Production process of rich fragrance wine

A production method and a strong-flavor technology, which are applied in the production field of strong-flavor wine, can solve problems such as environmental pollution and waste of resources, and achieve the effects of environmental protection, small site area and stable fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

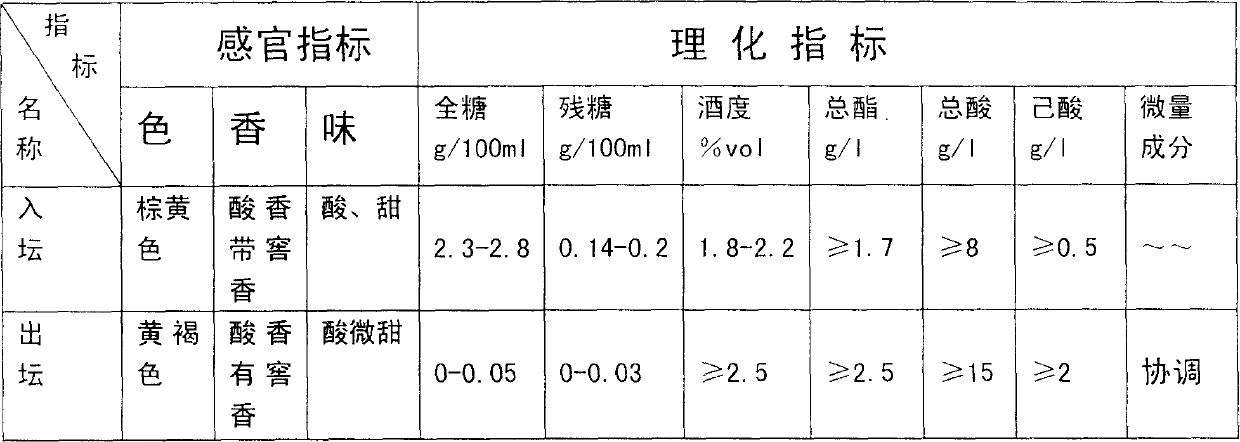

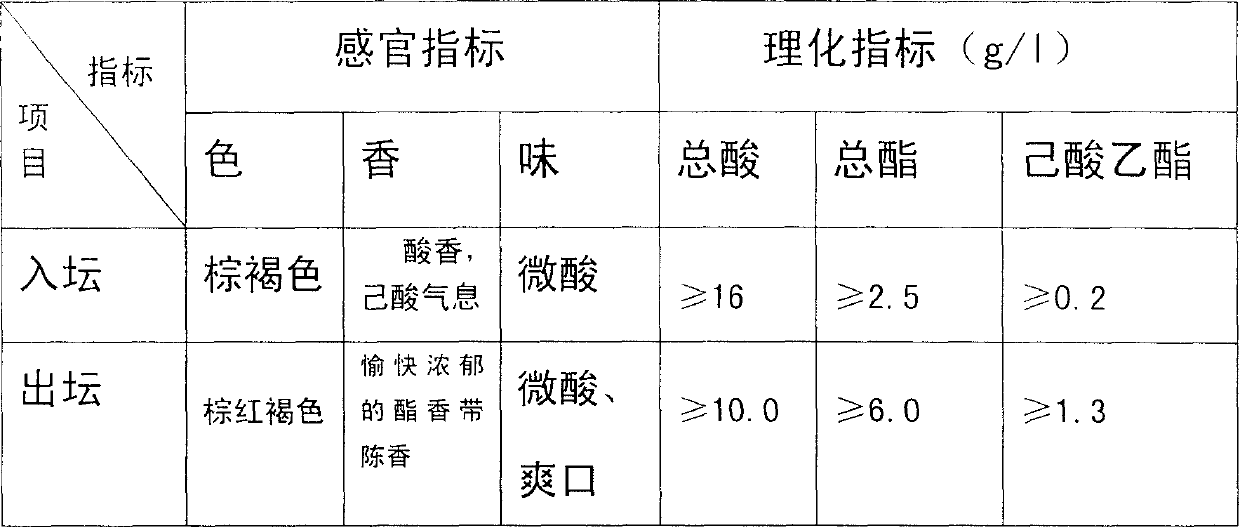

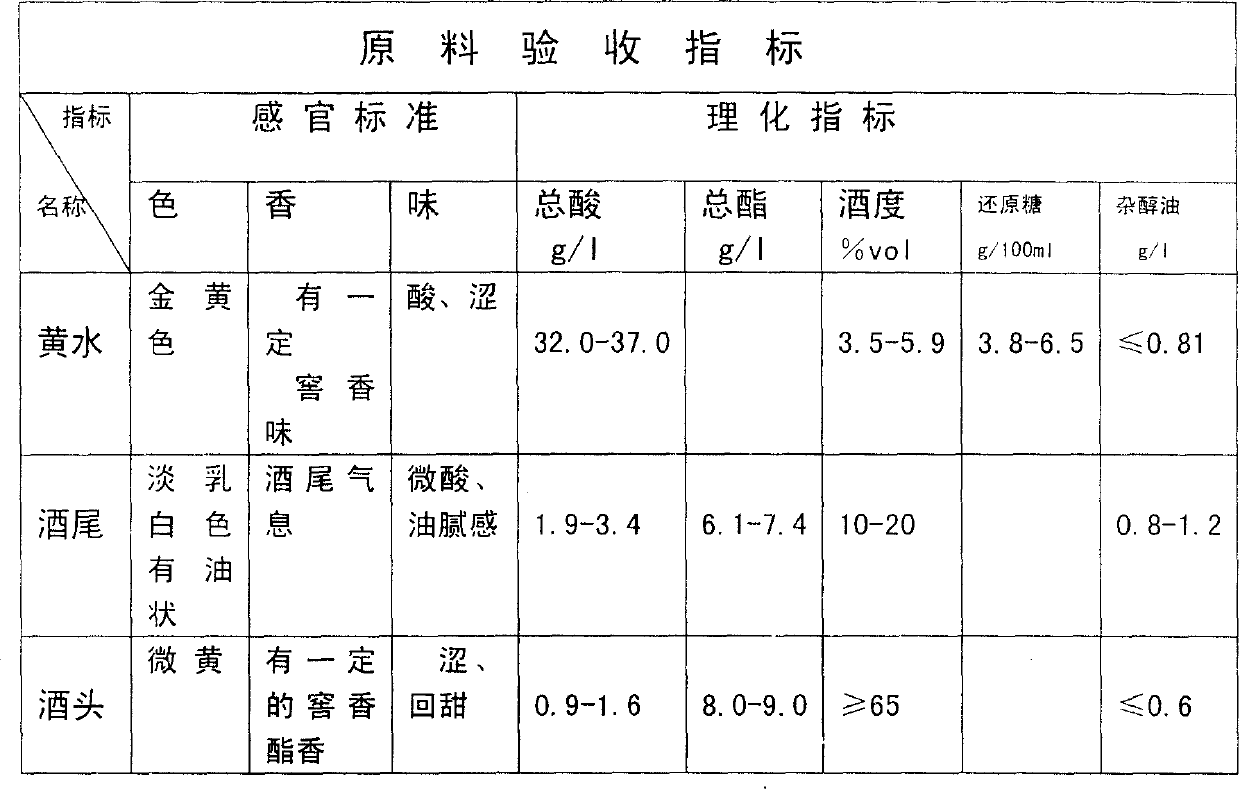

[0031] A method for producing Luzhou-flavor wine, which includes, in sequence, the production of waste-discharging extrusion liquid, raw material acceptance, raw material pretreatment, preparation of the first-level species of compound bacteria, preparation of second-level species of compound bacteria, production of fermented liquid, The production of esterification liquid, the filtration and distillation of esterification liquid, and the inspection and storage of Luzhou-flavor wine are composed of various processes. Kojic esterase, caproic acid, other foreign-grade solid wine, high-grade edible alcohol and tap water, other five-grain powder, yellow water, waste squeeze liquid, wine head and wine tail are all discarded by-products of the brewing industry.

[0032] The present invention brews Luzhou-flavor wine through liquid fermentation, and the main chemical composition of each raw material used and its role in fermentation are as follows:

[0033] name

[0034] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com