Patents

Literature

505 results about "Sludge cake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge cake. An accumulation of sludge hardened into a cake strong enough to bear the weight of a man.

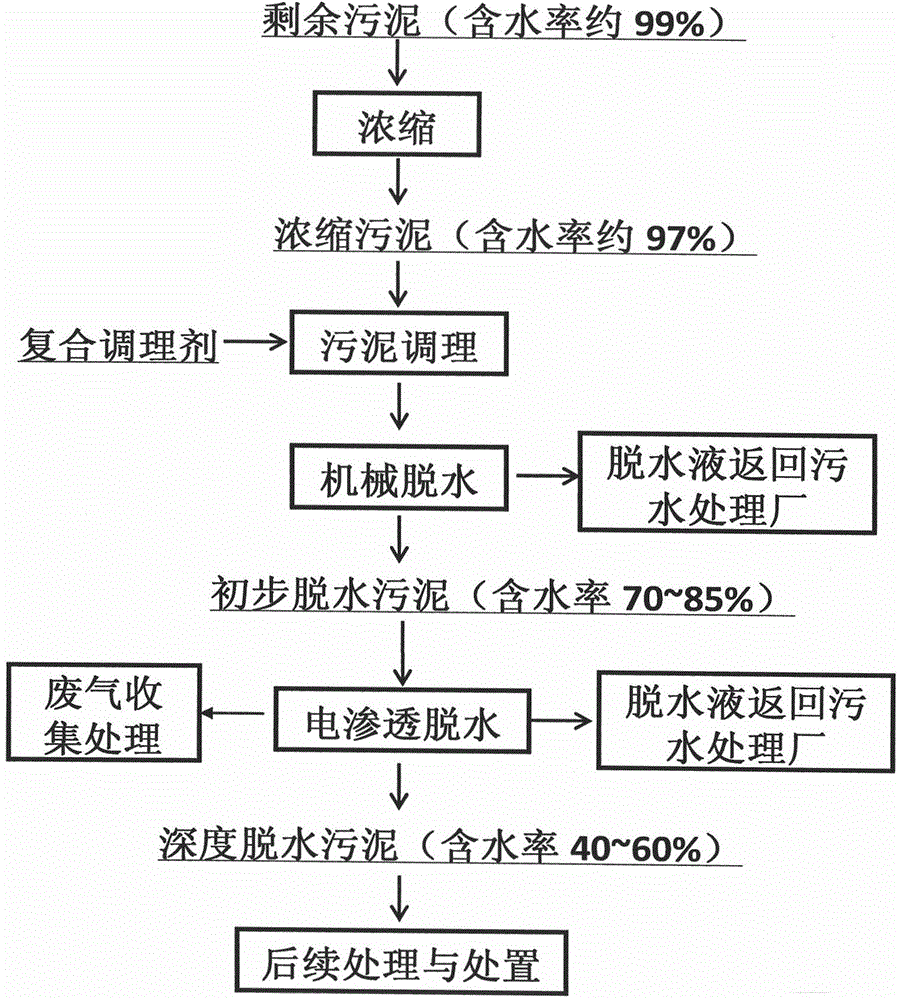

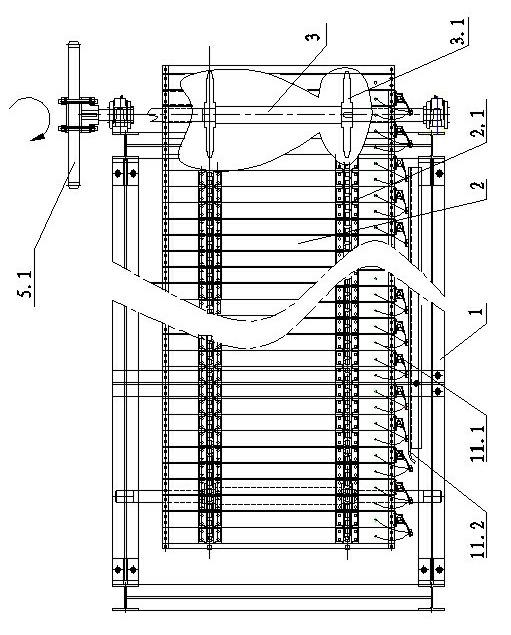

Municipal sludge two-stage deep dehydration method combining chemical regulation strengthening preliminary mechanical dehydration and electroosmosis

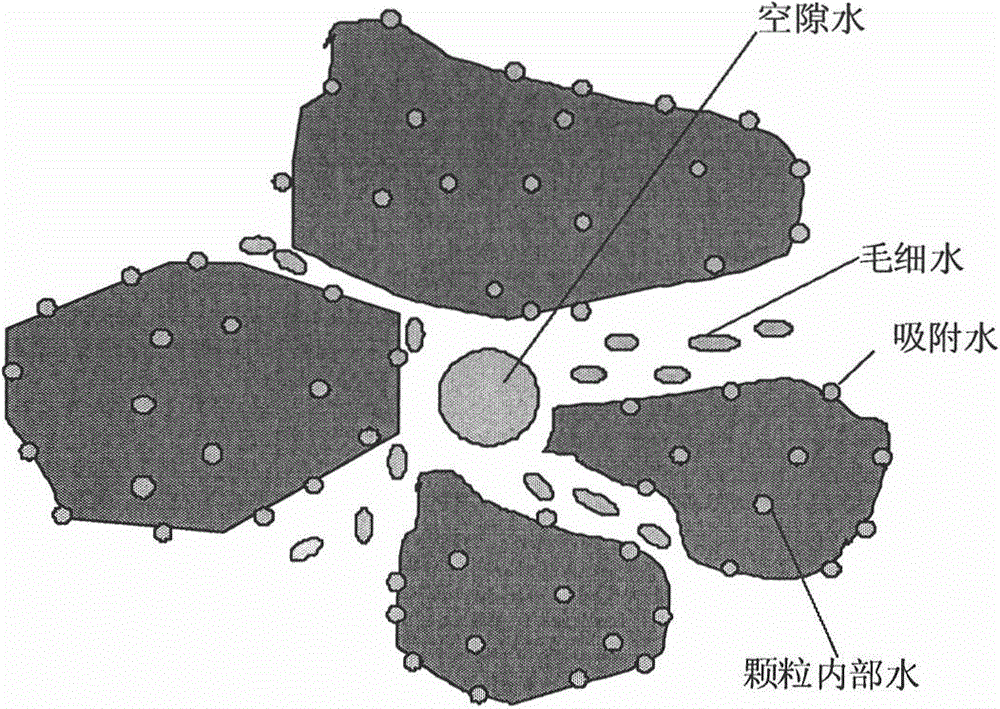

ActiveCN104098250AImprove the efficiency of primary mechanical dehydrationImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningSludge cakeBound water

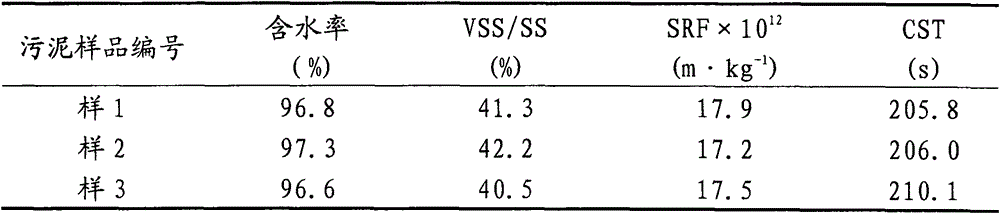

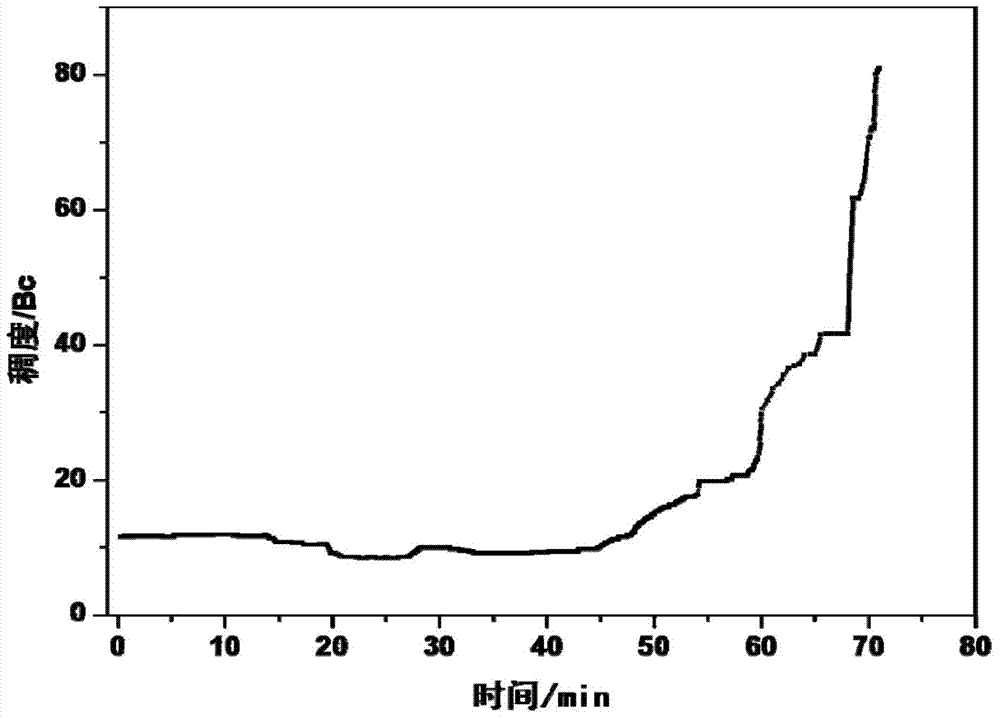

The invention relates to a municipal sludge deep dehydration composite conditioner and a dehydration method, the composite conditioner accounting for 3-30% by dry basis weight of sludge is added for conditioning modification of domestic sewage treatment plant concentrated sludge with the moisture content of about 97% to improve sludge preliminary mechanical dehydration and subsequent electroosmosis dehydration ability; the moisture content of the preliminarily dehydrated conditioned modified sludge is reduced to 70-85%; the preliminarily dehydrated sludge directly enters into electroosmosis dehydration equipment for deep dehydration, the moisture content of the sludge is reduced to 40 to 60%, landfill disposal, thermal conversion, use as building materials and other treatment, dispose and resource utilization can be directly carried out. The method can realize the continuous operation of sludge dehydration, is high in treatment efficiency, can effectively reduce the bound water content of the sludge, is good in dehydration effect, and low in moisture content of deeply dehydrated sludge cake, and is suitable for a newly-constructed sewage treatment plant and design requirements of reconstruction, expansion and contingency plans of sludge dehydration treatment of a sewage treatment plant in the prior art.

Owner:北京亿维德曼科技发展有限公司 +2

Solid-free anti-salt cleaning type well cementation spacer fluid and preparation method thereof

InactiveCN103756653AGood settlement stabilityImprove bonding qualityDrilling compositionSludge cakeEthylenediamine

The invention discloses a solid-free anti-salt cleaning type well cementation spacer fluid and a preparation method thereof. The spacer is prepared from the following components in parts by weight: 100 parts of water, 20-350 parts of soluble weighting agent, 0.1-1.0 part of additive, 0.2-0.5 part of thickening agent, 0.5-3.0 parts of fluid loss agent, 5-10 parts of non-ionic surfactant, 1.5-2.5 parts of anionic surfactant, 0.1-0.3 part of pH adjusting agent and 0.1-0.5 part of defoaming agent, wherein the additive is sodium tripolyphosphate, ethylenediamine tetraacetic acid disodium or ethylenediamine tetraacetic acid sodium. The solid-free anti-salt cleaning type well cementation spacer fluid is free of solid phase, so that virtual thick sludge cake cannot be formed on a well wall, the function of effectively spacing a drilling liquid from cement slurry is achieved, and meanwhile the well cementation is improved. In the preparation process, the substances are added to reaction in different batches, so that the operation method is simple.

Owner:CNPC BOHAI DRILLING ENG

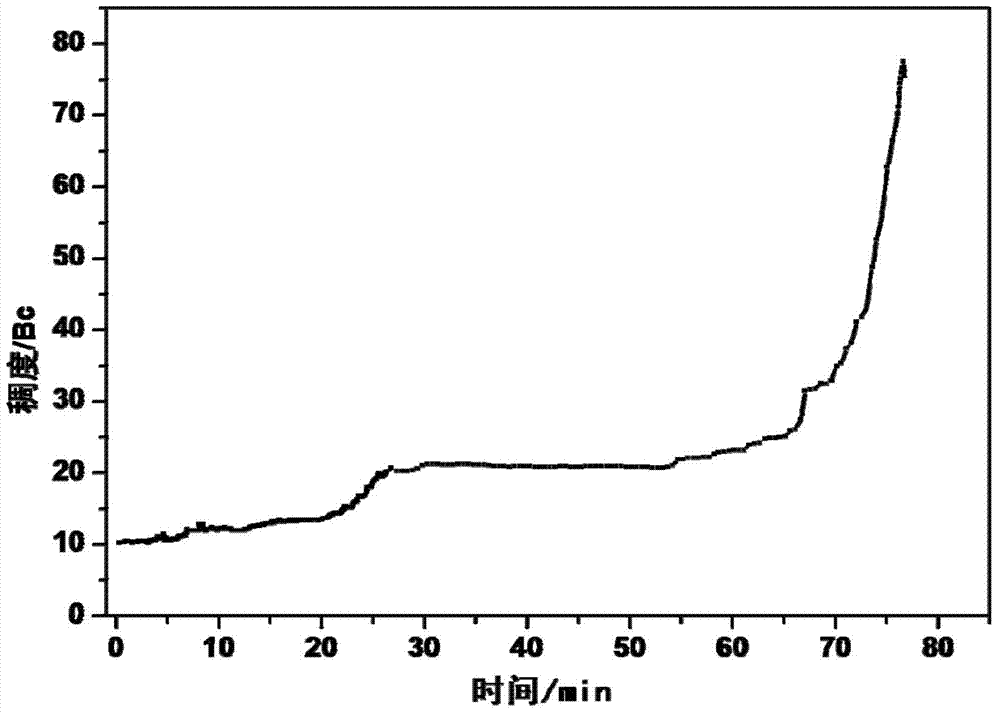

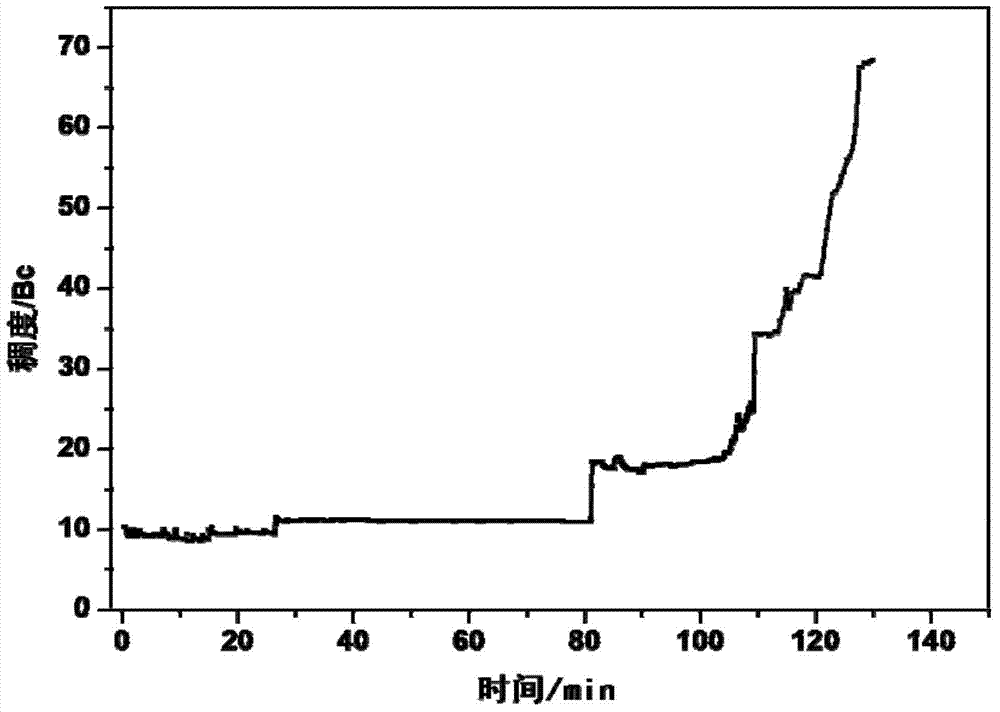

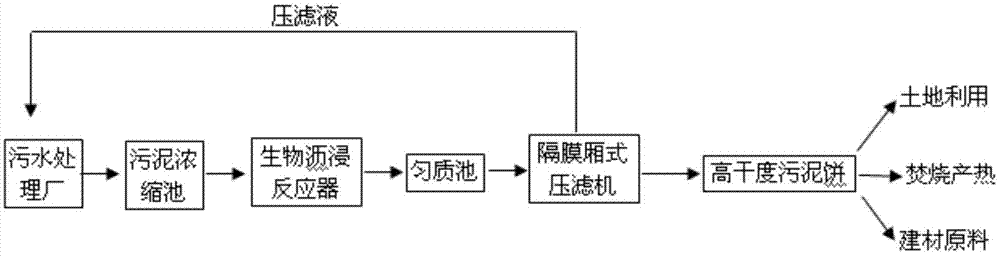

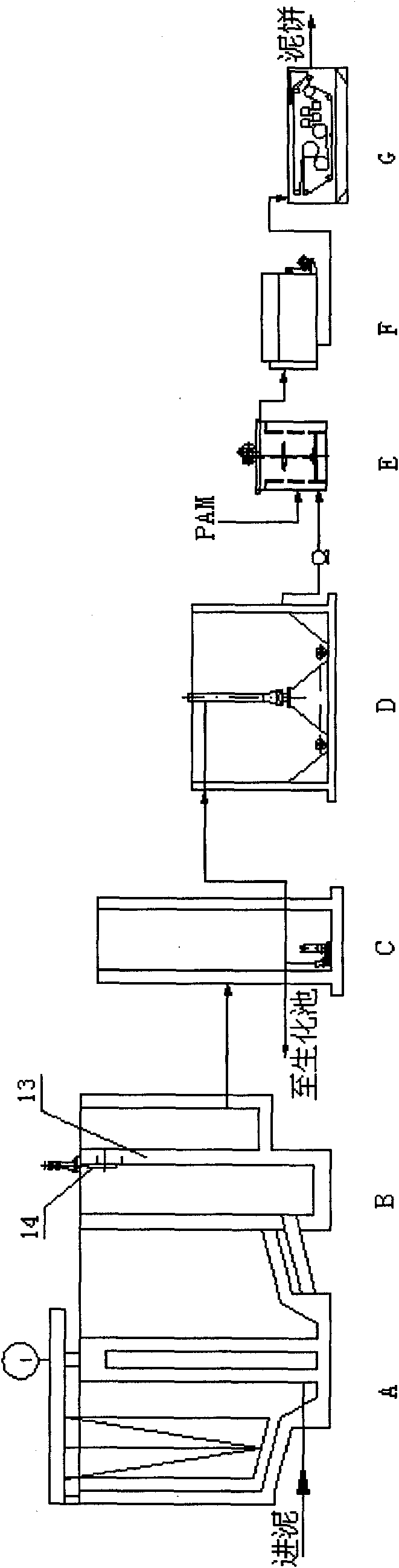

New method for deeply dewatering sludge through bio-leaching process rapid conditioning

ActiveCN103936246ASimple processLow running costSludge treatment by de-watering/drying/thickeningSludge processingSludge cakeResource utilization

The invention discloses a new method for deeply dewatering sludge through bio-leaching process rapid conditioning. The method comprises the steps of firstly performing bio-leaching conditioning on sludge, namely, directly pumping concentrated liquid sludge of a sewage treatment plant into a bio-leaching reactor which contains special composite microbial community, performing treatment for 1.5-2 days, changing bound water in the sludge into free water which can be removed relatively easily by virtue of the microbial substitution effect, biological oxidation effect and biological acidification effect, dissolving out heavy metals from the sludge at the same time, entering an aqueous phase, killing pathogens in the sludge, then collecting the sludge subjected to bio-leaching in a homogeneous pool, directly transporting to a common-pressure diaphragm chamber type filter press by virtue of a pump, and dewatering, wherein the moisture content of dewatered sludge cake is less than 60%, and no flocculant like PAM (polyacrylamide) is added during the preparation process. The method disclosed by the invention is performed under normal temperature and pressure, and has low cost; the dewatered sludge cake is low in moisture content, odorless, and yellowish-brown in color; and the organic matters, calorific values and nutrients of the dewatered sludge can not be reduced, thus facilitating the subsequent resource utilization.

Owner:NANJING AGRICULTURAL UNIVERSITY

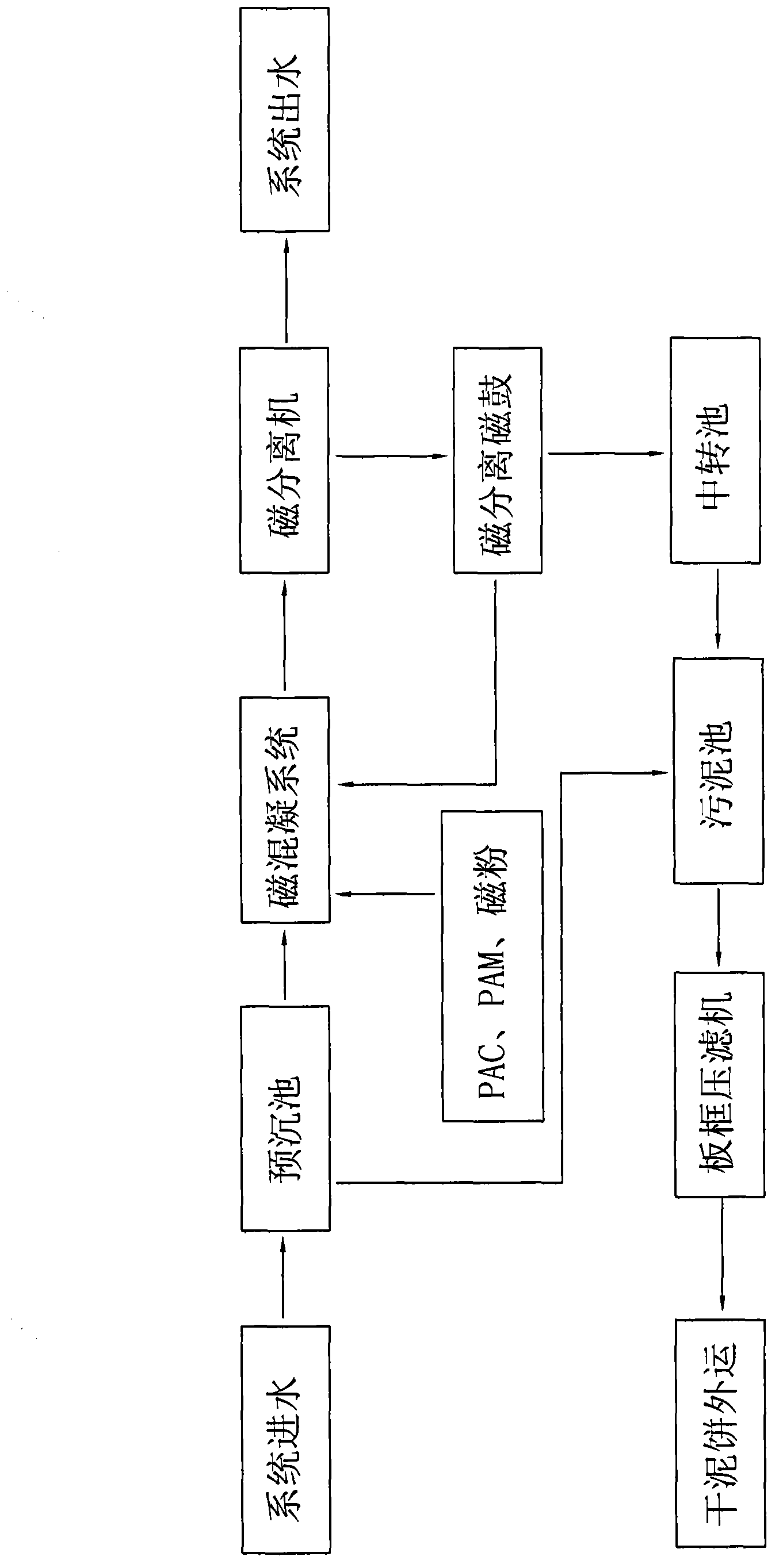

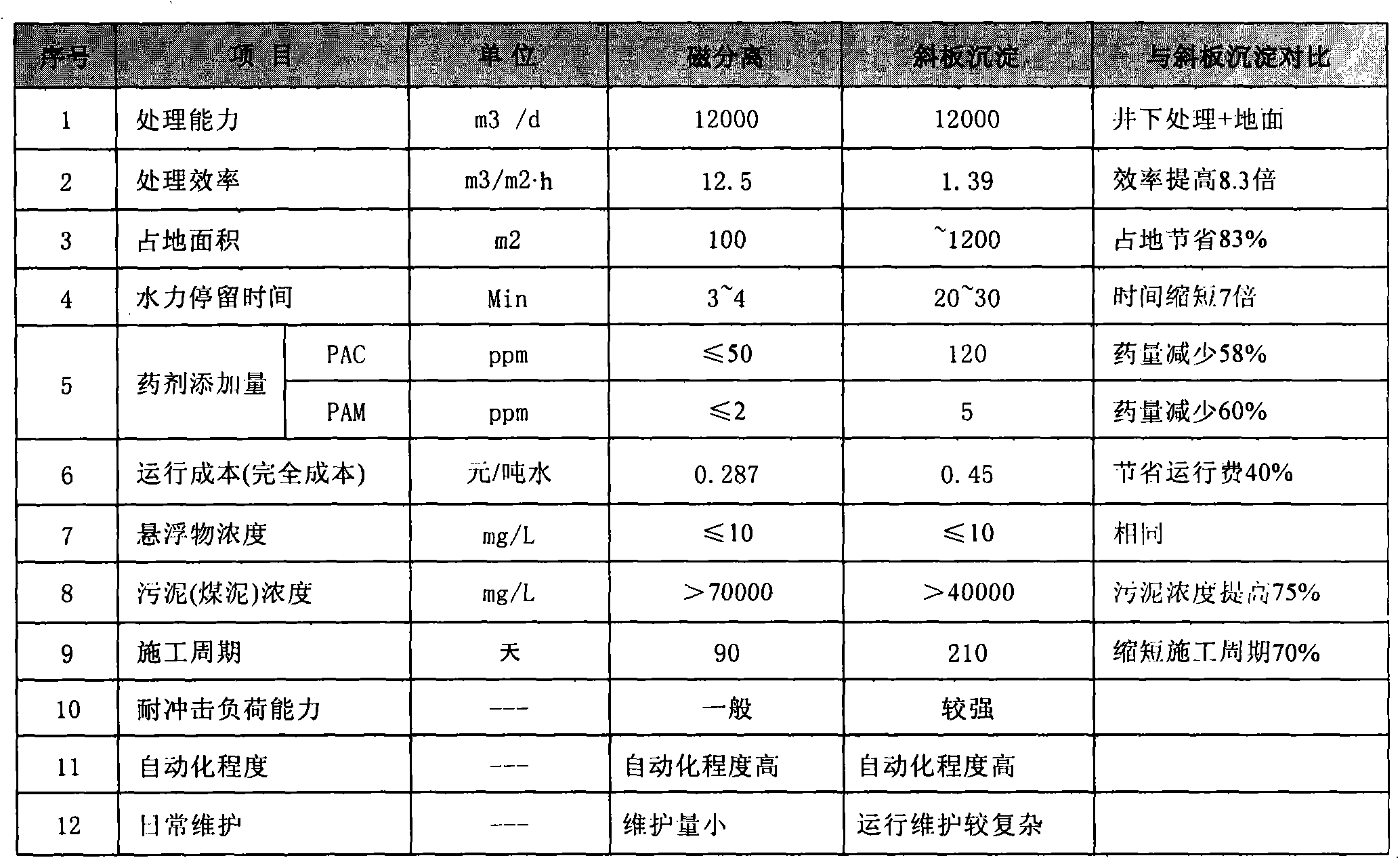

Magnetic coagulation mine water underground purification technology

InactiveCN104163536APurification and separation time is shortReduce dosageSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSludge cakeSlag

The invention discloses a magnetic coagulation mine water underground purification technology, relates to a method for carrying out a multistage treatment and purification on sewage generated in the mining industry, and aims to provides a purification technology having the advantages of capability of being carrying out in underground, short purification and separation time, little occupied space, little usage amount, low operation cost, and good purification effect. The technology comprises the following steps: converging the mine water to the front end of an underground central water chamber, filtering to remove the slag, introducing the water into a pre-precipitation tank, wherein in the pre-precipitation tank the sludge is periodically discharged into a sludge tank by a submerged sludge pump; introducing the water, which has been processed in the pre-precipitation tank, into a magnetic coagulation system, adding magnetic powder and a coagulating agent into the water, wherein in this process the suspended matters are transformed into micro floccules taking magnetic powder as the carriers; introducing the water into a magnetic separator after the coagulation, introducing the clean water into an underground water tank after the solid-liquid separation; transferring the coal sludge in the magnetic separator to a magnetic separating magnetic drum so as to absorb and recycle the magnetic powder, then discharging the coal sludge from which magnetic powder has been recycled into a sludge tank, and finally dehydrating the sludge in the sludge tank by a press filter so as to obtain dry sludge cakes.

Owner:BEIJING ZHONGLI XINDA ENVIRONMENTAL TECH CO LTD

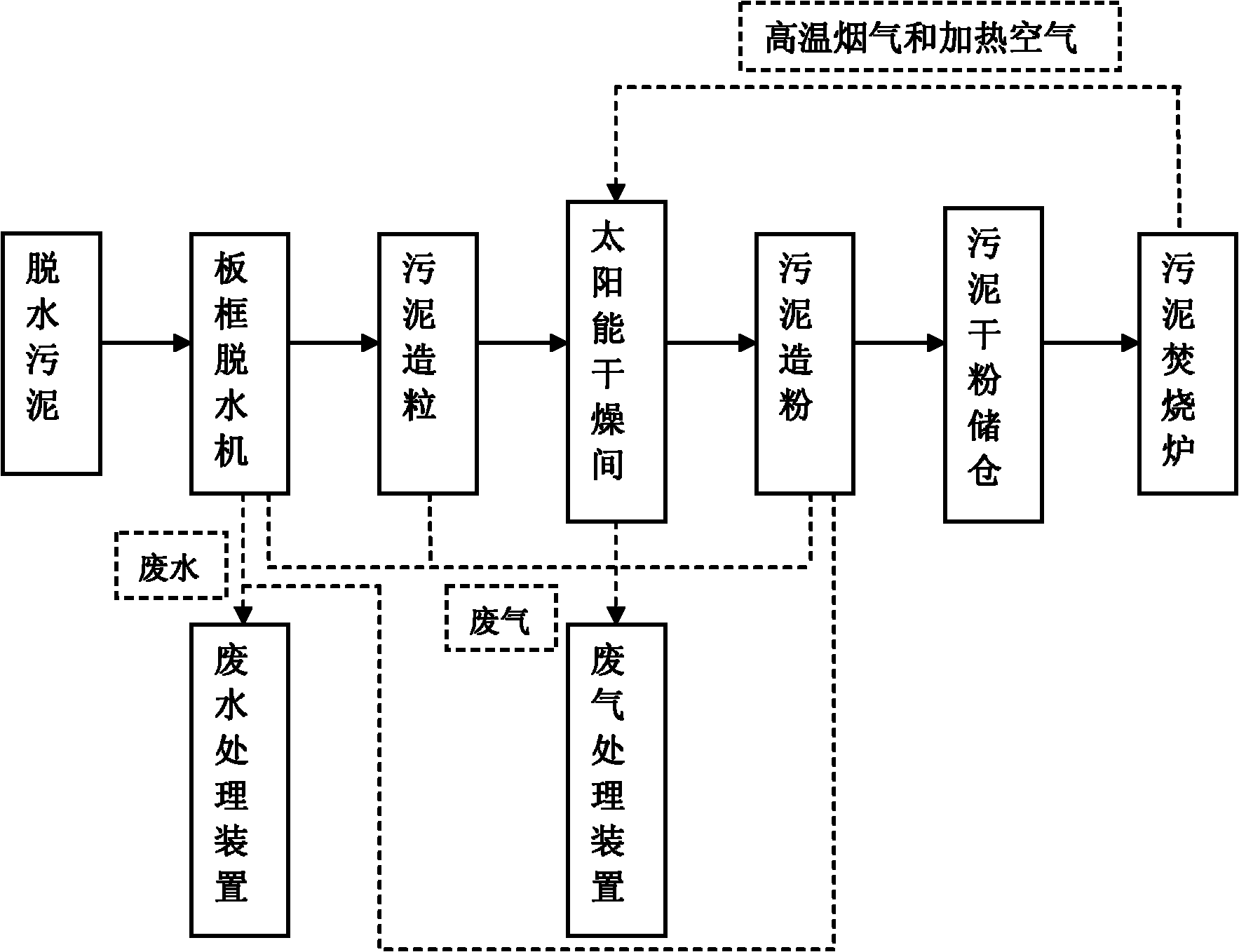

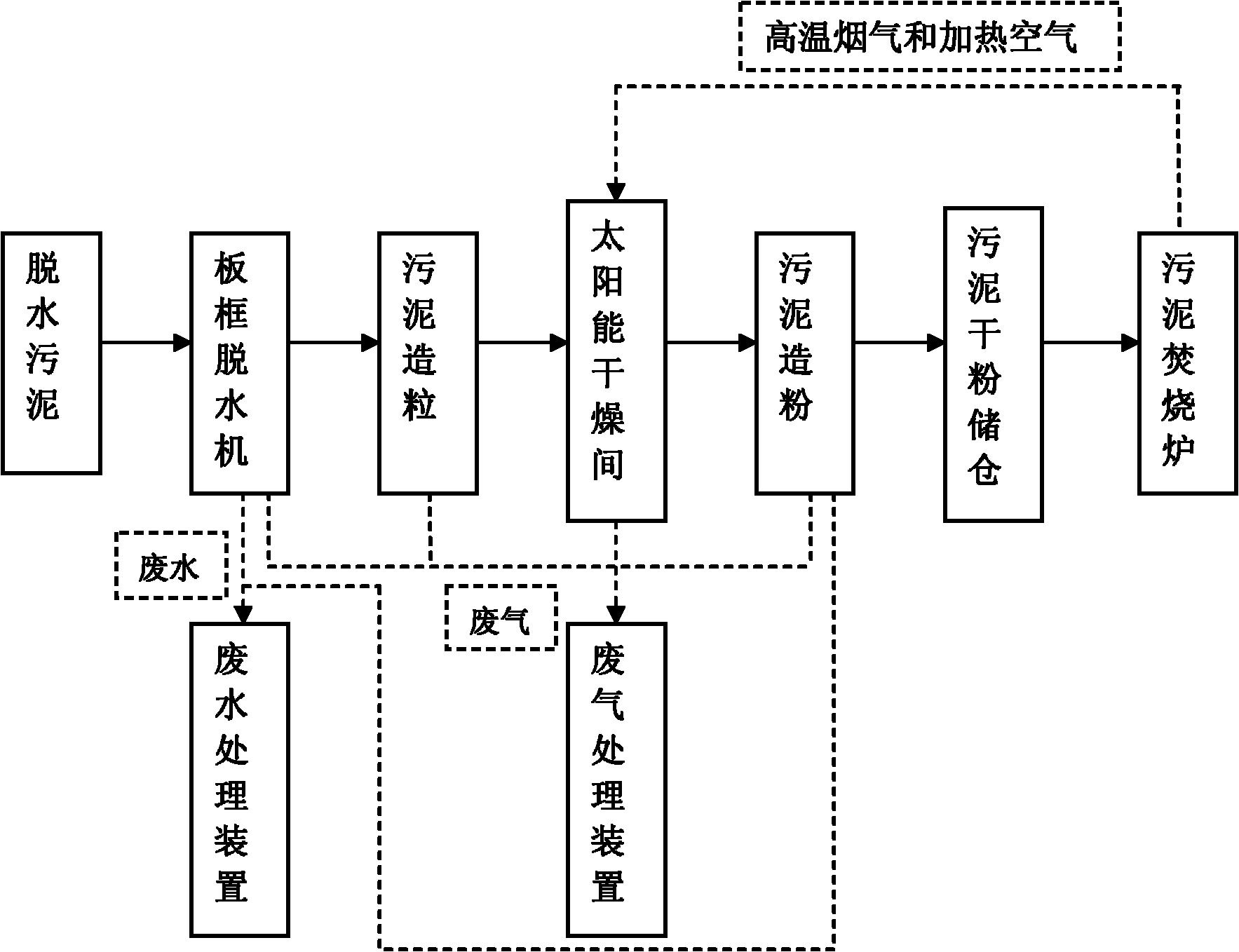

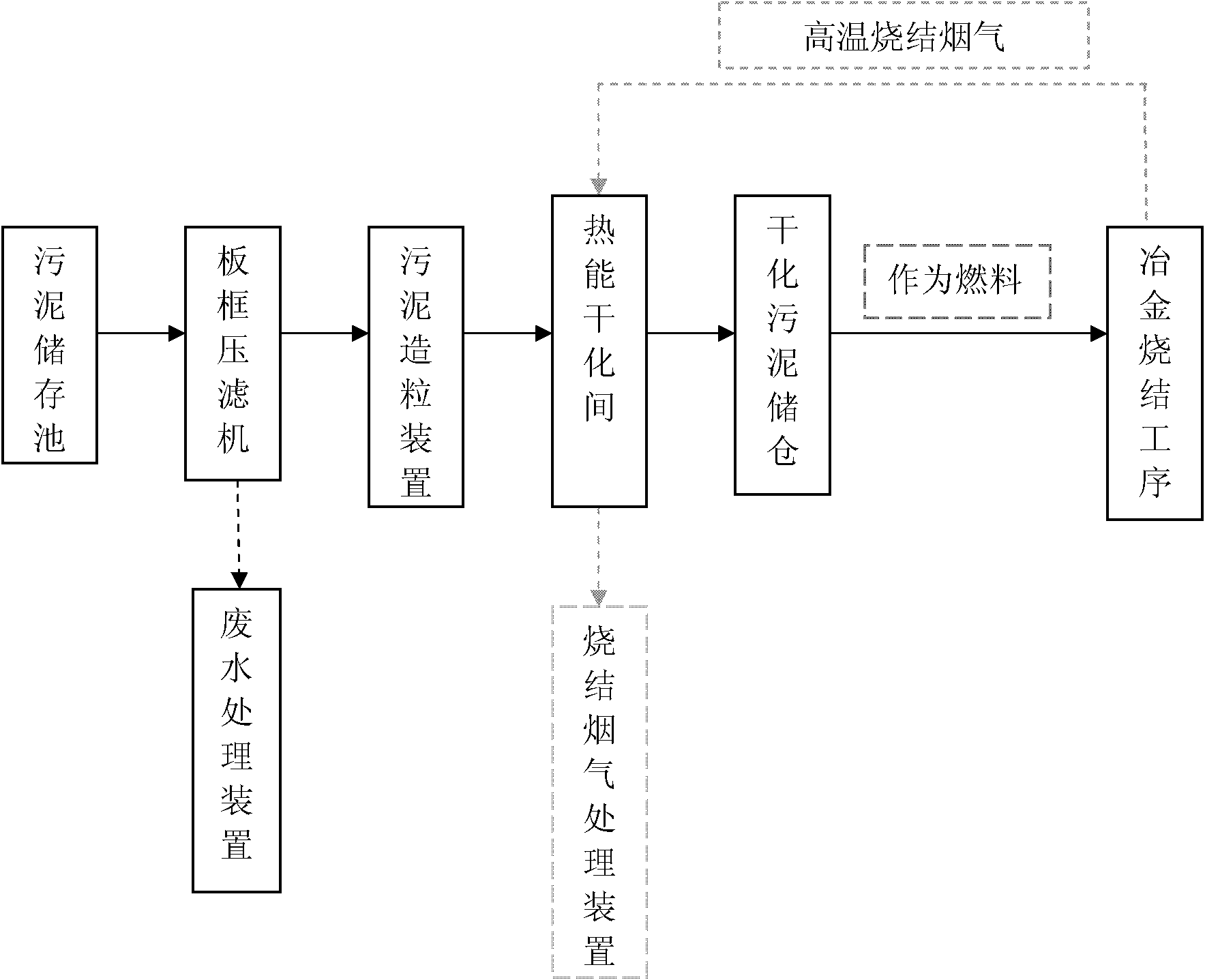

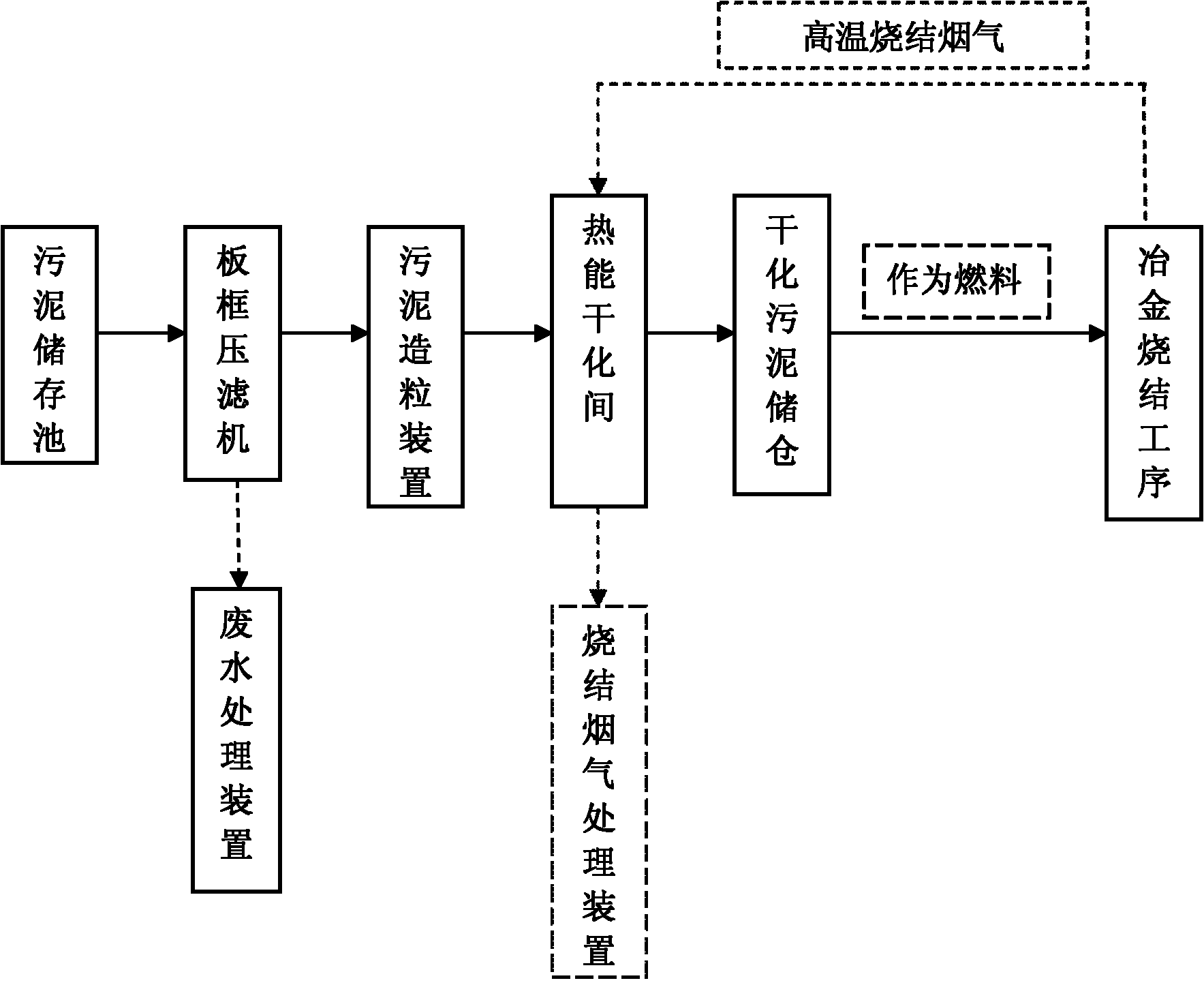

Treatment method of high calorific value excess sludge

ActiveCN102183027AEasy to incinerateReduce energy consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludge cakeWater filter

The invention provides a treatment method of high calorific value excess sludge. The method comprises the following steps of: feeding the excess sludge to be treated with moisture content of 80 to 90 percent into a plate-and-frame water filter press for dehydration to obtain a filter-pressing dehydrated sludge cake; feeding the obtained sludge cake into a sludge granulation device; crushing the sludge cake into coarse granules at normal temperature; further drying the sludge granules in a heat energy drying room; feeding the dried sludge granules into sludge powdering equipment for further treatment, wherein the grain diameter of the treated sludge powder is 150 to 300 meshes, and the water ratio is 5 to 15 percent; storing sludge dried powder into a sludge dried powder warehouse, and spraying the sludge powder having small grain diameter and having a calorific value of 2,000 to 4,000 kilocalories into a sludge burning furnace to completely burn with a small amount of fuels or without the fuels, wherein the interior temperature of the burning furnace is 800 to 1,000 DEG C, and secondary pollution is avoided; and then conducting high-temperature fume which is generated by burning into a waste heat drying device, and drying the sludge. By the process, the burning treatment of the sludge can be performed conveniently, the energy consumption of sludge drying is reduced, the excess sludge is treated properly, and the secondary environmental pollution is avoided.

Owner:北京方兴科创环境科技有限公司

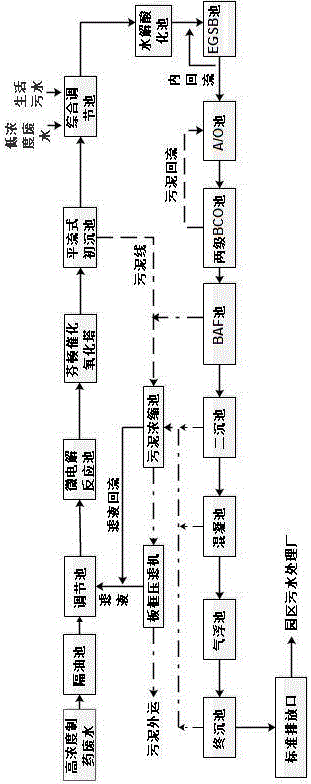

Micro-electrolysis-Fenton-EGSB-A/O-BCO-BAF-coagulation treatment pharmaceutical wastewater system

InactiveCN106830544AImprove B/C valueEfficient removalFatty/oily/floating substances removal devicesWater treatment compoundsProcess systemsSludge cake

The invention provides a micro-electrolysis-Fenton-EGSB-A / O-BCO-BAF-coagulation treatment pharmaceutical wastewater system. The system composition comprises an oil separation pool, a regulation pool, a micro-electrolytic reaction pool, a Fenton catalytic oxidation tower, a horizontal flow type primary sedimentation pool, an integrated regulation pool, a hydrolysis acidification pool, a swell granule sludge bed, an anoxia / aero-biotic pool, a two-stage biological contact oxidation pool, and a secondary sedimentation pool, a biological aerated filter pool, a coagulating pool, an air floating tank and an end sedimentation tank; wherein 200t / d low concentration pharmaceutical and 50t / d domestic sewage are input to the integrated regulation pool and fully mixed with wastewater, after the dilution, the COD concentration is reduced, and the biodegradability of the wastewater is increased, after jointly going into the follow-up process system for processing, the wastewater reaches the standard and is discharged; the flat flow type primary sedimentation pool, the secondary sedimentation pool, the coagulating pool, the BAF pool and the end sedimentation and the sludge concentration are connected, and are connected with the plate-and-frame press filter machine; the sludge of each pool is collected to a sludge concentrated pool, after being concentrated then dehydrated by the plate-and-frame press filter machine, finally the sludge cakes are transported to the outside. The system is stable in efficiency, strong in shock resistance load ability.

Owner:NANCHANG UNIV

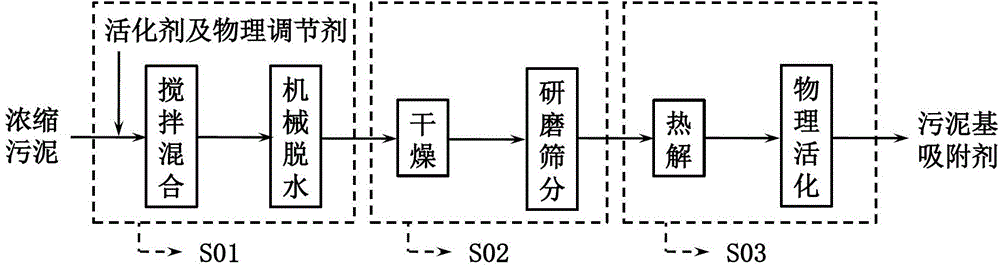

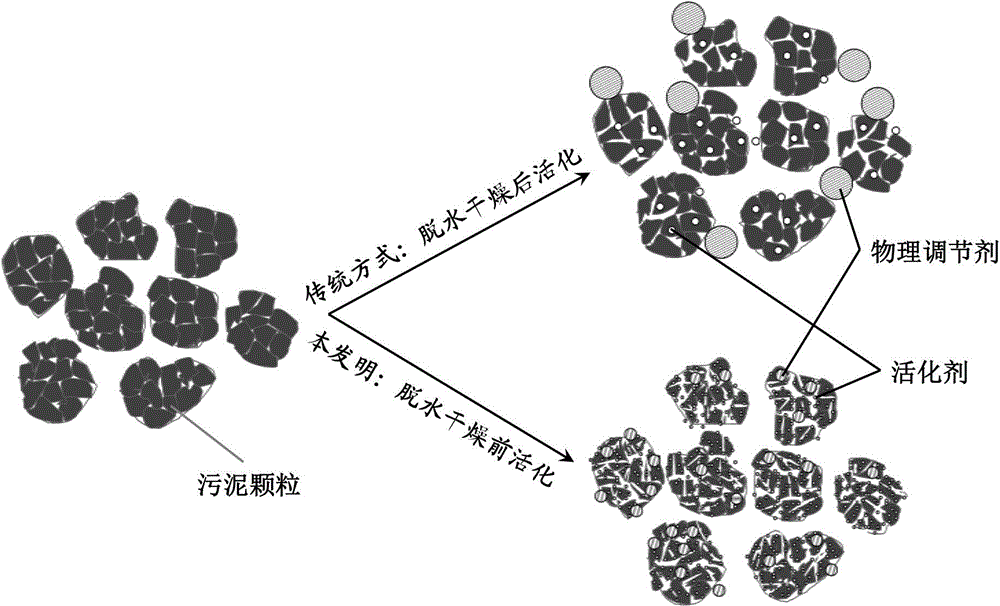

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

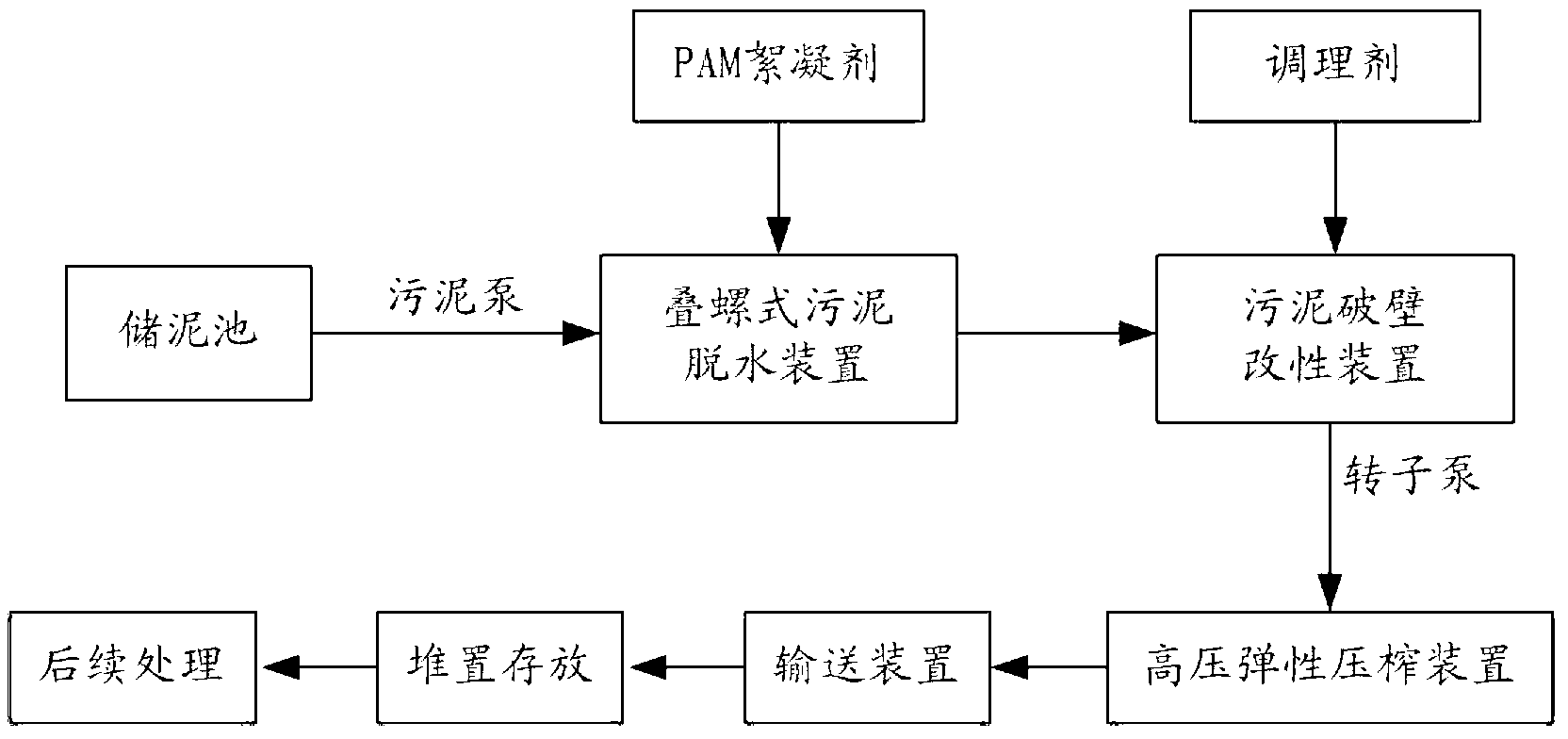

Sludge deep dewatering treatment system and process

InactiveCN103253842AHigh calorific valueSolve problems that are difficult to deal with effectivelySludge treatment by de-watering/drying/thickeningSludge cakeNational standard

Relating to the technical field of sludge treatment, the invention discloses a sludge deep dewatering treatment system and a process specific to the problems that the water content of dewatered sludge cannot reach the national standard and the heat energy loss is great in existing sludge dewatering technologies. The treatment system comprises a volute sludge dewatering device, a sludge wall breaking modification device, a high pressure elastic squeezing device, a sludge transportation device and a wastewater treatment discharge device that are connected in order. The treatment process includes the steps of: a. concentration: subjecting primary sludge to concentration by means of mechanical extrusion; b. modification: mixing the concentrated sludge with curing conditioners in the sludge wall breaking modification device uniformly to make the discharged sludge reach modification requirements; and c. filter pressing: carrying out filter pressing on the modified sludge so as to obtain a sludge cake with a water content of less than 60%-50%. The treatment system and process provided in the invention are especially suitable for deep dewatering on sludge.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

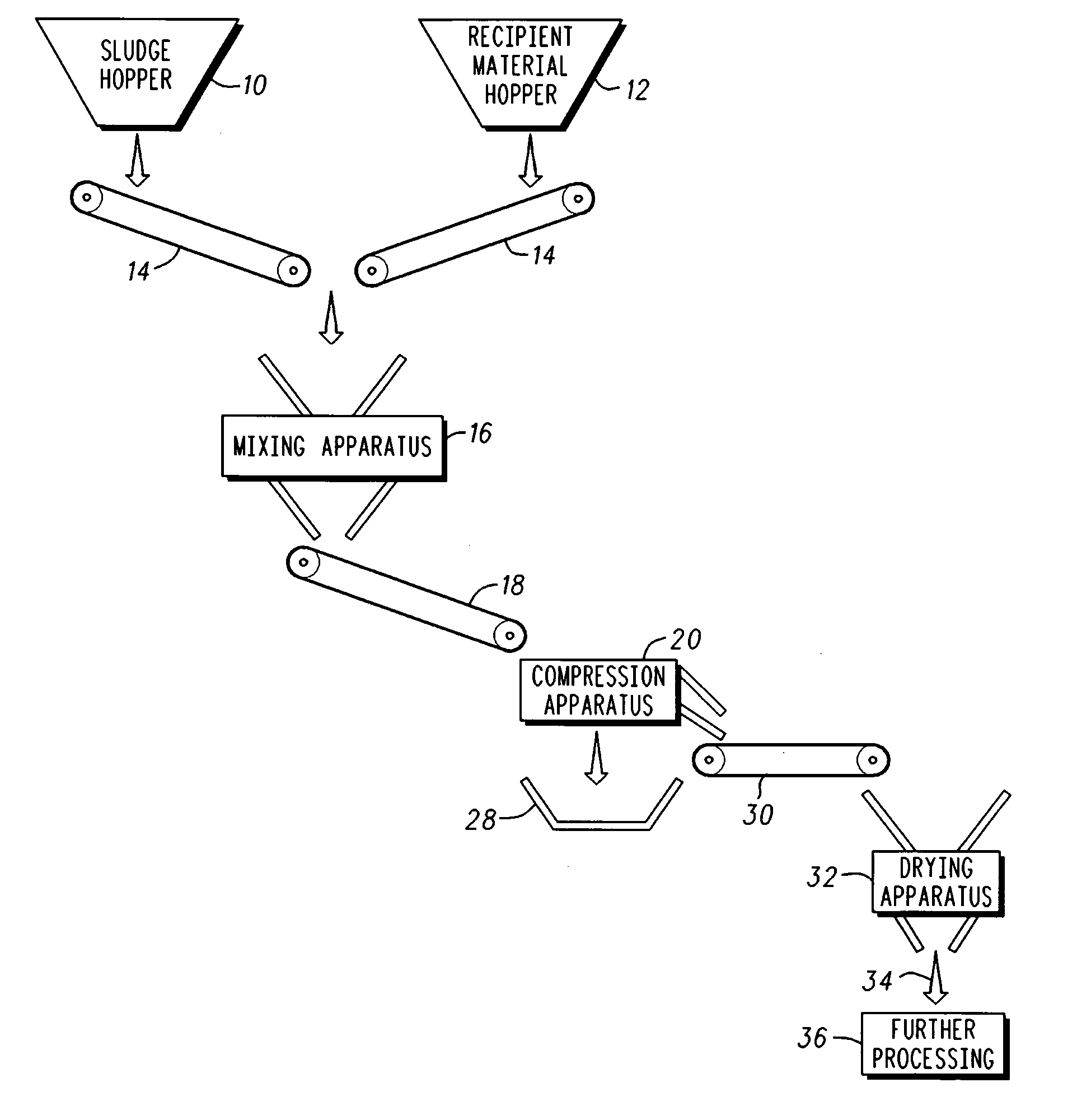

Waste treatment system

InactiveUS20100096336A1Drying using combination processesDrying solid materials without heatSludge cakeWater treatment system

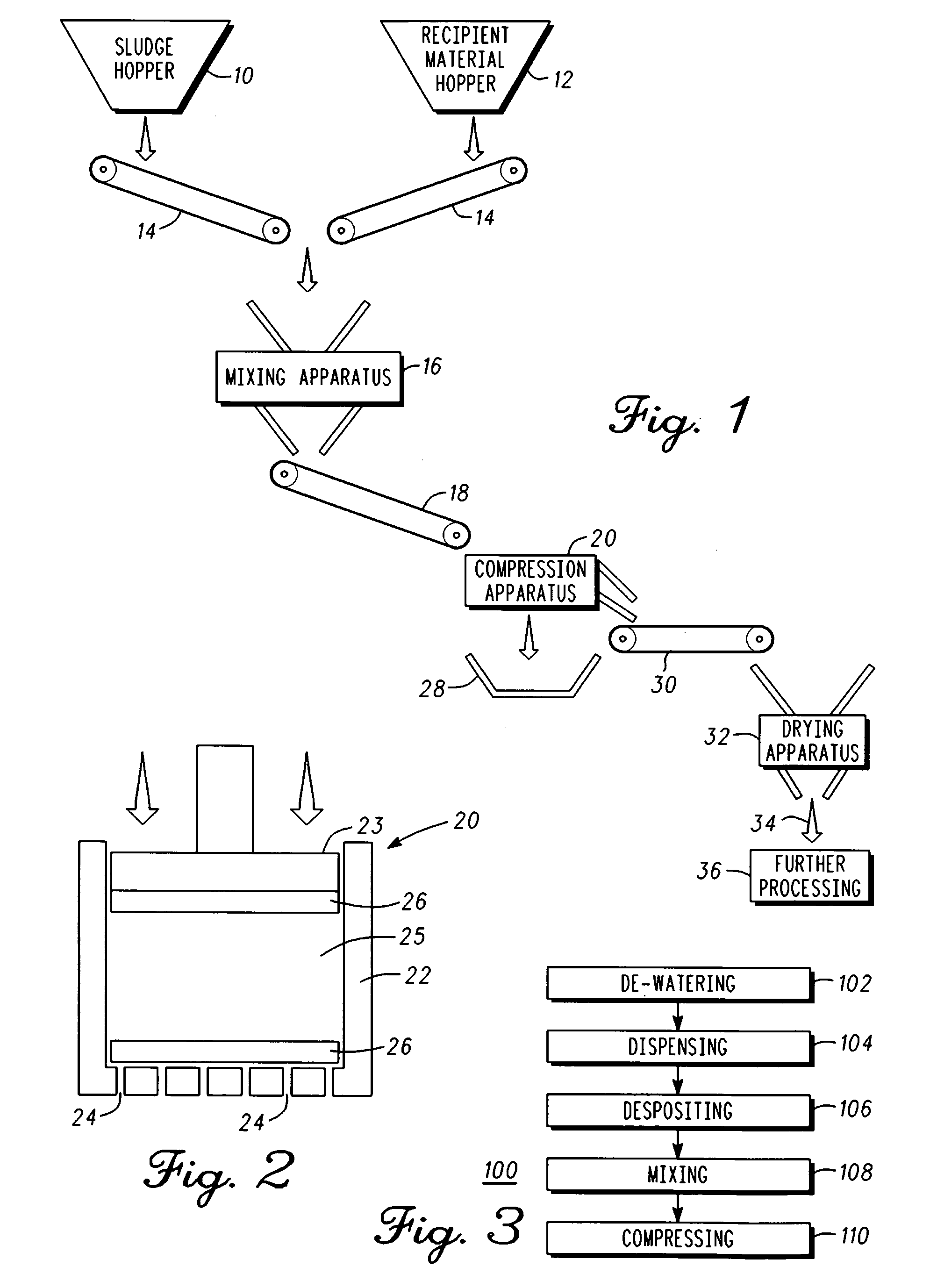

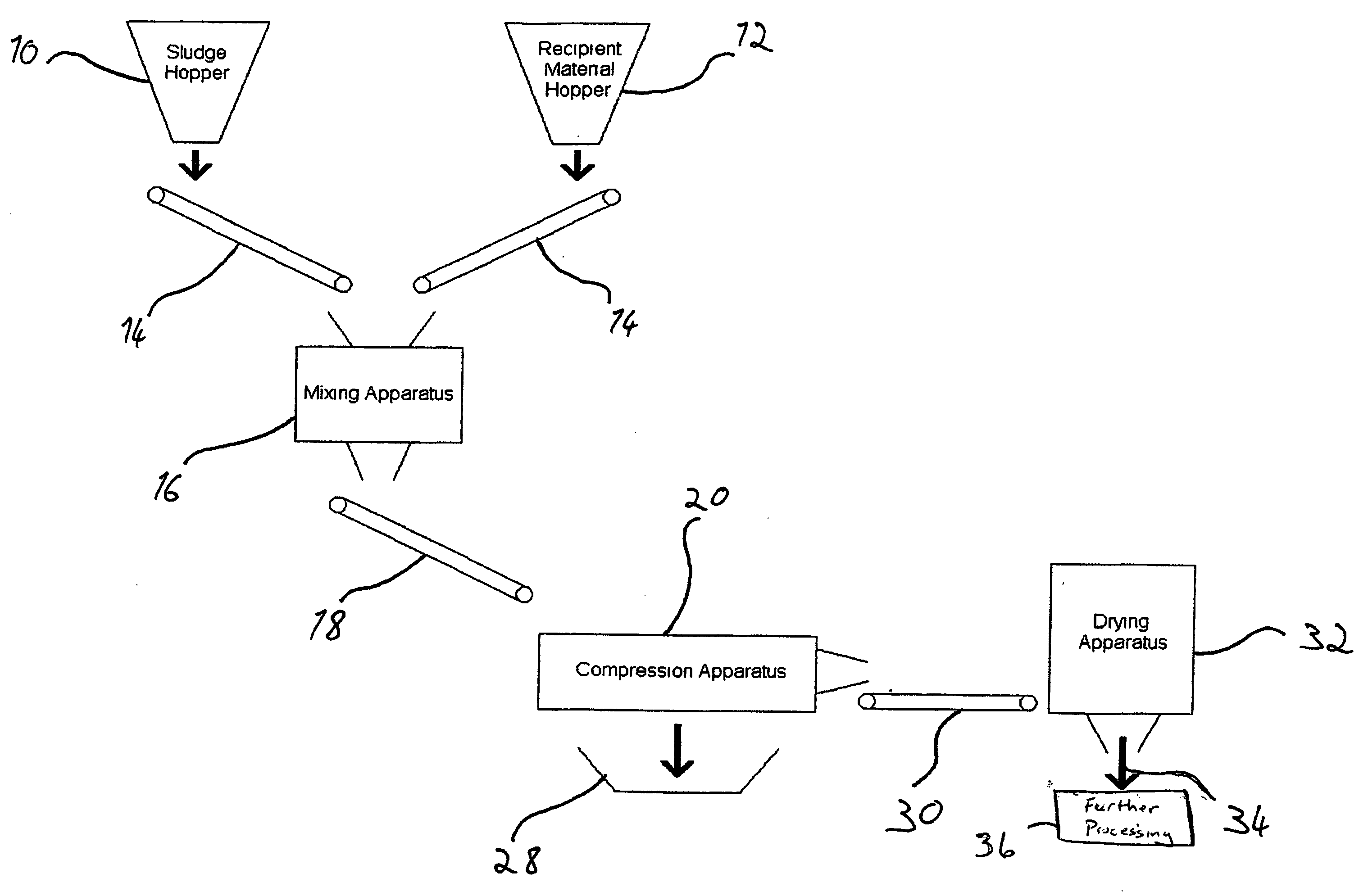

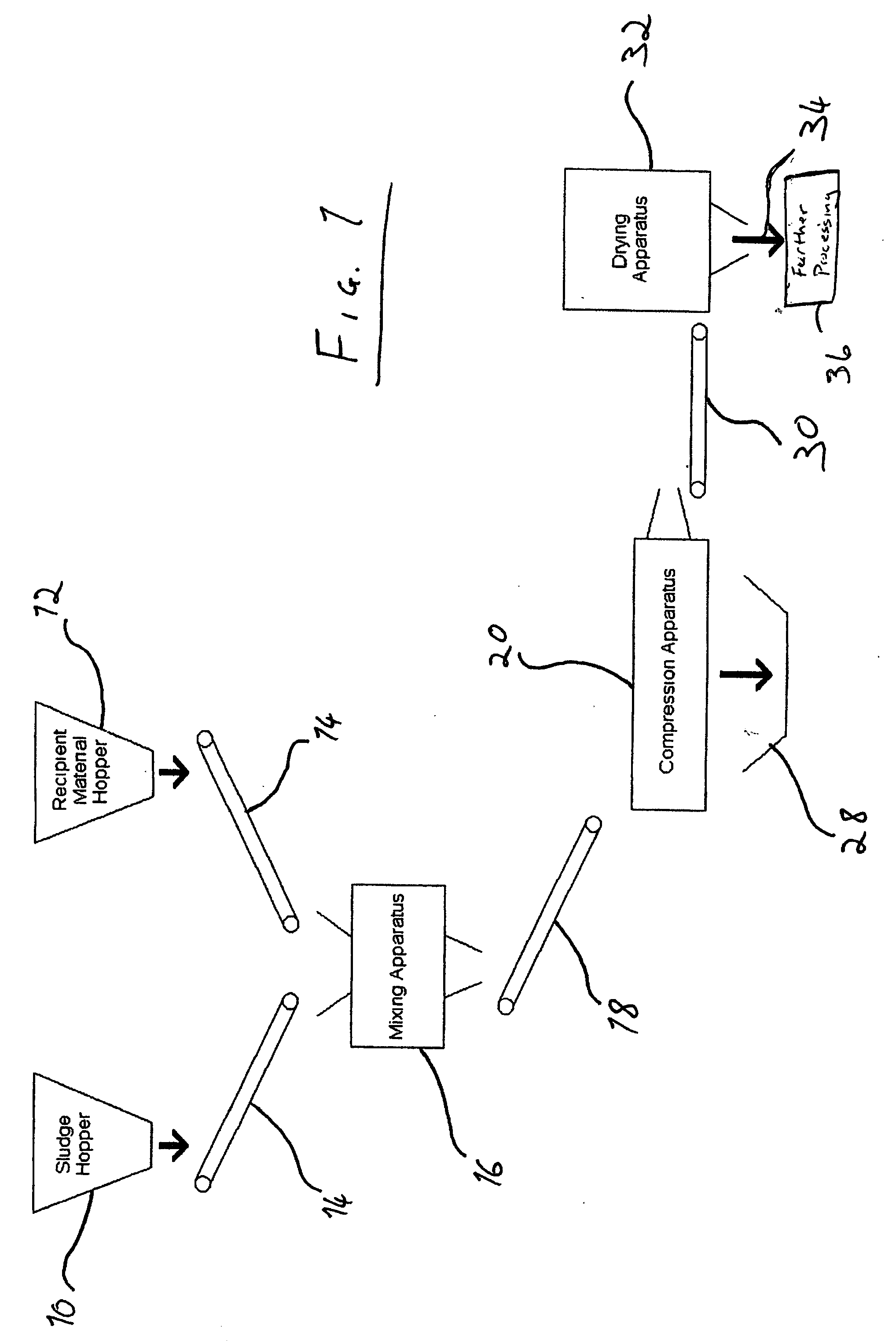

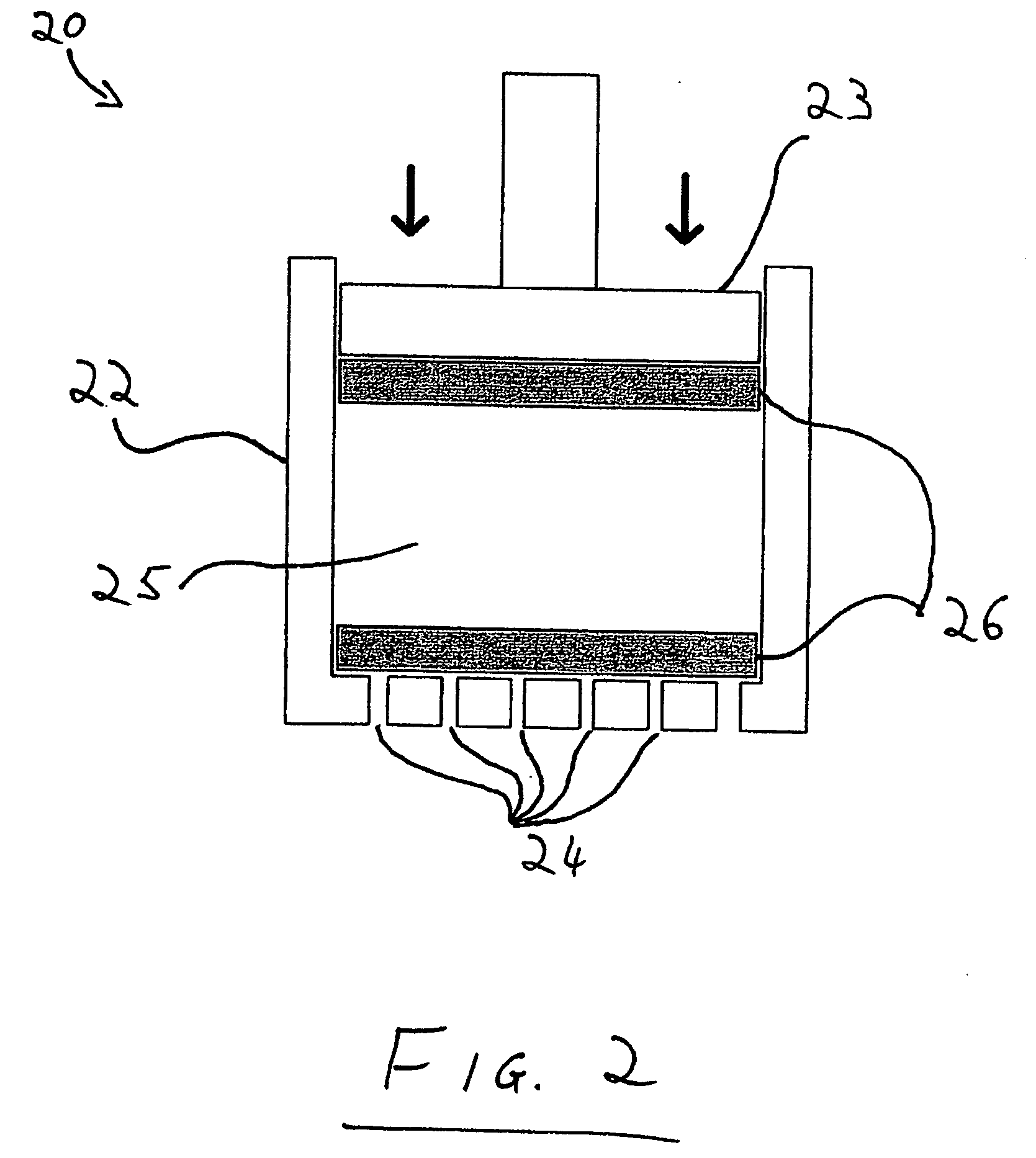

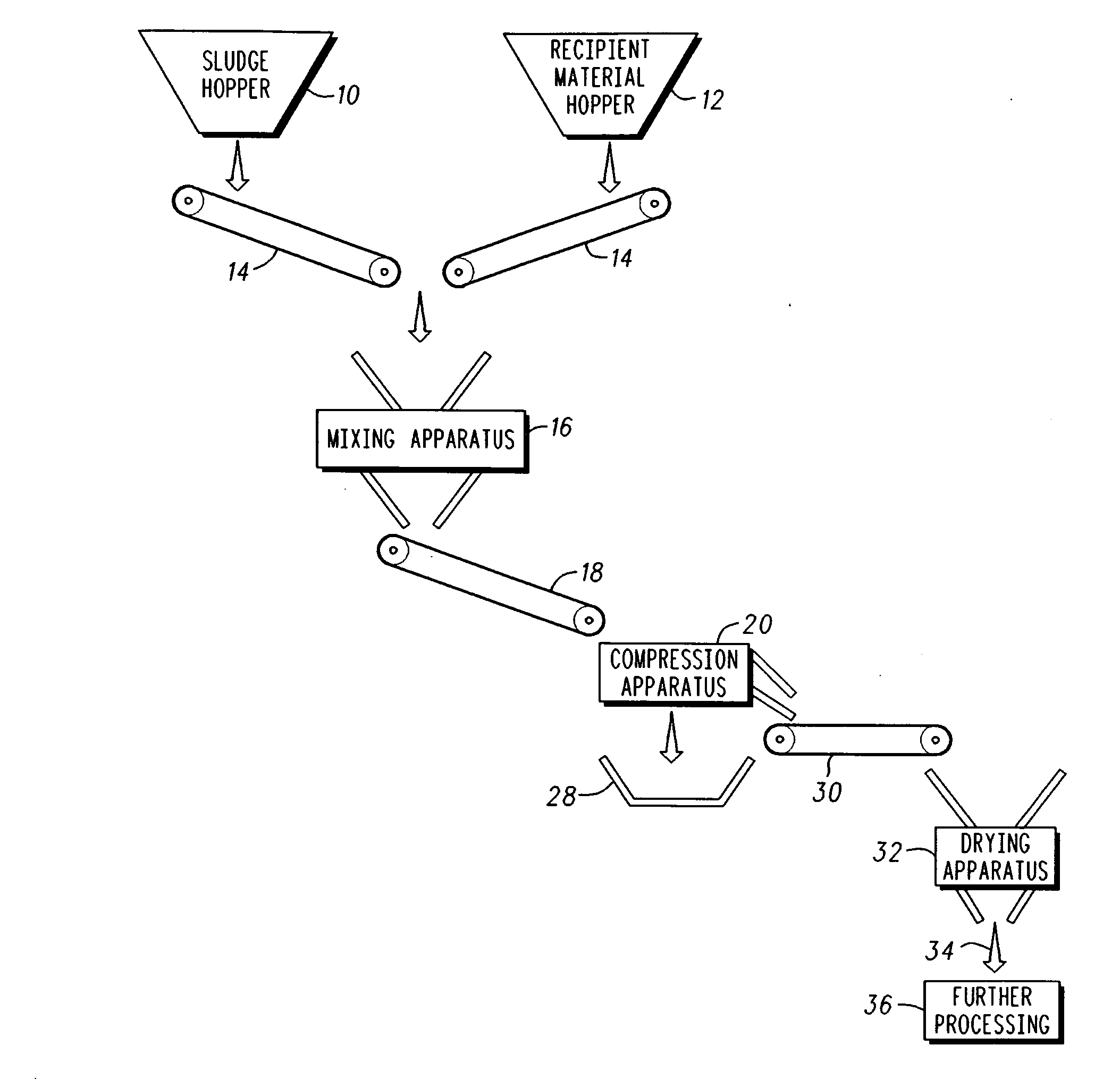

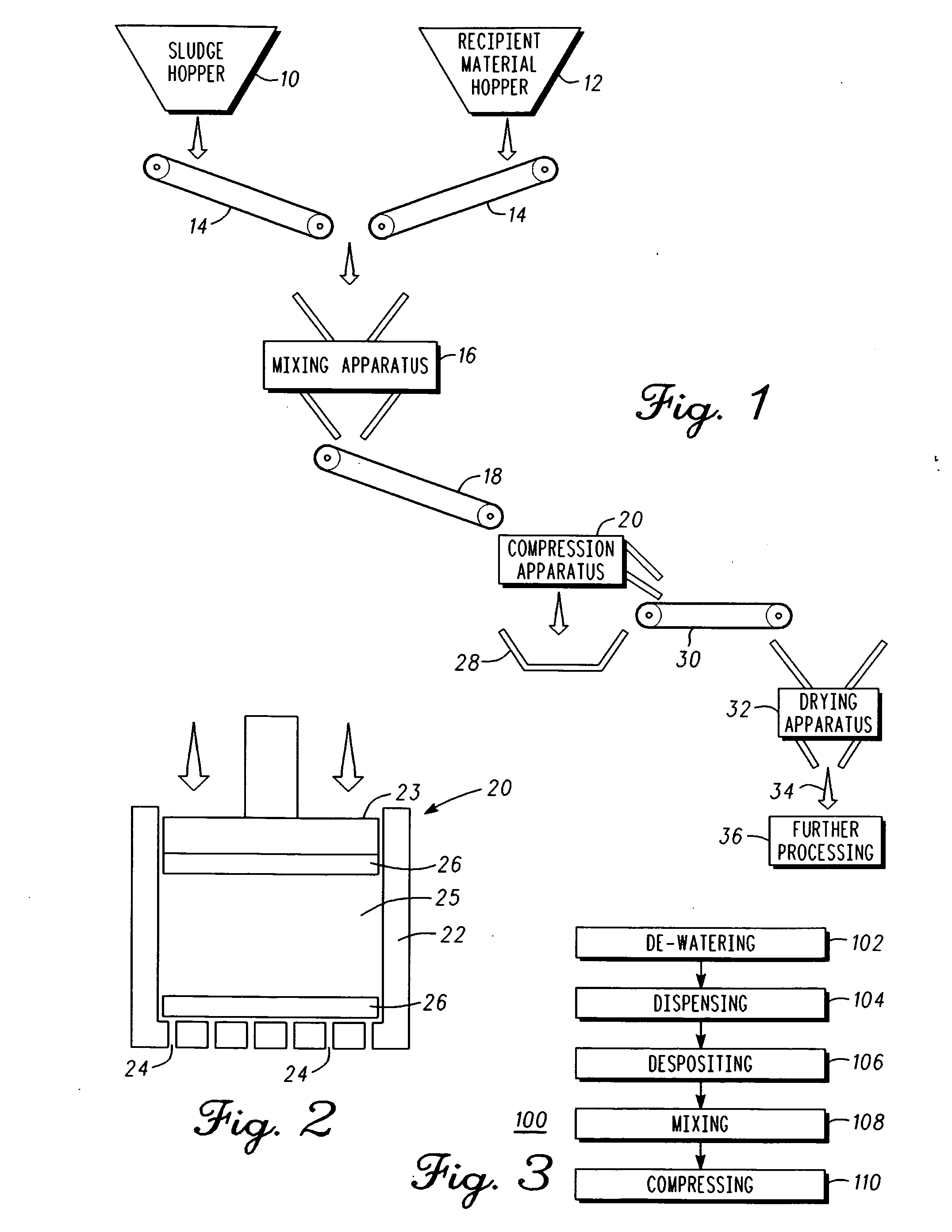

A system for removing water from sludge is disclosed. The system (100) includes: de-watering (102) sludge comprising an output from a wastewater treatment system to form a semi-solid sludge cake; dispensing (104) the sludge in a sludge hopper and dispensing a blending material in a recipient blending material hopper; depositing (106) the sludge and the blending material in a mixing device; mixing (108) the sludge and the blending material having a porous structure in a weight ratio of the sludge to the blending material of about from 2:1 to about 10:1; and compressing (110) the sludge and the blending material to release moisture. The system (100) provides an improved method of de-watering sludge, for more efficient processing, transporting and recycling, depending on the application.

Owner:HYDROPRESS HLDG

Inorganic composite conditioner for effective sludge dehydrating

ActiveCN102452782AImprove dehydration effectStrong synergySludge treatment by de-watering/drying/thickeningSludge cakeOrganic content

The invention discloses an inorganic composite conditioner for effective sludge dehydrating, comprising an inorganic high valent cation coagulant, quicklime and inorganic powder fine aggregate, wherein the weight percentages are as follows: 2-10% of the inorganic high valent cation coagulant, 30-50% of quicklime and 40-67% of inorganic powder fine aggregate. The invention also discloses a use method for the inorganic composite conditioner. The conditioner disclosed by the invention can obviously lower specific resistance of sludge (SRF) and capillary suction time (CST) so as to large raise the sludge dehydrating performance. In addition, the drugs of the conditioner are cheap, and the organic contents of the sludge cake after dehydrating are low, and the inorganic material compositions in the conditioner are helpful for forming the strength during the subsequent preparation of backfilling mulching soil and building materials, and the sludge cake after dehydrating can be used as a raw material for preparing the backfilling mulching materials and the building materials.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

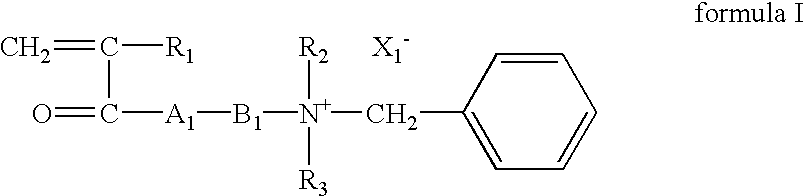

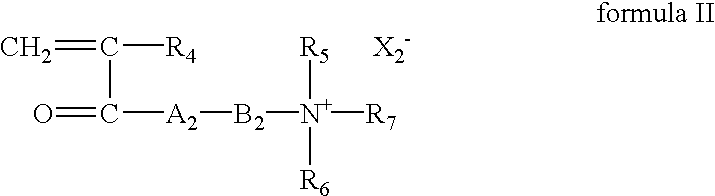

Method and composition of a hydrophilic polymer dispersion containing an inorganic flocculant to be used for the treatment of waste water

InactiveUS6531531B1High strengthReduce moistureSedimentation separationSolid electrolyte fuel cellsSludge cakeWastewater

The present invention relates to the method and composition of a hydrophilic polymer dispersion containing an inorganic flocculent to be used for the treatment of waste water. More particularly, it relates to the method and composition of a hydrophilic polymer dispersion containing an inorganic flocculent, which has the properties of declining and reducing the water content of flock as well as water content of sludge cake obtained after treating the waste water.

Owner:GREEN TECH LLC

Sludge dewatering integrated process

InactiveCN101786787ARaise the pHReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge cakeBrick

The invention discloses a sludge dewatering integrated process, which is characterized by adopting the following steps: (1), pumping sludge from a secondary sedimentation tank behind an aeration tank into a sludge concentration tank with a sludge lifting pump to concentrate the sludge for 13 to 20 hours so as to reduce volume of the sludge primarily; (2), pumping the sludge subjected to primary volume reduction into a quality-regulating tank with the sludge lifting pump, adding burnt lime in an amount of 1 to 3 percent based on the total weight of the sludge and alkaline industrial waste residue in an amount of 2 to 6 percent based on the total weight of the sludge into the quality-regulating tank, and stirring the mixture at a low speed to regulate quality for 4 to 6 hours; (3), dewatering the sludge subjected to quality regulation with a dewaterer to make sludge cakes; (4), naturally drying the dewatered sludge cakes for about 10 days; and (5), burning the naturally dried sludge cakes into raw materials for preparing cement, processing the naturally dried sludge cakes into raw materials for preparing bricks, processing the naturally dried sludge cakes into autoclaved geotechnical engineering materials or curing the naturally dried sludge cakes into daily covering materials for refuse landfills. The process of the invention has the advantages of effectively reducing water content of sludge, along with low processing cost.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

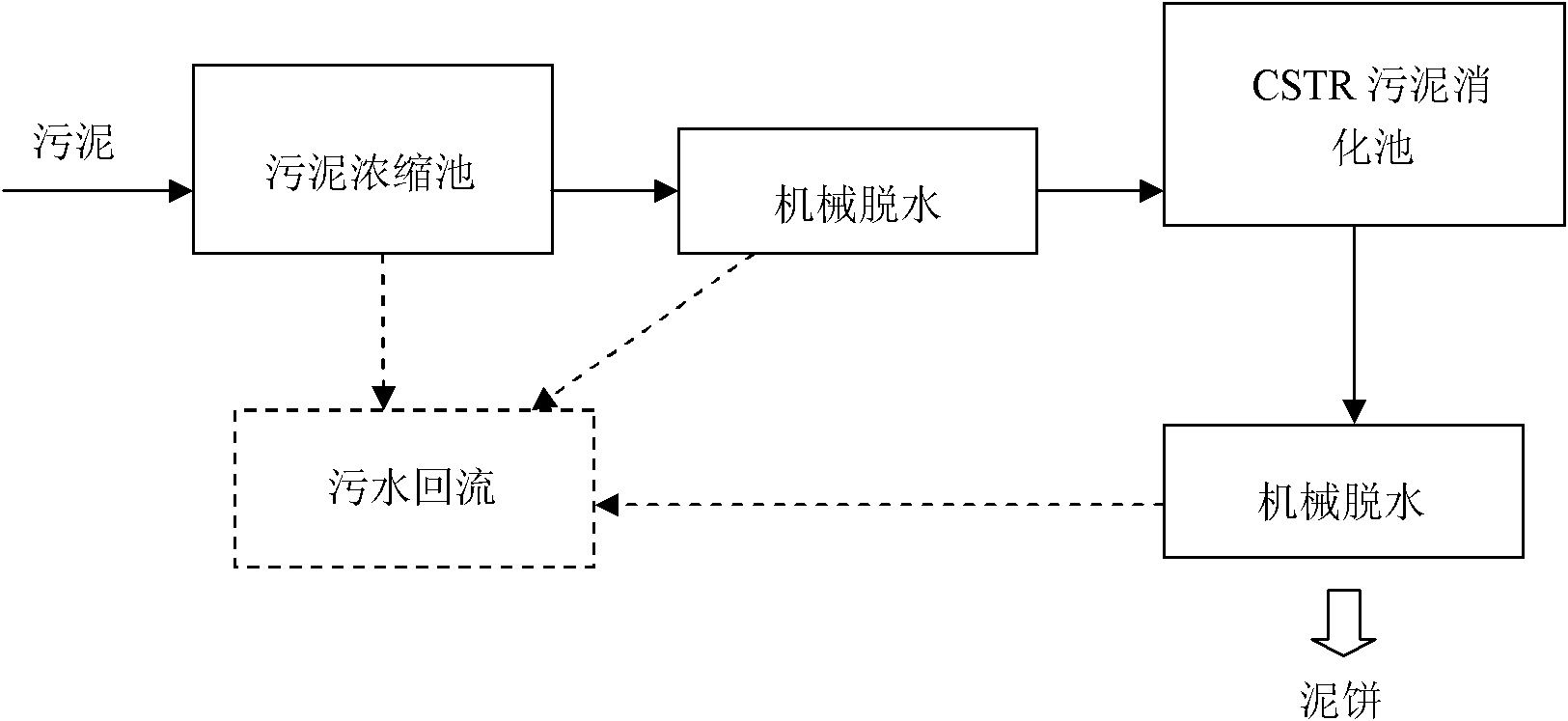

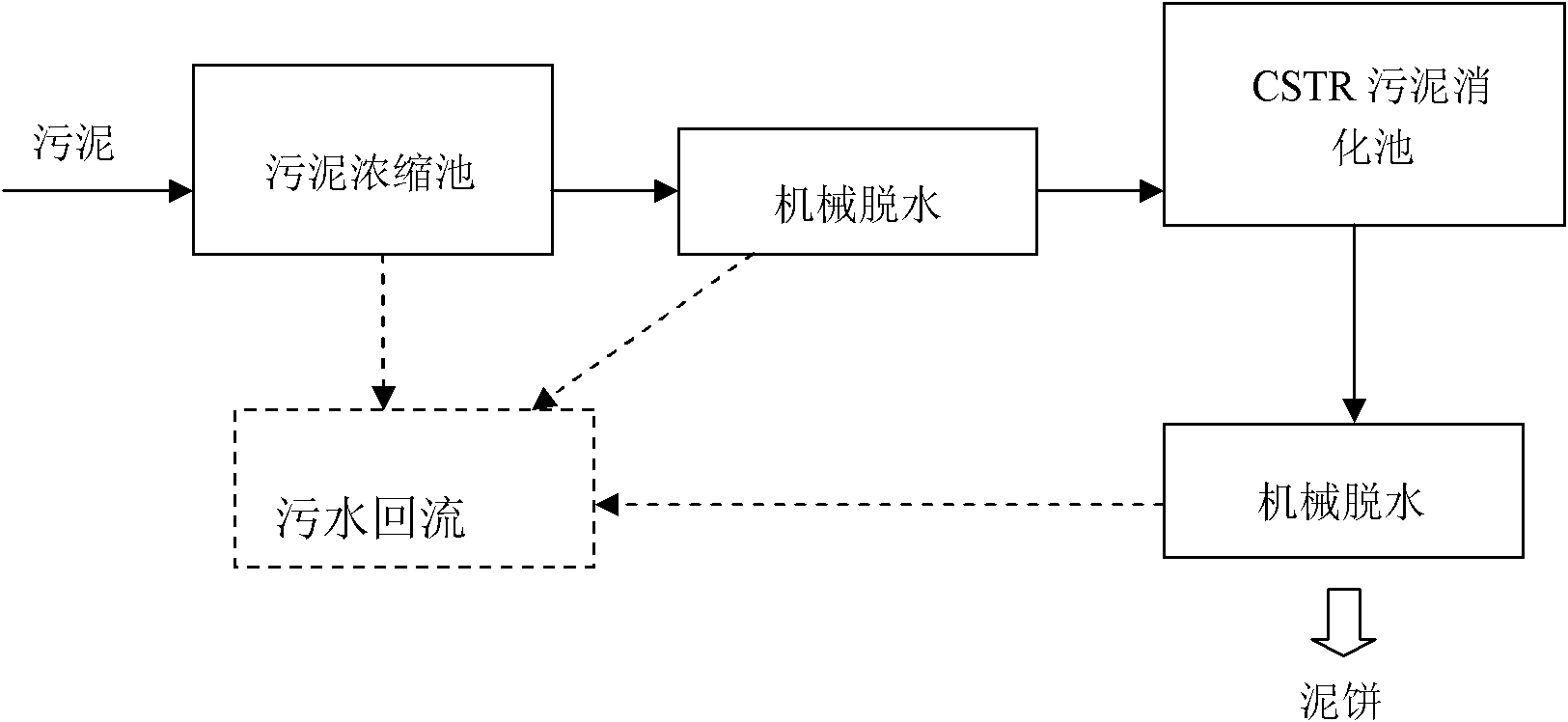

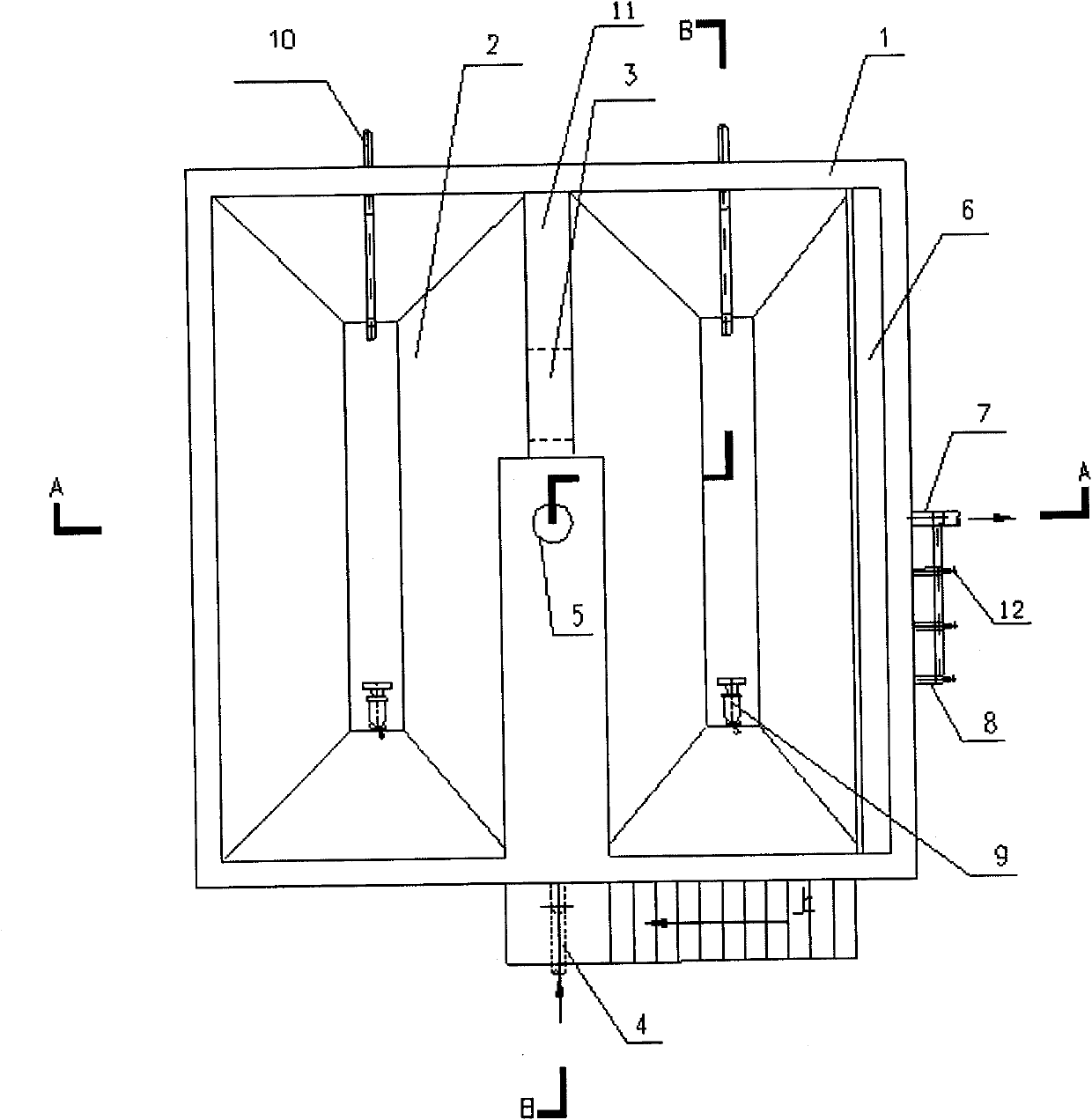

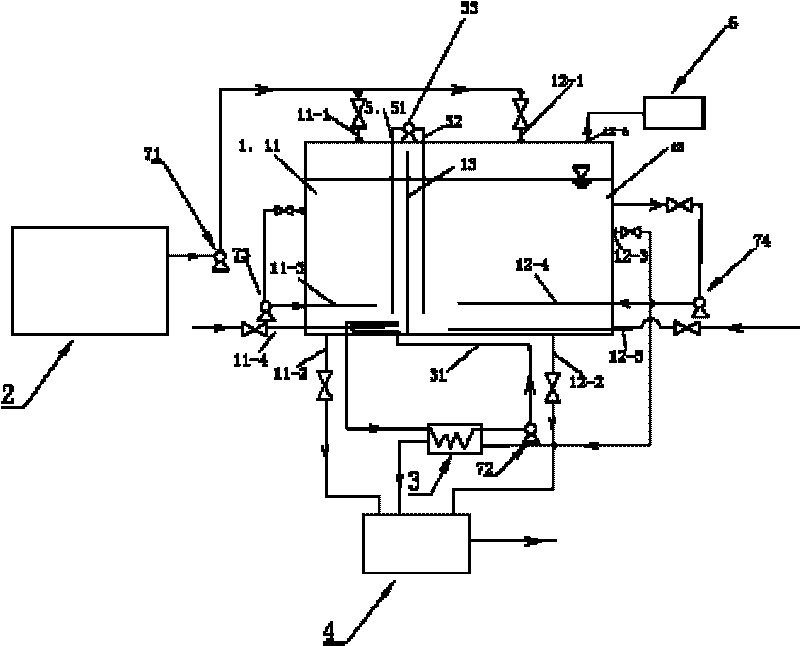

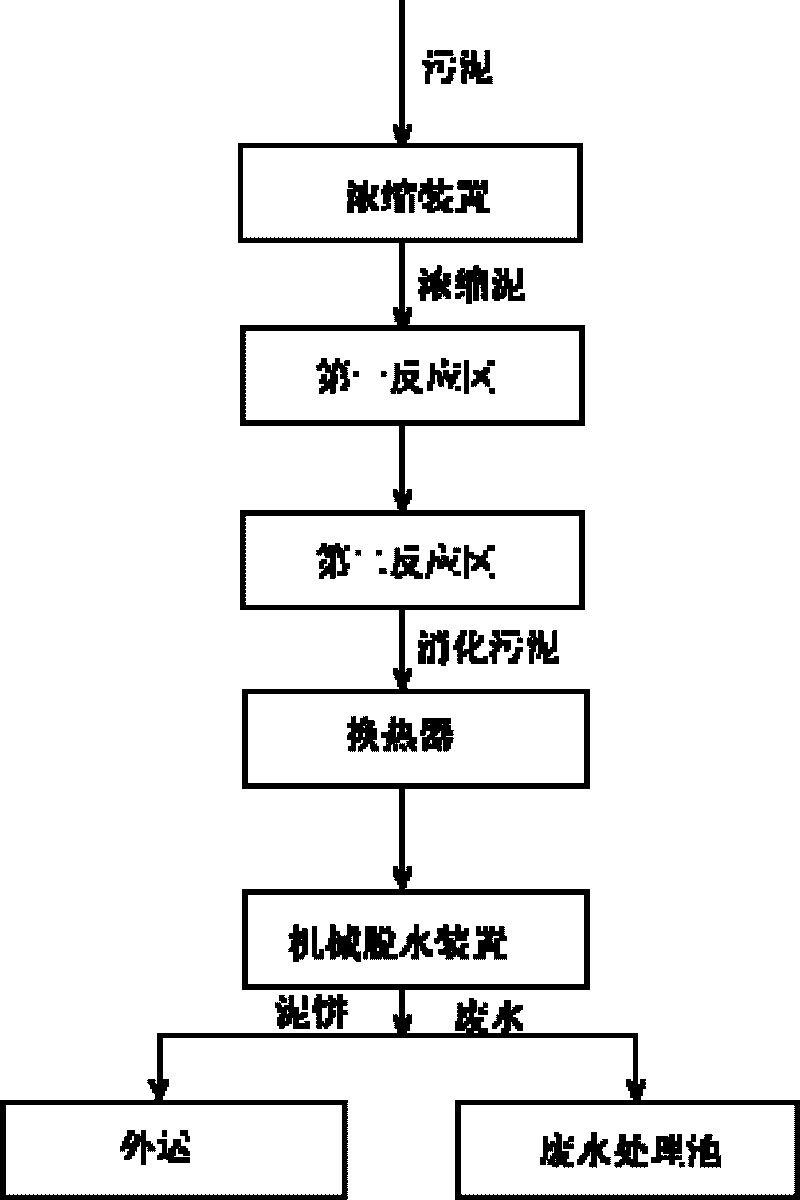

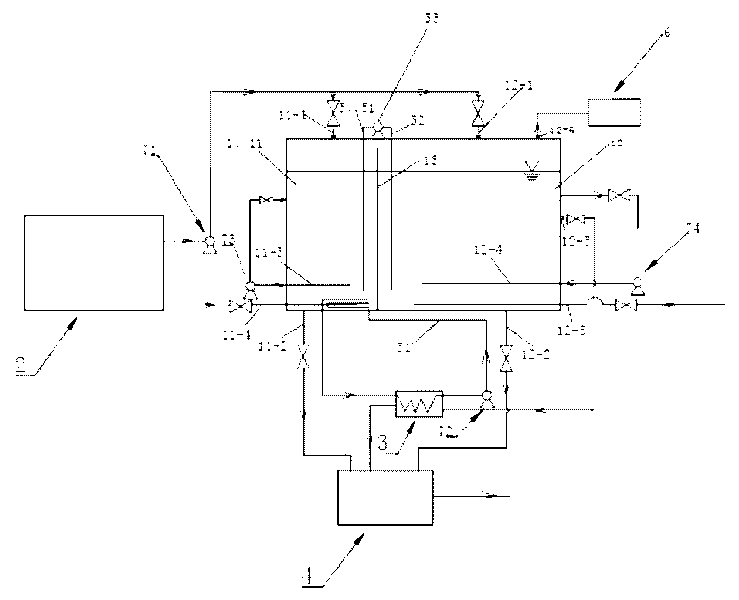

High-concentration anaerobic sludge digestion treatment process for carrying out mechanical dewatering on sludge

ActiveCN101948231AReduce moisture contentReduce volumeSludge treatment by de-watering/drying/thickeningBiological sludge treatmentHigh concentrationSludge cake

The invention relates to a high-concentration anaerobic sludge digestion treatment process for carrying out mechanical dewatering on sludge, comprising the following steps of: conveying sludge with high water content into a concentration tank, wherein the water content of the concentrated sludge is reduced to 97 percent, and a supernate reflexes to a sludge treatment system; carrying out mechanical pre-dewatering on the concentrated sludge, wherein the water content is about 88-90 percent after the mechanical pre-dewatering; then carrying out anaerobic digestion on the pre-dewatered sludge under the high concentration condition by adopting a CSTR (Continuous Stirred-Tank Reactor); and further dewatering the sludge after anaerobic digestion, wherein the water content of a treated sludge cake is about 75 percent. The invention has following advantages and positive effects: by adopting the technical scheme, the dewatering effect of the sludge is favorable, the volume of an anaerobic sludge digestion tank is greatly shortened, and the capital construction investment and the operation cost of a sewage treatment plant are reduced; the load of organic matters in the sludge can be effectively improved by carrying out pre-dewatering on the sludge; and the CSTR anaerobic sludge digestion which is suitable for the high-concentration solid materials is used for treatment, which is beneficial to sludge resource utilization.

Owner:NANJING YANJIANG ACAD OF RESCOURCES & ECOLOGY SCI CO LTD

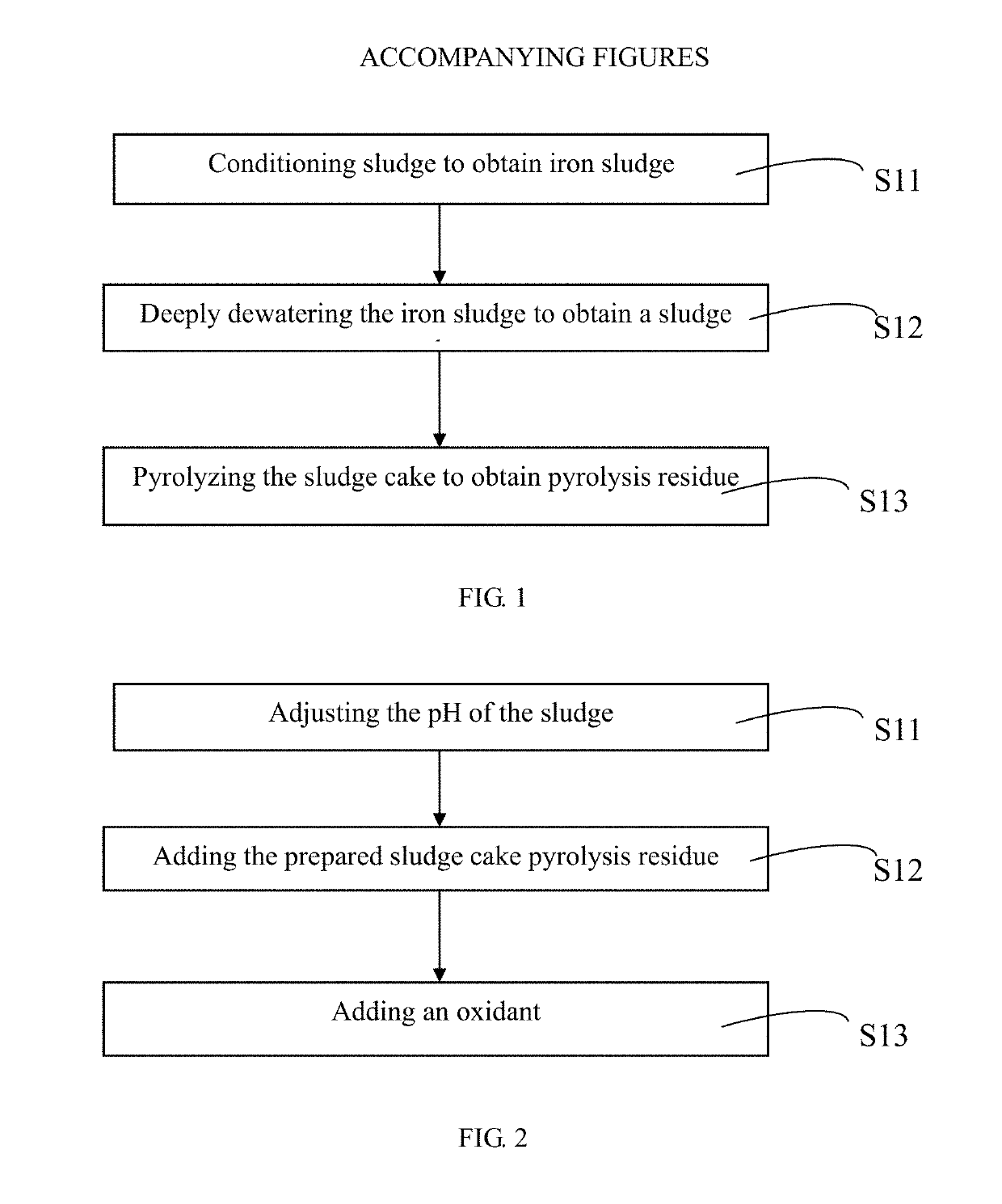

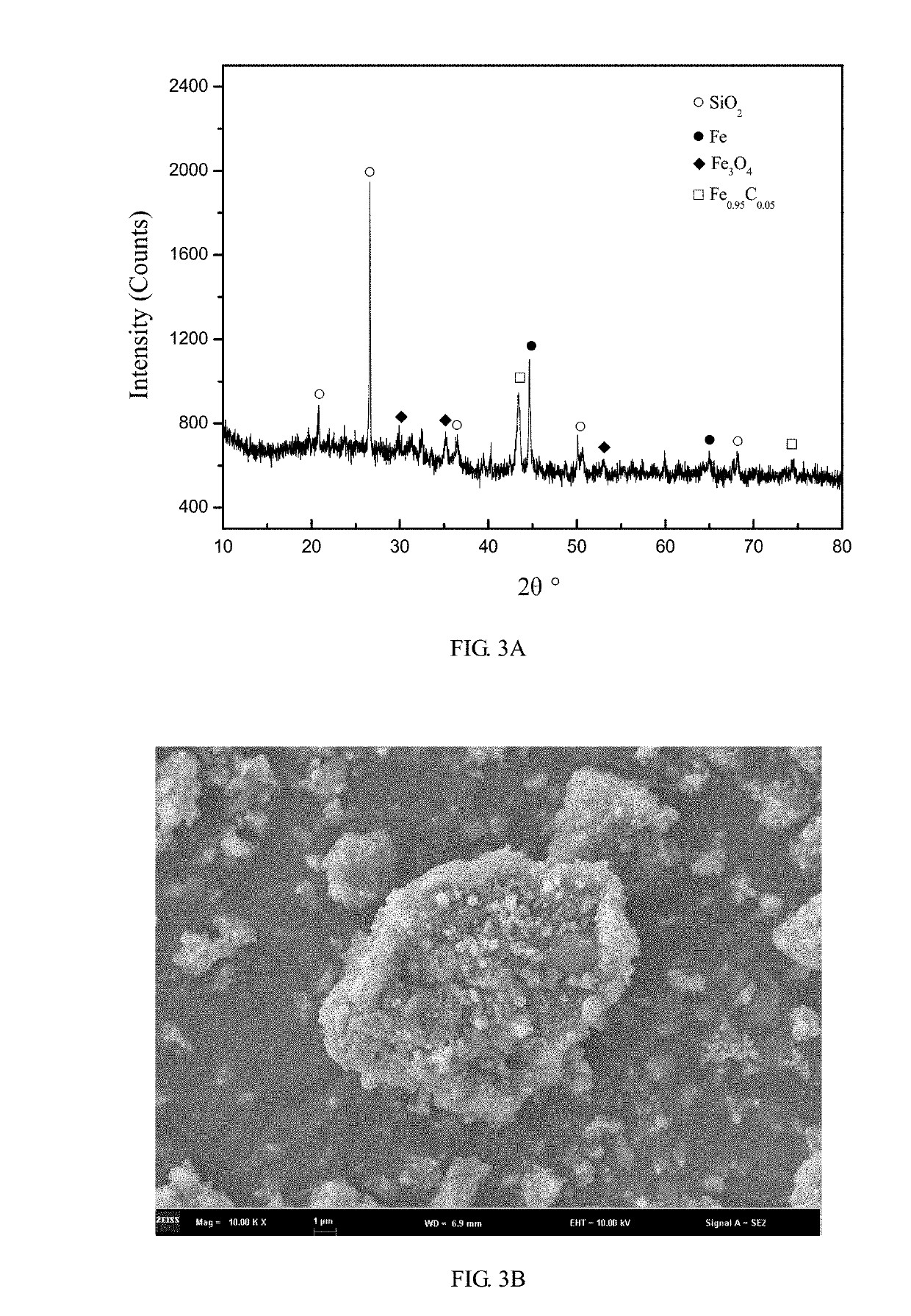

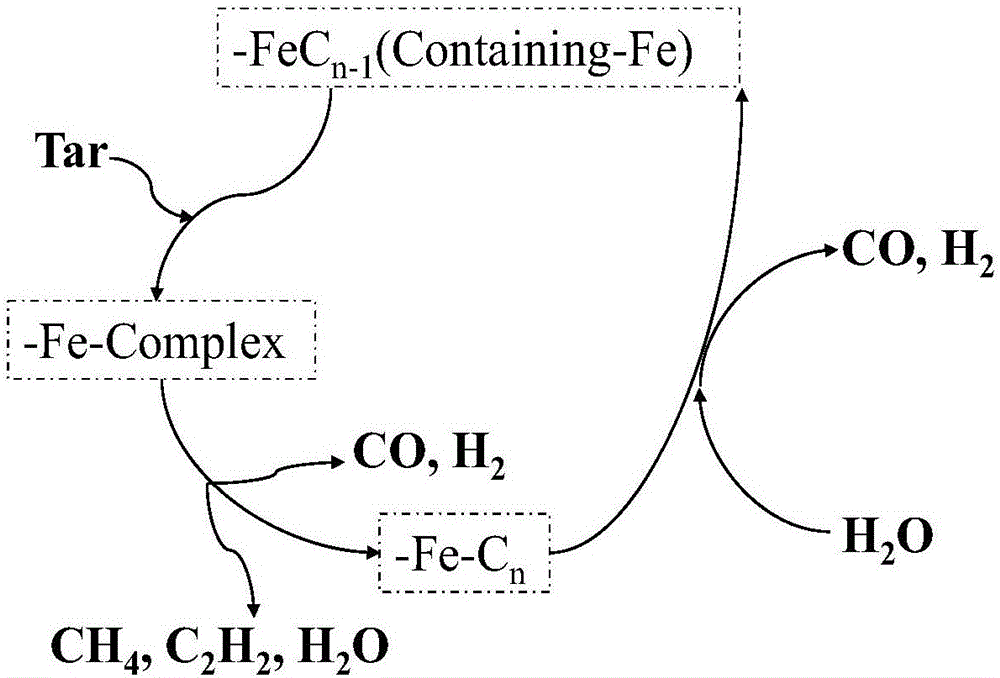

Sludge composite conditioner based on iron-containing sludge pyrolysis residue as well as preparation method and use thereof

PendingUS20190315645A1Good conditionSludge treatment by de-watering/drying/thickeningWater treatment parameter controlSludge cakeOxidizing agent

The present disclosure discloses a sludge composite conditioner based on iron-containing sludge pyrolysis residue as well as a preparation method and use thereof. The sludge composite conditioner comprises iron-containing sludge pyrolysis residue and an oxidant used in combination with the iron-containing sludge pyrolysis residue, in which the iron-containing sludge pyrolysis residue is pyrolysis residue obtained by dewatering iron-containing sludge to obtain an iron-containing sludge cake and then pyrolyzing the iron-containing sludge cake, the iron-containing sludge being obtained from an advanced oxidation technology involving an iron-containing reagent. In the present disclosure, through improvements of the subsequent overall treatment process, the reuse mode and specific reaction condition parameters of the respective subsequent treatment process steps of the iron-containing sludge cake, the problem of sludge cake treatment and disposal at the end of the existing sludge treatment and disposal technology can be effectively solved compared with the prior art, and then the iron-containing sludge cake is utilized to form a composite conditioner for deep dewatering of sludge, which is recycled as a sludge conditioner for sludge treatment, thereby realizing the full utilization of resources.

Owner:HUAZHONG UNIV OF SCI & TECH

Waste treatment system

ActiveUS20090008312A1Sludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakeWater treatment system

A system for removing water from sludge is disclosed. The system (100) includes: de-watering (102) sludge comprising an output from a wastewater treatment system to form a semi-solid sludge cake; dispensing (104) the sludge in a sludge hopper and dispensing a blending material in a recipient blending material hopper; depositing (106) the sludge and the blending material in a mixing device; mixing (108) the sludge and the blending material having a porous structure in a weight ratio of the sludge to the blending material of about from 2:1 to about 10:1; and compressing (110) the sludge and the blending material to release moisture. Advantageously, the system (100) provides an improved method of de-watering sludge, for more efficient processing, transporting and recycling, depending on the application.

Owner:HYDROPRESS HLDG

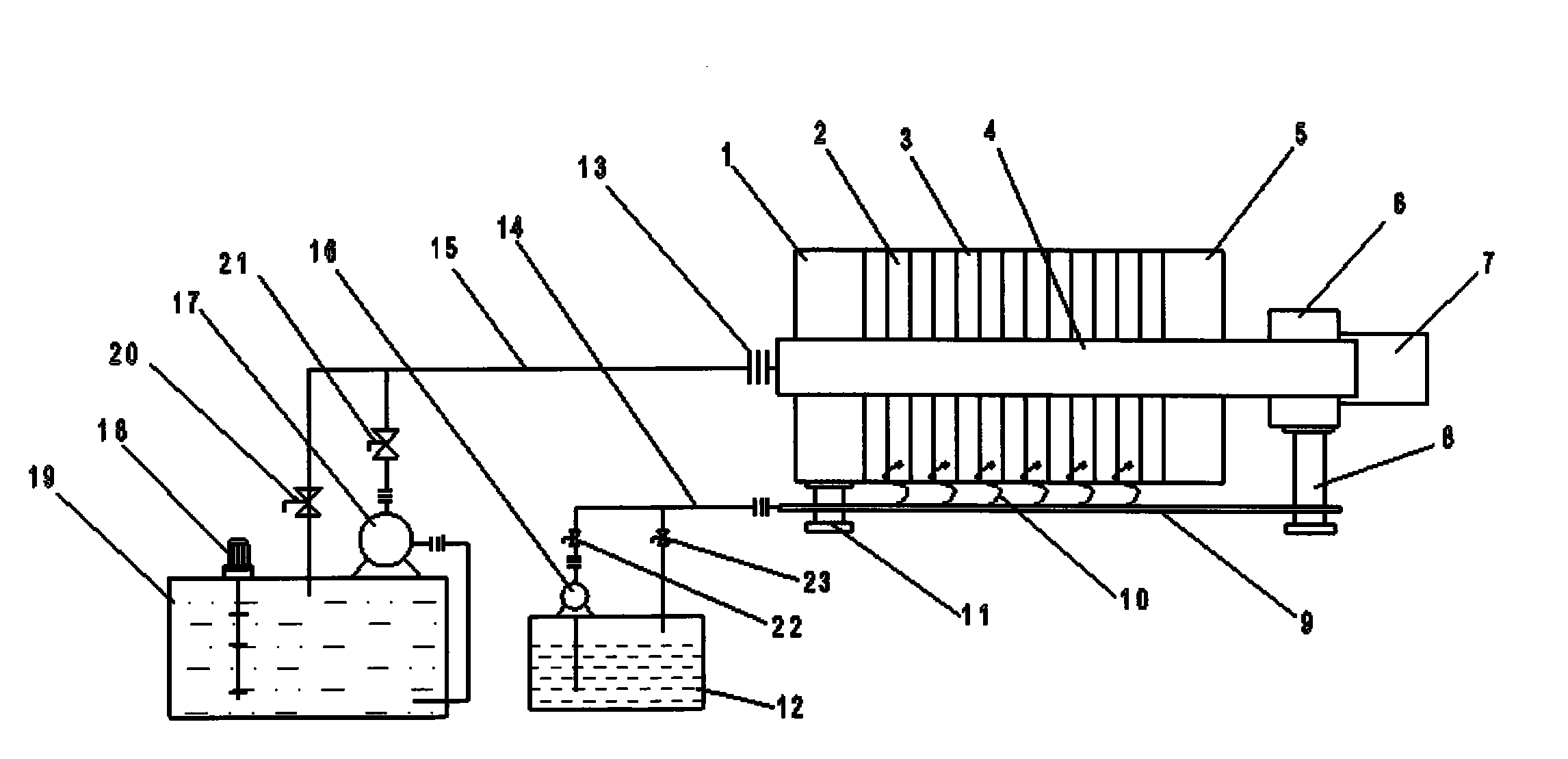

Sludge dewatering membrane filter press and filtration method thereof

InactiveCN102126820AEasy to separateEasy to transportSludge treatment by de-watering/drying/thickeningSludge cakeHydraulic cylinder

The invention relates to a sludge dewatering membrane filter press and a filtration method thereof. The membrane filter press mainly comprises a framework part, a filtration part, a hydraulic part and a PLC (Programmable Logic Controller) automatic control part, wherein the framework part comprises a main beam connection base and a thrust plate, and the upper end of a main beam is provided with a pressure plate; the filtration part comprises a membrane filter plate and a frame type filter plate and filter cloth; a hydraulic cylinder of the hydraulic part is installed on the base, and a piston rod of the hydraulic cylinder is connected with the pressure plate; and a sludge thickening tank is provided with a blender and a feeding pump, and a feeding pipeline is provided with a control valve and is connected with the feeding pump. The filtration method is characterized by adding an organic flocculant in the sludge thickening process. By using the sludge dewatering membrane filter press and the filtration method thereof provided by the invention, the sludge filtration speed is high, and the sludge can be subjected to quick solid-liquid separation under the thickening action of the added organic flocculant. Besides, the filtered sludge cakes can be used as organic fertilizers in the farm field, and can be also used for incineration power generation in a power plant to save the energy, thereby fully achieving the effect of waste reutilization.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

Sludge dehydration treatment technology

ActiveCN101767922AConform to the internal relationship of concentration progressionImprove concentrationSludge treatment by de-watering/drying/thickeningSludge cakeFiltration

The invention relates to a sludge dehydration treatment technology which includes the steps as follows: residual active sludge is treated for concentration sequentially in a continuous gravity concentration tank and an intermittent sludge concentration tank, then put in a chemical conditioning tank and guided into a tumbling centrifugal concentrator for further concentration after being chemically conditioned, and finally put into a belt filter press to be dehydrated to become sludge cake. The sludge dehydration treatment technology of the invention aims at the residual active sludge property characteristics to strengthen the concentration effect before mechanical dehydration and has the advantages of little addition dosage in dehydration, sludge cake chickening, low moisture content in sludge cake, easy washing of filtration fabric not stuck by sludge, low solid content in separation medium, and high solid recovery rate.

Owner:四川蓉信开工程设计有限公司

Waste treatment system

InactiveUS20110084029A1Sludge treatment by de-watering/drying/thickeningLavatory sanitorySludge cakeImproved method

A system and method for removing water from sludge is disclosed. The method (100) includes: de-watering (102) the sludge comprising an output from a wastewater treatment system to form a semi-solid sludge cake; dispensing (104) the semi-solid sludge cake in a hopper and dispensing a dewatering agent in a recipient dewatering agent hopper; depositing (10) the semi-solid sludge cake and the dewatering agent in a mixing device; mixing (108) the semi-solid sludge cake and the dewatering agent having a porous structure in a weight ratio of the semi-solid sludge cake to the dewatering agent of about from 1:1 to about 10:1; and compressing (110) the semi-solid sludge cake and the dewatering agent to release moisture. The system (100) provides an improved method of de-watering sludge, for more efficient processing, transporting and recycling, depending on the application.

Owner:HYDROPRESS HLDG

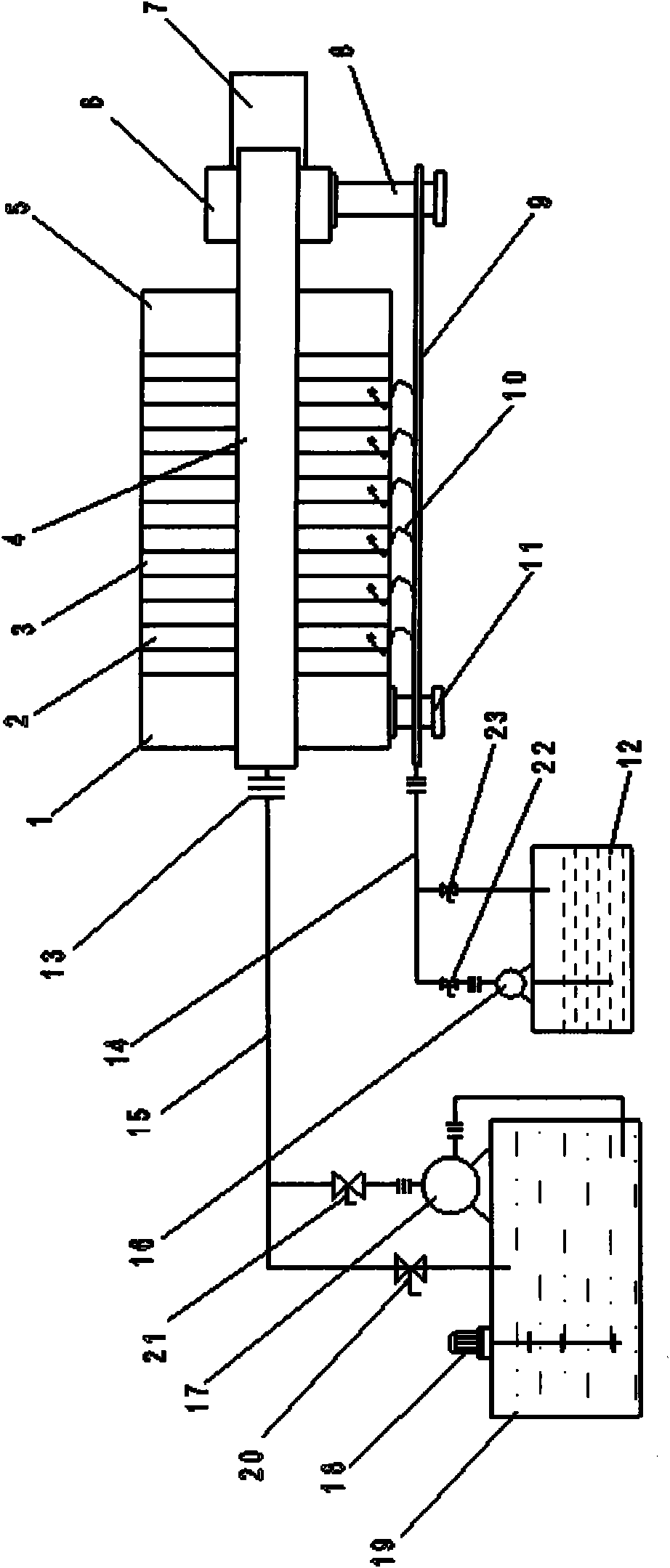

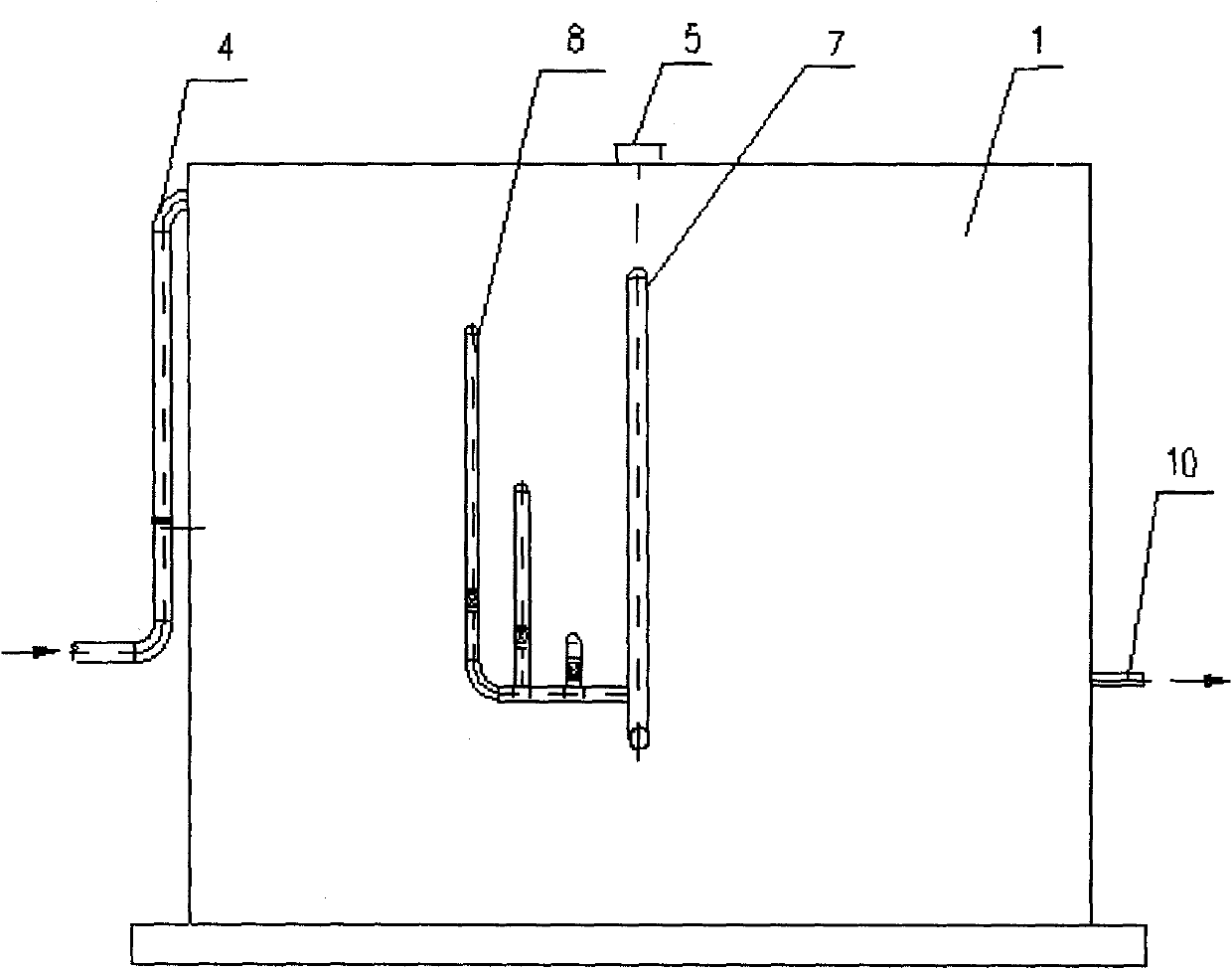

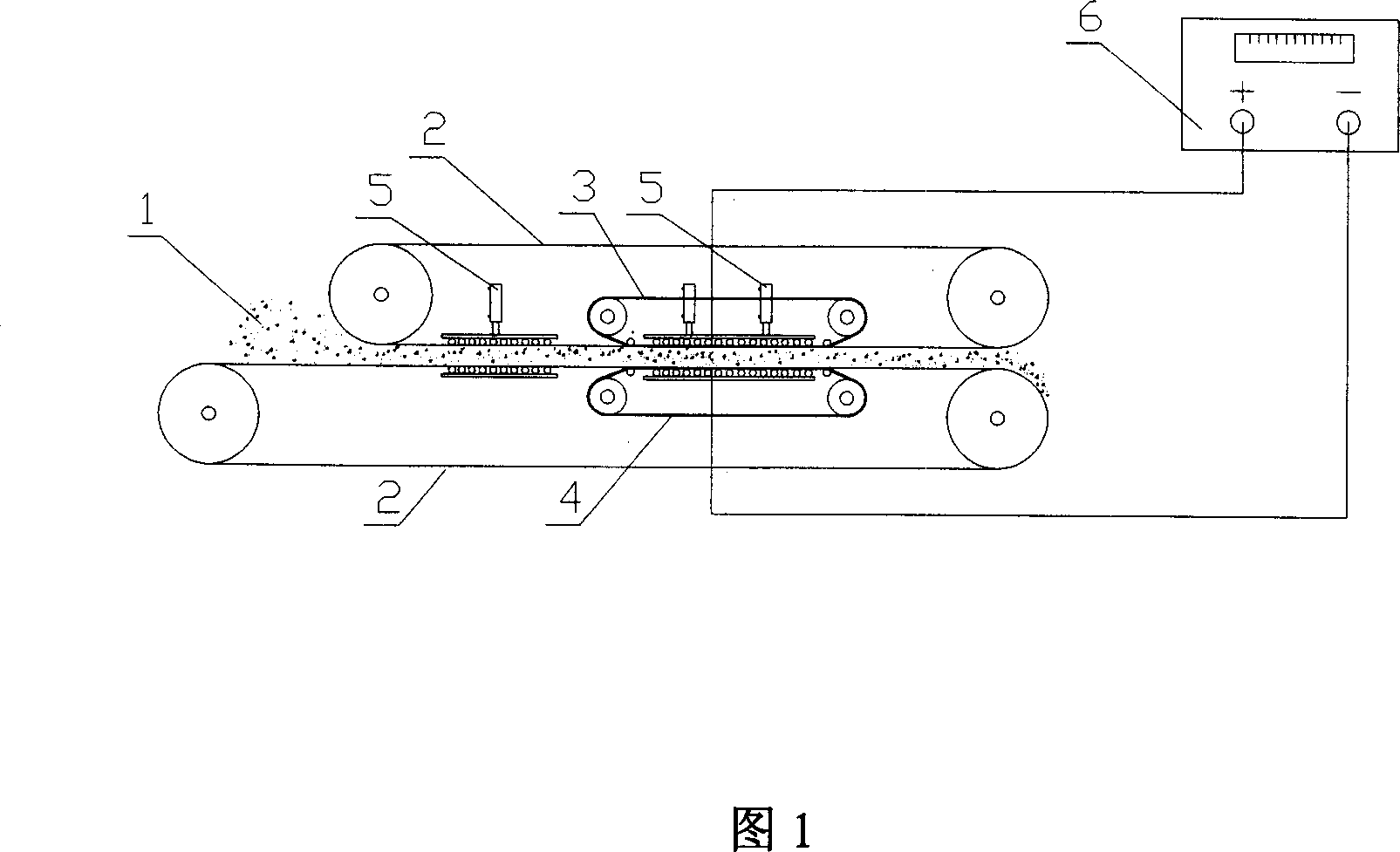

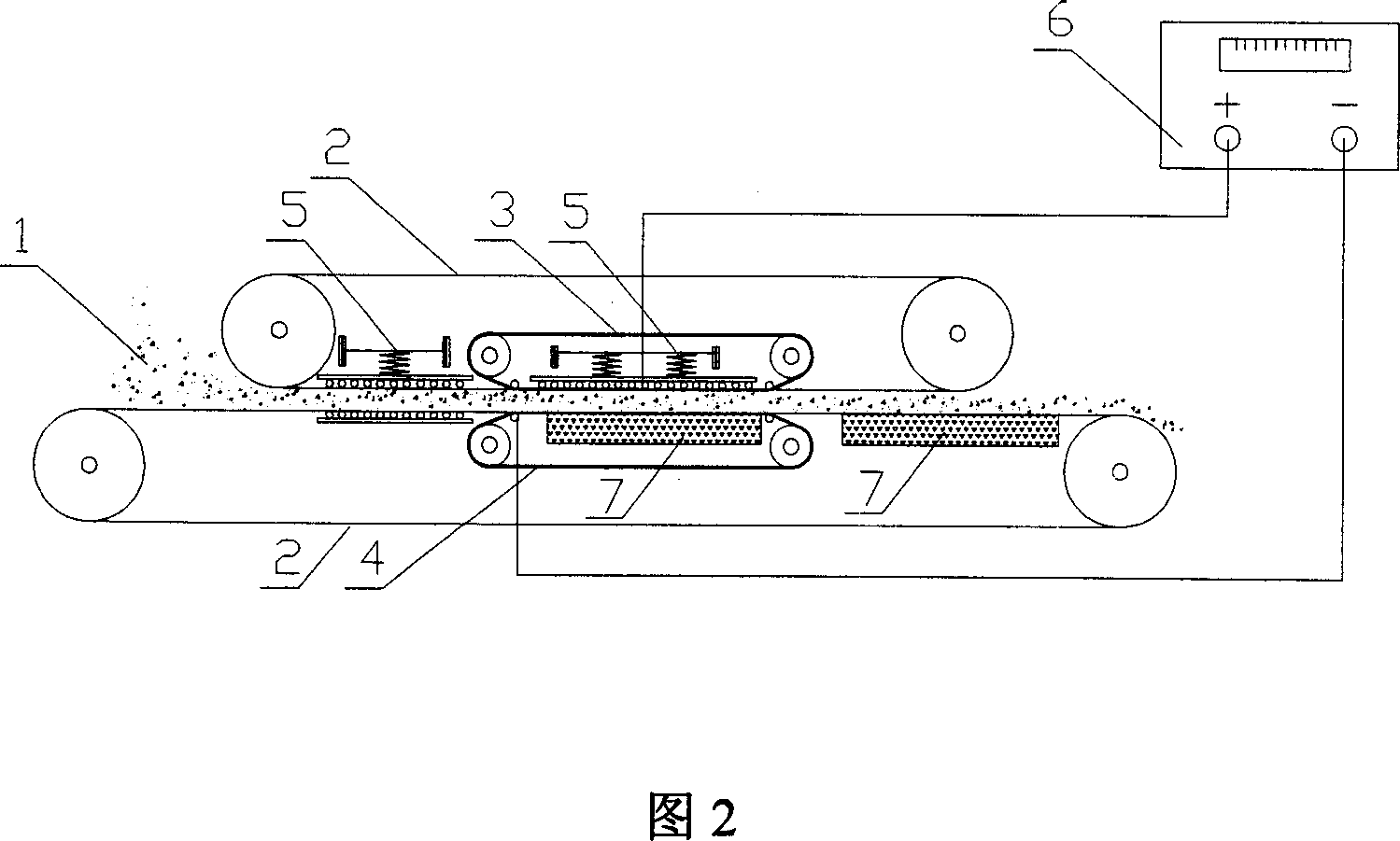

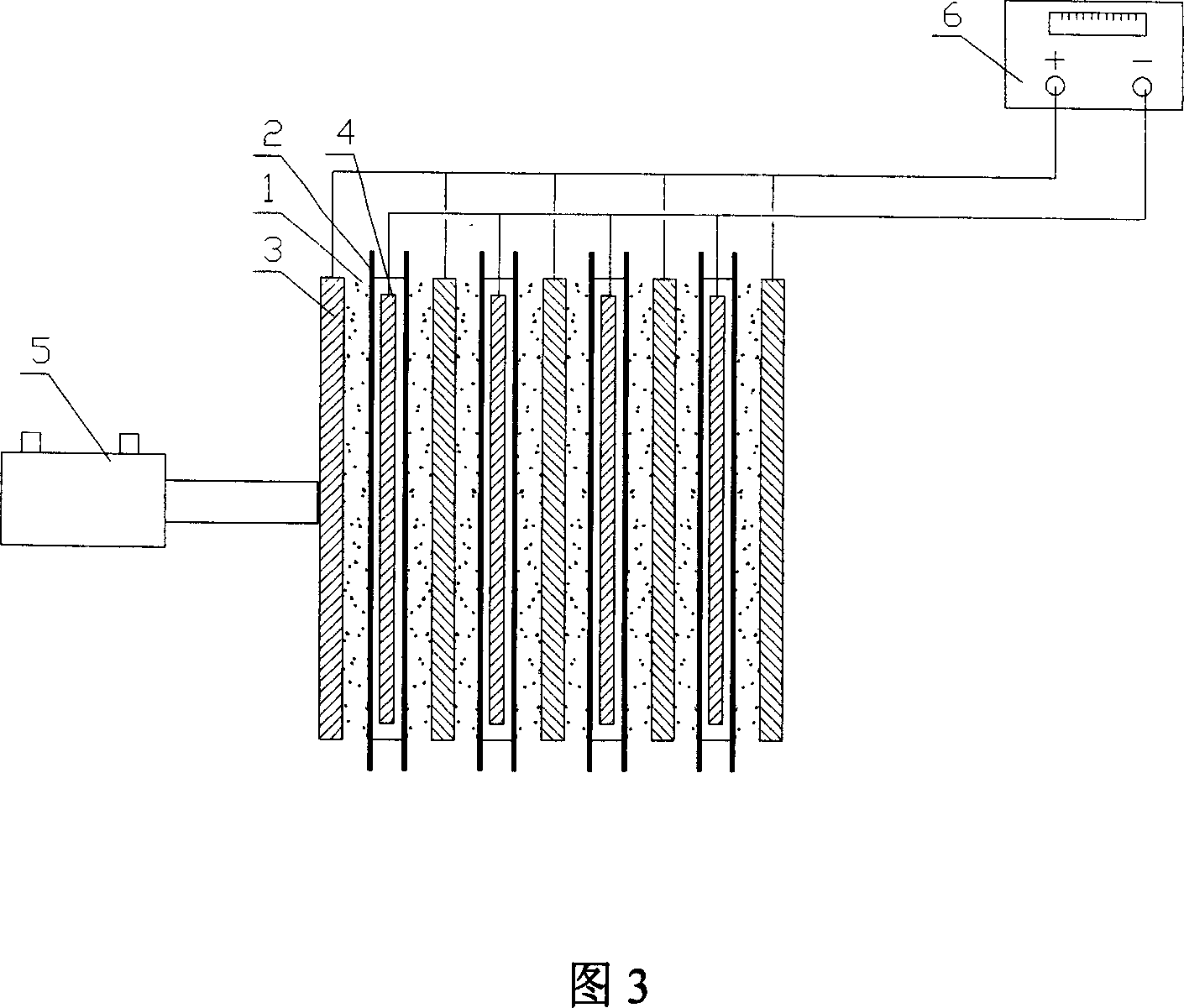

Electric field synergistic mud dewatering method and its device

The present invention relates to a method for sludge dehydration under the synergistic action of electric field and its equipment. Said dehydration method is characterized by that at two sides of sludge cake a negative electrode conductor and a positive electrode conductor are arranged so as to form an electric field, between the above-mentioned two conductors a mechanical pressure is applied, and the water content separated out from negative electrode conductor side can be separated from sludge by means of pervious material. Said equipment for implementing said method includes negative electrode conductor, positive electrode conductor, mechanical pressure device and pervious material layer.

Owner:TIANJIN UNIV

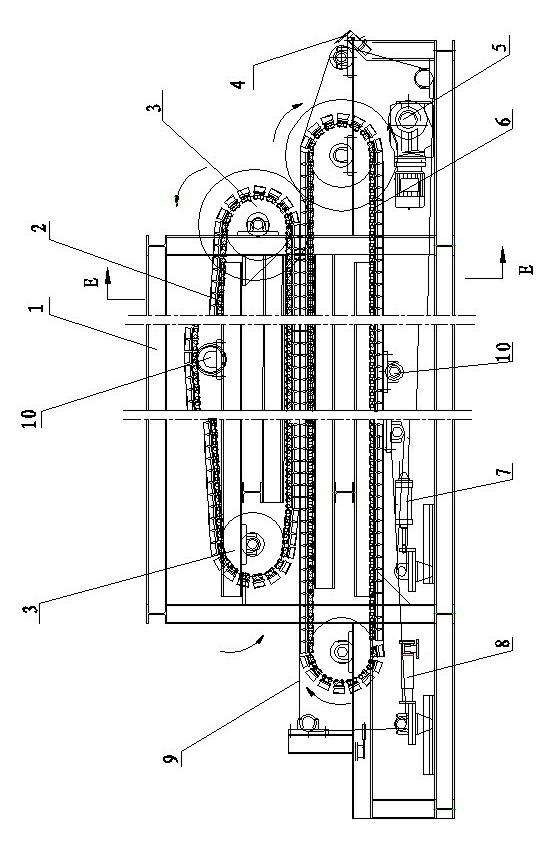

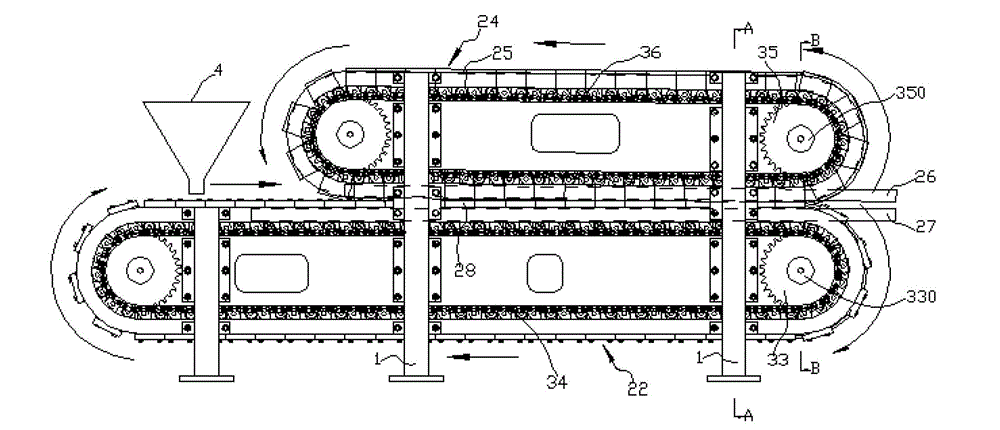

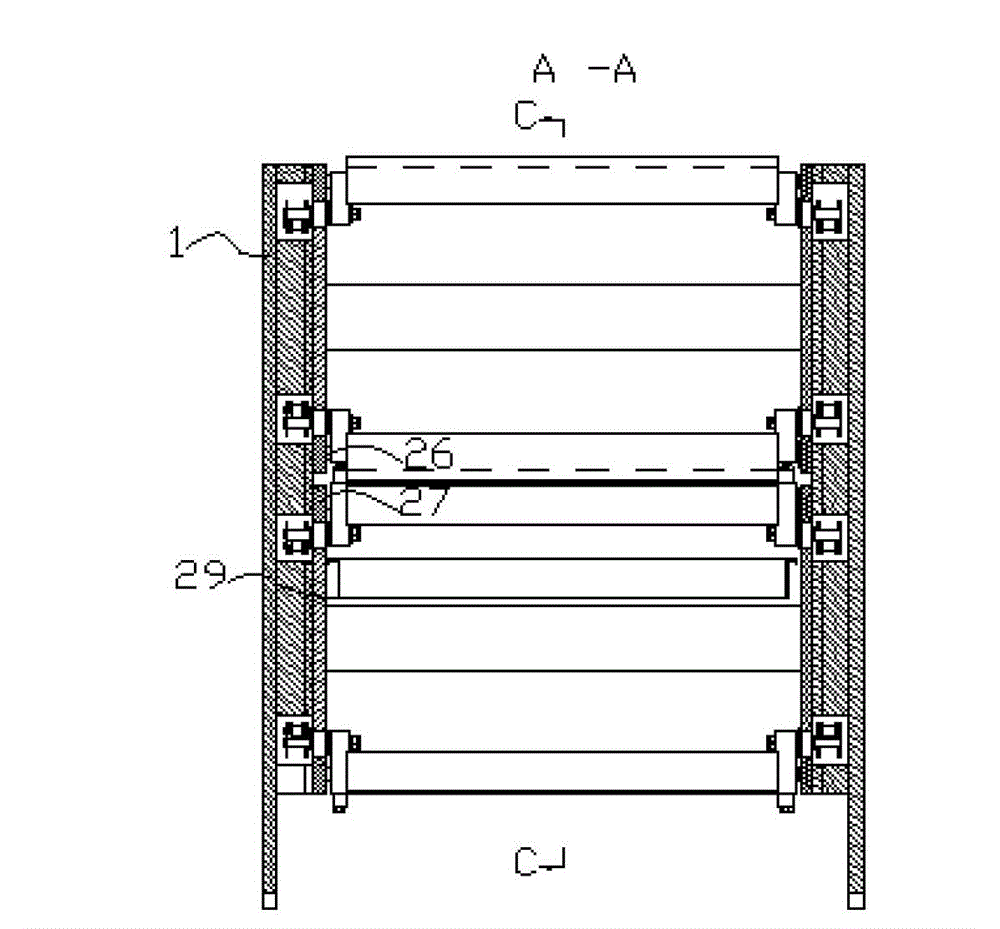

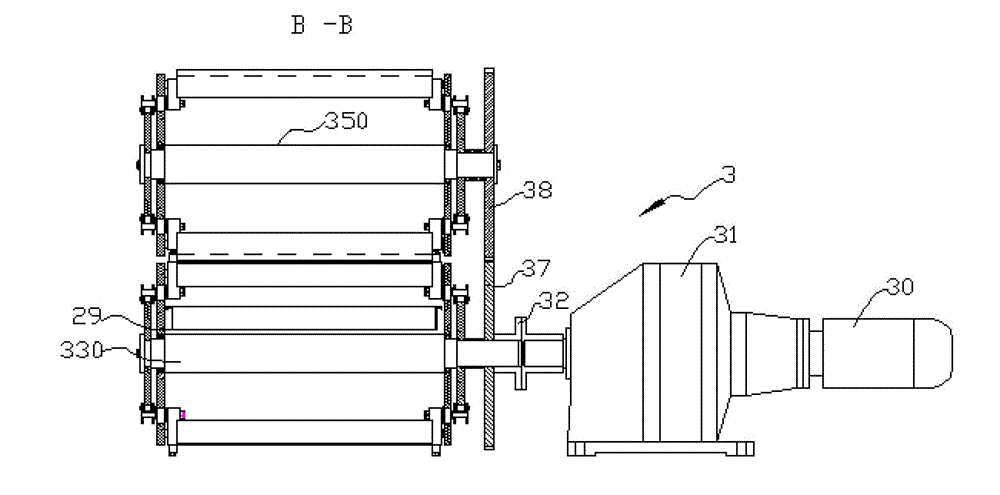

Electroosmosis belt type squeezing sludge dehydration equipment

ActiveCN102653438ASignificant reductionFacilitate flowSludge treatment by de-watering/drying/thickeningSludge cakeDrive shaft

The invention discloses electroosmosis belt type squeezing sludge dehydration equipment, which comprises a stander, an upper squeezing belt, transmission shafts, a scraper blade, power machinery, a lower squeezing belt, a tension device, a rectification device, a filter belt, supporting wheels and a power supply, wherein the upper squeezing belt and the lower squeezing belt which are supported and driven by the transmission shafts have the same structure, namely a track type structure which consists of two chains arranged at an interval and an upper bridge plate and / or a lower bridge plate which are / is transversely arranged according to pitches of the chains; the upper squeezing belt and the lower squeezing belt are respectively connected with the positive electrode and the negative electrode of the direct current power supply and clamp the filter belt to enter a wedged flat groove of the stander, namely a squeezing region under an electrophoresis condition, so that water molecules in sludge flow towards the lower bridge plates with negative levels; and therefore, the squeezing dehydration efficiency is greatly improved, the sludge is reduced obviously, and the produced high-dryness sludge cake is favorable for later-stage recycling application.

Owner:江苏百新环境工程有限公司

Method for processing sludge resources

InactiveCN101671588AFast dehydrationReduce moisture contentSludge treatment by de-watering/drying/thickeningBiofuelsSludge cakeProcess engineering

The invention discloses a method for processing sludge resources. The method comprises the following steps: (1) evenly mixing the crushed dry plant-based wastes generated in the industrial and agricultural production with sludge cake with moisture content of 80wt%-85wt%; the moisture content of the mixture is lower than 55 wt%-60wt%; (2) the mixture is heated and dried until the moisture content thereof is 20 wt%-25wt%; (3) fuel particles are produced through a granulating machine; and (4) the fuel particles are used for heat supply for the drying step. Since the plant-based wastes provided with low moisture content and generated in the industrial and agricultural production are mixed with the sludge cake, the dehydration speed of the mixture in a drying apparatus is higher than that of the single sludge cake, the drying temperature is lower, and the heat consumption is less. The fuel particles obtained by the method can be taken as the energy resources to replace the fossil energy forsewage treatment, and simultaneously, the obtained heated steam also can be taken as resource to sell.

Owner:天津紫荆能源技术有限责任公司

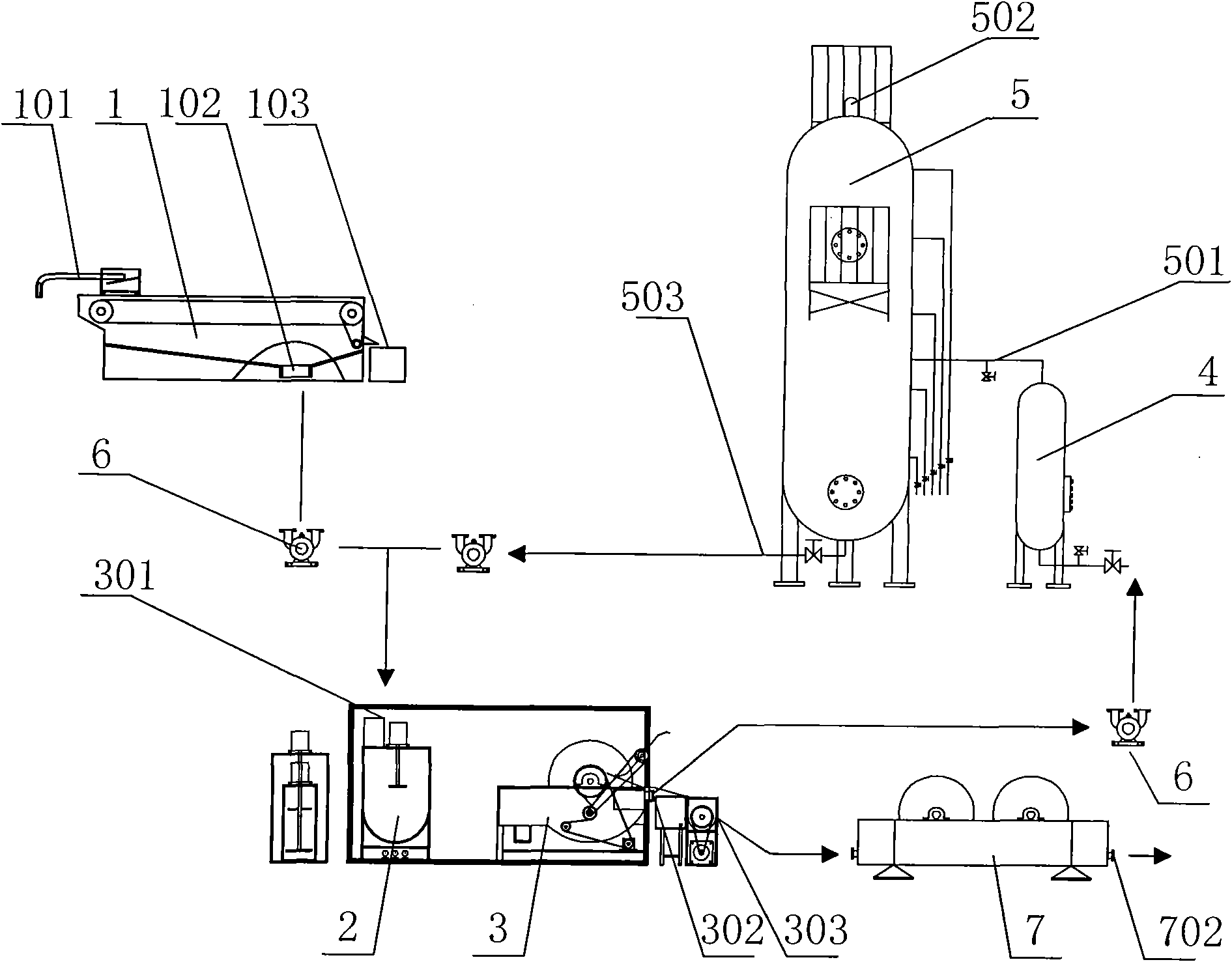

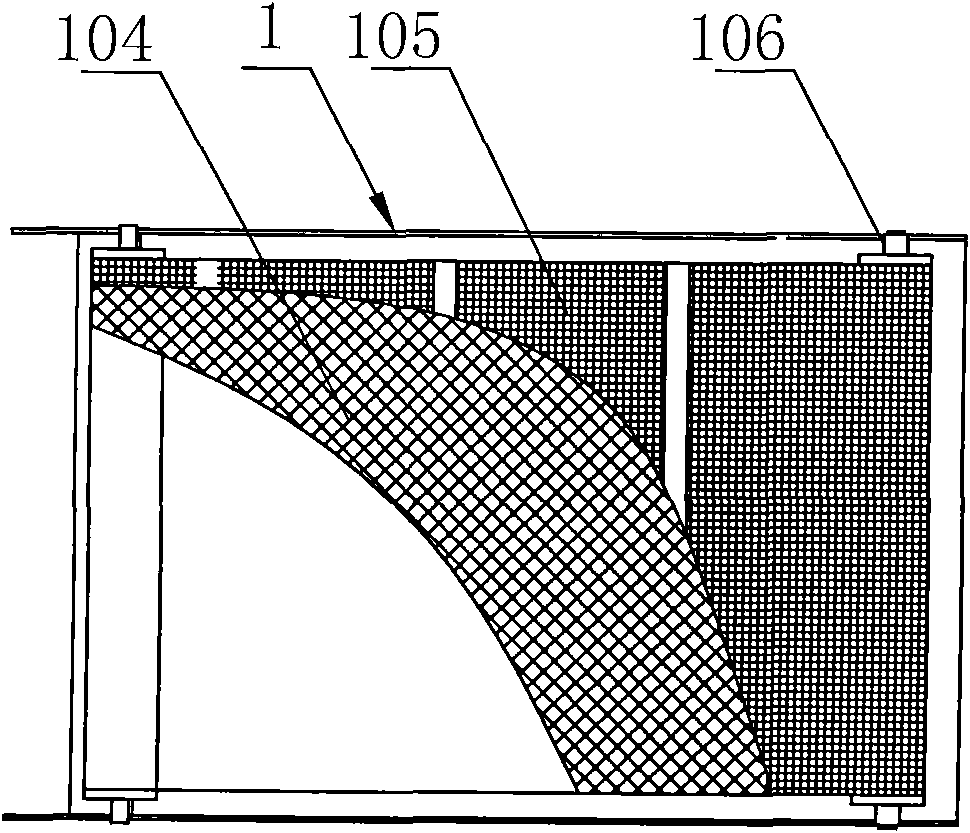

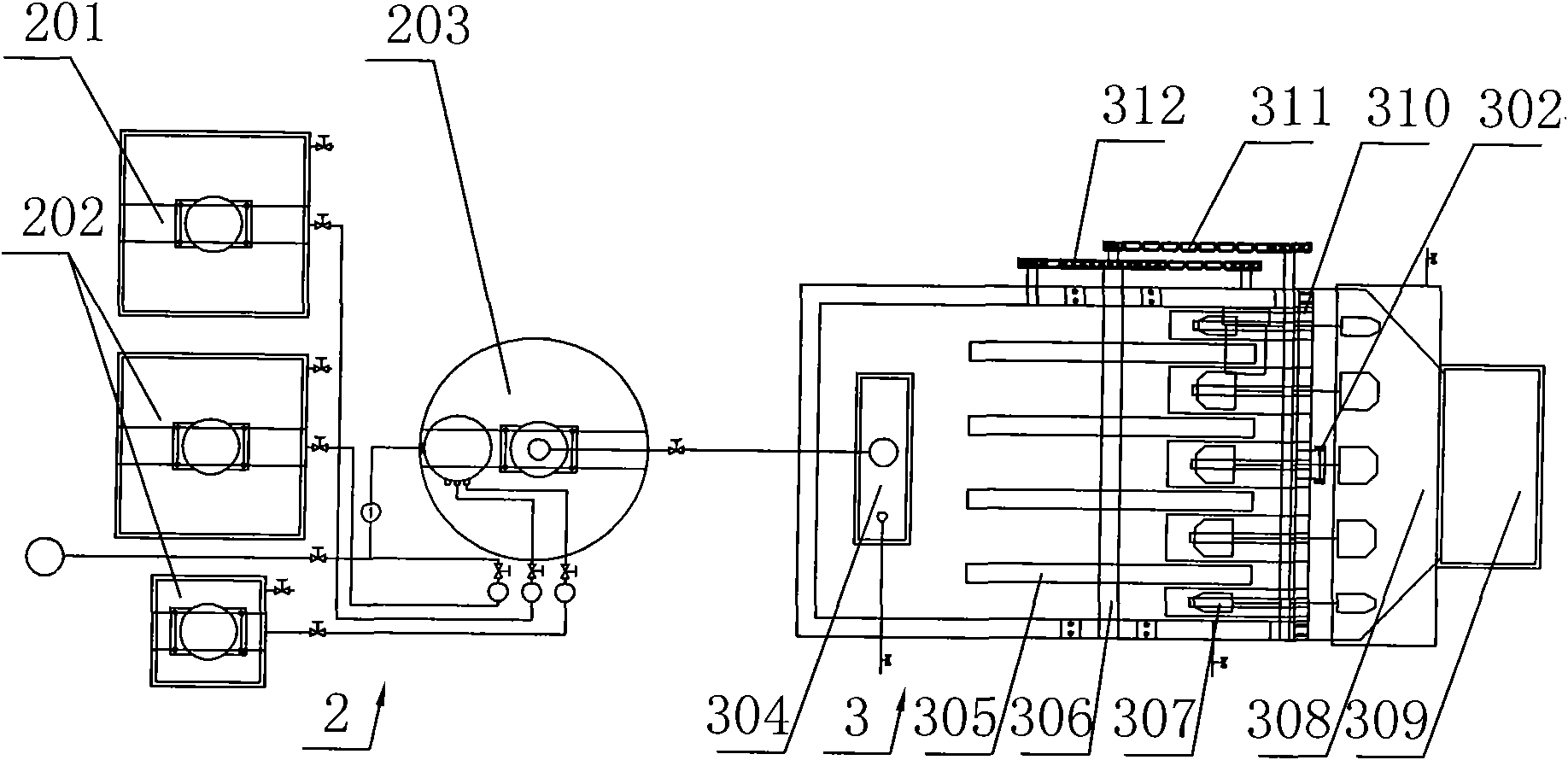

Device and method for magnetic separation of underwater sludge

InactiveCN101798166AHigh outputImprove processing efficiencySludge treatment by de-watering/drying/thickeningSludge cakePrimary standard

The invention relates to a device and a method for magnetic separation of underwater sludge. The device comprises a roller screen, a magnetic separator, a reaction tank and a sludge separation tower which are connected in series by pipelines, wherein a water outlet of the previous stage treatment device is connected with an inlet of the next stage treatment device, and a sludge outlet of the sludge separation tower is connected to an inlet of the magnetic separator. The device has the characteristics of small floor area, low energy consumption, non-clogging continuous operation, large sludge yielding quantity and the like, has good removability and can be conveniently arranged at a sludge treatment site; the device not only reduces the natural drying time of a sludge stock dump and improves the sludge treatment efficiency, but also greatly reduces the desilting cost; and during an actual operation, the output quantity of sludge cakes is large, the yielding water of the separation tower completely reaches a primary standard in discharge indexes (GB18918-2002).

Owner:中国船舶重工集团公司第七〇二研究所

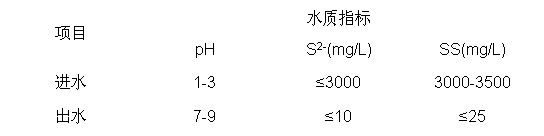

Oil and gas field high-sulfur-content waste water processing method

InactiveCN102992507AHarm reductionImprove securityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludge cakeSulfide

The invention relates to a processing method of oil and gas field high-sulfur-content waste water in fields of oil and gas exploration, mining, and transportation. The method comprises the steps that: a, waste water is added into a sealed reaction tank; a pH regulating agent and a desulfurization agent are added into the tank; b, hydrogen sulfide gas escaped in the sealed reaction rank is pumped into a biological desulfurization reaction device and is processed; c, a flocculating agent is added into the waste water after reaction, and a coagulation treatment is carried out; and d, after the coagulation treatment, sludge-water separation is carried out; separated filtrate is delivered into subsequent waste water processing process; and separated sludge cake is subjected to in-situ curing. With the method provided by the invention, hydrogen sulfide and sulfide pollutions are eliminated; hydrogen sulfide harm and safety risk during oil and gas mining and transportation process are reduced; environmental pressure is reduced; sulfide-removing treatment is thorough; and cost is low.

Owner:SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

Deep sludge dewatering process

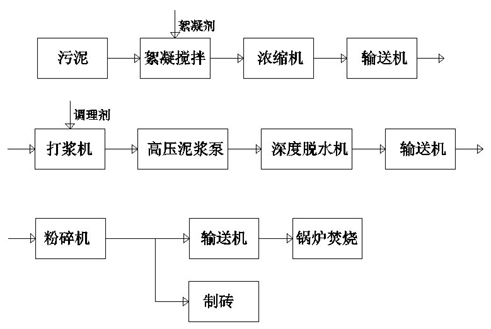

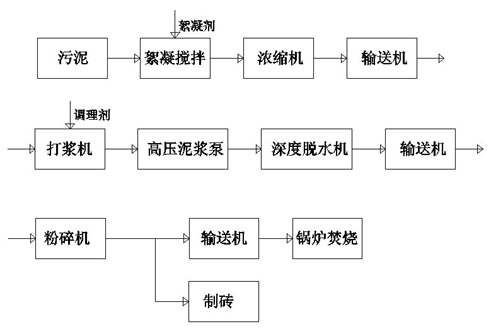

InactiveCN102001812AAchieve reductionSmall footprintSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludge cakeResource utilization

The invention belongs to the field of sludge treatment, in particular to a deep sludge dewatering process. The process comprises the following steps of: performing flocculation reaction on sludge with water content of over 96 percent which is produced after sewage treatment; overflowing the sludge subjected to the flocculation reaction to a concentrator for concentration and dewatering; pulping and conditioning in a pulping machine after the concentration and dewatering; conveying to a deep dewatering machine by a high-pressure sludge pump to perform deep dewatering; and finally conveying to a crusher to crush the sludge into powdery or blocky sludge and conveying the crushed sludge to a boiler for burning or recycling. In the process, processing is performed at normal temperature, noise, odor, secondary pollution and pollution mode transfer are avoided, the process does not depend on any boundary condition or consume a primary energy source, the sludge with the water content of 80 to 90 percent can be dehydrated to be sludge with the water content of below 45 percent, the dehydrated sludge cakes cannot be restored when contacting water, and sludge cakes can be crushed into small blocky or powdery sludge in order to make the resource utilization convenient and moisture can continuously evaporate in a natural state.

Owner:杭州苏堤环保实业有限公司

Method for treating excess sludge

ActiveCN102161557ADisposal realizedTo achieve the purpose of dehydration reductionSludge treatment by de-watering/drying/thickeningBiofuelsThermal energySludge cake

The invention discloses a method for treating excess sludge. The excess sludge is dried by utilizing sintering flue gas which is discharged in a metallurgical sintering process and has higher temperature. The method specifically comprises the following steps of: feeding excess sludge to be treated which has the water content of between 80 and 90 percent into a plate and frame filter press, dehydrating under the pressure of between 25 and 45MPa to obtain a filter-pressed dehydrated sludge cake with the water content of between 40 and 55 percent, feeding the sludge cake into a sludge granulation device to crush into coarse particles with the particle size of about between 3 and 5mm, introducing the particles into a thermal energy drying room, introducing flue gas which is discharged in the metallurgical sintering process and has the temperature of between 100 and 180 DEG C into the thermal energy drying room, and drying the sludge particles, wherein the calorific value of the dried sludge is 2,000 to 4,000 kilocalories and the water content is 5 to 10 percent. The method has the advantages that: the waste heat in the sintering flue gas in iron and steel metallurgical industry is effectively utilized, the dehydration of the excess sludge is reduced, the excess sludge with a higher calorific value is taken as fuel to be added into a sintering working procedure, and the final treatment of the excess sludge is realized.

Owner:北京方兴科创环境科技有限公司

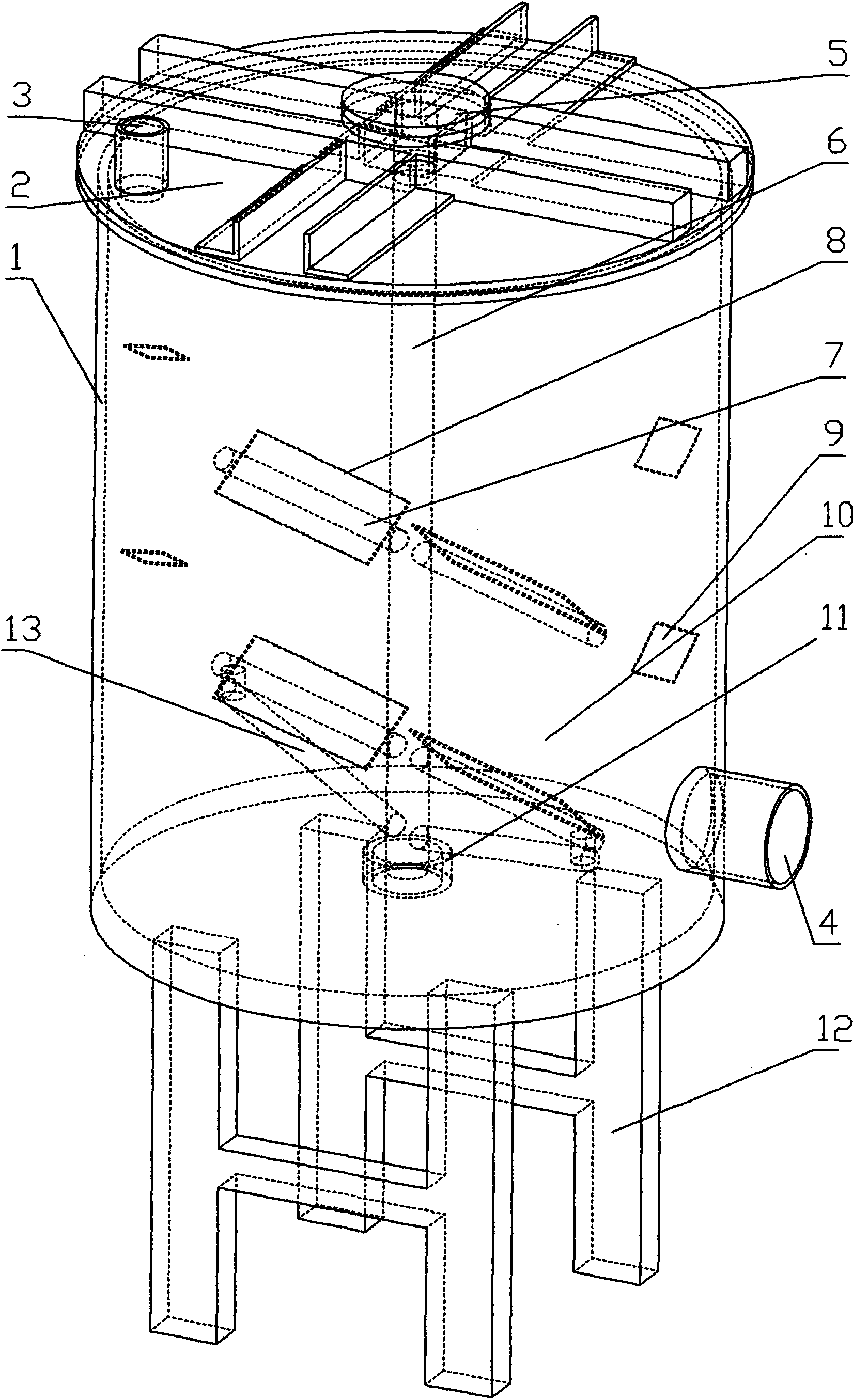

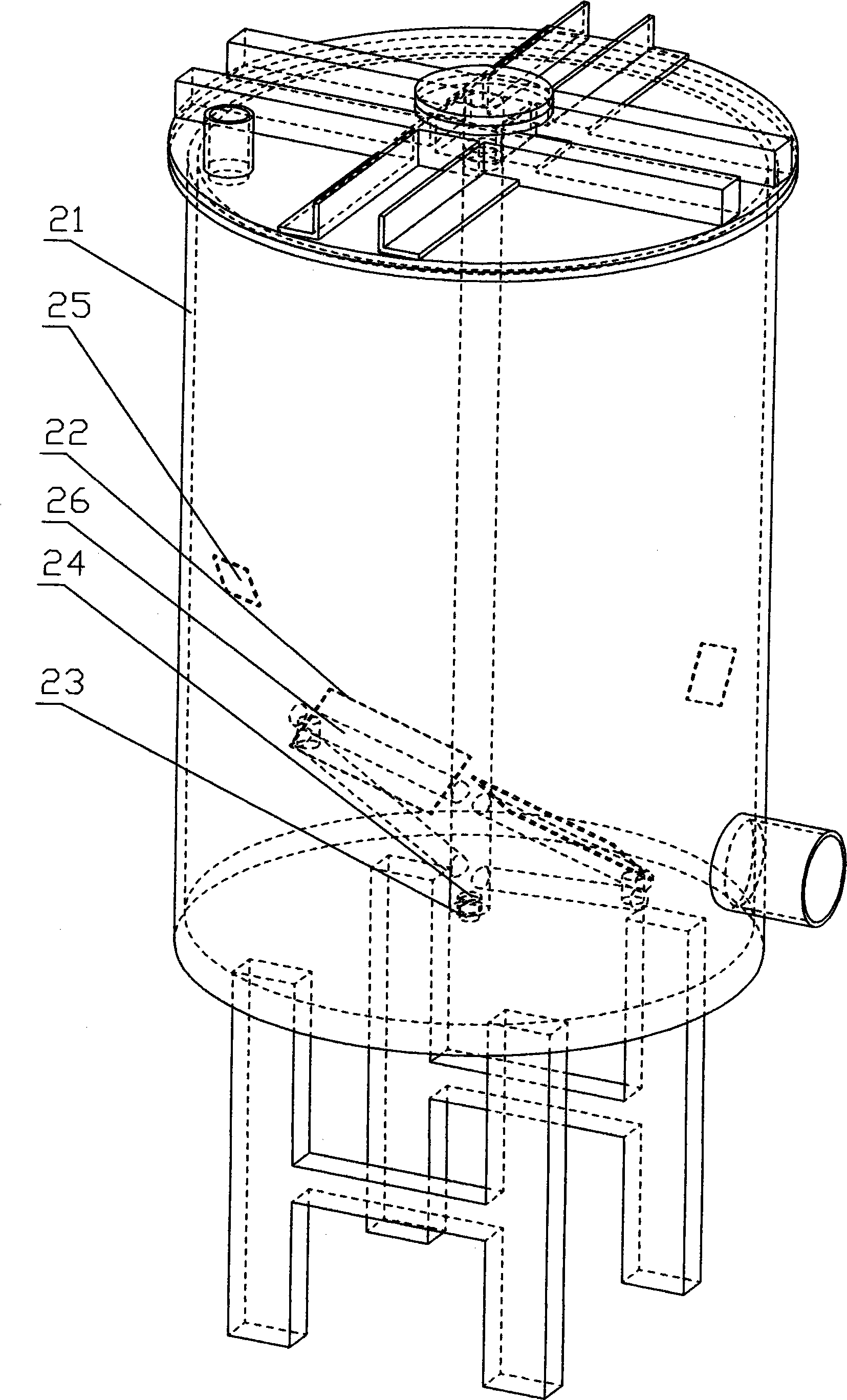

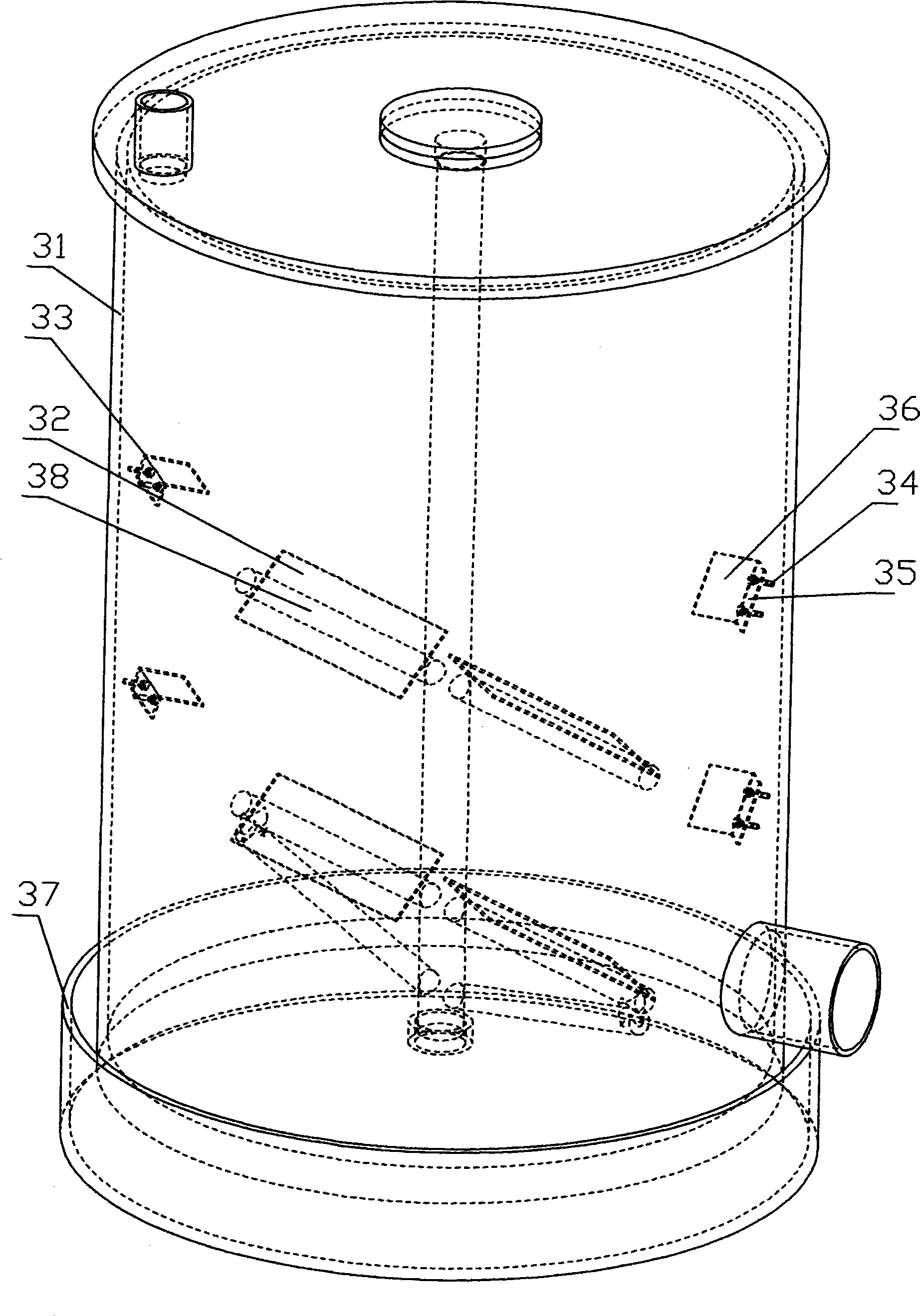

Sludge stirring system

InactiveCN101544461AReduce pollutionImprove working environmentSludge treatment by de-watering/drying/thickeningSludge cakePulp and paper industry

The invention discloses a sludge stirring system, comprising a stirring tank, a sludge output, a driving device, a stirring shaft arranged on the same shaft with the driving device, a stirring blade and a baffle. Every group of baffle is regularly arranged above the stirring blade of the corresponding group and has the same height with the inner side of the stirring tank. The vertical distance between the baffle and the corresponding stirring blade is more than 0.3 meter or equal to 0.3 meter. The installation direction of the baffle is opposite to the rotating direction of the stirring blade. An angle of 30 DEG to 60 DEG is kept between the baffle and the ground. The radical width of the baffle is 15 percent to 15 percent of the diameter of the stirring tank. The radical width of the baffle is more than or equal to 0.1 meter while the length of the baffle is more than or equal to 0.15 meter. The sludge stirring system has the advantages that the sludge particles are coarse, and solid-liquid separation is obvious, and insoluble additive covered in the sludge cannot be seen when opening the sludge cake, and additives not taking part in the action cannot be seen in the stirring tank. The water content of the sludge cake after dehydration is less than 60 percent.

Owner:GUANGDONG LVYOU ENVIRONMENTAL PROTECTION EQUIP CO LTD

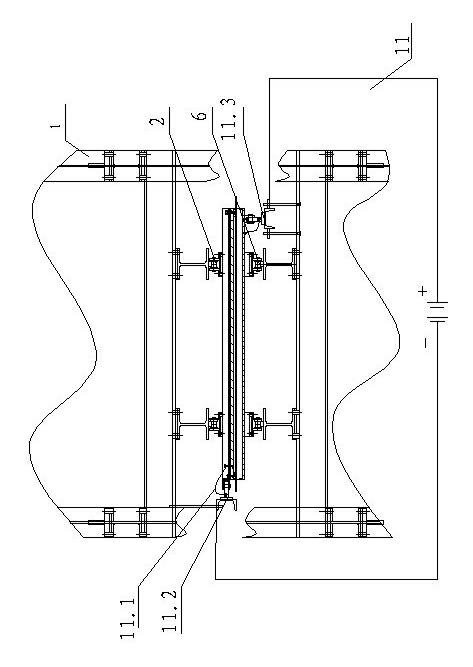

Electroosmosis sludge dewatering equipment

ActiveCN103332844AReduce moisture contentGive full play to the performance of electroosmosisSludge treatment by de-watering/drying/thickeningSludge cakePower efficient

The invention relates to electroosmosis sludge dewatering equipment. The electroosmosis sludge dewatering equipment comprises a frame, a sludge dewatering device, a driving mechanism, a power supply, an annular upper guide rail and an annular lower guide rail fixed on the frame, a plurality of mobile net plates which are capable of moving along the track of the annular lower guide rail, a plurality of extruding plates which are capable of removing along the track of the annular upper guide rail. The tracks of the lower part of the annular upper guide rail and the upper part of the annular lower guide rail are linear. The mobile net plates and the extruding plates are made of conductive materials, and are connected with the cathode and the anode of the power supply respectively; and a sludge extruding channel is formed between the mobile net plates which are arranged on the linear track of the annular upper guide rail and the extruding plates which are arranged on the linear track of the annular lower guide rail, and the width of the sludge extruding channel is narrowed down gradually from one end to the other end. The electroosmosis sludge dewatering equipment is capable of taking full advantage of electroosmosis, and decreasing water content of squeezed sludge cake to 50% or even lower than 40%. In addition, the structure of the electroosmosis sludge dewatering equipment is simple.

Owner:浙江科力尔环保设备股份有限公司

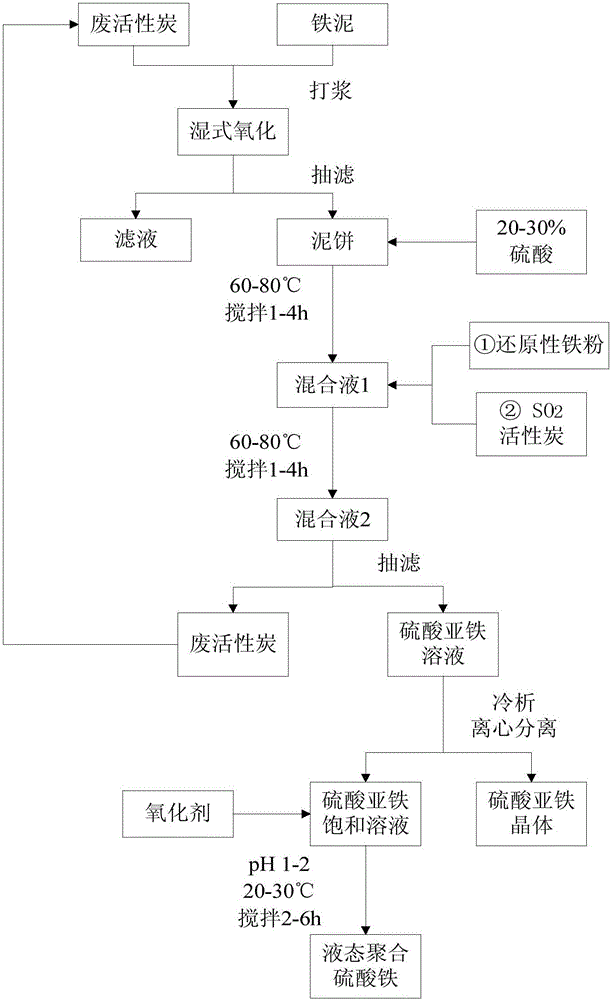

Resource utilization method for iron sludge

ActiveCN105016589AGood removal effectImprove qualitySludge treatment by thermal conditioningSludge treatment by oxidationSludge cakeResource utilization

The invention discloses a resource utilization method for iron sludge. The resource utilization method comprises the following steps: wet oxidation: pulping and dissolving the iron sludge, and separating to obtain an iron sludge cake after a wet oxidation reaction; acid dissolving: reacting the iron sludge cake through sulfuric acid dissolution to obtain a mixed liquor I; reduction: treating the mixed liquor I through an iron powder reduction method or a gas reduction method to obtain a mixed liquor II, and filtering to obtain a filter liquor and a filter residue; cold crystallization: performing cool crystallization on the filter liquor, and separating to obtain industrial grade FeSO4.7H2O and a ferrous sulfate saturated solution; and preparation of polymerized ferric sulfate: adjusting the pH value of the ferrous sulfate saturated solution to be 1-2, adding an oxidizing agent, and performing a heat preservation stirring reaction at the temperature of 20-30 DEG C for 2-6 h, and concentrating to obtain a polymerized ferrous sulfate solution. According to the resource utilization method for iron sludge provided by the invention, ferrous sulfate and polymerized ferric sulfate are produced by taking the solid waste iron sludge as a raw material, and thus the iron sludge is sufficiently utilized.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

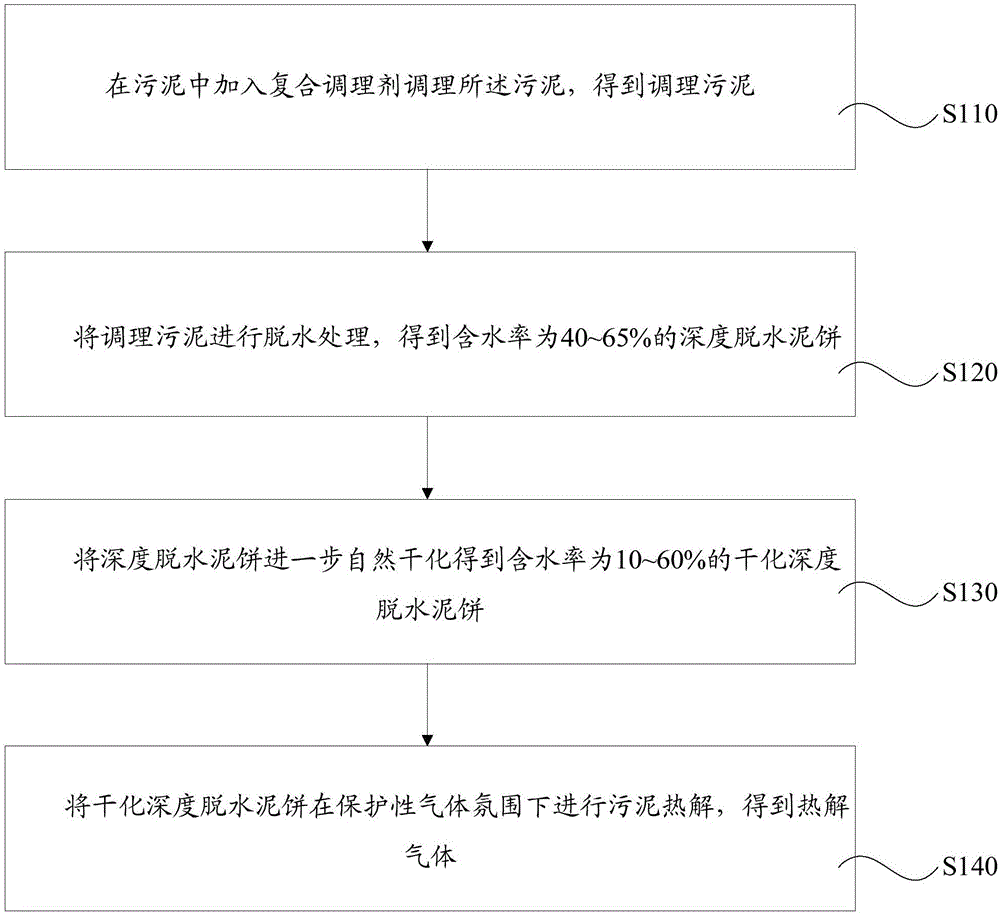

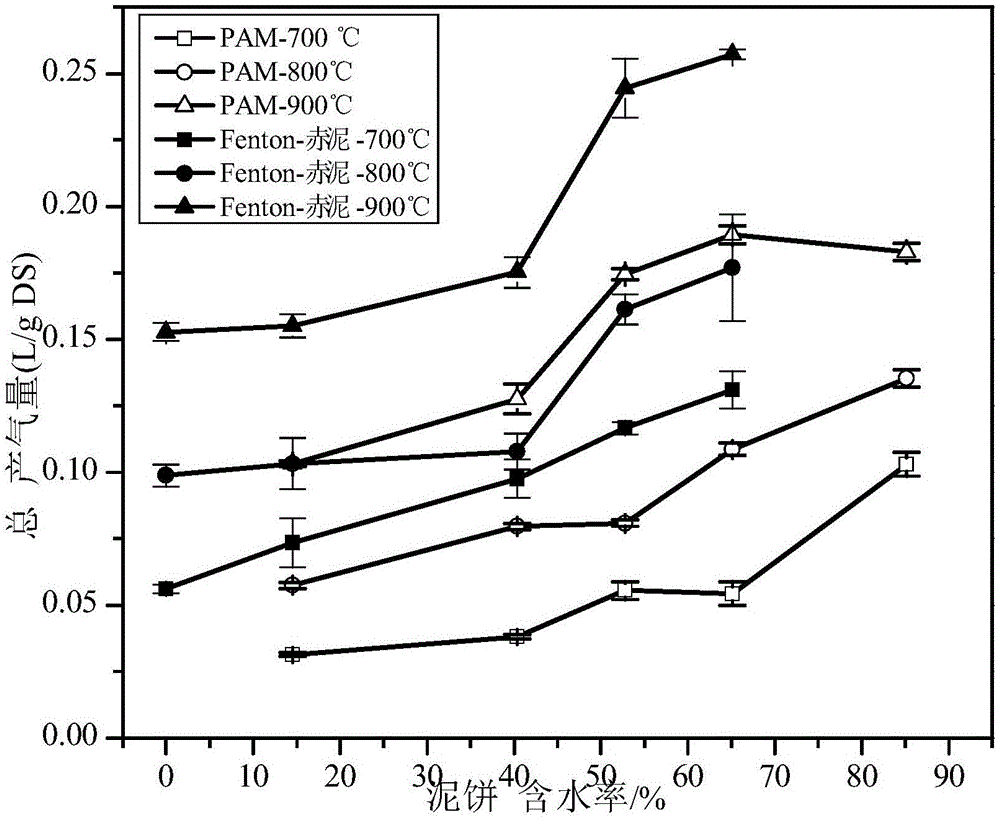

Recycling method for deeply dewatering municipal sludge and gasifying and pyrolyzing sludge cake by aid of water vapor to produce hydrogen

InactiveCN106219941AImprove dehydration effectReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludge cakeHydrogen

The invention discloses a recycling method for deeply dewatering municipal sludge and gasifying and pyrolyzing sludge cake by the aid of water vapor to produce hydrogen, and belongs to the field of technologies for dewatering, pyrolyzing and utilizing municipal sludge. The recycling method includes steps of adding composite conditioners into the sludge to condition and improve the dewatering performance of the sludge so as to obtain conditioned sludge and dewatering and treating the conditioned sludge to obtain deeply dewatered sludge cake with the moisture content of 40-65%; further naturally drying and treating the deeply dewatered sludge cake to obtain dried and deeply dewatered sludge cake with the moisture content of 10-60%; carrying out sludge pyrolysis on the dried and deeply dewatered sludge cake in protective gas atmosphere to obtain pyrolysis gas. The composite conditioners comprise oxidizing reagents and red mud. The recycling method has the advantages that pyrolysis processes are low in comprehensive energy consumption, the yield of the pyrolysis gas can be increased, and the quality of the pyrolysis gas can be improved.

Owner:DONGJIANG ENVIRONMENTAL +2

Method for recycling and processing organic sludge as resources

ActiveCN101698559AReduce the content of organic matterEliminate odorSludge treatment by de-watering/drying/thickeningClimate change adaptationSludge cakePotassium

The invention discloses a method for recycling and processing organic sludge as resources. After the solid content reaches the sludge entering standard by concentrating the sludge, the sludge enters a reactor; the organic sludge carries out the start of thermal digestion in the reactor first, and after the start is finished, the temperature of the sludge in the reactor automatically rises to 48-52 DEG C; after the start stage is finished, the sludge is in the operating stage of the thermal digestion, wherein the sludge is acidulated at high temperature by oxygen hydrolysis in a first reaction zone and is aerobically digested at high temperature in a second reaction zone; and after the temperature of the digested sludge discharged by the second reaction zone in the operating stage is lowered by a heat exchanger, the digested sludge is conveyed into a mechanical dehydrator for mechanical dehydration, and then, the sludge is manufactured into sludge cakes to be conveyed outside. The sludge can be processed by the method to be stabilized and harmless, and a large amount of nutrients, such as nitrogen, phosphorus, potassium and the like in the sludge are reserved, thus the sludge can be used as fertilizer or soil improving additives for safe agricultural use to achieve the purpose of using the sludge as resources.

Owner:JIANGSU UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com