Patents

Literature

2980 results about "Pre embedding" patented technology

Efficacy Topic

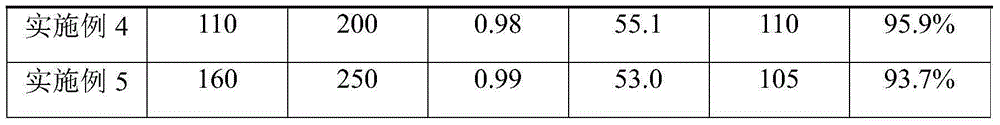

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

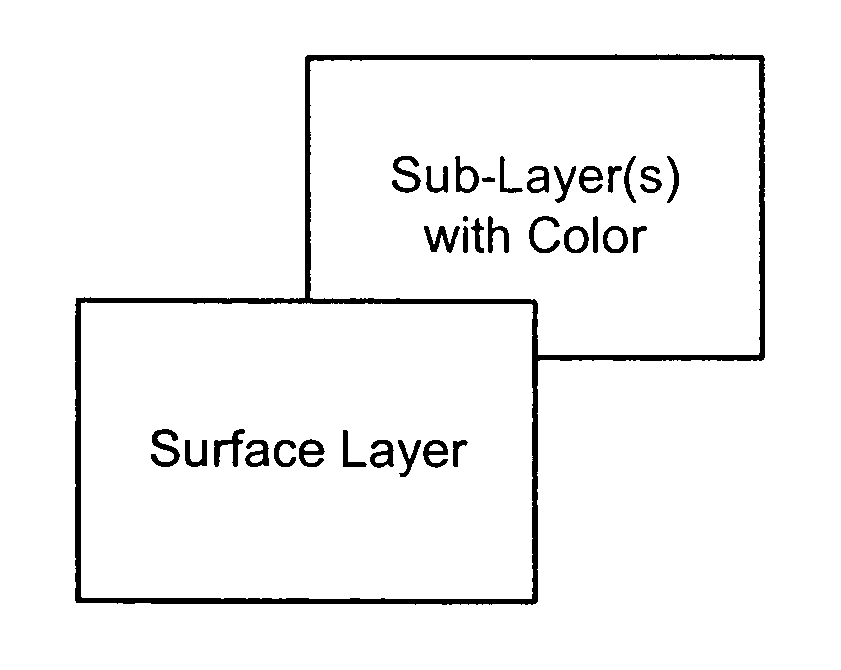

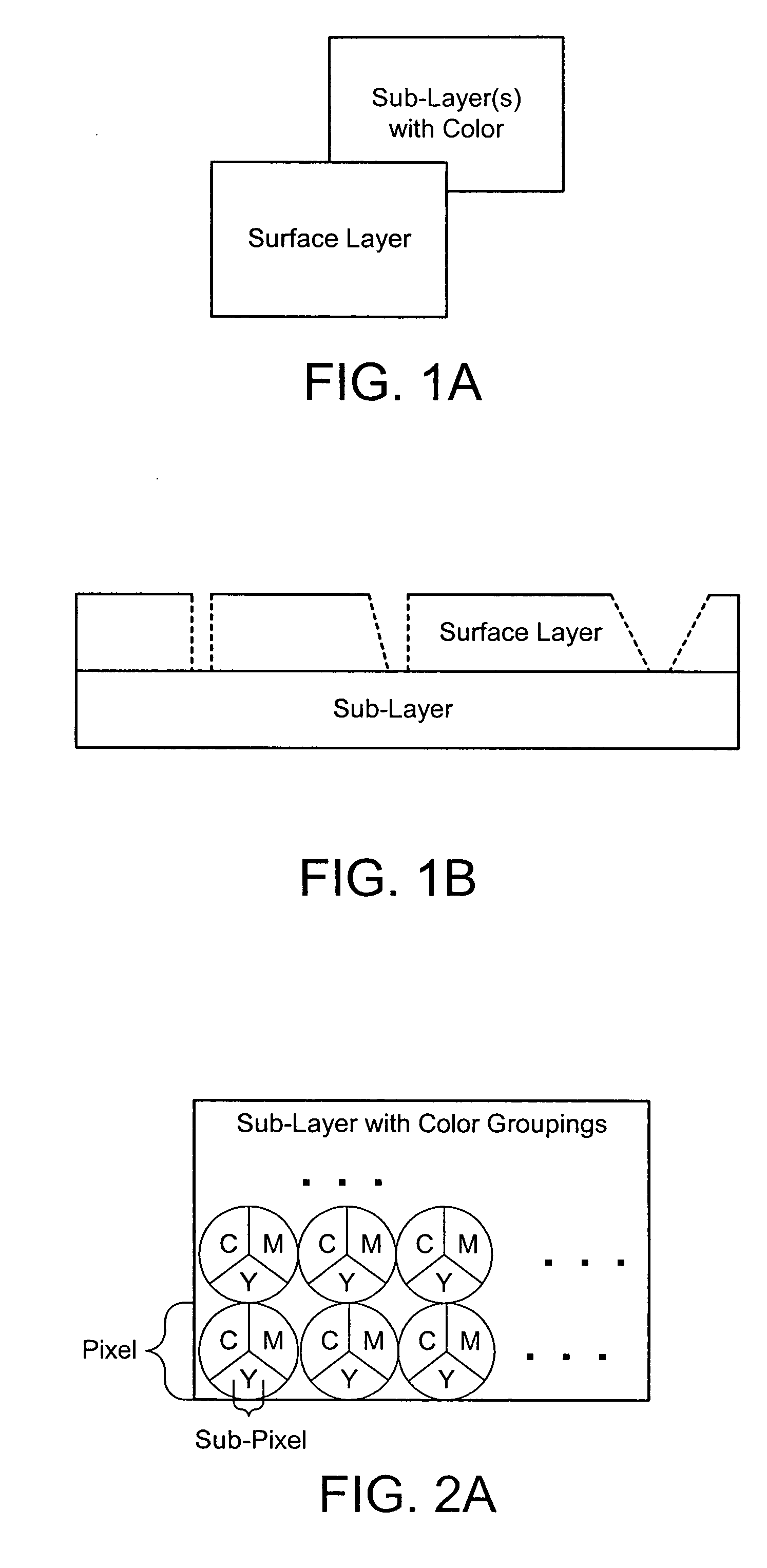

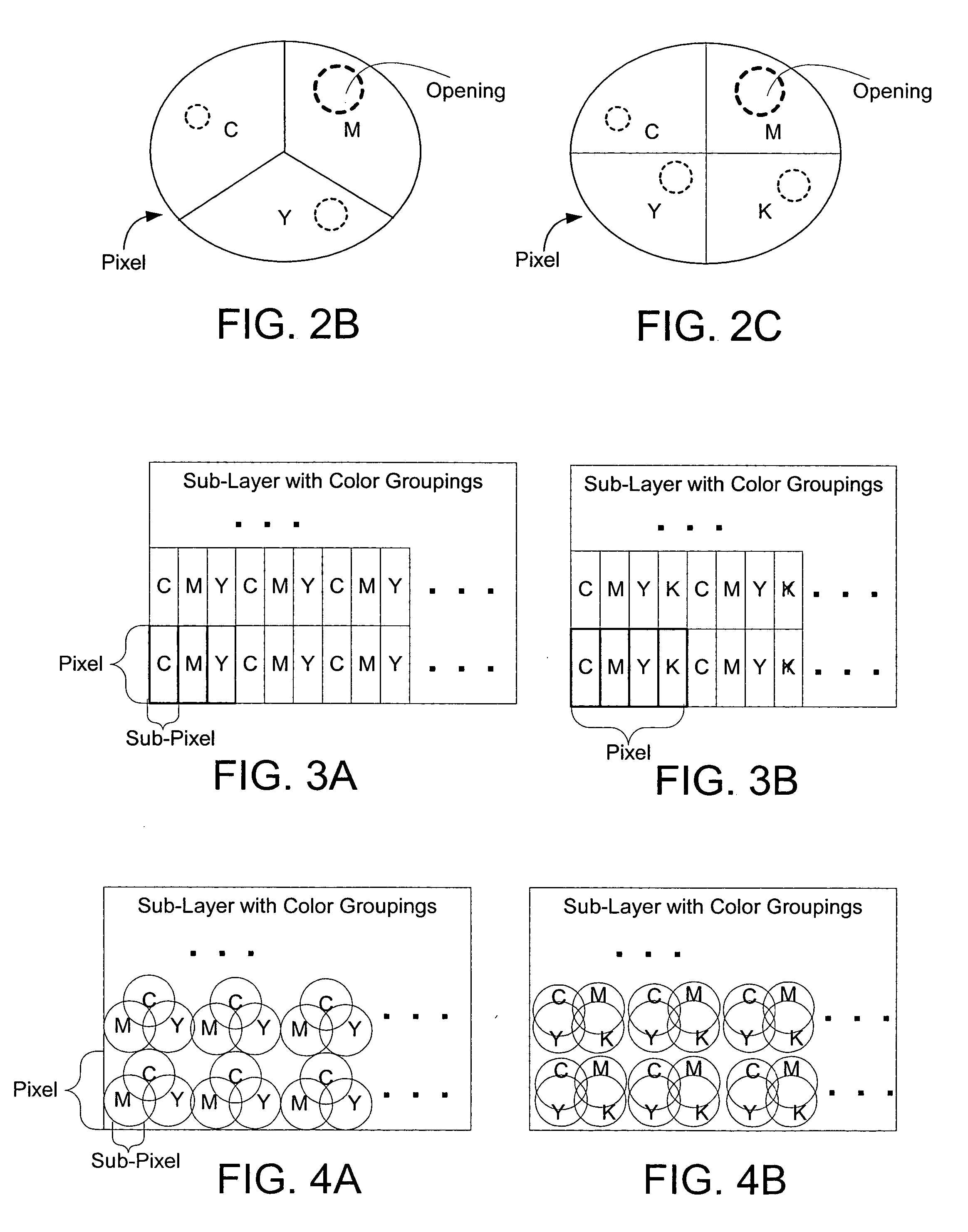

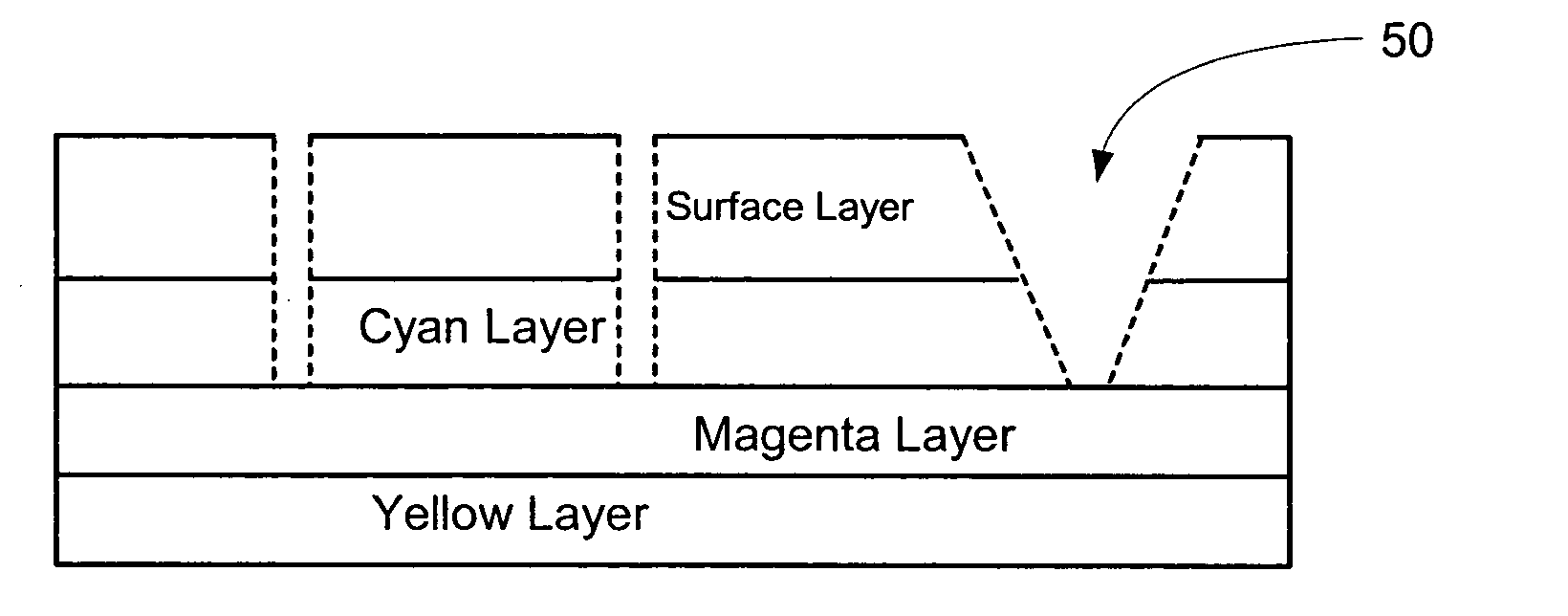

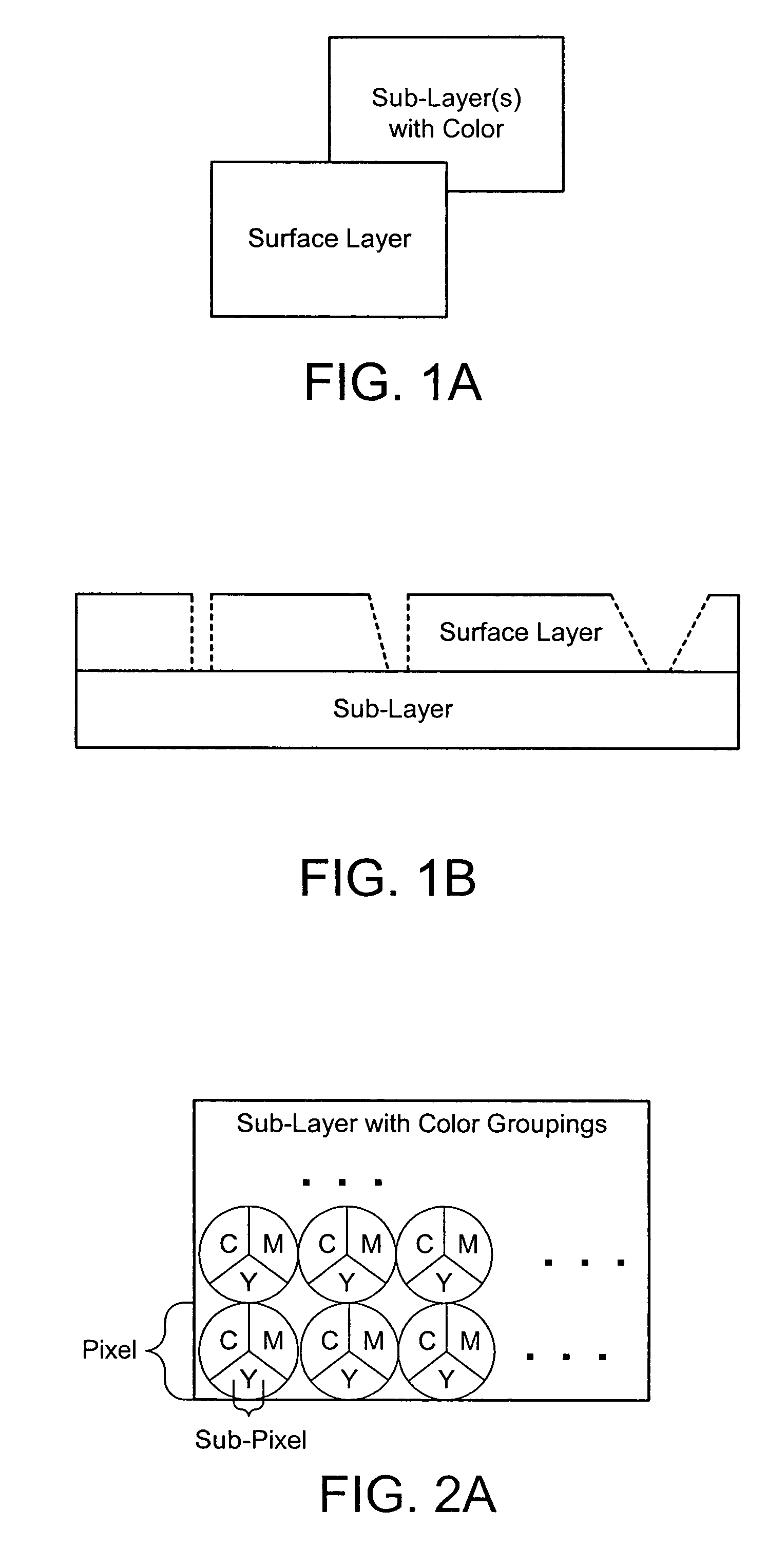

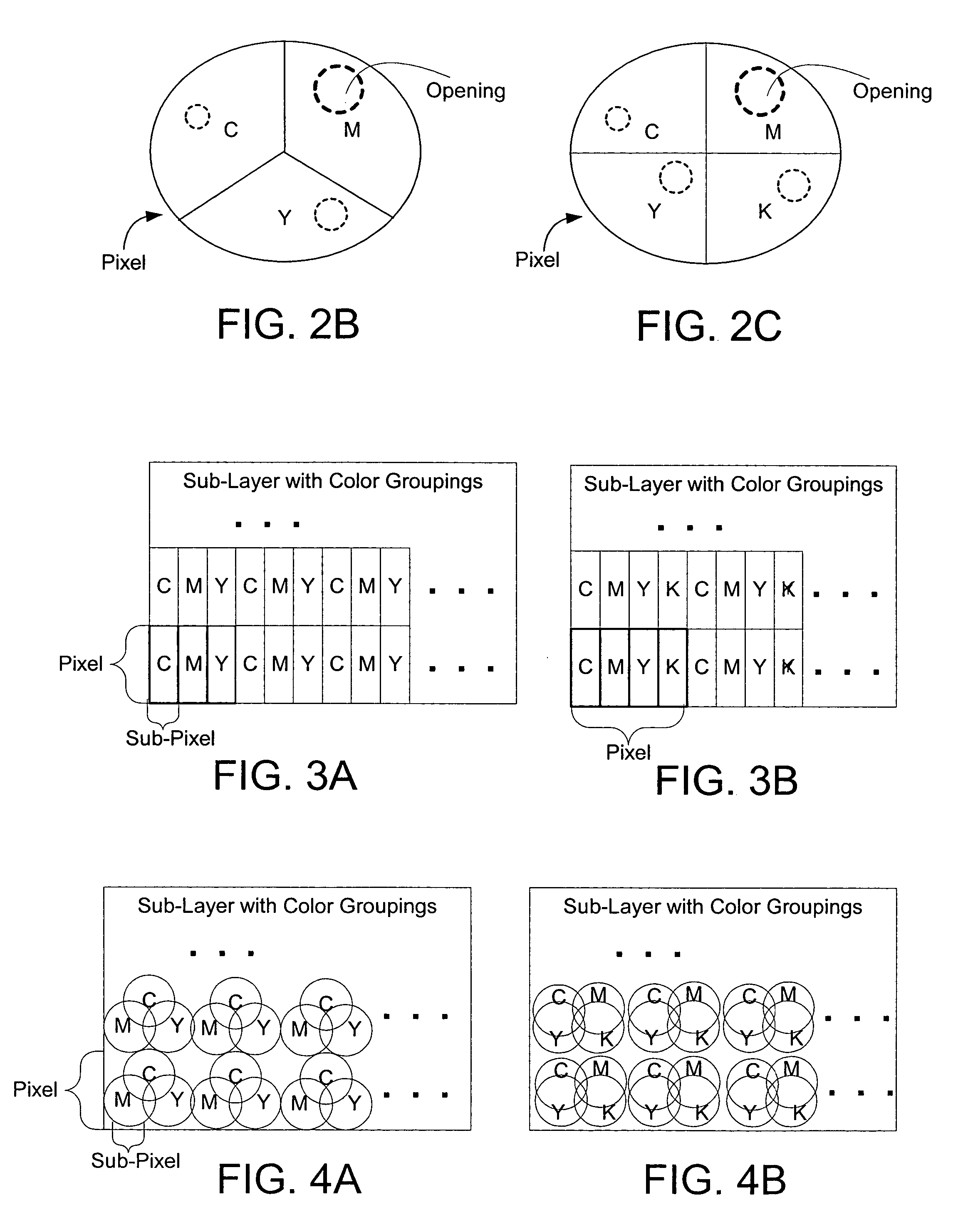

Color laser engraving and digital watermarking

A color laser engraving method engraves a document including a surface layer and one or more sub-layers. The sub-layer includes different colors and orientations of ink. A laser provides openings in the surface layer—to expose color ink in the sub-layer—to create color images and / or text. The different orientations of the colored inks include, e.g., circular, linear and overlapped groupings of ink. A sub-layer preferably includes many repeated instances of the grouping. A digital watermark is embedded in a document via transfer of the digital watermark in an embedded image or text, or by pre-embedding the document via altering intensity of colored inks on the original document card stock. A digital watermark can be carried via modulation with a pseudo-random noise sequence.

Owner:DIGIMARC CORP

Color laser engraving and digital watermarking

A color laser engraving method engraves a document including a surface layer and one or more sub-layers. The sub-layer includes different colors and orientations of ink. A laser provides openings in the surface layer—to expose color ink in the sub-layer—to create color images and / or text. The different orientations of the colored inks include, e.g., circular, linear and overlapped groupings of ink. A sub-layer preferably includes many repeated instances of the grouping. A digital watermark is embedded in a document via transfer of the digital watermark in an embedded image or text, or by pre-embedding the document via altering intensity of colored inks on the original document card stock. A digital watermark can be carried via modulation with a pseudo-random noise sequence.

Owner:DIGIMARC CORP

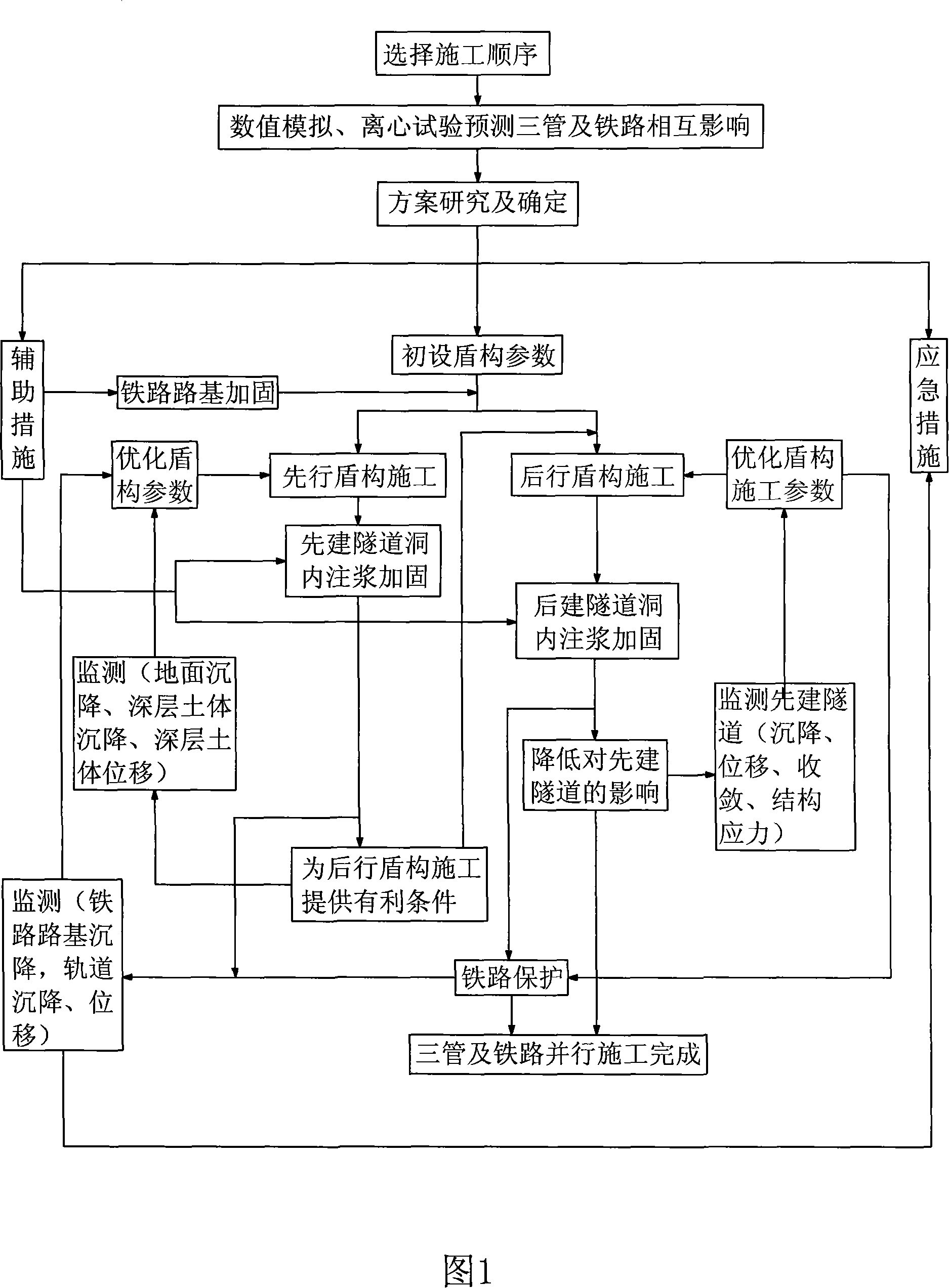

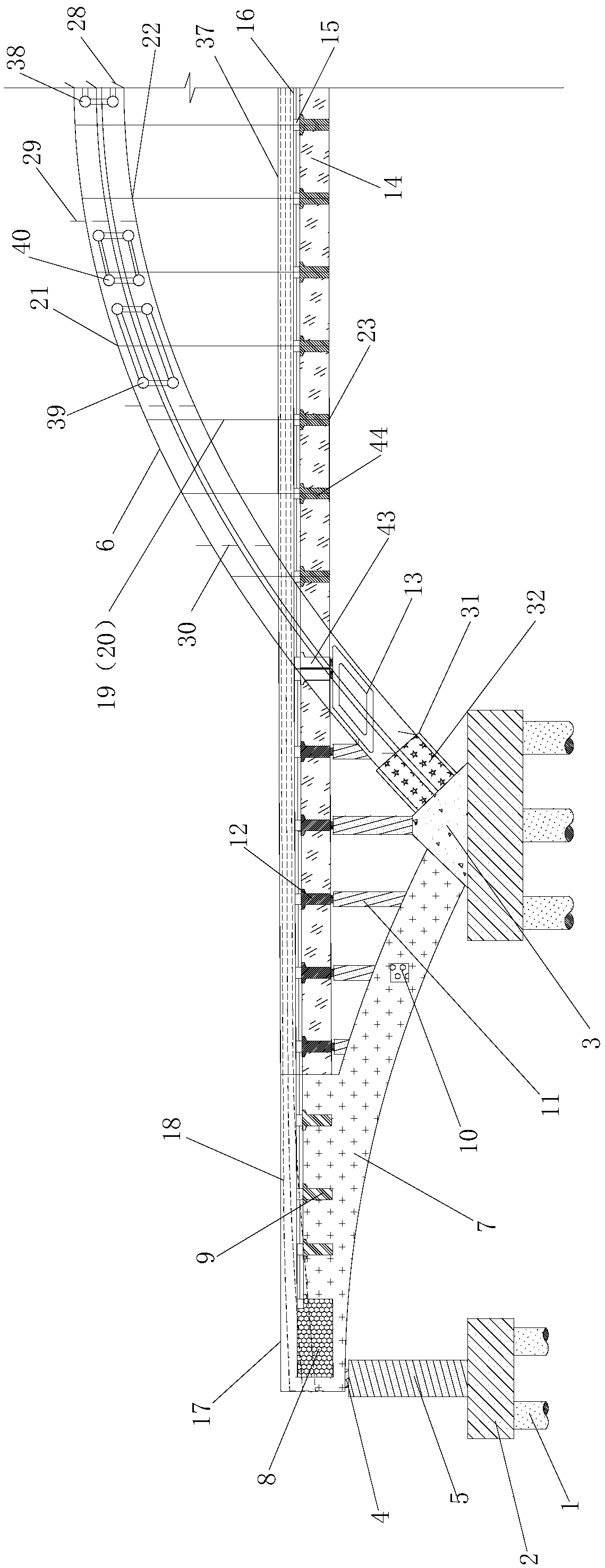

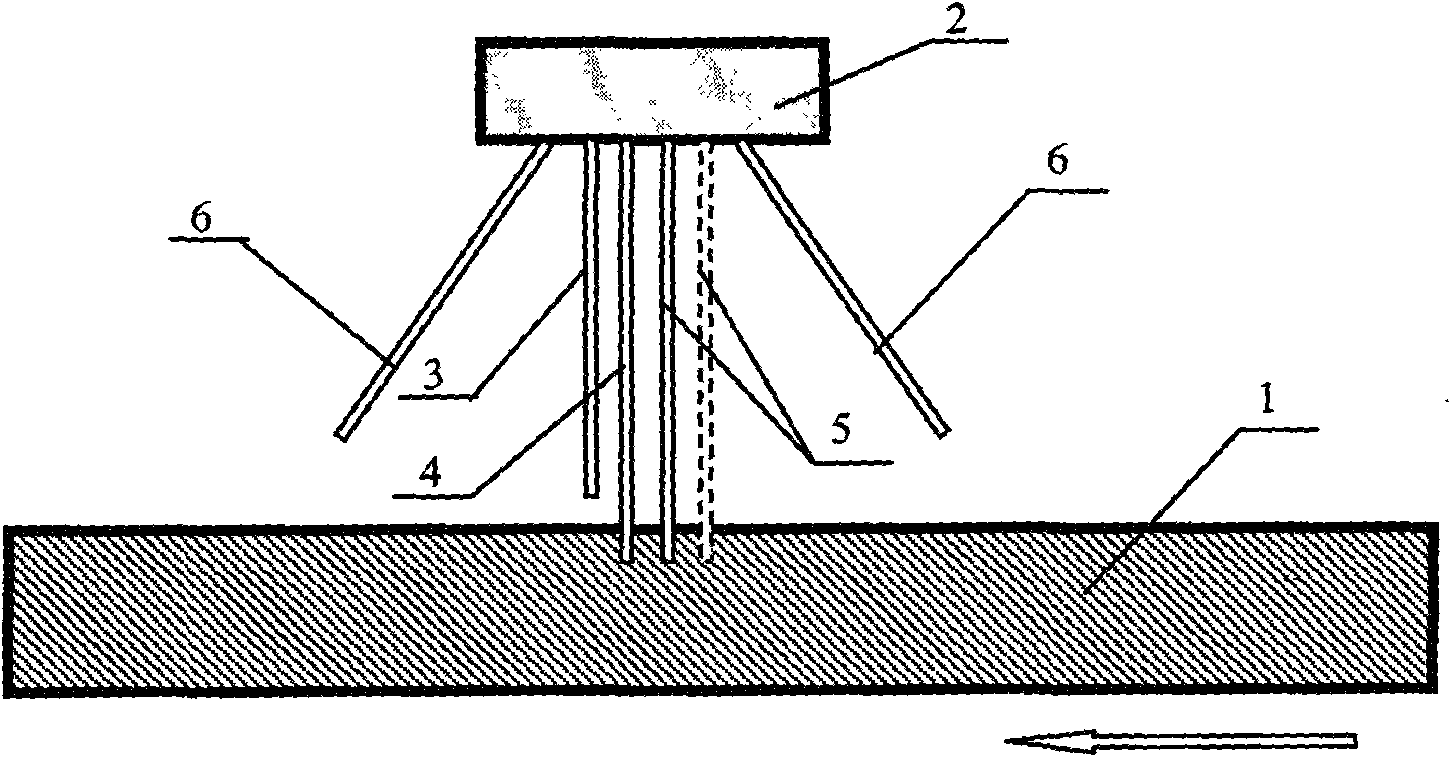

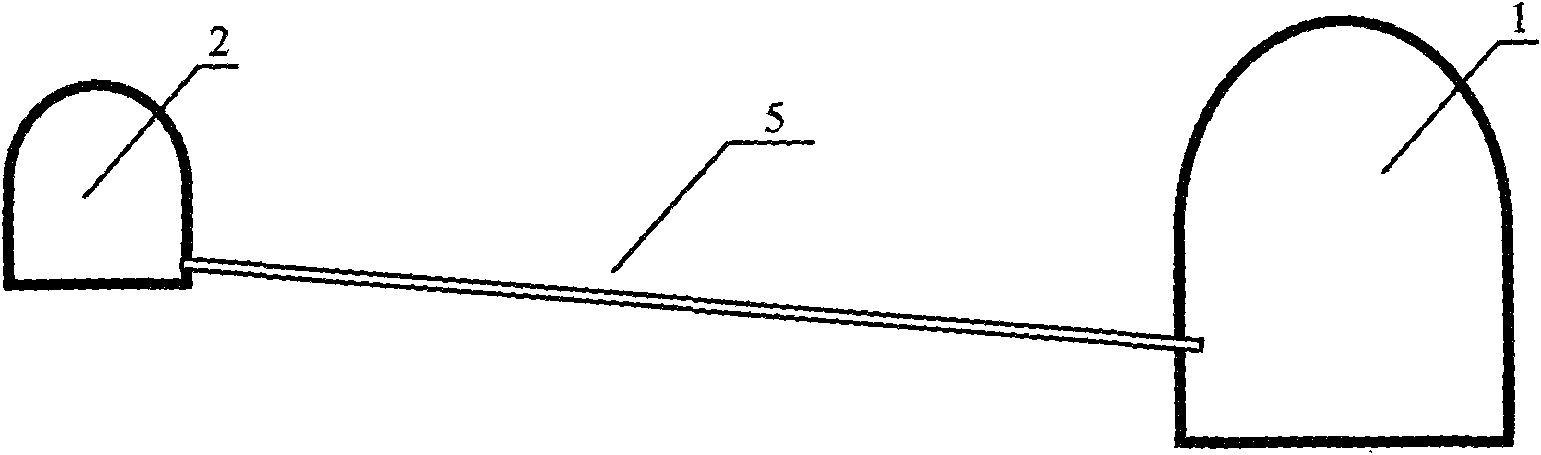

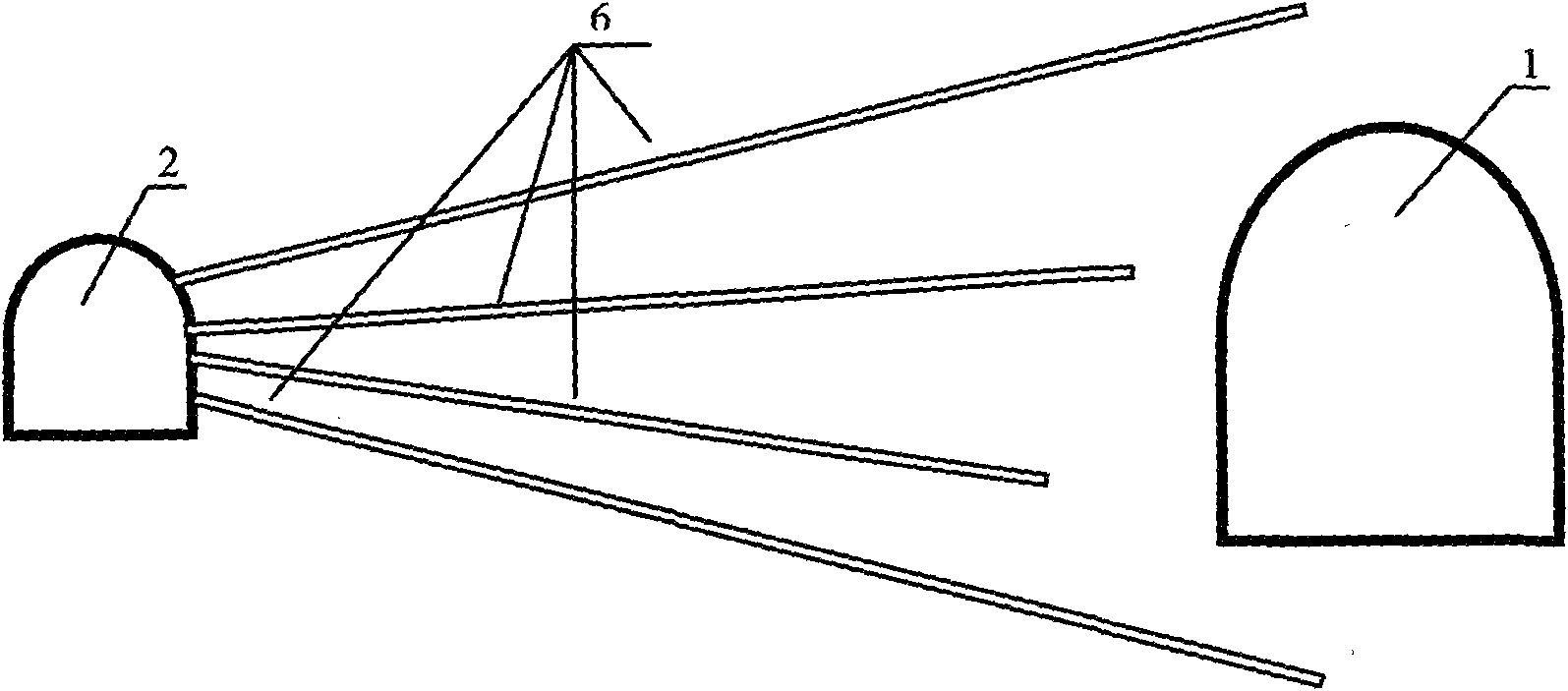

Shield construction method for three-line parallel under-passing trunk railway tunnel

ActiveCN101126318AEffective control of deformationEffective control of displacementUnderground chambersTunnel liningRailway tunnelEconomic benefits

The invention discloses a shield construction method of digging three parallel tunnels under a trunk railway, which belongs to the field of tunnel construction technology. The construction method of the invention comprises the procedure that: the model analysis on each construction sequence and method is made by a three-dimensional finite element and the shield construction sequence is selected; to select the reinforcement project of the railway bed is selected according to the influence degree of the dynamic stress, the load-carrying structural model is adopted to calculate and decide the shield area reinforcing bars enhancement project under the dynamic load of the railway train; the construction parameters are selected according to the test results and the performance of the shield machine, the front earth pressure is reasonably set , the synchronizing mortar injection is enhanced, the forward digging speed and the axis deviation are strictly controlled, the secondary mortar injection is made, the foam or mud is filled by utilizing a pre-embedded injection hole; the strict monitoring measures to monitor the shield construction process is adopted so that the construction unit can adjust the construction parameters in time and guarantee the construction safety. The invention not only guarantees the construction quality and the construction safety of the project but also creates good economic benefit.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

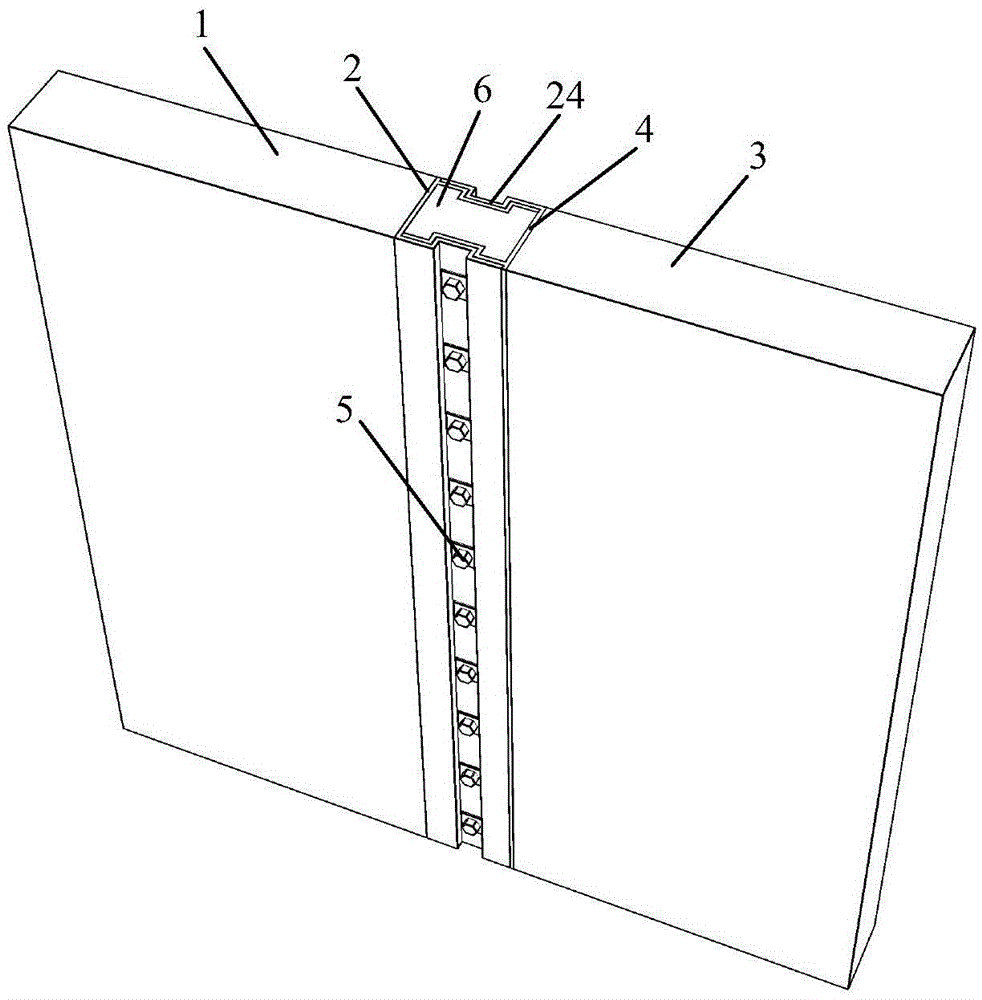

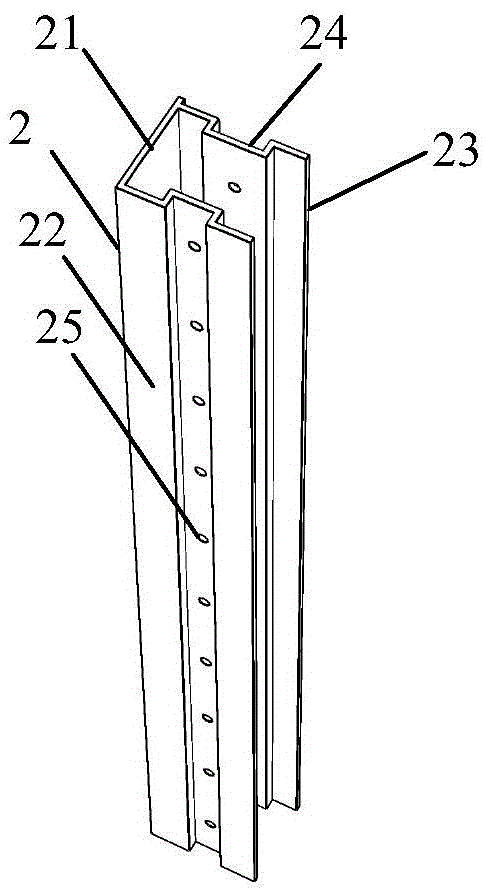

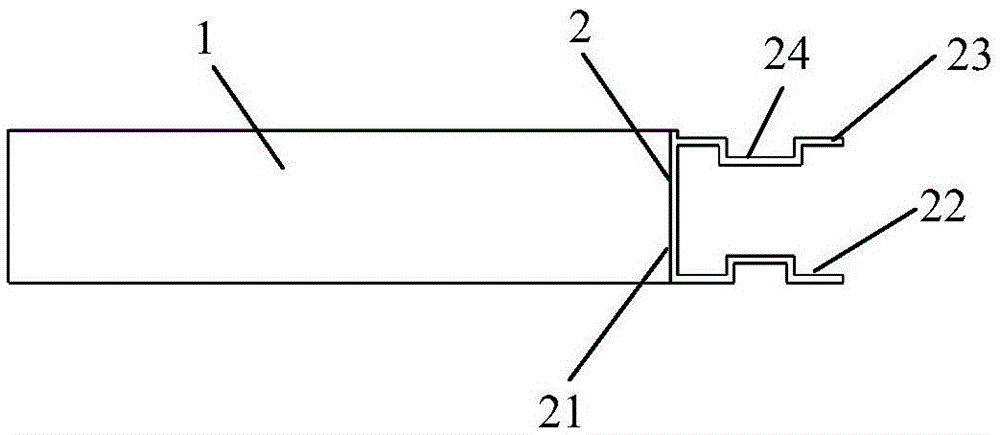

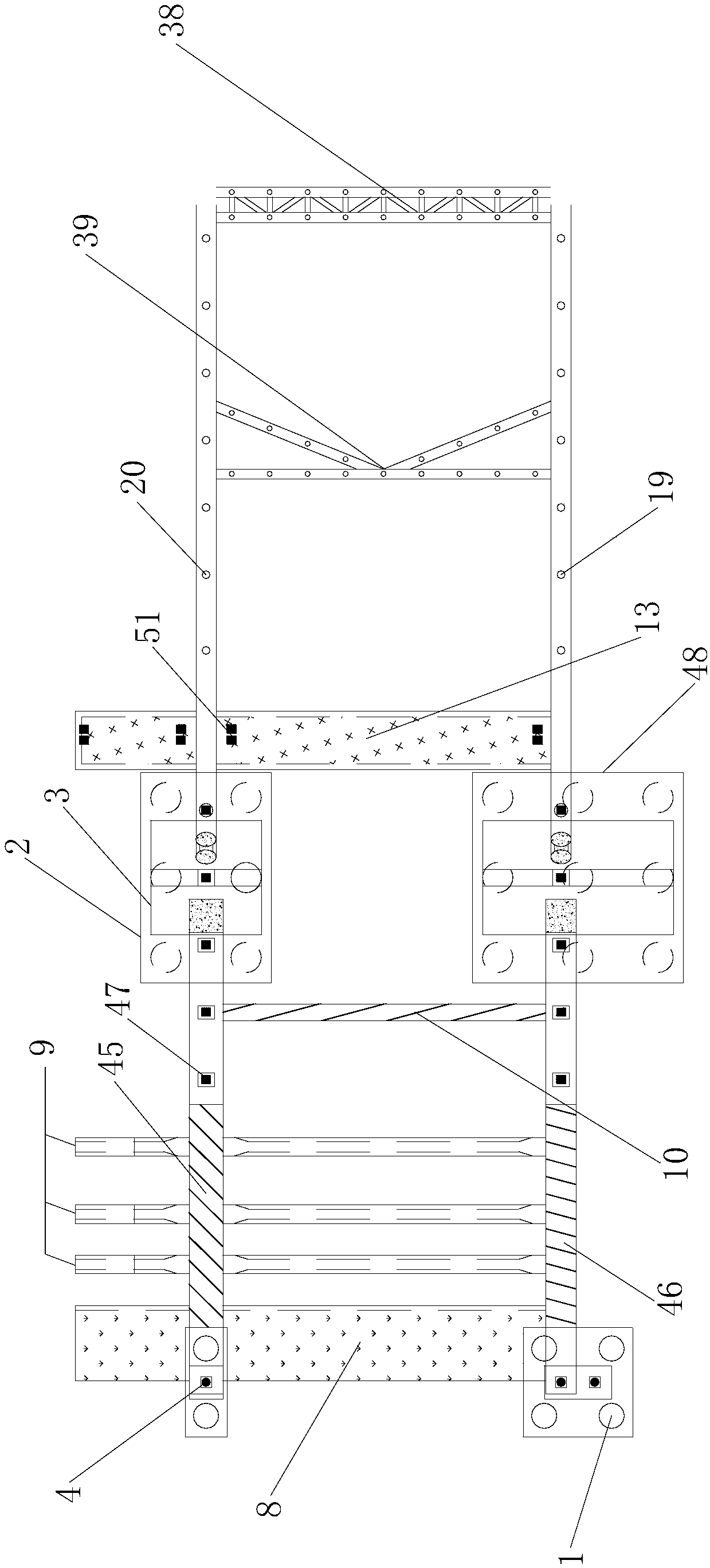

Prefabricated assembly type shear wall vertical slit connecting structure and construction method thereof

The present invention provides a prefabricated assembly type shear wall vertical slit connecting structure which comprises a left side shear wall, left side pre-embedded profile steel, a right side shear wall, right side pre-embedded profile steel, and a plurality of split bolts. The left side pre-embedded profile steel and the right side pre-embedded profile steel are disposed between the left side shear wall and the right side shear wall and have the same structure. The left side pre-embedded profile steel comprises a side plate, a front side plate and a rear side plate, the front side plate and the rear side plate are disposed at front and rear positions of the side plate, each of the front side plate and the rear side plate is inwardly provided with a groove, and the grooves are provided with a plurality of bolt holes. The split bolts are disposed in the bolt holes to lock and fix the left side pre-embedded profile steel and the right side pre-embedded profile steel. The present invention also provides a construction method of the prefabricated assembly type shear wall vertical slit connecting structure. The connecting structure is high in bearing capacity, high in stiffness, good in seismic ductility, excellent in integrity, convenient in construction and good in construction quality, and concrete is effectively restrained.

Owner:FUJIAN UNIV OF TECH

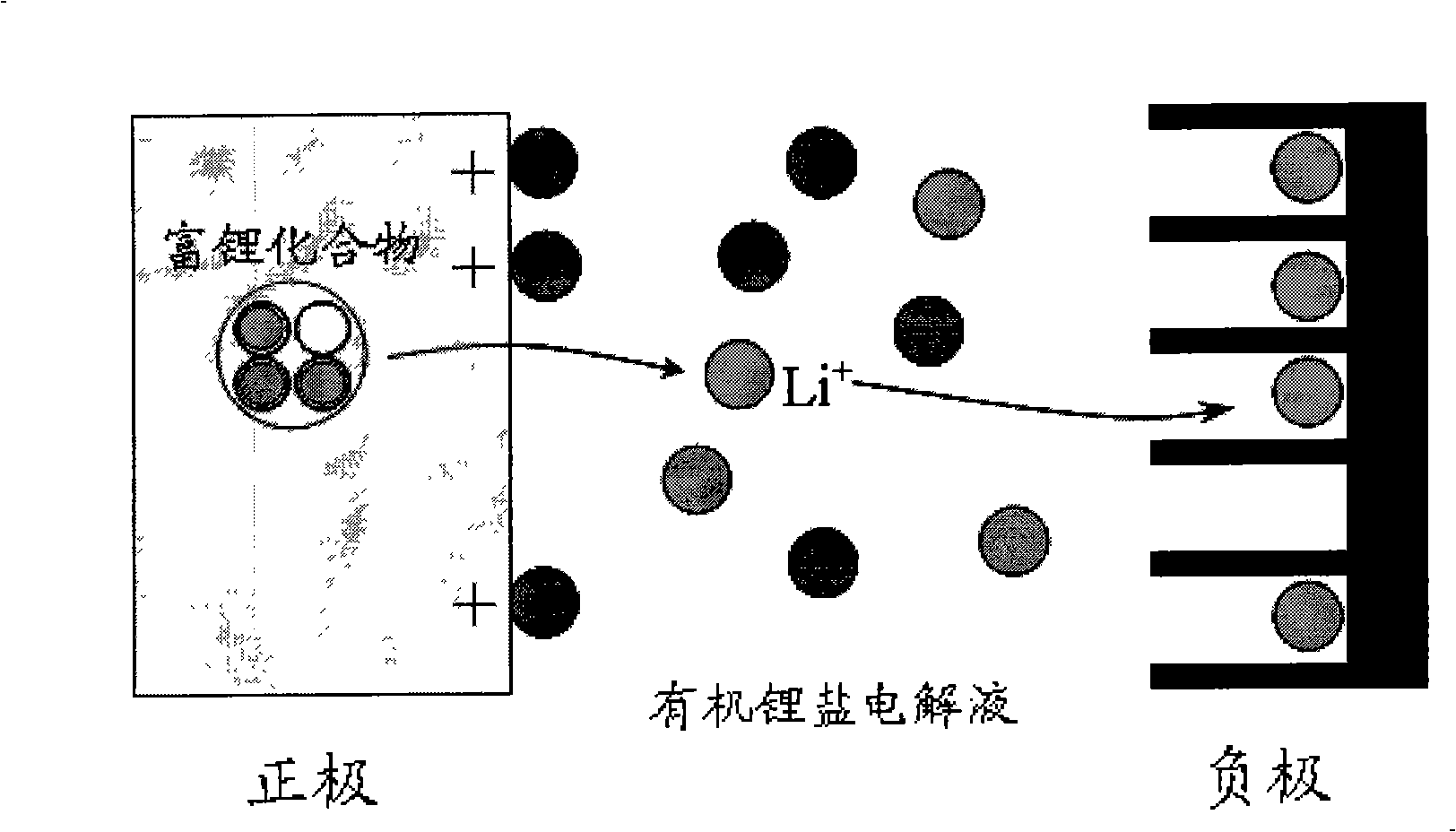

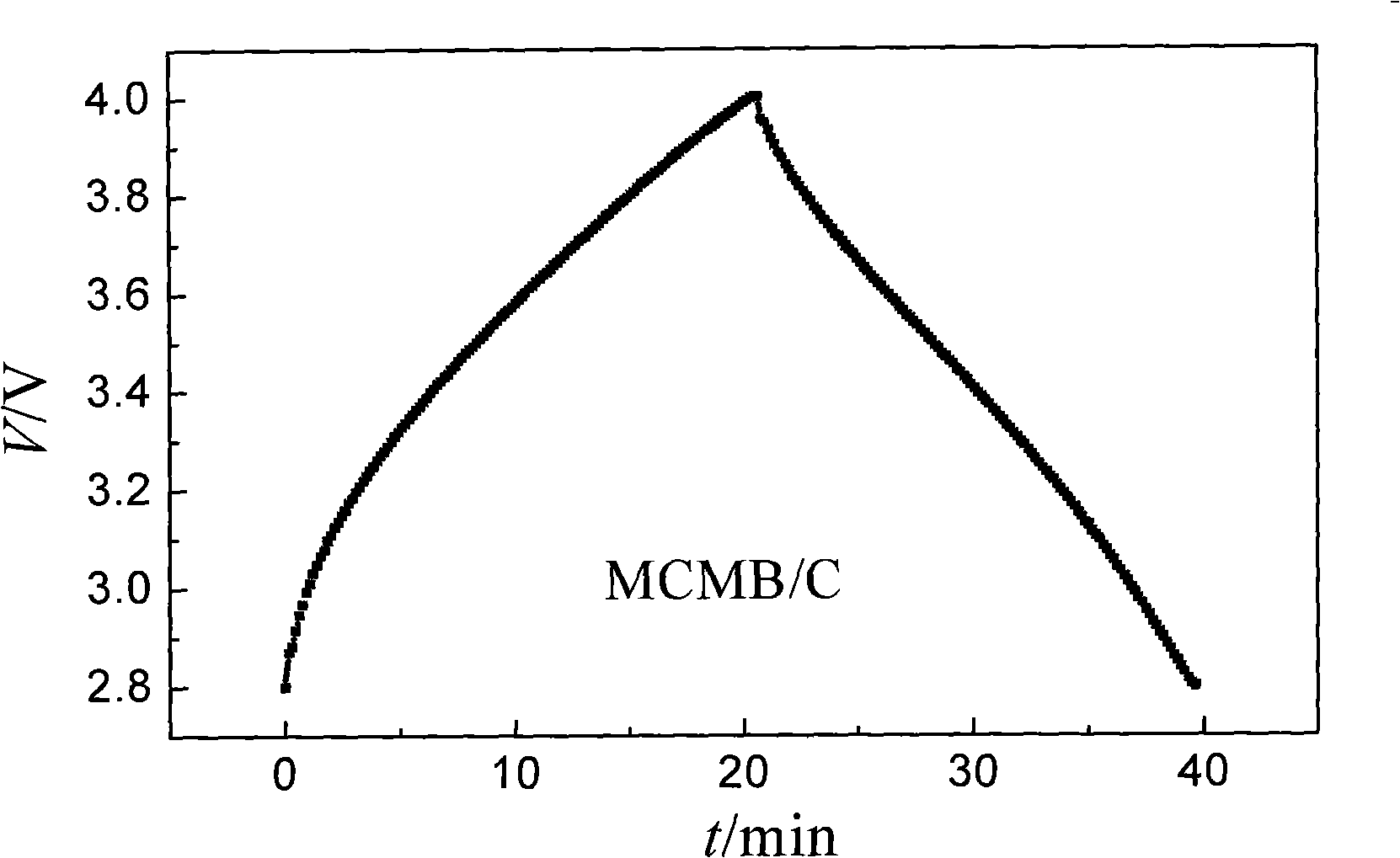

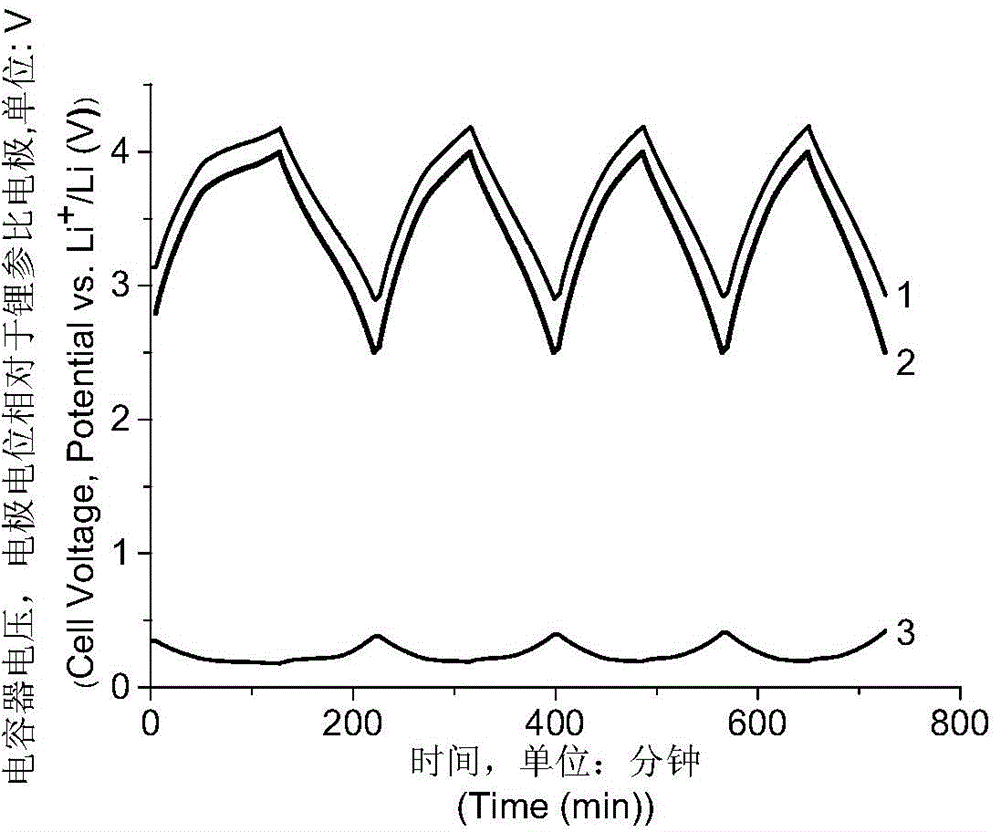

Pre-embedding method of lithium ion super capacitor cathode

InactiveCN101252043ASimplify the assembly processCapacitor safety performance improvementElectrode manufacturing processesElectrolytic capacitorsConductive polymerLithium compound

The invention discloses an easily implemented lithium pre-insertion novel method for a cathode of a lithium ion super capacitor, wherein, a nonmetal lithium third electrode is led into a novel lithium ion super capacitor system which takes porous charcoal materials, conductive polymers or compounds of the conductive polymers as an anode, lithium insertable metal oxides or charcoal lithium insertion materials as the cathode and organic lithium salt solution as electrolyte, and lithium pre-insertion processing of the cathode with a depth of 5 to 60 percent is performed so as to prevent reduction of the ion concentration of the electrolyte during the charging and discharging process and non-reversible absorption of anions on the anode and improve the charging and discharging characteristics of the capacitor. The essential component of the nonmetal lithium third electrode is lithium-rich compounds with non-reversible lithium-free property; during the preparation process of the porous charcoal material anode or the conductive polymer anode, the lithium-rich compounds of the third electrode are mixed by mass percent of 3 to 50 and can form the lithium ion super capacitor together with the lithium insertable cathode after being prepared into the electrode; during the activation process of the capacitor, lithium pre-insertion of the cathode is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

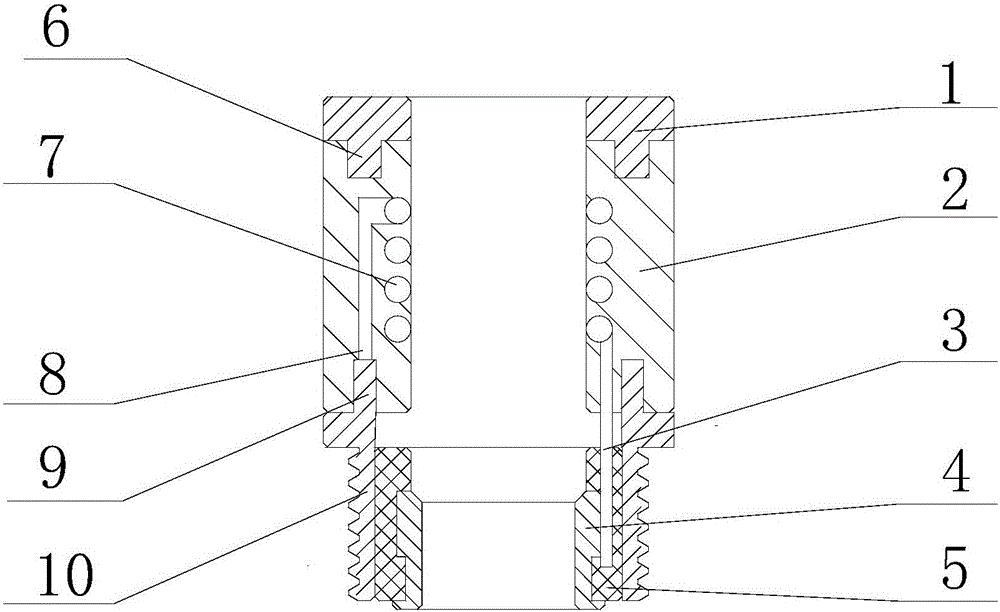

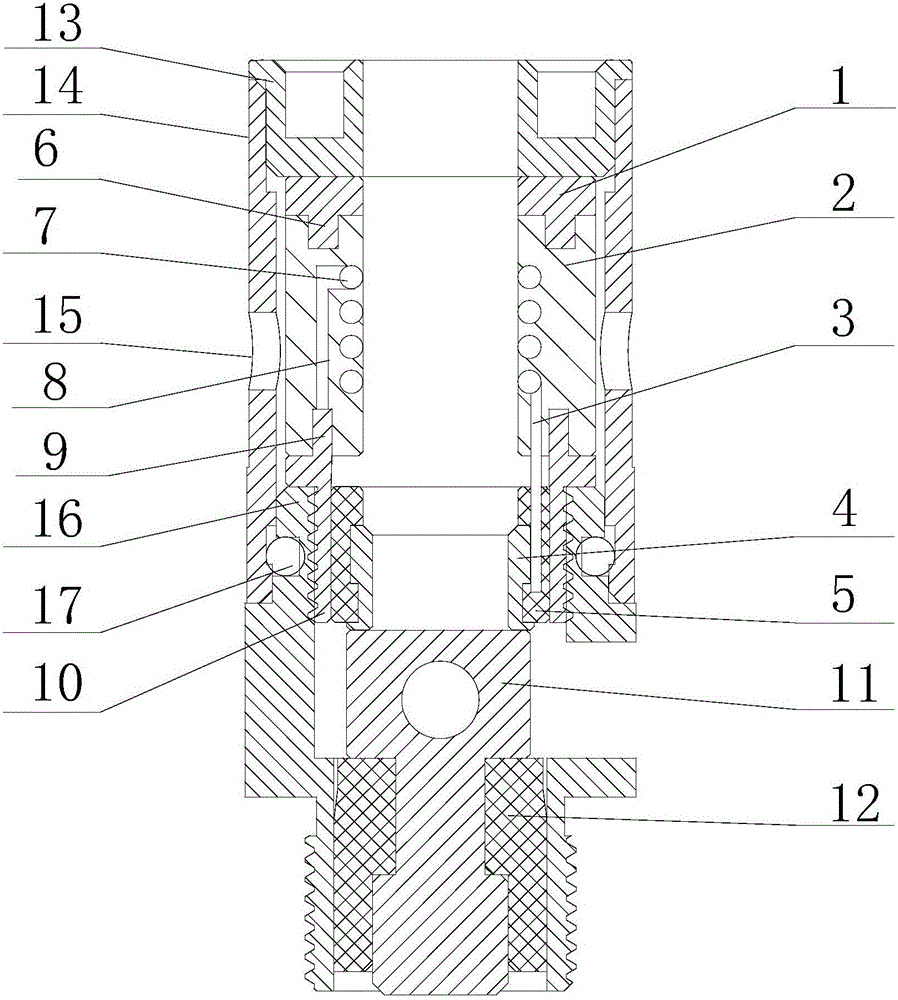

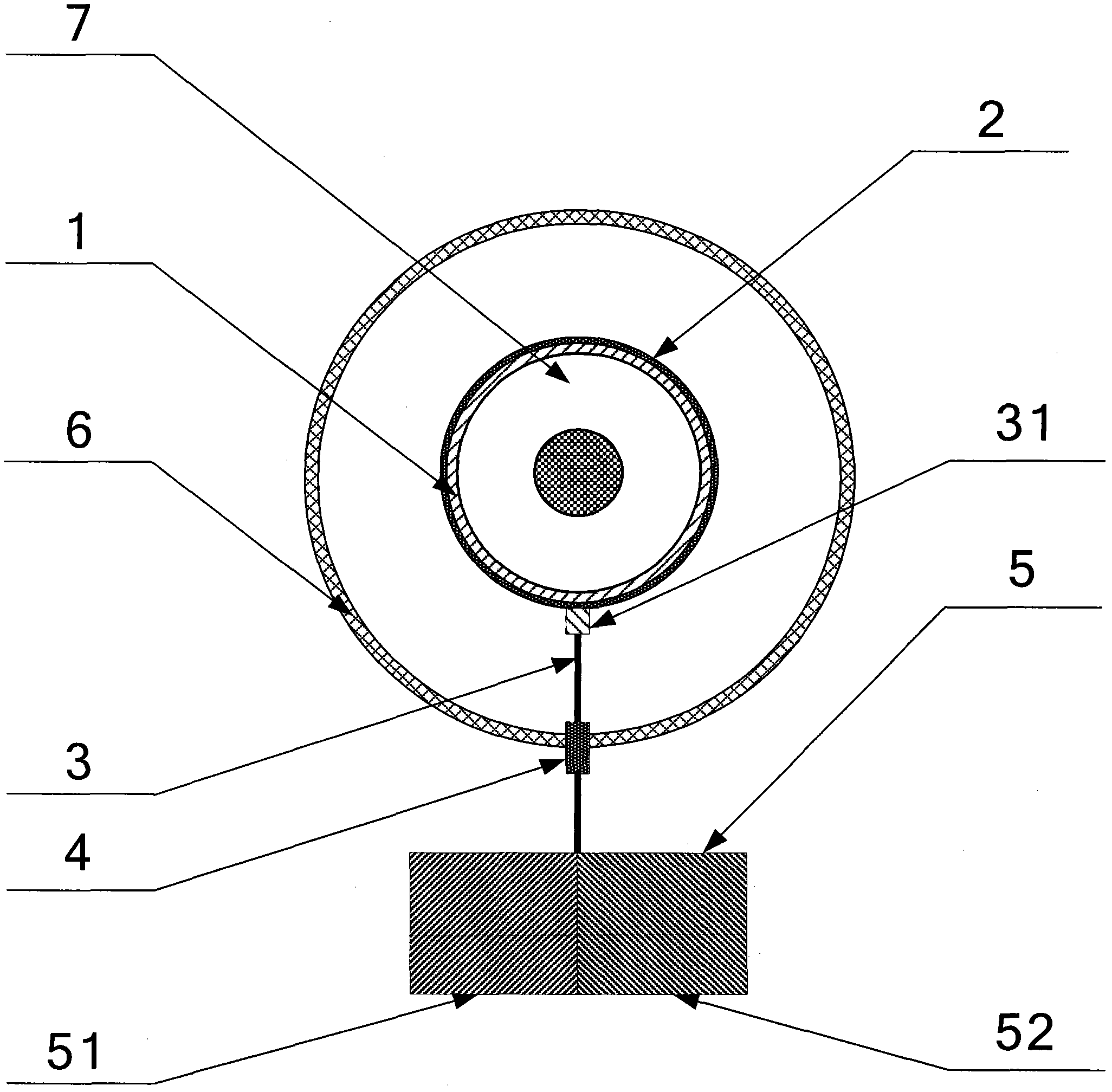

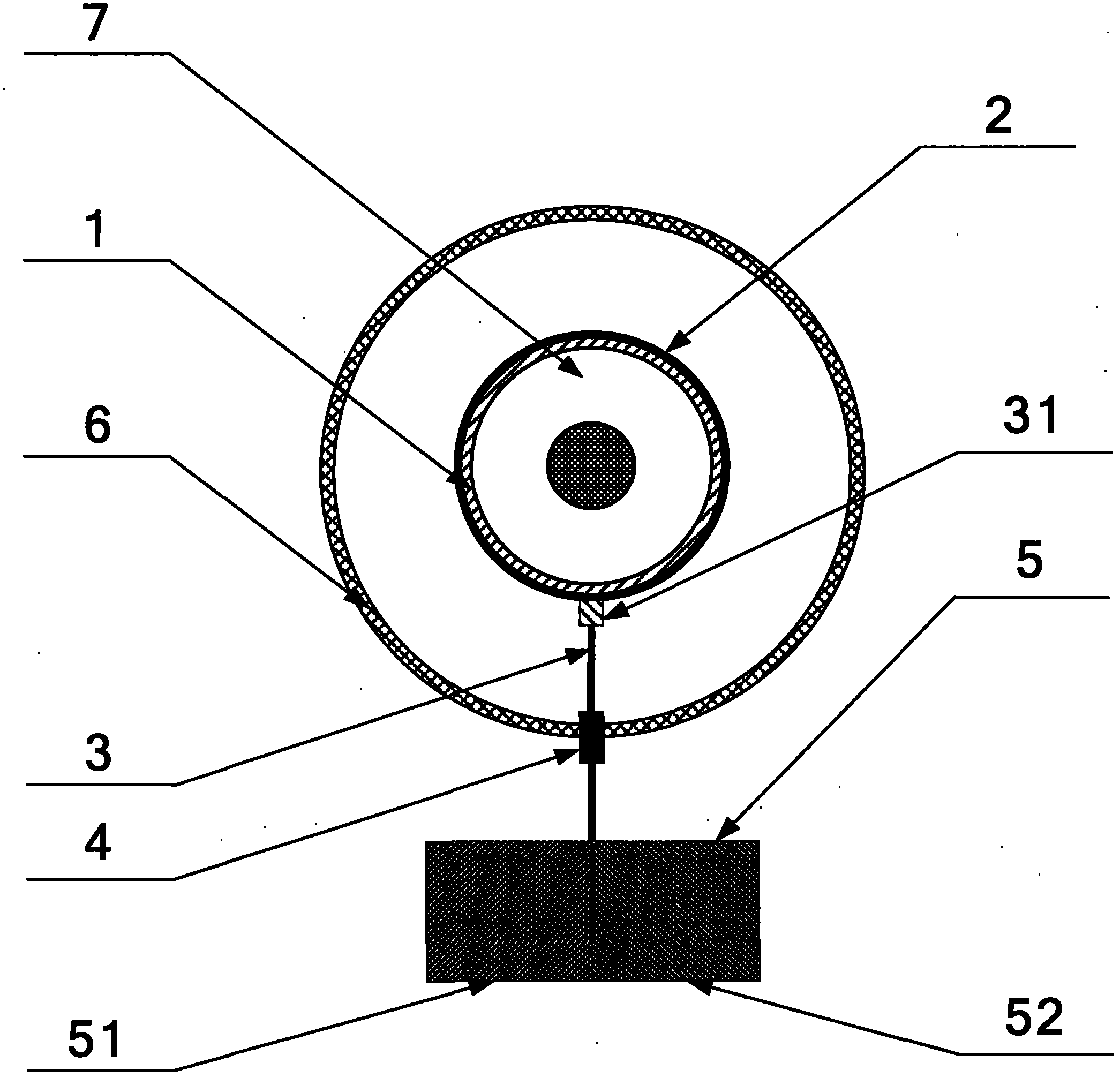

Friction energy consumption type node connection device for self-centering pier column structure

InactiveCN101936043AImprovement of local pressure problemsImprove performanceShock proofingPile capResidual deformation

The invention relates to a friction energy consumption type node connection device for a self-centering pier column structure, which is a device used for connecting a bridge pier or a frame column with a pile cap (a foundation), so as to improve the energy consumption of the pier column structure under the action of earthquake and eliminate or reduce the residual deformation and the injuries of the structure. The device comprises a pier column strengthening steel plate, a foundation pre-embedded steel plate, an angle steel, a friction bolt, a friction plate, unbonded prestressed tendons, an anchor bolt and the like. The device can connect a concrete pier column and the foundation into a whole through the unbonded prestressed tendons which are vertically arranged. When the earthquake strength achieves a certain degree, the pier column-foundation contact surface is open, and the pier column can produce a certain rotation relative to the foundation. A friction device can dissipate earthquake energy through friction at this time, and the prestress provided by the prestressed tendons can recover the structure to the initial position after the earthquake. A pre-embedded part at the end part of the pier column is used for improving the local bearing pressure of the concrete when the pier column rotates relatively.

Owner:SOUTHEAST UNIV

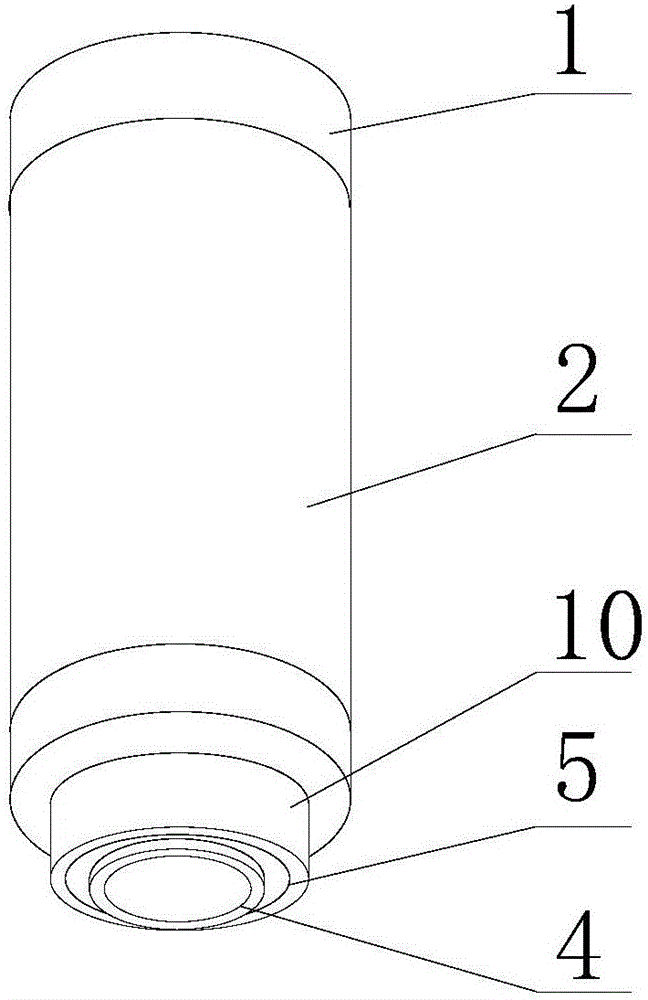

Ceramic composite electronic cigarette heating pipe and electronic cigarette atomizing core employing same

The invention discloses a ceramic composite electronic cigarette heating pipe which comprises an electric heating wire and a micro-porous ceramic pipe; a main body part of the electric heating wire is pre-embedded in the pipe wall of the micro-porous ceramic pipe; the electric heating wire is led out of the outside of the micro-porous ceramic pipe through connecting pins. A compact connecting piece is arranged at each of the upper and lower ends of the micro-porous ceramic pipe. The two connecting pins of the electric heating wire are lead out from the lower end of the micro-porous ceramic pipe; the compact connecting piece at the lower end is a metal connecting ring; a connecting pile protruding into the pipe wall of the micro-porous ceramic pipe is arranged on the upper side of the metal connecting ring. A double-electrode conductive connecting ring consists of an inner ring electrode and an outer ring electrode and is arranged on the lower side of the metal connecting ring; the outer ring electrode is electrically connected or integrally formed with the metal connecting ring; an insulating ring is arranged between the outer ring electrode and the inner ring electrode. The inner ring electrode and the outer ring electrode of the double-electrode connecting ring are respectively electrically connected with the two connecting pins of the electrical heating wire. When the heating pipe disclosed by the invention is in use, the double-electrode conductive connecting ring and a double-electrode conductive connecting column of an atomizing core are designed to be in threaded connection for realization.

Owner:INNOKIN TECH

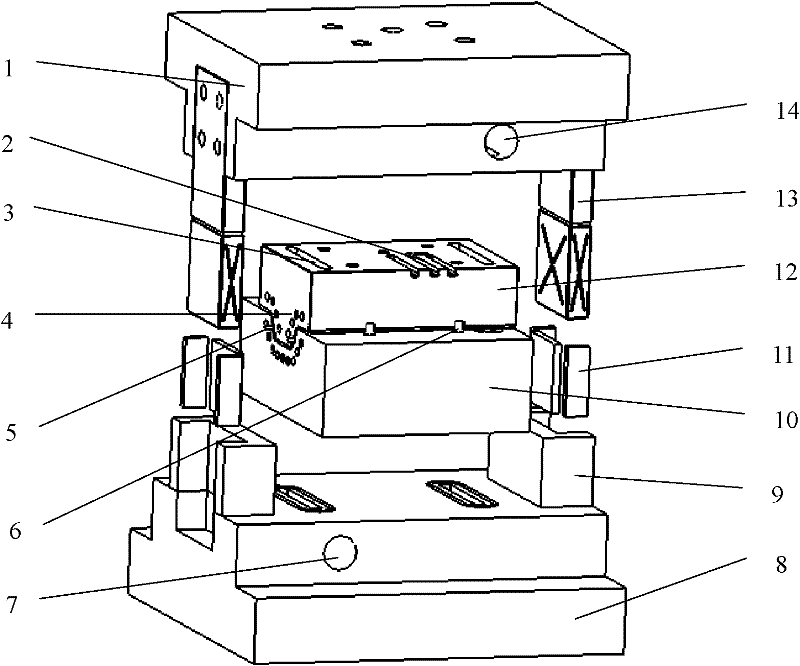

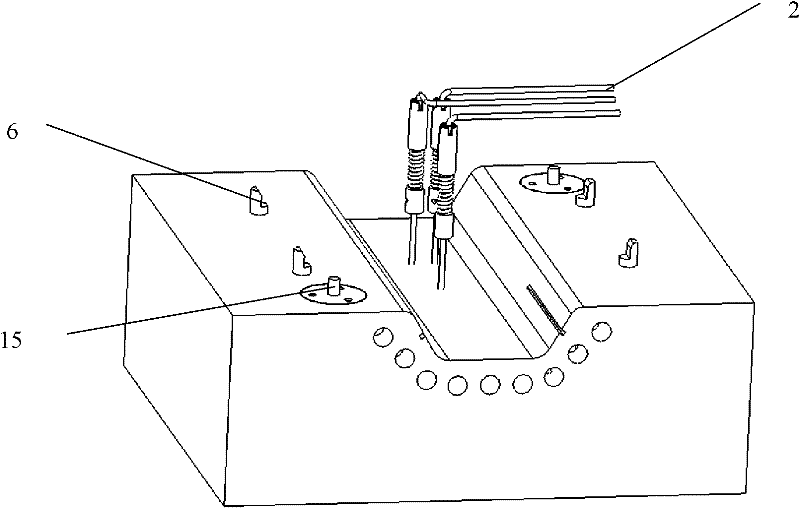

Hot stamping mould with temperature measuring system

InactiveCN102172719ARealize full cycle temperature monitoringAvoid cycleShaping toolsMetal working apparatusHot stampingTemperature curve

The invention discloses a hot stamping mould with a temperature measuring system. The hot stamping mould comprises a concave mould, a convex mould, a plate support and positioning device, a mould built-in cooling system, a mould built-in temperature measuring system and an external temperature recording device, and is characterized in that: the concave mould and convex mould are provided with a molded surface corresponding to the workpiece shape respectively; cooling pipelines are staggered in the concave mould and convex mould, and connected with a water inlet and a water outlet through a diversion groove; and multiple thermocouples are pre-embedded on specific positions on the surface of the concave mould as well as on the surface and inside of the convex mould, and connected with the multi-channel temperature recording device. The hot stamping mould disclosed by the invention realizes full-period temperature monitoring, can directly judge and predict the product quality according to a temperature curve so as to eliminate unqualified products immediately, shortens the inspection cycle and lowers the production cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

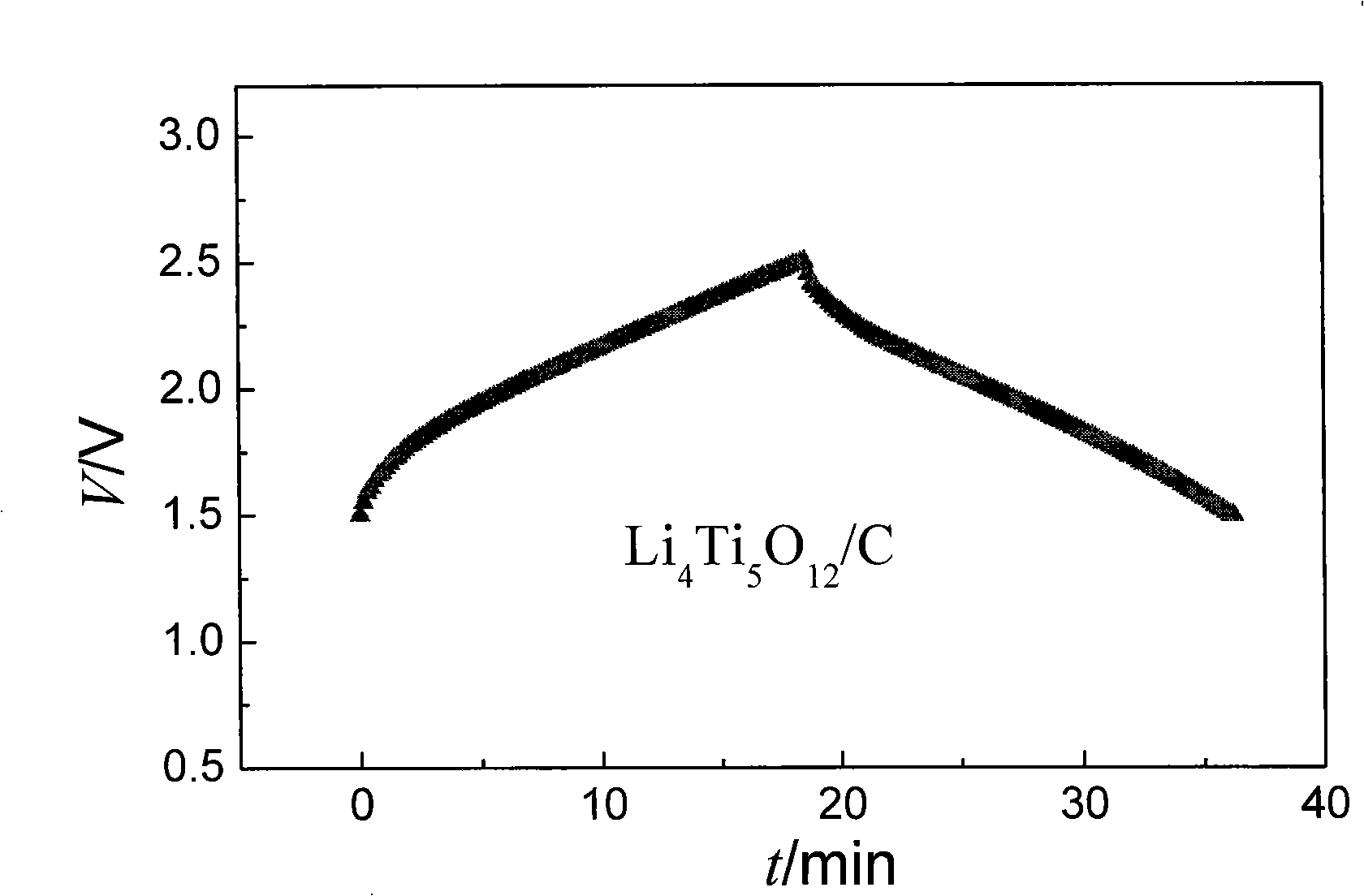

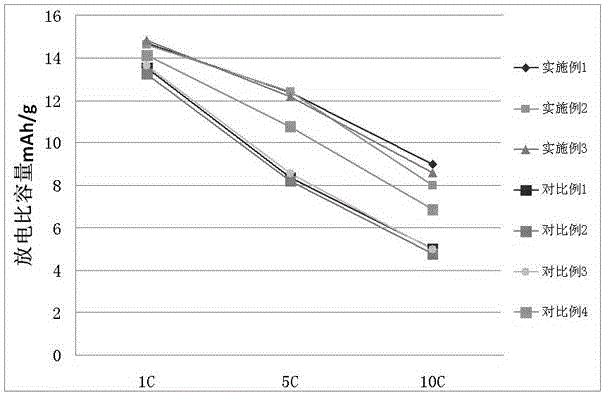

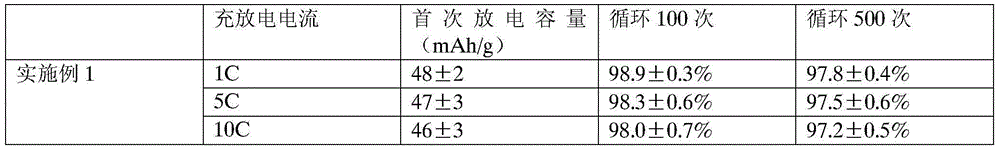

Novel lithium pre-embedding method of lithium ion capacitor

ActiveCN104681311ALow costImprove securityHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorLithium metalPre embedding

The invention provides a novel lithium pre-embedding method of a lithium ion capacitor. The method comprises the following steps that (1) a battery cell is assembled, and is soaked into an organic solution containing lithium salts; (2) a positive electrode and a negative electrode are respectively connected with a charging and discharging test instrument, and once discharging after once charging is used as a cycle, 1 to 1000 times of cycles are totally carried out, and the lithium pre-embedding on the negative electrode is completed; (3) the battery cell after the lithium pre-embedding completion is taken out and is put into a packaging case, the packaging case is filled with electrolyte and is assembled into a lithium ion capacitor single body. When the method is adopted, the problem of too high cost due to lithium metal, porous current collectors and the like can be effectively solved, the safety can be improved, the technical flow process can be simplified, and the method is applicable to industrial production.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

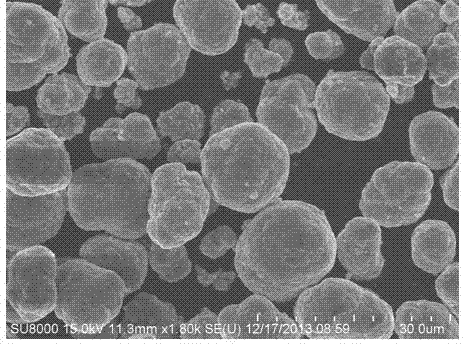

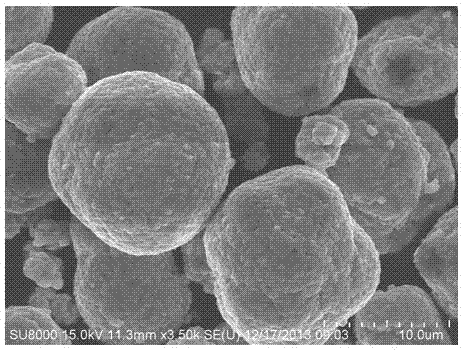

Lithium sulfide-porpous carbon compound positive material for lithium ion battery and preparation method thereof

InactiveCN102163720AImprove conductivityStop the spreadCell electrodesPorous carbonSodium-ion battery

The invention provides a lithium sulfide-porpous carbon compound positive material for a lithium ion battery and a preparation method thereof. The positive material is formed by compounding lithium sulfide and ordered porous carbon, wherein the mass fraction of the lithium sulfide in the compound material is 20-80%; and the lithium sulfide exists in the pore spaces of the porous carbon. The preparation method comprises the following steps: firstly, carrying out ball milling on the ordered porous carbon and sulfur in the presence of inert gas; then carrying out thermal processing on the milled mixture at the temperature of 145-155 DEG C so that the sulfur fully is dispersed into the porous carbon; and finally, reacting lithium with the sulfur so as to generate the lithium sulfide by a chemical or electrochemical method, thereby obtaining the positive material provided by the invention. According to the invention, the preparation process is simple, and the raw material source is wide; the prepared positive material is used in a mode of pre-embedding lithium in a positive electrode, metal lithium is not required to serve as a negative electrode, and a carbon negative electrode, a silicon negative electrode and the like are used, thereby improving the safety performance and the assembling performance; the positive material has the advantages of good conductivity, high capacity and good circulation performance; and the positive material has a wide application prospect and the preparation method is suitable for industrial production.

Owner:CENT SOUTH UNIV

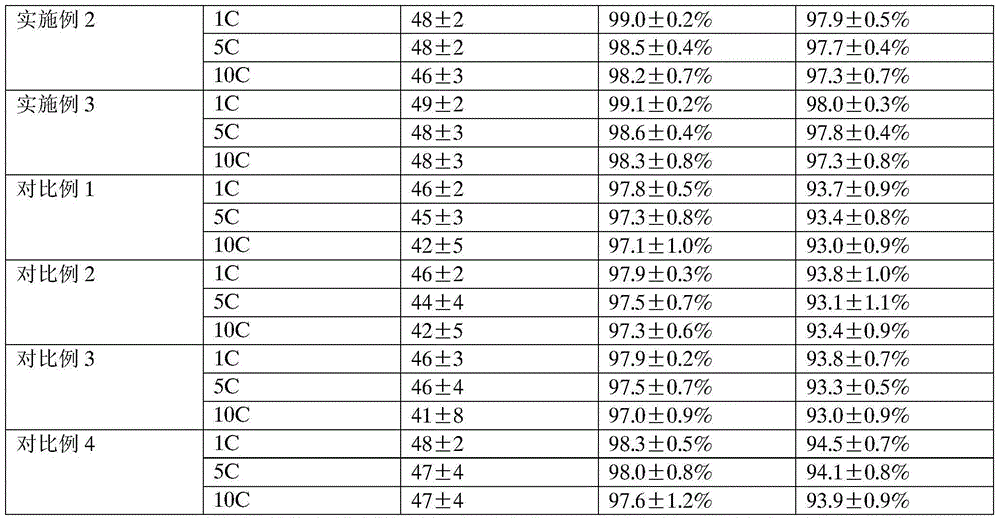

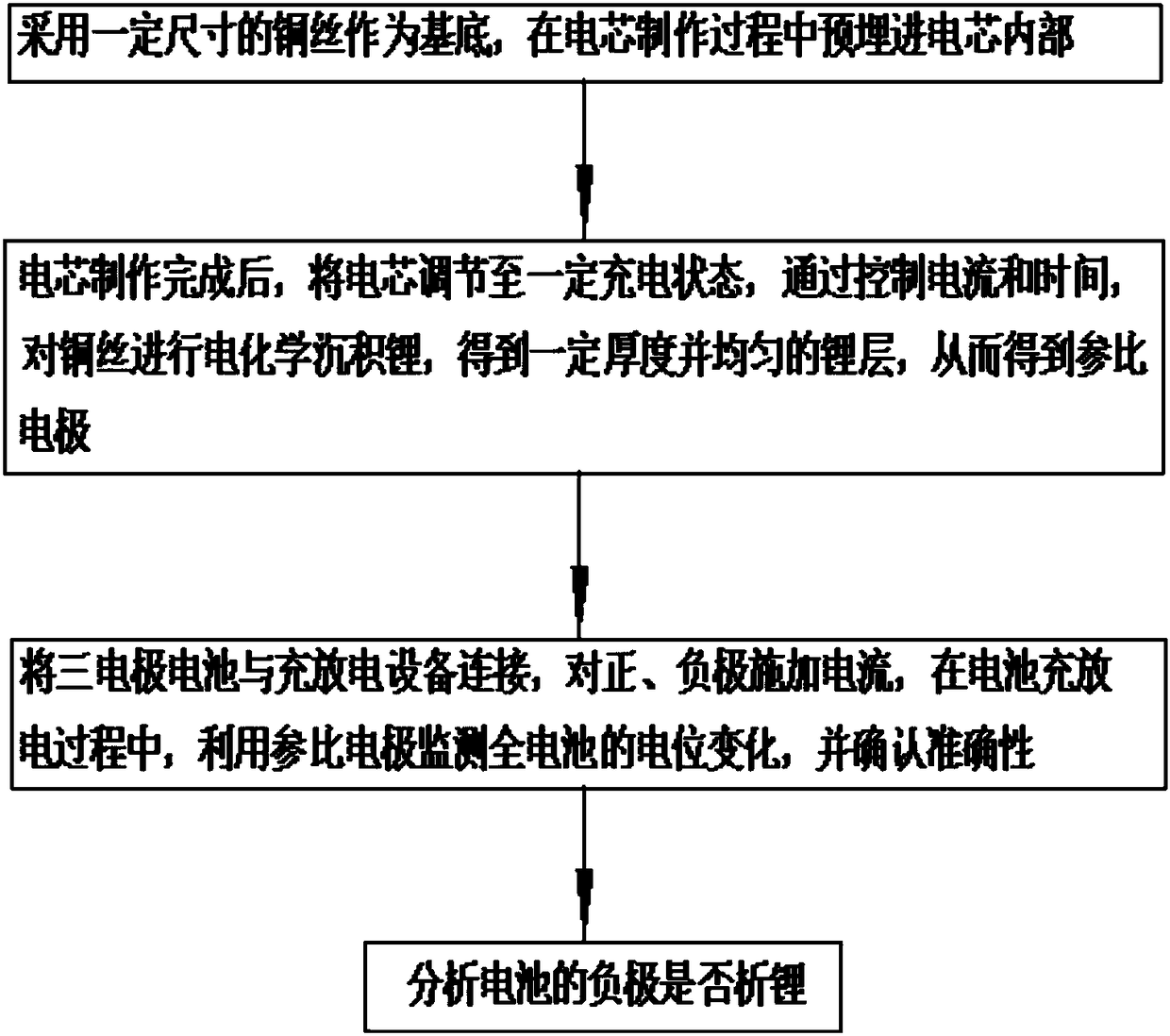

Experiment method for monitoring cathode lithium precipitation via use of reference electrode

InactiveCN108427077AIncrease credibilityFinal product manufactureElectrical testingElectrical batteryCharge discharge

The invention discloses an experiment method for monitoring cathode lithium precipitation via use of a reference electrode. The method comprises the following steps: a brass wire of a certain dimension is used as a substrate and is pre-embedded in an electrical core during electrical core making processes, the electrical core is adjusted to a certain charging state after the electrical core makingprocesses are finished, the brass wire is subjected to electrochemical deposition of lithium, a uniform lithium layer of a certain thickness is obtained, and therefore the reference electrode is obtained; a three electrode battery is connected with charge-discharge equipment, a current is applied to an anode and a cathode, electric potential change of a whole battery is monitored via user of thereference electrode during battery charging and discharging processes, and accuracy is confirmed; at last whether lithium precipitation occurs in the cathode of the battery is analyzed. The beneficialeffects of the method are that the electric potential change of all electrodes in the battery can be monitored via use of the reference electrodes through an electrochemical method, and breakdown points of cathode lithium precipitation can be determined; compared with a conventional disassembling observation method, the method disclosed in the invention is advantaged by simplicity, convenience, high credibility and high practicality.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

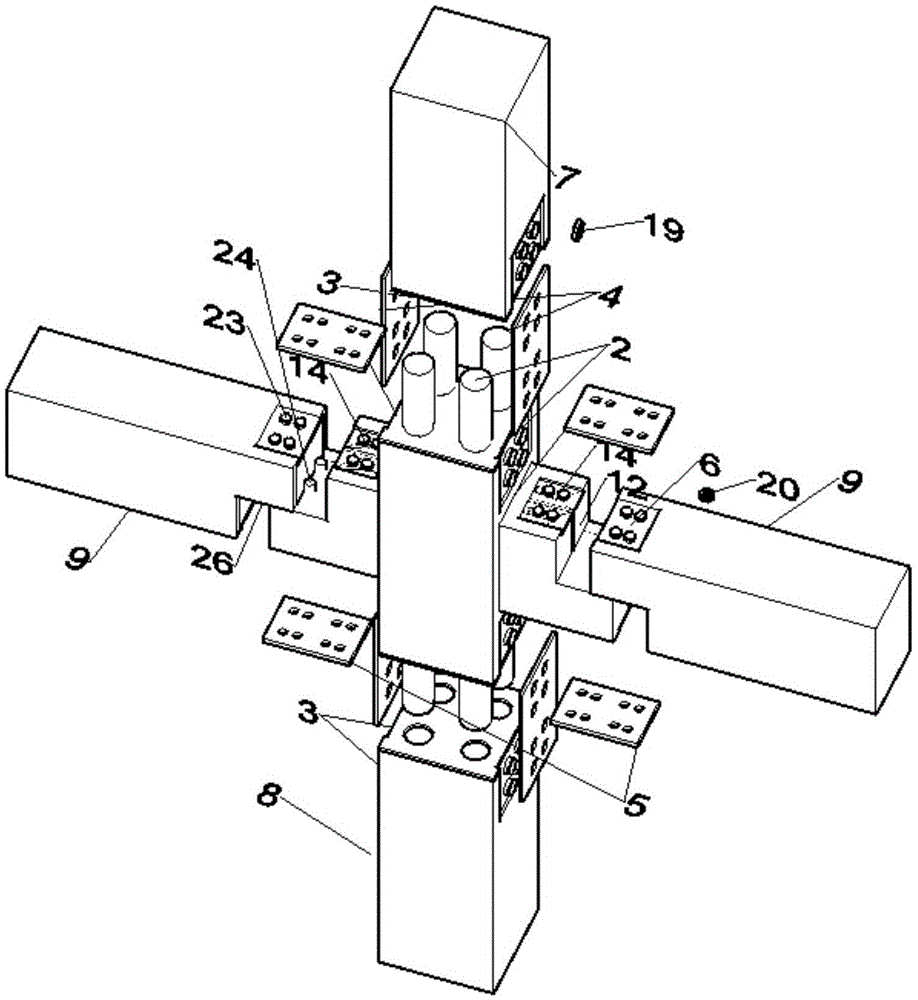

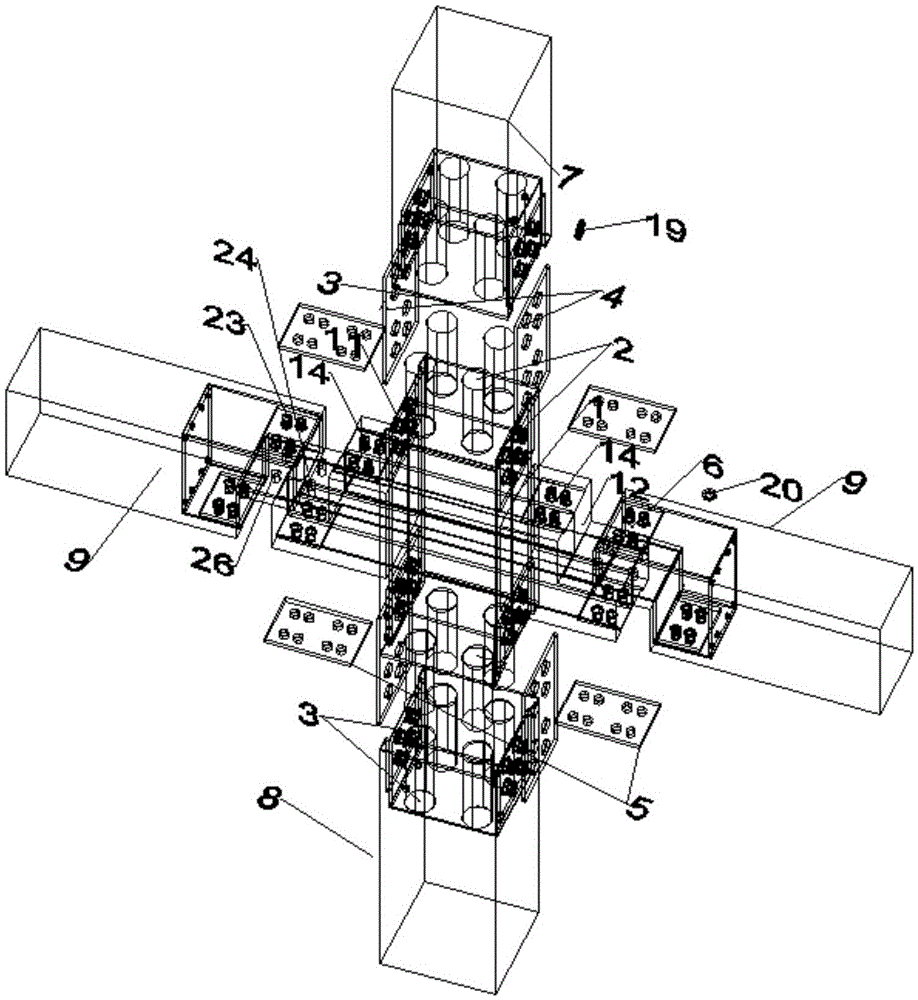

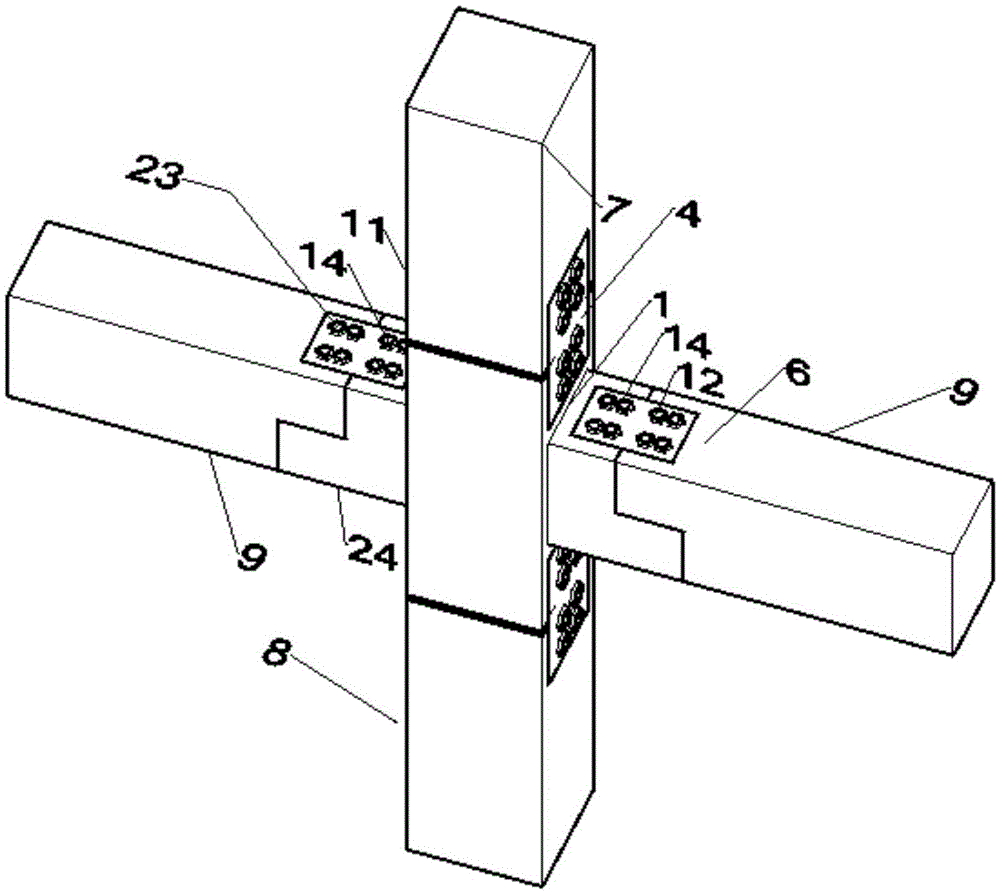

Precast beam and column connecting device and manufacturing method thereof

The invention provides a precast beam and column connecting device and a manufacturing method thereof, and relates to the technical field of civil engineering. The precast beam and column connecting device comprises a precast beam and column connecting joint, column-end pre-embedded steel components and beam-end pre-embedded steel components; the precast beam and column connecting joint comprises a first steel rib connecting piece and a second steel rib connecting piece; the first steel rib connecting piece and the second steel rib connecting piece fit crosswise and are integrally formed by casting; the column-end pre-embedded steel components are connected with the end face of the first steel rib connecting piece; the beam-end pre-embedded steel components are connected with the end face of the second steel rib connecting piece. Through the device, beam ends and column ends can be connected together only by adopting a lifting and splicing process in a construction site, so that construction progress is greatly increased; the precast beam and column connecting device is convenient in construction, rapid to operate, capable of shortening a construction period, in favor of environmental protection and noise control and convenient to transport, assemble and disassemble, and can be produced on a large scale in a short time.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

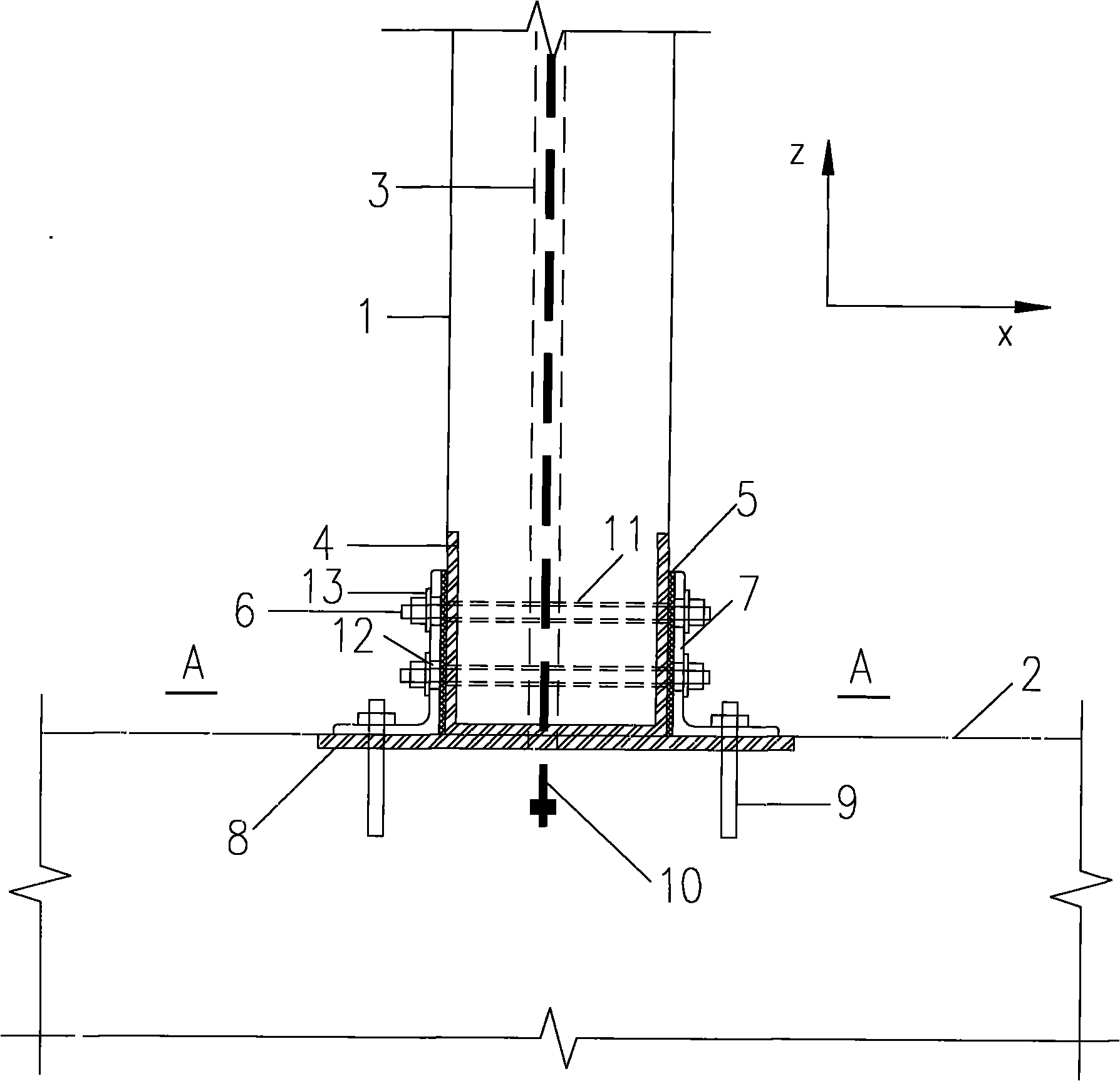

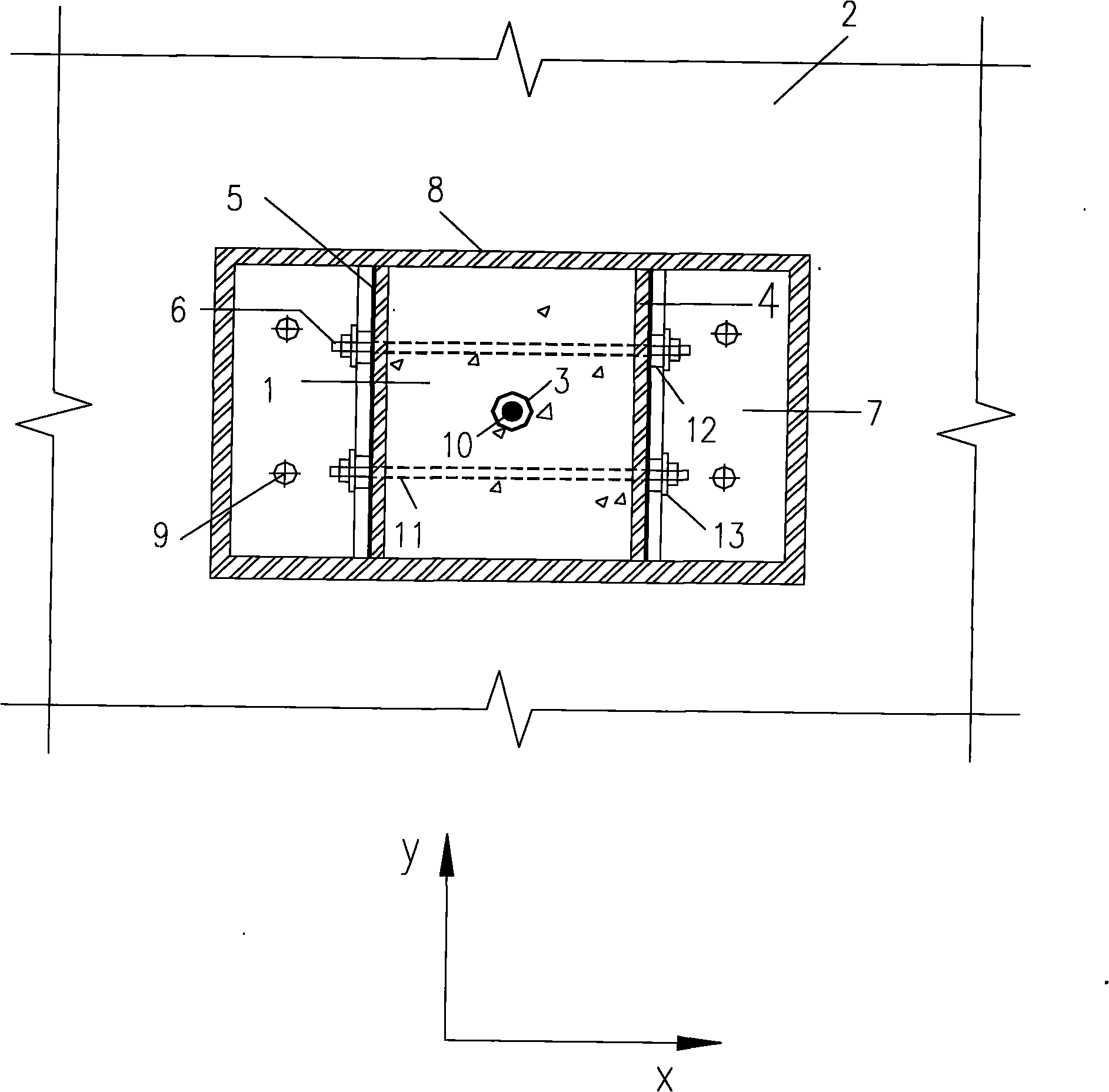

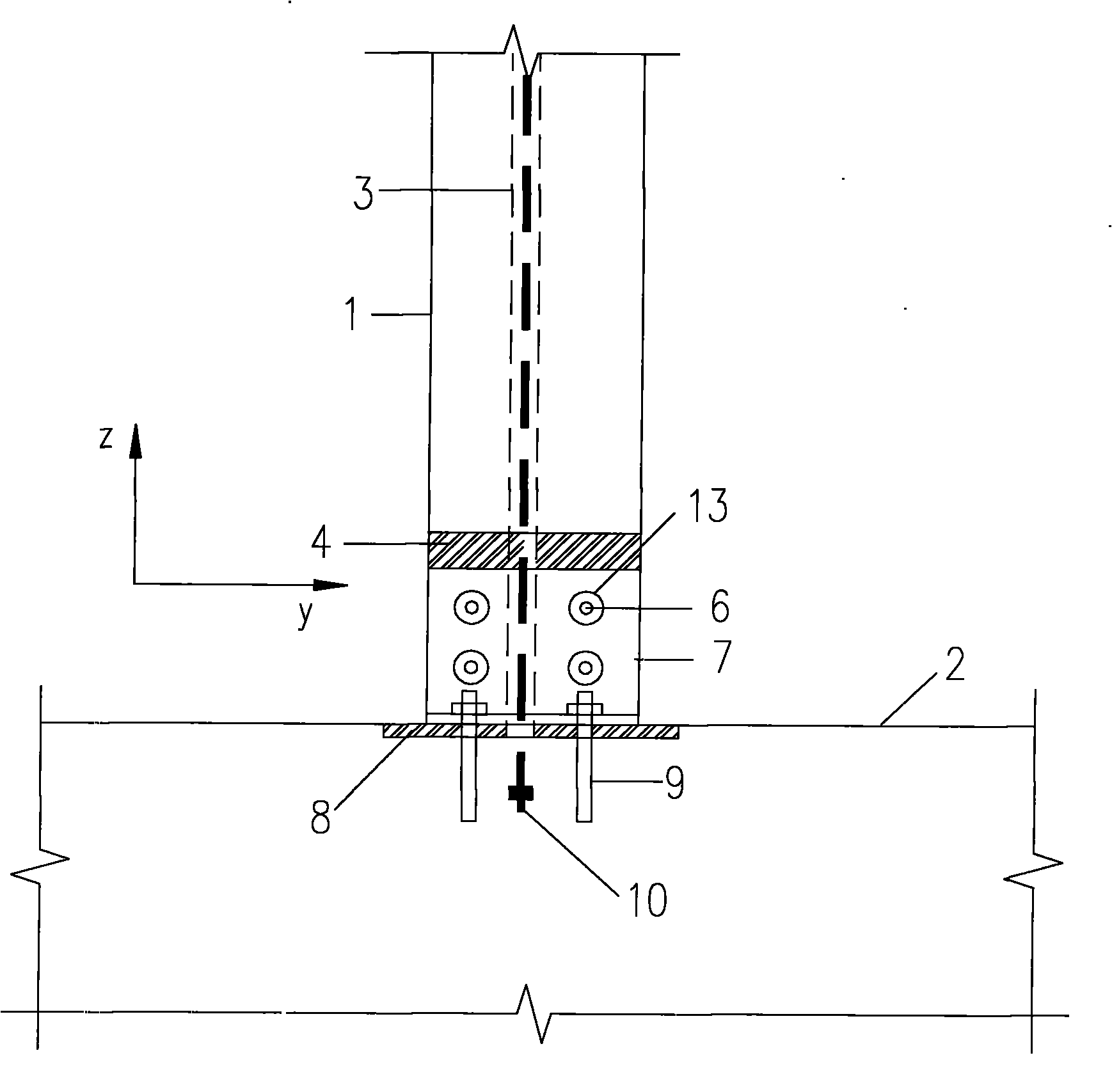

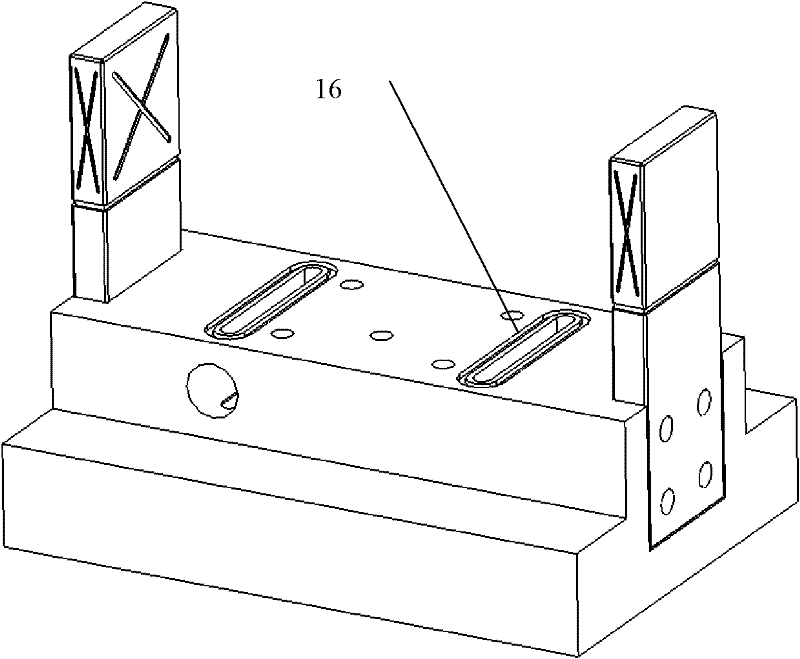

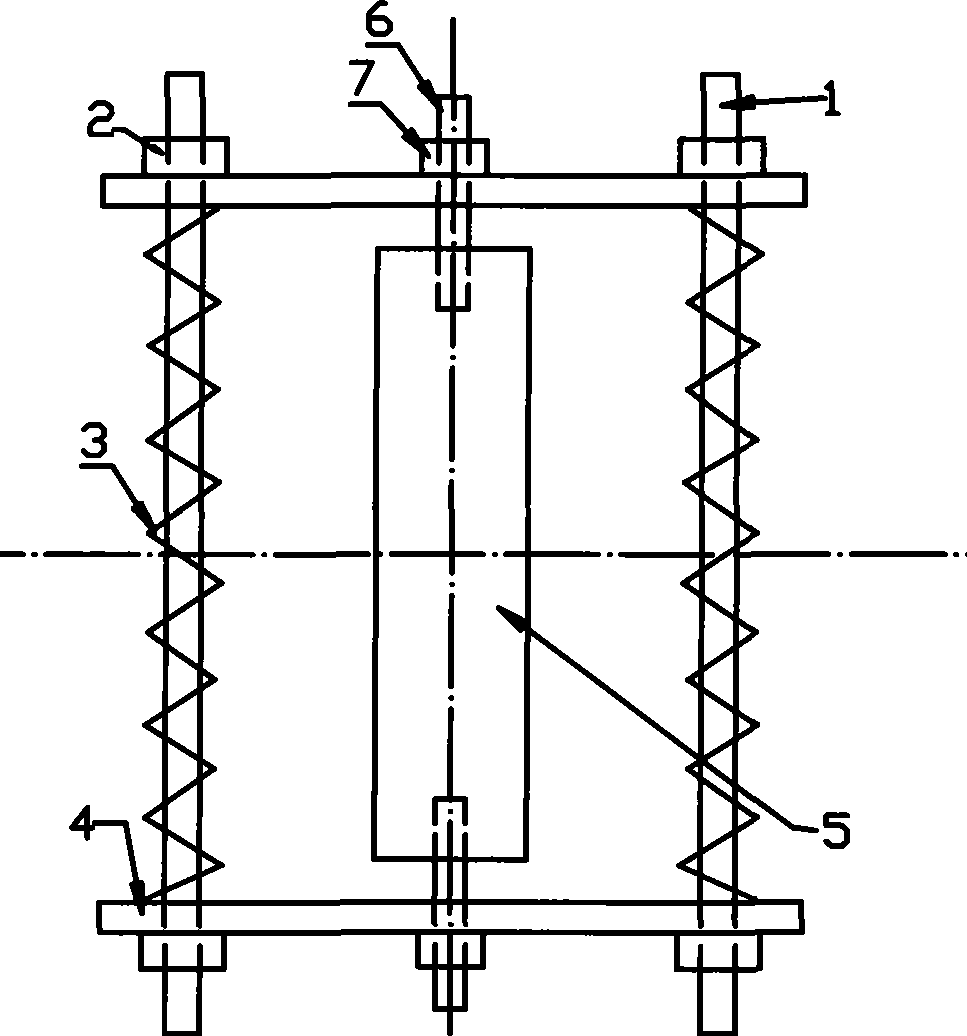

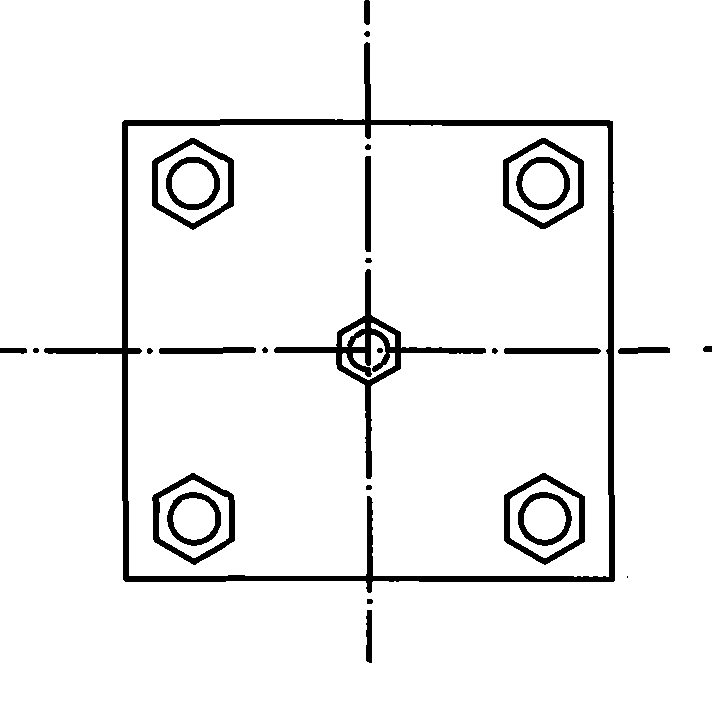

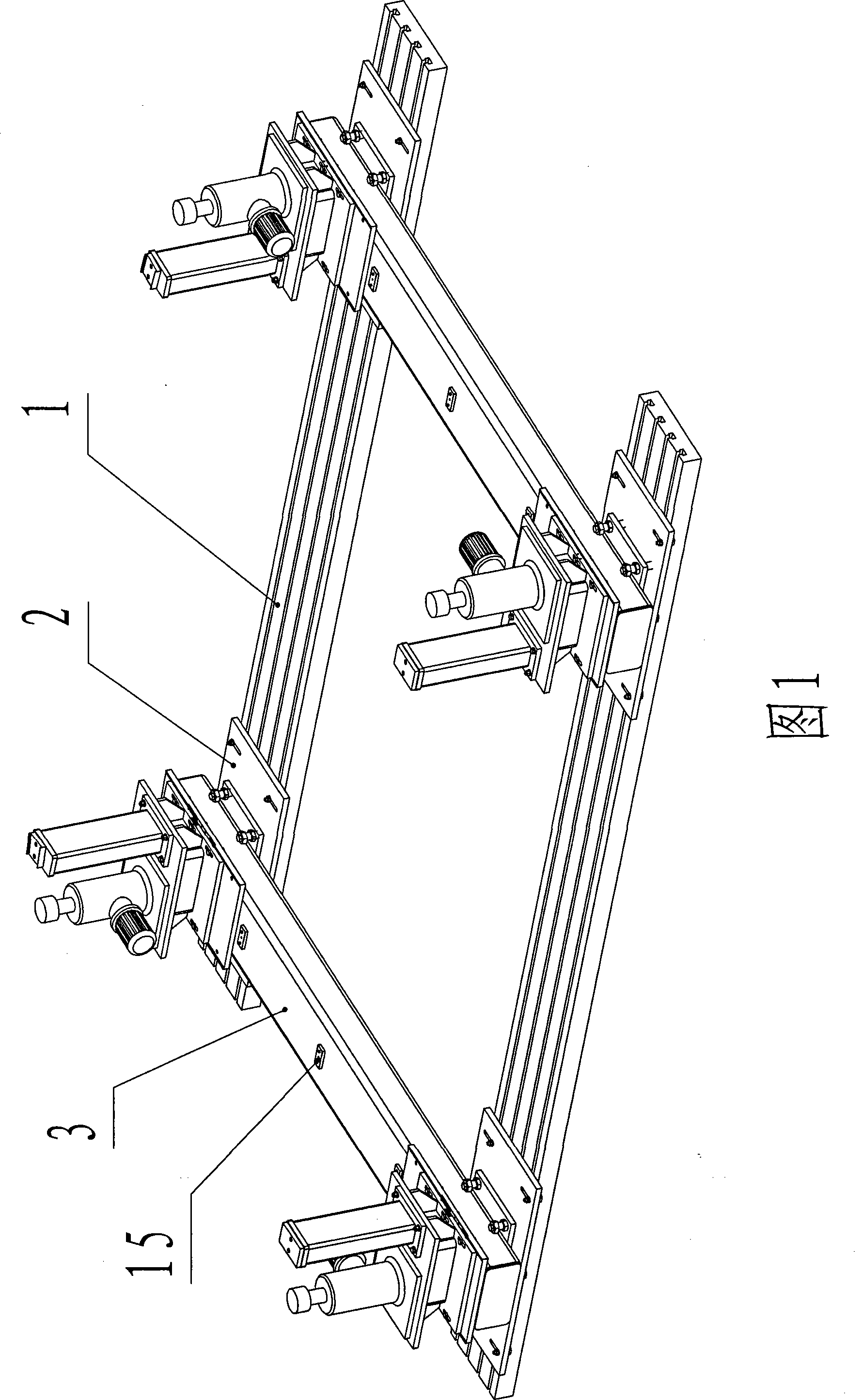

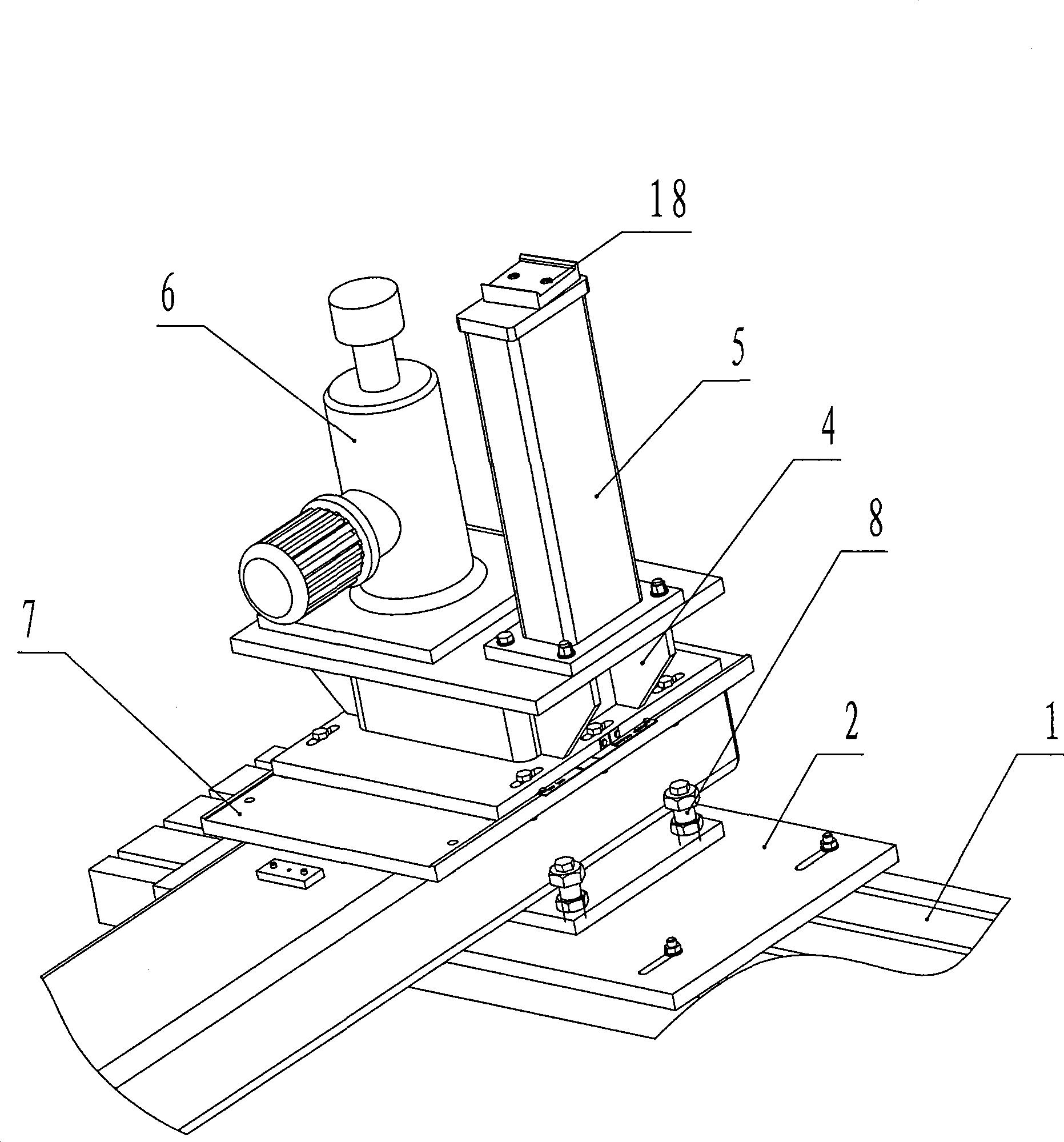

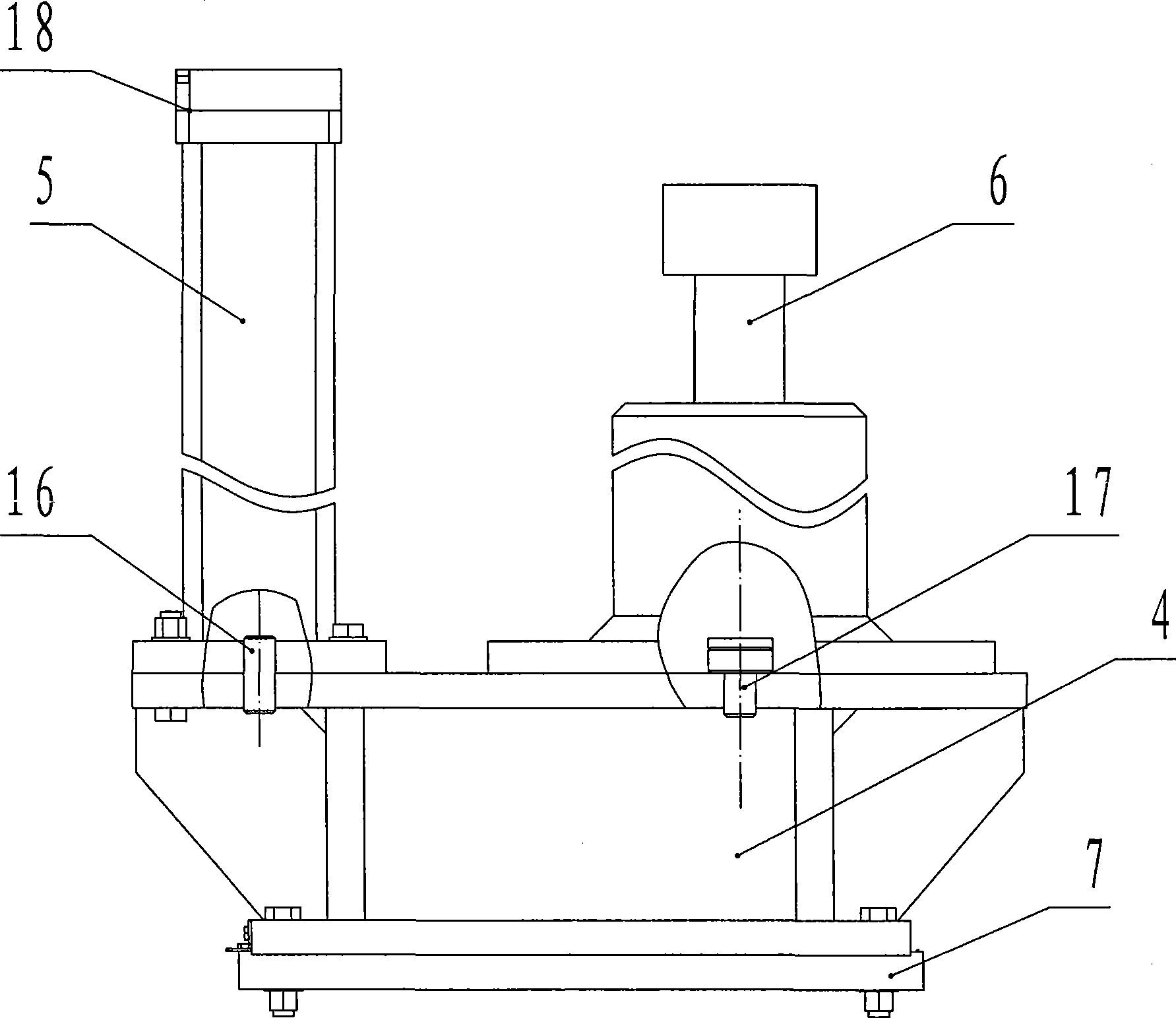

Uniaxial tension loading unit for testing concrete carbonizing performance under tensile stress and testing method

InactiveCN101387634AContinuous uniaxial tensionAchieve carbonization resistance durabilityMaterial testing goodsStrength propertiesSheet steelEngineering

The invention discloses a single shaft tension loading device for testing the carbonation property of the concrete under tensile stress and a test method, wherein the hex nuts pre-embedded at the axis of two ends of the tested element connect the cylinder or rectangle tested element between two parallel steel plates, four same compressed springs are sheathed on four steel columns of the diameters smaller than the inner diameter of the springs, the two steel plates can parallel move between the four steel columns, the material parameters and the compressed quantity of the springs can be used to calculate the axial tensile load on the tested element, the tested element is axially patched with three stress sheets to find the actual tensile stress at different parts. The characteristic parameters of the springs can be changed to obtain the carbonation test parameters under different tensile stresses.

Owner:SOUTHEAST UNIV

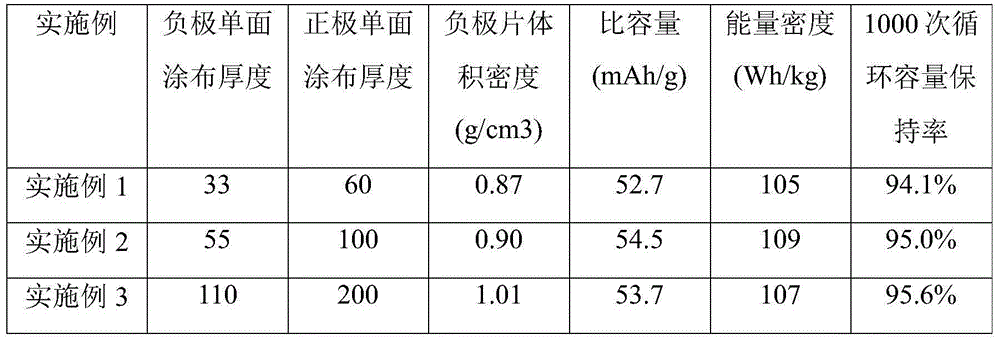

Cathode plate for lithium-ion capacitor and production method of cathode plate

InactiveCN104409224AExact energy matchExact mass matchingHybrid capacitor electrodesDouble layer capacitorsActivated carbonLithium metal

The invention relates to a cathode plate for a lithium-ion capacitor. The cathode plate comprises a current collector, a bottom coating and an upper coating. The bottom coating coats two sides of the current collector, and the upper coating coats the bottom coating. The bottom coating comprises a carbonaceous active material, a conductive agent and a binding agent I. The upper coating comprises stabilized lithium metal powder and a binding agent II. The invention further relates to a method for producing the cathode plate. The method is simple in production process, easy to operate on a large scale and capable of achieving pre-embedding without harsh environments; meanwhile, energy matching between the cathode plate and an activated-carbon anode plate of the lithium-ion capacitor is achieved easily by adjusting the coating thickness.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Wind turbine blade structure, processing and forming method and applications thereof

InactiveCN101666290AEasy to placeEvenly wrappedFinal product manufactureMachines/enginesFiberTurbine blade

The invention relates to a wind turbine blade structure, a processing and forming method and applications thereof. The blade consists of a root segment, a main beam and a covering that wraps the rootsegment and the external side of the main beam; the blade is fixed with a wind wheel by a connecting piece that is arranged at the root segment, thus forming a spatial cantilever beam structure; at the main beam area and the root segment, one or more solid or hollow wedge-shaped columns are arranged between a top paving layer and a bottom paving layer; the wedge-shaped column at the internal-mostside of the root end is solid and is internally provided with the connecting piece, wherein the fiber cloth is arranged at least among the adjacent wedge-shaped columns at the internal-most side of the root segment and continuously intersects and enwinds the wedge-shaped columns in a horizontal S-shaped, thus forming an interlayer; and the top paving layer, the bottom paving layer and the fiber cloth interlayer are dipped and solidified to form a framework with a honeycomb-shaped section. The structure and the method have the advantages of: leading the once pouring of resin and once solidifying and forming for the large blade and the realizing of the pre-embedding of the connecting piece of the root part to be possible, dispersing the synergistic effect and solidifying shrinkage quantity of solidified heating of the bottom paving layer and the top paving layer by the wedge-shaped columns, and leading the unsaturated resin used as a substrate material to be possible.

Owner:黄争鸣

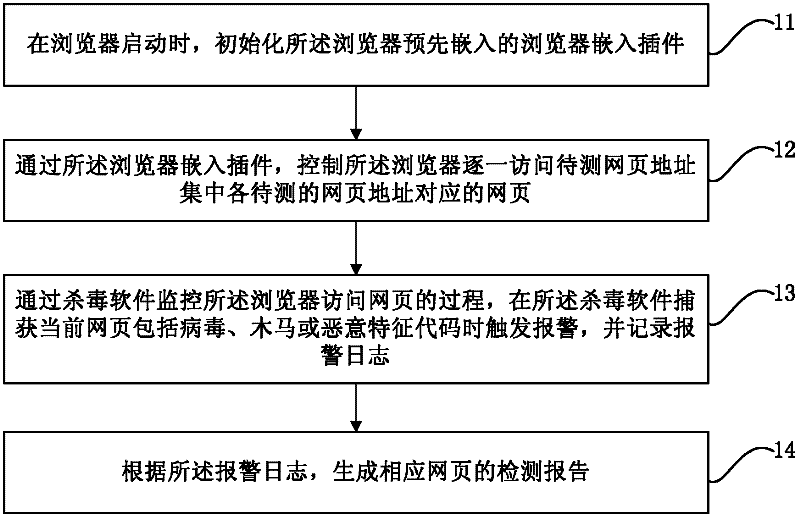

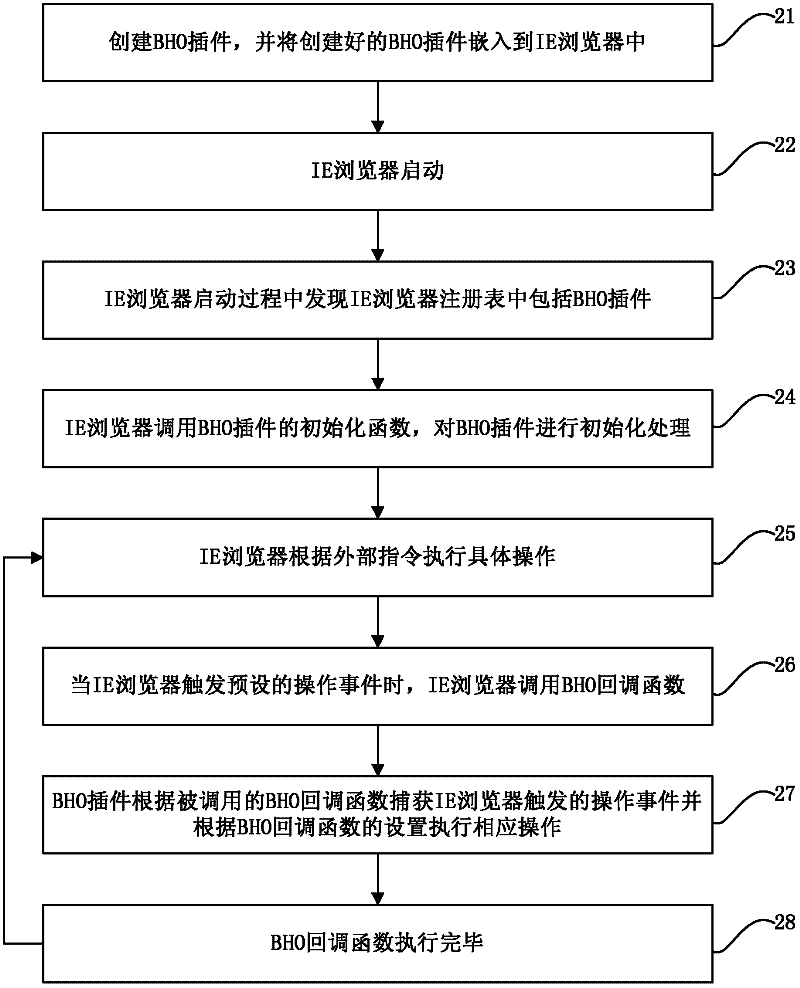

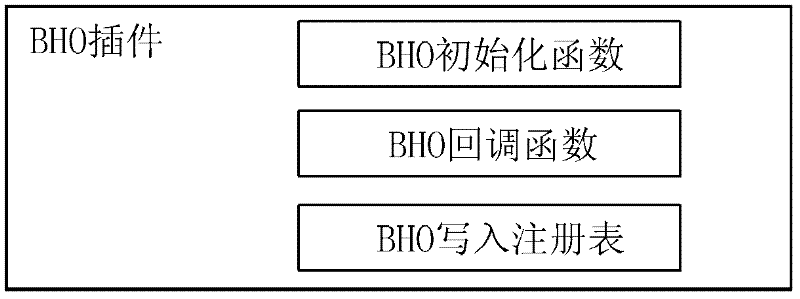

Webpage security detection method and system

ActiveCN102375951AComprehensive security testingLow costPlatform integrity maintainanceSpecial data processing applicationsWeb pagePre embedding

The invention discloses a webpage security detection method and system. The method comprises the following steps of: when switching on a browser, initializing a browser embedment plug-in which is pre-embedded in the browser; controlling the browser to gradually access a webpage, on which addresses of webpage to be detected are centralized, corresponding to each address of the webpage to be detected through the browser embedment plug-in; monitoring a process of accessing the webpage by the browser through an antivirus program, triggering to alarm when the antivirus program captures virus, Trojan virus or malicious feature codes of the present webpage, and recording an alarm logging; and generating a corresponding detection report of the webpage according to the alarm log. According to the webpage security detection method, the cost of the webpage security detection is reduced and the integrity of the webpage security detection is improved.

Owner:北龙中网(北京)科技有限责任公司

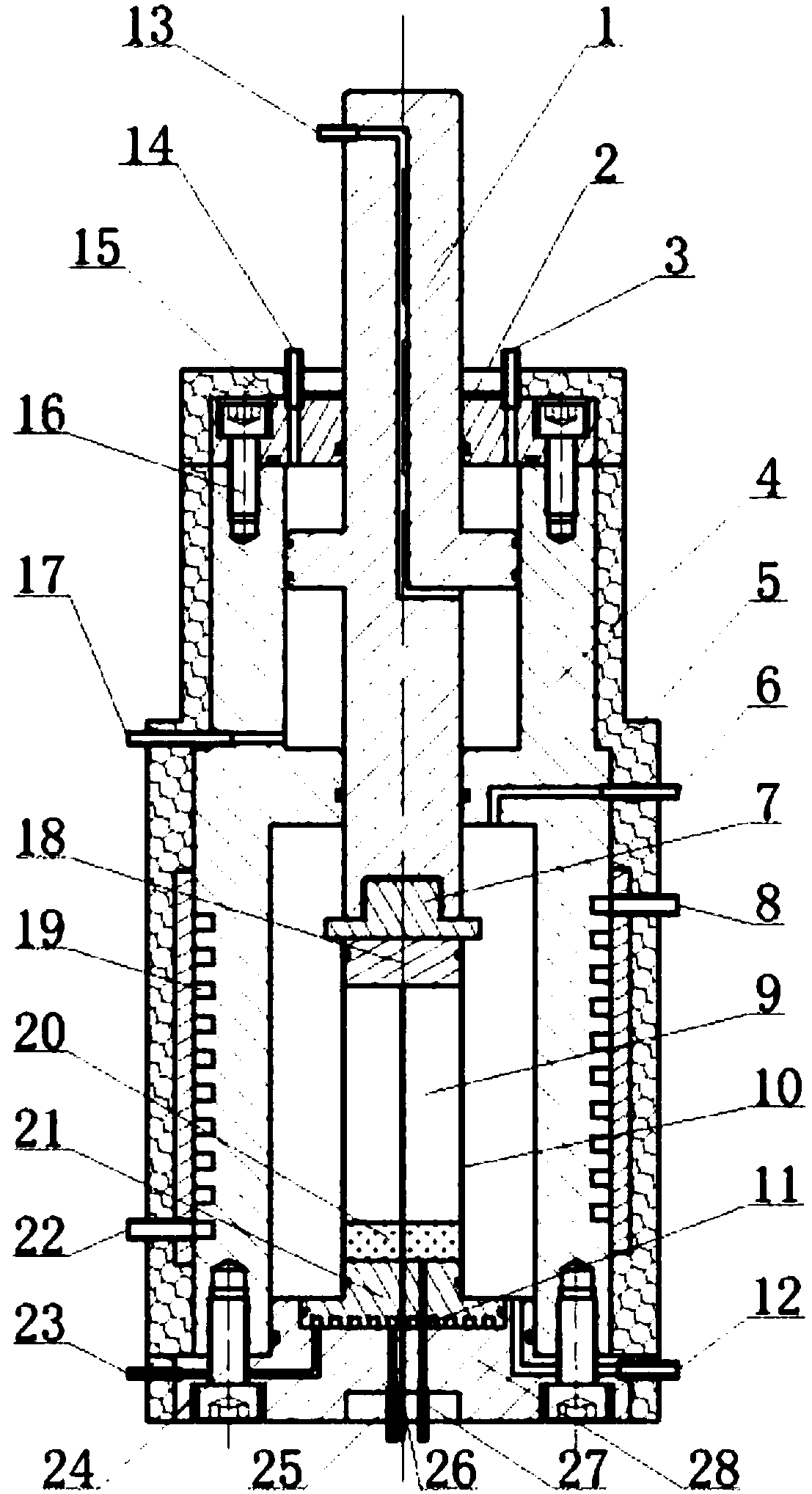

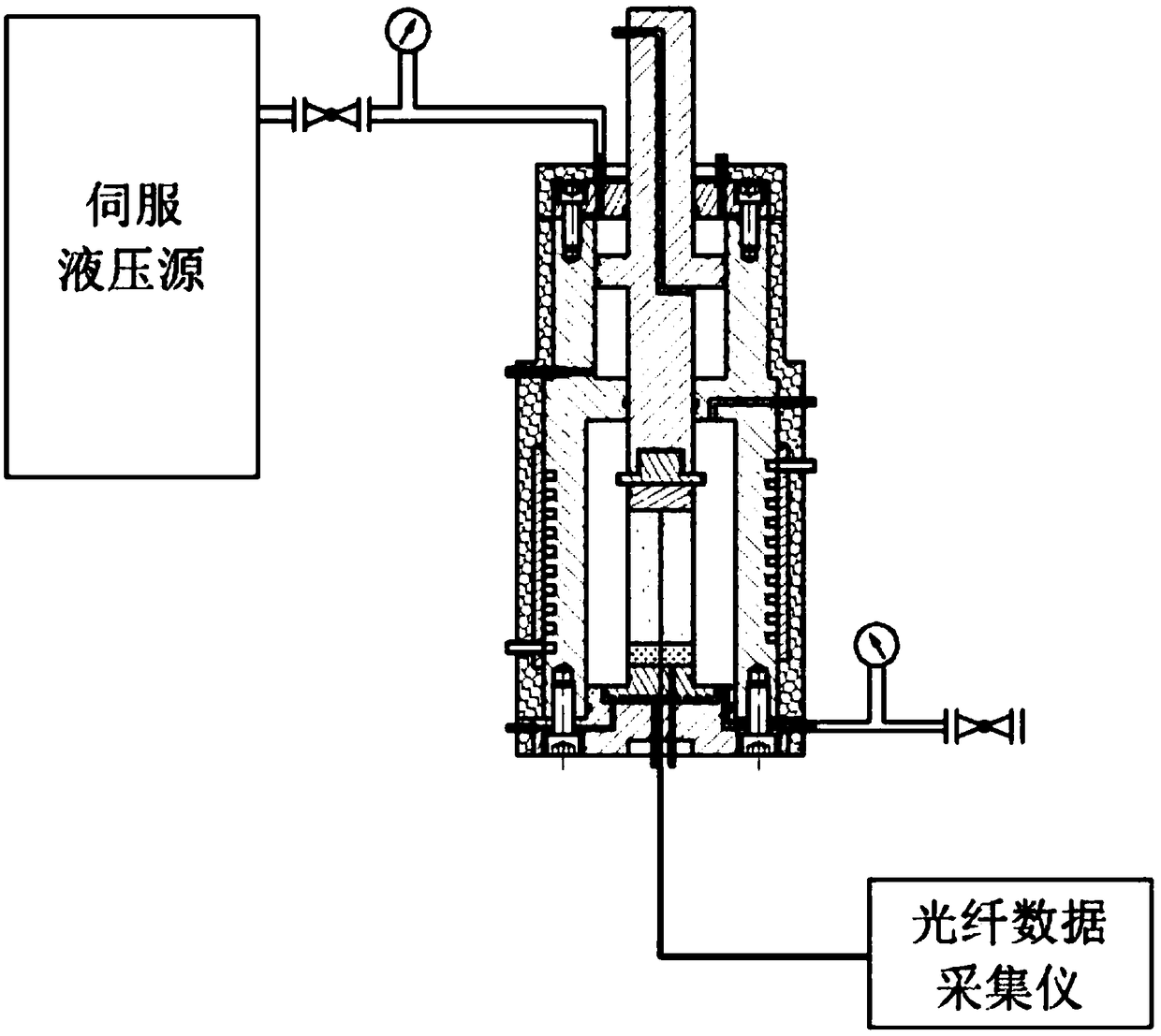

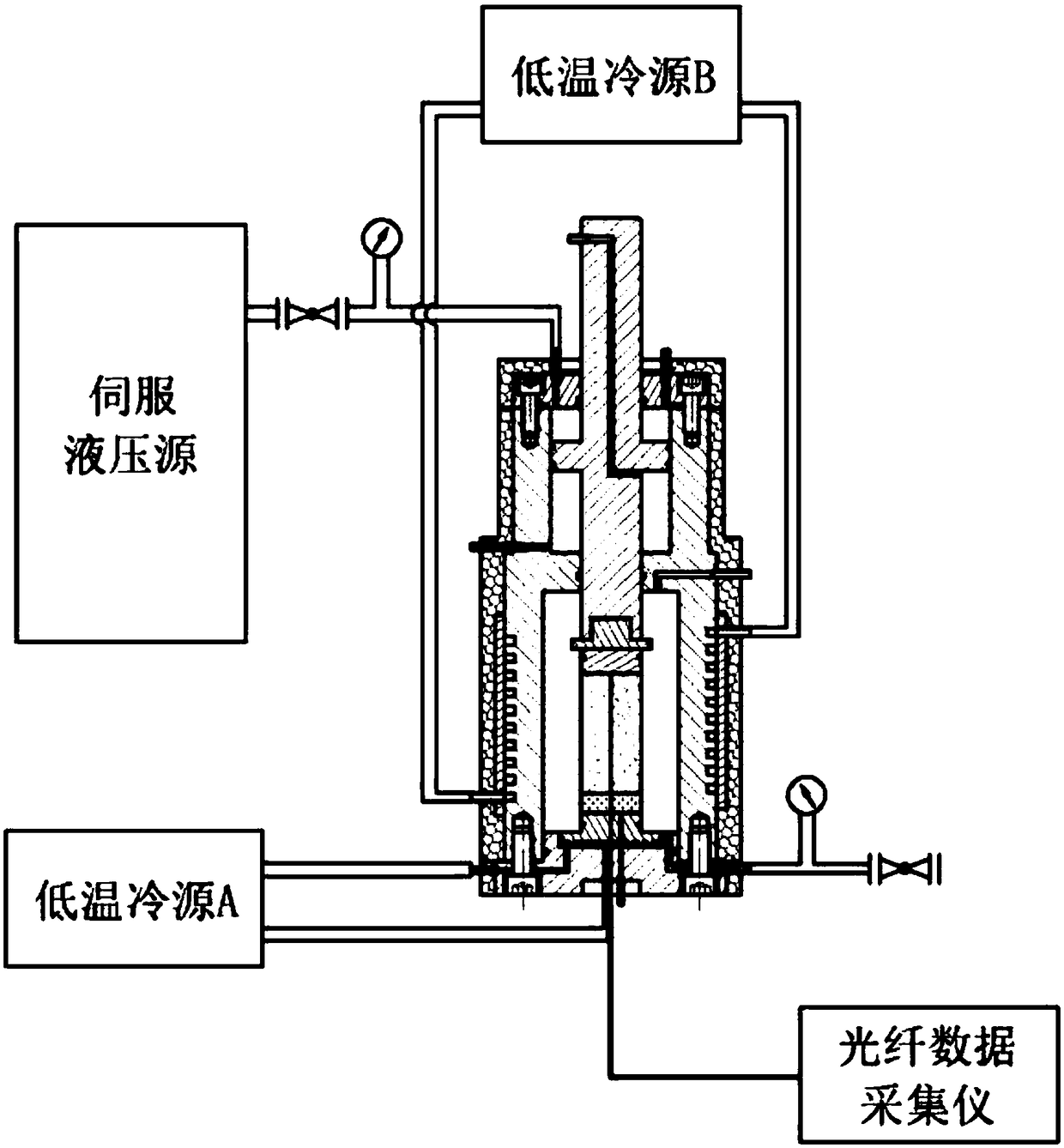

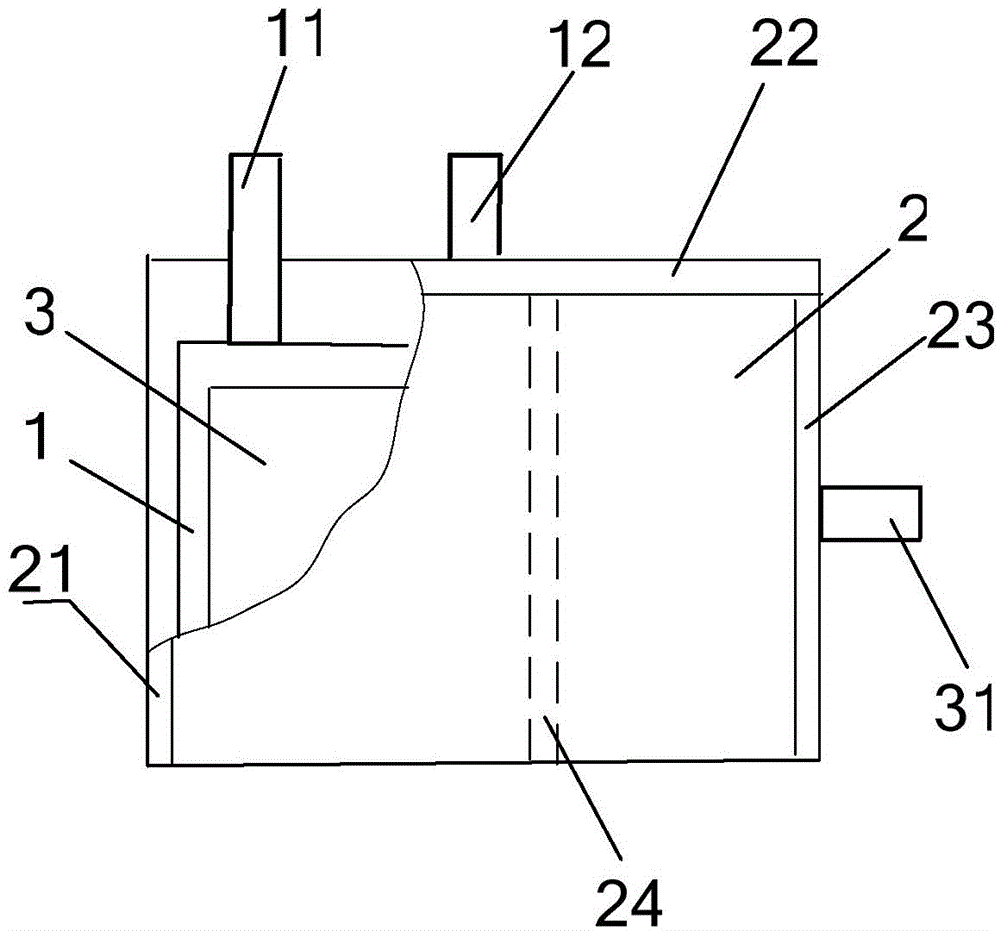

Triaxial mechanical test device and method capable of simulating formation condition of deep-buried artificial frozen soil

InactiveCN108344643APrevent freezingImprove test accuracyPreparing sample for investigationMaterial strength using tensile/compressive forcesMonitoring temperatureEngineering

The invention discloses a triaxial mechanical test device and method capable of simulating a formation condition of deep-buried artificial frozen soil. The device comprises a main body loading system,a freezing system and a sample testing system. In the main body loading system, a flange plate, a pressure bearing cylinder and a chassis form a pressure bearing shell, and the pressure bearing shellis provided with an outlet pipe and connected with an external existing hydraulic source. The freezing system is composed of a side wall freezing solution circulation channel and a bottom freezing solution circulation channel which are connected with an external existing cold source separately. In the sample testing system, an optical fiber sensor string pre-embedded in a sample is connected withan existing testing instrument and used for monitoring temperature and strain. The triaxial mechanical test device is matched with the existing servo control hydraulic source, the low-temperature cold source and the testing instrument or matched with an existing triaxial servo mechanical test machine (system), the formation condition of the deep-buried artificial frozen soil can be simulated, long-time high-pressure triaxial solidification of a soil sample is completed under the state of simulating original ground strain at first, then the soil sample is frozen under the pressure condition toform a frozen soil sample, and a triaxial mechanical test for the frozen soil sample is conducted.

Owner:CHINA UNIV OF MINING & TECH

Manufacturing method of lithium ion mixed type capacitor and lithium ion mixed type capacitor

ActiveCN104008893AReduce decompositionLow cycle lifeDouble layer capacitorsHybrid/EDL manufacturePower flowEngineering

A manufacturing method of a lithium ion mixed type capacitor comprises the following steps that (a) electrode pieces and a separation film are stacked or wound to form a cell according to the sequence of positive electrode / separation film / negative electrode; (b) the cell is put into an aluminum compound packing film shell body, the top edge and a first lateral edge of the aluminum compound packing film shell body are sealed in a heating mode, the electrode lugs of the positive electrode and the negative electrode of the cell extend out of the aluminum compound packing film shell body from the top edge; (c) a metal lithium electrode is put into the aluminum compound packing film shell body, is adjacent to the cell and is separated from the cell by the separation film, and the electrode lug of the metal lithium electrode extends out of the aluminum compound packing film shell body from a second lateral edge; (d) excessive electrolyte is injected into the aluminum compound packing film shell body, and then the second lateral edge of the aluminum compound packing film shell body is sealed in a heating mode; (e) in a constant current mode, the negative electrode serves as a working electrode, the metal lithium electrode serves as a counter electrode, and the negative electrode is pre-embedded; (f) the metal lithium electrode is taken out, the superfluous electrolyte is poured out, the second lateral edge of the aluminum compound packing film shell body is sealed in a vacuum heating mode, and the lithium ion mixed type capacitor is obtained.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

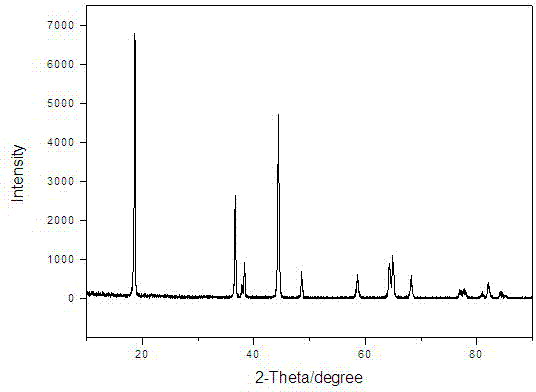

Divalent metal ion pre-embedded layered vanadium oxide nanometer material as well as preparation method and application thereof

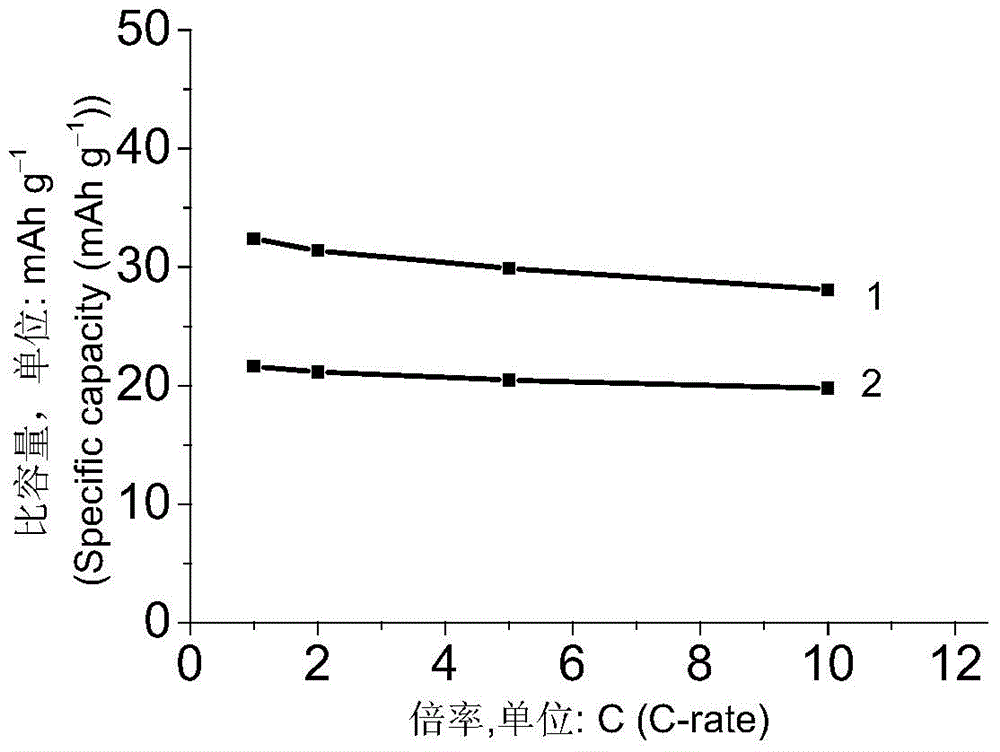

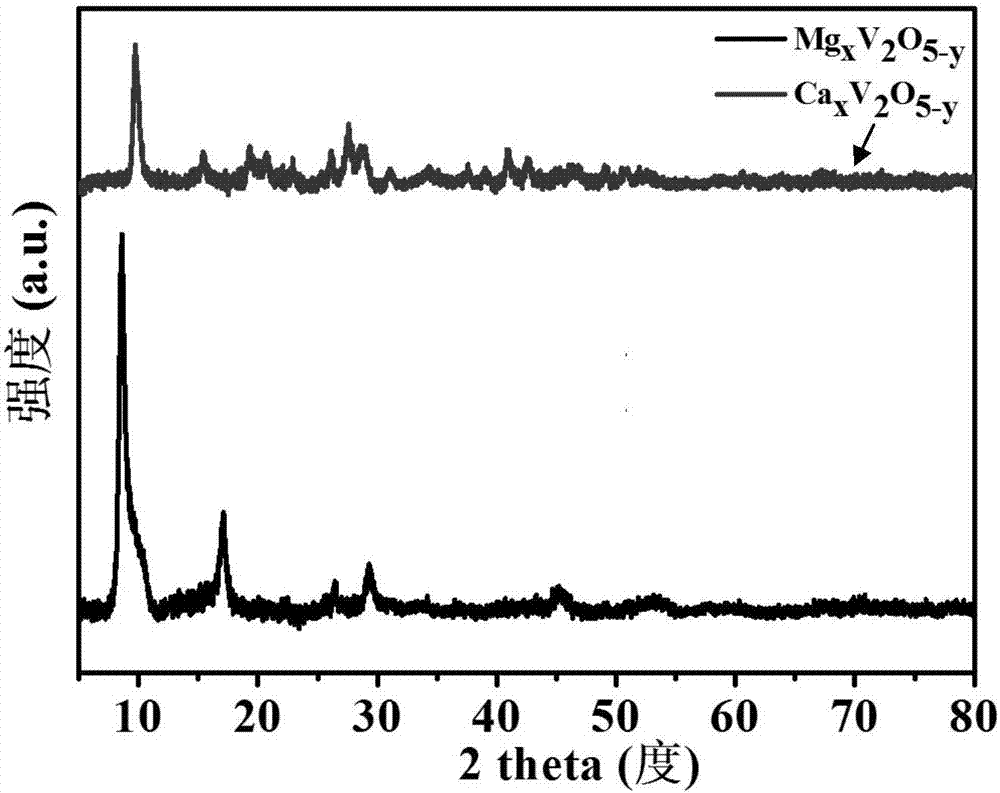

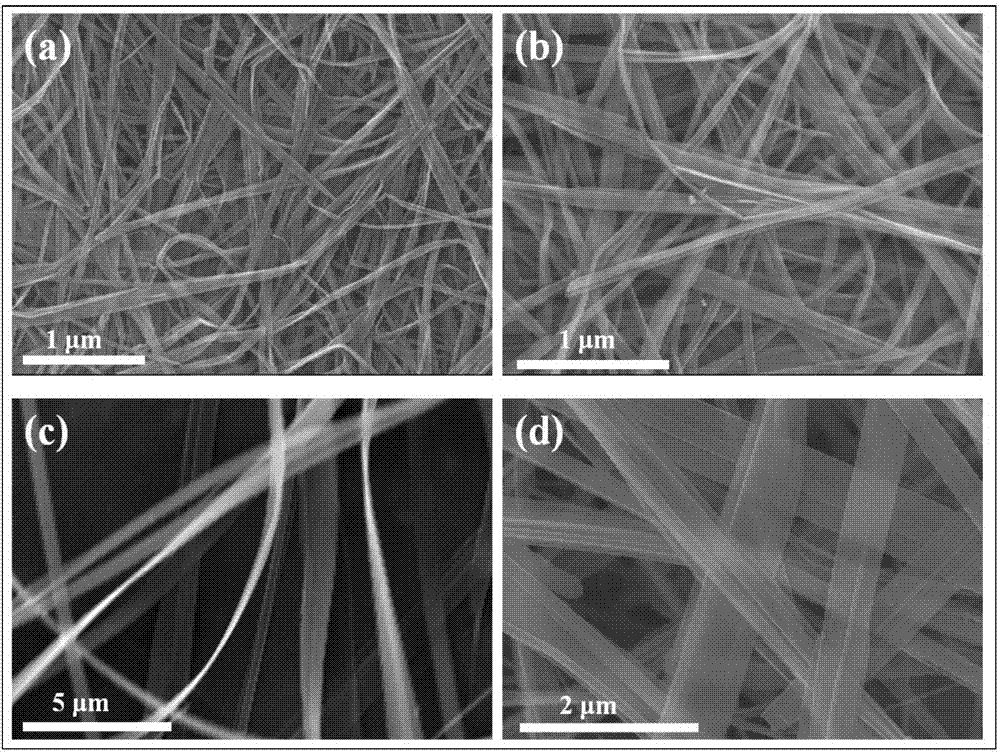

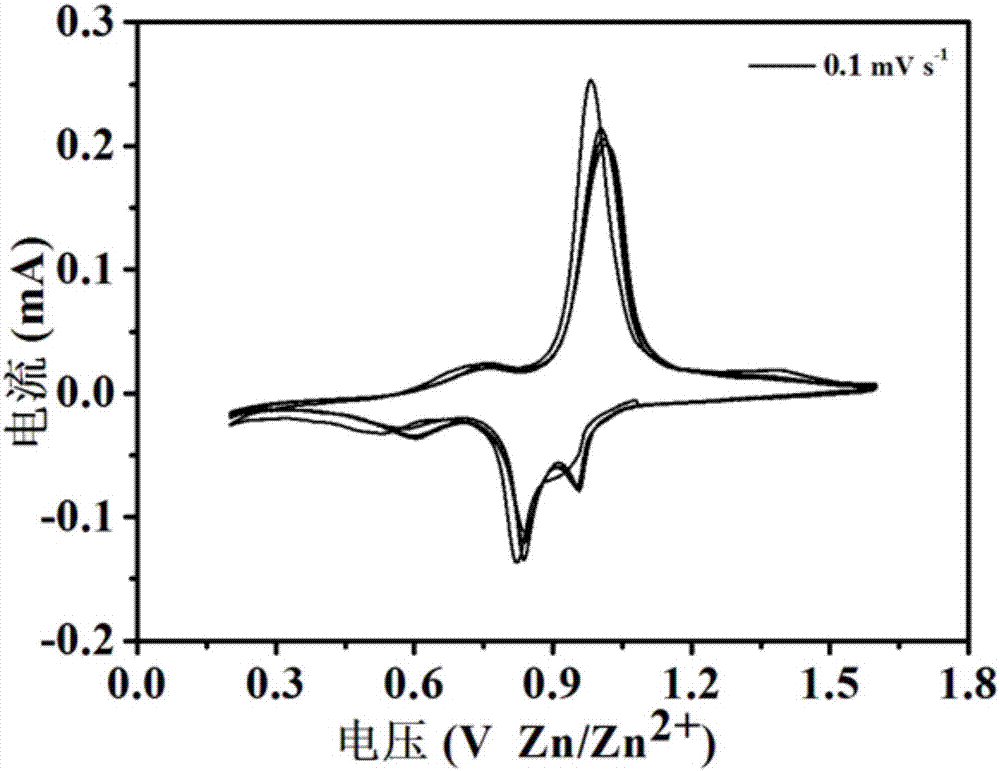

ActiveCN107170967ALow priceAchieving controllable synthesisMaterial nanotechnologyCell electrodesDivalent metal ionsVanadium oxide

The invention relates to a divalent metal ion pre-embedded layered vanadium oxide nanometer material as well as a preparation method thereof. The chemical formula of the nanometer material is AxV2O5-y, wherein A is Mg, Ca, Sr or Zn; the MgxV2O5-y has the nanoribbon diameter of 100-1500nm and the length of 5-50 microns or CaxV2O5-y has the nanoribbon diameter of 100-1000nm and the length of 5-50 microns or SrxV2O5-y has the nanoribbon diameter of 100-1000nm and the length of 5-50 microns or ZnxV2O5-y has the nanoribbon diameter of 100-300nm and the length of 5-50 microns or ZnxV2O5-y has the nanoflower diameter of 3-5 microns. The divalent metal ion pre-embedded layered vanadium oxide nanometer material disclosed by the invention has high specific capacity, excellent cycling stability and excellent rate capability and is a potential high-performance commercial zinc ion battery positive electrode material.

Owner:WUHAN UNIV OF TECH

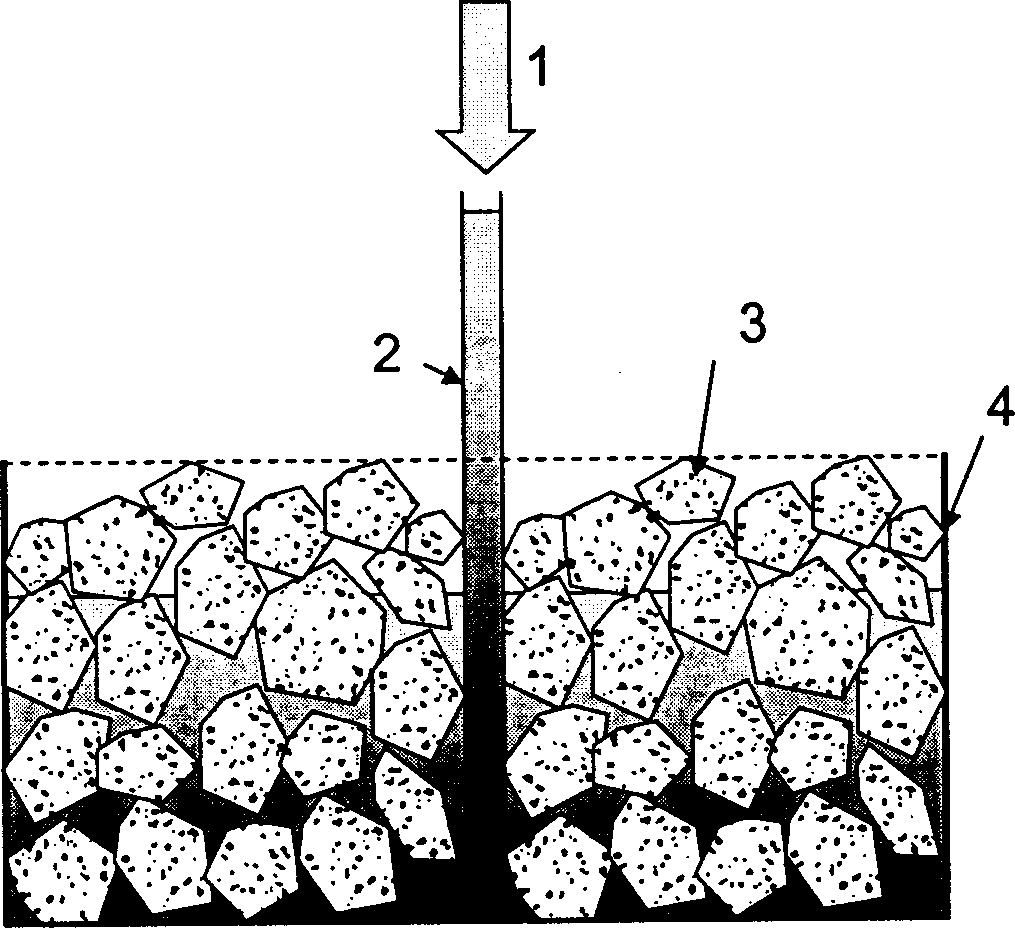

Construction method for rock-fill concrete dam

InactiveCN1521363AReduce adiabatic temperature riseLarge particle sizeBarrages/weirsFoundation engineeringPre embeddingConstruction aggregate

The construction method of rockfill-concrete dam is one dam constructing method as the combination of concrete construction technology and rockfill dam construction technology and adopting one kind of concrete material with good flowability and high material separating resistance. The construction method of the present invention includes using un-sieved or initially sieved rockfill, introducing coarse aggregate in rockfill dam constructing process, pre-embedding grouting pipes to parts to form concrete, grouting concrete via the grouting pipes to void in rockfill to from the rockfill-concrete dam. With rockfill as aggregate can reduce cement consumption, lower cost, speed construction, lower the hydration heat of concrete, simplify process and reduce construction links.

Owner:TSINGHUA UNIV

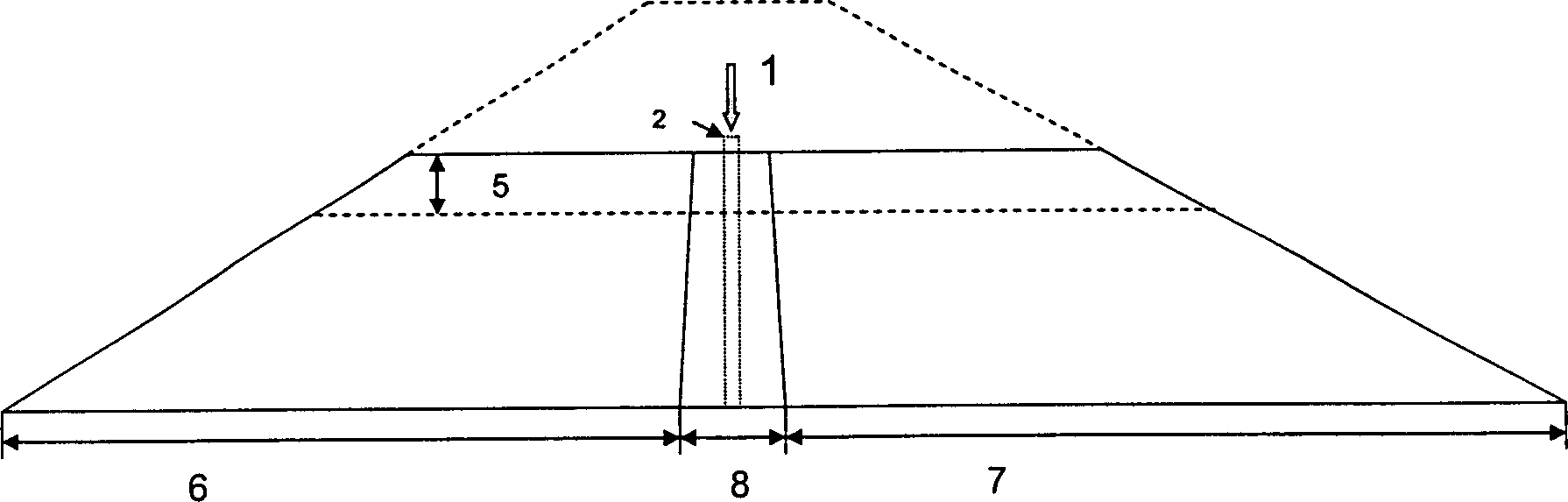

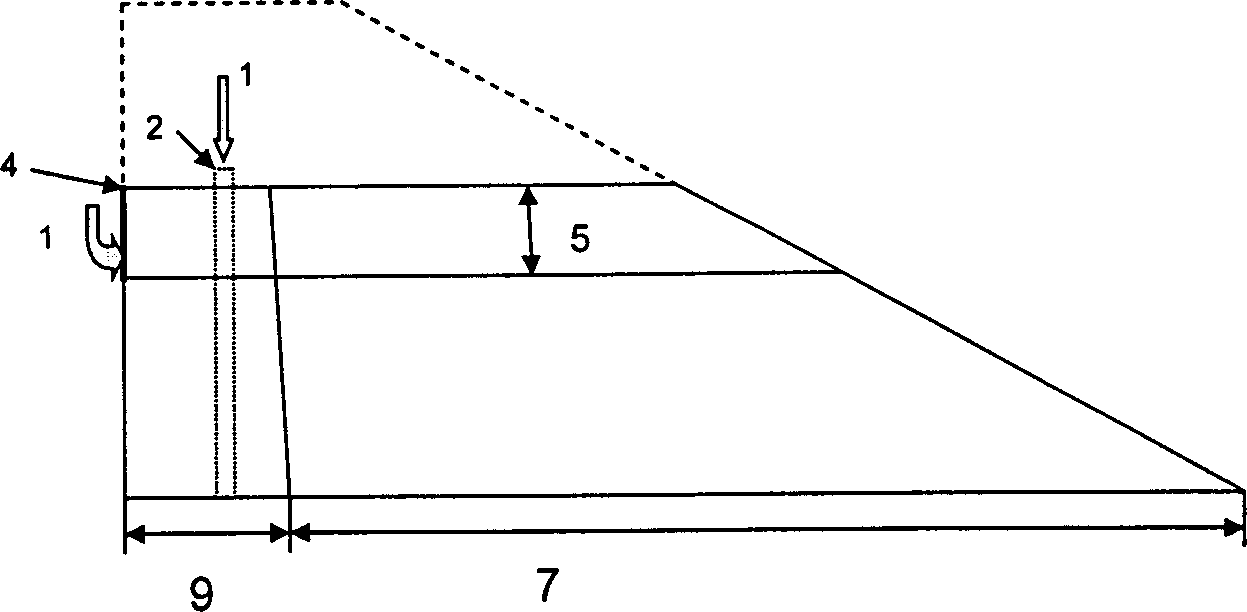

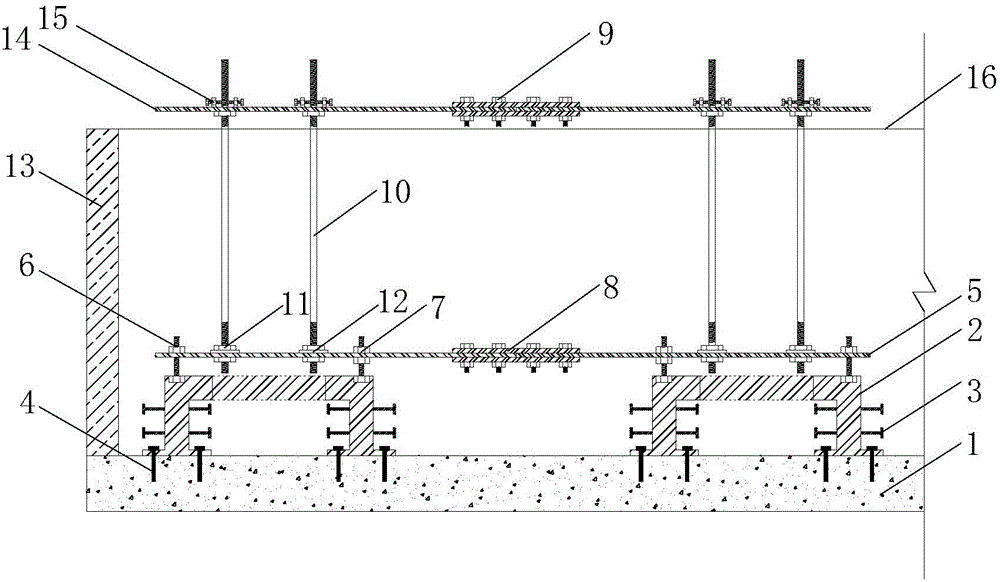

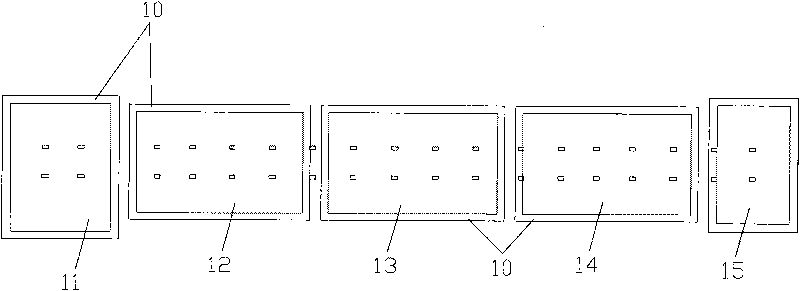

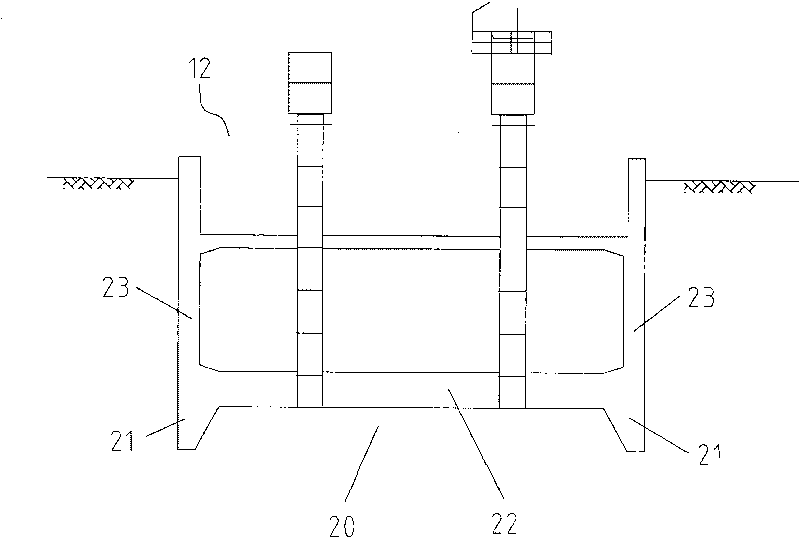

Construction method for raft plate basic high-precision overall pre-embedded large-diameter bolt group structure

InactiveCN104895101AAchieve regulationImprove embedding accuracyFoundation engineeringStructure of the EarthEmbedment

The invention relates to a raft plate basic high-precision overall pre-embedded large-diameter bolt group structure. The structure is characterized in that the structure comprises an upper-layer positioning plate, a lower-layer positioning plate, a bottom support seat, pre-embedded foundation bolts, connecting bolts, fine-adjustment bolts and leveling bolts; unit positioning steel plates are connected and assembled through node plates and the bolts to respectively form the upper- and lower-layer positioning plates, the pre-embedded foundation bolts are disposed between the upper- and lower-layer positioning plates, the pre-embedded foundation bolts and the upper-layer positioning plate are connected through the fine-adjustment bolts, the pre-embedded foundation bolts is in anchor connection with the lower-layer positioning plate; and the leveling bolts are disposed between the lower-layer positioning plate and the bottom support seat to perform connection, and the bottom support seat and a concrete cushion are connected through the pre-embedded bolts. The bolt group structure can perform three-dimensional dynamic adjustments on the pre-embedded bolts, ensures accuracy of center coordinates and scale heights of the bolts, achieves high-precision pre-embedment of a bolt group, and has a good economic technical benefit. The invention further provides a construction method for the raft plate basic high-precision overall pre-embedded large-diameter bolt group structure.

Owner:柳州市建筑工程集团有限责任公司

Four-angle weighing apparatus for vehicle

ActiveCN101398326AMeet the weighing needsHigh precisionStatic/dynamic balance measurementSpecial purpose weighing apparatusGravity centerEngineering

The invention provides car body four-corner weighing equipment, belonging to the field of weighing technique. The weighing equipment aims at solving the weighing problem and the positioning problem of the gravity center of motor train unit body; the technical proposal is that the car body four-corner weighing equipment consists of two horizontal T-shaped guideways which are arranged in parallel, two supporting crossbeams which are vertical to the T-shaped guideways and four car body weighing units; the T-shaped guideways are pre-embedded in cement ground surface; the upper part of the two ends of the supporting crossbeam is provided with an axial U-shaped sliding trough and the lower part thereof is provided with a connecting plate; the connecting plate is fixed on two T-shaped guideways by a T-shaped bolt; and the four car body weighing units are respectively fixed on the U-shaped sliding troughs which are arranged at two ends of the two supporting crossbeams. The car body four-corner weighing equipment can precisely weigh the weight of various car bodies, can work out the position of the gravity center of the car body according to the measured weight signal and can meet the weighing requirement of various high-speed motor train units.

Owner:CRRC TANGSHAN CO LTD

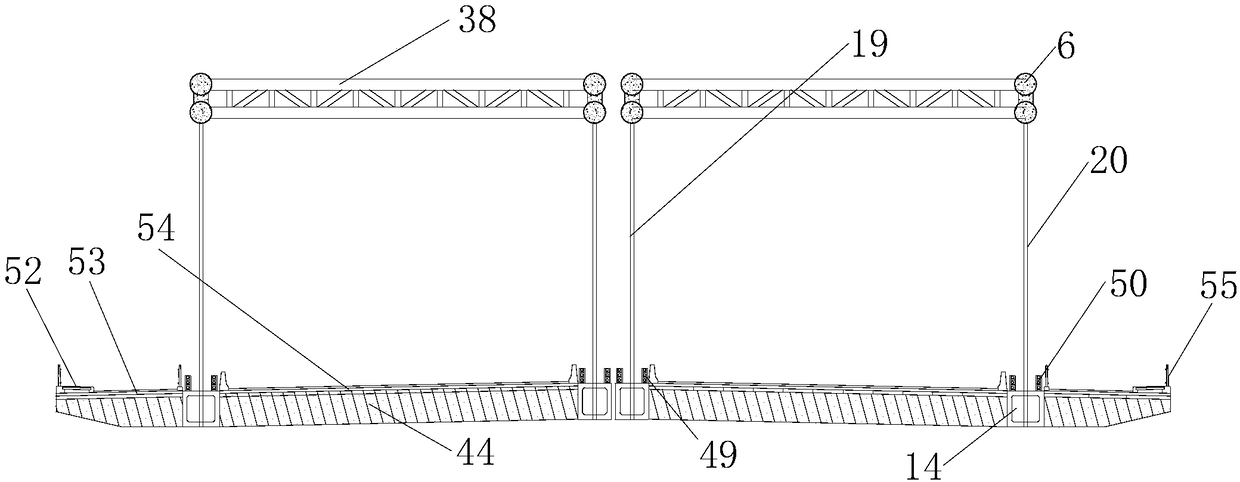

Concrete-filled steel tube arch bridge and construction method

PendingCN108660903AImprove stabilityGuaranteed docking accuracyBridge erection/assemblyArch-type bridgeReinforced concreteButt joint

The invention relates to a concrete-filled steel tube arch bridge. The concrete-filled steel tube arch bridge includes side arch ribs, main arch ribs, suspension bars, tie bars and a bridge pier and abutment structure. Side span structures include side arch supports, side span cast-in-place reinforced concrete arch ribs, cast-in-place side arch end cross beams, side span cast-in-place cross beamsbetween ribs, cast-in-place side arch rib tie beams, cast-in-place side upright posts, flexible prestressed tie bars and cast-in-place bridge deck slabs. Mid-span structures include abutments, mid-span concreted-filled steel tube arch ribs, main arch hollow cross beams between ribs, precast hollow longitudinal beams, flexible prestressed tie beams, tie-bar steel plate boxes, truss-type permanent upper wind braces, K-shaped permanent intermediate wind braces, temporary wind braces, arch foot pre-embedded sections, inner steel strand whole-bundle-squeezed inhaul cable suspension bars and outer steel strand whole-bundle-squeezed inhaul cable suspension bars. The concrete-filled steel tube arch bridge has the beneficial effects that steel tube arch rib fixation brackets involved in the concrete-filled steel tube arch bridge can improve the stability during installation and construction of steel tube arch ribs, and the accuracy of butt joint can be guaranteed effectively.

Owner:ANHUI HIGHWAY ENG CORP

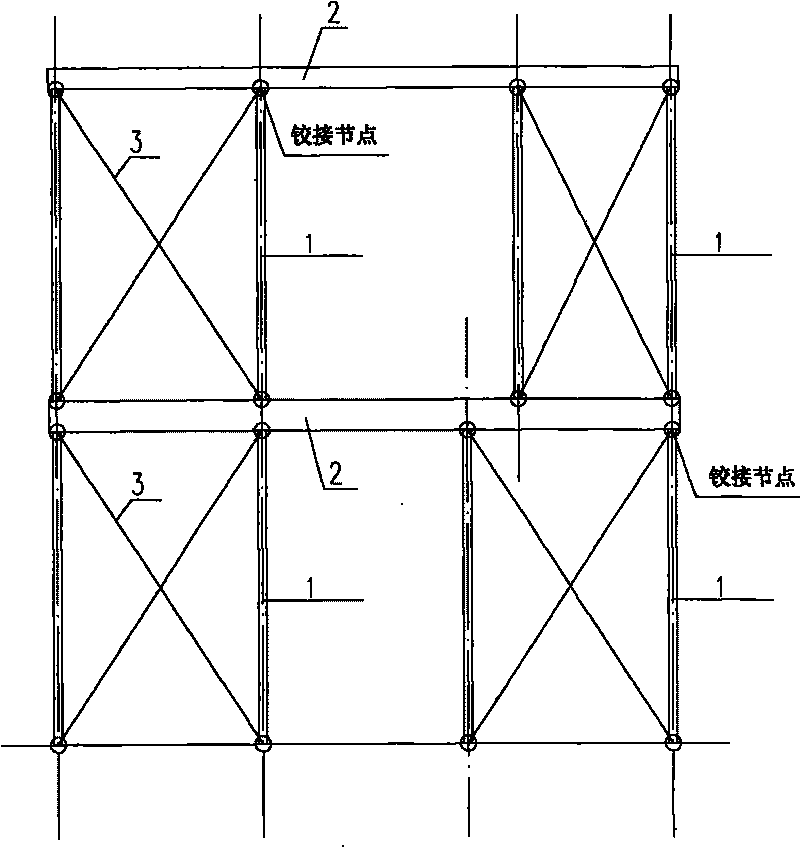

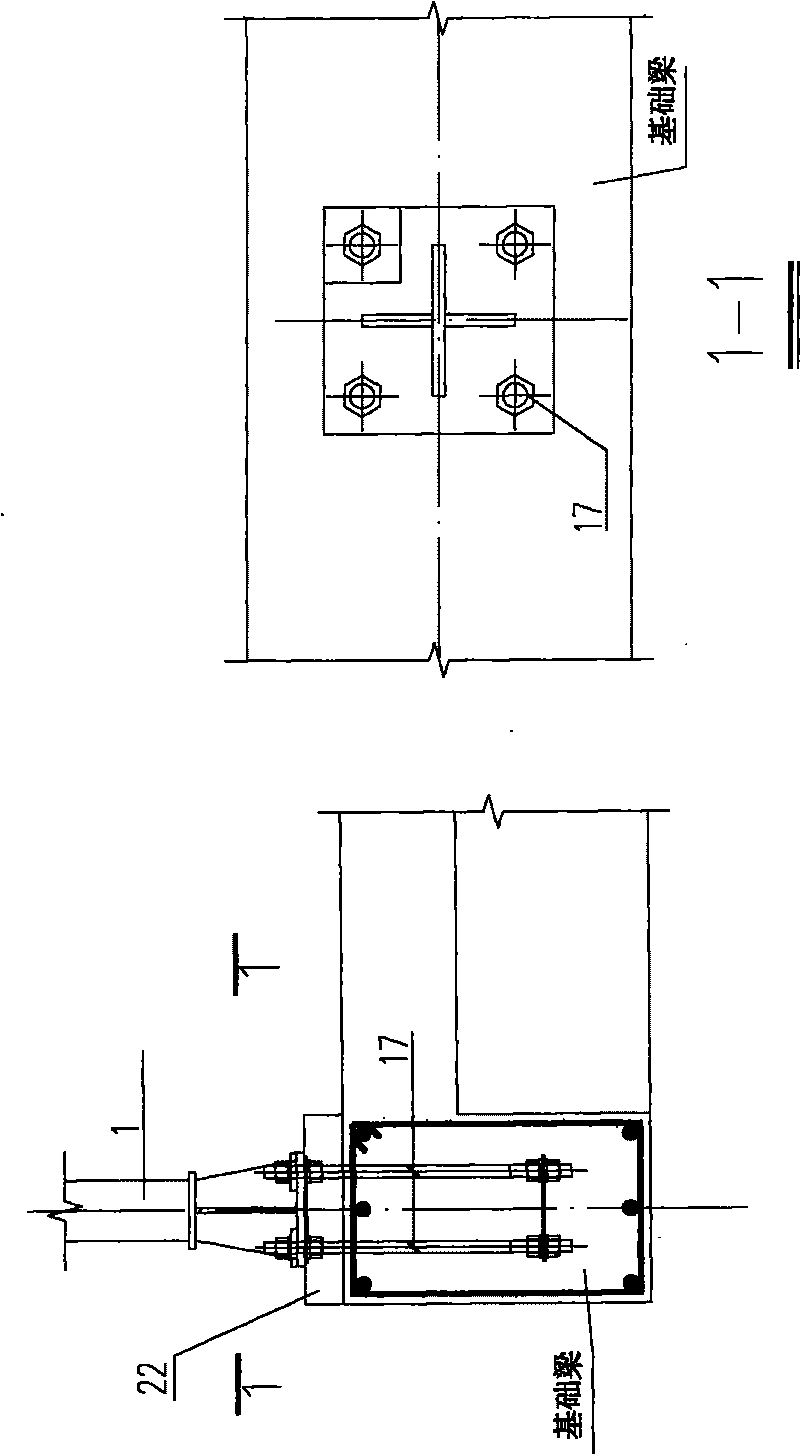

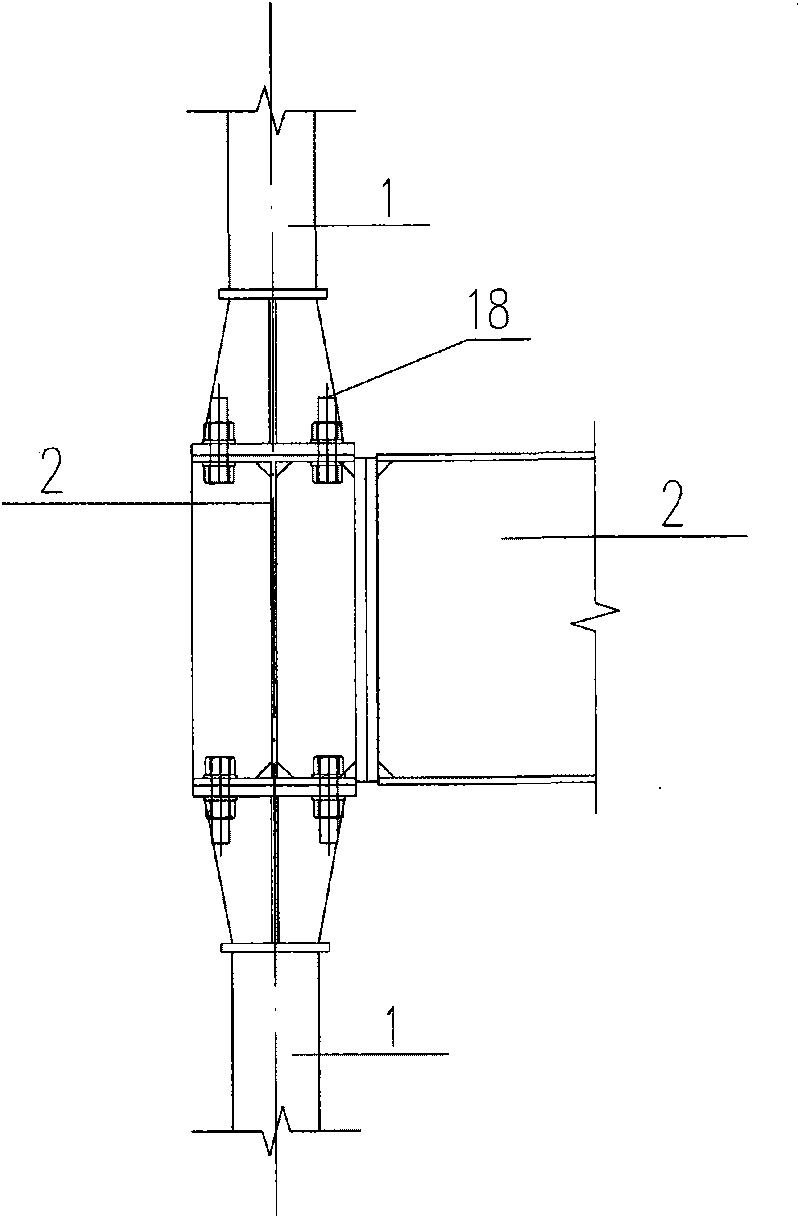

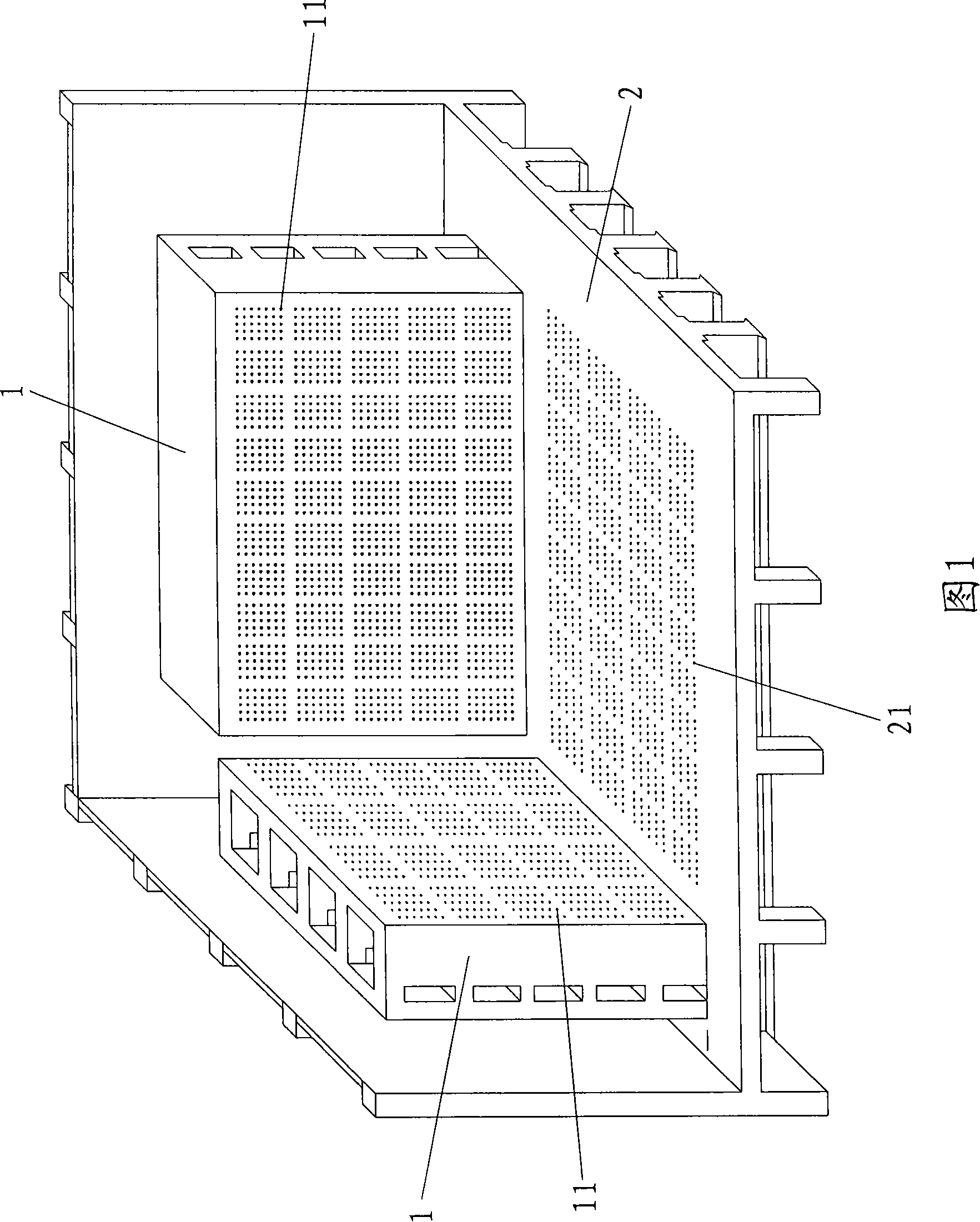

Structural system of industrial low storied dwelling

ActiveCN101748903AReasonable forceAvoid wastingBuilding constructionsDwelling buildingFloor slabSimple component

The invention belongs to the field of building structures, and in particular relates to a structural system of an industrial low storied dwelling adopting modularized design, factory production and field mounting. The structural system of the industrial low storied dwelling comprises steel columns, steel girders, inter-column supports, steel girder horizontal supports, floor slabs, connecting nodes between the steel columns and a foundation, the connecting nodes between the steel columns and the steel girders, the connecting nodes between the steel columns and the inter-column supports, the connecting nodes between the steel girders and the steel girder horizontal supports, rigid connection nodes between the steel girders, the connecting nodes between the steel girders and the floor slabs, roofing surrounding systems and wall surface surrounding systems, wherein the steel columns are connected with the foundation through pre-embedded bolts; the steel columns are connected with the steel girders through bearing type high-strength bolts; the steel columns are connected with the inter-column supports through ordinary bolts; the steel girders are connected with the steel girder horizontal supports through the ordinary bolts; the steel girders are in fully rigid connection through continuous girders; the slabs are connected with the steel girders through male pins or special fasteners; and each of the roofing surrounding systems and the wall surface surrounding systems is of a block type. The structural system of the invention has the characteristics of clear stress of the structure, simple component connection, convenient and quick mounting, attractive appearance, good rationality and economical efficiency of unit steel amount, and is favorable for industrial production.

Owner:宝业集团浙江建设产业研究院有限公司

Method for preparing ternary anode material of long-service-life and high-capacity lithium ion battery

ActiveCN103682316AIncrease capacityImprove cycle performanceCell electrodesCapacity lossMaterial synthesis

A method for preparing a ternary anode material of a long-service-life and high-capacity lithium ion battery and belongs to the technical field of material synthesis. The method comprises the following steps: weighing a lithium source and NixCoyMnz(OH)2, uniformly mixing, pre-burning at a temperature of 400-600 DEG C for 2-6 h, and forging at a temperature of 700-1000 DEG C for 6-16 h; uniformly mixing the ternary anode material, the lithium source and nanometer TiO2; forging at a temperature of 700-950 DEG C for 3-8 h to obtain the ternary anode material which is prepared by twice lithium adding and twice forging. The ternary anode material is prepared through twice lithium adding and twice forging, and the extra lithium source which is introduced through twice lithium adding and twice forging is electrochemically pre-embedded in an anode. Meanwhile, the Li+ diffusion rate can be effectively increased through the doping of Ti4+, and the irreversible capacity loss is reduced. In an interval of 2.3-4.6 V, a discharging platform is prolonged, and the first discharging capacity, the cyclic performance and the rate performance of the material are obviously improved. The method is simple, effective, economical and practical and has a remarkable industrial application effect.

Owner:HARBIN INST OF TECH

Method for constructing soft soil foundation continuous caisson

The invention discloses a method for constructing a soft soil foundation continuous caisson, which is used for forming a continuous caisson formed by communicating a plurality of single caissons in a soft soil foundation. The method at least comprises the following steps of: (1) constructing a working chamber; (2) constructing a caisson body and excavating soil for sinking; leading caisson body joints to form a steel seal door on adjacent ends by a steel member and setting a pre-embedded member; (3) jointing the caissons; and (4) disassembling the steel seal door to enable the single caissons to be communicated mutually to form the continuous caisson. In the constructing method, the seal door of the adjacent ends of the single caissons is formed by adopting the steel member; and compared with the current adopted concrete seal door, the invention is convenient for assembly and disassembly and can shorten the construction period. The steel member for forming the steel seal door can be recycled, the building material cost is reduced, the damage to the peripheral caisson structure when the concrete seal door is chiseled can be prevented, and the waste disposal link after chiseling is omitted.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

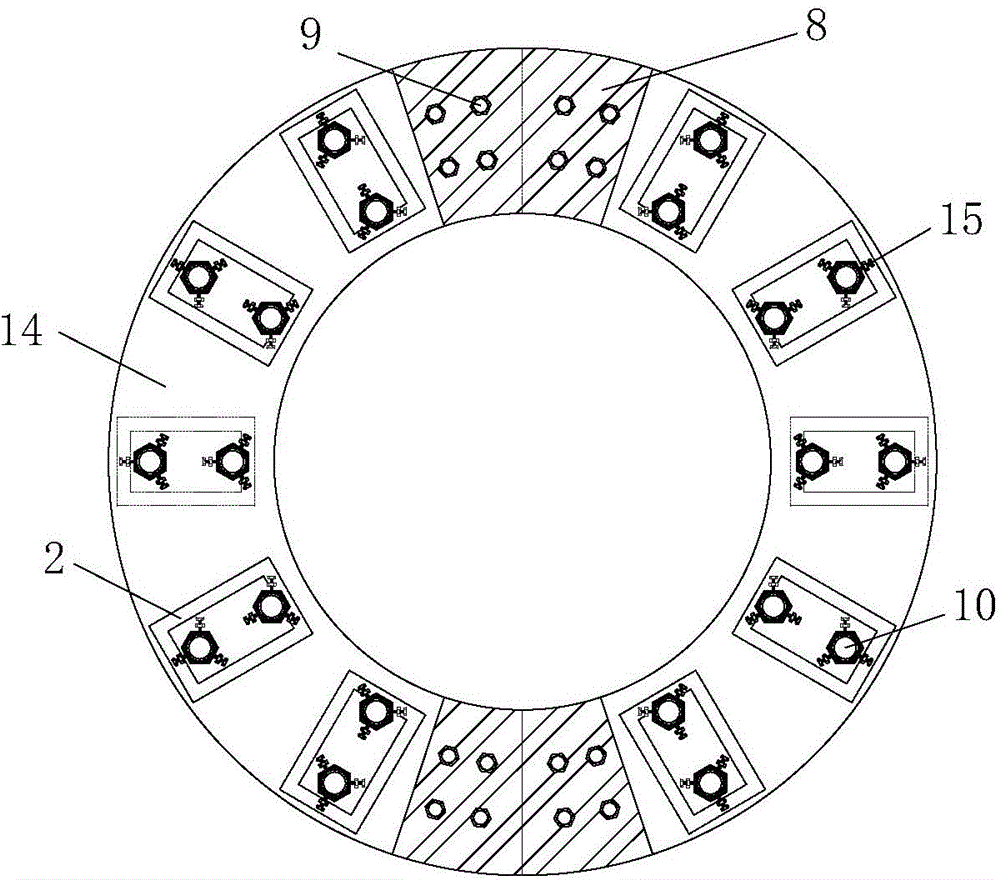

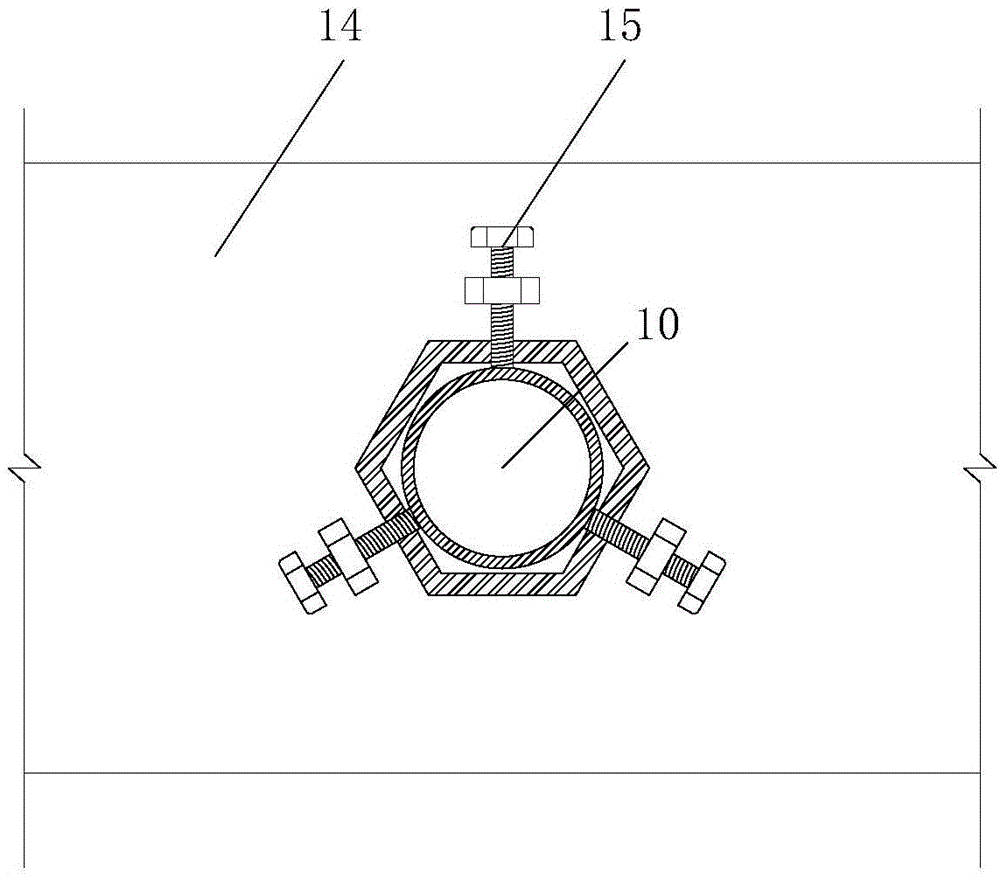

Pre-embedded sensor for local discharge detection of power cable accessory

ActiveCN102096027AImprove anti-interference abilityHigh sensitivityTesting dielectric strengthCapacitanceElectromagnetic coupling

The invention discloses a pre-embedded sensor for the local discharge detection of a power cable accessory, which comprises a buffer layer, an annular electrode, a connecting cable, a lead-out terminal and a signal conditioning unit. The invention integrates the advantages of an internal capacitance coupling method and an external electromagnetic coupling method and provides an embedded sensor for the local discharge detection of a power cable accessory, which has the advantages of strong anti-jamming capability and high sensitivity as well as dual characteristics of capacitance coupling and electromagnetic coupling.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

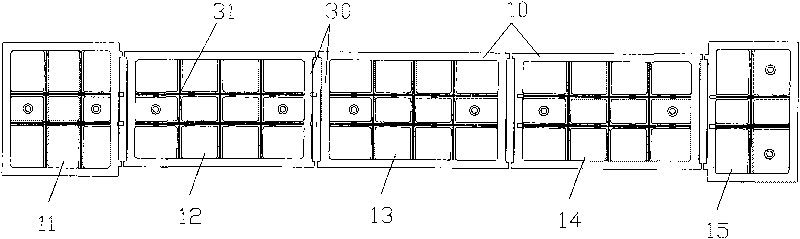

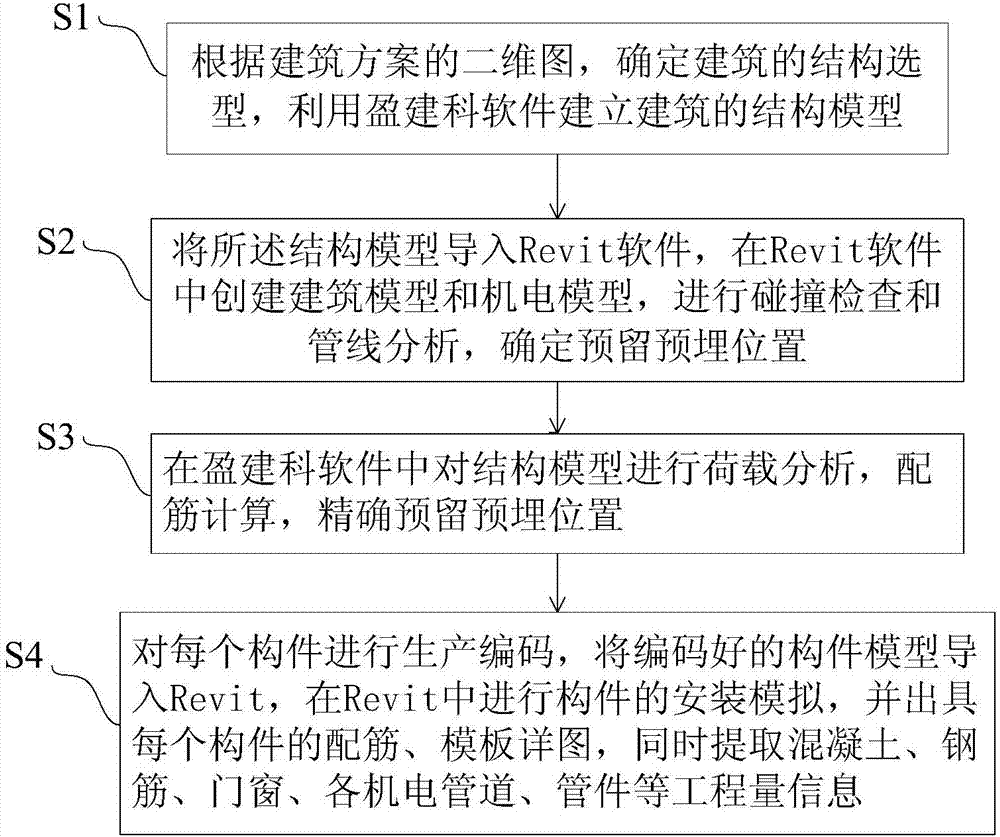

BIM technology-based fabricated concrete building design method

InactiveCN107977487ASimplify complexityOmit secondary modelingGeometric CADSpecial data processing applicationsComponent Object ModelBuilding design

The invention discloses a BIM technology-based fabricated concrete building design method. The method comprises the following steps of: determining a structure form selection of a building according to a two-dimensional diagram of a building scheme and establishing a structure model of the building by utilizing YJK software; importing the structure model into Revit software, creating a building model and an electromechanical model in the Revit software, and carrying out collision check and pipeline analysis to determine a reserved pre-embedded position; calculating, reinforcing and pre-embedding the structure model according to load information and the reserved pre-embedded position; carrying out production encoding on each component, importing an encoded component model into the Revit, carrying out installation simulation on the components in the Revit, and providing reinforcement and template detail drawings of each component. According to the method, the secondary design problem oftraditional fabricated concrete building components is avoided, so that different professional designers can carry out cooperative office, reserved pre-embedded position information of the componentsis accurate and the correctness of giving component machining detail drawings is improved.

Owner:山东住工装配建筑有限公司

In-situ testing method for deep underground engineering during rockburst preparation and evolution process

InactiveCN101914912AMutual verificationEasy to compare and analyzeMining devicesIn situ soil foundationPre embeddingEngineering

The invention relates to an in-situ testing method for deep underground engineering during a rockburst preparation and evolution process. The method comprises the following steps of excavating test branch tunnels, designing and laying testing bore holes, and selecting and testing test items. In the method, before excavating the test tunnels, monitoring bore holes and a testing sensor are preset and pre-embedded respectively along the direction of the test tunnels through the test branch tunnels; by adopting the combined in-situ testing method, variation characteristics of elastic waves, cracks, deformation and energy release rate of surrounding rock at monitored section areas of the test tunnels can be directly and continuously obtained in real time and in situ; and in-situ information of the test tunnels during the whole process of rockburst preparation and evolution in the case of excavation is obtained by testing, and comprehensive precursory rockburst basic data is acquired. The in-situ testing method of the invention is concise in technical scheme and reliable in testing instrument and can ensure comprehensive acquisition and comparative analysis of rock mass information during the rockburst preparation and evolution process; and the method can be widely applied to deep underground rock excavation engineering such as an underground testing ground, water conservancy and hydropower, traffic, mine and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

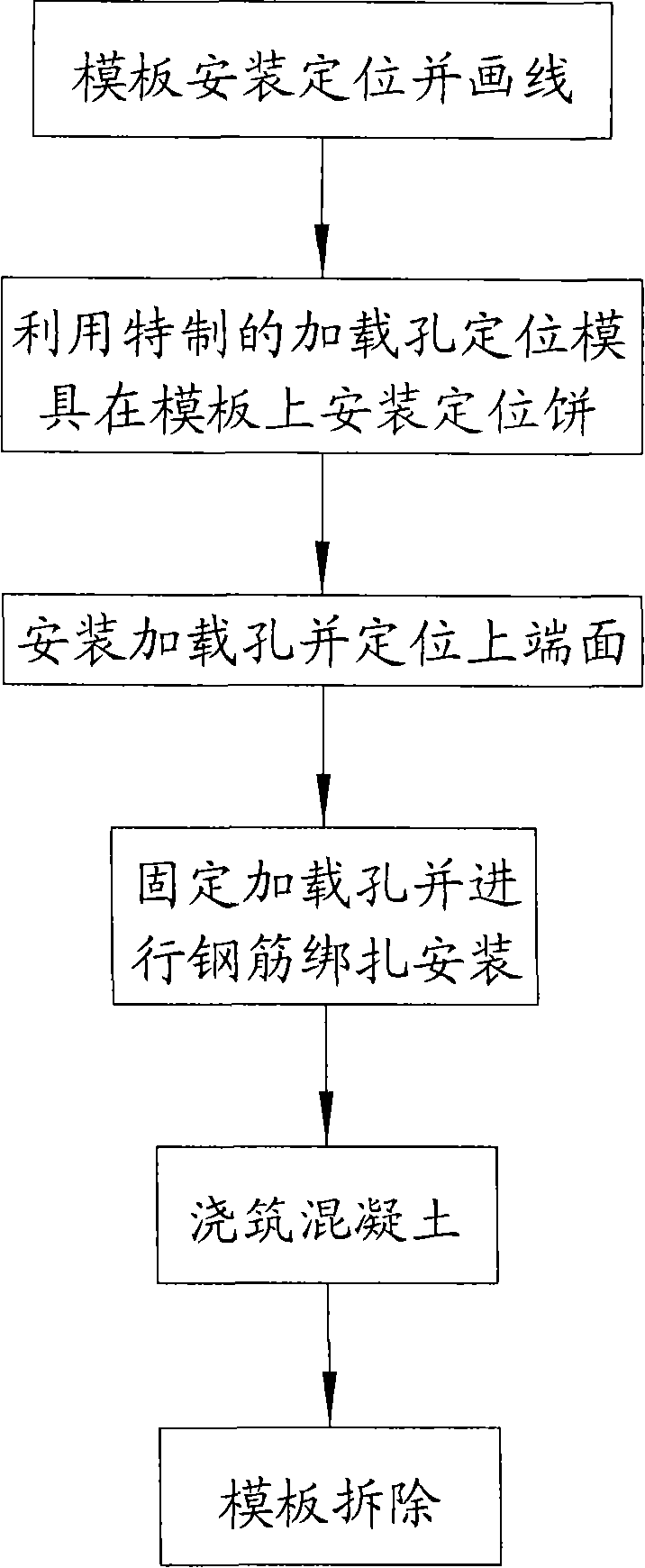

Construction method of inverse force wall and inverse force dado

ActiveCN101251448APrecise positioningHigh hole pitch accuracyPreparing sample for investigationMaterial testing goodsMan-hourEngineering

The invention discloses a reaction wall and a construction method of a reaction dado; a plurality of loading holes with a certain hole diameter or hole distance are pre-embedded in the reaction wall and the reaction dado; the construction method mainly utilizes a tailor-made loading hole positioning mould to position each loading hole; a plurality of loading hole positions meeting the standard of the loading hole diameter and hole distance are arranged on the loading hole positioning mould, then matched with positioning stuffs or positioning plugs; therefore, the loading holes can be positioned conveniently and accurately, then fixed; unlike the prior method which measures while fixing, therefore the construction method can greatly improve the hole distance precision of each loading hole and reduce construction man-hours.

Owner:FUJIAN JIULONG CONSTR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com