Construction method for raft plate basic high-precision overall pre-embedded large-diameter bolt group structure

A raft foundation and construction method technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of large number of bolts, discomfort, secondary deviation, etc., and achieve the effect of improving the embedding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this embodiment, the technical requirements for the concrete pouring construction of the cushion and the raft foundation, the technical requirements for the foundation external touch construction, the prefabrication process of the bolts involved, etc. will not be described in detail, and the high-precision overall pre-embedding of the raft foundation involved in the present invention will be focused on Implementation method of large-diameter bolt group structure construction.

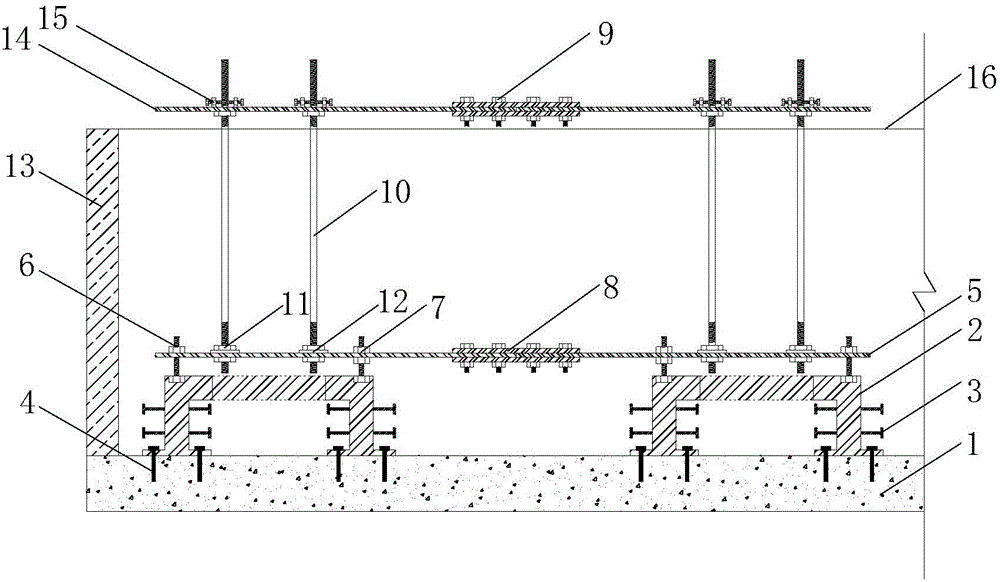

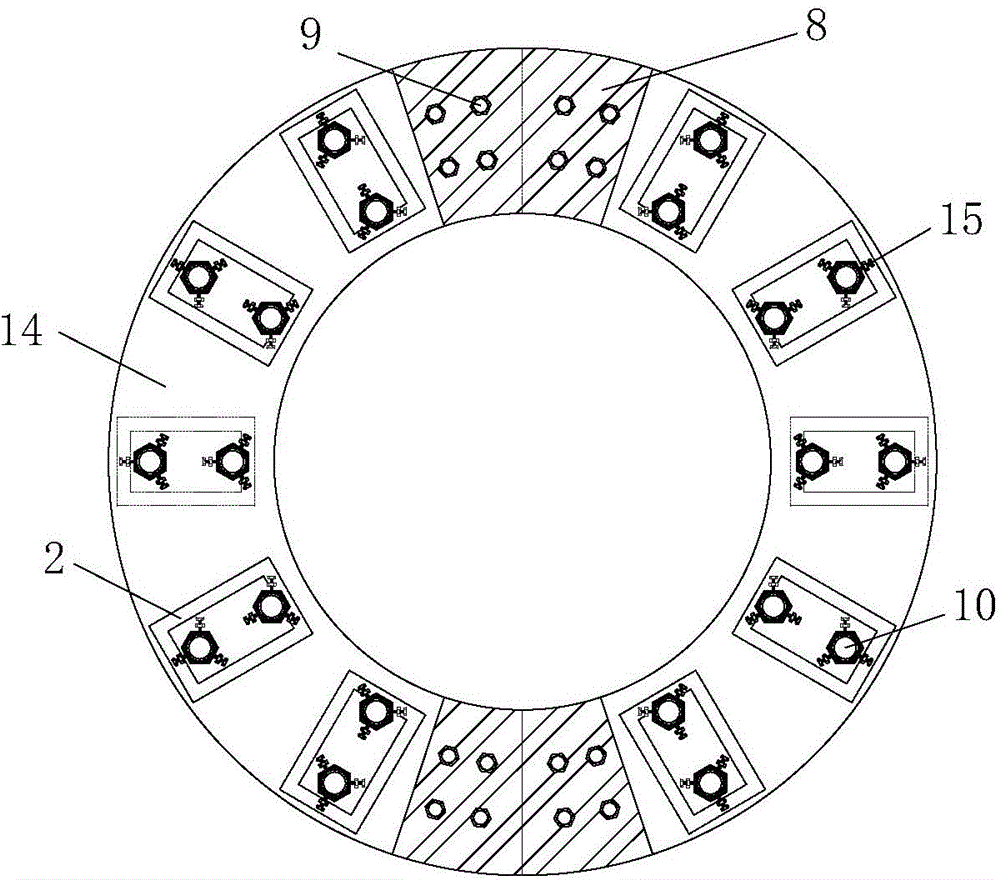

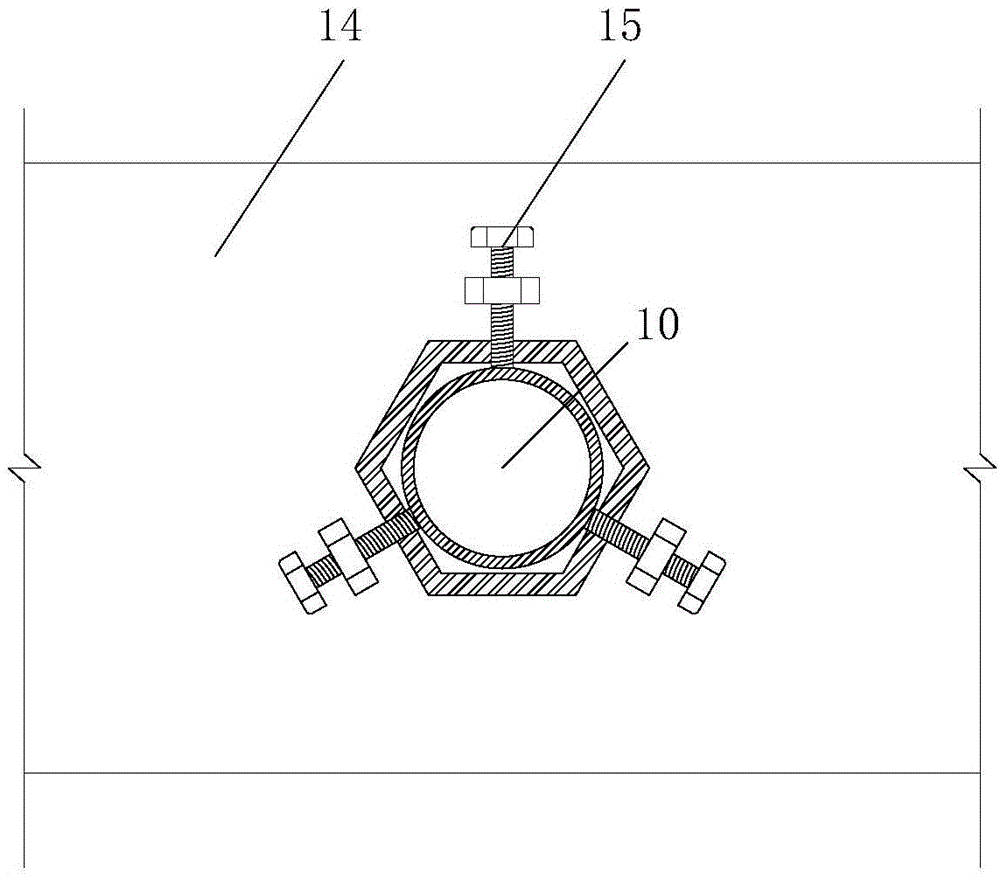

[0034] figure 1 It is a schematic diagram of the structure of the high-precision integral pre-embedded large-diameter bolt group of the raft foundation of the present invention, figure 2 It is a structural schematic diagram of the middle and upper positioning plate of the present invention, image 3 It is a schematic diagram of the fine-tuning bolt structure in the present invention, Figure 4 It is a schematic diagram of the structure of the bottom support in the present invention, Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com