Cold metal transfer connection method of aluminum/steel dissimilar metal

A technology of cold metal transition and dissimilar metals, applied in metal processing equipment, welding media, welding equipment, etc., can solve the problem of ineffective control of welding heat input and the thickness of intermetallic compounds at the interface layer of aluminum and steel, and uneven and smooth weld formation , affecting the mechanical properties of joints and other issues, to achieve the effect of no macro defects, improved mechanical properties, and effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

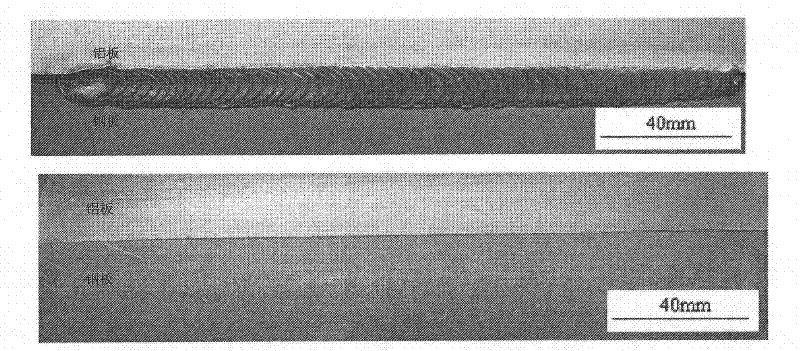

[0020] Example 1: Offset by 1mm

[0021] In this implementation case, the upper metal plate is a deformed aluminum alloy AA6061 plate with a thickness of 1 mm, and the lower galvanized plate is a HDG60 plate with a thickness of 1 mm, both of which have a size of 100×200 mm. Before welding, the aluminum alloy plate is mechanically treated to remove the oxide film on the surface, and then the surface grease is removed with an organic solvent such as acetone. Finally, the above-mentioned cleaned aluminum alloy is subjected to alkali cleaning and pickling, and air-dried or low-temperature dried for use. Use organic solvents such as acetone to remove water stains and oil stains on galvanized steel sheets, and dry them in a dry environment for later use. The welding wire used in welding is ER4043 (AlSi 5 ).

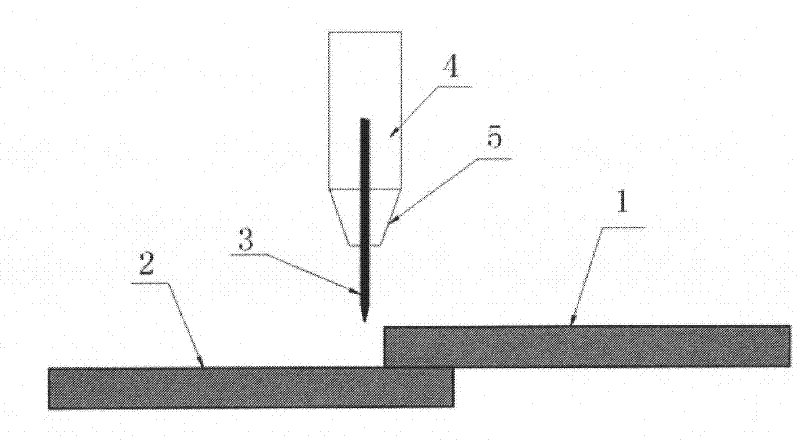

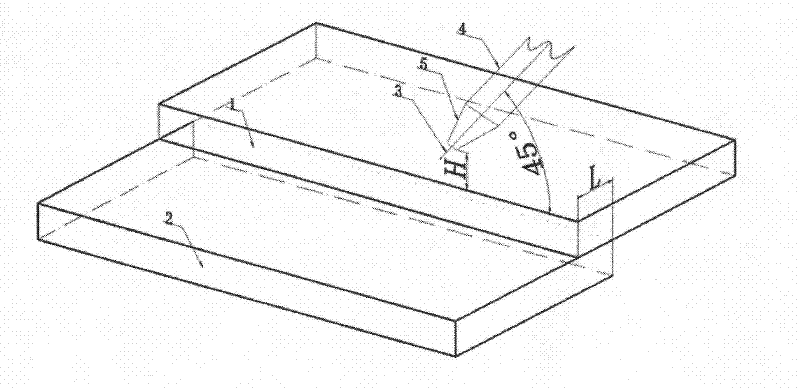

[0022] like figure 1 and figure 2 As shown, the overlapping welding method is adopted, the aluminum alloy 1 is on top, the galvanized steel plate 2 is on the bottom, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com