Patents

Literature

62results about How to "Good maintenance condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

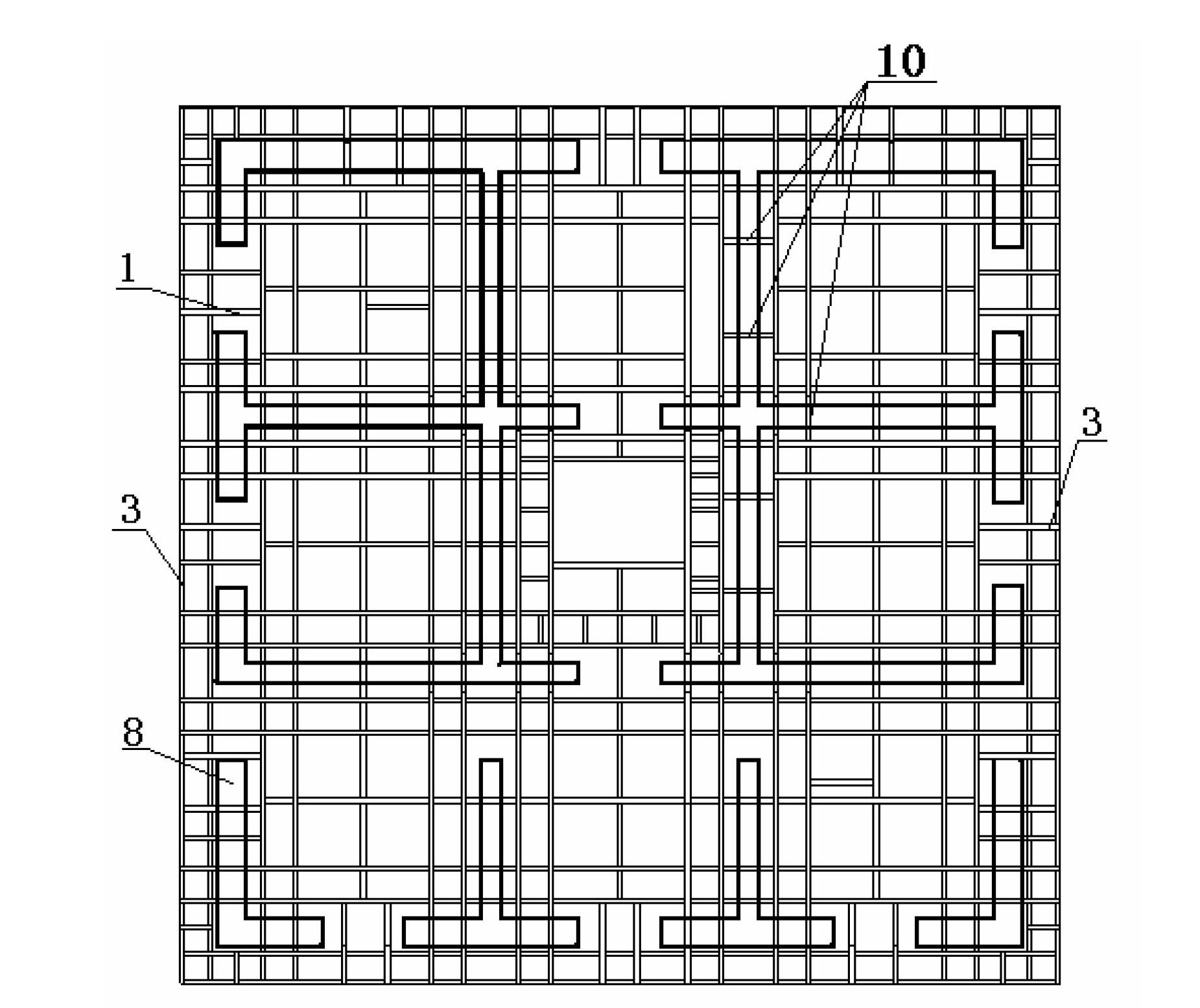

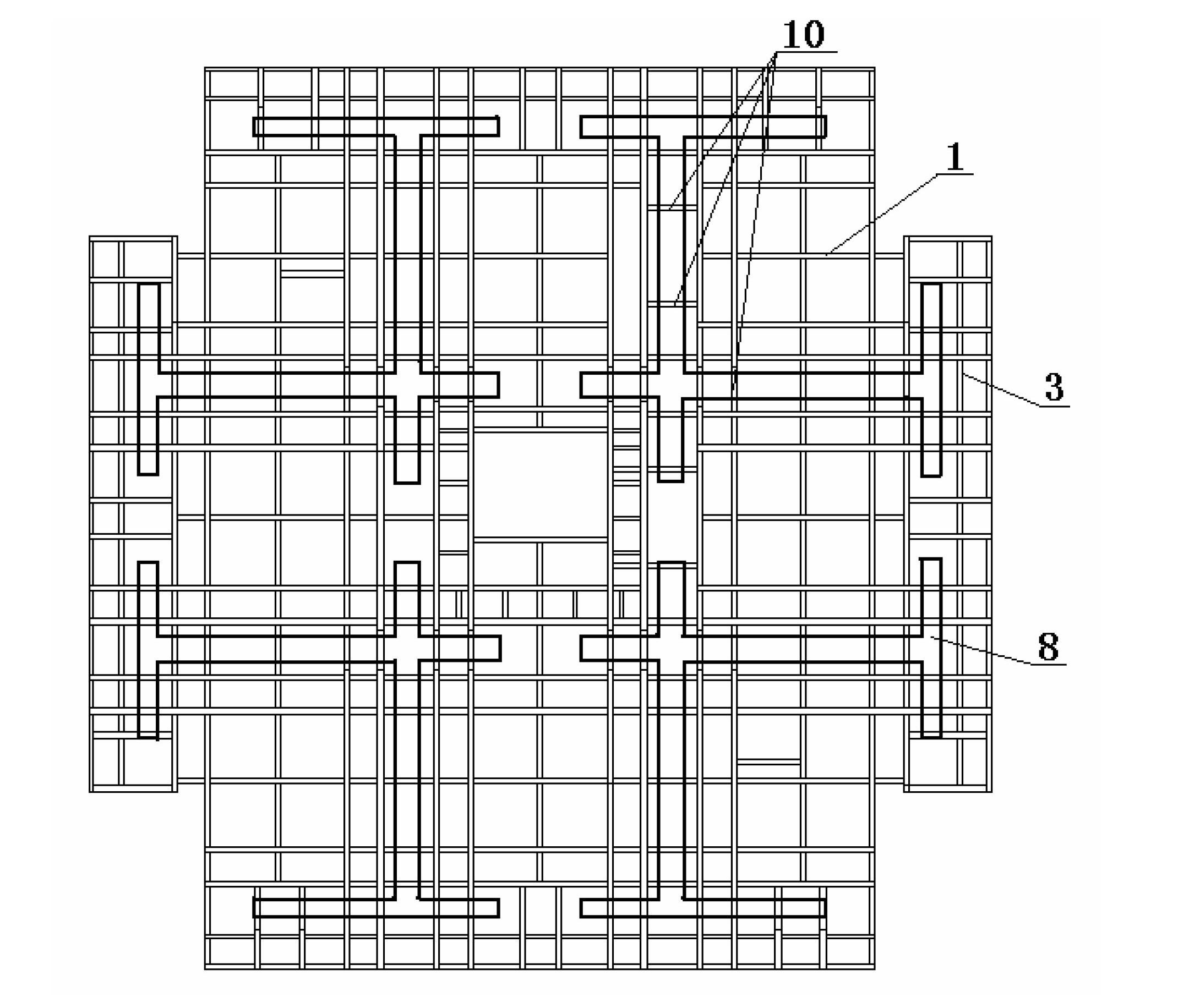

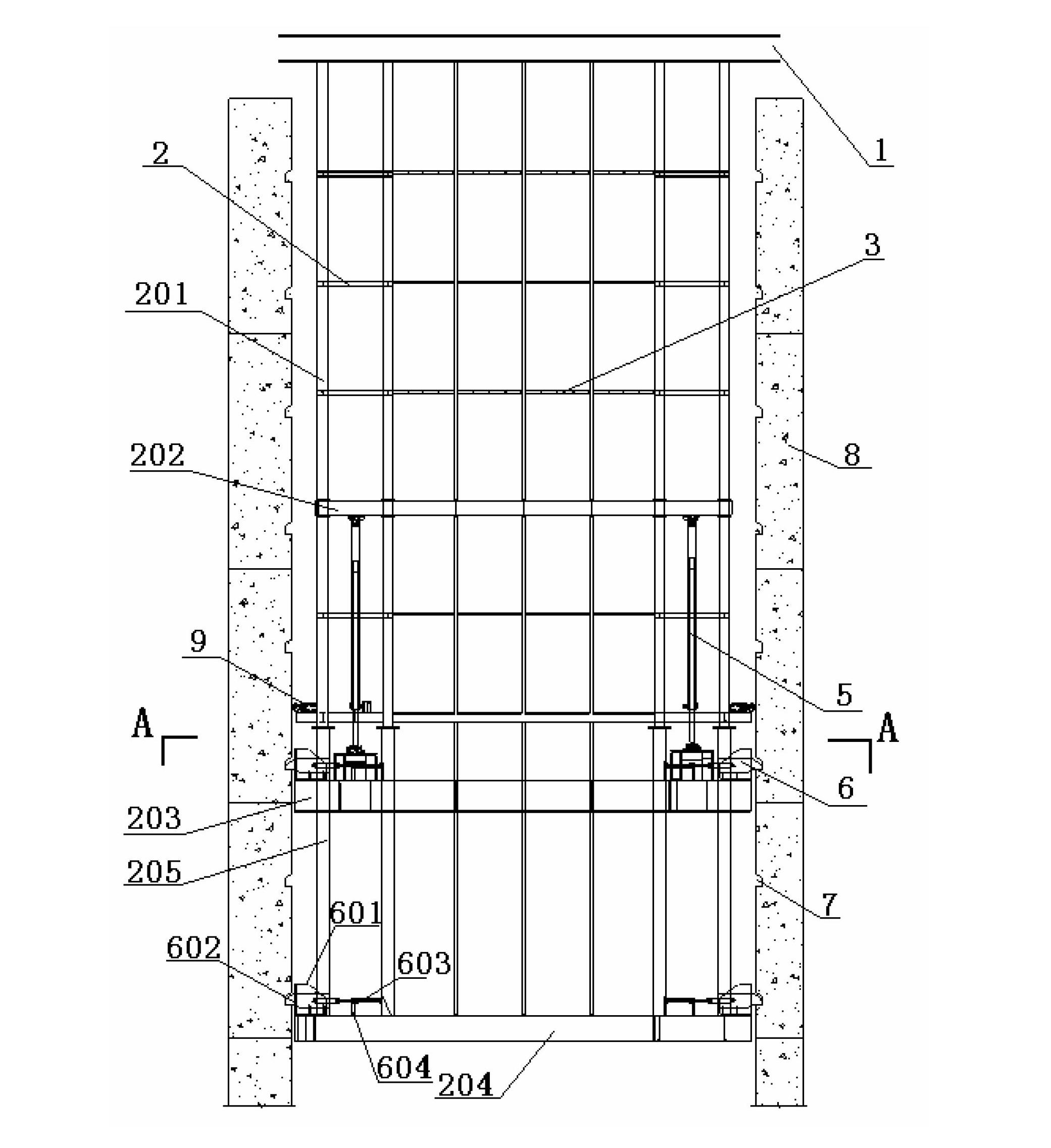

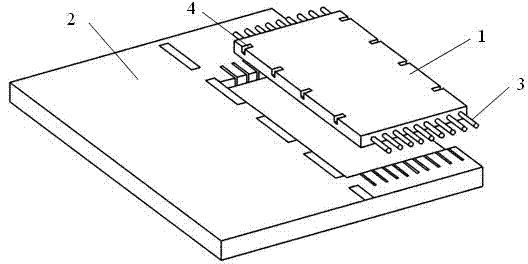

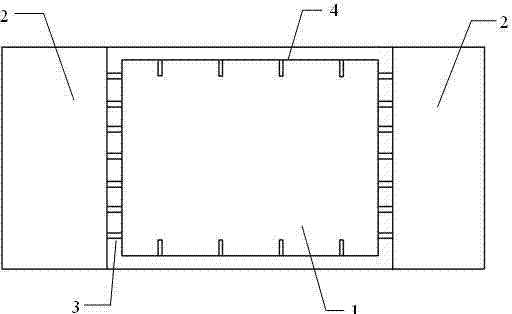

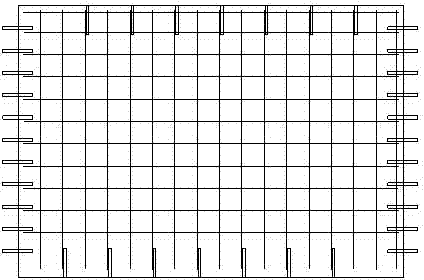

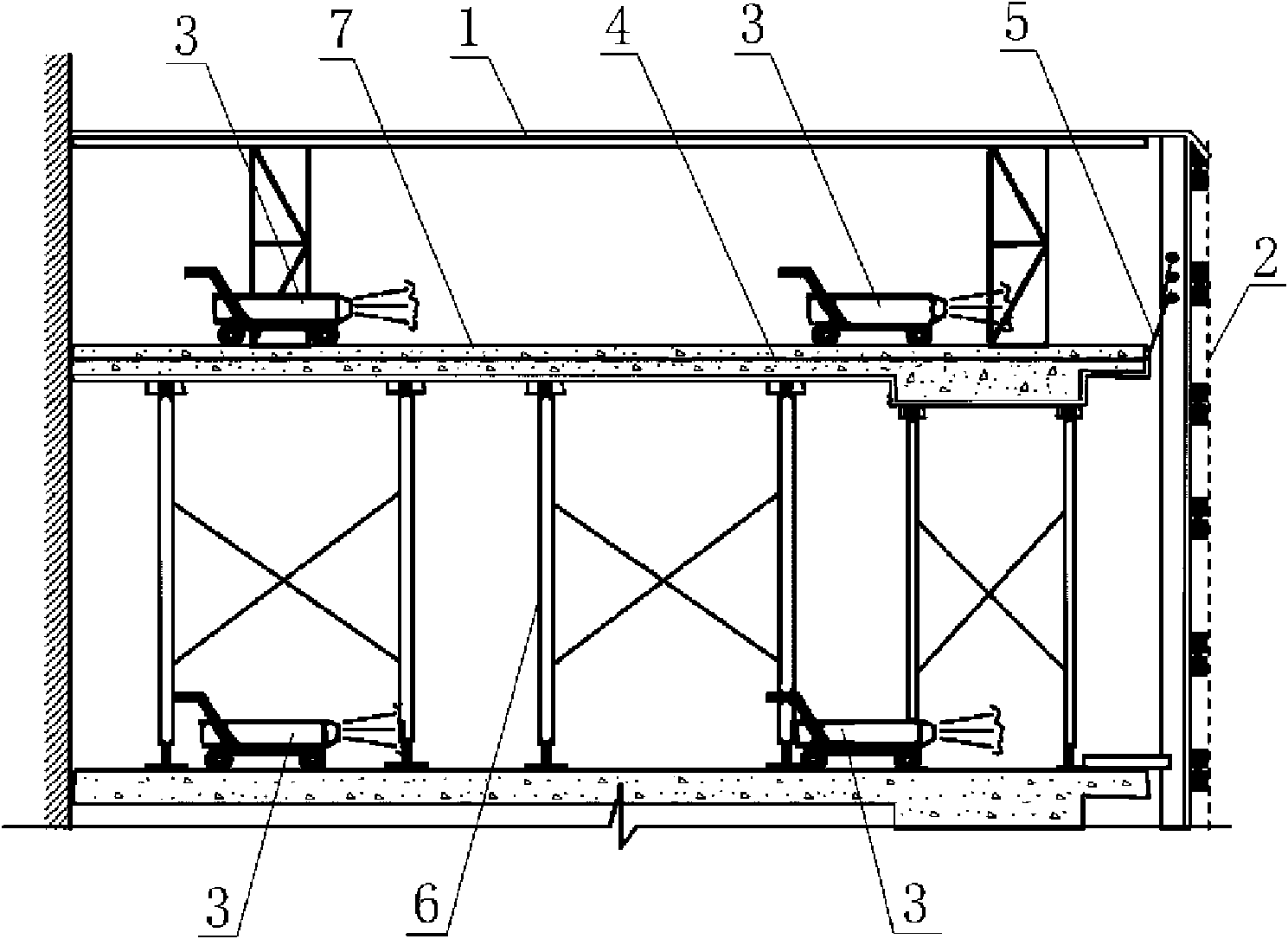

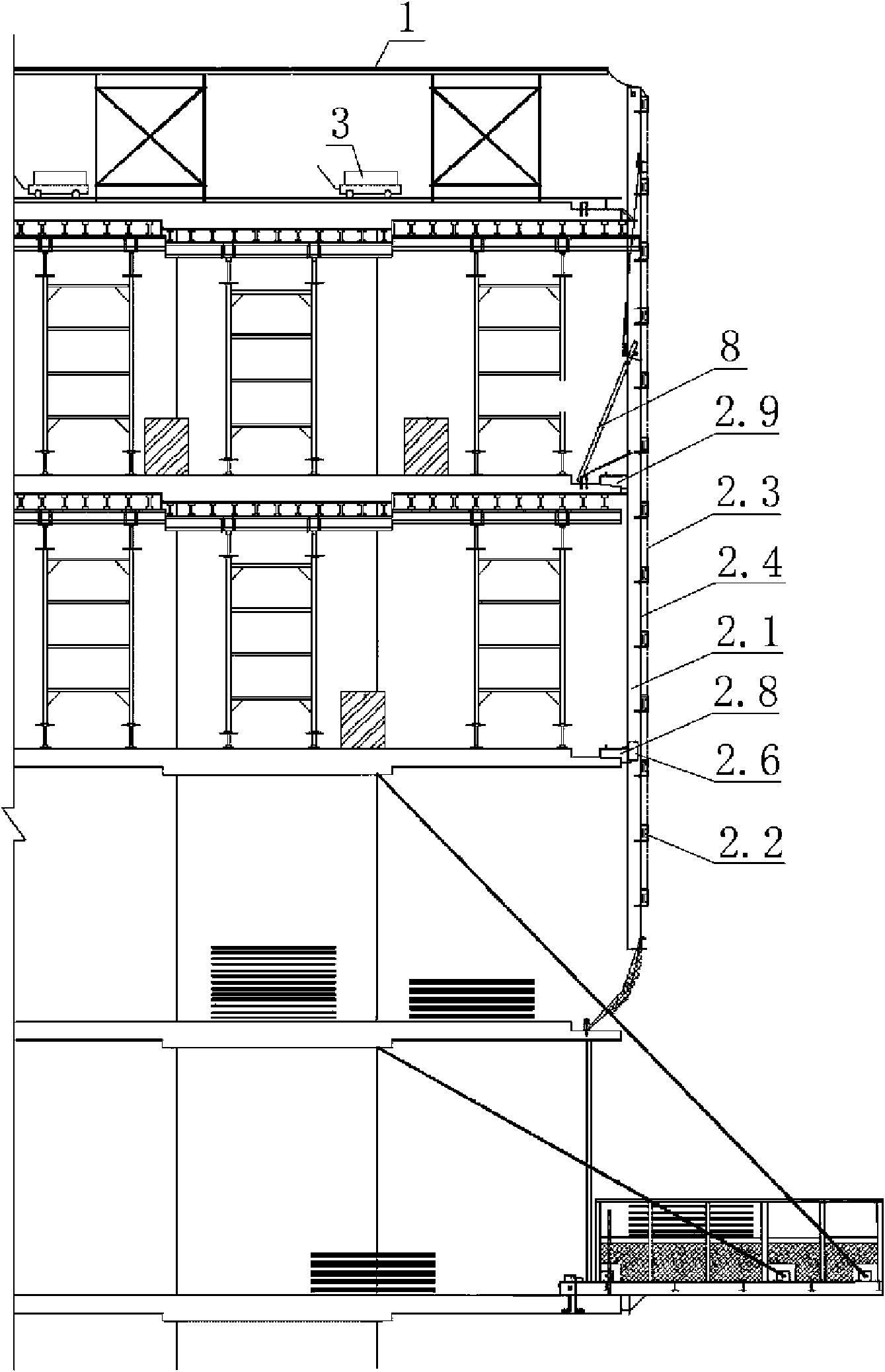

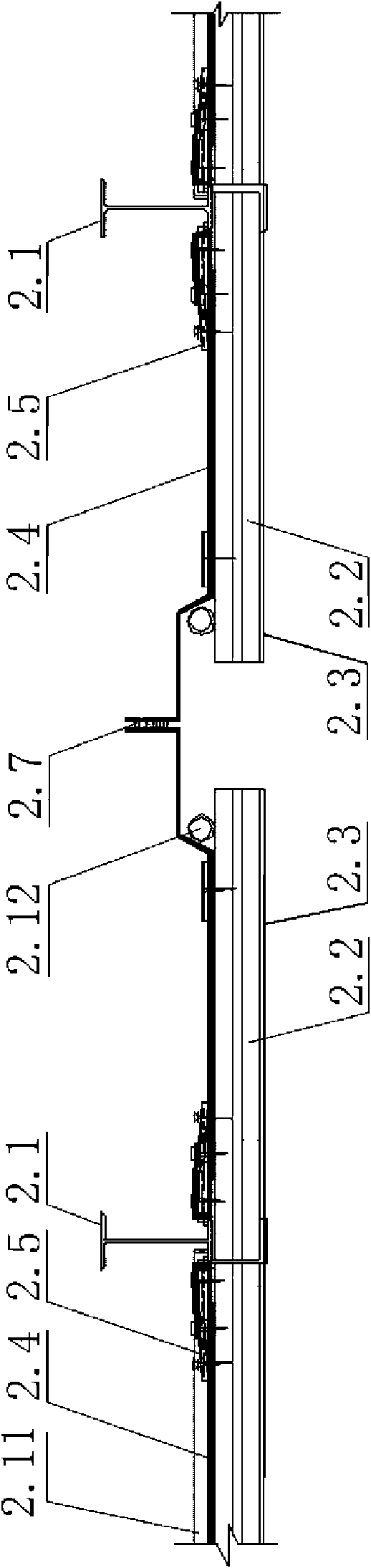

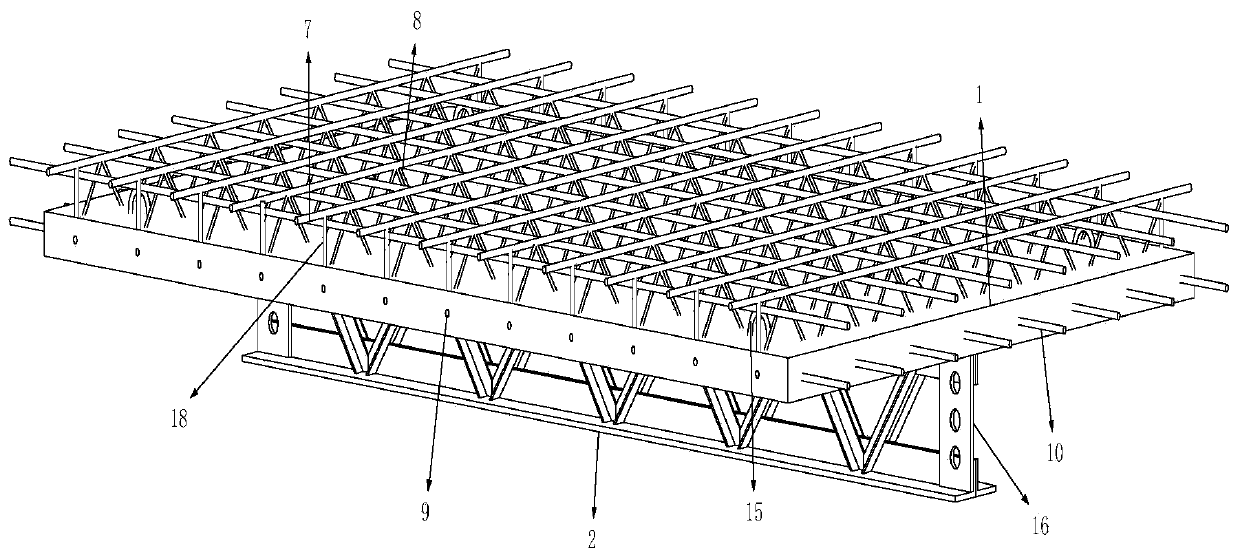

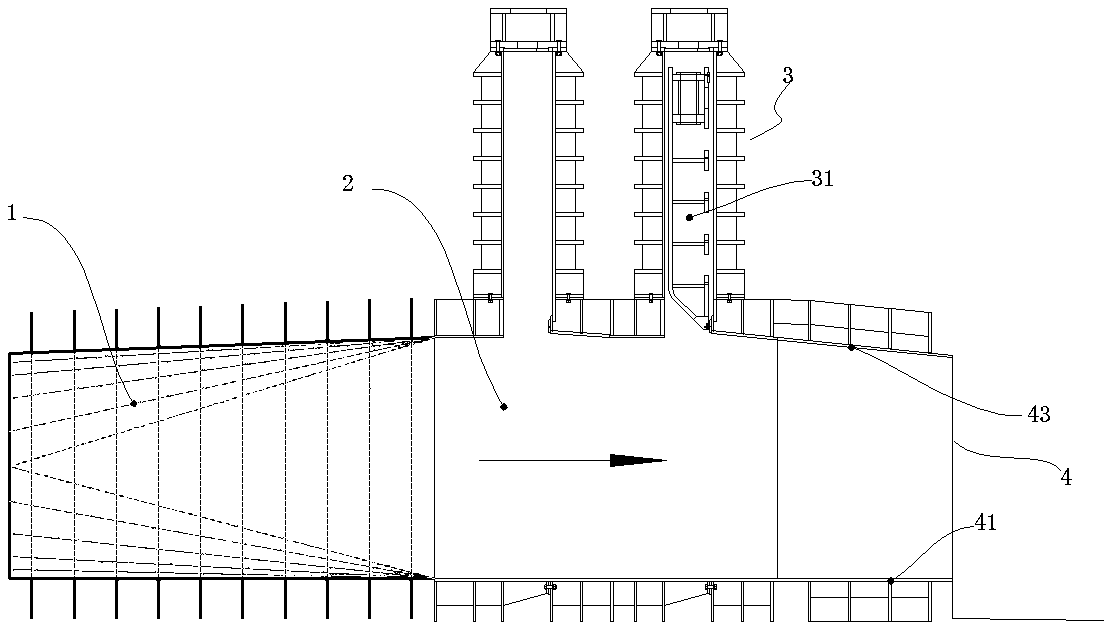

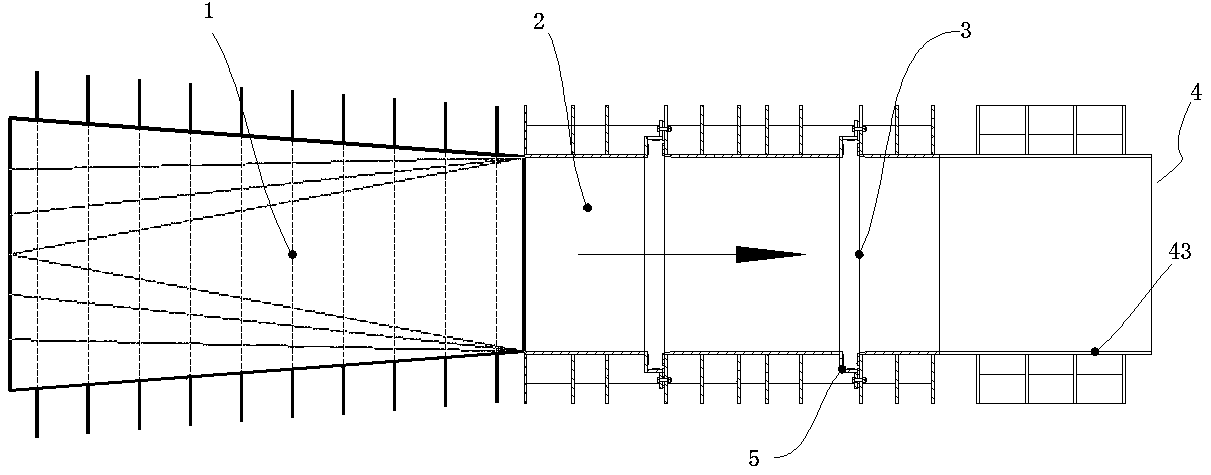

Drum frame supporting power built-in integrated jacking steel platform formwork system and construction method

ActiveCN102661039AEasy maintenanceAvoid the risk of falling objectsForms/shuttering/falseworksBuilding material handlingSteel columnsShear wall

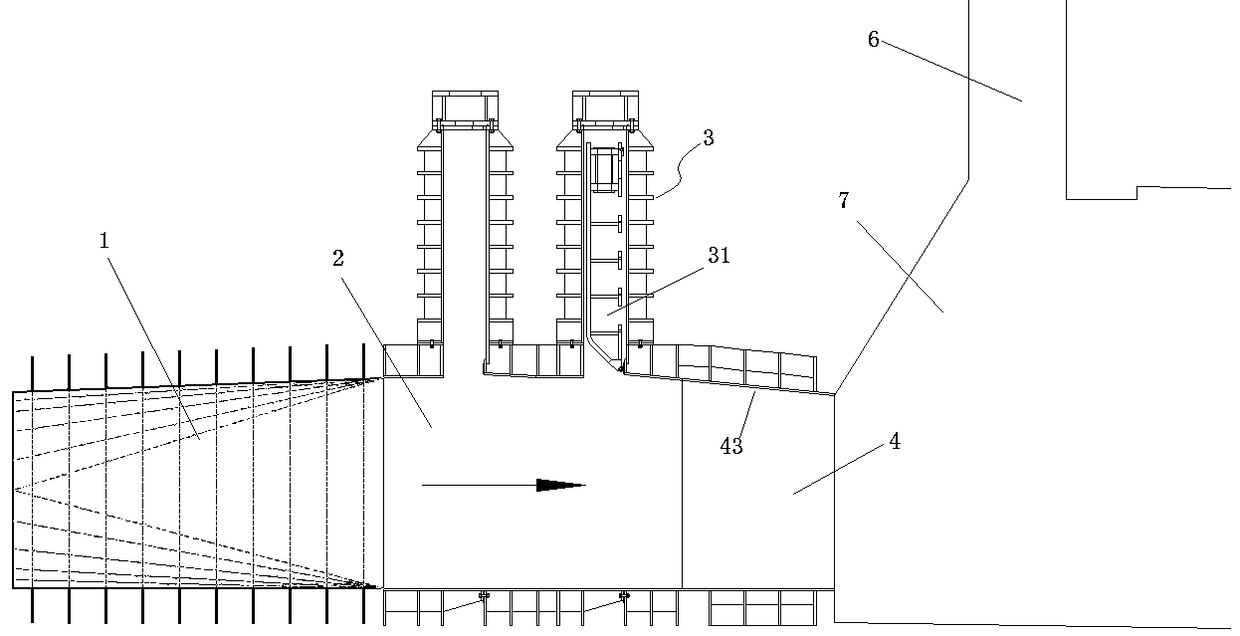

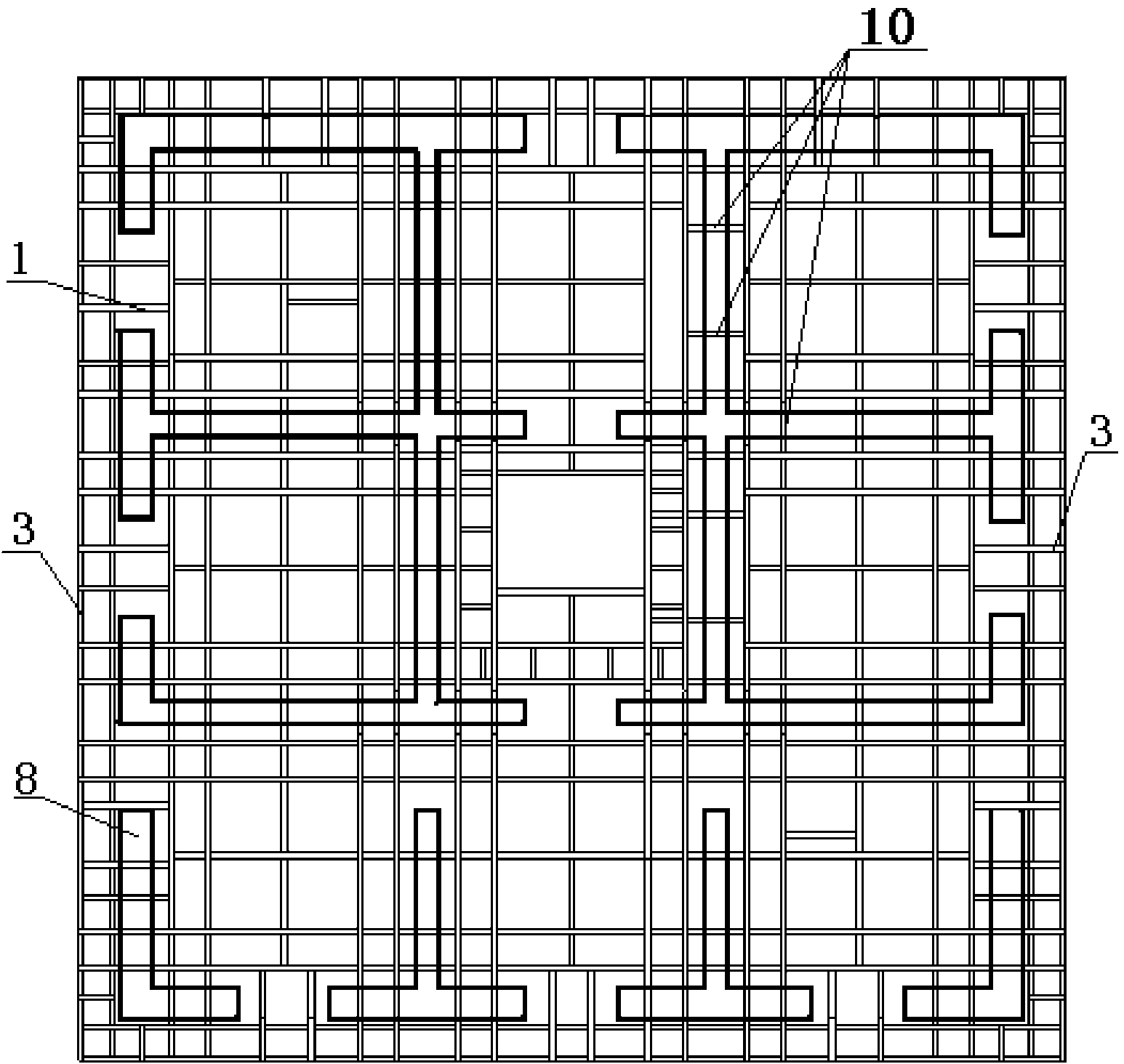

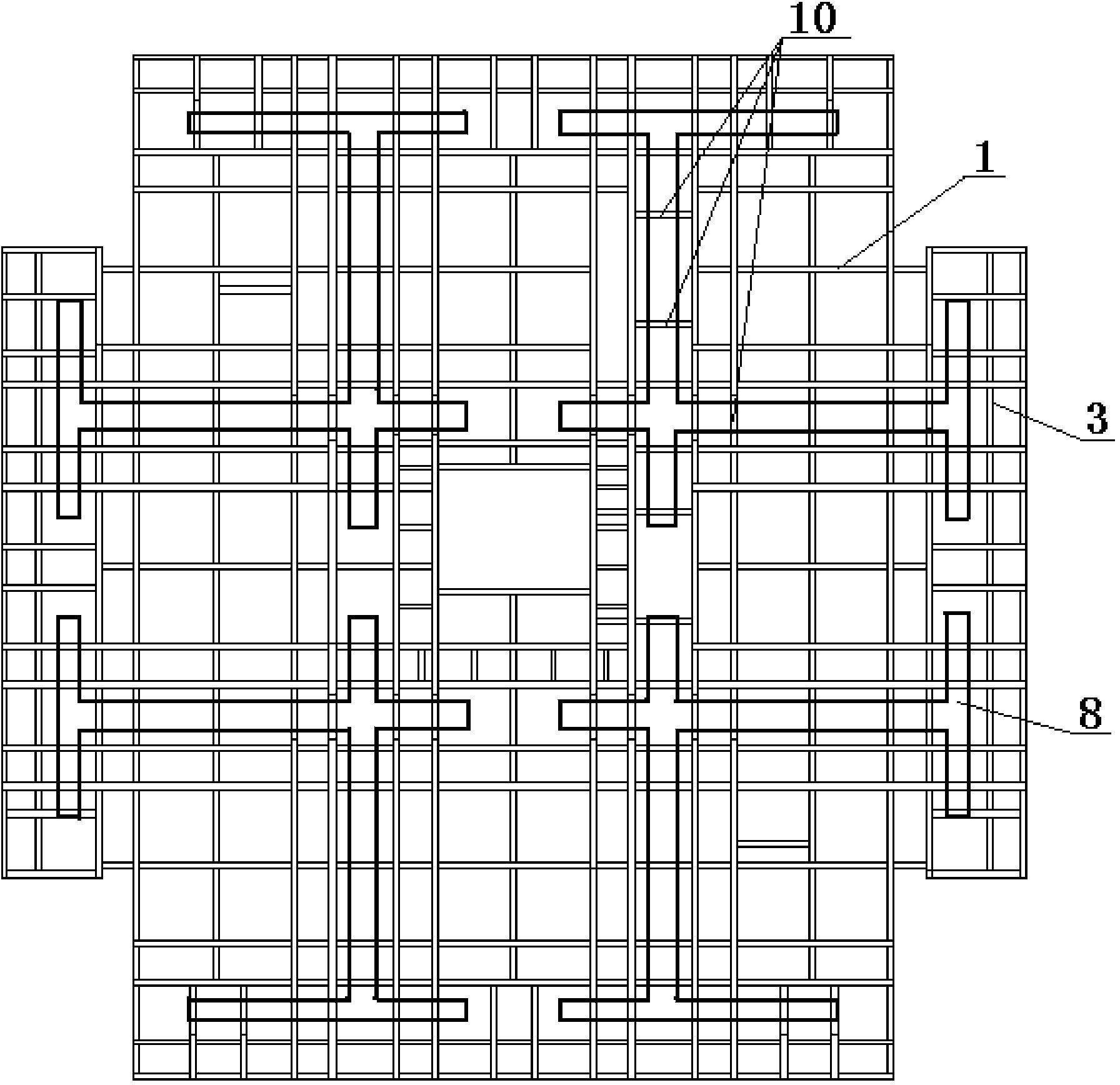

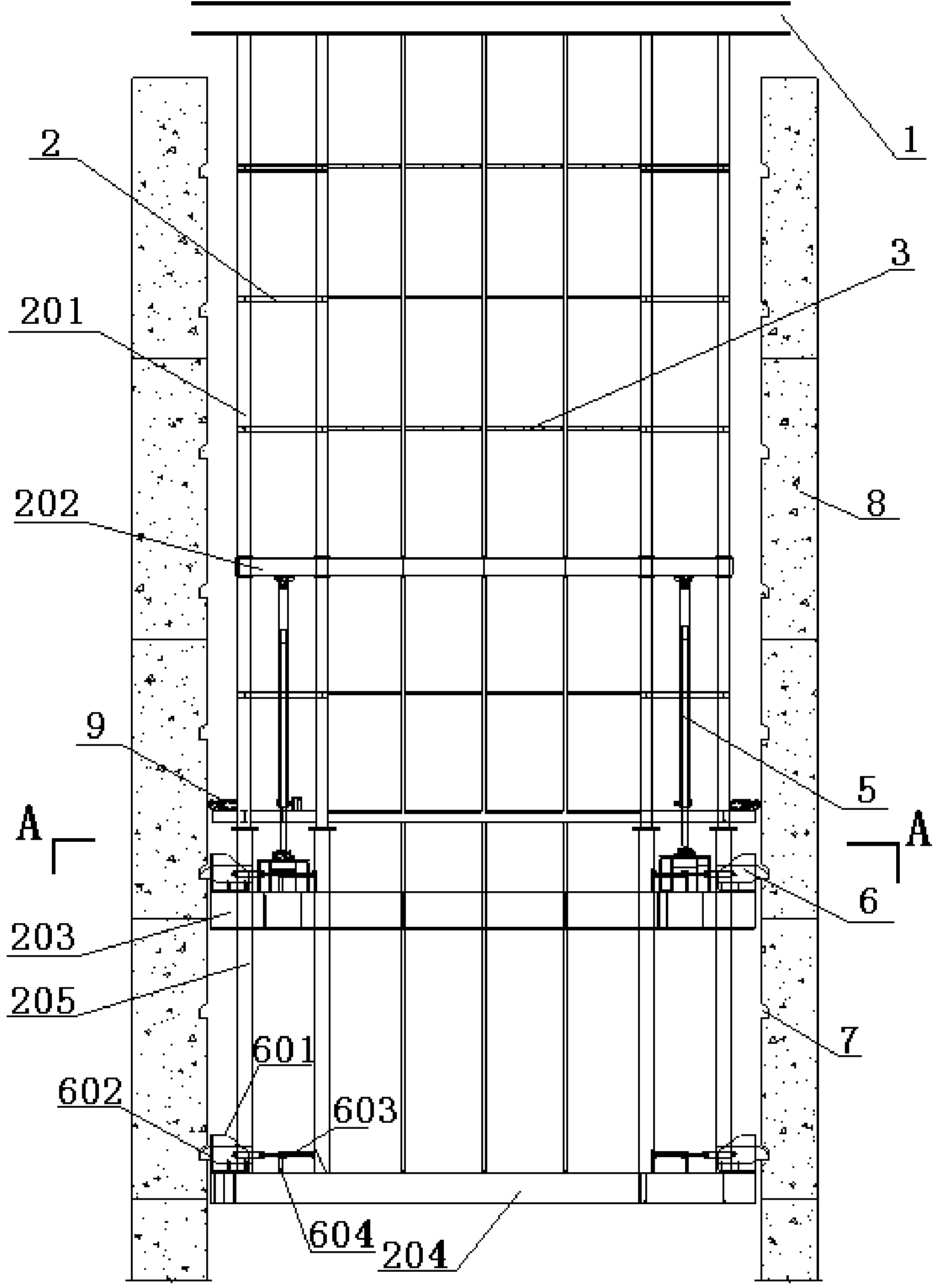

The invention discloses a drum frame supporting power built-in integrated jacking steel platform formwork system, comprising a steel platform, a support system, a suspended scaffold, a template system and a hydraulic jacking power system; the support system comprises a drum frame support and an internal framework support; the drum frame support is located under the steel platform, and comprises a steel platform support, an oil cylinder counter-force beam, a guide roller, a support steel column and a drum frame support beam; the internal framework support is arranged inside the drum frame support and located between the drum frame support beam and the oil cylinder counter-force beam; the hydraulic jacking power system comprises a hydraulic jacking oil cylinder and a power control system thereof; the hydraulic jacking oil cylinder is inverted between the oil cylinder counter-force beam and the internal framework support; telescopic brackets are arranged at the end portions of the internal framework support and the drum frame support beam, respectively; and the telescopic brackets are supported in a preformed hole in a shear wall. The drum frame supporting power built-in integrated jacking steel platform formwork system is capable of realizing the construction operation of a complex core drum, shortening the construction period and ensuring high altitude construction safety, and also capable of improving the green construction level.

Owner:SHANGHAI CONSTRUCTION GROUP +1

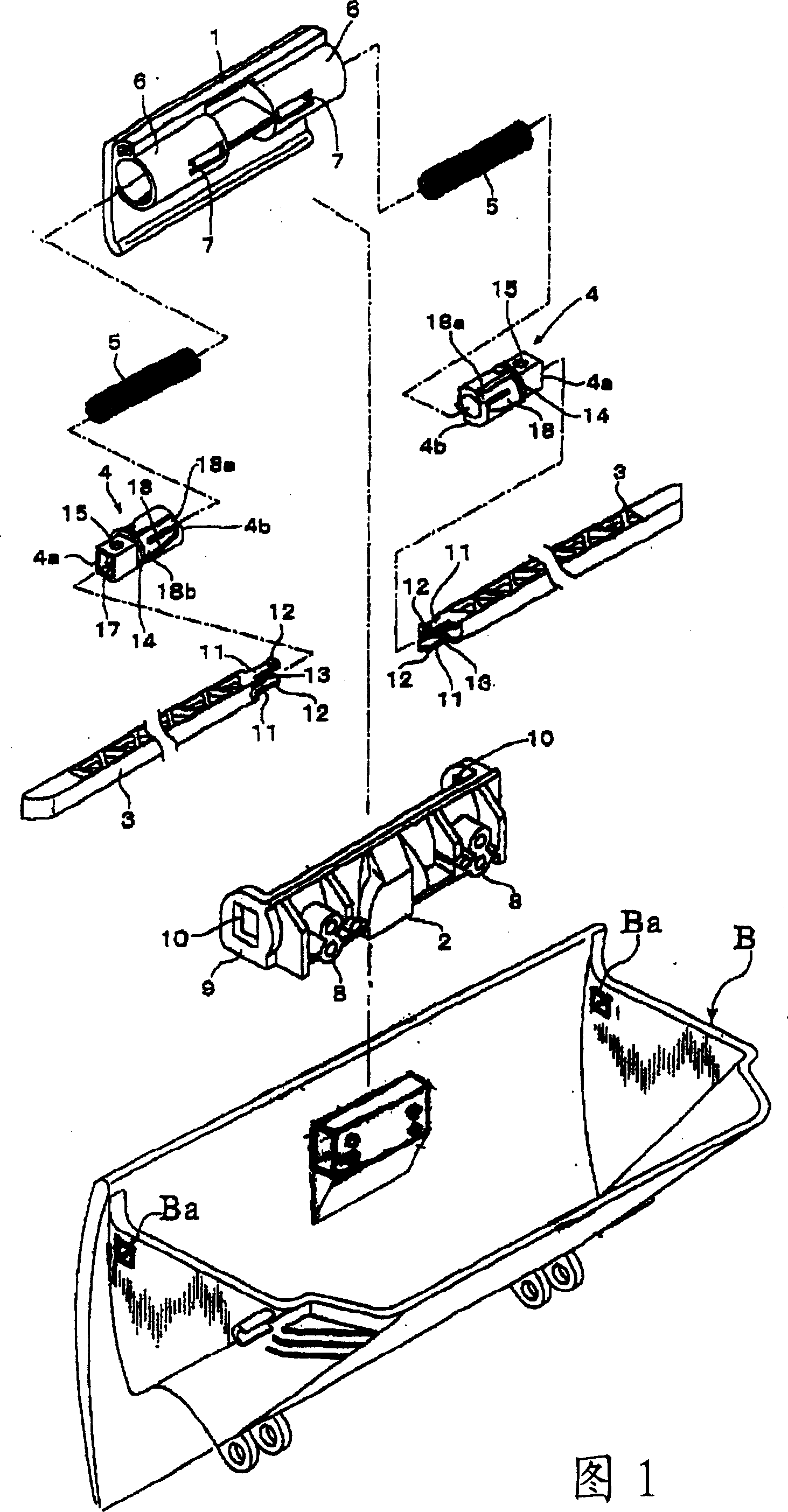

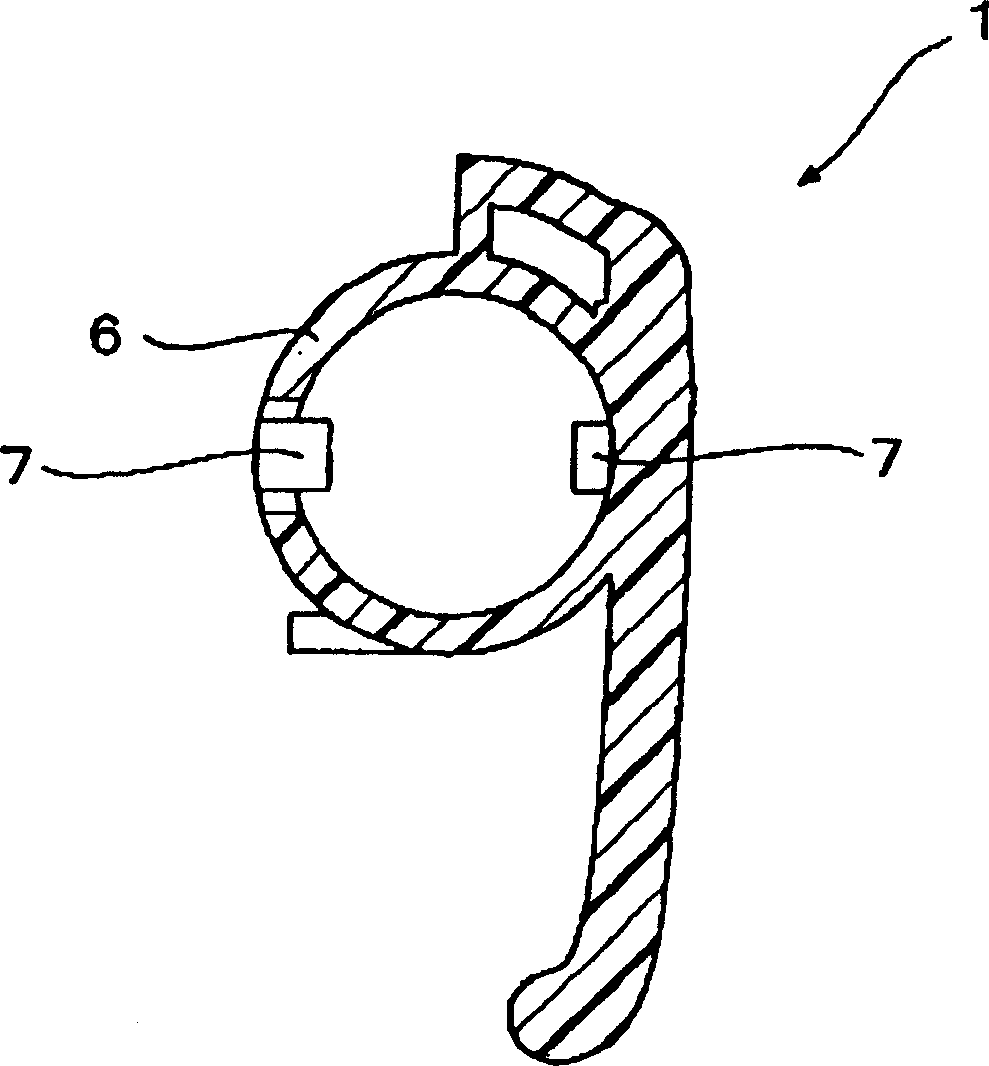

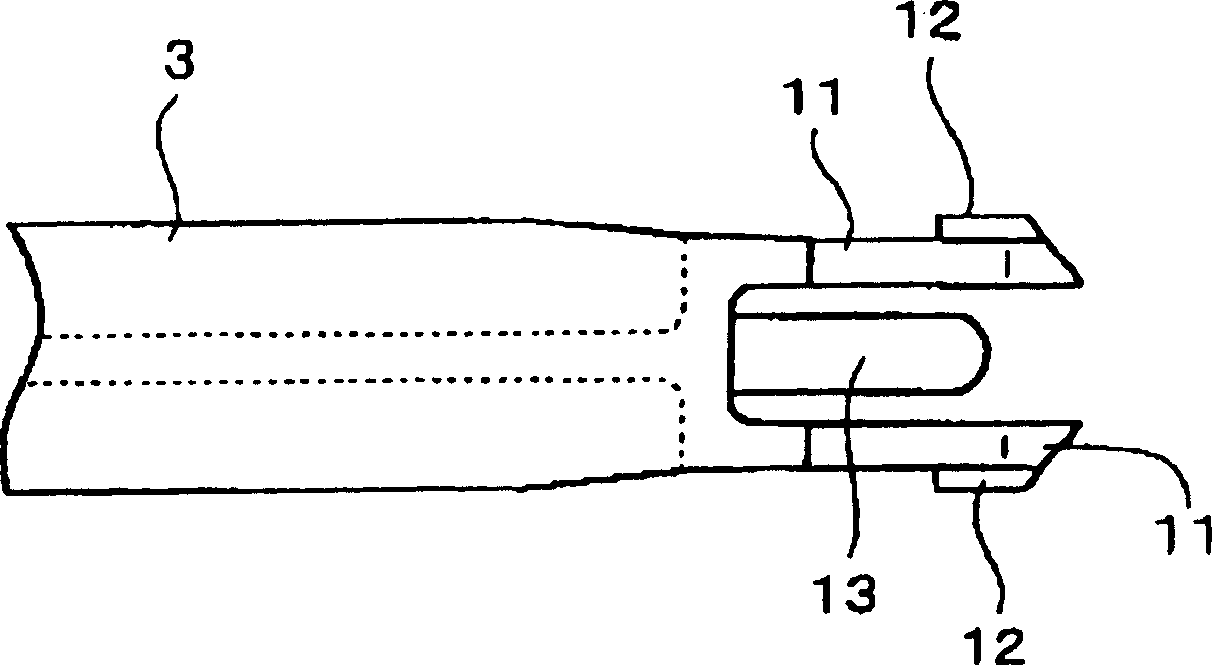

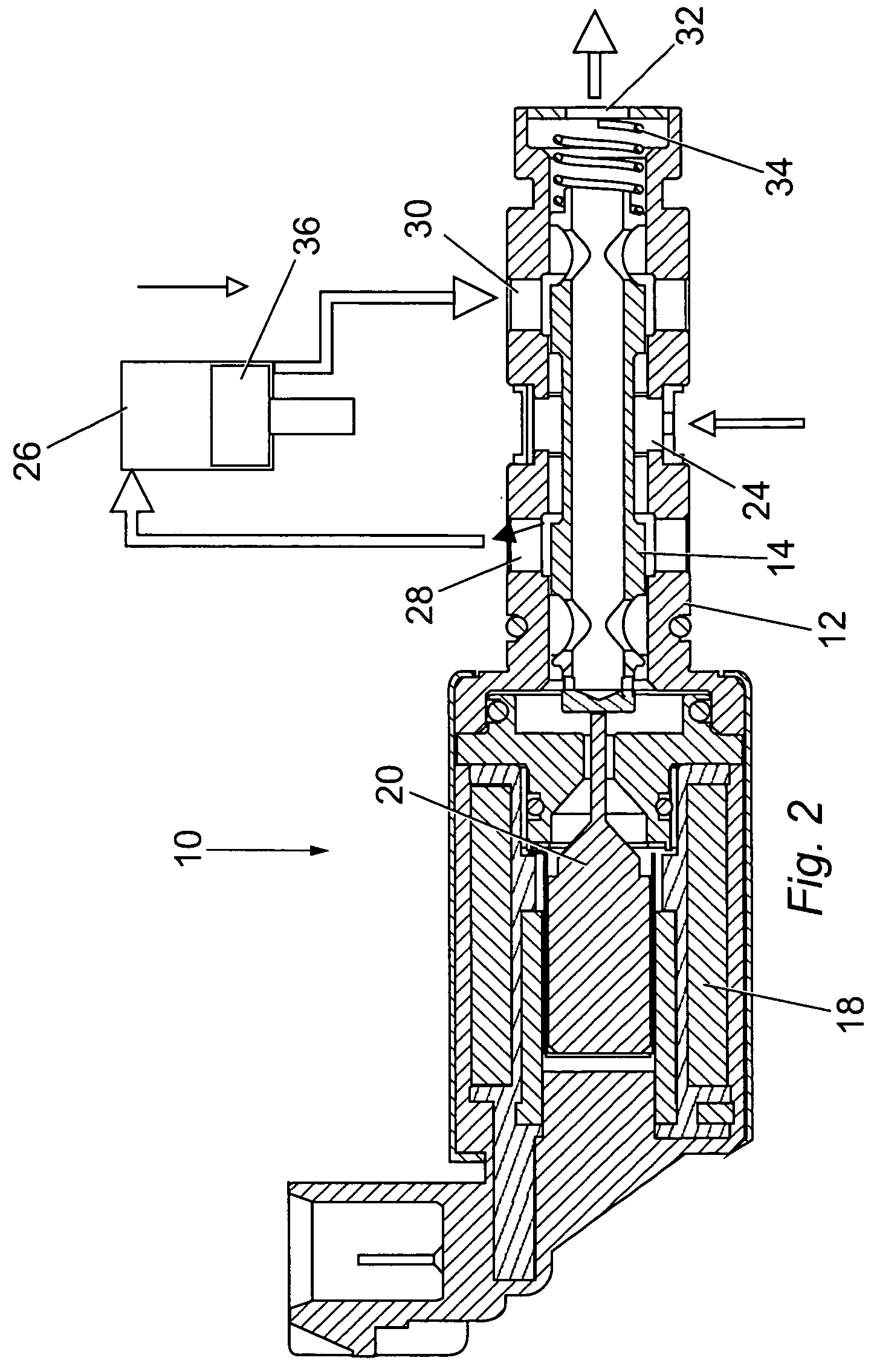

Locking means

InactiveCN1498791AGood maintenance conditionStable supportPassenger spaceVehicle locksEngineeringCam

A lock apparatus includes a operation handle, a pair of springs movably supported by the container member, a pair of slide pins urged in directions of lock holes defined on the support member by the springs, respectively, and a pair of cam members to which rear end portions of the slide pins are fitted, respectively, to urge each slide pin to project and retract. When the operation handle is operated in a swing manner, a front end portion of each slide pin is retracted from each lock hole of the support member against pressure of each spring. Engagement holes are defined on opposed surfaces of each front end portion of the cam member having a cylindrical shape. Each rear end portion of the slide pin is formed in a bifurcated structure to have elastic pieces. Each of elastic pieces has a protrusion for detachably engaging with each of engagement holes.

Owner:PIOLAX CO LTD

Green environmentally-friendly broken stone active powder concrete

The invention discloses green environmentally-friendly broken stone active powder concrete. The green environmentally-friendly broken stone active powder concrete is prepared from 485 to 580 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 105 to 145 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 100 to 130 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 510 to 590 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 795 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 15 to 18 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 136 to 165 weight parts of water, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The green environmentally-friendly broken stone active powder concrete has a low composite cost and wide raw material sources, adopts a large amount of industrial waste materials, has good chemical corrosion resistance, good carbonization resistance, good freeze thawing resistance, high compressive strength and flexural strength, and good self-sealing performances, reduces hydration heat and workability adjustment ranges, and satisfies different process requirements.

Owner:黄贺明

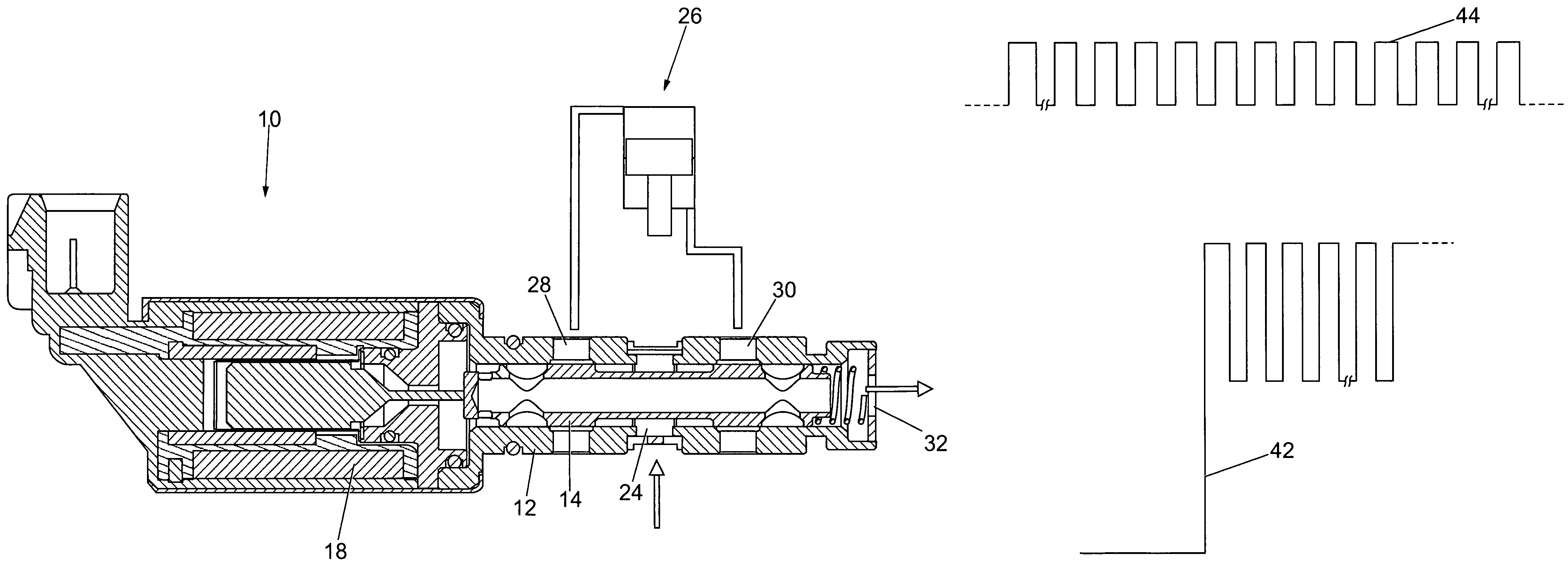

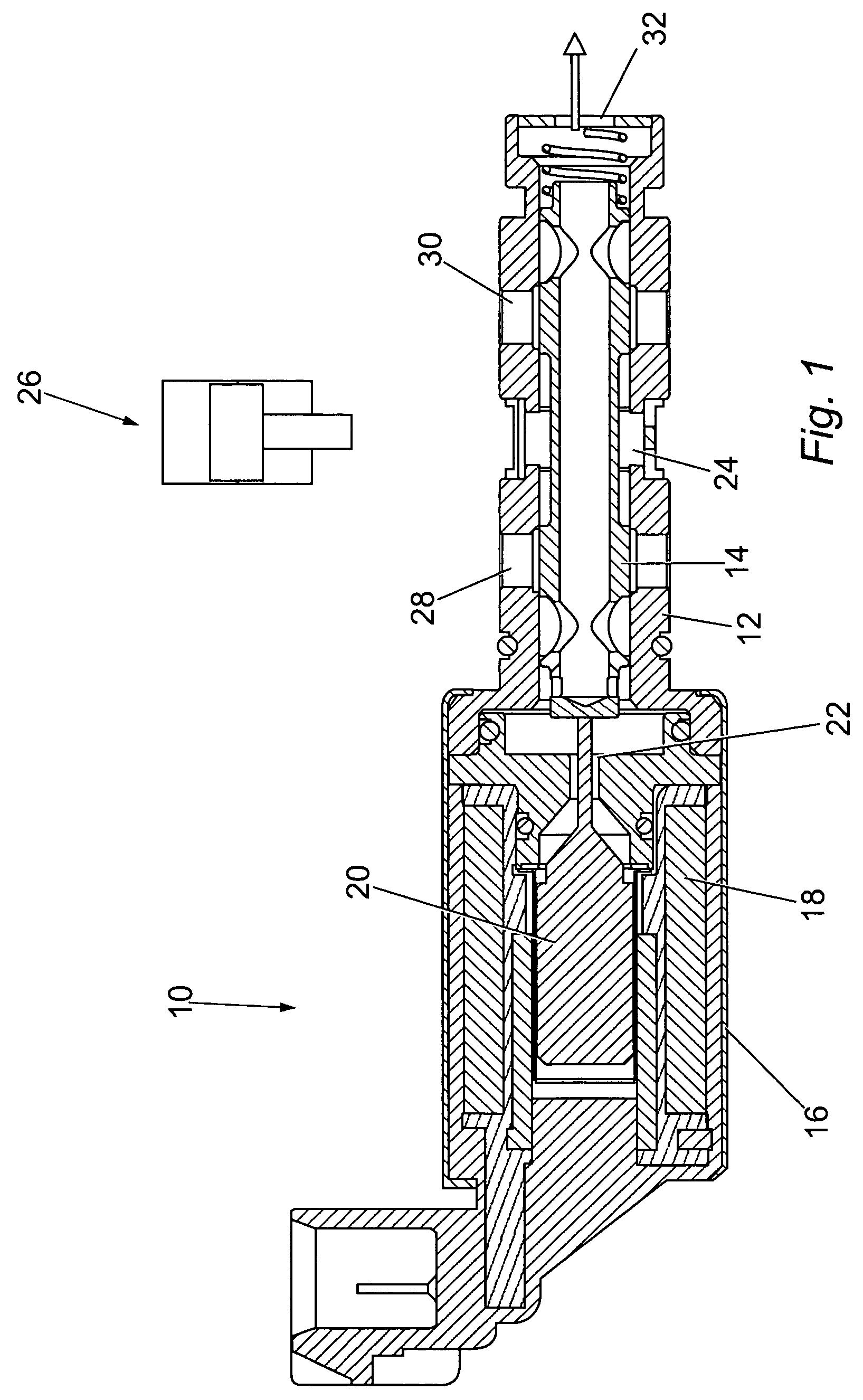

Method and apparatus for operating an oil flow control valve

Owner:DELPHI TECH INC

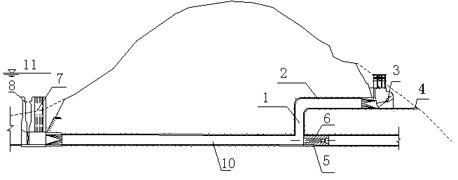

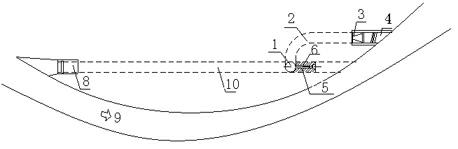

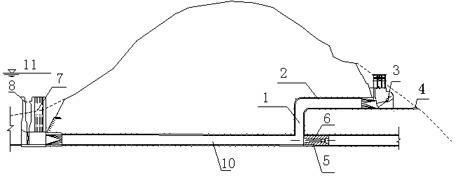

Design method for reconstructing diversion tunnel into flood discharge tunnel in 'tail-raising' mode

The invention relates to a design method for reconstructing a diversion tunnel into a flood discharge tunnel in a 'tail-raising' mode. The design method is used for reconstructing the diversion tunnel into the flood discharge tunnel in the 'tail-raising' mode, wherein, a vertical shaft section and a horizontal turning section are additionally arranged at the tail of the diversion tunnel so that the horizontal height of the horizontal turning section is higher than that of the diversion tunnel. The design method has the advantages that the flood discharge tunnel reconstructed by the design method has a simple structure, and the construction process is easy to operate; stress state of an operating gate can be improved; and the problem of downstream energy dissipation is easily solved, and the manufacturing cost is lowered.

Owner:POWERCHINA XIBEI ENG

Prefabricated cement pavement slab for quick pavement repair

InactiveCN103498397AQuality improvementReduce the impactSingle unit pavingsPaving detailsRoad surfaceRebar

The invention discloses a prefabricated cement pavement slab for quick pavement repair. The prefabricated cement pavement board comprises a cement concrete pavement slab, force transmission rods and internal steel bars, wherein the force transmission rods are arranged in the center of the total thickness of the two side plates of the slab at intervals; the internal steel bars are arranged in the slab and are used for preventing the slab from being warped. The pavement slab provided by the invention is fabricated in a factory building in advance and is transported to a pavement to be repaired for pavement replacement; the pavement replacement operation is performed at 10 p.m. and the pavement is opened to traffic at 5 a.m. on the next day, so that the prefabricated cement pavement slab is efficient and durable.

Owner:SOUTH CHINA UNIV OF TECH

Electrothermal heating maintenance device inside concrete

InactiveCN101579888AImprove maintenance qualityGuarantee the construction qualityCeramic shaping apparatusCross connectionSafety net

The invention provides an electrothermal heating maintenance device inside concrete, wherein a heating resistance wire is bundled on the structural reinforcing steel bar inside concrete of buildings in construction, the heating resistance wire is connected with a power supply via a low-voltage power supply cable outside the concrete, a lifting protective frame comprises a frame body and a safety net attached to the frame body, the frame body is formed by cross connection of a vertical main keel with transverse sub-keels, the left side and the right side of the frame body are connected with vertical edge steel tubes, the vertical main keel is connected with the floor of building via a wall-attached hanging part, the frame body is a steel-wood structure, the top of the vertical main keel is provided with H-shaped steel provided with lifting holes, and the vertical main keel is also used as vertical guide rail. By using the manner of internal heating, the device has high heat efficiency and low thermal loss, and can save a great deal of energy; the heating speed of concrete can be reliably guaranteed, and the temperature is easily controlled; the maintenance conditions of concrete are good, and the construction quality can be guaranteed; the early strength of concrete is high, thereby creating favorable conditions for continuous upper construction and shortening the construction period.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

Green environment-friendly light-weight high-strength powder concrete

ActiveCN103396064ANo weight lossImprove poor self-compactingSolid waste managementMetal fiberGreen environment

The invention relates to the technical field of concrete, and particularly relates to green environment-friendly light-weight high-strength powder concrete which is prepared from the following raw materials in parts by mass: 550-650 parts of silicate cement, 125-150 parts of silica fume, 90-115 parts of fly ash, 110-130 parts of ore powder, 650-800 parts of shale ceramsite sand, 21-26 parts of high-efficiency water reducing agent and 105-130 parts of water. According to the invention, metal fibers, quartz sand and other high-cost raw materials are eliminated by means of the powder concrete accumulation principle; and the light-weight ultrahigh-strength powder concrete of which the volume weight is 1950kg / m<3> or below is obtained by introducing the high-strength ceramsite sand.

Owner:黄贺明

Integration board for decorating, preventing fire and keeping warm

ActiveCN104563425AReduced post-bonding processQuick compound workCovering/liningsFiberglass meshFire retardant

The invention discloses an integration board for decorating, preventing fire and keeping warm, belonging to the field of composite board production. The integration board is manufactured in one-time formation by taking fire retardant boards as heat insulating layers and taking modified magnesium oxysulfate cementing materials and alkali-resistant fiberglass meshes as protective layers. The modified magnesium oxysulfate cementing material is prepared by mixing light calcined magnesia, magnesium sulfate solution, perlite, coal ash, polypropylene fiber and modifying agent according to a certain weight proportion. Compared with prior art, the integration board of the invention has the characteristics of high production efficiency, green and environmental protection and so on, and has good popularization and using values.

Owner:山东斯诺尔节能建材有限公司

Active macadam powder concrete

The invention discloses active macadam powder concrete which is made of the following raw materials in parts by mass: 485-580 parts of low-alkali Portland cement or common Portland cement of which theaverage particle size is 30-60mu m, 105-145 parts of silica fume of which the average particle size is 0.18mu m and the SiO2 content is greater than or equal to 85%, 100-130 parts of grade-I coal ashof which the average particle size is 10-20mu m, 100-130 parts of ore powder of a grade S95 or greater that the average particle size is 10-30mu m, 510-590 parts of quartz sand of which the particlesize is 0.16-1.63mm, 795-880 parts of macadam of which the particle size is 5-14mm, 15-18 parts of a composite efficient water reduction agent of which the water reduction rate is greater than 30%, 7-12 parts of a rusting retardant, 136-165 parts of water, and 80-160 parts of a copper-plated steel fiber of which the diameter is 0.18-0.25mm and the length is 10-15mm. The concrete is low in compressive manufacturing cost, wide in material source, large in industrial waste mixing amount, good in chemical corrosion resistance, carbon resistance, freeze thawing resistance and self-compaction property, high in compression and folding strength, low in hydration heat, large in working degree adjustment range and applicable to different construction process requirements.

Owner:安徽金兄弟环保科技股份有限公司

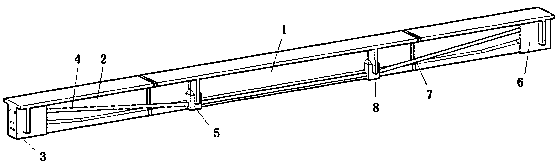

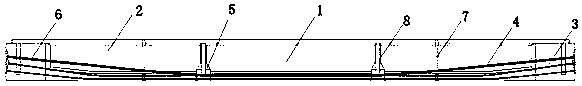

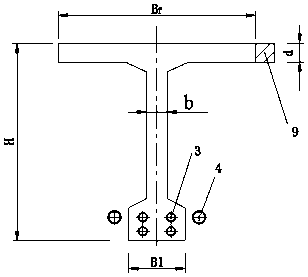

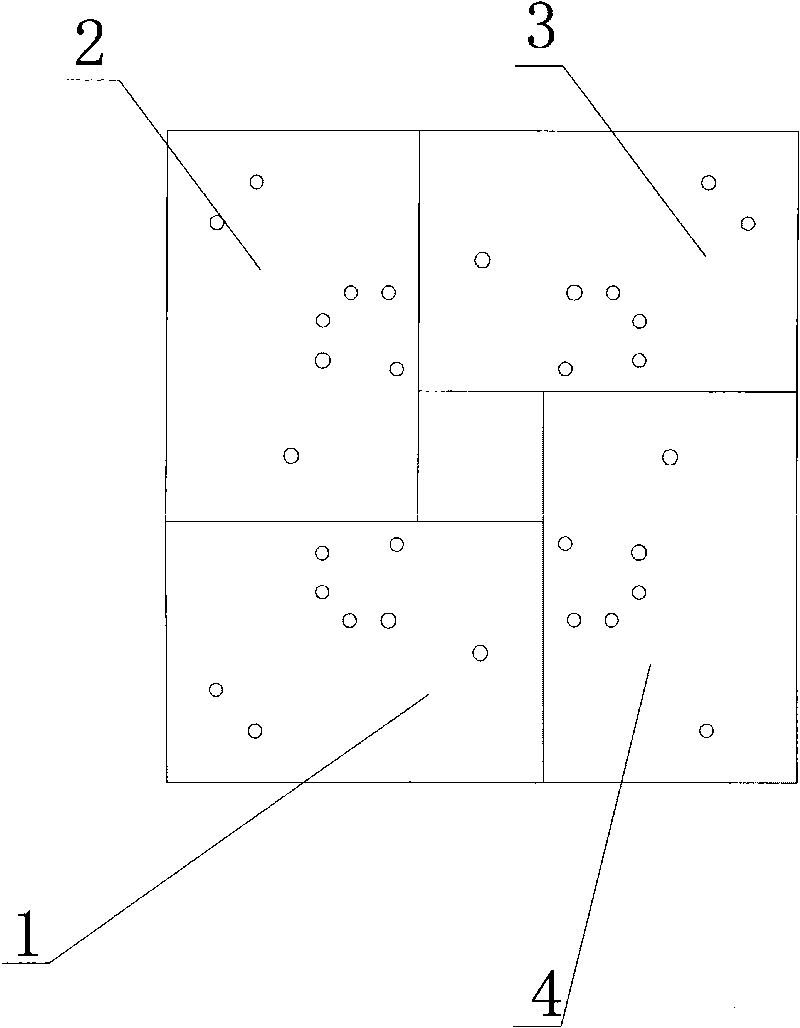

Segment-prefabricated T-beam bridge structure configured with internal and external prestressing tendons, and construction method for T-beam bridge structure

InactiveCN108842591ASmall sizeImprove transportation efficiencyBridge erection/assemblyBridge materialsT-beamPre stress

The invention discloses a segment-prefabricated T-beam bridge structure configured with internal and external prestressing tendons, and a construction method for the T-beam bridge structure. A T-beambridge is longitudinally divided into 3-5 segments along a bridge span; and the segments are prefabricated in a factory, transported to a location near a bridge site, and assembled and connected through internal and external mixed tendon allocation. A segment-prefabricated, assembled and simply supported T-beam comprises a central segment, beam end prefabricated segments, the internal prestressingtendons, the external prestressing tendons, cast-in-situ wet joints, diaphragm plates, external prestressing tendon steering blocks, and external prestressing tendon anchoring blocks, wherein the central segment and the beam end prefabricated segments of the T-beam are manufactured in the factory, transported to the bridge site and integrated through the cast-in-situ wet joints, and the internaland the external prestressing tendons are tensioned to complete assembly of a bridge span structure. The T-beam prefabrication and assembly technology provided by the invention is applicable to the bridge site without overall prefabrication conditions; segment prefabrication facilitates land transportation and achieves convenient hoisting; and the external prestressing tendons facilitate subsequent supplementary tensioning and overhauling, so that the comprehensive performance of the bridge is greatly improved.

Owner:SOUTHEAST UNIV

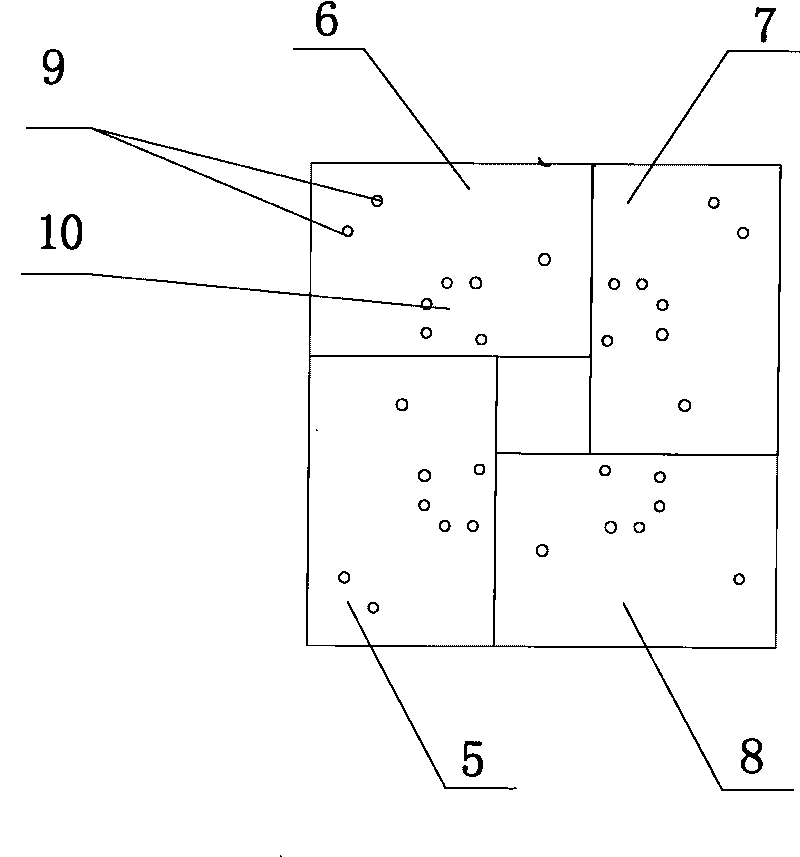

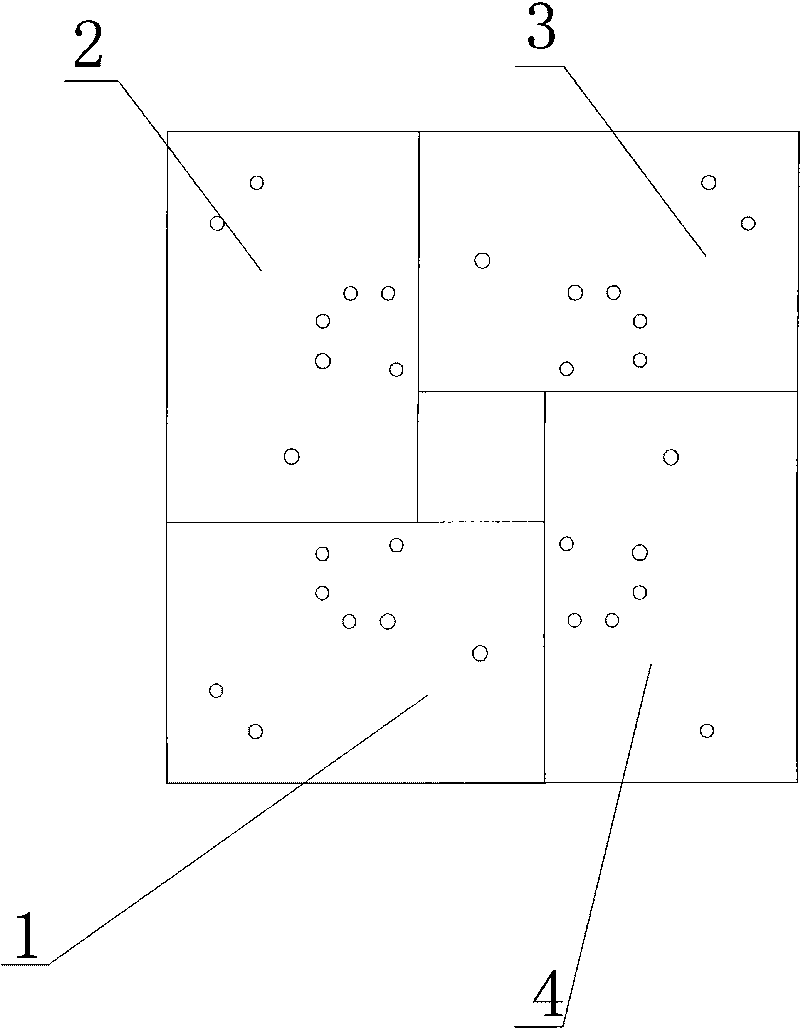

Reinforced concrete foundation for mounting assembled tower crane

ActiveCN101709584AShorten construction timeReduce use costFoundation engineeringReinforced concreteRebar

The invention relates to a reinforced concrete foundation for mounting an assembled tower crane, which is characterized by comprising eight rectangular reinforced concrete blocks of a completely identical shape and in a completely identical size, wherein every four rectangular reinforced concrete blocks are encircled into a rectangular-ambulatory-plane structure in an identical plane; the two rectangular-ambulatory-plane structures are superposed in a way that one is arranged above the other; every two adjacent rectangular reinforced concrete blocks are mutually staggered around the centre of the corresponding rectangular-ambulatory-plane structure for a phase angle of 90 degrees so that each rectangular reinforced concrete block of an upper layer presses the two rectangular reinforced concrete blocks of a lower layer; each rectangular reinforced concrete block is provided with a plurality of pre-embedded connecting holes; the rectangular reinforced concrete blocks of the upper and lower layers run through a part of the pre-embedded connecting holes through a bolt set to be connected into a whole; and the other pre-embedded connecting holes are connected with a tower body structure of a tower crane through the bolt set. The technical scheme has the characteristics of simple structure, good chemical property due to the rectangular-ambulatory-plane structures, quick and convenient mounting and disassembly and remarkable economical and social effect.

Owner:CHONGQING CONSTR ENG SECOND CONSTR CO LTD +1

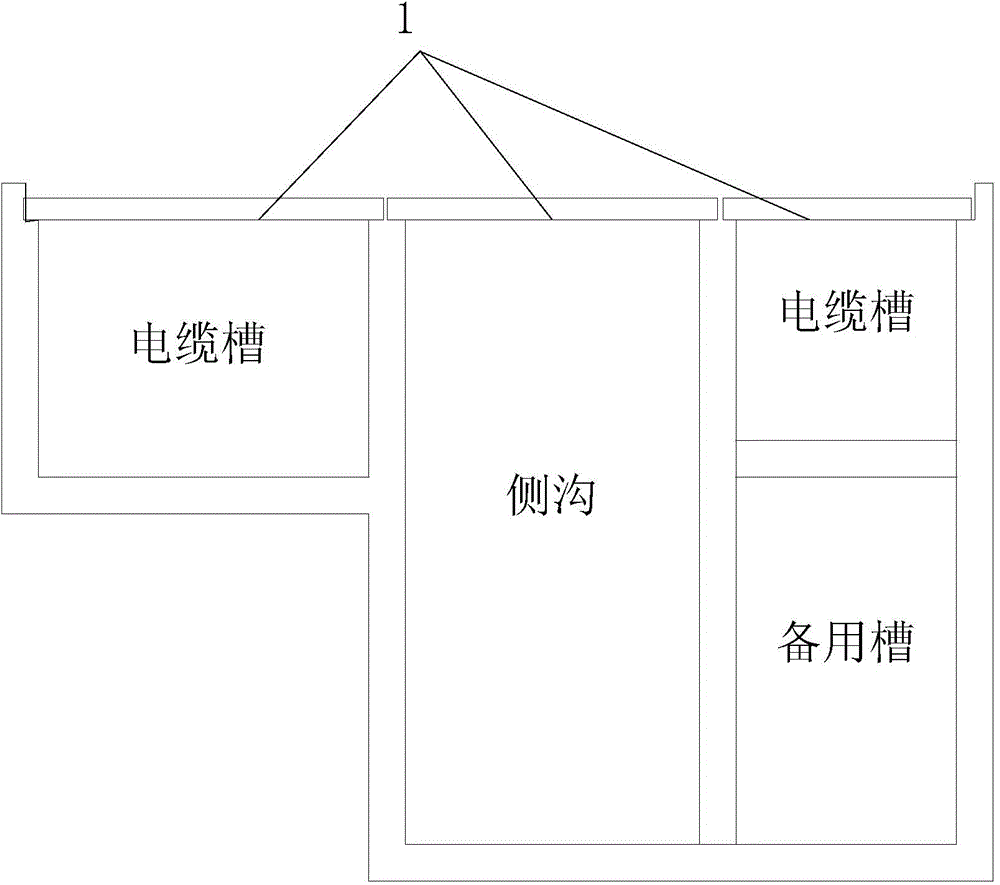

Side channel cable trough combined body, preparation method and side channel cable trough combined structure

ActiveCN104821534AEasy to install on siteImprove construction efficiencyCable installations on groundBuilding construction

The invention belongs to the underground engineering technical field and relates to a side channel cable trough combined body, a preparation method and a side channel cable trough combined structure. Two ends of the side channel cable trough combined body are connection ends; the side channel cable trough combined body is of a groove structure; and the interior of the groove of the groove structure is divided into a cable trough region, a side channel region and a standby trough region through separation, wherein the cable trough region, the side channel region and the standby trough region respectively extend from one connection end to the other connection end and are communicated with each other at end surfaces of the two connection ends. A plurality of side channel cable trough combined bodies are connected in series with one another so as to form the side channel cable trough combined structure, and the interval between two adjacent side channel cable trough combined bodies is smaller than 8 mm, and faulting of slab ends is smaller than 5 mm. The side channel cable trough combined body can be obtained through batching, mixing, in-mould vibration and molding, primary maintenance and final maintenance. With the preparation method adopted, the side channel cable trough combined body can be prepared outside a channel in advance, and the side channel cable trough combined body can be installed in the channel, and therefore, construction speed and construction quality can be improved.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

Green environment-friendly light-weight high-strength powder concrete

The invention relates to the technical field of concrete, and particularly relates to green environment-friendly light-weight high-strength powder concrete which is prepared from the following raw materials in parts by mass: 550-650 parts of silicate cement, 125-150 parts of silica fume, 90-115 parts of fly ash, 110-130 parts of ore powder, 650-800 parts of shale ceramsite sand, 21-26 parts of high-efficiency water reducing agent and 105-130 parts of water. According to the invention, metal fibers, quartz sand and other high-cost raw materials are eliminated by means of the powder concrete accumulation principle; and the light-weight ultrahigh-strength powder concrete of which the volume weight is 1950kg / m<3> or below is obtained by introducing the high-strength ceramsite sand.

Owner:黄贺明

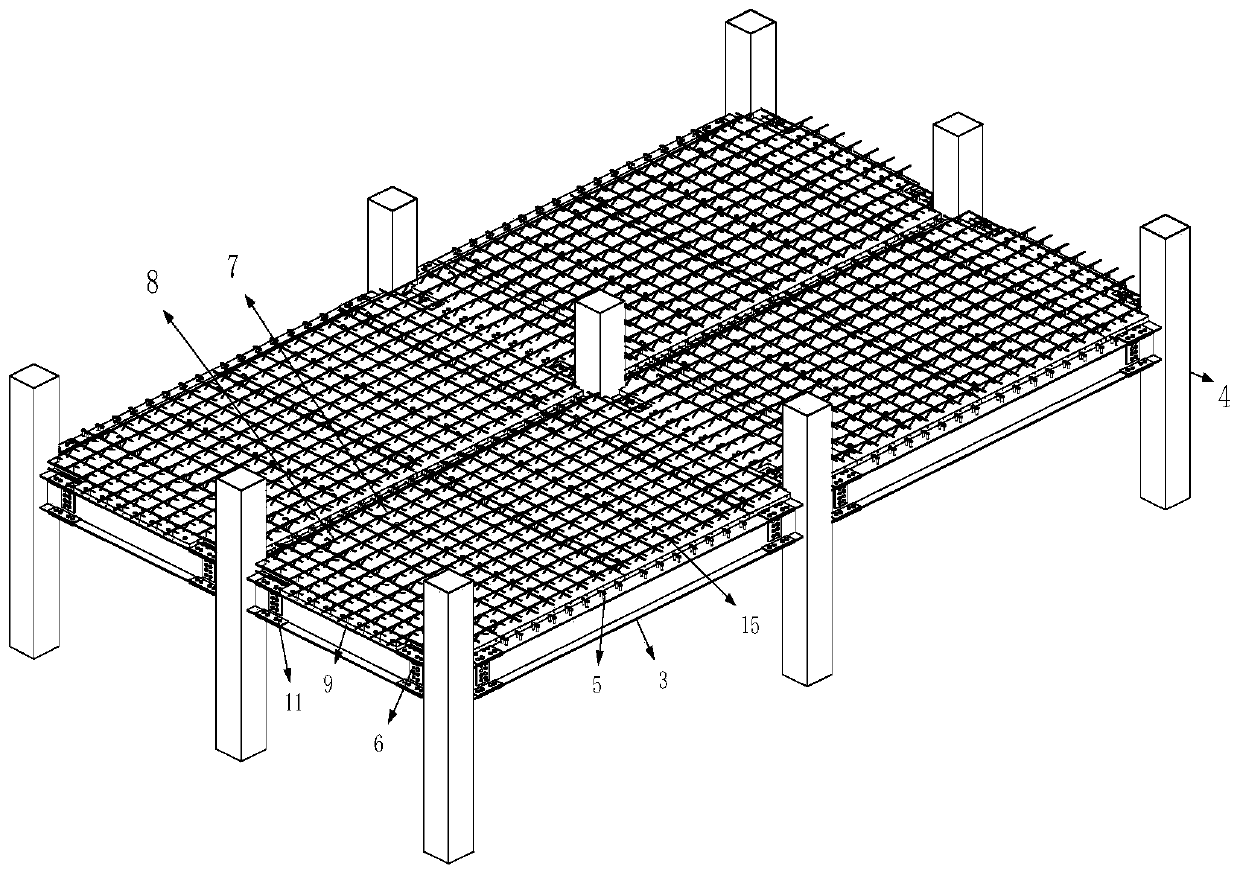

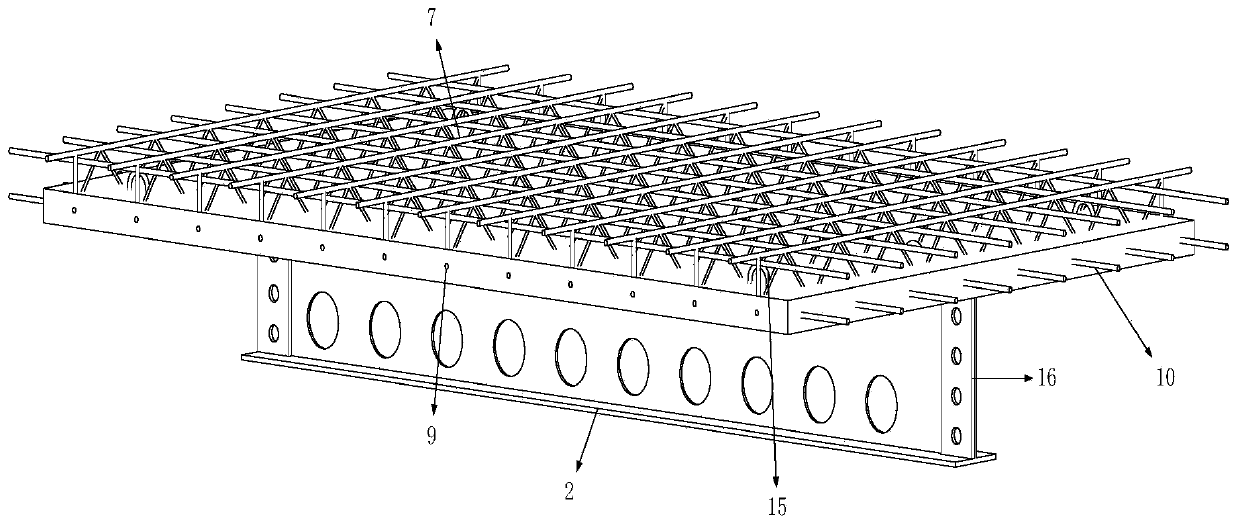

Steel beam-concrete composite floor slab combined assembly system

InactiveCN111411724AIncrease stiffnessSolve the stiffness problemFloorsFloor slabArchitectural engineering

The invention discloses a steel beam-concrete composite floor slab combined assembly system. The steel beam-concrete composite floor slab combined assembly system comprises truss floors, a secondary beam and a primary beam, wherein the multiple truss floors are built onto a main framework formed by the primary beam; a first fixed connector which is connected to the truss floors is arranged on theprimary beam; the secondary beam is fixedly arranged below the truss floors; a second fixed connector which is connected to the truss floors is arranged on the secondary beam; the two ends of the secondary beam are provided with connecting plates; and the secondary beam is connected to the primary beam through the connecting plates. According to the steel beam-concrete composite floor slab combined assembly system disclosed by the invention, the truss floors, the secondary beam and the primary beam are prefabricated together at a plant, so that the initial deflection problem, caused by wet concrete if the concrete is poured on a site, of floors and the beams is avoided, and therefore, the purpose of increasing floor strength and rigidity is achieved; and meanwhile, the assembly system alsocan greatly shorten the construction period, and improves construction efficiency.

Owner:BEIJING UNIV OF TECH

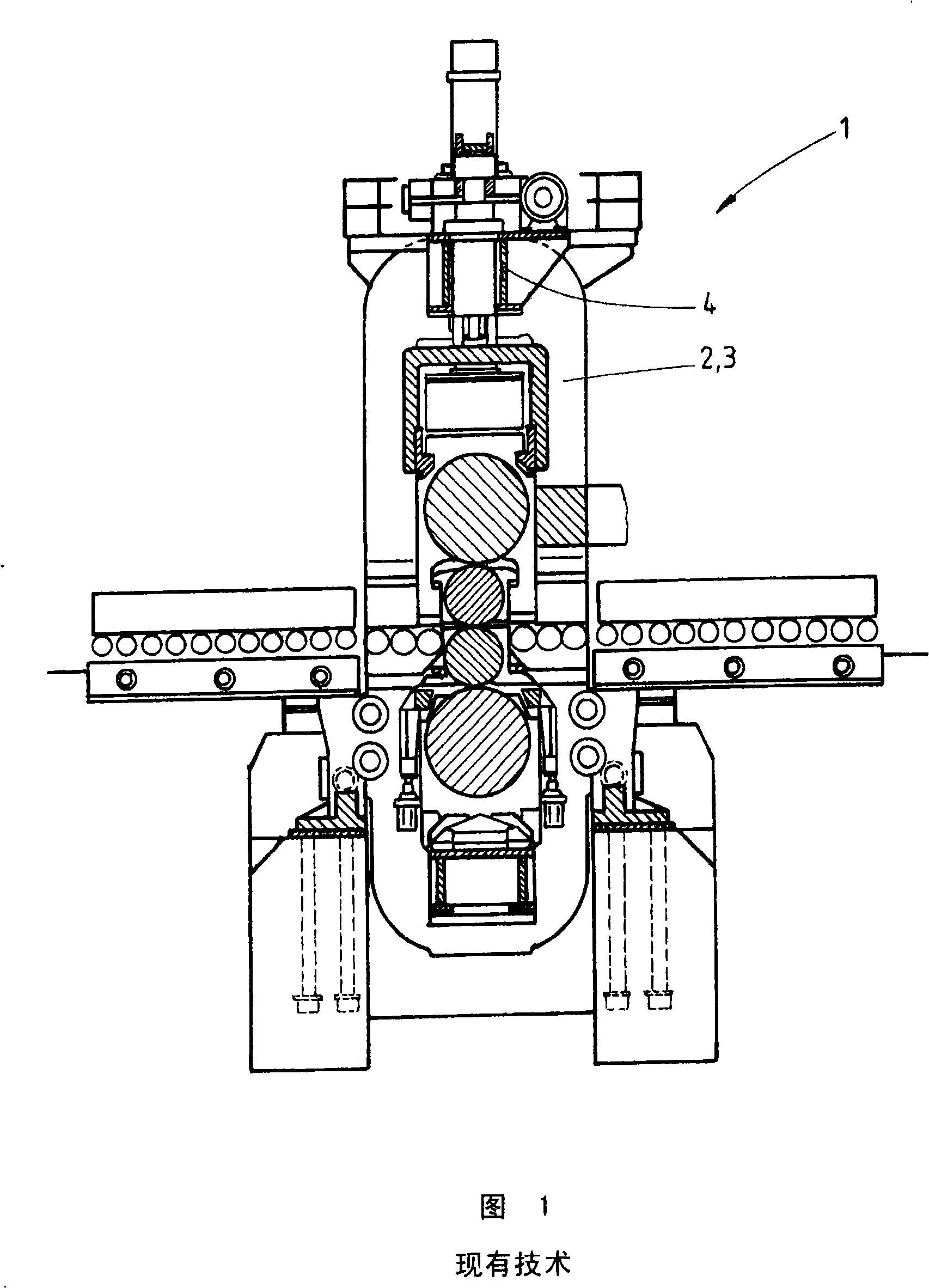

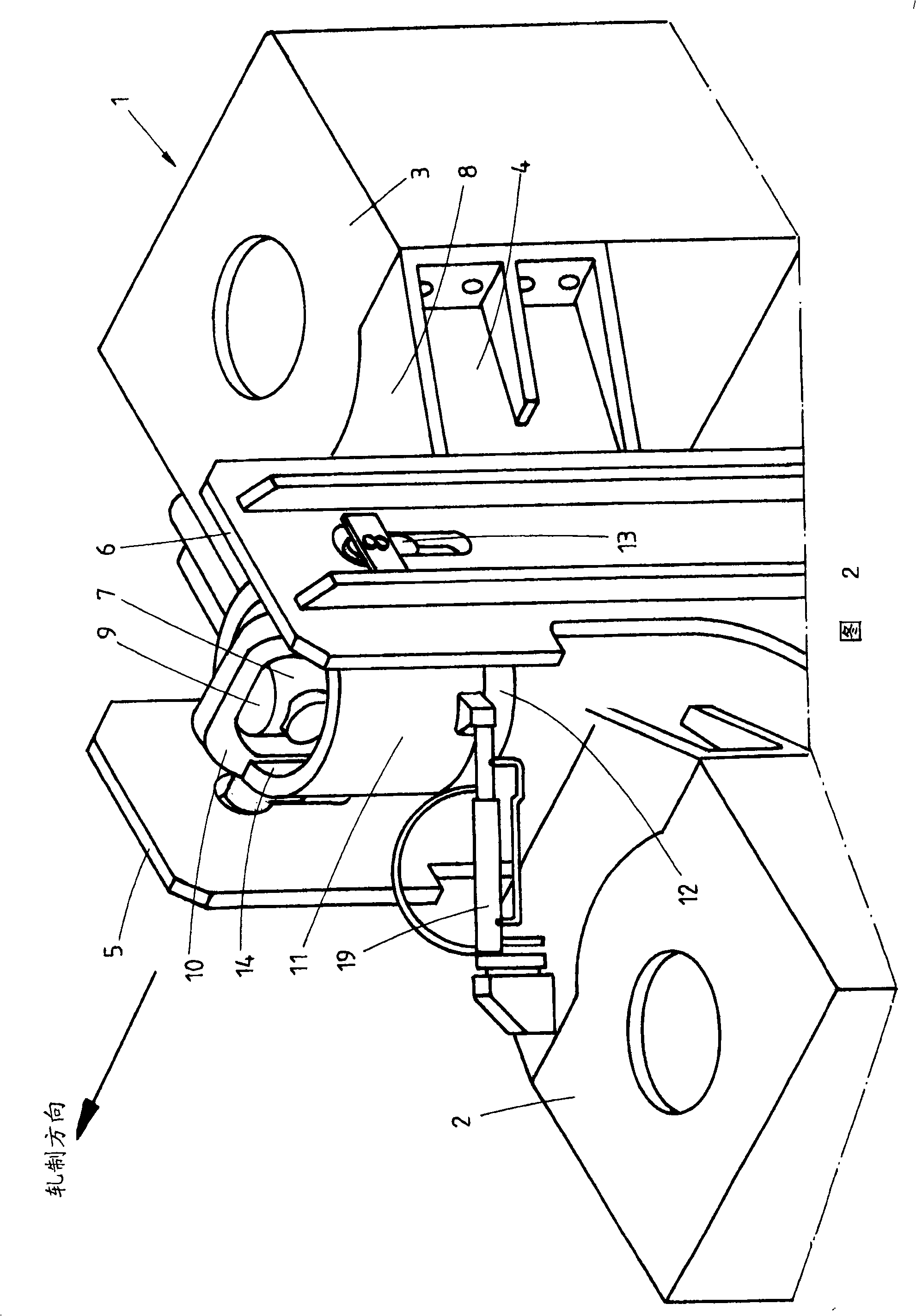

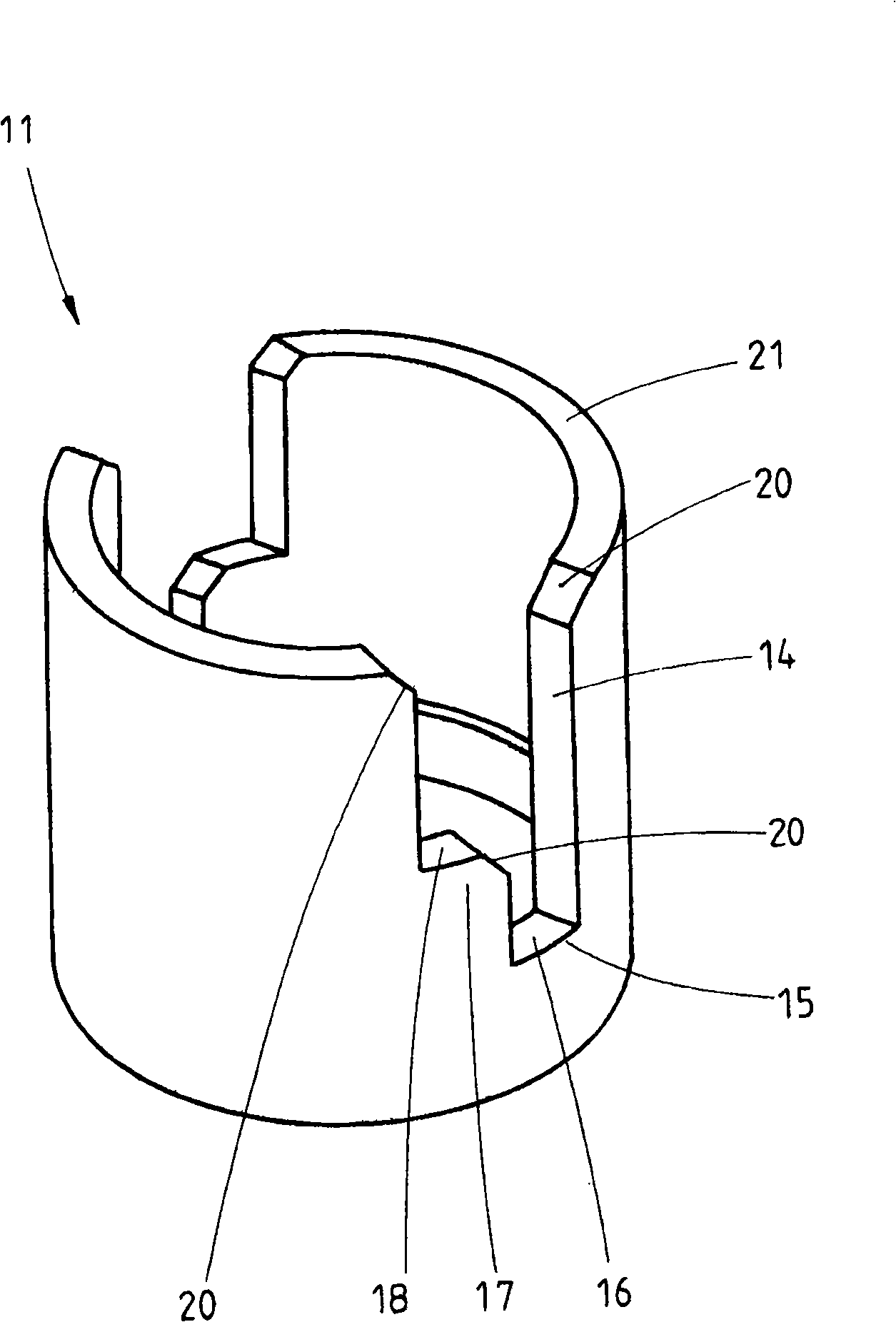

Device for rotationally locking the supporting roll balanced architecture of roll stands

ActiveCN101346195ALess maintenance costImprove securityMetal rolling stand detailsMetal rolling arrangementsStanding frameThick plate

With a roll stand (1), in particular a thick plate roll stand with a right stand frame (2), a left stand frame (3), an upper stand cross beam (4) connecting said frames, at least one pair of working rollers, and one pair of support rollers and the appertaining inserts, as well as a balancing device with holding arms (5, 6), and a piston rod (7) that protrudes through the cross beam in the upward direction and that projects above the top surface (8) of the cross beam (4). A brace (10), located on the outer end (9) of the piston rod (7), is aligned in the direction of the roller and engages with the holding arms (5, 6) of the balancing device. A rotational sleeve (11) arranged between the top edge (12) of the balance cylinder (22) and the bottom edge (13) of the brace (10) clasps around the piston rod (7) and is thus supported on the cross beam (4), and has at least one continuous groove (14) into which the brace (10) can dip.

Owner:SMS DEMAG AG

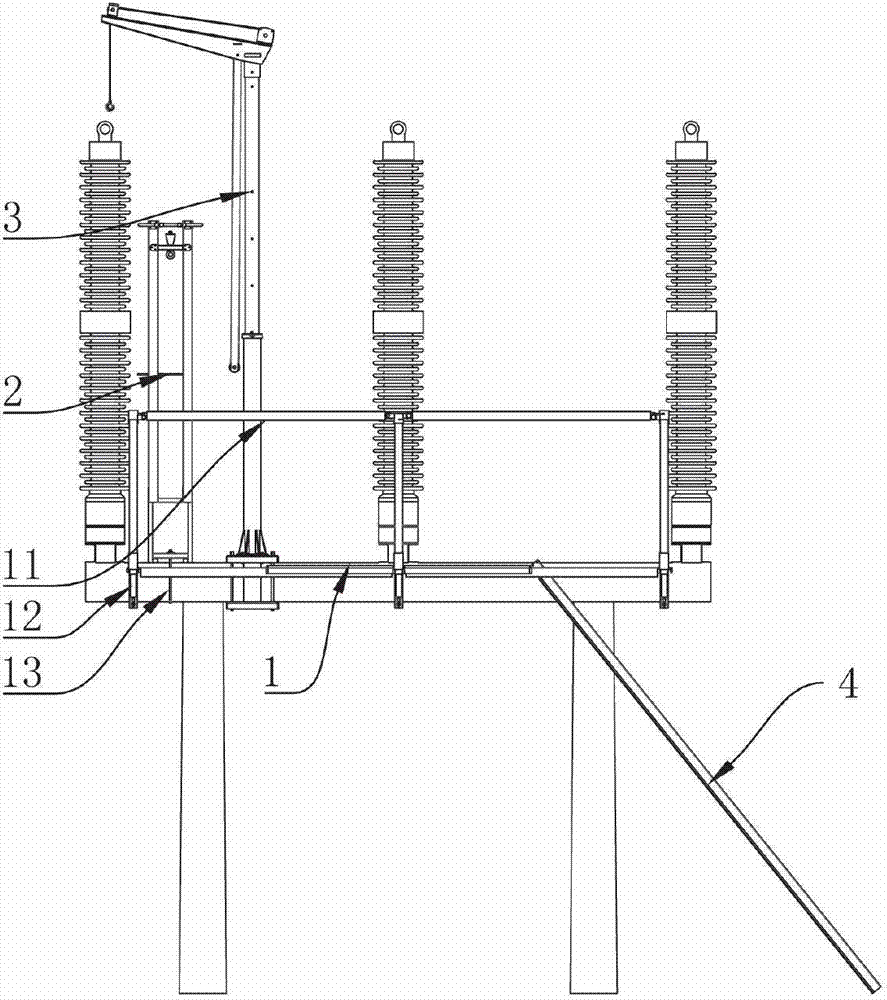

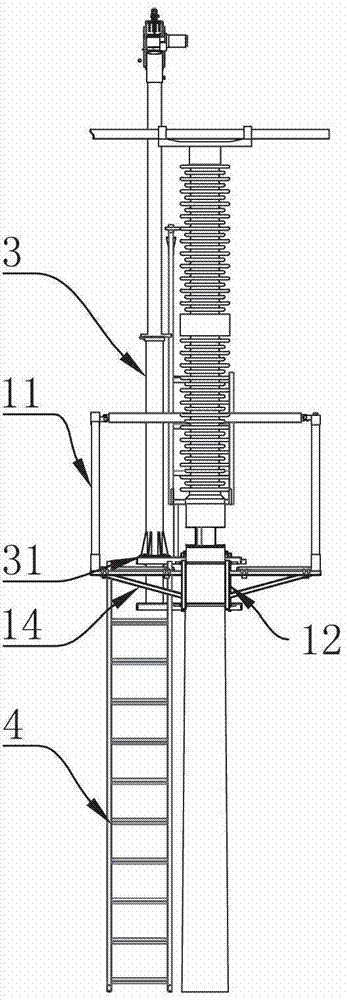

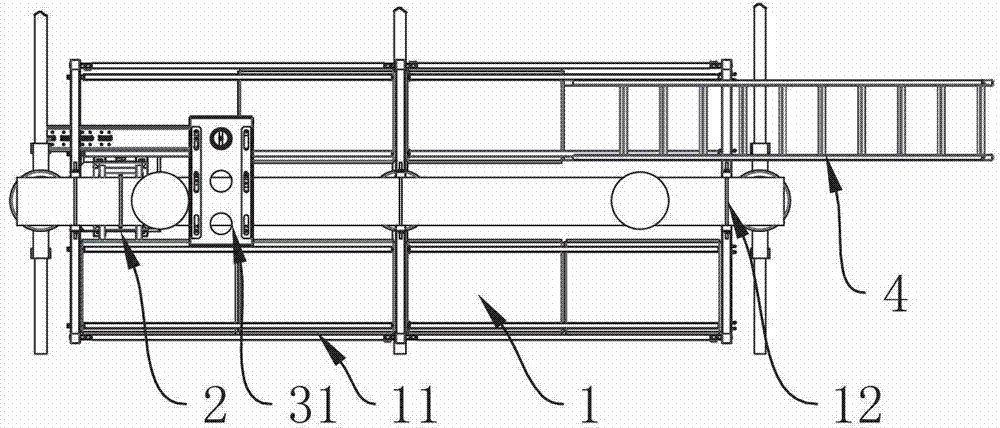

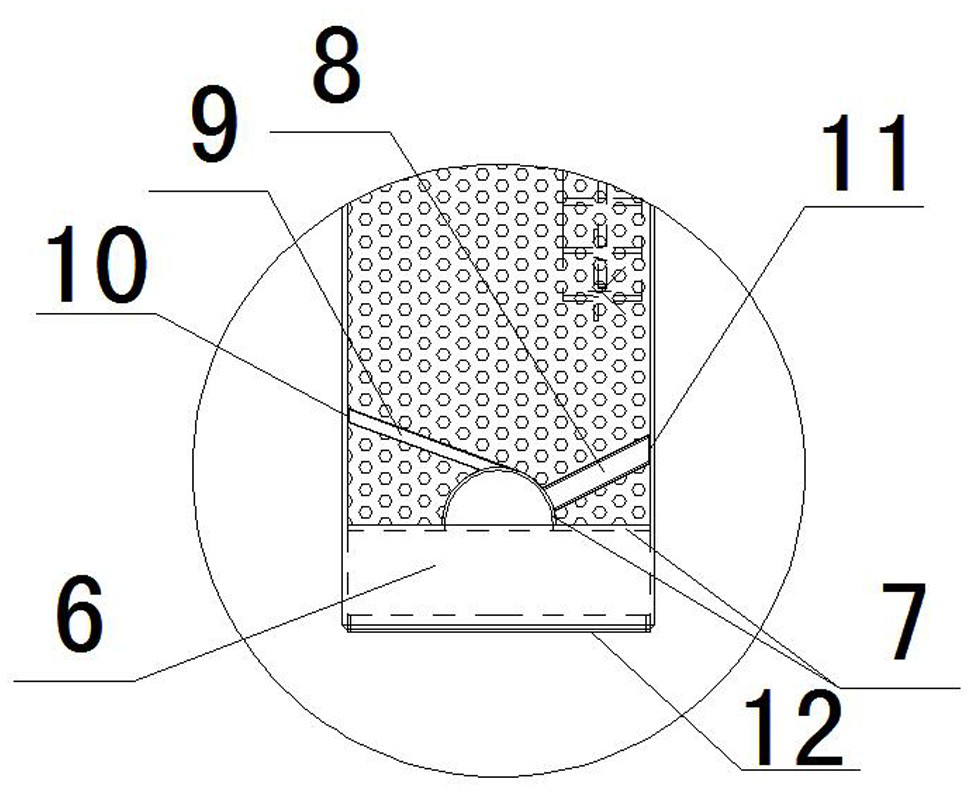

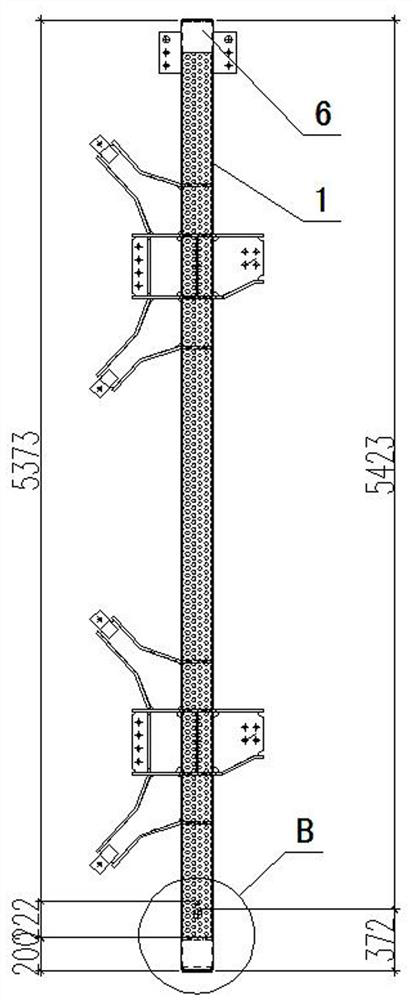

Tubular busbar post insulator overhaul platform

ActiveCN102891451AGood maintenance conditionFlexible combinationCable installation apparatusBusbarEngineering

The invention discloses a tubular busbar post insulator overhaul platform. The tubular busbar post insulator overhaul platform comprises a low-position big platform, a guardrail frame is mounted at four sides of the low-position big platform, the inner side of the guardrail frame is provided with a high-position small platform and a micro hoist, and the low-position big platform is fixed on a door-type bracket by a stud clamp and a U-shaped ring. Beneficially, the tubular busbar post insulator overhaul platform provided by the invention uses a large number of split structures, and based on the aim of being safe, convenient and rapid, the tubular busbar post insulator overhaul platform can be used for greatly improving the overhaul conditions of the tubular busbar post insulators, and saving much overhaul cost while ensuring the construction safety and the construction speed.

Owner:ZIGONG POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER +1

Tunnel central ditch, single body thereof and method for manufacturing single body

The invention relates to the technical field of underground engineering, in particular to a tunnel central ditch, a single body thereof and a method for manufacturing the single body. Connecting ends are respectively arranged at two ends of the single body of the tunnel central ditch, openings are formed in the connecting ends, the single body of the tunnel central ditch is of a groove structure, and a concrete cover plate covers an upper opening of the groove structure; mixture of quartz sand, steel fibers, 425R ordinary silicate cement, micro-silicon powder, mineral waste material powder, water reducing agents and water are poured on the side walls and the bottom of the single body of the tunnel central ditch. A plurality of single bodies of the tunnel central ditch are serially connected with one another to form the tunnel central ditch, the distance between each two single bodies is shorter than 8 millimeters, and altitude difference is smaller than 5 millimeters. The method includes portioning materials; mixing the materials to obtain the mixtures; feeding the mixtures into molds and molding the mixtures in a vibration manner; carrying out primary curing on the mixtures; carrying out final curing on the mixtures to obtain the single body of the tunnel central ditch. The tunnel central ditch, the single body and the method have the advantages that the structure of the single body of the tunnel central ditch is preliminarily manufactured outside a hole and then is mounted in a tunnel, accordingly, the construction speed can be increased, and the construction quality can be improved.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

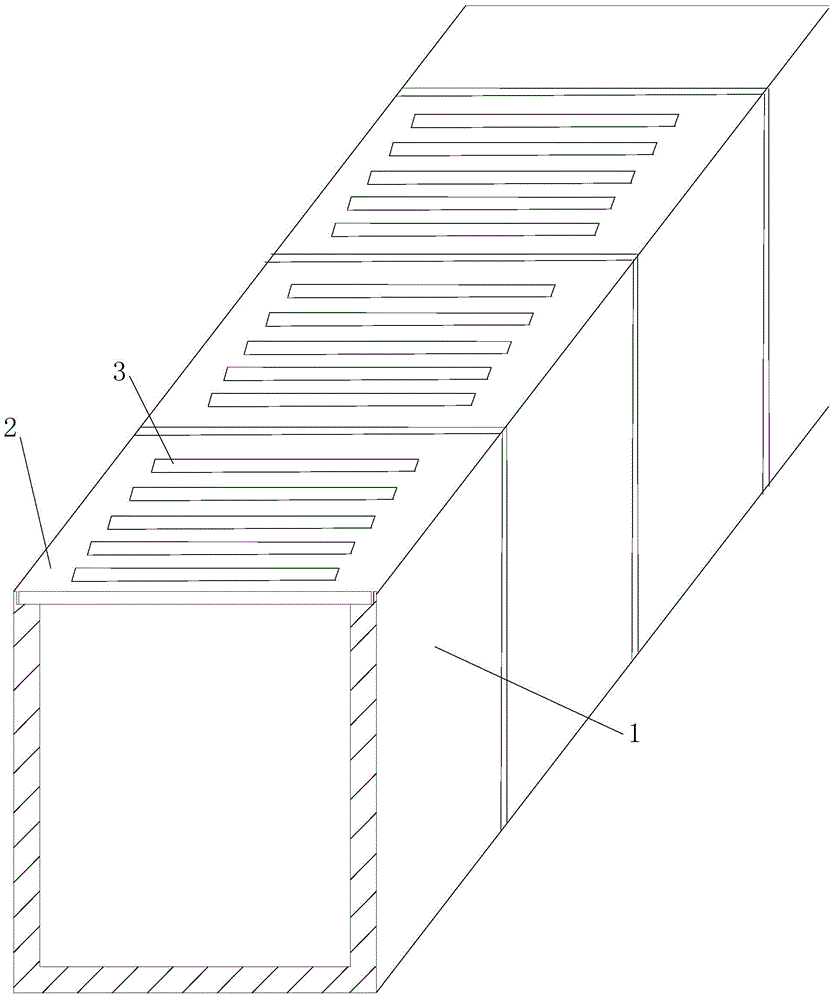

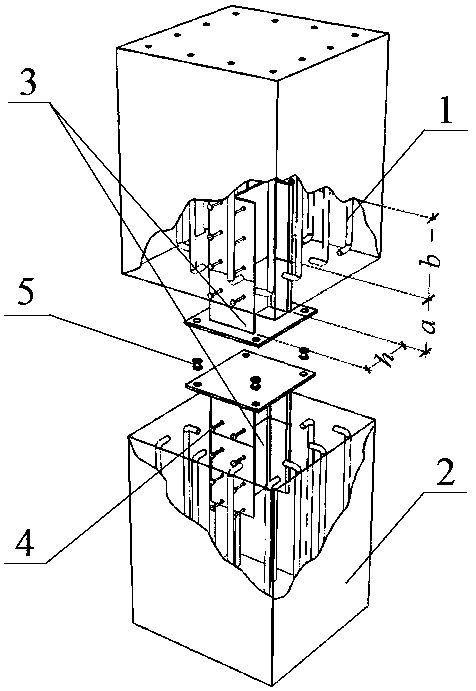

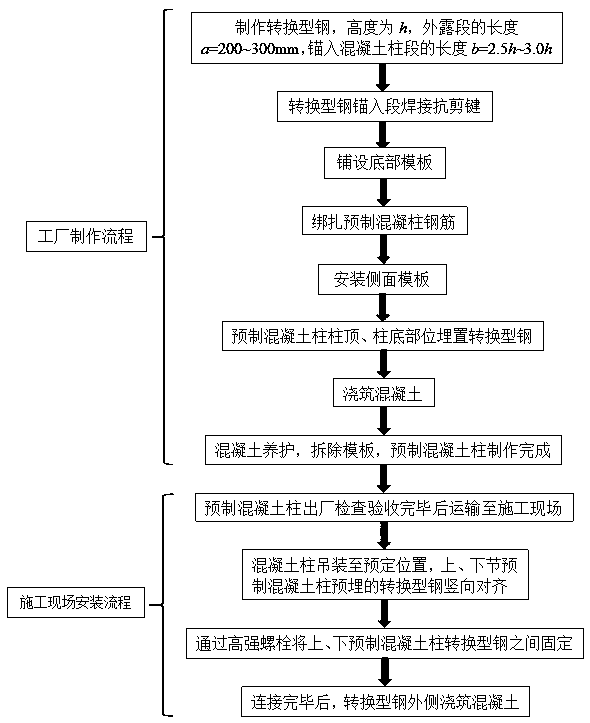

Prefabricated concrete column and column assembly connection node fabrication and installation method

PendingCN109025064AGood maintenance conditionComponent quality is controllableStrutsPillarsRebarPrecast concrete

The invention belongs to the field of fabricated concrete structures, and relates to a prefabricated concrete column and column assembly connection node fabrication and installation method. The prefabricated concrete column and column assembly connection node fabrication and installation method includes the following steps: making converting structural steels in a factory; anchoring the convertingstructural steels into a concrete section, and welding shearing keys; laying a bottom template of a prefabricated concrete column; tying steel bars of the prefabricated concrete column, and installing side templates; embedding the converting structural steels on the top and the bottom of the prefabricated concrete column; pouring concrete; curing the concrete, and demolishing the templates; transporting the prefabricated concrete column to a construction site after acceptance check; hoisting the prefabricated concrete column to a predetermined position at the construction site, wherein the outward-extended converting structural steels of an upper prefabricated concrete column and a lower prefabricated concrete column are aligned; fixing the converting structural steels by high-strength bolts; and pouring the concrete outside the converting structural steels. The concrete column adopts a factory prefabrication mode, and component quality is controllable; the upper prefabricated concrete column and the lower prefabricated concrete column can be connected by the converting structural steels and the high-strength bolts, the structure is simple, and the force transmission is reliable;the connection quality is convenient to check; construction and installation are quick and efficient, and requirements of prefabricated buildings can be met.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A decorative, fireproof and thermal insulation integrated board

ActiveCN104563425BReduced post-bonding processQuick compound workCovering/liningsFiberglass meshFire protection

The invention discloses an integration board for decorating, preventing fire and keeping warm, belonging to the field of composite board production. The integration board is manufactured in one-time formation by taking fire retardant boards as heat insulating layers and taking modified magnesium oxysulfate cementing materials and alkali-resistant fiberglass meshes as protective layers. The modified magnesium oxysulfate cementing material is prepared by mixing light calcined magnesia, magnesium sulfate solution, perlite, coal ash, polypropylene fiber and modifying agent according to a certain weight proportion. Compared with prior art, the integration board of the invention has the characteristics of high production efficiency, green and environmental protection and so on, and has good popularization and using values.

Owner:山东斯诺尔节能建材有限公司

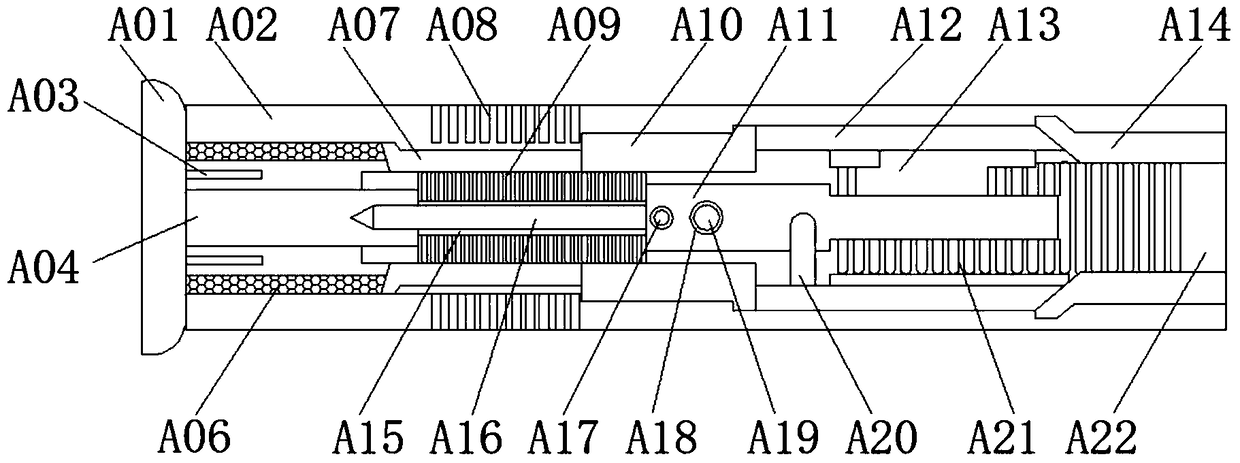

Powder-actuated tool with internal carbon ash removal and silencing functions

The invention discloses a powder-actuated tool with internal carbon ash removal and silencing functions. The powder-actuated tool comprises a dustproof cover, a movable sleeve and a sliding rail. A shell is arranged in the middle of the dustproof cover, and exhaust holes are embedded in the middle of the shell. Silencing cotton is arranged in the shell, and buffering holes are formed between the silencing cotton. A nail tube is arranged between the buffering holes, and silencing holes are distributed around the nail tube. A needle sleeve is arranged in the nail tube, and a firing pin is arranged in the needle sleeve. A return spring is arranged in the movable sleeve, and the movable sleeve is positioned on the right side of the firing pin. A fixing rod is mounted in the sliding rail. The sliding rail is positioned on the right side of the movable sleeve. An elastic pin is arranged in the fixing rod. According to the powder-actuated tool, the movable sleeve and the sliding rail are arranged, and the movable sleeve is wrapped with the sliding rail; and when the powder-actuated tool works, the movable sleeve moves in the horizontal center line direction of the sliding rail and assiststhe return spring in moving in the horizontal center line direction of the movable sleeve, and the return spring is prevented from shifting.

Owner:JIAXING NIYA OPTOELECTRONICS CO LTD

Embedded part structure and gate system thereof

The invention discloses an embedded part structure. The embedded part structure comprises a main body section with a rectangular cross section, a gate groove formed in the main body section and a pressing slope section. The pressing slope section structurally comprises a horizontally-arranged bottom plate face, two side wall surfaces perpendicular to the bottom plate face, and a top face. The bottom plate face, the side wall surfaces and the top face define a hollow structure with the periphery being closed and the two ends being opened. The top face refers to a slope face which is gradually tilted downwards from the upstream direction to the downstream direction. The pressing slope section forms a variable cross section structure with the caliber being gradually decreased. The upstream end of the pressing slope section is in butt joint with the downstream end of the main body section. By adoption of the embedded part structure, water flow flows to a non-pressure flow conversion area from a pressure flow area and is transferred to the downstream end of the pressing slope section from an original gate groove area, severe cavitation damage is also transferred to the downstream end ofthe pressing slope section from the gate groove area, and thus the gate groove area is protected. Meanwhile, the top face pressing slope of the pressing slope section is stable, water pressure in thegate groove area is increased, and cavitation damage to the gate groove area by high-speed water flow is reduced.

Owner:POWERCHINA ZHONGNAN ENG

Drum frame supporting power built-in integrated jacking steel platform formwork system and construction method

ActiveCN102661039BEasy to replaceEnsure safetyForms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention discloses a drum frame supporting power built-in integrated jacking steel platform formwork system, comprising a steel platform, a support system, a suspended scaffold, a template system and a hydraulic jacking power system; the support system comprises a drum frame support and an internal framework support; the drum frame support is located under the steel platform, and comprises a steel platform support, an oil cylinder counter-force beam, a guide roller, a support steel column and a drum frame support beam; the internal framework support is arranged inside the drum frame support and located between the drum frame support beam and the oil cylinder counter-force beam; the hydraulic jacking power system comprises a hydraulic jacking oil cylinder and a power control system thereof; the hydraulic jacking oil cylinder is inverted between the oil cylinder counter-force beam and the internal framework support; telescopic brackets are arranged at the end portions of the internal framework support and the drum frame support beam, respectively; and the telescopic brackets are supported in a preformed hole in a shear wall. The drum frame supporting power built-in integrated jacking steel platform formwork system is capable of realizing the construction operation of a complex core drum, shortening the construction period and ensuring high altitude construction safety, and also capable of improving the green construction level.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Stay cable and bridge tower anchored prefabricated prestressed concrete anchor beam structure

ActiveCN110886217AImprove economyReduce steel consumptionCable-stayed bridgeBridge structural detailsPre stressArchitectural engineering

The utility model discloses a stay cable and bridge tower anchored prefabricated prestressed concrete anchor beam structure, and aims to effectively reduce the steel consumption, the manufacturing, transportation, construction and maintenance difficulty, improve the durability of the structure and effectively reduce the construction cost. The structure comprises a ladder-shaped concrete prefabricated part, the ladder-shaped concrete prefabricated part comprises concrete vertical tower walls vertically extending on the two sides in the transverse direction and concrete anchor beams vertically arranged at intervals, and the two ends of each concrete anchor beam are fixedly connected with the concrete vertical tower walls on the same side; reserved steel bars embedded into cast-in-place concrete of the bridge tower concrete tower wall are arranged on the outer side wall of the concrete vertical tower wall, and the ladder-shaped concrete prefabricated parts are fixedly connected between the two side walls of the bridge tower concrete tower wall through prestressed steel beams distributed in the cross sections of the concrete anchor beams; stay cable anchoring tooth blocks are embeddedin the two ends of each concrete anchor beam.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

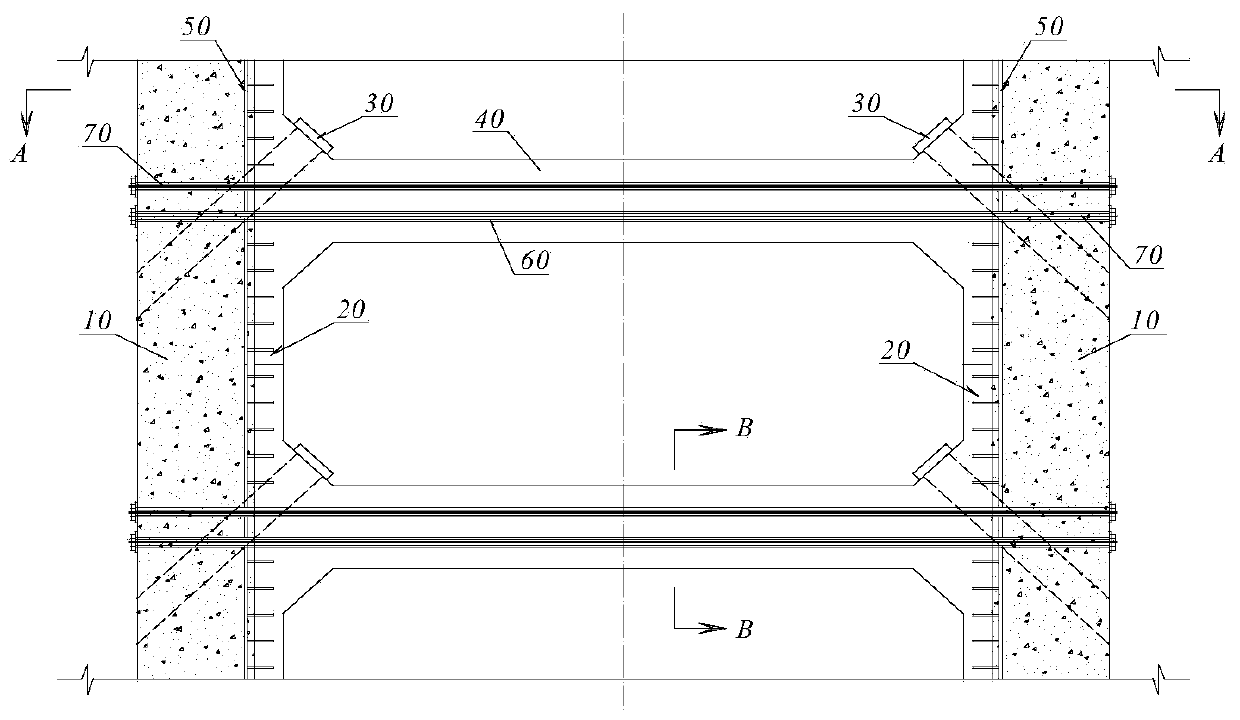

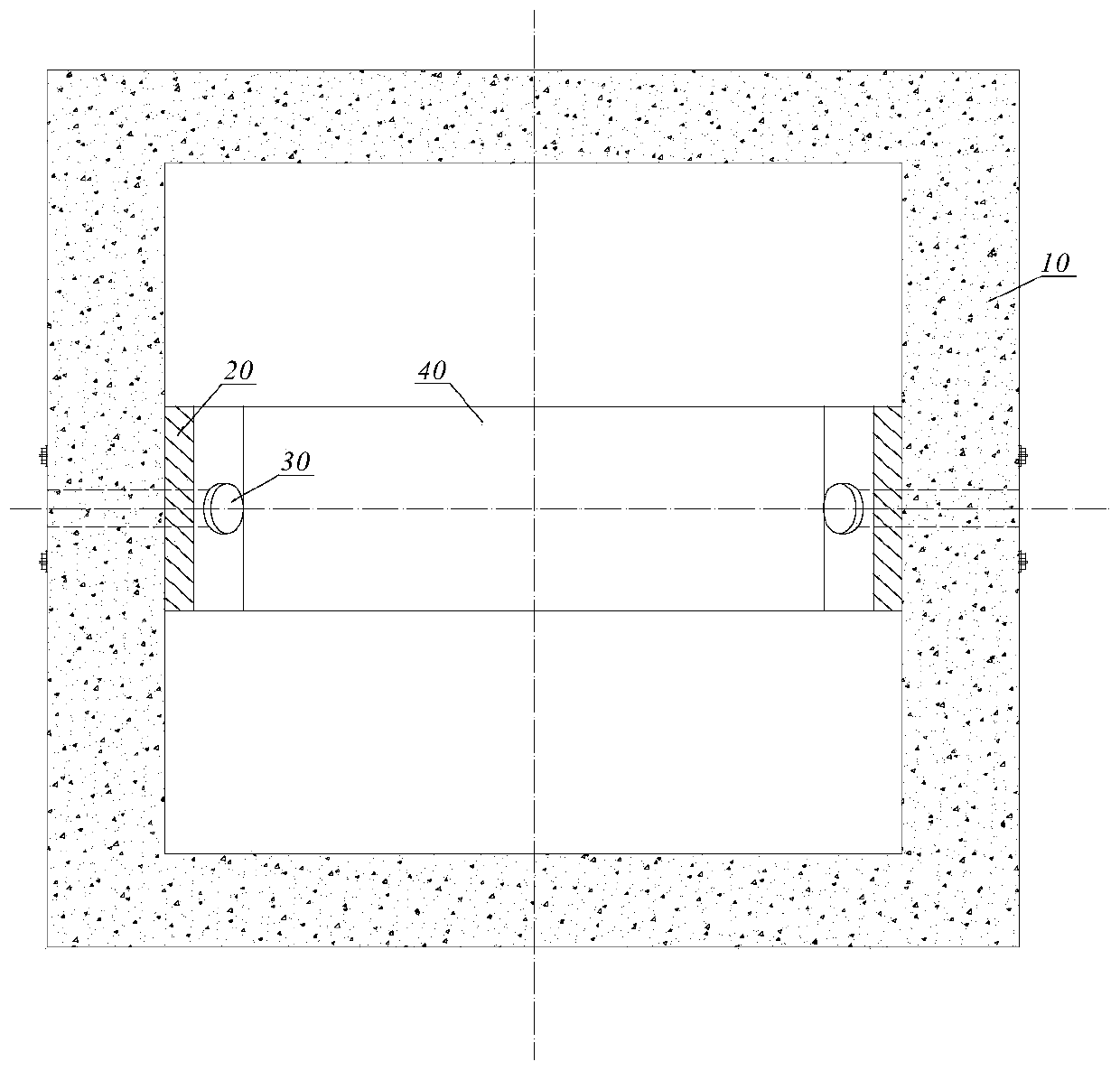

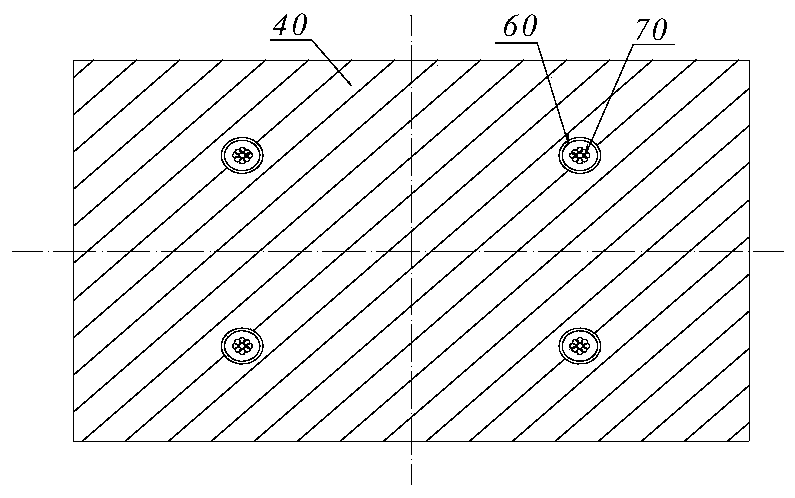

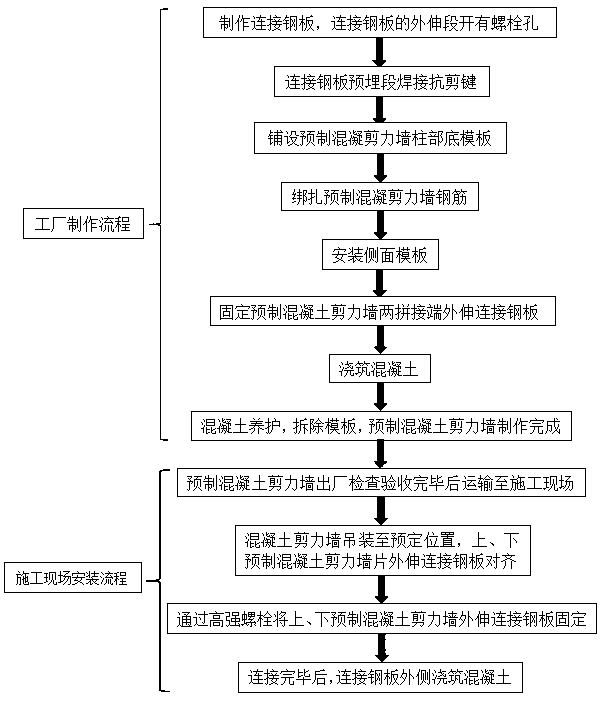

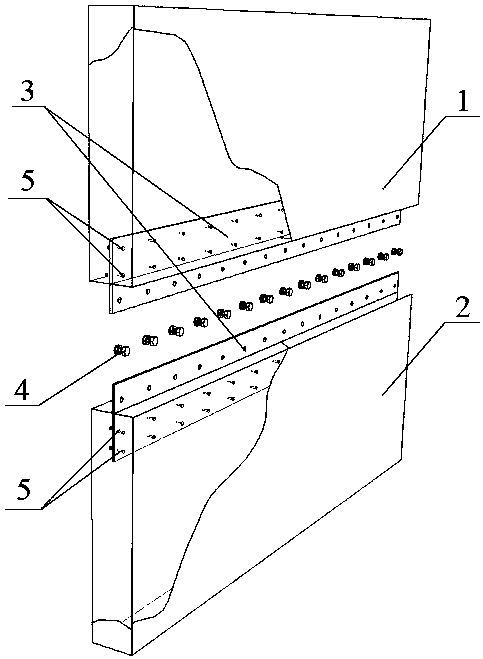

Prefabricated concrete shear wall fabricated connecting node manufacturing and installing method

InactiveCN109083412AGood maintenance conditionComponent quality is controllableBuilding material handlingRebarPre embedding

The invention belongs to the field of fabricated concrete structures, and relates to a prefabricated concrete shear wall fabricated connecting node manufacturing and installing method. The prefabricated concrete shear wall fabricated connecting node manufacturing and installing method comprises the following steps that a connecting steel plate is manufactured in a factory; a shear key is welded tothe pre-embedded section of the connecting steel plate; a prefabricated concrete shear wall bottom formwork is laid; prefabricated concrete shear wall reinforcing ribs are bound, and a side face formwork is installed; the two splicing ends of the prefabricated concrete shear wall are fixedly provided with an external extending connecting steel plate; concrete is poured; concrete curing is performed, and the formwork is removed; after acceptance inspection is completed, the steel plate is conveyed to a construction site; on the construction site, the prefabricated concrete shear wall is suspended to the preset position and aligned to an external extending connecting steel plate bolt hole; the connecting steel plate is fixed through a high-strength bolt; concrete is poured to the outer sideof the connecting steel plate. The concrete shear wall is prefabricated in the factory, and the component quality is controllable; upper and lower prefabricated concrete shear wall pieces are connected through the high-strength bolt, the structure is simple, and force transmission is reliable; connecting quality is convenient to inspect, and the finished product quality is controllable; construction and installation are rapid, the efficiency is high, and the requirement for prefabricated buildings is met.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

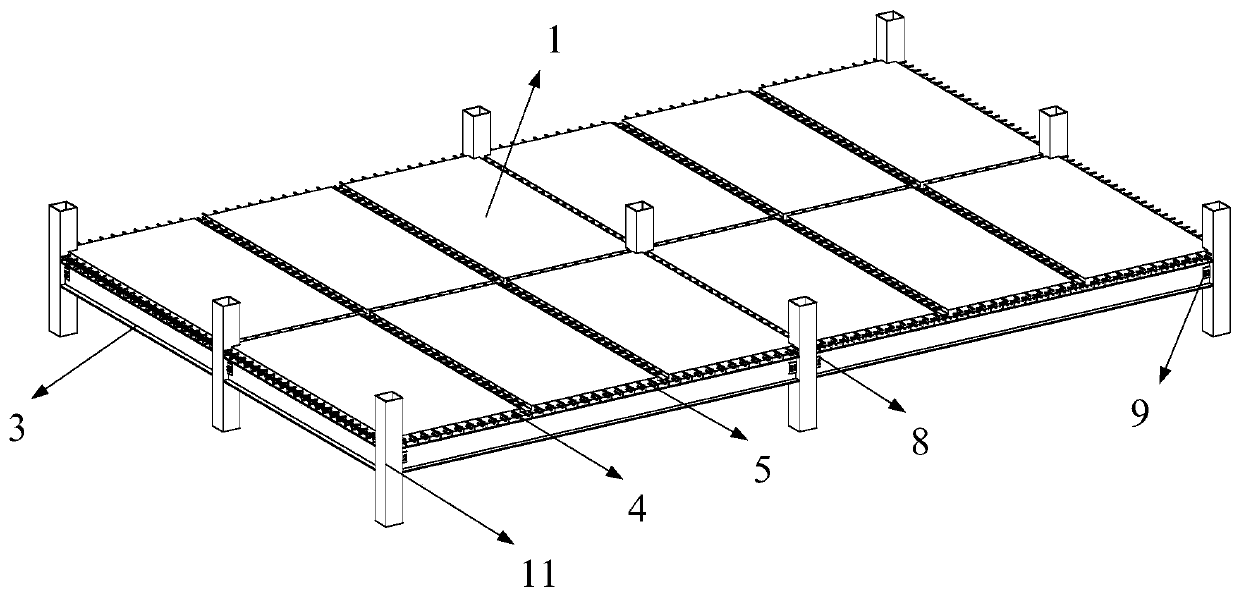

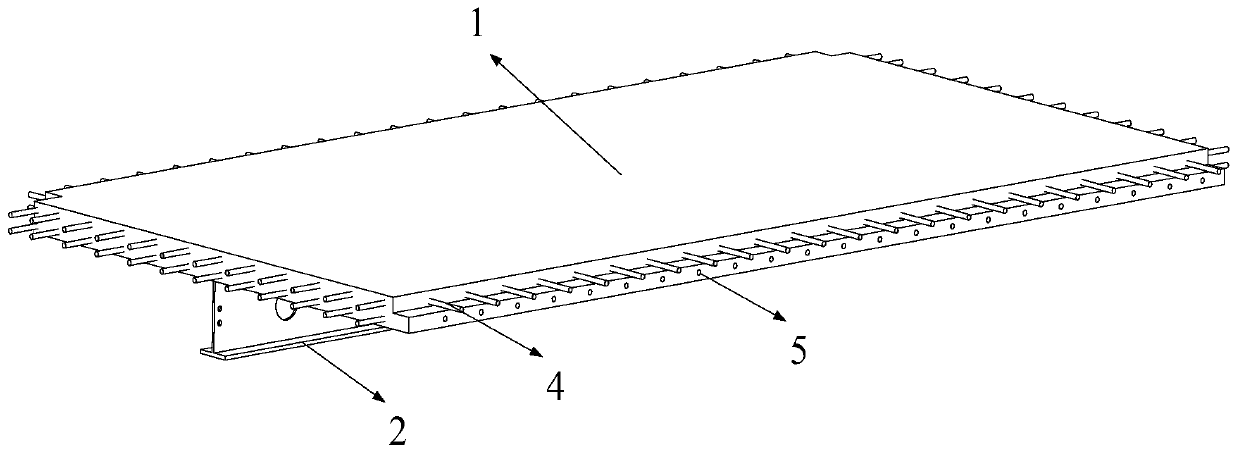

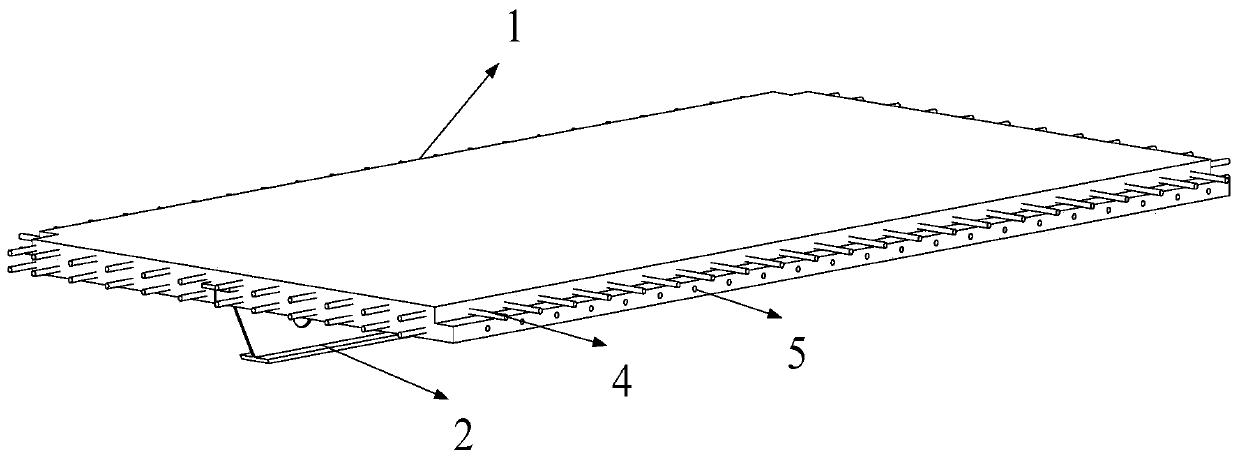

Concrete floor secondary beam combined prefabricated member and production method

PendingCN111424869AGood maintenance conditionReduce cumbersome proceduresFloorsFeeding arrangmentsFloor slabArchitectural engineering

The invention discloses a concrete floor secondary beam combined prefabricated member and a production method. The concrete floor secondary beam combined prefabricated member comprises a prefabricatedconcrete plate and an H-shaped steel secondary beam, and the prefabricated concrete plate is poured by concrete; and studs are welded to the upper surface of a top flange of a steel beam of the H-shaped steel secondary beam, and the studs are embedded in the lower surface of the prefabricated concrete plate. According to the technical scheme of the concrete floor secondary beam combined prefabricated member, the combined prefabricated member is integrally hoisted, is assembled to a whole through reserved steel bars and is connected with a structural girder, an integral floor system is formedthrough a small number of cast-in-place concrete, tedious processes of site form erecting are reduced, cast-in-situ concrete is avoided, the strength and stiffness of the concrete floor secondary beamcombined prefabricated member are obviously improved, floors cannot be damaged due to self-weight influence during hoisting, and the integral performance of the member is improved.

Owner:BEIJING UNIV OF TECH

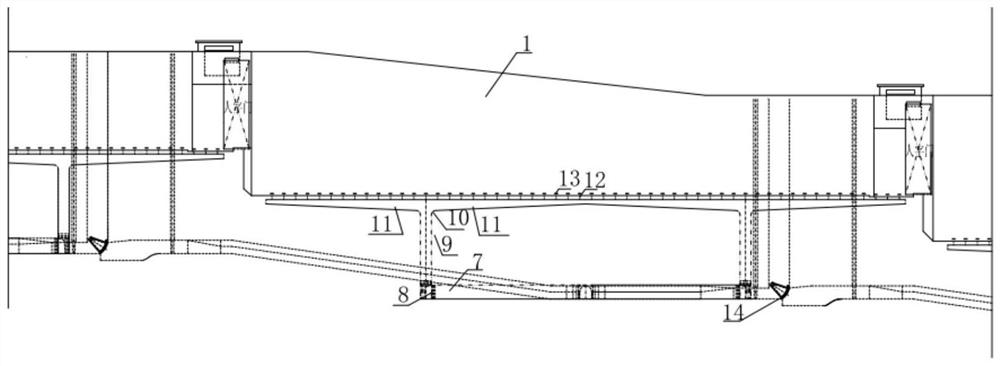

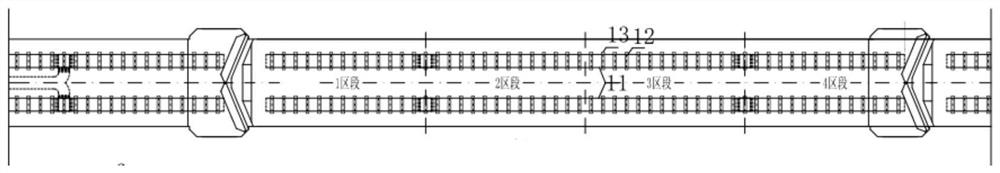

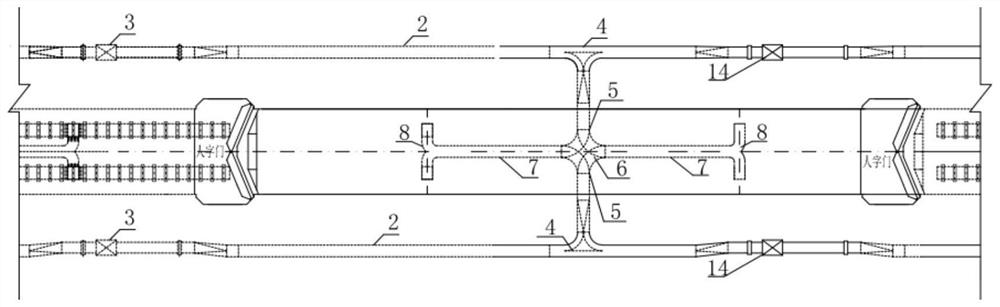

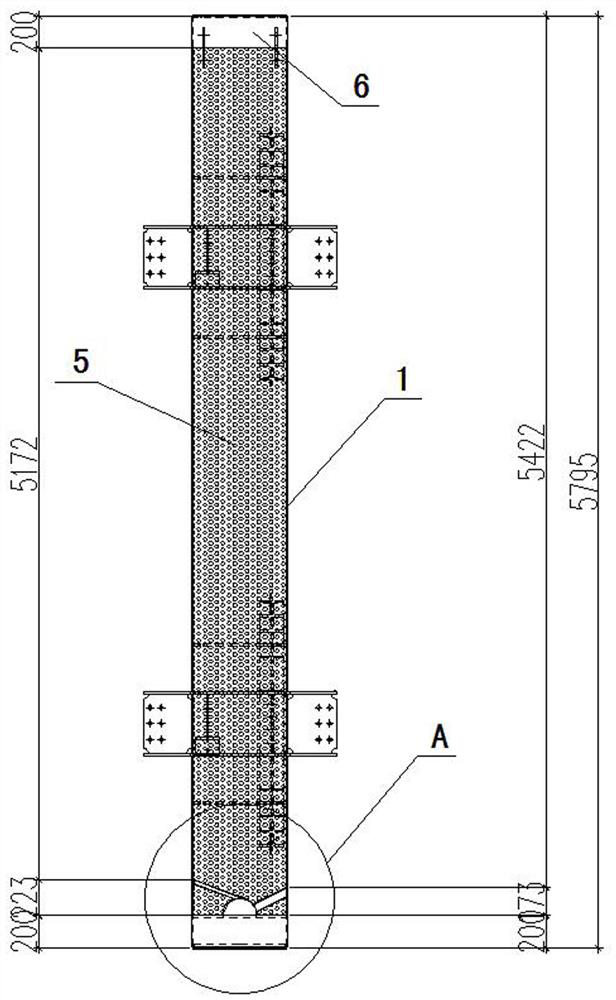

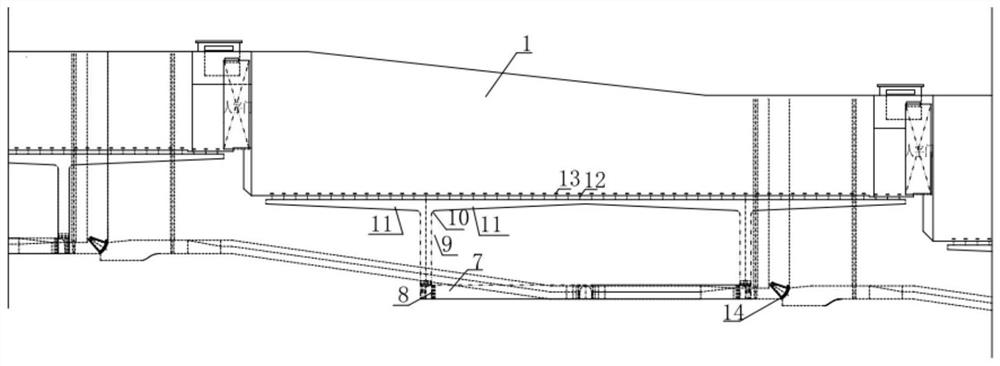

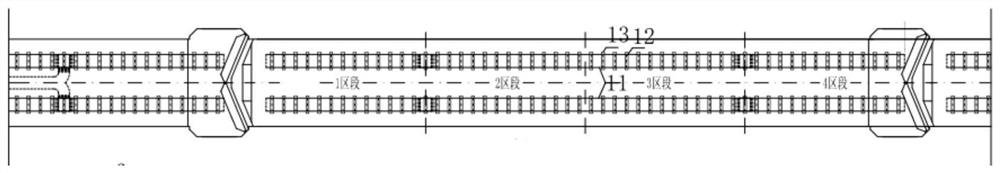

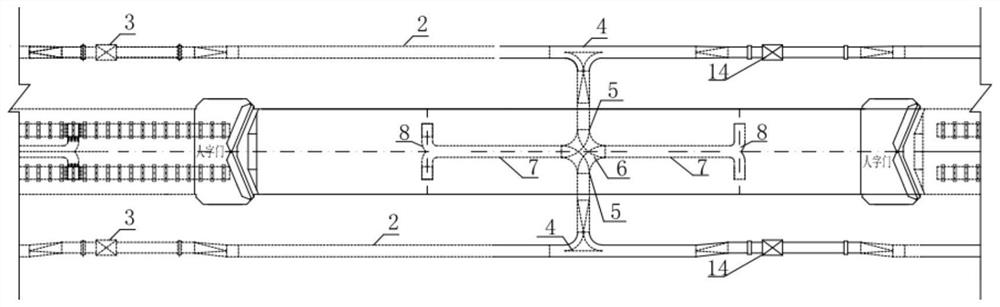

Ship lock double-layer water conveying system with longitudinally-through drainage type lock bottom

The invention relates to a ship lock double-layer water conveying system with a longitudinally-through drainage type lock bottom. The ship lock double-layer water conveying system comprises a ship lock chamber, a first diversion port, a middle branch gallery, a second diversion port, water conveying main galleries located on two sides of the ship lock chamber, filling valves arranged on the upstream portions of the water conveying main galleries, and drain valves arranged on the downstream portions of the water conveying main galleries; the water conveying main galleries communicate with an inlet of the first diversion port through T-shaped pipes, and an outlet of the first diversion port communicates with the second diversion port through the middle branch gallery; the second diversion port communicates with the third diversion port located in the upper layer through a vertical shaft, the third diversion port communicates with a water drainage branch gallery, and the water drainage branch gallery communicates with water drainage holes, and energy dissipation cover plates are arranged on the water drainage holes; and the elevations of the first diversion port, the middle branch gallery and the second diversion port are consistent with those of the drain valves, and the third diversion port, the water drainage branch gallery, the water drainage holes and the energy dissipation cover plates are located on the elevation surface of a lock chamber bottom plate. According to the ship lock double-layer water conveying system, the pressure characteristics of the diversion ports canbe improved to avoid cavitation and cavitation erosion, moreover, outflow can be dispersed to the maximum extent, and the water conveying safety and the water conveying efficiency of the ship lock are improved.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Steel structure fabricated residual prefabricated concrete-filled steel tubular column and manufacturing method thereof

The invention relates to the field of steel structure fabricated building construction engineering, in particular to a fabricated residual prefabricated concrete-filled steel tubular column and a manufacturing method thereof. The prefabricated concrete-filled steel tubular column comprises a steel tubular column, and is characterized in that a grouting hole and a vibrating hole are formed in a topplate of the steel tubular column, a concrete layer is poured into the steel tubular column, butt-joint cavities are correspondingly formed in the upper and lower butt-joint ends, the lower butt-joint cavity is internally provided with a special-shaped sealing plate for blocking the concrete layer, a prefabricated observation pipe and a prefabricated grouting pipe which communicate with the lowerbutt-joint cavity are correspondingly arranged on the special-shaped sealing plate, and the prefabricated observation pipe and the prefabricated grouting pipe are correspondingly connected with a steel column observation air hole and a steel column grouting hole in two side arms of the steel tubular column. According to the fabricated residual prefabricated concrete-filled steel tubular column, the concrete-filled steel tubular column is subjected to prefabrication grouting, according to the requirements of the construction site, the concrete-filled steel tubular column is prefabricated in advance in a factory, the concrete-filled steel tubular column is hoisted in place after prefabricated parts are transported to the site, the steel column factory prefabrication grouting is achieved, the construction progress of the project is accelerated, and the overall assembly rate of the project is improved.

Owner:唐山冀东发展燕东建设有限公司 +1

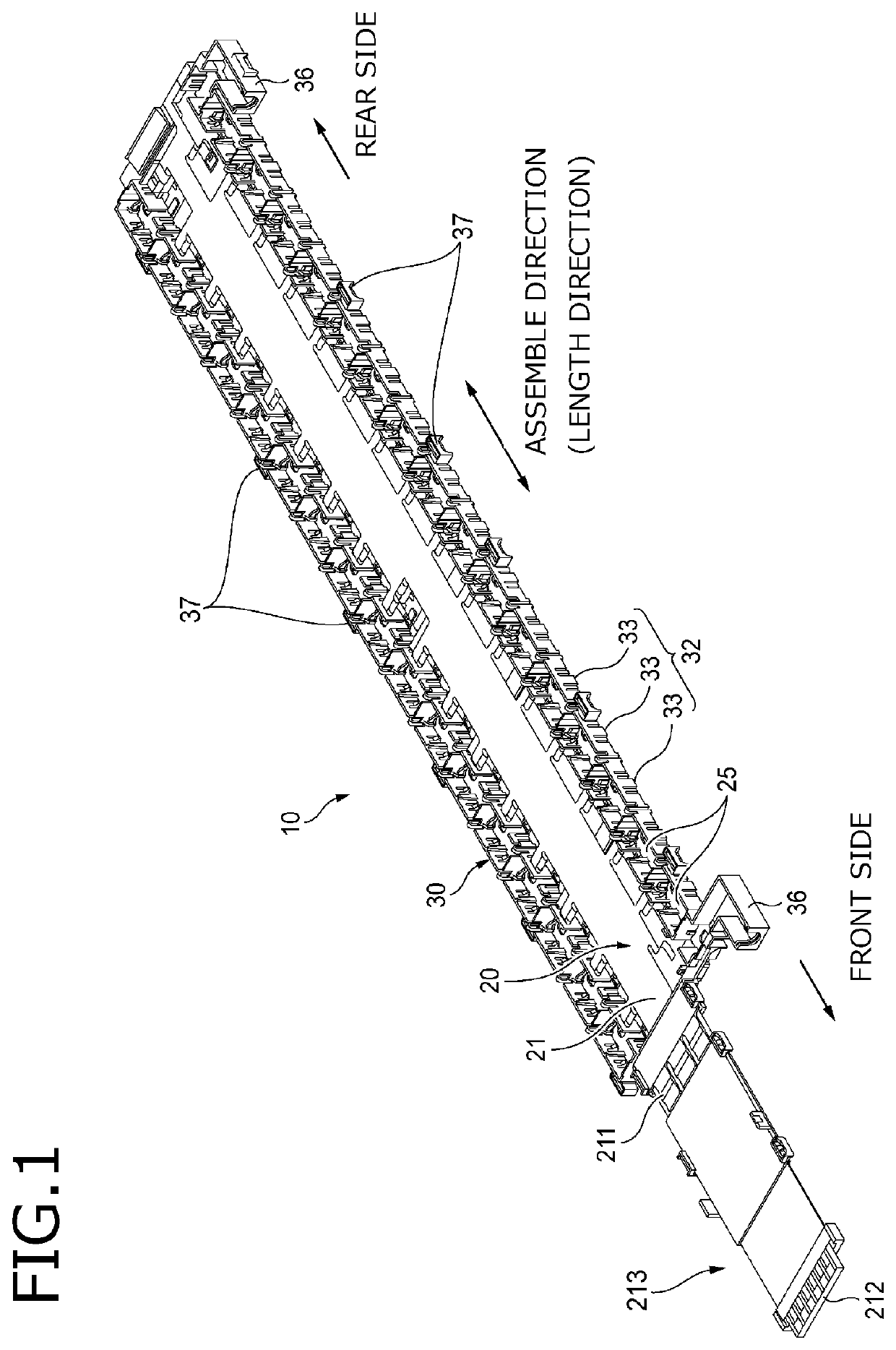

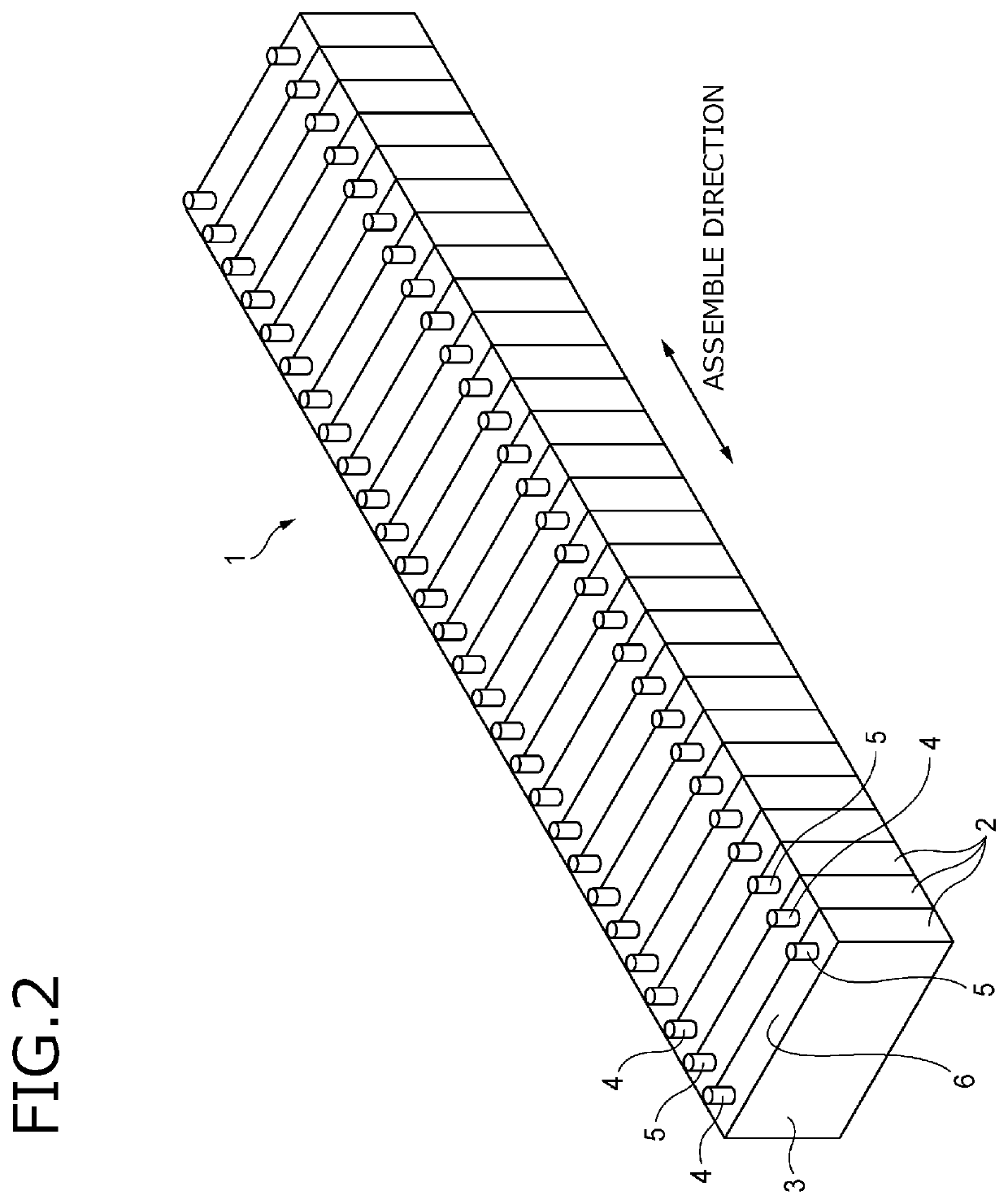

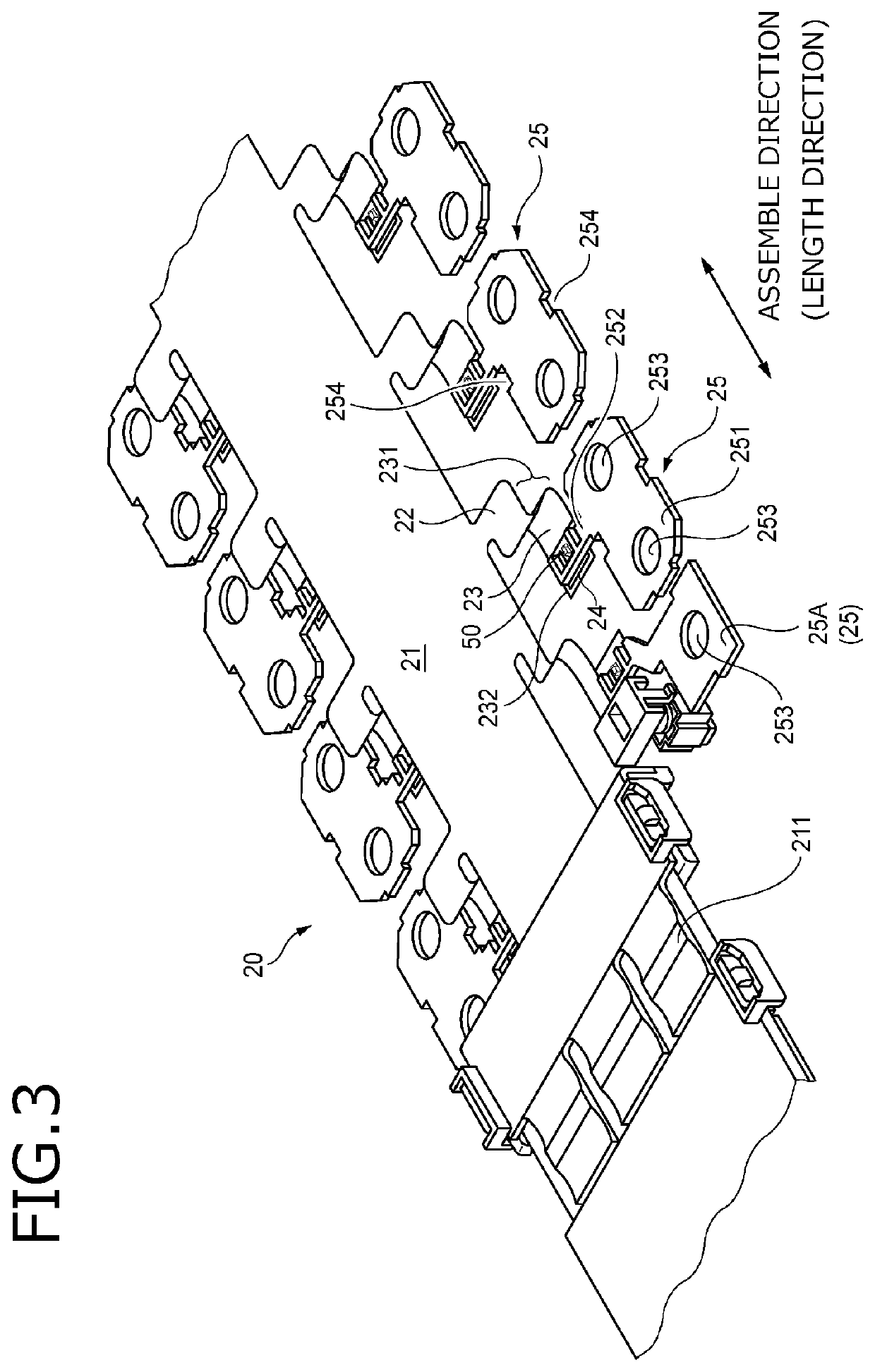

Bus bar module

ActiveUS20200020916A1Easy to punchGood maintenance conditionCells structural combinationCell component detailsHemt circuitsStructural engineering

A bus bar module is attached to a battery assembly having a plurality of single cells which are assembled to each other along a first direction. The bus bar module includes a circuit body, a bus bar, and a holder. The circuit body includes a main line that extends in the first direction, a branch line that extends from the main line so as to branch from the main line, and a connection portion provided in a position close to a distal end of the branch line rather than a folded portion of the branch line and configured to be connected to the bus bar.

Owner:YAZAKI CORP

A double-layer water delivery system for ship locks with vertically penetrating water outlets at the bottom of the lock

A double-layer water delivery system for a ship lock with longitudinally penetrating water outlet at the bottom of the lock, comprising a ship lock chamber, a first diversion port, a middle branch corridor, a second diversion port, main water delivery corridors located on both sides of the ship lock chamber, respectively The water filling valve and the water discharge valve are located upstream and downstream of the main water delivery corridor. The main water delivery corridor is connected to the inlet of the first diversion port through a T-shaped pipe, and the outlet of the first diversion port is connected to the first diversion port through the middle branch corridor. The two diversion ports are connected, the second diversion port is connected to the third diversion port on the upper floor through the vertical shaft, the third diversion port is connected to the water outlet branch corridor, the water outlet branch corridor is connected to the water outlet hole, and the upper part of the water outlet hole is provided with an energy dissipation cover , the elevation of the first diversion port, the middle branch corridor and the second diversion port are consistent with the elevation of the discharge valve, and the third diversion port, water outlet corridor, water outlet hole and energy dissipation cover are located at the bottom of the sluice chamber. The invention can improve the pressure characteristics of the diversion port to avoid cavitation and cavitation erosion, can also disperse the outflow to the greatest extent, and improve the safety and efficiency of water delivery of the ship lock.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com