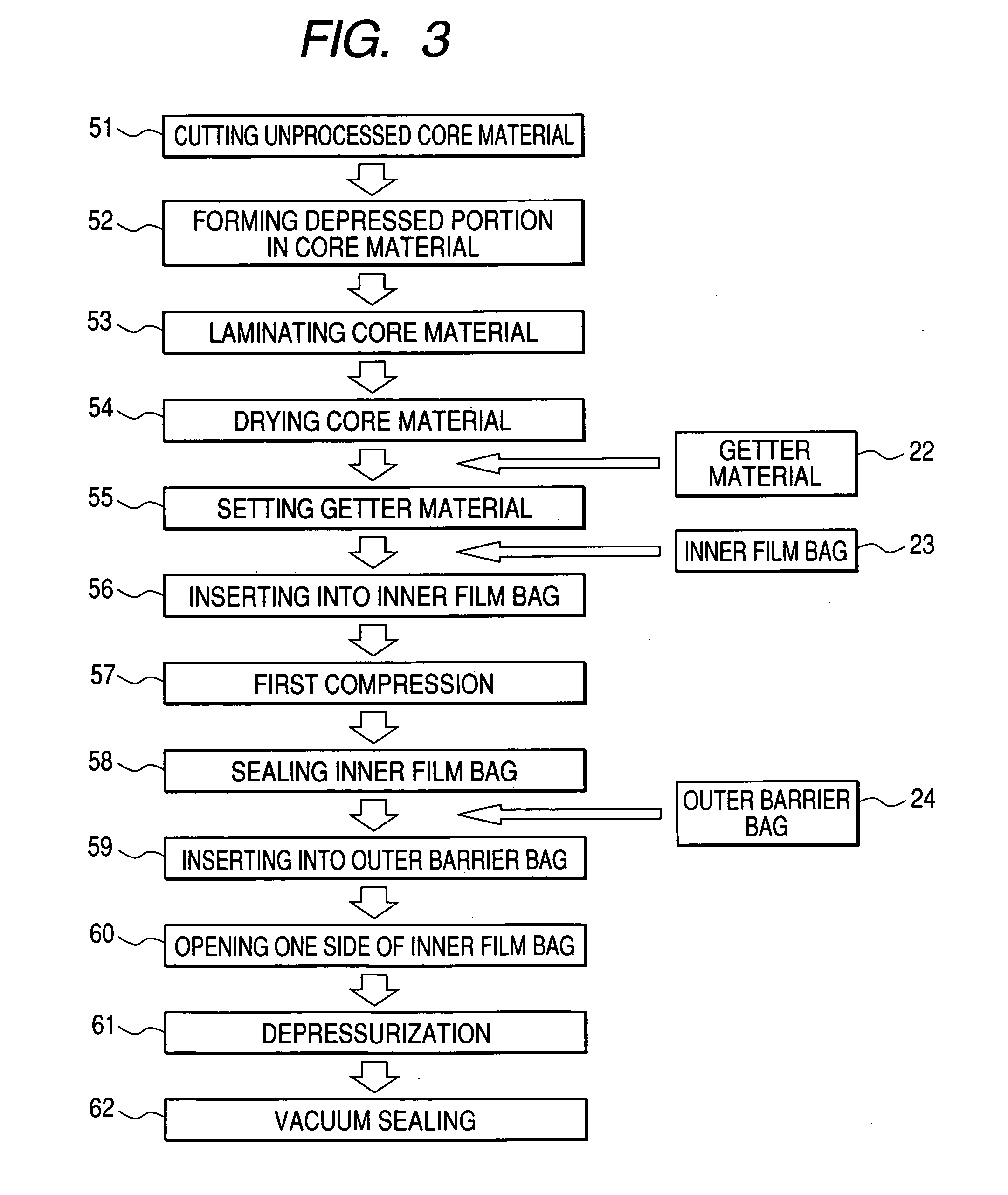

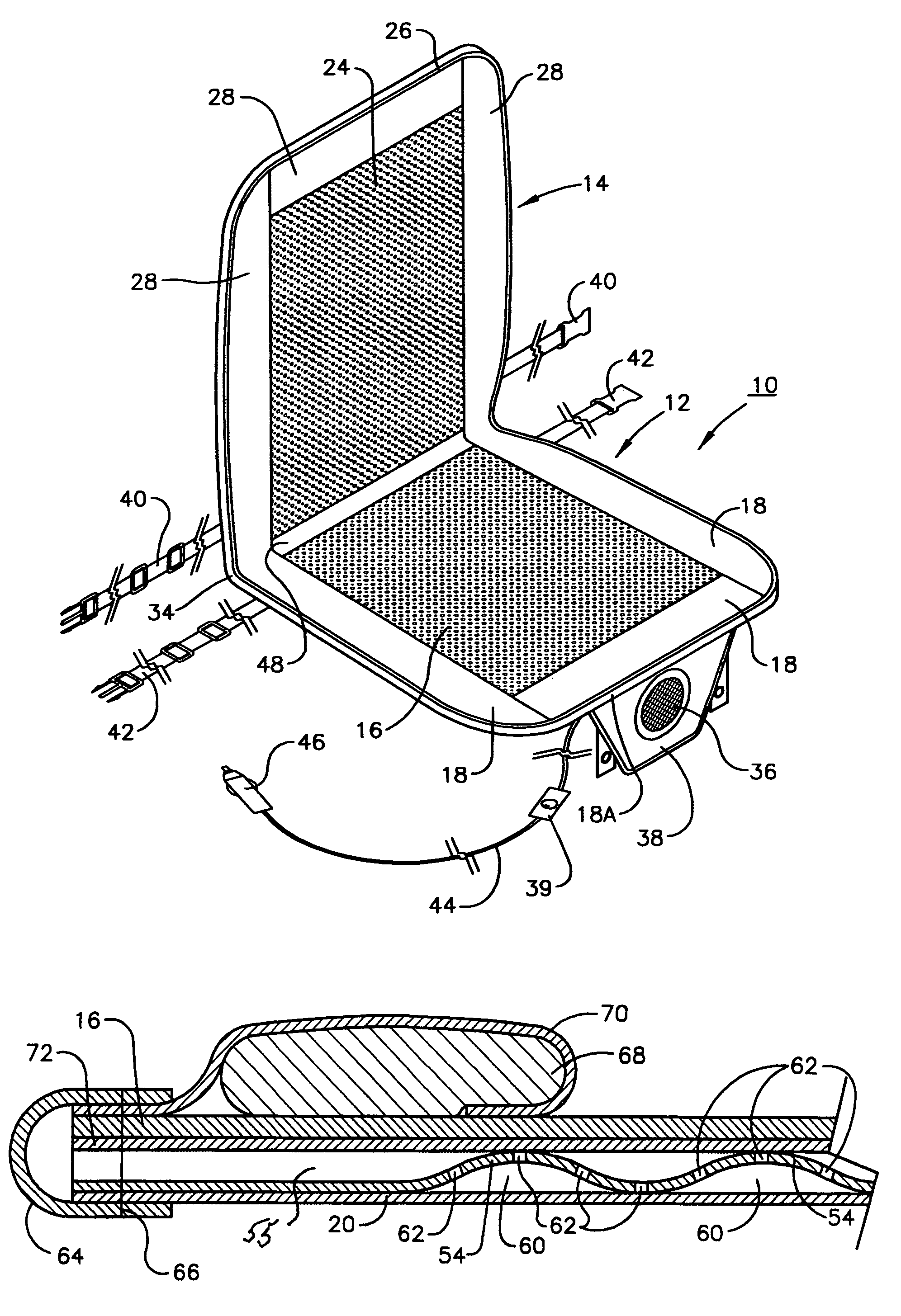

Vacuum insulation panel, refrigerator incorporating the same, and method for producing the same

InactiveUS20060076863A1Increased processing flexibilityHigh adsorption rateThermal insulationLayered productsAir cycleEngineering

The invention provides a vacuum insulation panel to which moisture and gas do not easily adsorb while it is being processed or being in storage in an unfinished state. The vacuum insulation panel includes a core provided with air circulation, a getter material which adsorbs moisture and gas from the core, an inner film bag which accommodates the core and the getter material, and an outer barrier bag which accommodates the inner film bag. The getter material is filled in an incision provided on the surface of the core. To prevent the getter material from getting out of the incision, the opening of the incision is narrowed by evacuating air from the interior of the inner film bag and, concurrently, compressing the inner film bag and the core.

Owner:HITACHI APPLIANCES INC

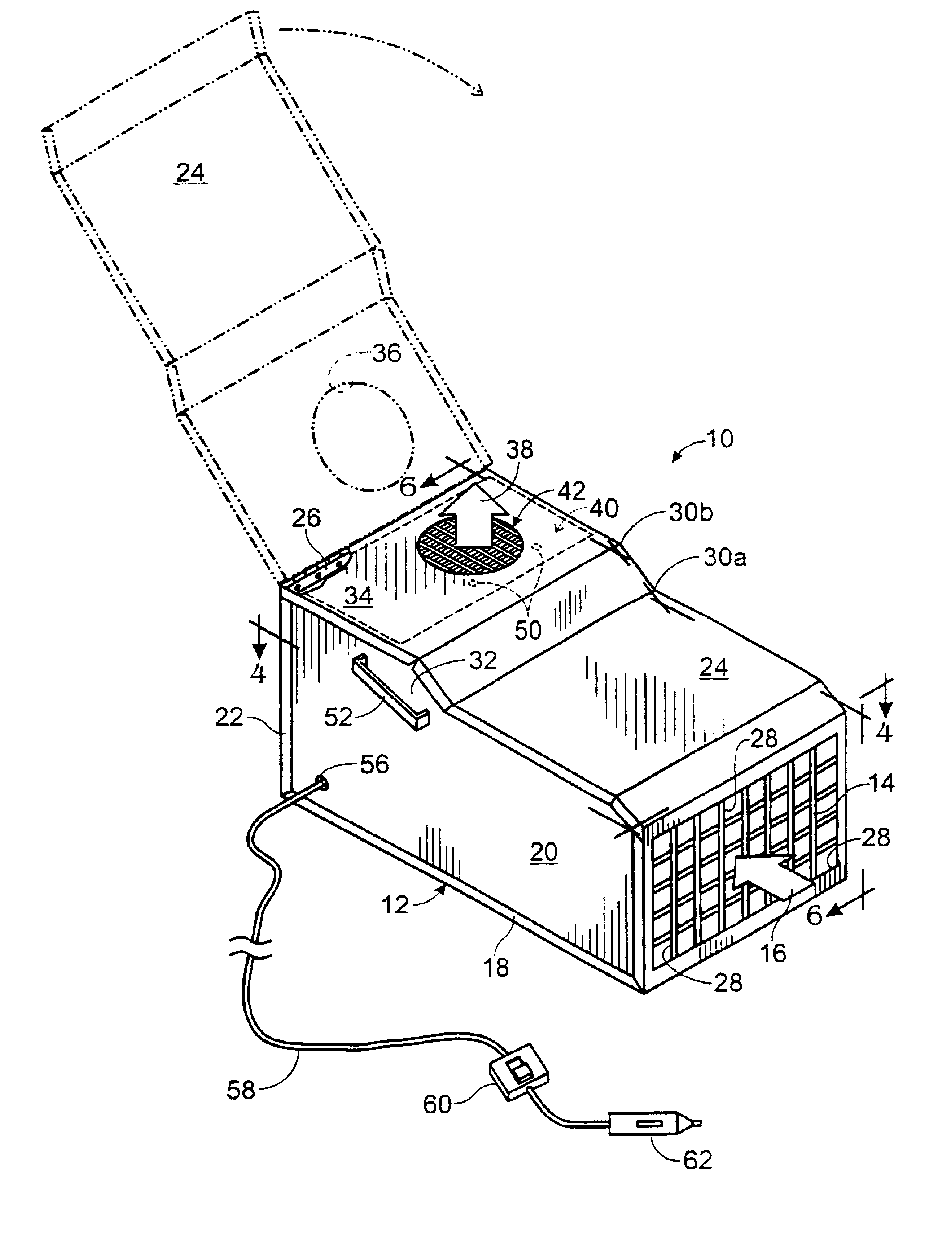

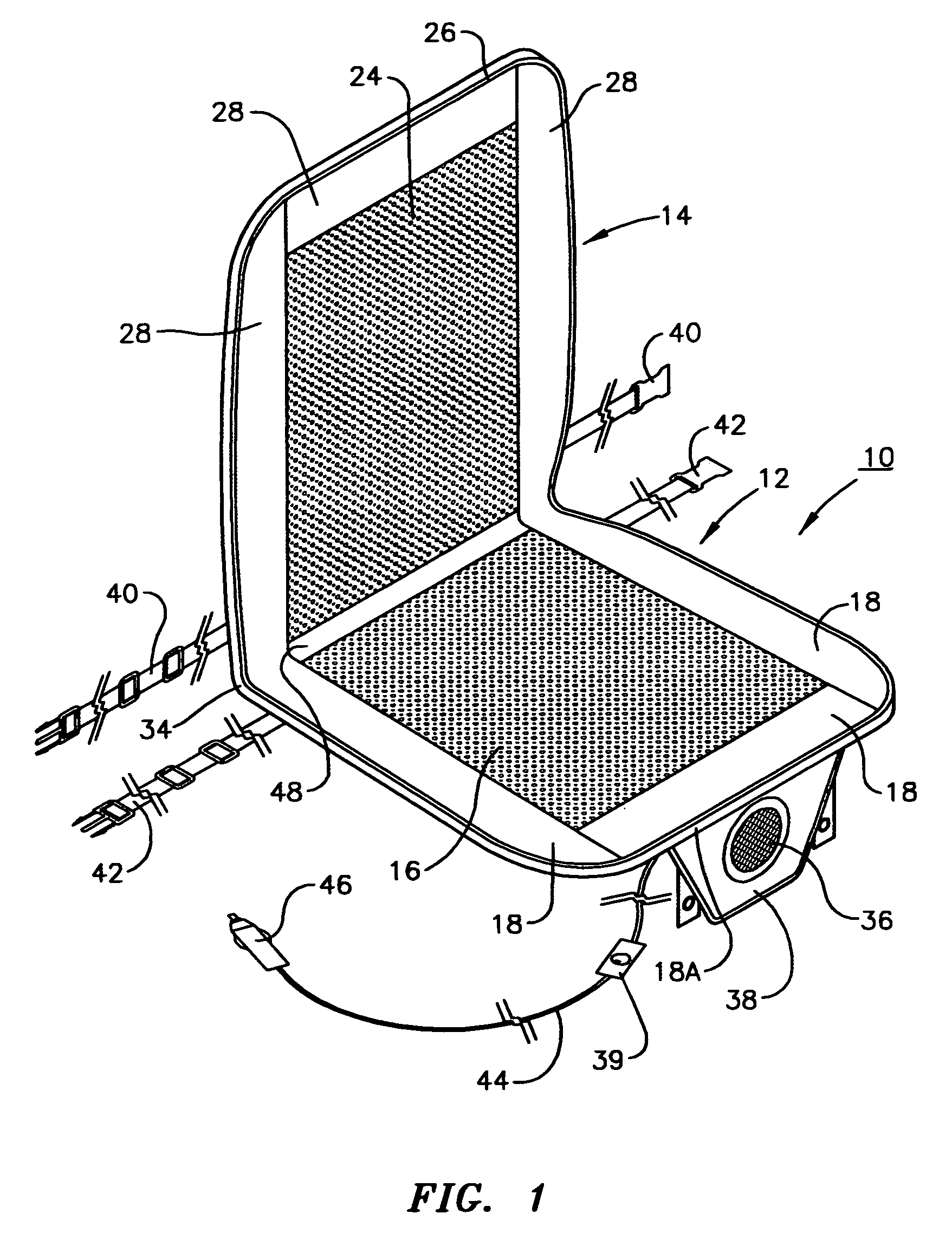

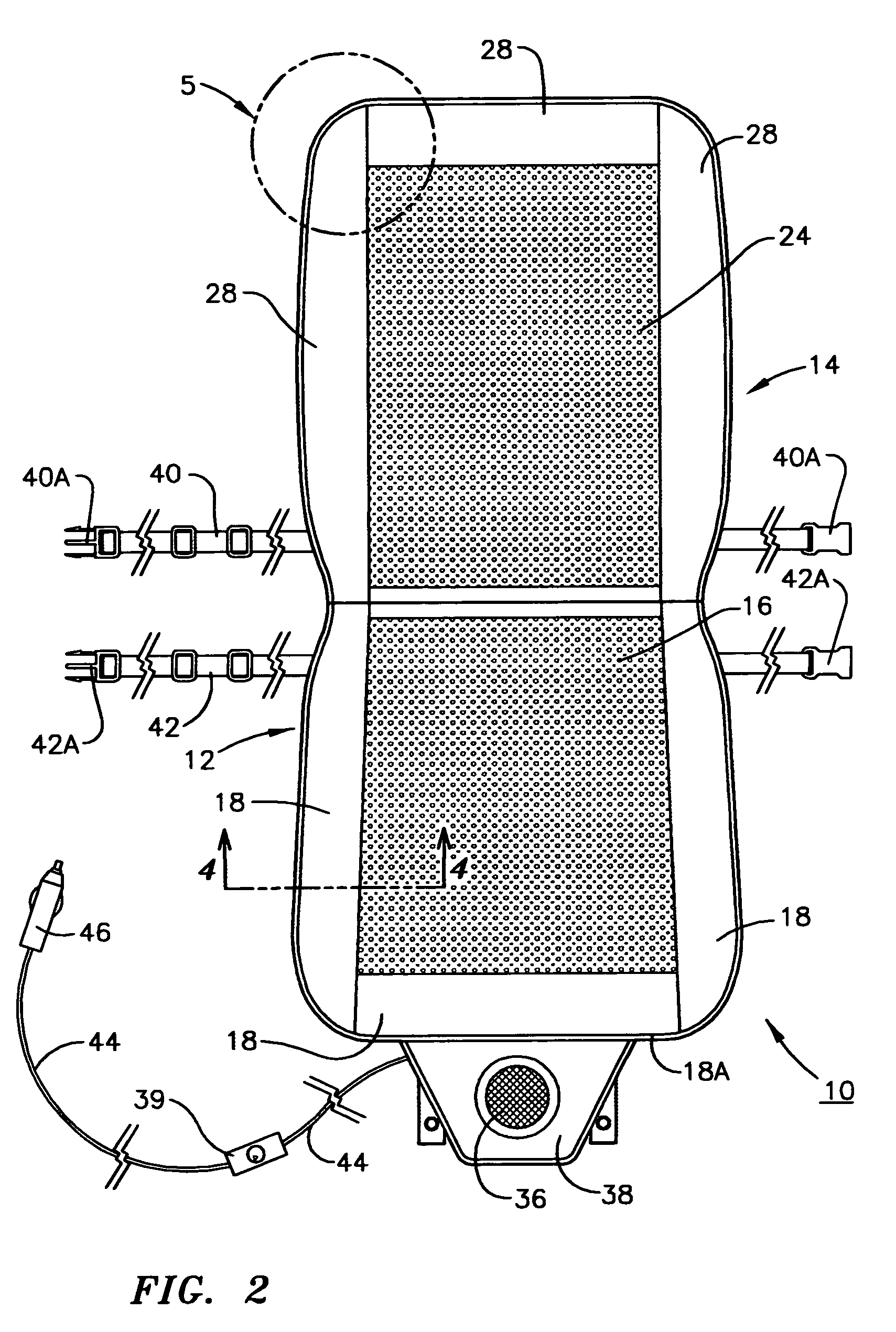

Portable seat cooler

A portable seat cushion comprising: A) a seat portion; B) a back portion; and C) an integral fan that circulates air through the seat and back portions, the front portion having a front surface, a perimeter, a rear surface and an interior between the rear and front surfaces and the back portion having a front surface, a top, a bottom, a perimeter, a rear surface and an interior between the rear surface and the front surface, the seat and back portions being joined by a flexible connection that permits the seat and back portions to rotate relative to each other and provides a mechanism for the passage of air from the seat portion to the back portion. The rear surfaces and perimeters of each of the seat and back portions is relatively air impermeable while the front surfaces of these members is air permeable. The interior of each of the back and seat portions includes a semi-rigid undulating member that defines passages for the movement of air from the incorporated fan to the seat and back portions and to the front surfaces of the seat and back portions through apertures therein.

Owner:WONG PETER H

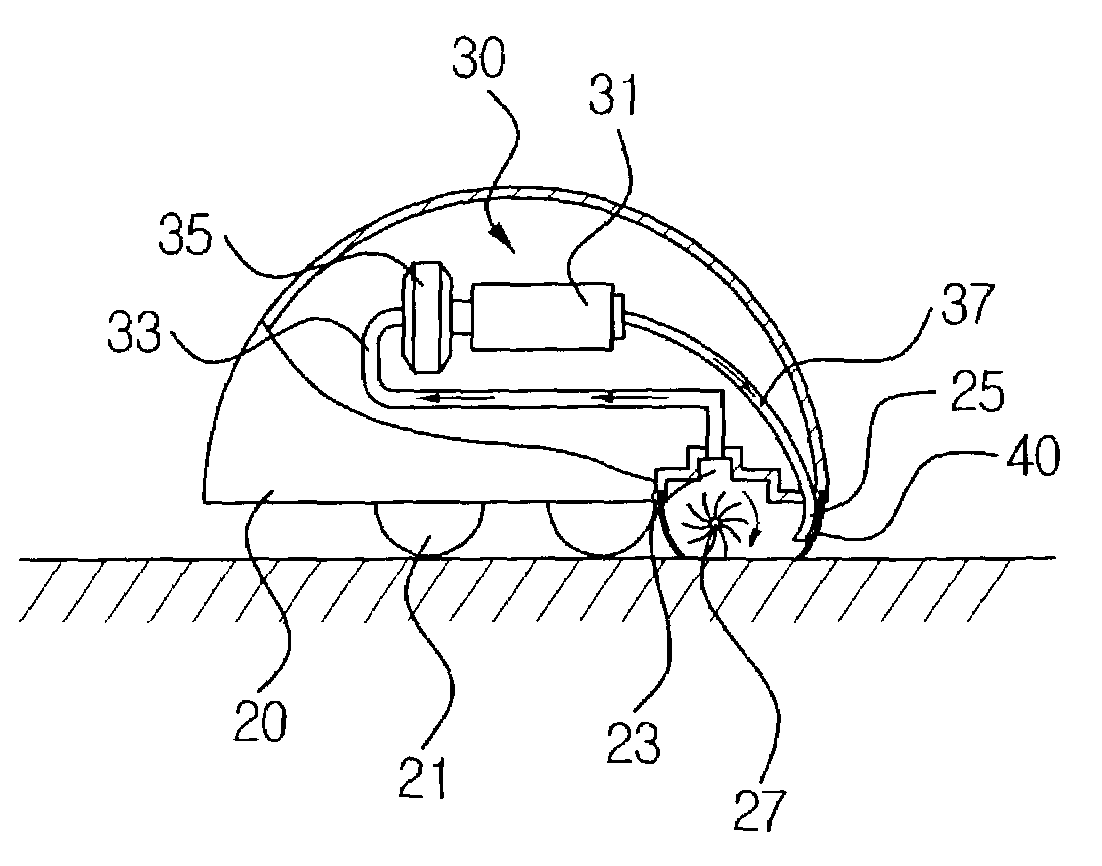

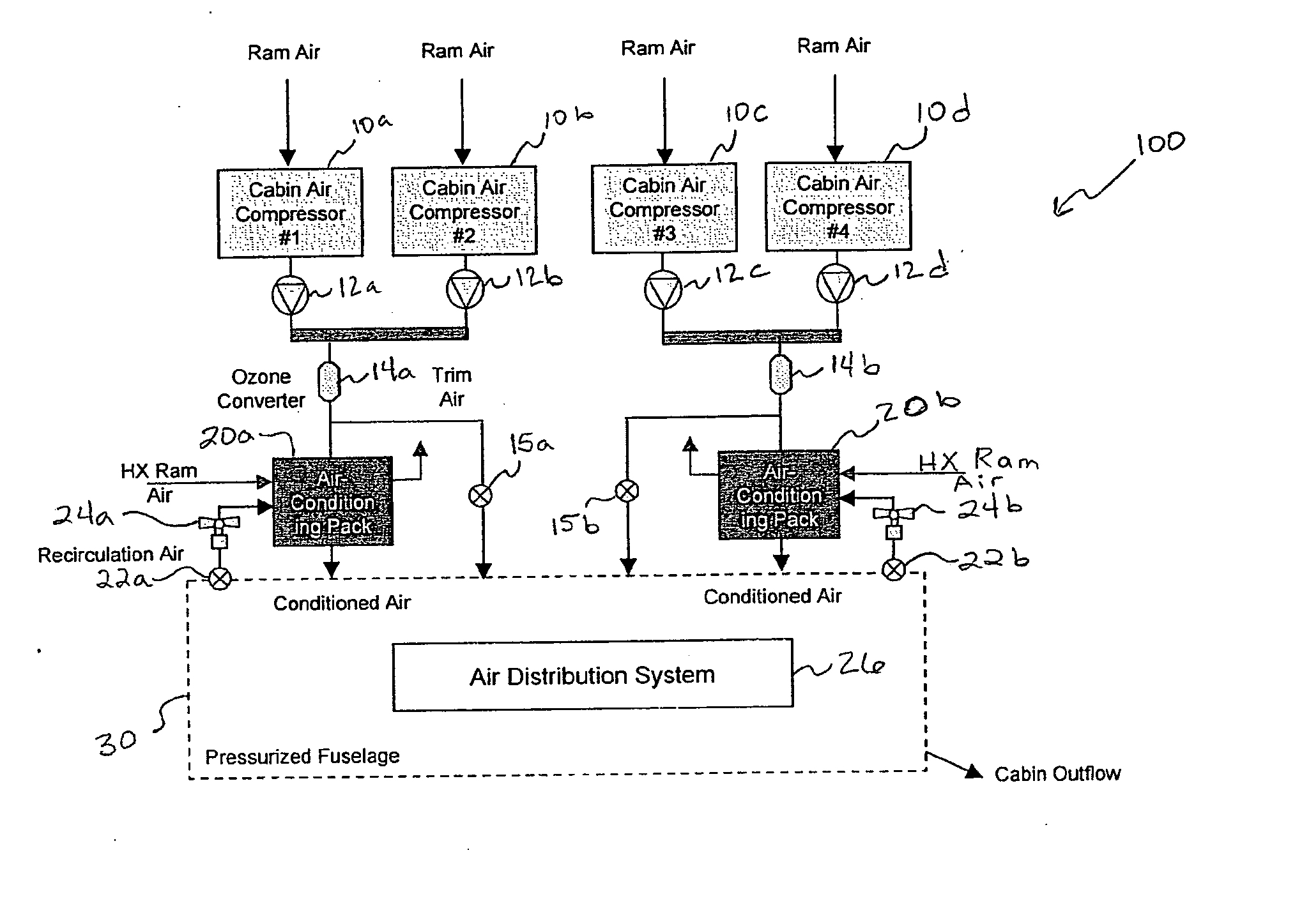

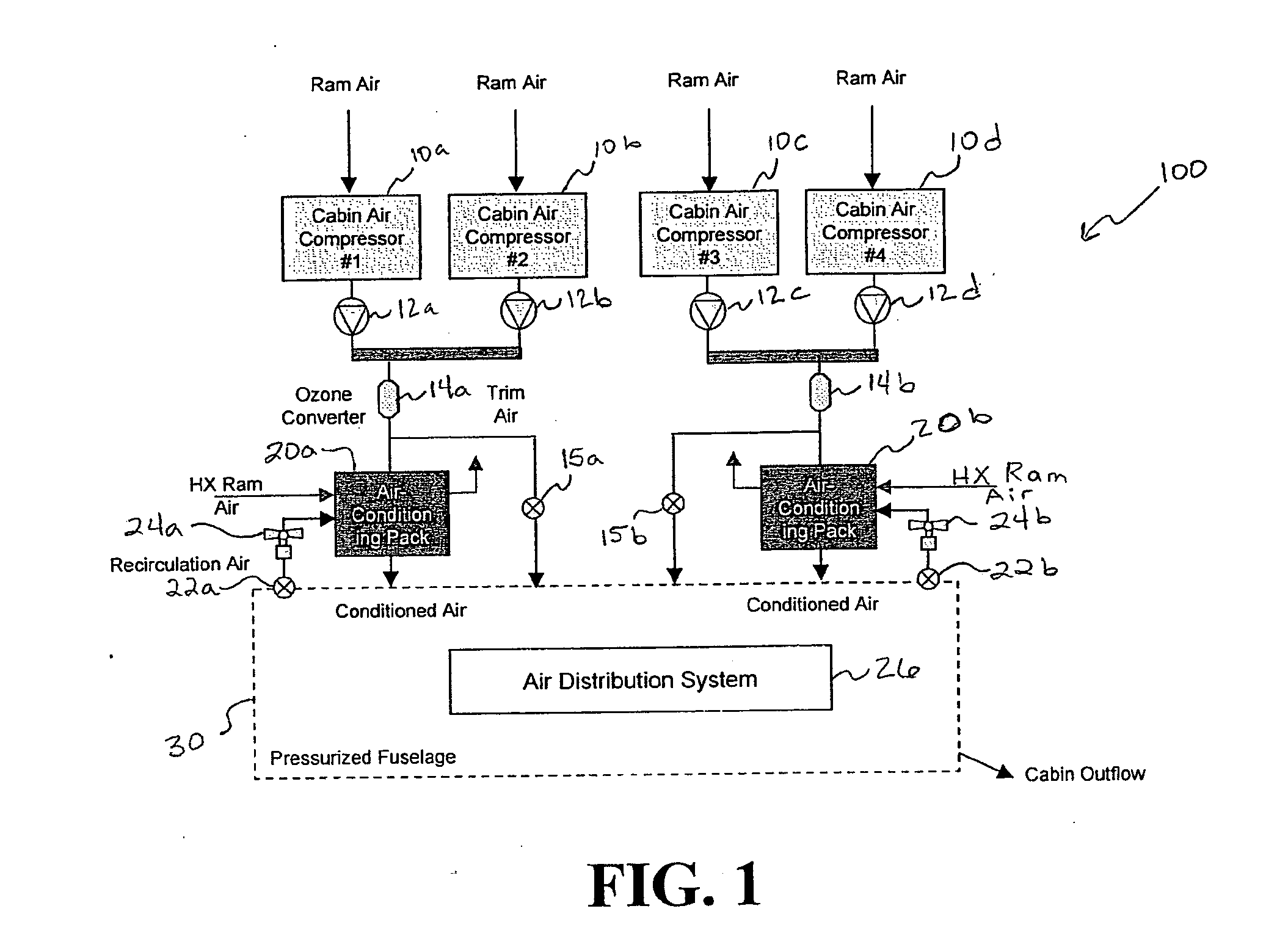

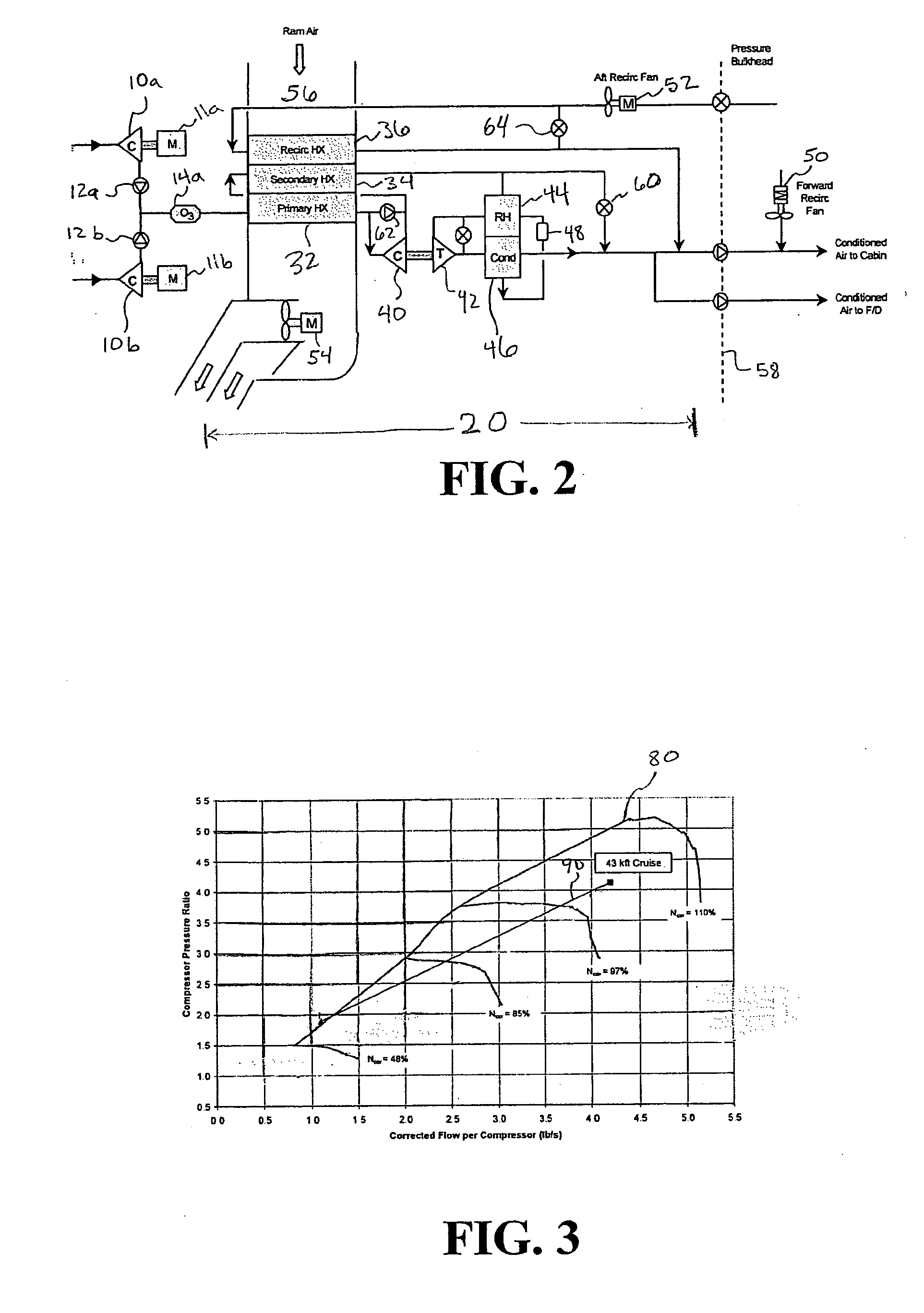

Low energy electric air cycle with portal shroud cabin air compressor

InactiveUS20070113579A1Domestic cooling apparatusAir-treatment apparatus arrangementsAir cycleElectricity

An environmental control system for an aircraft cabin includes a plurality of electrically-driven ported shroud cabin air compressors, each cabin air compressor compressing ram air received from the aircraft exterior, a heat exchange circuit comprising a primary heat exchanger receiving airflow from at least one of the cabin air compressors, and the secondary heat exchanger supplying airflow to the aircraft cabin, and an air cycle machine comprising a compressor adapted to receive airflow from the primary heat exchanger and supply compressed air to the secondary heat exchanger. The environmental control system may further comprise an air recirculation system, having an aft recirculation fan adapted to receive a portion of recirculation air from the aircraft cabin, and a recirculation heat exchanger, disposed in the heat exchange circuit in series with the primary and secondary heat exchangers, and adapted to receive airflow from the aft recirculation fan.

Owner:HONEYWELL INT INC

Drying machine

InactiveUS20050198852A1EfficientlyEfficient dryingDrying gas arrangementsDrying machines with non-progressive movementsAir cycleGas cooler

An object is to provide a drying machine capable of maintaining air discharged into a housing chamber while efficiently drying a matter to be dried in a short time. A drying machine provided with a housing chamber which houses the matter to be dried, and executing a drying operation of the matter to be dried in the housing chamber comprises: a gas cooler; an evaporator; a blower fan; an air circulation path for discharging air heated by the gas cooler into the housing chamber by the blower fan, sending the air passed through the housing chamber into the evaporator, and circulating the air in the gas cooler; and a closable outside air introduction port for mixing outside air with the air circulating in the air circulation path.

Owner:SANYO ELECTRIC CO LTD

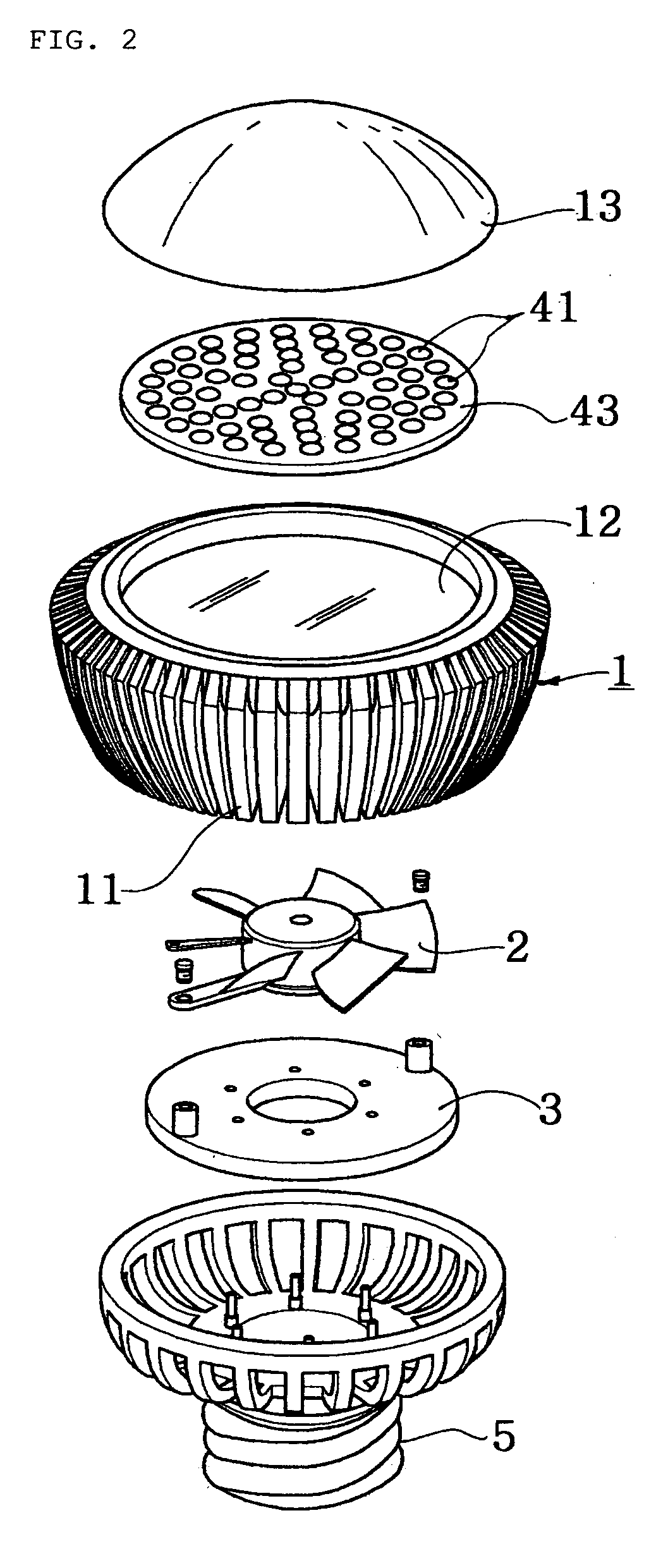

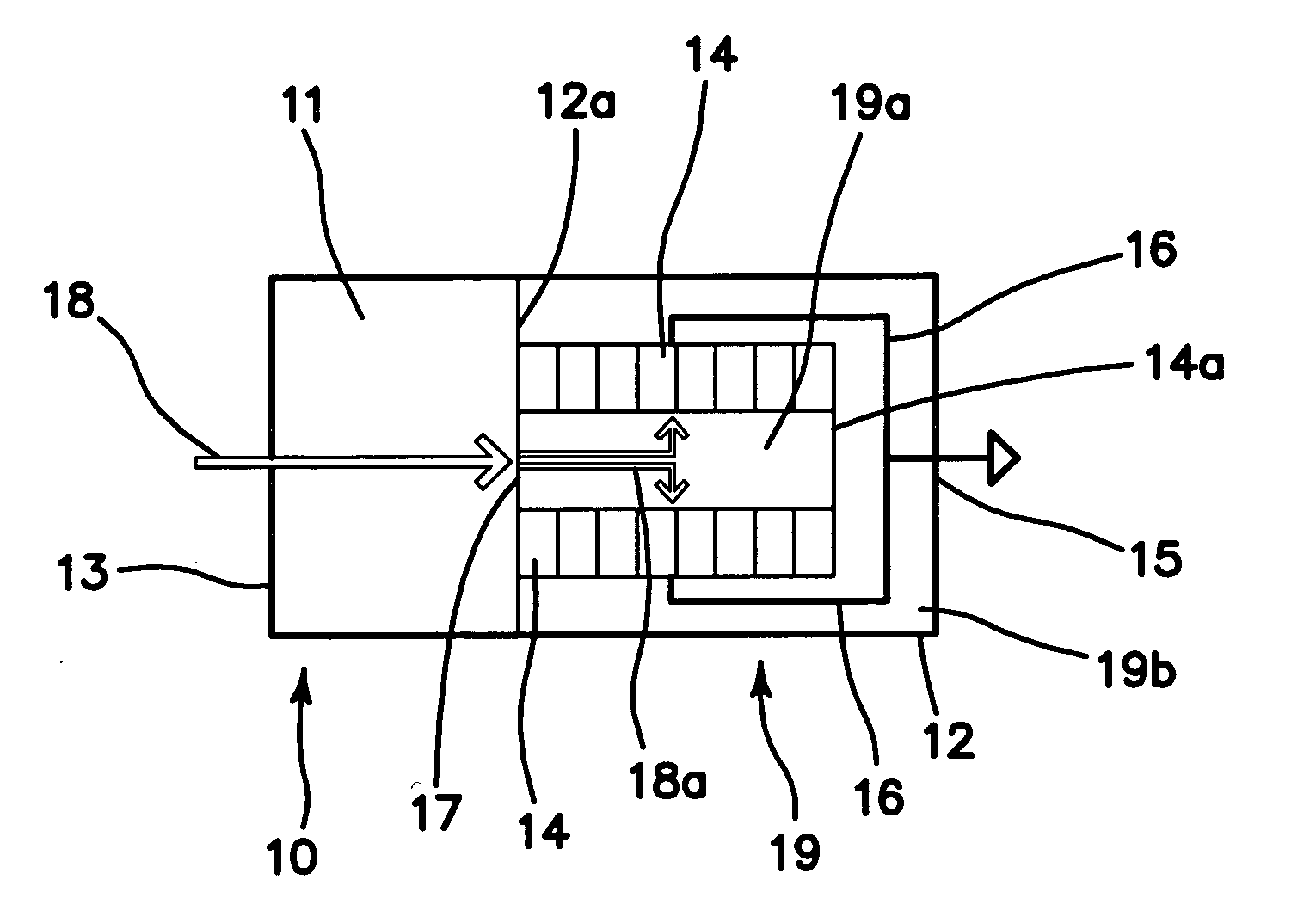

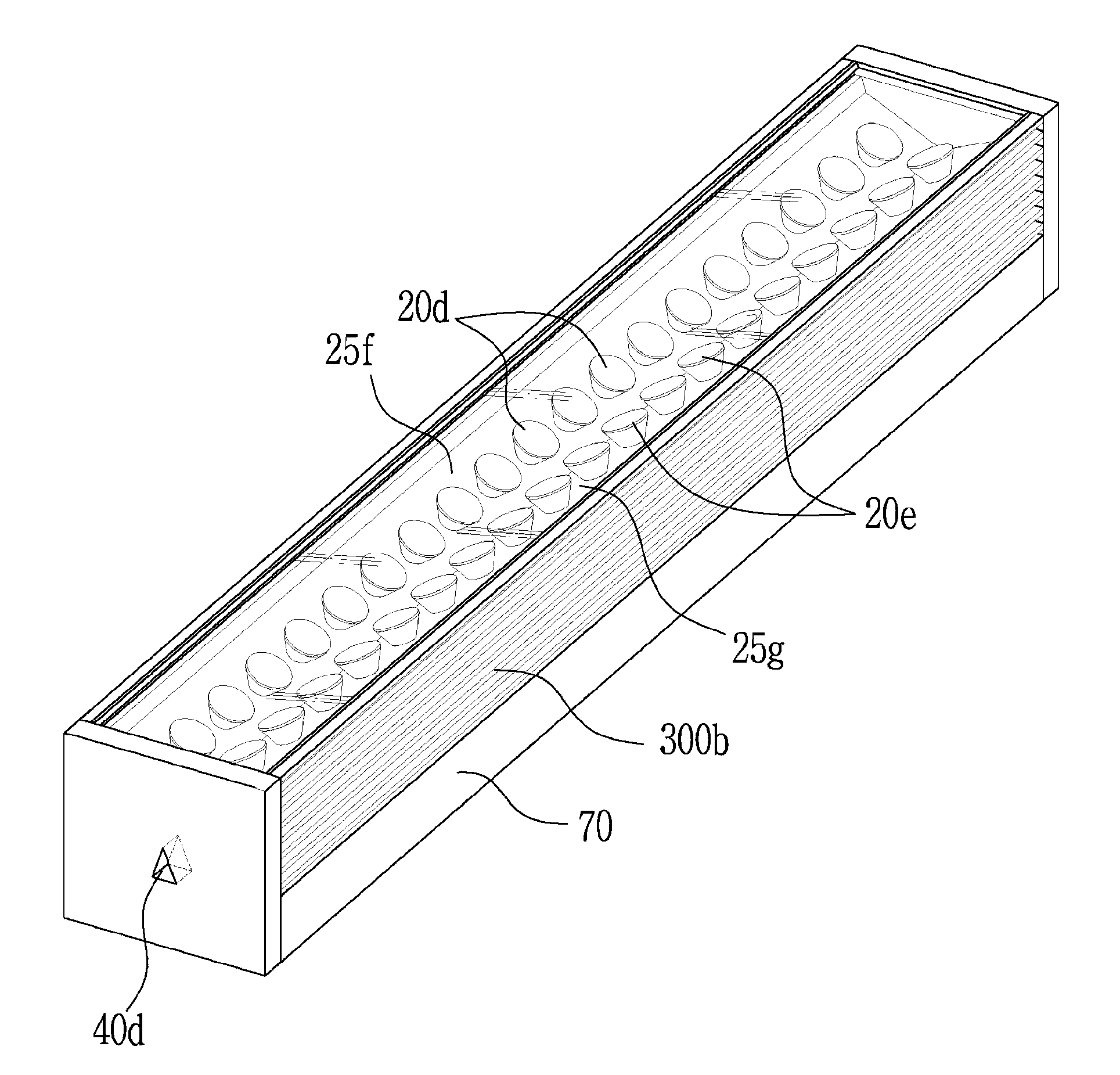

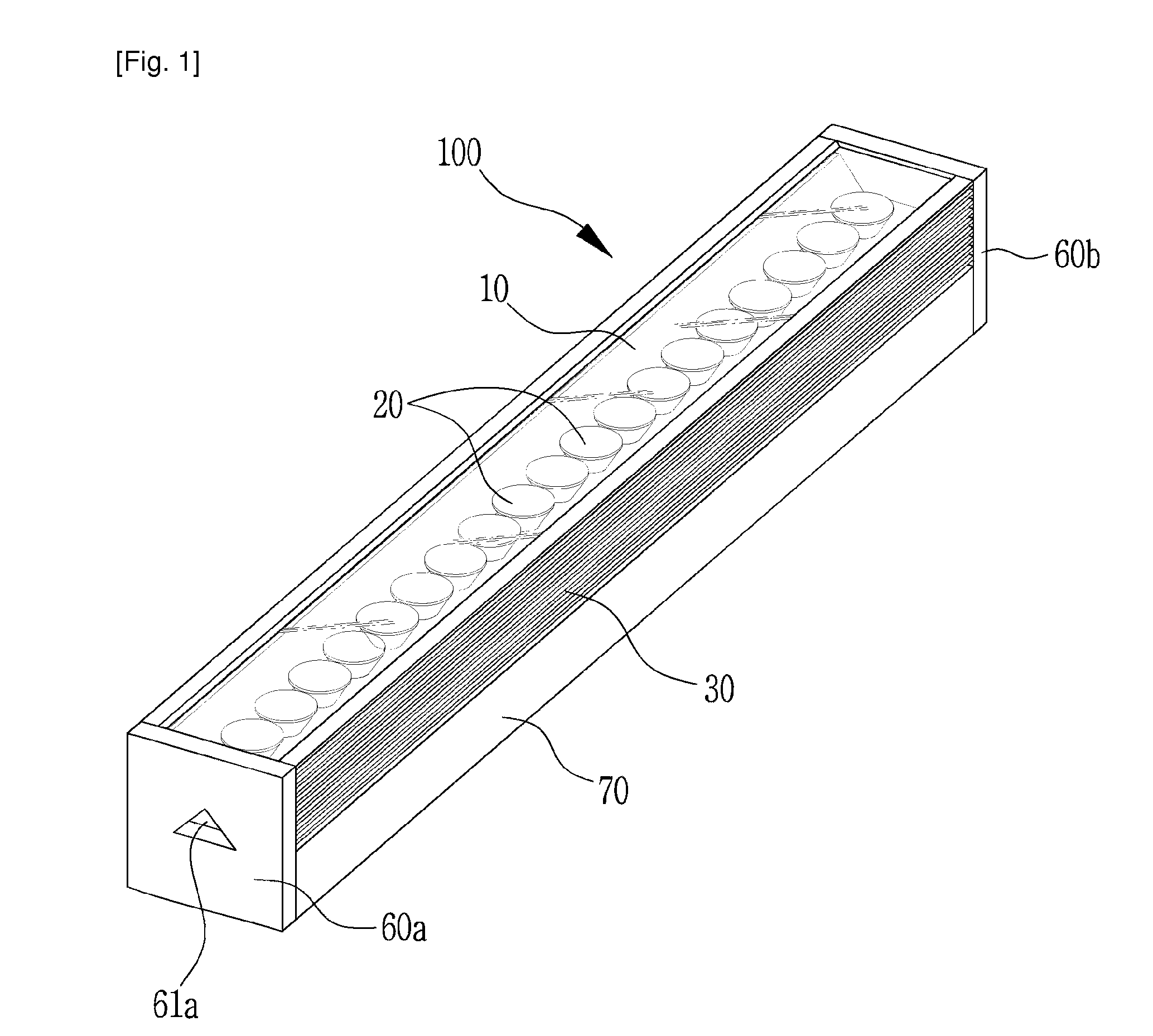

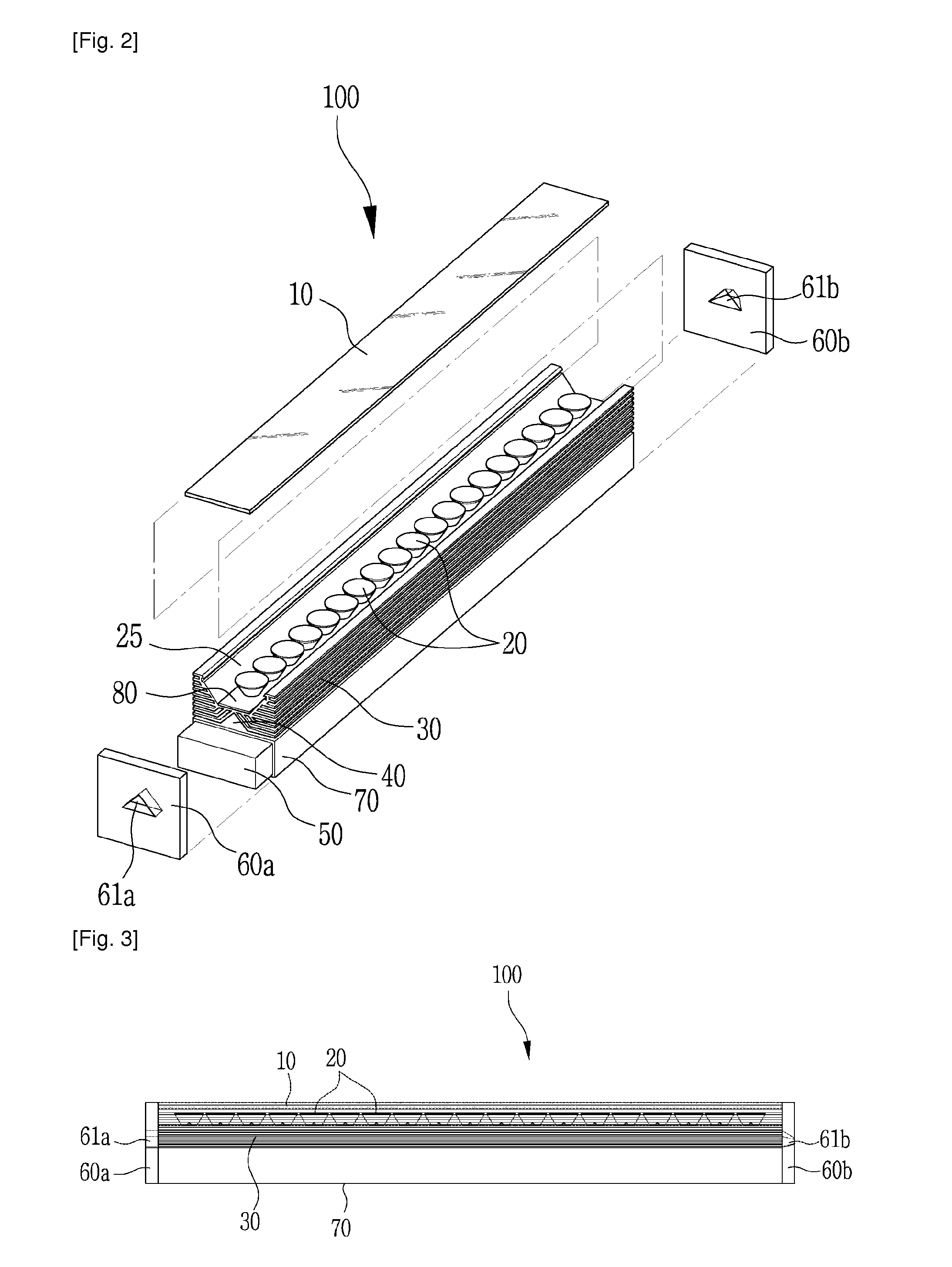

Lighting apparatus using light emitting diodes

ActiveUS20120218757A1Improve cooling effectEasy to implementNon-electric lightingPoint-like light sourceAir cycleAtmospheric air

Provided is a lighting apparatus using light emitting diodes (LEDs) having a lateral heat radiation unit structure that can maximize heat radiation effect by employing an air vent structure causing atmospheric pressure difference between both side ends of an air circulation path. The lighting apparatus comprising a housing having a power supply accommodation space therein, a heat radiation unit that comprises an LED module accommodation groove that is installed on the top of the housing and having at least one inclined surface or mounting surface on which the LED module is mounted, and a number of fins that are formed on the outer circumferential surface of the LED module accommodation groove, an air circulation path that is lengthily formed between the housing and the heat radiation unit.

Owner:AMOLUXE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com