Magnetic pulse connecting method and joint structure for thin-wall metal pipelines

A connection method and joint structure technology, which is applied in the field of connecting thin-walled metal pipelines with pulsed magnetic pressure loads, can solve the problems of difficulty in obtaining high-strength and high-corrosion-resistant joints, high production costs, and large stress gradients. Improved processing flexibility, high strength and corrosion resistance, high tensile strength and high torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

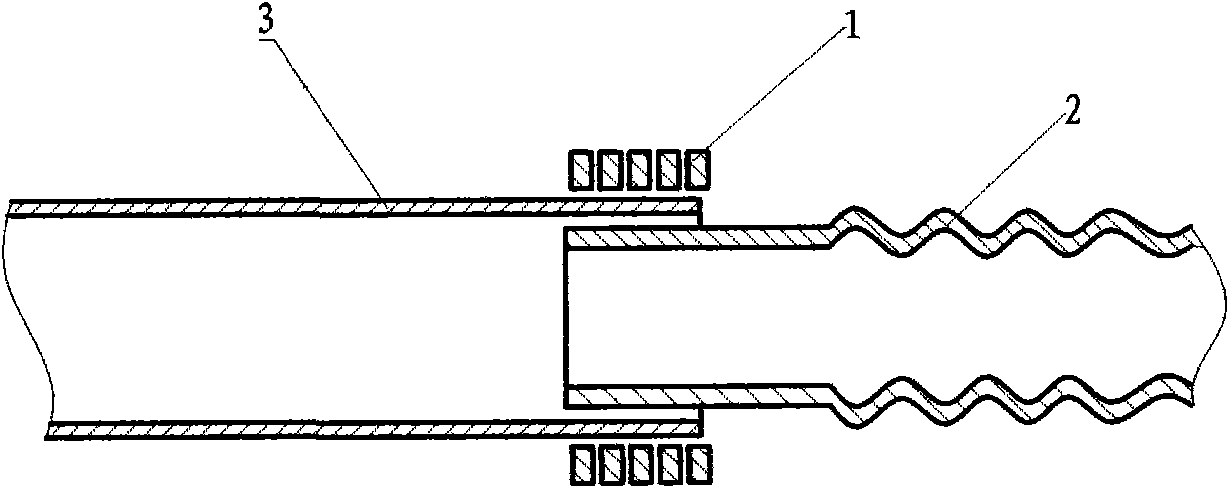

[0041] The tube-tube magnetic pulse connection method of the coil as the inductor:

[0042] The 3A21 tube of φ20×1.0mm is connected with the 20 steel pipe of φ16×2.0mm. The electromagnetic pulse forming equipment has a capacitance of 720μF, a discharge voltage of 5.5kV, a number of coil turns of 5, an inner diameter of 21mm, and a copper wire cross section of 5×7mm. The magnetic pulse connection process of the above-mentioned two material pipes is realized, and a welded joint with a wave interface and significant interface element diffusion is obtained. Magnetic pulse connection device such as figure 1 , The specific implementation process is as follows:

[0043] Step 1: Perform rust removal, degreasing and degreasing treatments on the corresponding surfaces of the overlapping area of the connecting pipe fitting 3 and the connected pipe fitting 2 of the length L to make them present a smooth metal interface.

[0044] Step 2: Place the connecting pipe 3 and the connected pipe 2 coa...

Embodiment 2

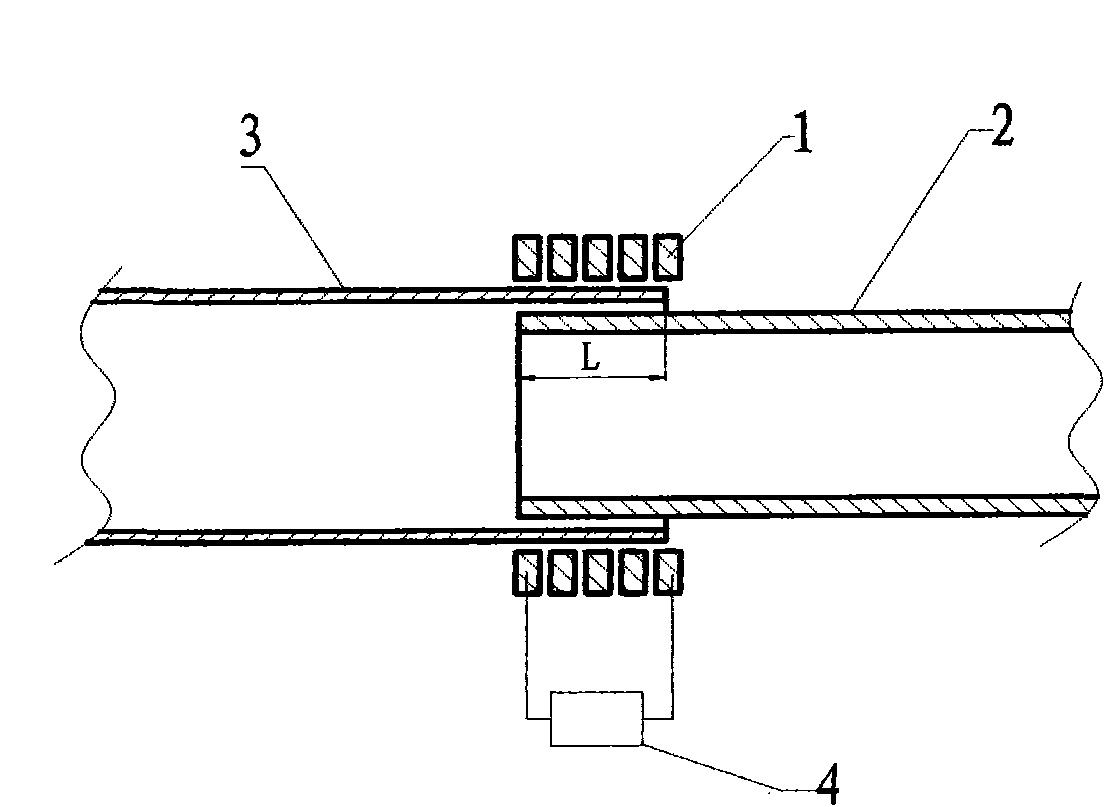

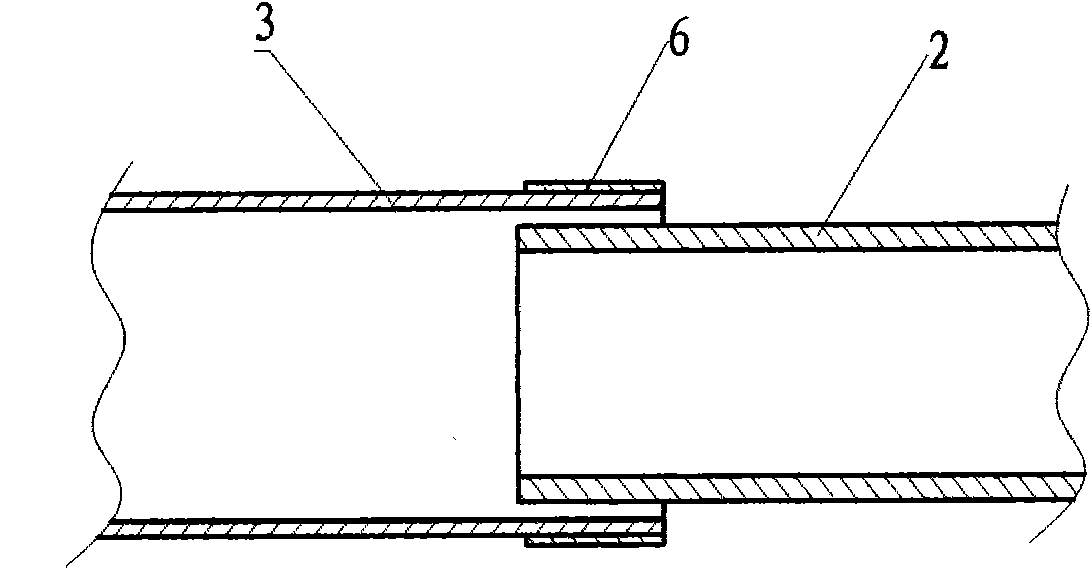

[0048] Coil-magnetic collector as the tube-tube magnetic pulse connection method of the composite inductor:

[0049] The 3A21 tube of φ32×1.0mm is connected with the 20 steel tube of φ28×2.5mm. The electromagnetic pulse forming equipment has a capacitance of 720μF and a discharge voltage of 6.5kV; the number of coil turns is 17, the inner diameter is 91mm, the cross section of the wire is 3×5mm, and the axial length is 100mm. ; The outer diameter of the magnetic collector is 91mm, the inner diameter is 33mm, the outer wall length is 100mm, the working area is 10mm long, and the longitudinal slit width is 0.5mm. The electromagnetic pulse connection process of the above-mentioned two material pipes is realized, and a welded joint with a wave interface is obtained. Magnetic pulse connection device such as figure 2 with image 3 . The specific implementation process is as follows:

[0050] Step 1: Perform rust removal, degreasing, and degreasing treatment on the corresponding surfac...

Embodiment 3

[0055] Tube-tube magnetic pulse connection method with driver:

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com