Patents

Literature

527 results about "Caproic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A saturated medium-chain fatty acid with a 6-carbon backbone. Caproic acid is found naturally in various plant and animal fats and oils.

Biodegradable packaging laminate, a method of producing the packaging laminate, and packaging containers produced from the packaging laminate

InactiveUS20020127358A1Improve adhesionExcellent gas barrier performanceAdhesive processesLiquid surface applicatorsLactideBiopolymer

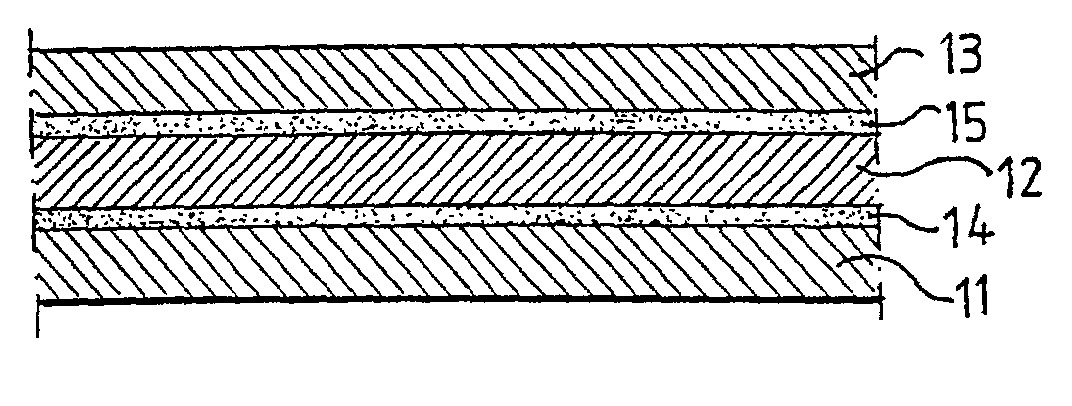

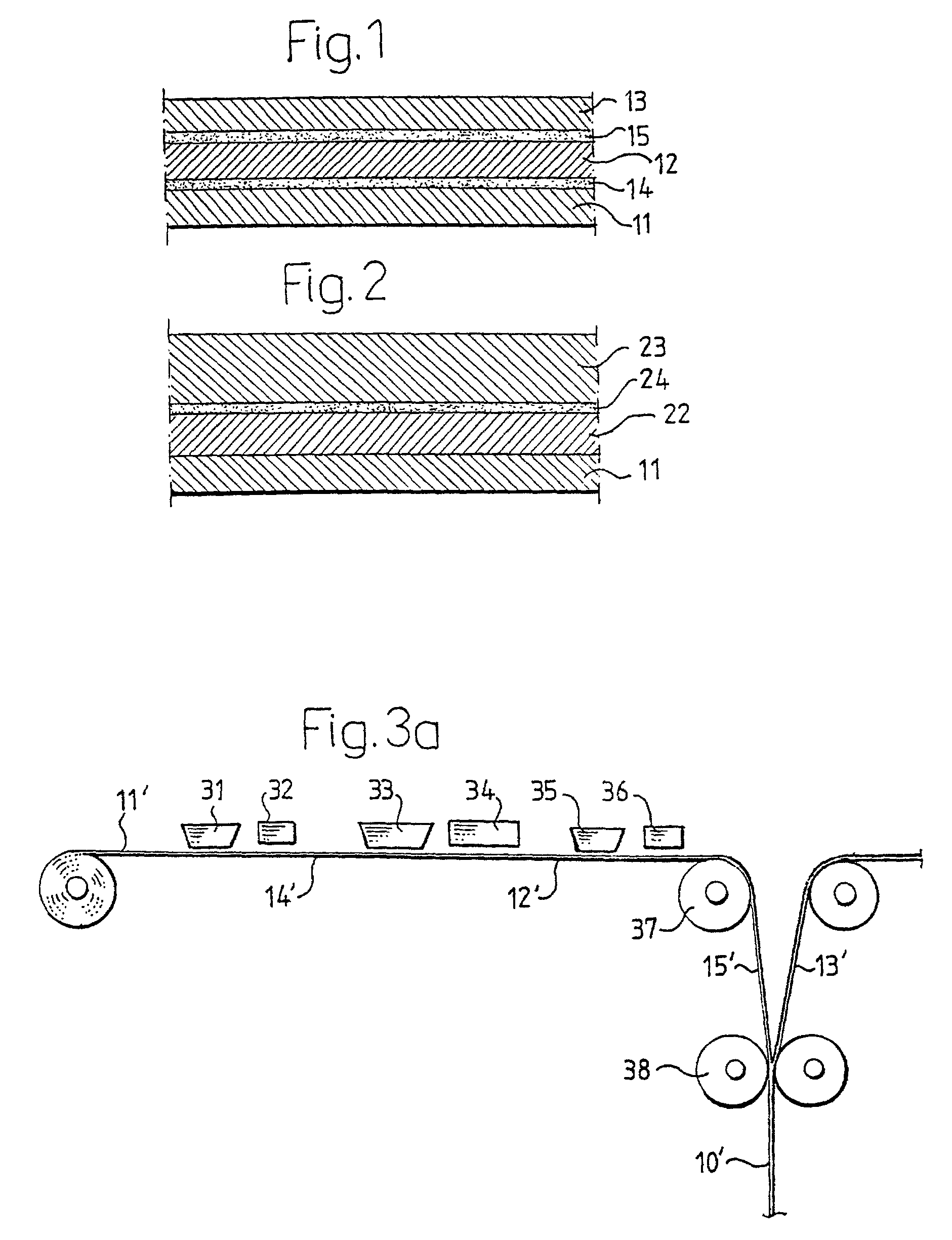

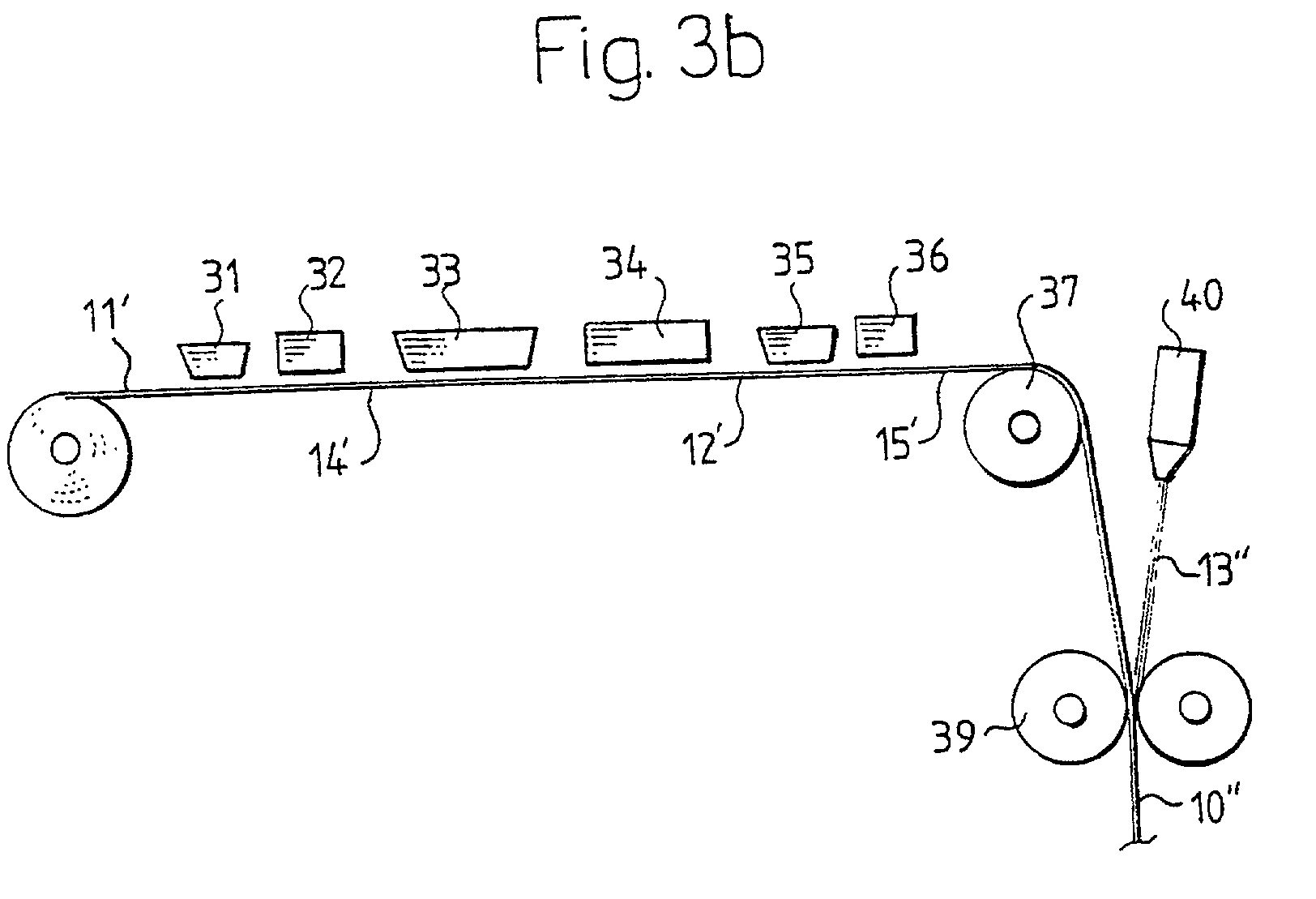

Packaging laminate for packages for liquid foods having excellent liquid and oxygen gas barrier properties in which all included layers are biodegradable. The packaging laminate includes at least one liquidtight layer (11, 13) of homo or copolymers of monomers selected from a group consisting of lactic acid, glycol acid, lactide, glycolide, hydroxy butyric acid, hydroxy valeric acid, hydroxy caproic acid, valerolactone, butyrolactone and caprolactone, as well as an oxygen gas barrier layer (12) of ethylene vinyl alcohol, polyvinyl alcohol, starch or starch derivatives. The oxygen gas barrier layer is preferably applied by a dispersion coating process. The layers may be laminated directly to one another or indirectly by means of interjacent adhesive layers. The packaging laminate may also include a core layer of, for example, paper or paperboard, or a biopolymer. The invention also realises a method of producing the biodegradable packaging laminate according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

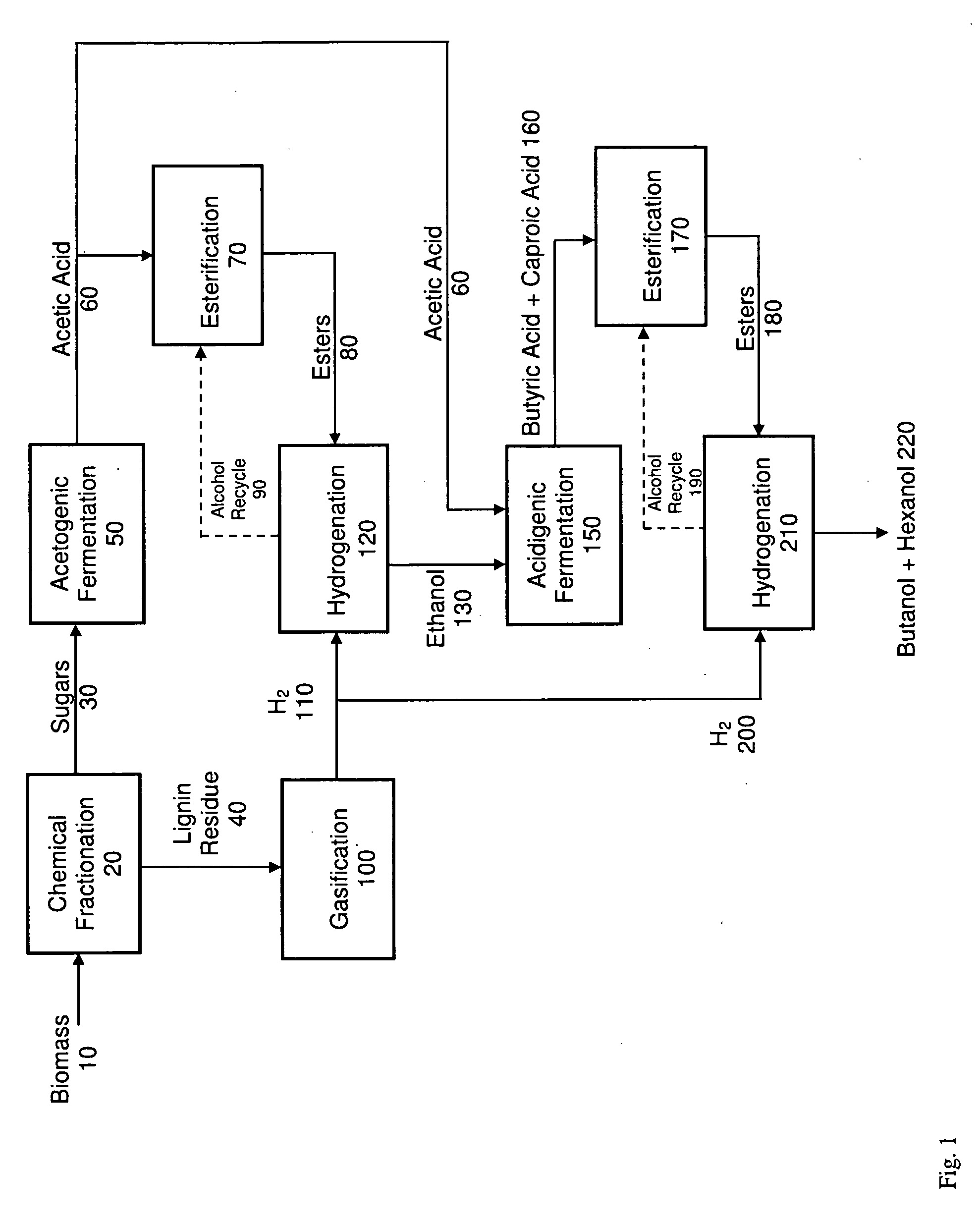

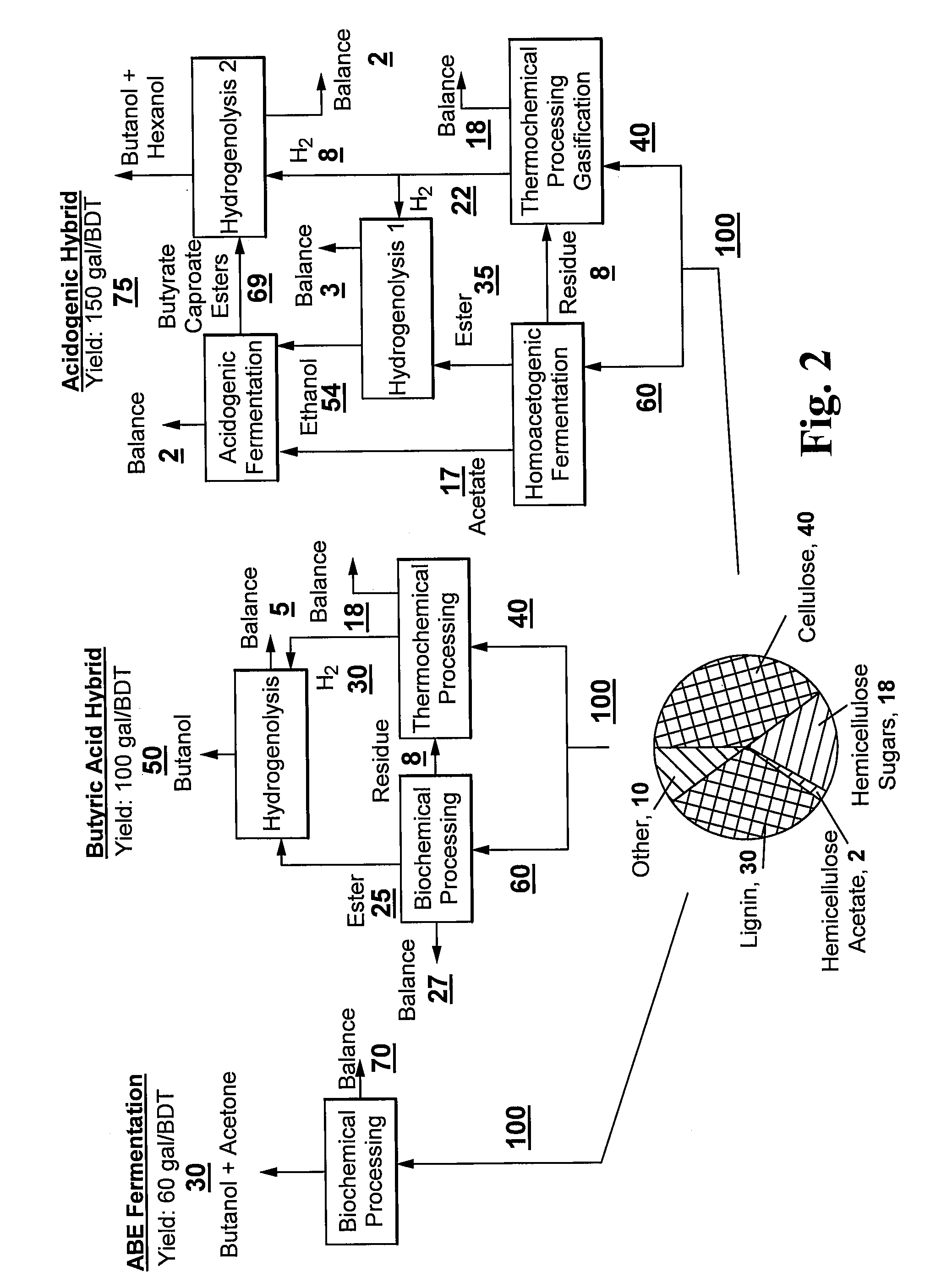

Indirect production of butanol and hexanol

InactiveUS20090203098A1Organic compound preparationHydroxy compound preparationAcetic acidButyric acid

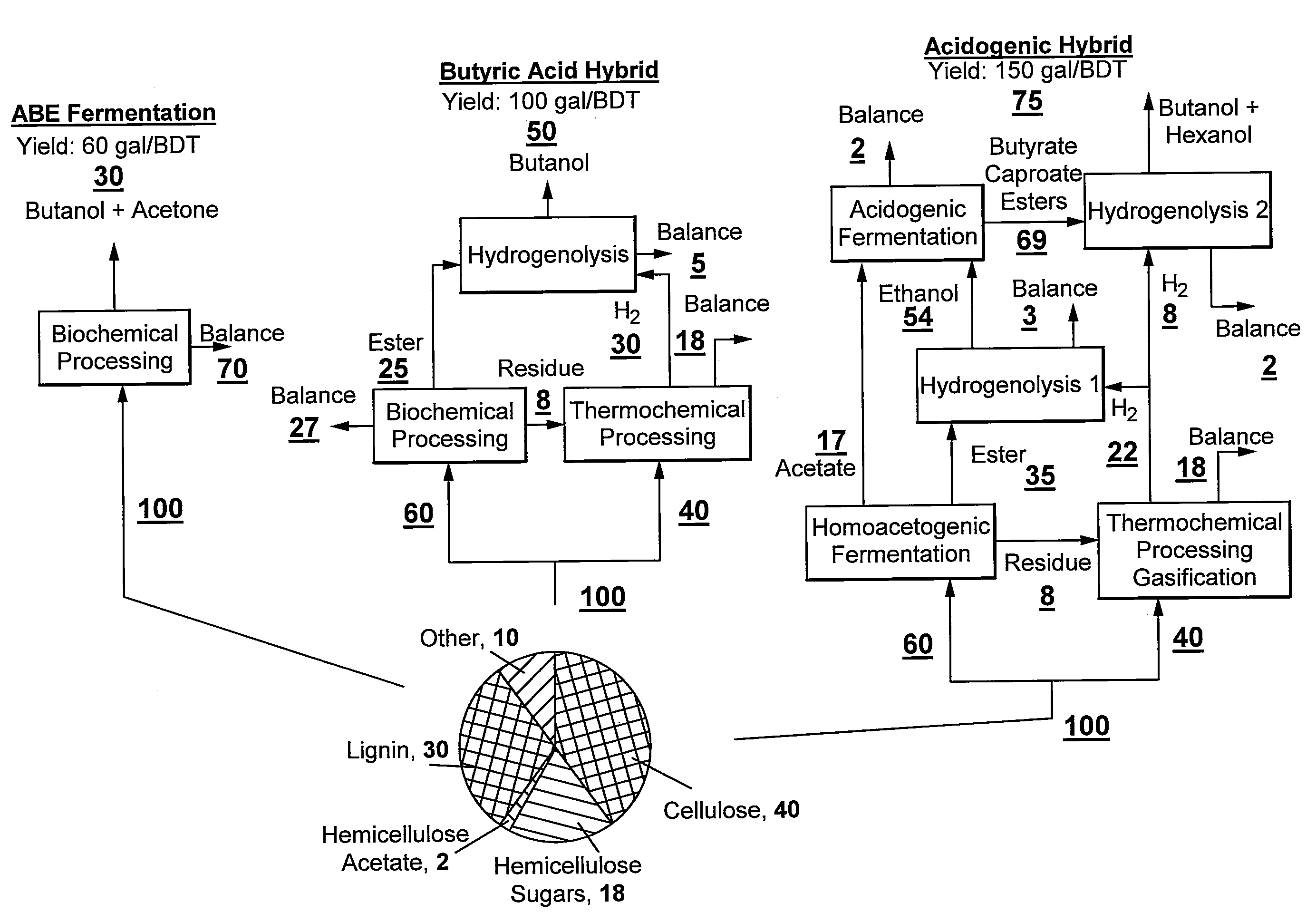

A process for the conversion of carbohydrates from any of a number of sources into butanol and hexanol for fuel or chemical use is disclosed. The process includes conducting a homoacetogenic fermentation to produce an acetic acid intermediate which is chemically converted to ethanol. The ethanol and a remaining portion of the acetic acid intermediate are used as a substrate in an acidogenic fermentation to produce butyric and caproic acid intermediates which are then chemically converted to butanol and hexanol.

Owner:ZEACHEM

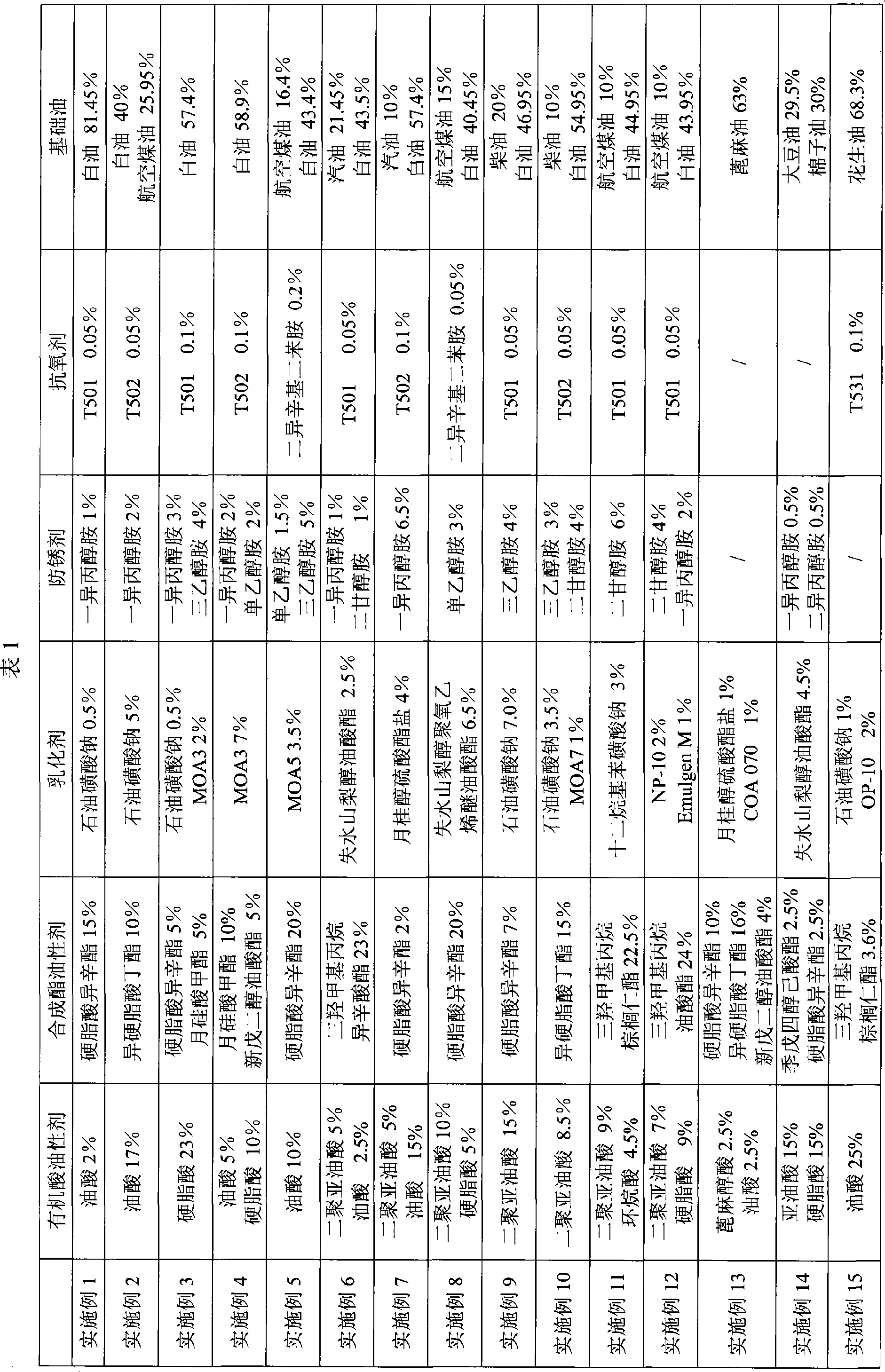

Drilling fluid lubricating agent

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

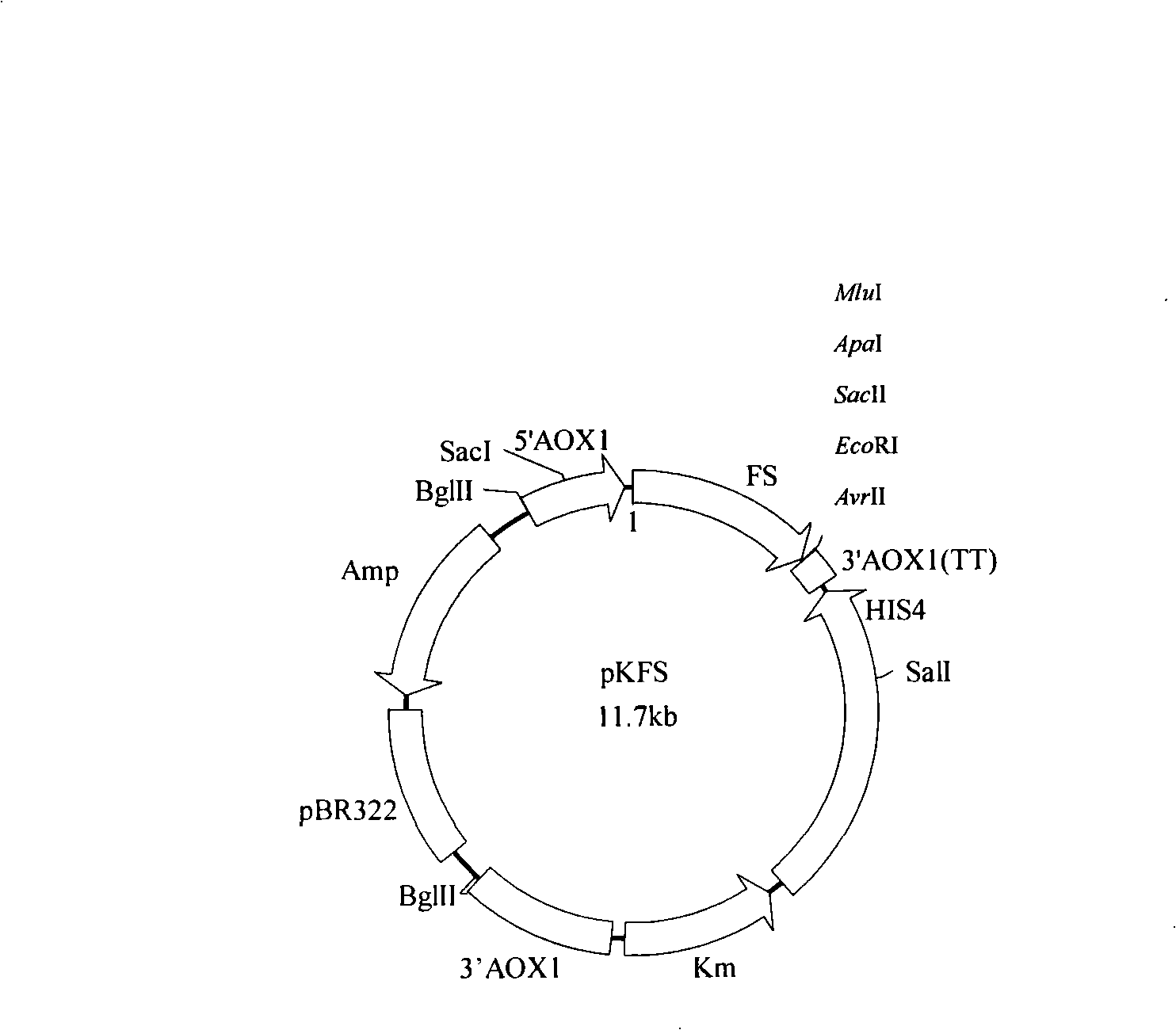

Process for synthesizing ethyl caproate by yeast display lipase synthesis

InactiveCN101285078AImprove operational stabilityHigh biosecurityFungiHydrolasesBiotechnologySurface display

The invention discloses a method for synthesizing ethyl caproate under the catalysis of yeast display lipase. The method comprises two steps, namely the production of full cellular zymin and the synthesis of ethyl caproate. The method comprises the following: a step of cloning the lipase gene into the Pichia yeast surface display vector pKFS to construct the Pichia yeast surface display expression vector pKFS-lipase which is transformed into the host bacteria of Pichia yeast through linearization, a yeast genetic engineering bacteria capable of displaying active pheron on the surface of the Pichia yeast being obtained through screening, and the engineering bacteria being fermented in a rocking bottle to obtain a thallus which is used to make the full cellular zymin after 24 hours of vacuum freeze drying; and then a step of adopting caproic acid and alcohol as raw material which is esterified at the action of the biocatalyst of yeast full cellular zymin with the lipase displayed on the surface to obtain the ethyl caproate product. The method is capable of collecting thalli centrifugally for reuse after the reaction with short reaction time, high yield and good operational stability, thereby greatly reducing production costs.

Owner:SOUTH CHINA UNIV OF TECH

Production process of highly-fragrant health care wine

InactiveCN101921685AMellow tasteDelayed spawn rateAlcoholic beverage preparationMicroorganism based processesPropanoic acidHazardous substance

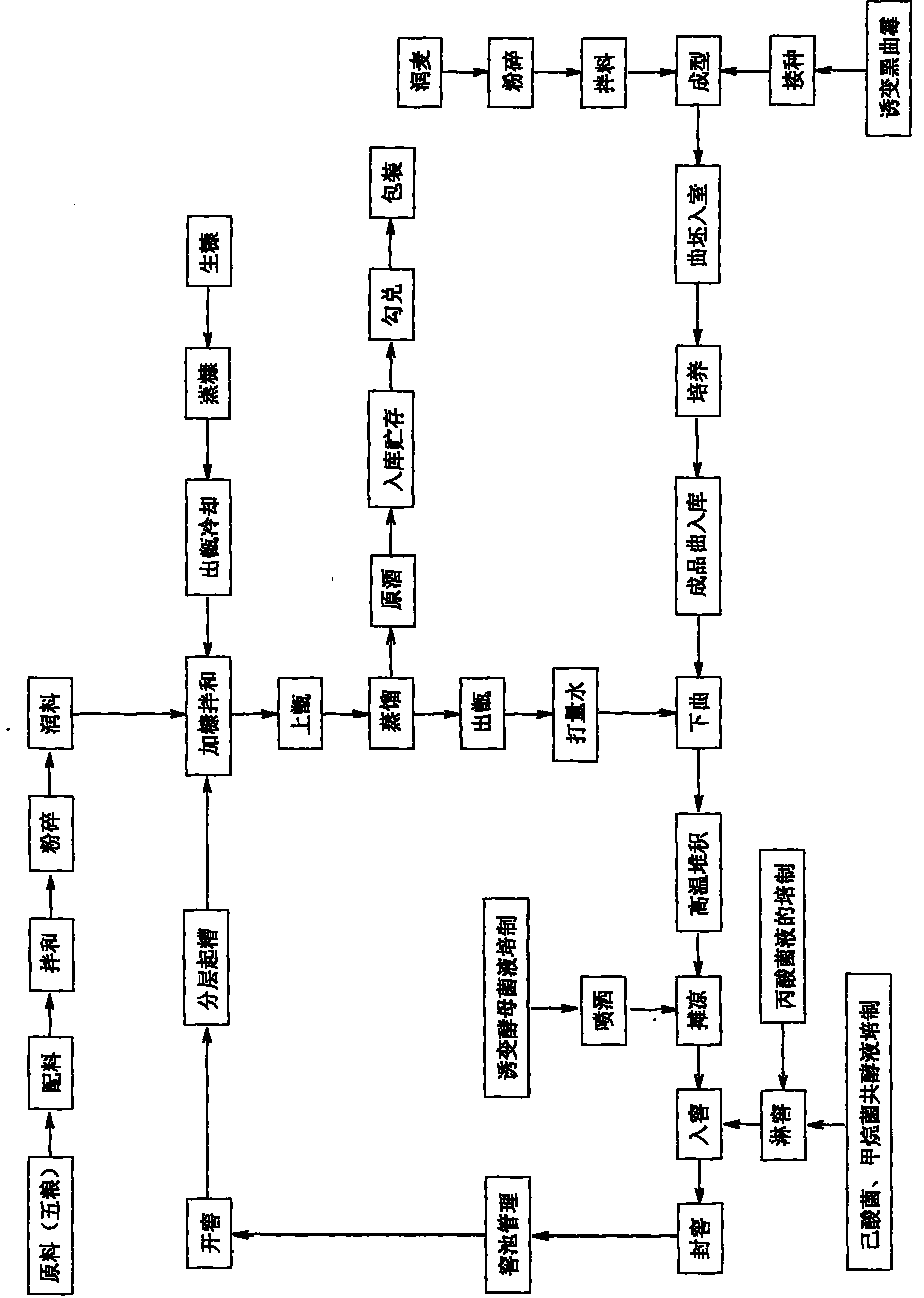

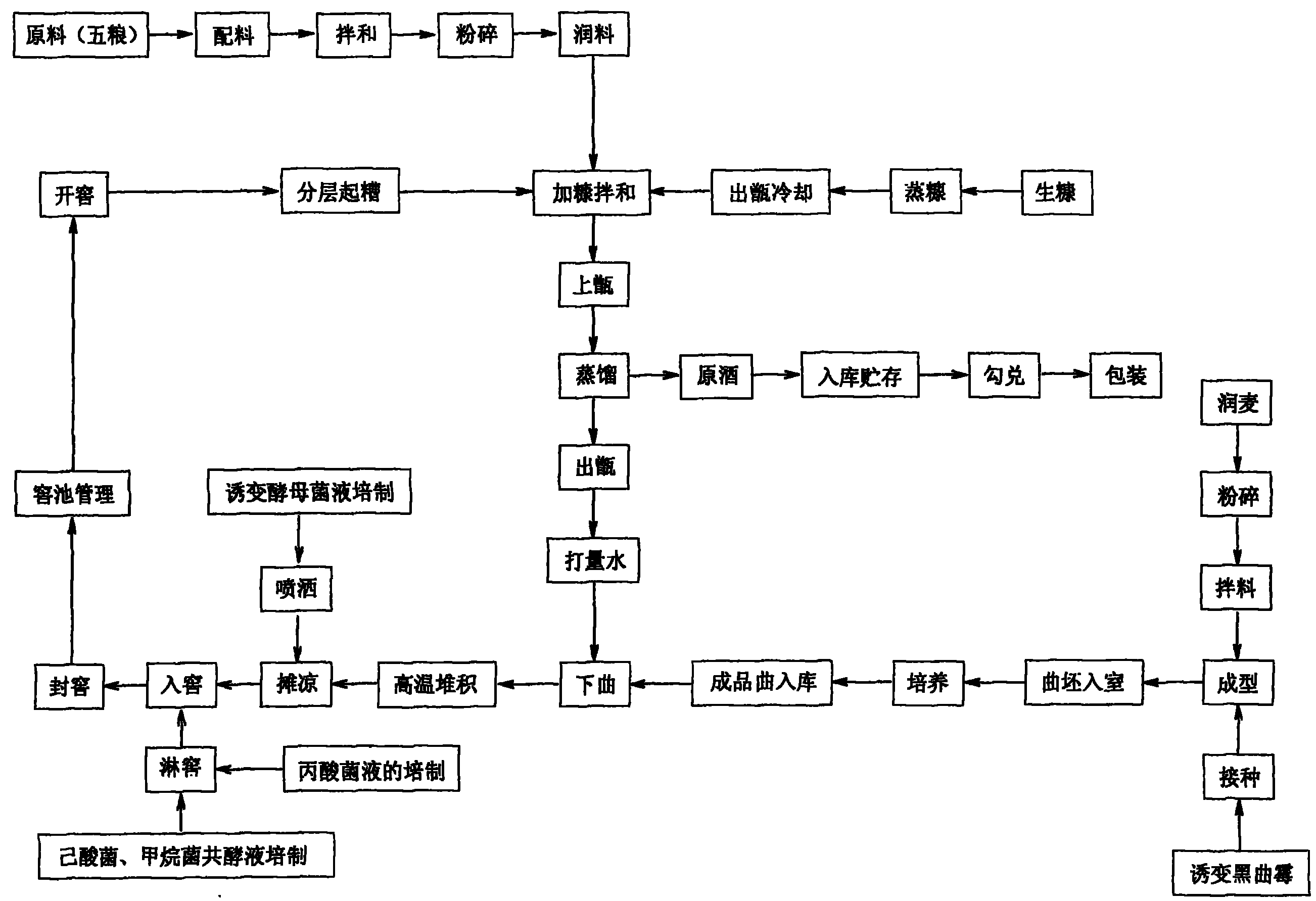

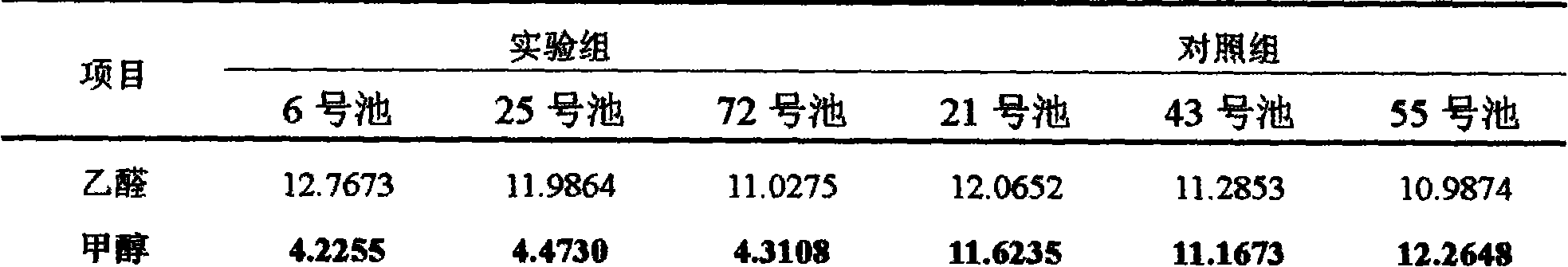

The invention relates to a production process of a highly-fragrant health care wine, which comprises the steps of manufacturing, fermentation and distillation of yeasts, storage and blending of raw wine and packaging of finished wine, wherein Aspergillus niger is added and manufactured into mouldy brans in the manufacturing process of yeasts, the mouldy brans are added to a yeast culture medium according to a ratio of 3% and manufactured into mould starters, and the mould starters are manufactured into the yeasts according to an input ratio of 10%; in the fermentation and distillation processes, a yeast culture liquid is spread over fermented grains before cellar entry, and a caproic acid bacterium, methane bacterium co-fermented liquid and a propanoic acid bacterium liquid are spread in the cellar; and other steps are the same with those in the conventional wine brewing process. By adding the propanoic acid bacterium liquid, the caproic acid bacterium and methane bacterium co-fermented liquid which can activate cellar environment and maintain fragrance in the cellar fermentation process, adding the Aspergillus niger in the yeast manufacturing process and combining other improvement measures in the traditional wine brewing production, the invention reduces the generation speed of harmful substances in the cellar, and simultaneously produces multiple active ingredients beneficial to human health, thereby maintaining the fragrance of the traditional wine and greatly reducing the generation of methanol and fusel oil.

Owner:湛江市新鸿业贸易有限公司

Controlled-release water-soluble fertilizer containing humic acid and preparation method of fertilizer

ActiveCN102875248AReduce churnImprove absorption and utilizationFertilizer mixturesPotassiumNutrients substances

The invention relates to a controlled-release water-soluble fertilizer containing humic acid. The fertilizer comprises the raw materials by weight percent: 5-10% of humic acid, 15-20% of zinc sulfate, 20-25% of borax, 45-60% of magnesium sulfate, 0.2-2% of poly-aspartic acid, 0.5-2% of ethylenediamine tetraacetic acid disodium and 0.1-0.5% of caproic acid diethylamino alcohol ester. In the fertilizer, potassium humate is taken as a raw material, a little amount of poly-aspartic acid and ethylenediamine tetraacetic acid disodium are added into the raw material, so that three elements including Zn, B and Mg are complexed after being dissolved or in the dissolving process, and slowly released to the soil, and then absorbed by crops, thus the fertilizer nutrient is prevented from running off, and the absorption utilization rate of the nutrient substance can be improved; the product is convenient to use, and can be used as seed fertilizer or base fertilizer; the product can be instantly and completely dissolved, and is applied by flushing or spraying and drop irrigation; the controlled-release water-soluble fertilizer containing humic acid is the first choice for realizing efficient water-saving agriculture and integrating water and fertilizer. The controlled-release water-soluble fertilizer containing humic acid is especially suitable for supplementing trace elements such as Zn, B and Mg for commercial crops such as vegetables, seed production corns, oil crops, fruit trees and grapes which have high requirement for the fertilizer application level.

Owner:ZHANGYE NEW GREAT BOW AGROCHEM

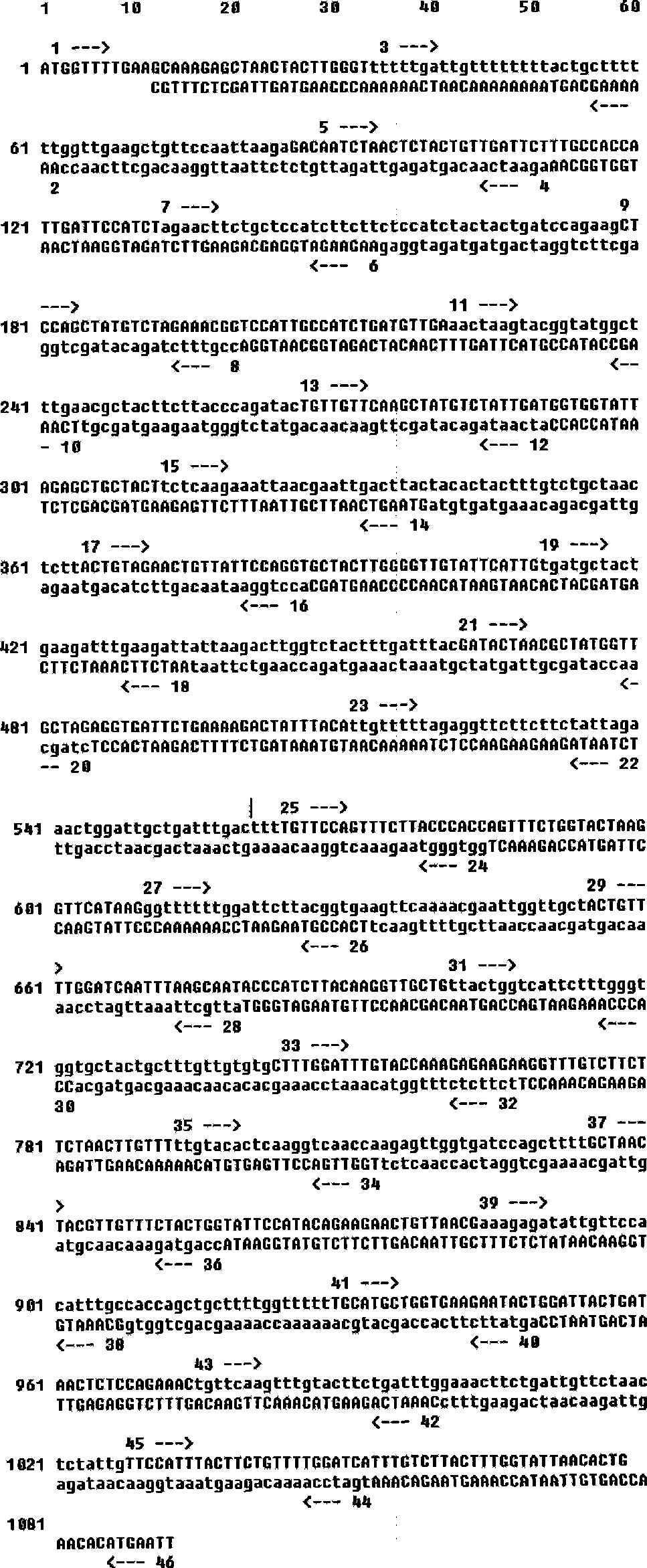

Improved Rhizomucor miehei lipase gene and use thereof in yeast display

ActiveCN101481695AIncrease vitalityImprove catalytic performanceFungiBacteriaBiotechnologyEscherichia coli

The invention relates to an improved rhizomucor miehei lipase gene and an application to yeast display. The sequence of the improved rhizomucor miehei lipase gene is SEQ.ID.No2, with respect to a recombinant vector pMD18-T-RML containing the gene, RML means lipase gene; and the collection number of a bacterial strain Escherichia coli TOP10 / pMD18-T-RML carrying the plasmid is CCTCC M 208136. In the invention, the gene is transferred into pichia stipitis host strain, so that the rhizomucor miehei lipase is displayed and expressed in the pichia stipitis. The provided pichia stipitis can effectively display the rhizomucor miehei lipase. The lipase can be widely applicable for producing fatty acid methyl ester, ethyl caproate, triglycerides which have different melting points but does not contain various types of fatty acid and a few 'reconstructed esters'.

Owner:DONGGUAN HUAQI BIOLOGICAL SCI & TECH +1

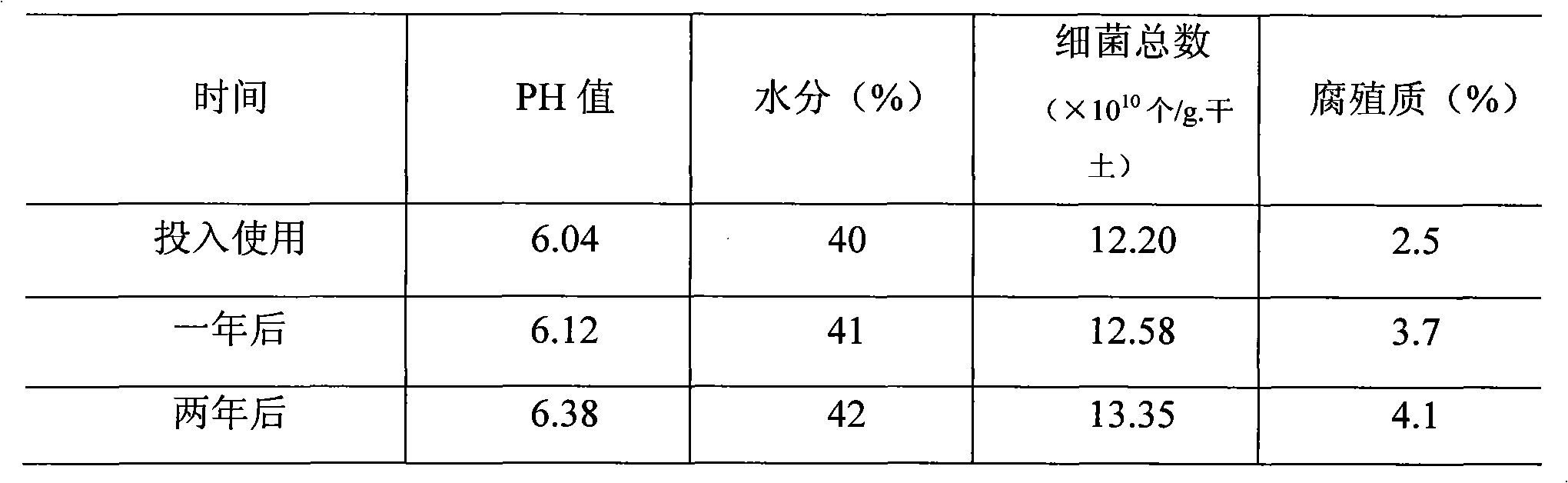

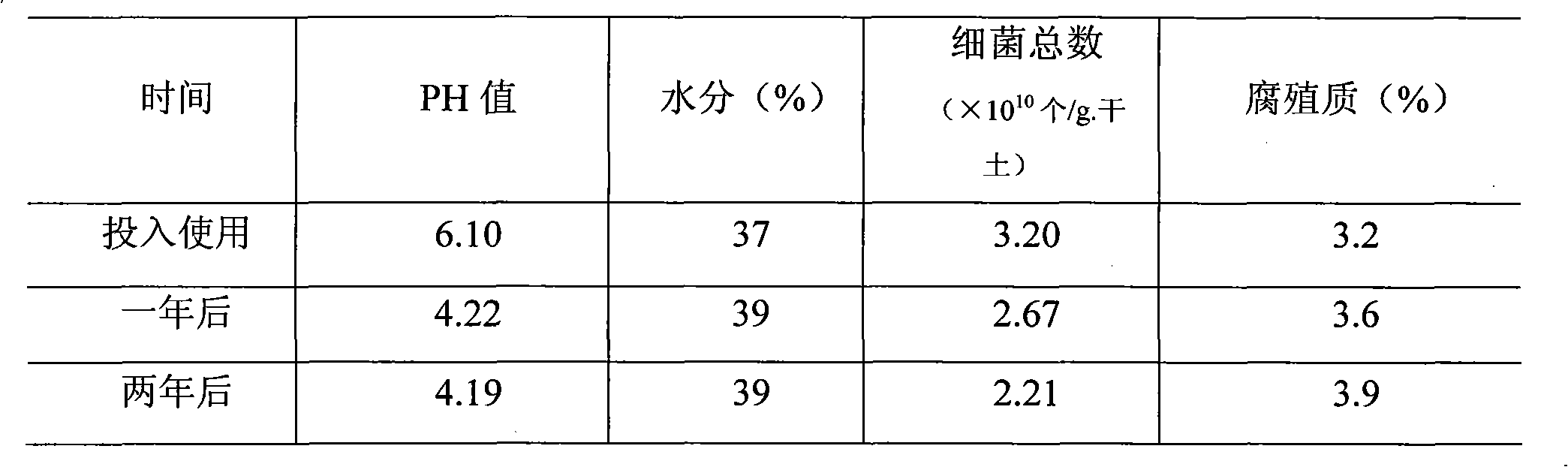

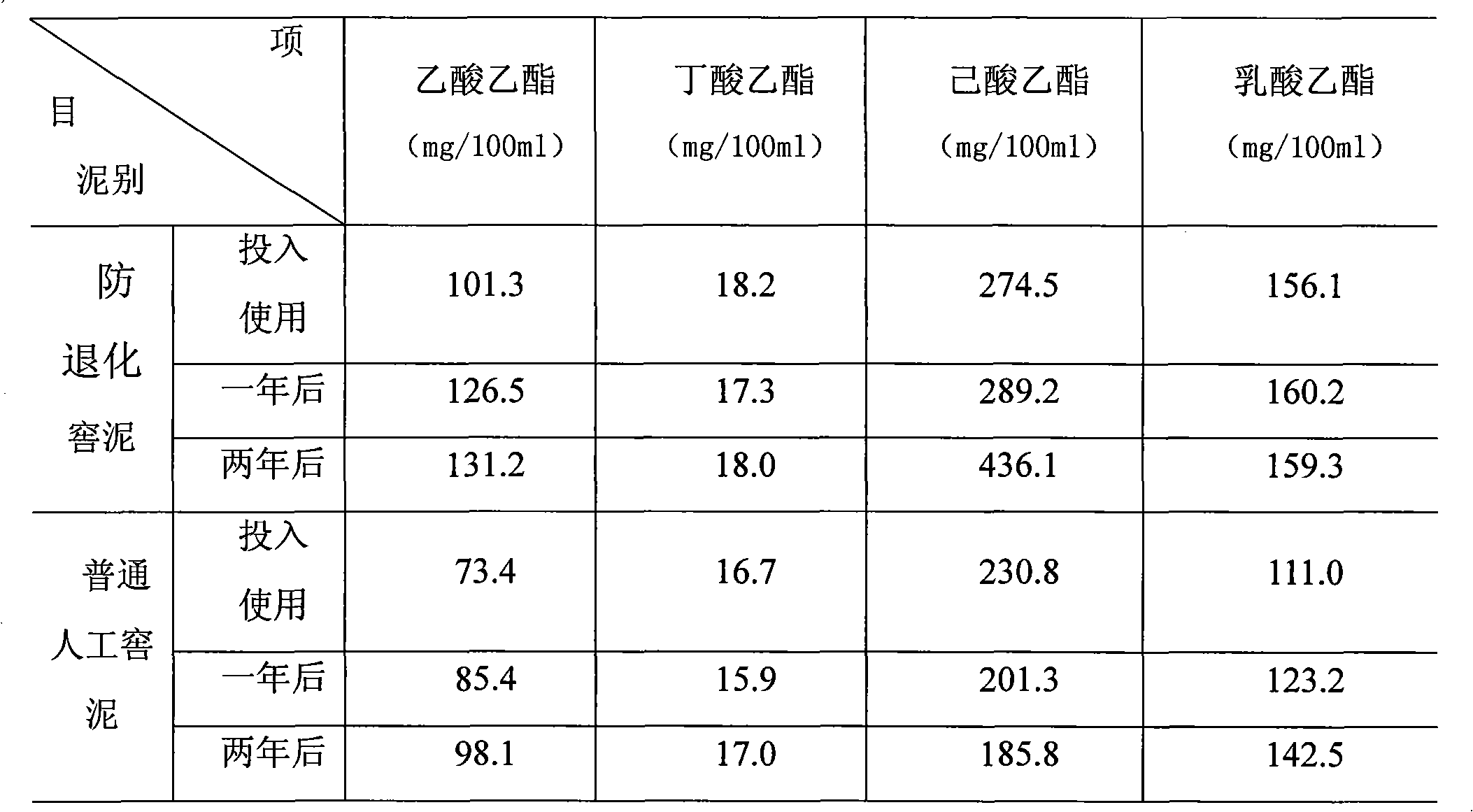

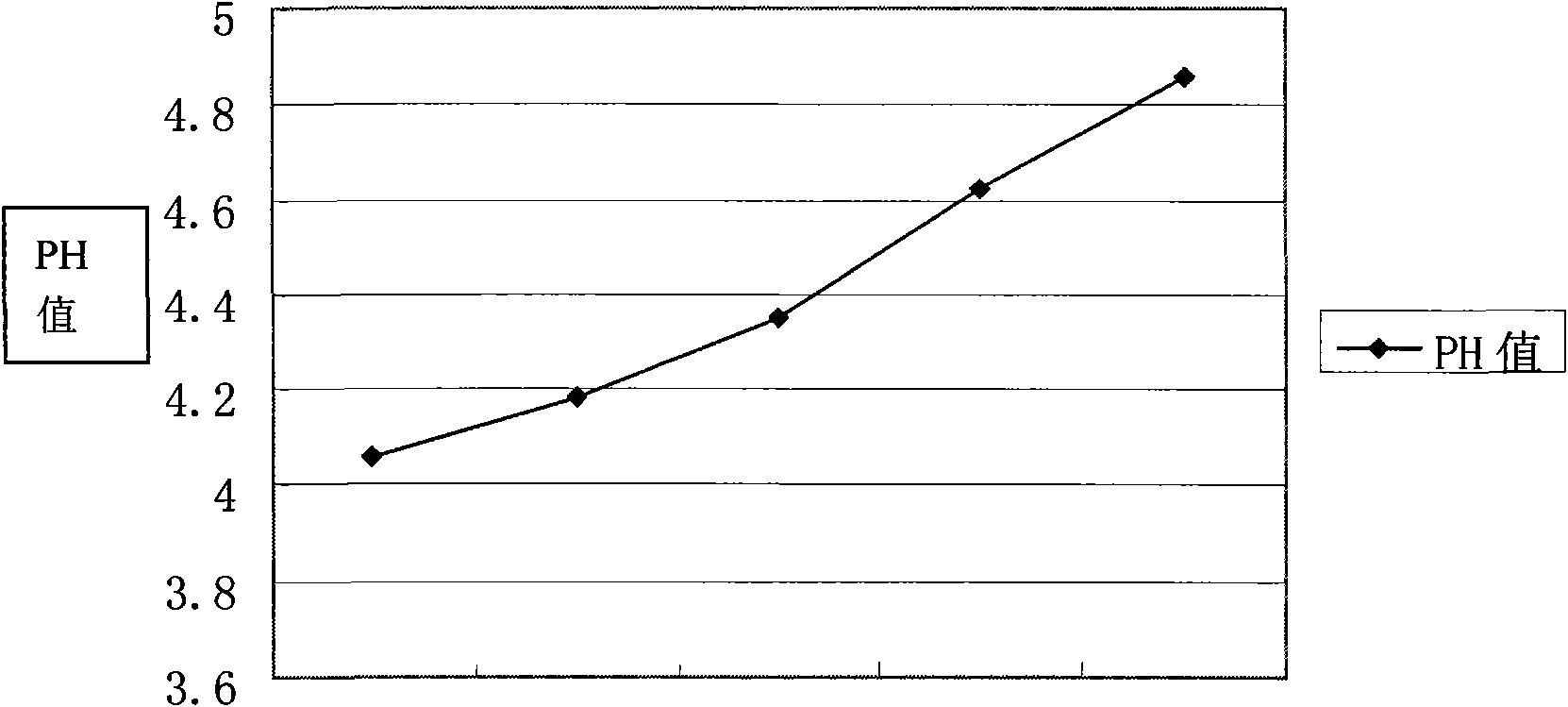

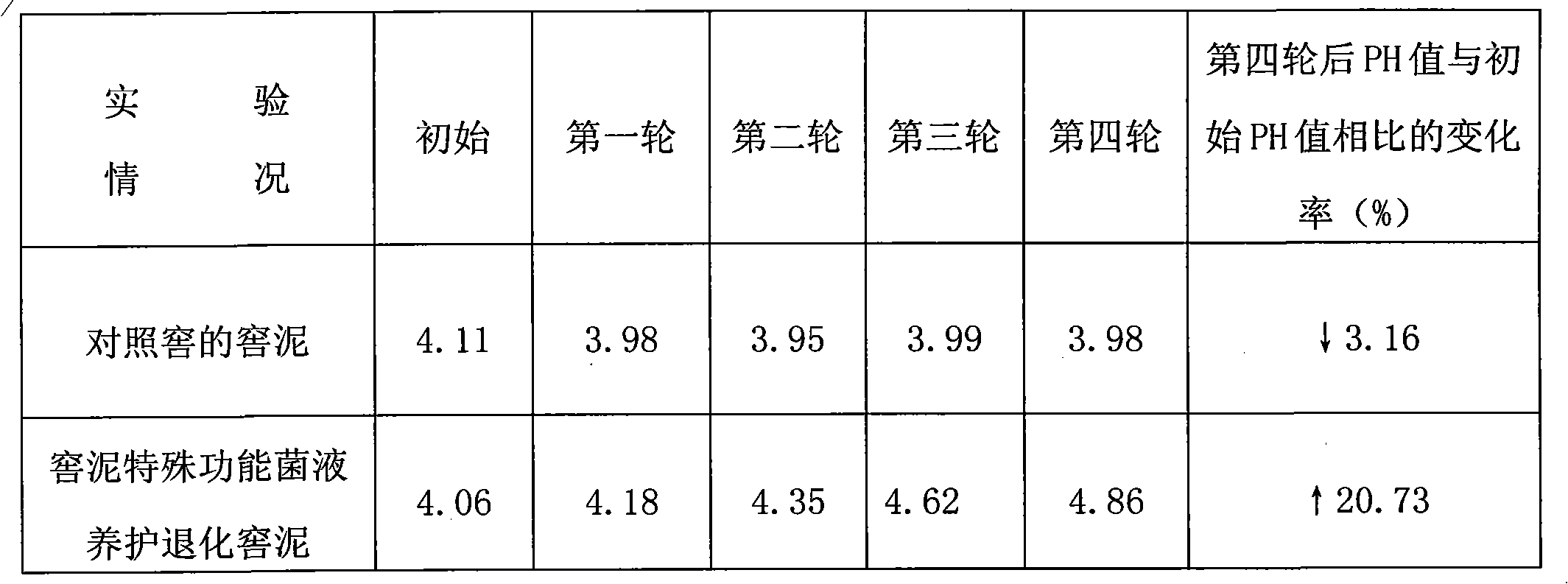

Anti-deterioration cellar mud and preparation method thereof

ActiveCN101914424AReasonable adjustmentAdjust ratioMicroorganism based processesAlcoholic beverage preparationMixed cultureYeast

The invention discloses anti-deterioration cellar mud and a preparation method thereof. Based on 100 percent of yellow clay, the anti-deterioration cellar mud comprises the following components: 3 to 5 percent of yeast powder, 8 to 10 percent of double bottom dreg, 5 to 8 percent of mixed culture solution of caproic acid bacteria and liquid cellar mud, 2 to 3 percent of M type microbial fermentation liquor, 15 to 20 percent of peat, 5 to 8 percent of cellar mud, 10 to 12 percent of yellow water, 1 to 2 percent of propionibacterium liquid, 4 to 6 percent of impure alcohol, 2 to 3 percent soybean cake powder and 0.05 to 0.1 percent of K2HPO4. The cellar mud realizes the rational regulation of pH value, moisture, humus, nutrient substance, N, P, K and the like by the regulation of a formula and the ratio of the mixed culture solution of the M type microbe to the propionibacterium liquid to the caproic acid bacteria to the liquid cellar mud is well regulated, so that the pH value of the active and excellent cellar mud is always maintained between 5 and 7.

Owner:SICHUAN MIANYANG FORGOOD DISTILLERY

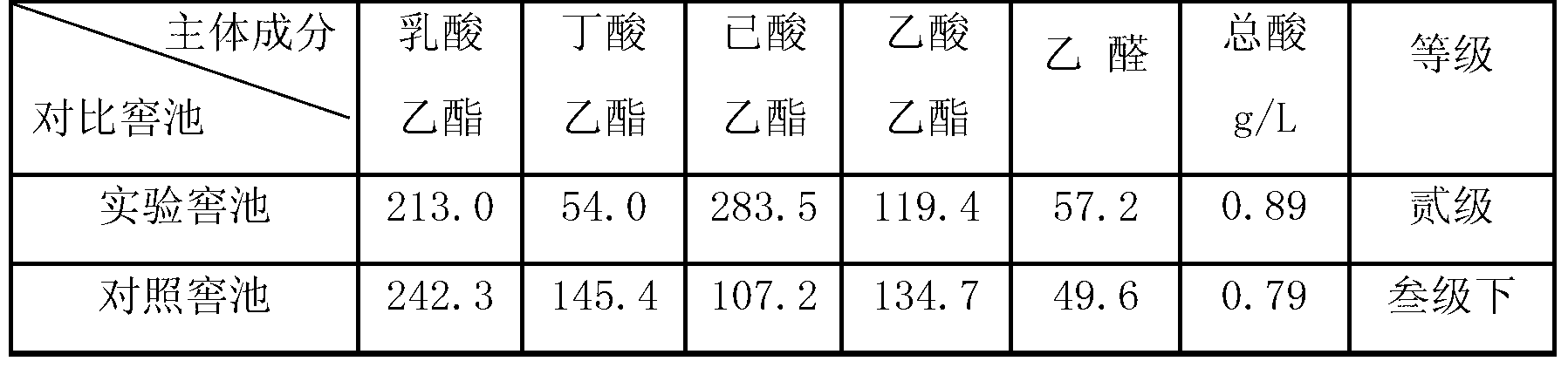

Production method of Luzhou-flavor liquor

ActiveCN102229874ASolve insufficient fermentationSolve the phenomenon of low ester yieldMicroorganism based processesAlcoholic beverage preparationFlavorDry weight

The invention relates to a production method of a Luzhou-flavor liquor, belonging to the technical field of liquor brewing. The technical problem to be solved is to provide the production method of the Luzhou-flavor liquor, by which spent grains can be fermented sufficiently. The production method of the Luzhou-flavor liquor comprises the following steps of: a, preparation of caproic acid bacterial liquid; b, preparation of pit mud enriching bacterial liquid; c, preparation of pit mud functional bacteria: mixing the caproic acid bacterial liquid and the pit mud enriching bacterial liquid, inoculating the mixed bacterial liquid to a culture medium of the pit mud functional bacteria to obtain the pit mud functional bacteria, and drying to obtain the dried pit mud functional bacteria; d, mixing the dried pit mud functional bacteria, flavor-producing yeast, B type enzymatic matters and red starter esterified enzyme together to obtain a compound microbial enzymic preparation, wherein the ratio of the dry weight of the dried pit mud functional bacteria to the weight of flavor-producing yeast to the weight of the B type enzymatic matters to the weight of the red starter esterified enzyme is 1:(0.25-0.35):(1-2):(0.30-0.45); and e, adding the compound microbial enzymic preparation to spent grains when the spent grains are fermented in a cellar, fermenting, taking the spent grains out of the cellar, steaming to finally obtain the Luzhou-flavor liquor, wherein the addition amount of the compound microbial enzymic preparation is 3-8% weight of the grains in the spent grains.

Owner:LUZHOU PINCHUANG TECH CO LTD

Clostridium butyricum

InactiveCN101942405AHigh yieldImprove the quality rateBacteriaMicroorganism based processesHigh concentrationAlcohol

The invention aims to provide a Clostridium butyricum GK13 bacterial strain CCTCCNO. M2010175. The bacterial strain has the characteristics of high caproic acid yield and good growth stability, can be applied in preparing high-concentration compound Clostridium butyricum liquid after strengthening functional bacteria, can be applied in cultivating artificial pit mud, obtains the effect of shortening the newly-built cellar pool aging period and rejuvenating the degrade cellar pool function in the practical production, improves the alcohol yield and the superior product rate, and solves the problems of rejuvenating a degrade old cellar pool, and shortening the newly-built cellar pool aging time and the like.

Owner:HUBEI UNIV OF TECH

Long-chain chondroitin sugar chain and method for producing the same and method for promoting synthesis of chondroitin

ActiveUS20090263867A1Efficient productionEasy to produceBacteriaSugar derivativesFiltrationChondroitinase ABC

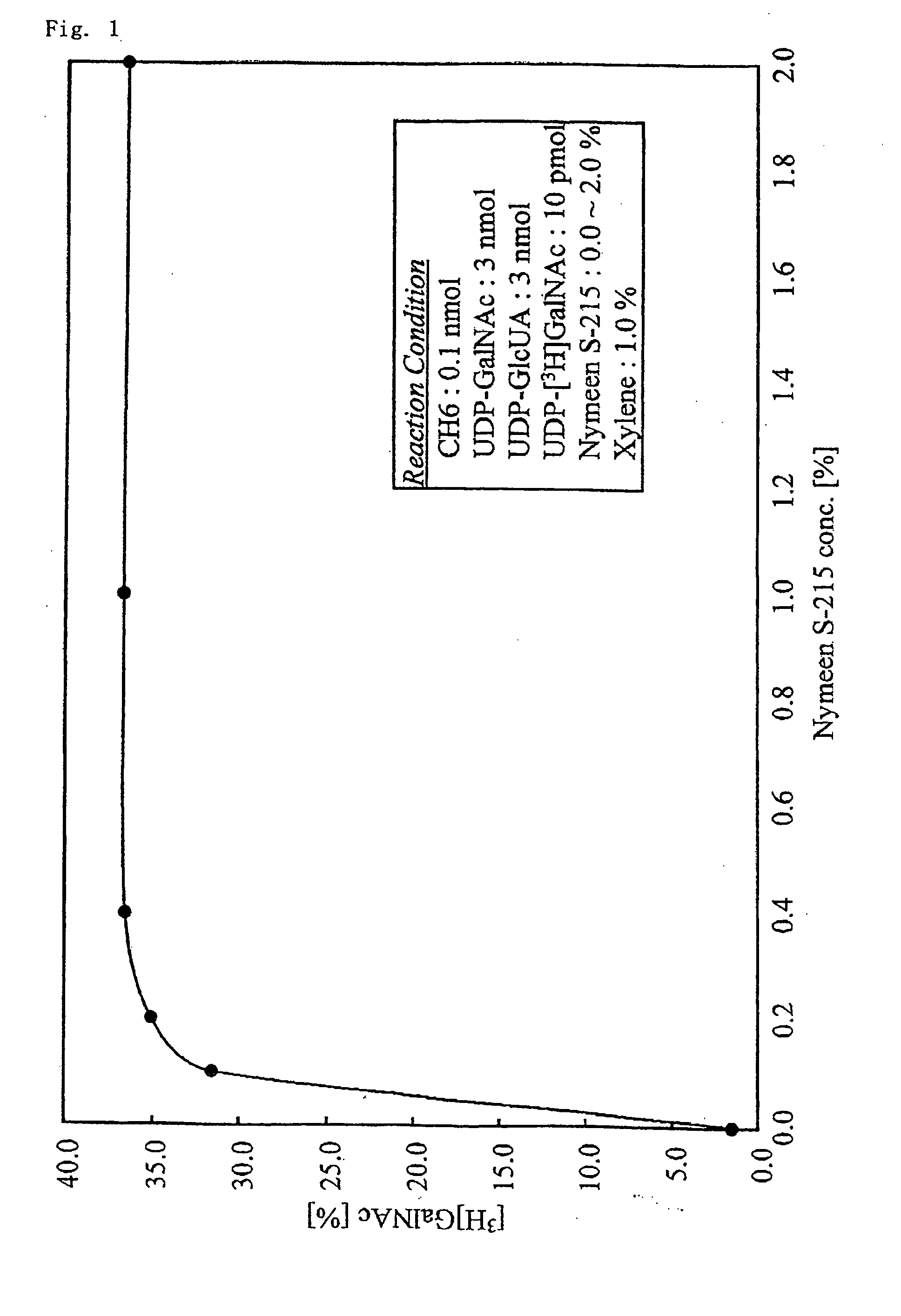

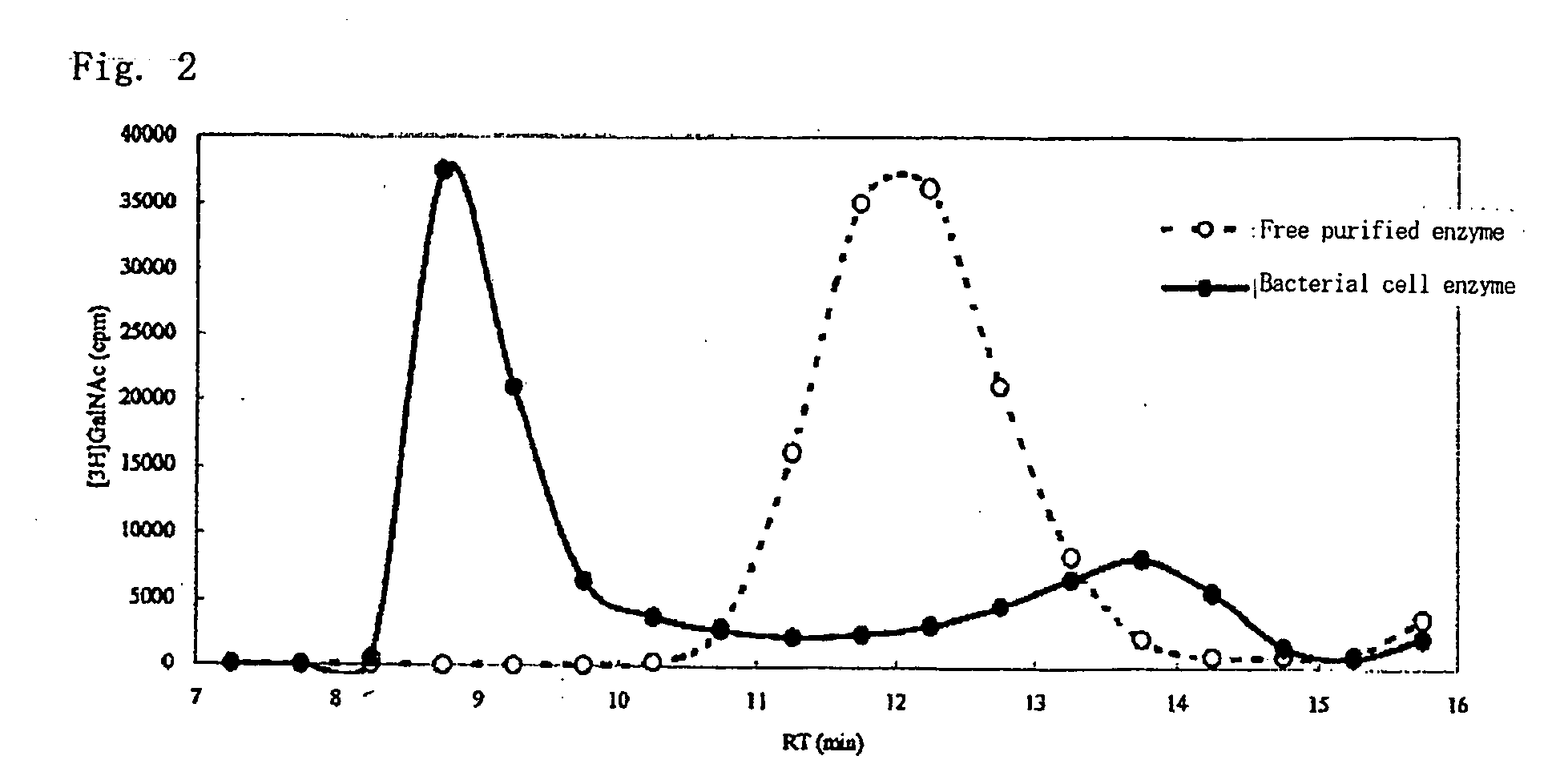

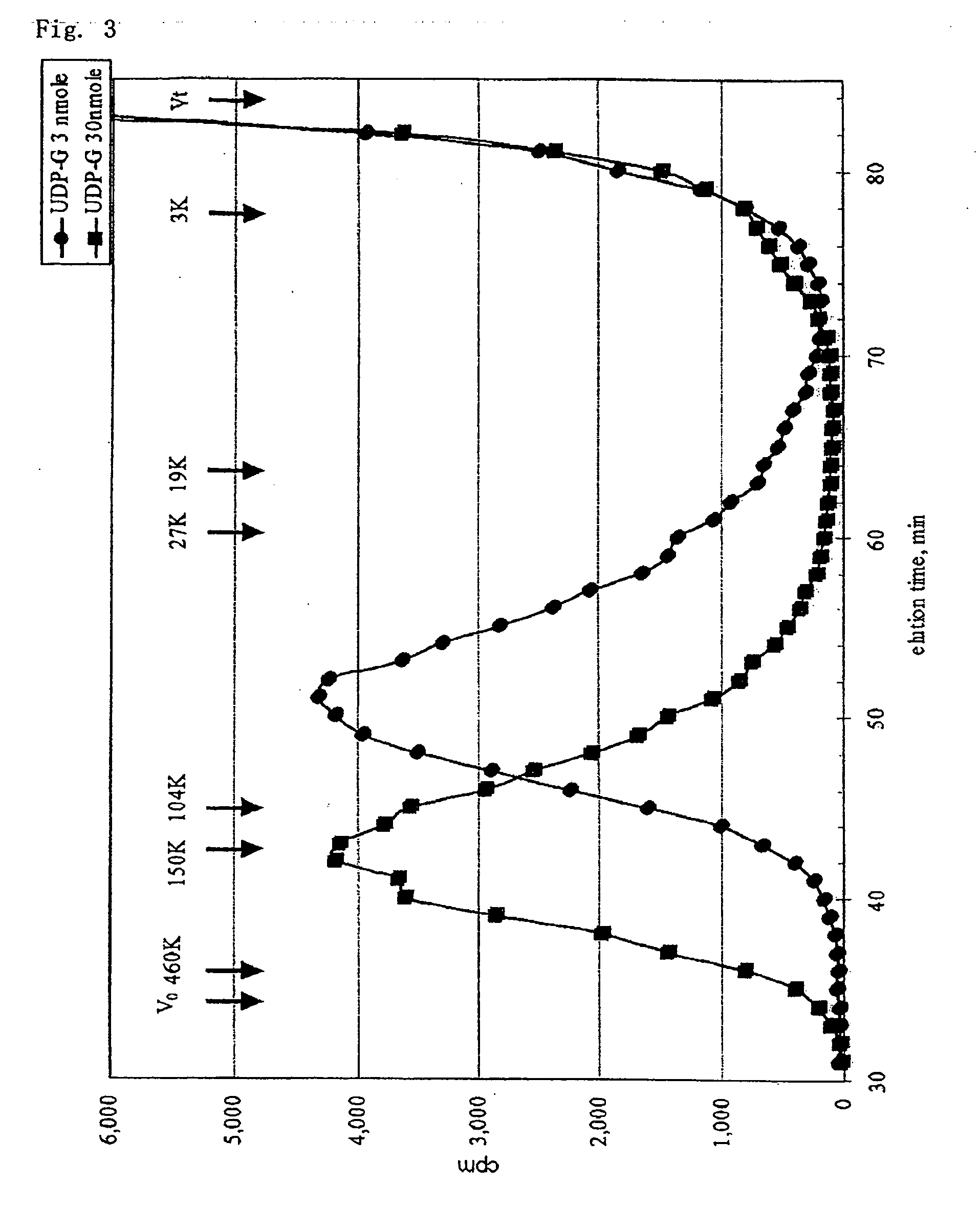

A method for producing a chondroitin sugar chain comprises at least the following step: a step of allowing “a glucuronic acid donor”, “an N-acetyl galactosamine donor”, “a sugar receptor” and “a bacterial cell enzyme which synthesizes chondroitin” to coexist in a reaction system in the presence of a surfactant. Here, the surfactant is preferably selected from n-nonyl-β-D-thiomaltopyranoside, sucrose monocaproate and sucrose monolaurate. The chondroitin sugar chain has all the following properties 1) to 3): 1) a weight average molecular weight: 50,000 or more when it is measured by gel filtration chromatography, 2) it is completely degraded to disaccharides with chondroitinase ABC, 3) when the sugar chain is decomposed with chondroitinase ABC and the decomposed products are subjected to a disaccharide analysis, substantially all of them correspond to an unsaturated disaccharide unit of chondroitin.

Owner:SEIKAGAKU KOGYO CO LTD

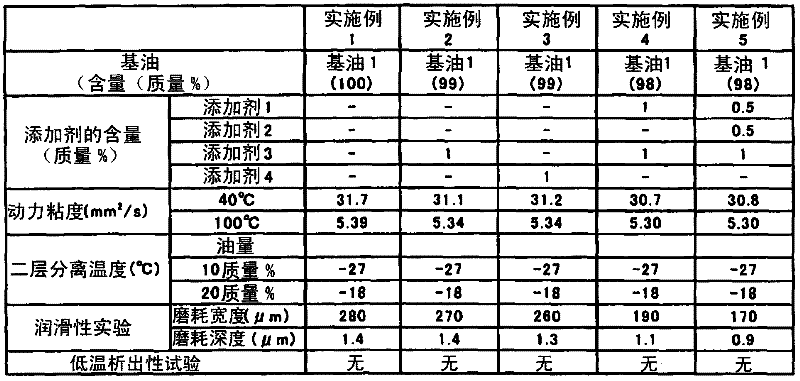

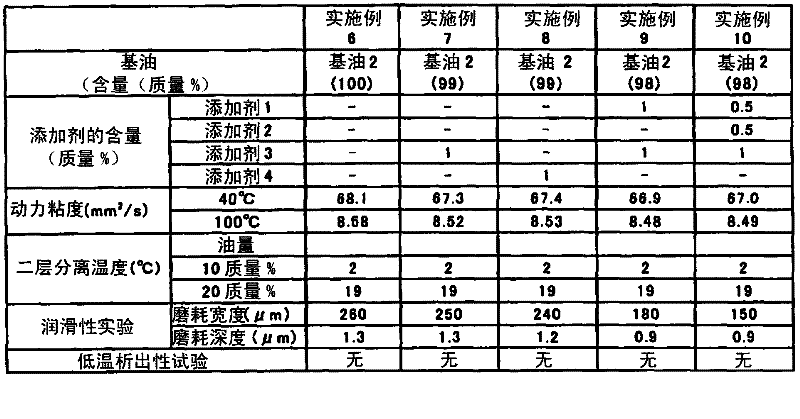

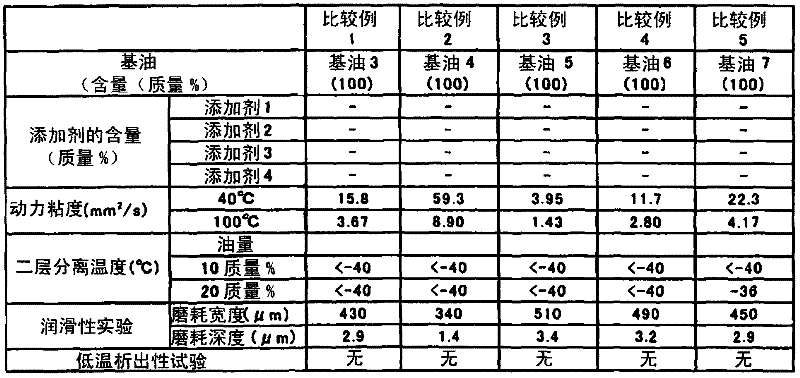

Refrigerating machine oil and working fluid composition for refrigerator

ActiveCN102191114AGood compatibilityAchieve lubricationHeat-exchange elementsBase-materialsPentaerythritolWorking fluid

The invention discloses refrigerating machine oil and a working fluid composition for a refrigerator. The refrigerating machine oil of the invention contains ester which is above 10% of the total amount of the refrigerating machine oil by weight and used together with difluoromethane refrigerating medium. The ester is ester of pentaerythritol and fatty acid. Wherein in the fatty acid, the mol ratio of fatty acid with a branched chain and whose carbon atom number is 6 to 3,5,5-trimethyl caproic acid is (20:80)-(80:20); the sum of the fatty acid whose carbon atom number is 6 and the 3,5,5-trimethyl caproic acid is above 20 mol% in the fatty acid; furthermore, the working fluid composition for the refrigerator contains the refrigerating machine oil and the difluoromethane refrigerating medium in the invention.

Owner:JX NIPPON OIL & ENERGY CORP

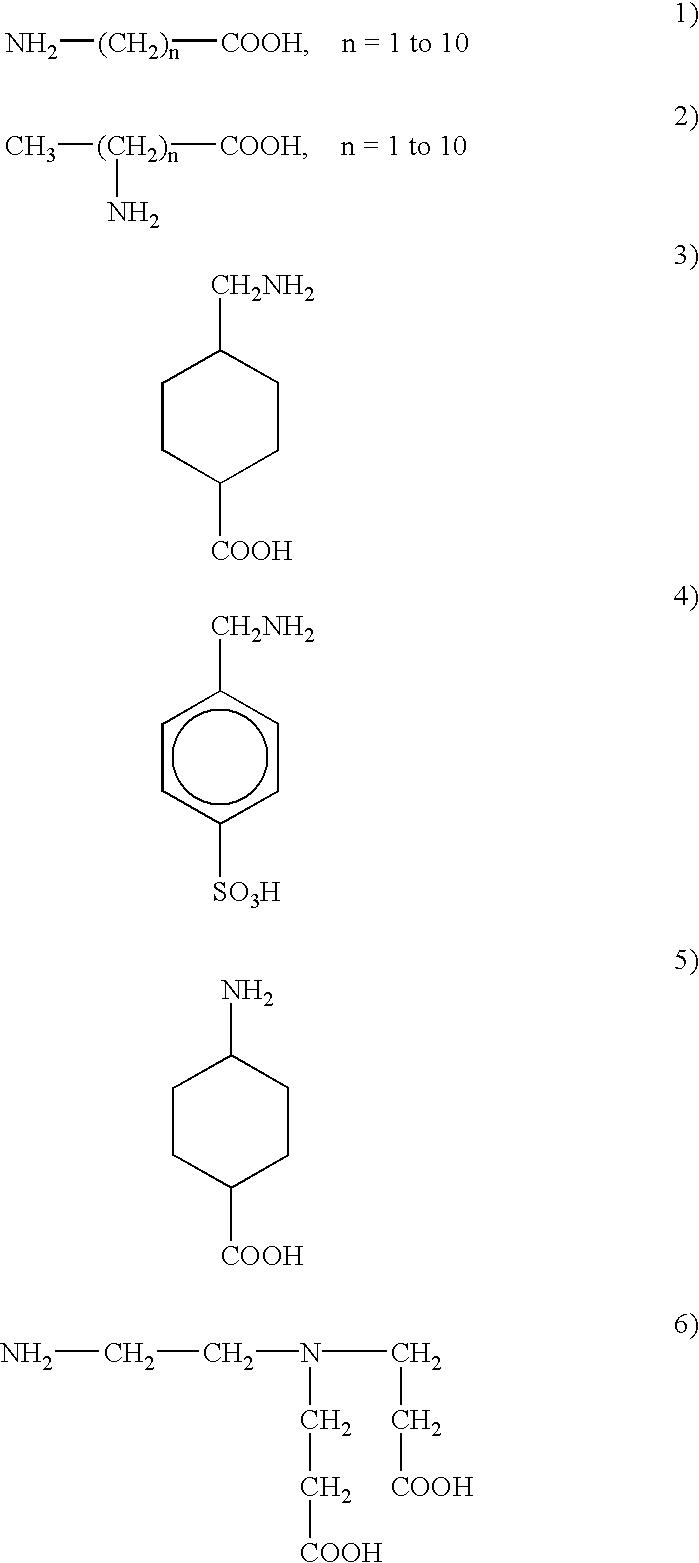

Method for prevention of fouling in basic solution by inhibiting polymerization and solubilizing deposits using amino acids

InactiveUS6986839B2Prevent scalingRemoving polymeric depositThermal non-catalytic crackingDistillation corrosion inhibitionHydrolysisCaproic Acid

A method for inhibiting and dissolving the deposits formed on caustic or alkaline scrubbers used in scrubbing acidic gases such as carbon dioxide, hydrogen sulfide, which are formed during the pyrolytic cracking of naphtha, ethane, and propane. The cracking operations produce certain oxygenated compounds such as vinyl acetate or acetaldehyde, which undergo polymerization under alkaline condition. The vinyl acetate on hydrolysis releases acetaldehyde under alkaline conditions. Amino acids such as 6 amino caproic acid and lactams such as epsilon caprolactam not only prevent but also dissolve the polymers formed by aldol condensation.

Owner:DORF KETAL CHEM (I) PTE LTD

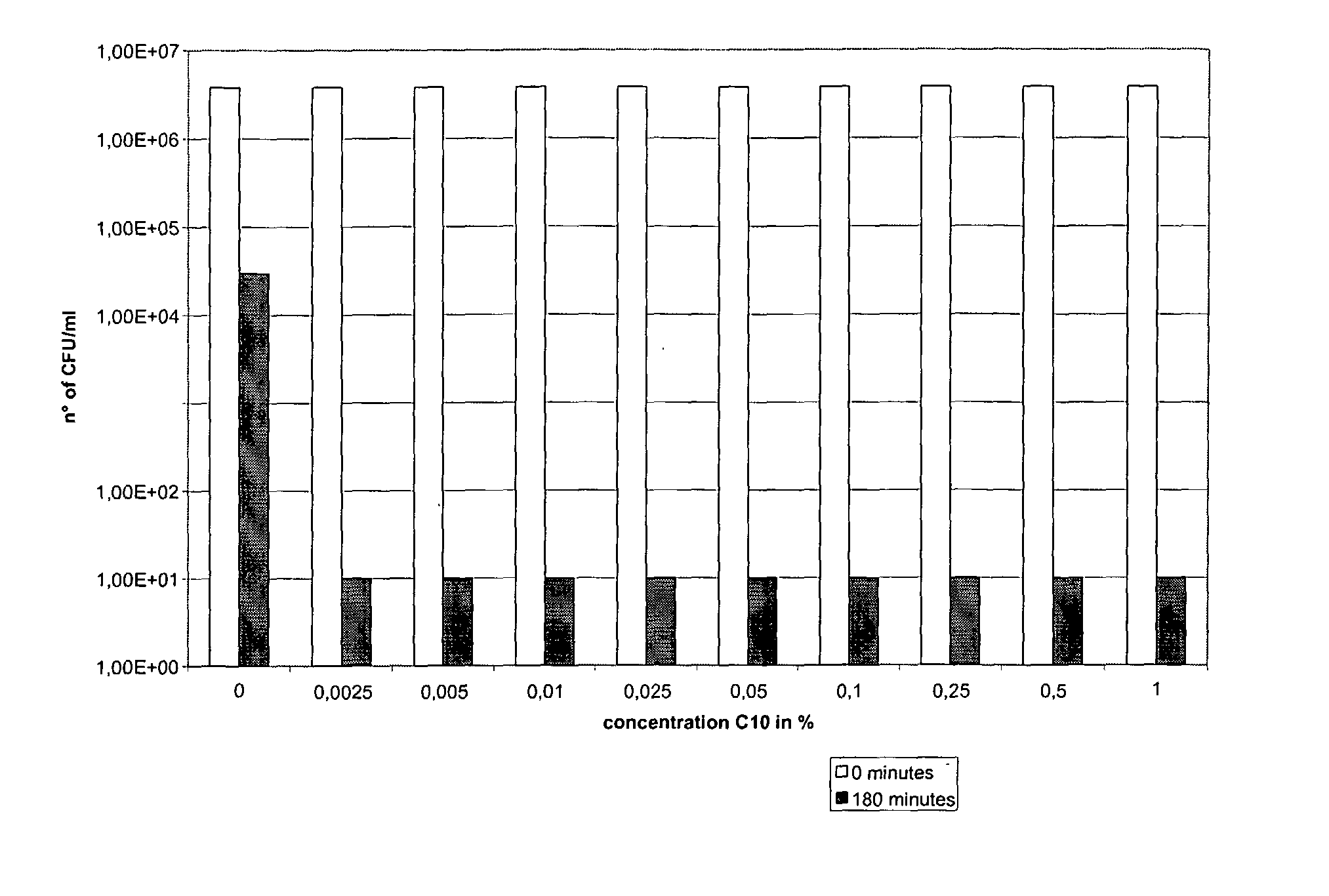

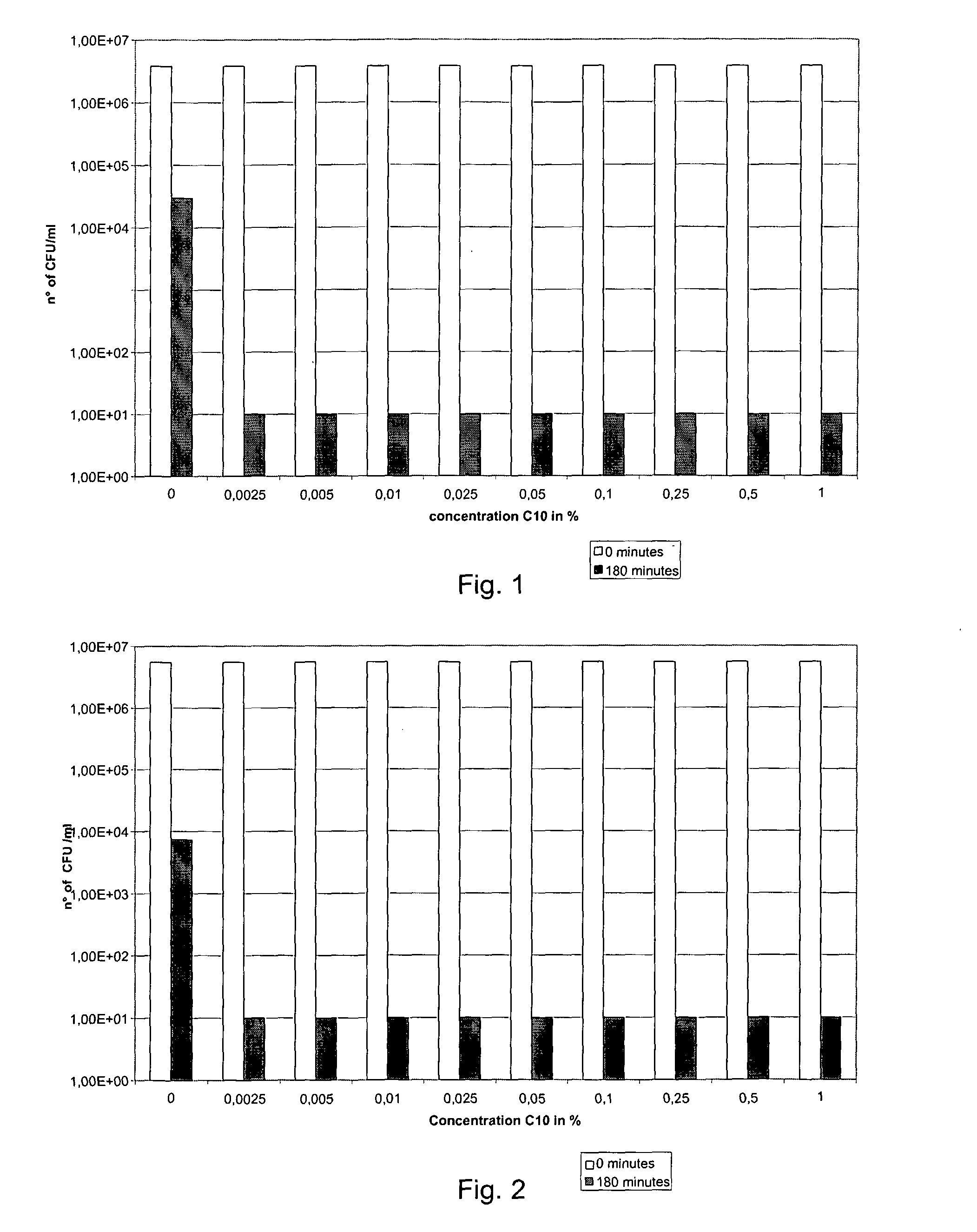

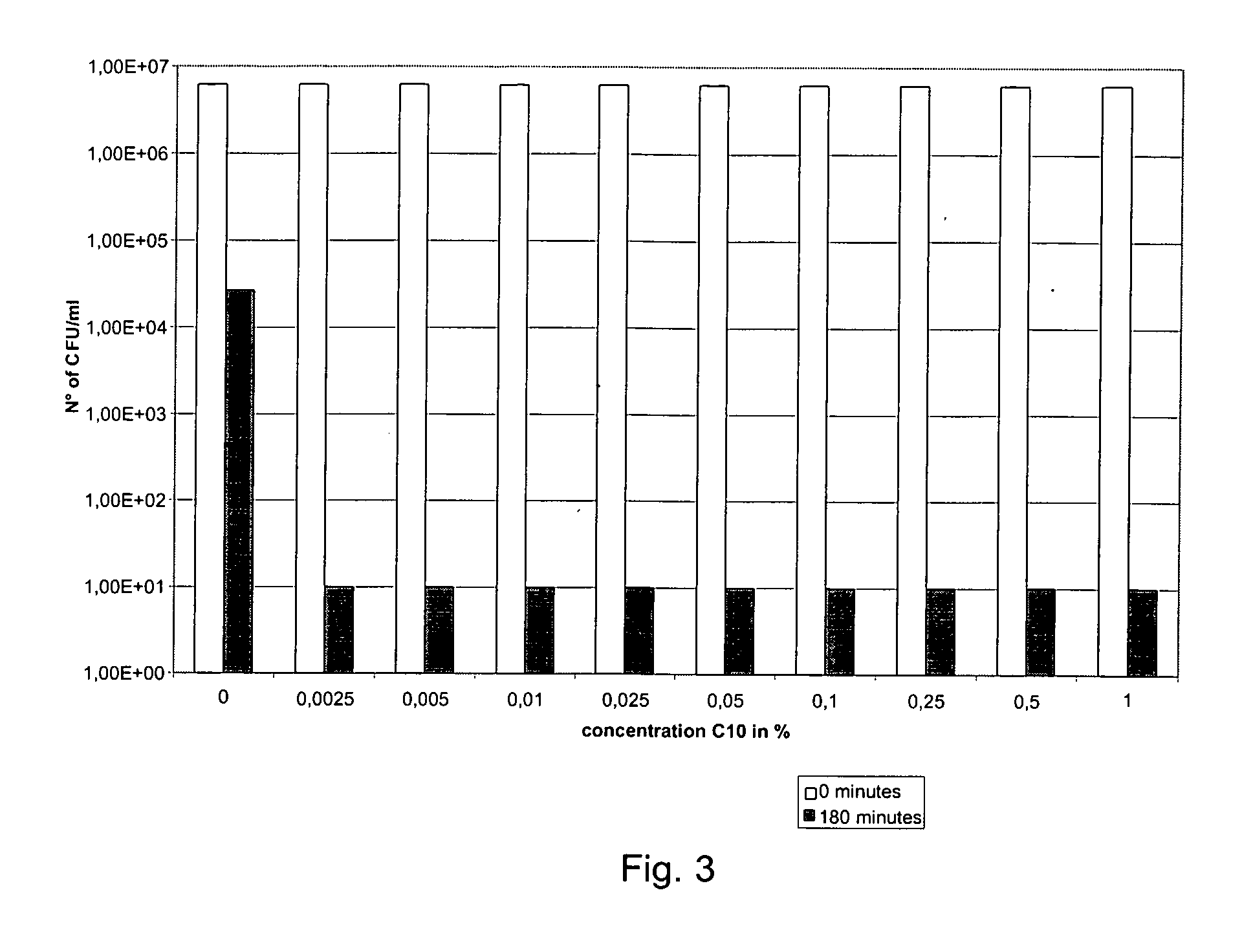

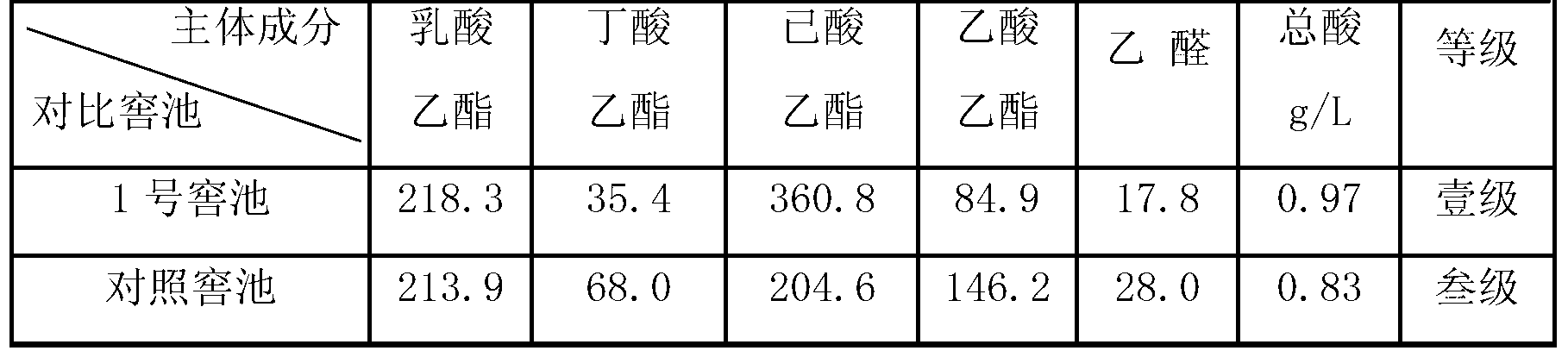

Medium Chain Fatty Acids Applicable as Anti-Microbial Agents

InactiveUS20070219270A1Good effectGrowth inhibitionAntibacterial agentsBiocideCapric AcidMicrobial agent

The present invention relates to the use of medium chain fatty acids (MCFA), chosen from the group consisting of caproic acid (C6), caprylic acid (C8) and capric acid (C10), salts, derivatives or mixtures thereof, in a total amount by weight comprised between 0.01% and 5% for inhibiting the growth of microbial pathogens.

Owner:NUTRITION SCI N V

Mixed culture bacterial solution for quickly aging new pit of strong aromatic Chinese spirits and maintenance method

InactiveCN103305448AFast agingSophisticated and fastBacteriaAlcoholic beverage preparationSodium acetateBiotechnology

The invention discloses a mixed culture bacterial solution for quickly aging a new pit of strong aromatic Chinese spirits and a maintenance method, and belongs to the field of microorganisms. The mixed culture bacterial solution mainly contains 5-20 parts by weight of methanobacterium culture solution, 1-7 parts by weight of caproic acid bacterium culture solution and 15-30 parts by weight of liquid old pit mud; and the mixed culture bacterial solution is prepared through the following steps of: putting maternal draff, yellow water, medium-high temperature yeast for making hard liquor, yeast extract, sodium acetate and dipotassium phosphate into a fermentation container, performing heat treatment by using boiling water and closing the fermentation container; when the temperature in the fermentation container drops to 40 DEG C, adding the methanobacterium culture solution, the caproic acid bacterium culture solution and the liquid old pit mud as well as an alcohol to the container, full filling the fermentation container with cool boiled water and regulating the pH value to 6.5 to 7.0, and then cultivating at 33 to 37 DEG C. The mixed culture bacterial solution provided by the invention is capable of aging the pit mud more quickly and more efficiently; and therefore, a new method for improving the quality of Chinese spirits is provided.

Owner:SICHUAN GUCHUAN WINE CO LTD

Thermosol of polyamide and preparation process thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

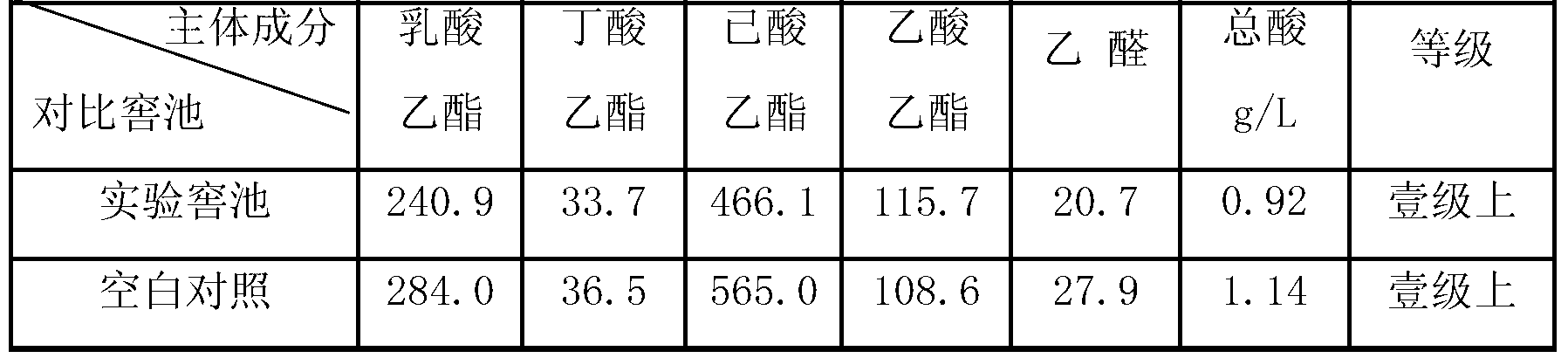

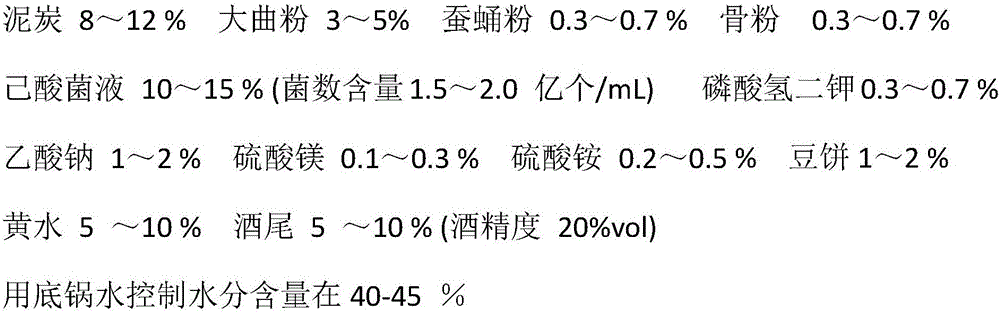

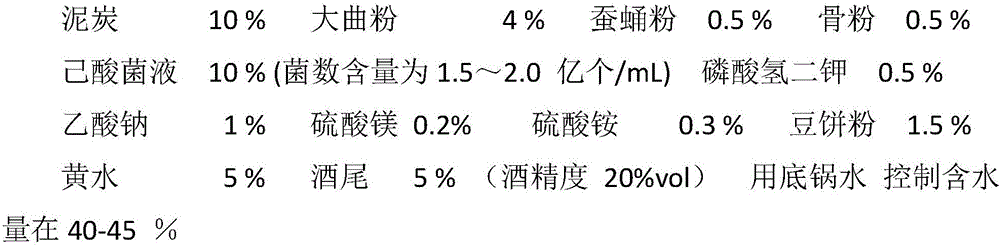

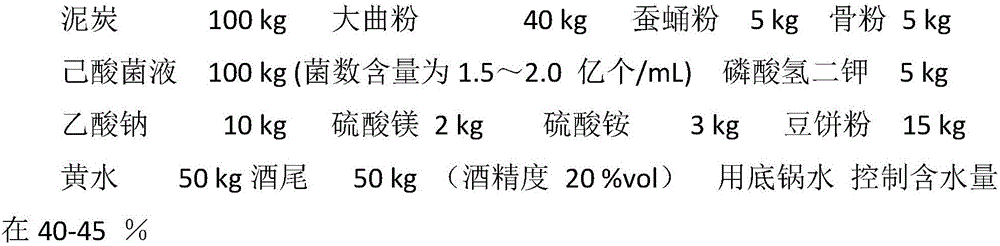

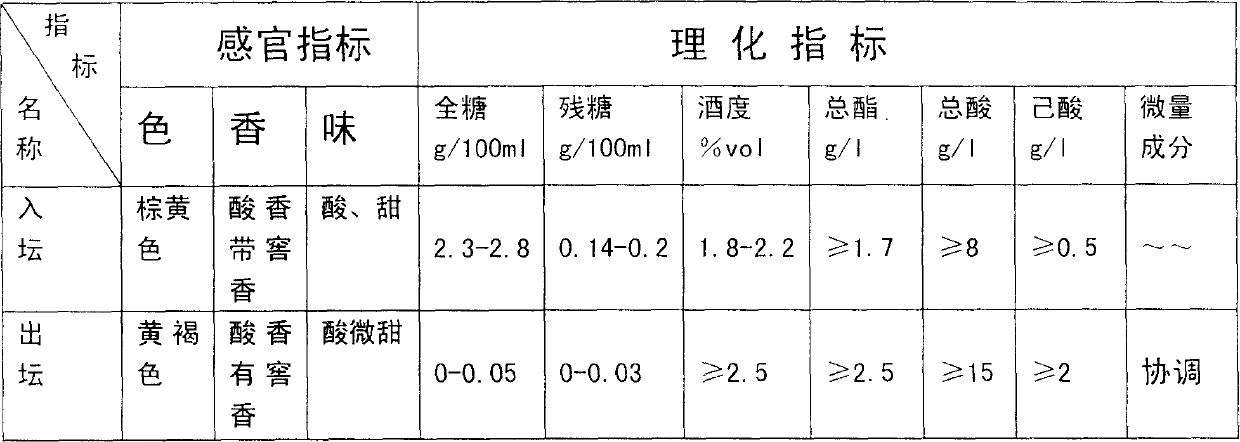

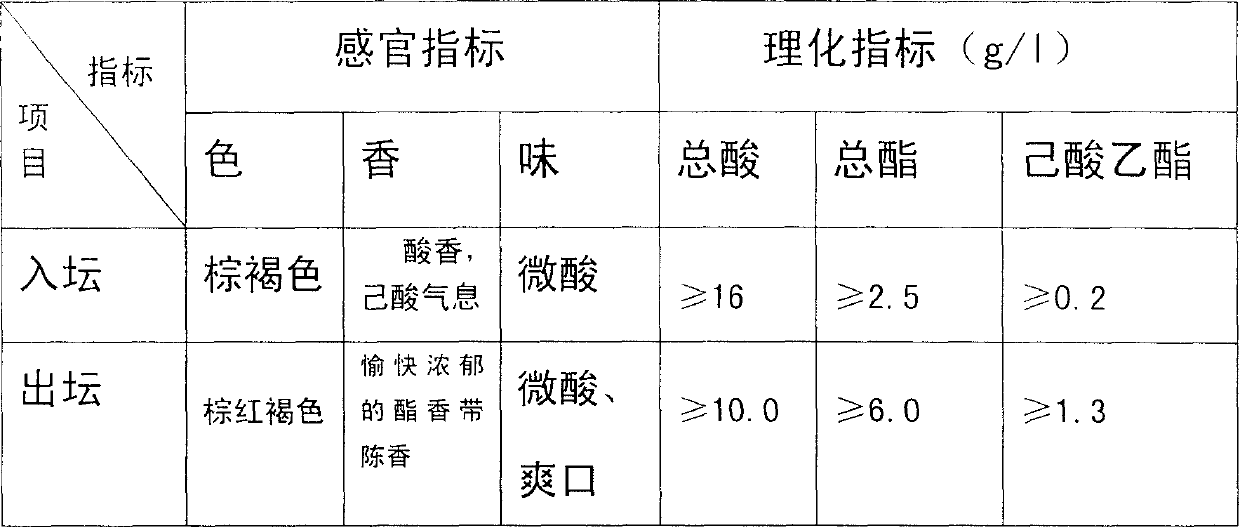

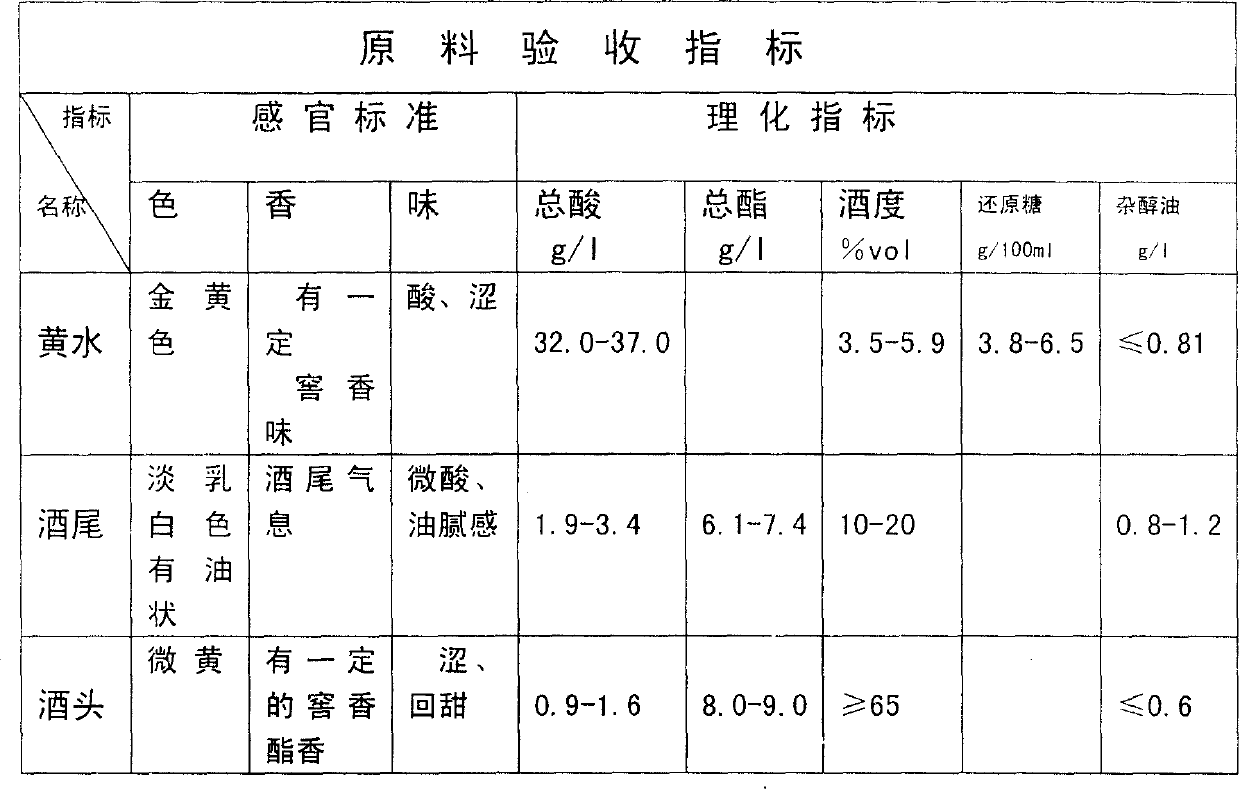

High-quality artificial pit mud in Baijiu production and preparation method thereof

InactiveCN106281860AEasy to prepareShort fermentation aging timeAlcoholic beverage preparationSodium acetateDipotassium phosphate

The invention provides high-quality artificial pit mud in Baijiu production and a preparation method of the high-quality artificial pit mud in the Baijiu production. The high-quality artificial pit mud comprises the components of loess, lotus pond mud, aged pit mud, peat, yeast powder, silkworm chrysalis powder, bone meal, caproic acid bacteria solutions, dipotassium phosphate, sodium acetate, magnesium sulfate, ammonium sulfate, soybean cake powder, yellow water, after-run, pot bottom water and the like. The preparation method comprises the following steps: 1) selecting raw materials according to requirements, and weighing each component according to the proportion; 2) preparing the high-quality artificial pit mud, namely mixing and stirring uniformly according to the dry-to-wet order, controlling the water content within 40 to 45% by pot bottom water, adjusting the pH value within 6.0 to 6.8, beating the mud into a pit, covering the pit mud tightly by plastic cloth, and tucking four sides tightly; 3)carrying out natural fermentation cultivation on the artificial pit mud, controlling the pit entering temperature at 30 to 35 DEG C, and lasting the fermentation time for 30 to 60 days; testing to reach standards, thus obtaining the high-quality artificial pit mud. The high-quality artificial pit mud disclosed by the invention is simple in preparation, short in fermentation and aging time and good in effect, can be used for replacing the high-quality aged pit mud and put into production, and further has very good economic benefits and social benefits.

Owner:NANYANG NORMAL UNIV +1

Production process of rich fragrance wine

InactiveCN1740303AEfficient use ofRealize closed loopAlcoholic beverage preparationOrganic acidAlcohol

The present invention discloses production process of one kind of rich fragrance wine, and the rich fragrance wine is produced with the side products of brewery, including grain powder, distilled grain, yellow liquor, first cut, and last cut as main material, and through enriching and culturing caproic acid bacteria, acetic acid bacteria, saccharomycete and other brewing functional bacteria; liquid phase fermentation and esterification to convert the hydrocarbon, organic acid, alcohols, amino acids and other organic matters into ethanol and other wine matters; and distillation to separate alcohols, acids, esters and esters to produce the rich fragrance wine. The present invention makes best of the said resource, and can avoid environmental pollution.

Owner:SICHUAN TUOPAI SHEDE WINE

Immunogen by using mutant CRM197 of diphtheria toxin as carrier, preparation method, and application

ActiveCN101050236AGood effectHigh recovery ratePeptide/protein ingredientsPeptide preparation methodsN-HydroxysuccinimideCarrier protein

This invention relates to a method for preparing immunogen G17CRM197 containing diphtherin mutant CRM197 as carrier. The method comprises: crosslinking diphtherin mutant CRM197 with gastrin G17 through epsiv-maleimidyl caproic acid N-hydroxysuccinimide eater (EMCS). Diphtherin mutant CRM197 is used as a carrier, and has such advantages as high recovery rate and easy purification. The method has such advantages as high product crosslinking rate, short preparation time, and low cost. Immunogen G17CRM197 can be used as an effective component in therapeutic vaccines, or used in anti-tumor drugs with appropriate immunoadjuvants.

Owner:QILU PHARMA HAINAN

Solid-state-method-based fermenting method of Luzhou-flavor liquor

ActiveCN104830620AIncrease the content of flavor substancesFlavor harmonyAlcoholic beverage preparationLiquid layerMicroorganism

The invention relates to a liquor making method and particularly relates to a solid-state-method-based fermenting method of Luzhou-flavor liquor. The method disclosed by the invention comprises the following steps: placing the fermented grains into a fermentation pit layer by layer and uniformly spraying yeast liquid layer by layer; sealing with pit skin mud which is 10-20cm thick to perform sealed fermentation; after fermenting for 30-35d, forming holes in the pit sealing mud and filling with caproic acid bacteria yellow water composite liquid into the upper-layer fermented grains and then quickly sealing the holes with the pit sealing mud; and after fermenting for 55-60d, forming holes repeatedly, filling with caproic acid bacteria yellow water composite liquid, ending the fermentation, discharging the fermented grains out of the pit, and steaming liquor to finally obtain Luzhou-flavor liquor. According to the solid-state-method-based fermenting method, a layer-by-layer yeast reinforced fermentation process is carried out on the fermented grains in the pit; the caproic acid bacteria yellow water composite liquid permeate into the fermented grains at the same time section by section in the middle stage of fermentation, so that functional bacteria and yellow water permeate into the fermented grains at the upper layer and the middle layer to participate in biochemical metabolism so as to improve the distribution status of microbes in the fermented grains, thus improving the content of flavor substances in liquor and ensuring the coordinating flavor.

Owner:CHENGDU SHUZHIYUAN WINE

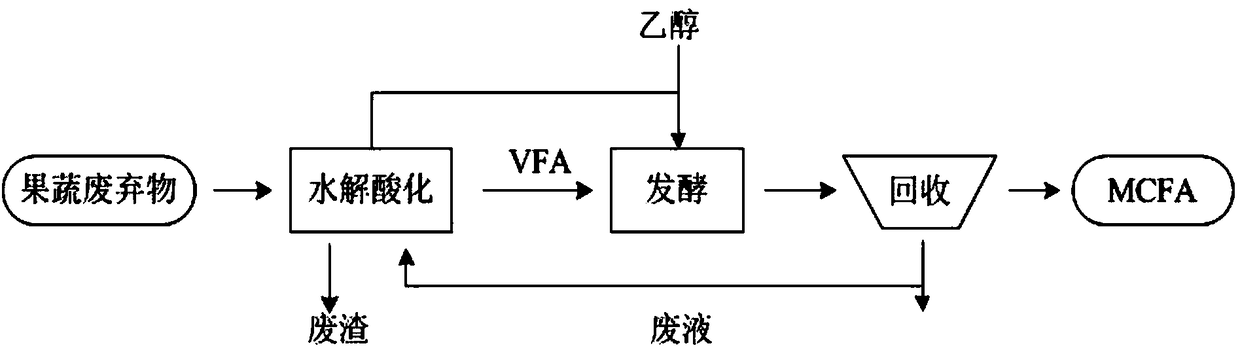

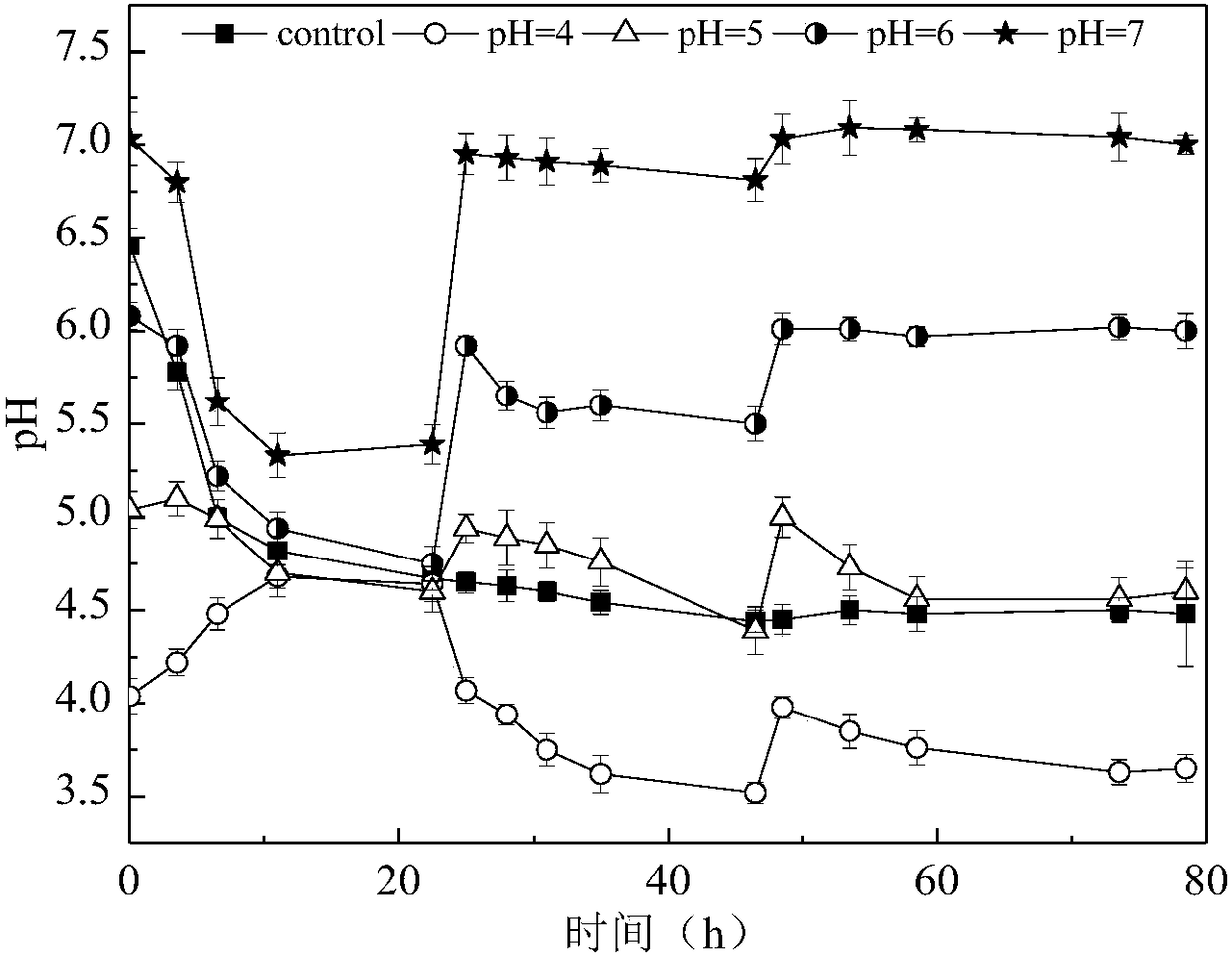

Method for preparing caproic acid through two-phase process anaerobic fermentation

The invention discloses a method for preparing caproic acid through two-phase process anaerobic fermentation, and belongs to the technical field of waste resource treatment techniques and environment-friendly purification treatment. The method utilizes fruit and vegetable waste as an acidogenic-phase substrate, and the fruit and vegetable waste serving as the acidogenic-phase substrate builds a stable acidogenic fermentation system at the temperature of 35 DEG C and with the pH value being 6.0; the acidogenic-phase fermented liquid serves as a substrate, the caproic acid yield can reach 12.85g.L<-1> under the conditions that the temperature is 30 DEG C, the pH value is 6.8-7.0, the alcohol acid ratio is 4 to 1, that is, the ethyl alcohol additive amount is 17.22g.L<-1>, and thus efficientgeneration of caproic acid is achieved.

Owner:江苏道同环境科技有限公司

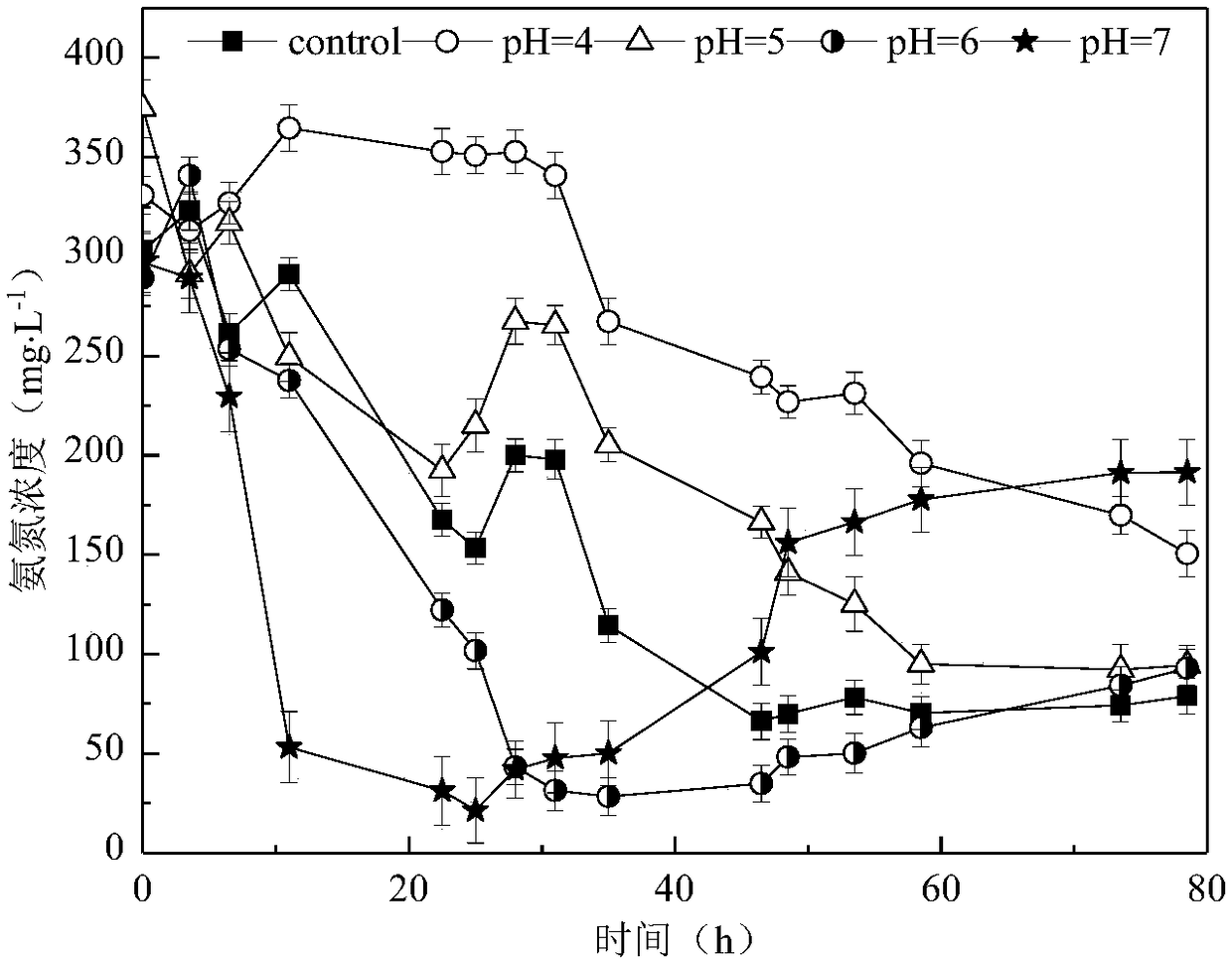

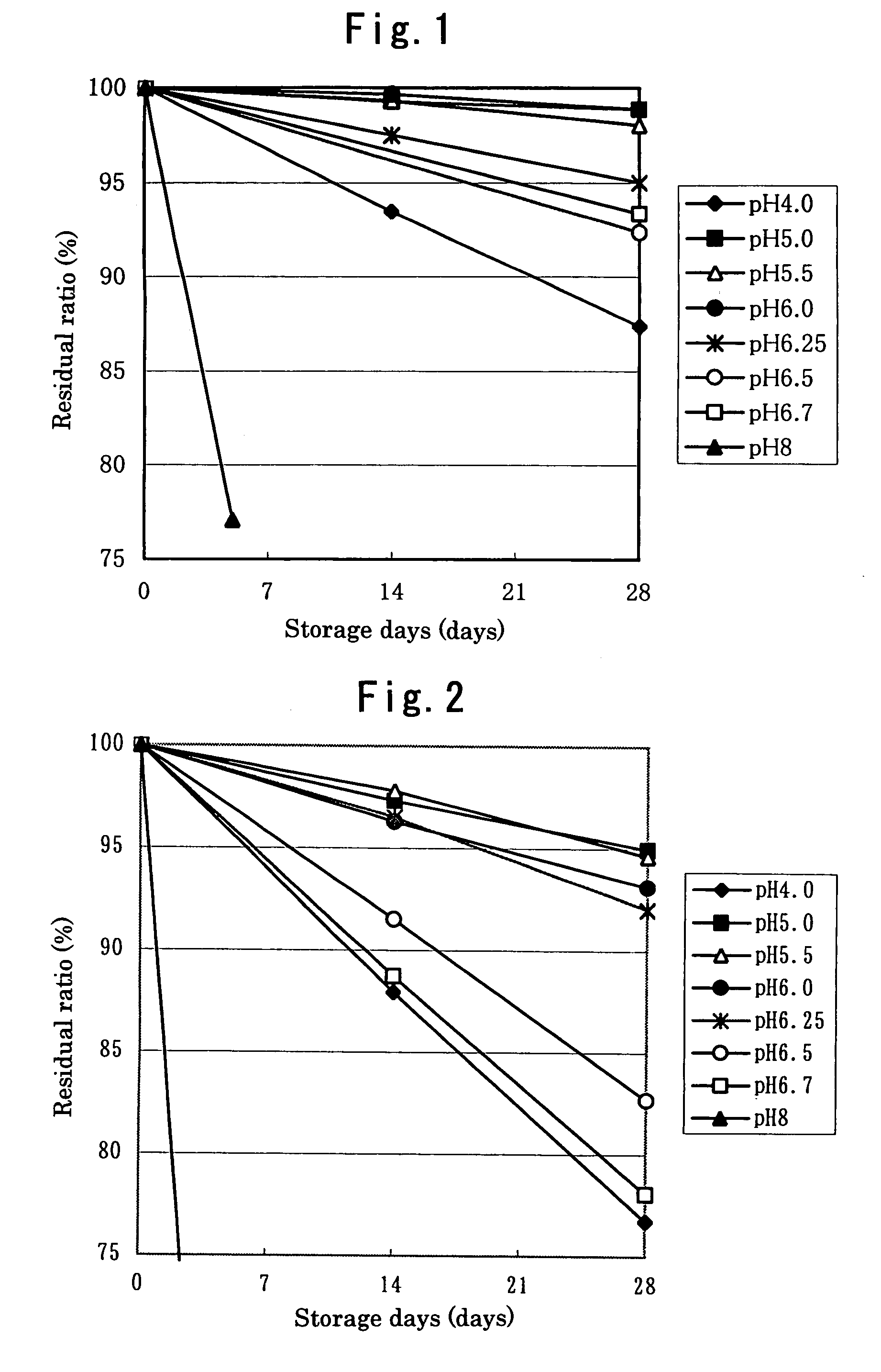

Stable eye drops containing latanoprost as the active ingredient

The present invention provides a latanoprost ophthalmic solution which can be stored at room temperature and is excellent in stability. The ophthalmic solution according to the present invention is an ophthalmic solution comprising latanoprost, wherein latanoprost is stabilized to be stored at room temperature by at least one means selected from the following 1) and 2); 1) adjusting pH of the solution to 5.0 to 6.25 and 2) adding ε-aminocaproic acid to the solution.

Owner:SANTEN PHARMA CO LTD

Wine making multi-bacteria functional bacterial liquid, and production method and application thereof

InactiveCN106434125AIncrease contentMinor ingredient coordinationAlcoholic beverage preparationSodium acetateBiotechnology

The invention relates to the field of brewage, particularly a wine making multi-bacteria functional bacterial liquid, and a production method and application thereof. The bacterial liquid comprises the following components in parts by weight: 12-20 parts of aged pit mud, 20-30 parts of caproic acid bacterium culture fluid, 250-300 parts of boiling water, 12-20 parts of moderate-temperature yeast powder, 15-25 parts of fresh mash, 0.5-1.5 parts of sodium acetate, 70-90 parts of yellow water, 0.2-0.8 part of yeast extract and 15-25 parts of feint. The production method comprises the following steps: sequentially adding the aged pit mud, caproic acid bacterium culture fluid and boiling water, uniformly mixing, adding the moderate-temperature yeast powder, fresh mash, sodium acetate, yellow water and yeast extract, and finally, adding the feint. The bacterial liquid can be used for new pit aging, flavoring by steaming and pit fermentation. The production of the functional bacterial liquid fully utilizes the aged pit mud, vinasse, yellow water, feint and other natural wine making byproducts, so that the wine has abundant varieties and quantities of beneficial bacteria; and the functional bacterial liquid can comprehensively enhance the compatibility of the mouthfeel of the Luzhou-flavor wine body in the production application process.

Owner:HUBEI ZHIJIANG LIQUOR INDUSTRY CO LTD +1

Pit mud compound functional bacterial liquid and preparation method thereof

The invention discloses pit mud compound functional bacterial liquid and a preparation method thereof. Based on 100 percent of grain-distilled immersion liquid, the pit mud compound functional bacterial liquid comprises the following components in percentage by weight: 5 to 8 percent of pit mud, 2 to 3 percent of soybean oil meal, 1 percent of yeast for making hard liquor meal, 0.3 to 0.5 percent of K2HPO4, 0.2 to 0.3 percent of NaAC, 0.01 to 0.02 percent of MgSO4, 2 to 4 percent of 95 percent alcohol and 5 to 15 percent of discolored water. M-type microorganisms are taken as a main material in the pit mud compound functional bacterial liquid obtained by the formula and a process provided by the invention, and the pit mud compound functional bacterial liquid contains a certain number of spore bacteria such as caproic acid bacteria, butylic acid bacteria and the like, has the functions of adjusting the pH value of the pit mud and generating fragrant substances such as caproic acid and the like, is used for curing degraded pit mud with a low pH value and can remarkably improve the quality of white spirit.

Owner:SICHUAN MIANYANG FORGOOD DISTILLERY

Pit mud functional bacteria and preparation method thereof

ActiveCN102260638AOptimizing solid-state culture conditionsReduce stepsBacteriaMicroorganism based processesMicroorganismMicrobiology

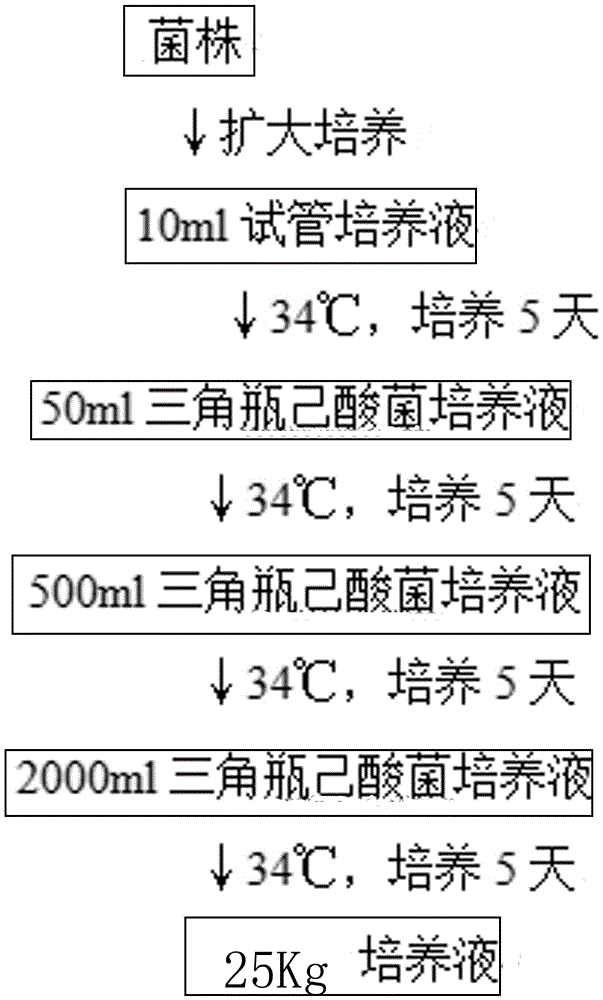

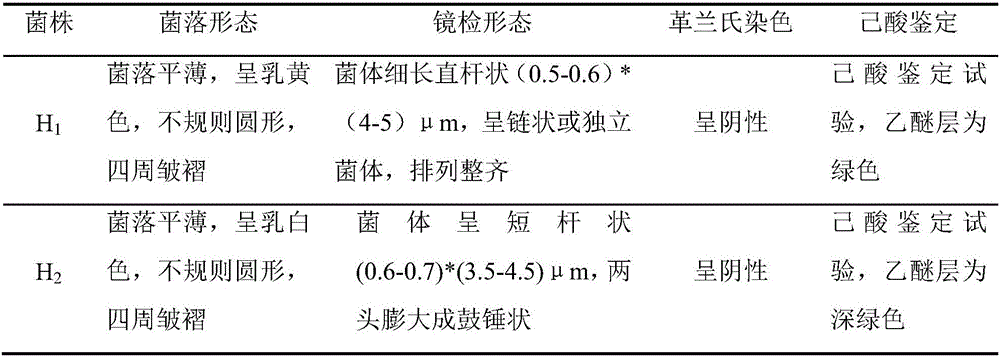

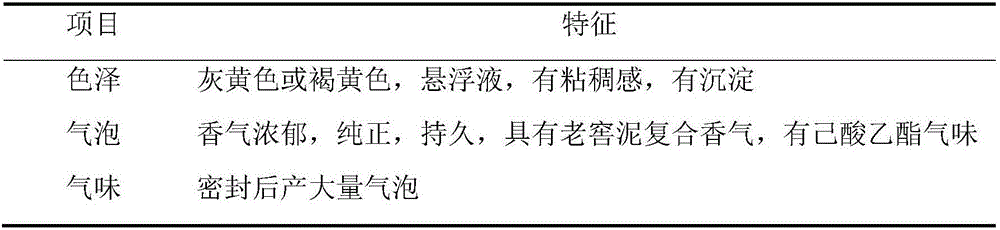

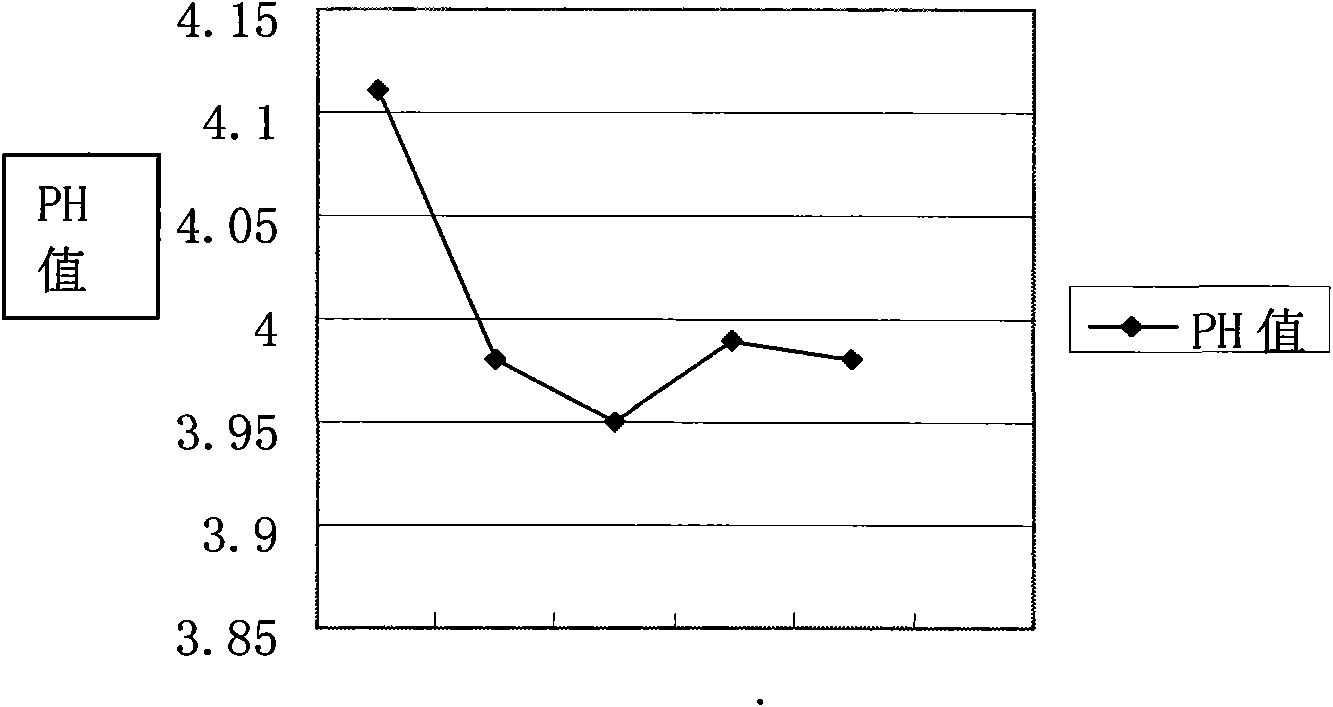

The invention relates to pit mud functional bacteria and a preparation method thereof, and belongs to the technical field of microbial fermentation. The technical problem to be solved is to provide the method for preparing the pit mud functional bacteria. The method for preparing the pit mud functional bacteria comprises the following steps of: a, preparing caproic acid bacterium solution, namely rejuvenating a caproic acid bacterium strain and performing amplification culture to obtain the caproic acid bacterium solution; b, preparing pit mud enriched bacterium solution, namely culturing strains in pit mud to obtain the pit mud enriched bacterium solution; and c, preparing the pit mud functional bacteria, namely mixing the caproic acid bacterium solution and the pit mud enriched bacterium solution, inoculating in a pit mud functional bacterium culture medium, and culturing for 22 to 27 days at the temperature of between 32 and 36 DEG C to obtain pit mud functional bacterium solution.

Owner:LUZHOU PINCHUANG TECH CO LTD

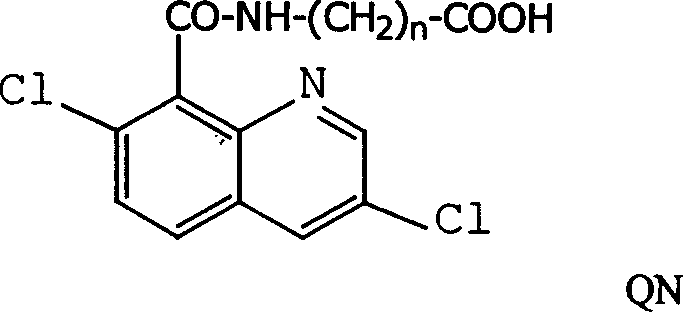

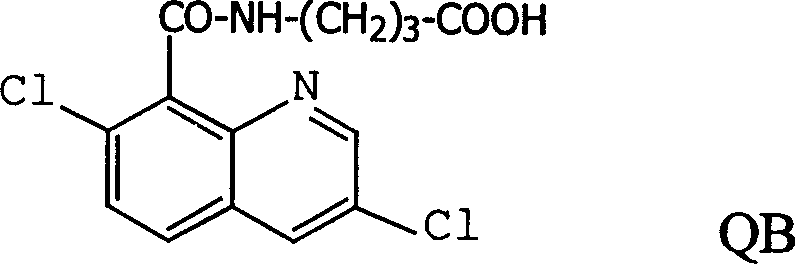

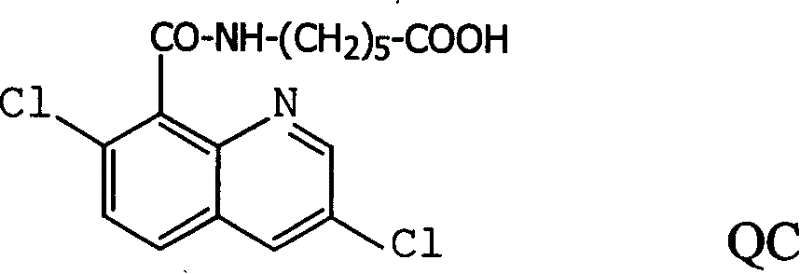

Production method and use for dichloro quinolinic acid artificial hapten, artificial antigen and specific antibody

InactiveCN1569835AEasy to handleFast and accurate analysis and detectionImmunoglobulinsTesting foodQuinolineCarboxylic acid

The invention discloses a process for preparing Quinclorac artificial semiantigen, artificial antigen, specific antibody and use thereof, wherein the preparation comprises, subjecting the dichloroquine (3,7-dichlorine-8-quinoline carboxylic acid) to sulfoxide chlorinated acylation, reacting with reanal and aminocaproic acid, thus obtaining semiantigen 4-(3,7-dichlorine-8-quinolineformyl) reanal or 6-(3,7-dichlorine-8-quinolineformyl) aminocaproic acid (QB or QC).

Owner:ZHEJIANG UNIV

Peroxycarboxylic acid-based capsules having a long shelf life

InactiveUS20070032396A1Improve stabilityGood storage stabilityInorganic/elemental detergent compounding agentsCosmetic preparationsInorganic saltsHair dyes

A method for producing multilayer capsules that are loaded with organic percarboxylic acids, particularly imido-percarboxylic acids (e.g., 6-phthalimido-peroxy-caproic acid), and comprise a shell which is based on at least one inorganic salt, and the use of the capsules produced according to said method in detergents and cleaners, especially liquid detergents and cleaners, especially liquid detergents and cleaners, dental care products, hair dyes, and decolorants or bleaching agents for technical applications.

Owner:HENKEL KGAA

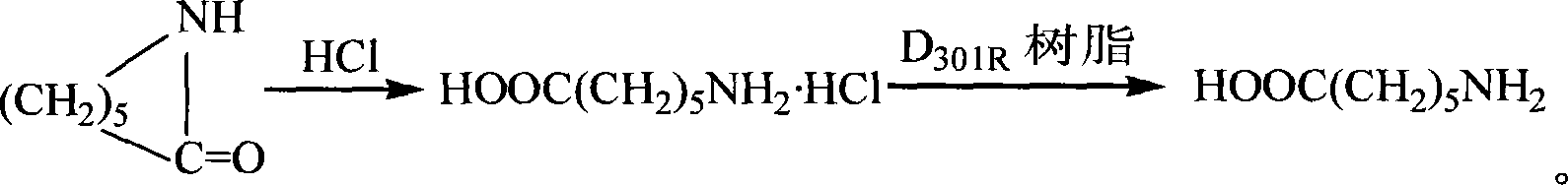

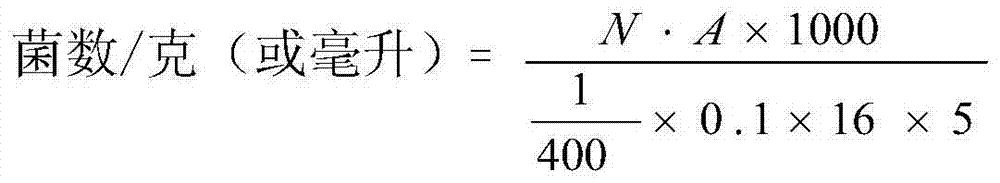

Method for preparing hemostatic 6-amino caproic acid

InactiveCN101125821ANot easy to mixEasy to achieve complianceOrganic compound preparationAmino-carboxyl compound preparationIon-exchange resinCaproic Acid

The invention discloses a preparation method of 6-aminocaproic acid which is a hemostatic. The preparation method is characterized in that caprolactam is dissolved in diluted hydrochloric acid, heated and refluxed to produce 6-aminocaproic acid hydrochloride which is neutralized by spherical macro-porous styrene type weak alkaline anion exchange resin, thereby acquiring the product after treatment. Compared with other preparation methods, the reaction condition of the method is mild, and metal ion can not be mixed easily, the method is more scientific and rational, the standard of the burn residue required by the original material quality can be realized more easily, white crystal can be obtained from the product without activated carbon decolorizing, the operation is simple, the synthesizing cost is reduced and mass production of the technology is more suitable.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

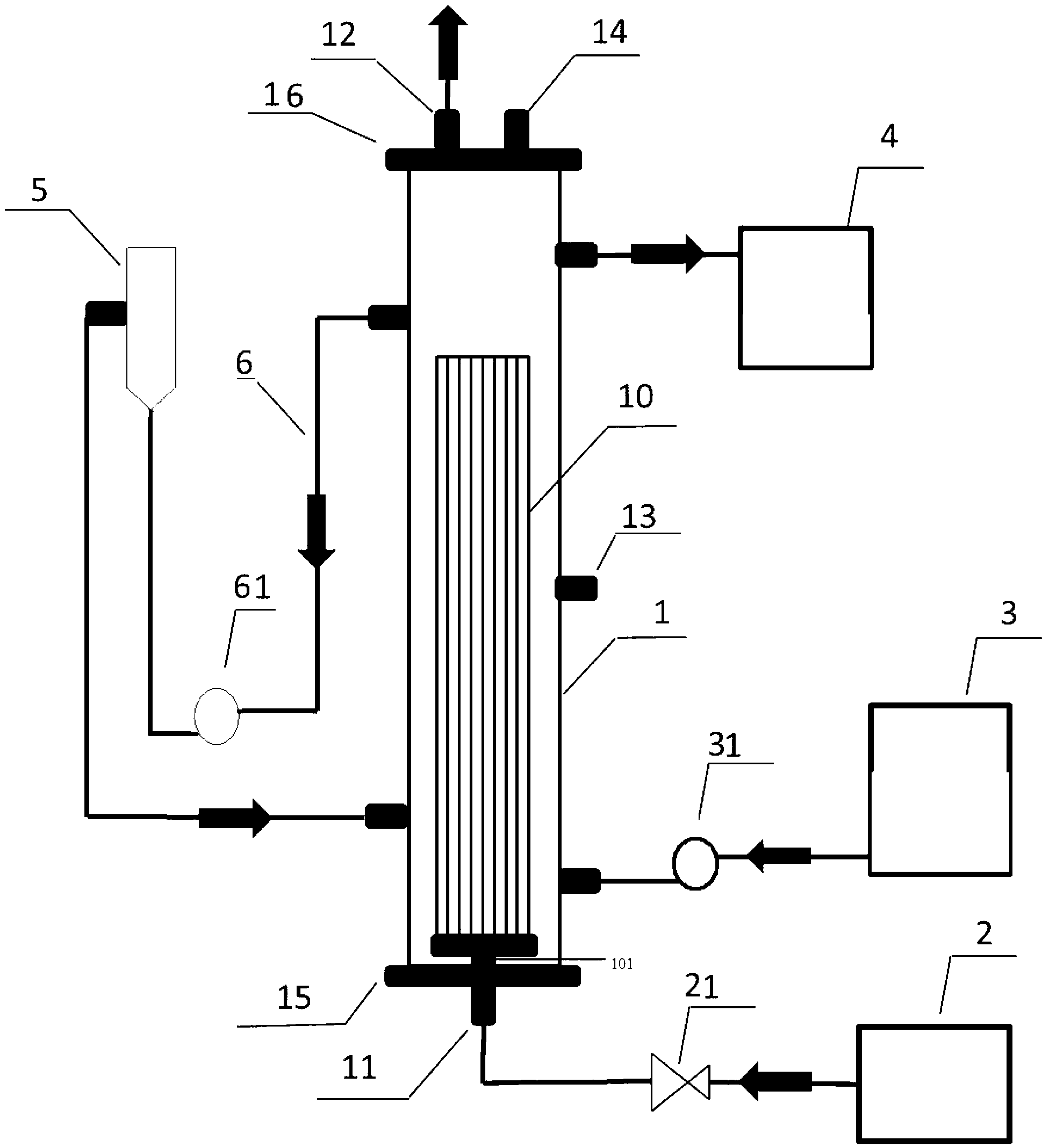

Method for producing fatty acid and device used therein

InactiveCN103233046AReduce churnImprove mass transfer efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsLong chain fatty acidReactor system

The invention provides a method for producing fatty acid. The method comprises the following steps of: thermally cracking and gasifying biomass to generate synthesis gas; and then providing a hollow fiber membrane as an attaching vector and in-situ gas supplying device and adopting the synthesis gas as a raw material to produce the fatty acid in an anaerobic fermentation manner. The invention also provides a device for producing the fatty acid. According to the method and device, the hollow fiber membrane is adopted and used as an attaching medium of microorganism, thus microorganism loss can be reduced; hollow fiber membrane silks are adopted and used for providing the synthesis gas in situ, thus, the mass transfer efficiency of the synthesis gas diffusing to the microorganism, as well as the utilization rate of the synthesis gas, can be improved. By adopting a reactor system and the method, enriched microorganism utilizing the synthesis gas can be gained within a shorter time, and thus the fatty acid, in particular medium-and long-chain fatty acid such as caproic acid and caprylic acid, can be produced.

Owner:UNIV OF SCI & TECH OF CHINA

Process for preparing fresh scent strong-flavor Chinese spirit

InactiveCN103666927AHas a strong fragrance styleOvercoming technical difficulties in anaerobic cultureAlcoholic beverage preparationAcetic acidYeast

The invention discloses a process for preparing fresh scent strong-flavor Chinese spirit. The process comprises distiller's yeast preparation, bacterial sludge preparation, construction of bacterial sludge pits and fermenting and distilling, wherein the step of bacterial sludge preparation comprises material pretreatment, culture of methane bacteria liquid and pit sludge fermentation and culture. Sludge pits in which methane bacteria serve as a primary flora and caproic acid bacteria serve as a secondary flora are constructed by adopting common conditions such as tile crocks and pits in common liquor factories, and conditions are created for producing fresh scent strong-flavor Chinese spirits. According to the process, the technical problem of factory-like methane bacteria anaerobic culture is overcome, and preparation of the sludge pits in which methane bacteria serve as the primary flora and caproic acid bacteria serve as the secondary flora is realized. The liquor is brewed by utilizing the prepared sludge pits and process thereof, and a fresh scent strong-flavor Chinese spirit with a primary component of ethyl acetate, a secondary component of ethyl caproate and an auxiliary material of 2,3-butanedione is formed. Partial characteristics of traditional daqu liquor and Xiaoqu wine processes are combined, and a process of the fresh scent strong-flavor Chinese spirit is formed.

Owner:DAZHOU CHUANHU FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com