Patents

Literature

178 results about "Metal transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

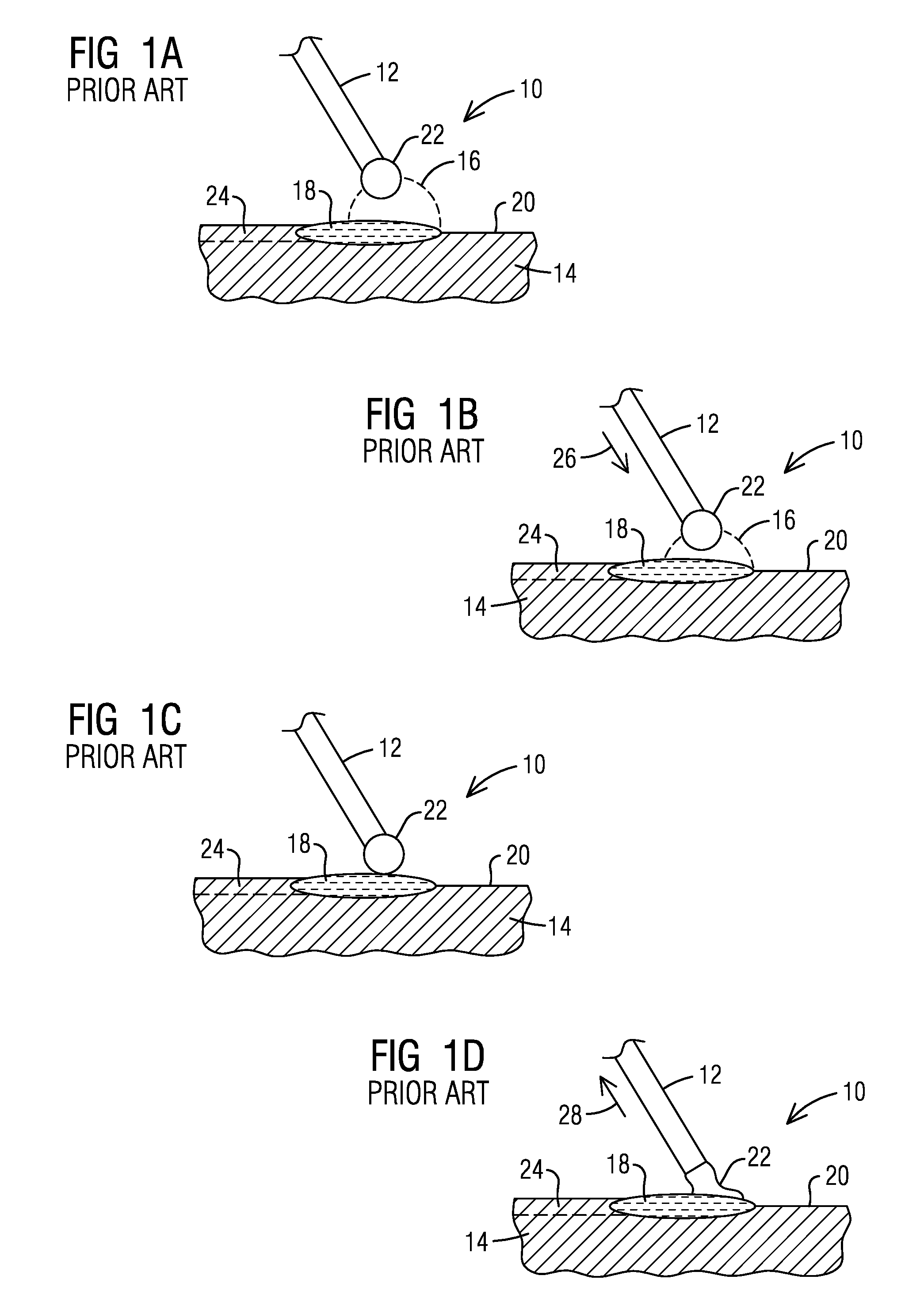

In short circuiting metal transfer, also known as ”Short Arc”, ”Dip Transfer”, and ”Microwire”, metal transfer occurs when an electrical short circuit is established. This occurs as the molten metal at the end of the wire touches the molten weld pool. In spray arc welding, small molten drops of metal are.

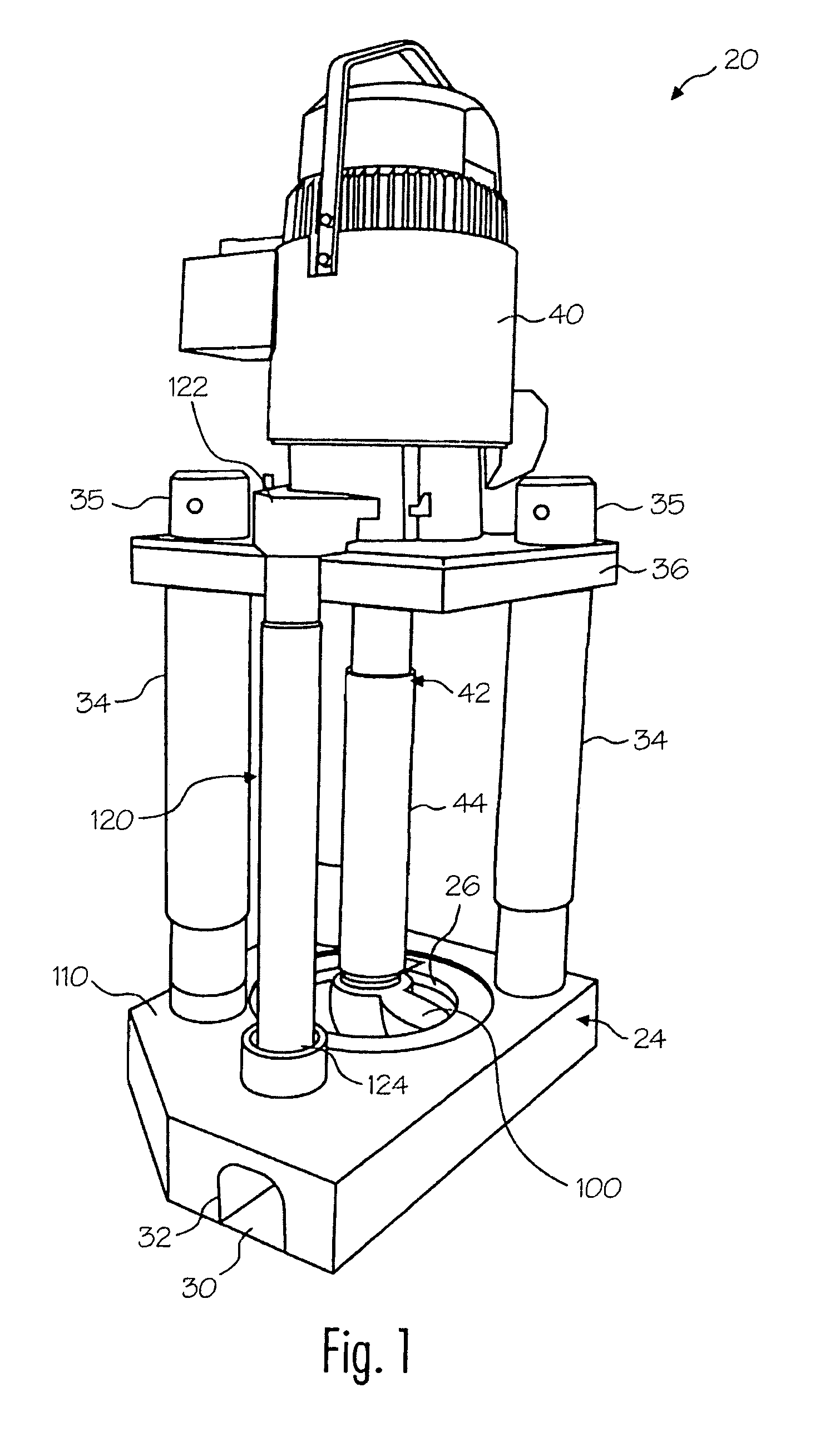

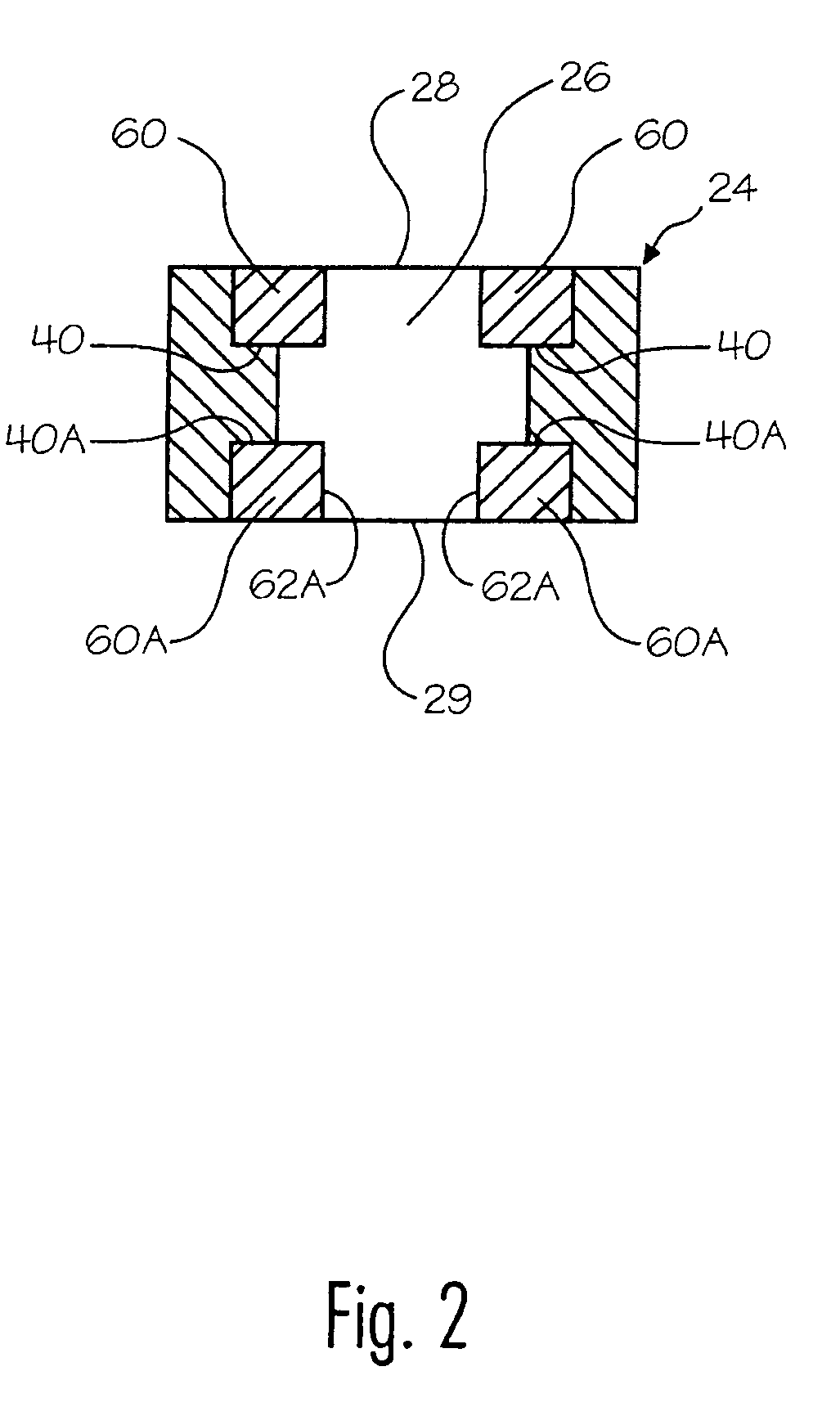

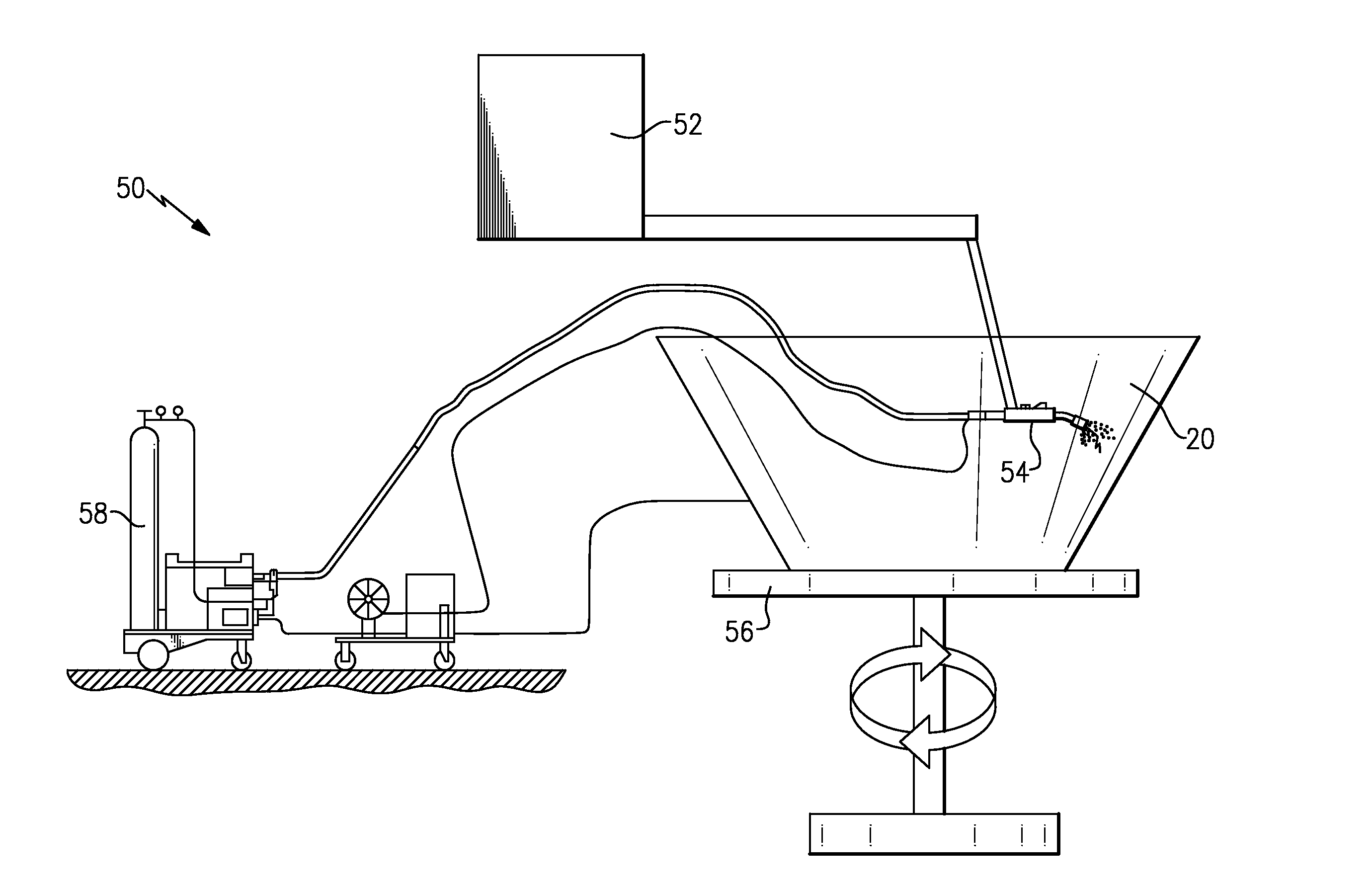

System for releasing gas into molten metal

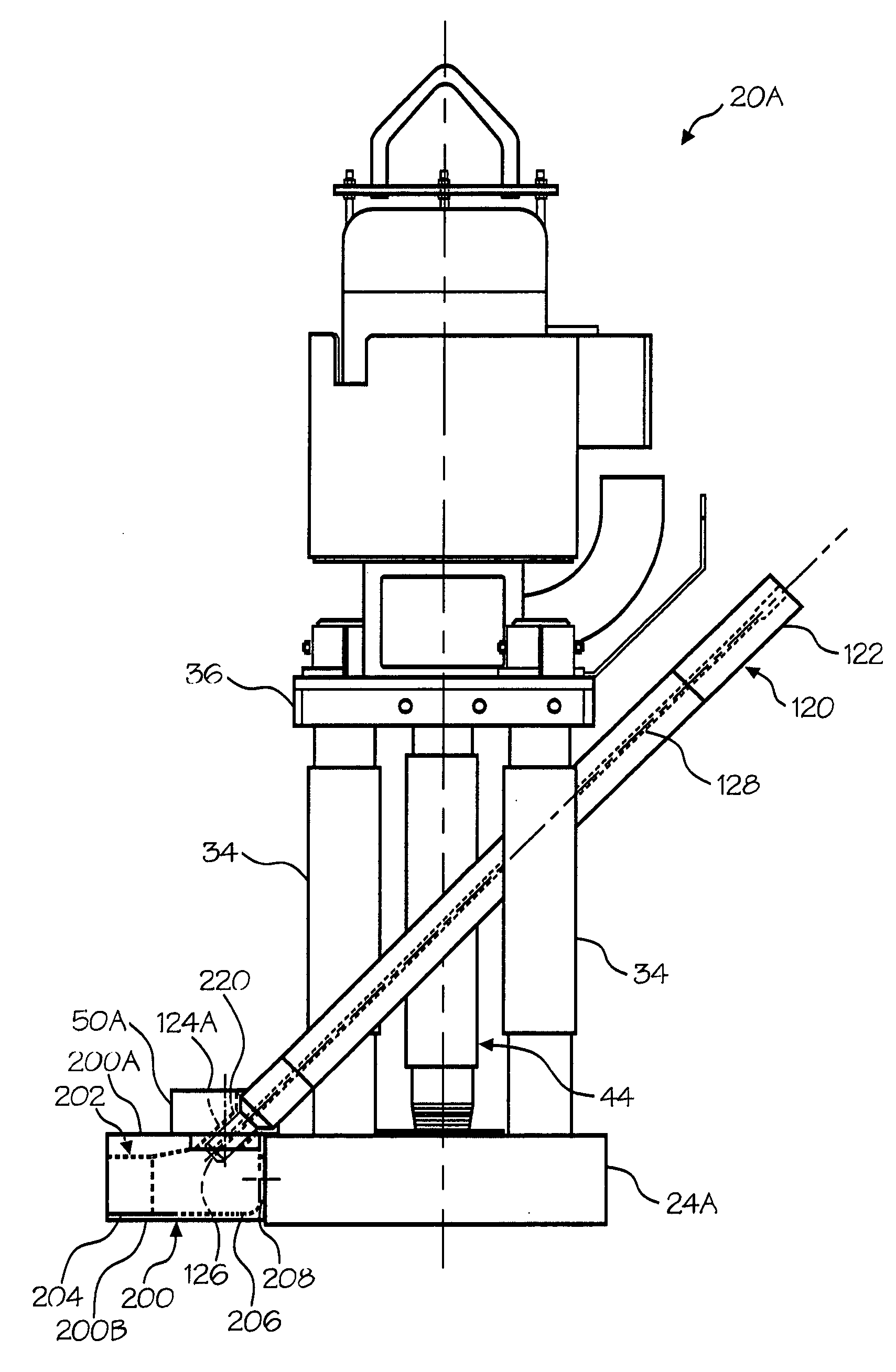

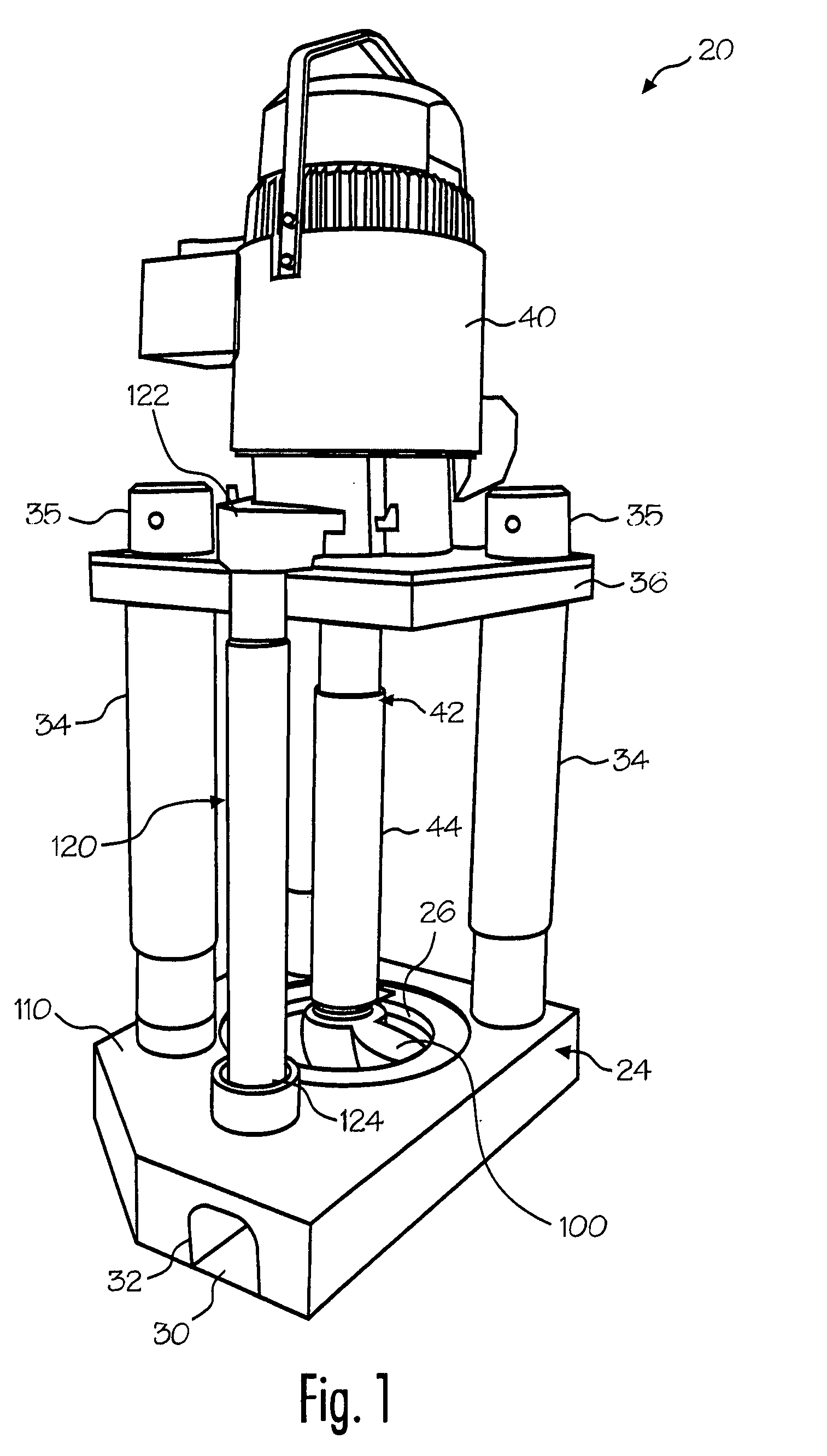

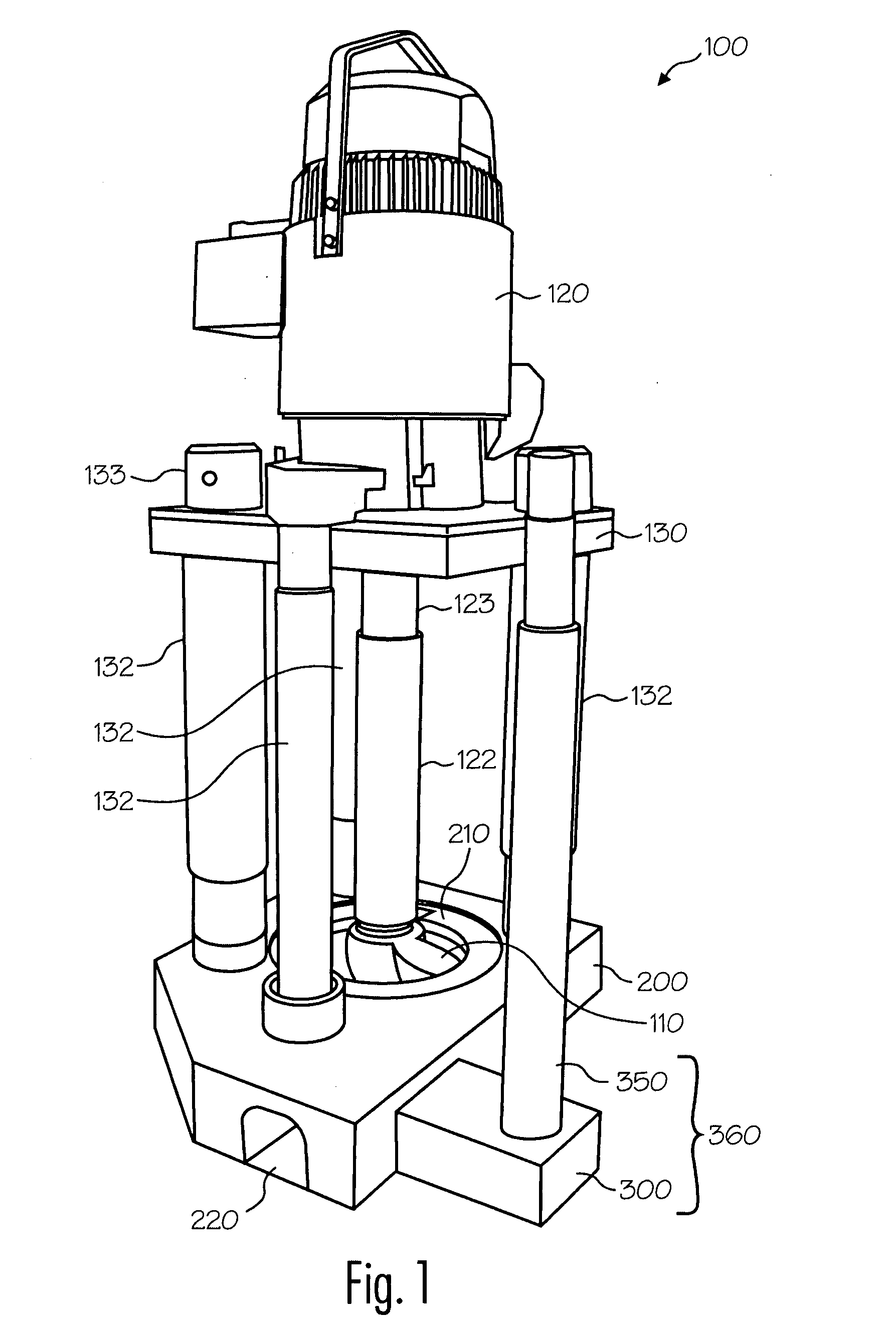

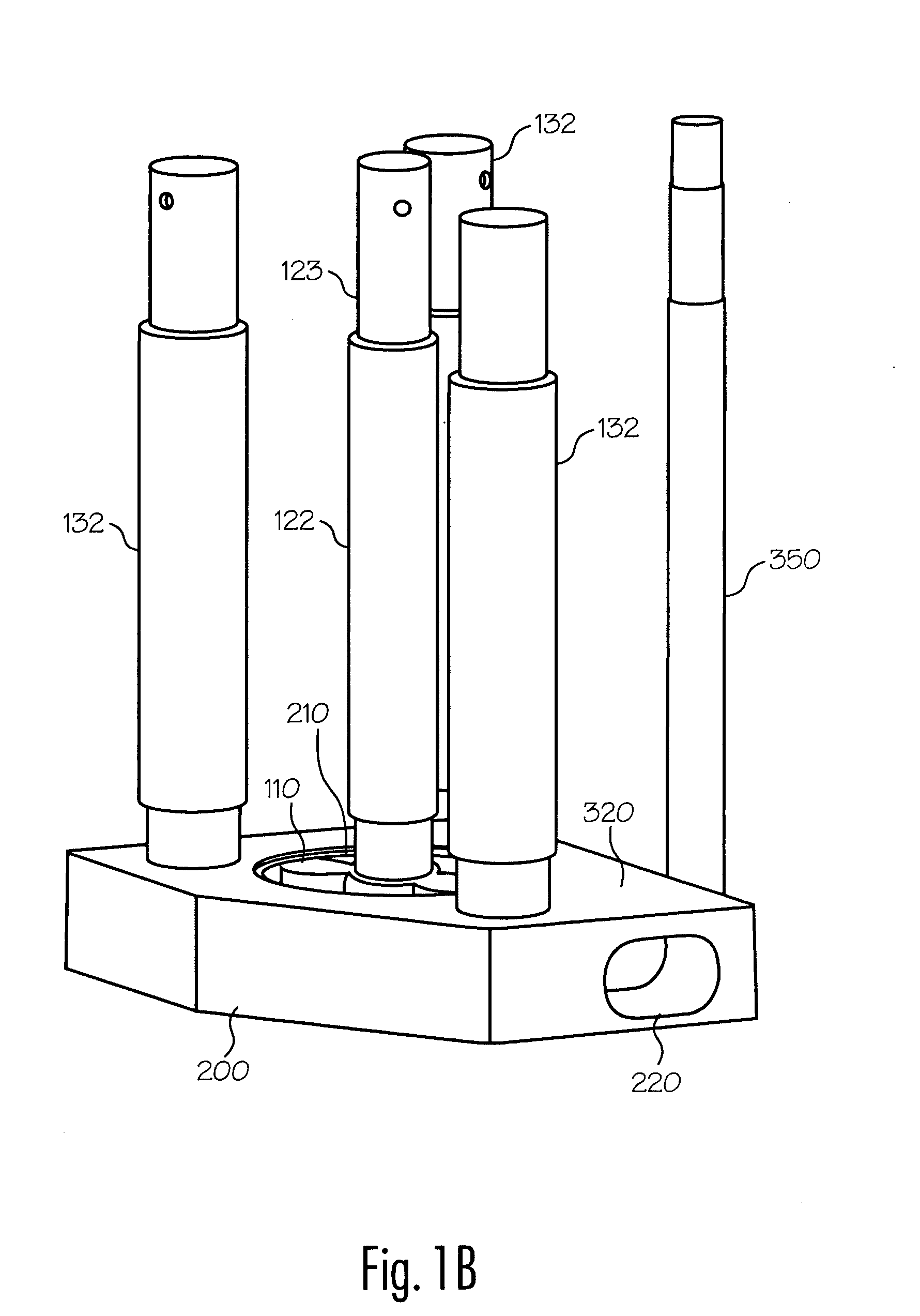

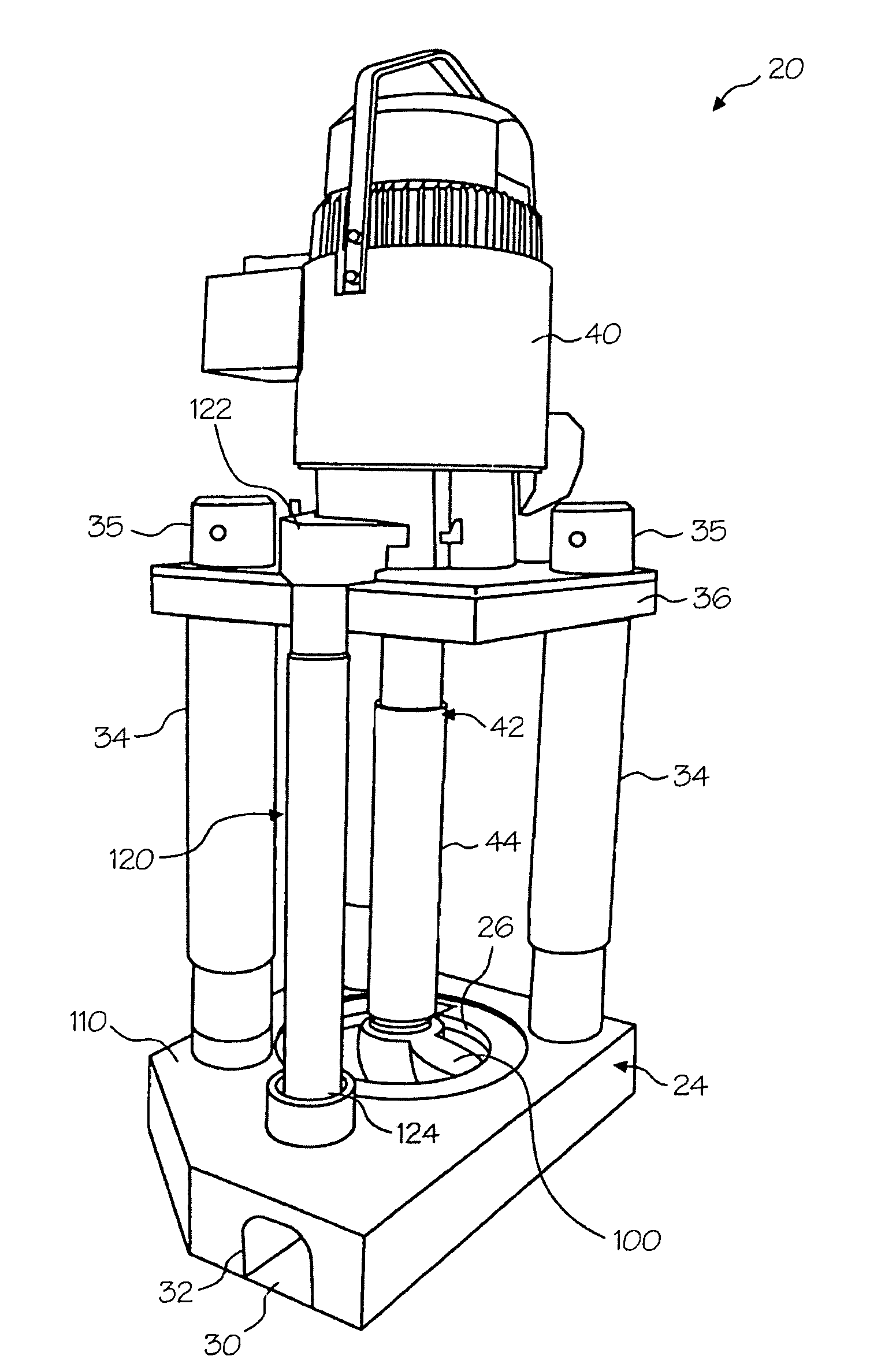

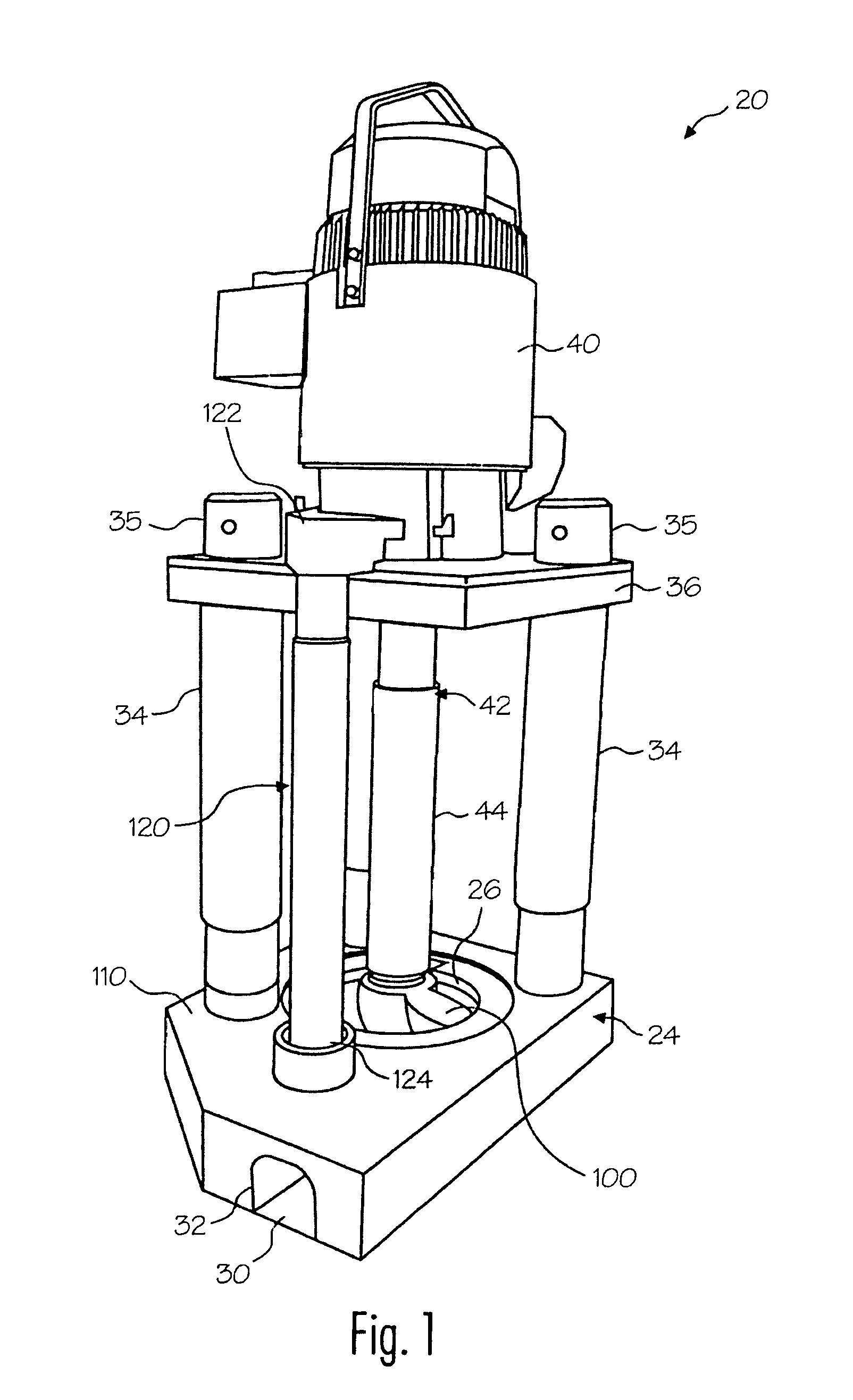

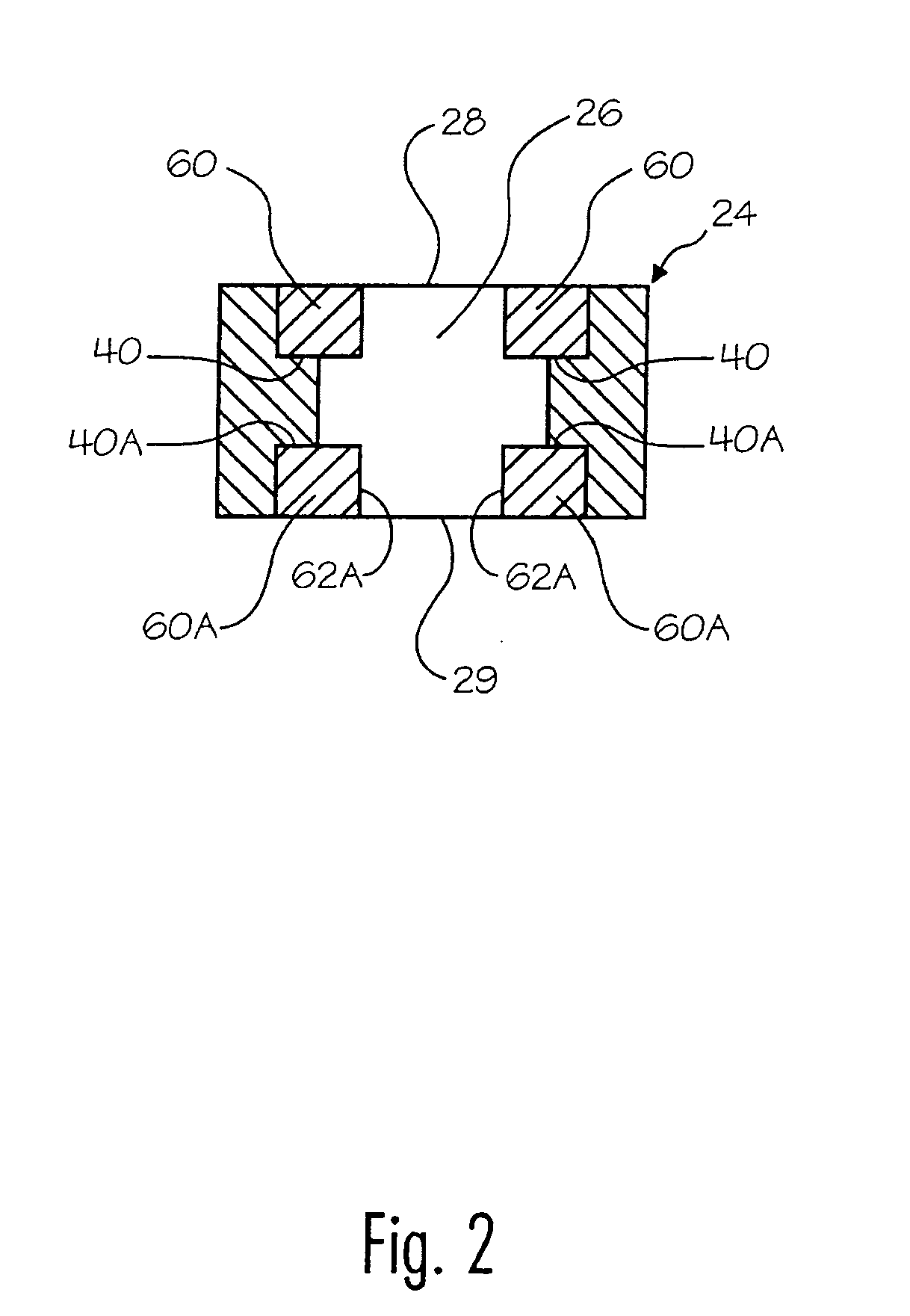

InactiveUS20050013715A1Reduce amountReduce stressSpecific fluid pumpsEngine manufactureMetallurgyGas release

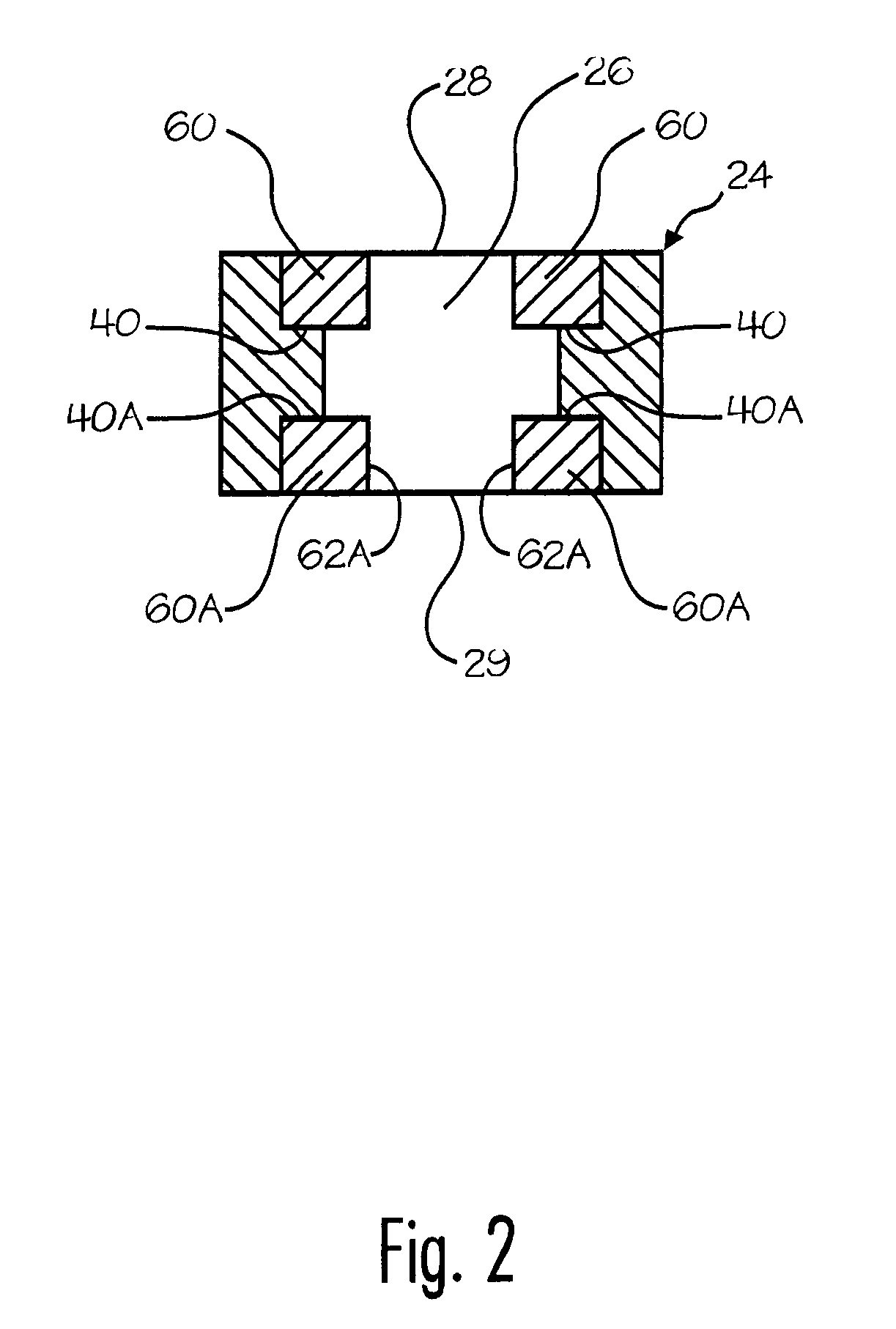

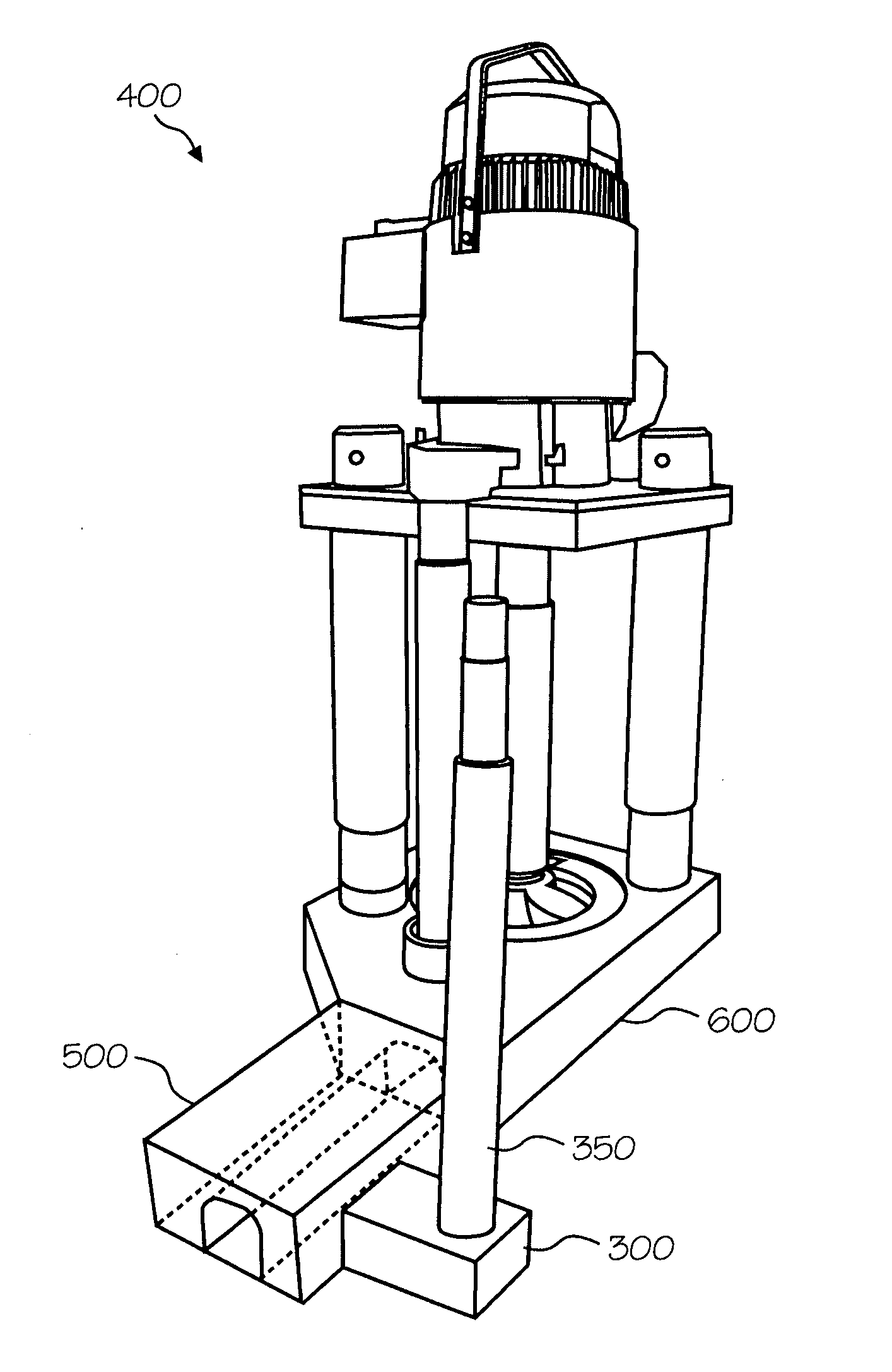

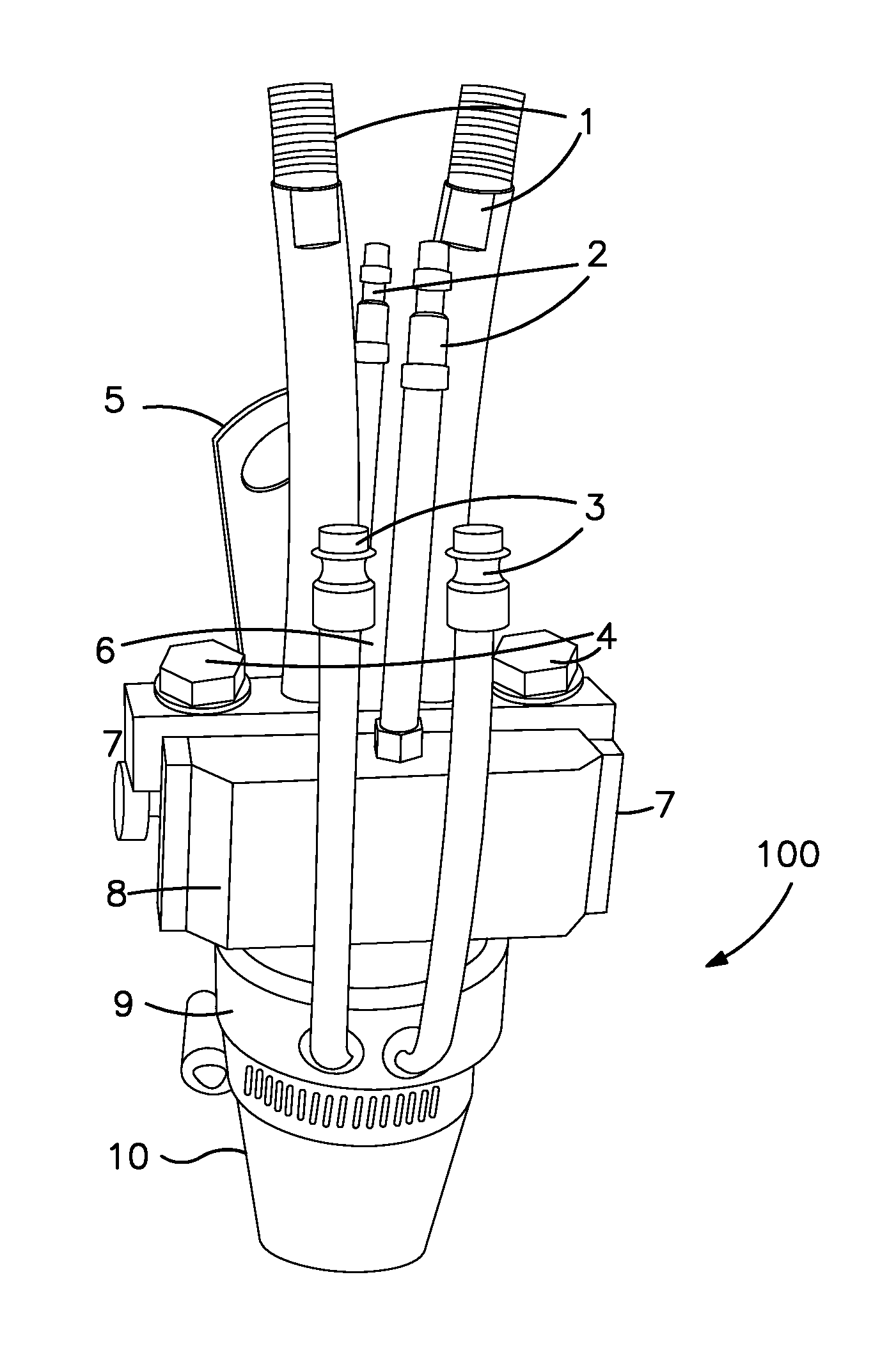

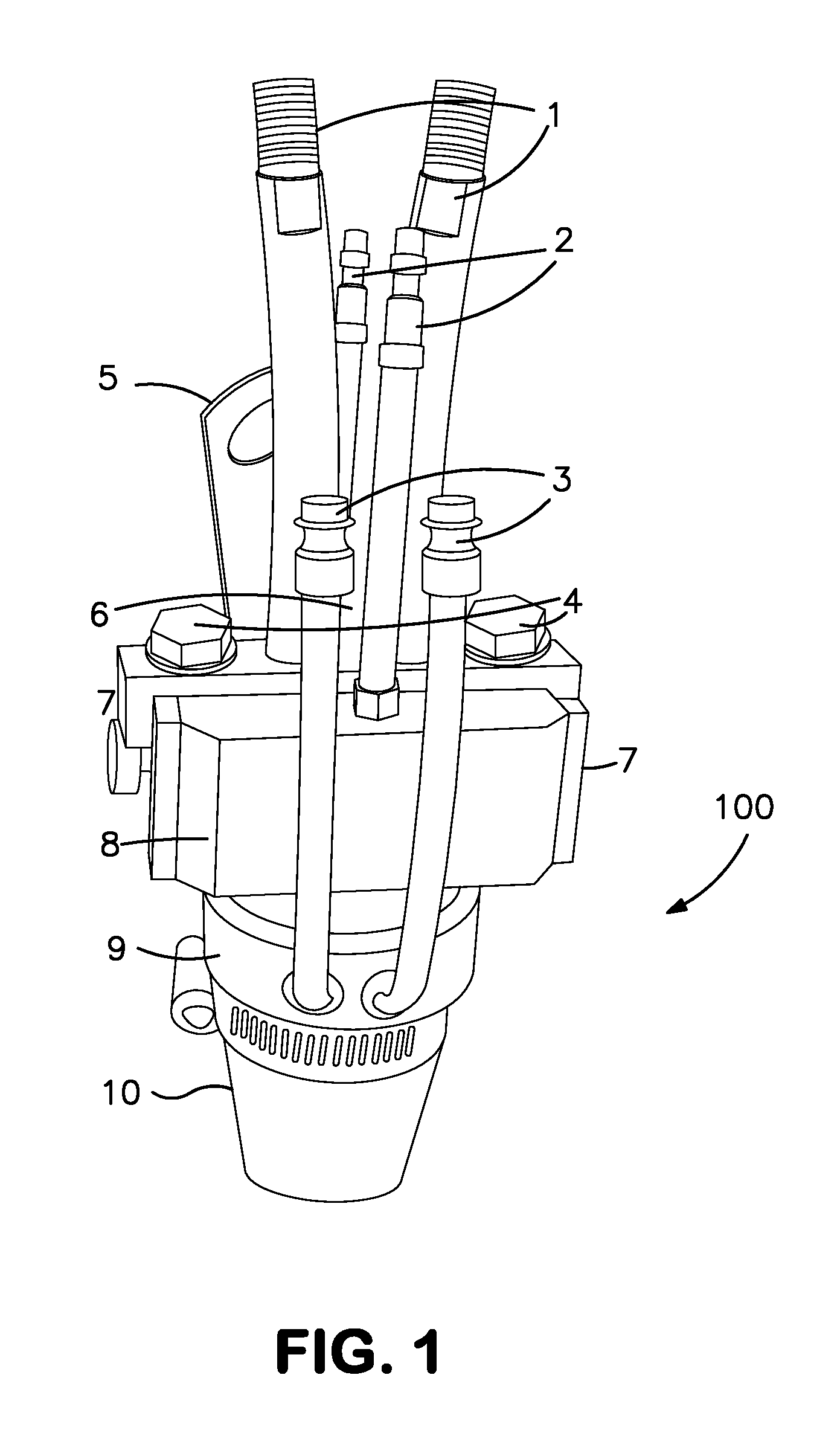

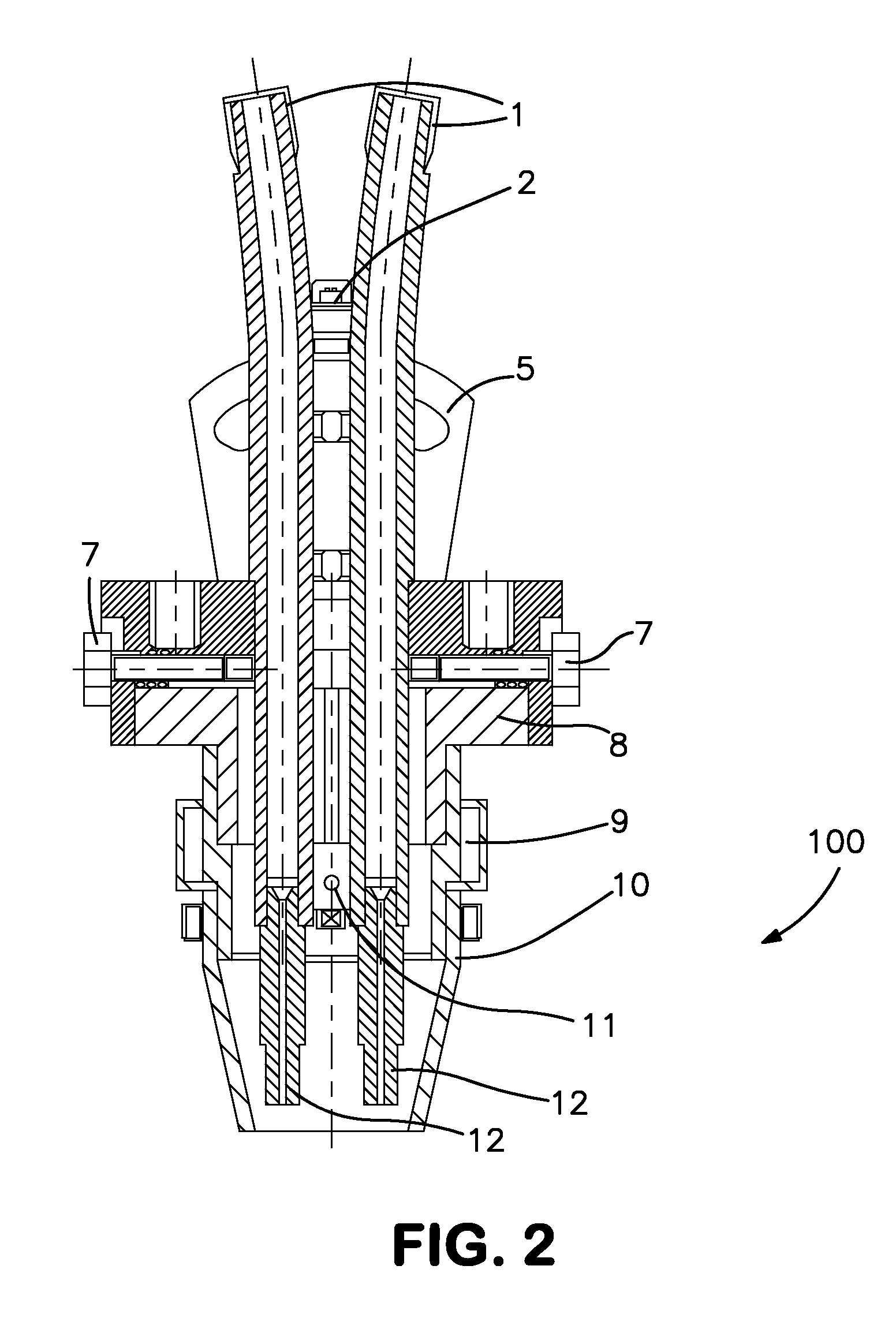

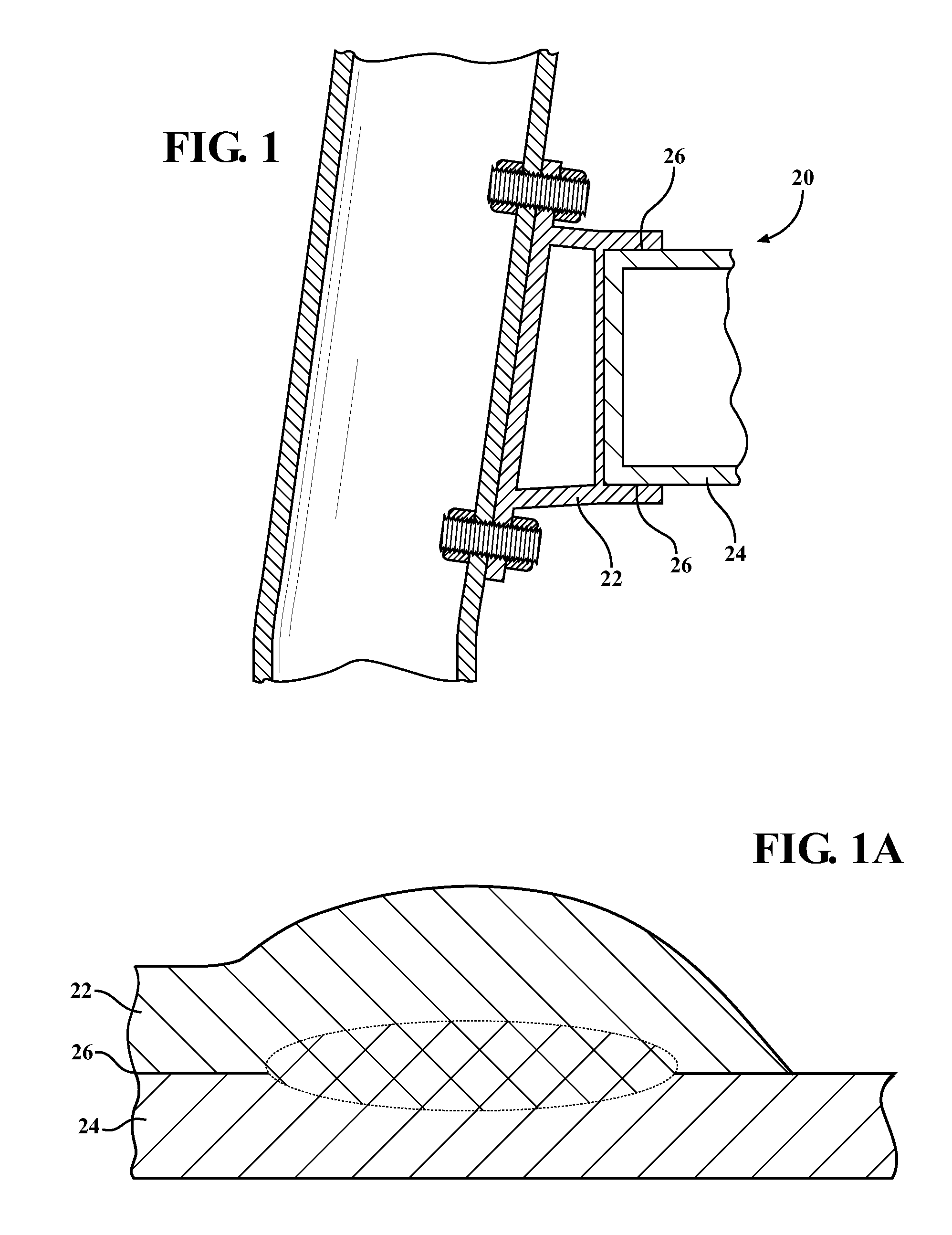

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:COOPER PAUL V

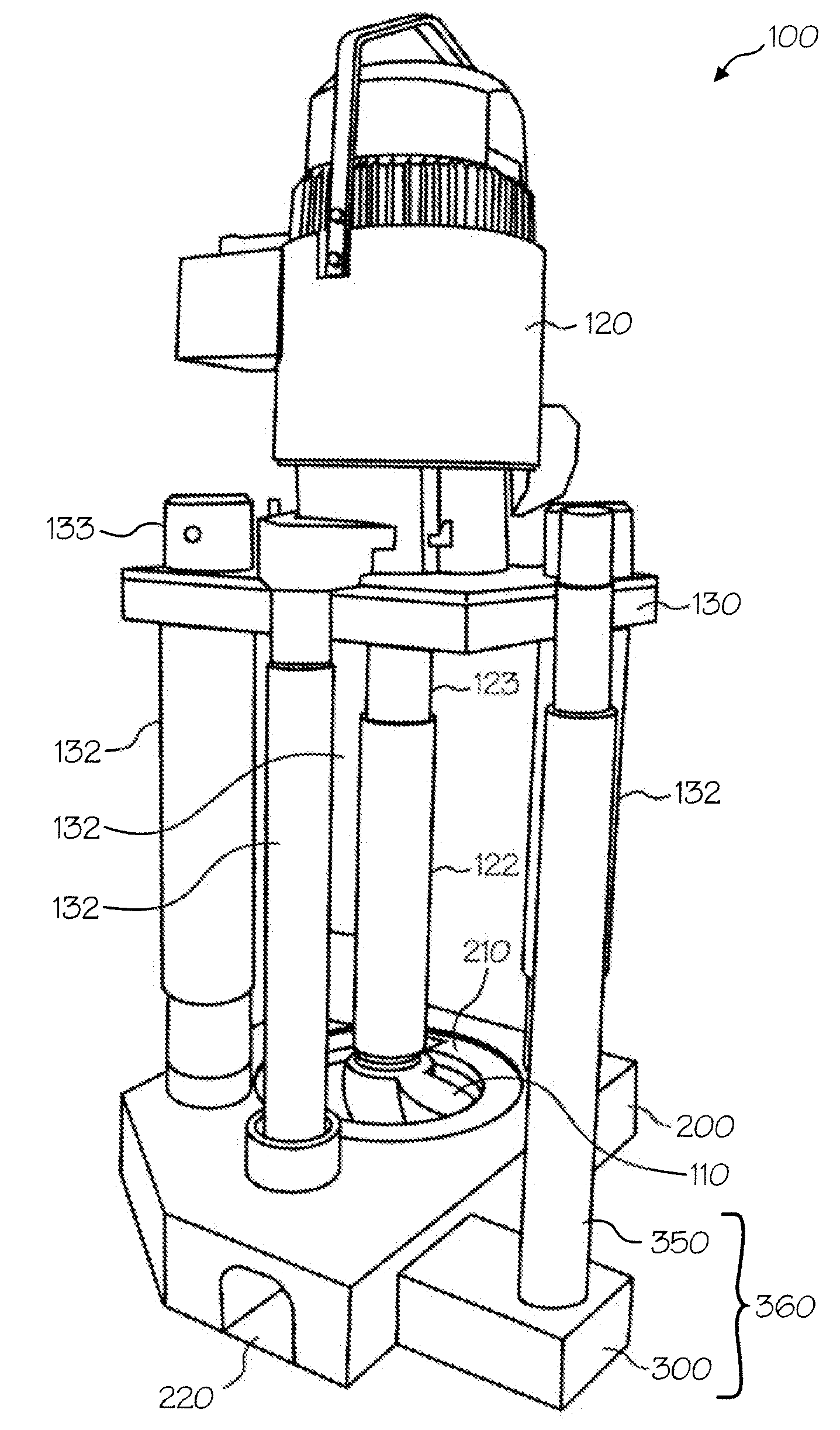

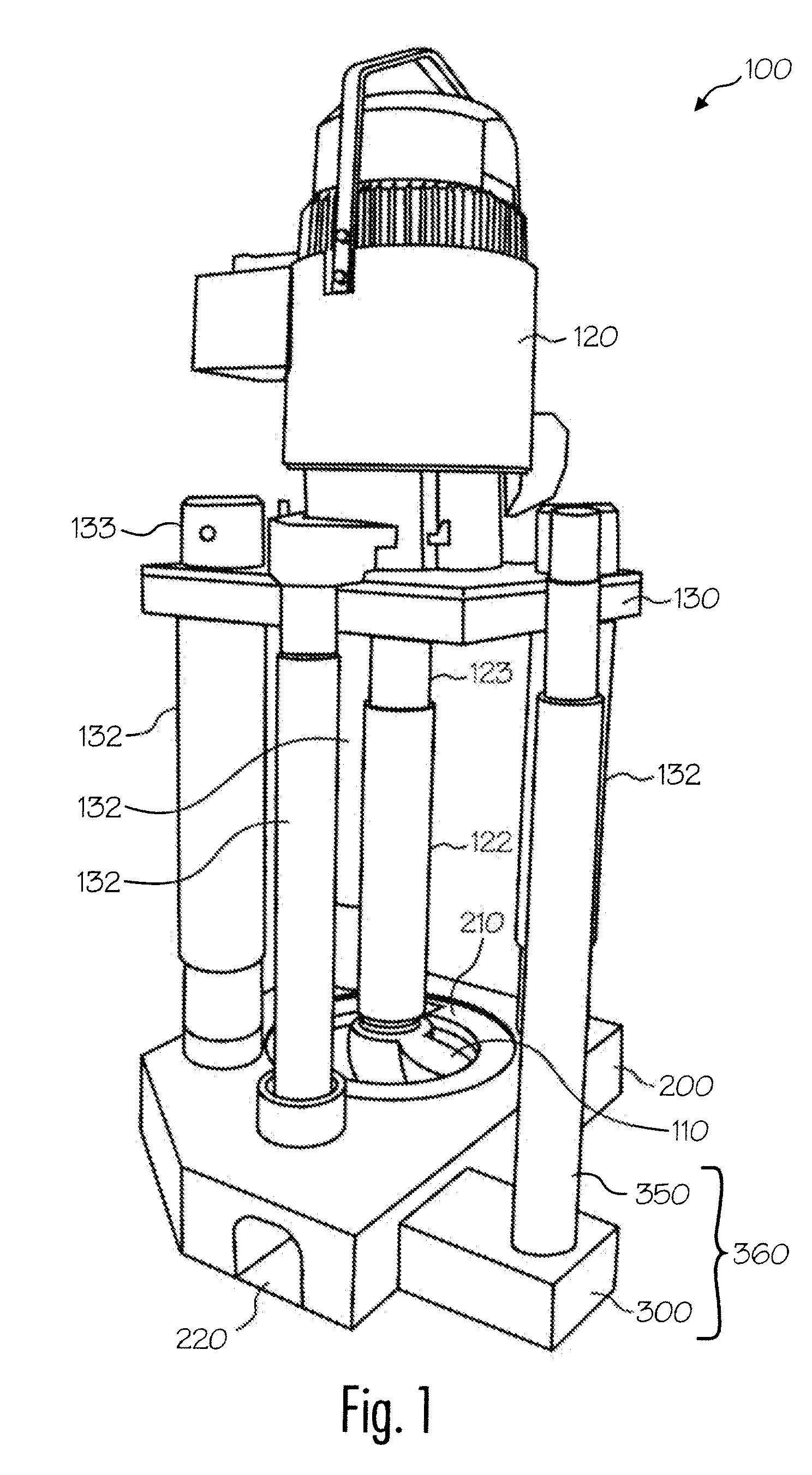

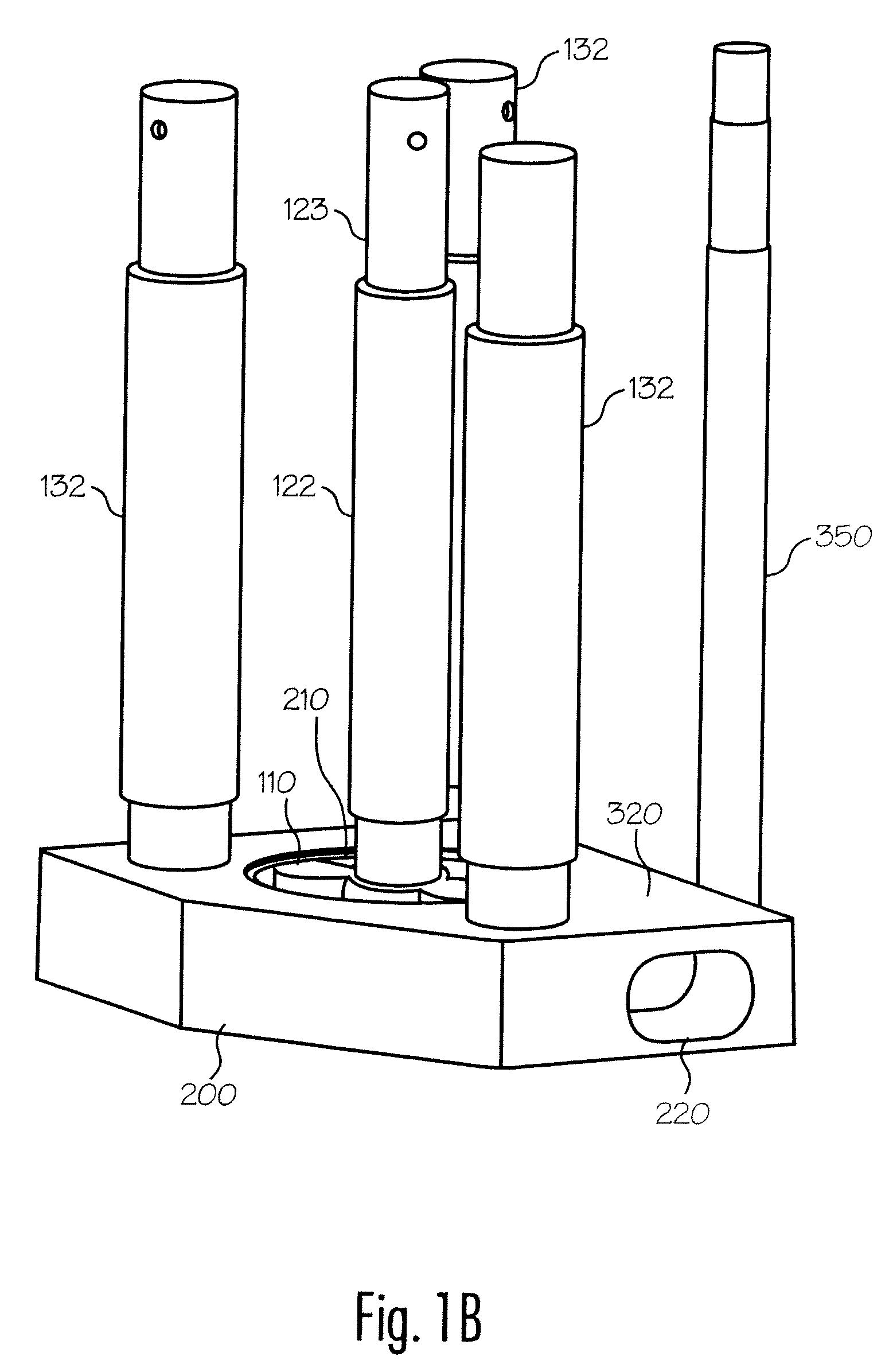

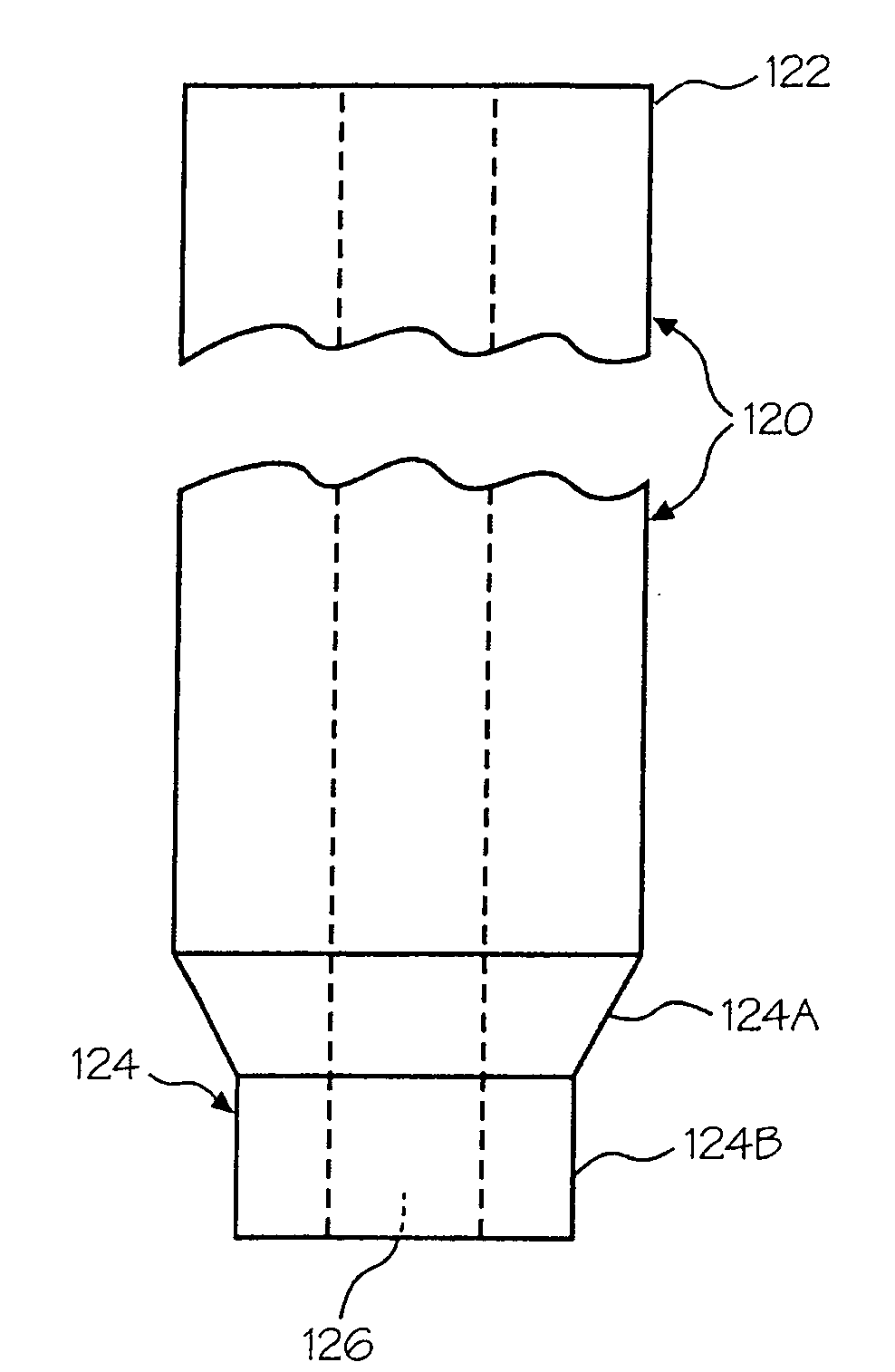

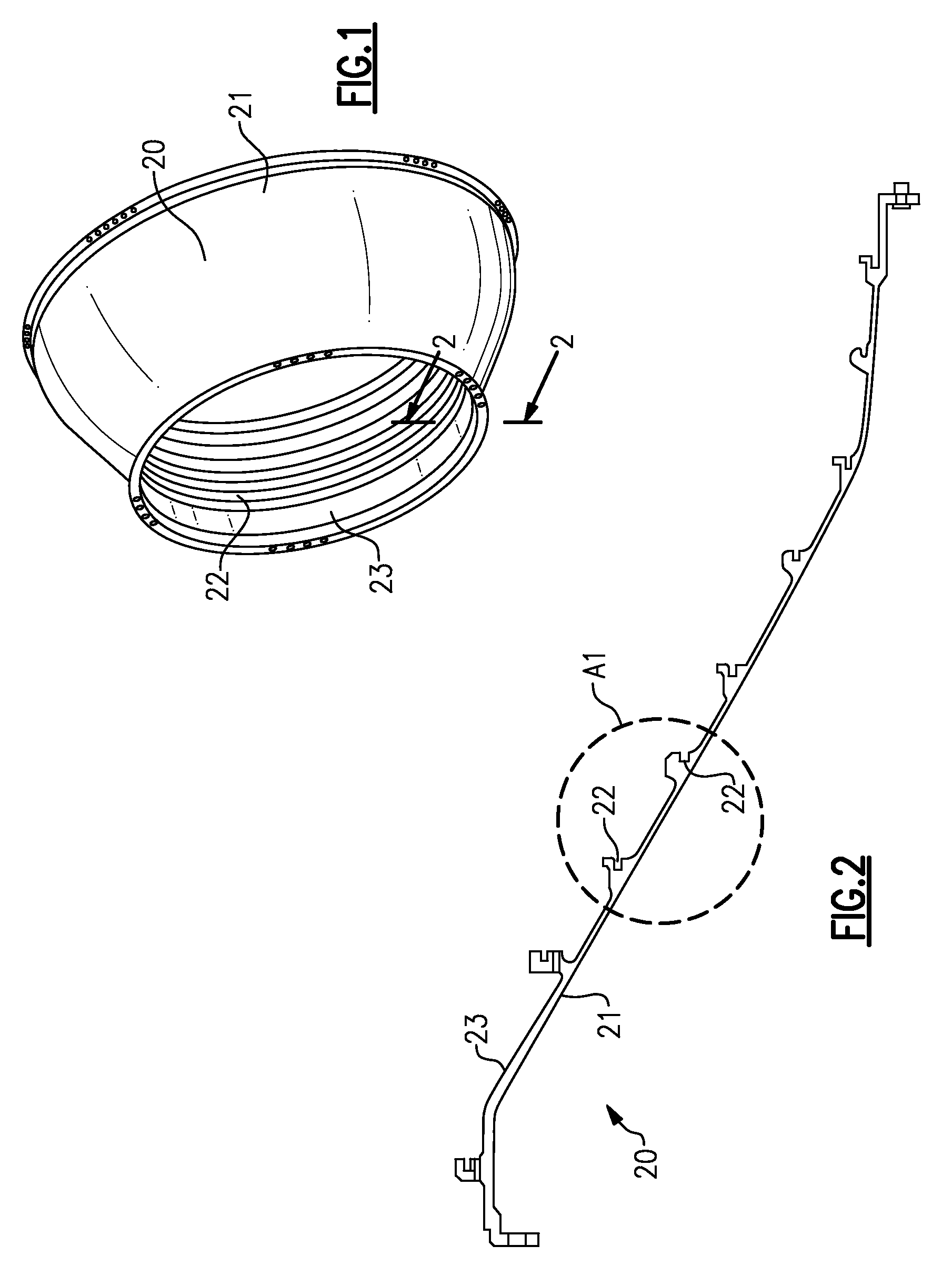

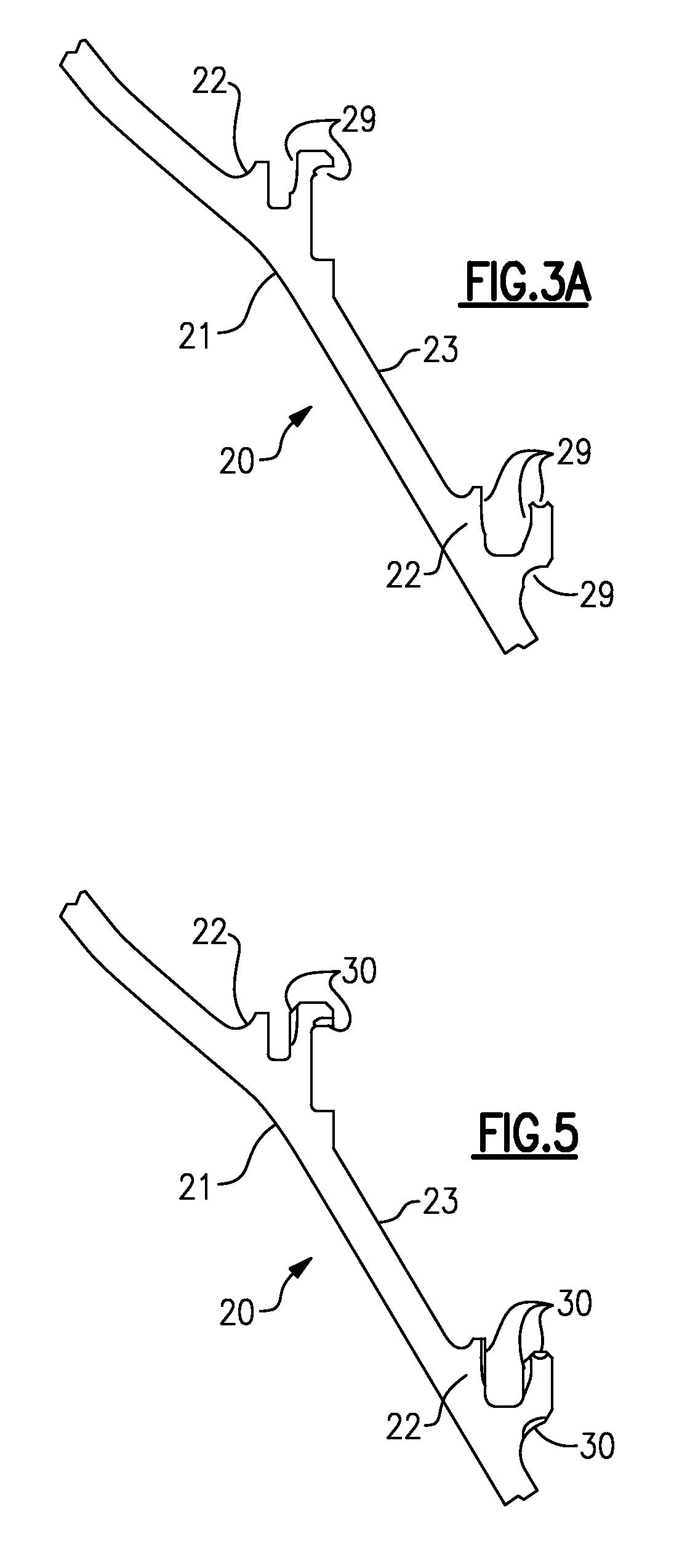

Gas-transfer foot

The present invention includes a molten metal pump and associated components that enable gas to be released into a stream of molten metal. The gas may be released into the molten metal stream (preferably into the bottom of the stream) flowing through a passage. Such a stream may be within the pump discharge and / or within a metal-transfer conduit extending from the pump discharge. The gas is released by using a gas-transfer foot that is positioned next to and is preferably attachable to the pump base or to the metal-transfer conduit. Preferably, the conduit (and / or discharge) in which the gas is released comprises two sections: a first section having a first cross-sectional area and a second section downstream of the first section and having a second cross-sectional area, wherein the second cross sectional area is larger than the first cross-sectional area. Preferably, the gas is released into or near the second section so that the gas is released into an area of relatively lower pressure.

Owner:COOPER PAUL

System for releasing gas into molten metal

InactiveUS20080213111A1Reduce amountIncrease the cross-sectional areaSpecific fluid pumpsEngine manufactureMetallurgyGas release

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Gas transfer foot

InactiveUS20090269191A1Specific fluid pumpsRotary non-positive displacement pumpsProduct gasEngineering

The present invention includes a molten metal pump and associated components that enable gas to be released into a stream of molten metal. The gas may be released into the molten metal stream (preferably into the bottom of the stream) flowing through a passage. Such a stream may be within the pump discharge and / or within a metal-transfer conduit extending from the pump discharge. The gas is released by using a gas-transfer foot that is positioned next to and is preferably attachable to the pump base or to the metal-transfer conduit. Preferably, the conduit (and / or discharge) in which the gas is released comprises two sections: a first section having a first cross-sectional area and a second section downstream of the first section and having a second cross-sectional area, wherein the second cross sectional area is larger than the first cross-sectional area. Preferably, the gas is released into or near the second section so that the gas is released into an area of relatively lower pressure.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

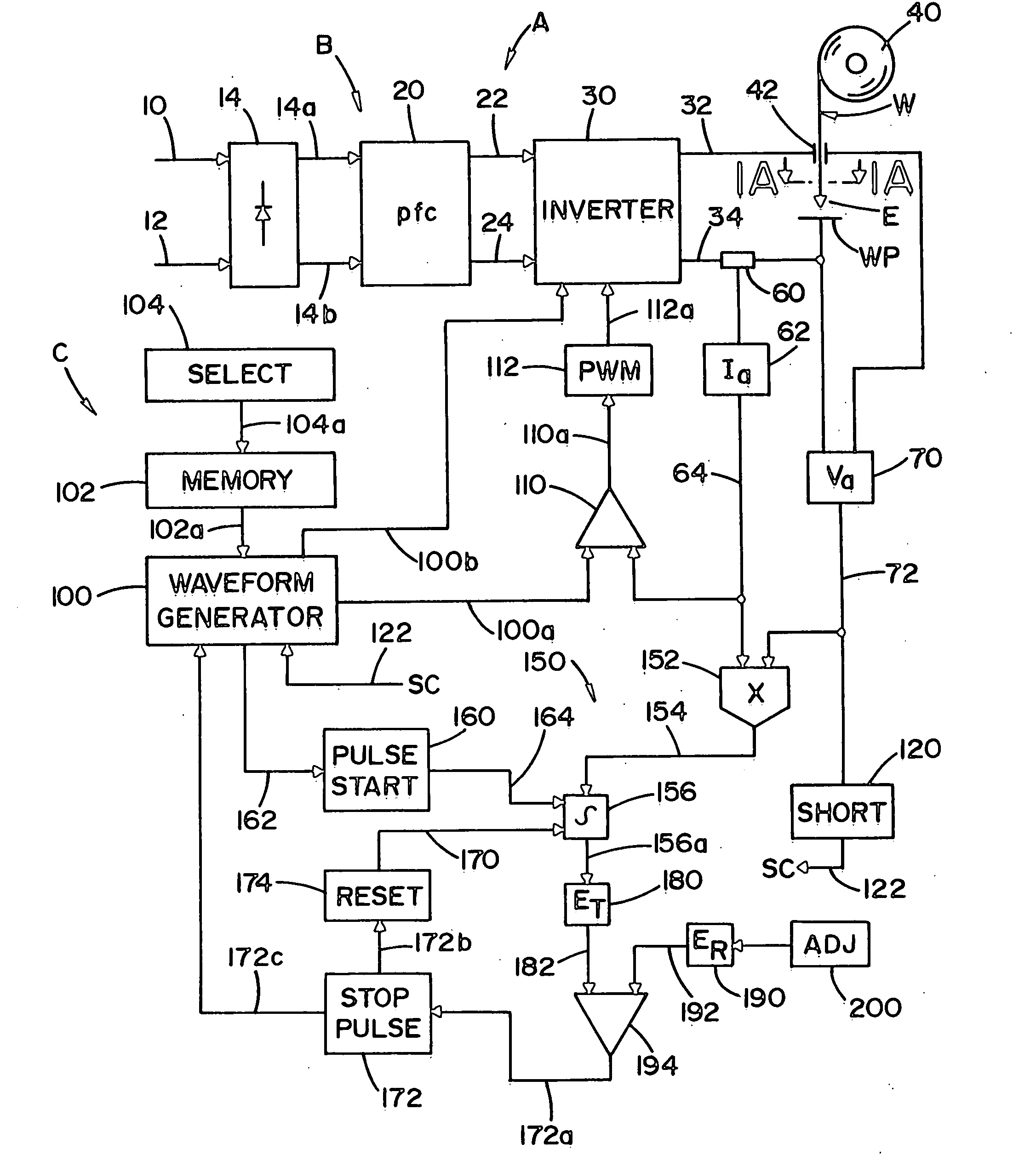

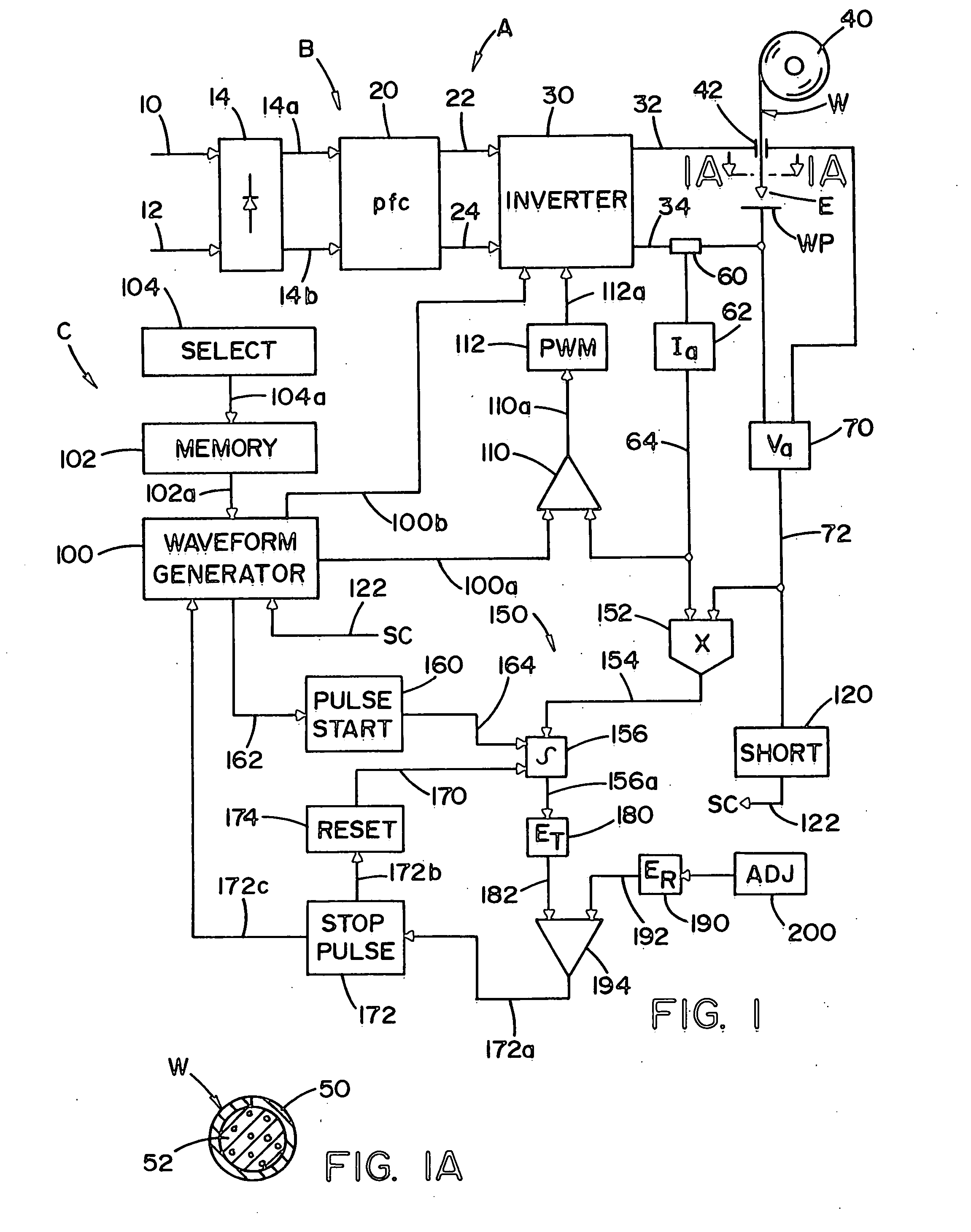

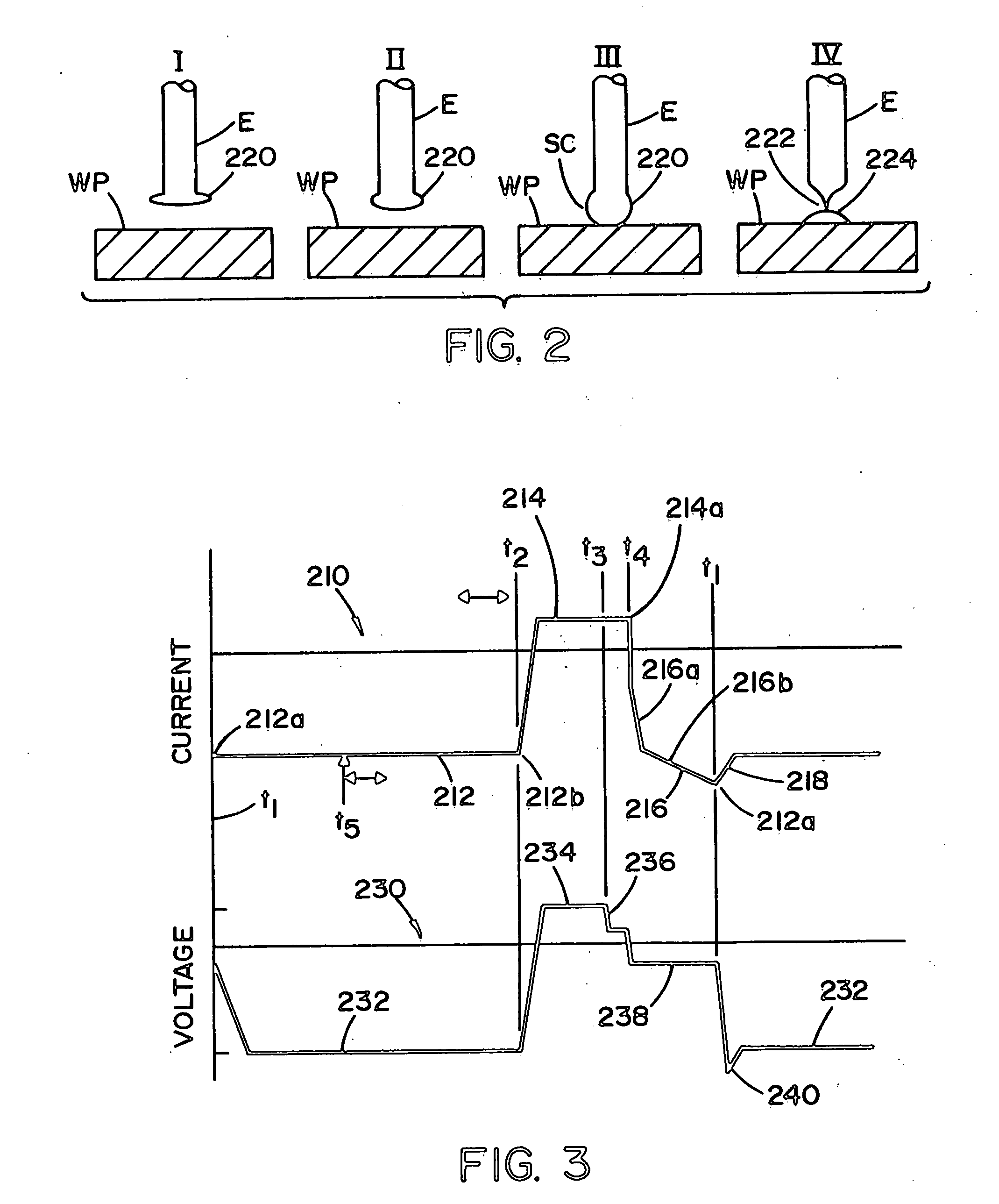

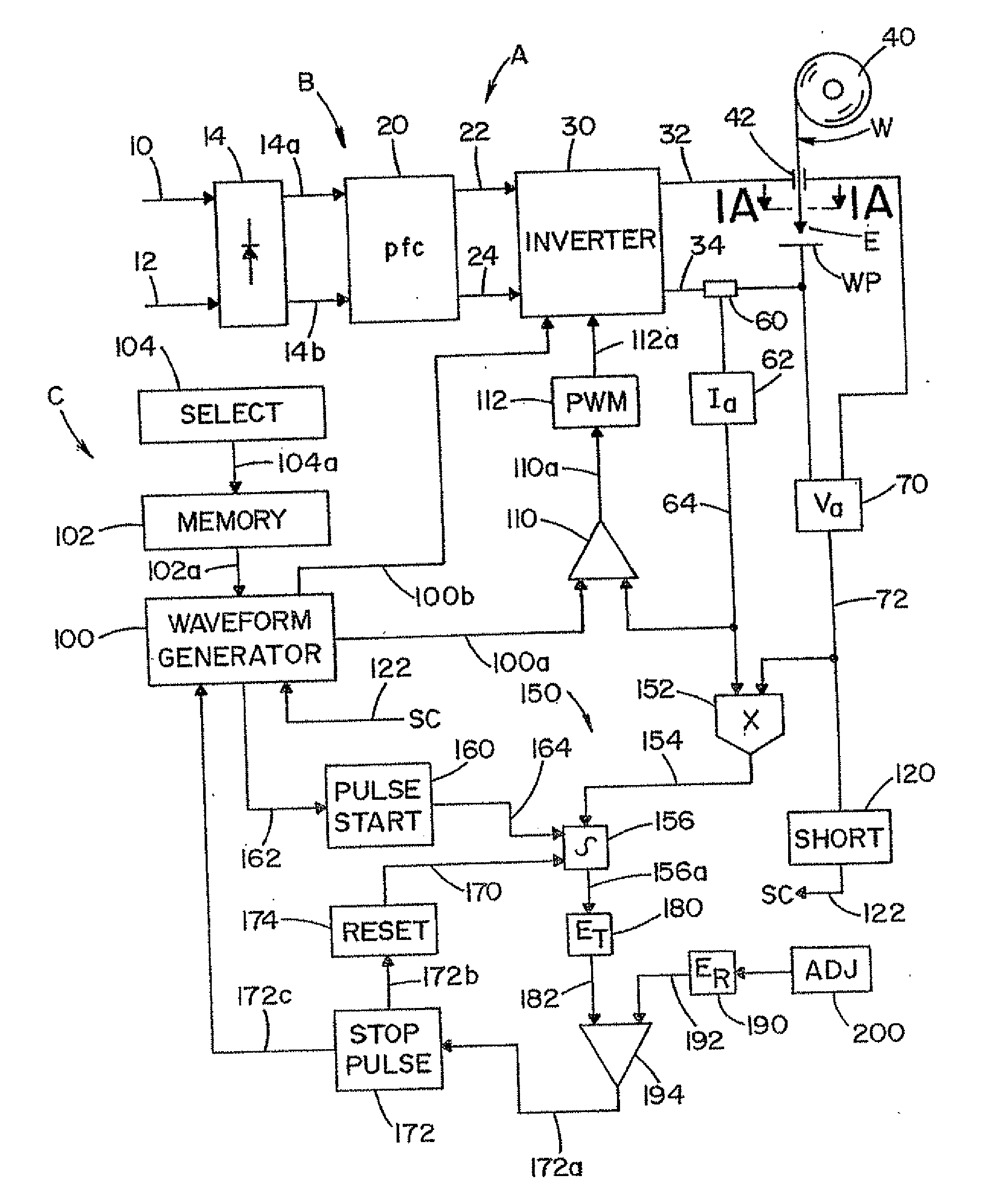

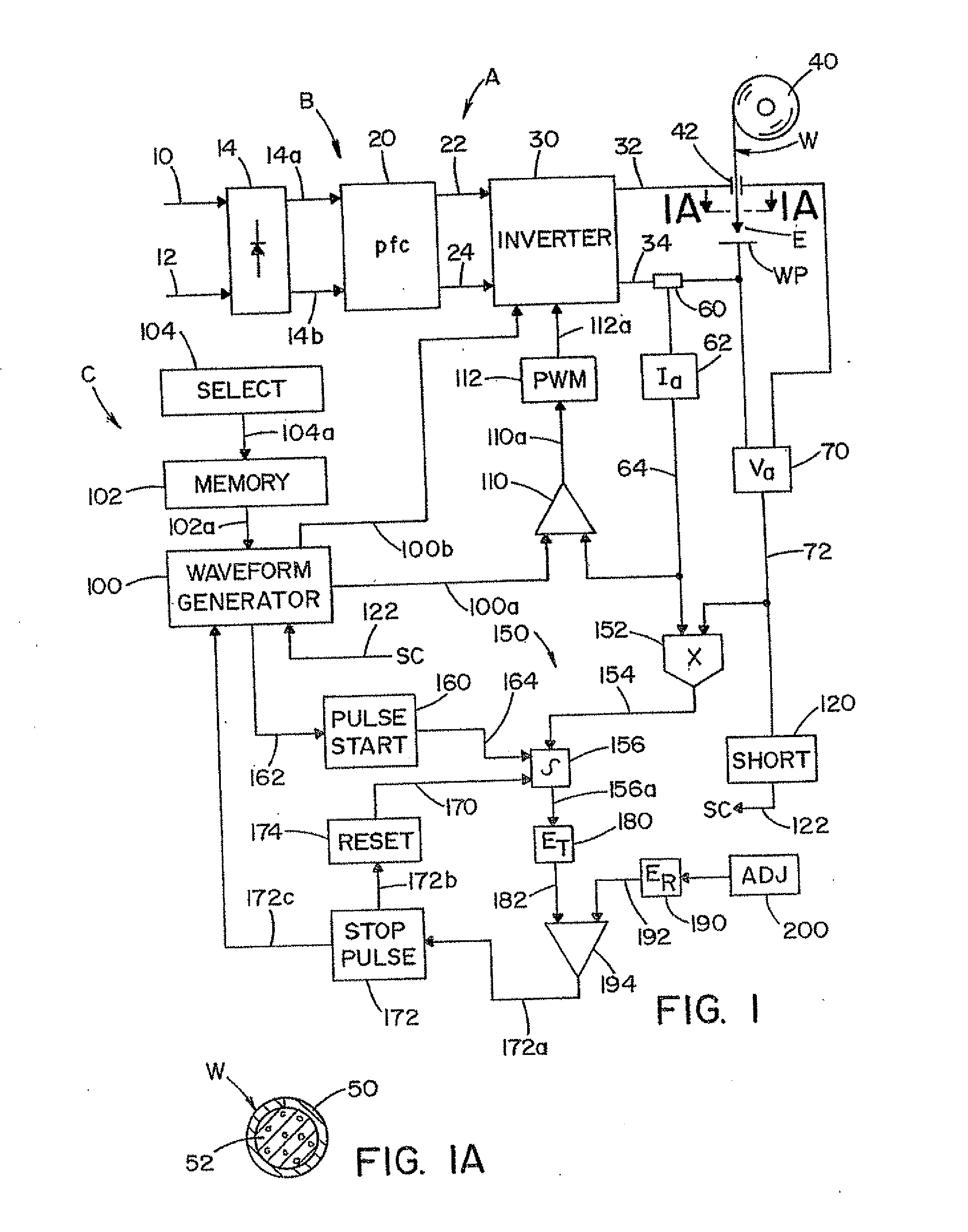

Synergistic welding system

ActiveUS20070170163A1Reduce pollutionShorten the lengthArc welding apparatusWelding/cutting media/materialsCombined useEngineering

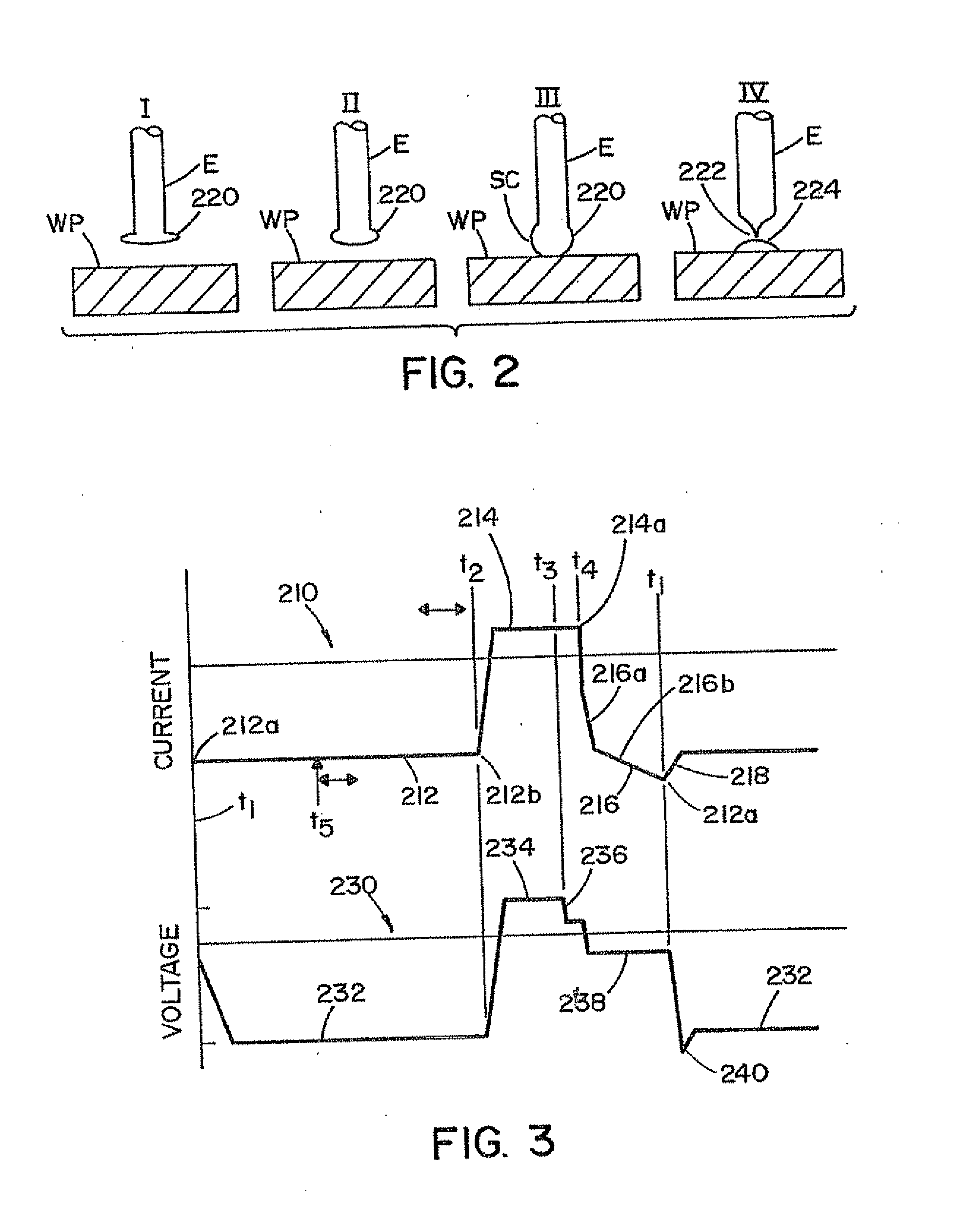

A welding system is disclosed for performing a short arc welding process between an advancing wire electrode and a workpiece. The system comprises a power source with a controller for creating a current pulse introducing energy into the electrode to melt the end of the electrode and a low current quiescent metal transfer section following the end of the melting pulse during which the melted electrode short circuits against the workpiece; a timer to measure the actual time between the end of the pulse and the short circuit; a device for setting a desired time from the pulse to the short circuit; a circuit to create a corrective signal based upon the difference between the actual time and the desired time; and, a circuit responsive to the corrective signal to control a given parameter of the current pulse. Also disclosed is a strategy for arc welding utilizing a cored electrode that produces welds with low levels of contaminants and which are strong, tough, and durable. The arc welding process generally utilizes an AC waveform. The cored electrode can be a self-shielded flux cored electrode (FCAW-S). Various electrode compositions are described that are particularly beneficial when used in conjunction with an AC waveform.

Owner:LINCOLN GLOBAL INC

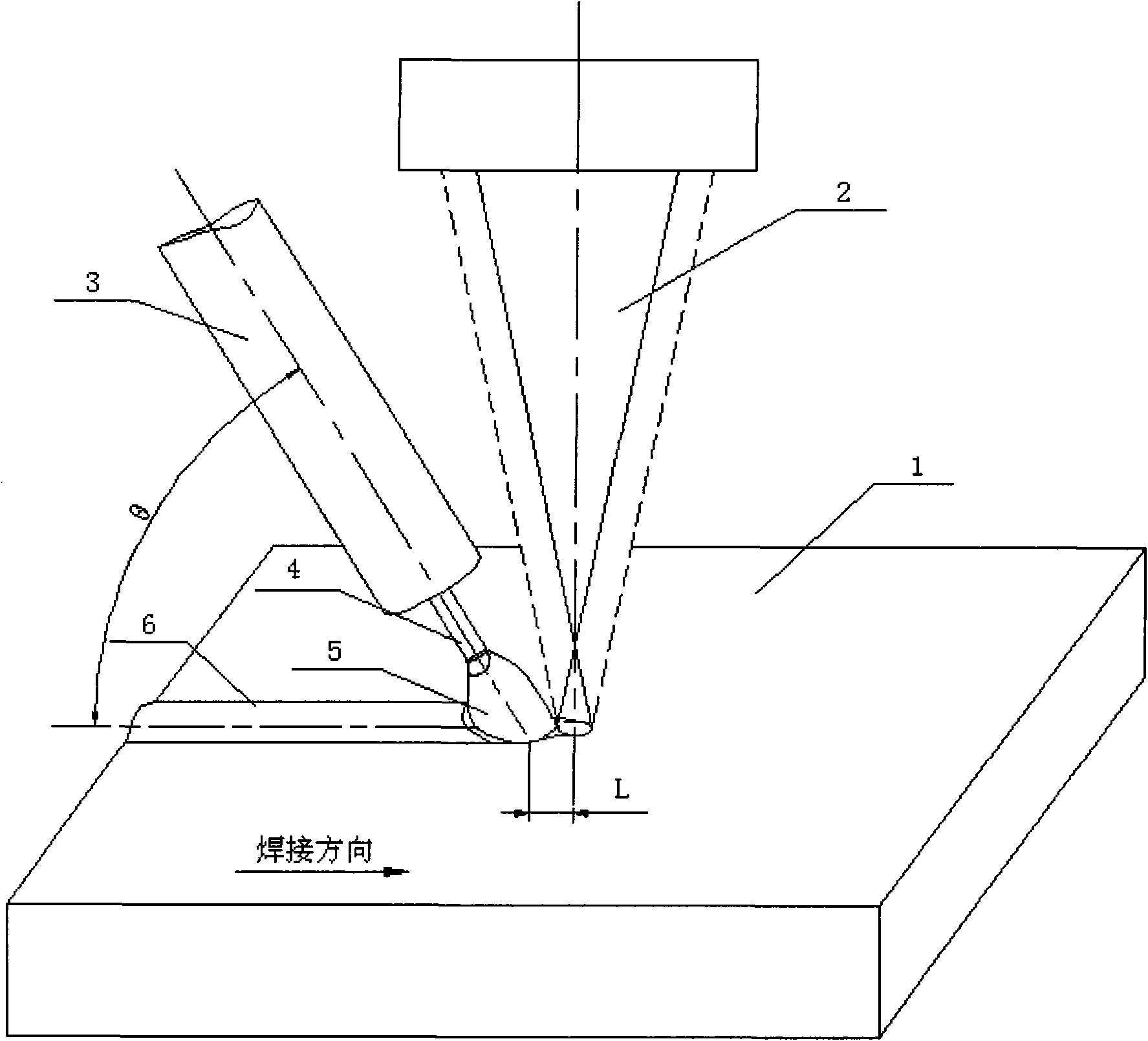

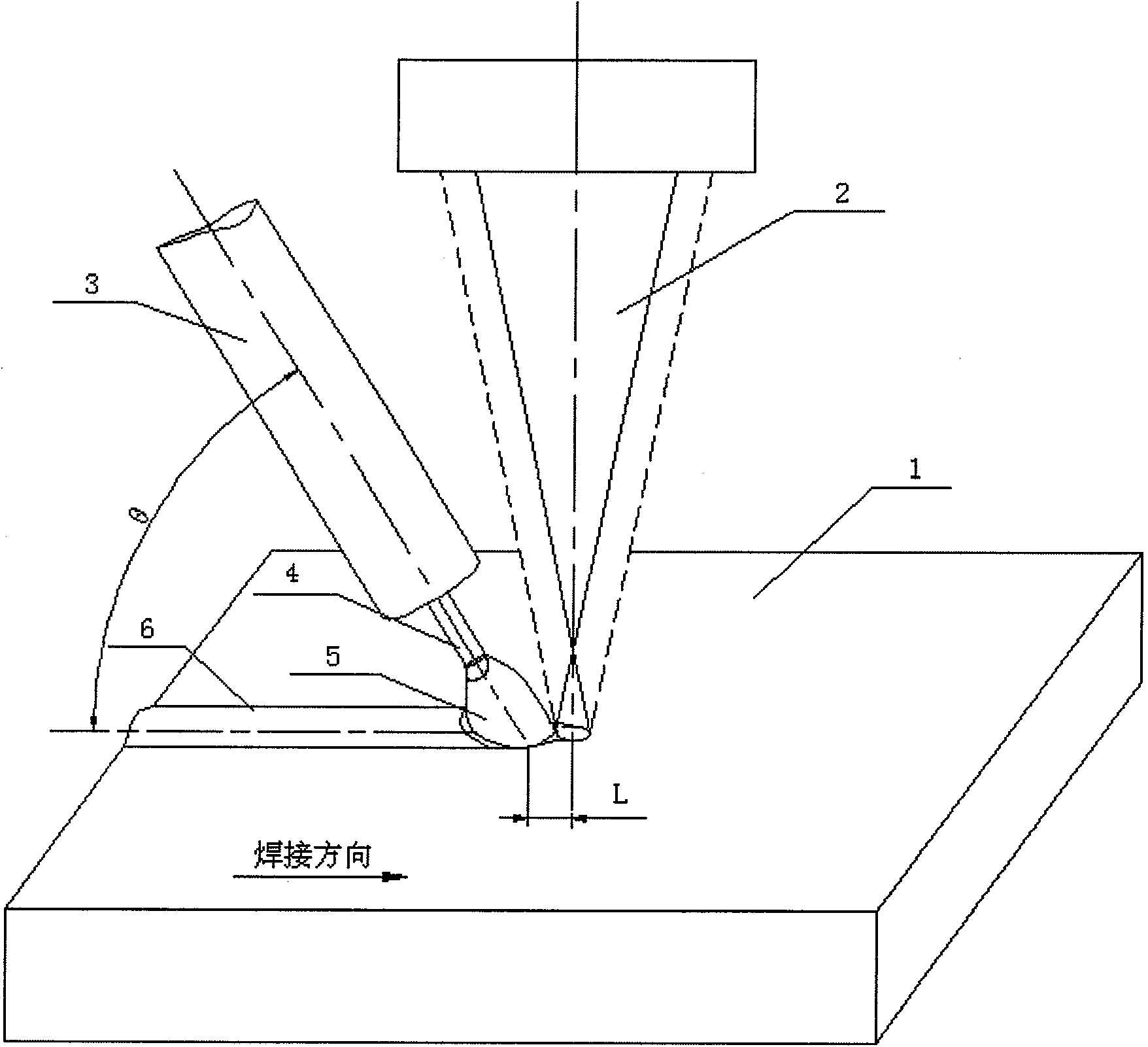

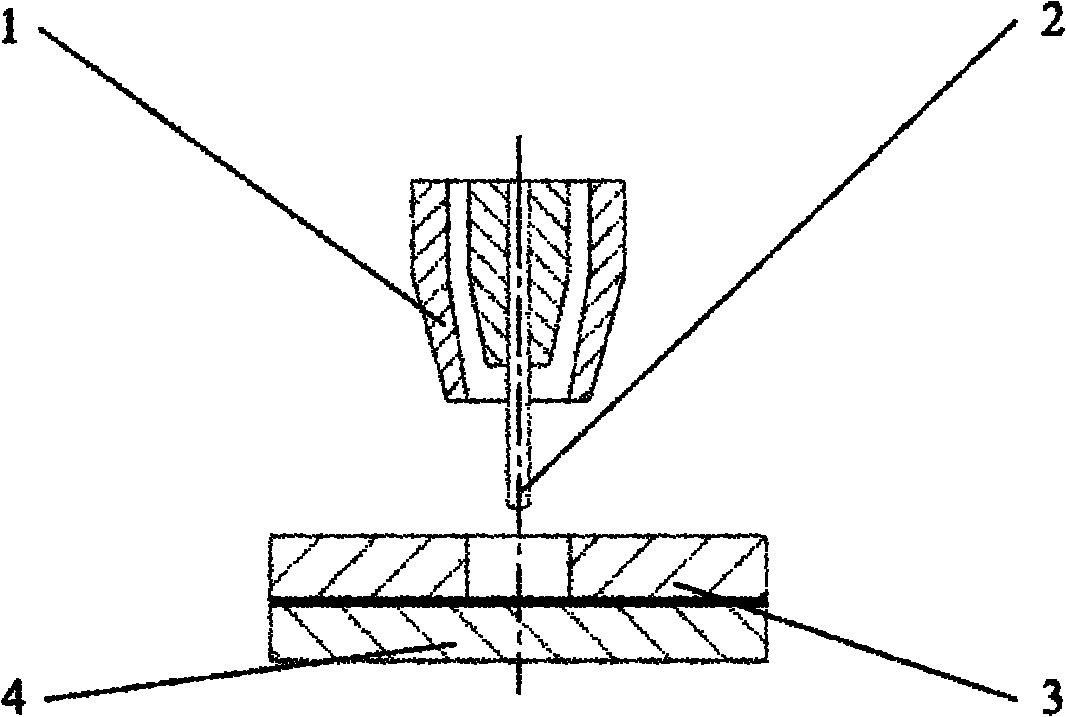

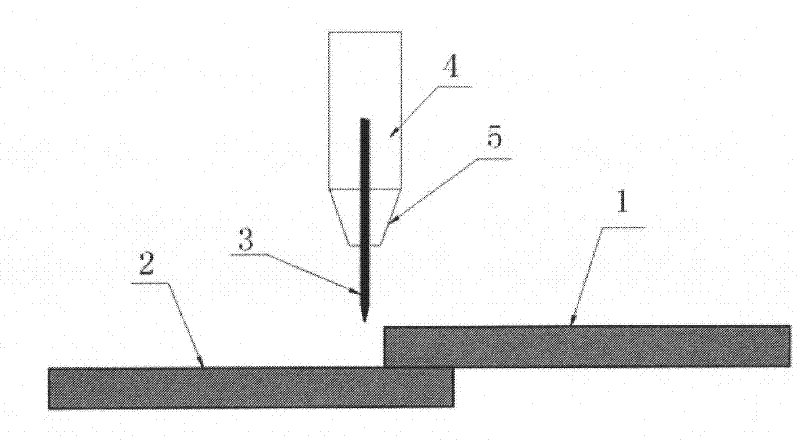

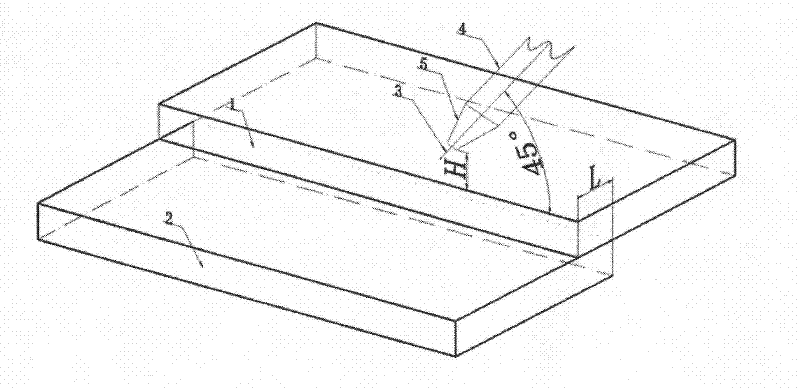

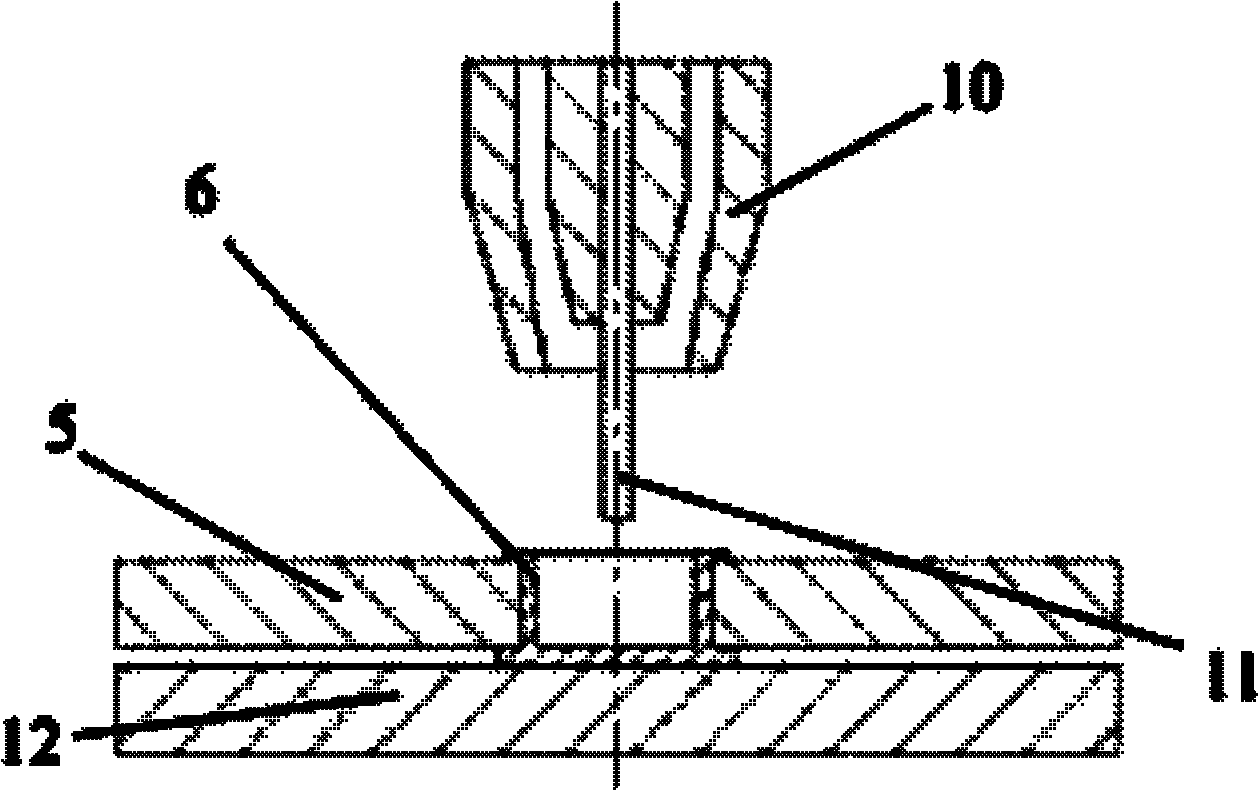

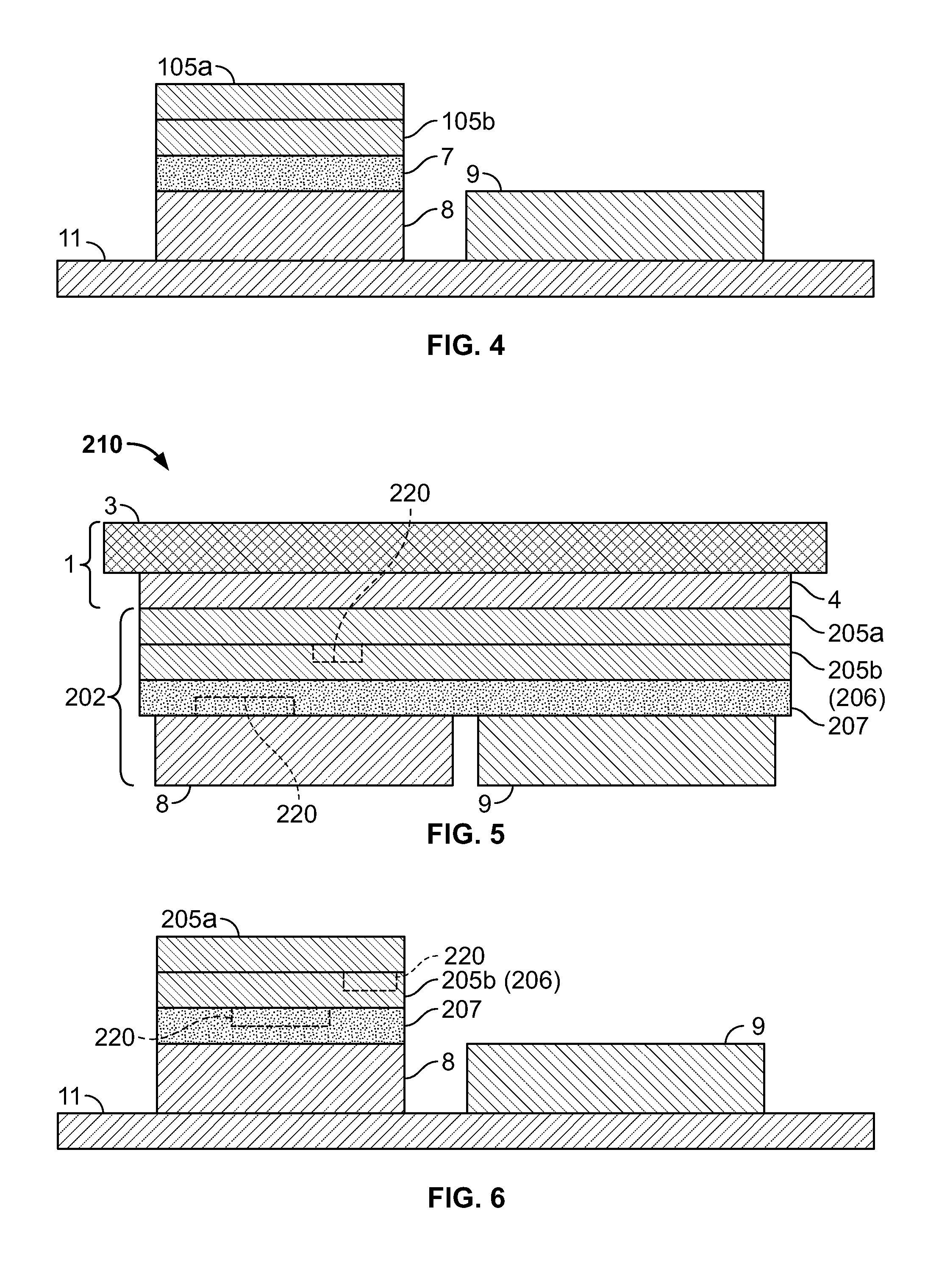

Method for welding with laser-cold metal transferred arc composite heat source

ActiveCN101811231ASolve the problem of poor spreadabilityImprove stabilityLaser beam welding apparatusArc stabilityAlloy

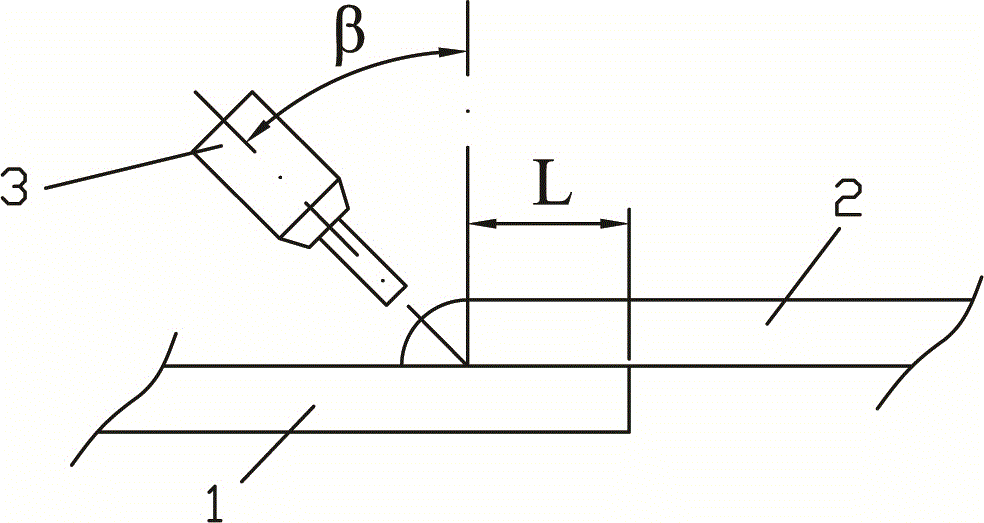

The invention provides a method for welding with a laser-cold metal transferred arc composite heat source, and belongs to the technical field of composite heat sources. The welding method solves the technical problems of low-quality welding lines and low arc stability of the pure Ar-protected cold metal transferred arc welding. The method comprises the following steps of: using pure Ar gas for protection during welding, and forming a novel composite heat source by using the cold metal transferred arc(5) and a laser beam (2) of which the power is more than or equal to 800, wherein the laser beam (2) is defocused, the diameter of a laser spot formed by the laser beam (2) on the surface of a workpiece (1) to be welded is 1 to 4mm, a spot of the cold metal transferred arc (5) can be arranged in front of or behind the spot of the laser beam (2), the central distance of the two spots is 0 to 8mm, and an included angle between a welding torch(3) of the cold metal transferred arc(5) and the horizontal plane is 45 and 75 degrees. The composite heat source is mainly used for welding plates and tubes made of stainless steel, high-strength steel and nickel-based alloy.

Owner:HARBIN WELDING INST LTD

System for releasing gas into molten metal

InactiveUS20080211147A1Reduce amountIncrease the cross-sectional areaMelt-holding vesselsSpecific fluid pumpsMetallurgyProduct gas

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

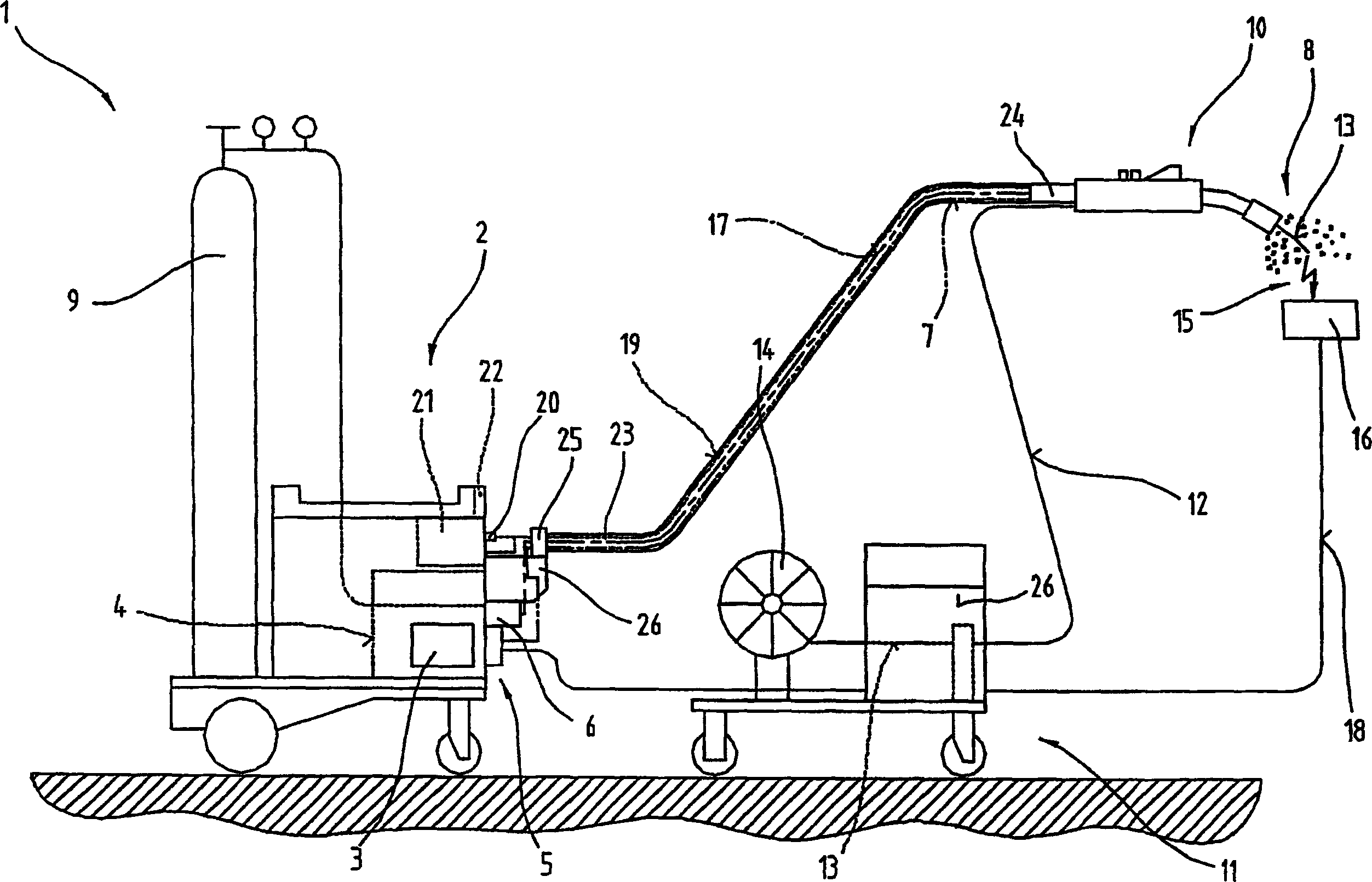

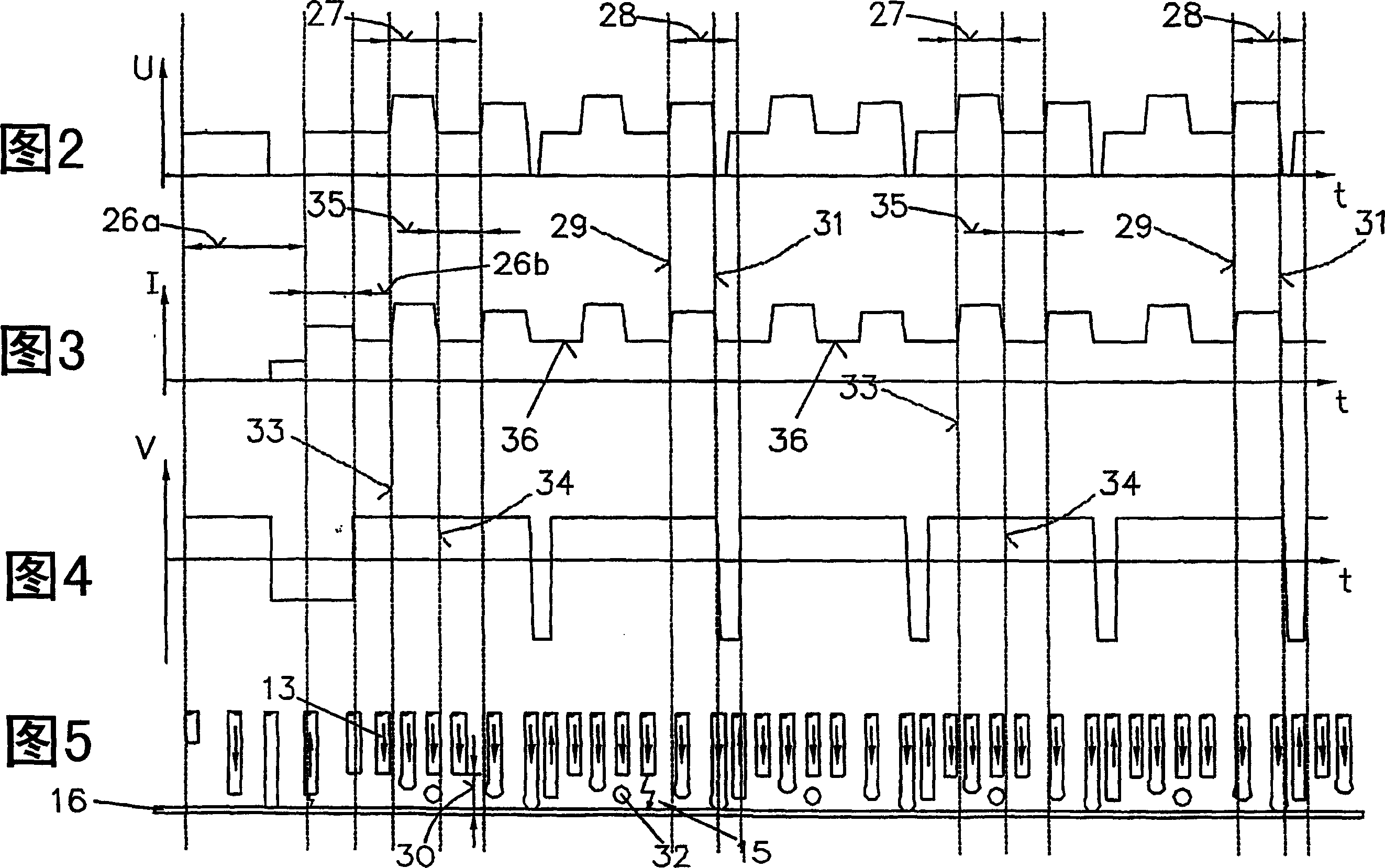

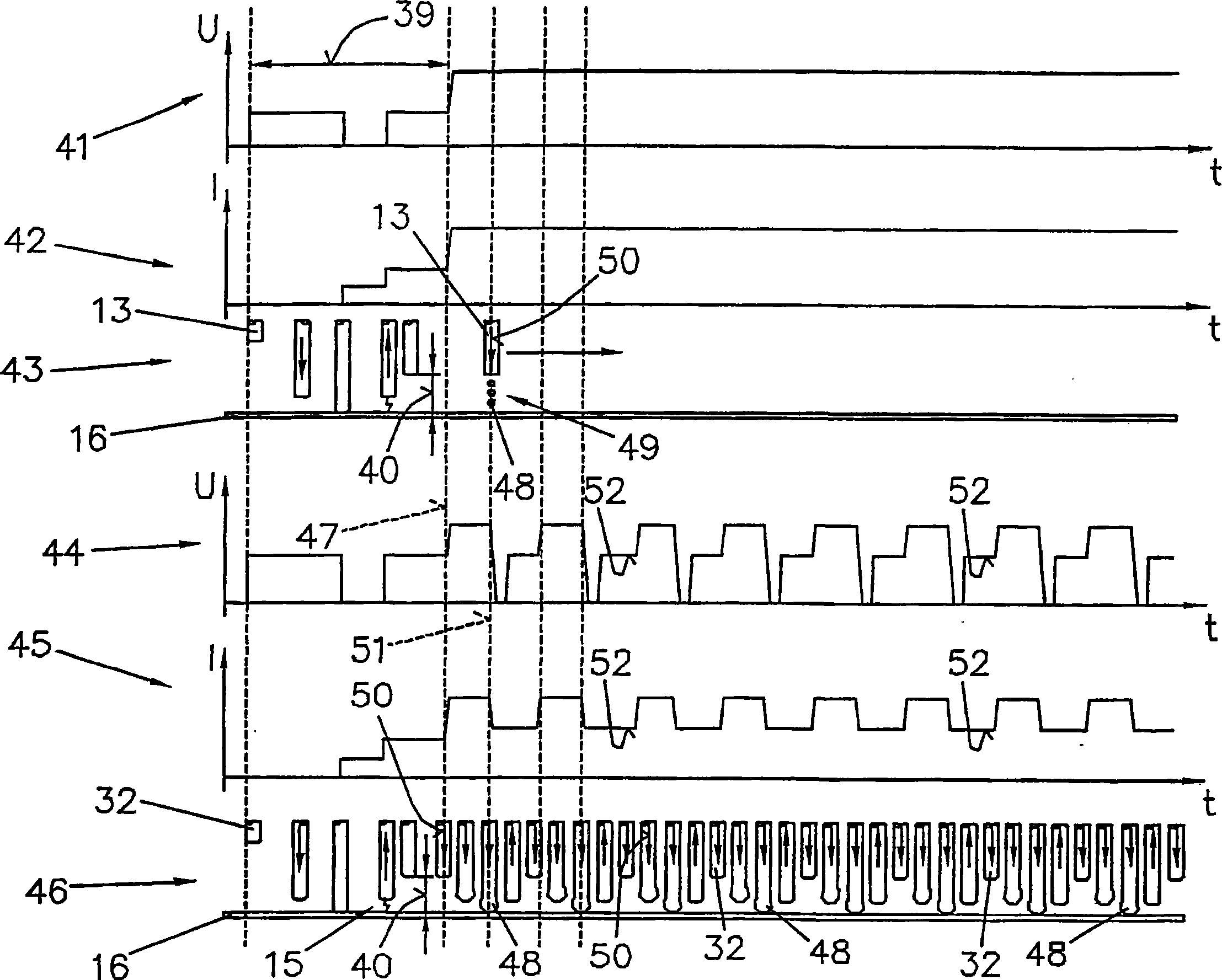

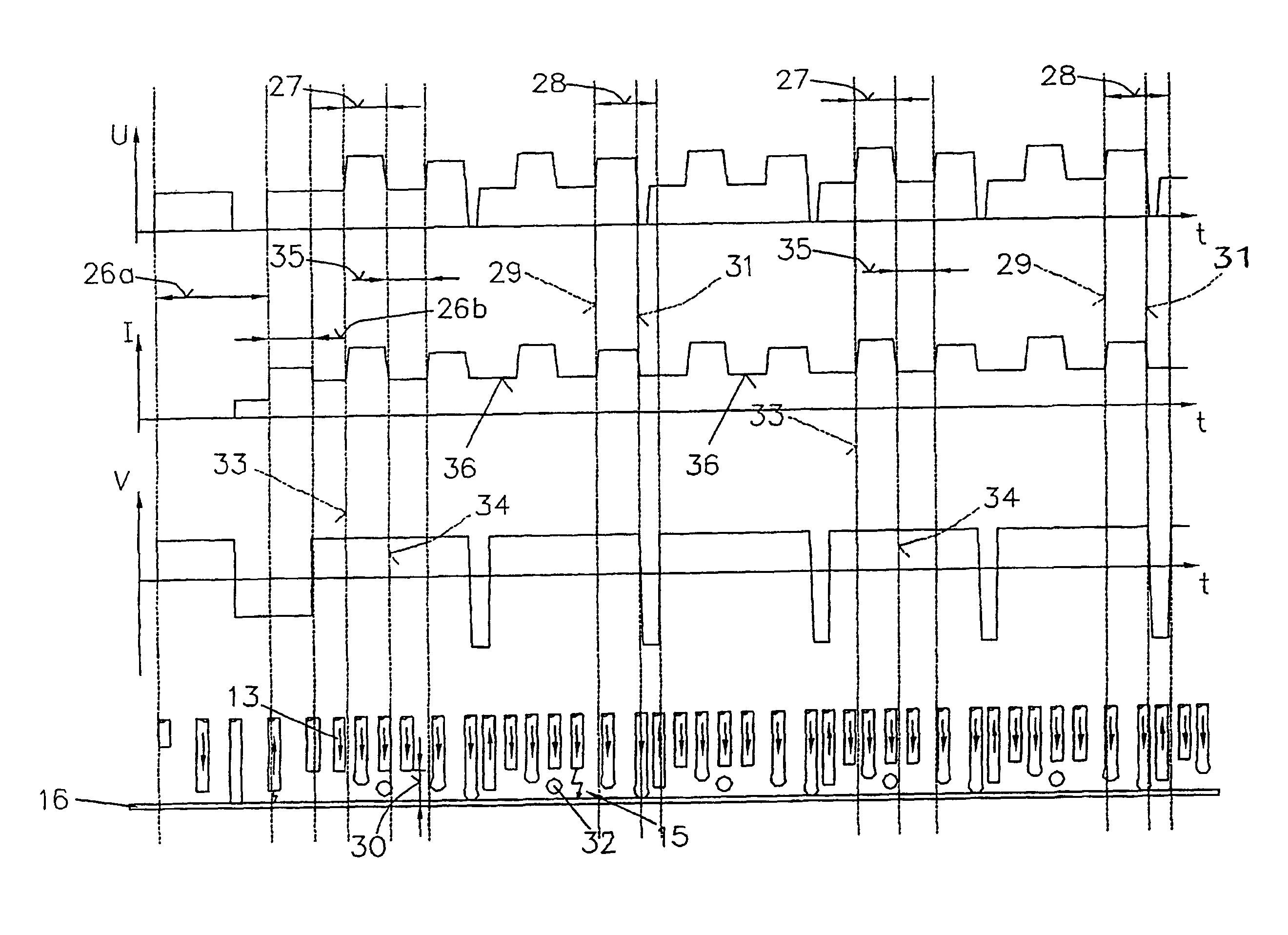

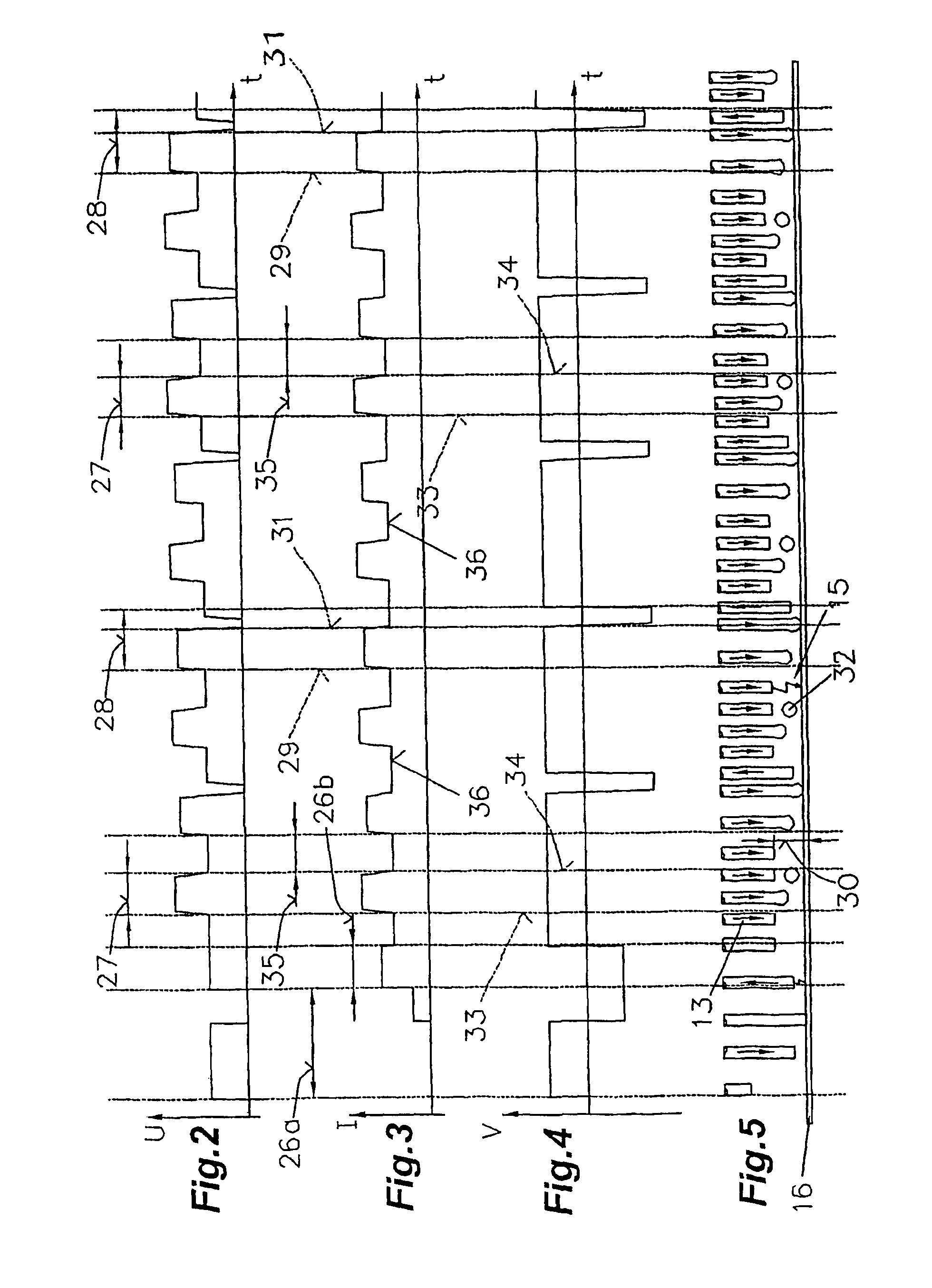

Method for controlling a welding process and welding device for carrying out a welding process

InactiveCN1871093ASimple Heat Balance ControlLow heat inputArc welding apparatusWelding power supplyProcess engineering

The invention relates to a method for controlling and / or adjusting a welding process, using a melting electrode, wherein after ignition of an electric arc, a welding process, which is adjusted on the basis of several different welding parameters, is carried out by means a welding current source (2), said process being controlled or adjusted by a control device (4). The invention also relates to a corresponding welding device used to carry out the process. In order to create said method, wherein the thermal heat economy is adjusted and / or regulated and / or controlled in order to introduce heat into the workpiece (16), at least two different process phases are cyclically combined, said process phases having different inputs of energy via different material transitions and / or arc types, such as a pulse current phase (27) and a cold metal transfer phase (28) in order to influence or control thermal heat economy, particularly the introduction of heat into the workpiece to be processed.

Owner:FRONIUS INTERNATIONAL GMBH

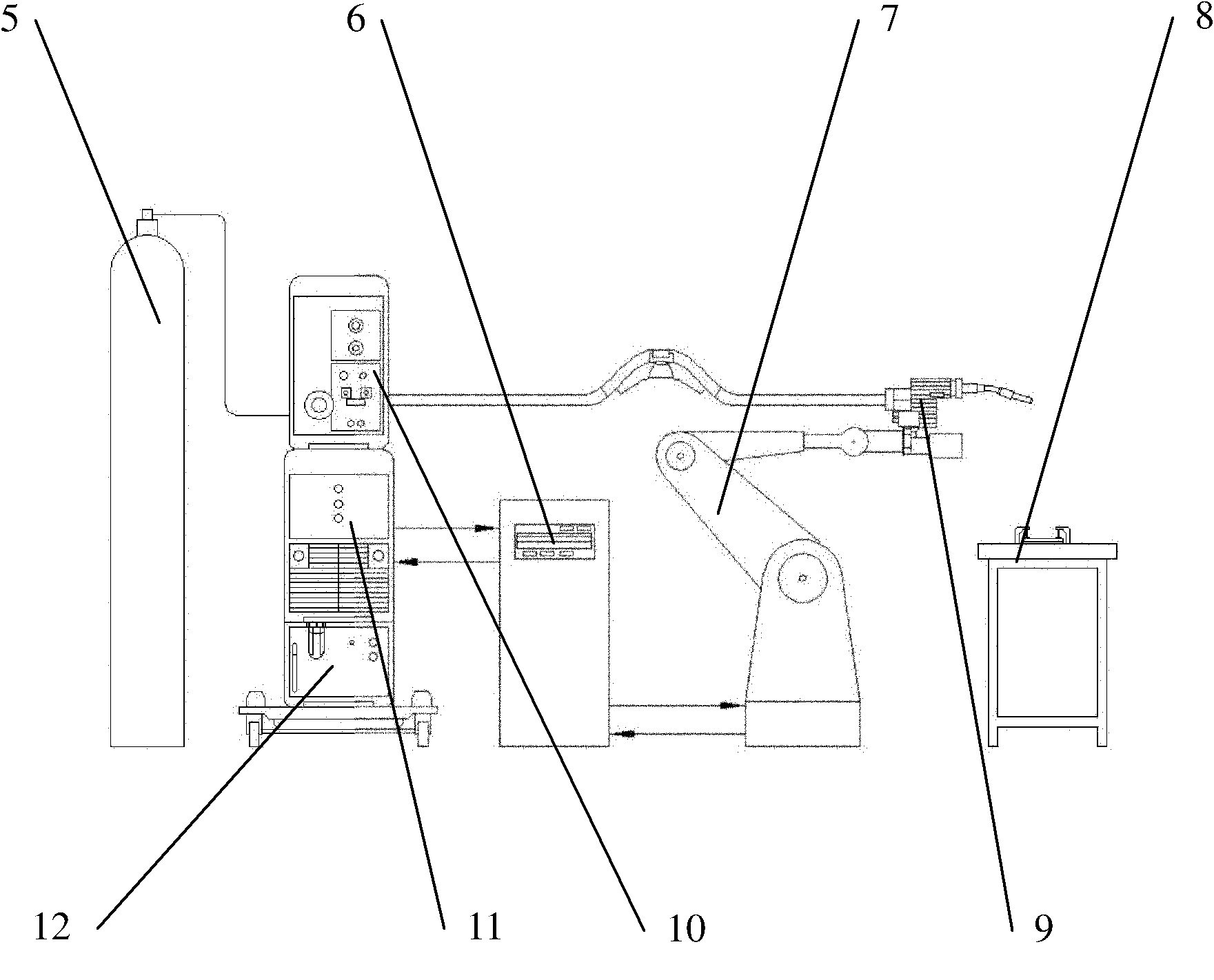

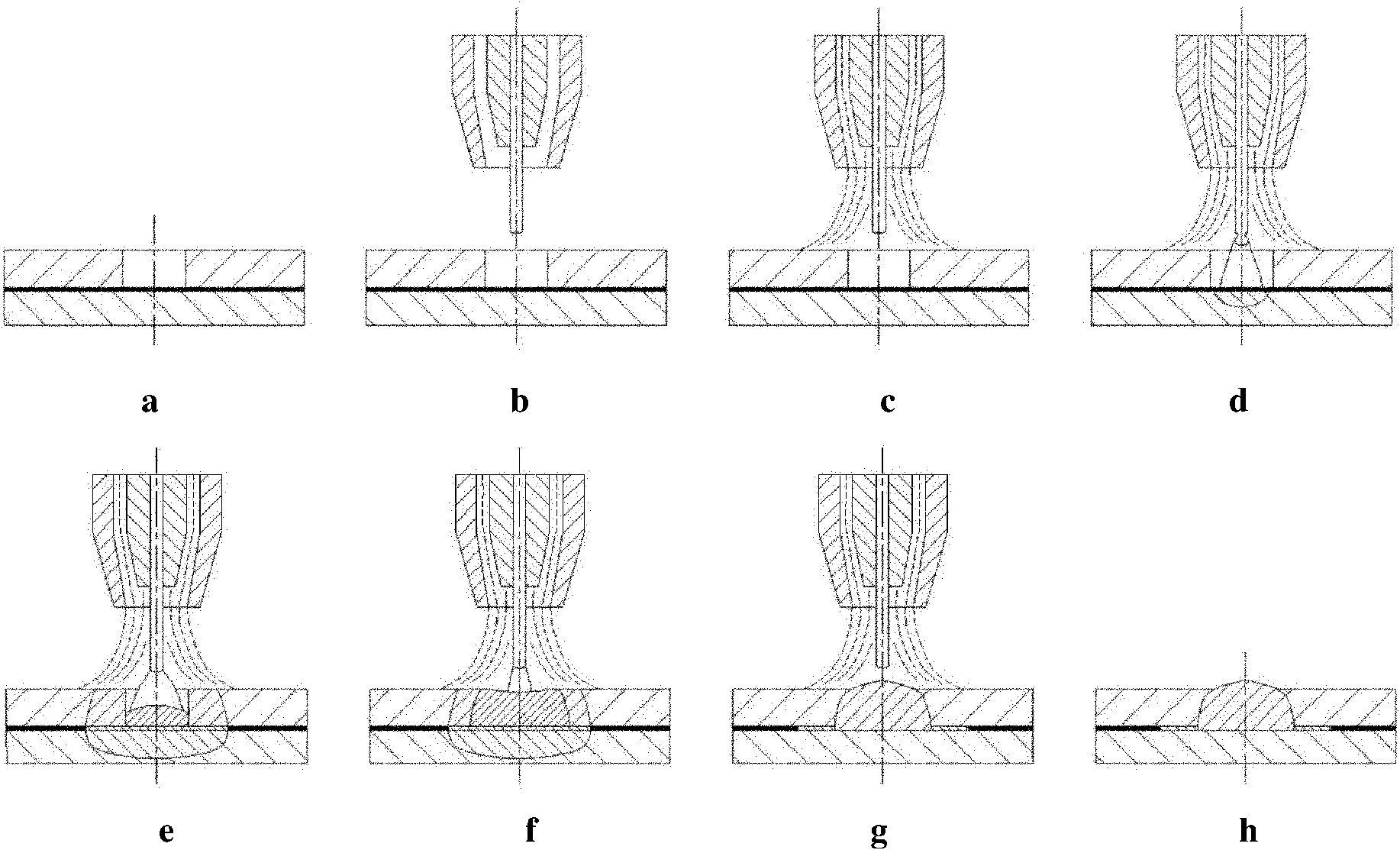

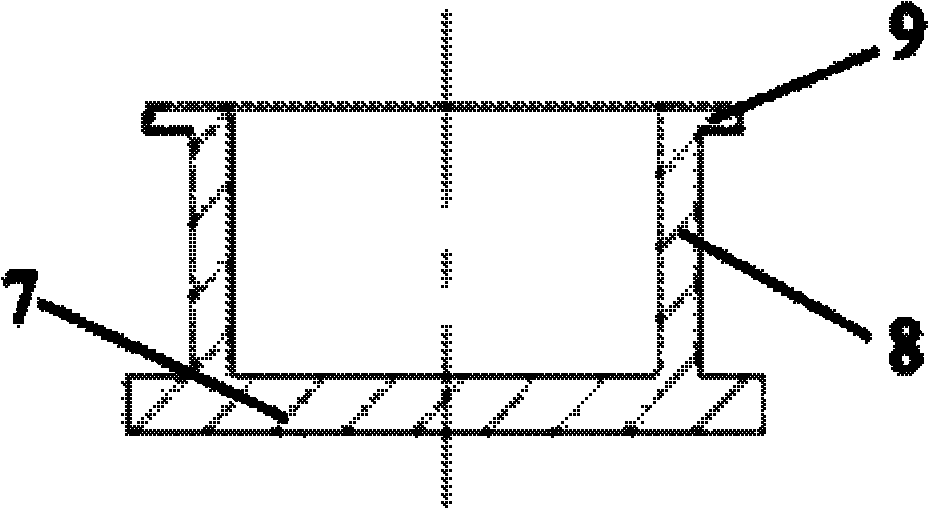

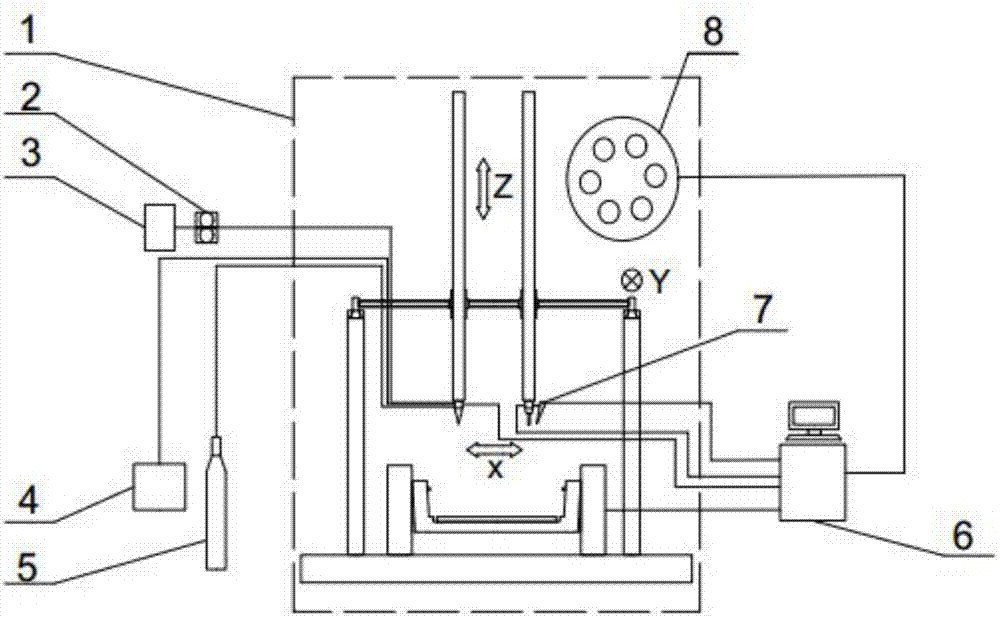

Dissimilar metal spot welding system of light metal and coated steel and welding method thereof

The invention provides a dissimilar metal spot welding system of light metal and coated steel and a welding method thereof, wherein the system comprises a CMT (cold metal transfer) arc welding system, an air bottle, a robot control module, a robot and a clamping device; the arc welding system is connected to the robot control module and used for transmitting a welding control signal; the air bottle is communicated with the CMT arc welding system; the robot control module is connected to the robot for transmitting a control signal of the movement of the robot. In the invention, a spot melting soldering joint is formed between light metal and coated steel to realize the spot connection of the light metal and the coated steel; the serious deformation of the joint during continuous seam welding is solved while the connecting quality of dissimilar metal is ensured; traditional vehicle body part joints primarily using resistance spot welding process are not influenced; and the design and manufacture costs of vehicle bodies are greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

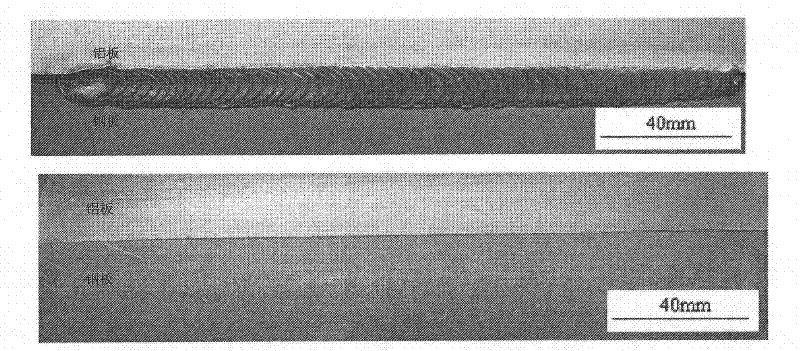

Cold metal transfer connection method of aluminum/steel dissimilar metal

InactiveCN102500853AImprove mechanical propertiesWell formed weldWelding/cutting media/materialsSoldering mediaSiliconMetal

The invention provides a cold metal transfer connection method of aluminum / steel dissimilar metal. The cold metal transfer connection method comprises the following steps of: utilizing an aluminum alloy welding wire containing aluminum and silicon elements to weld; through carrying out cold metal transfer welding, forming a melt welding connection at one side of an aluminum plate through melting the aluminum alloy welding wire and an aluminum alloy parent metal in the welding process; and meanwhile, keeping a steel plate at a solid state and realizing a braze welding connection at one side of the steel plate, so as to form a melt-braze welding overlap joint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

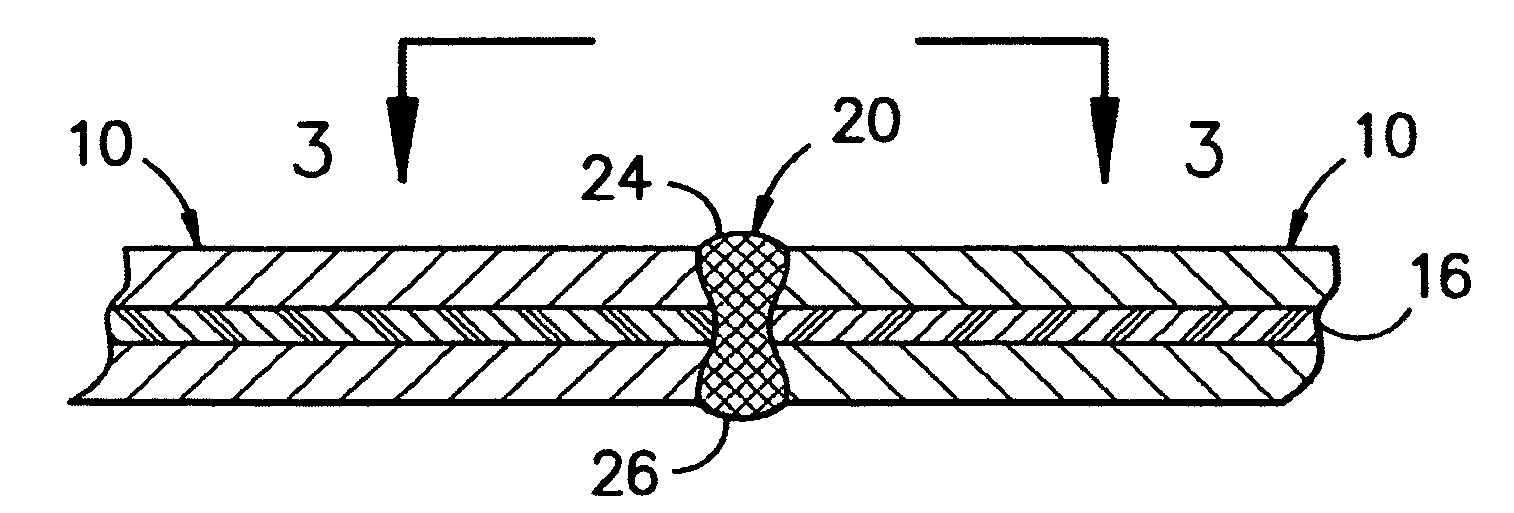

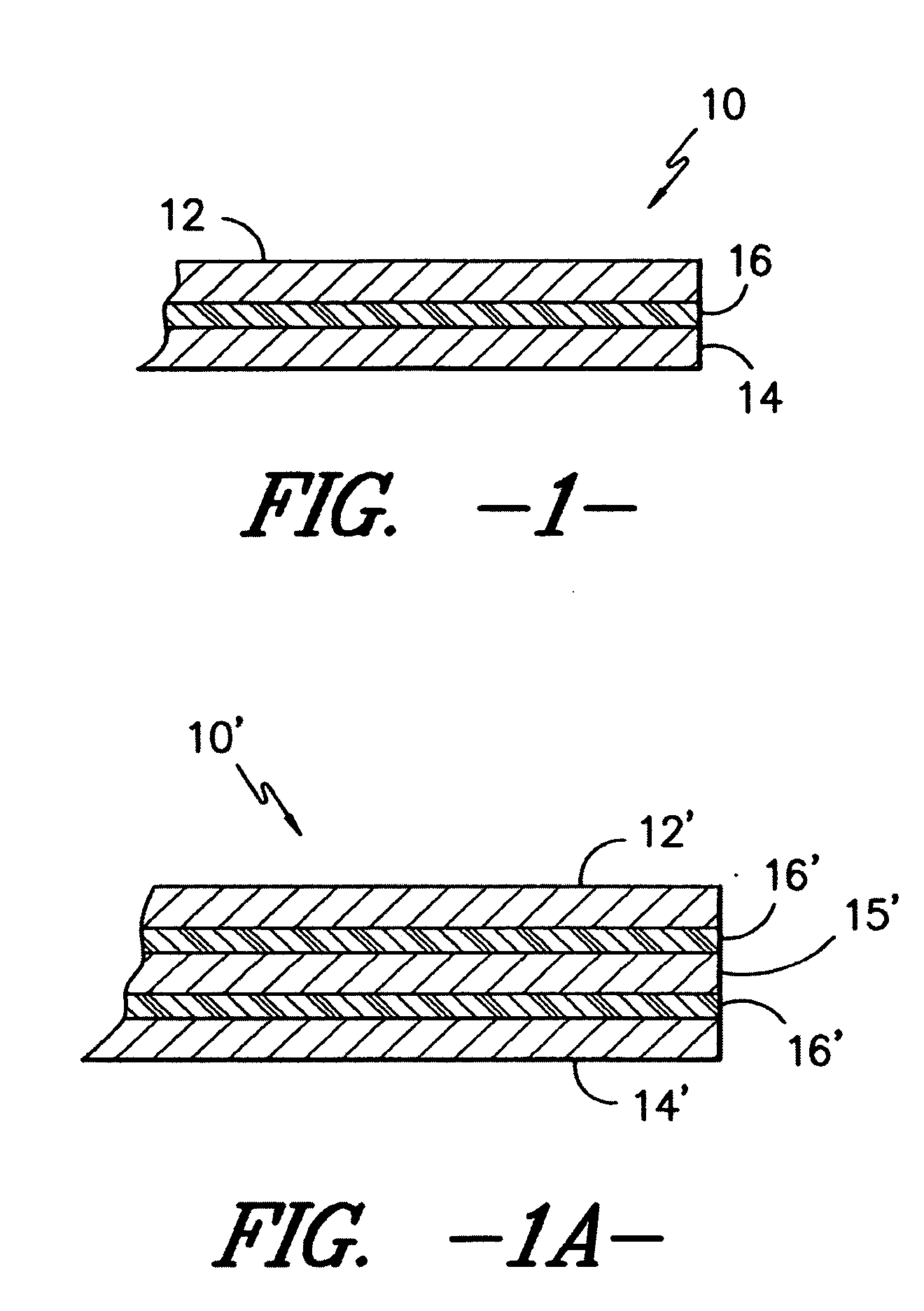

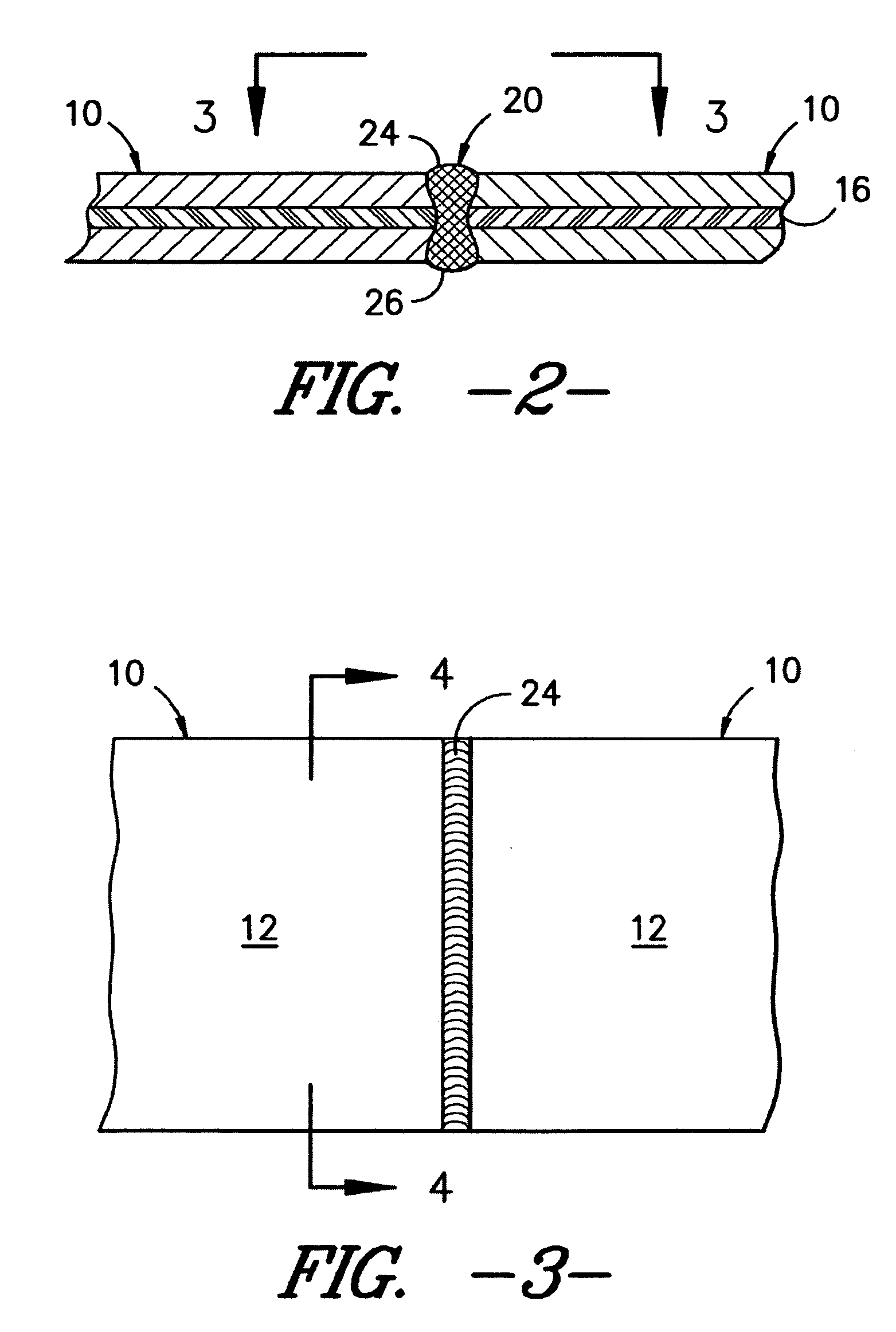

Method for joining or repairing metal surface parts

ActiveUS20070221631A1Easy to useThermal input to the work piece is minimizedArc welding apparatusElectron beam welding apparatusPolymerMetal transfer

A method of joining or repairing metal surface structures. Joinder and / or repair of metal or metal-polymer laminate panels may be carried out using so-called “cold metal transfer” gas metal arc welding techniques. Moreover, suitable zinc-copper-aluminum alloys may improve weldability, durability and strength. The reduced thermal input permits effective weld formation at the metal sheet layers without giving rise to temperature gradient sufficient to significantly damage the interior elements.

Owner:GM GLOBAL TECH OPERATIONS LLC

Light metal and bare steel plate spot-welding method based on bulk forming solder

ActiveCN102126064ALow costGood mechanical propertiesElectrode supporting devicesWelding/soldering/cutting articlesSheet steelShielding gas

The invention relates to a light metal and bare steel plate spot-welding method based on a bulk forming solder in the technical field of metal welding. The method comprises the following steps of: drilling a technology hole on a light metal plate, shaping the solder and embedding the solder into the technology hole; overlapping and clamping the light metal plate provided with the hole and the solder on a bare steel plate, and making a welding gun with a welding wire vertical to the metal plate and aligned with the center of the technology hole; and introducing protective gas into a position to be welded in advance, igniting electric arcs in a cold metal transfer (CMT) mode, combusting, filling a space between the technology hole and the solder, melting the boundary of the solder and the hole, and brazing with the lower-layer steel plate through the solder to form a melt-brazed joint. By adopting cold metal transfer arc welding, the spot melt-brazed joint is formed between the light metal and the bare steel plate, spot connection is realized between the light metal and steel, the differential metal connecting quality is ensured and the manufacturing cost of vehicle bodies is greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

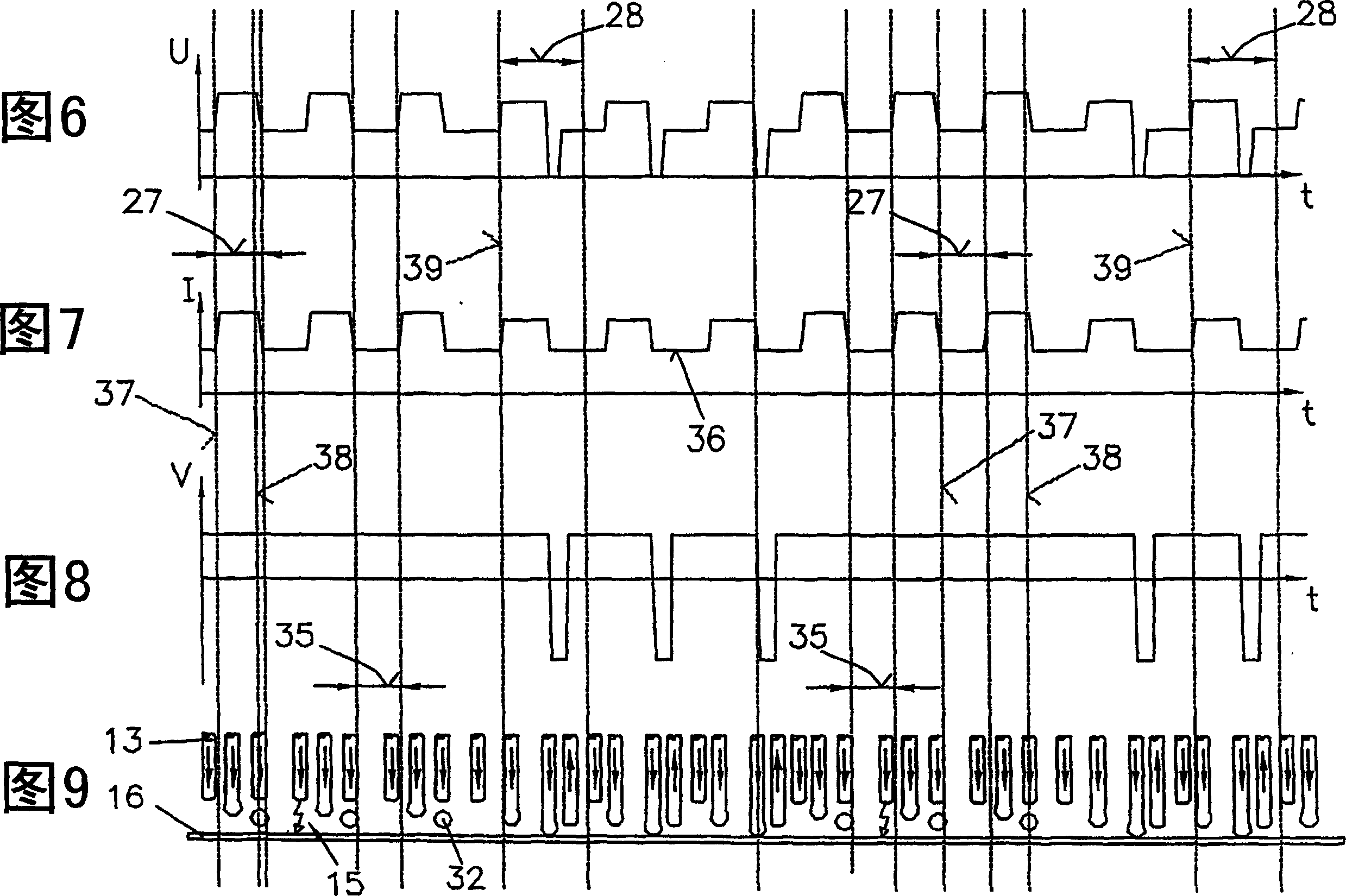

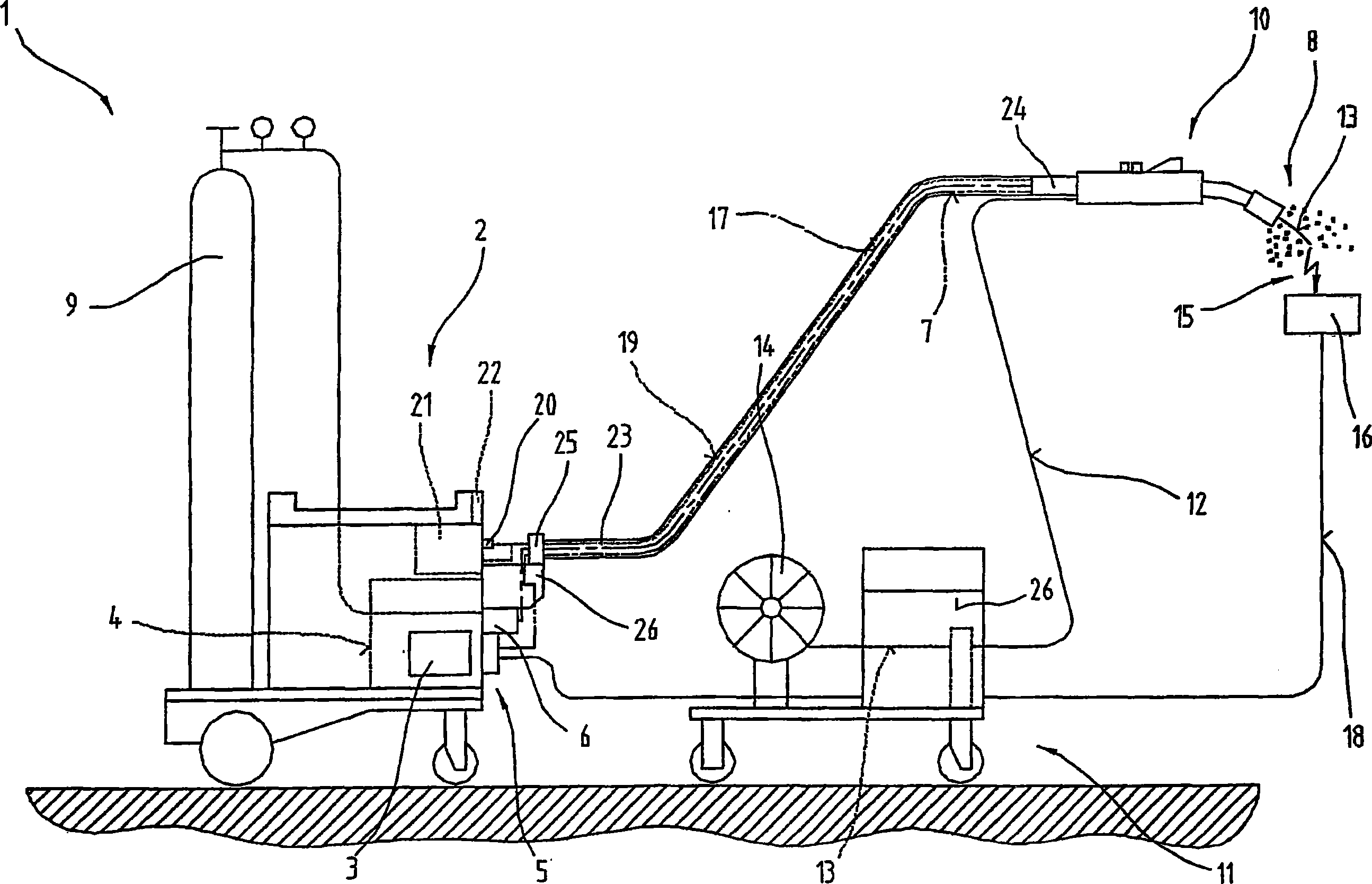

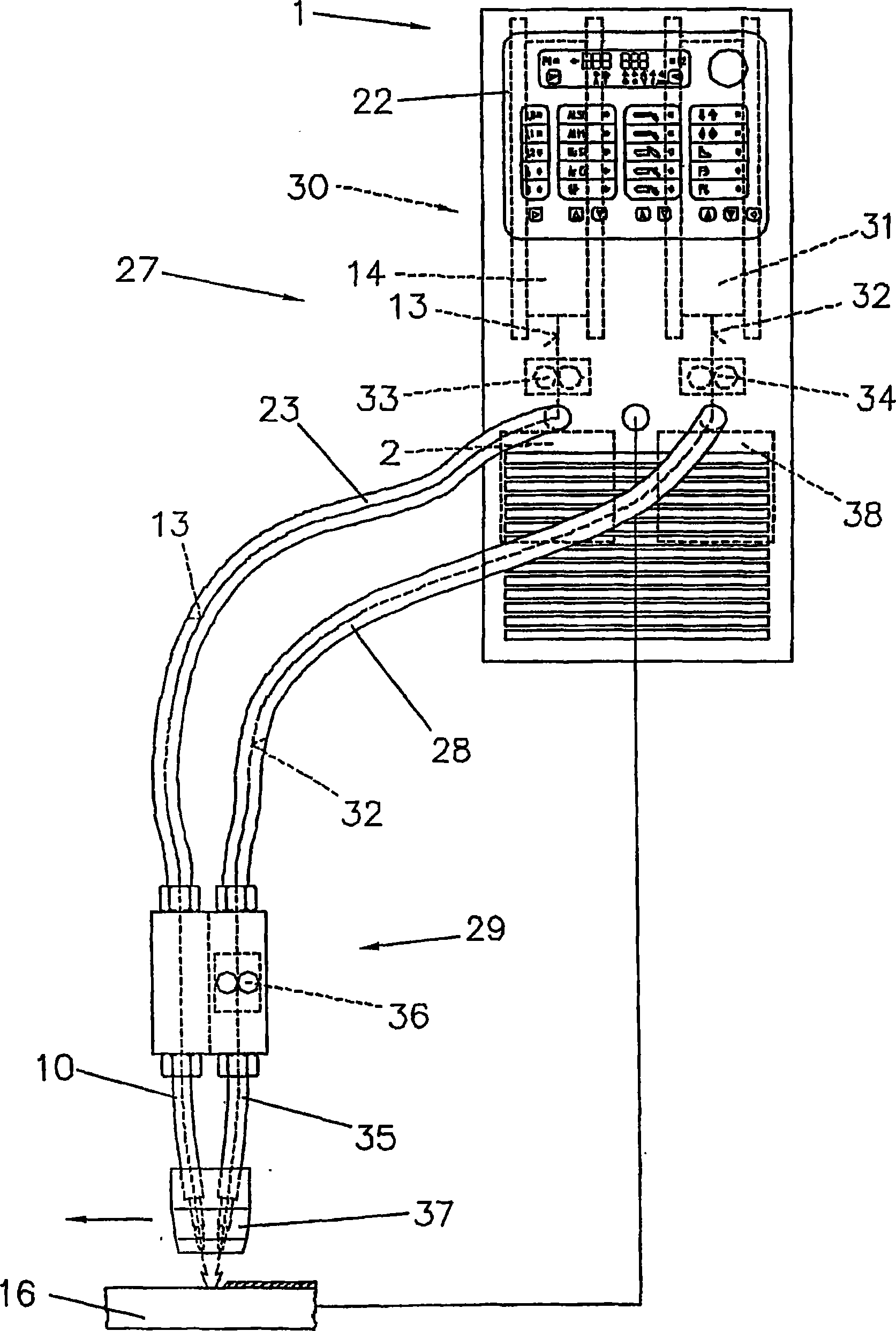

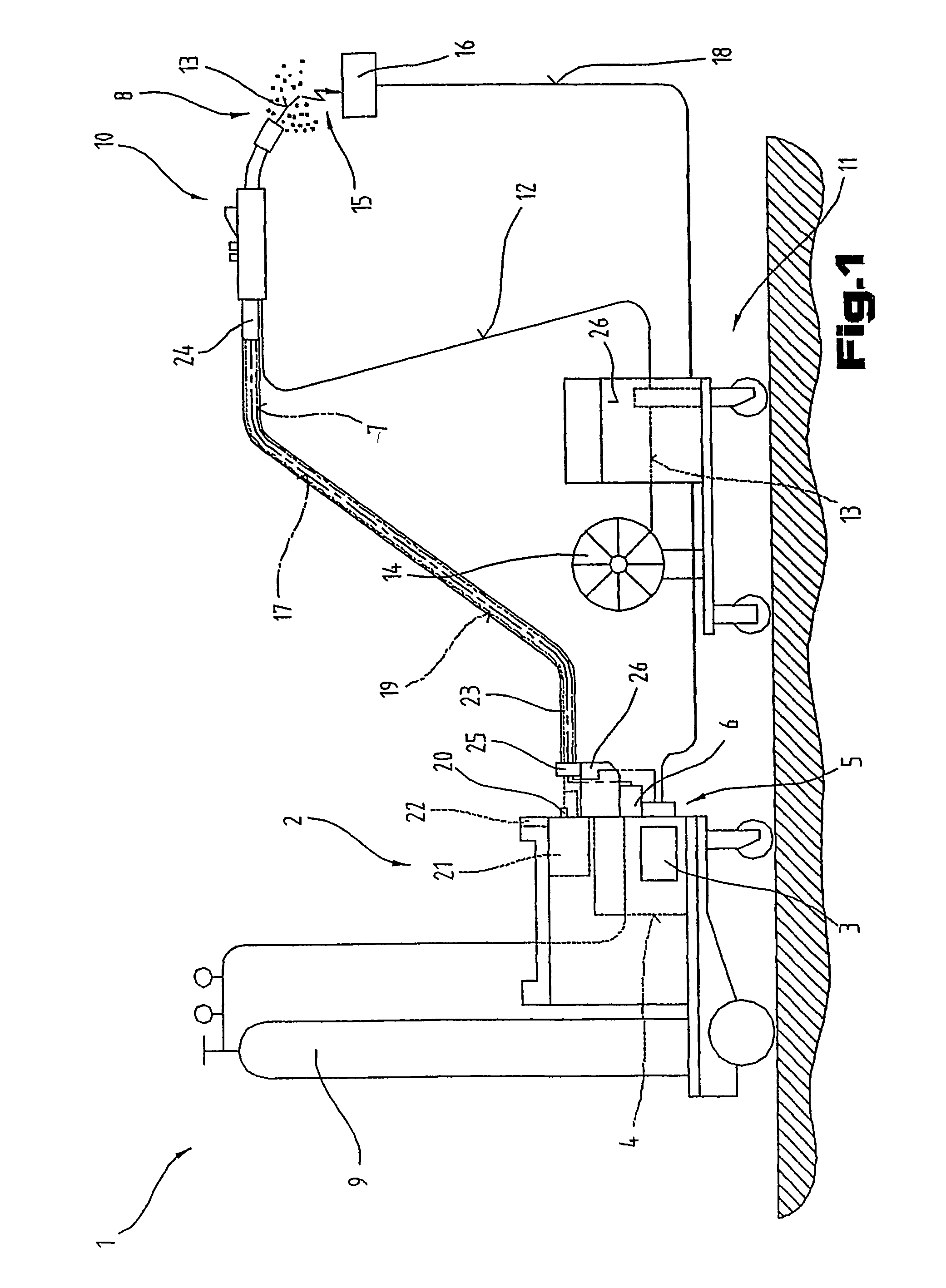

Welding unit and welding method by means of which at least two different welding processes may be combined

InactiveCN1894070AWeaken energyEnhanced Gap Bridging CapabilitiesArc welding apparatusLaser beam welding apparatusWelding power supplyEnergy supply

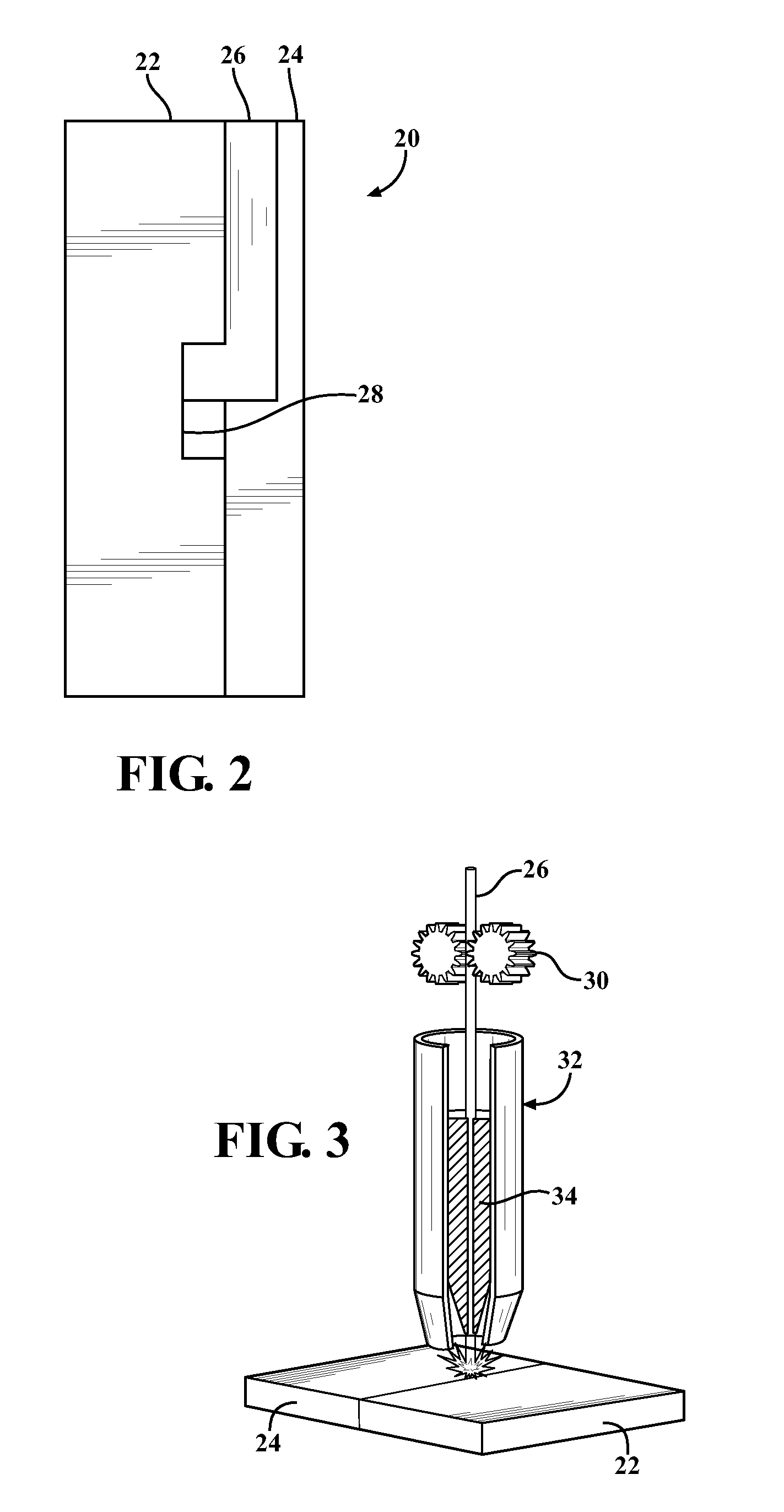

The invention relates to a welding unit (27), comprising a welding device (1), with a welding torch unit (29) which may be connected thereto by means of a tube group (23, 28). At least one controller (4), a welding power supply (2) and, optionally, a wire supply unit (30) are arranged in the welding device (1). The welding torch unit (29) comprises at least two separate welding burners (10, 35), embodied for carrying out at least two independent separate welding processes. The invention further relates to a welding method, in which at least two different welding processes can be combined. According to the invention, such a welding unit (27) and welding method can be achieved, in which the amount of introduction of additional material and the heat or energy supply into the workpiece (16) may be adjusted as independently from each other as possible, whereby the first welding burner (10) is embodied for carrying out a welding process and at least one second welding burner (35) is embodied for carrying out a cold metal transfer welding process with a back-and-forth movement of a welding rod (32) and for synchronisation of the welding processes carried out with the at least two welding burners (10, 35).

Owner:FRONIUS INTERNATIONAL GMBH

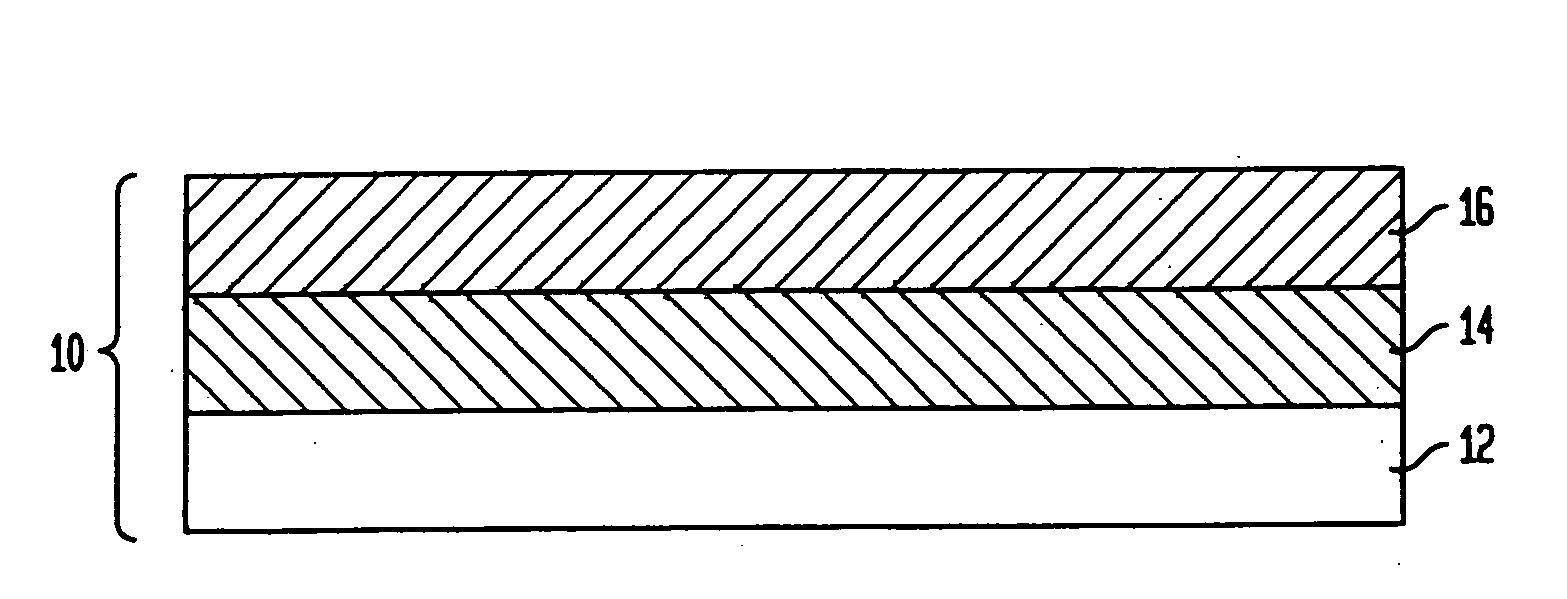

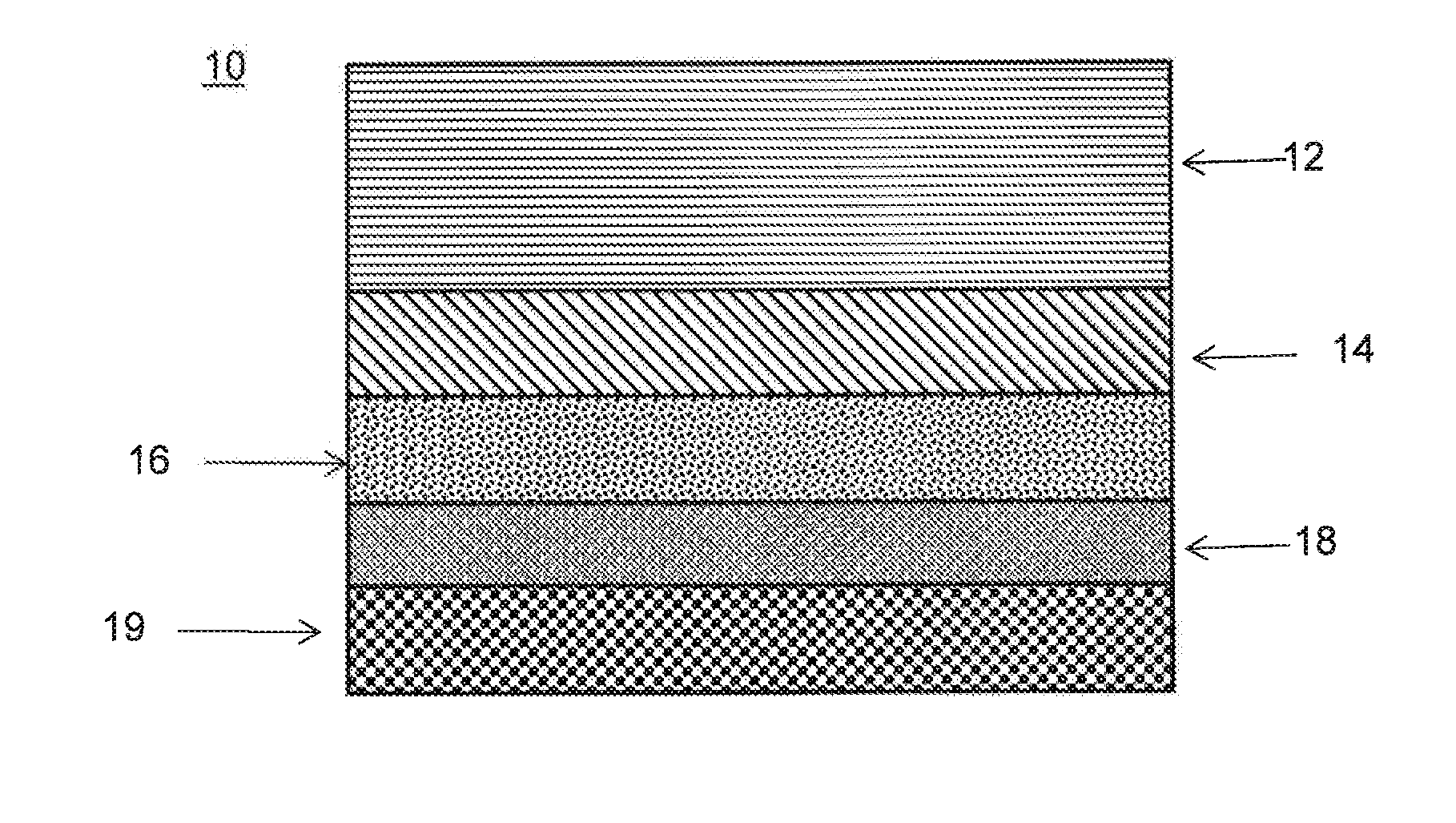

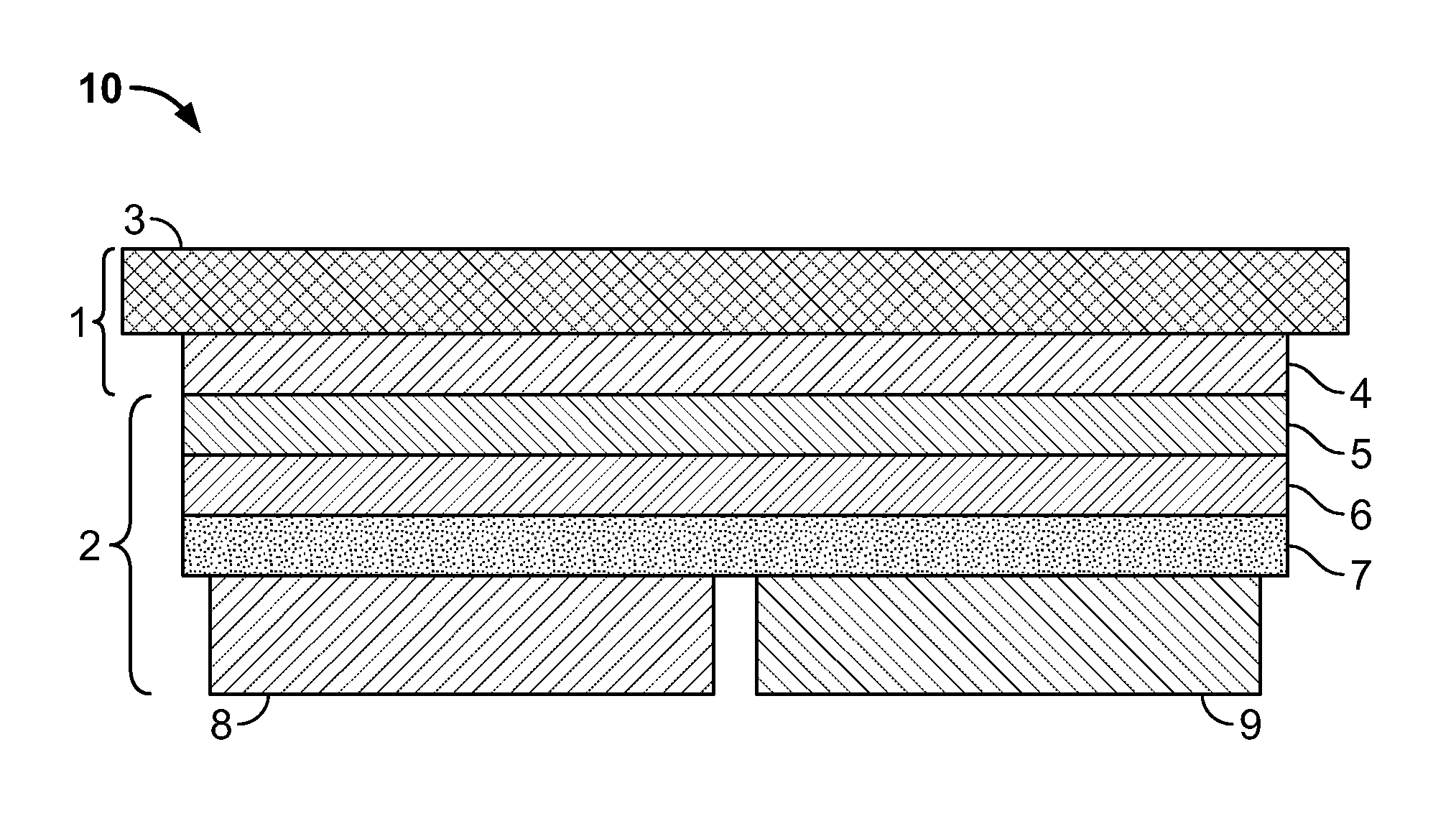

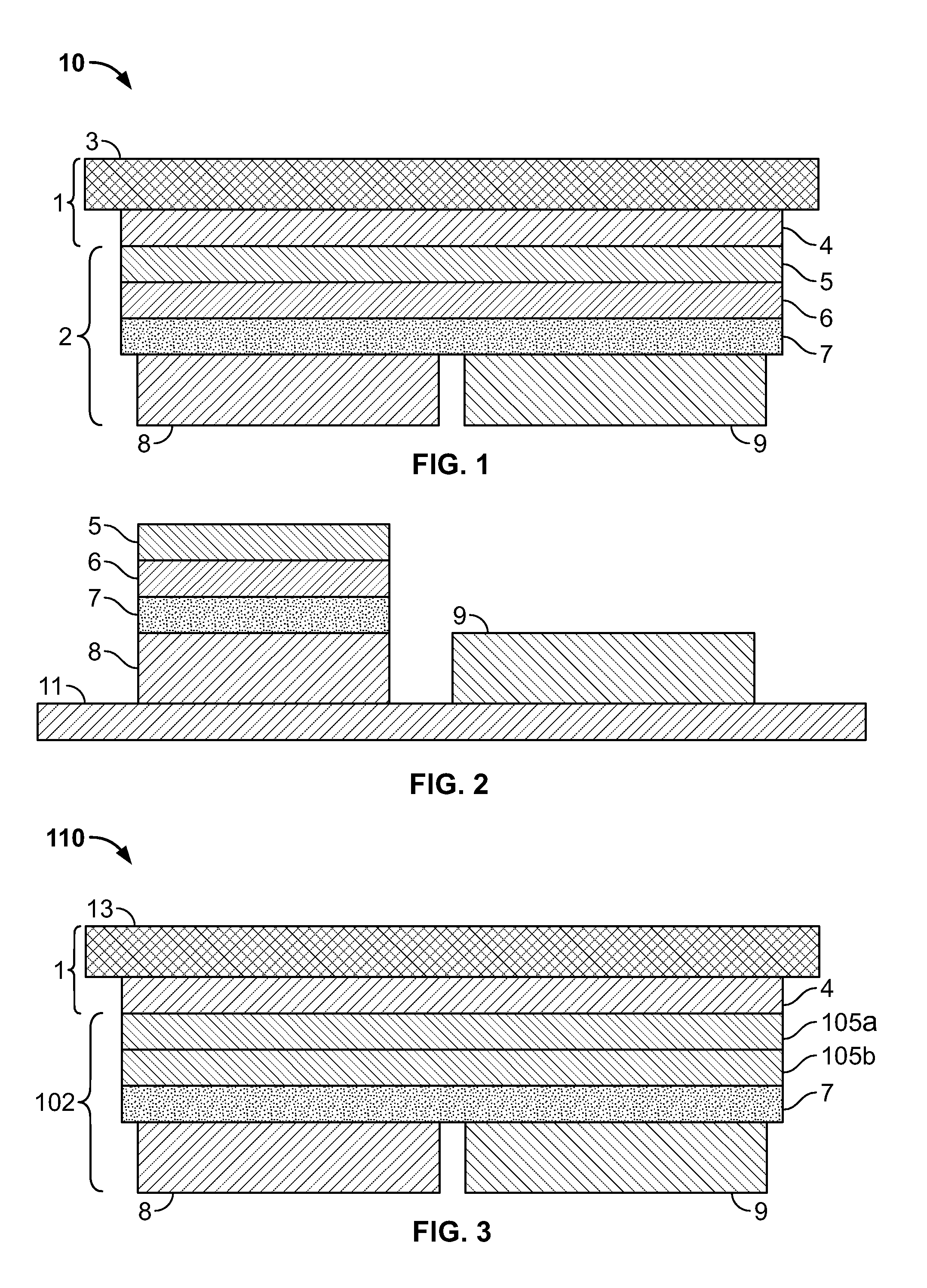

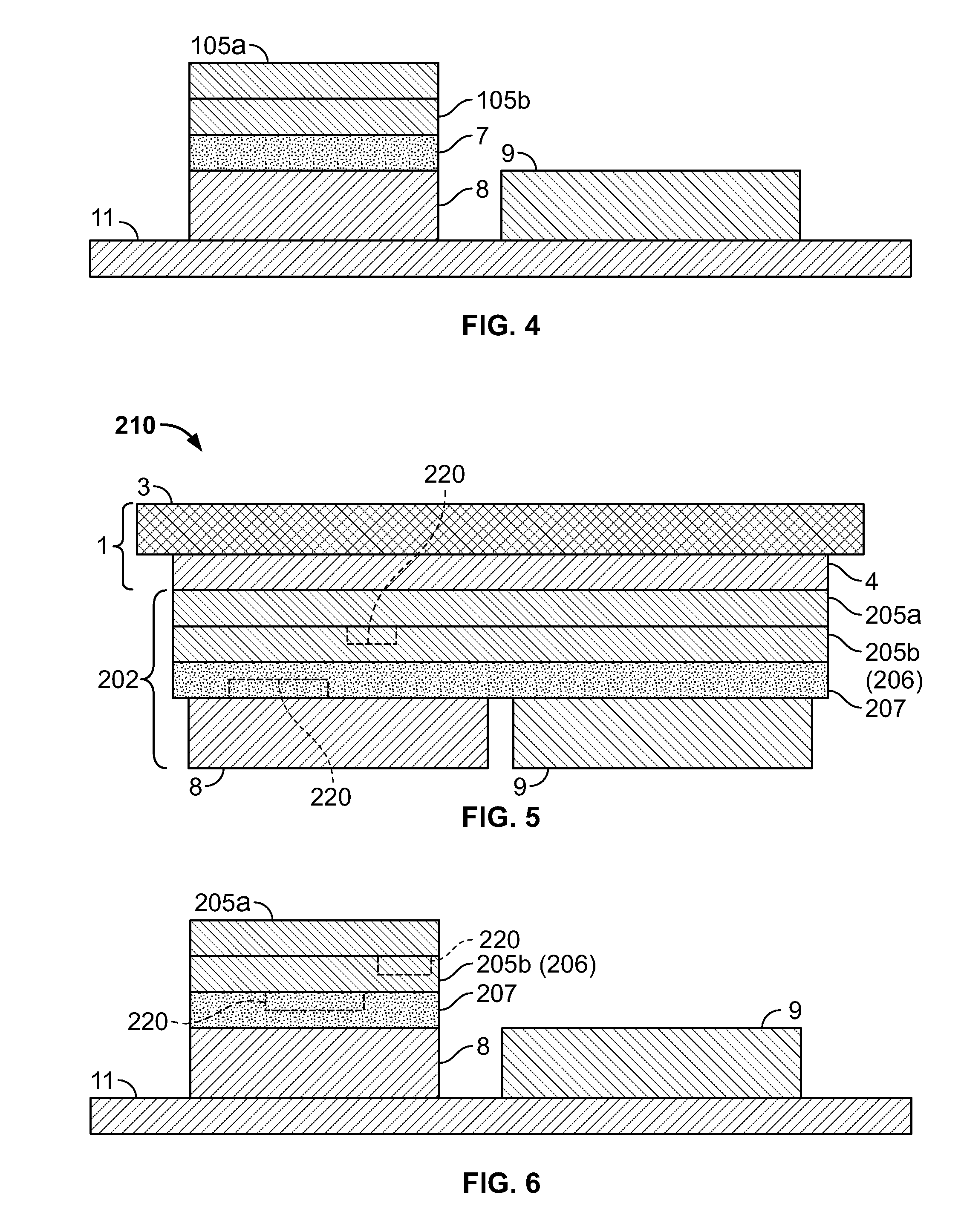

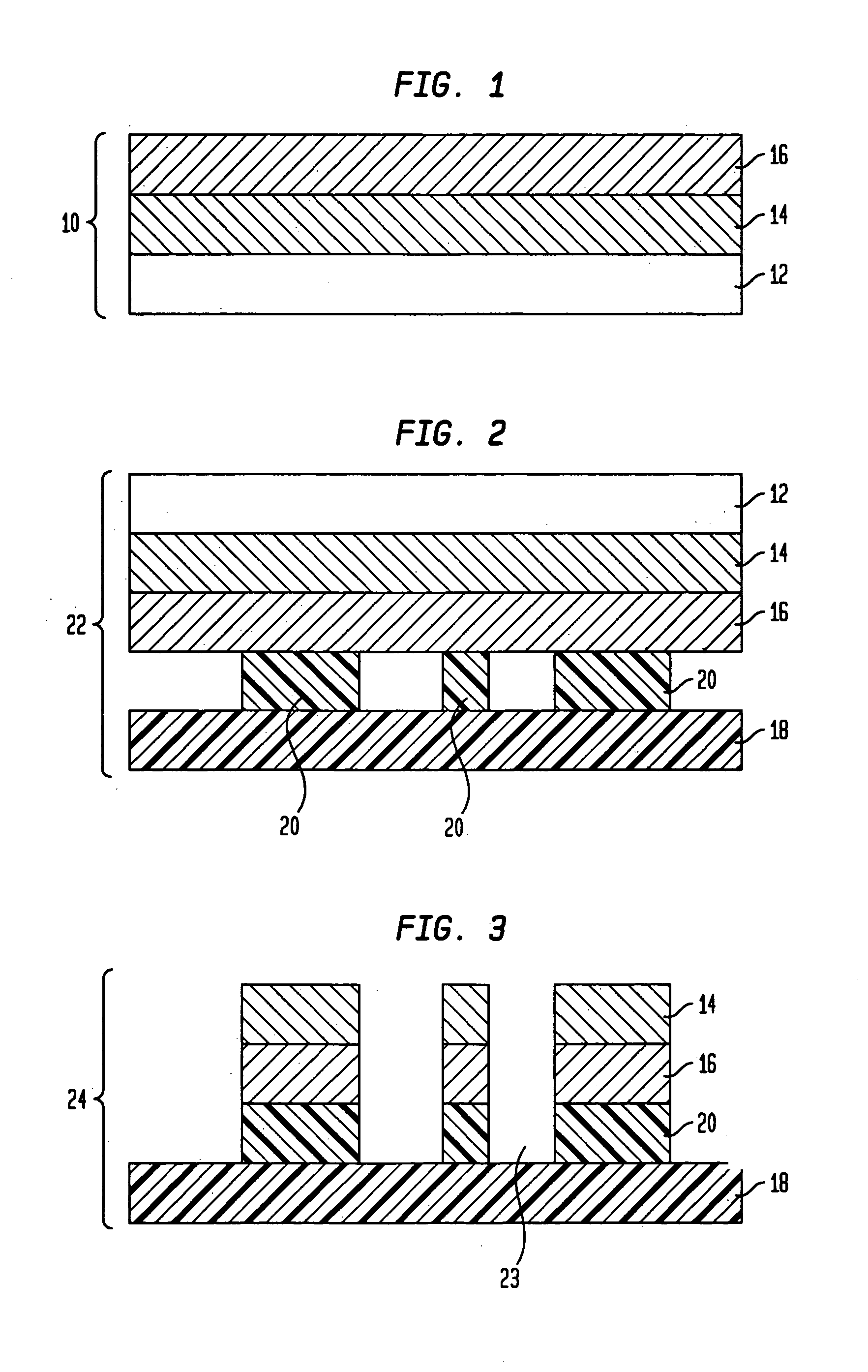

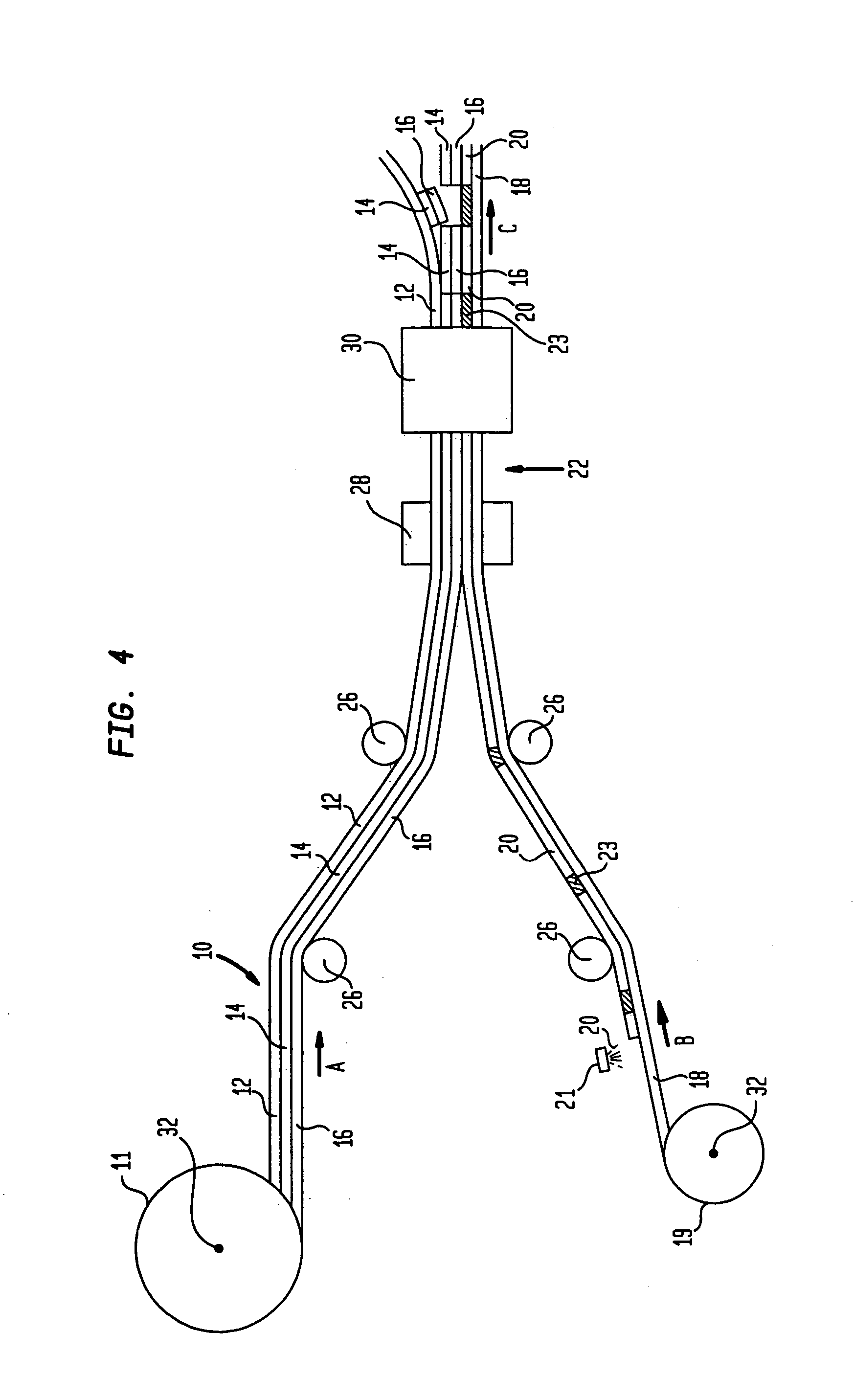

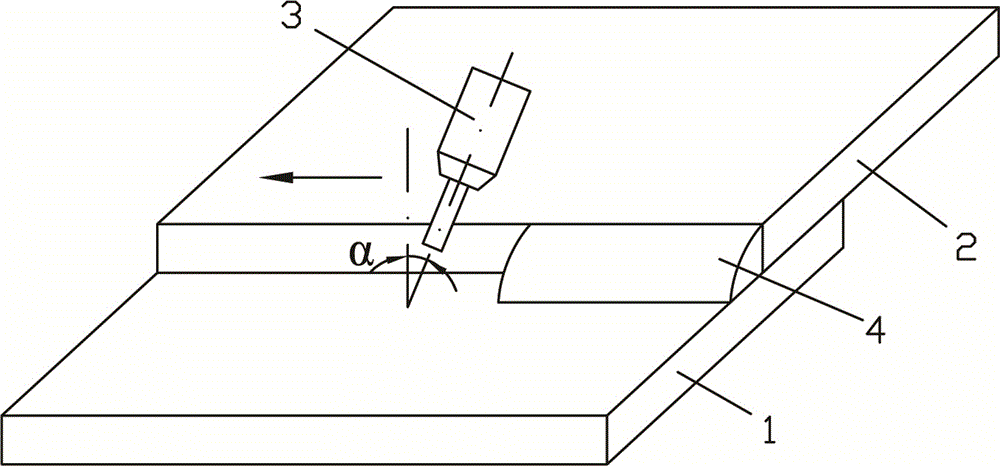

Metallization process and product produced thereby

A layered structure produced by metallizing a substrate including: (a) providing a transfer film including film layer and metal layer bonded together by a cured breakaway layer; (b) providing a substrate; (c) applying electron beam curable transfer adhesive to a portion of the substrate; (d) securing the transfer film to the substrate, where the transfer adhesive is between the metal layer and substrate, forming an intermediate product; (e) passing the intermediate product through an electron beam curing apparatus to cure the transfer adhesive; and (f) removing the transfer film. In the metallized product, the cured breakaway coating is bonded only to the metal. The cured breakaway layer preferably has a cured elongation at break, in tension, of less than about 20%. Precise metallized edges are produced, e.g., edge variation of about ±0.010 in., or better. The process can be utilized with total or selective metal transfer.

Owner:UNIFOIL CORP

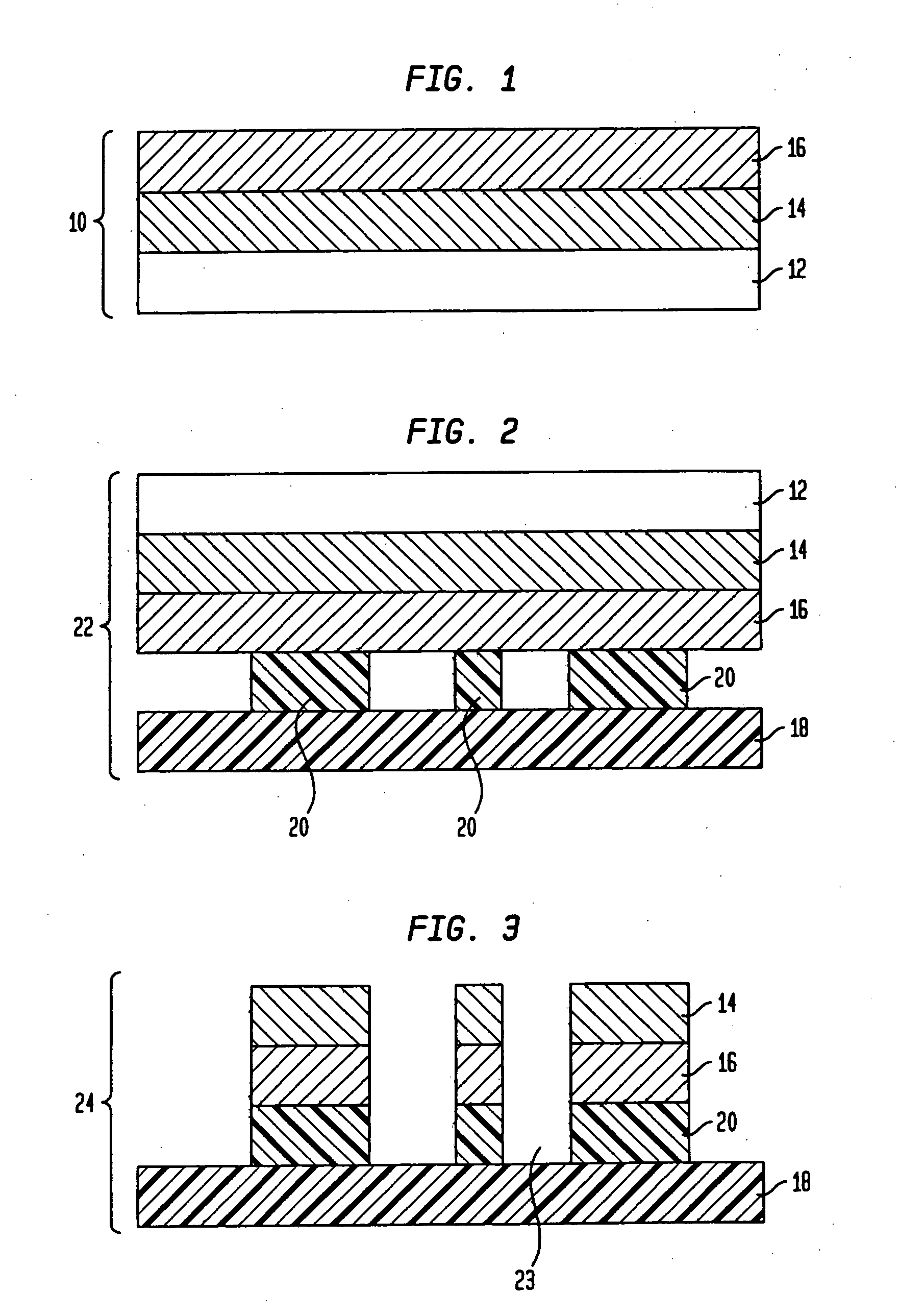

Method of metallizing dielectric film

InactiveUS20150231802A1Layered product treatmentPiezoelectric/electrostriction/magnetostriction machinesDielectricPolymer science

The present invention provides a method of producing a metallized polymer-electrode composite comprising transferring a conductive metal foil from a metal transfer film to a surface of a polymer film The inventive method may be used to produce a polymer film with optionally textured, conductive metal electrodes on one or both sides. The method of Hie invention may find utility in producing electroactive polymer transducers and other thin film devices requiring flexibility or stretchability such as thin film batteries, sensors, speakers, reflective plastic displays, solar cells, and supercapacitors.

Owner:PARKER HANNIFIN CORP

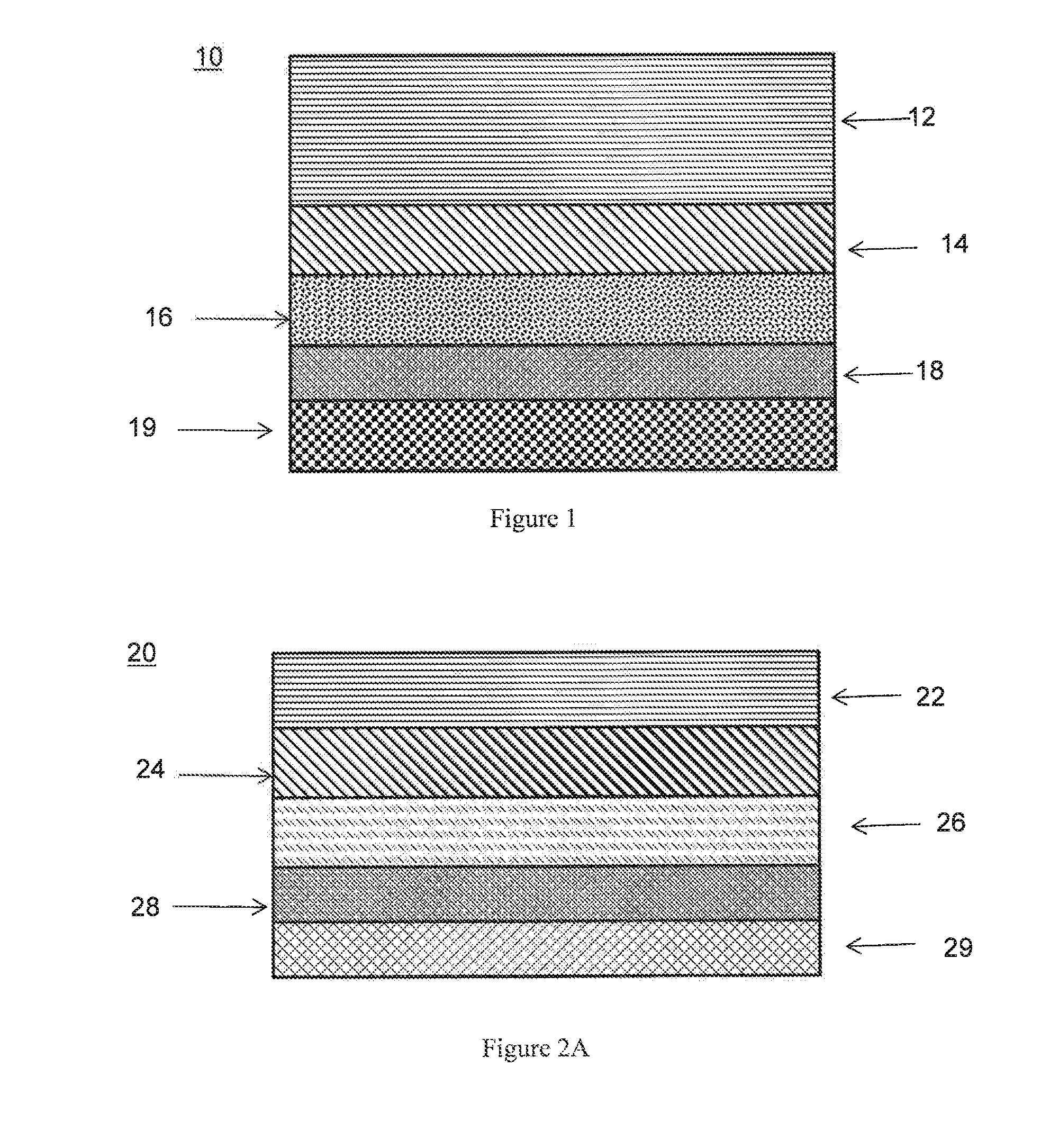

Selectively metallized heat transfer label

A selectively metallized heat transfer label for transfer to a substrate includes a support portion comprising a carrier layer and a release layer applied to the carrier layer, and a transfer portion comprising a protective layer applied to the release layer, a metallizable layer applied to the protective layer, a metal layer applied to the metallizable layer, a metal transferring adhesive layer applied to the metal layer and configured to adhere to both the metal layer and the desired substrate and a non-metal transferring ink layer applied to the metal layer and configured to adhere to the desired substrate but not to the metal layer. The protective layer and the metallizable layer can be formed from the same material, as separate layers. When heat and pressure are applied to the carrier layer using conventional heat transfer equipment, the metal transferring adhesive adheres to both the metal layer and the substrate while the non-transferring ink layer adheres only to the substrate. Thus, only the portion of the metal layer that is in contact with the metal transferring adhesive is transferred to the substrate, along with the corresponding portions of the metallizable layer and the protective layer, while the non-transferring ink section is transferred to the substrate without the corresponding portions of the metal layer, the metallizable layer and the protective layer.

Owner:ILLINOIS TOOL WORKS INC

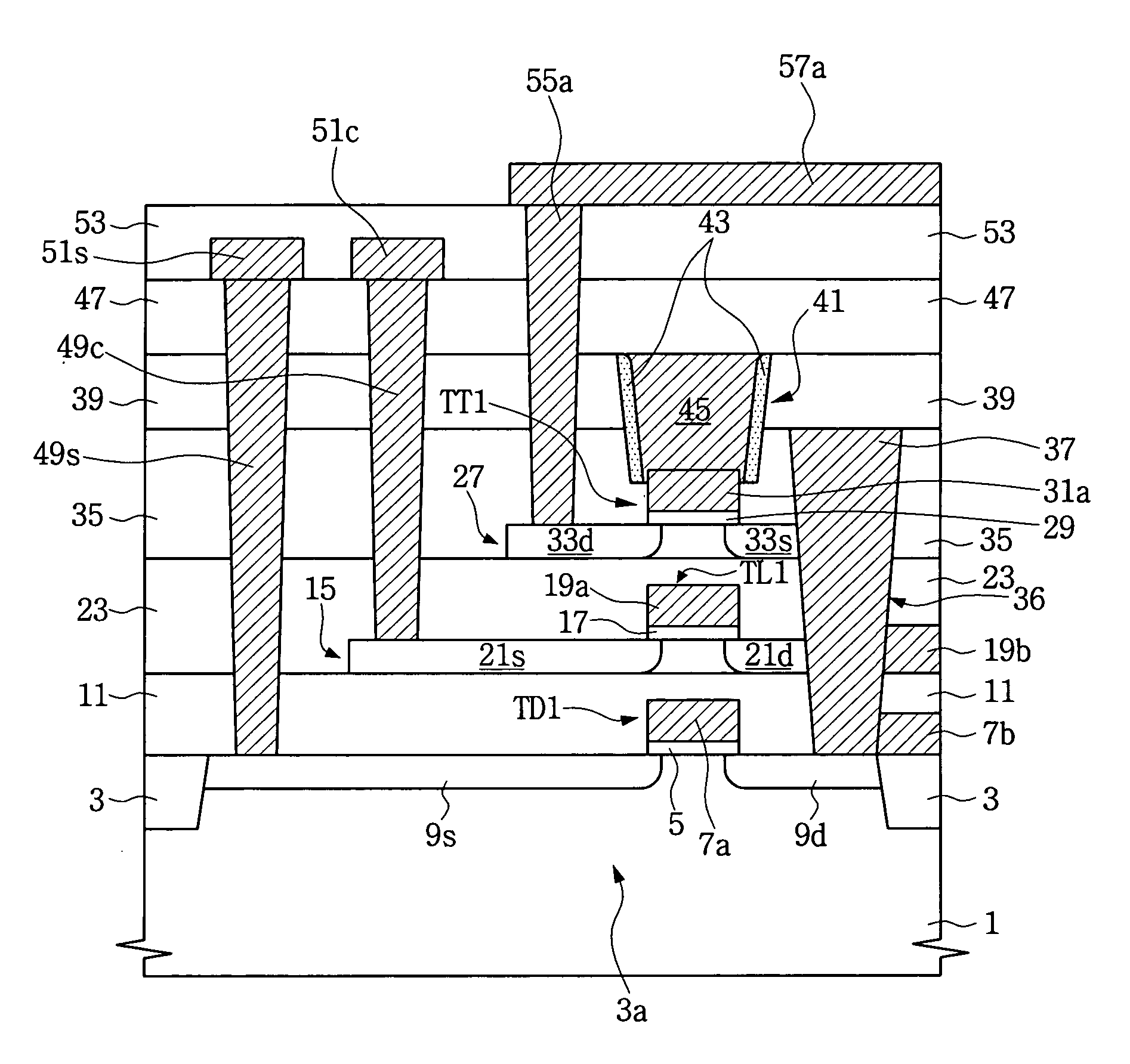

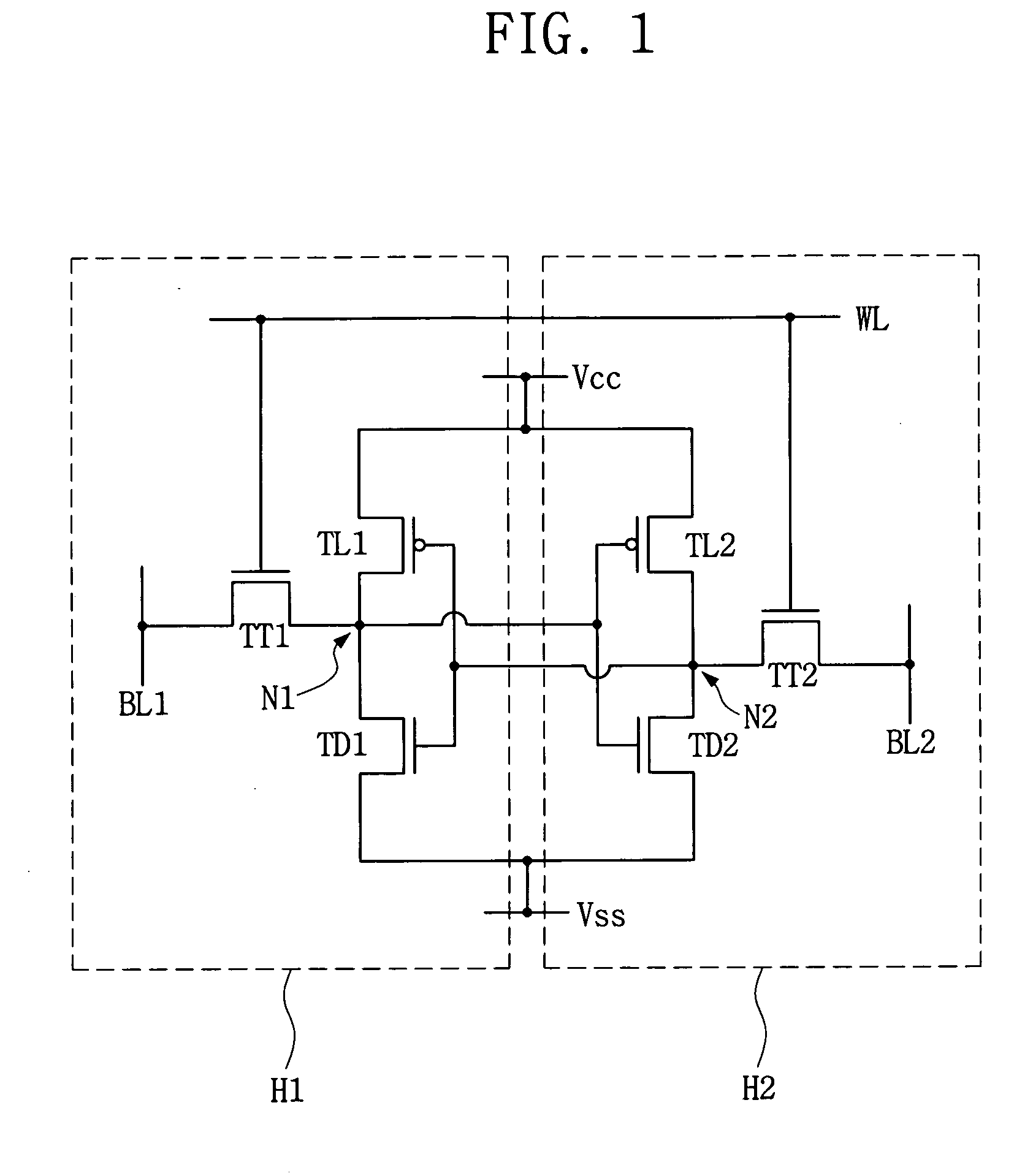

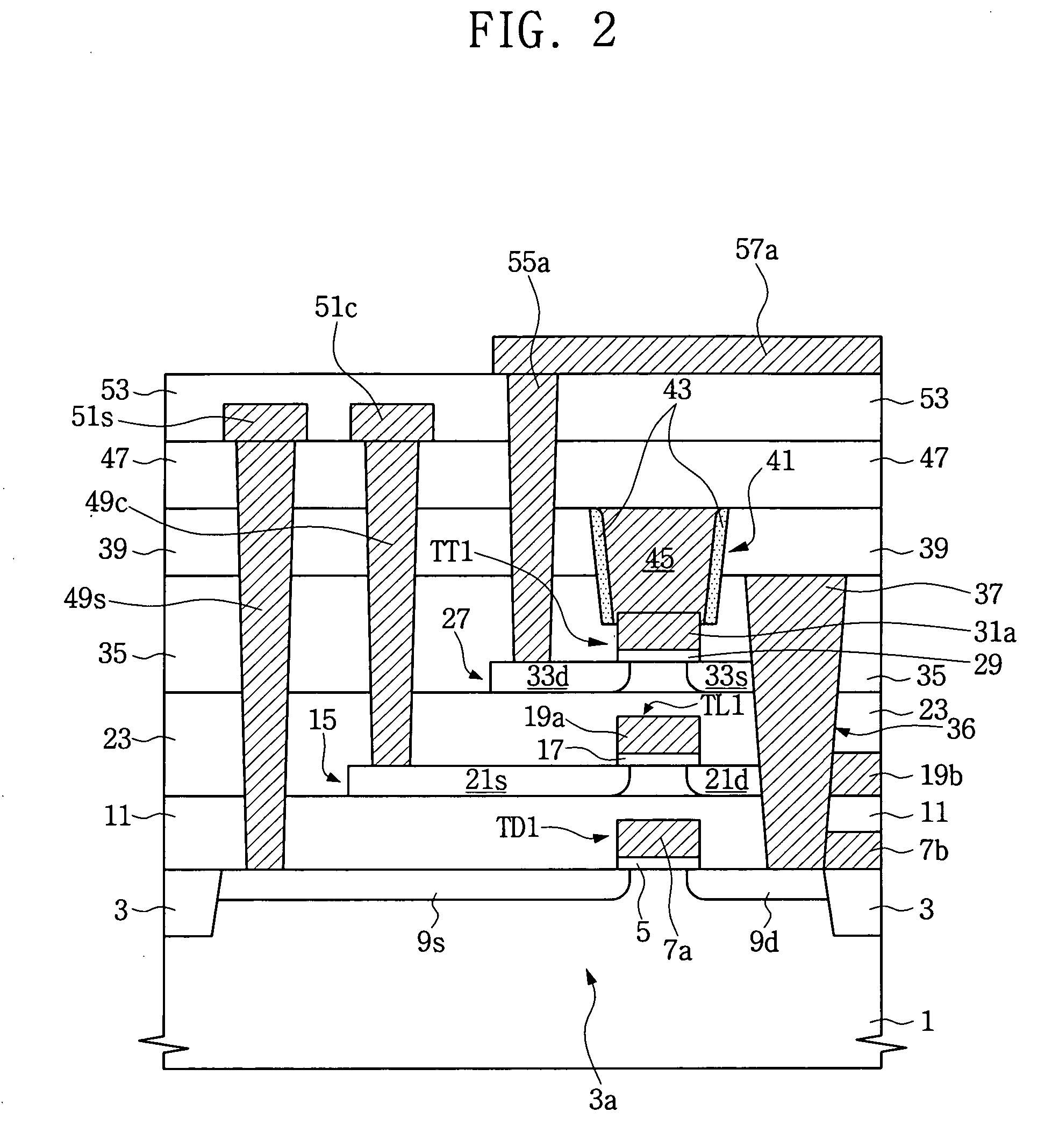

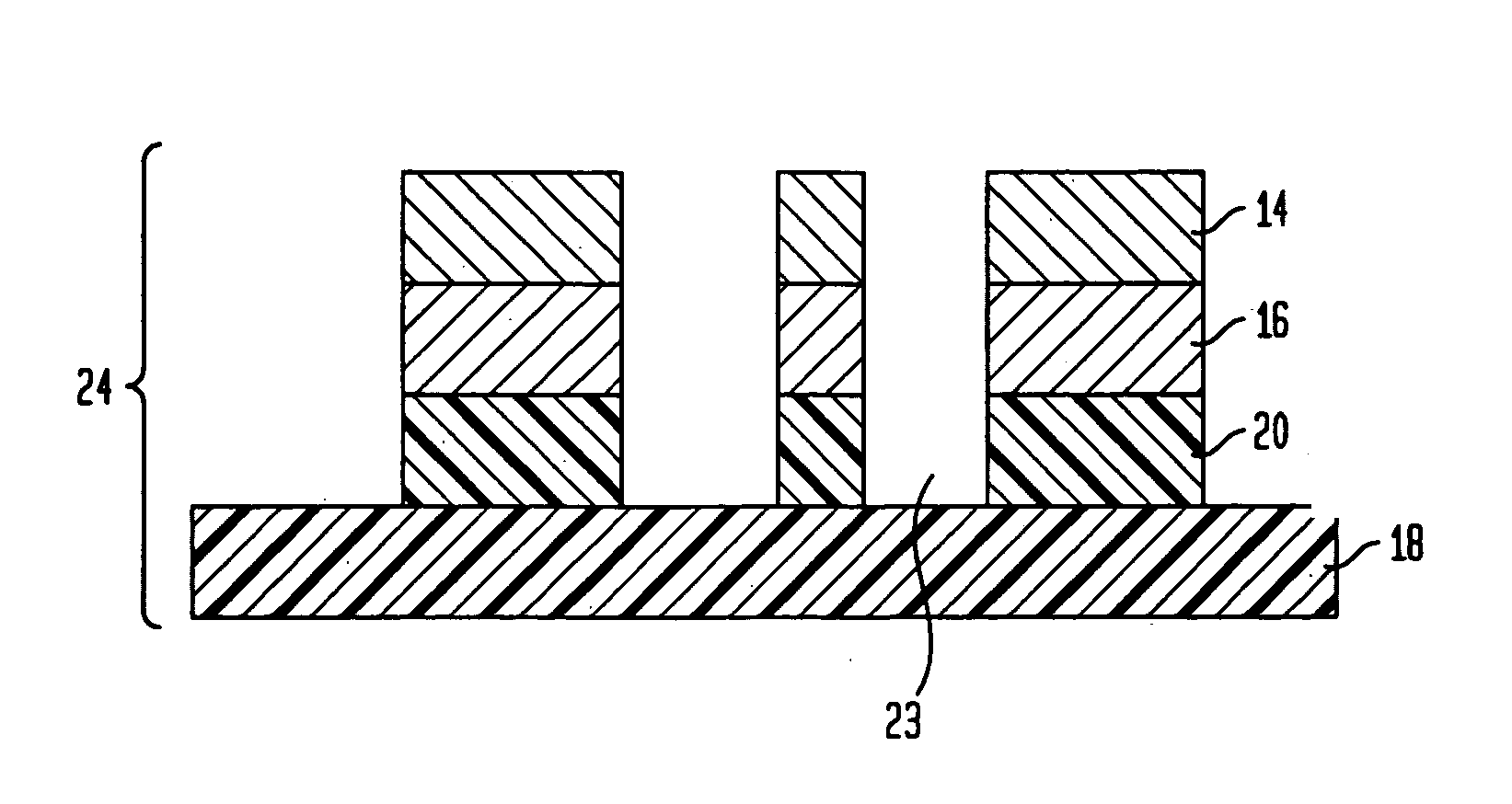

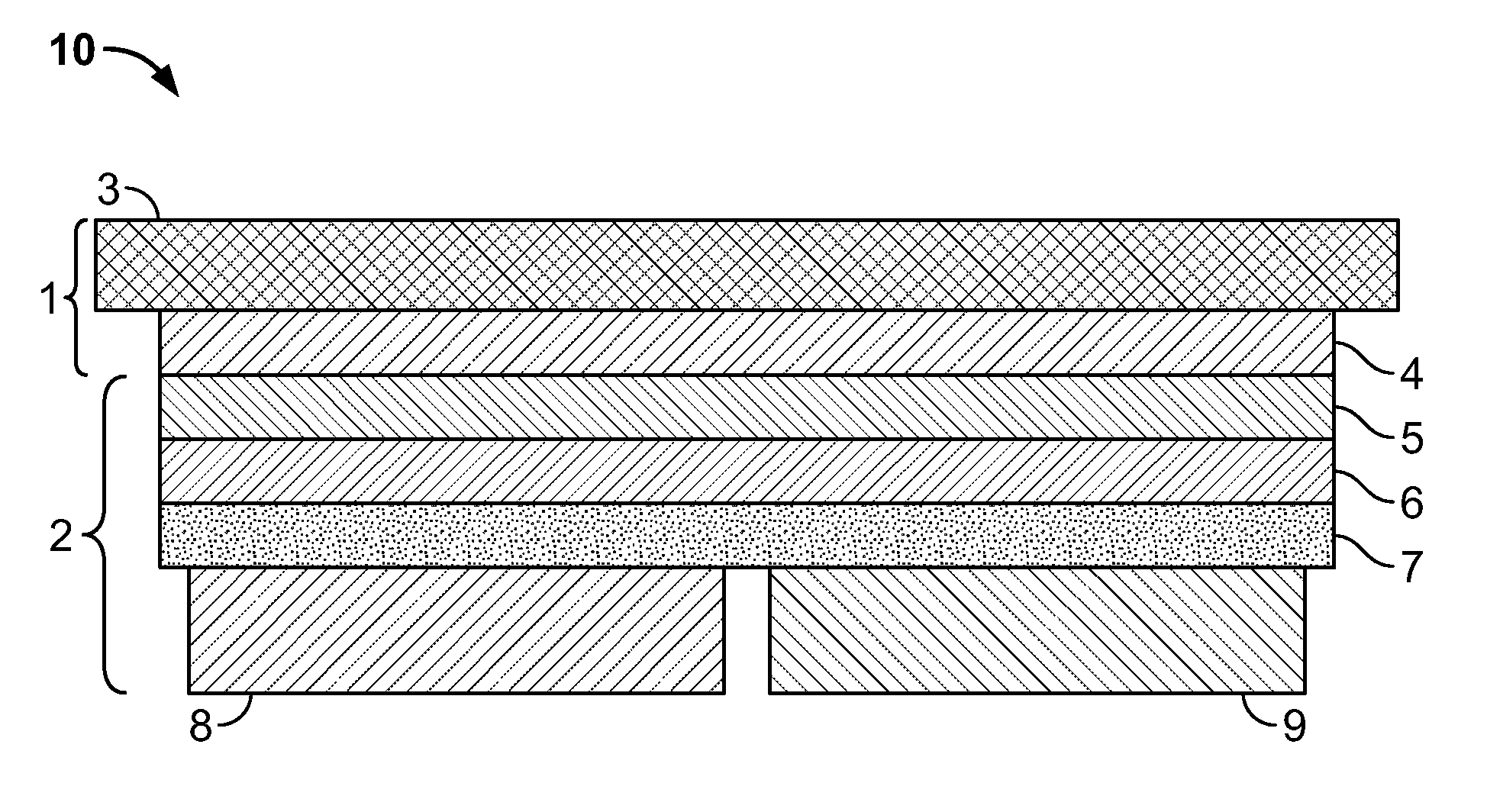

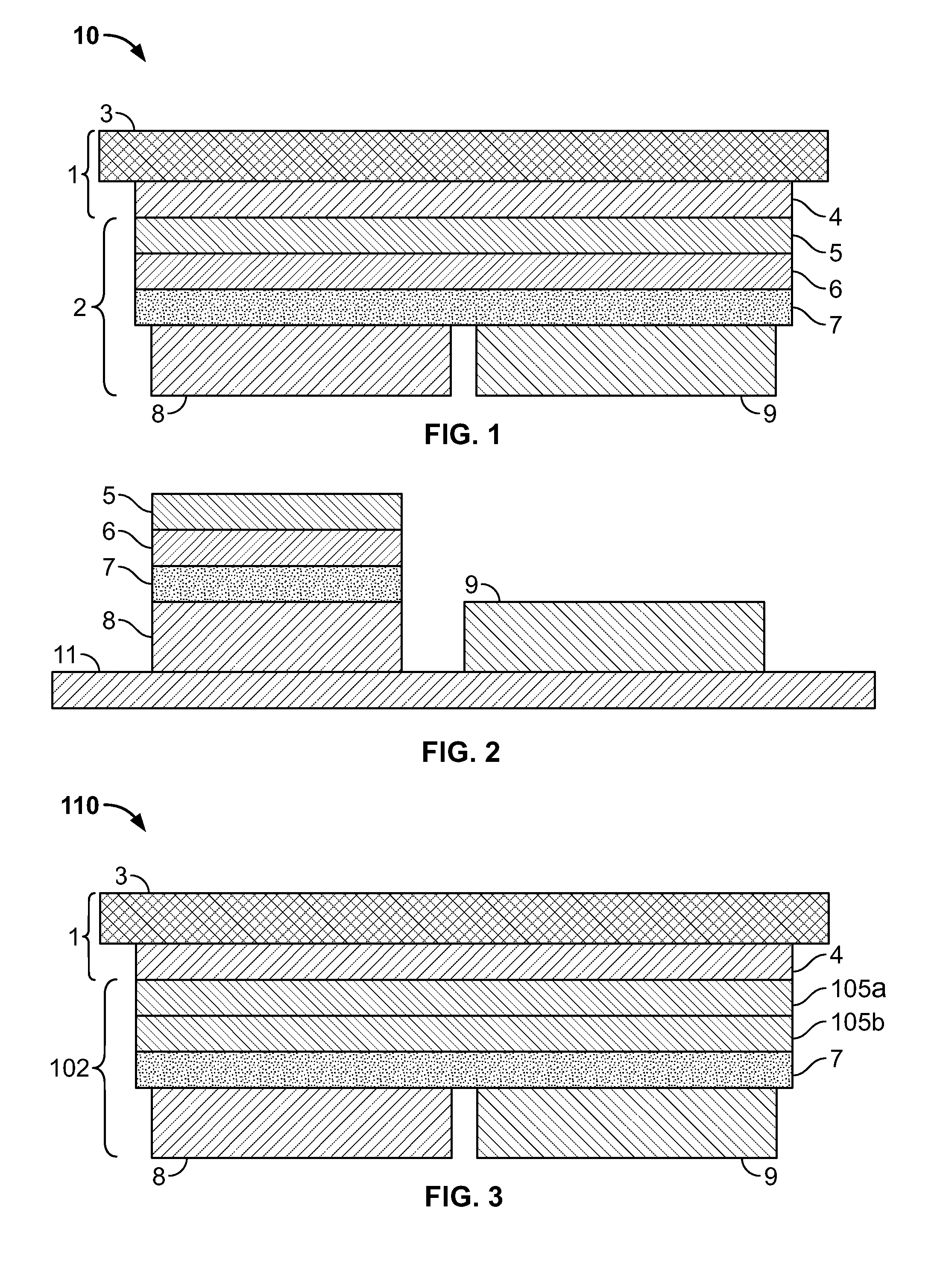

Semiconductor device having a plurality of stacked transistors and method of fabricating the same

A semiconductor device according to example embodiments may have a plurality of stacked transistors. The semiconductor device may have a lower insulating layer formed on a semiconductor substrate and an upper channel body pattern formed on the lower insulating layer. A source region and a drain region may be formed within the upper channel body pattern, and a non-metal transfer gate electrode may be disposed on the upper channel body pattern between the source and drain regions. The non-metal transfer gate electrode, the upper channel body pattern, and the lower insulating layer may be covered by an intermediate insulating layer. A metal word line may be disposed within the intermediate insulating layer to contact at least an upper surface of the non-metal transfer gate electrode. An insulating spacer may be disposed on a sidewall of the metal word line. A metal node plug may be disposed within the intermediate insulating layer and the lower insulating layer to contact the source region of the upper channel body pattern. Example embodiments also relate to a method of fabricating the above semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for controlling and/or adjusting a welding process and welding device for carrying out a welding process

A method for controlling and / or adjusting a welding process, uses a melting electrode, wherein after ignition of an electric arc, a welding process, which is adjusted on the basis of several different welding parameters, is carried out using a welding current source, the process being controlled or adjusted by a control device. Also a corresponding welding device is used to carry out the process. In order to create the method, wherein the thermal heat economy is adjusted and / or regulated and / or controlled in order to introduce heat into the workpiece, at least two different process phases are cyclically combined, the process phases having different inputs of energy via different material transitions and / or arc types, such as a pulse current phase and a cold metal transfer phase in order to influence or control thermal heat economy, particularly the introduction of heat into the workpiece to be processed.

Owner:FRONIUS INTERNATIONAL GMBH

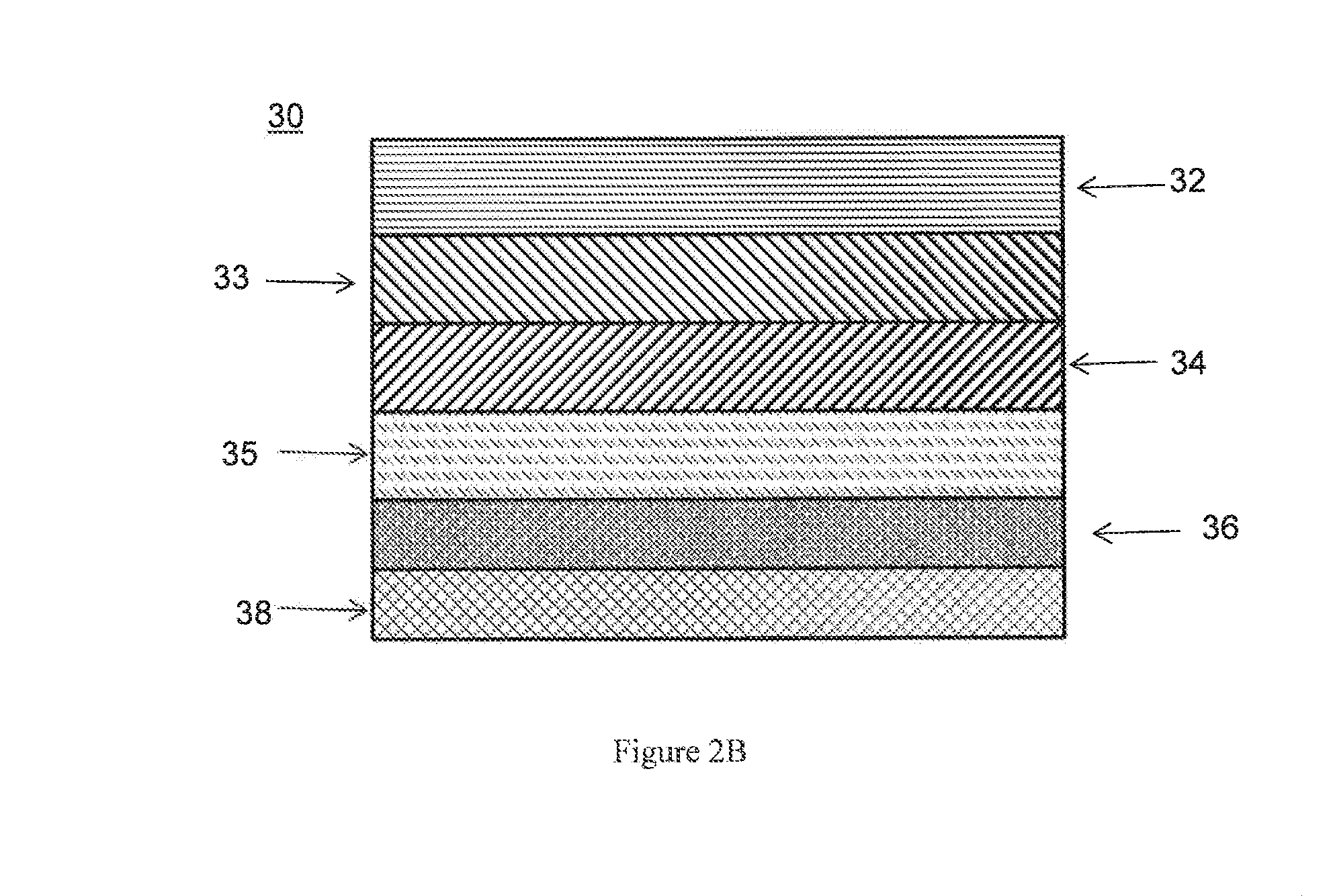

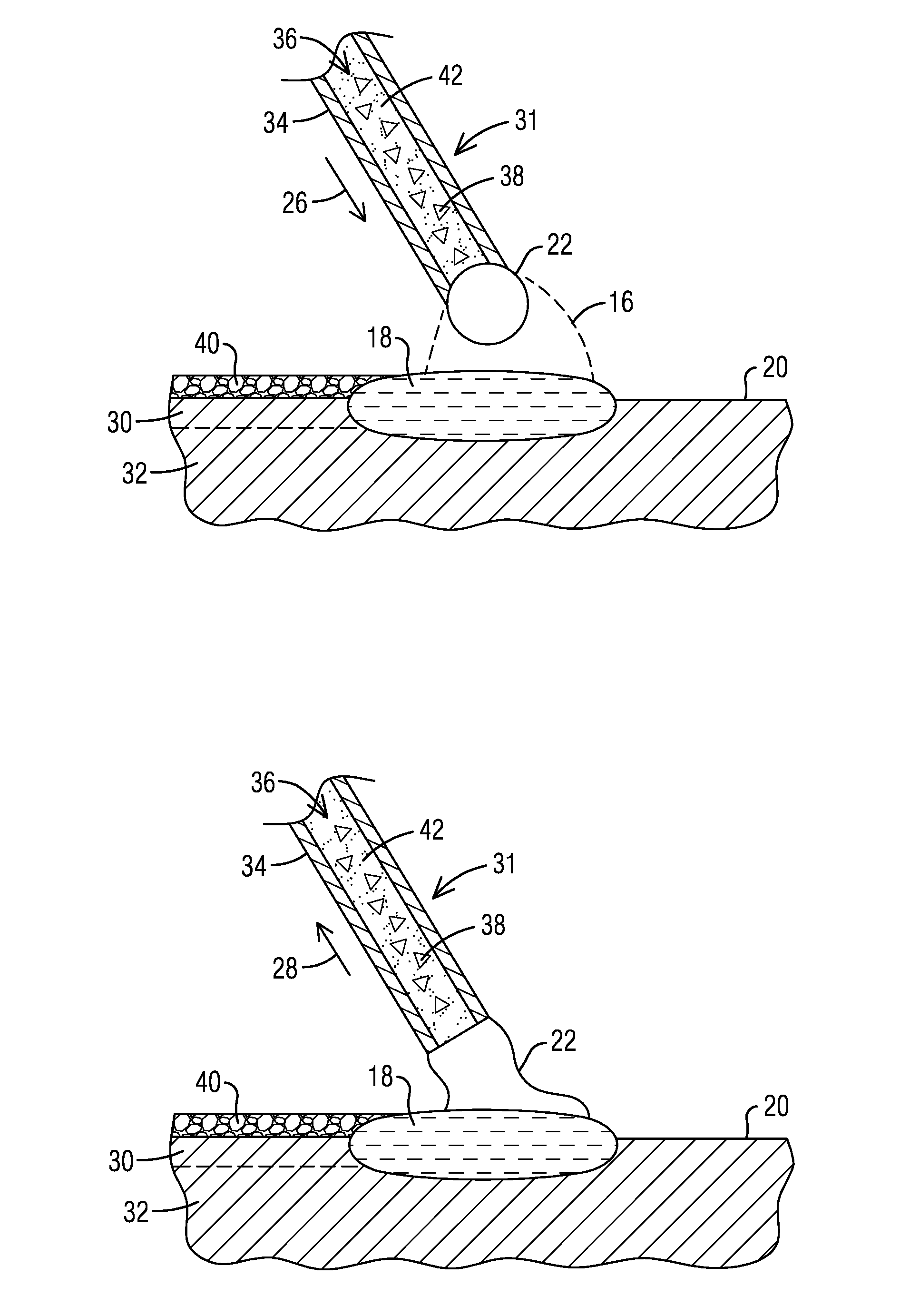

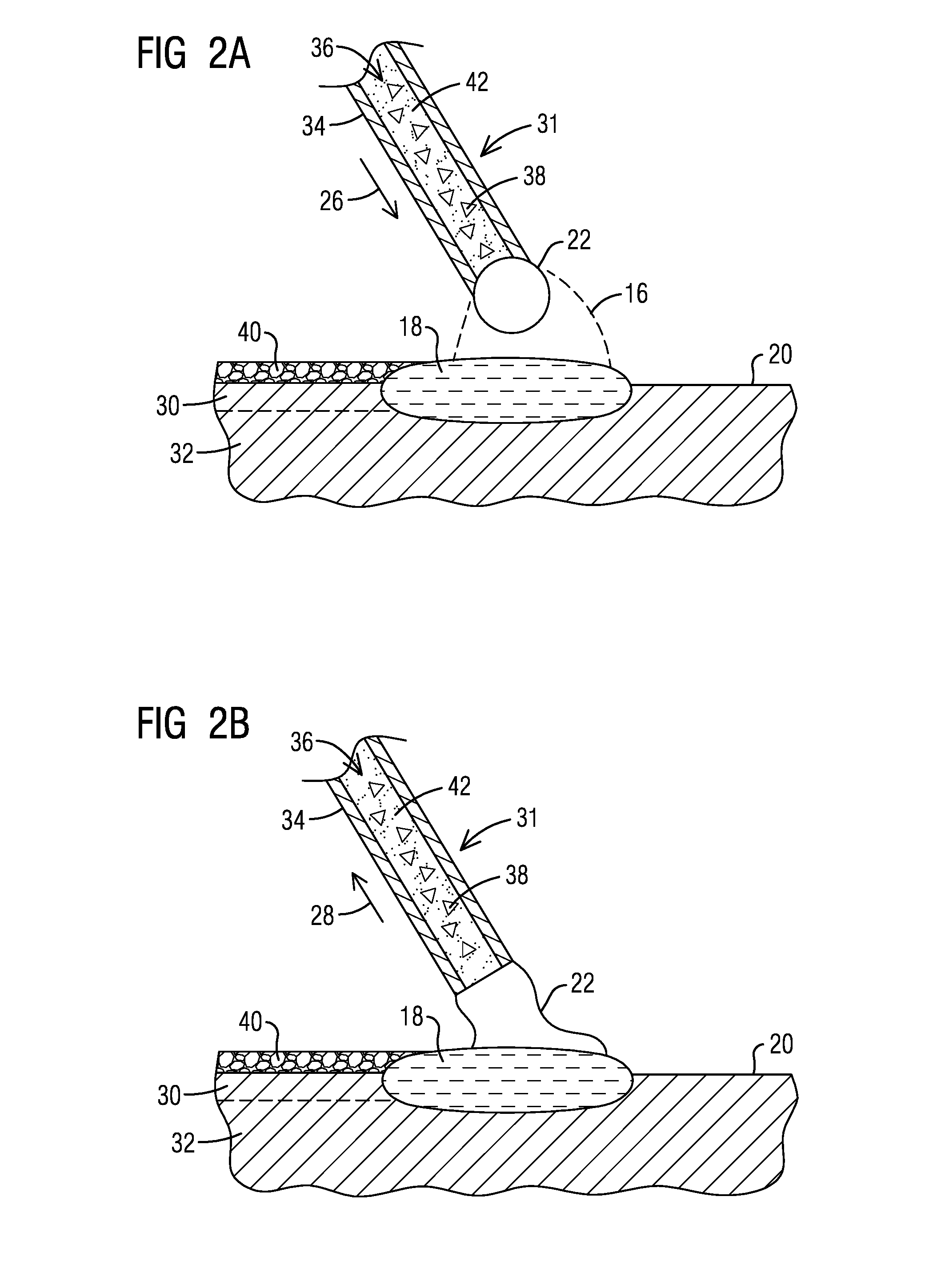

Low heat flux mediated cladding of superalloys using cored feed material

InactiveUS20160144441A1Metallic material coating processesWelding/cutting media/materialsHeat fluxSuperalloy

Methods are disclosed for melting a cored feed material (31) using a low heat input process. The feed material may be a sheath (34) consisting essentially of pure nickel, nickel-chromium, or nickel-chromium-cobalt, containing a powdered core material (36) having a powdered alloy material (42) and powdered flux material (38) which, when melted, form a desired superalloy material. Flux materials for use with the methods are disclosed. The process may be a cold metal transfer process wherein the feed material is oscillated at greater than 130 oscillations per second.

Owner:SIEMENS ENERGY INC

Repaired internal holding structures for gas turbine engine cases and method of repairing the same

Owner:RAYTHEON TECH CORP

Metallization process and product produced thereby

A layered structure produced by metallizing a substrate including: (a) providing a transfer film including film layer and metal layer bonded together by a cured breakaway layer; (b) providing a substrate; (c) applying electron beam curable transfer adhesive to a portion of the substrate; (d) securing the transfer film to the substrate, where the transfer adhesive is between the metal layer and substrate, forming an intermediate product; (e) passing the intermediate product through an electron beam curing apparatus to cure the transfer adhesive; and (f) removing the transfer film. In the metallized product, the cured breakaway coating is bonded only to the metal. The cured breakaway layer preferably has a cured elongation at break, in tension, of less than about 20%. Precise metallized edges are produced, e.g., edge variation of about ±0.010 in., or better. The process can be utilized with total or selective metal transfer.

Owner:UNIFOIL CORP

Gas-less process and system for girth welding in high strength applications including liquefied natural gas storage tanks

InactiveUS20070221643A1Minimize contaminationLength minimizationArc welding apparatusWelding/cutting media/materialsPetroleumPetroleum engineering

A welding system and method is disclosed for girth welding high strength materials, including liquefied natural gas storage tanks, using a short arc welding process and a self-shielding electrode. The welding system contains a welding apparatus which advances the self-shielding electrode towards a workpiece to be welded and controls the arc length and the operation of the apparatus so that the weld satisfies the requirements for welding at least American Petroleum Institute Grade X-80 line pipe, or can weld liquefied natural gas storage tanks. The system additionally contains a power source with a controller for creating a current pulse introducing energy into the electrode to melt the end of the self-shielding electrode and a low current quiescent metal transfer section following the end of the melting pulse during which the melted electrode short circuits against the workpiece.

Owner:LINCOLN GLOBAL INC

Titanium and titanium alloy component arc welding adding material remanufacturing method

ActiveCN104014912ASmall sizeImprove performanceWelding/cutting media/materialsWelding/soldering/cutting articlesAttitude controlShielding gas

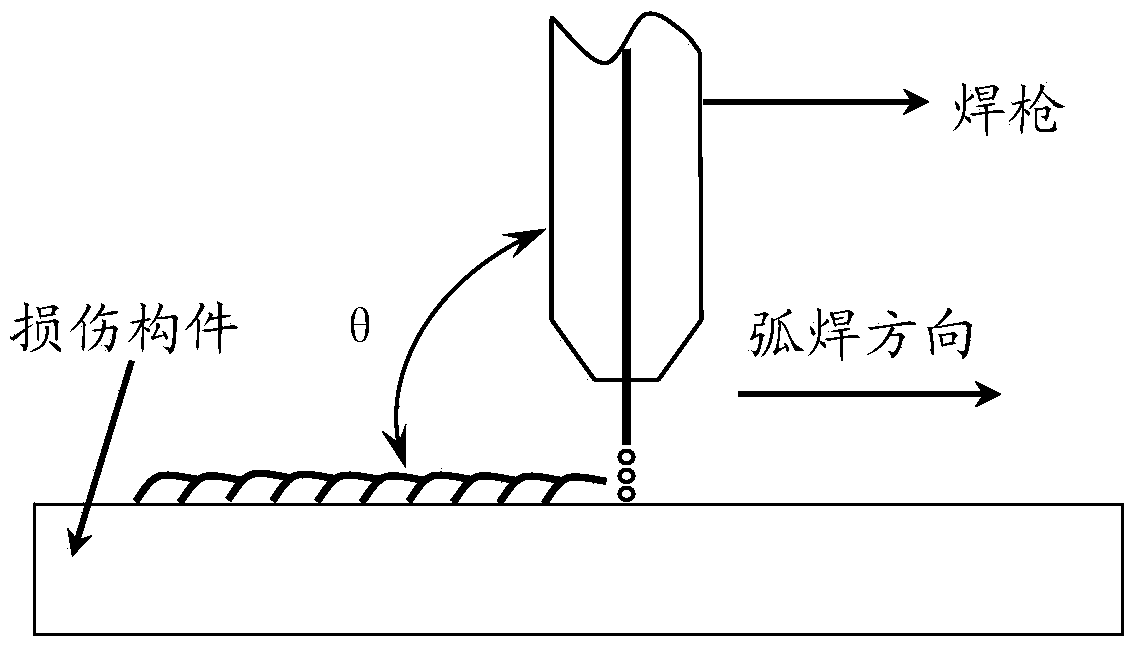

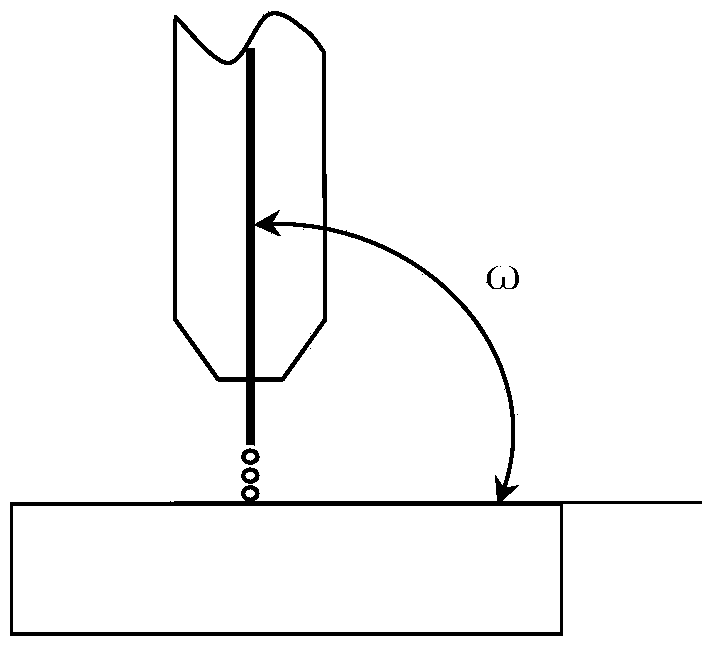

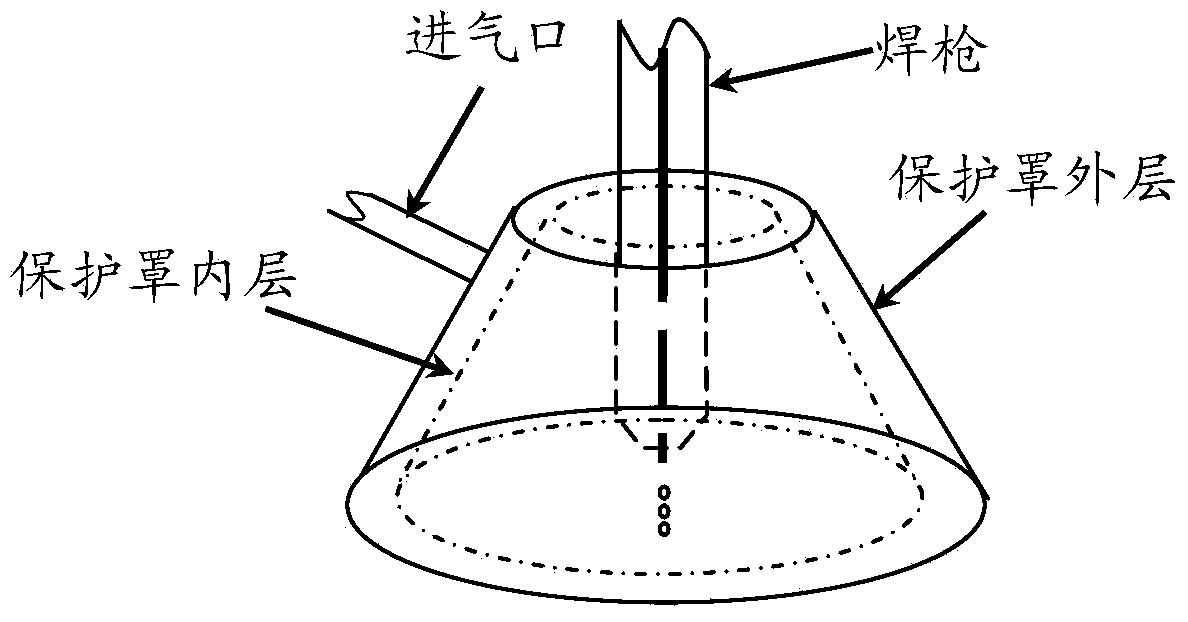

The invention discloses a titanium and titanium alloy component arc welding adding material remanufacturing method. In the arc welding adding material remanufacturing process, the pulse MIG welding technology is adopted, the mode of metal transfer is spray transfer, a double-microdomain adjusting mode is adopted in gas protection, the appearance structure is a bell jar type or a ship type, and a front stretching and back extending mode is adopted in protection gas supplying and non-supplying; the inclination angle theta and the inclination angle omega of opposite welding lines of a welding gun are controlled; argon or argon-helium or helium-argon or helium is adopted as the double-microdomain protection gas; an arc welding robot is adopted to control the moving speed and posture of the welding gun. The titanium and titanium alloy component arc welding adding material remanufacturing method solves the problems of gas protection, technology optimization and quality control in the titanium and titanium alloy component MIG arc welding adding material remanufacturing, adding material remanufacturing of abraded or broken titanium and titanium alloy components is achieved, the gas protection structure is simple, easy to use and good in protection effect, a sealing gas chamber is not needed, more than 40 percent of materials can be saved, the thermal input can be reduced by more than 20 percent, and the titanium and titanium alloy component arc welding adding material remanufacturing quality is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Selectively metallized heat transfer label

A selectively metallized heat transfer label for transfer to a substrate includes a support portion having a carrier layer and a release layer applied to the carrier layer, and a transfer portion including a protective layer applied to the release layer, a metallizable layer applied to the protective layer, a metal layer applied to the metallizable layer, a metal transferring adhesive layer applied to the metal layer and configured to adhere to both the metal layer and the desired substrate and a non-metal transferring ink layer applied to the metal layer and configured to adhere to the desired substrate but not to the metal layer. When heat and pressure are applied to the carrier, the metal transferring adhesive adheres to both the metal layer and the substrate while the non-transferring ink layer adheres only to the substrate.

Owner:ILLINOIS TOOL WORKS INC

Method for preparing steel-aluminum dissimilar metal overlap joint by adopting CMT technology

InactiveCN106624281ALow heat inputIncrease heat inputArc welding apparatusWelding/soldering/cutting articlesMetalPerpendicular distance

The invention provides a method for preparing a steel-aluminum dissimilar metal overlap joint by adopting the CMT technology. The method comprises the following steps: an aluminum alloy plate is placed on a galvanized steel plate in an overlap manner and fixed by utilizing a fixture, wherein the overlap amount ranges between 5 mm and 20 mm; and a CMT welding machine is utilized, a welding gun is inclined towards the aluminum alloy plate to form an angle of 1-45 degrees with the vertical direction, the welding gun is inclined towards the forward direction by 5-30 degrees, the perpendicular distance between the welding gun and the galvanized steel plate is 10-20 mm, and the welding speed is 0.4-1.0 m / min. According to the method provided by the invention, the CMT technology is improved based on an original MIG welding power source, thereby converting molten droplet transfer into cold metal transfer, and reducing the metal spatter when the heat input during a welding process is reduced; and accordingly, the method is very suitable for welding of the aluminum alloy plate and the galvanized steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

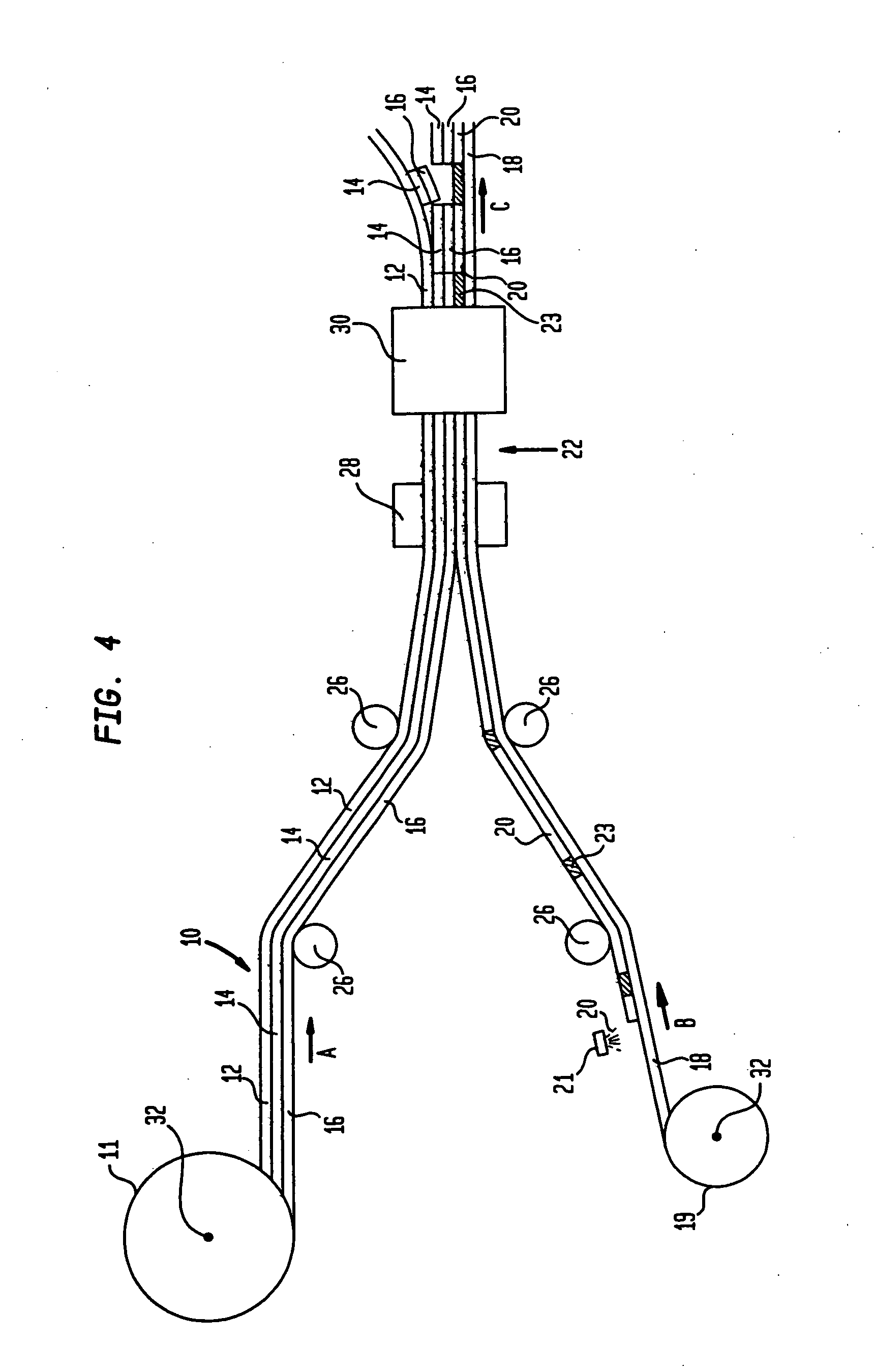

Double wire gmaw welding torch assembly and process

ActiveUS20120055911A1Arc interactionImprove processing stabilityElectrode supporting devicesMechanical engineeringWelding process

A double wire GMAW welding apparatus having a wire spacing adjustable torch assembly is disclosed. The double wire torch assembly has a wire spacing adjusting mechanism, by means of wire spacing adjustment the torch assembly can be used for a non-synchronized metal transfer weld process. The wires remain parallel before, during, after wire spacing adjustment.

Owner:ALEXANDER BINZEL SCHWEISSTECHN GMBH & CO

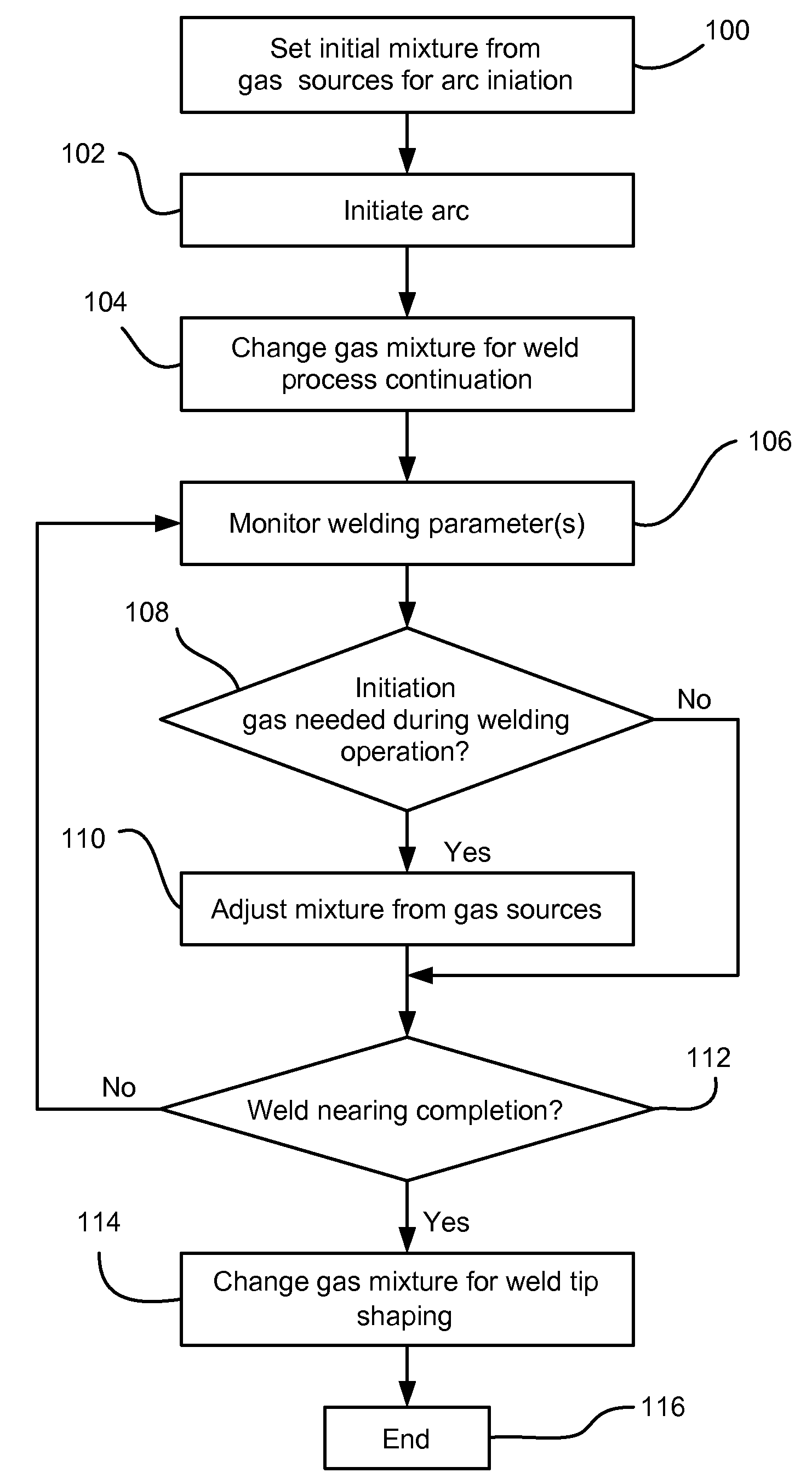

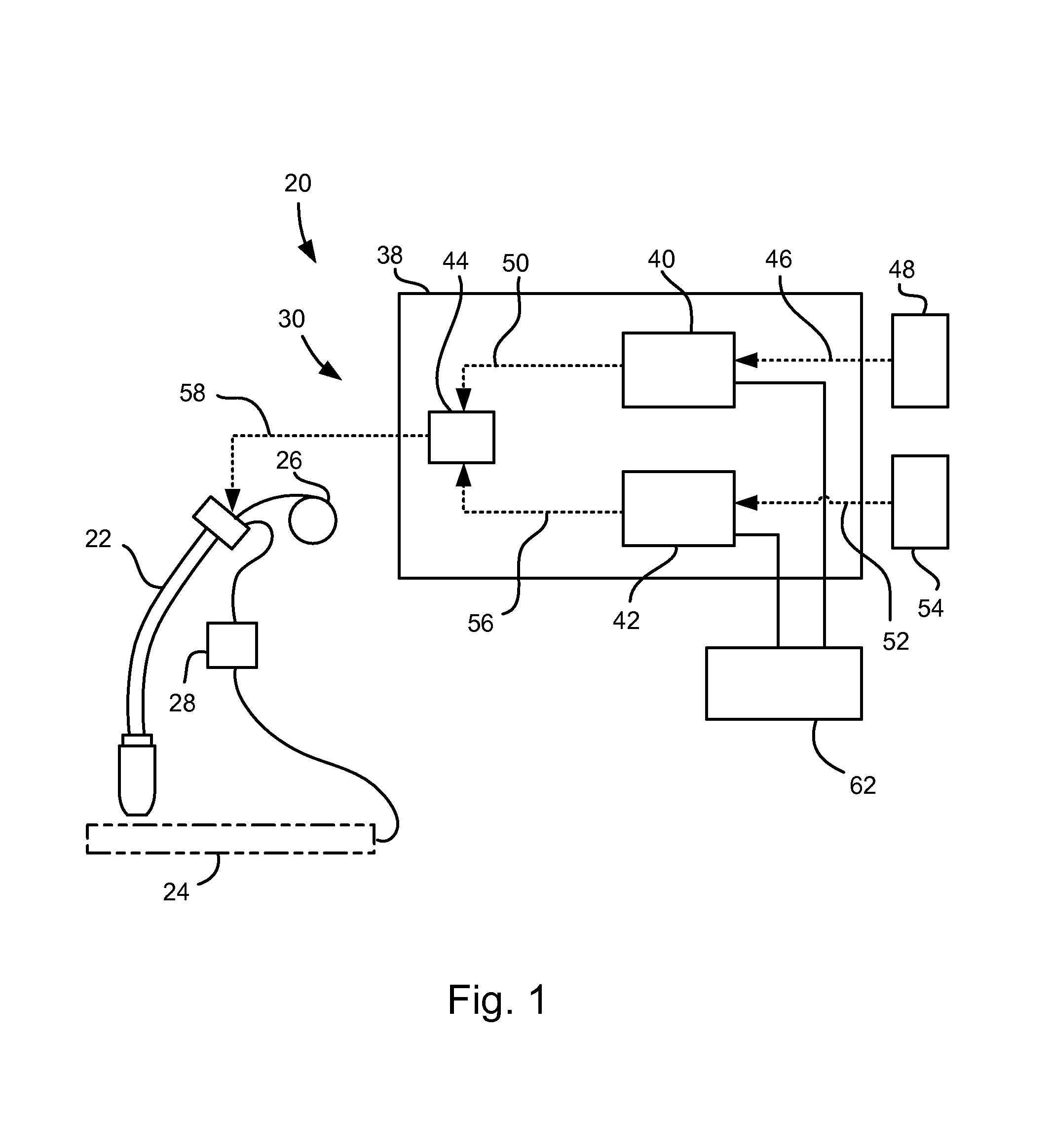

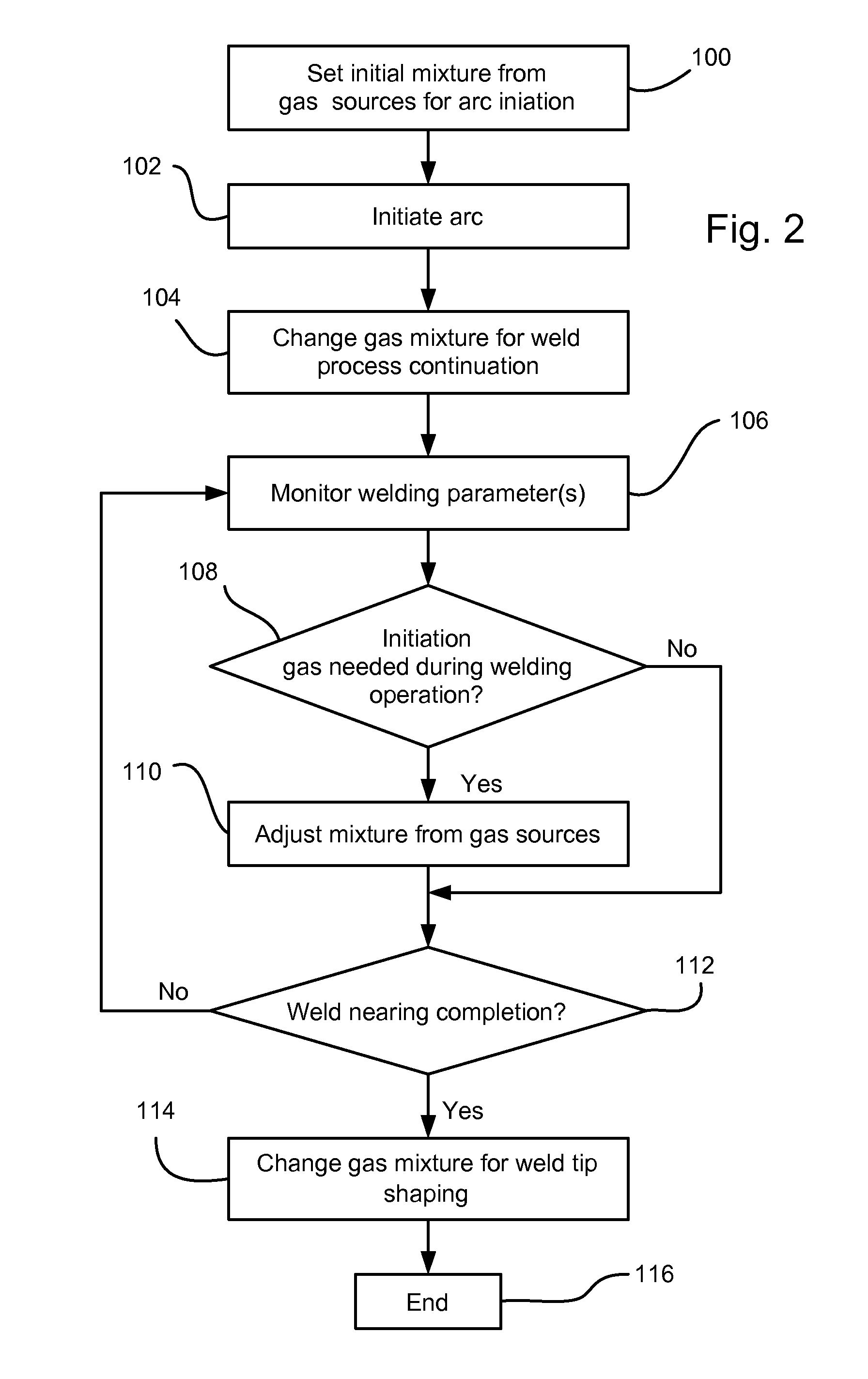

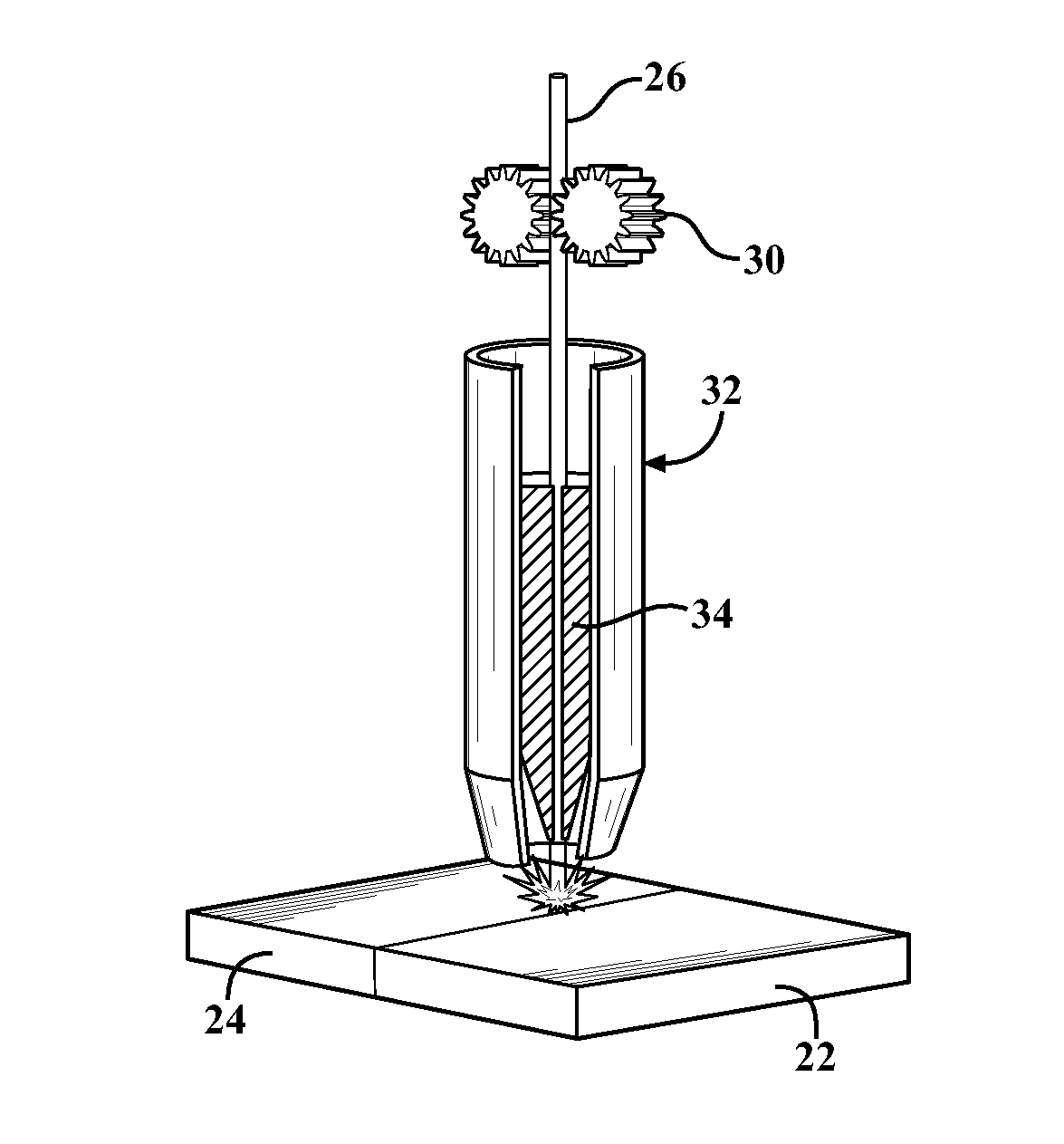

Arc Welding Initiation System and Method

ActiveUS20090107959A1Improve reliabilityReduce the amount requiredArc welding apparatusWelding/cutting media/materialsCarbon Dioxide / HeliumShielding gas

A method and apparatus for controlling arc shielding gas during an arc welding operation is disclosed. The method may include the steps of actuating a first valve connected to an arc initiation source of gas to selectively allow arc initiation gas to flow through a mixing chamber; initiating an arc; actuating a second valve connected to a primary shielding source of gas to selectively allow primary shielding gas to flow through the mixing chamber; actuating the first valve to reduce, if needed, the arc initiation gas flow from the arc initiation source of gas; and continuing with the arc welding operation. The arc welding operation may also include actuating the first valve to cause the arc welding operation to operate in a different metal transfer mode when it is desirable, or when the arc welding operation is nearing completion.

Owner:GM GLOBAL TECH OPERATIONS LLC

Joining of dissimilar materials

ActiveUS20160059340A1Exceptional strengthHigh strengthHot-dipping/immersion processesExtrusion containersMetalCHEEK DIMPLES

A method for joining a first part formed of an aluminum material to a second part formed of a steel material by metal inert gas welding and cold metal transfer is provided. An aluminum filler material forms a fillet joint between the parts and provides a structure for automotive body applications, such an aluminum bumper extrusion joined to a steel crush box connection. The first part includes a notch for hiding the start and end of the joint. A transition plate formed of a mixture of aluminum material and steel material can be disposed between the first part and the second part to provide the notch. The second part can include a mechanical fastener further joining the parts together. In another embodiment, the second part includes a plurality of dimples and is welded to the first part along the dimples.

Owner:MAGNA INTERNATIONAL INC

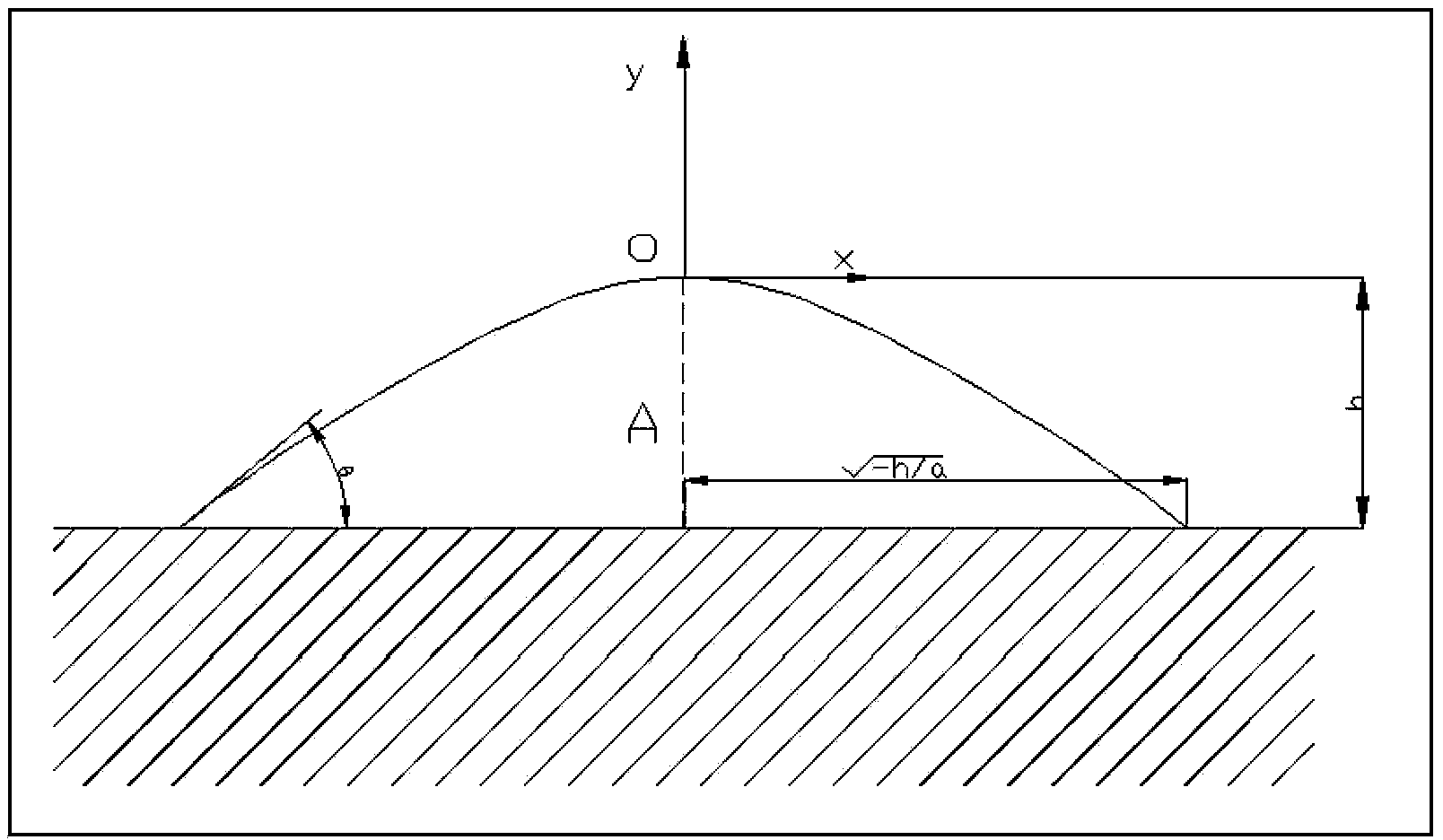

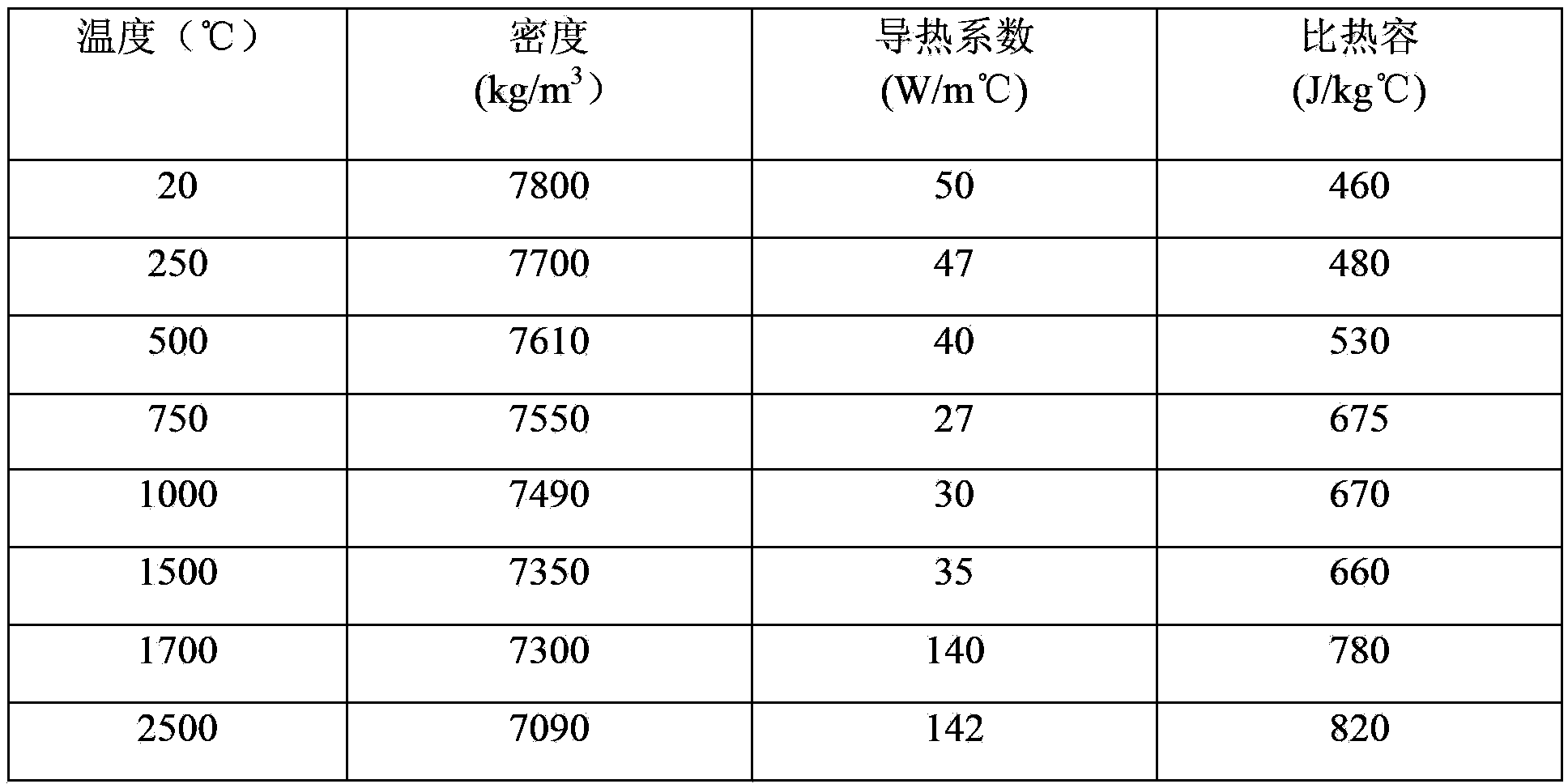

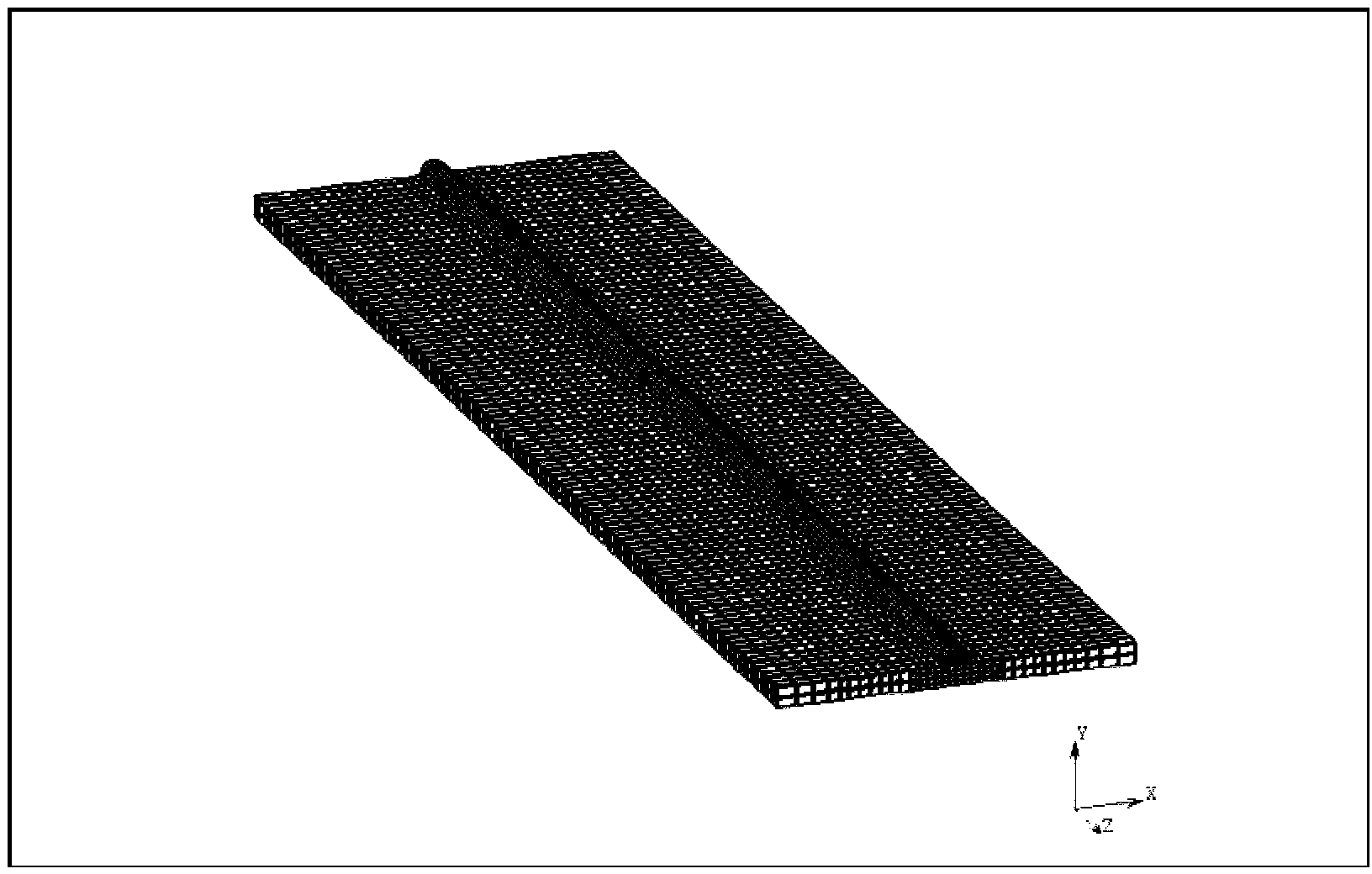

Method for predicting shape and size of CMT welding seam based on ANSYS

InactiveCN103366044AThe result is objectivePowerfulSpecial data processing applicationsElement analysisEvaporation

The invention discloses a method for predicting a shape and a size of a CMT (Cold Metal Transfer) welding seam based on ANSYS. The method comprises the steps that S1, data during a CMT welding course is acquired; S2, a finite element analysis model is established, and reinforcement of the welding seam is processed; S3, mesh dividing is performed; S4, heat source treatment is performed; S5, a governing equation is established; and S6, an transient temperature field is obtained, temperature field distribution is calculated, a time step is calculated, a self-adaption step is adopted, and the shape and the size of the cross section of the welding seam are obtained according to a calculation result of a welding temperature field, and compared with a full size of the welding seam. The prediction is performed based on the following assumptions that a boundary heat transfer condition and a geometrical shape in a width direction are symmetrical, the heat physical property of a material changes with the temperature, and evaporation of metal in a molten pool is not considered. The method is simple, convenient and quick; influences of various force on the molten pool are considered; a result is objective; very high prediction precision of the shape and the size of the CMT welding seam and detailed information of the temperature distribution of the whole CMT welding course can be obtained; set and optimized parameters can be provided for the welding course; and the applicability is high.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

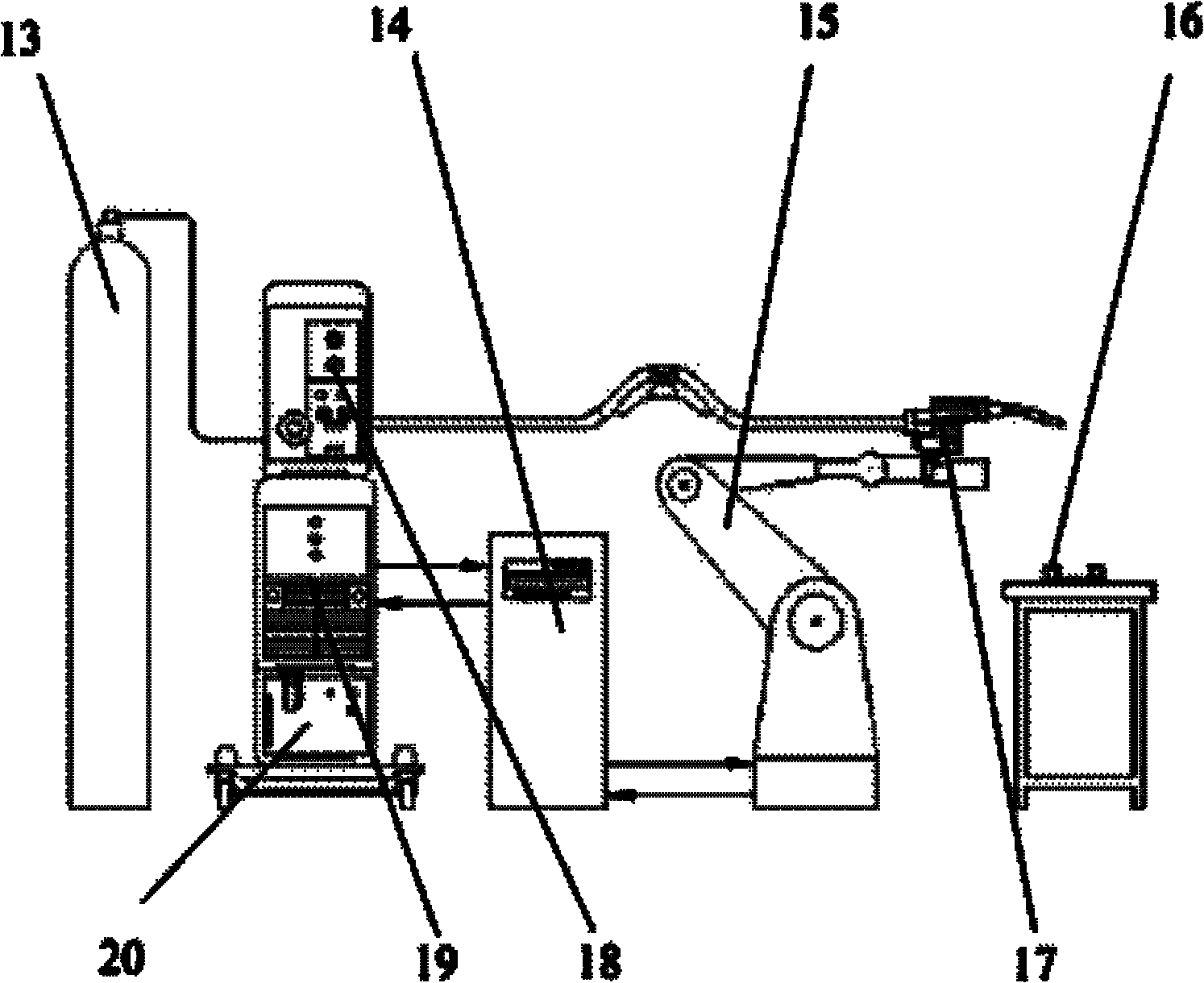

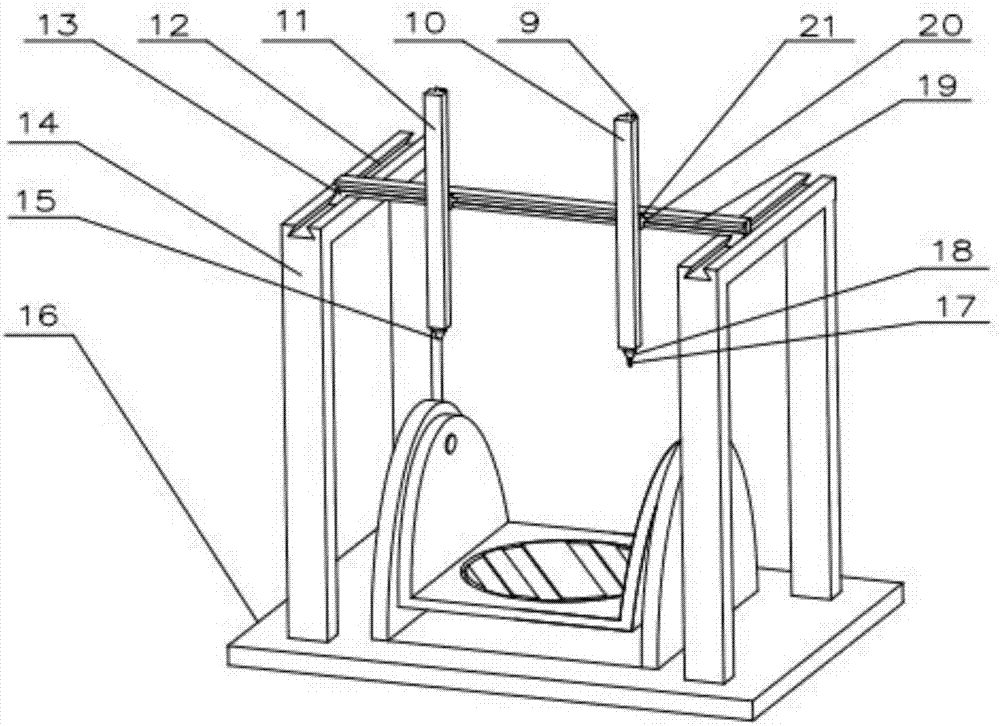

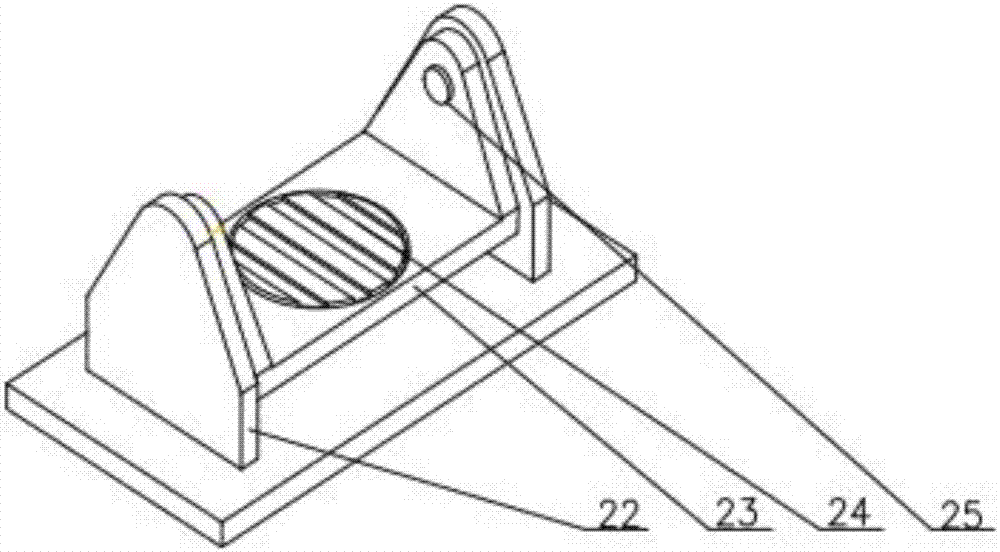

Additive and subtractive composite 3D printing equipment and method based on (cold metal transfer) CMT welding and multi-axis numerical control machine tool

ActiveCN106964993ARealize processingImprove processing qualityAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlGas cylinder

The invention discloses additive and subtractive composite 3D printing equipment and method based on cold metal transfer (CMT) welding and a multi-axis numerical control machine tool. The equipment is composed of a forming equipment driving mechanism, a metal wire feeding mechanism, a water cooling machine, a high-pressure Ar protection gas cylinder, a central control system, a tool changer, a cooling liquid system and the like. The forming equipment driving mechanism comprises Z-direction moving guide rails, a milling mechanical arm used for loading a milling cutter, a welding mechanical arm used for loading a cold metal welding gun, a Y-direction controller, Y-direction moving guide rails arranged on guide rail supporting racks, an X-direction moving guide rail, an X-direction controller and a Z-direction controller. A positioner is arranged on a 3D printer base. Additive manufacturing is achieved by adoption of the cold metal welding gun of the equipment, and the part production efficiency is improved compared with a 3D printer with laser as the heat source; and meanwhile, the milling cutter is adopted for milling a welding machined surface, and the part surface quality is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com