Portable unlimited rotary numerical control beveled opening pipe cutting machine and beveled opening processing method

A technology of pipe cutting machine and rotary motor, which is used in metal processing equipment, manufacturing tools, welding/cutting auxiliary equipment, etc., can solve the problem of inability to complete the groove processing of intersecting lines, and achieves easy disassembly, assembly and transportation, and simple control. , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

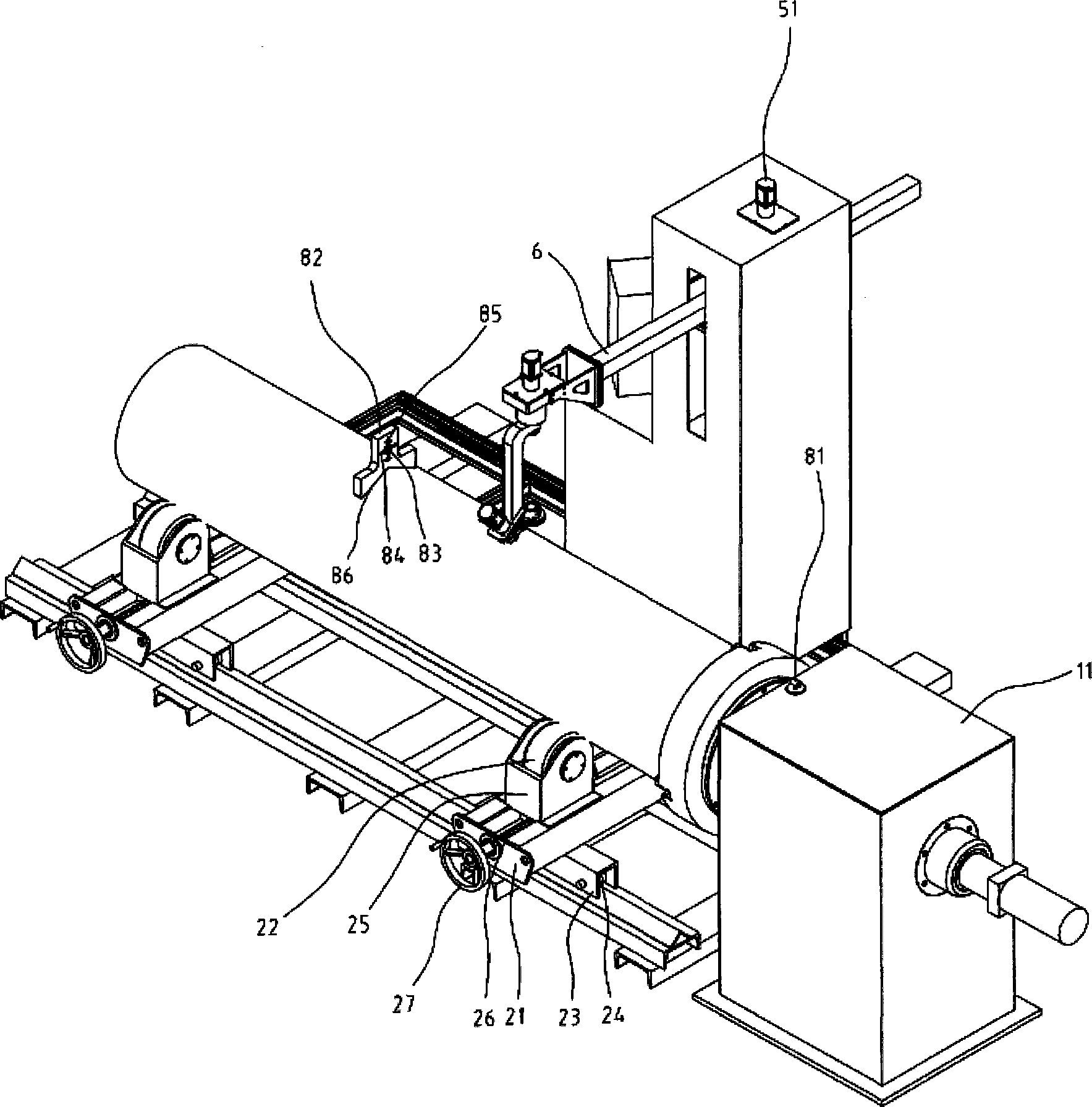

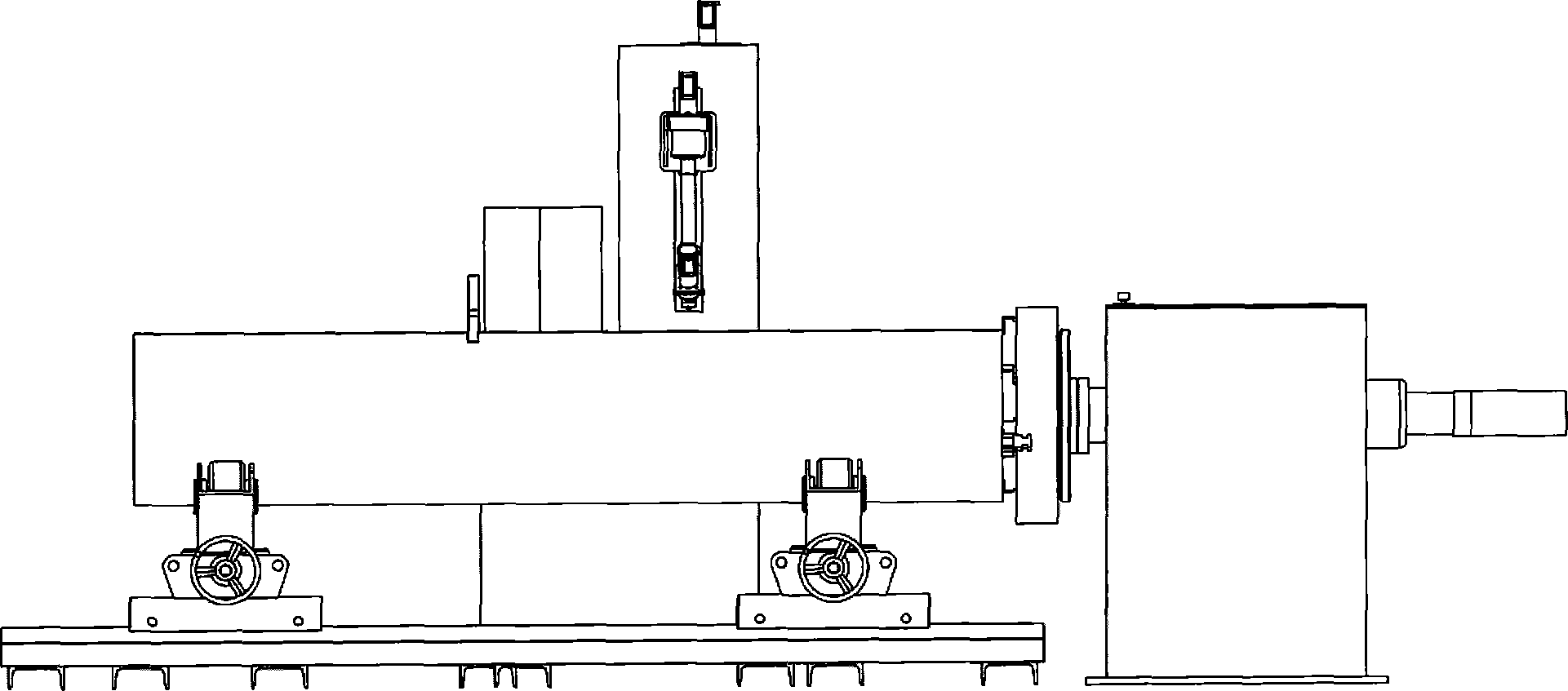

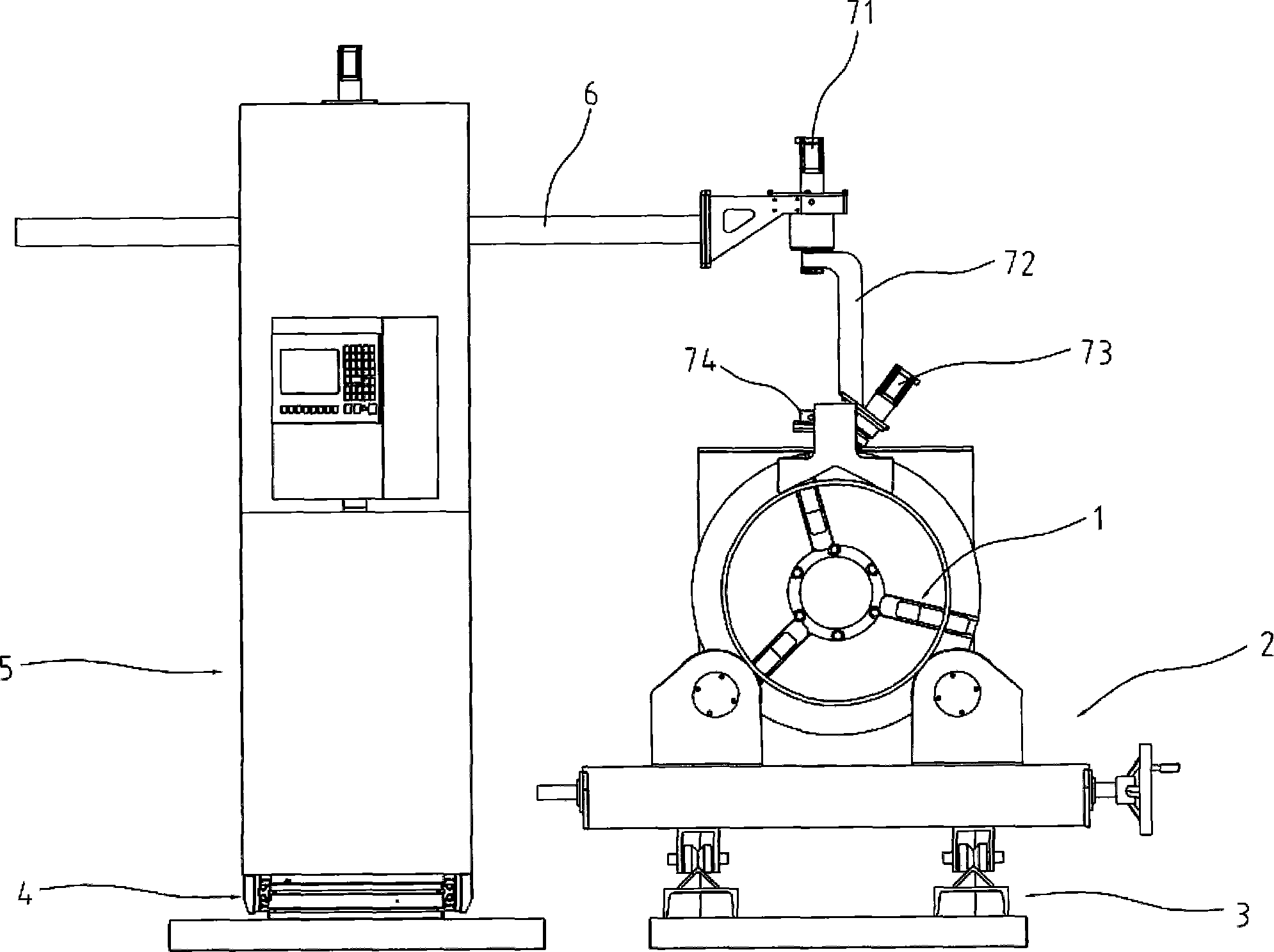

[0030] Example as Figures 1 to 3 As shown, the bevel pipe cutting machine includes processing parts, a bearing part for carrying the pipe to be processed and a numerical control system. The roller frame 2, the chuck 1 is arranged on the chuck seat 11, the roller frame 2 is installed on the longitudinal guide rail 3 and moves along its guide rail path on the longitudinal guide rail 3;

[0031] In addition, there is a second longitudinal guide rail 4 parallel to the longitudinal guide rail 3, the second longitudinal guide rail 4 is provided with a casing 5 moving thereon, the casing 5 is provided with a cross arm 6, and the casing 5 is provided with a The vertical guide rail and the driving device for the cross arm to move up and down. The cross arm 6 has a length extending in a direction perpendicular to the moving direction of the box body 5 on the second longitudinal guide rail 4. The cross arm 6 is connected with a rotary for driving the rotary arm 72 to rotate. Motor 71, ...

Embodiment 2

[0039] Example two such as Figure 4 As shown, the profile assembly frame of the pipe cutting machine is assembled by two rail beams 101 on which longitudinal guide rails 3 are installed, two bottom beams 102, and a plurality of support stands 103 and support cross frames 104 that assemble the rail beam bottom beams into one The chuck seat 11 is placed on the longitudinal guide rail 3, the height adjustment device is installed on the bottom of the bottom beam 102, and the vertical guide rail 105 is installed on the supporting horizontal frame 104 at one end of the frame. Fine adjustment (available with the help of figure 1 In the method of using a laser transmitter to irradiate the laser beam to the central axis of the cutting torch) the distance between the vertical guide rail 105 and the longitudinal guide rail can be fixed after adjustment, and the movement of the cross arm will realize the cutting torch and pipe fittings of different sizes in the future. cooperation.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com