Additive and subtractive composite 3D printing equipment and method based on (cold metal transfer) CMT welding and multi-axis numerical control machine tool

A CNC machine tool and 3D printing technology, applied in the field of 3D printing, can solve problems such as low production efficiency, small printing size, and low printing accuracy, and achieve the effects of improving processing efficiency, processing accuracy, and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

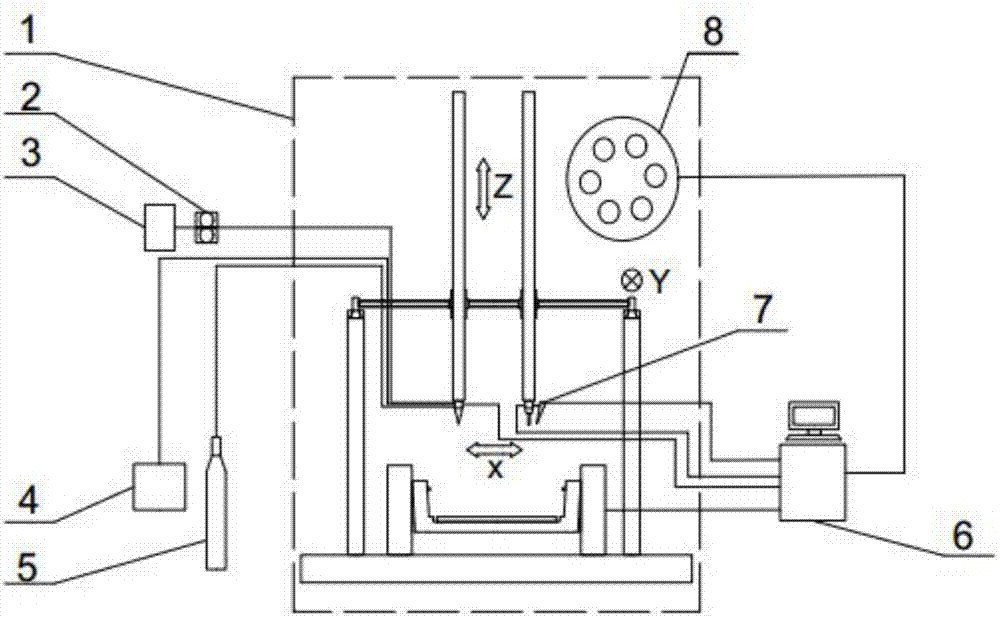

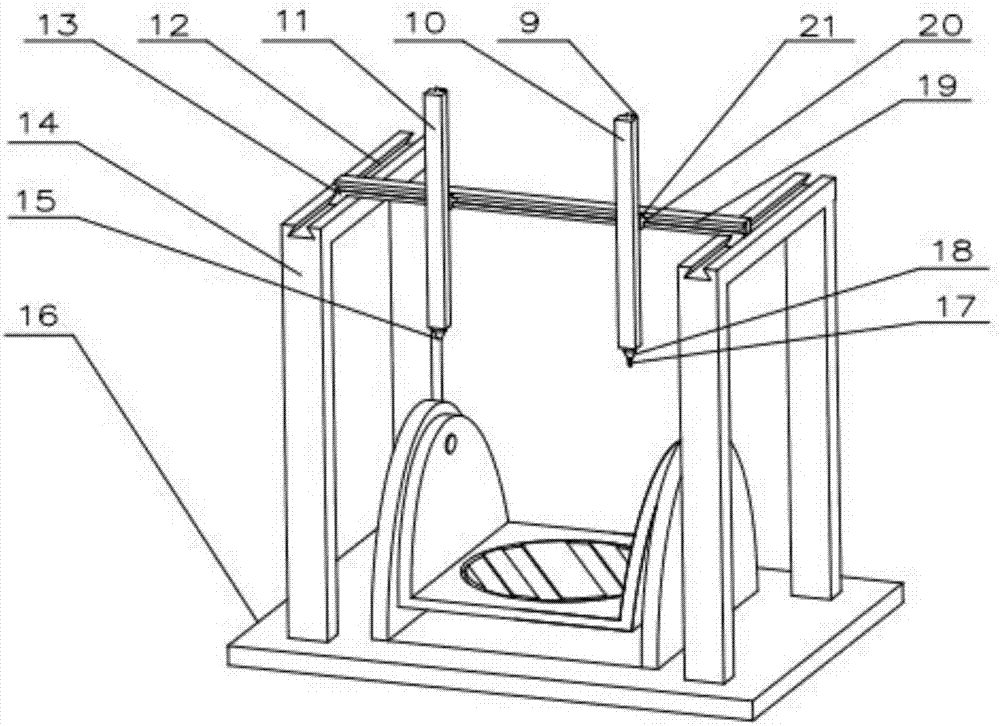

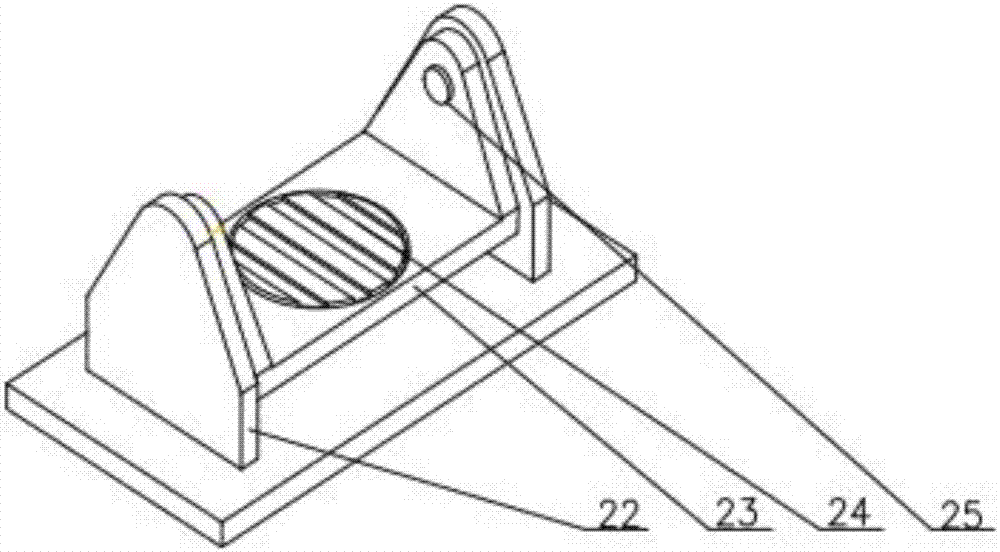

[0036] Such as Figures 1 to 3 shown. The invention discloses a composite 3D printing equipment for adding and subtracting materials of a CMT and a multi-axis CNC machine tool, including a molding device drive mechanism 1 placed in a sealed molding chamber, a metal wire feeding mechanism 2, a central control system 6, and a 3D printer base 16 ; The 3D printer base 16 is provided with a displacer 33 ;

[0037] The forming device driving mechanism 1 includes a Z-direction moving guide rail 9, a milling robot arm 10 for carrying a milling cutter 17, a welding robot arm 11 for carrying a cold metal welding torch 15, a Y direction controller 13, and a rail support frame. Y direction moving guide rail 12 on 14, X direction moving guide rail 19, X direction controller 20, Z direction controller 21;

[0038] The Y direction moving guide rail 12 and the Y direction controller 13 jointly form a Y direction moving mechanism, wherein the Y direction controller 13 is fixed on the X direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com