Patents

Literature

83 results about "Scorodite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

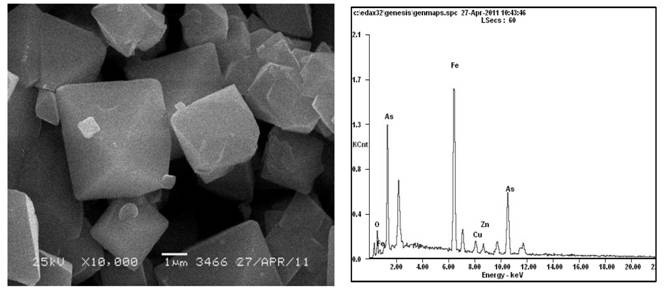

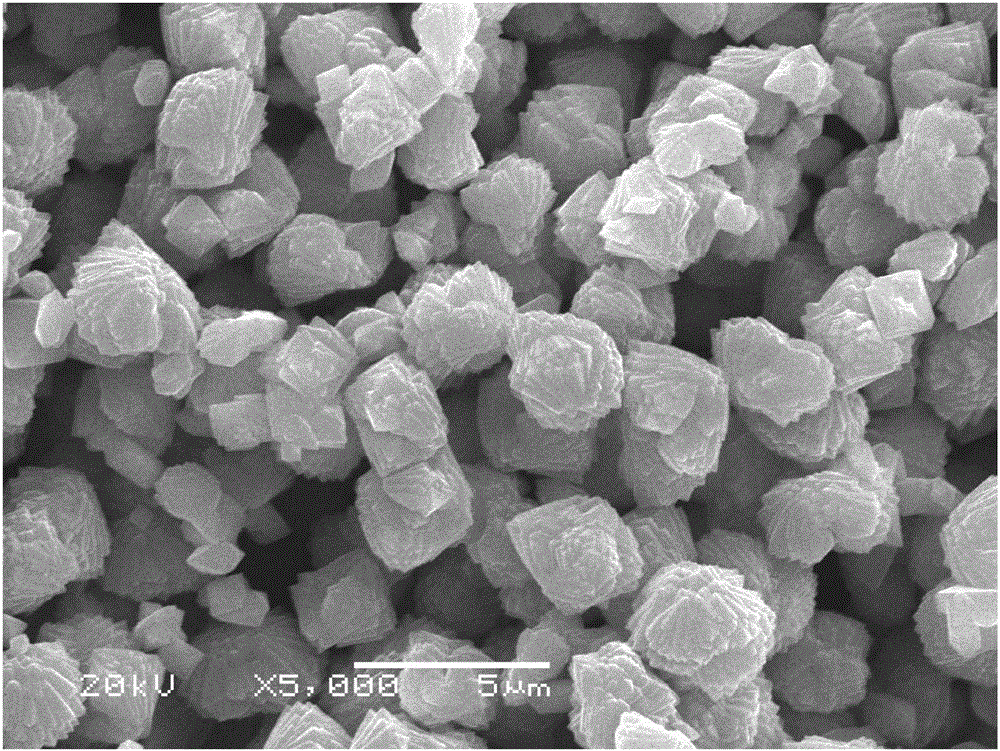

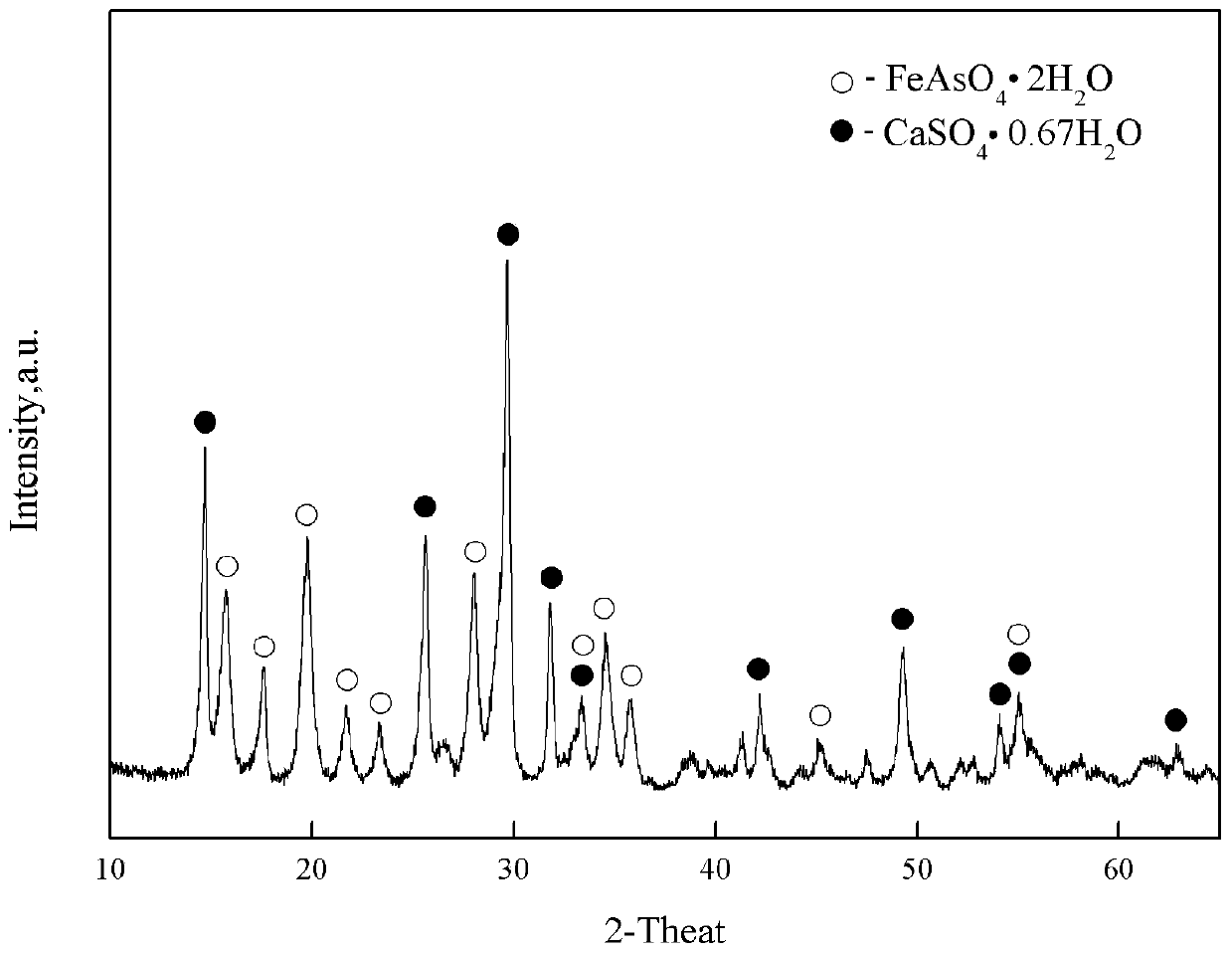

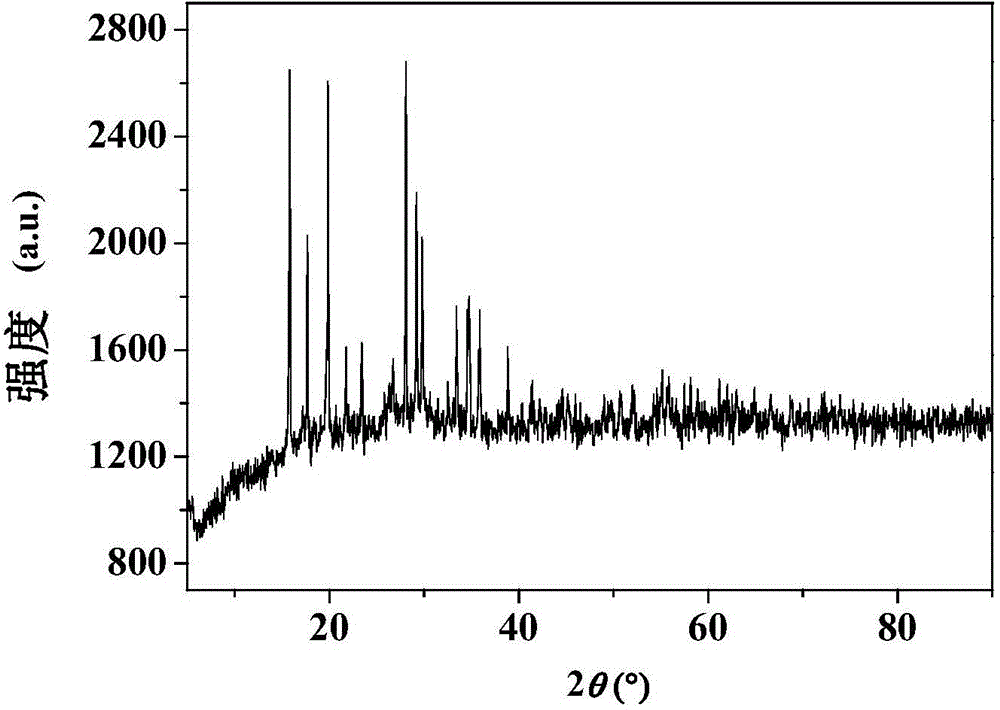

Scorodite is a common hydrated iron arsenate mineral, with the chemical formula FeAsO₄·2H₂O. It is found in hydrothermal deposits and as a secondary mineral in gossans worldwide. Scorodite weathers to limonite.

Method for precipitating and stabilizing As from As-containing solution

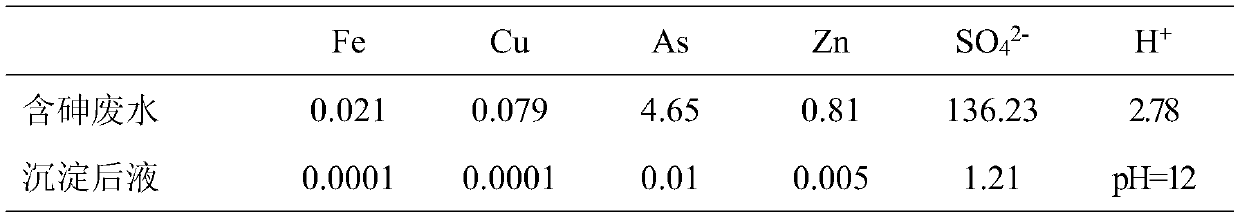

ActiveCN102674526ASimple preparation processLow equipment requirementsWater contaminantsWater/sewage treatment by oxidationFerrous saltsLimit value

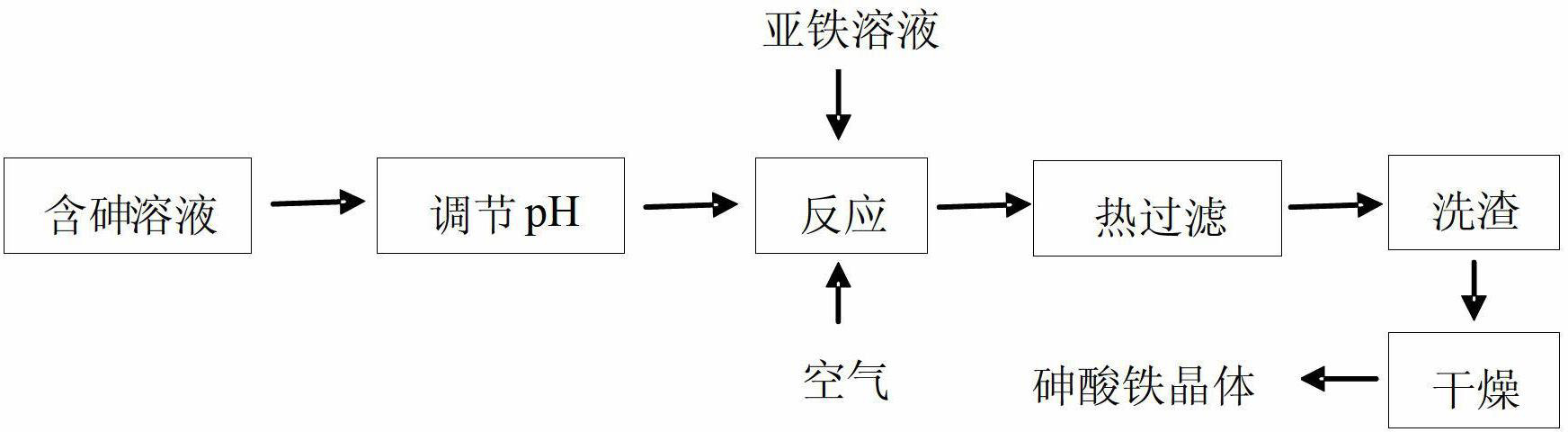

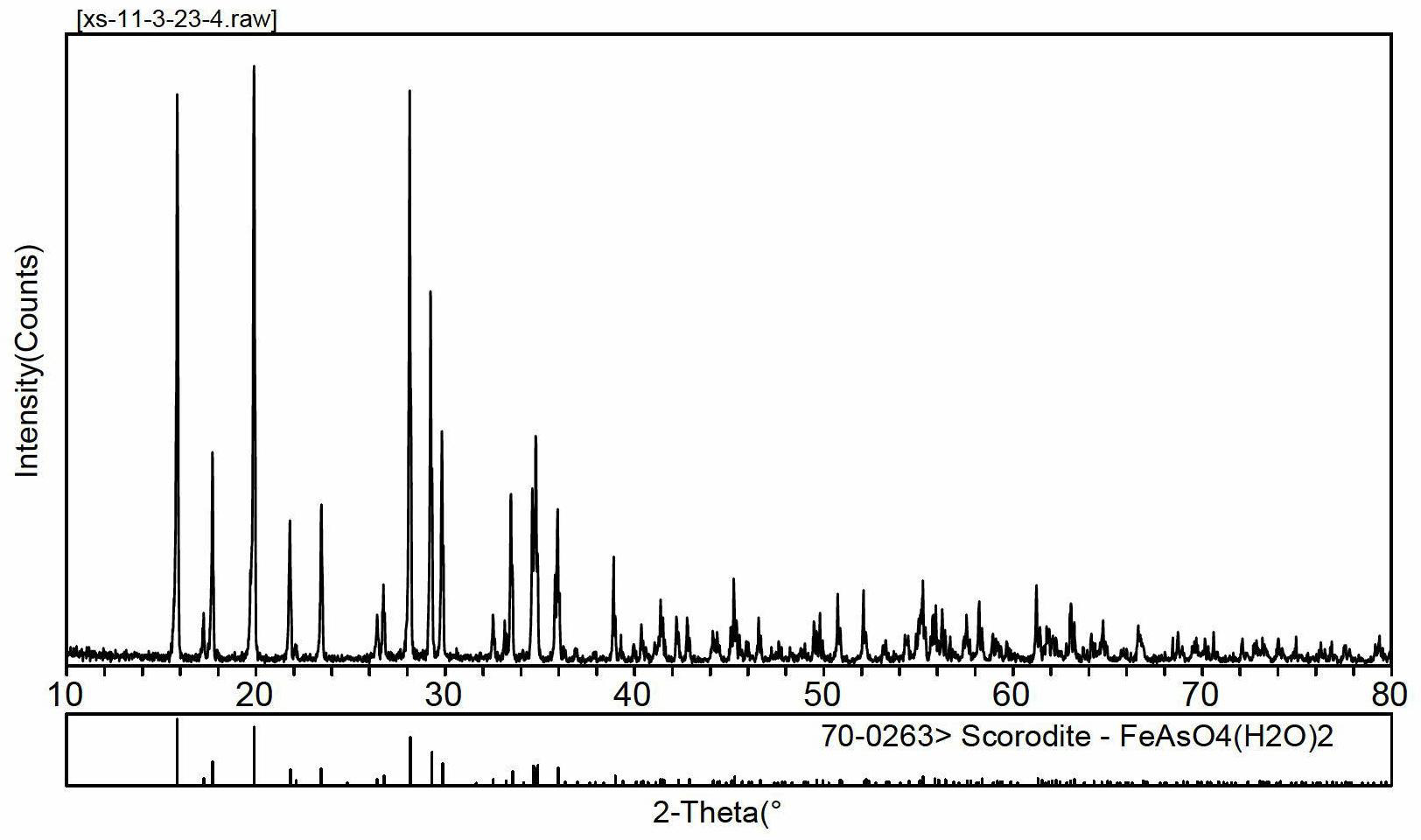

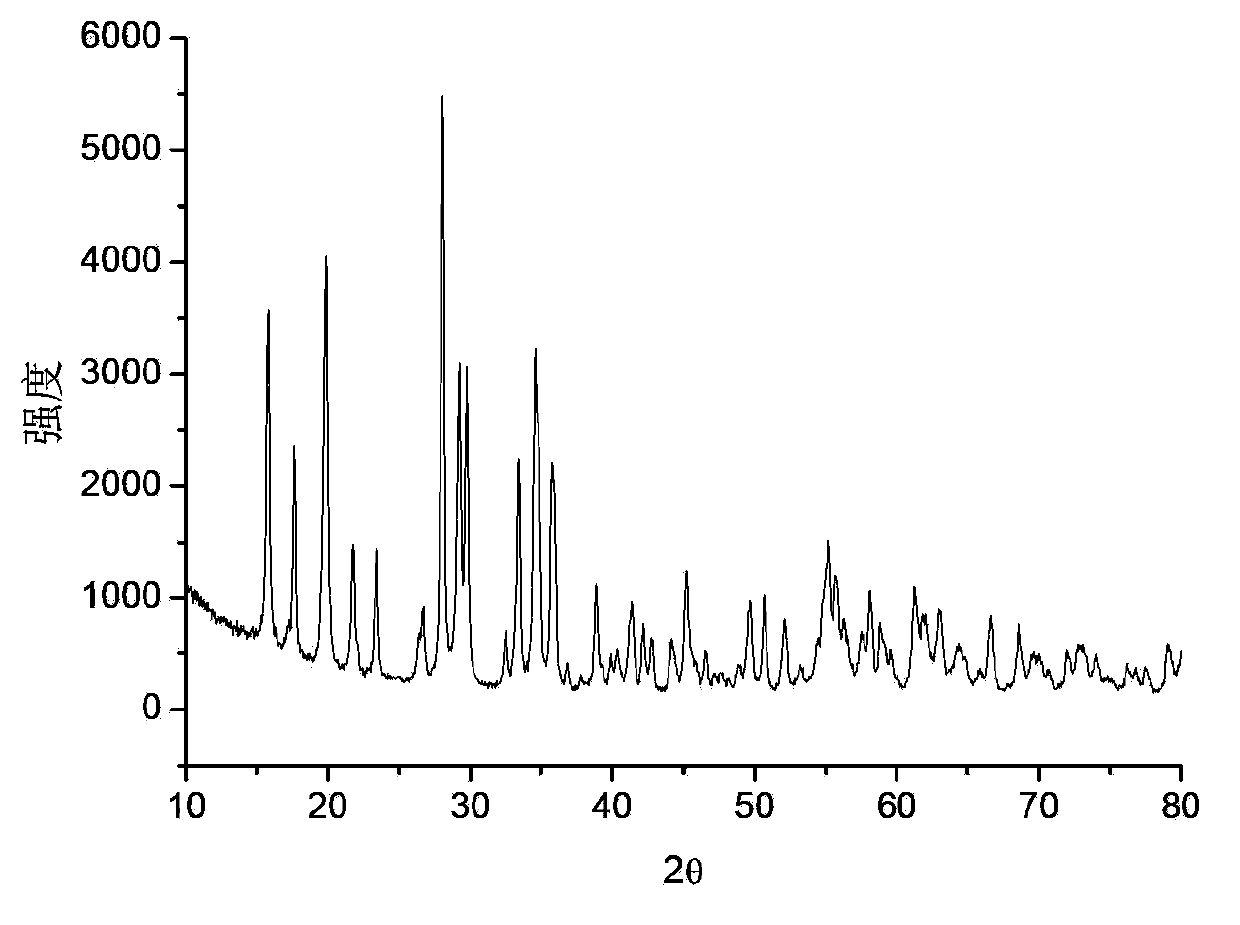

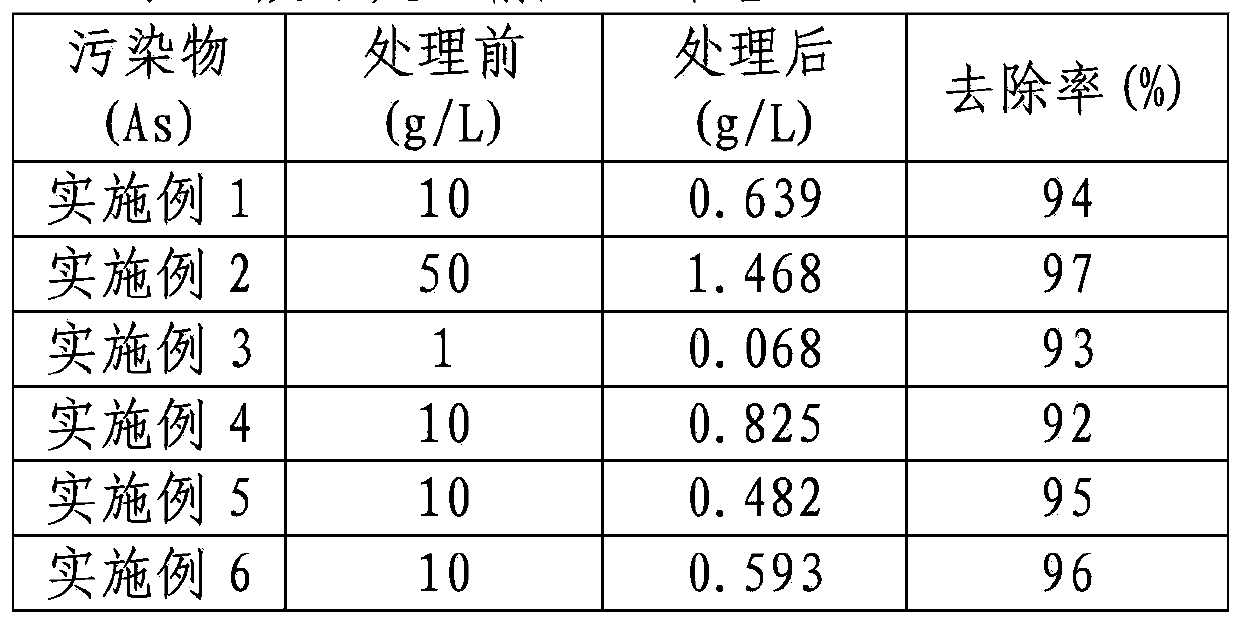

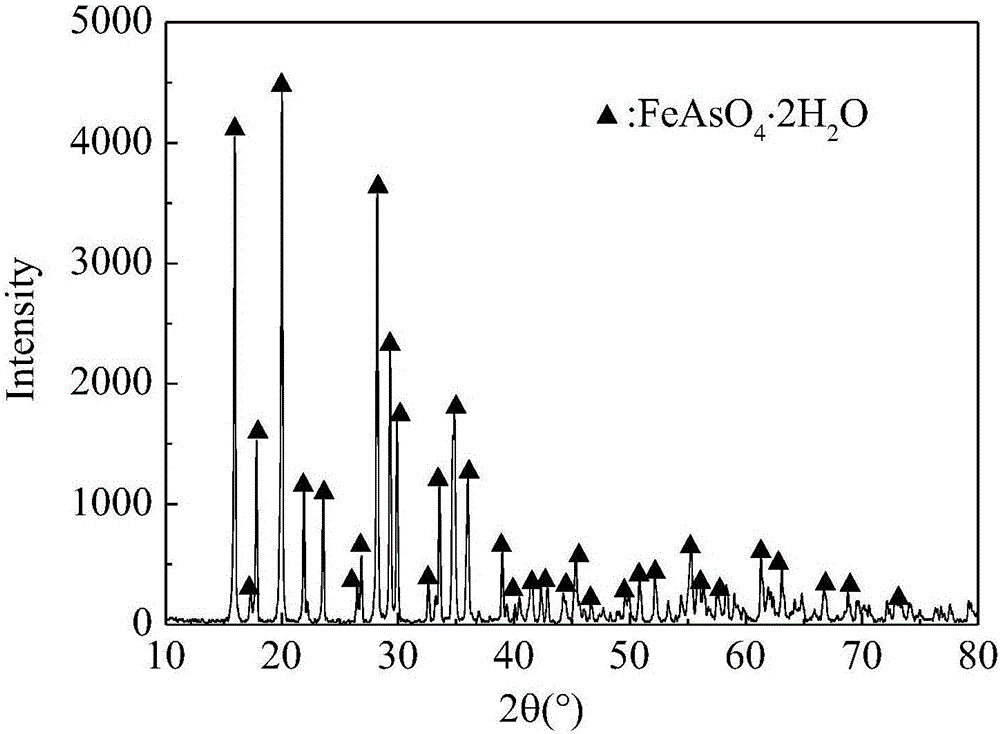

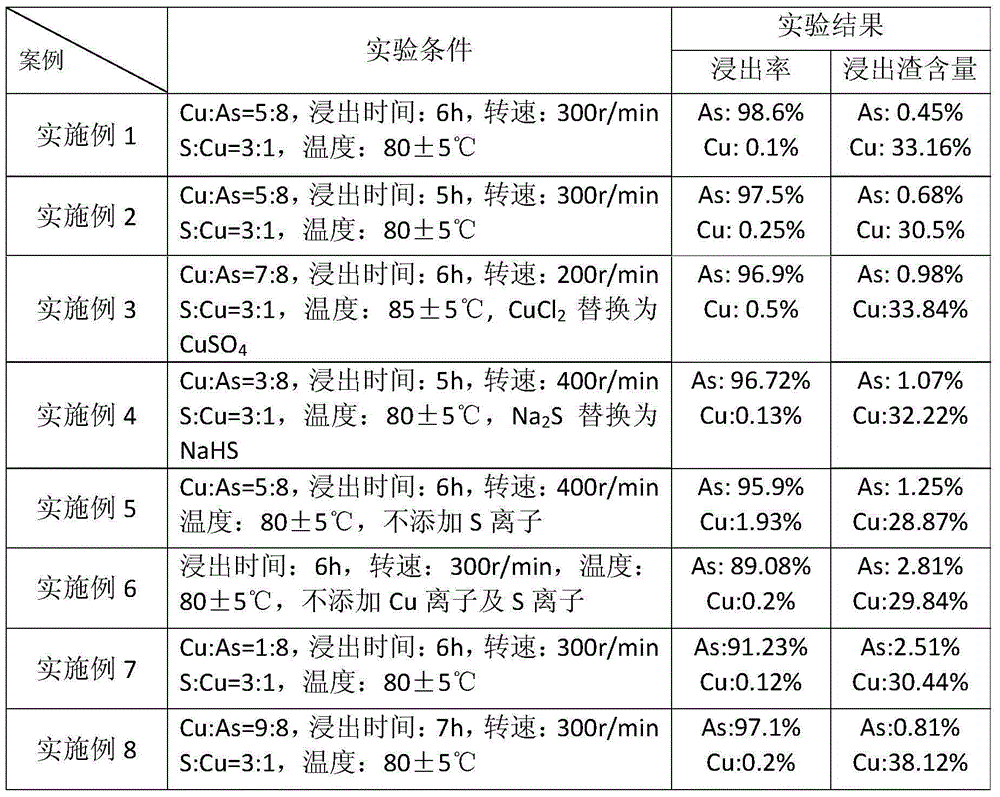

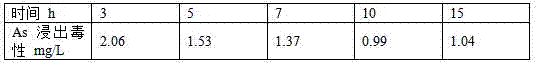

The invention discloses a method for precipitating and stabilizing As from As-containing solution. According to the method, ferrous salt is used as As precipitator; through the air oxidation in the As-containing solution in a weak acid condition, Fe<2+> is oxidized into Fe<3+>; and Fe<3+> reacts with As to generate precipitate with high stability and low As leaching toxicity. The method is simple in technology, and generates the precipitate which is ferric arsenate crystalline compound-scorodite crystal FeAsO4. 2H2O under the conditions that the pH value is 4-6, the temperature is 70-95 DEG C, the molar ratio between Fe and As is 1-1.5, the air flow rate is 120-200L / h and the reaction time is 5-7h; the precipitate As has the leaching toxicity concentration of 1-2mg / L which is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007); and the harmless stabilizing treatment for the As-containing solution can be realized.

Owner:CENT SOUTH UNIV

Method for treating arsenic-containing industrial wastewater

ActiveCN103964601AReduce productionReduce the risk of secondary pollutionMultistage water/sewage treatmentEnvironmental resistanceWastewater

The invention belongs to the wet metallurgy and environmental protection technical fields, and particularly, discloses a method for treating arsenic in arsenic-containing industrial wastewater. Under a condition of high temperature, an iron solution is slowly added into the arsenic-containing industrial wastewater, arsenic in the wastewater forms a stable scorodite crystal (FeAsO4.2H2O), and thus arsenic in the wastewater is removed. The method is simple in process, can obtain the stable arsenic-containing solid waste, and reduces secondary pollution caused to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

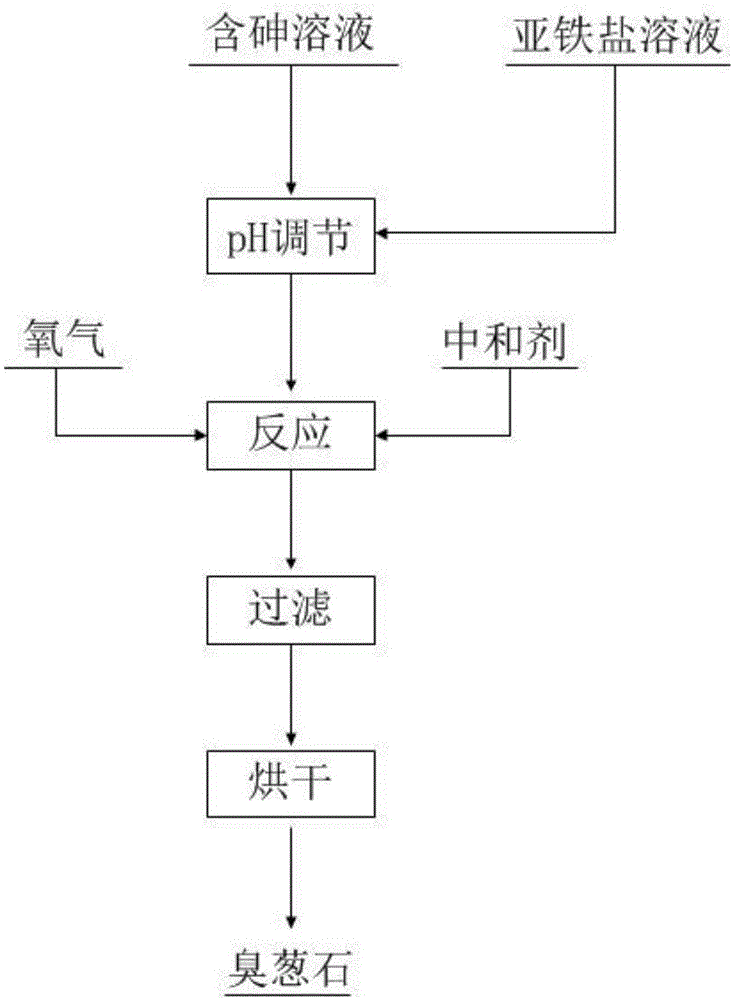

Method for obtaining high-leaching stability scorodite by precipitating arsenic-containing solution

The invention relates to a method for obtaining high-leaching stability scorodite by precipitating an arsenic-containing solution. The method comprises the following steps: adding a ferrite solution as an arsenic precipitating agent in a continuous feeding mode, and simultaneously adding a neutralizing agent in a certain concentration; continuously introducing oxygen for oxidizing ferrous ions into ferric ions, and then reacting with arsenic in the solution, thus generating the high-leaching stability scorodite. The obtained scorodite can be stably stacked and stored within a pH (Potential of Hydrogen) value range of 2 to 11 and under a strong reducing condition.

Owner:CENT SOUTH UNIV

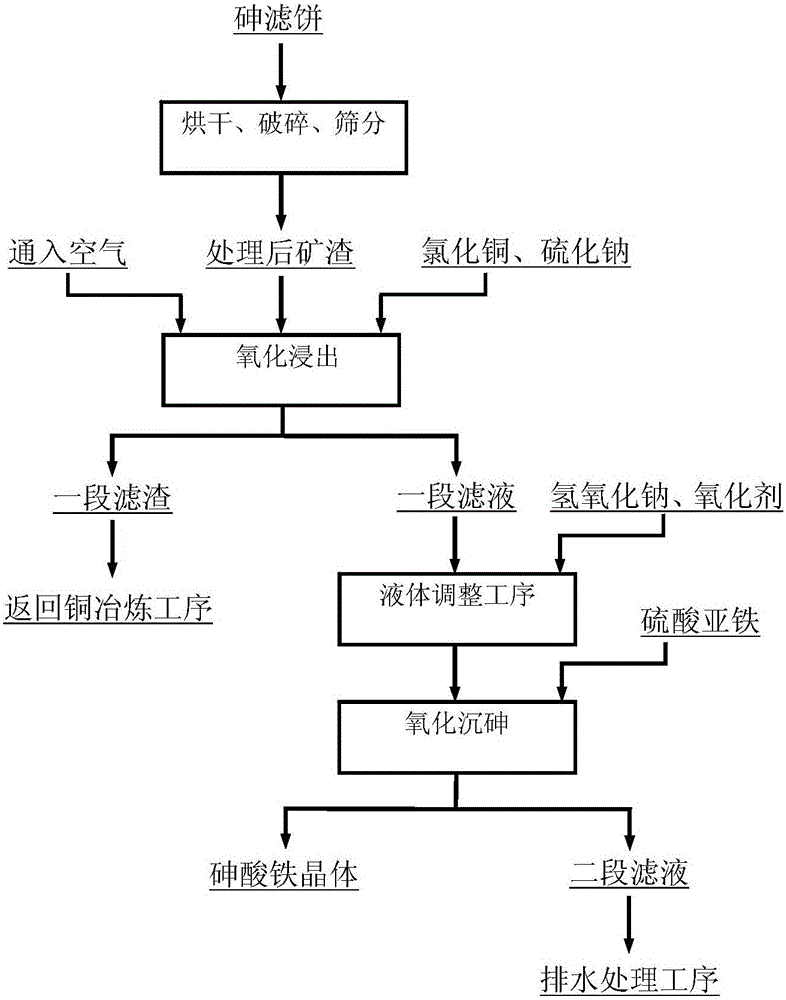

Treatment method for separating copper and arsenic in arsenic filter cakes

ActiveCN105154679AAchieve stabilizationImprove separation rateProcess efficiency improvementWater bathsPregnant leach solution

The invention discloses a treatment method for separating copper and arsenic in arsenic filter cakes. The method comprises the following steps: (1) drying, grinding and sieving raw residues of the arsenic filter cakes; (2) mixing the sieved residues with water and pulping; (3) adding copper chloride into a solution; (4) placing the solution in a water bath stirrer at 80-85 DEG C and simultaneously introducing air and reacting for 6 hours; and (5) reacting for 1-3 hours, then adding sodium sulfide into the solution, introducing the generated sodium sulfide into leaching residues, wherein a leaching solution is an arsenic-containing solution. According to the treatment method for separating copper and arsenic of the arsenic filter cakes, the purpose of separating copper and arsenic can be effectively achieved; the leaching residue is returned to the smelting process and is used; then the leaching solution is oxidized; the pH is regulated; ferrous sulfate is used for depositing arsenic to generate scorodite crystals. The method effectively reaches high recovery rate of copper and harmless treatment of arsenic in the arsenic filter cakes with low cost.

Owner:CENT SOUTH UNIV

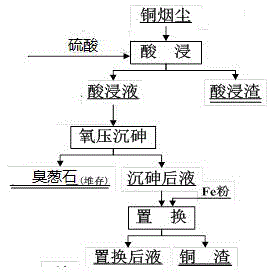

Method for recovering copper from copper dust and immobilizing arsenic from copper dust into scorodite

ActiveCN105734300AHigh recovery rateStable in natureIron compoundsProcess efficiency improvementIron powderPollution

The invention discloses a method for recovering copper from copper dust and immobilizing arsenic from copper dust into scorodite. The method comprises the following steps: subjecting the copper dust to acid leaching under the conditions that a sulfuric acid concentration is 14 to 30 g / L and reaction time is 2 to 3 h so as to obtain acidic leaching liquid; carrying out oxygen-pressure arsenic precipitation on acidic leaching liquid under the conditions that oxygen partial pressure is 0.6 to 1.3 MPa and reaction time is 2 to 3 h so as to obtain scorodite and a post-arsenic-precipitation solution; and adding iron powder into the post-arsenic-precipitation solution and carrying out a reaction for 25 to 40 min so as to displace copper slag and obtain post-displacement liquid. The method provided by the invention carries out oxidative arsenic precipitation at a high temperature, so sulfuric acid in waste acidic leaching liquid is made full use of; a high arsenic removal rate is realized, eventually produced iron arsenate has stable properties, and the post-arsenic-precipitation solution has low arsenic content; and the method has the advantages of high heavy metal recovery rate, low recovery cost, environment-friendly treatment process and small pollution to the environment.

Owner:云南云铜锌业股份有限公司

Acid recycling and arsenic curing method for acidic waste water

InactiveCN107459166AImprove resource utilizationRealize synchronous processingGas treatmentWater contaminantsNon-ferrous extractive metallurgyOxygen

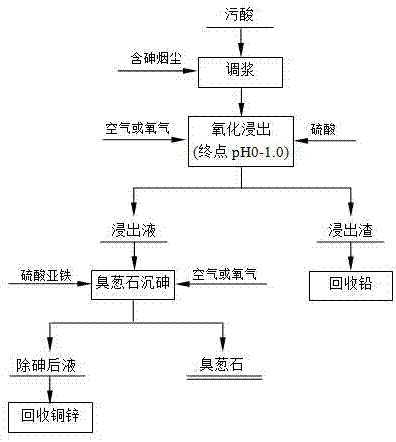

The invention relates to an acid recycling and arsenic curing method for acidic waste water and belongs to the technical field of the non-ferrous metallurgical industry. The acid recycling and arsenic curing method comprises the following steps: performing size mixing on arsenic soot and acidic waste water, then pumping in air or oxygen to perform oxidation leaching, controlling the pH value of a leaching end point, and performing normal-pressure scorodite arsenic curing on an arsenic-containing leaching agent. According to the acid recycling and arsenic curing method, arsenic-containing soot and acidic waste water mixed size mixing, oxidation leaching and scorodite arsenic curing technologies are adopted to treat acidic waste water, a new thought is provided for recycling of acidic waste water and harmless arsenic treatment of the non-ferrous metallurgical industry, and the acid recycling and arsenic curing method mainly focuses on efficient utilization of acid in acidic waste water and harmless arsenic treatment. Arsenic-containing soot generated in the non-ferrous metal smelting process is taken as a neutralizer, and arsenic-containing soot and arsenic-containing acidic waste water are synchronously treated, so that effective utilization of acid in acidic waste water is realized, meanwhile, obtained scorodite crystals are convenient to pile up, and the characteristics of complete arsenic and acid separation, low treatment cost and the like are achieved.

Owner:KUNMING UNIV OF SCI & TECH

Method for treating arsenic-containing wastewater and solidifying arsenic

ActiveCN111170510AHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateArsenous acid

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. The method comprises the following steps: separating and enriching arsenic in the arsenic-containing wastewater in the form of calcium arsenate or / and calcium arsenite precipitate; and oxidizing the obtained arsenic enriched product in a ferric sulfate or ferrous sulfate solution, and carrying outnormal-pressure reaction or pressurized hydrothermal reaction or normal-pressure hydrothermal reaction, so that arsenic in the arsenic enriched product is solidified in the form of scorodite crystals.The obtained scorodite crystals are complete in grain development, uniform in grain distribution and stable in structure under acidic conditions. The method has the advantages of high operation efficiency, good arsenic fixation effect, convenience in operation, low arsenic solidification treatment cost and the like, and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

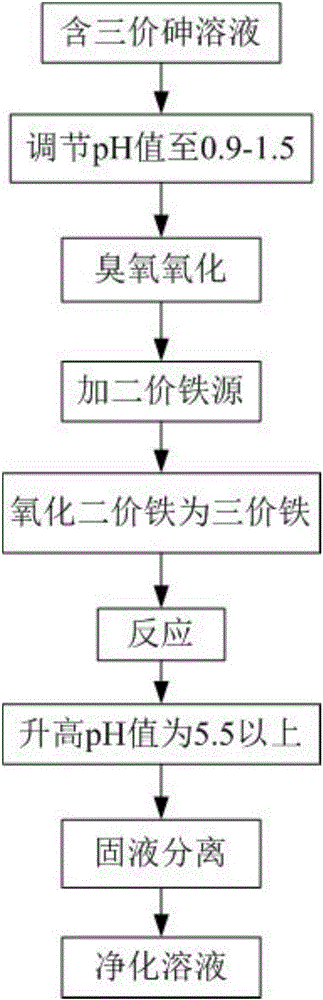

Method for removing trivalent arsenic

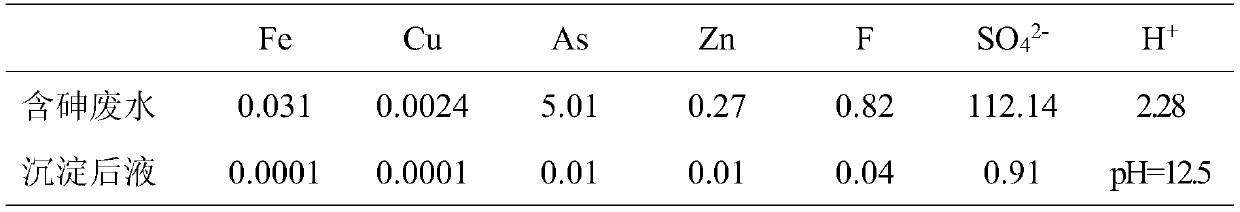

ActiveCN105753218AAvoid removalAvoid formingMultistage water/sewage treatmentWater/sewage treatment by neutralisationWastewaterGoethite

The invention provides a method for removing trivalent arsenic, comprising the following steps: (1), oxidizing trivalent arsenic in an arsenic solution into pentavalent arsenic at pH of 0.9-1.5 by using ozone to obtain pentavalent arsenic solution; (2), adding a soluble divalent iron source into the pentavalent arsenic solution, oxidizing divalent iron at a temperature higher than 70 DEG C at pH less than 1.5 into trivalent iron, and reacting the pentavalent arsenic with trivalent iron to obtain a solution containing scorodite crystal precipitate, goethite precipitate and divalent iron; (3), adjusting pH of the solution obtained in step (2), oxidizing the divalent iron in the solution to form iron peroxide gel, and carrying out solid-liquid separation to obtain a purified solution.The method enables low-concentration arsenic in waste water to be removed, arsenic content of the purified solution is lower than 0.05 mg / L, the precipitates generated in the arsenic removal process are easy to remove, and the method is simple to perform and is widely applicable to purifying waste water containing low-concentration arsenic.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

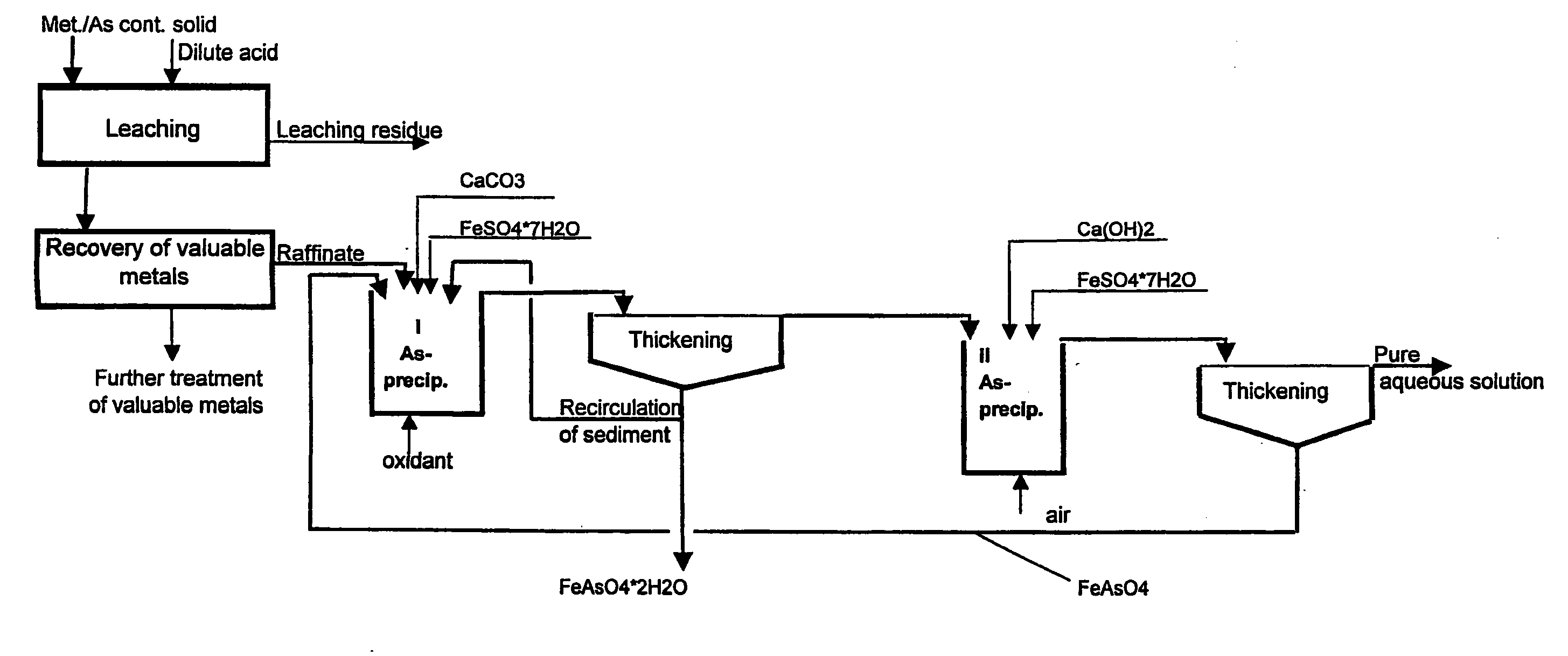

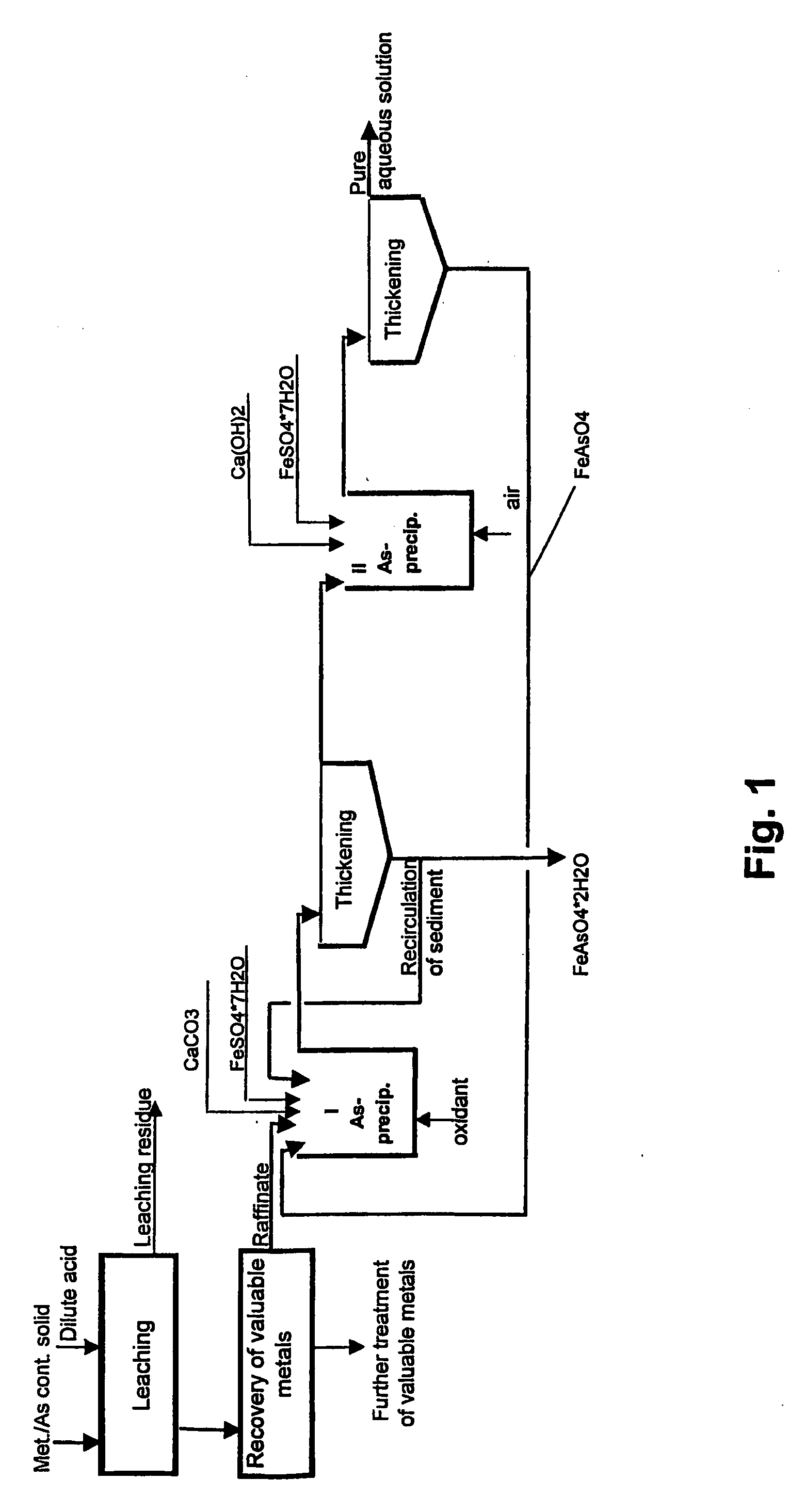

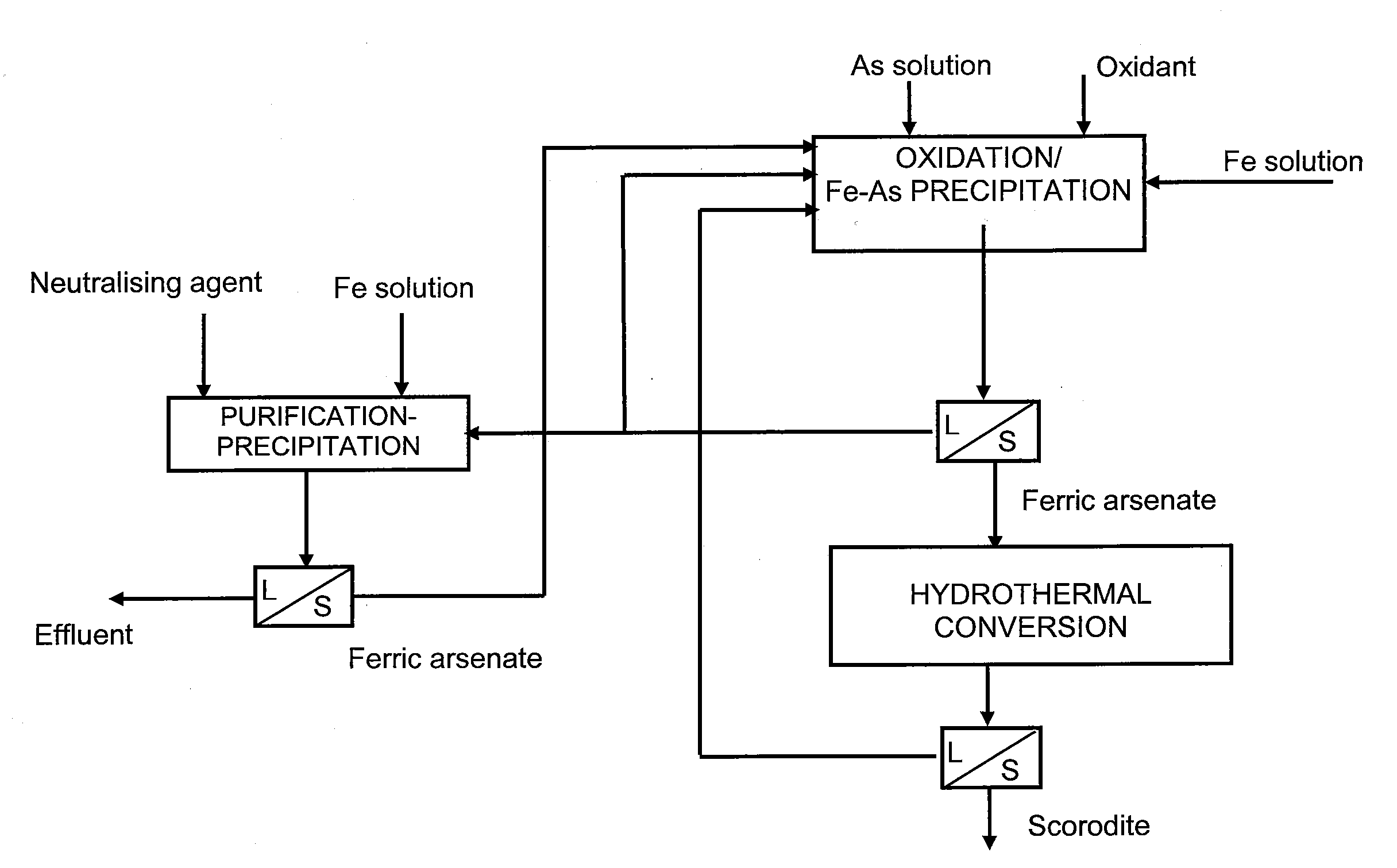

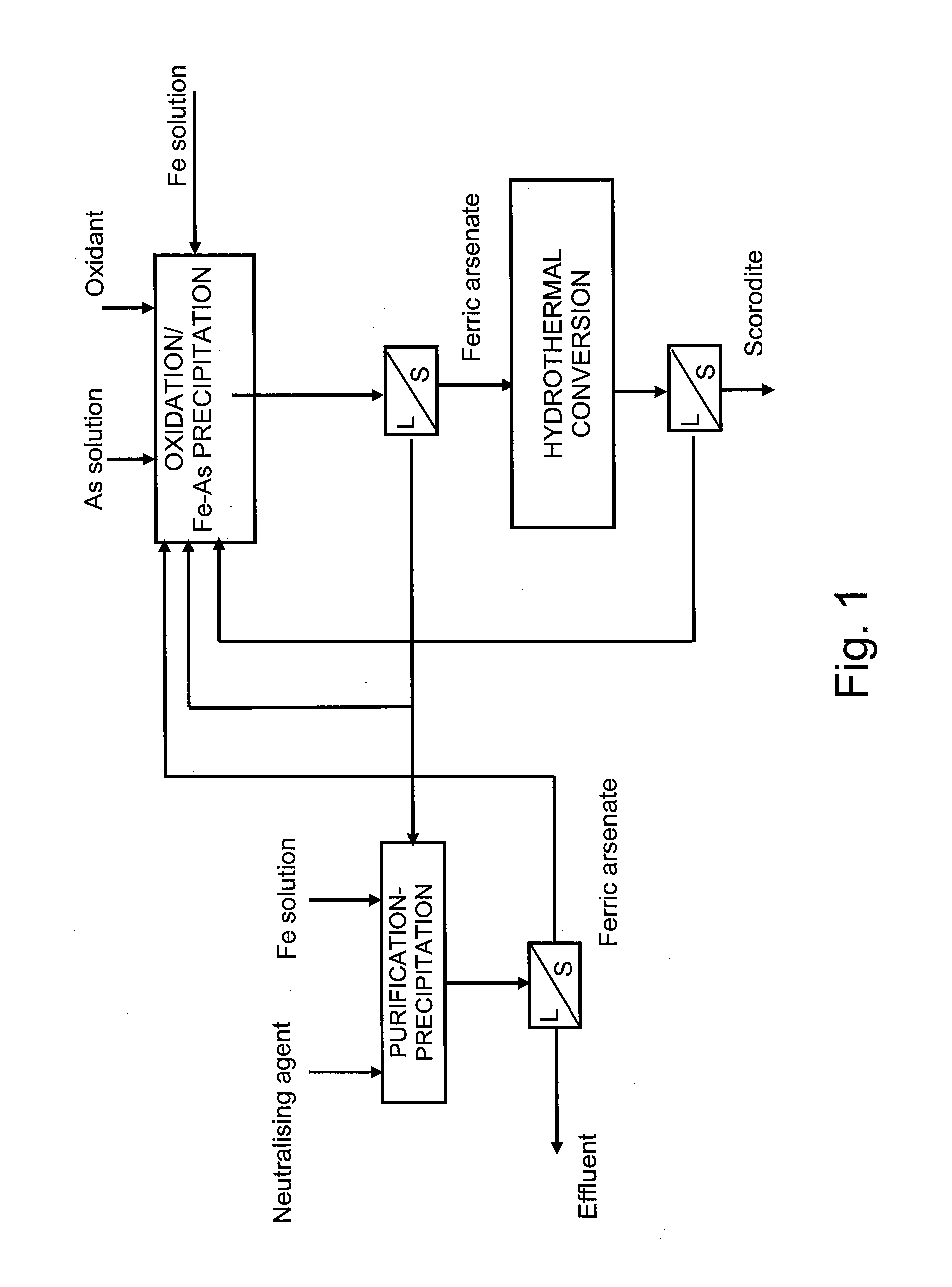

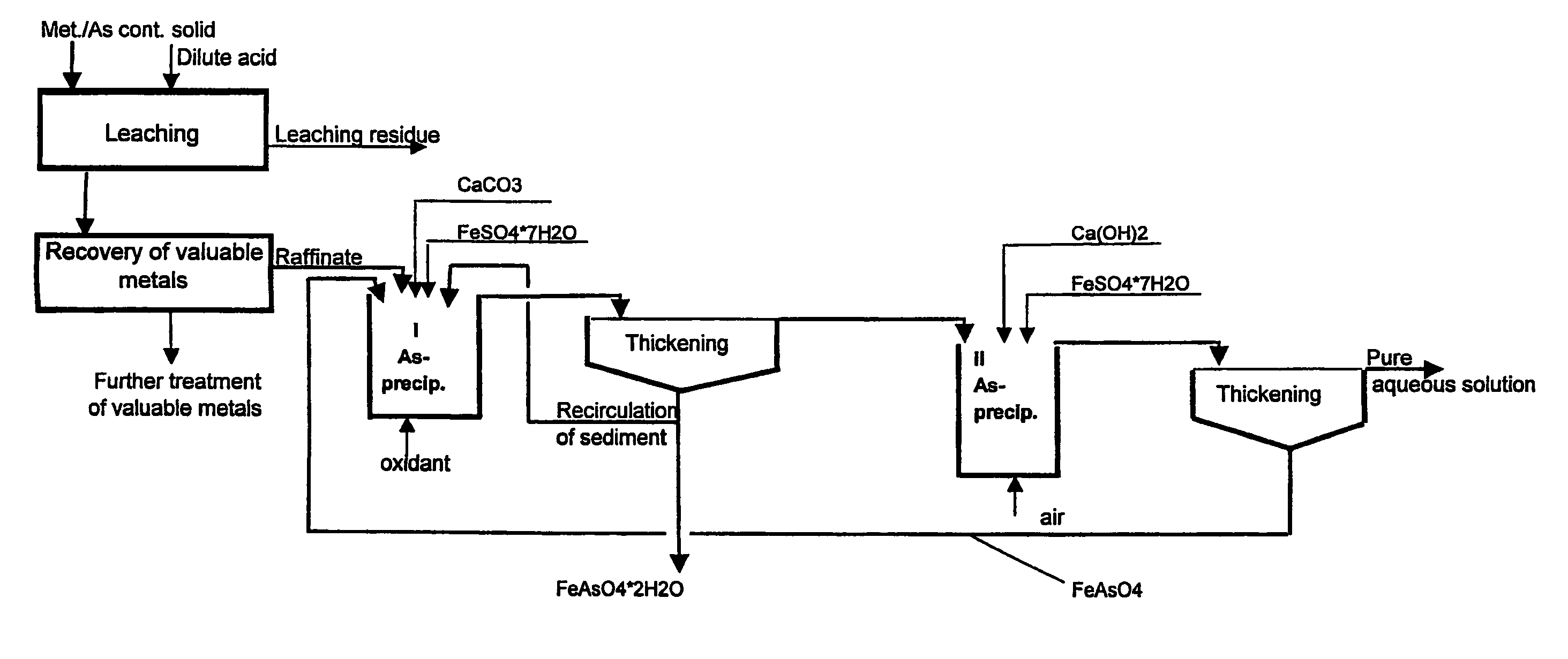

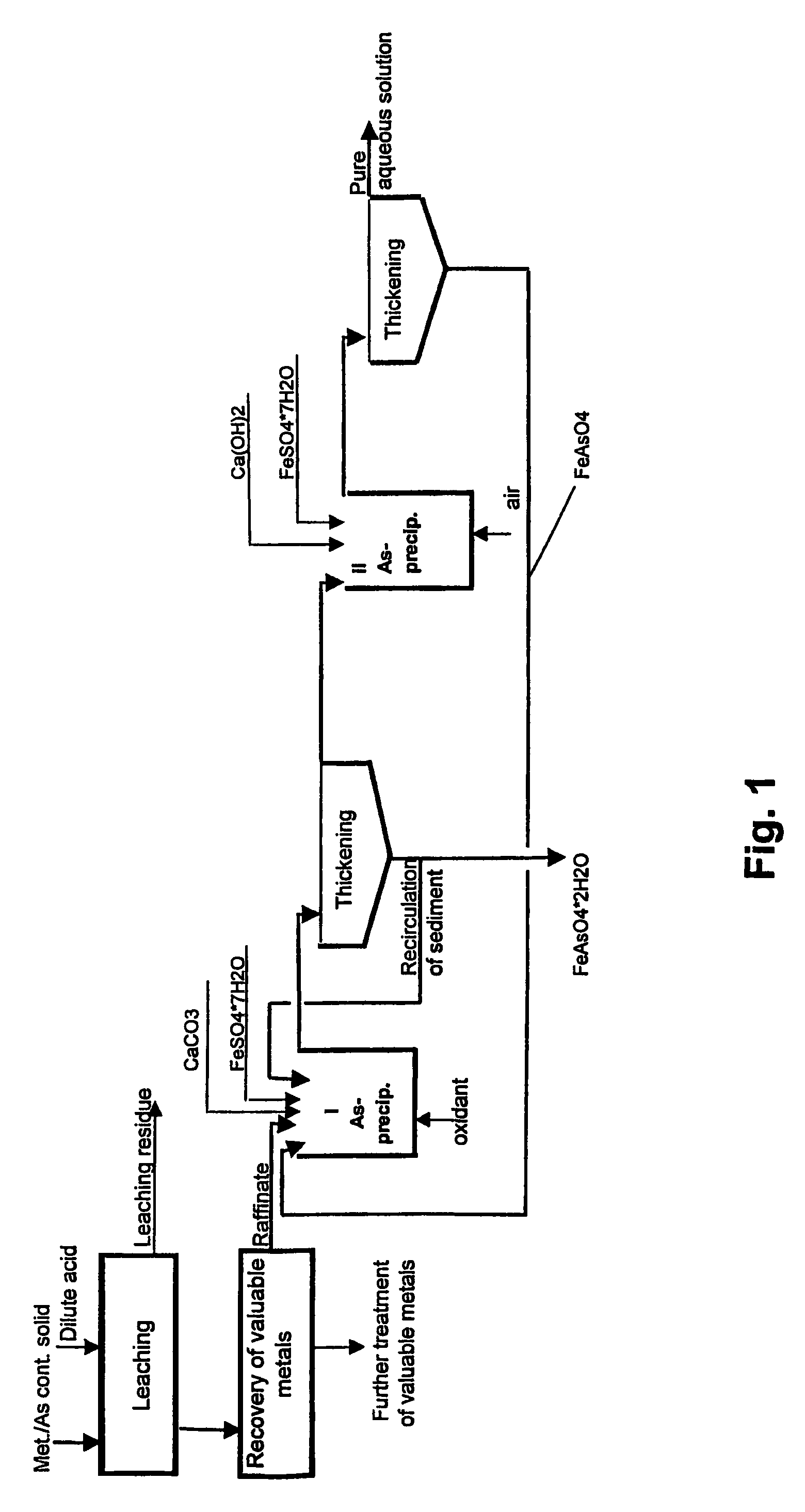

Method for the recovery of valuable metals and arsenic from a solution

ActiveUS20090022639A1Low content of valuable metalsSolvent extractionSolid sorbent liquid separationAqueous solutionSediment

The invention relates to a method for the treatment of material containing at least one valuable metal and arsenic to form a valuable metal-depleted scorodite sediment and a pure aqueous solution to be discharged from the process. According to the method, the valuable metals are first removed from the material to be treated and then arsenic precipitation from the solution is performed in two stages. By means of the method, the aim is to obtain as low a valuable metal content as possible in the scorodite sediment that will be formed. Likewise, the arsenic and valuable metal content of the aqueous solution that is formed during arsenic precipitation also remains so low that the water can be released into the environment.

Owner:OUTOTEC OYJ

Method for leaching and simultaneously stabilizing arsenic sulfide slag

InactiveCN105967232AImprove stabilityFacilitate solid-liquid separationArsenites/arsenatesSlagCulture mediums

The invention relates to a method for leaching and simultaneously stabilizing arsenic sulfide slag. The method comprises the following steps: preparing ore pulp from arsenic sulfide slag under the acid condition, adding ferrous sulfate, thermophilic iron oxide microbial strains and microbial culture medium salt, filling air and stirring, oxidizing and leaching arsenic sulfide slag under the temperature of 70-95 DEG C and a pH value of 0-2.0 by taking trivalent iron generated by microbial ferrous oxide, simultaneously adsorbing iron and arsenic by using microbial cell surface and accelerating generation of scorodite crystals. The method is simple in process flow and low in cost; the concentration of arsenic leached by the generated scorodite crystals meets the stipulation of solid waste identification standard which is leaching toxicity identification (GB5085.3-2007); the arsenic can be safely piled and stored; the leaching solution can be reused.

Owner:SCI RES ACADEMY OF GUANGXI ENVIRONMENTAL PROTECTION

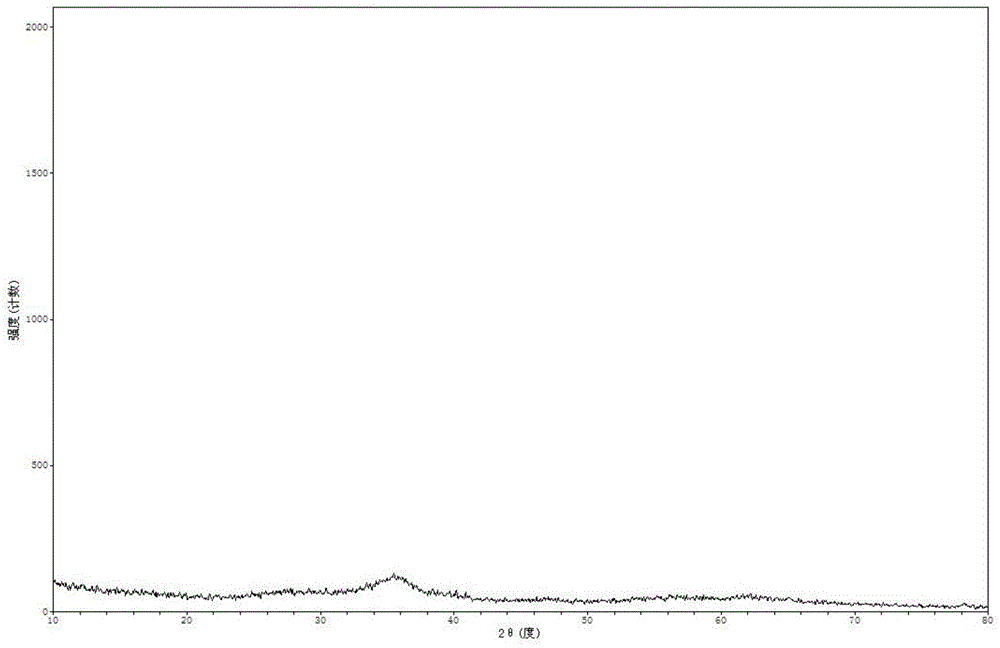

Preparation method for amorphous FeOOH water-purifying agent

InactiveCN105800762AHigh arsenic removal efficiencyEfficient removalWater/sewage treatmentAluminum IonHydrolysis

The invention provides a preparation method for an amorphous FeOOH water-purifying agent. The preparation method comprises the following steps: preparing a ferrous sulfate solution from industrial ferrous sulfate heptahydrate; adding a proper amount of sulfuric acid into the ferrous sulfate solution so as to provide an acidic environment; adding hydrogen peroxide into the solution and allowing ferrous sulfate to be oxidized into ferric sulfate under the condition of hydrolysis promotion by sulfuric acid; subjecting an industrial alkali source and the ferric sulfate solution to a precipitation reaction so as to produce iron hydroxide colloid; and dehydrating the iron hydroxide colloid under proper conditions so as to prepare the amorphous FeOOH water-purifying agent. The amorphous FeOOH water-purifying agent can effectively arsenic in water, has arsenic removal efficiency of 98% or above, does not contain aluminum ions or pose secondary pollution to a water body; after arsenic removal with the water-purifying agent, scorodite stably existing in the nature is produced, so pollution is not posed to the environment; moreover, raw materials used in the invention are of an industrial grade, and the preparation method is low in production cost and simple to operate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

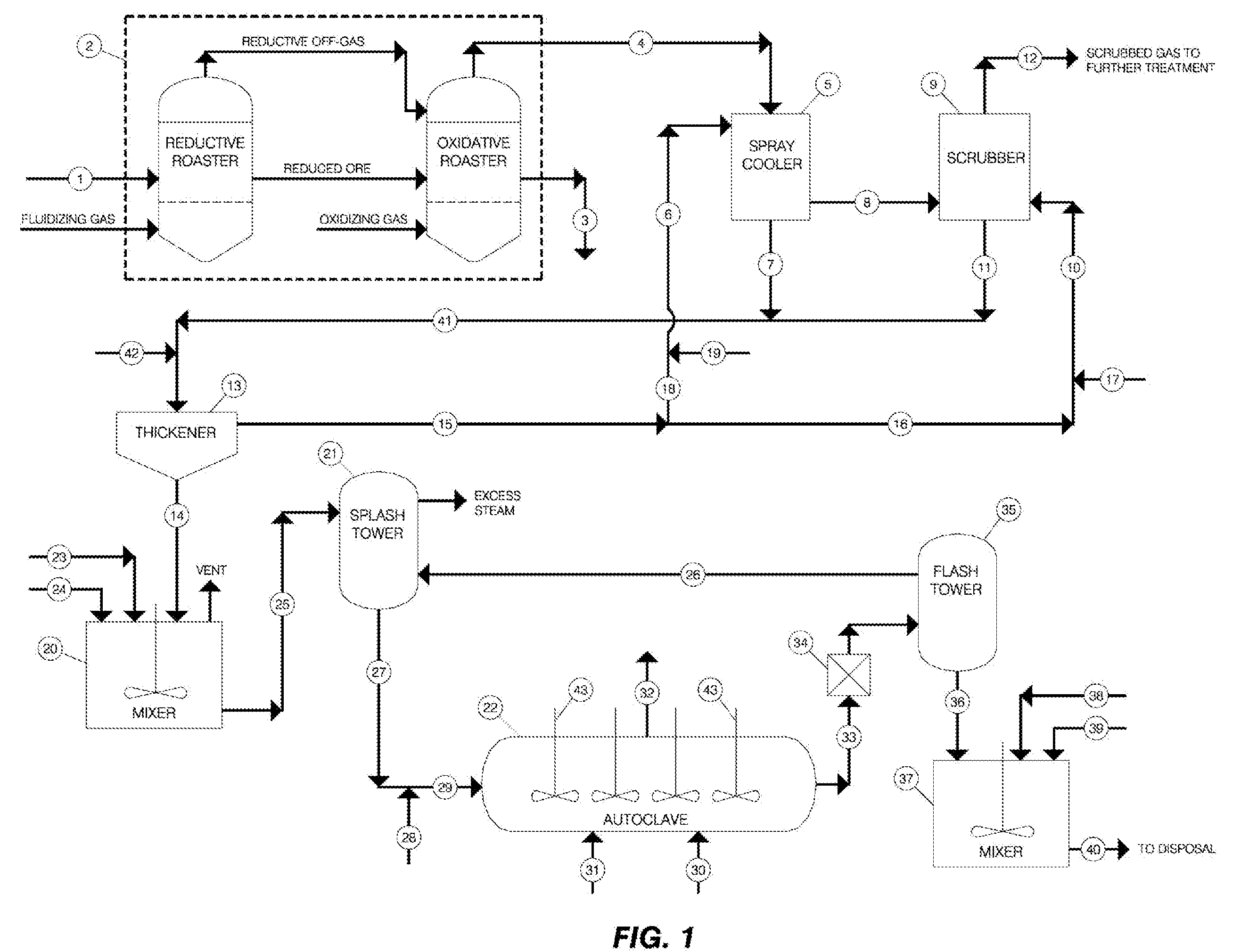

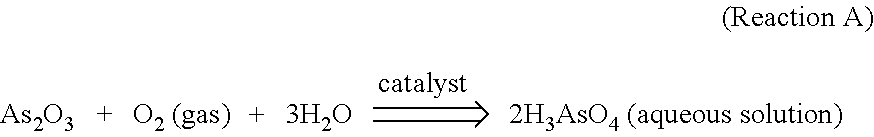

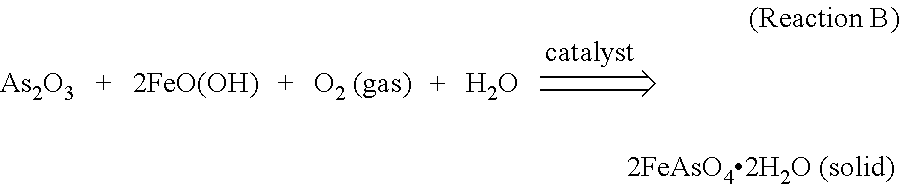

Stabilization of Arsenic-Containing Wastes Generated During Treatment of Sulfide Ores

InactiveUS20120164041A1Safe disposalEffective pressureArsenites/arsenatesAntimony compoundsChemical reactionIodide

A method is provided for the efficient stabilization, removal and disposal of arsenic-containing wastes generated in metal recovery processes that employ roasting techniques and the like. The conversion of the mostly trivalent arsenite compounds in the wastes to mostly pentavalent solid arsenate precipitates is accomplished by mixing the wastes with water and a ground iron-containing mineral, such as goethite, to form an aqueous slurry of wastes and ground iron-containing mineral, acidifying the slurry to a pH of less than about 1.0, treating the acidified slurry with oxygen gas in a pressurized vessel at a temperature higher than about 120° C. and providing an oxidation catalyst comprised of a water-soluble nitrate and a water-soluble iodide. The overall efficiency of the controlling chemical reactions is improved by the addition and use of the catalyst. The resulting solid arsenate precipitates, in the form of scorodite, are ideally suited for safe disposal with minimum or no further treatment. Unconverted soluble trivalent arsenic compounds remaining in solution may be converted and precipitated as additional scorodite by mixing and agitating the slurry with soluble iron salts under controlled conditions. The resulting precipitates meet or exceed environmental requirements for impoundment and safe disposal.

Owner:ALTYNALMAS GOLD A CANADA CORP

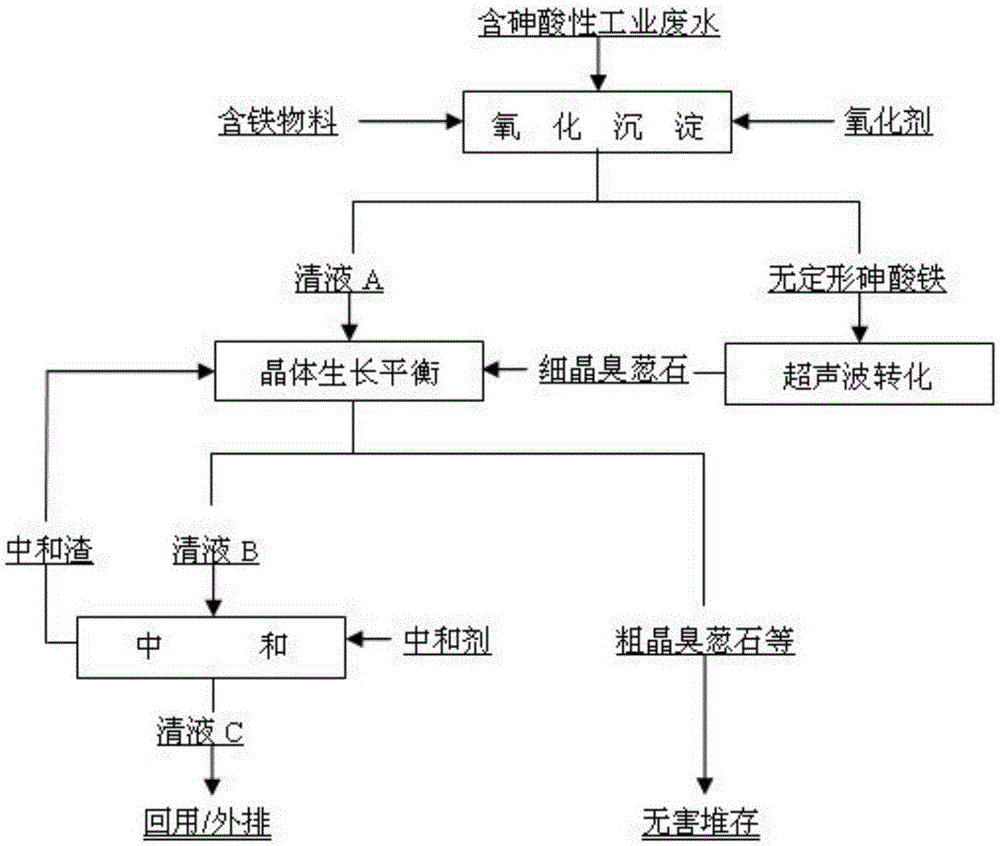

Treatment technology for high-arsenic acid industrial wastewater

InactiveCN105461110AReduce processingReduce energy consumptionWater contaminantsWaste water treatment from gaseous effluentsSludgeSlurry

The invention provides a treatment technology for high-arsenic acid industrial wastewater. The technology comprises steps as follows: Step 1: an iron-containing material is added to the arsenic-containing acid industrial wastewater, and amorphous ferric arsenate sediment and a clear liquid A are formed; Step 2: the amorphous ferric arsenate sediment obtained in Step 1 is placed in a reactor with an ultrasonic wave source, and a slurry material is converted into fine-grain scorodite under the action of ultrasonic waves; Step 3: the fine-grain scorodite and the clear liquid A are led into a reaction tank and stirred to have reaction equilibrium for 0.5-8 h, and coarse-grain-scorodite-containing sediment (for harmless stockpiling) and a clear liquid B are obtained; Step 4: a neutralizer is added to the clear liquid B, the pH is adjusted to be neutral, a clear liquid C is produced (for reuse / discharge), and neutralization sludge produced in a neutralization reaction returns to Step 3 for reaction equilibrium. According to the treatment technology, an ultrasonic wave technology is applied to the grain form transformation process, a precipitation technology is designed again, contaminated acid treatment energy consumption is obviously reduced, and the self-cleanliness of the treatment process is improved.

Owner:昆明泉淳环保科技有限公司 +1

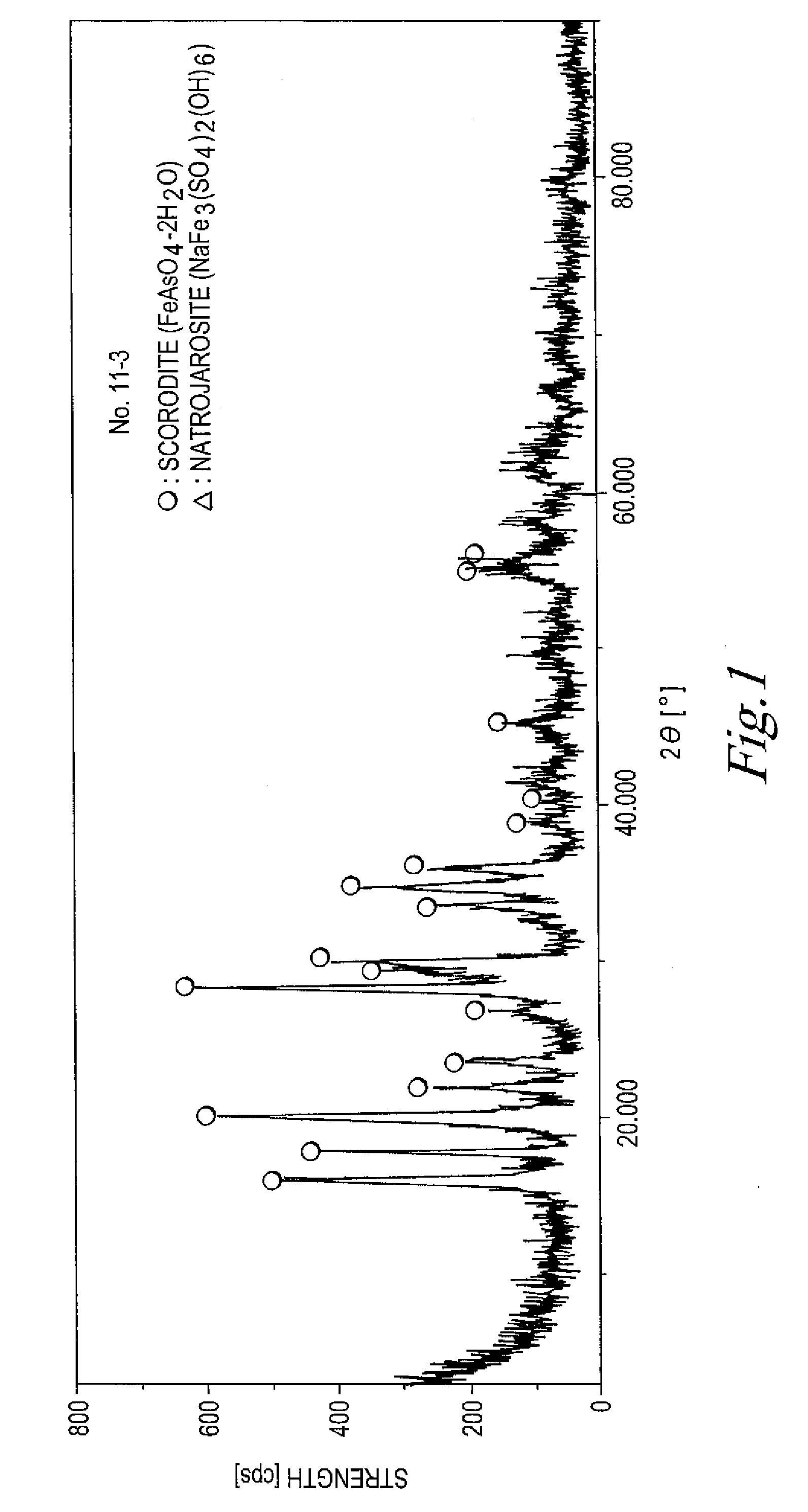

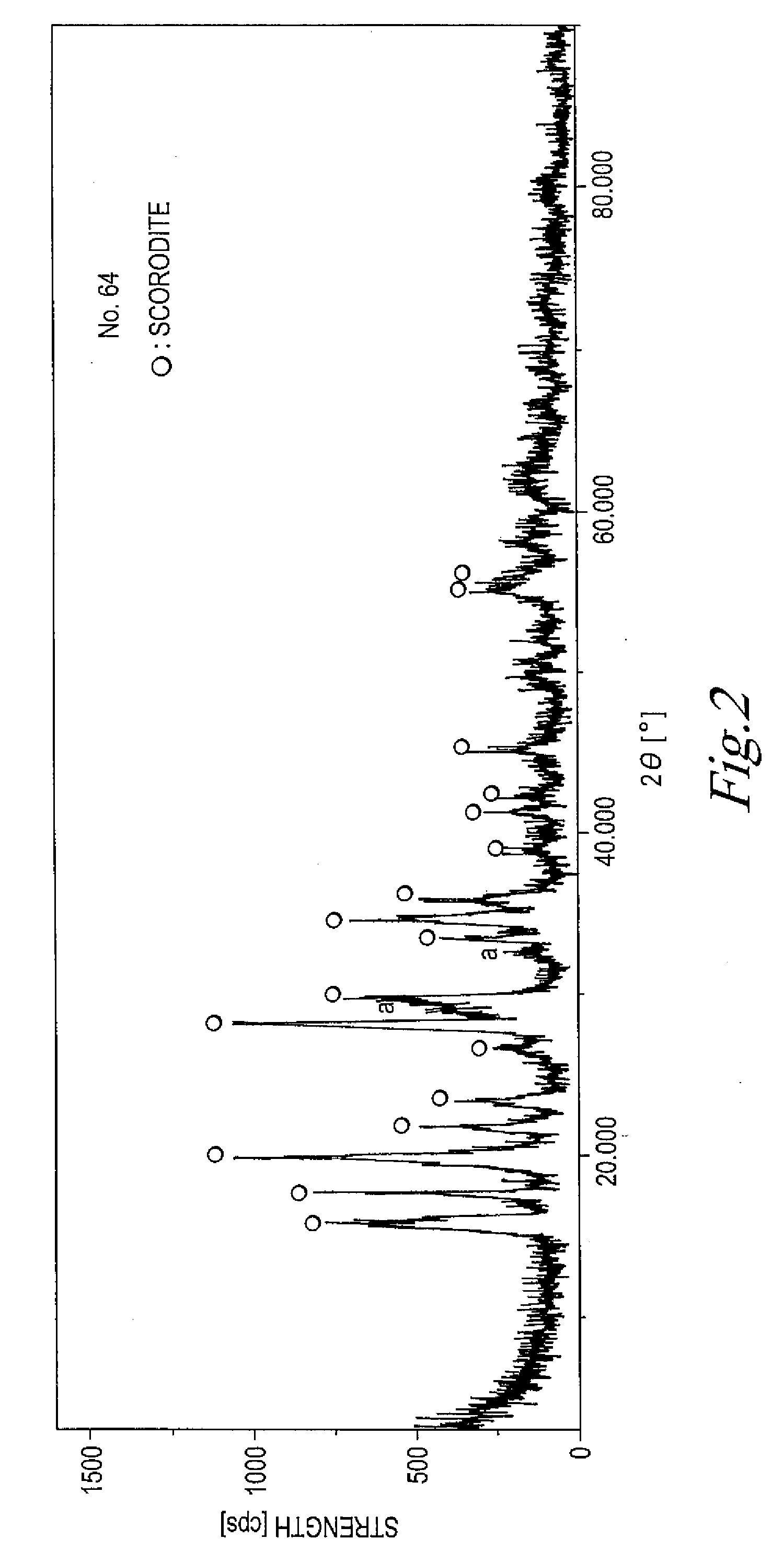

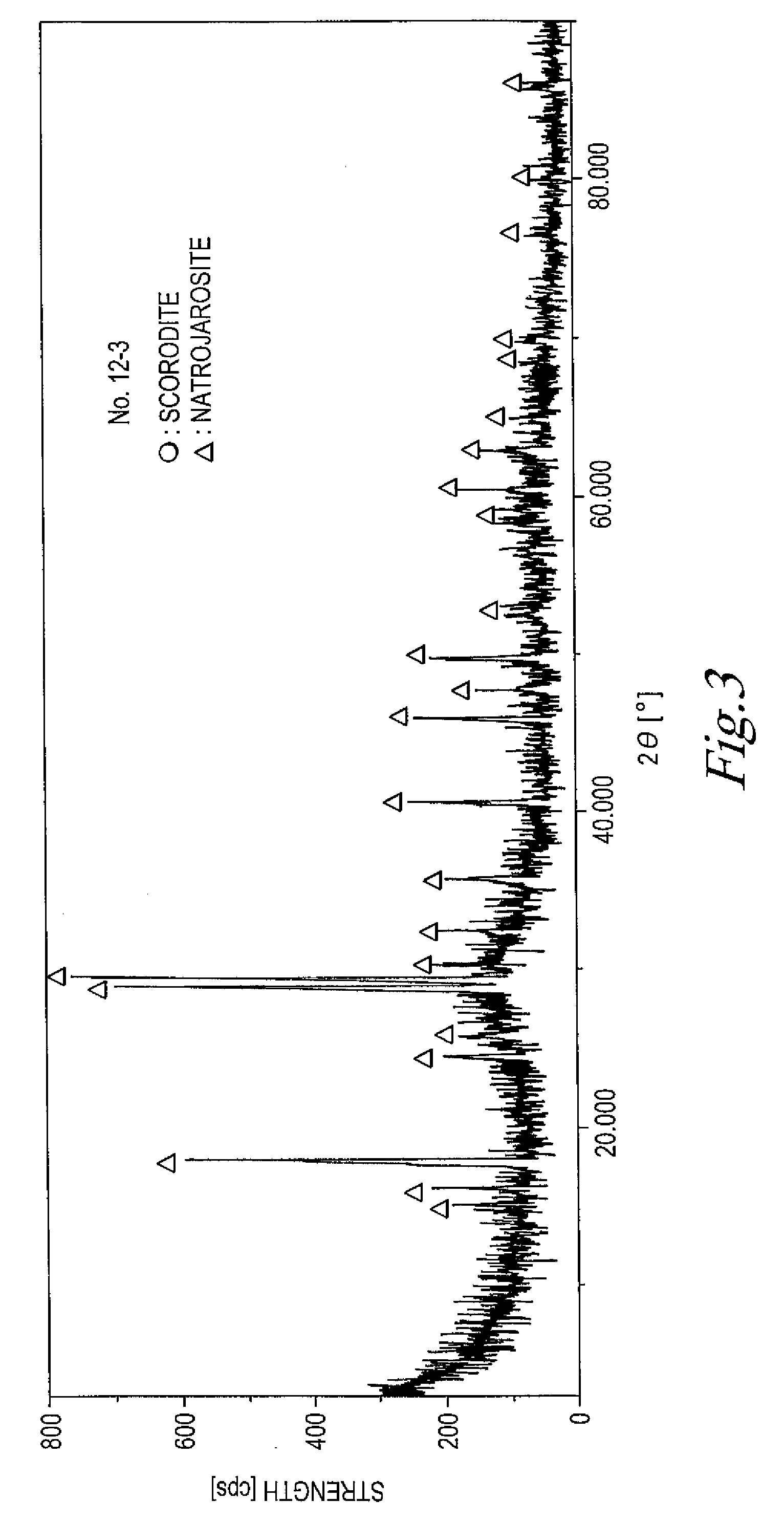

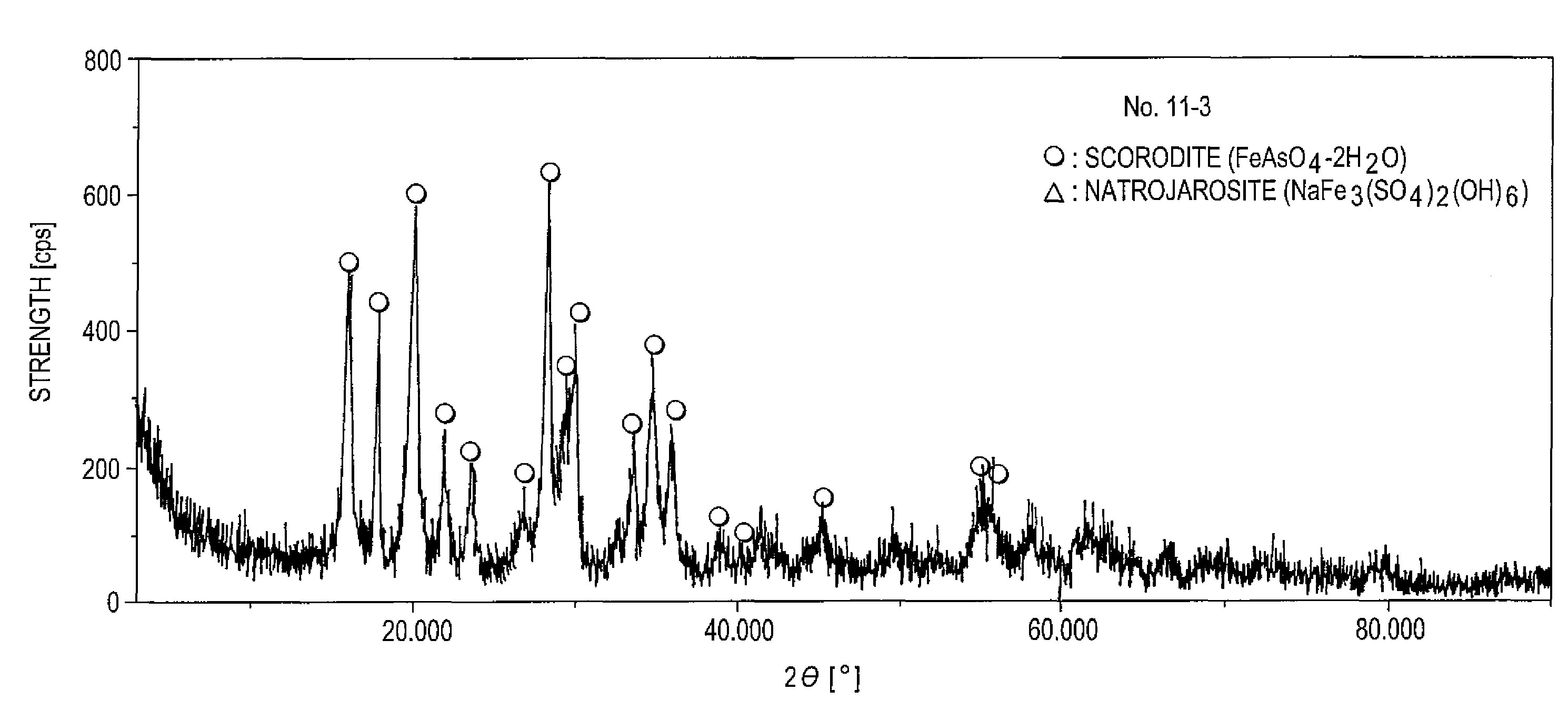

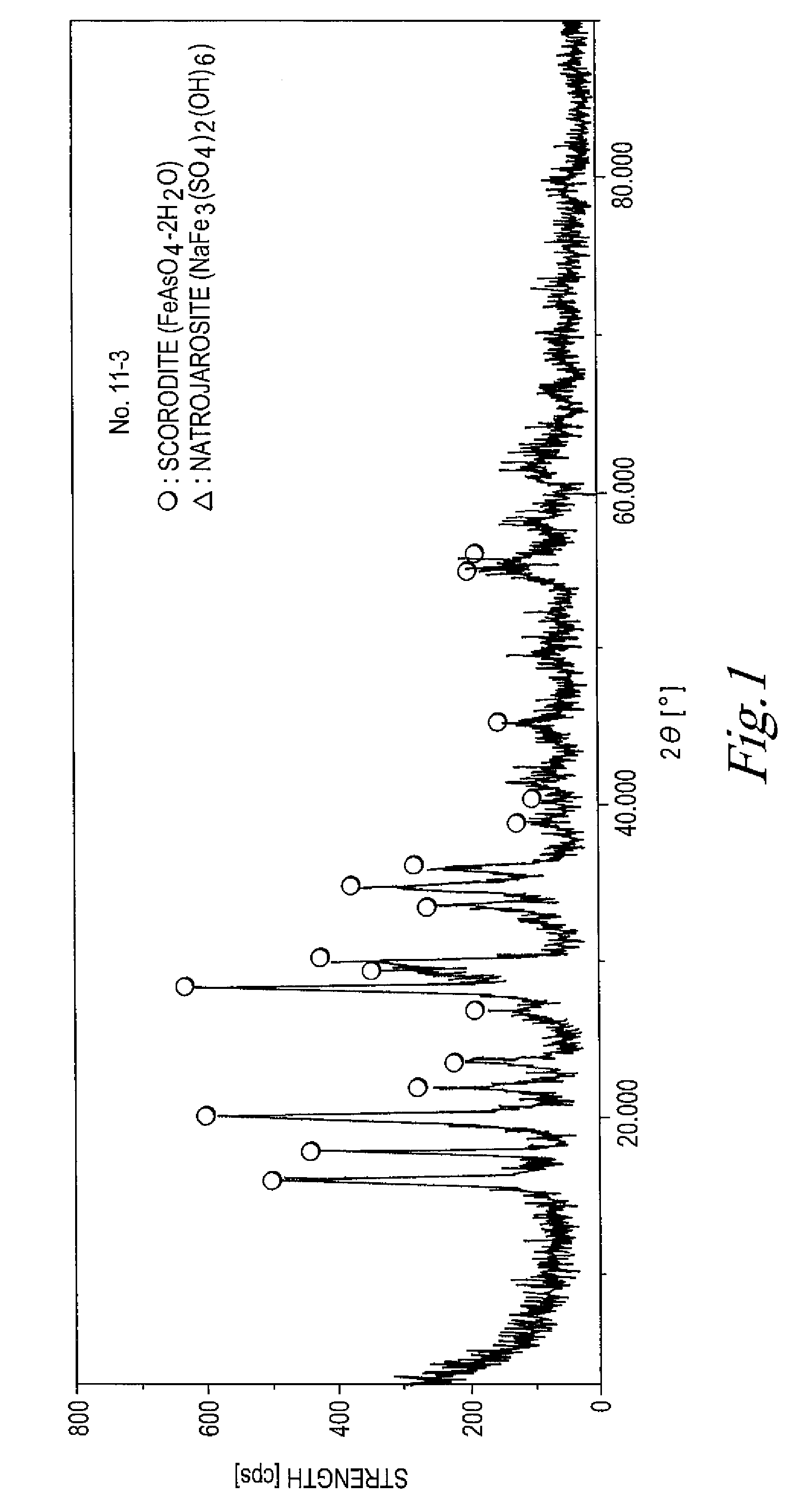

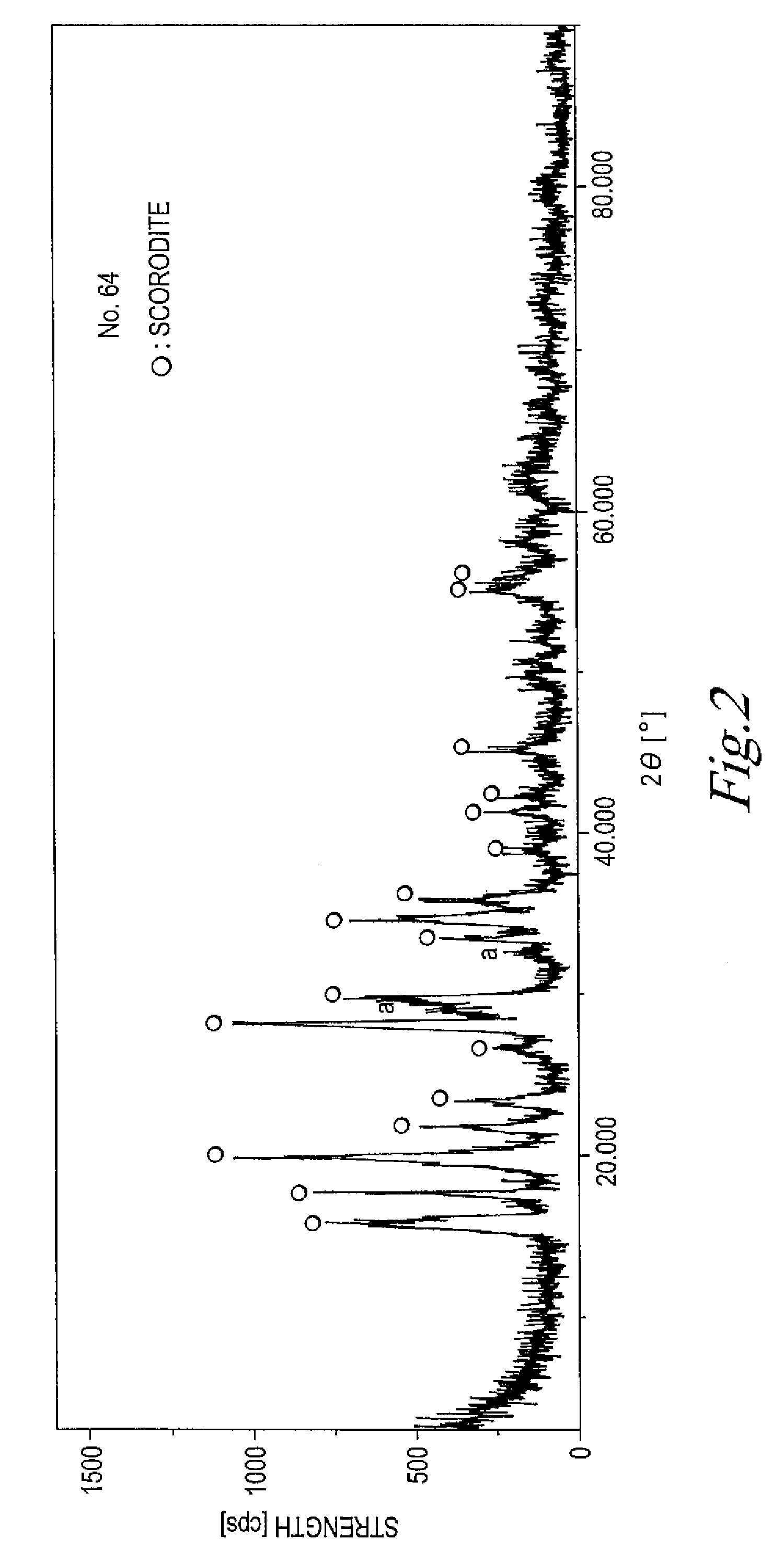

Method for manufacturing scorodite

InactiveUS20080233023A1Inhibition formationIncrease the concentration ratioArsenites/arsenatesAntimony compoundsTM compoundAqueous solution

The present invention provides a method for manufacturing scorodite in which scorodite may be obtained at high production efficiency and a high As concentration ratio. The present invention provides a method for manufacturing crystalline scorodite from acidic aqueous solution containing pentavalent As and trivalent Fe, the method comprising a step for adding a basic sodium compound to the acidic aqueous solution such that the sodium concentration in the acidic aqueous solution becomes larger than 0 g / L and equal to or less than 4 g / L.

Owner:JX NIPPON MINING& METALS CORP

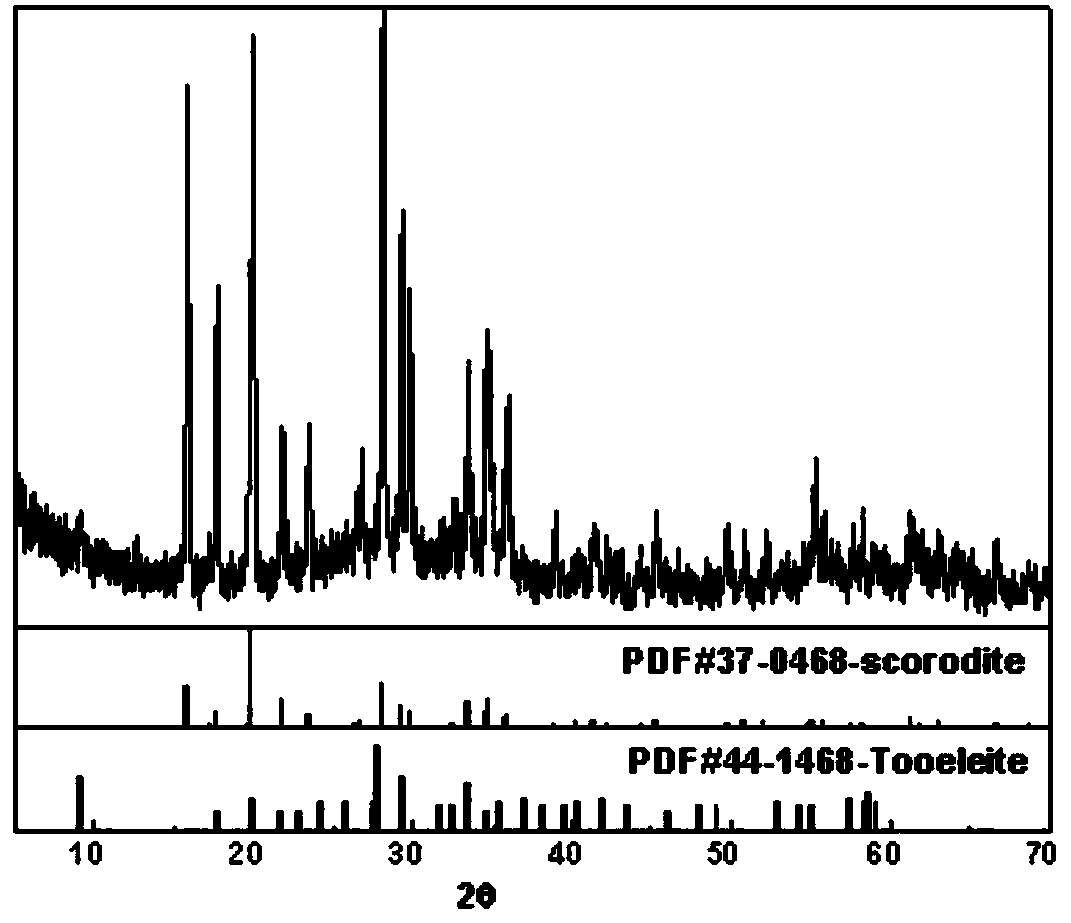

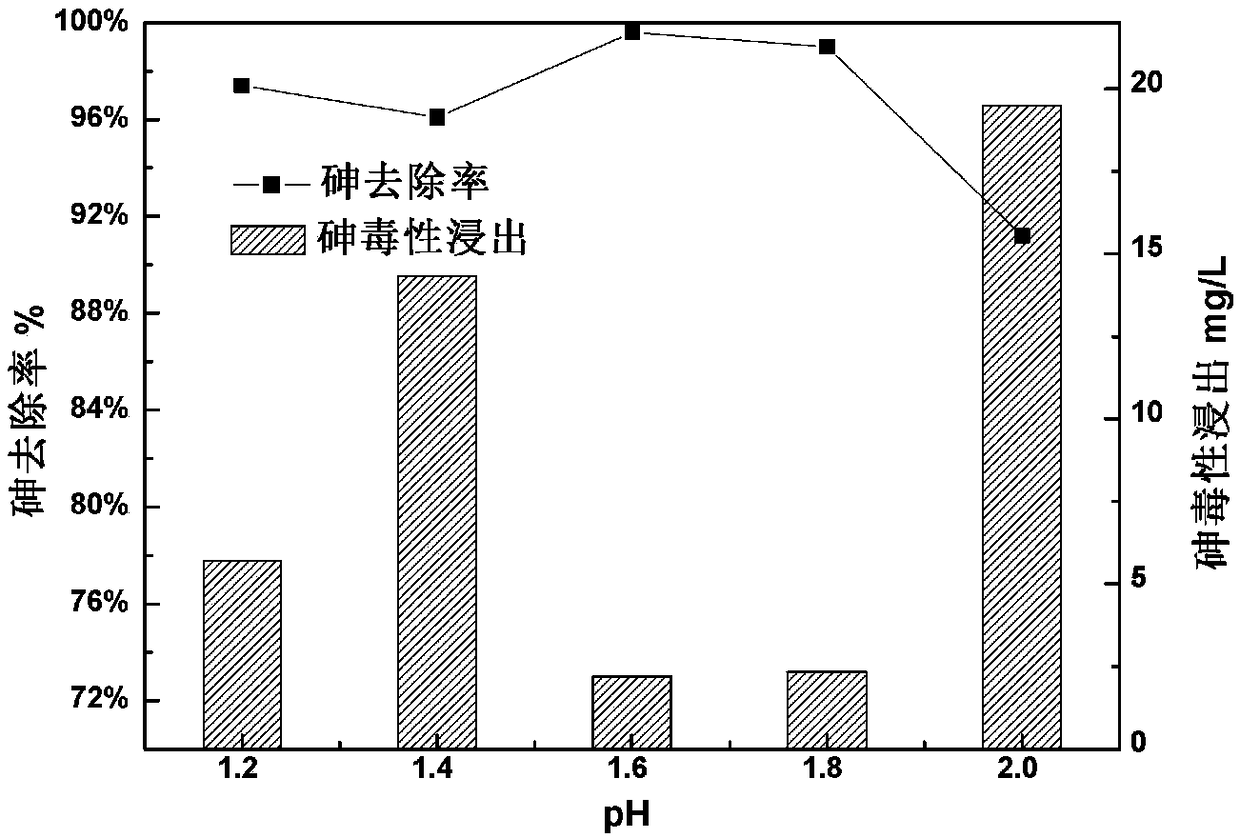

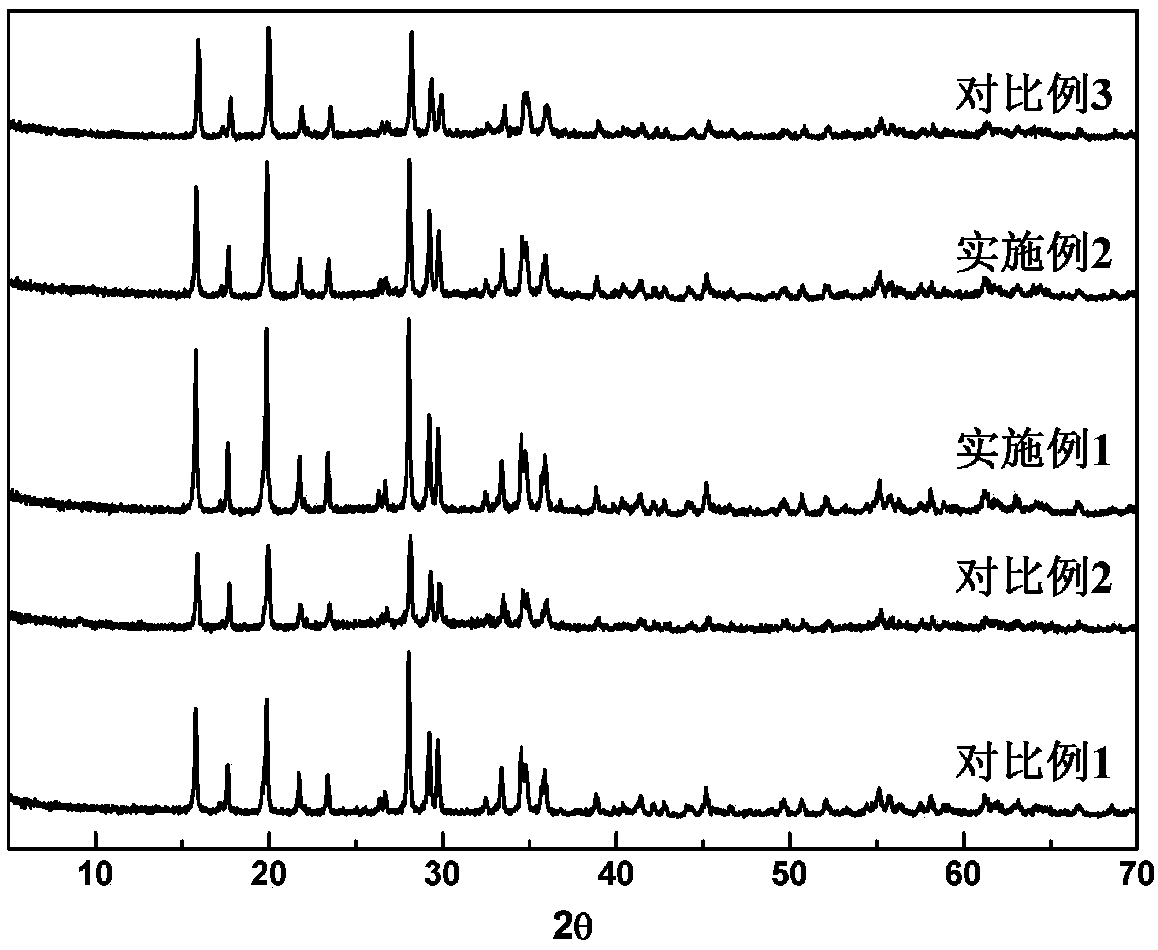

Method used for treating high arsenic waste water

ActiveCN108483690AWell mixedImprove stabilityWater treatment parameter controlWater contaminantsArsenic toxicityIron salts

The invention relates to a method used for treating high arsenic waste water. The method comprises following steps: trivalent arsenic containing waste water to be treated, an iron salt solution, and asulfate solution are mixed to be uniform, the pH value of an obtained mixed solution is adjusted to 1.2 to 2.0, the mixed solution is introduced into a reaction vessel, reaction is carried out at 135to 200 DEG C so as to generate a precipitate, and the precipitate is removed, wherein the precipitate comprises scorodite and tooeleite minerals. The stability of the method is excellent; no secondary pollution is caused; arsenic removing rate is high at the synergism effect of scorodite and tooeleite minerals, and is as high as 89.8 to 99.6%; arsenic toxicity leaching concentration is as low as2.2 to 29.82mg / L.

Owner:CENT SOUTH UNIV

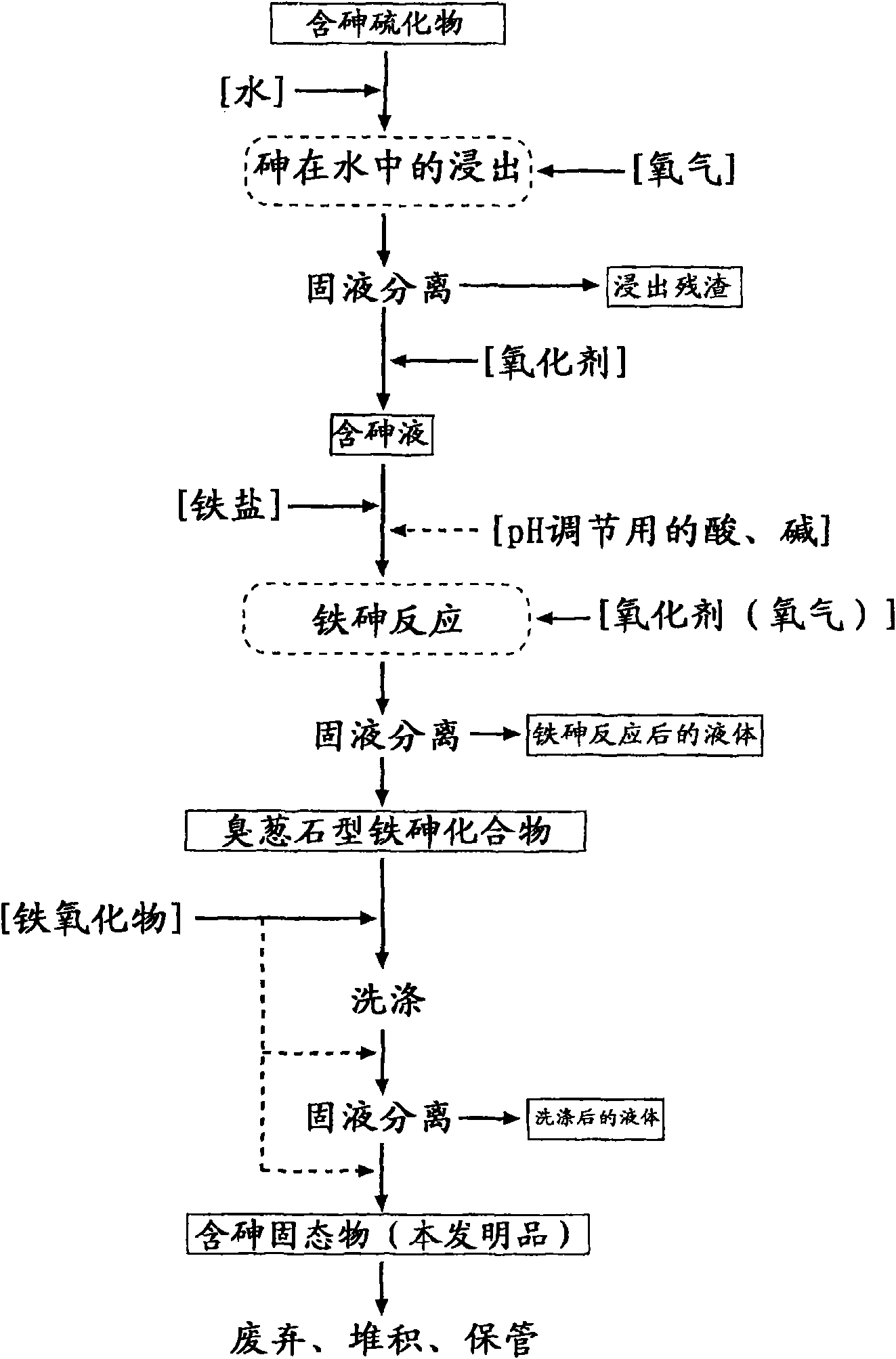

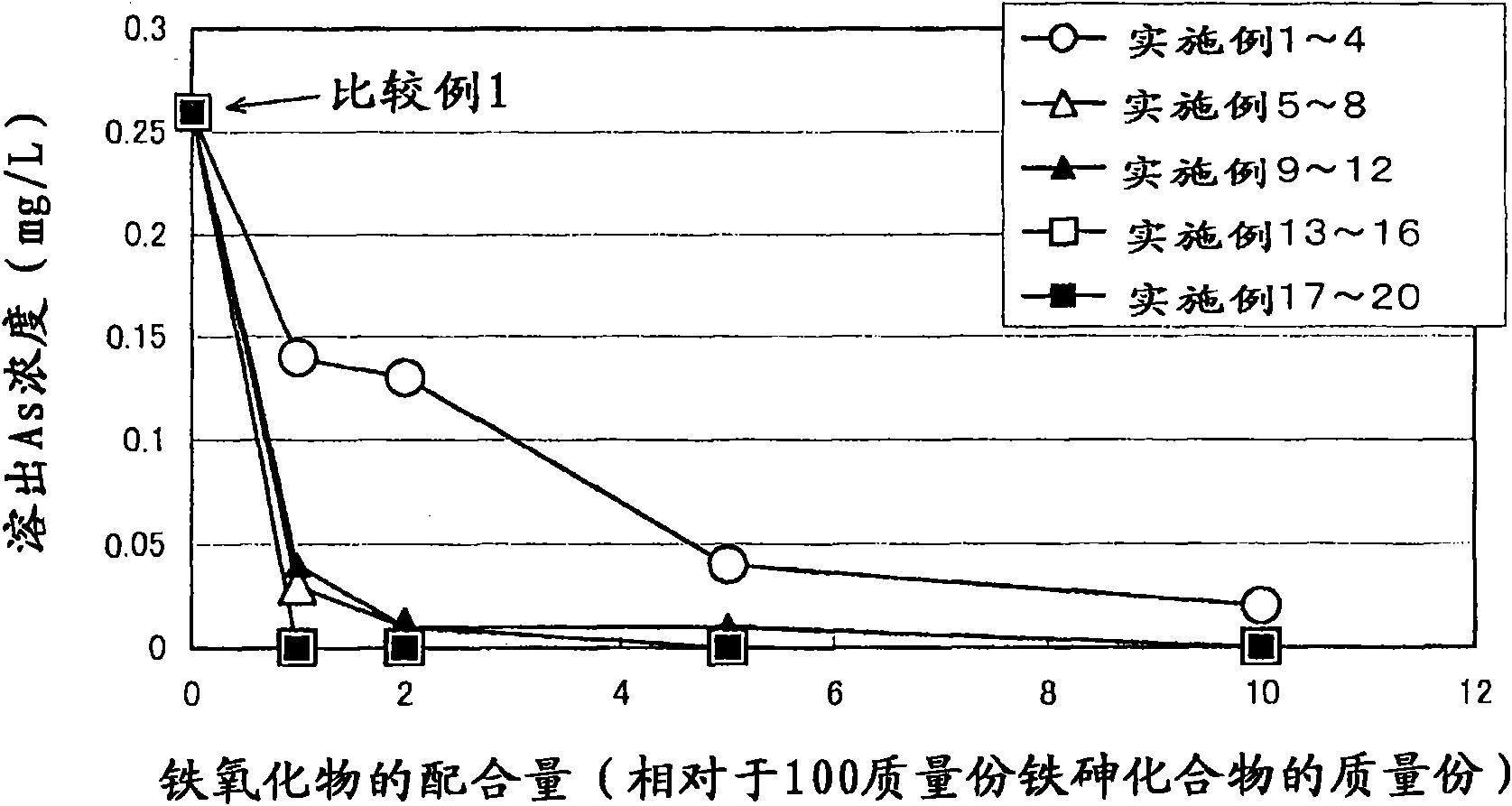

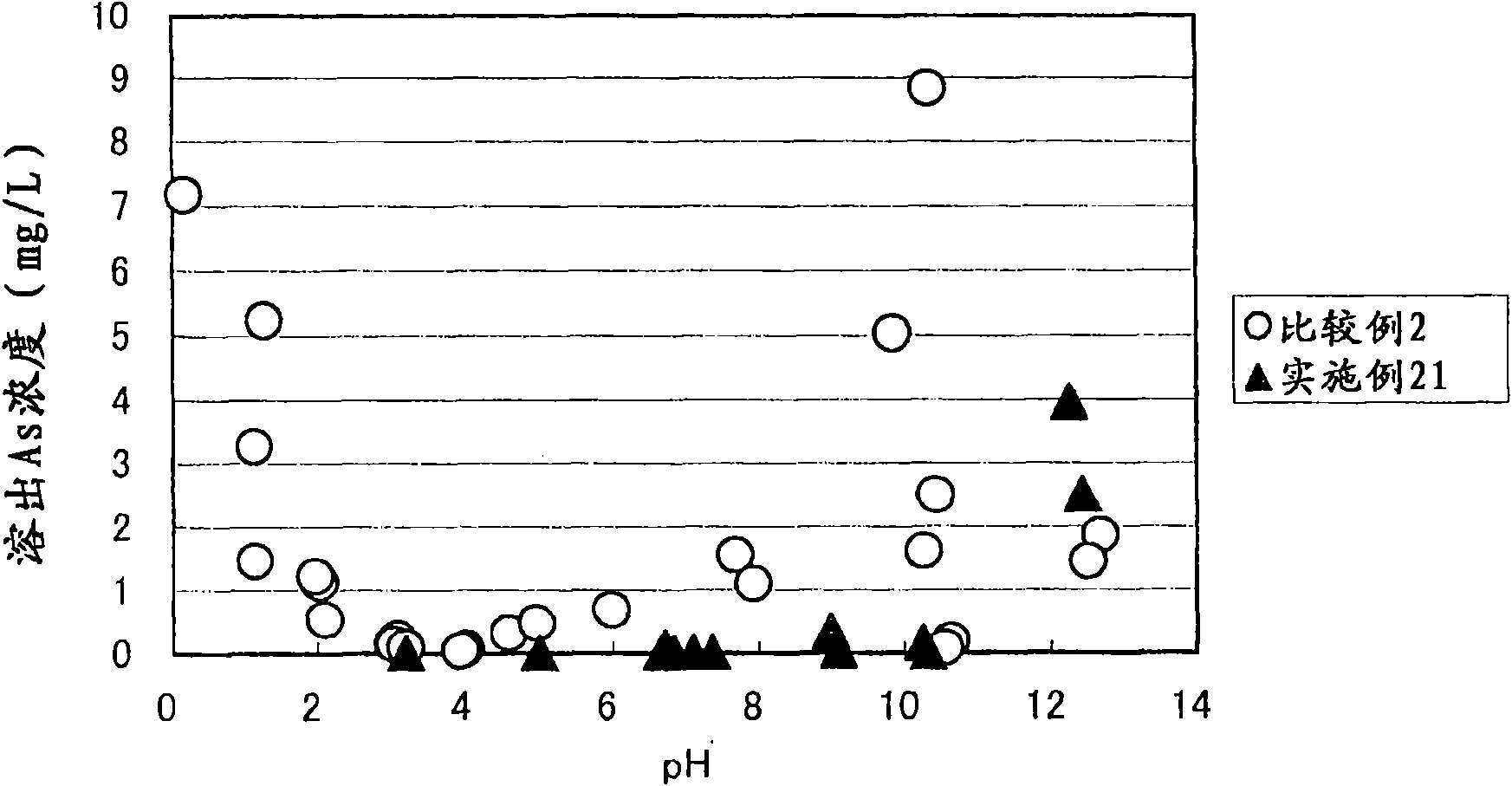

Arsenic-containing solid material and method for production thereof

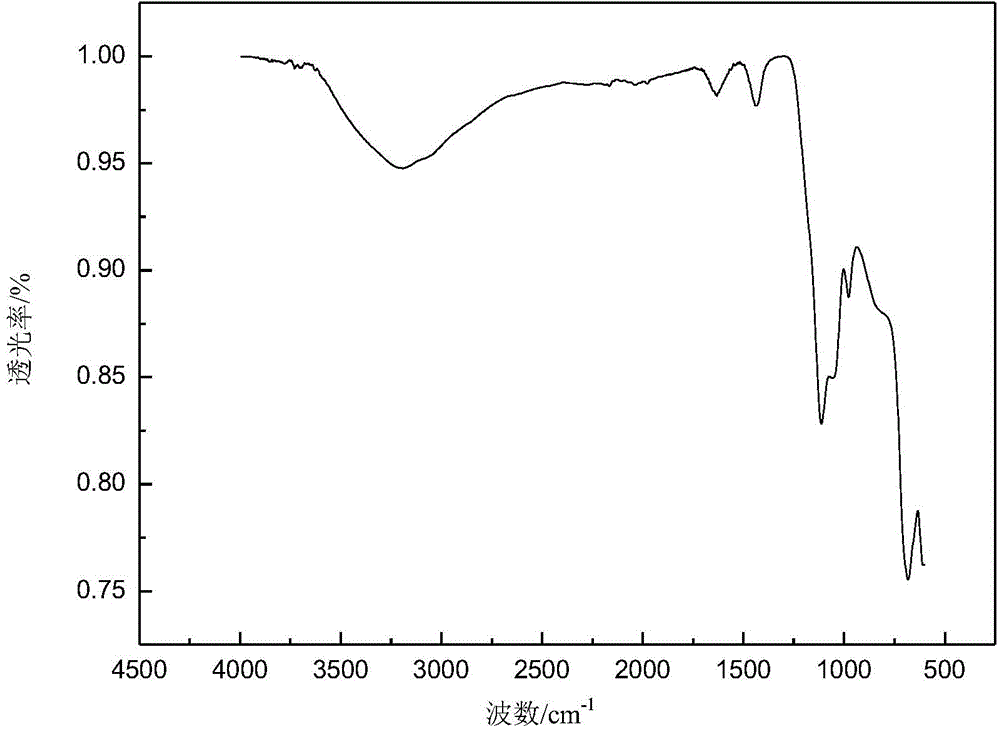

InactiveCN101636352AStable and excellent dissolution prevention effectShort reaction timeArsenites/arsenatesSolution crystallizationGoethiteAqueous solution

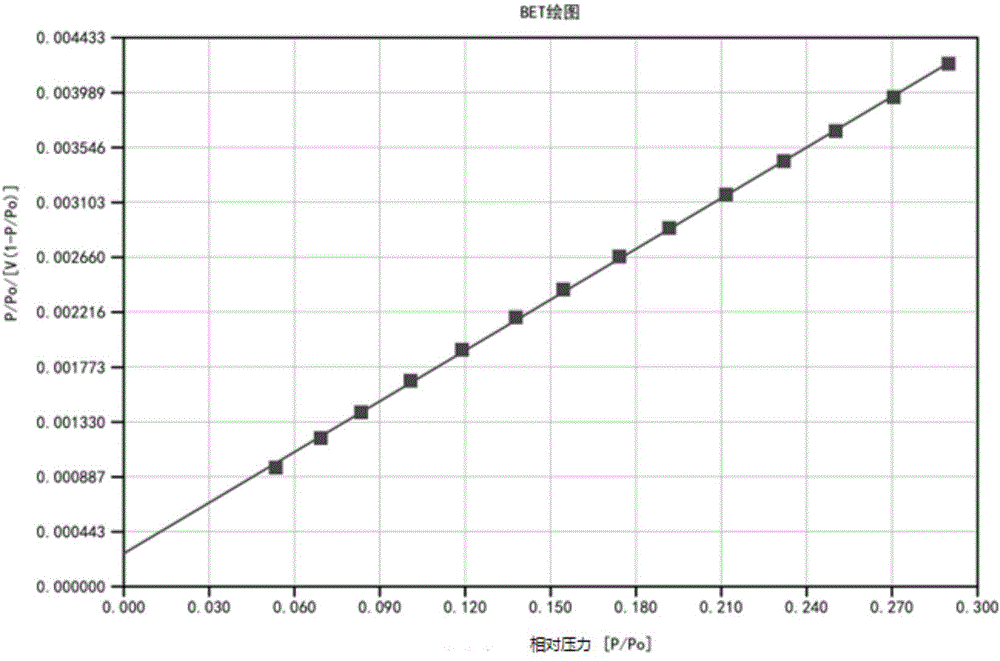

The invention provides an arsenic-containing solid material comprising 100 parts by mass of a scorodite-type iron-arsenic compound and 1 part by mass or more of an iron oxidation compound, wherein the scorodite-type iron-arsenic compound is synthesized by adding an oxidizing agent to an acidic aqueous solution containing a pentavalent arsenic ion and a bivalent arsenic ion to cause the precipitation of the iron-arsenic compound to proceed while agitating the solution, and terminating the precipitation at a pH value of 1.2 or lower. The iron oxidation compound may be goethite, hematite, or a mixture thereof. It is preferred to use an iron oxidation compound having a BET specific surface area of 3 m<2> / g or more, preferably 20 m<2> / g or more.

Owner:DOWA METALS & MINING CO LTD

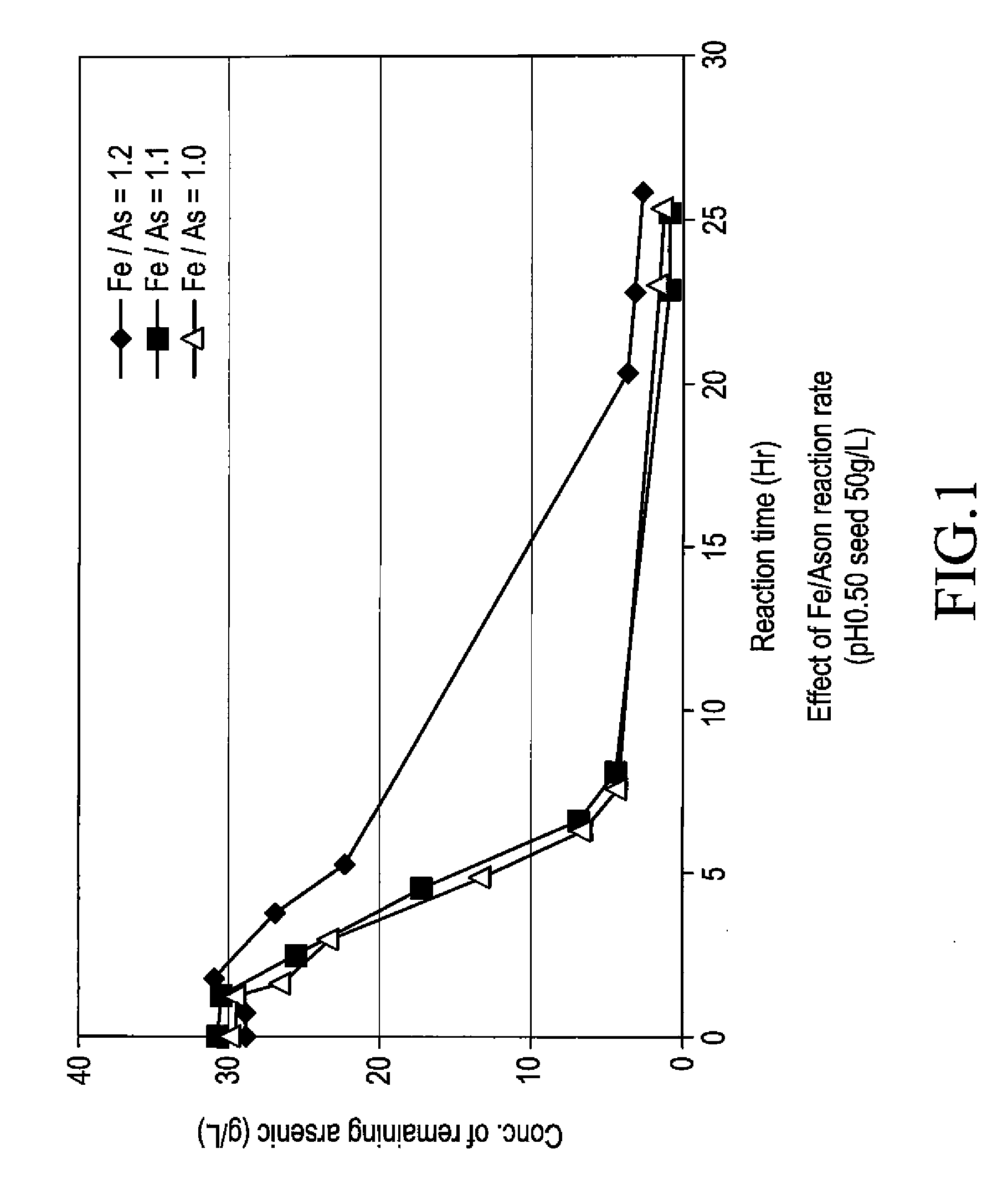

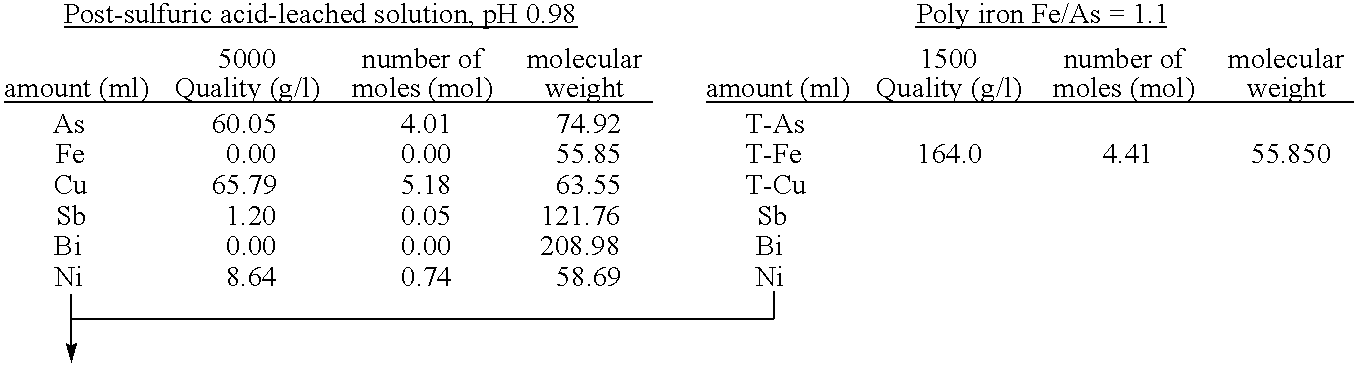

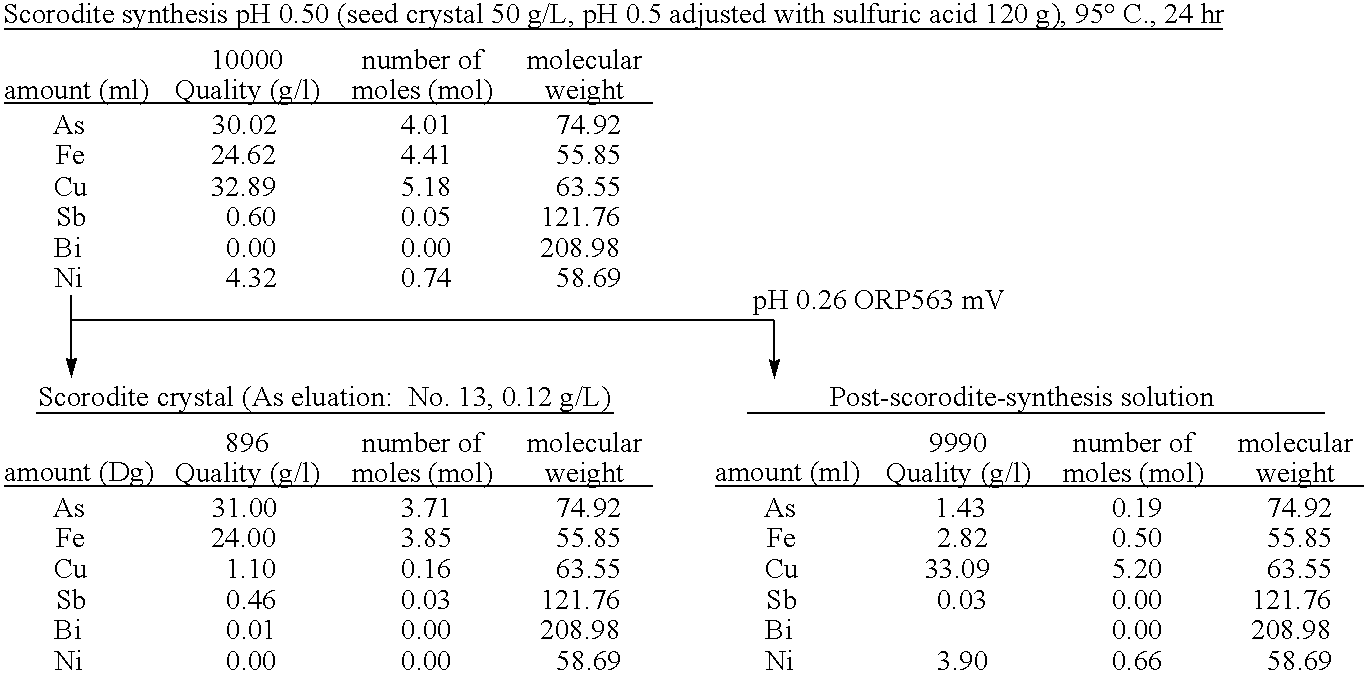

Process for producing scorodite and recycling the post-scorodite-synthesis solution

InactiveUS20090078584A1Shorten the timeIncrease productionElectrolysis componentsPhotography auxillary processesAqueous solutionFerric

The present invention is to provide a process for producing a scorodite that can shorten the time required for synthesizing the scorodite, and further can improve the yield of arsenic and iron into the scorodite. Accordingly, a process for producing a crystalline scorodite from an acidic aqueous solution containing pentavalent As and trivalent Fe, wherein the synthesis of the crystalline scorodite is performed after the molar ratio of trivalent Fe to pentavalent As contained in the acidic aqueous solution is adjusted to be equal to or more than 0.9 and equal to or less than 1.1 is provided.

Owner:JX NIPPON MINING& METALS CORP

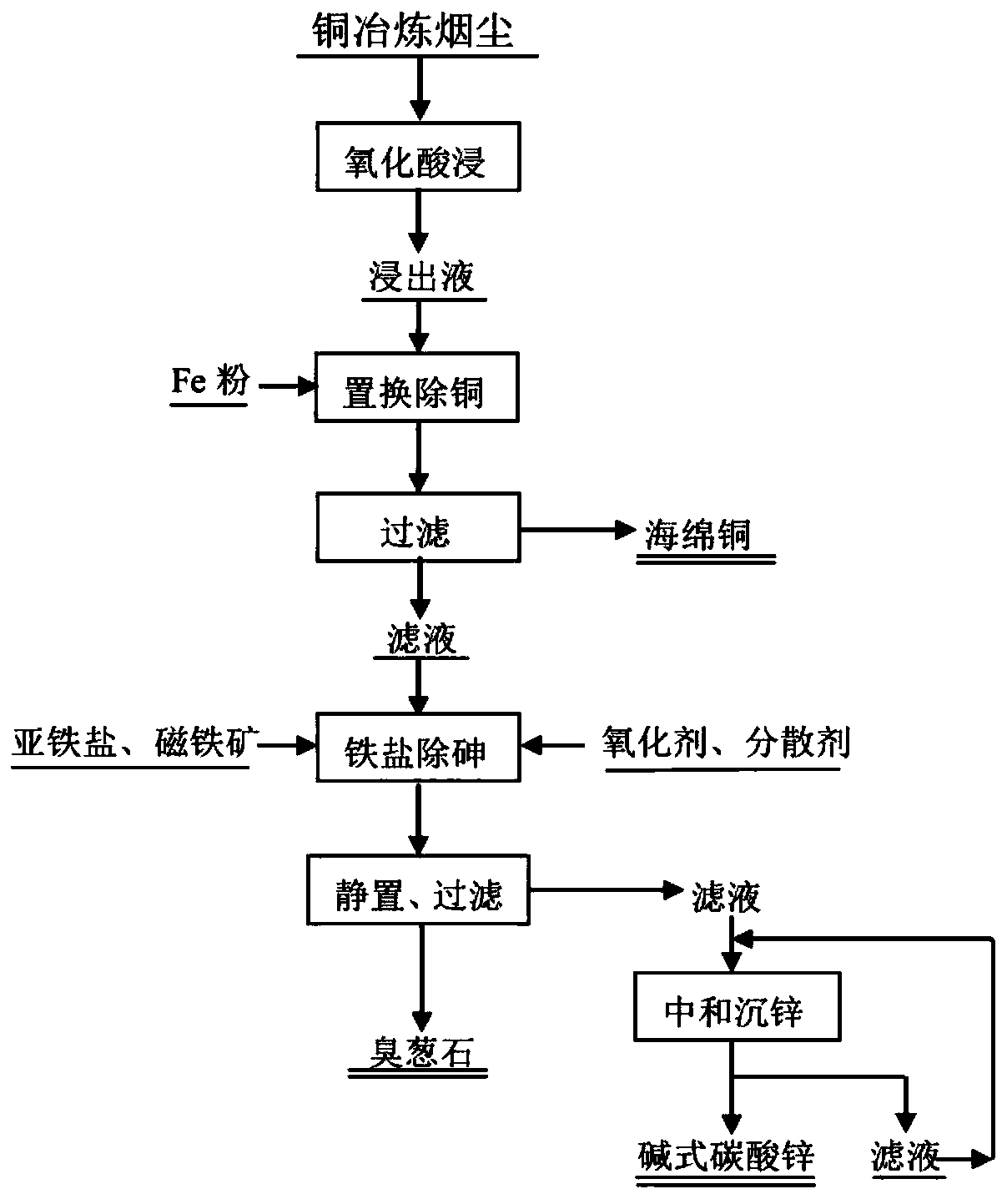

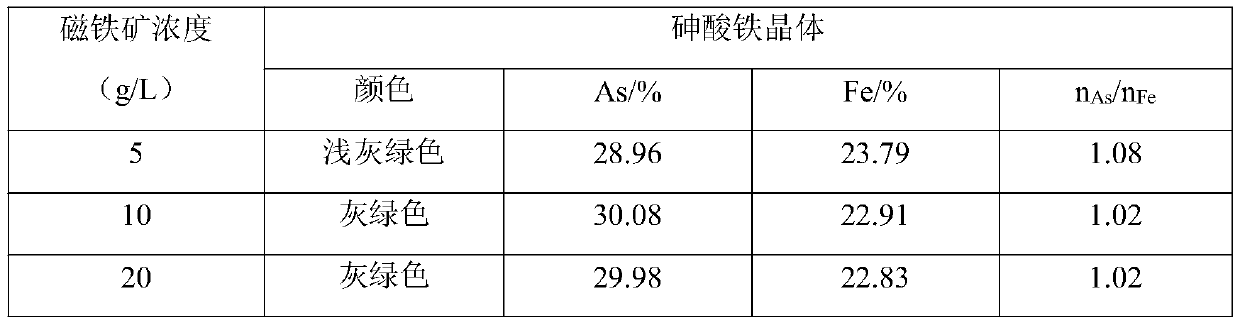

Method for removing arsenic from acidic arsenic-containing solution by using iron salt

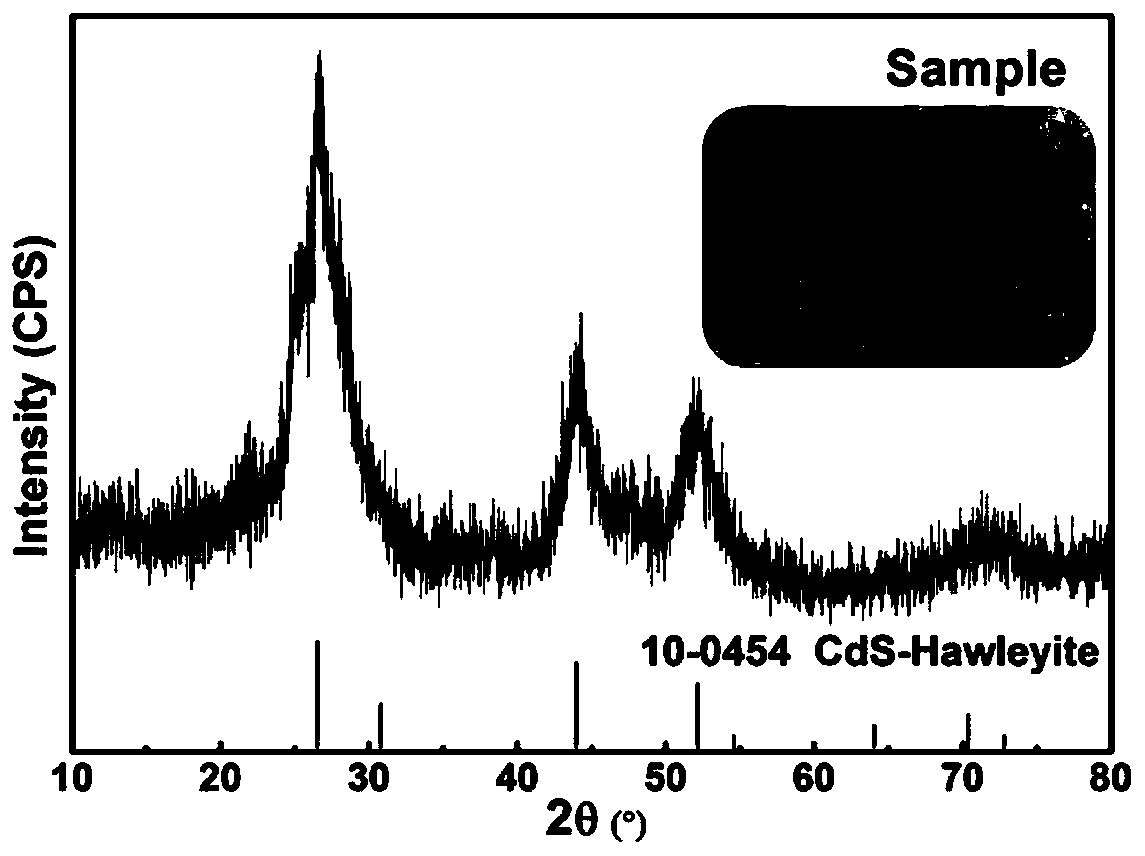

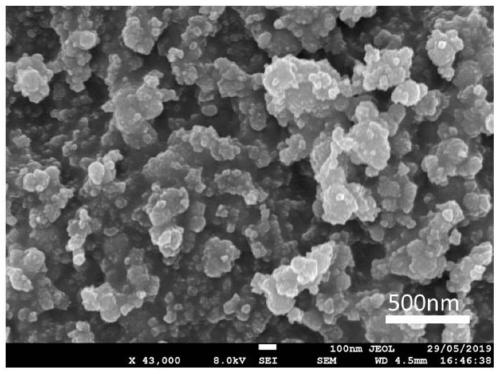

ActiveCN110104753AHigh in arsenicImprove long-term stabilityWater contaminantsWaste water treatment from metallurgical processIron saltsFerrous salts

The invention discloses a method for removing arsenic from an acidic arsenic-containing solution by using an iron salt. The method comprises the following steps: (1) adjusting the pH value of the acidic arsenic-containing solution, stirring and heating the adjusted solution, and adding a ferrous salt to obtain a mixed solution; and (2) adding magnetite to the mixed solution, adding an oxidant, stirring, heating and reacting the obtained solution, and filtering the solution to remove scorodite filter residues in order to complete the removal of arsenic in the acidic arsenic-containing solution.A precipitate obtained after arsenic precipitation of new highly-active crystal seeds is iron arsenate with a good crystal form, and has the advantages of high arsenic content, small size, complete crystal form structure, low toxicity leaching concentration of arsenic, good long-term stability, and easiness in clarification, filtration and separation. The method has the advantages of mild processconditions, simple process, convenience in operation, small dosages of reagents, small amount of arsenic iron residues, low price and low cost of the raw material, and realization of the production of the iron arsenate precipitate-scorodite with the good crystal form from the acidic arsenic-containing solution of copper smelting flue dust.

Owner:CENT SOUTH UNIV

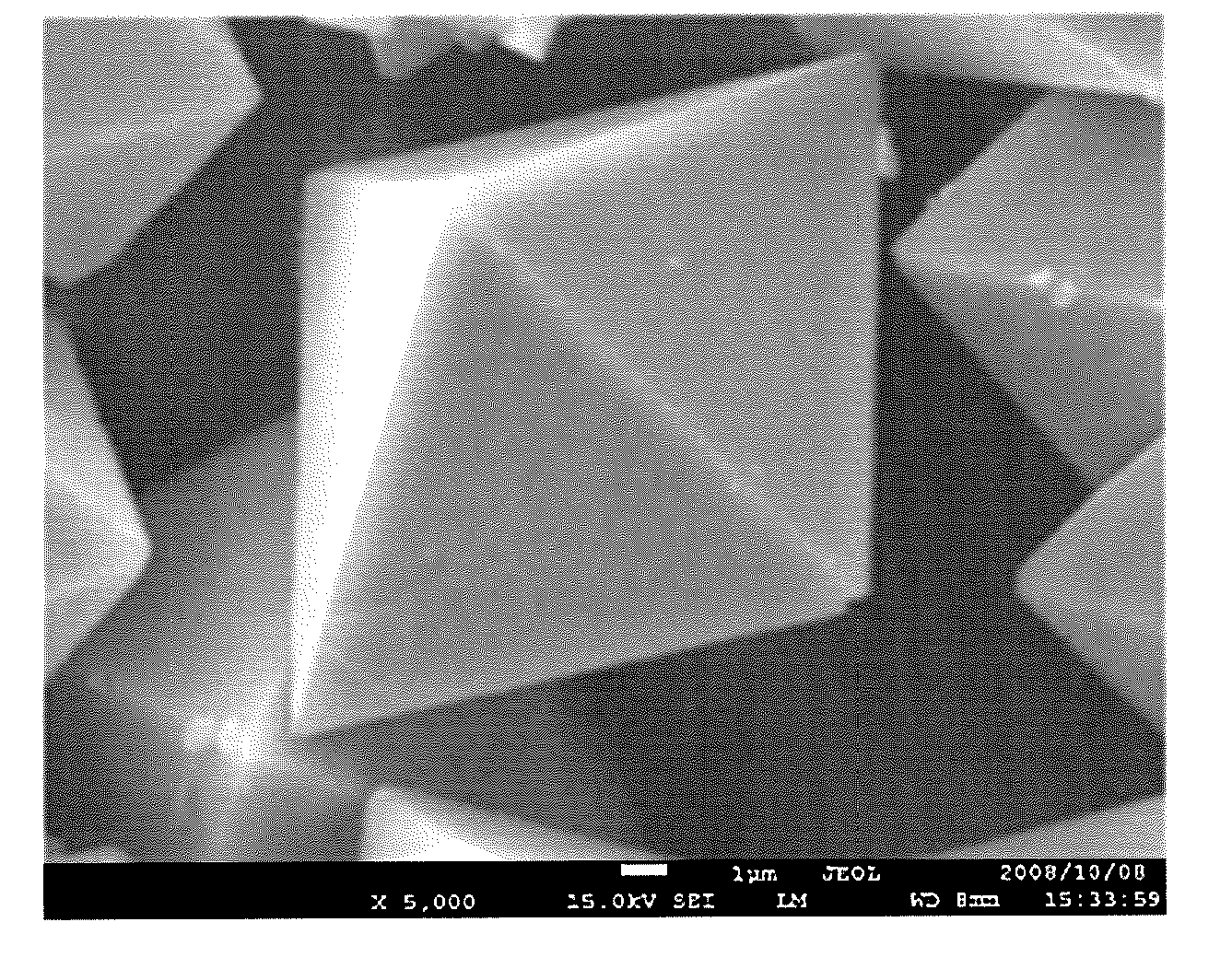

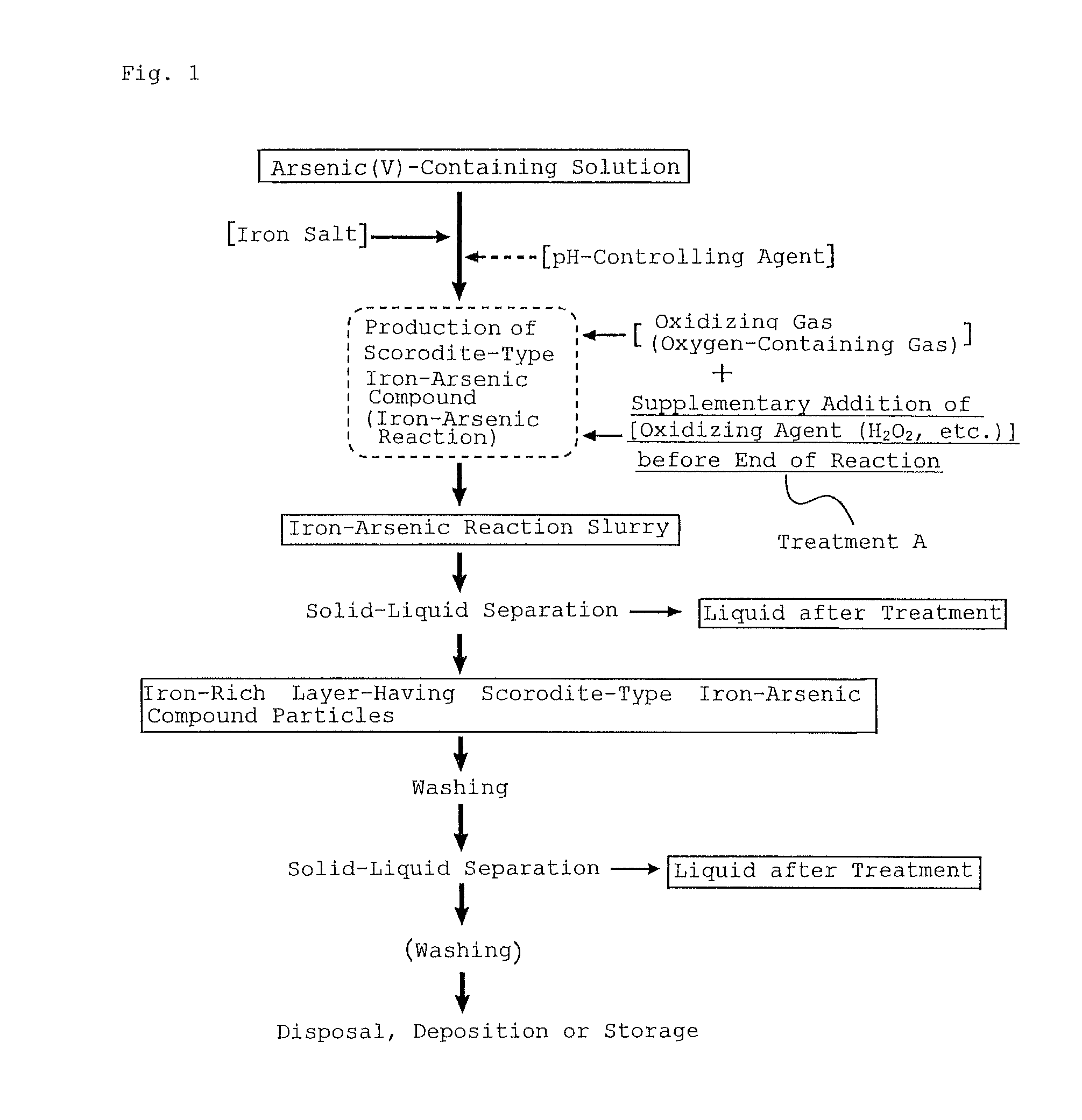

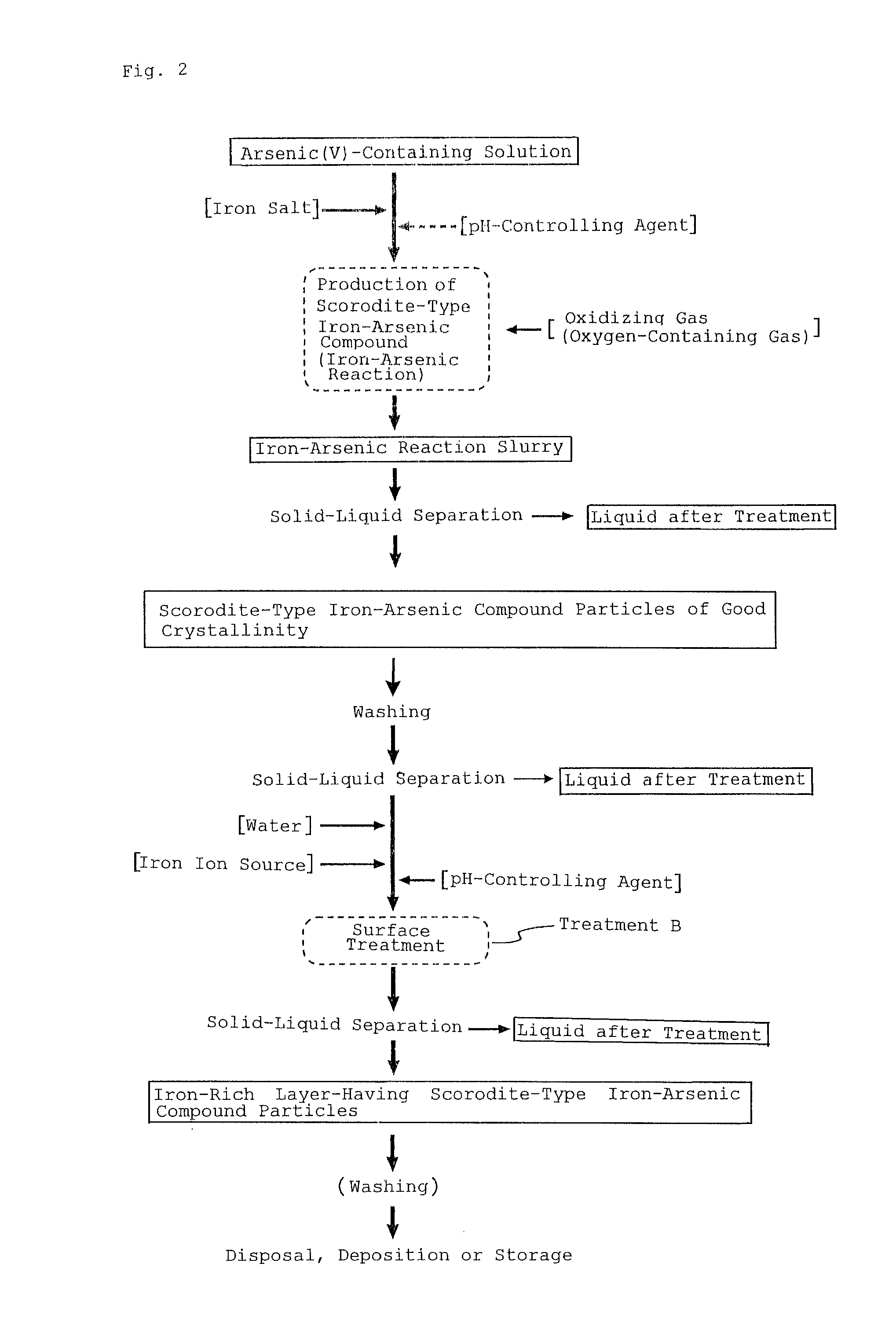

Scorodite-type iron-arsenic compound particles, production method thereof, and arsenic-containing solid

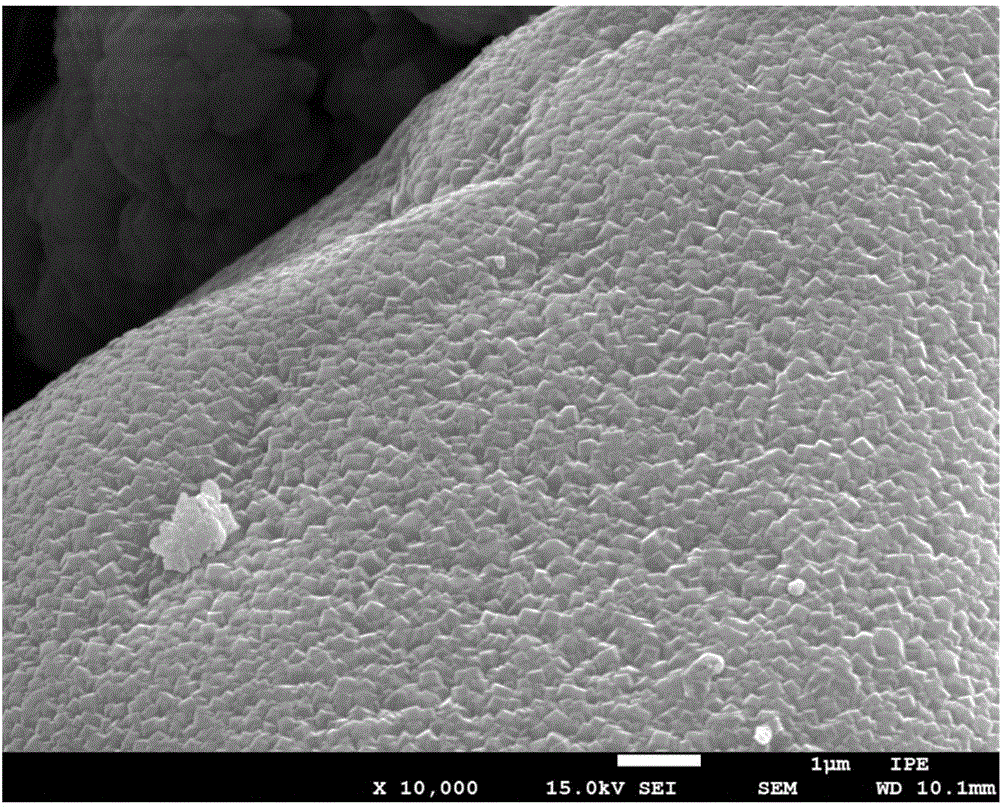

InactiveUS20120045382A1Improve filtering effectSuitableIron oxides/hydroxidesThiosulfates/dithionites/polythionitesSurface layerCrystallinity

Scorodite-type iron-arsenic compound particles in which the particle surface layer part comprise an iron-rich layer having an Fe / As molar ratio of at least 1.24. The particles can be obtained in a reaction process of feeding an oxygen-containing gas to an aqueous solution containing an arsenic(V) ion and an iron(II) ion to precipitate a scorodite-type iron-arsenic compound crystal at a pH of at most 2, in which an oxidizing agent is further added to the liquid before the end of the reaction (treatment A). The particles may also be obtained by a method comprising keeping a scorodite-type iron-arsenic compound particle of good crystallinity in contact with an iron ion-containing aqueous solution having a controlled pH of from 2 to 9 at 0 to 90° C. (treatment B). The scorodite-type iron-arsenic particles have good filterability and excellent arsenic release-preventing effect.

Owner:DOWA METALS & MINING CO LTD

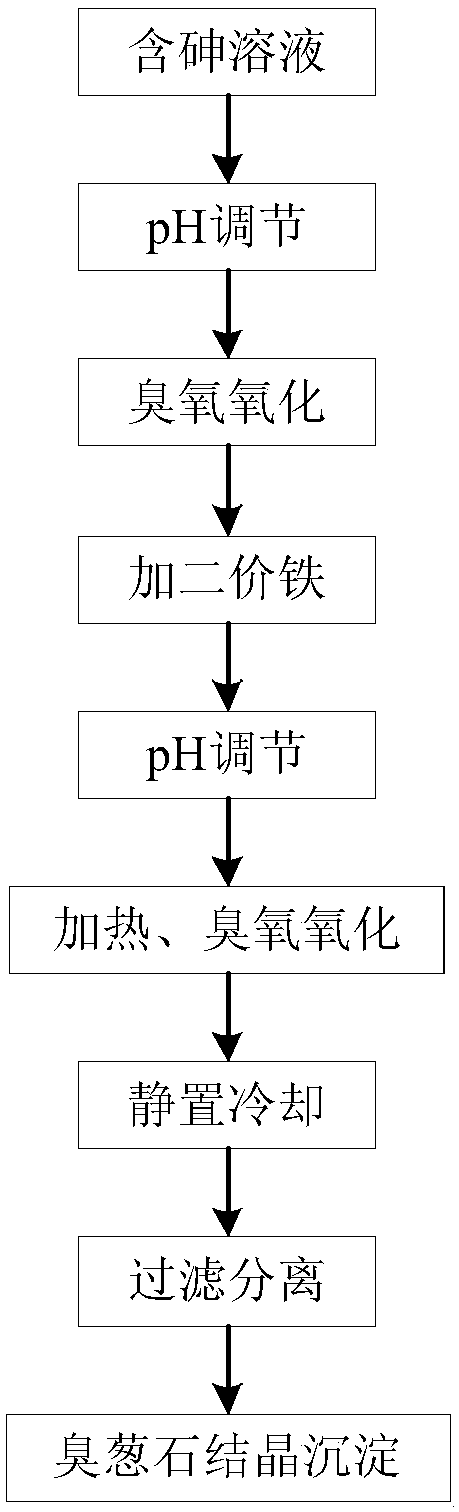

Immobilization method of arsenic in arsenic-containing solution

InactiveCN108164030AFast oxidationFast growthWater contaminantsMultistage water/sewage treatmentFerrous saltsWastewater

The invention provides an immobilization method of arsenic in arsenic-containing solution. The immobilization method of arsenic in arsenic-containing solution comprises following steps: under acidic conditions, an oxidizing agent is added into an arsenic-containing solution for oxidation so as to obtain a solution containing pentavalent arsenic; a ferrous salt is added, the pH value and the temperature of the solution are adjusted, the oxidizing agent is added for reaction so as to obtain scorodite crystal precipitate. According to the immobilization method, utilization of the strong oxidationperformance of ozone is adopted, oxidation of trivalent arsenic and ferrous is carried out successively, the scorodite crystal precipitate is obtained, crystal growth speed is accelerated, reaction process is simplified via controlling reaction conditions; and in addition, the immobilization method can be used for treating low concentration arsenic-containing solution, is suitable for treatment of most industrial arsenic-containing waste water, no pre-condensation treatment is needed, cost is low, and the application range is wide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

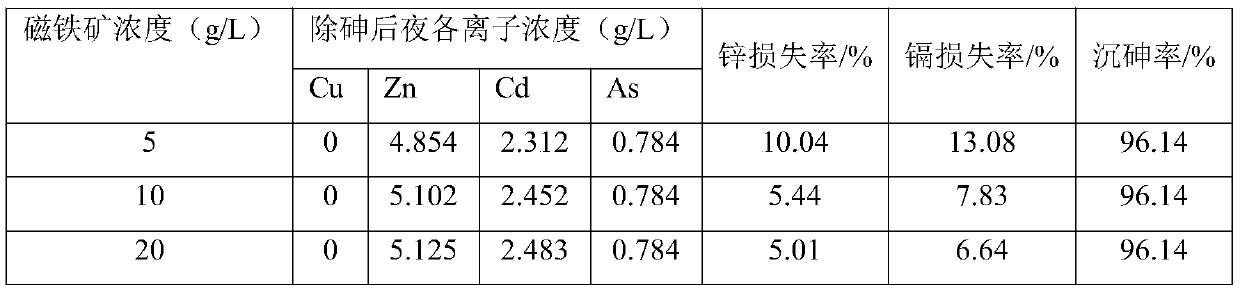

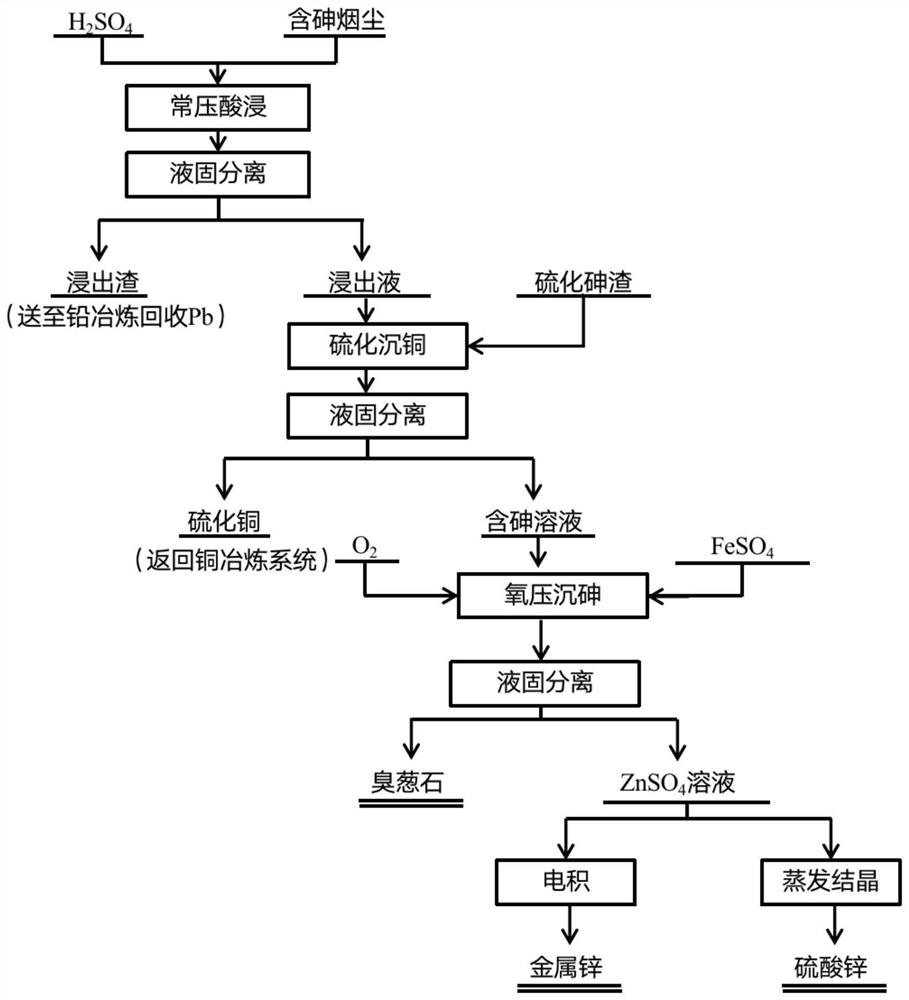

Method for co-processing arsenic sulfide slag and arsenic-containing smoke in copper smelting

InactiveCN113684368AImprove leaching rateEasy to operateZinc sulatesPhotography auxillary processesSulfate zincLead smelting

The invention relates to a method for co-processing arsenic sulfide slag and arsenic-containing smoke in copper smelting. The method comprises the following steps that copper, zinc, iron, arsenic and like enter a solution through normal-pressure acid leaching of arsenic-containing smoke, lead is recovered from leaching slag through a lead smelting system, copper in smoke acid leaching liquid is precipitated through sulfuration of the arsenic sulfide slag, ferrous sulfate is added into the solution after copper precipitation, high-stability scorodite is obtained through reaction under the condition of oxygen pressure, the loss of valuable metal in the arsenic precipitation process is small, and the arsenic-removed solution with few impurities can be directly fed to a zinc electrodeposition process to obtain electrodeposited zinc or evaporated and crystallized to obtain a zinc sulfate product. According to the method, the valuable metal recovery rate is high, operation is easy, the problems that the arsenic sulfide slag is low in value and difficult to treat are effectively solved through arsenic sulfide slag sulfuration copper precipitation, and efficient utilization of dangerous solid waste and harmless treatment of arsenic are achieved.

Owner:CENT SOUTH UNIV

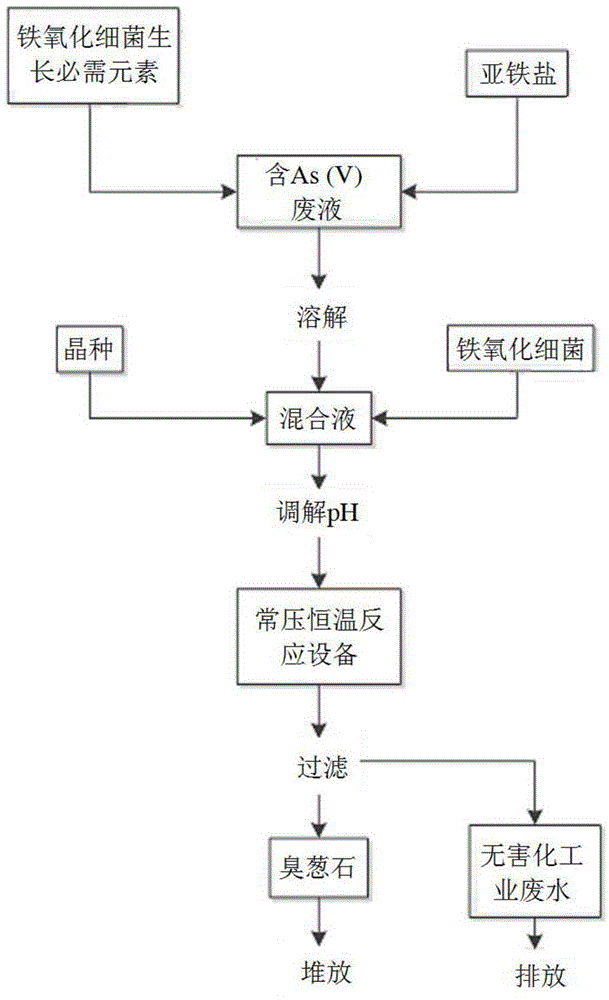

Method for treating acid waste water containing arsenic

ActiveCN104609573AEasy to separateAchieve the purpose of processingWater contaminantsBiological water/sewage treatmentPollutionCulture mediums

The invention discloses a method for treating acid waste water containing arsenic. The method comprises the following steps of (1) adding essential elements for growing of iron-oxidizing bacterium to waste water containing arsenic to obtain a culture medium, adding ferrite, adding seed crystal after the ferrite is totally dissolved, inoculating the iron-oxidizing bacterium, and adjusting the PH value to 1.2-3.0; (2) moving mixed liquid obtained in step (1) into a reactor, reacting for 5-10 days under normal pressure at a temperature below 55 DEG C, and depositing arsenic in the waste water in a scorodite state so as to finish the treatment of the acid waste water containing arsenic. According to the method disclosed by the invention, the waste water containing arsenic with the concentration of 0.1-5g / L can be treated, the removal rate of arsenic in the waste water can reach more than 97% within short treatment time, besides, the raw material used in the method is easy to get, the condition is mild, the operation is simple, the synthesized scorodite is a crystal particle, and is easy to separate, high in arsenic content, and good in stability, and secondary pollution is not caused.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

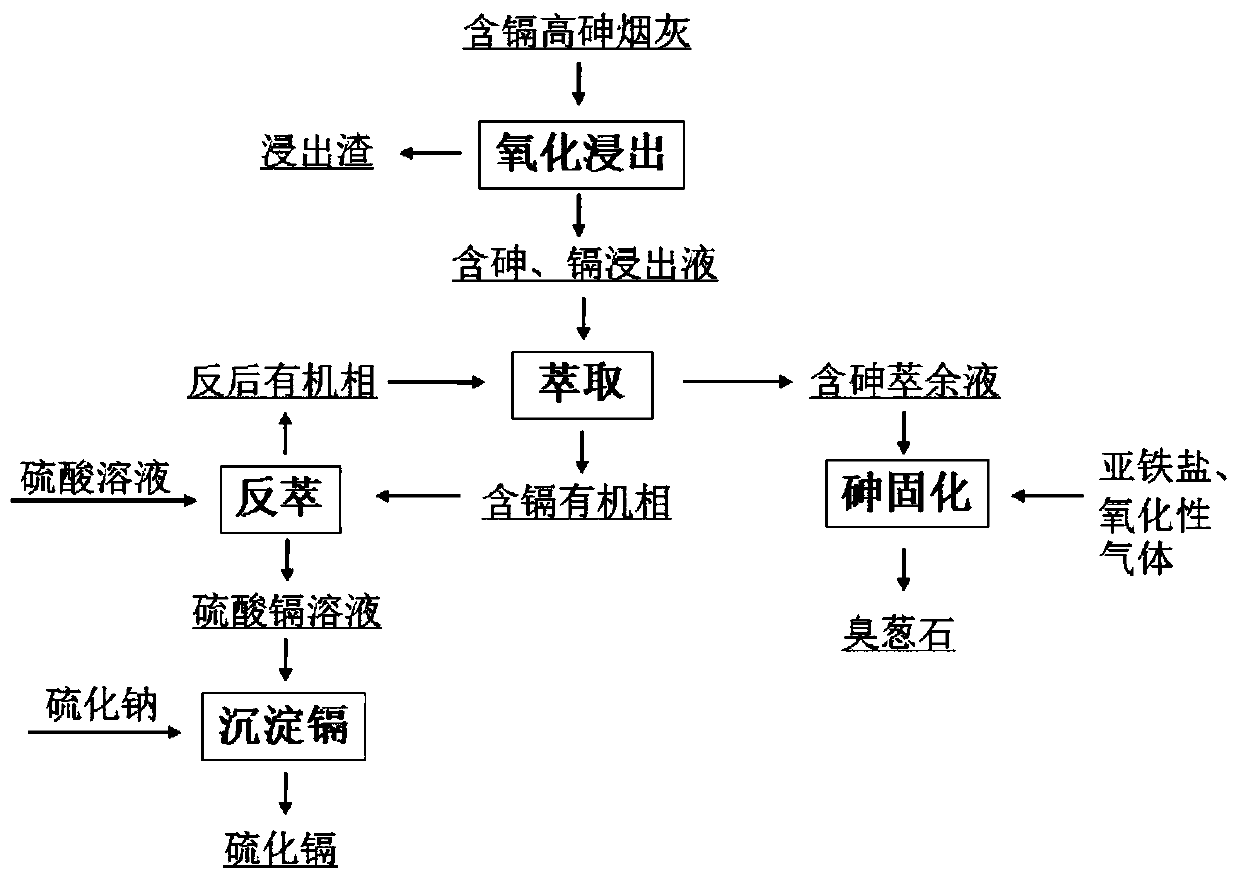

Method of recovering cadmium from cadmium-containing high-arsenic soot

ActiveCN111041221AHardened securityCuring Handling SafetyIron compoundsProcess efficiency improvementFerrous saltsSoot

The invention discloses a method of recovering cadmium from cadmium-containing high-arsenic soot. The method includes the following steps of firstly, oxidizing leaching, wherein oxidizing leaching isperformed on the cadmium-containing high-arsenic soot, and filtering is performed to obtain a leachate containing cadmium and arsenic and leach residues containing valuable metals; secondly, extracting, wherein extracting is performed on the leachate containing cadmium and arsenic after the pH is adjusted to be 2.5-3.0, and a cadmium-containing organic phase and a arsenic-containing extraction solution are obtained; thirdly, reverse extracting, wherein a cadmium sulfate solution is obtained after reverse extracting is performed on the cadmium-containing organic phase through a sulfuric acid solution; fourthly, cadmium precipitation, wherein precipitation reaction is performed on the cadmium sulfate solution through sodium sulphide to obtain cadmium sulfide; and fifthly, arsenic curing, wherein soluble ferrite is added to the arsenic-containing extraction solution, a gaseous oxidant is introduced for reaction, and scorodite crystals are obtained. According to the method, cadmium in thecadmium-containing high-arsenic soot is effectively extracted through an extracting method, cadmium is separated from lead, iron, bismuth and the like, meanwhile the safe disposal of arsenic is realized, highly toxic arsine gas is prevented from being generated in the technological process, and the method is economical and friendly to the environment.

Owner:CENT SOUTH UNIV

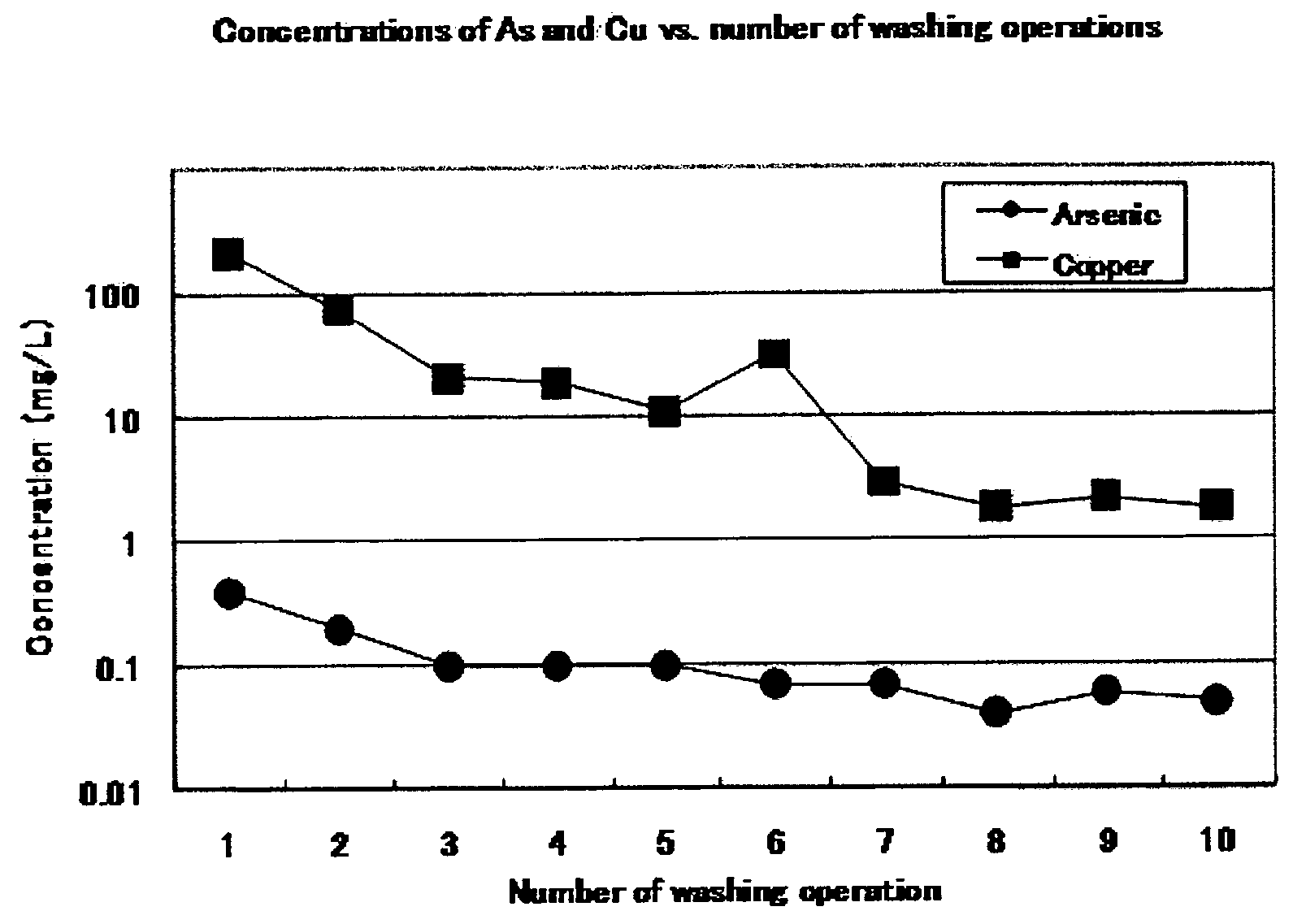

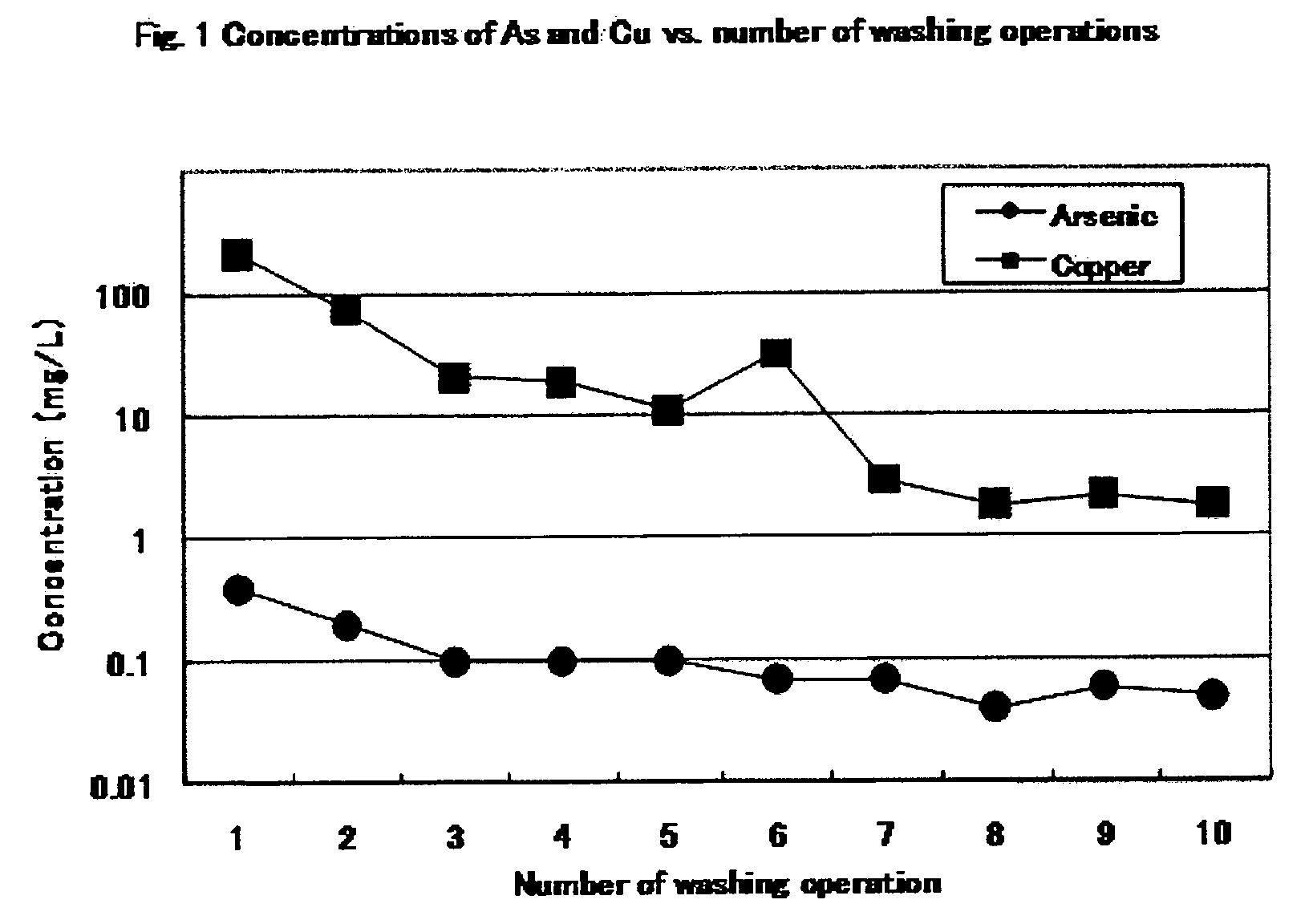

Methods of making and washing scorodite

InactiveUS20090104107A1Low arsenic elutionLow in elutionIron oxides/hydroxidesProcess efficiency improvementAqueous solutionFerric

A method of making scorodite includes the following steps: (1) an acidic aqueous solution containing pentavalent As and trivalent Fe is heated at a temperature for a time, the temperature and the time being effective for synthesis of crystalline scorodite; (2) the synthesized scorodite is separated from the post-reaction solution by solid-liquid separation; and (3) the scorodite is washed with water and is separated from the washing solution by solid-liquid separation. Step (3) is repeated until the concentration of at least one component of the post-reaction solution contained in the washing solution used for washing the scorodite decreases to a predetermined level.

Owner:JX NIPPON MINING& METALS CORP

Method for manufacturing scorodite

InactiveUS7935328B2Inhibition formationArsenites/arsenatesIron oxides/hydroxidesConcentration ratioAqueous solution

Owner:JX NIPPON MINING & METALS CORP

Method for the recovery of valuable metals and arsenic from a solution

ActiveUS7615199B2Promote recoveryReduce concentrationSolvent extractionSolid sorbent liquid separationAqueous solutionSediment

Owner:METSO OUTOTEC (FINLAND) OY

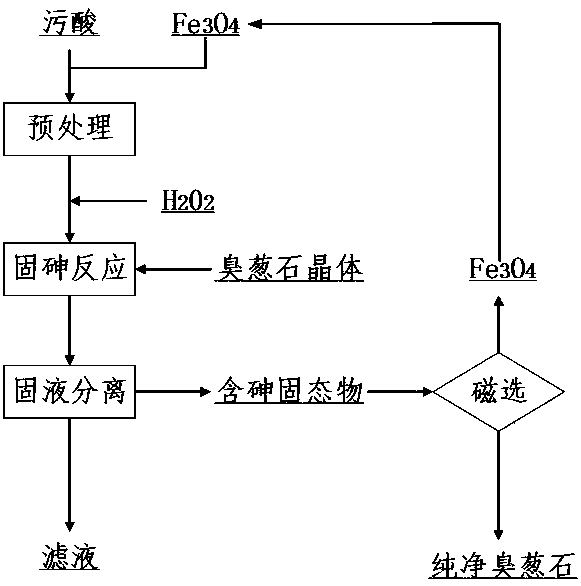

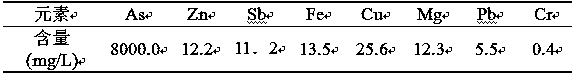

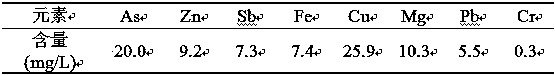

Method for treating arsenic in nonferrous smelting waste acid by using magnetic Fe3O4

InactiveCN110028192AStable physical propertiesEasy to operateWater treatment parameter controlWater contaminantsArsenic pollutionPhysical property

The invention relates to a method for treating arsenic in nonferrous smelting waste acid by using magnetic Fe3O4, and belongs to the technical field of heavy metal arsenic pollution treatment. The method comprises the following steps: uniformly mixing magnetic Fe3O4 and contaminated acid, conducting pre-treating for 12-24 hours under a stirring condition to obtain a solution A, adding H2O2 and a scorodite crystal into the solution A, and conducting uniform mixing to obtain a solution B; carrying out an arsenic removal reaction on the solution B for 8-12 hours at the temperature of 70-90 DEG Cunder a stirring condition, and carrying out solid-liquid separation to obtain an arsenic-containing solid substance and a filtrate C; conducting ball milling and magnetic separation on the arsenic-containing solid substance to separate out magnetic Fe3O4 and pure scorodite, returning the magnetic Fe3O4 for circulation, and safely treating the pure scorodite. The method is simple in working process and obvious in arsenic removal effect, and the generated scorodite is stable in physical property.

Owner:KUNMING UNIV OF SCI & TECH

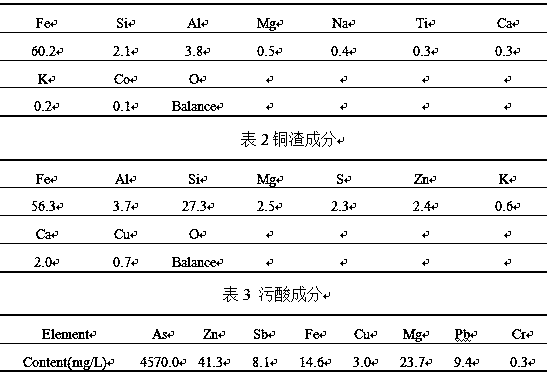

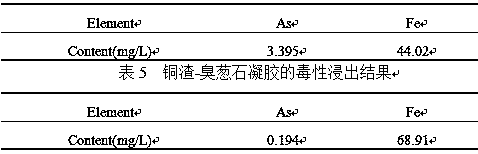

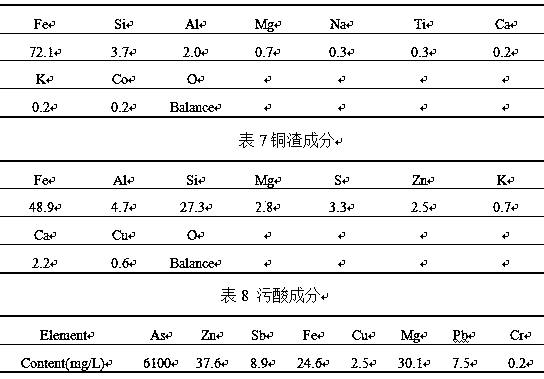

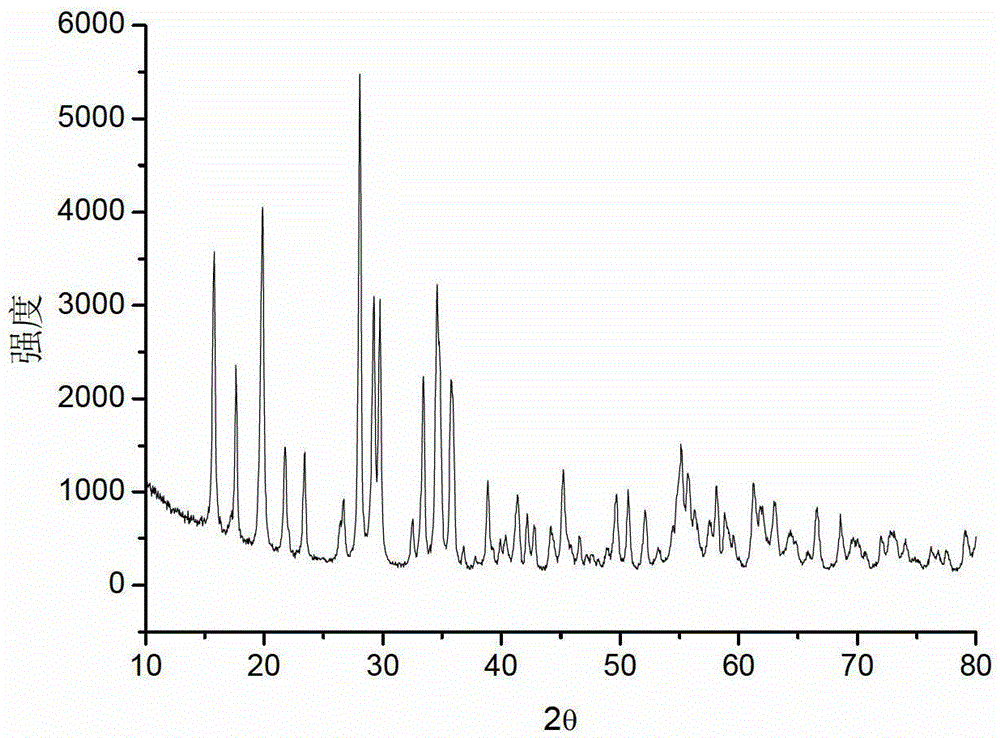

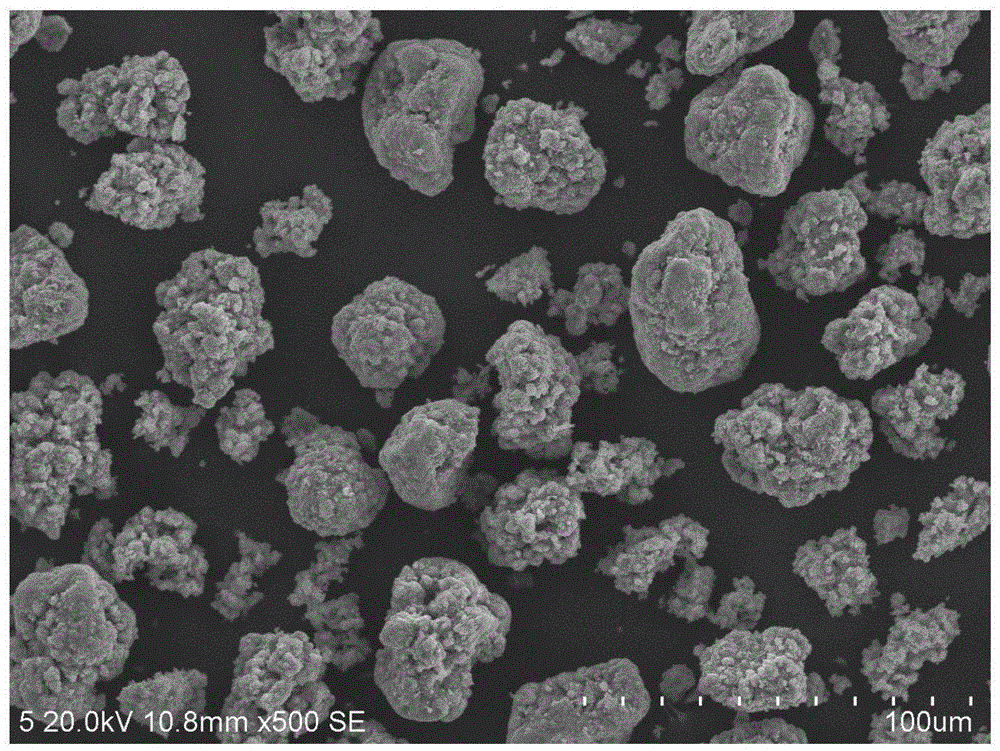

Method for making copper slag gel be wrapped around and stabilize scorodite

InactiveCN111069228AImprove stabilityReduce complexityTransportation and packagingSolid waste disposalMagnetitePhysical chemistry

The invention relates to a method for making copper slag gel be wrapped around and stabilize scorodite, and belongs to the technical field of heavy metal pollution treatment. The method comprises thefollowing steps that ground magnetite is screened to obtain magnetite slag powder; the magnetite slag powder and H2O2 are added into waste acid for uniform mixing, and stirring is performed for an oxidation pretreatment reaction for 6 h to 8 h under normal pressure at room temperature to obtain a solid-liquid mixture; the pH value of the solid-liquid mixture is adjusted to be 1.3 to 1.7, stirringis performed for the arsenic removal reaction for 12 h to 14 h under normal pressure at the temperature of 85 DEG C to 95 DEG C, solid-liquid separation is performed to obtain arsenic-containing magnetite and a filtrate, and the filtrate undergoes deep arsenic removal treatment; the arsenic-containing magnetite is dried, and then undergoes magnetic separation, so that the magnetite and the scorodite are separated out, and the magnetite returns back for the oxidation pretreatment reaction; a H2SO4 solution is slowly added into copper slag powder to be stirred until the copper slag gel is formed; and the copper slag gel and the scorodite are uniformly mixed to obtain copper slag-scorodite gel, and aging is performed for 10 h to 20 h at the temperature of 120 DEG C to 160 DEG C. According tothe method, the copper slag is adopted to be wrapped around the scorodite, then the gel is formed, and the subsequent stabilization treatment of the scorodite is realized.

Owner:KUNMING UNIV OF SCI & TECH

A method for treating arsenic-containing industrial wastewater

ActiveCN103964601BReduce productionReduce the risk of secondary pollutionMultistage water/sewage treatmentEnvironmental resistanceWastewater

The invention belongs to the wet metallurgy and environmental protection technical fields, and particularly, discloses a method for treating arsenic in arsenic-containing industrial wastewater. Under a condition of high temperature, an iron solution is slowly added into the arsenic-containing industrial wastewater, arsenic in the wastewater forms a stable scorodite crystal (FeAsO4.2H2O), and thus arsenic in the wastewater is removed. The method is simple in process, can obtain the stable arsenic-containing solid waste, and reduces secondary pollution caused to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com