Preparation method for amorphous FeOOH water-purifying agent

An iron oxyhydroxide, water purifying agent technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of ineffective removal of arsenic, high aluminum ion content, secondary water Pollution and other problems, to achieve low production costs, improve economic benefits, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of preparation method of amorphous iron oxyhydroxide water purifying agent, it comprises the following steps:

[0033] (1) take titanium dioxide factory by-product and dissolve it in water, prepare the ferrous sulfate solution that molar concentration is 1.7mol / L;

[0034] (2) in the ferrous sulfate solution described in step (1), adding concentration is the sulfuric acid of 27wt%, and the mol ratio of controlling described sulfuric acid and ferrous sulfate is 0.5:1, obtains the ferrous sulfate solution of acidification, is the next step Oxidation provides an acidic environment;

[0035] (3) under stirring condition, adopting plunger pump to add the hydrogen peroxide that concentration is 30wt% in the acidified ferrous sulfate solution described in step (2), the pump mouth of described plunger pump stretches below the liquid level and controls all The mol ratio of hydrogen peroxide and ferrous sulfate is 0.75:1, and the control ad...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of amorphous iron oxyhydroxide water purifying agent, it comprises the following steps:

[0046] (1) take technical grade ferrous sulfate heptahydrate and dissolve it in water, and prepare the ferrous sulfate solution that molar concentration is 1.5mol / L;

[0047] (2) in the ferrous sulfate solution described in step (1), adding concentration is the sulfuric acid of 27wt%, and the mol ratio of controlling described sulfuric acid and ferrous sulfate is 0.6:1, obtains the ferrous sulfate solution of acidification, is the next step Oxidation provides an acidic environment;

[0048] (3) under stirring condition, adopt plunger pump to add the hydrogen peroxide that concentration is 35wt% in the acidified ferrous sulfate solution described in step (2), the pump mouth of described plunger pump stretches below the liquid level and controls all The molar ratio of hydrogen peroxide and ferrous sulfate is 0.85:1, and th...

Embodiment 3

[0053] The present embodiment provides a kind of preparation method of amorphous iron oxyhydroxide water purifying agent, it comprises the following steps:

[0054] (1) take industrial grade ferrous sulfate heptahydrate and dissolve it in water, and prepare the ferrous sulfate solution that molar concentration is 1.2mol / L;

[0055] (2) in the ferrous sulfate solution described in step (1), adding concentration is the sulfuric acid of 27wt%, and the mol ratio of controlling described sulfuric acid and ferrous sulfate is 0.5:1, obtains the ferrous sulfate solution of acidification, is the next step Oxidation provides an acidic environment;

[0056] (3) under stirring condition, adopting plunger pump to add the hydrogen peroxide that concentration is 40wt% in the acidified ferrous sulfate solution described in step (2), the pump mouth of described plunger pump stretches below the liquid level and controls all The mol ratio of hydrogen peroxide and ferrous sulfate is 1:1, and the...

PUM

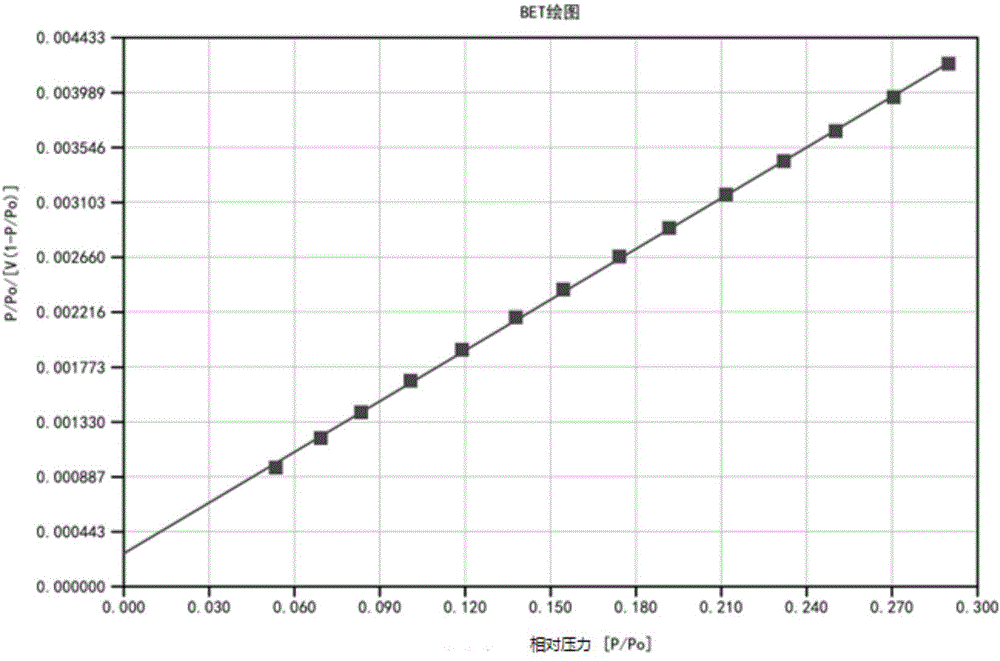

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com