Prefabricated concrete shear wall fabricated connecting node manufacturing and installing method

A technology of precast concrete and connecting nodes, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficult construction, large on-site workload, prone to slurry leakage and voids, etc., and achieves convenient connection quality. , The effect of fast construction and installation, and controllable quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

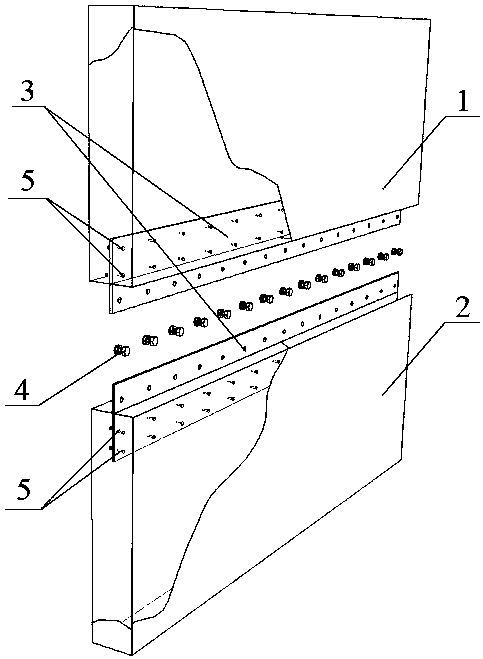

[0027] The manufacturing and installation method of prefabricated concrete shear wall prefabricated connection joints includes an upper precast concrete shear wall piece 1, a lower precast concrete shear wall piece 2, a connecting steel plate 3, a shear key 4, and a high-strength bolt 5. Precast concrete shear walls are first fabricated in a factory and then transported to the construction site for installation.

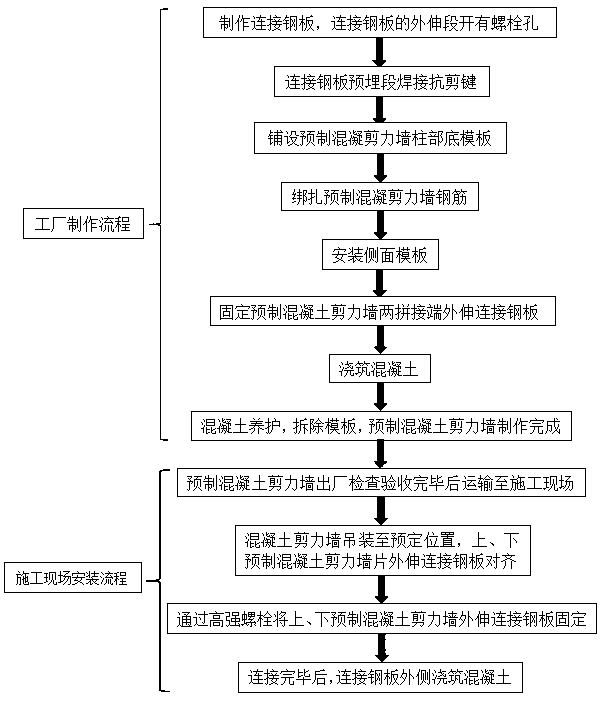

[0028] The fabrication and installation method of the prefabricated concrete shear wall assembly connection node includes the following steps:

[0029] The first step is to make the connecting steel plate 3, and the overhanging section of the connecting steel plate 3 is provided with bolt holes;

[0030] The second step is to weld the shear key 4 on the surface of the pre-embedded section of the connecting steel plate 3;

[0031] The third step is to lay the bottom formwork of precast concrete shear walls 1 and 2, and the formwork size matches the design size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com