Patents

Literature

573results about How to "Meet construction needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

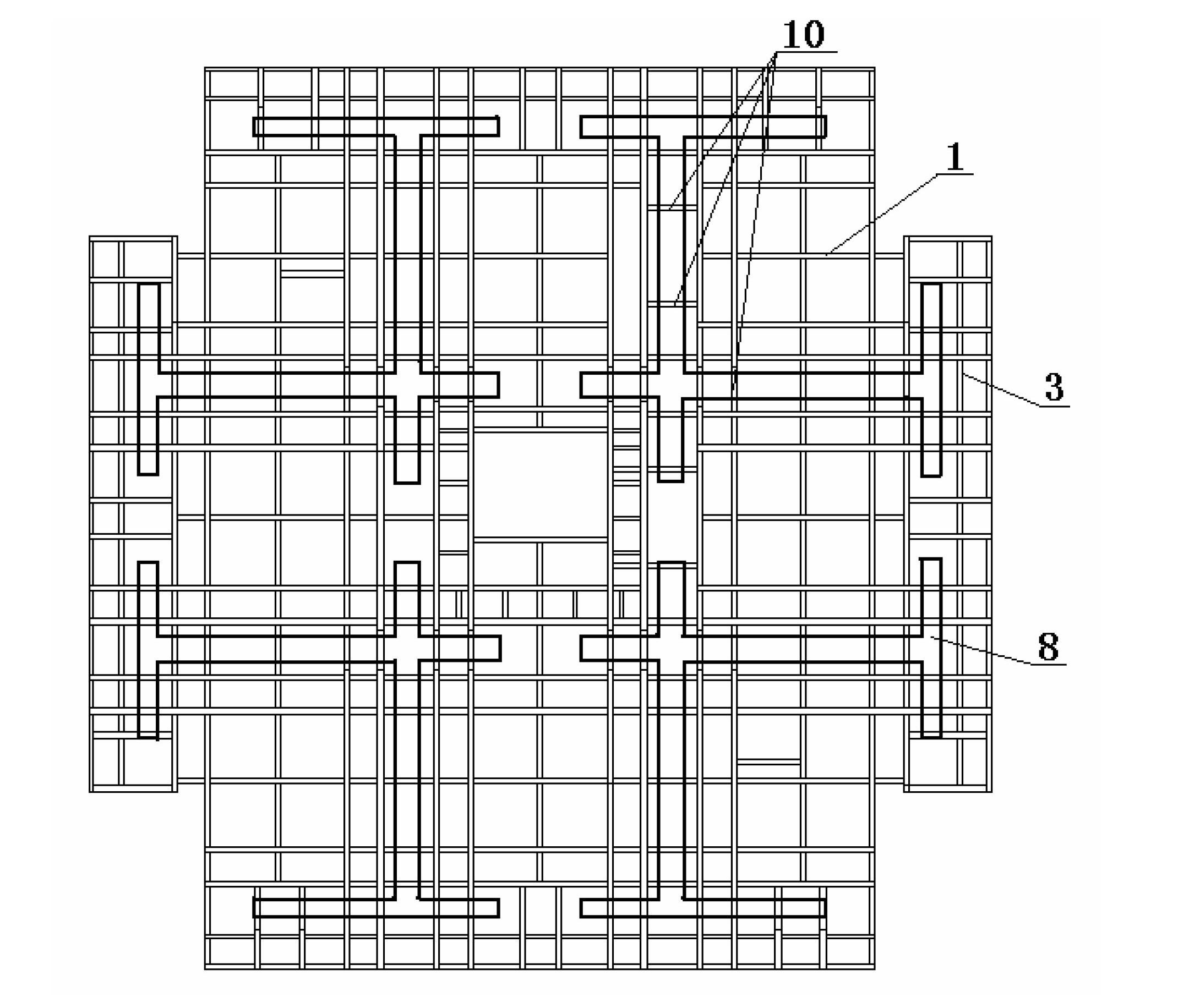

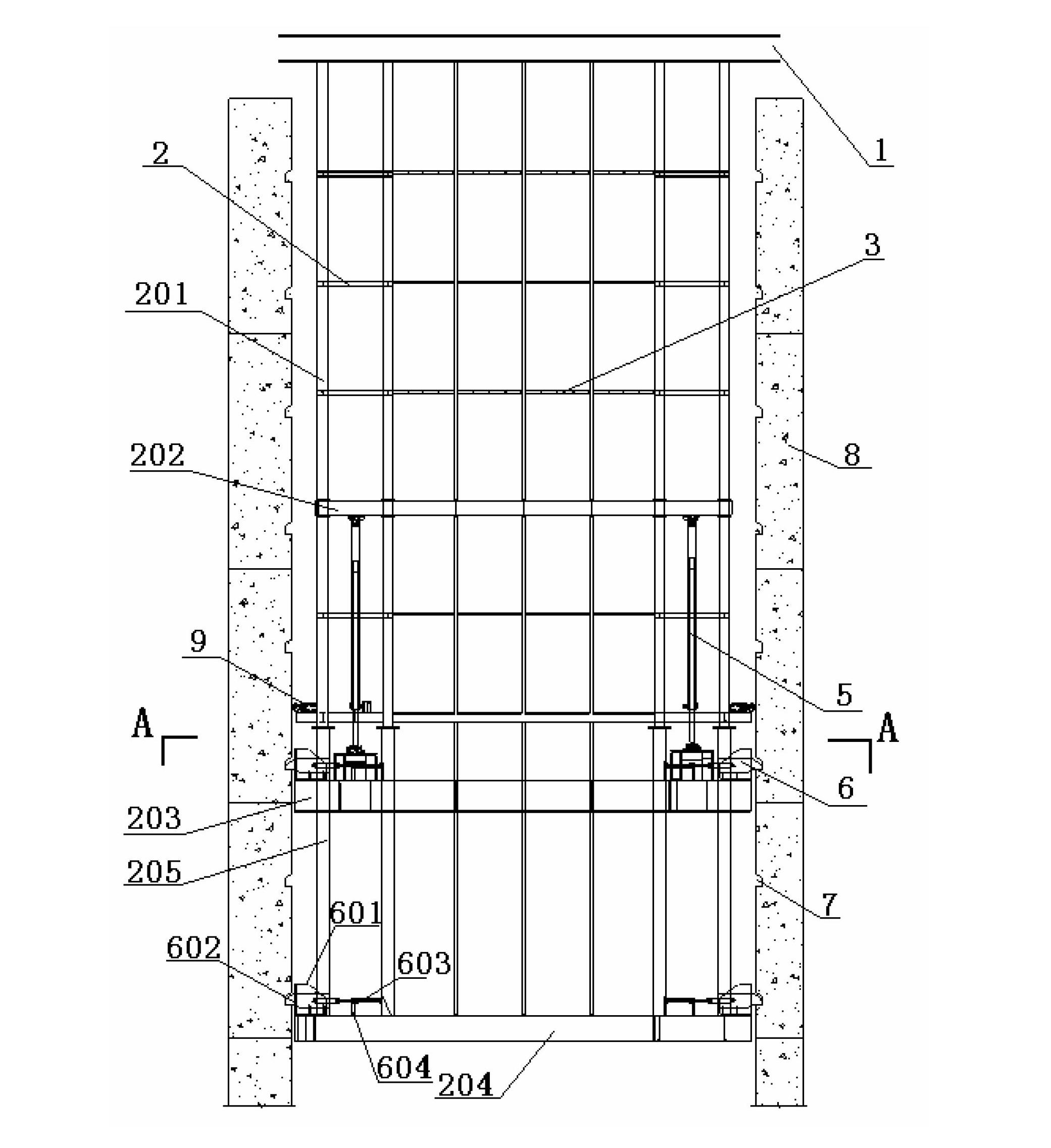

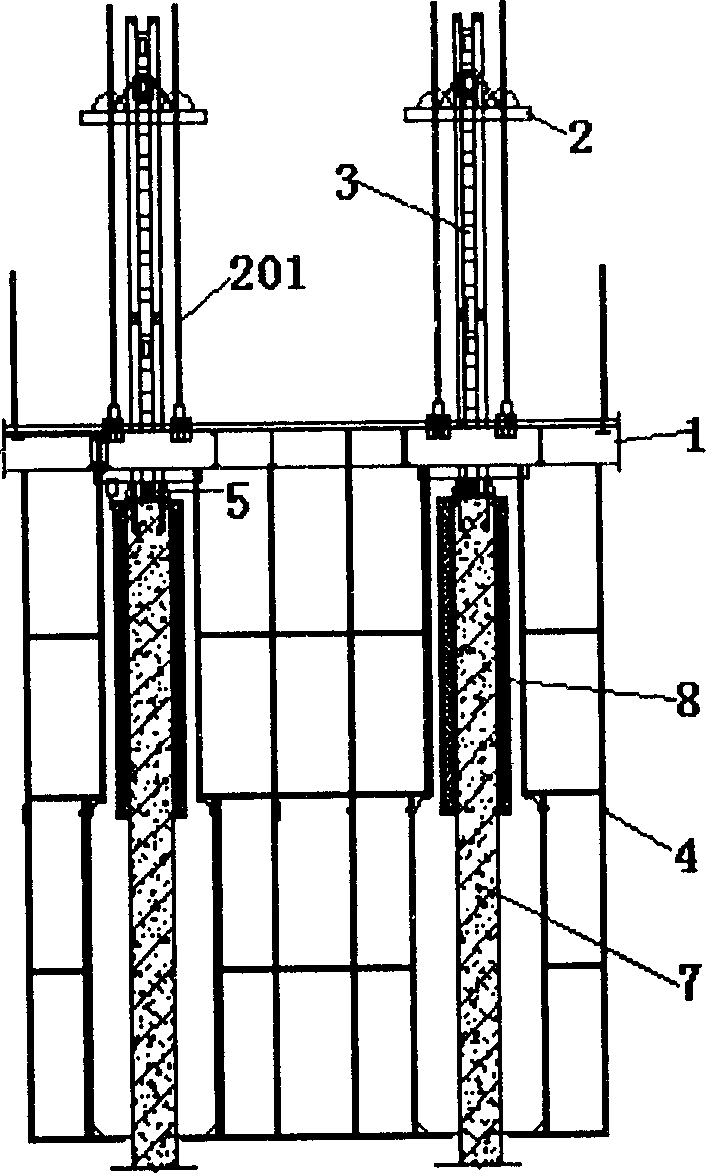

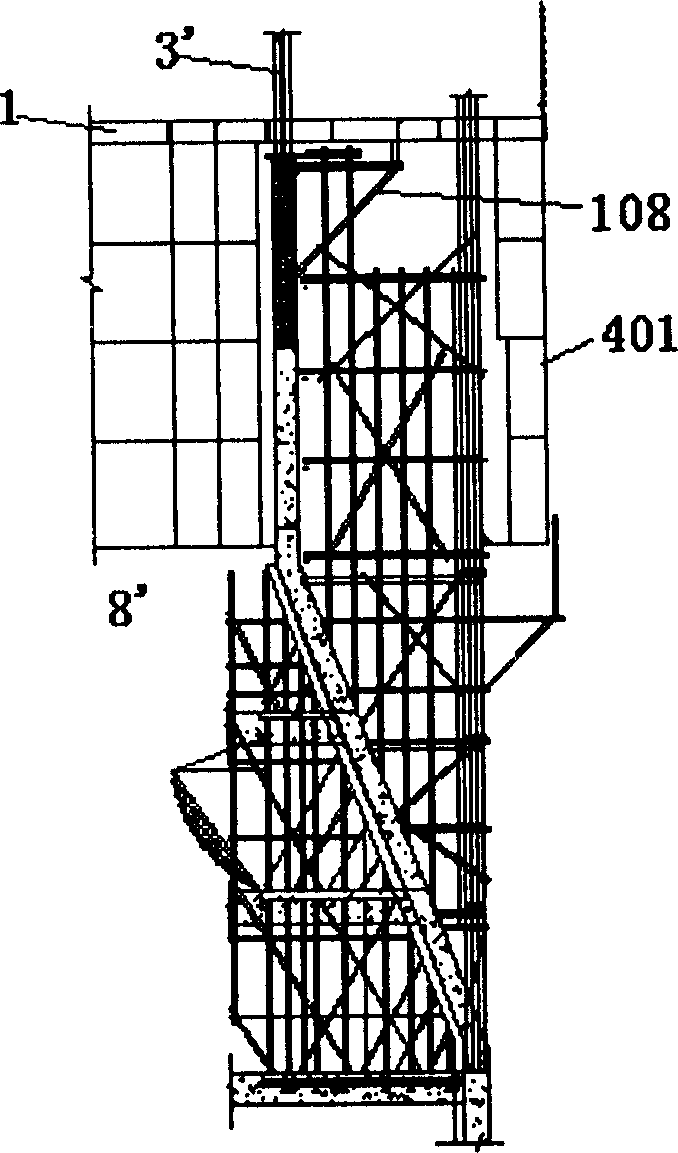

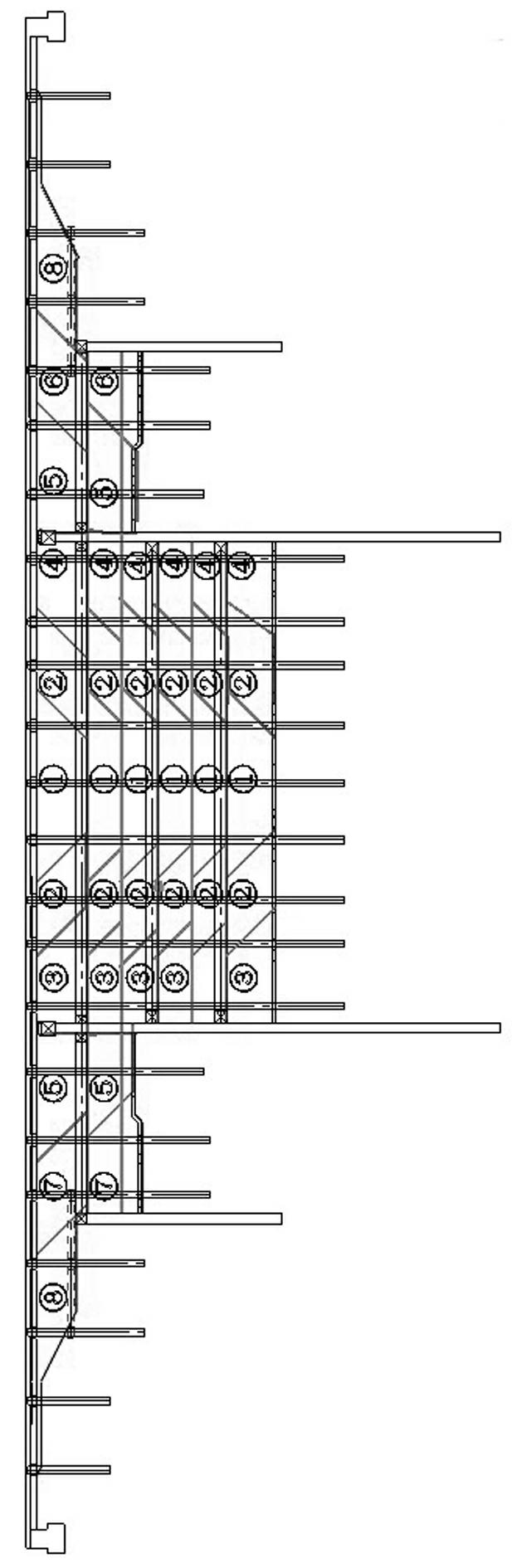

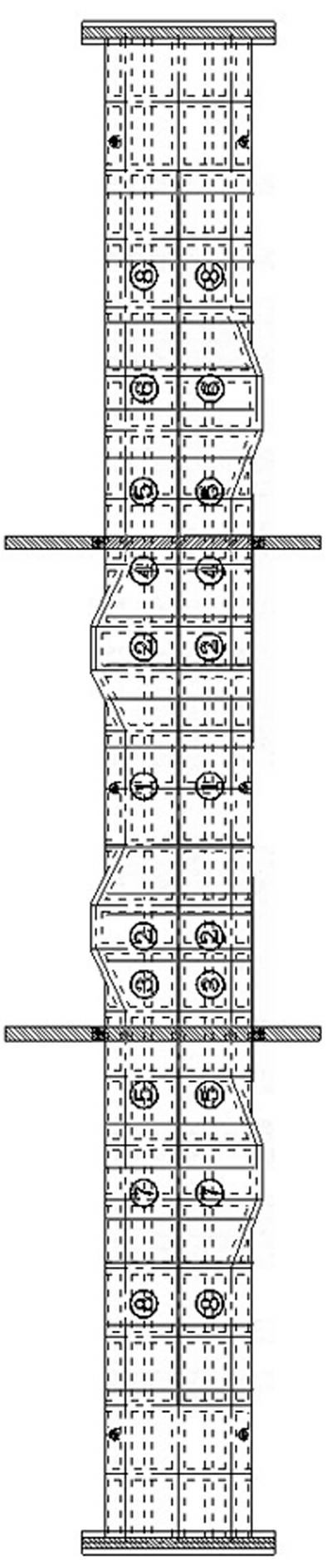

Drum frame supporting power built-in integrated jacking steel platform formwork system and construction method

ActiveCN102661039AEasy maintenanceAvoid the risk of falling objectsForms/shuttering/falseworksBuilding material handlingSteel columnsShear wall

The invention discloses a drum frame supporting power built-in integrated jacking steel platform formwork system, comprising a steel platform, a support system, a suspended scaffold, a template system and a hydraulic jacking power system; the support system comprises a drum frame support and an internal framework support; the drum frame support is located under the steel platform, and comprises a steel platform support, an oil cylinder counter-force beam, a guide roller, a support steel column and a drum frame support beam; the internal framework support is arranged inside the drum frame support and located between the drum frame support beam and the oil cylinder counter-force beam; the hydraulic jacking power system comprises a hydraulic jacking oil cylinder and a power control system thereof; the hydraulic jacking oil cylinder is inverted between the oil cylinder counter-force beam and the internal framework support; telescopic brackets are arranged at the end portions of the internal framework support and the drum frame support beam, respectively; and the telescopic brackets are supported in a preformed hole in a shear wall. The drum frame supporting power built-in integrated jacking steel platform formwork system is capable of realizing the construction operation of a complex core drum, shortening the construction period and ensuring high altitude construction safety, and also capable of improving the green construction level.

Owner:SHANGHAI CONSTRUCTION GROUP +1

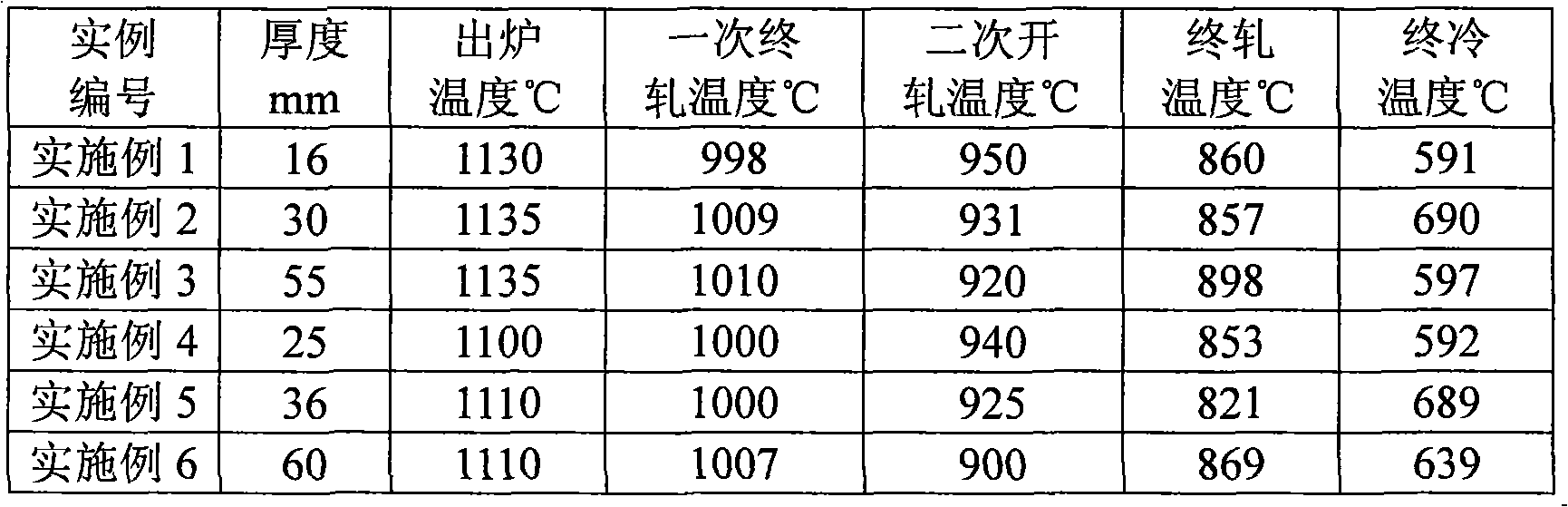

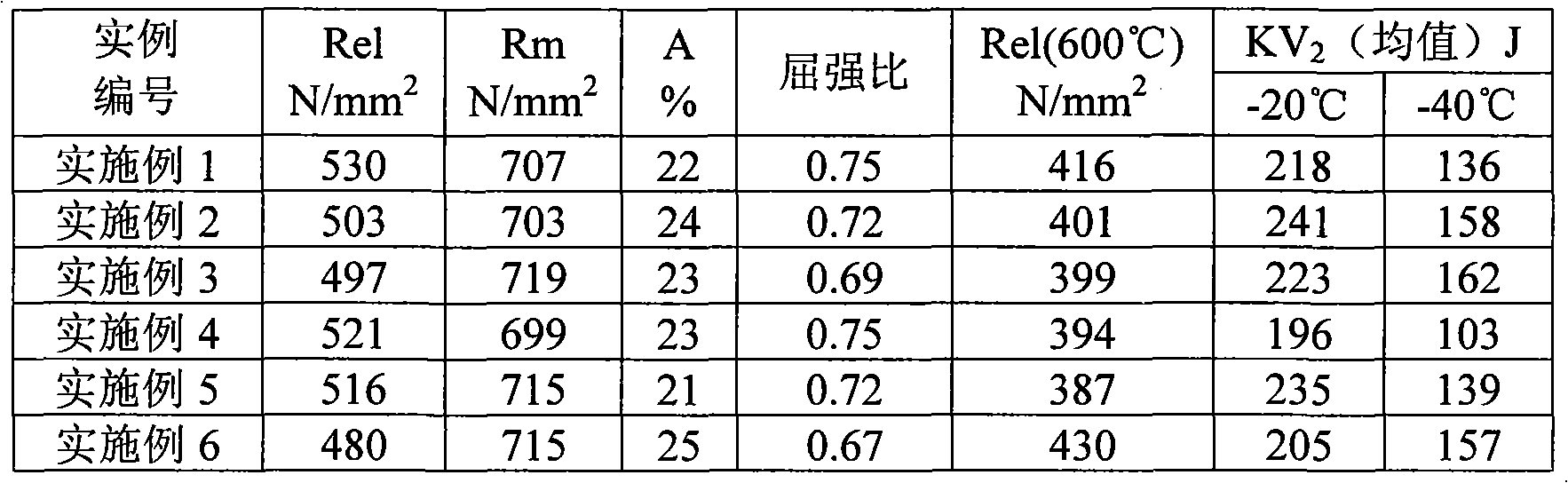

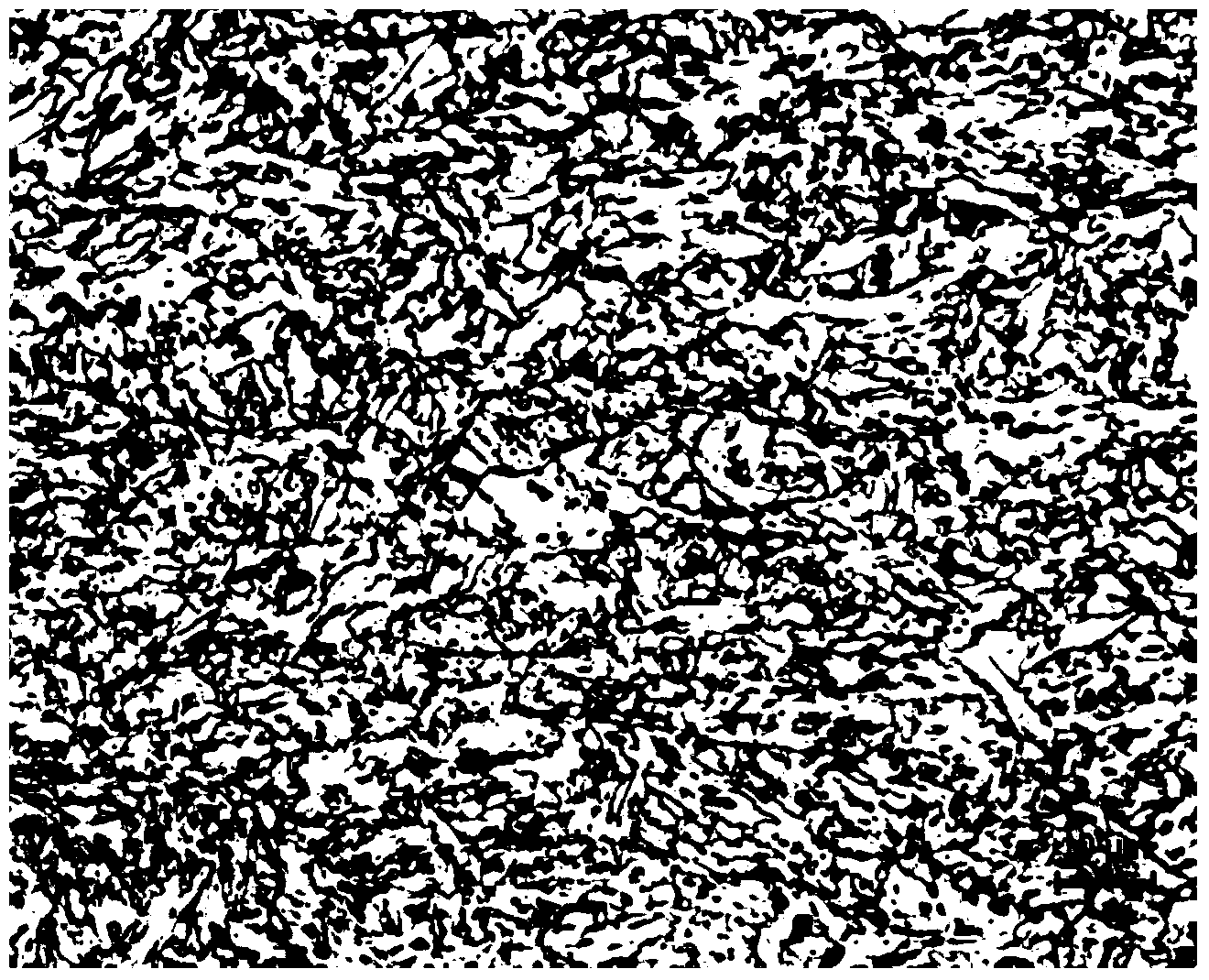

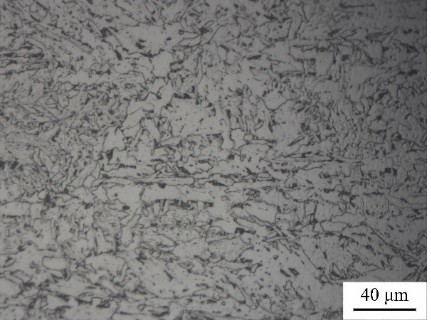

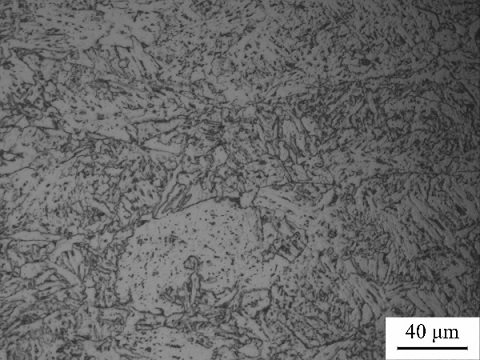

High-performance building structure refractory steel plates and manufacturing method thereof

ActiveCN101906585AMeet design needsMeet construction needsTemperature control deviceChemical compositionHeating time

The invention discloses high-performance building structure refractory steel plates and a manufacturing method thereof. The high-performance building structure refractory steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.12 percent of C, 0.05 to 0.50 percent of Si, 0.08 to 1.50 percent of Mn, 0.010 to 0.050 percent of Nb, 0.010 to 0.040 percent of Ti, 0.010 to 0.050 percent of Als, 0.20 to 0.60 percent of Cr, 0.20 to 0.40 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.0040 percent of N, less than or equal to 0.0020 percent of O and the balance of Fe and inevitable impurities. The production process of the high-performance building structure refractory steel plates is characterized in that: the steel blank heating temperature is 1,100 to 1,250 DEG C; the heating time is 60 to 110s / cm; two-stage controlled rolling is adopted; the final rolling temperature is kept between 800 and 900 DEG C; cooling is started 30 to 120 seconds later after final rolling; the final cooling temperature is kept between 500 and 750 DEG C; the steel plates are stacked quickly, cooled slowly and kept at a constant temperature; the stacking temperature is kept between 650 and 300 DEG C; and the temperature is kept for 10 to 24 hours. The plates have the characteristics of simple chemical components, low cost, and high refractability.

Owner:ANGANG STEEL CO LTD

Foam concrete

The invention discloses a foam concrete, which comprises admixture, cementing material and chemical auxiliary agent, wherein the weight percentage of the admixture in the foam concrete is 25-40%, the weight percentage of the cementing material in the foam concrete is 45-75%, the weight percentage of the chemical auxiliary agent in the foam concrete is 5-25%, the cementing material comprises cement clinker, calcium oxide and bone gelatin powder, and the mass ratio of the three ingredients in the cementing material is 2: 2: 1. The invention further discloses a preparation method of the foam concrete. The preparation method comprises the following steps: foam technology, slurry processing, chemical auxiliary agent processing, mixing, shaping and curing. The foam concrete has the advantages that the cementing material is made of cement clinker, calcium oxide and bone gelatin powder and the use of a great amount of cement is avoided, so that the coal resources required for producing cement is reduced, which not only relieves the tension of energy utilization, but also can improve the compressive strength, leakage resistance, sound insulation effect of the foam concrete.

Owner:王寿光

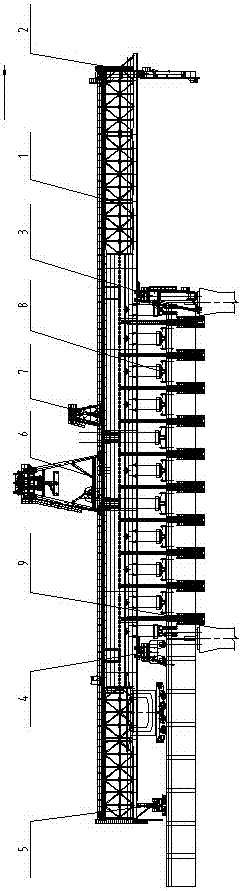

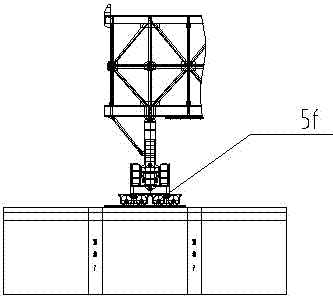

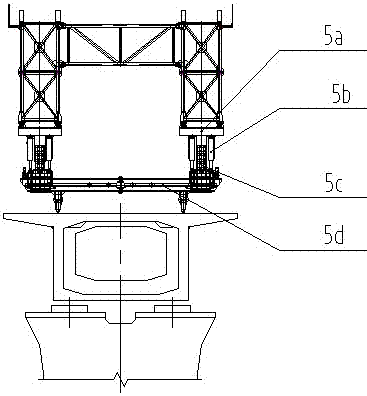

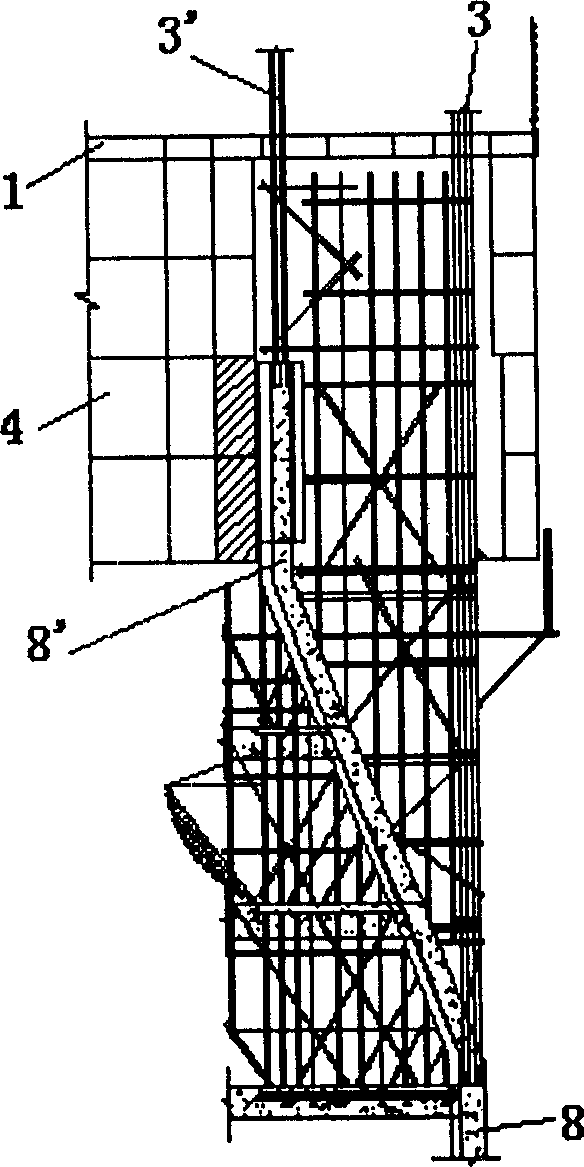

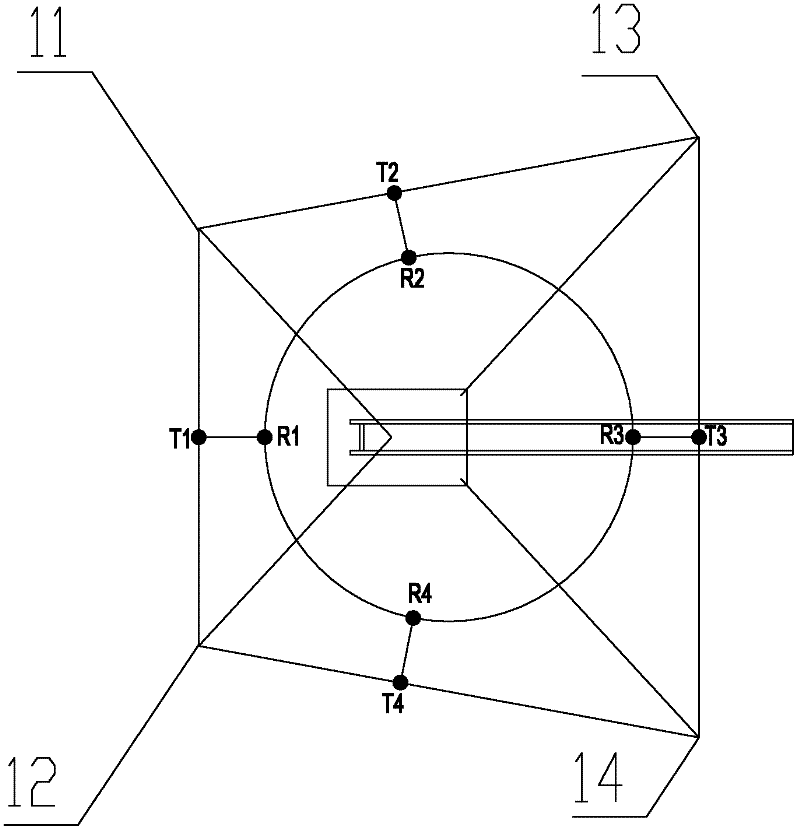

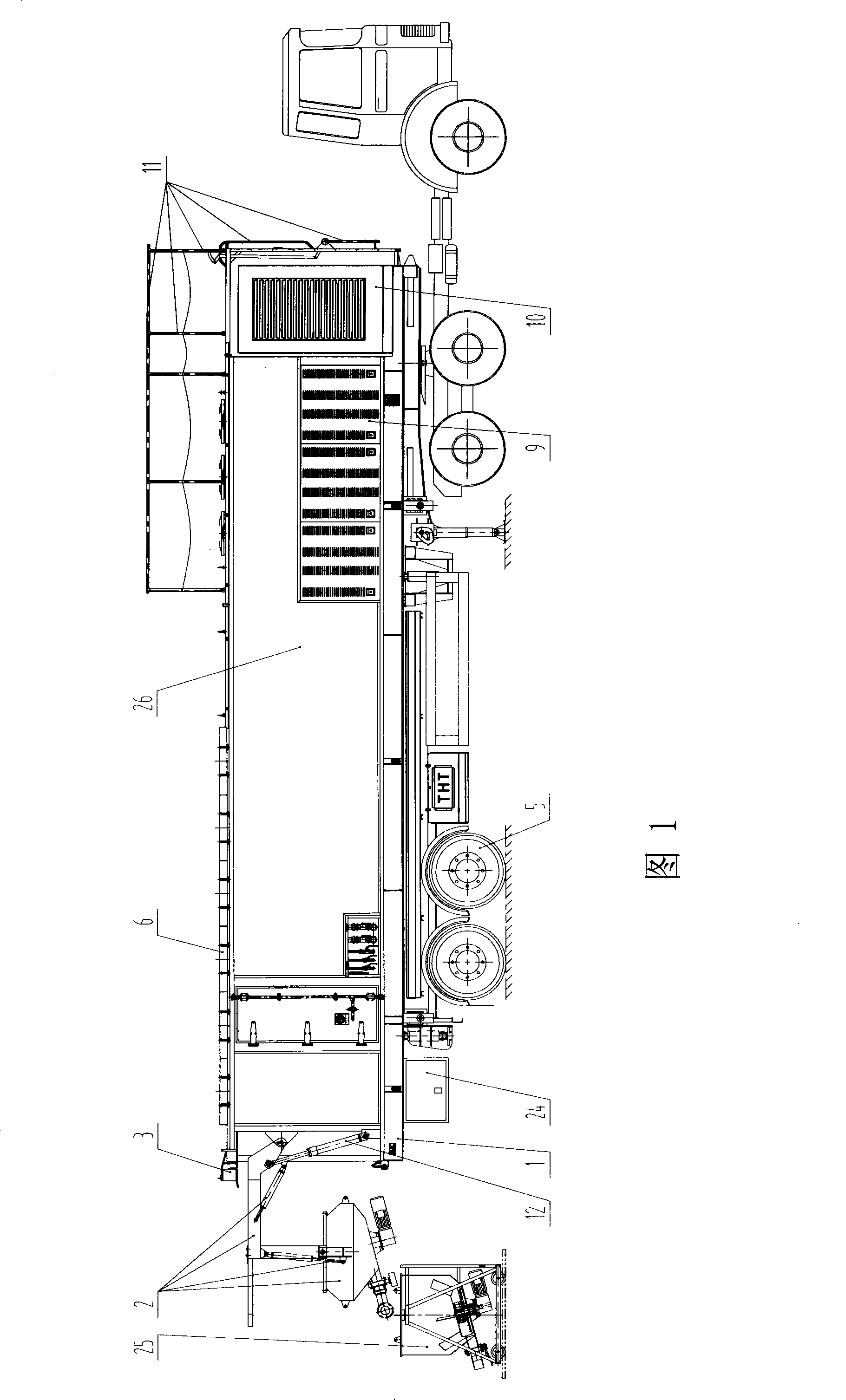

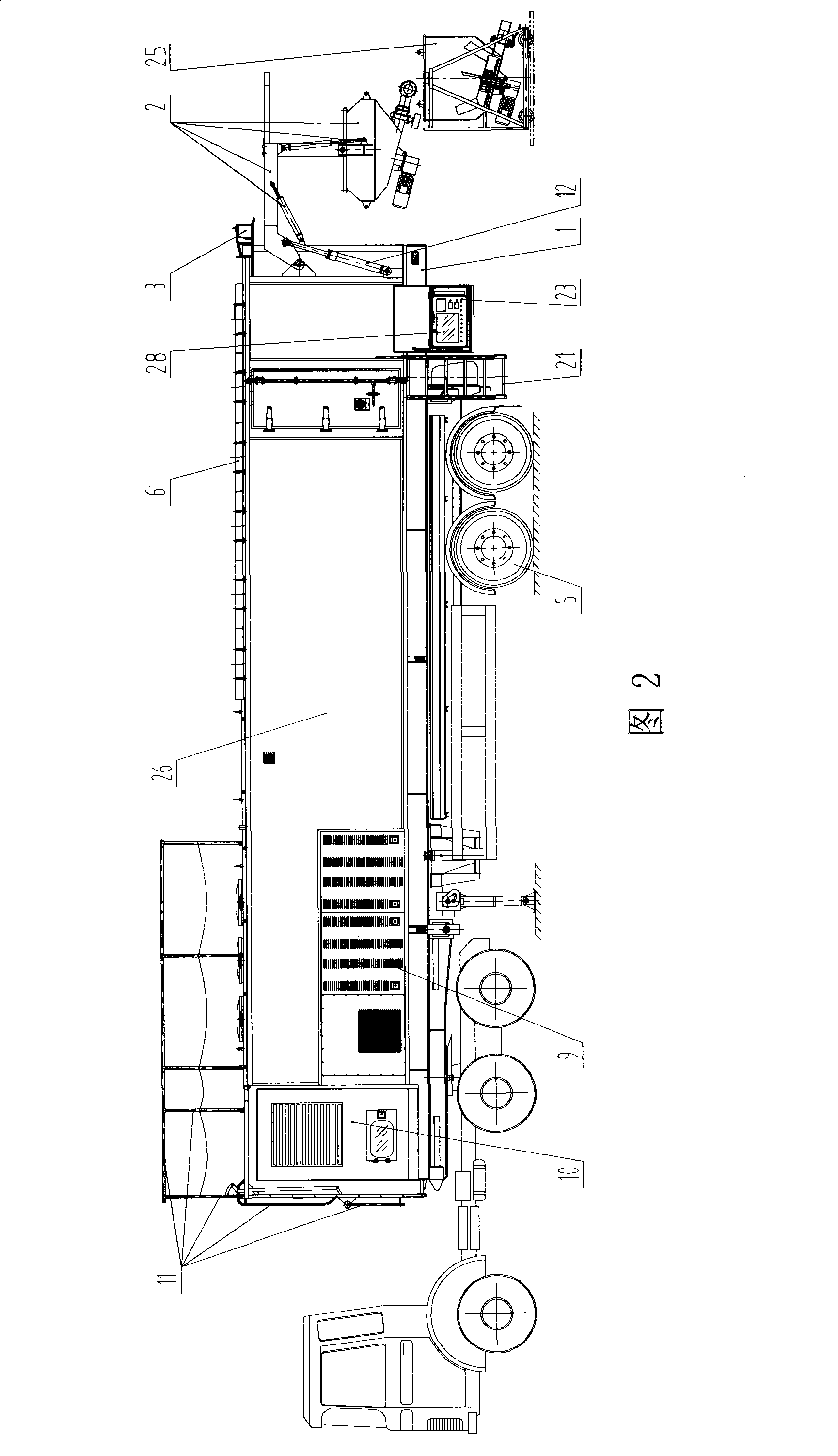

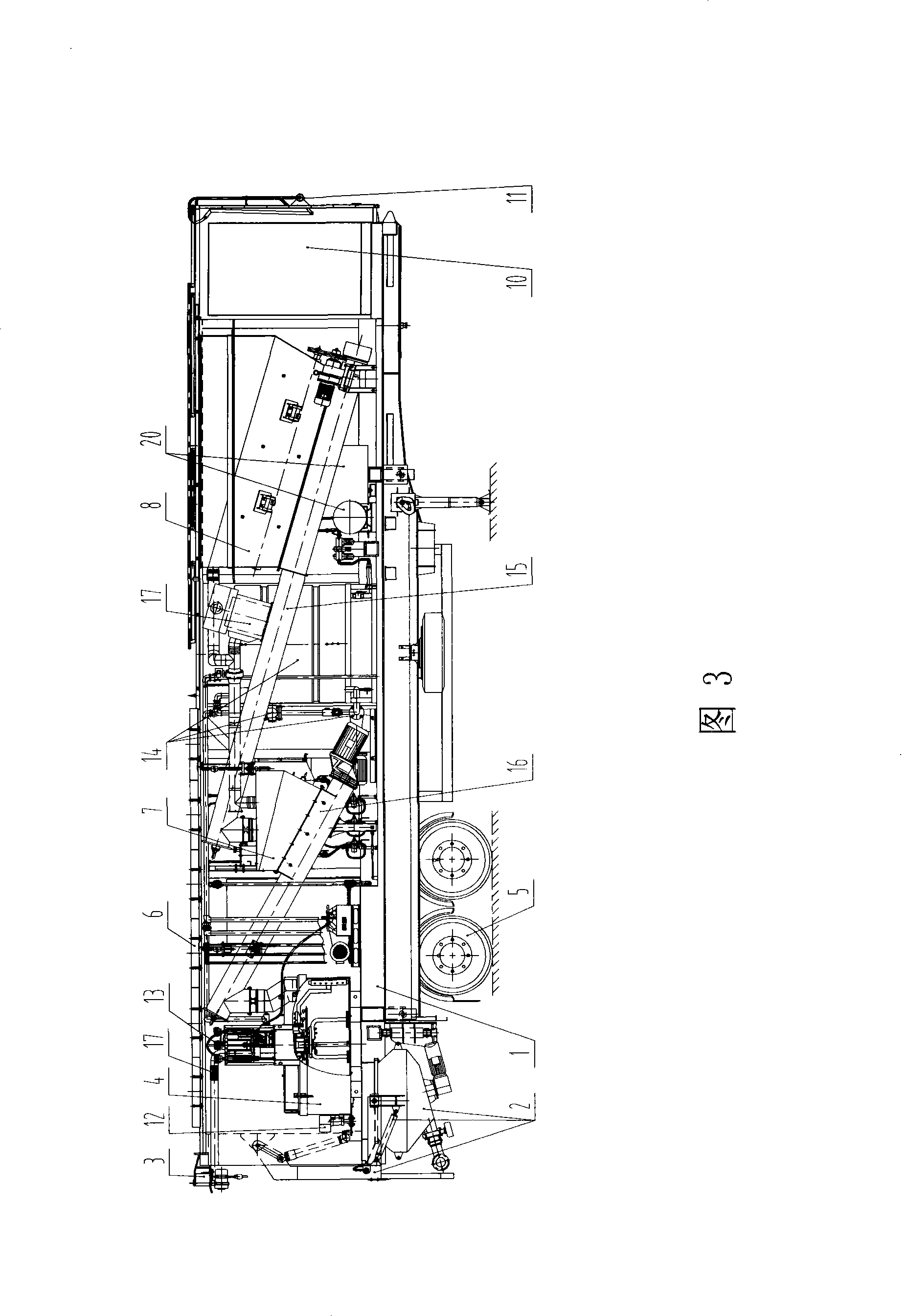

Bridge erecting machine for precast segmental beam span by span construction and construction method thereof

ActiveCN107059640ASmooth rotationNo need for staggered placementBridge erection/assemblyArchitectural engineeringHeavy load

The invention discloses a bridge erecting machine for precast segmental beam span by span construction and a construction method thereof. The bridge erecting machine for the precast segmental beam span by span construction comprises a main frame, a support leg system, a hanging system, a wet joint template system and an overhead travelling crane system. The support leg system comprises a number one support leg, a number two support leg, a number three support leg and a number four support leg, which sequentially arranged at the lower portion of the main frame from front to back, wherein the number one support leg and the number four support leg are located on two ends of the main frame as a auxiliary supporting support leg correspondingly, the number two support leg and the number three support leg are used as a heavy load supporting support leg, the hanging system is connected to the bottom of the main frame, the wet joint template system is connected to the outside of the main frame, the overhead travelling crane system is arranged on a longitudinal moving rail at the top of the main frame; and the construction method of the bridge erecting machine for precast segmental beam span by span construction comprises beam erecting process of the bridge erecting machine and bridge erecting machine through-hole process. The bridge erecting machine for the precast segmental beam span by span construction and the construction method thereof have the advantages that the construction demands of the precast segmental beam of high speed railway are met, the construction efficiency is high, and the construction is convenient and highly efficient.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

Preparation of solidification type dead burning structure glue in low-temperature and humidity surroundings

InactiveCN101314706ALow viscosityEasy curingNon-macromolecular adhesive additivesEpoxy resin adhesivesCompressive strengthUltimate tensile strength

A method for preparing steel-bonding structural adhesive curable in low-temperature and humid environment comprises the following steps: preparing a component A; preparing a component B; and mixing the component A with the component B at a weight ratio of 1:(0.3 to 0.5) to obtain the steel-bonding structural adhesive curable in low-temperature and wet environment. The steel-bonding structural adhesive can fully meet the requirement for steel-bonding construction in the environment with a temperature of subzero 10 to 0 DEG C and a relative humidity larger than 65 percent. A test shows that, 168 hours after the curing, the compressive strength of the adhesive is equal to or larger than 65 MPa, steel-steel tensile shear strength is equal to or larger than 15 MPa, steel-steel adhesion tensile strength is equal to or larger than 33 MPa, and the normal tensile bonding strength with concrete is equal to or larger than 2.5 MPa.

Owner:镇江市天益工程科技有限公司

Intelligent scenic spot open ecological platform based on cloud computing

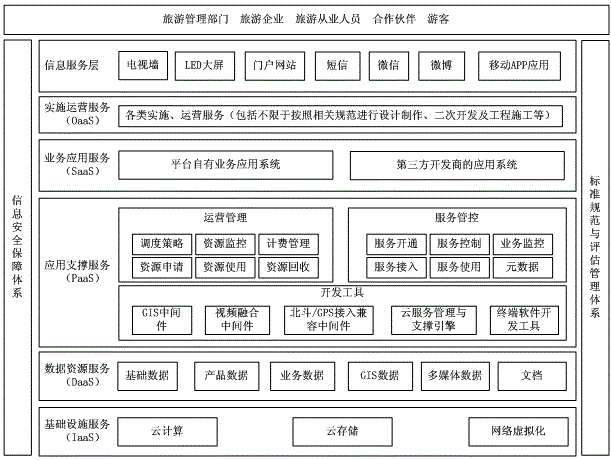

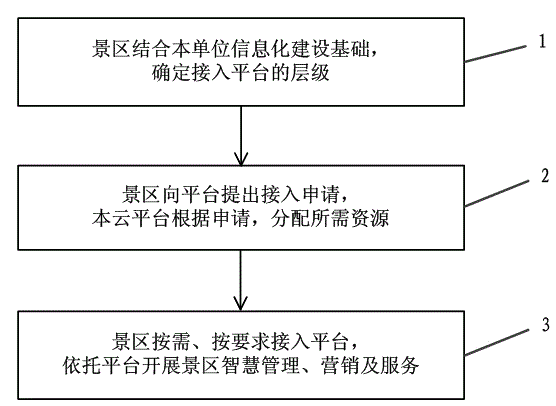

InactiveCN104899805AShort development cycleVersatileData processing applicationsComputer scienceSupport services

The invention discloses an intelligent scenic spot open ecological platform based on cloud computing. The platform comprises six layers in total, namely an infrastructure service layer, a data resource service layer, an application supporting service layer, a service application service layer, an operation enforcement service layer and an information service layer. The intelligent scenic spot open ecological platform based on cloud computing realizes technical effects of comprehensive function, wide application, easy disposition, high safety, high reliability and convenient expansion. Furthermore the intelligent scenic spot open ecological platform covers total industrial links in travelling.

Owner:成都中科大旗软件股份有限公司

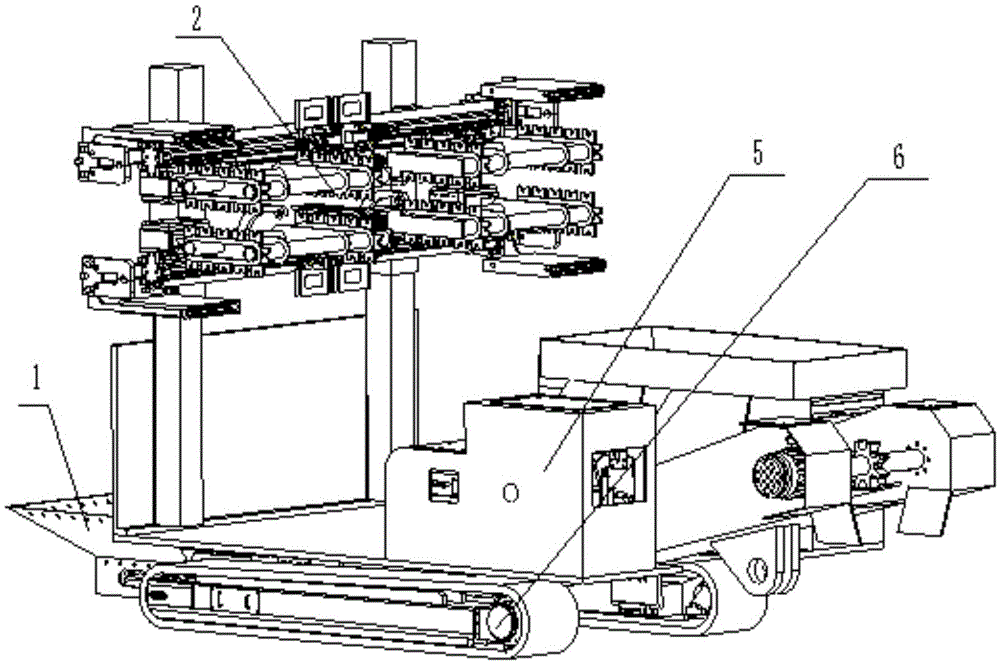

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

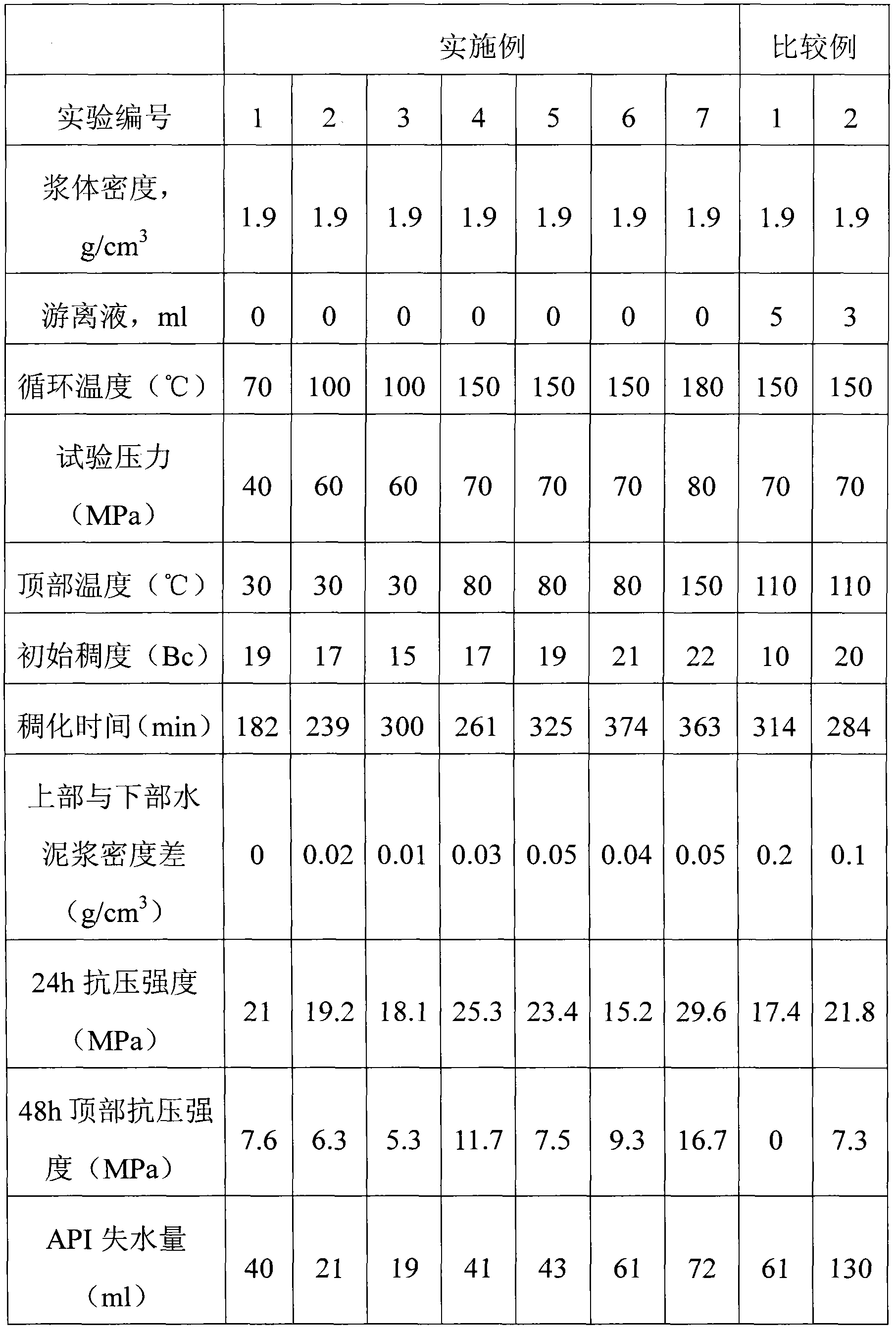

Cementing slurry system suitable for large range of temperature

ActiveCN102127404AImprove performanceRapid development of strengthDrilling compositionPhosphateDiethylenetriamine

The invention relates to a cementing slurry system suitable for large range of temperature. The cementing slurry system comprises the following components in parts by weight: 100 parts of cement, 0-40 parts of high temperature stabilizer, 2-6 parts of filtrate reducer, 0.3-3 parts of retarder and 40-55 parts of water, wherein the cement is G-grade high sulfate-resistant oil well cement; the filtrate reducer is 2-acrylamido-2-methylpropane sulfonic acid (AMPS)-acrylamide polymer, the molar ratio of AMPS to acrylamide polymer monomer is 7:3 and the number average molecular weight is 0.7-1.5 millions; the retarder is a diethylenetriamine derivative with carboxyl groups, phosphate groups and sulfonate groups, the molar ratio of the carboxyl groups to the phosphate groups and sulfo groups is 3:2:1; and the high temperature stabilizer is amorphous silica of which purity is more than 95% and average diameter is 0.1-0.15 micron. The circulating temperature range of the cementing slurry is 70-180 DEG C; under high temperature, the cementing slurry has good slurry stability, low fluid loss water amount and no free liquid; and the cementing slurry system can meet the deep well cementing construction requirement and can be used to increase the cementing quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

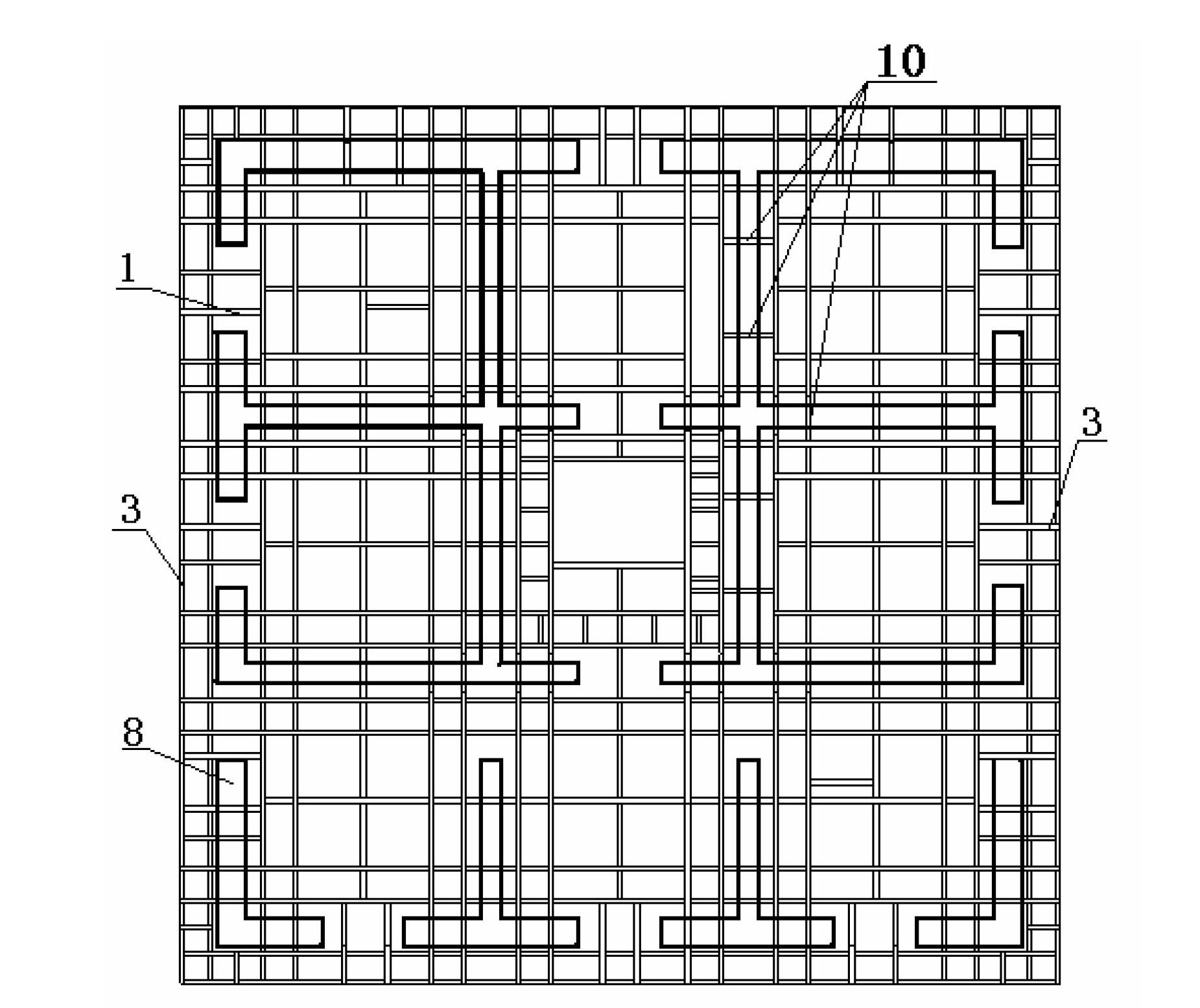

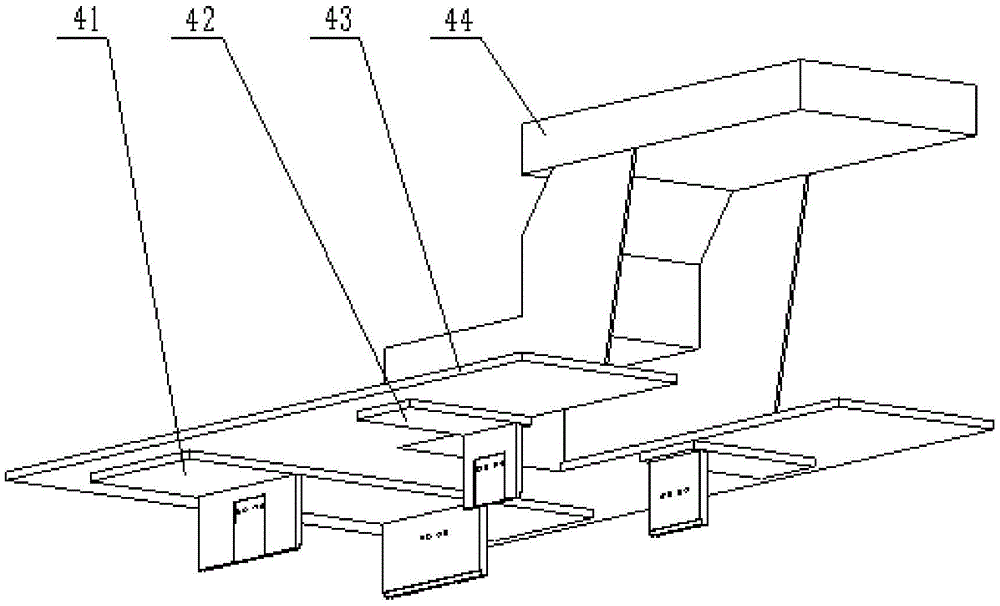

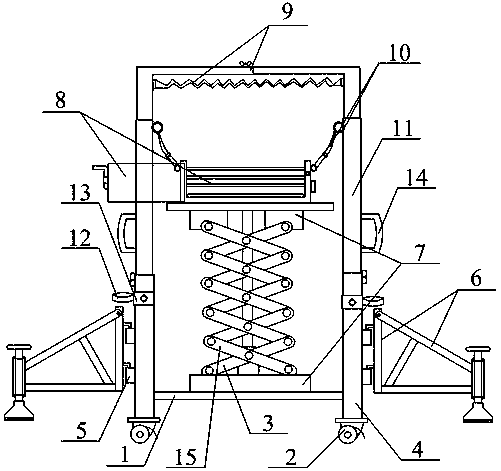

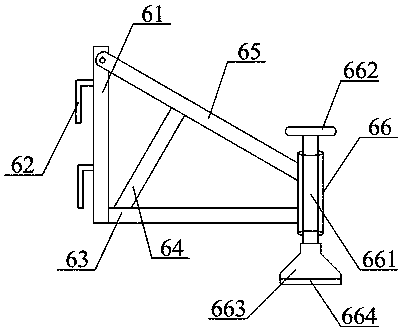

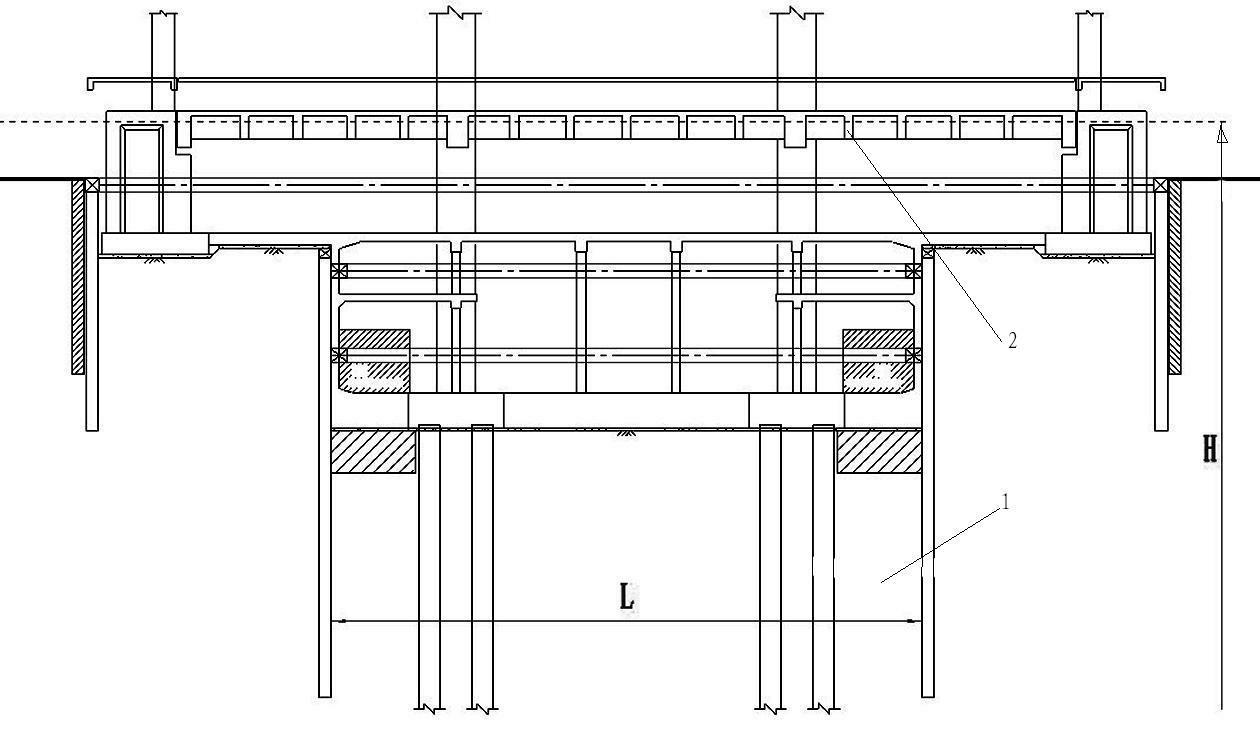

Autolifting type variable-shape diassembllable integrated lifting steel plateform system and construction method thereof

ActiveCN1793590AMeet construction needsImprove integrityForms/shuttering/falseworksBuilding support scaffoldsFalseworkSteel columns

The invention discloses a self-rising deformable removable integral lifting steel platform system for ultrahigh varying-layer plane construction and the construction method thereof, comprising steel platform, plate lifter, flexible steel column, hanging staging and bearing pin, where the hanging staging is fixed with the steel platform, the steel platform is deformable and comprises primary and secondary beams, the junction of the two beams is provided with a rolling device, the secondary beam can take the primary beam as orbit to move relative to the primary through the rolling device. The invention uses the various construction columns installed in core tube sharing walls as support and climbing guide rails, uses the plate lifter as power, lifts the whole steel platform system by lifting screw rods connected with the steel platform, and arranges trolleys on partial secondary steel beams to make them able to move inward along the primary steel beam to the preset position at last, and completes the plane deformation of the steel platform and meets construction requirements for the core tube variation.

Owner:SHANGHAI CONSTR NO 1 GRP

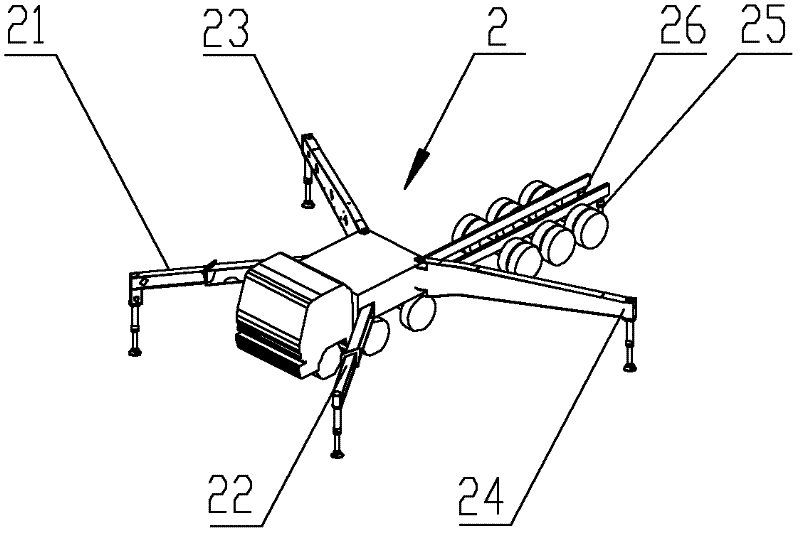

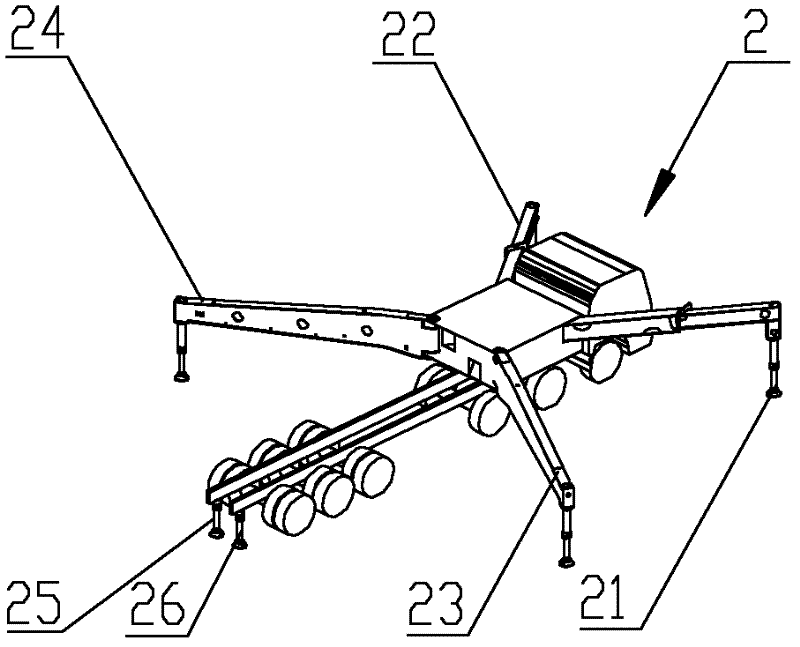

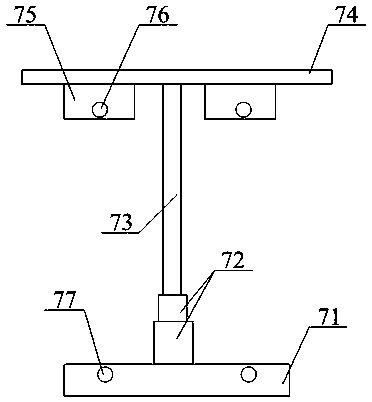

Supporting system and engineering machine with same

ActiveCN102582590AImproved rollover capabilityStable supportBase supporting structuresBraking devices for hoisting equipmentsSupporting systemGravity center

The invention discloses a supporting system of an engineering machine, which comprises a first supporting leg, a second supporting leg, a third supporting leg and a fourth supporting leg which are arranged on the engineering machine. Additional supporting legs are arranged between the third supporting leg and the fourth supporting leg, and the minimum distance from a ligature of a supporting point of the third supporting leg and a supporting point of the fourth supporting leg to the circumference of a gravity center circle of the engineering machine is shorter than the minimum distance from a ligature of supporting points of each two adjacent of the third supporting leg, the fourth supporting leg and the additional supporting legs to the circumference of the gravity center circle of the engineering machine. By the aid of the additional supporting legs, anti-tipping capacity and supporting capacity of a whole vehicle are improved, and when being shortened, the supporting legs do not need to occupy sites with large site and can keep stability as same as those in the prior art, so that the engineering machine with the supporting system can be operated in limited space and meet construction needs of the narrow sites, and the application range of the engineering machine is widened. The invention further discloses the engineering machine comprising the supporting system.

Owner:SANY AUTOMOBILE MFG CO LTD

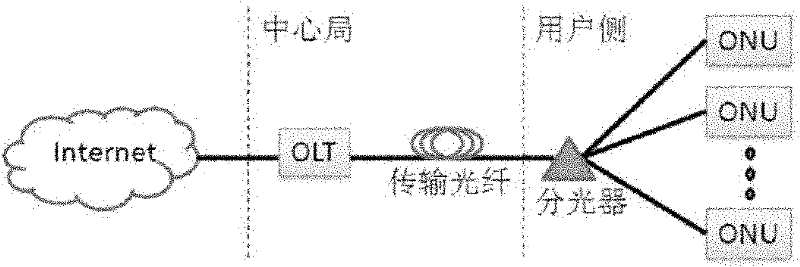

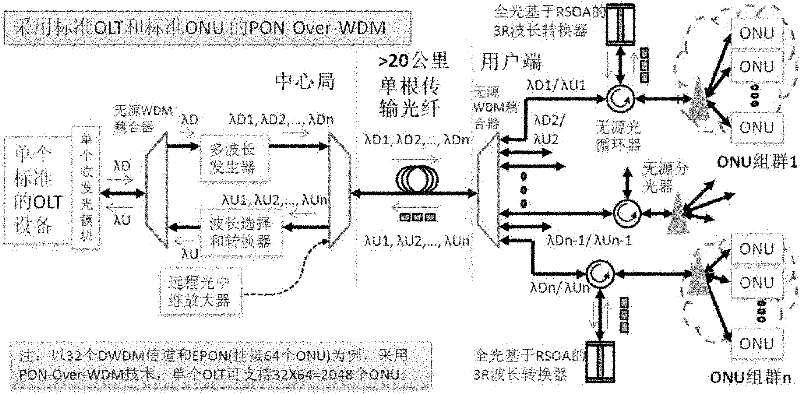

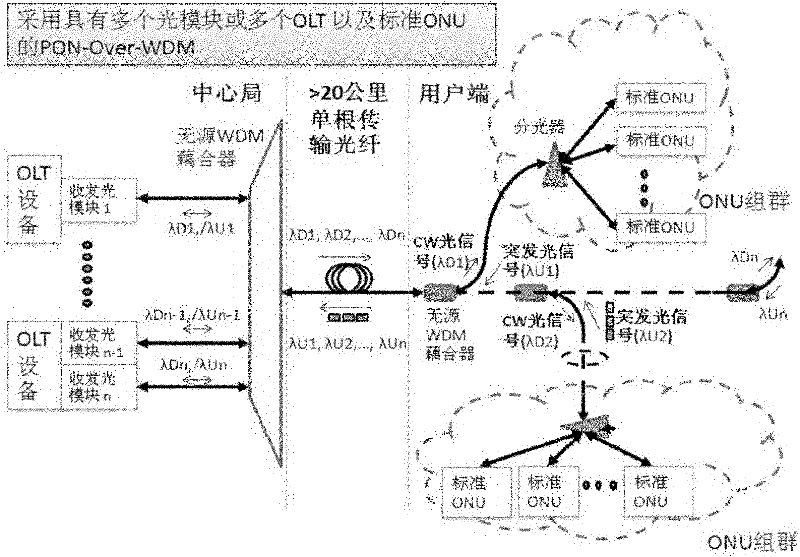

Passive optical network over wavelength division multiplexing

ActiveCN102695101ALow costIncrease costMultiplex system selection arrangementsWavelength-division multiplex systemsTransverterCoarse wavelength division multiplexing

The invention relates to a passive optical network over wavelength division multiplexing (PON-Over-WDM). The network includes a first WDM coupler, an ONU terminal, a light circulator and a first wavelength converter, wherein the light circulator directs a burst optical signal transmitted by the ONU terminal to the first wavelength converter, and the first wavelength converter is used for performing wavelength conversion of the optical signal and transmitting the wavelength-converted optical signal to the first WDM coupler for coupling after which the optical signal is transmitted through a single optical fiber. The network of the invention is low in cost and flexible in expansion. The network can be accessed by high-capacity ONU equipments or terminal users and is compatible for different equipment suppliers and service providers. The network can be applied to optical communication networks.

Owner:SUZHOU CREALIGHTS TECH

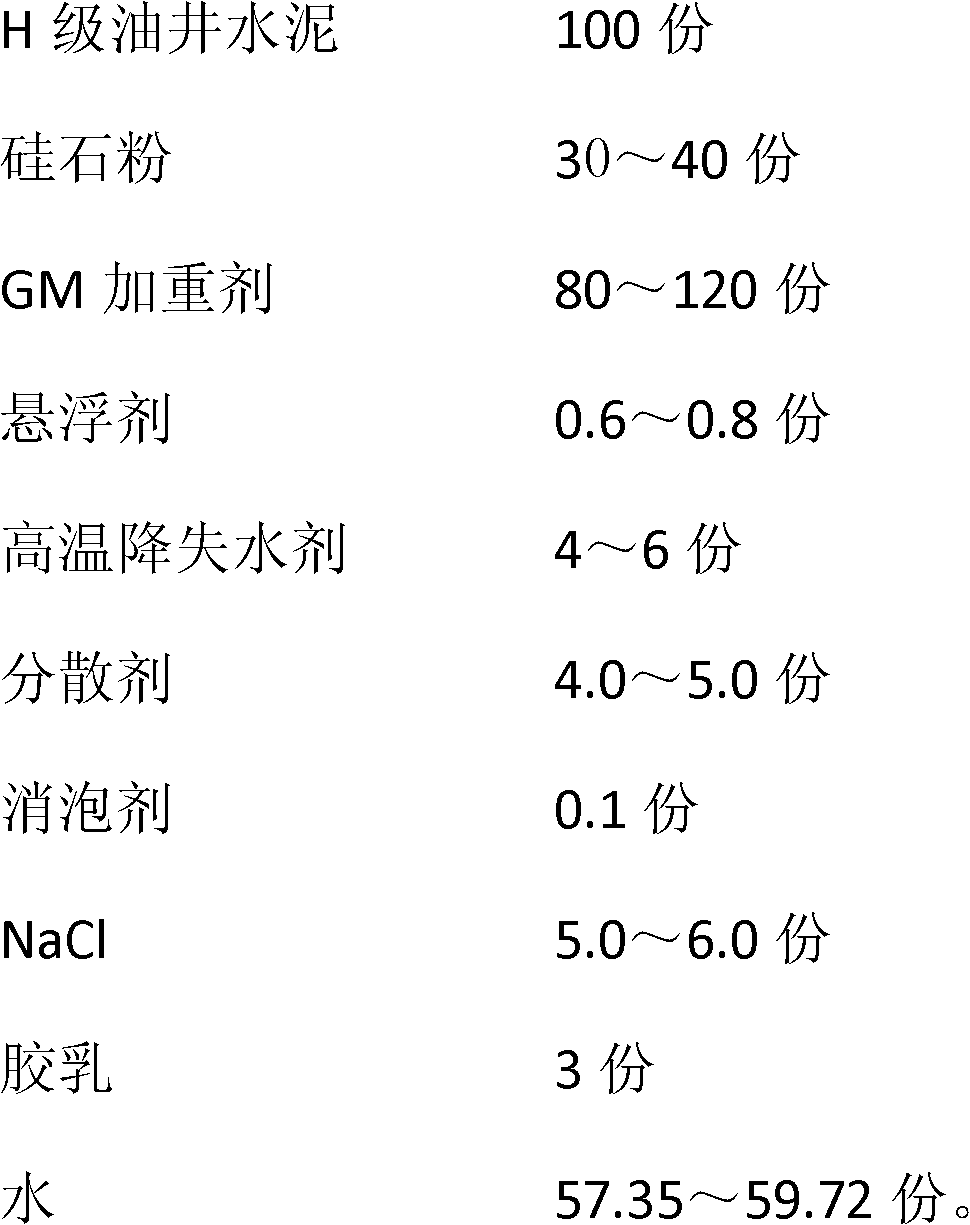

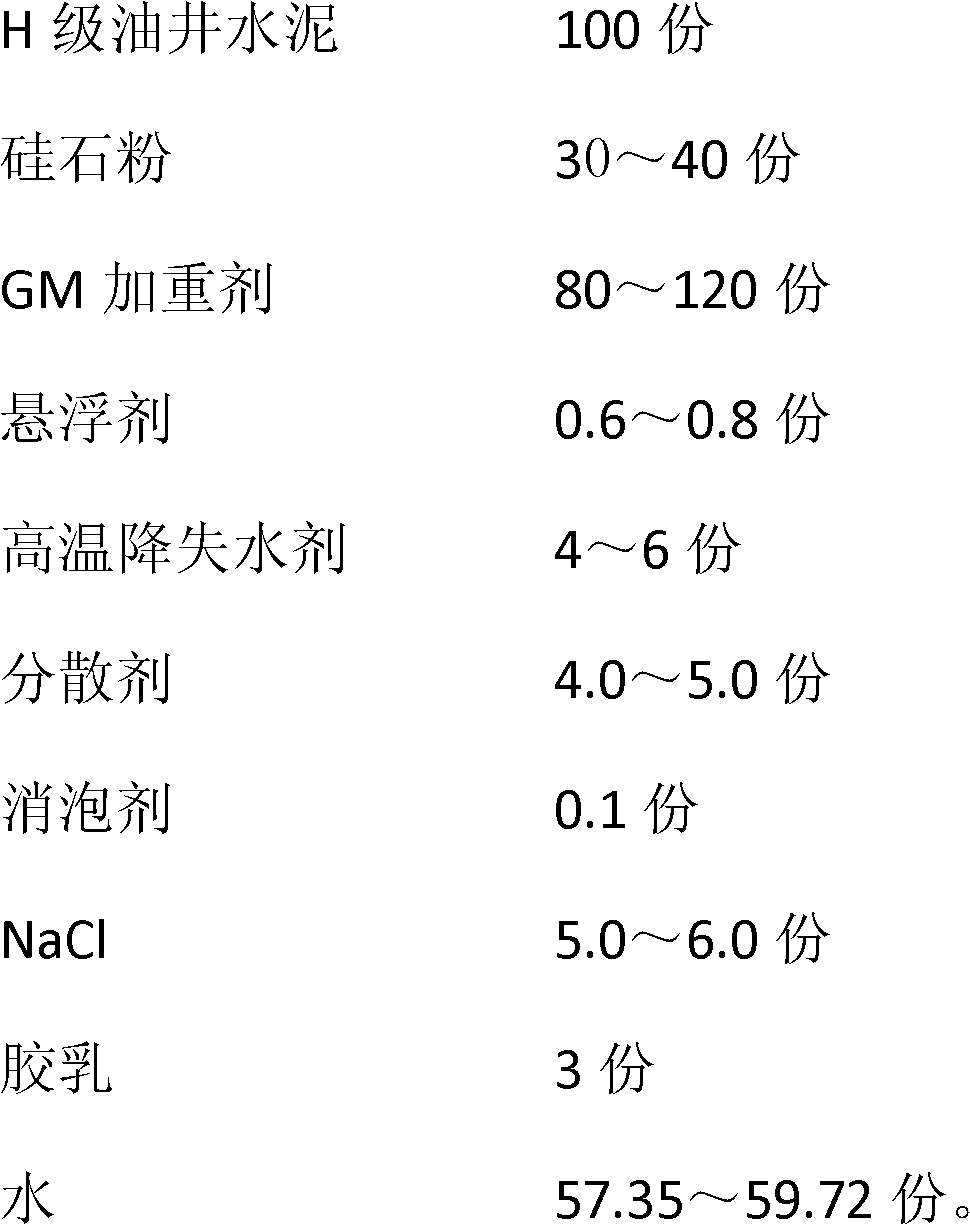

Cementing slurry with high temperature, high density and high toughness

ActiveCN102516965AHigh densityGood settlement stabilityDrilling compositionHigh densitySuspending Agents

The invention discloses a cementing slurry with high temperature, high density and high toughness, which comprises the following ingredients by weight 100 parts of H grade oil well cement, 30-40 parts of silicon powder, 80-120 parts of a GM weighting agent, 0.6-0.8 parts of a suspending agent, 4-6 parts of a high temperature fluid loss reducer, 4.0-5.0 parts of a dispersant, 0.1 parts of an antifoaming agent, 5.0-6.0 parts of NaCl, 3 parts of latex and 57.35-59.72 parts of water. The density of the cementing slurry can reach 2.40-2.50gcm3, the cementing slurry can resist a temperature of 160 DEG C, and the cementing slurry has the advantages of good rheological property under high temperature, good settlement stability and good cement stone toughness, is suitable for cementing depth wellsand ultra-deep wells, and is in favor of improving the sealing quality and raising the quality of the wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

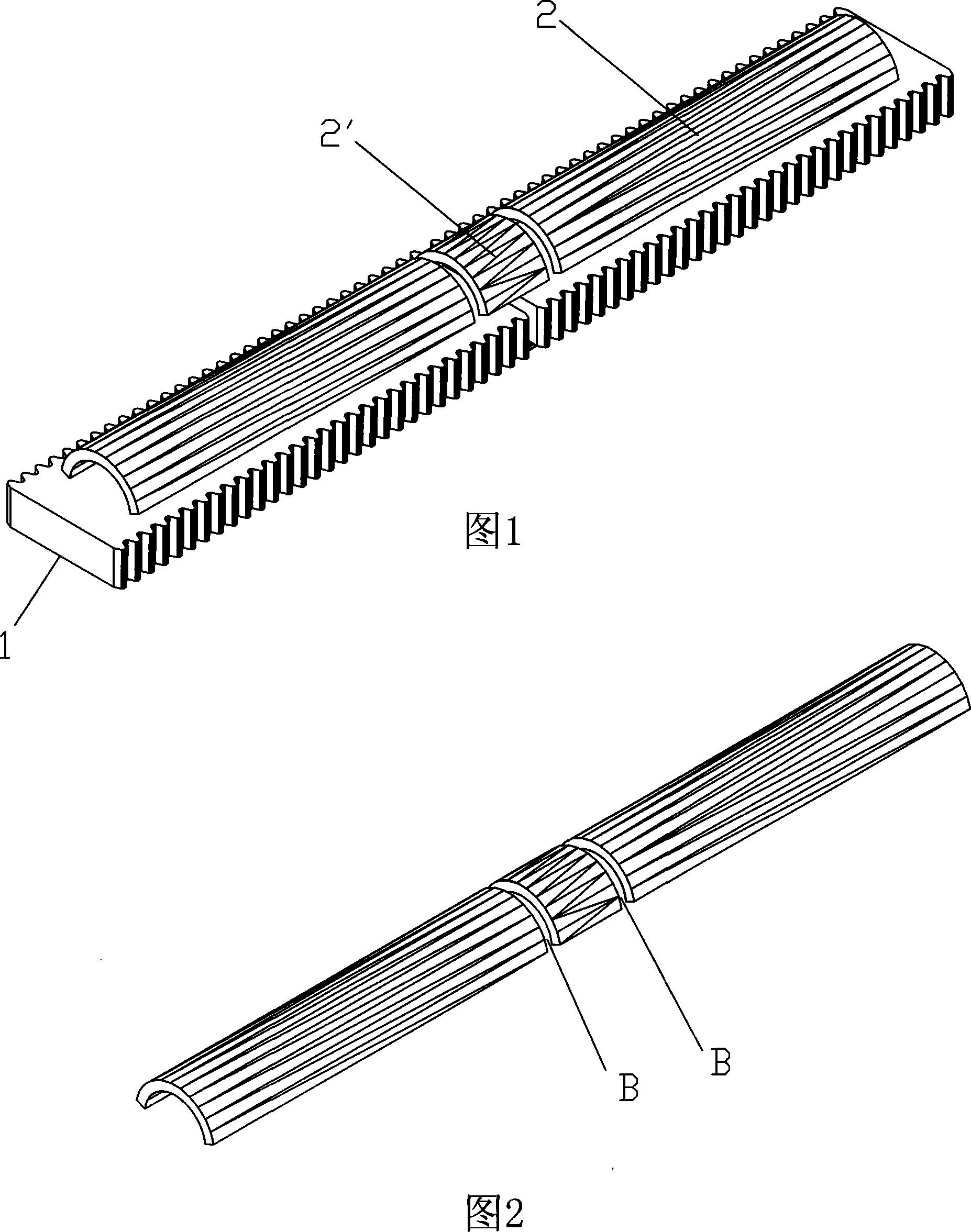

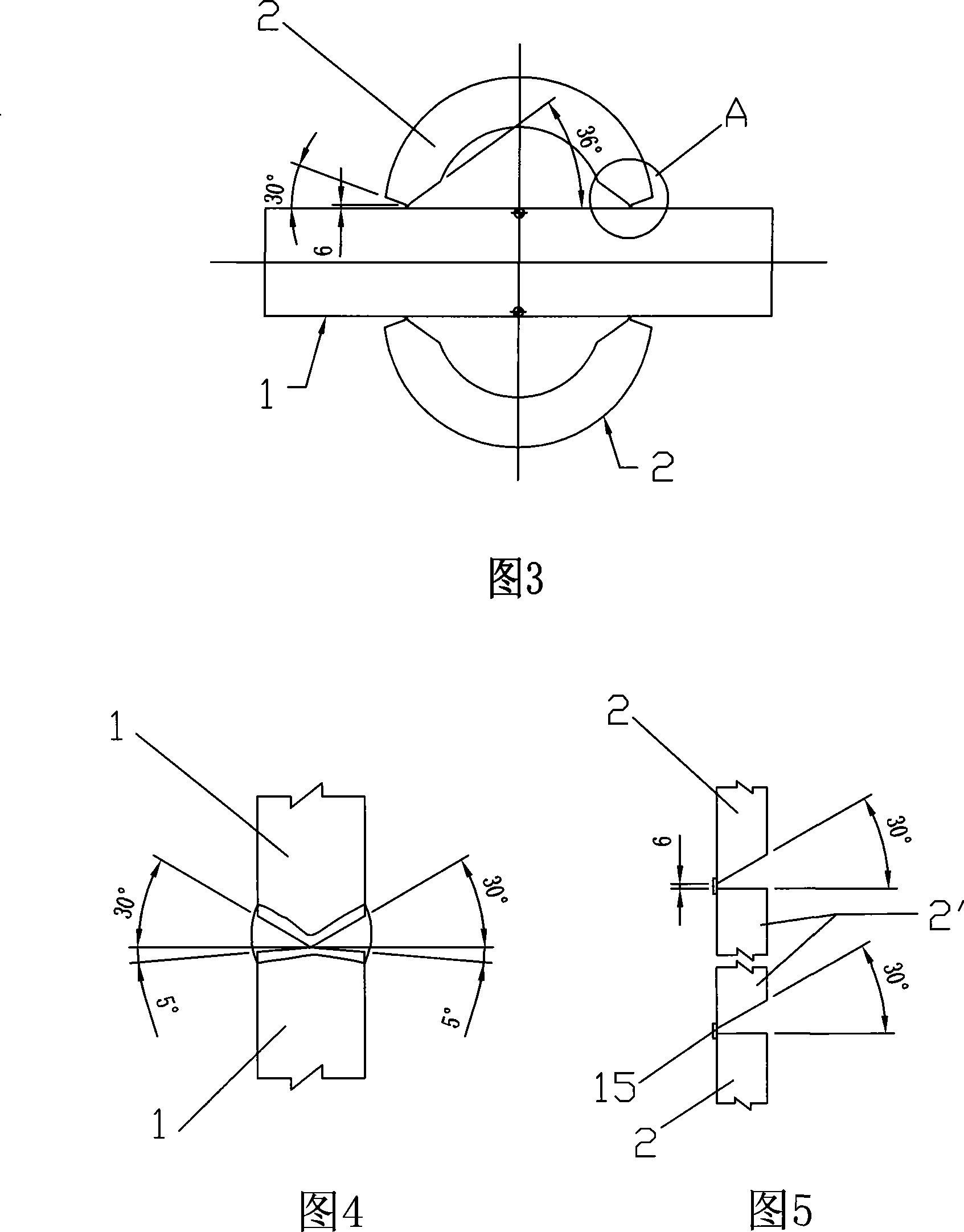

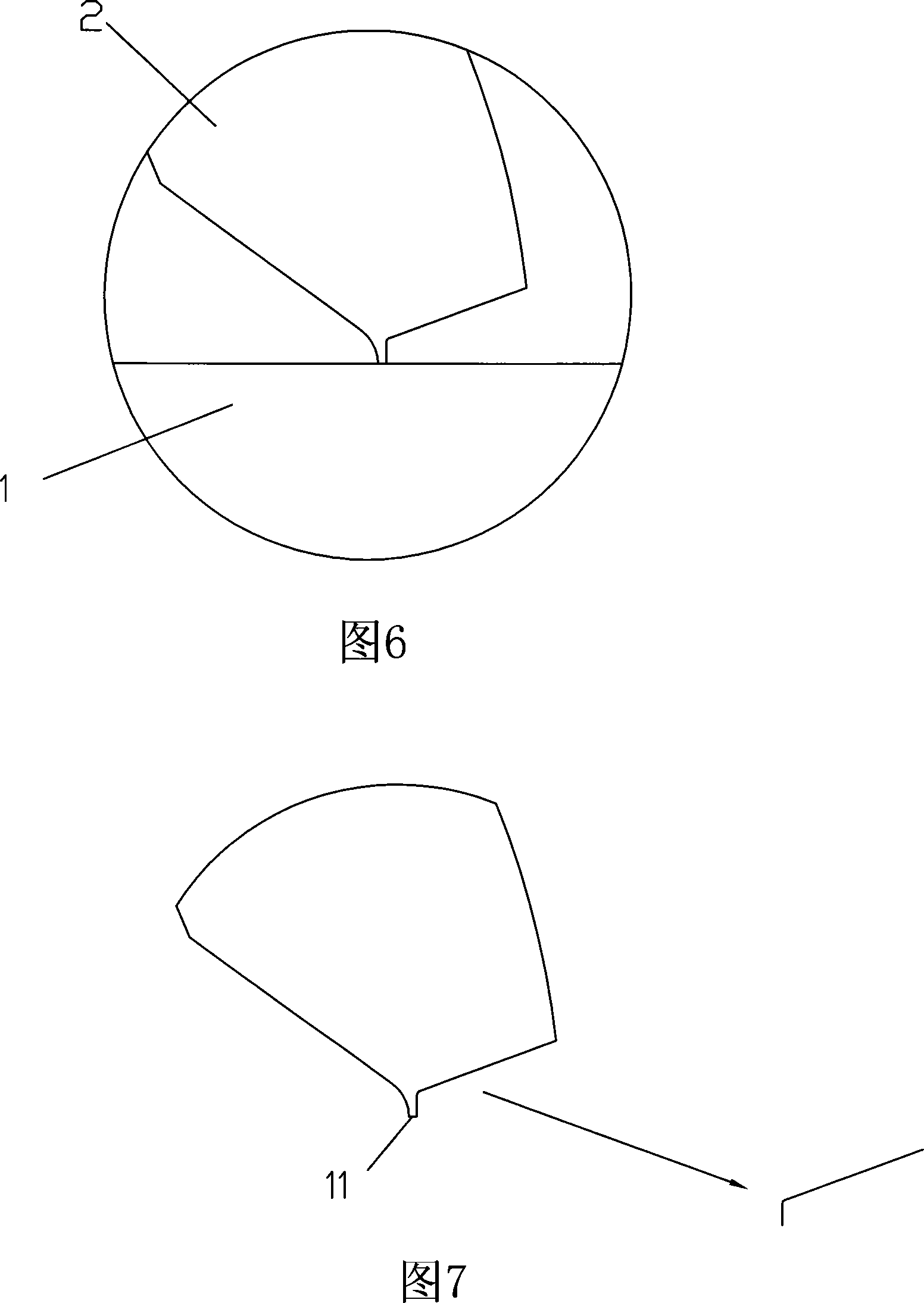

Construction welding method for main chord pipe inside platform legs

ActiveCN101225653AImprove accessibilityEliminate negative effectsArtificial islandsUnderwater structuresArchitectural engineeringWorkload

The invention discloses a construction welding method for a major side pipe in a pile leg, comprising a plurality of connecting sections composed of a plurality of semicircle plates and rack plates. The welding procedure is described as follows: a. the two side semicircle plates are welded with the rack plate into the form of a unilateral U-shaped groove joint, with the semicircle plate positioned in the middle of the rack plate and shorter than the rack plate; b. the terminals of the two sections of rack plate are welded into the form of an unsymmetrical X groove joint; c. a filling semicircle plate is filled in between two connecting sections of semicircle plates in the form of a V-shaped groove joint through welding. The construction welding method for a major side pipe in a pile leg has the advantages that the accessibility of the welding construction is enhanced while the welding joint is reduced; workload is decreased while work efficiency is enhanced and mechanical properties of the welding joint are improved. After welding procedure evaluating test, every index of the mechanical properties of the welding joint meets the requirements of a classification society.

Owner:DALIAN SHIPBUILDING IND

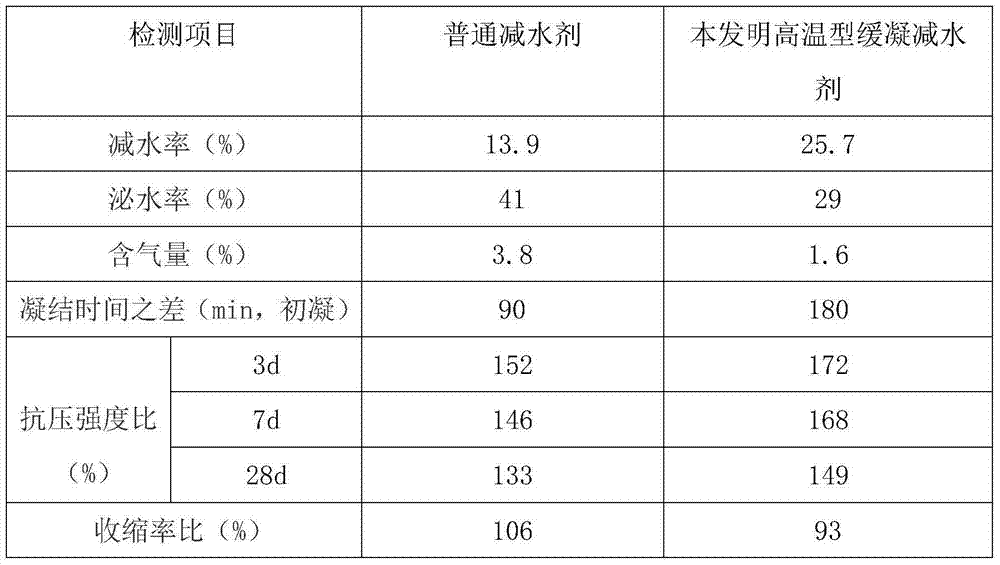

High-temperature retarding and water reducing agent

InactiveCN104119017AImprove high temperature resistanceSuitable for a wide temperature rangeSlagPENTAERYTHRITYL DISTEARATE

The invention discloses a high-temperature retarding and water reducing agent prepared by mixing the following raw materials in parts by weight: 35-45 parts of polycyclic aromatic hydrocarbon sulfonated formaldehyde condensates, 20-30 parts of acyclic hydroxyl sulfonate condensates, 10-15 parts of diethylenetriaminepenta(methylene-phosphonic acid), 8-16 parts of calcium saccharate, 12-18 parts of alunite powder, 5-10 parts of xanthan gum powder, 4-8 parts of barium metaborate, 3-6 parts of sodium lauryl sulfate, 2-4 parts of pentaerythrite di-n-stearate, 6-12 parts of maleic anhydride-styrene sulfoacid copolymers, 10-15 parts of blast furnace slag powder, 5-10 parts of waste saccharide slag powder, 7-13 parts of nekal and 4-7 parts of auxiliary. The water reducing agent disclosed by the invention is excellent in high temperature resistance, relatively wide in applicable temperature range (150-250 DEG C), capable of reducing cement hydration heat release, reducing the temperature stress of the concrete, avoiding generating temperature cracks and completely meeting the construction requirement for high-temperature and high-pressure well cementation, suitable for continuously pouring mass concrete under a high temperature condition, remarkable in water reducing enhancement effect, good in slump loss resistance and wide in market prospect.

Owner:WUHU SANXING CONCRETE ADMIXTURE

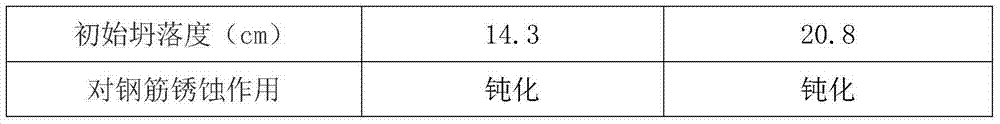

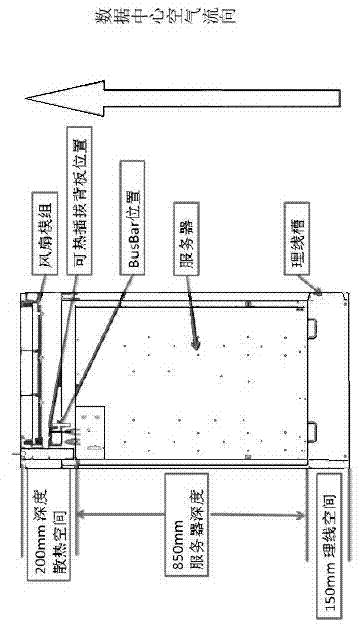

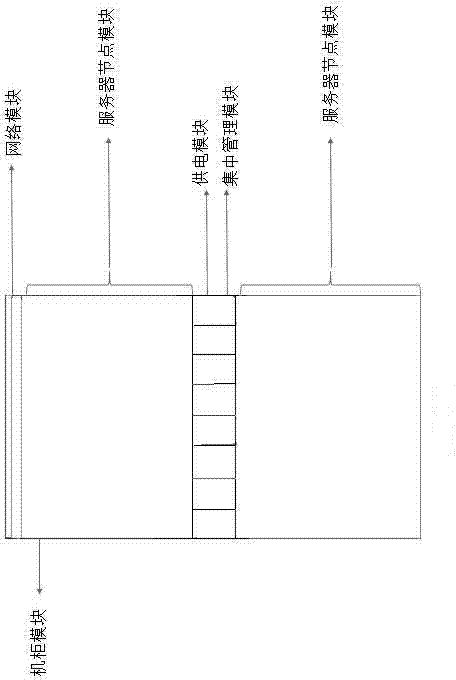

A system based on a whole cabinet server ultra-large-scale deployment

InactiveCN104331130AReduce procurement costsImprove procurement efficiencyDigital processing power distributionData switching networksData centerThe Internet

The invention provides a system based on a whole cabinet server ultra-large-scale deployment, and belongs to the technical field of a whole cabinet server ultra-large-scale deployment. The system uses a modular design manner, and is divided into six parts including a cabinet module, a network module, a power supply module, a server node module, a centralized fan heat dissipating module, and a centralized management module. The invention meets the demand of large scale Internet application and data center building, and standardization is achieved in a larger range by the modular design to ensure that customers get lower procurement cost, higher purchasing efficiency and faster deployment efficiency.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Spiral submerged-arc welded pipe for oil and gas transmission suitable for low temperatures and manufacturing method thereof

ActiveCN103451570AImprove impact toughnessMeet construction needsArc welding apparatusCold areaImpurity

The invention discloses a spiral submerged-arc welded pipe for oil and gas transmission suitable for low temperatures and a manufacturing method thereof. A base metal of the steel pipe comprises the following components in percentage by weight: 0.01-0.08% of C, 0.2-0.45% of Si, 0.8-1.8% of Mn, 0.3-1.5% of Ni, 0.1-0.3% of Mo, 0.2-0.5% of Cr, 0.1-0.3% of Cu, 0.005-0.05% of Ti, 0.001-0.005% of N, 0.005-0.05% of Al, less than or equal to 0.015% of P, less than or equal to 0.002% of S, and the balance of Fe and inevitable impurities. The base metal of the steel pipe also comprises 0.0001-0.0050% of B. The spiral submerged-arc welded pipe and manufacturing method thereof disclosed by the invention have the beneficial effects that by using the method disclosed by the invention, the impact toughness of the base metal and welded position of pipeline pipe can be effectively improved without heat treatment; and a spiral submerged-arc welded pipe for oil and gas transmission produced by using the method disclosed by the invention can satisfy the construction needs of oil and gas transmission pipelines at cold areas with a temperature of above minus 40 DEG C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

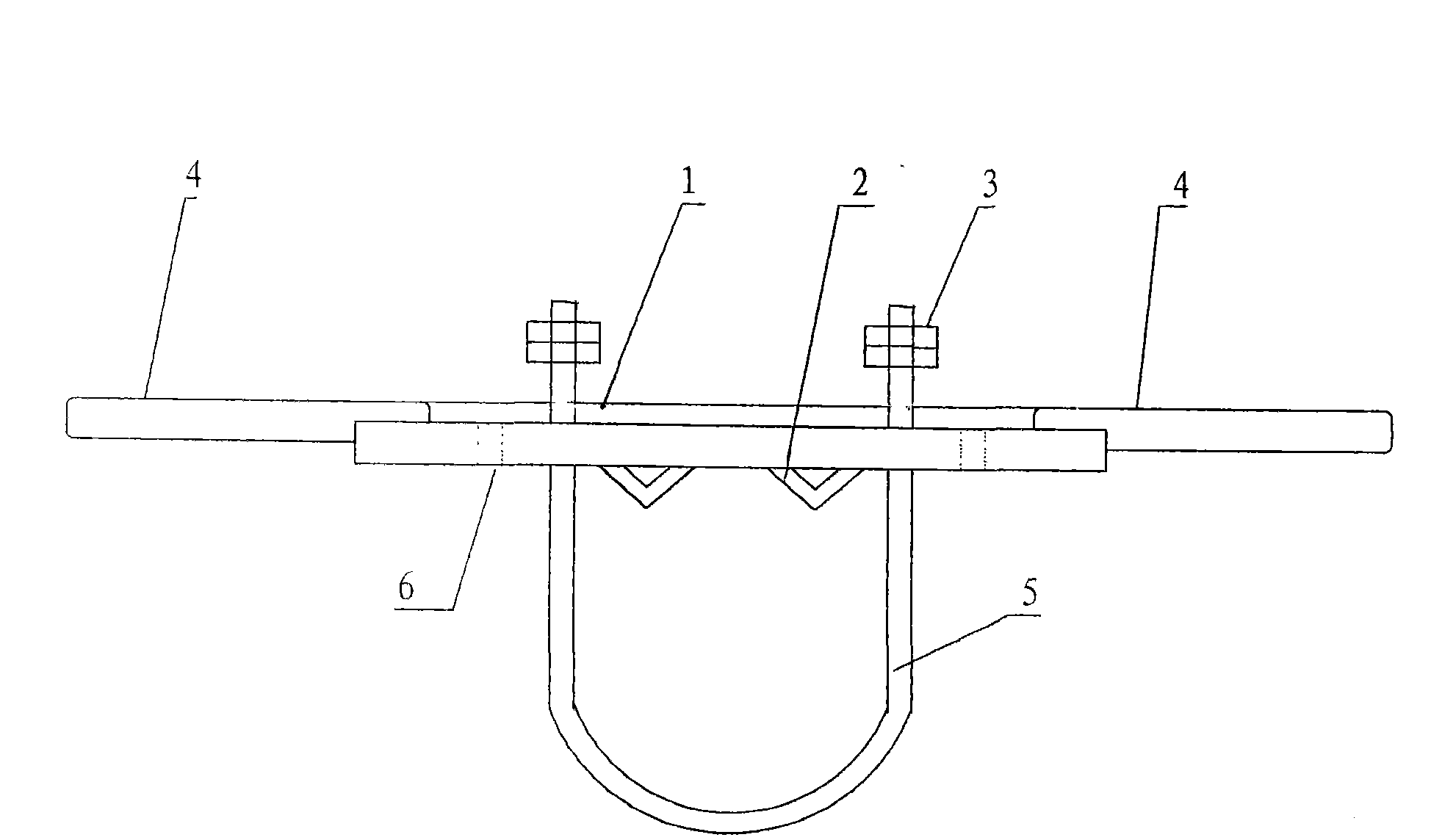

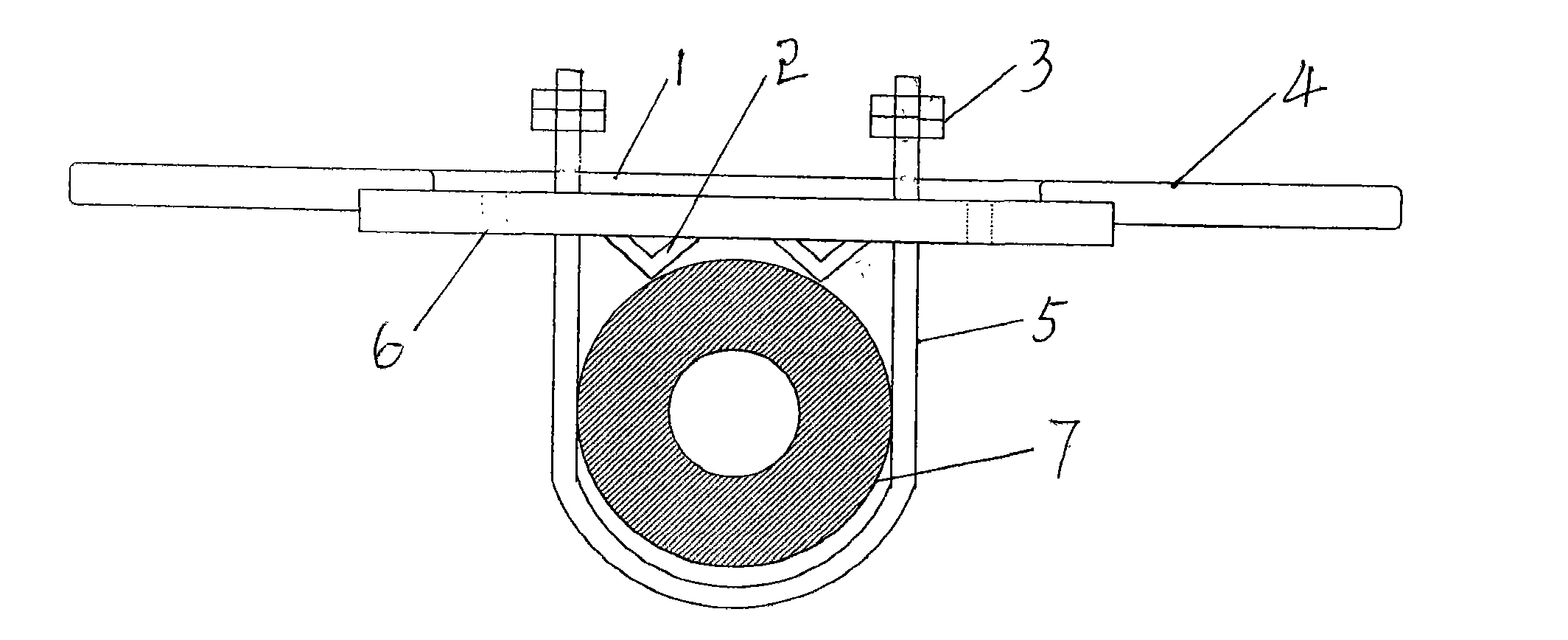

Rod correcting device

InactiveCN101634198AMeet construction needsReduce labor intensityTowersArchitectural engineeringScrew thread

The invention discloses a rod correcting device which comprises a strip-shaped base, and at least one pair of screw rod passing holes that are symmetrically arranged on a longitudinal centre line of the base, wherein a pair of screw rod passing holes are internally provided with a U-shaped anchor ear, the two sides of which are respectively connected with a nut by screw thread on the other side of the base; the base is fixed with two blocking teeth correspondingly to an arc-shaped surface of the anchor ear, and the two ends of the base are symmetrically fixed with handles extending outwards. The base can be made of channel steel, and the handles are made of steel tubes. When in use, a telegraph pole is sheathed with the anchor ear and fastened with the nuts, so as to be clamped by the blocking teeth and the anchor ear, and easily moved and rotated by the two handles; therefore, the device can rapidly adjust the telegraph pole, reduce the labor intensity, improve the construction quality and meet the construction needs of the telegraph poles with different specifications.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

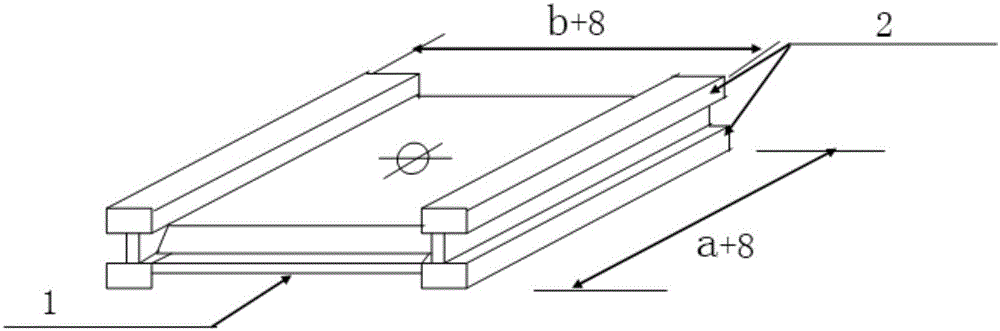

Adjustable multifunctional building construction platform

The invention provides an adjustable multifunctional building construction platform. The adjustable multifunctional building construction platform comprises a supporting transverse base plate, movingwheels, a left folding rod, supporting pipes, fixing inserting pipes, rotatable fixing disk structures, adjustable lifting seat structures, a construction worktable structure with protective guards, anoise-reduction protective cover structure, an anti-falling safety belt device, telescopic rods, clamping rings, adjusting pipe cylinders, pushing handles and a right folding rod. The supporting transverse base plate is transversely welded between the lower portions of the inner sides of the supporting pipes, and the moving wheels are connected to the lower surfaces of the supporting pipes in a bolted mode. Through arrangement of fixing lead screw rods, adjusting handles, fixing disks and rubber cushions, the heights of fixing disks are advantageously adjusted, thus the fixing disks are tightened and fixed to the ground, and the stability of the building construction platform is improved; a telescopic protective cover is filled with a noise-absorbing sponge layer, thus the effect of noiseabsorbing is advantageously achieved, and noise diffusion in the construction process is reduced; and through arrangement of the moving wheels and the pushing handles, the building construction platform is conveniently moved and fixed advantageously.

Owner:田锋刚

Self-levelling elastic mortar

InactiveCN101195528AImprove flexural strengthFlexibleSolid waste managementUltimate tensile strengthPolymer emulsion

The invention belongs to a technical field of building materials, providing self-leveling elastic mortar. The component and weight percentage of the self-leveling elastic mortar are that cement takes 10-35%, quartz sand takes 30-70%, admixture takes 0-10%, polymer emulsion takes 5-25%, water reducing agent takes 0.1-2%, defoamer takes 0.1-1.5% and water takes 0-20%. The film of the mortar of the invention is provided with elasticity and strength, simultaneously, the self-leveling of the mortar is good, which satisfies construction requirements.

Owner:熊永强 +1

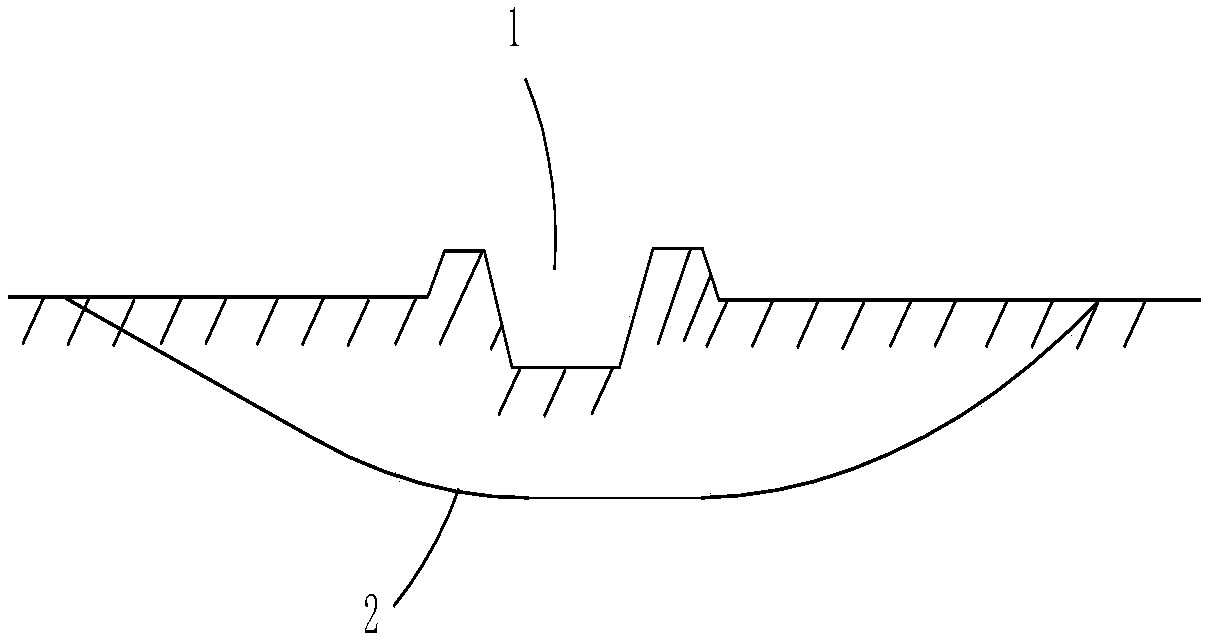

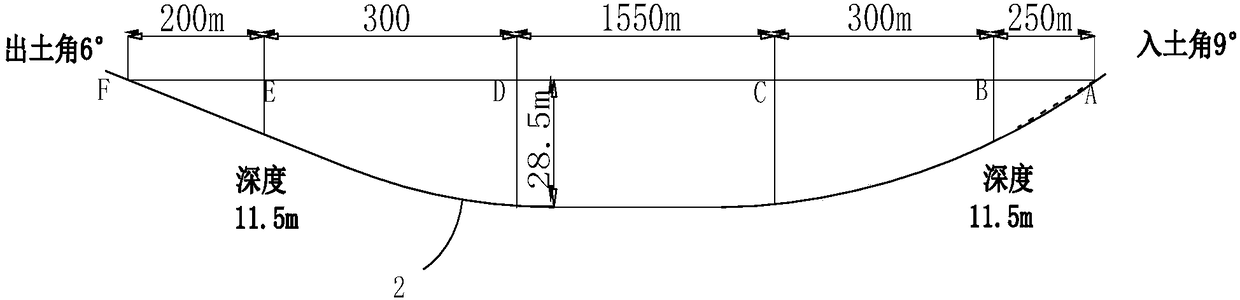

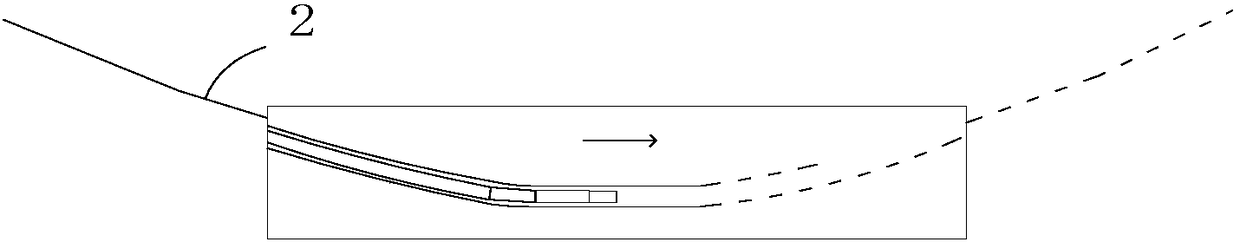

Long-distance directional drill construction method

InactiveCN108071341AEnsure safetyReduce the risk of crossing constructionDirectional drillingFlushingEngineeringViscosity

The invention discloses a long-distance directional drill construction method. The long-distance directional drill construction method includes the steps that guide drilling is carried out according to a drill path, and the mud pressure and balance and stability of discharge capacity are maintained during drilling; holes are expanded; the concentration of mud and the mud pressure are observed in real time when the holes are expanded to enable the pressure in the holes acted by the mud to be larger than the pressure in the holes acted by hole wall; the holes are cleaned; the viscosity of the mud maintains by above 55s when the holes are cleaned, and a sand carrying agent is added in the mud; and a hole-in angle of pipelines are regulated to keep consistent with an earth-out angle, and conduits are pulled back. According to the long-distance directional drill construction method, long-distance and large-diameter directional drill smooth construction can be achieved.

Owner:CHINA MCC 2 GRP CO LTD

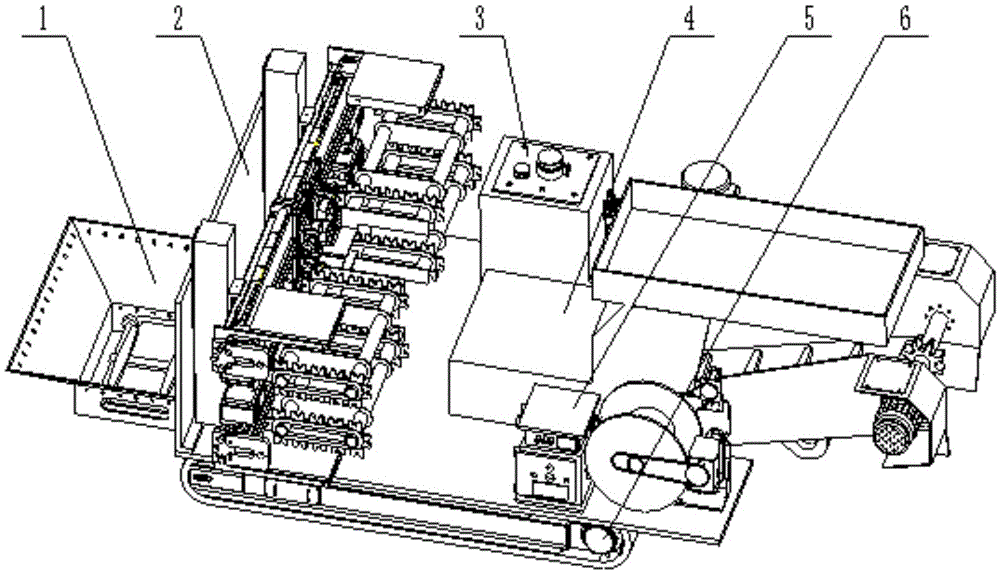

Asphalt cement mortar cart

InactiveCN101387093AHigh degree of automationImprove the mixing effectBallastwayControl systemCement mortar

The invention provides an asphalt cement mortar vehicle, which comprises a chassis and an upper assembly arranged on the chassis, wherein the upper assembly comprises a dry powder weighing-charging assembly, an asphalt metering-charging assembly, a water metering-charging assembly, an admixture metering-charging assembly, a stirring host assembly, a mortar pouring plate assembly, a power system and a control system; two or more than two sets of leveling oil cylinders, two sets of guiding forks, an angle sensor used for detecting the levelness of the upper assembly in real time, as well as a leveling control unit are arranged between the chassis and the upper assembly; the two or more than two sets of leveling oil cylinders are symmetrically and respectively arranged on the left and right sides of the mortar vehicle chassis; the angle sensor is connected with the input end of the leveling control unit; and the output end of the leveling control unit is connected with the leveling oil cylinders. The asphalt cement mortar vehicle has the advantages of high automation degree, great stirring capacity, high construction efficiency, convenient comfortable operation, safety and environment protection.

Owner:SANY HEAVY IND CO LTD (CN)

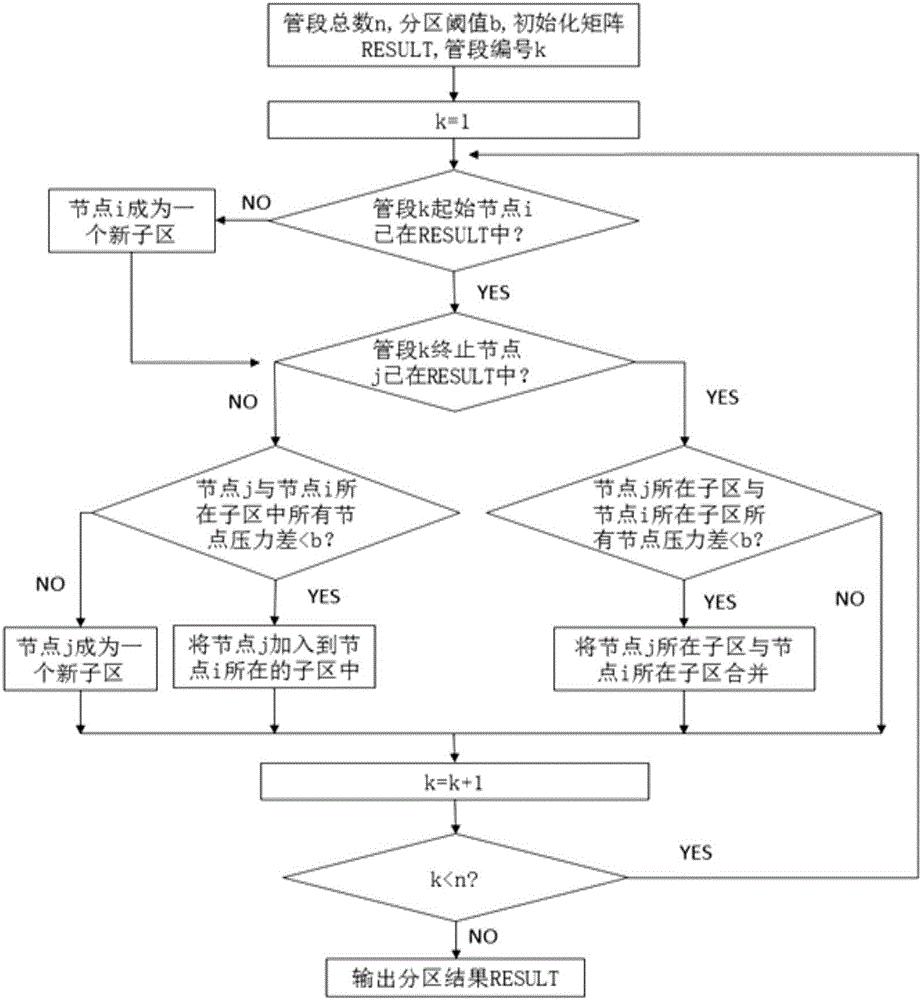

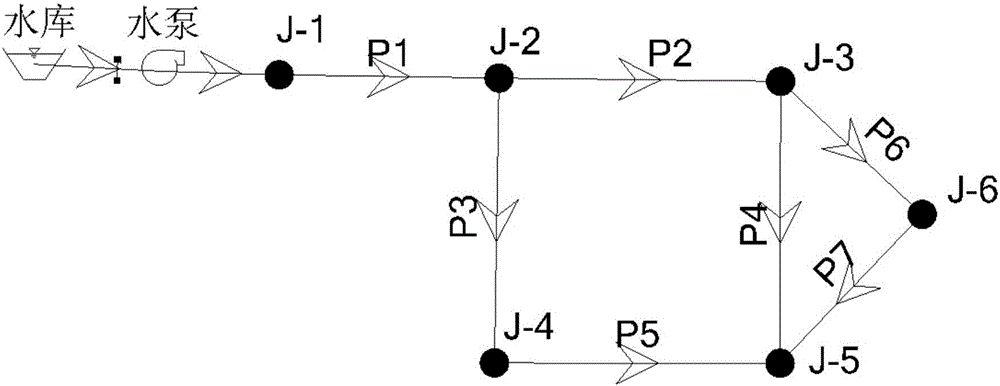

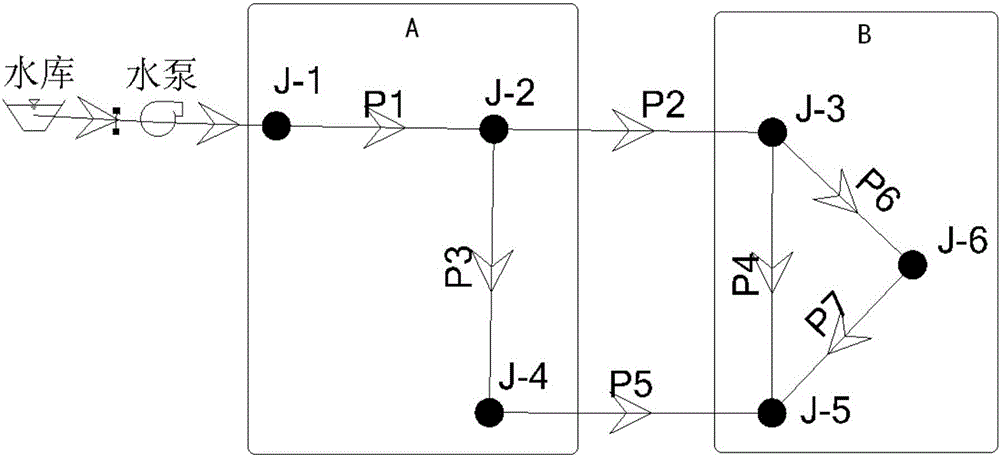

Arrangement method of pressure test points of water supply pipe network

InactiveCN105938505ASimple calculationSmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsUrban water supplyNetwork on

The present invention provides an arrangement method of pressure test points of a water supply pipe network. The arrangement method comprises the following two steps of partitioning the pipe network on basis of node pressure, and dividing nodes, positions of which are adjacent and pressure values of which are similar, into the same water supply sub area; and addressing the pressure test points of the pipe network by utilization of a sensitivity coefficient method for each water supply sub area so as to select the pressure test points from the nodes in the water supply sub areas. According to the arrangement method of the pressure test points of the water supply pipe network, the construction demand of a large-scale urban water supply pipe network can be satisfied, the calculating process of arrangement positions of the pressure test points is simple, and the calculated amount can be simplified.

Owner:GUANGZHOU JINGWEI INTELLIGENT TECH

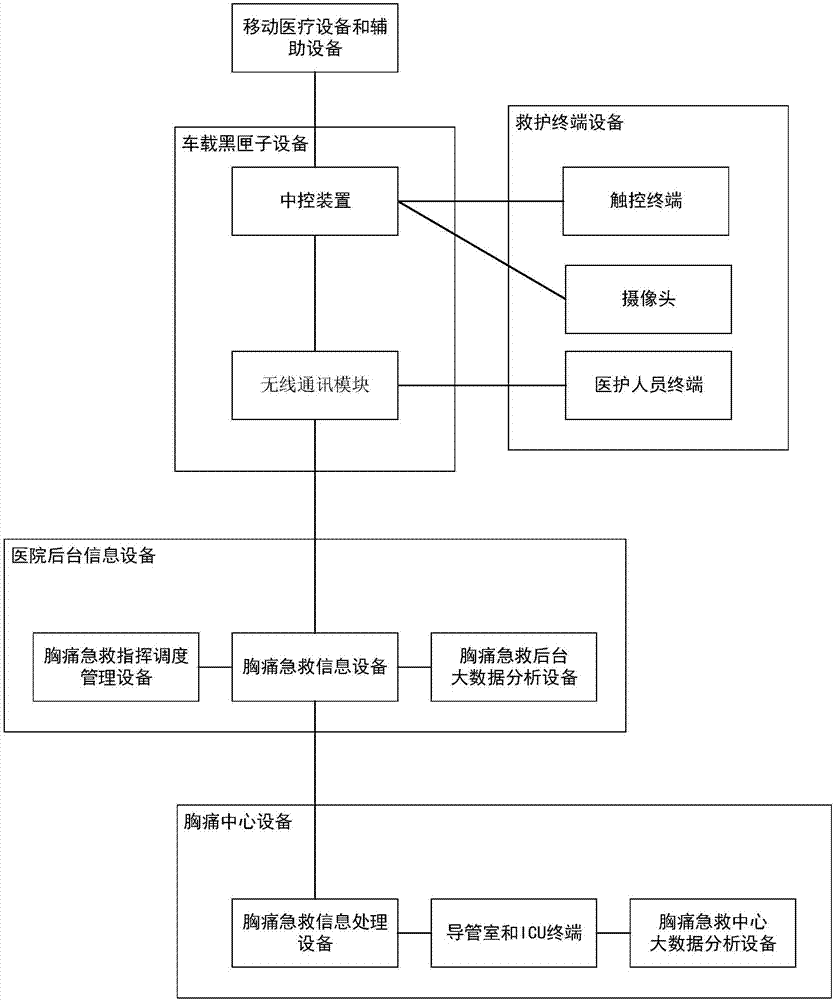

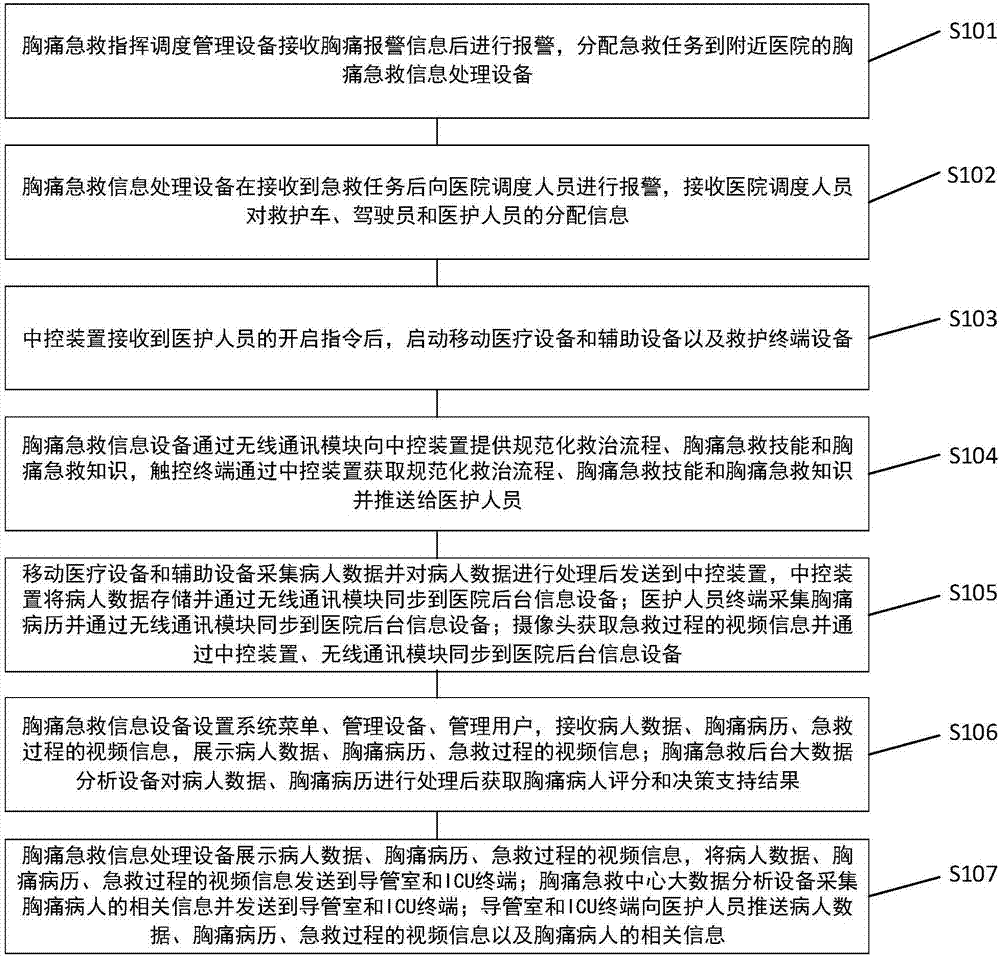

Chest pain first-aid medical internet system and application method thereof

InactiveCN107103179AImprove the level of diagnosis and treatmentStrengthen mutual learningMedical communicationHealth-index calculationMedical recordThe Internet

The invention provides a chest pain first-aid medical internet system and an application method thereof. A chest pain first-aid calling and dispatching command system, a chest pain first-aid flow risk control management system, a patient data real-time acquisition and remote transmission system, a chest pain first-aid electronic medical record system, an ambulance and salvage scene real-time video monitoring system, a remote first-aid and monitoring system, and a chest pain scoring system are integrated to form a chest pain first-aid management and quality control platform; and a hospital internal part and a hospital external part cooperate with each other, the treatment flow is optimized and normalized, the treatment time is shortened, the treatment efficiency is improved, and the casualty rate and medical disputes can be reduced.

Owner:严治

Method for excavating deep foundation pits under temporary bridge of main line railway

InactiveCN102505697ASolve the technical problems of cross constructionReduce the impactExcavationsReinforced concreteRebar

The invention belongs to the technical field of construction of deep foundation pits, particularly relates to a method for excavating deep foundation pits under a temporary bridge of a main line railway, and provides a construction method which is suitable for excavating large-scale deep foundation pits of an existing railway with double underpasses. The method includes steps that earthwork of a deep foundation pit is vertically excavated in a layered manner, the earthwork in each layer is symmetrical in directions from the longitudinal center of the temporary bridge of the main line railway to two ends of the bridge, and is excavated step by step or disorderly, each excavating unit adopts a pier body structural column of the temporary bridge of the railway as a center and extends to pier body lattice columns of two adjacent sides of the temporary bridge of the railway, earthwork is excavated through in a transverse direction relative to the bridge at one step, then step-slope excavation is realized in a longitudinal direction relative to the bridge according to the ratio of 1:1, and a scissors support can be mounted in time in an excavation process, and is used as reinforced concrete ring beams in the local section. The construction method effectively resolves the technical difficult problem of crossed construction of large-scale underground structures, deep foundation pit ranges and railway lines in station modification construction, follows the principle of giving consideration to construction and transportation, reduces influence to driving to the greatest extent, simultaneously meets requirements of construction of newly built projects, and can greatly shorten construction period.

Owner:CHINA RAILWAY NO 17 BUREAU GRP

Low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention and preparation method of low-temperature 3PE dry film hot melt adhesive

InactiveCN110028915AMeet construction needsSolve the needs of joint anticorrosion constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention. The low-temperature 3PE dry film hot melt adhesive is prepared by kneading a rubber elastomer, bonding resin, tackifying resin, a plasticizer, an antioxidant and a filler and conducting extruding, wherein the rubber elastomer is two or more of a styrene-isoprene-styrene block copolymer, a styrene-ethylene-butene-styrene block copolymer, butyl rubber and ethylene propylene diene monomer; the bonding resin is one or two of an ethylene-vinyl acetate maleic anhydride grafted modified material and an ethylene-acrylate-maleic anhydride terpolymer; the tackifying resin is one or more of terpene resin, C5 petroleum resin and rosin glyceride; and the plasticizer is polyisobutene or naphthenic oil. The low-temperature dry film hot melt adhesive disclosed by the invention is used for pipeline joint coating and corrosion prevention, meets the construction requirements in an extremely cold environment, and meets the pipeline joint coating and corrosion prevention construction requirements in cold regions; and the adhesive has the advantages of excellent adhesion and sealing property, good low-temperature flexibility, higher peel strength and stable performance.

Owner:江苏达胜热缩防护用品有限公司

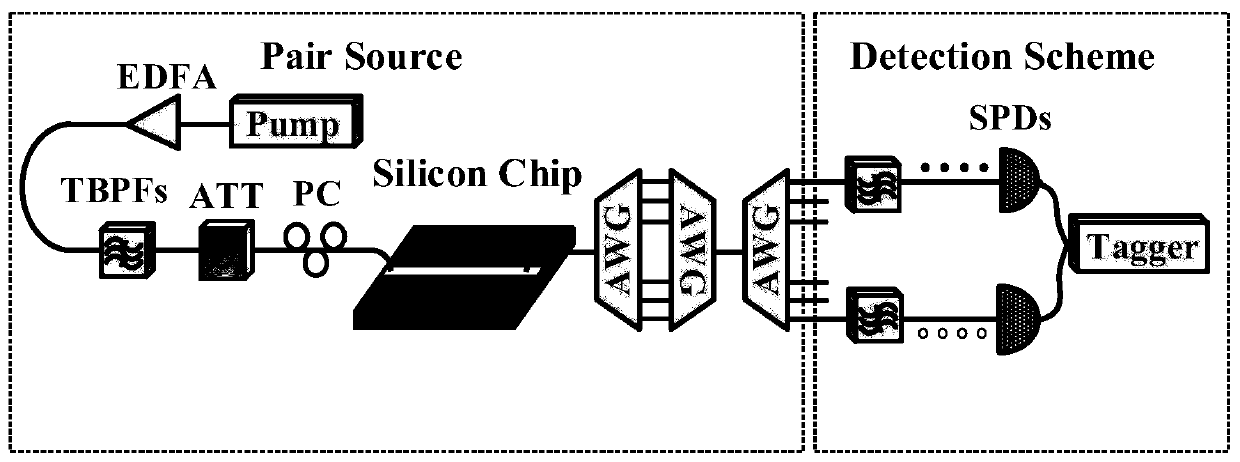

Quantum communication networking method and system based on multi-wavelength entangled light source

ActiveCN111510225ALarge-scale networkingShort communication distanceWavelength-division multiplex systemsPhotonic quantum communicationFiber-optic communicationMulti wavelength

The invention discloses a quantum communication networking method and system based on a multi-wavelength entangled light source. The method comprises the steps: by a multi-wavelength entangled light source, generating entangled single photons which are equal in frequency interval and paired; performing wavelength channel configuration on the entangled single photons by using a relatively mature dense wavelength division multiplexing technology in a classical optical fiber communication system; and constructing a quantum network server independent of the users and distributing the entangled photons of each wavelength to each user, thereby ensuring that every two users can share a pair of independent entangled single photons, and finally realizing a quantum communication network in which multiple users are randomly interconnected.

Owner:军事科学院系统工程研究院网络信息研究所

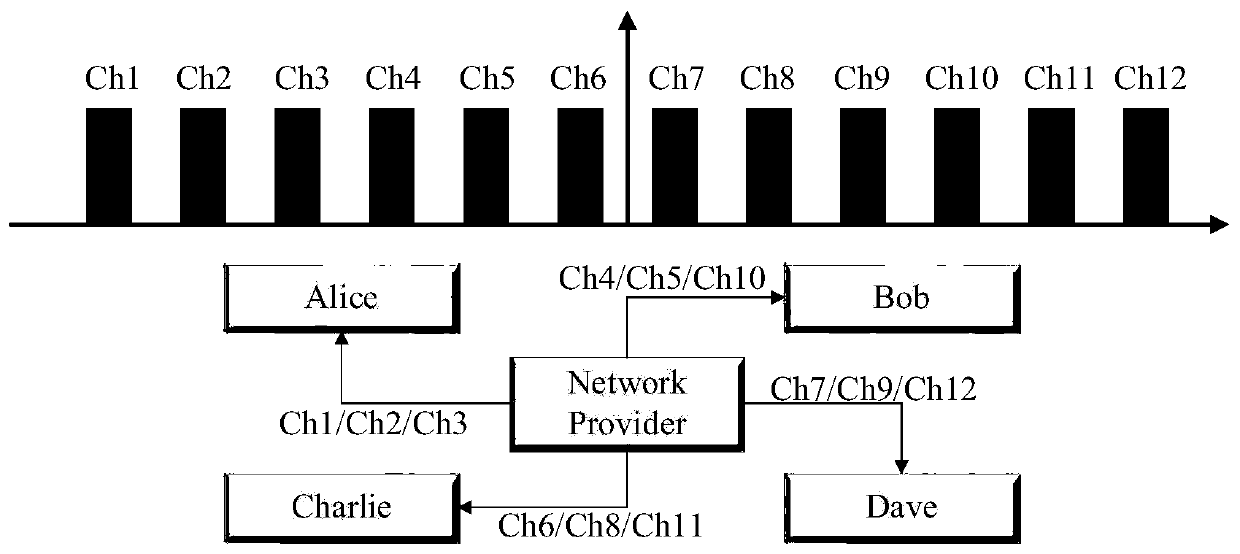

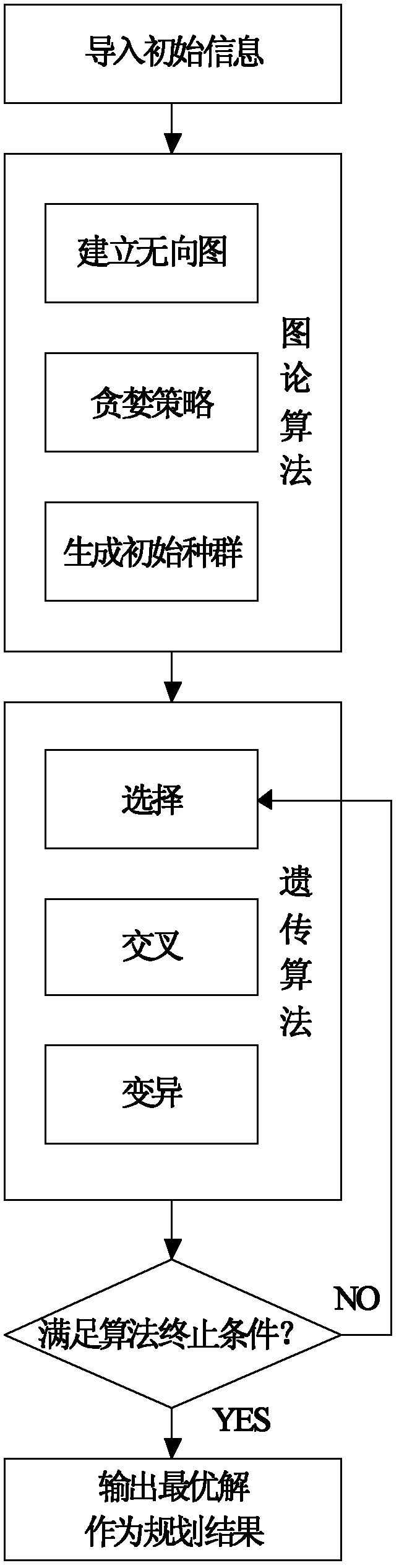

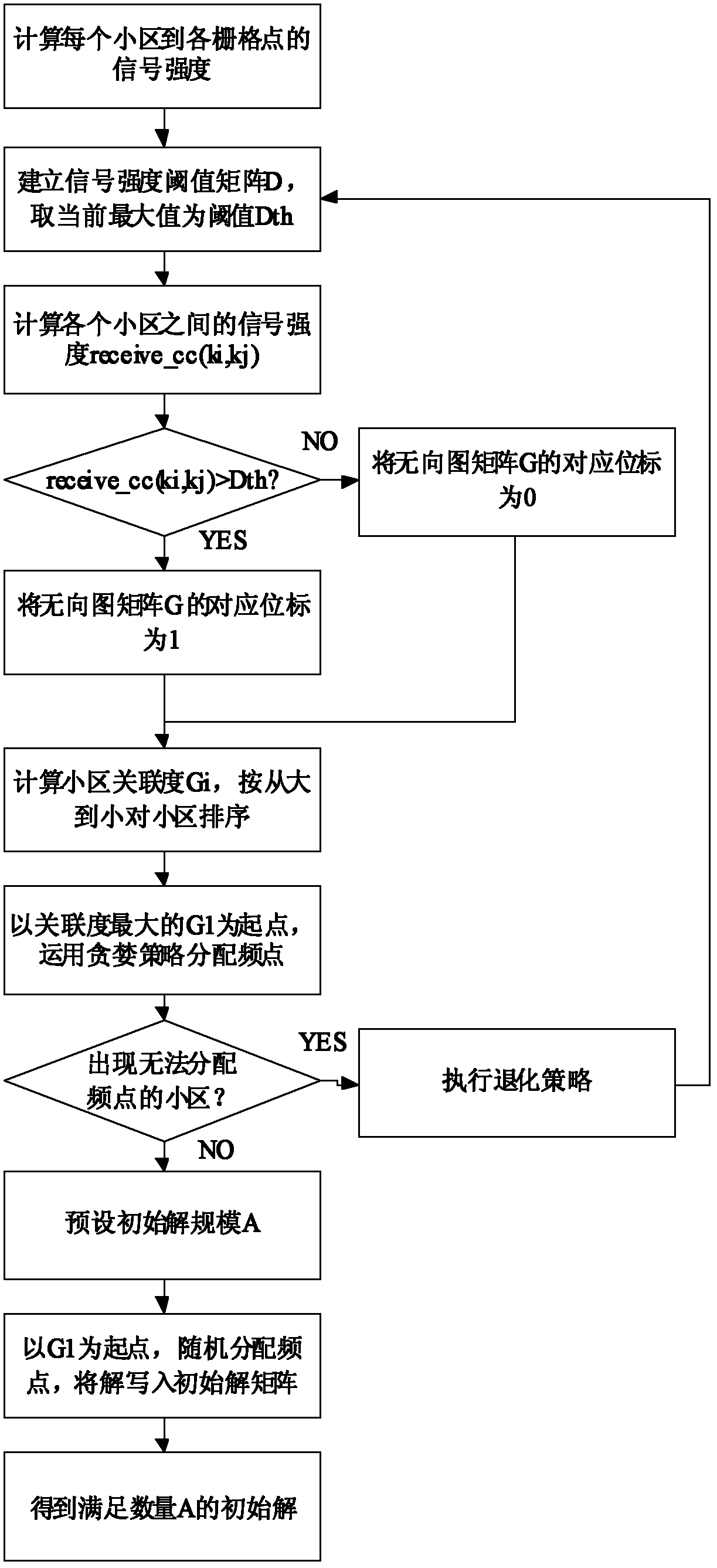

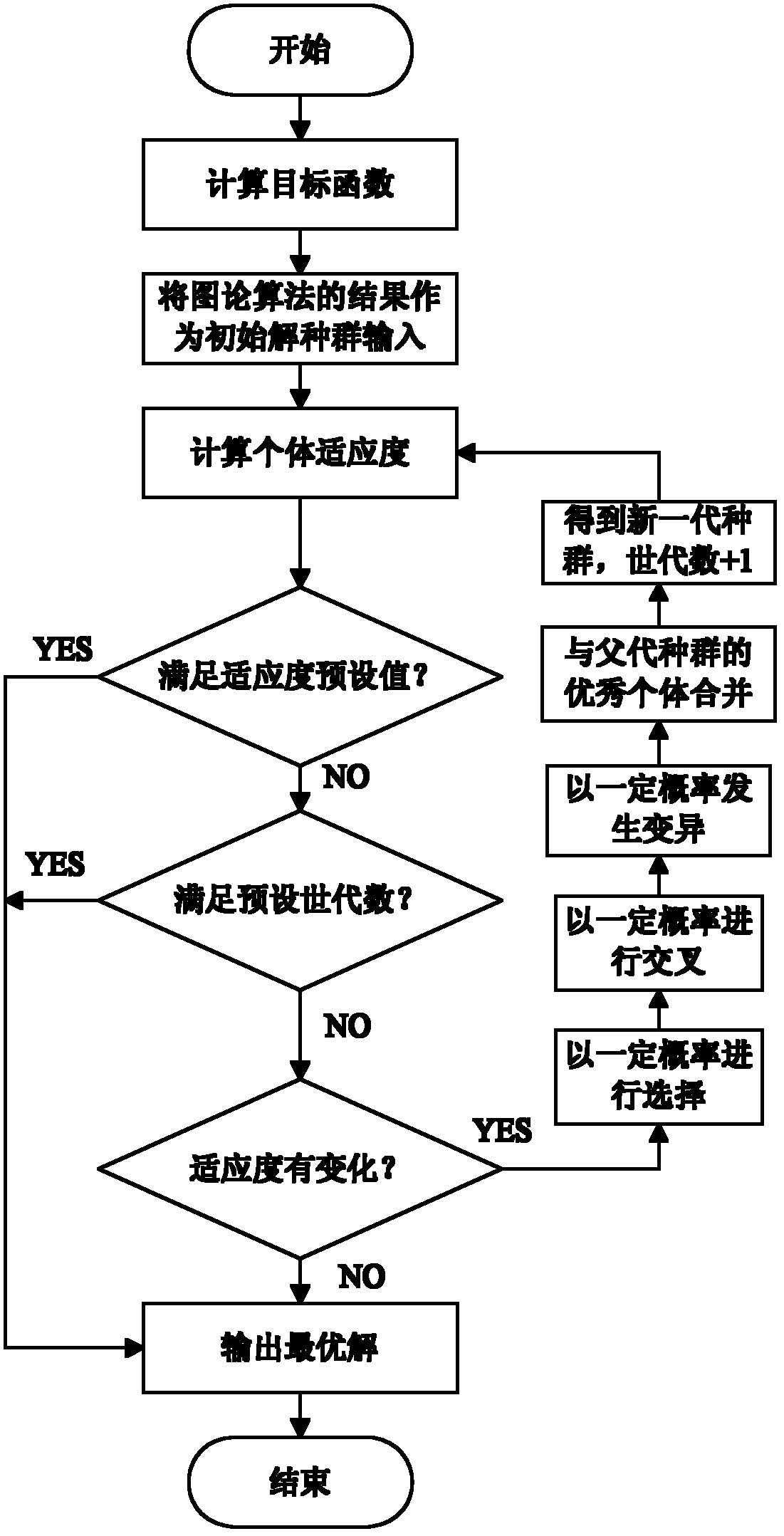

Method for automatically planning mobile communication frequency based on combination of graph theory and genetic algorithm

ActiveCN102572849AMeet construction needsSmall amount of calculationNetwork planningCurrent cellUndirected graph

The invention provides a method for automatically planning mobile communication frequency based on the combination of a graph theory and a genetic algorithm, relating to the mobile communication field. The method comprises the steps of: 1, obtaining the strength of the signal received by each cell from other cells within a planned area, making a comparison between the strength of the received signal and the signal strength threshold, and establishing a cell relation undirected graph matrix; 2, selecting one cell from the planned area as the current cell; 3, allocating a first frequency point of the current cell based on the cell relation undirected graph matrix; carrying out the step 2 if the first frequency point is obtained successfully until the allocation of the first frequency point is carried out by all the cells; reducing the signal strength threshold if the operation fails, and carrying out step 1, and reestablishing the cell relation undirected graph matrix; 4, producing initial frequency planning solution as an initial solution group of the genetic algorithm according to the cell relation undirected graph matrix; 5, carrying out an genetic operation to the initial solution group by the genetic algorithm until meeting the end condition of the genetic algorithm, and outputting the best individual of the current group as the frequency planning result; and 6, allocating the frequency point to each cell within the planned area.

Owner:XIAMEN UNIV +1

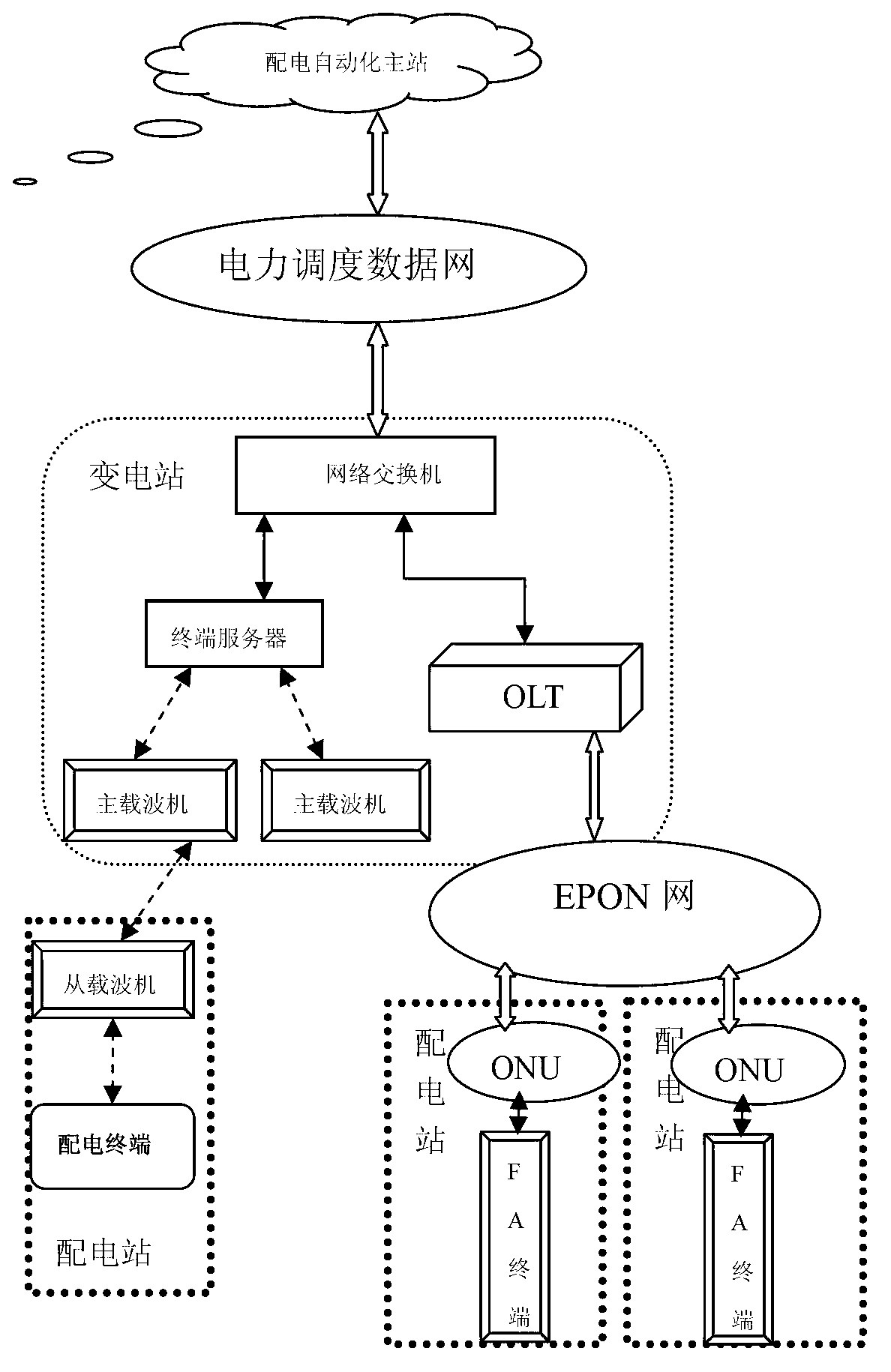

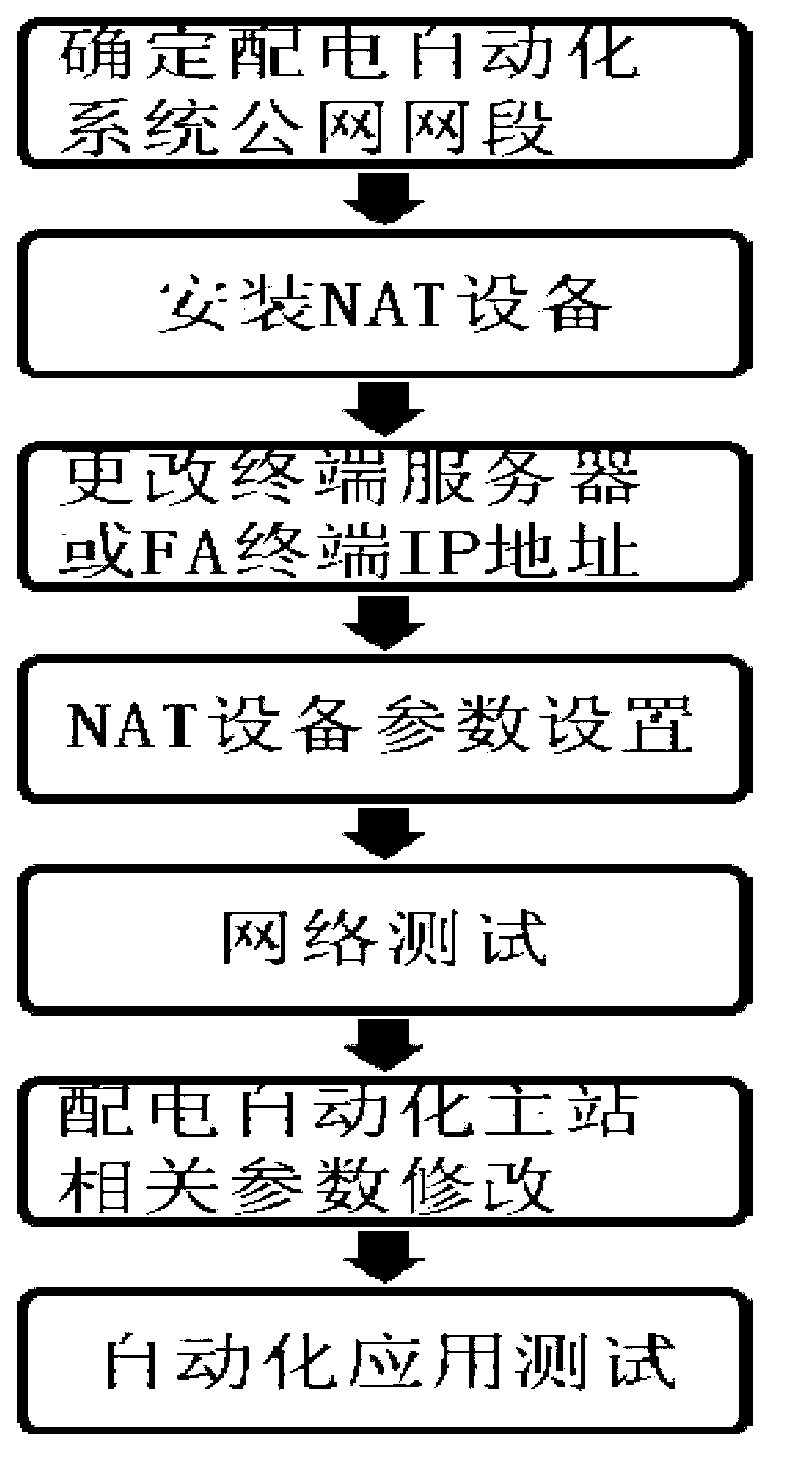

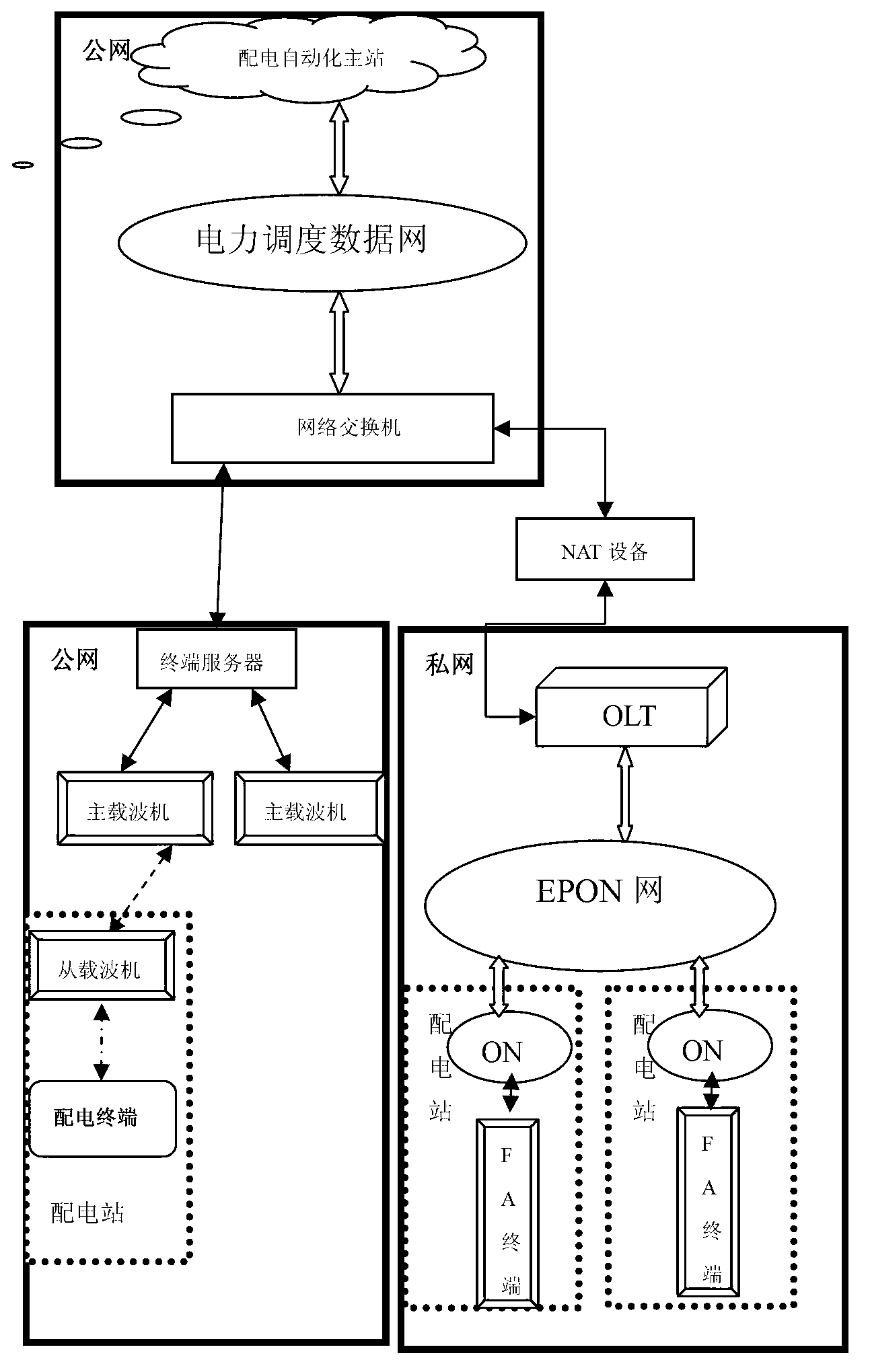

Method for connecting power distribution terminal into scheduling data network through NAT (Network Address Translation) manner

The invention provides a method for connecting a power distribution terminal into a scheduling data network through a NAT (Network Address Translation) manner and belongs to the field of power automation. The method is characterized in that NAT equipment is arranged between a side network switch of a transformer substation and side optical line terminal equipment, a power distribution automation terminal of the substation and a communication system forms a private network, a one-to-many secondary network model is formed on the basis of a conventional public network, multi-channel protocols are subjected to analysis of message information of application layers and conversion of private-public network addresses, IP addresses or ports needing to be subjected to address conversion in each substation are correspondingly converted and treated, thus the correctness of communication of the application layers is ensured, the problem of shortage of IP addresses occurring when a distribution network automation terminal is connected into a distribution network main station system through the scheduling data network is solved through the NAT manner, the available space of IP addresses of the public network is saved and extended, and the construction requirements of the automation systems of power distribution networks are satisfied. The method can be widely applied to the design and construction of a power scheduling data network and reorganization and expansion of conventional power scheduling data networks.

Owner:STATE GRID CORP OF CHINA +1

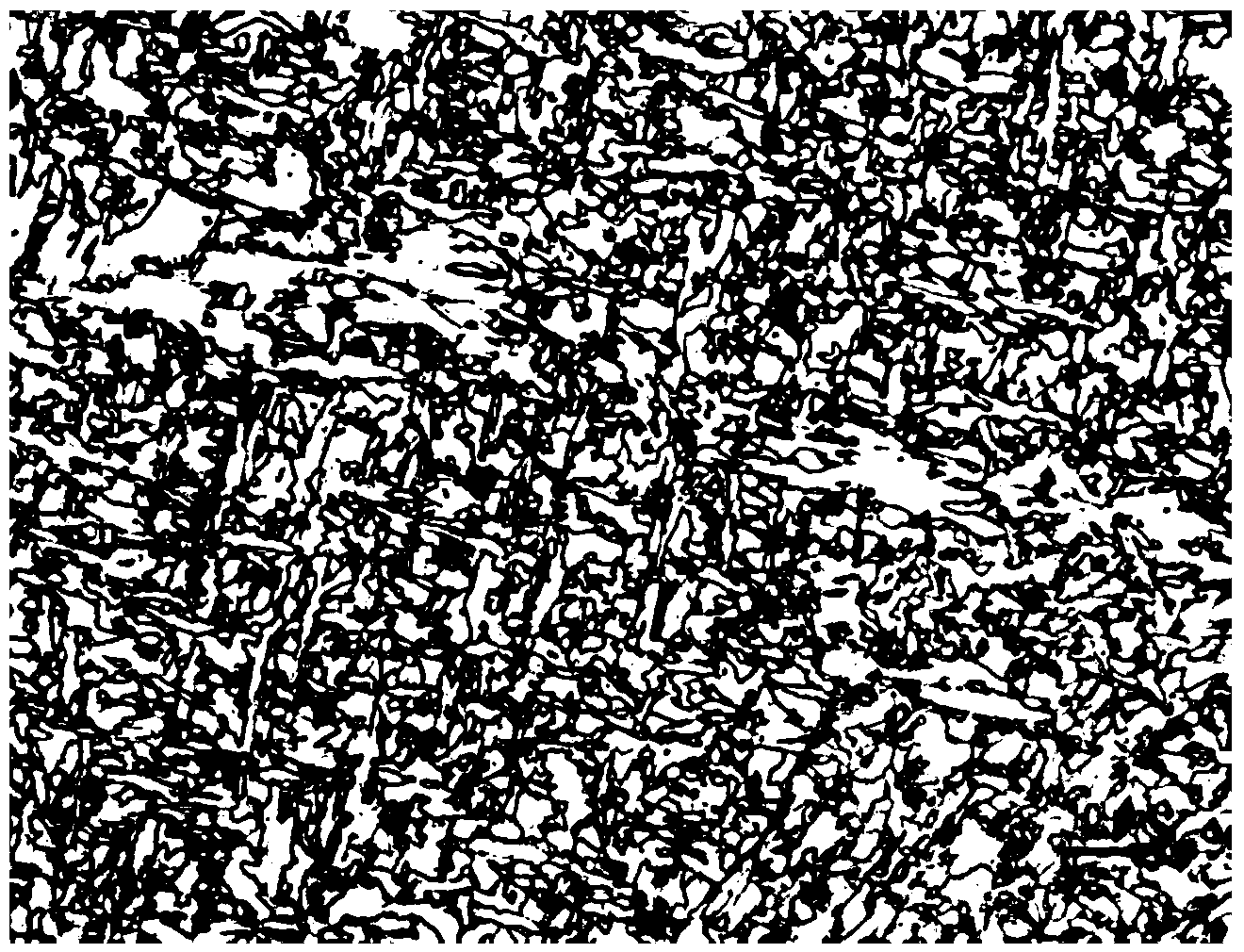

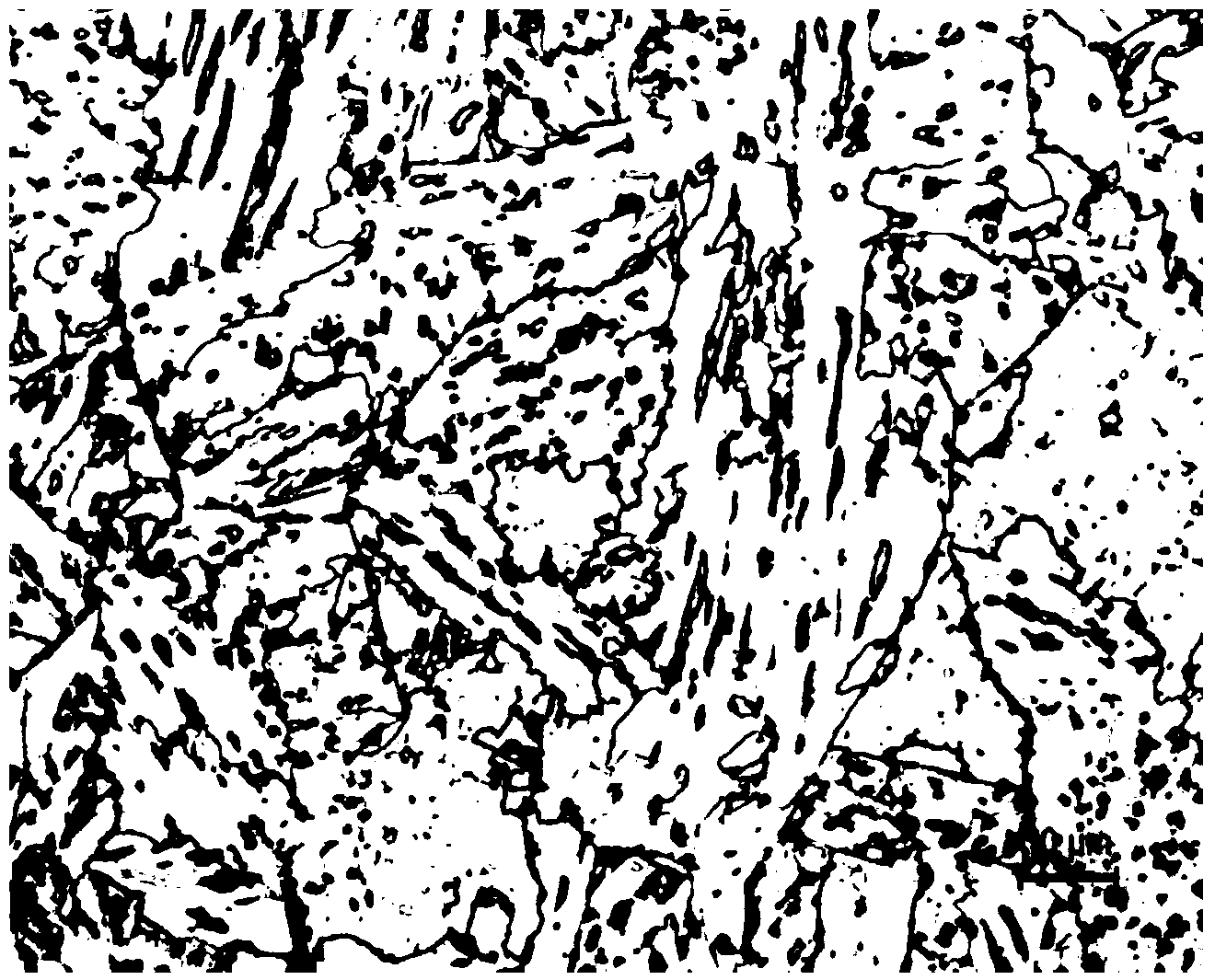

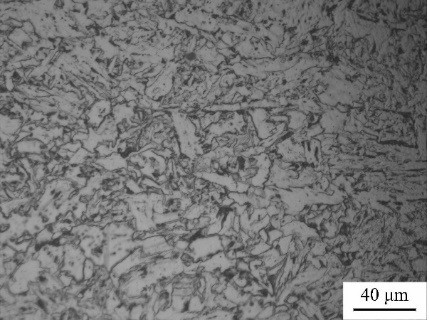

420MPa-grade weather-resistant bridge steel and production method thereof

The invention discloses 420MPa-grade weather-resistant bridge steel and a preparation method thereof. The 420MPa-grade weather-resistant bridge steel is prepared from the chemical components including, by mass, 0.05%-0.07% of C, 0.25%-0.50% of Si, 1.10%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.28%-0.35% of Cu, 0.20%-0.30% of Ni, 0.45%-0.55% of Cr, less than or equal to 0.10% of Mo, 0.008%-0.030% of Nb, 0.010%-0.030% of Ti, 0.005%-0.015% of V, 0.020%-0.035% of Als, 0.0020%-0.0050% of Ca, less than or equal to 0.0040% of O, 0.0025%-0.0080% of N, and the balance Fe and inevitable impurities; and Nb / C+V / N is larger than or equal to 1.8 and is less than or equal to 3.5. The low-C-proper-Si and Mn-trace Nb-V-N alloying thought is adopted, the low-cost thought of high Cr and low Cu and Ni is adopted, a proper amount of Cu-Cr-Ni is added, the weather resistance is guaranteed, and the 420MPa-grade weather-resistant bridge steel which is low in cost, excellent in comprehensive performance, wide in production process window and capable of easily achieving batch industrial production is obtained, the composition system is matched with the optimized TMCP+tempering preparation technology, the requirement for the capacity of production equipment is reduced, and the steel is suitable for batch industrial production of small and medium-sized steel mills.

Owner:TANGSHAN IRON & STEEL GROUP +2

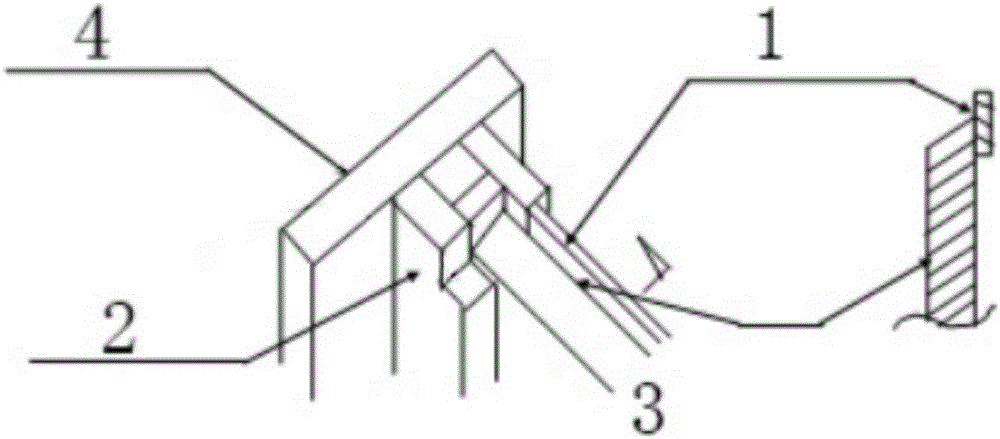

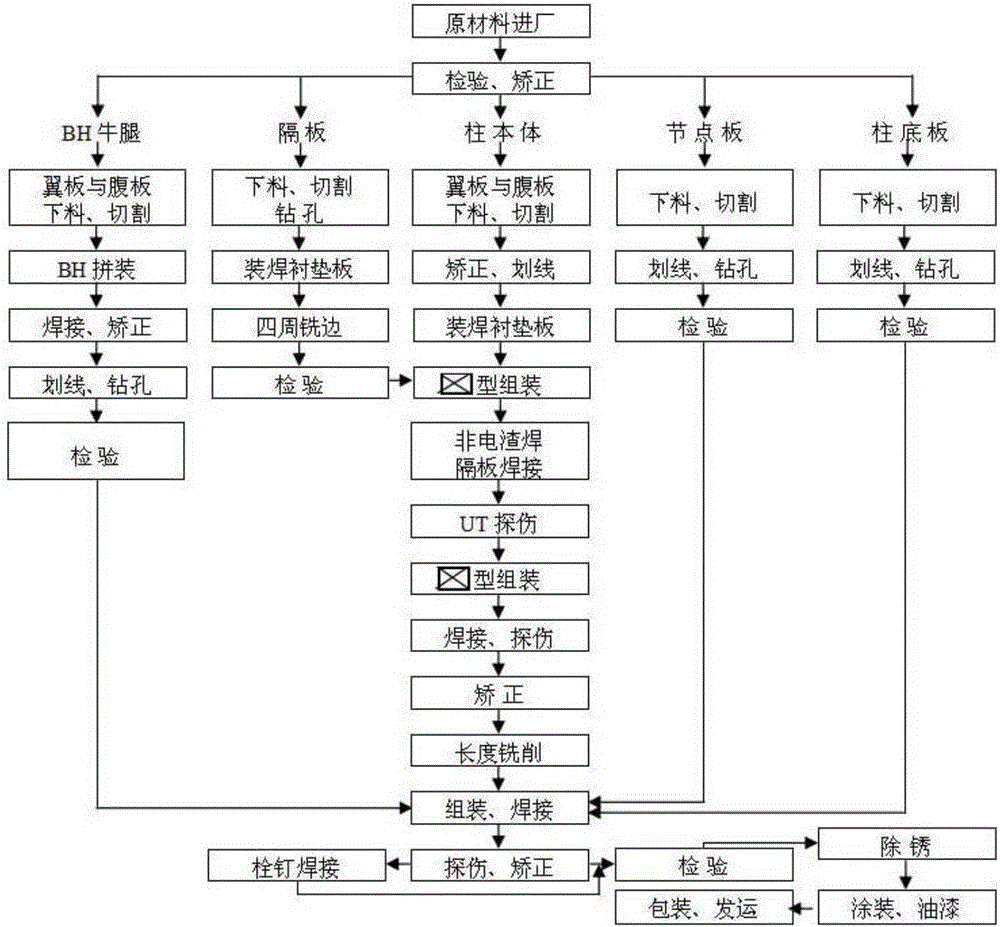

Construction process of removable special-shaped three-dimensional steel-frame structure

InactiveCN105937264ANovel methodImprove construction efficiencyBuilding constructionsBasementGusset plate

The invention relates to the technical field of building construction, in particular to construction process of a removable special-shaped three-dimensional steel-frame structure. The process comprises following steps: pre-embedment construction of a foundation, a basement and supporting pipelines, construction of a steel structure, mechanical and electrical installation and construction and installation of internal and external decoration machines. A removable special-shaped three-dimensional steel frame is composed of connection between different special-shaped box-shaped steel structure columns. The special-shaped box-shaped steel structure columns comprise brackets, partition plates, box column-shaped bodies, gusset plates, H-shaped steel and column bottom plates. The machining steps of the special-shaped box-shaped steel structure columns comprise machining of the partition plates, machining of the box column-shaped bodies, assembly columns brackets, the gusset plates, and other parts. During assembly, positive allowance is utilized to plus and minus welding shrinkage allowance. The distance between column centers and floor elevations and bolt holes can be controlled. The positioning assembly can be carried out on the brackets and the gusset plates with angles. The construction process of the removable special-shaped three-dimensional steel-frame structure featuring novelty, high construction efficiency, and high construction safety factor is provided in order to satisfy construction demands of different buildings.

Owner:SHANGHAI GREENLAND CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com