Patents

Literature

396results about How to "Solve secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

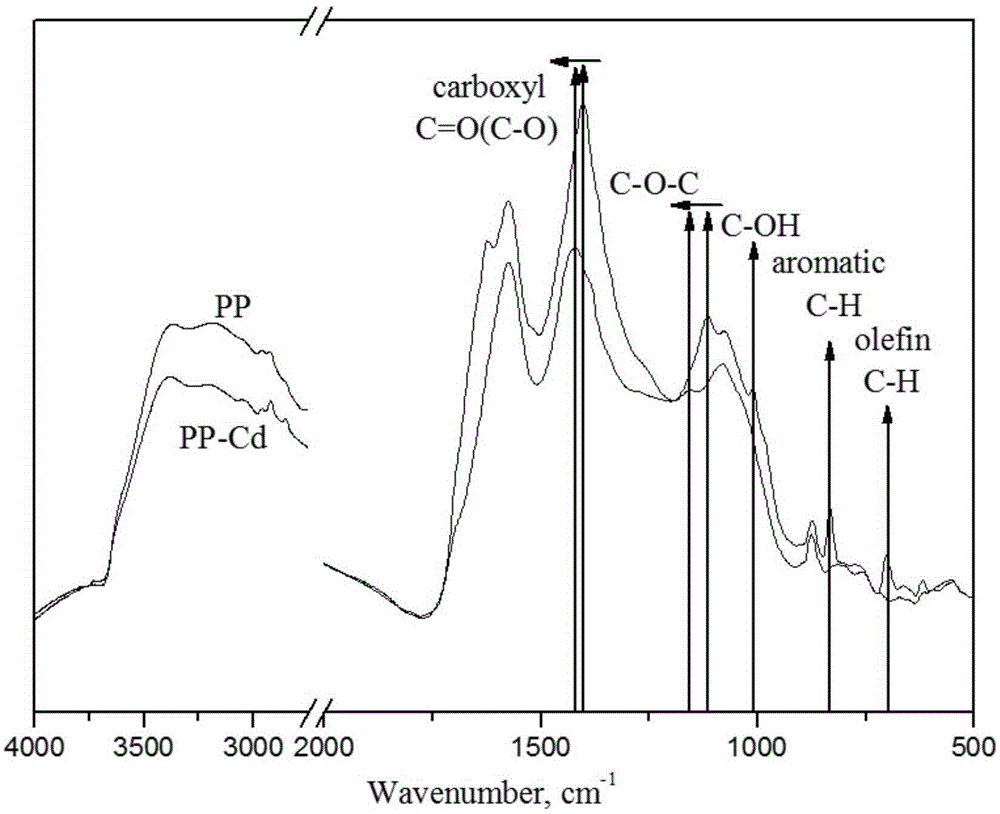

Preparation method of modified bagasse cellulose based heavy metal adsorbent

InactiveCN102716728ASolve the use problemSolve secondary pollutionOther chemical processesWater/sewage treatment by sorptionWater bathsCellulose

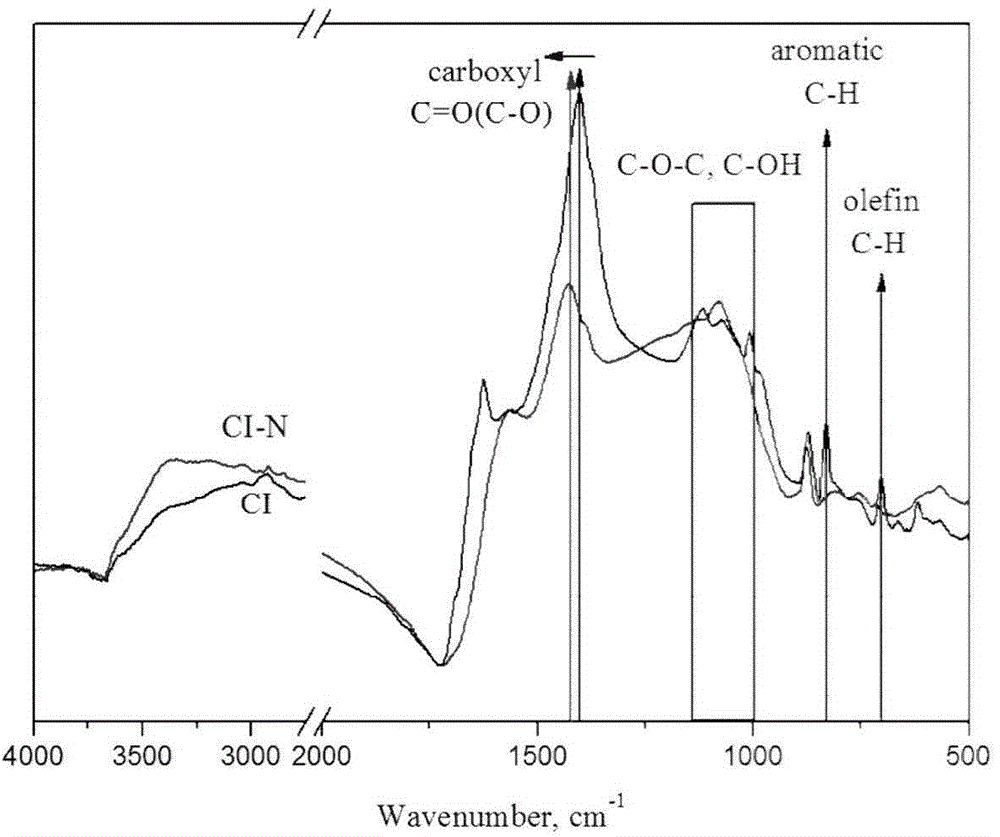

The invention relates to a preparation method of a modified bagasse cellulose based heavy metal adsorbent. The preparation method comprises the technological steps of: defibering natural fibers, washing with distilled water and ethanol, stirring and activating in NaOH solution, putting the fibers into dimethyl sulfoxide for water-bath heating and gelatinization, adding deionized water and initiators, feeding in nitrogen for initiation and adding acrylic acid monomers for reaction to obtain graft copolymerization products; adding polyethylene polyamine monomers for reaction, washing and drying to obtain crude cellulose based heavy metal adsorbent; and washing with deionized water, soaking and rinsing in ethanol, rewashing with deionized water, extracting by using acetone and drying to obtain the refined heavy metal adsorbent. The preparation method provided by the invention has the advantages that the method is simple, the cost is low, the environmental friendliness is good, the adsorption effect is excellent, the method is compliant with the concept of circular economy and sustainable development, the problem of secondary pollution caused by bagasse combustion is solved, the water bodies which are polluted by heavy metals are purified and the economic advantage is remarkable.

Owner:GUANGXI UNIV

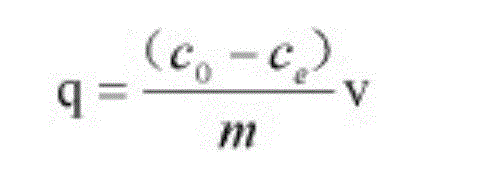

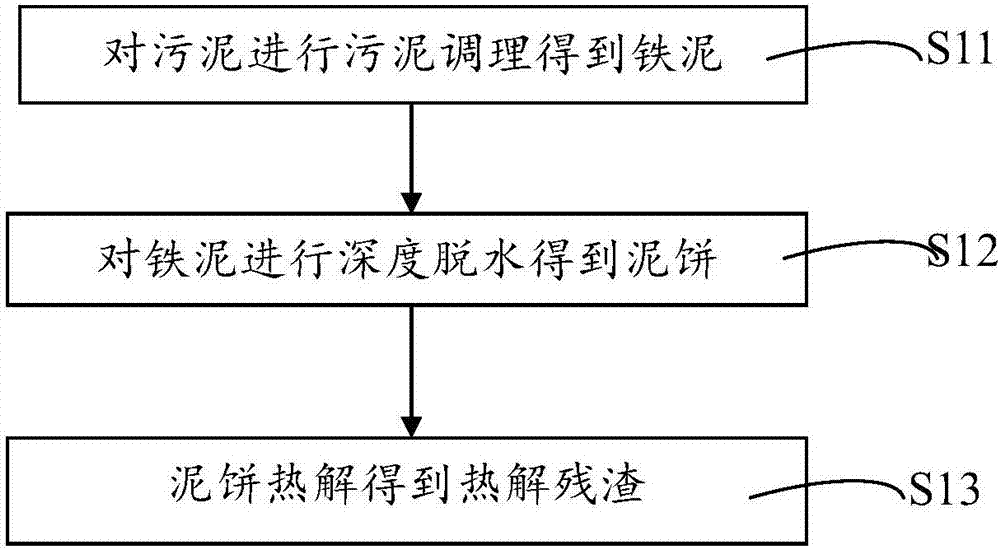

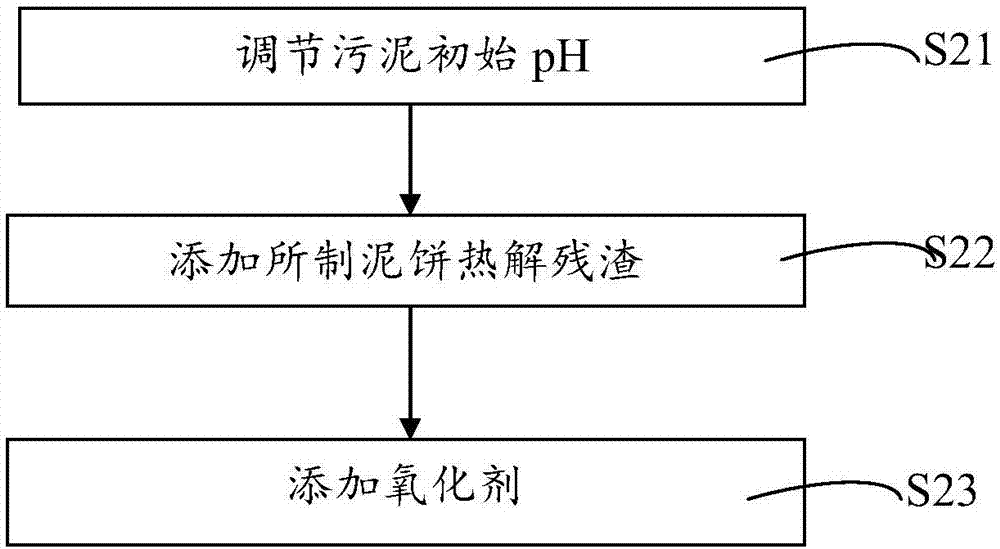

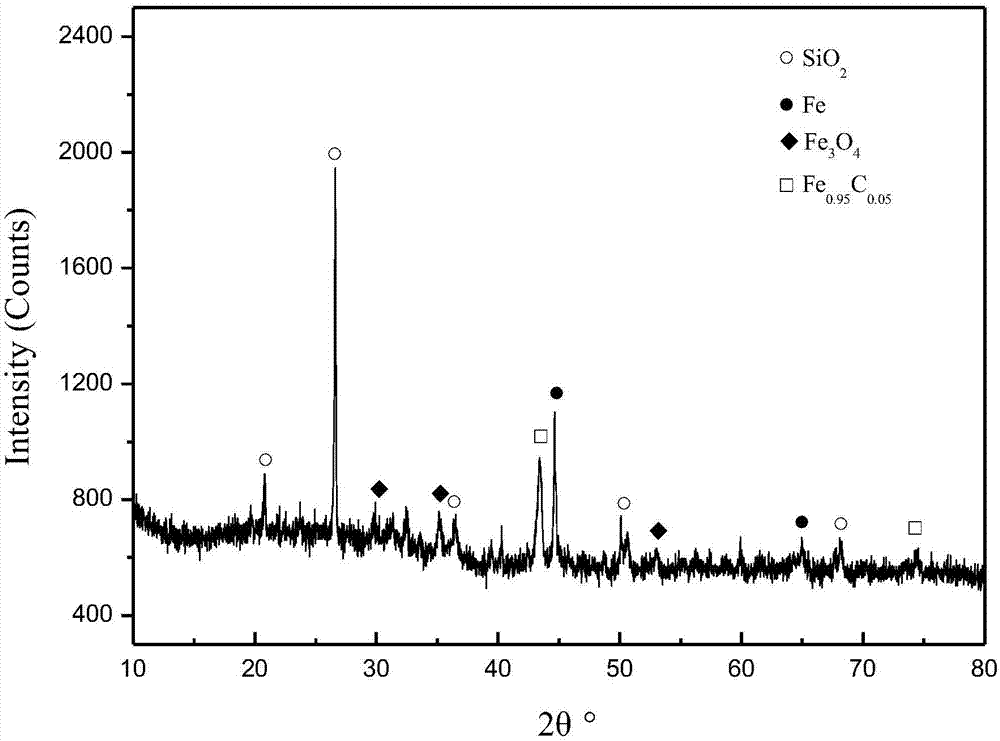

Composite sludge conditioner based on iron-containing sludge pyrolysis residue as well as preparation and application of composite sludge conditioner

ActiveCN107459237AGood conditionFully activatedSludge treatment by de-watering/drying/thickeningWater treatment parameter controlSludgeOxidizing agent

Owner:HUAZHONG UNIV OF SCI & TECH

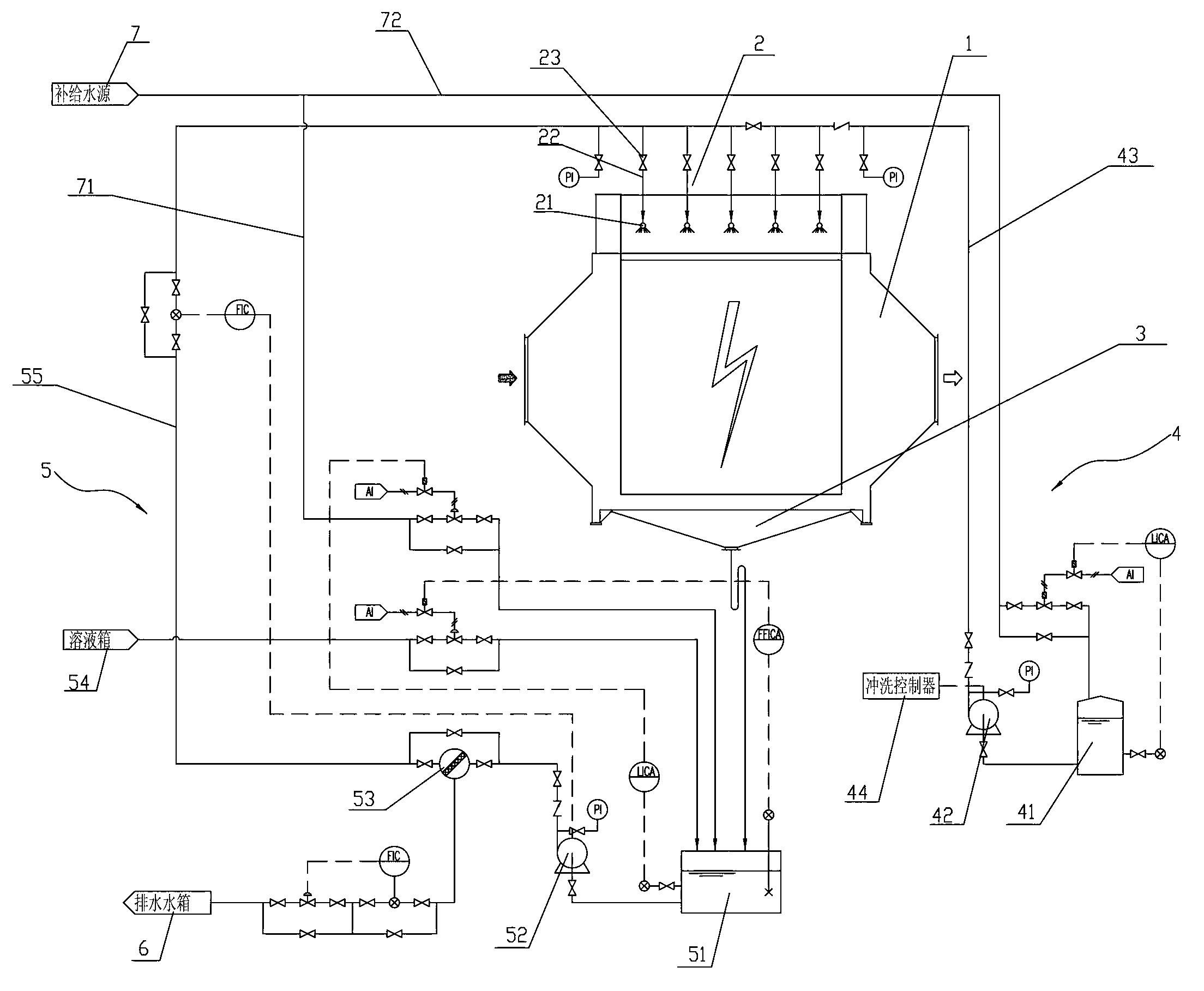

Ash water circulation treatment system of wet-type electric dust remover

ActiveCN103056031AAvoid secondary pollutionLower water costsMultistage water/sewage treatmentExternal electric electrostatic seperatorWater dischargeWater circulation

The invention discloses an ash water circulation treatment system of a wet-type electric dust remover. The ash water circulation treatment system comprises an ash water tank used for collecting ash water discharged from the wet-type electric dust remover, a supplementary branch and a circulating branch, wherein the supplementary branch comprises a supplementary water tank and a flush water pump; a water inlet of the flush water pump is connected with the supplementary water tank; a water outlet of the flush water pump is connected with the spraying mechanisms of the wet-type electric dust remover through a water conveying pipe; the circulating branch comprises a circulating water tank, a circulating water pump, a solution tank filled with an alkali solution and an automatic filter; a water outlet of the ash water tank and a water outlet of the solution tank are connected with the circulating water tank respectively; a water inlet of the circulating water pump is connected with the circulating water tank; a water outlet of the circulating water pump is connected with a water inlet of the automatic filter; and a water outlet of the automatic filter is connected with the spraying mechanisms of the wet-type electric dust remover through the water conveying pipe. The ash water circulation treatment system is simple in structure and scientific and reasonable in arrangement; water can be continuously supplied for self circulation; the water consumption is greatly reduced; the water consumption cost is saved; and the ash water can be prevented from causing secondary pollution.

Owner:FUJIAN LONGKING

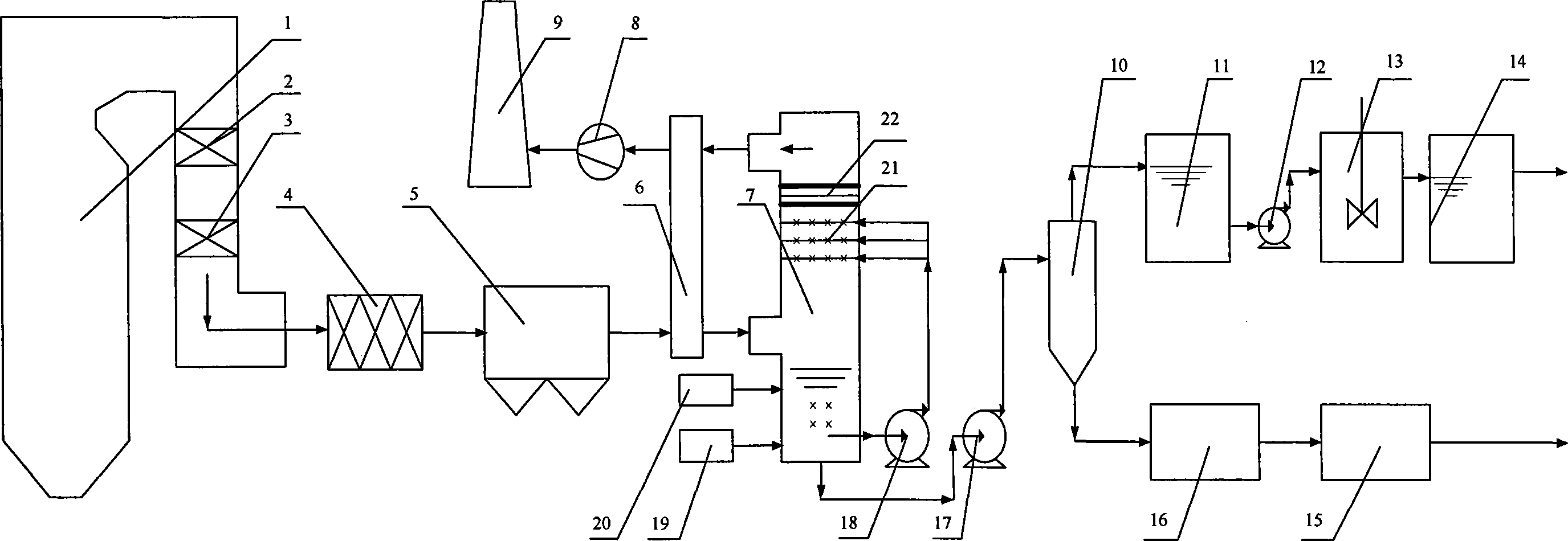

Wet-type ammonia flue gas spiritualization technics of associated desulfuration demercuration

The invention relates to a wet ammonia flue gas purification process for the combined sulfur and mercury removing and the system thereof. The process adopts chlorine gas as oxidizing agent to completely oxidize elemental mercury in the flue gas, and gas phase divalent mercuric ion after being oxidized is converted into liquid phase divalent mercuric ion through the improved wet ammonia desulphurization process, and further the liquid phase divalent mercuric ion is converted into stable mercuric sulfide sendimentation through liquid phase divalent mercuric ion stabilizing agent. The system comprises a flue gas oxidizing demercuration preprocessing system composed of an oxidizing agent injection device and an electrostatic precipitator, a wet ammonia flue gas sulfur and mercury removing system composed of a reaction absorbing tower, a sulfur removing accessory substance processing system composed of a cyclone cleaner, a dewaterer, and a dryer, and a mercuric sulfide HgS sendimentation processing system composed of a wastewater buffer pool, a liquid phase mercuric ion reaction chamber, and a settling pond. The process and the system can effectively improve the oxidation rate of the elemental mercury in the flue gas, overcome the defaults that the divalent mercuric ion is easy to be reduced and released and the secondary pollution problem is caused by excess oxidizing agent, and greatly improve the efficiency of sulfur removing and mercury removing.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

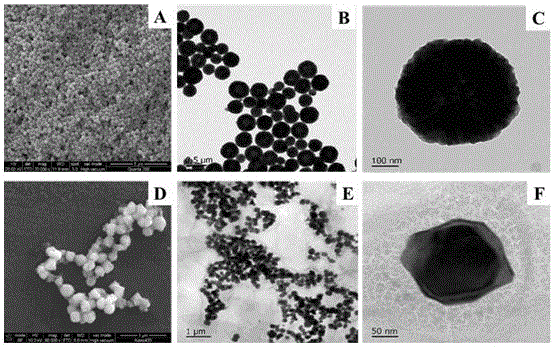

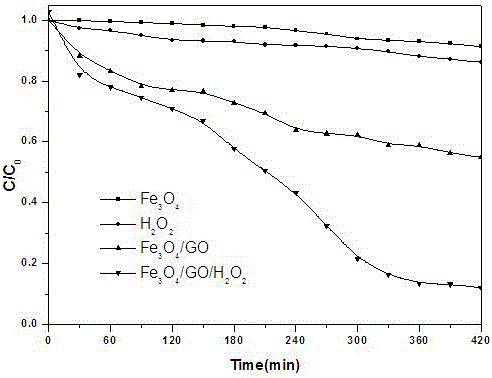

Method for preparing core-shell ferroferric oxide/graphene oxide composite nano-catalyst

InactiveCN105964256AHigh reactivityHigh synthesis efficiencyWater treatment compoundsWater contaminantsNano catalystOxide composite

The invention provides a method for preparing a core-shell ferroferric oxide / graphene oxide composite nano-catalyst. The method comprises the following steps of preparing nanometer ferroferric oxide by utilization of a hydrothermal method, preparing graphene oxide by utilization of a modified Hummers method, preparing the core-shell ferroferric oxide / graphene oxide composite nano-catalyst by utilization of an electrostatic self-assembly method. The catalyst prepared according to the method provided by the invention has the advantages that the adsorptive property is excellent, the stability is good, the catalyst can be cyclically utilized, and an excellent adsorption effect can be achieved during the process of degrading simulated dye rhodamine B.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

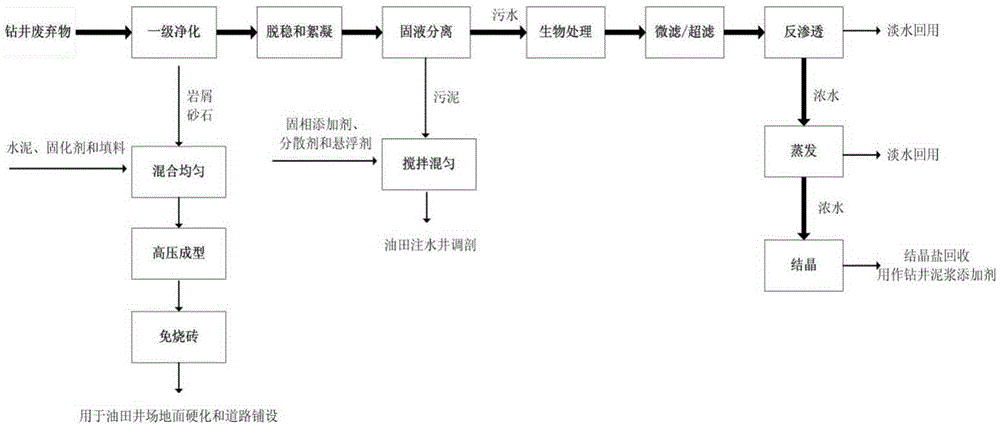

Drilling wastes recycling method

ActiveCN105347609AAdapt to dispersionAdapt to mobilityWaste water treatment from quariesWater treatment compoundsSludgeEvaporation

The invention belongs to the technical field of sewage processing, and concretely relates to a drilling wastes recycling method. The method comprises the following steps: performing primary purifying, removing rock debris and sandstones; performing destabilizing and flocculating treatment, conglomerating the suspending granules into a flocculent body; performing solid-liquid separating, using a separated sludge for profile control of a water injection well in an oil field; performing biological treatment on the separated sewage to reduce COD, carrying out microfiltration and ultrafiltration processing for removing a suspension and a colloid as well as reducing SDI, performing reverse osmosis to obtain fresh water for reuse, evaporating concentrated water obtained by reverse osmosis and crystallization, reusing the fresh water obtained by evaporation, and reusing the common salt and potassium chloride obtained by crystallization as an additive of a drilling fluid. The method realizes harmlessness and recycling of the drilling wastes, eliminates pollution on surrounding environment, and is in favor of protection of resources such as soil, air and underground water at periphery of a well field. The method can be widely used in a recycling treatment process of the drilling wastes in the oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

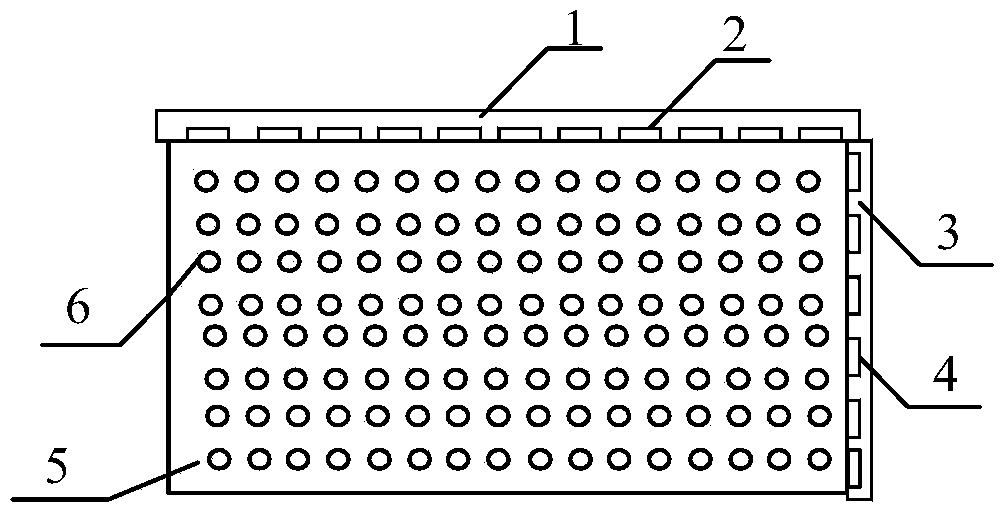

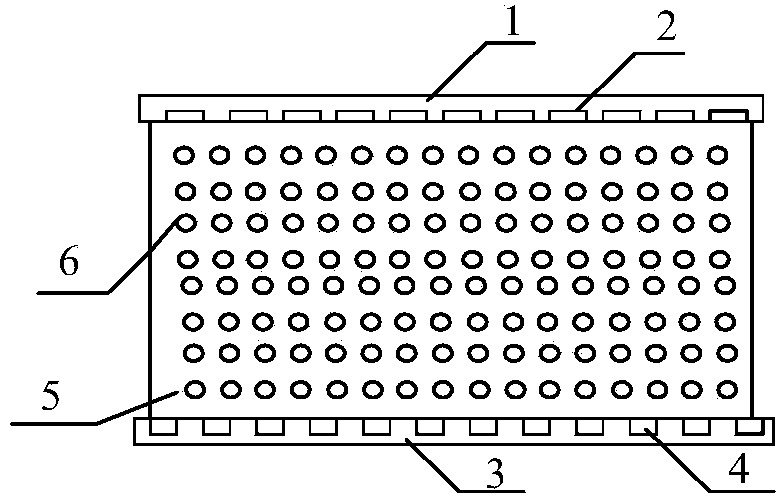

Backlight module and display device

InactiveCN103775919ASterilization is convenient and quickSimple structurePoint-like light sourceElectric light circuit arrangementUltraviolet lightsDisplay device

The invention provides a backlight module and a display device, belongs to the technical field of display, and aims at solving the problem that the display screen of the conventional display device is inconvenient to clean. The backlight module comprises a plurality of light sources, wherein the light sources comprise an ultraviolet light source for sterilization and a display light source for display. The backlight module provided by the invention is particularly applicable to touch screen display devices.

Owner:HEFEI BOE DISPLAY LIGHT +1

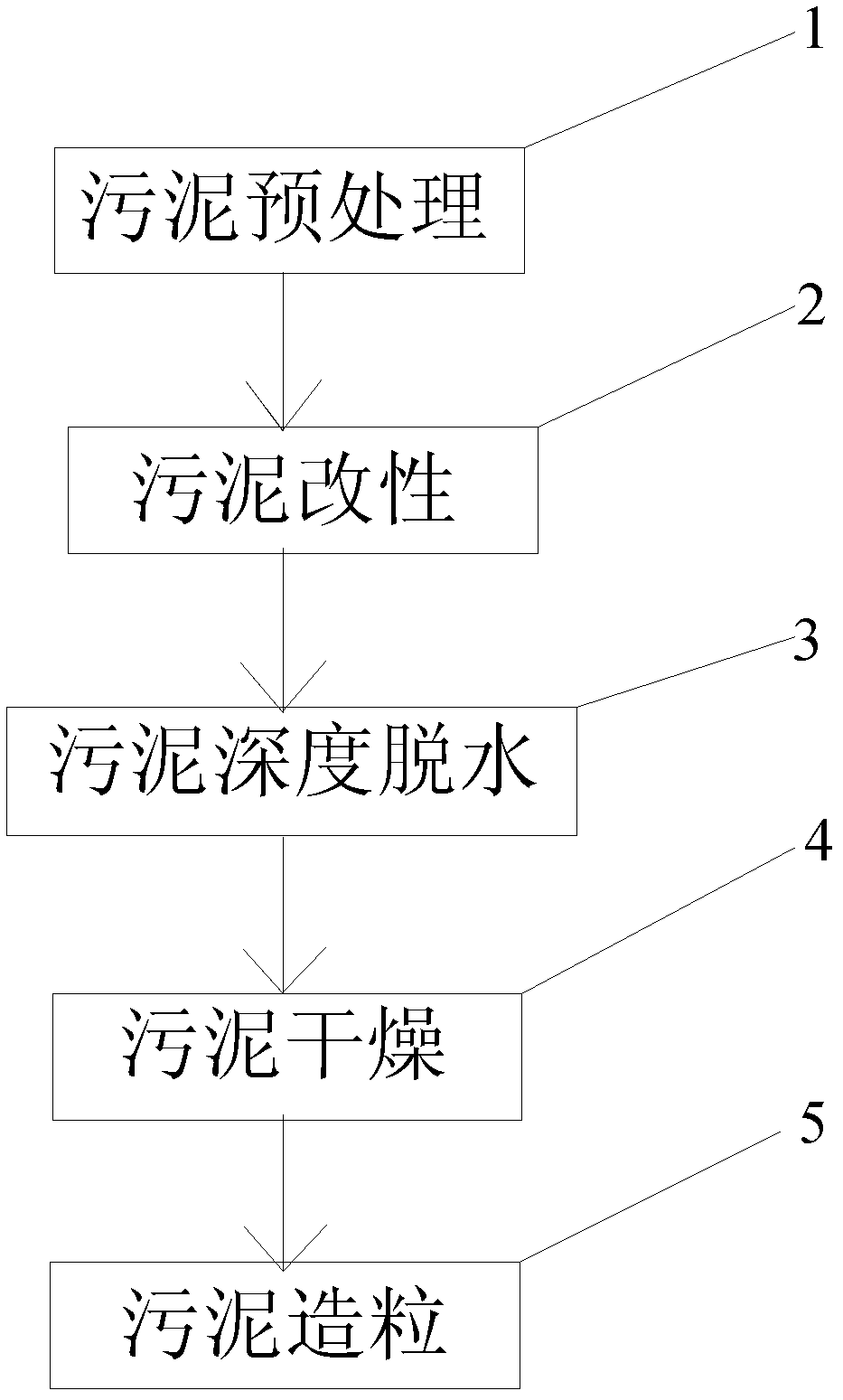

Production method of sludge biomass environment-friendly fuel

ActiveCN102491608ASimple processLess investment in equipmentSludge treatment by de-watering/drying/thickeningBiofuelsBiomassHeavy metals

The invention discloses a production method of a sludge biomass environment-friendly fuel. The method comprises the following steps: 1) sludge pretreatment: conveying sludge to a pretreatment pool, adding deodorant and bactericide and stirring uniformly; 2) sludge modification: conveying pretreated sludge to a reaction tank, adding modifier, sulfur fixing agent and heavy metal stabilizing agent, reacting uniformly and adding crushed biomass; 3) sludge depth dehydration: carrying out depth dehydration on the modified sludge; and 4) sludge drying: fragmenting the sludge cake treated with depth dehydration and drying. Compared with a prior art, the production method of sludge biomass environment-friendly fuel provided by the invention can realize quantitative reduction, harmlessness, stabilization and resource of sludge treatment, effectively solve a problem of secondary pollution of sludge and obtain the biomass environment-friendly fuel; besides, the fuel can substitute coal for combustion in boiler, make up sludge treatment cost as well as effectively solve a social problem of energy shortage.

Owner:深圳市泽源能源股份有限公司

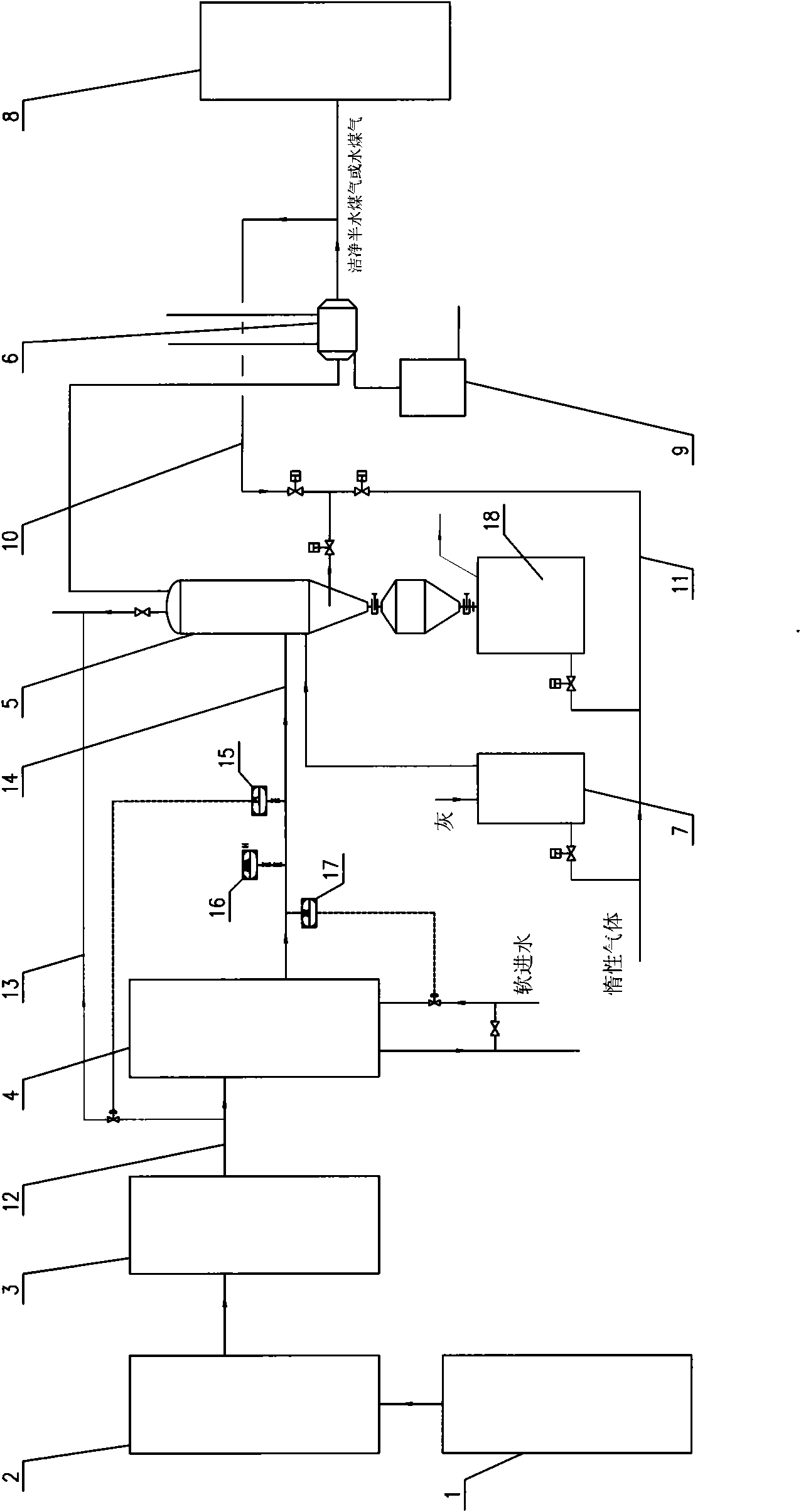

Gasification dry dedusting technology

ActiveCN101550362AAvoid direct contactSolve secondary pollutionCombined combustion mitigationGas dust removalPositive pressureSoft water

The invention discloses gasification dry dedusting technology which comprises the following technological steps: 1) the semi-water gas or the water gas from a normal-pressure or micro-positive pressure gasification furnace with gasification pressure of smaller than or equal to 0.1 MPa of smaller (gauge pressure) is dedusted by a cyclone dust collector to remove most of the dust, and then the gas enters a combined waste pot to exchange heat with soft water and saturated vapor to reduce temperature; 2) after temperature reduction, the semi-water gas or the water gas enters a soft water heater, the flow of the soft water is adjusted to reduce the temperature of the semi-water gas or the water gas going through the soft water heater once again; 3) after further temperature reduction, the semi-water gas or the water gas enters a bag-type dust collector to be dedusted and purified, wherein the air in the bag-type dust remover is replaced by inert gases; and 4) after fine dedusting, the semi-water gas or the water gas enters a spacing exchanger to reduce the temperature to 35-45 DEG C by a coolant and is prepared for producing or synthesizing ammonia or methanol. The technology has the advantages of avoiding the direct contact of the semi-water gas or the water gas with water, reducing the water consumption, enhancing the dedusting efficiency, protecting the environment, saving investment and operating expenses, and having great significance in environmental protection and large economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +2

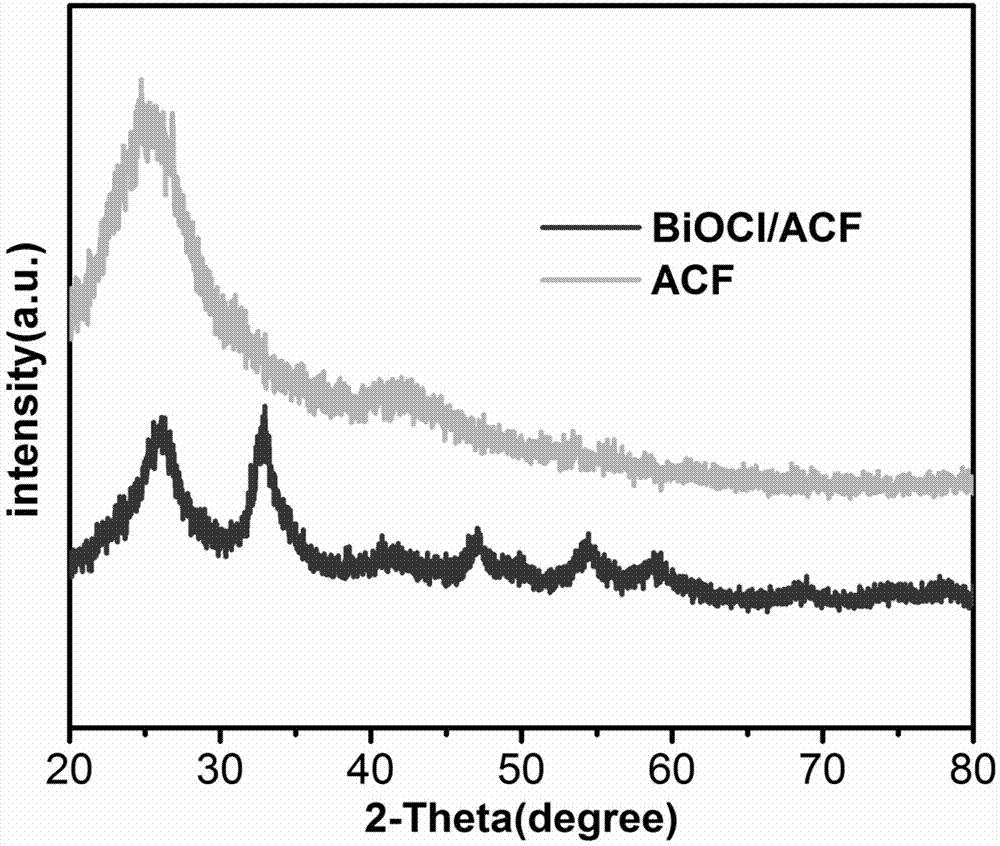

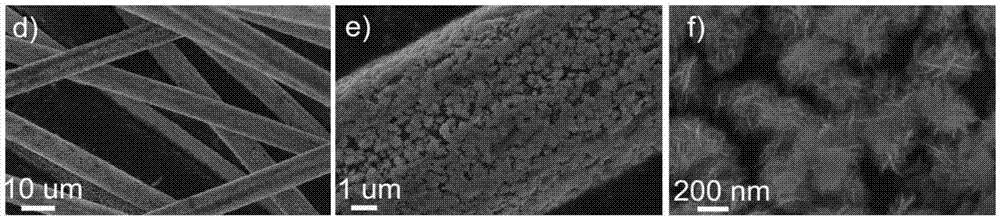

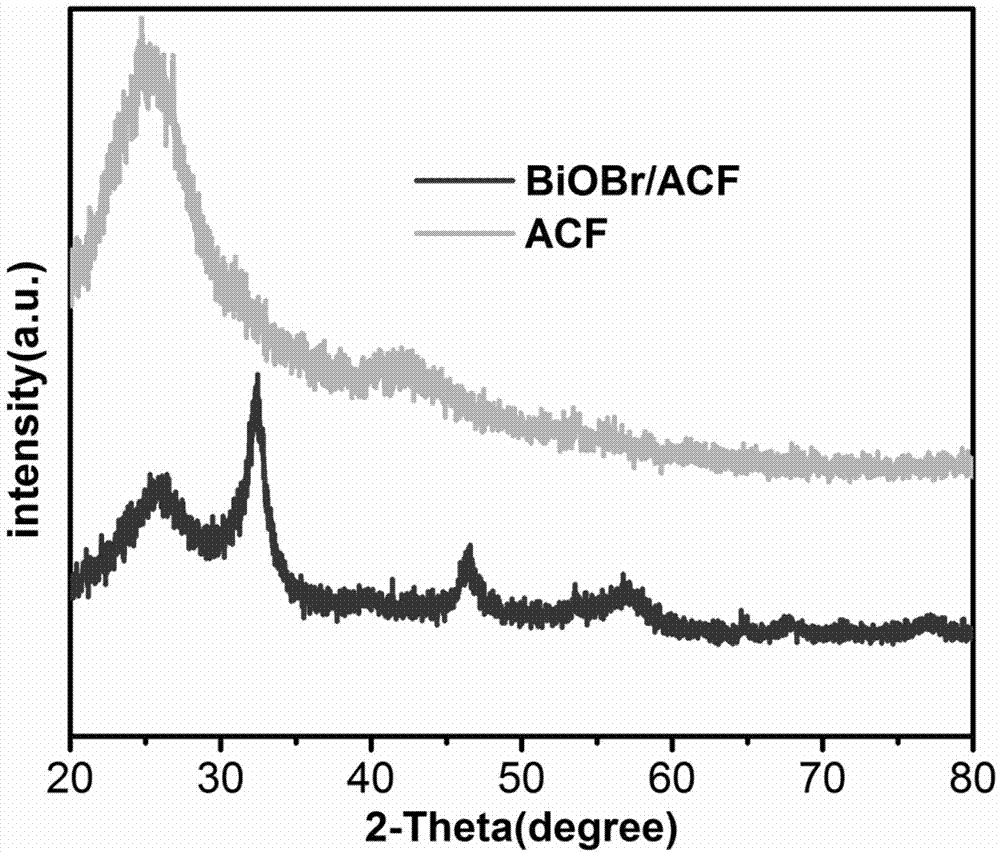

Nitrated carbon fiber loaded bismuth oxyhalide nanoflower and preparation method of nanoflower

ActiveCN103920508AReduce pollutionReduce manufacturing costPhysical/chemical process catalystsOther chemical processesFiberCarbon fibers

The invention relates to a nitrated carbon fiber loaded bismuth oxyhalide nanoflower and a preparation method of the nanoflower. The preparation method of the nanoflower comprises the following steps: respectively dissolving a halogenous ionic solution and bismuth nitrate in ethylene glycol monomethyl ether, slowly adding the halogenous ionic solution into a bismuth nitrate solution after the halogenous ionic solution and the bismuth nitrate are fully dissolved in the ethylene glycol monomethyl ether, evenly stirring and mixing the mixed solution, pouring the mixed solution to a high-pressure reaction kettle with a polytetrafluoroethylene liner, then placing nitrated carbon fiber in the kettle, reacting for 0.5-6 hours in a drying oven at the temperature of 150-160 DEG C, naturally cooling and then washing and drying to obtain a product. Through the nitrated carbon fiber loaded bismuth oxyhalide nanoflower, the BiOX is reused and the problem of secondary pollution is solved; ACF (Active Carbon Fiber) is excellent in adsorption property and capable of absorbing organic pollutants and facilitating the photo-catalysis.

Owner:SHANDONG UNIV

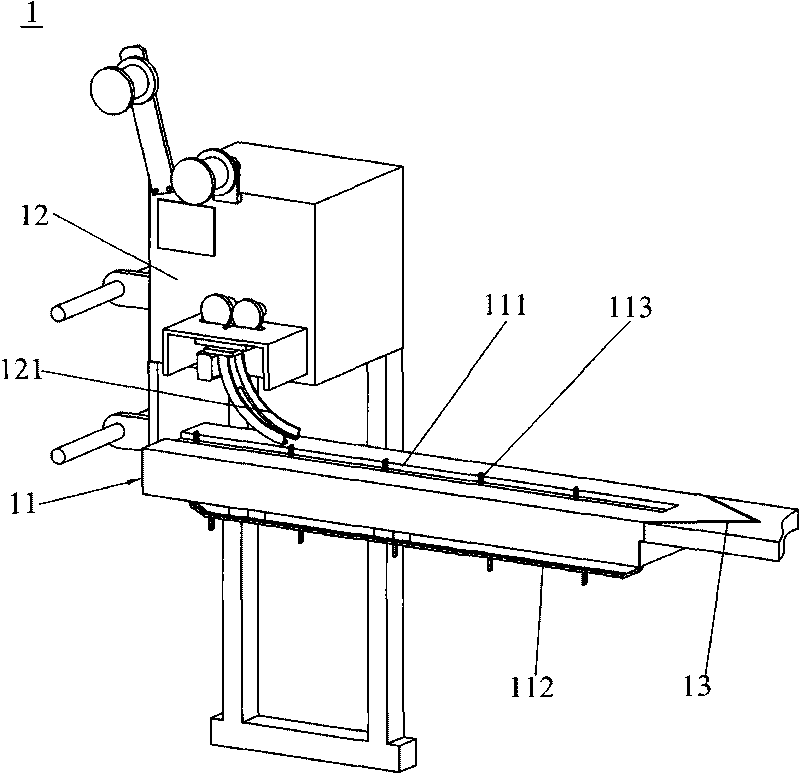

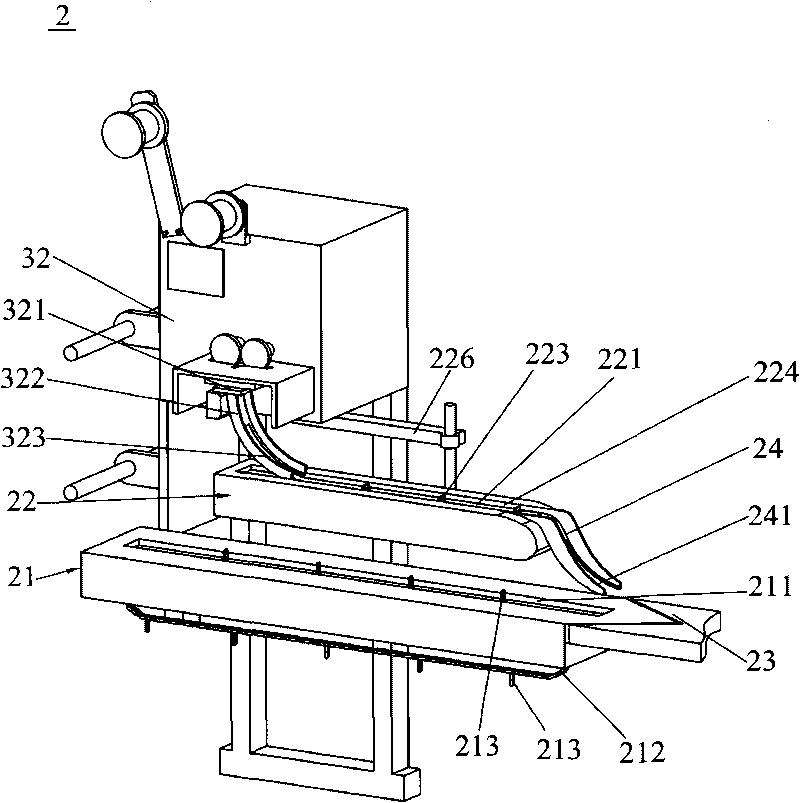

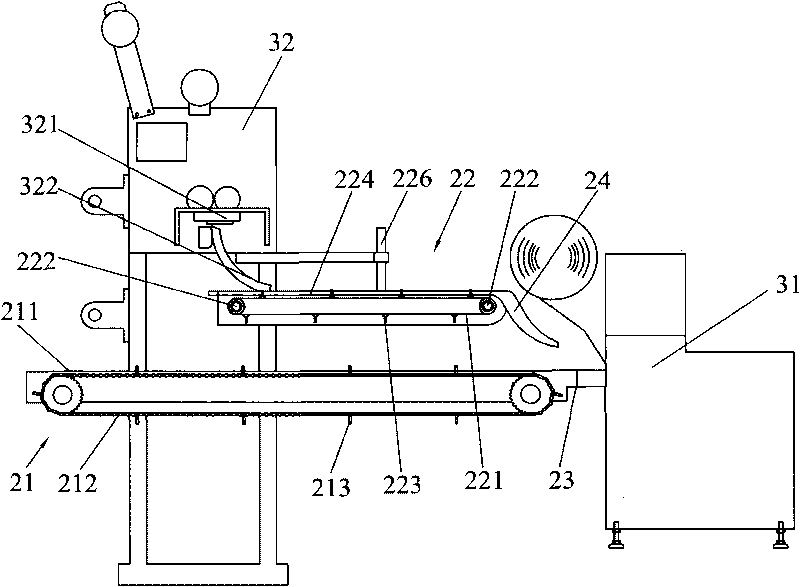

Conveying device of a packing machine

The invention provides a conveying device of a packing machine, which is used for the conveying of the packing machine with secondary feeding. The conveying device comprises a main conveying mechanism, a connecting opening for connecting the main conveying mechanism and the inlet of the packing machine, a segmented parcel delivery machine used for secondary feeding, a secondary feeding conveying mechanism and a feeding sliding chute. The main conveying mechanism comprises a main conveying chute and a main conveying chain installed below the main conveying chute; the main conveying chain is provided with an equidistant push rod which passes through the main conveying chute and extends upwards above the main conveying chute. One end of the secondary feeding conveying mechanism is connected with the discharge opening of the segmented parcel delivery machine, and the other end is connected with the inlet of the feeding sliding chute; and the outlet of the feeding sliding chute is arranged above the connecting opening. Since the secondary feeding conveying mechanism used for conveying auxiliary products is arranged additionally, the conveying device of the packing machine avoids secondary pollution, reduces the falling rate, performs secondary feeding quality inspection and has the advantages of safety, reliability and no pollution.

Owner:GUANGDONG GUANGYI TECH IND

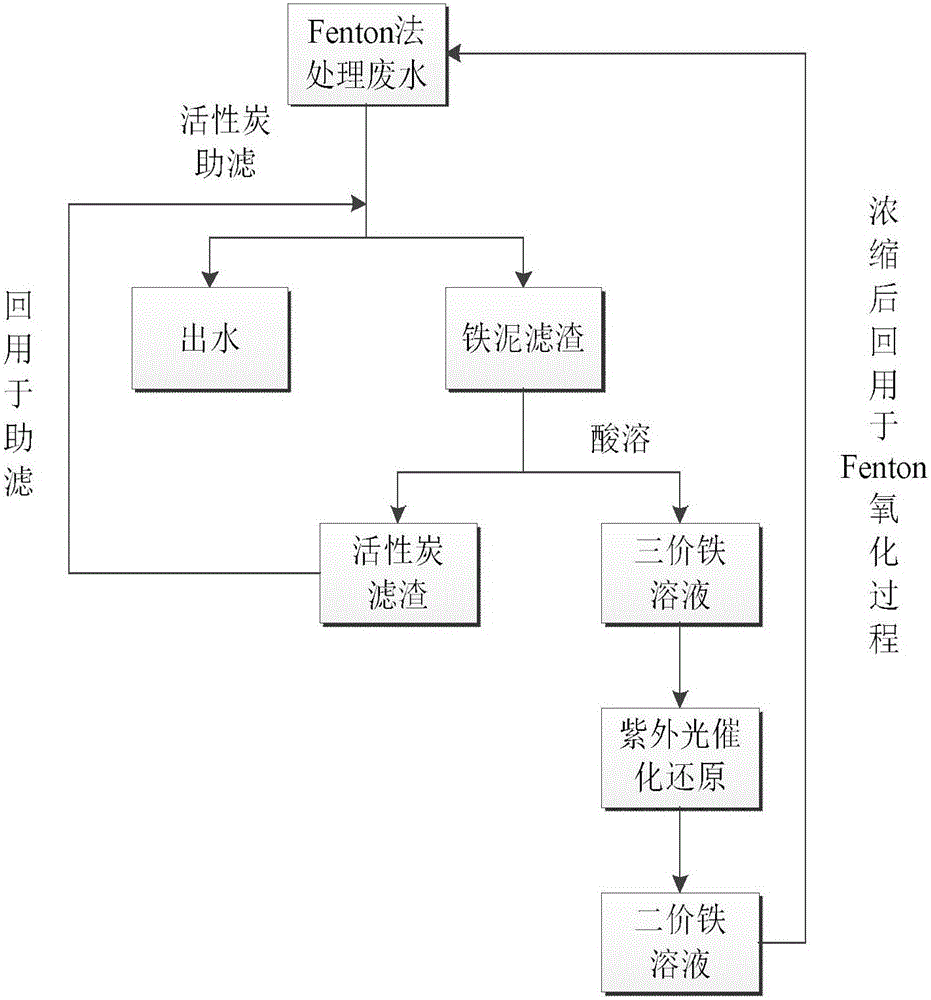

Method for recycling Fenton iron mud

ActiveCN105668759ATake advantage ofSolve secondary pollutionWater treatment compoundsWater/sewage treatment by oxidationActivated carbonMud systems

The invention discloses a method for recycling Fenton iron mud. The method for recycling the Fenton iron mud comprises the following steps: 1, treating wastewater by adopting a Fenton process, after reaction is finished, adding 0.05-1% activated carbon for adsorbing and aiding filtration, stirring and reacting for 0.5-1 h, filtering and separating to obtain water and iron mud filter residue; 2, adding sulphuric acid into the iron mud filter residue, stirring and dissolving for 0.5-2 hours at the temperature of 60-80 DEG C, filtering and separating to obtain a Fe<3+> solution and activated carbon filter residue; and 3, placing a solution containing Fe<3+> into an ultraviolet light reaction tank, wherein the reaction tank contains a supported semiconductor catalyst, reducing Fe<3+> in the solution into Fe<2+> under the ultraviolet light catalytic condition, concentrating a Fe<2+> solution and then reusing the concentrated Fe<2+> solution in a Fenton oxidation wastewater treatment process in the step 1, so that self circulation of an iron mud system is formed. The method for recycling the Fenton iron mud has the advantages that the problem that iron mud secondary pollution is produced by the Fenton oxidation process is solved, recycling of iron resources and activated carbon is realized, and wastewater treatment cost is reduced.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

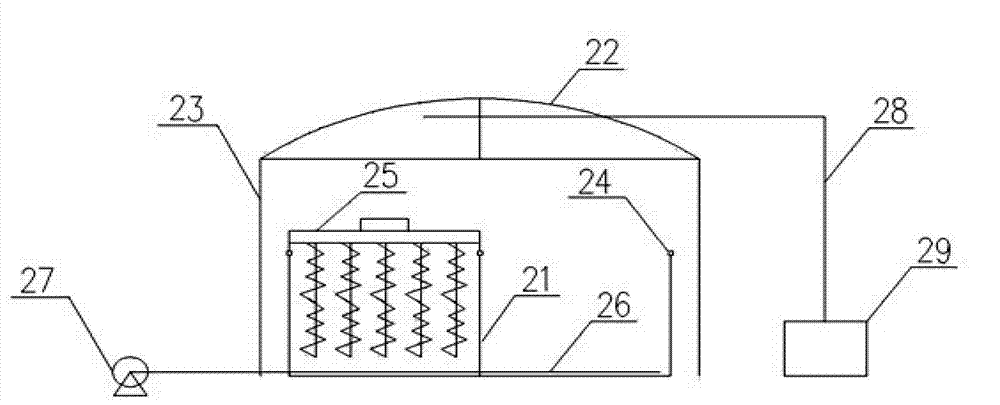

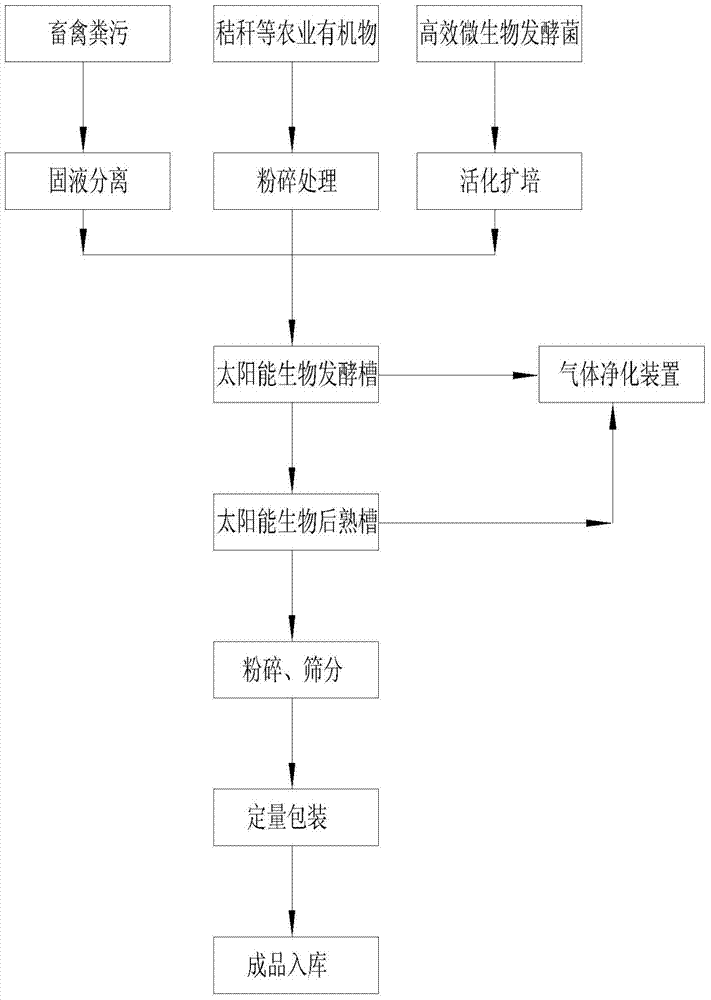

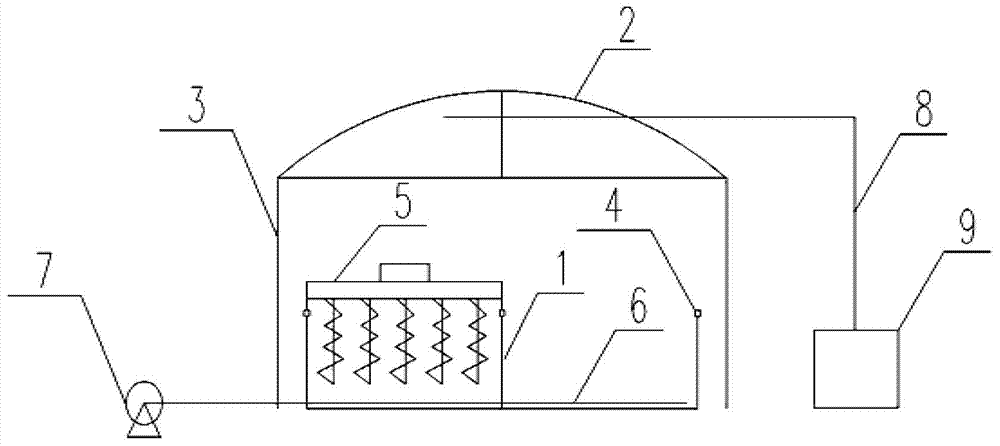

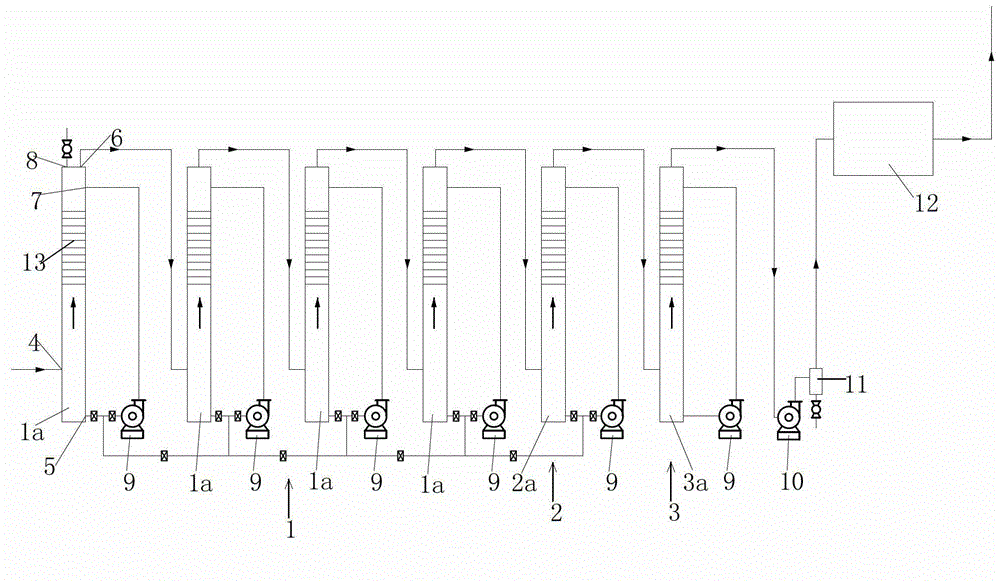

Method and device for disposing animal manure to produce organic fertilizer by solar energy

InactiveCN103204719AFully killShorten the timeClimate change adaptationExcrement fertilisersEngineeringFermentation

The invention discloses a method and device for disposing animal manure to produce an organic fertilizer by solar energy. The method comprises the following steps of: mixing with organic waste after carrying out solid-liquid separation on animal manure, adding efficient high-temperature microorganism fermentation bacteria; firstly, feeding into a solar biological fermentation tank to carry out primary fermentation, feeding to a solar biological post-fermentation tank to carry out secondary post fermentation; leading the gas generated during fermentation into a gas purifier to purify through a gas collecting pipeline; taking ferrous sulfate solution as spray absorption liquid; crystallizing by a crystallization tank, fixing ammonia and hydrogen sulfide into effective fertilizer components, and crushing and sieving the fermented materials to obtain a high-quality organic fertilizer. The method has the beneficial effects that the organic wastes such as animal manure and straws are taken as materials; the wastes are converted into precious materials; the bacteria, worms and ovum are killed by solar energy; the time of reducing moisture in the fertilizer is shortened; the fermentation efficiency is improved; and the problem of secondary pollution caused by total nutrient loss and waste gas in the fermentation process is solved.

Owner:广西玉林市大智生物科技有限公司

Oxynitride waste gas treatment device and oxynitride waste gas treatment method

ActiveCN102974200ASolve secondary pollutionDispersed particle separationAir quality improvementVapor–liquid separatorAcid washing

The invention belongs to the technical field of waste gas treatment, and particularly relates to an oxynitride waste gas treatment device and an oxynitride waste gas treatment method. The oxynitride waste gas treatment device comprises an acid washing unit, a water washing unit, an alkali washing unit and a draft fan, wherein the acid washing unit is provided with a plurality of acid washing absorption towers which are connected in series; the water washing unit is arranged at the latter station of the acid washing unit and connected with the acid washing unit in series, and comprises a water washing absorption tower; the alkali washing unit is arranged at the latter station of the water washing unit and connected with the water washing unit in series, and comprises an alkali washing absorption tower; the bottom of each absorption tower is respectively provided with a waste gas inlet and a liquid outlet, and the top is respectively provided with a waste gas discharge port and a liquid inlet; the top of the first acid washing absorption tower is provided with an air inlet; each absorption tower is provided with a suction pump of which the inlet and outlet are respectively connected with the liquid outlet and the liquid inlet; an inlet of the draft fan is connected with a waste gas discharge port of the alkali washing absorption tower, and an inlet of the draft fan is connected with an inlet of a gas-liquid separator; and a gas outlet of the gas-liquid separator is connected with a gas inlet of a dry-type adsorption tower. The invention solves the following problems: the existing treatment device can not absorb NO, but only can absorb NO2, and abundant industrial waste salts generated in the waste gas treatment process can bring about secondary pollution.

Owner:SHOUGUANG FUKANG PHARMA

Method utilizing waste and bacterium dreg generated during process of producing edible fungi from straw raw materials to produce microorganism organic bacterium fertilizer

The invention relates to a method utilizing waste and bacterium dreg generated during the process of producing edible fungi from straw raw materials to produce a microorganism organic bacterium fertilizer. The method takes the waste and bacterium dreg generated in the process of producing edible fungi from straw as the raw material, and then subjects the raw materials to technology processes of bacterium dreg pretreatment, preparation of an activating and fermenting liquid, and microorganism secondary fermentation so as to produce the microorganism organic bacterium fertilizer. The product can be used as a normal microorganism bacterium fertilizer, can improve the agricultural crop output by 3% or more, and achieves the goals of soil structure modification, soil pH value adjustment, fertilizer cost reduction, output and quality improvement, and pesticide residue degradation, and the like. The method provided by the invention has the advantages of mature and practicable technology route, abundant and wide source of raw material for production, low cost, and convenient preparation; has production technology innovation and an application promotion value, solves the problems of resource waste and secondary pollution existing in the straw cyclic utilization, increases the economic income for farmers, and achieves the goal of agricultural development.

Owner:孙悦迎

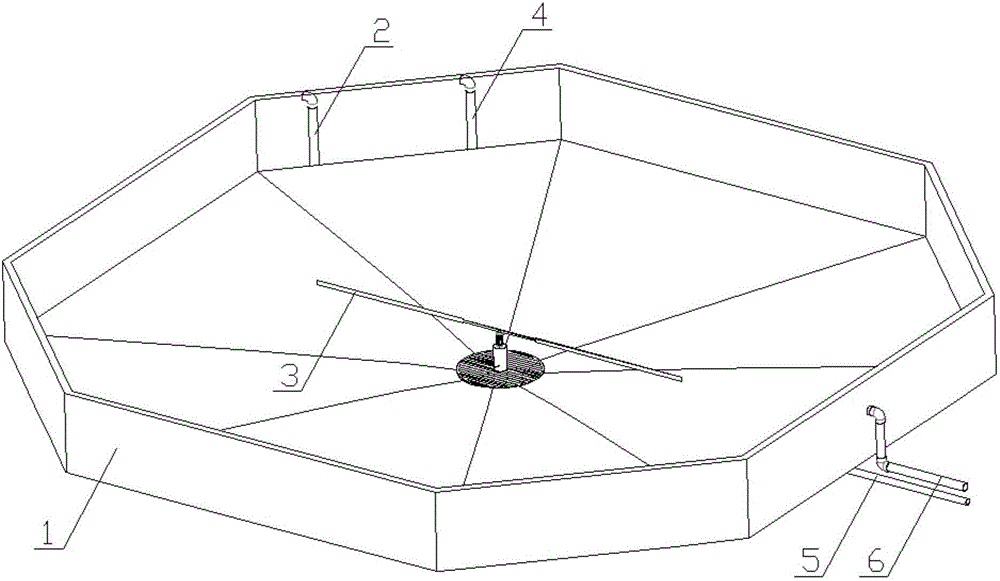

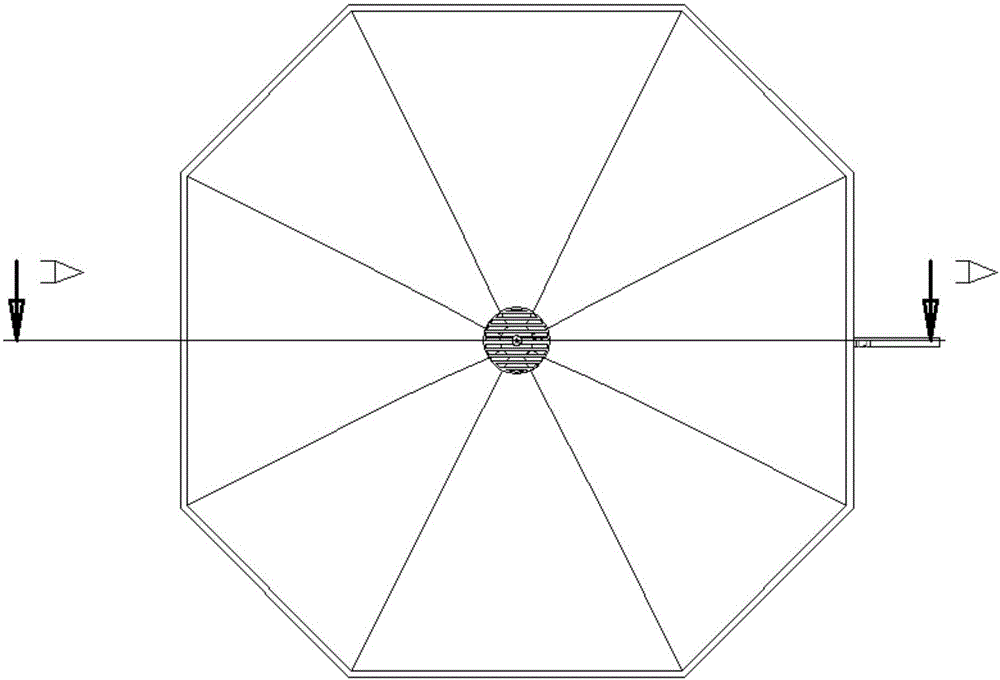

Culture pond system realizing rotational-flow dirt collection

The invention relates to a culture pond system realizing rotational-flow dirt collection. The culture pond system comprises a circular or a regularly polygonal pond body, wherein the center of the pond body is tapered downwards to a certain extent; a rotational-flow dirt-collecting device is arranged at the bottom of the pond body and is provided with a motor, the motor drives a horizontal supporting rod to rotate, and one end of the supporting rod is connected with a propeller; the distance from the propeller to the bottom of the pond body is smaller than 1 m; a supporting column is arranged below the motor and fixedly connected with a dirt collecting tank, the dirt collecting tank collects solid particles and is communicated with a bottom particle discharge pipe, and sewage is discharged out of the pond body through the bottom particle discharge pipe; a clean water discharge pipe is arranged on the side wall of the pond body, and a water inlet pipe and an aeration oxygenation pipe are arranged in positions near the side wall of the pond body; upper-layer clean water discharged through the clean water discharge pipe accounts for 80%-90% of the total amount of discharged water and flows back to the pond body through the water inlet pipe after being purified by a water purifying system; sewage discharged through the bottom particle discharge pipe accounts for 10%-20% of the total amount of discharged water.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Organic modified granular bentonite/attapulgite absorbent and preparation method thereof

InactiveCN104069803ASimple processLarge particle sizeOther chemical processesWater/sewage treatment by sorptionCation-exchange capacityActive agent

The invention relates to an organic modified granular bentonite / attapulgite absorbent and a preparation method thereof. The preparation method adopts the technical scheme that bentonite powder and attapulgite powder are taken as main raw materials and mixed at the mass ratio of 1:(0.1-0.5); the mixture of the bentonite powder and the attapulgite powder is uniformly mixed with water at the mass ratio of 1:(1.2-2),dried for 16-32h at 90-110 DEG C, crushed into granular bentonite / attapulgite with the grain size of 0.2-2 mm and then calcined for 2-2.5 h at 550-850 DEG C; finally, the calcined granular bentonite / attapulgite is modified with a surface active agent, which is 50-400 percent CEC (Cation Exchange Capacity) of the calcined granular bentonite / attapulgite, under a stirring condition to obtain the organic modified granular bentonite / attapulgite absorbent. The preparation method is simple in process and causes no secondary pollution; the prepared organic modified granular bentonite / attapulgite absorbent has the characteristics of large grain size, excellent adsorption property and high strength and is applicable to treatment of wastewater containing chlorophenol.

Owner:WUHAN UNIV OF SCI & TECH

Straw/ash magnesium-oxy-chloride cement hollow slat or hollow building block and preparation method thereof

InactiveCN101817670AReduce energy consumptionSave energySolid waste managementMixing operation control apparatusFiberResource saving

The invention discloses a straw / ash magnesium-oxy-chloride cement hollow slat or hollow building block and a preparation method thereof. The preparation method comprises the steps of: firstly, adding a modifying agent into an MgCl2 solution prepared by a normal bittern's slice to be stirred uniformly, wherein the mass ratio of MgO to MgCl2 is 5:1-6:1, the ash accounts for 10-30 percent by mass of the MgO and the modifying agent accounts for 0.5-2 percent of MgO; secondly, mixing and stirring with uniformly stirred MgO powder and ash to obtain a magnesium-oxy-chloride cement gelled material; thirdly, adding straw fibers into the magnesium-oxy-chloride cement gelled material according to the proportion that the straw fibers account for 10-40 percent of the total volume of the straw fibers and the magnesium-oxy-chloride cement gelled material, uniformly stirring by adding water until the fluidity of a mixture reaches 110-140 mm according to the straw water absorption, and die-filling, vibrating and molding or reducing the water to binder ratio and then pressurizing and molding to obtain the straw / ash magnesium-oxy-chloride cement hollow slat or hollow building block after slurry shows better fluidity. The invention has good watertightness, high strength, good temperature and heat insulating effect, resource saving and environment load reduction.

Owner:SOUTHEAST UNIV

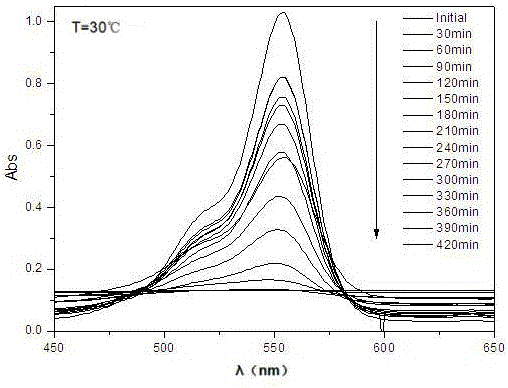

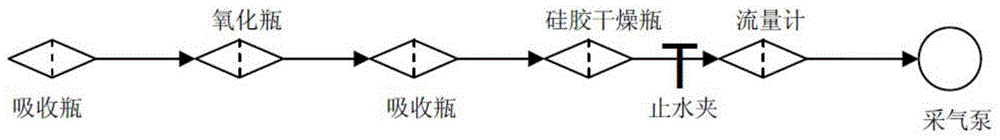

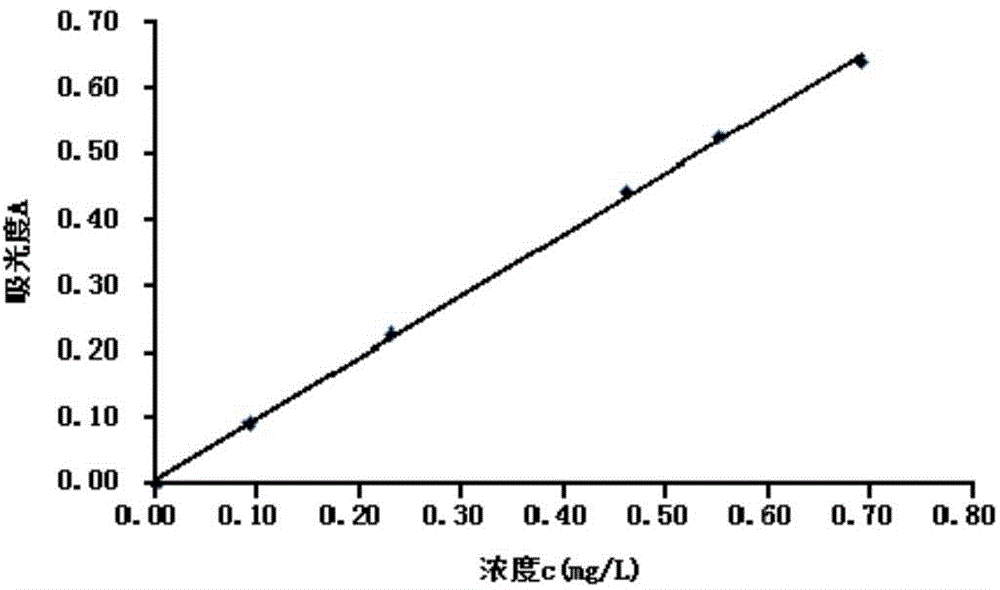

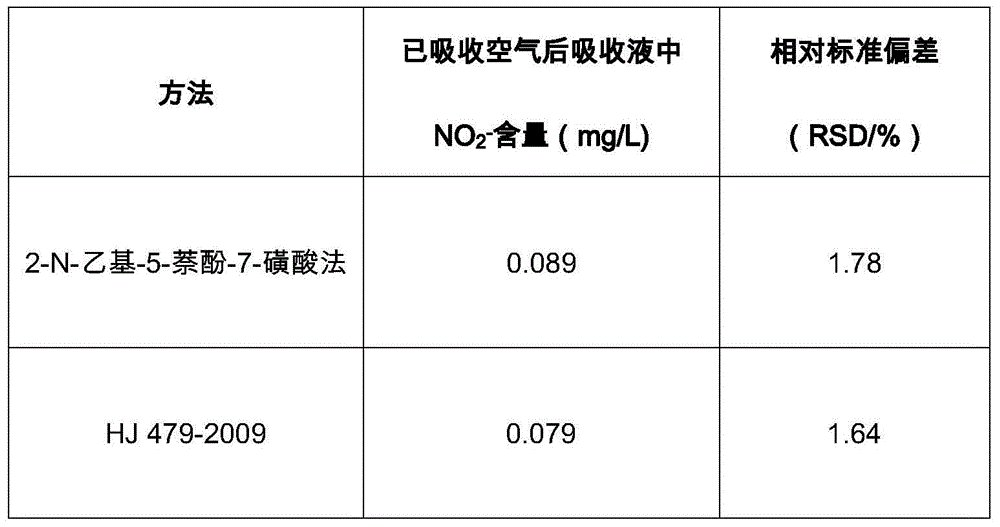

Method for determining content of oxynitride in air

InactiveCN104458619ADamage minimizationSolve secondary pollutionColor/spectral properties measurementsNitrogen oxideNitrite concentration

The invention relates to a method for determining the content of oxynitride in air. The method comprises the following steps: continuously enabling air collected in atmosphere with a predetermined flow and at a preset time to pass through a first absorption tube, an oxidization bottle and a second adsorption tube which are connected in series to absorb oxynitride in reaction air; putting an absorption liquid which is reacted with air in absorption reaction in the first and second adsorption tubes into a reaction bottle filled with a diazo reaction liquid for diazo reaction; putting a diazo reaction liquid which is reacted in diazo reaction in the reaction bottle filled with the diazo reaction liquid into a reaction bottle of a coupled reaction liquid for azo reaction; and by taking a blank liquid of a reagent as a reference liquid, determining the absorbancy of the diazo reaction liquid after azo reaction and calculating concentration of oxynitride in air based on a standard work curve, wherein the vertical coordinate and horizontal ordinate of the standard work curve are respectively absorbancy and nitrite concentration. The determining method is convenient and efficient to operate, relatively high in sensitivity, accurate in result and suitable for popularization.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

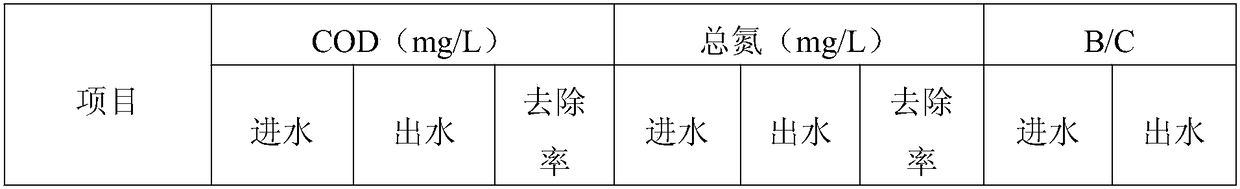

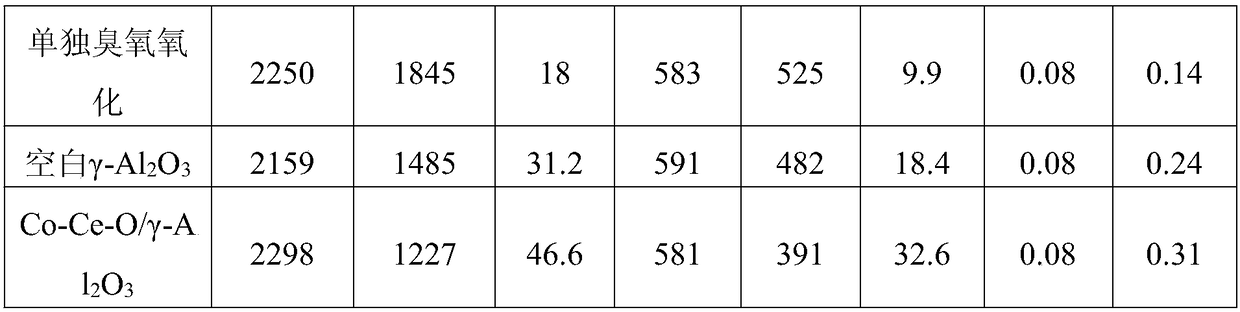

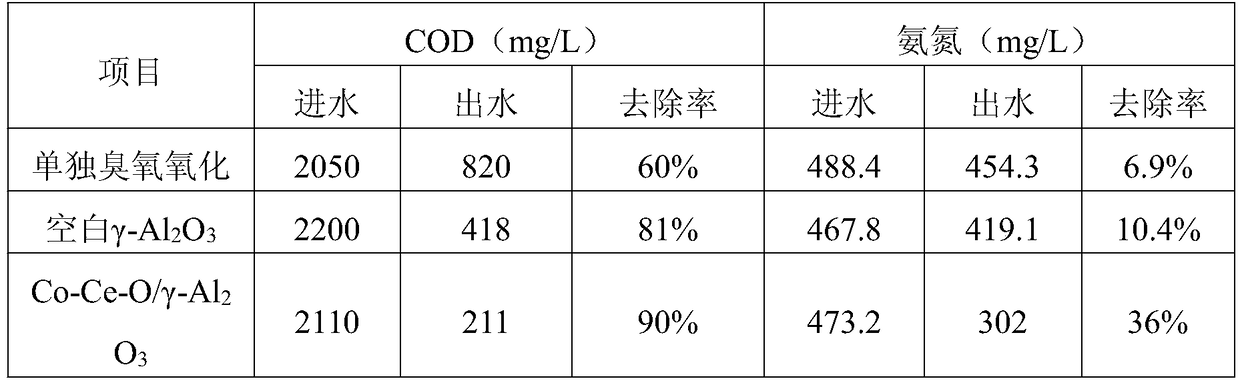

Preparation method of ozone oxidation catalyst for removing organic matters and total nitrogen in water

InactiveCN108970620ALow toxicityReduce nitrogen contentWater contaminantsNature of treatment waterTotal nitrogenBULK ACTIVE INGREDIENT

The invention belongs to the field of environment sewage treatment, and particularly relates to a preparation method of an ozone oxidation catalyst for removing organic matters and total nitrogen in water. Mesoporous alumina is used as a carrier; metallic oxides are doped and loaded onto the surface of the carrier of alumina and an inside pore passage structure; a prepared catalytic material is porous; the specific surface area is large; the adsorption performance is high; certain mechanical strength and physicochemical stability are realized; a novel ozone oxidation catalyst is obtained; ozone molecules are adsorbed at the pore passage at the catalyst surface and are in full contact with active ingredients and contaminants; the utilization efficiency of ozone molecules is greatly improved; the ozone reaction speed is improved; the organic matters and total nitrogen in industrial wastewater can be effectively removed.

Owner:大连海川博创环保科技有限公司

Aerated concrete block produced by iron ore tailings and preparation method thereof

InactiveCN102659361AEfficient use ofEconomic useSolid waste managementCeramic shaping apparatusPortland cementGypsum

The invention relates to the technical field of iron ore tailings treatment, in particular to an aerated concrete block produced by iron ore tailings and a preparation method thereof. The aerated concrete block produced by iron ore tailings is characterized in that the aerated concrete block is prepared by activated iron ore tailings, lime, ordinary Portland cement, gypsum, aluminum powder and water; the weight percentage of the raw materials is as follows: 60% to 65% of the activated iron ore tailings, 17% of the lime, 15% to 20% of the ordinary Portland cement and 13% of the gypsum; the sum of the weight percents of the activated iron ore tailings, the lime, the ordinary Portland cement and the gypsum is 100%; the addition quantity of the aluminum powder is 0.08% of the total weight of the activated iron ore tailings, the lime, the ordinary Portland cement and the gypsum; and the ratio of water and materials is 0.6-0.65. The aerated concrete block produced by iron ore tailings and the preparation method thereof solve the problems of large quantity and high cost of building material cement by using iron ore tailings as main raw materials and secondary pollution caused by recycling of iron core concentrate currently.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

Semidry-process sintering desulphurization slag autoclaved building block and production method thereof

InactiveCN102674799ASolve the problem of land occupationSolve secondary pollutionCeramic shaping apparatusBrickSlag

The invention relates to a semidry-process sintering desulphurization slag autoclaved building block and a production method thereof. The building block is made of the following components in percent by weight in a combined autoclaving way: 5-30 percent of semidry-process sintering desulphurization ash, 30-60 percent of steel slag, 25-30 of superfine slag powder and 1-10 percent of pebble. The production method comprises the steps of vibrating and molding the components according to the percent by weight and autoclaving after molding to obtain the semidry-process sintering desulphurization slag autoclaved building block. The semidry-process sintering desulphurization slag autoclaved building block and the production method thereof have the advantages that the desulphurization ash, waste steel slag and slag of iron and steel enterprises are fully utilized, the wastes are turned into valuable things, the materials such as lime, carbide slag, binder, early strength agent and cement are not added, the energy is saved, the mixing quantity of the waste slag is high, the strength of the produced bricks are higher, the production cost is low, the product quality is high and all technical indexes satisfy the national standard on building bricks; and the treatment and disposal efficiency of the waste slag of the iron and steel enterprises is improved, the development level of secondary resources is improved, the quantity of the used cement in the building material industry can be reduced and the economic and environmental values are higher.

Owner:武钢集团有限公司

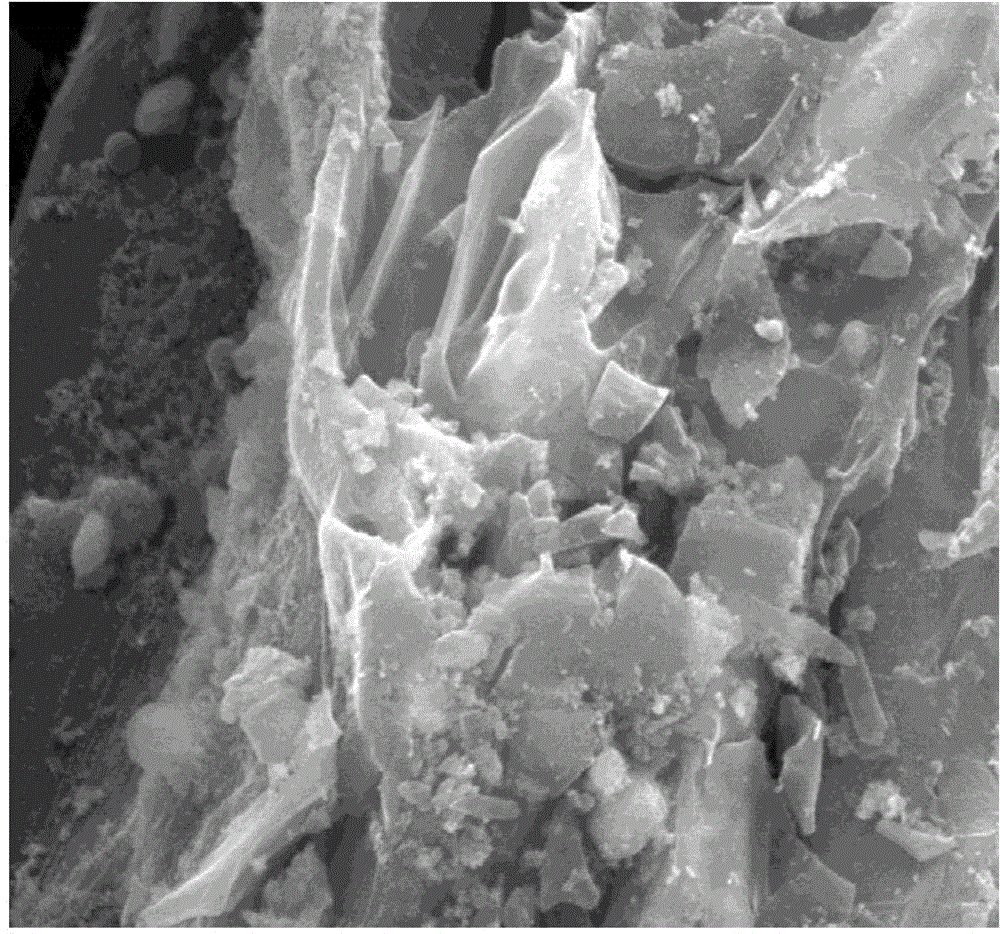

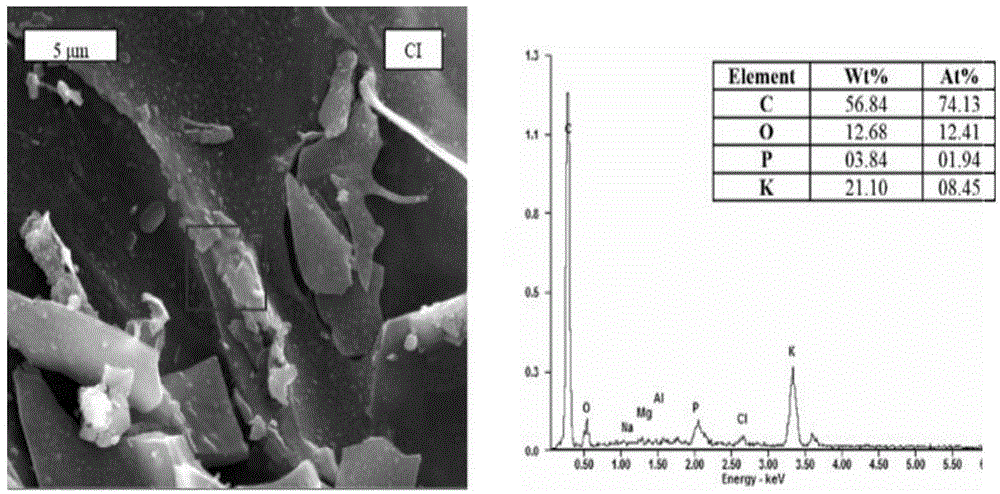

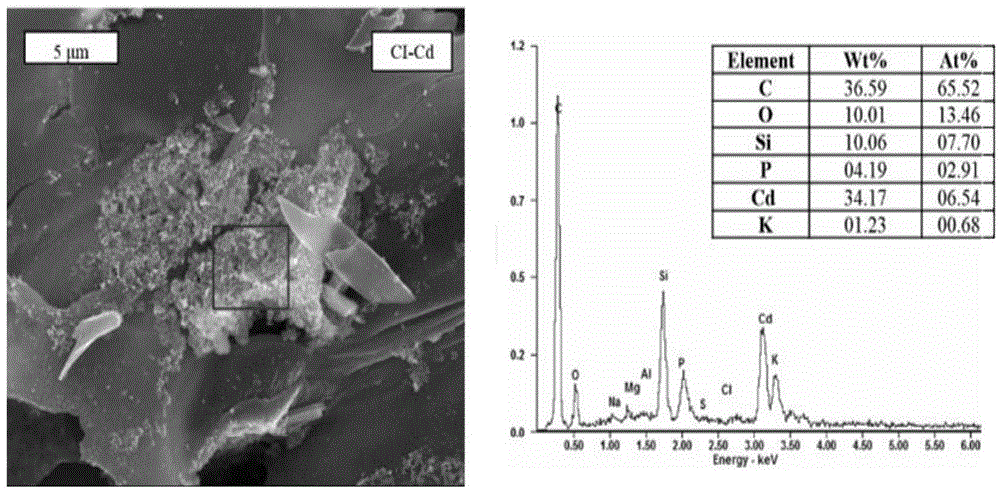

Preparation method of biological activated carbon capable of safely adsorbing cadmium in water

ActiveCN104549154AHigh preparation requirementsImprove removal efficiencyOther chemical processesWater/sewage treatment by sorptionCarbonizationCadmium Cation

The invention discloses a preparation method of biological activated carbon capable of safely adsorbing cadmium in water. The preparation method of the biological activated carbon capable of safely adsorbing cadmium in the water comprises the following steps: 1) removing impurities from harvested napiergrass, carrying out air drying, and then sequentially smashing and drying; 2) putting smashed and dried napiergrass into a carbonization furnace, heating to 480-520 DEG C at a rate of 4-6 DEG C / min, and carrying out oxygen-free carbonization reaction for 1.8-2.2 hours while heat preservation is carried out; and 3) cooling the carbonized napiergrass obtained in the step 2) to room temperature, smashing, and sieving, so that the biological activated carbon capable of safely adsorbing cadmium in the water is obtained. The preparation method of the biological activated carbon capable of safely adsorbing cadmium in the water has the advantages that the three problems that the adsorption efficiency is low, secondary pollution can be easily caused and cost is high when the existing adsorption technology is used for treating heavy metal wastewater are solved; meanwhile, carbon in plant waste is stably stored, carbon dioxide release is reduced, and obvious ecological benefit is realized.

Owner:ZHEJIANG UNIV

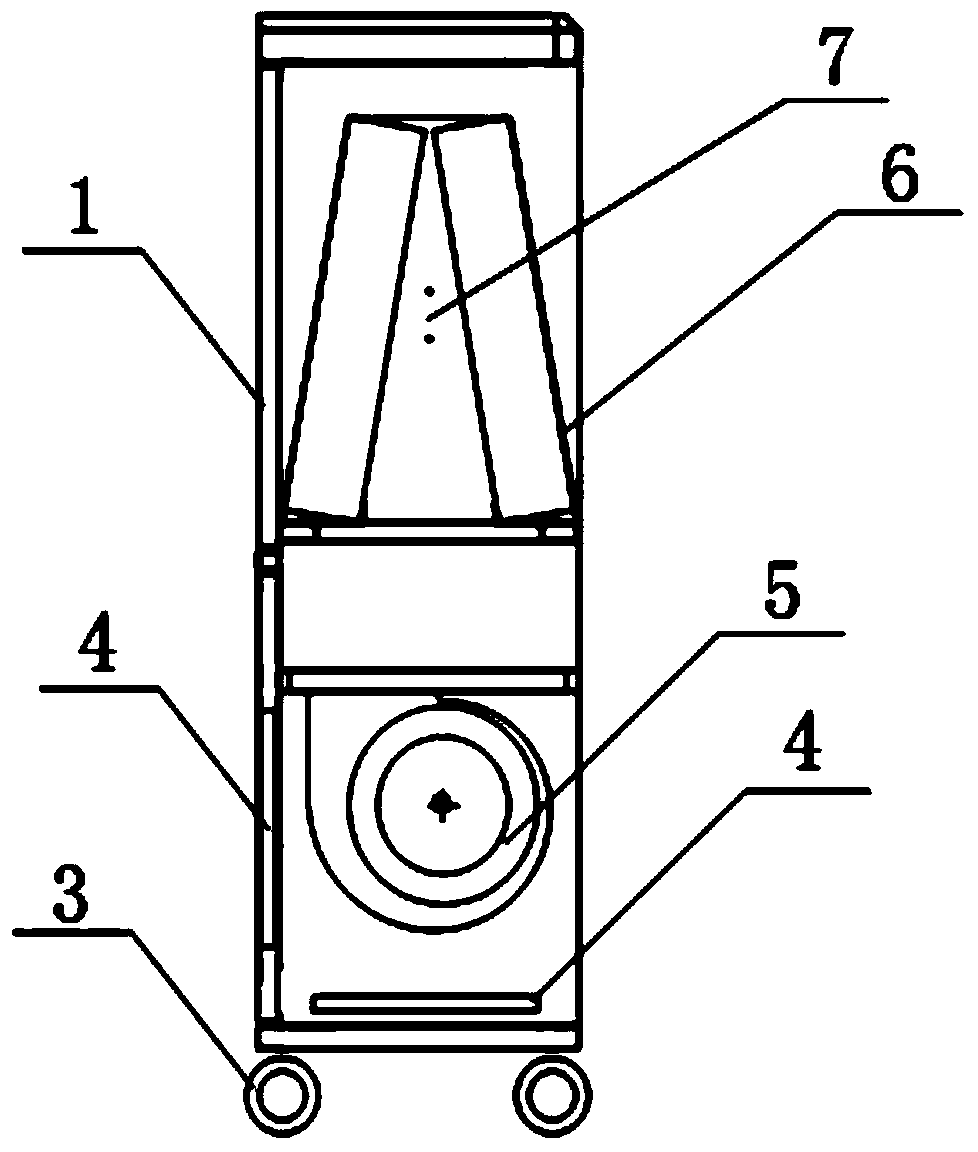

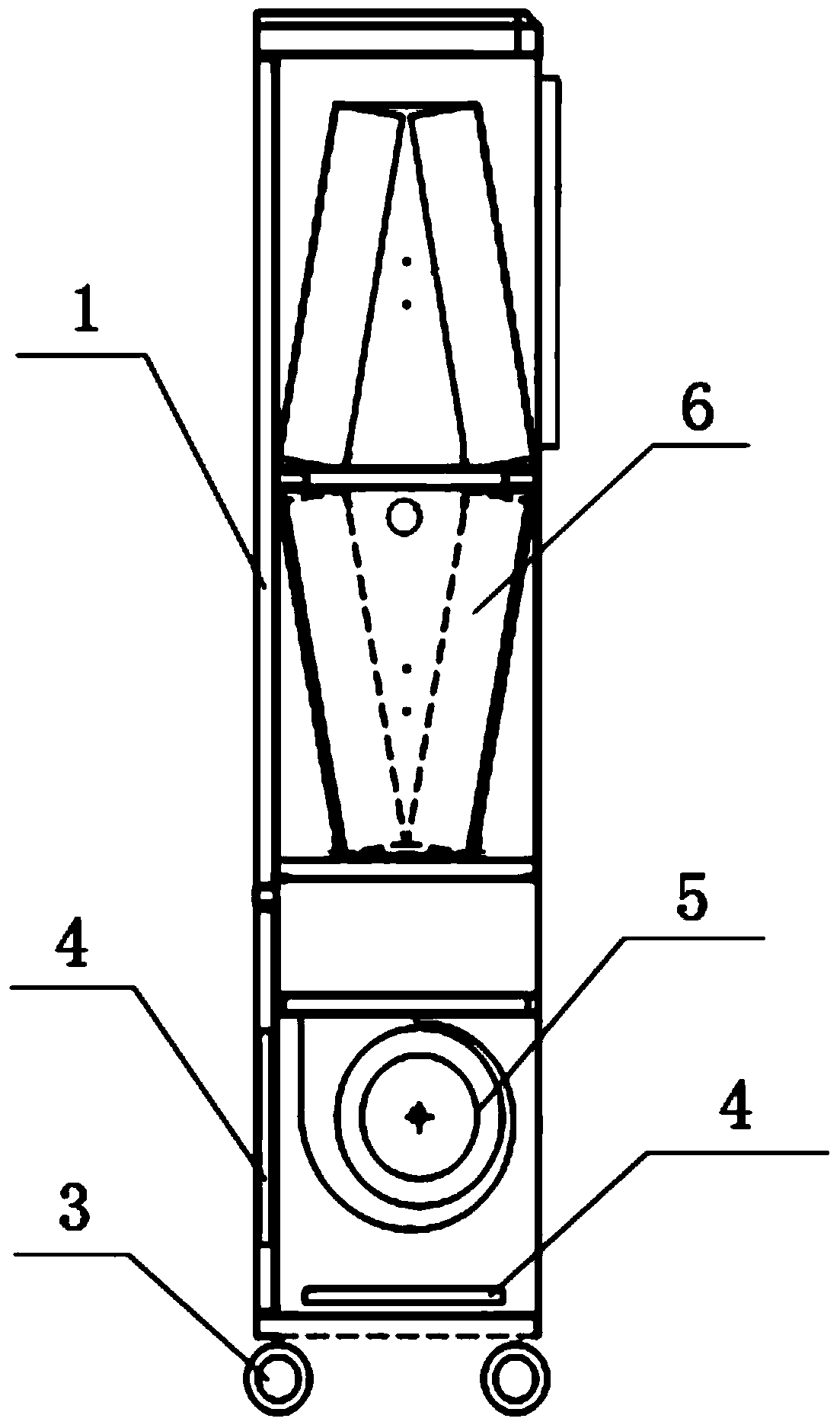

Large-area horizontal air supply type air purifier

InactiveCN103912921AReduce noiseInhibition of reproductionLighting and heating apparatusDispersed particle separationOrganic compoundCentrifugal fan

The invention relates to the technical field of purifying equipment, in particular to a large-area horizontal air supply type air purifier. The large-area horizontal air supply type air purifier comprises a shell, a prefilter, a double-output-shaft double-wheel four-air-inlet low-noise centrifugal fan, a highlight ionizer, a medium adsorption layer, a catalysis filtering layer, an ozone filtering layer, a low-resistance high-efficiency filter and a light reflection device. The shell is internally provided with an upper cavity and a lower cavity, the prefilter is arranged on one side, close to an air inlet, in the lower cavity, the double-output-shaft double-wheel four-air-inlet low-noise centrifugal fan is arranged in the lower cavity, and a cavity type purifying module is arranged in the upper cavity of the shell. The highlight ionizer is arranged in the middle of the cavity type purifying module which comprises the medium adsorption layer, the catalysis filtering layer, the ozone filtering layer, the low-resistance high-efficiency filter and the light reflection device. The large-area horizontal air supply type air purifier has the advantage that by the aid of the cavity type purifying module, the highlight ionizer, the low-resistance high-efficiency filter and the like, harmful gases such as PM2.5 (particulate matter 2.5), formaldehyde, TVOC (total volatile organic compound) and the like in the air can be cleared efficiently.

Owner:上海龙禹环保科技有限公司

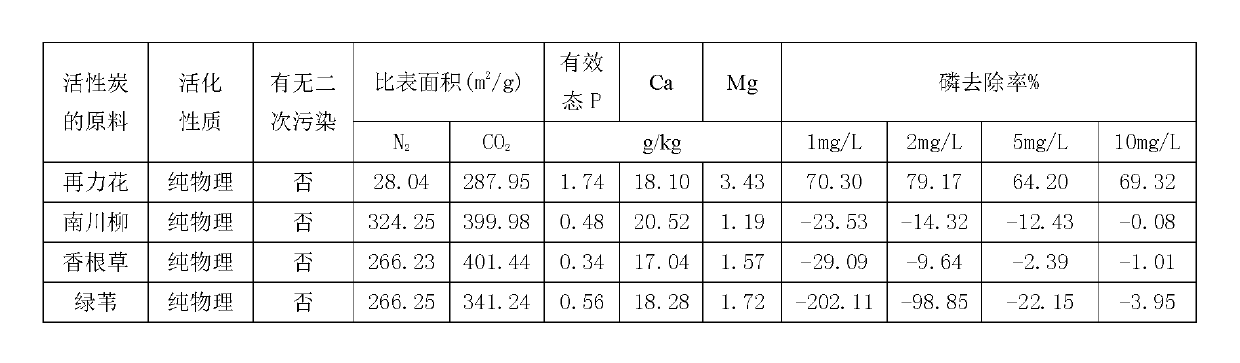

Efficient and safe preparation method for active carbon material for adsorbing phosphorus in water body

ActiveCN102992319ASolve processing problemsSolve secondary pollutionOther chemical processesCarbon compoundsCarbonizationNitrogen gas

The invention relates to preparation for an active carbon material, aiming at providing an efficient and safe preparation method for an active carbon material for adsorbing phosphorus in a water body. The method comprises the following steps of: naturally air-drying thalia dealbata for 7 days, chopping, grinding into a powder, sieving, and then placing in an oven and drying for 3 hours; placing the dried powder in a carbonization furnace, performing high-temperature carbonization while charging nitrogen, heating to 500 DEG C, insulating heat for 2 hours, and then cooling to a room temperature; and performing high-temperature activation while charging carbon dioxide gas in the carbonization furnace, heating to 600 DEG C, insulating heat for 2 hours, and then cooling to a room temperature to obtain the product. Via the preparation method disclosed by the invention, the problem of plant waste treatment in water body purification is solved, the possibility that plant branches and leaves contaminate the water body after being withered is prevented, and waste is turned into wealth; and the prepared biomass active carbon is used for further purifying the water body, thus solving the problem of the possibility of secondary pollution in the water body which is purified by active carbon. The preparation method has the advantages of being high in treatment efficiency, economic and practical, green and environment-friendly, cyclic in purification and the like, as well as achieves the expected effect of efficient decontamination.

Owner:ZHEJIANG UNIV

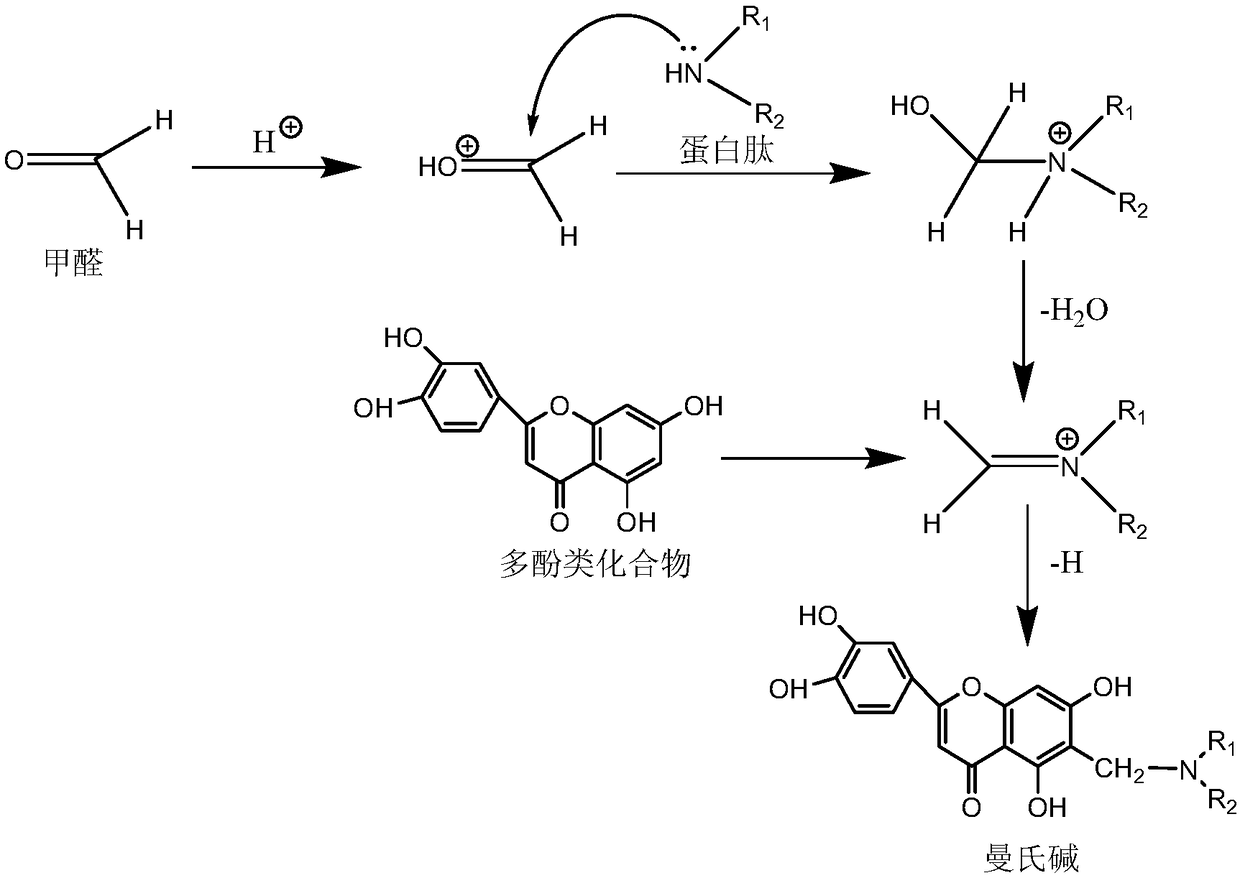

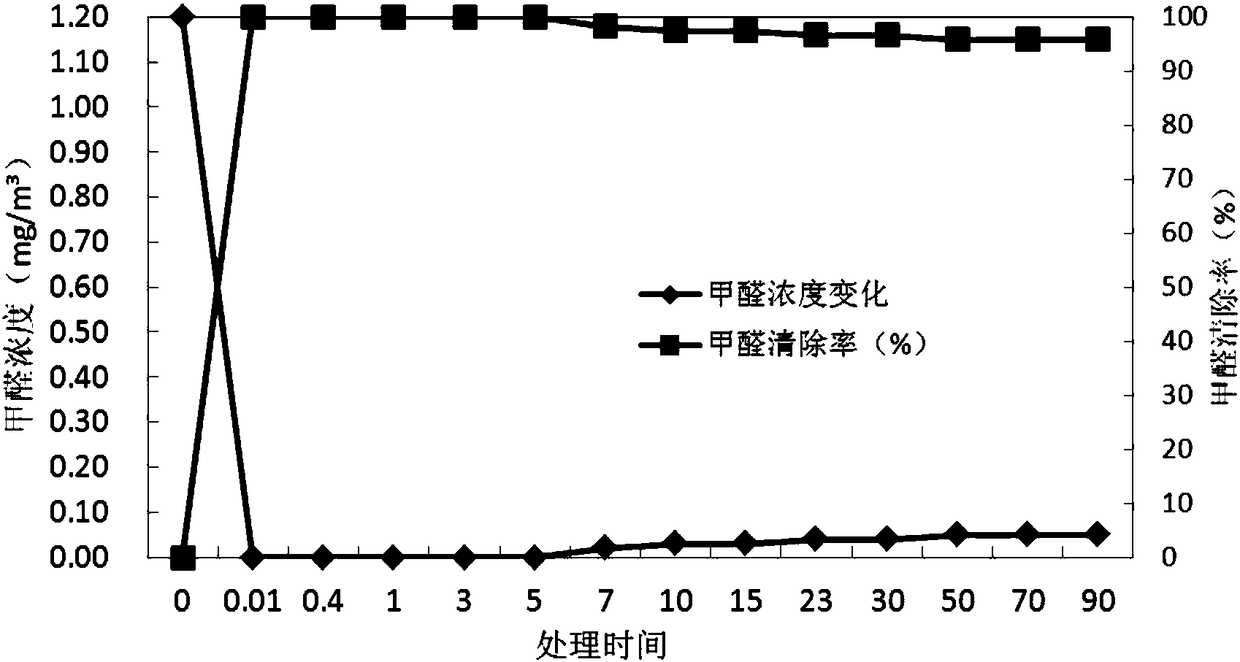

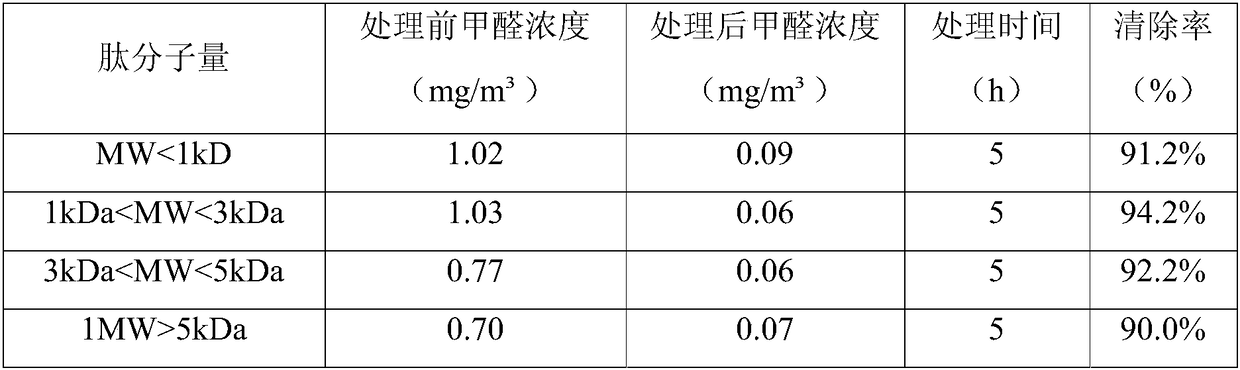

Collagen polypeptide rich in glycine and formaldehyde scavenger prepared therefrom

InactiveCN108130355AAchieve high valueHigh viscosityConnective tissue peptidesDispersed particle separationGlycineFormaldehyde product

The invention belongs to the technical field of functional polypeptides and discloses a collagen polypeptide rich in glycine and a formaldehyde scavenger prepared therefrom. The collagen polypeptide is prepared from the following steps: extracting collagens by means of a hot water extraction method; and then preparing the collagen polypeptide rich in glycine by enzymolysis of the collagens by means of protease by taking Tilapia mossambica waste as a raw material. By being combined with plant polyphenol compounds, the quick, long-acting, safe and edible formaldehyde scavenger is prepared. The formaldehyde removal rate of the formaldehyde scavenger can reach 95% or above within 10 min, so that the problem that a single amino acid is not ideal in removing formaldehyde is solved. A colloid film which is 2-10 microns can be formed on the surface of an object such as furniture if being dried to inhibit further release of formaldehyde. The formaldehyde removal rate can be kept at 95% or abovewithin three months, an effect of removing formaldehyde for a long time is achieved, and the problem that existing formaldehyde removal products are rebound in effect and short in effective period issolved.

Owner:SOUTH CHINA UNIV OF TECH

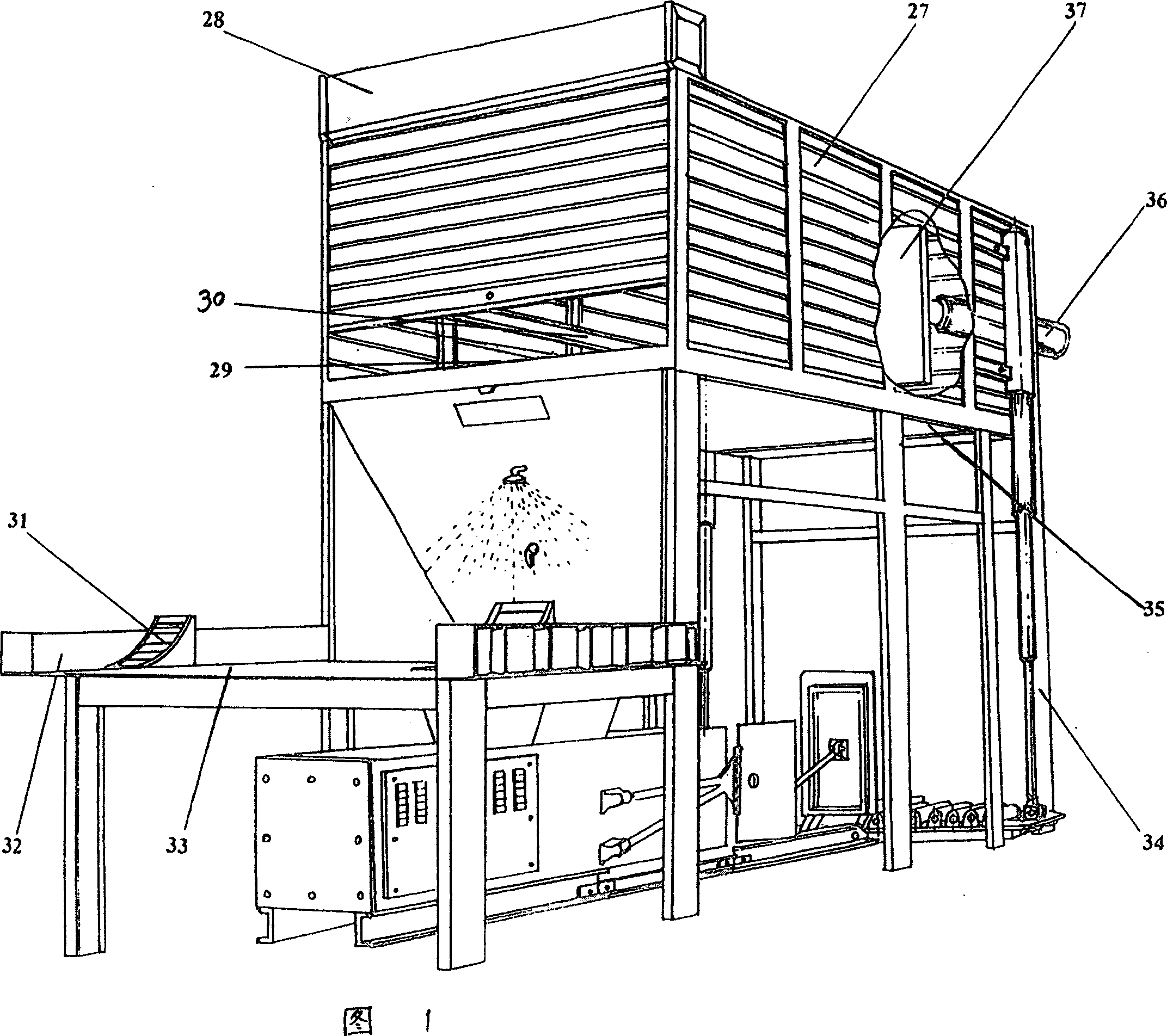

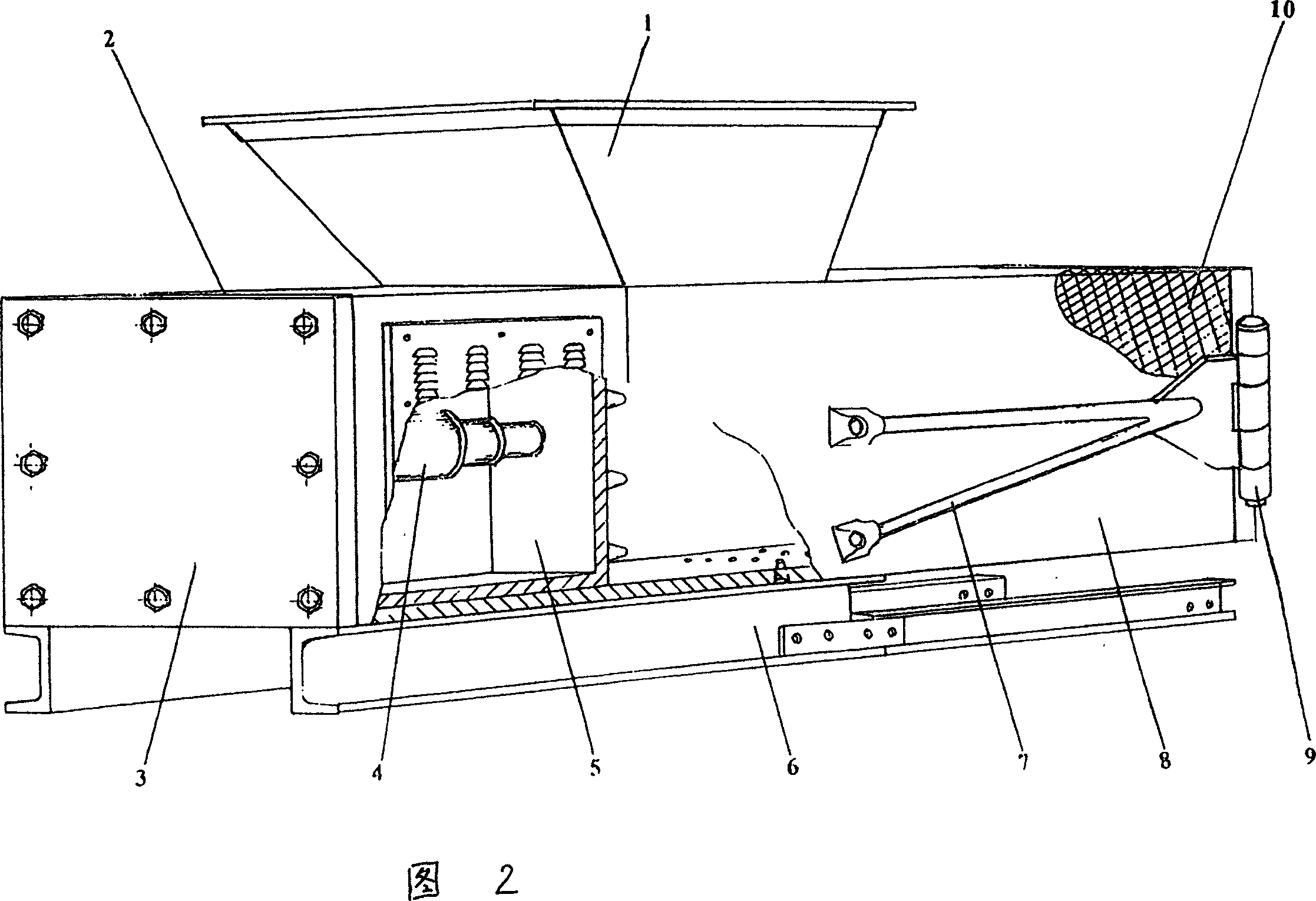

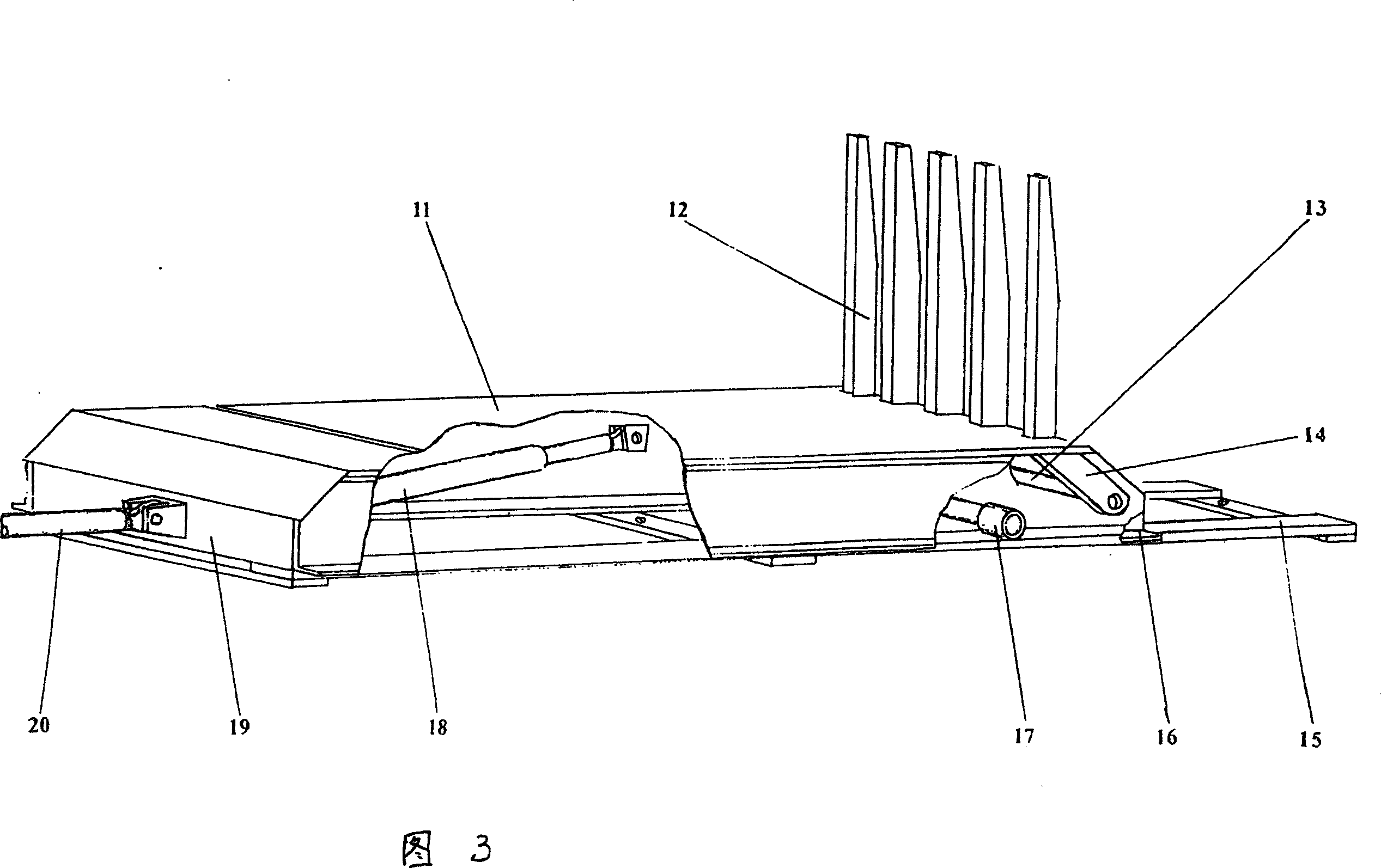

Closed type apparatus for compressing, stalling and transporting garbage

InactiveCN1958408AIncrease the compression ratioIncrease capacityRefuse transferringStorage devicesMode of transportLitter

An enclosed garbage compressing and transporting apparatus is composed of garbage compressing and baling unit, garbage bale moving and turning-over unit, garbage bales queuing and lifting unit, and a top case for storing garbage bales and loading them on truck.

Owner:刘强 +1

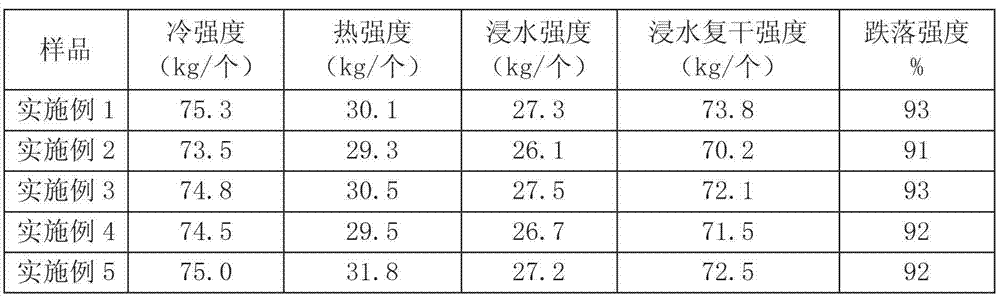

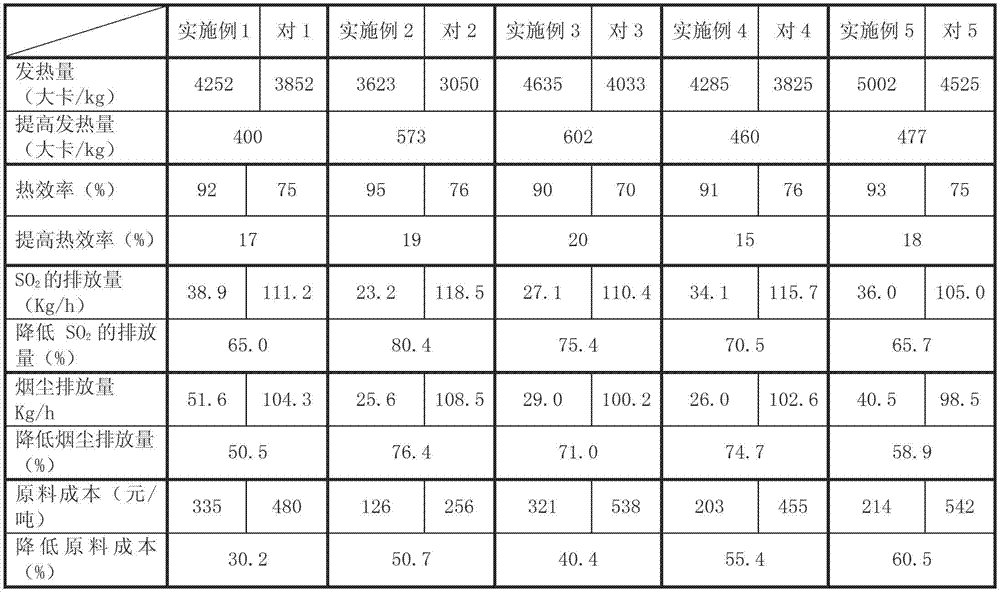

Filter mud containing clean coal and preparation method thereof

The invention discloses filter mud containing clean coal and a preparation method thereof. The filter mud containing clean coal comprises braize, filter mud, a combustion synergist, a composite binder, a sulphur-fixing agent and a deodorant. The filter mud is obtained by a cleaning process in a sulfurous method in the sugar industry. The combustion synergist is potash nitrate and sodium chloride. The composite binder is pregelatinized starch, clay and polyvinyl alcohol. The sulphur-fixing agent is calcium hydroxide and sodium carbonate. The deodorant is ascorbic acid and ferrous sulfate. According to the invention, filter mud of a sugar plant is adequately utilized, so that secondary pollution to the environment is avoided and waste is turned to wealth. The clean coal prepared has the advantages of inflammability, higher thermal efficiency, small discharge of harmful gas, high cold and hot strengths, good waterproof performance, low production cost, environmental-friendliness and the like.

Owner:广西桂晟新能源科技有限公司

Preparation method for Canna biological carbon capable of simultaneously adsorbing ammonia nitrogen and cadmium

InactiveCN104923153AHigh preparation requirementsImprove removal efficiencyOther chemical processesWater contaminantsCarbonizationRoom temperature

The invention discloses a preparation method for Canna biological carbon capable of simultaneously adsorbing ammonia nitrogen and cadmium. The method comprises the following steps: step 1, preparation of raw materials: a step of removing impurities of harvested Canna and then carrying out air-drying, and successively carrying out crushing and drying; step 2, oxygen isolation carbonization: a step of placing the crushed and dried Canna in a carbonization furnace, then carrying out oxygen isolation carbonization reaction by heating the crushed and dried Canna to 480 to 520 DEG C with a heating rate of 4 to 6 DEG C / min, and carrying out heat-preserving reaction for 1.8 to 2.2 hours; and step 3, subjecting the carbonized Canna obtained in the step 2 to cooling to room temperature, and carrying out crushing and sieving so as to obtain the Canna biological carbon. The preparation method for the Canna biological carbon provided by the invention solves the problems of capability of only aiming at single pollutant, low adsorption efficiency, easiness to cause secondary pollution, high cost and the like in the prior art of adsorption; meanwhile, the wastes of waterbody remediation plants are reasonably utilized; secondary pollution is prevented; moreover, carbon in plants is stably sealed; carbon dioxide emission is reduced; and significant ecological benefits are obtained.

Owner:ZHEJIANG UNIV

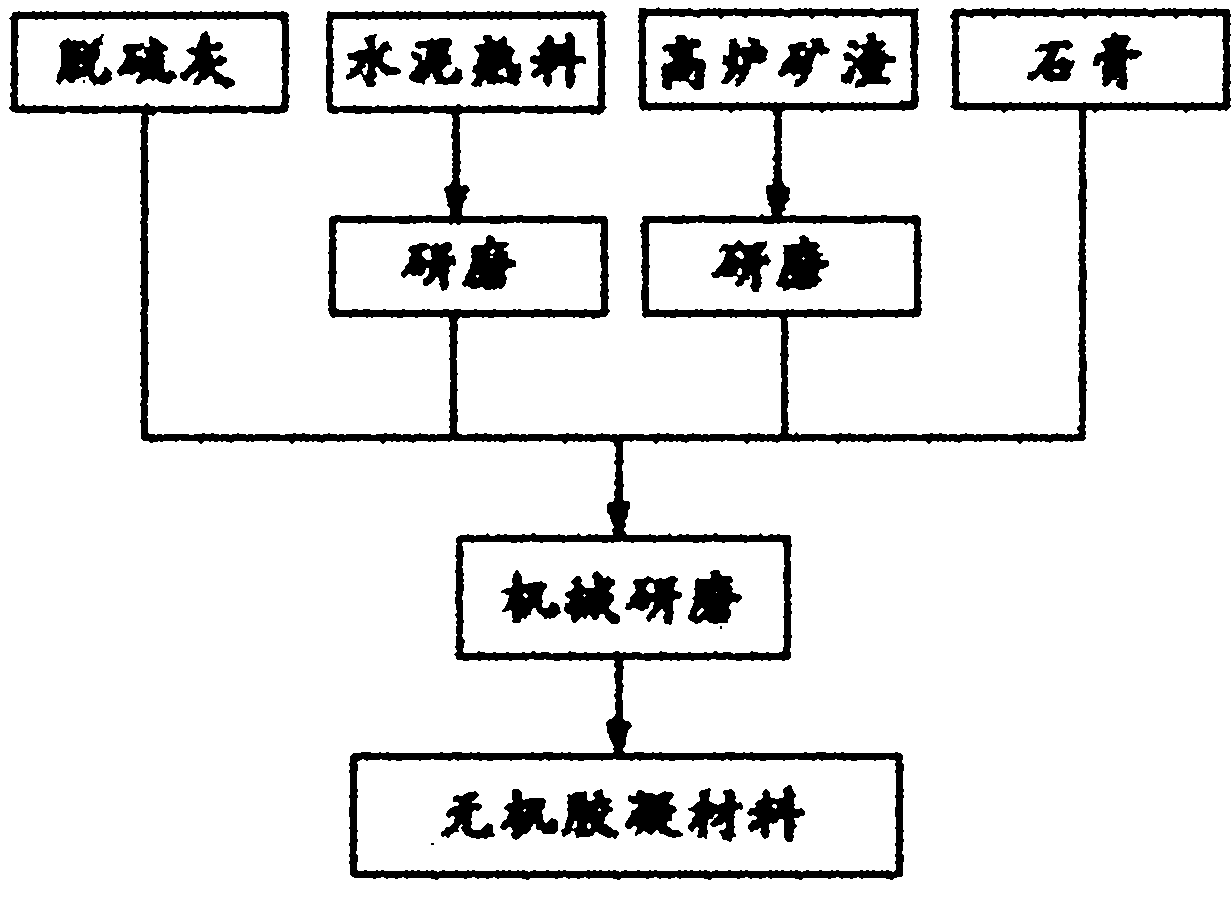

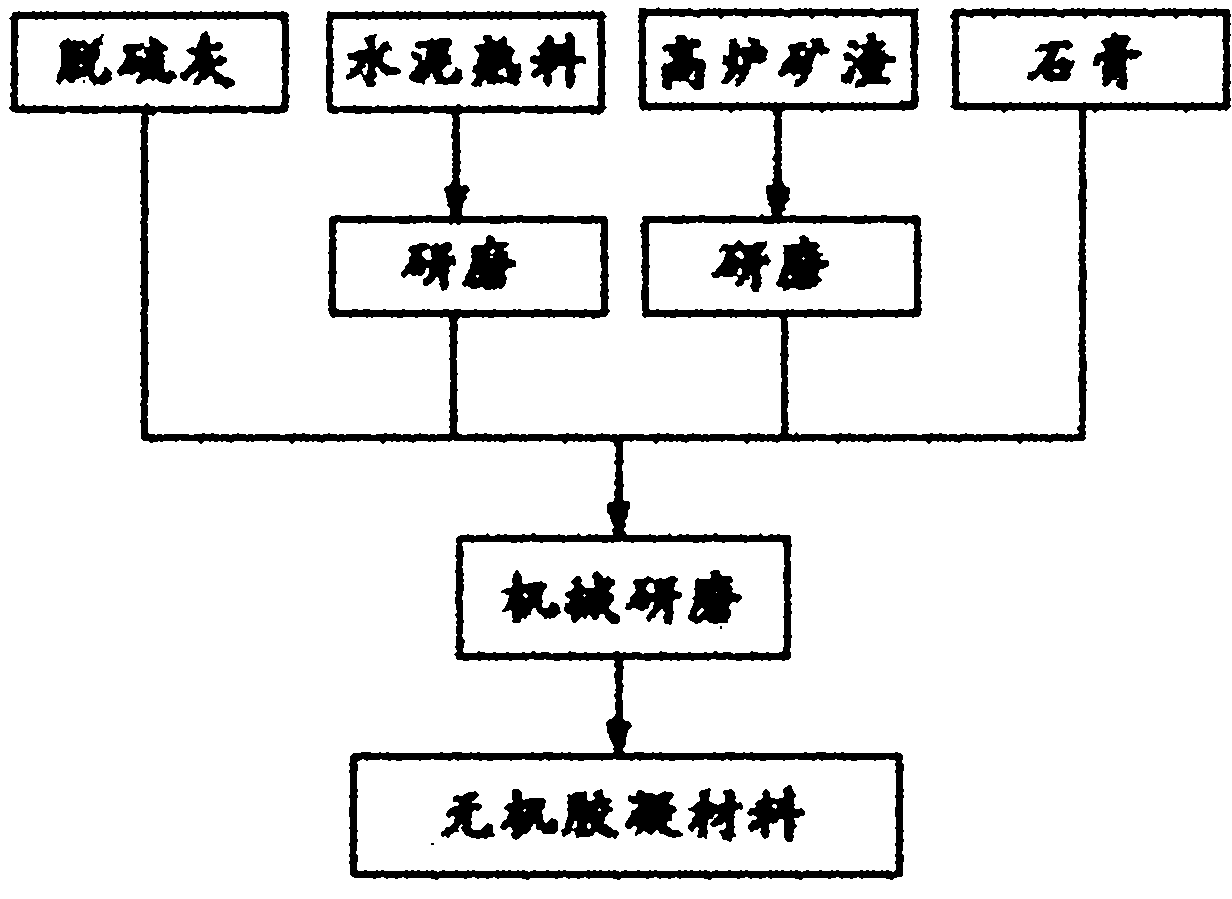

Flue gas desulfurization byproduct-based inorganic gelled material and preparation method thereof

InactiveCN101973719AIncrease profitSolve secondary pollutionClinker productionNatural resourceHigh energy

The invention discloses a flue gas desulfurization byproduct-based inorganic gelled material and a preparation method thereof. In the material, desulfurization ash generated in flue gas desulfurization treatment of a coal fired power plant is used as a main material; and slag, gypsum and cement clinker are mixed and ground with the main material to form the inorganic gelled material. The inorganic gelled material comprises the following components in percentage by weight: 30 to 40 percent of desulfurization ash, 45 to 55 percent of slag, 3 to 5 percent of gypsum and 8 to 12 percent of cement clinker. Because the desulfurization ash is used as a raw material for preparing the inorganic gelled material, no or little natural resource is used, and secondary pollution of the desulfurization ash is reduced. The preparation method comprises the steps of raw material selection, pre-grinding, mixing and grinding. Because the mechanical means is adopted, the raw materials do not need high-temperature calcination treatment, the manufacturing process is very compact, the production cost is extremely low, high energy consumption and high pollution caused by calcination can be avoided, the energy can be greatly saved, and the requirements of energy conservation and emission reduction are met. By detection, various inspection indexes of the inorganic gelled material meet the requirement of 22.5 strength level in GB / T3183-2003 Masonry Cement, and the inorganic gelled material can fully replace the traditional product.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com