Patents

Literature

342results about How to "Reduced material required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

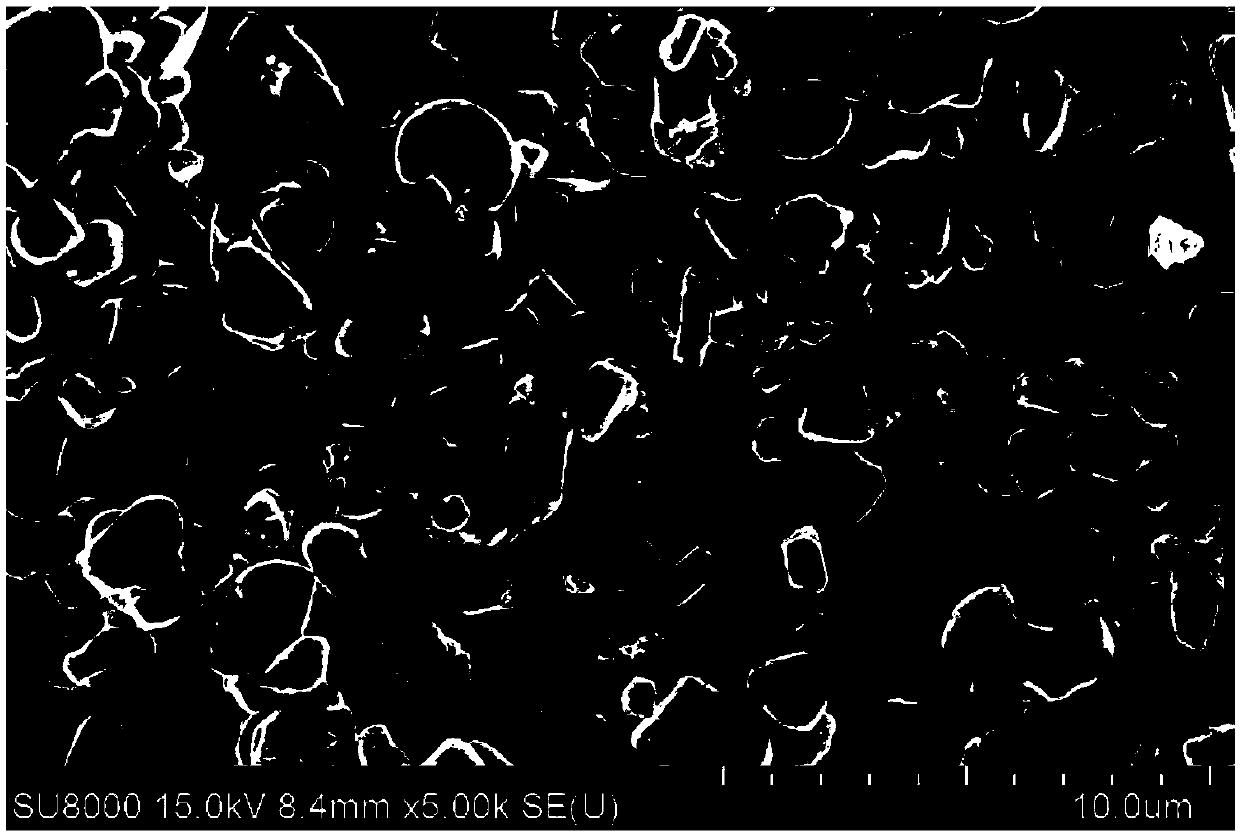

High-nickel ternary positive electrode material with monocrystal morphology and preparation method of high-nickel ternary positive electrode material

InactiveCN108023078AImprove particle size distributionIncrease the coating processCell electrodesSecondary cellsLithium compoundLithium electrode

The invention discloses a high-nickel ternary positive electrode material with monocrystal morphology and a preparation method of the high-nickel ternary positive electrode material. The preparation method comprises the following steps of (1) mixing a soluble nickel salt, a soluble cobalt salt, a soluble manganese salt, a precipitant and a complexing agent, and performing heating reaction to obtain a precursor; (2) mixing the precursor, a lithium compound and a doping metal compound, and sintering in an oxygen atmosphere to obtain a base material; (3) mixing the base material and a detergent,performing stirring, centrifuging and drying, and uniformly mixing with a coating agent to obtain a coated product; and (4) sintering the coated product to obtain the high-nickel ternary positive electrode material with monocrystal morphology. The high-nickel positive electrode material prepared by the method has morphology similar to that monocrystal, and is high in compaction density and energydensity, low in resided alkali amount and good in processability; and meanwhile, with the introduction of a doping element, a lithium ion battery prepared from the high-nickel positive electrode material has relatively high cycle property, and the cycle property and the safety of the material are also improved by the coating layer.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

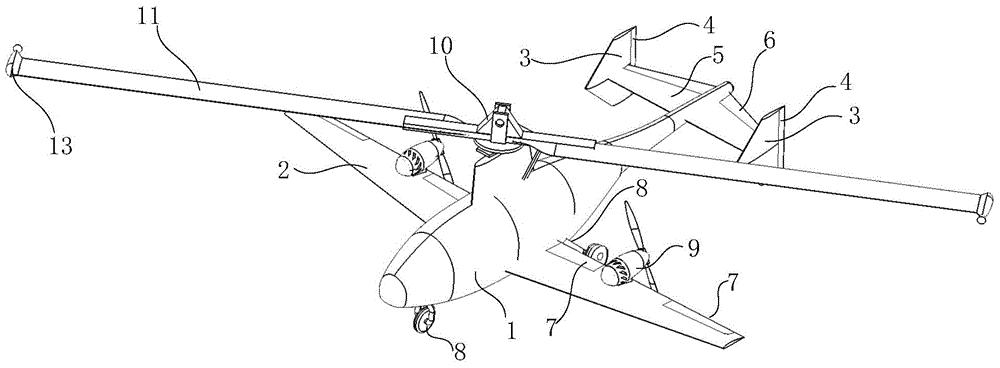

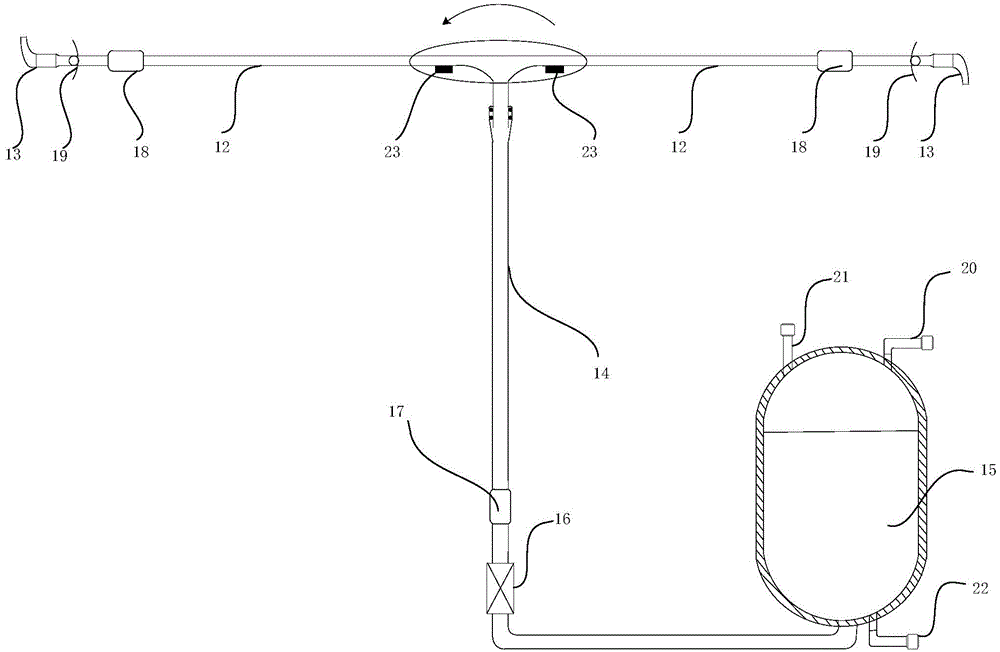

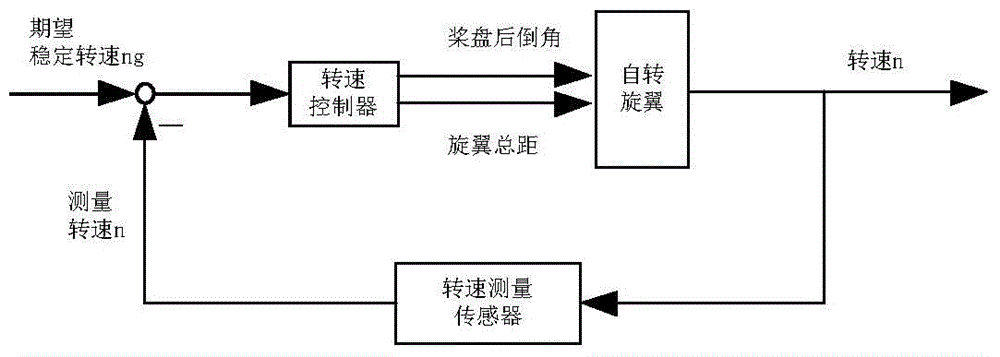

Composite type multi-mode multi-purpose aircraft

InactiveCN104477377AImprove performanceWith verticalAircraft navigation controlWeight reductionFlight vehicleTail rotor

Owner:BEIHANG UNIV

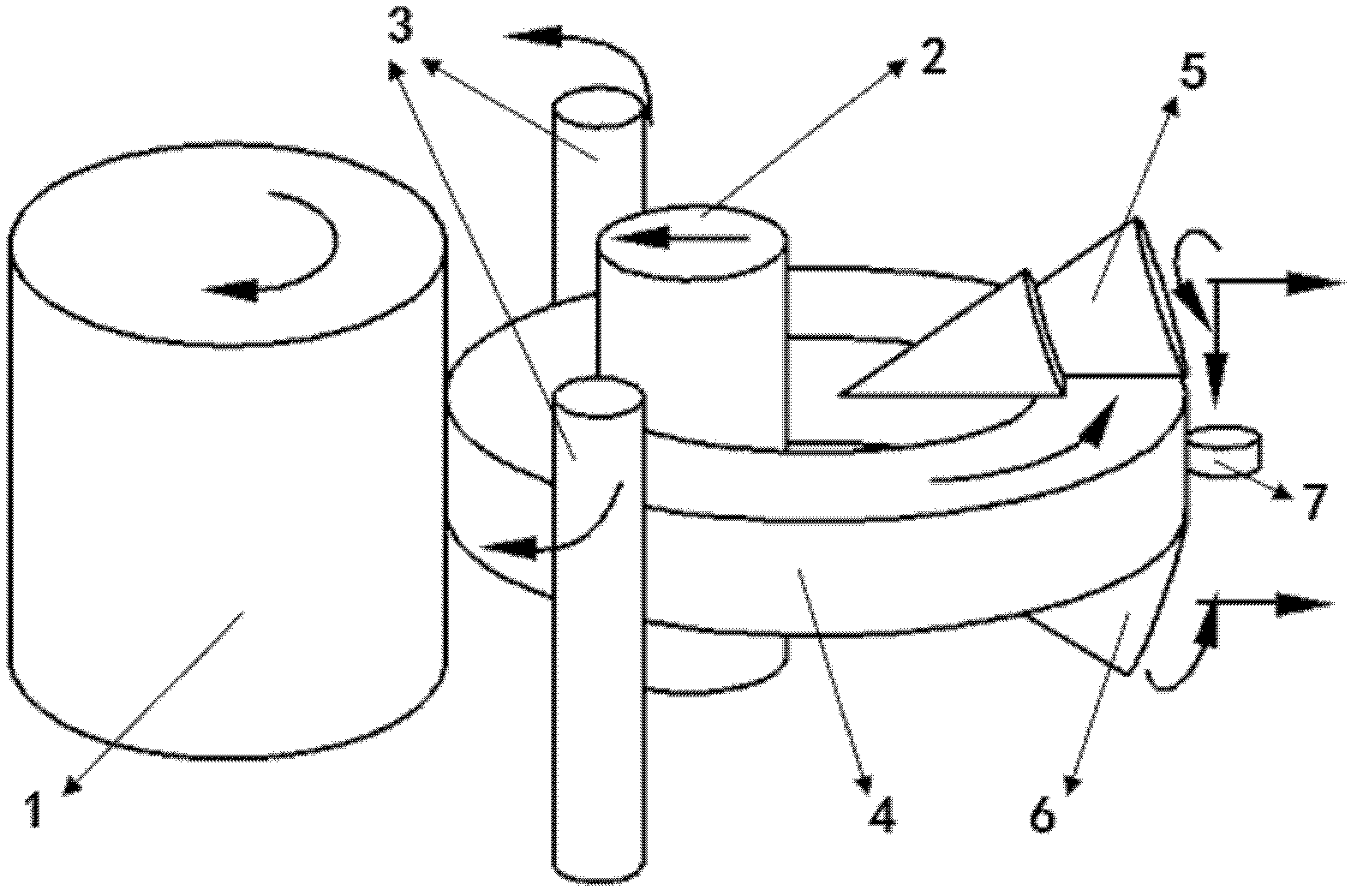

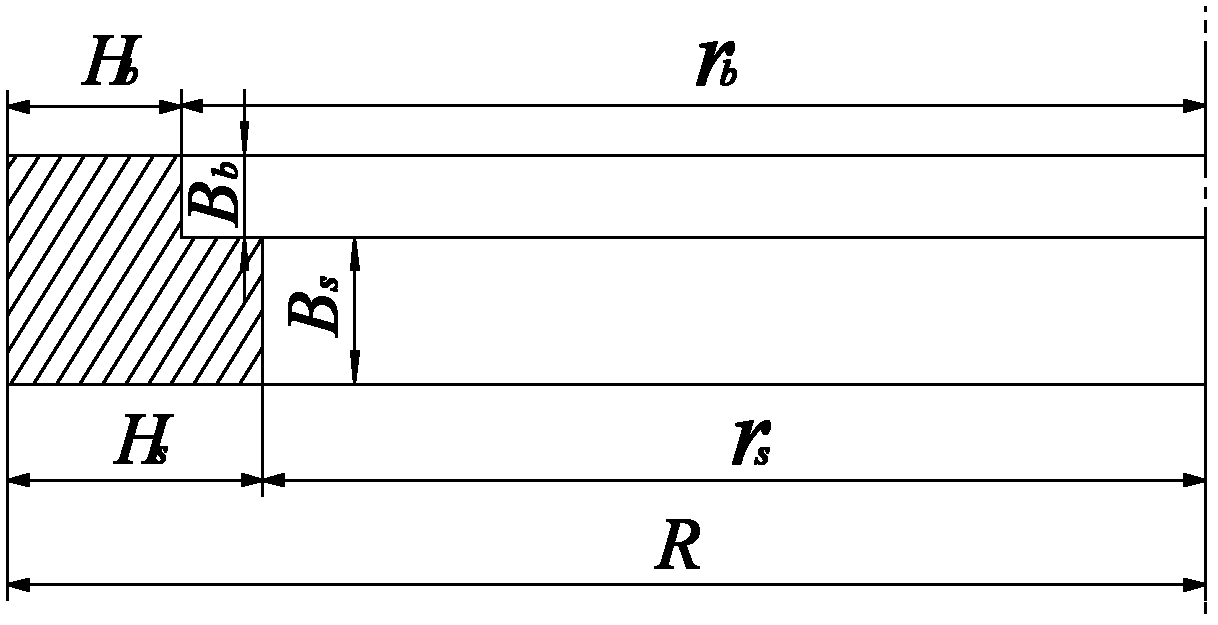

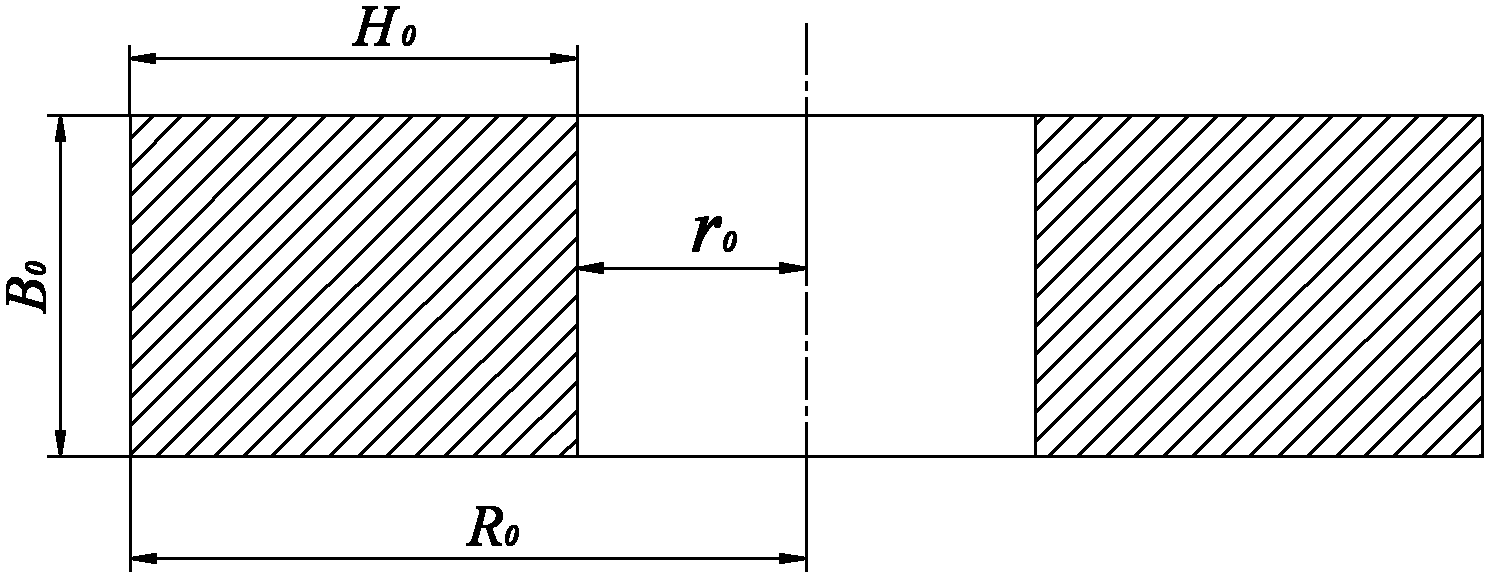

Radial and axial roll-forming method for large internal-stage annular piece

The invention relates to a radial and axial roll-forming method for a large internal-stage annular piece. The method comprises the following steps of: (1) making a blank, namely performing hot-forging, upsetting, punching and slug-stamping on a bar material, and thus obtaining an annular piece blank for rolling; (2) designing a roll hole pattern, namely determining the size of the roll hole pattern according to a roll linear speed, an equipment parameter, a roll deformation condition and the size of the annular piece blank, and determining the size of the axial roll hole pattern according to the roll linear speed, the equipment parameter, the annular piece blank and the size of the annular piece blank; and (3) roll-forming, namely putting the obtained annular piece blank on an annular rolling machine for rolling, controlling an upper conical roller and a lower conical roller to move backwards in real time during rolling to make the bottom end of the annular rolling machine always contact outer diameters of the upper end face and the lower end face of the annular piece, controlling the rolling process by rationally distributing a feeding speed and a feeding amount according to three stages, namely pre-rolling, rolling and shaping rolling, and when the outer diameter of the detected annular piece reaches a preset value, finishing the rolling process. The method has the characteristics of high production efficiency, low production cost and high product quality.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

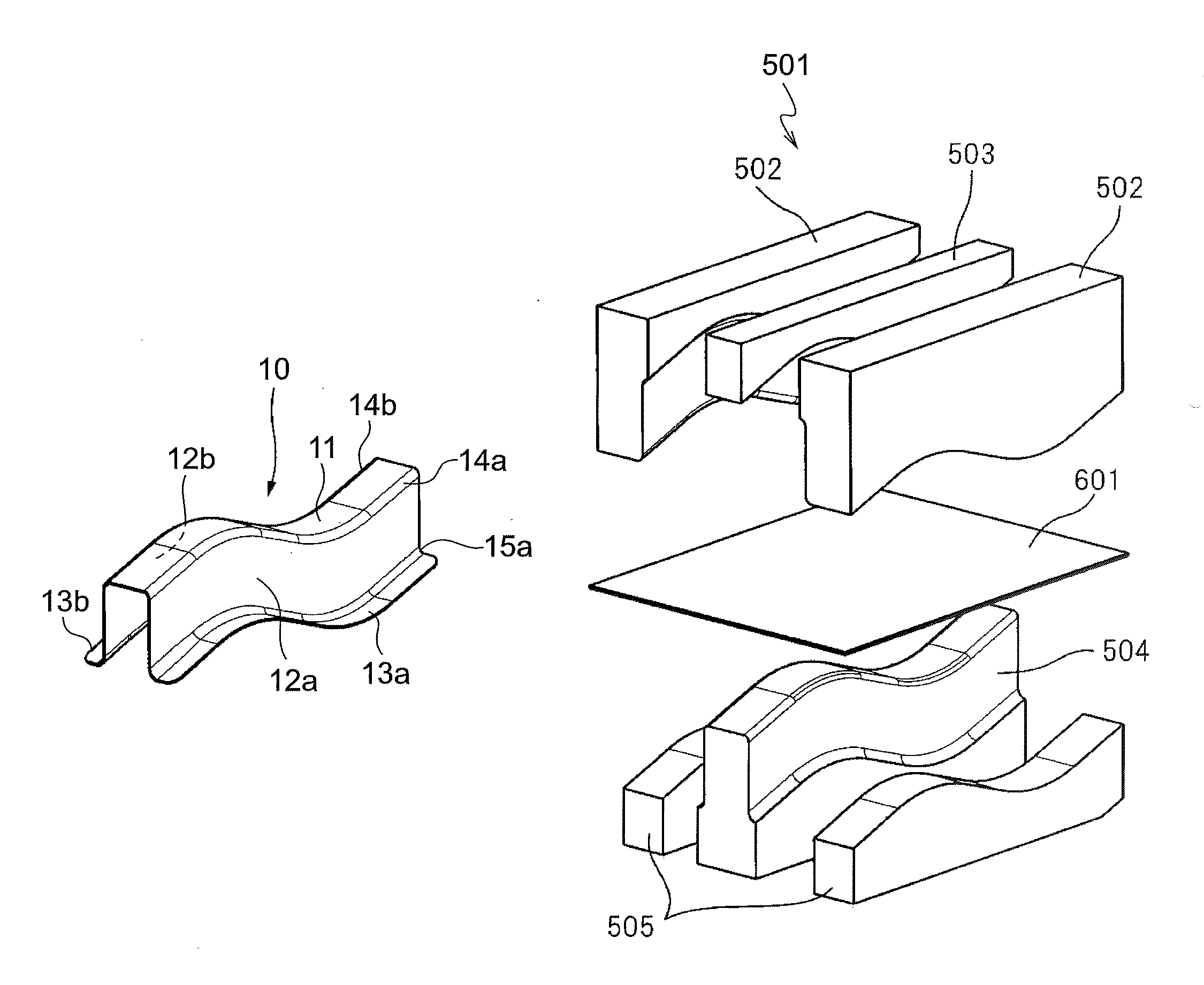

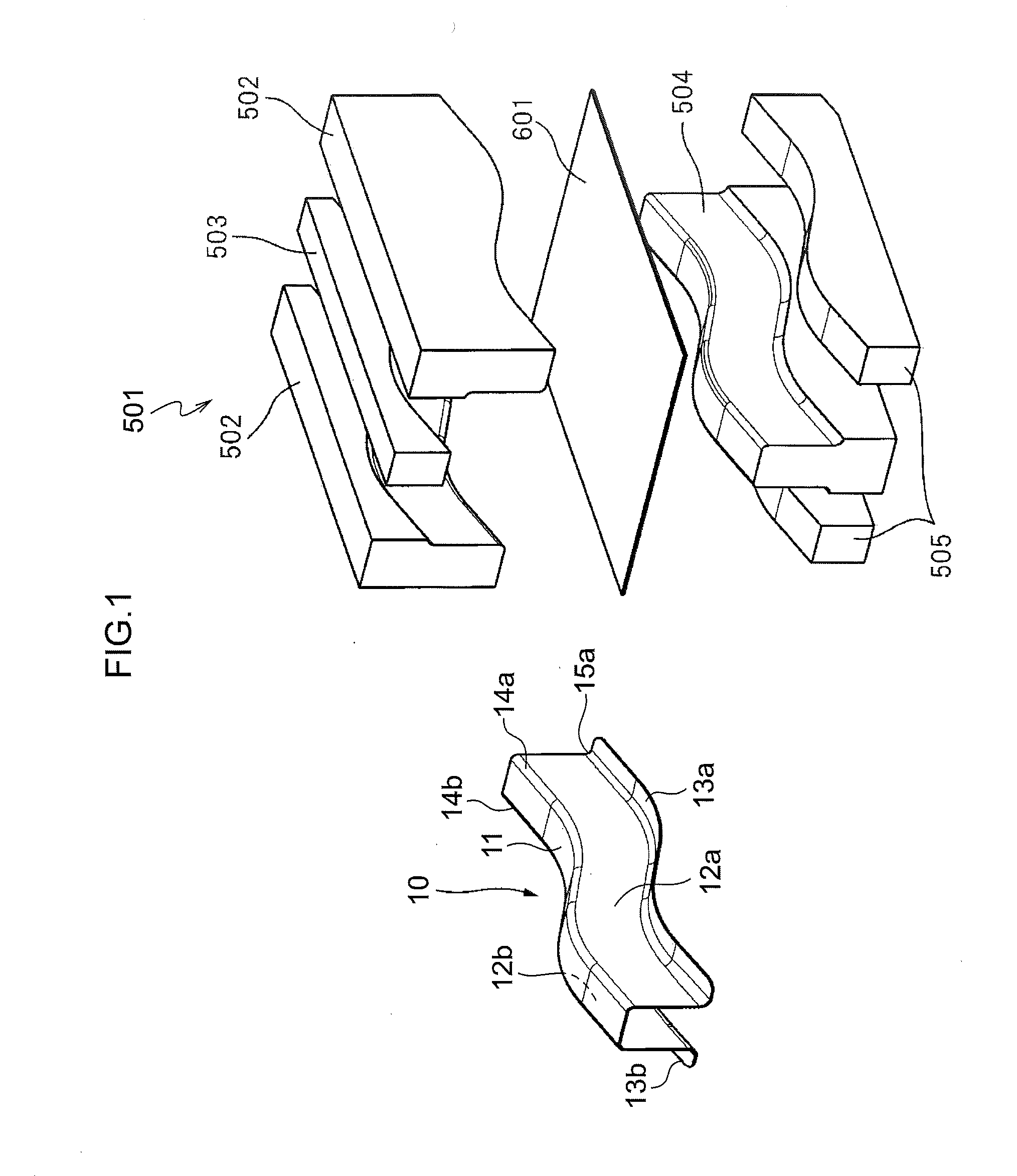

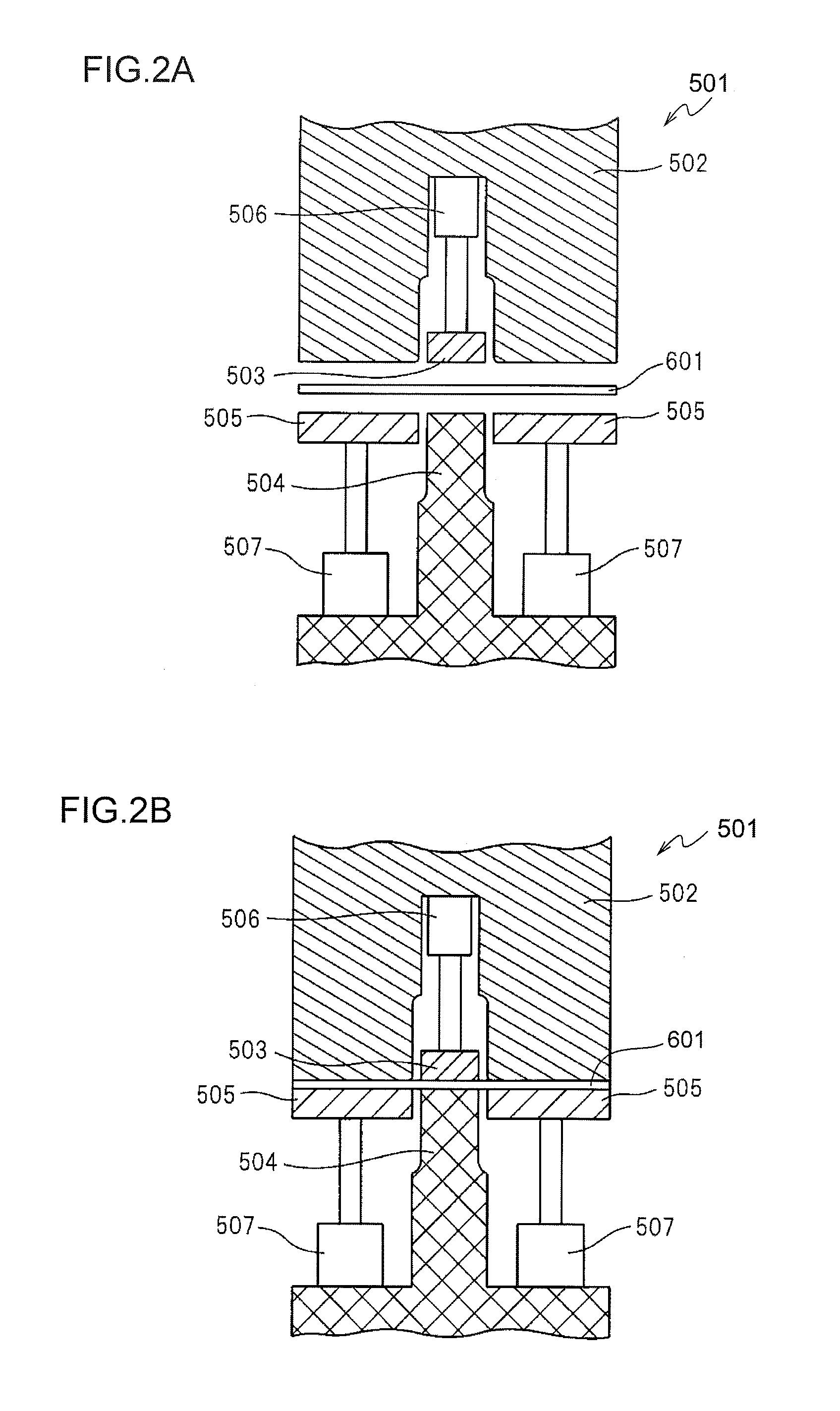

Method for producing curved part, and skeleton structure member of body shell of automobile

ActiveUS20150224563A1Avoid it happening againReduce decreaseSuperstructure subunitsThin material handlingLeading edgeWrinkle skin

A curved part 10 having a hat-shaped cross section is produced by press-forming without causing cracks and wrinkles. When producing a curved part 10, which is made up of a top plate 11, vertical walls 12a and 12b extended in parallel with each other along ridgelines 14a and 14b of the top plate, and outwardly directed flanges 13a and 13b which connect to leading edges of the vertical walls, and has a generally hat-shaped cross section, by press forming, the metal material sheet 601 is interposed and constrained by the die 502 and the blank holder 505 and is press-formed while the metal material sheet 601 being interposed and constrained by the pad 503 and the punch 504.

Owner:NIPPON STEEL CORP

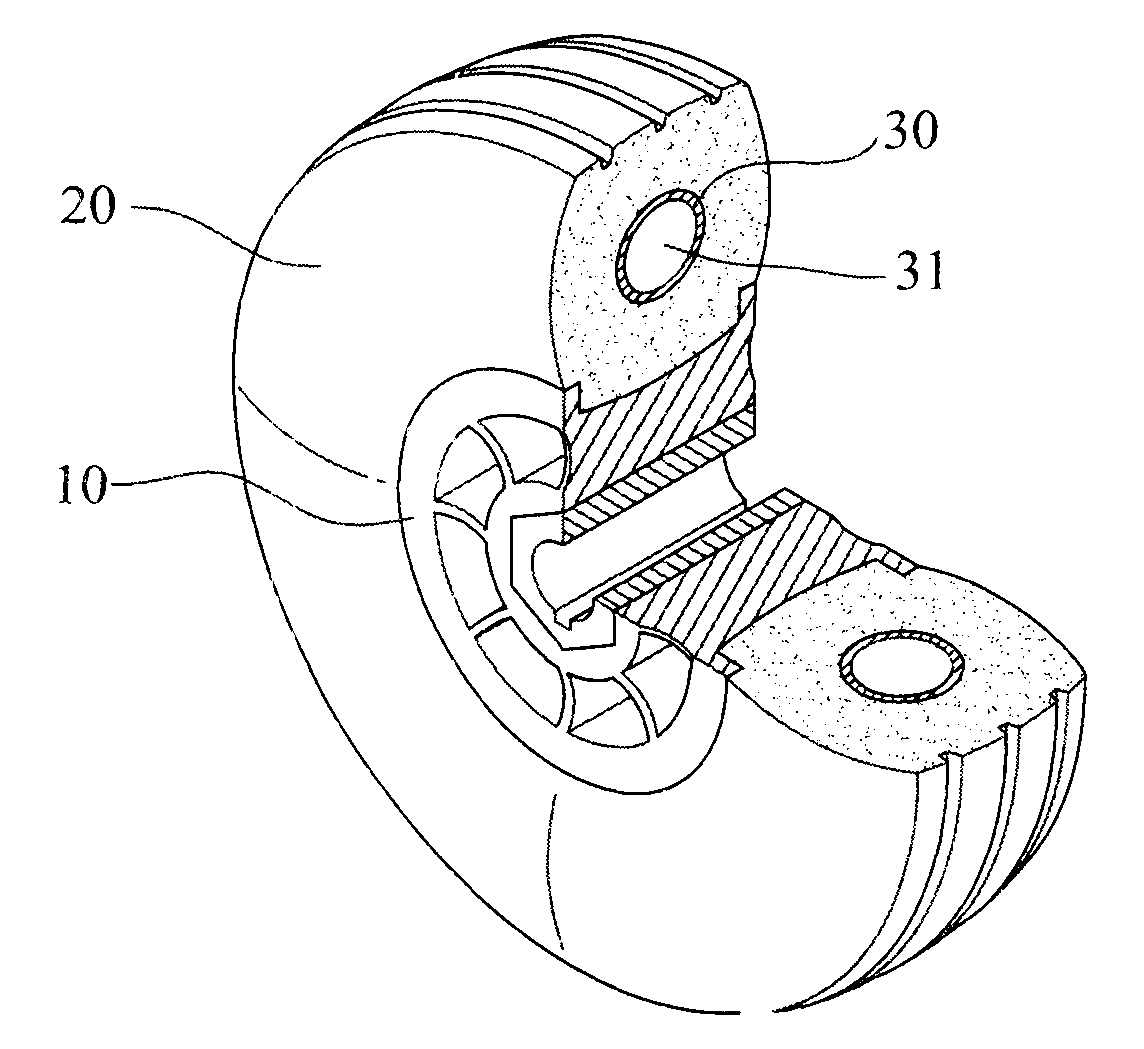

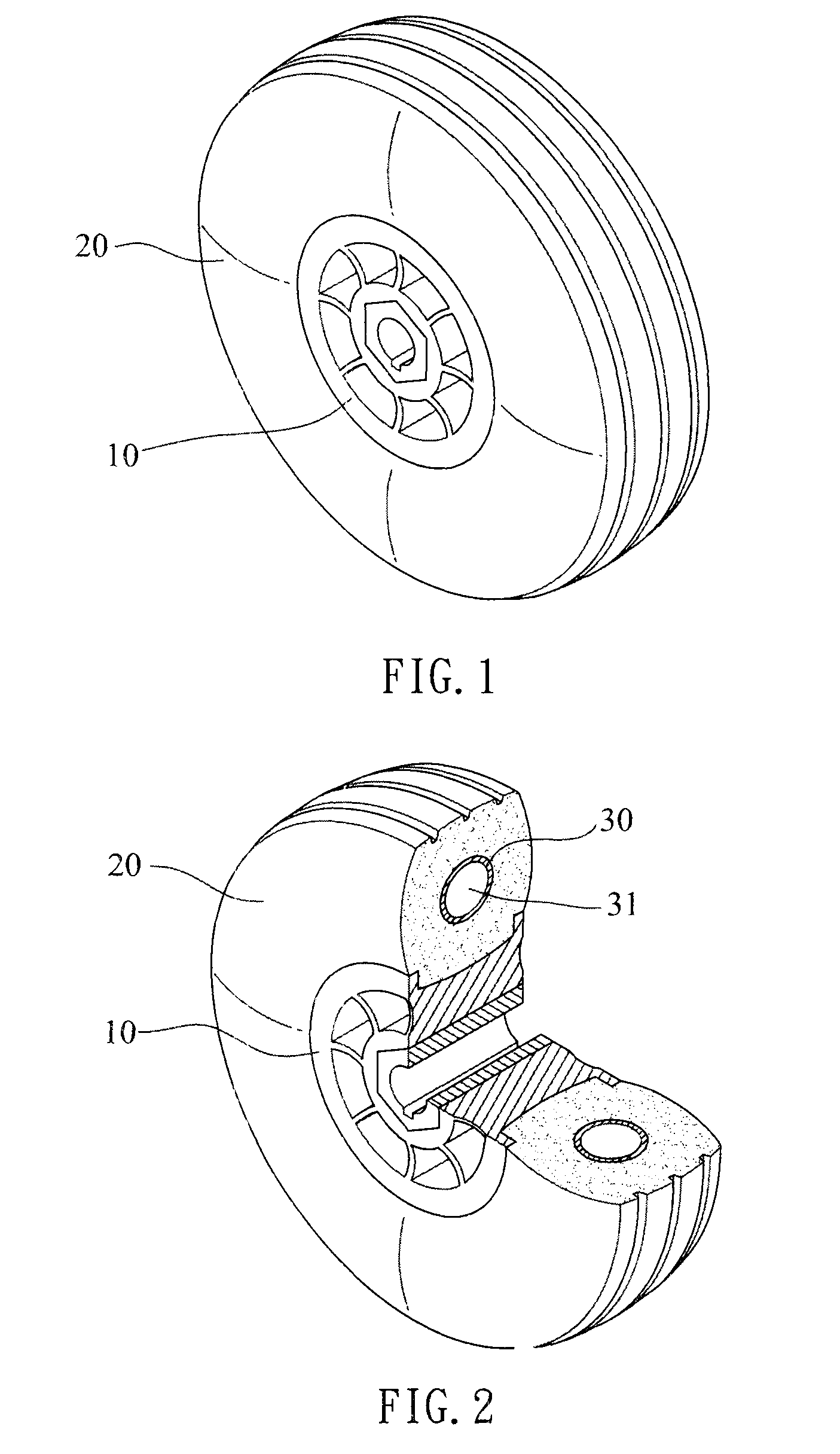

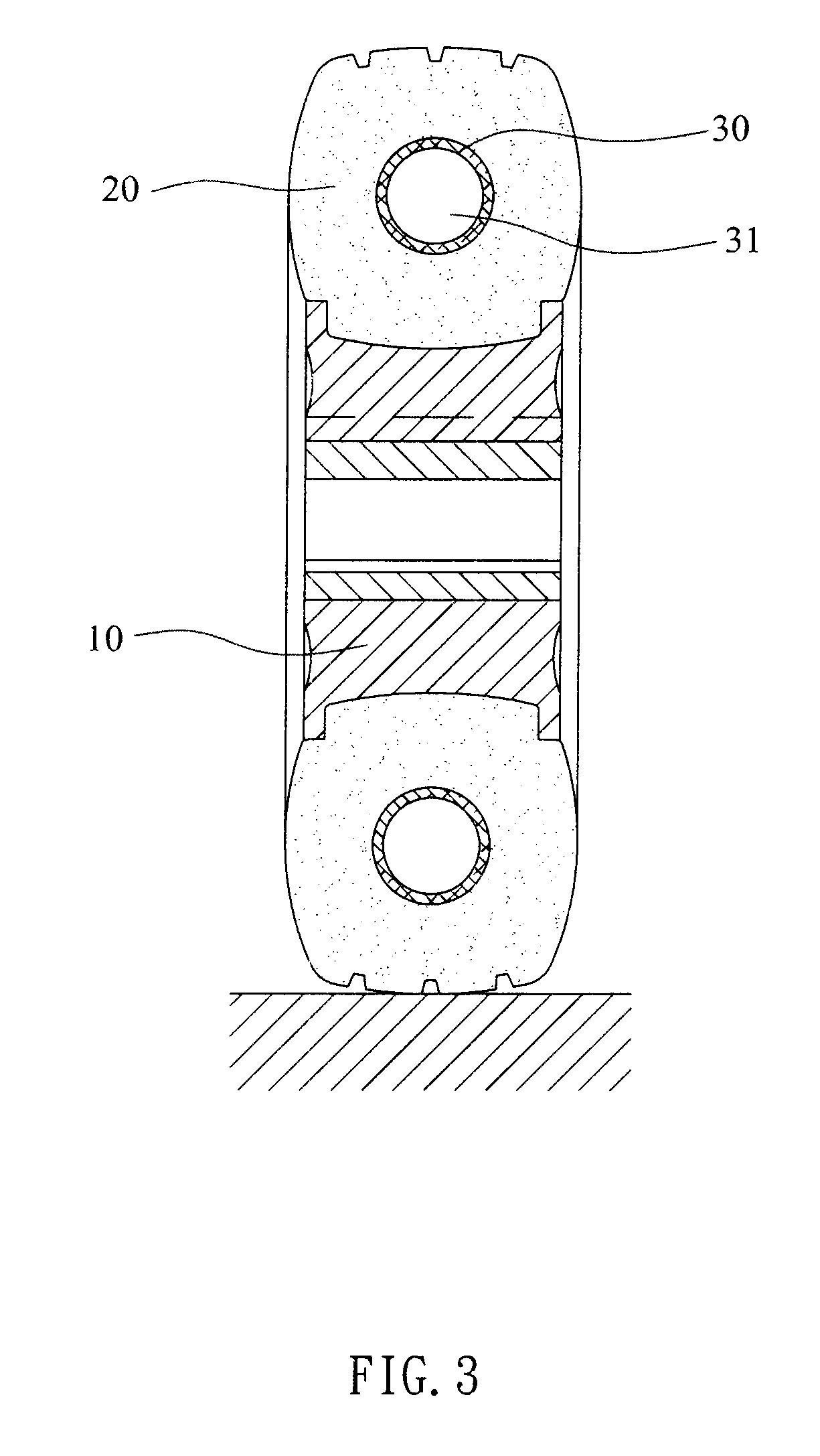

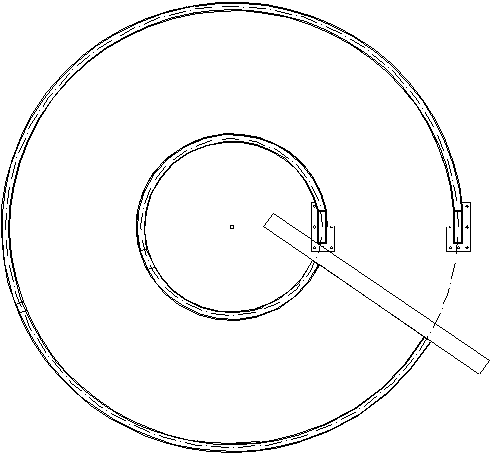

Tire with foam portion and resilient portion

InactiveUS20100122758A1Guaranteed flexibility and precisionReduced material requiredNon-inflatable tyresInflatable tyresTweelPlastic materials

Owner:HUANG SHU JU

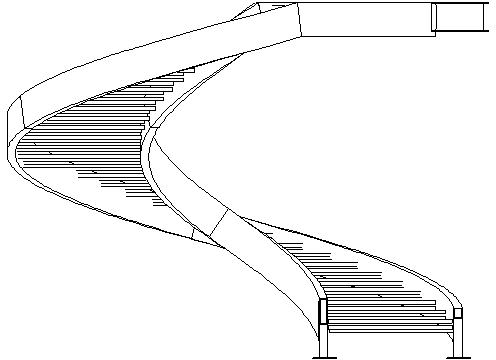

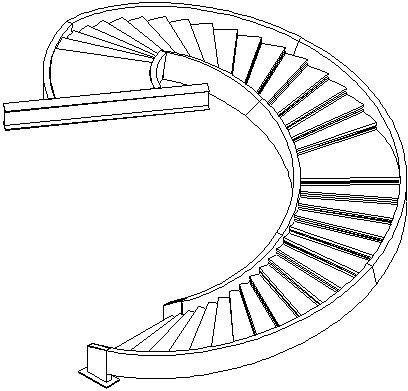

Production method of 360-degree spiral stair with cambered box beams

The invention relates to a production method of a 360-degree spiral stair with cambered box beams. The stair is formed by assembling and mounting of the cambered box beams on two sides, steps and bottom uprights. The method includes the steps: adopting a computer to perform part lofting according to three-dimensional spatial point coordinates of flange plates and webs in design details and X-Y coordinates expanded in a two-dimensional plane; accurately blanking on a numerical control cutting machine according to programming; producing and assembling a moulding bed; adopting a total station to measure positioning points of bottom flanges of the stair beams on the moulding bed; subjecting cambered plates to rolling and pressing shaping; assembling segments by an 'integral assembly, end to end connection and section falling head' mode; subjecting the box stair beams to integral welding and correction; assembling and welding step plates; measuring and correcting overall dimensions; and inspecting, and coating after sand blasting. By the production method, used energy, materials and labor can be reduced, production cycle and construction difficulty are reduced, and quality of a finished product is improved.

Owner:CHINA CONSTR STEEL STRUCTURE WUHAN

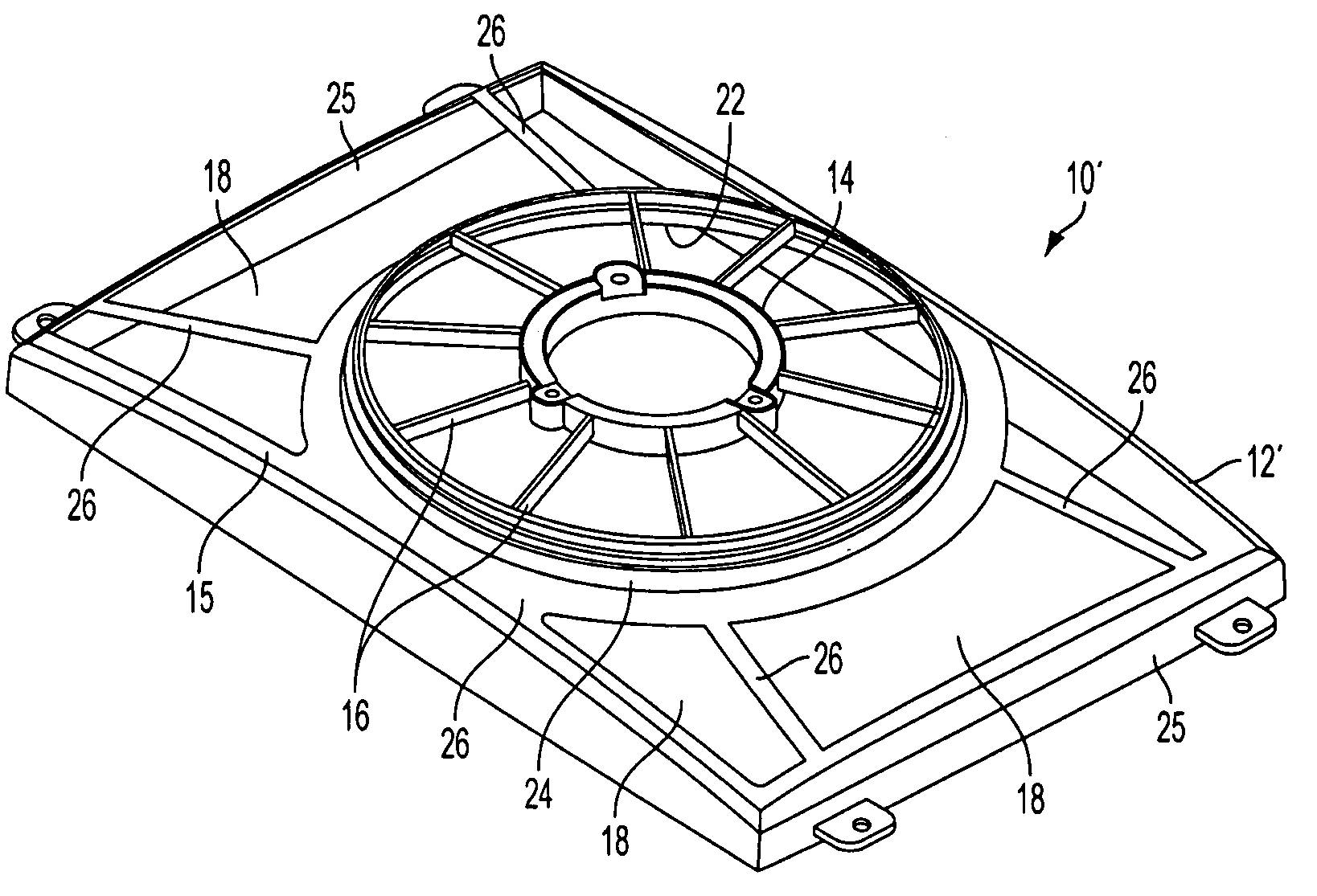

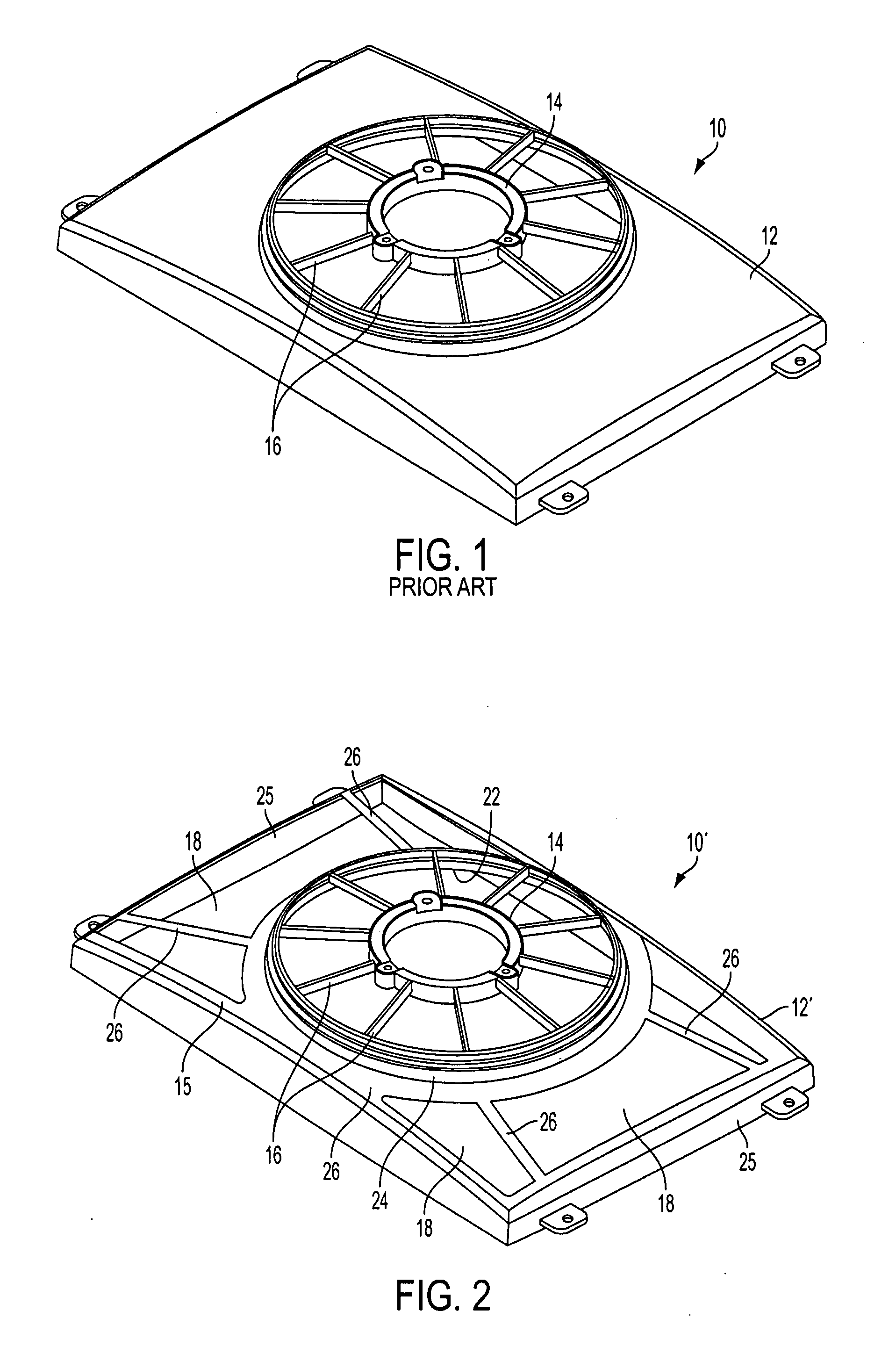

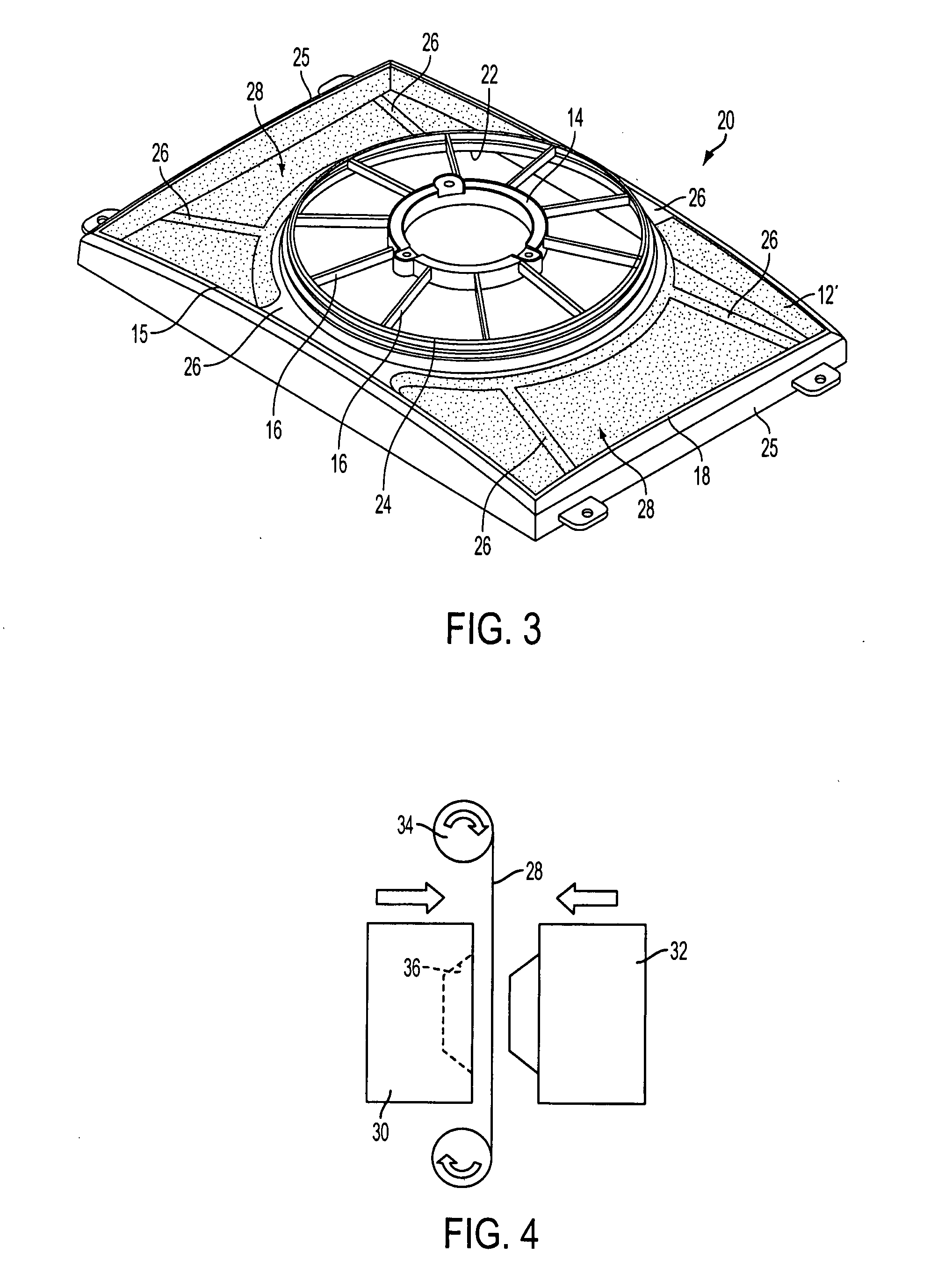

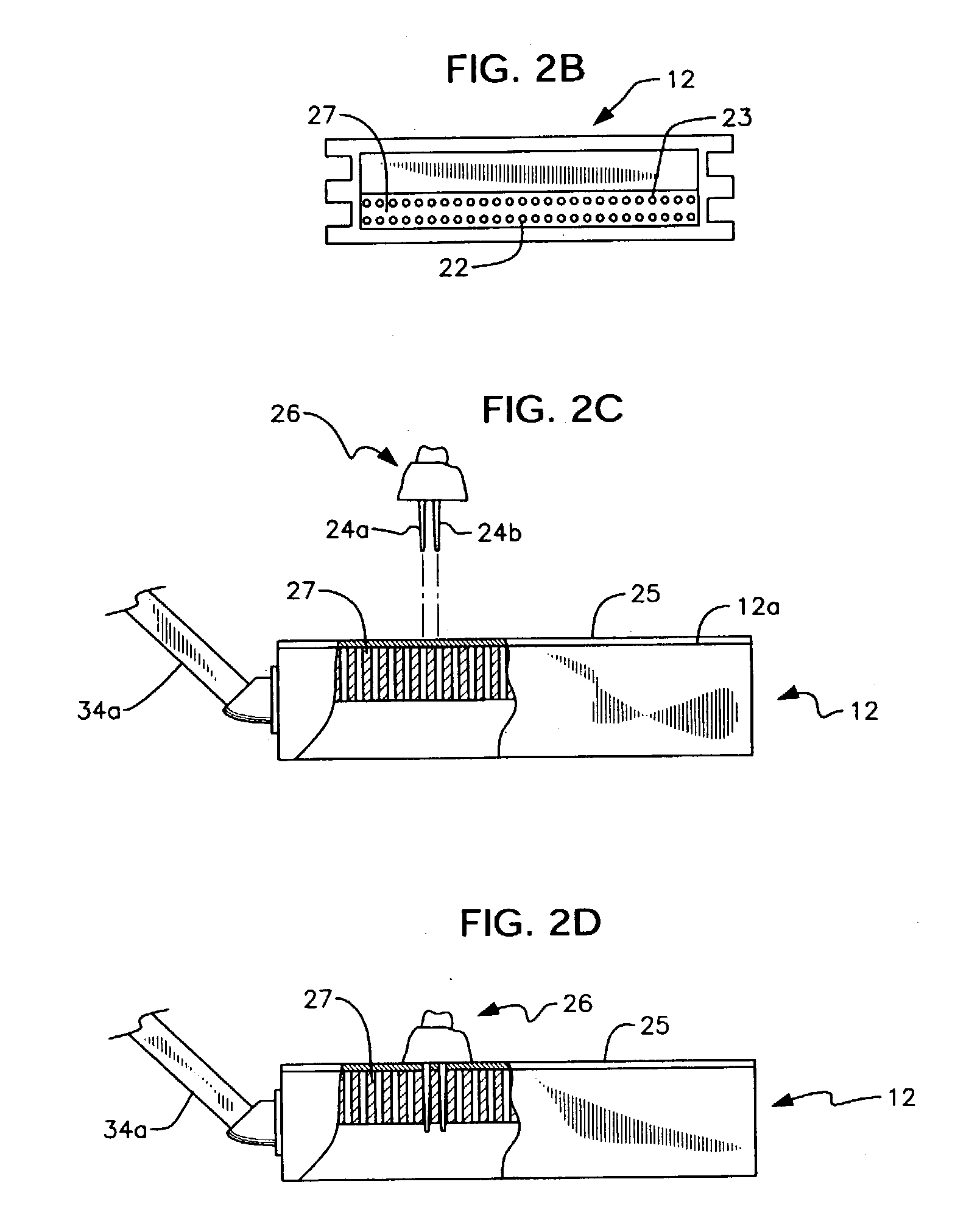

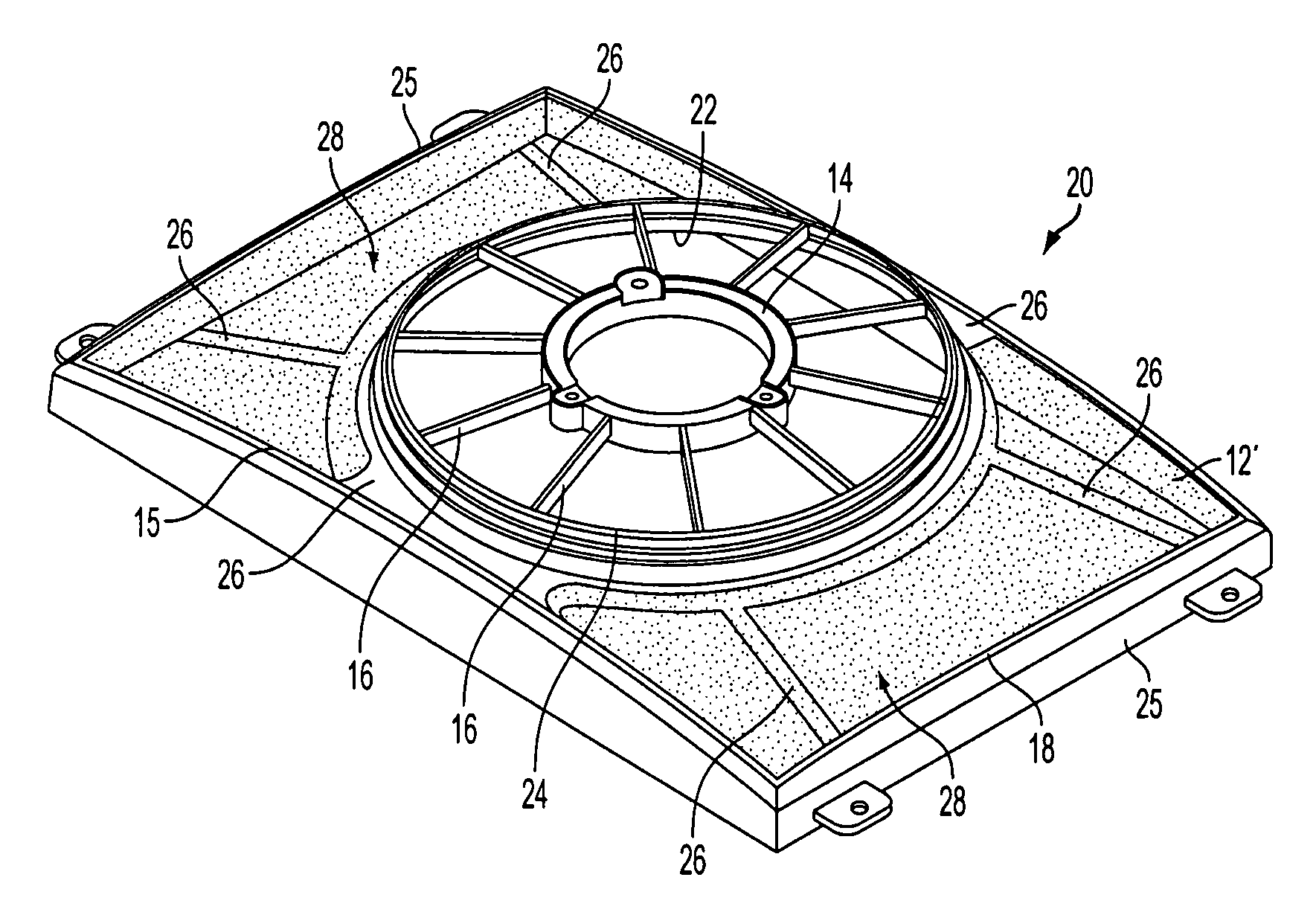

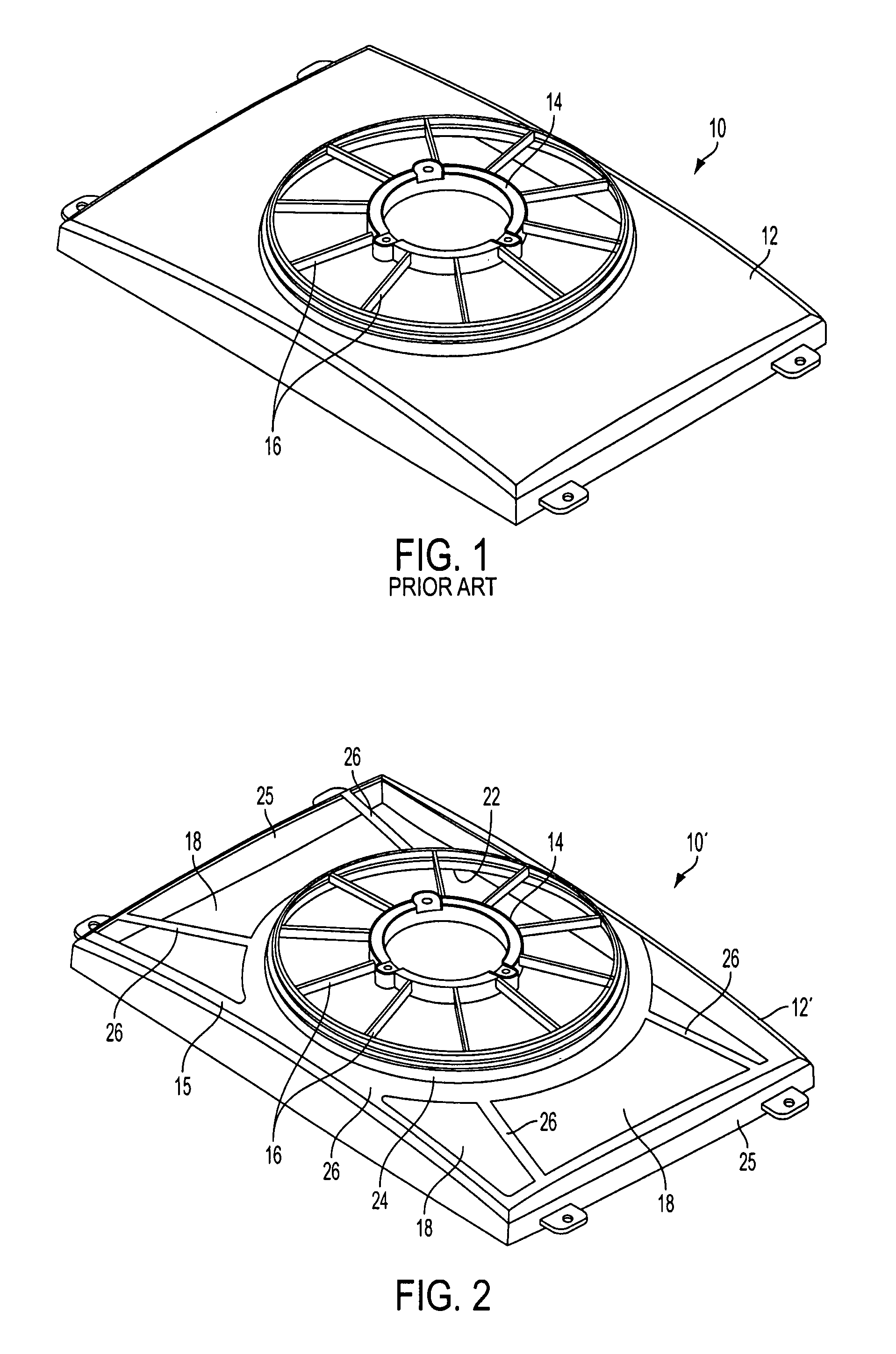

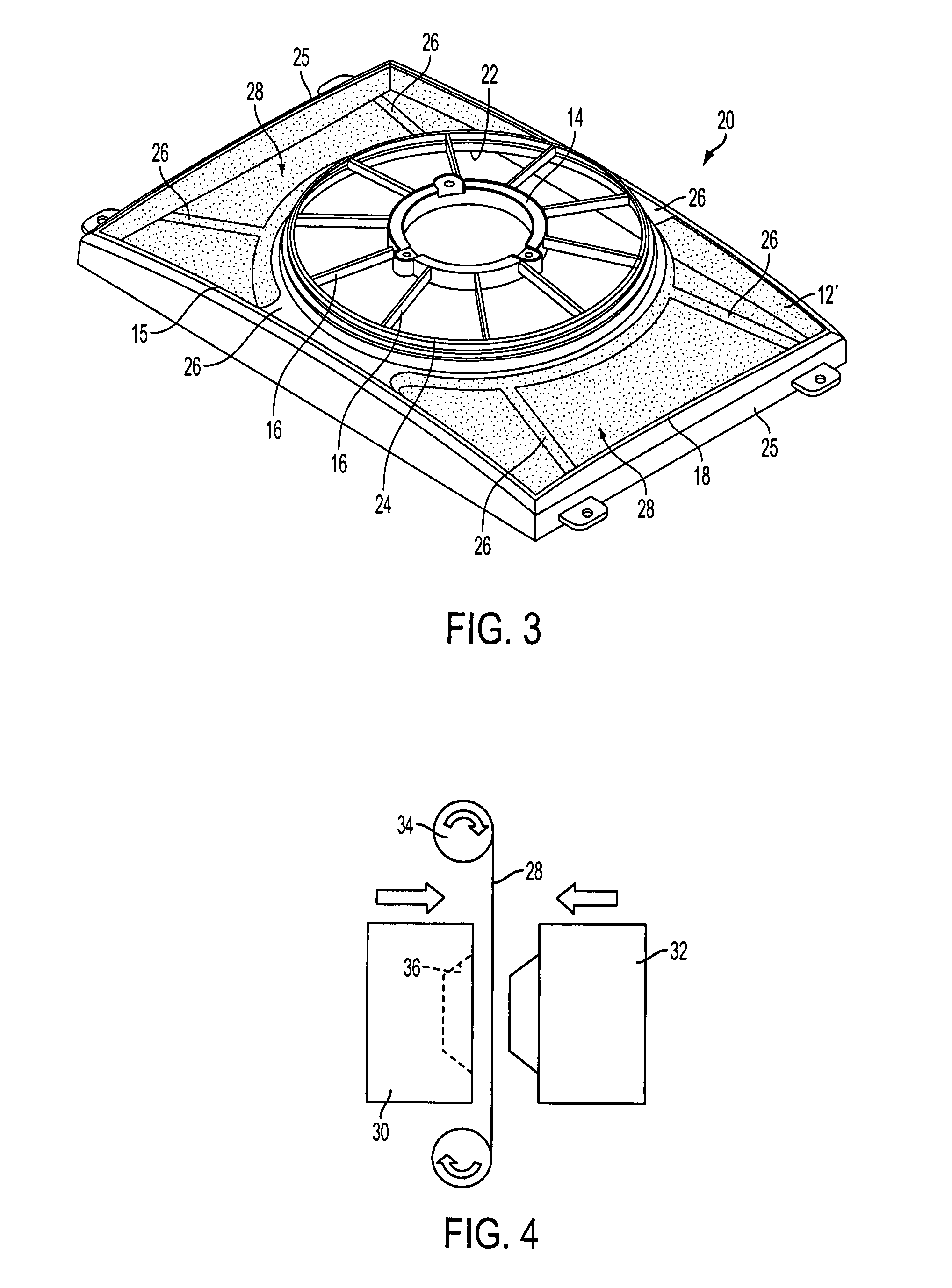

Low mass fan shroud with integrated membrane barrier

ActiveUS20080072851A1Reduce material usageReduced material requiredPump componentsExhaust apparatusEngineeringFilm material

An engine cooling fan shroud structure (20) for a vehicle includes a skirt (12′) defining a frame. The frame has a certain wall thickness and defines an opening (22) therein constructed and arranged to permit air to pass through the skirt. The skirt includes motor mount structure (14) supported in the opening and constructed and arranged for mounting a fan motor thereto. The frame defines passageways (18) there-through to reduce an amount of material of the skirt. A film material (28) has a wall thickness substantially less than the certain wall thickness and covers the passageways such that air may flow mainly through the opening.

Owner:SIEMENS VDO AUTOMOTIVE CORP

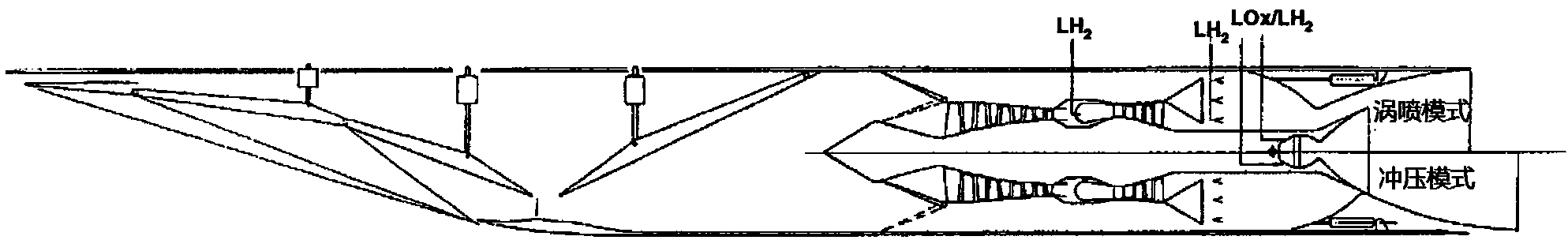

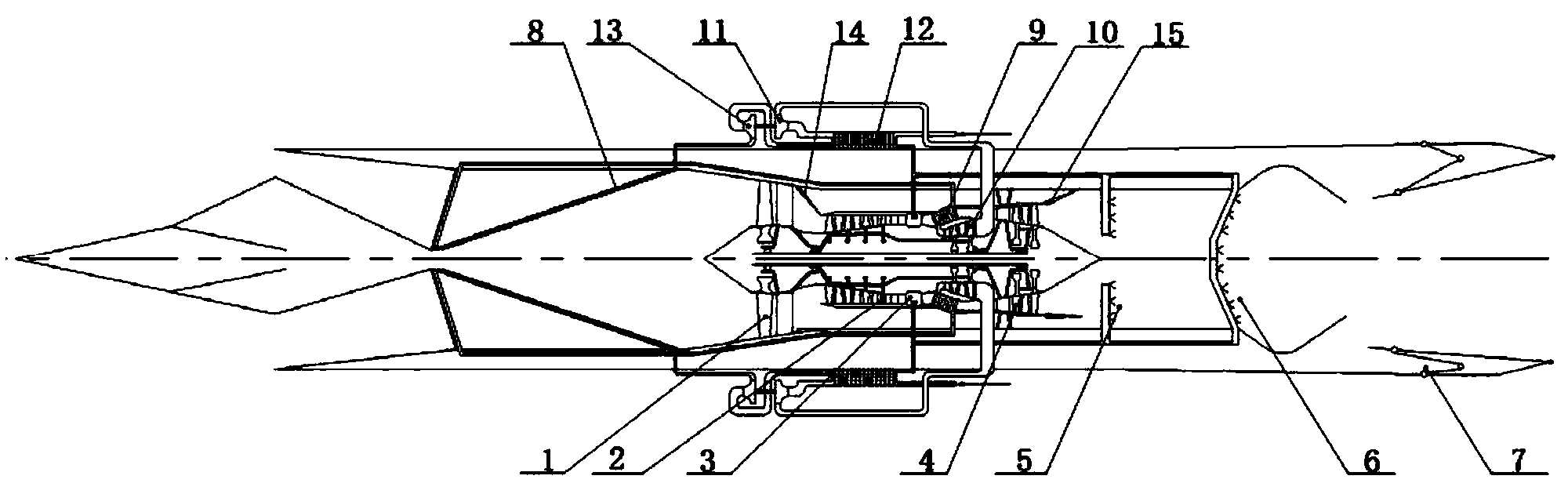

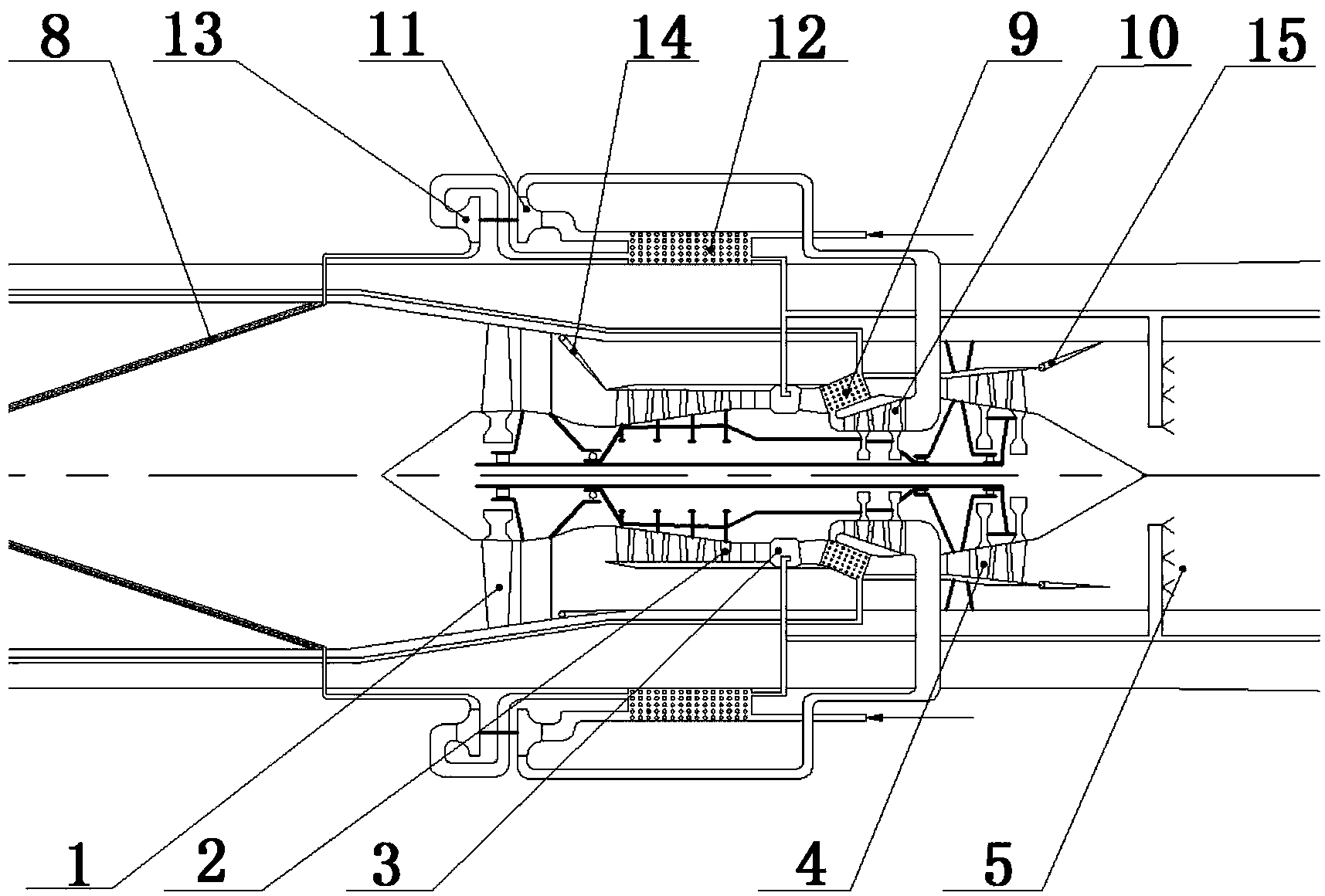

New concept high-speed aerocraft propulsion system layout method

ActiveCN104110326AEfficient cruiseLarge heat capacityRam jet enginesComposite engine plantsSpacecraft propulsionBrayton cycle

The invention provides a new concept high-speed aerocraft propulsion system layout method. Two cycles are built in a propulsion system, namely a Brayton cycle with the air as the working medium and a closed cycle with supercritical state fluid as the working medium. The two cycles are coupled through a supercritical microscopic scale heat exchange technology, a supercritical state fluid turbine and compressor power balance. By adjusting related valves, the propulsion system can be in a turbofan engine model when taking off or flying at a low speed and in a turbine rocket engine model when flying at a high Mach number, so that it is guaranteed that the aerocraft can effectively cruise for a long time in both a subsonic state and a supersonic state. Through the supercritical microscopic scale heat exchange technology, the gas flow temperature at an inlet of a compressor can be effectively reduced when the propulsion system is flying at a high speed, and when the supercritical microscopic scale heat exchange technology is applied in combination with a closed cycle technology, optical distribution of energy of the propulsion system can be achieved. By means of the method, the defects of the propulsion system of an existing high-speed aerocraft are overcome, and working performance of the high-speed aerocraft propulsion system is remarkably improved when Ma ranges from 0 to 5.

Owner:BEIHANG UNIV

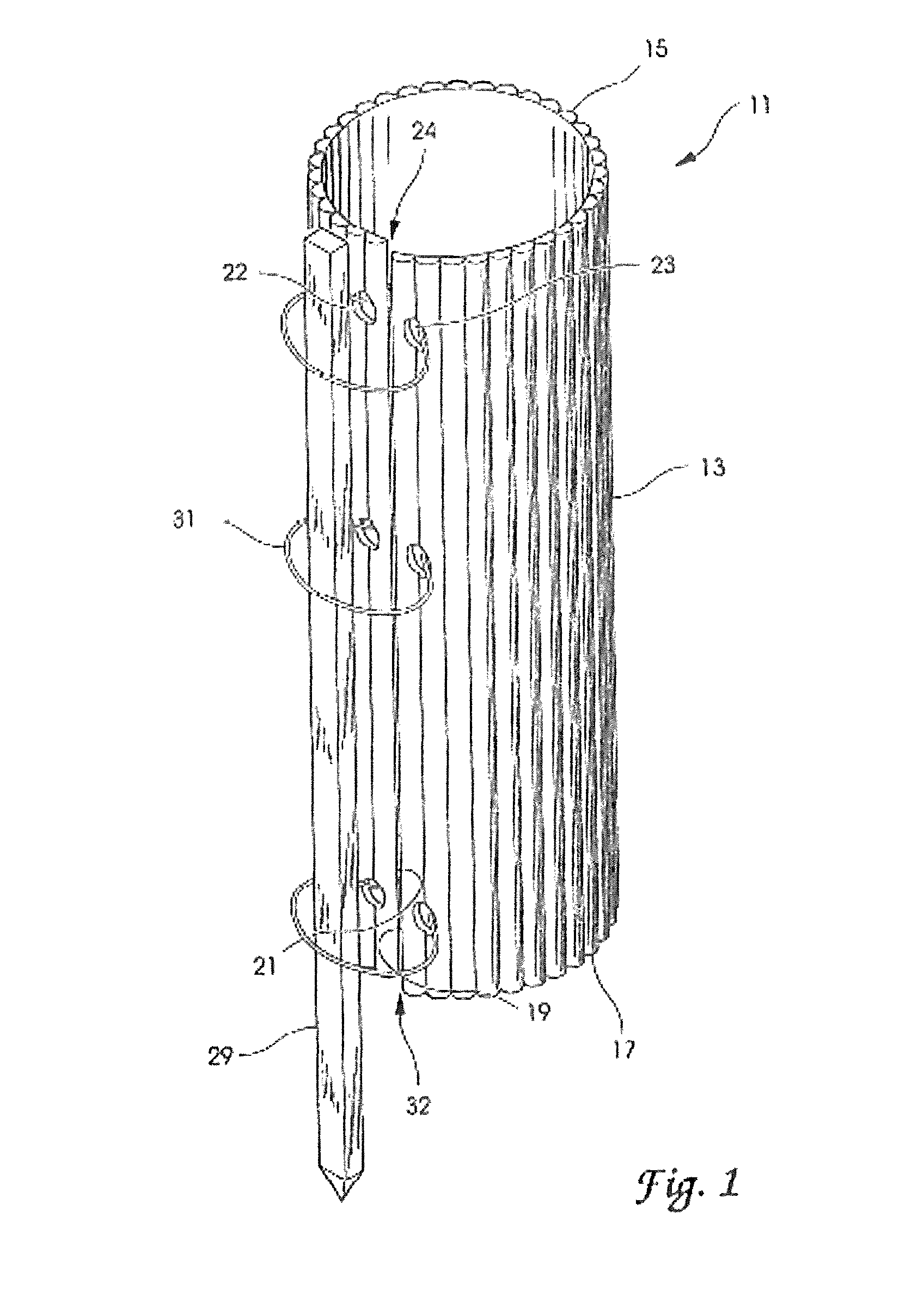

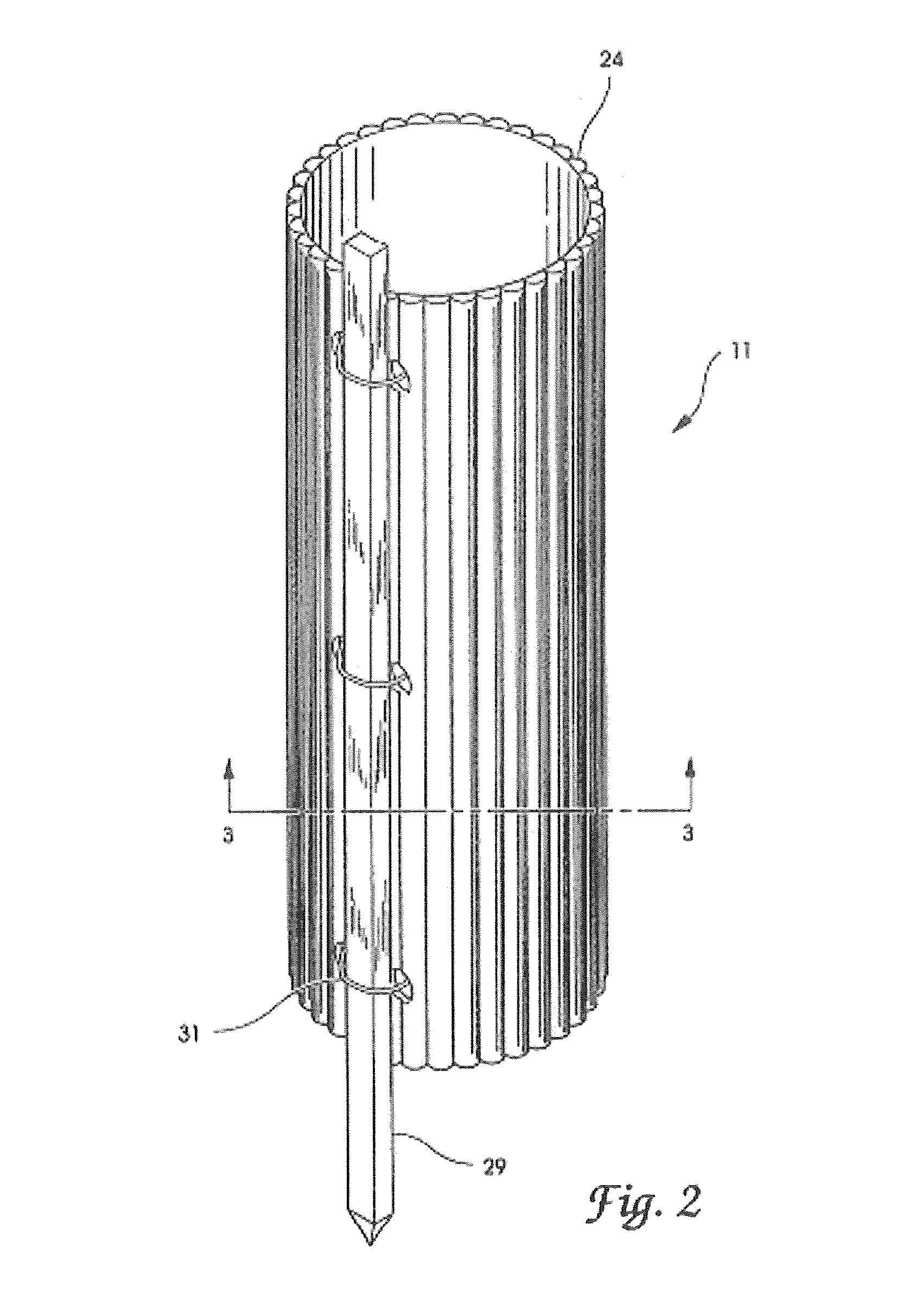

Protective device for plants, seedlings, and trees

InactiveUS8745920B1Reduced material requiredReduce weightPlant protective coveringsWindbreakEngineering

Disclosed is a plant protection device that combines the functionality of a solid walled style plant protector that is good for the establishment of a new plant / seedling and perforated style plant protector that is good for an established plant. The wall of a tree / plant protector and growth device has thin areas inherent in the wall that degrade faster than other parts of the same device wall. This occurs based on the weather conditions (wind / rain / cold), UV degradation, biodegradation, and other factors. Over time these areas open up, allowing air, sun light and other environmental elements to reach the plant / tree within the protector. Strategically placing the thinner areas allows for designs for different plant / tree species and applications. Applications for climatic regions—northern, aired, wetlands, etc. Other applications examples are reforestation, vineyards, windbreaks, etc. The degradation of the thin areas can be controlled by using different materials, UV stabilizer levels and other methods.

Owner:MILLS THOMAS

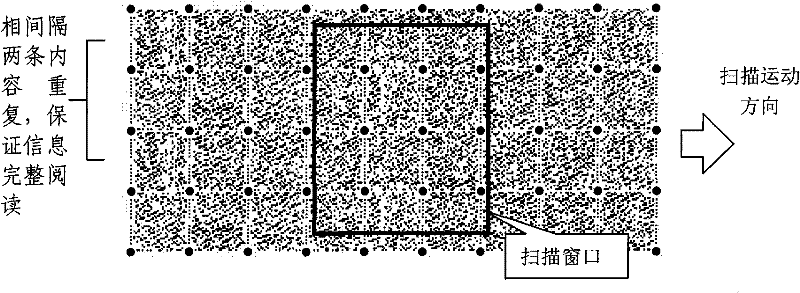

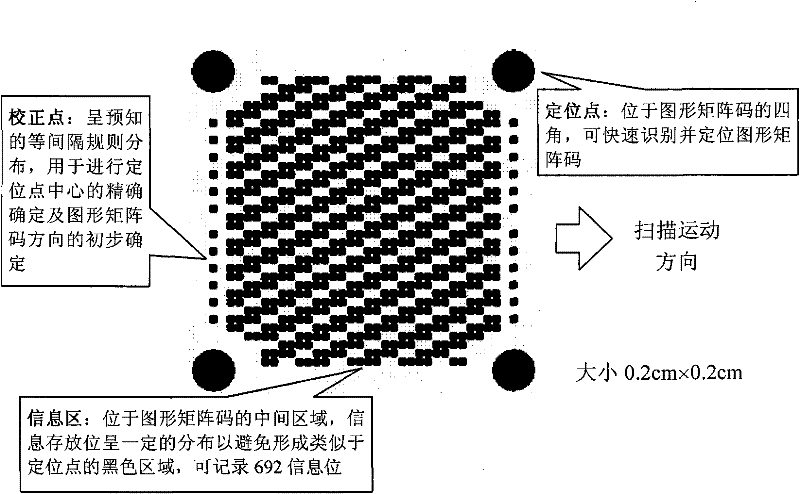

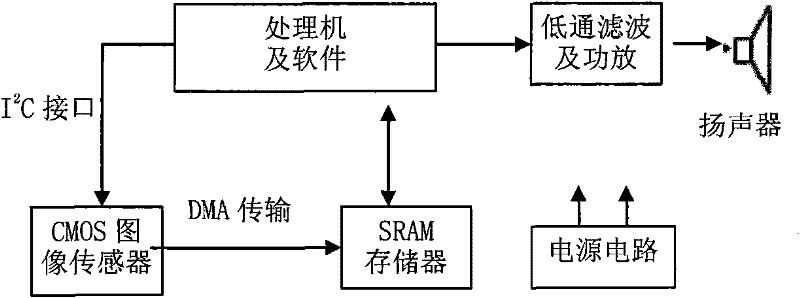

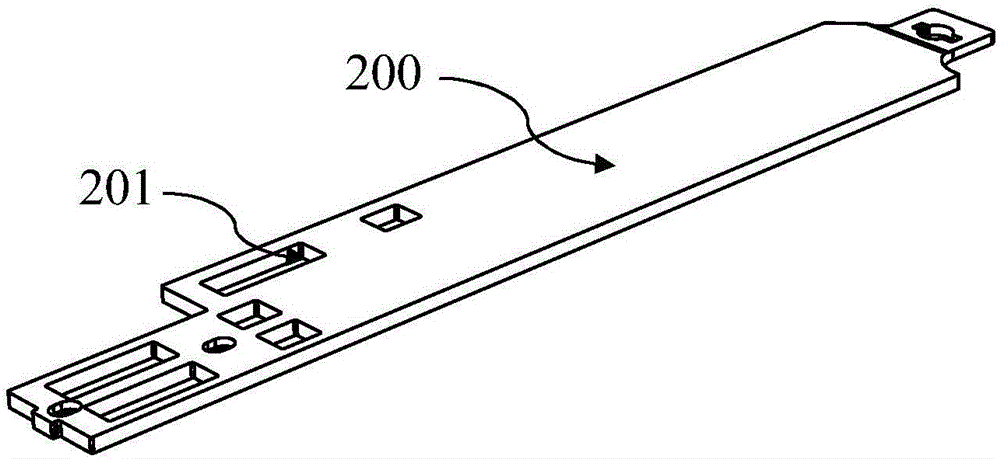

High-capacity two-dimensional barcode capable of recording voice message and reader

InactiveCN101751591ADevelopment of social and cultural undertakingsReduced material requiredRecord carriers used with machinesSensing by electromagnetic radiationGraphicsBarcode

The invention belongs to the barcode technical field and particularly relates to a high-capacity two-dimensional barcode capable of recording voice message and a reader. The two-dimensional barcode consists of graphic matrix codes with the variable quantity, the width of the barcode is the four graphic matrixes regularly, and the length thereof is of the graphic matrix codes with uncertain quantity, so as to form the rectangular shape; each graphic matrix code is composed of a locating point, a correction point and an information area; and the information area comprises an identification area for storing identification information and a data area for storing user data. The two-dimensional barcode can be printed on a piece of common paper in black and white and can record the voice message, and the capacity of the barcode can be changed freely within thousands of words according to the voice message. Based on the invention, a novel voice message access technology and a novel talking book technology can be formed, so that the talking book technology can be realized completely in a form of paper medium, thereby having obvious meaning in the aspects of cost, volume, energy consumption, environmental protection and the like.

Owner:FUDAN UNIV +1

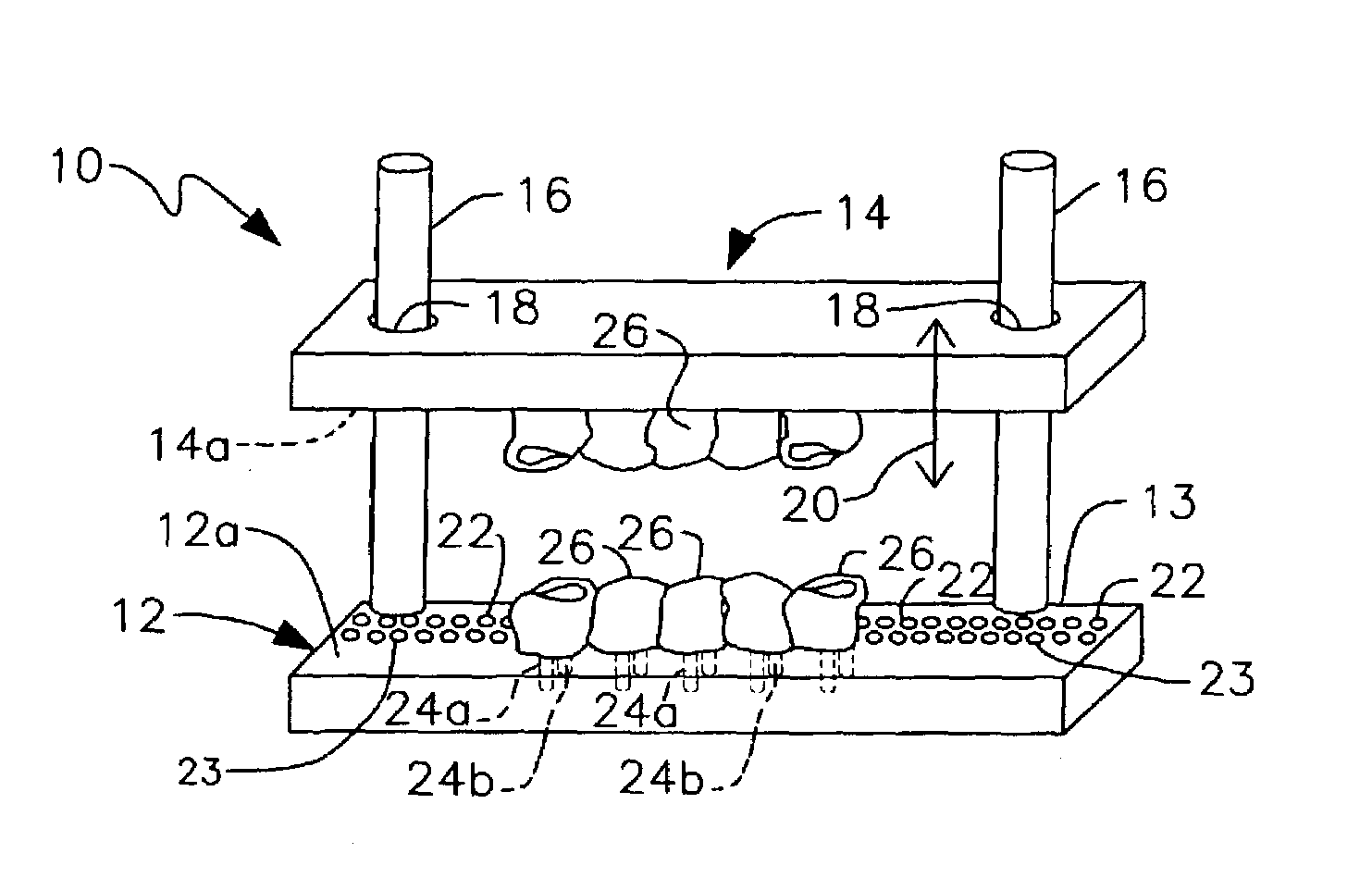

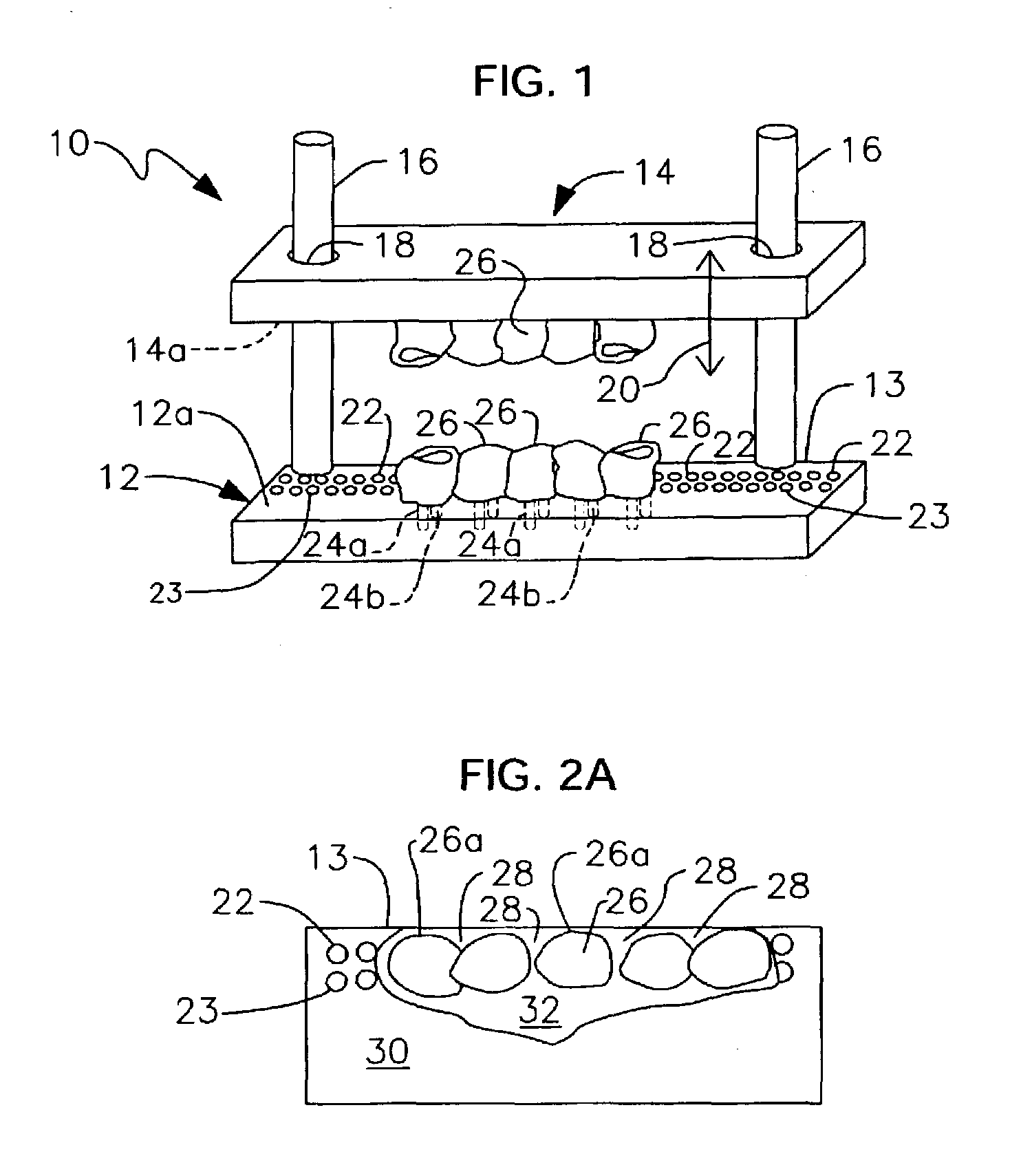

Two-piece model and die system

InactiveUS6932608B1Reduced material requiredLow skill level requiredImpression capsDental articulatorsEngineeringMechanical engineering

A model and die system has a working quadrant of parallelepiped construction and a opposing quadrant of the same construction. The working quadrant has an upper flat surface disposed in confronting relation to a lower flat surface of the opposing quadrant. Pin-receiving bores are formed in the working quadrant and mounting members depend from the opposing quadrant. Each cast tooth supported by the working quadrant has a pin depending from it and is fully seatable against the upper flat surface. Each cast tooth mounted on the upper flat surface is secured to a mounting post that depends from the upper flat surface. In a first embodiment, the quadrants are held in spaced apart, adjustable vertical relation to one another by a pair of parallel guideposts. In a second embodiment, an articulated hinge performs that function. In a third embodiment, a semicircular base opposes a semicircular top member.

Owner:GBASE INC

Handheld electronic product

InactiveCN103078974AReduce shockCushion the shockDigital data processing detailsTelephone set constructionsEngineering

Owner:HUAWEI DEVICE CO LTD

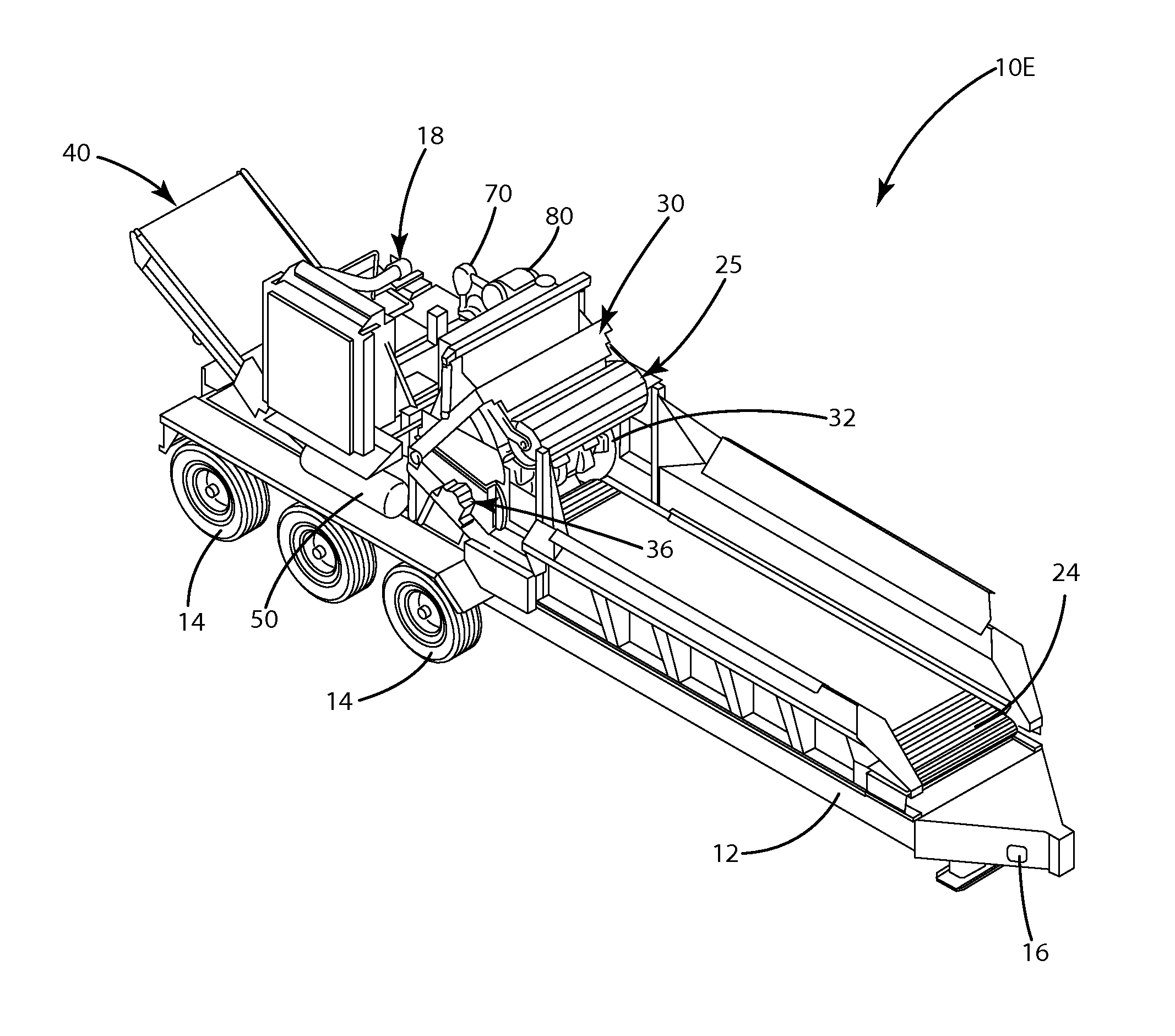

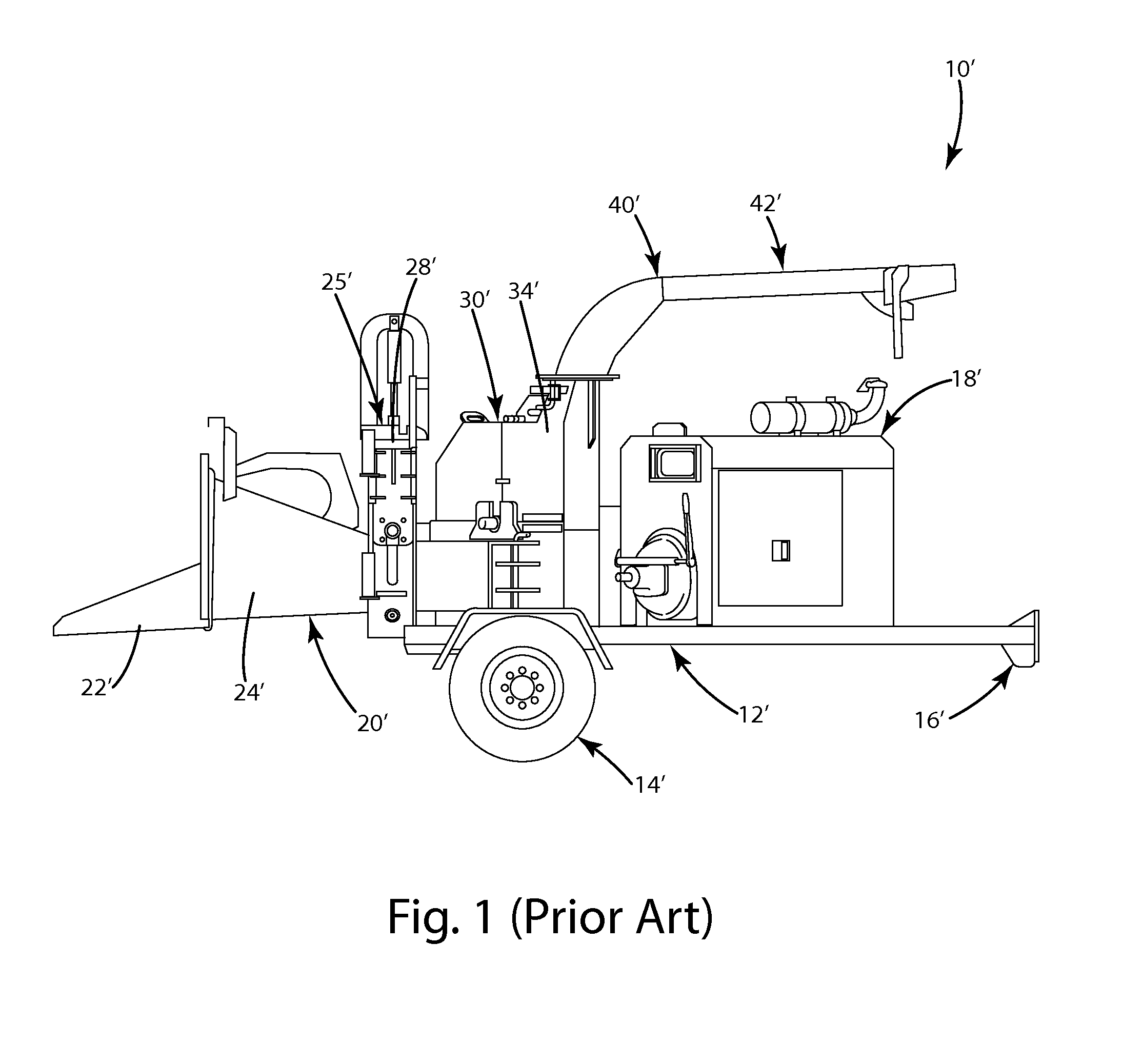

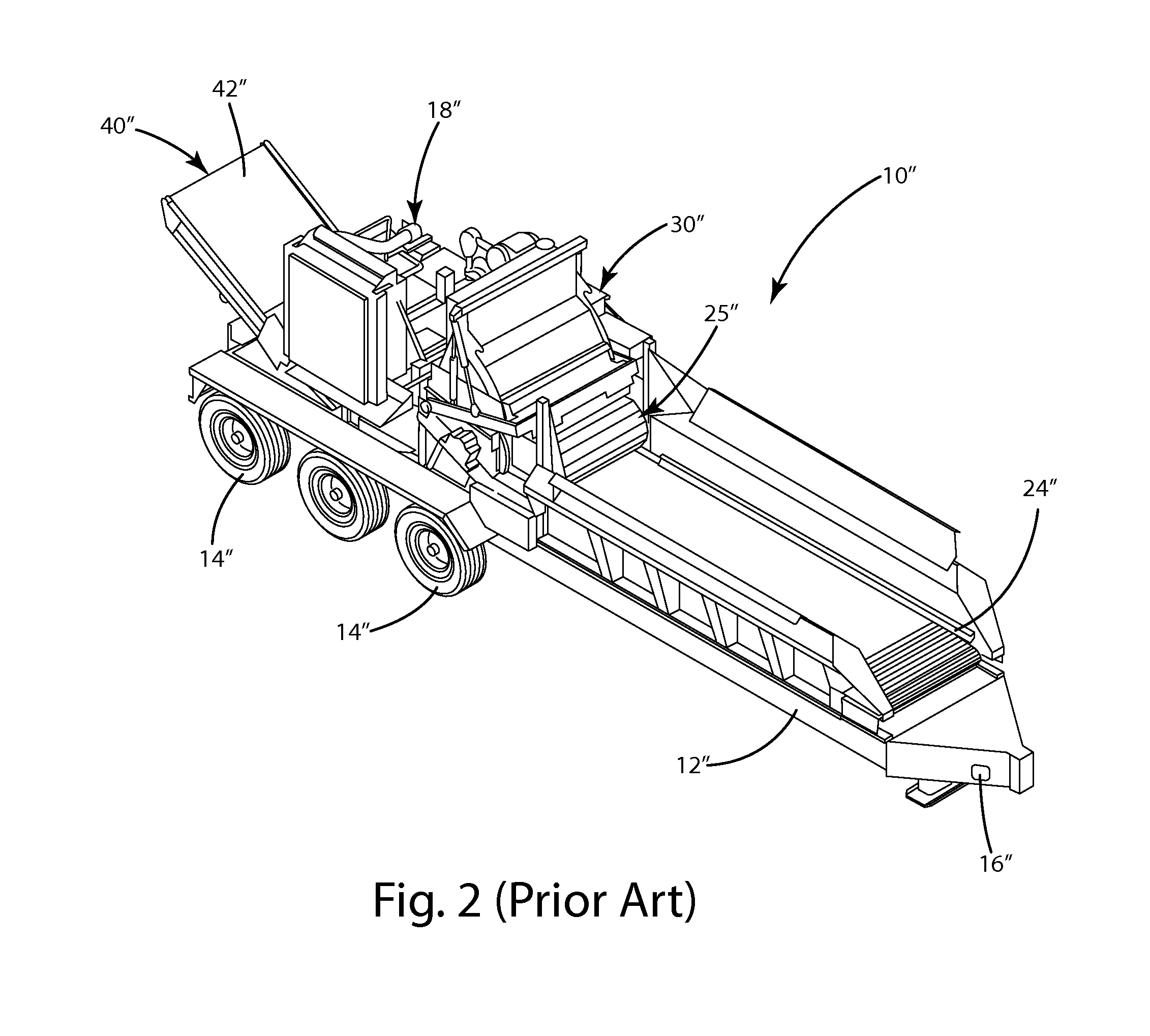

Waste processing system, machine and method thereof

ActiveUS20120234949A1Reduced material requiredMowersPlant waste comminutingWaste processingWood waste

a waste processing machine for reducing wood waste comprises an accumulator operatively connected to the cutting system so as to power the cutting system upon discharge thereof. The accumulator is adapted to receive, store, and release a charge developed from a charging device operatively connected to the accumulator and one or more systems of the waste processing machine.

Owner:BANDIT IND

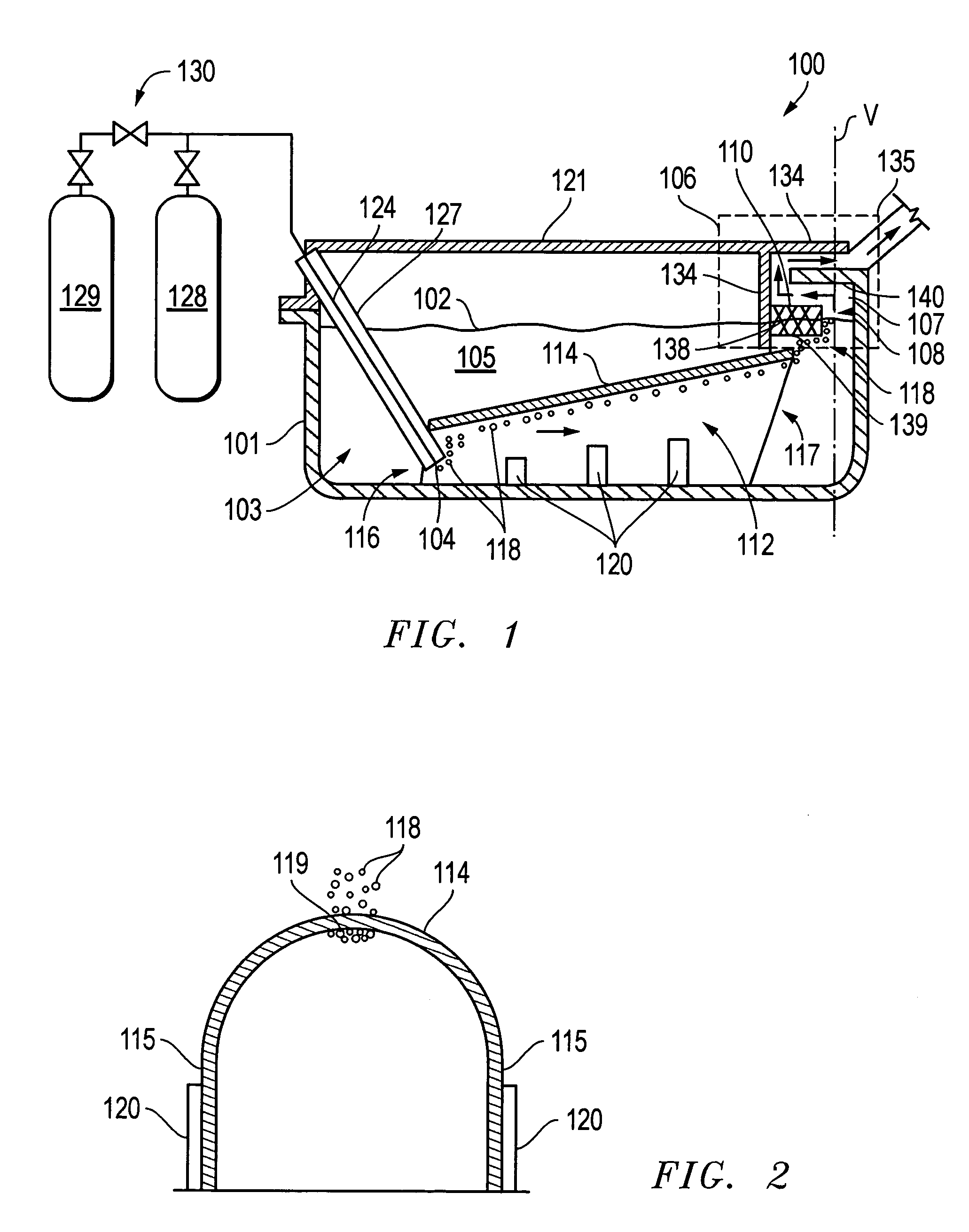

Reactant liquid system for facilitating the production of carbon nanostructures

InactiveUS20060008403A1Reduced material requiredMaterial nanotechnologySingle-walled nanotubesCarbideNanostructure

A method includes isolating carbon atoms as conditioned carbide anions below a surface of a reactant liquid. The conditioned carbide anions are then enabled to escape from the reactant liquid to a collection area where carbon nanostructures may form. A carbon structure produced in this fashion includes at least one layer made up of hexagonally arranged carbon atoms. Each carbon atom has three covalent bonds to adjoining carbon atoms and one unbound pi electron.

Owner:CLEAN TECH INT

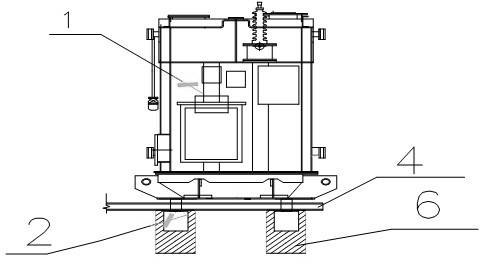

Sliding mounting method for large-sized transformer

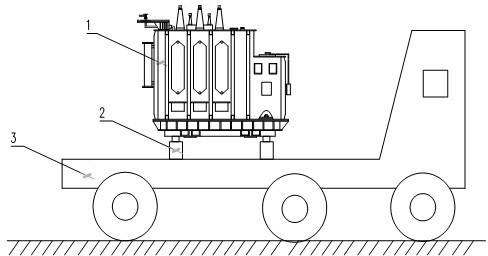

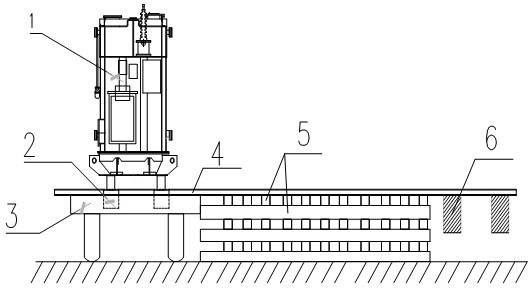

InactiveCN102682959AReduce shiftsEasy to installTransformers/reacts mounting/support/suspensionSwitchgearTransformerEngineering

The invention discloses a sliding method for a large-sized transformer. An oil pump station, hydraulic jacks, a heavy object on-rail pusher, a rail, sleepers and the transformer are involved. The method specifically comprises the following working steps that: after the transformer is transported to a proper position, the sleepers are laid in advance, the transformer is jacked, the steel rail is inserted, and the transformer is pushed to a mounting position in the center of a foundation by utilizing the on-rail pusher. By the method, large-sized hoisting equipment machine teams, manpower and materials can be reduced, the transformer can be easily and conveniently mounted, and the method is low in labor intensity and high in safety.

Owner:CHINA MCC17 GRP

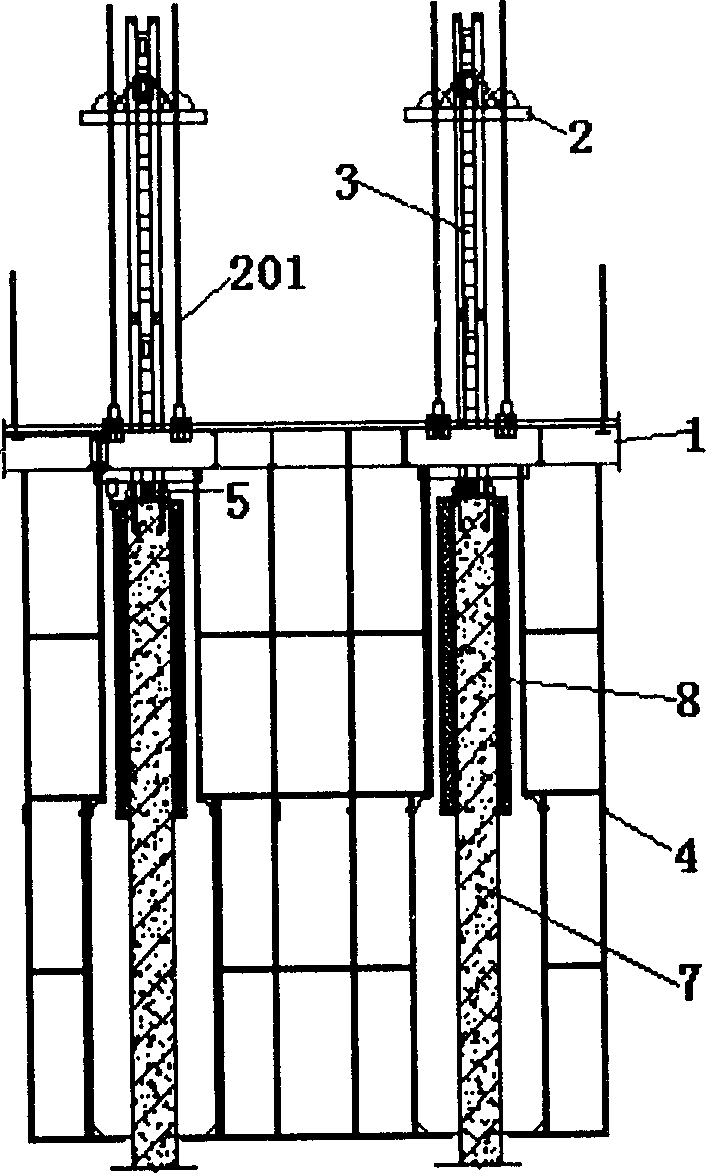

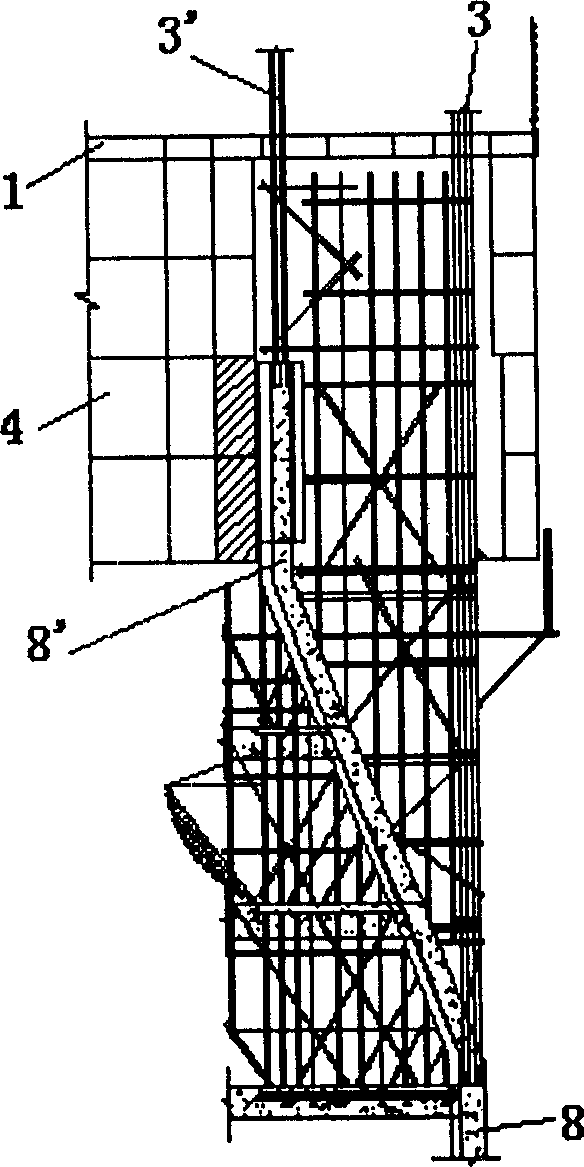

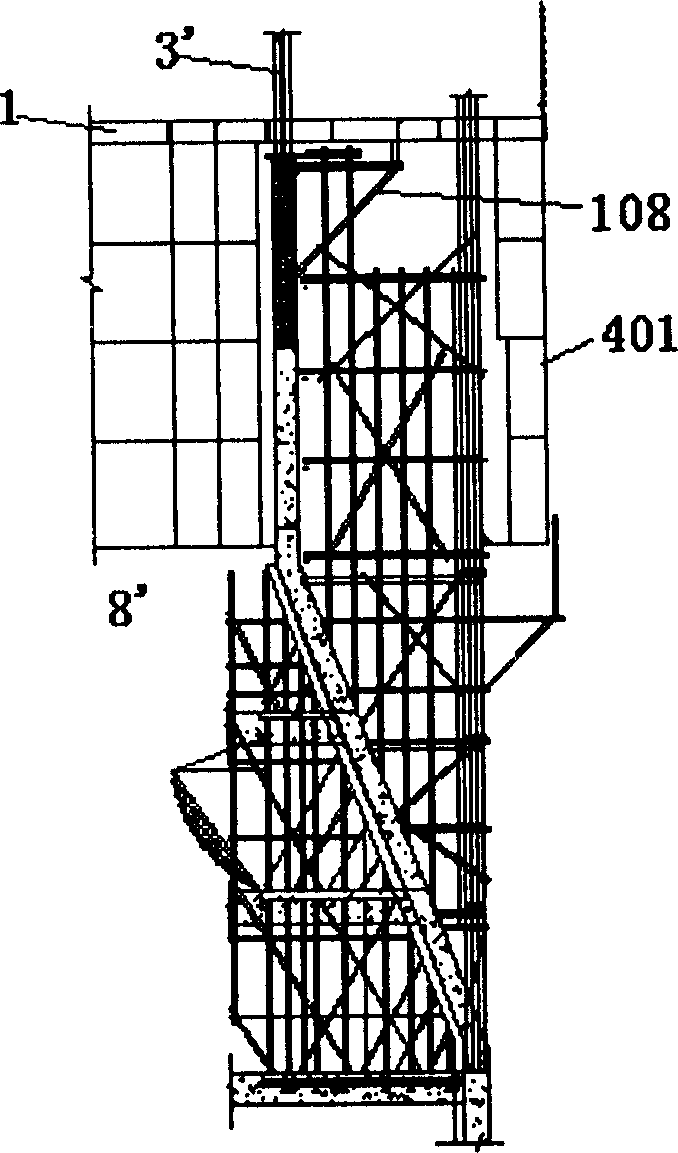

Autolifting type variable-shape diassembllable integrated lifting steel plateform system and construction method thereof

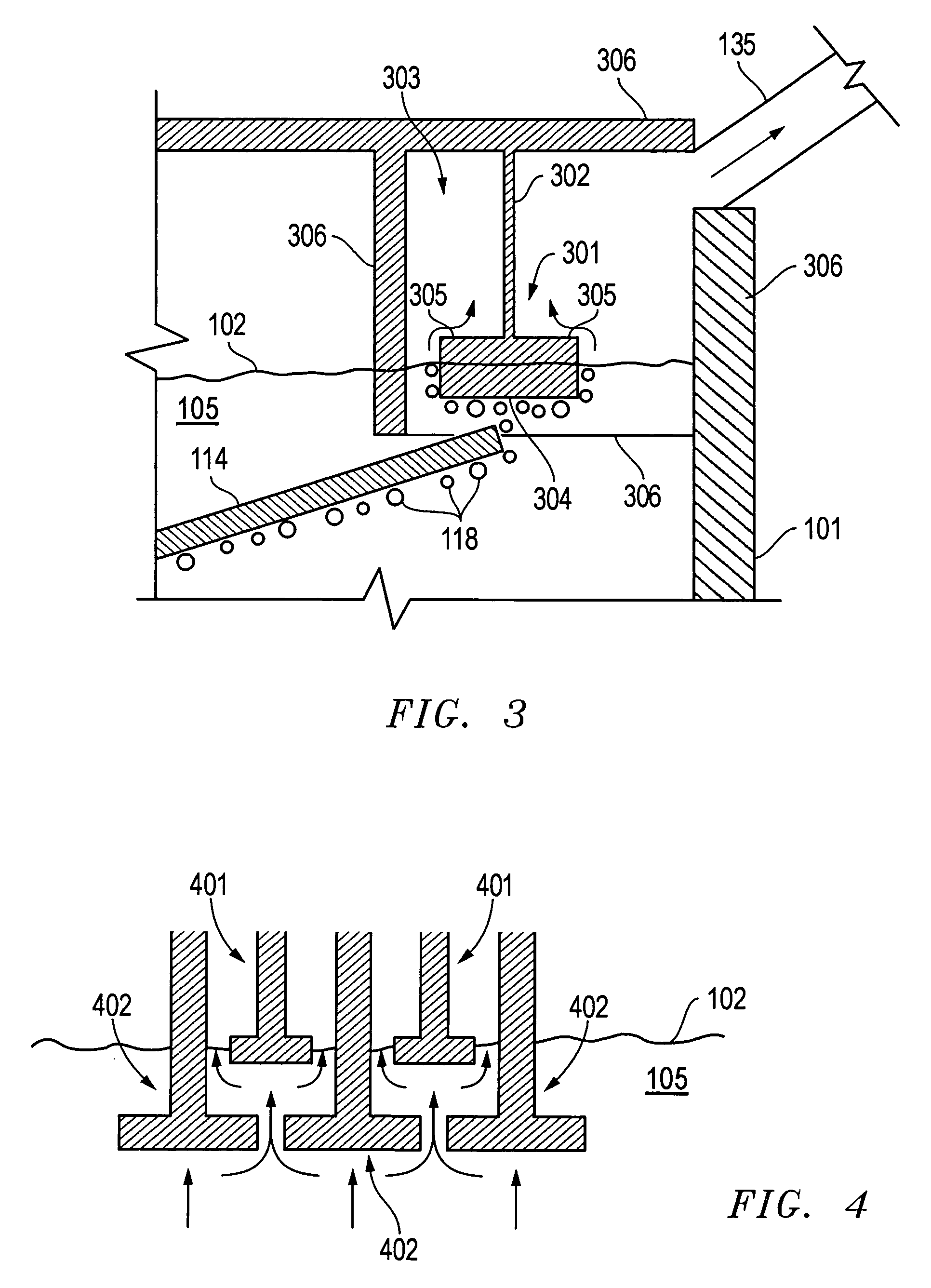

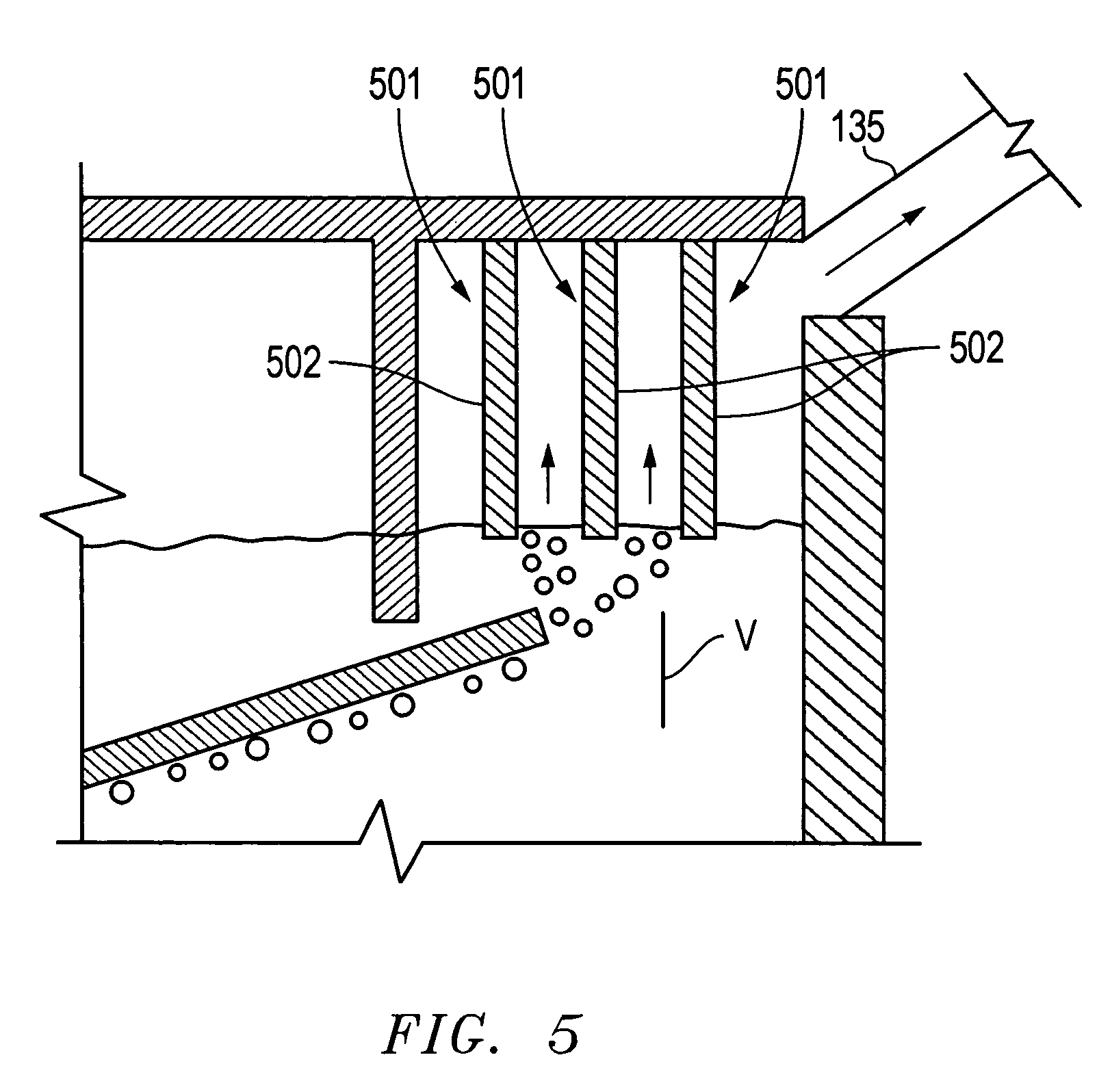

ActiveCN1793590AMeet construction needsImprove integrityForms/shuttering/falseworksBuilding support scaffoldsFalseworkSteel columns

The invention discloses a self-rising deformable removable integral lifting steel platform system for ultrahigh varying-layer plane construction and the construction method thereof, comprising steel platform, plate lifter, flexible steel column, hanging staging and bearing pin, where the hanging staging is fixed with the steel platform, the steel platform is deformable and comprises primary and secondary beams, the junction of the two beams is provided with a rolling device, the secondary beam can take the primary beam as orbit to move relative to the primary through the rolling device. The invention uses the various construction columns installed in core tube sharing walls as support and climbing guide rails, uses the plate lifter as power, lifts the whole steel platform system by lifting screw rods connected with the steel platform, and arranges trolleys on partial secondary steel beams to make them able to move inward along the primary steel beam to the preset position at last, and completes the plane deformation of the steel platform and meets construction requirements for the core tube variation.

Owner:SHANGHAI CONSTR NO 1 GRP

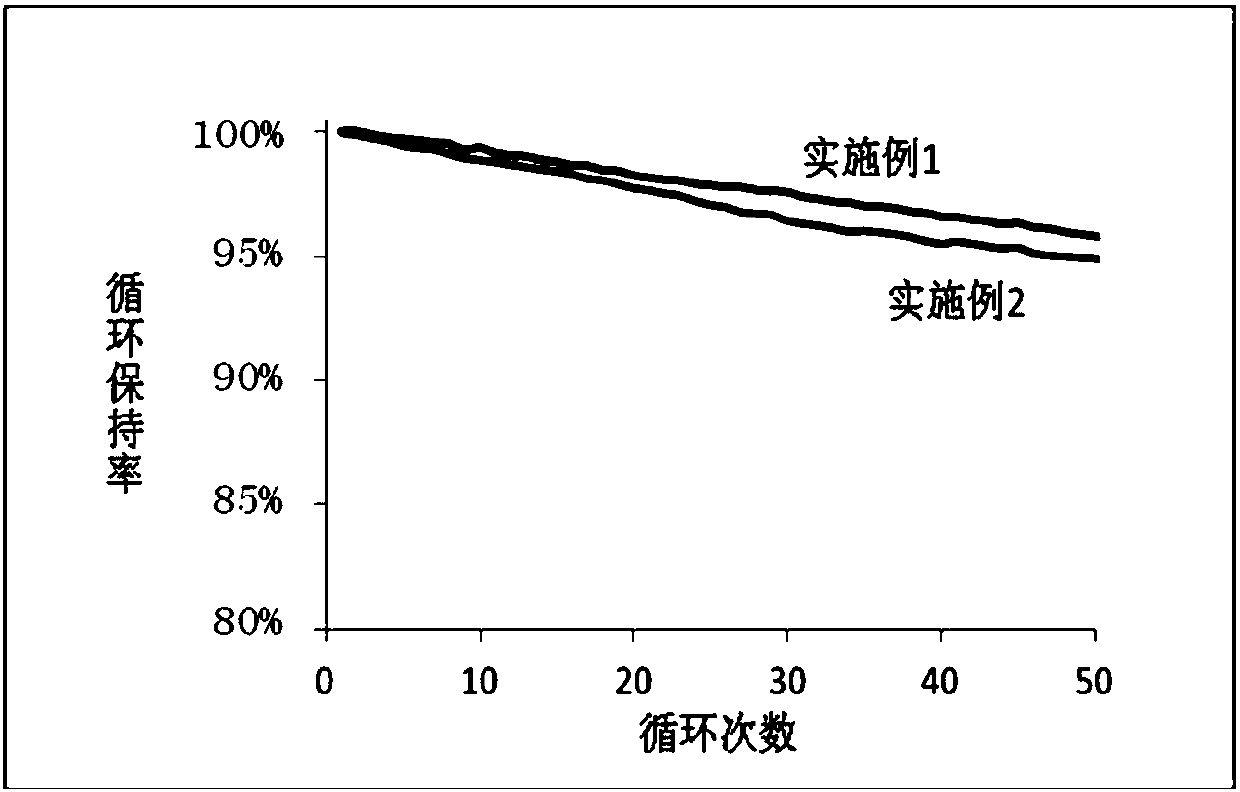

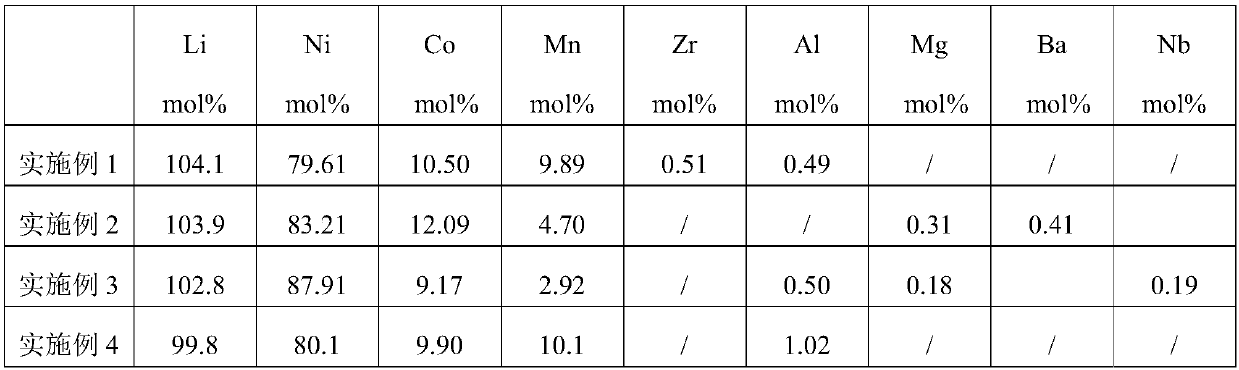

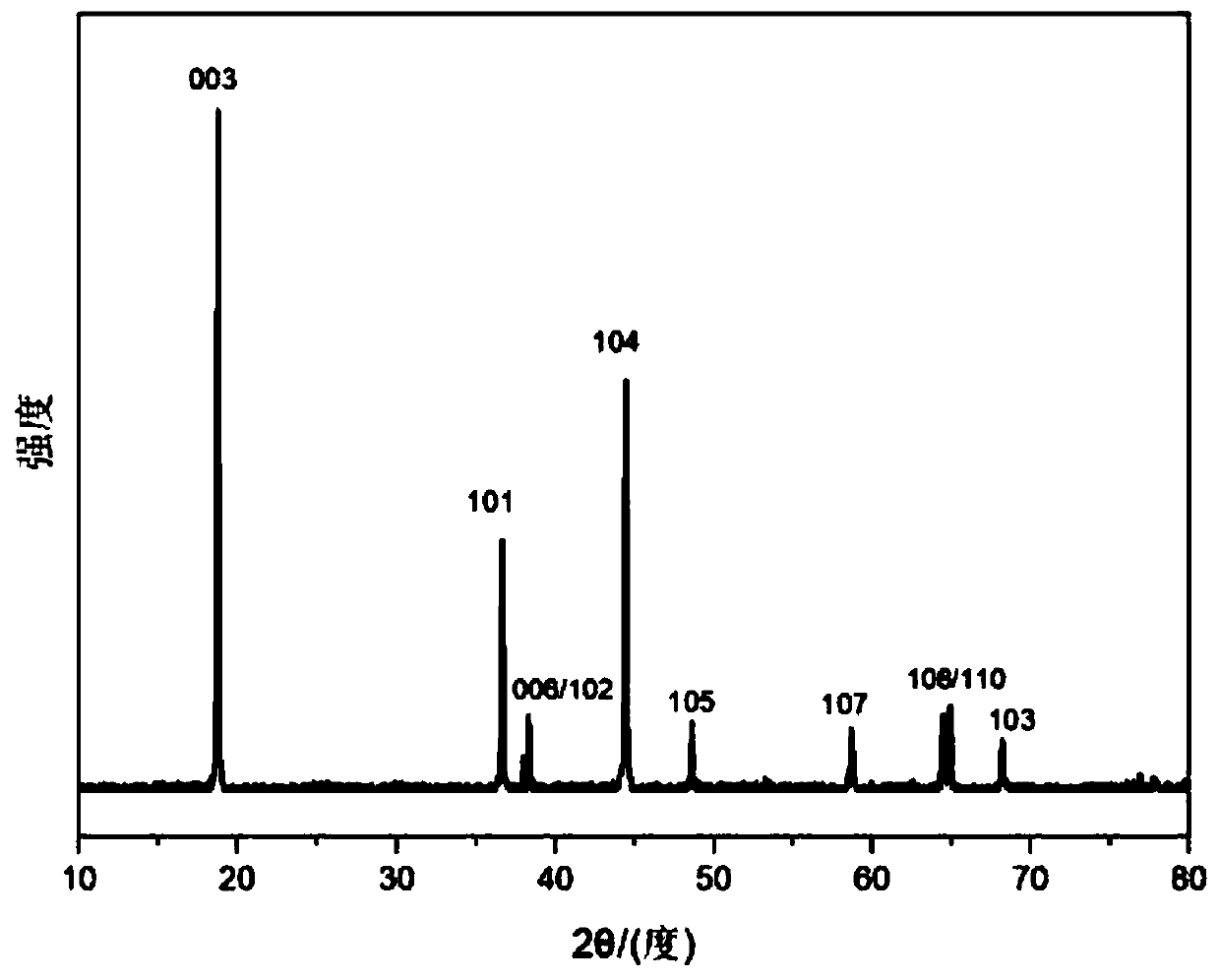

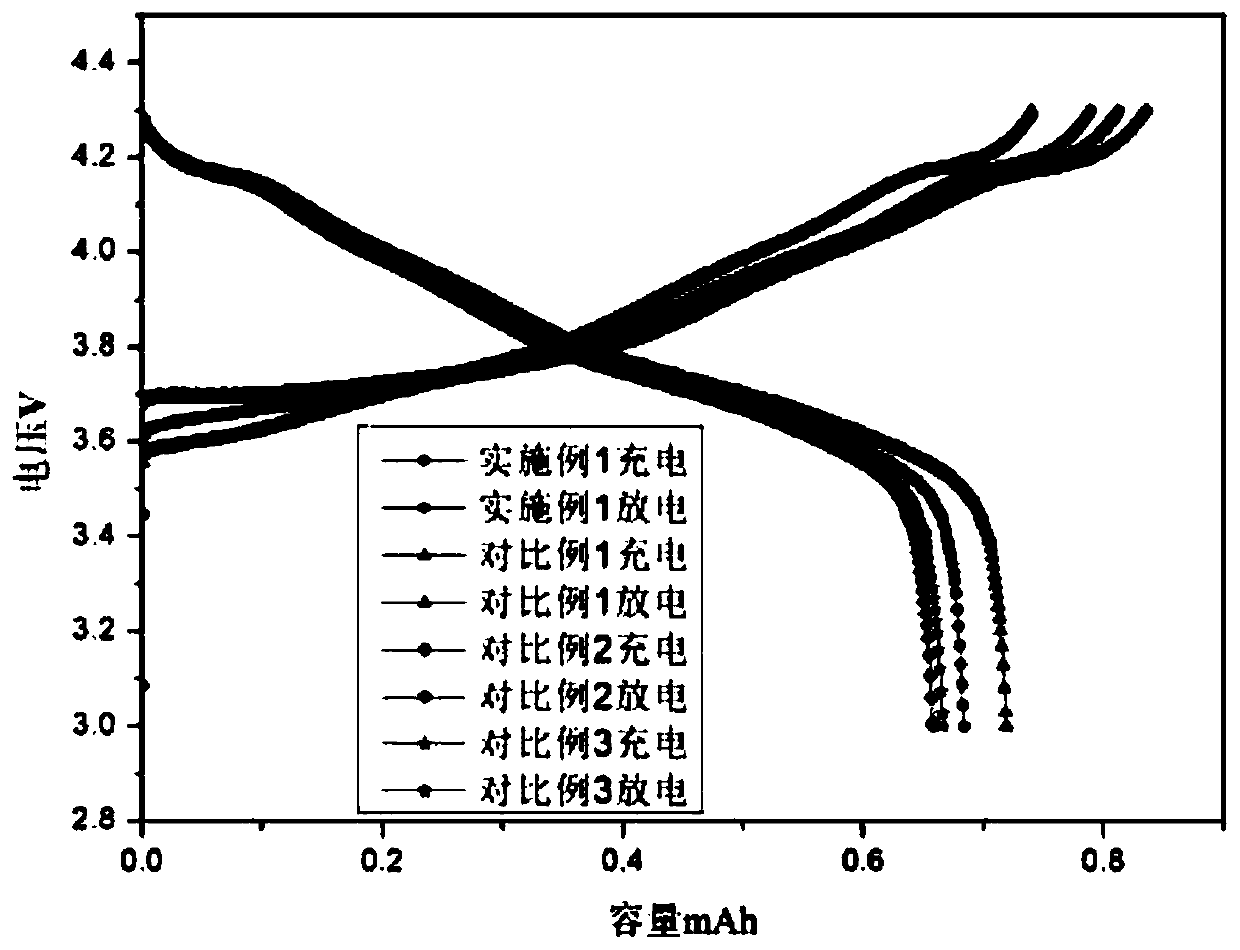

High nickel ternary positive electrode material applied to lithium secondary battery and preparation method thereof

ActiveCN110690416AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention relates to the technical field of lithium ion batteries. In order to solve the problems of poor compatibility and poor cycle performance, rate performance, processability, and safety ofexisting high nickel ternary materials and electrolytes, the invention provides a high nickel ternary positive electrode material applied to a lithium secondary battery and a preparation method thereof. The high nickel ternary positive electrode material applied to the lithium secondary battery comprises a base material and a composite coating layer outside the base material. The chemical formulaof the base material is Li1.02Ni1-x-yCoxMnyMZO2. M is selected from the group consisting of Al, Mg, Ti, and Si. (1-x-y), x, y, and z are the molar ratios of Ni, Co, Mn, and M respectively. (1-x-y) isgreater than or equal to 0.6 and less than 1. x is greater than 0 and less than 0.4. y is greater than 0 and less than 0.4. z is greater than 0 and less than or equal to 0.02. According to the invention, the high nickel ternary positive electrode material applied to the lithium secondary battery has the advantages of low surface alkalinity, good processability, excellent electrochemical performance, high safety, and good compatibility with electrolytes; and the battery made of the material has the advantages of significantly improved cycle life and excellent electrochemical performance.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL +1

Low mass fan shroud with integrated membrane barrier

ActiveUS8128358B2Reduce material usageReduced material requiredPump componentsStatorsEngineeringMechanical engineering

Owner:SIEMENS VDO AUTOMOTIVE INC

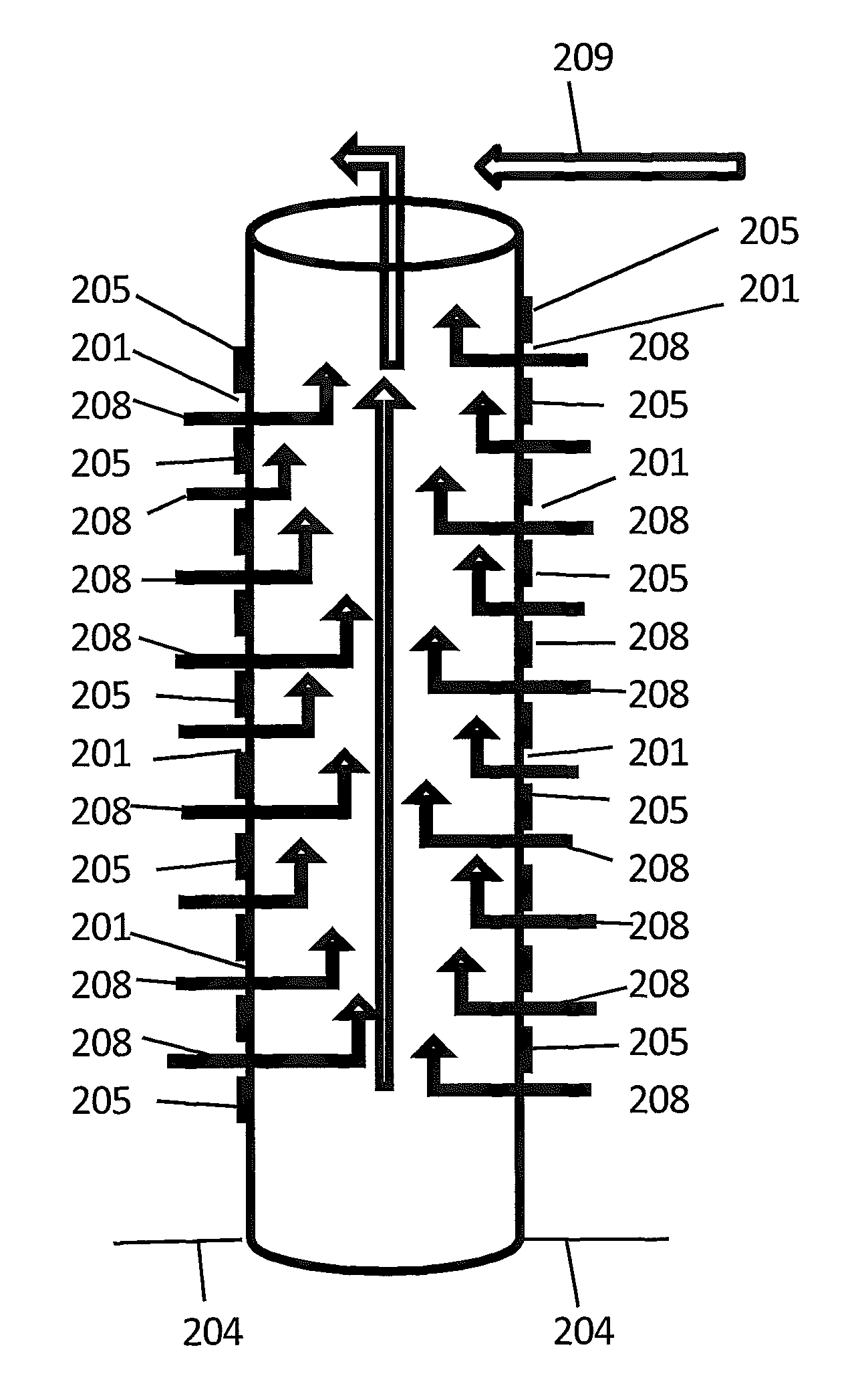

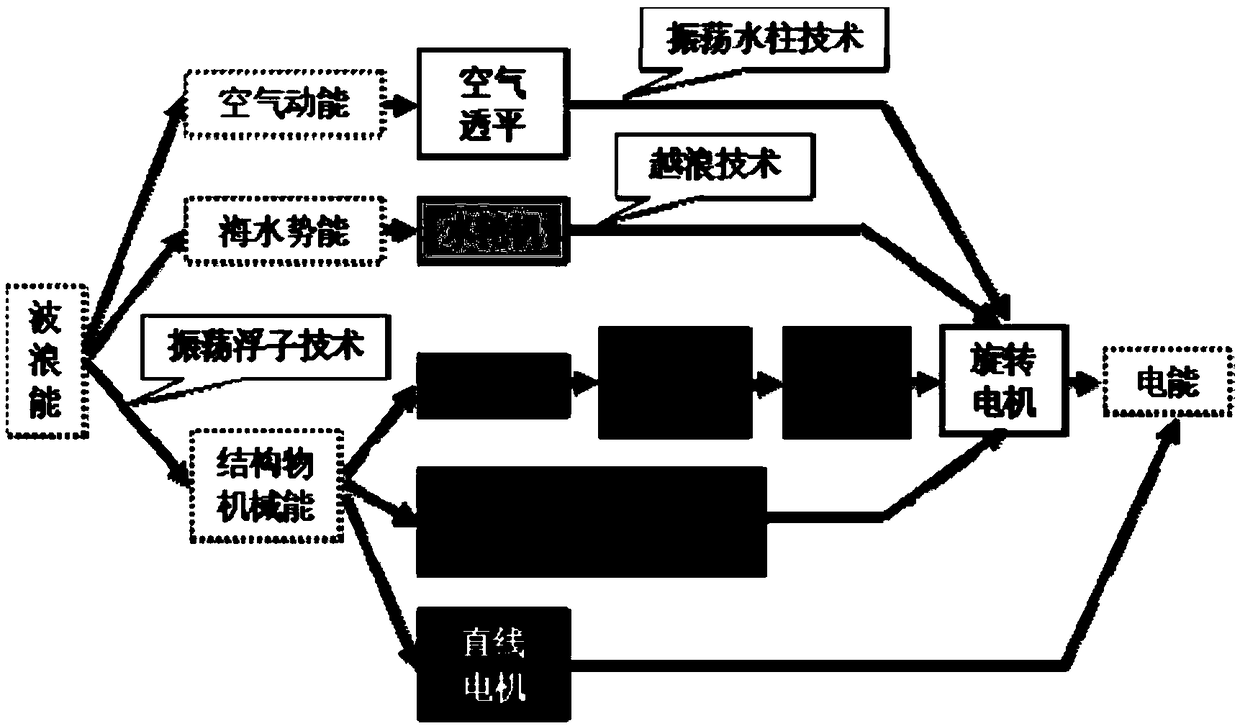

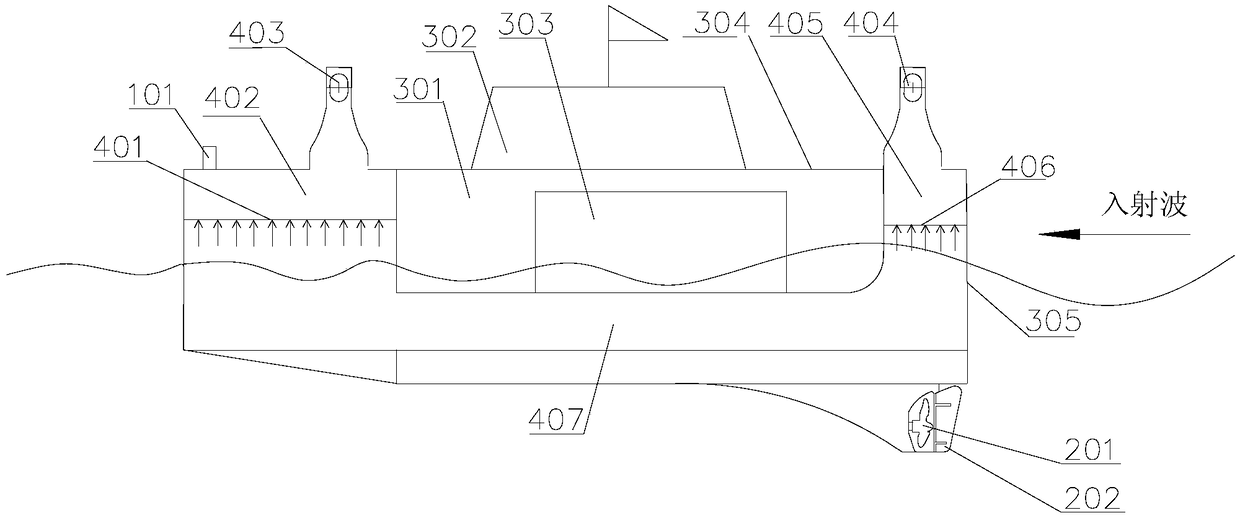

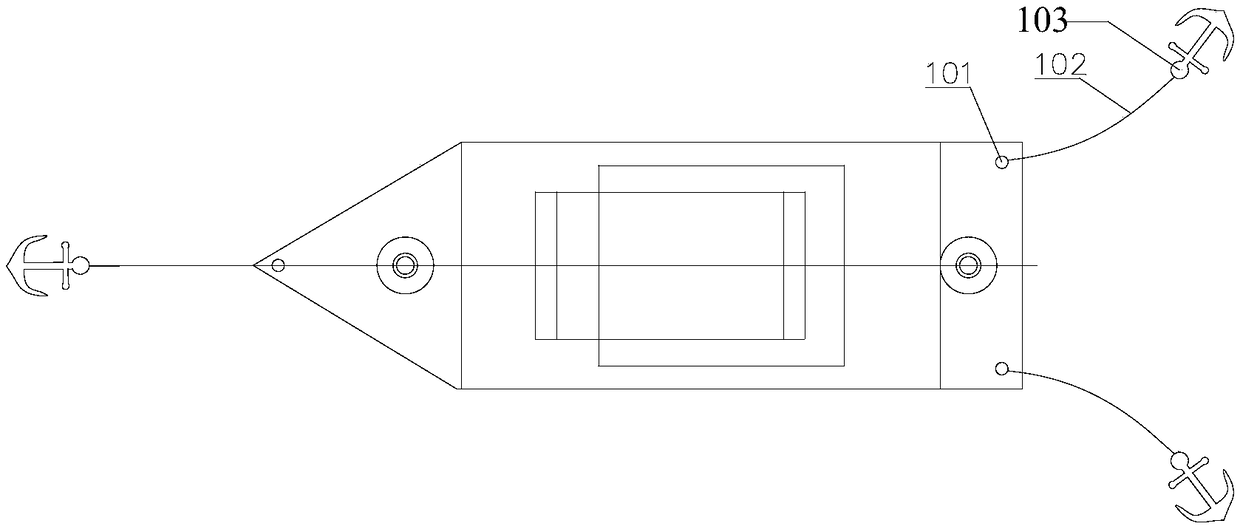

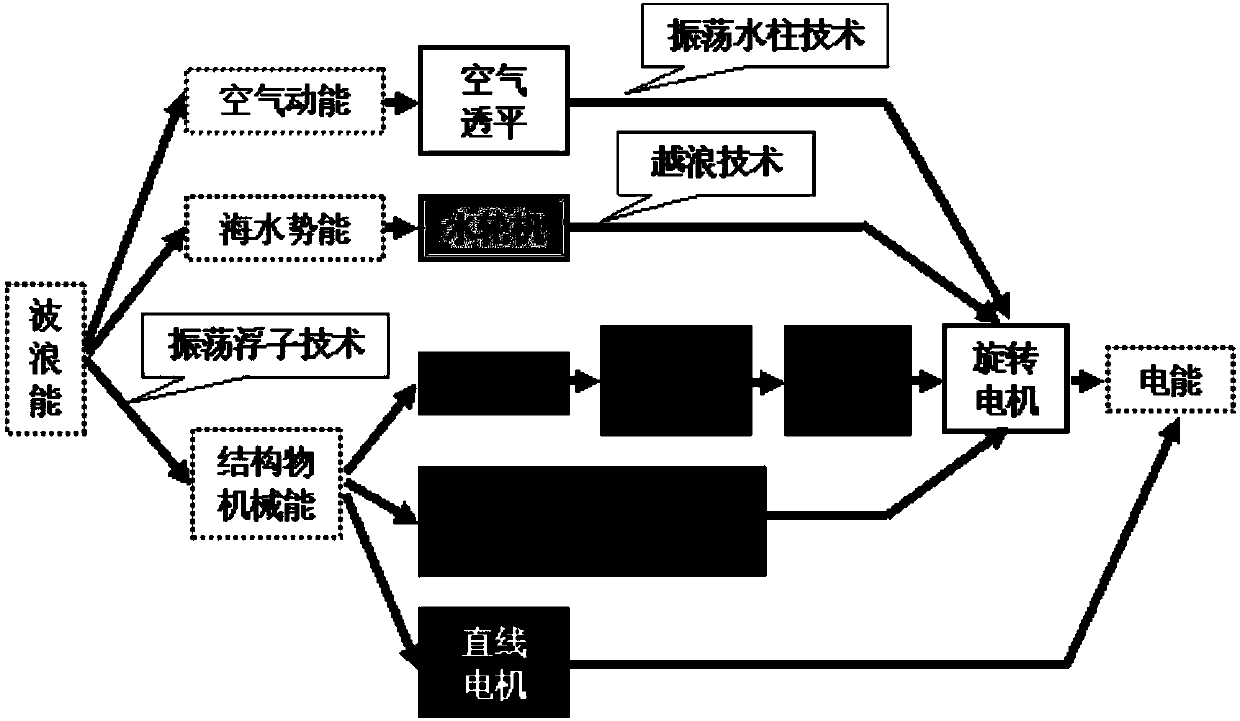

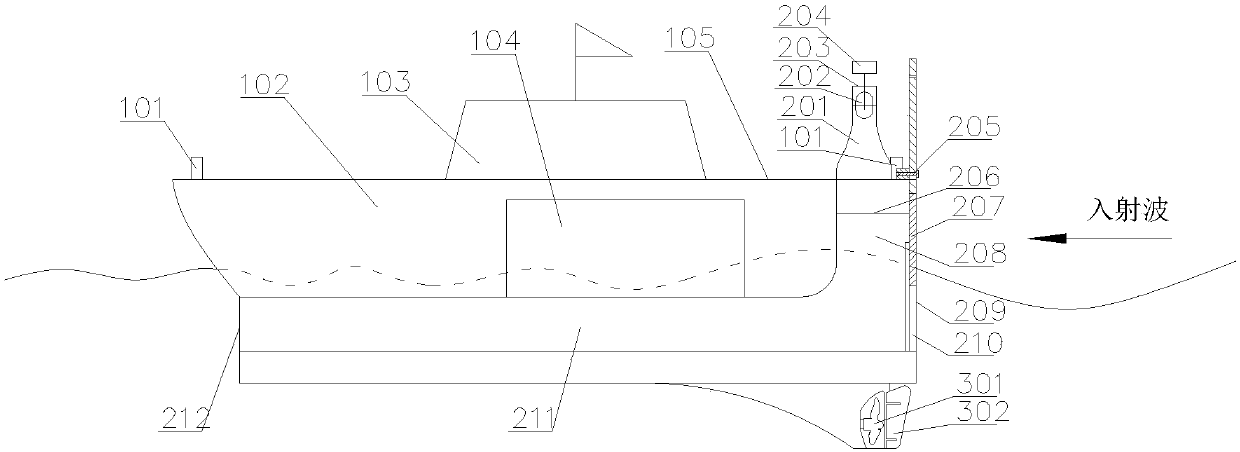

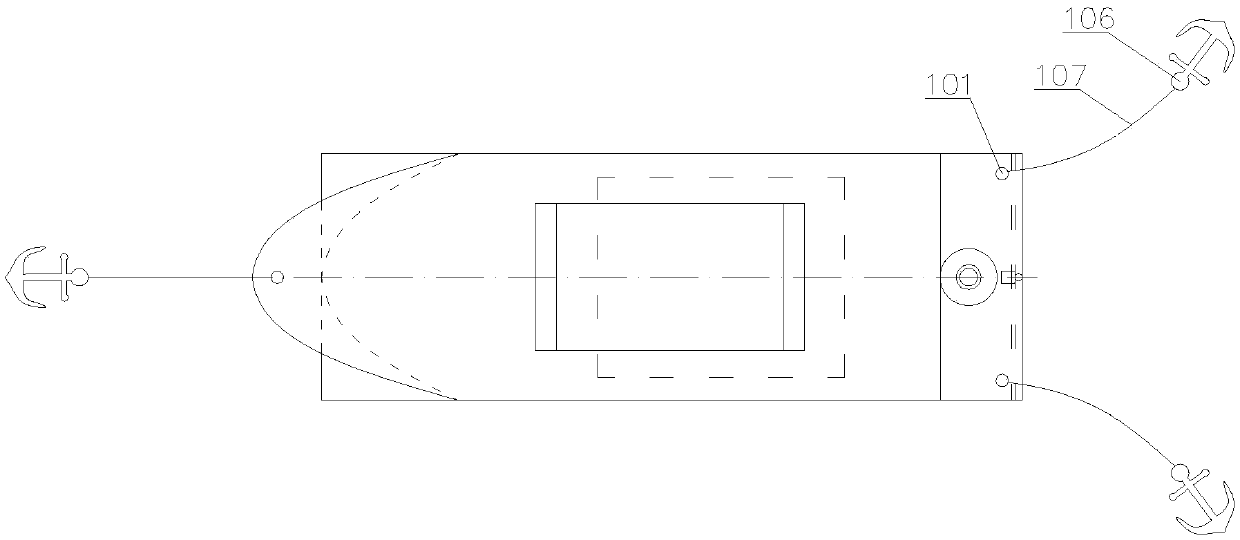

U-shaped self-propelled wave power generation device

ActiveCN108716449AChange response frequencyReduced resistance to swaying motionPropulsion power plantsMachines/enginesWave power generationEngineering

The invention discloses a U-shaped self-propelled wave power generation device. The wave power generation device comprises a ship body, a wave energy collection and conversion mechanism and a propelling mechanism; the ship body comprises a cabin, a cockpit, a device chamber, a deck and a tail plate, wherein the deck is arranged at the upper part of the cabin, the cockpit is arranged on the deck, the device chamber is arranged inside the cabin, and the tail plate is arranged at the tail part of the cabin; the wave energy collection and conversion mechanism comprises a front vertical pipe, a front air turbine generator set, a rear air turbine generator set, a rear vertical pipe and a horizontal pipe; and the horizontal section of the front vertical pipe is approximately triangular, and the horizontal section of the rear vertical pipe is quadrilateral, the vertical section of the horizontal pipe is pentagonal, and the front vertical pipe, the horizontal pipe and the rear vertical pipe sequentially communicate to form a U-shaped channel. The wave power generation device has the advantages that a foundation is laid for low cost, the wide sea area and high-efficiently utilization of thewave energy.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

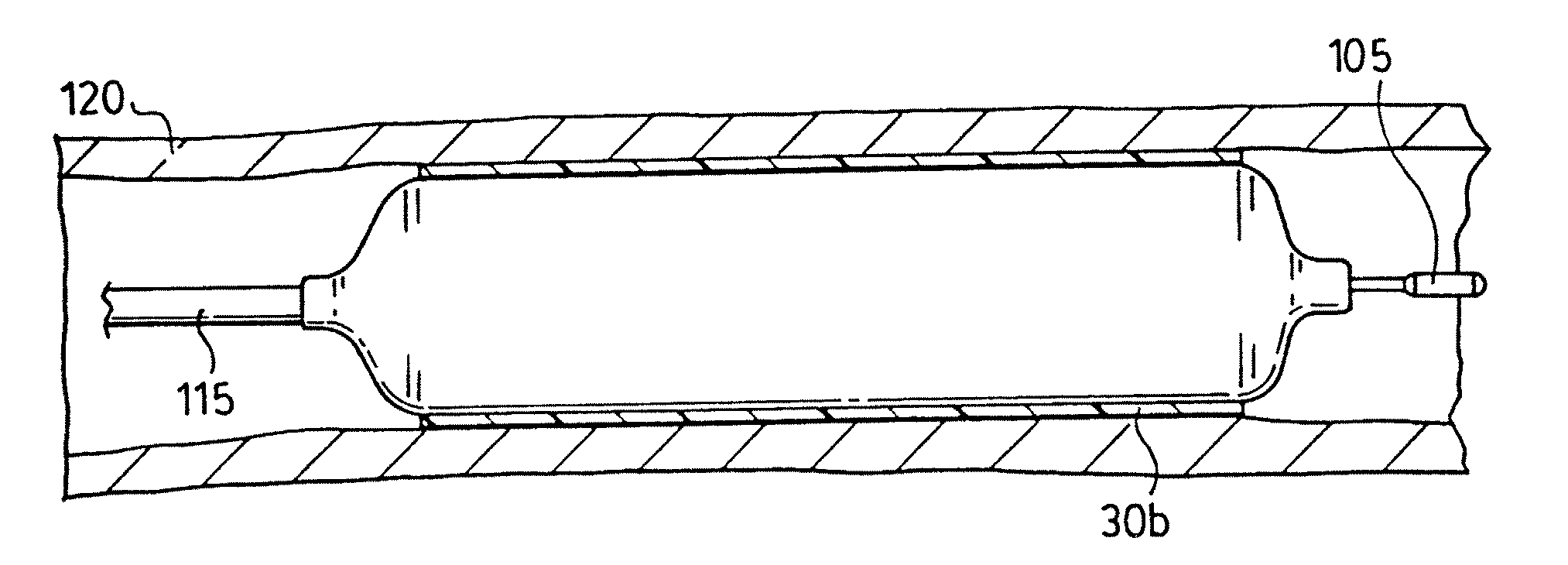

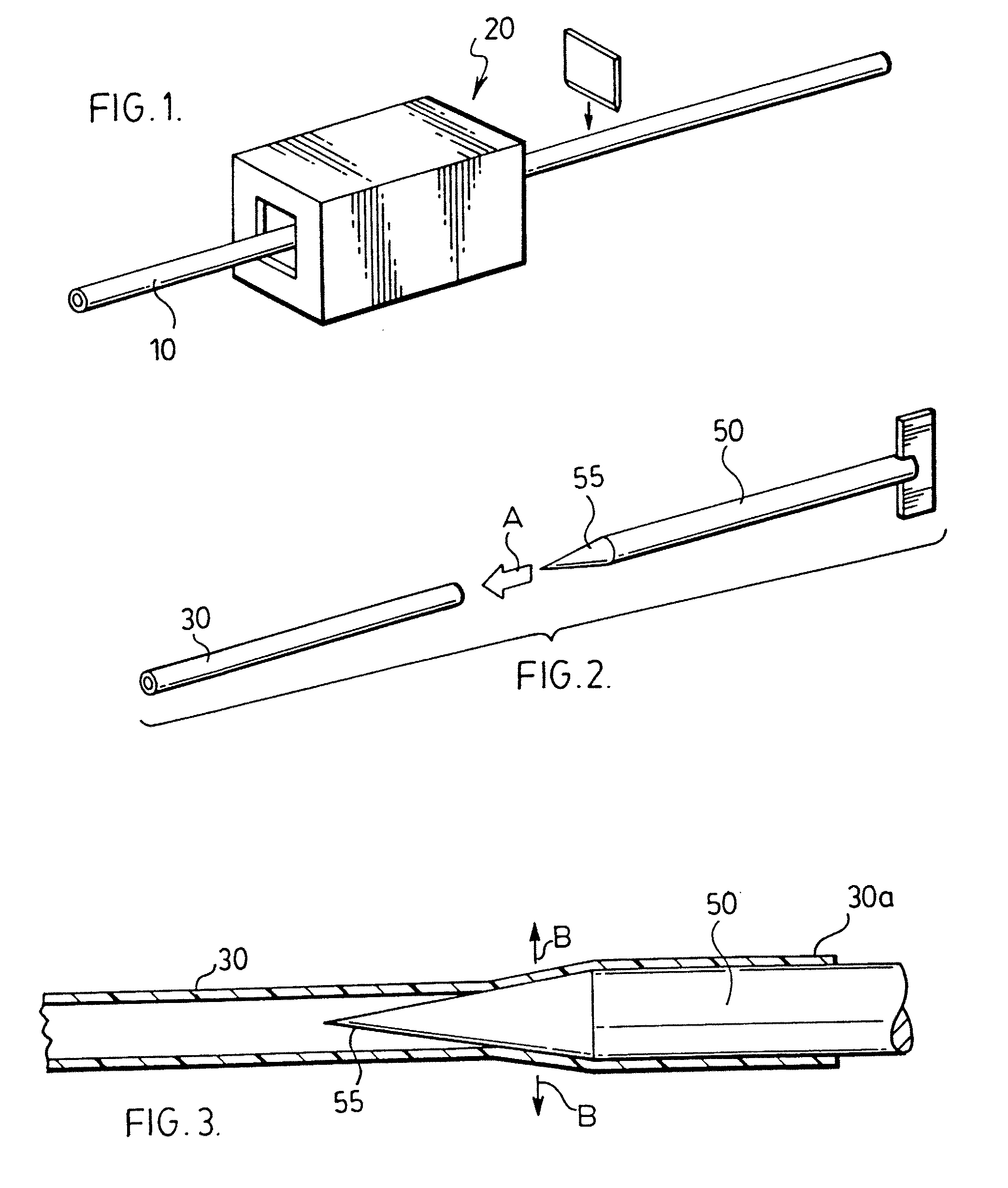

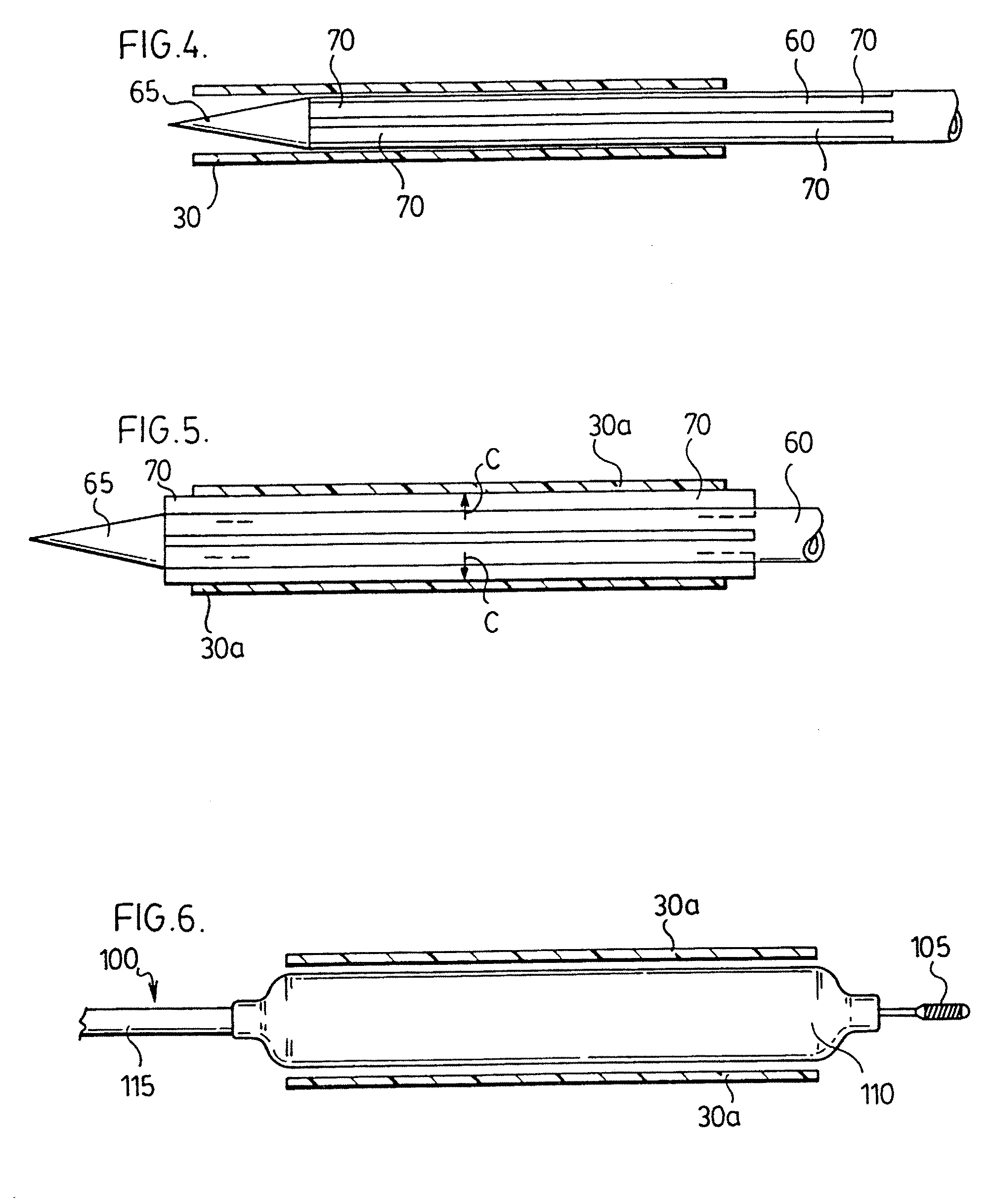

Small vessel expandable stent and method for production of same

A partially expanded stent comprising a proximal end and a distal end in communication with one another, a tubular wall disposed between the proximal end and the distal end, the tubular wall having a longitudinal axis and a porous surface defined by a plurality of interconnecting struts. The partially expanded stent has been expanded ex vivo by the application of a radially outward force thereon from a first unexpanded position to a second pre-expanded position at which the stent has reached a point of plastic deformation. The partially expanded stent is further expandable in vivo upon the application of a radially outward force thereon from the second pre-expanded position to a third expanded position wherein the stent will undergo plastic deformation to reach a maximum yield point.

Owner:RICCI DONALD R +3

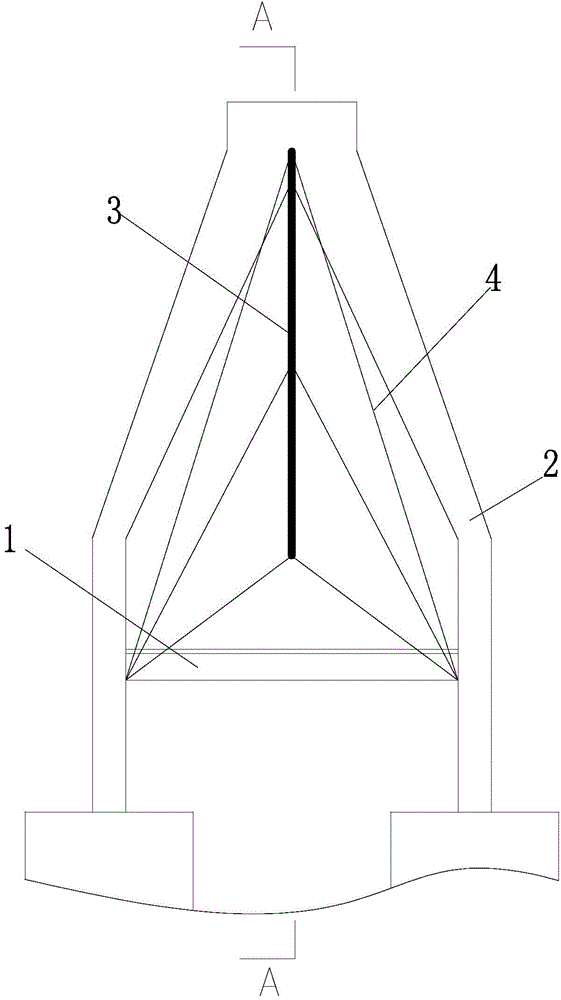

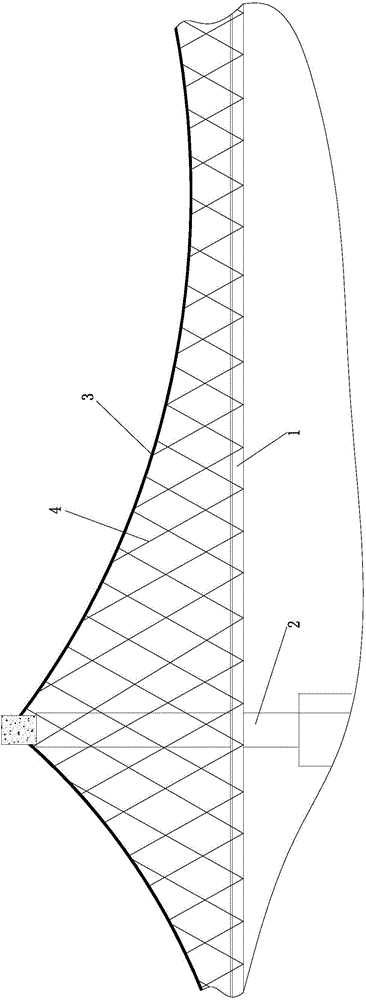

Suspension bridge with high torsional rigidity

ActiveCN104594178AIncrease the critical wind speedEnsure safetySuspension bridgeInstabilityTorsional rigidity

The invention discloses a suspension bridge with high torsional rigidity. The suspension bridge comprises a main beam, a cable bent tower, a main cable and suspension rods, wherein the main cable is arranged on a longitudinal central elevation of the main beam, the suspension rods are arranged on two transverse sides of the main beam and used for suspending the main beam by virtue of the main cable, so that the main cable, the suspension rods and the main beam form a structure with the cross section in a space triangular shape; by utilizing the stability of the triangle, a box-beam structure like the triangle is formed, the overall torsional rigidity and torsional vibration frequency of the suspension bridge can be fundamentally improved, the critical wind speed for torsional instability under the calm wind can be directly improved, the ratio of the torsional vibration frequency and the vertical vibration frequency also can be increased, the critical wind speed of the vibration can be increased, and the safety of the large-span suspension bridge can be guaranteed; moreover, materials and cost of the existing suspension bridge are not increased, the cross section can be increased only by adopting one main cable, the number and cross section of the suspension rods can be increased, and the torsional rigidity can be further improved.

Owner:林同棪国际工程咨询(中国)有限公司

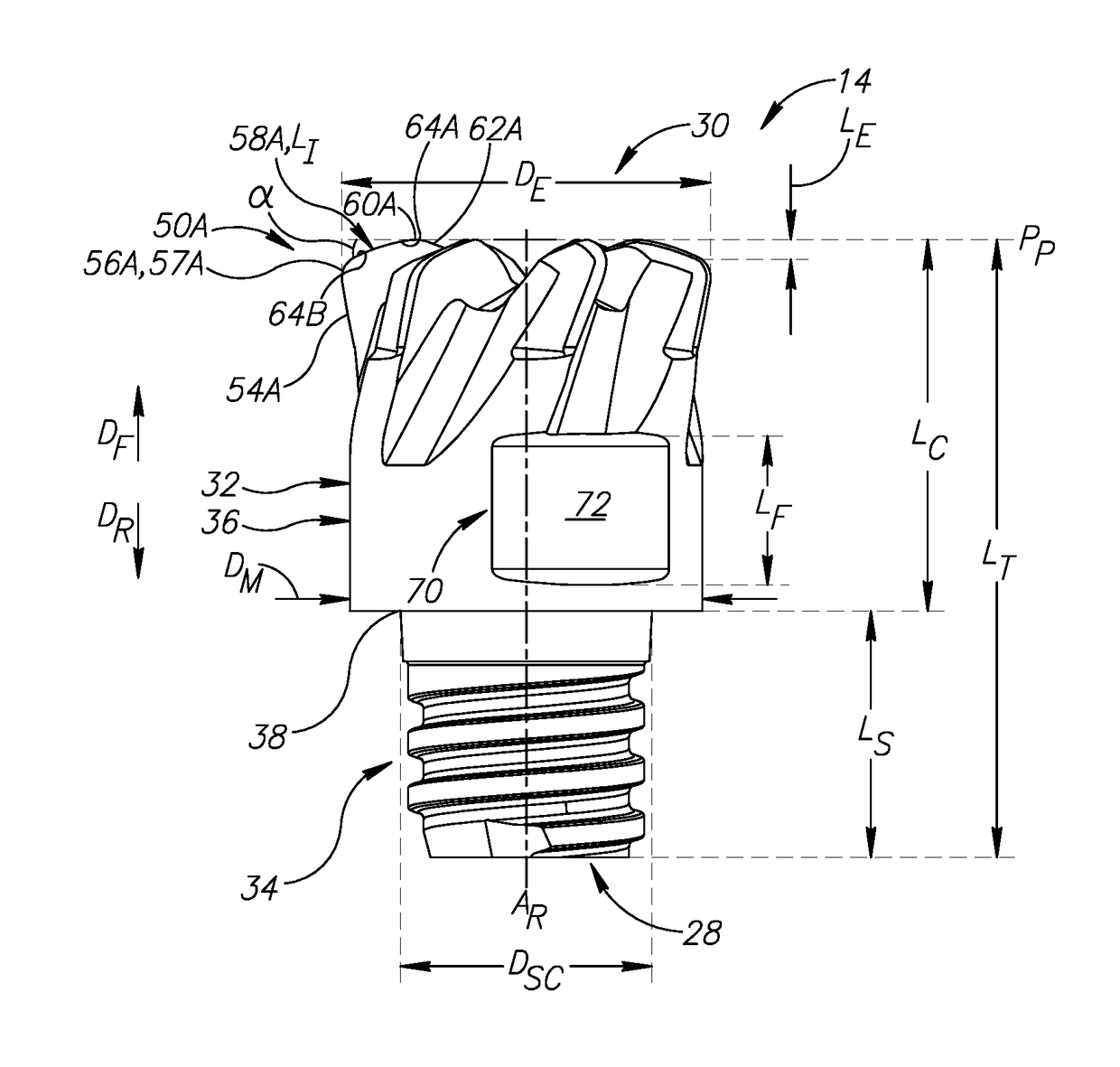

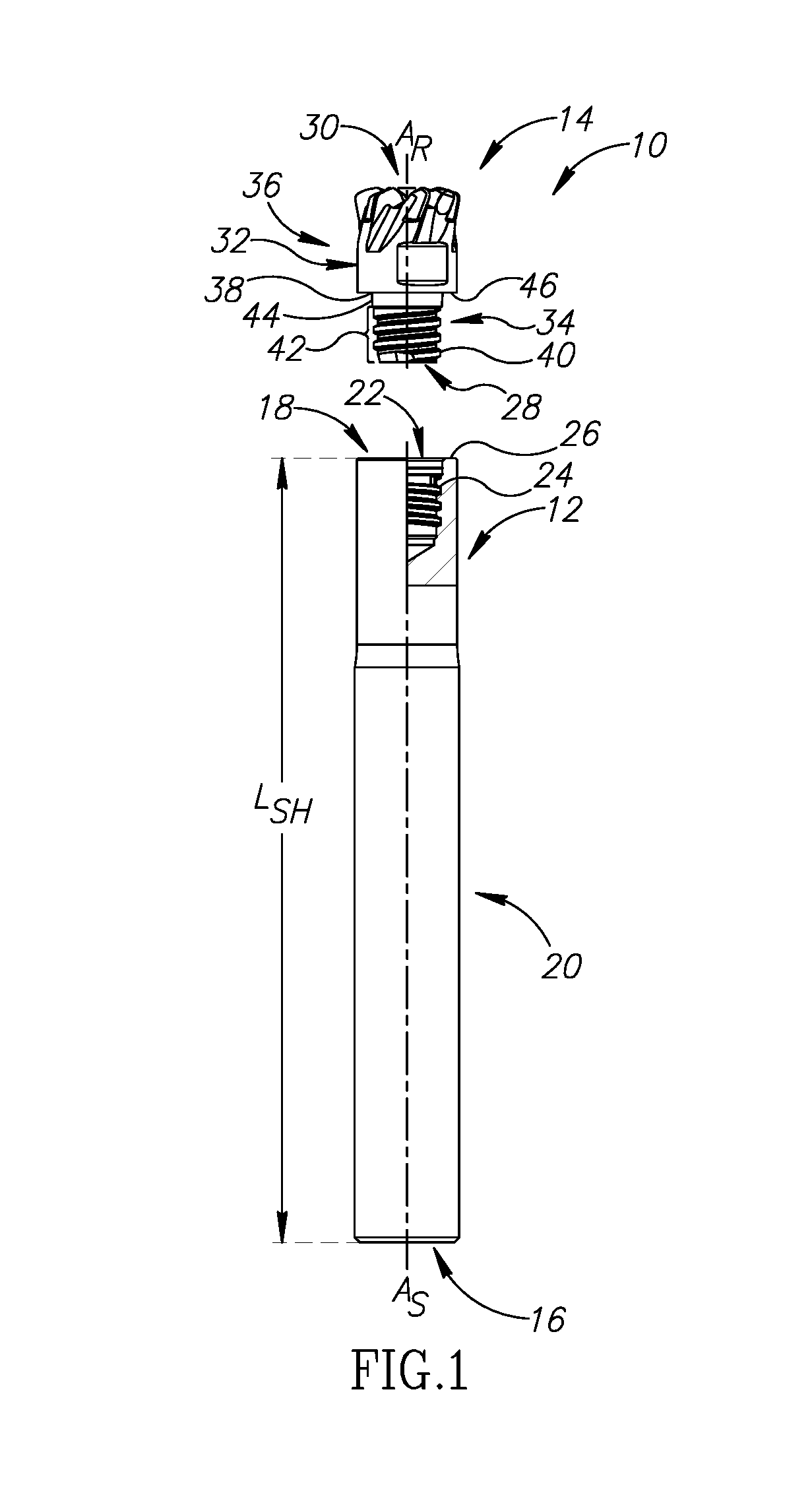

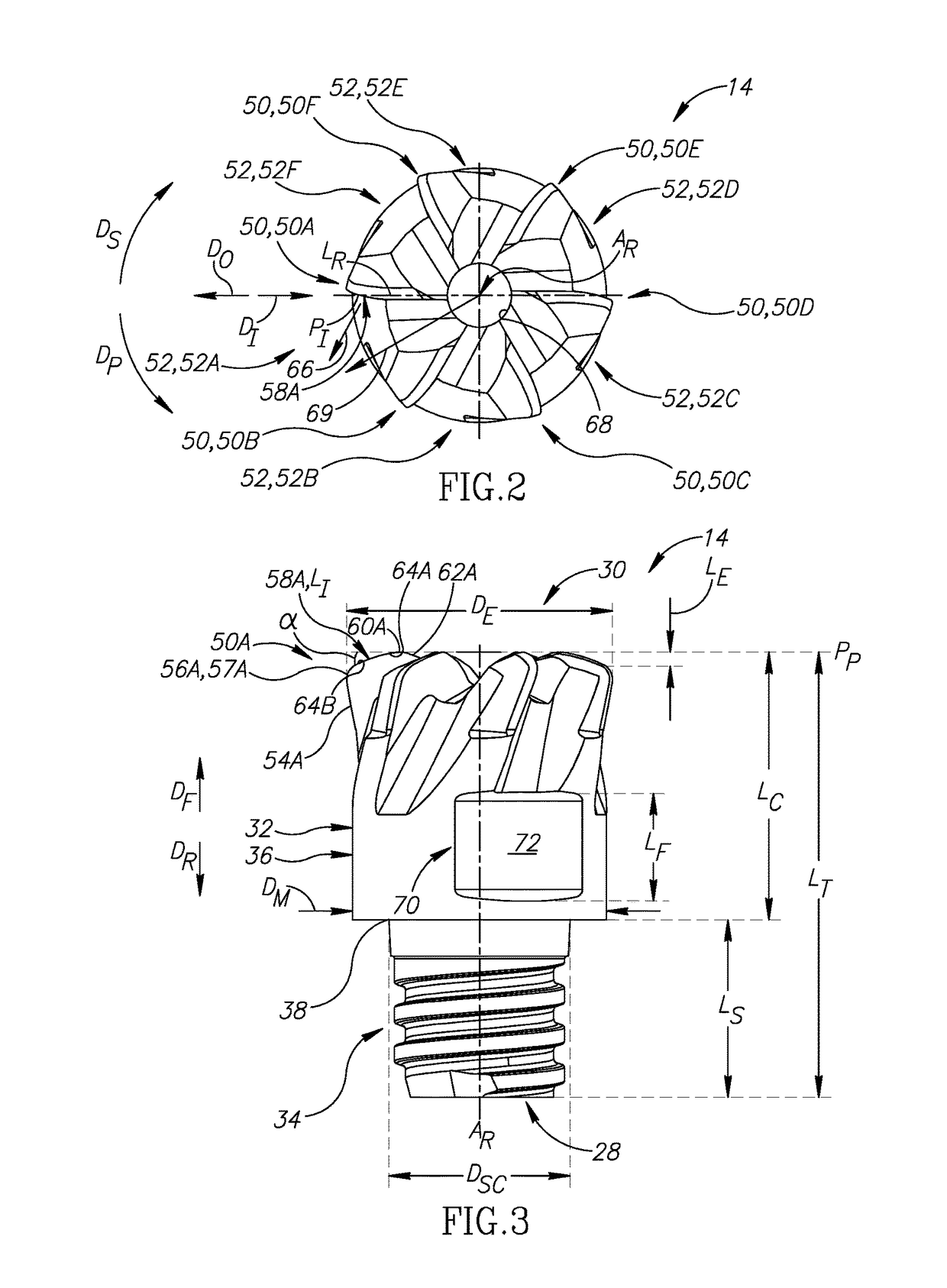

Replaceable Face-Milling Head With Integrally Formed Threaded Shank-Connector

ActiveUS20170291230A1Reduce heat transferReduce production stepsMilling cuttersAdverse effect compensationMilling cutterDiameter ratio

A replaceable face-milling head configured for rotating about a central rotation axis AR. The head includes a cutting portion and an integrally formed threaded shank-connector portion, the latter of which being configured for connecting to a shank. A length-diameter ratio LDR, defined as a cutting portion length LC divided by a cutting portion diameter DE, fulfills the condition: LDR≦1.00.

Owner:ISCAR LTD

Nanometer waterborne woodware paint

The invention discloses a nanometer waterborne woodware paint. The paint is prepared by stirring the following raw materials in parts by weight: 65-70 parts of polyacrylate emulsion, 10-15 parts of linseed oil, 5 parts of talcum powder, 10-15 parts of candelilla wax, 6 parts of sodium hexametaphosphate, 20 parts of propylene glycol, 16 parts of alkali lignin, 2 parts of zircon isocaprylate, 13 parts of nano-TiO2 slurry, 5 parts of defoaming agent and 4 parts of wetting agent. Experiments prove that the product of the invention has good wetting property, flexibility and weather resistance, excellent sealing property and grindability and simpler material and technology and can be widely used in the surface finishings of solid wood furniture and panel type furniture.

Owner:WUJIANG LONGJING HONGBEI INTERIOR DECORATION

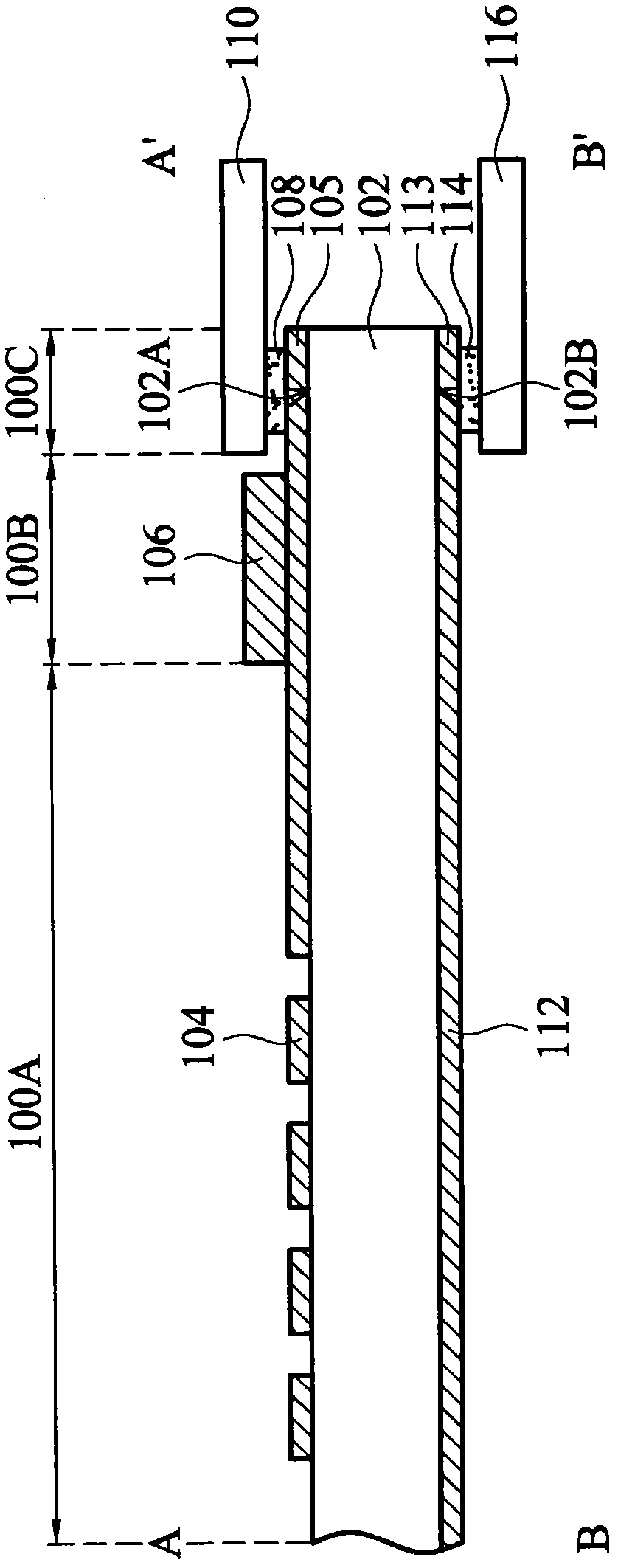

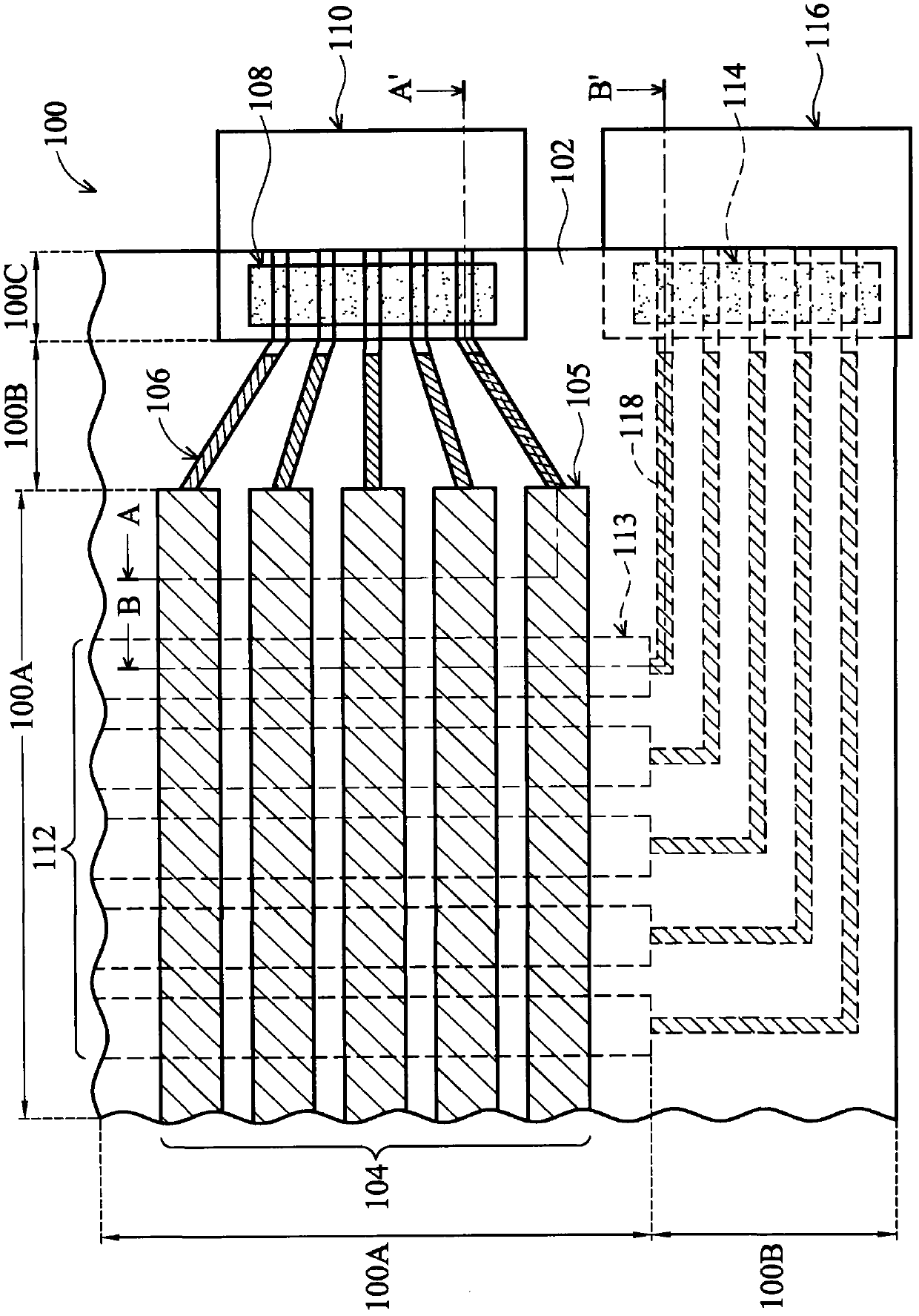

Flat display panel frame

InactiveUS20080192412A1Save materialEfficiency of material can be promotedSubstation/switching arrangement detailsNon-linear opticsPunchingButt joint

The present invention provides an improved flat display panel frame, wherein two L-shape workpieces or four strip-like workpieces are butt-jointed to form a frame body, and the perimeter of the frame body is bent to form an external bent portion, and thus, an flat display panel frame is completed. In the present invention, as the frame body is formed via butt-jointing multiple workpieces, the punching process for the metallic workpiece is more flexible, and an optimal workpiece arrangement can be used to achieve the highest manipulation efficiency of material. Thus, the material is saved, and the material cost is reduced. Further, the scrap is decreased, and the scrap-processing cost is also reduced.

Owner:JOCHU TECH

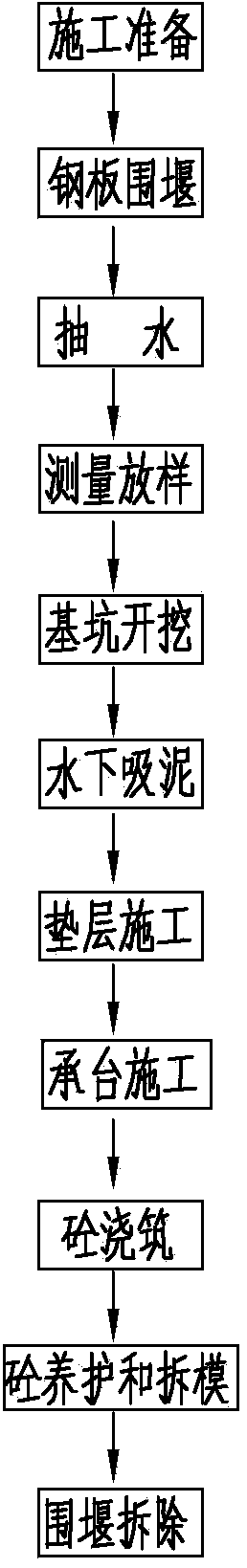

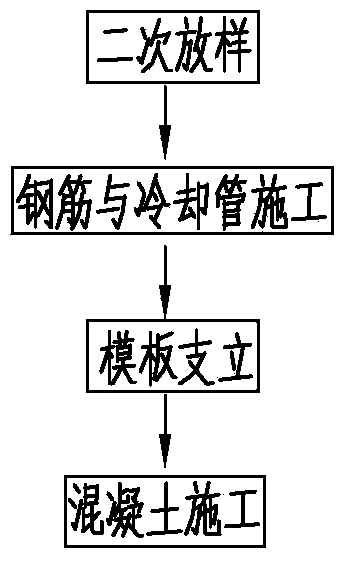

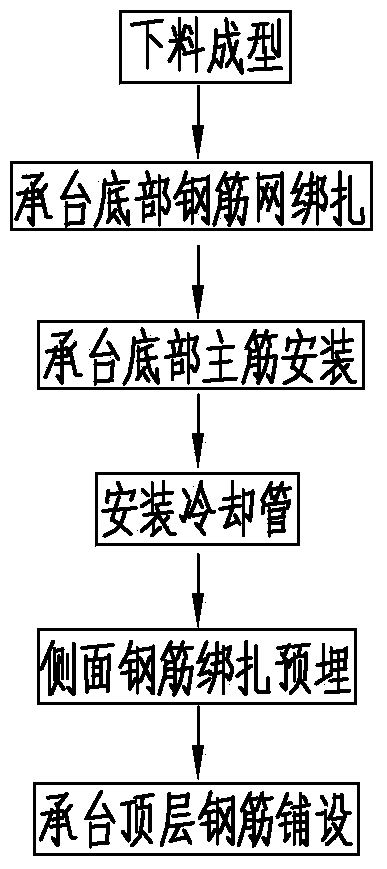

Underwater bearing platform construction method

ActiveCN104074199AFast constructionShorten the construction periodFoundation engineeringUnderwaterCofferdam

The invention discloses an underwater bearing platform construction method. The underwater bearing platform construction method includes the following steps of (1) construction preparation, (2) steel plate coffering, (3) water pumping, (4) staking out in survey, (5) excavation of foundation pit, (6) pile head removing by chiseling, (7) underwater slush pumping, (8) cushion construction, (9) bearing platform construction, (10) concrete pouring, (11) concrete maintaining and form removal and (12) cofferdam removal. By means of the underwater bearing platform construction method, a bearing platform is stable and firm, meanwhile, a construction scheme is optimized, the construction period is further shortened, manpower and material resources are greatly reduced, economic benefits are remarkable, flying dust can not occur during construction, environment protection can be achieved, the accuracy during construction is effectively improved by the aid of secondary setting out of the bearing platform, the deviation is reduced, construction qualities are improved, and a whole pier column is stable.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

Flexible circuit board connected structure of electronic device

ActiveCN103327729APrevent disengagementImprove reliabilityPrinted circuit aspectsPrinted circuit manufactureAnisotropic conductive filmFlexible circuits

The invention provides a flexible circuit board connected structure of an electronic device. The electronic device comprises a visible range, a wire range and a connected range. The wire range is arranged between the visible range and the connected range, and the flexible circuit board connected structure comprises a substrate. A transparent conducting layer is arranged on the substrate and extends to the connected range from the wire range, a metal wire layer is arranged on the transparent conducting layer of the wire range and does not extend to the connected range, an anisotropic conductive film is arranged on the transparent conducting layer of the connected range and is directly contacted with the transparent conducting layer, and a flexible circuit board is connected to the anisotropic conductive film. The reliability of the flexible circuit board connected structure of the electronic device can be improved.

Owner:HANNSTAR DISPLAY CORPORATION

Dielectric phase shifter with novel conducting cavities

ActiveCN106067577AReduce the number of partsSave assembly timeWaveguide type devicesAntennasDistortionEngineering

The invention discloses a dielectric phase shifter with novel conducting cavities. The dielectric phase shifter includes an outer shell, dielectric sheets, a circuit board and coaxial cables; two rectangular cavities are formed in the outer shell; one conducting cavity is formed at one side of each cavity, wherein the conducting cavity is connected with the cavity; each conducting cavity is hollow and is a circular hole of which the diameter is 3.6 mm, and a small groove of which the width is 1.2 mm formed at one side of the hole; in each conducting cavity 4, a portion with a reserved width is maintained to be original at a position where the outer conductor of a corresponding coaxial cable is welded to the conducting cavity 4, and a portion of which the width is 15mm is machined downwards so as to be removed, and therefore, the coaxial cable can extend into the conducting cavity so as to be welded to the conducting cavity; the circuit board is designed into a rectangle with four grooves formed at one side; and the four grooves are corresponding to the edges of circuit board pads for welding the inner conductors of the coaxial cables. When welding is carried out, only one-time clamping is required, and therefore, a welding technique is better, and the economical efficiency of welding is improved; and the conducting cavities are utilized to excellently wrap the outer conductors of the coaxial cables, distortion can be avoided, bending stress of the coaxial cables can be avoided, the risk that welding spots and the circuit board are damaged can be lowered, and hidden hazard points in intermodulation can be decreased.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

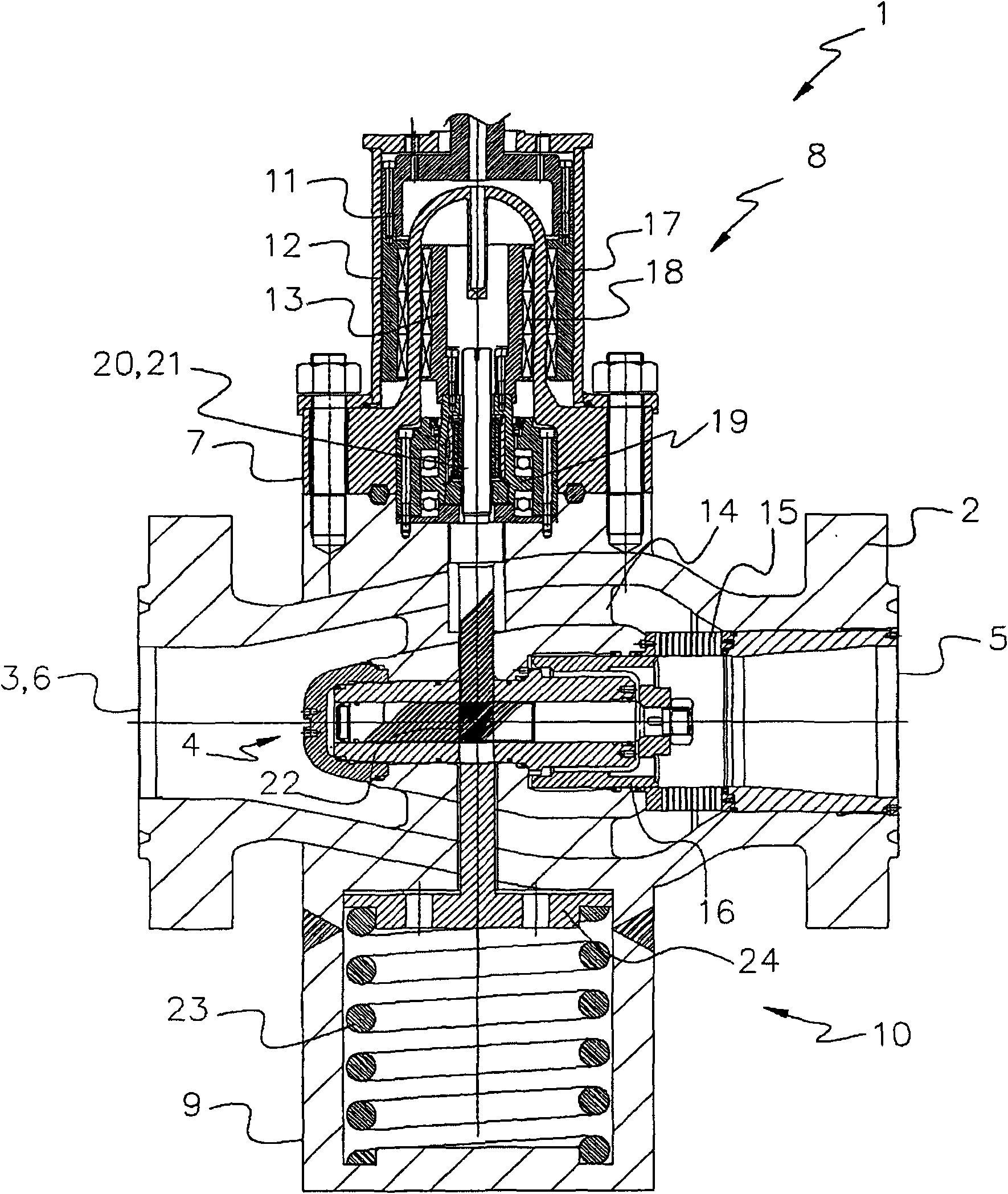

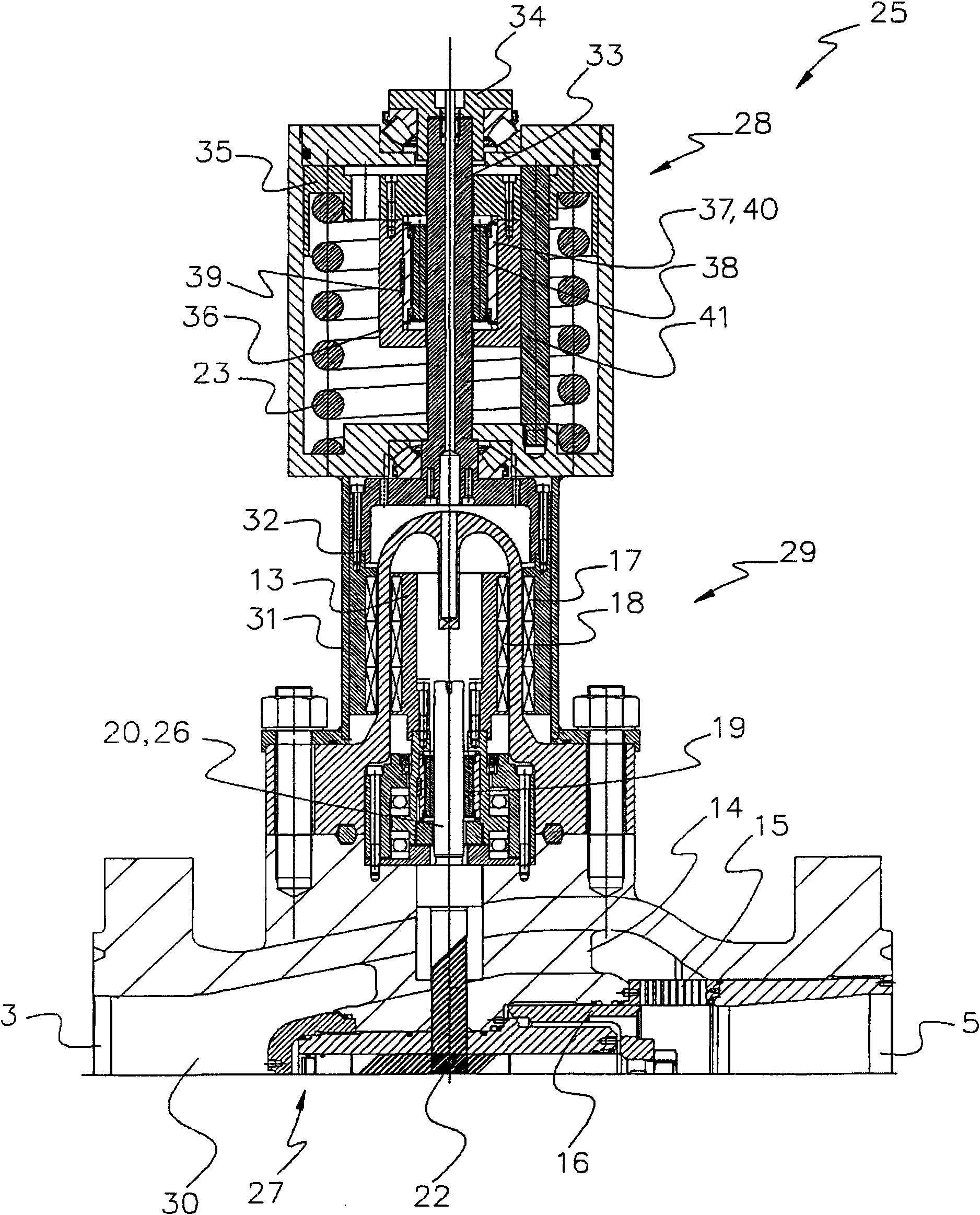

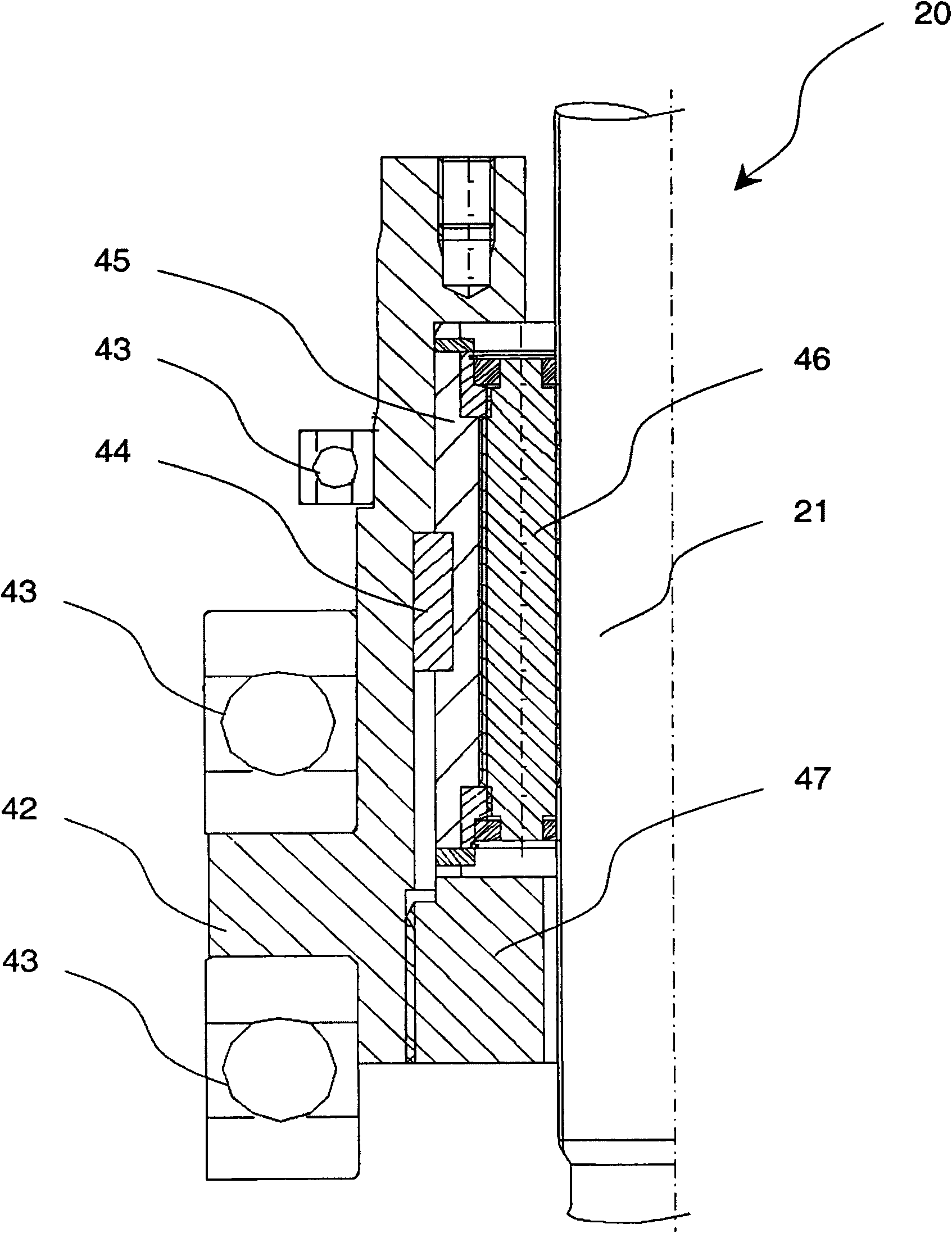

Throttle valve

ActiveCN101631977AAvoid unreliabilitySmall adjustment torqueOperating means/releasing devices for valvesLift valveCouplingOil and natural gas

Disclosed is a throttle valve (1, 25), having a housing (2), comprising an inlet opening (3) for a fluid under an inlet pressure, a throttle (4, 27), by means of which the fluid can be throttled to an outlet pressure, and an outlet opening (5) for the fluid, and an actuation element (11) at the outside of the housing (2), a rotatable shaft (13), and a piston (16), which is axially movable within the housing (2) in a tubular throttle cage (15), wherein a rotation of the shaft (13) can be induced by the actuation element (11) and an axial movement of the piston (16) can be induced by the rotation of the shaft (13) and by the axial movement of the piston (16) a throttle cross section of the throttle (4, 27) can be adjusted, For under water application, in particular in oil and gas drilling with large pipe cross sections the throttle valve according to the invention is improved, so that primary magnets are mounted to the actuation element (11, 32), secondary magnets are mounted to the shaft (13), and a roller body screw drive (20) is mounted to the shaft (13), wherein a rotation of the actuation element (11, 32) is transferred to the shaft (13) by means of magnetic coupling of the primary magnets with the secondary magnets, and converted into the axial movement of the piston (16) by means of the roller element screw drive (20).

Owner:MOKVELD VALVES BV

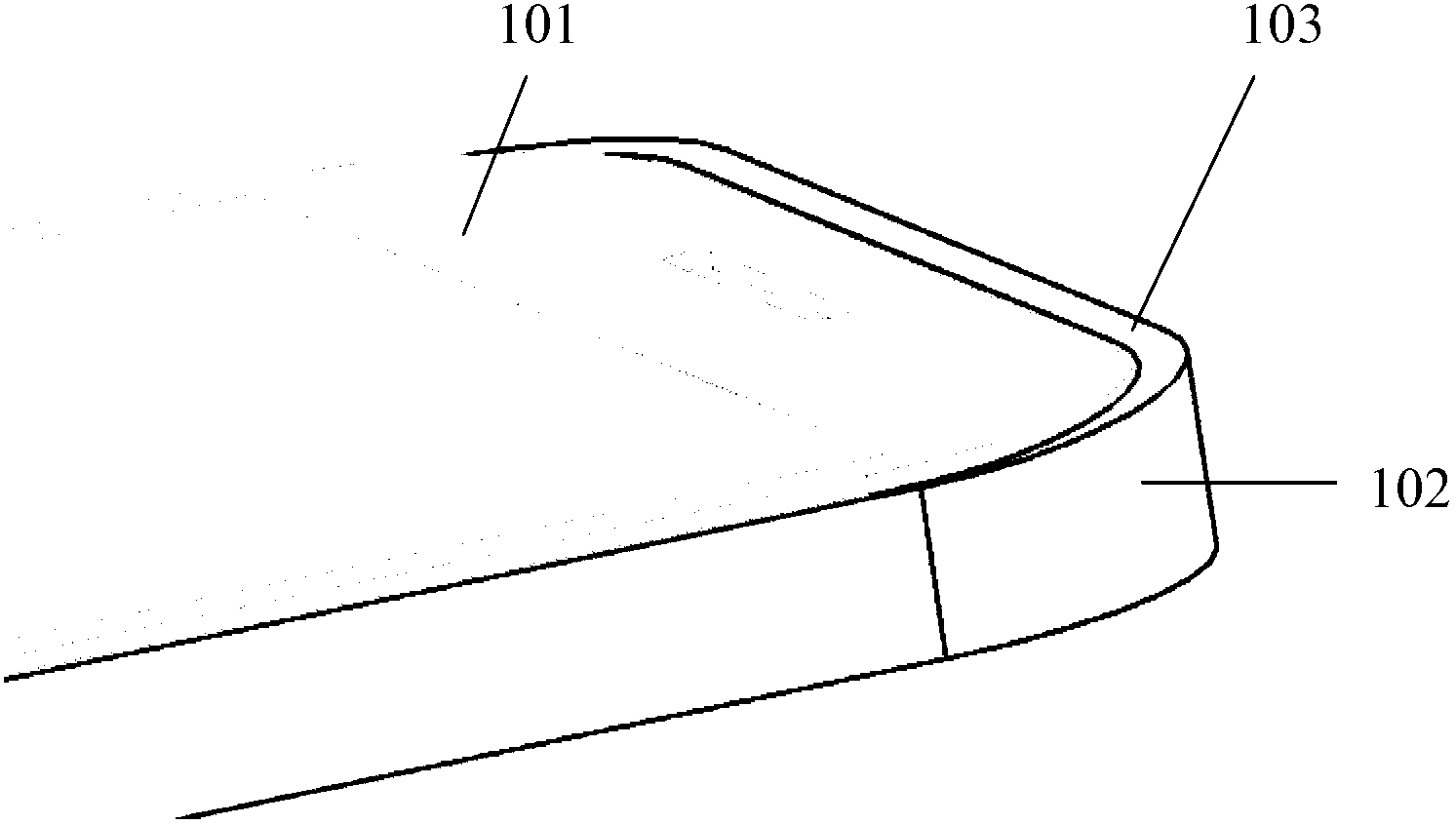

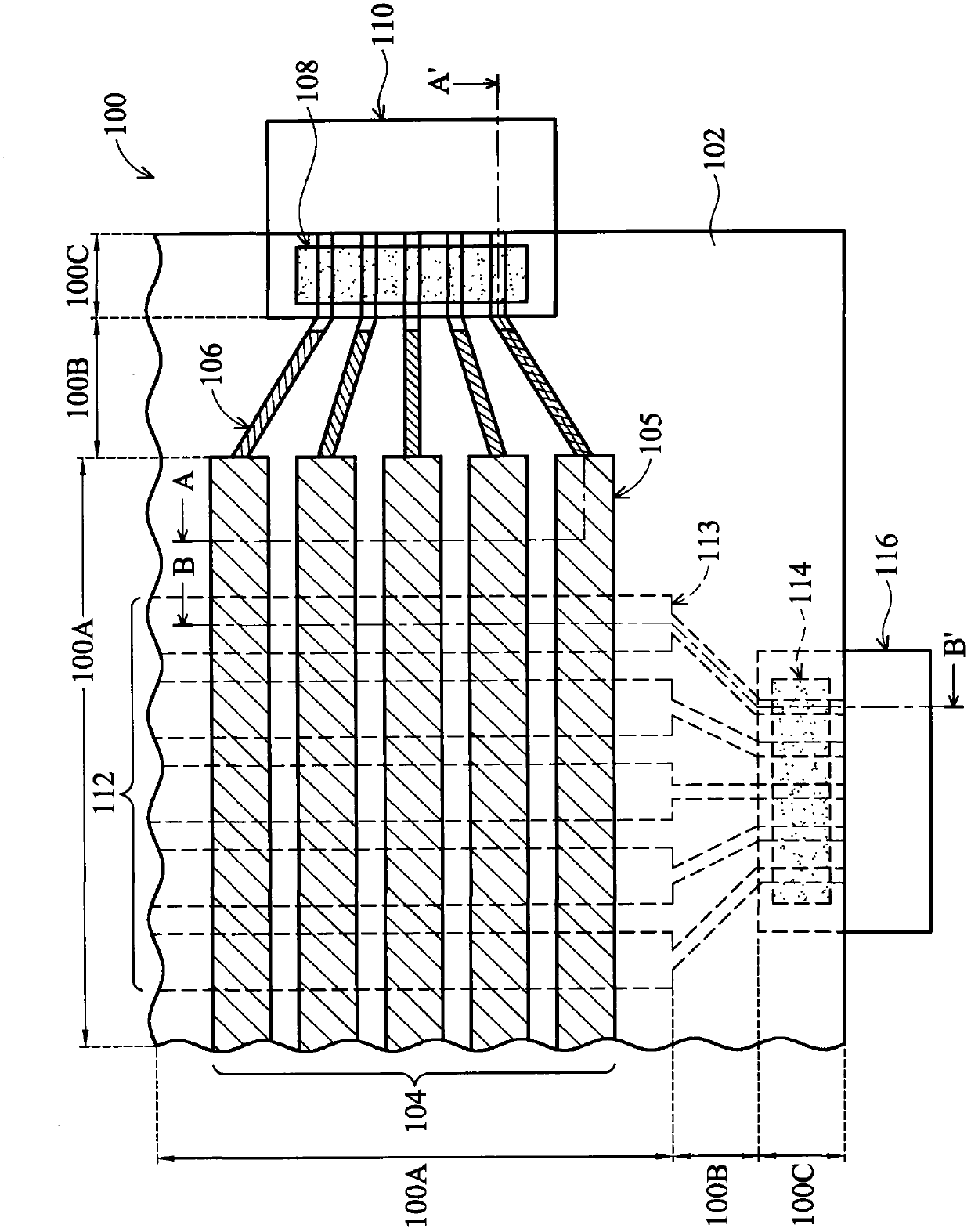

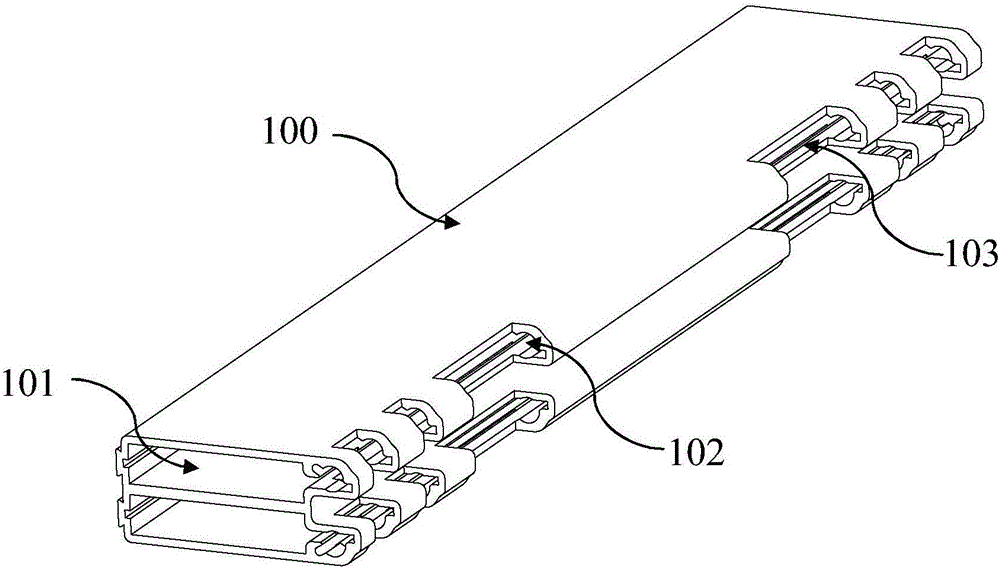

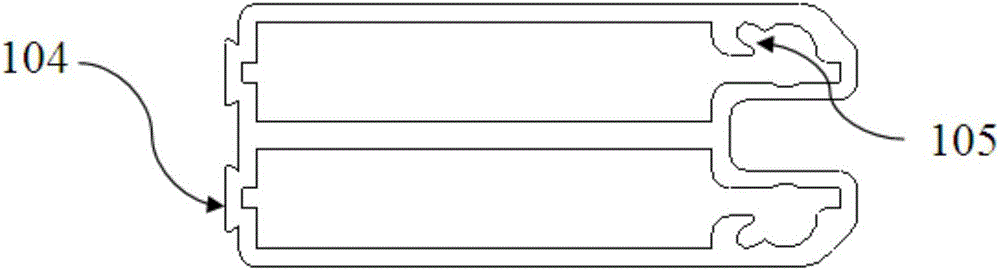

Efficient energy-saving self-propulsion type wave-power generating device

InactiveCN107605646ASimple structureLow costHydro energy generationMachines/enginesEngineeringTurbine

An efficient energy-saving self-propulsion type wave-power generating device comprises a hull, a wave energy collection and conversion mechanism and a propelling mechanism. The hull comprises a cabin102, a cockpit 103, an equipment room 104, a deck 105, anchor piles 101, anchor chains 107 and anchors 106. The wave energy collection and conversion mechanism comprises a horizontal pipe 211, a vertical pipe 208, an air chamber 201, an air turbine 202, an air chamber outlet end 203, a generator 204, a gate 207 and a gate opening and closing mechanism 205. The efficient energy-saving self-propulsion type wave-power generating device has the advantages that the material cost and the construction cost of the device are reduced, design difficulty of an anchoring system for resisting the severe environment is lowered, the material and ocean engineering costs are reduced, and the safety of the device is improved, and lays a foundation for achieving the low cost, the wide sea area and efficientutilization of wave energy.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

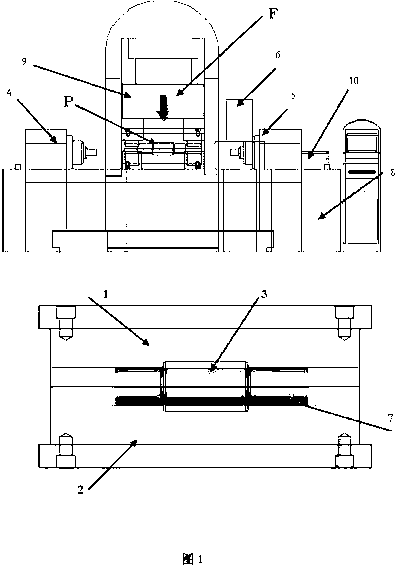

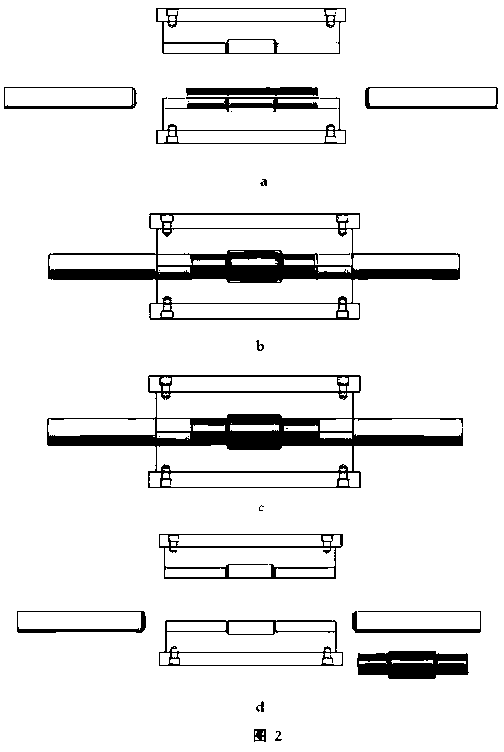

Variable-mold-clamping-force pipe internal high-pressure forming device and method

ActiveCN103212619AReduced pressure holding performance requirementsSmall tonnageEngineeringAxial force

The invention relates to a variable-mold-clamping-force pipe internal high-pressure forming method, which comprises the steps that after an upper mold and a lower mold are clamped, forming media with certain pressure is filled into a mold cavity, pushing heads on a left side and a right side simultaneously push pipe blanks into the mold cavity from the left side and the right side, the pipe blanks are pressed into the mold cavity to be formed through internal pressurization and axial force application and material compensation under the joint effect of the pressure of the forming media and the material compensation of the pushing heads, and finally the pipe blanks are in fit with the mold cavity to realize part formation. Since different mold clamping forces are adopted at different stages, the defects that the pressure required by the traditional constant-mold-clamping-force tube internal high-pressure forming method is high, the requirements on machine performance, mold performance, sealing performance and mold lubricating performance are high, the machine cost is high, the situation of mold lifting is apt to occur, the part forming pressure is high, large-deformation complex parts cannot be formed, the working efficiency is low and the like are overcome.

Owner:NINGBO POWER PRECISION HYDRAULIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com