Patents

Literature

1278 results about "Dissimilar metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Dissimilar metals Dissimilar metals means those metals which are incompatible with one another in the presence of moisture, as determined from their relative positions in the Electrochemical Series, or from test data.

Thermocouple

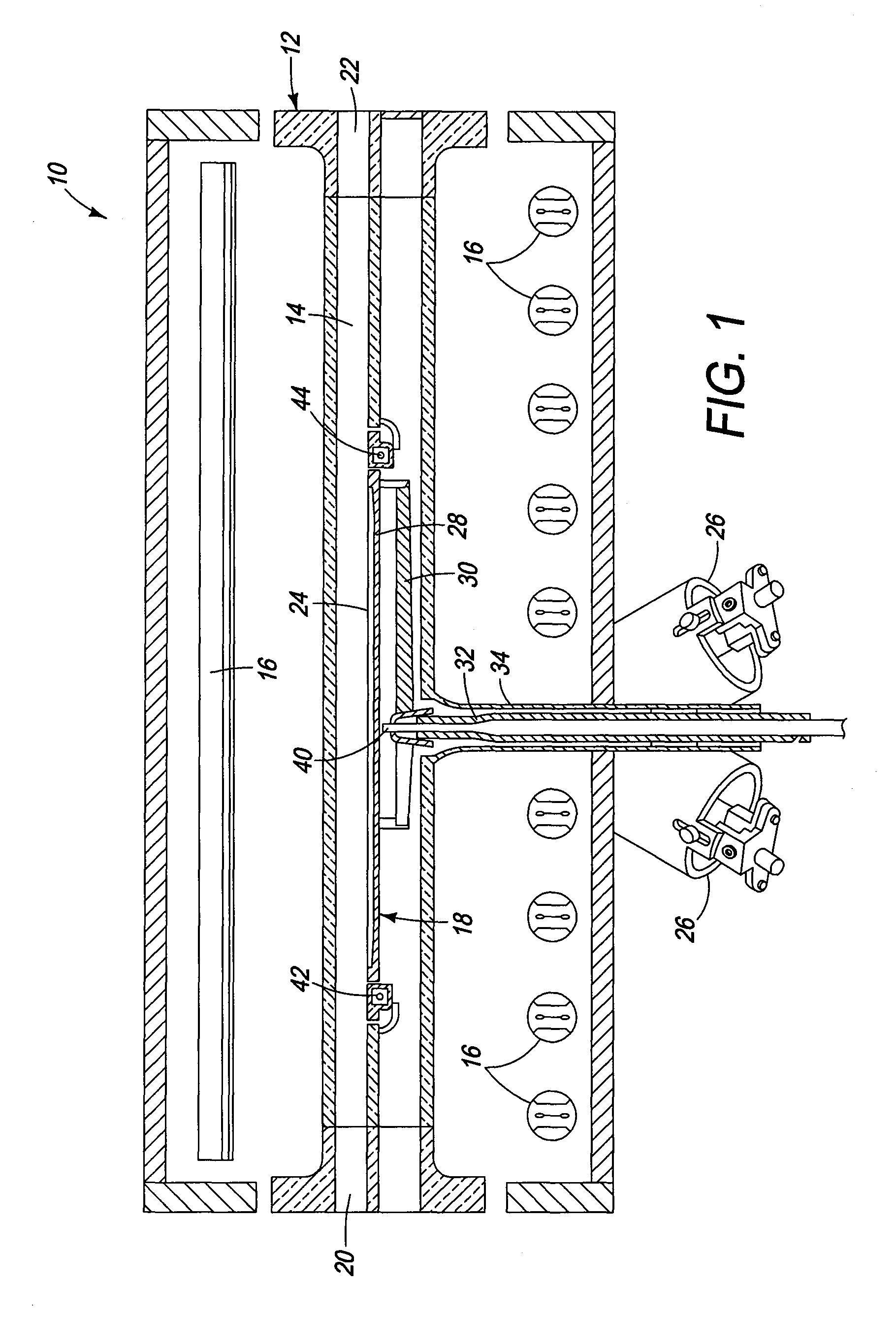

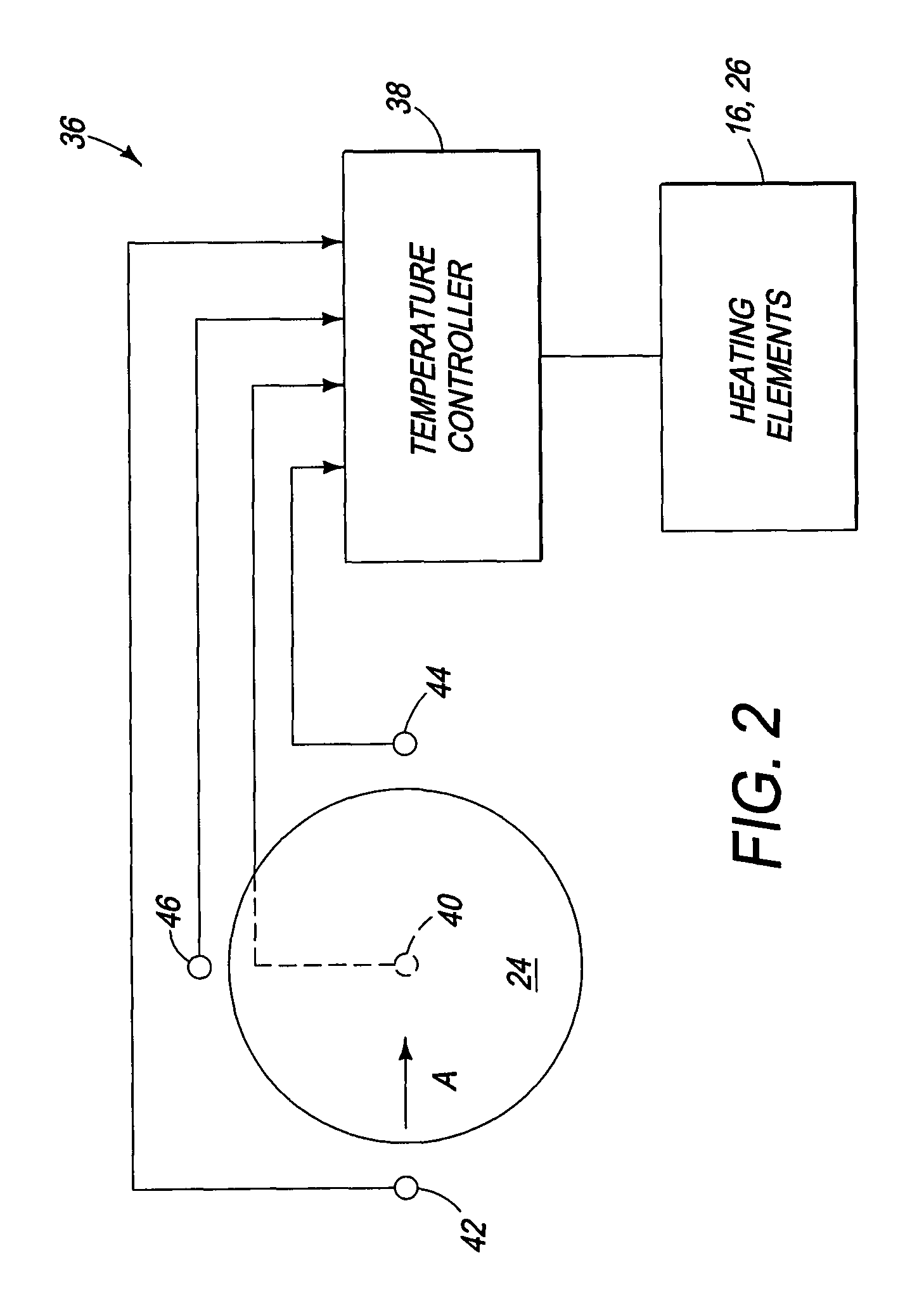

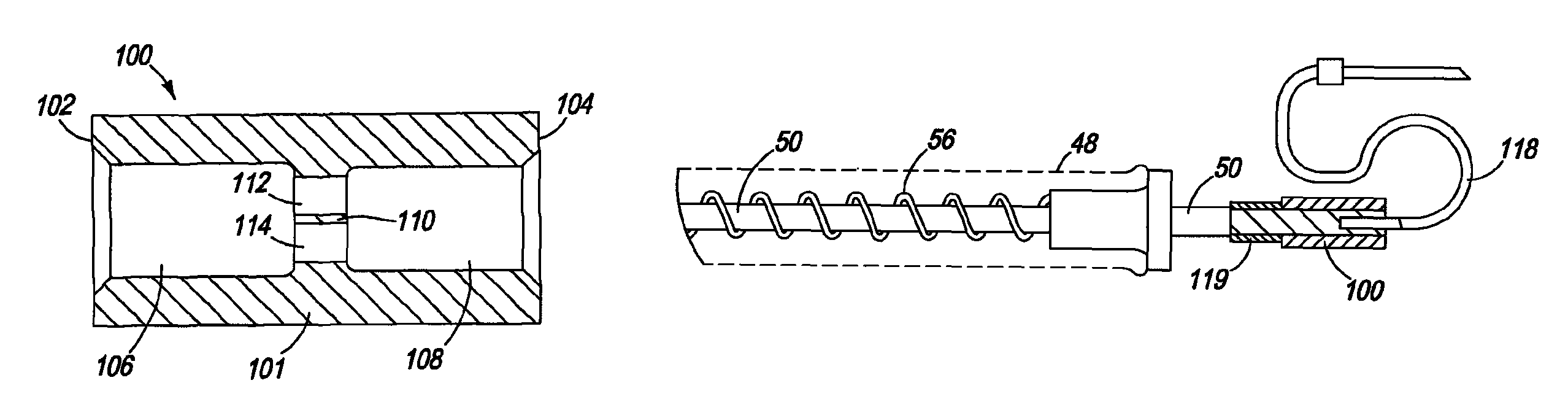

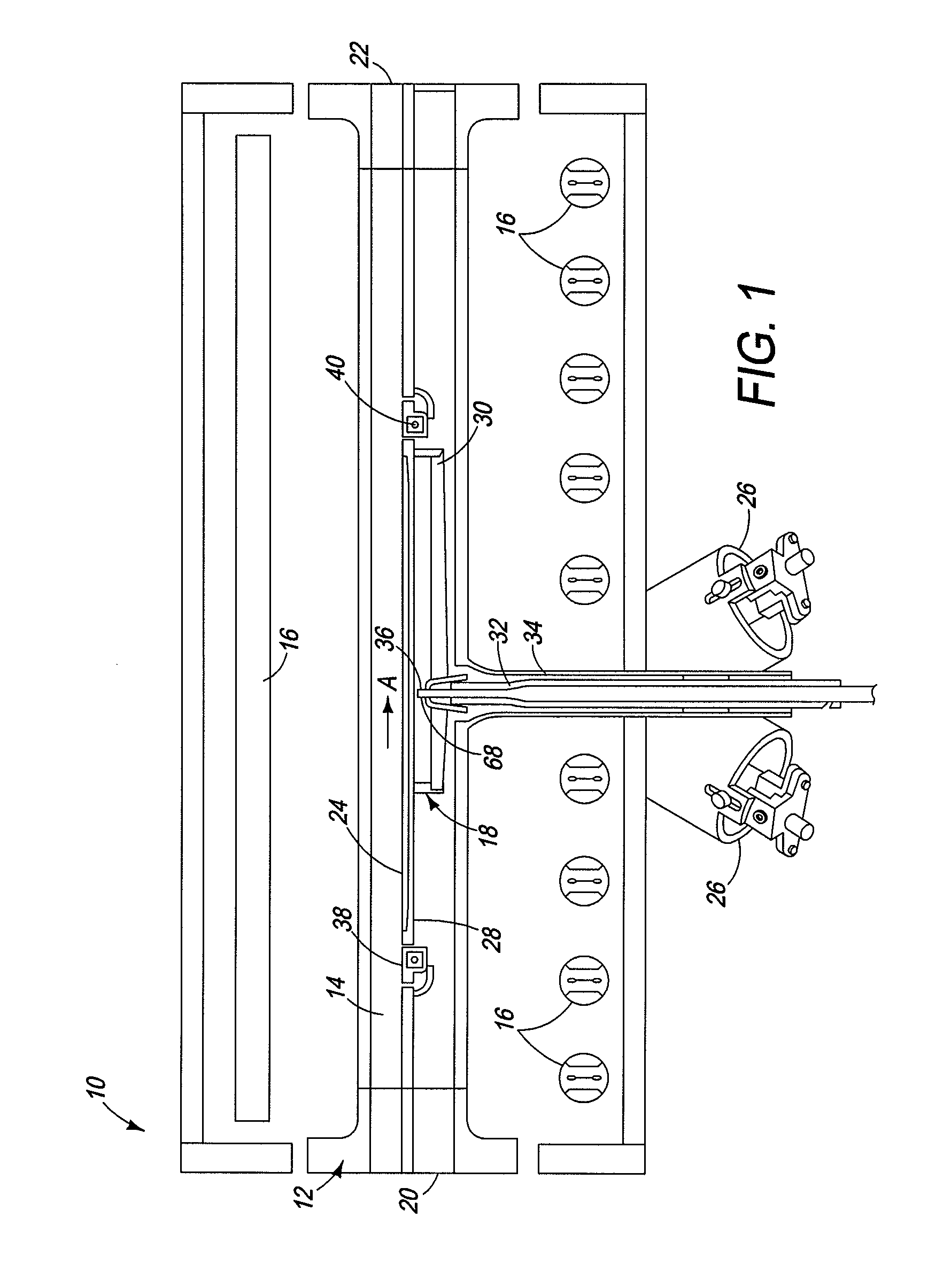

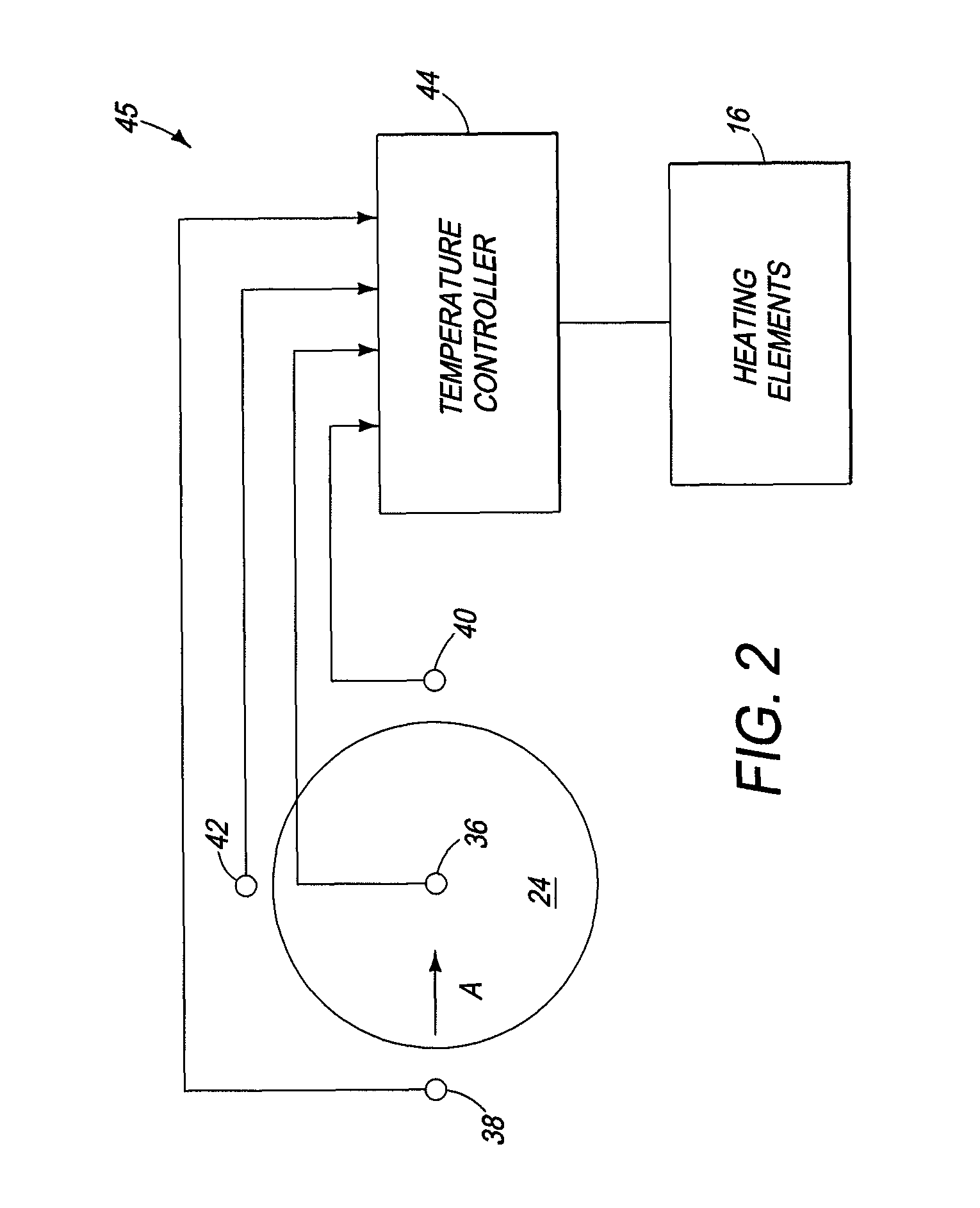

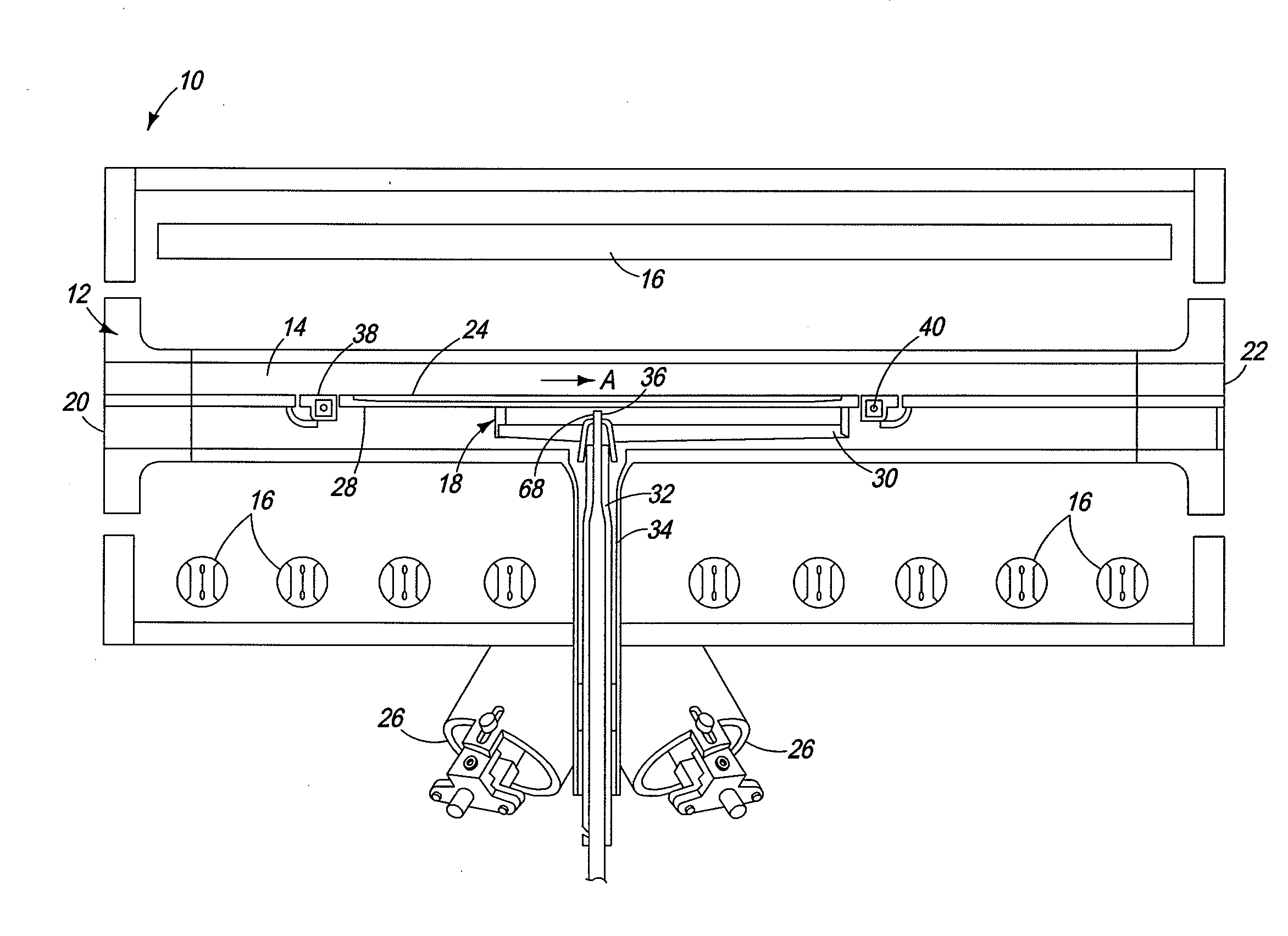

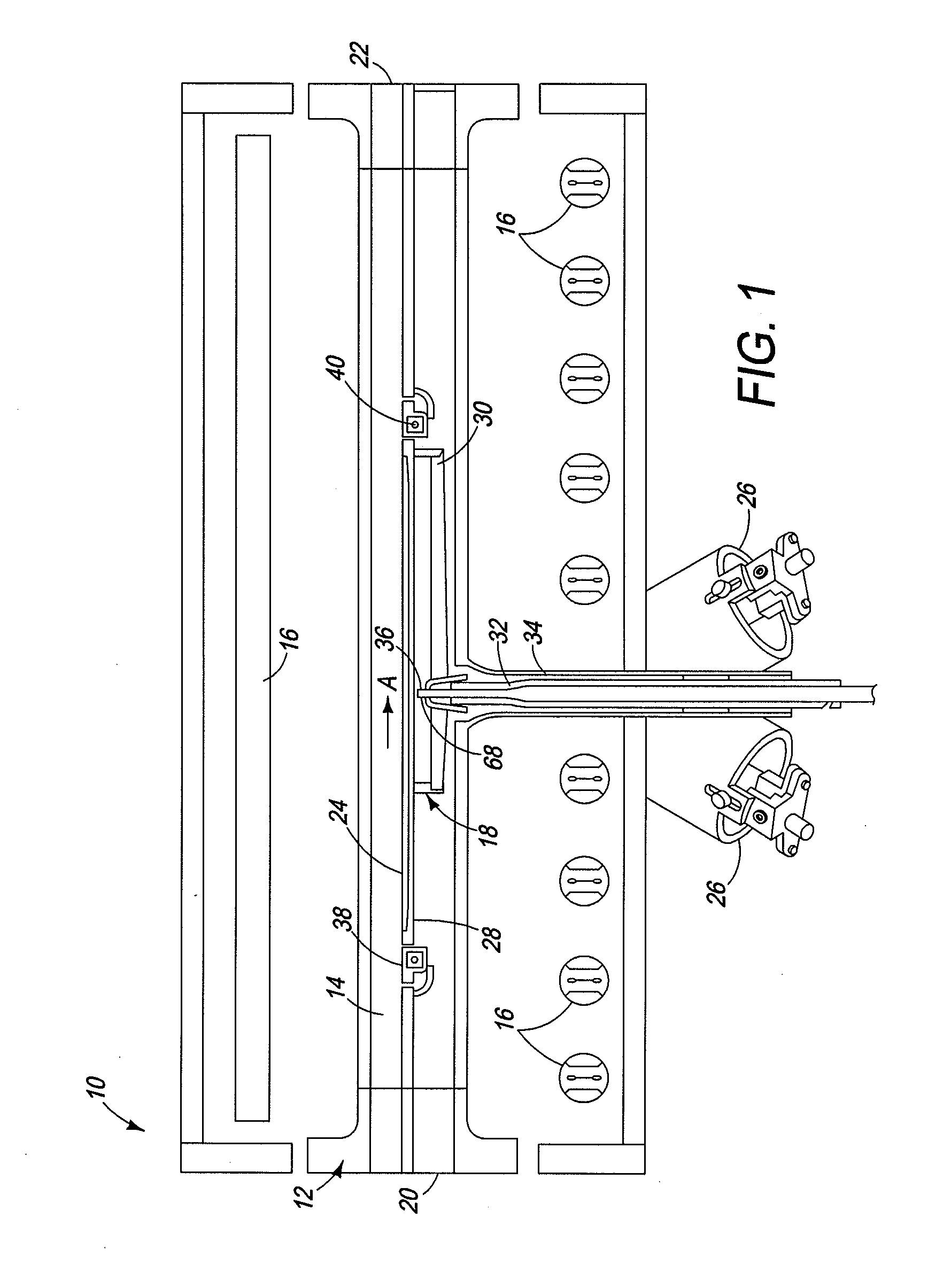

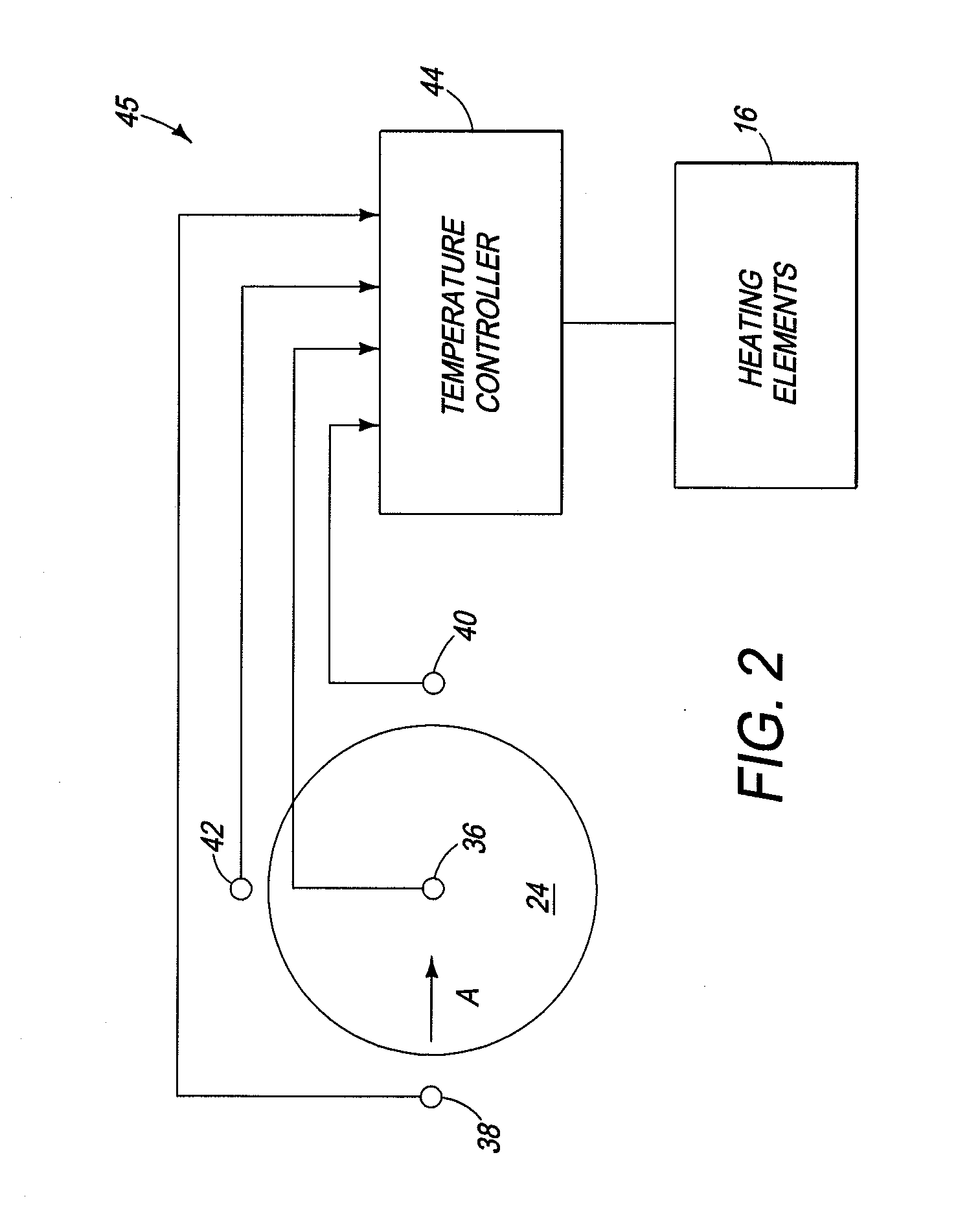

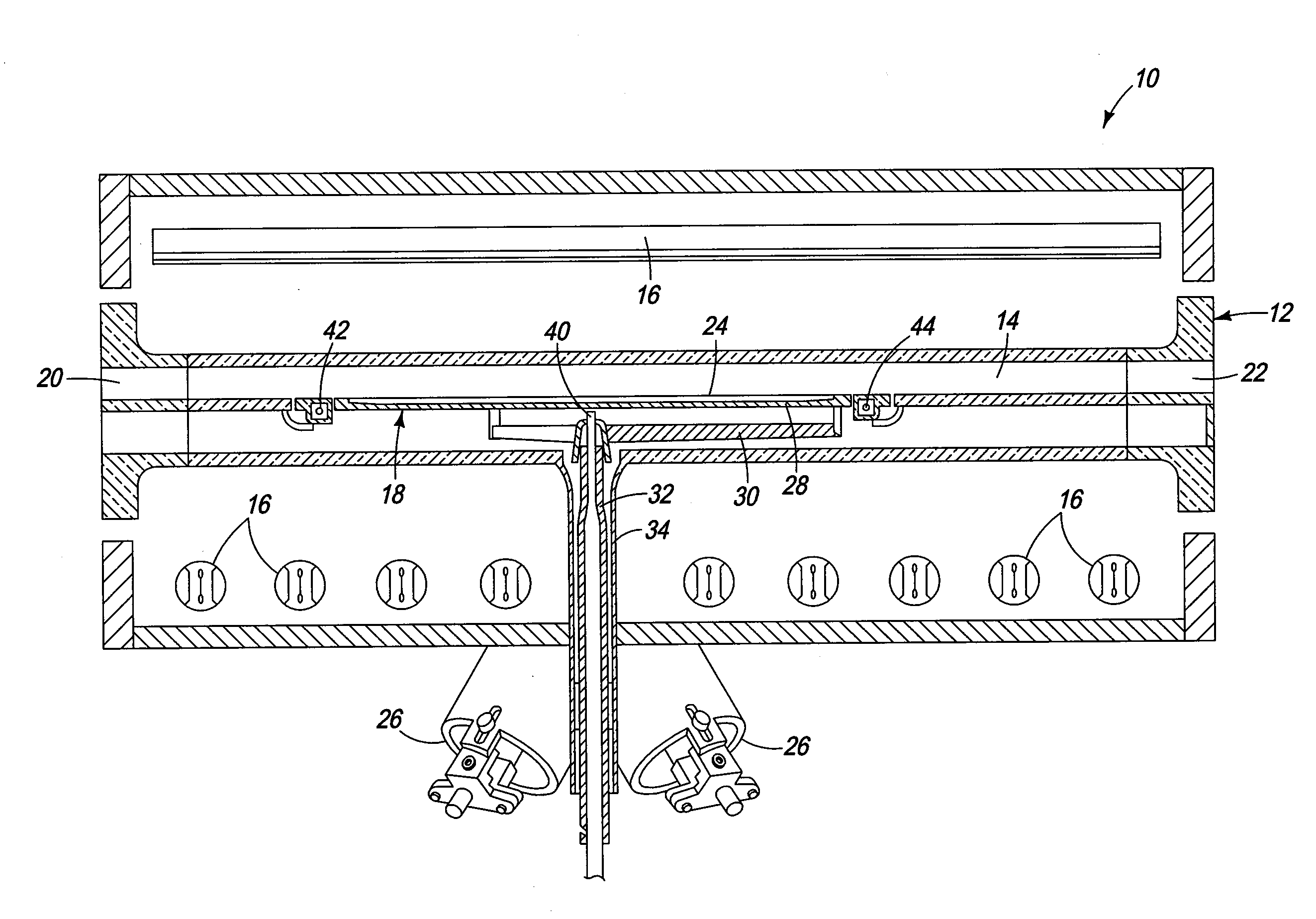

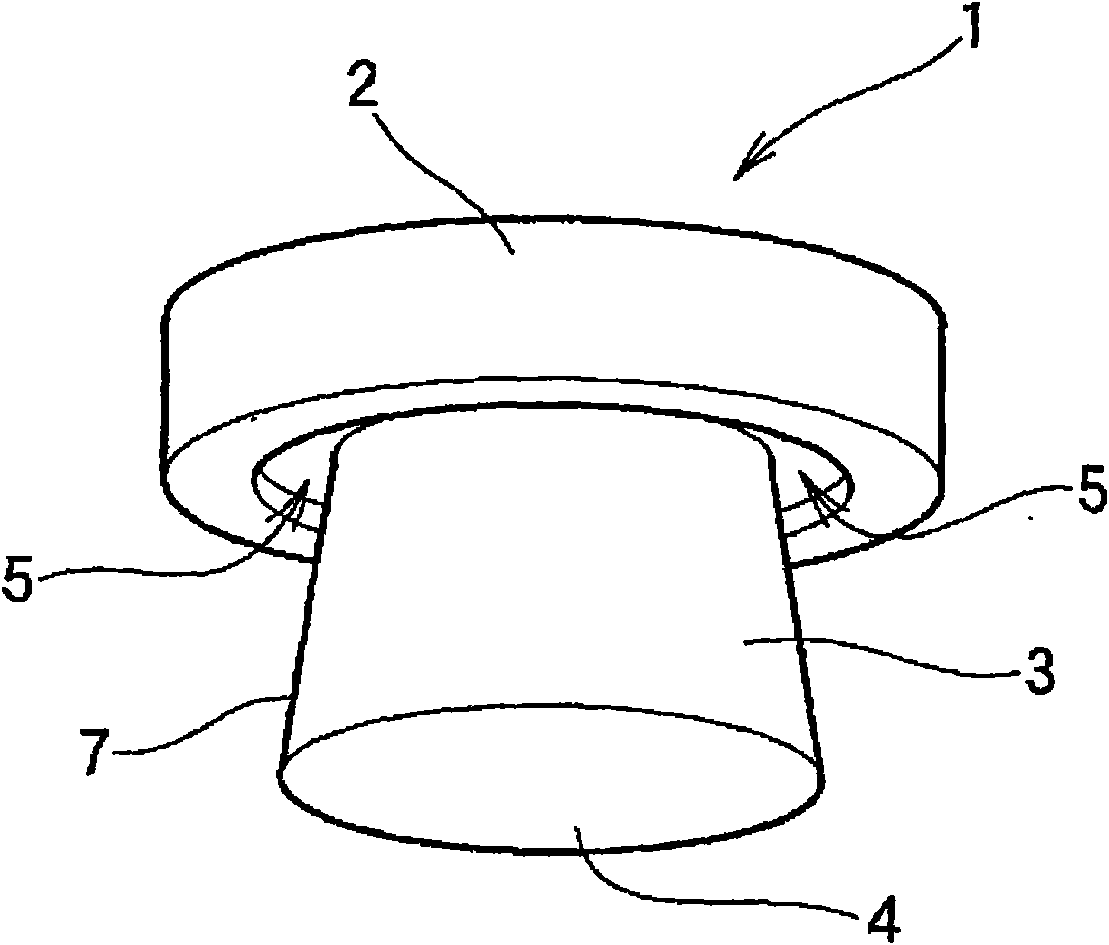

ActiveUS7946762B2Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

A thermocouple for use in a semiconductor processing reactor is described. The thermocouple includes a sheath having a measuring tip at one end and an opening at the other end. A support member having bores formed along the length is disposed within the sheath. A pair of wires formed of dissimilar metals are disposed within the bores, and one end of the wires is fused together to form a junction. The wires extend along the length of the bores. As the wires exit the bore, they are spatially or physically separated to prevent a short circuit therebetween. The ends of the wires exiting the bore are also free to thermally expand in the longitudinal manner, thereby reducing or eliminating the potential for the wires to fail due to grain slip.

Owner:ASM IP HLDG BV

Thermocouple

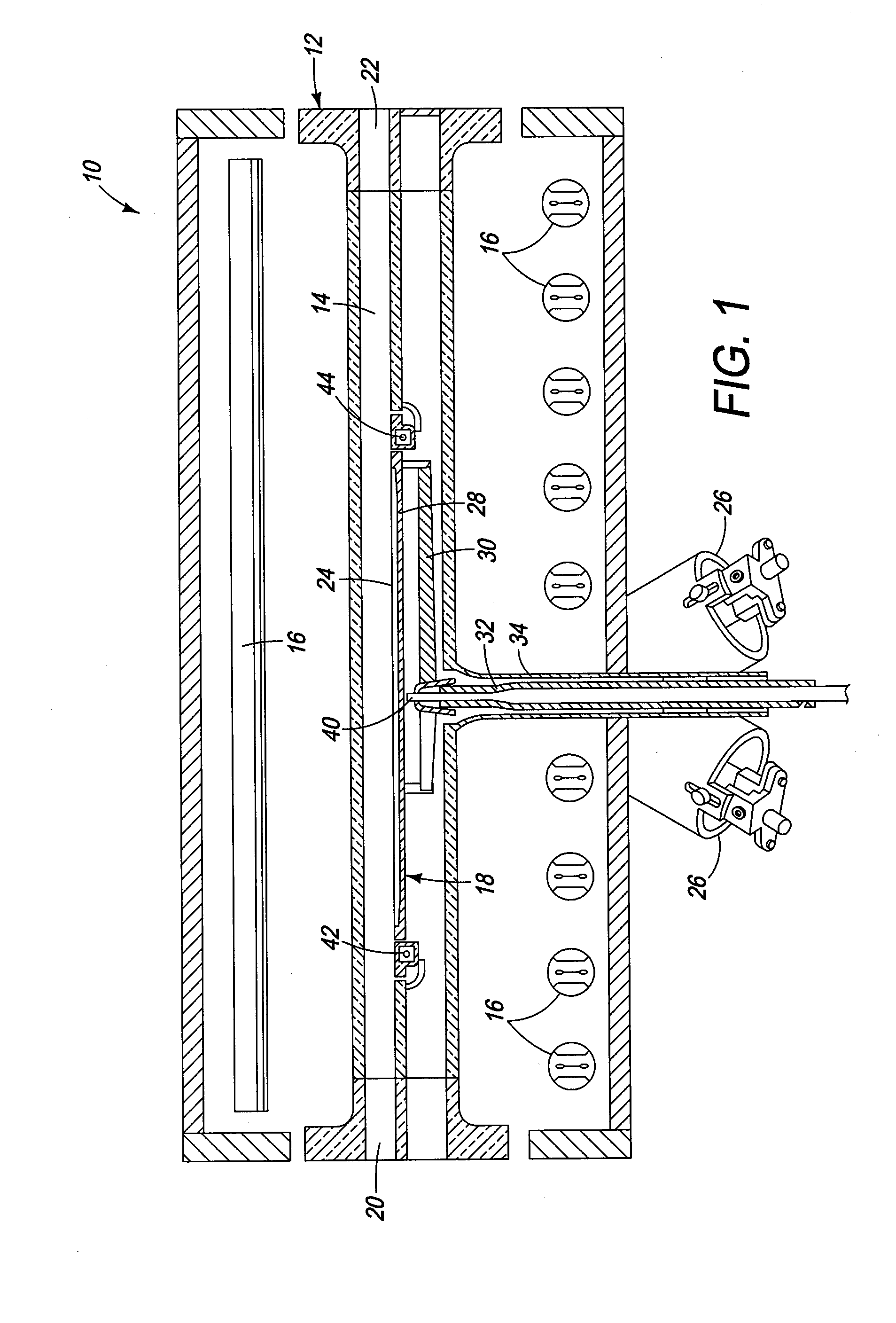

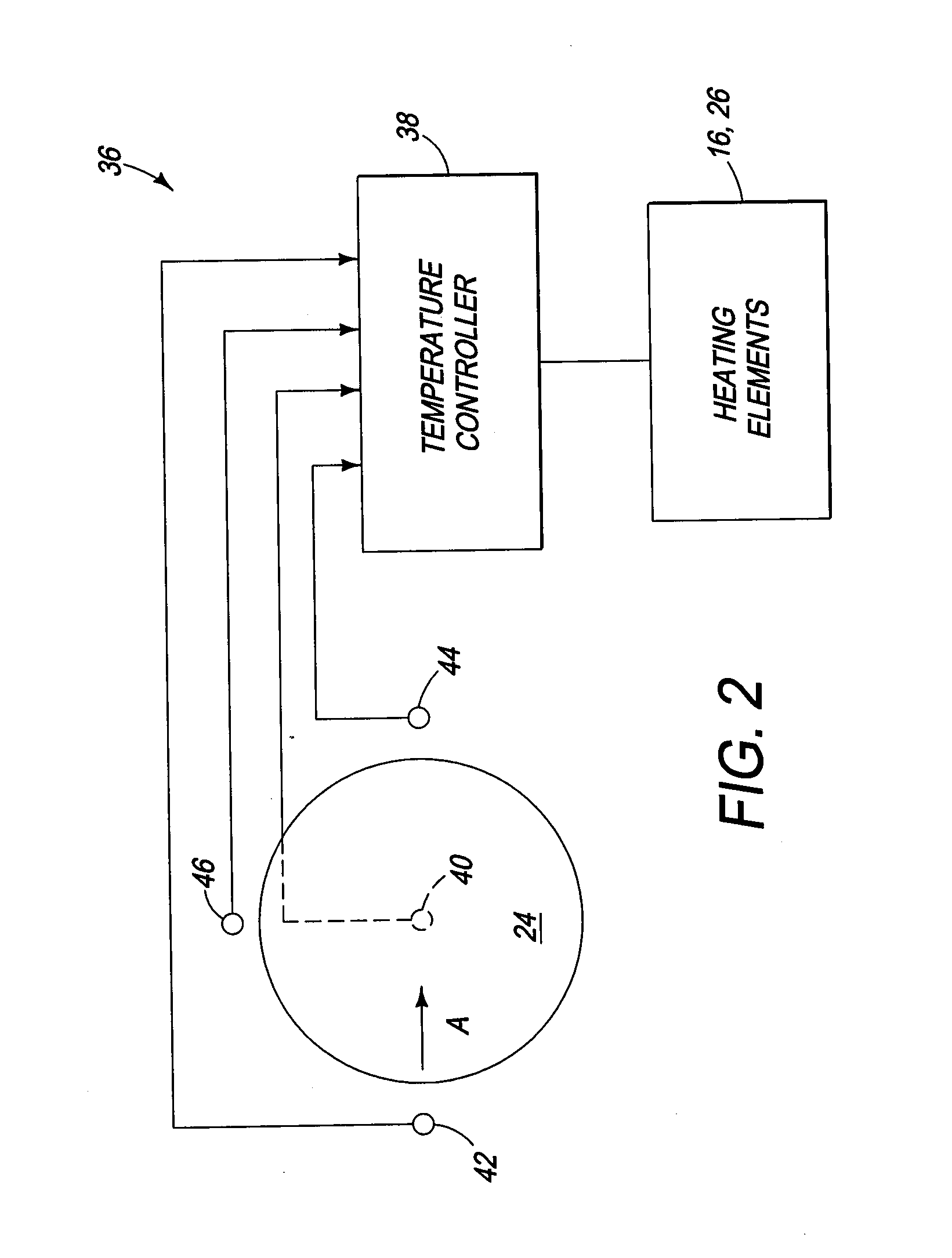

ActiveUS7874726B2Thermometer detailsThermometers using electric/magnetic elementsThermal expansionEngineering

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Thermocouple

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Thermocouple

ActiveUS20090308425A1Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

A thermocouple for use in a semiconductor processing reactor is described. The thermocouple includes a sheath having a measuring tip at one end and an opening at the other end. A support member having bores formed along the length is disposed within the sheath. A pair of wires formed of dissimilar metals are disposed within the bores, and one end of the wires is fused together to form a junction. The wires extend along the length of the bores. As the wires exit the bore, they are spatially or physically separated to prevent a short circuit therebetween. The ends of the wires exiting the bore are also free to thermally expand in the longitudinal manner, thereby reducing or eliminating the potential for the wires to fail due to grain slip.

Owner:ASM IP HLDG BV

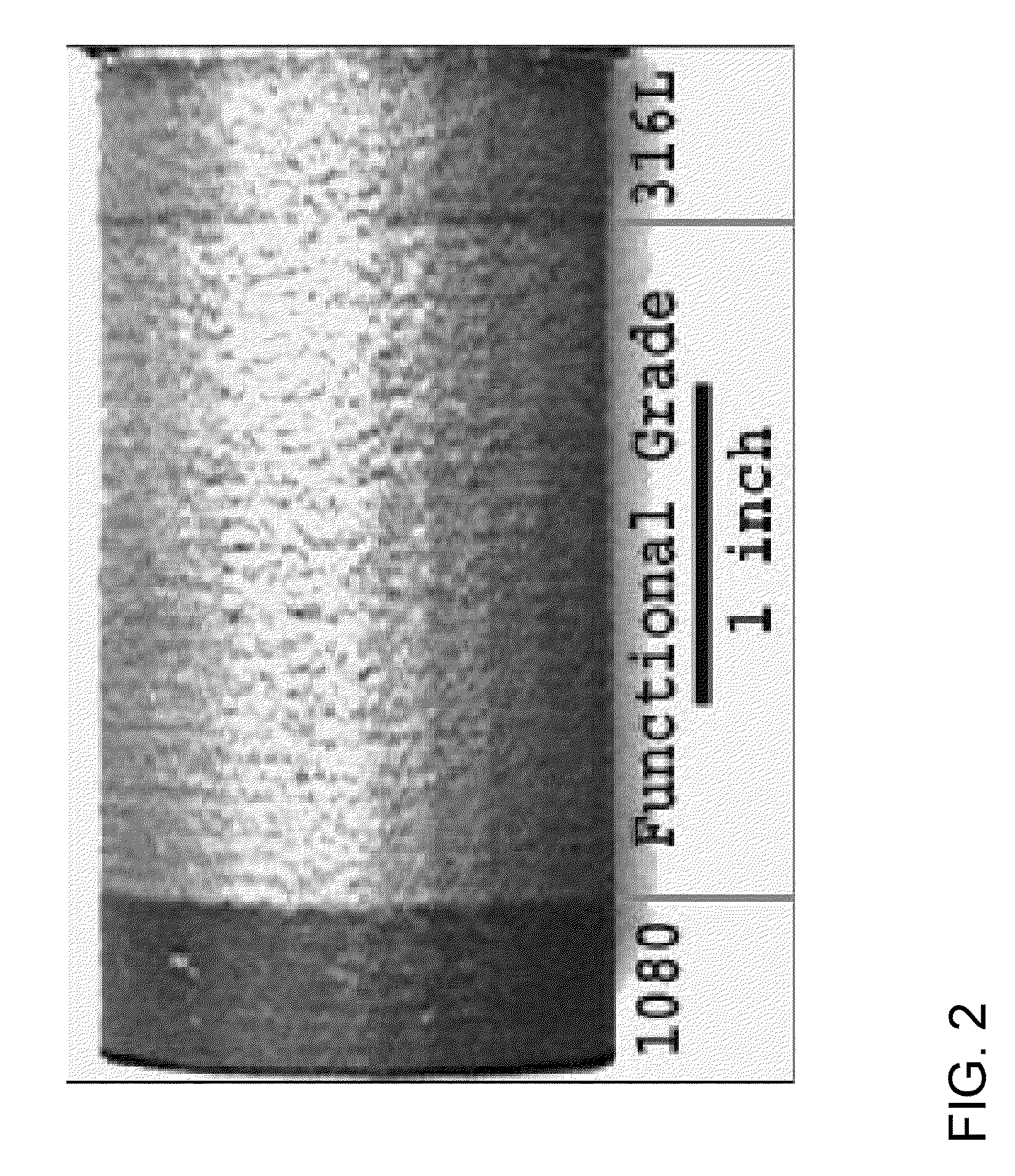

Powder feeder for material deposition systems

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

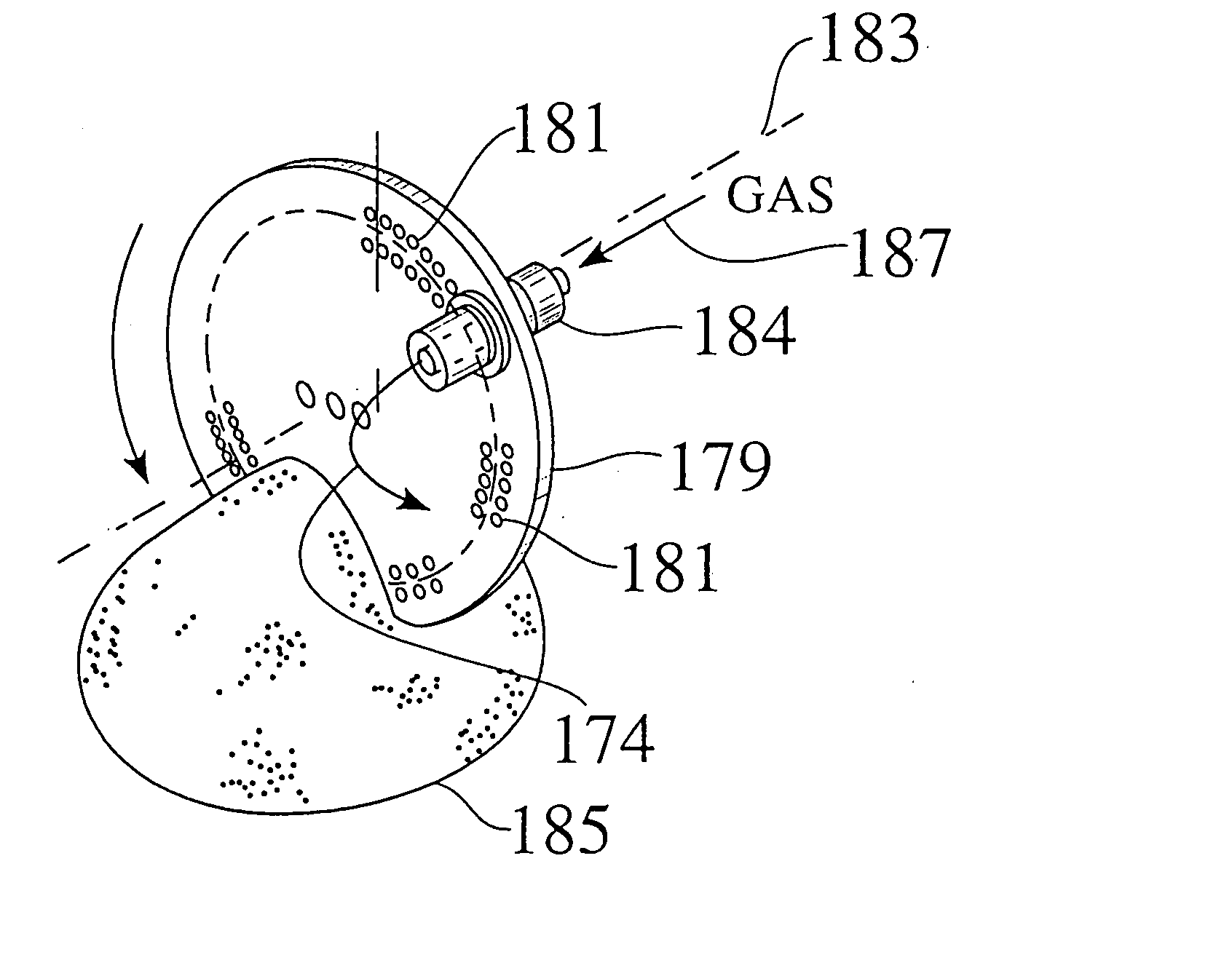

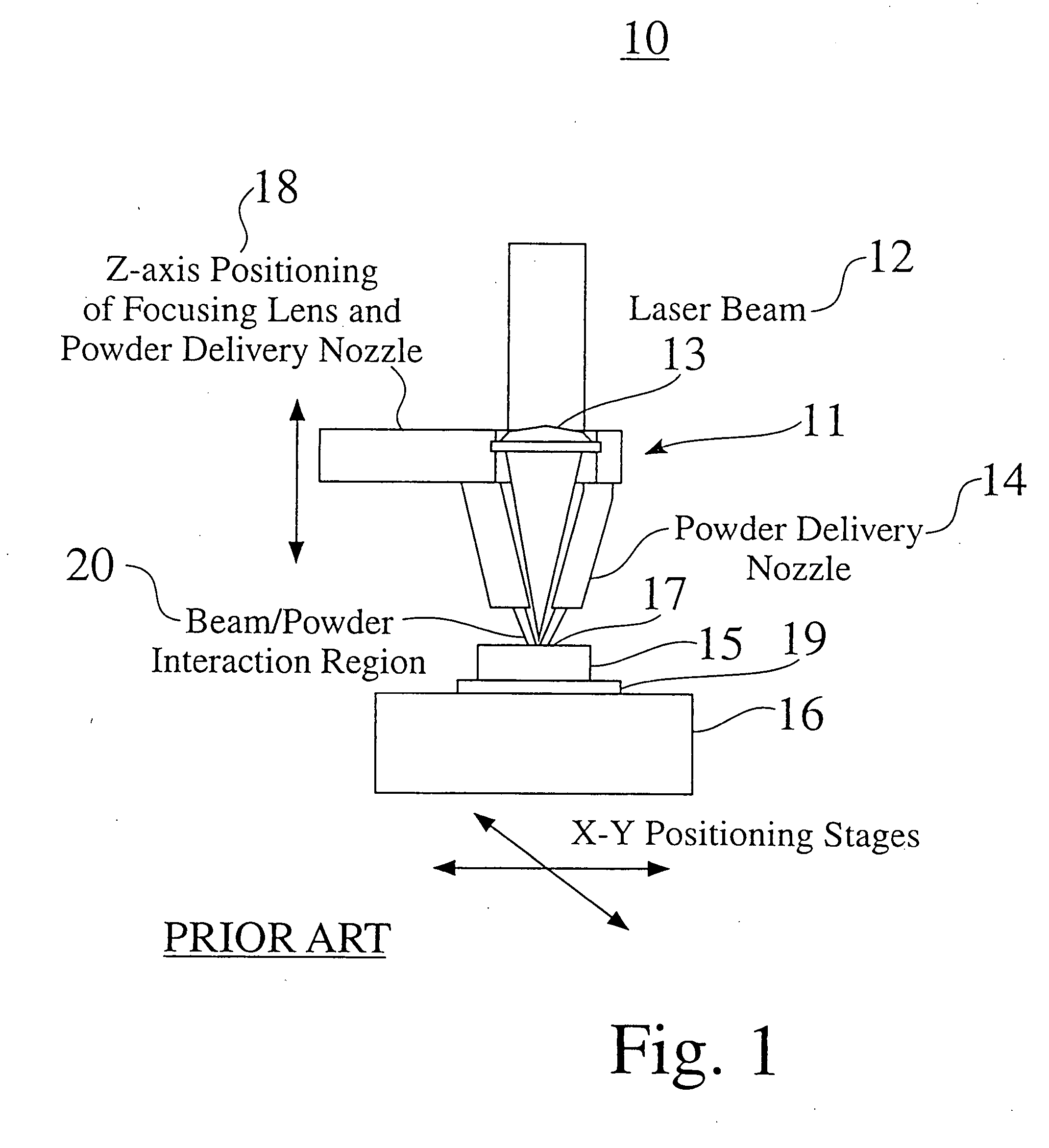

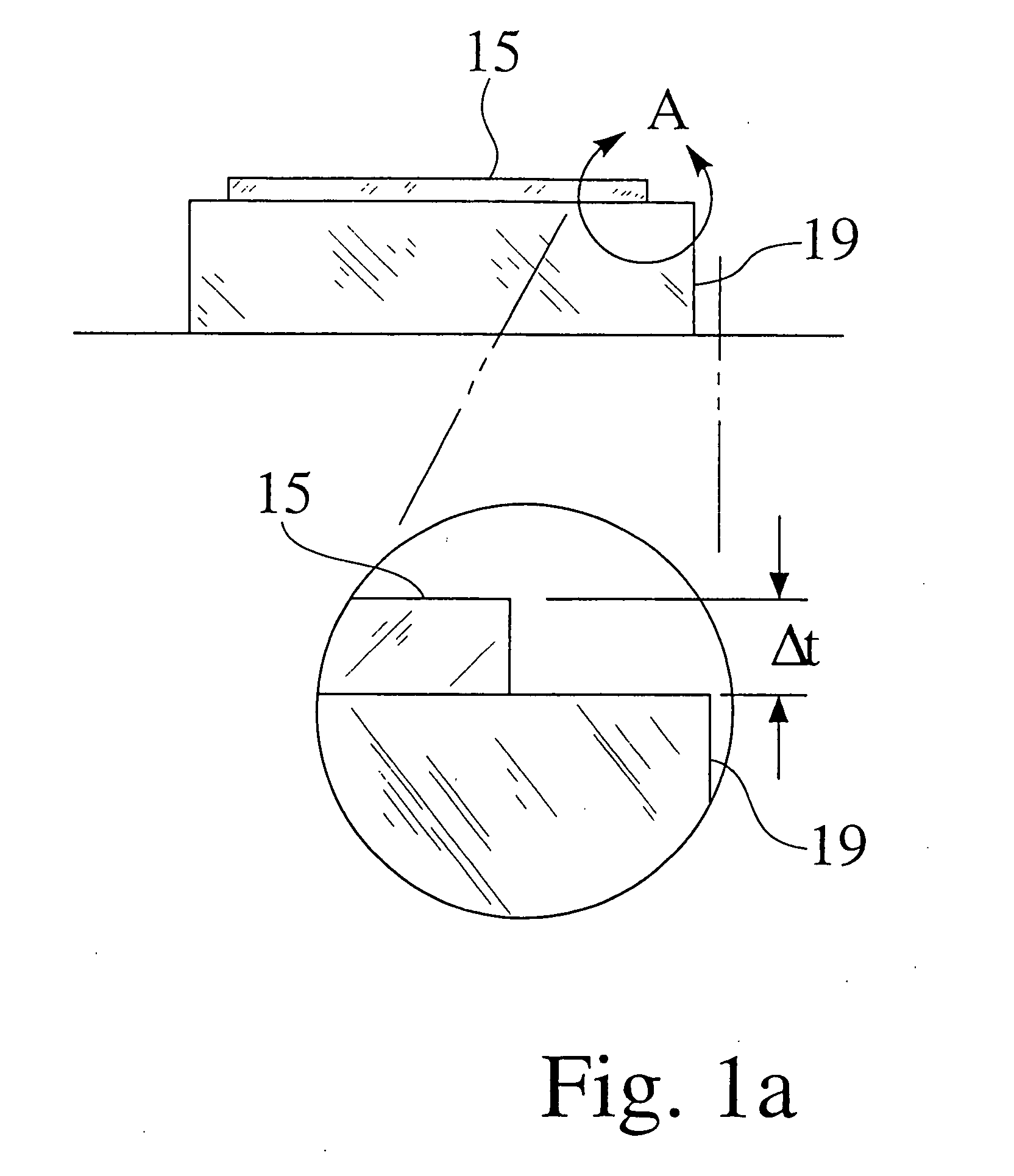

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

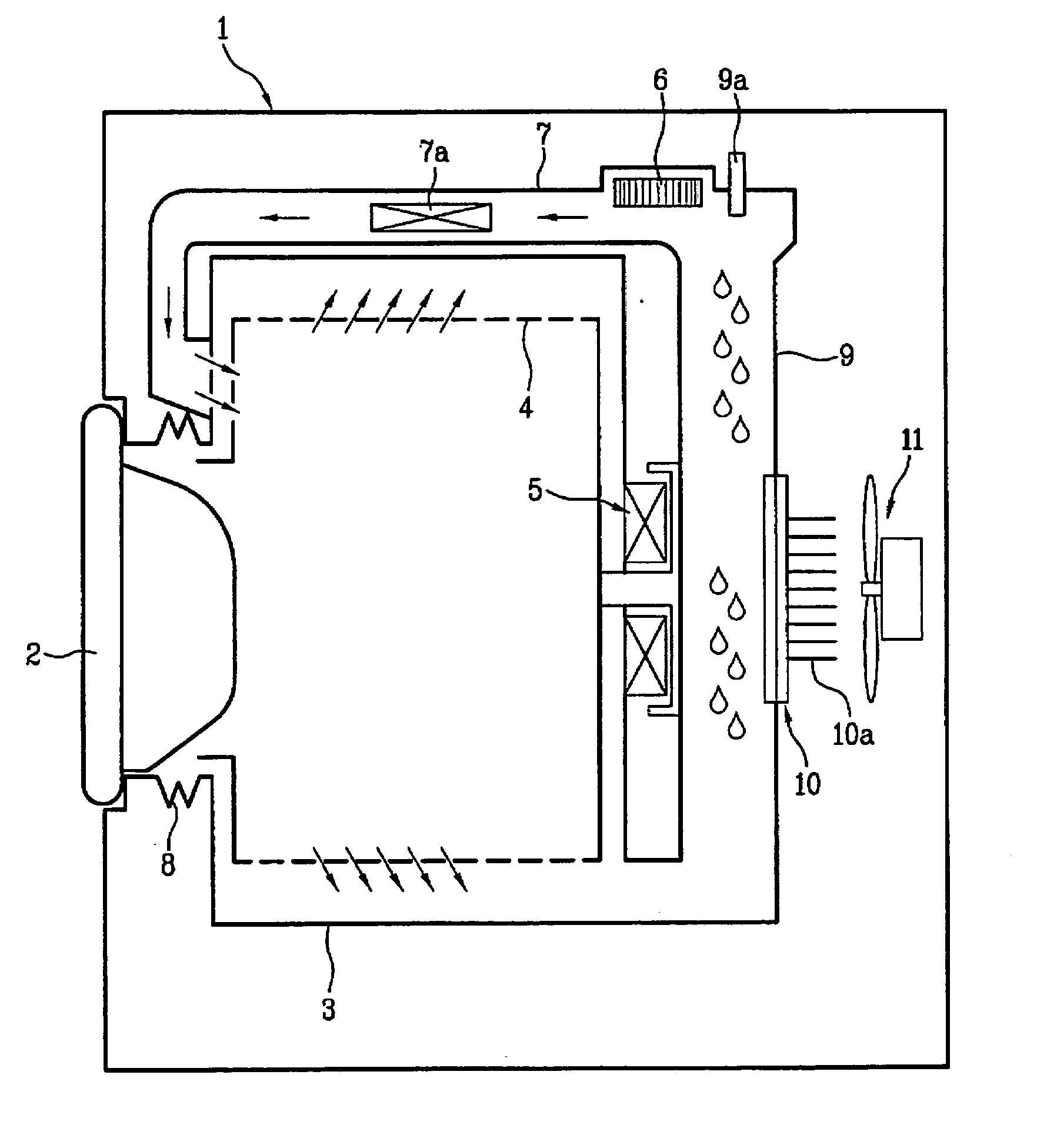

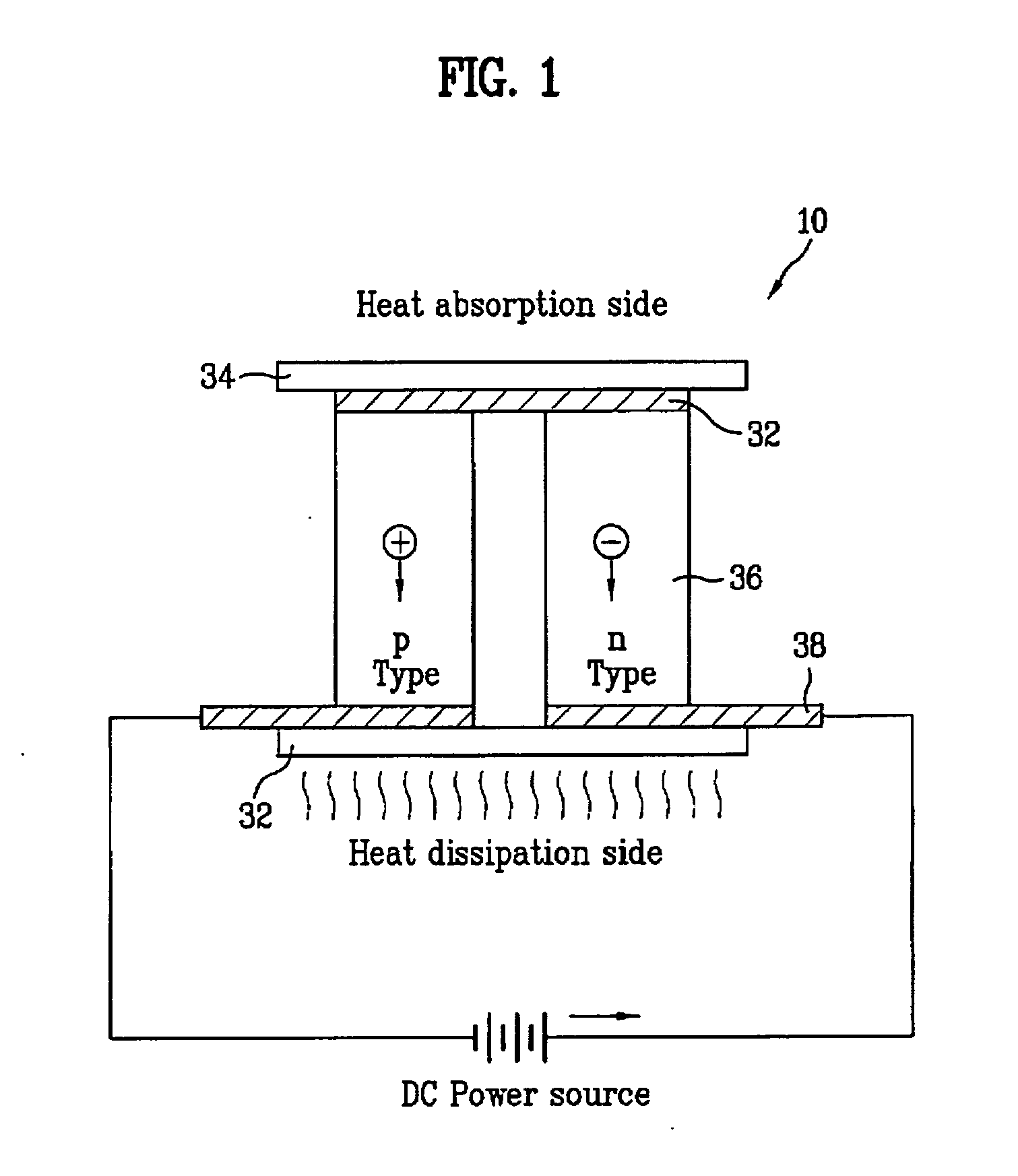

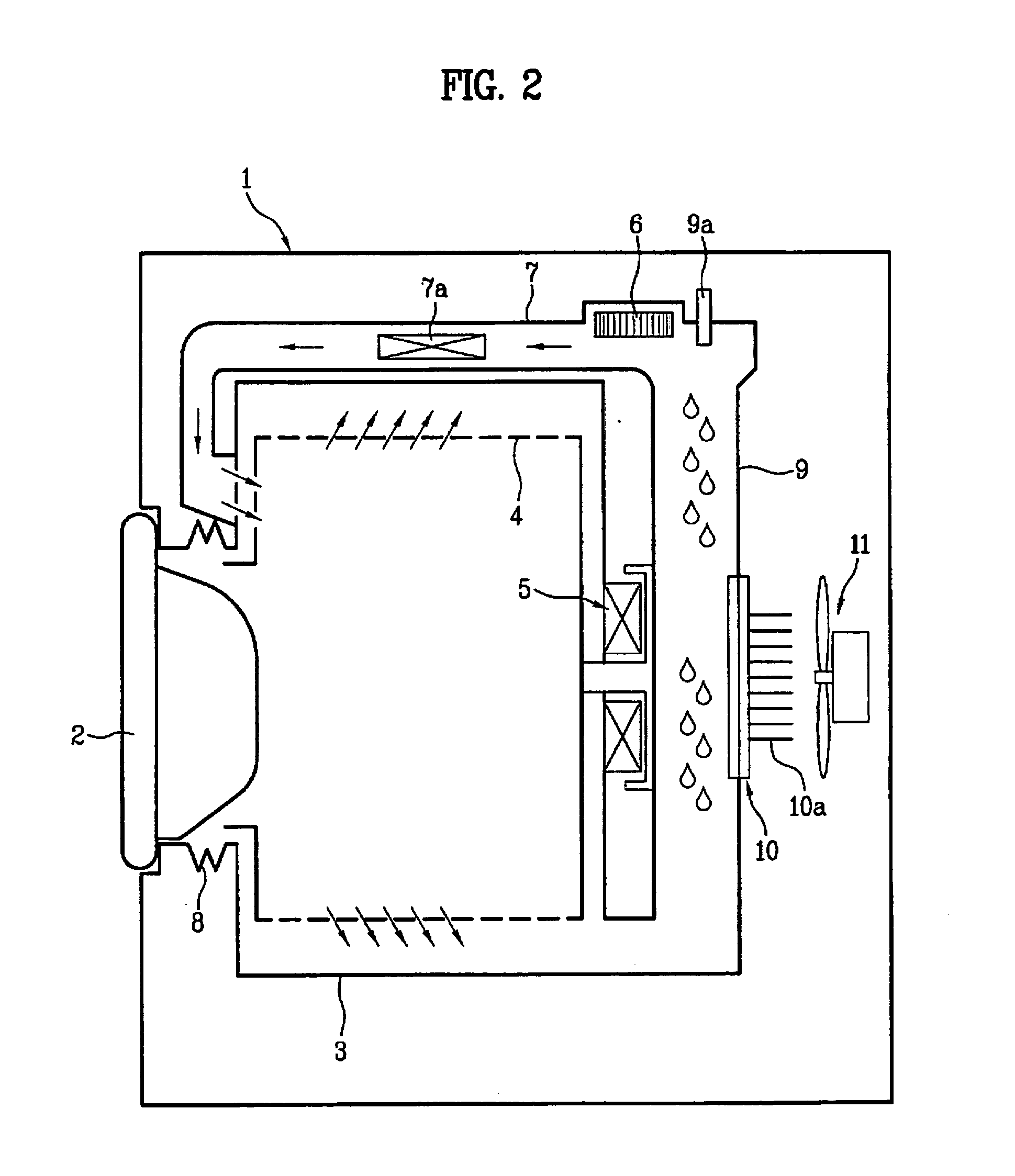

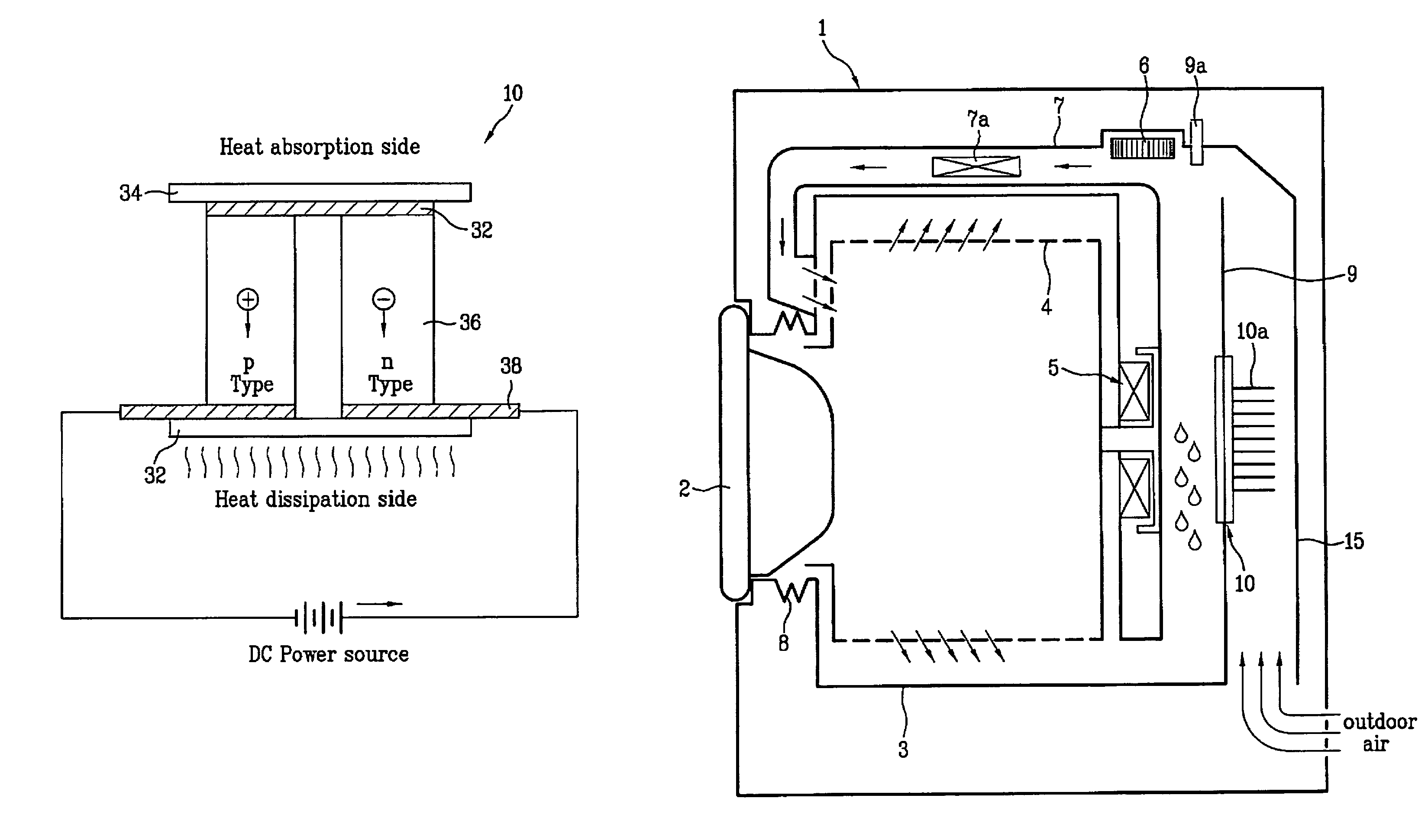

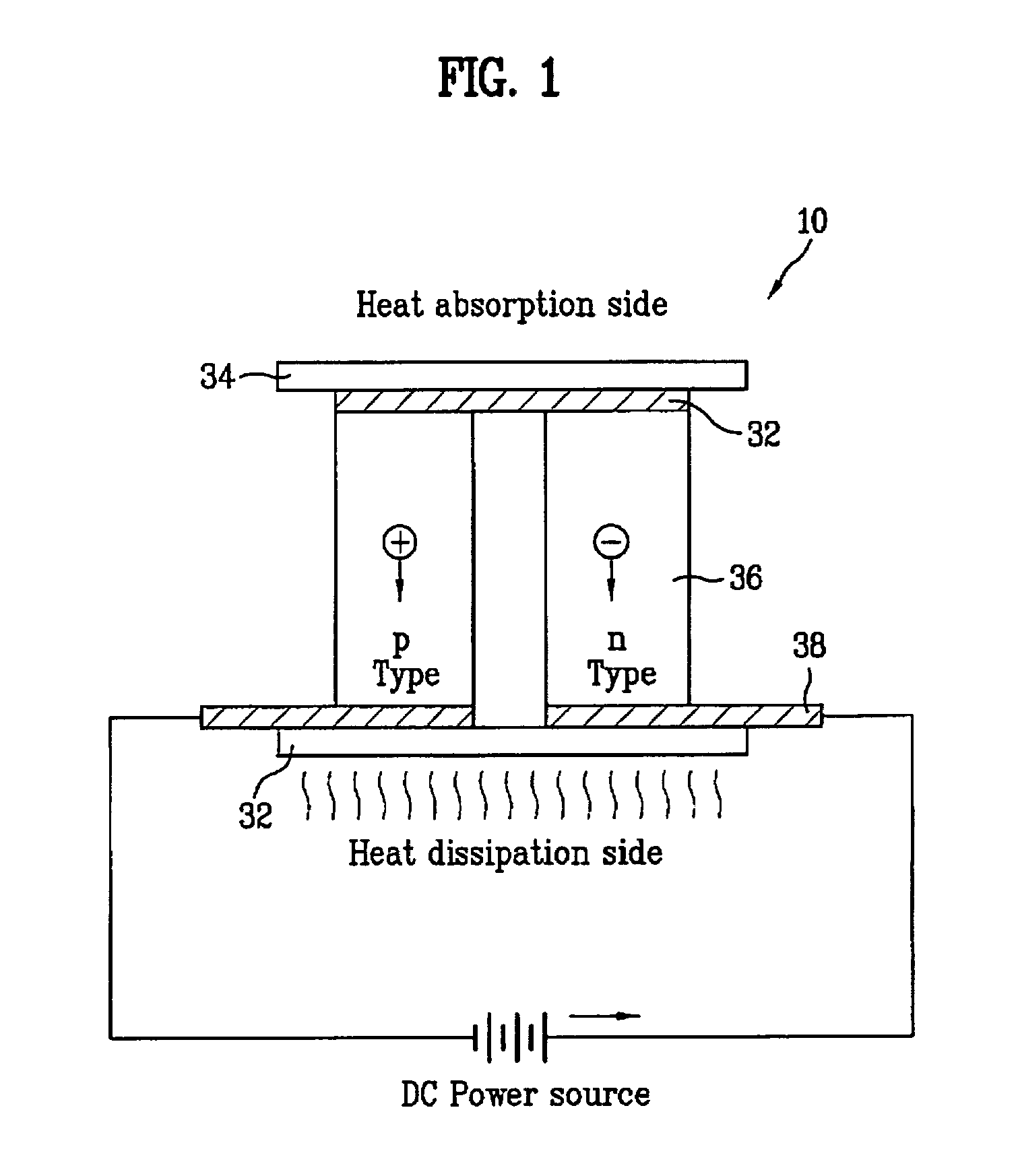

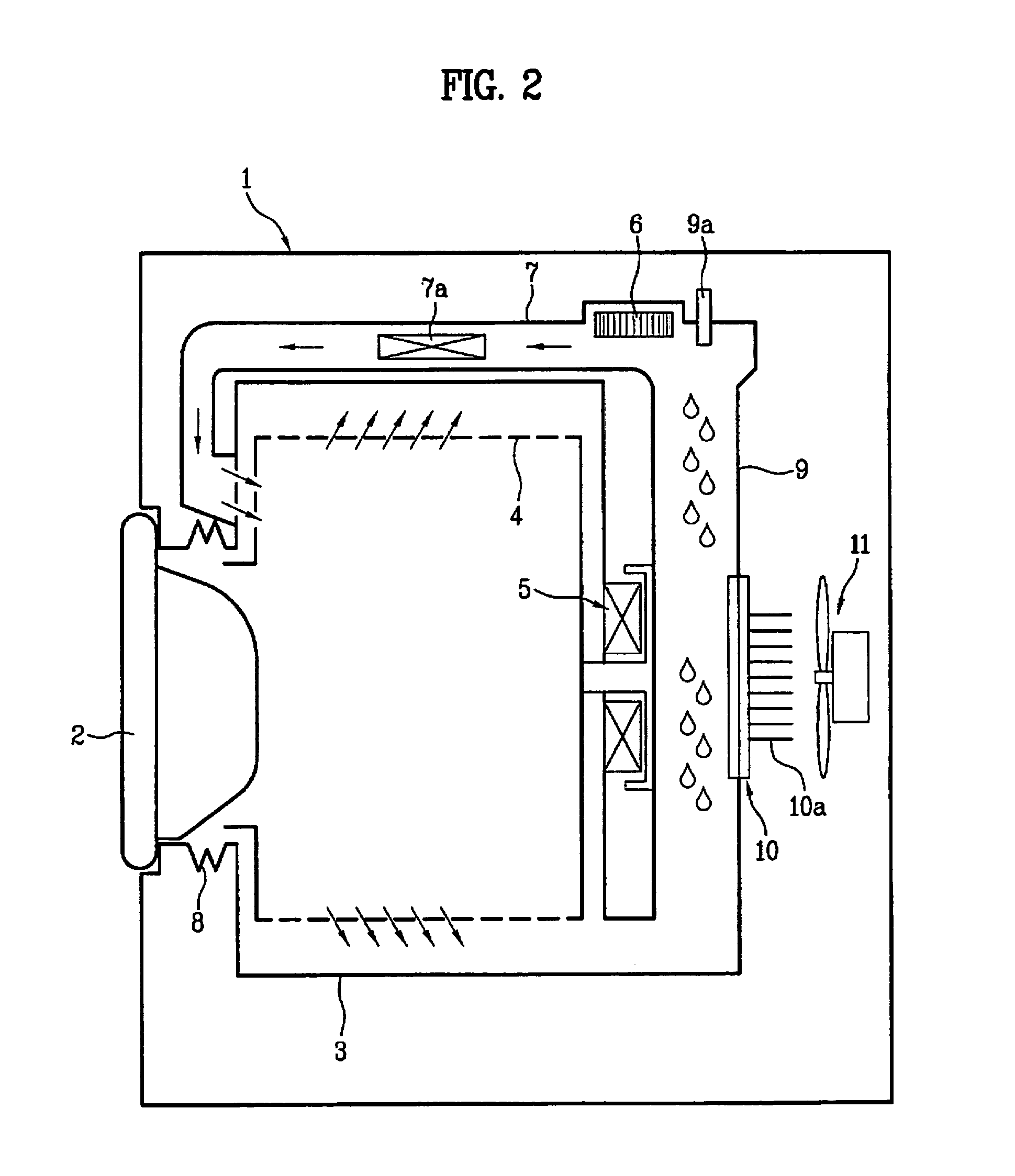

Drum washing machine and clothes dryer using thermoelectric module

InactiveUS20070101602A1Improve drying efficiencyImprove energy efficiencyAgriculture tools and machinesDrying gas arrangementsProcess engineeringElectrical current

A drum washing machine and a clothes dryer equipped with a thermoelectric module are disclosed. The thermoelectric module includes a heat absorption side and a heat dissipation side which absorbs and dissipates heat at a junction between two dissimilar metals depending on direction of current flow through the junction. The heat absorption side is disposed at a hot air flowing passage. Accordingly, the drying apparatus can increase energy efficiency with minor structural modification and becomes environmentally friendly unlike a conventional drying apparatus using a heat pump.

Owner:LG ELECTRONICS INC

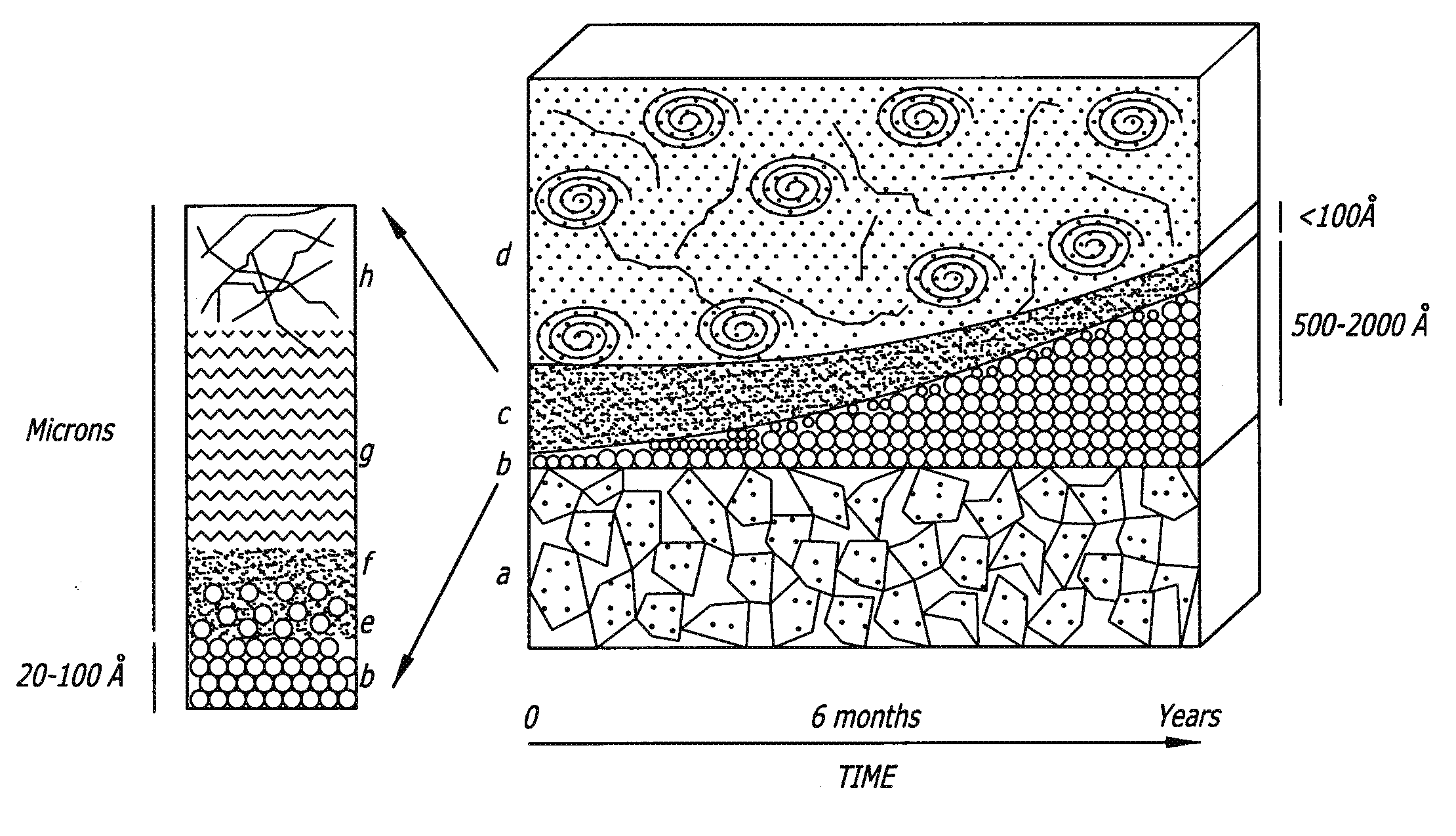

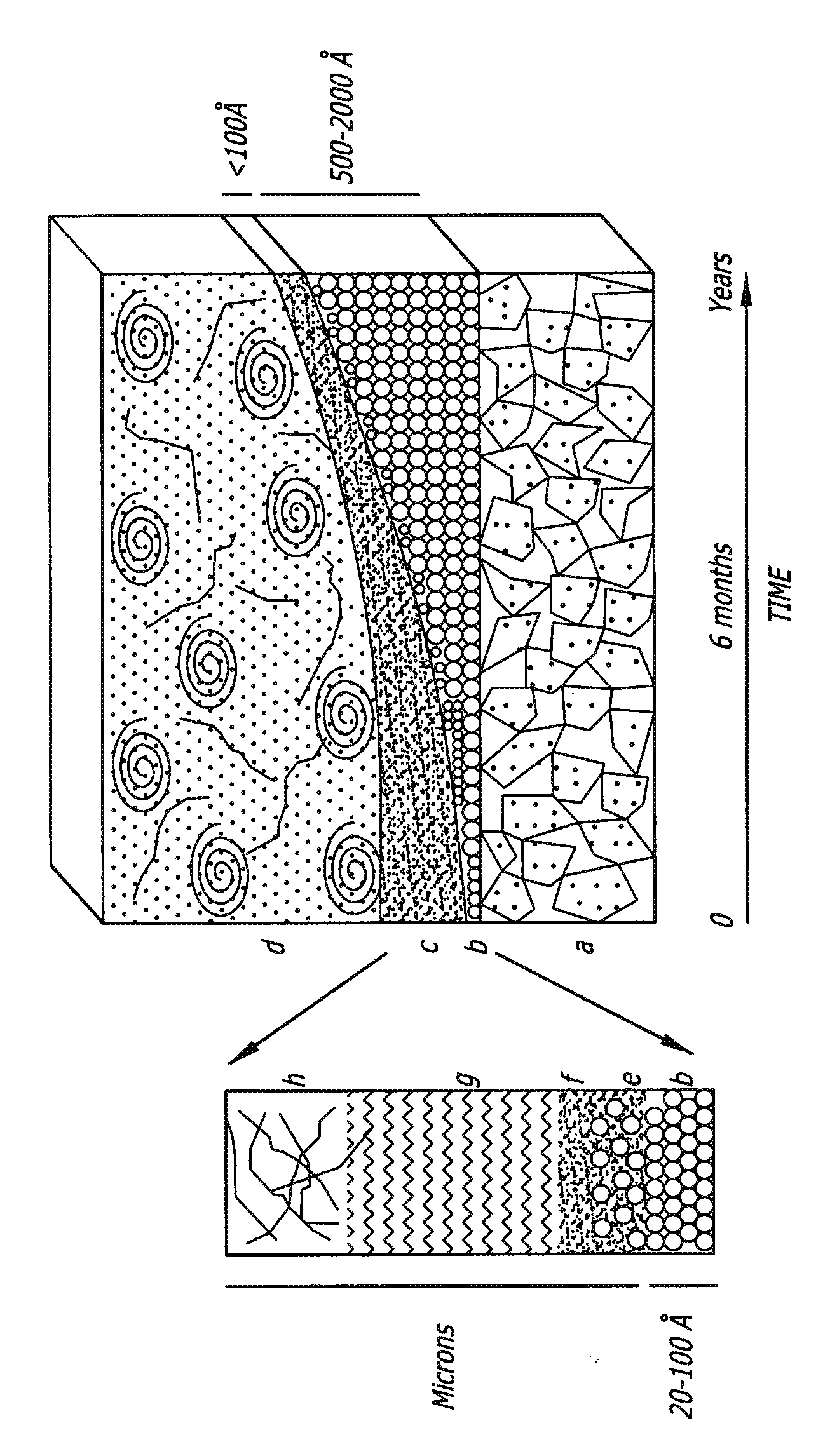

Osseointegration and biointegration coatings for bone screw implants

Novel orthopaedic bone screws / spinal pedicle screws and implants that include coatings to help promote a structurally stable interface between the implant and the patient's bone / tissue, and methods of coating such screws and implants are provided. The implants and methodologies described involve at least a coating that facilitates osseous integration, and additionally at least one coating that either reduces the risk of infection in immunologically suppressed patients and / or for utilization in patients who have infection, but who require stabilization, or coatings that permit the use of dissimilar metals and prevent galvanic corrosive reactions.

Owner:AEOLIN

Drum washing machine and clothes dryer using peltier thermoelectric module

InactiveUS7526879B2Drying efficiencyDrying energyAgriculture tools and machinesDrying gas arrangementsPower flowEngineering

A drum washing machine and a clothes dryer equipped with a thermoelectric module are disclosed. The thermoelectric module includes a heat absorption side and a heat dissipation side which absorbs and dissipates heat at a junction between two dissimilar metals depending on direction of current flow through the junction. The heat absorption side is disposed at a hot air flowing passage. Accordingly, the drying apparatus can increase energy efficiency with minor structural modification and becomes environmentally friendly unlike a conventional drying apparatus using a heat pump.

Owner:LG ELECTRONICS INC

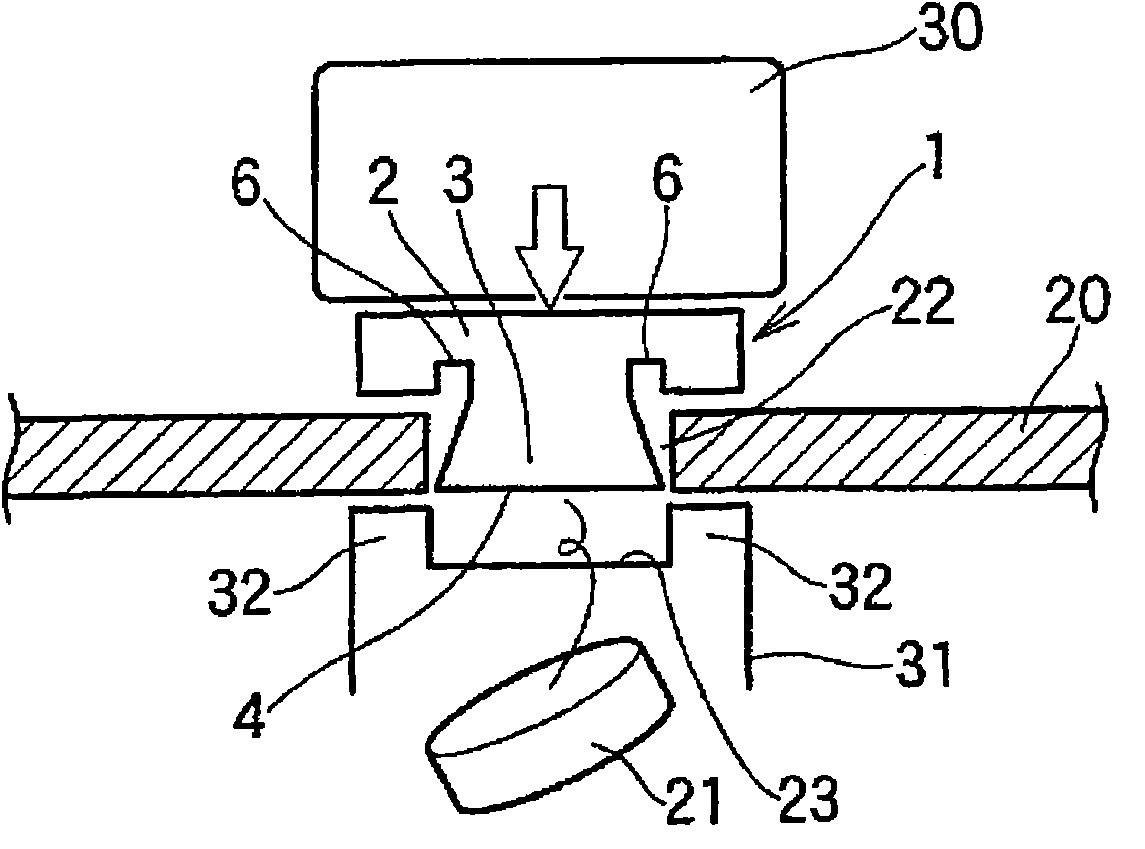

Method for joining dissimilar metals of steel product and light metal product with each other

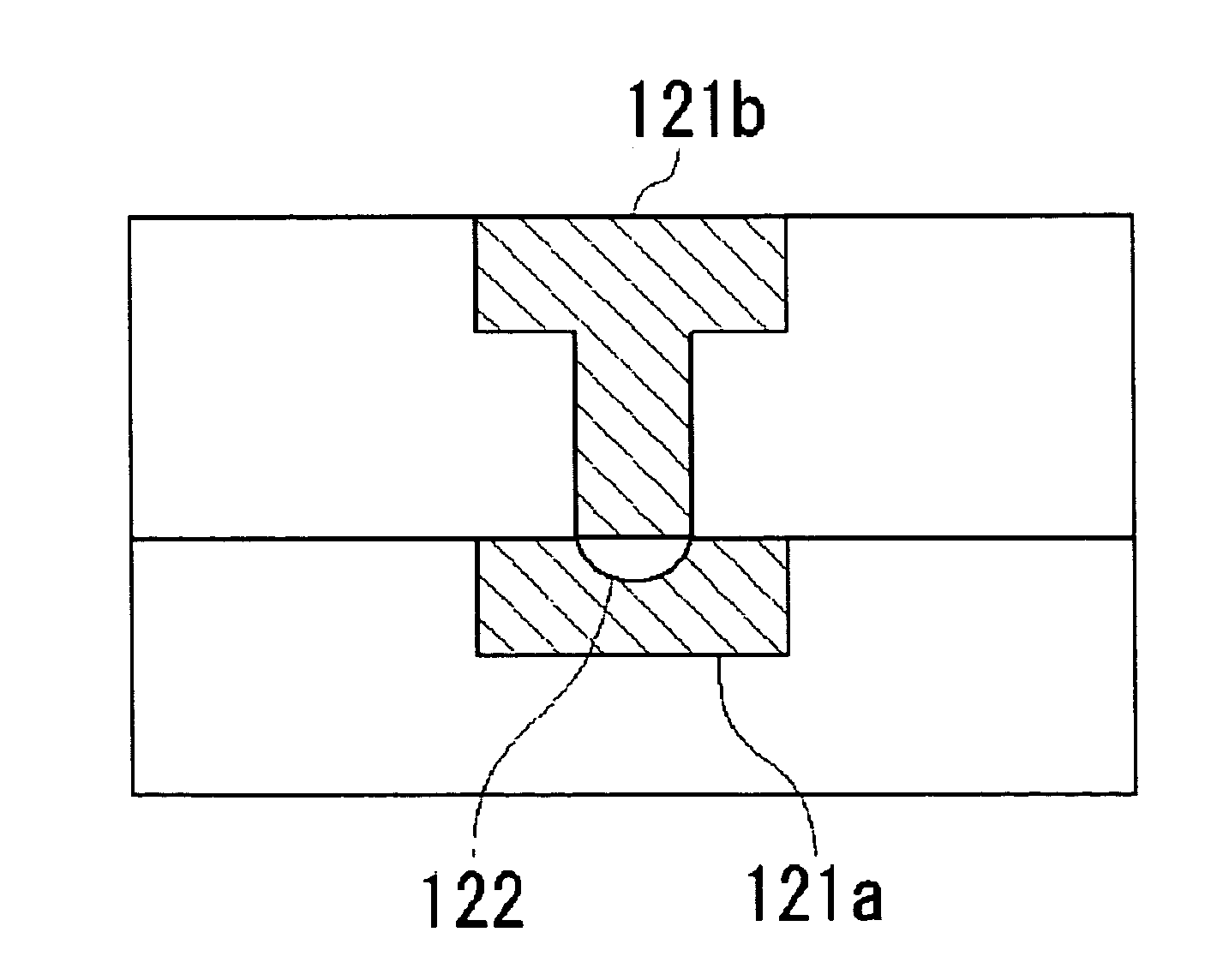

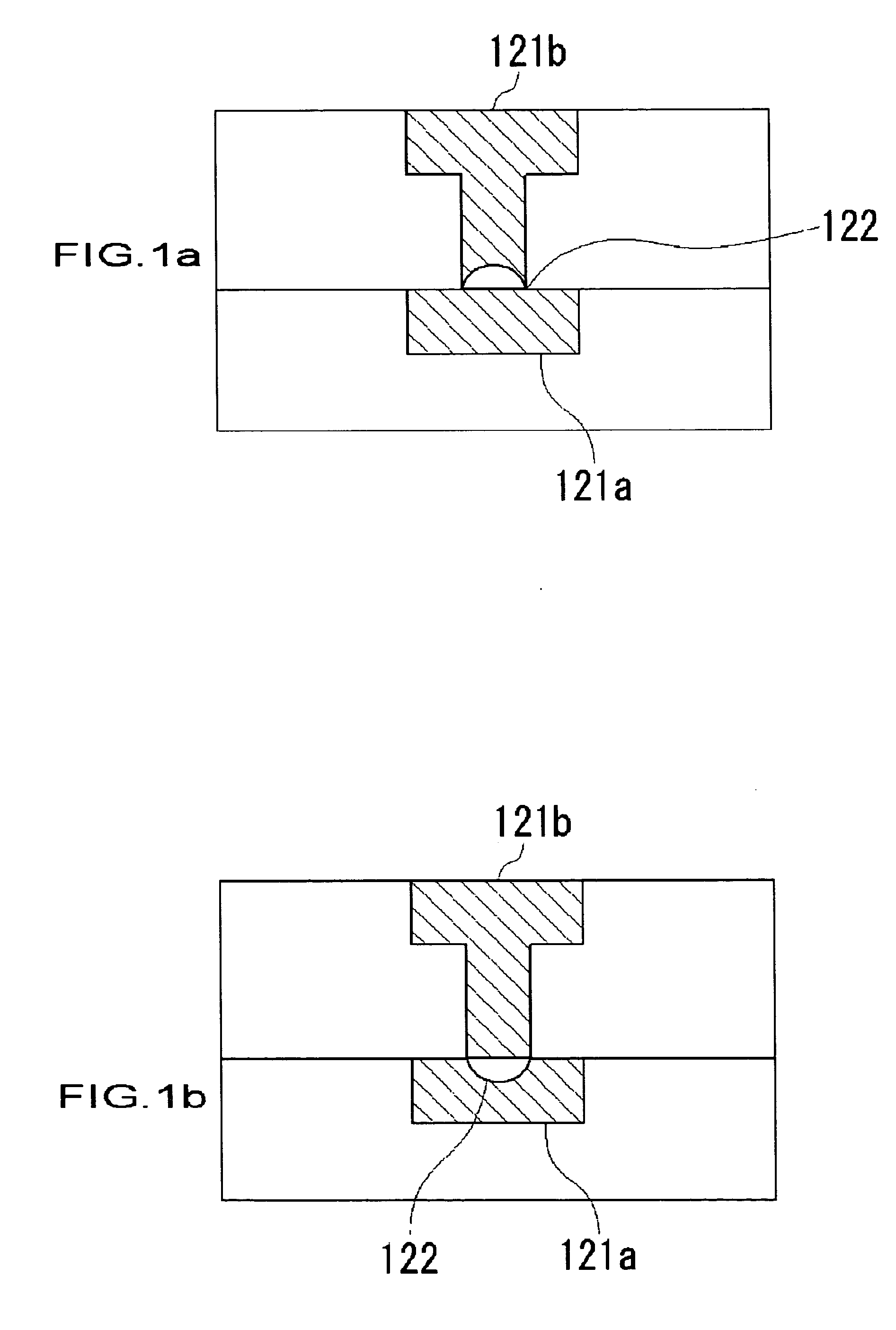

InactiveUS20090294410A1Overcome limitationsImprove joint strengthShrinkage connectionsSheet joiningSpot weldingUltimate tensile strength

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron—iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

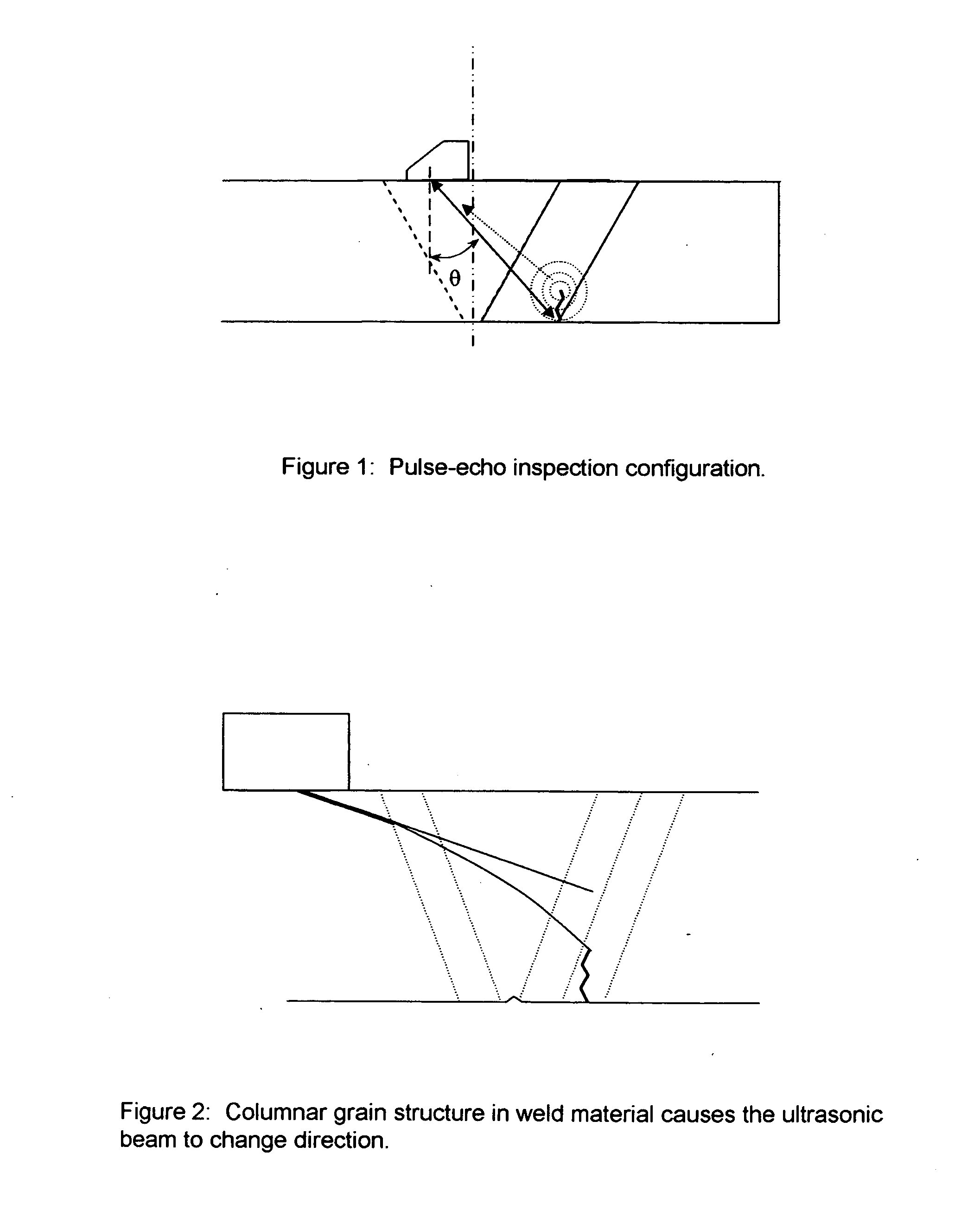

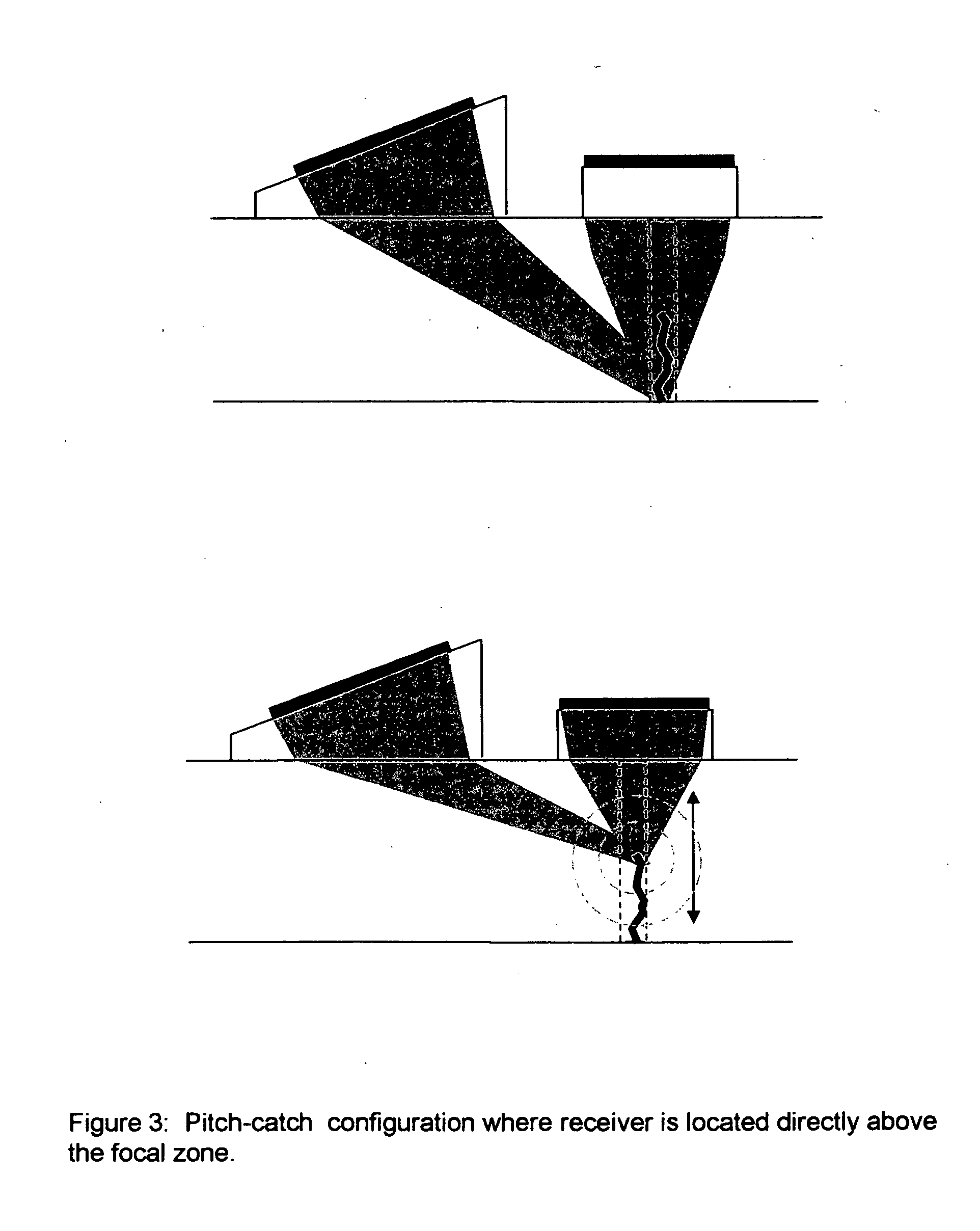

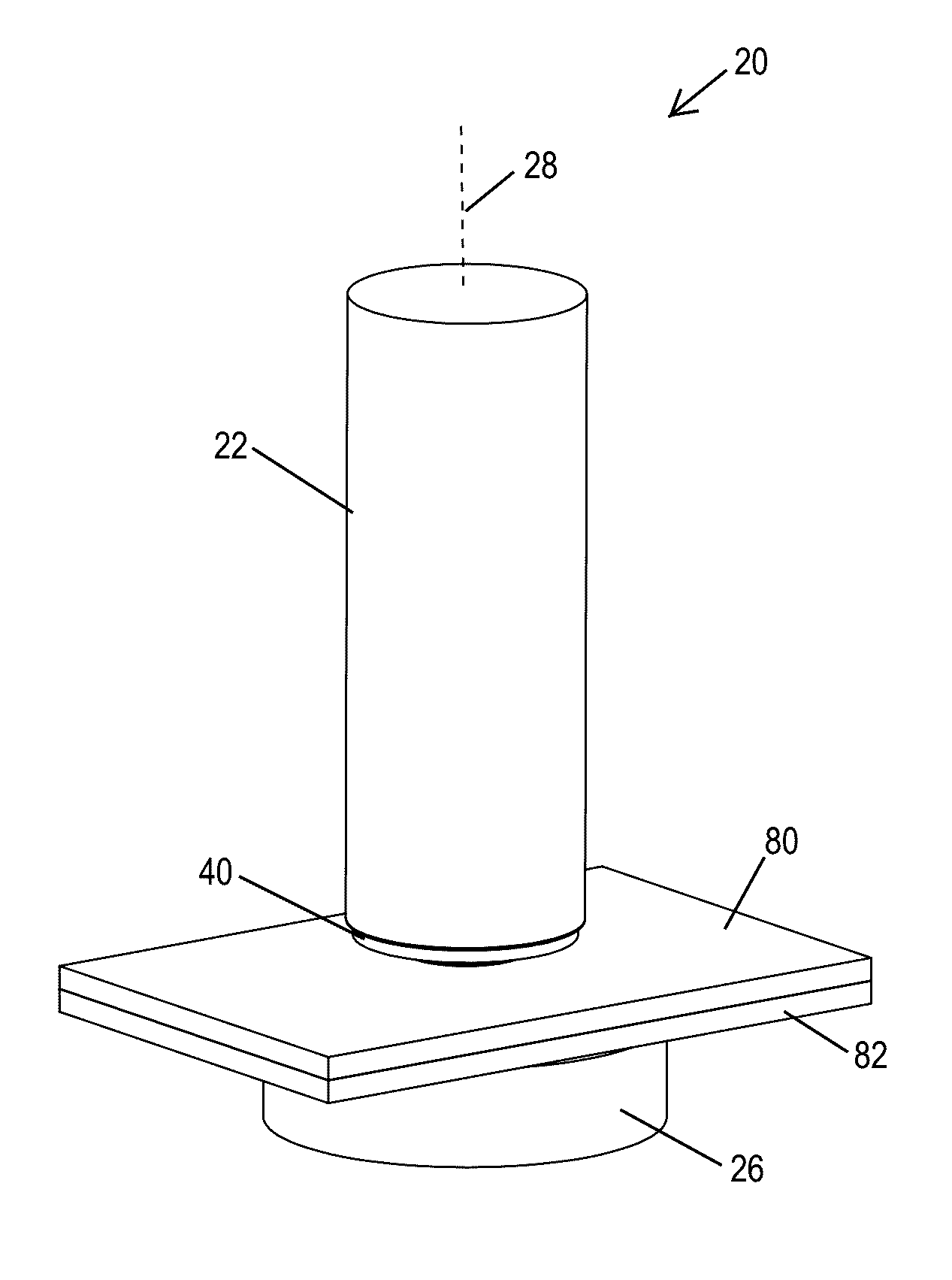

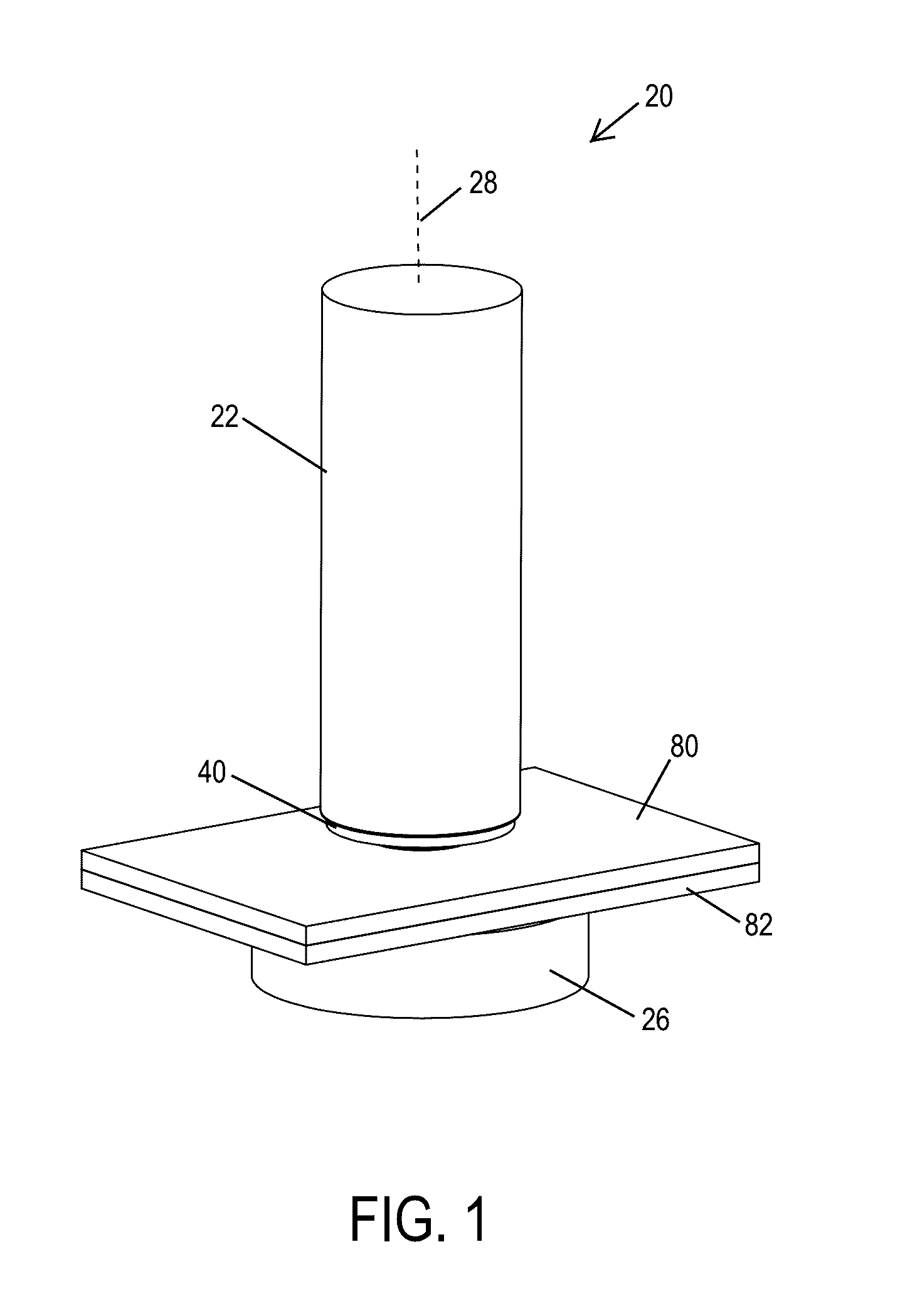

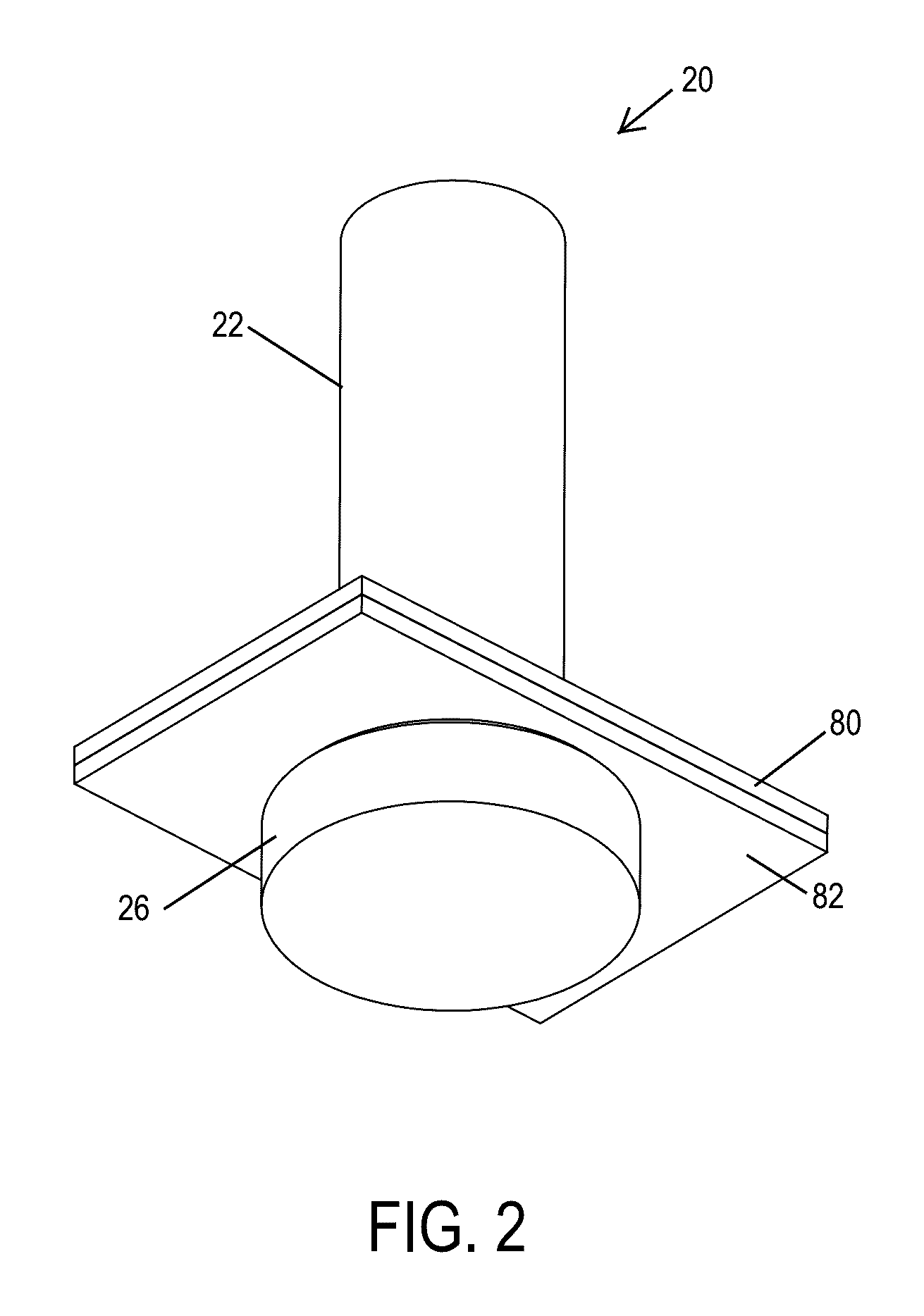

Ultrasonic method for the accurate measurement of crack height in dissimilar metal welds using phased array

InactiveUS20070000328A1Guaranteed normal transmissionEfficient receptionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesLight beamPhased array

An ultrasonic method and apparatus utilizing phased array technology for obtaining accurate crack height measurements in materials where crystallographic structure creates beam reduction effects.

Owner:BUTSTREETCAR JONATHAN

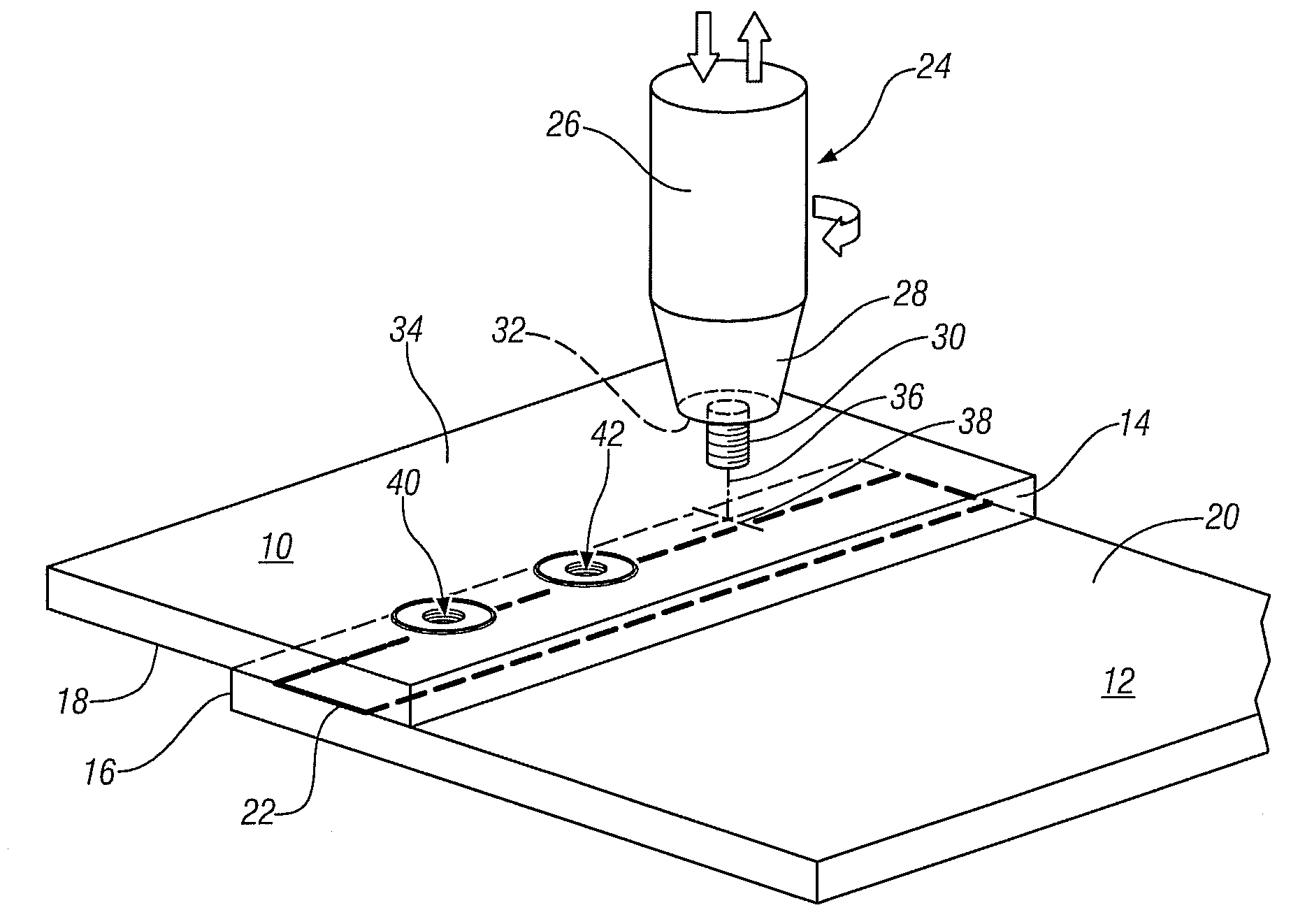

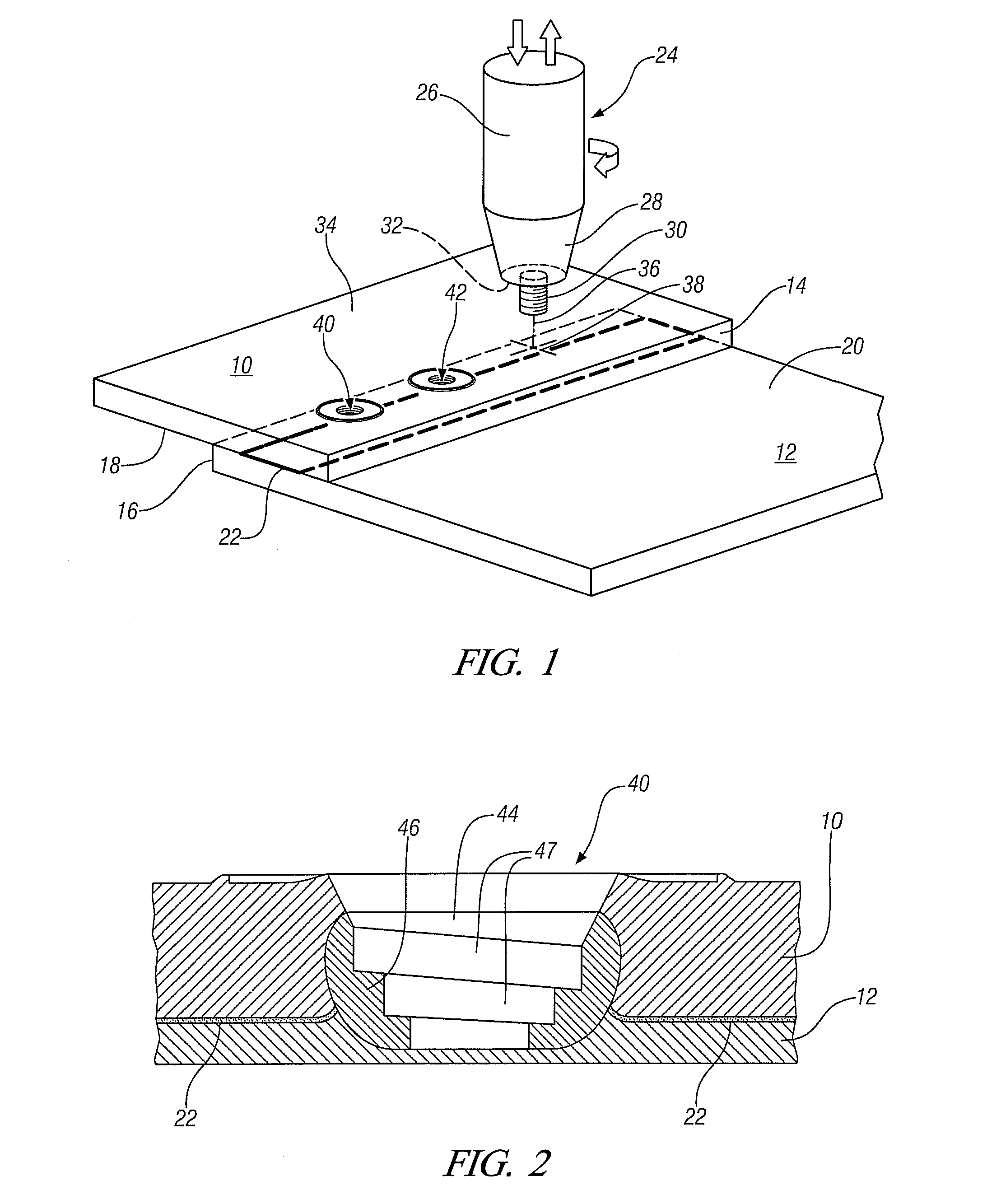

Friction stir welding fastener

ActiveUS9555580B1Joining is strengthenedReduce the amount requiredLaminationLamination apparatusMulti materialEngineering

A heat assisted friction stir welding system and fastener for use therewith allows the joining a variety of dissimilar materials, including joining composites and plastics to metal, in which the fastener becomes part of the bond. The fastener can be constructed from multiple materials, allowing for the joining of dissimilar metals. Heating the materials to be joined reduces the clamping force and torque required by the friction stir weld process. The result is a bond that is stronger with less energy input.

Owner:TEMPER IP

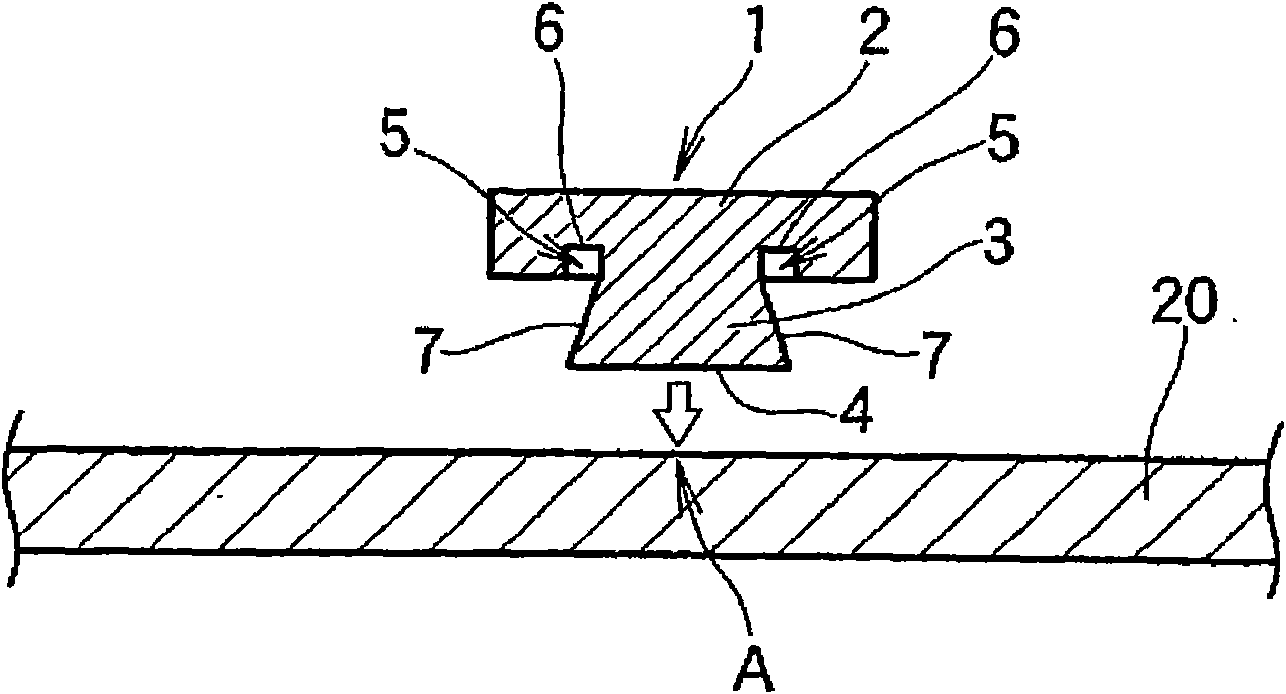

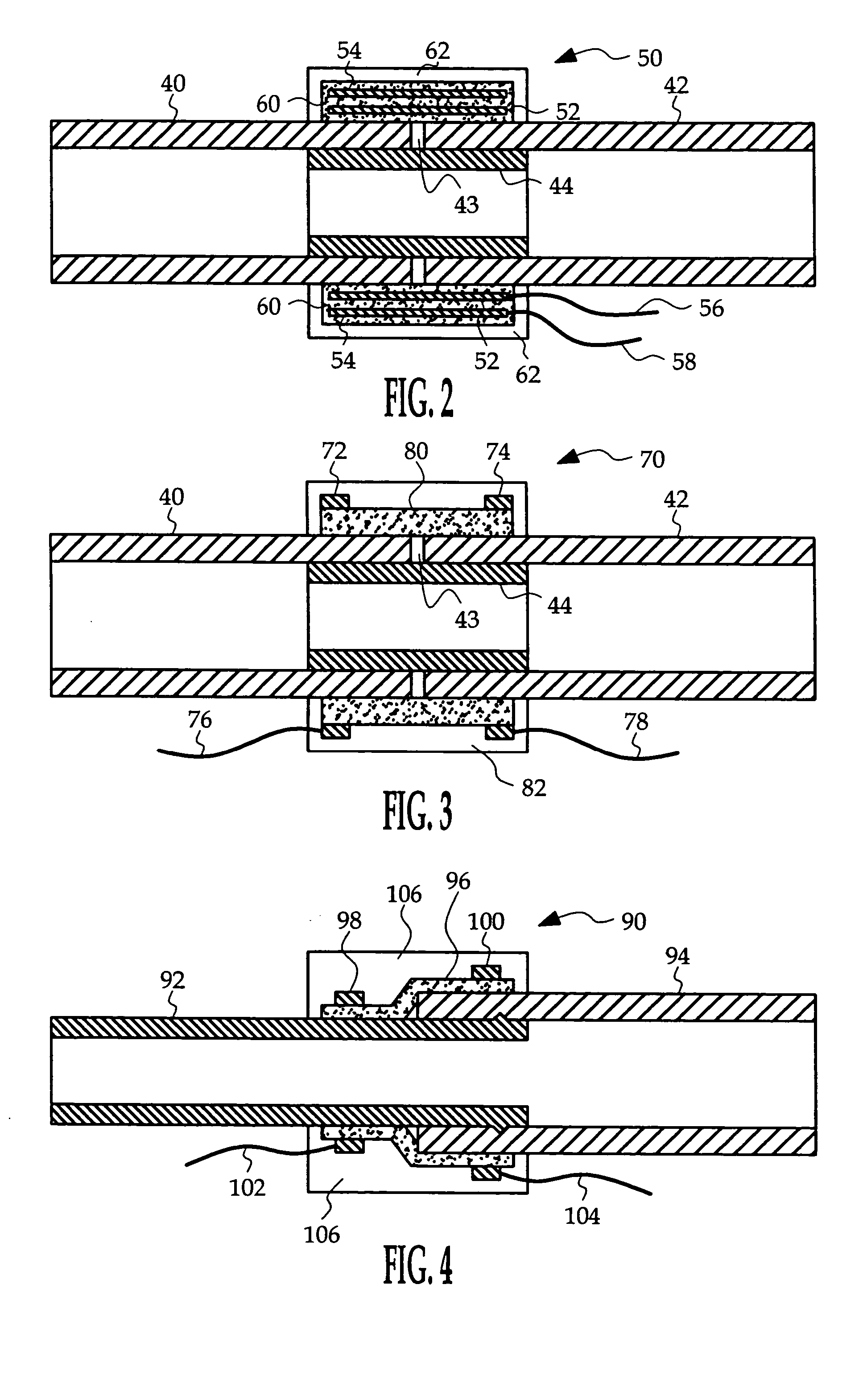

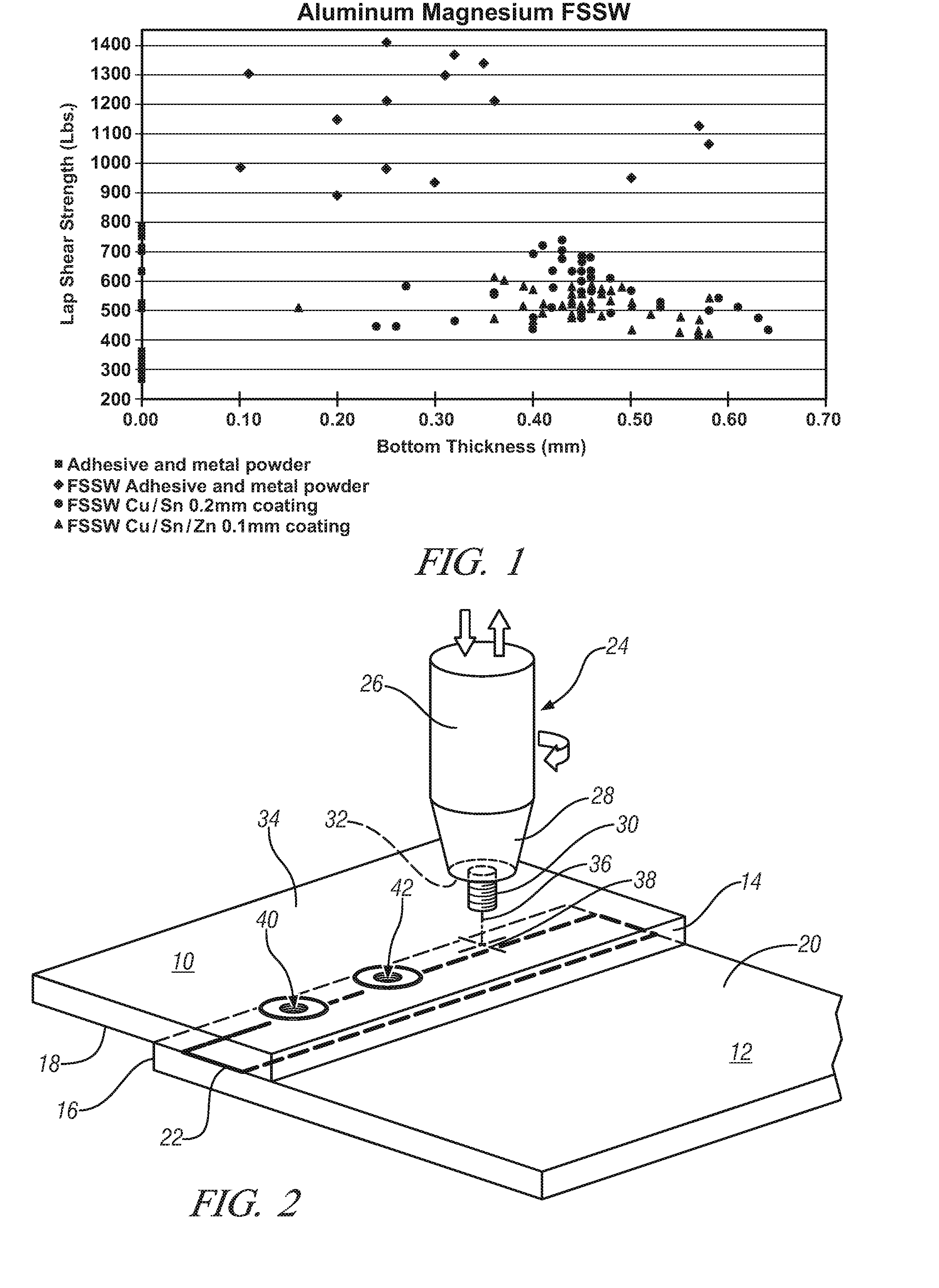

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for joining dissimilar metals of steel product and light metal product

InactiveCN101590598AOvercome limitationsRemove constraintsShrinkage connectionsSheet joiningMetallic materialsSpot welding

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron-iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

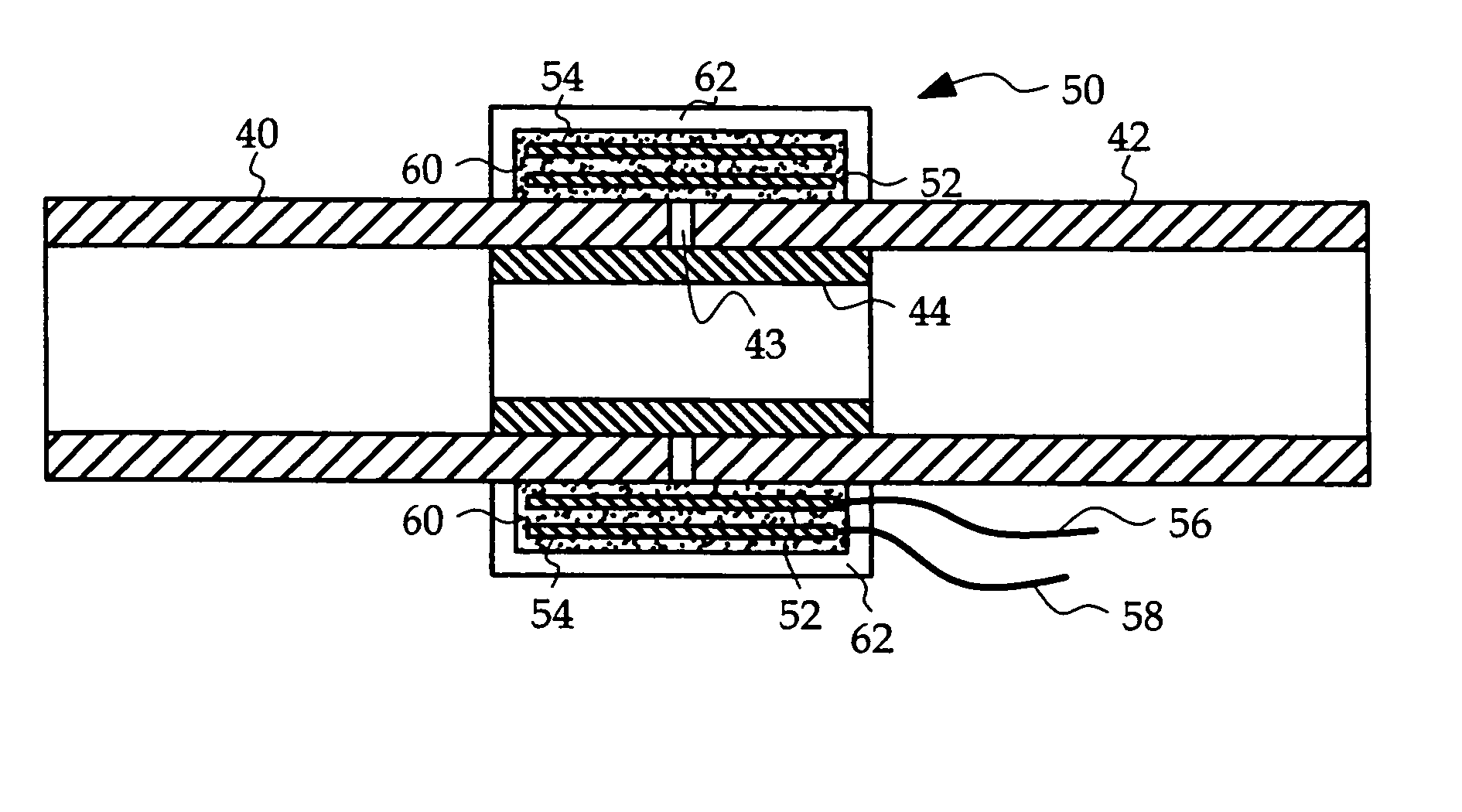

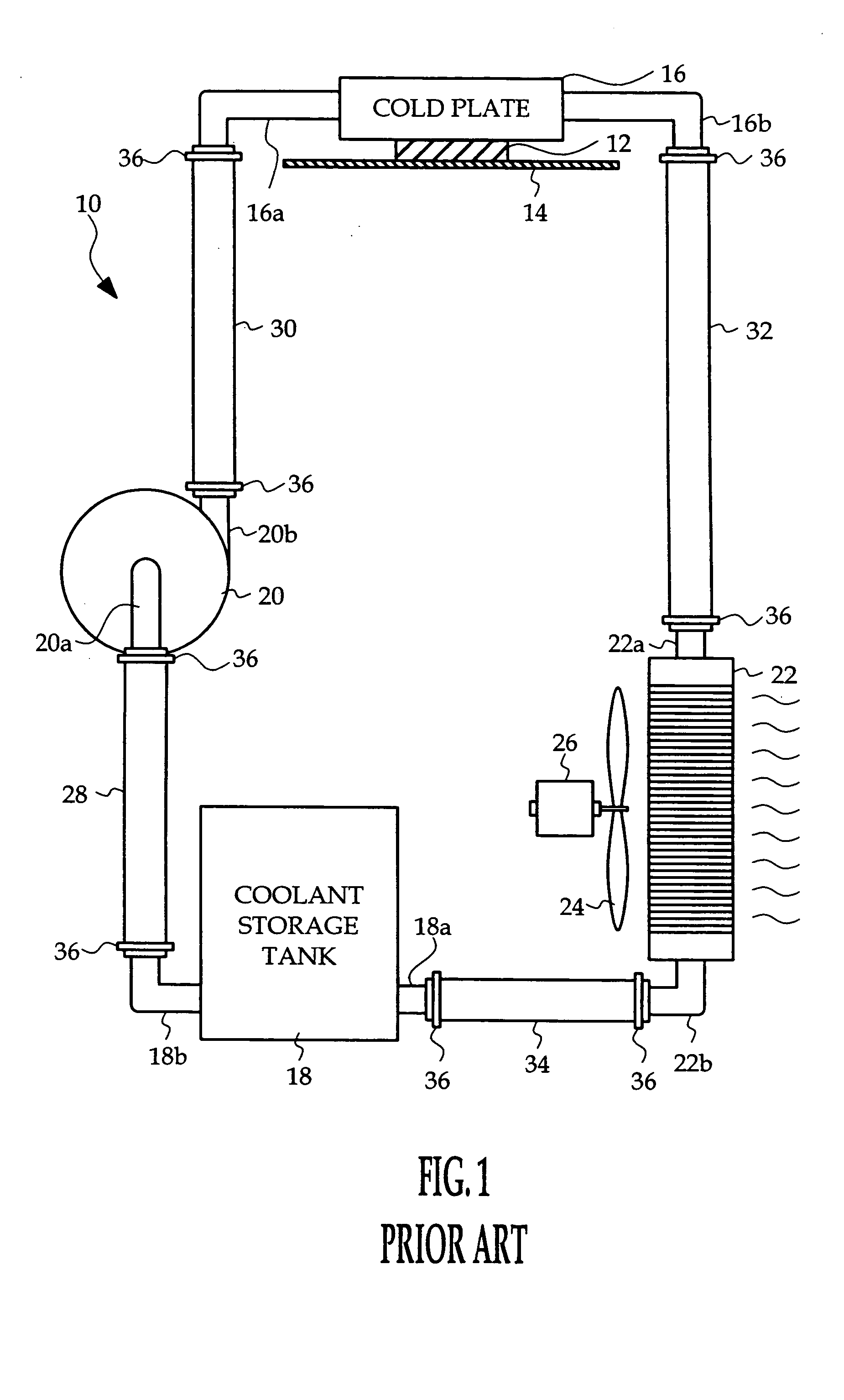

Leak detection apparatus for a liquid circulation cooling system

InactiveUS20050092070A1Lower resistanceDetection of fluid at leakage pointElectricityElectrical resistance and conductance

A leak detection apparatus includes one or more detection devices that envelope the various pipe joints of a liquid circulation cooling system. In one approach, the detection devices include a pair of conductors separated by a wicking material impregnated with a crystalline salt that provides a low resistance electrical path between the conductors in the presence of a leak. In another approach, the detection devices include a pair of dissimilar metal mesh electrodes separated by an electrolyte-impregnated wicking material to form a water-activated battery that energizes an alarm in the presence of a leak. In either case, the electrodes and wicking material may be encased with a water-activated sealing material that hardens in the presence of a leak to contain the leakage.

Owner:DELPHI TECH INC

Friction stir welding of dissimilar metals

InactiveUS20100089976A1Improve adhesionImprove joint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesAdhesiveMaterials science

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions including an adhesive placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of an adhesive with copper, tin, zinc, and / or other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

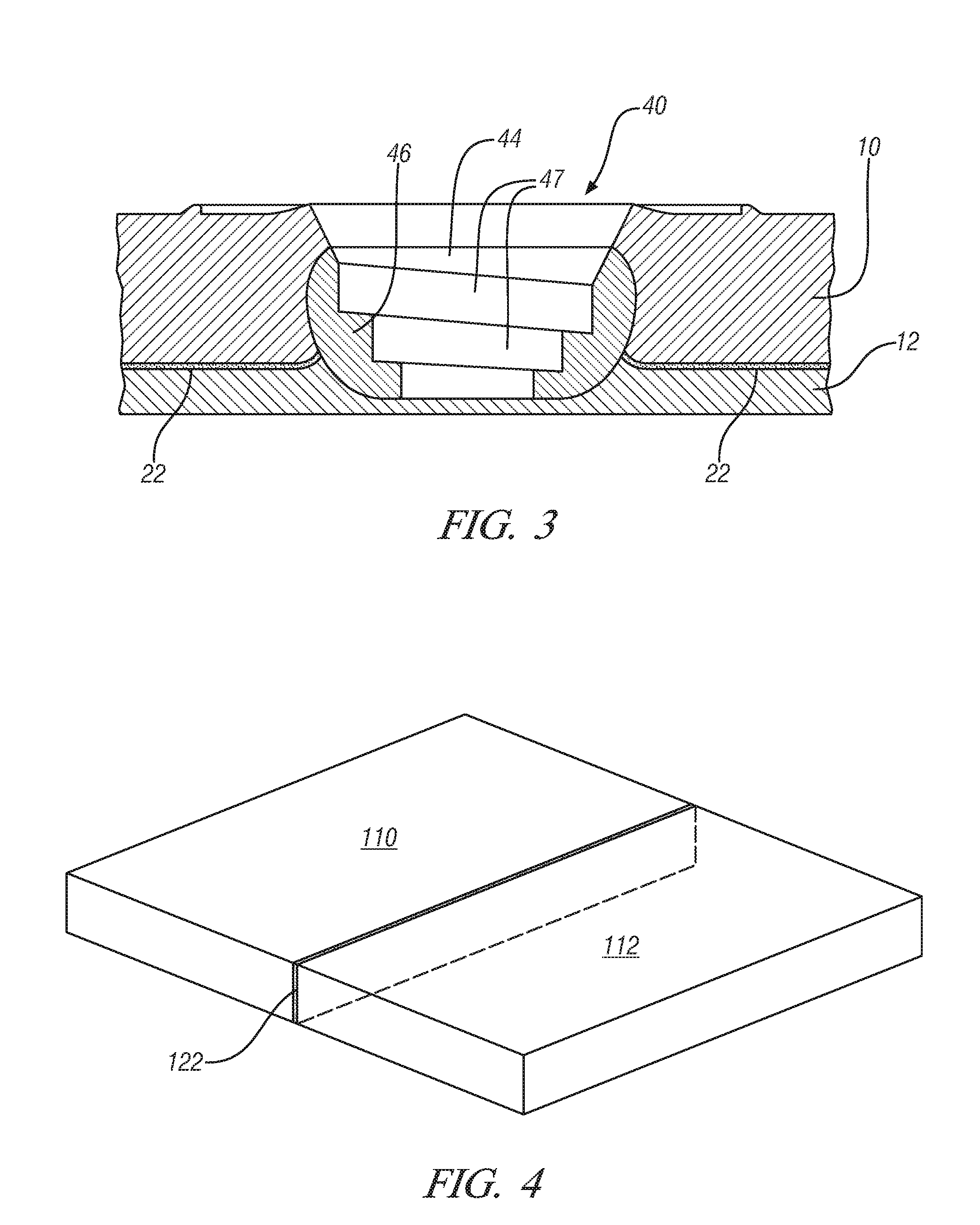

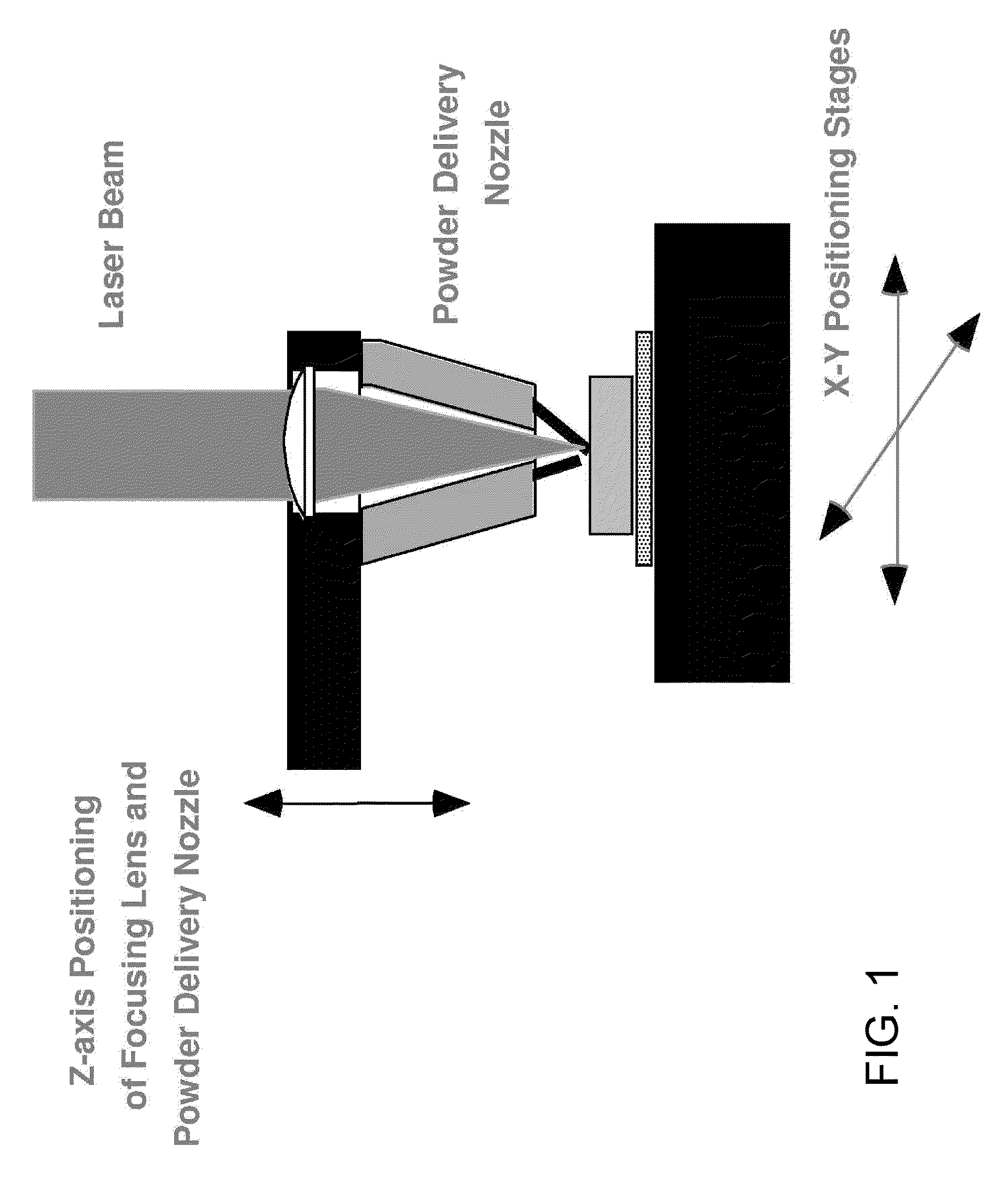

Graded transitions for joining dissimilar metals and methods of fabrication therefor

InactiveUS20090208773A1Cooking-vessel materialsAdditive manufacturing apparatusChemical compositionControl manner

A transition joint for joining dissimilar metals with the chemical composition of the joint varied in a controlled manner from end to end. The transition joint has a first end of having a chemical composition similar to that of one of the metals to be joined and a second end having a chemical composition similar to that of the other metal with a gradual composition variation between the first and second ends.

Owner:LEHIGH UNIVERSITY

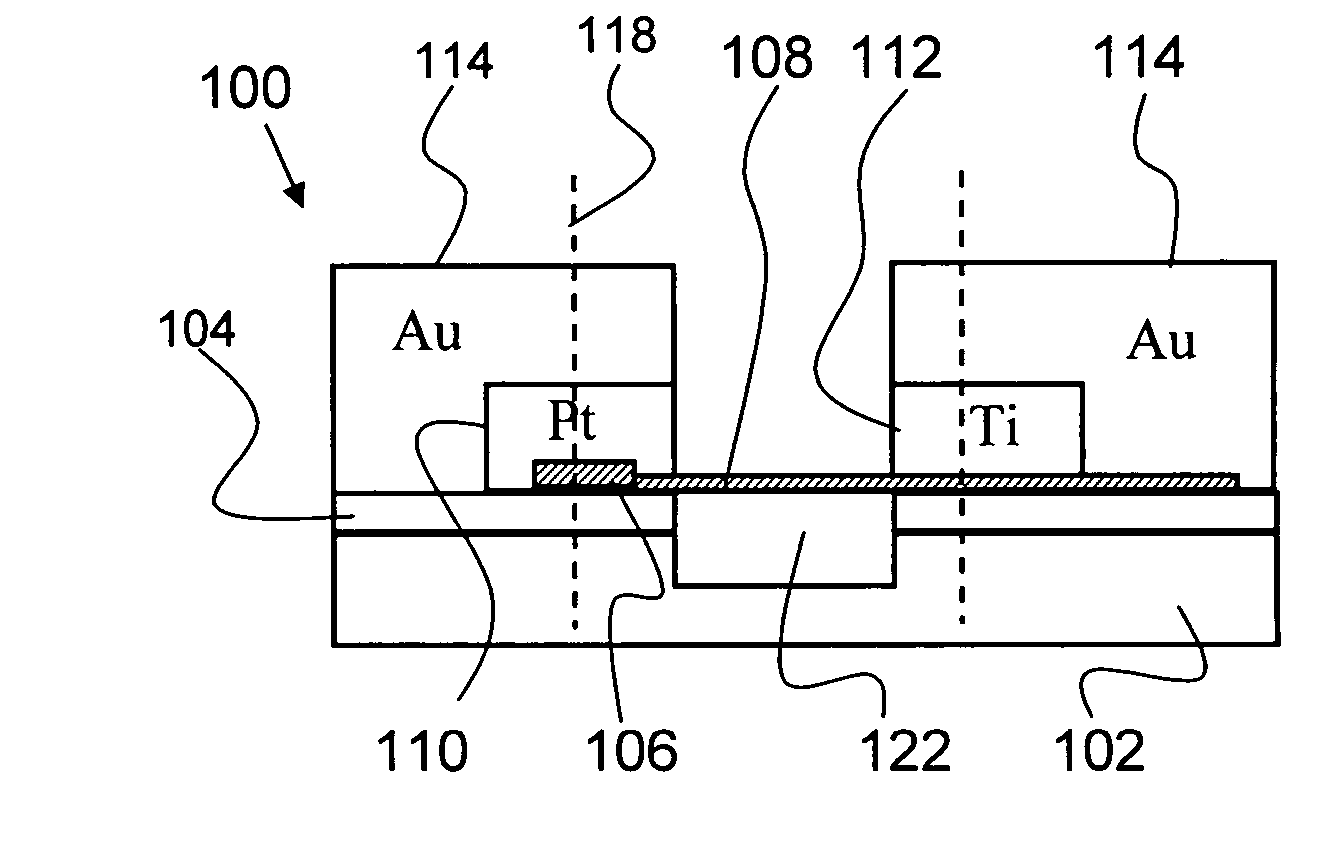

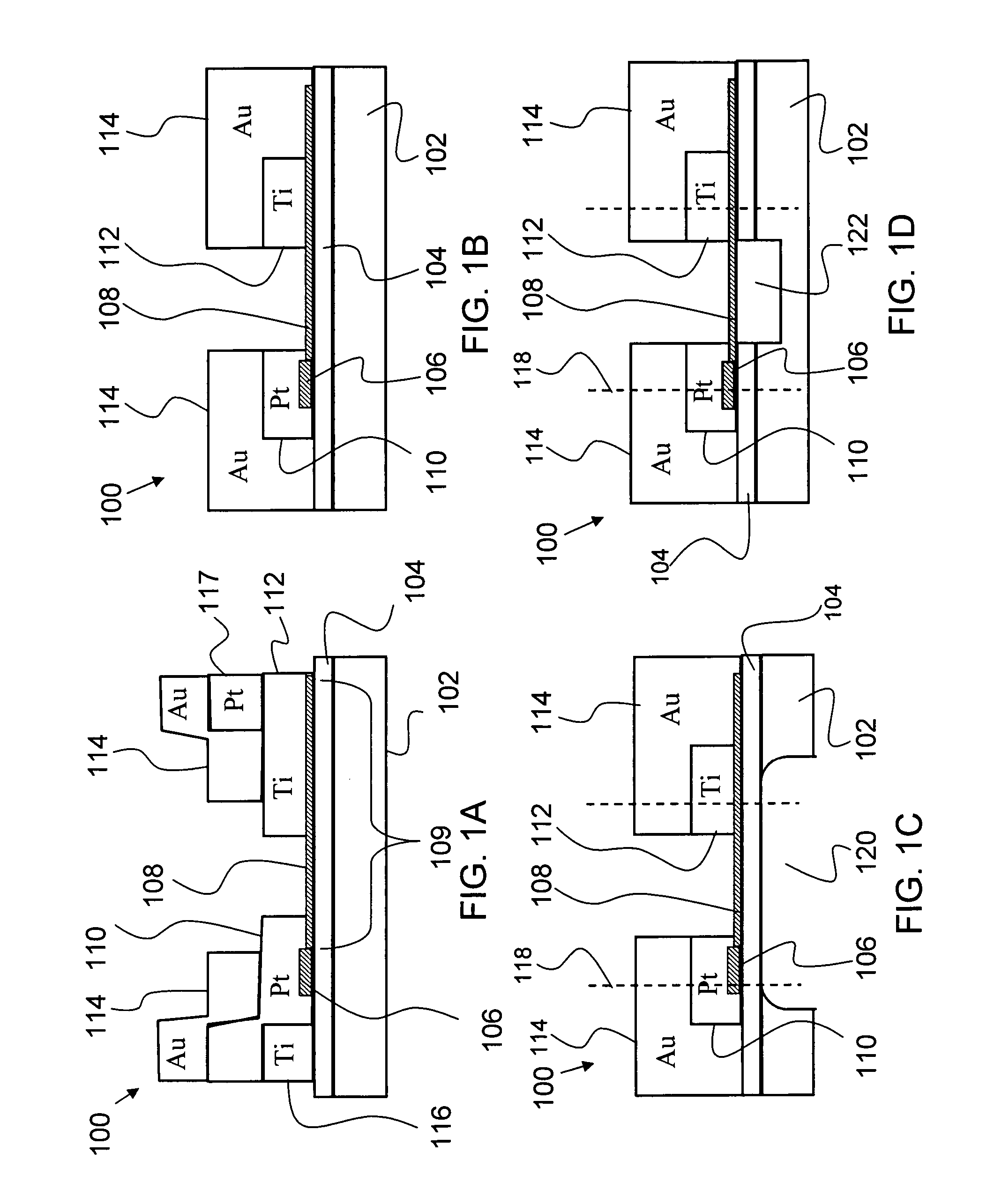

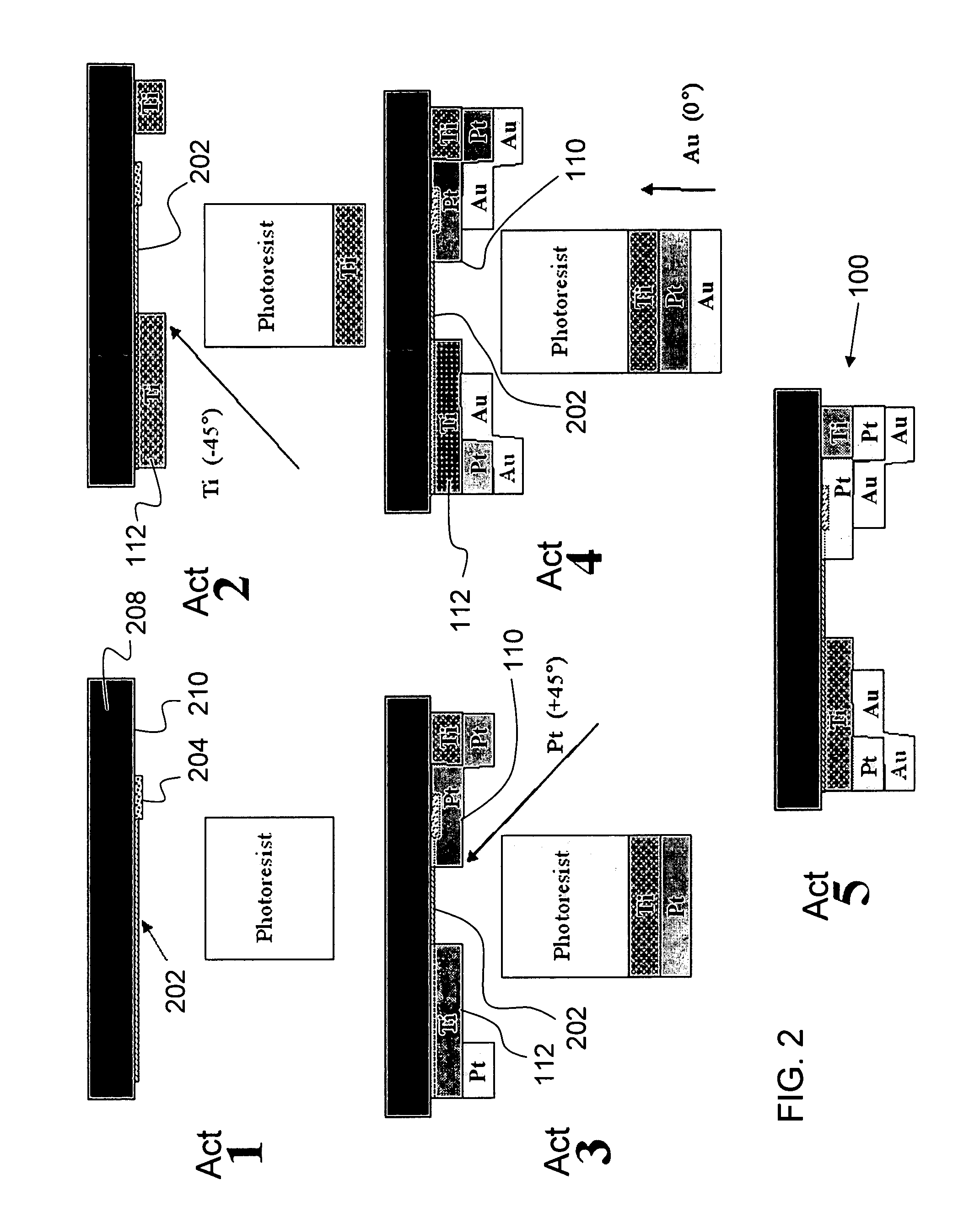

Nanotube Schottky diodes for high-frequency applications

InactiveUS20060261433A1Lower work functionImprove work functionNanoinformaticsSemiconductor/solid-state device manufacturingEvaporationNanotube

Described is a Schottky diode using semi-conducting single-walled nanotubes (s-SWNTs) with titanium Schottky and platinum Ohmic contacts for high-frequency applications. The diodes are fabricated using angled evaporation of dissimilar metal contacts over an s-SWNT. The devices demonstrate rectifying behavior with large reverse-bias breakdown voltages of greater than −15 V. In order to decrease the series resistance, multiple SWNTs are grown in parallel in a single device, and the metallic tubes are burnt-out selectively. At low biases, these diodes showed ideality factors in the range of 1.5 to 1.9. Modeling of these diodes as direct detectors at room temperature at 2.5 terahertz (THz) frequency indicates noise equivalent powers (NEP) comparable to that of the state-of-the-art gallium arsenide sold-state Schottky diodes, in the range of 10-13 W / square-root (√) Hz.

Owner:CALIFORNIA INST OF TECH

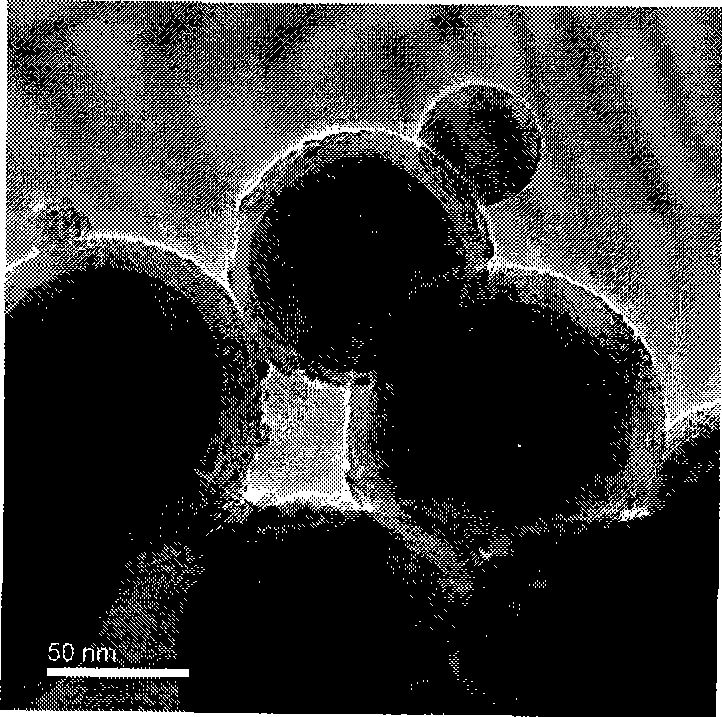

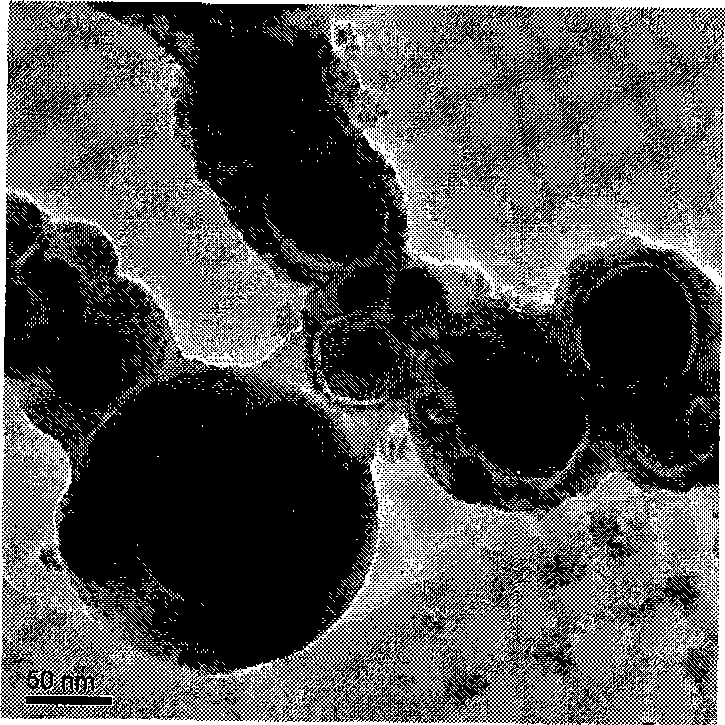

Synthesis method of metallic oxide coated dissimilar metal 'core/shell'nano-particles

The invention relates to a method for synthesizing a metal oxide-coated heterogeneous metal core-shell type nanometer particle, which belongs to the technical field of synthesizing nanometer composite material. The method is characterized in that metal and heterogeneous metal oxide micron powder is used as raw material and evenly mixed and pressed into block target material to be used as an anode. Hydrogen plasma is utilized as the heat source; the block target material is evaporated, and the core-shell type nanometer composite particle material is formed after the transformation of gaseous state-liquid state-solid state. The effect and advantage of the invention lies in that the root position-coating of the metal oxide pottery material to heterogeneous metal is realized in the process of evaporation and condensation; the invention is characterized by a simple method, low cost, little impurity, regular shape of the particle, and application to large scale production. The method can be used for preparing the core-shell type nanometer composite particles of a large variety of matters, and has wide application prospect in the fields of electromagnetic absorption / shielding, biomedicine, optoelectronic material, magnetic material, electrorheological fluid, and functional paint, etc.

Owner:DALIAN UNIV OF TECH

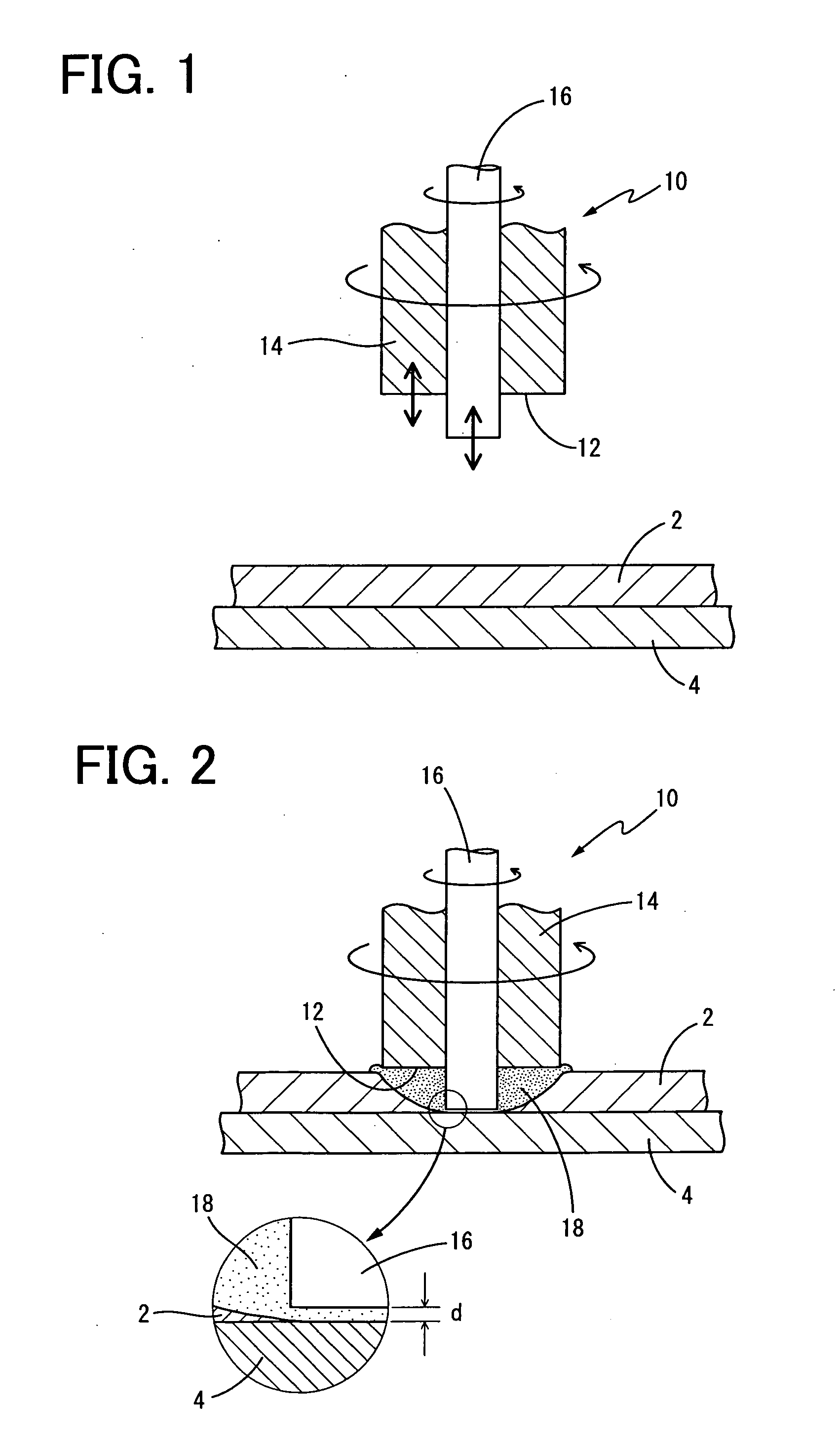

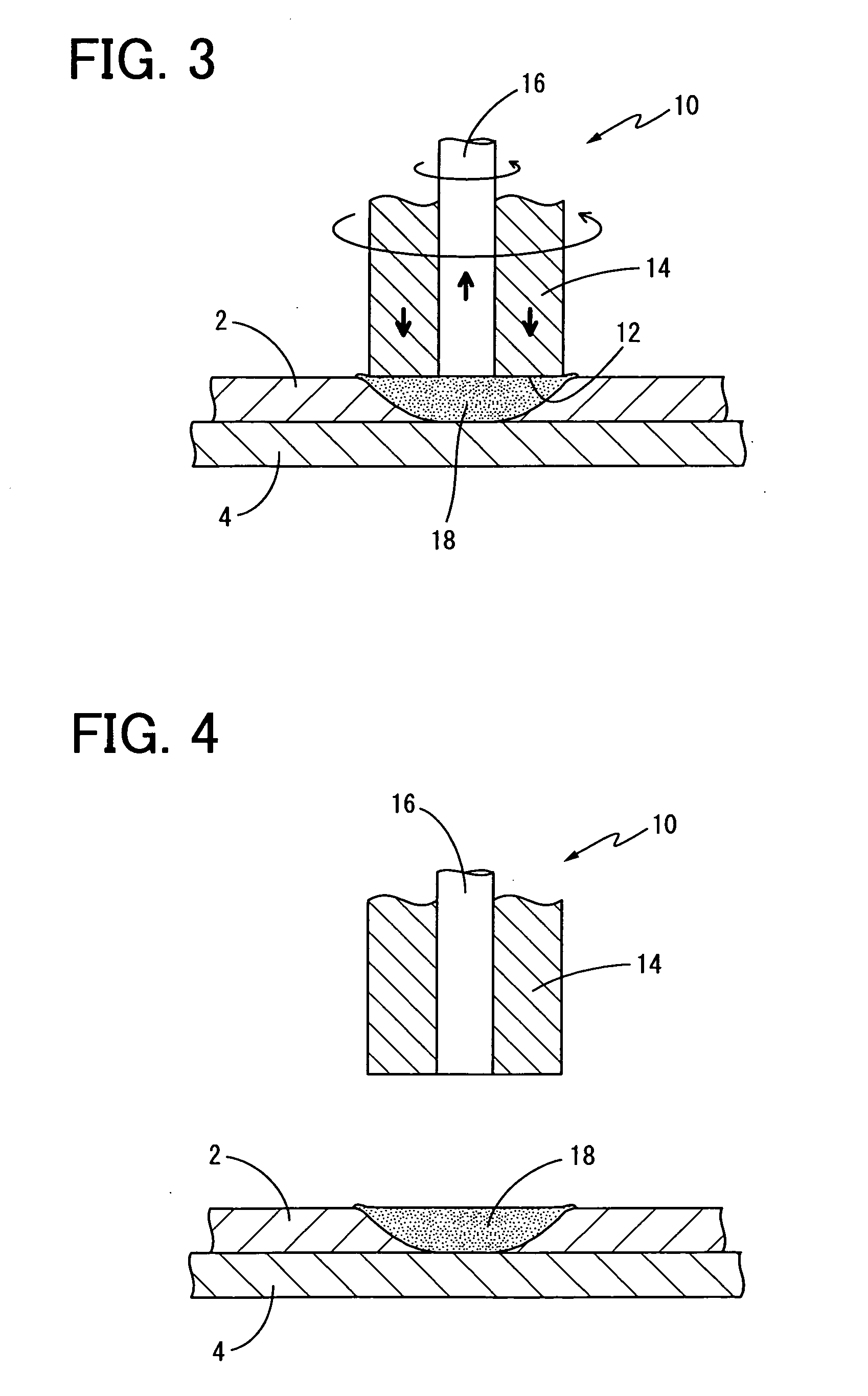

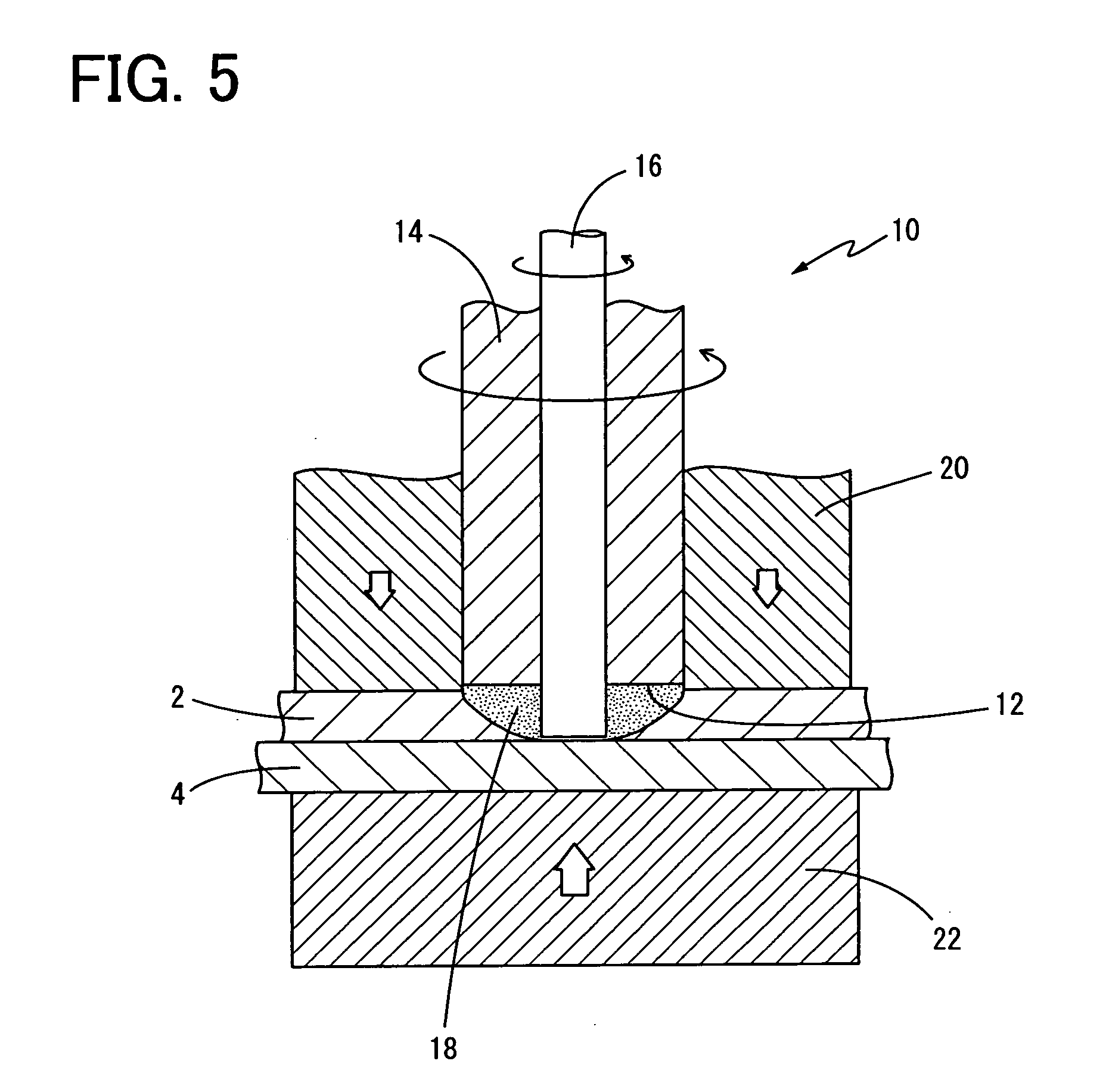

Method of joining together dissimilar metal members

InactiveUS20080029581A1Improve soundnessAny anxiety of causing galvanic corrosionCooking-vessel materialsWelding/soldering/cutting articlesSheet steelEngineering

A method of joining together dissimilar metal members, by superposing a first member formed of an aluminum plate and a second member formed of a steel plate on each other, and performing a friction stir welding operation by rotating a probe located coaxially with and at an end of a shoulder member of a rotary tool, while the probe is inserted into the first member in a way that a tip of the prove reaches right above the second member, wherein a double-acting rotary tool is used as the rotary tool, and after the friction stir welding operation is performed, the probe is removed from thus formed friction stir zone while a probe hole formed by the removal of the prove is filled by a material flown from another part of the friction stir zone other than a part, from which the probe is removed.

Owner:SUMITOMO LIGHT METAL INDS LTD

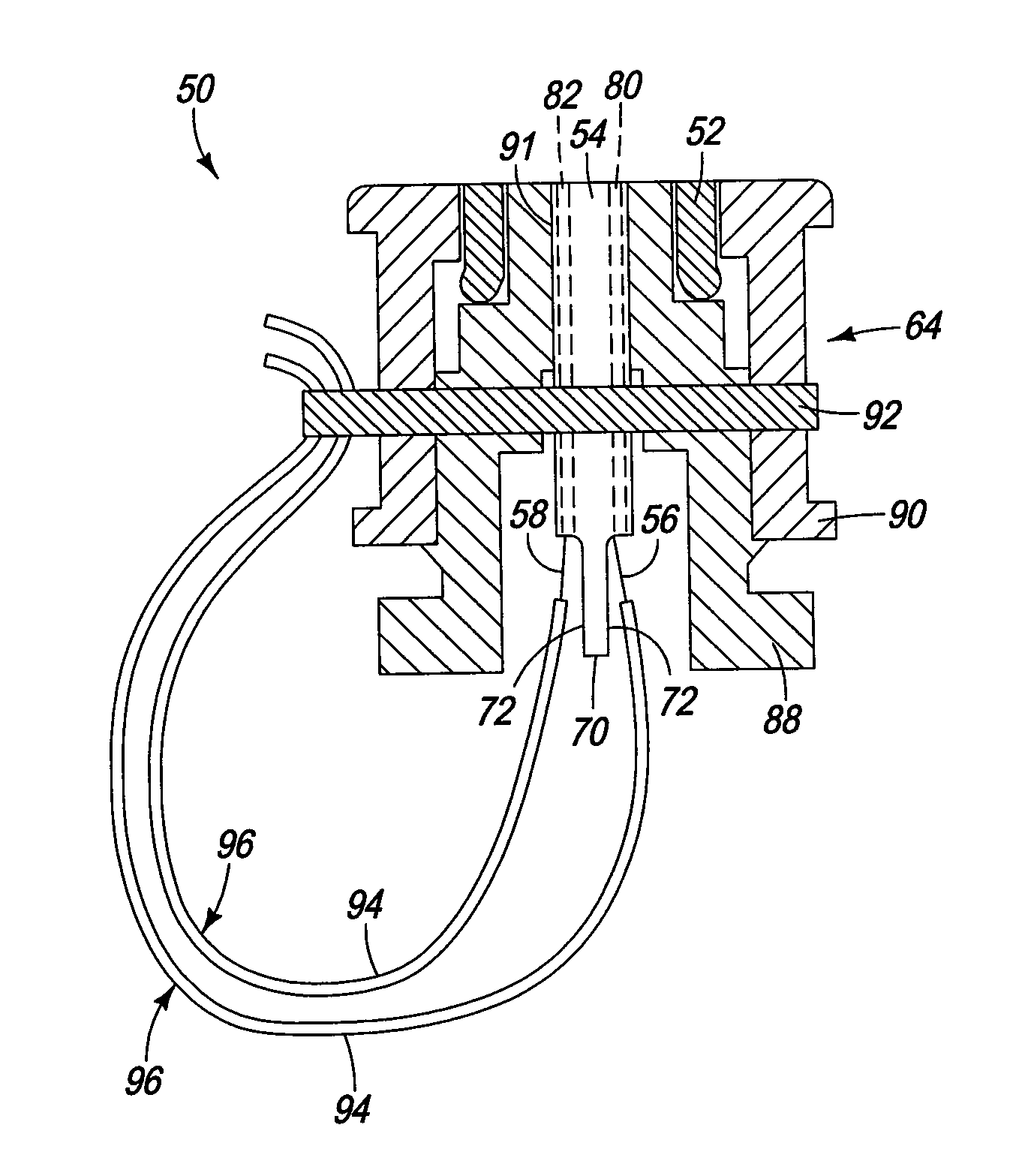

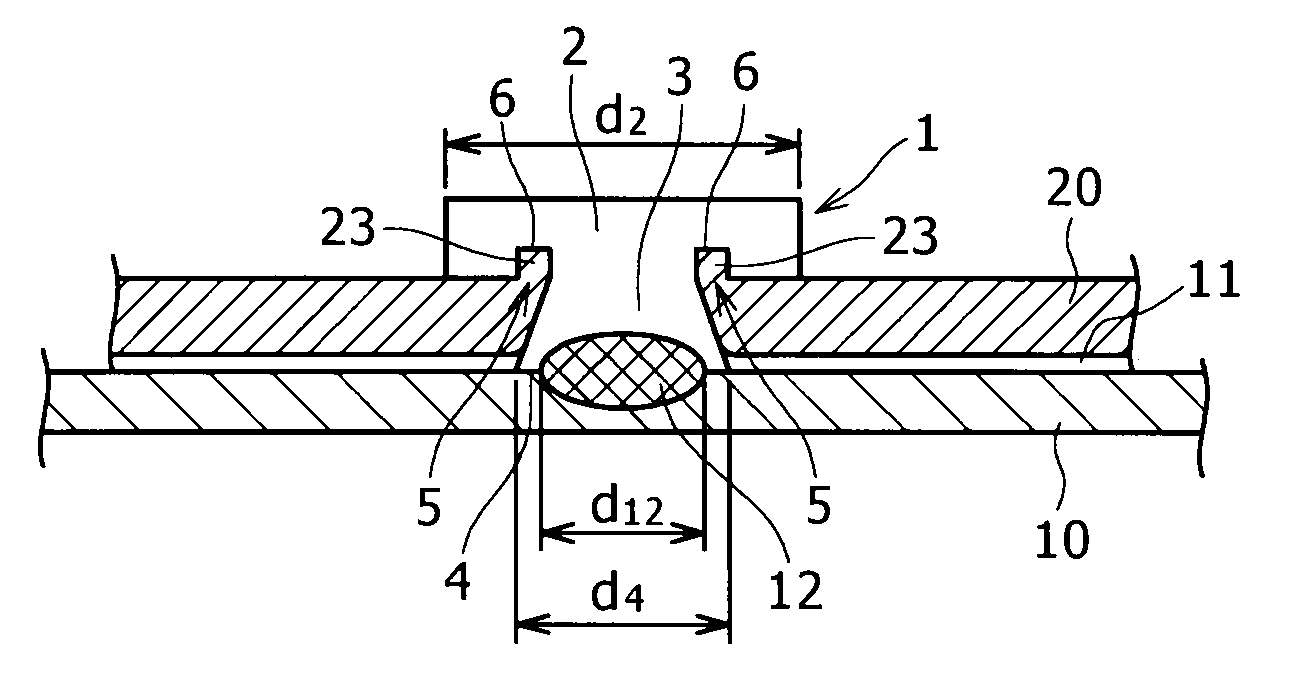

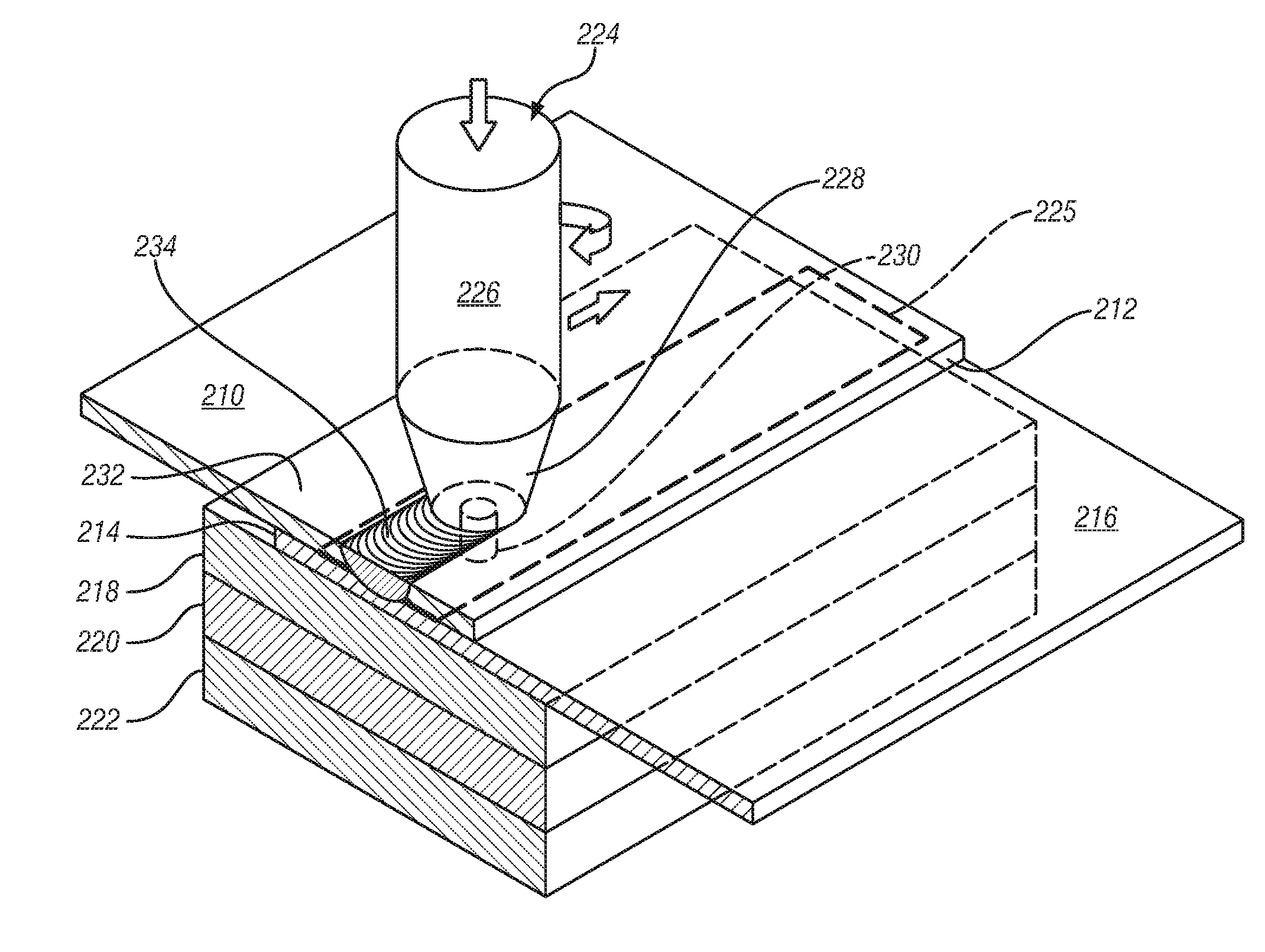

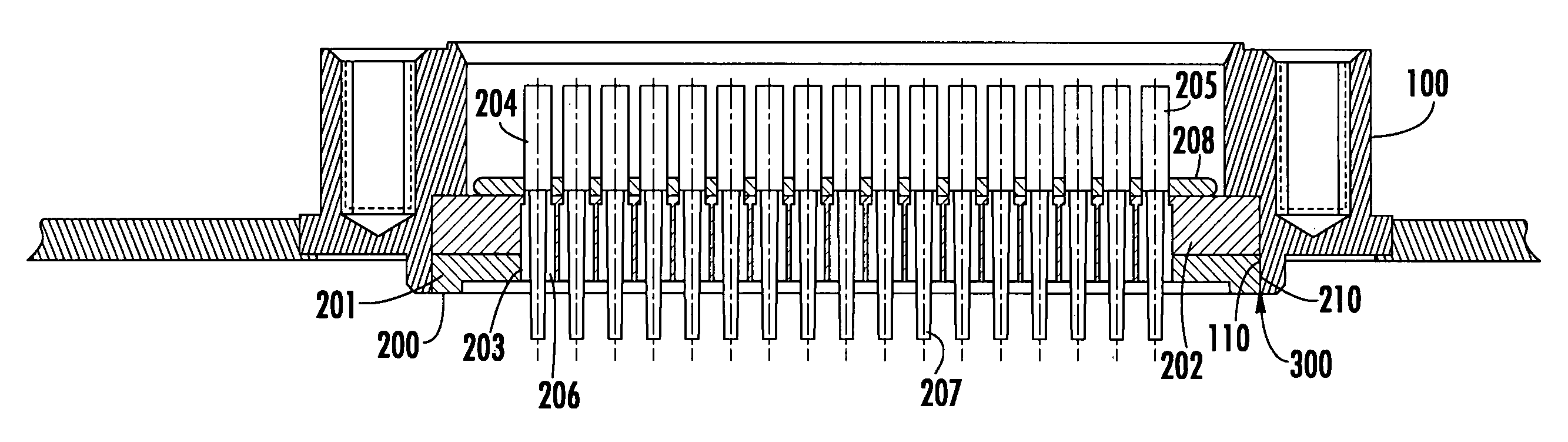

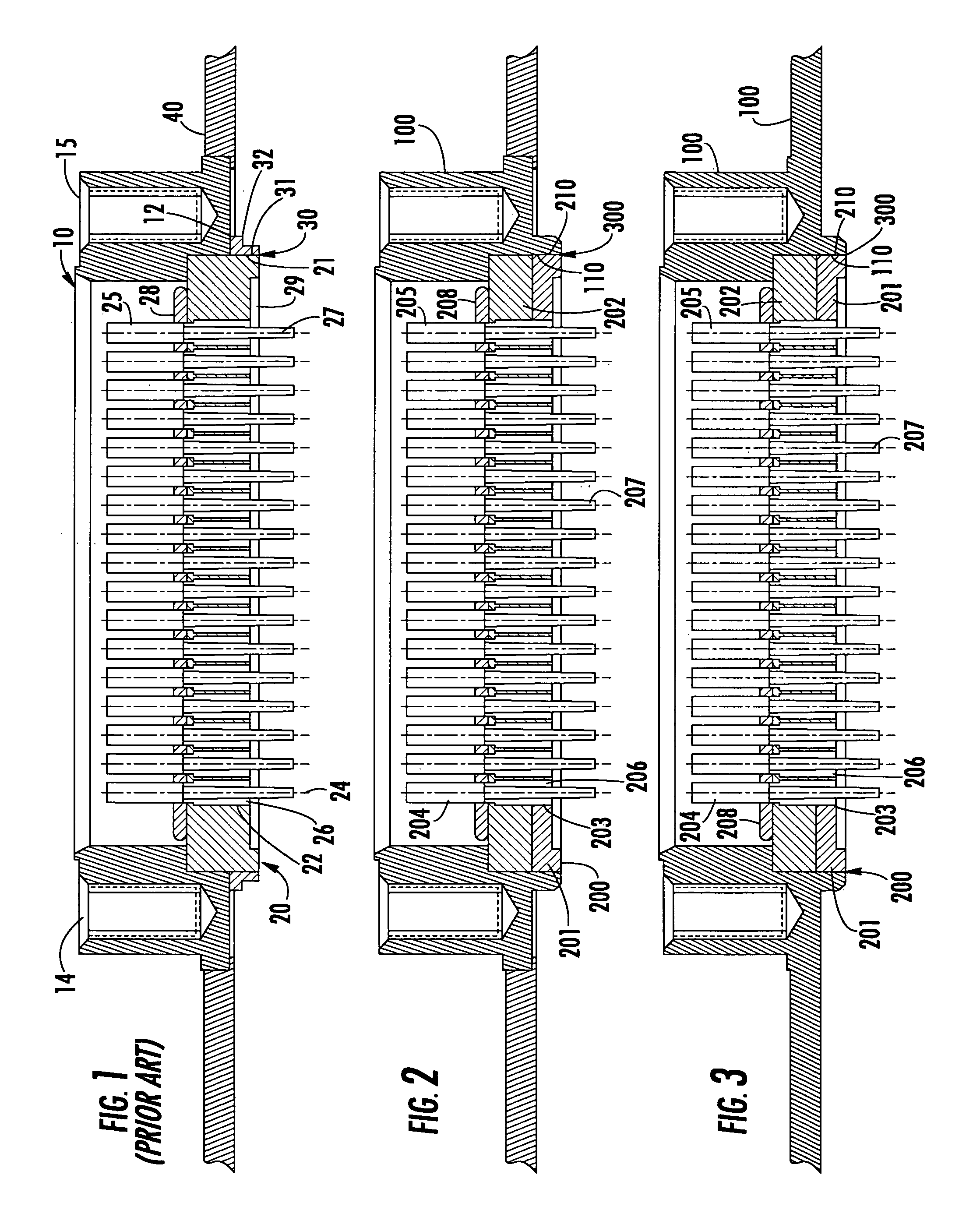

Dissimilar metal hermetic connector

ActiveUS6932644B1Improve bindingFirmly connectedSubstation/switching arrangement detailsContact member cases/bases manufactureThermal expansionEngineering

A hermetically sealed connector comprises an outer metallic shell having an aperture that receives a multipin-retaining, multi-metallic insert. The insert is a laminate of dissimilar metals, including a first metal extending to a first side of the insert and having a first coefficient of thermal expansion (CTE), and a second metal extending to a second side of the insert and having a second CTE different that the first CTE. A plurality of bores extend between first and second sides of the insert and contain connector pins that are hermetically sealed with the first metal of the insert by a dielectric material formed between the pins and sidewalls of the bores. A bond joint is formed between the second metal of the insert and the side of the outer metallic shell adjacent to the second side of the metallic insert.

Owner:WINCHESTER INTERCONNECT HERMETICS LLC

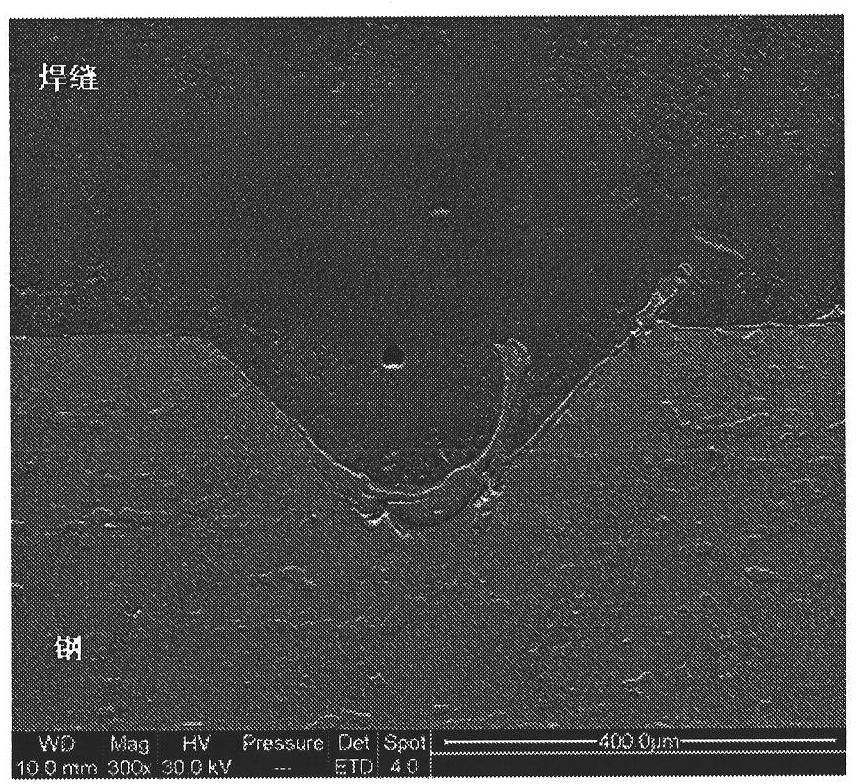

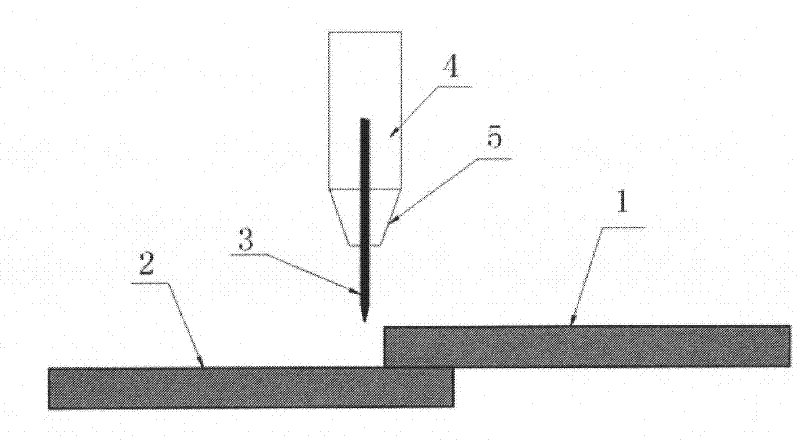

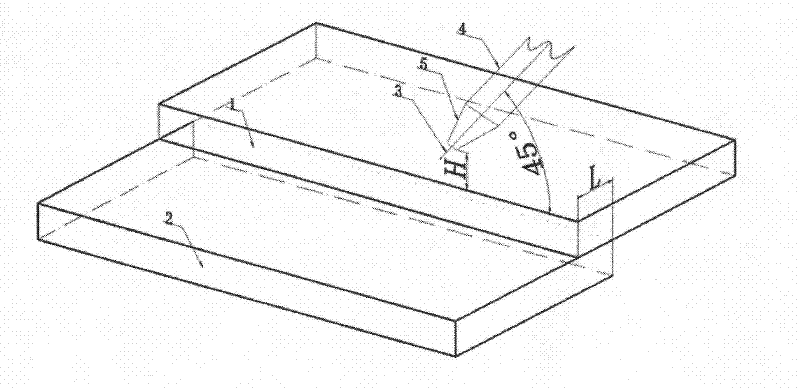

Method for connecting aluminum alloy and steel by laser filler wire

InactiveCN101941119AAchieve fusion-braze connectionPrecise control of heat inputLaser beam welding apparatusLap jointLaser beams

The invention relates to a method for connecting an aluminum alloy and steel by a laser filler wire, which is suitable for the field of dissimilar material connection and particularly suitable for the connection between dissimilar materials of which fusion points and thermal physical properties differ from each other greatly. The method comprises the following steps of: assembling a lap joint in which an aluminum plate is arranged on a steel plate, wherein a laser beam, a wire feeding nozzle and a protective gas nozzle are fixed in the same plane, the laser beam is vertically incident, and a laser focus, a wire dropping point of a welding wire and a protective gas feeding point are guaranteed to be consistent during welding; and melting the fed aluminum welding wire by using the laser to ensure that the molten aluminum welding wire is in fusion connection with the aluminum plate, simultaneously a micro fusion layer is formed on one side of the steel plate and then a fusion-braze welding connection is formed, thus the lap joint between dissimilar metals such as the aluminum alloy and the steel is realized. The method improves the connection efficiency between the dissimilar metals such as the aluminum alloy and the steel, and the tensile strength of the joint is over 149.6N / mm. The method solves the problems of long preparation time, low automation degree and poor reproducibility of welding results in the process of connecting pre-coated layers of the dissimilar materials such as welded-aluminum and the steel.

Owner:BEIJING UNIV OF TECH

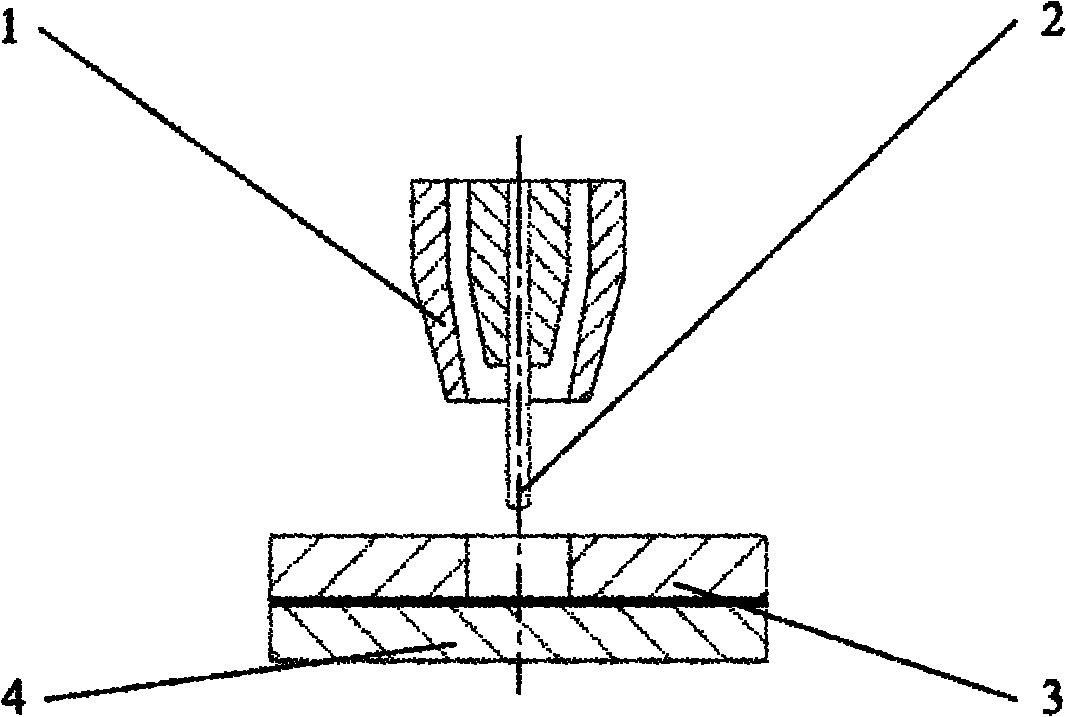

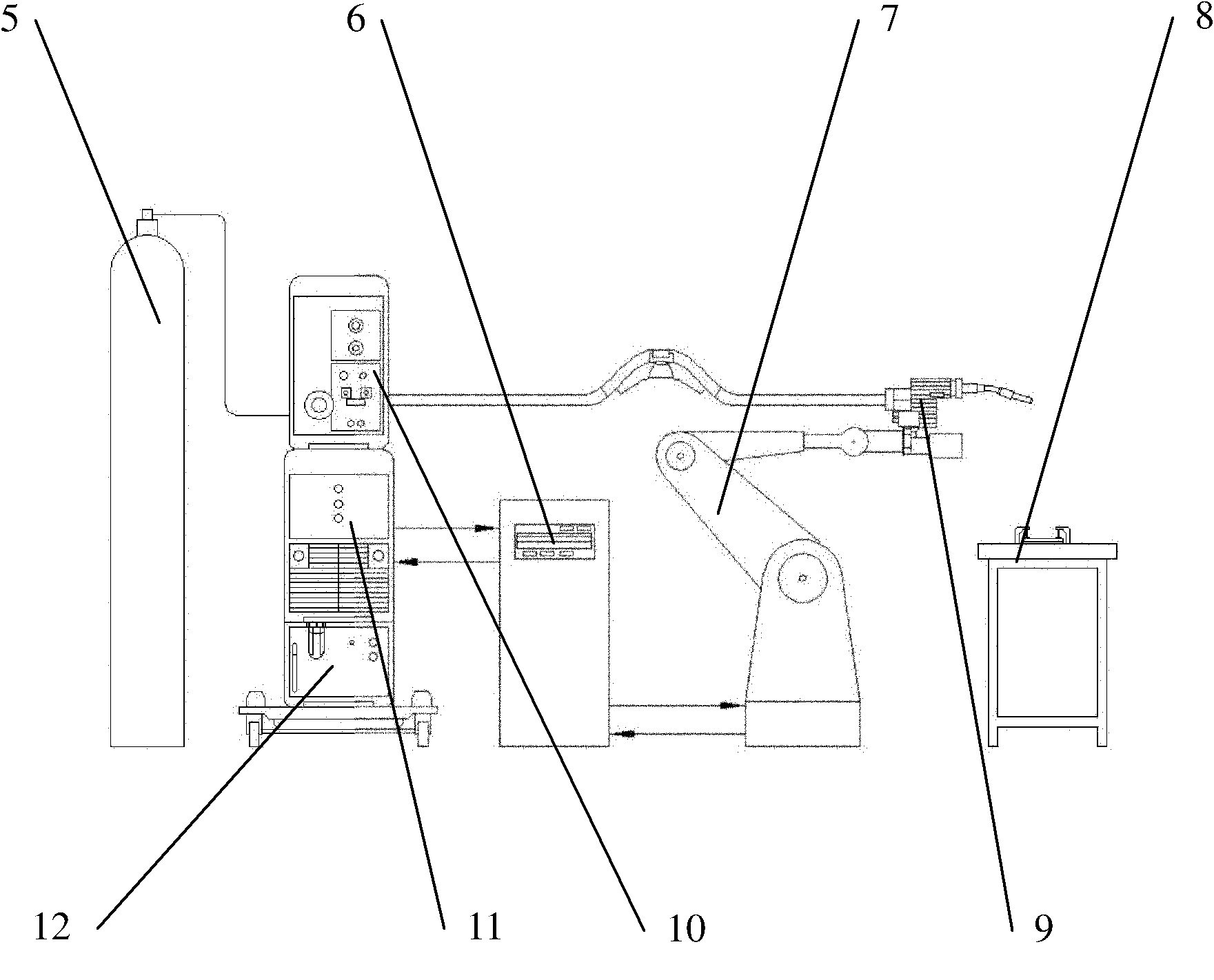

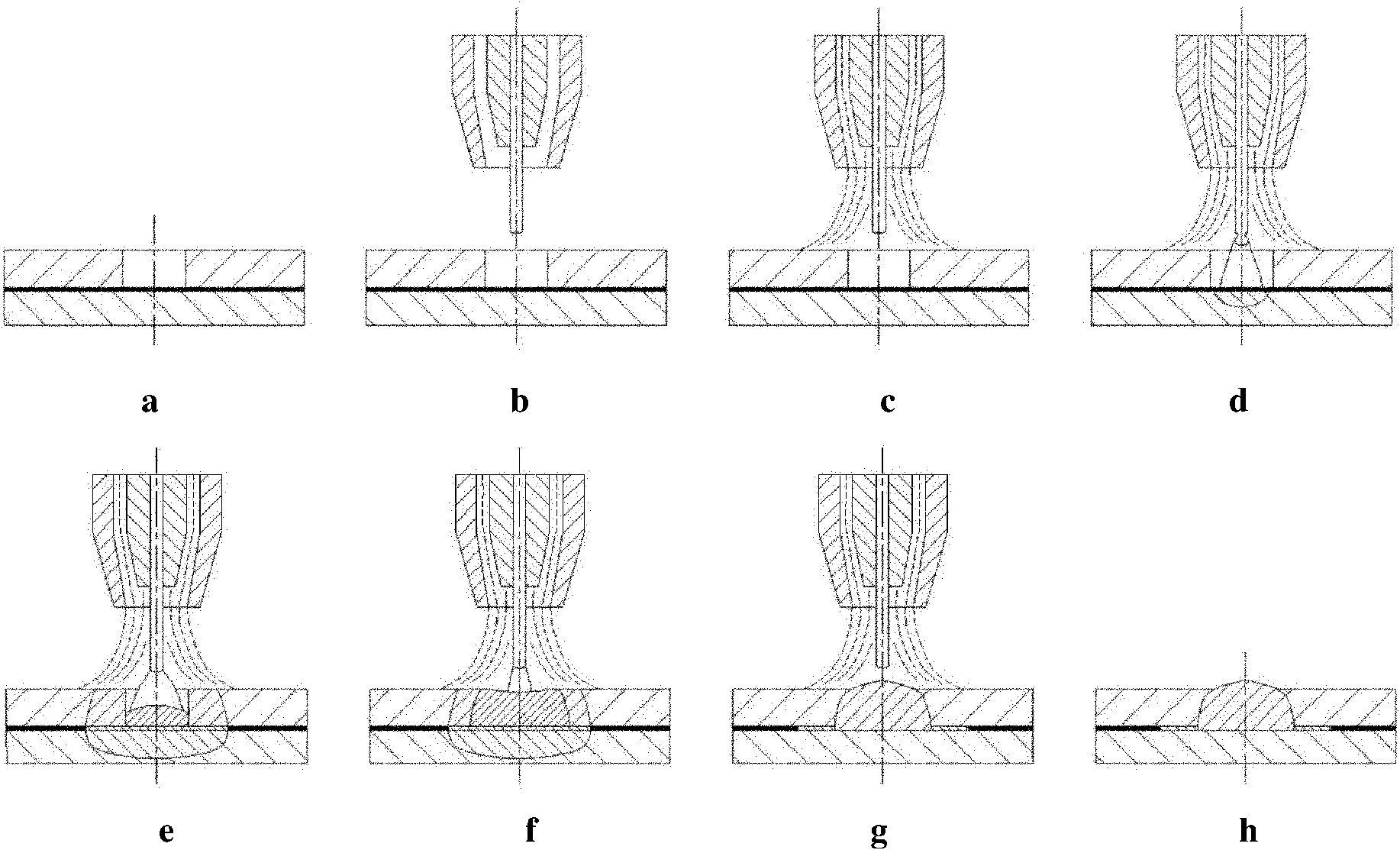

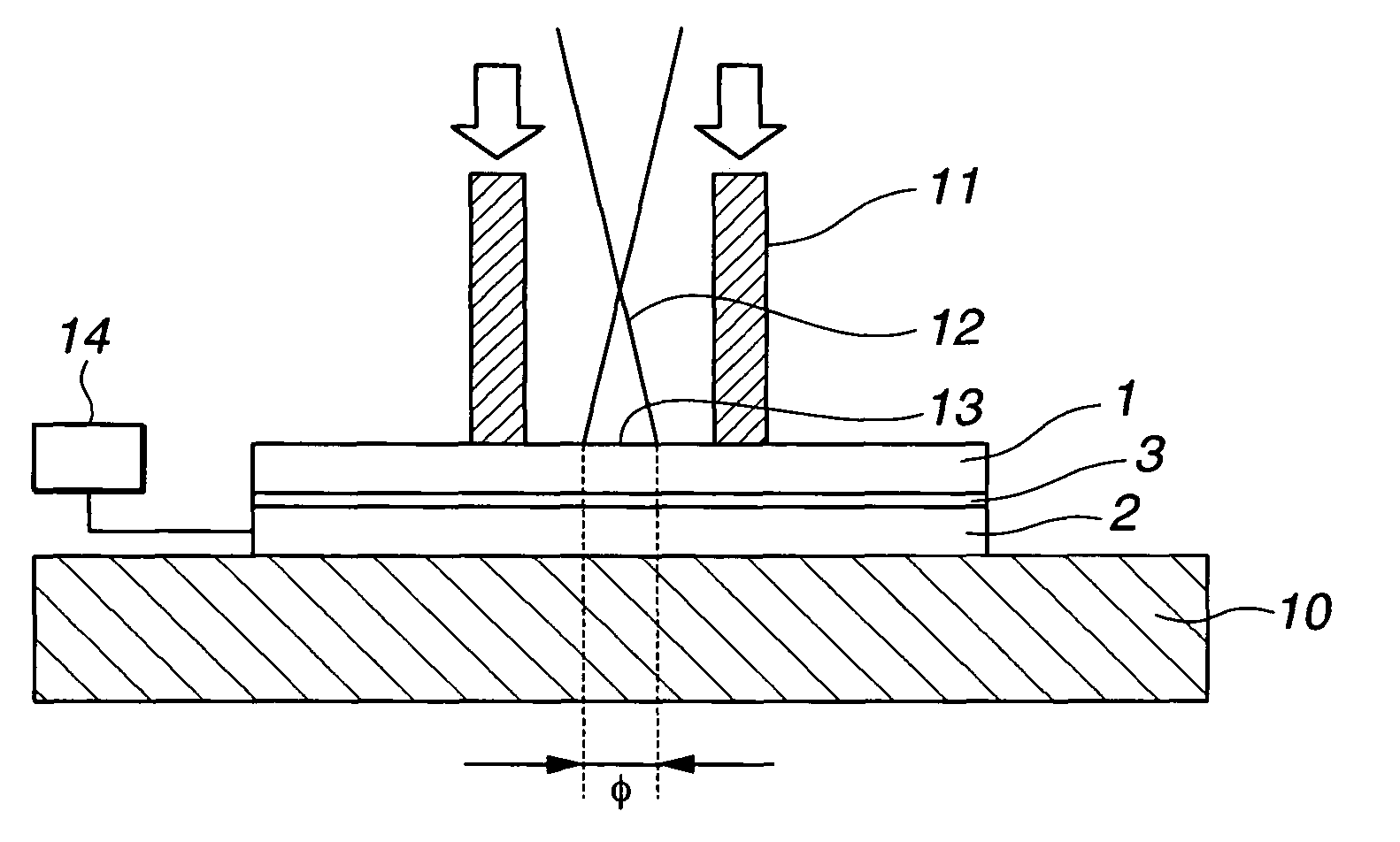

Dissimilar metal spot welding system of light metal and coated steel and welding method thereof

The invention provides a dissimilar metal spot welding system of light metal and coated steel and a welding method thereof, wherein the system comprises a CMT (cold metal transfer) arc welding system, an air bottle, a robot control module, a robot and a clamping device; the arc welding system is connected to the robot control module and used for transmitting a welding control signal; the air bottle is communicated with the CMT arc welding system; the robot control module is connected to the robot for transmitting a control signal of the movement of the robot. In the invention, a spot melting soldering joint is formed between light metal and coated steel to realize the spot connection of the light metal and the coated steel; the serious deformation of the joint during continuous seam welding is solved while the connecting quality of dissimilar metal is ensured; traditional vehicle body part joints primarily using resistance spot welding process are not influenced; and the design and manufacture costs of vehicle bodies are greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

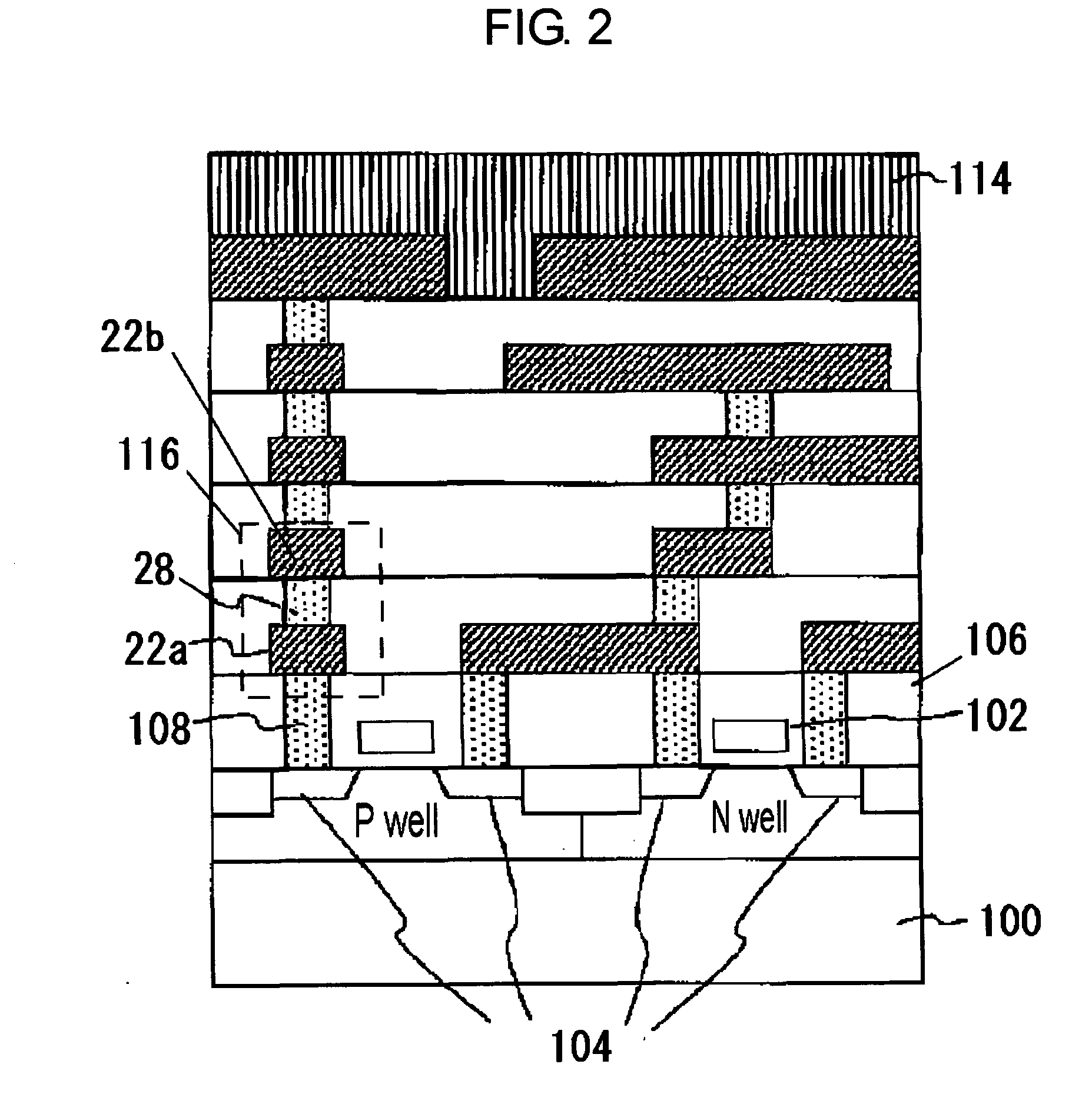

Semiconductor device and manufacturing method thereof

InactiveUS20040014312A1Increase resistanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCopperDielectric layer

An interconnect trench is formed on a dielectric layer 12 and a first HSQ layer 14 formed on a semiconductor substrate, and a tantalum family barrier metal layer 24a is formed all over the substrate. Then a seed copper-containing metal layer 60 and a plated copper layer 62 are formed so as to fill a part of the interconnect trench. After that, a bias-sputtered copper-containing metal layer 64 is formed on the plated copper layer 62 so as to fill the remaining portion of the interconnect trench and then heat treatment is performed. As a result, a dissimilar metal contained in the bias-sputtered copper-containing metal layer 64 diffuses uniformly into the plated copper layer 62.

Owner:RENESAS ELECTRONICS CORP

Method of manufacturing an assembly of brazed dissimilar metal components

InactiveUS6503640B2Improve abilitiesHigh strengthBuilding componentsElectron beam welding apparatusTitanium coatingSS - Stainless steel

Owner:DANA CANADA CORP

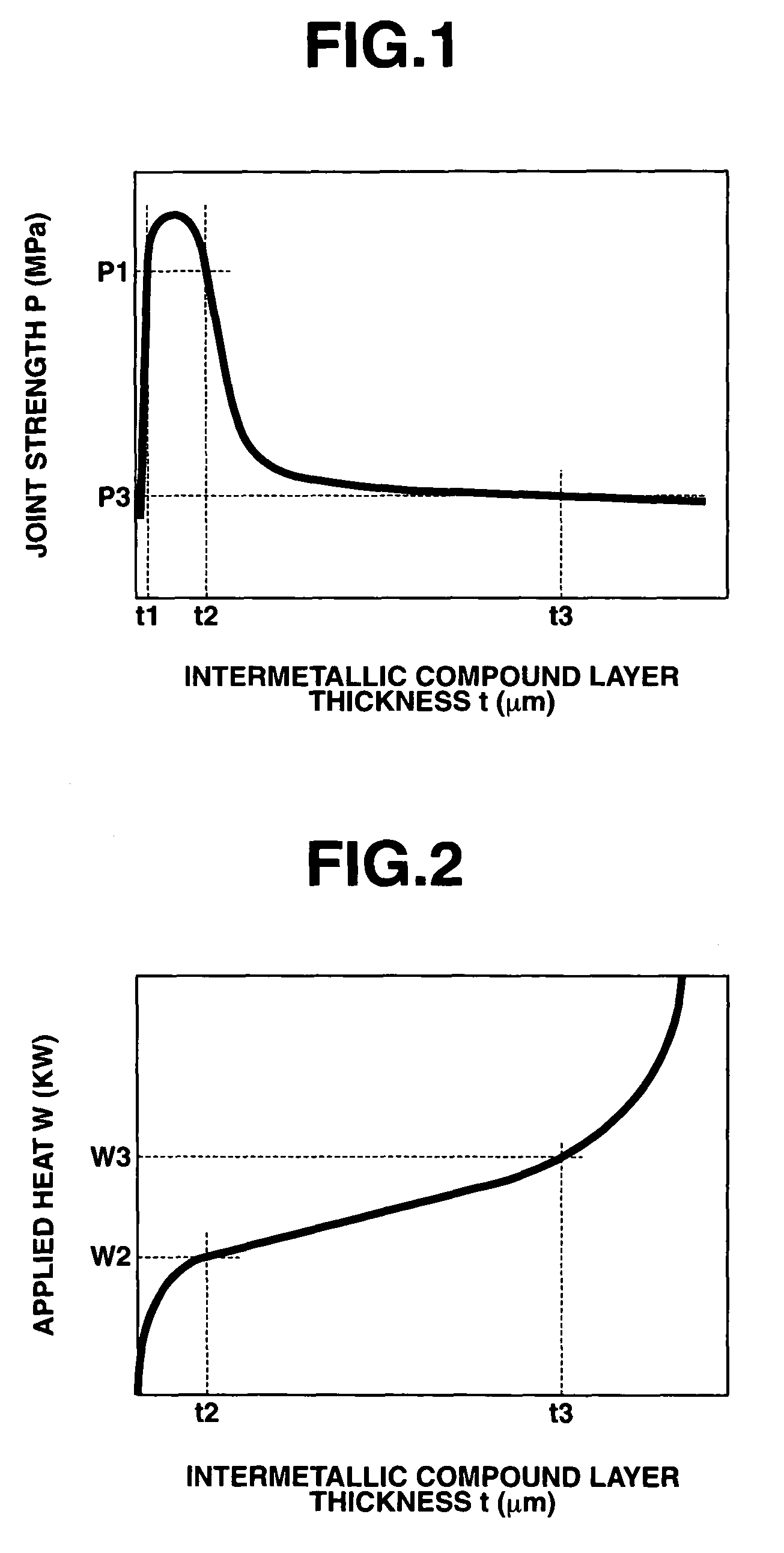

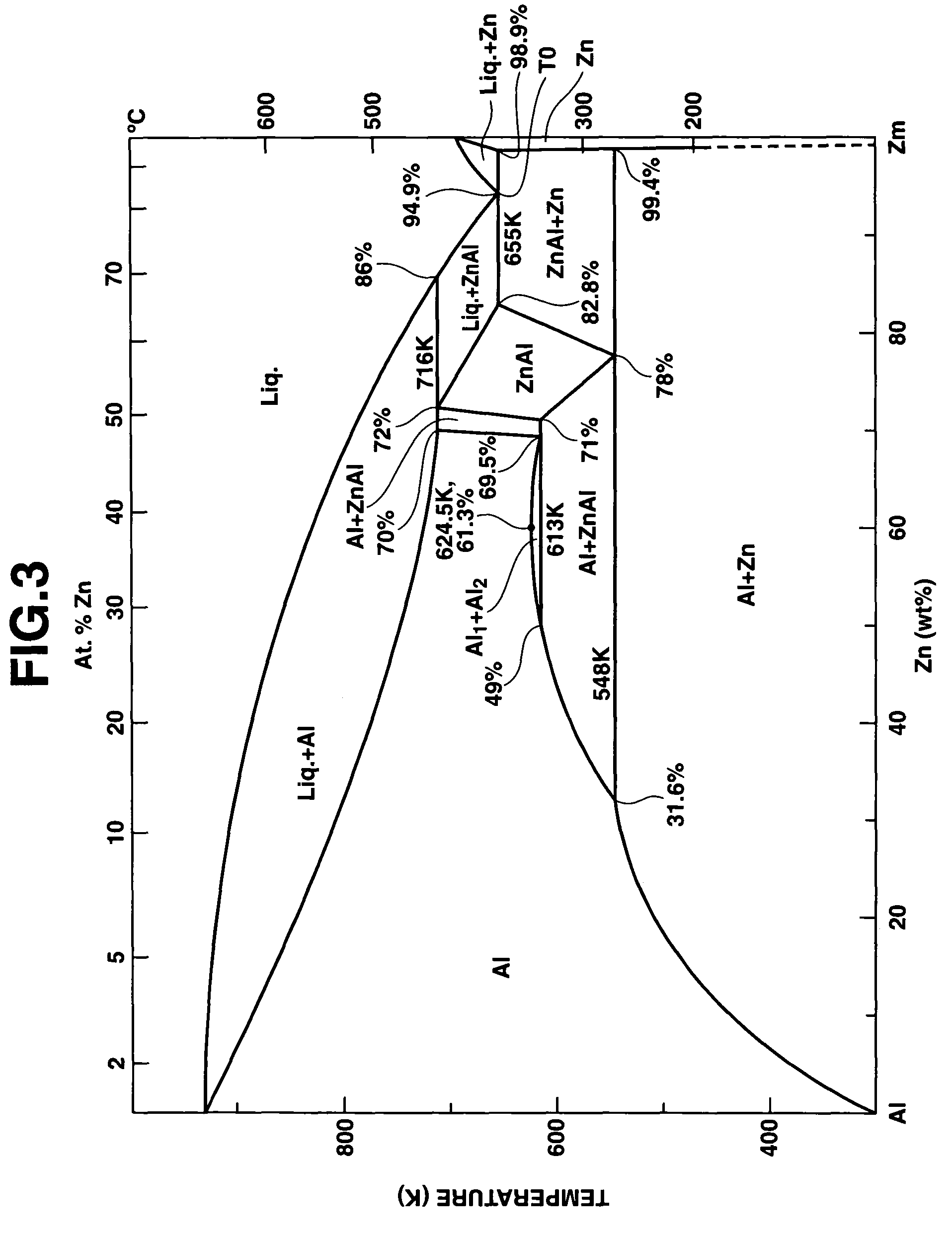

Dissimilar metal joining method

ActiveUS7850059B2Resist formationWelding/cutting media/materialsWelding/soldering/cutting articlesMetallic materialsMetal

According to a metal joining method of the present invention, first and second dissimilar metals are joined together by interposing between the first and second metal materials a third metal material dissimilar to the first and second metal materials and causing eutectic melting at least either at an interface between the first and third metal materials or at an interface between the second and third metal materials.

Owner:NISSAN MOTOR CO LTD +1

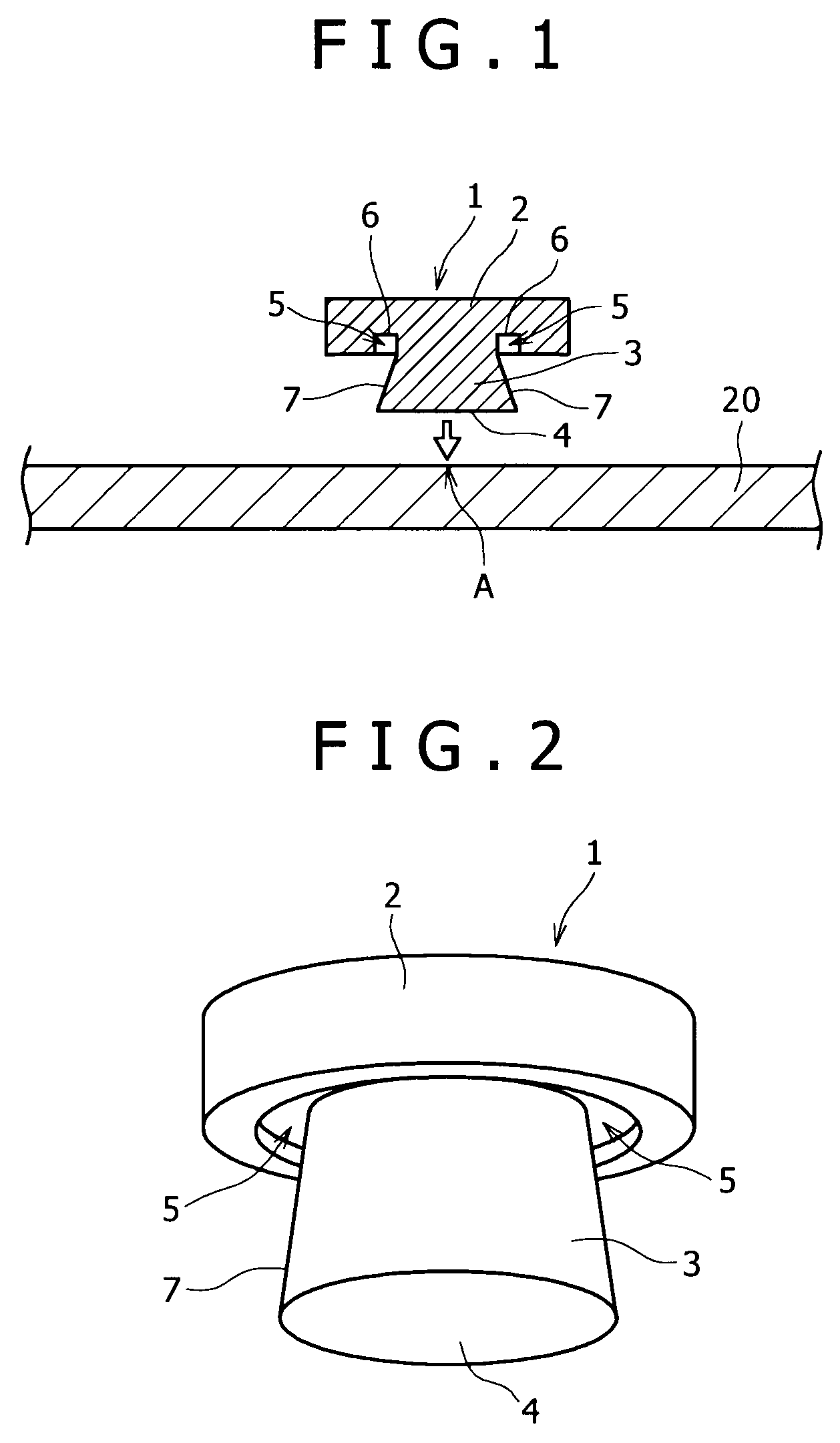

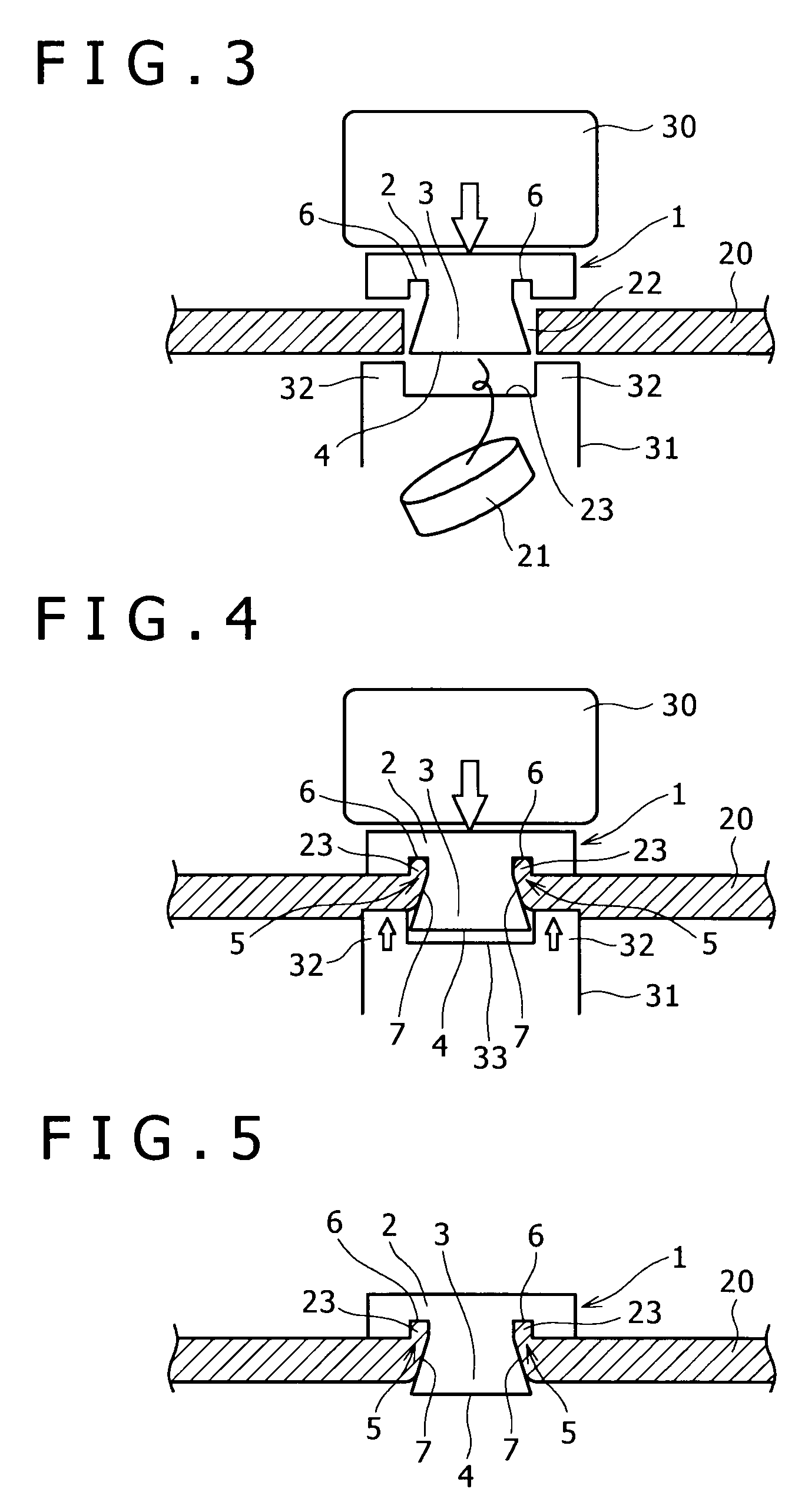

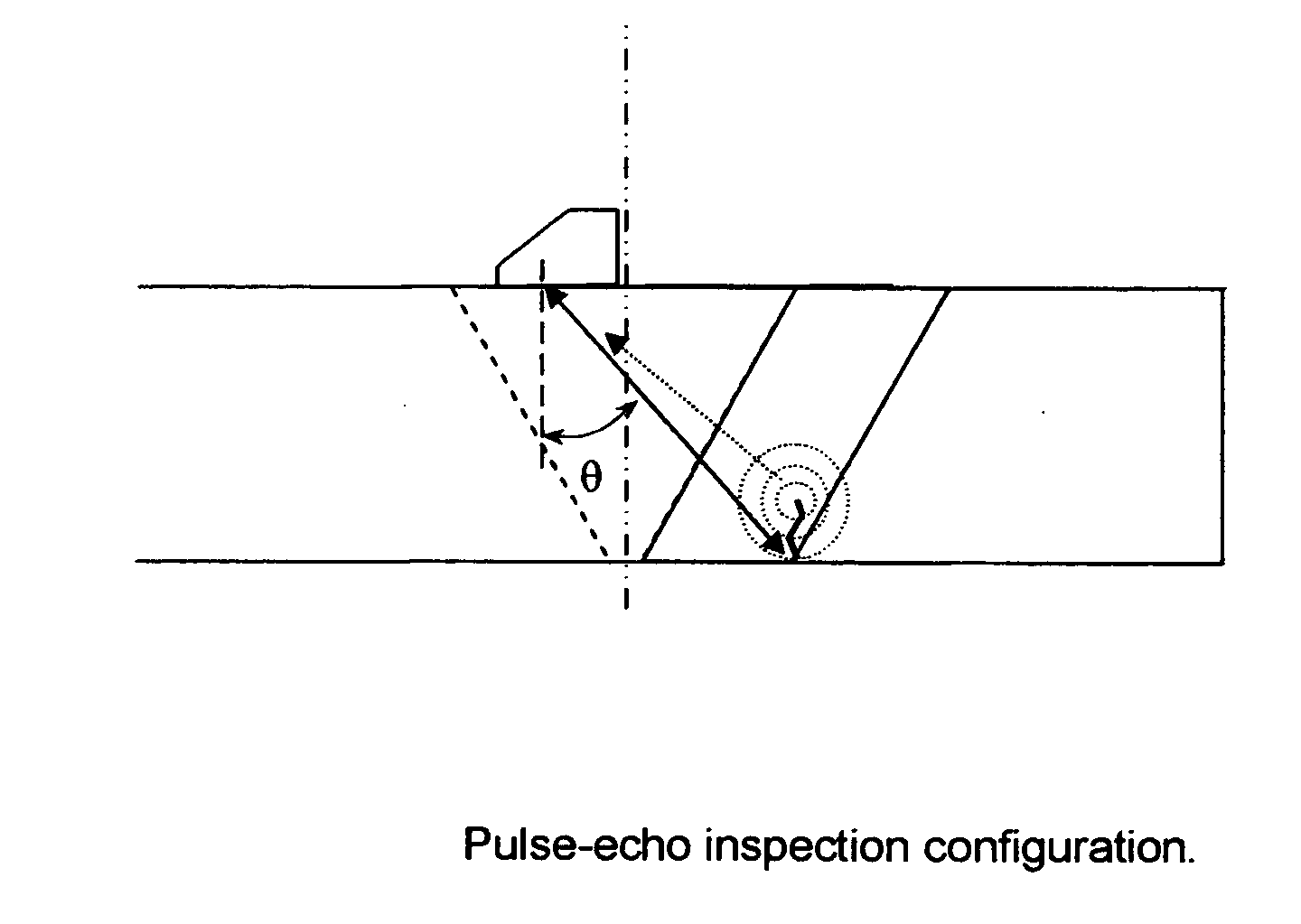

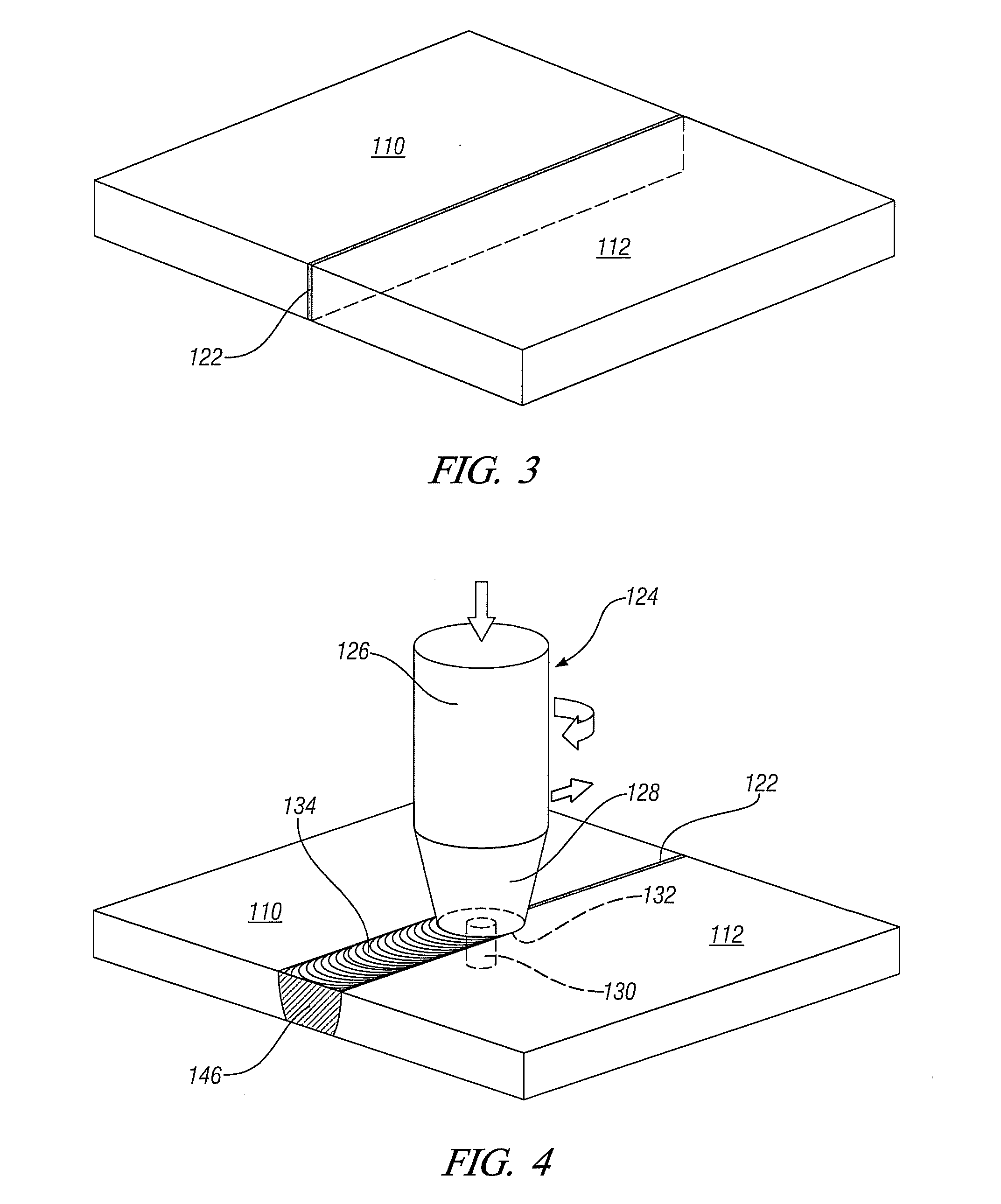

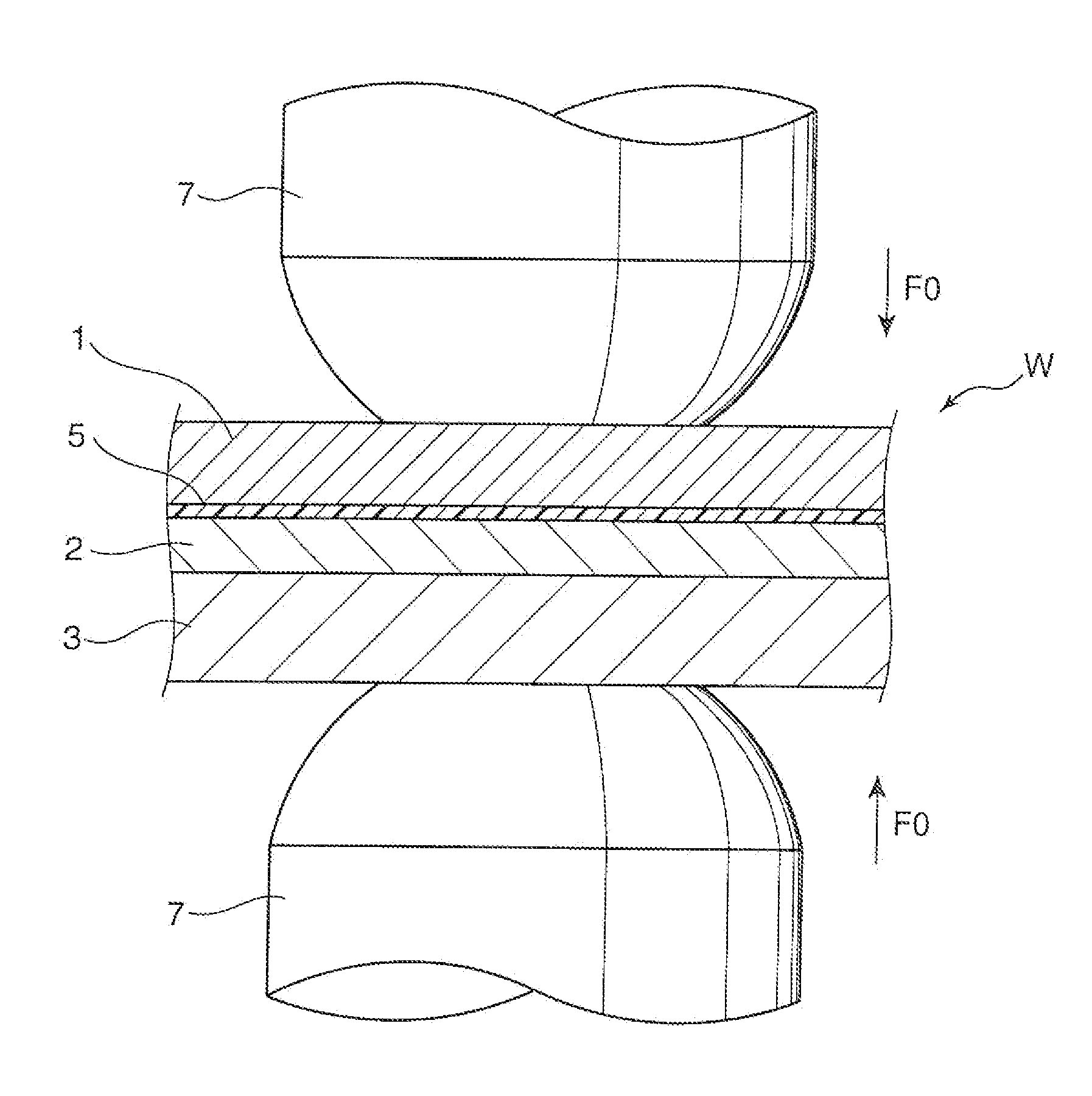

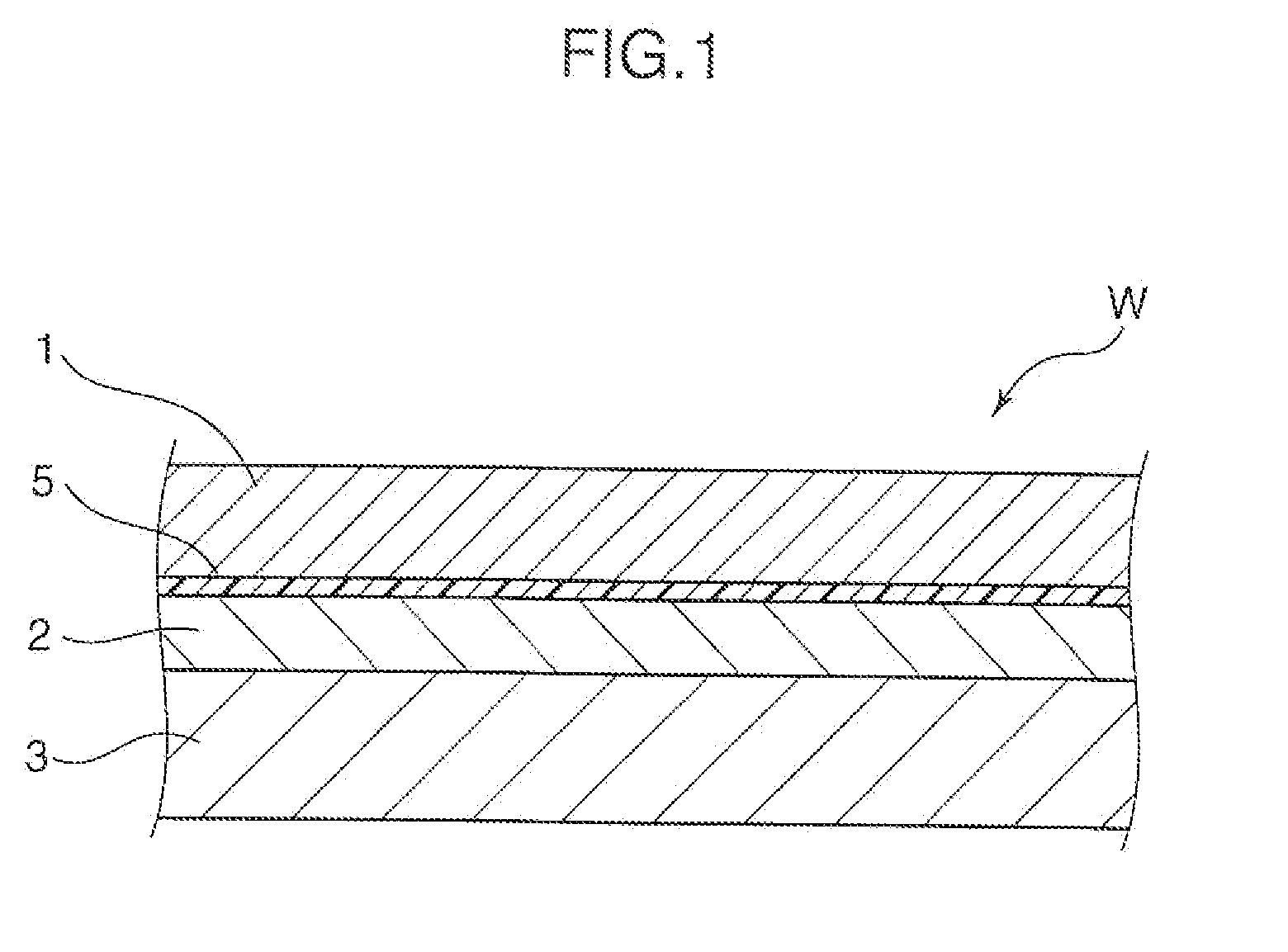

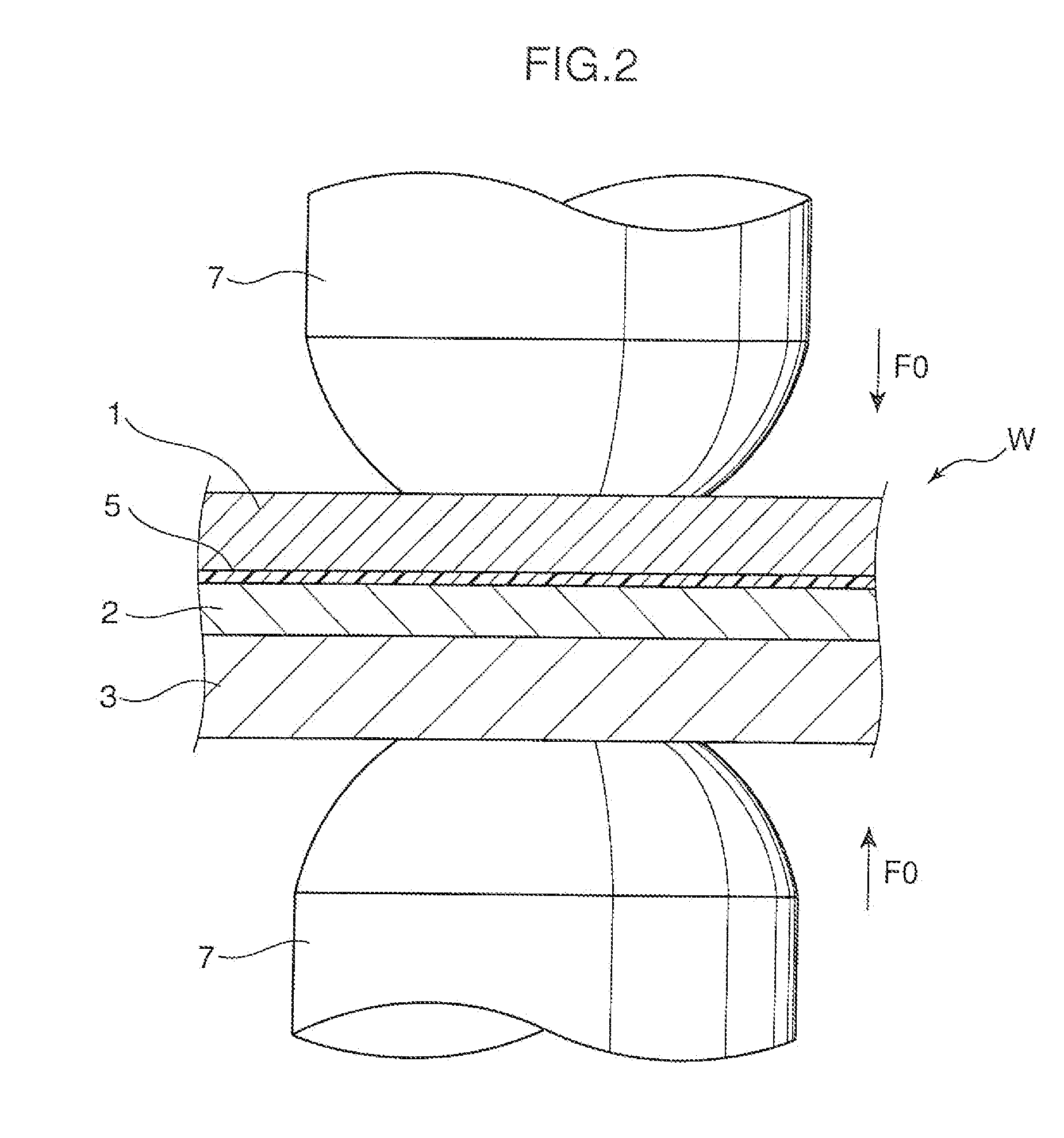

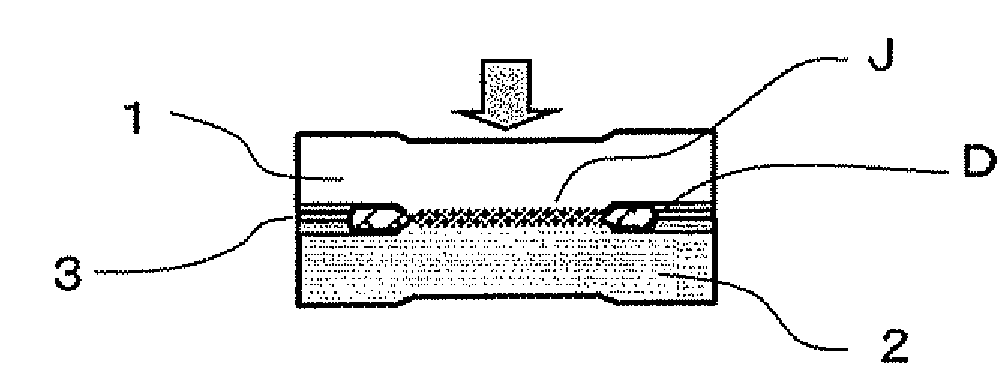

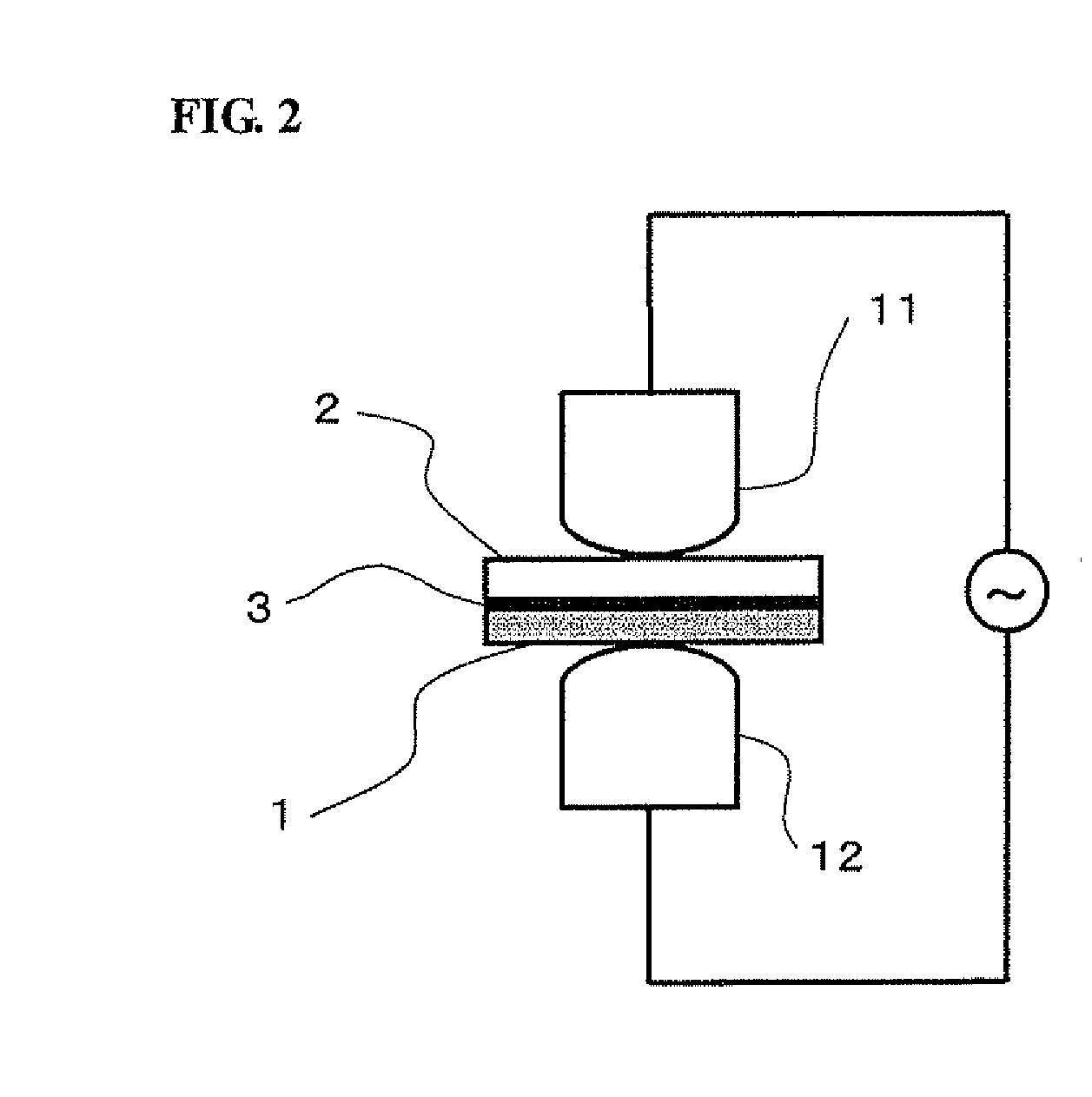

Joining method of dissimilar metal plates and dissimilar metal joined body

ActiveUS20110097594A1Improve joint strengthWelding electric supplyArc welding apparatusPower flowAdhesive

The joining method of the present invention includes a lapping step of lapping the aluminum alloy plate (1) and the plated steel plate (2) via the adhesive (5), a pre-heating step of clamping both of the metal plates (1, 2) that have been lapped in the lapping step between a pair of electrodes (7, 7) for spot welding and applying pressure thereto, and applying a current between the pair of electrodes (7, 7), a cooling step of pressurizing, after the pre-heating step, both of the metal plates (1, 2) at a pressing force which is higher than that at the start of the pre-heating step in a state where conduction between the electrodes (7, 7) is stopped, and continuing this pressurization over a predetermined cooling time, and a welding step of pressurizing, after the cooling step, both of the metal plates (1, 2) at a pressing force which is higher than that at the start of the pre-heating step, and welding both of the metal plates (1, 2) by applying a current which is higher than the conduction current value in the pre-heating step between the pair of electrodes (7, 7). It is thereby possible to firmly join the dissimilar metal plates (1, 2) by combining adhesion due to an adhesive and spot welding.

Owner:MAZDA MOTOR CORP +1

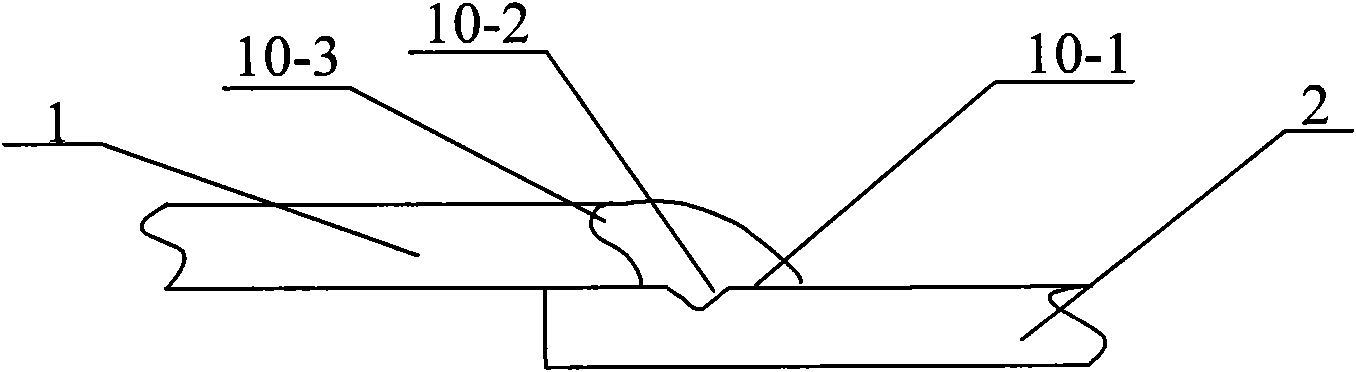

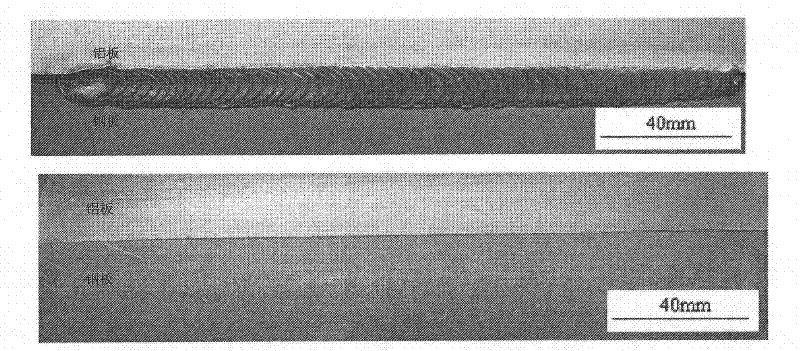

Cold metal transfer connection method of aluminum/steel dissimilar metal

InactiveCN102500853AImprove mechanical propertiesWell formed weldWelding/cutting media/materialsSoldering mediaSiliconMetal

The invention provides a cold metal transfer connection method of aluminum / steel dissimilar metal. The cold metal transfer connection method comprises the following steps of: utilizing an aluminum alloy welding wire containing aluminum and silicon elements to weld; through carrying out cold metal transfer welding, forming a melt welding connection at one side of an aluminum plate through melting the aluminum alloy welding wire and an aluminum alloy parent metal in the welding process; and meanwhile, keeping a steel plate at a solid state and realizing a braze welding connection at one side of the steel plate, so as to form a melt-braze welding overlap joint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

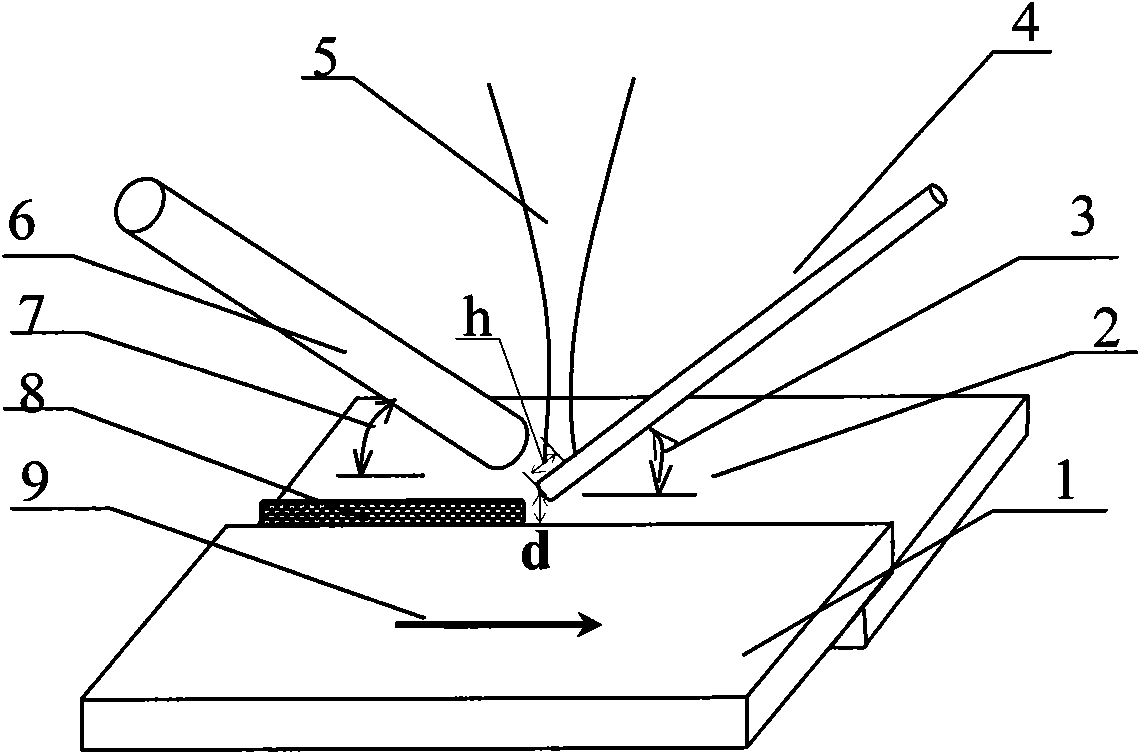

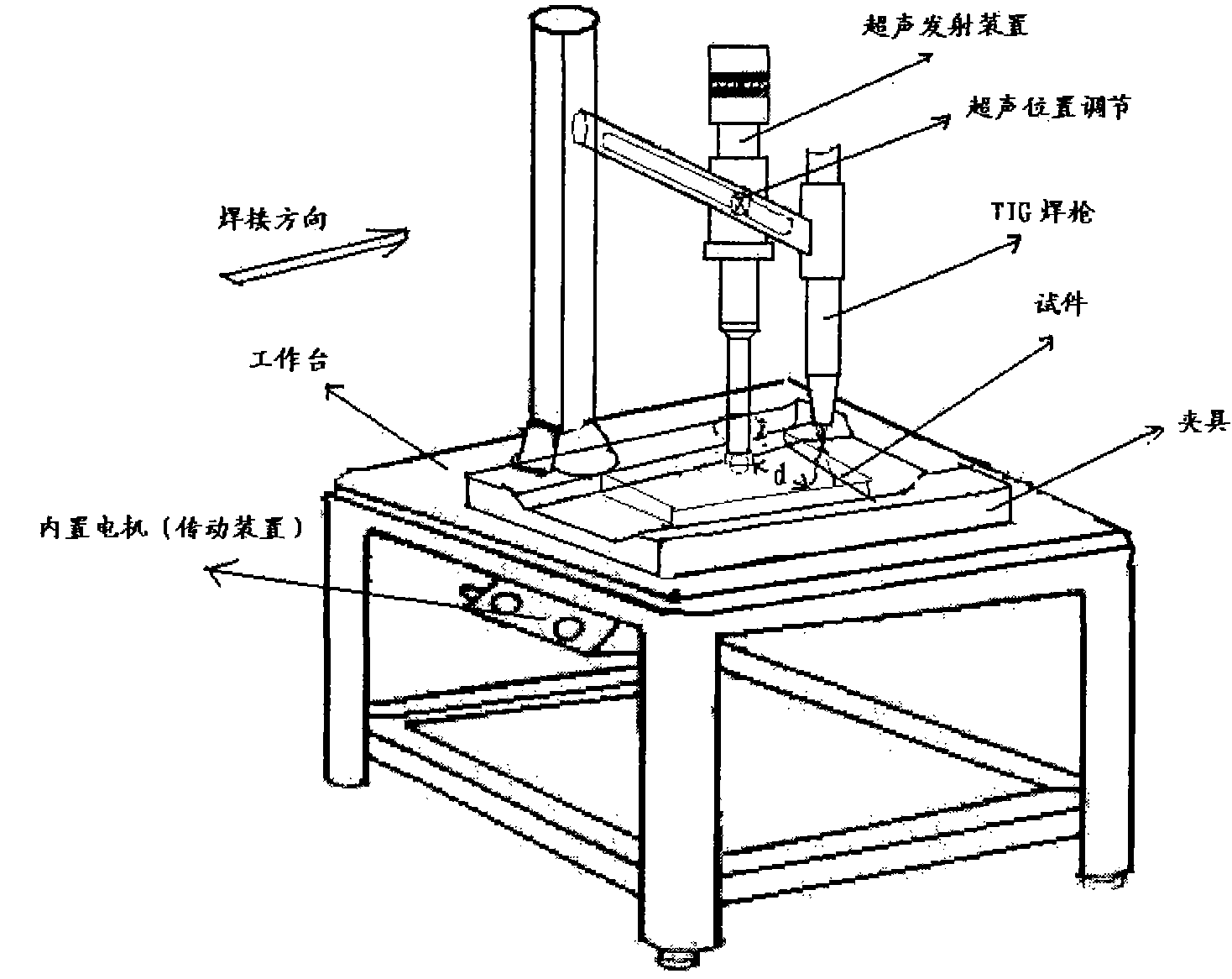

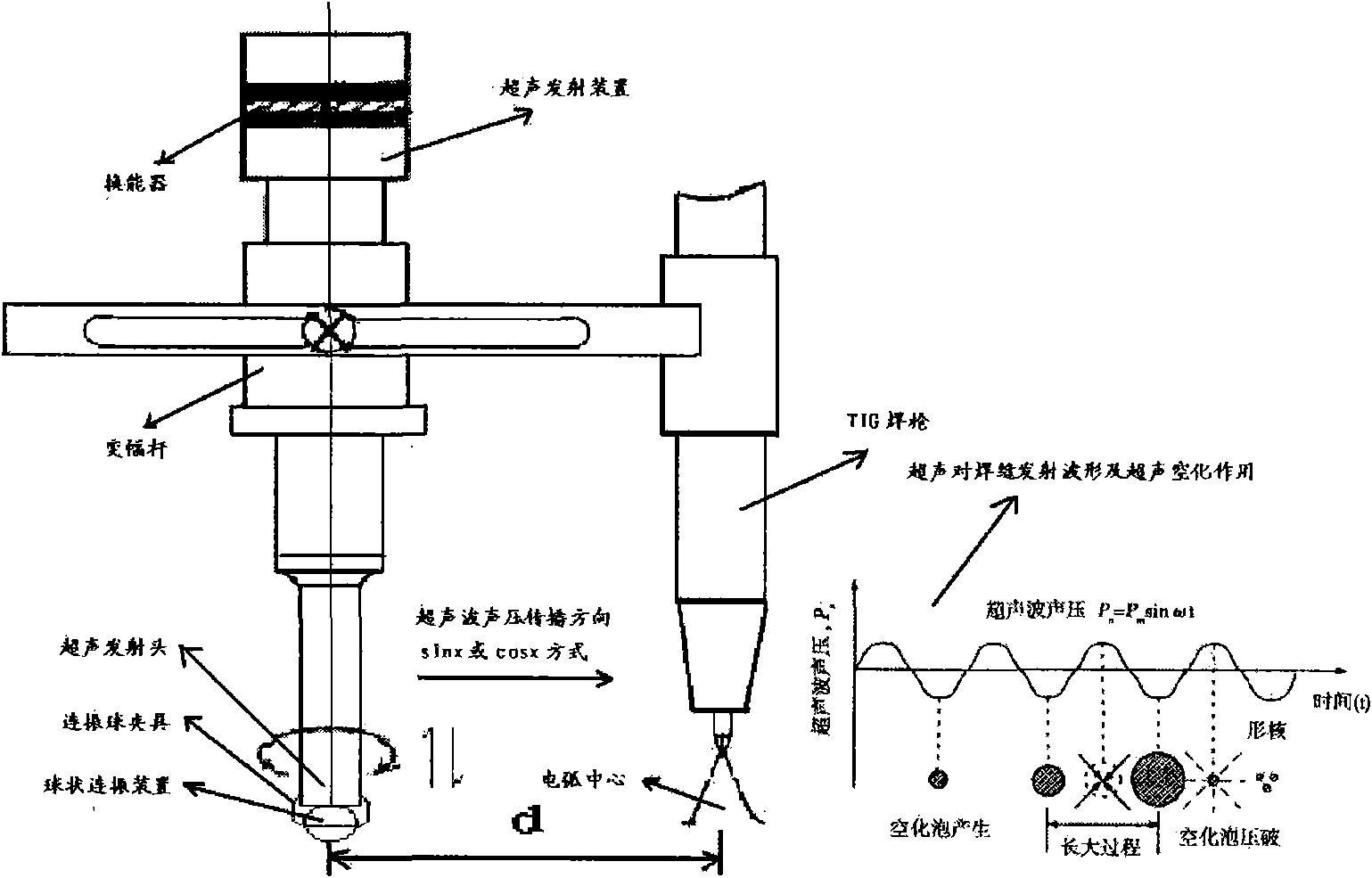

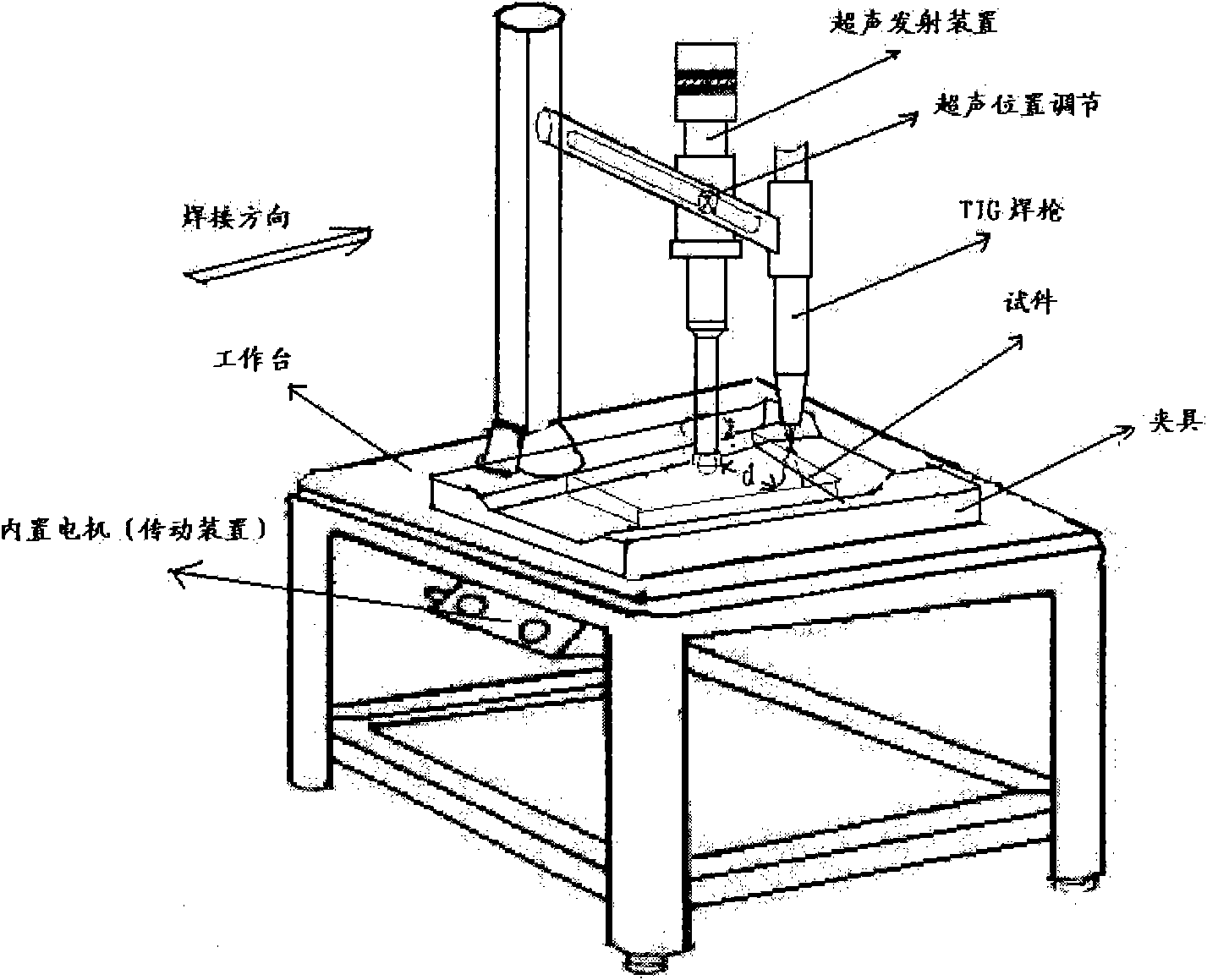

Ultrasonic welding method of Al/Ti dissimilar metal TIG (Tungsten Inert Gas) electrical arc micro-melting brazing and following welding

The invention provides an ultrasonic welding method of Al / Ti dissimilar metal TIG electrical arc micro-melting brazing and following welding, wherein an isochronous and stable ultrasonic vibration system is added in the TIG micro-melting brazing process, and the simultaneous and equi-directional welding of TIG micro-melting brazing and following welding is realized through a spherical interlinking device. The method comprises the following steps of: enabling a welding gun tungsten electrode and a test piece to reach reasonable welding height by vertically adjusting the position of a welding gun; enabling a continuous vibration ball to cling to the surface of the test piece by vertically adjusting an ultrasonic transmitting device; measuring the distance d from the contact point of the continuous vibration ball and the surface of the test piece to a TIG welding gun tungsten electrode by horizontally adjusting an ultrasonic generating device to enable d to satisfy welding requirements; and reasonably matching an ultrasonic vibration device and a TIG welding gun by adjusting d, and adjusting the acting position of ultrasonic vibration by adjusting d. The invention has strong process applicability and good stability, realizes the semi-automatic welding of Al / Ti dissimilar metal connection, and has wider usability and good improving action for the welding joints of TIG micro-melting brazing for various dissimilar metals.

Owner:HARBIN INST OF TECH

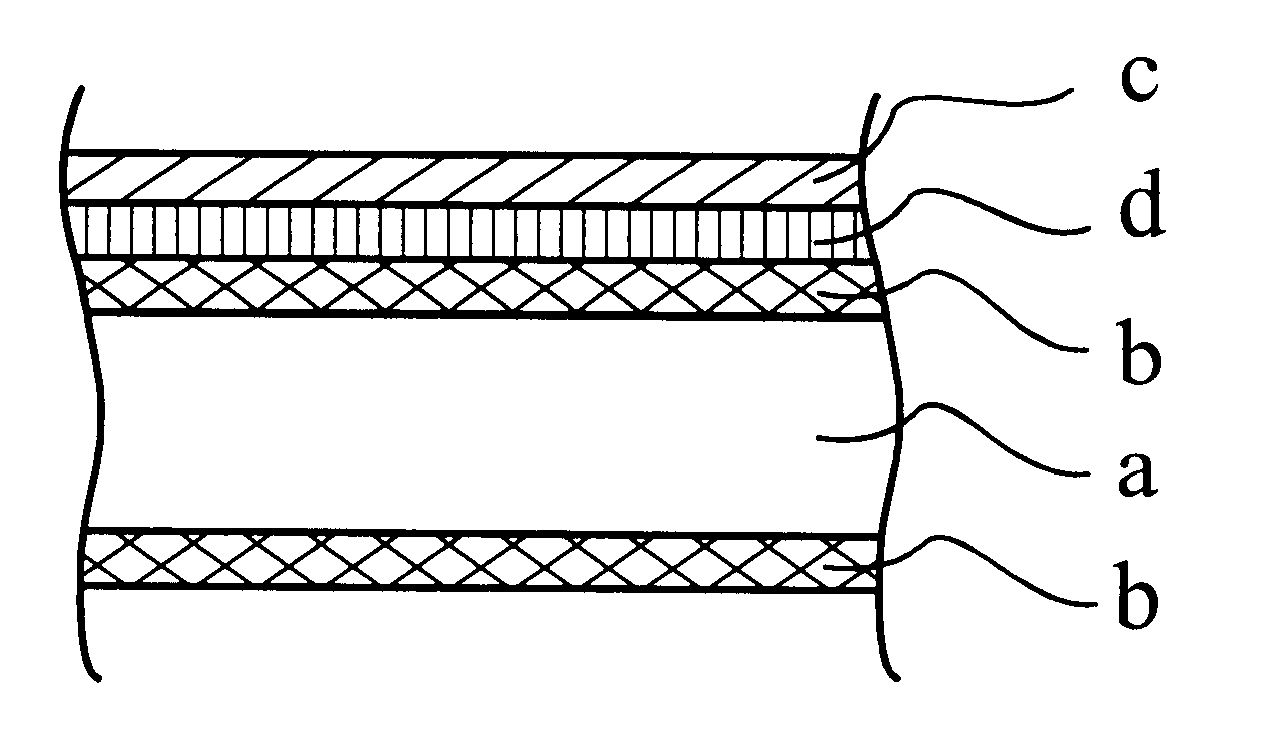

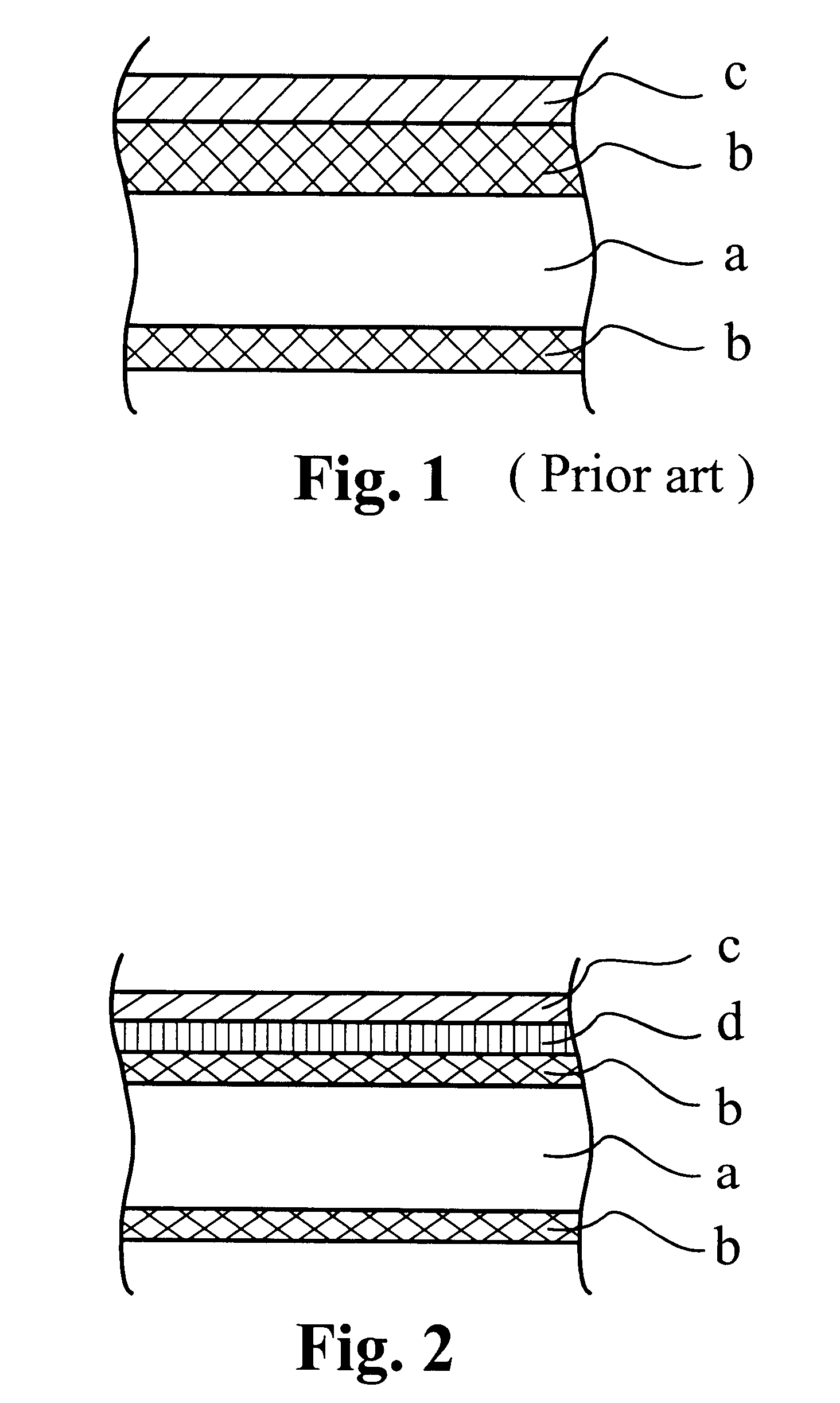

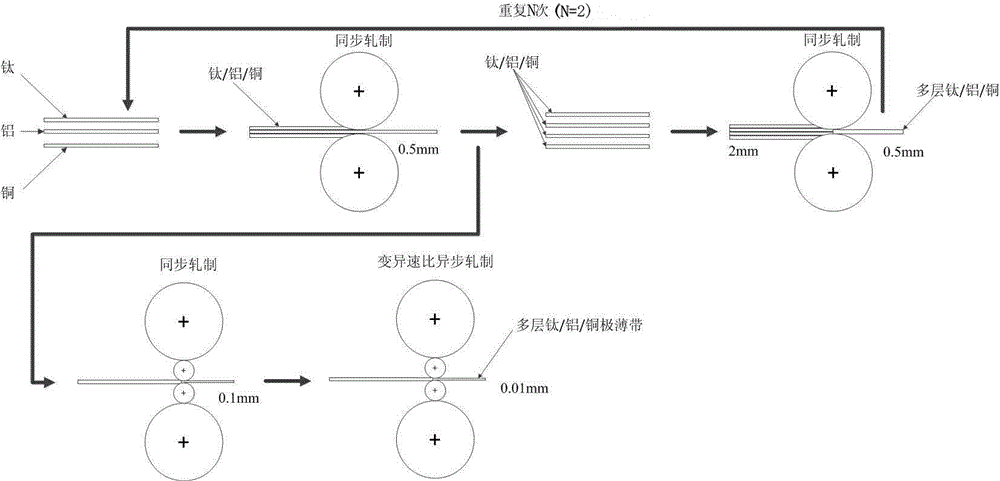

Preparation method for multilayer dissimilar metal composite ultra-thin strip

ActiveCN105170652AWide range of choicesEliminate intermediate heating processMetal rolling arrangementsRoll speed control deviceThinningMetal

The invention provides a preparation method for a multilayer dissimilar metal composite ultra-thin strip. The preparation method includes the process steps that (1) different metal materials are synchronously cold-rolled for first thinning; (2) metal thin strips are polished and cleaned; (3) the upper surfaces and lower surfaces of two or more metal thin strips are closely attached; (4) two-roll synchronous cold rolling is conducted on dissimilar metal combined strips; (5) the upper surfaces and lower surfaces of 2-10 dissimilar metal thin strips subjected to preliminary combination are closely attached and then the procedures of the step (1) to the step (4) are repeated 2-10 times; (6) reversible four-roll synchronous cold rolling is conducted on a multilayer dissimilar metal composite thin strip; and (7) reversible four-roll asynchronous cold rolling is conducted on the multilayer dissimilar metal composite thin strip, and the multilayer dissimilar metal composite ultra-thin strip with the thickness being 0.01 mm-0.02 mm is obtained. According to the method, the selection range of the metal materials is wide, the requirement for equipment capacity is low, and the surface quality of the ultra-thin strip can be improved remarkably; besides, production resources are saved, production cost is reduced, and the method is suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

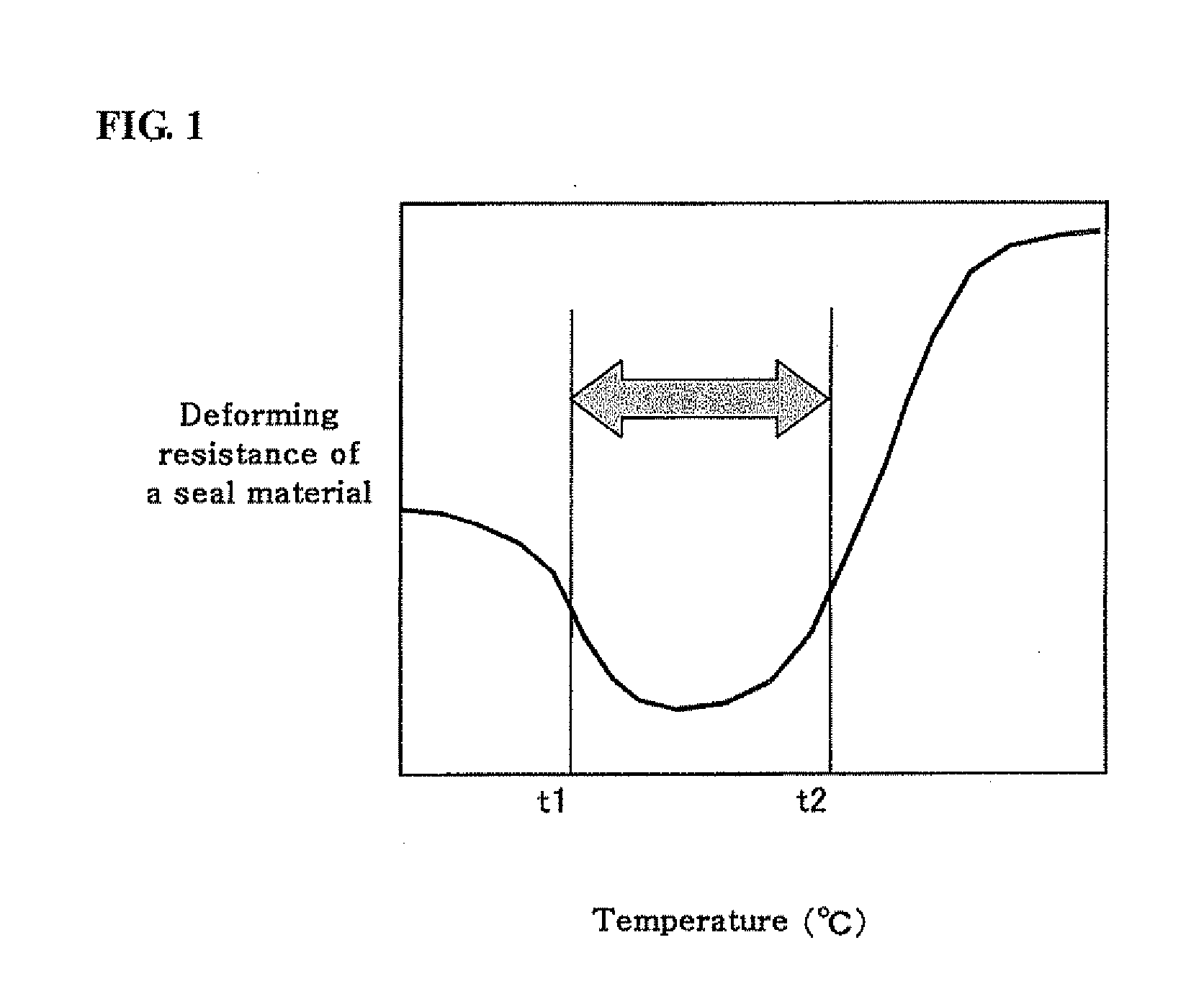

Method and apparatus for bonding dissimilar materials made from metals

ActiveUS20080026247A1Resistance electrode holdersWelding/cutting auxillary devicesBond interfaceUltimate tensile strength

A method of bonding dissimilar metals, a bonding structure formed by such a method and a bonding apparatus for performing such a method. The resulting bond is capable of preventing corrosion (e.g., electric corrosion) resulting from contact of the dissimilar metals and obtains a dissimilar material joint exhibiting anti-corrosive property and bonding strength at low costs. The method includes overlapping two materials made from dissimilar metals having a seal material interposed therebetween and discharging the seal material from a bonding interface and bonding the two materials in direct contact with each other.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com