A kind of auxiliary installation equipment for the manufacture of shock absorber assembly

A technology for installing equipment and shock absorbers, used in manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of shock absorber waste, change of spring installation position, troublesome replacement of shock absorbers, etc., to achieve rapid production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

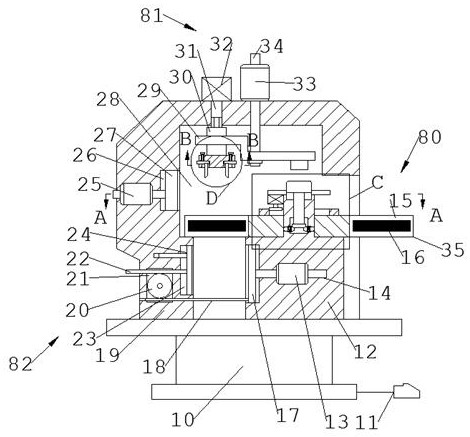

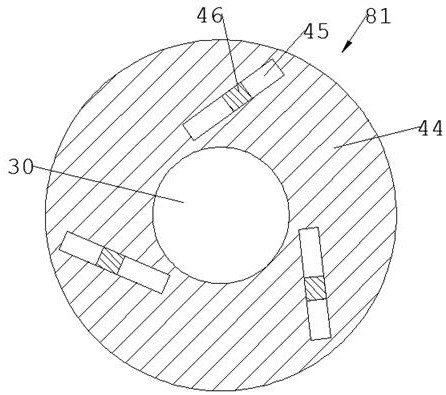

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

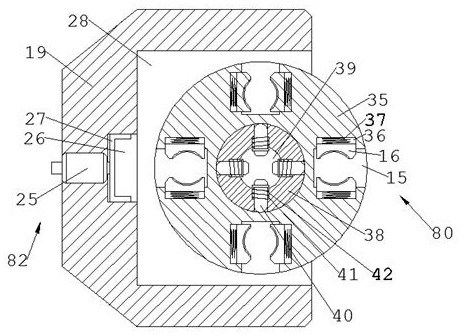

[0019] refer to Figure 1-5 , according to an embodiment of the present invention, an auxiliary installation device for shock absorber assembly production, including a base 10 placed on the ground, a housing box 19 and a fixed turntable 12 are fixedly installed on the top surface of the base 10 , the housing box 19 is provided with a work space 28, the fixed turntable 12 is installed in the work space 28, the fixed turntable 12 is installed with a turntable 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com