Patents

Literature

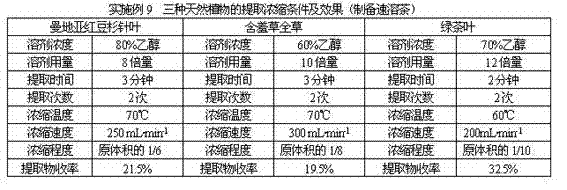

118results about How to "Fast concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

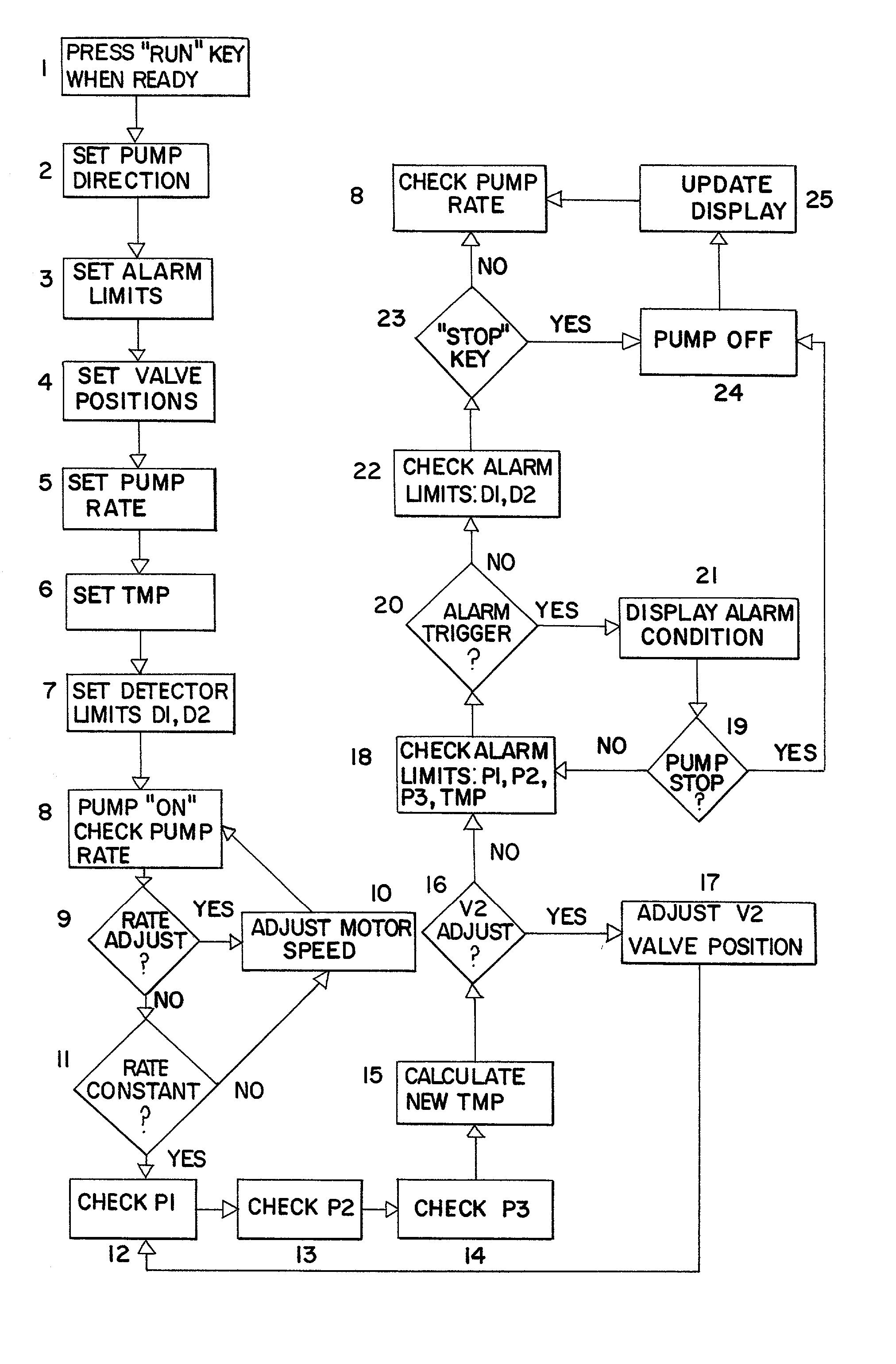

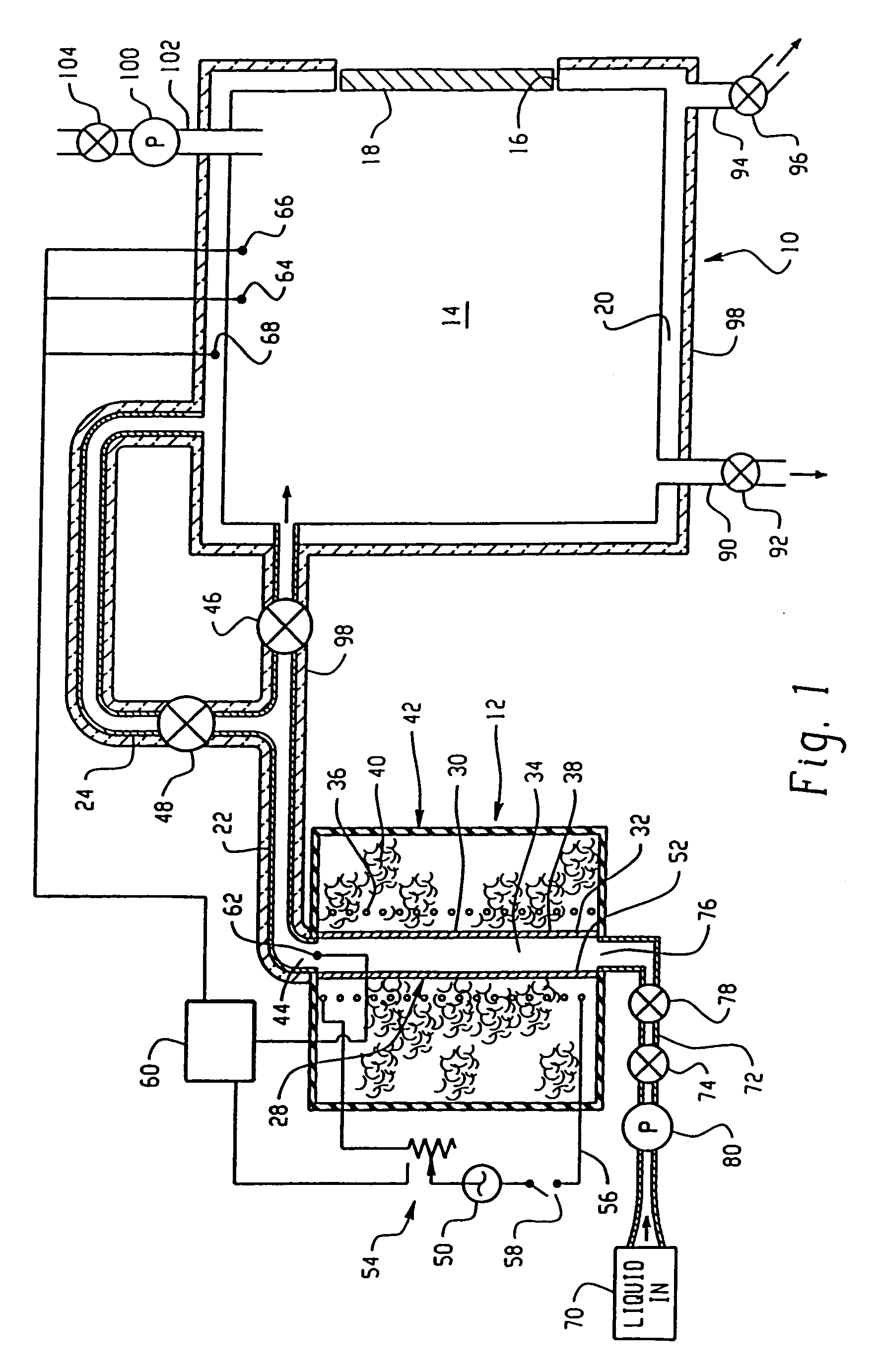

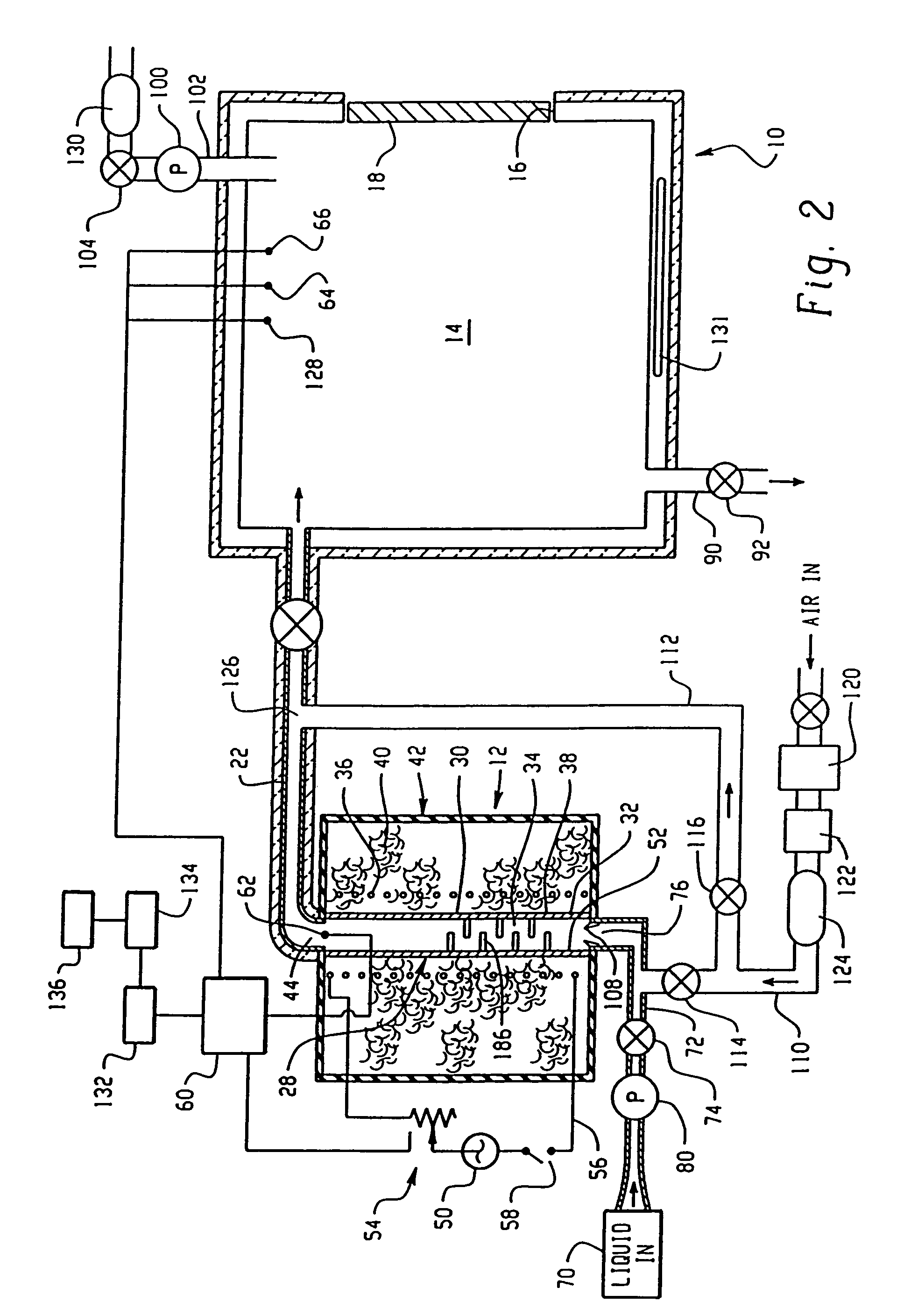

Enhancing filtration yields in tangential flow filtration

InactiveUS6350382B1High precision separationEasy to separateLiquid separation auxillary apparatusMembranesEngineeringPeak pressure

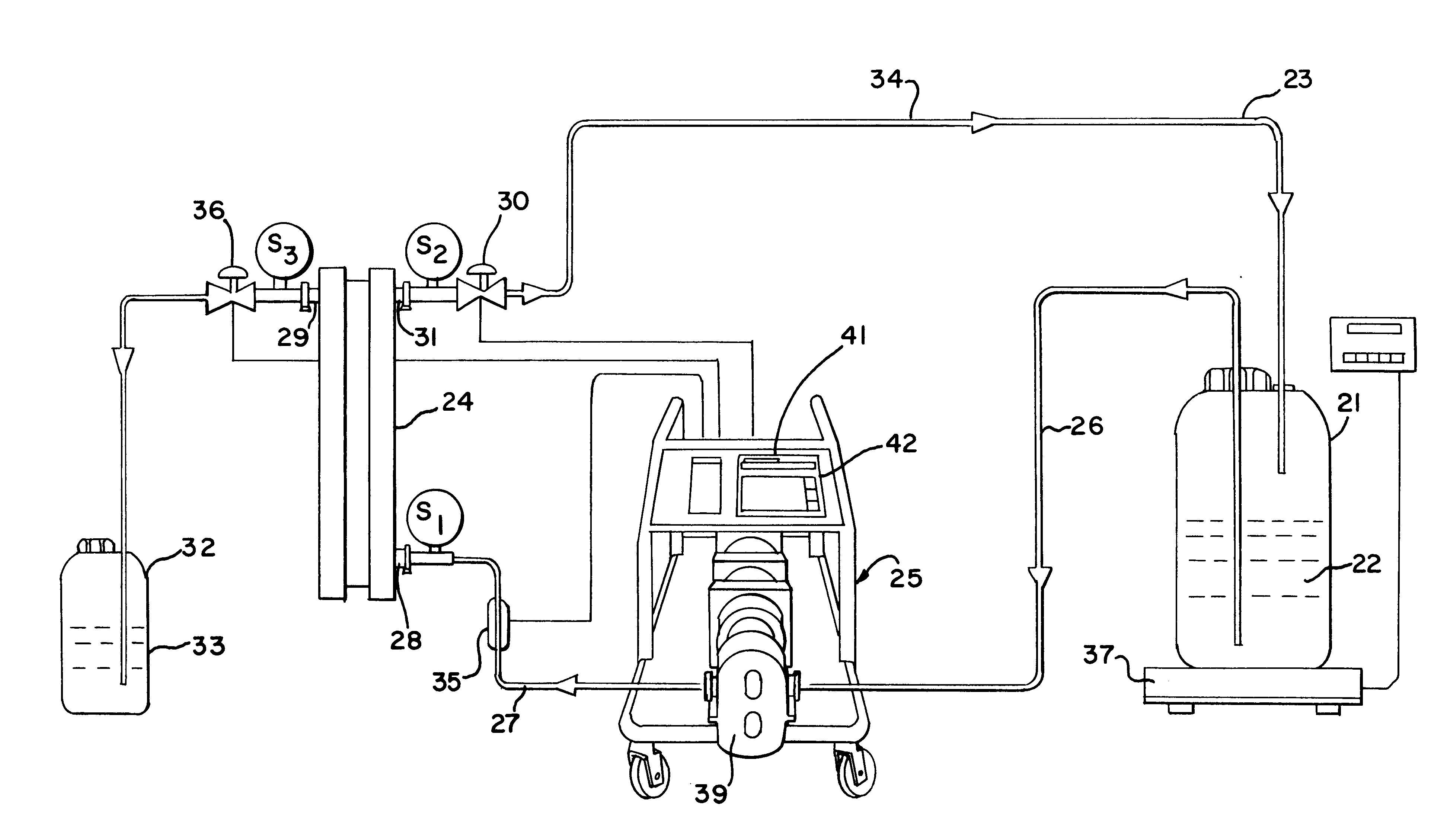

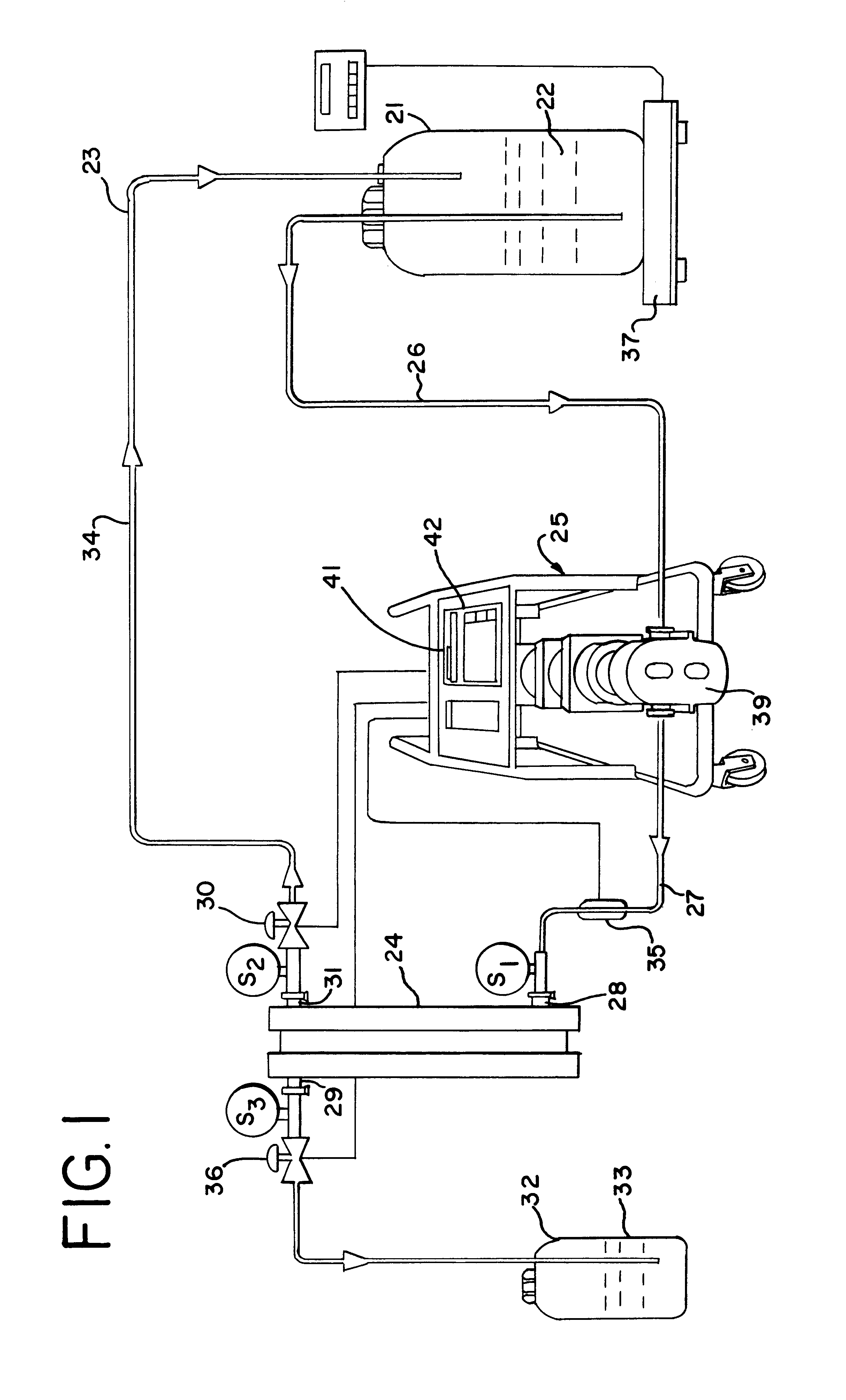

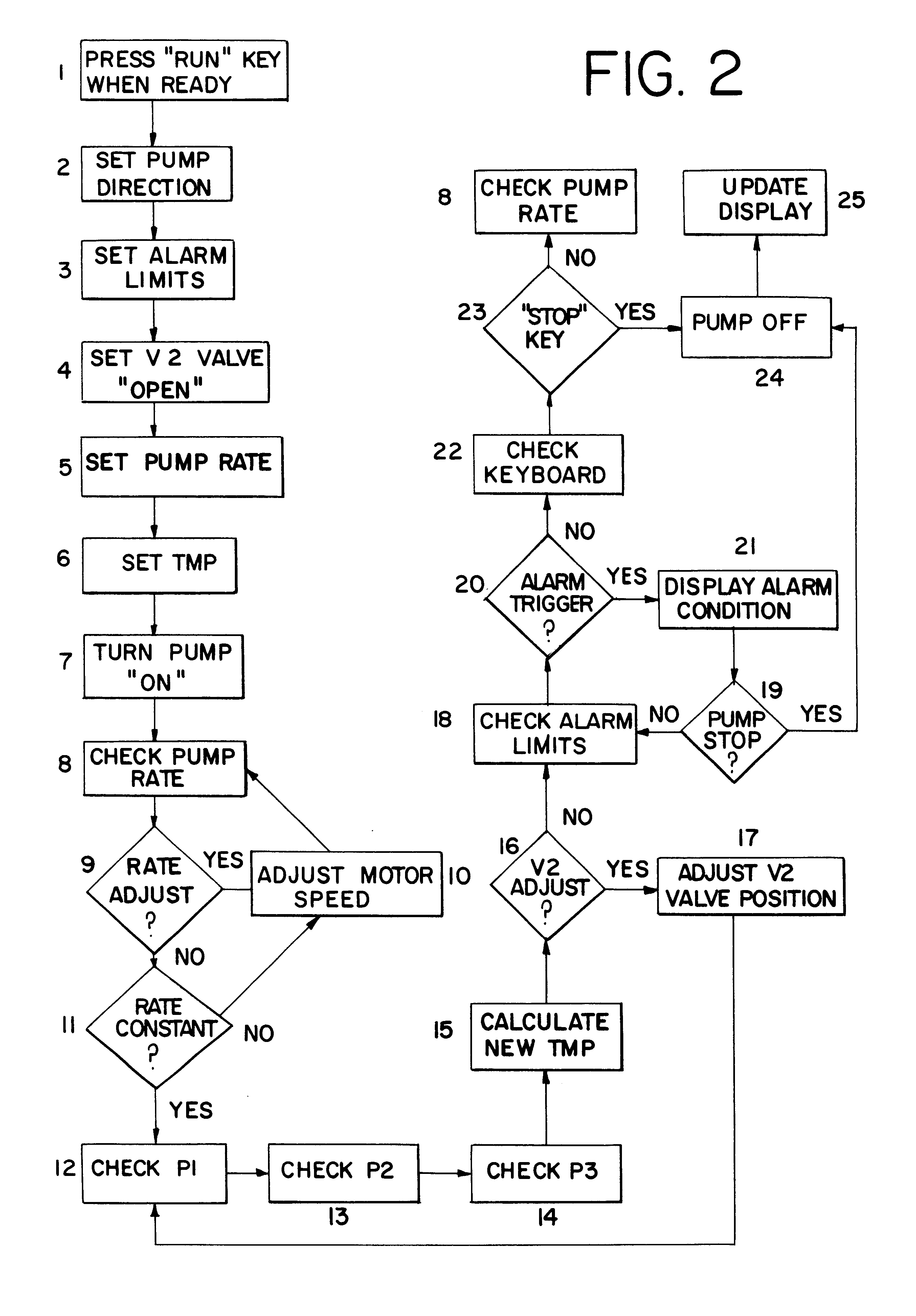

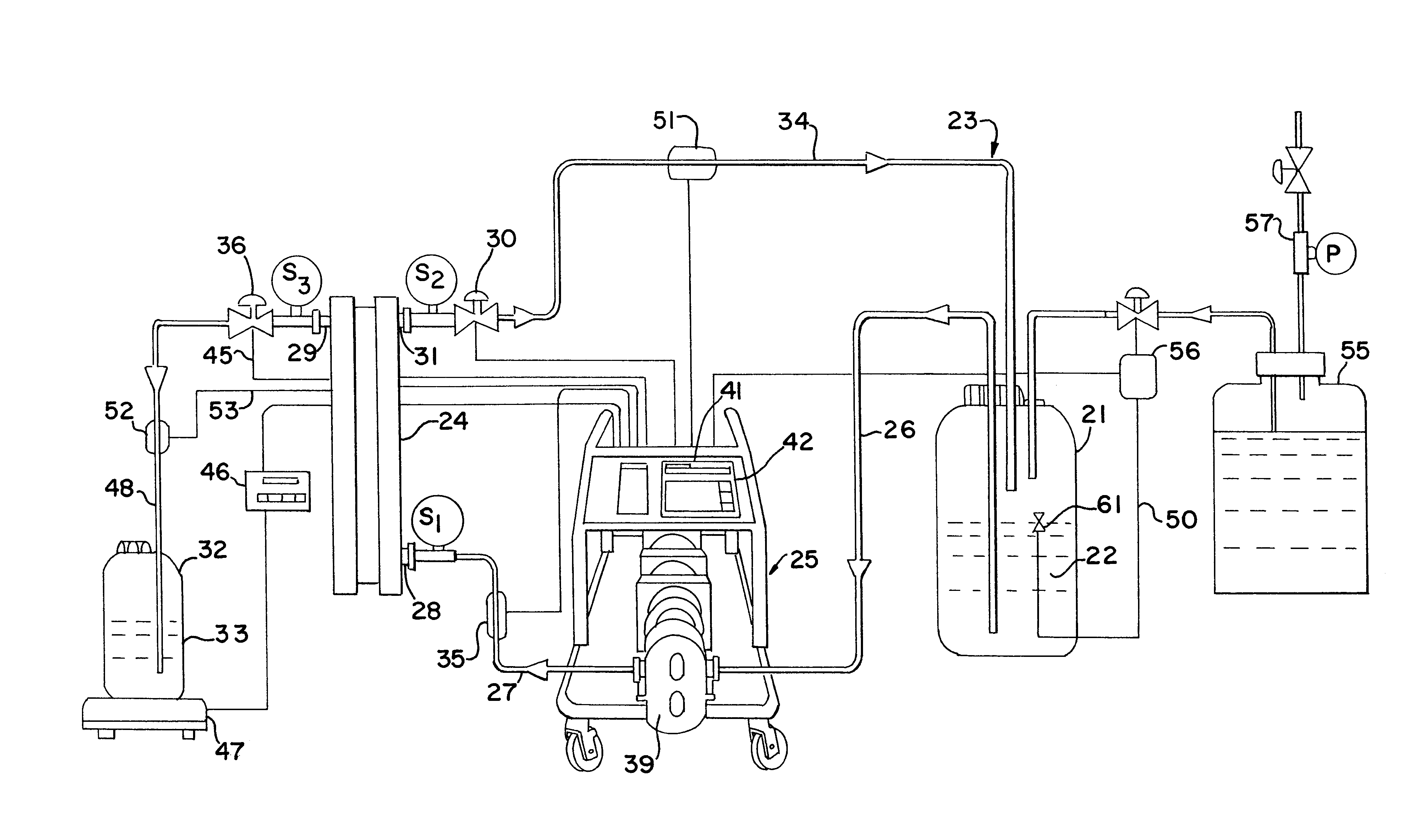

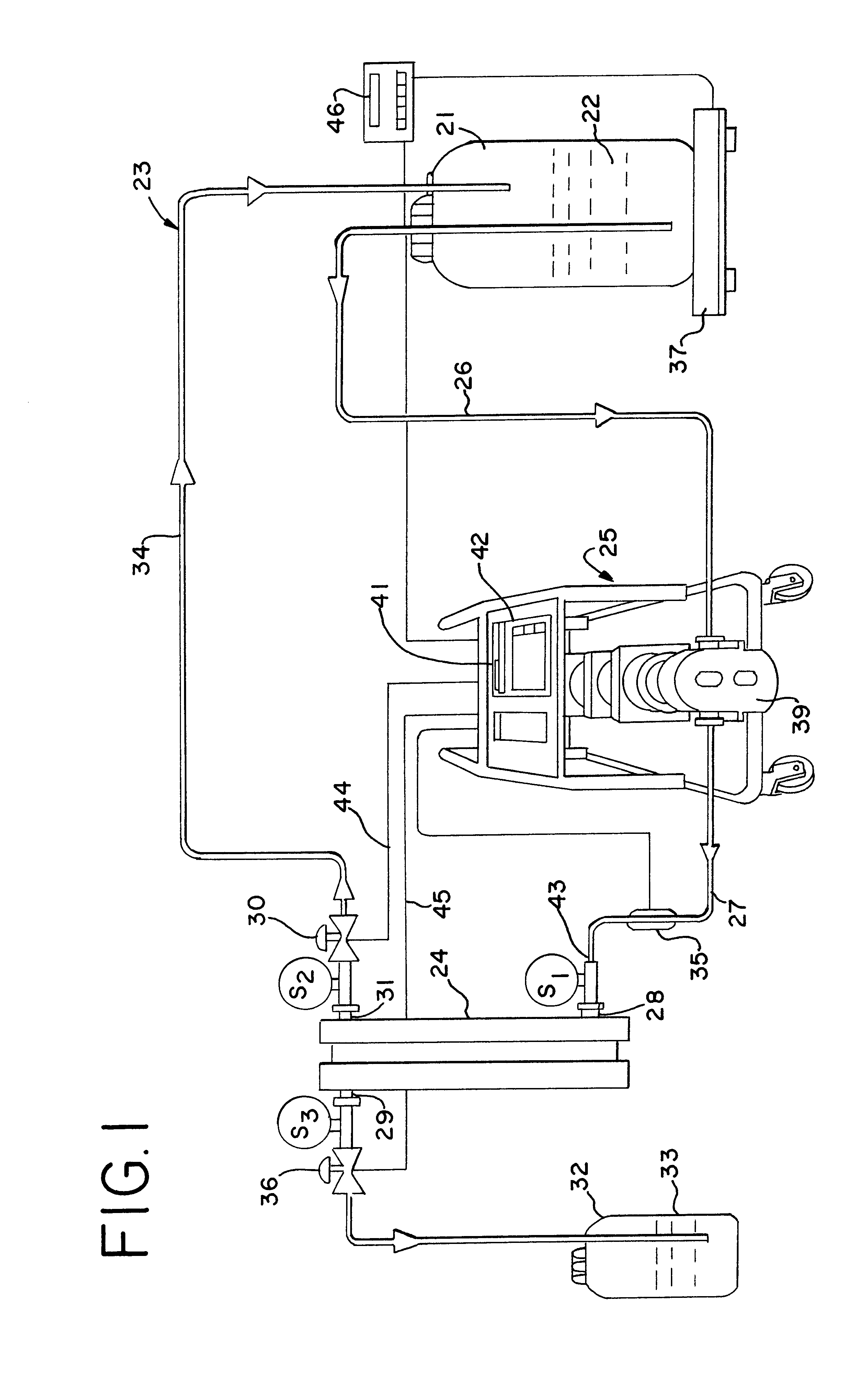

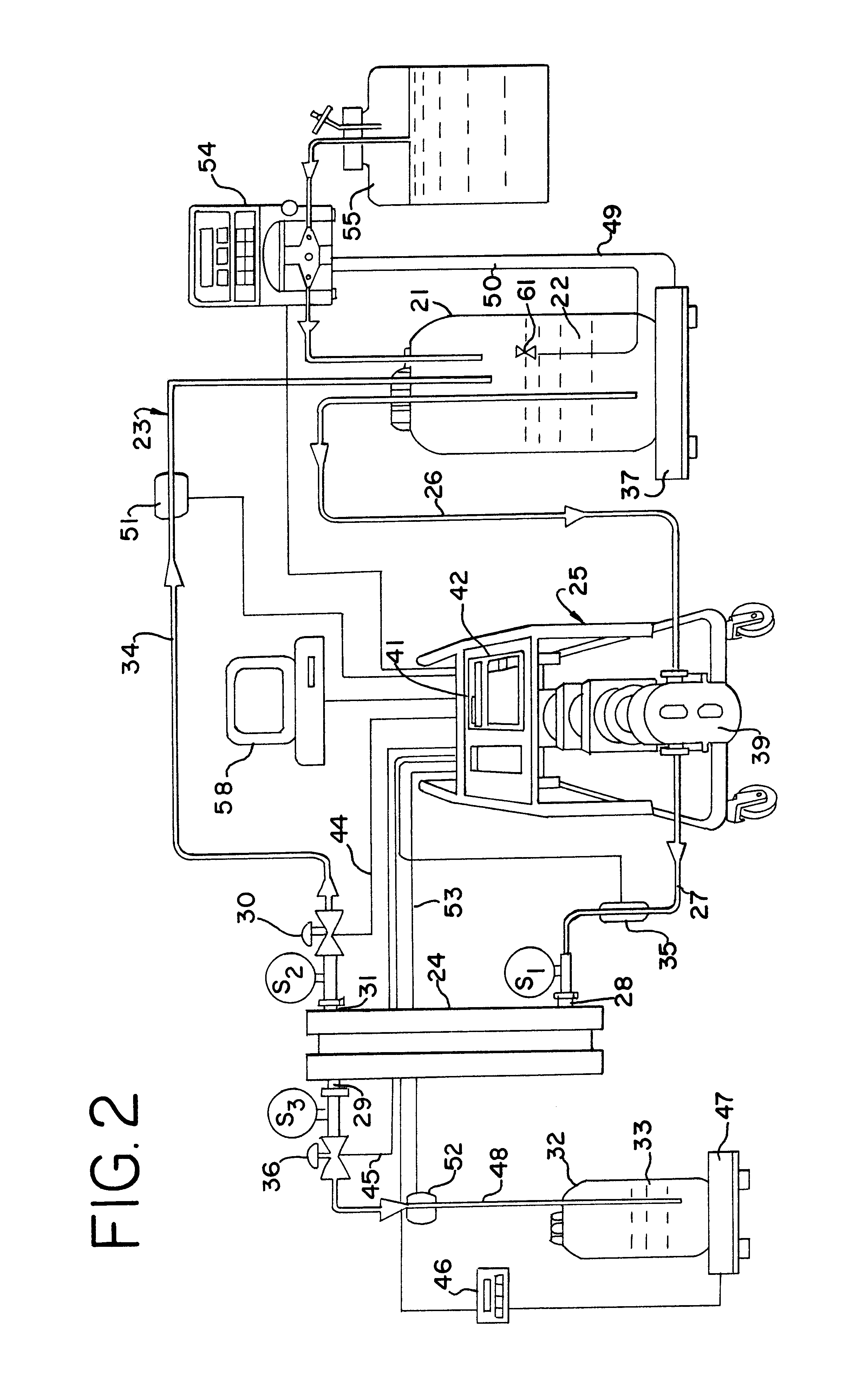

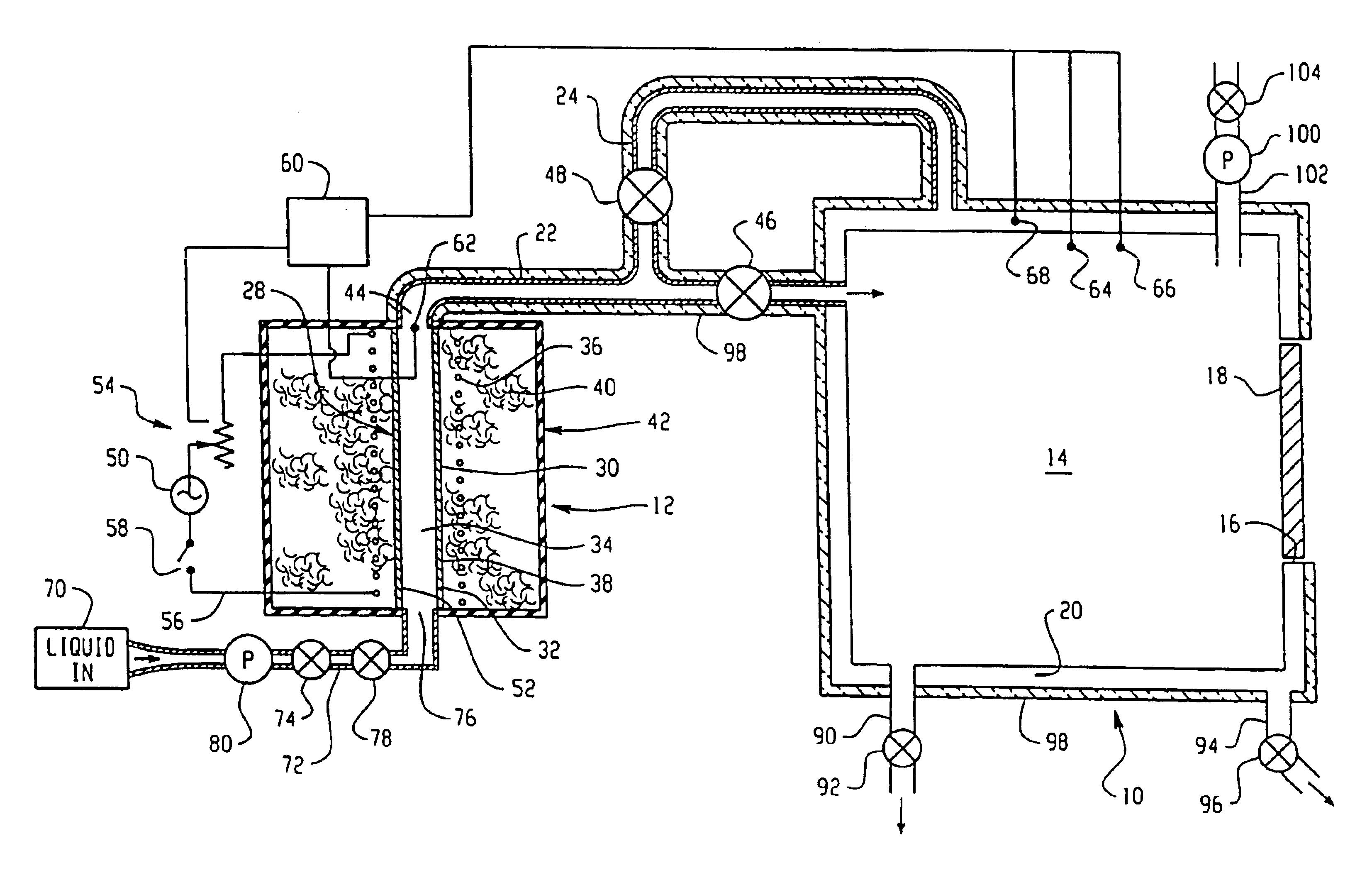

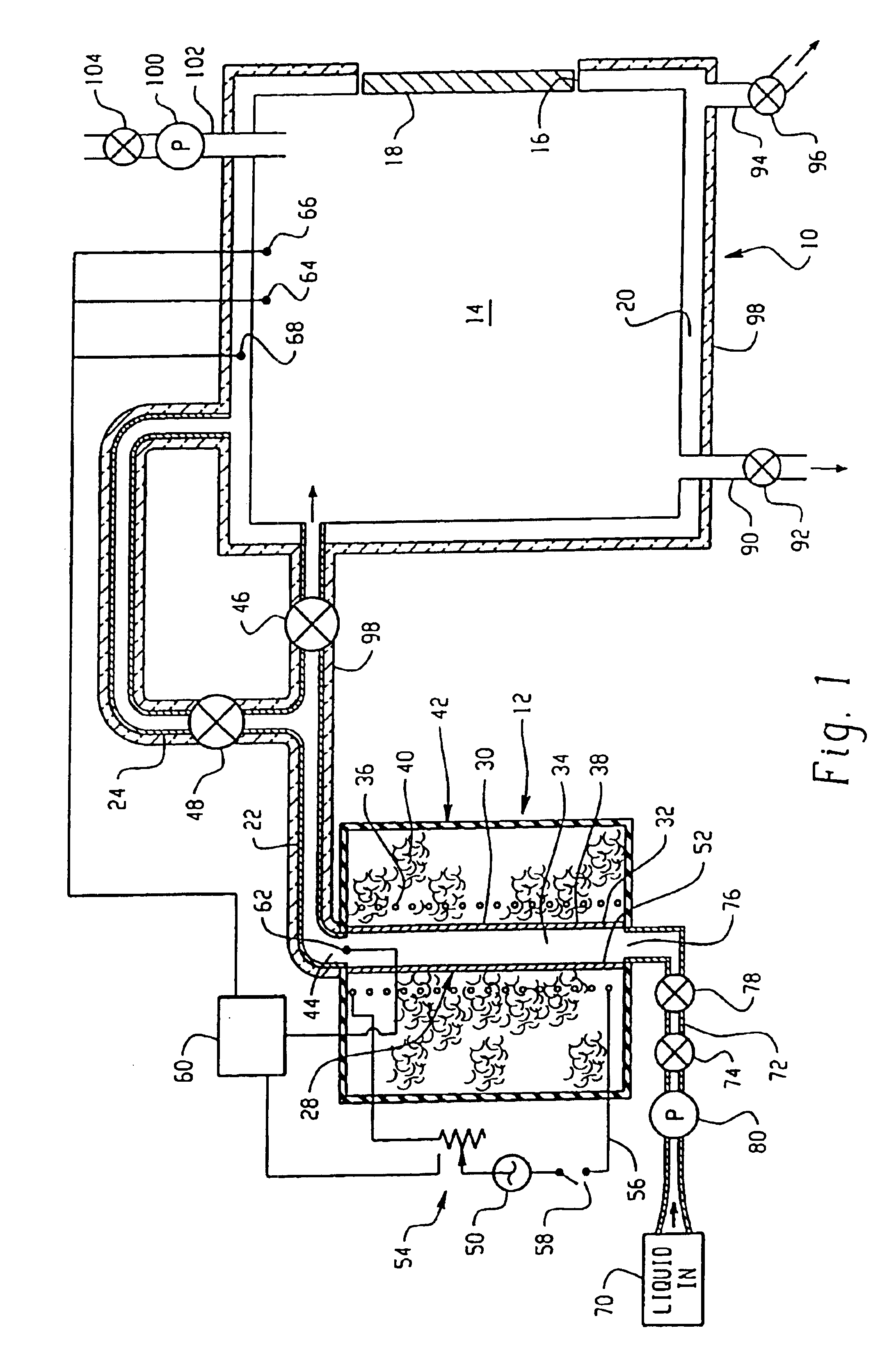

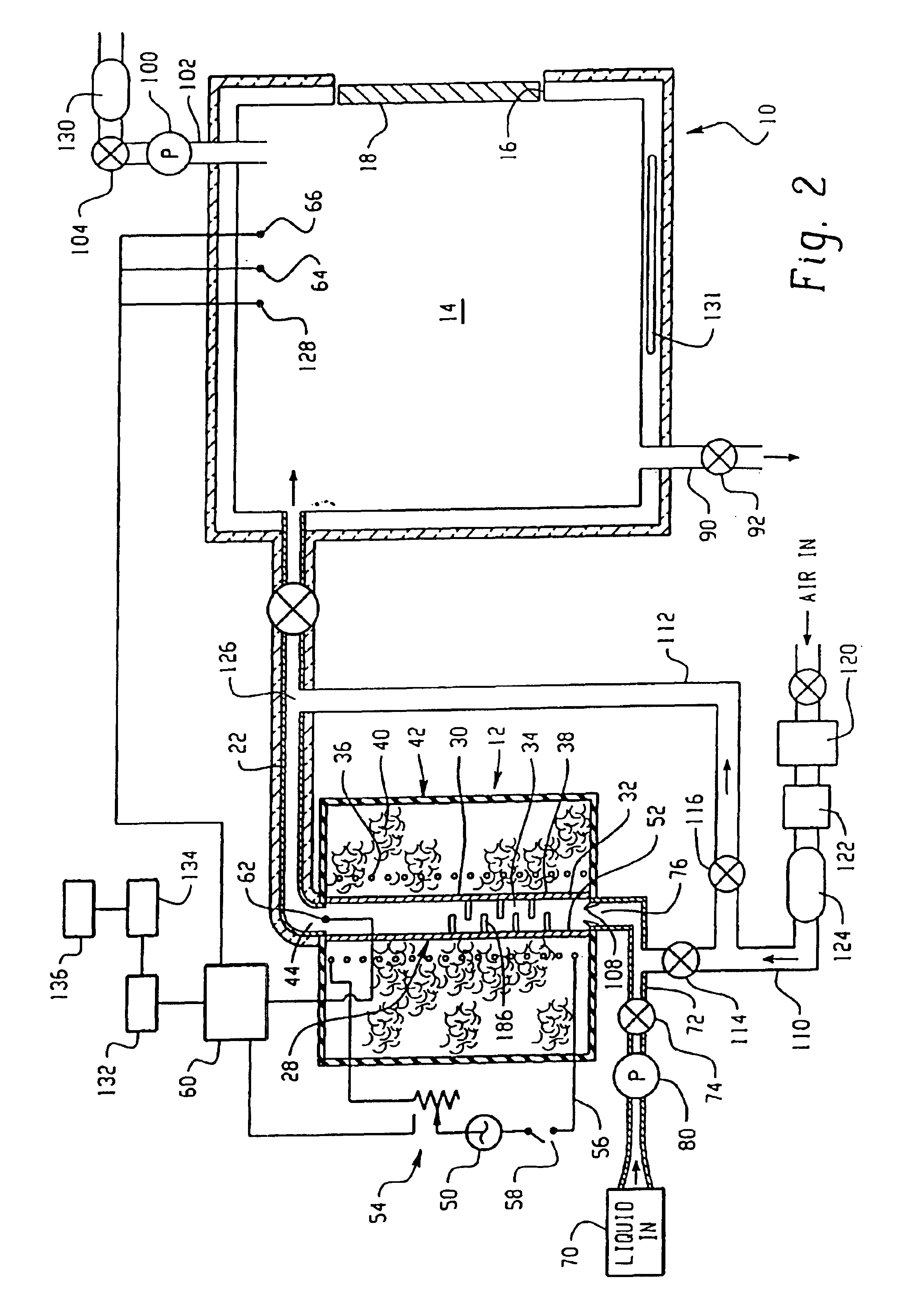

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained. Approaches also are described for determining optimal filtration conditions, including trans-membrane pressure and feed rate. Also described is a system and method for determining pressures in a pulsating system with enhanced accuracy by using a peak pressure mode.

Owner:PARKER INTANGIBLES LLC

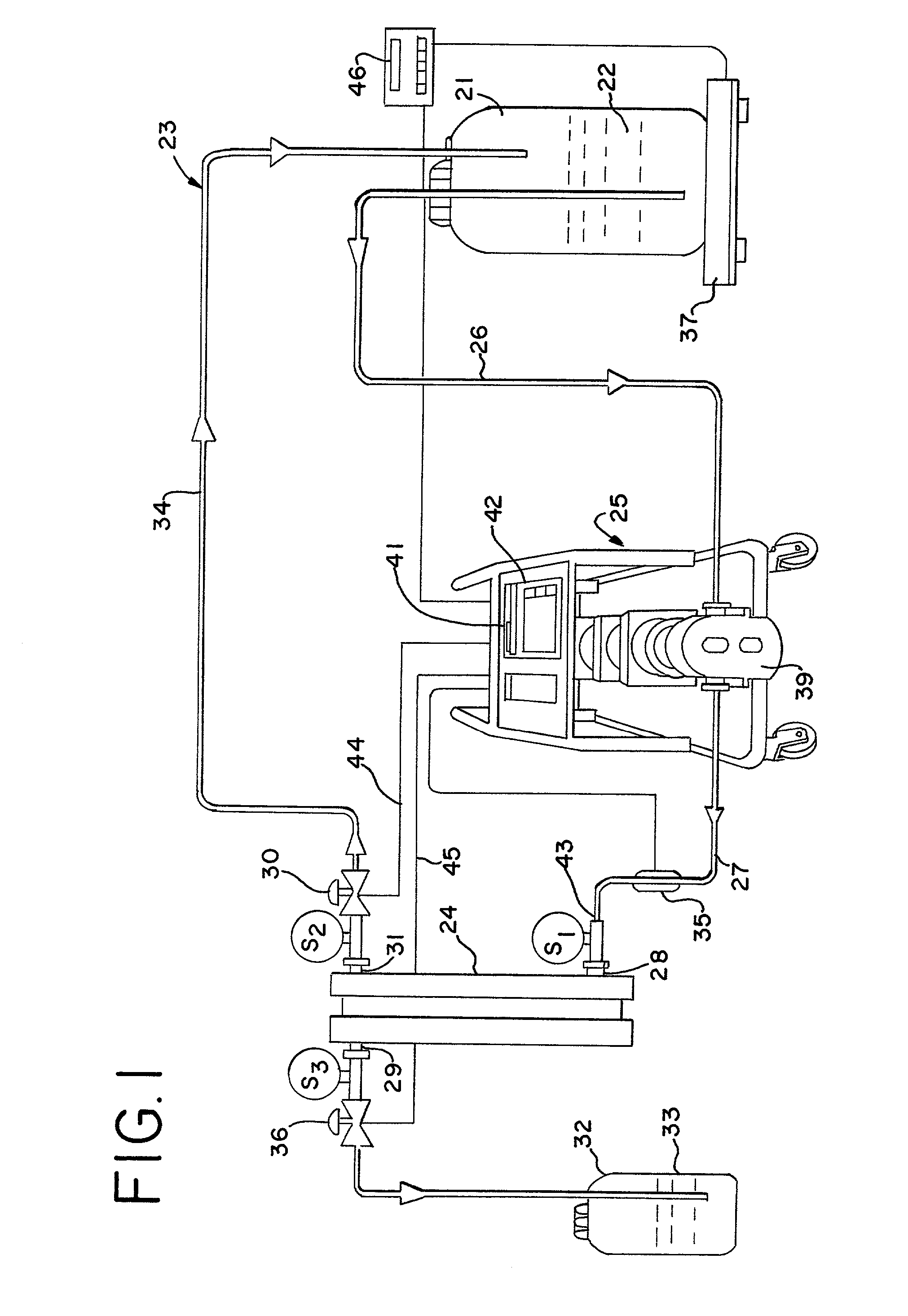

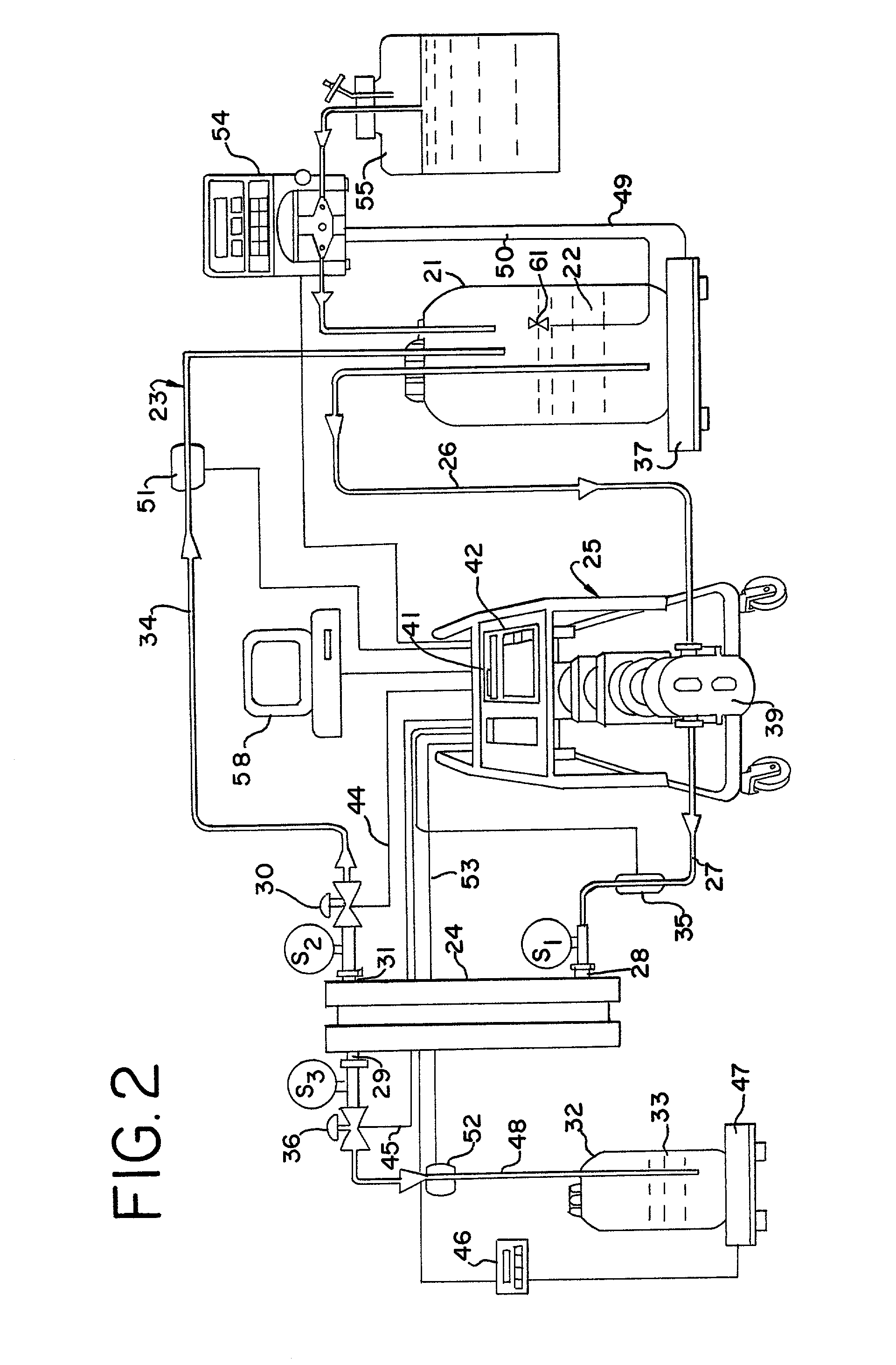

Method and apparatus for enhancing filtration yields in tangential flow filtration

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained.

Owner:PARKER INTANGIBLES LLC

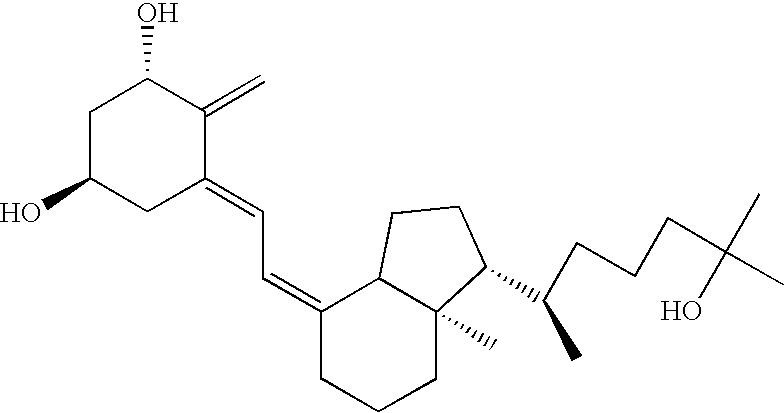

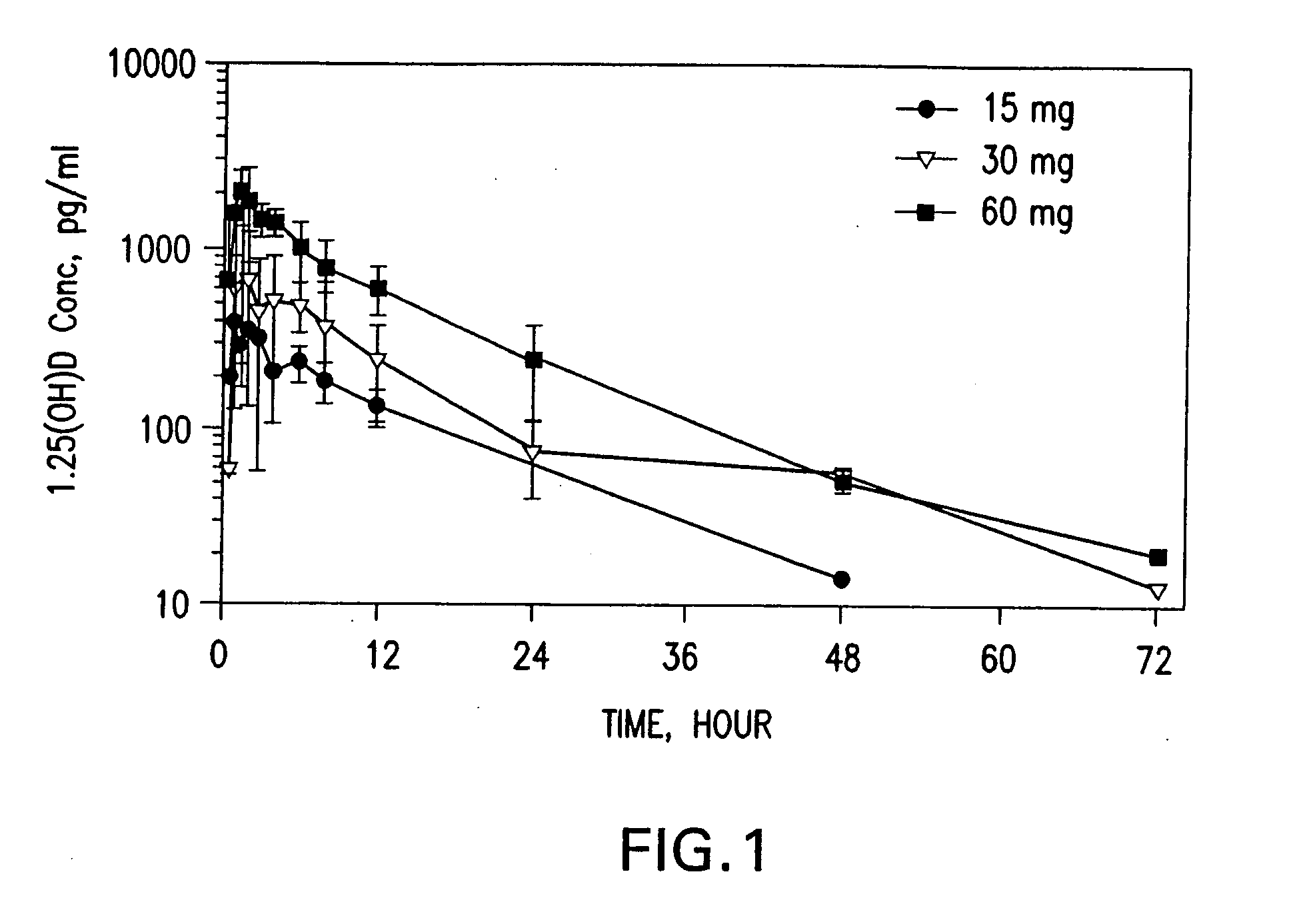

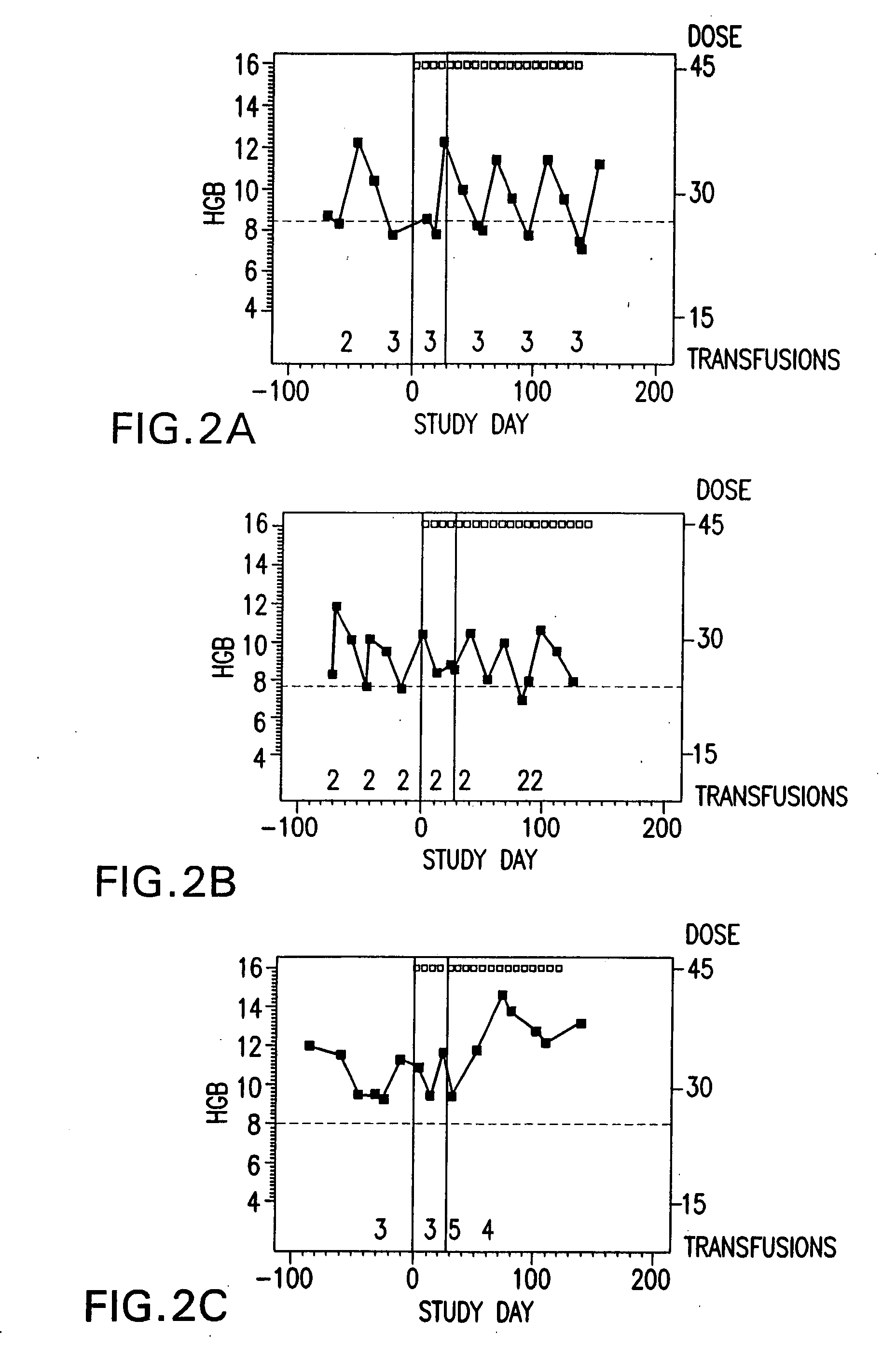

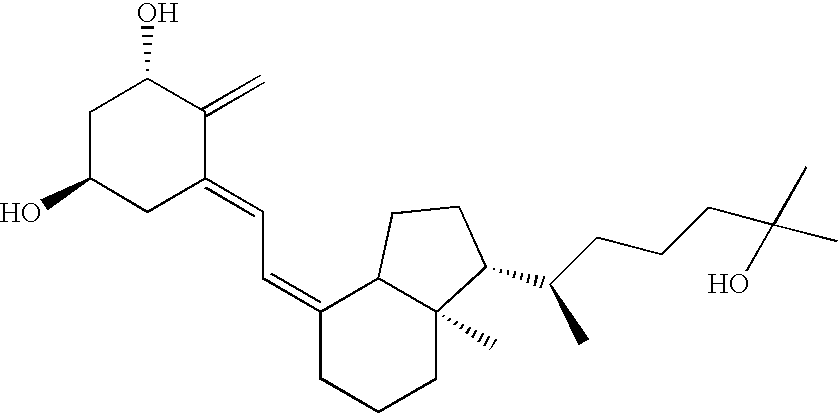

Methods of using vitamin D compounds in the treatment of myelodysplastic syndromes

InactiveUS20050101576A1Minimizing and avoiding effectUseful in treatmentOrganic active ingredientsBiocideActive agentHigh doses

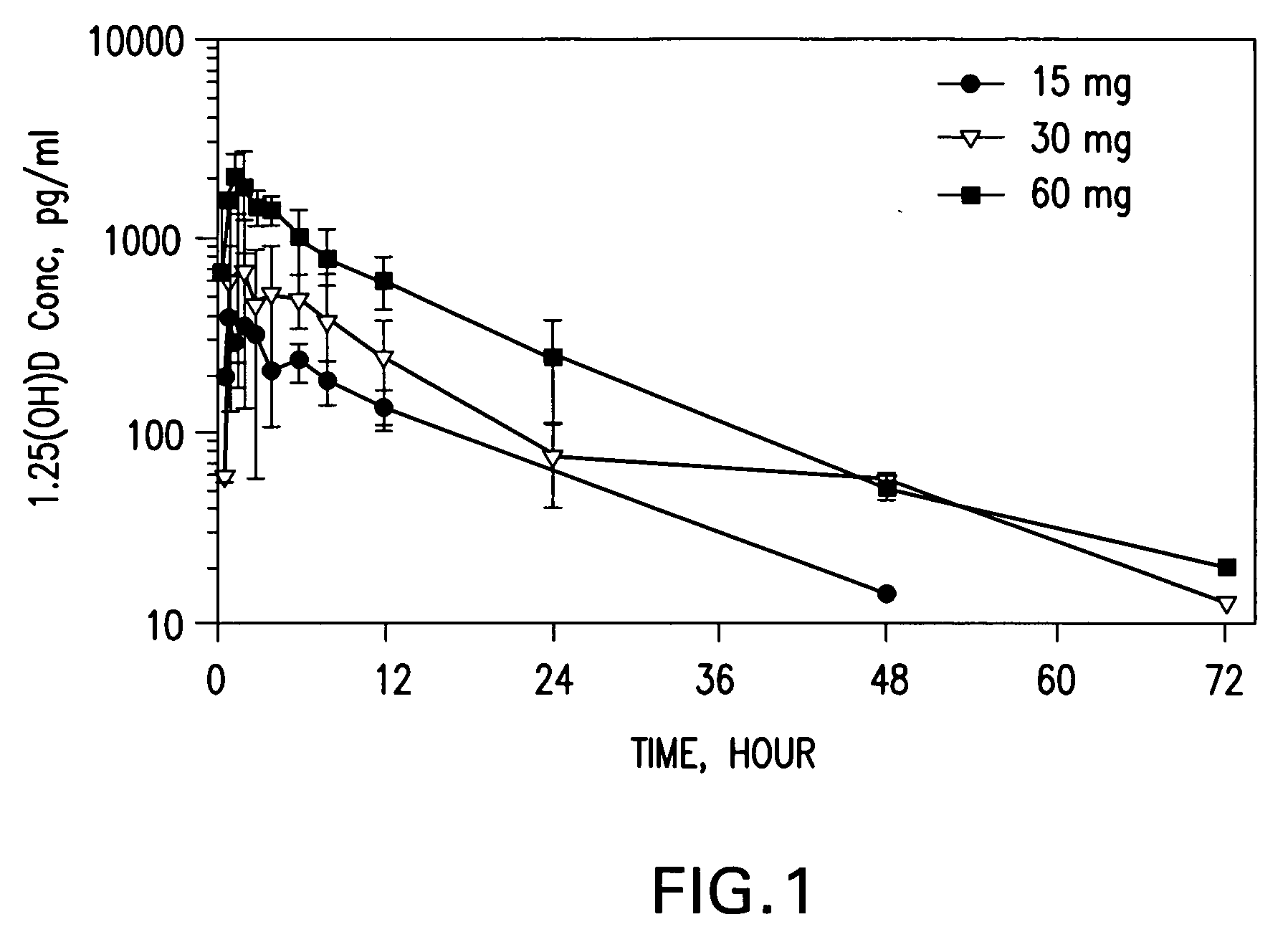

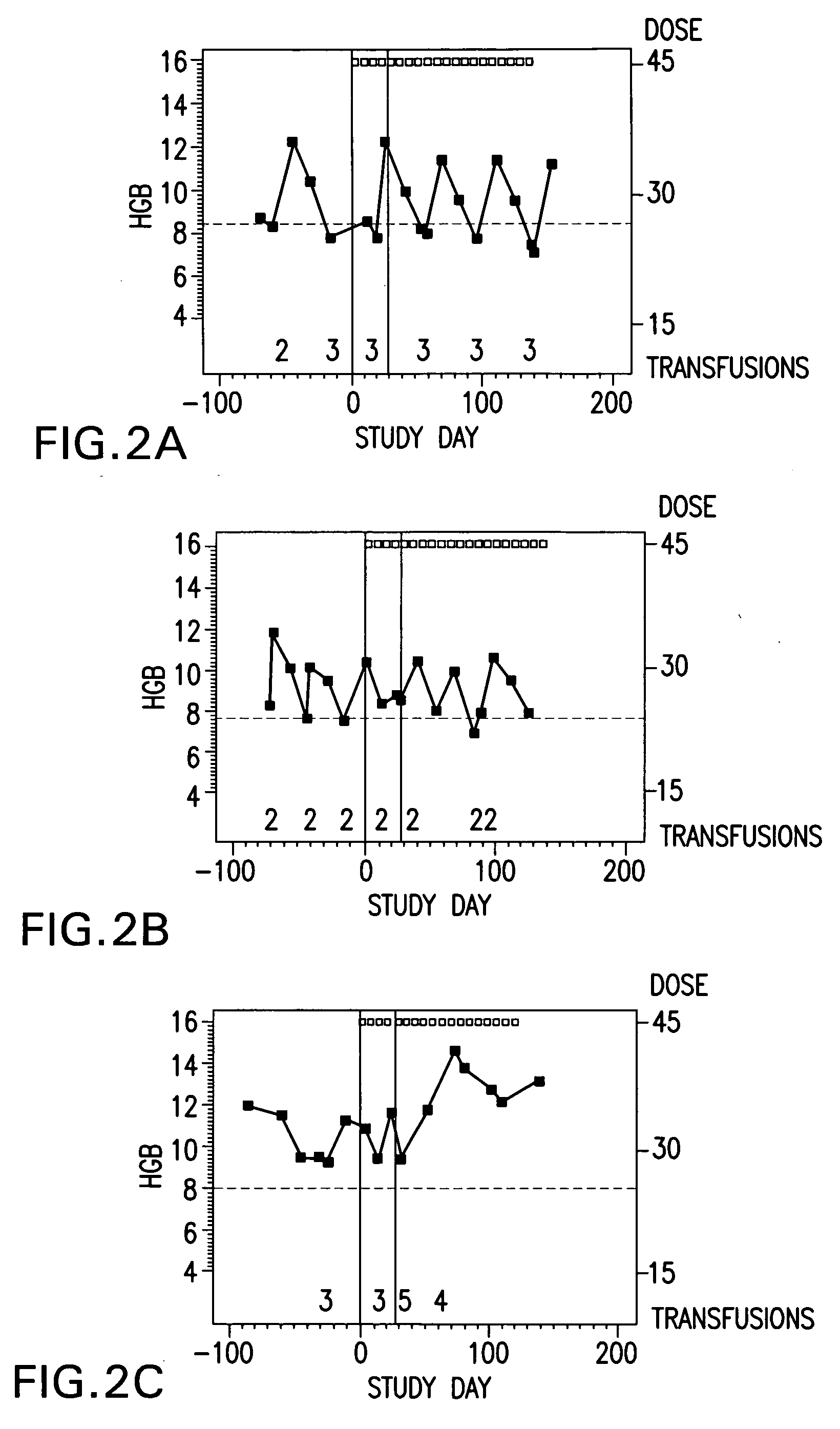

Methods of treating MDS, or ameliorating a symptom thereof, are disclosed. Specific methods encompass the administration of one or more vitamin D compounds, or a pharmaceutically acceptable salt, solvate, hydrate, stereoisomer, clathrate, or prodrug thereof, alone or in combination with one or more additional active agents. Other methods include intermittent administration of a high dose of one or more vitamin D compounds, or a pharmaceutically acceptable salt, solvate, hydrate, stereoisomer, clathrate, or prodrug thereof, alone or in combination with one or more additional active agents. Such intermittent administration allows high doses of the vitamin D compounds to be administered while minimizing or eliminating hypercalcemia.

Owner:NOVACEA INC

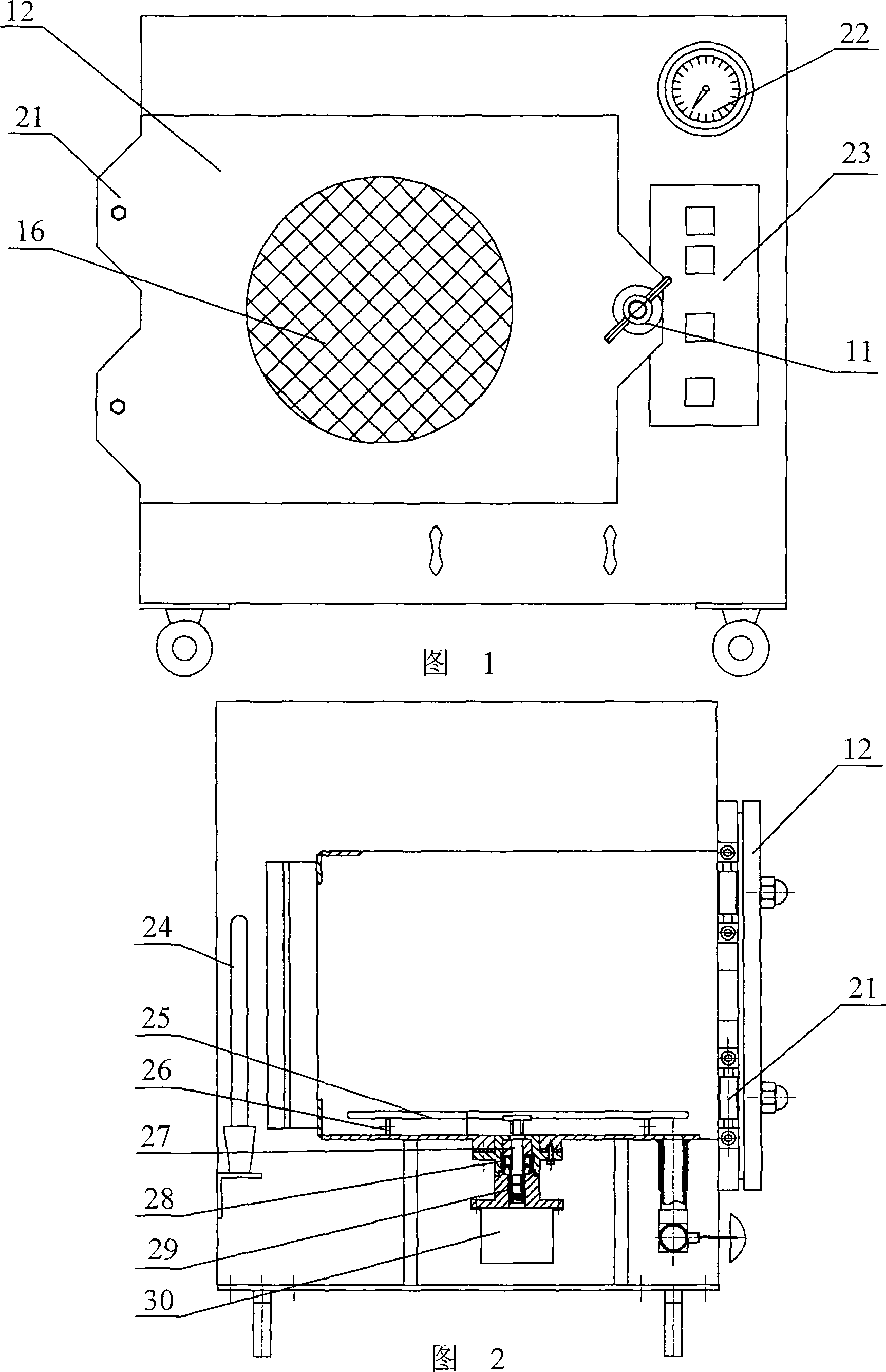

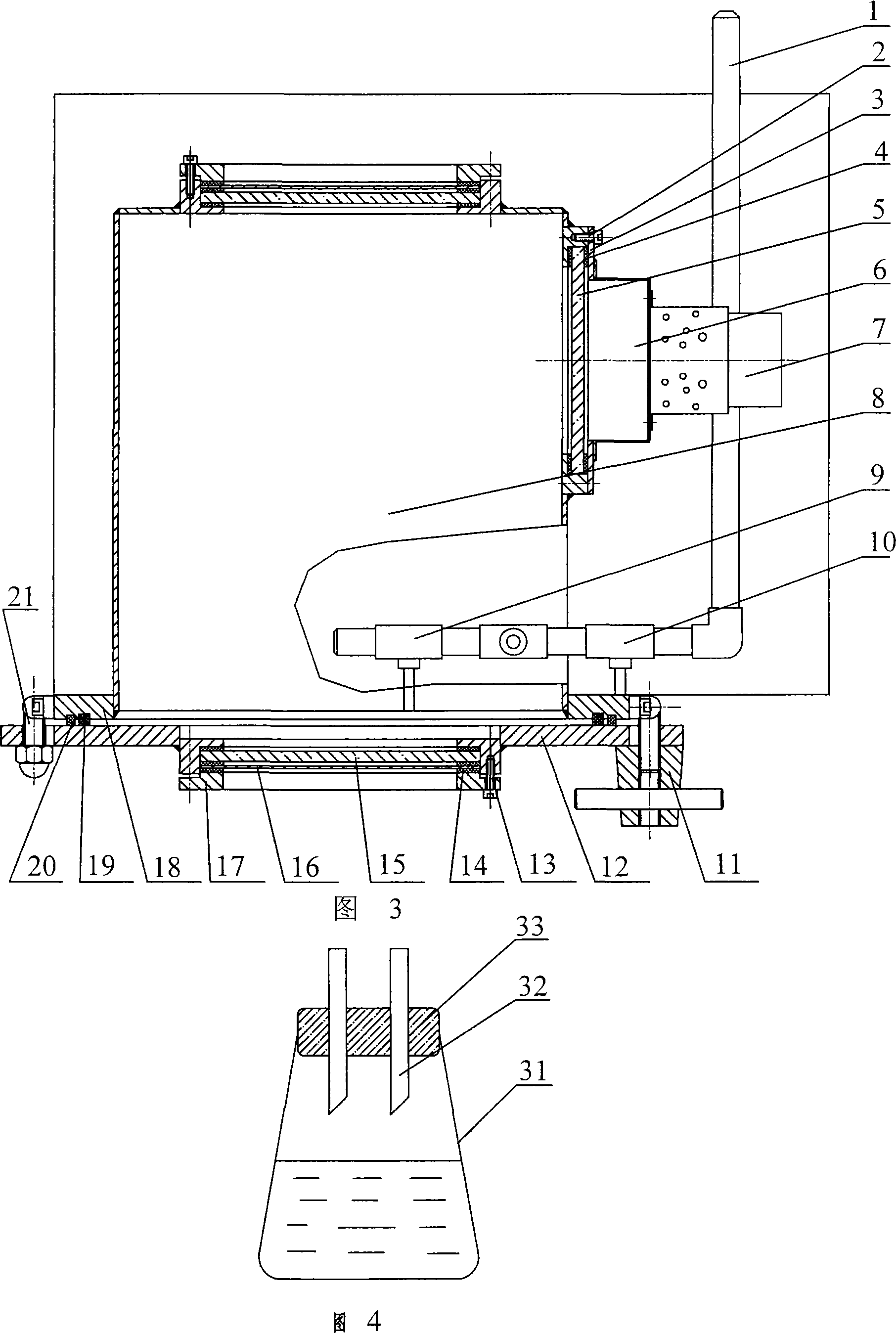

Micro-wave vacuum equipment

InactiveCN101082464AFast dryingFast concentrationDrying solid materials with heatDrying chambers/containersVacuum pumpingMicrowave

This invention relates to a sort of integral dry and dewatering set of the microwave and vacuum system, it consists of a hothouse of hermetic estate which is used to pose the materiel, the on-off door body which is propitious to gain and put materiel is fitted on the wall of the hothouse, the microwave produced by the microwave generator can cross the wall of the hothouse and it use the microwave to heat the materiel of the hothouse, there has the vacuum connector tub which is extended to the hothouse on the wall of the hothouse, the vacuum connector tub connects with the vacuum-pumping set. Because thin invention makes the microwave heating system connects with the vacuum system in the organic way, the speed of its dryness and condensation is fast, the temperature is low (25 to 45 deg. C), It very fit to the use of the lab, and fit to desiccate and condense the multifarious hydrous, and specially fit to food materiel of the heat sensitivity, and so on, and it is widely used to desiccate and condense the multifarious hydrous in the way of small-scale in the lab, such as the food, the medication, the chemical production.

Owner:JIANGNAN UNIV

Method and apparatus for enhancing filtration yields in tangential flow filtration

InactiveUS20020043487A1High precision separationEasy to separateMembranesUltrafiltrationFiltrationEngineering

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained.

Owner:PARKER INTANGIBLES LLC

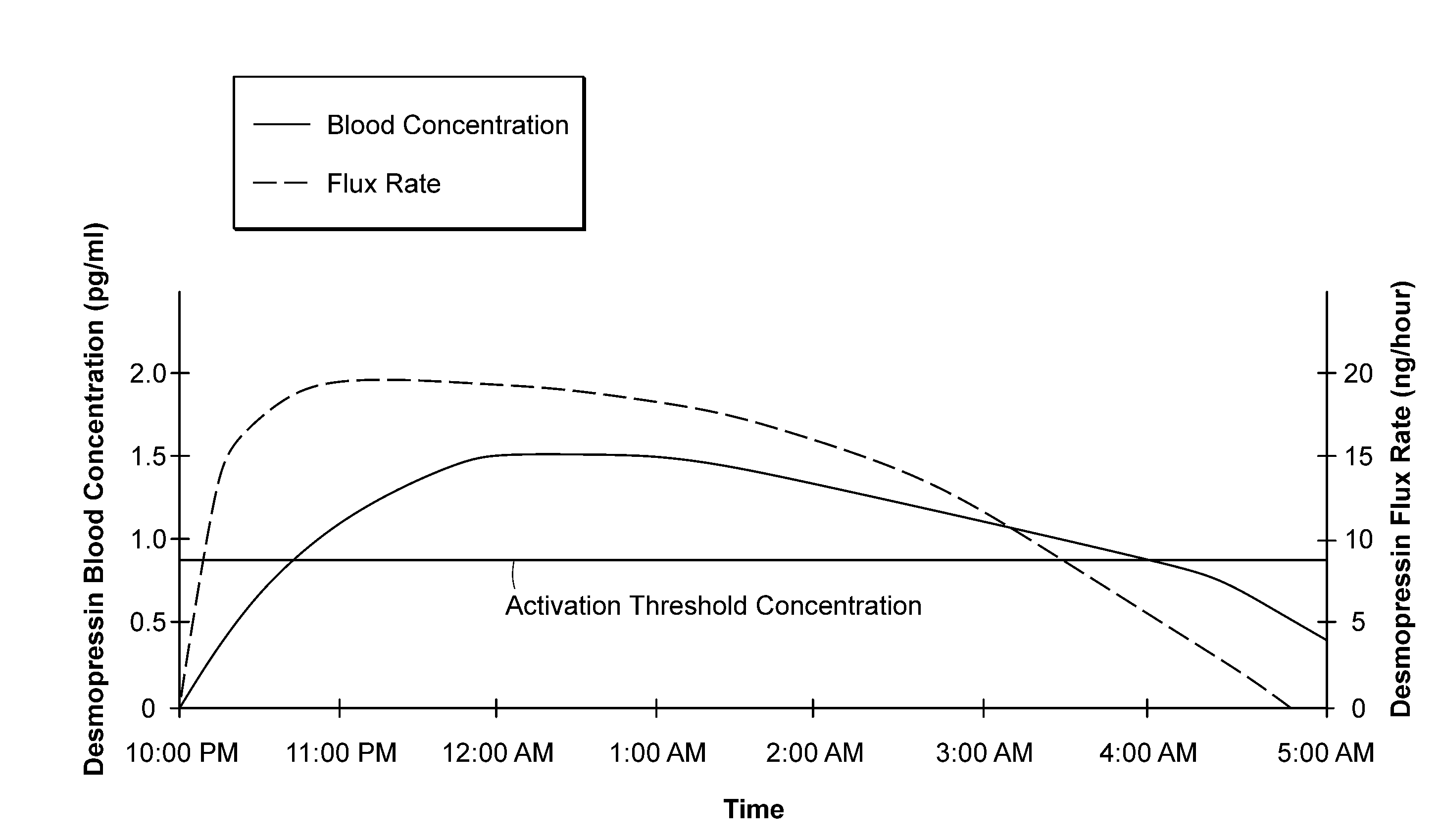

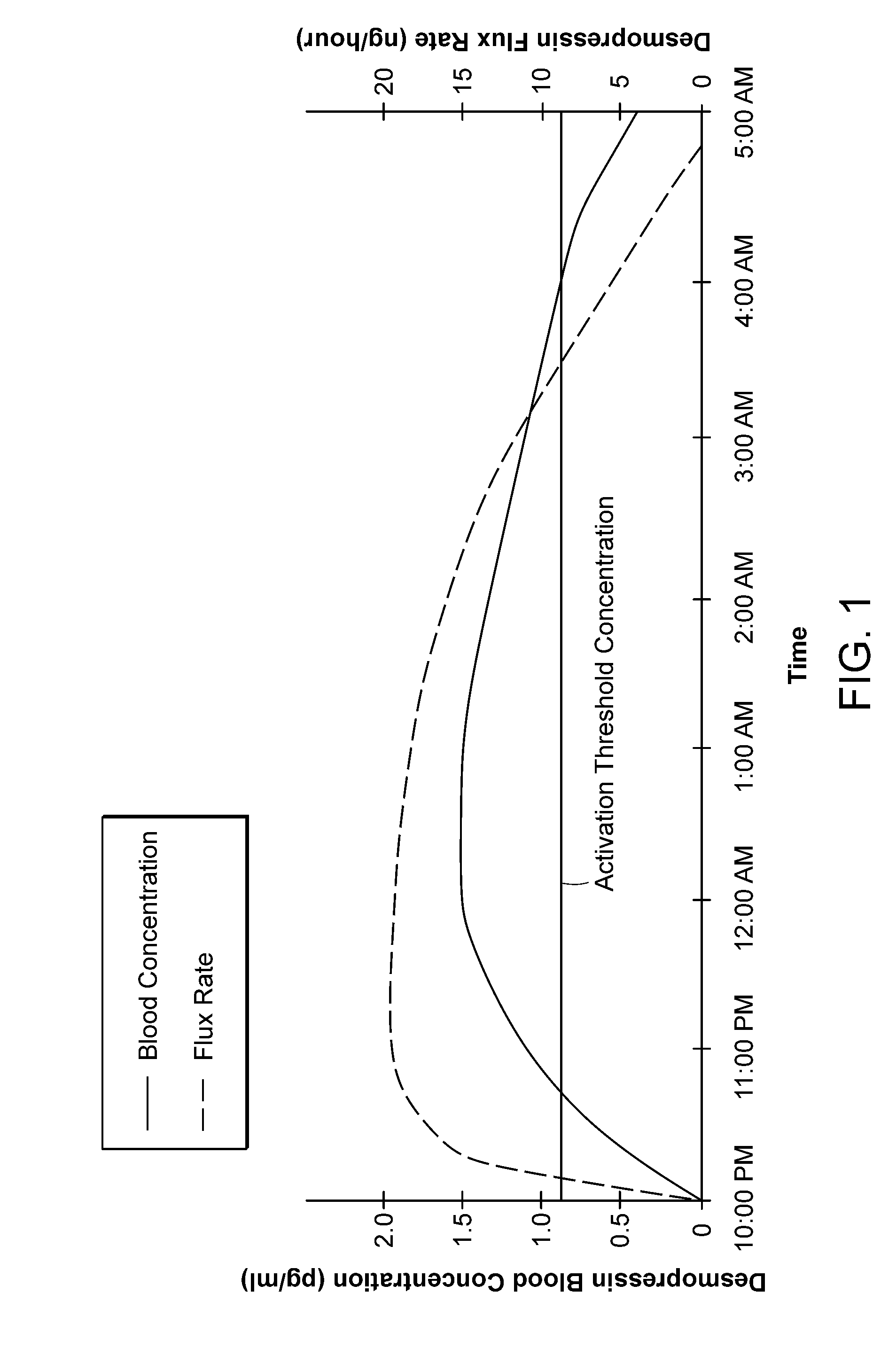

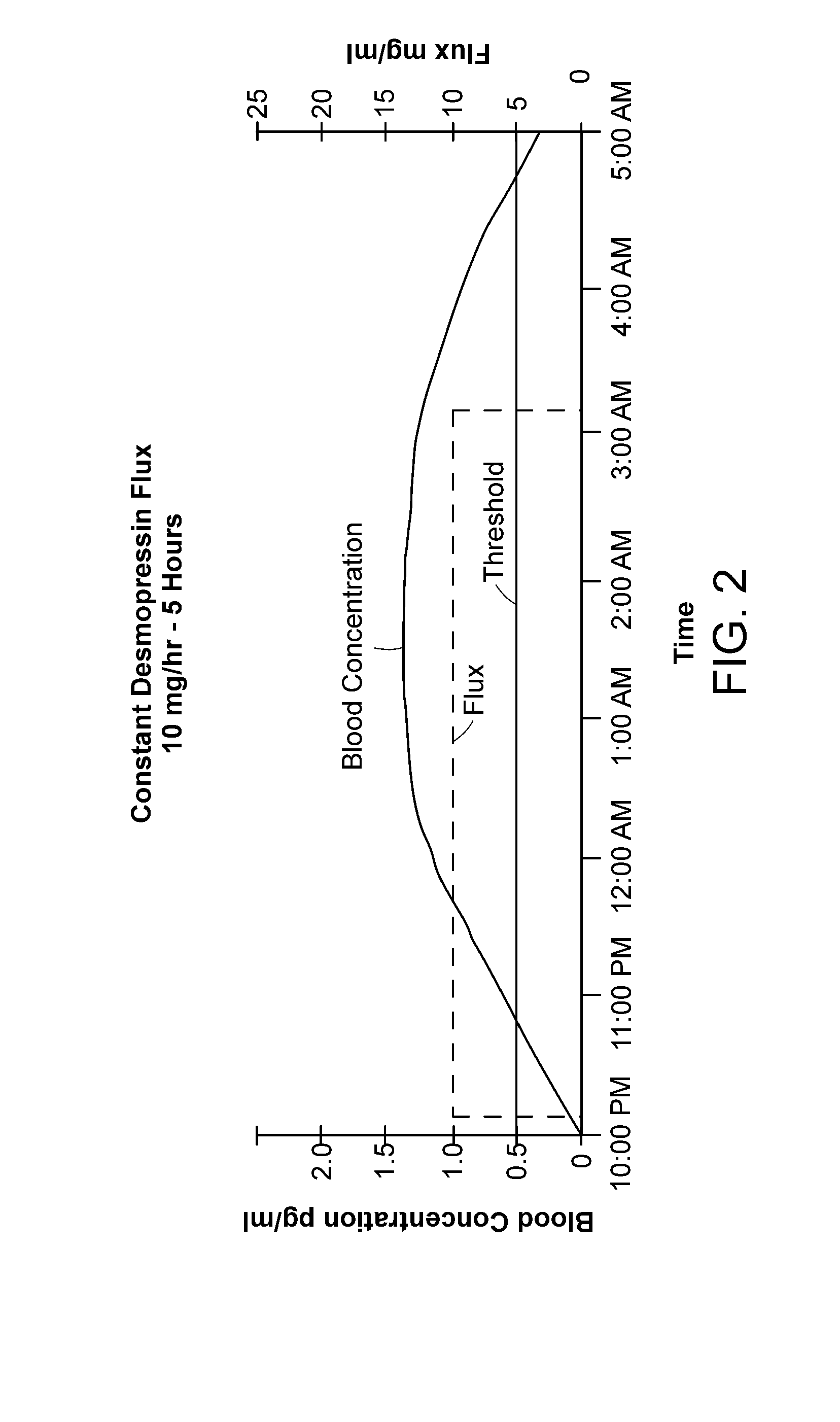

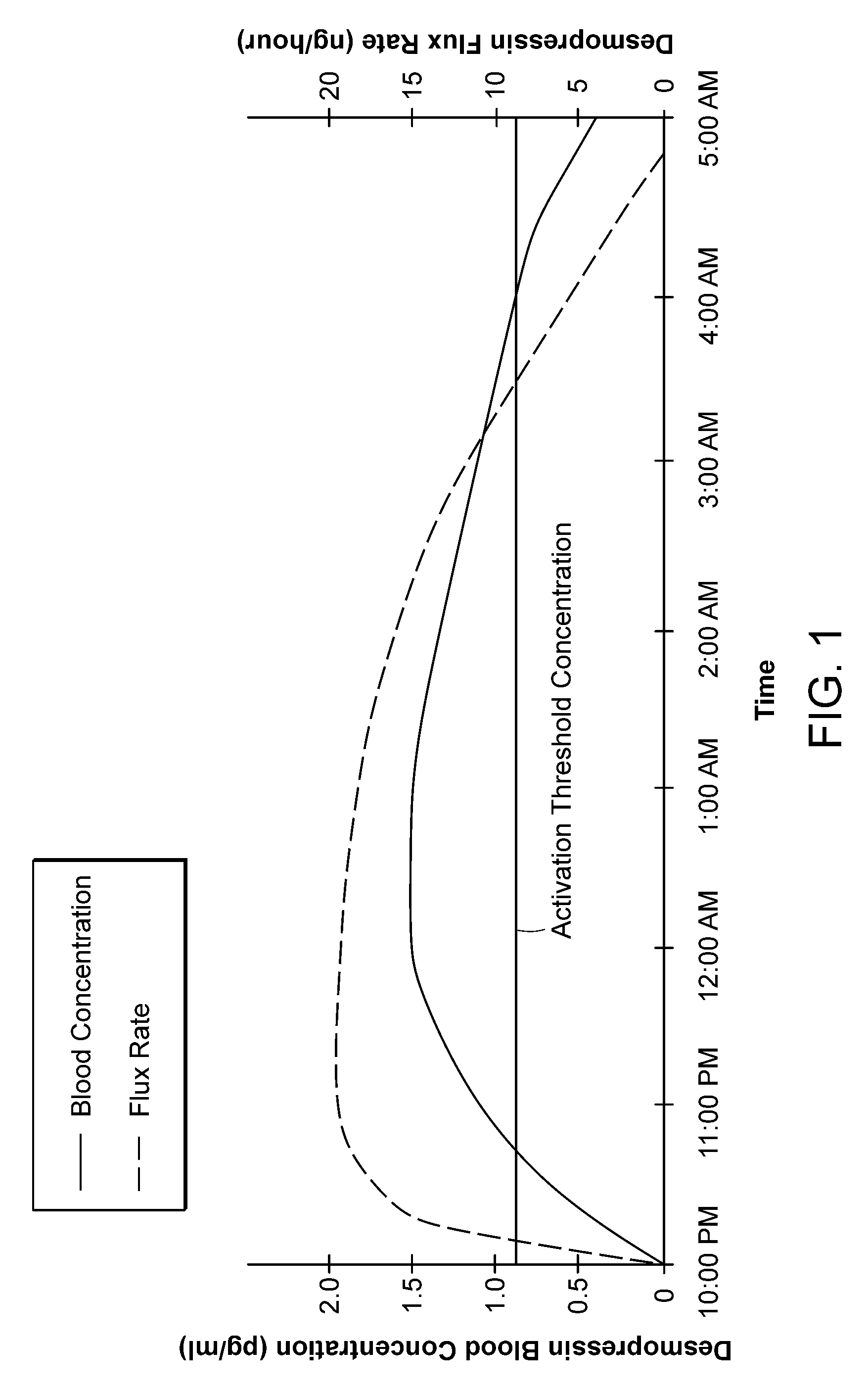

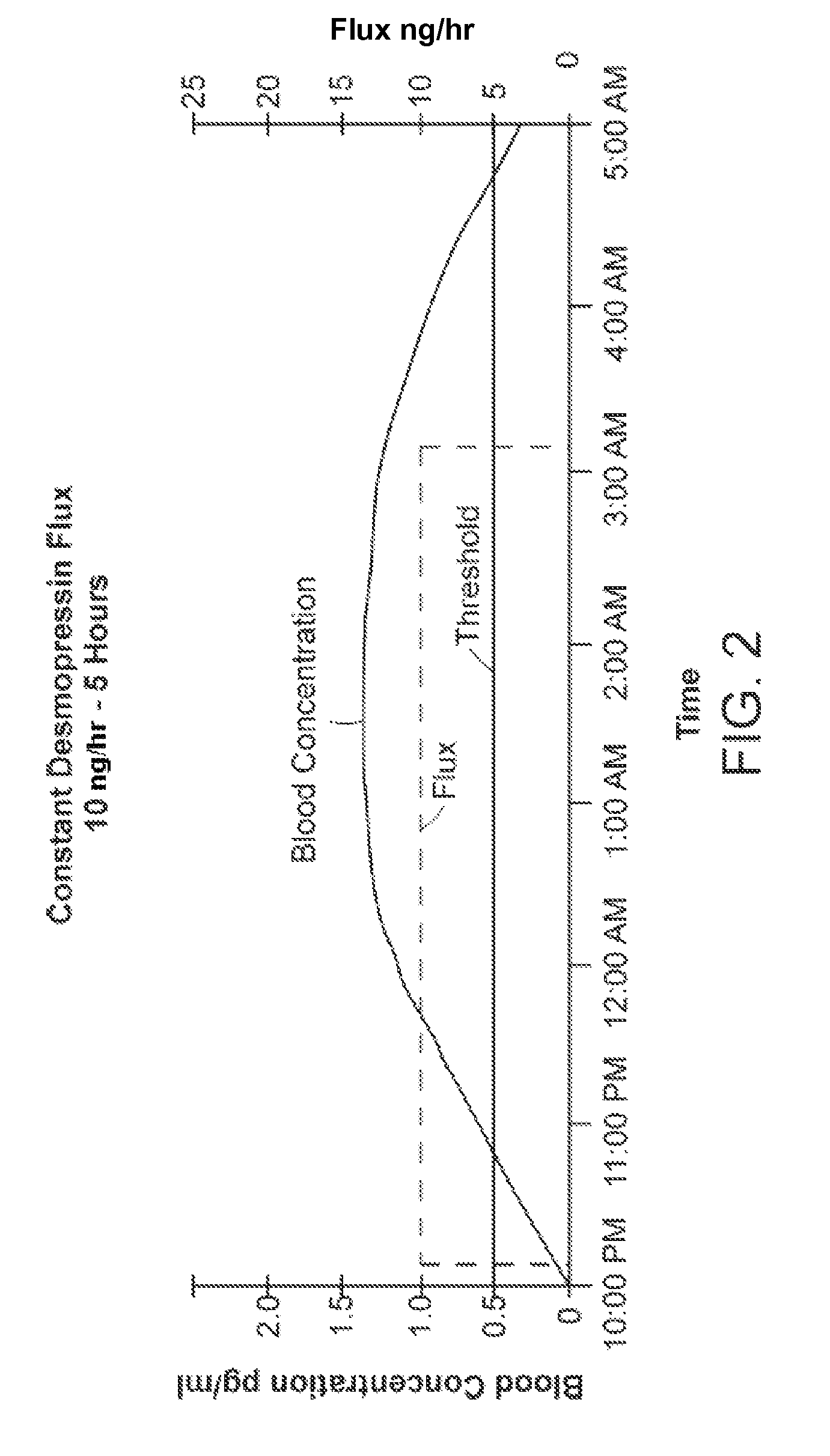

Methods and devices for desmopressin drug delivery

InactiveUS20090042970A1Reduce urine productionRestore normal urine productionBiocidePowder deliveryDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

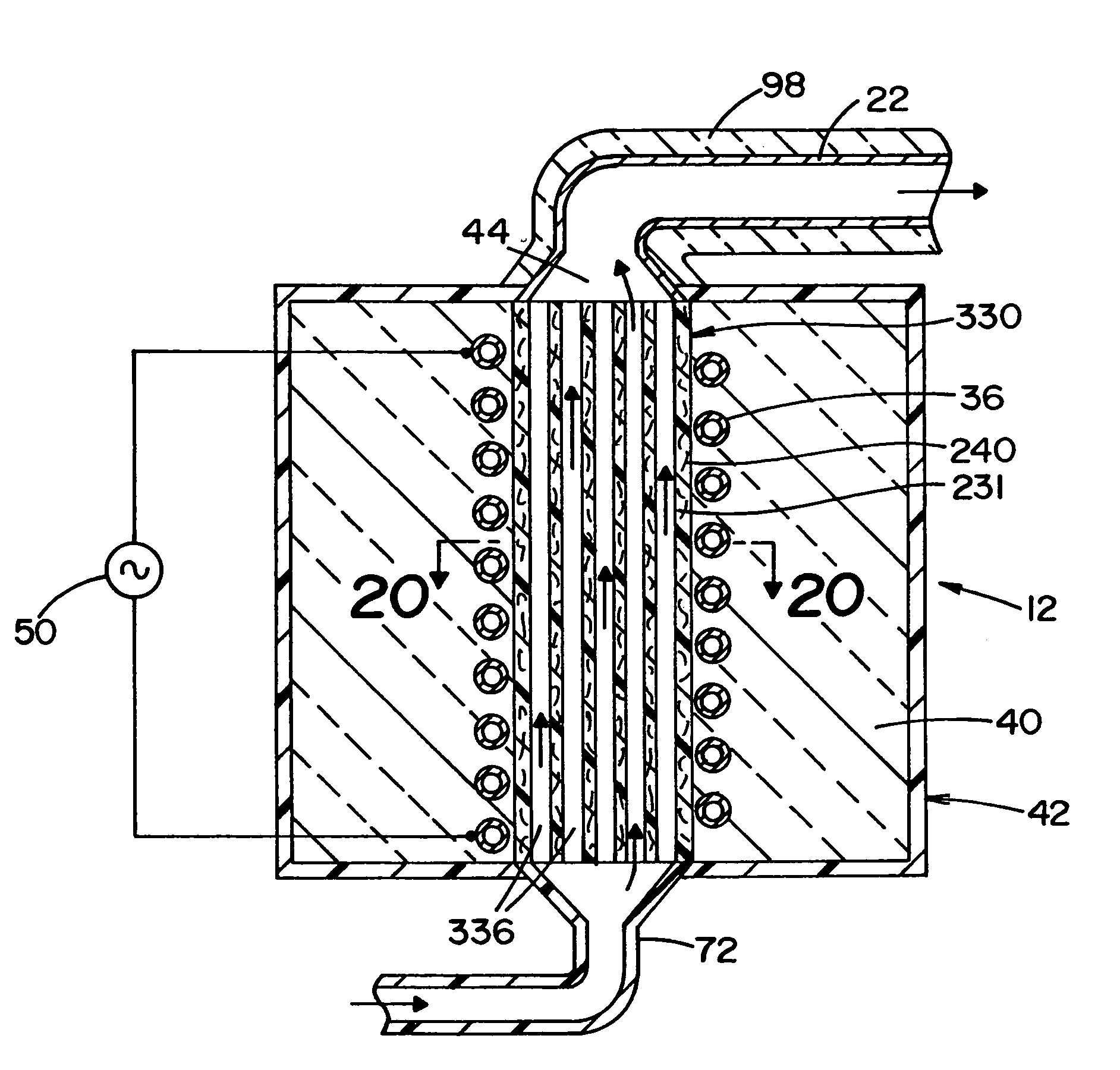

Method for vaporizing a fluid using an electromagnetically responsive heating apparatus

InactiveUS6967315B2Increase productionGrow fastSteam generation heating methodsGrinding feed controlConductive materialsEngineering

A method of microbially decontaminating at least one of a defined area and an item within the defined area. The method includes the steps of (a) inductively heating a block comprising an electrically non-conductive material and an electromagnetically responsive material; (b) passing an atomized liquid into an interior passage defined by the block, wherein the inductively heated block vaporizes the atomized liquid that contacts walls of the passage to form an antimicrobial vapor; and (c) flowing the vapor out of the block to the defined area to microbially decontaminate at least one of the defined area and the item.

Owner:AMERICAN STERILIZER CO

Electromagnetically responsive heating apparatus for vaporizer

InactiveUS6906296B2Increase productionReduced resistive electrical power loadSteam generation heating methodsGrinding feed controlParticulatesMicrowave

A vaporizer heating apparatus is comprised of electromagnetically responsive material and electrically non-conductive material. A antimicrobial fluid to be vaporized, such as water or hydrogen peroxide solution, is supplied to the heating apparatus where it is converted to a vapor. In one embodiment of the present invention, electromagnetically responsive material particulate is embedded into the electrically non-conductive material. In another embodiment of the present invention, a microwave generator is used to produce heat.

Owner:AMERICAN STERILIZER CO

Methods of using vitamin D compounds in the treatment of myelodysplastic syndromes

InactiveUS20070027120A1Fast concentrationQuick eliminationOrganic active ingredientsBiocideActive agentHigh doses

Owner:WHITEHOUSE MARTHA J +1

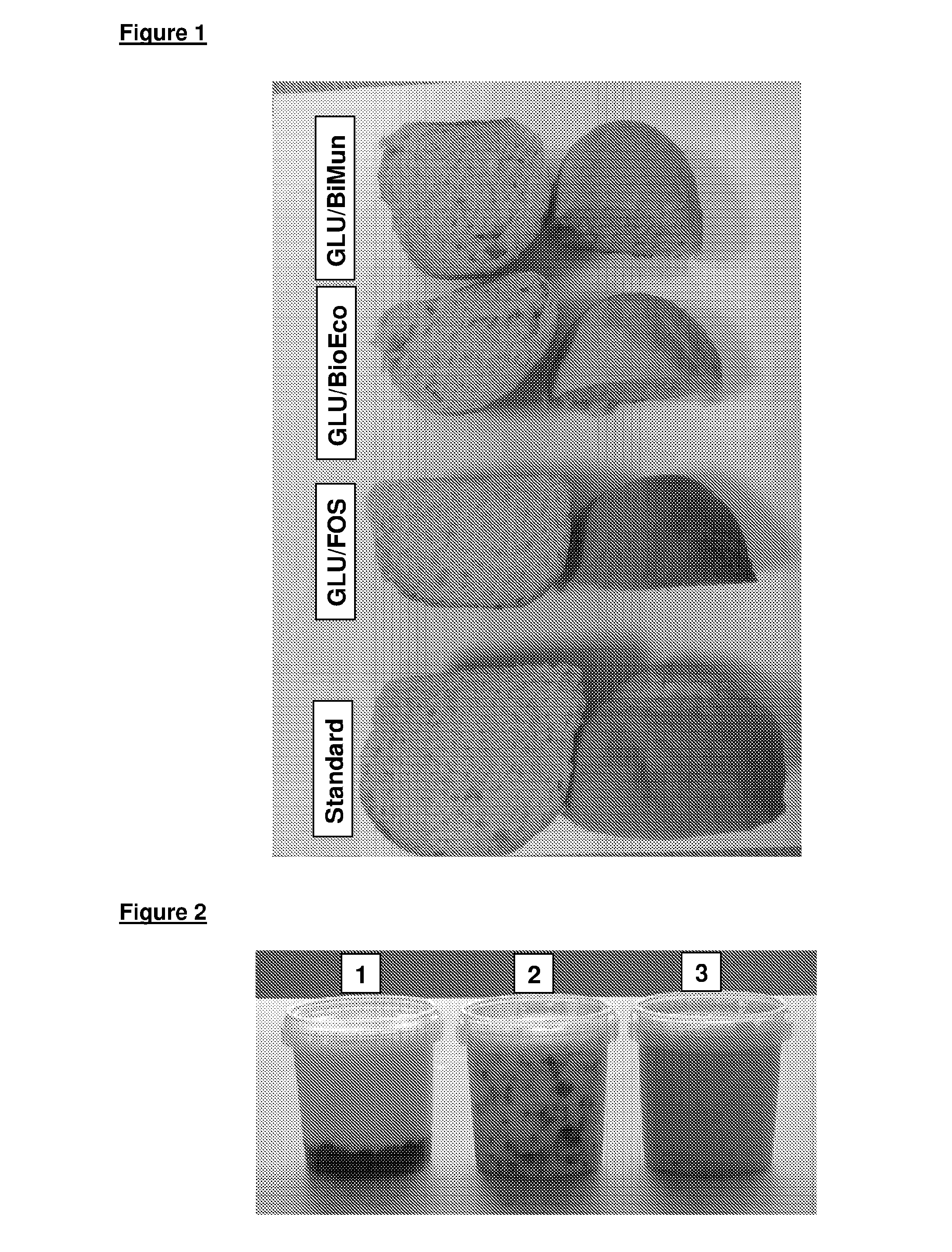

Composition

ActiveUS20160263153A1Increase metabolic rateMaintain blood sugar levelsHeavy metal active ingredientsOrganic active ingredientsMedicineCholesterol

The present invention relates to compositions for weight management comprising: a) a microbiome modifying component; b) a satiety modifying component; and c) a metabolic modifying component. The composition may also be used for the treatment of obesity, elevated cholesterol, diabetes, hypertension or heart disease.

Owner:OPTIBIOTIX

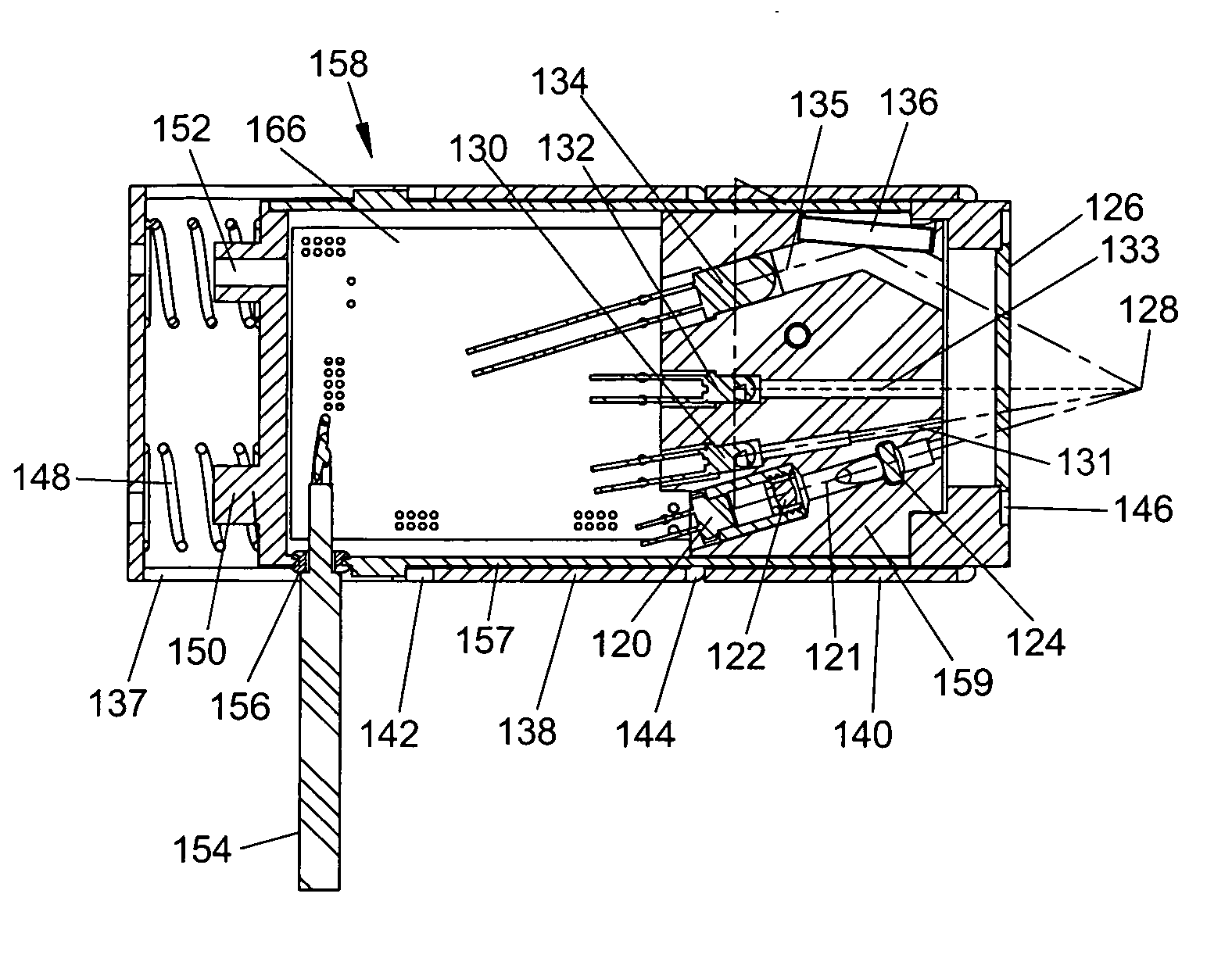

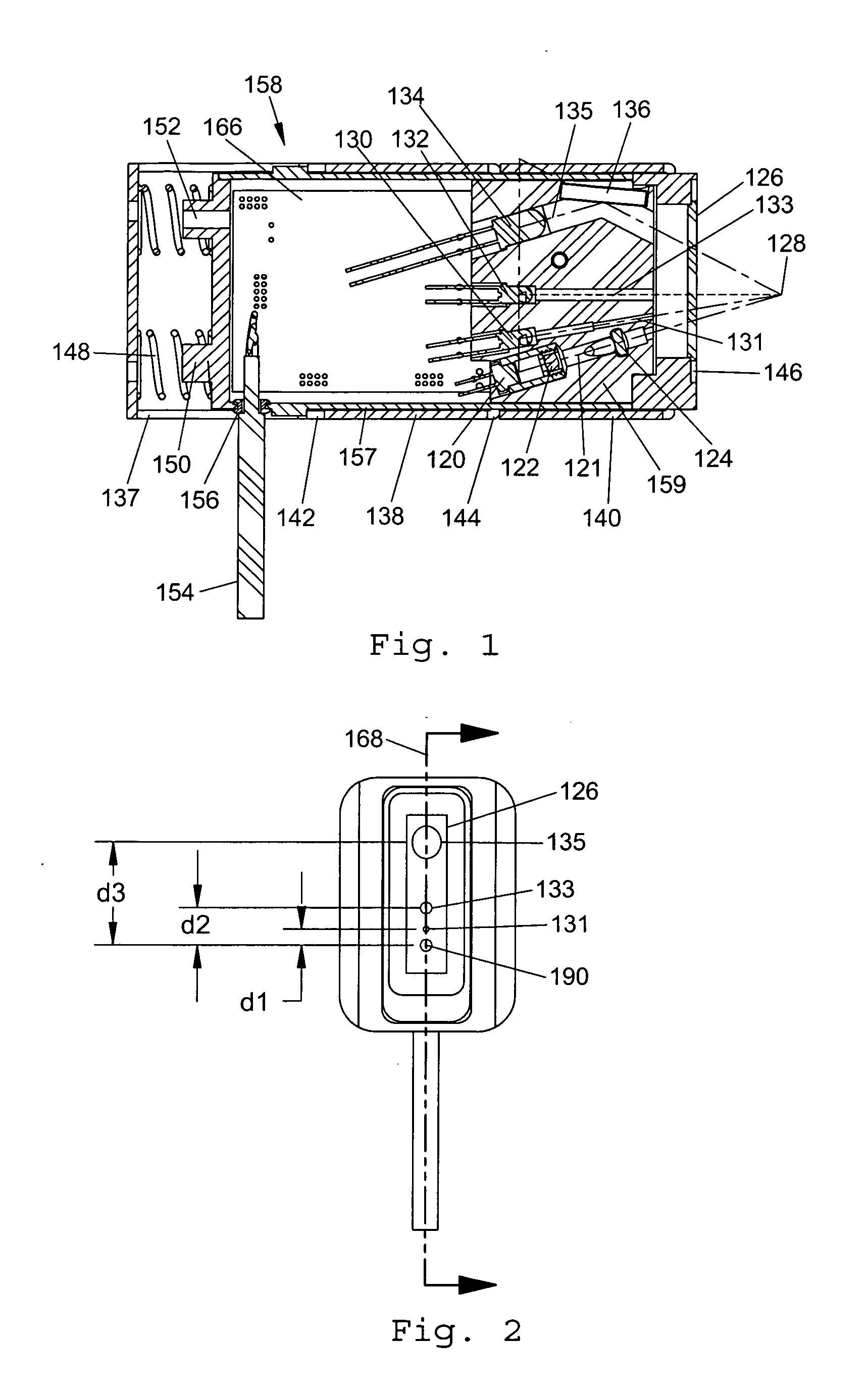

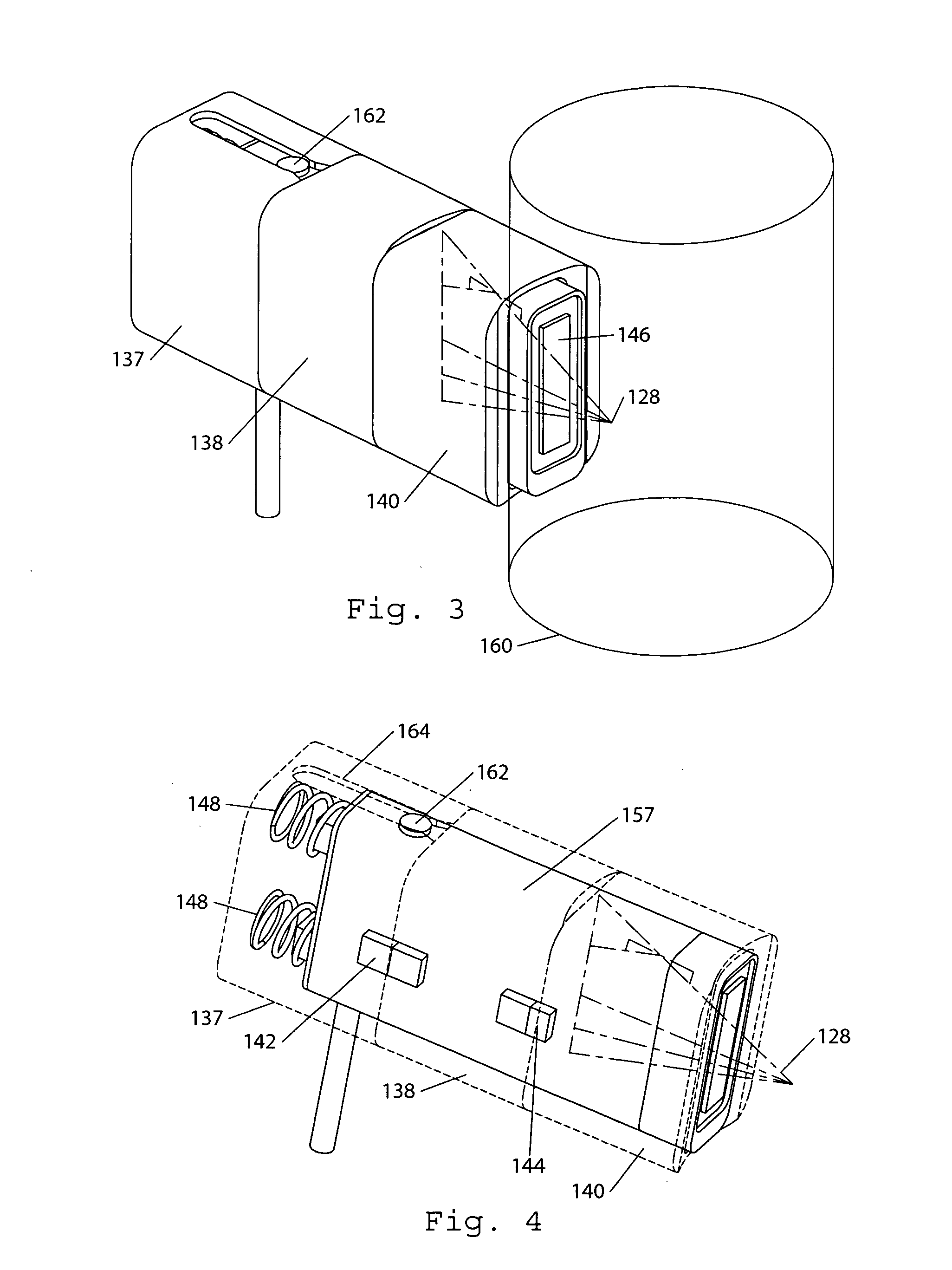

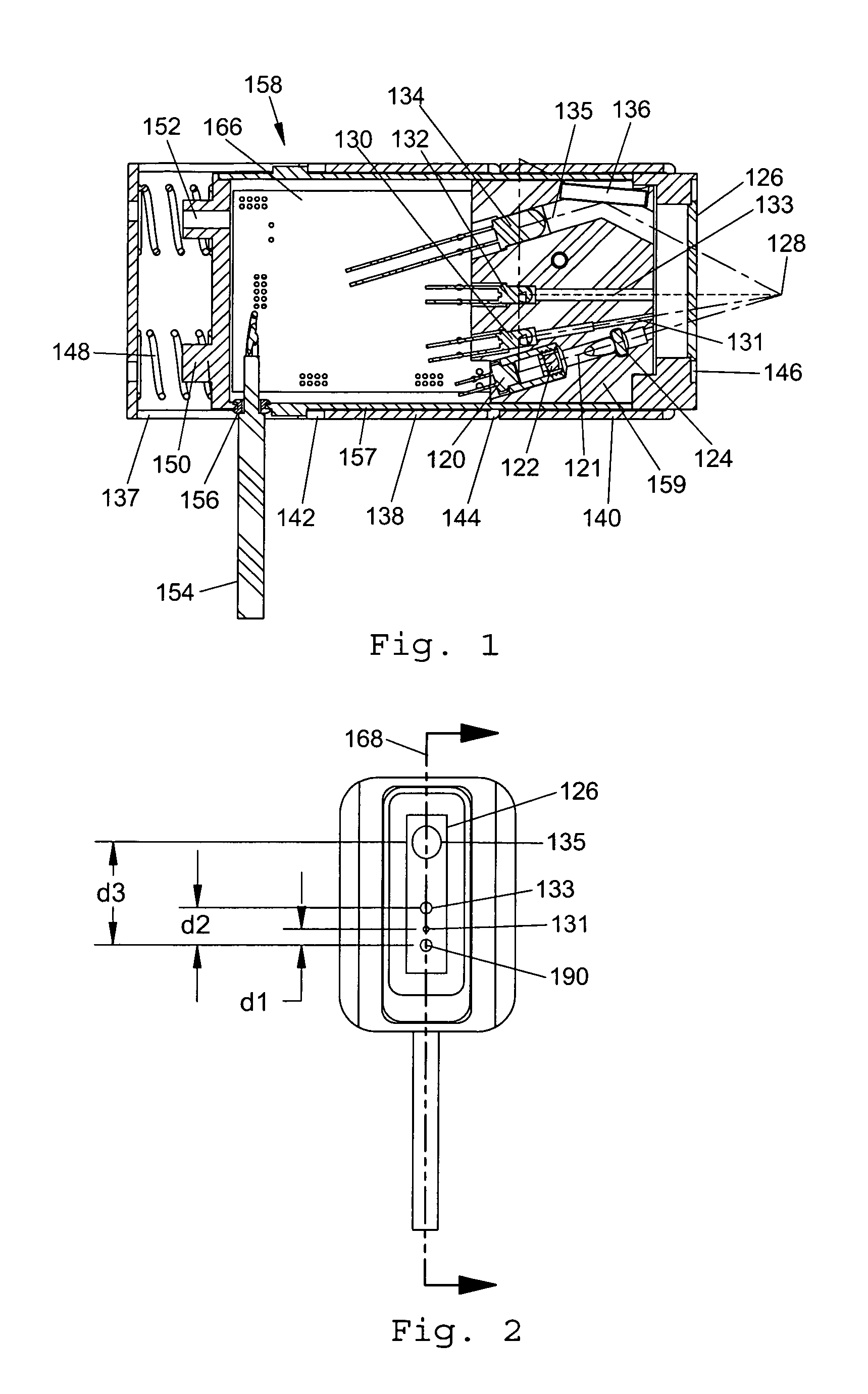

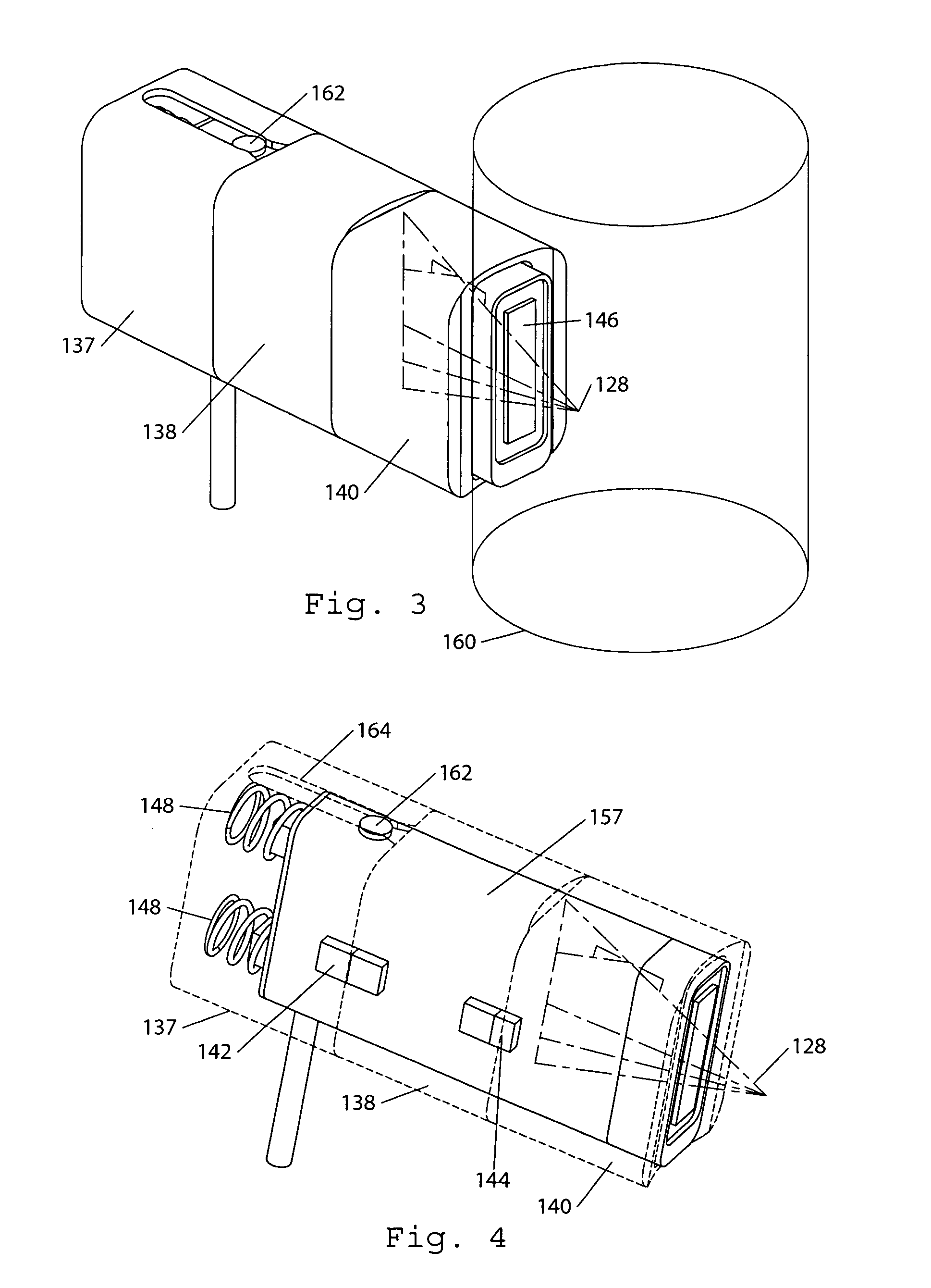

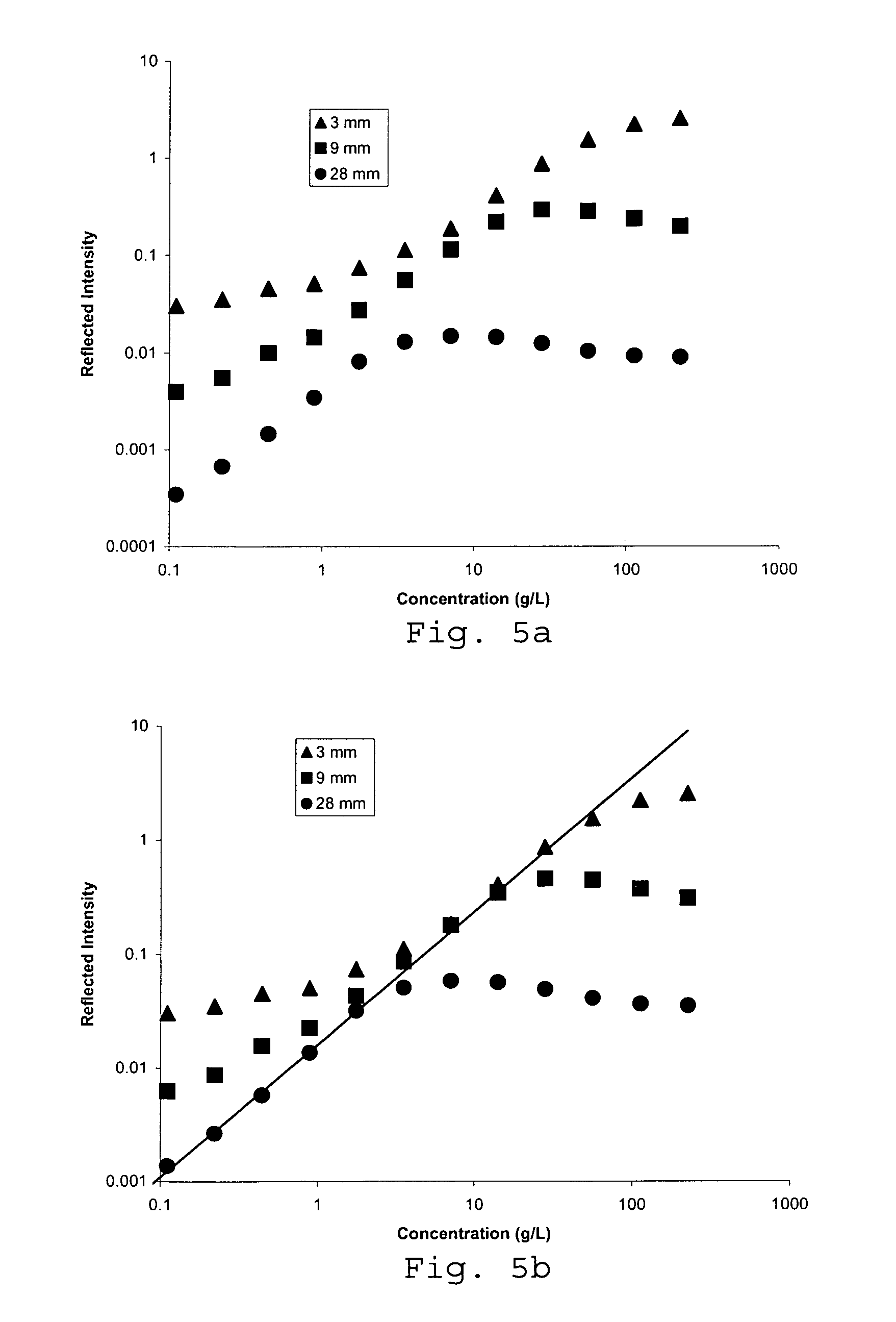

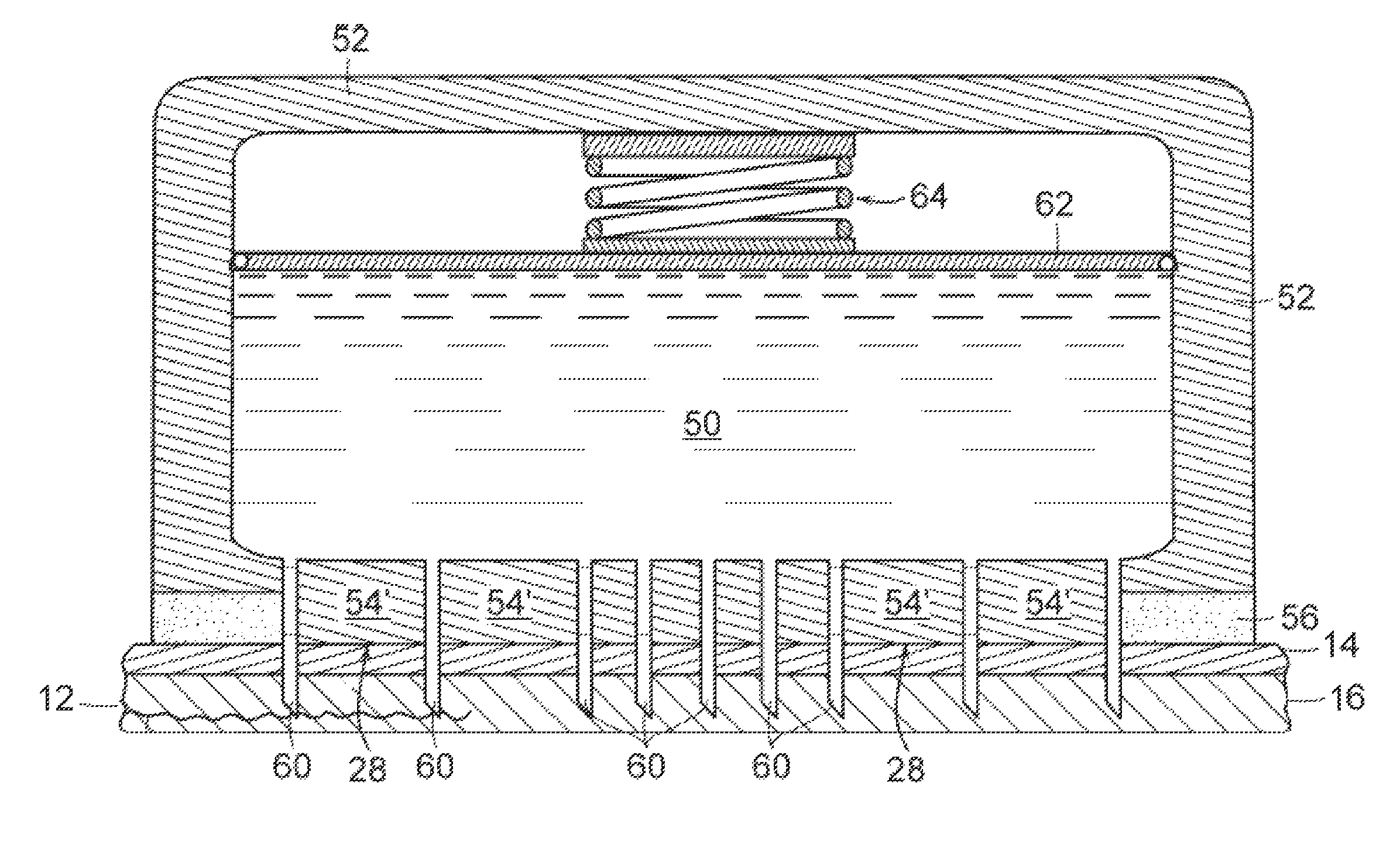

Particle sensor with wide linear range

ActiveUS20090075248A1Reduce sensitivityRapid of particle concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsParticulatesSpecific volume

This invention provides a novel methods and devices for measurement of particle concentration or changes in particle concentration over a wide linear range. The invention comprises one or more radiation sources and one or more detectors contained in a housing which is interfaced to a medium containing particulate matter. The one or more radiation sources are directed into the medium, scattered or transmitted by the particulate matter, and then some portion of the radiation is detected by the one or more detectors. Methods for confining the measurement to a specific volume within the medium are described. Algorithms are provided for combining the signals generated by multiple source-detector pairs in a manner that results in a wide linear range of response to changes in particle concentration. In one embodiment the sensor provides non-invasive measurements of biomass in a bioreactor. In another embodiment an immersible probe design is described, which may be suited for one-time use. In an addition embodiment, a sensor is provided which is well suited to the rapid sequential measurement of particle concentration in multiple vessels, such as assessment of biomass in series of shake flasks.

Owner:ABER INSTR INC

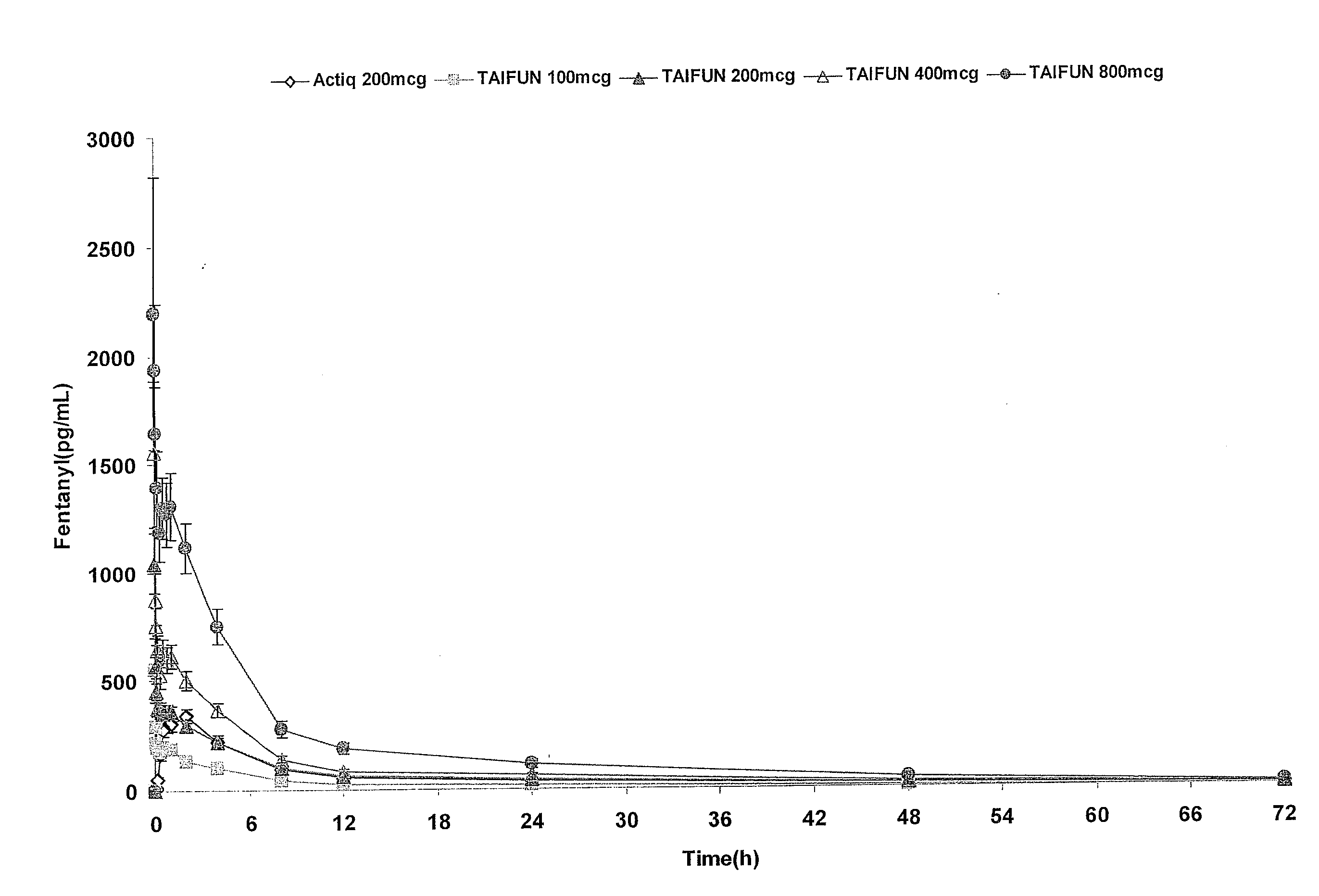

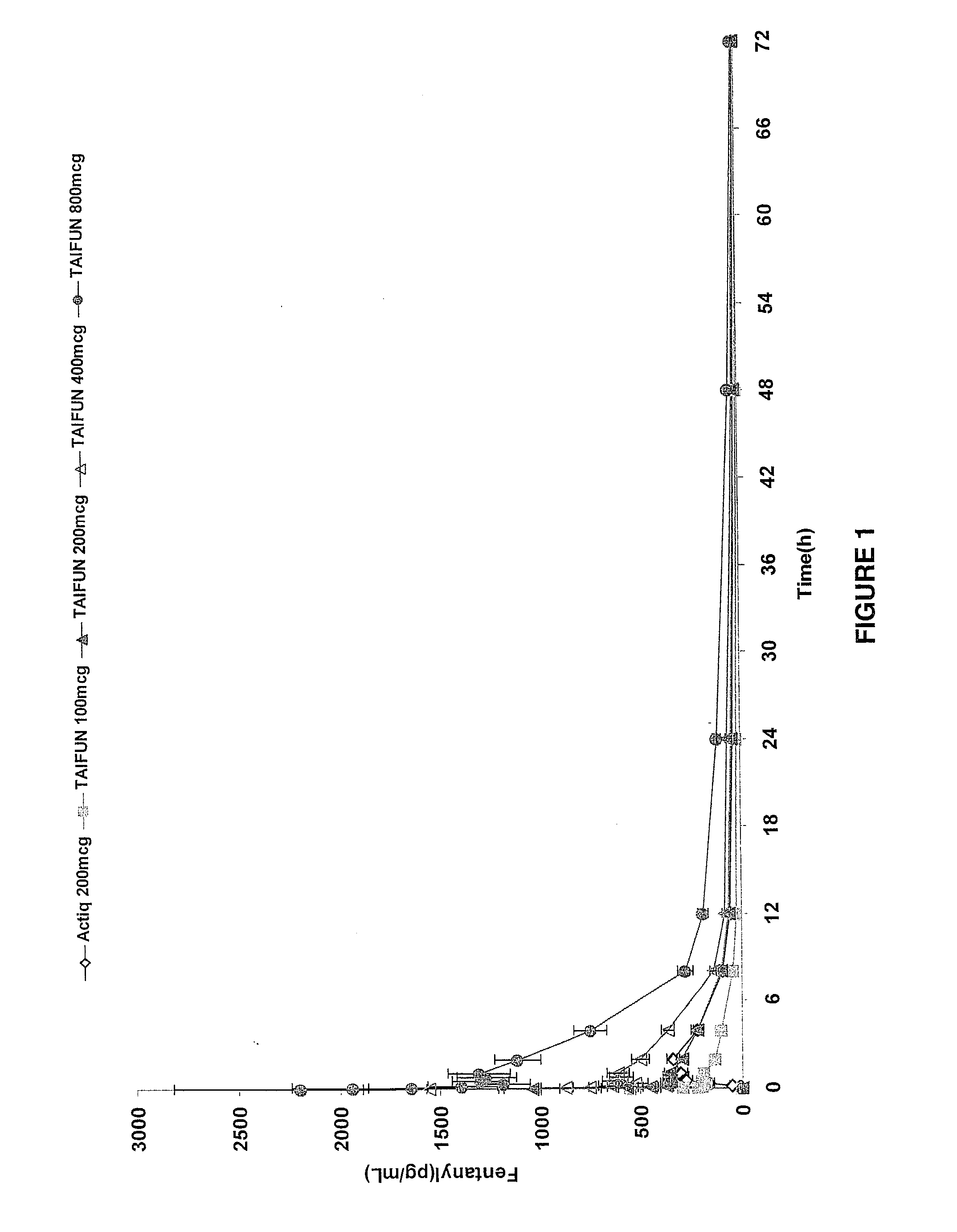

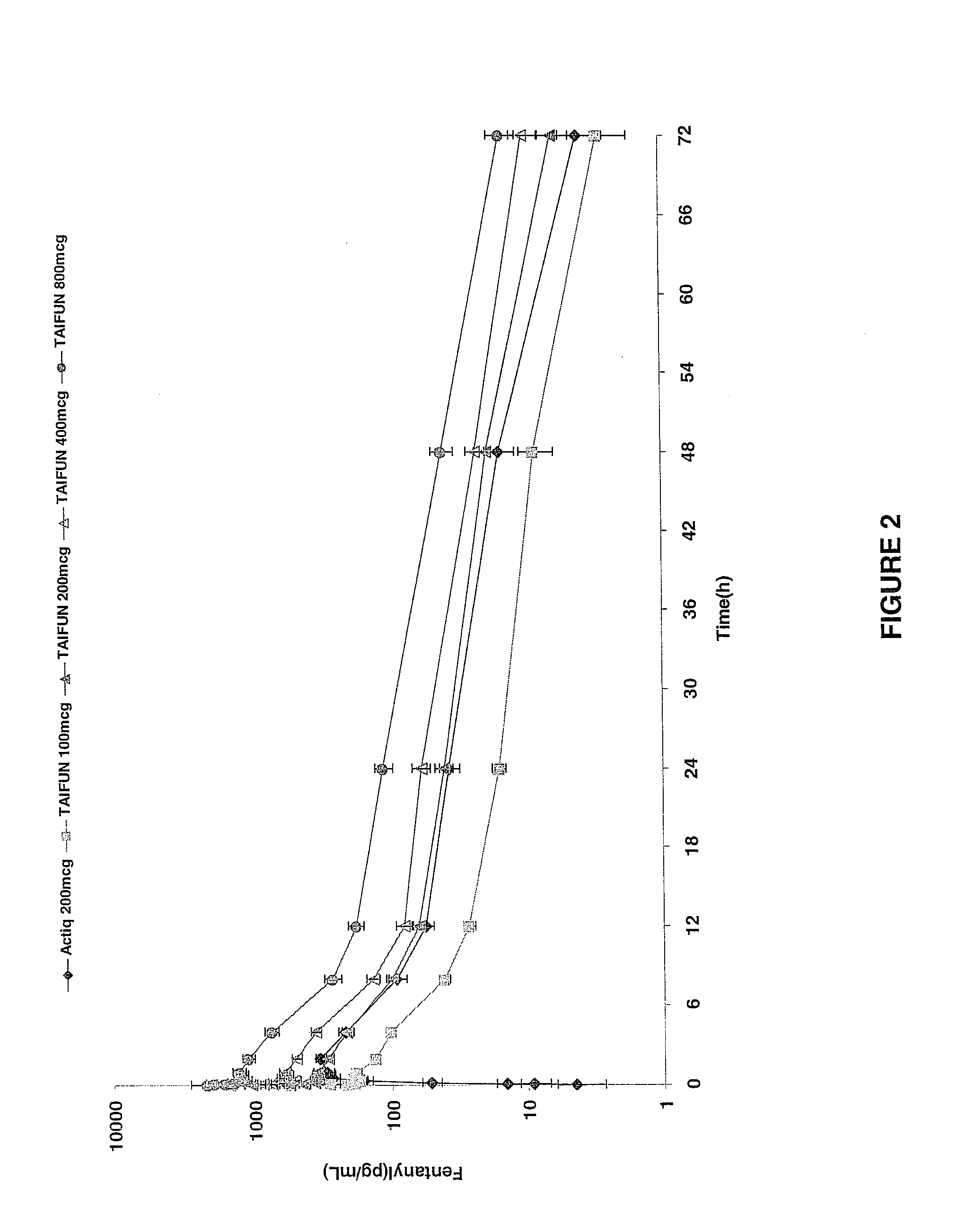

Breakthrough pain management

InactiveUS20090011030A1Treatment and alleviation of painAct quicklyBiocidePowder deliveryPulmonary inhalationFentanyl

The present invention is directed to a powdered formulation comprising an analgesic, preferably fentanyl, for use in pulmonary inhalation administration for the rapid analgesic titration of pain, in particular breakthrough pain. Upon administration, the powdered formulation is able to provide a narrower titration range in patients suffering from pain, as well as effective analgesic amounts of fentanyl in a shorter time and at lower dose levels of administered fentanyl when compared to fentanyl administered by an oral transmucosal route.

Owner:LAB INT

Particle sensor with wide linear range

ActiveUS8603772B2Reduce sensitivityFast concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous measurementParticulates

This invention provides a novel methods and devices for measurement of particle concentration or changes in particle concentration over a wide linear range. The invention comprises one or more radiation sources and one or more detectors contained in a housing which is interfaced to a medium containing particulate matter. The one or more radiation sources are directed into the medium, scattered or transmitted by the particulate matter, and then some portion of the radiation is detected by the one or more detectors. Methods for confining the measurement to a specific volume within the medium are described. Algorithms are provided for combining the signals generated by multiple source-detector pairs in a manner that results in a wide linear range of response to changes in particle concentration. In one embodiment the sensor provides non-invasive measurements of biomass in a bioreactor. In another embodiment an immersible probe design is described, which may be suited for one-time use. In an addition embodiment, a sensor is provided which is well suited to the rapid sequential measurement of particle concentration in multiple vessels, such as assessment of biomass in series of shake flasks.

Owner:ABER INSTR INC

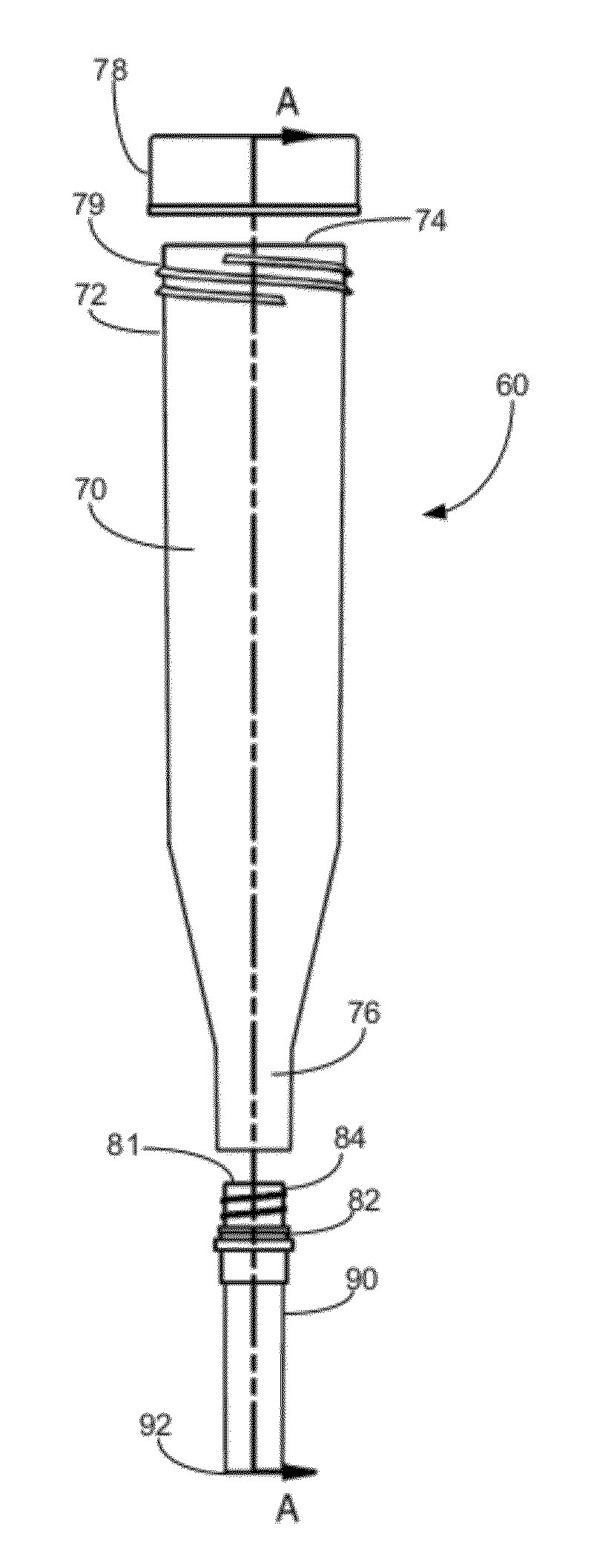

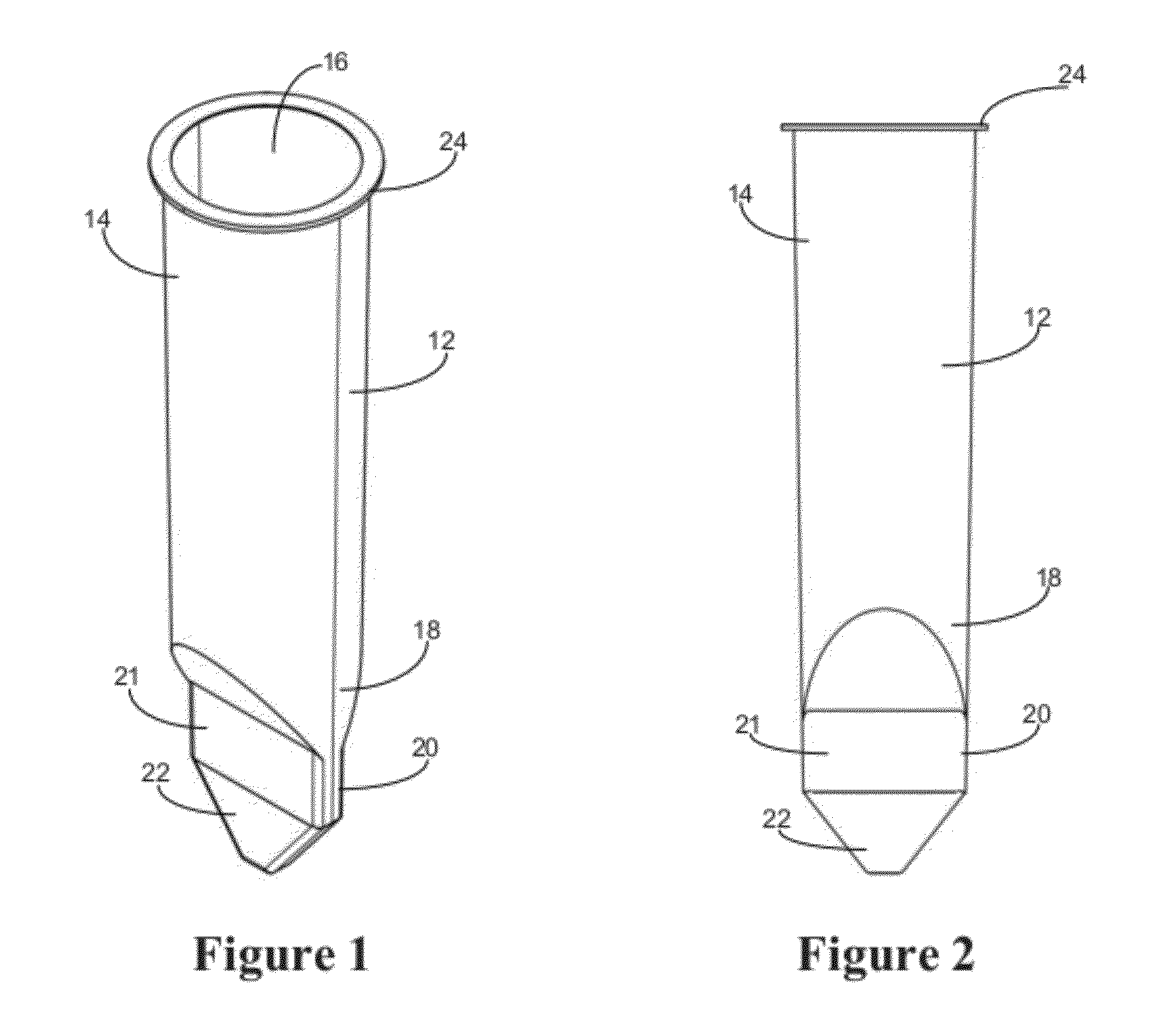

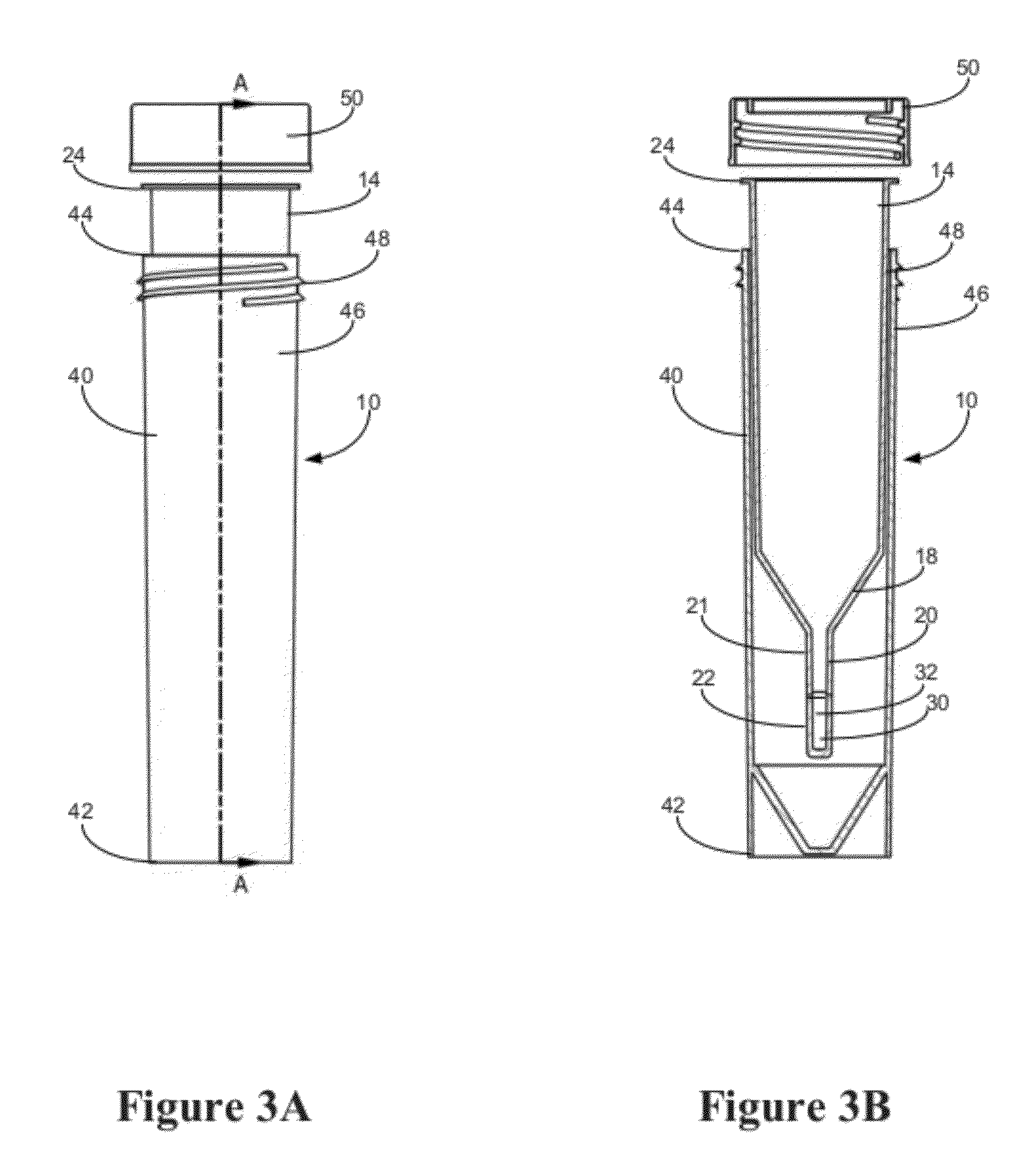

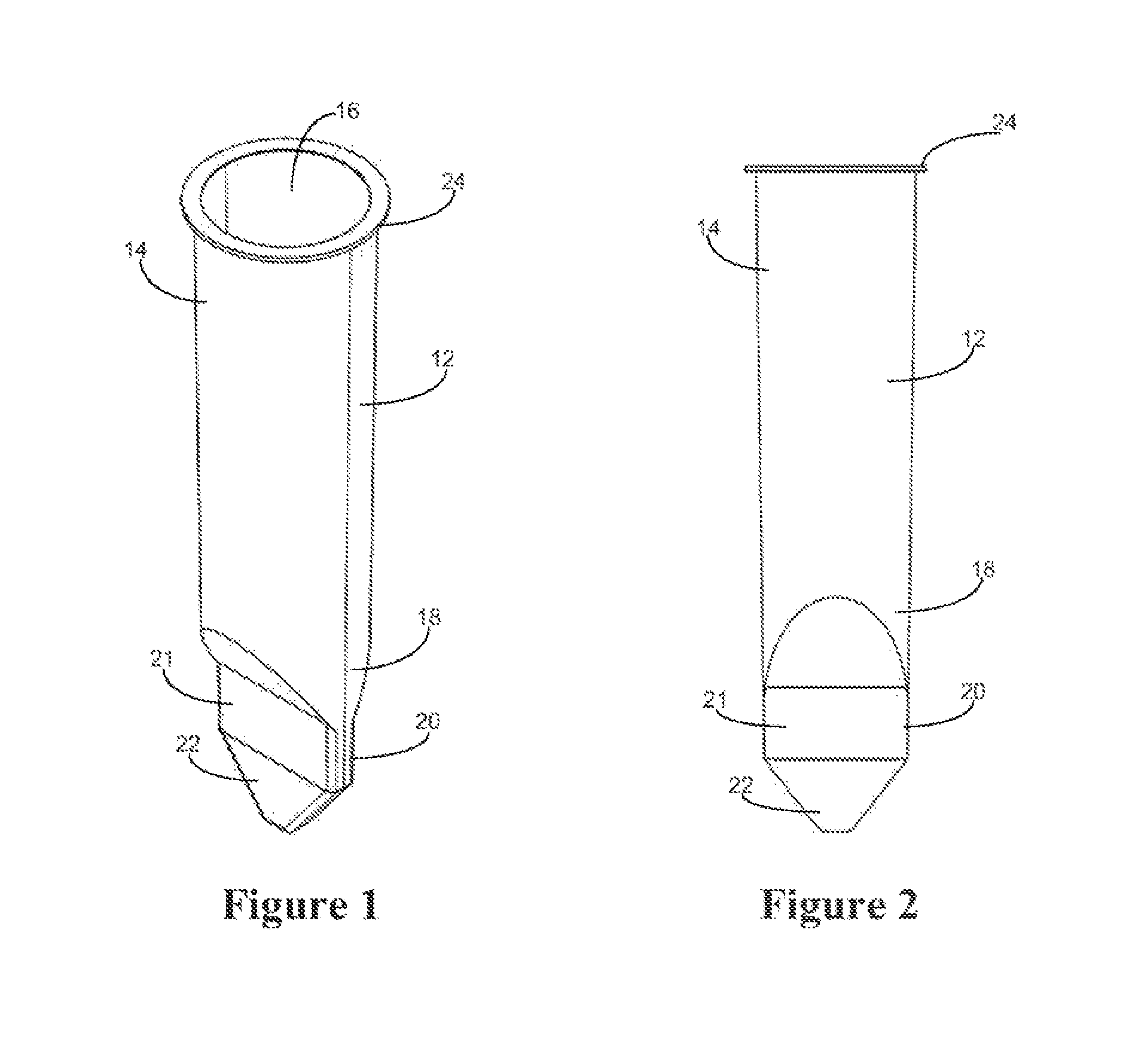

Methods and Devices for Rapid Urine Concentration

InactiveUS20120021407A1Quick focusFast concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsParticulatesAnalyte

The present invention provides a device for the concentration of one or more target analytes contained in a urine sample. The device comprises a tube comprising an upper portion defining an opening for receiving the urine sample and a lower tapered portion terminating in collection reservoir. The tube contains a predetermined amount of a particulate binding agent which specifically binds the one or more target analytes and of a predetermined amount of a binding buffer. The device comprises means for seating the opening of the tube. The present invention further provides methods and kits for concentrating one or more target analytes in murine sample.

Owner:NORGEN BIOTEK CORP

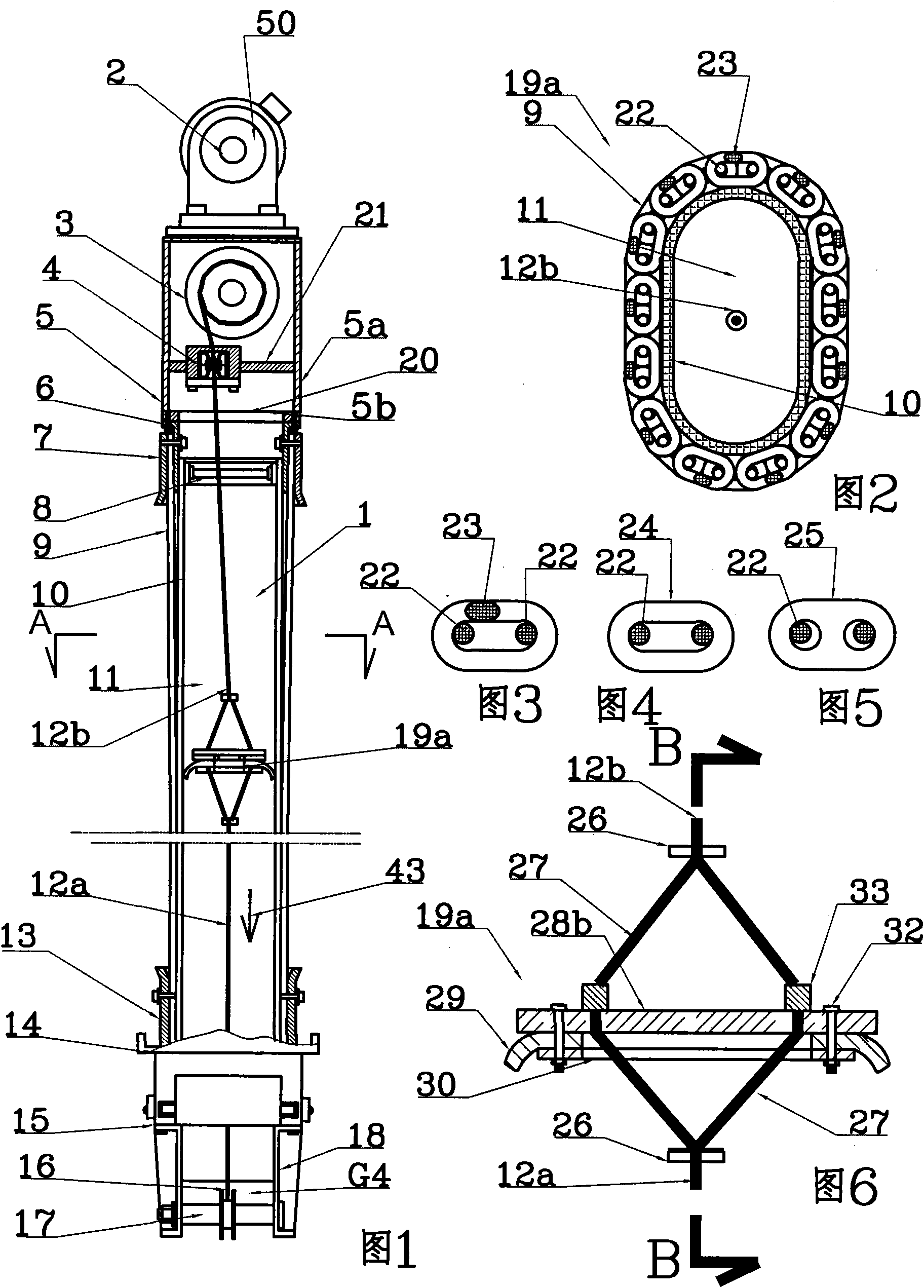

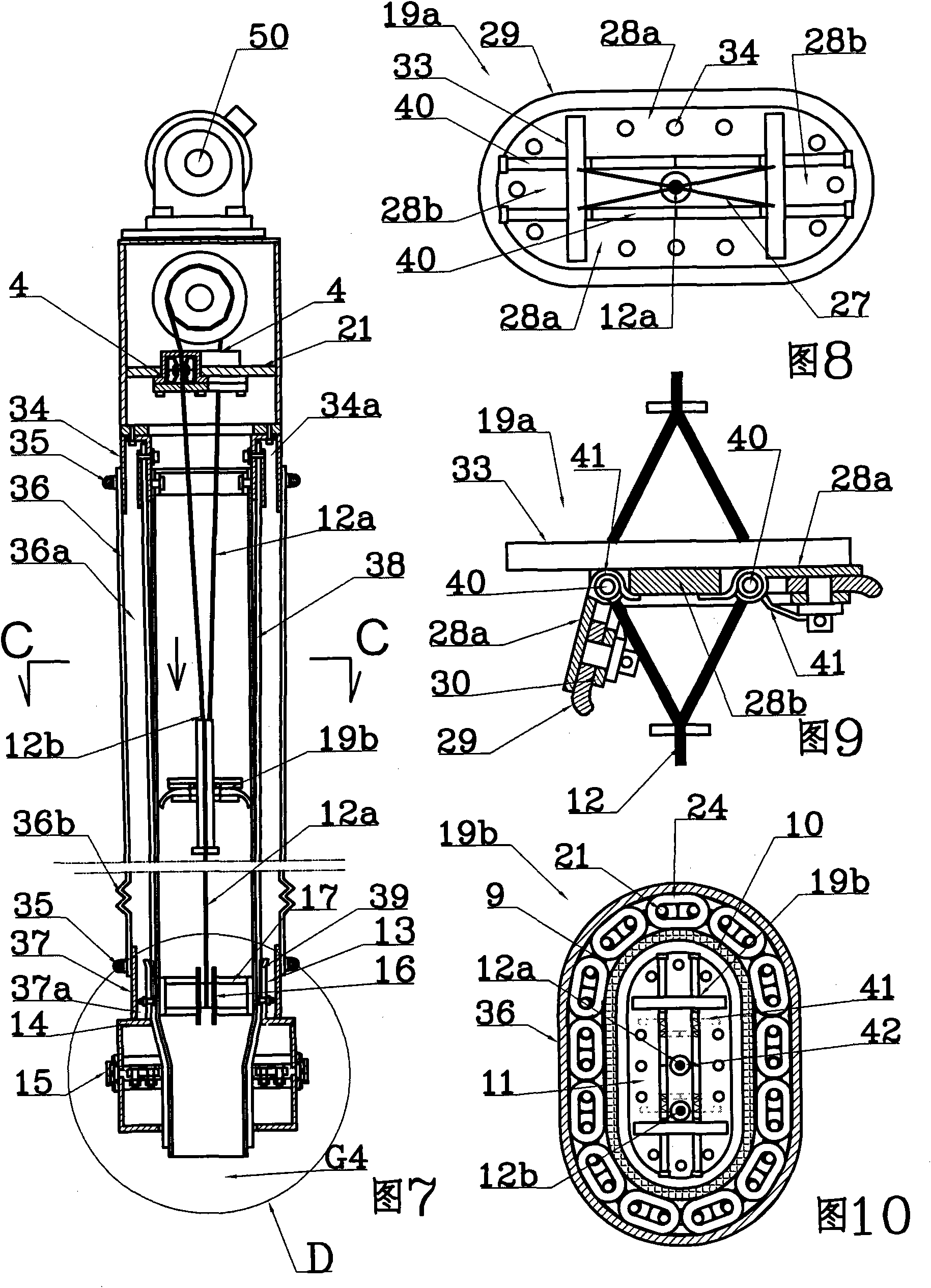

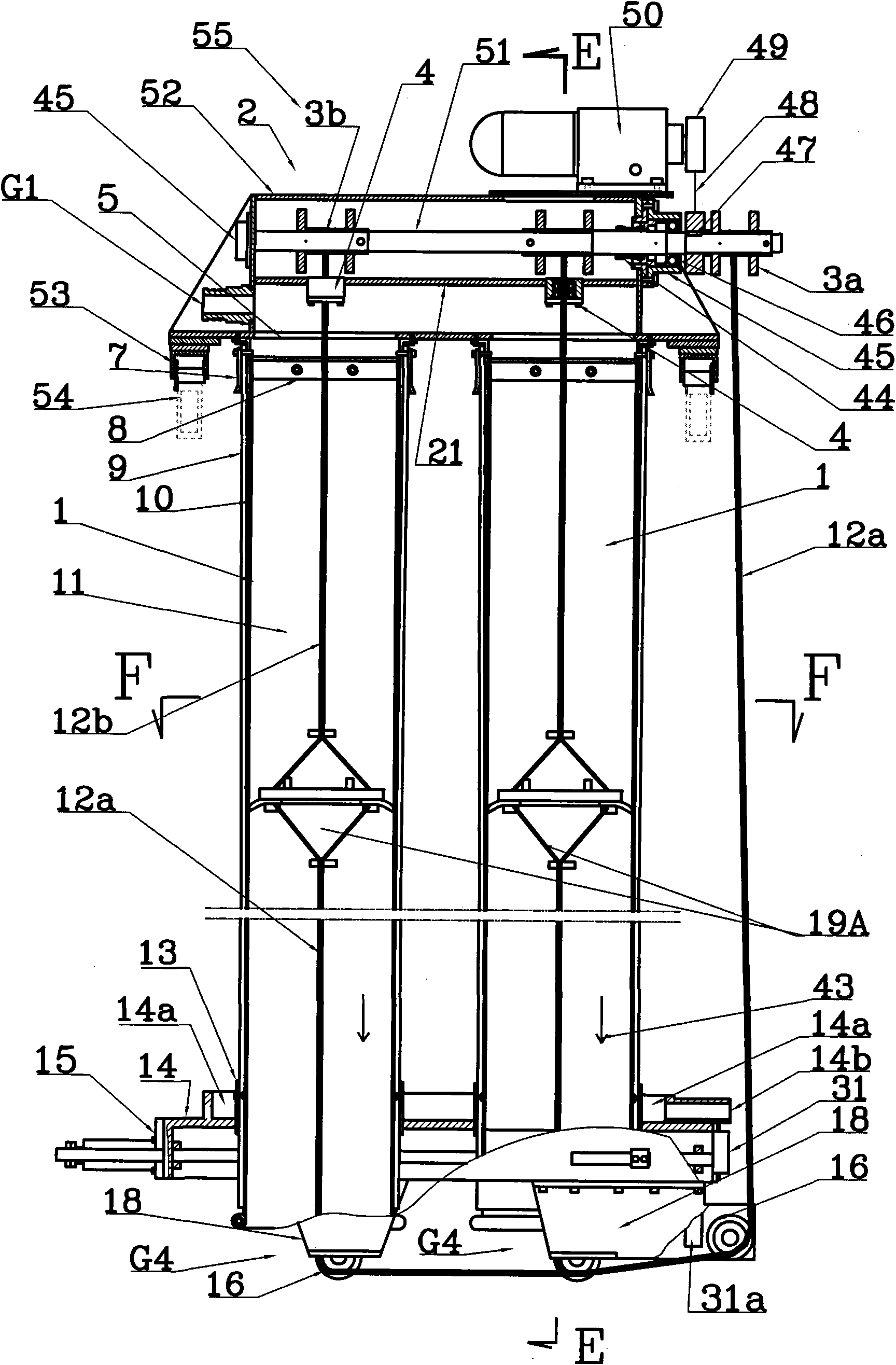

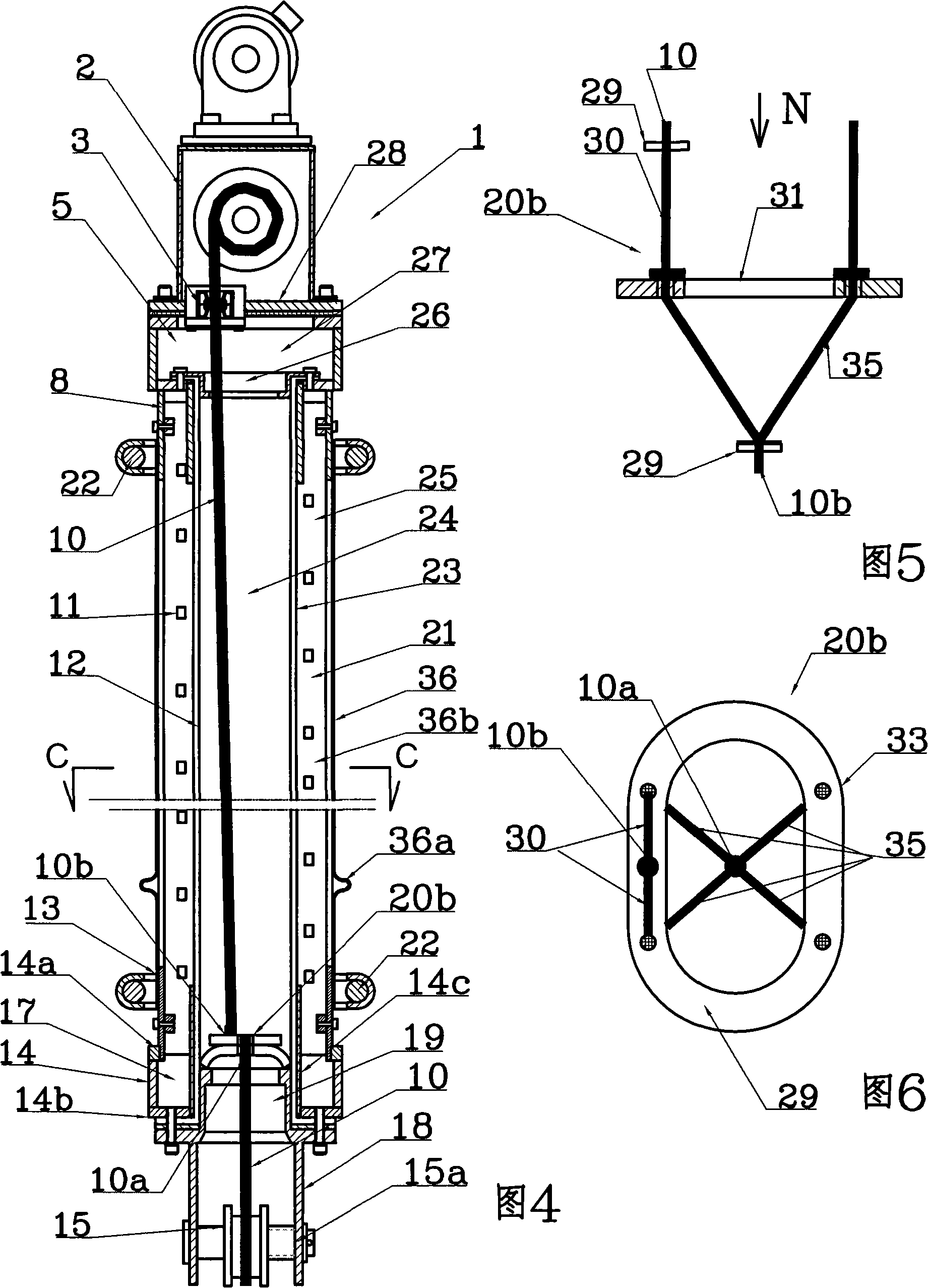

High-pressure compressing solid-liquid separation device of flexible pipe

InactiveCN101574593AUniform humidityFast concentrationStationary filtering element filtersVolume variationFilter media

The invention relates to a high-pressure compressing solid-liquid separation device of a flexible pipe. Pipe-shaped filtering medium at the utmost outside layer adopts a steel wire braid conveyer belt, and filter residue left on the filtering medium is removed in filtering by using a piston scrapper plate; the solid-liquid separation is accomplished in compressing by utilizing the principle of filter chamber variable-volume compression, the filter chamber is almost close to zero in volume after volume variation, and does not need a high-pressure pump to convey raw materials and does not need an additional compression water pump system or compression compressed air system as the filter pushing force of a filter press; and a pressing assembly of a pressing application system adopts an pressing reinforced connection rod mechanism, not only the pushing force is increased by dozens of times, but also the pressure is maximal when the pressing stroke is over with the filter pressure up to 2.5MPa. The device can adopt repeated treading and filtering, the alternating change of the thickness and the thinness of the raw materials in compression improves the filtering speed, washing speed and efficiency; the humidity of a filter cake is uniform; the washing regeneration of filter mediums is automatically accomplished; the residue discharge is automatically accomplished; the production process can realize complete automazation, so that the energy consumption is reduced, and the production efficiency is higher; and the manufacture cost is low due to the utilization of screw rod for clamping and compression.

Owner:张民良

Cosmetic containing natural plant extractives and preparation method thereof

ActiveCN102113987AImprove wrinklesIncrease elasticityCosmetic preparationsToilet preparationsMicroorganismGrape seed

The invention relates to a cosmetic containing natural plant extractives and a preparation method thereof, belonging to the technical field of cosmetics. The cosmetic containing natural plant extractives is characterized by being prepared from the following components in percentage by weight: 1.0-2.2 percent of okra fruit extractive, 1.0-2.0 percent of grape seed extractive, 0.5-1.2 percent of sapindus extractive and the balance of aid and carrier. The favorable synergy and excellent efficacy in aspects of improving skin winkles, whitening and beautifying skin, clearing radicals, lightening speckles and decomposing melanin is presented due to simultaneously using the okra fruit extractive, the grape seed extractive and the sapindus extractive, and the favorable antimicrobial preservative action of the sapindus extractive ensures that the microorganism index of the product can accord with the cosmetic production requirements.

Owner:三生(中国)健康产业有限公司

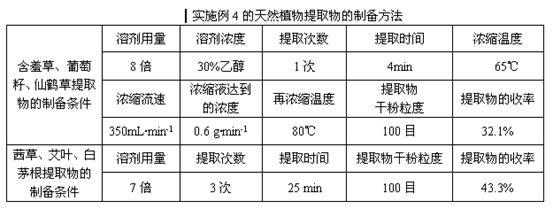

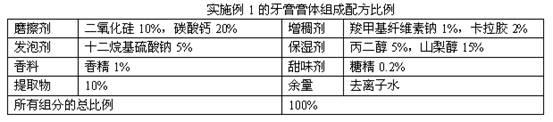

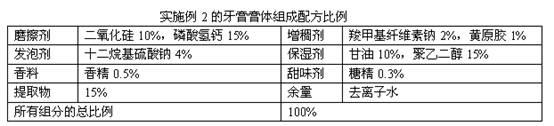

Toothpaste containing natural plant extractive and preparation method thereof

InactiveCN102151241AExtended shelf lifeEasy to solveCosmetic preparationsToilet preparationsDiseaseGrape seed

The invention relates to toothpaste containing natural plant extractive and a preparation method thereof. The toothpaste comprises the following components by weight percentage: 85-60 of toothpaste paste matrix and 10-15 of natural plant extractive. The natural plant extractive comprises the following components by weight percentage: 50-70 of sensitive plants, grape seeds and herba agrimoniae extractives and 30-50 of madder, folium artemisiae argyi and lalang grass rhizome extractives. The toothpaste has the effects of remarkably diminishing the inflammation, relieving the pain, stanching, tooth whitening and the like, has the remarkable effects on gum bleeding, hemodia, halitosis and other common oral diseases caused by periodontitis and gingivitis and simultaneously has the advantages that the toothpaste has good mouthfeel, wide antibacterial range and good absorption effect, can whiten teeth after use, is simple to prepare and has low manufacturing cost and the like.

Owner:云南东方不老生物技术有限公司

Preparation method for extracting general flavone from Chinese medicinal herbs

InactiveCN102145066AReduce dosageImprove efficiencyAntipyreticAnalgesicsFood additiveMedicinal herbs

The invention relates to a preparation method for extracting general flavone from Chinese medicinal herbs, belonging to the technical field of plants. The preparation process comprises the following steps of: percolating and extracting dense cornel as a raw material by using aqueous ethanol as a solvent; flashing the extract, concentrating and recovering the solvent; separating and enriching the concentrated solution through macroporous resin columns, carrying out gradient elution with an aqueous solvent, mixing a certain proportion of aqueous solvent eluate, flashing, concentrating and recovering the solvent; and continuously drying in vacuum to form dry powder. The invention has the advantages of simple process, superior extraction and concentration methods, convenience for operation, environmental protection and high efficiency; the extractive contains 6.12-15.58 percent of general flavone, the extraction rate of the general flavone is up to 5.25-10.43 percent, and the transfer rate of the general flavone is up to 45.63-62.88 percent. Proved by primary in-vitro bioassay tests, the dense cornel general flavone extractive has certain activities, such as oxidation resistance, bacteriostasis, and the like, can be used as a food additive, an antioxidant, a preservative, and the like and has certain development and application values.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Solution for diagnosing or treating tissue pathologies

InactiveUS20030158258A1Increase synthesisFast concentrationUltrasonic/sonic/infrasonic diagnosticsBiocideAmino-Levulinic AcidDelta aminolevulinate

The invention concerns a 5-aminolevulinic acid ester (E-ALA) solution for producing a pharmaceutical preparation useful for diagnosing and / or treating tissue and / or cell pathologies by local radiation exposure using radiation emitted by a light source energy followed, in the case diagnosis, by detection of fluorescent protoporphyrin IX (Pp1X). The E-ALA concentration in the solution is less than 1% and ranges between 0.01% and 0.5%. The low E-ALA concentration in the solution increases Pp1X synthesis and homogenises its distribution in the cell layers while highly reducing the secondary toxicity for the treated cells.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL) +1

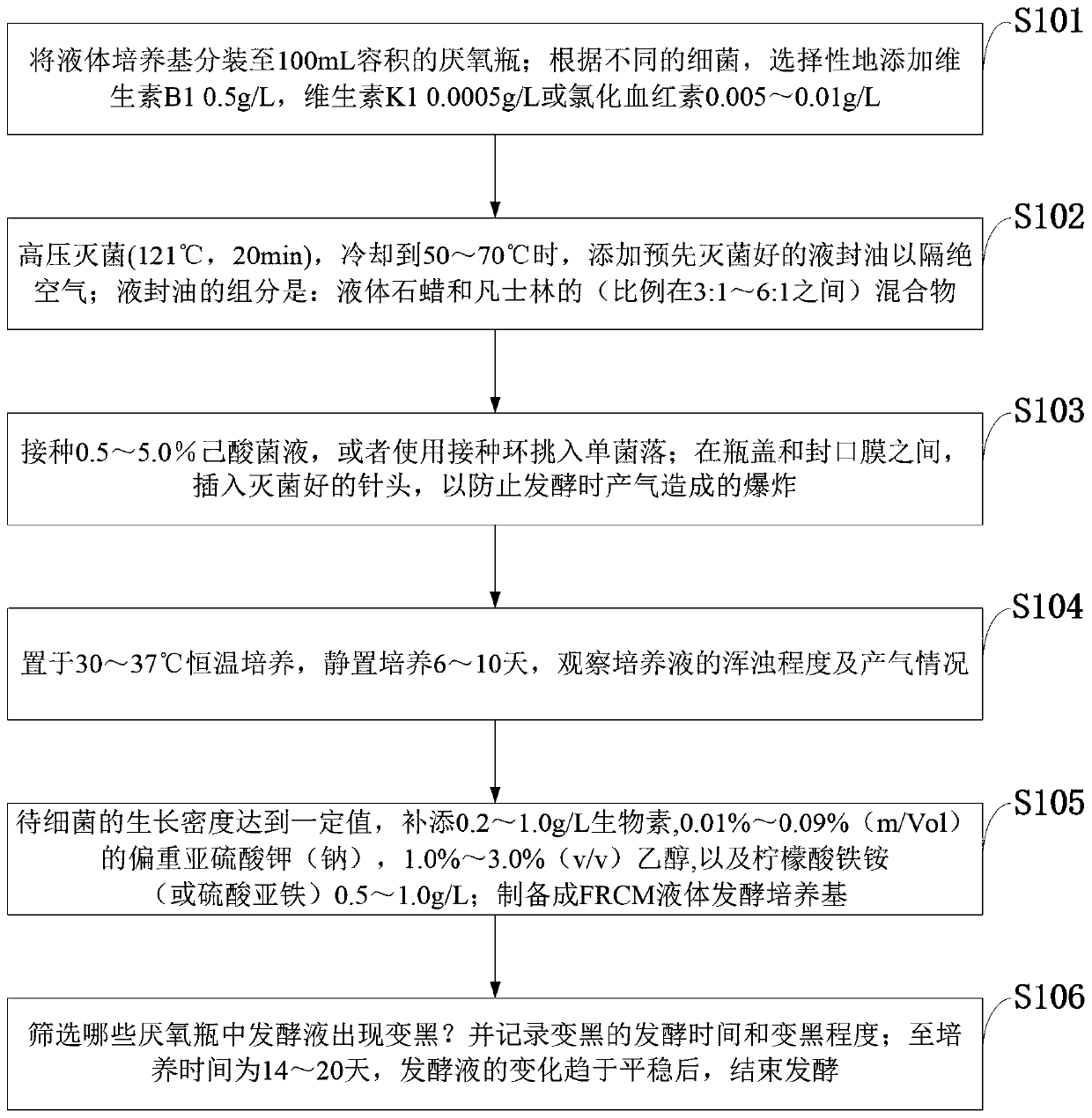

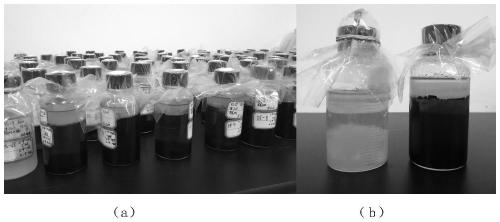

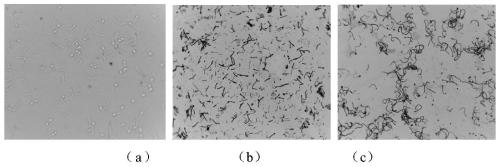

Caproic acid bacterium proliferation culture medium and caproic acid fermentation and caproic acid bacterium screening method

PendingCN109971686AToxic reductionIncrease bacterial densityBacteriaComponent separationNutrientLactic acid fermentation

The invention belongs to the technical field of bacterial fermentation and functional bacteria screening, and discloses a caproic acid bacterium proliferation culture medium and a caproic acid fermentation and caproic acid bacterium screening method. The proliferation culture medium comprises 10.0 g / L of peptone, 10.0 g / L of beef powder, 3.0 g / L of yeast powder, 1.0-5.0 g / L of glucose, 1.0 g / L ofsoluble starch, 5.0 g / L of sodium chloride, 3.0-6.0 g / L of sodium acetate, 0.5 g / L of cysteine hydrochloride, 0.3-1.0 g / L of ascorbic acid, 0.5-2.0 g / L of agar and distilled water composition. Nutrients such as 0.005-0.01 g / L of hemin are selectively added, so that the growth and division of some extreme bacteria are facilitated, the cell density is increased, and the screening range of caproic acid bacteria is expanded. Ethanol and sodium butyrate are added midway to promote the synthesis of hexanoic acid. A fermentation container is transparent, and fermentation liquor is preliminarily screened according to the conditions of gas production and acid production in the fermentation liquor, so that the screening efficiency is improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Methods and devices for desmopressin drug delivery

InactiveUS8399410B2Prevent adverse side effectsReduce productionElectrotherapyMicroneedlesDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

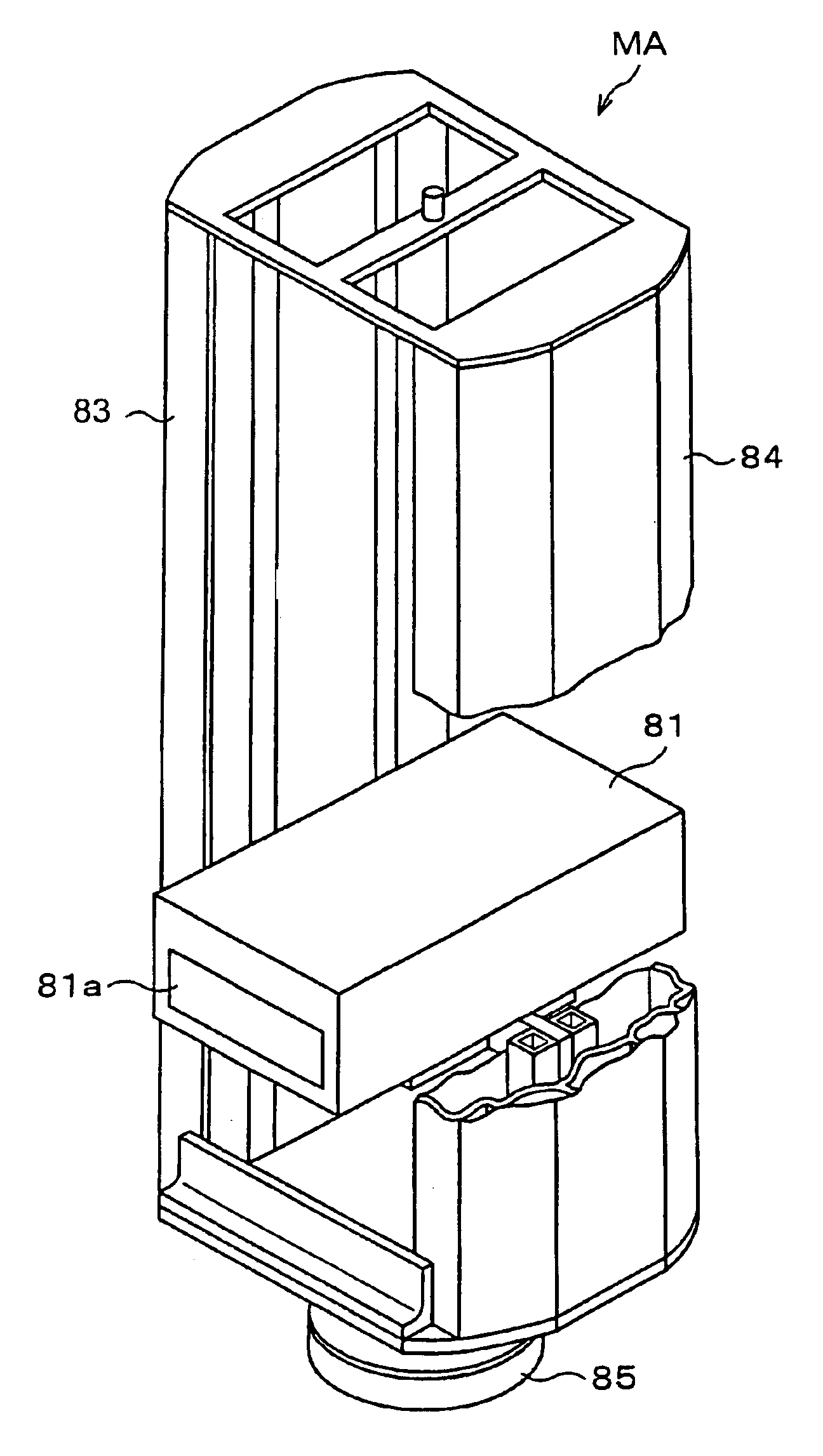

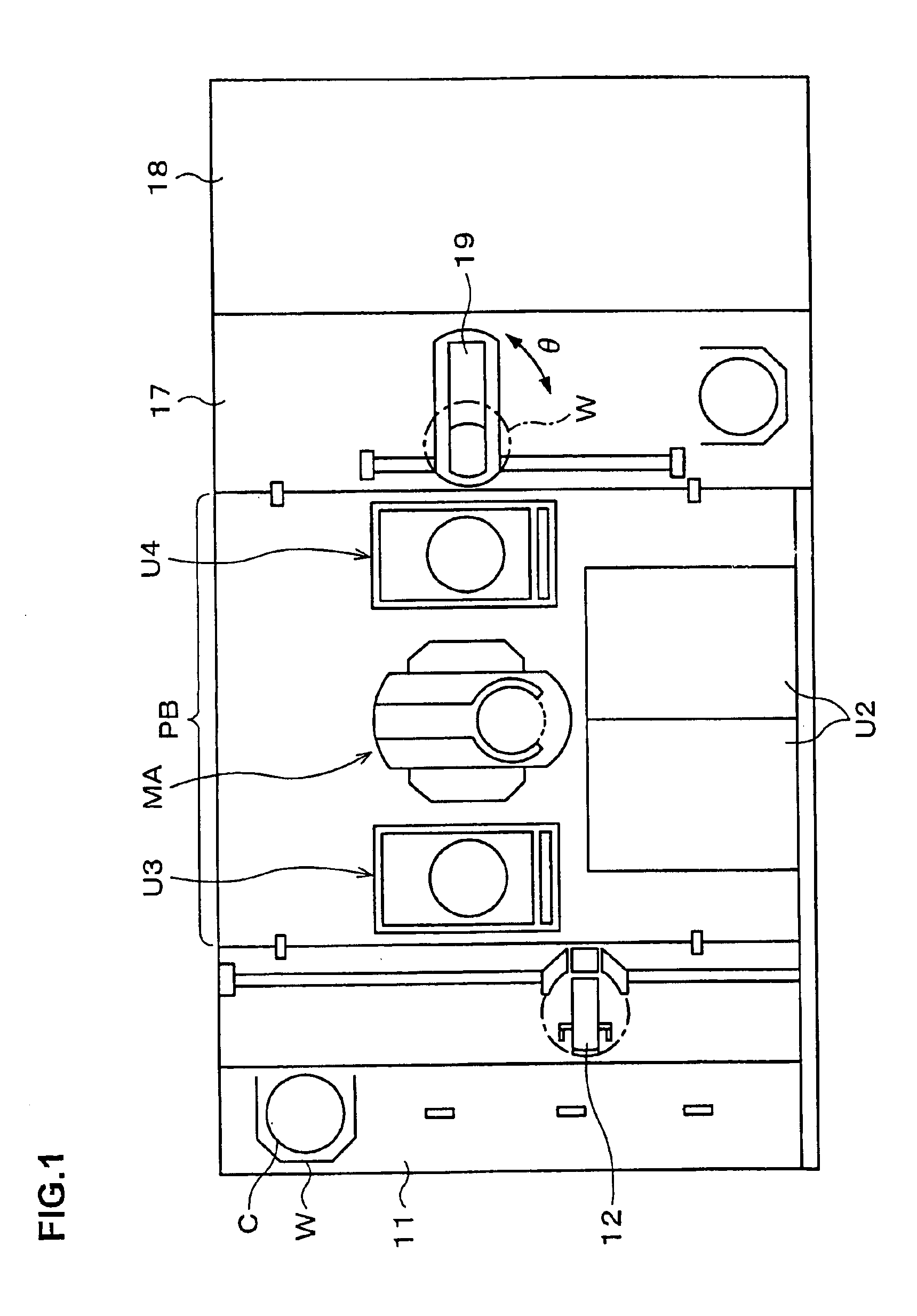

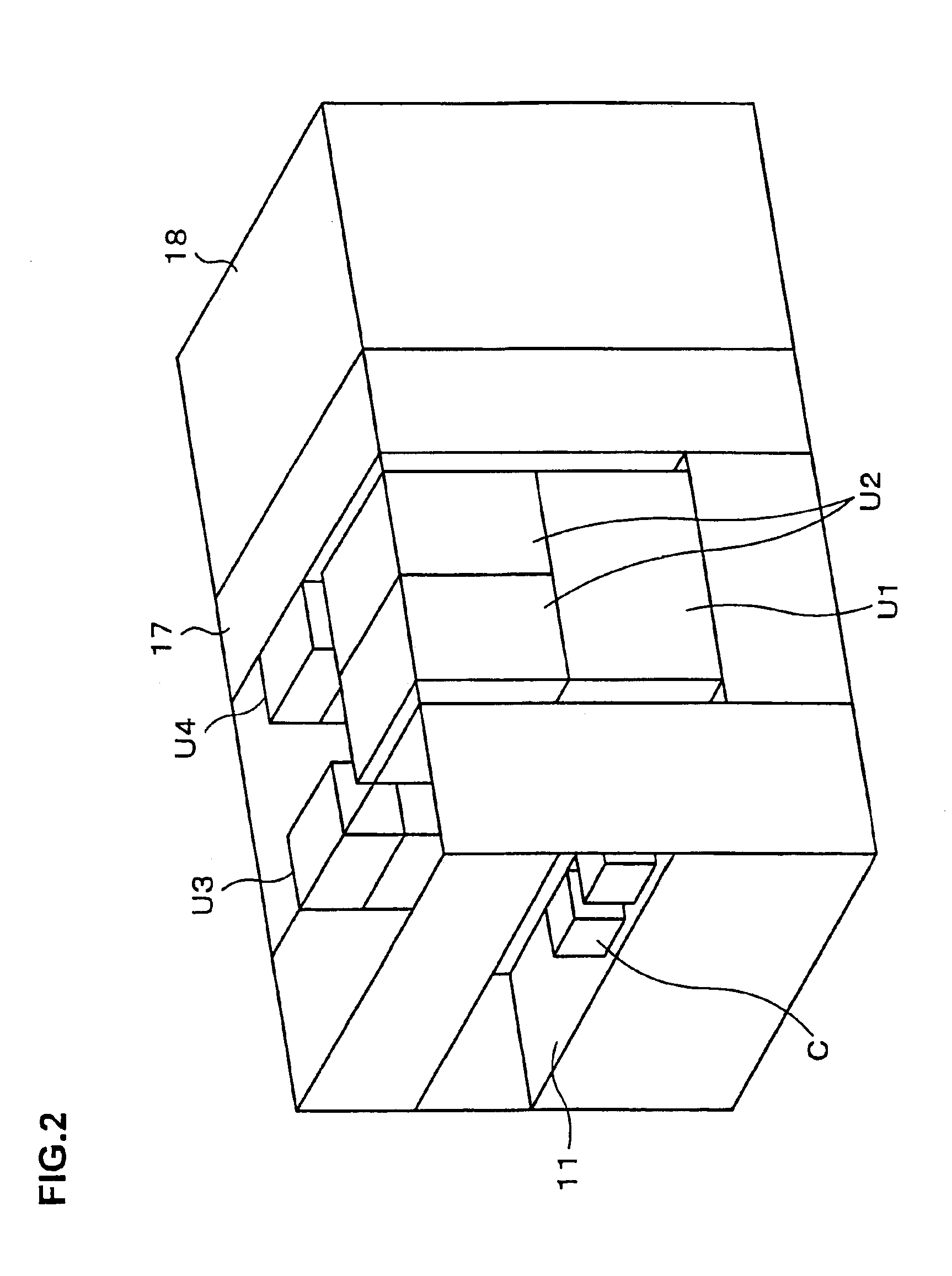

Coating film forming apparatus and coating unit

InactiveUS6936107B2High yieldUniform temperatureLiquid surface applicatorsVacuum evaporation coatingResistSpray nozzle

A coating film forming apparatus for forming a film by applying a coating solution to a substrate, which is provided with a cassette section, coating unit, developing unit, pre-treatment / post-treatment units and a main arm for transferring the substrate between the respective units. In the coating unit, provided is a coating section in which a resist is applied on the substrate in a manner of single stroke by intermittently moving the substrate in a Y-direction and by moving a nozzle in an X-direction, and provided is a reduced-pressure drying section for drying under reduced pressure the substrate after being applied, and further provided is equipment for removing the coating film adhered to a periphery of the substrate. Additionally, when the reduced-pressure drying section is arranged outside the coating unit, the main arm is covered with a cover so that the inside thereof is under a solvent atmosphere.

Owner:TOKYO ELECTRON LTD

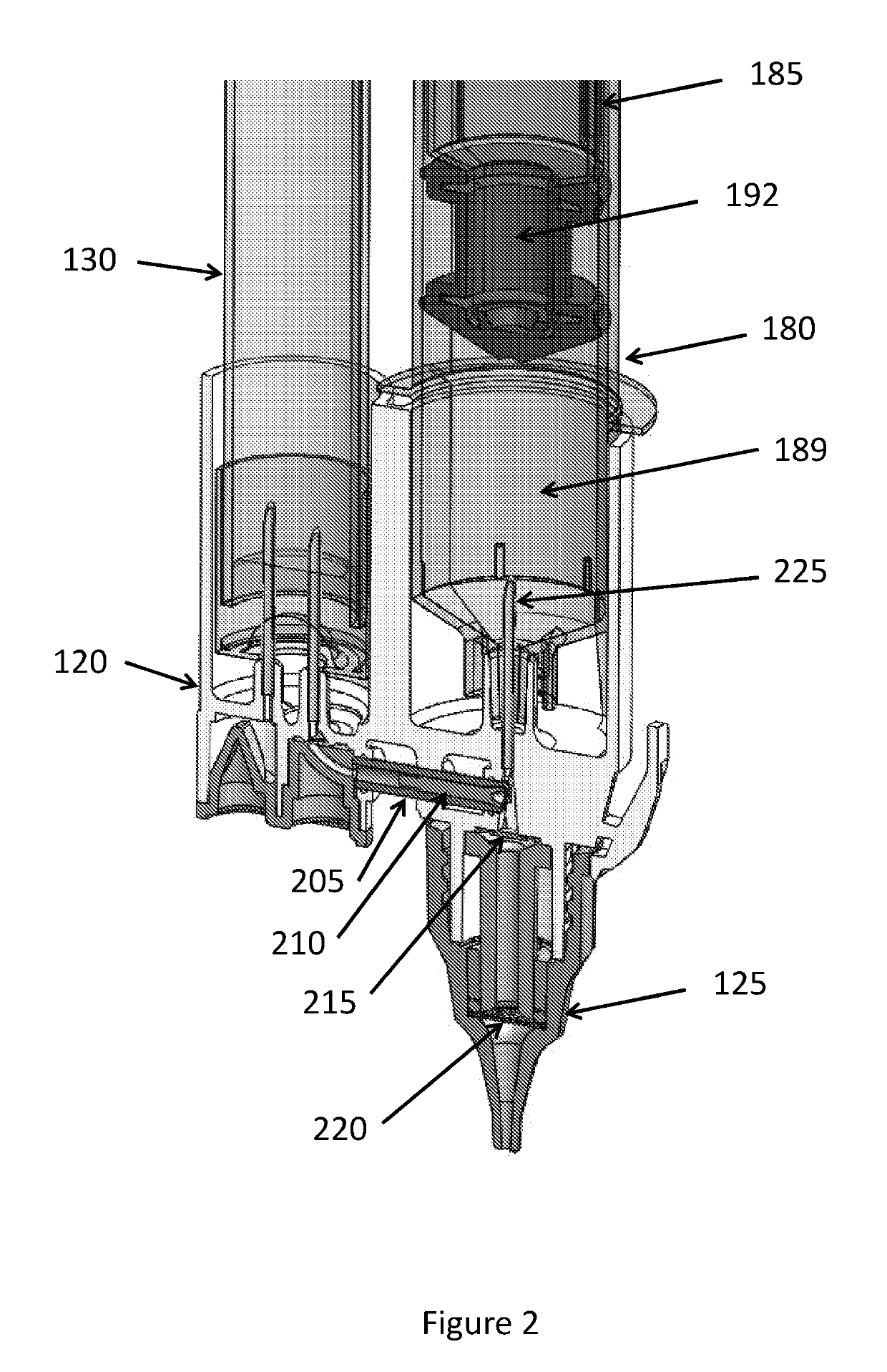

Device for Rapid Urine Concentration

InactiveUS20140255271A1Quick focusFast concentrationMicrobiological testing/measurementWithdrawing sample devicesParticulatesAnalyte

The present invention provides a device for the concentration of one or more target analytes contained in a urine sample. The device comprises a tube comprising an upper portion defining an opening for receiving the urine sample and a lower tapered portion terminating in a collection reservoir. The tube contains a predetermined amount of a particulate binding agent which specifically binds the one or more target analytes and of a predetermined amount of a binding buffer. The device comprises means for sealing the opening of the tube. The present invention further provides methods and kits for concentrating one or more target analytes in a urine sample.

Owner:NORGEN BIOTEK CORP

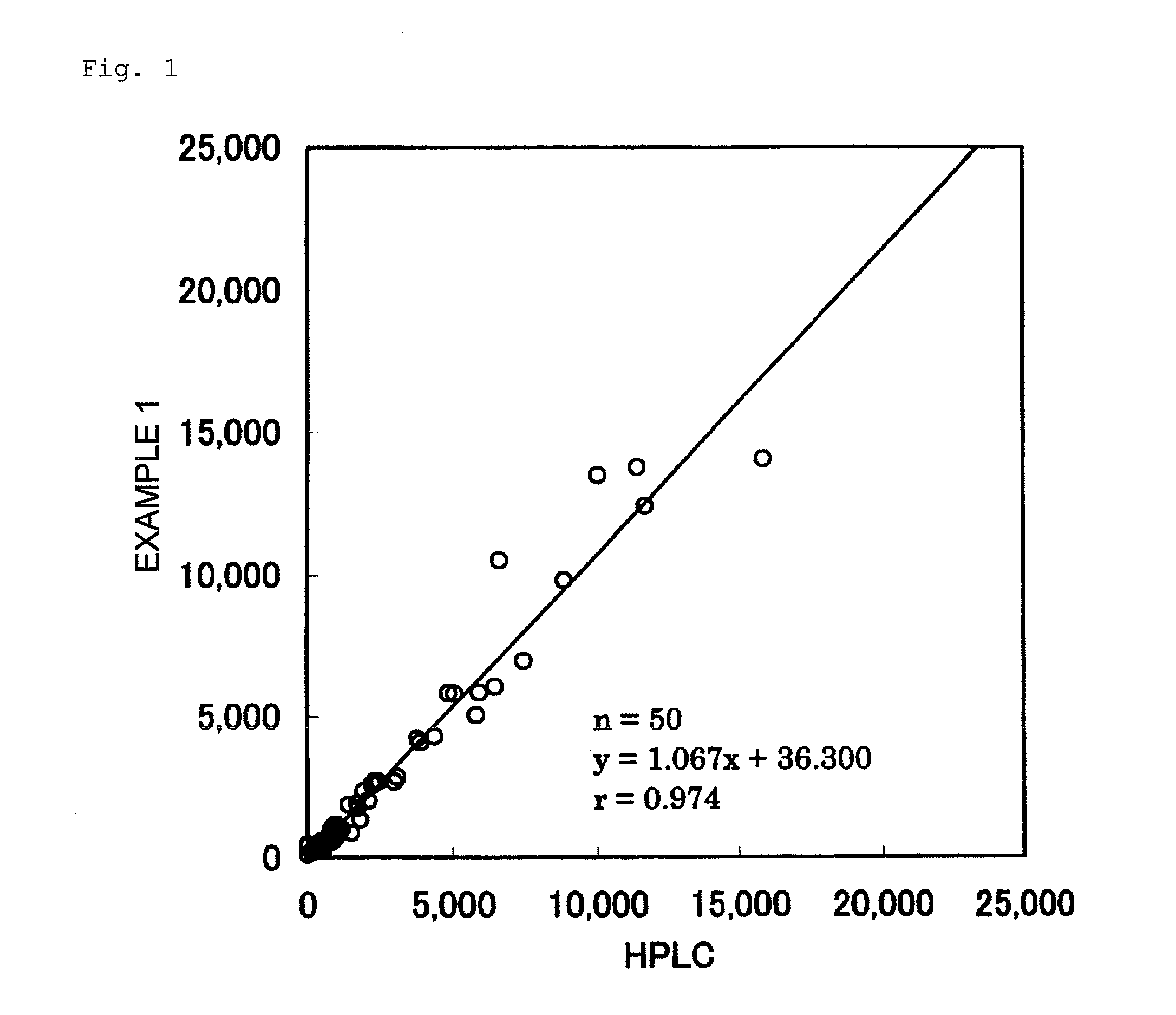

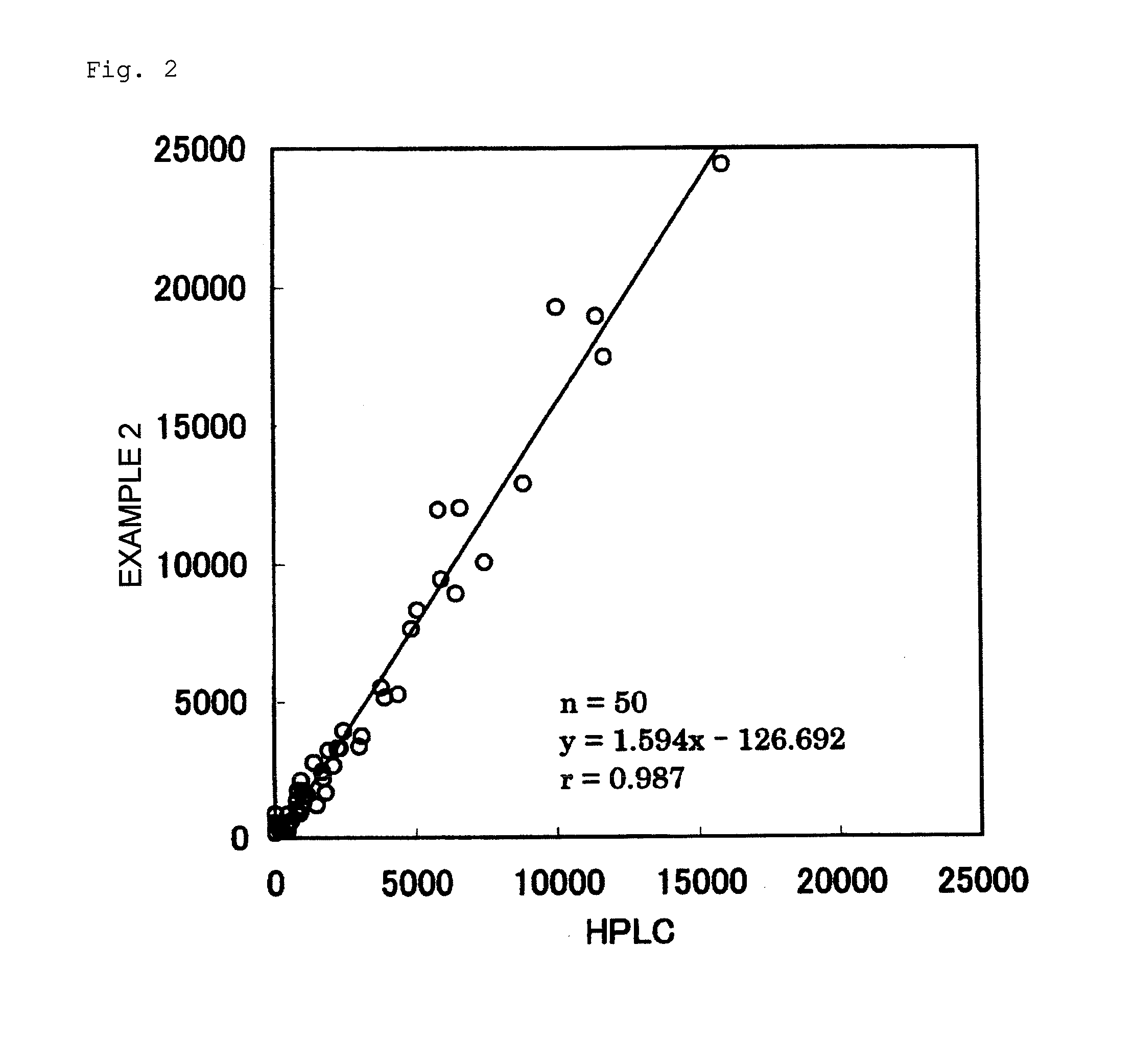

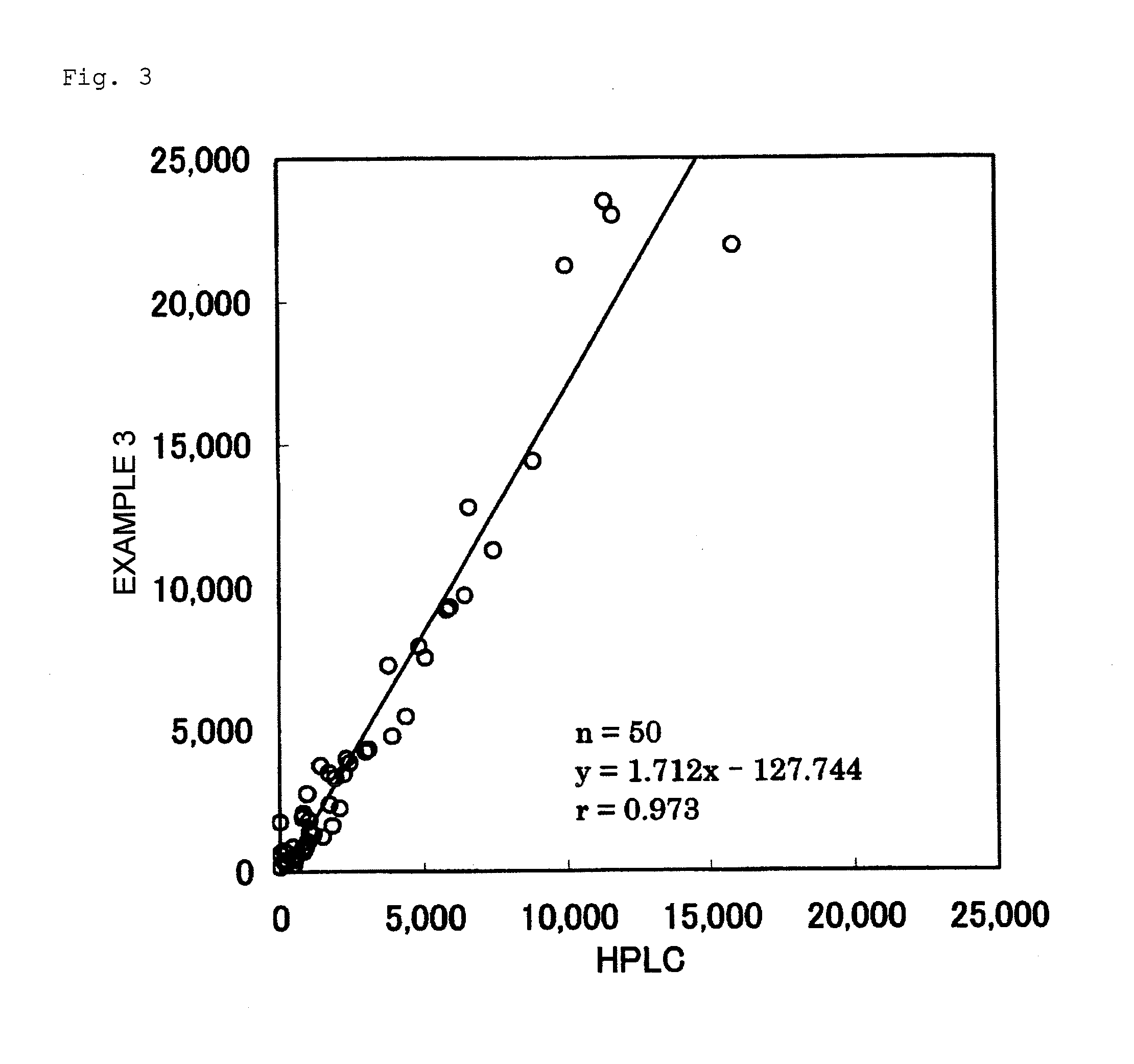

Method for measurement of equol in biological sample by immunoassay, kit for the measurement, and method for determination of equol production ability of subject

ActiveUS20120064550A1Suppress nonspecific reactionAccurate measurementAnalysis by subjecting material to chemical reactionImmunoglobulinsAntigenEquol

An object of the present invention is to provide a method for measuring equol in a biological sample by an immunological method, a kit for the measurement, and a method for determining equol-producing ability of a subject.The measurement method of the present invention is characterized in that S-equol is used as at least one antigen selected from the group consisting of a standard antigen used for the preparation of a standard curve and a labeled antigen that competes with equol in a biological sample. The kit of the present invention is characterized in including S-equol as at least one antigen selected from the group consisting of the standard antigen and the labeled antigen. The determination method of the present invention includes steps of measuring equol in a biological sample derived from a subject who has ingested soybean isoflavone by an immunological method using S-equol as at least one antigen selected from the group consisting of the standard antigen and the labeled antigen, and determining an equol-producing ability of the subject based on the measured value of equol obtained in the above step.

Owner:OTSUKA PHARM CO LTD

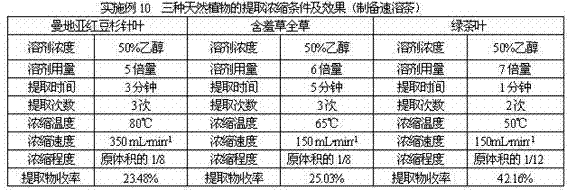

A kind of tea drink containing natural plant or natural plant extract and its preparation method and use

InactiveCN102258094AEasy to prepareEasy to carry and drinkPre-extraction tea treatmentPsoriasisEpigallo-catechin gallate

The invention relates to tea drink containing natural plants or natural plant extracts, and a preparation method and application thereof, and belongs to the technical field of tea drink. The tea drink containing the natural plants or the natural plant extracts is characterized by consisting the following materials in percentage by weight: 50 to 80 percent of taxus media needle, 10 to 20 percent of whole mimosa pudica and 10 to 30 percent of green tea, or 45 to 70 percent of taxus media needle, 10 to 20 percent of extractive of whole mimosa pudica and 20 to 35 percent of extractive of green tea. The tea drink is natural, fresh and healthy, has a simple preparation method, can leach active ingredients quickly and is convenient to carry and drink. The product has the effects of clearing heatand releasing toxin, resisting bacteria and sterilizing, removing heat and toxin, relieving exterior syndrome and dispelling wind, promoting blood circulation and removing blood stasis, eliminating bacteria and diminishing inflammation, and relieving itching and removing tinea, and can effectively prevent and treat psoriasis, eczema and pruritus.

Owner:ZHEJIANG FORESTRY UNIVERSITY

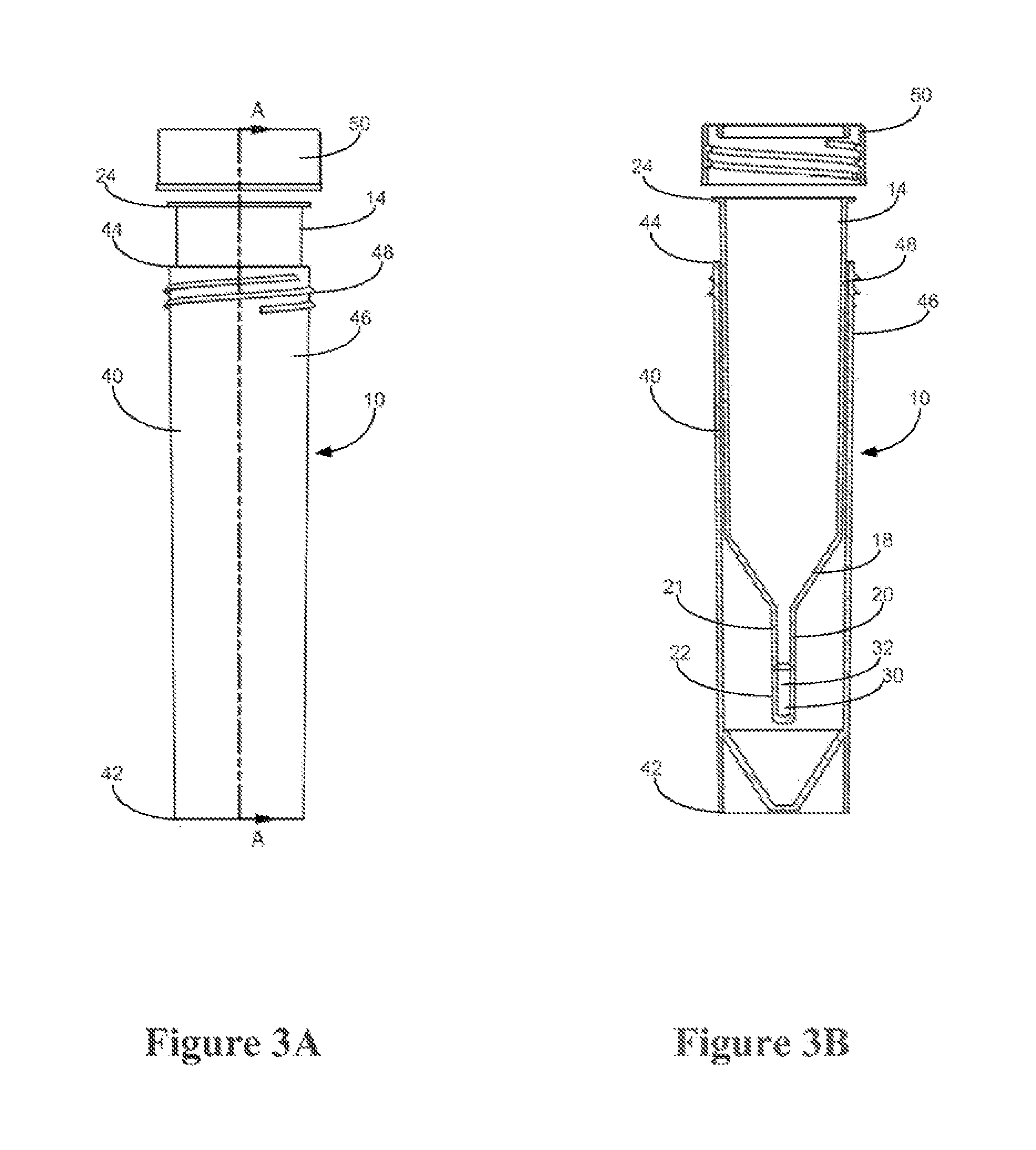

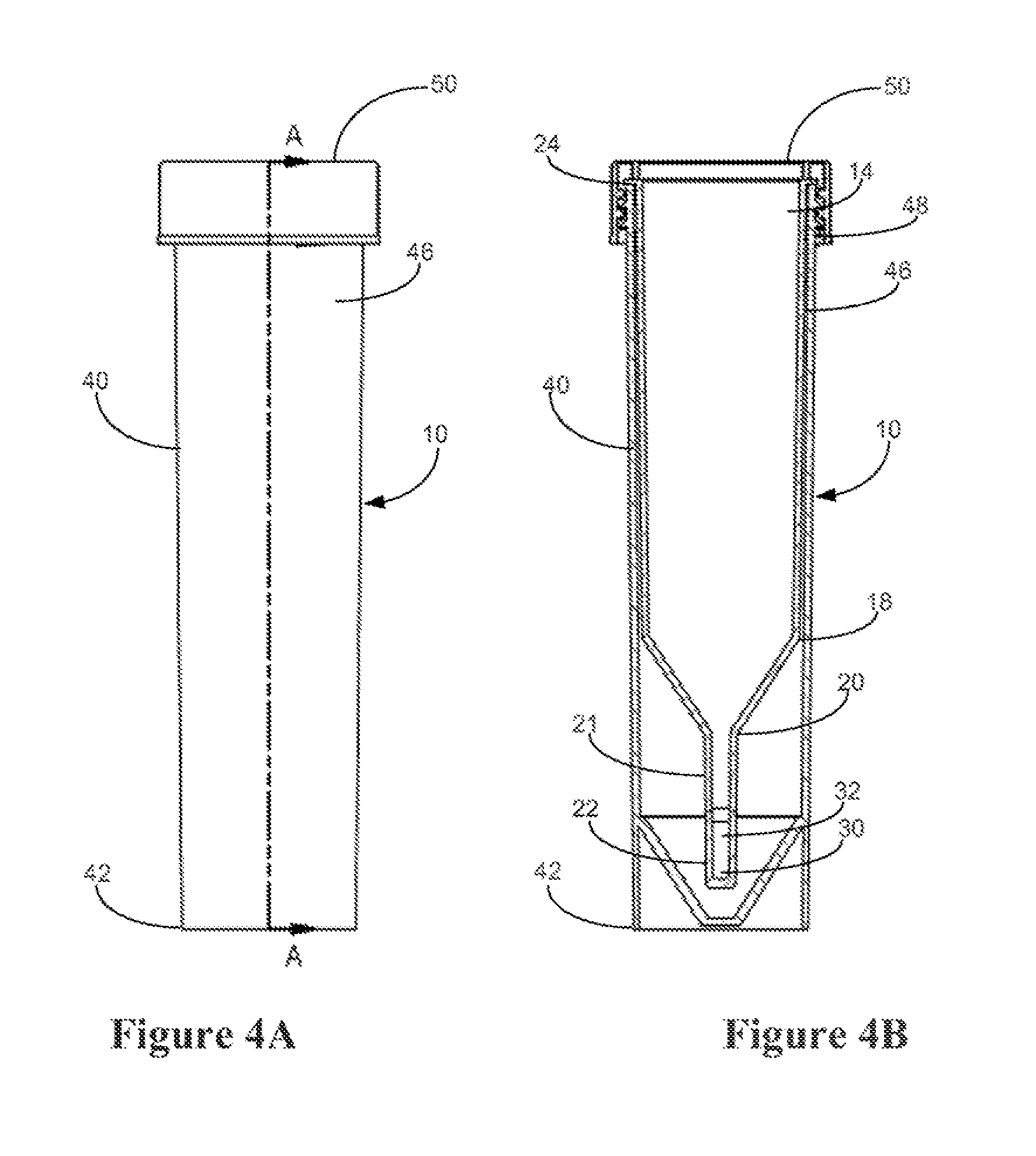

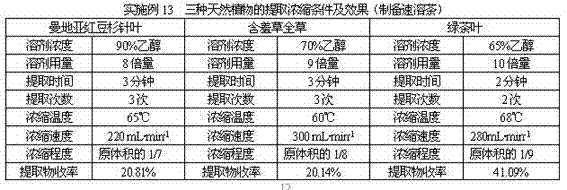

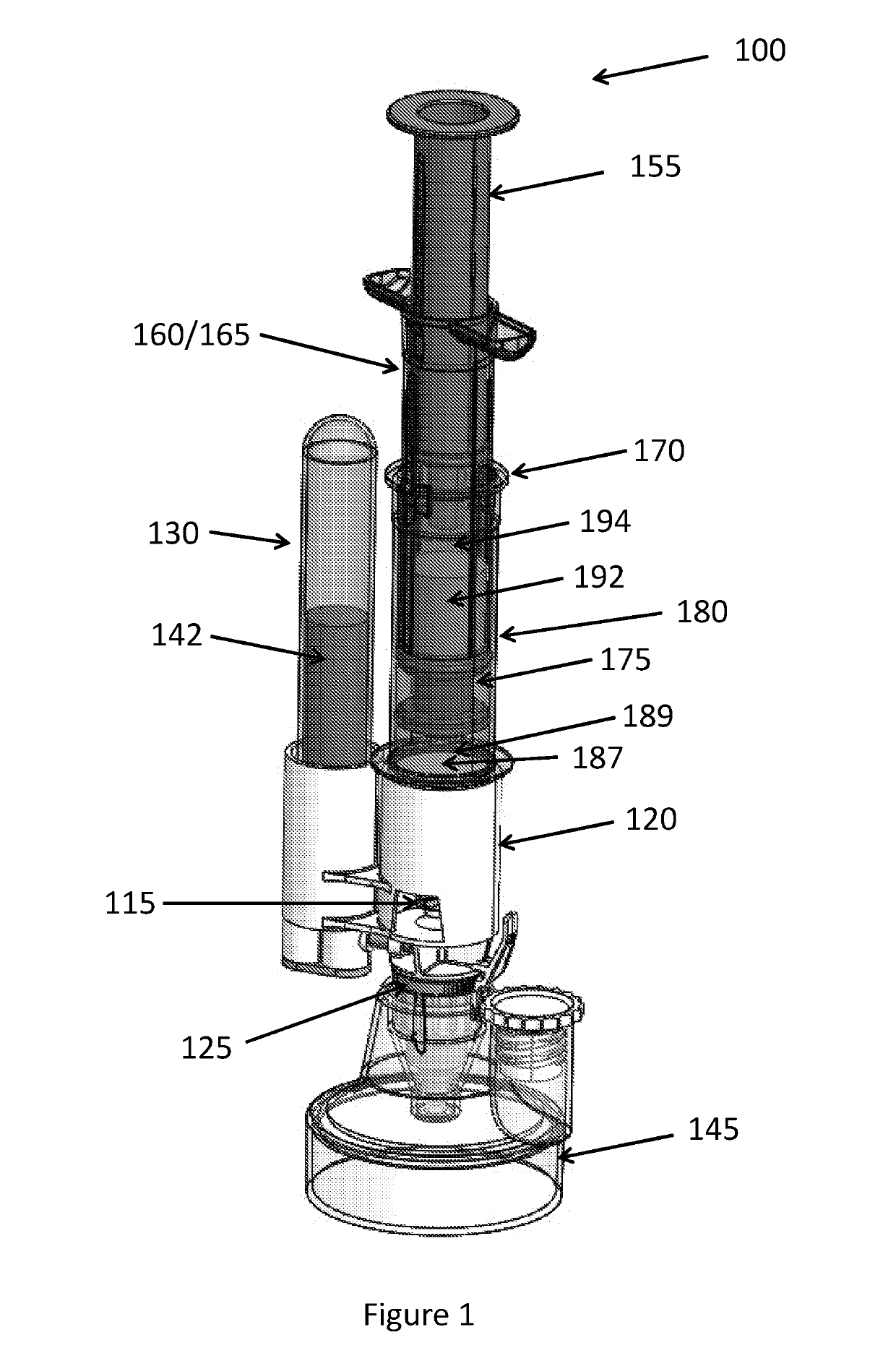

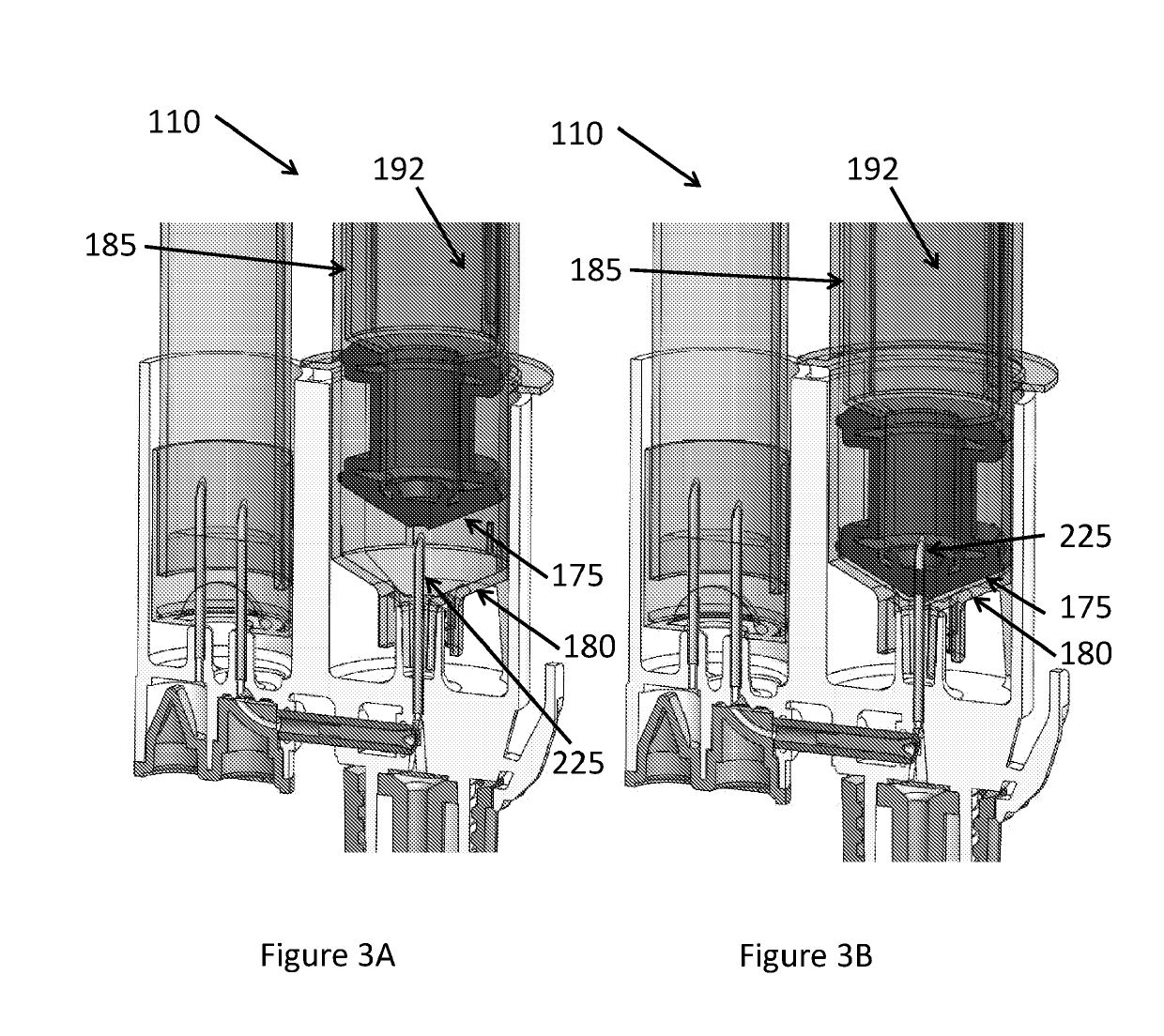

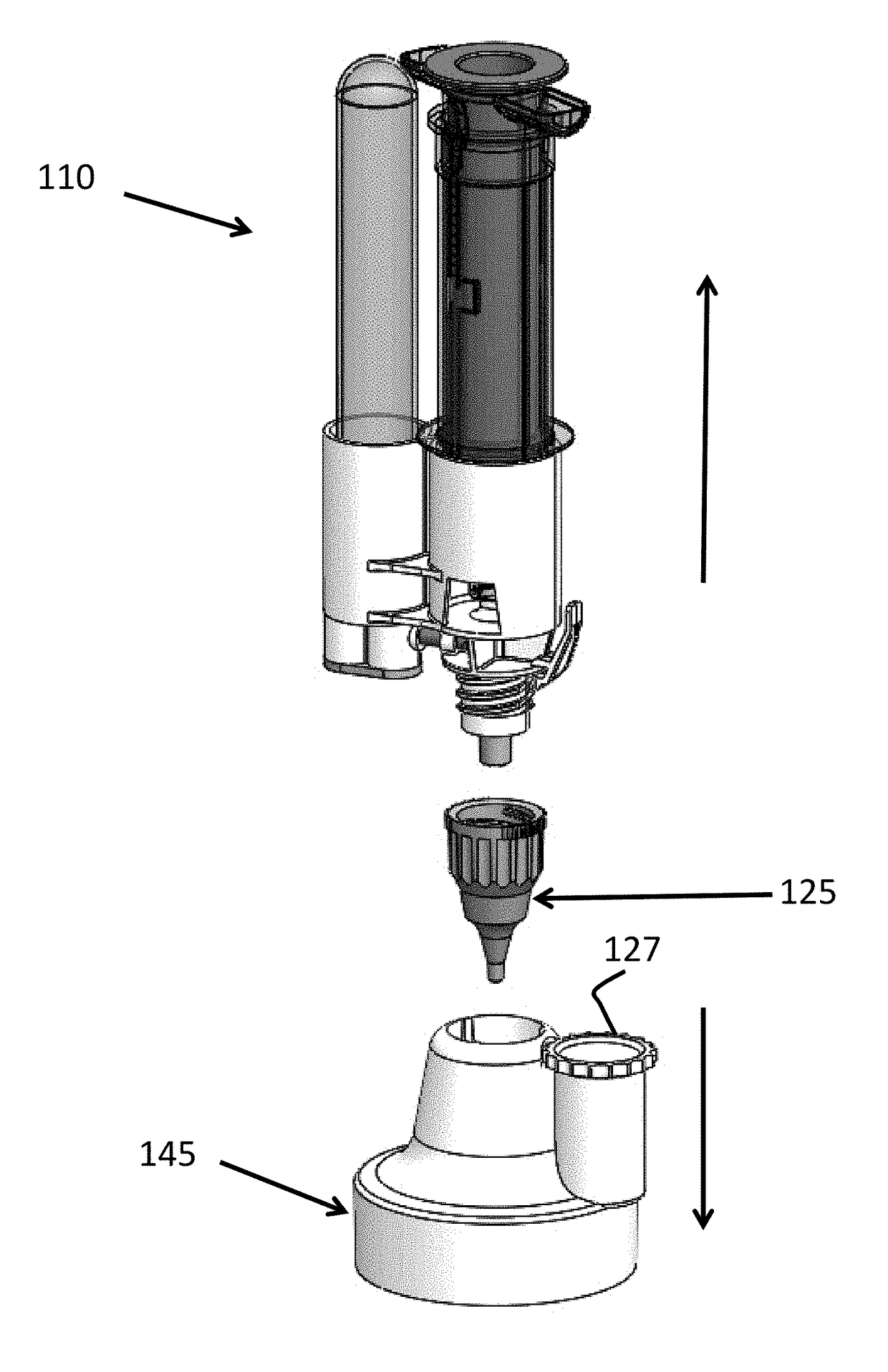

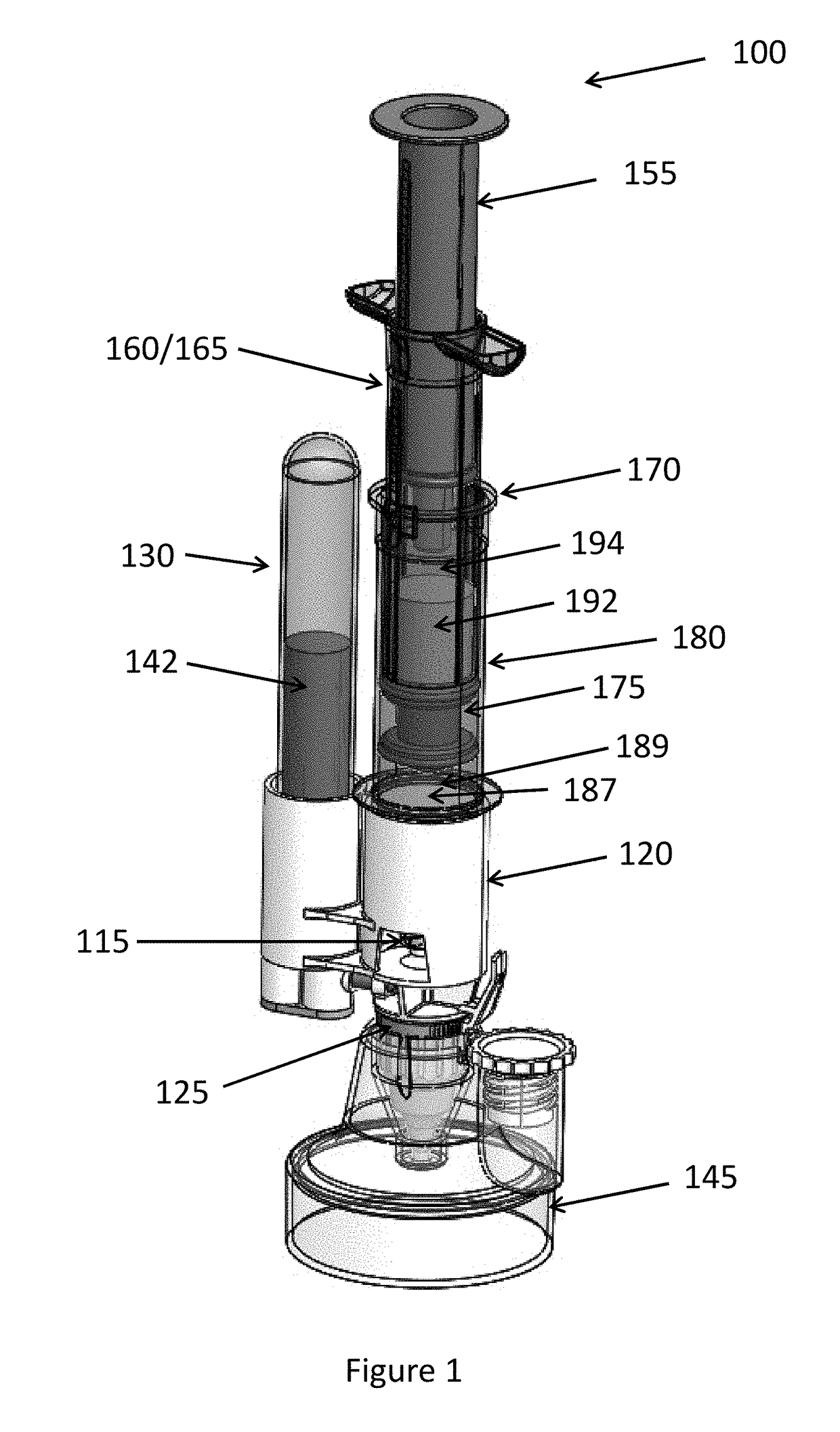

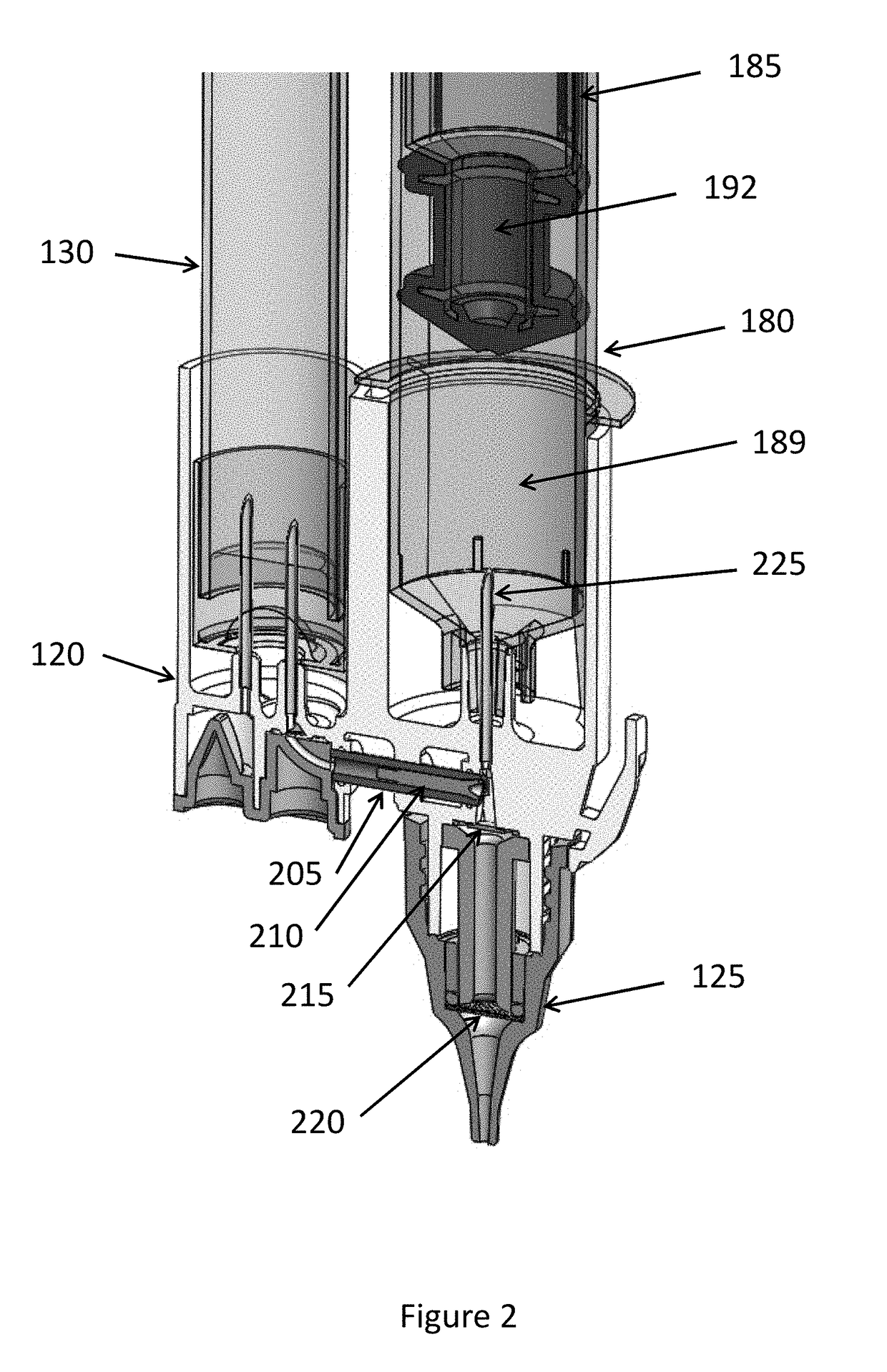

Apparatus and method for extracting pathogens from biological samples

ActiveUS20190091681A1Fast concentrationRapid isolationMicrobiological testing/measurementWithdrawing sample devicesMicroorganismBioinformatics

The disclosed embodiments related to an apparatus and methods for biological sample processing enabling isolation and concentration of microbial or pathogenic constituents from the sample. Sample may be obtained directly from a specimen container, such as a vacutainer, and processed directly without risk of user exposure. The disclosed methods and apparatus provide a convenient and inexpensive solution for rapid sample preparation compatible with downstream analysis techniques.

Owner:TANGEN BIOSCIENCES INC

Apparatus and method for extracting pathogens from biological samples

ActiveUS20170274376A1Minimizes and eliminates user exposureMinimizes and eliminates and potential contamination issueMicrobiological testing/measurementWithdrawing sample devicesSpecimen containersBioinformatics

The disclosed embodiments related to an apparatus and methods for biological sample processing enabling isolation and concentration of microbial or pathogenic constituents from the sample. Sample may be obtained directly from a specimen container, such as a vacutainer, and processed directly without risk of user exposure. The disclosed methods and apparatus provide a convenient and inexpensive solution for rapid sample preparation compatible with downstream analysis techniques.

Owner:TANGEN BIOSCIENCES INC

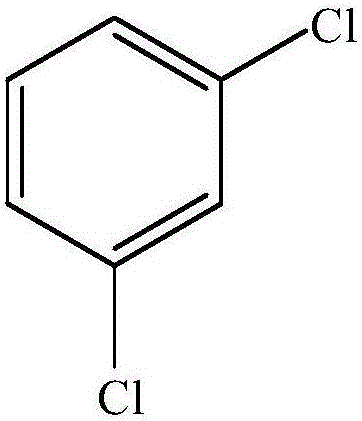

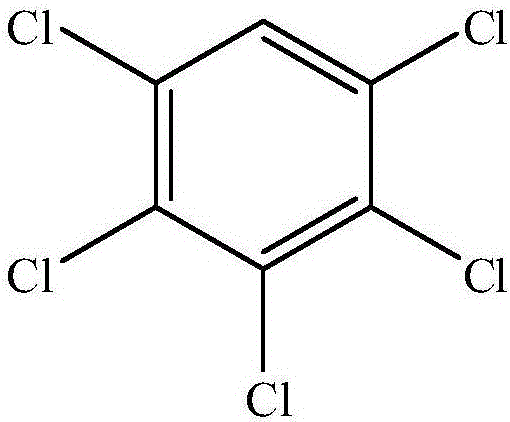

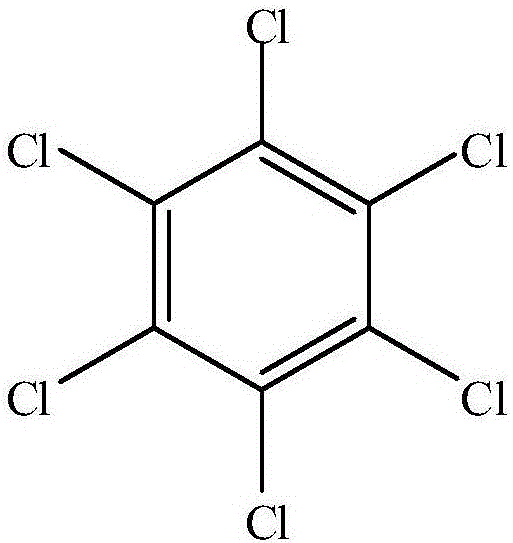

Method using ultrasonic extraction-gas chromatography-mass spectrum to measure chlorobenzene compounds in textiles

InactiveCN106404979AThe pre-processing process is simpleEasy pretreatmentComponent separationGas liquid chromatographicMass spectrometry

The invention discloses a method using ultrasonic extraction-gas chromatography-mass spectrum to measure chlorobenzene compounds in textiles. The method includes: preparing a to-be-measured sample, extracting the sample, preparing a standard work solution and detecting a to-be-measured sample solution. The method using ultrasonic extraction-gas chromatography-mass spectrum to measure the chlorobenzene compounds in the textiles has the advantages that the chlorobenzene organic pollutants in the textiles can be measured at the same time, the method is accurate, fast and high in sensitivity, and a reliable detecting method support is provided for the fast detection of the textiles.

Owner:韩超

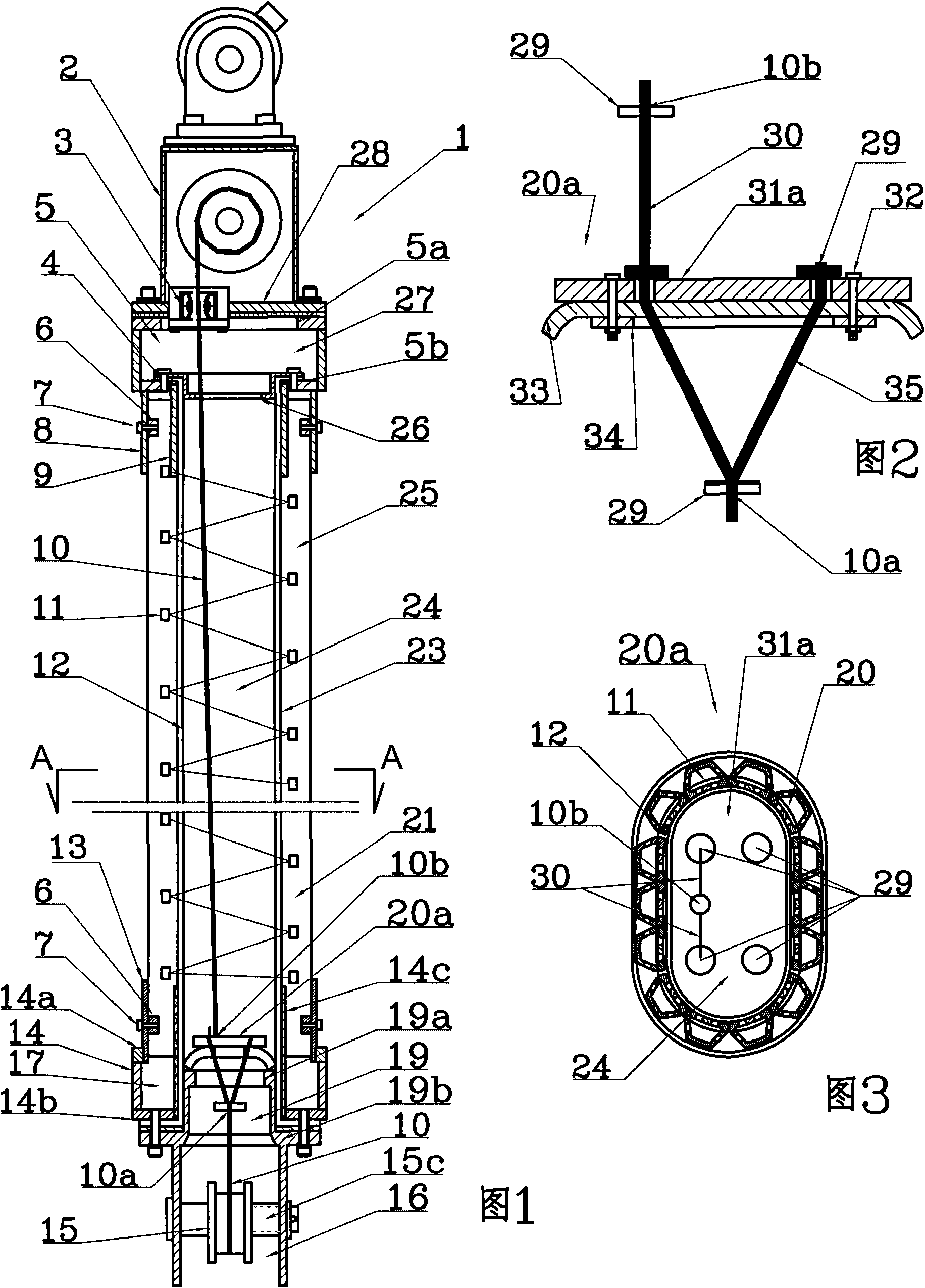

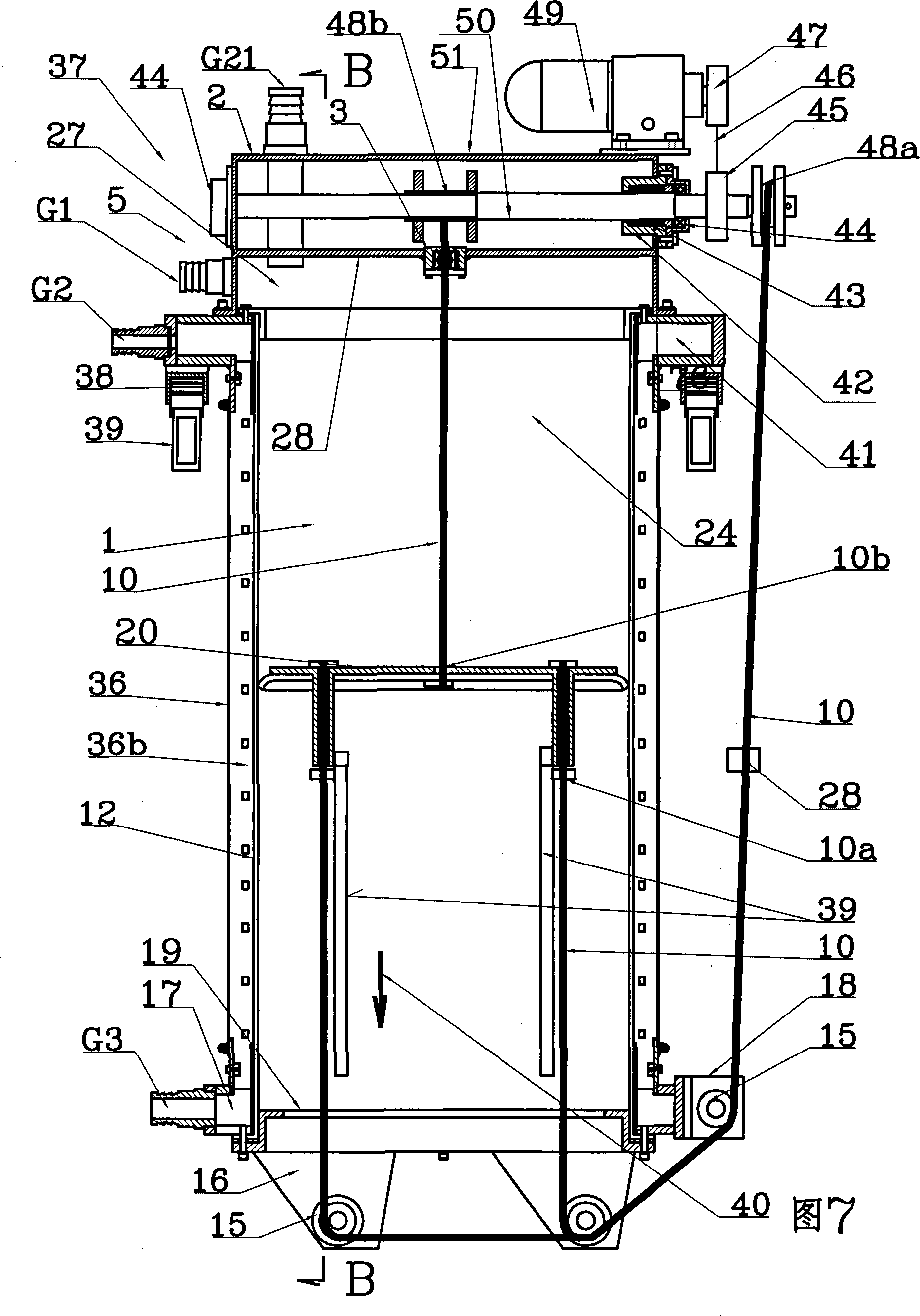

High-speed filtering, high-temperature, high-pressure squeezing and drying flexible tube type solid-liquid processing equipment

InactiveCN101352624ARelieve pressureUniform humiditySemi-permeable membranesStationary filtering element filtersSlagHigh pressure

The invention provides a high-speed filtration and high-temperature and high-pressure squeezing and drying flexible pipe typed solid / liquid processing device; during the filtrating process, a piston slag scraper is used for removing the filtrated slag remained on the filter medium and replace a compressor and a filter machine at the same time; during the squeezing process, the solid / liquid separation is completed by a squeezing principle of changing volume of a filter chamber; the volume of the filter chamber can be near zero after the volume is changed; high pressure pump can not be needed to convey the raw material and additional squeezing water pump systems or squeezing air systems are not required to be taken as the filter pushing force of a press-filter; the mechanical pushing force is large and the pressurizing is quicker; repeated nipping filtration can be adopted; the washing filter slag is dipped; during the squeezing process, the alternative change of the thickness of the raw material improves the filtration speed, the washing speed and the efficiency; the humidity of a filter cake is uniform; the filtration and squeezing can be carried out at the same time when the vacuum or steam drying is carried out; the production quantity of each sequence batch is easily changed according to the requirement of production capability; the washing regeneration of the filter medium is automatically completed; the slag drainage is automatically completed; during the production process, automation can be completely realized, the energy dissipation is reduced and the production efficiency is high.

Owner:张民良

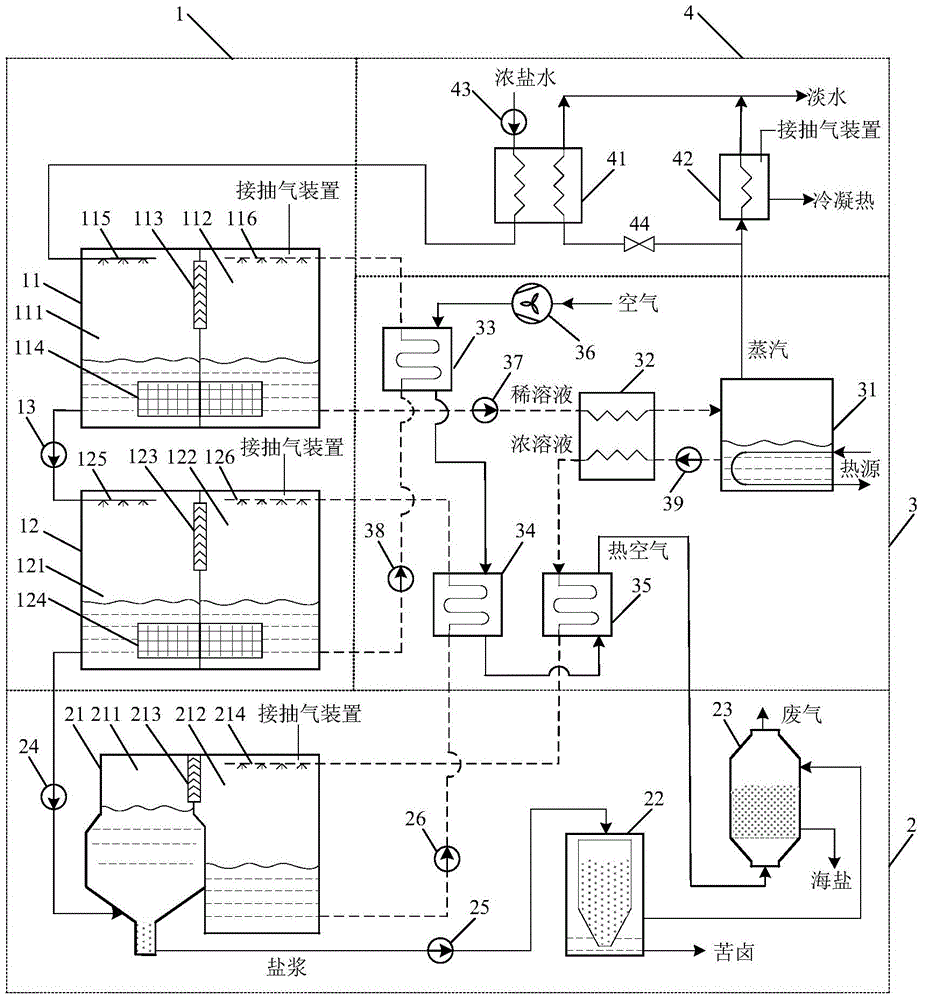

Trigeneration system of fresh water, sea salt and heat energy based on deep concentration of sea water desalination strong brine

InactiveCN104528850AImprove economyLow costGeneral water supply conservationSeawater treatmentWater desalinationSaline water

The invention discloses a trigeneration system of fresh water, sea salt and heat energy based on deep concentration of sea water desalination strong brine and relates to strong brine treatment. The invention provides the trigeneration system of fresh water, sea salt and heat energy based on deep concentration of sea water desalination strong brine, which is efficient, energy-saving, compact in structure and good in economical benefit. The system is provided with a deep concentration sub system, a salt manufacturing sub system, a solution regeneration sub system and a condensation sub system, wherein the deep concentration sub system is provided with at least one evaporation-absorber which is provided with an evaporation chamber, an absorption chamber, a liquid baffle plate, a heat tube exchanger, a strong brine spray tube and an evaporation-absorber lithium bromide solution spray tube; the solution regeneration sub system is provided with a generator, a solution heat exchanger and an air cooler; the condensation sub system is provided with a brine preheater and a condenser.

Owner:JIMEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com