Method for recycling and processing organic sludge as resources

A technology for organic sludge recycling and treatment, applied in sludge treatment, biological sludge treatment, dehydration/drying/concentrated sludge treatment, etc., to achieve the effect of eliminating sludge odor, killing pathogenic bacteria, and low aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The organic sludge resource recycling treatment method of this embodiment processes sludge in spring and autumn.

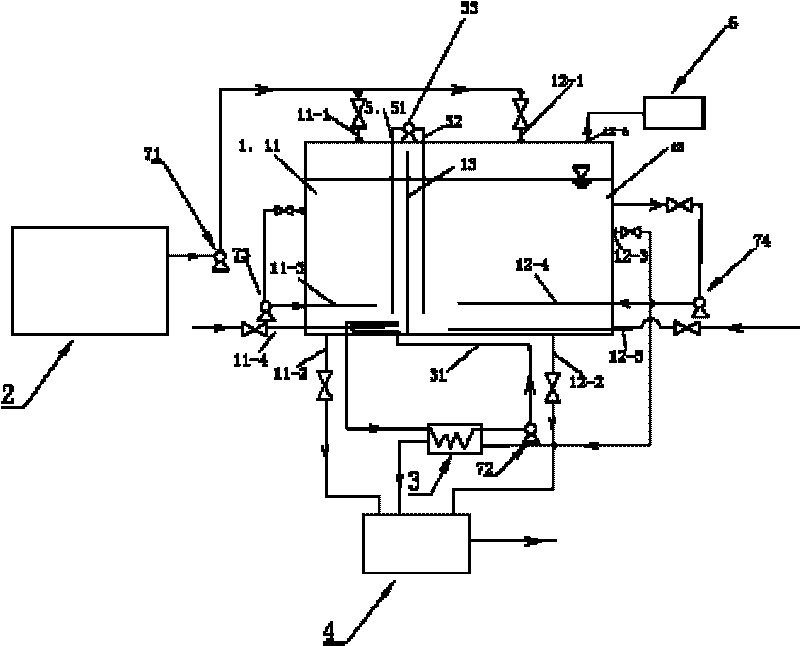

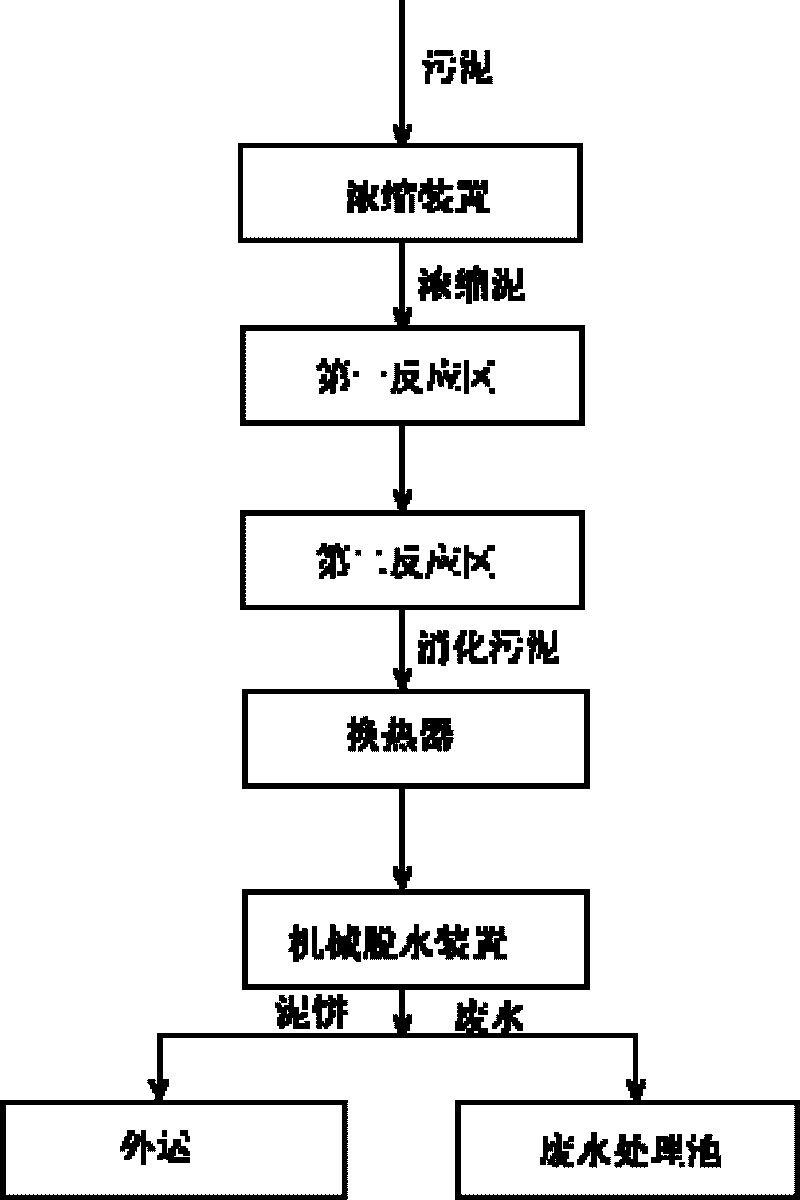

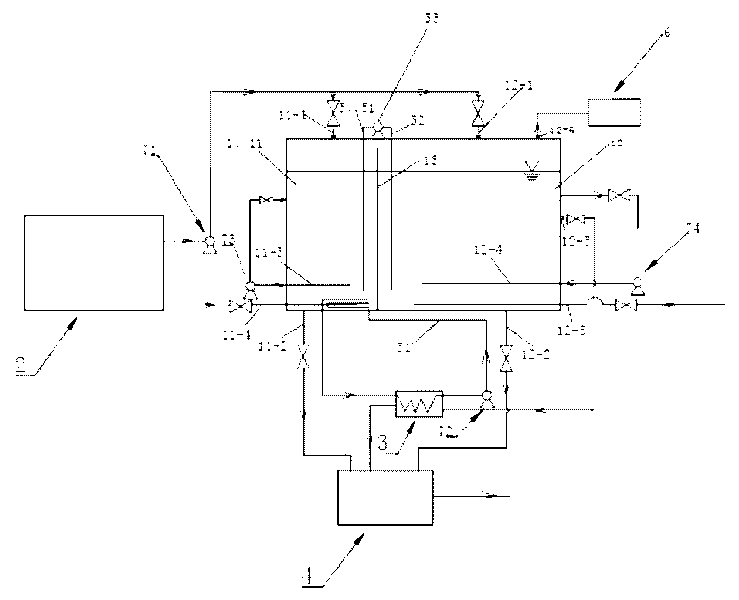

[0047] see figure 1 , The organic sludge treatment system of this embodiment includes a reactor 1, a thickening device 2, a heat exchanger 3, a mechanical dehydration device 4, a sludge conveying device 5, a membrane treatment device 6, a mud pump 71, a circulating water pump 72, a first The sludge return pump 73, the second sludge return pump 74 and corresponding valves and pipes, wherein the thickening device 2 used is a thickening tank.

[0048] The reactor 1 is closed. The reactor 1 is divided into a first reaction zone 11 and a second reaction zone 12. The two reaction zones are separated by a partition 13 whose height is lower than that of the four walls of the reactor. Height, and the volume of the second reaction zone 12 is 4 times the volume of the first reaction zone 11; the periphery of the reactor 1 is wrapped with insulation materials; the sludge in...

Embodiment 2

[0067] The sludge processed in this embodiment is summer sludge, and the waste water discharged into the sewage plant in summer has lower COD than other seasons, resulting in a small amount of sludge. The difference between the processing system used and the processing system of Example 1 is that the concentration device 2 used is a centrifugal dehydration device, and the method used is basically the same as that of Example 1, except that:

[0068] In step ①, the solid content of the concentrated sludge is 7%, the fresh sludge VSS / TSS (volatile suspended solids / total suspended solids) = 58% to 62%, and the VSS concentration is 35 g / L to 37 g / L.

[0069] In step ③, the entire organic sludge treatment system is in the normal operation stage, and the second reaction zone 12 discharges 5 / 48 of the total volume of the second reaction zone for the first time, which is the total amount of sludge in the reactor 1. After the sludge is discharged, the transfer pump 53 is turned on to supplem...

Embodiment 3

[0073] This embodiment treats sludge in winter. The treatment system used is different from the treatment system of embodiment 1 in that the thickening device 2 used is a centrifugal dehydration device, and the method used is basically the same as that of embodiment 1. the difference lies in:

[0074] In step ①, the solid content of the concentrated sludge is 6% to 7%, the fresh sludge VSS / TSS (volatile suspended solids / total suspended solids) = 65% to 75%, and the VSS concentration is 37g / L to 40g / L.

[0075] In step ②, the two reaction zones are filled with aeration and continuously mixed uniformly. Under the action of microorganisms and agitation, the temperature in the reactor 1 rises continuously, and the temperature in the reactor 1 rises to 45°C on the 5th day , No more rise on the sixth day, open the valve at the vent pipe 11-2 in the first reaction zone and the vent pipe 12-2 in the second reaction zone. Under the action of gravity, both reaction zones discharge 2 / 3 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com