Patents

Literature

523results about How to "Good clarification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

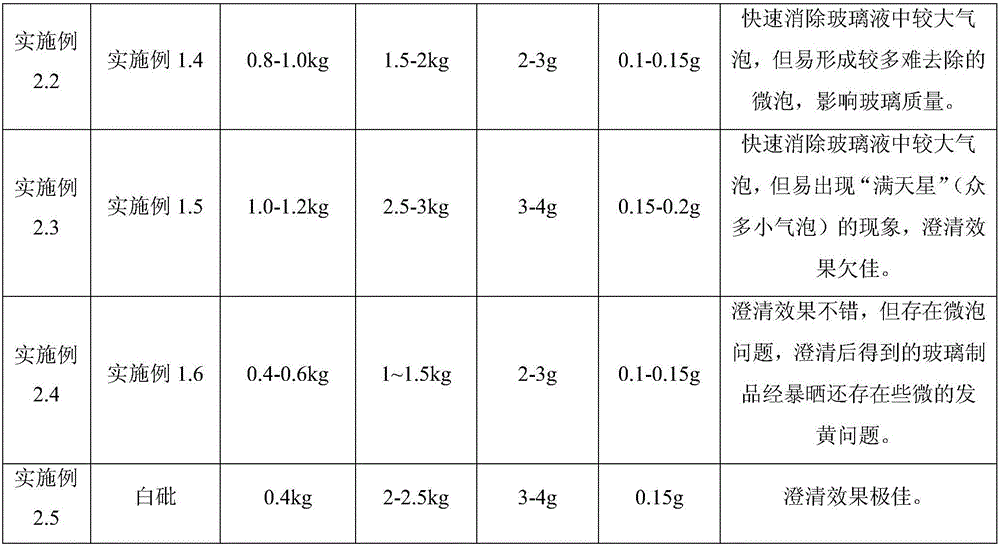

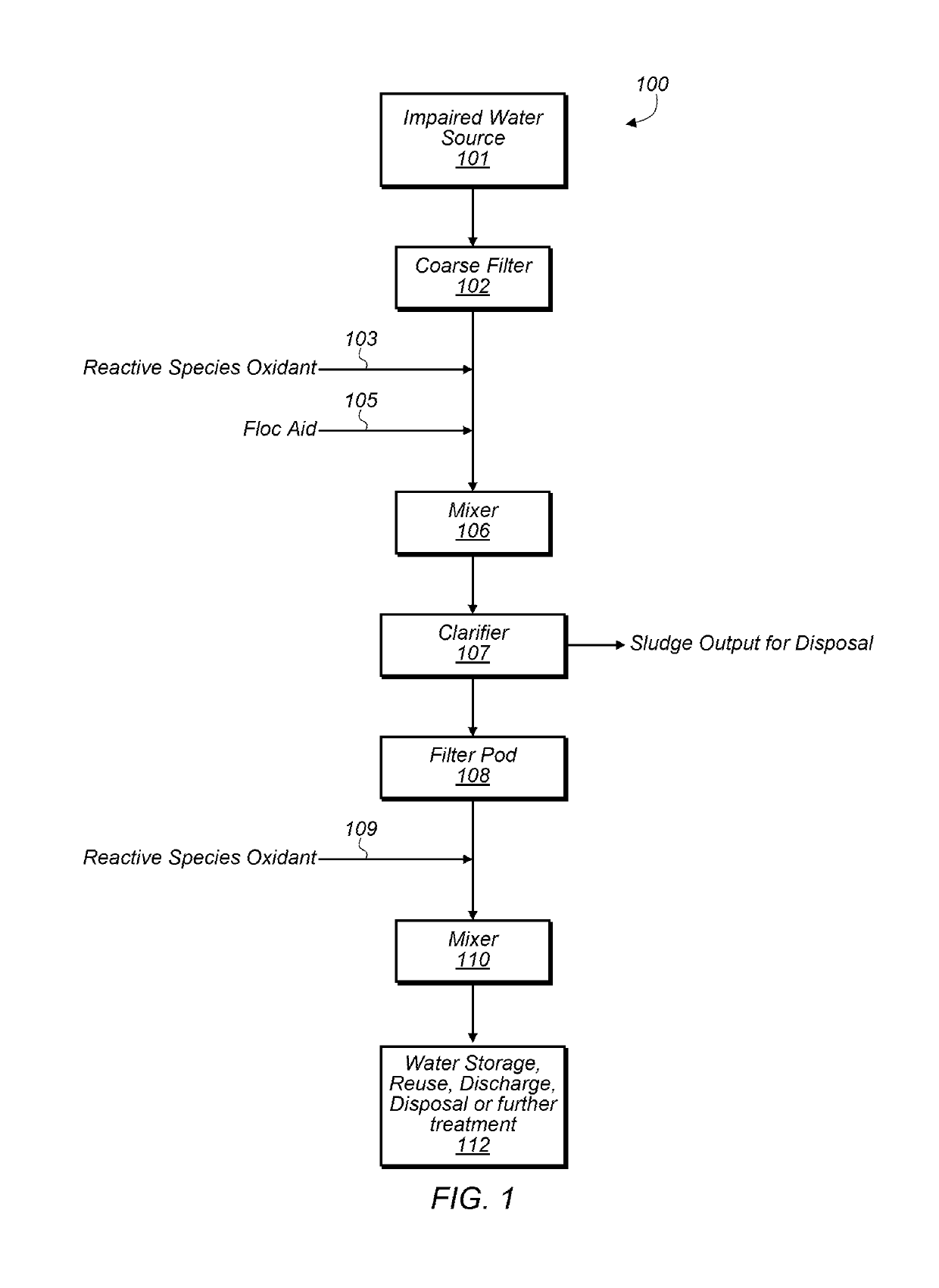

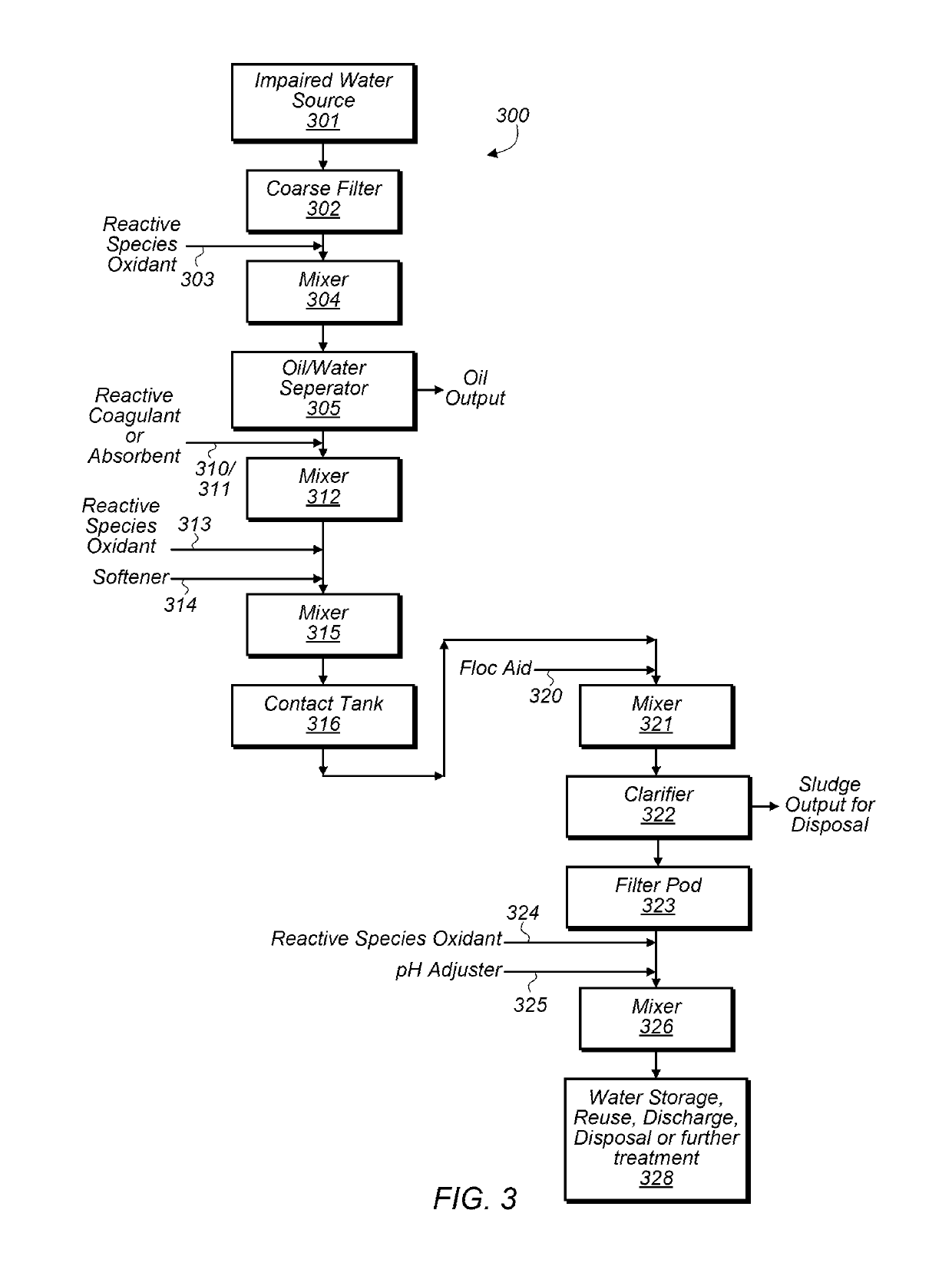

Systems and method of water treatment utilizing reactive oxygen species and applications thereof

ActiveUS20160068417A1Enhancing clarification and microbial controlEnhanced separationWaste water treatment from quariesSolid sorbent liquid separationPollutantEnvironmental chemistry

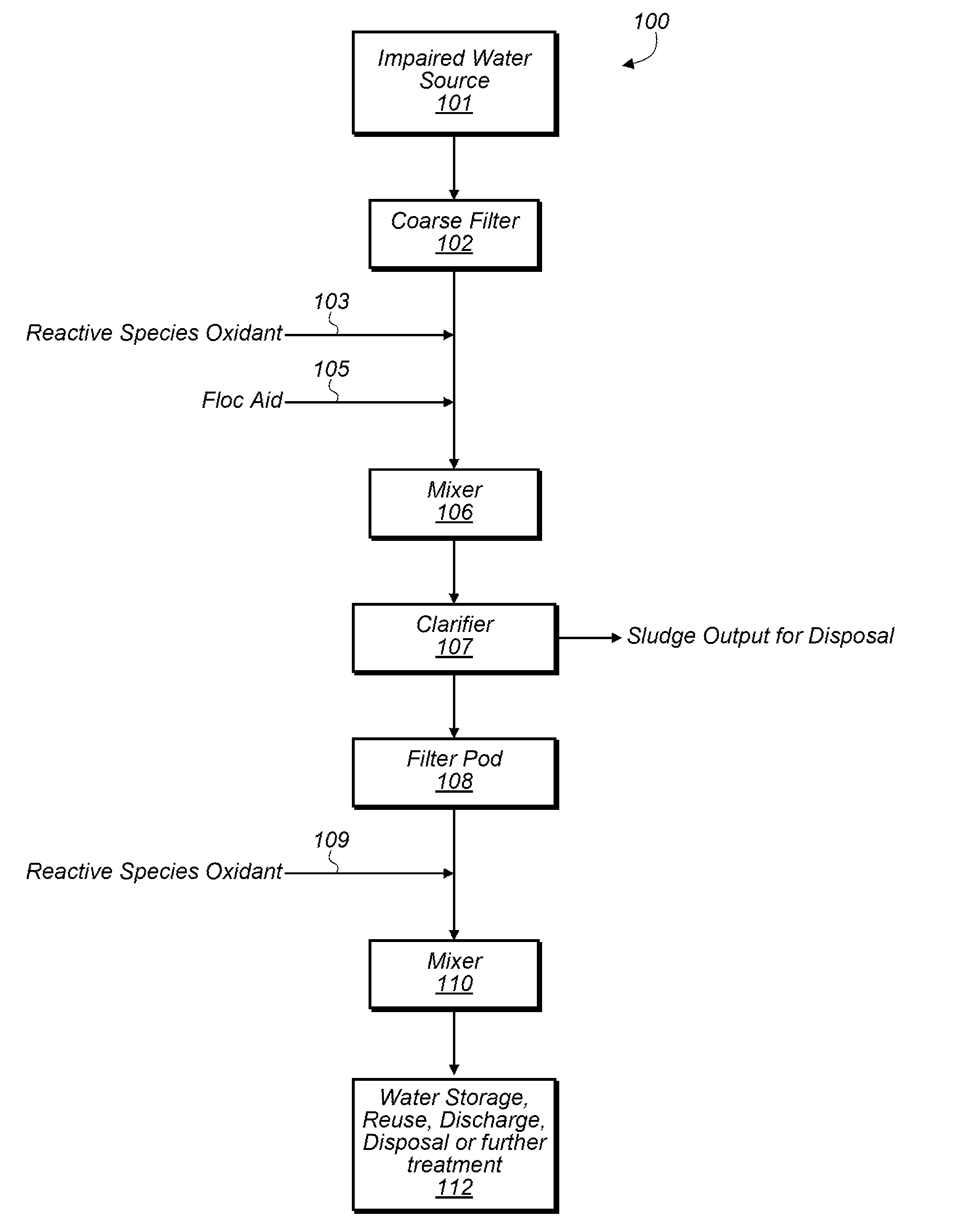

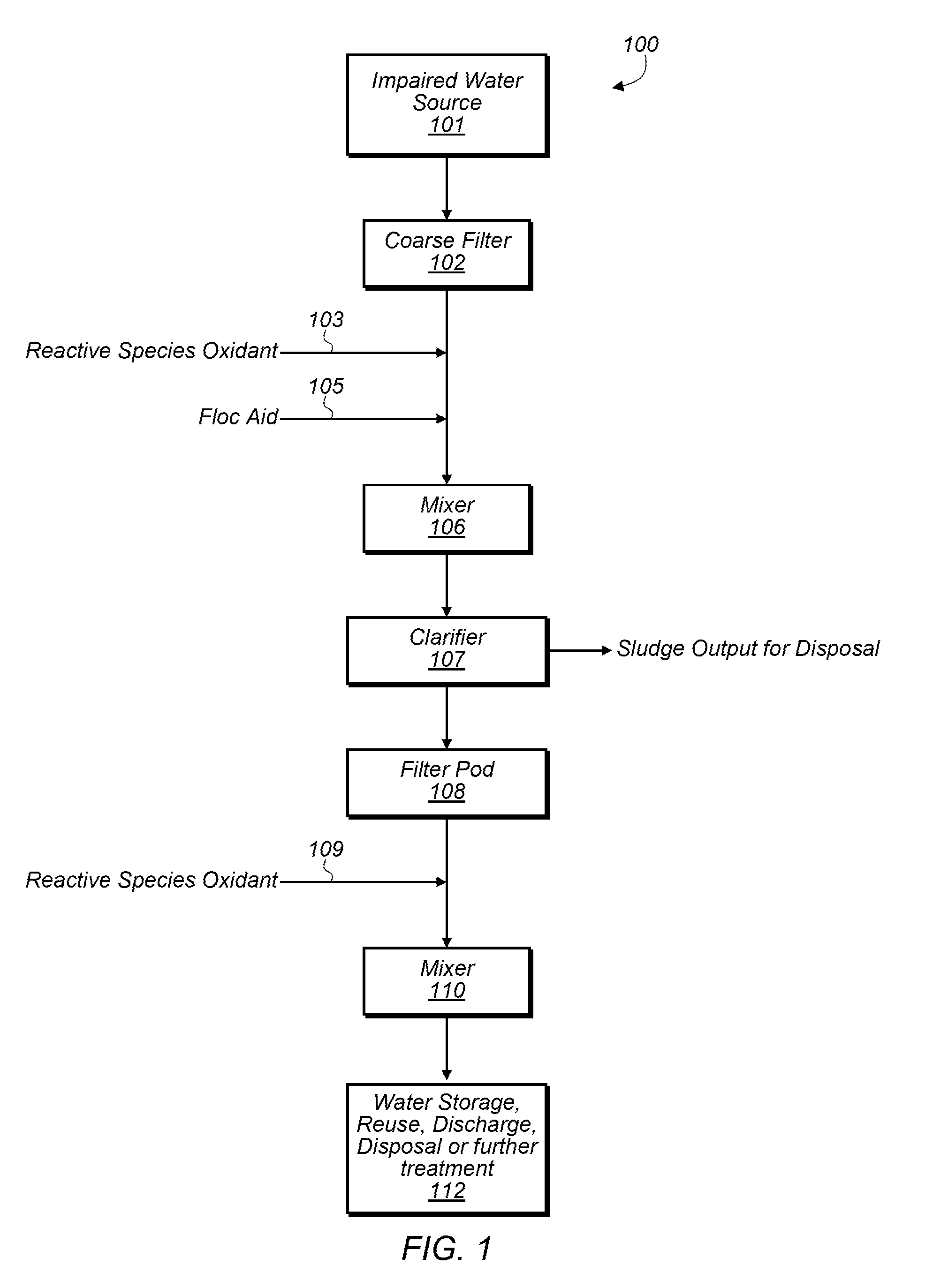

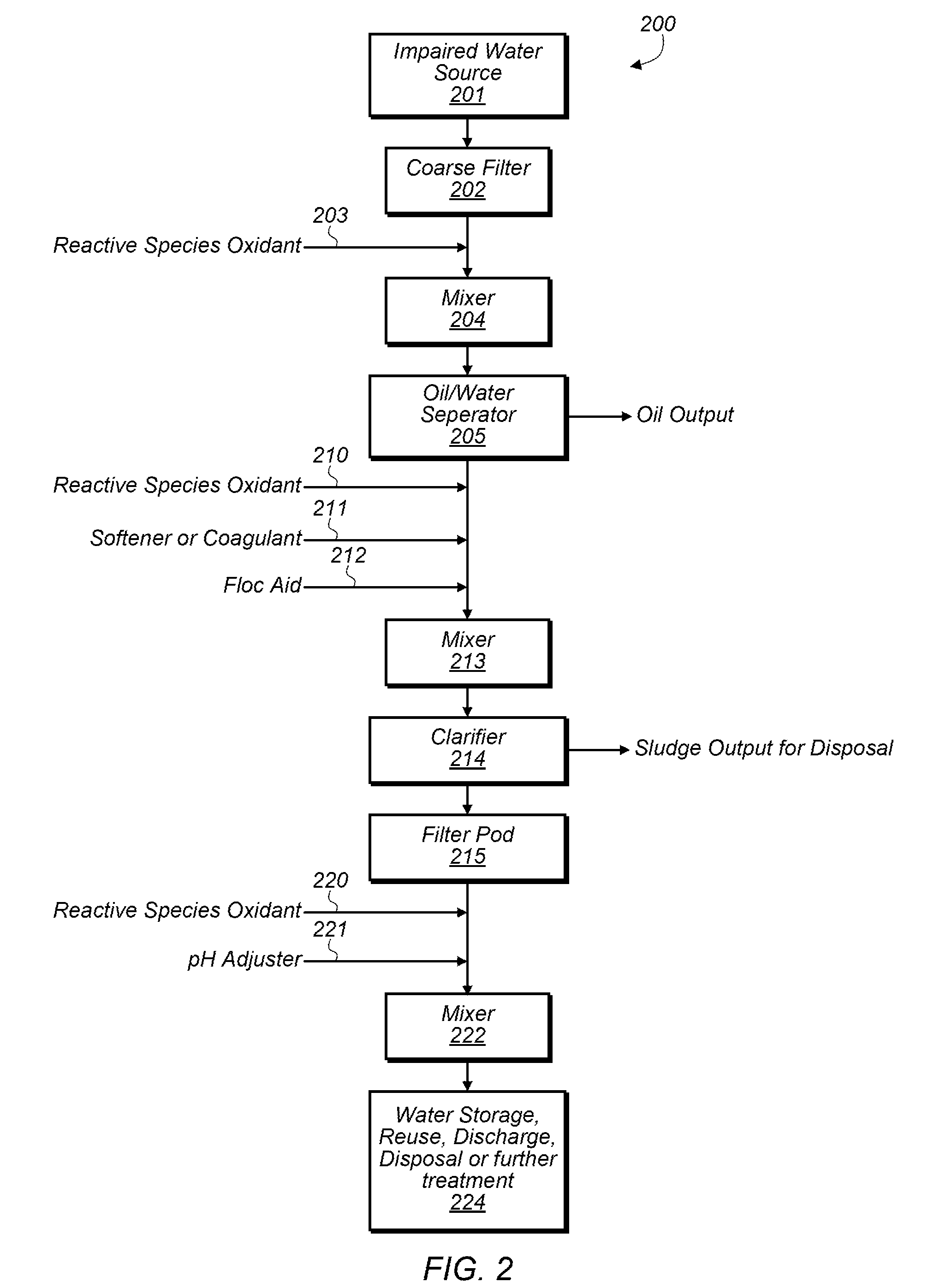

In some embodiments, a method may include separating contaminants from impaired water. The method may include contacting impaired water with a peracetate oxidant solution. The method may include mixing said impaired water with the peracetate oxidant solution. The method may include separating the impaired water oxidant solution mixture into solids and a water phase. In some embodiments, the peracetate oxidant solution may include peracetate anions and a peracid. The peracetate oxidant solution may have a pH from about 10 to about pH 12. The peracetate oxidant solution may have a molar ratio of peracetate anions to peracid ranging from about 60:1 to about 6000:1. In some embodiments, a peracetate anion to hydrogen peroxide molar ratio is greater than about 16:1. In some embodiments, a reactive coagulant, a softener, and / or a floc aid may be added to the impaired water.

Owner:CLEAN CHEM

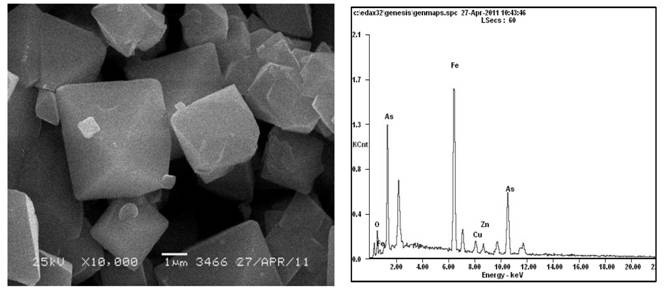

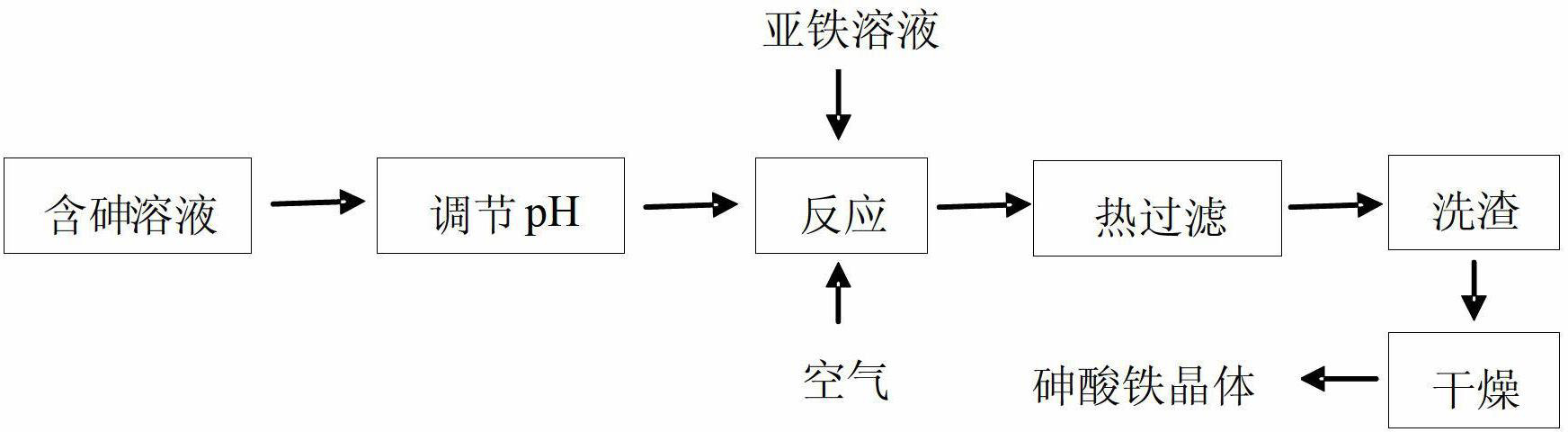

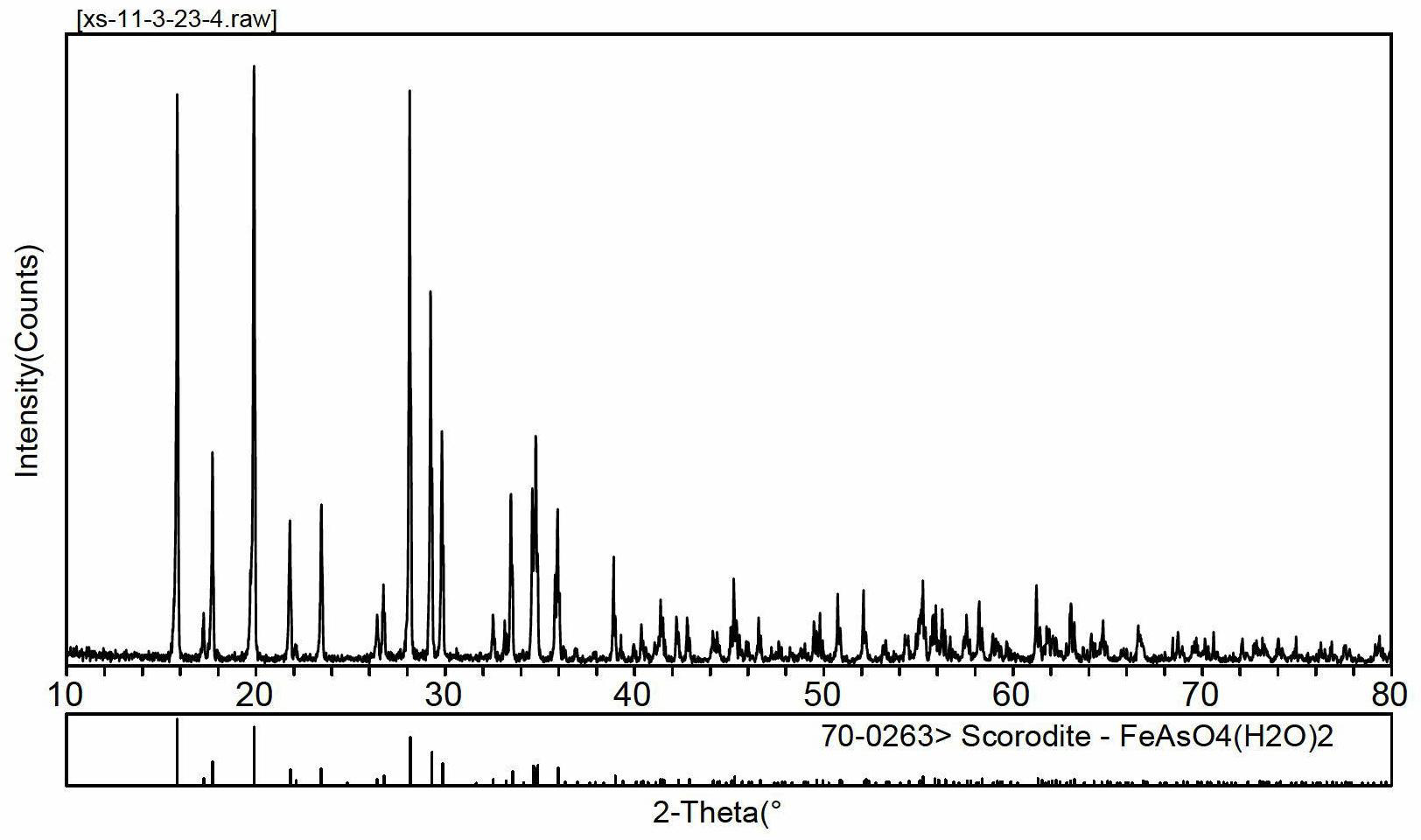

Method for precipitating and stabilizing As from As-containing solution

ActiveCN102674526ASimple preparation processLow equipment requirementsWater contaminantsWater/sewage treatment by oxidationFerrous saltsLimit value

The invention discloses a method for precipitating and stabilizing As from As-containing solution. According to the method, ferrous salt is used as As precipitator; through the air oxidation in the As-containing solution in a weak acid condition, Fe<2+> is oxidized into Fe<3+>; and Fe<3+> reacts with As to generate precipitate with high stability and low As leaching toxicity. The method is simple in technology, and generates the precipitate which is ferric arsenate crystalline compound-scorodite crystal FeAsO4. 2H2O under the conditions that the pH value is 4-6, the temperature is 70-95 DEG C, the molar ratio between Fe and As is 1-1.5, the air flow rate is 120-200L / h and the reaction time is 5-7h; the precipitate As has the leaching toxicity concentration of 1-2mg / L which is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007); and the harmless stabilizing treatment for the As-containing solution can be realized.

Owner:CENT SOUTH UNIV

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

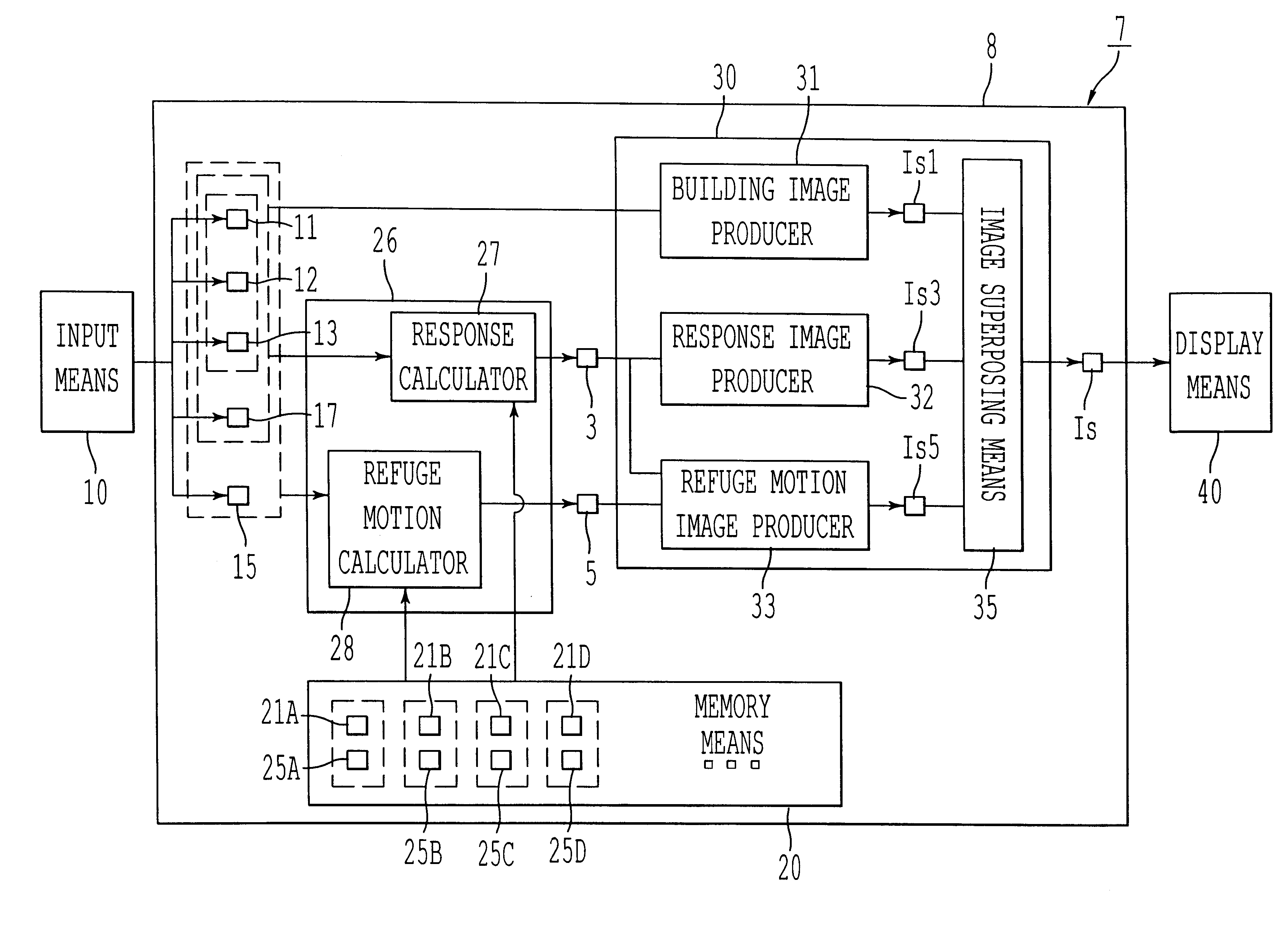

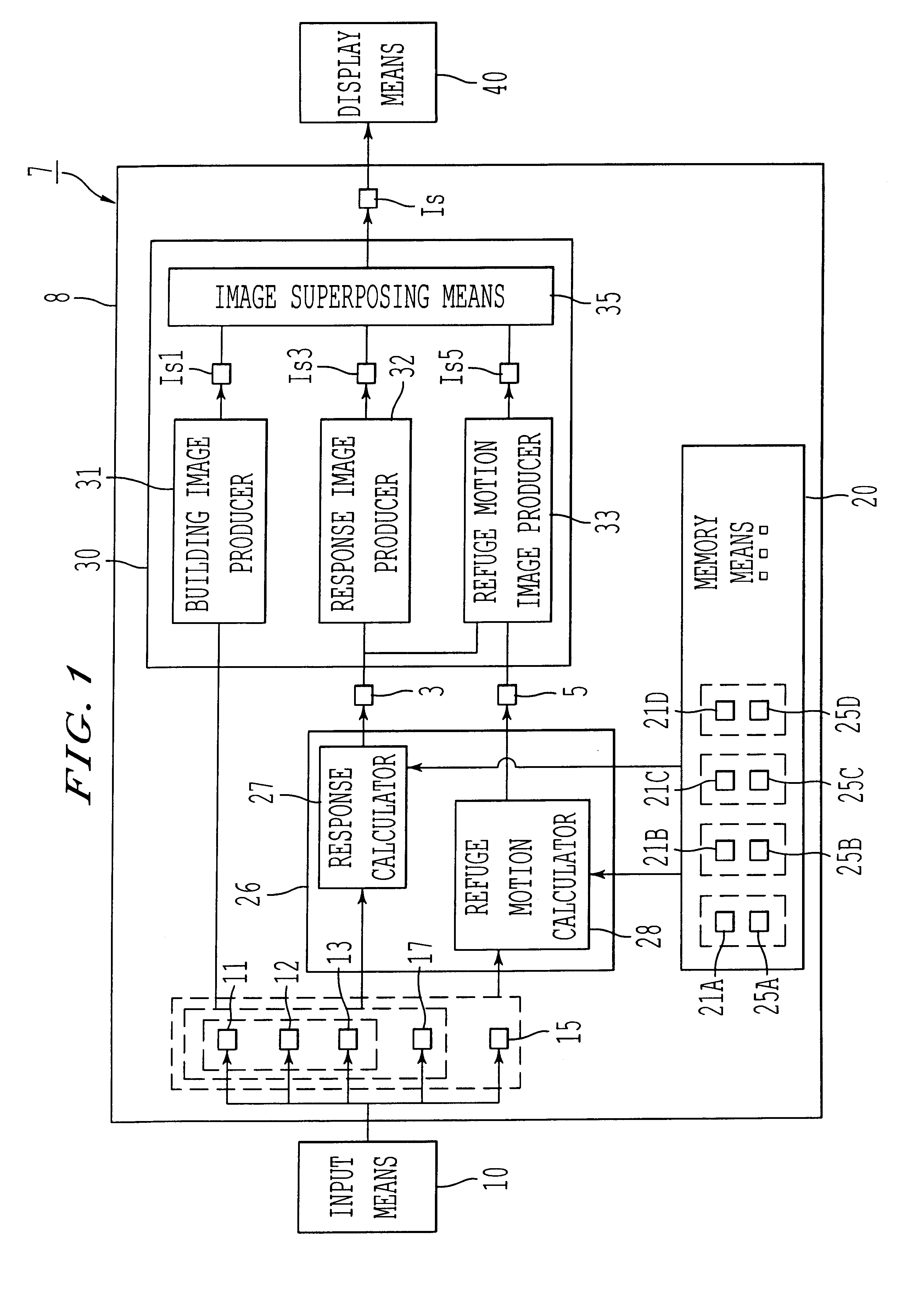

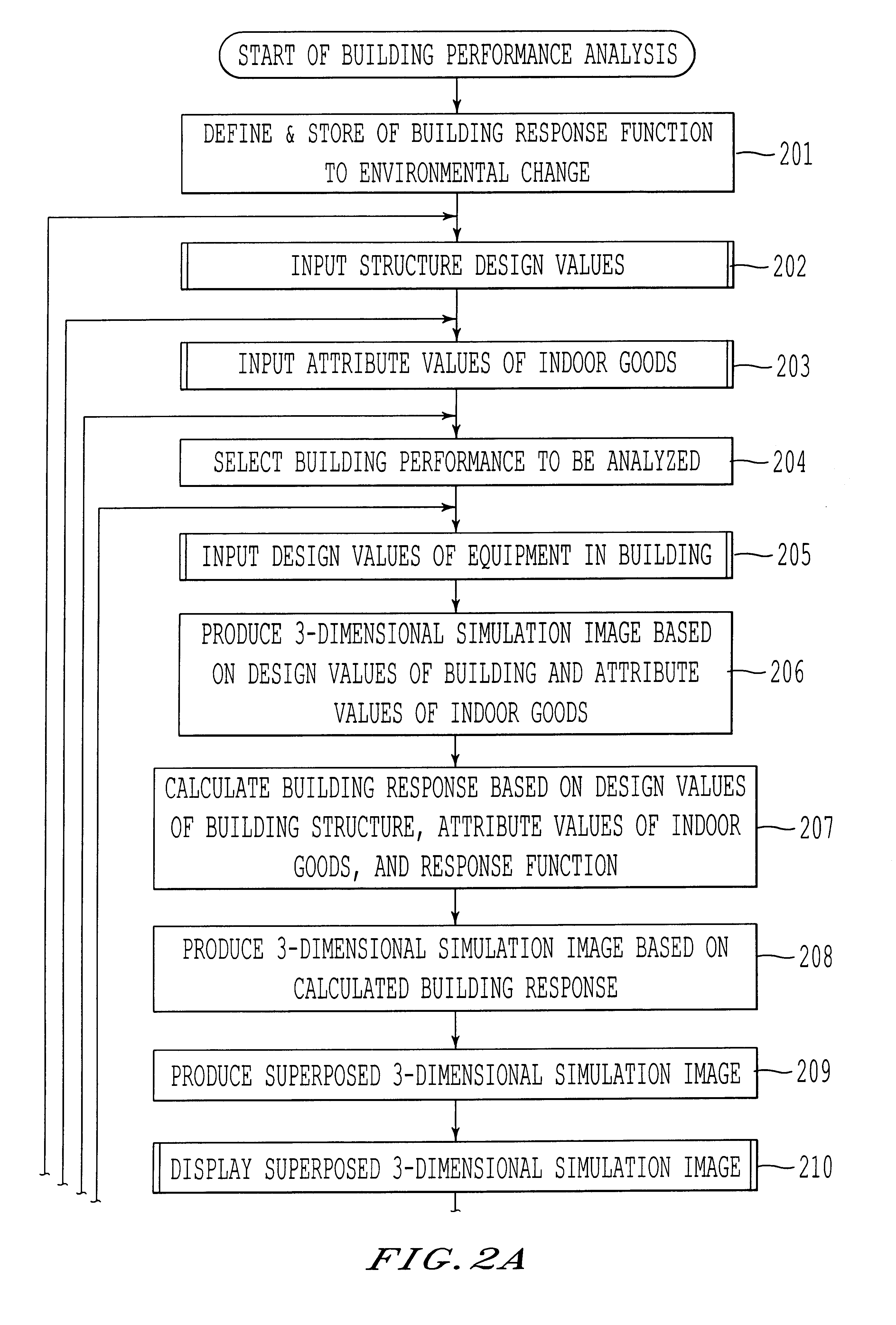

Method and apparatus for analyzing building performance

InactiveUS6701281B2Easy assessment processSmooth formation of consensusGeometric CADBuilding constructionsThree dimensional simulationComputer graphics (images)

A building response function defining a response of a building to specific environmental change, e.g., occurrence of a fire, in terms of the building structure, is stored in a computer. Also stored is a refuge motion function defining the refuge motion of individuals in terms of attributes of the individuals and the building response. The building response is computed by substituting design values of the building structure into the response function. Attributes of persons are inputted to the computer, and individuals' refuge motion is computed by using both inputted attributes and the computed building response. With the inputted and computed values, three-dimensional (3D) simulation images of the building structure, of the building response, and of individuals' refuge motion are computed. Then, a superposed 3D simulation image of the three images is displayed to facilitate analysis of the building performance.

Owner:KAJIMA CORP

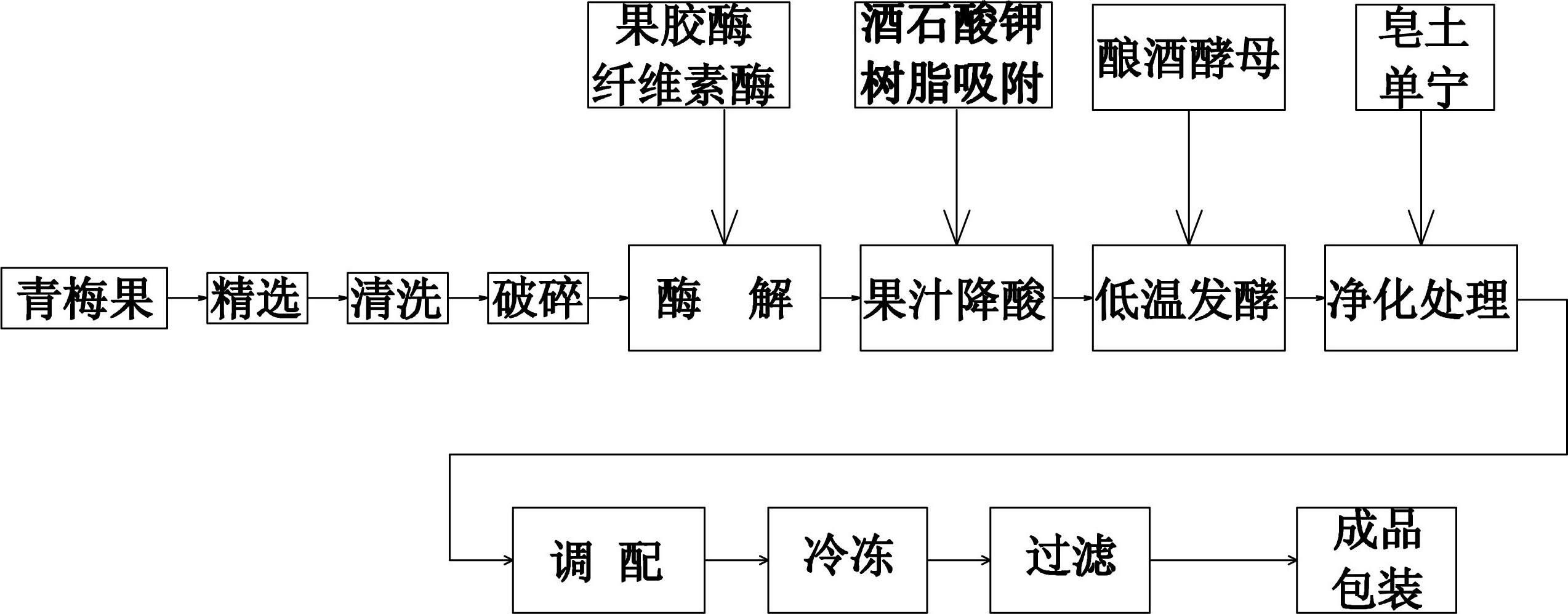

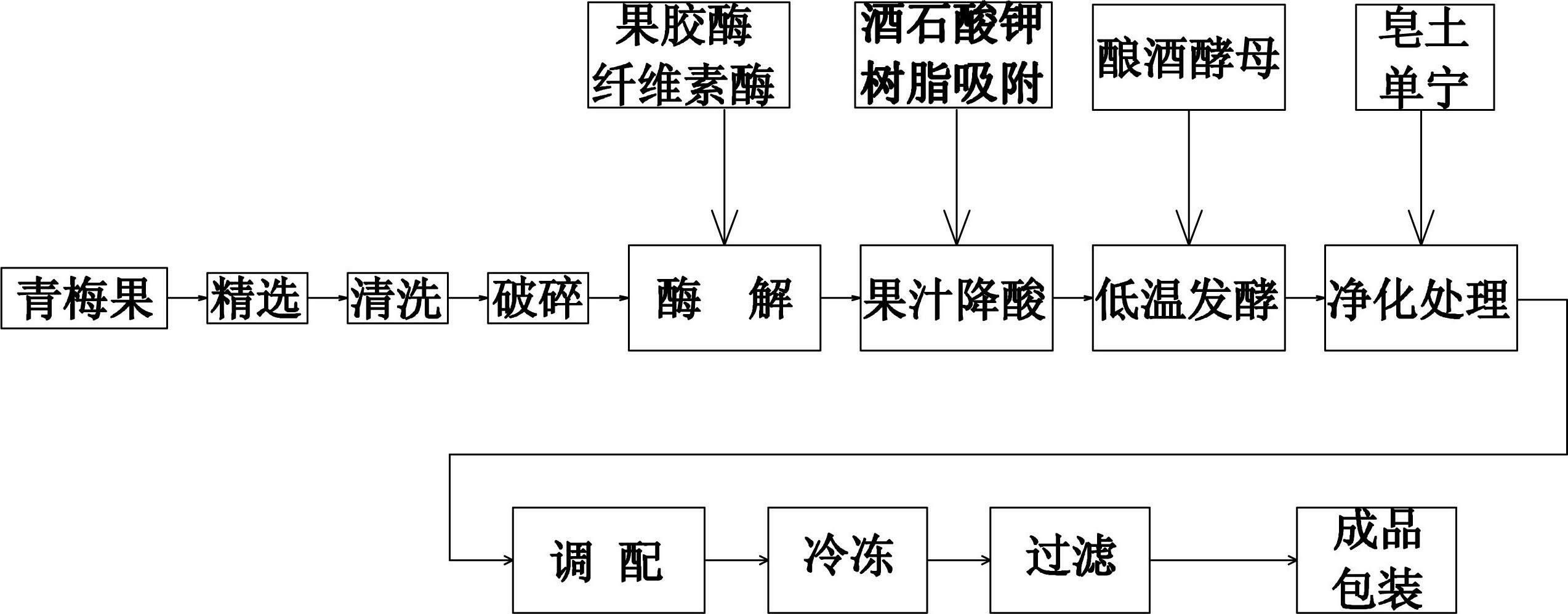

Production method and product of fermented green plum wine

InactiveCN102286320AReduce acidityPromote fermentationMicroorganism based processesAlcoholic beverage preparationFruit winePectinase

The invention discloses a production method of a fermented green plum fruit wine and a product thereof. The production method comprises the following steps: picking, cleaning and smashing on fresh green plum fruit utilized as a raw material, adding pectinase and cellulase to perform enzymolysis at 15-18 DEG C, then adding potassium tartrate to adjust and reduce the acidity at minus 6 DEG C to minus 8 DEG C, and using anion exchange resin to perform adsorption and reduce the acidity to 15g / L which is favorable for fermentation; placing clear juice in a fermentation tank, adding Saccharomyces cerevisiae to perform low-temperature fermentation; and adding bentonite and tannin in the fermented wine solution to perform compound purification, then performing low temperature freezing and clarification, blending, removing bacteria and filtering. The method has the advantages of good acidity-reducing effect and high composite enzymolysis juice yield; and by adopting the composite purification and freezing, the stability of the wine can be enhanced. The method is suitable for the production of the fermented green plum fruit wine.

Owner:YUNFU HUANAN LIQUOR

Neutral boron silicate glass used for medicinal mold-formed bottle and manufacturing method thereof

InactiveCN101186437AImprove performanceSmall coefficient of thermal expansionElectric furnaceGlass productionSilicate glassHeat stability

Neutral borosilicate glass used for moulding medicinal bottles is provided, which pertains to the technology filed of glass containing aluminum, boron, 40 percent to 90 percent (by weight) of silicon dioxide and provides neutral borosilicate glass meeting the standard of medical packaging container (material) YBB00292002, YBB00322002. The glass contains 8-12 percent of B2O3 with expansion coefficient of 4.0-5.0 multiplied by 10<-6> / K, as well as a series of excellent physical and chemical properties such as good heat stability, strong acid-resistance, alkali-resistance, water-resistance and erosion-resistance. The invention adopts cold furnace top and deep bed, recycles volatiles of boron during the course of melting, thus effectively reducing boron volatilization, preventing unfavorable phenomenon from taking place, for example, the combined material layer from incrustation and reversing, and obtaining comparatively good economic benefit and quality benefit.

Owner:SHANDONG PHARMA GLASS

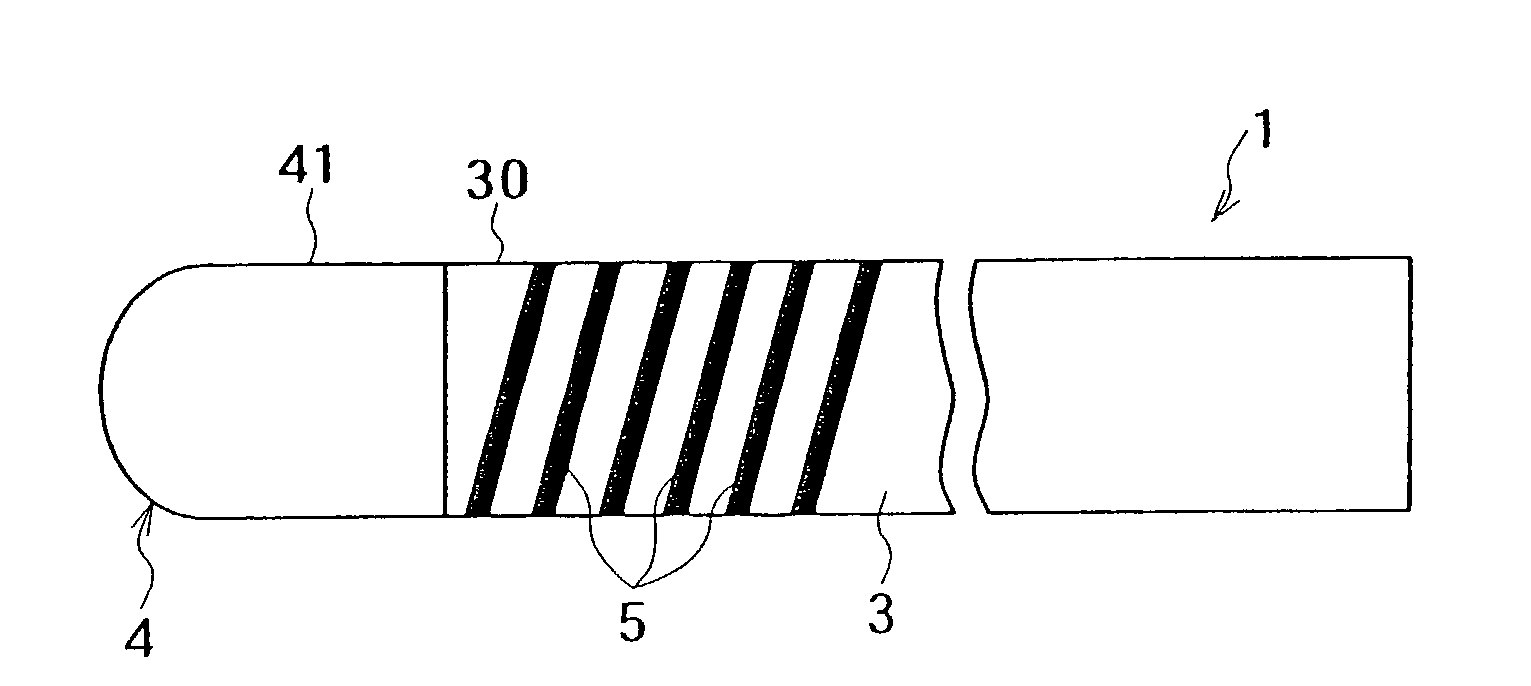

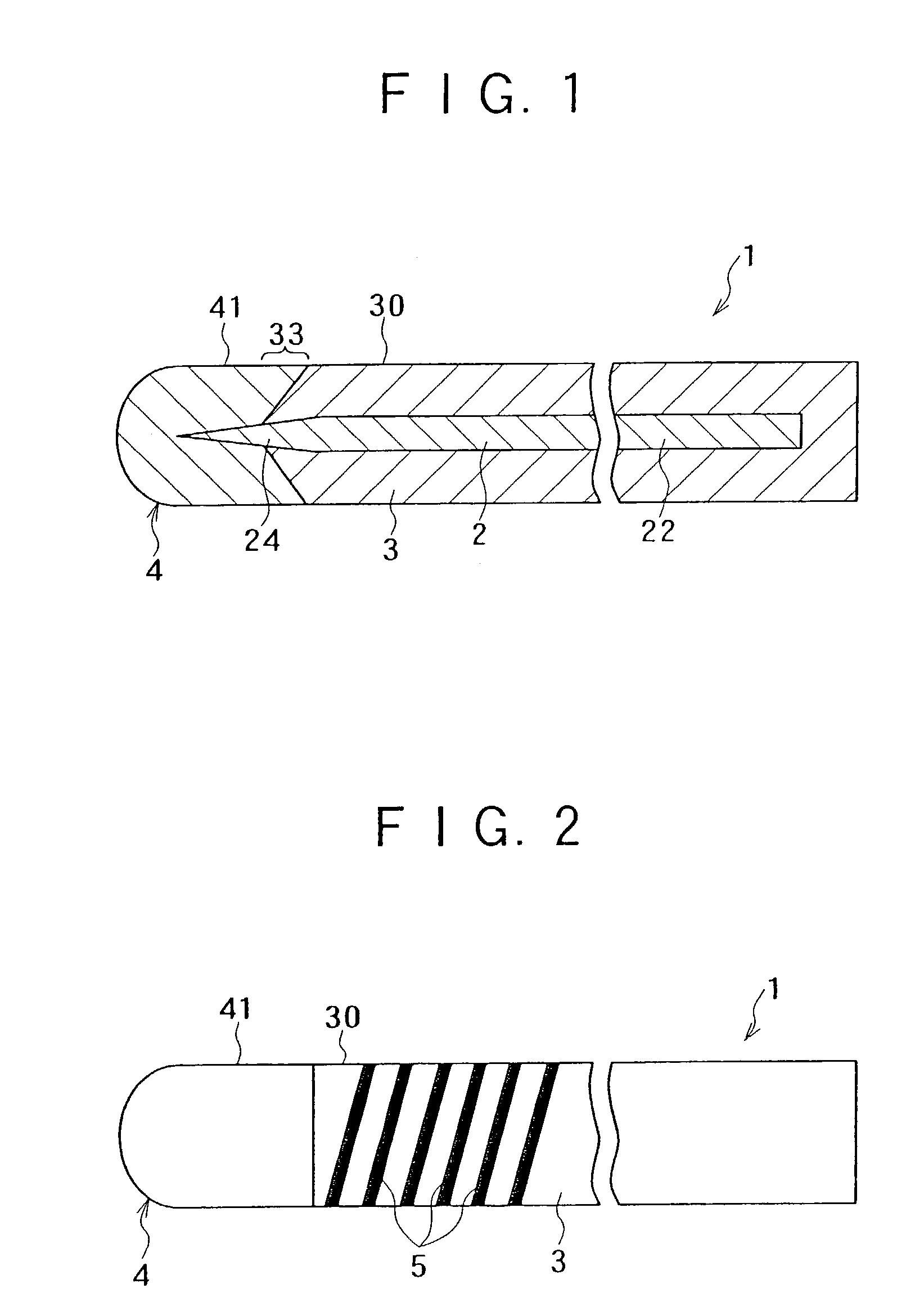

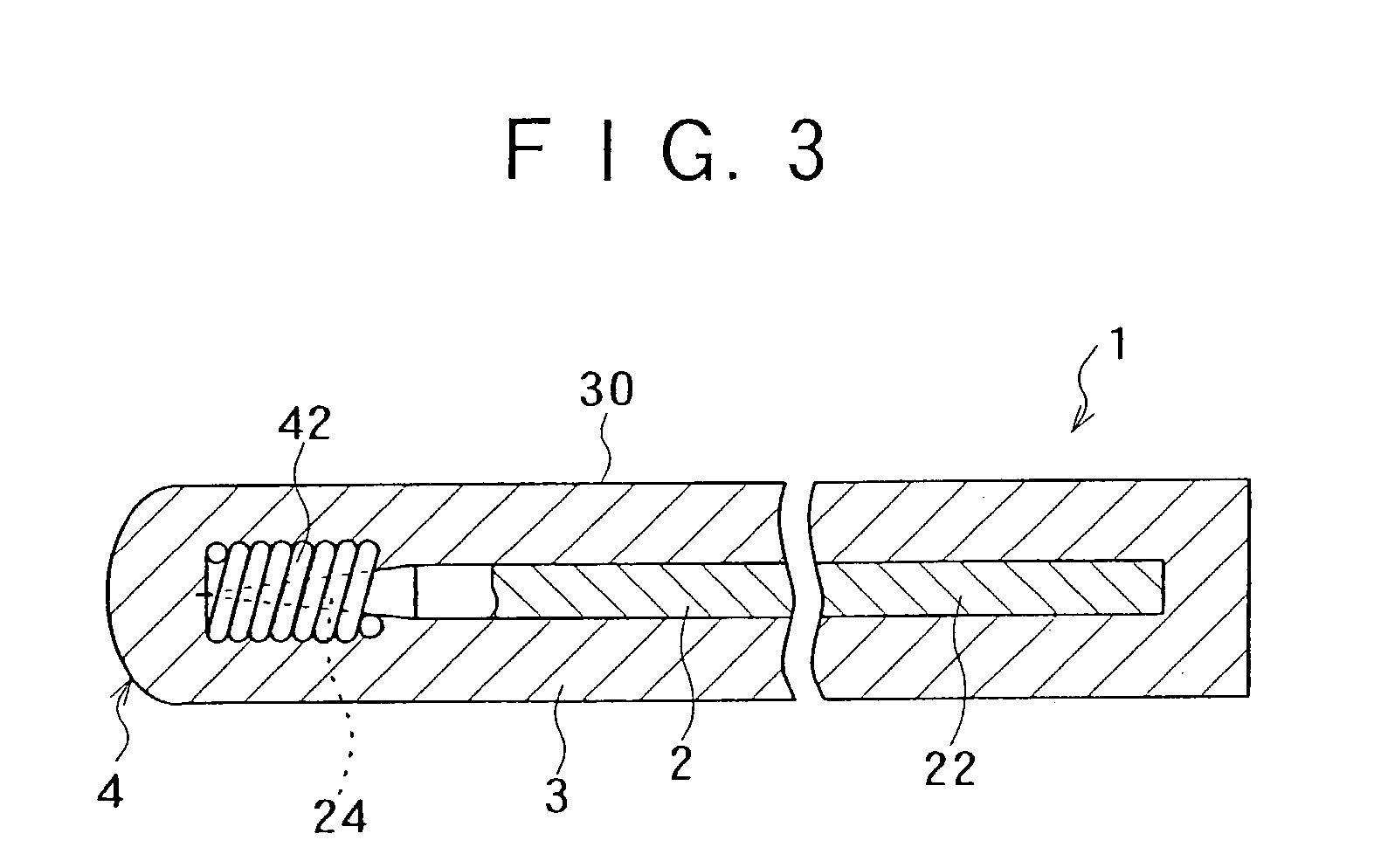

Guide wire

ActiveUS7278973B2Increase awarenessImprove visibilityGuide wiresDiagnostic recording/measuringEngineeringLaser light

A guide wire is configured to have a less lossy marker formed at a desired position and providing a relatively high degree of contrastability under X-ray fluoroscopic guidance or the like. The guide wire includes a linear core member, a resin layer covering a main body portion of the core member, and a contrasting portion covering the distal end portion of the core member. The resin layer contains a color developing agent which develops color by laser light irradiation, and a contrast agent composed of a metal oxide powder. The contrasting portion is made from a resin containing a contrast agent composed of a metal powder and has a contrasting function higher than the resin layer. A visible marker is formed on the outer surface of the resin layer through color development of the color developing agent by irradiating the surface of the resin layer with laser light.

Owner:TERUMO KK

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas, greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

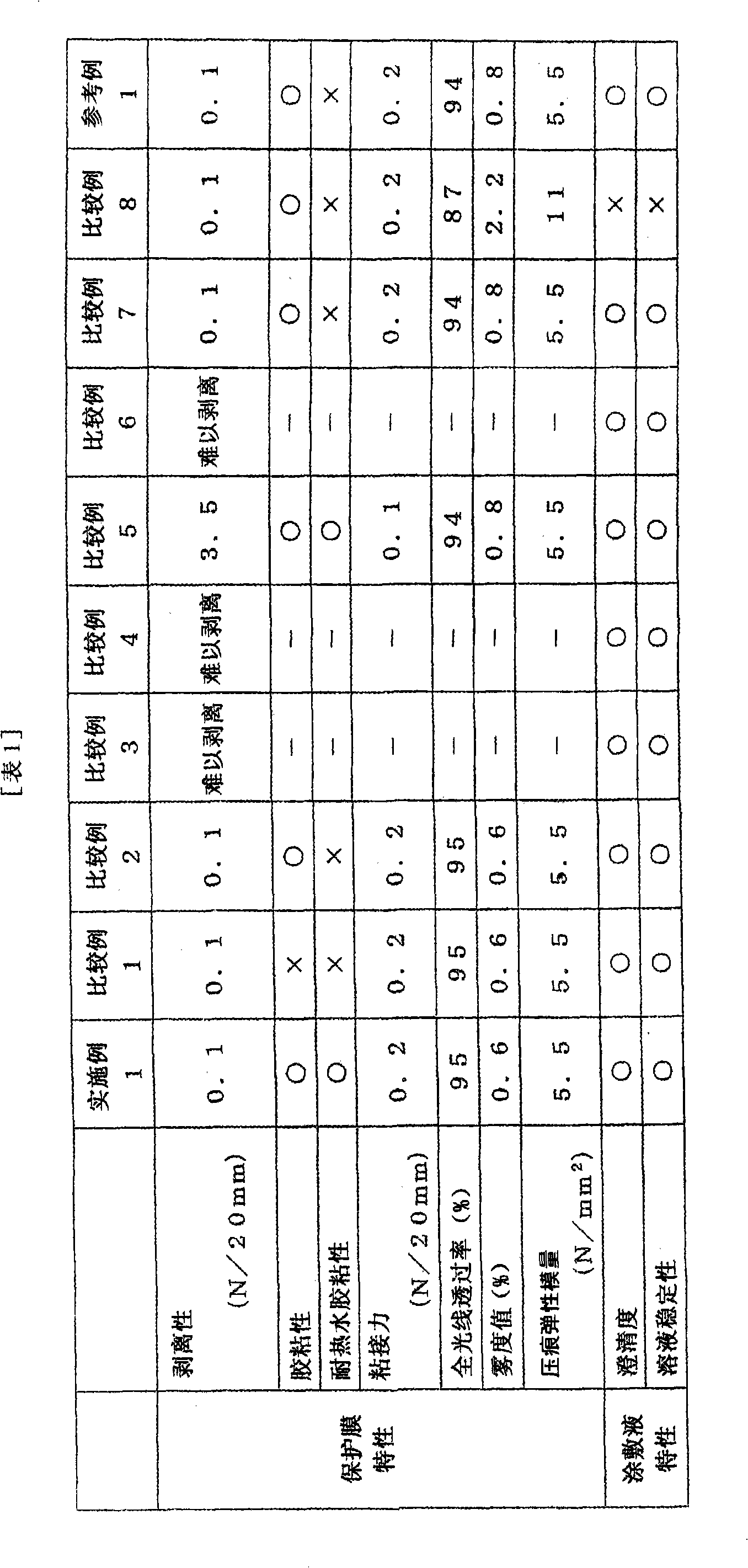

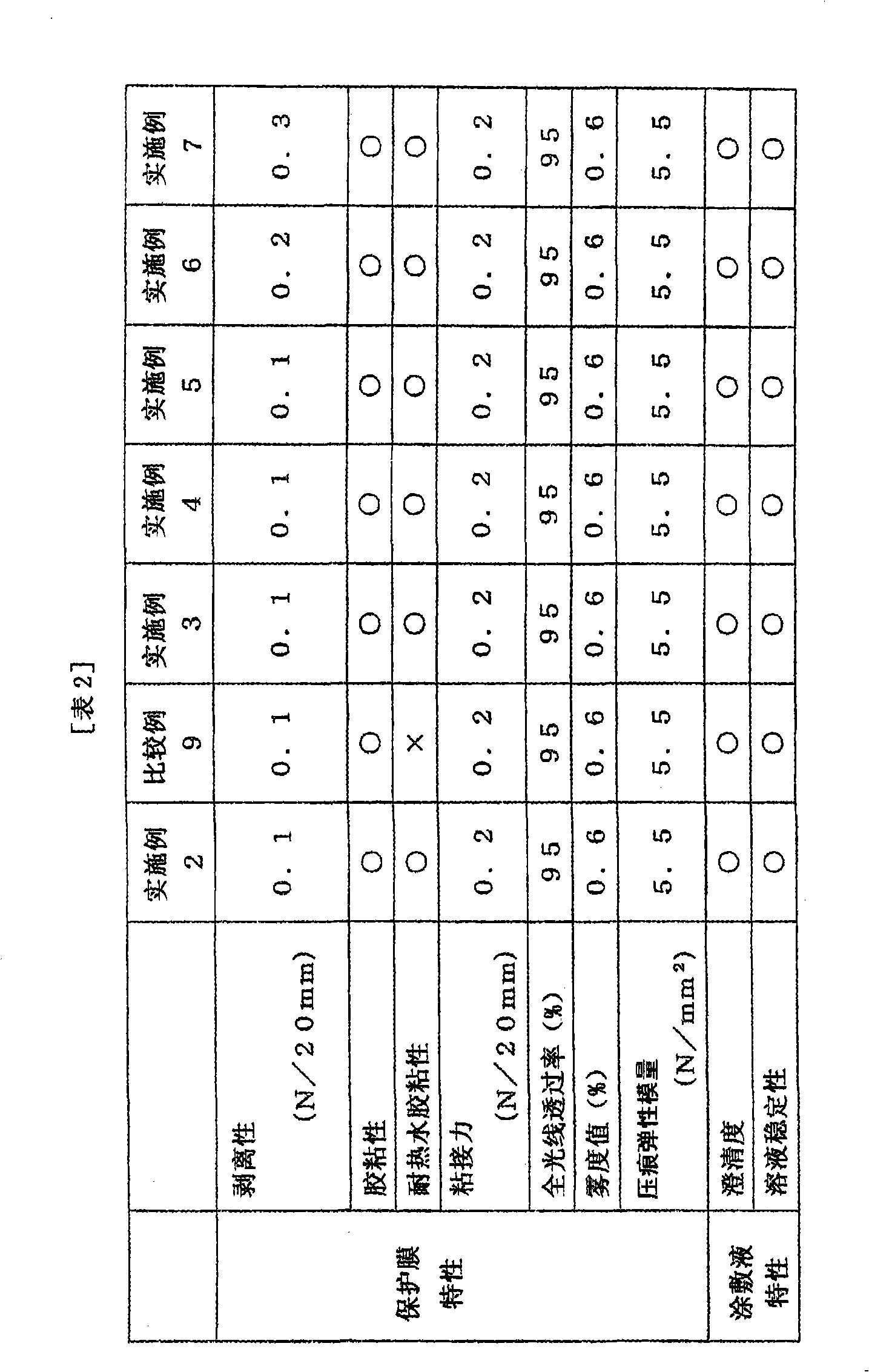

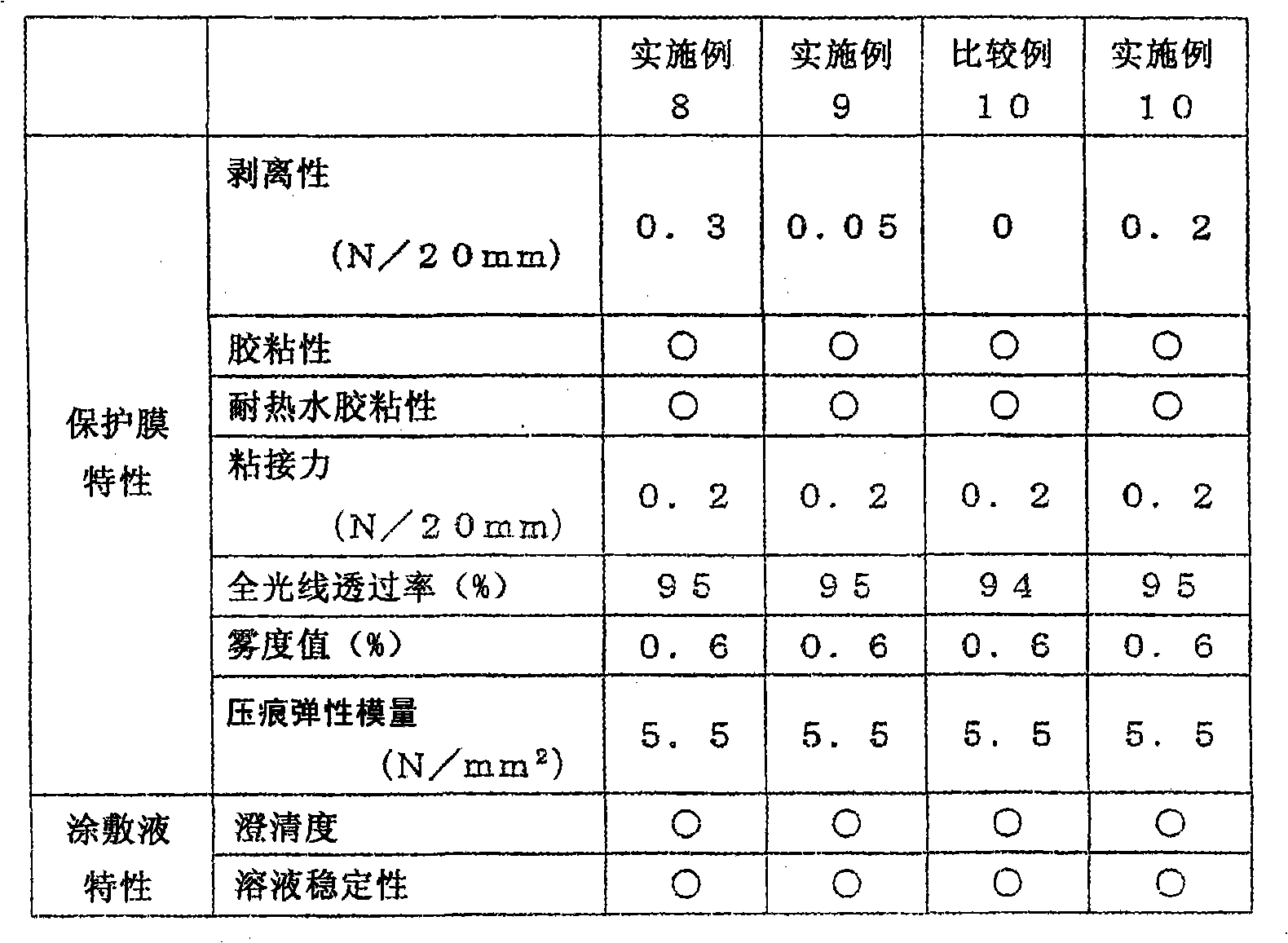

Adhesive sheet, upper electrode for touch panel, and image display device

InactiveCN101802122AEasy to peelHigh transparencyFilm/foil adhesivesAdhesive articlesPolyesterAdhesive

Disclosed is an adhesive sheet wherein at least a polyester base film (A), a crosslinked silicone rubber adhesive layer (B) having a polydimethylsiloxane skeleton, a releasing layer (C) and a polyester film (D) are laminated in this order through or not through another layer. This adhesive sheet is characterized in that when the hot water adhesion resistance is evaluated by the method defined in the description, the silicone rubber adhesive layer (B) is not separated from the polyester base film (A), and the peel strength between the silicone rubber adhesive layer (B) and the releasing layer (C) is within the range of 0.03-1.0 N / 20 mm.

Owner:MAXELL HLDG LTD +1

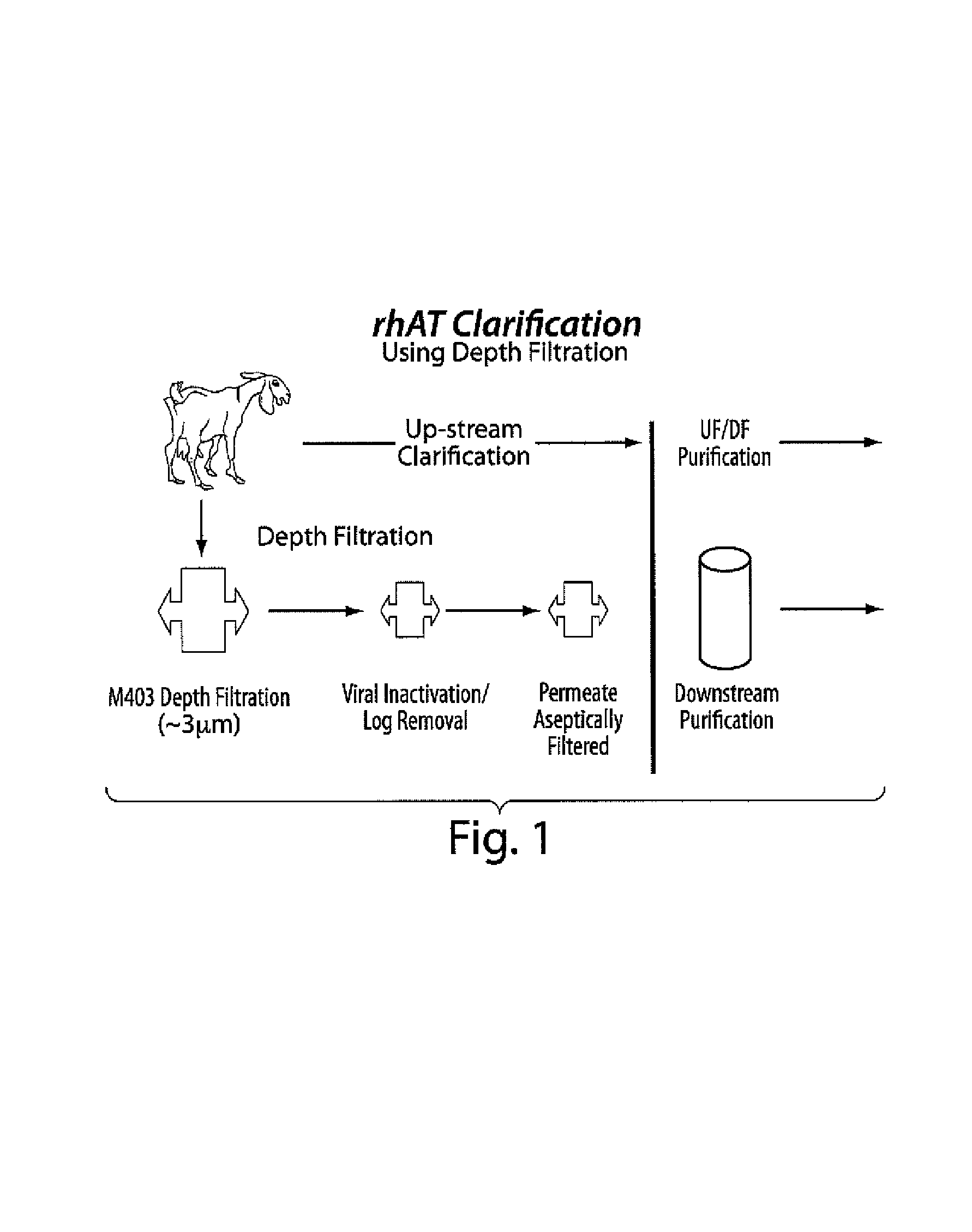

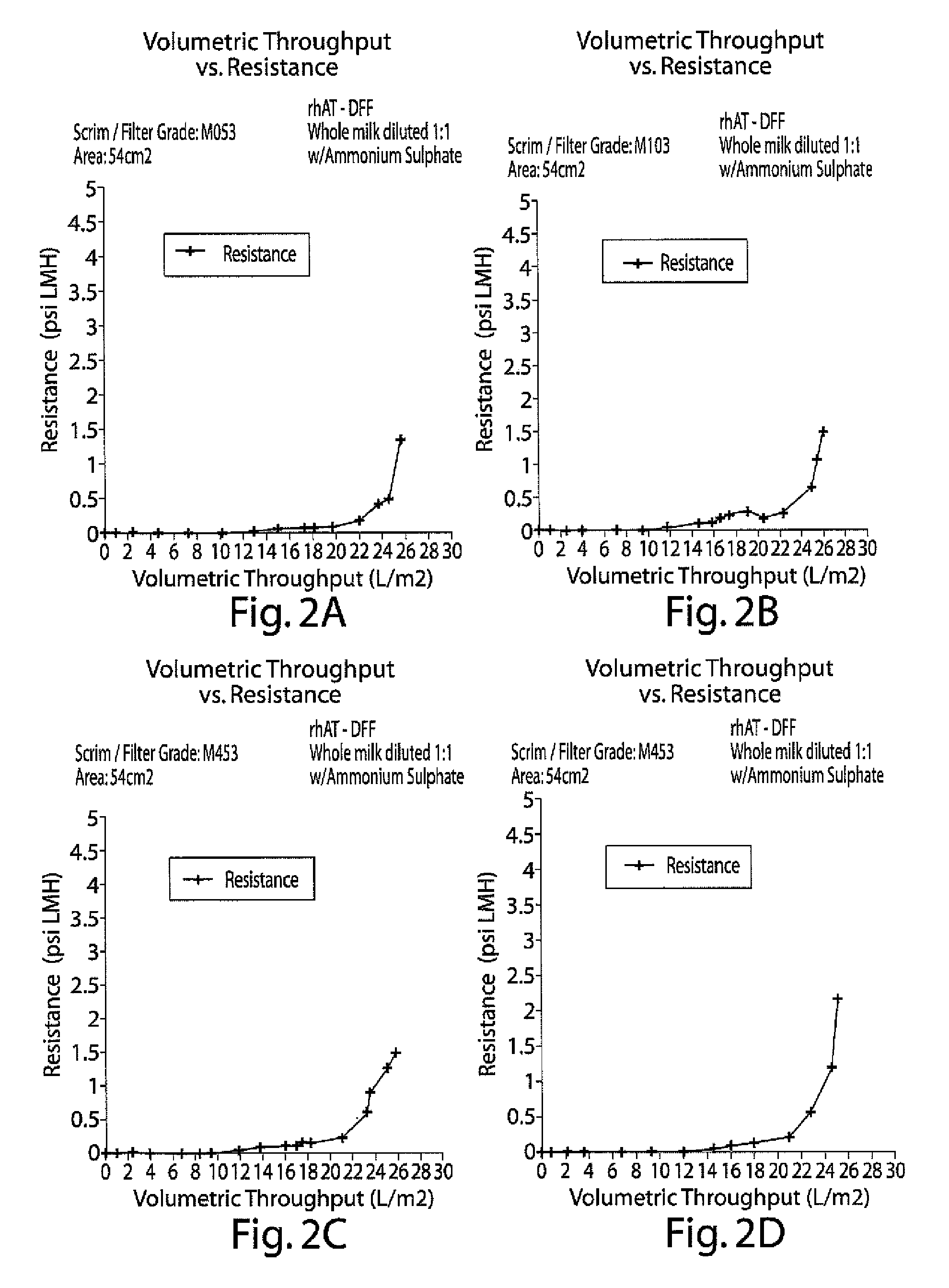

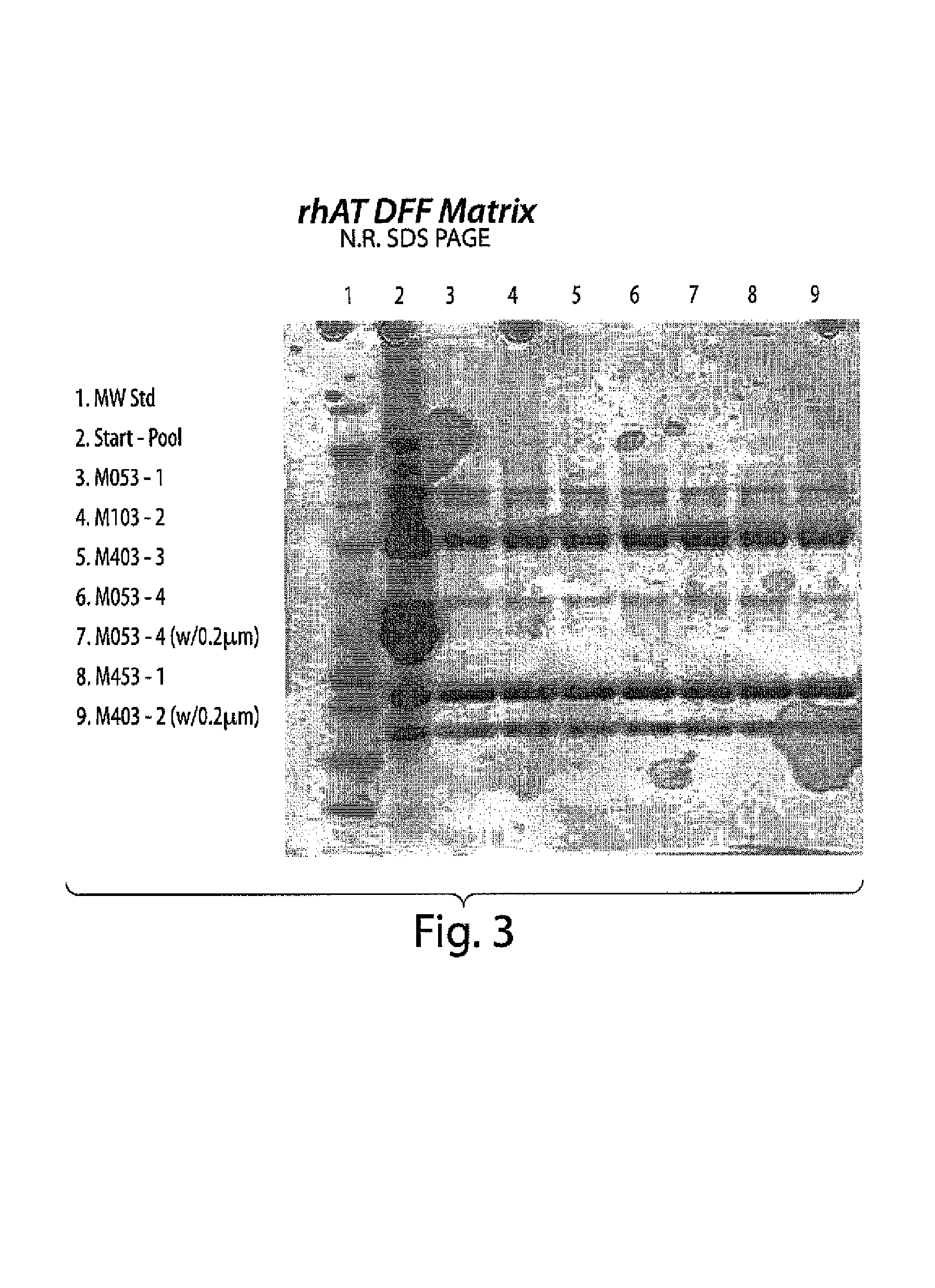

Clarification of transgenic milk using depth filtration

ActiveUS7531632B2Good clarificationImprove fractionationPeptide/protein ingredientsHydrolasesFiltrationBacilli

Processes and apparati are provided for separating molecules of interest from a mixture by depth filtration (DF). The DF of the invention is useful in the clarification and processing of various feedstreams for the removal of a molecule of interest. According to a preferred embodiment, a transgenic milk feedstream is stabilized and particulate matter such as fat, casein miscelles and bacteria are removed. An aseptic filtration step was also developed to remove any bacteria remaining in a clarified transgenic milk feedstream.

Owner:LFB USA

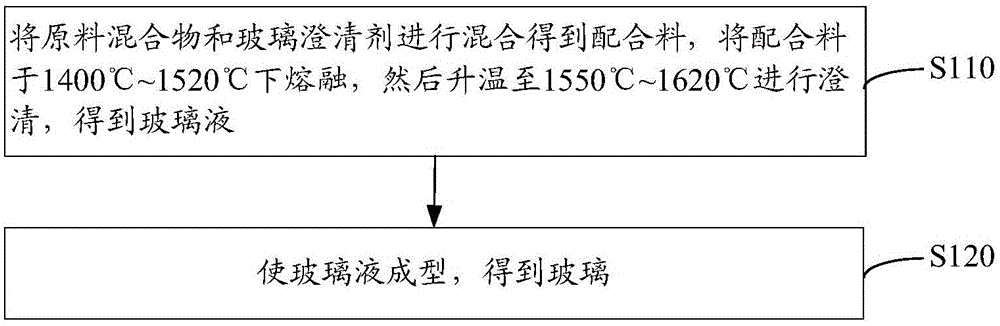

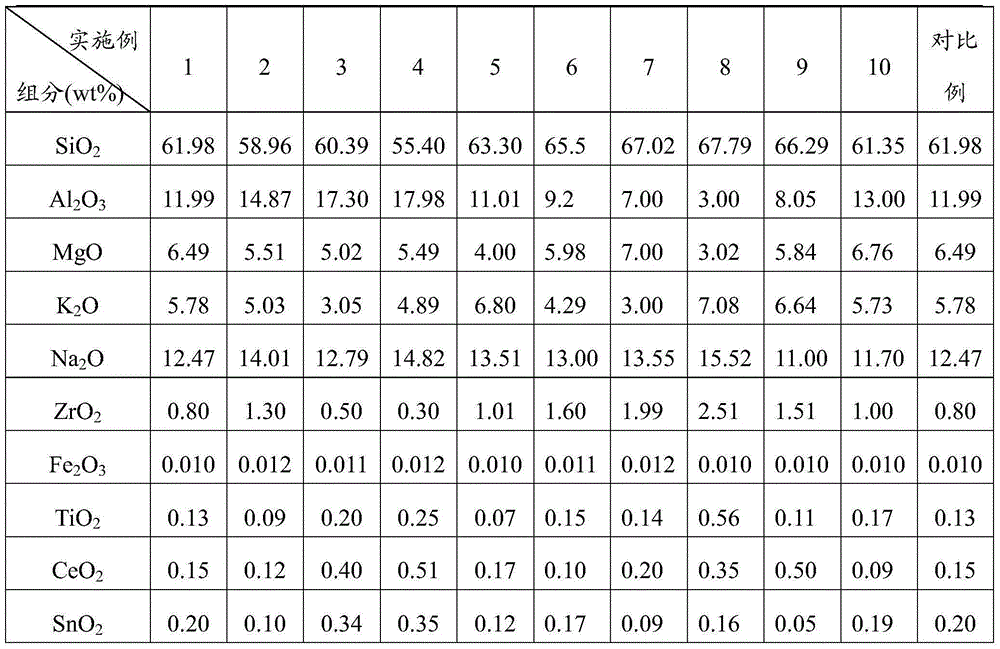

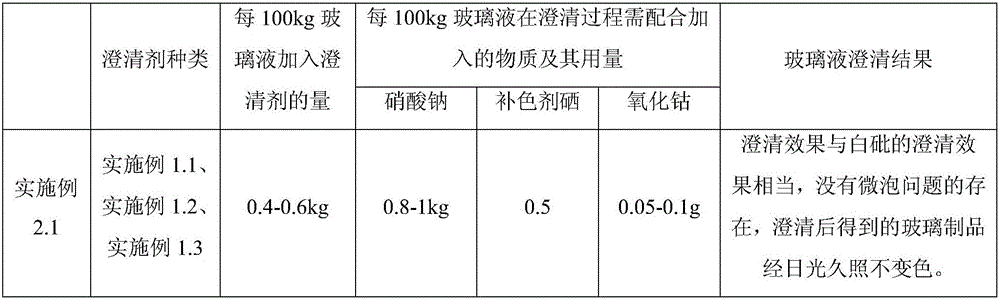

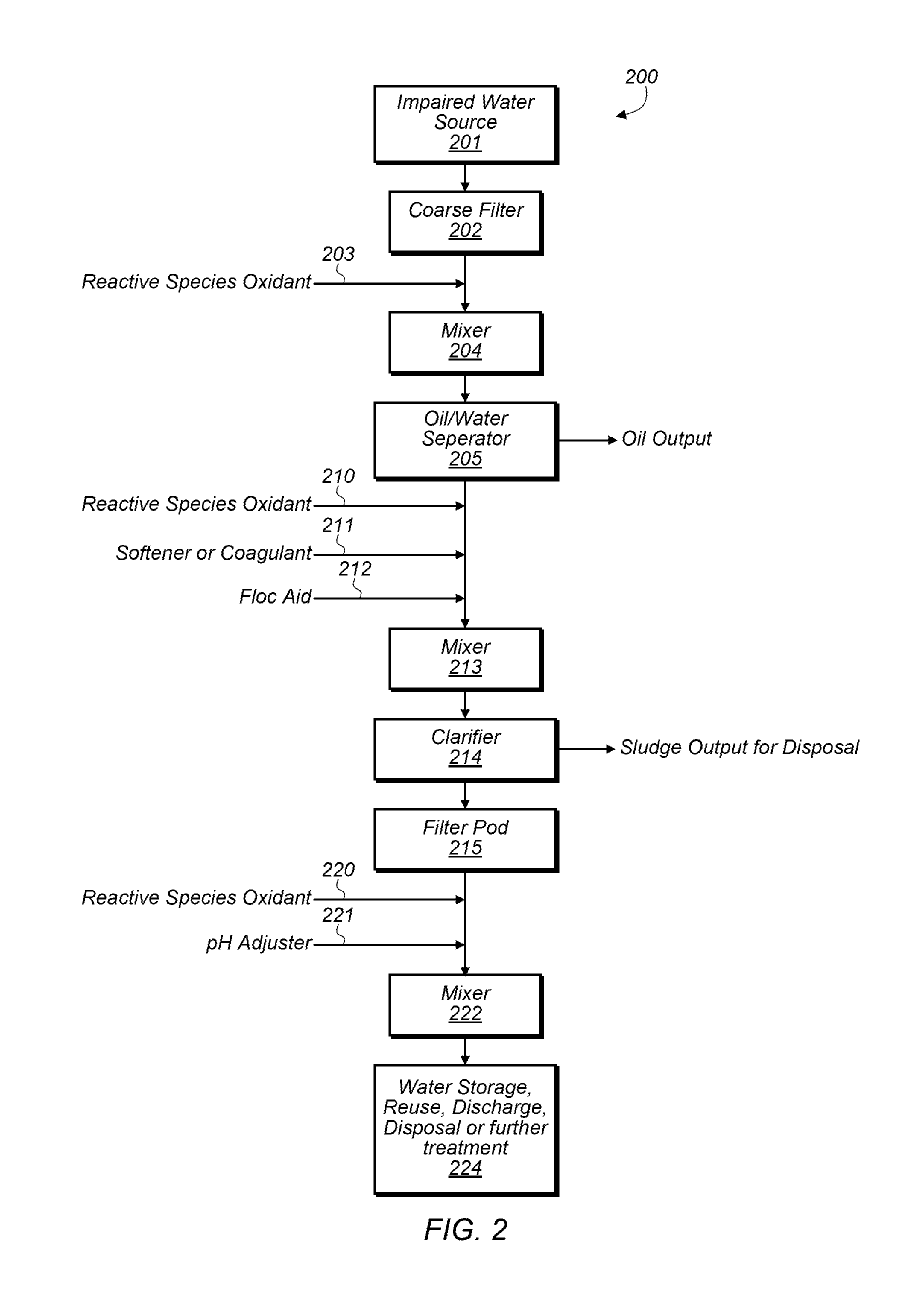

Glass clarifier and glass preparation method

ActiveCN105084756AReduce air bubble contentInhibition releaseGlass furnace apparatusGlass productionNitrateSodium sulfate

The invention relates to a glass clarifier and a glass preparation method. The glass clarifier contains nitrate, sodium sulfate, ceria and stannic oxide, wherein the mass ratio of nitrate to sodium sulfate to ceria to stannic oxide is (0.2-3.0): (1.0-3.0): (0.01-2.0): (0.01-1.5). Thus, the glass clarifier is non-toxic and harmless and is relatively good in clarification effect.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD

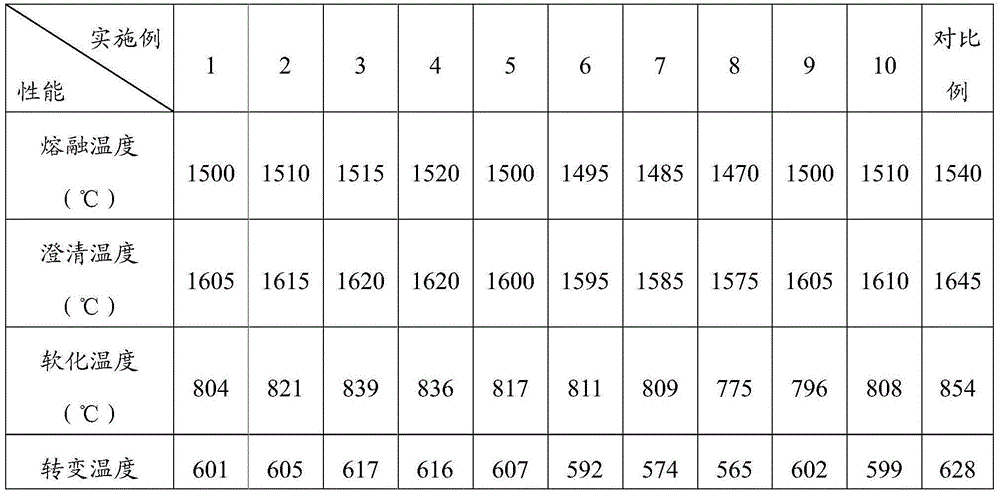

Preparation process of blueberry concentrated juice with high content of anthocyanin

The invention provides a preparation process of blueberry concentrated juice with high content of anthocyanin. According to the preparation process provided by the invention, pectase is adopted for performing enzymolysis on blueberry pulp, chitosan is adopted as a clarifying agent for obtaining clear blueberry juice, a decompression concentration process is adopted for preparing the blueberry concentrated juice, and microwave sterilization is adopted for sterilizing the blueberry concentrated juice. The preparation process comprises the following steps of: selecting blueberry fruits in vaccinium ashei gardenblue species; extracting the blueberry juice, and adding the pectase to perform the enzymolysis on the blueberry pulp; clarifying the blueberry juice, and adding the chitosan as the clarifying agent for obtaining the clear blueberry juice; concentrating the blueberry juice, and adopting the decompression concentration to obtain the blueberry concentrated juice; and performing sterile filling on the blueberry juice, and adopting the microwave sterilization to sterilize the blueberry concentrated juice, wherein the content of soluble solids in the blueberry concentrated juice is 60%-75%, and the content of the anthocyanin is 1.925g / L-3.384g / L. The preparation process provided by the invention can not only effectively prevent the loss of the anthocyanin in the blueberry concentrated juice, but also shorten the concentration time, control the production cost of the preparation process and effectively protect color, luster, fragrance and other sensory qualities of the blueberry juice.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of high-purity cerium hydroxide

InactiveCN101633516AGood clarificationGood filtration performanceRare earth metal compoundsSal ammoniacChemistry

The invention discloses a preparation method of high-purity cerium hydroxide, comprising the following steps: taking liquid cerium nitrate as a raw material, hydrogen peroxide as oxidant and ammonia water as neutralizer, oxidizing trivalent cerium into tetravalent cerium in cerium nitrate solution in a weak acidic medium with the PH value being equal to 5 to 6 so as to form precipitate, then carrying out thermal decomposition, washing pressure filtration and drying on the precipitate to obtain high-purity cerium hydroxide product. The high-purity cerium hydroxide product prepared by the invention has high purification, wherein, the Ce ratio CeO / TREO is greater than or equal to 99.9%, the oxidation rate CeO<4+> / sigma Ce is greater than or equal to 97.0%, non-rare earth impurity magnesium oxide MgO is less than or equal to 2.5PPm, and the solubility of nitric acid is good. The process flow is short, the operation is convenient, and scale production is easy to be realized. The obtained Ce(OH)4 nitric acid is dissolved clearly, the oxidation rate of cerium is high, the content of non-rare earth impurities is low, thereby meeting the requirement of clients on quality of Ce(OH)4 products.

Owner:甘肃稀土新材料股份有限公司

LCD sheet glass

The invention discloses a base plate glass with rare-earth element to dope liquid crystal display device (TFT-LCD), which is characterized by the following: comprising glass basic oxide, lanthanum oxide, cerium oxide, neodymium oxide and or yttrium oxide; setting the mass ratio at (60. 5-195):(0. 003-28) of the glass basic oxide and all rare-earth oxide; adding at least three rare-earth oxide; improving the fusion of the glass; accelerating clarification and equalization in the course of formation; preventing glass crystallizer; decreasing the liquid phase temperature; delaying devitrification speed of the glass; fitting for productive technology of float glass; improving chemical stability of the glass; decreasing the expansion coefficient; fitting for large scale float glass procession.

Owner:CHINA BUILDING MATERIALS ACAD

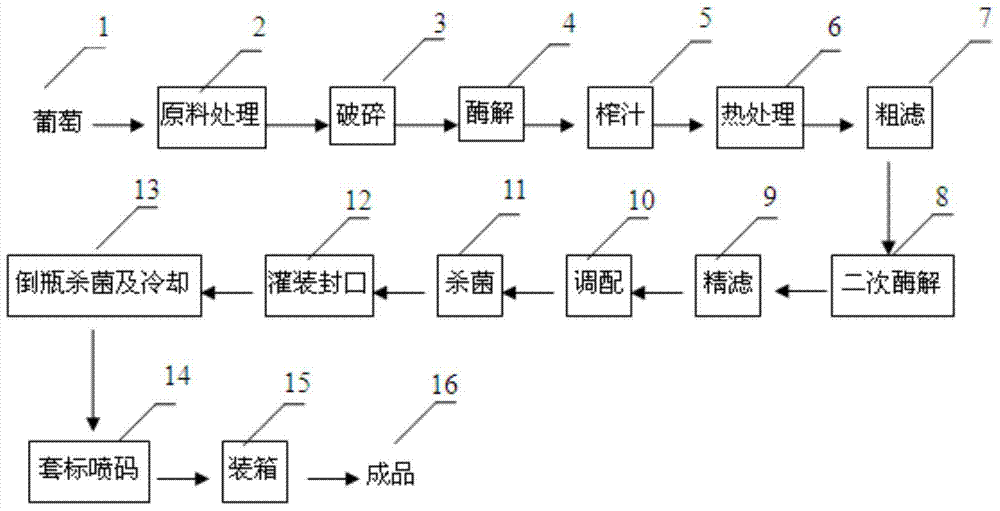

Pure grape juice beverage and production method thereof

InactiveCN103876226AFactors Inhibiting Quality DeteriorationPrevent precipitationFood sciencePurplish redBottle

The invention discloses a pure grape juice beverage and a production method thereof. The production method is characterized by taking fresh grape as raw material and comprising the following steps: processing the raw material, crushing, carrying out enzymolysis, juicing, heating, roughly filtering, carrying out secondary enzymolysis, finely filtering, mixing, sterilizing, filling and sealing, reversing bottle for sterilizing and cooling, putting on labels and spraying codes, and packing to produce a clear type pure grape juice beverage which is delicious and has the characteristics and taste of the grape. The method is capable of carrying out large-scale industrial production; the produced grape beverage is purplish red in color, clear and transparent, and long in quality guarantee period; the grape beverage is stored, circulated and sold at normal temperatures.

Owner:SICHUAN UNIV

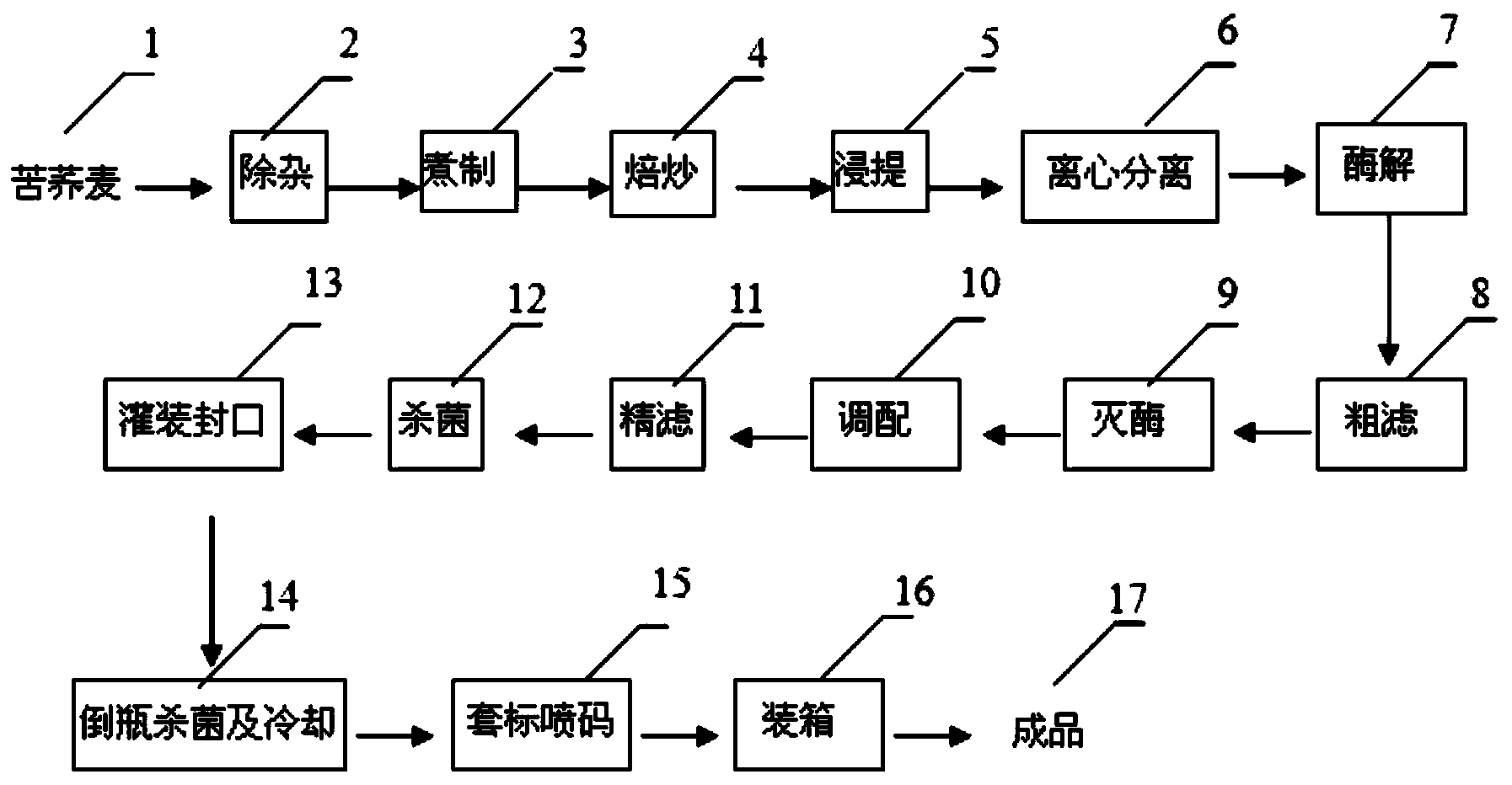

Clear sugar-free tartary buckwheat tea and production method thereof

The invention discloses clear sugar-free tartary buckwheat tea and a production method thereof. The clear sugar-free tartary buckwheat tea is characterized by being prepared through the following processes: removing impurities of tartary buckwheat with skin taken as raw material, boiling, roasting, digesting, centrifugally separating, carrying out enzymolysis, roughly filtering, deactivating enzyme, allocating, finely filtering, sterilizing, filling and sealing, carrying out inverted bottle sterilization and cooling, labeling and spraying code, and packing; the prepared tartary buckwheat tea has flavor of roasted tartary buckwheat, is fresh and tasty, and contains bioactive substances, namely flavonoids compounds. According to the method disclosed by the invention, industrial production on a large scale can be realized; the produced tartary buckwheat tea beverage is golden, clear and transparent, and effectively reserves bioactive substances, namely flavonoids compounds, in the tartary buckwheat; the tartary buckwheat tea can be stored, circulated and sold at normal temperature, and is relatively long in shelf life.

Owner:SICHUAN UNIV +1

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

Composite clarifying agent, and preparation method and application thereof

InactiveCN102559466AFor the purpose of clarificationLow application costAlcoholic beverage preparationFood preparationCelluloseFruit juice

The invention relates to a composite clarifying agent, and a preparation method and application thereof. The composite clarifying agent comprises K solution and S solution, wherein the K solution is aqueous solution comprising 0.8 to 1.2 percent (w / v) of chitosan and 0.8 to 1.2 percent (v / v) of acetic acid; and the S solution is aqueous solution comprising 0.8 to 1.2 percent (w / v) of carboxymethylcellulose. The composite clarifying agent has low application cost and a good clarifying effect and is applicable to clarification of wine, vegetable and fruit juice, tea or health-care products. During clarification, flocs are combined tightly, so the composite clarifying agent is easy to separate, low in application cost, good in clarifying effect and high in speed, does not influence the liquid flavor, can effectively remove macromolecular substances such as excessive protein, pectin, tannin and the like and suspended matters from the liquid, and is convenient to use and simple to operate.

Owner:HUBEI UNIV OF TECH

Seabuckthorn fruit juice and preparing method thereof

The invention discloses a seabuckthorn fruit juice and a preparing method thereof, and belongs to the field of juice processing. The preparing method includes the following steps of (1) raw seabuckthorn juice preparing; (2) material taking, wherein 40-75 by weight parts of the raw seabuckthorn juice, 10-30 by weight parts of white sugar, 1-5 by weight parts of xanthan gum, 3-8 by weight parts of honey, 0.5-3 by weight parts of gelatin, 1-3 by weight parts of aspartame, 40-100 by weight parts of water and 10-30 by weight parts of raw apple juice are taken; (3) preparing and clarifying; (4) sterilizing, wherein sterile clarified liquid is obtained through high-voltage pulse electric field sterilization; (5) seabuckthorn fruit juice obtaining, wherein the seabuckthorn fruit juice is obtained in a sterile-filling mode. By means of the eabuckthorn fruit juice and the preparing method thereof, nutrient ingredients and flavor substances in seabuckthorn fruits can be effectively reserved.

Owner:新疆慧华沙棘生物科技有限公司

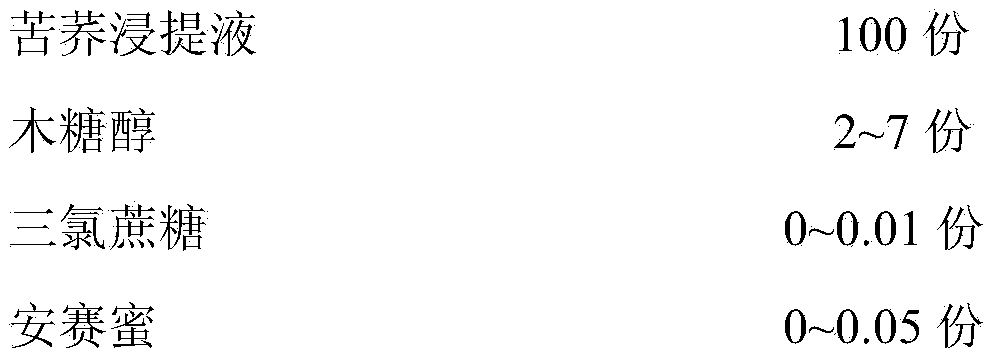

Environment-friendly modified bentonite and preparation method thereof

The invention discloses an environment-friendly modified alta-mud and making method, which comprises the following steps: adopting natural polysaccharide without toxicity and harm such as chitosan as modifier to modify sodium-based alta-mud; disposing original mud; allocating chitosan acetic solution; weighing 50-60ml chitosan solution with density at 0. 5-1. 0% and diacetyl degree at 90%; allocating 50g alta-mud into paste-shaped material; stewing; infiltrate the alta-mud completely; placing the paste-shaped material into microwave oven; heating to dry; grinding finely; sieving in the screen at 0. 16mm; obtaining the product with low price, good property and environment friendly without any polluting; fitting for disposing industrial waste water, manufacturing drug and food industry.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Clarification method of alumina silicate glass melts

InactiveCN102976587AImprove clarification qualityExtended clarification timeGlass furnace apparatusGlass productionChemical treatmentNitrate

The invention discloses a clarification method of alumina silicate glass melts. The method comprises physical treatment and chemical treatment to the alumina silicate glass melts, wherein the physical treatment is to control the air pressure of clarifying parts of the alumina silicate glass melts to 100 to 9*10<4>Pa; and the chemical treatment is to add a composite clarifying agent to the alumina silicate glass mixture, wherein the composite clarifying agent is the composition formed by mixing two or more than two of sulfate or / and nitrate of K, sulfate or / and nitrate of Na and sulfate or / and nitrate of Li with two or more than two of Sn oxide, Sb oxide and Ce oxide. According to the clarification method, the composite clarifying agent is adopted and realizes gradient chemical clarification under different temperatures, so that the clarifying agent in the glass melts can be molten at different temperature ranges during melting, and gas is continuously generated by the glass melts, and the clarifying time of the glass melts is prolonged; and the physical clarifying way under reduced pressure is adopted while the chemical clarifying way is carried out, so that the bubble can be faster generated and overflowed, and the clarifying effect of the high-viscosity alumina silicate glass can be optimized.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Low dielectric constant glass plate and preparation method thereof

The invention discloses a low dielectric constant glass plate and a preparation method thereof. The glass batch of the glass plate comprises the following components in percentage by mass: 55-75 % of SiO2, 5-15 % of Al2O3, 0-10 % of MgO, 1-15 % of K2O, 0-10 % of Na2O, 0-5 % of Li2O, 0-10 % of CaO, 0-10 % of B2O3, 5-20 % of ZrO2 and 0.5-2 % of clarifier, wherein the total mass percentage is 100 %; the clarifier is a mixture of SnO2 and CeO2, wherein the CeO2 accounts for 20-50 % of the total quantity of the clarifier. The low dielectric constant glass plate disclosed by the invention can be directly used as a circuit board, obtains higher heat stability and is suitable for working in electronic components under a severe environment for a long time; through the adding of a zirconium element, the dielectric constant can be adjusted, so that dielectric constant and dielectric loss at a lower level are achieved; through the integral formula composition of the glass and the adoption of a composite clarifier, the glass plate obtains better clarifying quality; moreover, the characteristics of the low dielectric constant glass plate disclosed by the invention are suitable for large-scale production in a floating or overflow down draw process; and the manufacturing cost is reduced.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Dry type kiwi wine and preparation method thereof

InactiveCN103773651AEfficient separationEasy to separateAlcoholic beverage preparationYeastPectinase

The invention discloses a dry type kiwi wine and preparation method thereof, belonging to the technical field of preparing fermented fruit wine. The preparation method comprises the steps of: 1) freezing and peeling kiwi fruit, stripping and slicing, soaking in color protection solution and standing, and then extruding and pulping to obtain fruit pulp; 2) adding pectinase for enzymolysis, then carrying out heating treatment and filtering, adding concentrated fruit juice into filtrate and regulating the needed concentration to obtain kiwi juice; 3) adding Angel active yeast into the kiwi juice for twice, carrying out primary fermentation and after fermentation until the amount of the residual sugar in the fermentation liquor is less than or equal to 4g / L, thus obtaining after-fermentation wine; 4) carrying out deacidification, astringency removal and clarifying, bottling and sterilizing, to obtain dry type kiwi wine. The preparation method is simple to operate, and the dry type kiwi wine prepared by adopting the method is low in the amount of residual sugar, high in alcohol degree, rich in nutrition values, and excellent in wine taste.

Owner:陕西秦驰鲜辉实业有限公司

Water integrative treatment technique for prawn cultivation

InactiveCN101054246ABalance pHImprove water qualitySeawater treatmentMultistage water/sewage treatmentAquaculture industryPrawn

The invention belongs to water treatment technology of aquaculture, in particular to a comprehensive treatment technology of prawns raising seedling water, comprising following steps: a first level filtering-a depositing reservoir-a secondary sand filtering-water body disinfection-throwing in larva. The comprehensive treatment technology of prawns raising seedling water adopts synthetic system for processing water which combines physical, chemical, medication and different kinds of control measures, can efficiently balance the acid-base value of water body, clear away or reduce the poisonous material in water body such as ammonia nitrogen and nitrite, remain chlorine (free chlorine), can extinguish germ and fungus in water, extinguish and clear away various harmful biology in water body, optimize water quality fully, furthest decrease foot phenomenon of seedlings, raise emergence rate, raise output and optimize quality.

Owner:GUANGDONG OCEAN UNIVERSITY

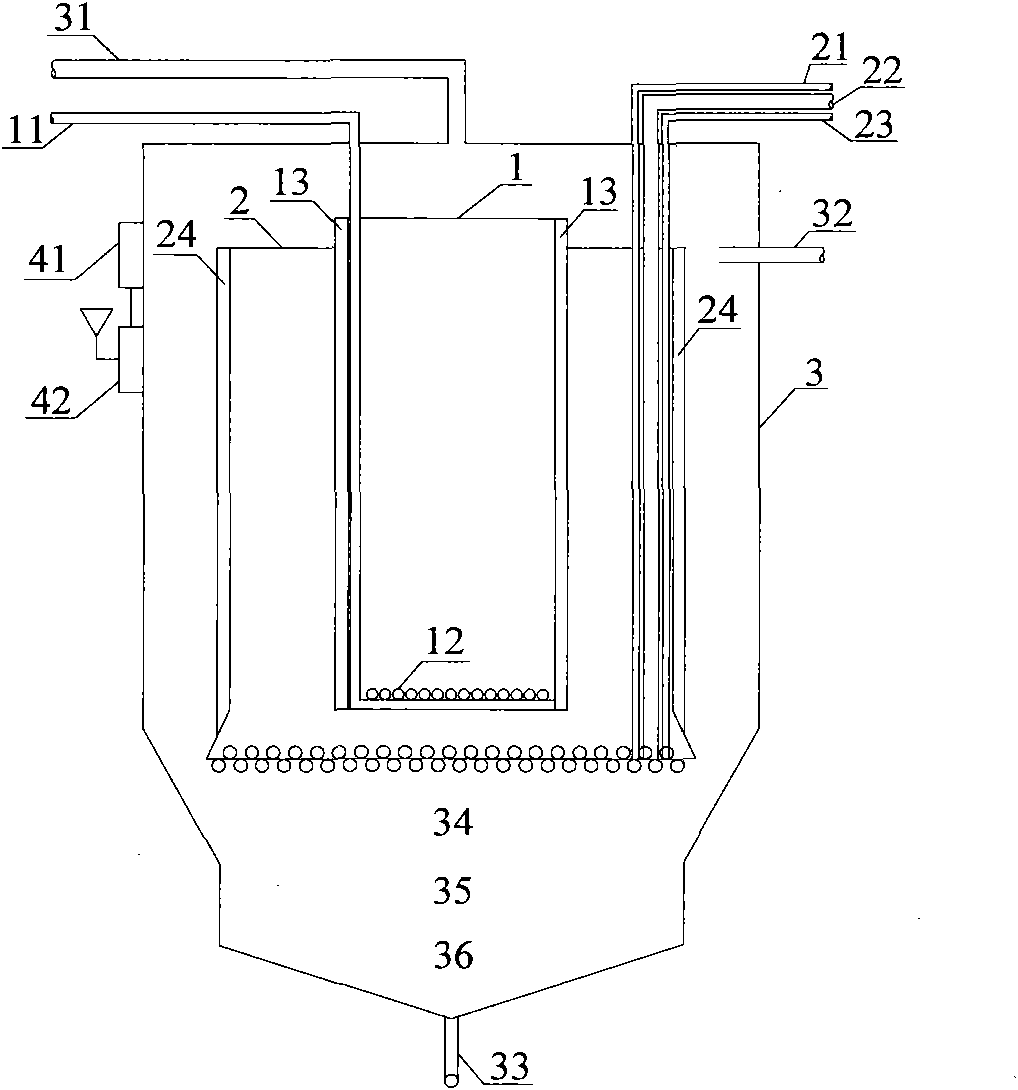

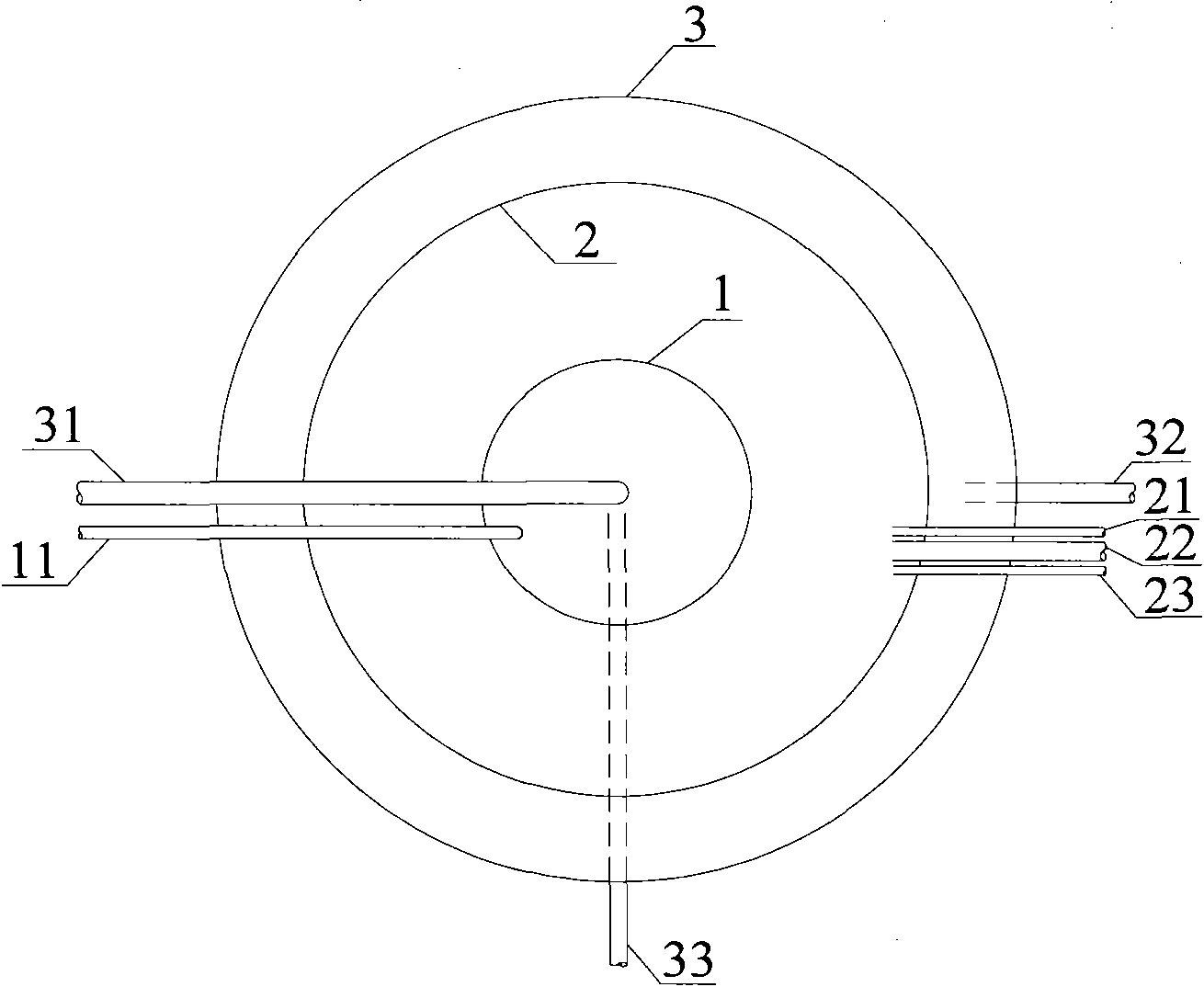

Device and method for cultivating microalgae

InactiveCN101914430ASimple structureEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsCarbon dioxideEngineering

The invention provides a device for combining microalgae cultivation and sewage treatment. The device comprises a first container, a second container and a third container which are made of a light-transmitting material, wherein a water outlet of the first container is connected with a water inlet of the second container; the second container is sleeved in the third container; an aerating device is arranged at the bottom of the first container; a carbon dioxide spraying device, a microalgae liquid spraying device and an oxygen collecting device are arranged at the bottom of the second container; the bottom of the second container is communicated with the third container; the bottom of the third container is conical, and a spoil disposal pipe is arranged at the bottom of the third container; and a microalgae harvesting pipe is arranged on the side wall of the third container. The device can provide ideal intergrowth environment for algae and bacteria, cultivate the microalgae for producing biodiesel and perform sewage treatment to remove organic matters and phospho-nitrogen from water effectively and reduce the chance of bursting blue-green algae in a large area in water bodies of China. The device has the advantages of short cultivating period and high yield of the microalgae, can realize the industrial production of the microalgae, and is favorable for environmental protection.

Owner:张建洲

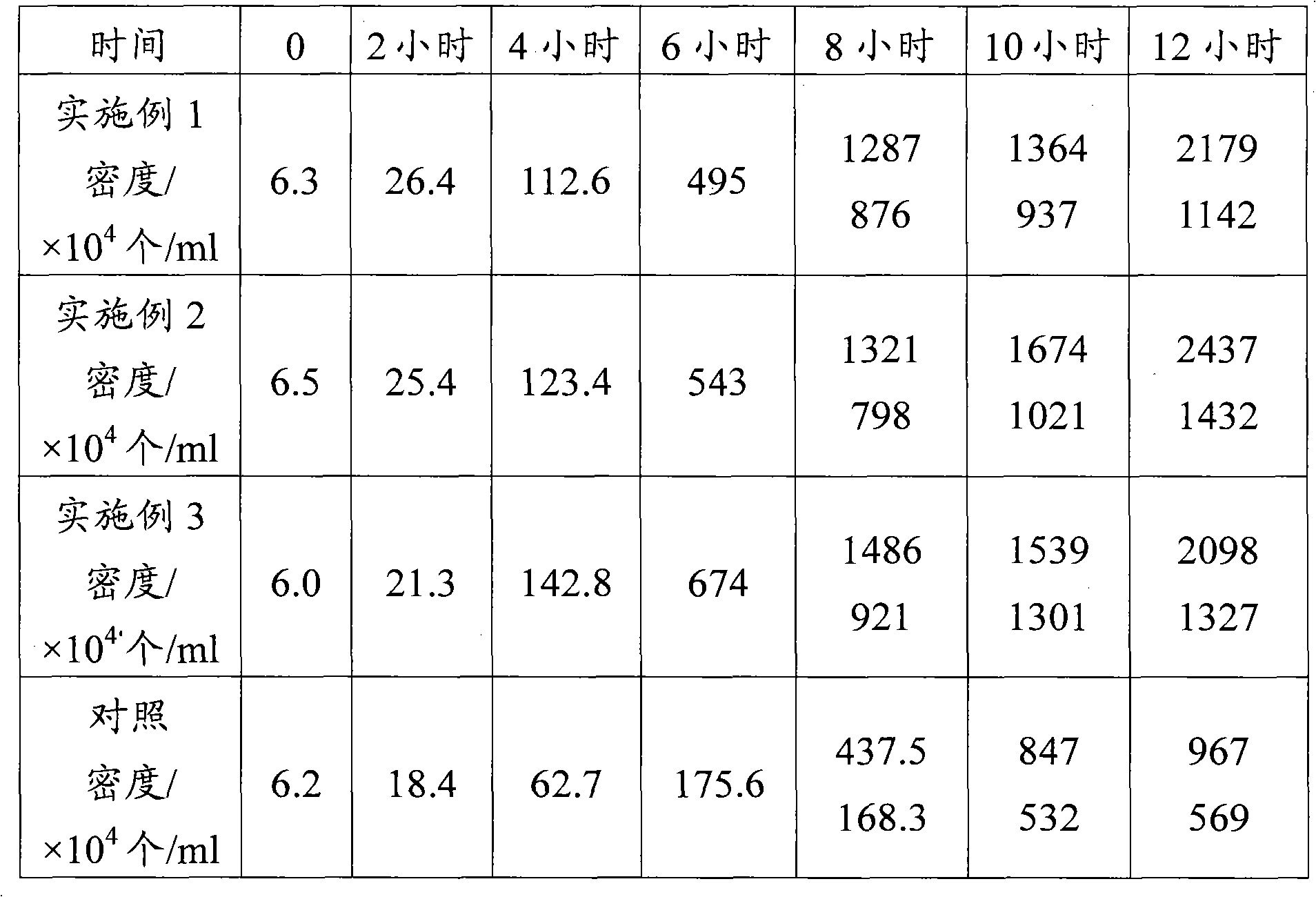

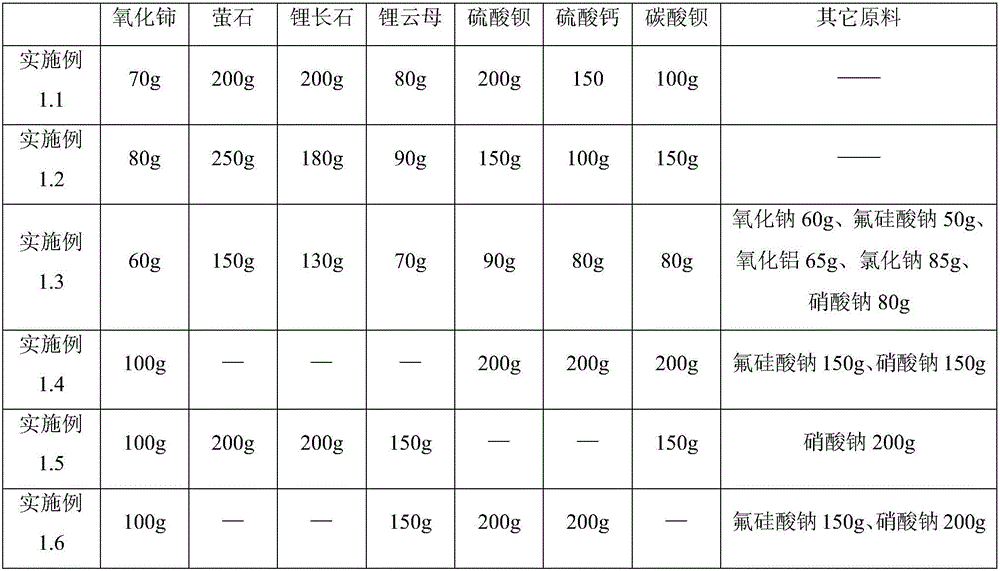

Glass clarifying agent and preparation method thereof

The invention provides a glass clarifying agent. The glass clarifying agent is prepared from components of raw materials in parts by weight as follows: 5-10 parts of cerium oxide, 10-25 parts of fluorite, 10-25 parts of lithium feldspar, 5-10 parts of lepidolite, 5-20 parts of barium sulfate, 5-15 parts of calcium sulfate and 5-15 parts of barium carbonate. The glass clarifying agent has excellent clarifying effect, can realize the clarifying effect the same as that of arsenic trioxide, can also remarkably reduce the use quantity of production raw materials introduced through matching with the clarifying agent and reduces the production cost of glass, and the comprehensive effect is better than that of arsenic trioxide; besides, the problem of glass defects caused by high probability of microbubbles on a glass panel with the adoption of a cerium oxide and sulfate composited clarifying agent is solved by means of the glass clarifying agent. The preparation method of the glass clarifying agent is simple, realizes safe production, prevents environmental pollution and is applicable to large-scale production.

Owner:郑国利

Systems and method of water treatment utilizing reactive oxygen species and applications thereof

ActiveUS10259729B2Good clarificationEasy to controlWaste water treatment from quariesWater softeningAcetic acidWater treatment system

Owner:CLEAN CHEM

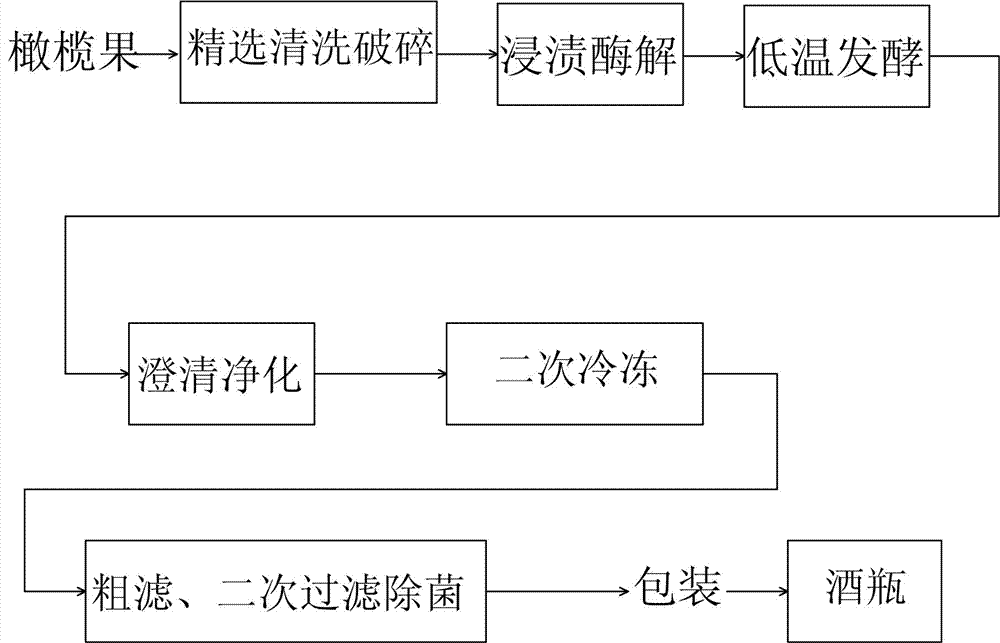

Production method of fermented olive wine and product thereof

InactiveCN102816666AGood enzymatic effectHigh alcoholAlcoholic beverage preparationCardboardAlcohol content

The invention relates to a production method of a fermented olive wine and a product thereof. The production method comprises the following steps of crushing and impregnating olive fruit and carrying out composite enzymatic hydrolysis with bentonite and gelatin for six hours to 10 hours; fermenting for 7 days to 10 days at a temperature of 15 DEG C to 20 DEG C and transferring to another tank, and post-fermenting a clear juice for 15 days to 20 days, wherein the final alcohol content is 10% vol to 12% vol; aging for one month at a temperature of 20 DEG C, carrying out freezing treatment twice, filtering and sterilizing, freezing and keeping still for 8 days at the temperature which is 0. 4 DEG C higher than the freezing point of wine, and keeping still at the temperature which is 0. 8 DEG C higher than the freezing point of wine; and finally, coarsely filtering and carrying out filtering twice by using a cardboard filter and a membrane filter, and precipitating tartrazine and black oily precipitate. The production method provided by the invention has a good low-temperature fermentation effect and high alcohol content; clarification is accelerated, the stability of wine is increased, and wine legs can be completely separated; and low-temperature freezing is carried out twice, and the tartrazine is precipitated, so that the stability of wine is further improved, and the flavor is kept. The method is applicable to the production of fermented olive wine.

Owner:YUNFU HUANAN LIQUOR

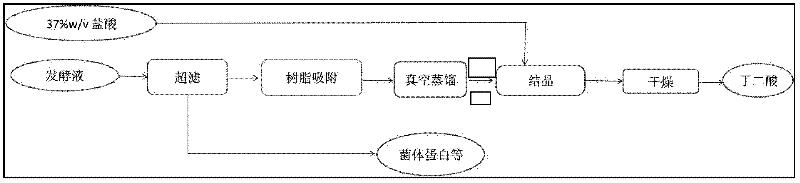

Method for separating and purifying succinic acid from fermentation broth

InactiveCN102363594AHigh viscosityHigh clarityCarboxylic compound separation/purificationUltrafiltrationSuccinic acid

The invention belongs to a technology for separating succinic acid from fermentation products, and specifically relates to a method for separating and purifying succinic acid from fermentation broth. According to the invention, separation and purification of succinic acid can be realized by the operations of appropriate units and effective combinations of the units, such that defects of existing succinic acid separation and purification technologies of complicated process and poor economical efficiency can be overcome. Therefore, a novel economic technology for separating and purifying succinic acid from fermentation broth is established. Specifically, the fermentation broth is clarified through ultrafiltration. Resin decoloration is used for replacing traditional active carbon decoloration, such that the final succinic acid yield can be improved. Succinic acid crystals are directly obtained through crystallization. With the technology, the purity of the separated succinic acid reaches 99.5%, and the yield is higher than 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Black food beer and production technology thereof

InactiveCN102851162AGood health effectTo promote metabolismBeer brewingBiotechnologyPolygonum fagopyrum

The invention relates to black food beer and a production technology thereof. Raw materials of the black food beer comprise: by weight, 10 to 20 parts of triticale, 20 to 50 parts of triticale malt, 2 to 5 parts of black fragrant rice, 2 to 5 parts of black glutinous rice, 2 to 5 parts of black buckwheat, 10 to 30 parts of caramel malt, 2 to 5 parts of black sesame, 2 to 5 parts of walnut, 2 to 5 parts of black peanut and 2 to 5 parts of dried edible plant pistil. The production technology comprises the following steps of immersion, crushing, blending, gelatinization, saccharification, filtration, boiling, fermentation, filtration and canning. The black food beer has good foam retention, a harmonious and mellow taste and a strong ester fragrance and has effects of reinforcing intelligence, strengthening brain, resisting aging, relieving cough and asthma, accelerating human body metabolism, promoting digestion and preventing constipation.

Owner:黄金洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com