Patents

Literature

773results about How to "Low skill level required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital eye camera

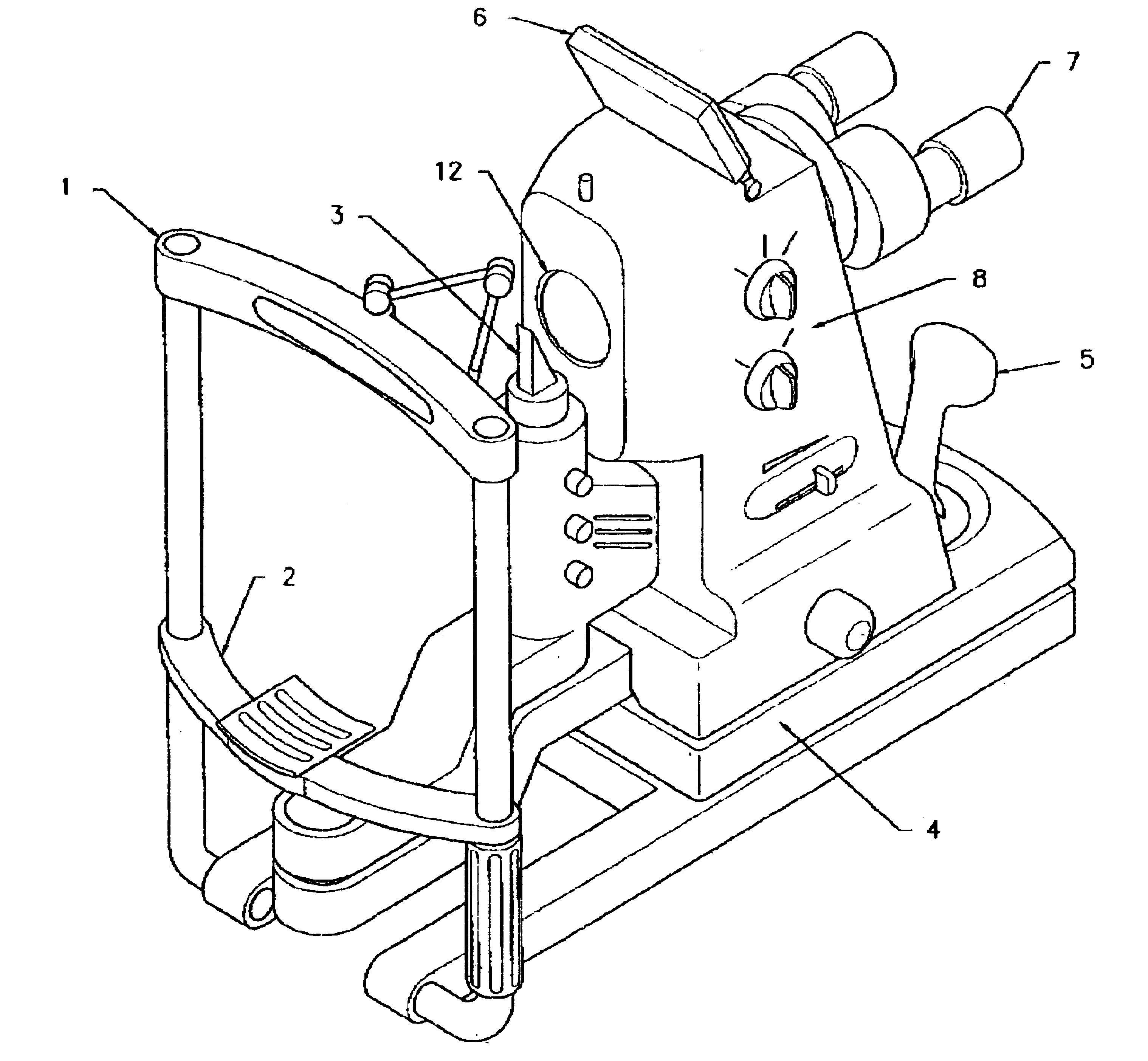

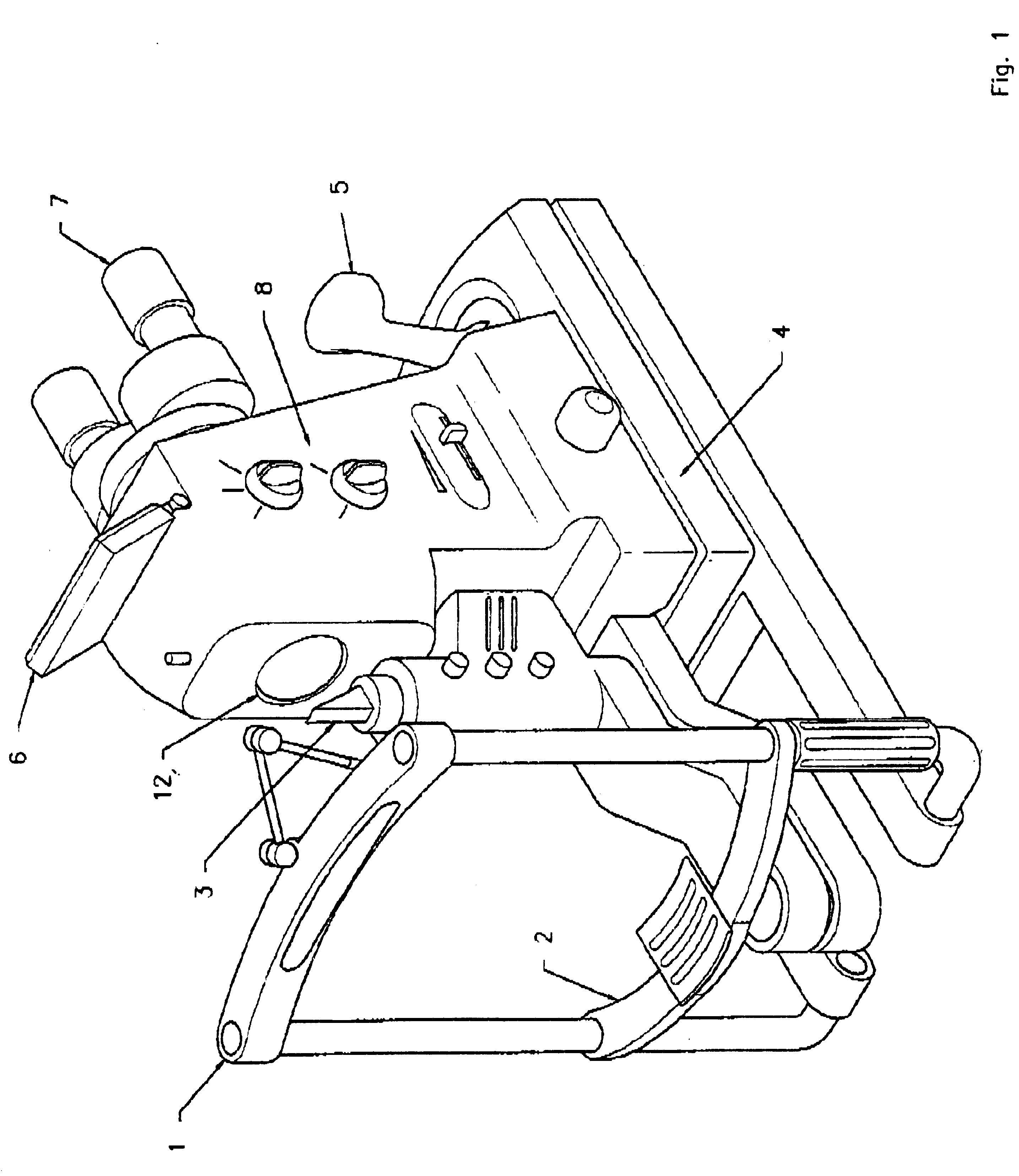

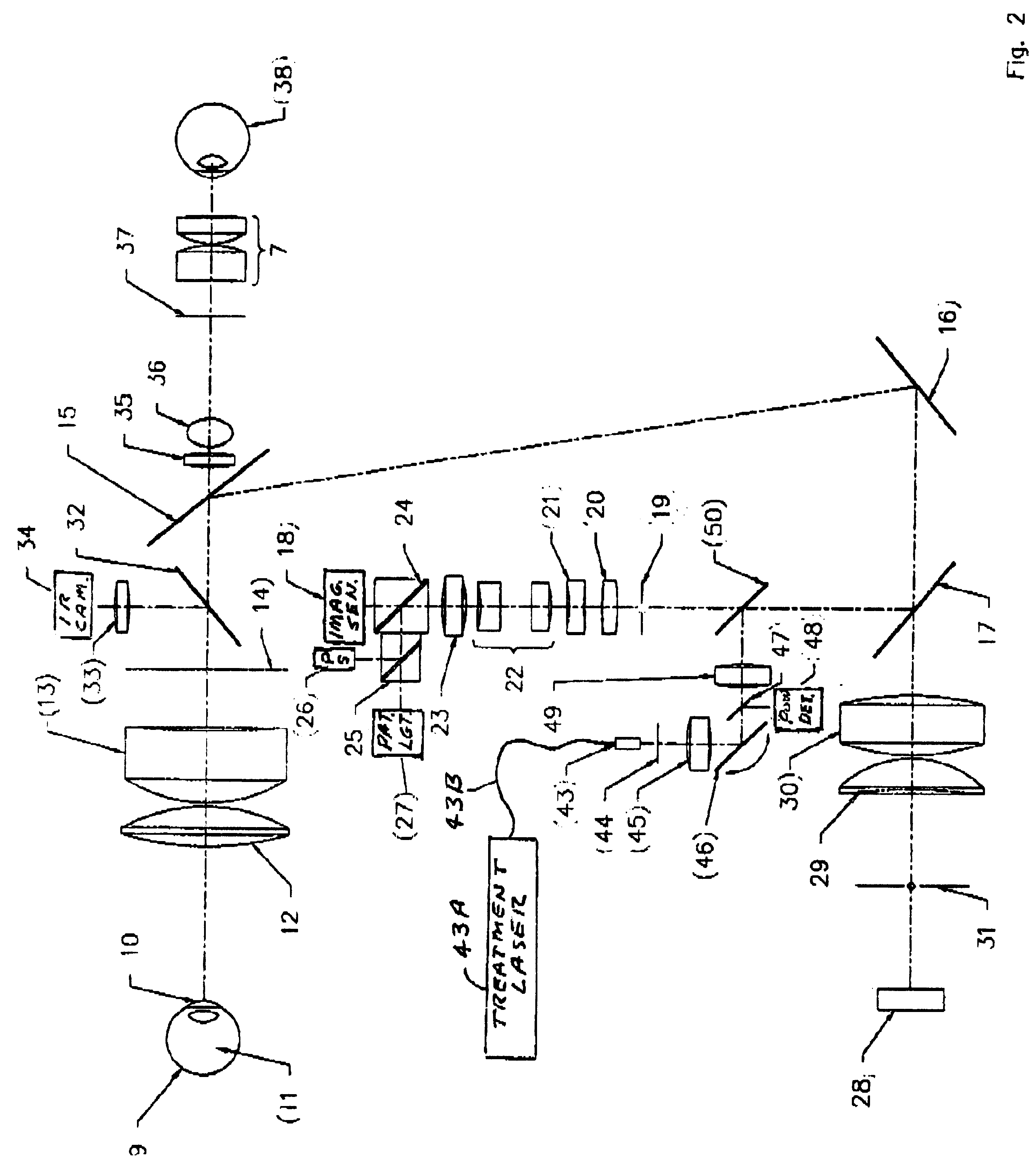

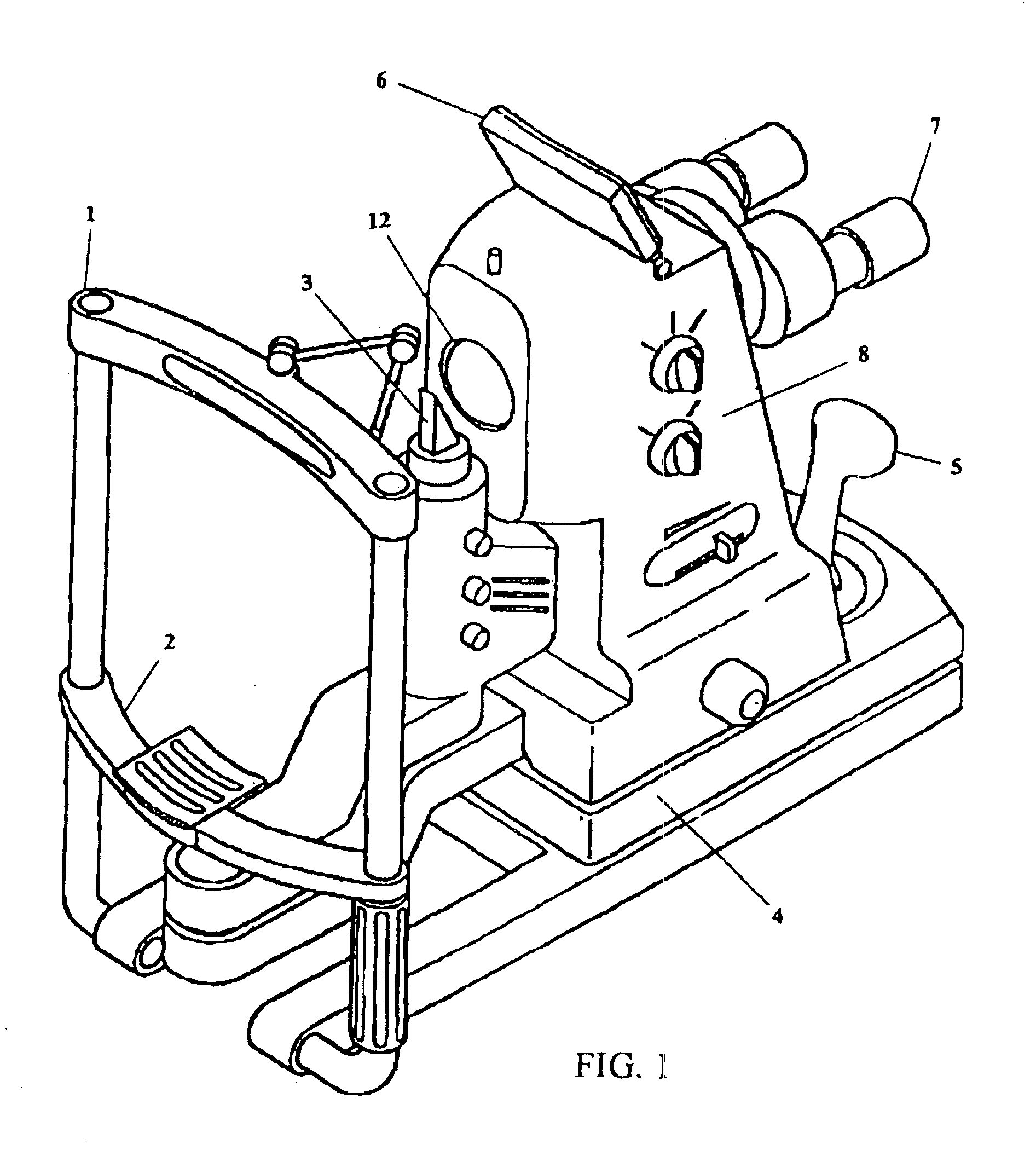

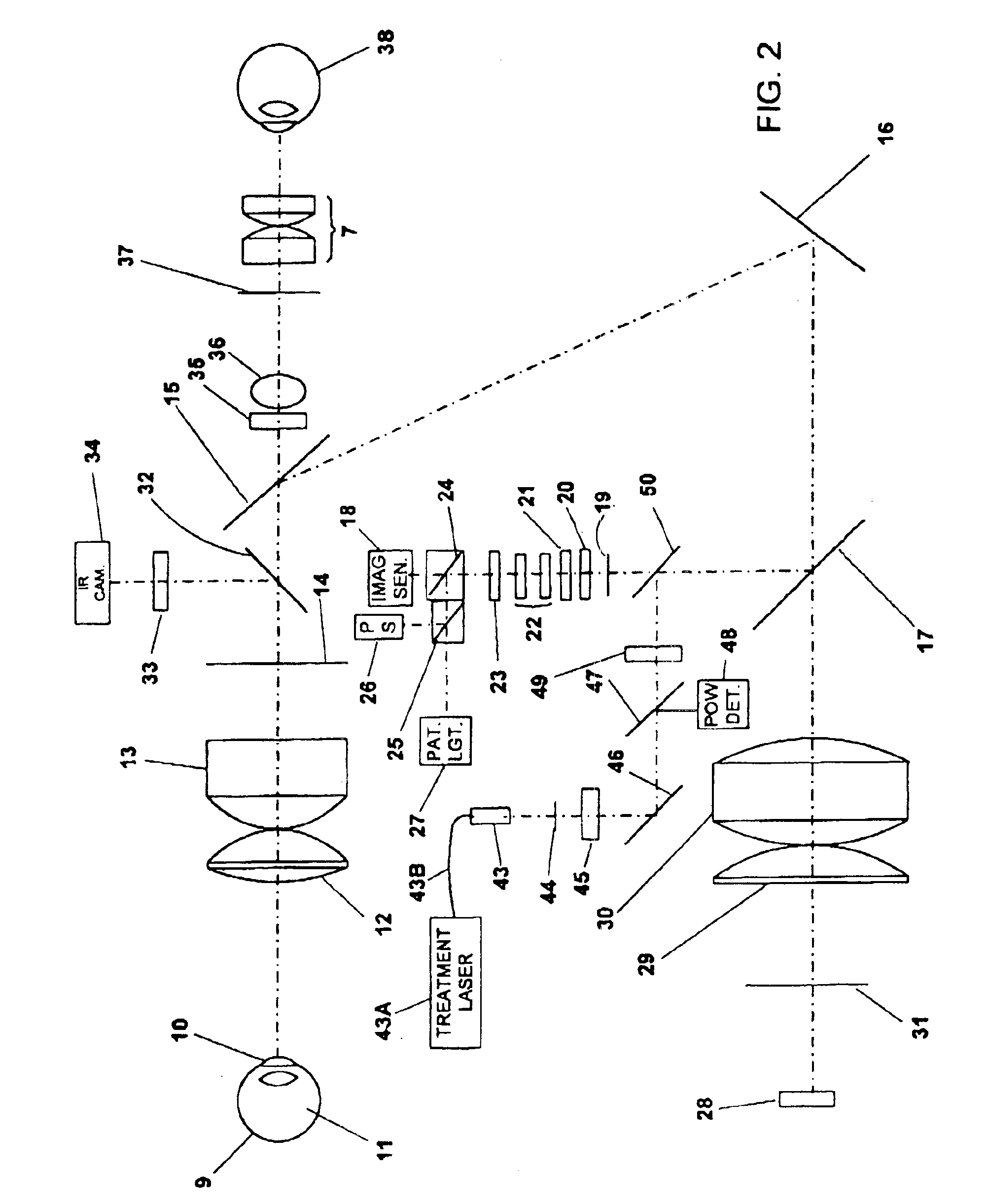

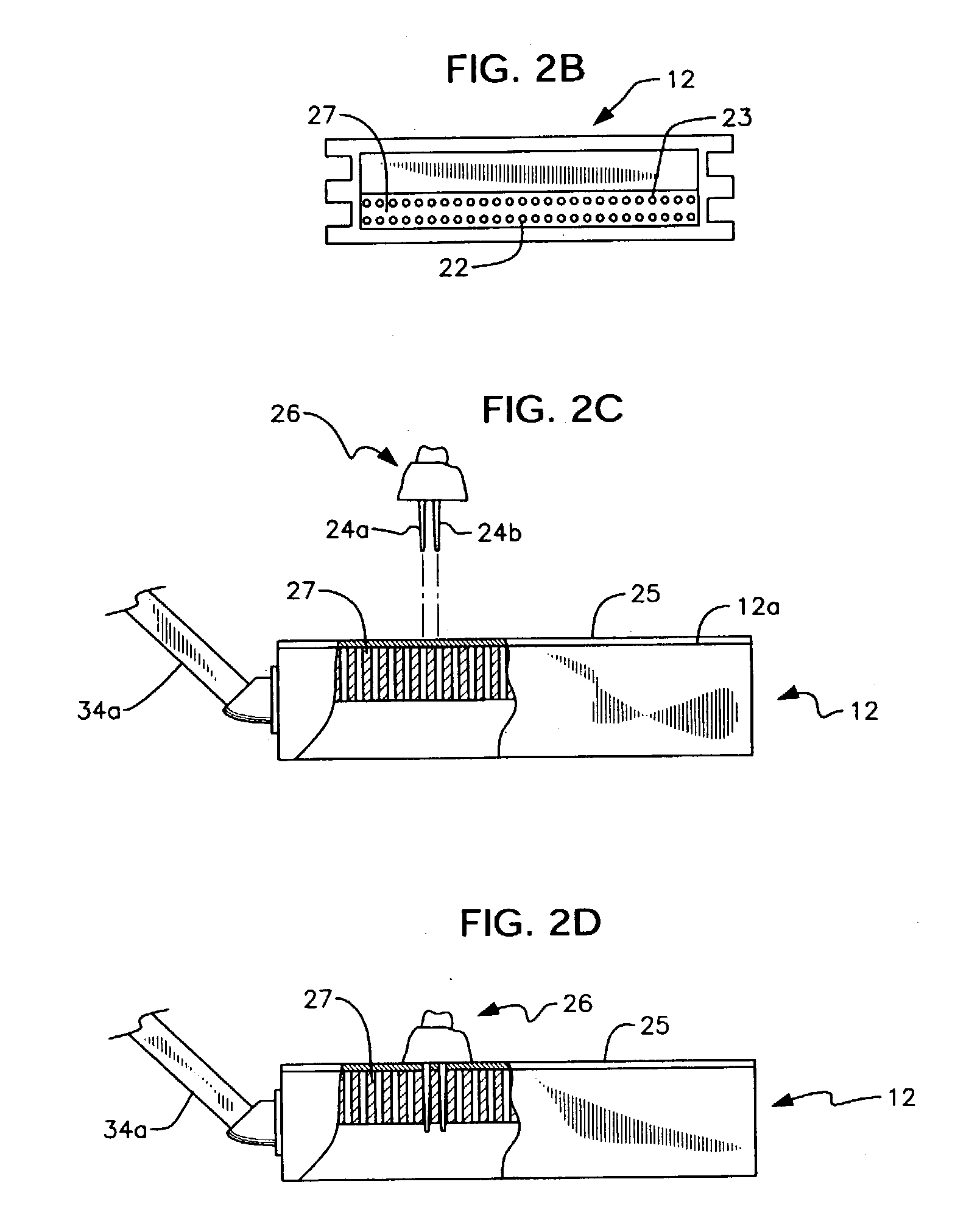

InactiveUS6361167B1High resolutionIncrease contrastLaser surgerySurgical instrument detailsEyepieceRetina

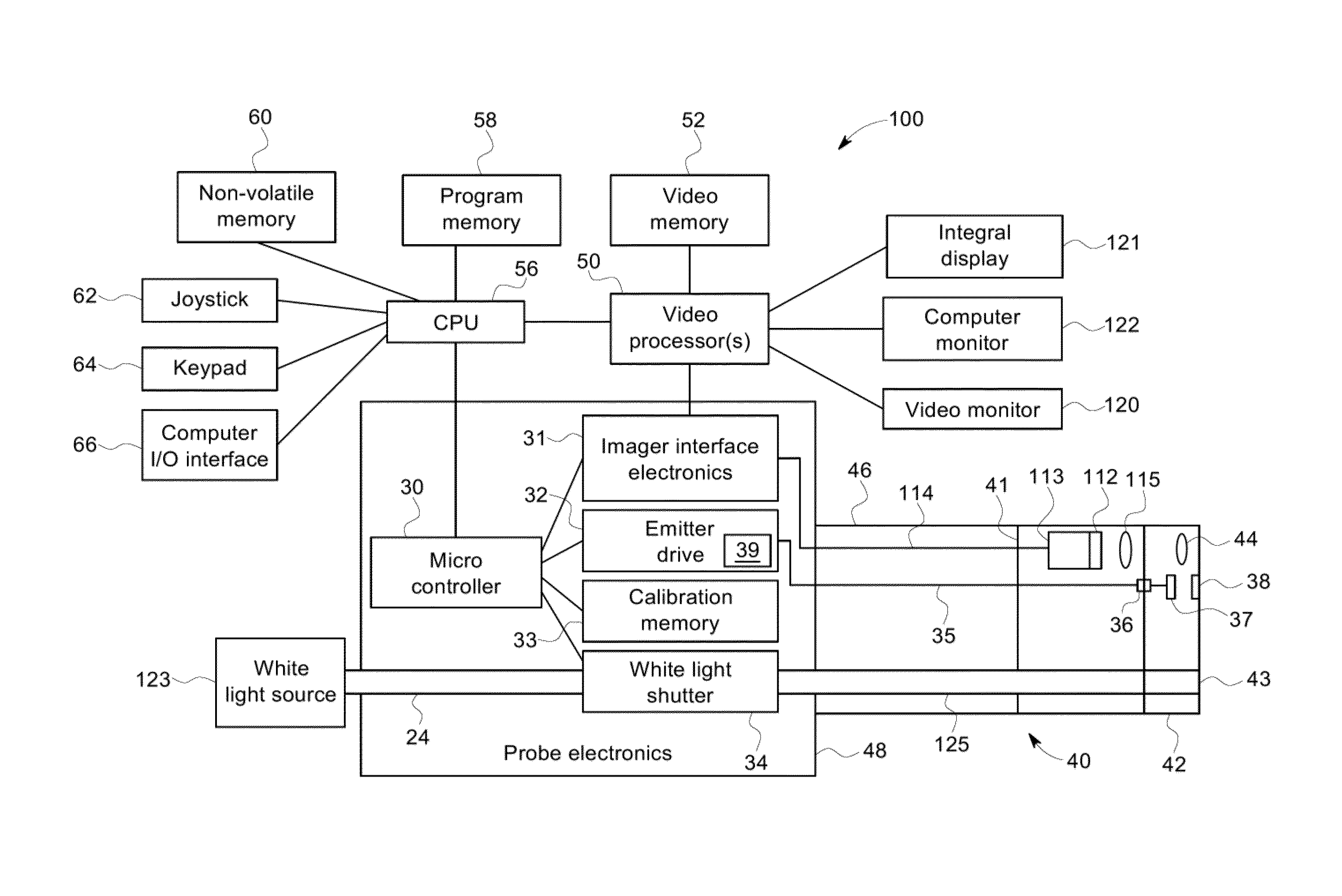

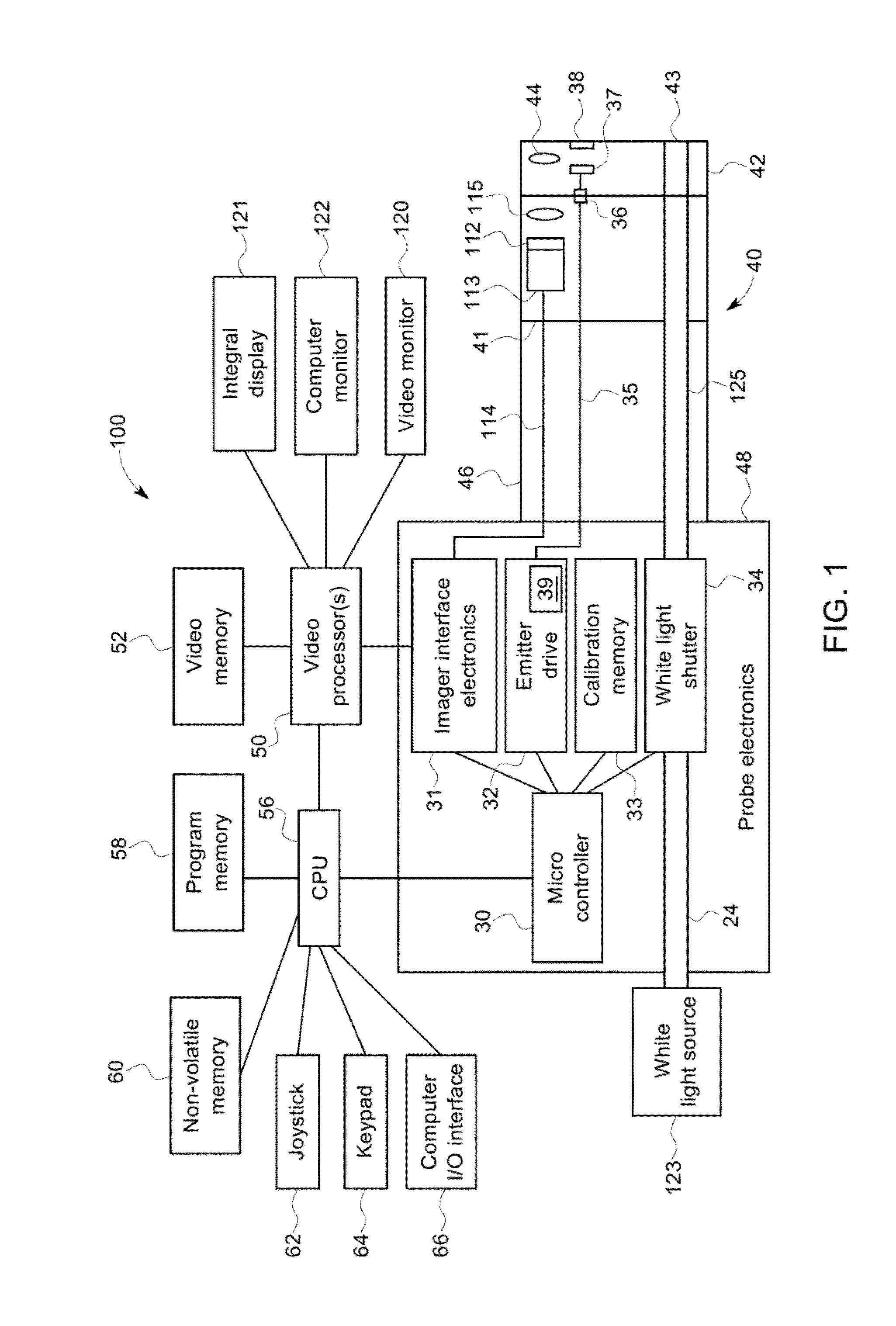

A digital camera that combines the functions of the retinal camera and corneal camera into one, single, small, easy to use instrument. The single camera can acquire digital images of a retinal region of an eye, and digital images of a corneal region of the eye. The camera includes a first combination of optical elements for making said retinal digital images, and a second combination of optical elements for making said corneal digital images. A portion of these elements are shared elements including a first objective element of an objective lens combination, a digital image sensor and at least one eyepiece for viewing either the retina or the cornea. The retinal combination also includes a first changeable element of said objective lens system for focusing, in combination with said first objective element, portions or all of said retinal region at or approximately at a common image plane. The retinal combination also includes a retinal illuminating light source, an aperture within said frame and positioned within said first combination to form an effective retinal aperture located at or approximately at the lens of the eye defining an effective retinal aperture position, an infrared camera for determining eye position, and an aperture adjustment mechanism for adjusting the effective retinal aperture based on position signals from said infrared camera. The cornea combination of elements includes a second changeable element of said objective lens system for focusing, in combination with said first objective element, portions or all of said cornea region at or approximately at a common image plane.

Owner:CLARITY MEDICAL SYST

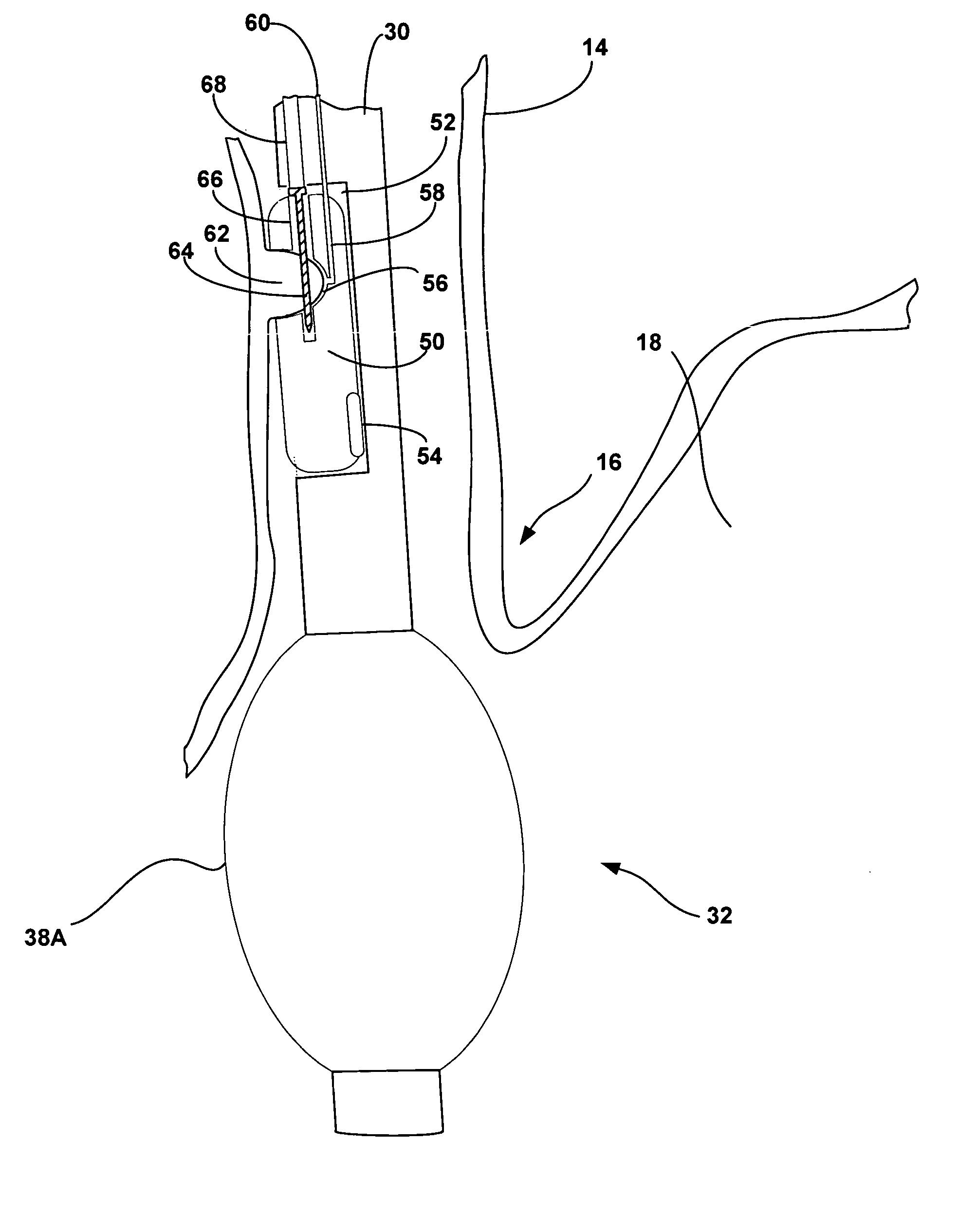

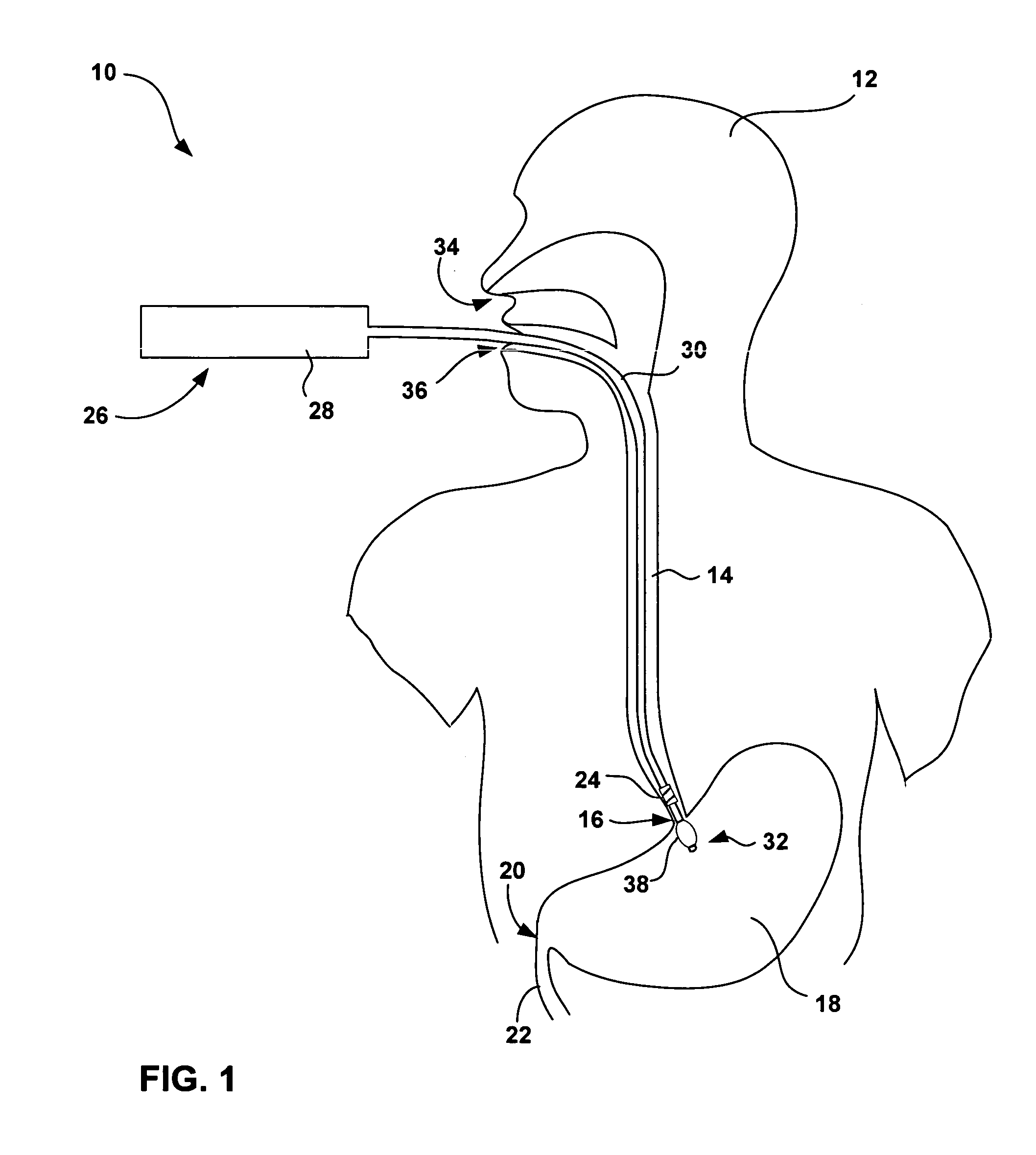

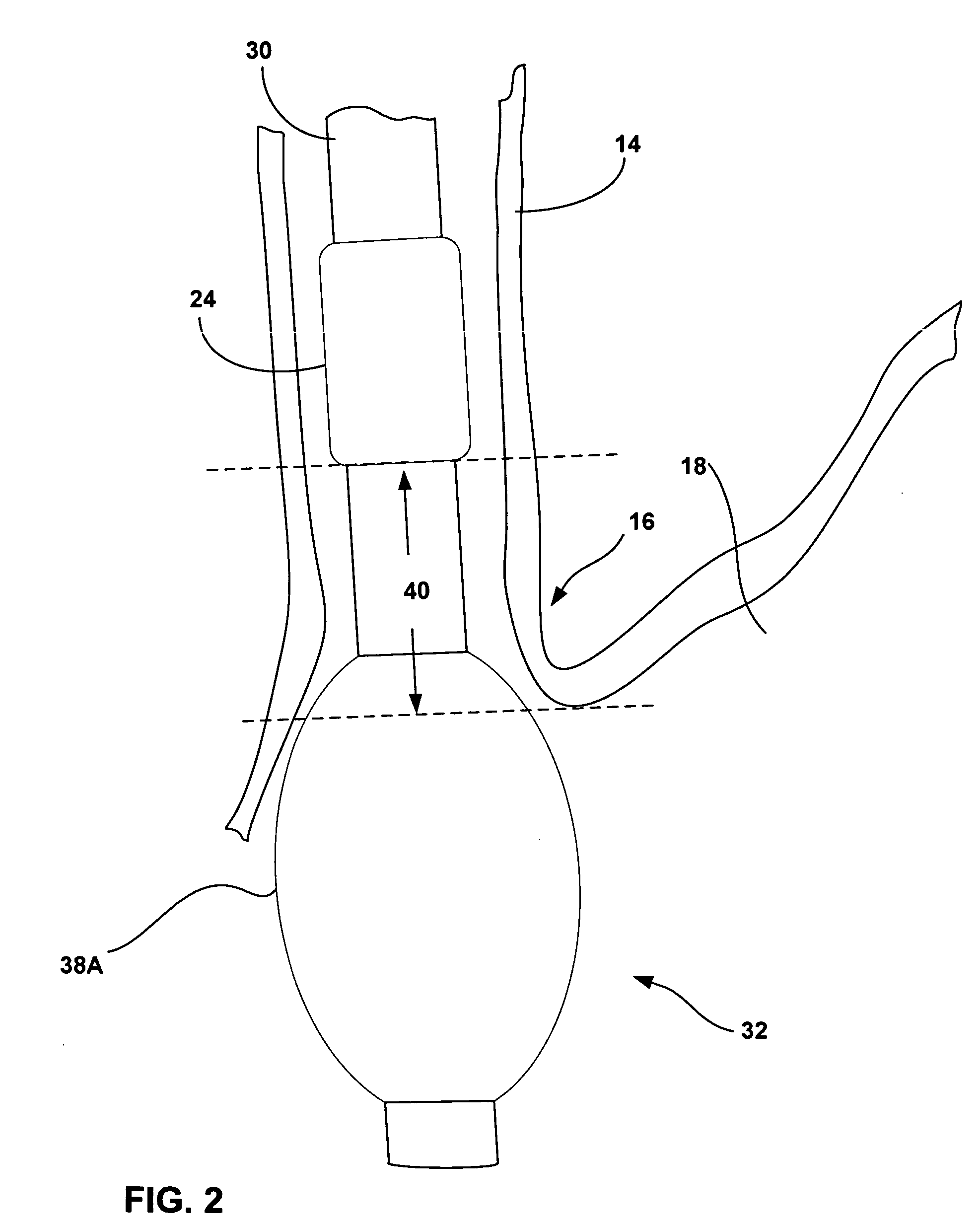

Esophageal delivery system and method with position indexing

InactiveUS20050245788A1Precise positioningQuick and convenient and accurate placementGastroscopesOesophagoscopesImaging equipmentEndoscope

An esophageal delivery system includes features that facilitate the precise positioning of a medical device within the gastrointestinal tract. The system supports indexed positioning without relying solely on endoscopic viewing or external imaging equipment to identify the location of the medical device. A fixation element holds an elongated delivery device at a selected position within the gastrointestinal tract. The medical device is carried at a position that is a fixed and known distance away from the fixation element. Once the fixation element is positioned at a known location, precise positioning of the medical device within the esophagus can be achieved with greater certainty. As an illustration, the fixation element may take the form of a balloon an expandable frame or other device capable of engaging the lower esophageal sphincter (LES) to provide a reference position for a medical device to be placed at a precise distance above the LES.

Owner:MEDTRONIC INC

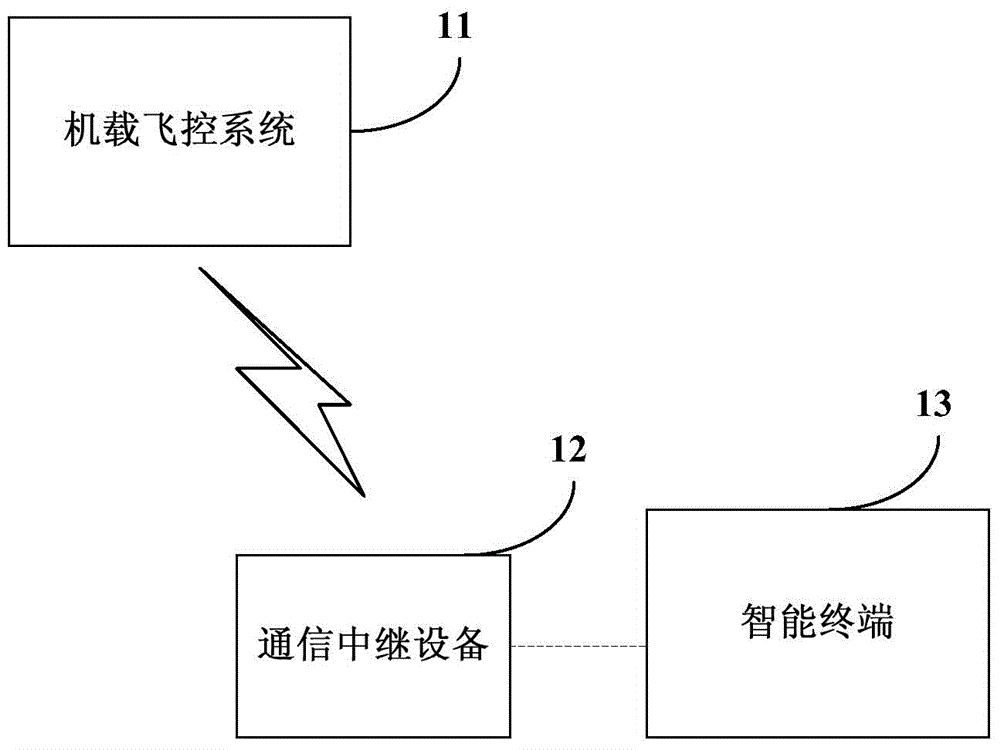

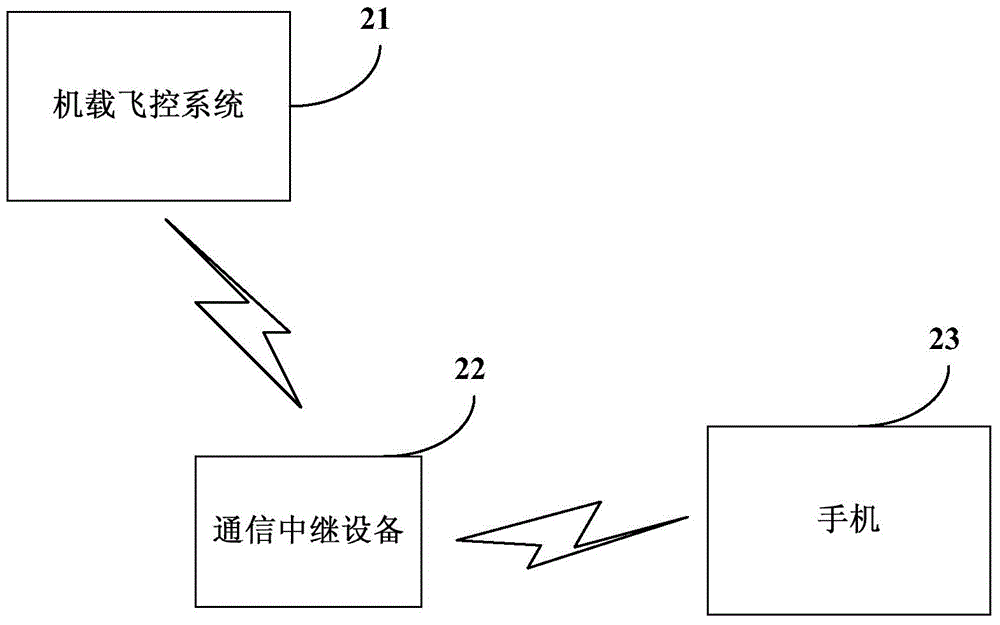

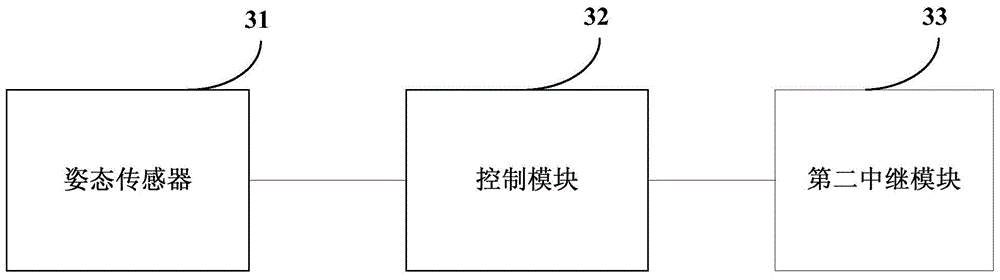

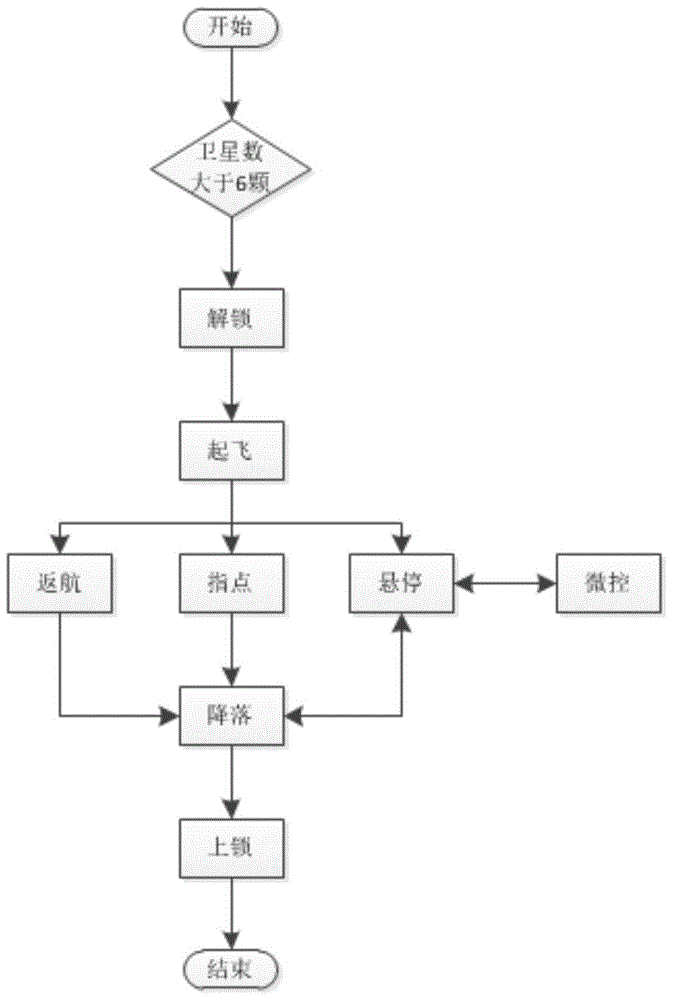

Intelligent terminal-based somatosensory flight operation and control system and terminal equipment

ActiveCN104808675ASimple and easy flight controlAchieve beyond visual range flightAircraft componentsTelemetry/telecontrol selection arrangementsControl systemFlight vehicle

The invention discloses an intelligent terminal-based somatosensory flight operation and control system and terminal equipment. The somatosensory flight operation and control system comprises an airborne flight control system, communication relay equipment and the intelligent terminal, wherein the intelligent terminal is used for acquiring attitude information of the intelligent terminal, generating a flight instruction according to the attitude information, and sending the flight instruction to the airborne flight control system via the communication relay equipment; the attitude information at least comprises a yaw angle of the intelligent terminal; the flight instruction at least carries the yaw angle for indicating the airborne flight control system to control an aircraft where the airborne flight control system is located to fly at the yaw angle; and the airborne flight control system is used for controlling flight of the aircraft according to the flight instruction. Thus, a multi-rotor aircraft is convenient to operate and control, and beyond visual range flight is facilitated.

Owner:GUANGZHOU EHANG INTELLIGENT TECH

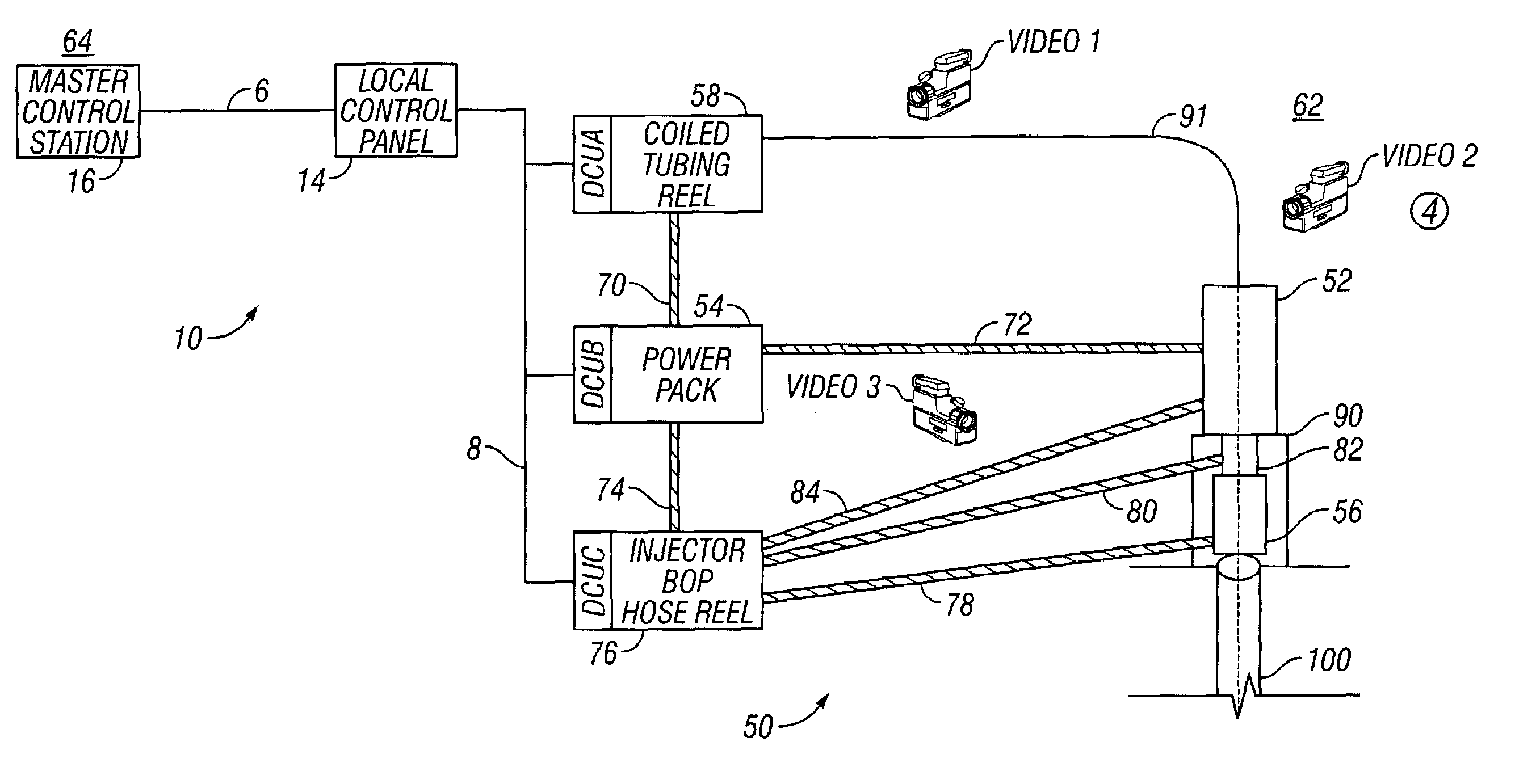

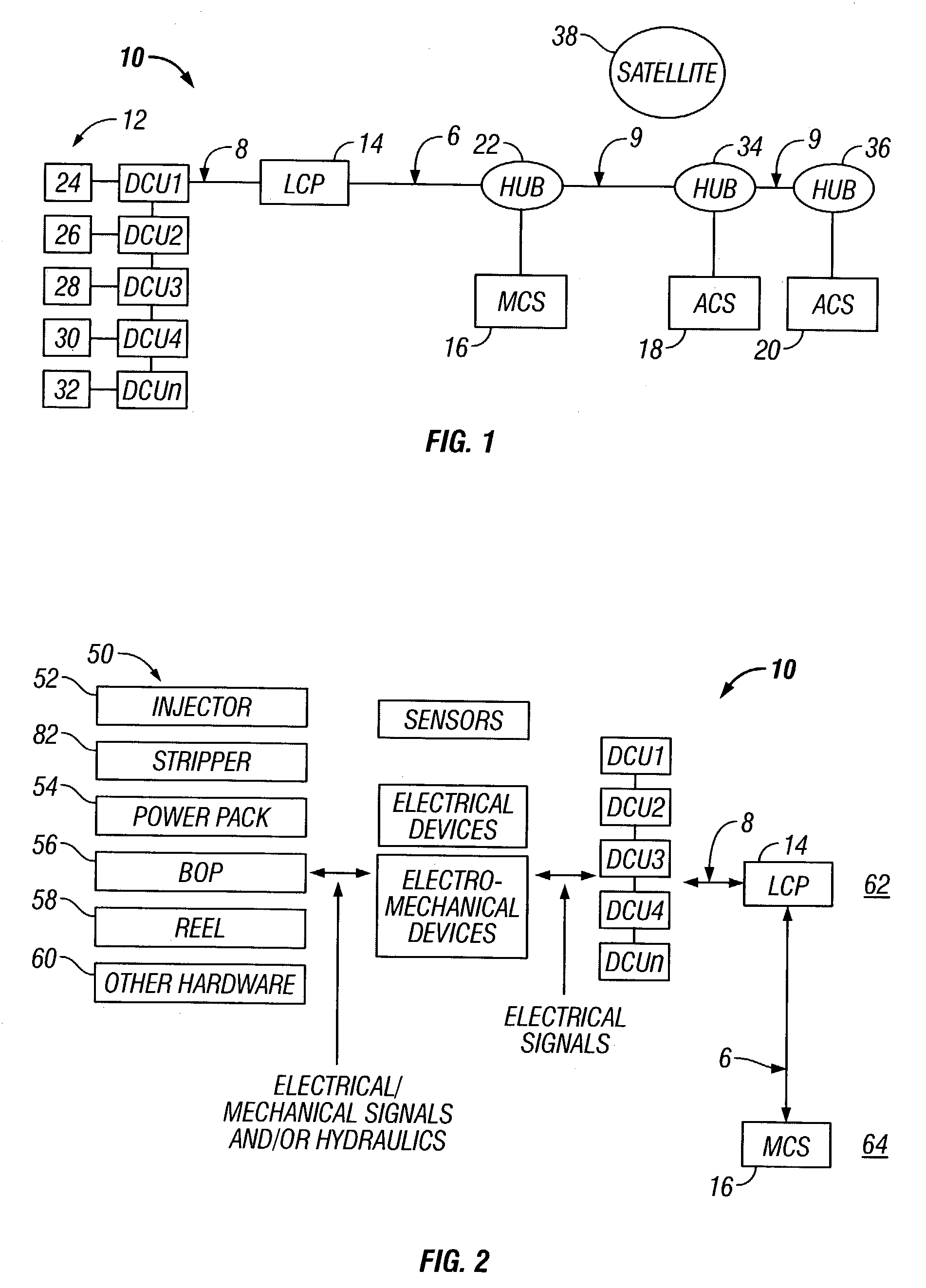

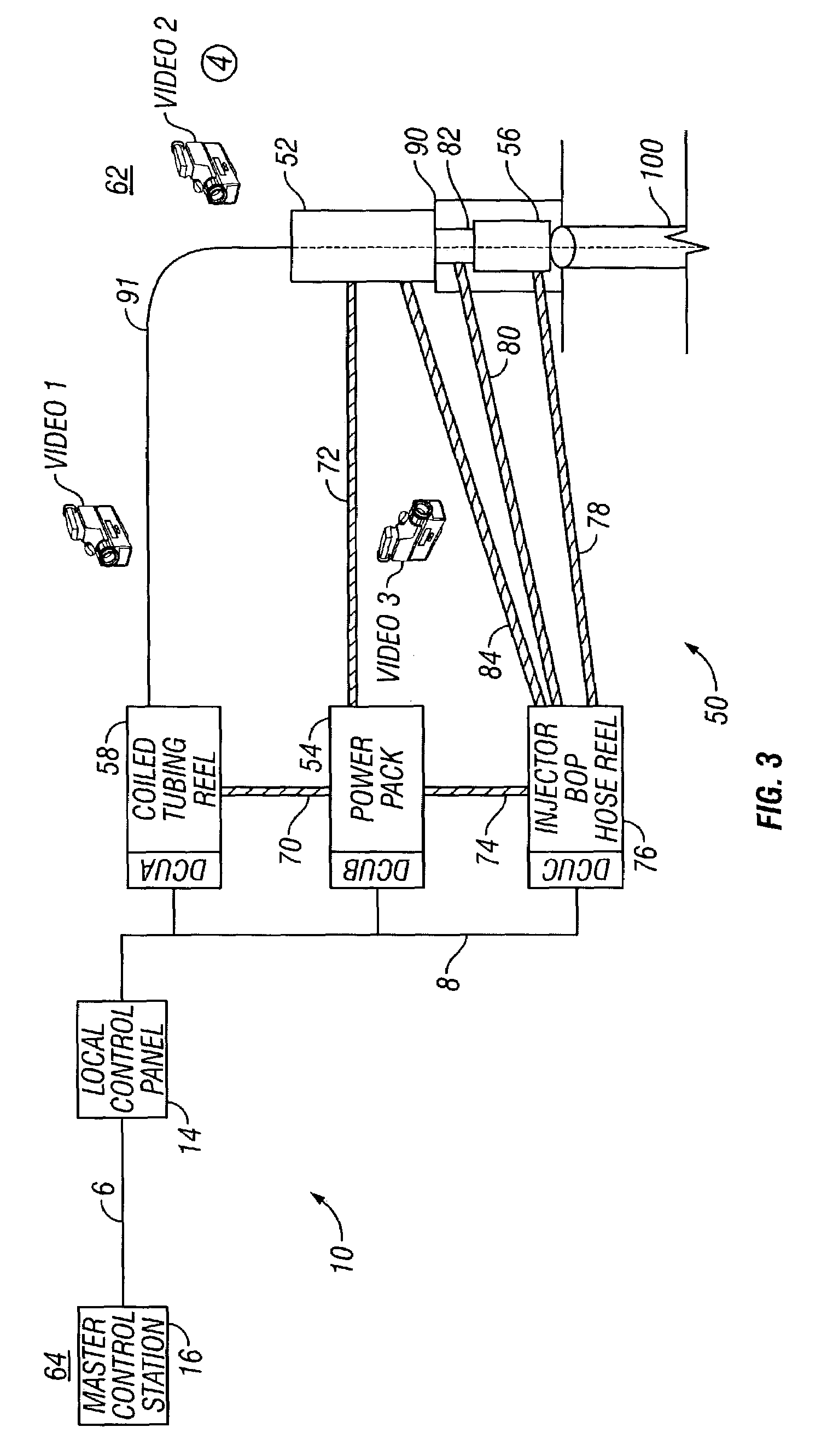

Distributed control system

InactiveUS6968905B2Improve securityLow skill levelDrilling rodsDigital data processing detailsNon real timeArea network

A distributed control system for local or remote control of equipment. The distributed control system provides a communication bridge through a local control panel between a non-real-time network, and a real-time network, such as a controller area network. Both soft real-time and hard real-time networks are suitable, but hard real-time is preferred. Multiple distributed control units are used to control various equipment components. The distributed control system may be applied in any environment. The distributed control system may be applied to a skid-mounted coiled tubing unit.

Owner:SCHLUMBERGER TECH CORP

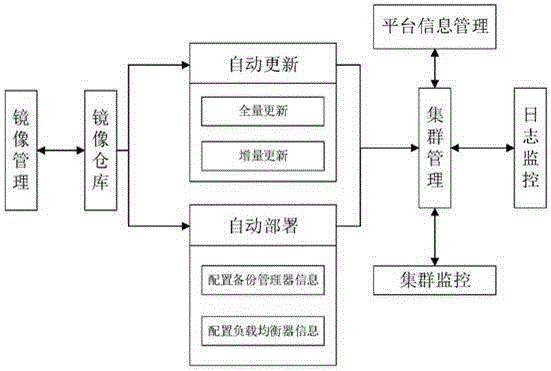

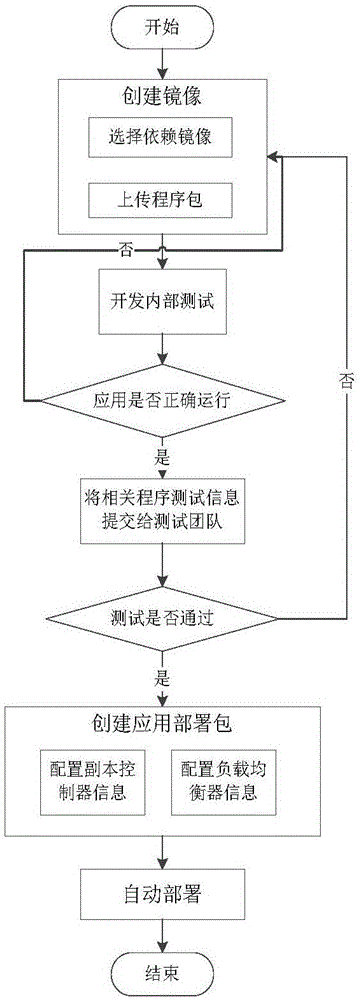

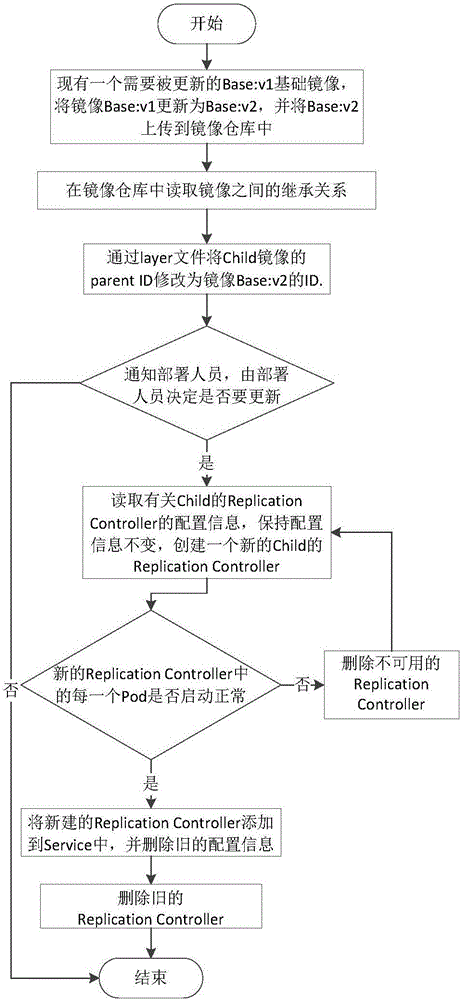

Development, testing, operation and maintenance integration system, deployment and full-quantity and incremental updating method

ActiveCN106293820ARealize integrationImplement automatic deploymentSoftware testing/debuggingProgram loading/initiatingApplication softwareMirror image

The invention discloses a development, testing, operation and maintenance integration system, deployment and a full-quantity and incremental updating method. The system comprises an automatic deployment module and an automatic updating module, wherein the automatic deployment module configures corresponding backup controller information and load balancer information according to mirror images in a mirror image warehouse at a developer end, automatically generates an application deployment script, and automatically / manually spreads the application deployment script to a testing deployment end; the testing deployment end automatically deploys an application to the testing, operation and maintenance environment by executing an application deployment script file, the automatic updating module updates an application program according to the mirror images in the mirror image warehouse at the developer end, generates an update pack file in a full-quantity or incremental updating mode and automatically / manually spreads the update pack file to the testing deployment end; the testing deployment end automatically deploys the updated application to the testing, operation and maintenance environment by executing the update pack file. Cooperation obstacles among development, testing, operation and maintenance are reduced, the cooperation efficiency is improved, application deployment processes are simplified, a developer pays close attention to business flows, and the requirement for technological levels of operation and maintenance staffs is lowered.

Owner:SHANDONG UNIV

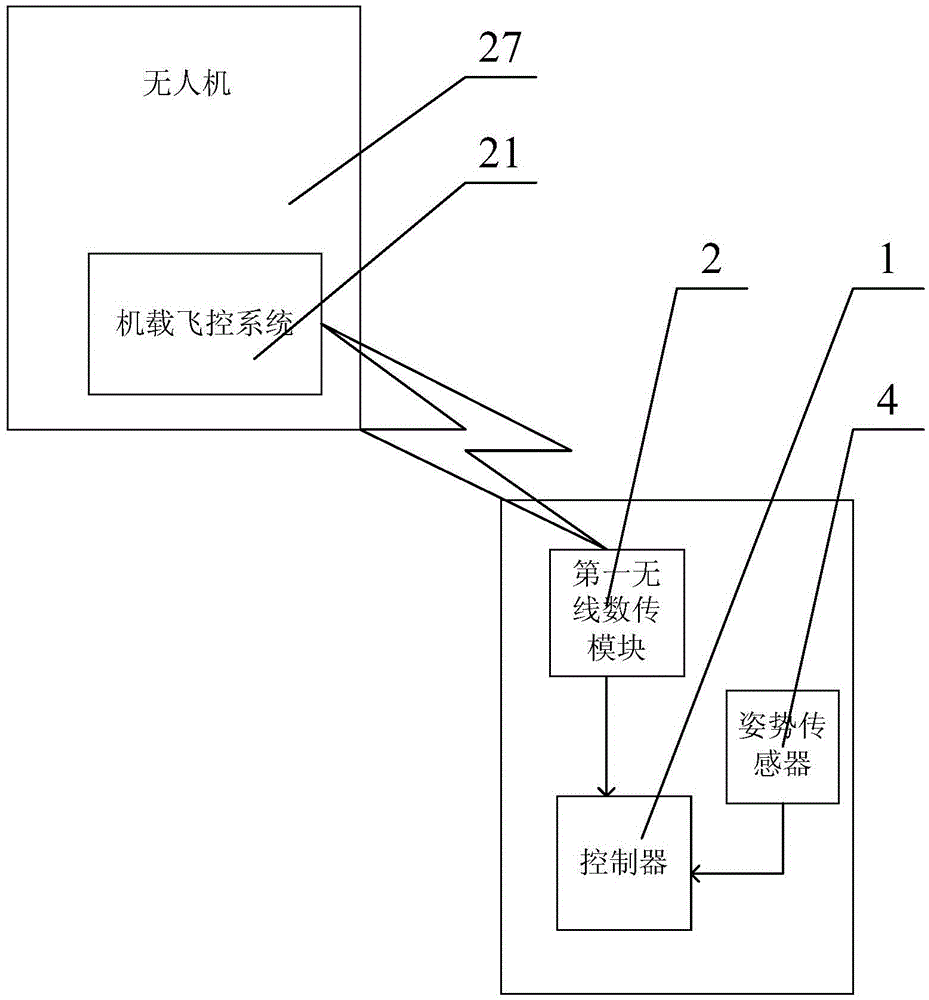

Somatosensory remote control and somatosensory remote control flying system and method

ActiveCN105469579AEasy to controlLow skill level requiredTransmission systemsAttitude controlElectricityRemote control

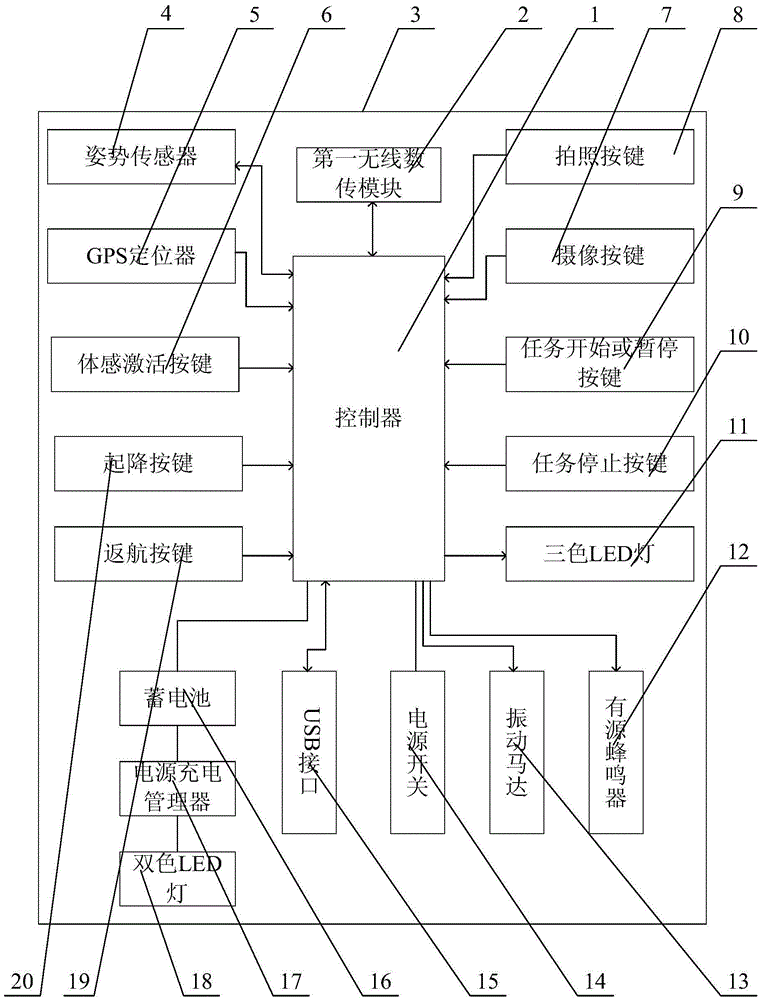

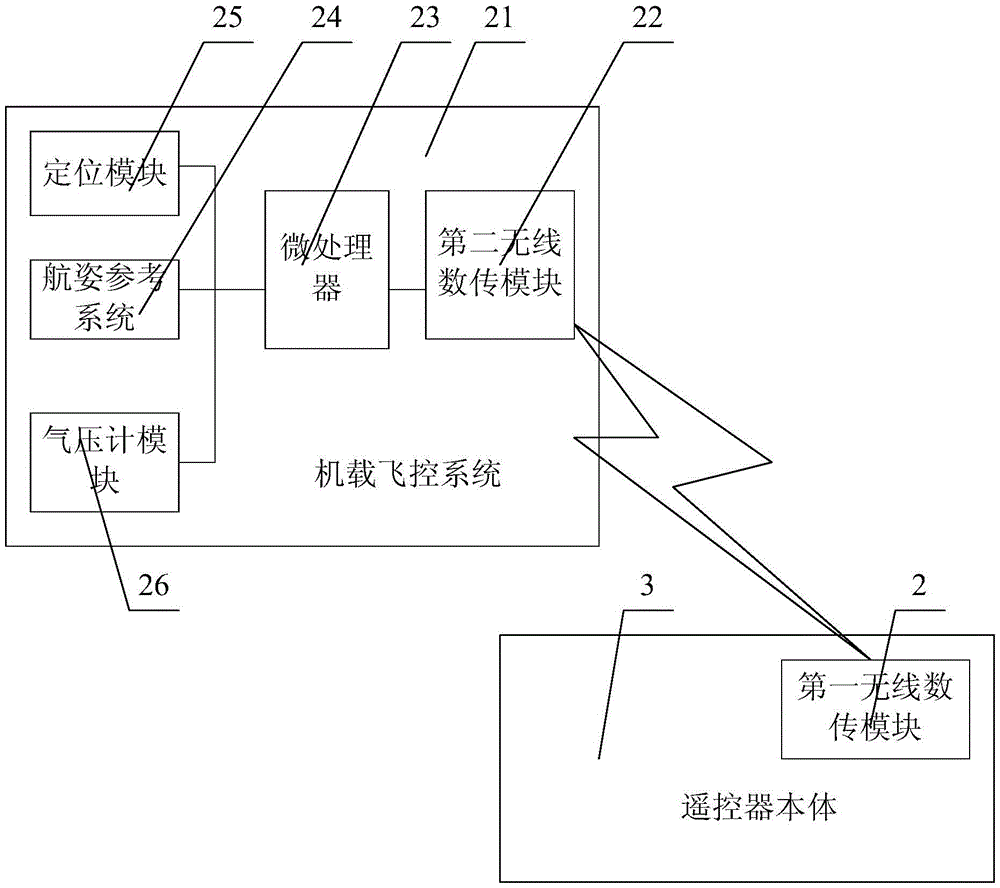

The invention relates to the technical field of electronic equipment, in particular to a somatosensory remote control and a somatosensory remote control flying system and method. The somatosensory remote control comprises a posture sensor, a controller, a first wireless data transmission module and a remote control body, wherein the posture sensor, the first wireless data transmission module and the controller are all arranged on the remote control body, the posture sensor and the first wireless data transmission module are both electrically connected with the controller, the posture sensor is used for acquiring the initial state information of the current position of the remote control body and the moving information of the remote control body and transmitting the information to the controller, the controller is used for acquiring a flying instruction according to the initial state information and the moving information, and the flying instruction is sent out through the first wireless data transmission module. Due to the fact that any position can serve as the center point of the somatosensory remote control, the requirement for the technical skill of an operator is reduced, and operation is facilitated for the operator.

Owner:POWERVISION ROBOT INC

Method and system for detecting known measurable object features

ActiveUS20150317816A1Improve efficiencyLow skill level requiredImage enhancementTelevision system detailsRadiologyNuclear medicine

A method and system for detecting a known measurable object feature using a video inspection system. The method and system displays an image of a viewed object and detects a known measurable object feature on the viewed object. The method and system then displays a set of available measurement types including a measurement type associated with the detected known measurable object feature and / or automatically positions a plurality of measurement markers on the displayed image based on the measurement type associated with the detected known measurable object feature.

Owner:BAKER HUGHES INC

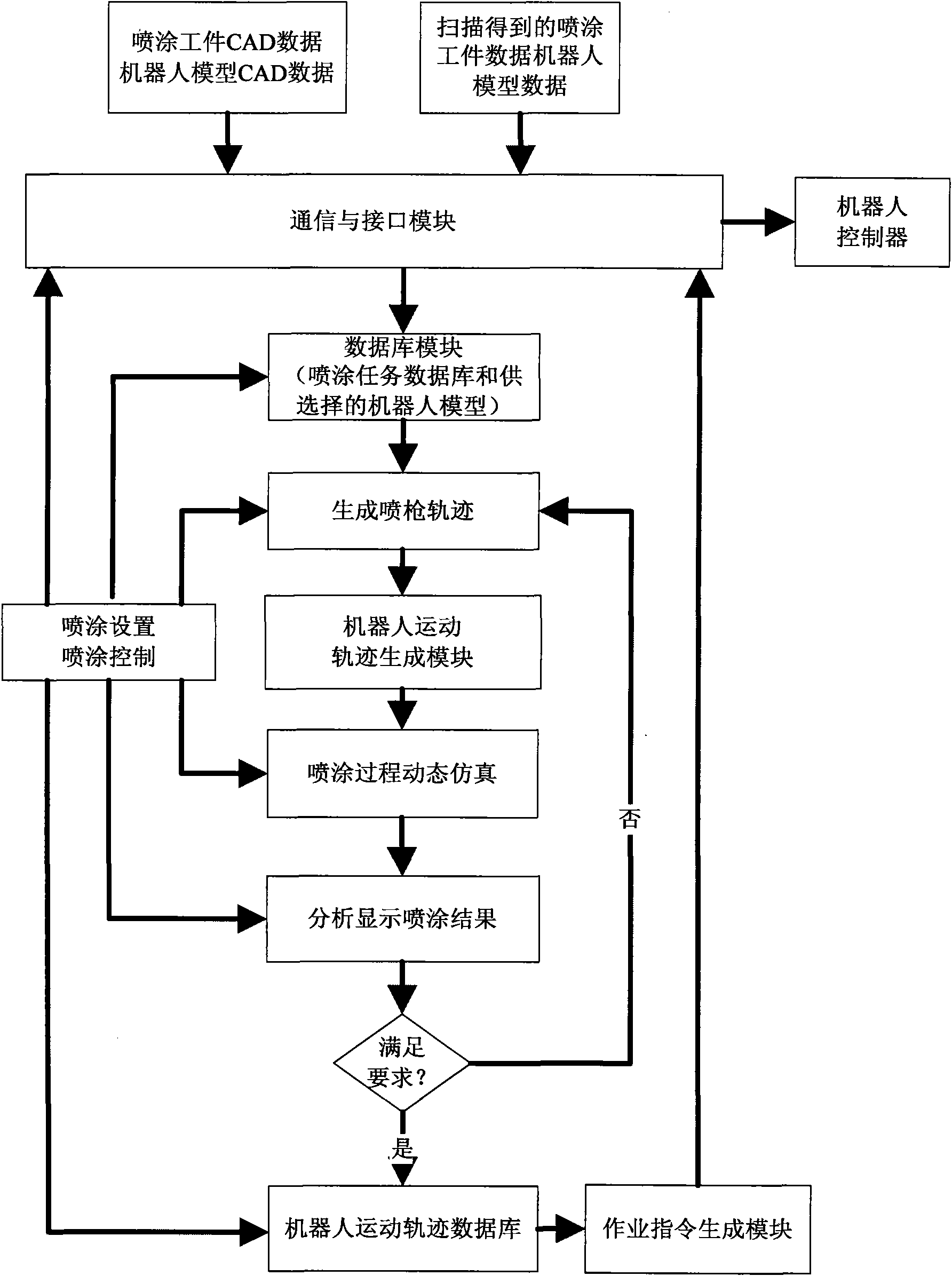

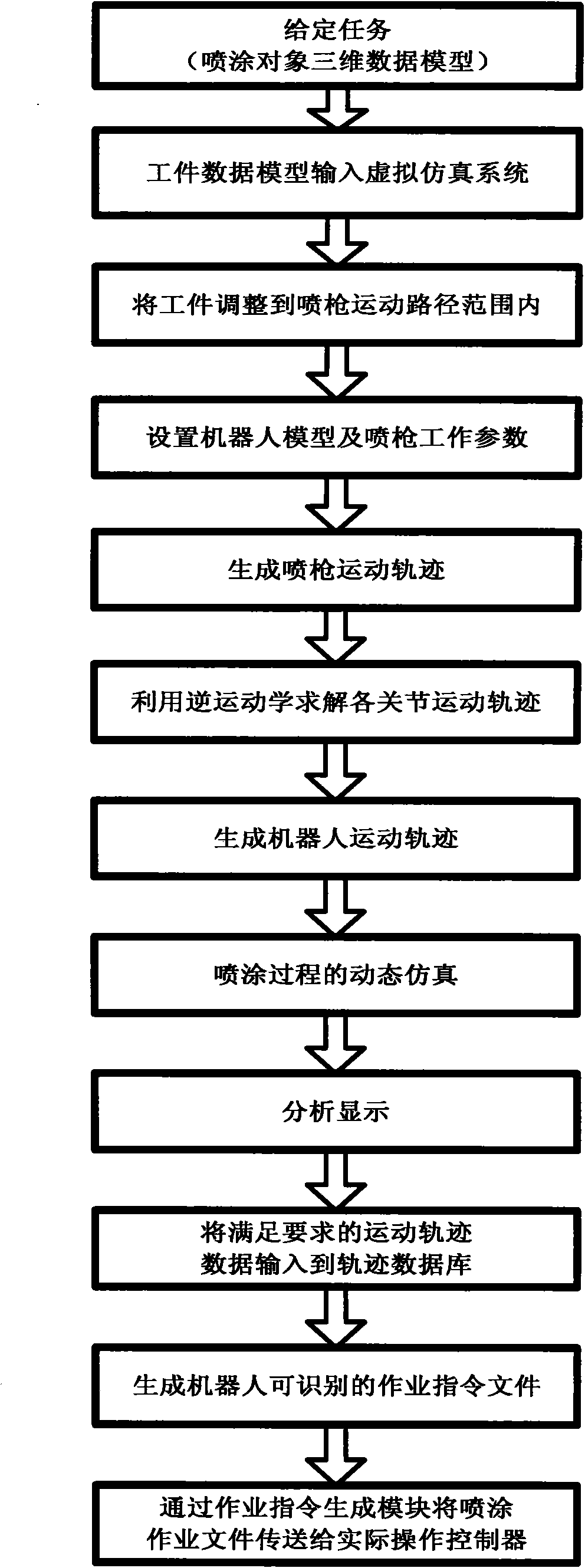

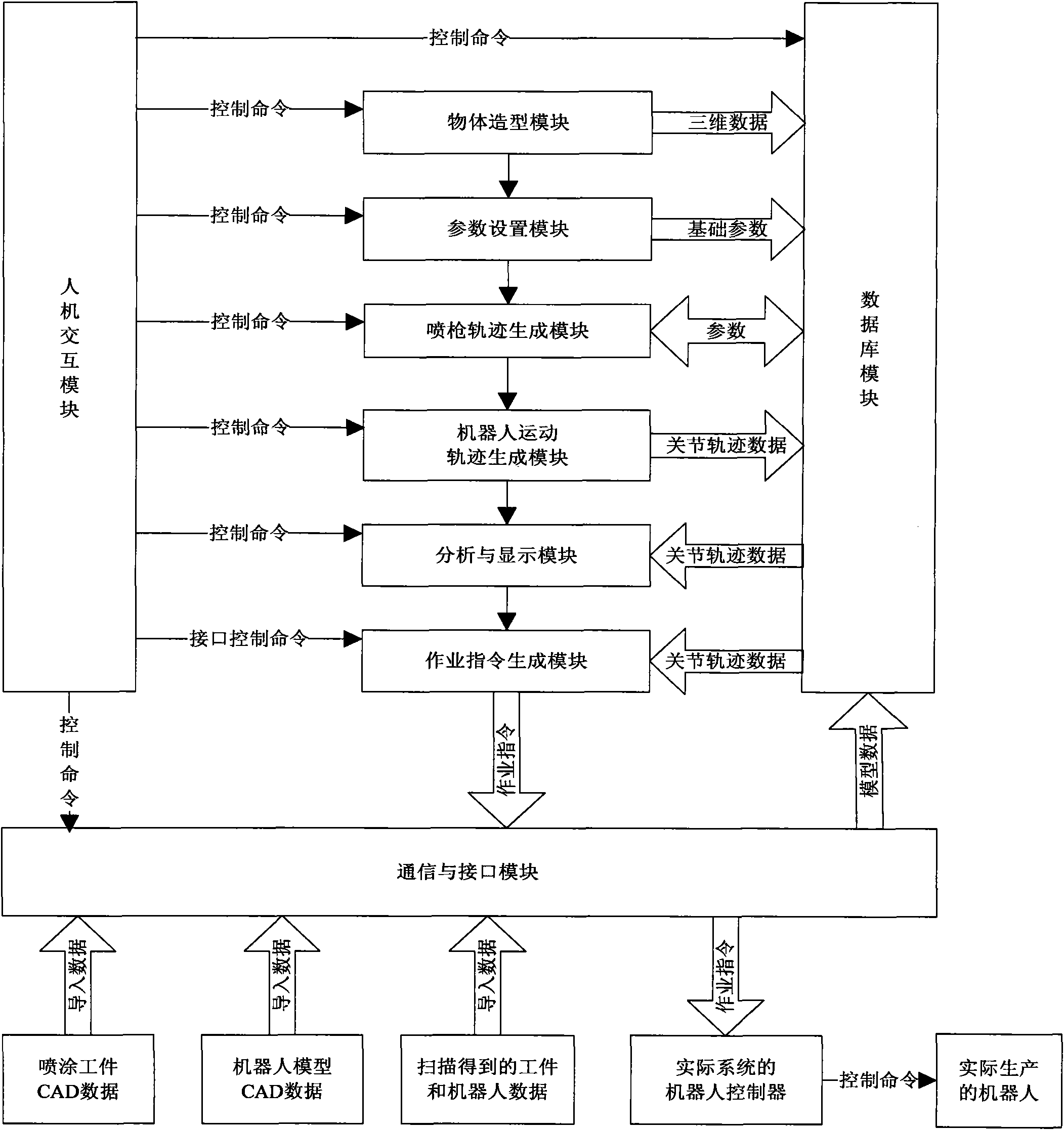

Industrial robot comprehensive control platform and control method thereof

InactiveCN101850552AReduce in-circuit debugging timeDoes not take up working timeManipulatorProduction ratePath generation

The invention relates to an industrial robot comprehensive control platform and a control method thereof. The industrial robot comprehensive control platform comprises an object modeling module, a parameter setting module, a database module, a spray gun path generation module, a robot motion path generation module, a man-machine interaction module, an analysis and display module, an operation command generation module and a communication and interface module. The invention has the advantages that the functions are complete, the commonality is high, the robot program development cycle is shortened, the painting accuracy of the system is improved, the production cost is reduced, the production efficiency is improved, the requirements on the technical capability of operators are reduced, the economic benefit is high and the platform can be easily accepted by users.

Owner:GUANGDONG UNIV OF TECH

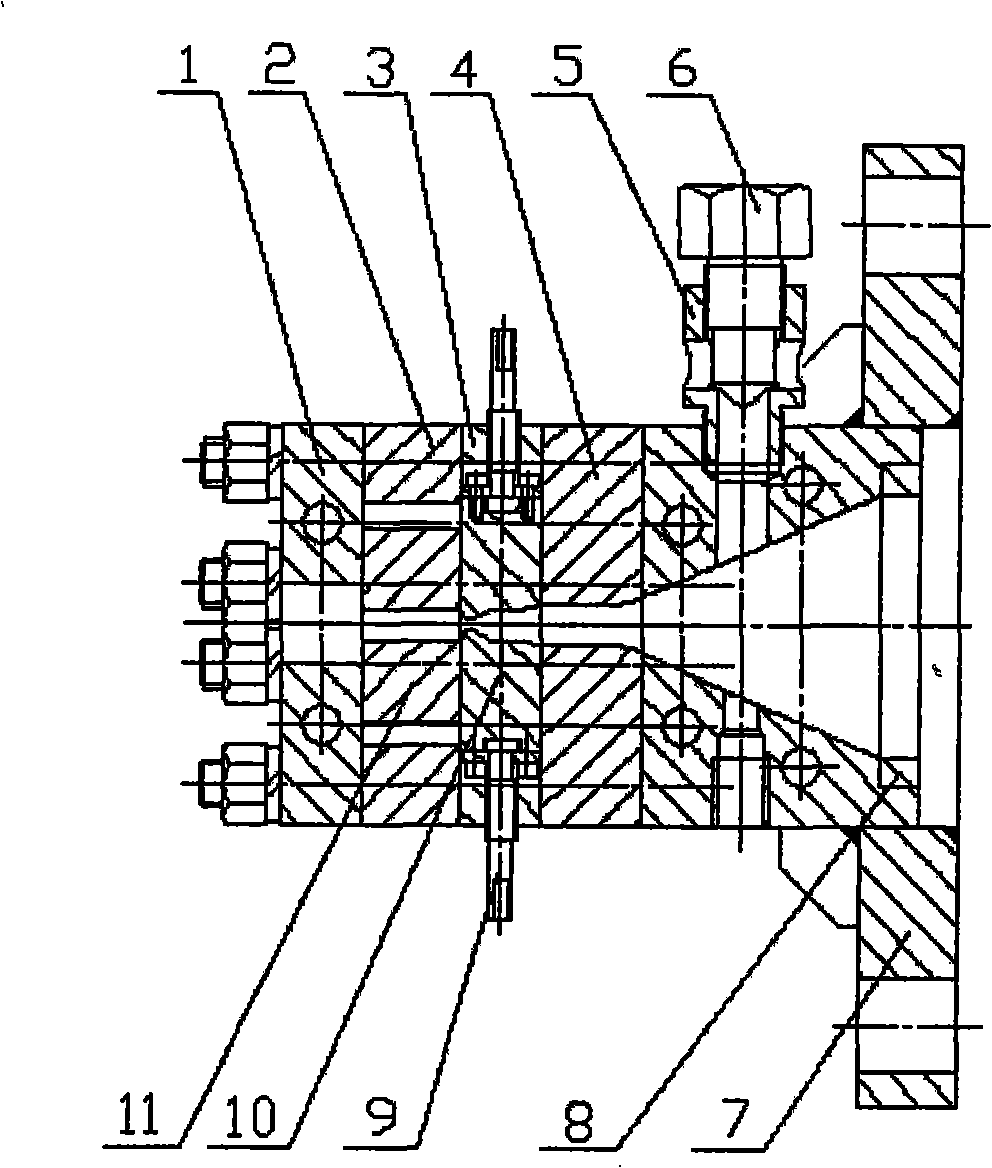

Method for extruding and forming short fiber reinforced-rubber composite material in radial direction

The invention relates to a short fiber reinforced rubber composite material radial orientation extrusion molding method and the procedures are as follows: at first, rubber molten mass containing short fiber is carried out with the extrusion processing in an extruder; at the end of the screw rod in the extruder tube, the rubber is extruded into an axial orientation channel, the flow direction of the rubber mass is adopted for orientation, and the axial orientation of the short fiber is realized in the axial orientation channel of a machine head; the rubber mass which goes through the axial orientation passes through a resistance dam formed by contracting the thickness of the channel under the function of extrusion pressure; the rubber is characterized by extrusion swelling, so the short fiber is inclined owing to rolling over after the rubber mass passes through the resistance dam; the expanded rubber mass keeps flowing along the channel, the inclined degree of the part in middle and at edge is increased owing to velocity gradient, the radial orientation of the short fiber is increased and then the radial orientation is realized. The method of the invention has the advantages of simple and easily-controlled technique procedures, wide application range, good radial orientation quality of products, and low cost.

Owner:QINGDAO UNIV OF SCI & TECH

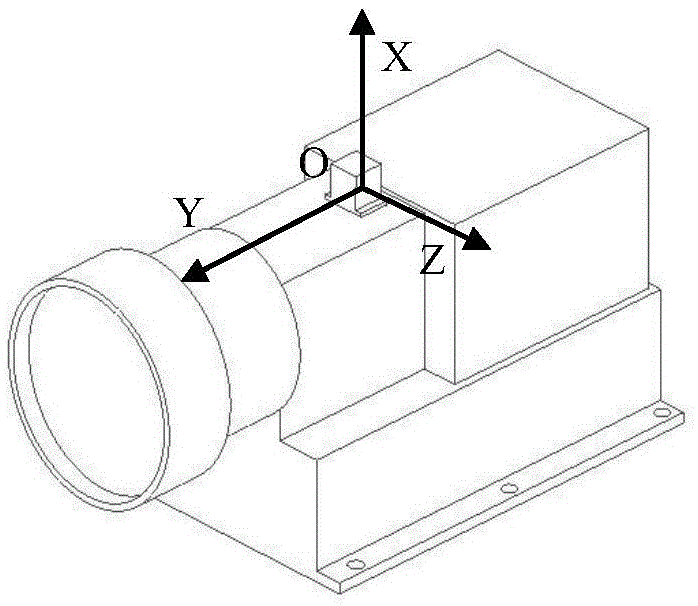

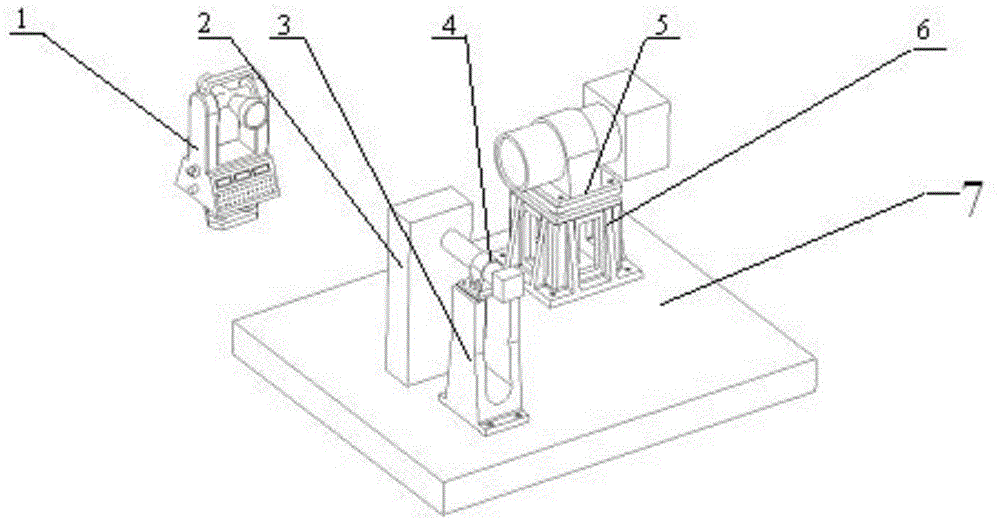

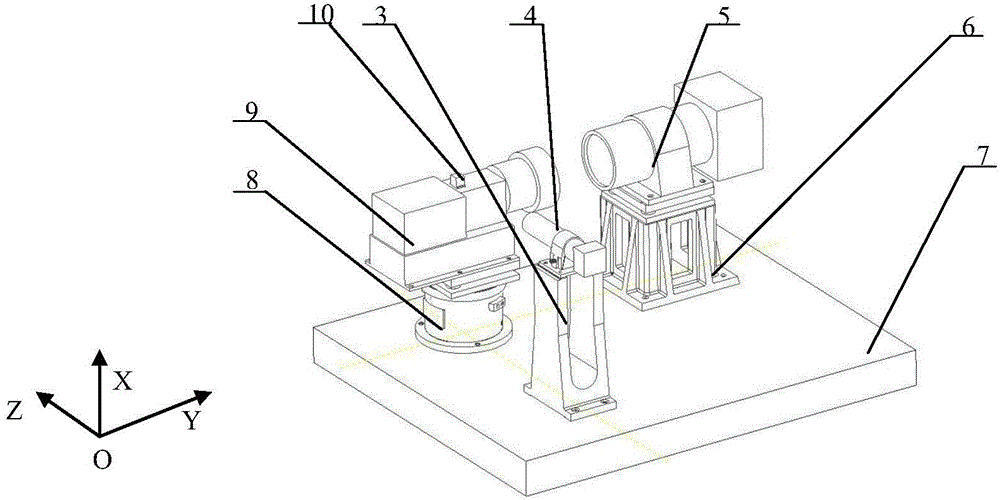

Star sensor reference cube-prism installation error calibration apparatus

ActiveCN105318891AHigh precisionQuick installation error calibrationMeasurement devicesSingle starTheodolite

The present invention belongs to the technical field of optoelectronic equipment calibration, and particularly relates to a star sensor reference cube-prism installation error calibration apparatus. According to the present invention, a photoelectric autocollimator and a single star simulator are respectively placed on two orthogonal axes of a reference plane, a detected star senor is placed at the intersection point position of the two axes so as to make the normal lines of the two orthogonal light reflection surfaces of the detected star senor reference prism be respectively parallel to the two orthogonal axes, the optical axes of the photoelectric autocollimator and the single star simulator are respectively adjusted to parallel to the reference plane through a theodolite, the star sensor is installed on a star sensor three-dimensional adjustment reference base, the input optical axis of the star sensor and the output optical axis of the single star simulator are adjusted to achieve a parallel state through the star sensor three-dimensional adjustment reference base, a detected reference cube-prism is arranged on the upper surface of the housing of the detected star senor, the installation angle error of the reference cube-prism round the X-axis and the Y-axis is measured by using photoelectric autocollimation, the star sensor three-dimensional adjustment reference base rotates 90 DEG, and the installation angle error of the reference cube-prism round the Z-axis is measured.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

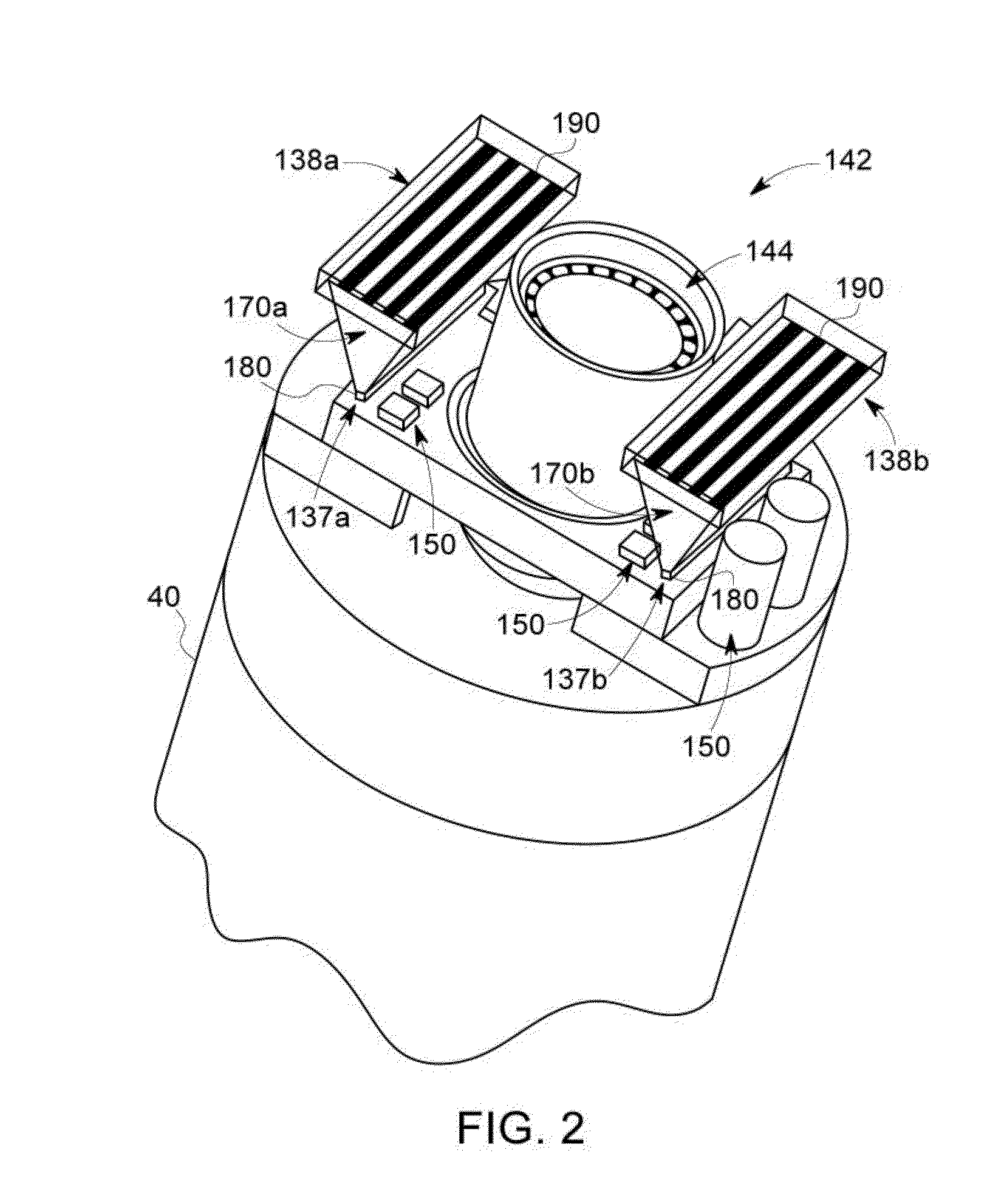

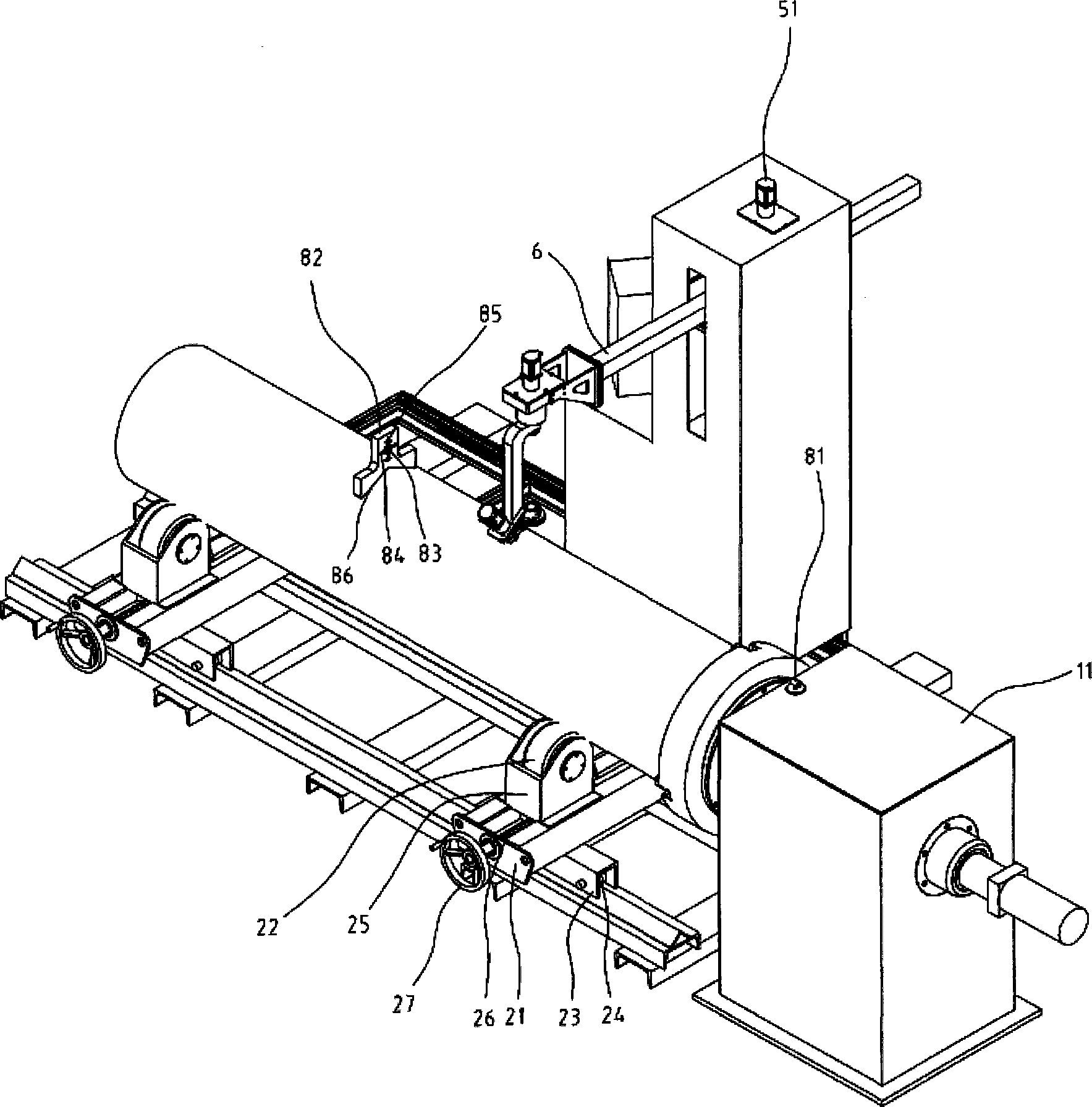

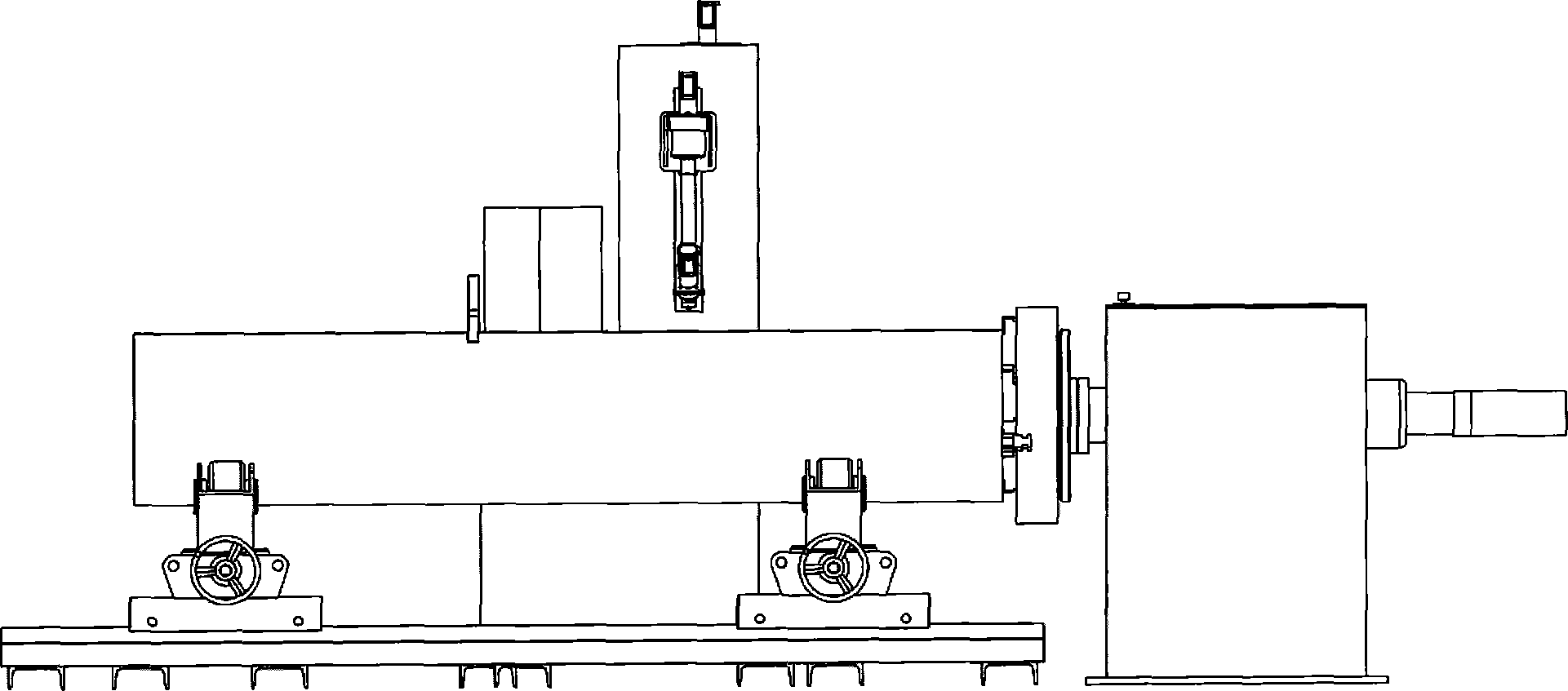

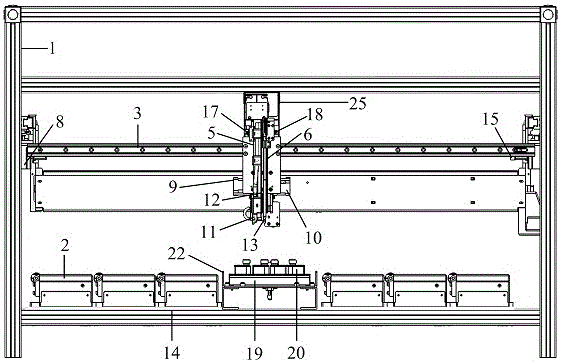

Portable unlimited rotary numerical control beveled opening pipe cutting machine and beveled opening processing method

ActiveCN103433591ARealize processingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingNumerical control system

The invention discloses a portable unlimited rotary numerical control beveled opening pipe cutting machine, which comprises a machine frame, a processing component, a bearing component and a numerical control system, wherein the machine frame is used for assembling sectional materials, the processing component and the bearing component are arranged on the machine frame, the numerical control system controls the processing component and the bearing component, the bearing component comprises a chuck seat and a chuck used for clamping a workpiece to be processed, the processing component comprises a transverse arm and a rotary arm with at least one bending part, the transverse arm and the rotary arm are connected through a rotary motor, the lower end of the rotary arm is connected with a cutting gun disc through an included angle connecting element, the rotary motor can drive the rotary arm to rotate so that the lower end of the rotary arm does circumferential movement around the rotating axial line of the rotary arm, in addition, the cutting gun disc is driven to rotate through the included angle connecting element, and a longitudinal guide rail used for the chuck seat to move on and a vertical guide used for the transverse arm to vertically move on are arranged on the machine frame. The invention also discloses a beveled opening processing method, i.e. a method for cutting a pipe fitting by using the pipe cutting machine. The beveled opening pipe cutting machine disclosed by the invention has the advantages that the structure is simple and clear, the shape processing of the pipe beveled opening is accurate, and the processing efficiency is extremely high. The beveled opening processing method has the advantages that the work procedure is simple, and the control is convenient.

Owner:北京大合兄弟科技发展有限公司

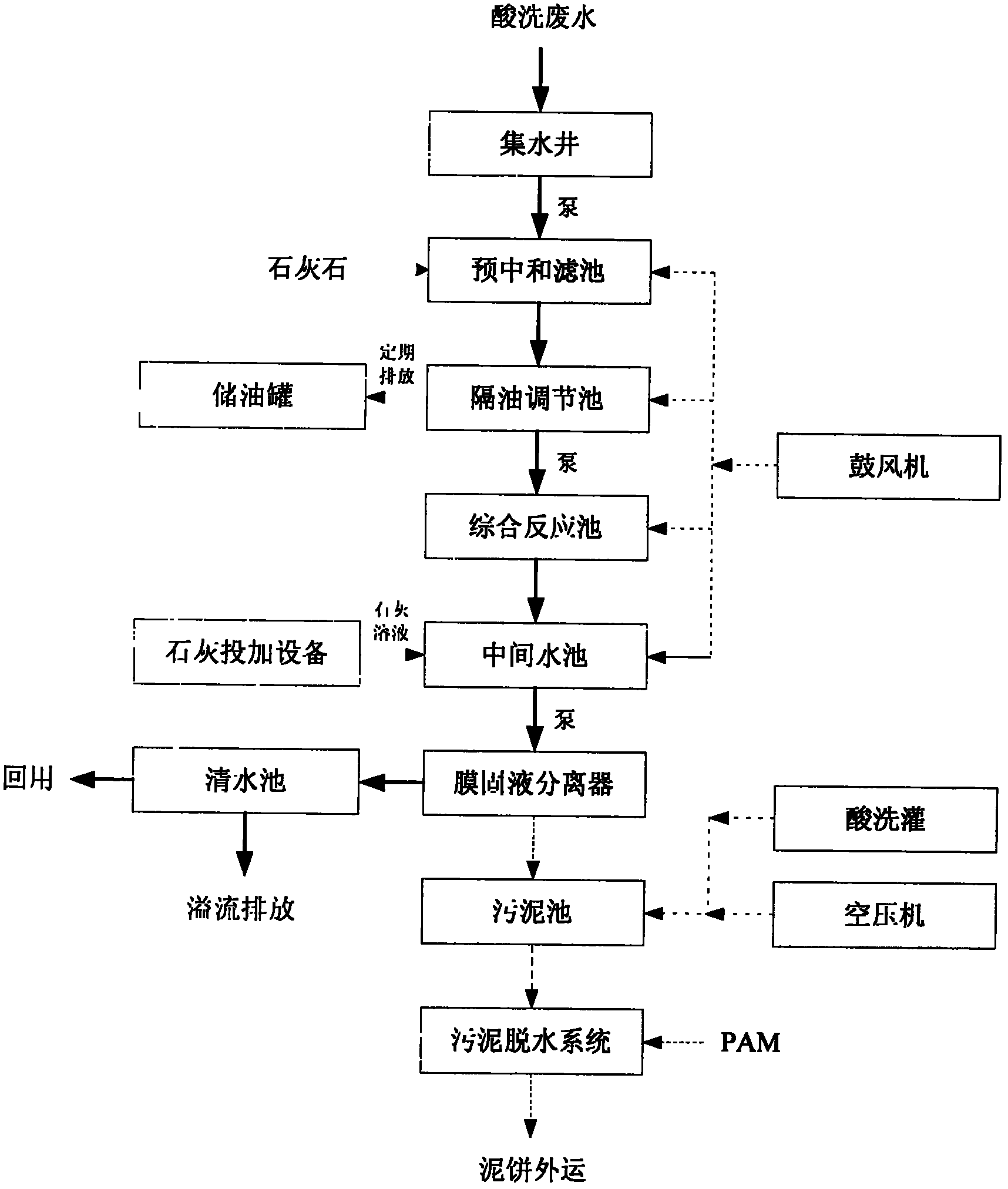

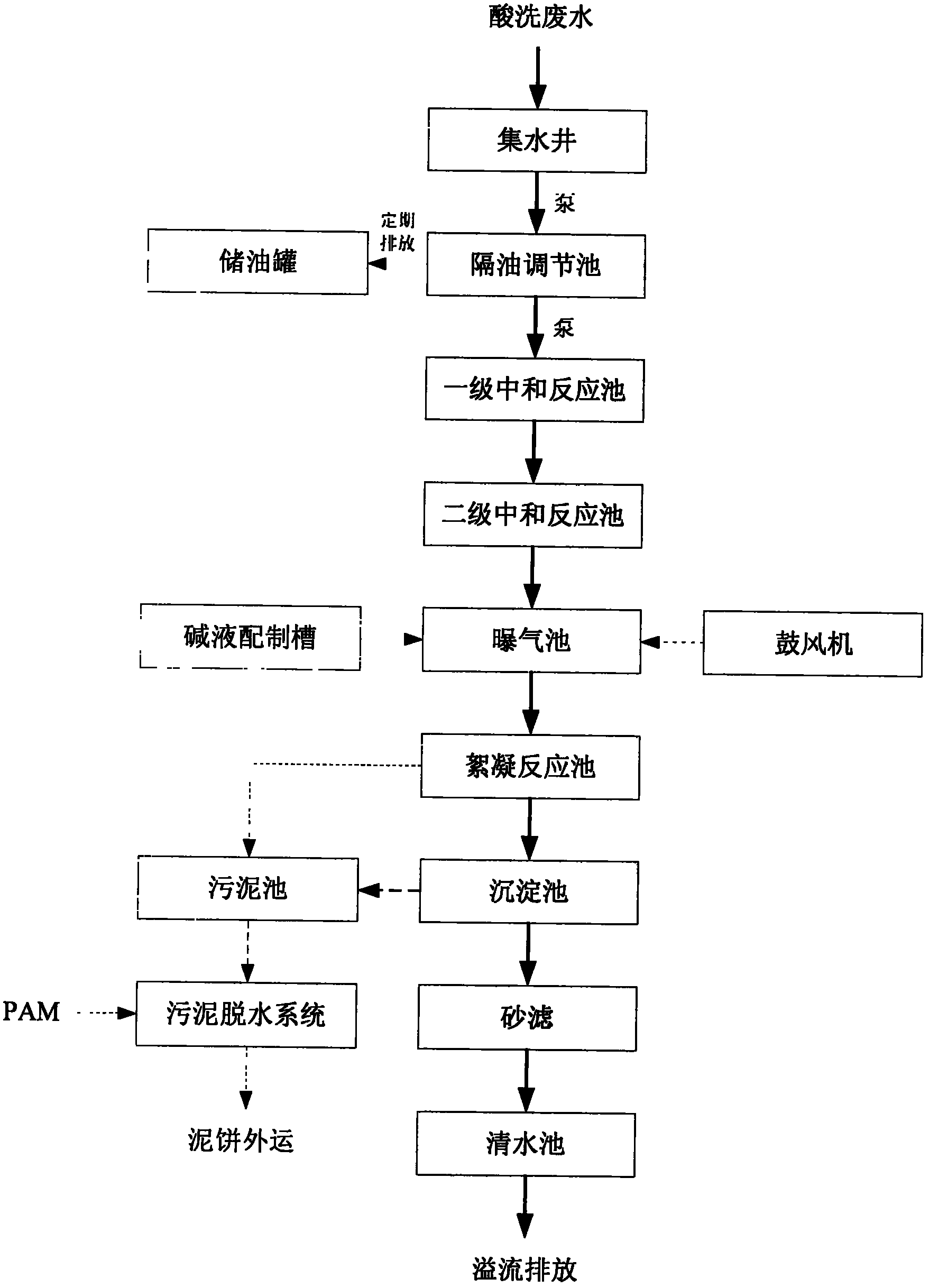

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

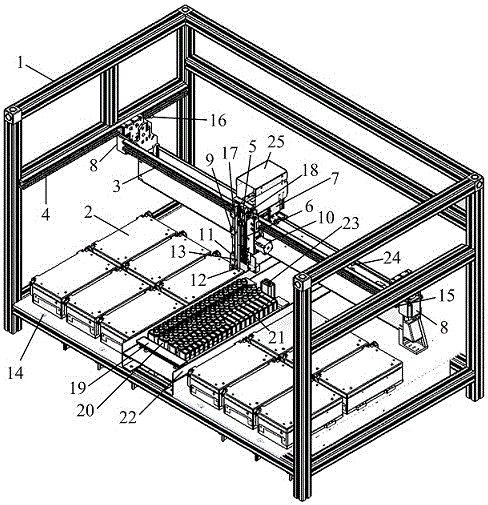

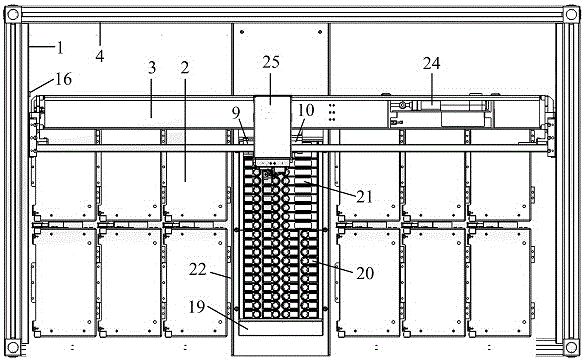

Full-automatic staining instrument for staining tissue samples on glass slides and method for applying full-automatic staining instrument

InactiveCN105699156AGood consistency and reproducibilityConducive to standardization of operating procedures and quality controlPreparing sample for investigationBiomedical engineeringStain tissue

The invention provides a full-automatic staining instrument for staining tissue samples on glass slides. The full-automatic staining instrument is characterized by comprising a support frame and an object stage; the object stage is arranged in the support frame, a plurality of staining modules and a reagent frame are arranged on the object stage, a movable mechanical arm and mechanical arm movement mechanisms are arranged on the support frame, and a sample injection head and a sample injection probe are arranged on the mechanical arm. The full-automatic staining instrument has the advantages that immunohistochemistry or immunocytochemistry staining work can be conveniently implemented, staining effects are excellent in consistency and repeatability, and the full-automatic staining instrument is favorable for operational program standardization and quality control; the full-automatic staining instrument is short in running time and high in handling capacity and work efficiency; technicians have low probability of contact with toxic reagents, and accordingly the full-automatic staining instrument is high in safety; the full-automatic staining instrument has relatively low requirements on professional knowledge backgrounds and technical level of operators.

Owner:FUZHOU MAIXIN BIOTECH CO LTD

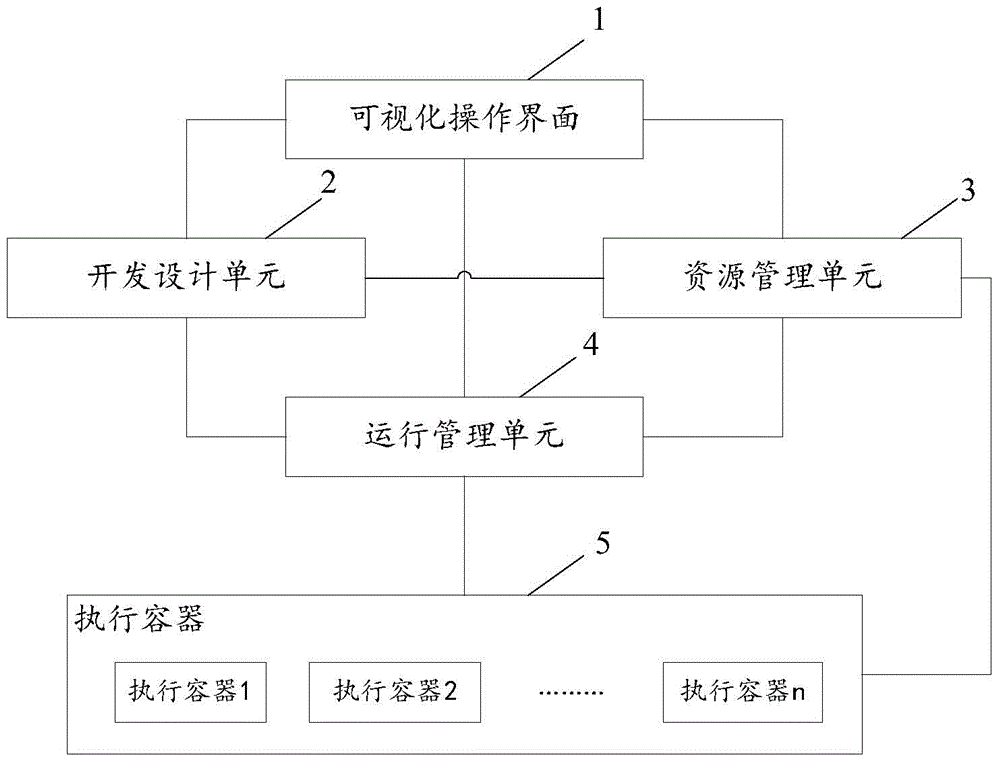

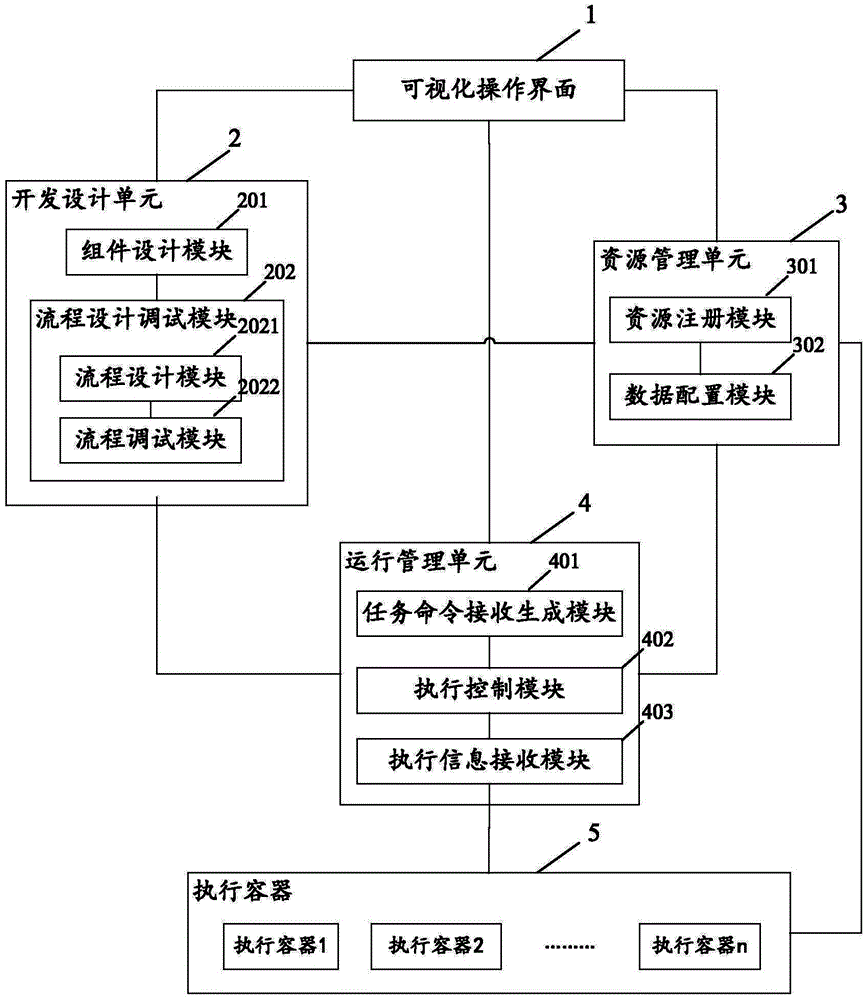

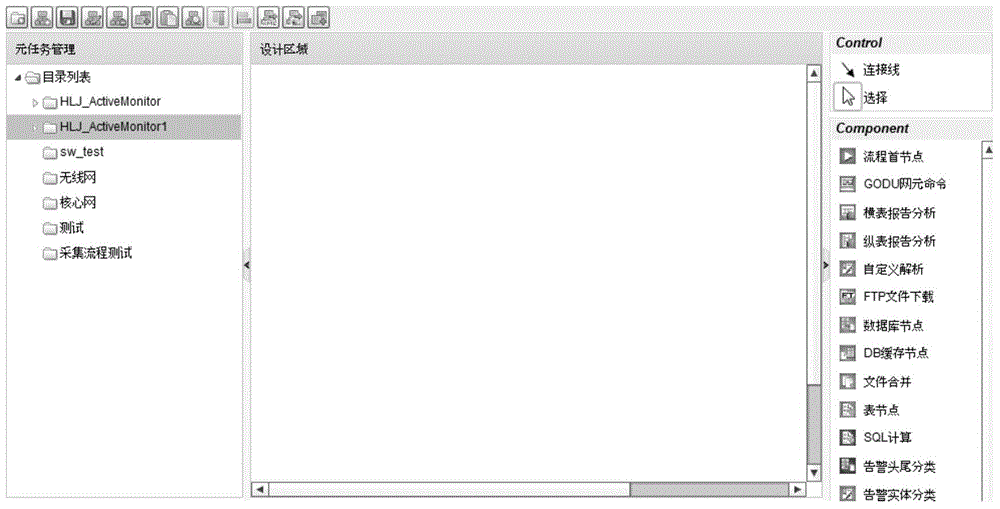

Flow path customized development platform and method

ActiveCN104679488AImprove visibility accuracyImprove efficiencyResourcesSpecific program execution arrangementsVisibilityManagement unit

The invention discloses a flow path customized development platform. The flow path customized development platform comprises a visual operation interface, a development design unit, a resource management unit, an operation management unit and an execution vessel. The flow path customized development platform can achieve customized development and online debugging of a flow path. The flow path customized development platform improves visibility and accuracy of flow path development, and is simple and easy to operate. When the flow path needs to be modified, a user only needs to modify the flow path in a development design module through the visual operation interface, and does not need to repeatedly compile development codes, and therefore manpower resources and cost of hardware and software are saved. The invention further discloses a flow path customized development method.

Owner:BEIJING BOCO COMM TECH

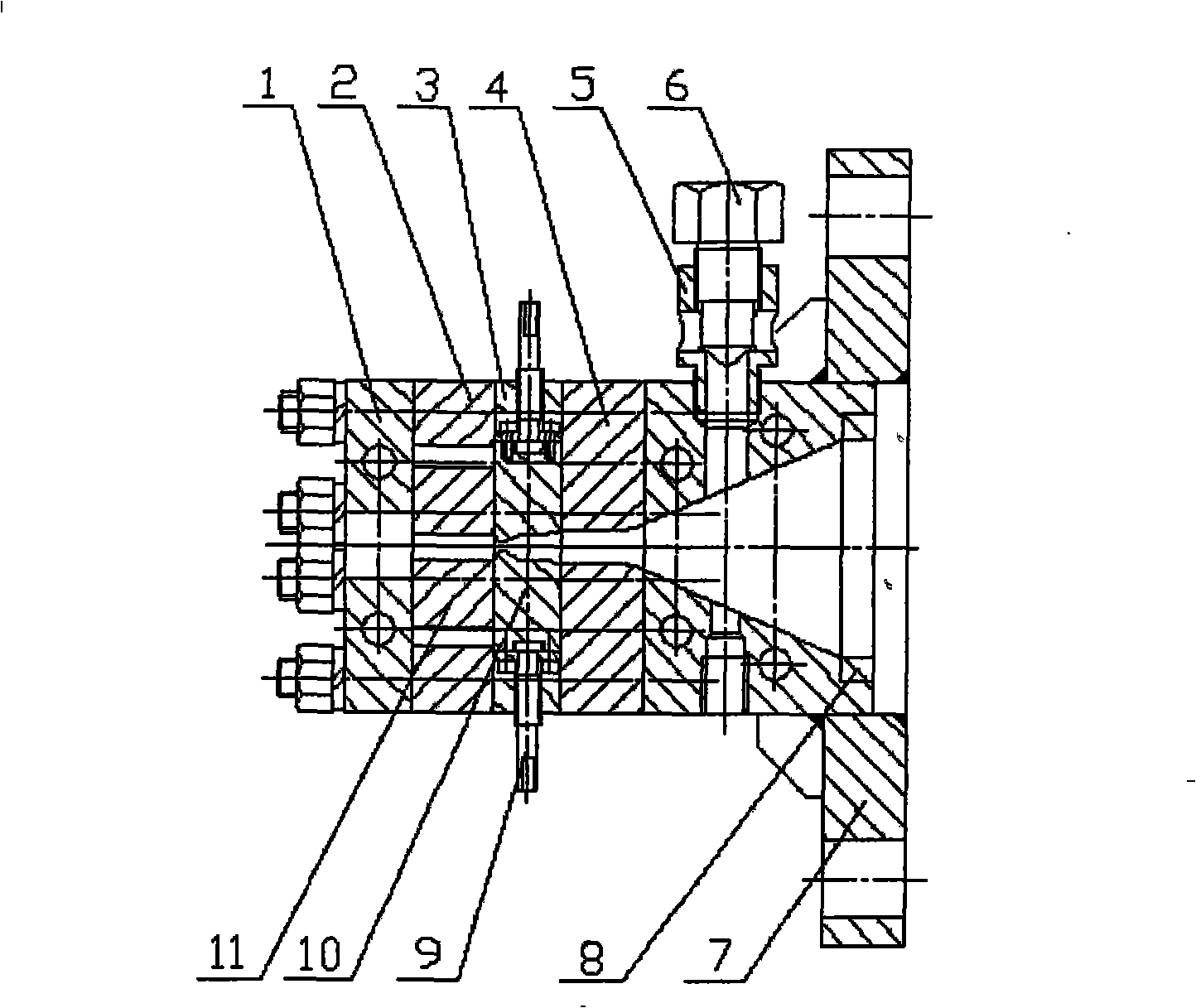

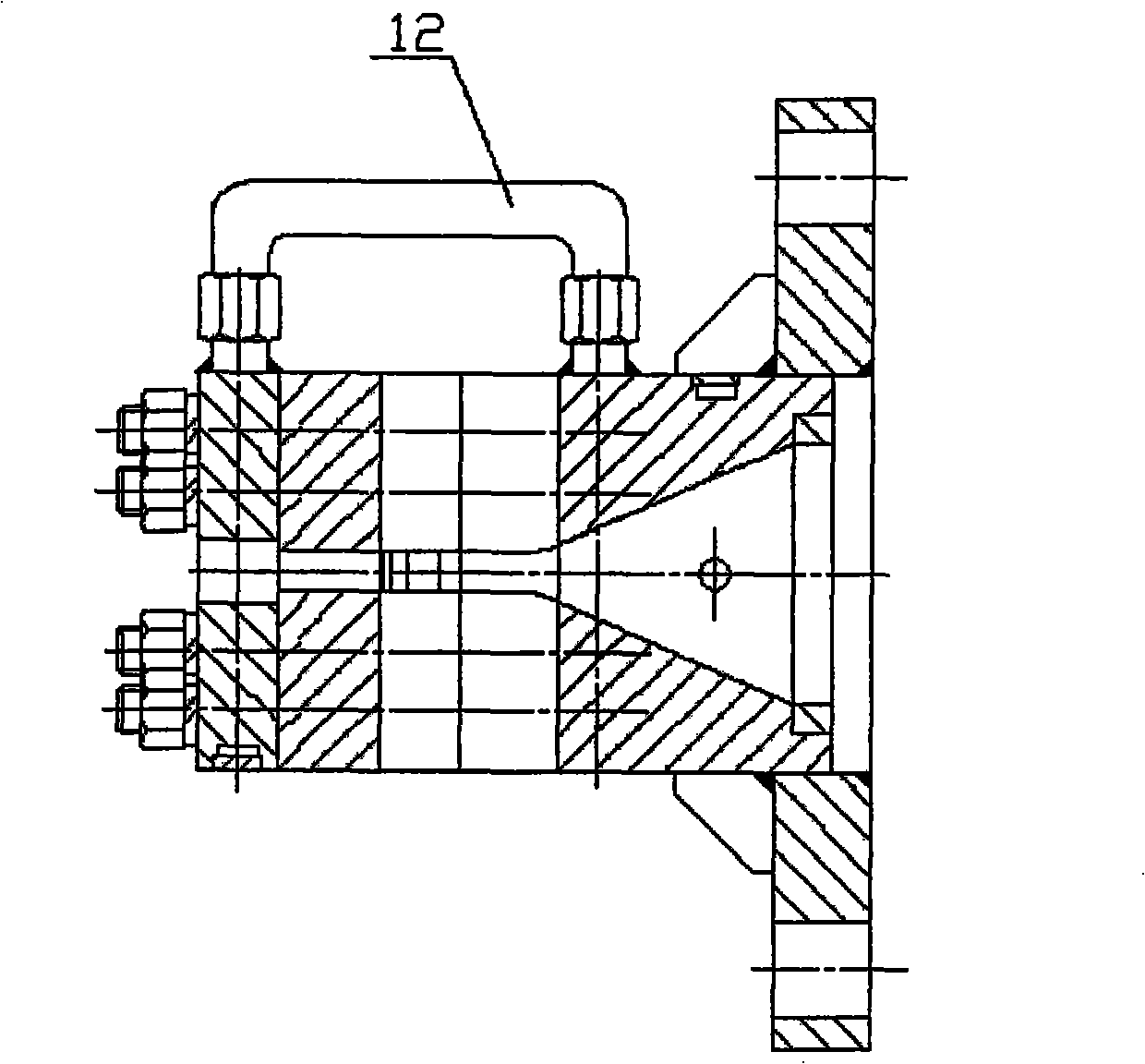

Radial extruding forming device of cut-fiber reinforcement rubber composite material

The invention relates to a radial extrusion molding device for the composite material of short fiber reinforced rubber, in particular to a device for realizing the radial direction of short fiber in rubber material. Eight threaded holes are produced on the front side of the flange of the device, eight double threaded screws and nuts are used for connecting the flange, a flow channel plate, a blocking supporting plate, a shaping plate and a machine head pressing plate into a whole in sequence, a rubber overflow valve is installed above the flange, and a threaded hole is drilled under the flange to install a pressure sensor; a pair of blocking adjusting blocks is positioned in the middle of the blocking supporting plate, one end of a blocking adjusting bolt is fixed with the blocking adjusting blocks, the other end thereof is connected with the blocking supporting plate through thread, and the blocking adjusting bolt is used for controlling the blocking gap; a pair of shaping adjusting blocks is positioned in the middle of the shaping plate to adjust the shaping gap, the shaping adjusting blocks are clamped between the blocking supporting plate and the machine head pressing plate and fixed through screws. The device has the advantages of simple structure, reliable principle, broad application range, low cost, good production efficiency, high product quality and stable performance.

Owner:QINGDAO UNIV OF SCI & TECH

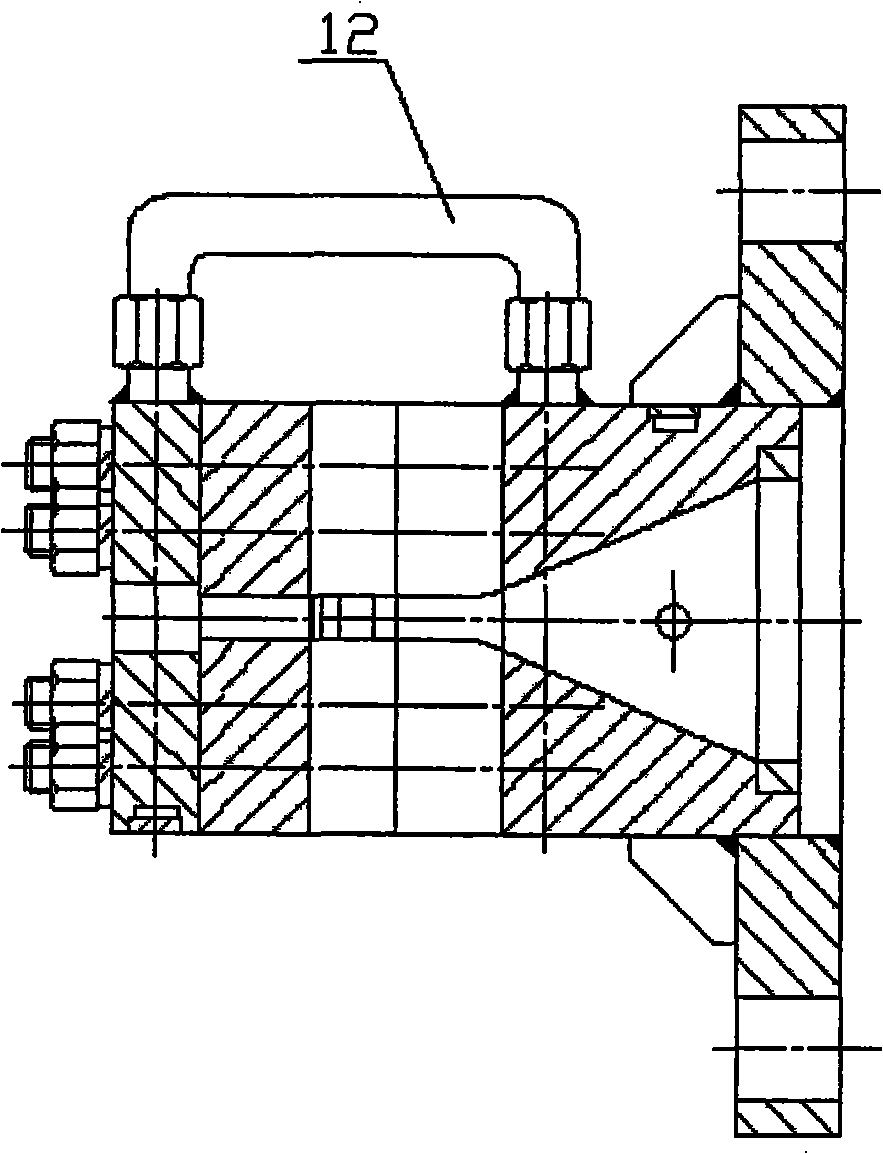

Aircraft control method and device

InactiveCN104932527AReduce flight environment requirementsLow skill level requiredPosition/course control in three dimensionsControl systemInput device

The invention discloses an aircraft control method and device. The aircraft control method comprises the following steps that step one, a flight instruction inputted by a user through input equipment of an intelligent terminal is sensed, and the flight instruction includes any one of course reversal, direction and hovering; and step two, the flight instruction is transmitted to the airborne flight control system of an aircraft. According to the aircraft control method, input of the user sensed by the intelligent terminal through the input equipment is acquired to act as the flight instruction, and the flight instruction is transmitted to the airborne flight control system and flight of the aircraft is controlled by the airborne flight control system so that the technical level requirement for an aircraft operator is greatly reduced, the flight environment requirement for the aircraft is also reduced and real-time operation can be performed.

Owner:GUANGZHOU EHANG INTELLIGENT TECH

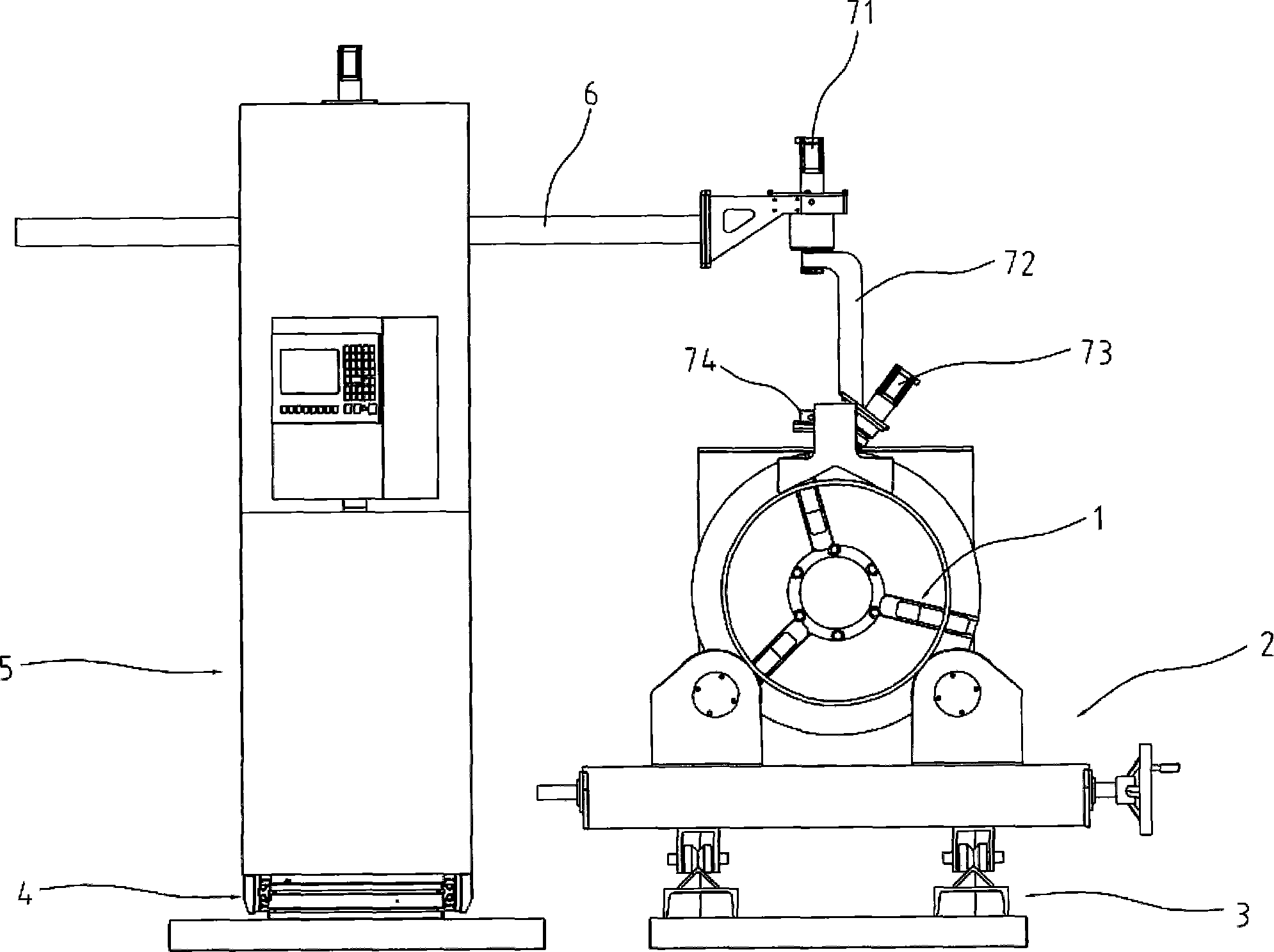

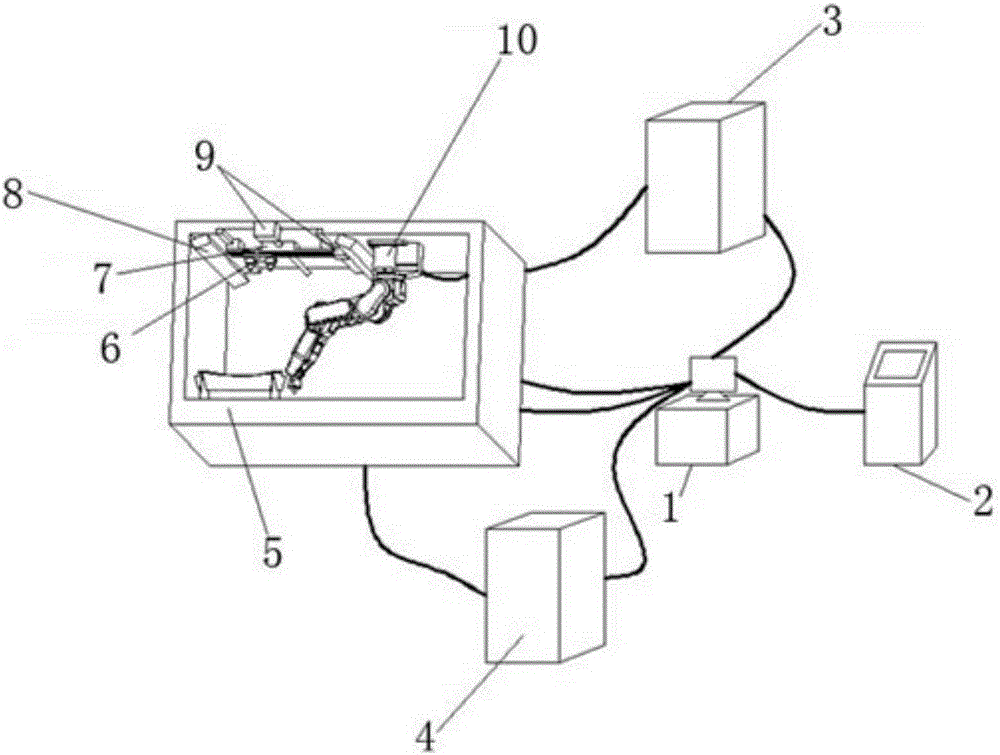

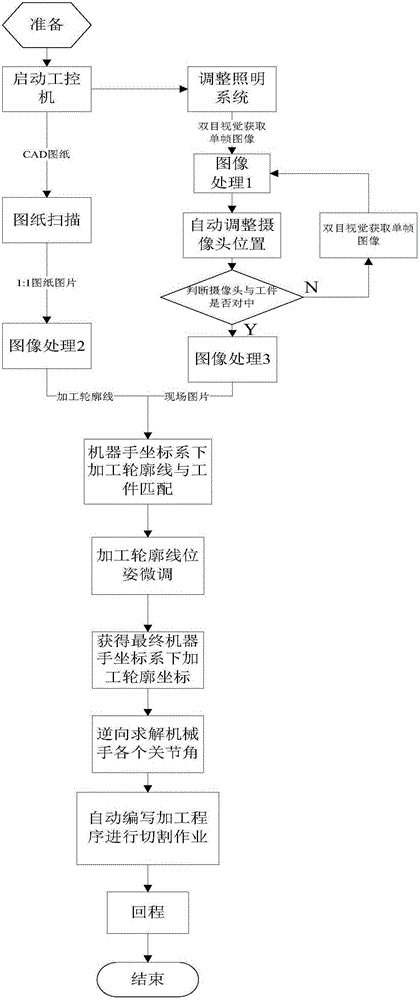

Intelligent laser trimming system and method based on binocular vision

InactiveCN105149794ALow skill level requiredHigh degree of intelligenceLaser beam welding apparatusPersonal computerLighting system

The invention discloses an intelligent laser trimming system and method based on binocular vision. The system comprises an industrial personal computer, a scanner and a box-type cutting platform. A mechanical hand, servo motors, a vision moving platform, a lighting system and a CCD binocular vision camera are installed in the box-type cutting platform. The industrial personal computer controls the CCD binocular vision camera installed on the vision moving platform to move through the servo motors. The mechanical hand is connected with the industrial personal computer through an arranged mechanical hand control cabinet. The vision moving platform is connected with the industrial personal computer through an arranged vision moving platform control cabinet. The system is high in intelligence degree, the automatic calibration and automatic scanned drawing programming functions are achieved, and production efficiency is greatly improved.

Owner:HOHAI UNIV CHANGZHOU

Digital eye camera

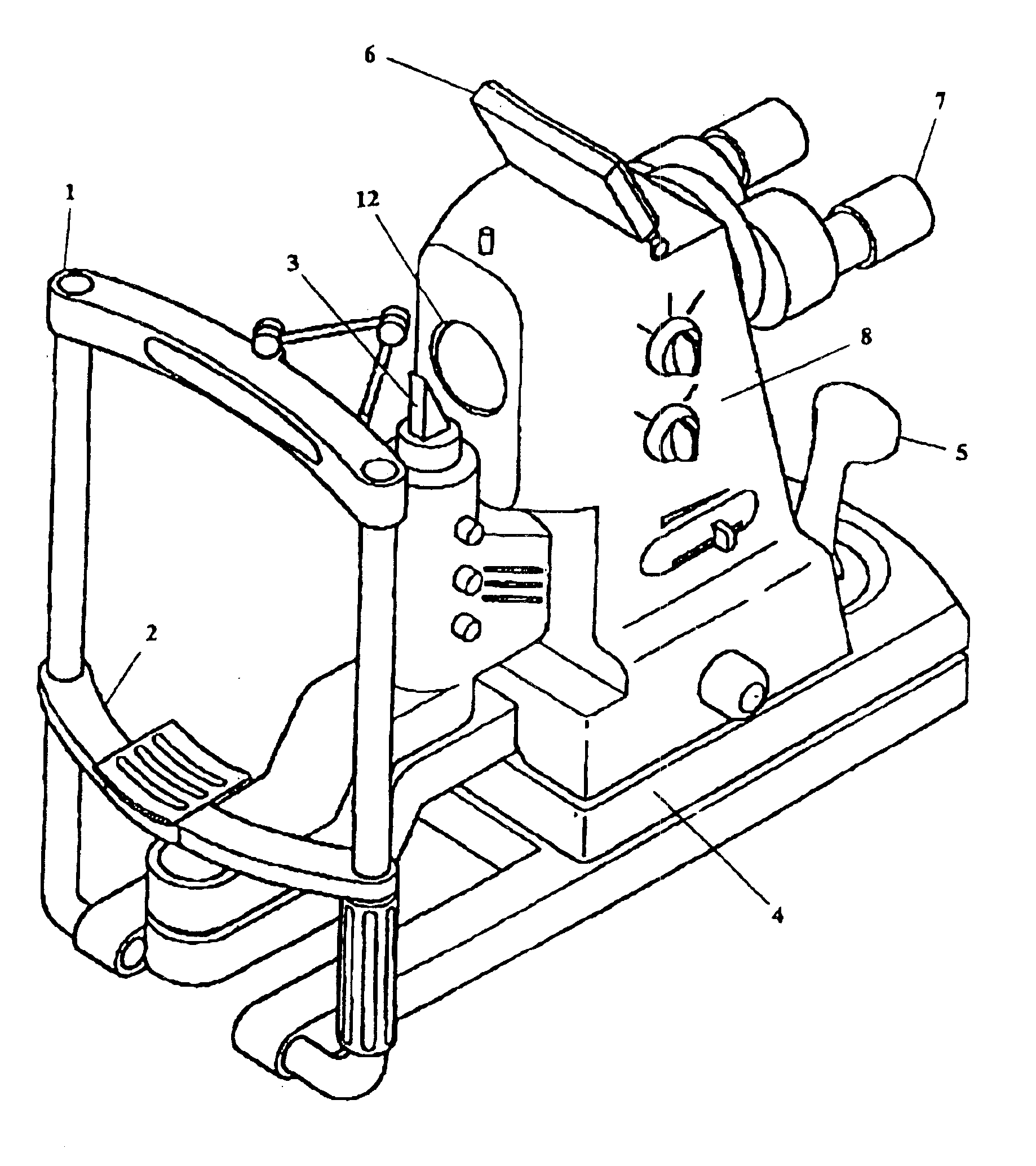

InactiveUS6921169B2Relieve pressureComfortable postureLaser surgerySurgical instrument detailsEyepieceRetina

A digital camera that combines the functions of the retinal camera and corneal camera into one, single, small, easy to use instrument. The single camera can acquire digital images of a retinal region of an eye, and digital images of a corneal region of the eye. The camera includes a first combination of optical elements for making said retinal digital images, and a second combination of optical elements for making said corneal digital images. In a preferred embodiment, a portion of these elements are shared elements including a first objective element of an objective lens combination, a digital image sensor and at least one eyepiece for viewing either the retina or the cornea. Also, preferably, the retinal combination also includes a first changeable element of said objective lens system for focusing, in combination with said first objective element, portions or all of said retinal region at or approximately at a common image plane. Also, preferably, the retinal combination also includes a retinal illuminating light source, an aperture within said fame and positioned within said first combination to form an effective retinal aperture located at or approximately at the lens of the eye defining an effective retinal aperture position, an infrared camera for determining eye position, and an aperture adjustment mechanism for adjusting the effective retinal aperture based on position signals from said infrared camera. Also, preferably, the cornea combination of elements includes a second changeable element of said objective lens system for focusing, in combination with said first objective element, portions or all of said cornea region at or approximately at a common image plane.

Owner:MASSIE RES LAB

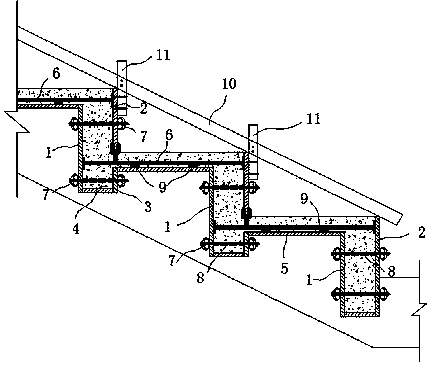

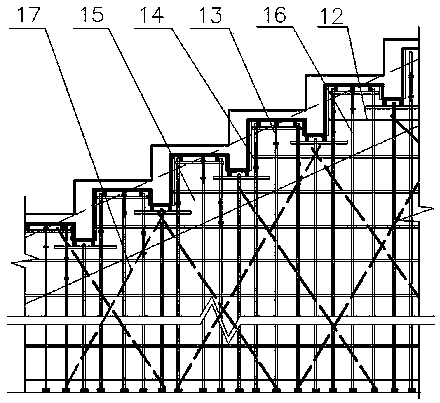

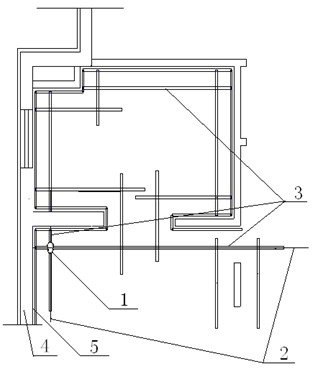

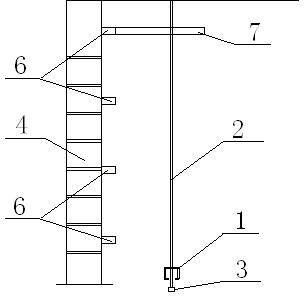

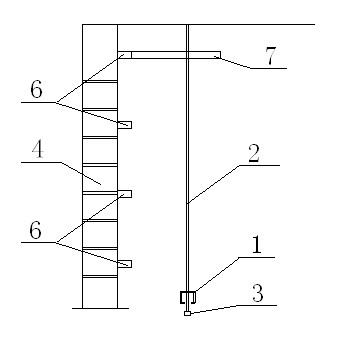

Template structure and method for template support of cast-in-place concrete arc-shaped terrace

ActiveCN103362300AMeet construction requirementsEasy constructionForms/shuttering/falseworksBuilding material handlingShaped beamEngineering

The invention discloses a template structure and a method for template support of a cast-in-place concrete arc-shaped terrace. The template structure comprises a template support frame body and a template fixing system, wherein the template fixing system comprises arc-shaped beam bottom plate templates, seat plate bottom templates, arc-shaped beam outside upper templates, arc-shaped beam outside lower templates and arc-shaped beam inside templates, wherein the arc-shaped beam outside lower templates are positioned below the arc-shaped beam outside upper templates; internal supports are arranged between the arc-shaped beam outside upper templates and the arc-shaped beam inside templates for supporting and enable the arc-shaped beam outside upper templates and the arc-shaped beam inside templates to keep set intervals; split bolts are used for connecting and fixing the arc-shaped beam outside upper templates and the arc-shaped beam inside templates; split bolts are used for connecting and fixing the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the arc-shaped beam bottom plate templates are respectively connected and fixed with the bottom ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the seat plate bottom templates are respectively connected and fixed with the upper ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

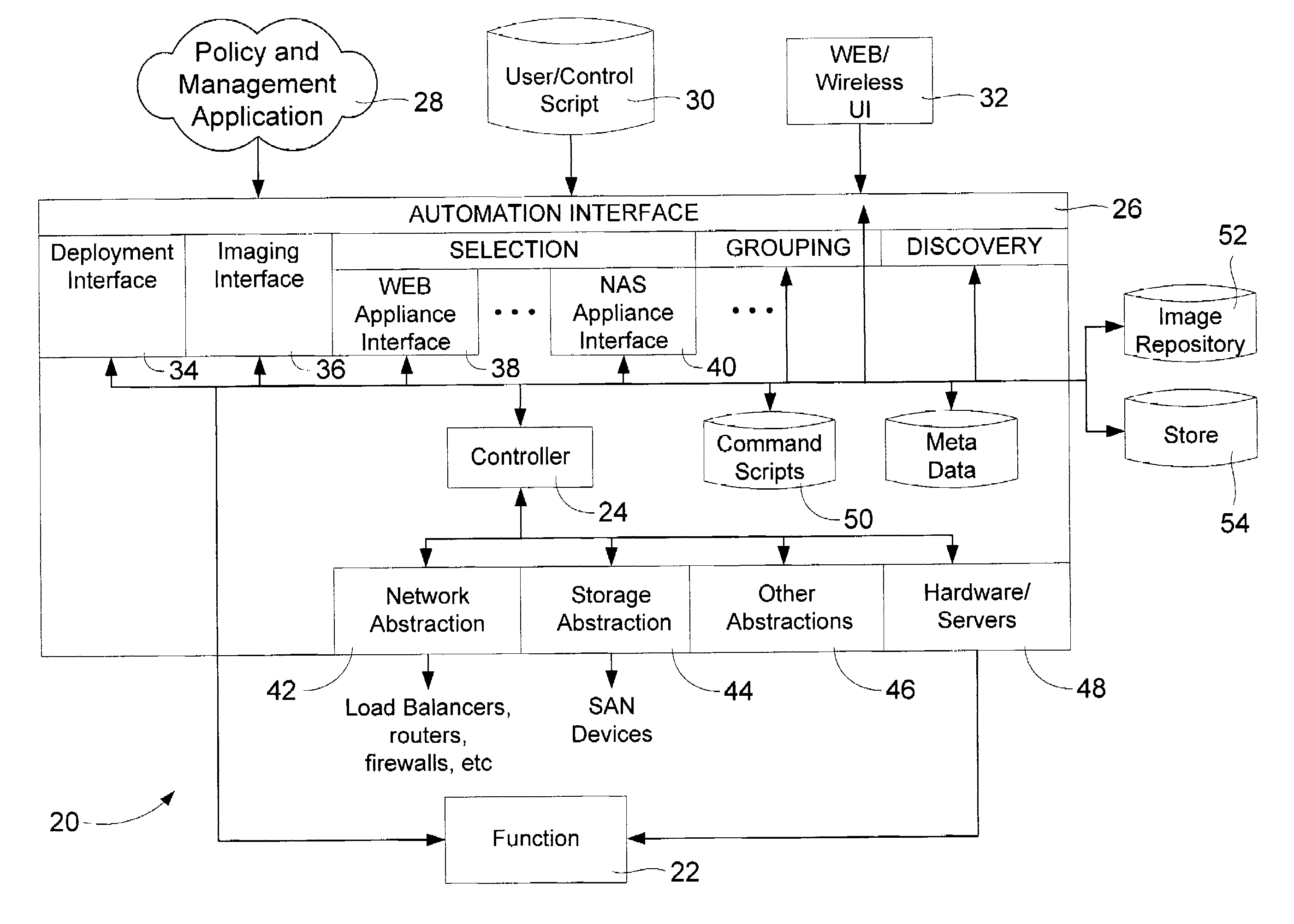

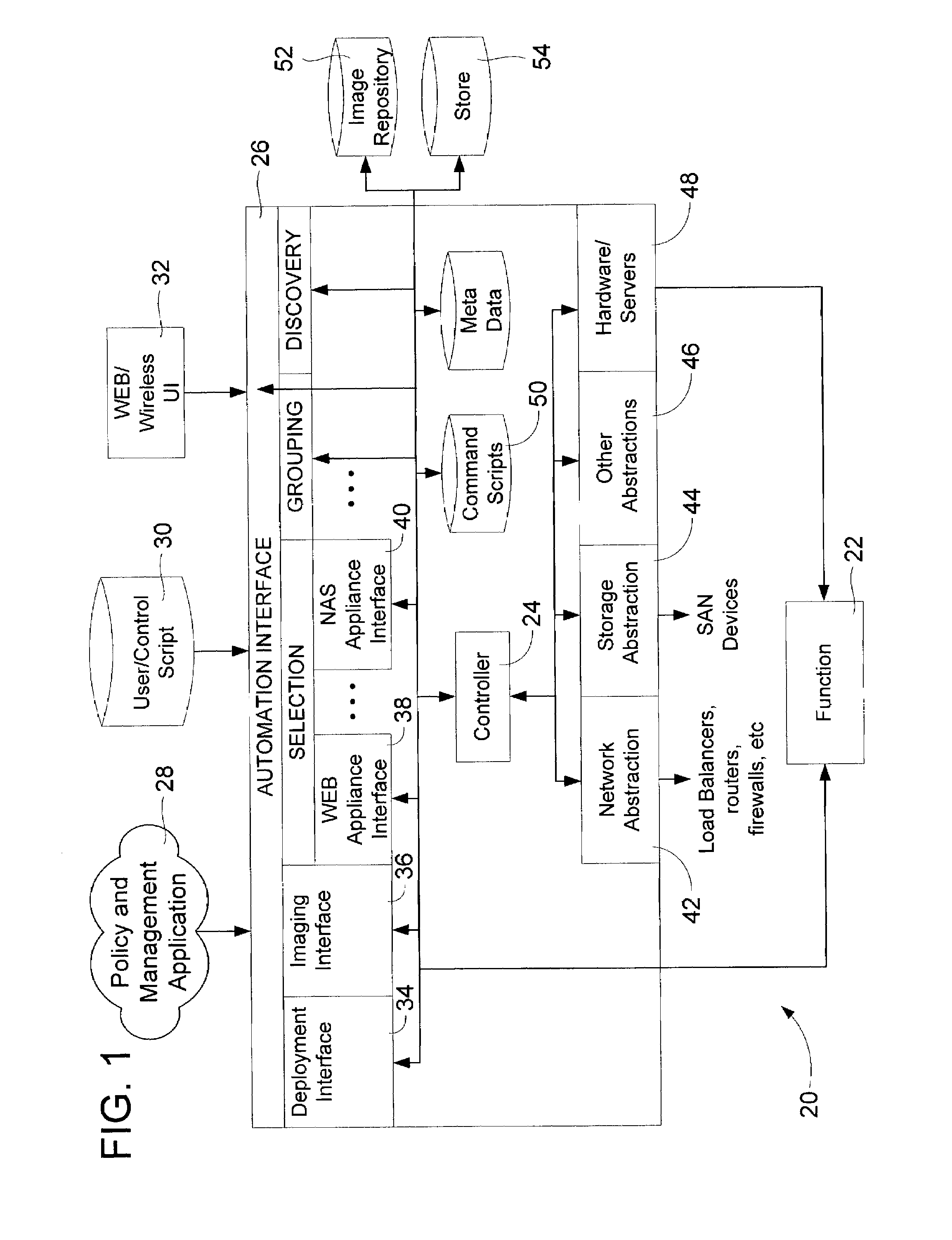

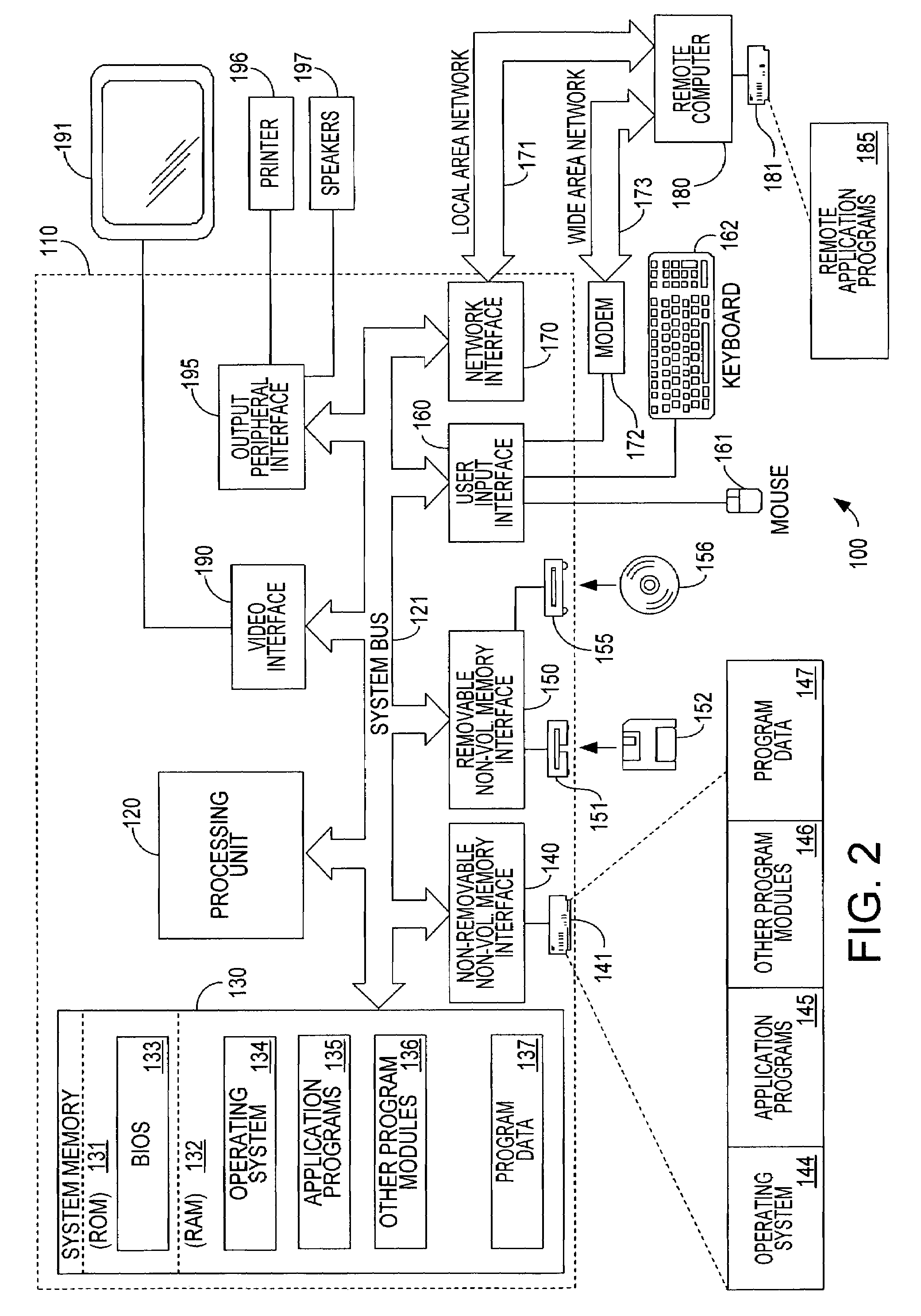

System and method to automate the management of computer services and programmable devices

ActiveUS7065740B2Reduce the amount requiredLow skill level requiredDigital computer detailsProgram loading/initiatingProgrammable logic deviceAutomation

An apparatus and method to automate the deployment, provisioning, and management of a programmable device for the life cycle states of the programmable device is presented. The system includes an automation interface for a developer to develop modules to aid in the automation of the deployment, provisioning, and management of the programmable device and for a user to direct the system to enter into a state of the life cycle. A controller moves the programmable device into states of the life cycle in response to triggering events occurring.

Owner:MICROSOFT TECH LICENSING LLC

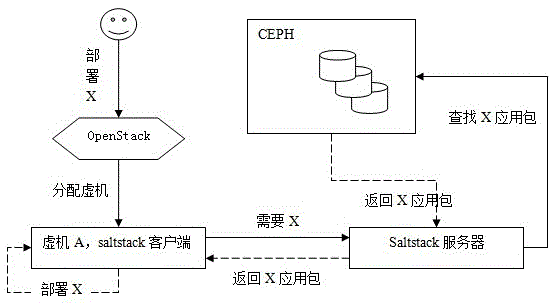

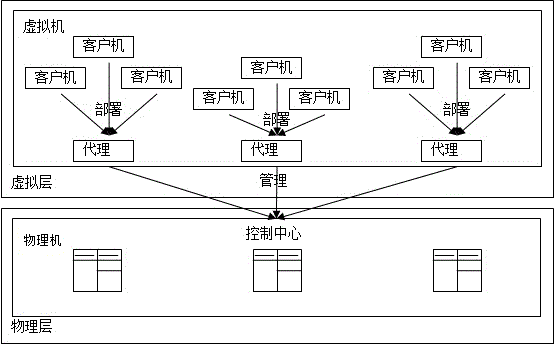

Automatic deployment method for application system based on cloud computing

InactiveCN105553741ALower service costsReduce management costsData switching networksQuality of serviceOpen source

The invention discloses an automatic deployment method for an application system based on cloud computing. The automatic deployment method comprises the steps that a step 1, the Salt Minion of an open source remote deployment tool SaltStack is embedded in a standard template of an open source cloud computing management platform OpenStack; a step 2, the OpenStack receives request information of issuing the application system sent by a client and obtains a first cloud computing host list conforming to the requirements from an OpenStack environment; a step 3, the OpenStack continues to filter the first cloud computing host list according to different cabinets to obtain a second host list; a step 4, the OpenStack continues to filter the second host list to select an optimal host to establish a virtual machine; a step 5, the virtual machine automatically downloads and installs a necessary middleware from Ceph according to the demand of the application system through a SaltStack server; a step 6, the virtual machine downloads an application system package in a middleware installation directory through ftp; and a step 7, the virtual machine automatically starts the middleware through a SaltStack client to issue the application system, in order to provide application system service. The cost is lowered and the quality of service is improved.

Owner:INFORMATION & COMM BRANCH OF STATE GRID JIANGSU ELECTRIC POWER +2

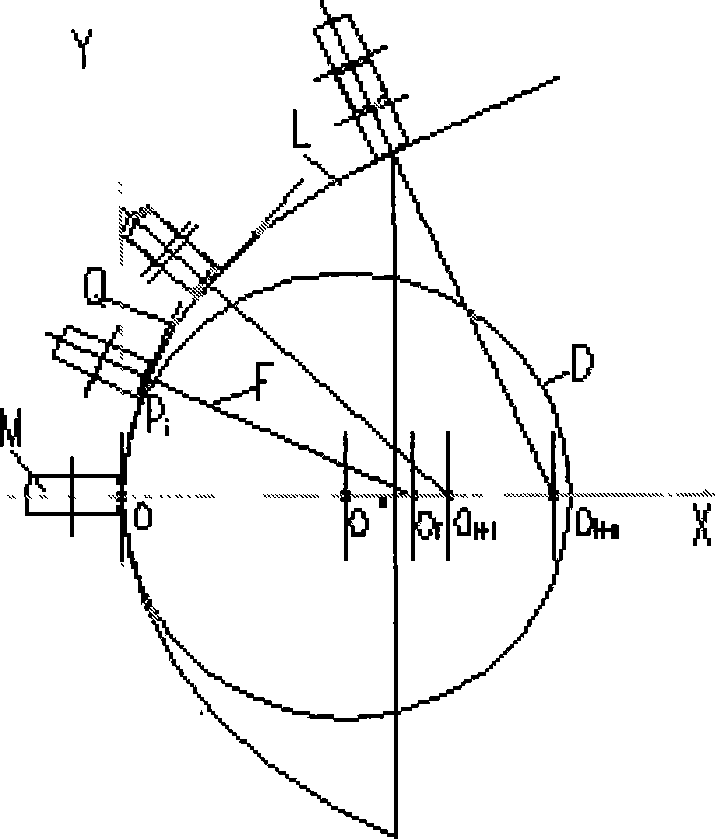

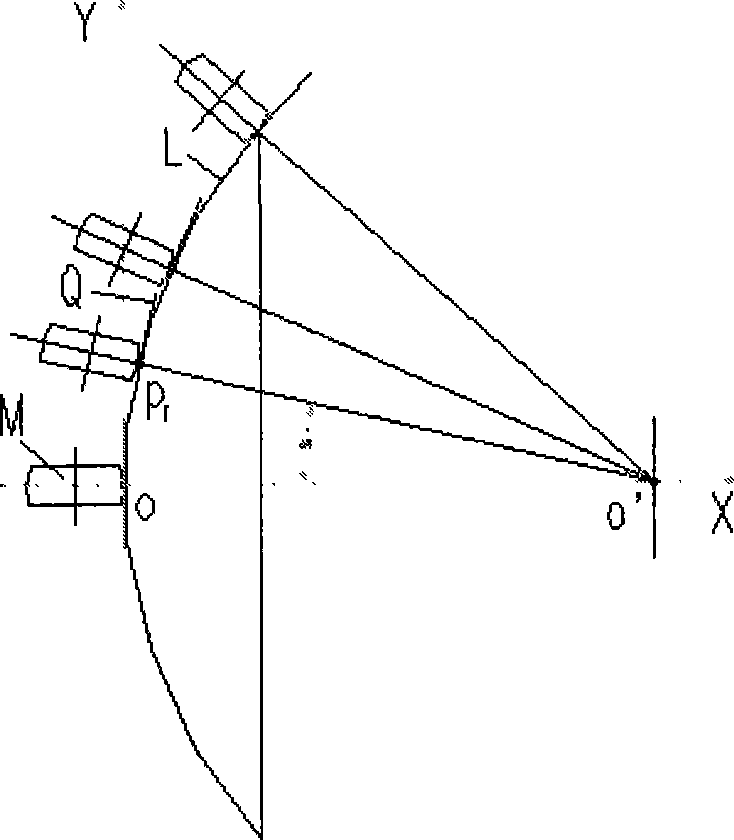

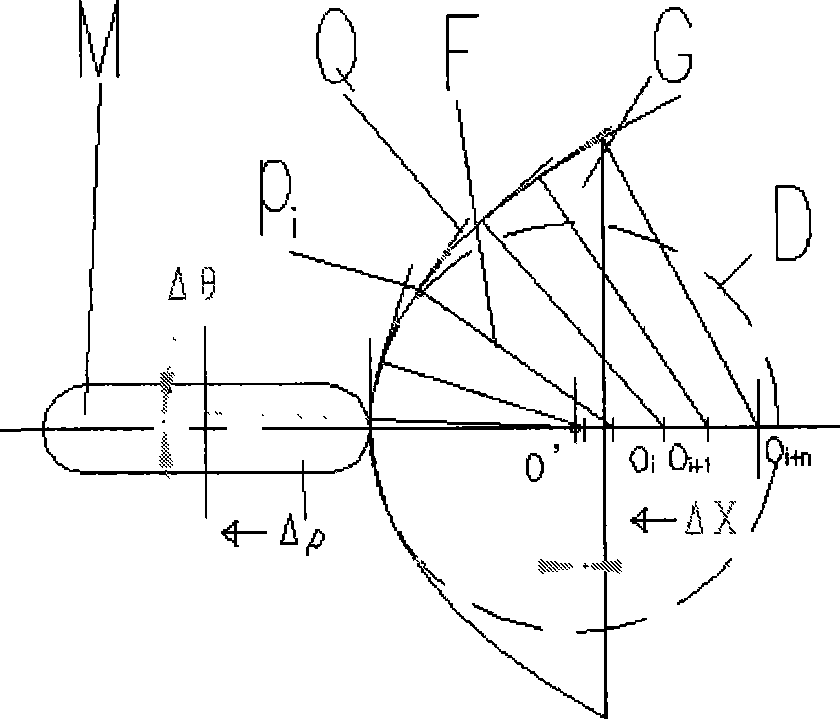

Processing method and device for forming aspheric surface part by numerical control tangent line turning method

InactiveCN101376229ARequirements to ensure surface accuracyEasy to ensure surface accuracy requirementsLensNumerical controlSurface roughness

The invention provides a non-spherical surface element shaping and processing method by using a numerical control tangent revolution method and a device thereof, and relates to an optical element processing technique. The processing method and the device can always conduct the tangent point processing for the meridional profile curve of any designed and given axisymmetrical non-spherical surface (including higher order and quadric spherical surface) and spherical surface element, so as to obtain a theoretical continuous smooth high precision surface without corrugation. The tangent point processing of the non-spherical surface is realized through the rotation of a workpiece and an abrasive wheel, and the numerical control linkage of an oscillating shaft, a workpiece shat and an abrasive axle. The tangent point processing of the spherical surface is realized through the rotation of the workpiece and the abrasive wheel, the oscillation of the oscillating shaft and the fixation of the abrasive axle at a certain distance. The processing technique has the advantages of good commonality, high precision and processing efficiency, easily ensured surface roughness and surface texture, low processing cost and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH +2

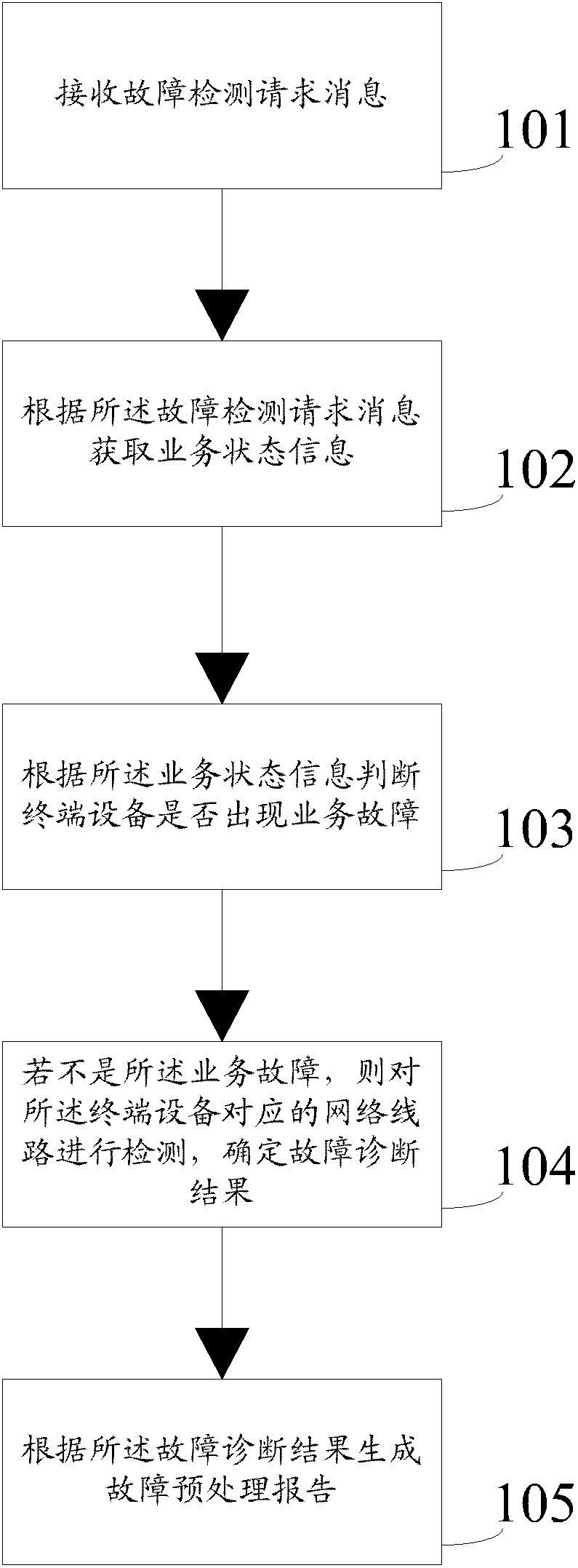

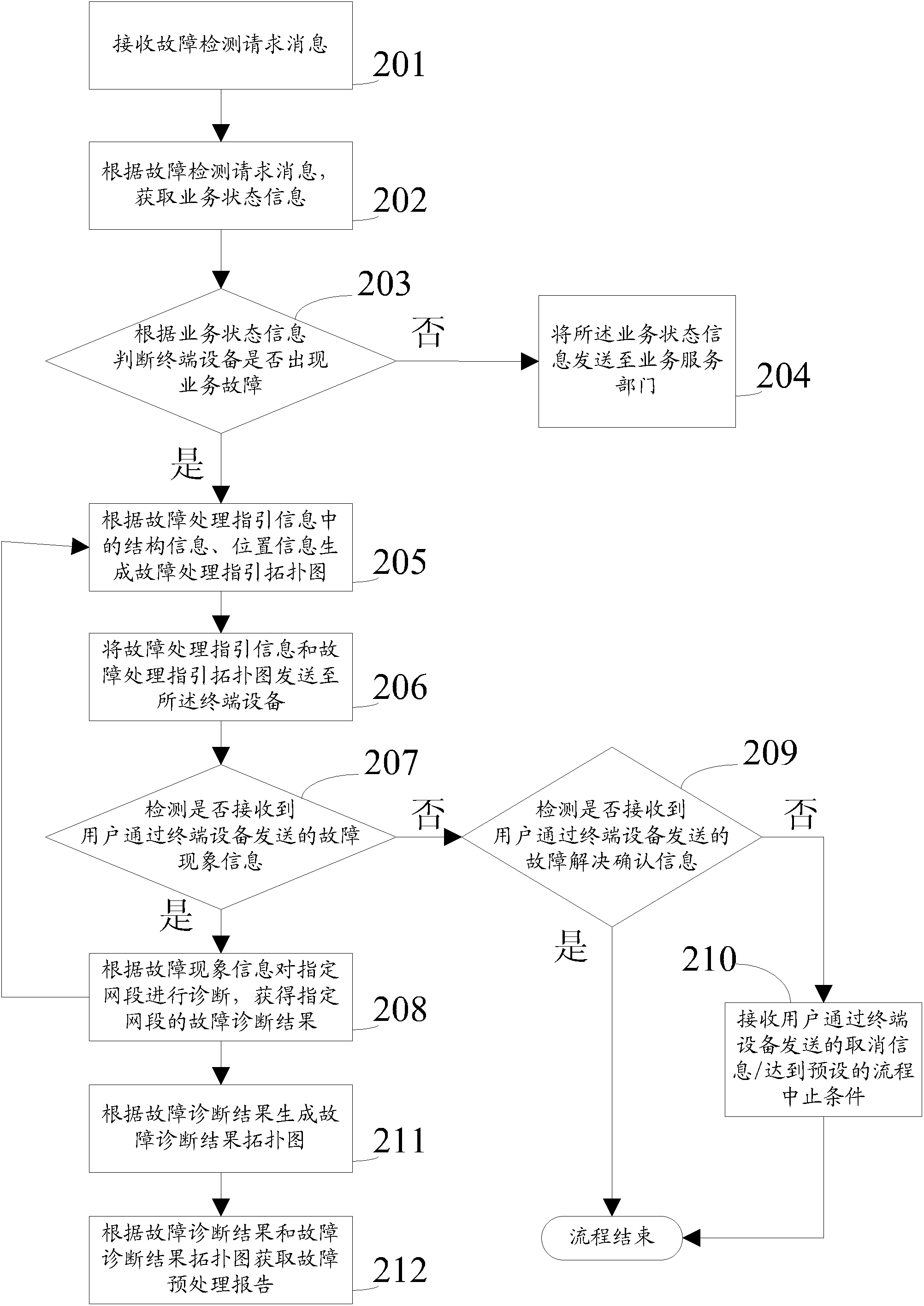

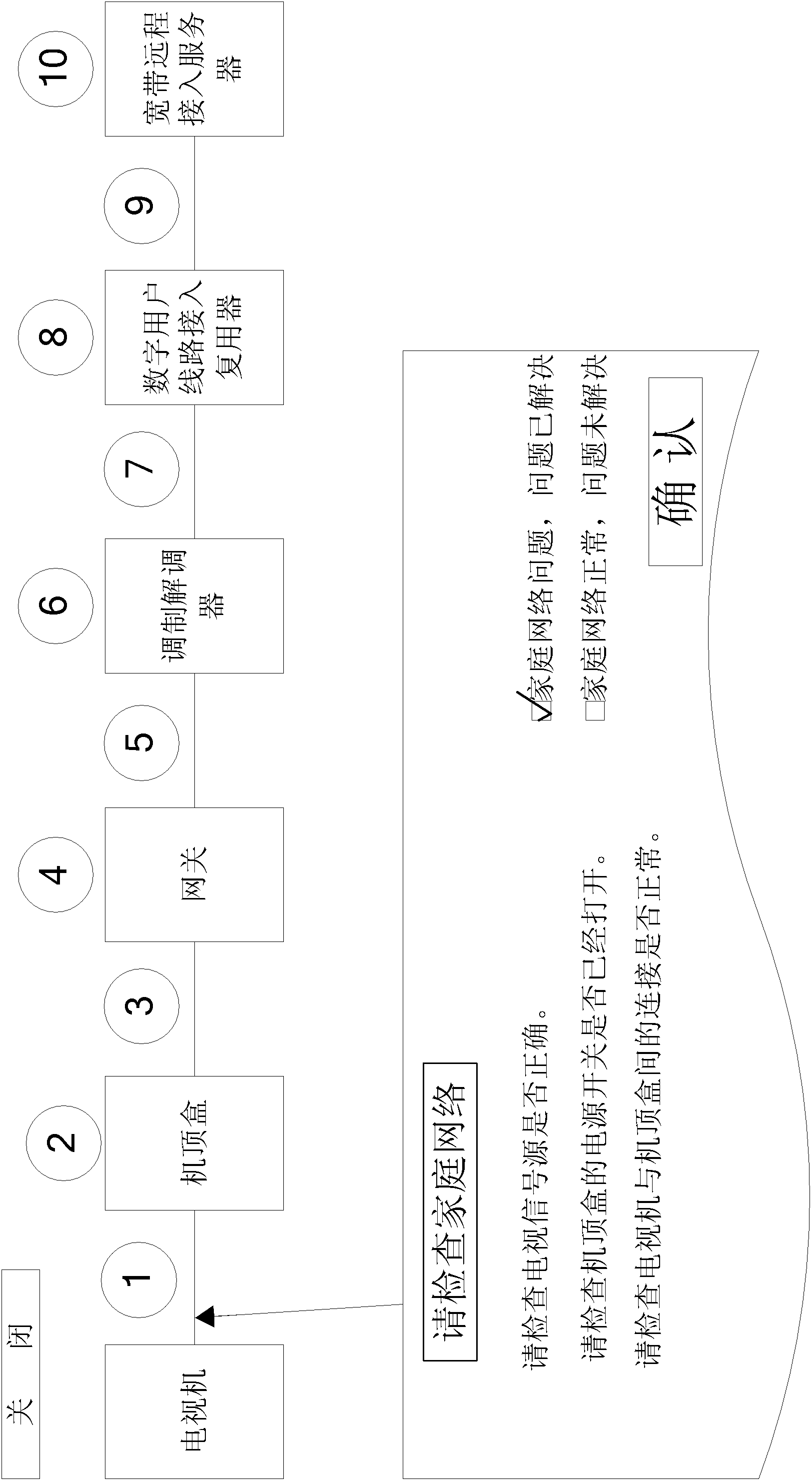

Method and device for preprocessing network television fault

InactiveCN102611917ALow skill level requiredIncreased training costsSelective content distributionTerminal equipmentComputer terminal

The embodiment of the invention discloses a method and device for preprocessing a network television fault and relates to the field of network television fault processing. The network television fault can be automatically preprocessed, and steps and information in the fault processing process are visually shown in the manner of imaging. The method disclosed by the invention comprises the following steps of: receiving a fault detection request message; according to the fault detection request message, acquiring business state information; judging whether a business fault is generated in terminal equipment or not according to the business state information, wherein the business fault is a fault caused by the abnormal change of a business state; if the business fault is not generated, detecting a network line which corresponds to the terminal equipment to determine a fault diagnosis result, wherein the fault diagnosis result comprises the position of the fault position and the content of the fault; and generating a fault preprocessing report according to the fault diagnosis result. The method and device for preprocessing the network television fault is used for preprocessing the network television fault.

Owner:广东汇威高科技有限公司

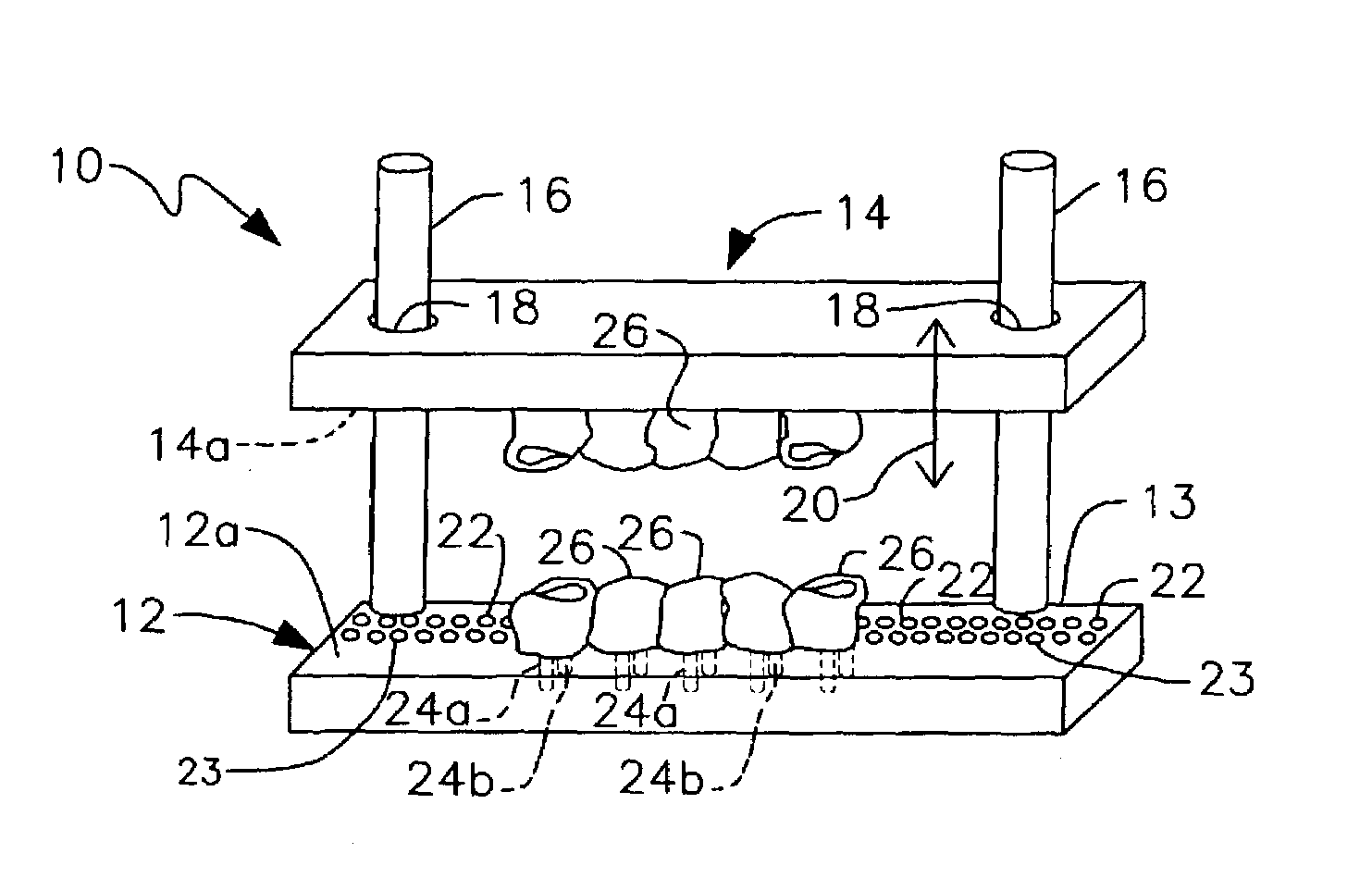

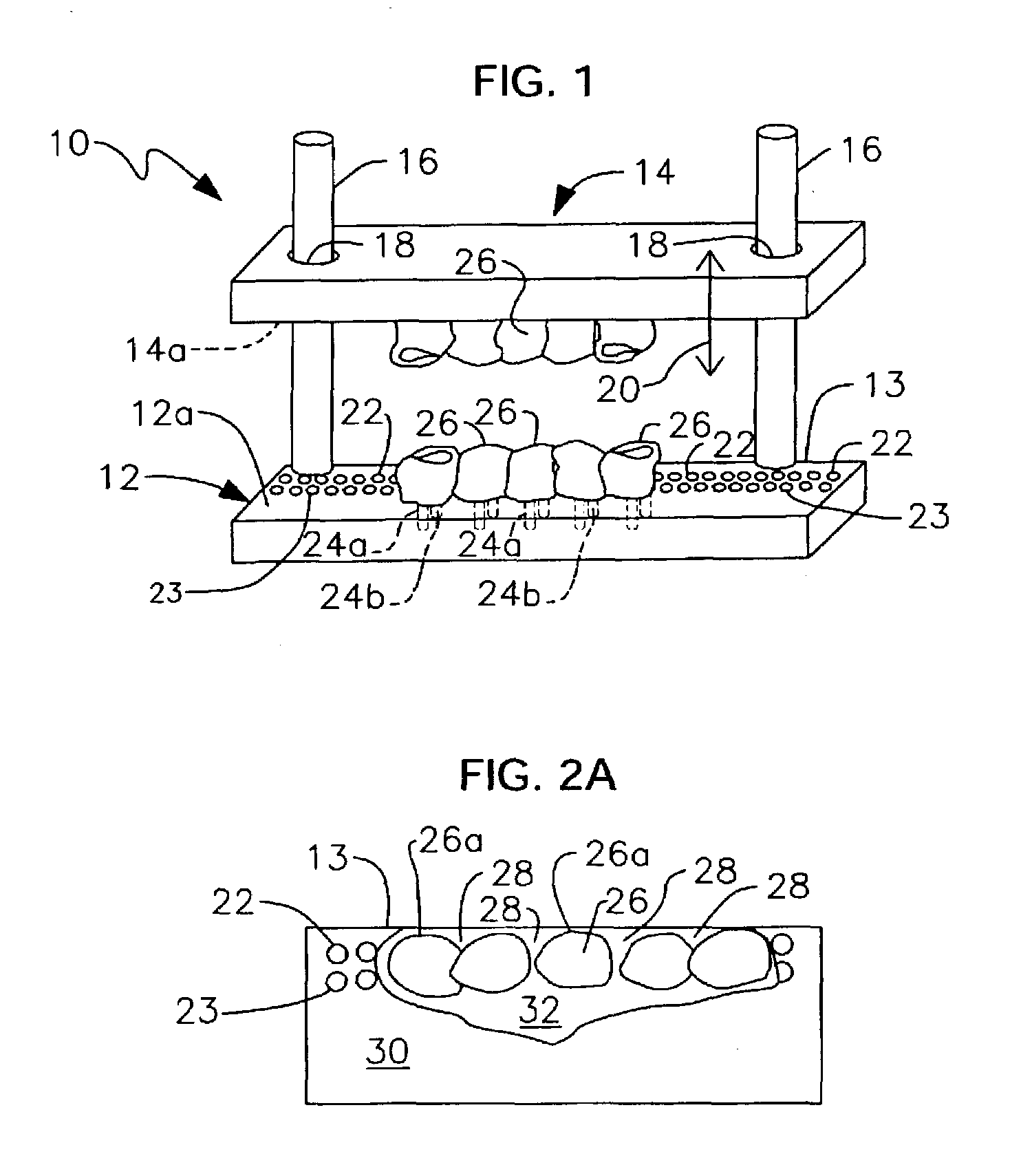

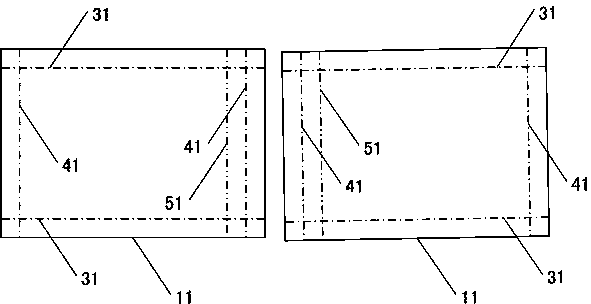

Two-piece model and die system

InactiveUS6932608B1Reduced material requiredLow skill level requiredImpression capsDental articulatorsEngineeringMechanical engineering

A model and die system has a working quadrant of parallelepiped construction and a opposing quadrant of the same construction. The working quadrant has an upper flat surface disposed in confronting relation to a lower flat surface of the opposing quadrant. Pin-receiving bores are formed in the working quadrant and mounting members depend from the opposing quadrant. Each cast tooth supported by the working quadrant has a pin depending from it and is fully seatable against the upper flat surface. Each cast tooth mounted on the upper flat surface is secured to a mounting post that depends from the upper flat surface. In a first embodiment, the quadrants are held in spaced apart, adjustable vertical relation to one another by a pair of parallel guideposts. In a second embodiment, an articulated hinge performs that function. In a third embodiment, a semicircular base opposes a semicircular top member.

Owner:GBASE INC

Method for sticking cakes in plastering engineering by using laser

InactiveCN102071792AEasy to operateLow skill level requiredSurveying instrumentsBuilding constructionsControl lineLaser

The invention discloses a method for sticking cakes in plastering engineering by using laser. The method comprises the step that: the cakes are stuck by taking a crossed vertical laser surface output by a laser marking gauge as a reference surface for sticking the mud cakes, namely, a control line is set on a floor of a building which is required to be subjected to plastering construction in a conventional mode, and the laser marking gauge is placed on the control line to keep a straight line projected to laser cross on the floor coincided or parallel with the control line; thus the mud cakes can be stuck by taking the laser surface which is coincided or parallel with the control line as the reference surface for sticking the cakes, the distance from the end face of each mud cake to the laser surface serving as the reference surface is measured by using an angle steel ruler, and the distance from the end face of each stuck mud cake to the laser surface serving as the reference surface is kept same. The method has the advantages of high construction efficiency, good quality, low construction cost, low requirement on the technical level of the construction personnel and the like, and is easy and convenient to operate, and the raw materials are saved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

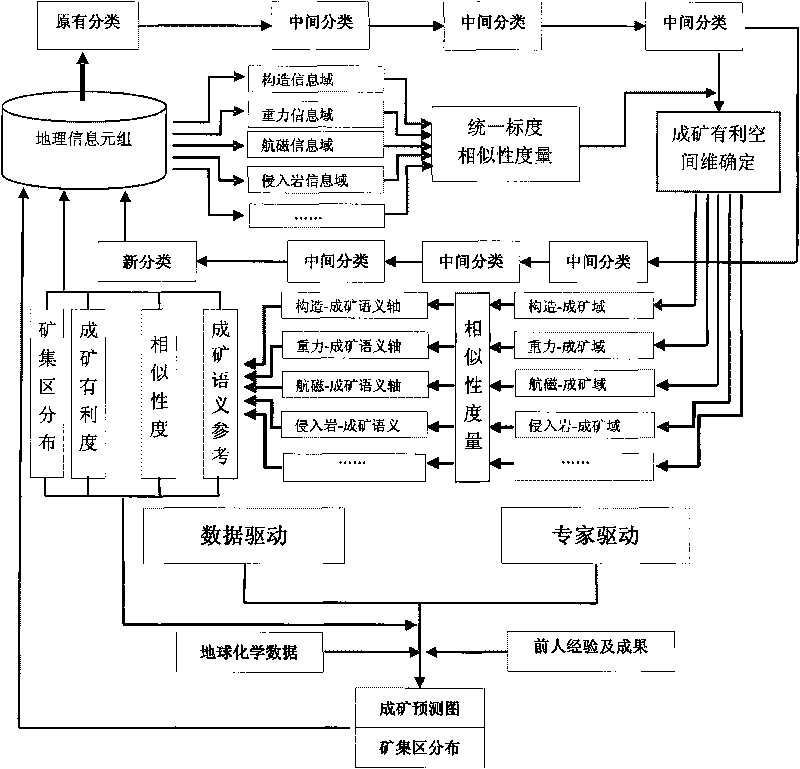

Geographic tuple based quantitative prediction method of ore concentration areas

InactiveCN101706589ALow skill level requiredEasy to operateGeological measurementsMineral SourcesCentral asia

The invention relates to a geographic tuple based quantitative prediction method of ore concentration areas, which is characterized by establishing the quantitative prediction method of mineral resources in the Central Asia region by analyzing the time-space evolution process of the mineral resources in the region, taking GIS as a platform, applying the nonlinear theory and the artificial neural network technology, integrating multivariate information such as geology, geophysics, geochemistry, remote sensing and the like, carrying out analogy on the geological characteristics of the minerals at different levels and the metallogenetic geological setting and dividing favorable metallogenetic areas at different levels. The method solves the problem of failure of quantitative prediction in the prior art.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

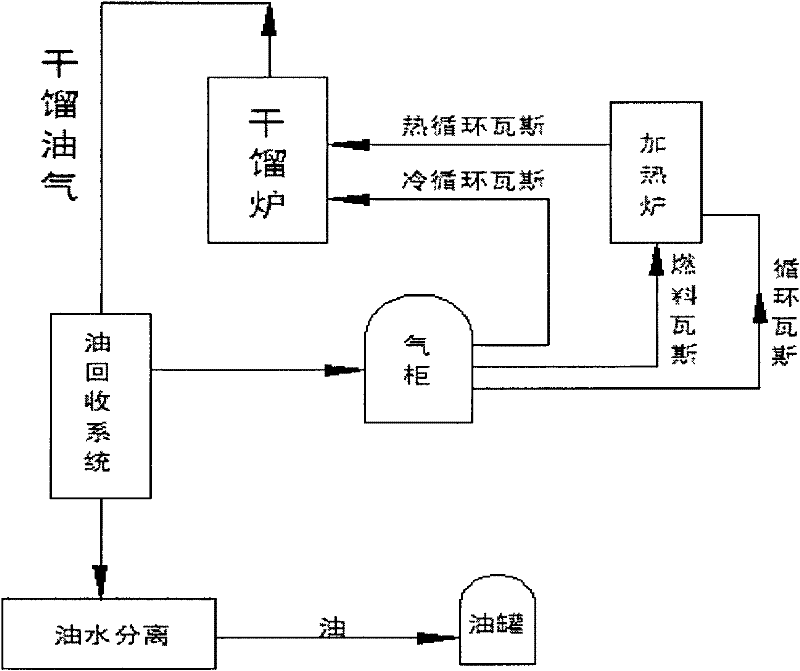

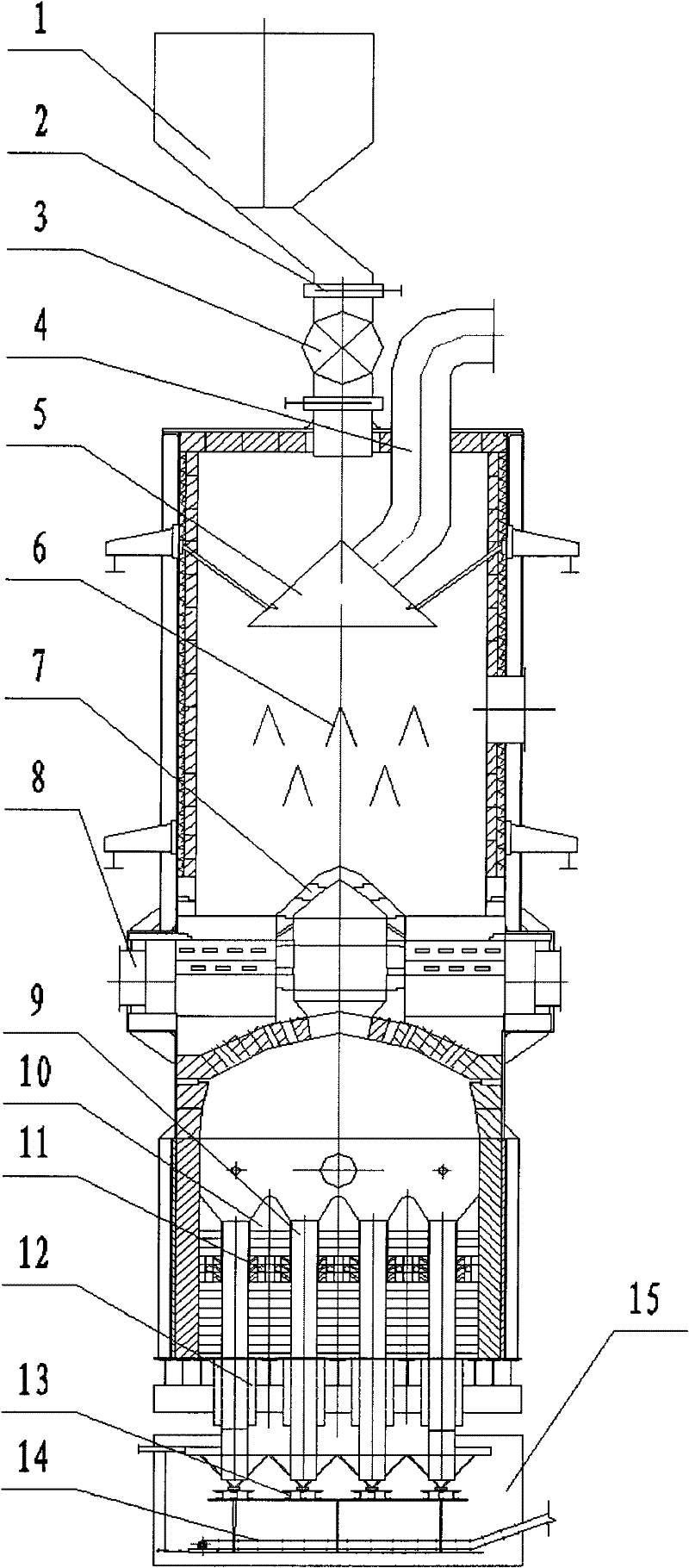

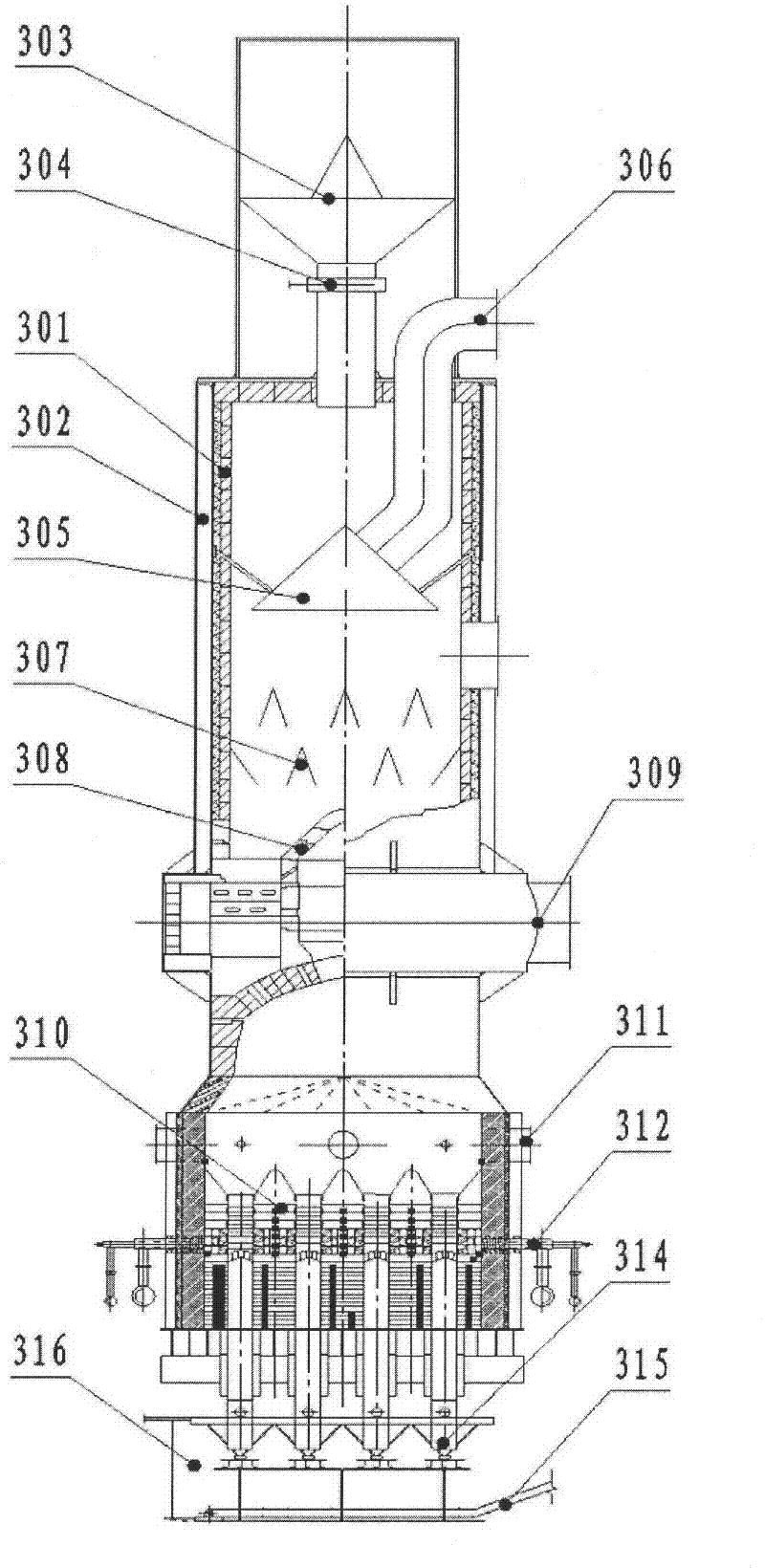

Methane-circulating retort capable of handling 500 to 1,000 tons of oil shale daily

InactiveCN102260509ASmall pressure lossReduce masonry costsDirect heating destructive distillationSpecial form destructive distillationWater contentChemistry

The invention discloses a process and a device for refining oil by dry distillation of oil shale. The process is characterized in that methane generated in the dry distillation process of the oil shale can be repeated used as a hot carrier in the dry distillation of the oil shale. The retort for realizing the dry distillation oil refining process is characterized in that: the retort has a vertical round-square structure, namely the cross section of the upper part is round, the cross section of the lower part is square, and the inside diameters of the upper and lower parts are the same; and array umbrellas, a herringbone baffle plate, a device shaped like a Ding(ancient cooking vessel of China) or in an Asi structure, an air distribution and material distribution tracery wall, a coke discharging tank, a cooling water jacket, a water seal pool, a coke pushing machine and a scraper conveyor are arranged in the retort from top down in turn. The daily handling capacity of the retort is 500 to 1,000 tons. The invention is suitable for refining oil by dry distillation of oil shale with low methane content, low solid carbon content, low water content and a particle size of 5 to 75 milliliters, and the recovery rate of the oil is 85 to 90 percent.

Owner:辽宁成大能源科技有限公司

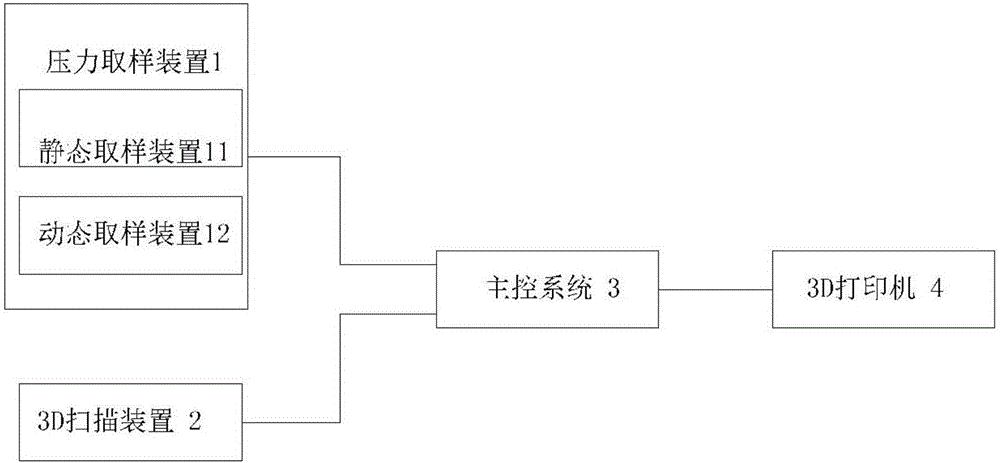

Intelligent insole 3D (Three Dimensional) printing system and printing method

InactiveCN106273498ALow experience requirementLow skill level requiredAdditive manufacturing apparatusDomestic articlesControl systemBiomechanics

The invention provides an intelligent insole 3D (Three Dimensional) printing system and printing method and belongs to the field of insole production equipment. The printing system comprises a pressure sampling device, a 3D scanning device, a main control system and a 3D printer; the pressure sampling device is used for acquiring pressure data of different positions of a foot; the 3D scanning device is used for scanning a foot image to obtain three-dimensional model data of the foot; the main control system is electrically connected with the pressure sampling device and the 3D scanning device; the 3D printer is electrically connected with the main control system; the 3D printer is used for printing an insole according to insole hardness data and insole shape data which are output by the main control system. According to the intelligent insole 3D printing system, the insoles meeting biomechanics of human bodies are customized for users according to foot conditions of different users and health-care or disease prevention and treatment functions are realized. The production efficiency is high and the requirements on experience and skill levels of related personnel are low; the intelligent insole 3D printing system can be widely applied to the field of medicine or the field of health-care sports.

Owner:COOLNAME SHANGHAI INT TRADE CO LTD

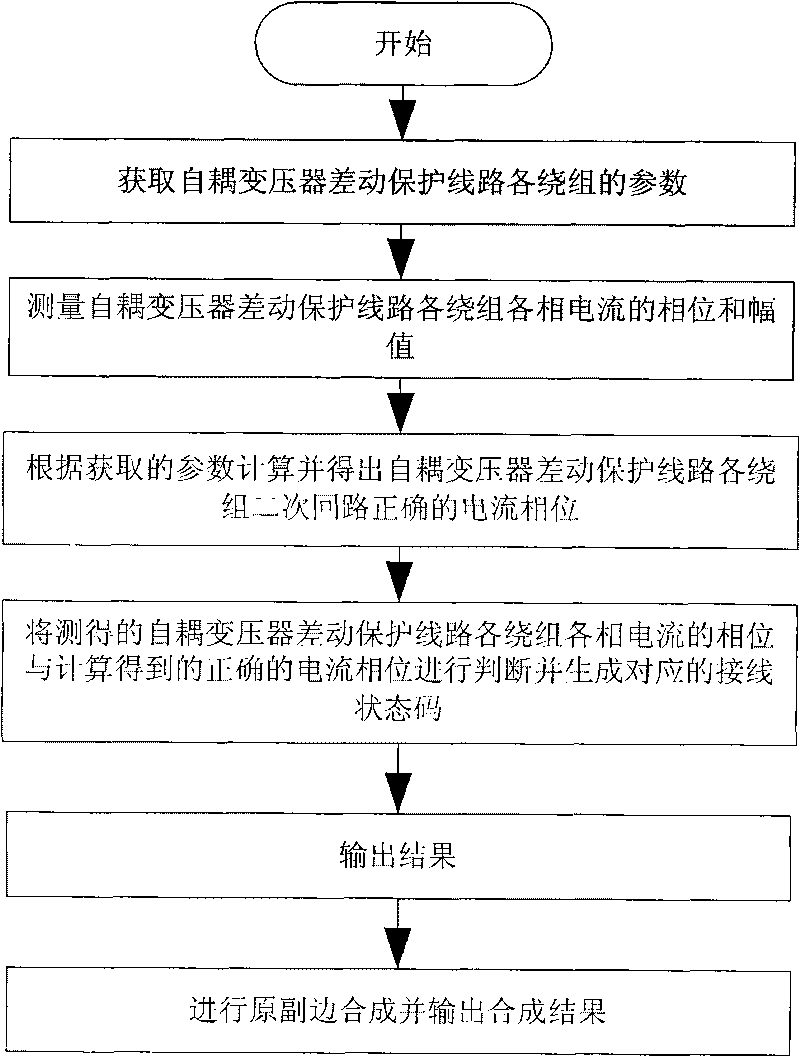

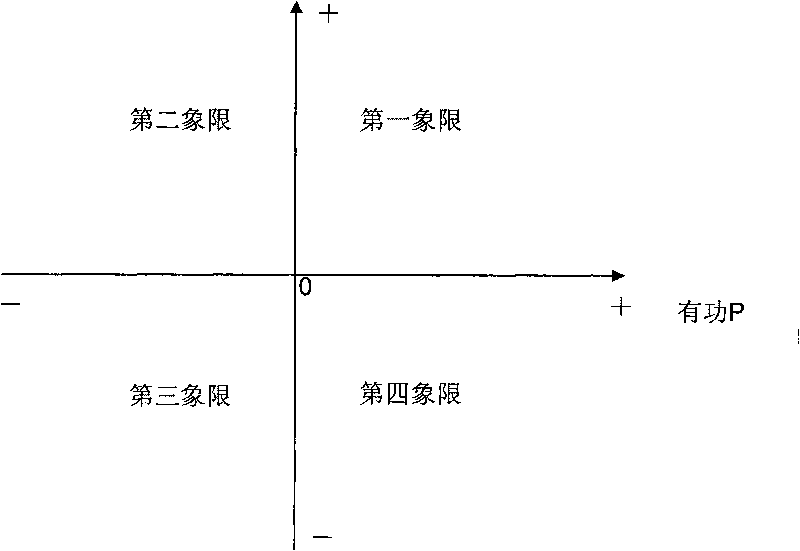

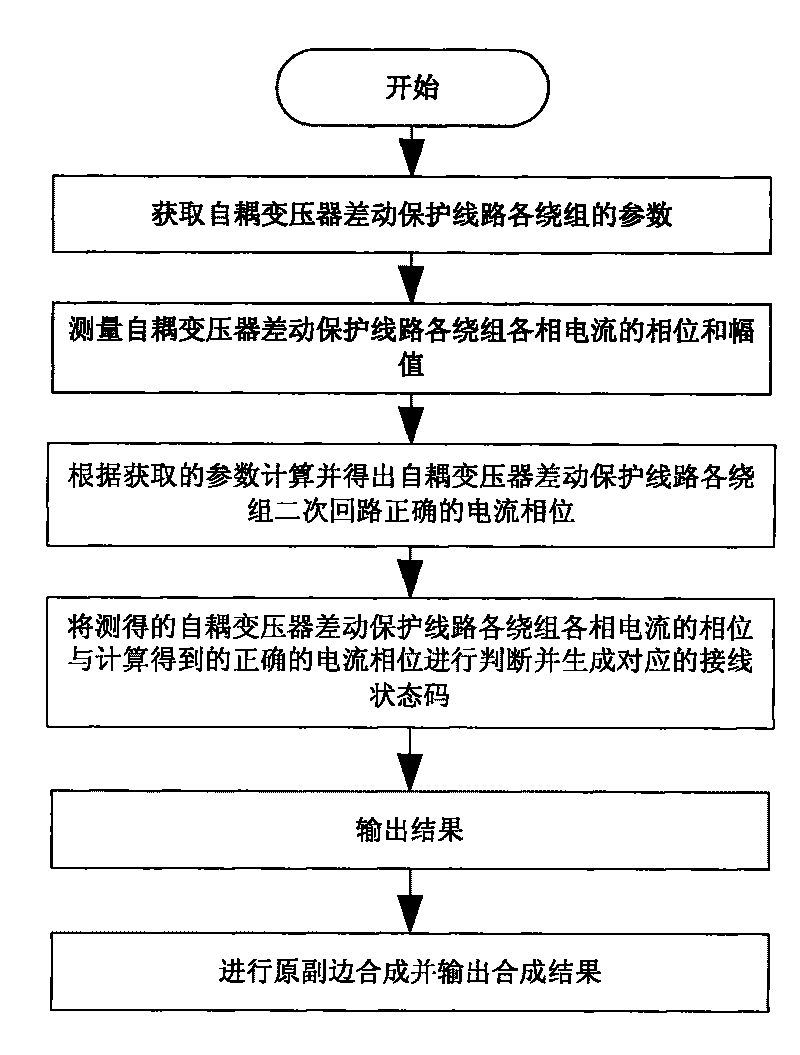

Method for analyzing autotransformer differential protection CT circuit connection

ActiveCN101762768AAnalytical results are reliableImprove accuracyEmergency protective circuit arrangementsVoltage-current phase angleAutotransformerPhase currents

The invention provides a method for analyzing autotransformer differential protection CT circuit connection. The method comprises the following steps of: (1) acquiring parameters of all windings in the autotransformer differential protection circuit; (2) measuring phases and amplitude values of phase currents of the windings in the autotransformer differential protection circuit; (3) calculating according to the acquired parameters to obtain the correct current phases of secondary circuits of the windings in the autotransformer differential protection circuit; (4) comparing to judge the correctness of the measured autotransformer differential protection circuit connection, and generating the corresponding connection status code; (5) outputting the result; and (6) synthesizing the primary windings and the secondary windings, and outputting the synthesis result. The invention has the advantages of high reliability, safe and simple use and convenient operation, and solves the technical problem of complex process for artificial judgment of connection correctness in the prior art.

Owner:西安爱邦电子系统有限公司

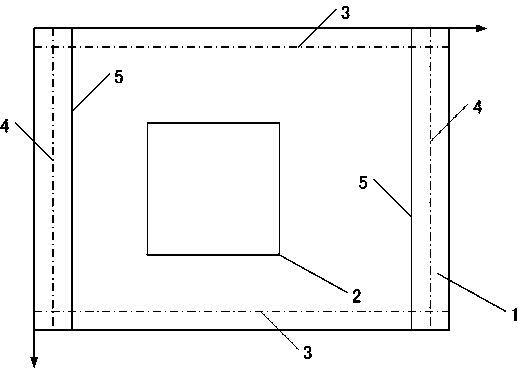

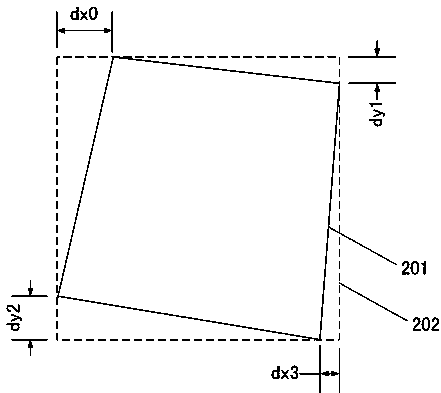

Calibration method for multi-projection splicing

InactiveCN103533279AQuick calibrationLow skill level requiredTelevision system detailsPicture reproducers using projection devicesHorizontal and verticalComputer science

The invention discloses a calibration method for multi-projection splicing. The method is characterized by comprising the steps as follows: two horizontal calibration lines and two perpendicular calibration lines are generated by a system and added to split pictures of a source picture; at the same time, the system generates an initial rectangular frame picture for each split picture of the source picture; four peaks of each initial rectangular frame picture are adjusted by limiting one direction of the horizontal position direction and the perpendicular position direction, so that an initial calibration window corresponding to the initial rectangular frame picture becomes a final rectangular frame picture; horizontally spicing is performed, and projection split pictures are moved perpendicularly and horizontally, so that horizontal calibration lines of a projection are aligned to each other vertically and respectively, and perpendicular calibration lines of splicing sides of the projection split pictures are overlapped; and when vertically splicing is performed, the projection split pictures are moved horizontally and perpendicularly, so that perpendicular calibration lines of the projection are aligned to each other horizontally and respectively, and at the same time, horizontal calibration lines of splicing sides of the projection split pictures are overlapped. Compared with the prior art, the method has the advantage that the calibration process and the calibration speed are simplified.

Owner:SHENZHEN GENIUSUN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com