Production method of sludge biomass environment-friendly fuel

A production method and biomass technology, which can be applied to biofuels, waste fuels, fuels, etc., can solve the problems of large investment in sludge incineration, unsuitable for large-scale promotion of sludge incineration disposal methods, and high processing costs, so as to solve the energy shortage. , Make up for the sludge treatment cost and the effect of less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

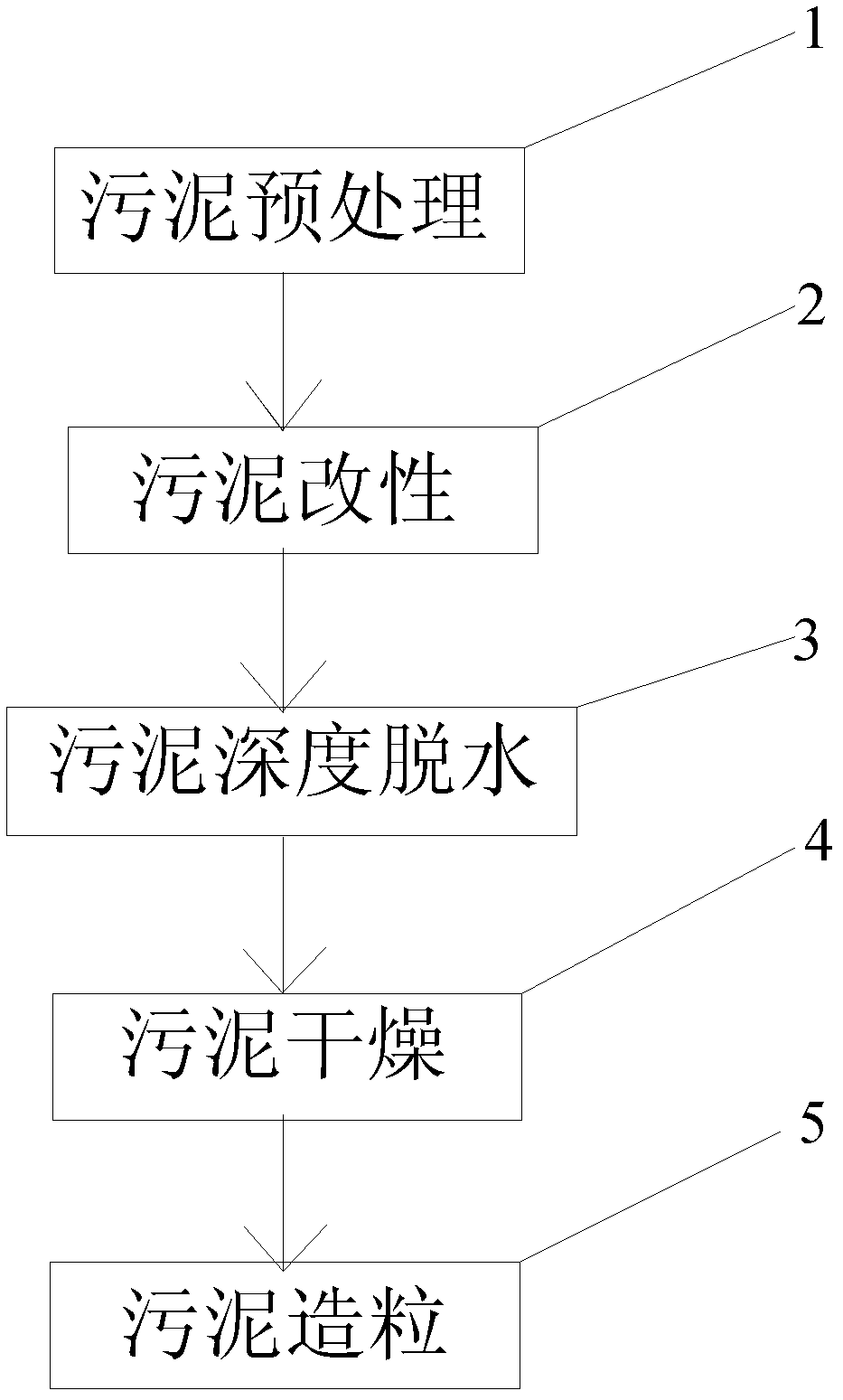

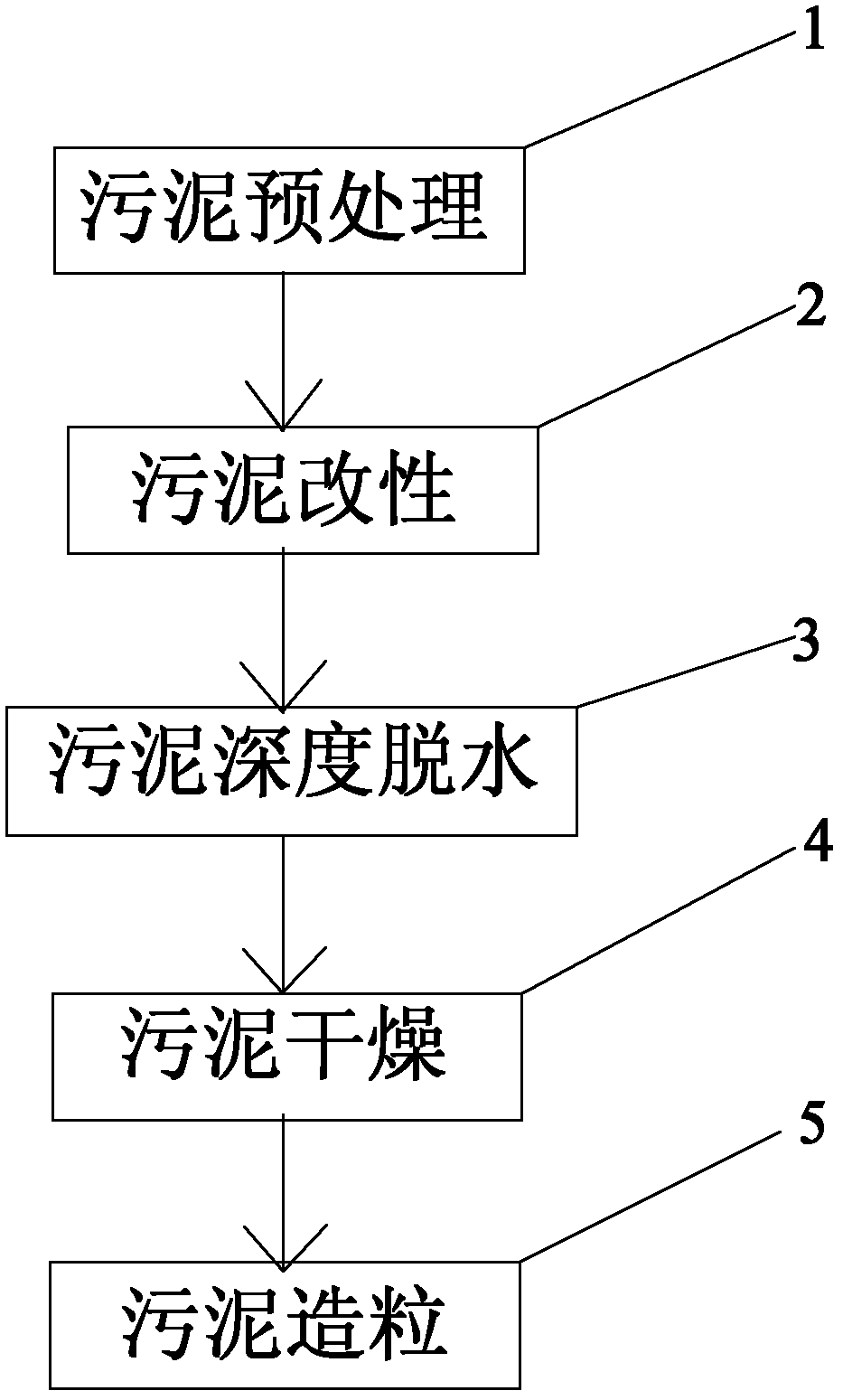

[0029] A method for manufacturing sludge biomass environment-friendly fuel mainly consists of the following steps:

[0030] 1) Sludge pretreatment: Transport the wet sludge with a moisture content of 82% to the pretreatment tank, add water to dilute, mix evenly, add deodorant to remove odor, and then add fungicide to kill pollution microorganisms, pests and pathogens in mud;

[0031] 2) Sludge modification: transport the pretreated sludge to the reaction tank, keep stirring continuously, and add modifiers, sulfur fixers, and heavy metal stabilizers according to the amount, and the time for adding each agent The interval is about 10 minutes. After all the chemicals are added, stir continuously for 1 hour before adding the crushed sawdust. The dosage of sawdust is 40% of the weight of the sludge;

[0032] 3) Deep dehydration of sludge: Use a screw pump to transport the sludge into the filter press for deep dehydration. After deep dehydration, the moisture content of the sludge ...

Embodiment 2

[0036] A method for manufacturing sludge biomass environment-friendly fuel mainly consists of the following steps:

[0037] 1) Sludge pretreatment: Pipeline the sludge with a moisture content of 98% to the pretreatment tank, add deodorant to remove odor, and then add bactericide to kill microorganisms, pests and pathogens in the sludge.

[0038] 2) Sludge modification: transport the pretreated sludge to the reaction tank, keep stirring continuously, and add modifiers, sulfur fixers, and heavy metal stabilizers according to the amount, and the time for adding each agent The interval is about 10 minutes. After all the chemicals are added, stir continuously for 1 hour before adding the crushed shavings, the amount of shavings added is 40% of the weight of the sludge;

[0039] 3) Deep dehydration of sludge: Use a screw pump to transport the sludge into a filter press for deep dehydration. After deep dehydration, the moisture content of the sludge is reduced to below 20%. After t...

Embodiment 3

[0043] A method for manufacturing sludge biomass environment-friendly fuel mainly consists of the following steps:

[0044] 1) Sludge pretreatment: Pipeline the sludge with a moisture content of 93% to the pretreatment tank, add deodorant to remove odor, and then add bactericide to kill microorganisms, pests and pathogens in the sludge.

[0045] 2) Sludge modification: transport the pretreated sludge to the reaction tank, keep stirring continuously, and add modifiers, sulfur fixers, and heavy metal stabilizers according to the amount, and the time for adding each agent The interval is about 10 minutes. After all the chemicals are added, stir continuously for 1 hour before adding the crushed dead branches and leaves. The dosage of dead branches and leaves is 20% of the weight of the sludge;

[0046] 3) Deep dehydration of sludge: Use a screw pump to transport the sludge into a filter press for deep dehydration. After deep dehydration, the moisture content of the sludge is redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com