Numerical-control electric frame truck for airplane engine mounting

An aircraft engine and electric technology, applied in aircraft assembly, aircraft parts, ground equipment and other directions, can solve the problems of low installation efficiency, low design accuracy, large load deformation, etc., to improve installation efficiency, reduce labor intensity of workers, and achieve high precision. Effects of quick adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

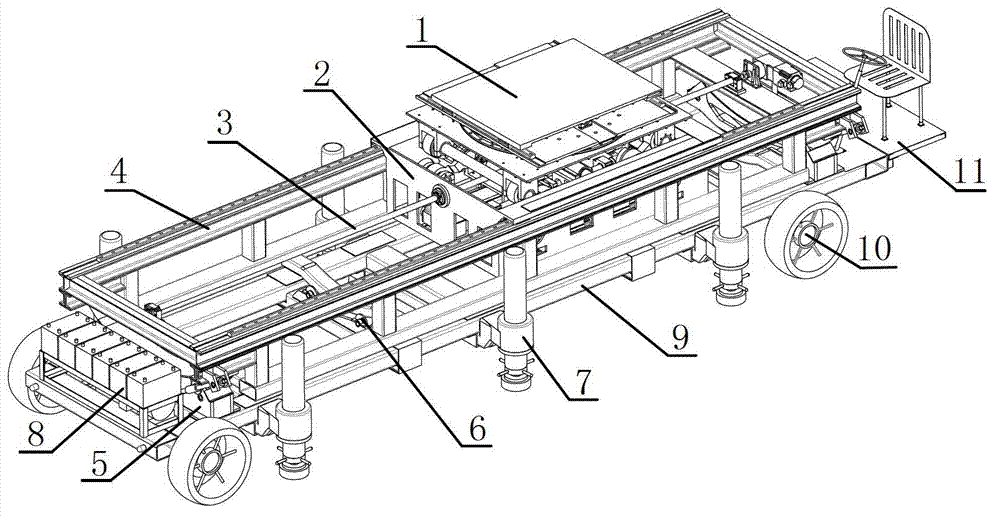

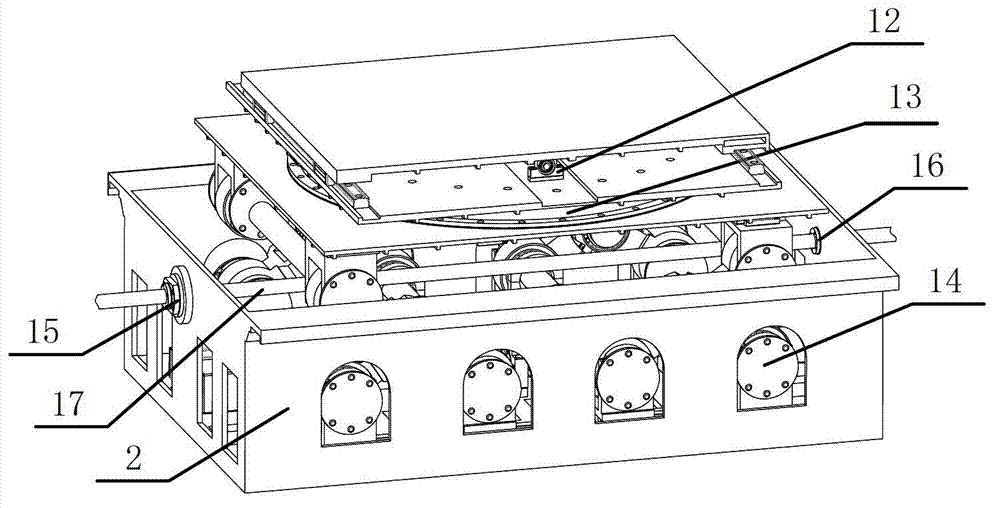

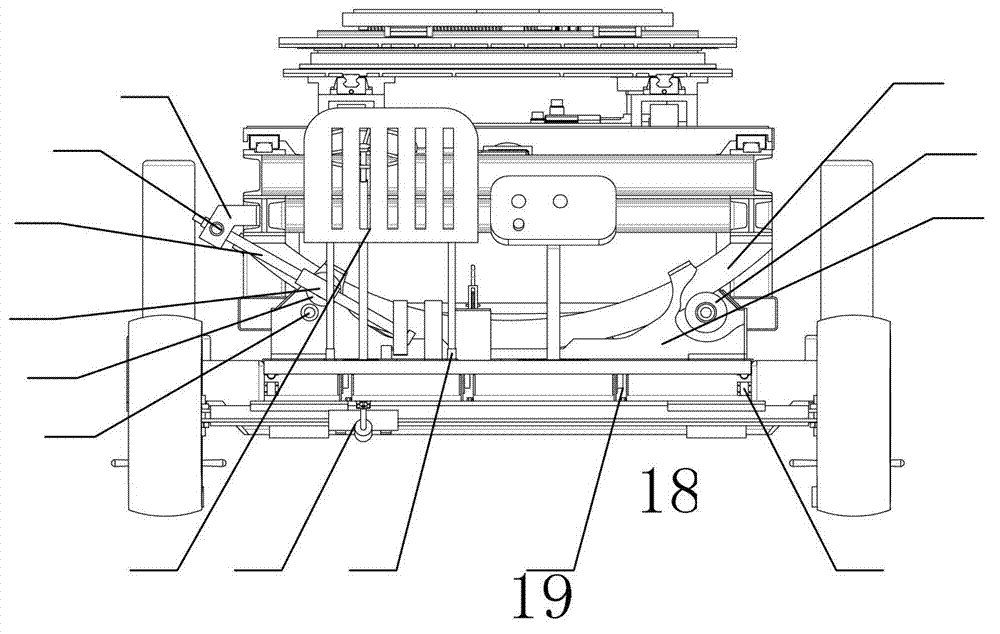

[0020] Such as figure 1 As shown in the figure, the CNC electric frame vehicle for aircraft engine installation includes a multi-axis attitude adjustment platform 1, an attitude adjustment platform frame 2, a long axis feed mechanism 3, a body frame 4, a left and right rotation mechanism 5, an auxiliary support mechanism 6, a hydraulic Outrigger 7, driving wheel train 8, car body underframe 9, steering wheel train 10, driver's cab 11, hydraulic control system and servo control system, wherein two sets of left and right turning mechanisms 5 and two sets of auxiliary support mechanisms 6 form the car body to rotate Mechanism, six identical hydraulic support legs 7 and a hydraulic control system form a hydraulic support system, and these four parts of a driving wheel train 8, a vehicle body chassis 9, a steering wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com