Patents

Literature

419results about How to "Increased processing flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

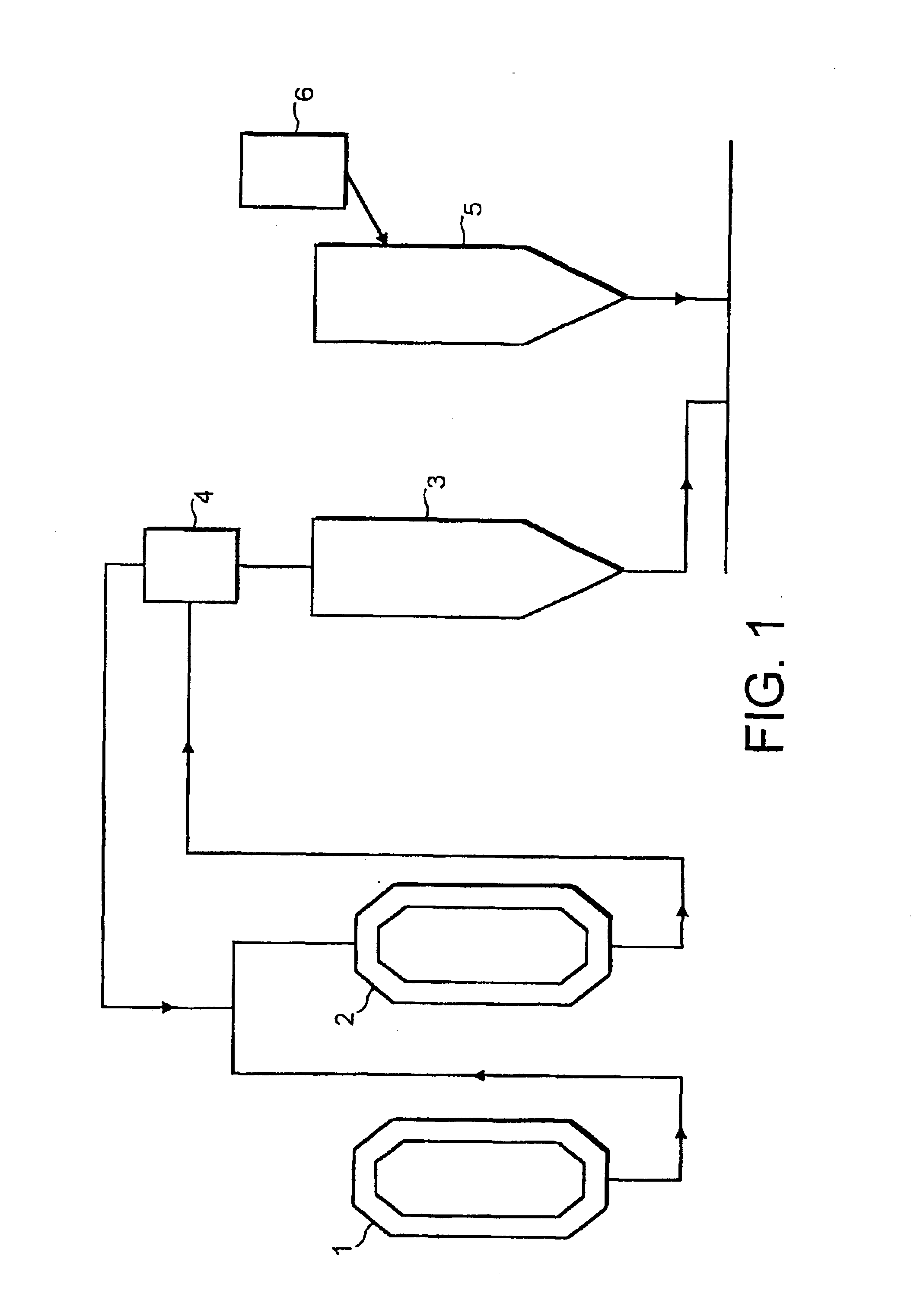

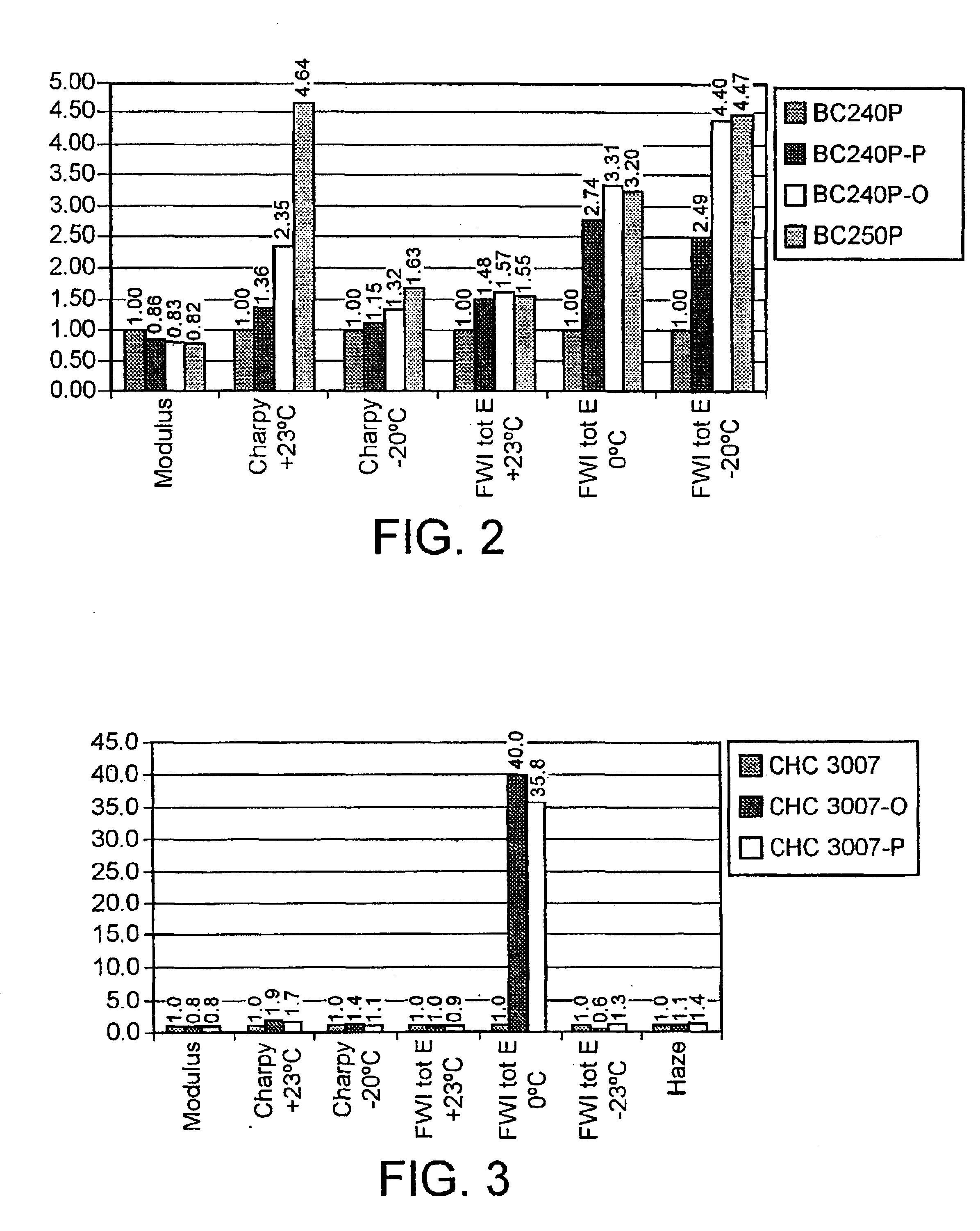

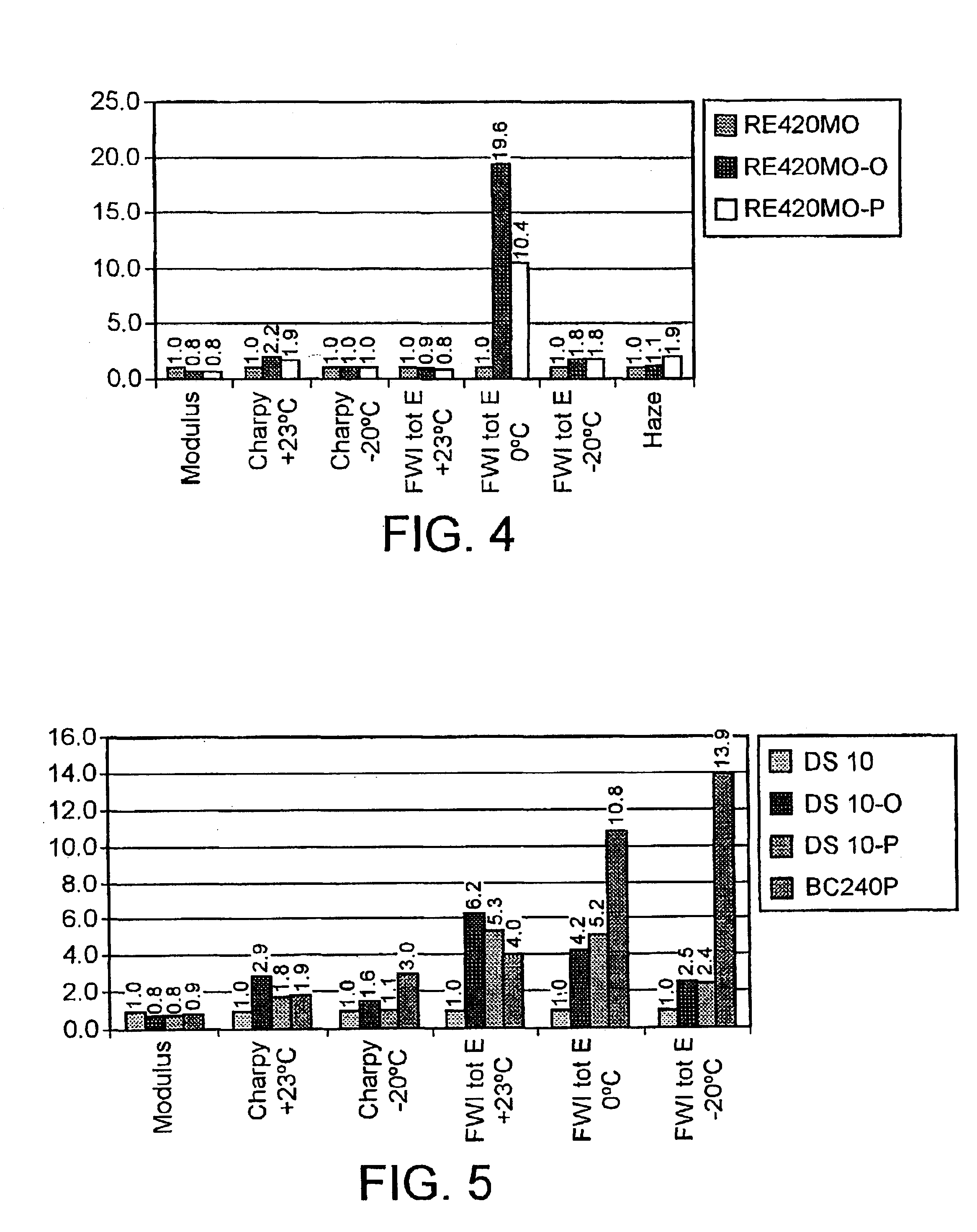

Process for producing propylene based polymer compositions

A process for the production of a propylene based polymer, the process comprising the following steps: (a) a first polymerization stage comprising homopolymerizing propylene or copolymerizing propylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce a polypropylene component; (b) a second polymerization stage comprising copolymerizing ethylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce an ethylene / alpha-olefin copolymer component; and (c) blending the polymer components produced in steps (a) and (b) whereby to produce a polymer blend, wherein the first and second polymerization stages are effected in separate polymerization reactors connected in parallel. Also provided are polymer compositions comprising: (i) 30 to 97% by weight, based on the total weight of the polymer composition, of a propylene based polymer; and (ii) 3 to 70% by weight, preferably 5 to 20% by weight, based on the total weight of the polymer composition, of an ethylene copolymer plastomer (e.g., an ethylene-propylene plastomer) containing at least 60% by weight ethylene.

Owner:BOREALIS TECH OY

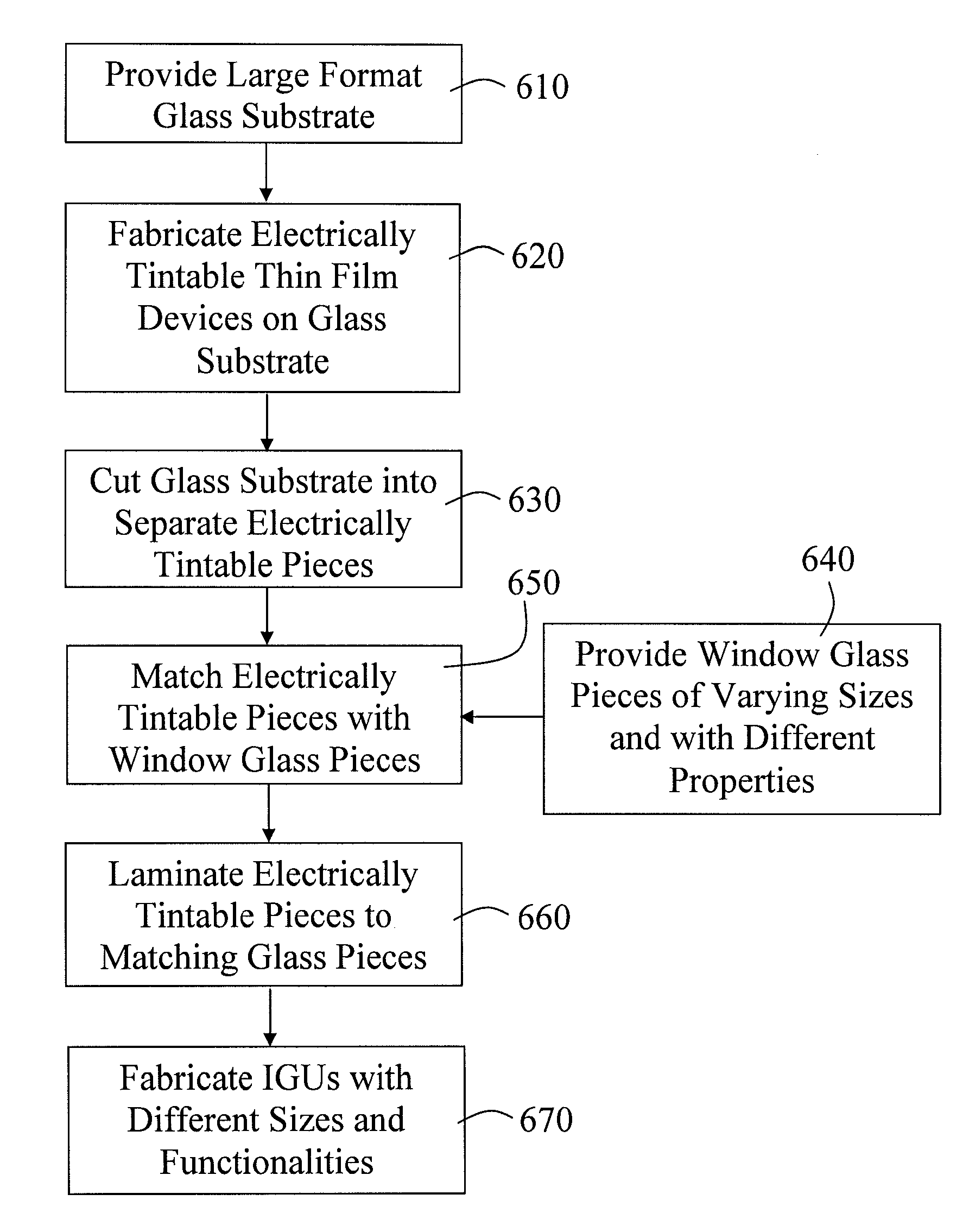

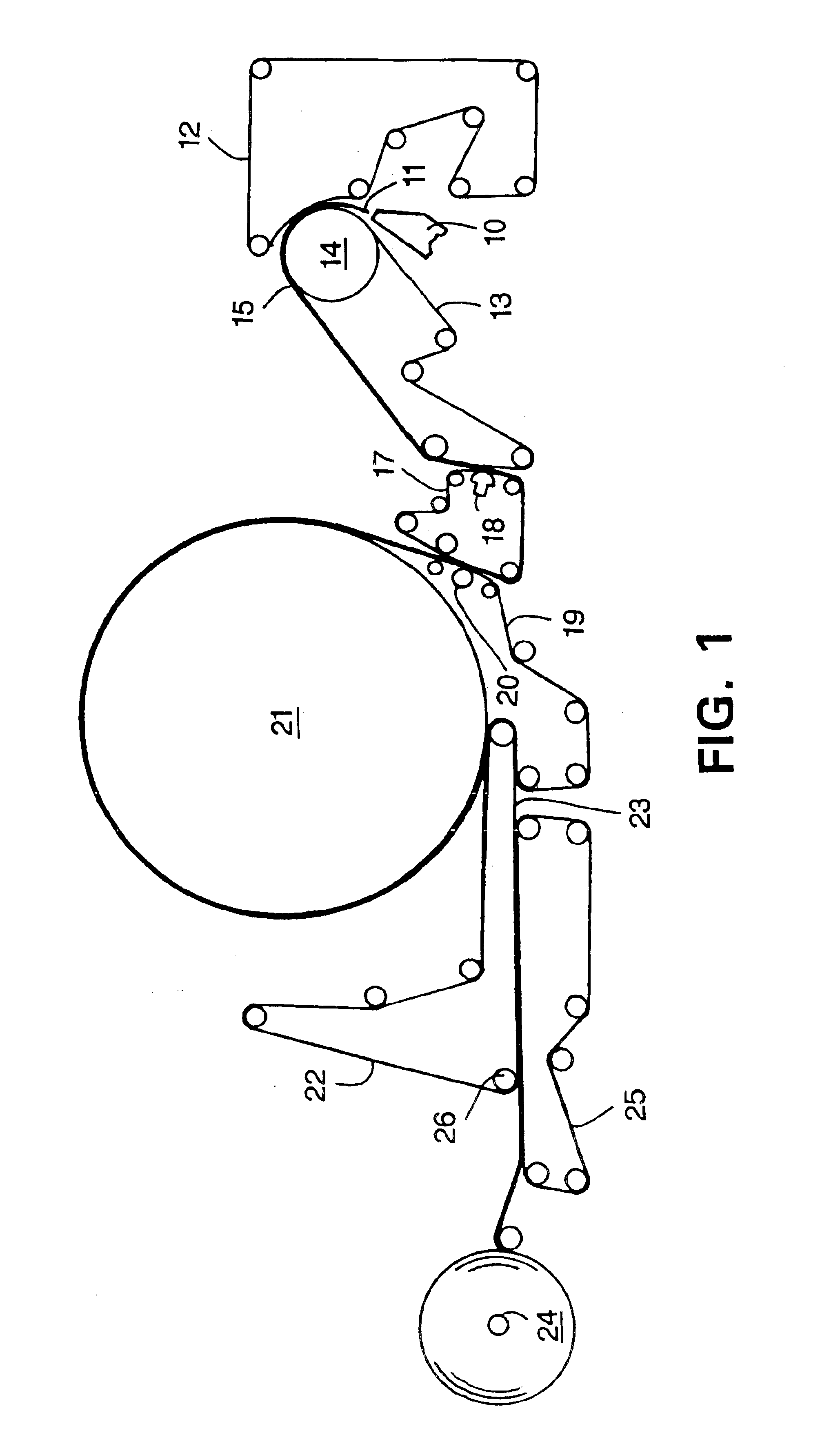

Laminated electrically tintable windows

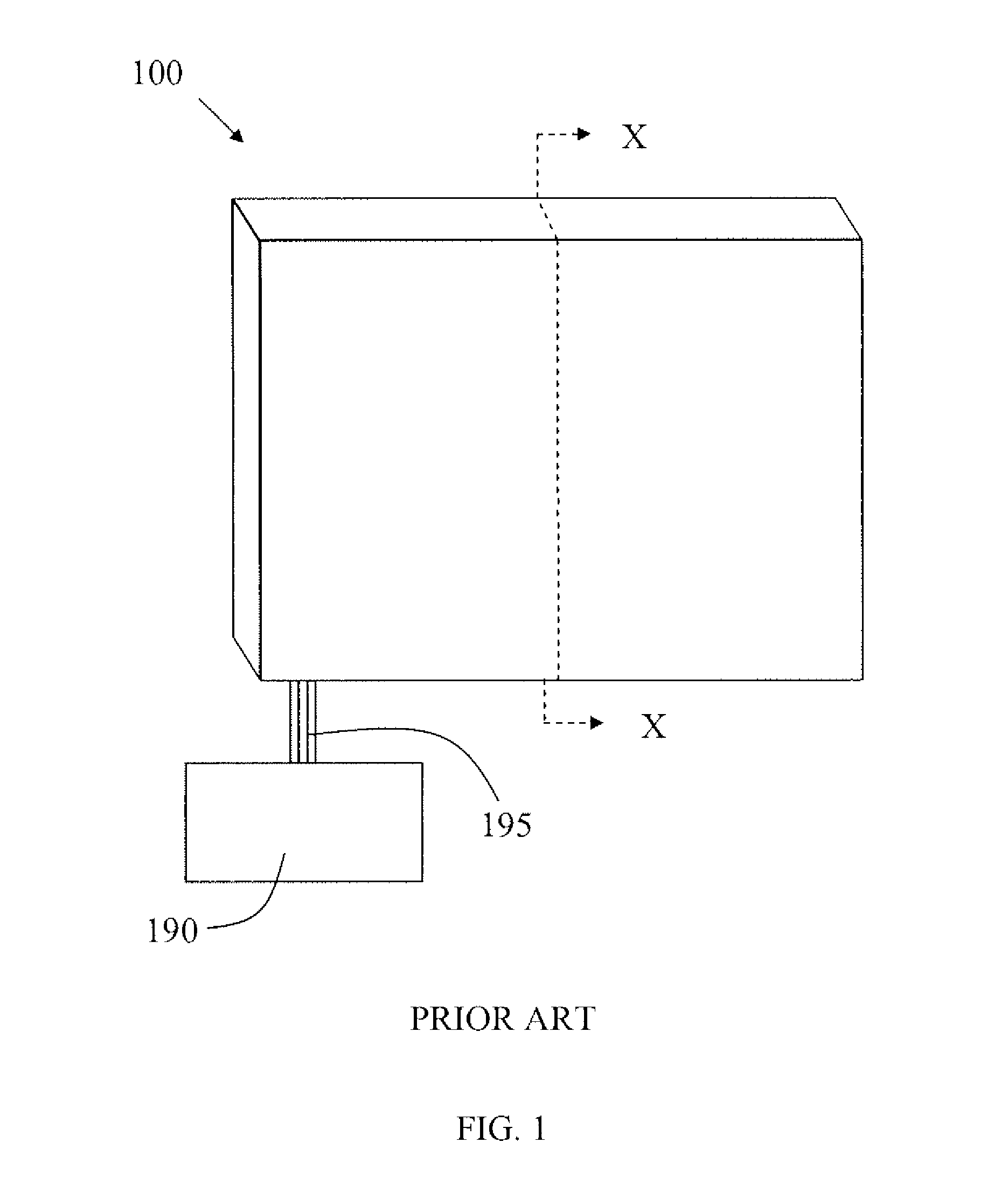

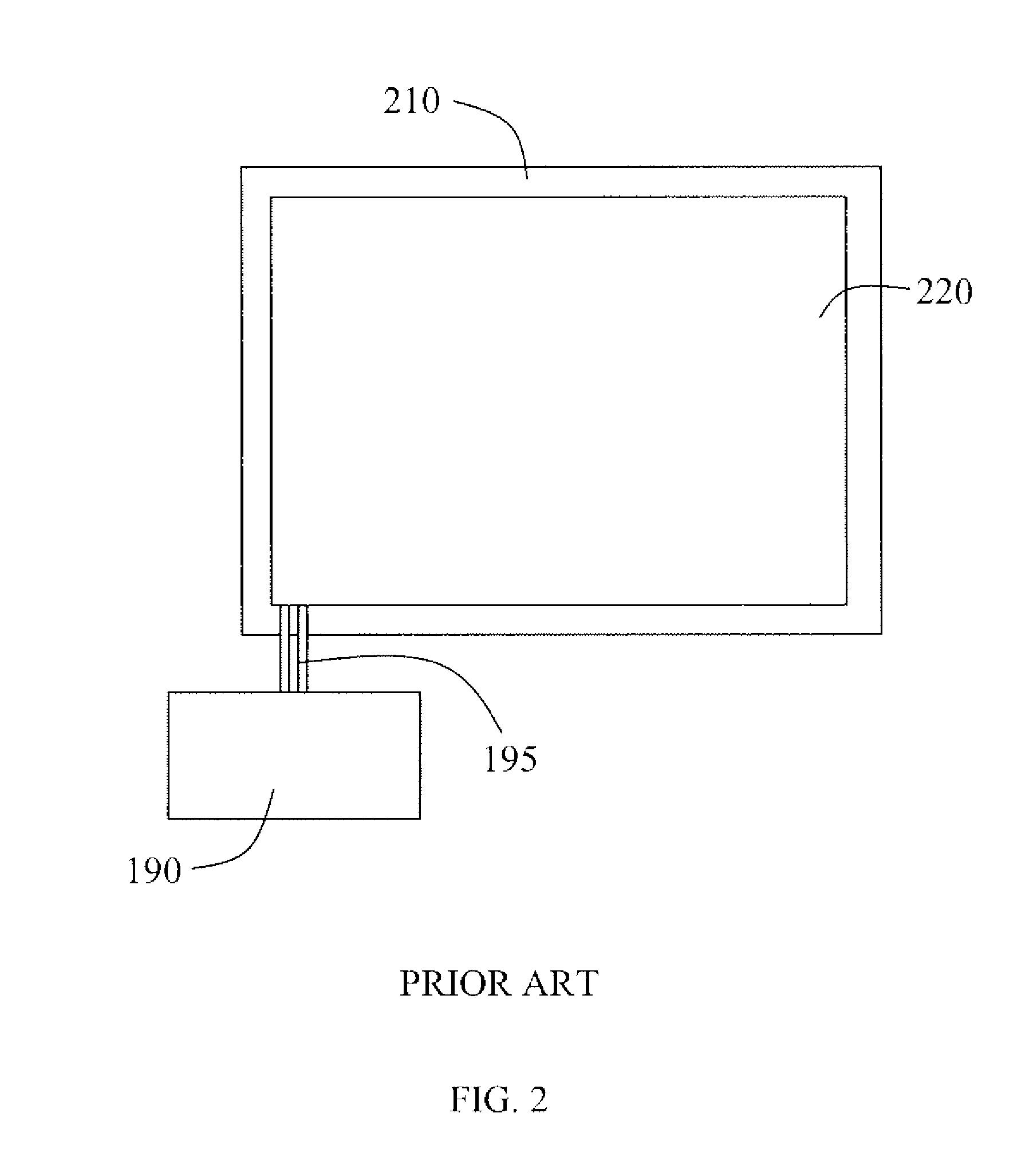

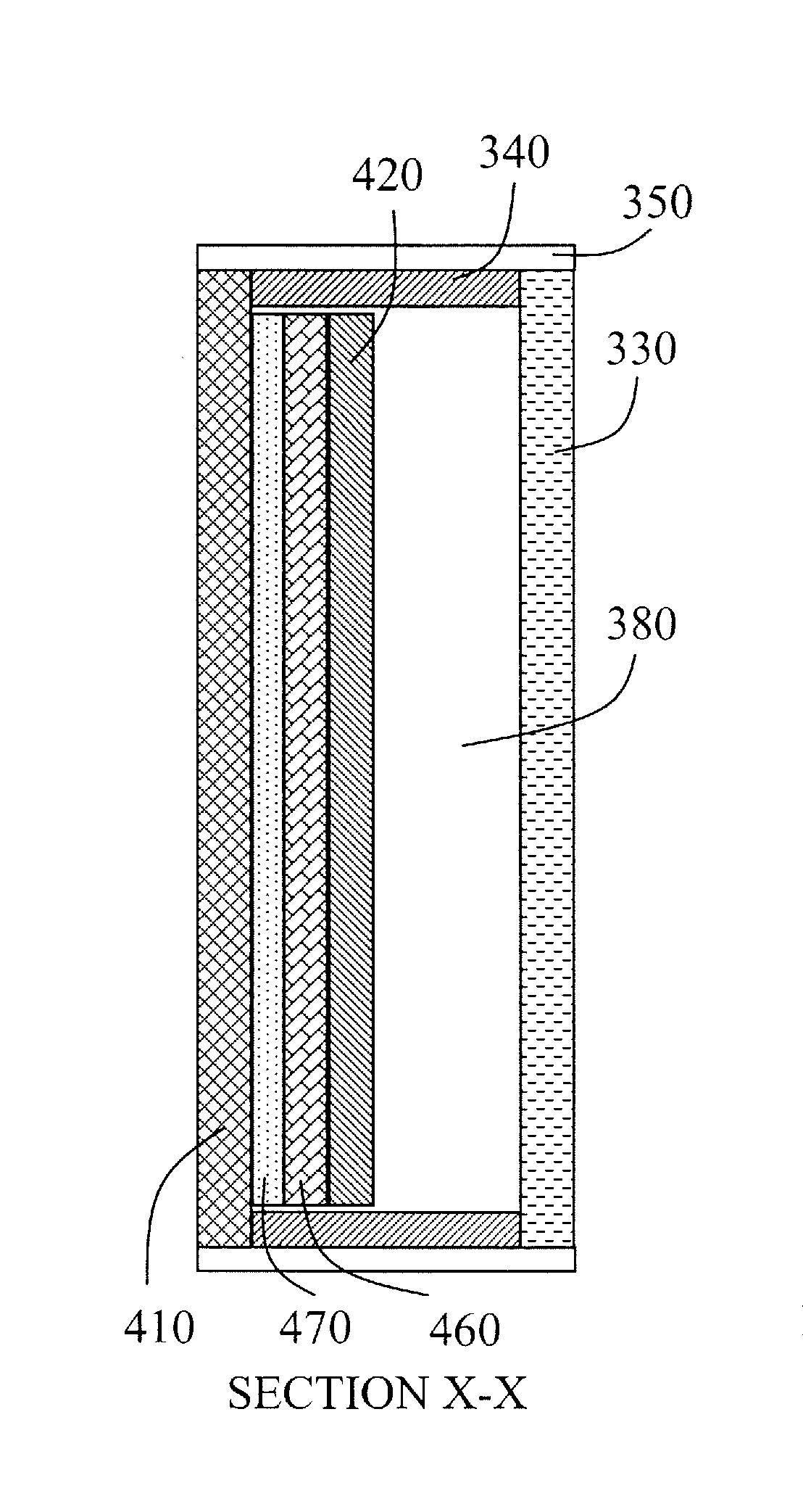

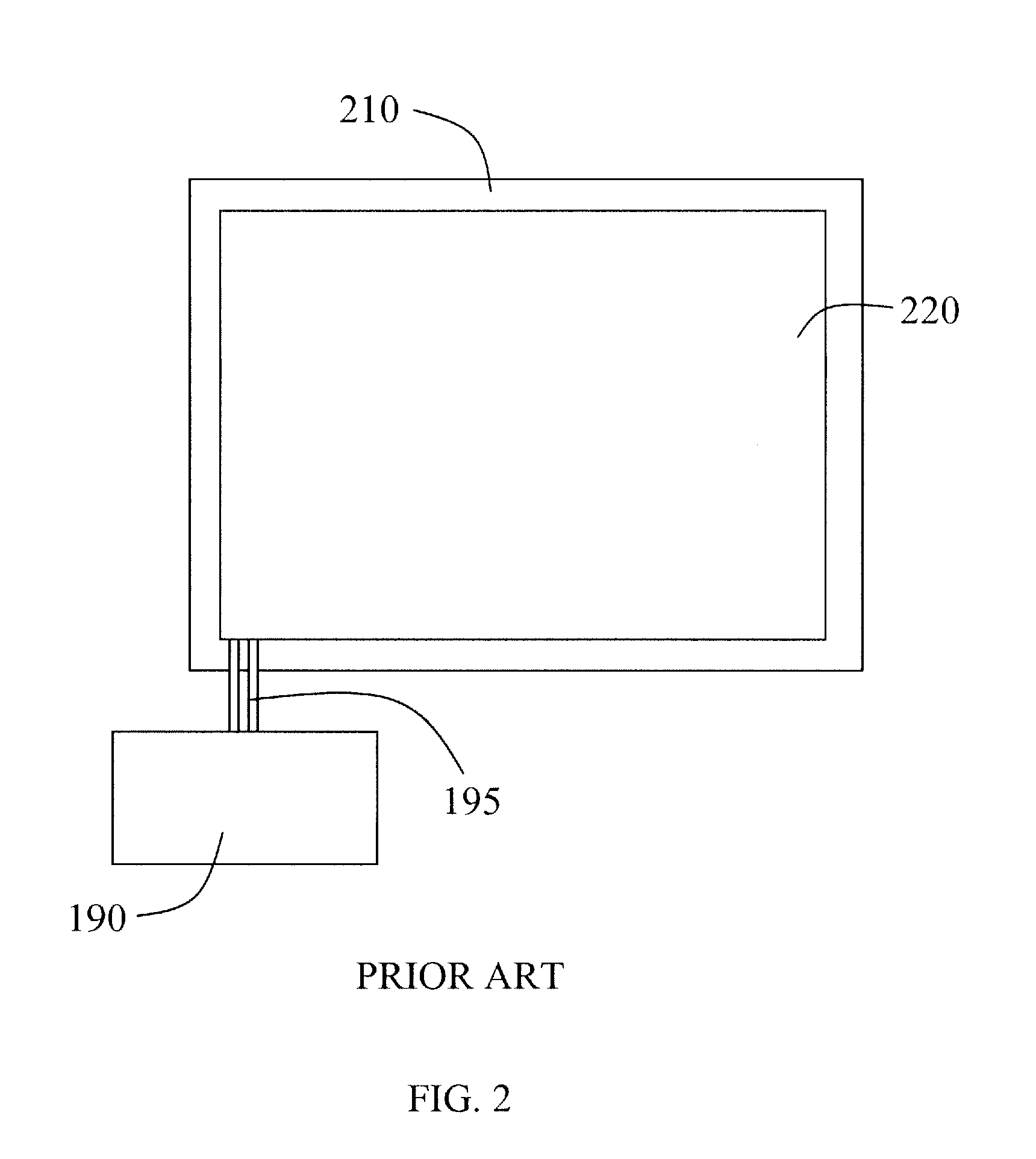

InactiveUS7710671B1Function increaseIncreased processing flexibilityLight protection screensGlass/slag layered productsElectroplatingElectrochromism

A method of manufacturing electrically tintable window glass with a variety of sizes and functionalities is described. The method comprises: (a) providing a large format glass substrate; (b) fabricating a plurality of electrically tintable thin film devices on the large format glass substrate; (c) cutting the large format glass substrate into a plurality of electrically tintable pieces, each electrically tintable piece including one of the plurality of electrically tintable thin film devices; (d) providing a plurality of window glass pieces; (e) matching each one of the plurality of electrically tintable pieces with a corresponding one of the plurality of window glass pieces; and (f) laminating each of the matched electrically tintable pieces and window glass pieces. The lamination may result in the electrically tintable device either being sandwiched between the glass substrate and the window glass piece or on the surface of the laminated pieces. The electrically tintable device is an electrochromic device.

Owner:APPLIED MATERIALS INC

Laminated Electrically Tintable Windows

InactiveUS20100208326A1Function increaseIncreased processing flexibilityLight protection screensGlass/slag layered productsElectrochromismElectroplating

A method of manufacturing electrically tintable window glass with a variety of sizes and functionalities is described. The method comprises: (a) providing a large format glass substrate; (b) fabricating a plurality of electrically tintable thin film devices on the large format glass substrate; (c) cutting the large format glass substrate into a plurality of electrically tintable pieces, each electrically tintable piece including one of the plurality of electrically tintable thin film devices; (d) providing a plurality of window glass pieces; (e) matching each one of the plurality of electrically tintable pieces with a corresponding one of the plurality of window glass pieces; and (f) laminating each of the matched electrically tintable pieces and window glass pieces. The lamination may result in the electrically tintable device either being sandwiched between the glass substrate and the window glass piece or on the surface of the laminated pieces. The electrically tintable device is an electrochromic device.

Owner:APPLIED MATERIALS INC

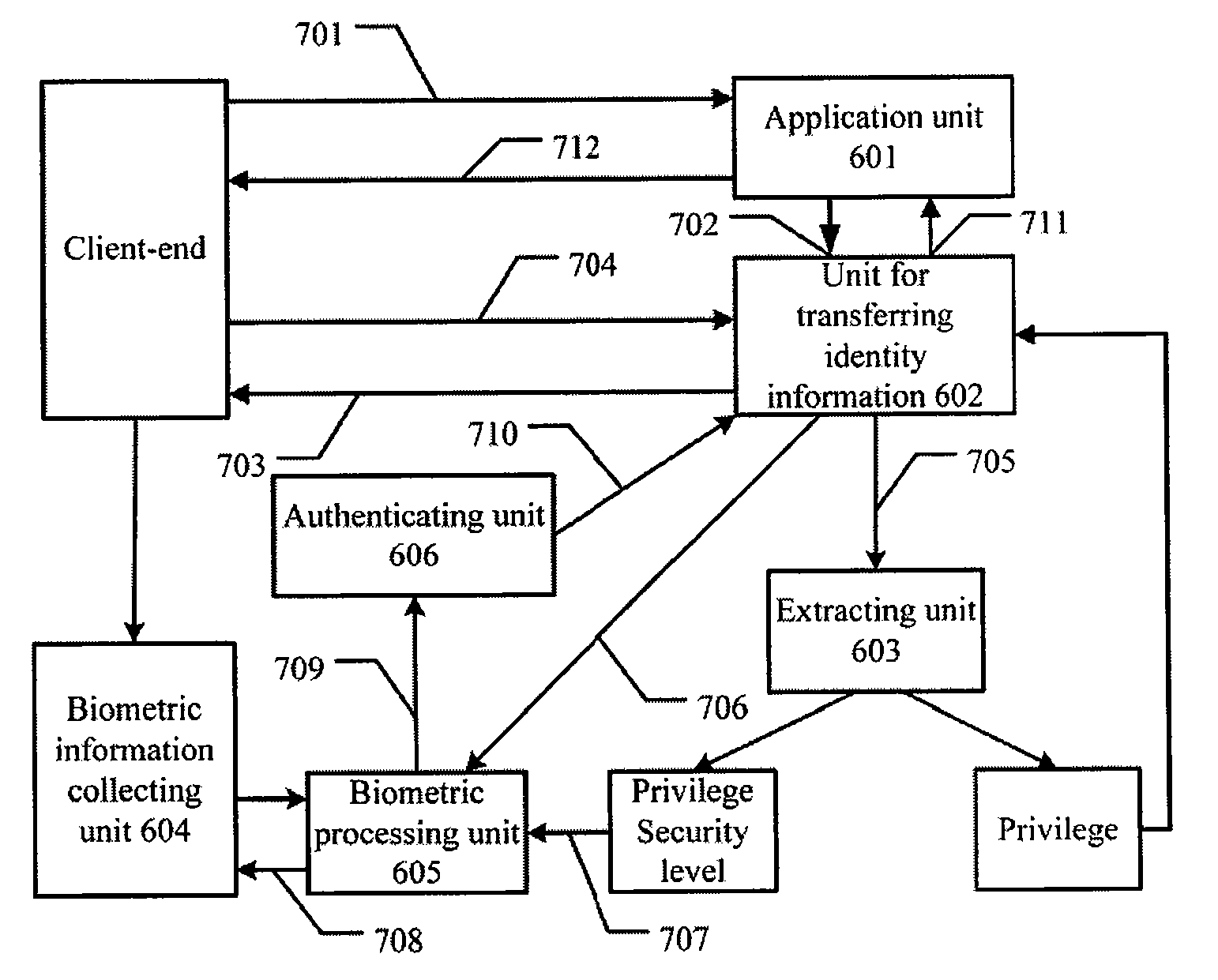

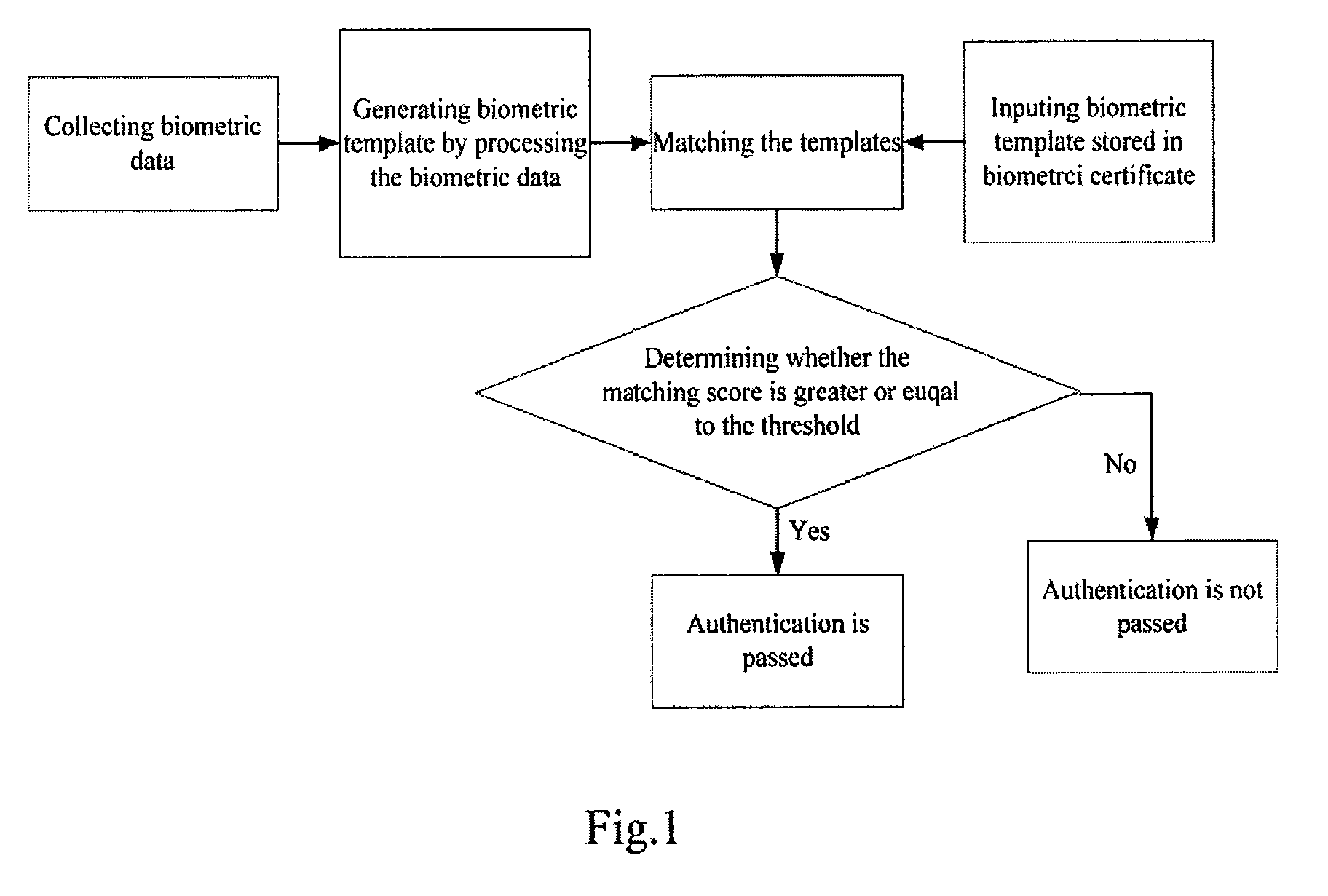

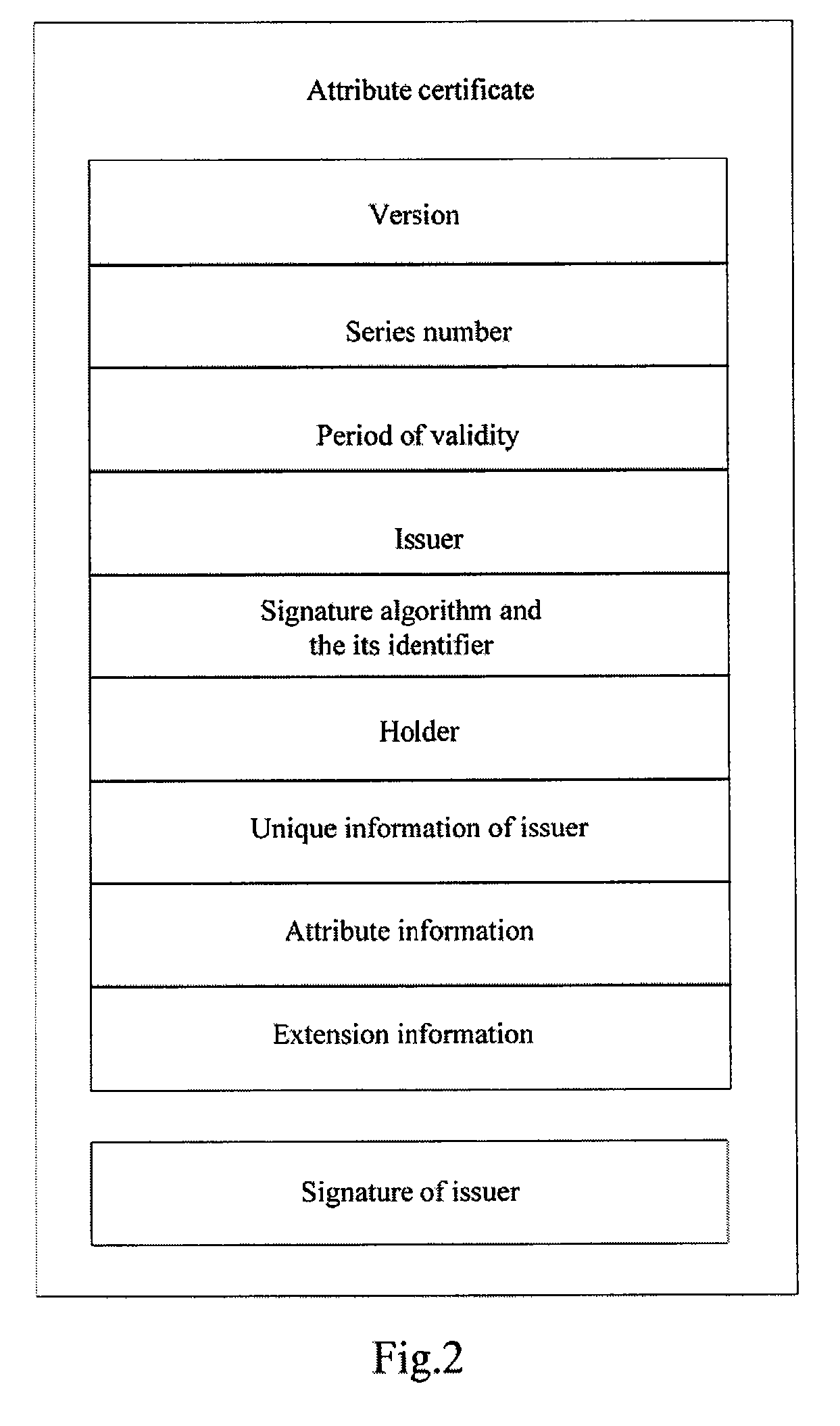

Methods and systems for authentication

InactiveUS20090271635A1Increased processing flexibilityIncrease flexibilityAcutation objectsMultiple keys/algorithms usageClient-sideSecurity level

The present invention discloses a method and system for authentication. The method for authentication includes: acquiring the privilege security level corresponding to a client-end; inquiring the identity security level corresponding to the privilege security level according to an established relation of association between privilege security level and identity security level; determining the authentication parameters for identity authentication according to the identity security level; performing identity authentication on the client-end using the authentication parameters; and obtaining an authentication result. The identity authentication and privilege authentication are combined, and identity authentication is performed according to the identity security level in accord with the privilege security level so that rules of identity authentication can be adjusted, and the flexibility of the process of authentication may be improved.

Owner:HUAWEI TECH CO LTD

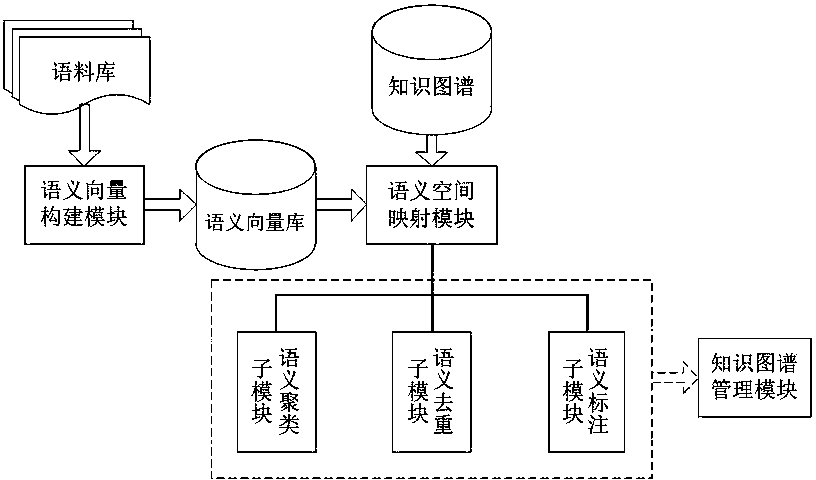

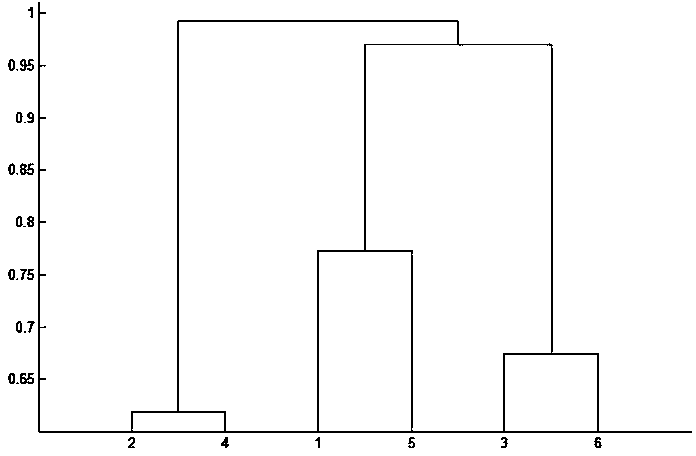

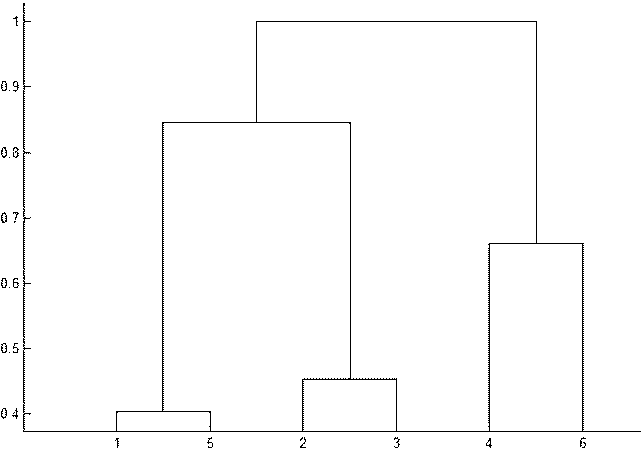

Knowledge graph management method and system based on semantic space mapping

InactiveCN104035917AIncreased processing flexibilityImprove accuracySpecial data processing applicationsSemantic vectorTheoretical computer science

The invention belongs to the technical field of text semantic processing and semantic webs, and particularly relates to a knowledge graph management method and system based on semantic space mapping. The method comprises the steps of semantic vector construction, semantic space mapping and knowledge graph management, wherein the step of knowledge graph management comprises three sub-steps of semantic clustering, semantic duplication eliminating and semantic annotation. A text unit describing edge / nodal points of a knowledge graph is projected to a semantic space, and vector representation of the edge / nodal points on the semantic space is obtained by vector accumulation; on the basis, multiple management tasks of the knowledge graph are achieved. The system correspondingly comprises a semantic vector construction module, a semantic space mapping module and a knowledge graph management module. The defects that a conventional knowledge graph management method is sensitive to factors such as word deformation, synonym variation and grammatical form variation are overcome, the situation of difference of the number of words can be easily handled in a vector accumulation mode, and further knowledge graph management tasks such as semantic clustering, semantic duplication eliminating and semantic annotation are easily achieved.

Owner:FUDAN UNIV

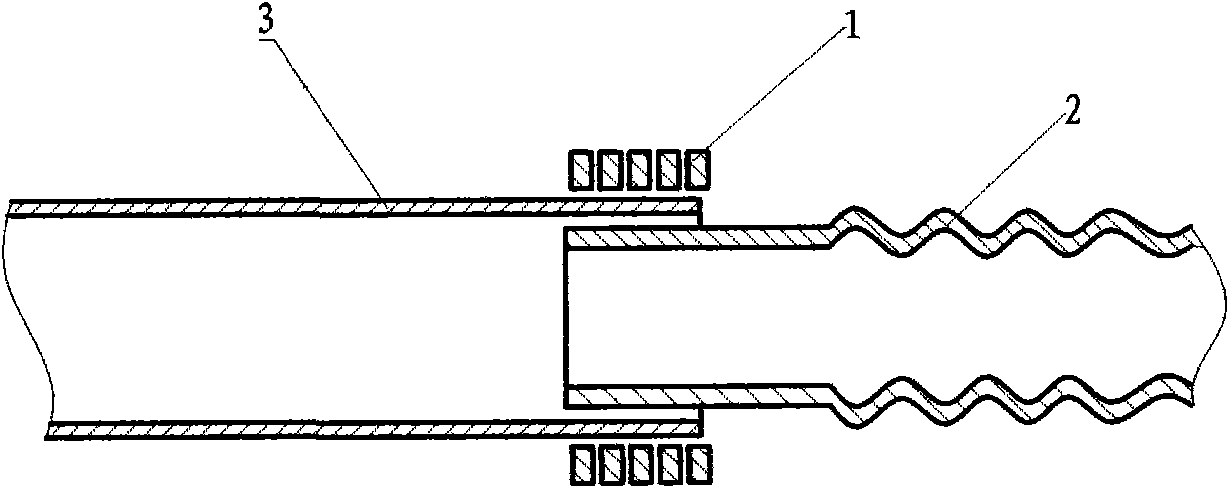

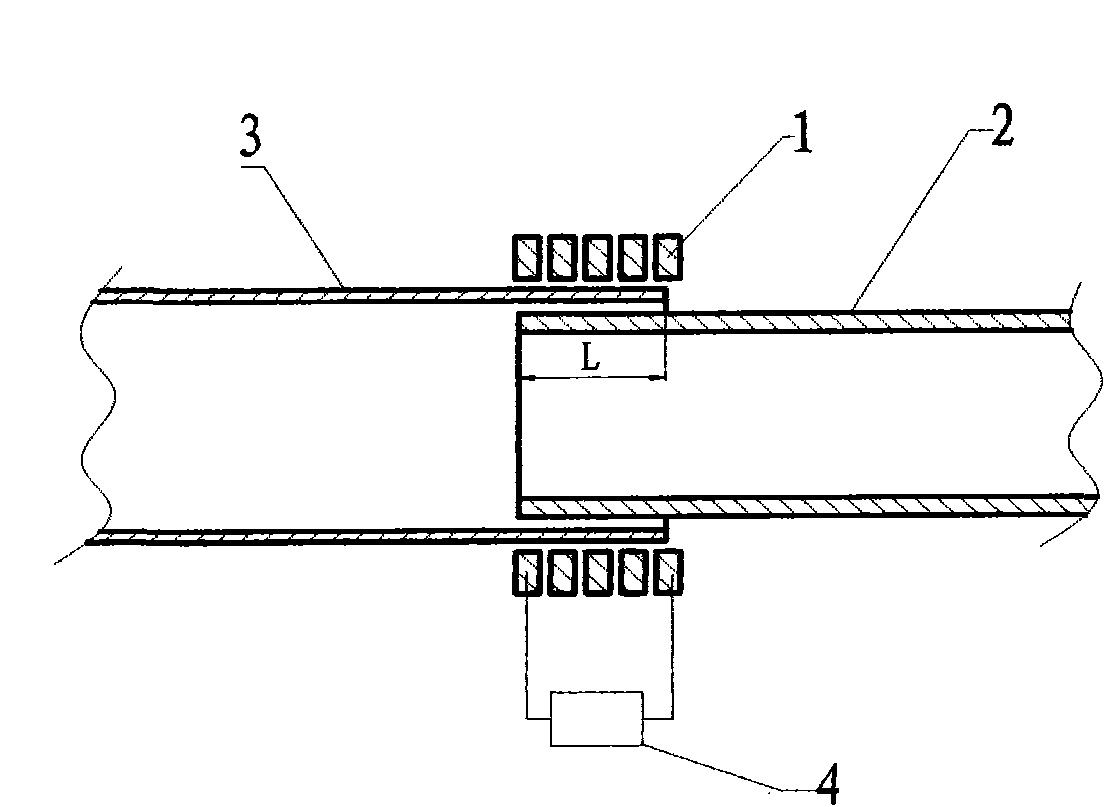

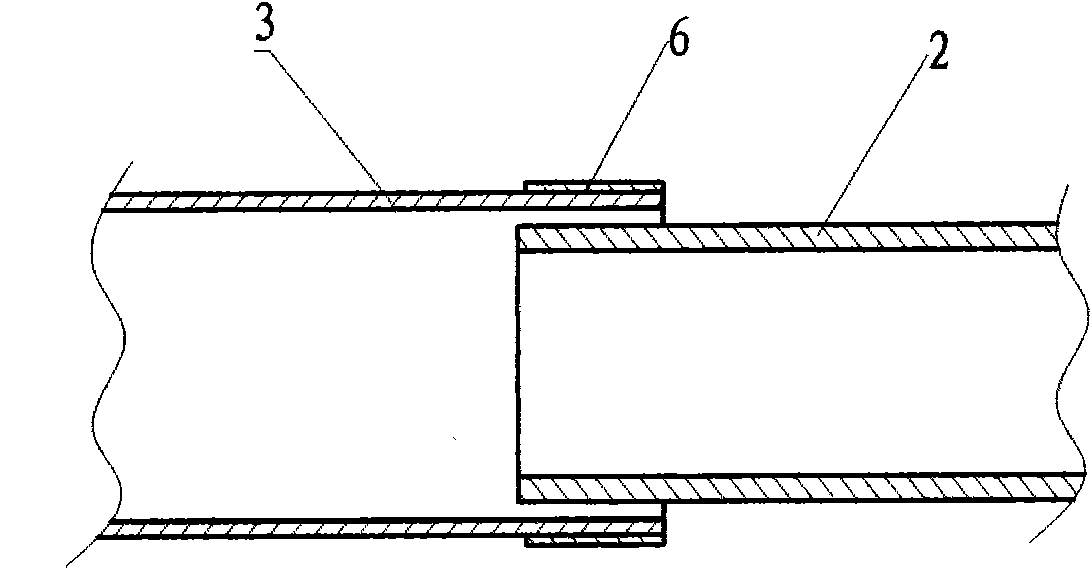

Magnetic pulse connecting method and joint structure for thin-wall metal pipelines

InactiveCN101905375AIncreased processing flexibilityHigh strengthNon-electric welding apparatusHeat-affected zoneEngineering

The invention discloses a magnetic pulse connecting method and a joint structure for thin-wall metal pipelines and provides a safe and high-efficiency magnetic pulse connecting method and a magnetic pulse connecting joint structure for similar and dissimilar thin-wall metal pipelines. A coil-magnetic concentrator composite inductor or a coil inductor is connected with electromagnetic pulse forming equipment so that the pipelines of various metal materials or various structure shapes can be connected in a magnetic pulse way. The transition area of the joint connecting interface is small, the brittle phase or intermetallic compound almost cannot be generated, and the joint almost has no heat affected area and torsion deformation and has high strength and corrosion-resistance property; the tension strength and torsion strength of the joint are respectively higher than those of weak base metal; the subsequent cleaning procedure and post-weld heat treatment are not needed; and the connected pipeline satisfies certain rigidity requirement, cannot be subjected to the plastic deformation in the magnetic pulse connecting process and has high process flexibility.

Owner:HARBIN INST OF TECH

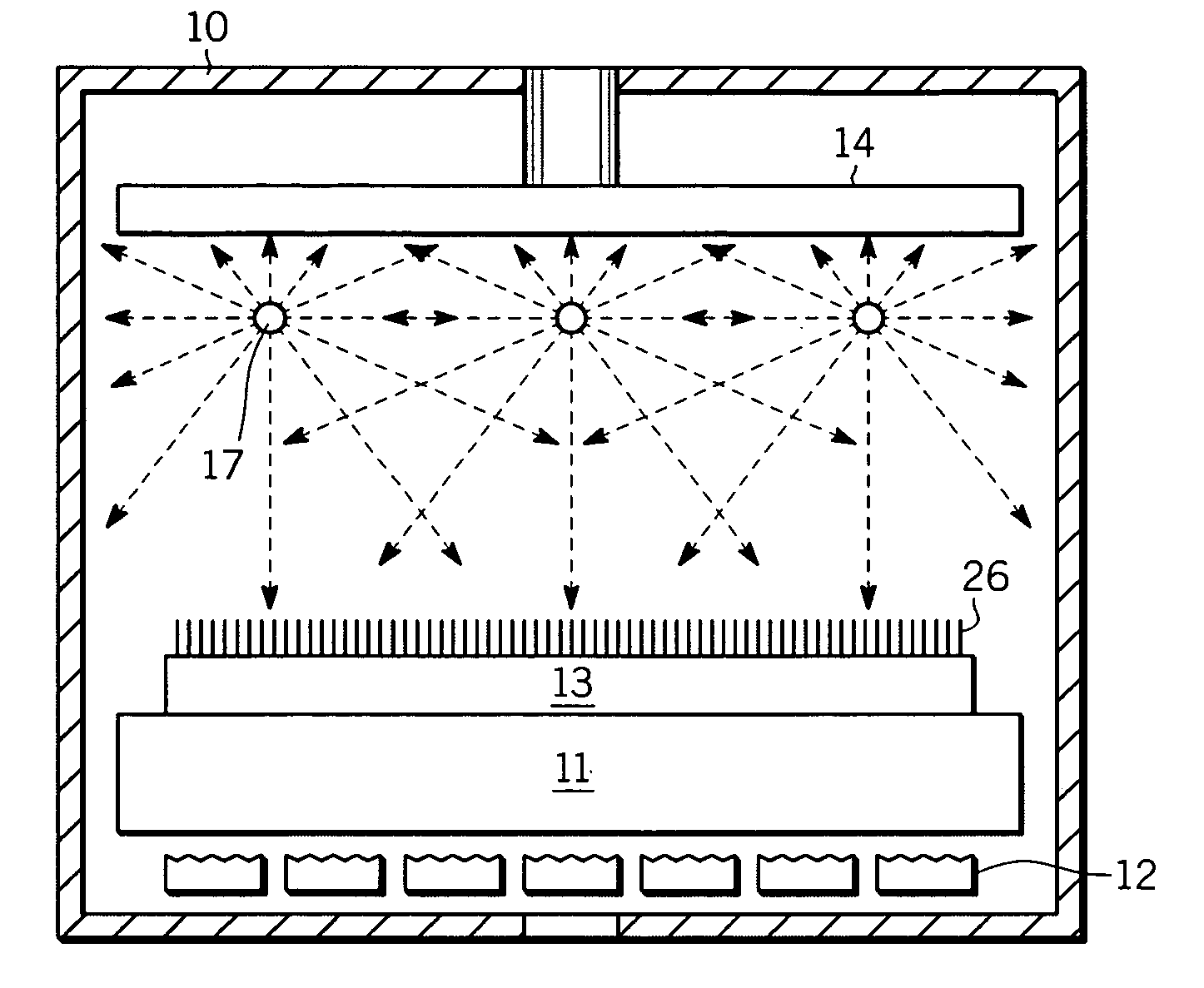

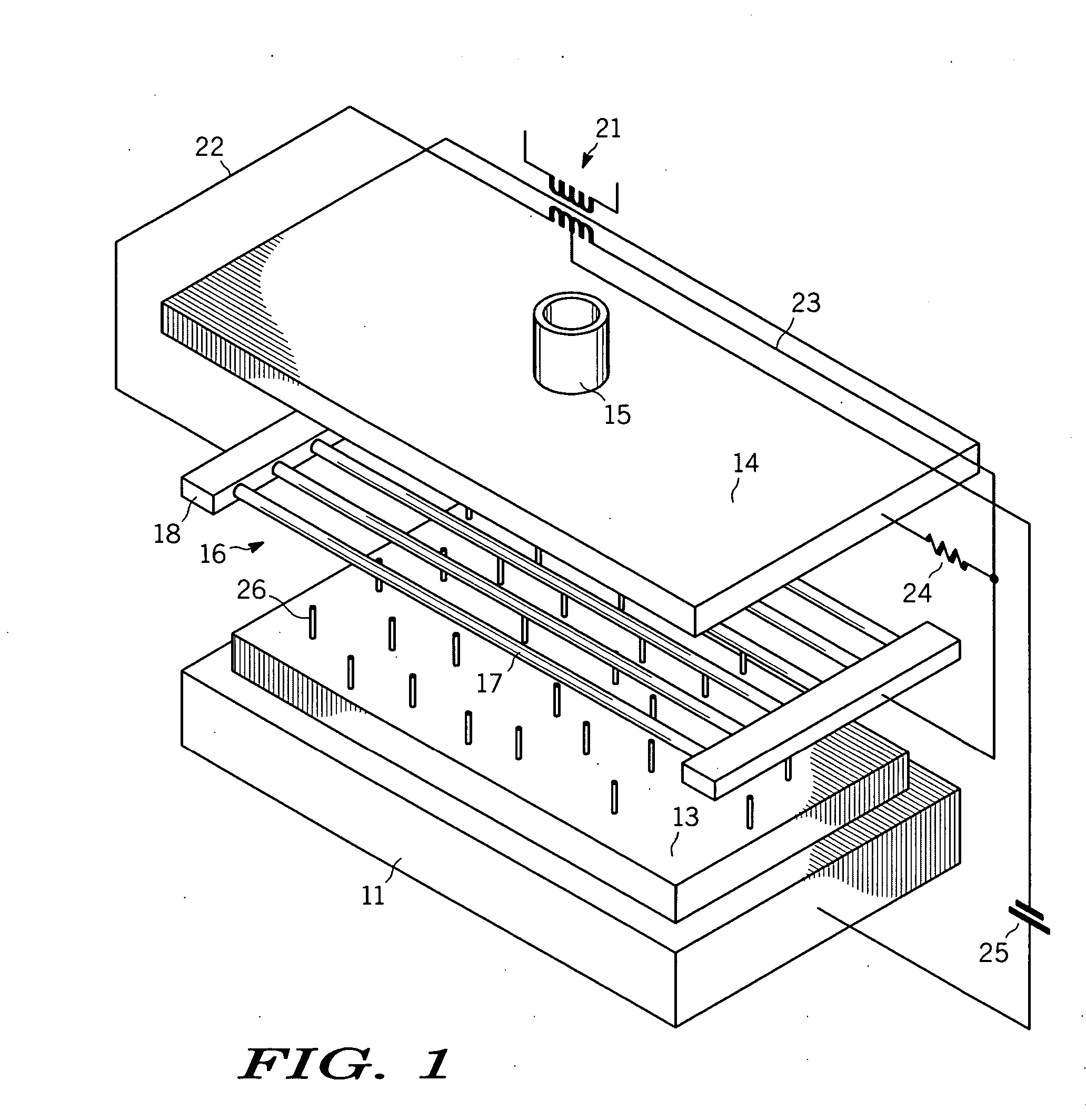

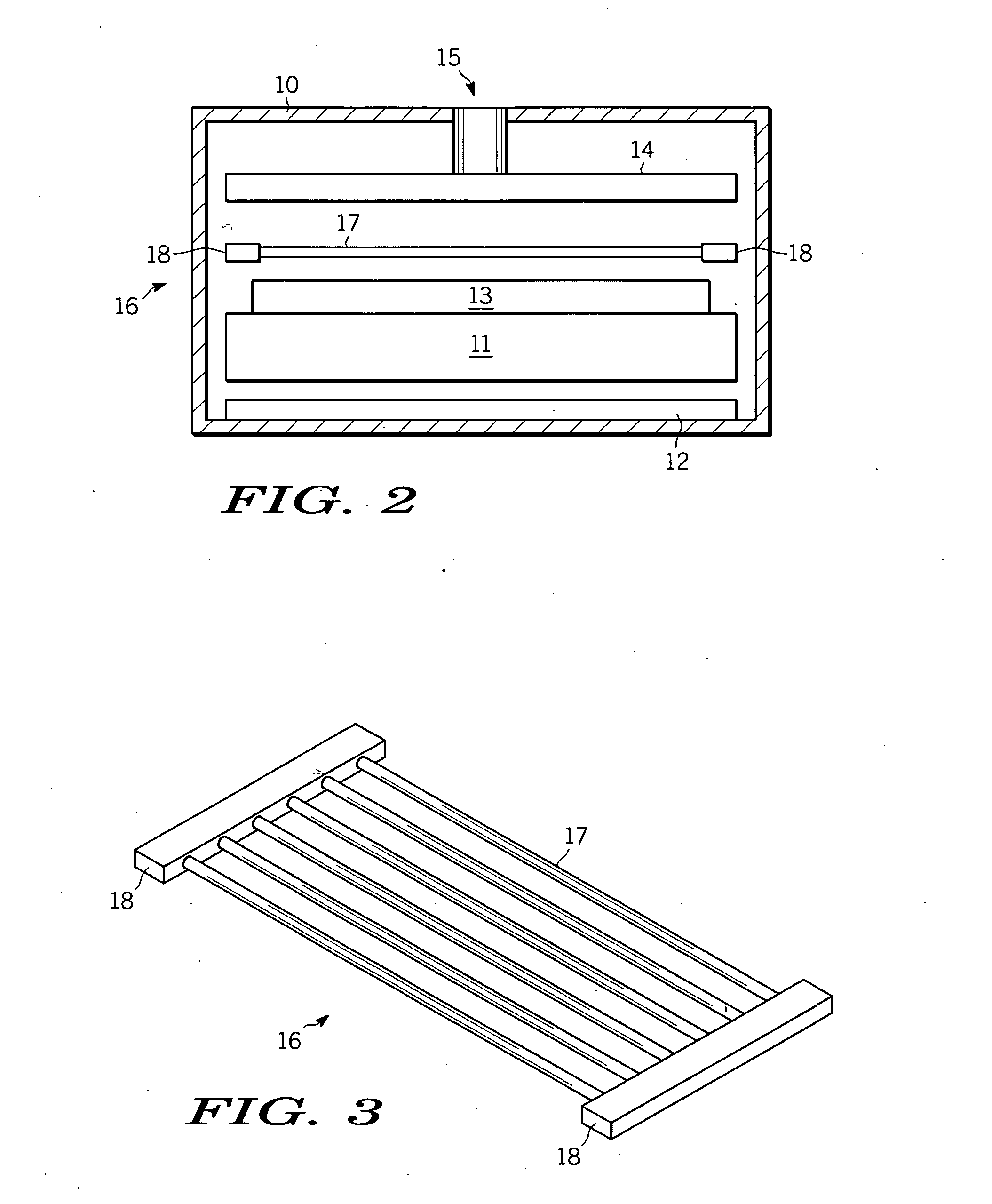

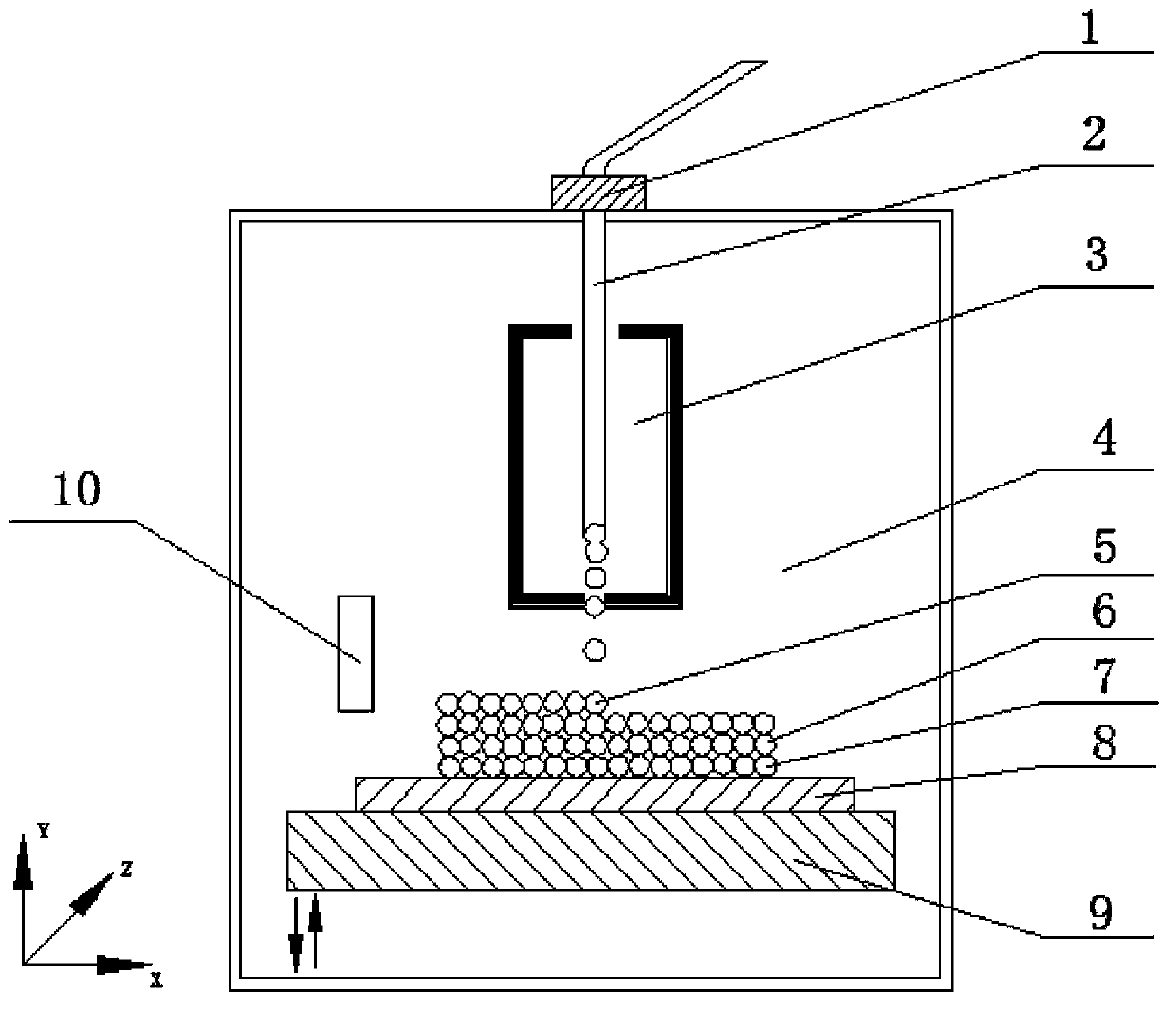

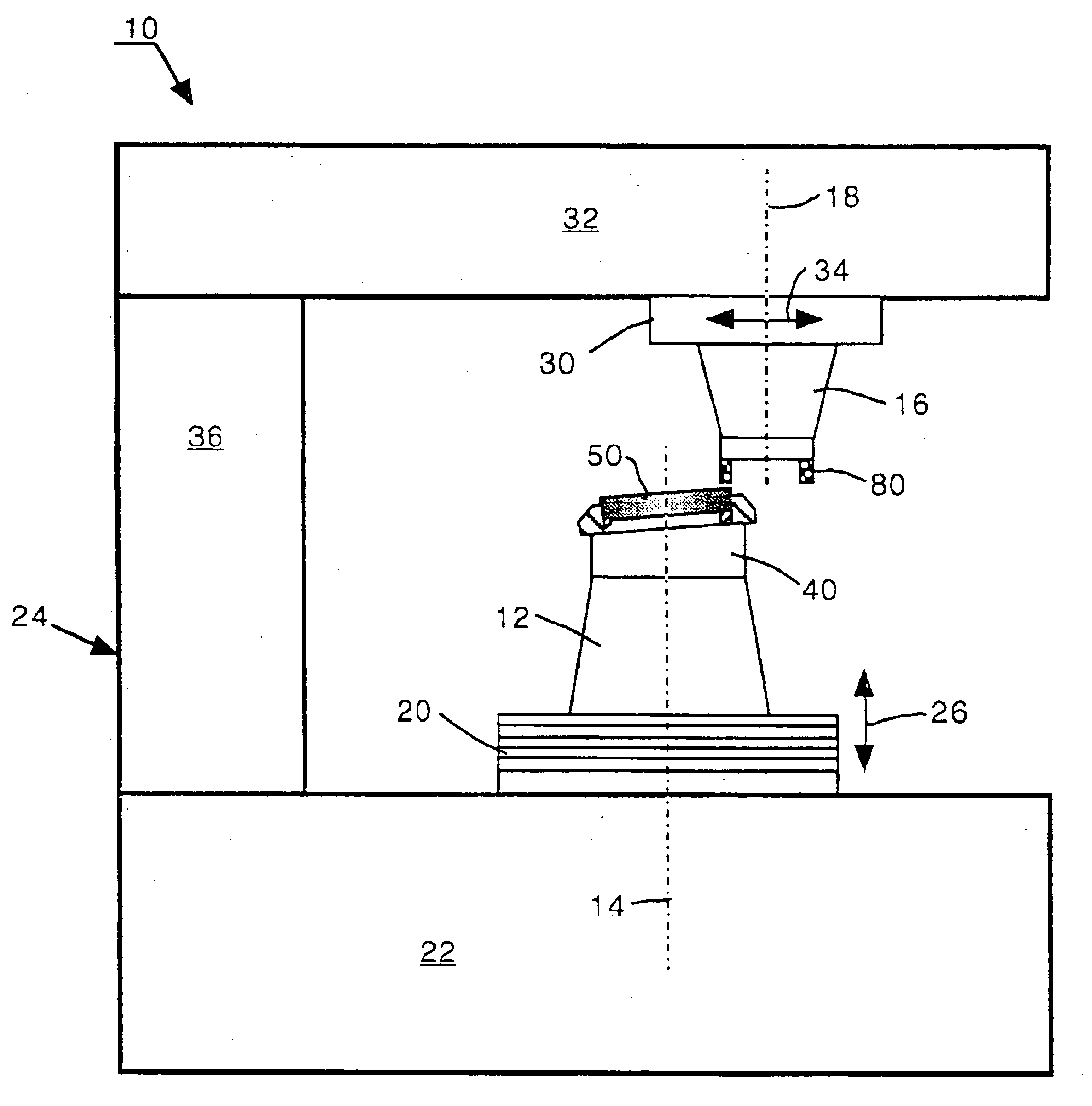

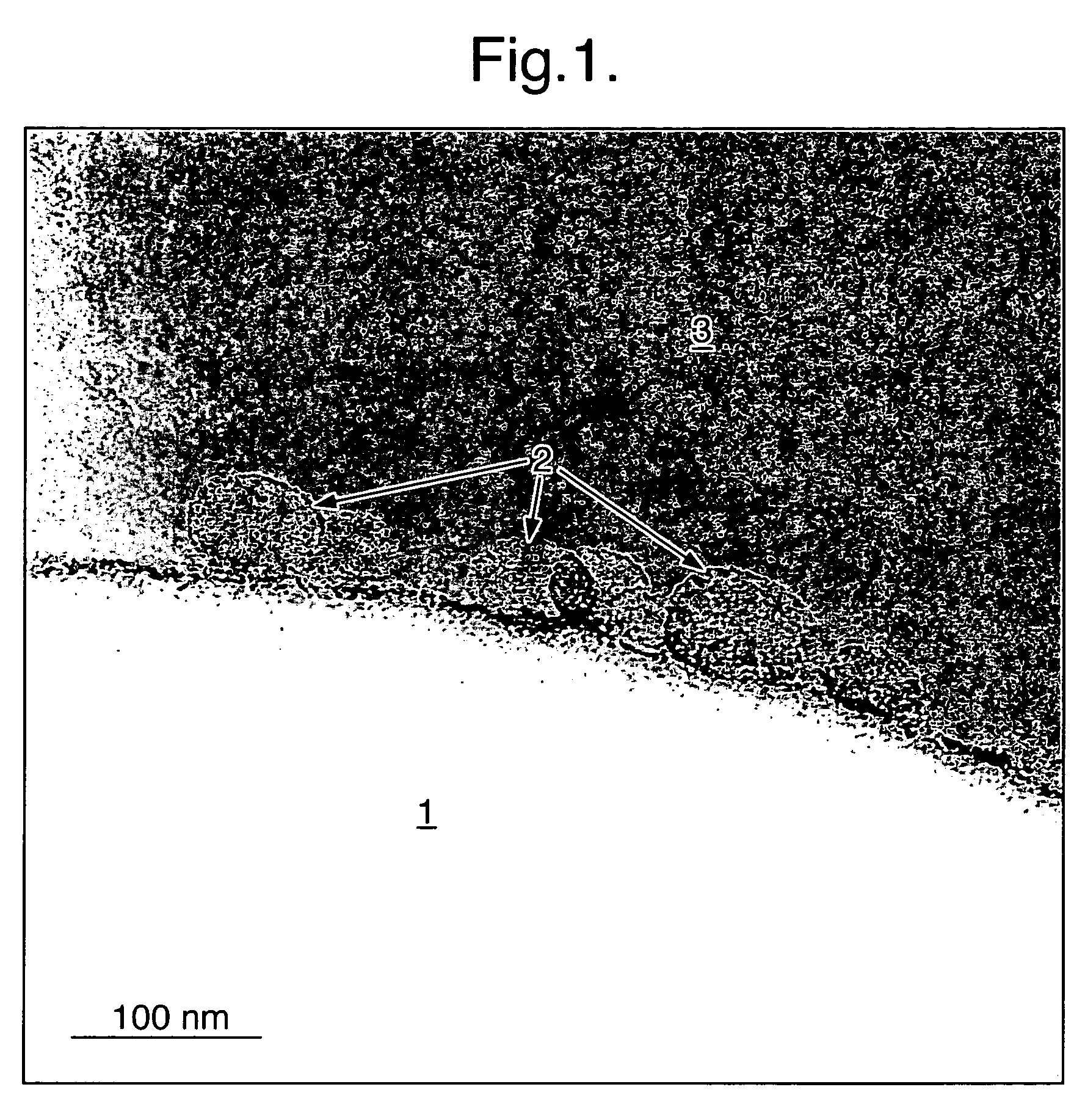

Apparatus and process for carbon nanotube growth

InactiveUS20060185595A1Improve rendering capabilitiesIncreased processing flexibilityMaterial nanotechnologySpecific nanostructure formationCarbon nanotubeAspect ratio

An apparatus is provided for growing high aspect ratio emitters (26) on a substrate (13). The apparatus comprises a housing (10) defining a chamber and includes a substrate holder (12) attached to the housing and positioned within the chamber for holding a substrate having a surface for growing the high aspect ratio emitters (26) thereon. A heating element (17) is positioned near the substrate and being at least one material selected from the group consisting of carbon, conductive cermets, and conductive ceramics. The housing defines an opening (15) into the chamber for receiving a gas into the chamber for forming the high aspect ratio emitters (26).

Owner:MOTOROLA INC

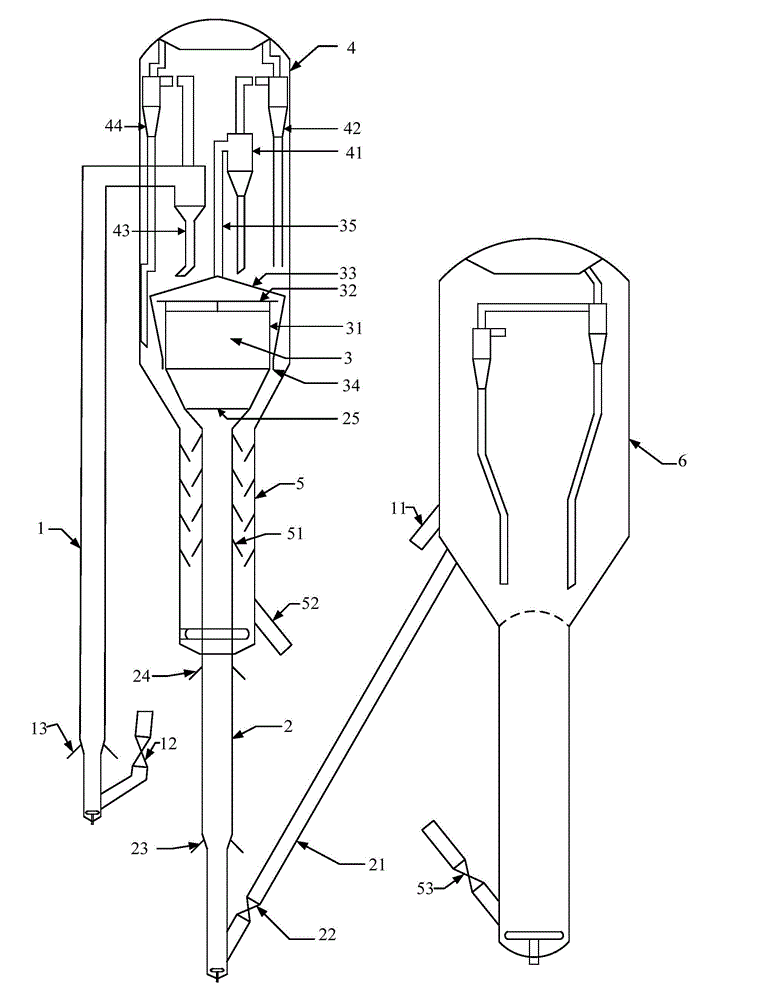

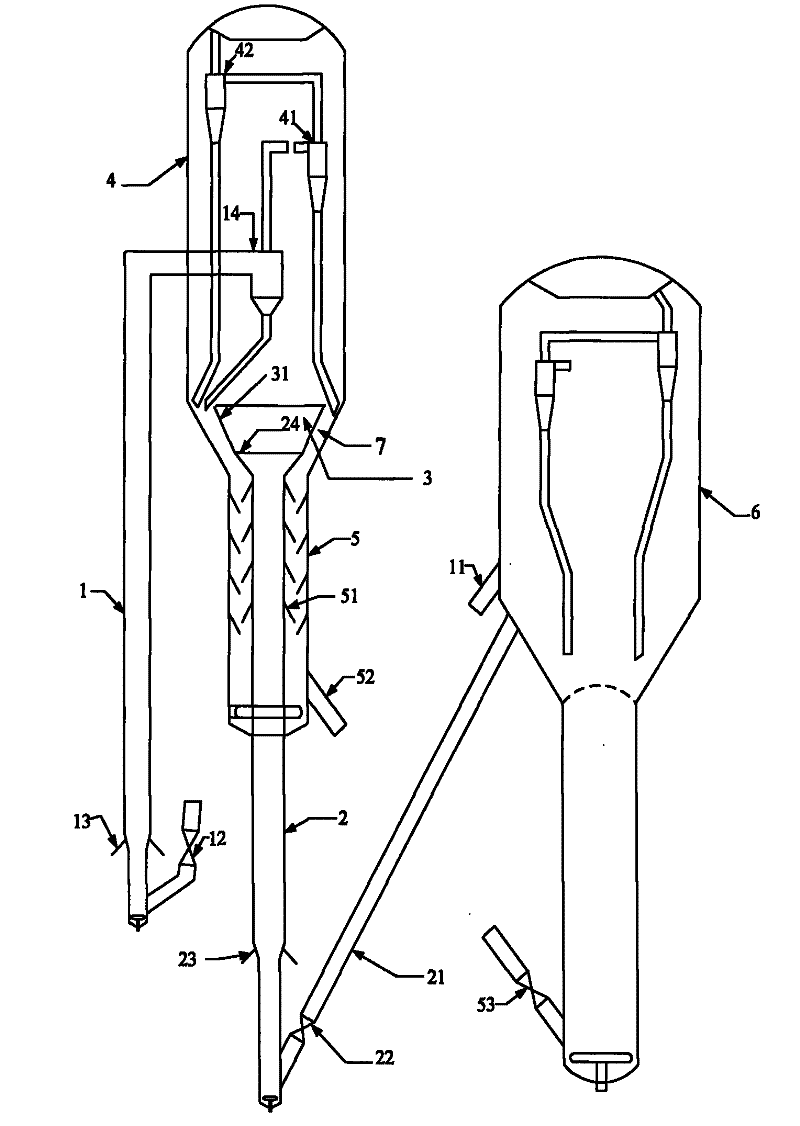

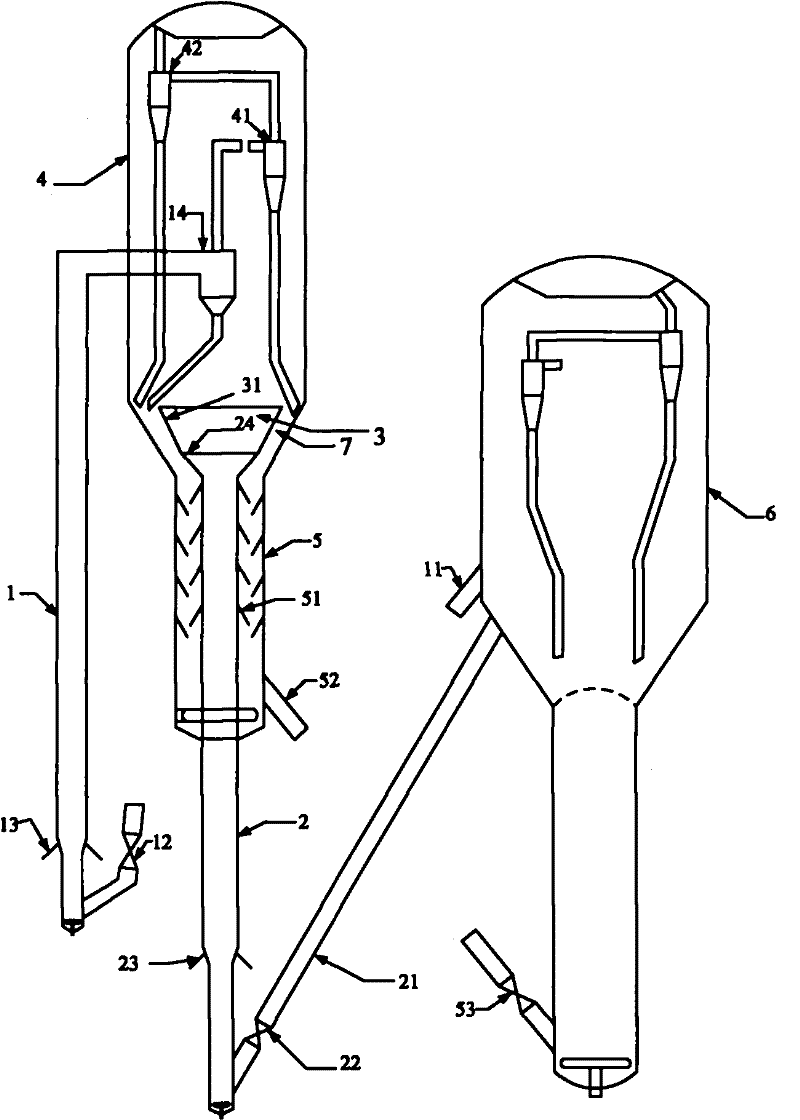

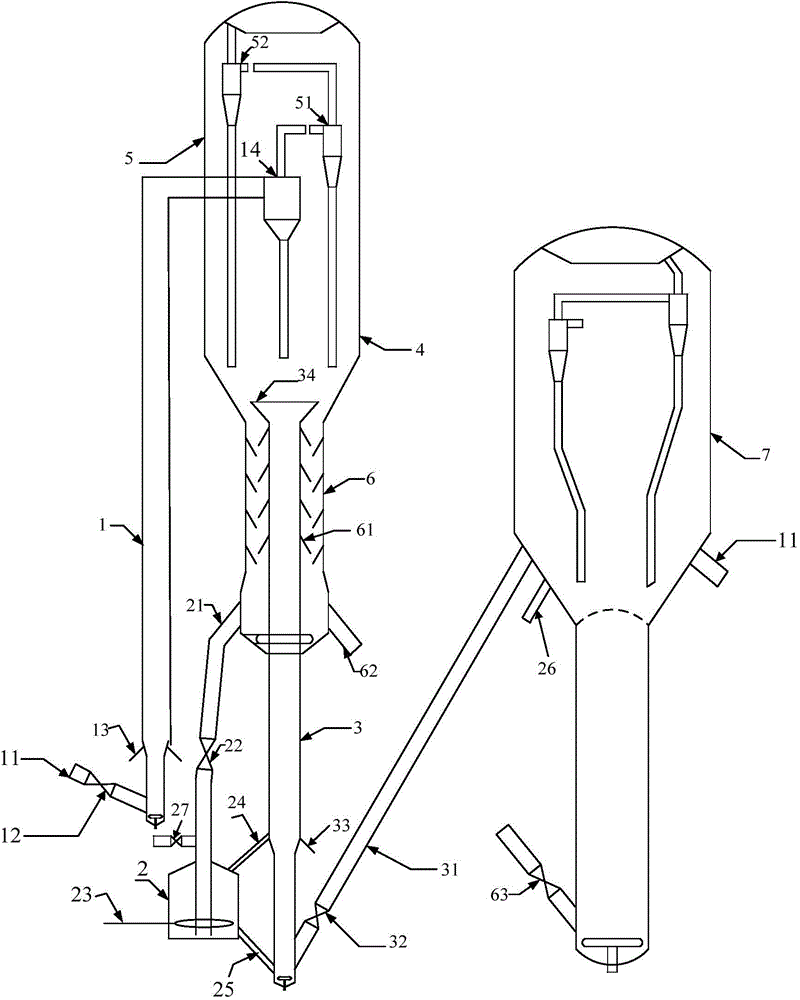

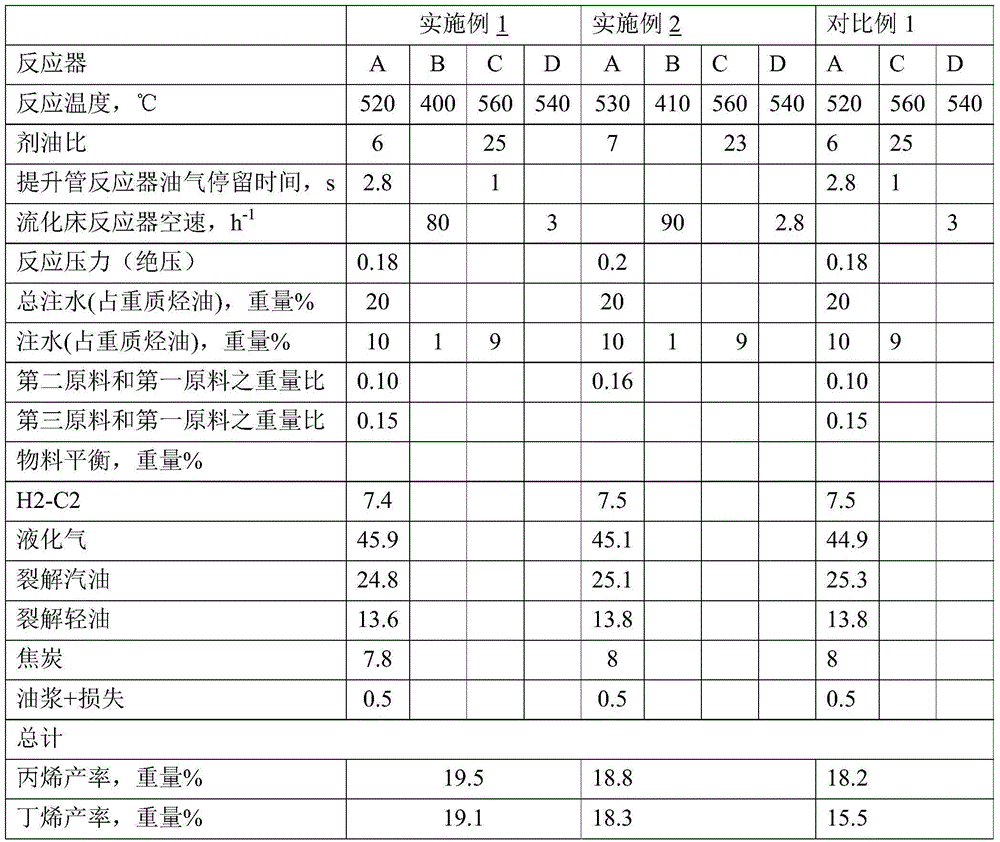

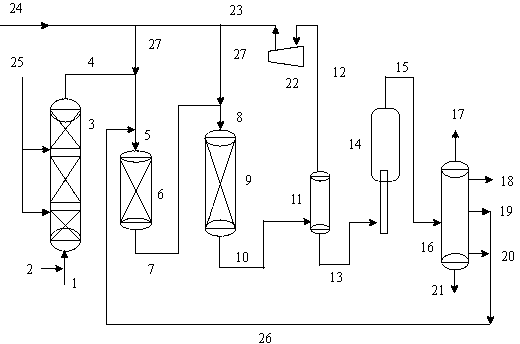

Hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon

ActiveCN104560154AInhibition of hydrogen transfer reactionsFast carbanion cracking reactionTreatment with plural serial stages onlyCarbon depositAromatic hydrocarbon

The invention relates to a hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon. The method comprises steps as follows: a heavy hydrocarbon raw material and a cracking catalyst are contacted in a first reactor and have a catalytic cracking reaction, a first carbon deposit catalyst and a first reaction product are obtained through separation; a light hydrocarbon raw material is injected from the upstream part of a second reactor, a medium hydrocarbon raw material is injected from the middle of the second reactor, and the mixture has a catalytic cracking reaction; a reaction mixture produced in the second reactor is introduced to the third reactor and continuously has a reaction, and a second carbon deposit catalyst and a second reaction product are obtained through separation; the cracking catalyst adopts a cracking catalyst containing modified beta zeolite, and the modified beta zeolite adopts phosphorus and transition metal M modified beta zeolite. With adoption of the method, higher propylene yield and light aromatic hydrocarbon yield can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

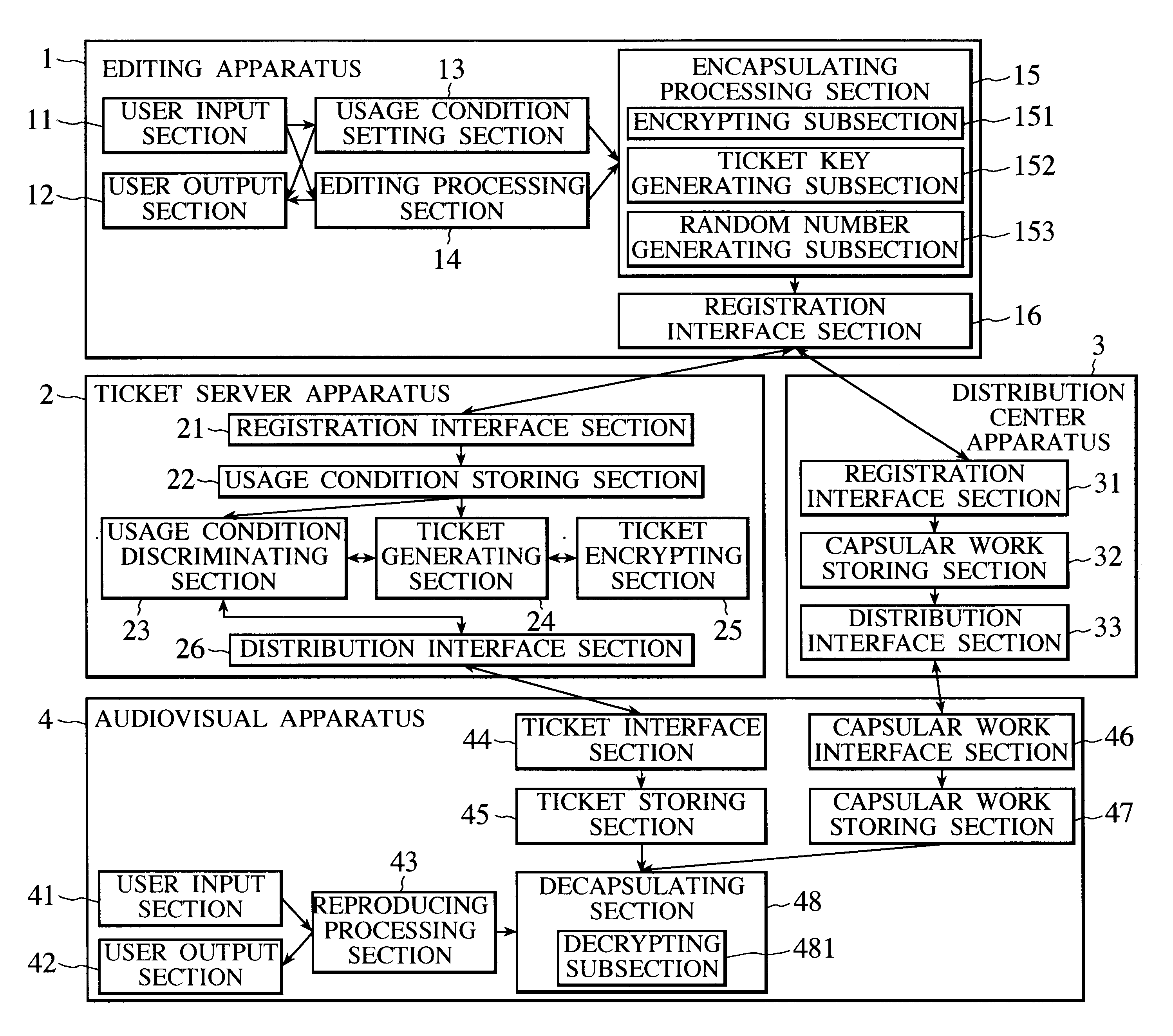

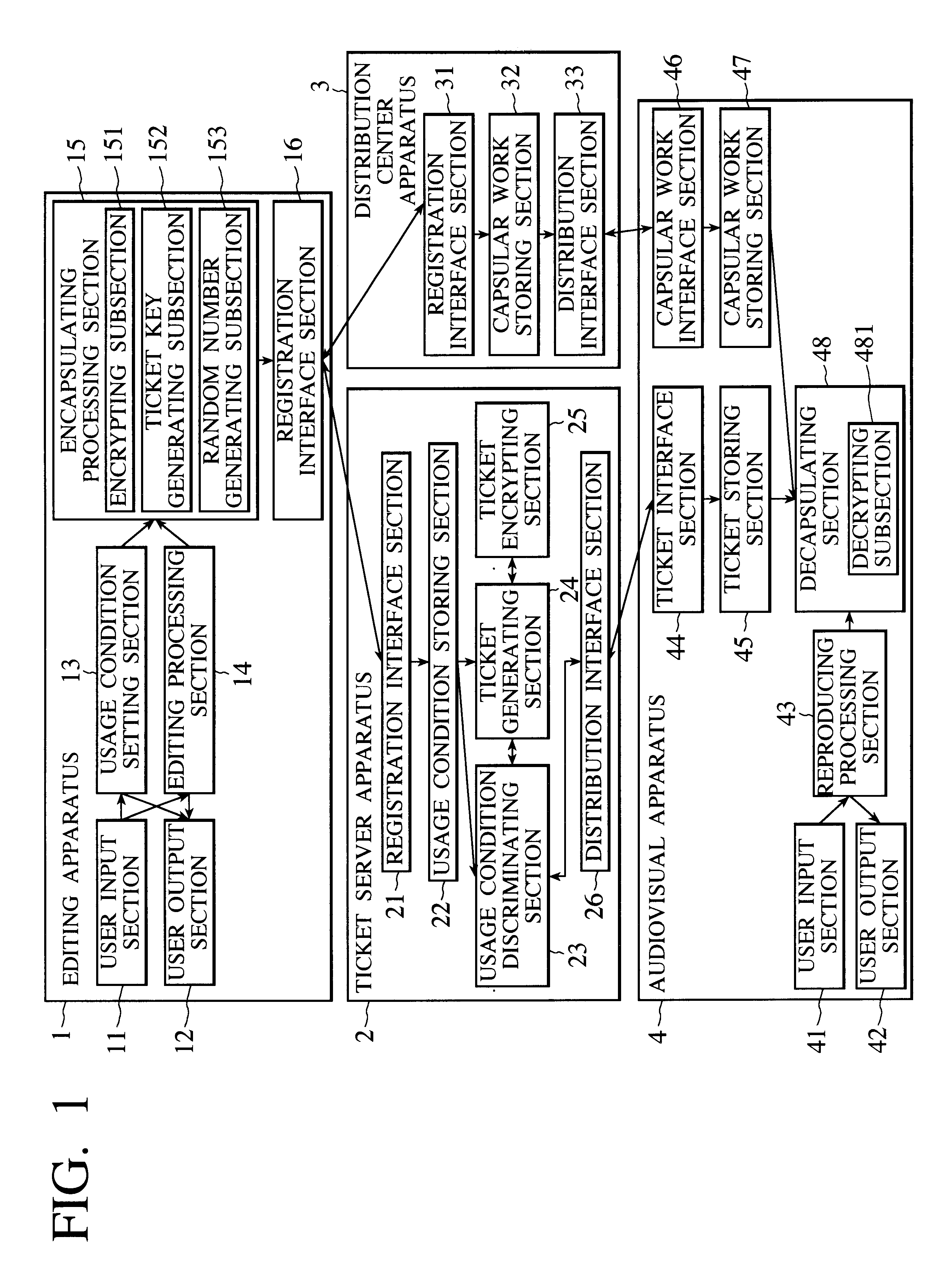

System and method for distributing digital works, apparatus and method for reproducing digital works, and computer program product

InactiveUS6857071B1Improve securityImprove throughputKey distribution for secure communicationProgram control using stored programsAudiovisual deviceServer appliance

An editing apparatus generates a capsular work in which usage conditions for each of plural usages and usage secret information, obtained by encrypting a decryption key encrypted work data with ticket keys which differ depending on usage from each other, are encapsulated together with the encrypted work data. A ticket server apparatus, which manages the usage conditions and the ticket keys, issues a ticket containing a ticket key in the case of allowing a user to practice the usage requested by the user. A distribution center apparatus, which manages the capsular work, distributes the capsular work in accordance with the user's request. An audiovisual apparatus acquires the capsular work from the distribution center apparatus and requests the ticket necessary to make use of the capsular work from the ticket server apparatus. The audiovisual apparatus decrypts the encrypted work data contained in the capsular work and reproduces the work data only in the case where the audiovisual apparatus has acquired the ticket.

Owner:NEC CORP

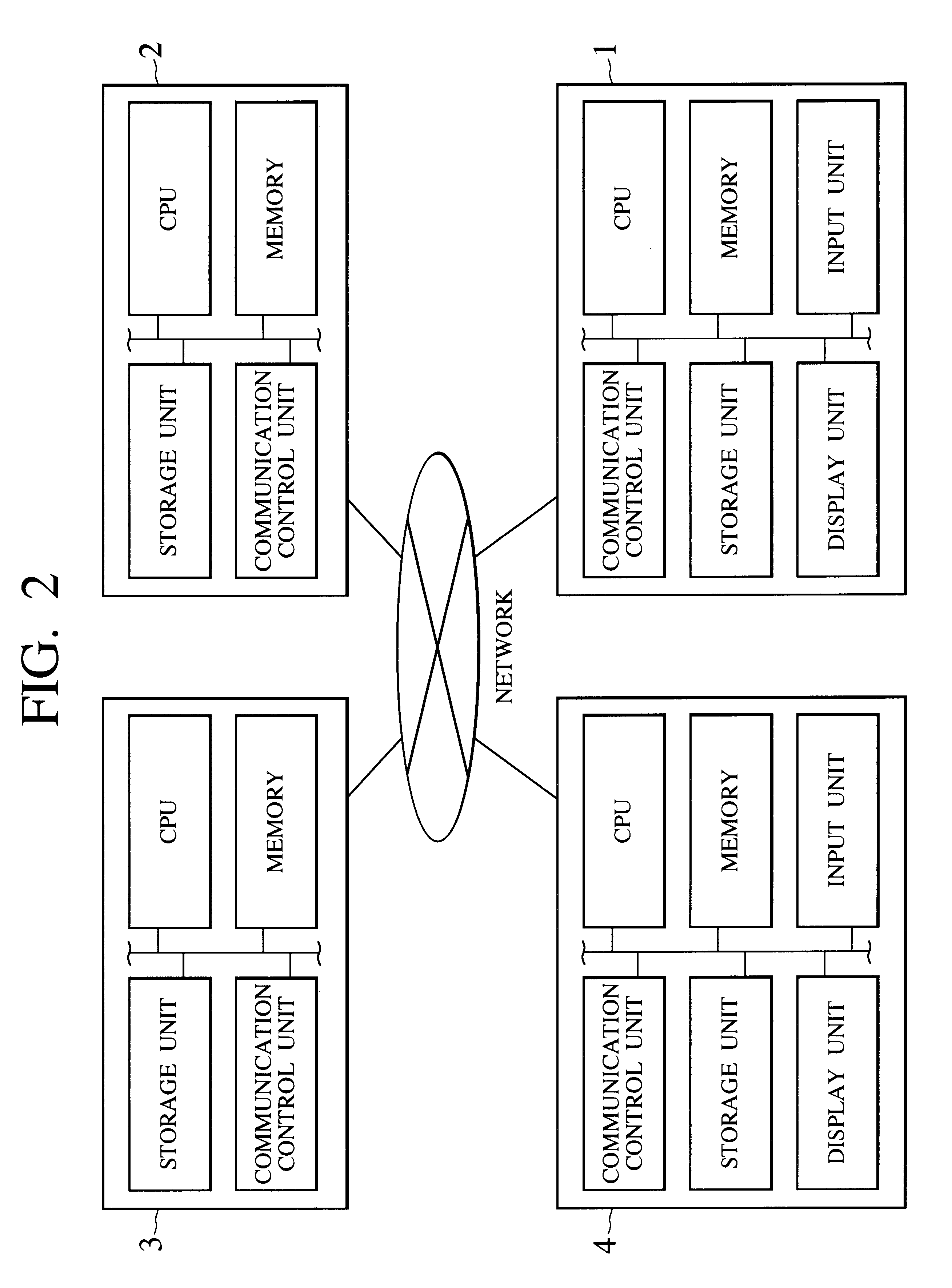

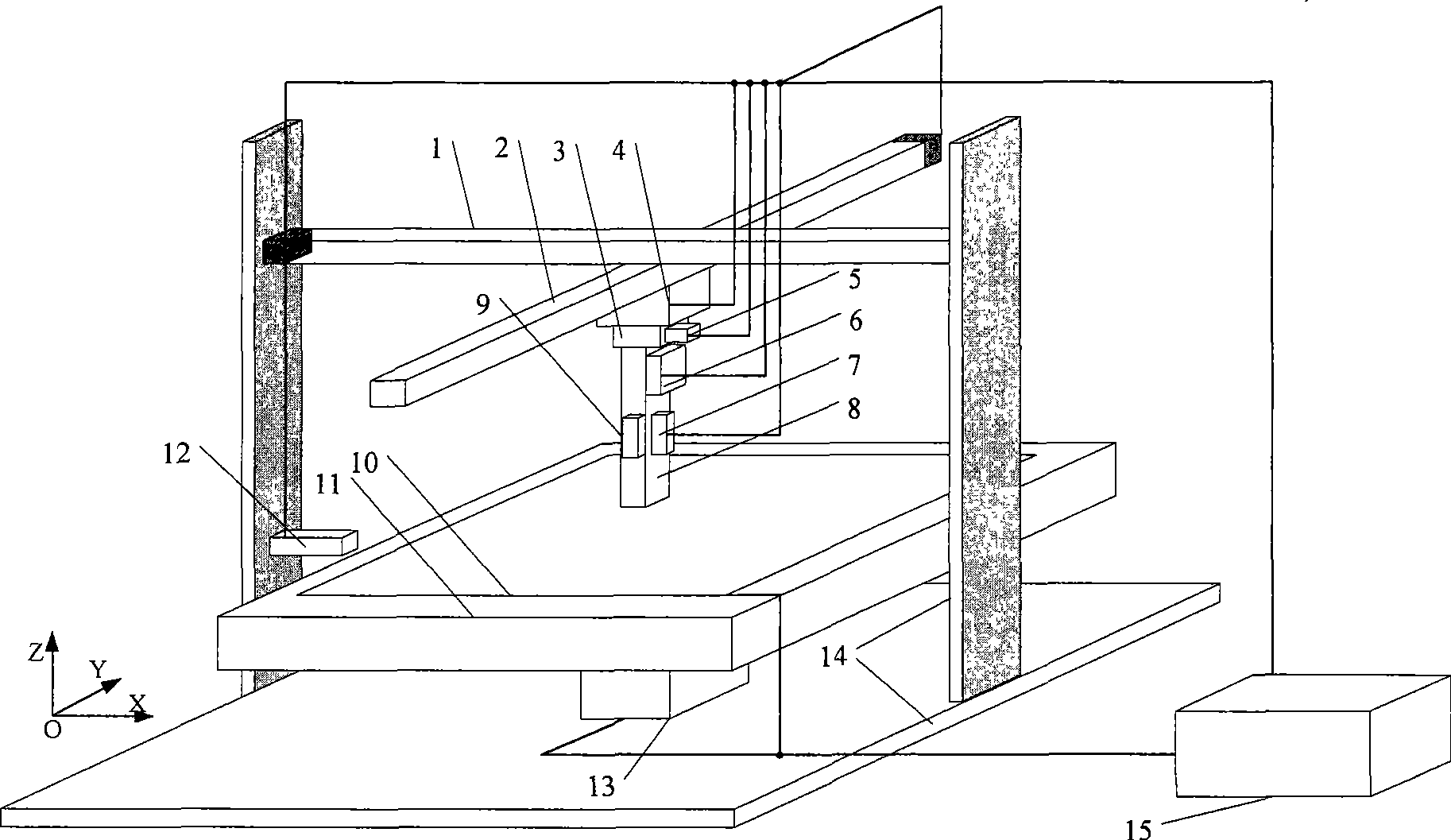

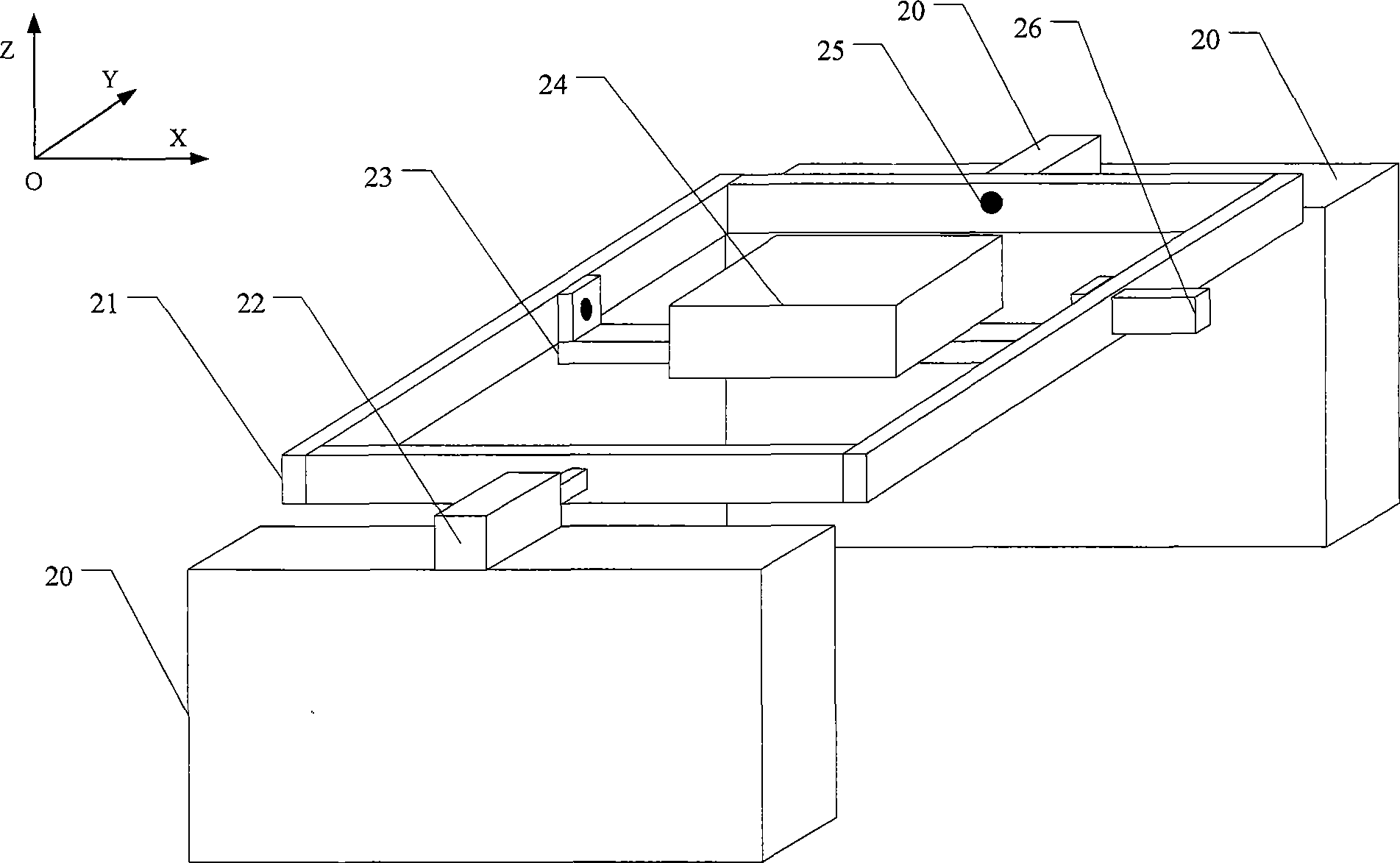

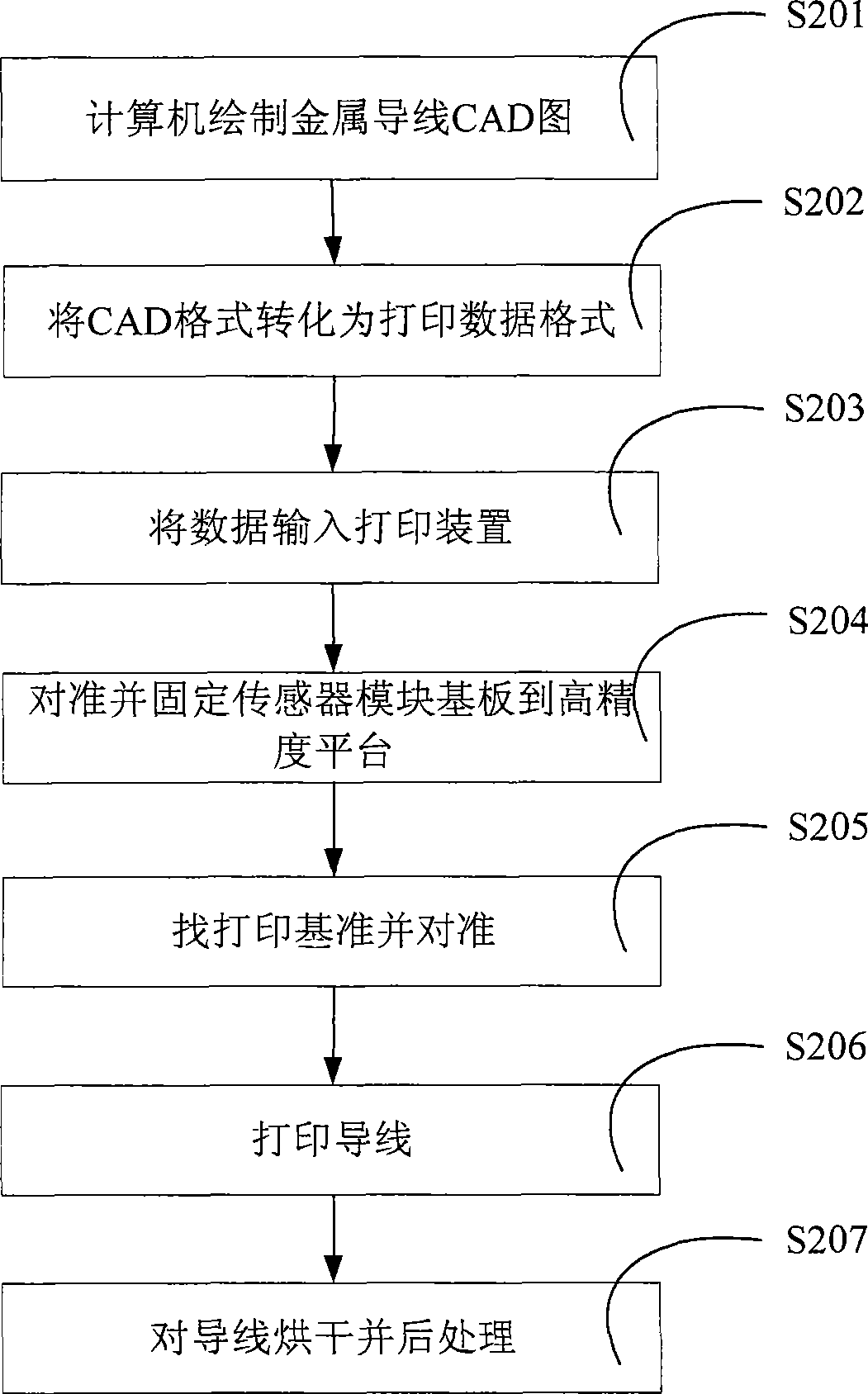

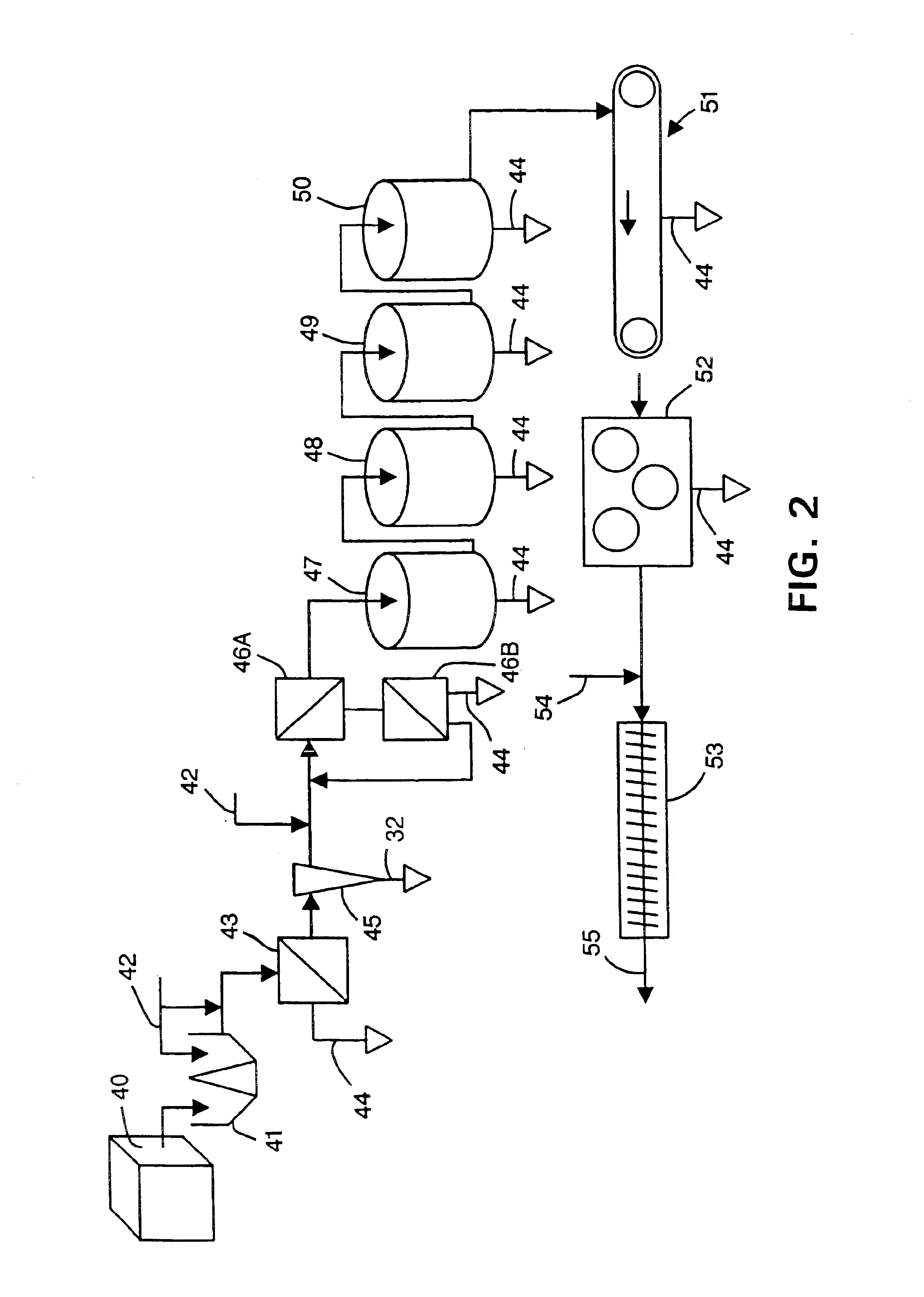

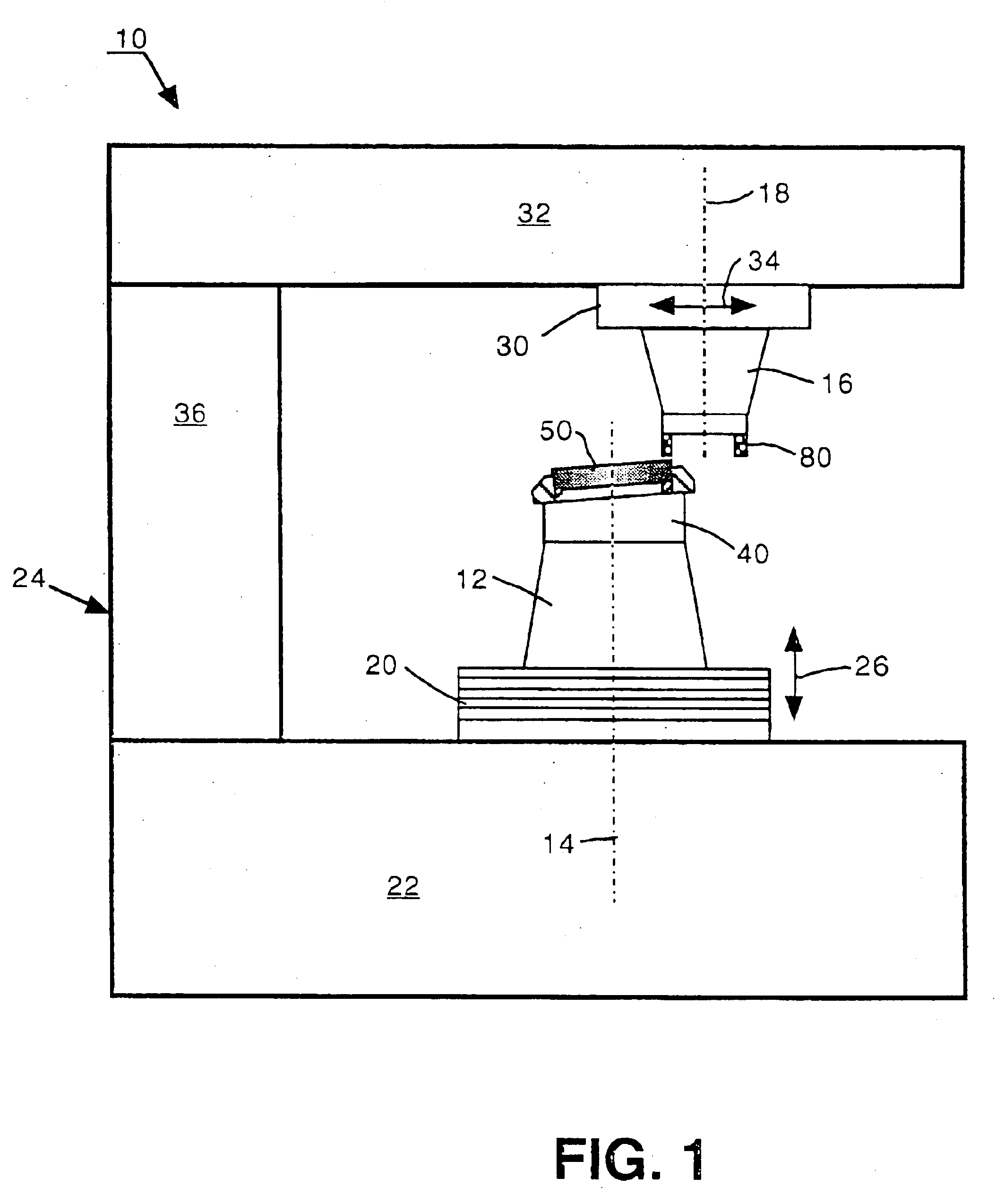

Printing device and printing method for integrating electronic components

ActiveCN101462414AImprove efficiencyIncreased processing flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingHead movementsComputer module

The invention relates to a printing device, which can perform precise conductive pattern printing on a step shaped substrate, and comprises a platform module, a printing module, and a head movement module, wherein at least one of the platform module and the head movement module is provided with a rotating movement unit, and the rotating movement unit can drive a platform or a head to rotate around an X axis and a Y axis respectively, thereby ensuring that the head aligns a step surface which has an angle a with an X-Y plane to print; and the angle a is an angle which is more than 0 degree and is less than or equal to 90 degrees. A main innovation point is that the printing device can continuously print on the step shaped substrate; and the rotating movement unit is arranged on the printing device, or a step of real-time rotating printing of the head is added in a printing method, or the printing is respectively performed in a horizontal plane and a step plane, so as to solve the continuous problem of physical property of a metal conducting wire printed on the surface of the step shaped substrate, and ensure that the printed metal wire is not interrupted and has good electrical conductivity.

Owner:CARERAY DIGITAL MEDICAL TECH CO LTD

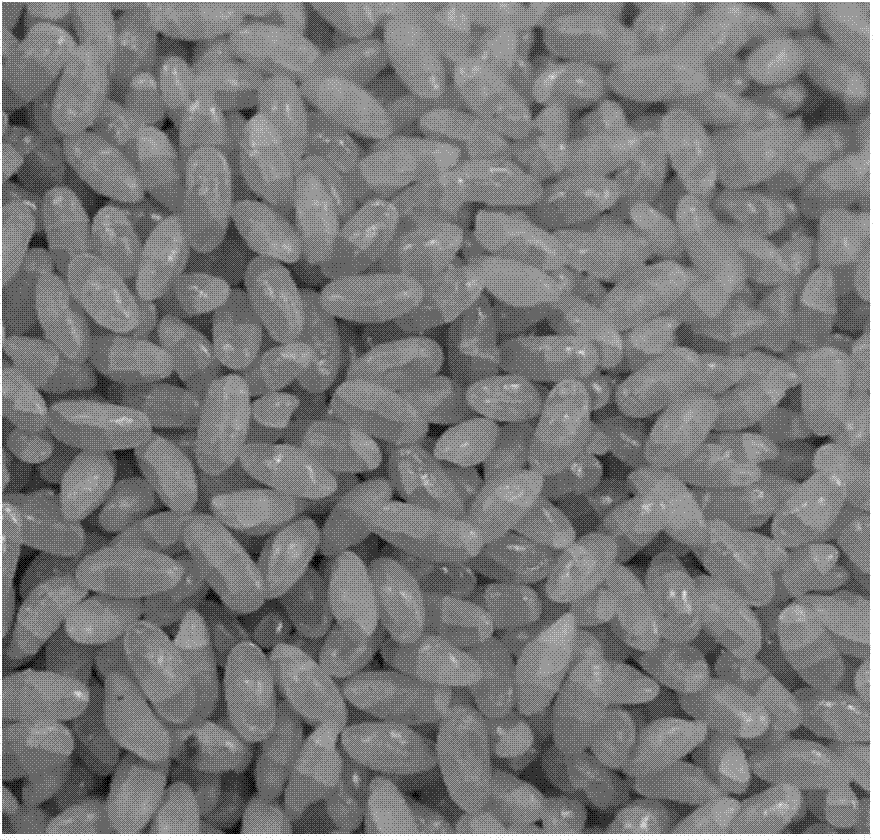

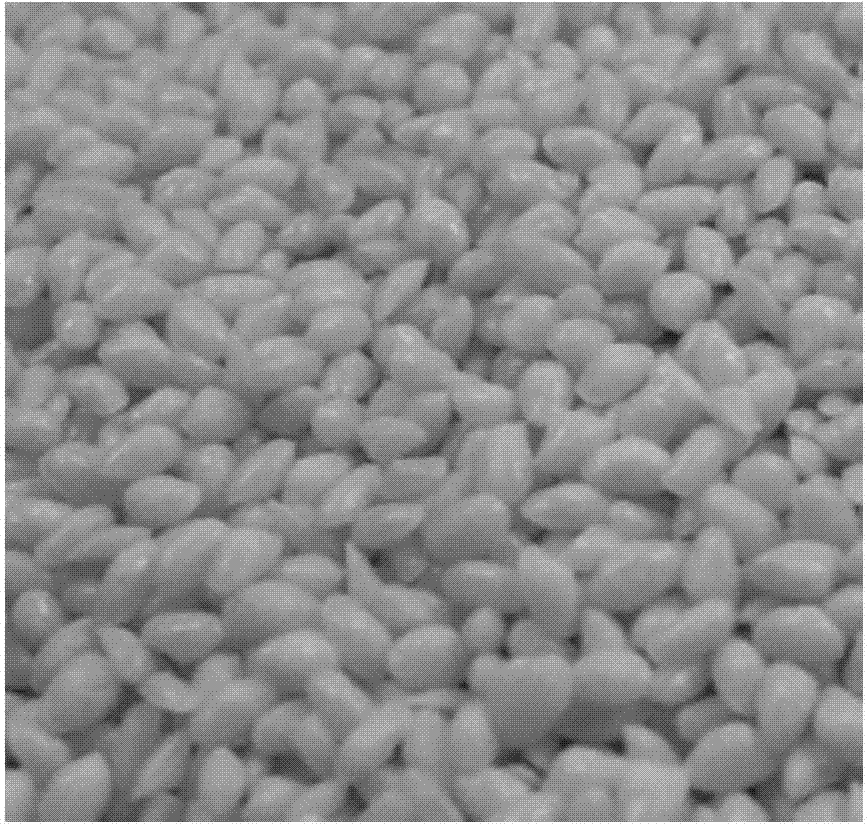

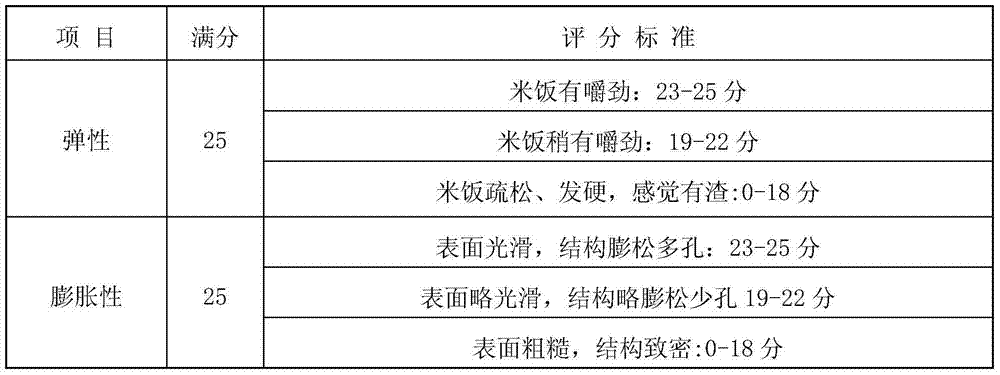

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Hydrocarbon catalytic conversion method for producing propylene and light aromatic hydrocarbon

ActiveCN102206509AImprove utilization efficiencyImprove conversion rateTreatment with plural parallel stages onlyLiquid hydrocarbon mixture productionCatalytic transformationPtru catalyst

A method for producing propylene and light aromatic hydrocarbon comprises the steps of contacting heavy hydrocarbons and / or grease with a cracking catalyst containing modified beta zeolite in a first reactor for catalytic cracking reaction, contacting C4 hydrocarbon fraction and / or light gasoline fraction with the cracking catalyst containing modified beta zeolite in a second reactor for catalytic cracking reaction, and then leading the reaction products into a third reactor for reaction. The hydrocarbon-gasoline conversion method provided by the invention has the advantages of higher propylene yield and light aromatic hydrocarbon yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

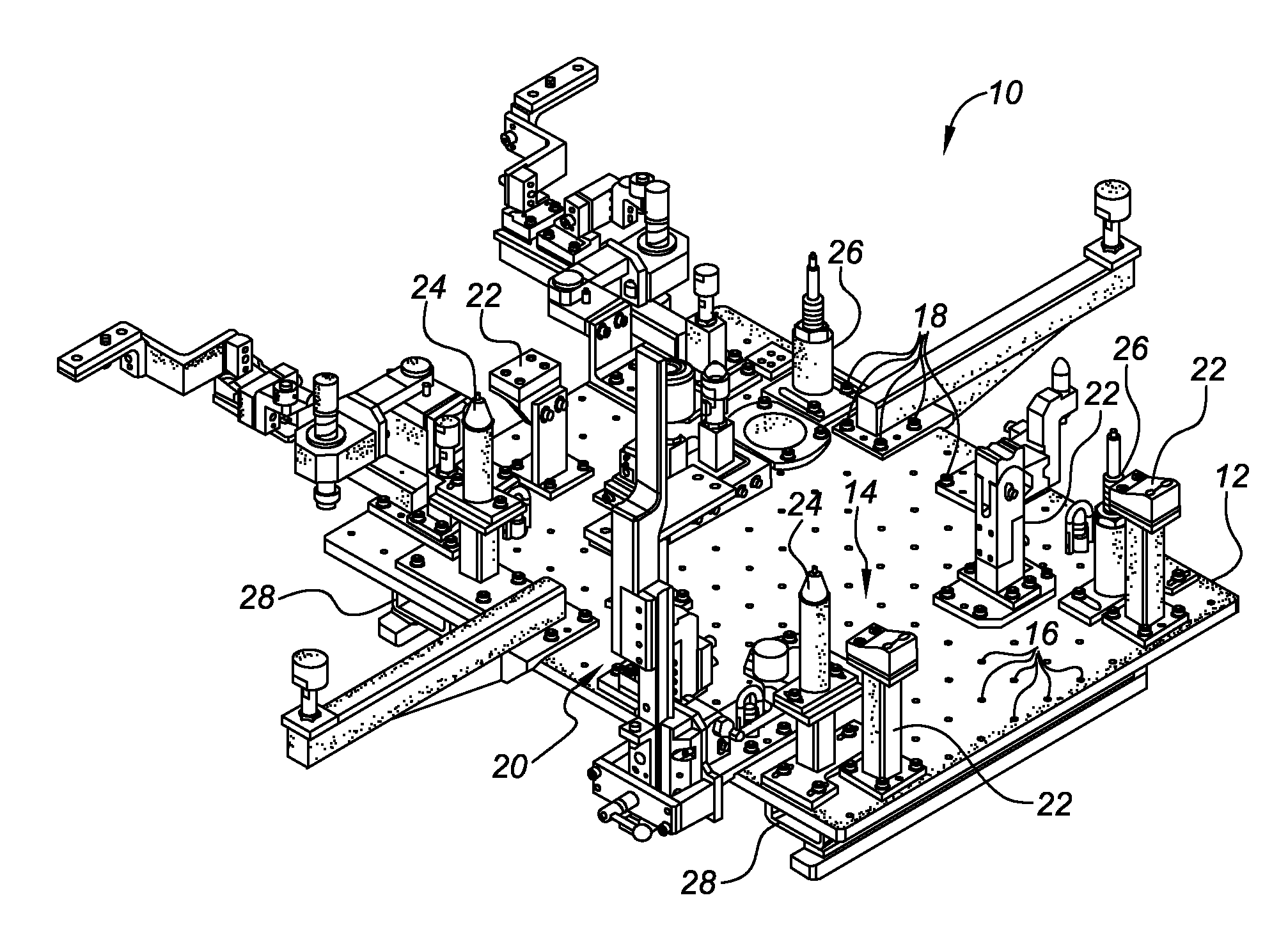

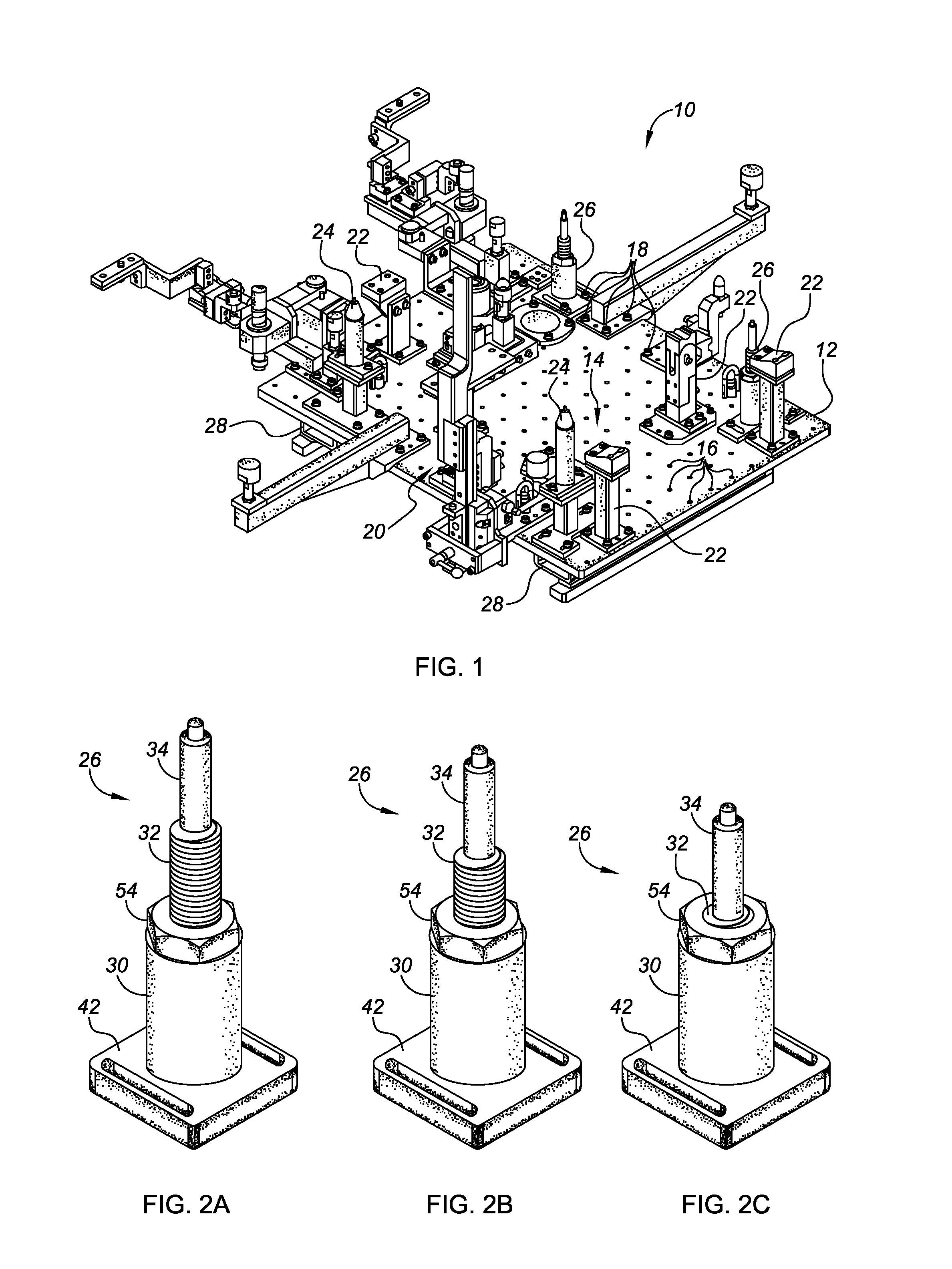

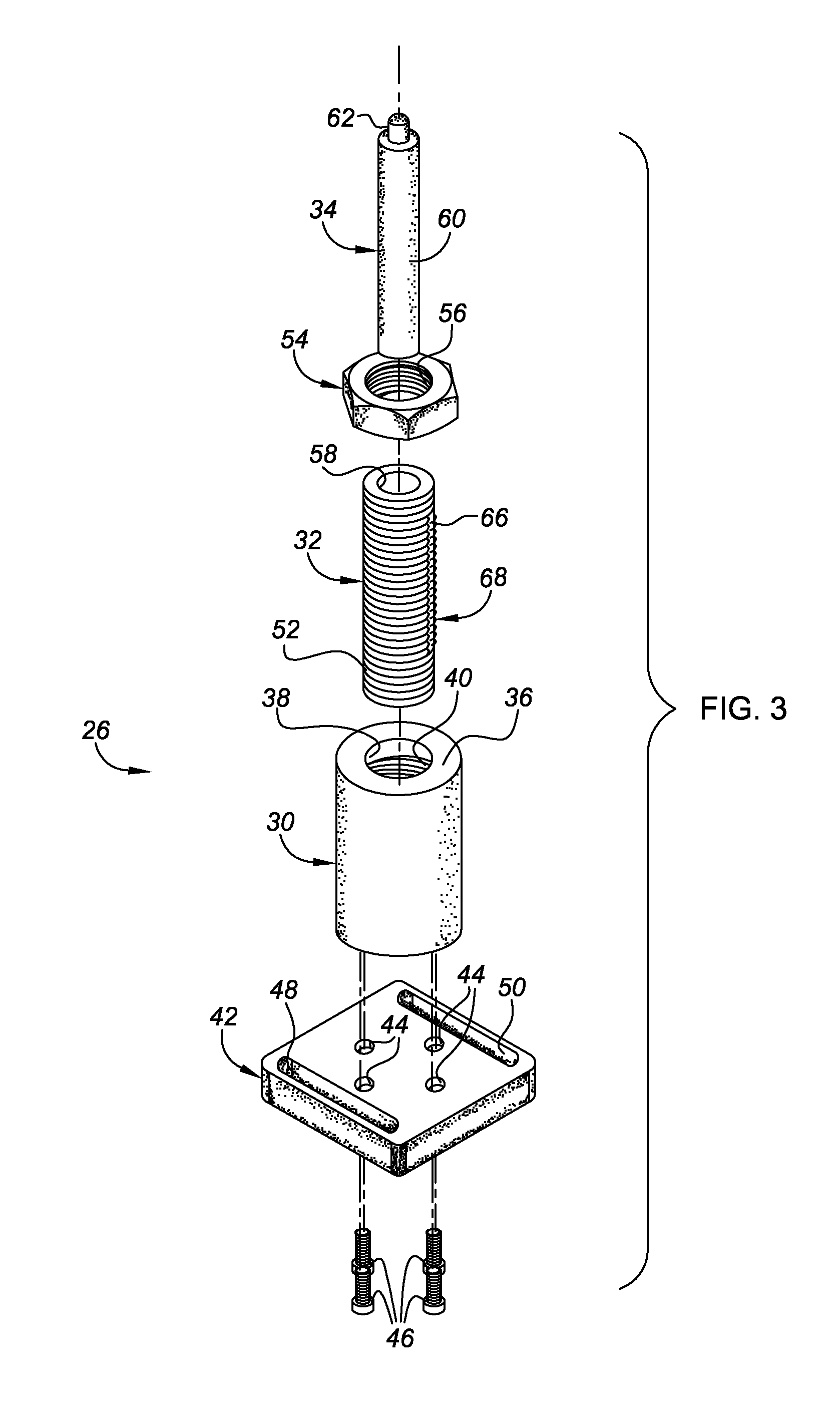

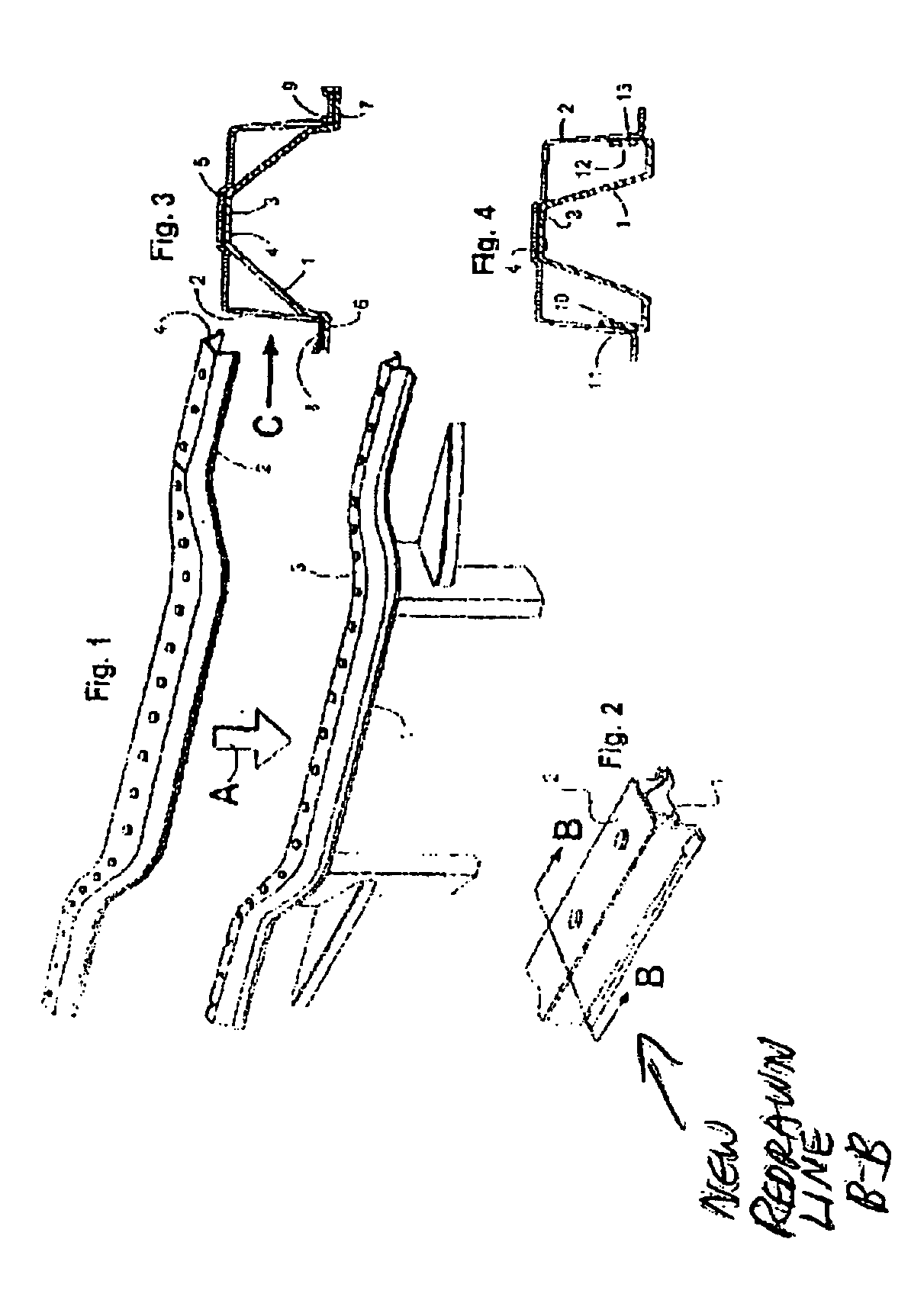

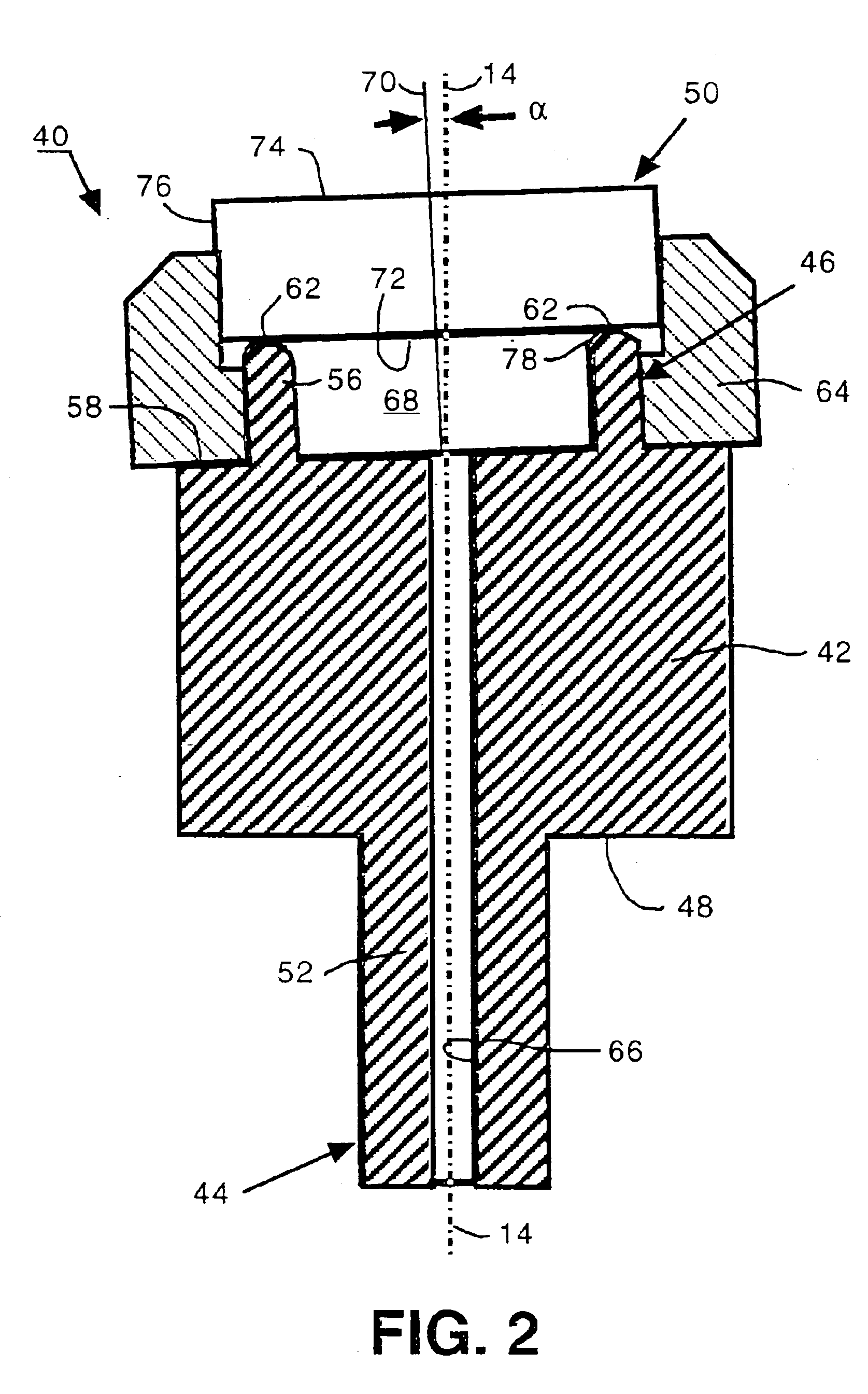

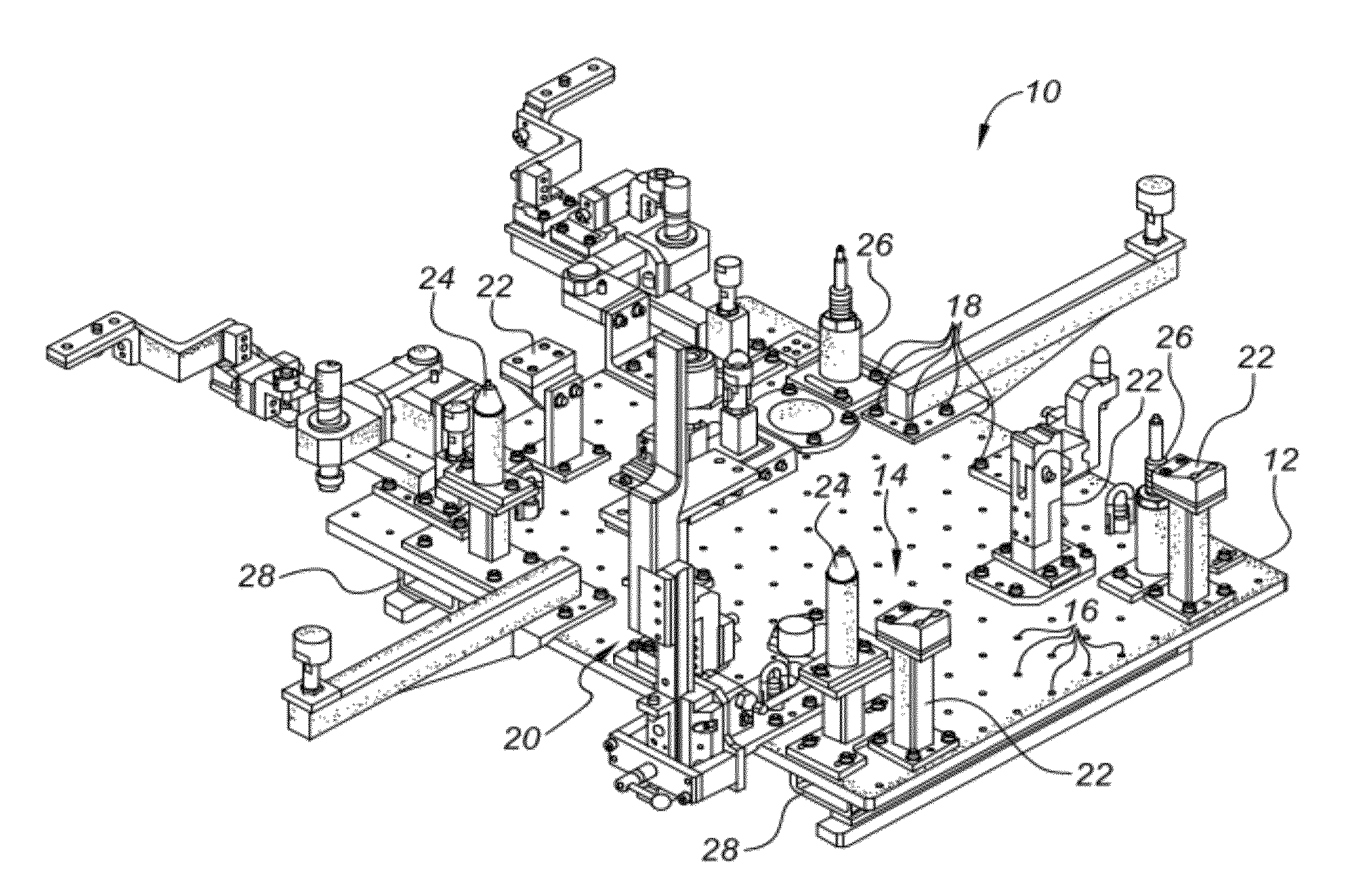

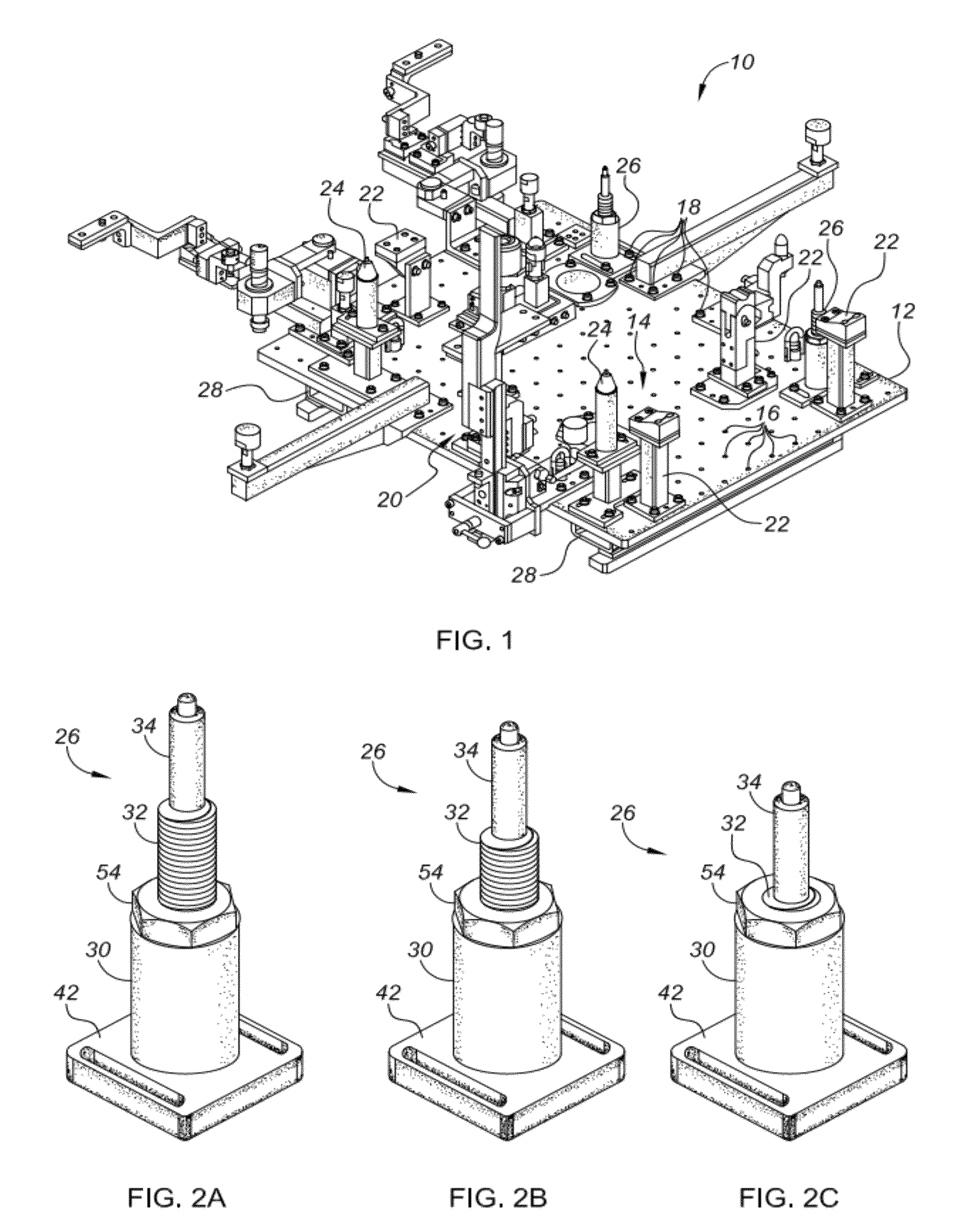

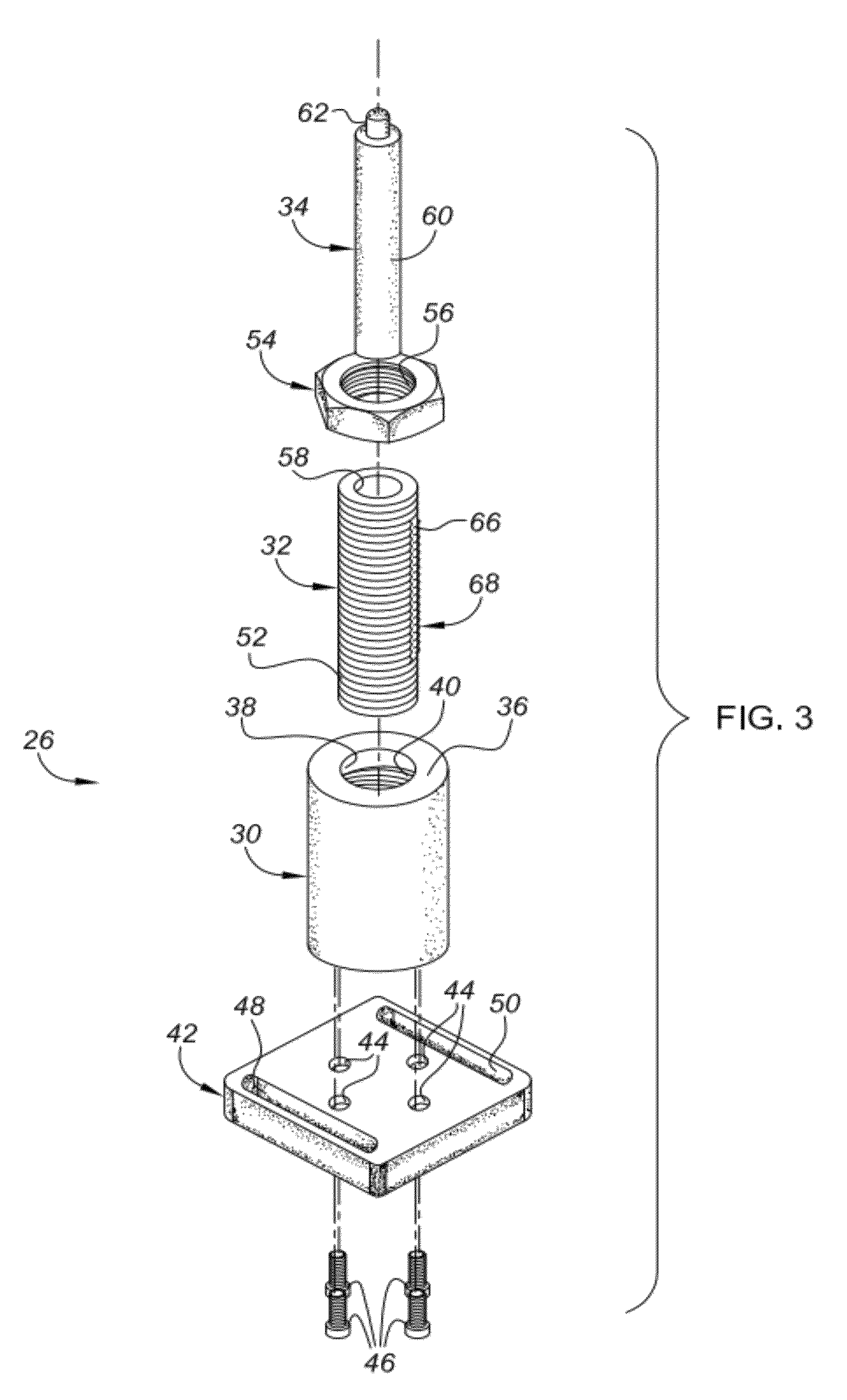

Flexible support assembly for vehicle tooling plates

InactiveUS20100140860A1Easy to adjustEasy and quick modificationVehicle componentsPositioning apparatusScrew threadEngineering

The present invention provides a flexible support assembly for supporting and / or locating a fixture on a tooling plate. The support assembly includes a stanchion with a bore, and a threaded portion on an inner-diameter surface thereof. A base plate is attached to, and configured to repositionably fix the stanchion to the tooling plate. A cylindrical sleeve with a threaded portion on an outer-diameter surface thereof is threadably engaged with the stanchion, whereby the sleeve is operable to telescope with respect to the stanchion between a first, lowest position and a second, highest position. A nut is threadably engaged with the sleeve to lock the sleeve at any predetermined position between the first and second positions. A locator pin is releasably engaged with the sleeve at a first end thereof. The locator pin has a protrusion projecting outward from a second opposing end thereof for engaging a pinhole in the fixture.

Owner:GM GLOBAL TECH OPERATIONS LLC

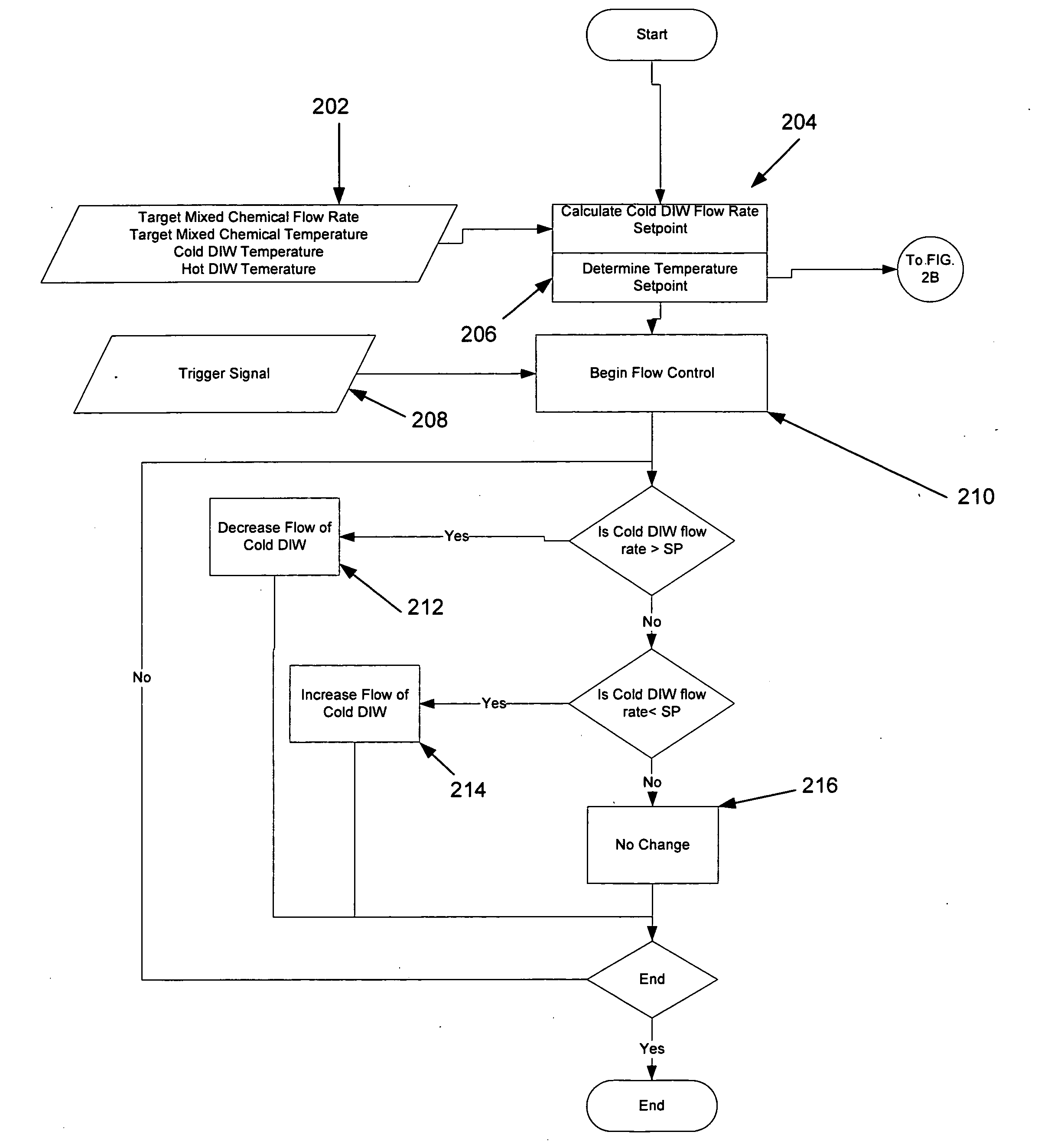

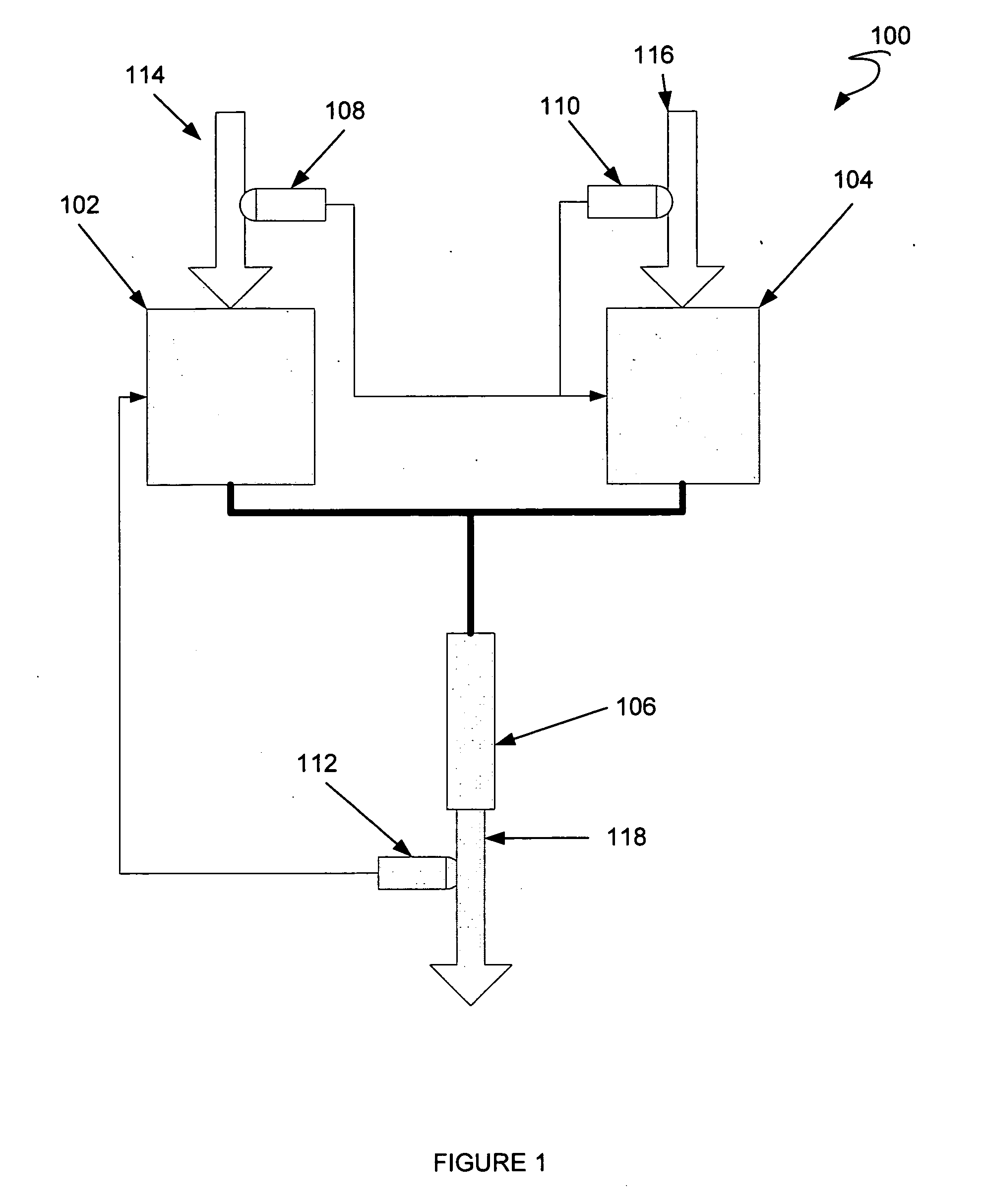

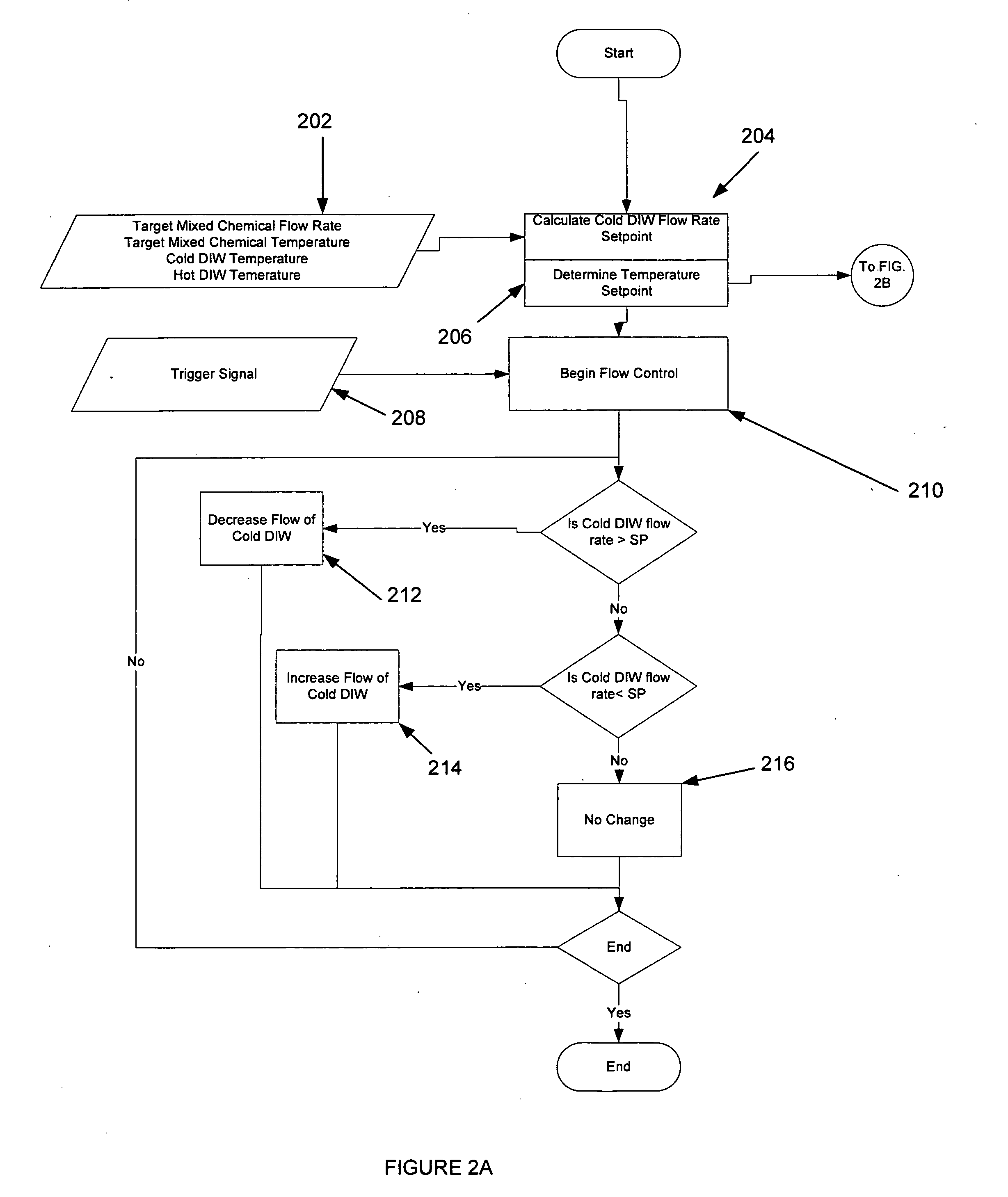

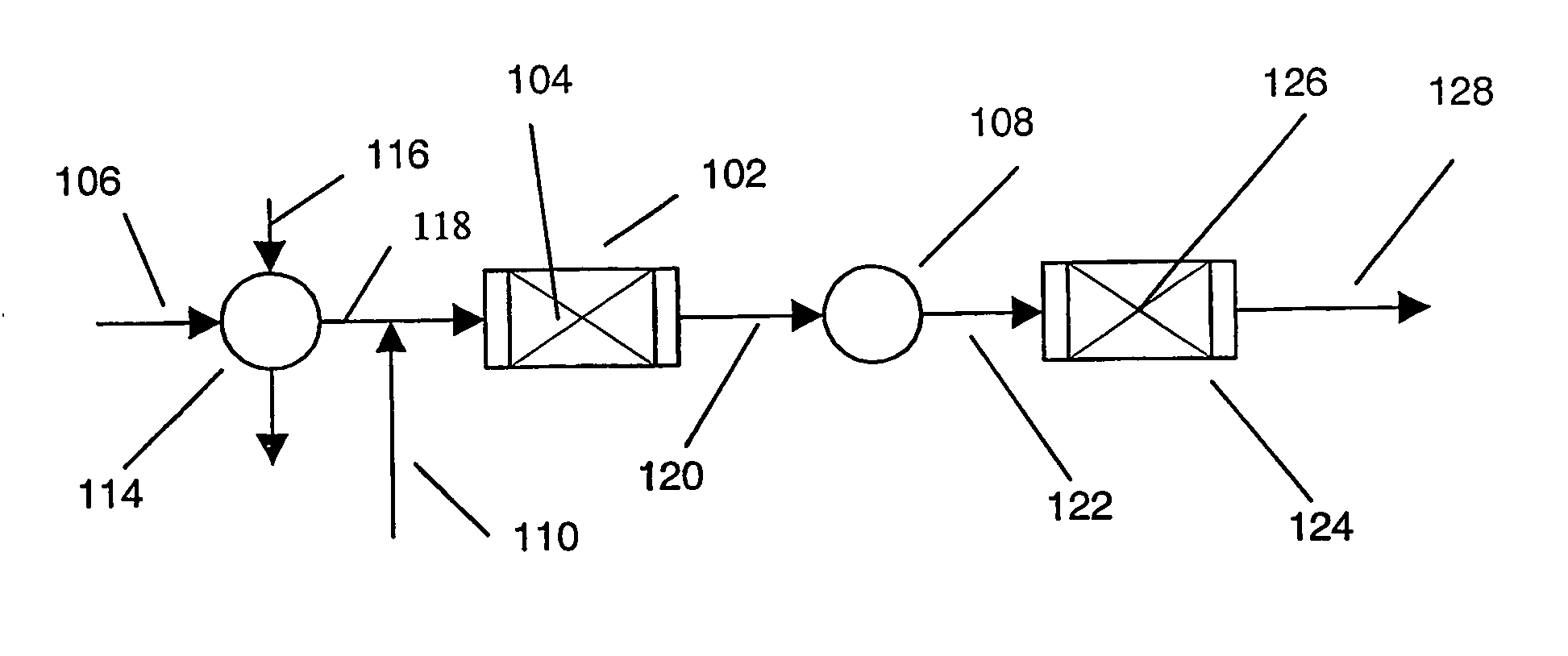

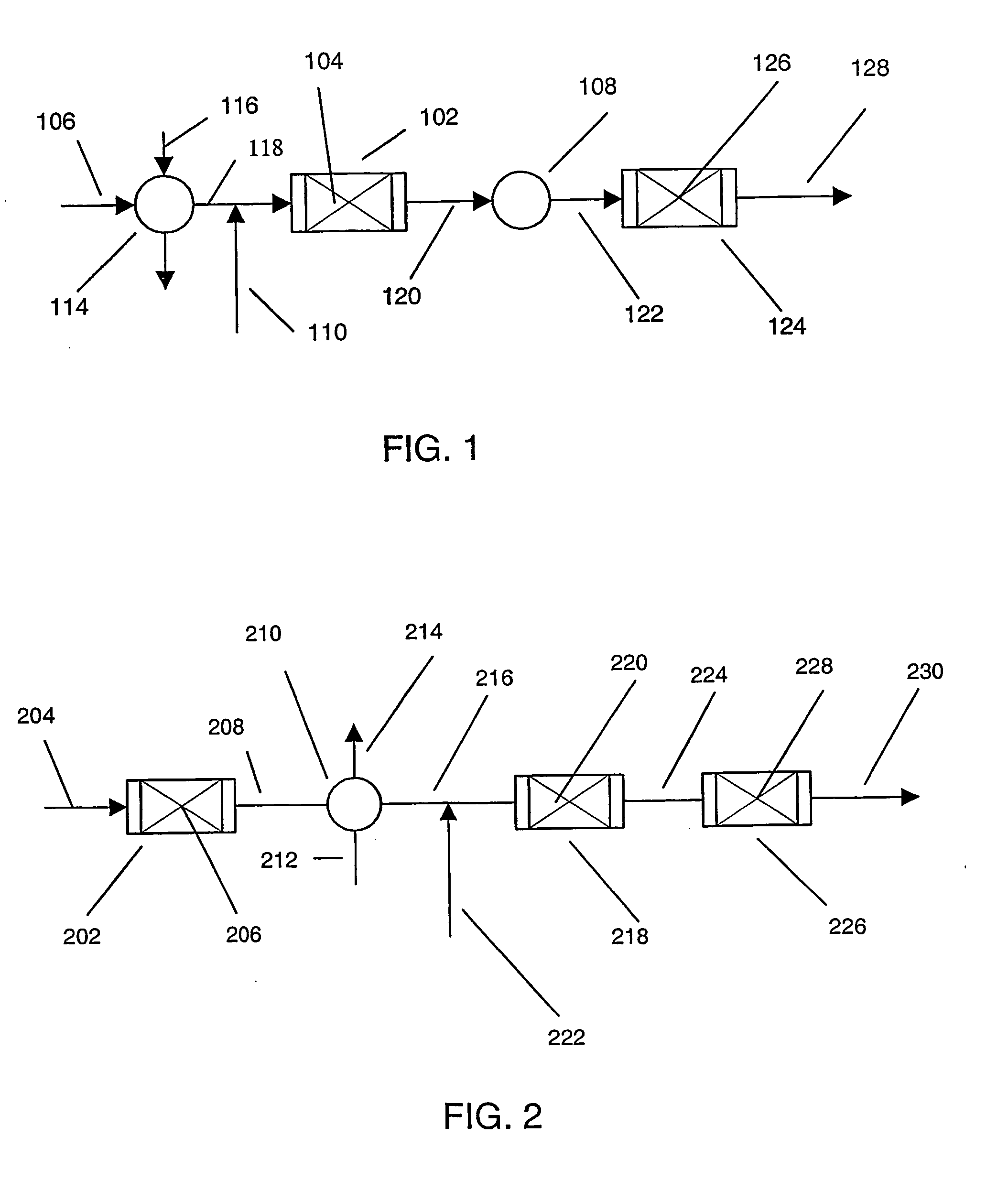

System and method for controlled mixing of fluids

InactiveUS20070206436A1Increased processing flexibilityImprove throughputControlling ratio of multiple fluid flowsTemperatue controlWater flowEngineering

Embodiments of the present invention provide a system and method for continuous flow production of mixed fluids. The mixed fluids can comprise a mixture of different fluids or a mixture of the same fluid having different input properties such as temperature. In general, two streams of fluid of varying temperature are supplied to a mixer. The flow rate of each of the input fluids can be regulated to produce a mixed fluid at a desired flow rate and temperature. As an example, mass flow controllers can regulate the flow rates of a hot and cold stream of de-ionized water to produce a stream of de-ionized water at a desired flow rate and temperature.

Owner:ENTEGRIS INC

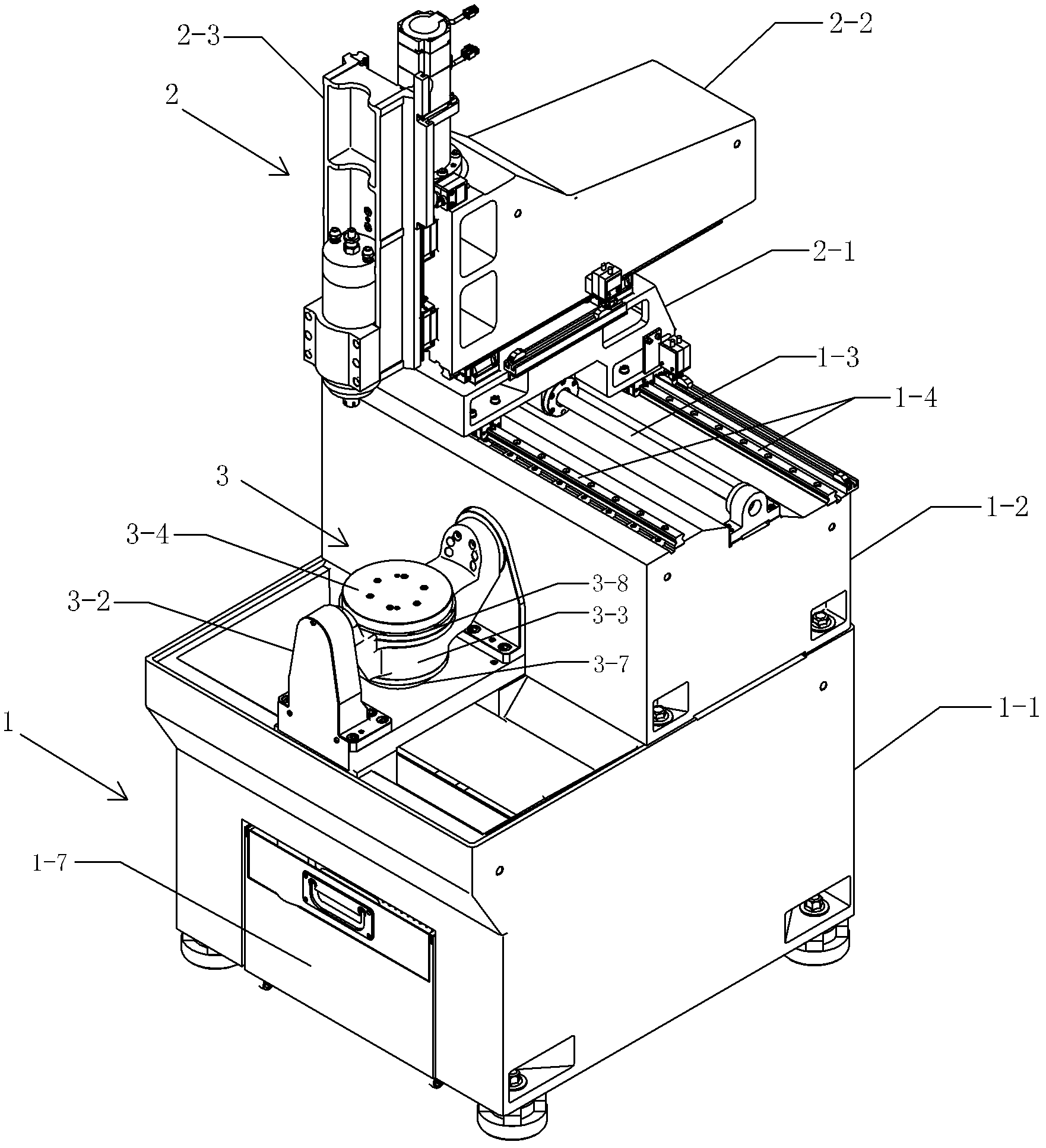

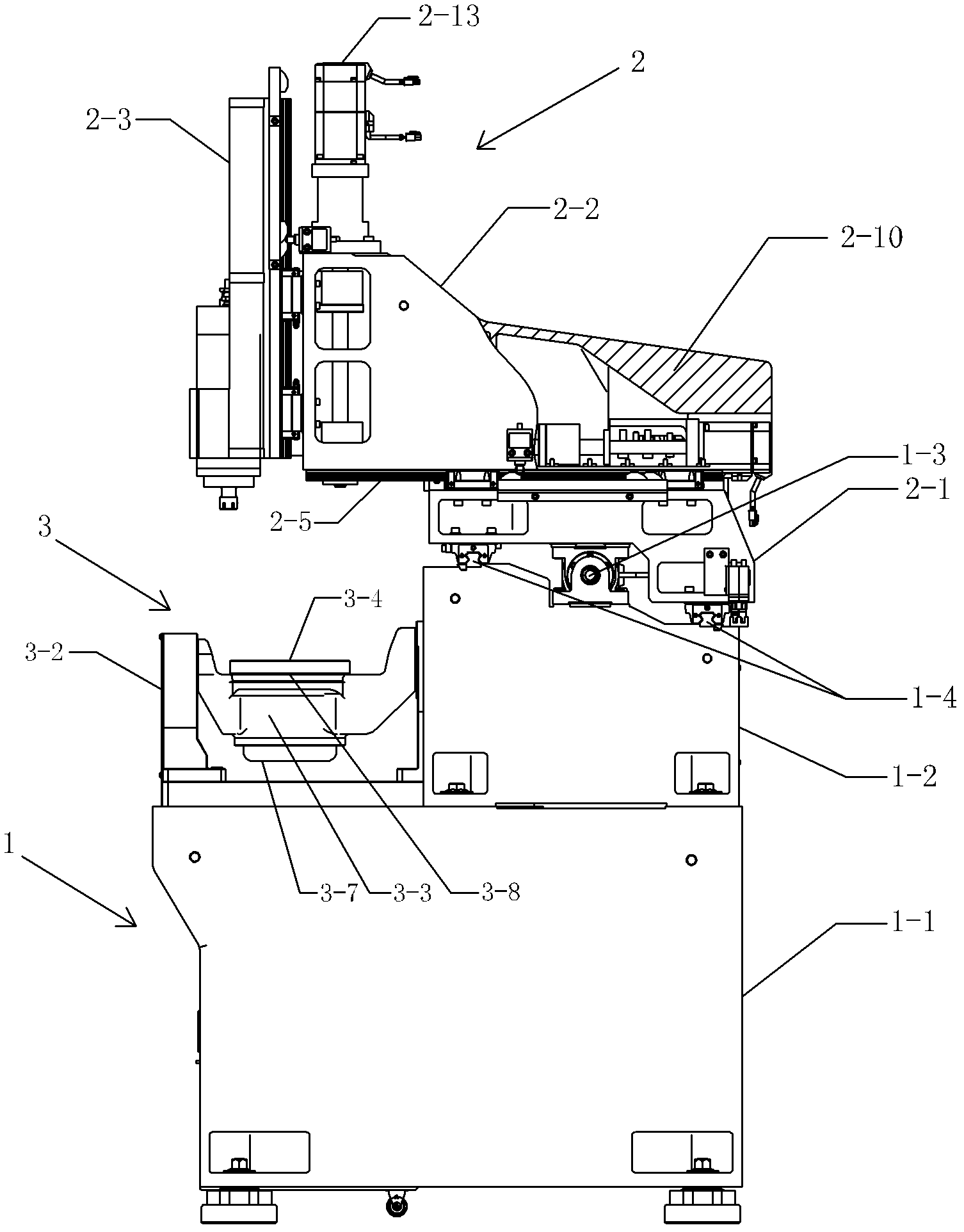

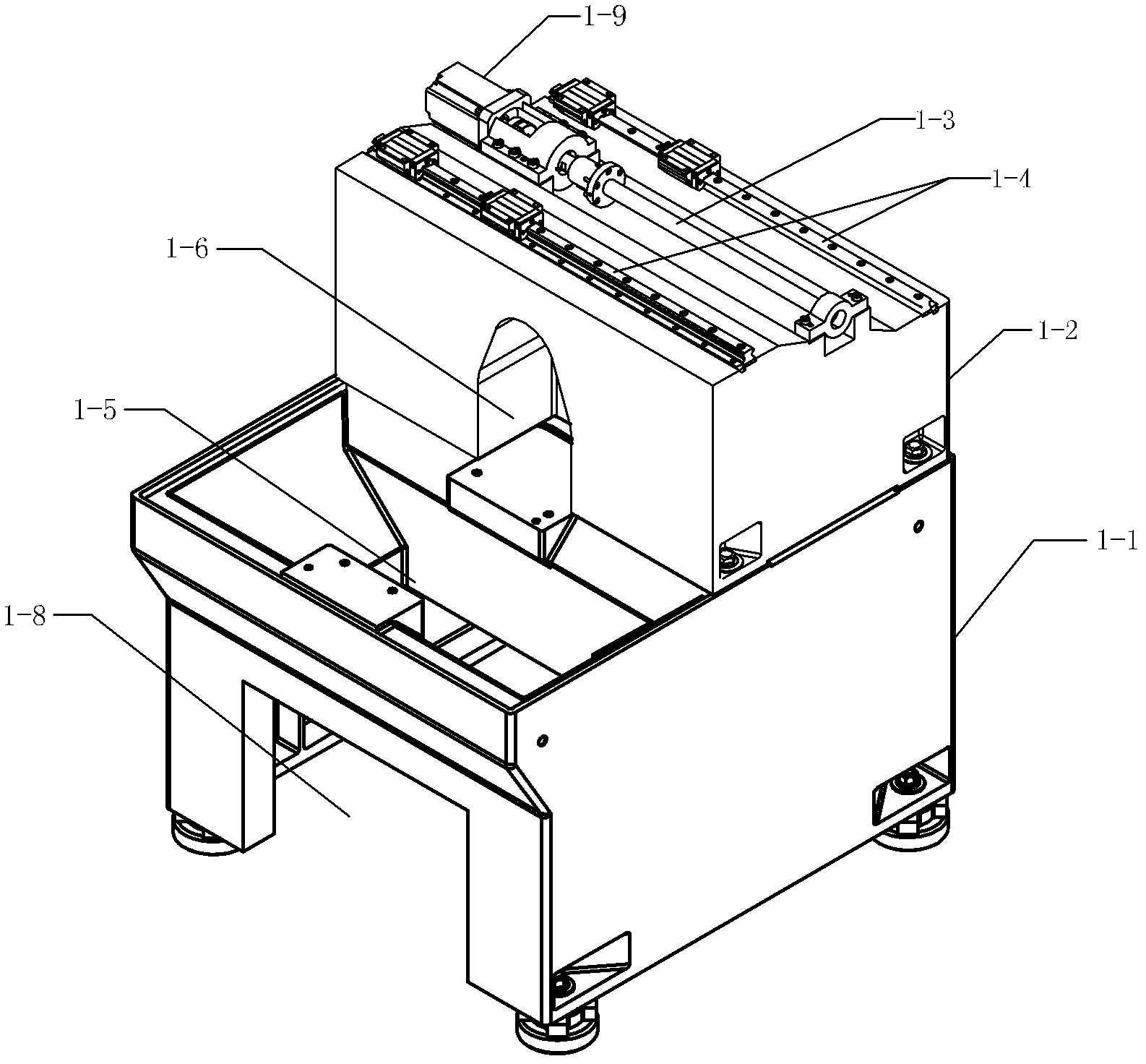

Small-sized five-axis machining center

InactiveCN102672472AReduce weightEasy to planLarge fixed membersMetal working apparatusBall screwEngineering

The invention relates to a small-sized five-axis machining center which comprises a base structure (1), an XYZ vertical shaft structure (2) and a BC rotary table (3). The small-size five-axis machining center is characterized in that the base structure (1) is L-shaped and comprises an X-axis substrate (1-2) and an internally hollow machine tool base (1-1); the X-axis substrate (1-2) is arranged on the machine tool base (1-1) and the X-axis substrate and the machine tool base are of integral structures or fixation connection molding structures; an X-axis ball screw (1-3), a Y-axis ball screw (2-6), a Z-axis ball screw (2-4), two X-axis guide tracks (1-4), two Y-axis guide tracks (2-7) and two Z-axis guide tracks (2-5) are arranged on the X-axis substrate (1-2); the BC rotary table (3) is arranged on a table plate of the machine tool base (1-1) and is arranged beside the positive plane of the X-axis substrate (1-2); a funnel-shaped structure chip discharge port (1-5) is arranged on the table plane of the machine tool base (1-1); and a connecting hole (1-6) of the BC rotary table (3) is arranged at the positive plane of the X-axis substrate (1-2). The small-sized five-axis machining center has the characteristics of being convenient to operate, high in production efficiency, low in cost and attractive and harmonious.

Owner:广州市技师学院

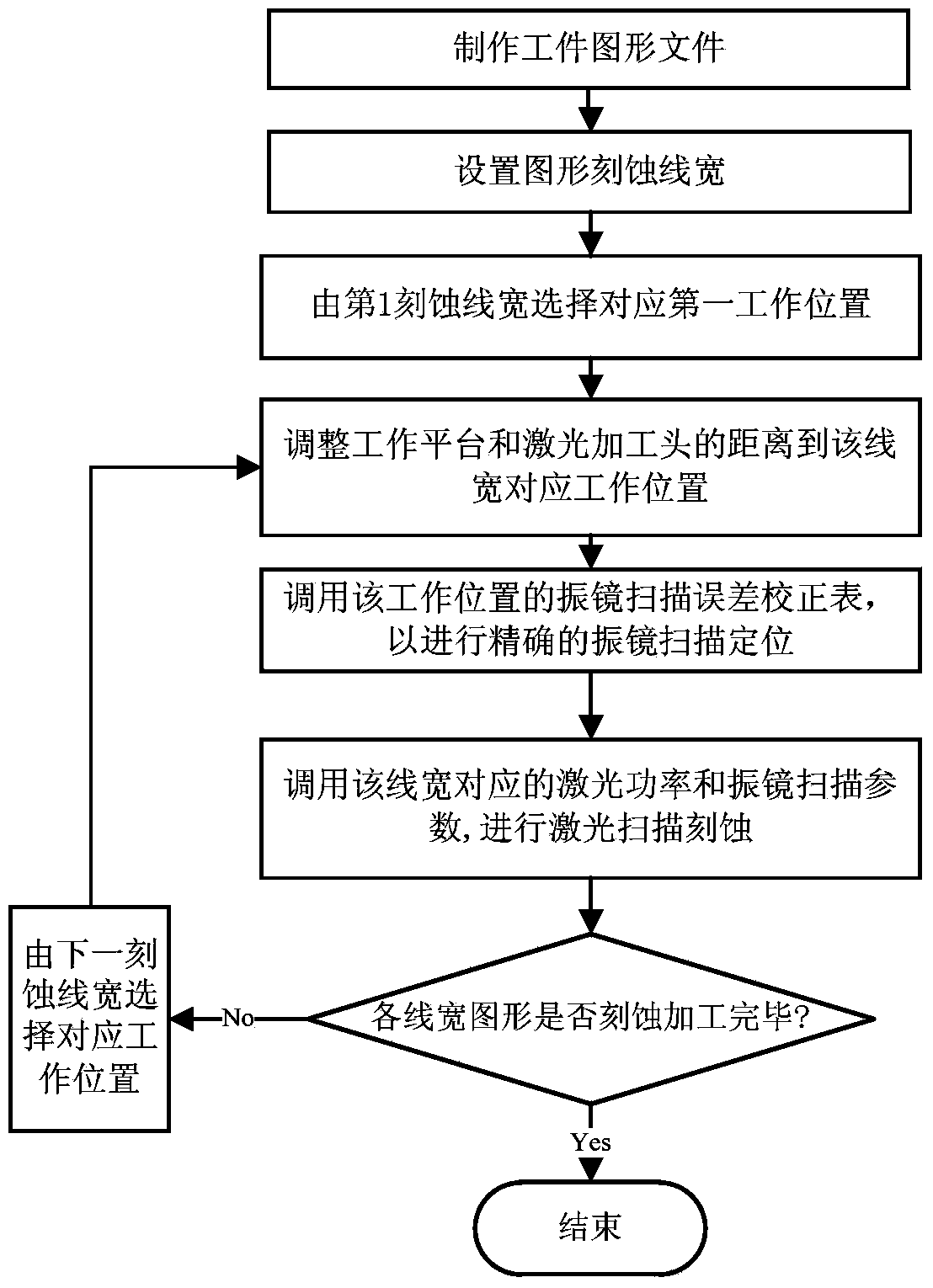

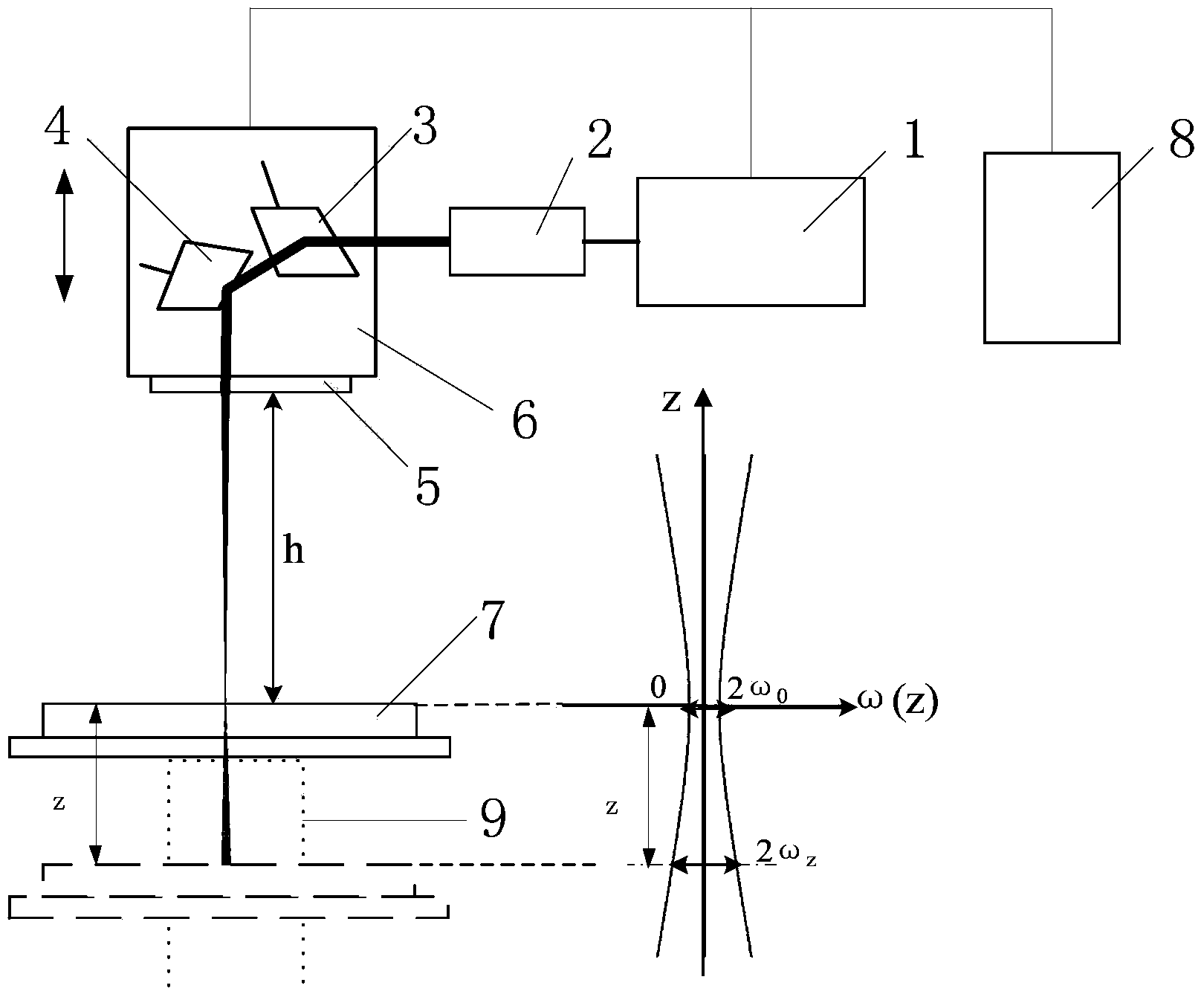

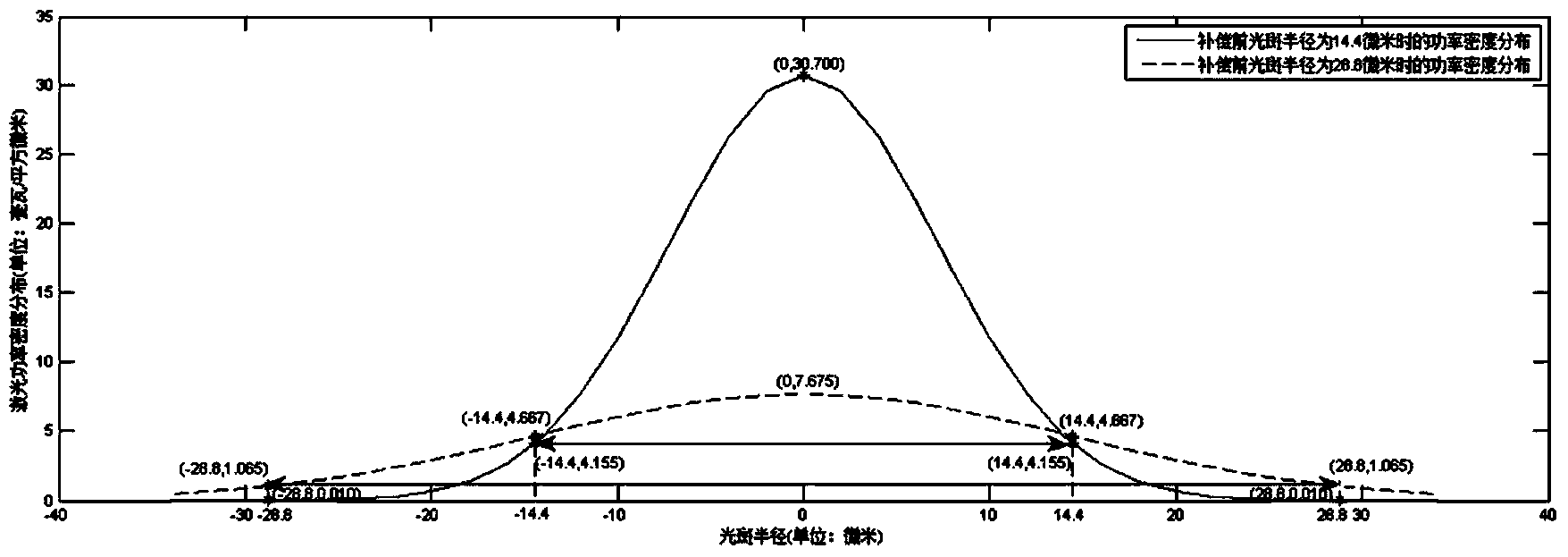

Wire-width-variable laser galvanometer scanning quick etching method and device

ActiveCN103801838AIncreased processing flexibilityImprove processing efficiencyLaser beam welding apparatusGratingLight spot

The invention discloses a wire-width-variable laser galvanometer scanning quick etching method and device. The principle that after laser beam is defocused, the power density gradient becomes small, and a light spot becomes large is used, a high-speed galvanometer scanning error accurate correcting method is used, by setting different focusing and defocusing laser processing distances and corresponding power parameters and laser galvanometer scanning parameters, the size of the laser light spot is controlled, large light spot raster scanning filling after defocusing is carried out is on an image filling zone, and then an image contour is subjected to vector scanning drawing. For different working distances, galvanometer scanning error correcting is carried out first, a high-accuracy galvanometer scanning locating table is formed, and the fact that the same high-accuracy galvanometer scanning locating effect is obtained at different laser processing distances is guaranteed. Quick accurate etching on images with different wire widths can be achieved, etching accuracy and processing speed are considered at the same time, the method and device can be widely used a plane etching system and a three-dimensional laser etching system, and the processing efficiency of equipment is improved.

Owner:武汉飞能达激光技术有限公司

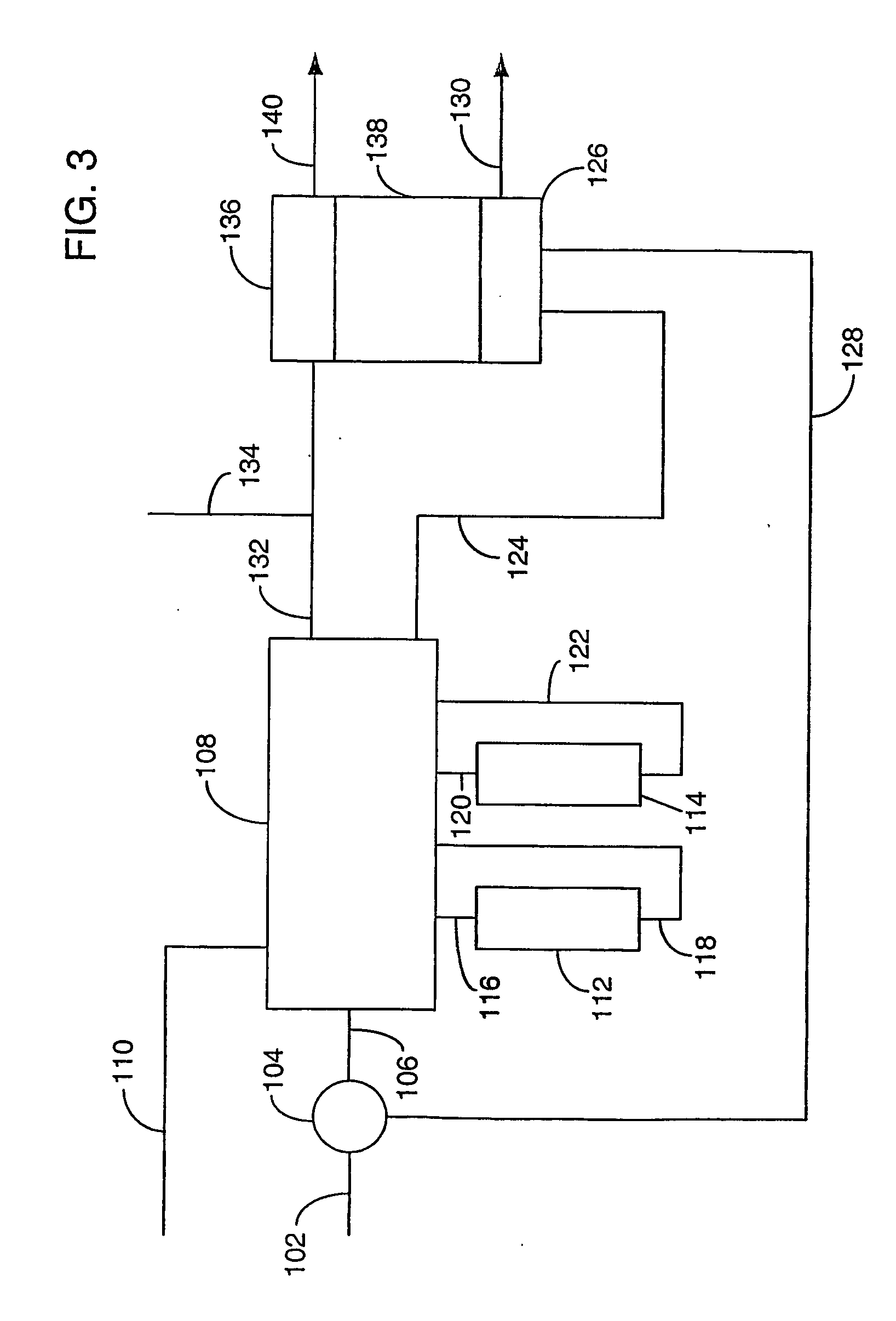

Hydrogen generator having sulfur compound removal and processes for the same

InactiveUS20060140852A1Efficient desulfurizationApparatus can be relatively compactHydrogenGas treatmentElectricityHydrogen

Apparatus and processes for the generation of hydrogen from hydrocarbon feeds are provided in which organosulfur compound is removed from the feed. The apparatus and processes are particularly advantageous as smaller scale hydrogen generators including those generators intended for residential use to produce hydrogen for fuel cells to produce electricity. In the processes and apparatus, the feed is contacted with solid sorbent to remove organosulfur compound.

Owner:HYRADIX INC

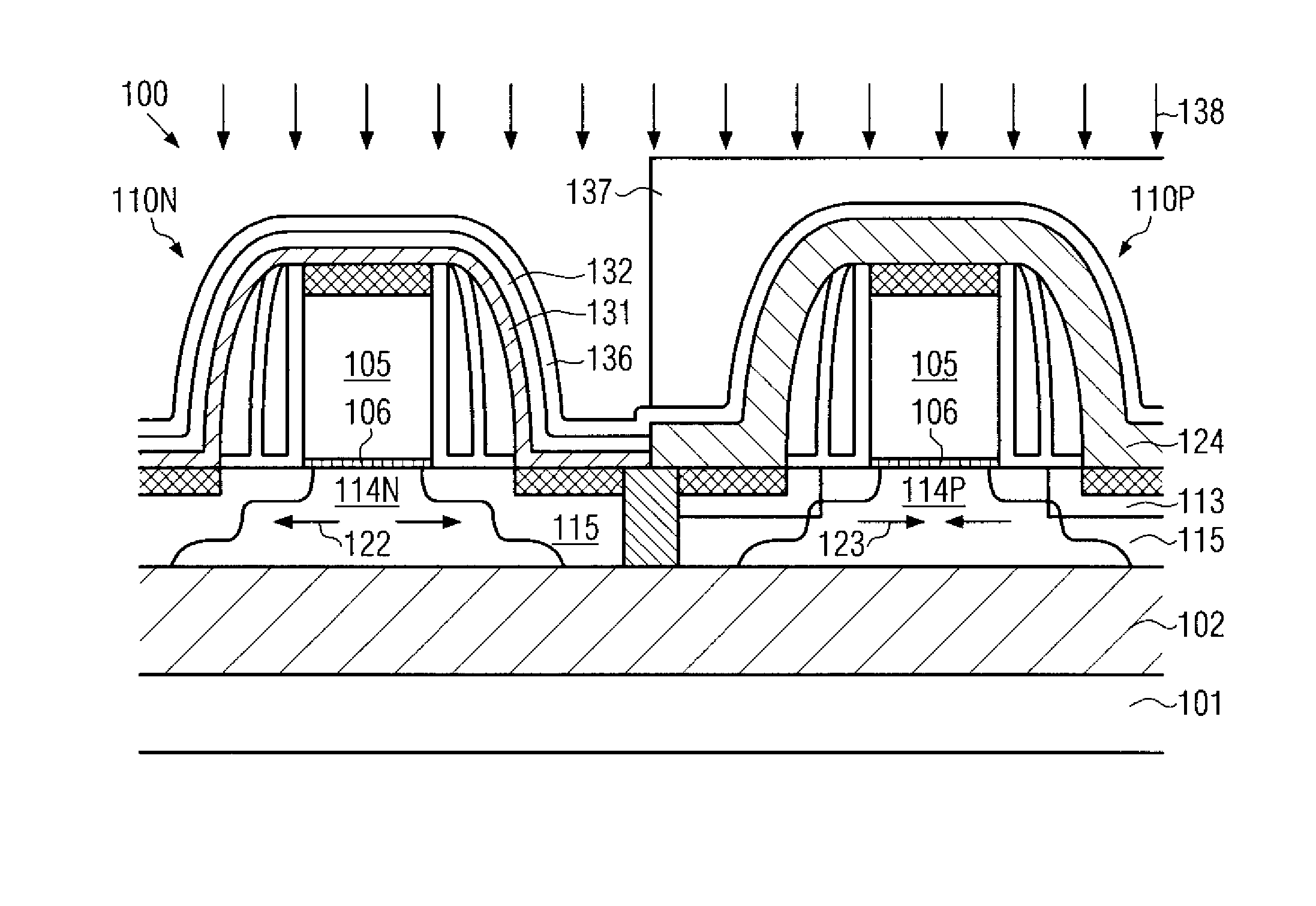

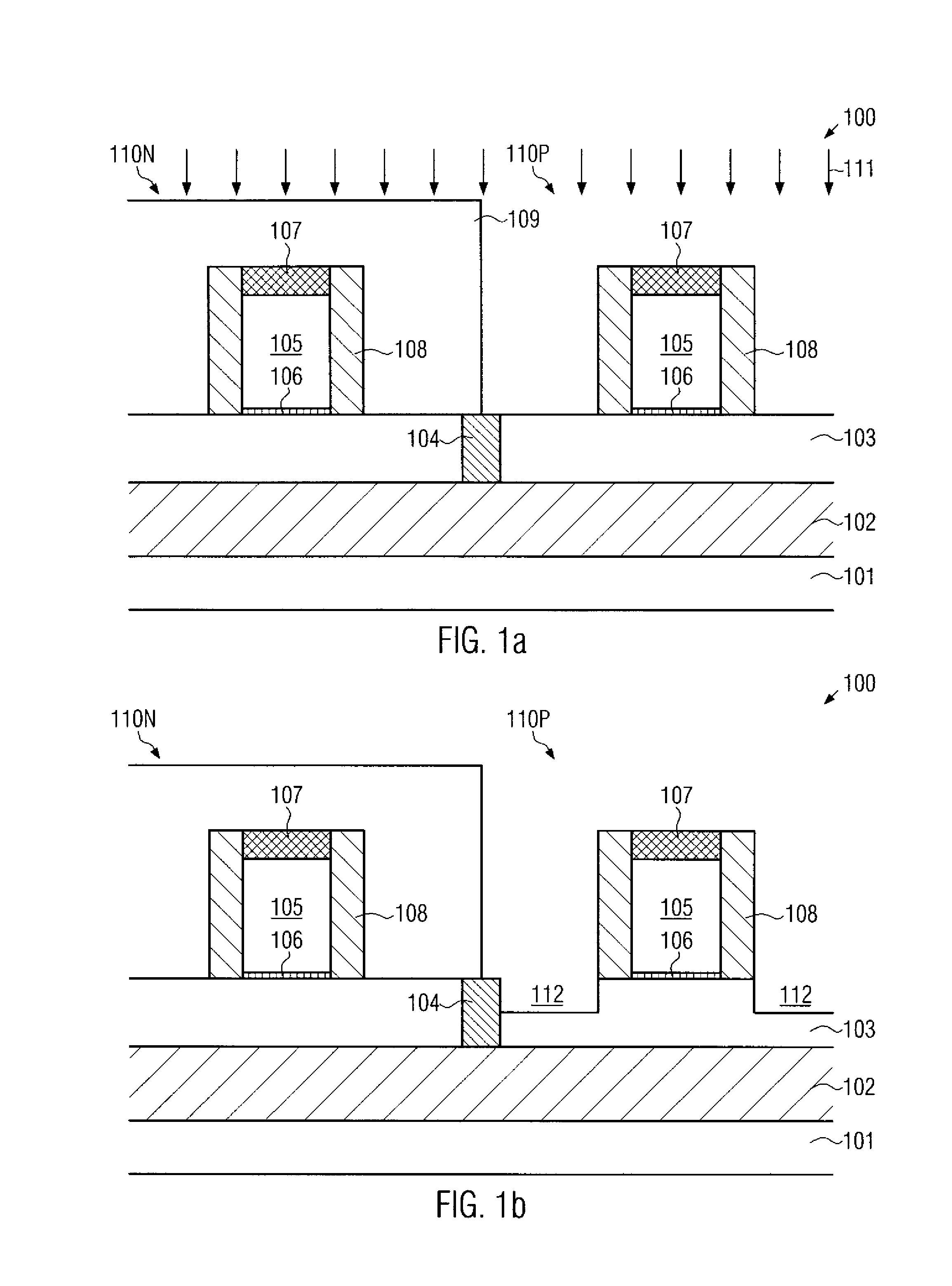

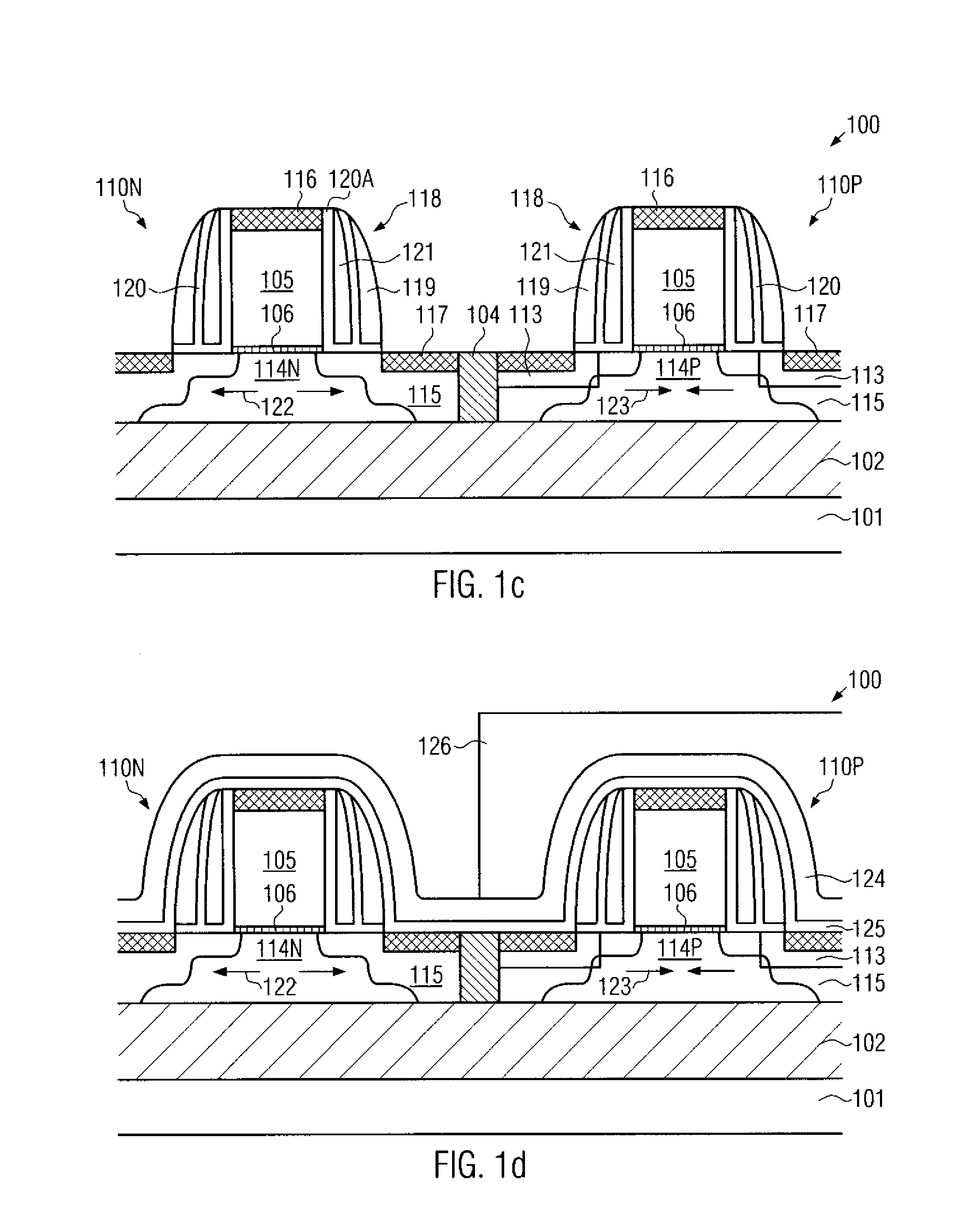

Technique for providing multiple stress sources in NMOS and PMOS transistors

ActiveUS7329571B2Efficient transferIncreased processing flexibilityTransistorSemiconductor/solid-state device detailsStress inducedEngineering

By combining a plurality of stress inducing mechanisms in each of different types of transistors, a significant performance gain may be obtained, thereby providing enhanced flexibility in adjusting product specific characteristics. For this purpose, sidewall spacers with high tensile stress may be commonly formed on PMOS and NMOS transistors, wherein a deleterious effect on the PMOS transistor may be compensated for by a corresponding compressively stressed contact etch stop layer, while the NMOS transistor comprises a contact etch stop layer with tensile stress. Furthermore, the PMOS transistor comprises an embedded strained semiconductor layer for efficiently creating compressive strain in the channel region.

Owner:ADVANCED MICRO DEVICES INC

Hydrocarbon catalytic conversion method of productive butene

ActiveCN104560149AHigh yieldIncreased processing flexibilityChemical recyclingBulk chemical productionButeneCarbon deposit

The invention relates to a hydrocarbon catalytic conversion method of productive butene. The method comprises steps as follows: a first hydrocarbon raw material and a regenerative cracking catalyst are contacted in a first reactor and have a catalytic cracking reaction, a first carbon deposit catalyst and a first reaction product are obtained through separation; a second hydrocarbon raw material and a spent cracking catalyst are contacted in a second reactor and have a catalytic cracking reaction; oil gas produced in the second reactor is contacted with a third hydrocarbon raw material and a cracking catalyst and has a catalytic cracking reaction; a reaction mixture produced in a third reactor is introduced to a fourth reactor and continuously has a reaction, and a second carbon deposit catalyst and a second reaction product are obtained through separation; the cracking catalyst adopts a cracking catalyst containing modified beta zeolite, and the modified beta zeolite adopts phosphorus and transition metal M modified beta zeolite. With adoption of the method, higher butene yield and propylene yield can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for improving metal cladding deposition additive manufacturing accuracy by means of laser edge cutting

ActiveCN103394807AIncreased processing flexibilityProduct quality is stableMetallic material coating processesLaser beam welding apparatusBatch productionLaser

The invention discloses a method and a device for improving the metal cladding deposition additive manufacturing accuracy by means of laser edge cutting. The method includes 1), depositing a first layer of metal droplets, and cutting and machining side surfaces of the first layer of deposited metal by the aid of laser; 2), depositing a second layer of metal droplets, and cutting and machining side surfaces of the second layer of deposited metal by the aid of laser; 3), depositing an N layer of metal droplets, and cutting and machining side surfaces of the N layer of deposited metal by the aid of laser; 4), repeating the same procedure until metal droplets are completely deposited and side surfaces of the last layer of deposited metal are cut and machined so that the metal cladding deposition forming accuracy is improved. The method and the device have the advantages that the machining flexibility is high owing to a laser edge cutting mode, the quality of products is stable, a heat affected zone is small, the follow-up machining amount is low, the micro-machine precision machining accuracy and efficiency are effectively improved, the probability of batch production of parts of micro-machines is effectively increased, and the machining cost is lowered.

Owner:徐州中伦光伏材料有限公司

Soft tissue

InactiveUS6849157B2Increase in sizeLow stiffnessNon-fibrous pulp additionNatural cellulose pulp/paperFiberHardness

Soft throughdried tissues, which are sufficiently soft to serve as premium bathroom tissues, can be made without the use of a Yankee dryer. The typical Yankee functions of building machine direction and cross-machine direction stretch are replaced by a wet end rush transfer and the throughdrying fabric design, respectively. It is particularly advantageous to form the tissue with chemimechanically treated fibers in at least one layer. The resulting tissues have high bulk (about 6 cubic centimeters per gram or greater) and low stiffness.

Owner:KIMBERLY-CLARK WORLDWIDE INC

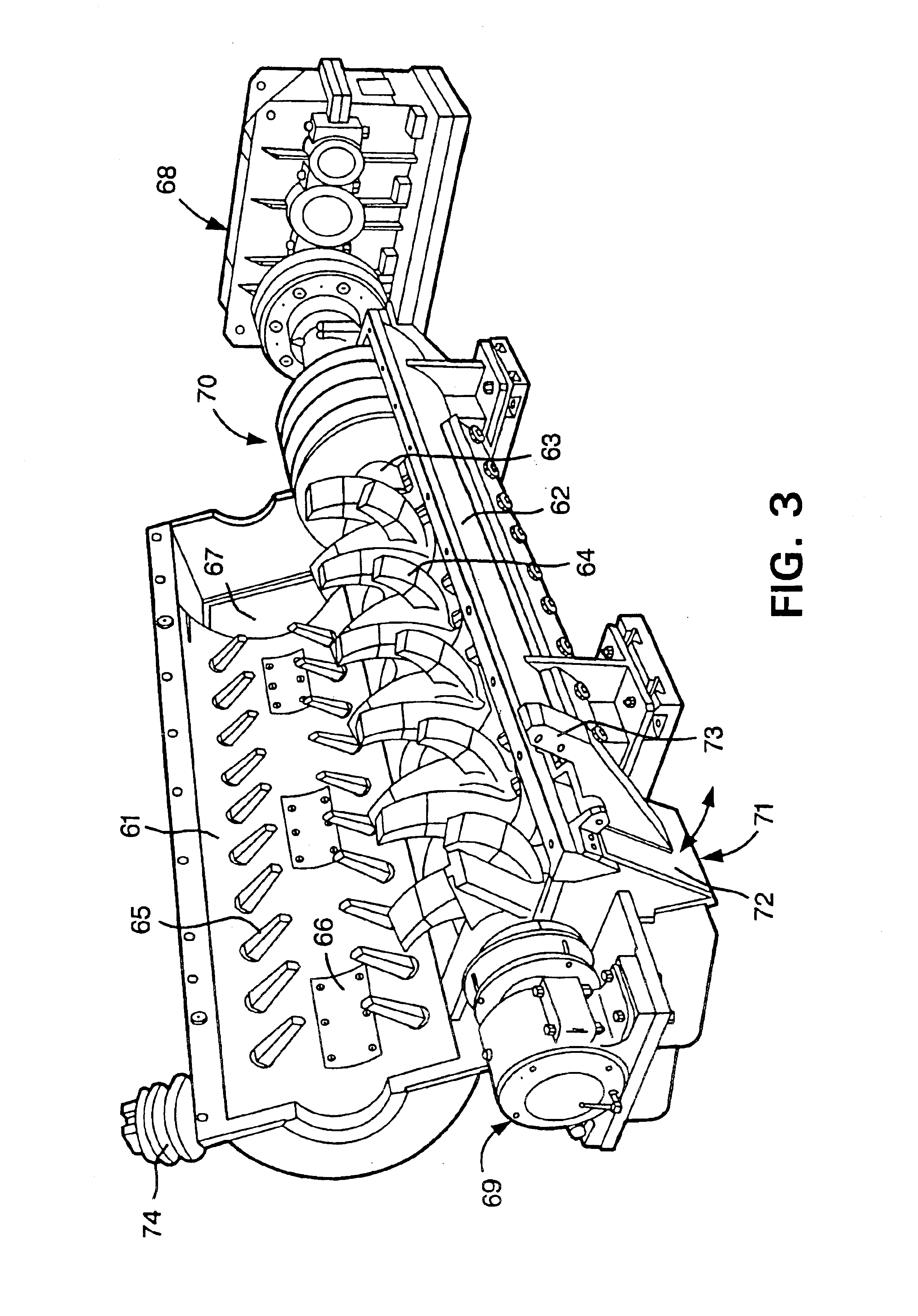

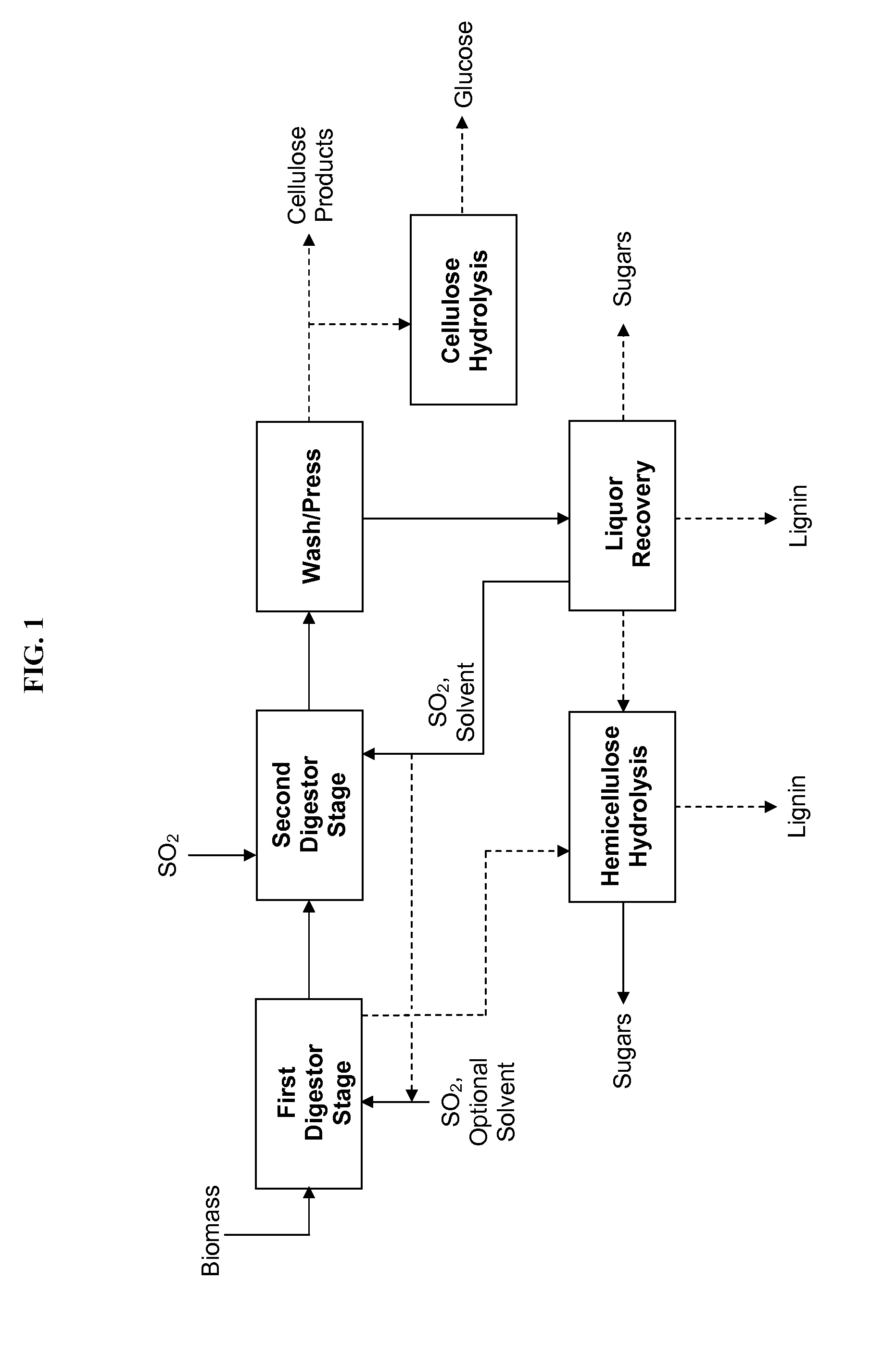

Biomass fractionation processes employing sulfur dioxide

ActiveUS20140186899A1Good removal effectIncreased processing flexibilityPulping with acid salts/anhydridesPulp by-products recoveryFractionationD-Glucose

The present invention provides a process for fractionating lignocellulosic biomass, comprising: contacting biomass with SO2, water, and optionally a first solvent, to produce intermediate solids; then contacting the intermediate solids with SO2, water, and a second solvent, to produce cellulose-rich solids and a liquid phase comprising hemicelluloses and lignin. The first concentration of SO2 may be lower or higher than the second concentration of SO2. It is desirable to vary the SO2 and solvent concentrations in different stages to optimize the removal of hemicellulose versus lignin. The resulting cellulose-rich material can contain very low hemicellulose, very low lignin, or both low hemicellulose and low lignin. High-purity cellulose is useful both for producing glucose as well as for cellulose products or derivatives. The hemicelluloses may be hydrolyzed to produce monomeric sugars, and the lignin may be recovered as a co-product.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

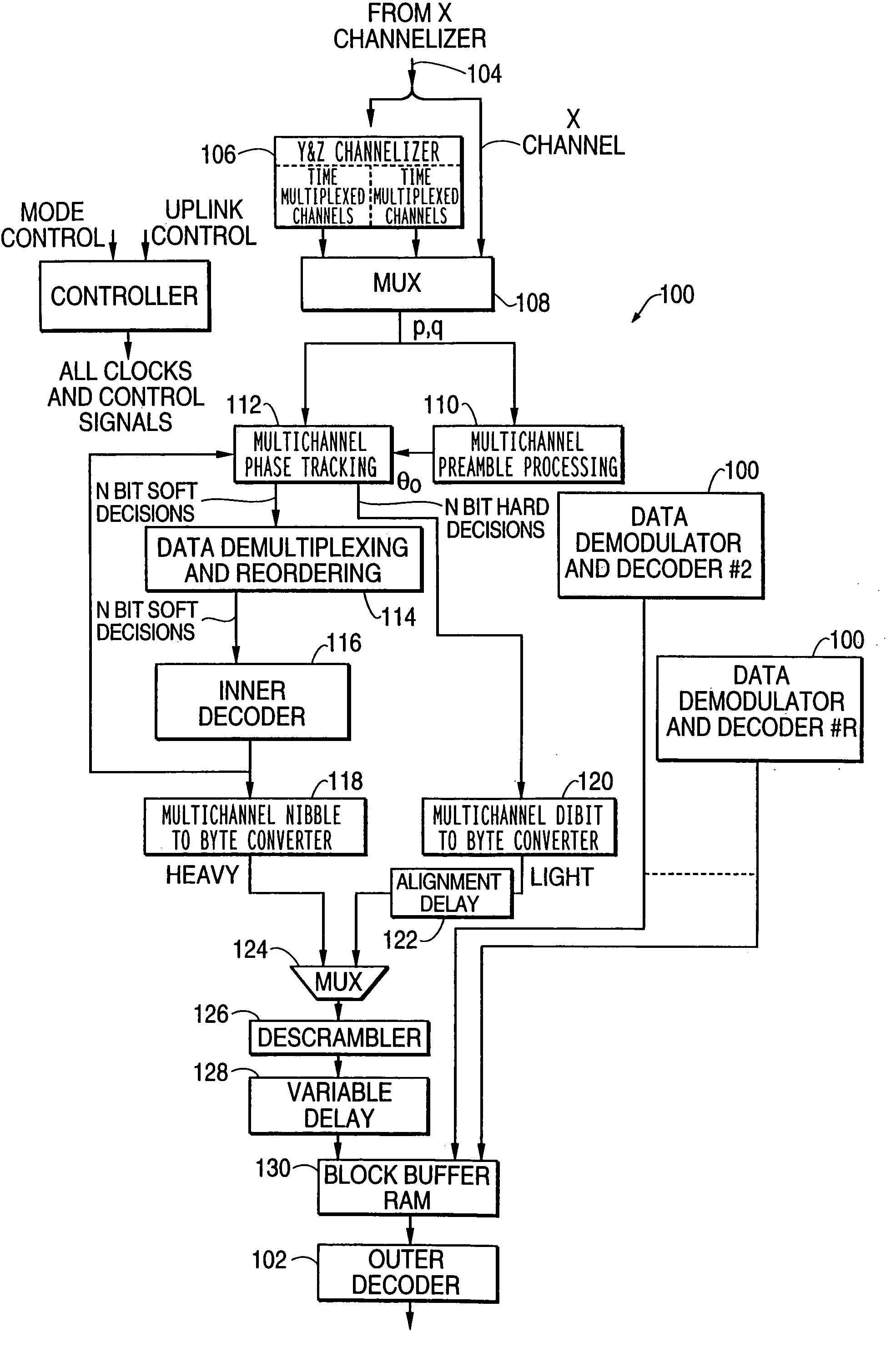

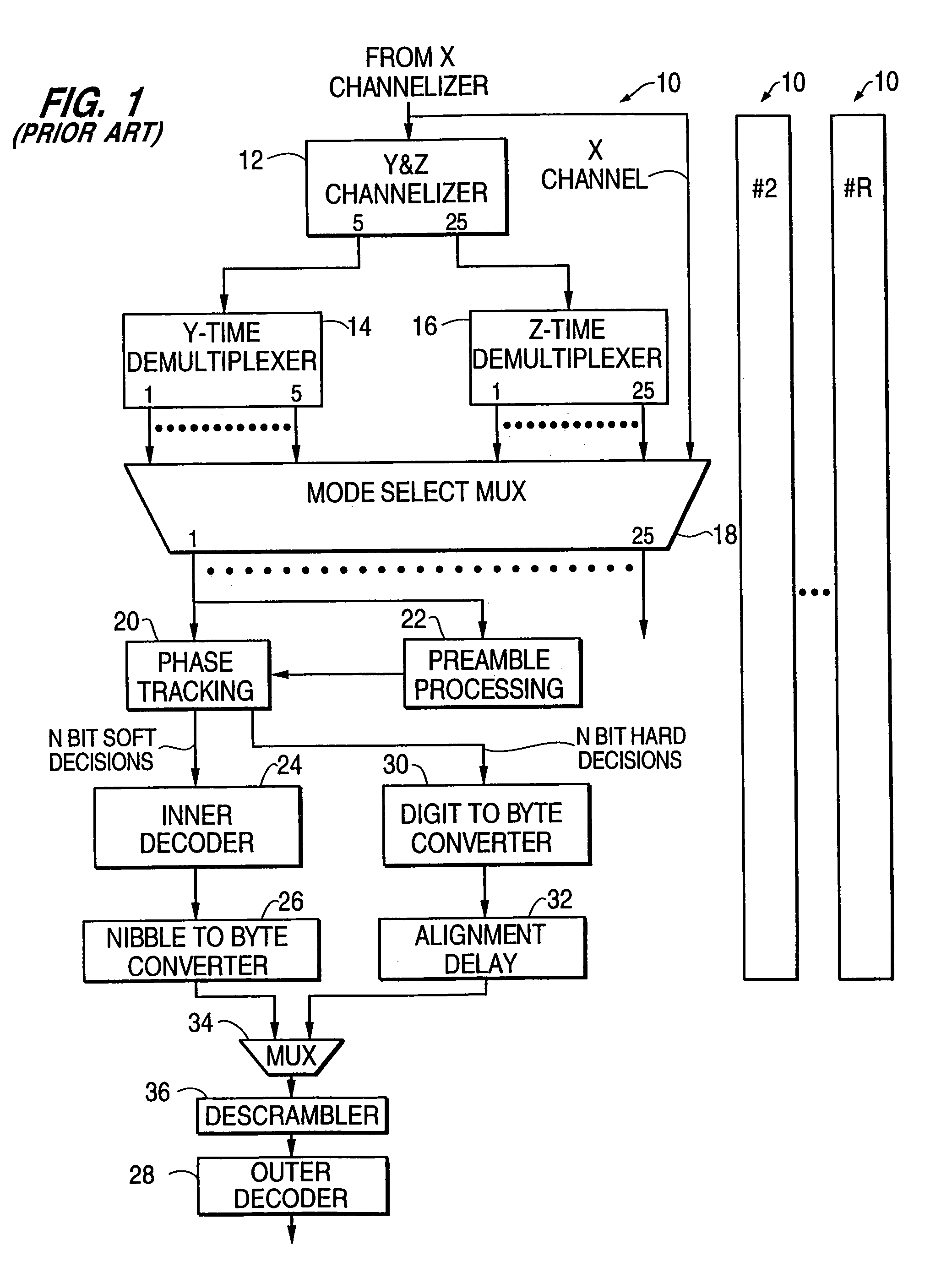

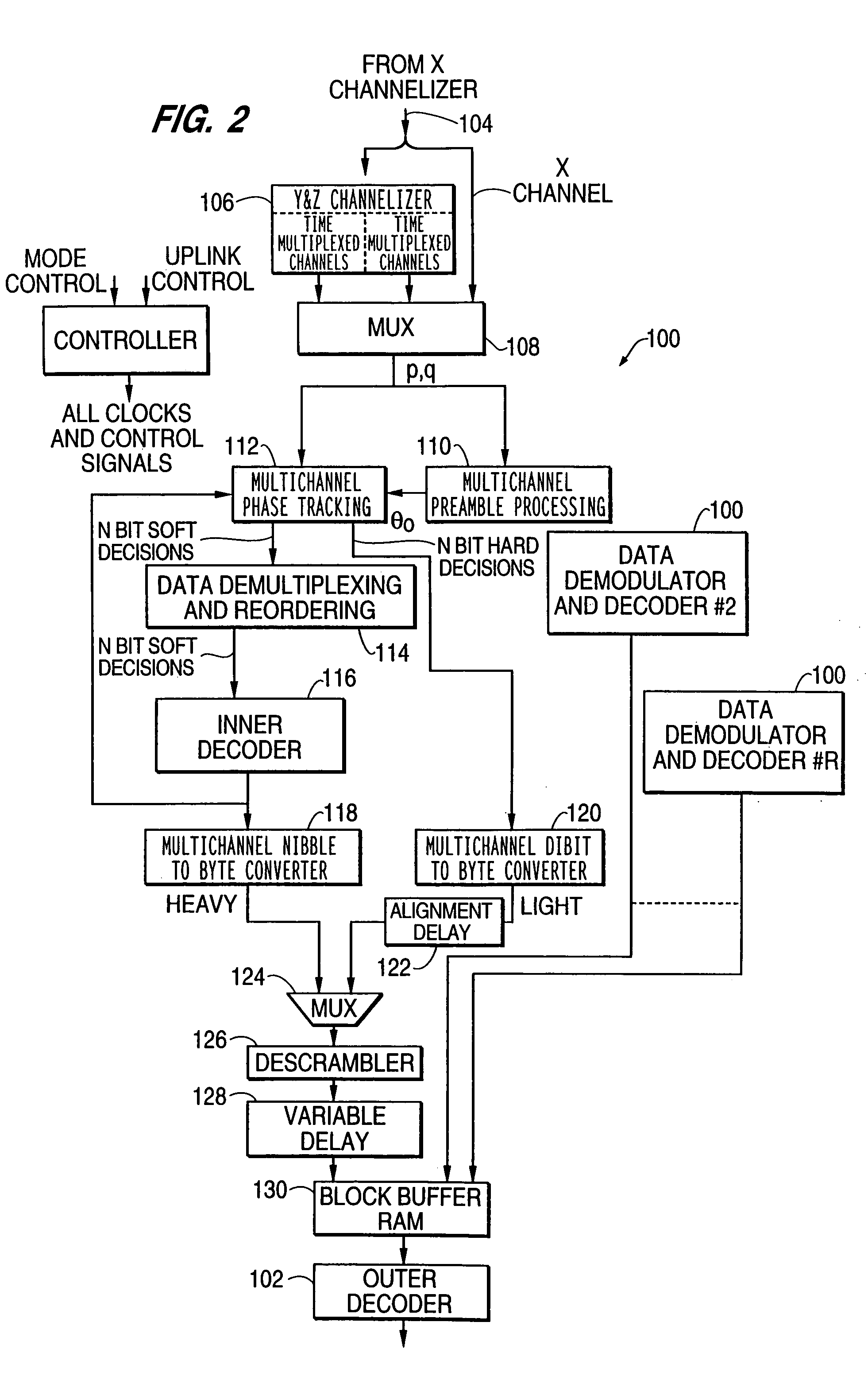

Buffering and sequencing of soft decisions of multiple channels into a single shared biorthogonal decoder

InactiveUS6947500B1Improve data processing efficiencyRedundancy of processingError preventionOther decoding techniquesComputer hardwareData Applied

The invention is a receiver and a method of receiving data having a preferred application in a satellite receiver in accordance with the invention includes a memory (114) including an addressable storage array which stores a sequence of data samples contained in a time division multiplexed signal from a plurality channels (X, Y and Z) and outputs the stored data samples in a sequence of data groups with each data group containing a plurality of samples from one of the plurality of channels; and a decoder (116), responsive to the data groups, which decodes the data samples within the data groups and outputs decoded data samples.

Owner:NORTHROP GRUMMAN SYST CORP

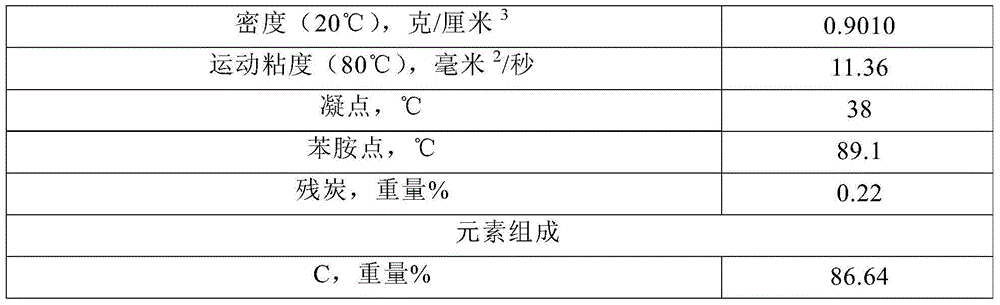

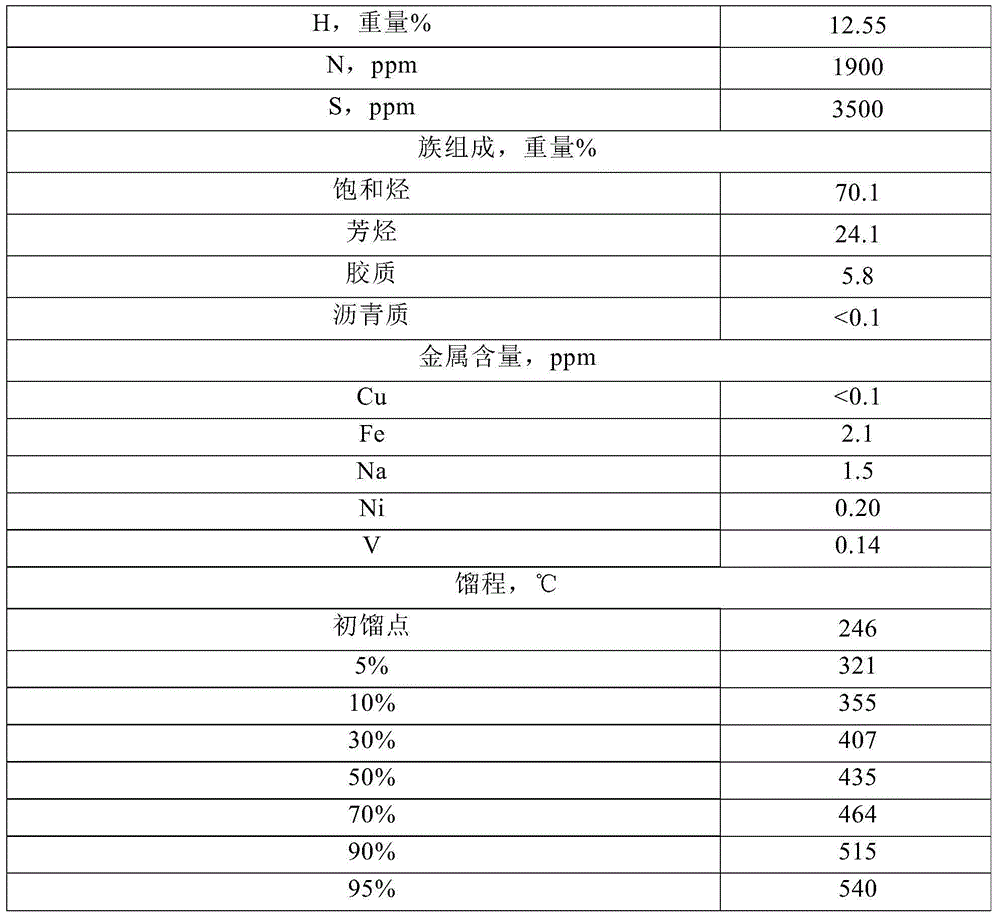

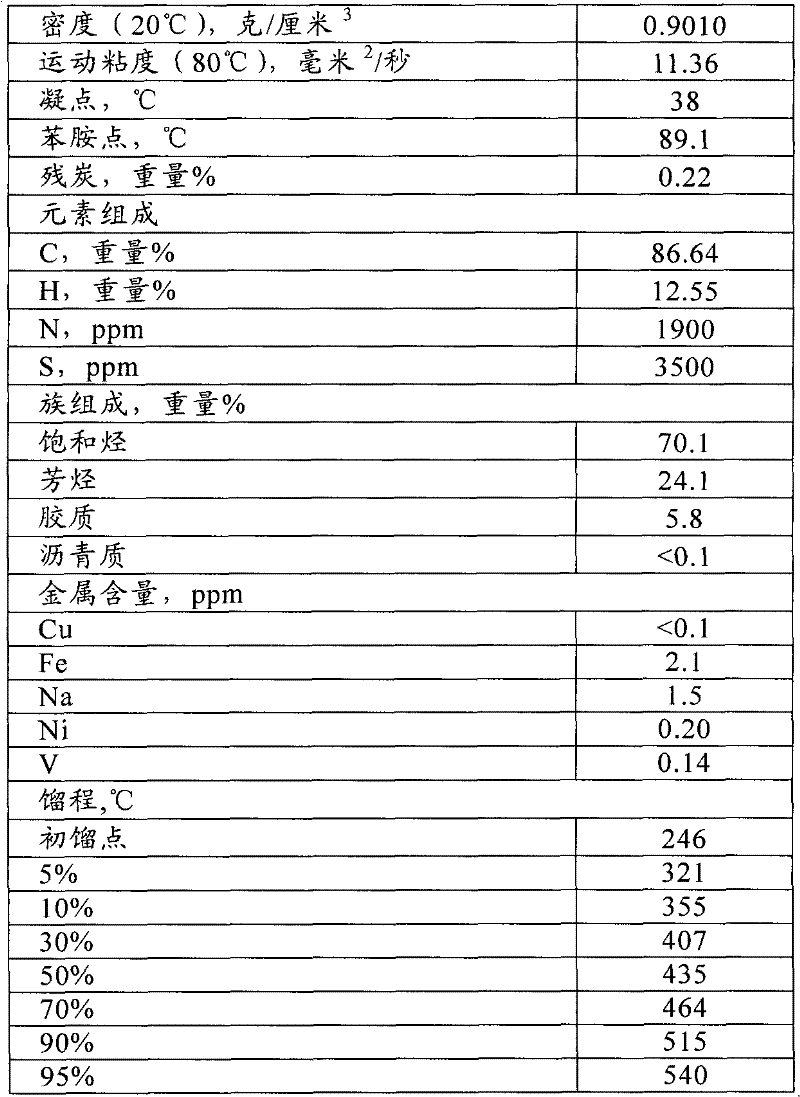

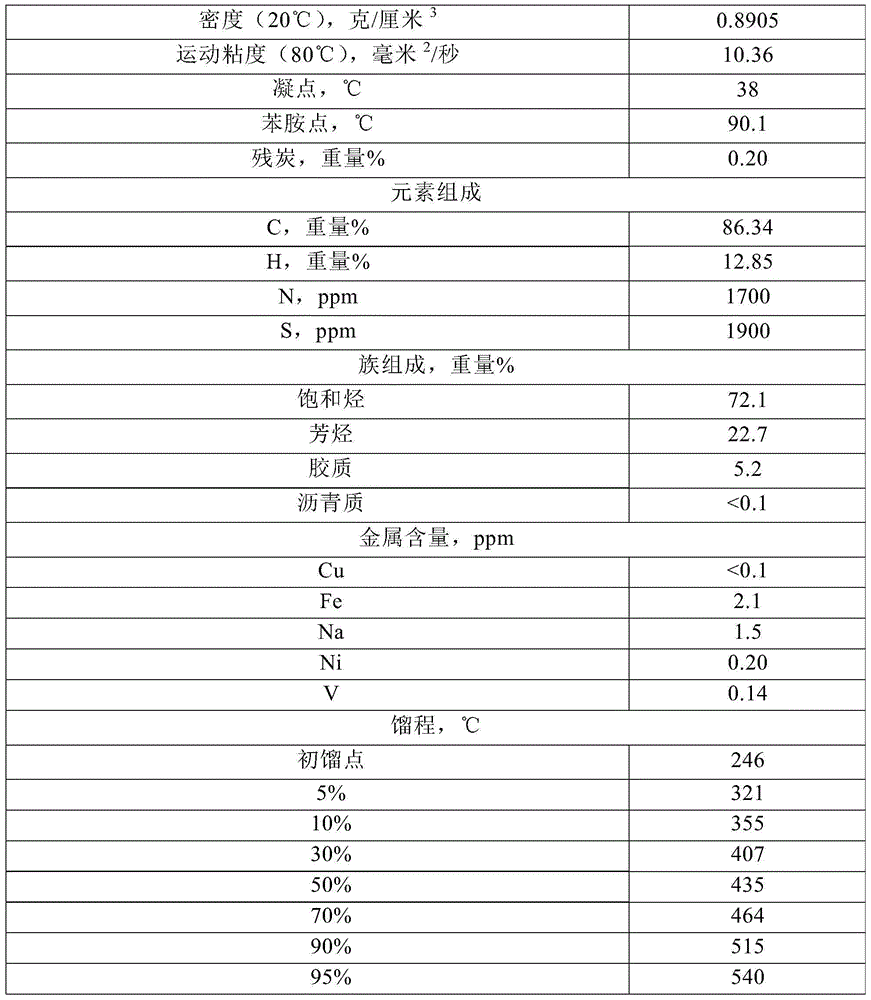

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377AReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

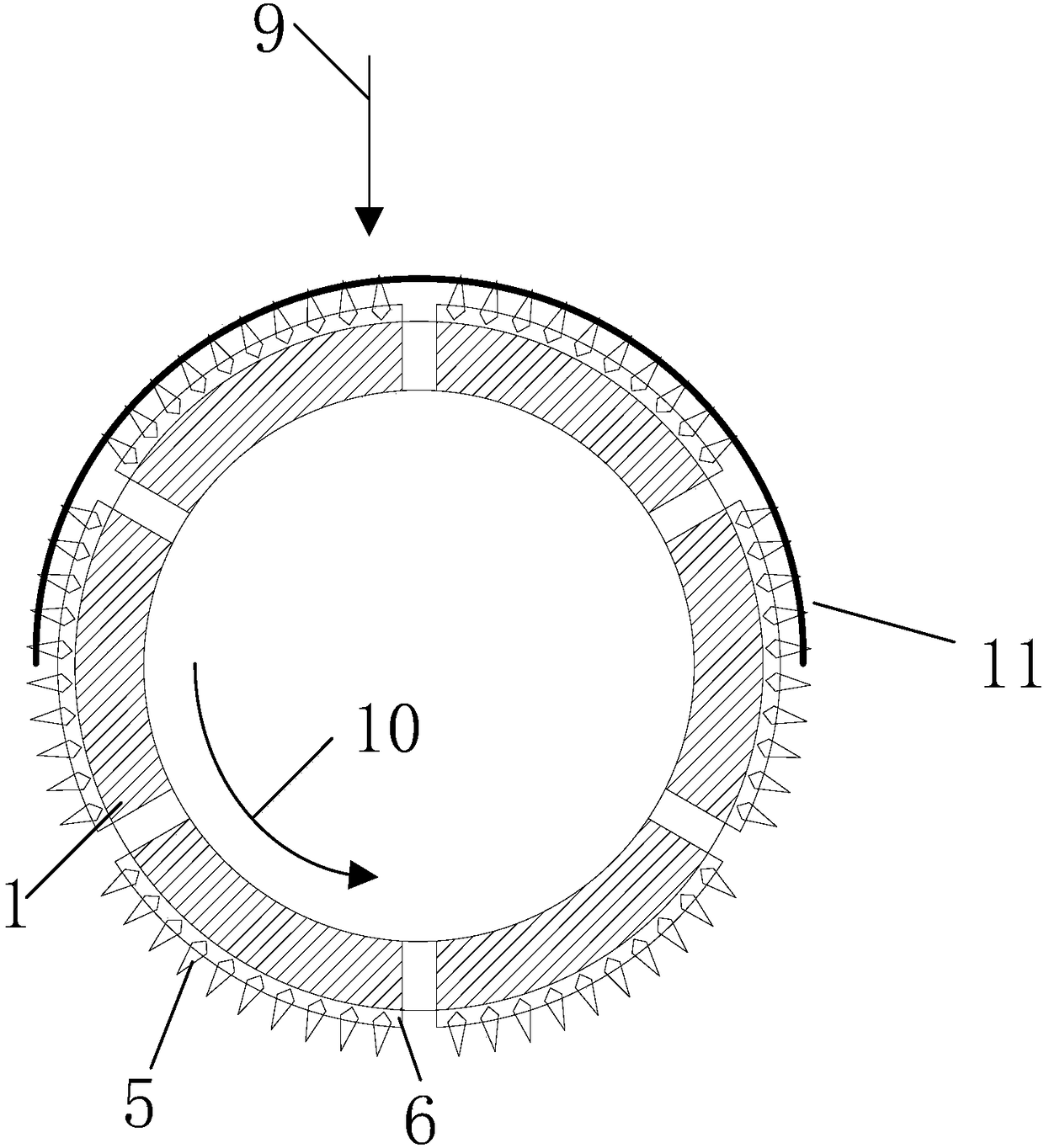

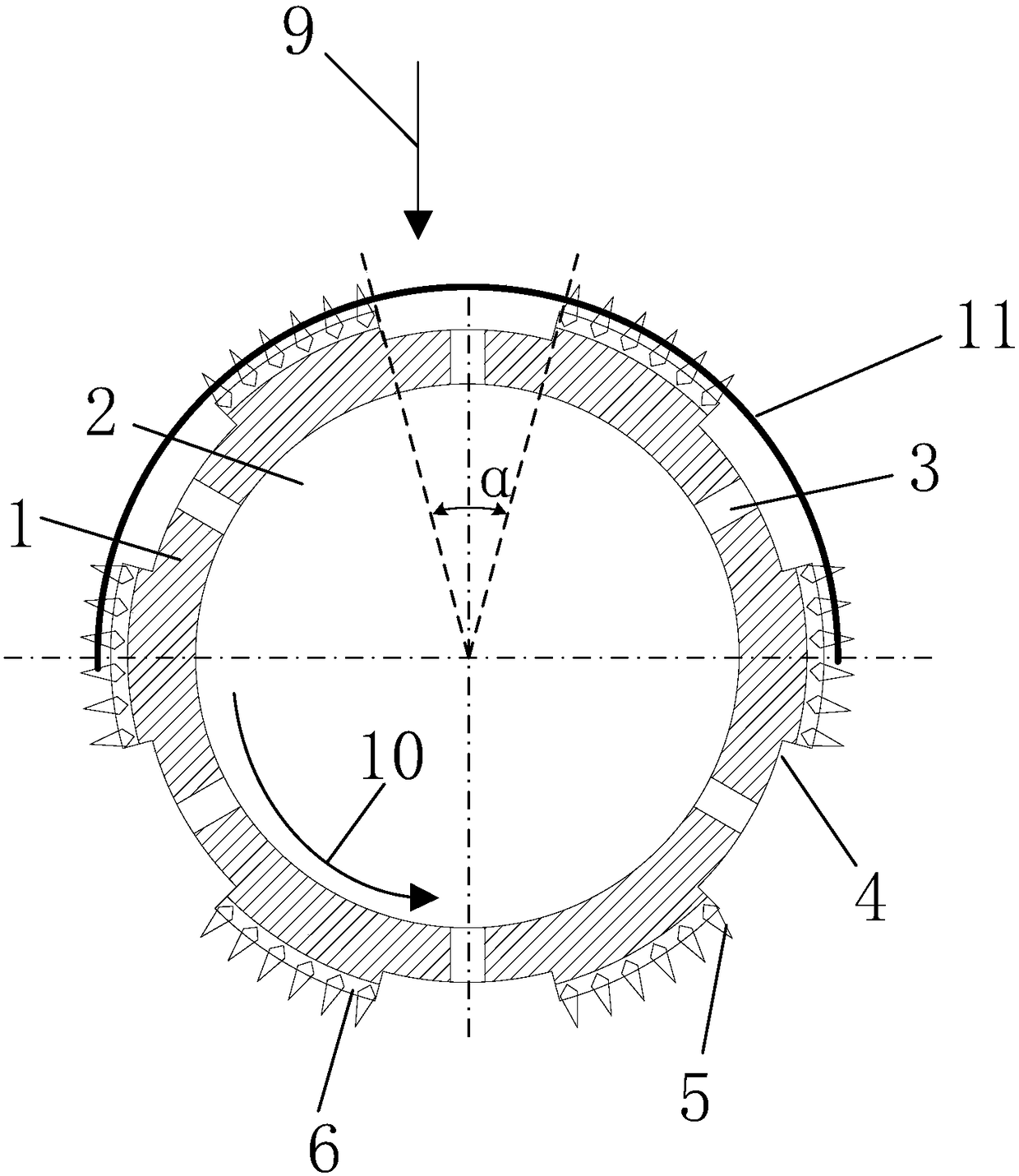

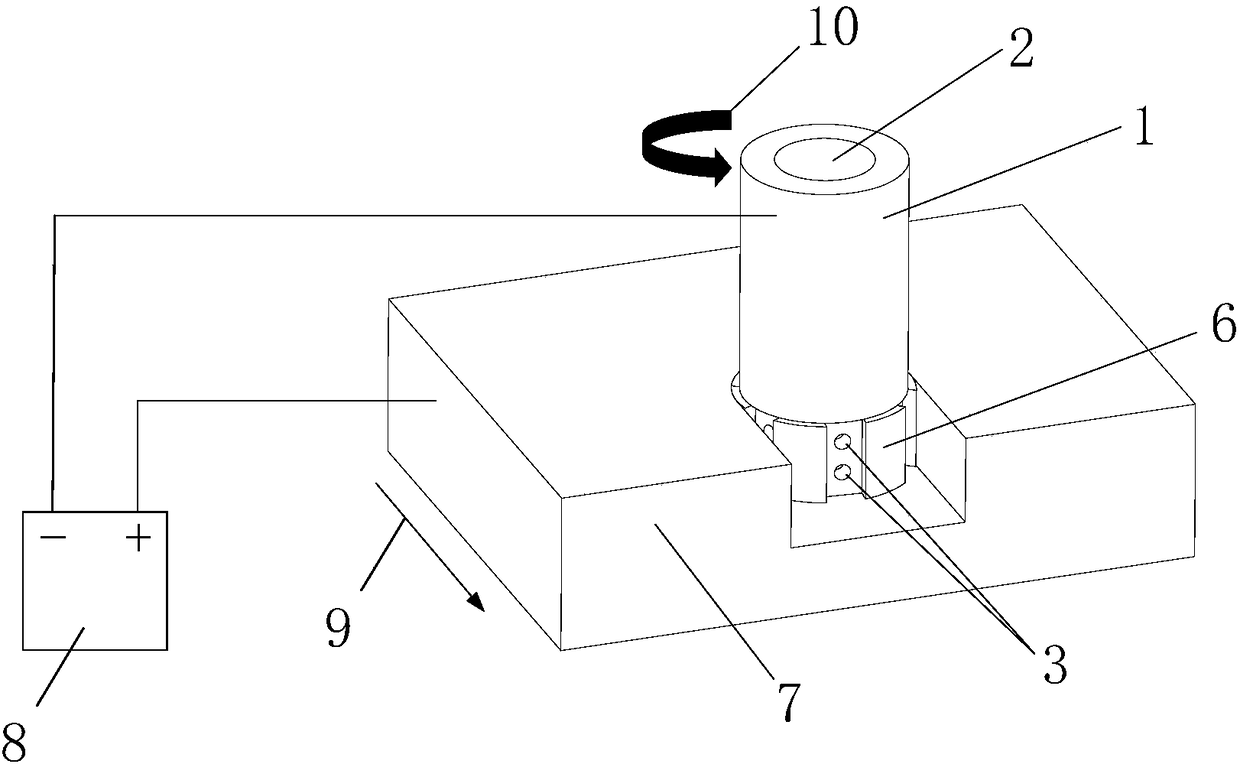

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

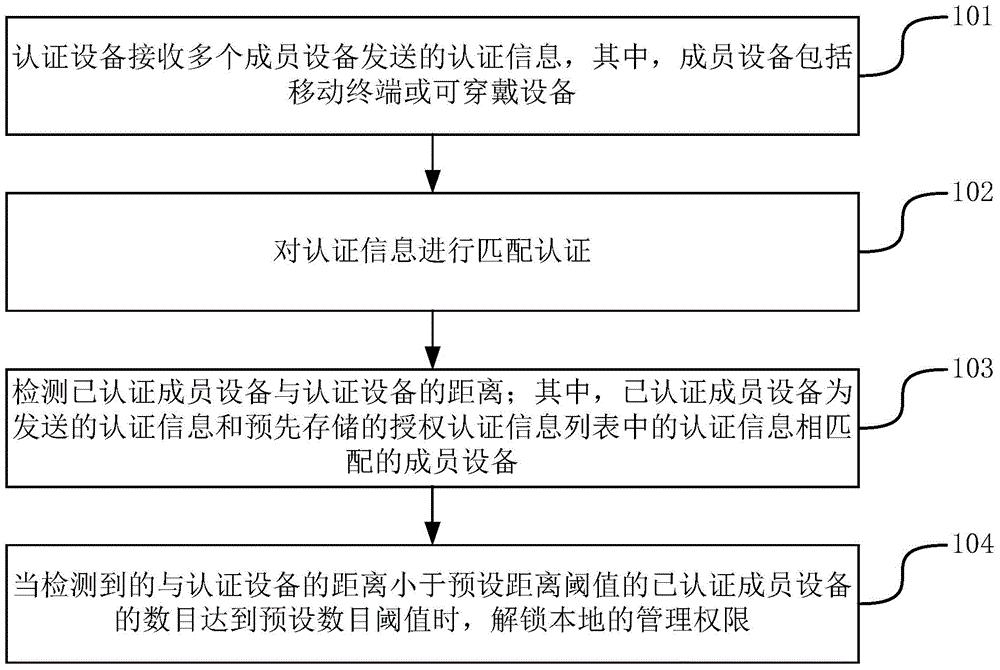

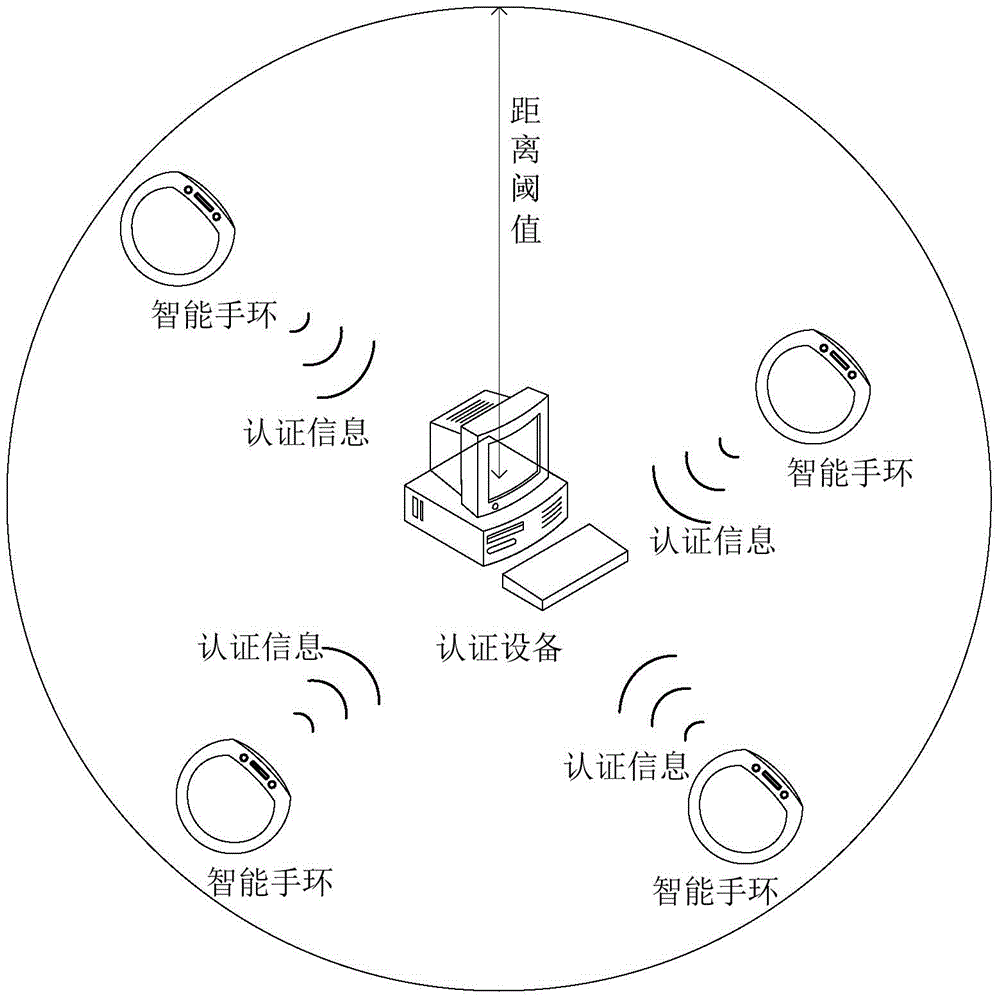

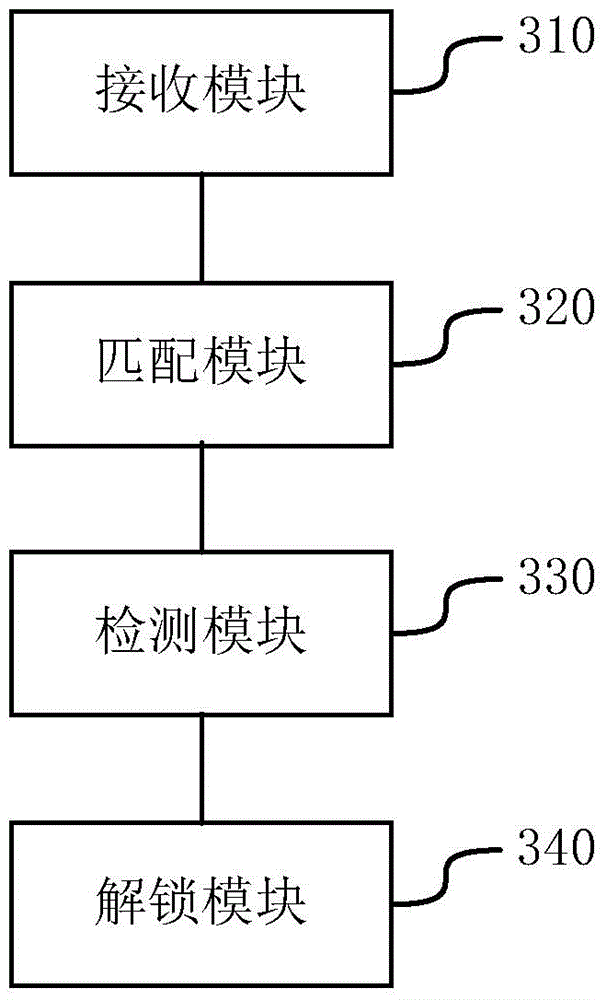

Method and authentication device for unlocking administration authority

ActiveCN104573473AAchieve unlockIncreased processing flexibilityNear-field transmissionUser identity/authority verificationDistance thresholdAuthentication information

The embodiment of the invention relates to a method and an authentication device for unlocking administration authority, and belongs to the technical field of the information safety of a computer. The method comprises the steps: receiving authentication information transmitted by a plurality of member devices by virtue of the authentication device, wherein each member device comprises a mobile terminal or a wearable device; carrying out matching authentication for the authentication information; detecting the distance from an authenticated member device to the authentication device, wherein the authenticated member device is the member device with the transmitted authentication information being matched with the authentication information prestored in an authority authentication information list; unlocking the local administration authority when the detected distance to the authentication device is less than a preset distance threshold value and the quantity of the authenticated member devices reaches a preset quantity threshold value. By adopting the method and the authentication device, the processing flexibility for unlocking the administration authority can be improved.

Owner:XIAOMI INC

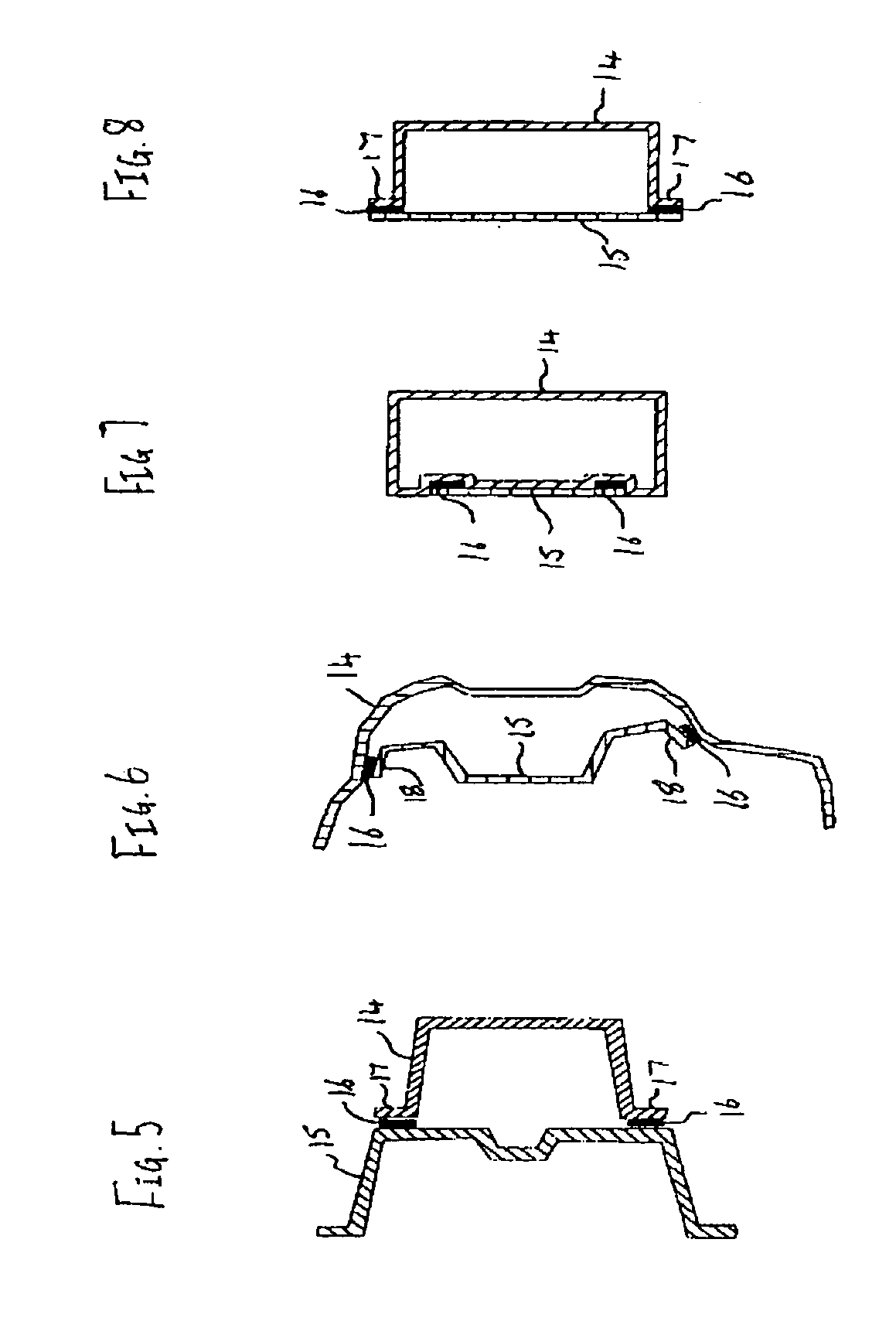

Automobile assembly

InactiveUS20050035609A1Increased processing flexibilityIncrease costAdhesive processesUnderstructuresAdhesiveEngineering

A method is provided for making an automobile assembly having a moulded plastics structural member and a reinforcing member in which a polymerisable adhesive is employed to bond the two members together and an automobile assembly having a bonded structural member and a reinforcing member. The assembly is suitably used as a “front end carrier” or a bumper system in an automobile.

Owner:CATE PETER J +2

Part-holding fixture for grinding wedged optical flats

InactiveUS6855036B1Low costAvoid interfering with grinding processEdge grinding machinesOptical surface grinding machinesWedge angleOptical flat

A part-holding fixture is adapted for rotation about a work spindle axis and includes a mounting land that seals a back surface of an optical flat for securing the optical flat to the part-holding fixture and that inclines the back surface of the optical flat through a wedge angle for grinding wedged optical flats at repeatable wedge angles.

Owner:CORNING TROPEL

Flexible support assembly for vehicle tooling plates

InactiveUS8292282B2Easy to adjustEasy and quick modificationWork holdersVehicle componentsMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Process for the preparation of an emulsion

InactiveUS20050214432A1Reduce processing timeIncreased processing flexibilityEdible oils/fats ingredientsFood preparationPolymer chemistryFood products

The invention provides a process for the preparation of a stable ungelatinised starch-containing oil-in-water emulsion in the absence of an added emulsifier which comprises subjecting a mixture of flour and / or starch, an oil and an aqueous liquid to high shear. A stable oil-in-water emulsion containing ungelatinised starch obtainable by the above process is also provided as well as a food product obtainable by heating the emulsion.

Owner:CONOPCO INC D B A UNILEVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com