Patents

Literature

96 results about "Winemaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Winemaking or vinification is the production of wine, starting with the selection of the fruit, its fermentation into alcohol, and the bottling of the finished liquid. The history of wine-making stretches over millennia. The science of wine and winemaking is known as oenology. A winemaker may also be called a vintner. The growing of grapes is viticulture and there are many varieties of grapes.

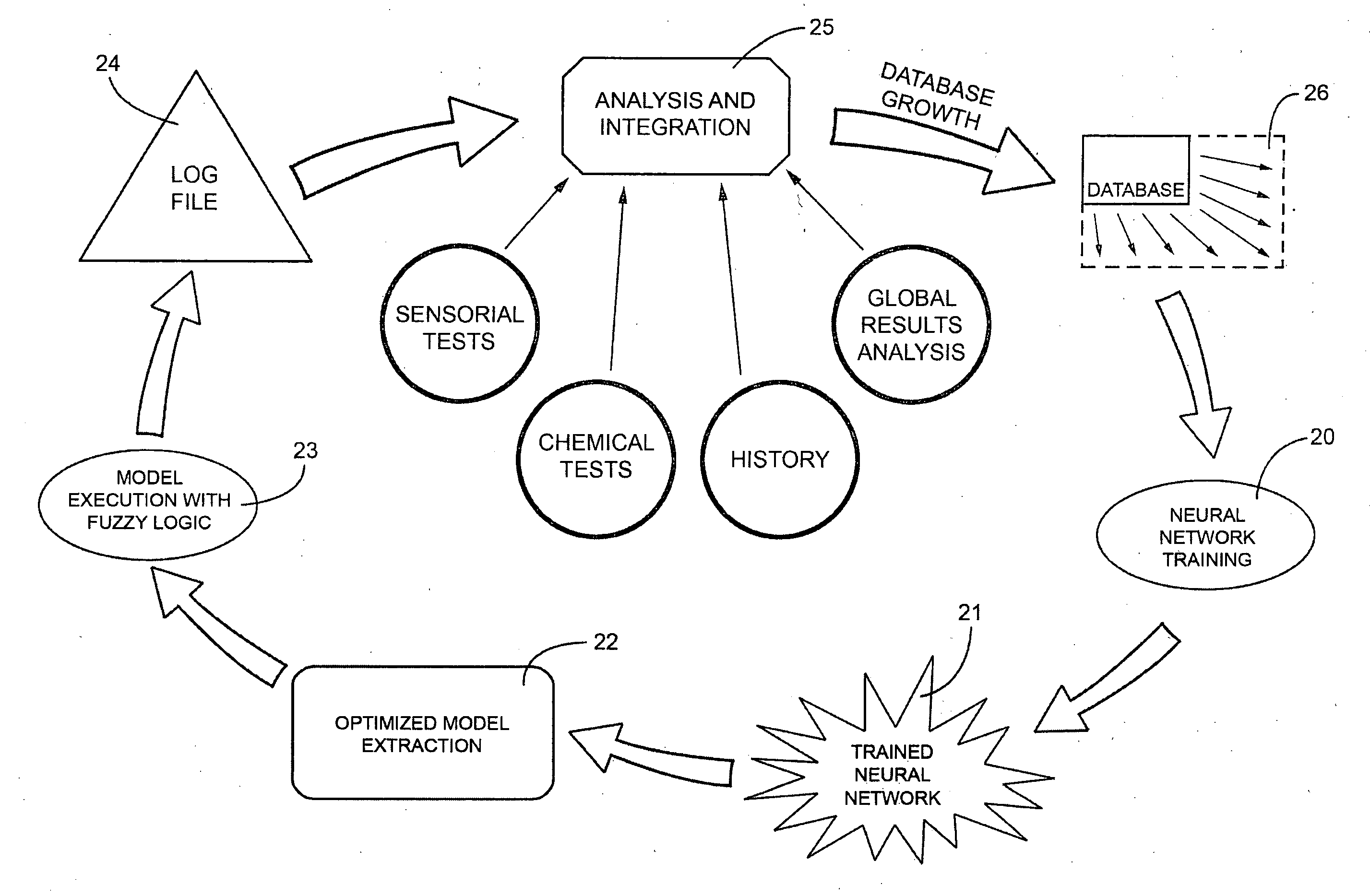

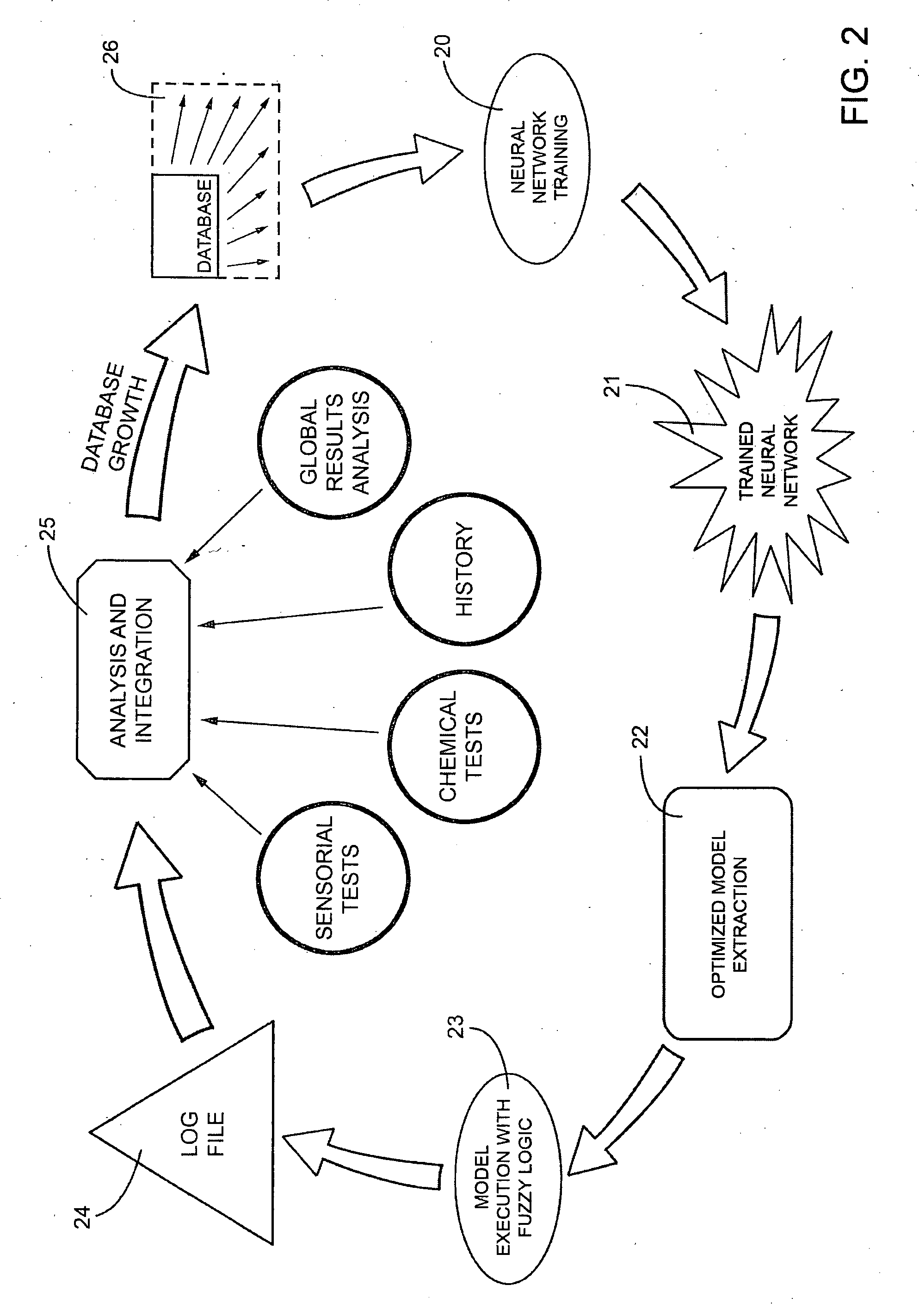

Automated winemaking system and winemaking method thereof

An automatic winemaking system is disclosed, which controls the execution of a winemaking process for the alcoholic fermentation of must obtained from a batch of grapes and the transformation thereof into wine in a winemaking tank. The system is provided with a database for storing winemaking data related to reference winemaking processes; a first processing unit for generating an optimized winemaking model, according to the winemaking data contained in the database, according to input data including characteristics of the batch of grapes and / or must; and a second processing unit for controlling and driving actuators acting on the winemaking tank according to the optimized winemaking model, so that winemaking process parameters are optimized for the features of the batch of grapes and / or must. The second processing unit is further capable of signaling fermentation kinetics faults and / or signaling alarms during the winemaking process.

Owner:FAROTTO CARLO

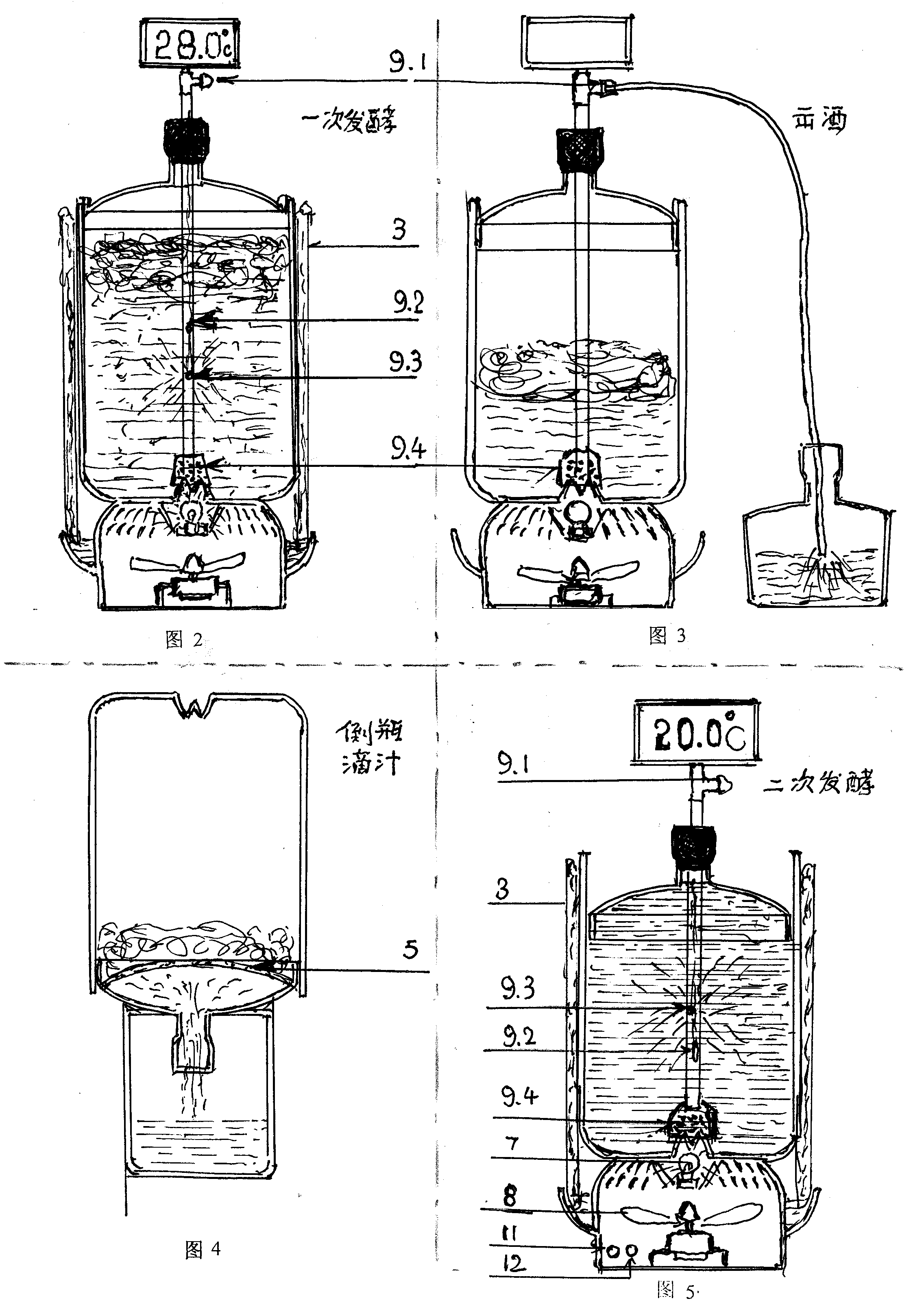

Dry red wine brewing process

The invention provides a dry red wine brewing process and belongs to the field of red wine brewing. The process comprises the following main process steps of a, selecting raw materials, removing stems and crushing the materials; b, performing dipping and fermentation: adding 25ppm SO2, pectinase and yeasts in sequence after the materials enter a jar; adding tannin 12 hours after the jar is full, and when the PH value is greater than 3.6, adding tartaric acid; performing fermentation at 25-28 DEG C; c, performing skin residue separation and squeezing: when the fermentation time is greater than 7 days and the measured proportion of grape wine is reduced to less than 1,000, storing free run wine at 18-20 DEG C; performing extraction and squeezing on skin residues to obtain squeezed wine; performing secondary extraction and squeezing on pomace such as grape skin, seeds, stems and the like after extraction and squeezing to obtain extract; d, performing secondary fermentation: fermenting the free run wine, the squeezed wine and the extract at the same time; e, performing reverse filling, and adding 50mg / L of SO2; f, performing mixing, clarifying and filtering; g, performing freezing, sterilizing, filtering and filling, wherein the jar is kept full and sealed during freezing; and h, performing sterilizing, filtering and filling. The dry red wine brewing process provided by the invention has the advantages of rich healthcare factors, perfect balance of fruity fragrance and tannin, and secondary extraction, squeezing and efficient utilization of the skin residues.

Owner:新疆大漠福鹰文化俱乐部有限公司

Green plum fruit wine and preparation method thereof

ActiveCN105349391ASolve thin and not typical problemsHigh substance contentAlcoholic beverage preparationFruit wineFood flavor

The invention belongs to the field of winemaking, particularly relates to green plum fruit wine and a preparation method thereof and aims to solve the technical problem about provision of the preparation method of the green plum fruit wine. The preparation method of the green plum fruit wine comprises steps as follows: fermentation type green plum raw wine, various kinds of green plum aroma improving wine and various kinds of green plum aromatic wine are prepared, at least one of the green plum aroma improving wine or the green plum aromatic wine is uniformly mixed with the fermentation type green plum raw wine and white granulated sugar, then the mixture is subjected to post-processing, and a variety of flavors of green plum fruit wine is obtained. The green plum fruit wine prepared with the method has multiple good flavors, and the problem that the aroma of full-juice fermentation type green plum fruit wine is light and is not typical enough is solved.

Owner:WULIANGYE +1

Amaranthus hypochondriacus miscellaneous grain crop health liquor and making method thereof

ActiveCN104099213AUnique tastePromote productionAlcoholic beverage preparationPolygonum fagopyrumCoix

The invention belong to the technical field of microbial winemaking, and aims to solve problem that the conventional miscellaneous grain crop liquor is single in varieties, simple in taste, bitter in taste, and pale in aroma, and cannot meet mass consumer tastes. An amaranthus hypochondriacus miscellaneous grain crop health liquor and a making method thereof are provided to improve the edibility of the amaranthus hypochondriacus. The amaranthus hypochondriacus miscellaneous grain crop health liquor is made by pulverizing amaranthus hypochondriacus leaves, black bean, rye, bitter buckwheat, oat, coix seeds and millet, cooking the pulverized mixture, performing fermentation mixed with yeast, performing mixing distillation, and the like. The amaranthus hypochondriacus miscellaneous grain crop health liquor provided by the invention is bright in color, mellow and soft in taste, and unique in taste, has lots of nutritional ingredients and mellow and soft taste, and can meet double requirements of consumers on nutrition and taste; the liquor contains flavonoid compounds, so that oxygen free radicals in a body can be effectively removed, the antioxidant capacity of the liquor is ten times higher than that of the Vitamin E, the degeneration and aging of cells can be prevented, the occurrence of cancer can be prevented, and the immunity of the body can be enhanced; the liquor has an effect of reducing blood fat, blood pressure and blood sugar.

Owner:AGRI BIOTECH RES CENT OF SHANXI PROVINCE

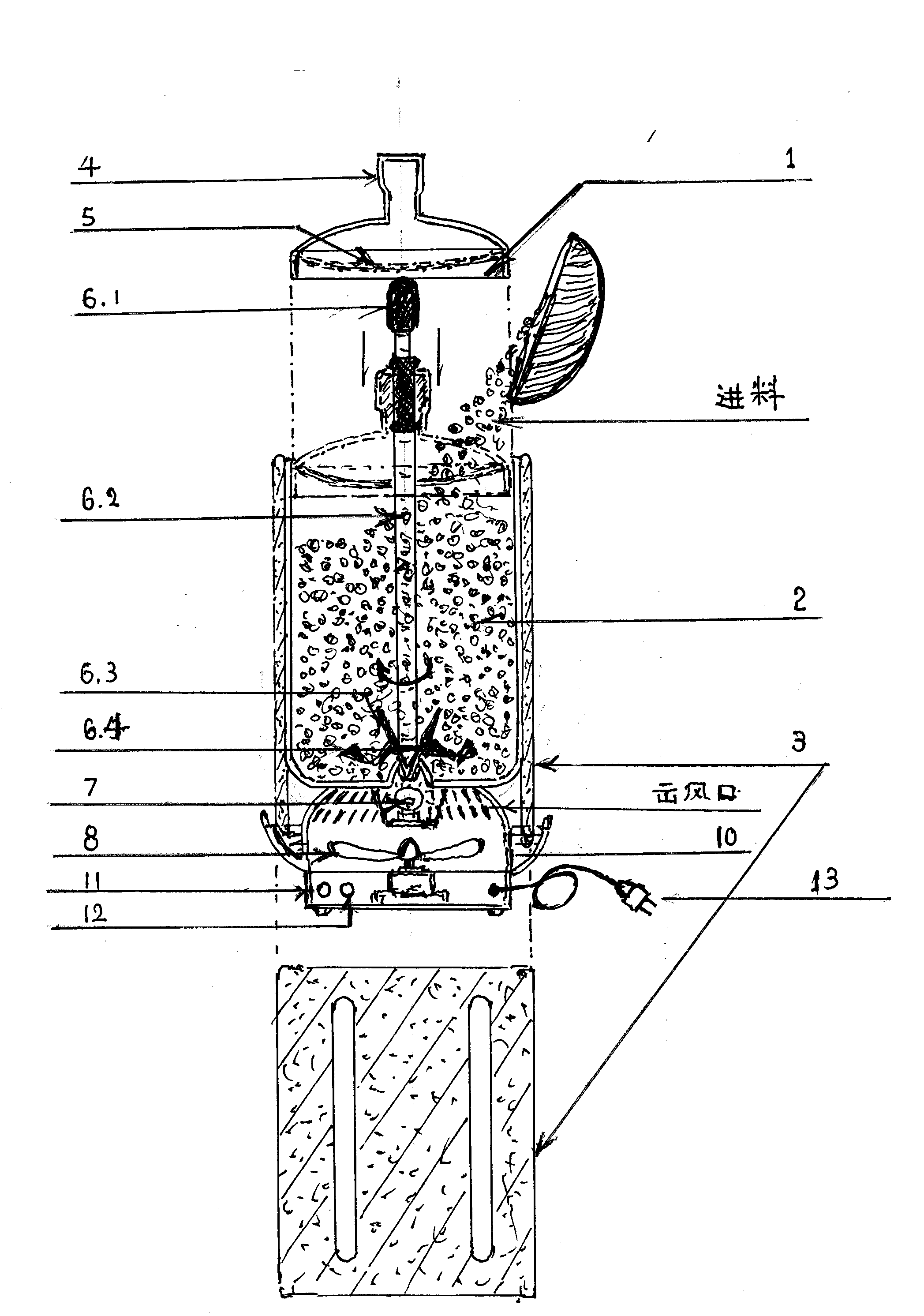

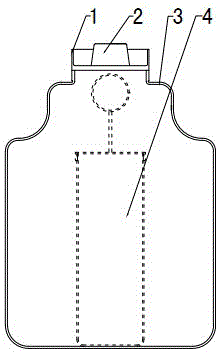

Small household winemaking machine

The invention relates to a small household winemaking machine comprising a characteristic of integrating functions such as fruit particle crushing, fermentation temperature controlling, wine-residual separation, filtering and clarifying, and storing. The machine is characterized in that a piston-cap-type transparent bottle is adopted as a main body; fruit particles are crushed by using a manual pressure rotation level cutter-head; proper fermentation is carried out; and bottom residual is removed. The prepared wine has good clarification level and no odor. Also, winemaking is closely related to seasons and temperatures, and is usually carried out from late summer to autumn, and then to winter. The machine is also characterized in that, with cheap siphon water evaporation forced air cooling, stepped cooling from hot-dipping to pre-fermentation, post-fermentation, and storing is satisfied. Therefore, the process from fruit particle to wine is smooth.

Owner:任心民 +1

Product for the prevention and the treatment of grapevine infections and method of preparation thereof

InactiveUS20070071831A1Eliminate destructionIncrease speedBiocideInorganic active ingredientsMedicineAlkaline earth oxides

A product is described for the prevention and / or treatment of grapevine infections, obtained by the partial or total neutralization of lees originating from winemaking processes, for example by means of alkali or alkali-earth metal oxides or hydroxides; such product generally has a pH comprised between 6.0 and 8.0 and a humidity content of 70% or less; a composition for the prevention and / or treatment of grapevine infections, comprising such product and a process for the preparation of the above-mentioned product, comprising the addition of lees originating from a winemaking process, having a pH generally of 3.0 or less, a basic reactant to bring its pH to a value of 6.0 or above and an optional concentration step to bring the humidity content of the product to a value of 70% or less, are also described.

Owner:VOMM IMPIANTI E PROCESSI

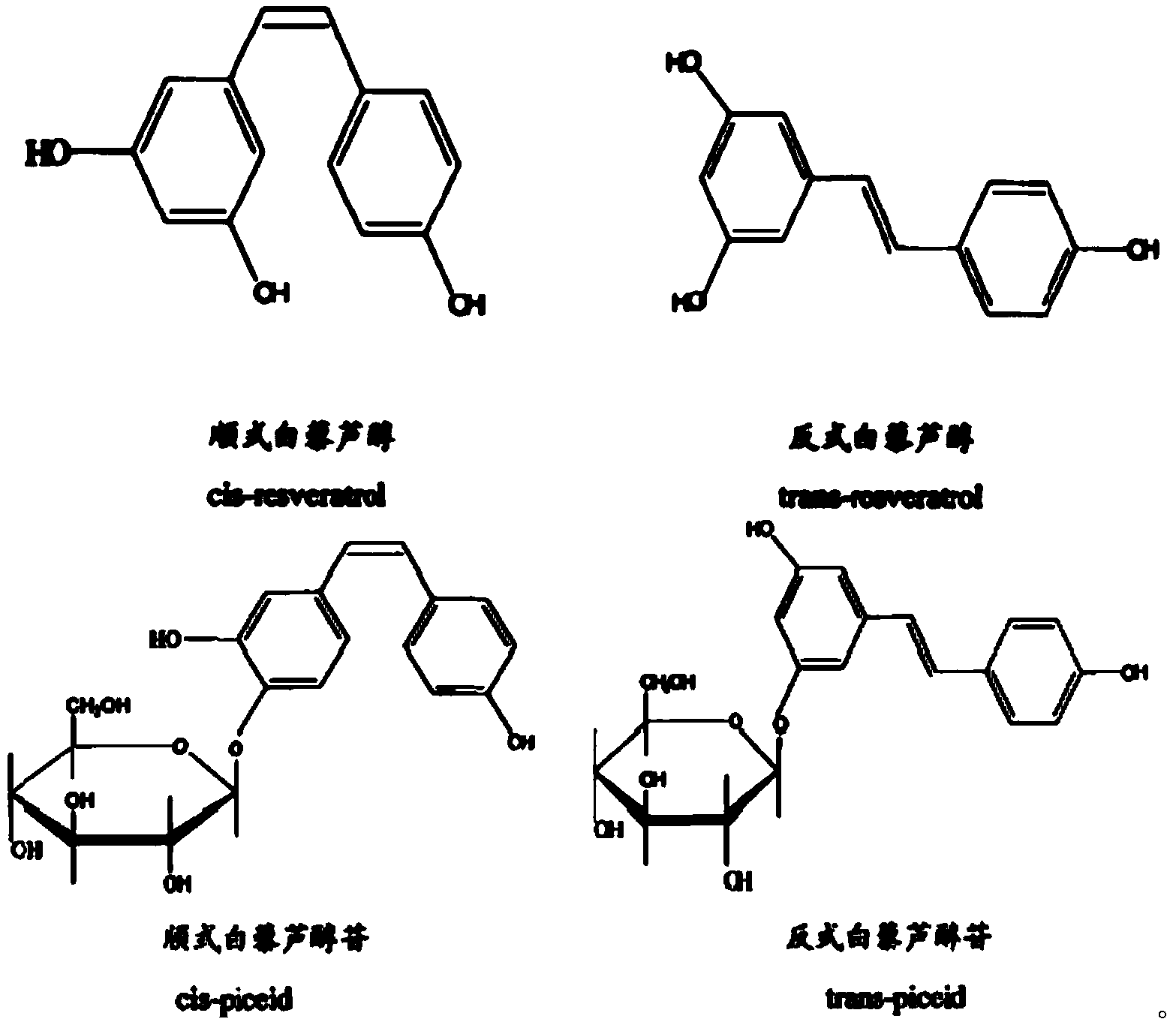

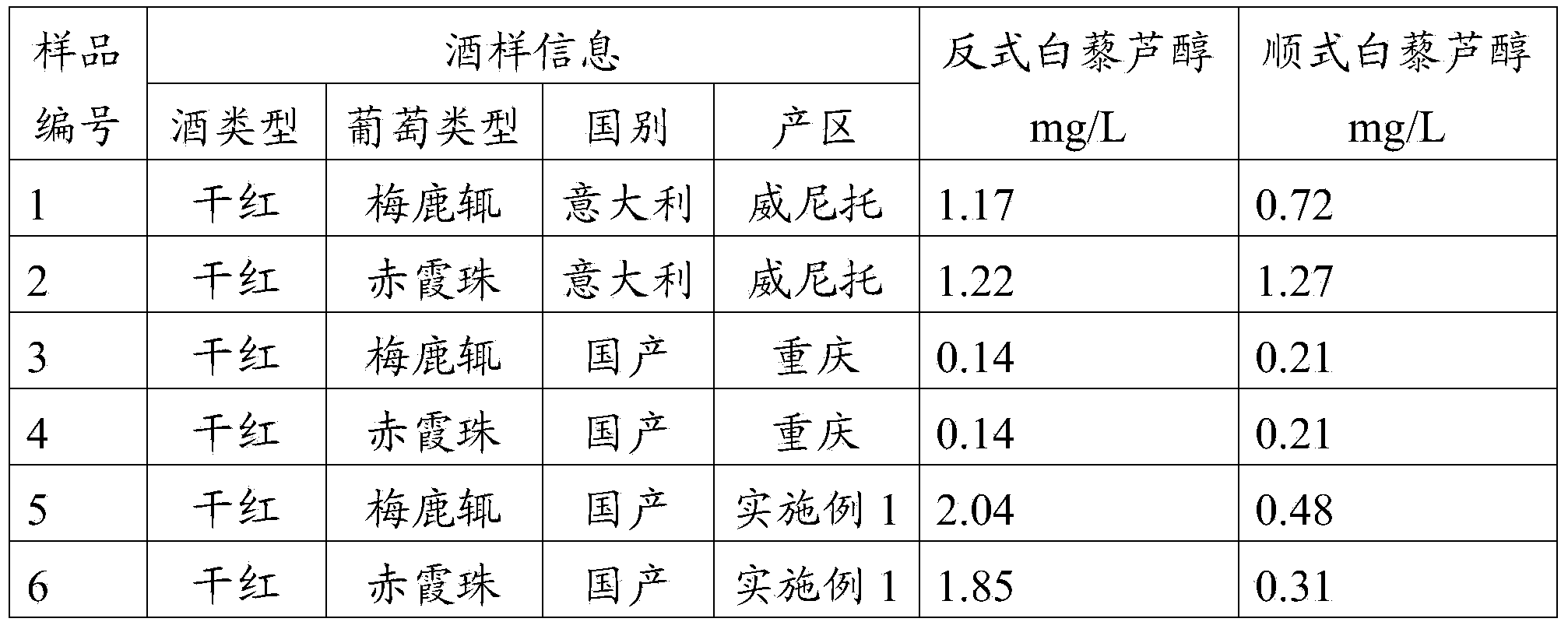

Grape wine as well as preparation method and application thereof

ActiveCN104388236AIncreased resveratrol contentIncrease contentWine preparationUrinary disorderSide effectGrape wine

The invention belongs to the field of brewing grape wine and discloses a grape wine with high resveratrol content as well as a preparation method and application of the grape wine. The grape wine is prepared from the following traditional Chinese materials, which are in homology of medicine and food, including medlar, pachyma cocos, peanut vines, sealwort, cinnamon, mulberry fruits and grapes. The grape wine has the health preservation efficacy of the grape wine and also has the health preservation drug efficacy of the traditional Chinese materials. According to the grape wine disclosed by the invention, the deficiency of the traditional health wine of poor taste is improved, and the strong and mellow taste of the grape wine is also kept. Proved by experiments, as the resveratrol content of the grape wine is obviously higher than that of the traditional grape wine, the grape wine is good in quality. The grape wine accords with the requirements of compatibility of the traditional Chinese materials, does not have toxic and side effects, achieves the purposes of balancing and tonifying yin and yang, is suitable for both males and females, is capable of gently tonifying kidney, aiding liver and the kidney, invigorating blood and essence and strengthening bones and muscles and has the obvious efficacies of tonifying yang, improving sexuality, resisting fatigue and ageing, strengthening immunity, softening blood vessels, whitening face, keeping facial appearance, delaying ageing and the like.

Owner:重庆利莫里亚生物科技有限公司

Production process of tea flavor type liquor

InactiveCN106635702AThe wine is yellowish and clearHarmonize tea fragranceAlcoholic beverage preparationMicroorganism based processesYeastCooling down

The invention relates to the field of winemaking, particularly to a production process of a tea flavor type liquor. The production process specifically includes the steps of mixing and steaming sorghum, rice and glutinous rice, cooling down the mixture, adding in yeast, mixing with tea leaching solution, performing fermentation storage, distilling, aging and blending operations and the like. The tea flavor type liquor obtained through the production process is rich in tea flavor and soft and sweet in taste.

Owner:吴中区穹窿山福顺生物技术研究所

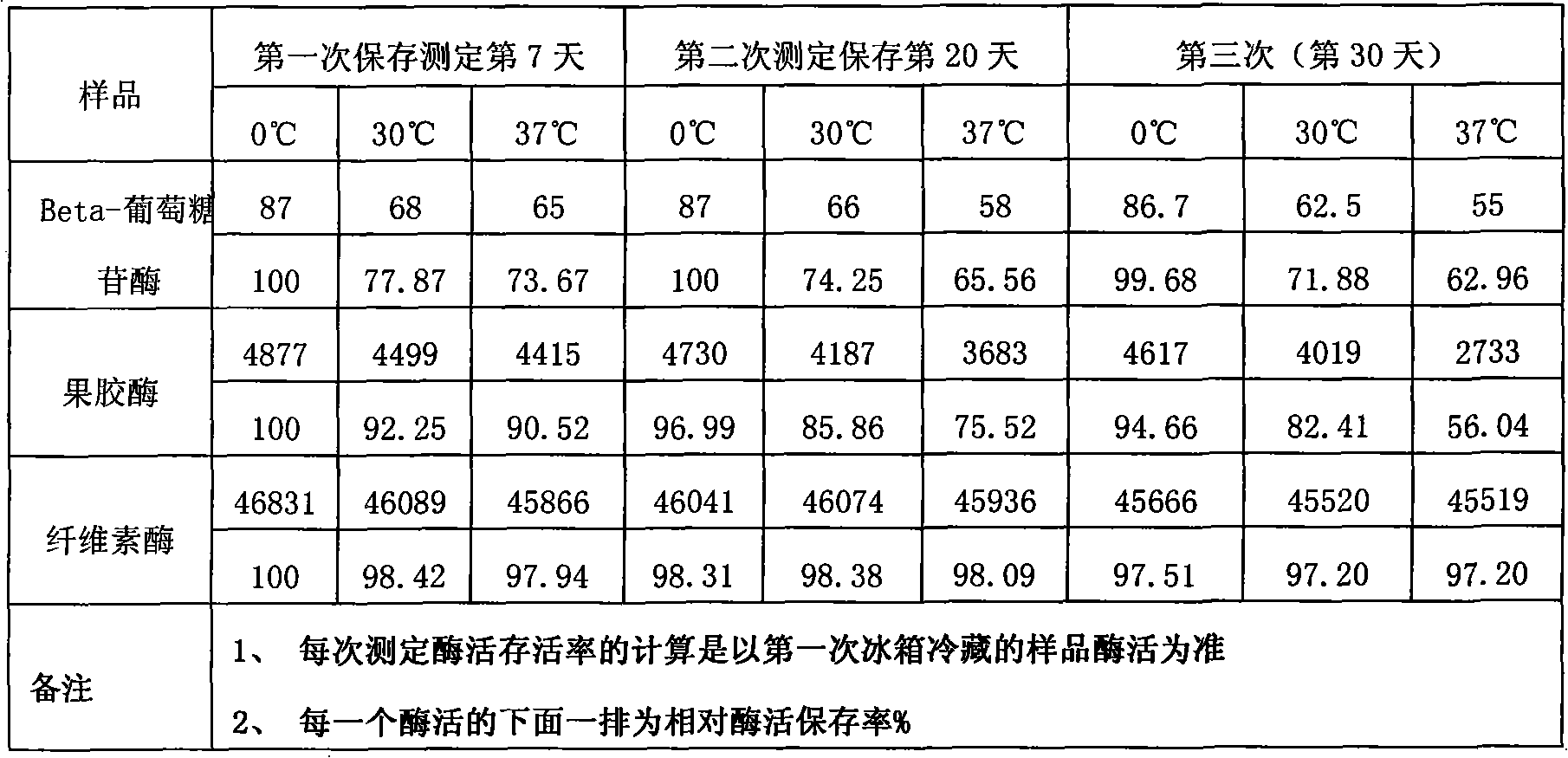

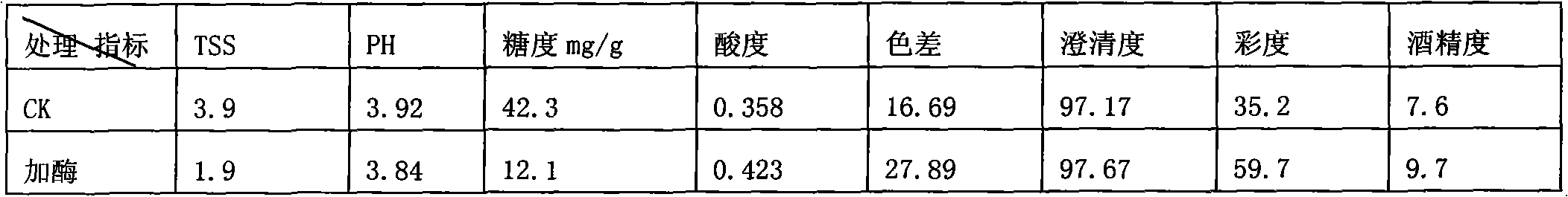

Liquid complex enzyme for use in brewing red wine and use thereof

The invention discloses a liquid complex enzyme for use in brewing red wine, which is prepared by blending three basic enzymes, which are acidic pectinase, acidic cellulose and beta-glucuroide, in a ratio, wherein the pectinase A and the cellulose A are mixed in a ratio of 1:1-4 and stirred uniformly to prepare two-enzyme mixed solution first; and then the beta-glucuroide is added in an amount of10 to 50 microliters of the beta-glucuroide per milliliter of enzyme solution to prepare the liquid complex enzyme. The invention also provides a method for using the liquid complex enzyme in the production of red wine. The cellulose, hemicellulase and pectinase in the liquid complex enzyme coordinate and promote mutually in a red wine production process, so a good clear and release effect is achieved, the color of the wine is improved, and the fragrance of the wine is increased.

Owner:无锡蔚蓝生物科技有限公司

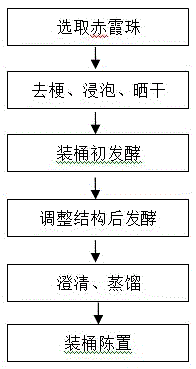

Dry red wine capable of maintaining beauty and brewing method thereof

The invention relates to the field of wine brewing, in particular to dry red wine capable of maintaining beauty and a brewing method thereof. The method includes: using mature Cabernet sauvignon, dried sweet osmanthus, dried lemon peel, clove, ginger and the like to brew the dry red wine capable of maintaining beauty, to be more specific, using purple black Cabernet sauvignon with medium-density fruit and grass flavor as the raw material of the wine, removing stems, soaking, airing, crushing, barreling and feeding sulfur dioxide, performing primary fermentation, performing secondary fermentation, clarifying, distilling, and barreling and aging to obtain the dry red wine capable of maintaining beauty. The dry red wine capable of maintaining beauty has the advantages that the dried sweet osmanthus and the dried lemon peel are used to increase the acidity and fragrance of the Cabernet sauvignon; the clove and the ginger are added to increase the thickness and structure of the wine. The brewing method is simple in flow, the Cabernet sauvignon, the dried sweet osmanthus and dried lemon peel are fully utilized to brew the dry red wine, and the beauty maintaining effect is intensified.

Owner:陈燕妮

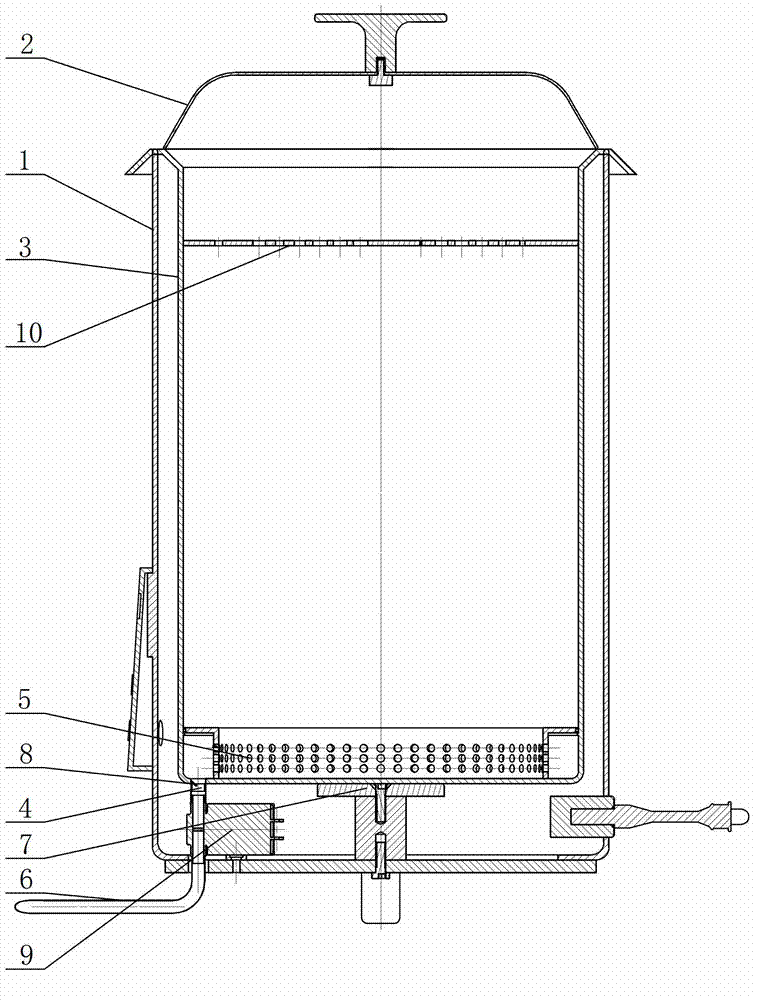

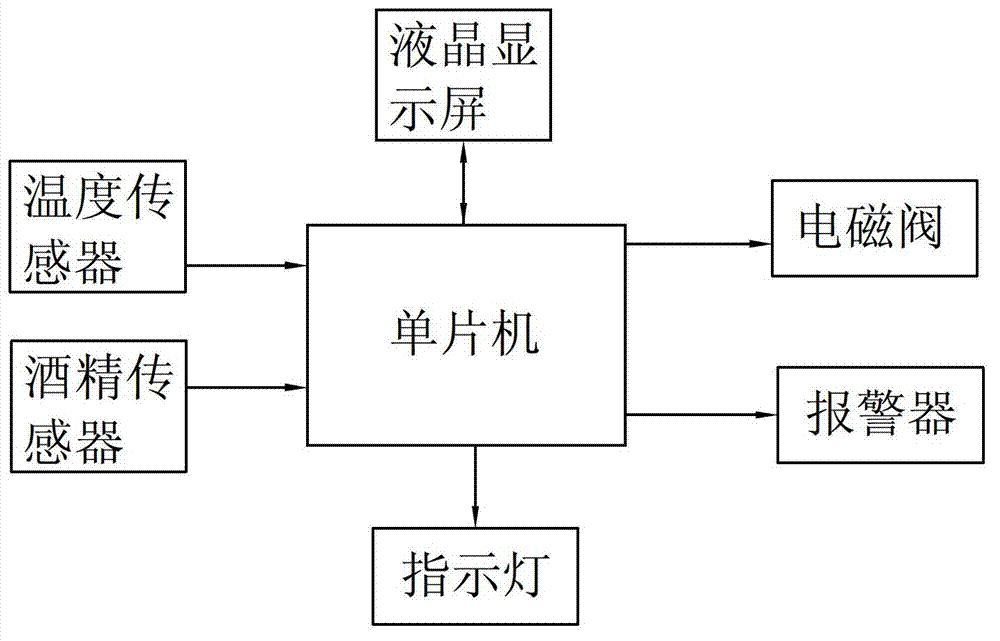

A wine-brewing machine

InactiveCN103289853AMeeting the needs of home-brewed wineSimple structureWine preparationLED displaySolenoid valve

The invention discloses a wine-brewing machine comprising a hollow outer pot body with an opening upper part and a lid has a vent hole, and also comprising a hollow inner pot with an opening upper part, a control assembly and a liquid discharge assembly. The inner pot is nested in the outer pot body, and a liquid discharge port is arranged at the bottom of the inner pot; the control assembly comprises a control module, a temperature sensor for detecting the temperature of the inner pot, an alcohol sensor for detecting the alcohol concentration in liquid, an LCD display and an alarm. The temperature sensor is arranged at the lower part of the inner pot, the alcohol sensor is arranged on the liquid discharge port, and the temperature sensor and the alcohol sensor are respectively connected with the input end of the control module; the LED display and the alarm are respectively connected with the output end of the control module; and the liquid discharge assembly comprises a solenoid valve arranged on the liquid discharge port and used for control open or close of the liquid discharge port, and the solenoid valve is connected with the output end of the control model. The wine-brewing machine is simple in structure and convenient in use, and can meet the need of family for DIY wine.

Owner:QINZHOU UNIV

Kidney-tonifying schisandra chinensis health-care wine

InactiveCN102952672AEasy to prepareTake care of your healthDigestive systemAlcoholic beverage preparationNephropathyWinemaking

The invention relates to a kidney-tonifying schisandra chinensis health-care wine. According to the invention, corn and glutinous rice are adopted as raw material, and a traditional distillation winemaking method is adopted, such that pure-grain wine is prepared; 16 parts of schisandra chinensis, 17 parts of papermulberry fruit, 13 parts of fistular onion seed, 18 parts of medicinal morinda root, 18 parts of manyprinckle acanthopanax, 18 parts of English walnut seed, and 20g of rock candy are placed into 2L of the pure-grain wine; the mixture is sealed and placed for 3 months, wherein oscillation is carried out every two days, such that the kidney-tonifying schisandra chinensis health-care wine is prepared. The kidney-tonifying schisandra chinensis health-care wine provided by the invention has the advantages of simple preparation method, a kidney-tonifying function, and suitability for both men and women. When the wine is taken for a long time, the wine assists in tonifying kidney, protecting kidney health, and preventing kidney diseases.

Owner:钱国祥

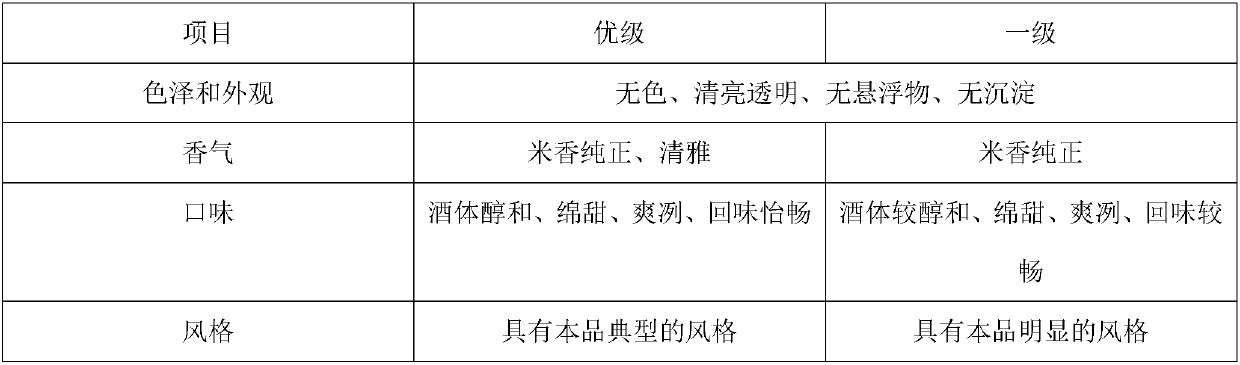

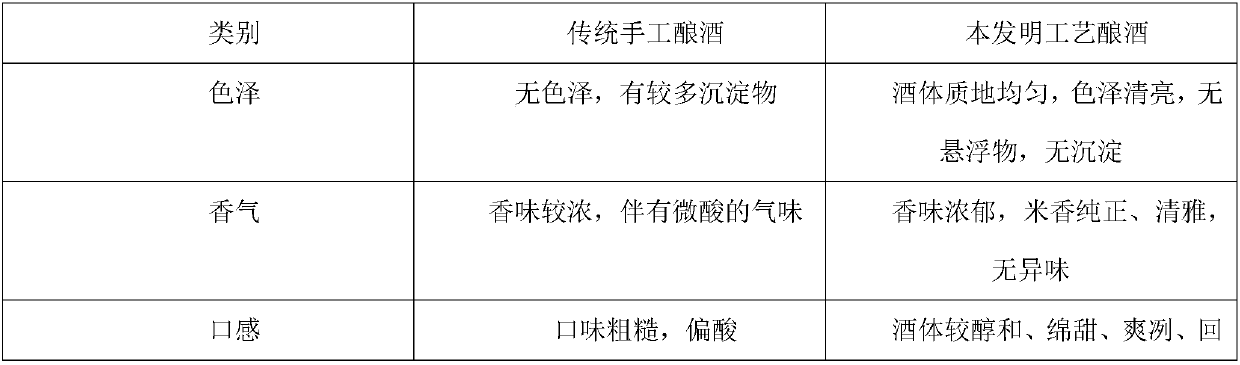

Method for brewing rice scented wine

InactiveCN108048286AStrong fragranceGood for healthAlcoholic beverage preparationDistillationEconomic benefits

The invention discloses a method for brewing rice scented wine. The method comprises the following steps of: selecting material, soaking, cleaning, controlling rice, cooking, drying, adding koji, first fermentation, secondly adding koji, secondary fermentation and tertiary fermentation. The method for brewing the rice scented wine applies traditional artisanal winemaking process and carries out tertiary fermentation on the basis of the steps of dosing, cooking, mixing, fermentation, distillation, and cellaring. The prepared rice scented wine has a rich aroma and has a good health-care effect after drinking, and after prepared rice scented wine is drunk, the prepared rice scented wine does not dry out, does not make a drinker feel dizzy, and sobers up quickly. Compared with traditional simple techniques, both taste and nutrition of the prepared rice scented wine are greatly improved, and the prepared rice scented wine has a broad market and vast economic benefits. According to the method for brewing the rice scented wine, rice mixed with one or more of millet, yellow rice, basmati rice, and rice is selected as raw material rice, the prepared rice scented wine is clear and transparent in color, full-bodied and mellow in taste. The nutrients of the raw material rice are greatly retained, and consumer diversified needs for alcoholic foods are satisfied.

Owner:内蒙古大正酒业有限公司

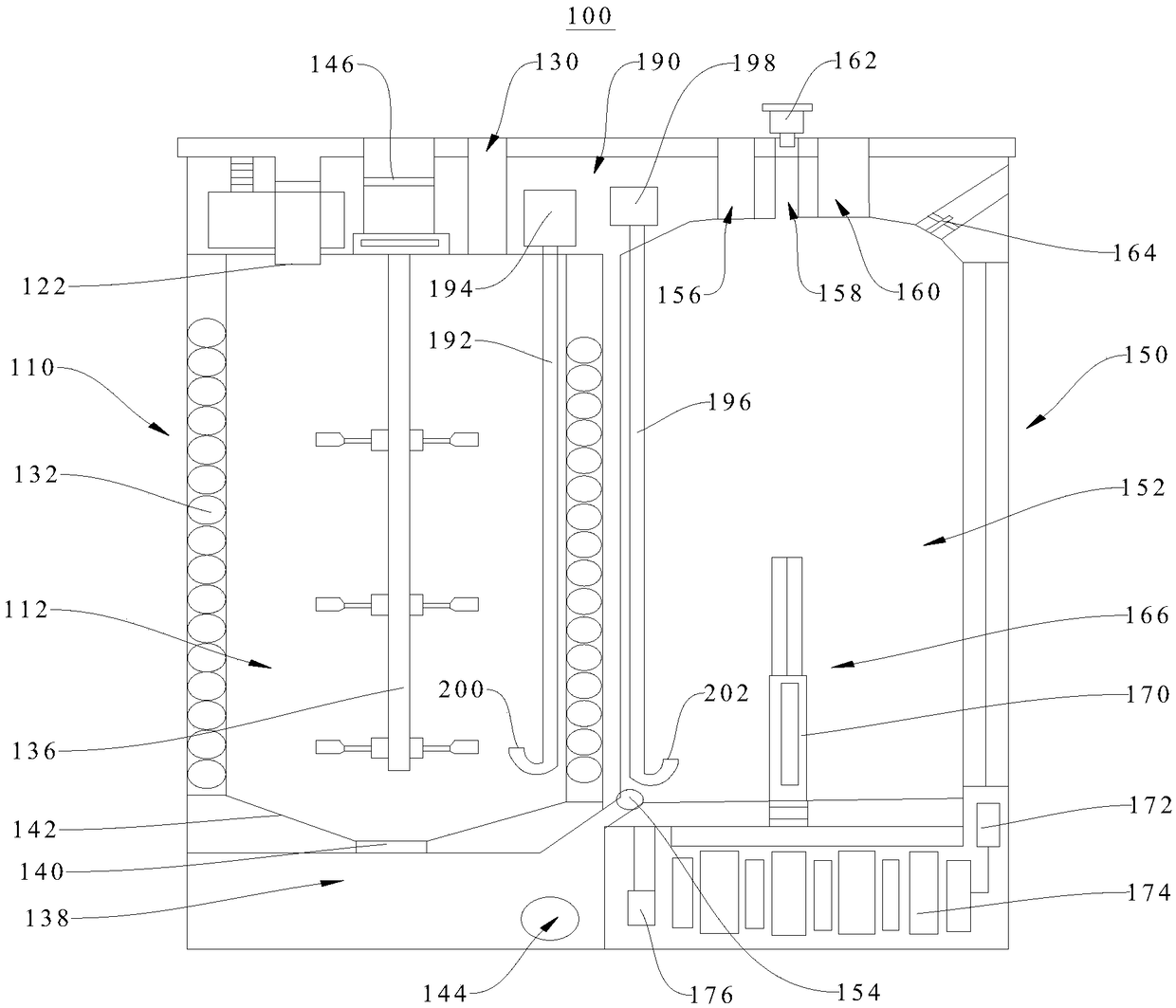

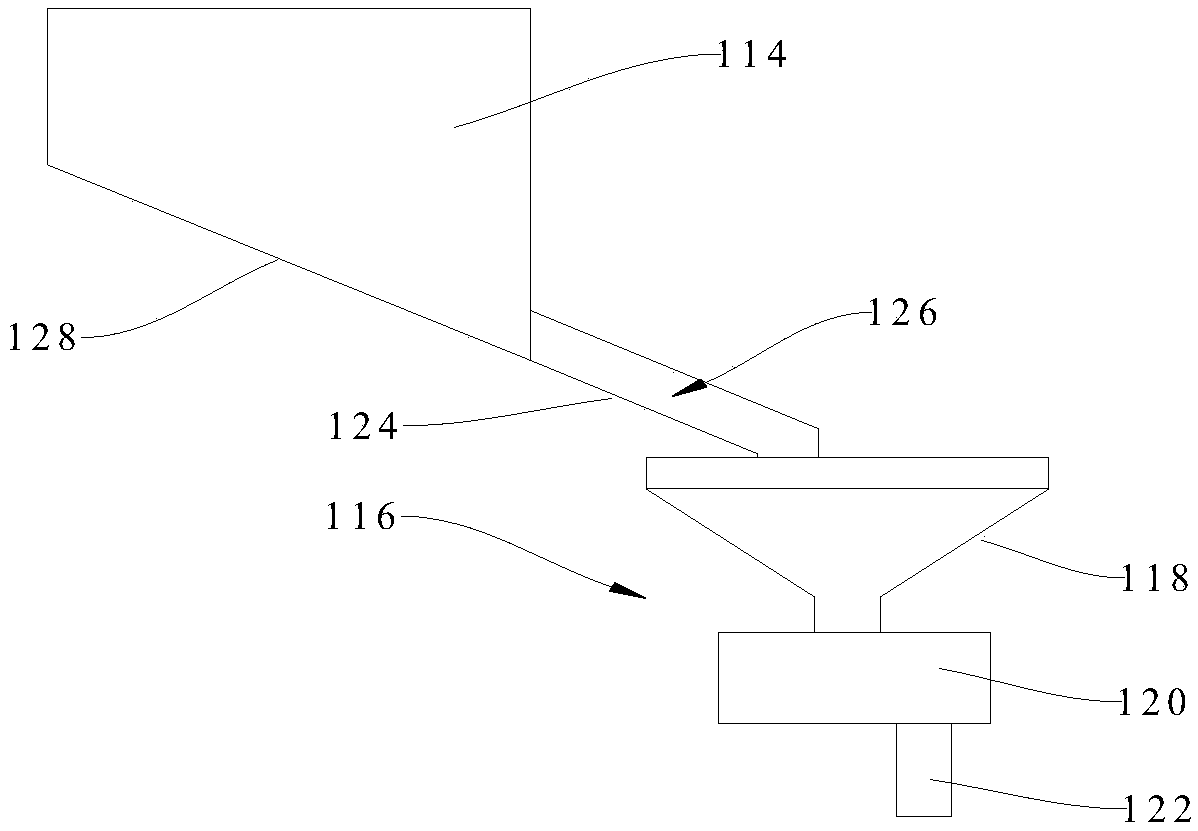

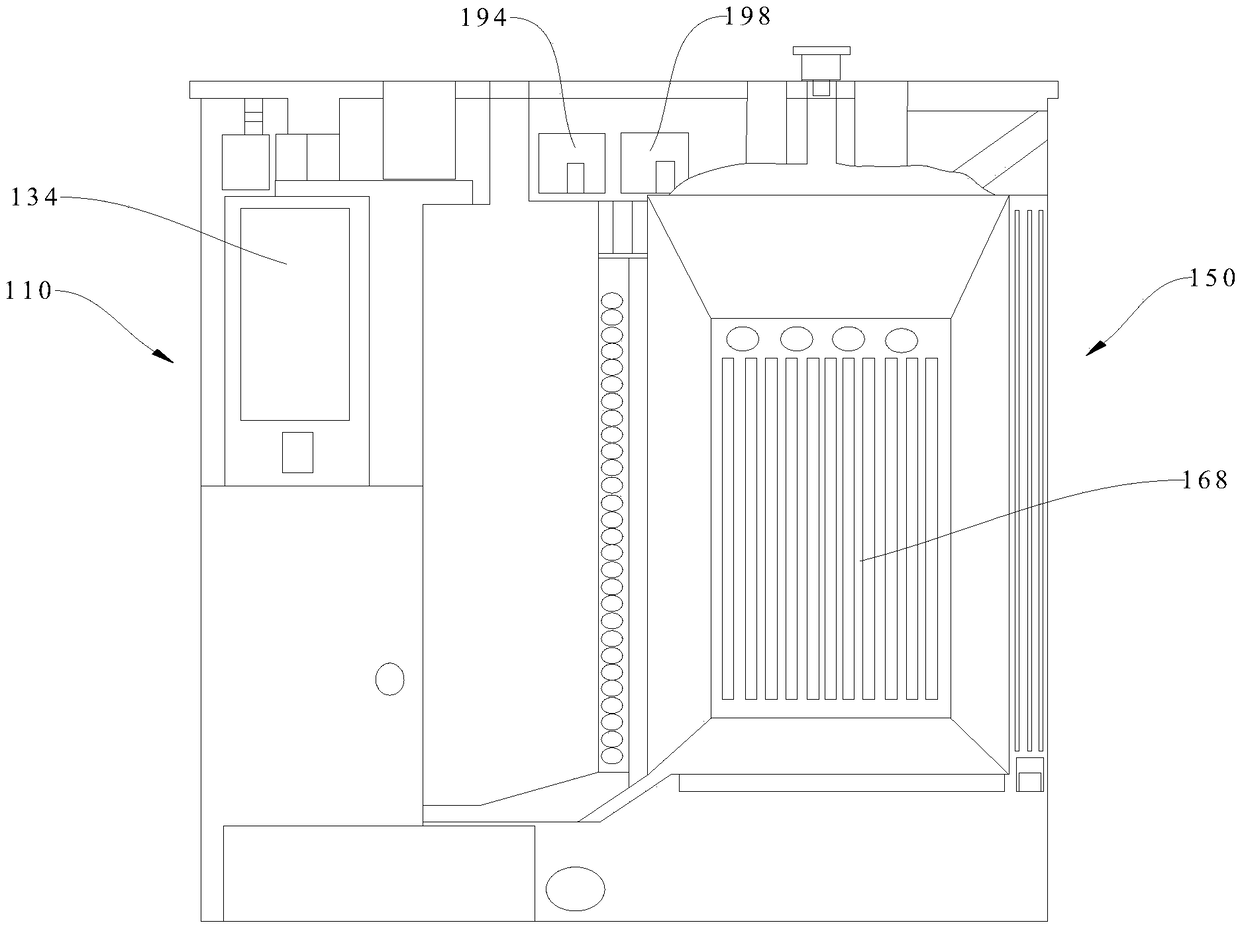

Winemaking machine and control system thereof

The invention relates to the field of winemaking equipment and provides a winemaking machine and a control system thereof. The winemaking machine mainly comprises a first drum, a second drum and a pumping component. The first drum is provided with a first storage cavity, the second drum is provided with a second storage cavity, and the first storage cavity and the second storage cavity are communicated mutually through the pumping component. Liquid in a winemaking process can be repeatedly stored in the first storage cavity or the second storage cavity through the pumping component. By winemaking with the pumping component for communication of the two drums, compared with a traditional home winemaking process, the winemaking machine has advantages that quantity of equipment can be sharplydecreased, high physical output in a winemaking process is avoided, and the sanitation level is raised. The control system of the winemaking machine mainly comprises a controller, a first temperaturesensor, a second temperature sensor and a liquid level sensor. In different winemaking steps, specific control behaviors of the controller are different, and accordingly the intelligent degree of thewinemaking machine is greatly increased, and convenience in winemaking is provided for users.

Owner:冯小虎

Preparation method of grape skin superfine powder with coffee aroma and solid grape skin beverage with coffee aroma

ActiveCN105595144ARuddy colorBitter coffeeFood shapingFood ingredient as flavour affecting agentFreeze-dryingCholesterol

The invention relates to a preparation method of grape skin superfine powder with a coffee aroma. The preparation method comprises the steps that wet grape skin is freeze-dried, coarsely smashed and then ground and smashed step by step to obtain the grape skin superfine powder with the coffee aroma. The obtained grape skin superfine powder can be used as a solid beverage to be directly and instantly drunk with hot water, and the beverage is ruddy in color and luster, has the bitter aroma of coffee and the aroma of grape fruits, is rich in nutrition, and has the healthcare functions of losing weight, reducing blood fat and cholesterol, protecting blood vessels and the like. In addition, the preparation method is simple and safe, and an efficient reutilization method is provided for grape skin waste residues generated in the wine brewing production process. Meanwhile, the invention relates to the solid grape skin beverage with the coffee aroma, and the healthy and delicious beverage is provided for people.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method and Device for Estimation of Alcohol Content in Fermentation or Distillation Vessels

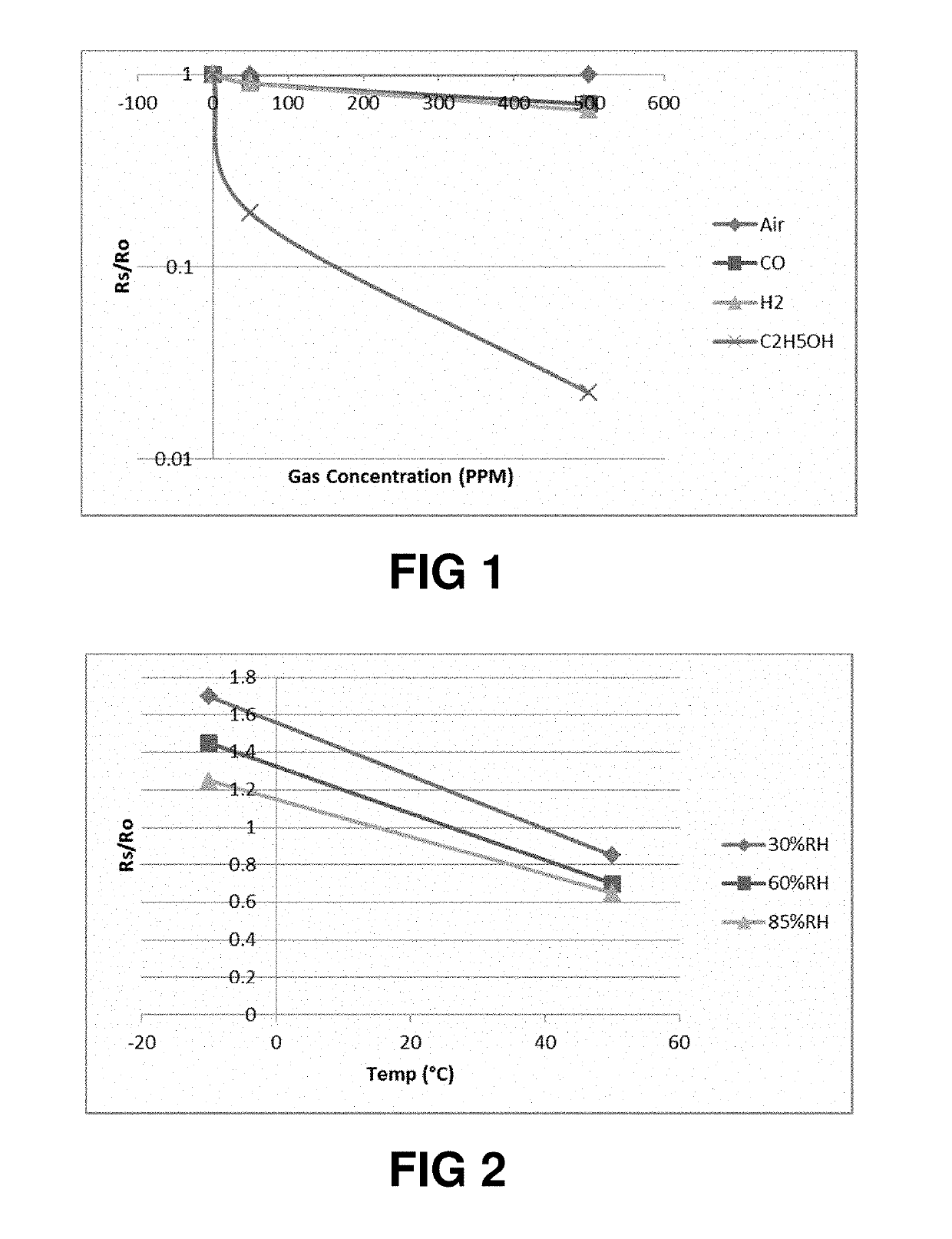

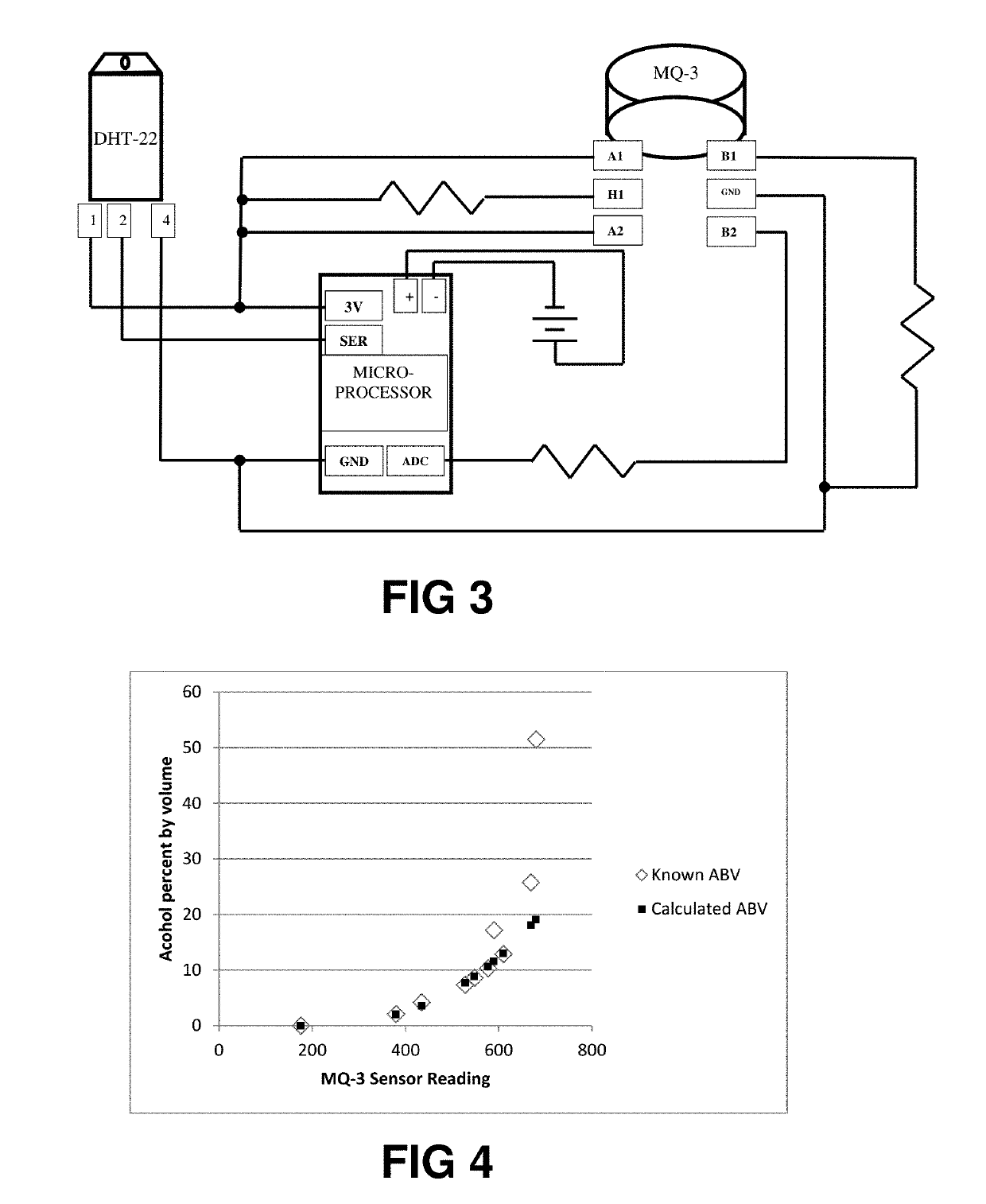

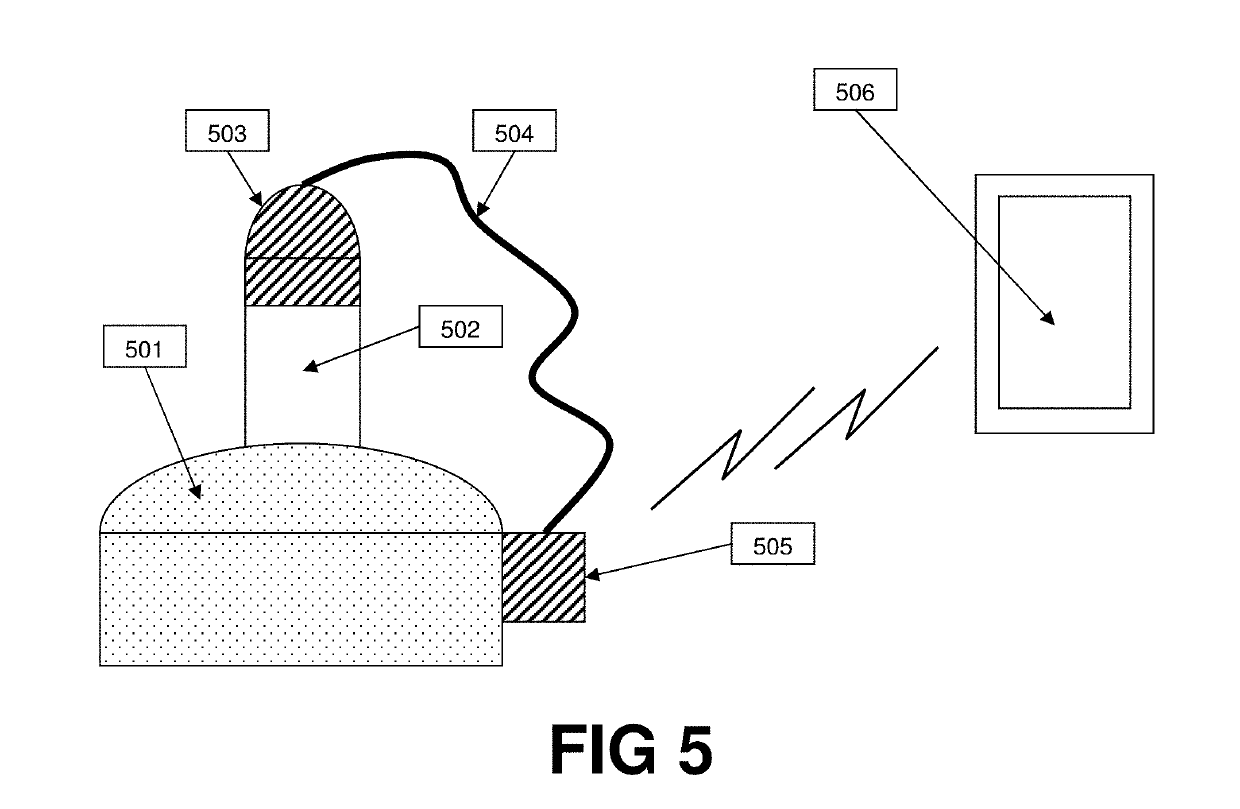

InactiveUS20190145947A1Low costTesting beveragesWithdrawing sample devicesAlcohol contentDistillation

The subject matter described herein relates to a device and method for estimating the alcohol-by-volume (ABV) of a liquid inside a fermentation or distillation vessel, without opening the vessel or requiring a liquid sample. Other properties of the liquid may also be estimated using this method, by including additional sensors in the device. This method has particular, but not exclusive, application in the home brew, microbrew, home and small batch winemaking, and small-batch distillery industries.

Owner:MCCARTHY WIL

Myrciaria cauliflora low-sugar biscuit and making method thereof

The invention discloses a myrciaria cauliflora low-sugar biscuit and a making method thereof. The making method of the myrciaria cauliflora low-sugar biscuit includes: subjecting myrciaria cauliflora wine dregs to drying, smashing and screening, mixing the myrciaria cauliflora wine dregs with butter, xylitol, eggs, stevia rebaudianum powder, mint powder and low-gluten flour evenly, kneading to form a dough, shaping, and baking to obtain the myrciaria cauliflora low-sugar biscuit. Being obtained after myrciaria caulifloras are fermented to make red wine and then reutilized to make baijiu by distilling, the wine dregs are low in sugar content, the xylitol and the stevia rebaudianum powder are added to serve as sweetening agents, and accordingly the made biscuit is low in sugar content and suitable for diabetics. The myrciaria cauliflora low-sugar biscuit and the making method thereof has the advantages that the biscuit is made without addition of any pigment or food additive in the making process, is brown in color and rich in myrciaria cauliflora taste, milk flavor and a cooling taste of mint, a slight aroma of wine, specific sour and sweet flavors, looseness and softness in mouthfeel and sweetness and aroma in aftertaste are provided, health efficacies of oxidation resisting and blood sugar decrease assisting are achieved, and accordingly the biscuit is natural food suitable for people of all ages and the diabetics, and by-products obtained in the myrciaria cauliflora wine brewing process are turned into wealth.

Owner:FUJIAN ACADEMY OF AGRI SCI SUBTROPICAL AGRI RES INST

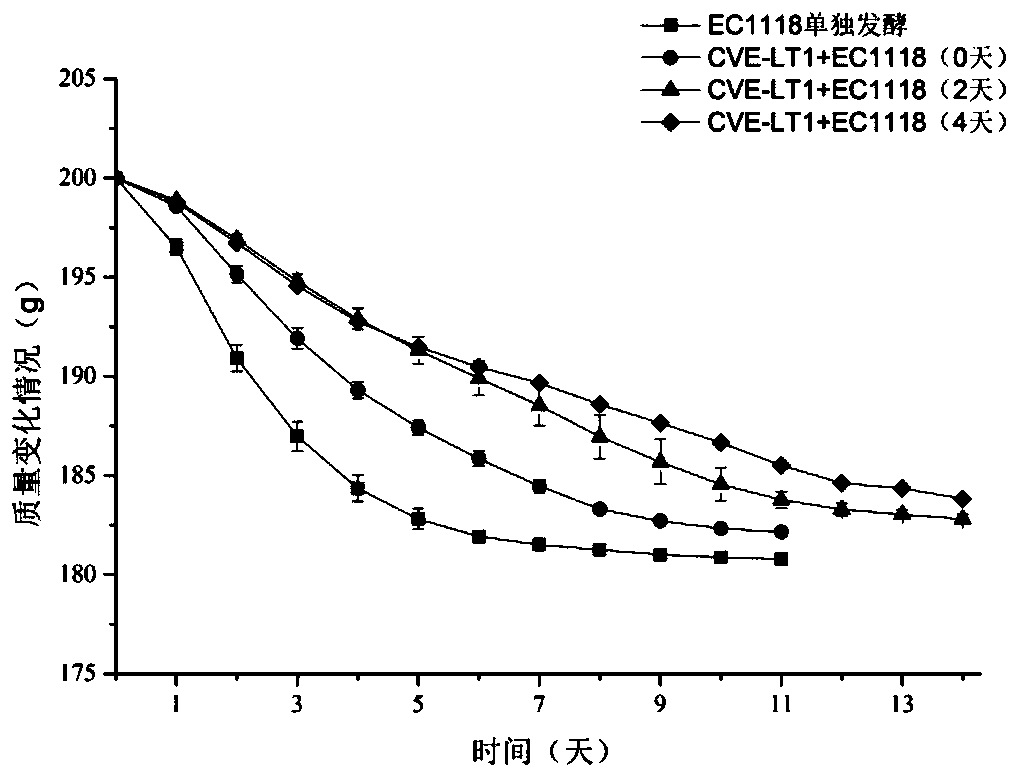

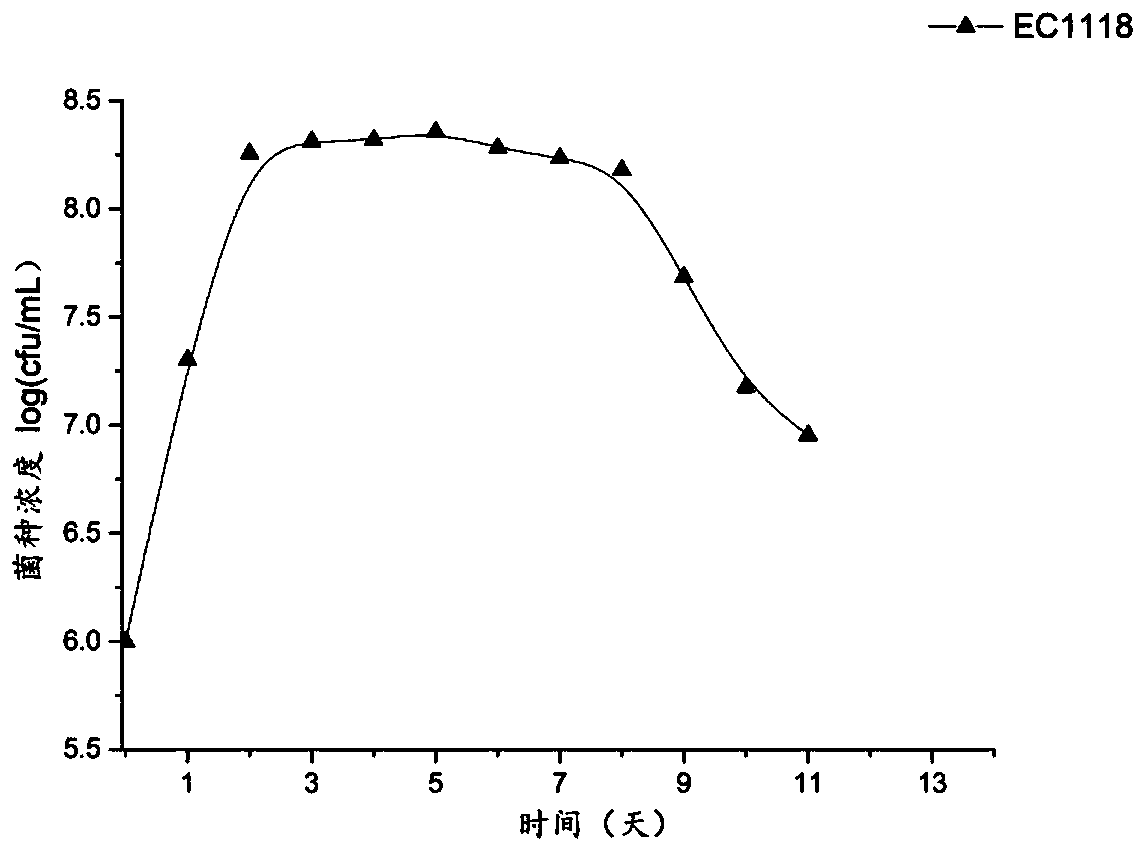

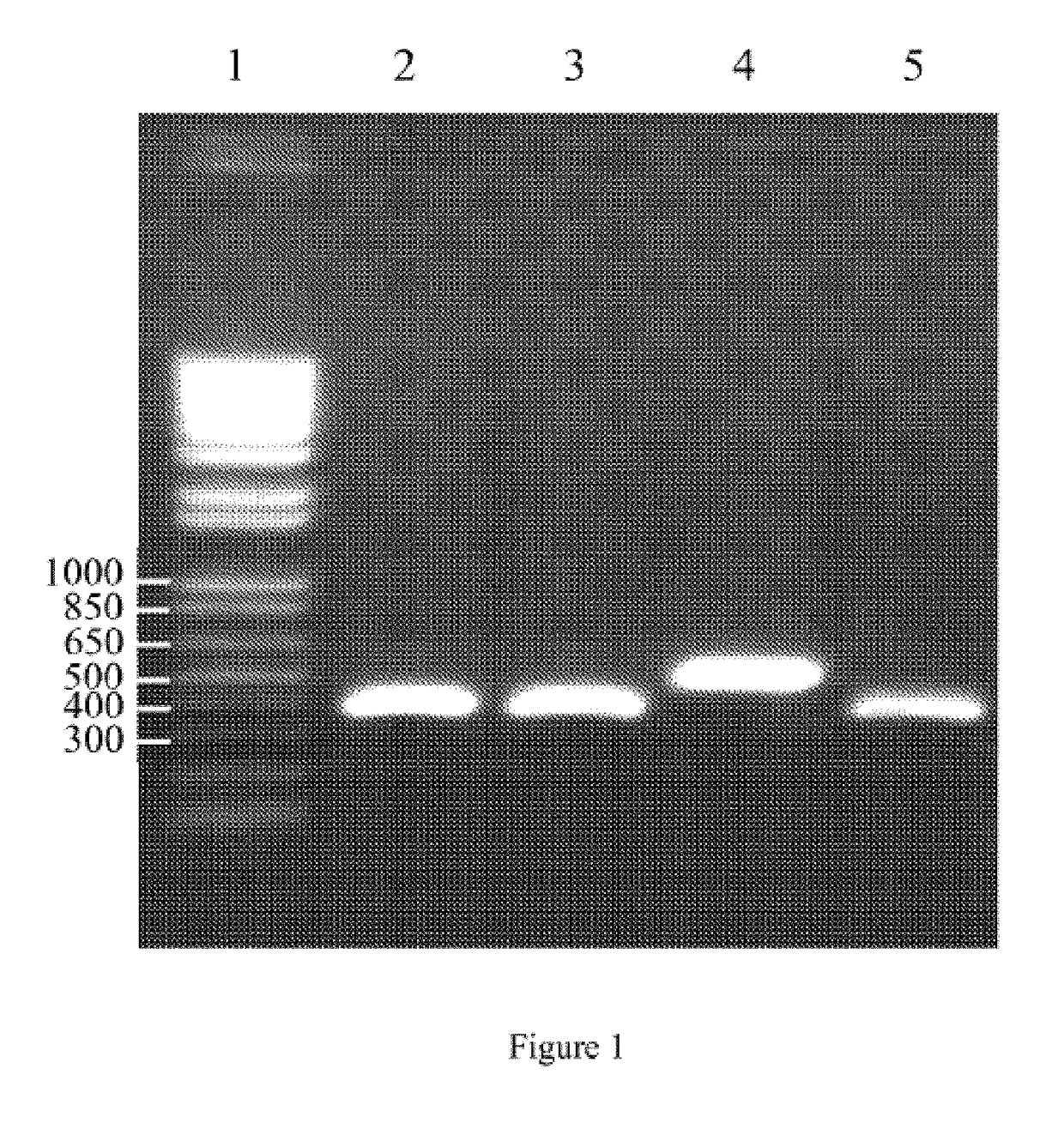

Kluyveromyces thermotolerans CVE-LT1 and application thereof in winemaking

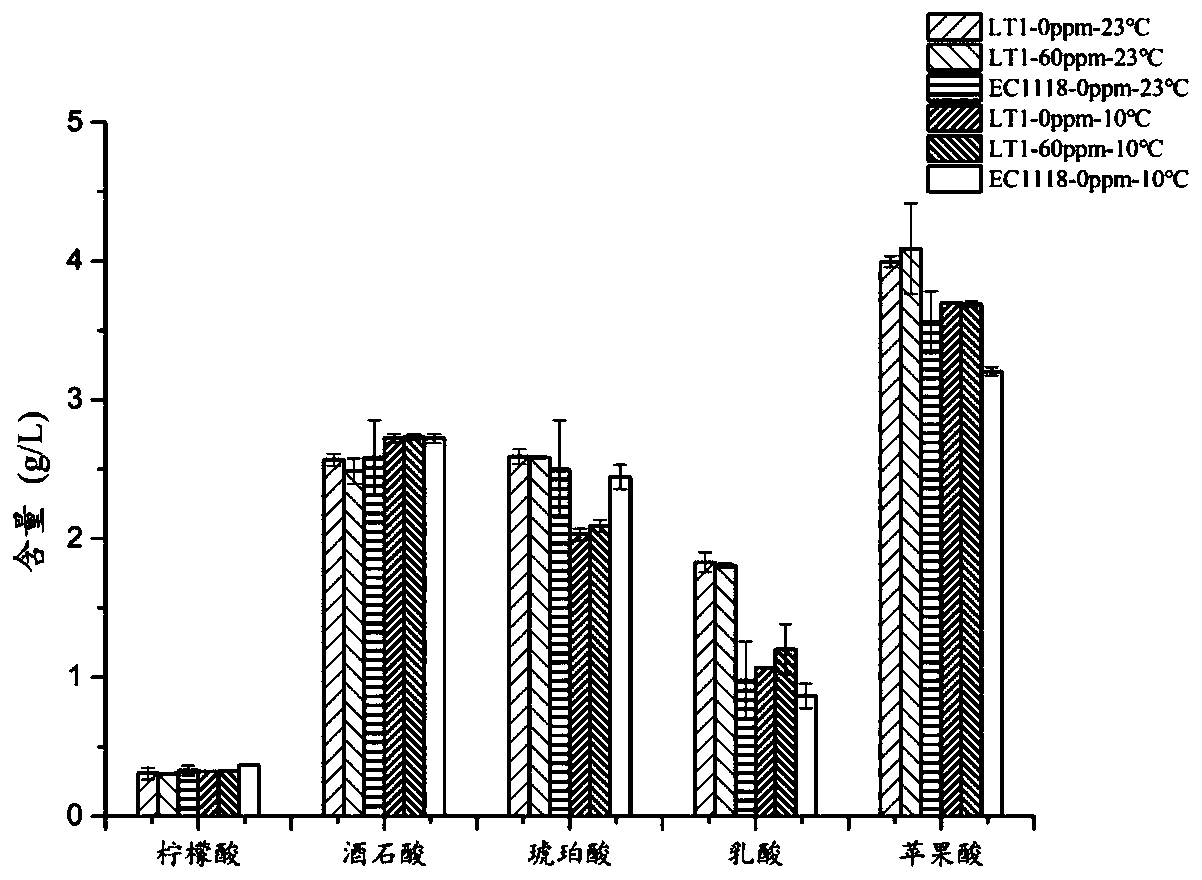

ActiveCN109929766AIncrease acidityIncrease aromaFungiMicroorganism based processesMicroorganismGrape wine

The invention relates to the technical field of microorganisms and particularly relates to heat-resistant kluyveromyces thermotolerans and application thereof in winemaking. The kluyveromyces thermotolerans CVE-LT1 is preserved in China General Microbiological Culture Collection Center in January 8, 2018 with the deposit number of CGMCC No. 15161. The kluyveromyces thermotolerans CVE-LT1 can increase the lactic acid content of the wine, increase the acidity of the wine, improve the final aroma of the wine to a certain extent, and enhance the floral and fruity aroma of the wine. The kluyveromyces thermotolerans is suitable for the grape region with low acidity, can enhance the aroma quality of the wine and is especially suitable for Xinjiang region.

Owner:ANGELYEAST CO LTD

Method for producing natural wine-flavored spice

PendingCN108841547AEfficient resource utilizationTake advantage ofAlcoholic beverage preparationMicroorganismFlavor

The invention discloses a method for producing natural wine-flavored spice by utilizing fermentation of winemaking by-products, and belongs to the technical field of food fermentation. The method mainly comprises two steps: step 1: fermenting and extracting fatty acids by using the winemaking by-products to obtain natural fatty acid wine-flavored spice; step 2: esterifying the fatty acids in fermentation broth in situ or esterifying the fatty acids in fermentation broth after purification to obtain natural fatty acid ester wine-flavored spice, wherein, the fatty acids are obtained by fermentation of microorganisms, and comprise at least one of acetic acid, lactic acid, butyric acid and hexanoic acid; esterification is carried out by firstly esterifying the fatty acids in the fermentation broth in situ and then extracting a product, or firstly extracting the fatty acids in the fermentation broth and then esterifying. The technology provided by the invention is green and safe, and the prepared product has natural fragrance.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

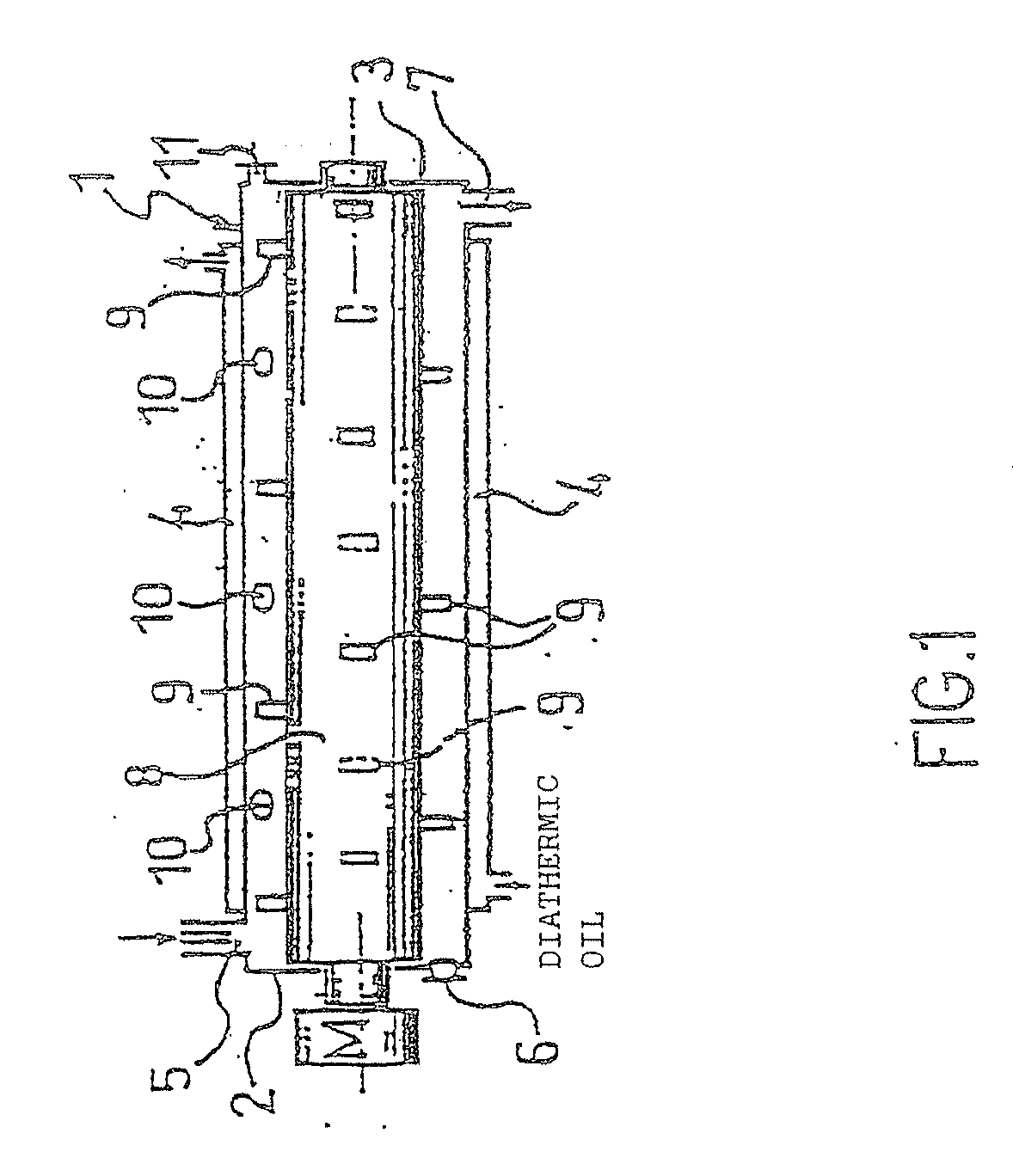

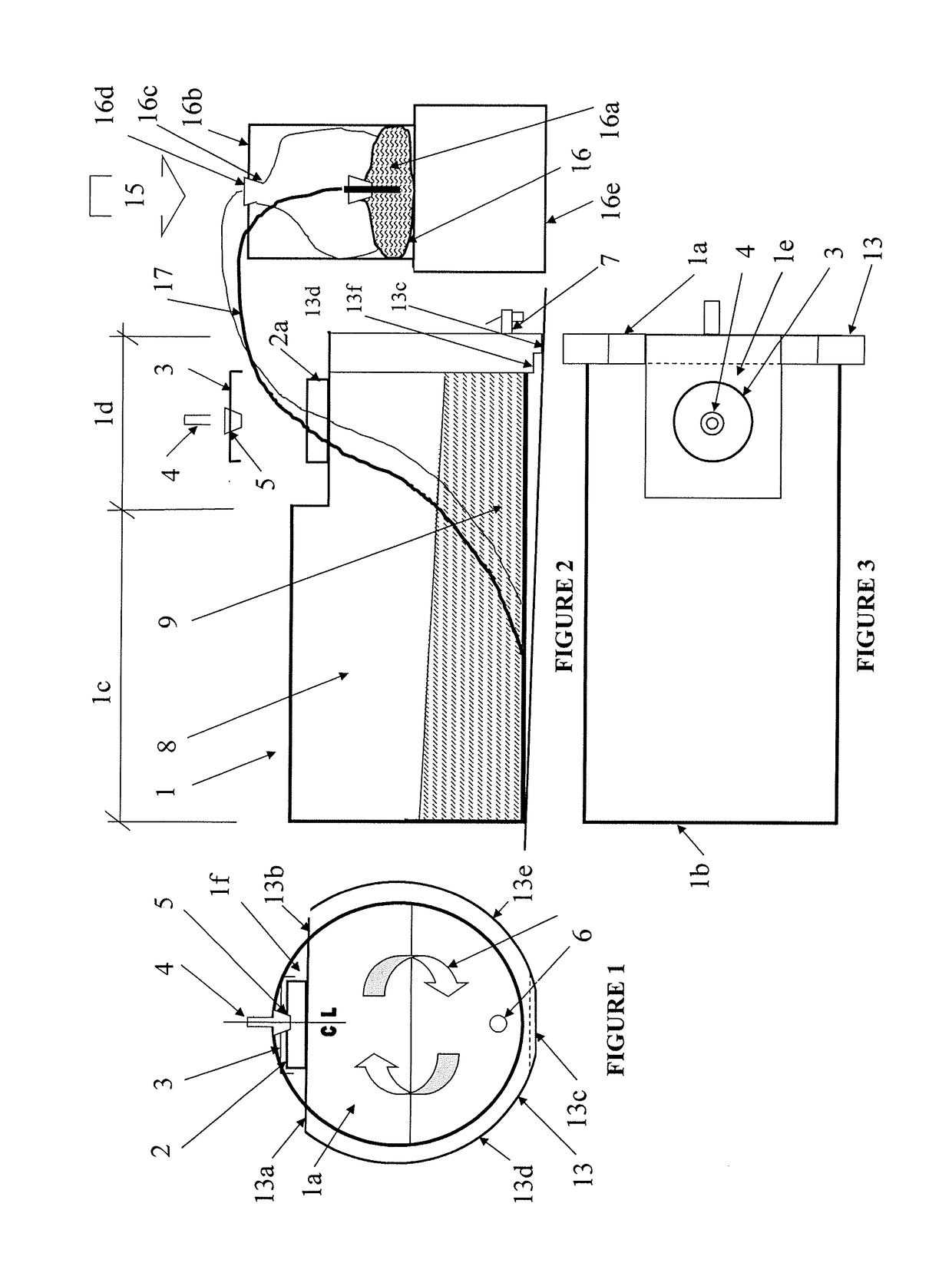

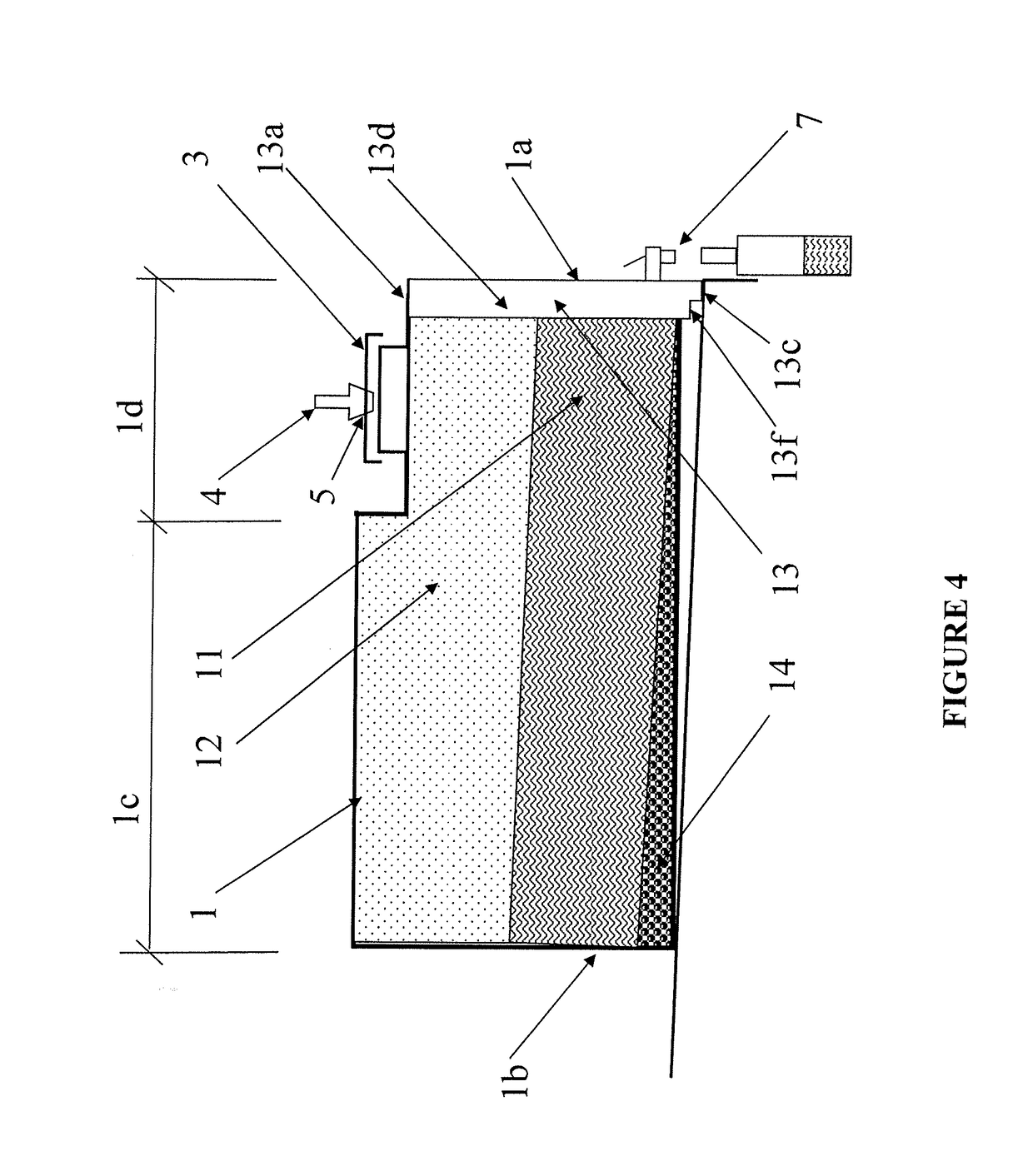

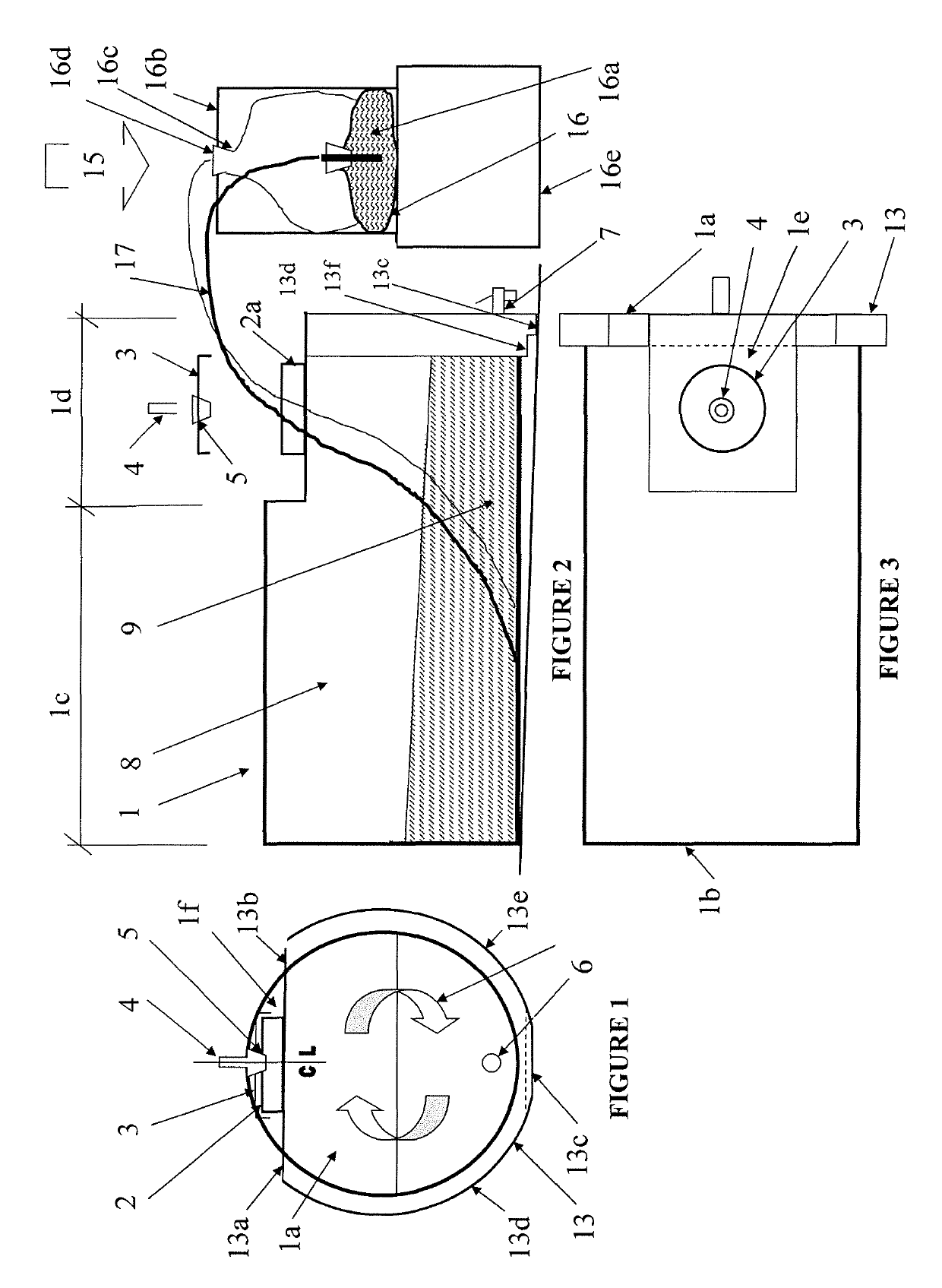

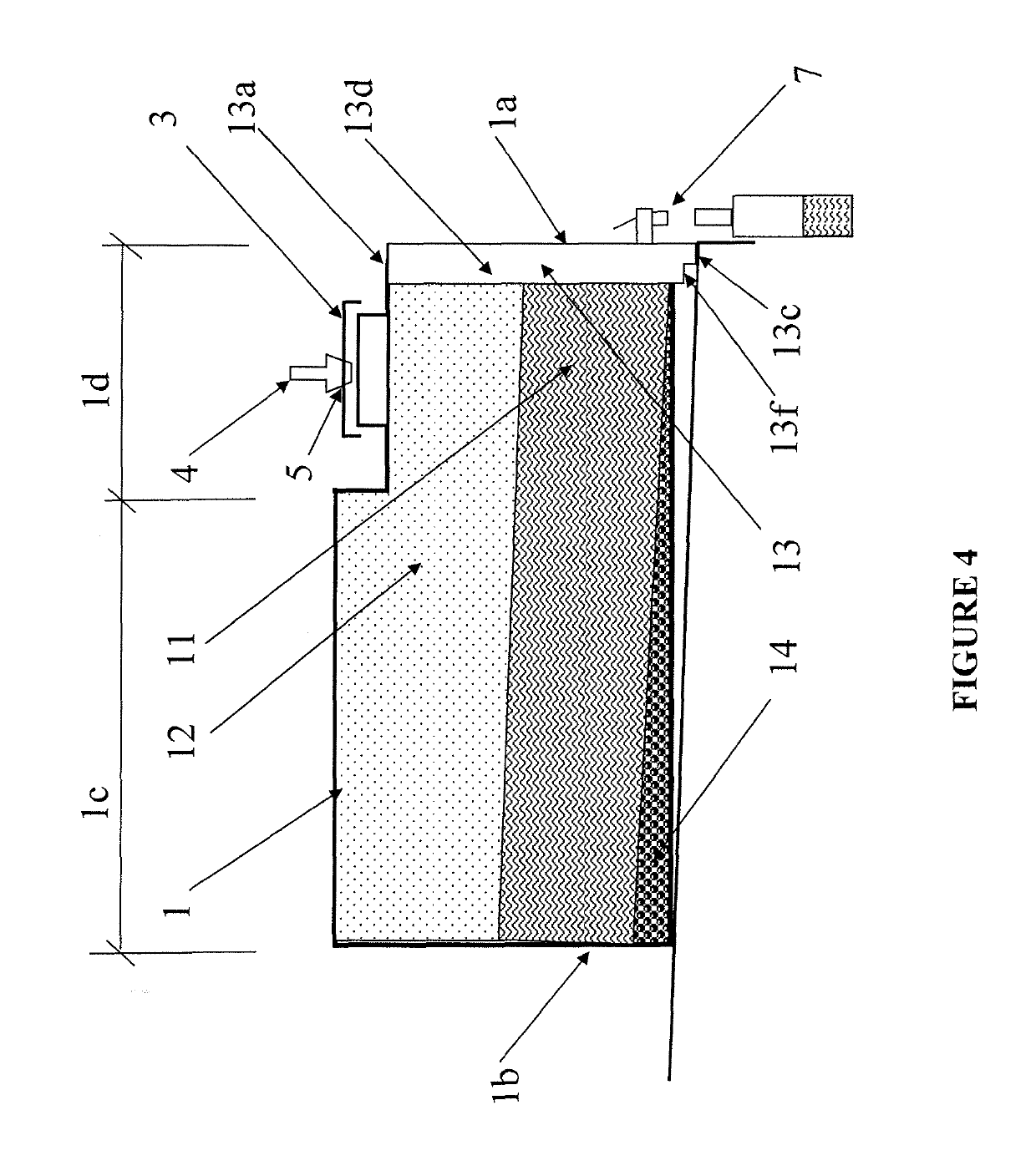

Single Stage Winemaking Apparatus and Method

A novel fermentation method uses a novel single stage horizontal cylindrical or partial cylindrical fermentor, larger in volume than the target volume of wine, which bounds the entire winemaking process. Fermentor has at least one opening for ingredient insert / removal, one-way venting gaseous closure, fermentor tilting prop, cavity space and bottling tap. Fermentor's cavity space and convex curvature underside provides for a fermentor rocking motion creating agitation and splashing for mixing the wine must and inducing ambient air / oxygen therein. A cavity space for fermentation foam expansion, heavier fermentation emitted CO2 gas purges out the ambient air / oxygen then retains CO2 gas providing a safe substantially oxygen free environment for a manually applied to the fermentor rocking motion creating agitation and splashing for mixing, degassing and resting the wine to clear in a safe substantially oxygen free environment until ready for direct bottling via bottling tap.

Owner:WINEMAKER WINE LTD

Jabuticaba sugar-free beverage and production method thereof

InactiveCN107279643ALow acquisition rateShort sweet aftertasteFood ingredient functionsFood additiveLithocarpus

The invention discloses a jabuticaba sugar-free beverage and a production method thereof. The jabuticaba sugar-free beverage is prepared from jabuticaba wine residue, which is generated after fermentation of wine, as a main material and lithocarpus polystachyus dry leaves and xylitol as auxiliary materials and through the steps of water boiling and filtration. The jabuticaba wine residue is obtained after the fermentation of wine and is free of sugar; by adding the lithocarpus polystachyus, the beverage has abundant taste; by adding the xylitol as a sweetener, the beverage is improved in taste. The beverage is sugar-free, and is very suitable for diabetic patients. During production, there is no pigment and food additive added, and the beverage has a browny-red color and has a sweet and soft taste. The beverage has a delicate fruity taste and slight sour and astringent mouth feel, has a pleasant sour and sweet taste and abundant mouth feel, and is sweet and has long aftertaste. The beverage also has health-care effects of clearing heat to removing toxin, engendering fluid to moistening lung, reducing blood glucose, resisting oxidization, reducing fat and resisting tumor, so that the beverage is an excellent natural health-care product. The production method also turns waste byproducts, generated during the brewing process of jabuticaba wine, into useful resources.

Owner:FUJIAN ACADEMY OF AGRI SCI SUBTROPICAL AGRI RES INST

Rice wheat koji for winemaking and preparation process thereof

InactiveCN110317691AImprove performanceMeet the physical and chemical index requirements of distiller's yeastFungiAlcoholic beverage preparationSporeMicroorganism

The invention belongs to the field of winemaking, and particularly provides a rice wheat koji for winemaking and a preparation process thereof. According to the preparation process, on the basis of the traditional cooked wheat koji, raw materials and microbial composition of the koji are changed, specifically, wheat and rice are adopted and mixed in a certain proportion as raw materials for the rice wheat koji, and aspergillus oryzae Su-16 and sake aspergillus oryzae (AOK 139) as inoculating microorganisms are adopted as inoculating microorganisms to prepare composite spore suspension and areused as koji inoculating microorganisms. Under the premise of the liquefaction enzyme activity and the saccharification enzyme activity of the rice wheat koji are equivalent to that of the traditionalcooked koji, the amount of the wheat used in the koji-making raw materials of the rice wheat koji is greatly reduced, thus the wine brewed with the rice wheat koji has a lower amino acid nitrogen content, lower chromaticity, less taste of wine soy sauce, comfortable mouthfeel and better color.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Yeast strains for the production of biomass on a substrate comprising a C5 sugar

The present invention concerns novel Saccharomyces cerevisiae yeast strains capable of multiplying on a substrate comprising at least one C5 sugar with a speed and rate of multiplication compatible with the industrial production of yeast. It also concerns novel strains which, when cultured, make it possible to obtain yeasts having an application efficiency, i.e. an efficiency that is satisfactory in applications and uses of interest in industries such as breadmaking, biomass production, flavour production, the production of secondary metabolites, protein production, ethanol production, brewing, winemaking or the production of yeast extract.

Owner:LESAFFRE & CIE

Single stage winemaking apparatus and method

A novel fermentation method uses a novel single stage horizontal cylindrical or partial cylindrical fermentor, larger in volume than the target volume of wine, which bounds the entire winemaking process. Fermentor has at least one opening for ingredient insert / removal, one-way venting gaseous closure, fermentor tilting prop, cavity space and bottling tap. Fermentor's cavity space and convex curvature underside provides for a fermentor rocking motion creating agitation and splashing for mixing the wine must and inducing ambient air / oxygen therein. A cavity space for fermentation foam expansion, heavier fermentation emitted CO2 gas purges out the ambient air / oxygen then retains CO2 gas providing a safe substantially oxygen free environment for a manually applied to the fermentor rocking motion creating agitation and splashing for mixing, degassing and resting the wine to clear in a safe substantially oxygen free environment until ready for direct bottling via bottling tap.

Owner:WINEMAKER WINE LTD

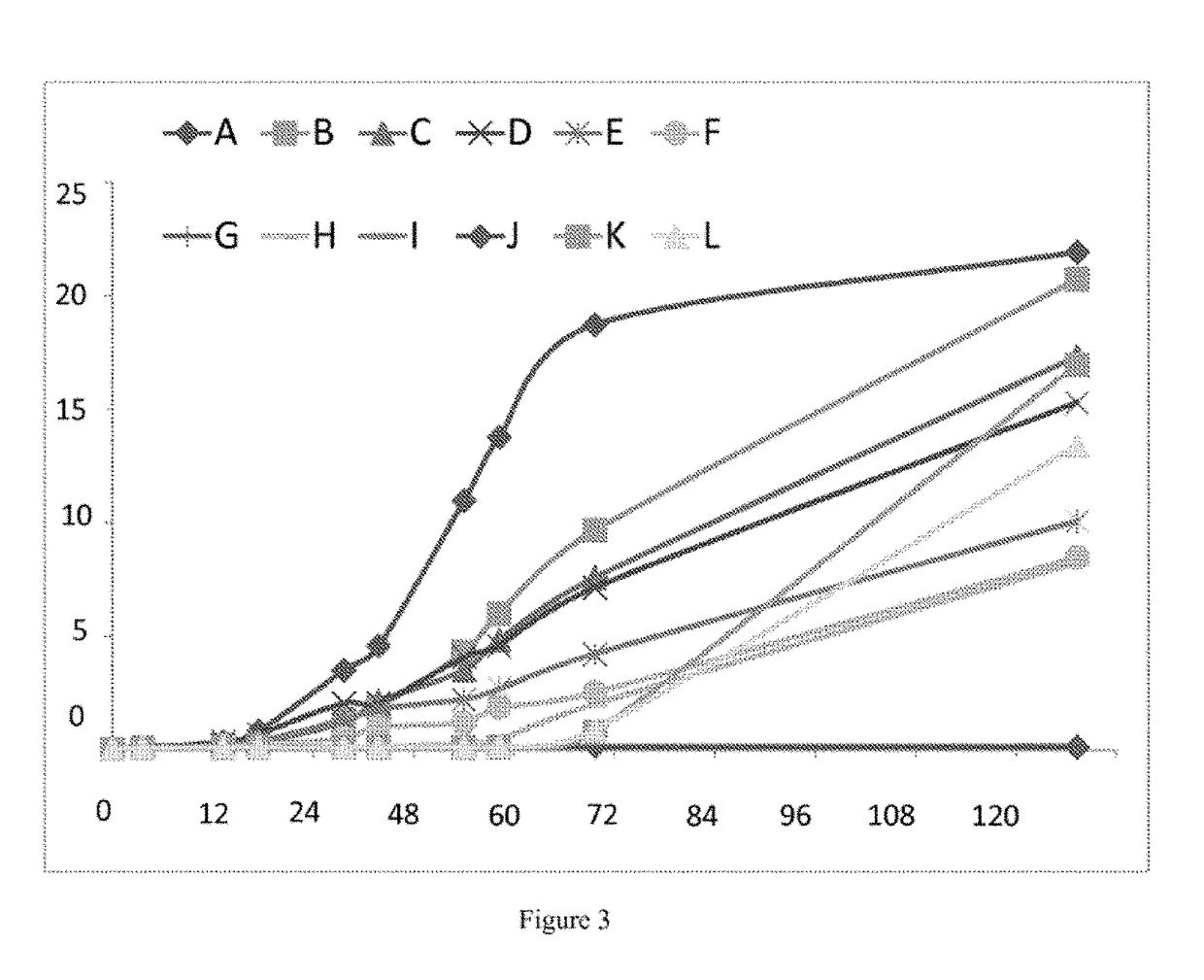

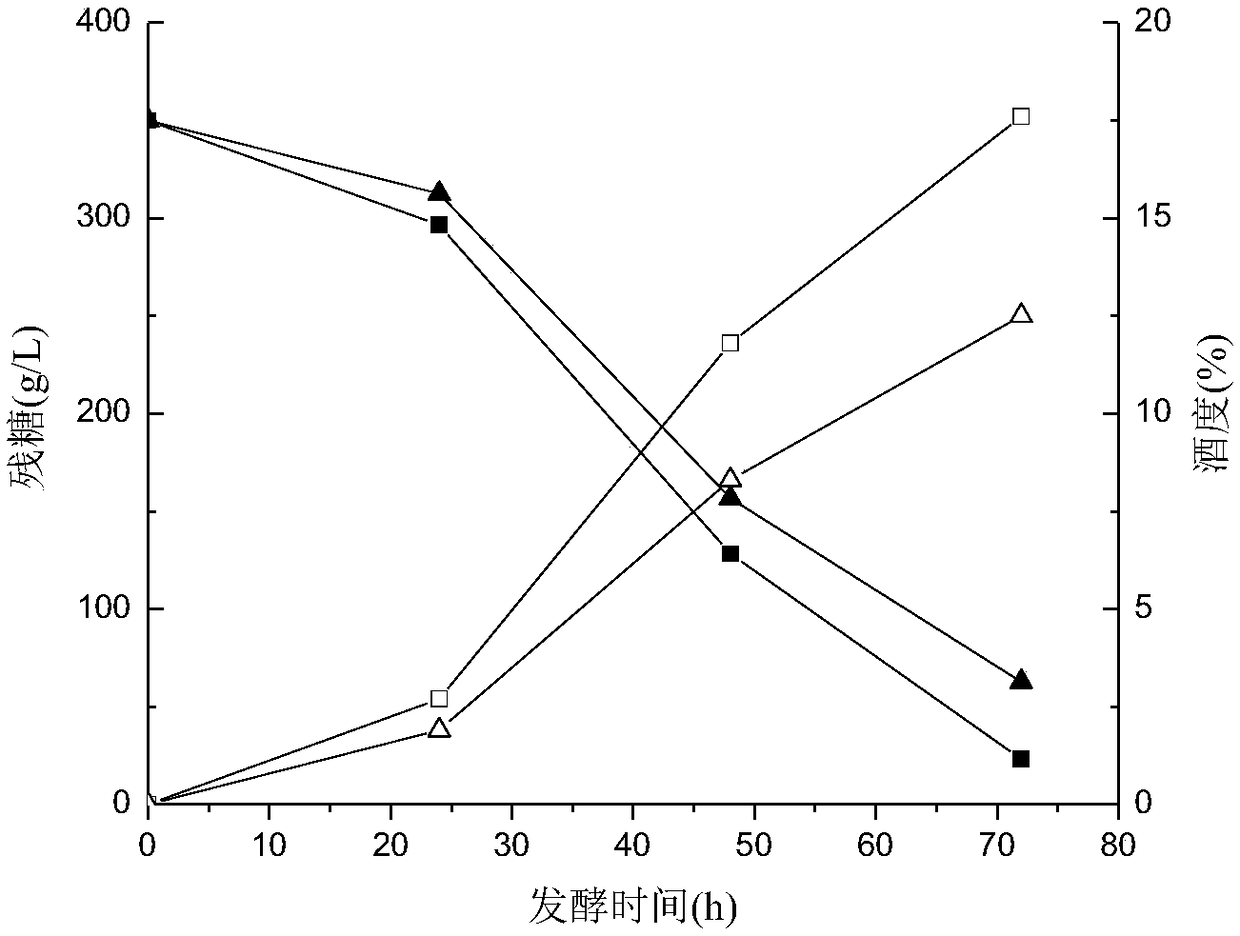

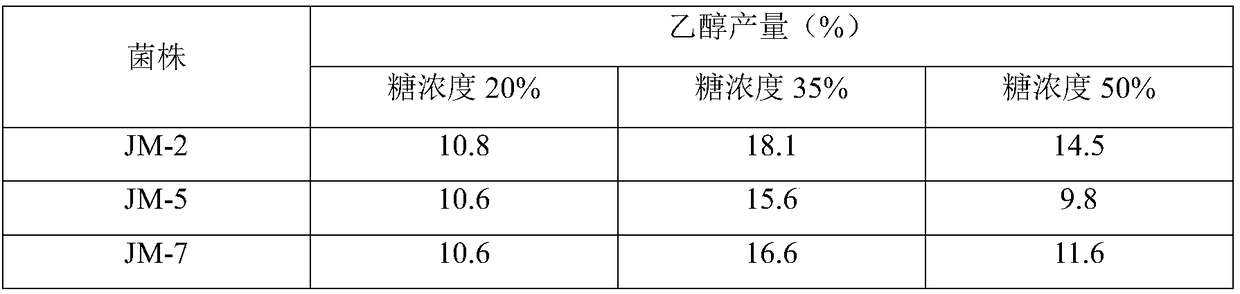

Sugar-tolerant ethanol-resistant brewing yeast and application thereof

ActiveCN108624517AIncrease profitImprove ethanol production capacityFungiMicroorganism based processesHigh concentrationBiotechnology

The invention belongs to the technical field of winemaking, and in particular relates to a new sugar-tolerant ethanol-resistant brewing yeast and application thereof. In view of the fact in the wine industry that higher sugar concentration or higher ethanol concentration inhibits yeast fermentation, a sugar-tolerant ethanol-resistant yeast is needed to increase the yield of ethanol. The inventionprovides a new strain of the sugar-tolerant ethanol-resistant brewing yeast, and the strain is preserved at the CGMCC with the preservation number of CGMCC No. 14069. The brewing yeast disclosed by the invention can tolerate 35% of sugar and 18% of ethanol, and is a new ethanol-producing yeast strain resistant to high concentration of sugar and high concentration of ethanol. The new valuable strain provided by the invention can effectively improve the utilization rate of raw materials for high-concentration sugar fermentation and improve the ethanol production ability, and has very high application value.

Owner:SICHUAN JIANNANCHUN GRP CO LTD

Grape wine brewing method with oak pieces

InactiveCN108485858AIncrease the sense of structureIncrease softnessWine preparationGrape wineBottle

The invention discloses a grape wine brewing method with oak pieces. The grape wine brewing method comprises the following steps: I, preparing oak pieces from waste oak buckets after wine storage; II,preparing fruit pulp from fresh organic wine brewing grapes, pumping the fruit pulp into an alcohol fermentation tank, adding the oak pieces at an amount of each kilogram of the fruit pulp corresponding to 2.5g of the oak pieces, uniformly mixing with the fruit pulp, and performing temperature controlled fermentation; after fermentation is completed, standing for 10 days, filtering, and taking out the oak pieces; III, putting new organic grape wine obtained through fermentation into a newly purchased oak bucket which is cleaned and sterilized, soaking other oak pieces for 30 minutes with 75%alcohol, draining off the water, soaking by adding 3g of the alcohol per kilogram of grape wine, threading the oak pieces with a small line, suspending in the oak bucket, sealing the oak bucket, storing the oak bucket for 1.5 years or greater at a constant temperature and constant humidity without noise, taking out, and putting wine into bottles. Due to the adoption of the oak pieces, plateau organic grape wine can be stable in wine color, the fragrance of the wine can be improved, and the texture property of the wine can be improved.

Owner:甘孜州康定红葡萄酒业有限公司

External member and method for wine brewed by household local method

The invention discloses an external member and a method for wine brewed by a household local method and belongs to the technical field of local wine brewing method. The external member is characterized by comprising a grape skin and seed filter (4), a grape skin squeezer (5), a grape skin crusher (6) and a grape juice extractor (7). The method is characterized by comprising the following steps: crushing grape seeds in the grape skin crusher (6); matching the grape skin squeezer (5) with a screen cylinder; allowing the grape skins and seeds to immerse in a fermentation container (3) in the grape skin and seed filter (4) so as to ferment; and transferring the fermented grape juice into a secondary fermentation container by utilizing the grape juice extractor (7) after the fermentation is ended. According to the external member for wine brewed by the household local method provided by the invention, the parts can be matched with one another and also can be independently used, the brewing efficiency and quality of the local method wine can be effectively improved, and the operation is convenient and sanitary.

Owner:张义胜

Lotus seed wine and processing technology thereof

InactiveCN110016404AGreat tasteIncrease alcohol productionAlcoholic beverage preparationProduction rateChaff

The present invention relates to the technical field of winemaking and particularly relates to lotus seed wine and a processing technology thereof. The lotus seed wine is prepared by the following technology: the lotus seed wine is characterized by being prepared from the following raw materials in parts by weight: 1,000 parts of raw lotus seeds, 180 parts of chaff, 50 parts of medium temperaturelarge koji blocks, 50 parts of low temperature large koji blocks and 2 parts of small koji blocks. The lotus seed wine is characterized in that the raw materials are subjected to crushing material feeding and more ground powder feeding, the crushing and grinding are combined to ensure a certain wine production rate, and at the same time, mouthfeel of the wine reaches the best; and a first materialsteaming and a final material steaming both uses steaming in clear soup, eight rounds are steaming and distilling together, and a wine-making amount of the lotus seeds is greatly improved.

Owner:龙游县铜鸟食品厂

Fruit juice lactic acid natural yeast and application of natural yeast in brewing of grape wine

InactiveCN105441346AIncrease soluble sugar contentHigh nutritional valueFungiWine preparationFruit juiceThermal insulation

The invention discloses fruit juice lactic acid natural yeast. The fruit juice lactic acid natural yeast is prepared in steps as follows: components including, in parts by weight, 7-10 parts of raisin, 13-16 parts of banana peels, 22-25 parts of corn juice and 15-18 parts of yogurt are mixed and put in a disinfected glass bottle, 17-20 parts of distilled water and 4-7 parts of maltitol are added, the mixture is uniformly stirred, the glass bottle is sealed, heating and thermal insulation are performed, 3-6 parts of honey are added, the mixture is uniformly stirred and subjected to thermal insulation, and the fruit juice lactic acid natural yeast is obtained. The invention further discloses an application method of the fruit juice lactic acid natural yeast in brewing of the grape wine. The fruit juice lactic acid natural yeast has high nutritional value and stable quality, can be preserved for a long time and is not prone to mildewing; the prepared grape wine tastes fine and has sufficient fruity flavor, heavy fragrance and good quality, the fermentation speed is high, breeding of contaminating microorganisms is avoided, the fermentation quality of raw wine is improved, and the nutritional value is higher.

Owner:福建北记食品有限公司

Flavored vinegar making process

InactiveCN108330053AAvoid brewingThe method of making vinegar is simpleVinegar preparationFruit wineWinemaking

The invention discloses a flavored vinegar making process. The flavored vinegar making process comprises mixing, soaking and washing the raw materials of sticky rice, wheat, medlar and sea buckthorn inside a washed vat, then steaming the raw materials inside a steamer; preparing wine from the steamed rice, and mixing fruit wine into the prepared wine until wine mash is thoroughly fermented; performing starter propagation to obtain thoroughly fermented vinegar mash; clarifying the vinegar mash and the wine mash to obtain aged mash, sealing the aged mash inside vats for fermentation; decocting vinegar for seasoning, performing filtering, sterilization, clarification for 2-4 days and then storage and bottling. The flavored vinegar making process produces vinegar through the new raw materials,a mixture of wheat, medlar, sea buckthorn and sticky rice, and adds in the fruit wine for seasoning during a winemaking process, thereby avoiding existing production of single and poor-taste vinegar.

Owner:镇江市恒升酿造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com