Method for adsorbing and removing arsenic by using iron-manganese oxide/mesoporous silica adsorbent

A technology of mesoporous silicon oxide and iron-manganese oxide, which is applied in the fields of alkali metal oxides/hydroxides, chemical instruments and methods, and silicon compounds, and can solve the problems of limited arsenic removal rate and unsuitability for large-scale applications. Achieve the effects of increasing porosity, simple preparation, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

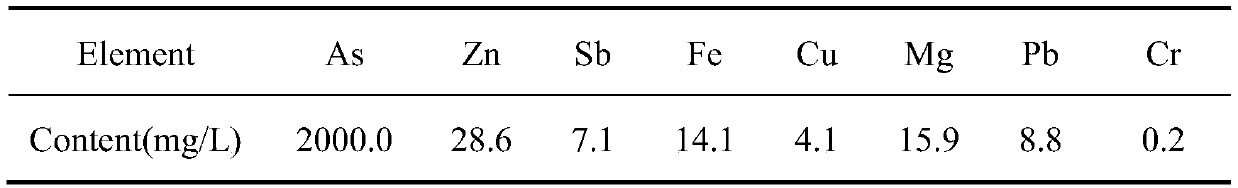

[0022] Example 1: The pollution acid in this example comes from the pollution acid containing a large amount of impurities such as arsenic after washing the smelting flue gas in the sulfuric acid workshop of a zinc smelter in the southwest region. The main components are shown in Table 1;

[0023] Table 1 Contaminated acid composition

[0024]

[0025] A method for removing arsenic by iron-manganese oxide / mesoporous silica adsorbent, the specific steps are as follows:

[0026] (1) Add mesoporous silica to deionized water, and ultrasonically disperse for 0.5h to obtain a mesoporous silica suspension; wherein the solid-to-liquid ratio of mesoporous silica to deionized water (mg:mL) is 1:1.1;

[0027] (2) Adjust the pH value of the mesoporous silica suspension in step (1) to 7;

[0028] (3) Add KMnO to the mesoporous silica suspension in step (2) 4 And FeSO 4 ·7H 2 O, mix uniformly to obtain mixture A, place mixture A at a temperature of 65°C and react for 3 hours, then cool to room temper...

Embodiment 2

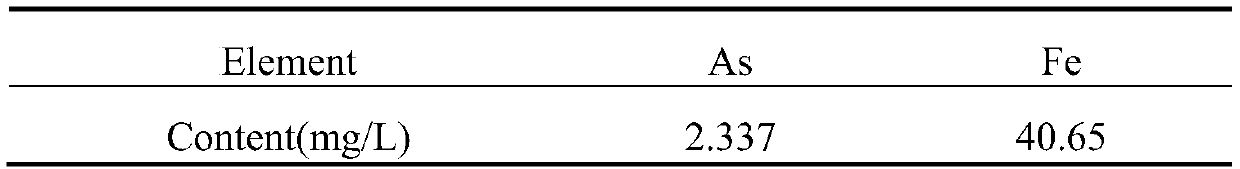

[0039] Example 2: The pollution acid in this example comes from the pollution acid containing a large amount of impurities such as arsenic, which is produced after washing the smelting flue gas in the sulfuric acid workshop of a zinc smelter in the southwestern region. The main components are shown in Table 4;

[0040] Table 4 Contaminated acid composition

[0041]

[0042] A method for adsorbing and removing arsenic by iron-manganese oxide / mesoporous silica adsorbent, the specific steps are as follows:

[0043] (1) Add mesoporous silica to deionized water, and ultrasonically disperse for 1.0 h to obtain a mesoporous silica suspension; wherein the solid-to-liquid ratio of mesoporous silica to deionized water (mg:mL) is 1:0.9;

[0044] (2) Adjust the pH value of the mesoporous silica suspension in step (1) to 8;

[0045] (3) Add KMnO to the mesoporous silica suspension in step (2) 4 And FeSO 4 ·7H 2 O, mix evenly to obtain mixture A, place mixture A at a temperature of 55℃ to react for 2...

Embodiment 3

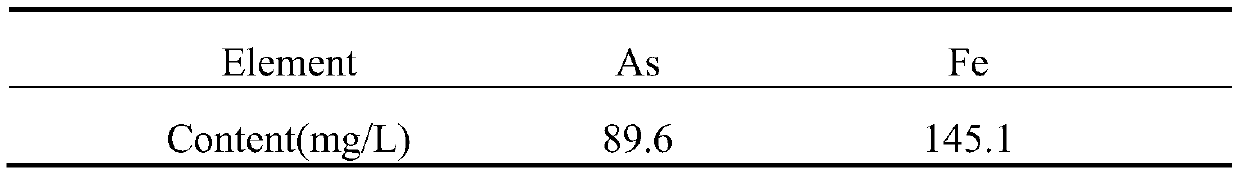

[0056] Example 3: The pollution acid in this example comes from the pollution acid containing a large amount of impurities such as arsenic, which is produced after washing the smelting flue gas in the sulfuric acid workshop of a zinc smelter in the southwestern region. The main components are shown in Table 7;

[0057] Table 7 Contaminated acid composition

[0058]

[0059] A method for adsorbing and removing arsenic by iron-manganese oxide / mesoporous silica adsorbent, the specific steps are as follows:

[0060] (1) Add mesoporous silica to deionized water, and ultrasonically disperse for 0.75h to obtain a mesoporous silica suspension; wherein the solid-to-liquid ratio of mesoporous silica to deionized water (mg:mL) is 1:1.0;

[0061] (2) Adjust the pH value of the mesoporous silica suspension in step (1) to 7.5;

[0062] (3) Add KMnO to the mesoporous silica suspension in step (2) 4 And FeSO 4 ·7H 2 O, mix evenly to obtain mixture A, place mixture A at a temperature of 60°C for 2.5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com