Patents

Literature

1100 results about "Mud pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

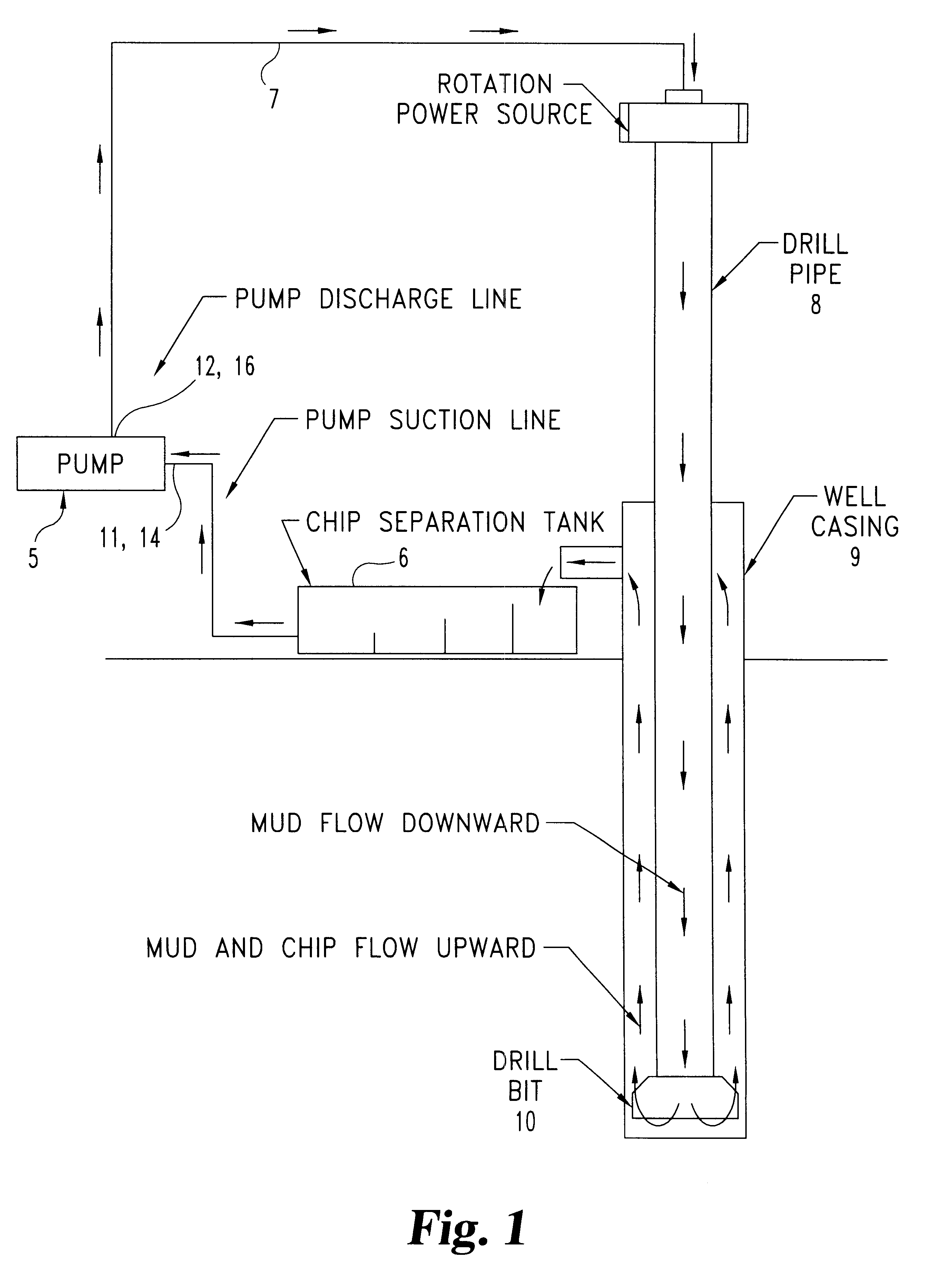

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

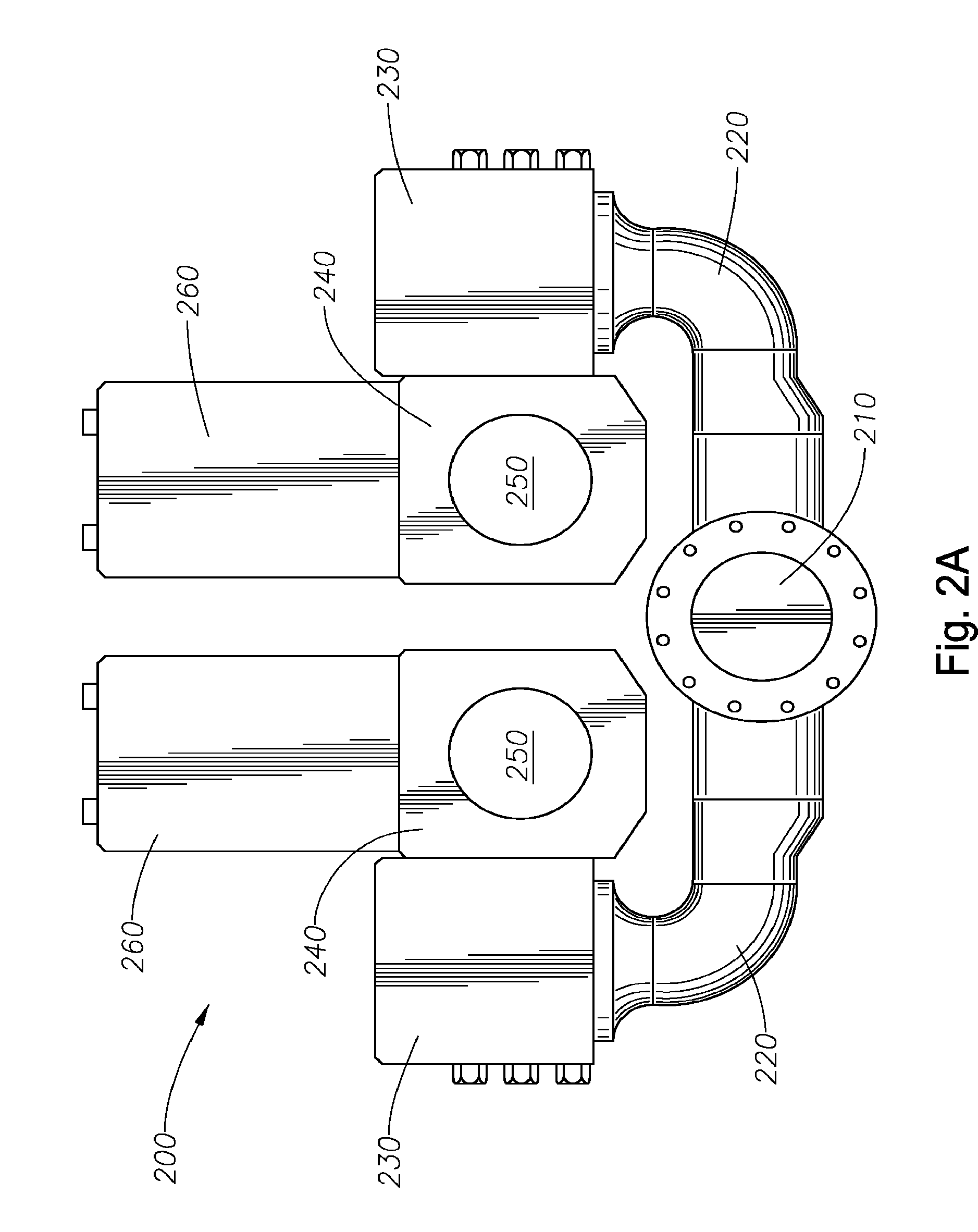

Subsea mud pump and control system

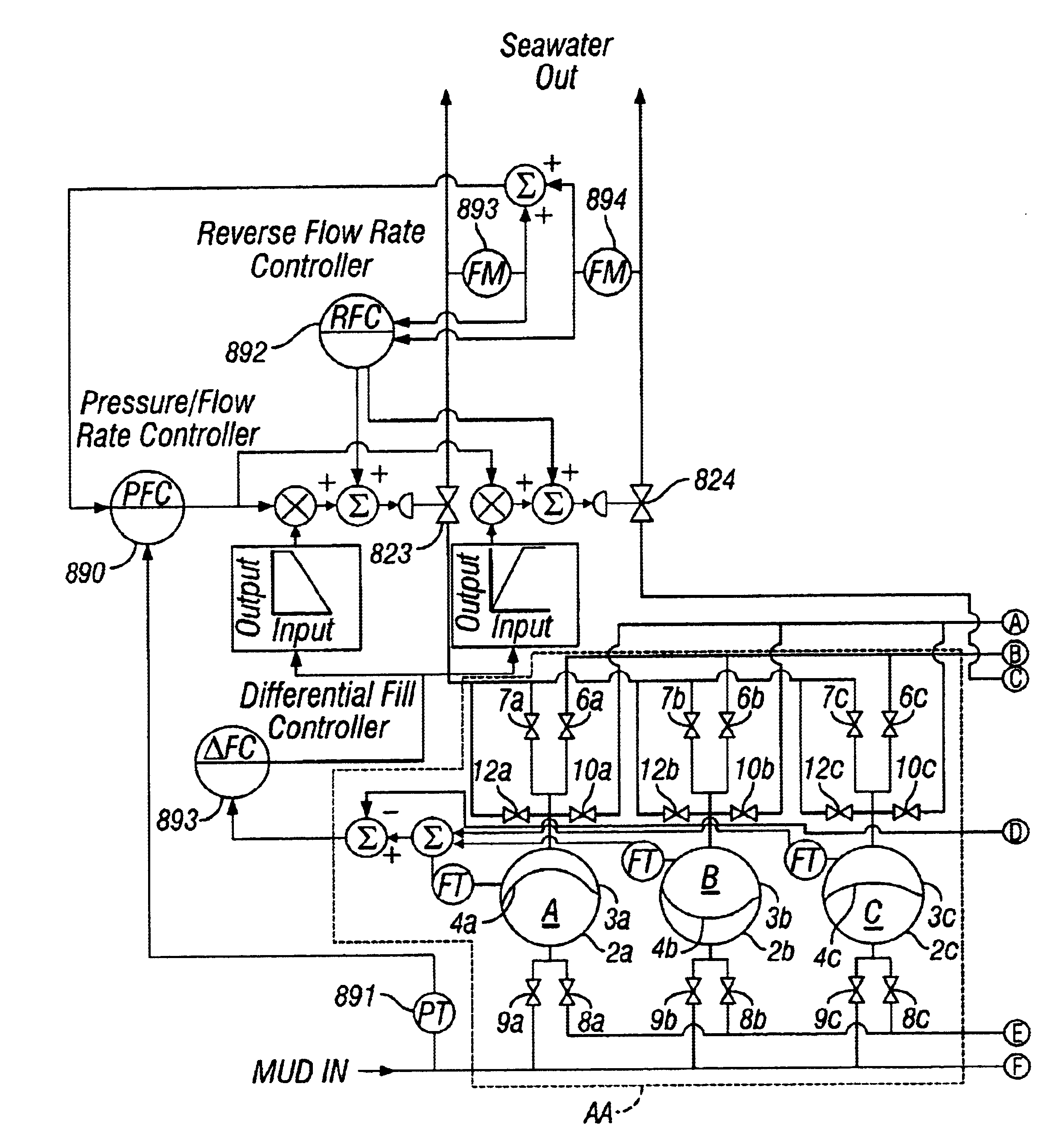

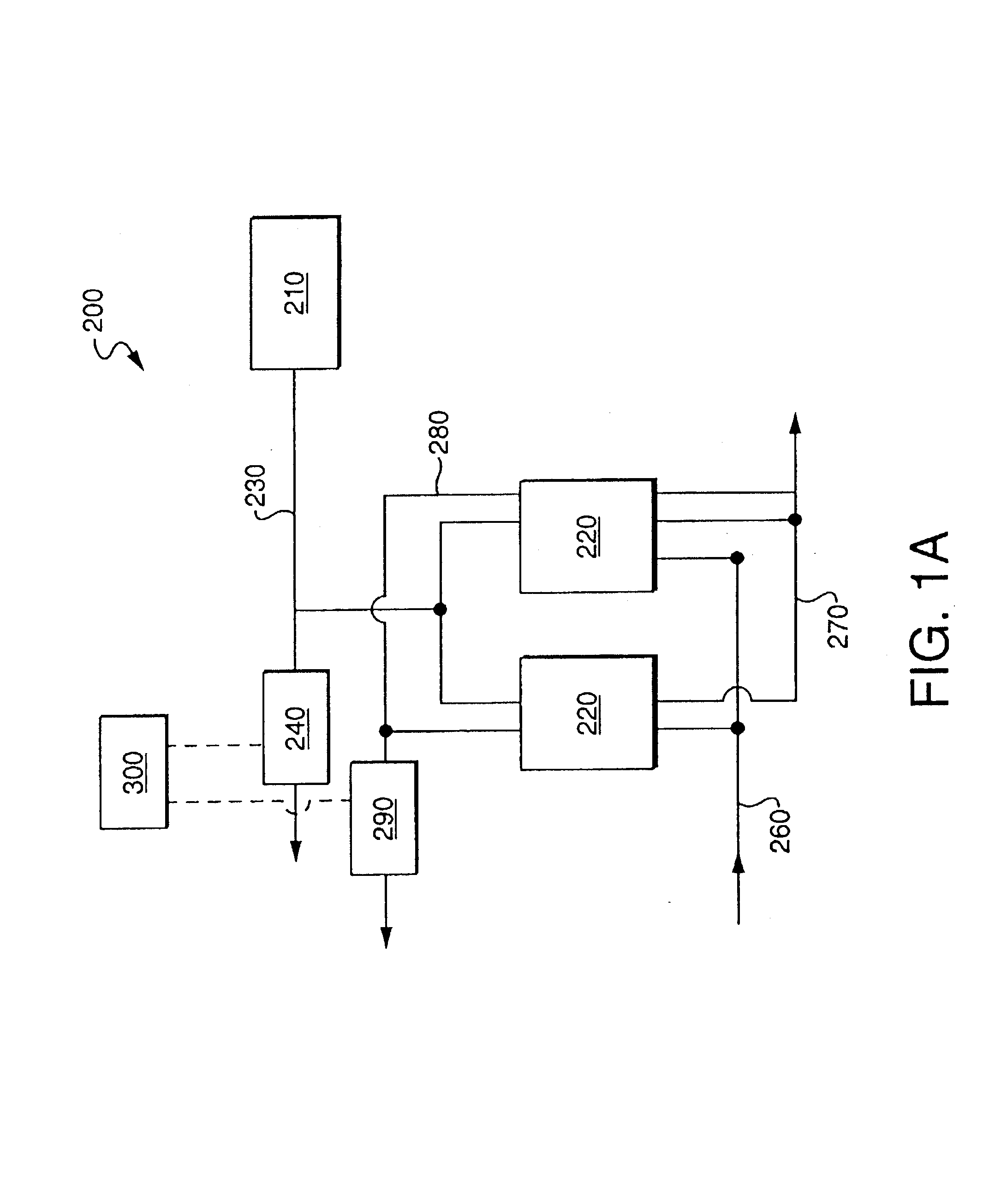

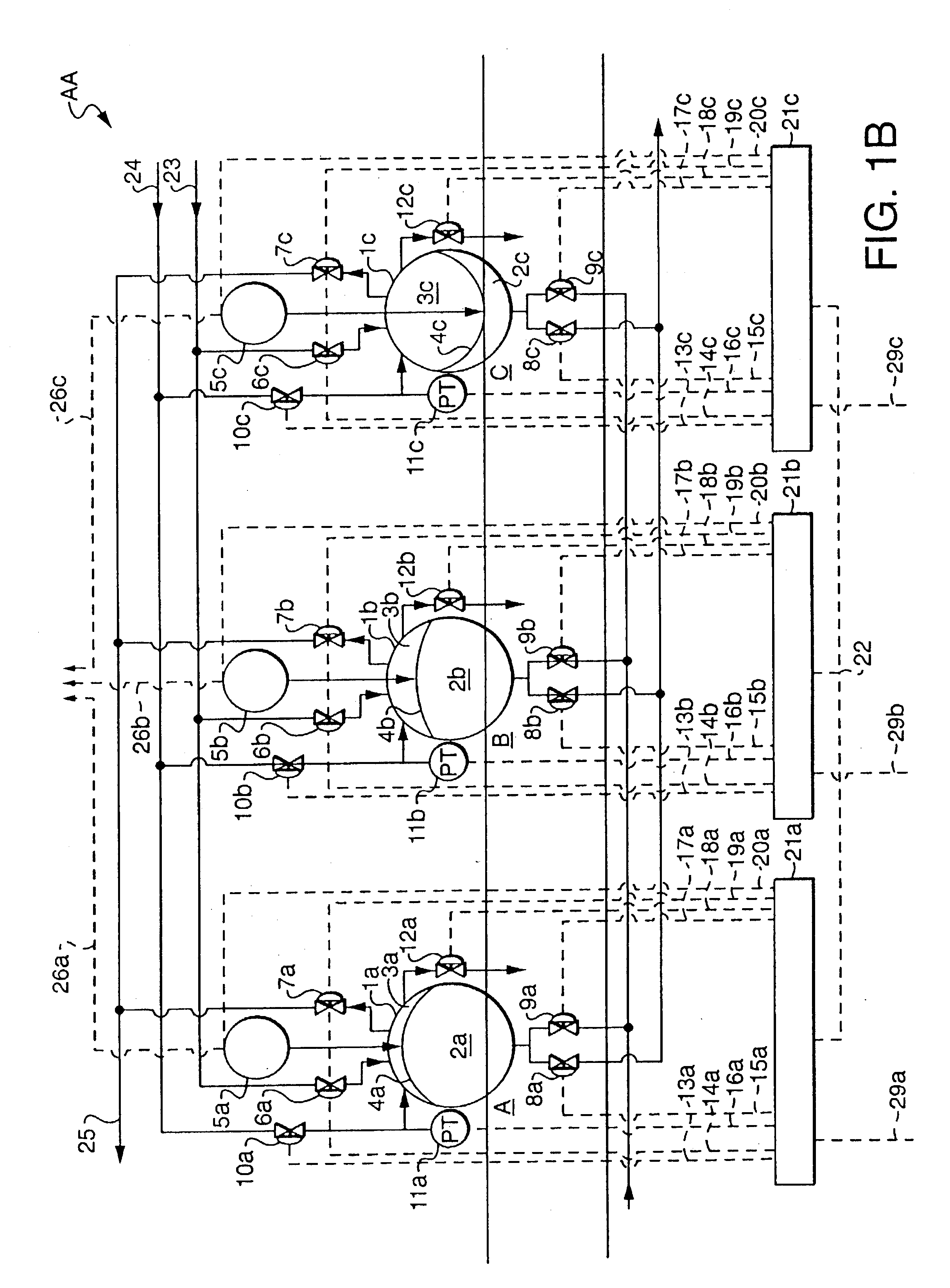

A sub-sea mud pump system includes a plurality of pump units, and each pumping unit includes a plurality of pumping elements. Each pumping element includes a pressure vessel with a first and a second chamber, a separating member between the first and second chambers, a measurement device adapted to measure the volume of at least one of the first and second chambers, a hydraulic inlet control valve and a hydraulic outlet control valve coupled to the first chamber, a mud suction valve and a mud discharge valve coupled to the second chamber. The first chamber is hydraulically coupled to receive and discharge a hydraulic fluid, and the second chamber is hydraulically coupled to receive and discharge a drilling fluid. The separating member is adapted to move within its the pressure vessel in response to a pressure differential between the first and second chambers. The pump system also includes a hydraulic control unit adapted to control the plurality of pump units.

Owner:HYDRIL USA MANUFACTURING LLC

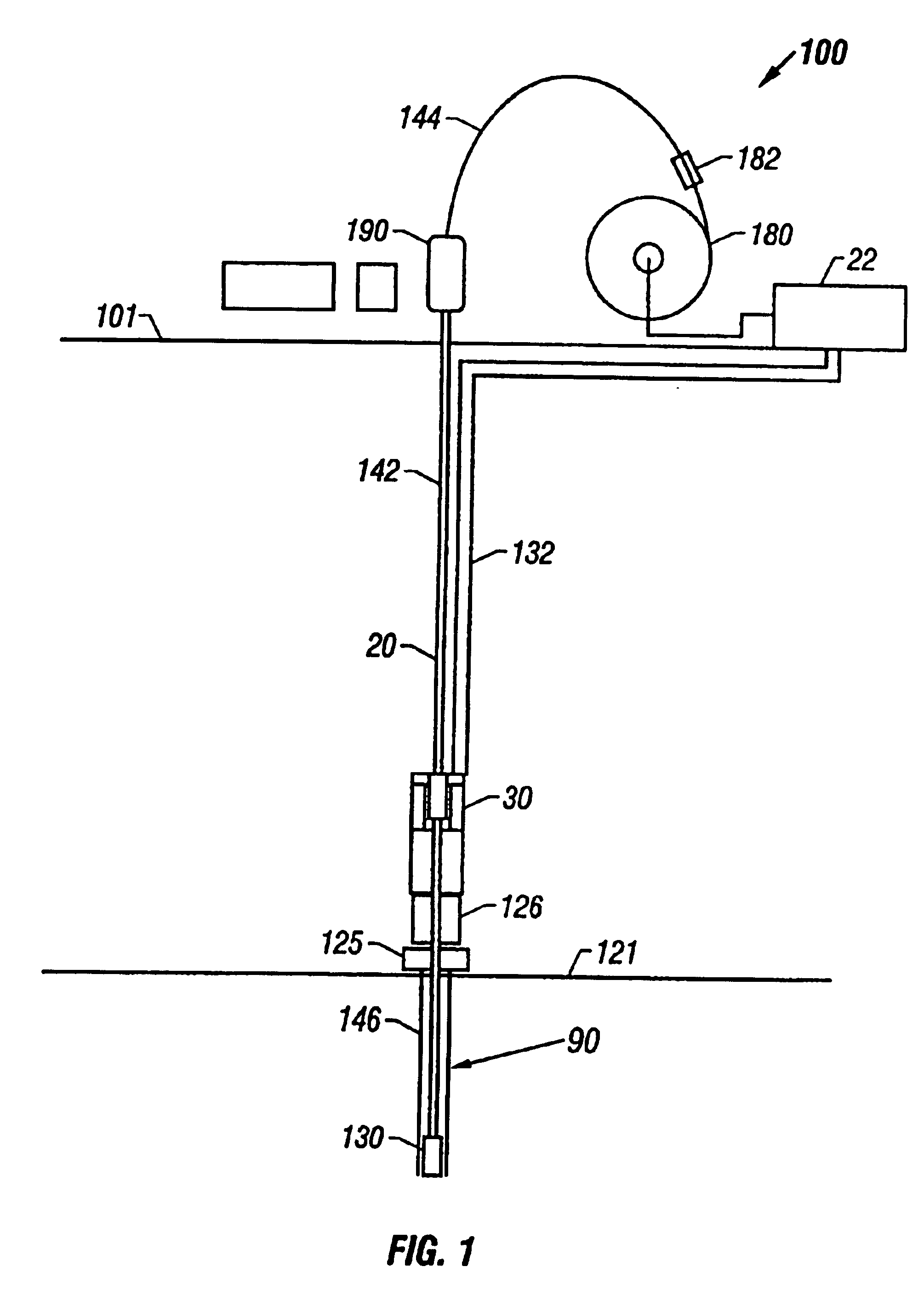

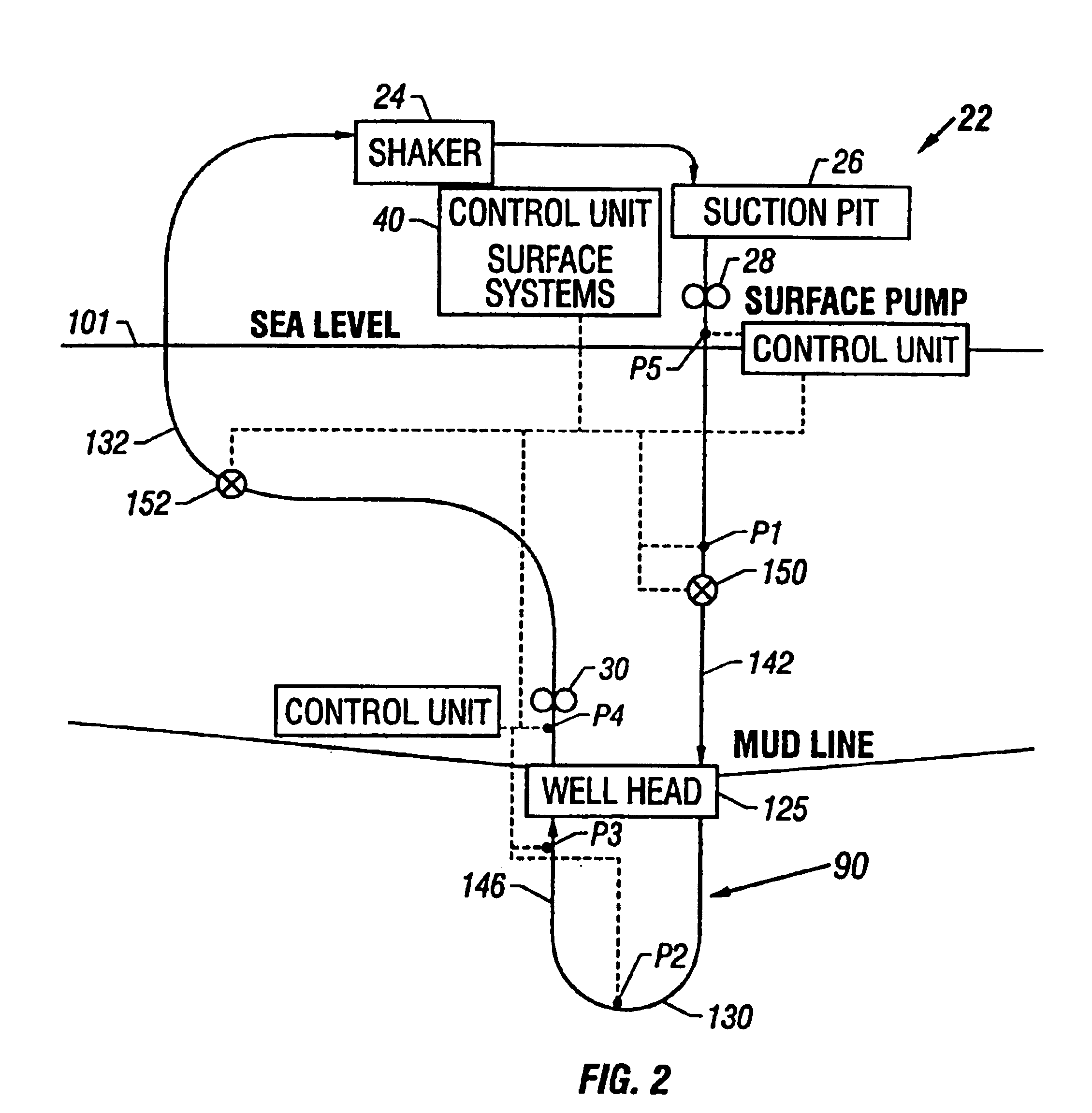

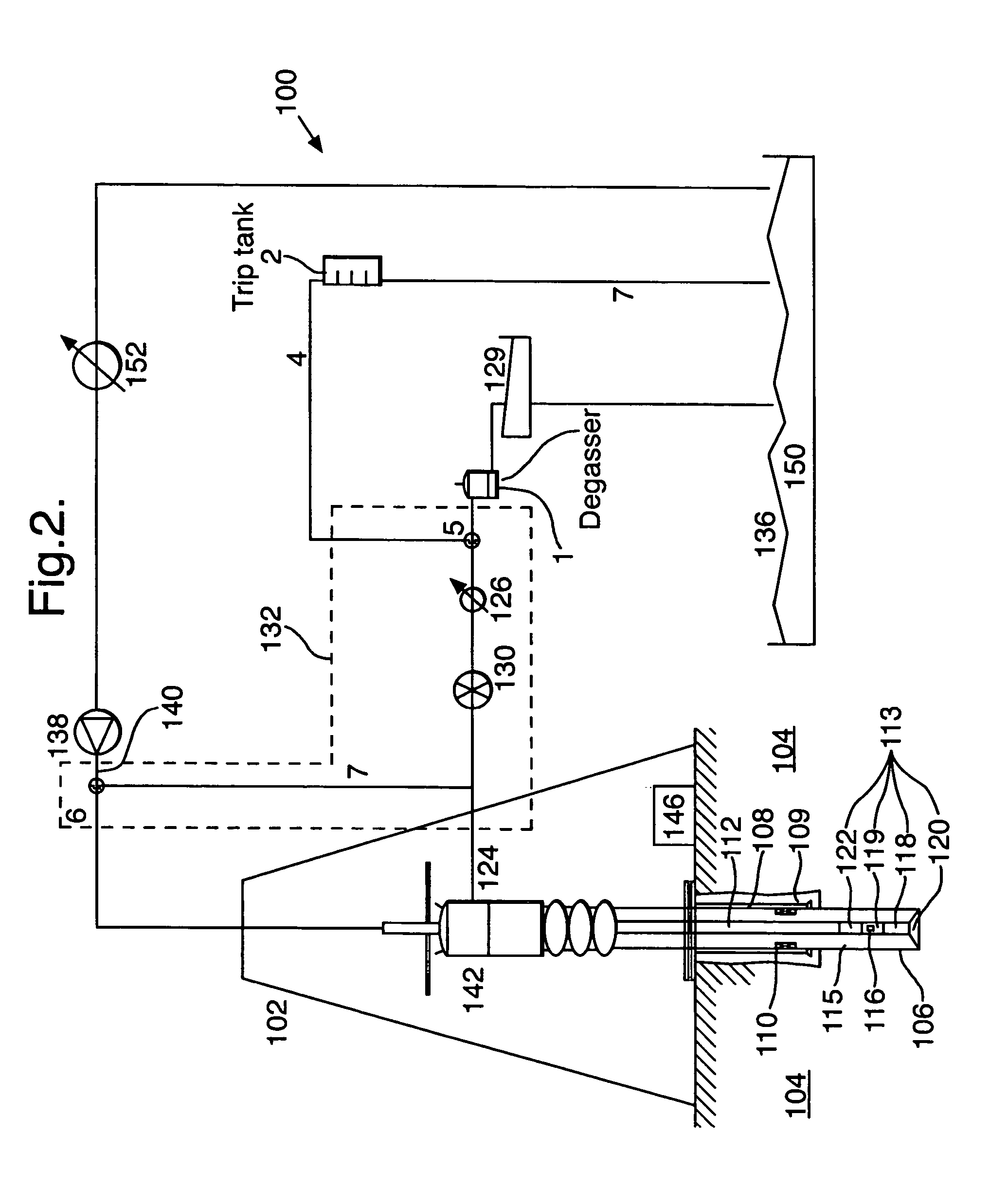

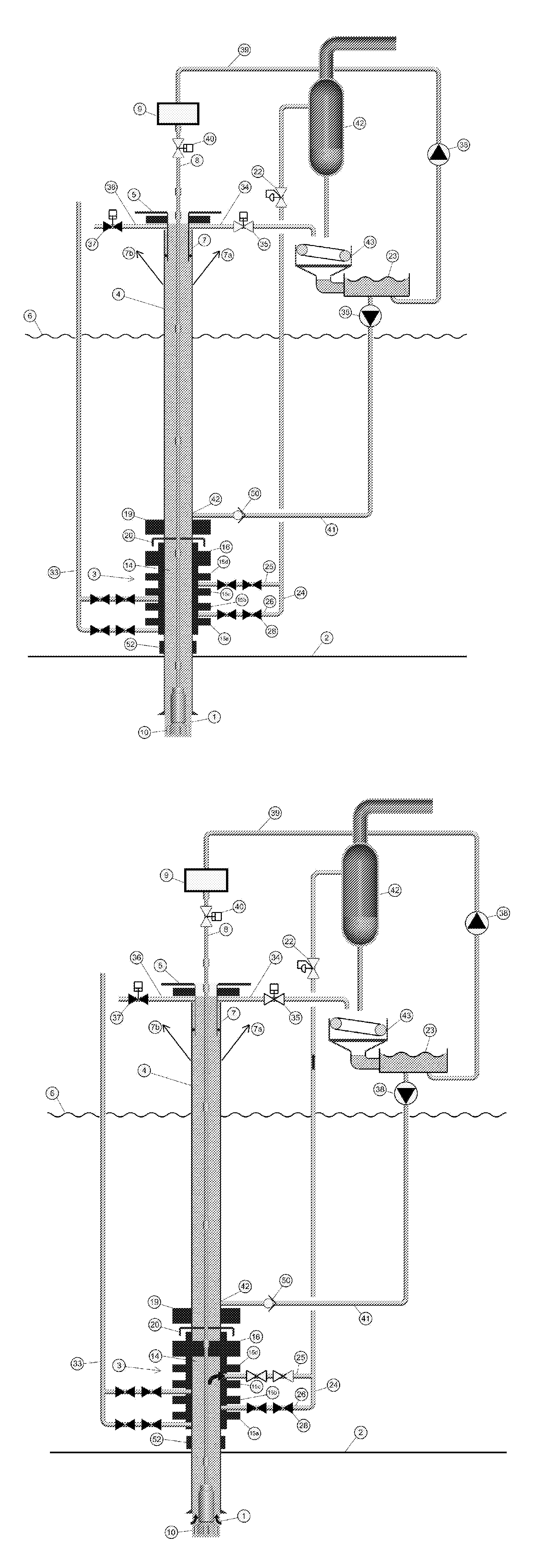

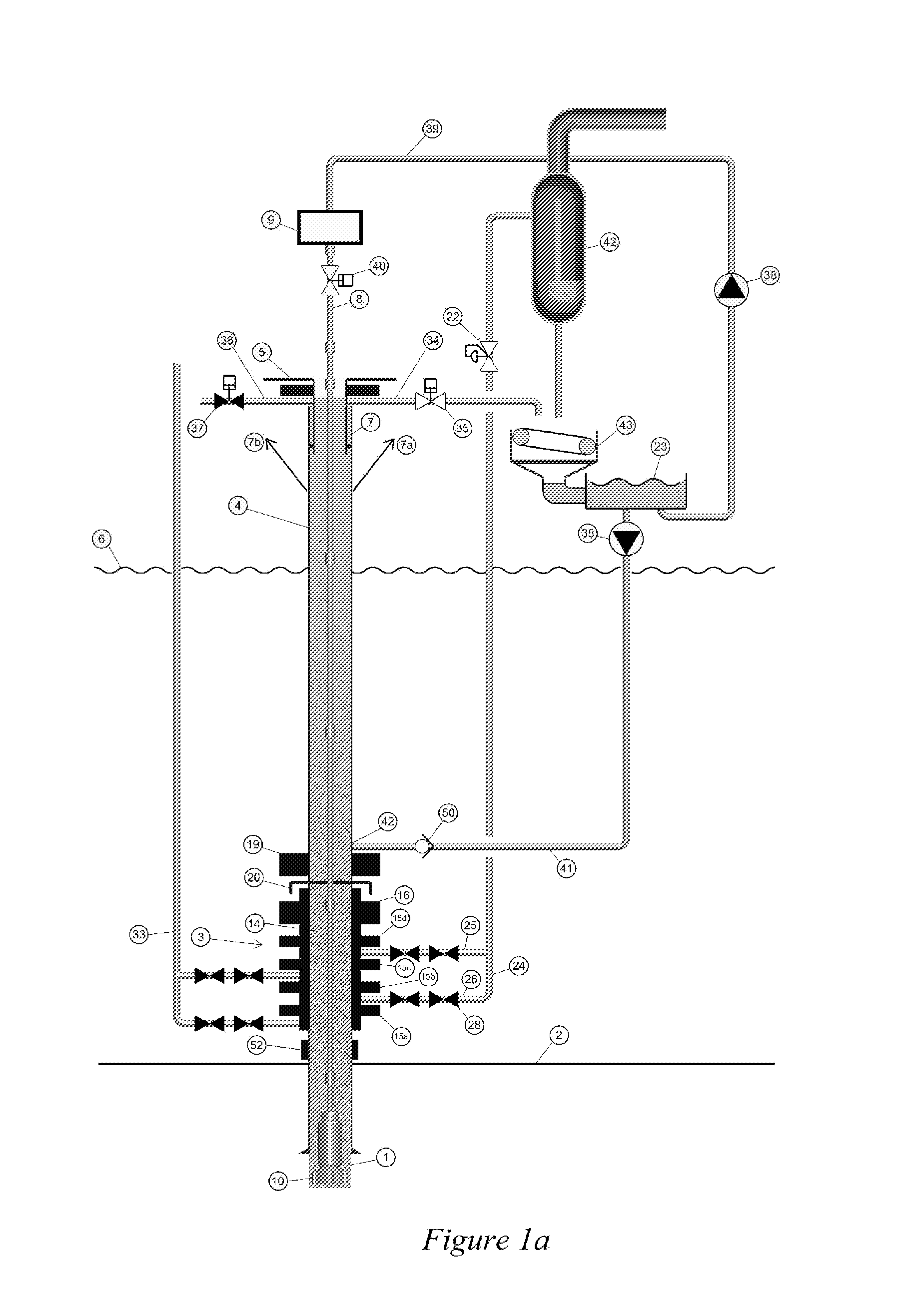

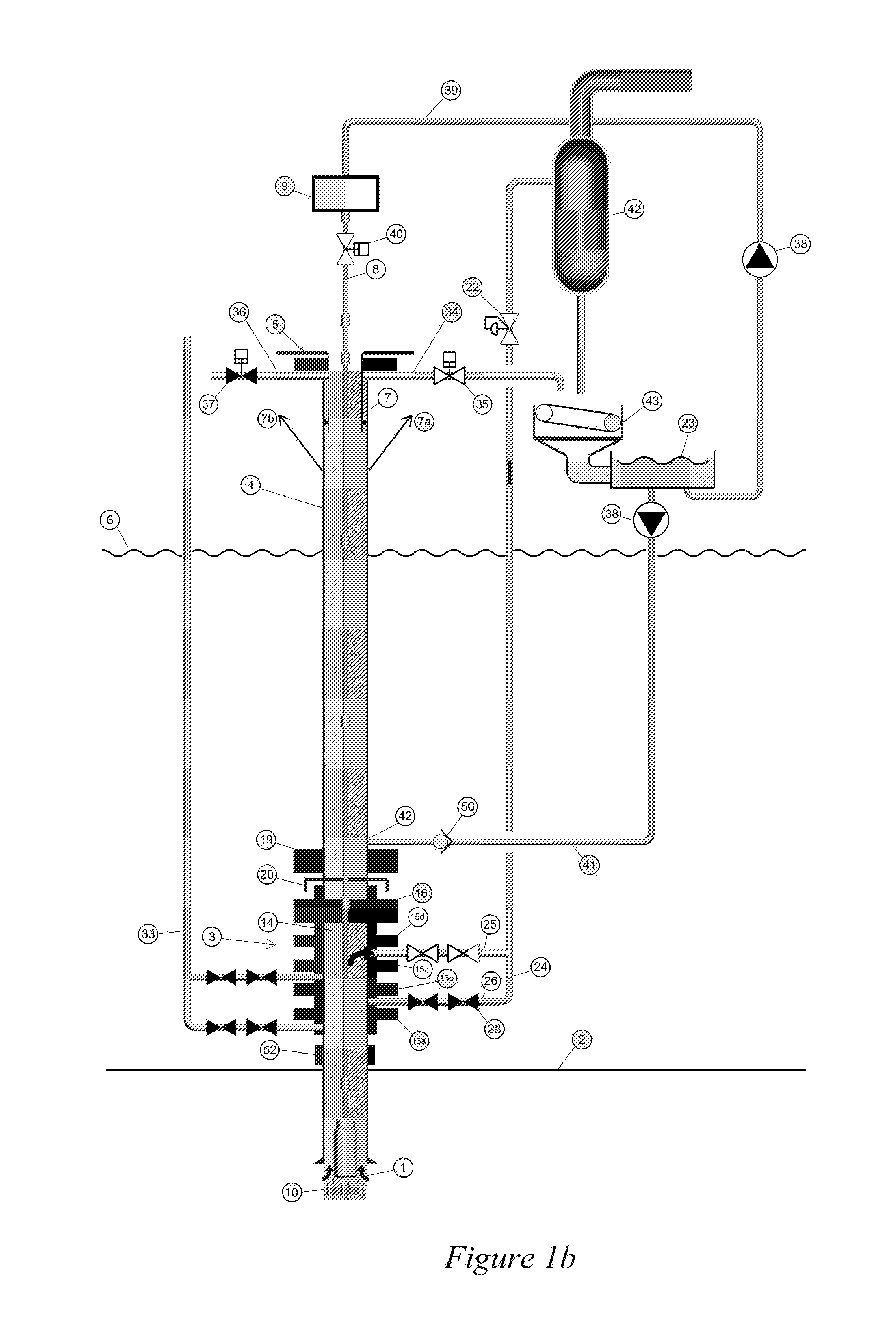

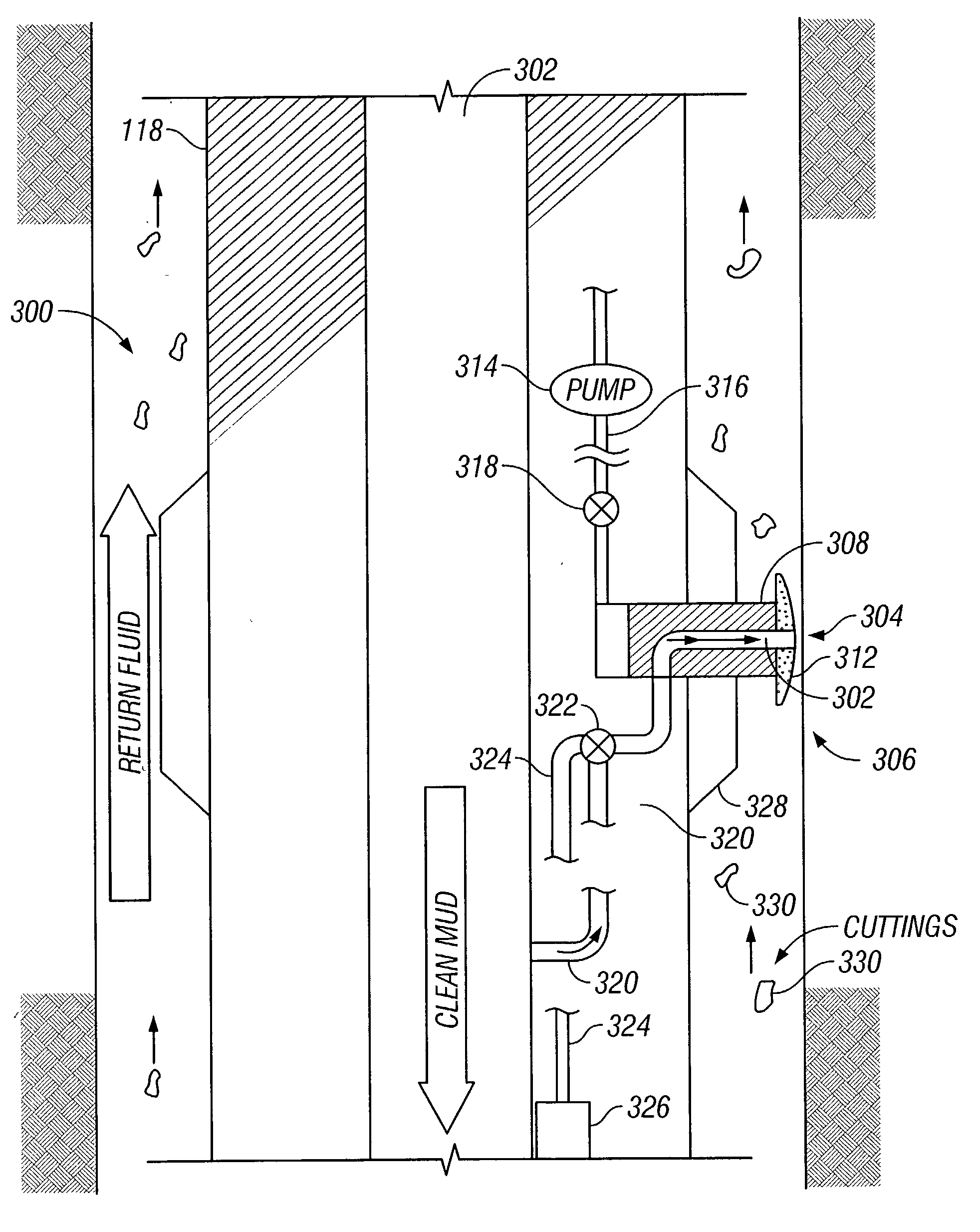

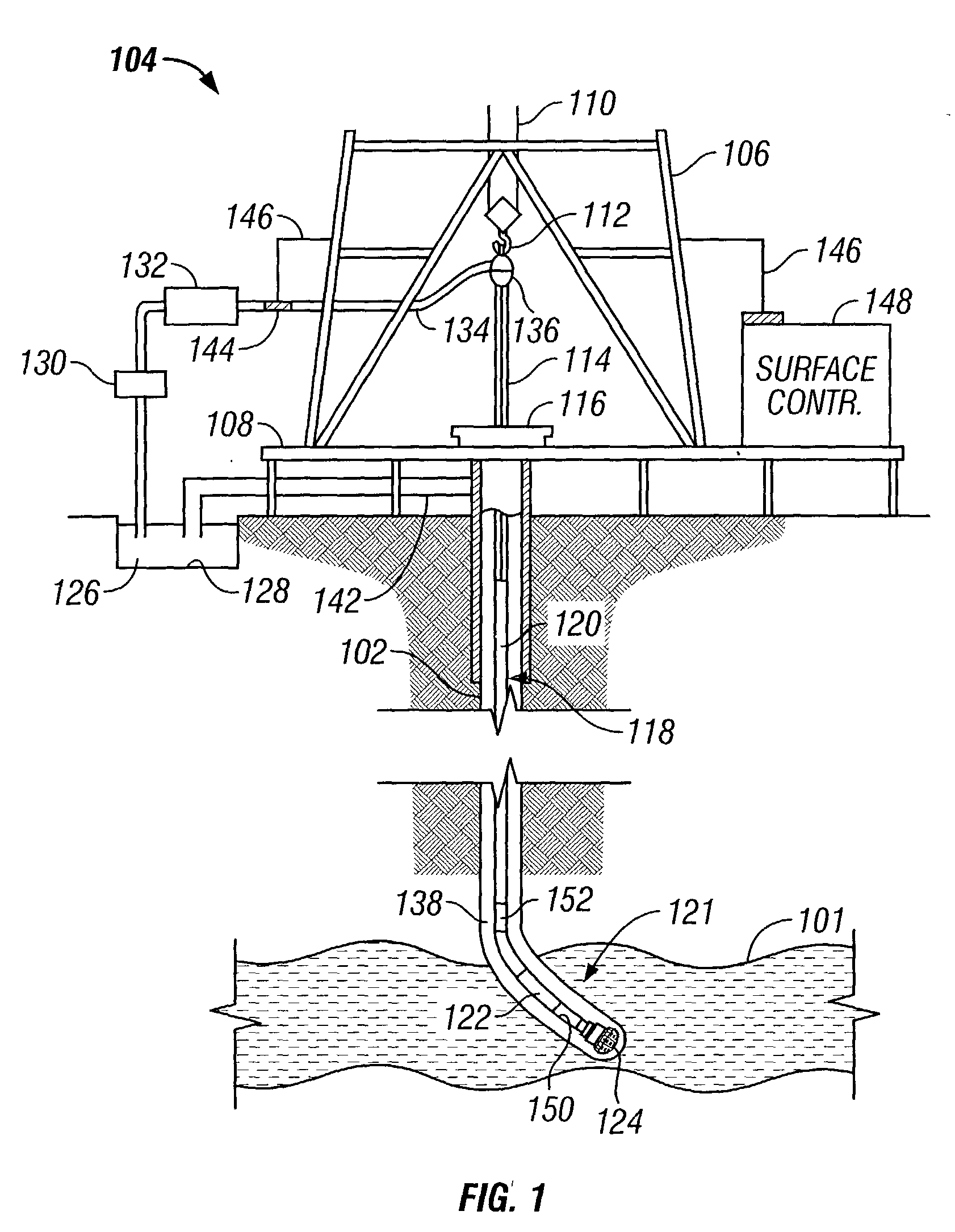

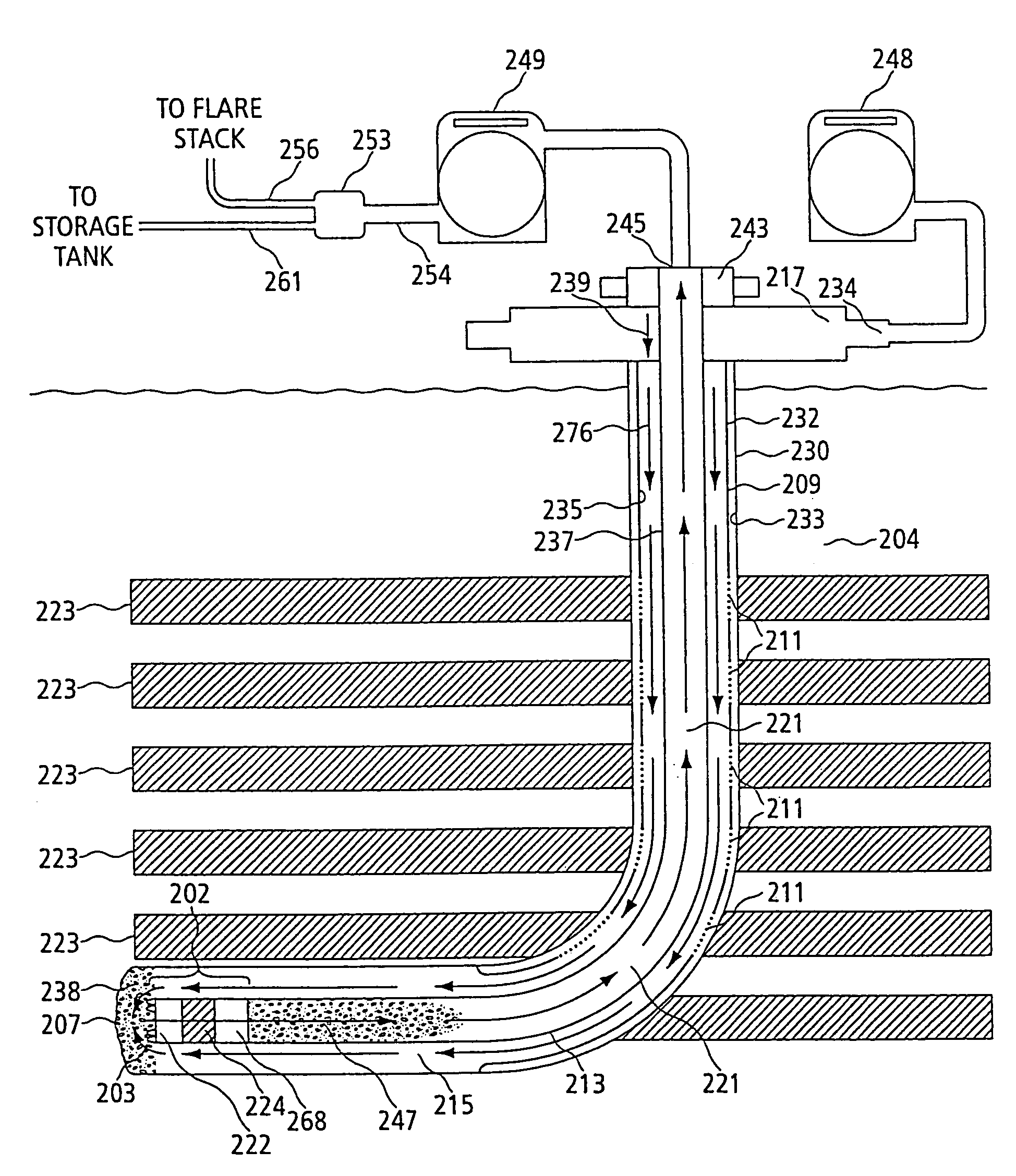

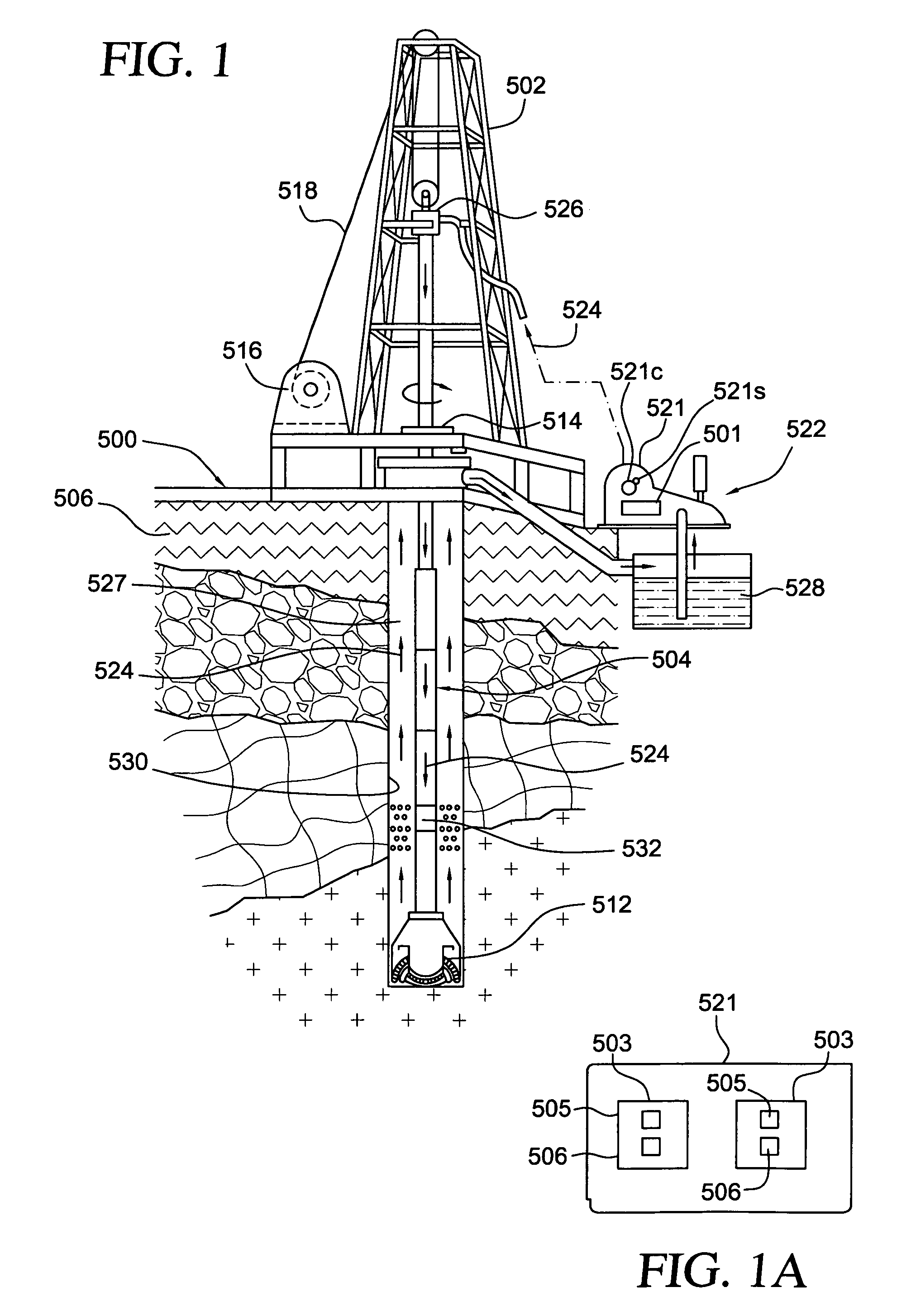

Subsea wellbore drilling system for reducing bottom hole pressure

InactiveUS6854532B2Easy to deployFaster and effective subsea downhole operationDrilling rodsConstructionsDelivery systemBottom hole assembly

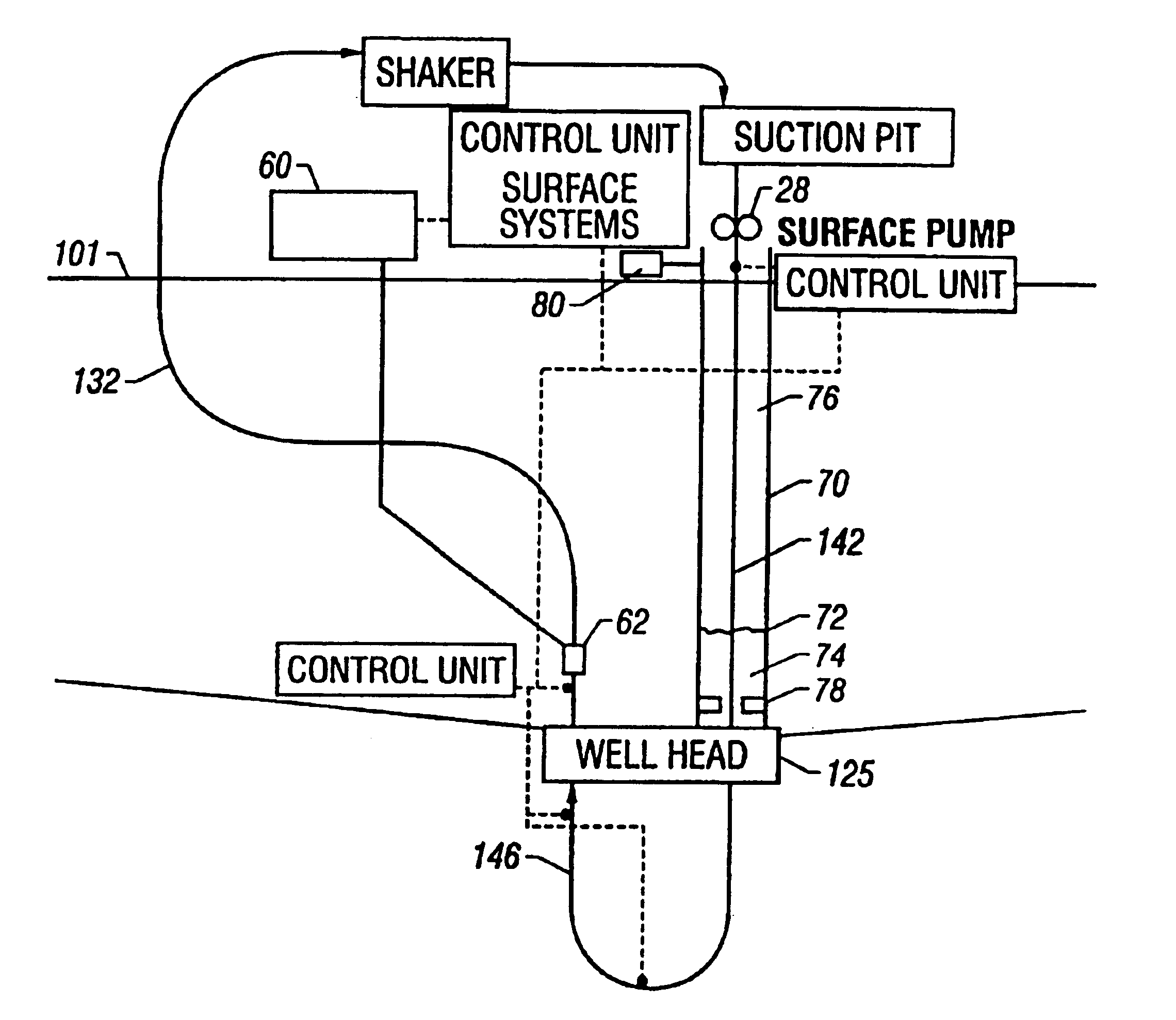

The present invention provides drilling systems for drilling subsea wellbores. The drilling system includes a tubing that passes through a sea bottom wellhead and carries a drill bit. A drilling fluid system continuously supplies drilling fluid into the tubing, which discharges at the drill bit bottom and returns to the wellhead through an annulus between the tubing and the wellbore carrying the drill cuttings. A fluid return line extending from the wellhead equipment to the drilling vessel transports the returning fluid to the surface. In a riserless arrangement, the return fluid line is separate and spaced apart from the tubing. In a system using a riser, the return fluid line may be the riser or a separate line carried by the riser. The tubing may be coiled tubing with a drilling motor in the bottom hole assembly driving the drill bit. A suction pump coupled to the annulus is used to control the bottom hole pressure during drilling operations, making it possible to use heavier drilling muds and drill to greater depths than would be possible without the suction pump. An optional delivery system continuously injects a flowable material, whose fluid density is less than the density of the drilling fluid, into the returning fluid at one or more suitable locations the rate of such lighter material can be controlled to provide supplementary regulation of the pressure. Various pressure, temperature, flow rate and kick sensors included in the drilling system provide signals to a controller that controls the suction pump, the surface mud pump, a number of flow control devices, and the optional delivery system.

Owner:BAKER HUGHES INC

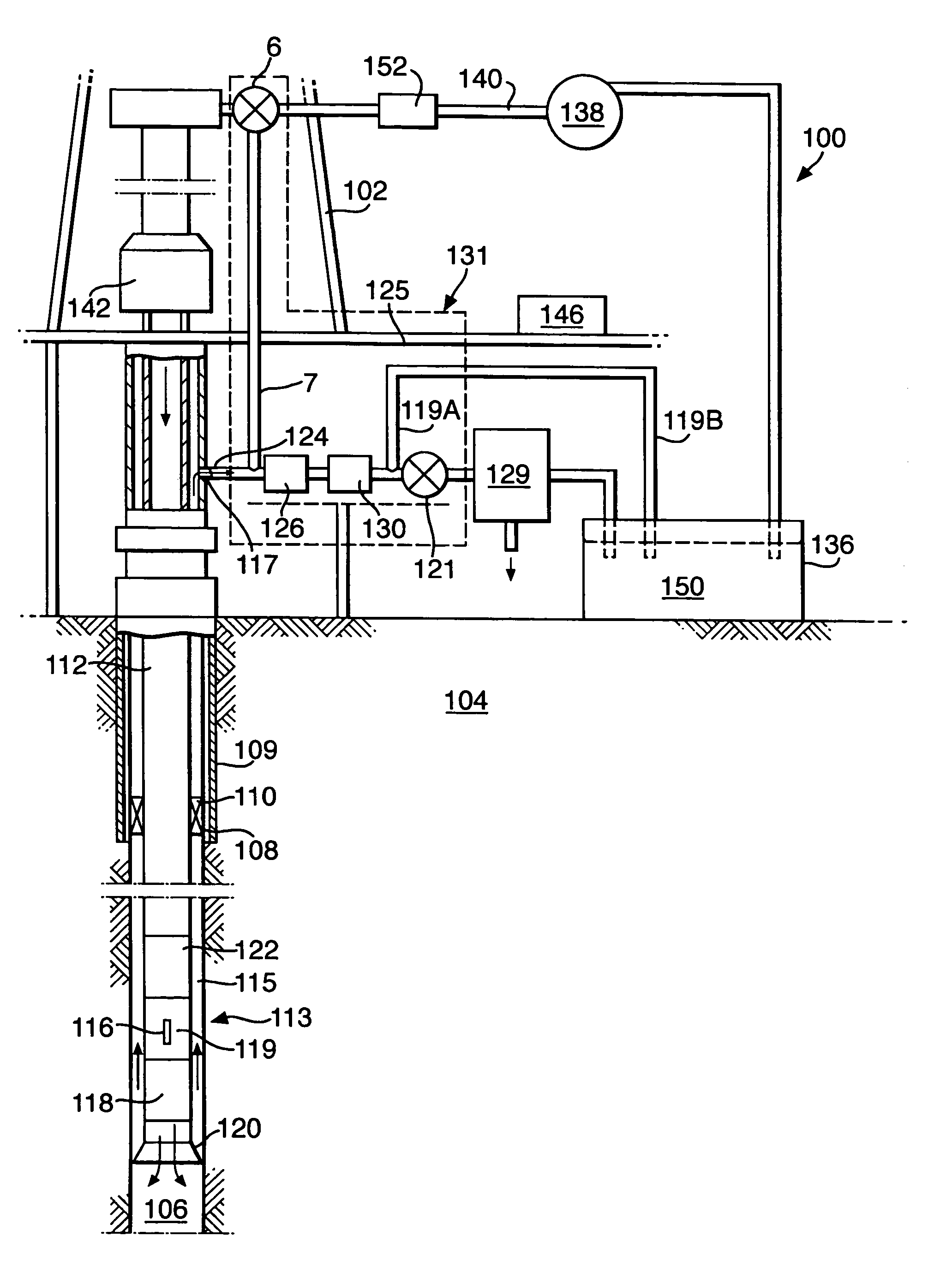

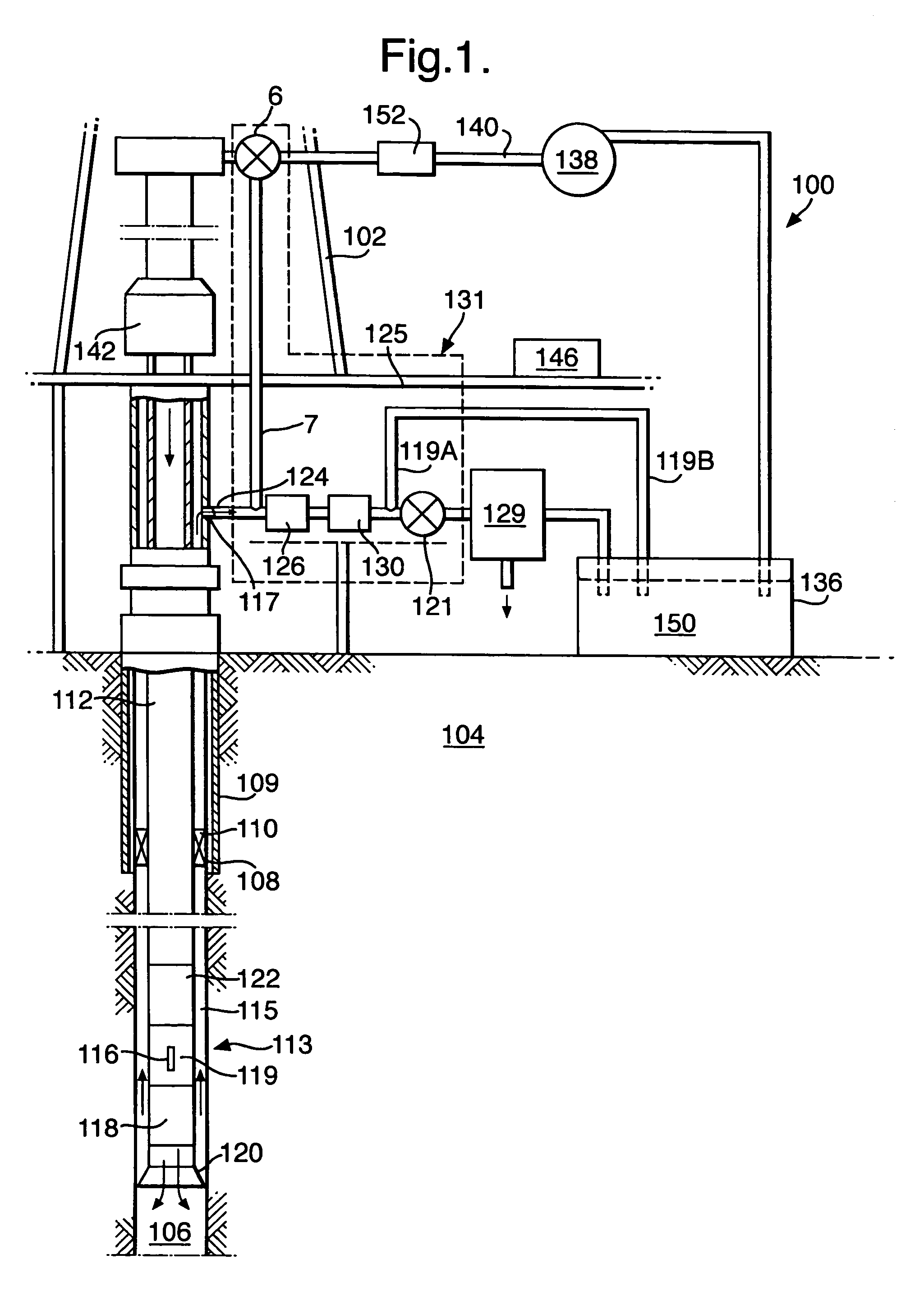

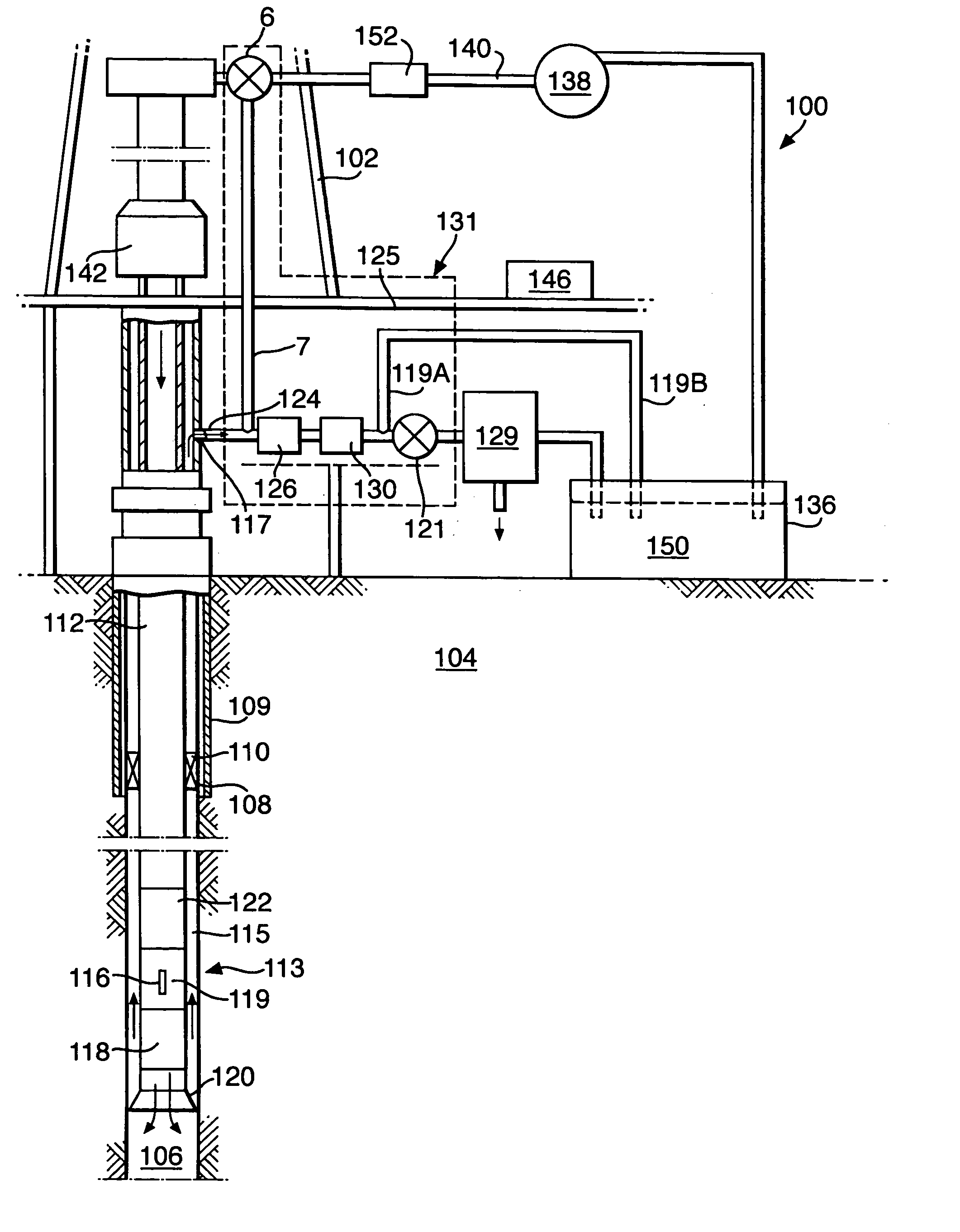

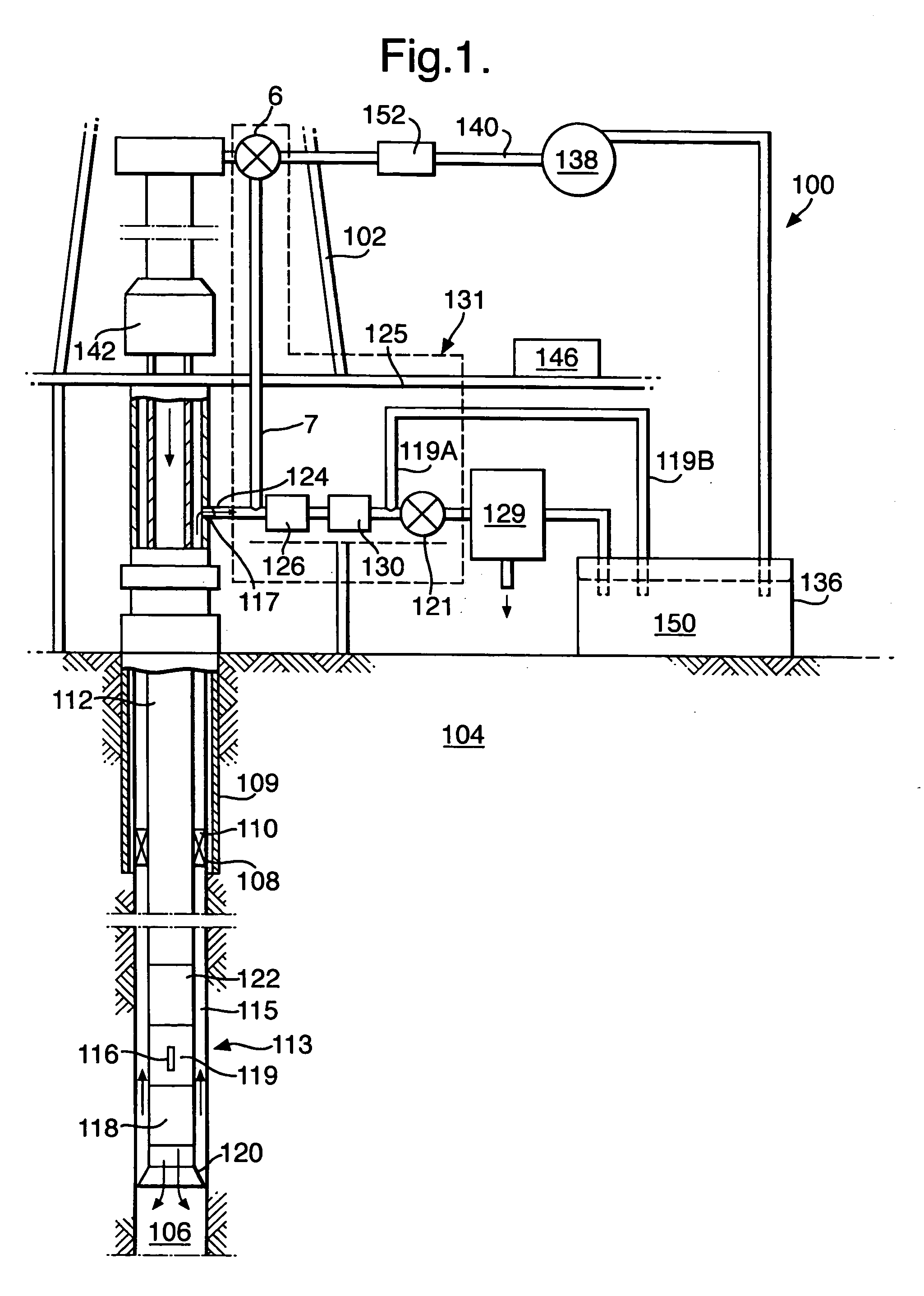

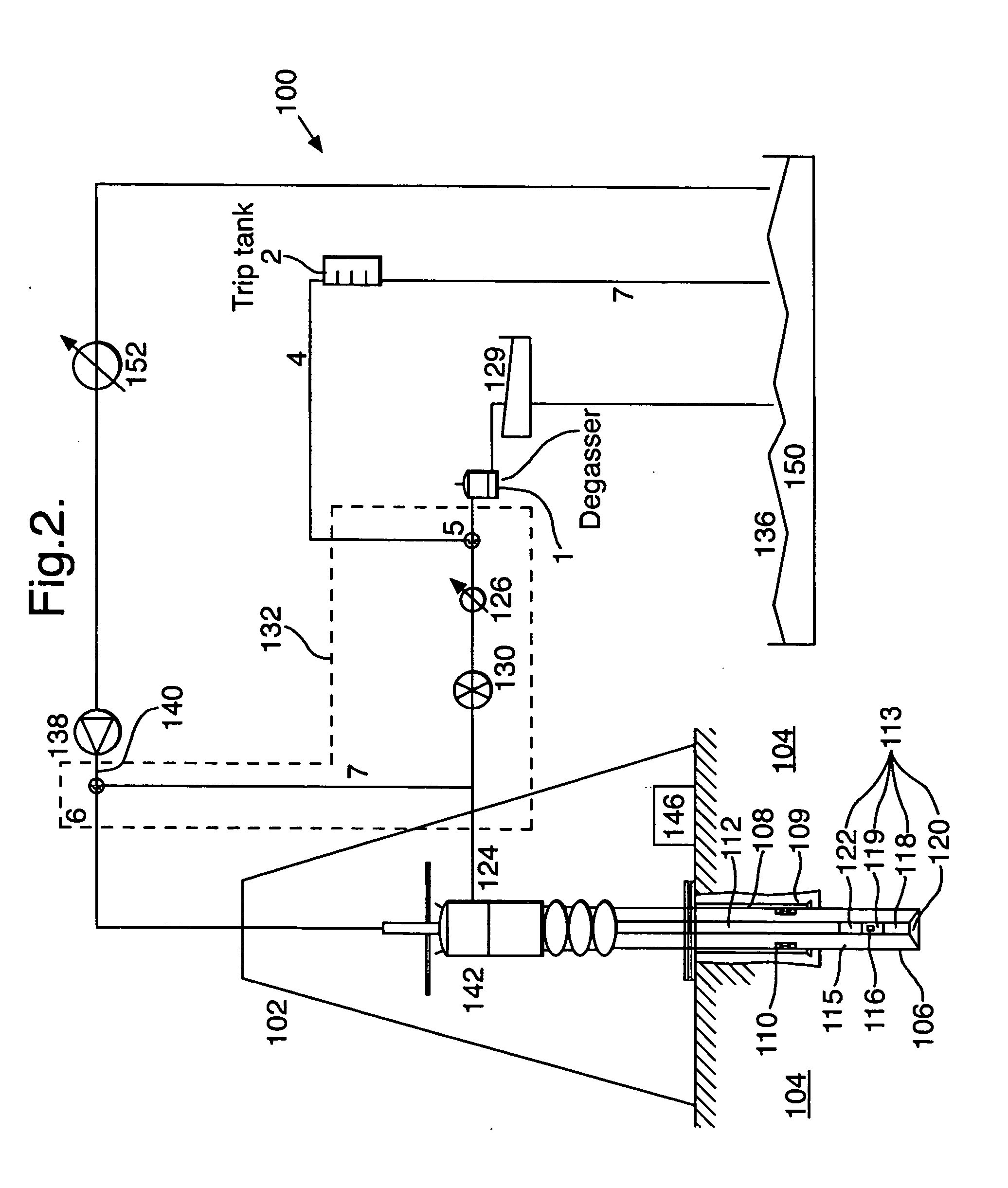

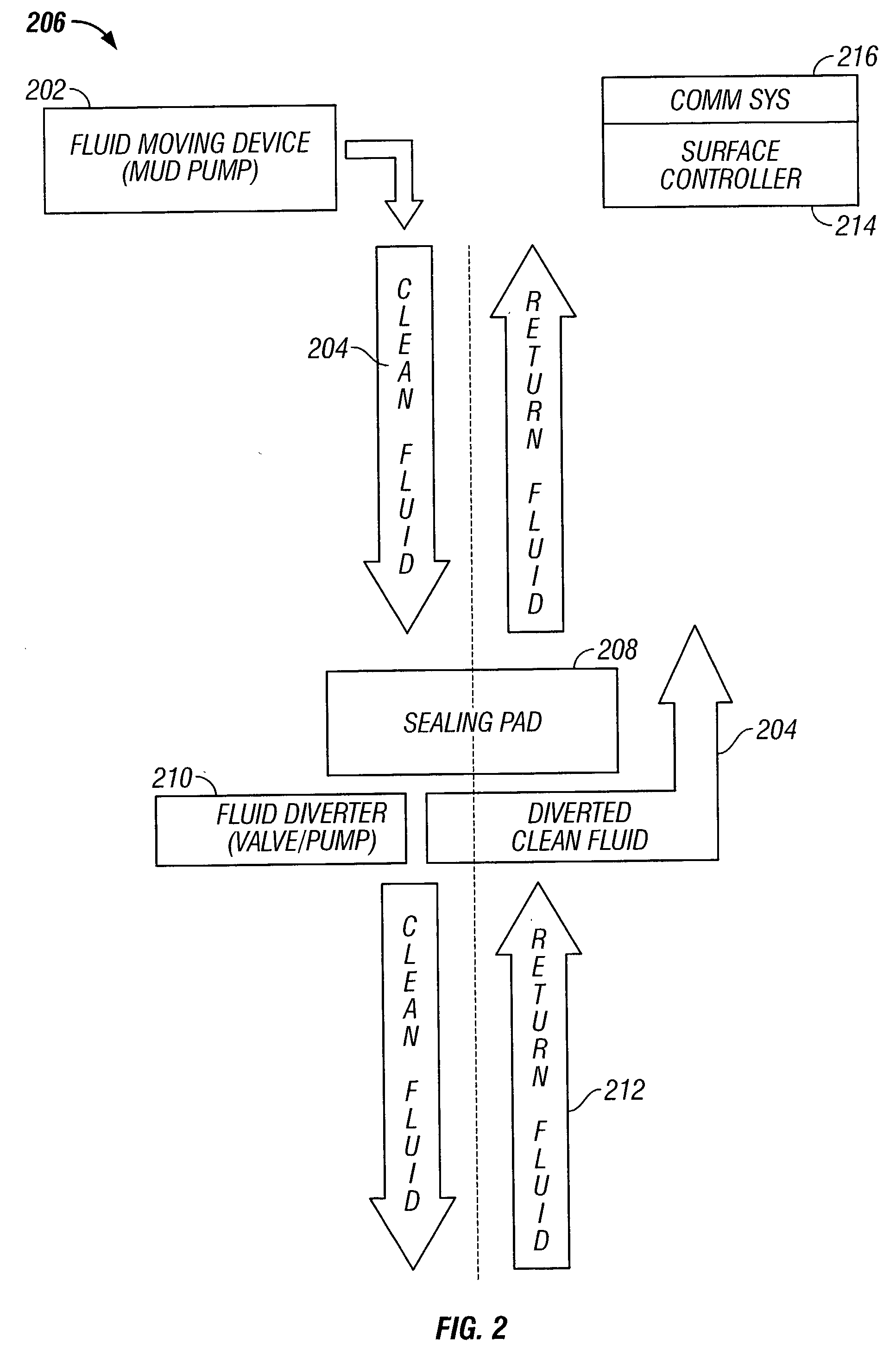

Dynamic annular pressure control apparatus and method

A drilling system for drilling a bore hole into a subterranean earth formation, wherein at least a portion of the mud flow from the primary mud pump is diverted to the mud discharge outlet, thereby creating a backpressure system to readily increase annular pressure.

Owner:SHELL OIL CO

Dynamic annular pressure control apparatus and method

InactiveUS20040178003A1Increased annular pressureEasy to controlConstructionsFlushingWell drillingEngineering

A drilling system for drilling a bore hole into a subterranean earth formation, wherein at least a portion of the mud flow from the primary mud pump is diverted to the mud discharge outlet, thereby creating a backpressure system to readily increase annular pressure.

Owner:SHELL OIL CO

System and method for drilling a subsea well

ActiveUS20120227978A1Increase the differential pressureFluid removalUnderwater drillingBottom hole pressureSuction stress

A subsea mud pump can be used to return heavy drilling fluid to the surface. In order to provide a less stringent requirement for such a pump and to better manage the bottom hole pressure in the case of a gas kick or well control event, the gas should be separated from the drilling fluid before the drilling fluid enters the subsea mud pump and the pressure within the separating chamber. The mud pump suction should be controlled and kept equal or lower than the ambient seawater pressure. This can be achieved within the cavities of the subsea BOP by a system arrangement and methods explained. This function can be used with or without a drilling riser connecting the subsea BOP to a drilling unit above the body of water.

Owner:ENHANCED DRILLING

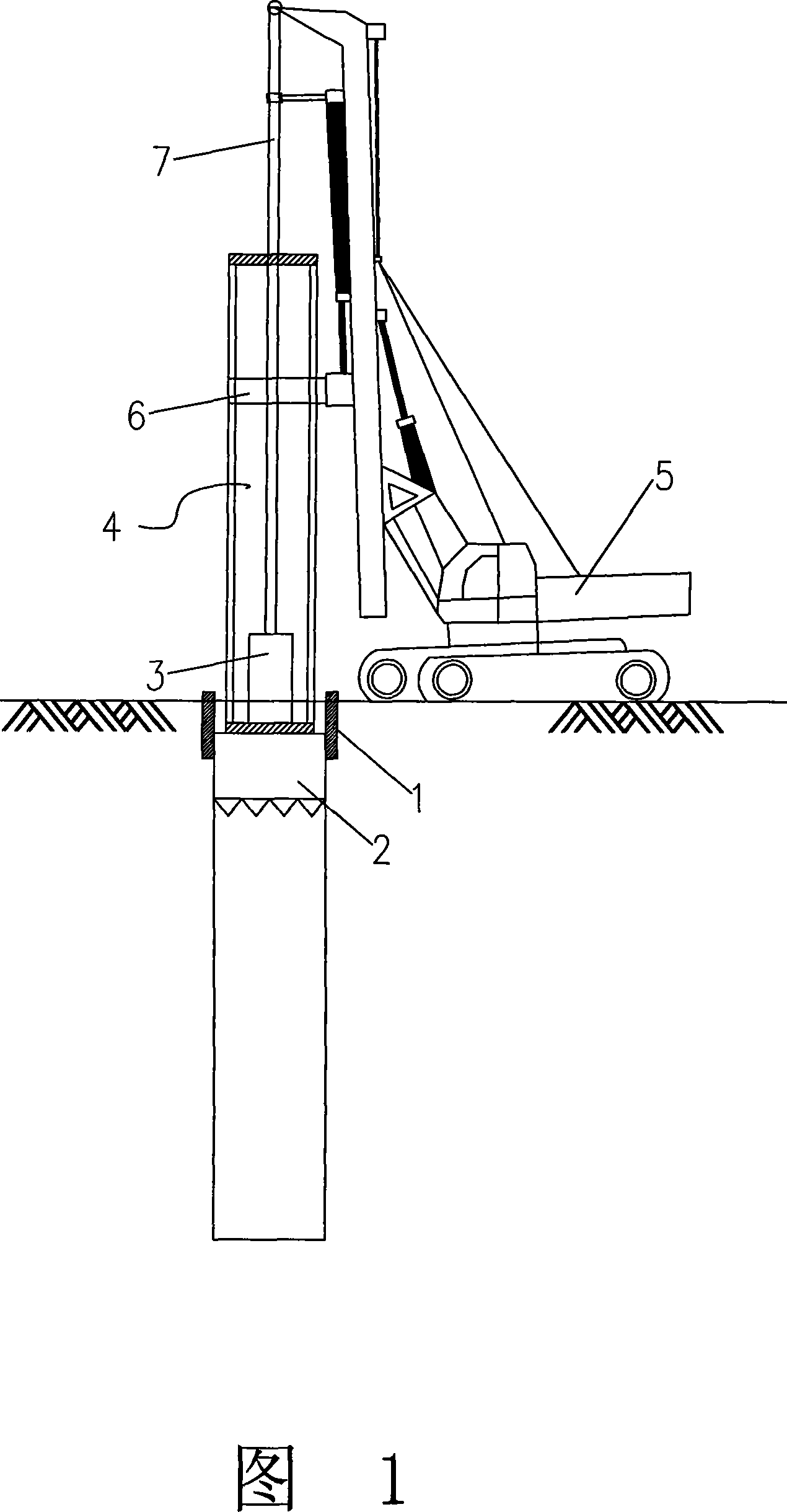

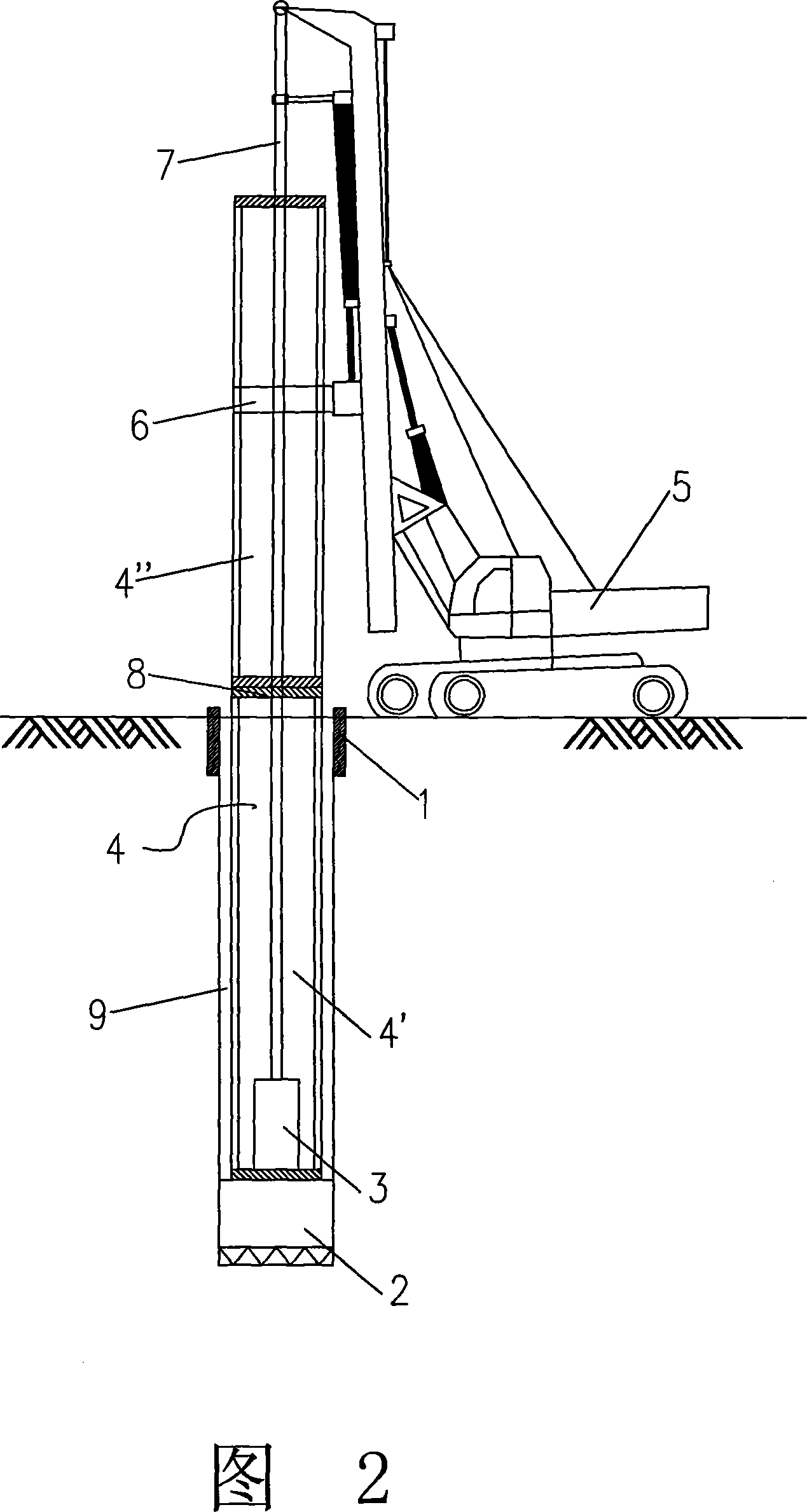

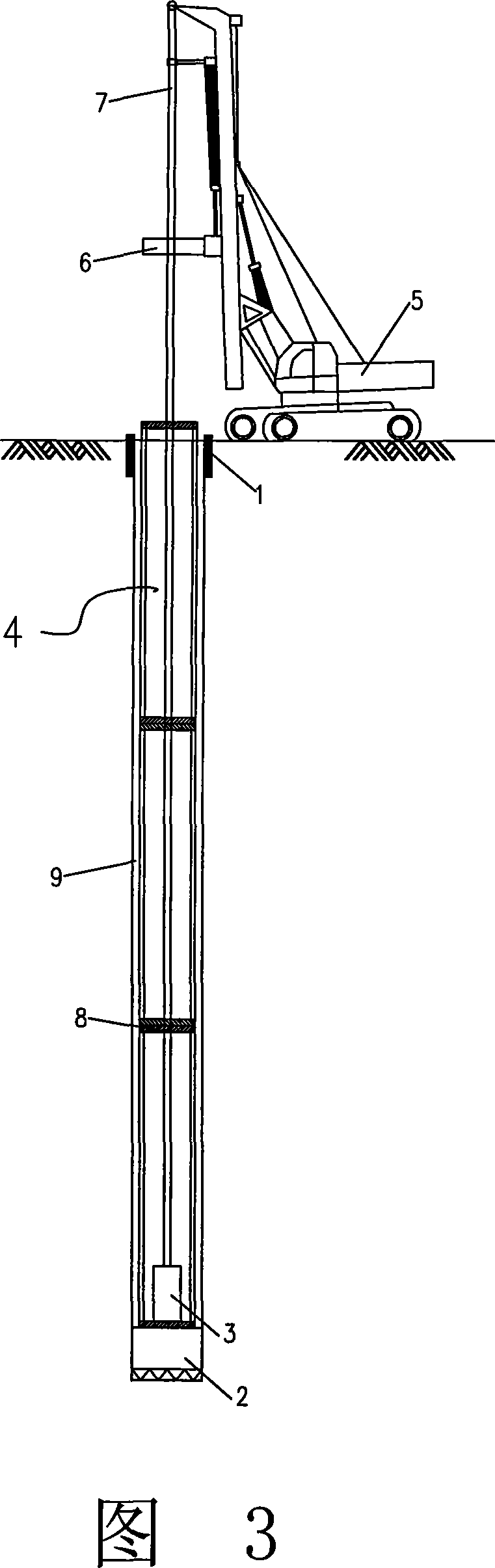

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

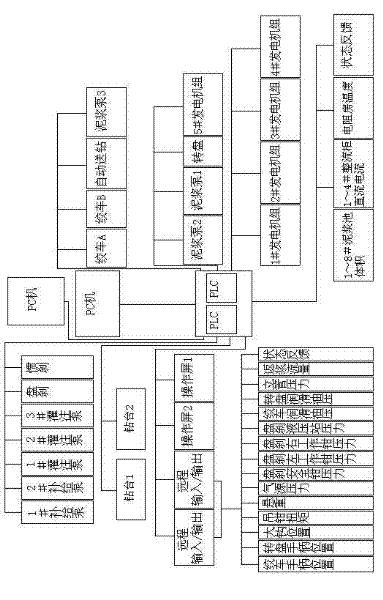

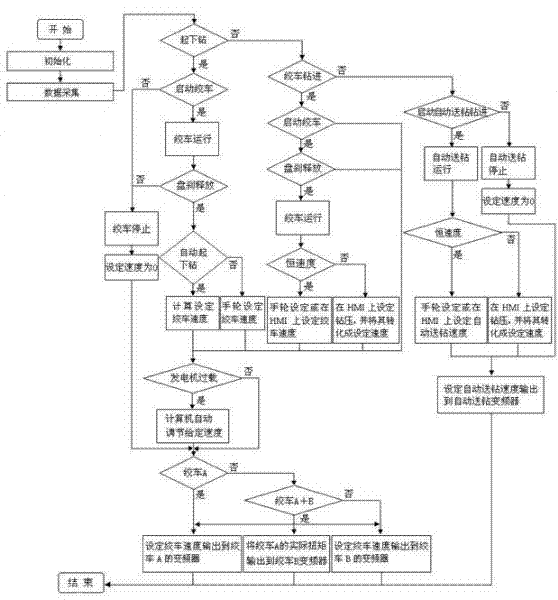

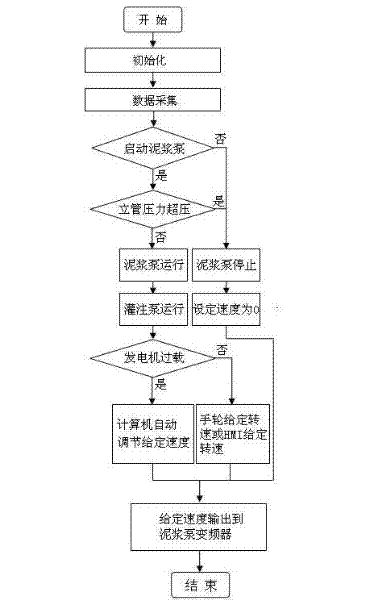

Automatic control system and method of petroleum drilling machine

ActiveCN102305059AEasy to operateRealize centralized controlFlushingAutomatic control for drillingAutomatic controlAutomatic train control

The invention relates to the field of oil-field drilling operation and provides an automatic control system and method of a petroleum drilling machine. The automatic control system comprises a master station and a plurality of slave stations, wherein a winch, an automatic driller, a rotary table and a mud pump are centrally controlled so that processes of well drilling operation can be dynamically, accurately and automatically controlled and good operation environment and work environment are provided for operating personnel.

Owner:四机赛瓦石油钻采设备有限公司

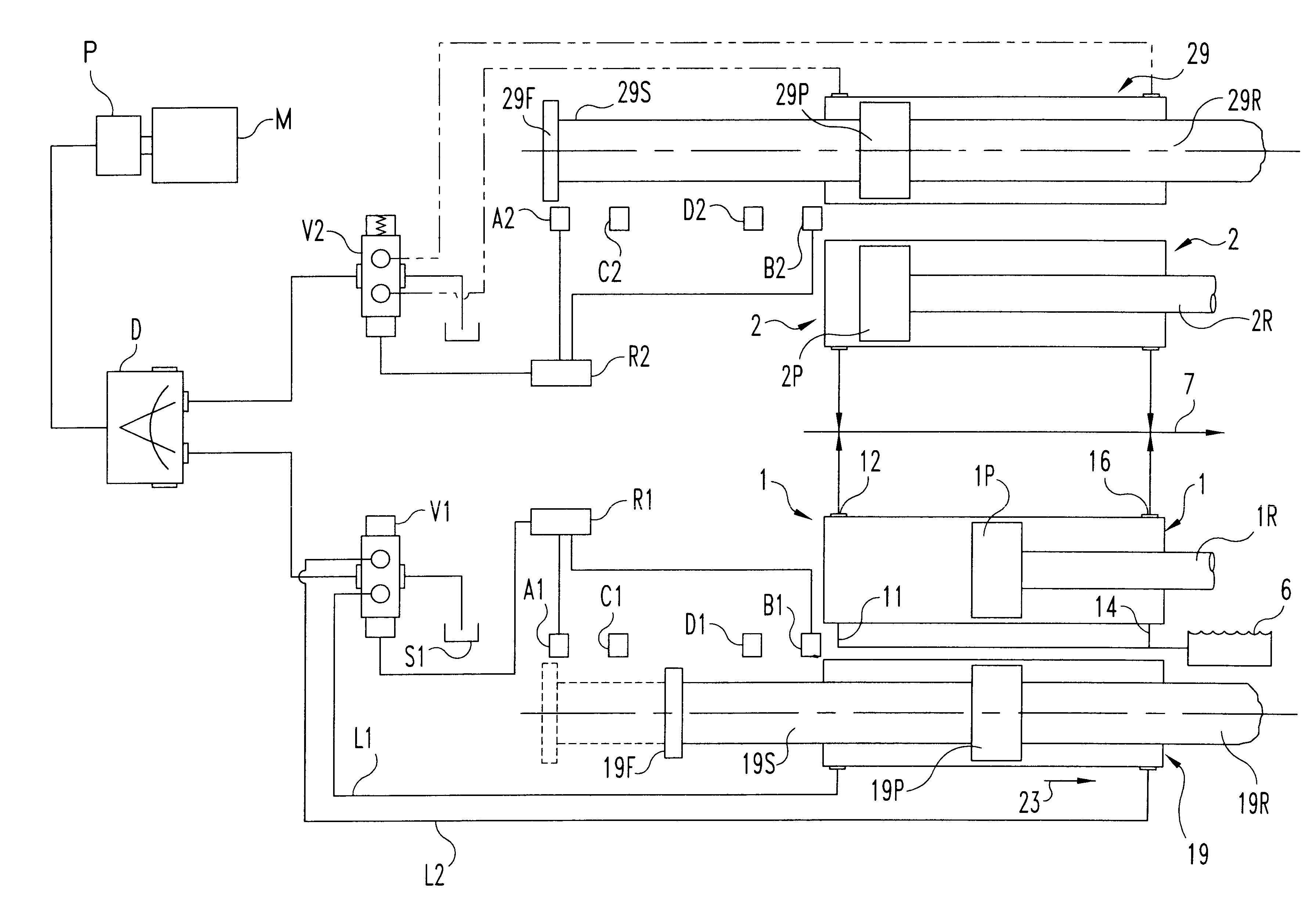

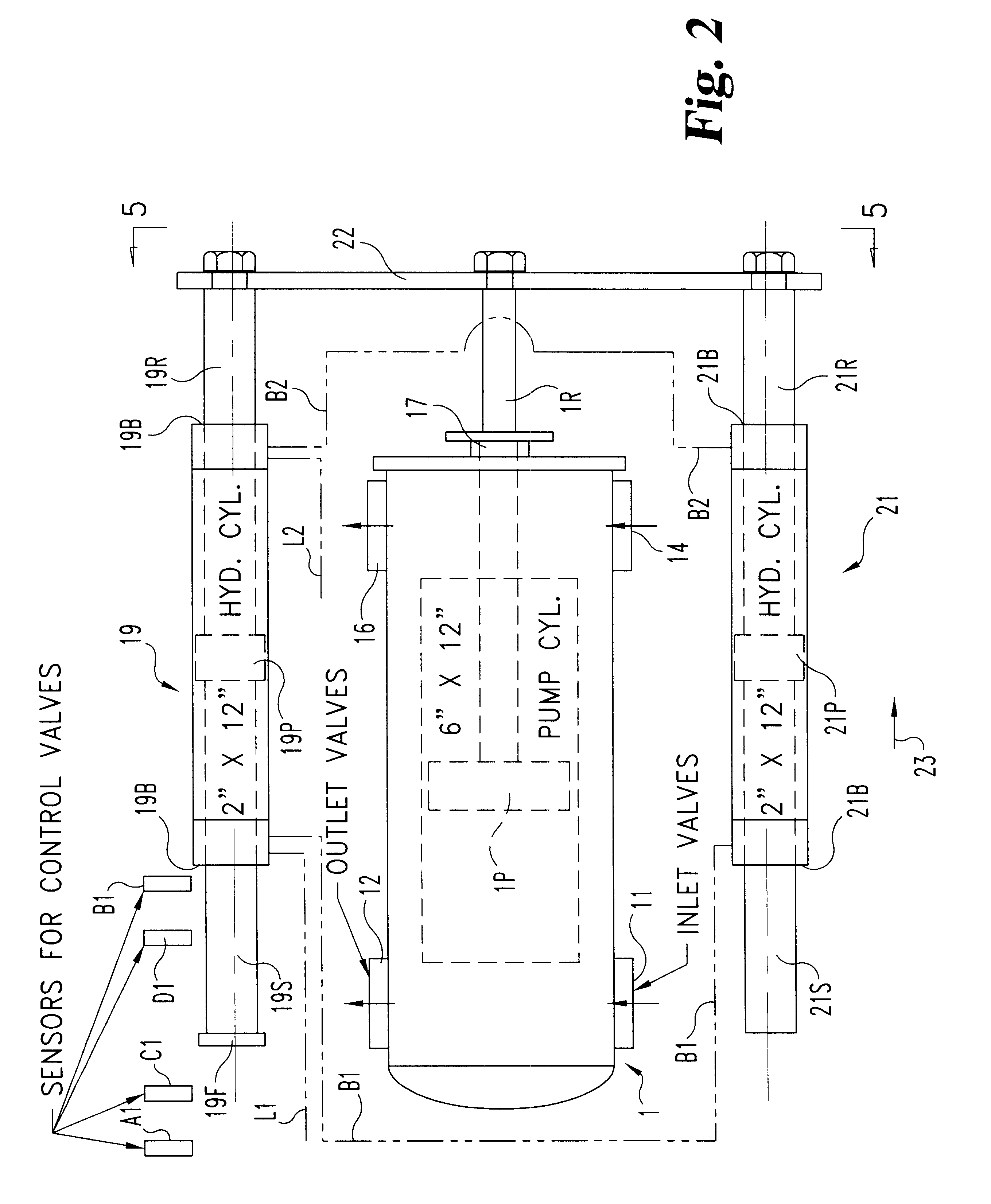

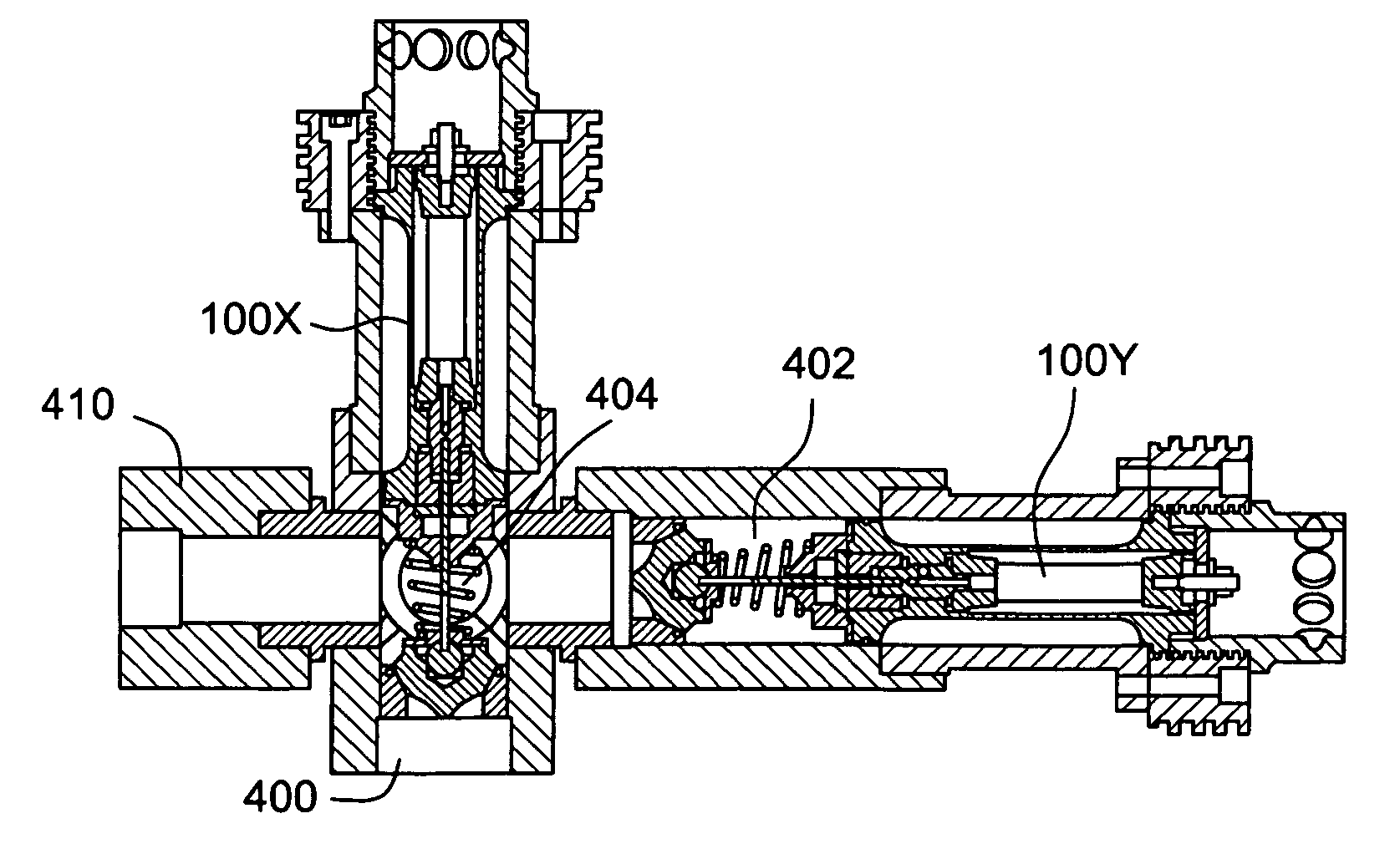

Hydraulic cylinder powered double acting duplex piston pump

A mud pump is provided with two cylinders for pumping mud in connection with water well drilling, and two sets of hydraulic oil cylinders with pistons connected to and driving the pistons of the mud pump by piston rod connecting plates. A flow divider located downstream from a hydraulic oil power supply pump applies hydraulic power evenly to two sets of mud pump driving cylinders, but the flow divider accommodates re-routing of hydraulic oil to one driving cylinder during a directional valve shift for the other driving cylinder. Rod position sensing switches coupled to an electro-hydraulic control system coordinates the action of the sets of pump driving cylinders and thereby of the mud pumping cylinders, to control and phase the mud driving pistons produce a steady mud pump output simulating the effect of constant velocity pistons.

Owner:LAIBE CORP

Apparatus and method for reclaiming, purifying and reutilizing boring mud

InactiveCN1803680ARealize automatic continuous operationSimple structureWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningParticulatesMicrowave oven

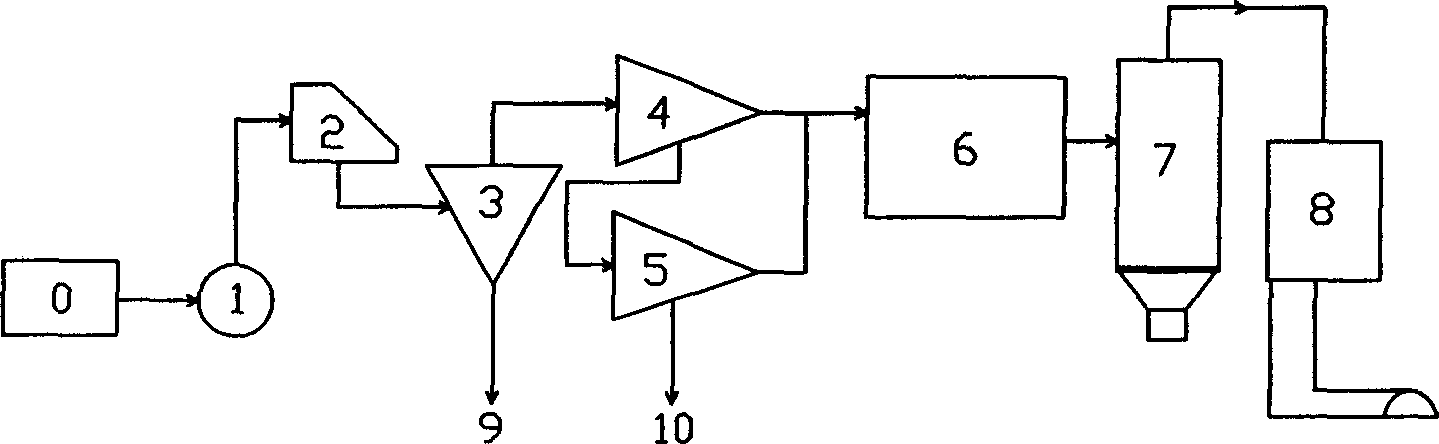

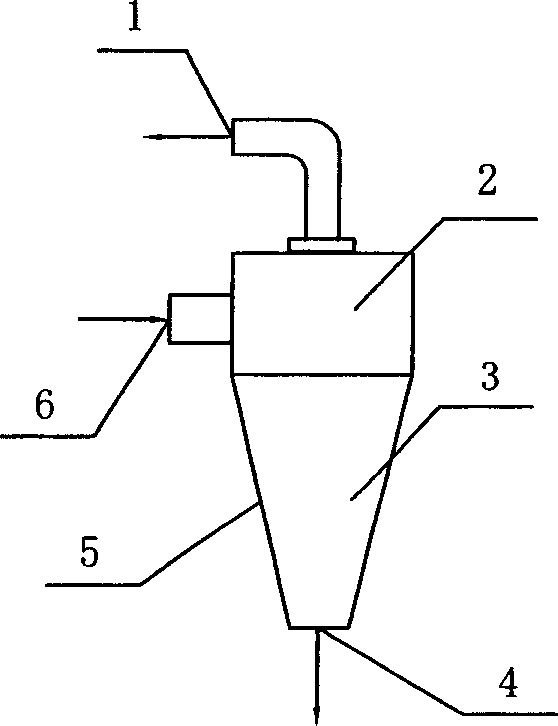

The invention discloses a device system to recover and re-use the drilling mud, which comprises connected by turns: a storage tank to store the waste drilling mud, a vibration screen for coarse purification, a hydrocyclone to separate the mud conveyed by a mud pump and discharge the particulate from its lower end, a first-stage centrifuge for filter and purification, a microwave oven to dry the mud, a crusher to crush the mud again, and an automatic packaging machine to pack and recover the mud. This invention is simple and convenient, has low cost and no pollution danger, and brings hundred millions economic benefits every year.

Owner:王鸿飞 +1

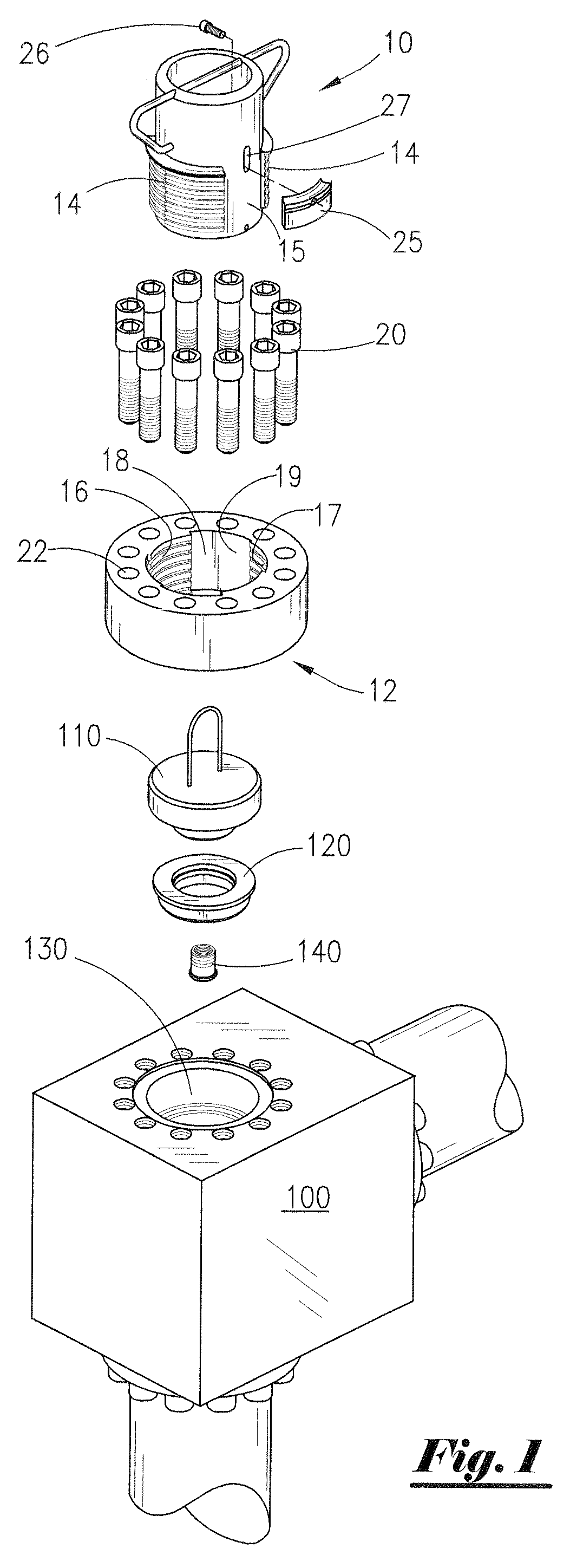

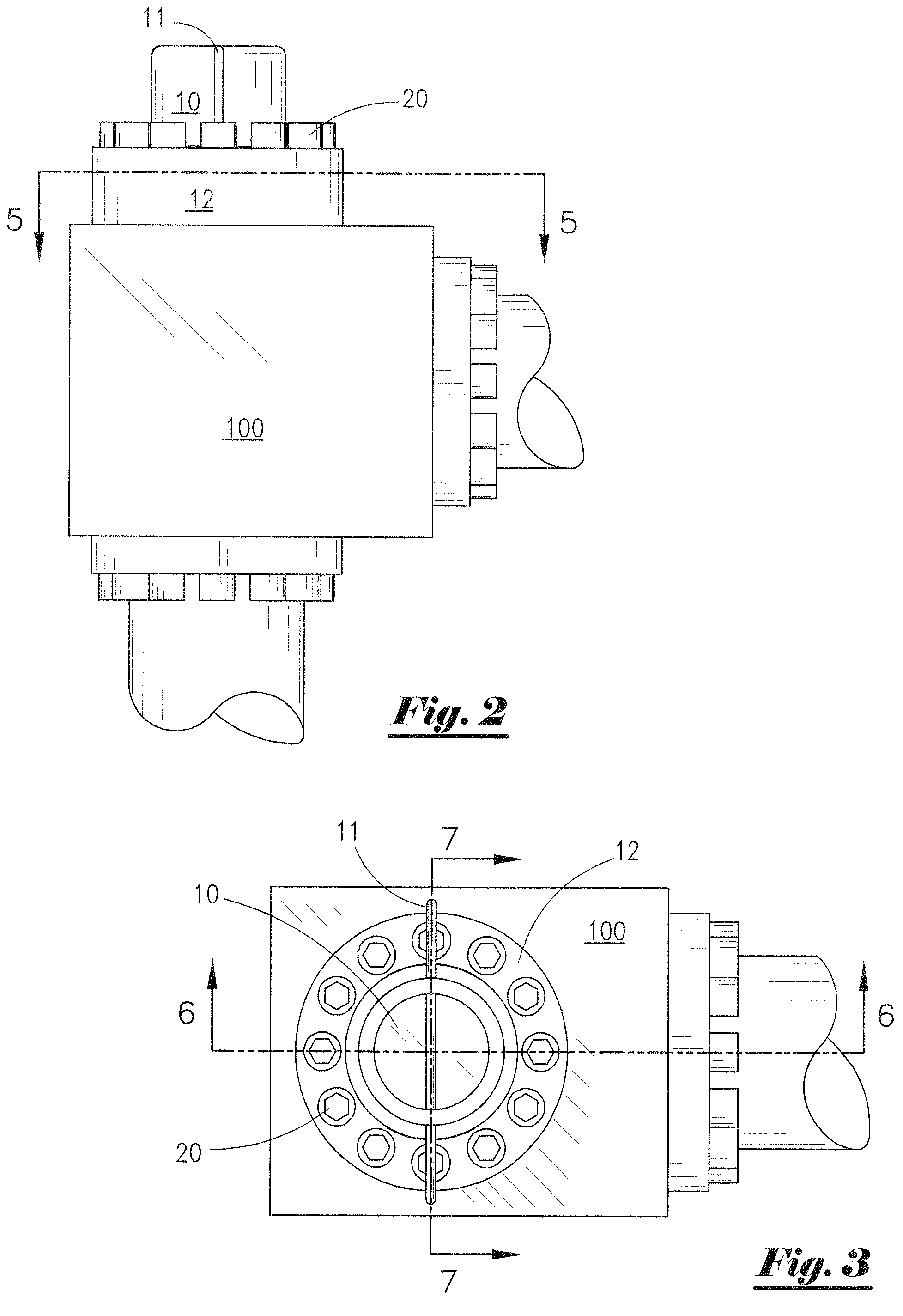

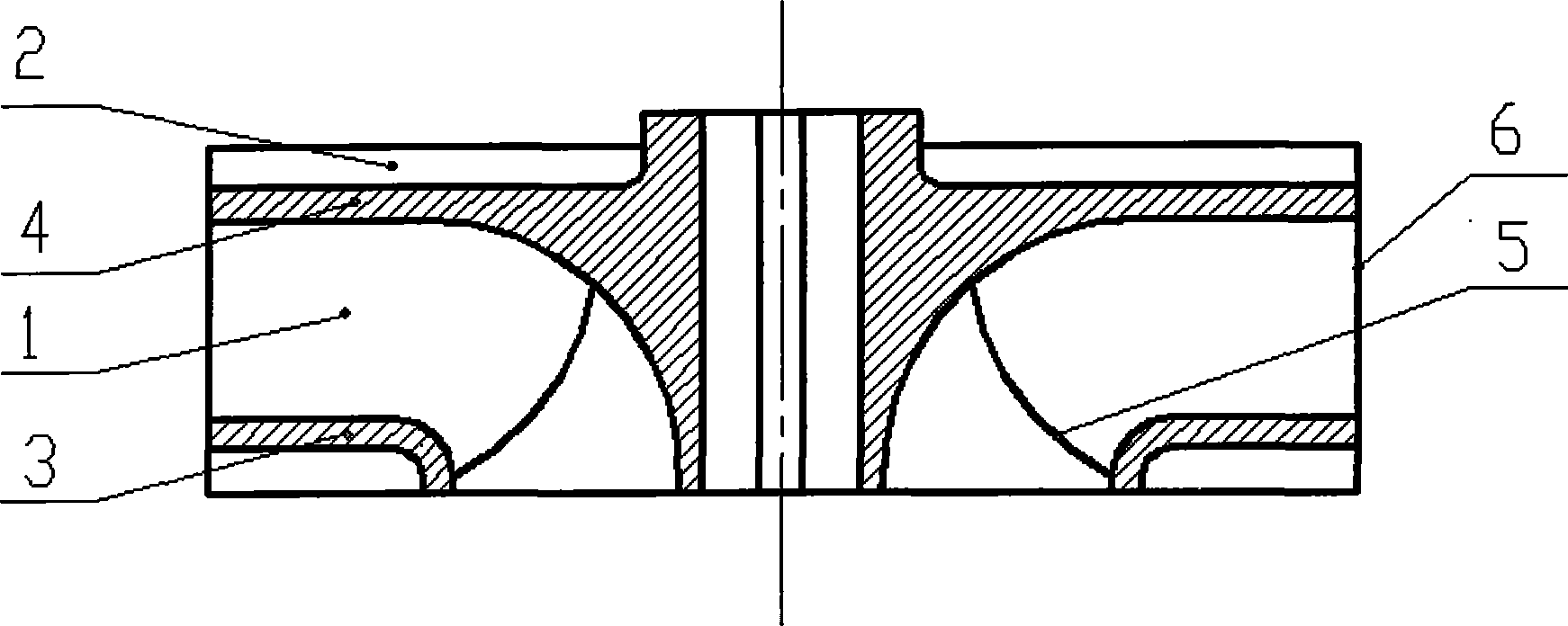

Mud pump receiving flange and plug retainer

A plug retainer and receiving flange for a mud pump fluid module pipe comprising a plug retainer and a receiving flange. The threads of the plug retainer are configured into at least two segments that are axially disposed opposite each other upon the periphery of the plug retainer. Each segment of plug retainer threads has at least two columns of threads that are progressively stepped outward from said the periphery of said plug retainer. The receiving flange has at least two segments of flange threads axially disposed upon the periphery of the flange bore that are disposed opposite each other on the flange bore to form gaps between each of the thread segments, each segment of receiving flange threads has at least two columns of threads that are progressively stepped inward and are configured to correspond with the plug retainer thread segments. A means to rotate the plug retainer within the bore of the receiving flange is provided to engage the plug retainer threads with the receiving flange threads. The plug retainer threads and the receiving flange threads may be horizontally disposed and a lock plate may be provided to avoid inadvertent turning of the plug retainer in the receiving flange.

Owner:WALTERS JIMMY A

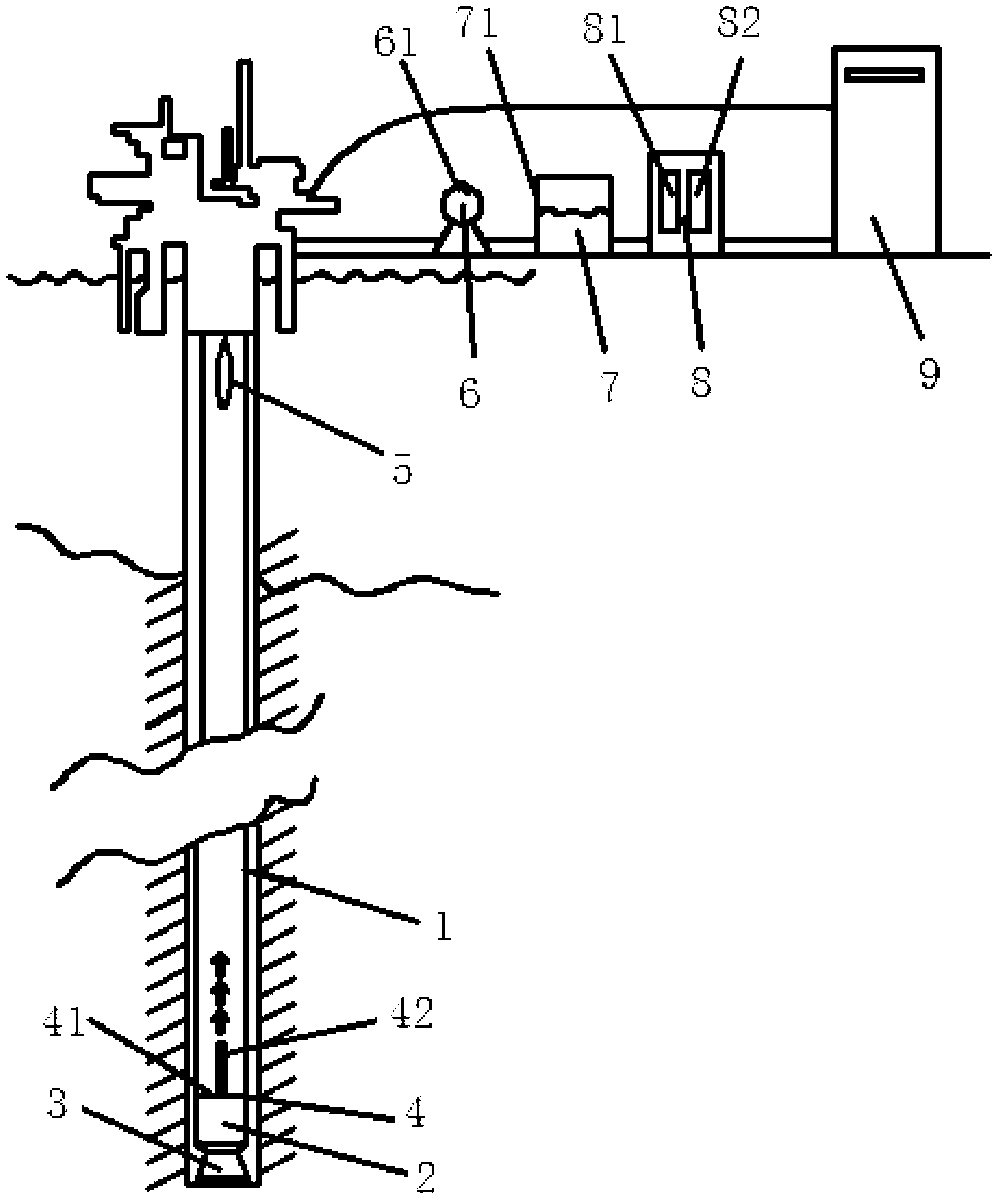

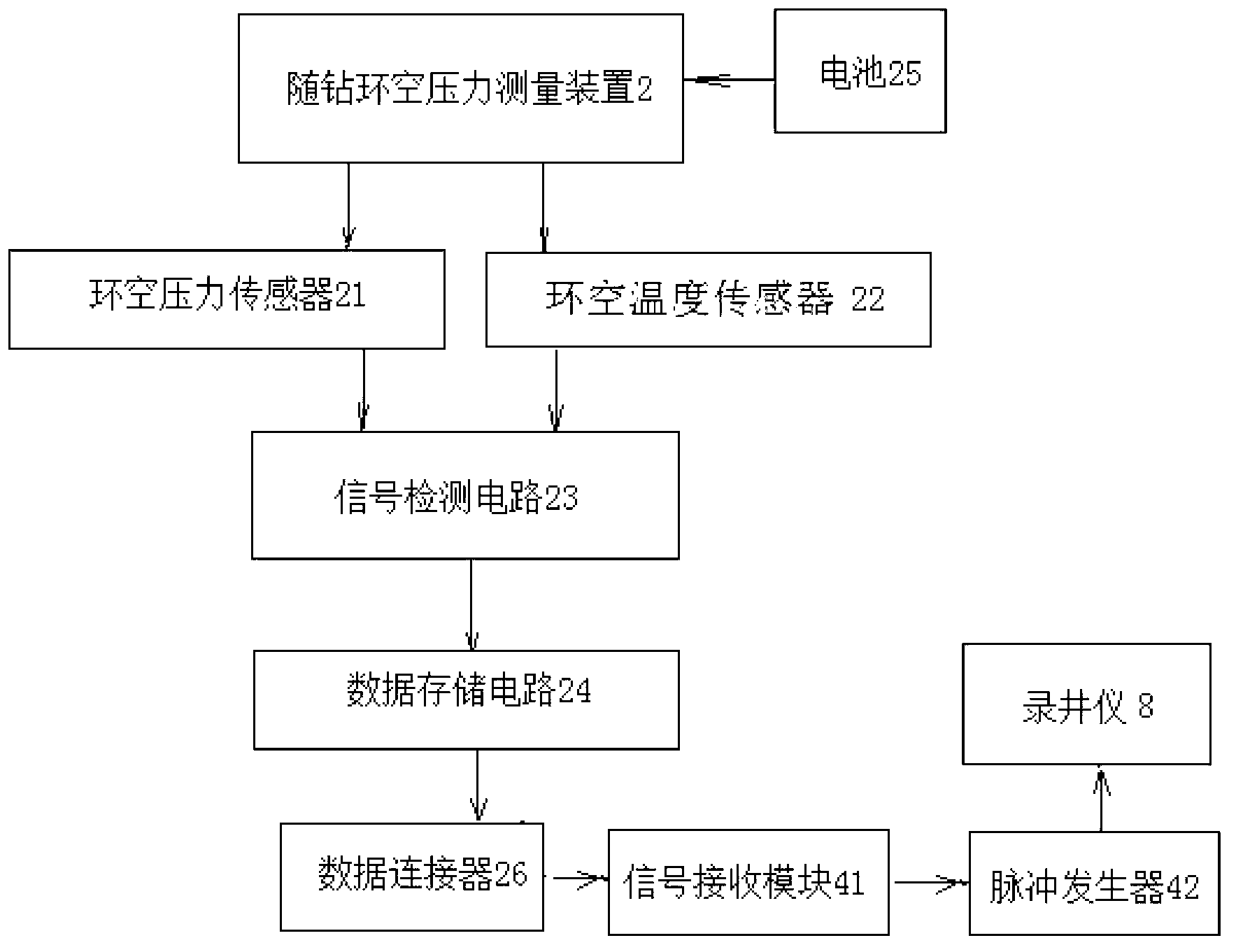

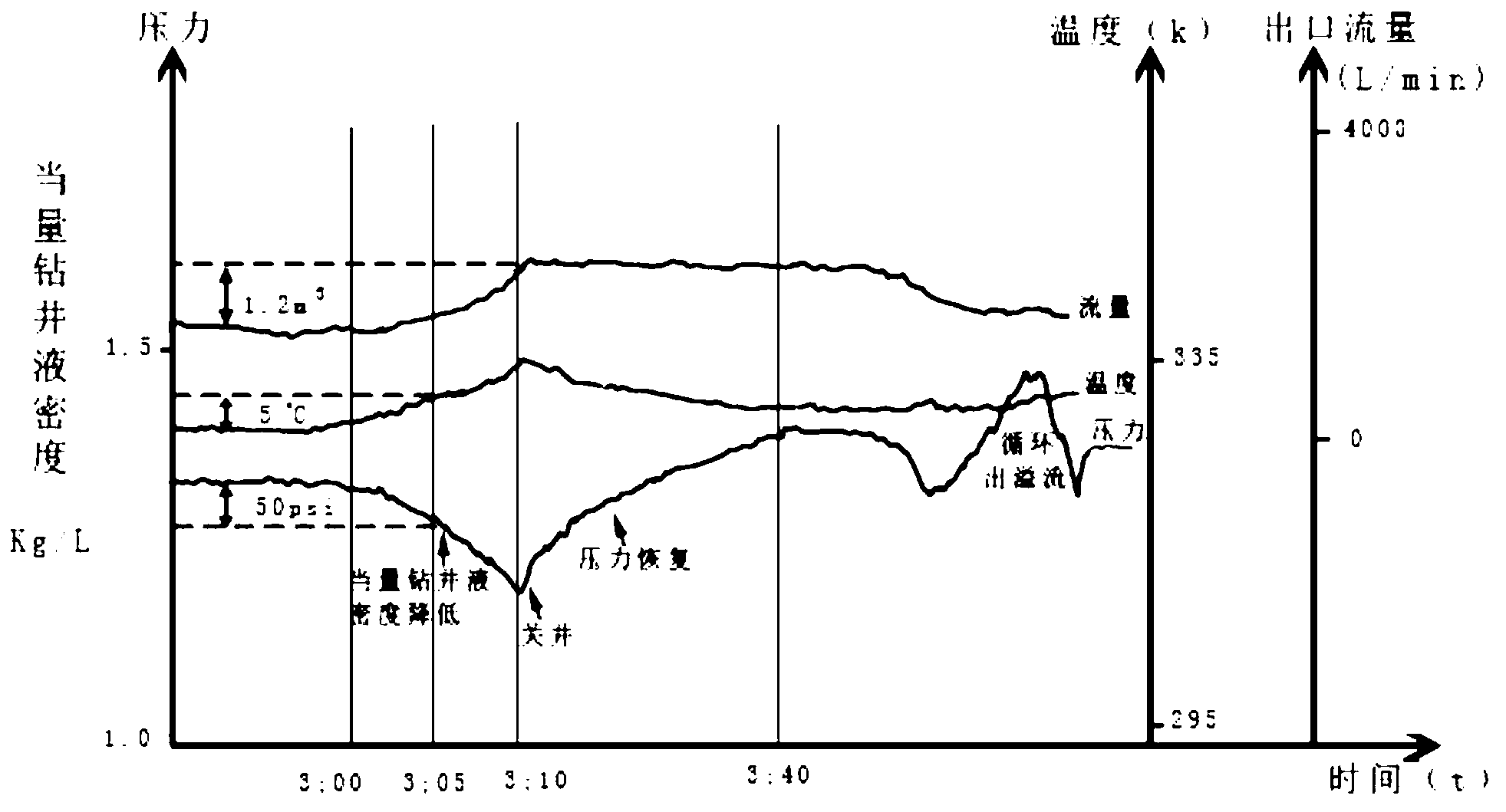

Method and device both based on annulus pressure measuring while drilling and for early monitoring gas invasion of wellhole

The invention relates to a method and a device both based on annulus pressure measuring while drilling and for early monitoring gas invasion of a wellhole. The device is characterized in that the device comprises a drilling column arranged in the wellhole, the bottom of the drilling column is connected with an annulus pressure measuring while drilling device and a drilling bit, the annulus pressure measuring while drilling device comprises an annulus pressure sensor, an annulus temperature sensor, a signal monitoring circuit, a data storage circuit, a battery and a data connector, the top of the annulus pressure measuring while drilling device is connected with a measuring while drilling device which comprises a signal receiving module and a pulse generator, a drilling fluid returning flowmeter is arranged on the upper portion of the drilling column, one side of a wellhead is connected with a mud pump and a mud circulating pool through a pipeline, a mud pressure sensor is mounted on the mud pump, a mud level meter is arranged in the mud circulating pool, the drilling fluid returning flowmeter, the mud pressure sensor and the mud level meter are in wire connection with a well logging instrument respectively, a filter module and a signal measuring module are arranged in the well logging instrument, and the well logging instrument is connected with a data analyzing and alarming module through a wire. The method and the device can be applied to deepwater oil drilling operations.

Owner:CHINA NAT OFFSHORE OIL CORP +2

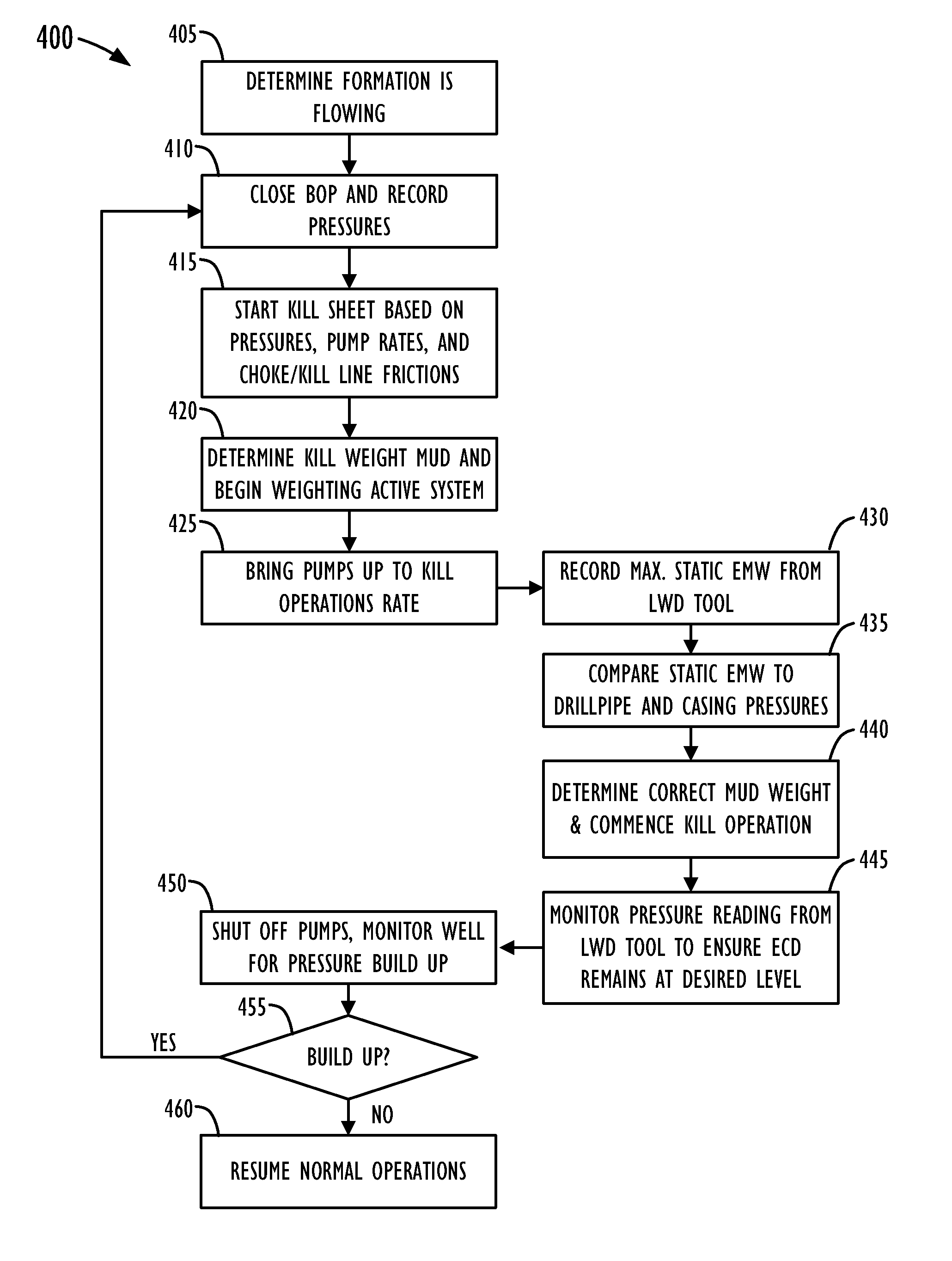

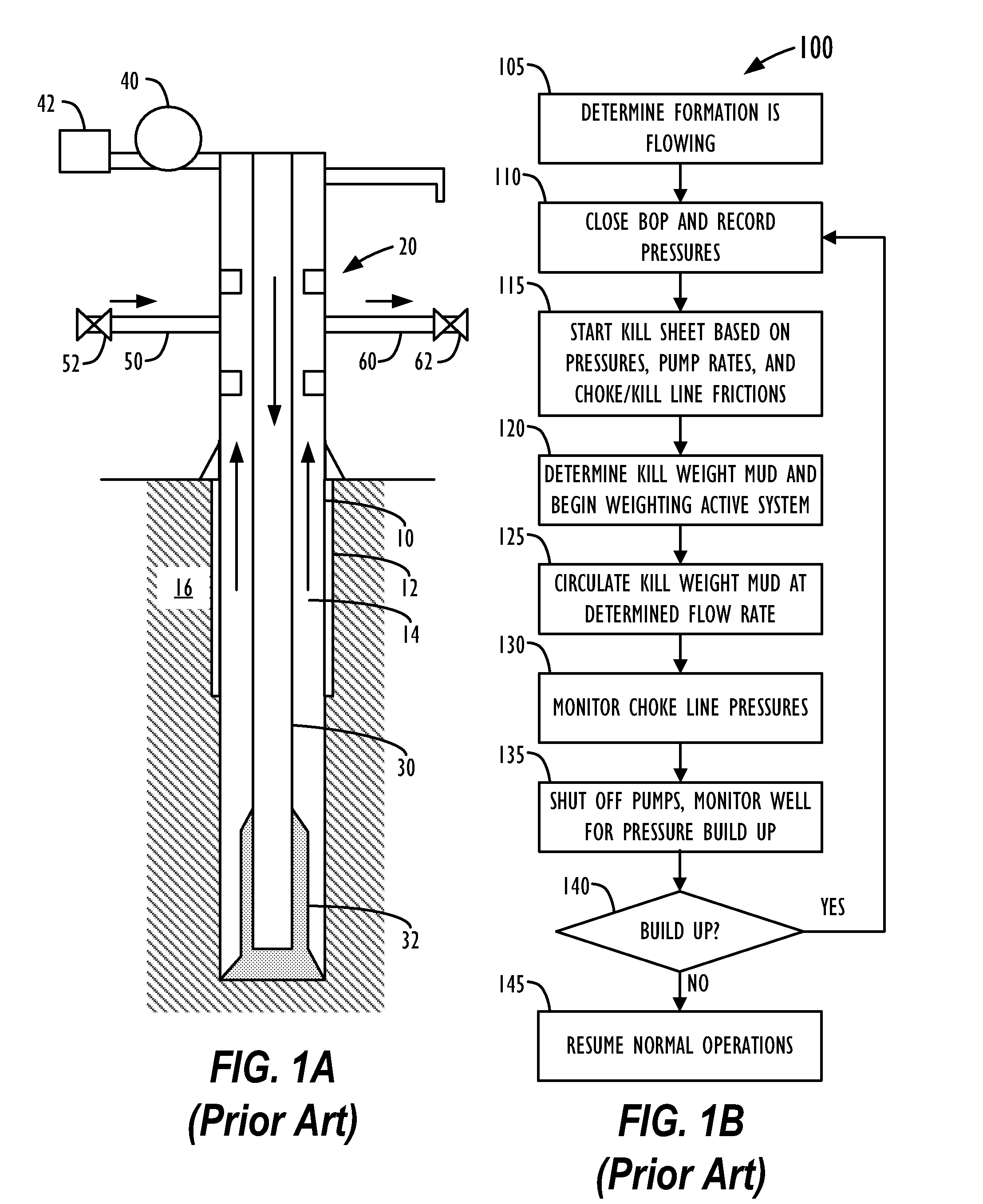

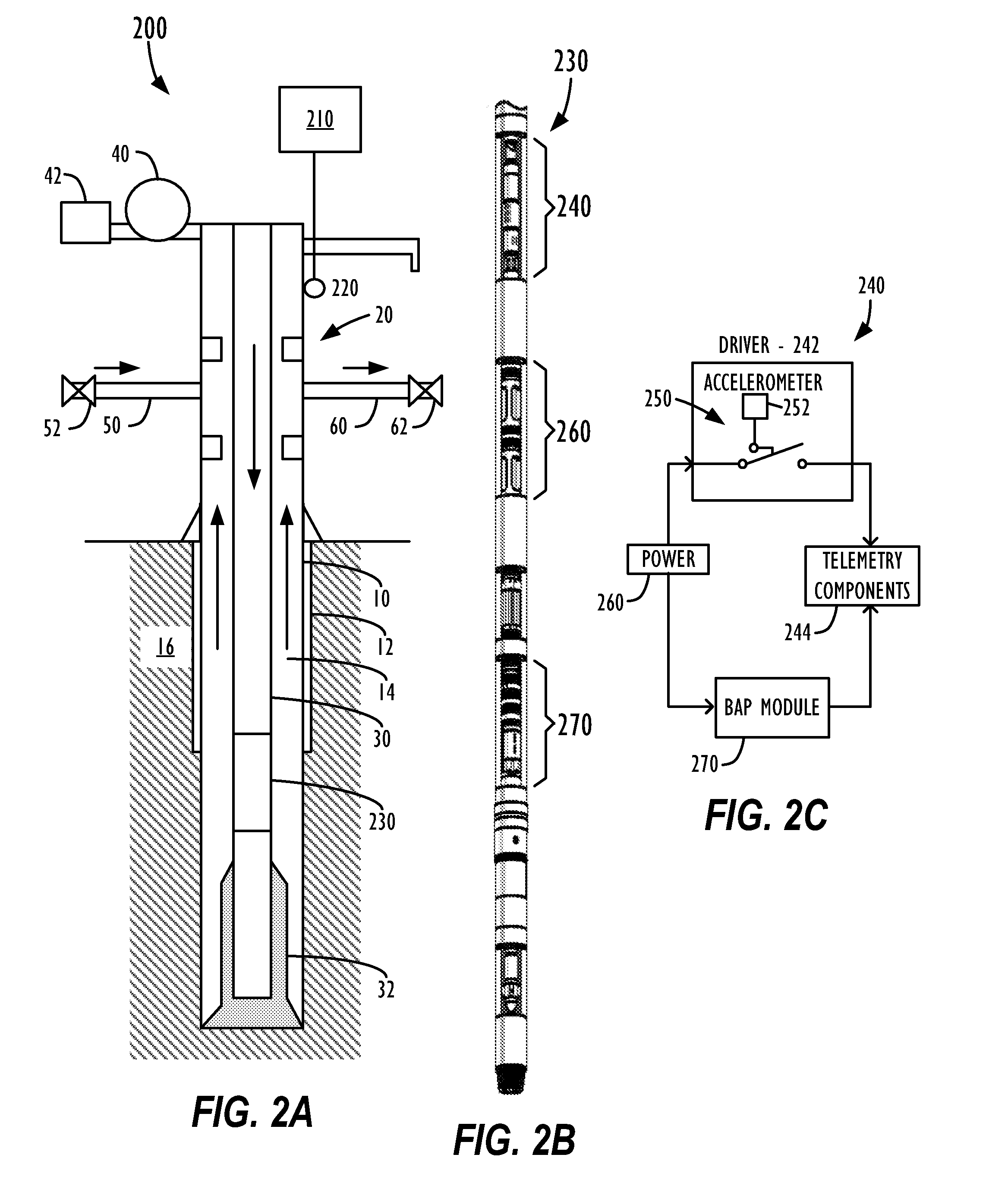

System and Method for Obtaining and Using Downhole Data During Well Control Operations

InactiveUS20090063055A1Electric/magnetic detection for well-loggingSurveyPressure dataMechanical engineering

In a well control system and method, a tool driver on a toolstring is configured to activate a telemetry tool in response to a predetermined threshold of accelerometer data measured by an accelerometer. For example, the predetermined accelerometer data threshold preferably corresponds to an acceleration level expected while drilling mud is being pumped at a slow pump rate of a well control operation through the drill pipe of the well. When a fluid influx occurs during drilling, the well is shut-in so that the tool driver turns off the telemetry tool. The drill pipe and casing pressures of the shut-in well are obtained. Then, drilling mud having a first weight is pumped into the drill pipe at a slow mud pump rate. Because the tool driver is set to activate the telemetry tool in response to accelerometer data at the slow pump rate, the telemetry tool begins sending downhole pressure data to the surface. In this way, rig operations can change the mud weight and adjust the choke line during the kill operation based on an analysis of the downhole pressure data obtained during the well control operation.

Owner:WEATHERFORD TECH HLDG LLC

Process for producing methane by dry-type fermentation of stalks

InactiveCN101338325ALess investmentReduce operating costsBio-organic fraction processingClimate change adaptationSlagSlurry

The invention provides a technique for producing biogas by utilizing stalk dry fermentation which includes the steps: I, cracking the stalks into 2 to 8mm by a cracking machine; II, transmitting the cracked stalks into a pre-treatment pool, adding hot water of 40 to 53 DEG C and a stalk fermentation agent in the pre-treatment pool to carry out pre-treatment; the cracked stalks and the biogas slurry refluxed by the anaerobic digester of the pre-treatment pool are mixed according to a proportion of 2 to 1; after stirring, the solid content rate of the stalk liquid is 20 to 35 percent; III, using a mud pump to equally transmit the stalk liquid to the top part of the anaerobic digester with a fermentation temperature of 40 to 53 DEG C; IV, the biogas generated by fermentation is purified to be clean fuel by gas-liquid separation. The technique can lead the stalks of 1.5kg to generate the biogas of 1m<3> (the content of methane is larger or equal to 55 percent); the degrading rate is more than 90 percent. The technique of the invention can continuously feed and discharge; the biogas slurry can be repeatedly used; only biogas slag is discharged; the biogas slag is manufactured into organic fertilizer by processing and can not cause any pollution to the environment.

Owner:HENAN FUCHENG ECOLOGICAL ENERGY TECH

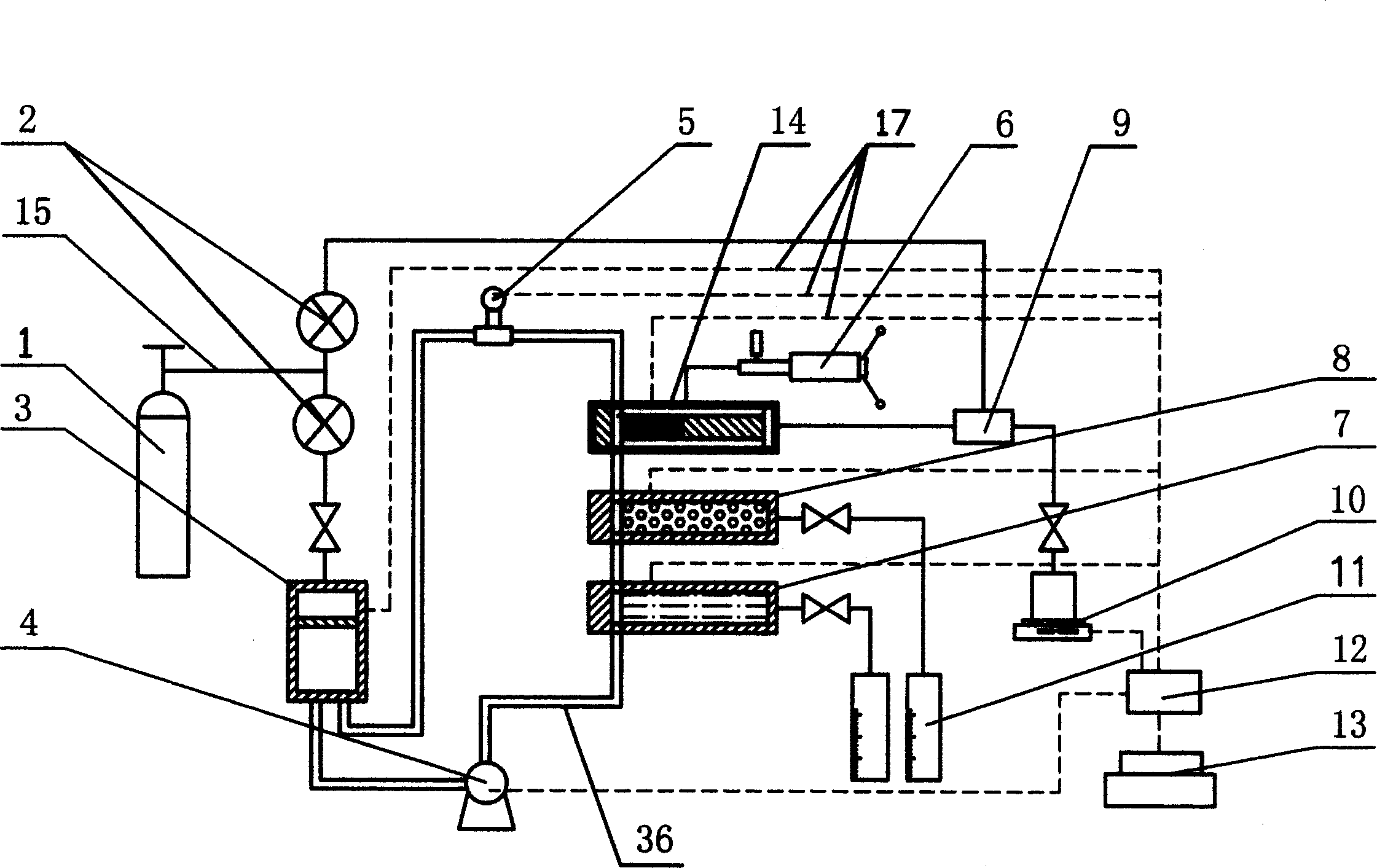

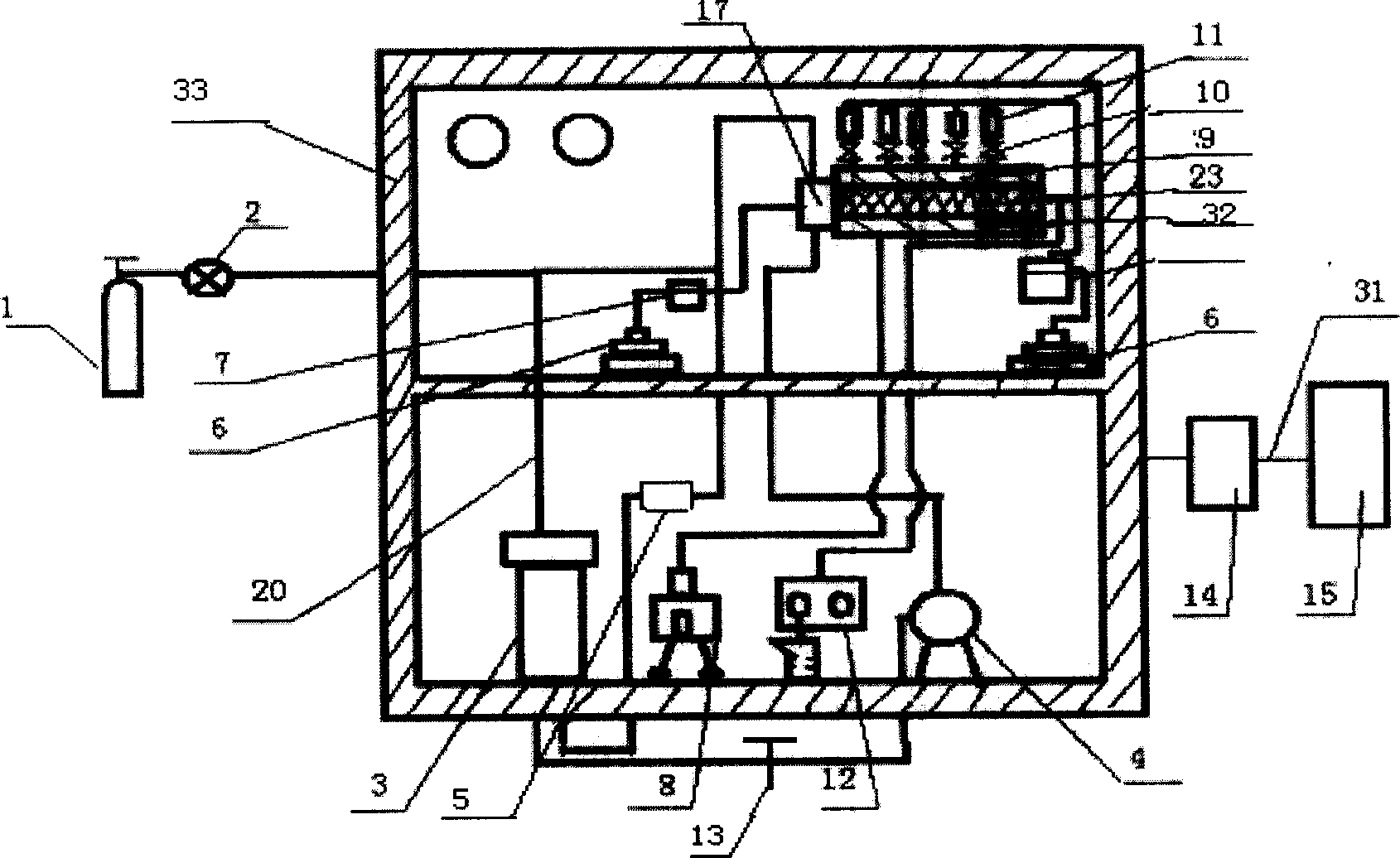

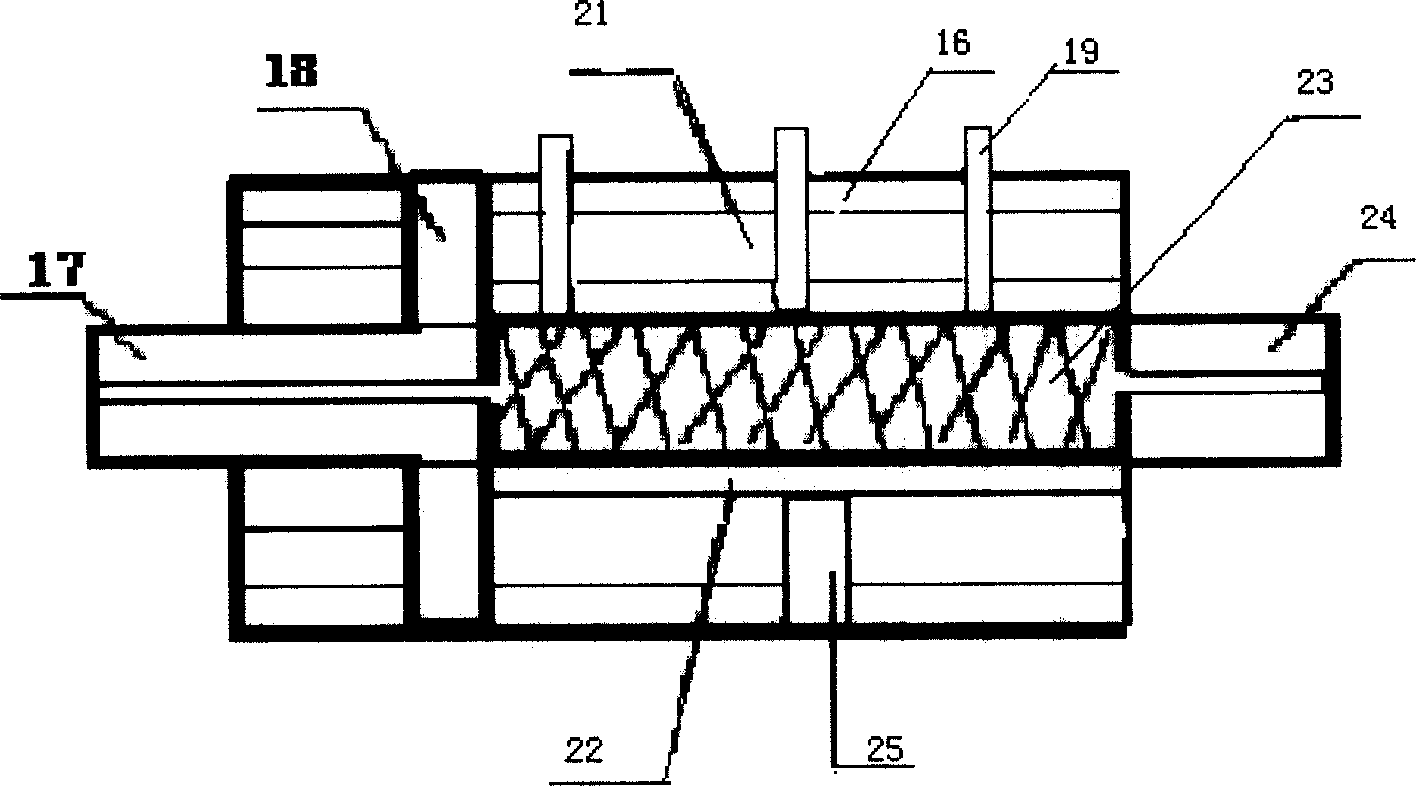

Intelligent high-temperature high-voltage experimental instrument for dynamic leak stopping evaluation

InactiveCN1731176AGood plugging effectFluid-tightness measurement using fluid/vacuumMaterial analysisControl lineData acquisition

The invention relates to an intellectual high temperature high pressure dynamic stopping leak appraisal device in the field of oil exploration and development excremental device. it is formed by a gas source, a mud pump, a piston-type high temperature high pressure mud bottle, a steel leaked bed holder, a work holder, a rock core holder, a flow-meter, an electric dissimilar, a ring pressure pump, a return pressure controller, a liquid circulating pipe, a control line, a data collector, a computer and a printer and so on. It arranges the drilling fluid of the leak agent into the mud bottle on the condition of temperature, pressure, flow speed of the simulated formation; it then uses mud pump to drive the borehole fluid of the piston-type high temperature high pressure mud bottle and dose leak damage experiment to the steel leaked bed holder, the artificial slit plate and the formation rock core to achieve the indoor correct evaluation of the leak effect of the drilling fluid and the well completion fluid.

Owner:JINGZHOU MODERN PETROLEUM TECH DEV CO LTD

Method for cleaning and sealing a well borehole portion for formation evaluation

A borehole wall cleaning apparatus and method for obtaining an improved seal between a fluid sampling device and a portion of the borehole wall. Clean drilling fluid is pumped into a drilling tool using a mud pump. A fluid diverter in the tool diverts all or part of the clean drilling fluid through a port to clear a portion of a borehole wall. A sealing pad is moved against the clean portion. A sampling port is exposed to the sealed portion for sampling and / or testing fluid from the formation.

Owner:BAKER HUGHES INC

High temperature, high pressure core dynamic harm valuation test instrument

InactiveCN1677082AReduce volumeLow costPermeability/surface area analysisData acquisitionEngineering

The invention is a high pressure high temperature rock core dynamic damage estimate apparatus. It comprises straight pump mud pump, high pressure liquor tank, side plane circulating multi test point rock core pick, flow meter, gas source, pressure sensor, round pressing pump, return pressure controller, data gatherer and computer. Based on simulated rock temperature, pressure, flow speed, first obtain the original percolation rate on each section of rock core, then the mud pump drives the well liquor in the high pressure liquor container, obtain the percolation rate of each section of rock core without taking out the rock core, finally make out an evaluation of the damage the well liquor to the rock core so to pick out the drill liquor protective to the oil layer and the complete well liquor system.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

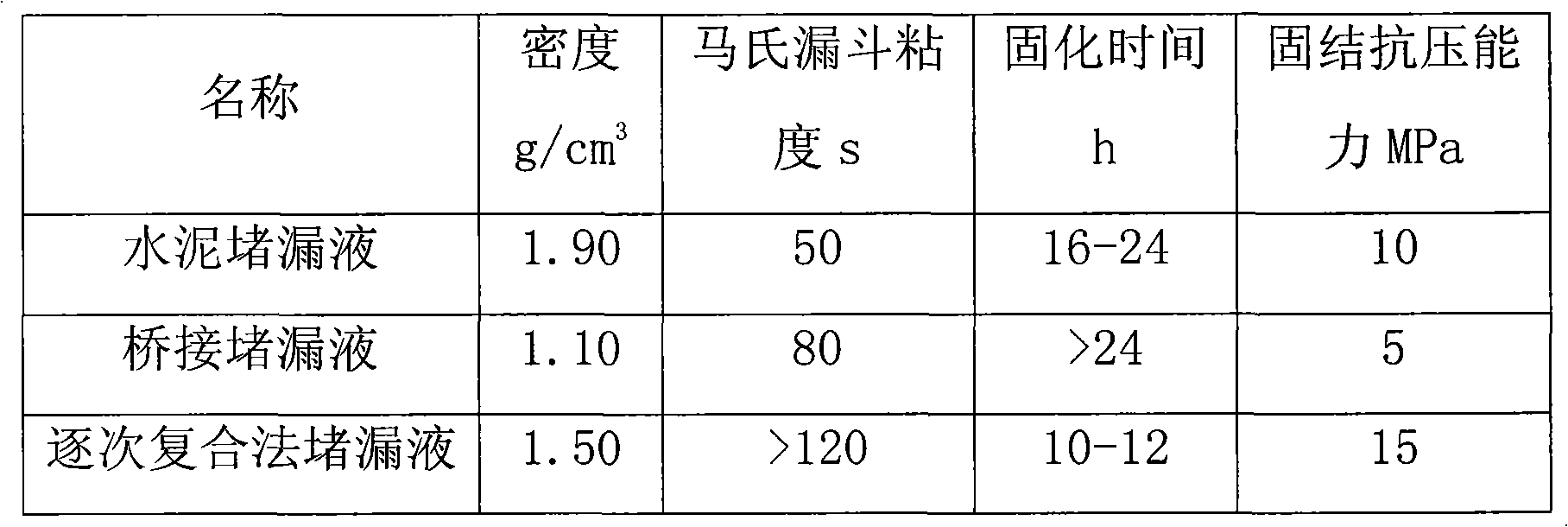

Successive-compounding-process based plugging method for well drilling

InactiveCN102434124AImprove pressure bearing capacitySolve the problem of low plugging success rateDrilling compositionSealing/packingWell drillingPorous medium

The invention discloses a successive-compounding-process based plugging method for well drilling. In the plugging method, a well-cementing cement pump or a mud pump is used for pumping two or more than two kinds of plugging fluids with different components and properties into an underground leakage zone successively in proportion. By means of the plugging method, the applicable range of the plugging fluids can be broadened, the loading capacity of a barefoot interval stratum can also be greatly increased, and the problem of low plugging success rate can be solved. According to the plugging method, a retention layer can be formed in porous media; the purpose of increasing the loading capacity and compressive strength of the stratum can be achieved by compounding the plugging fluids with different components and different properties; in addition, the construction process is simple, the plugging success rate is high, and the well drilling cost is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

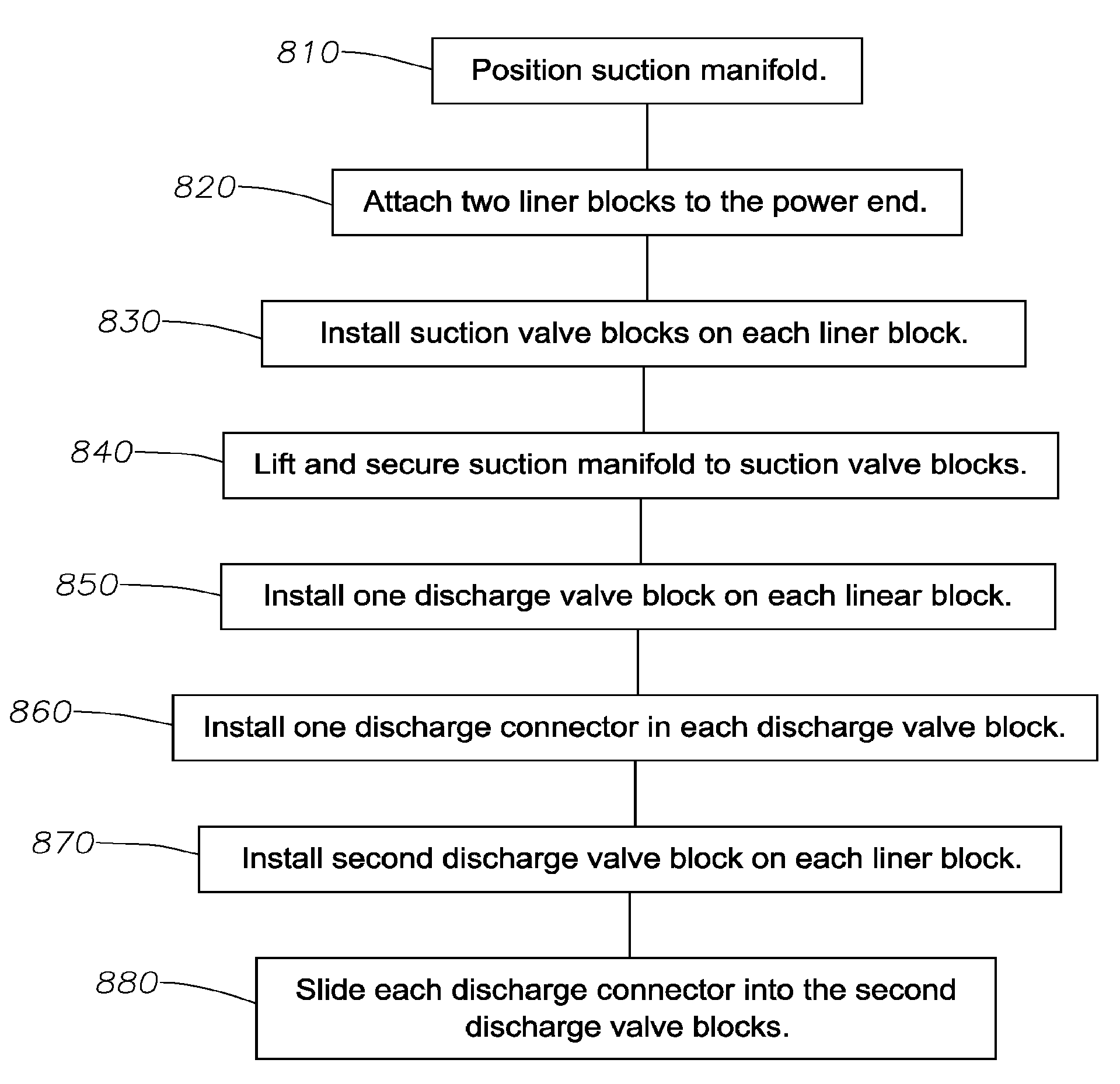

Method for assembling a modular fluid end for duplex pumps

A fluid end for a duplex mud pump. In one implementation, the fluid end includes two liner blocks, each having a central passage. The fluid end further includes two fluid inlets disposed on a side portion and two fluid outlets disposed on a top portion and a suction manifold displaced from the two liner blocks. The suction manifold comprises four flanges. The fluid end further includes four suction valve blocks, each having a bottom portion removably coupled to one of the four flanges and a side portion removably coupled to the side portion of the liner block, and four discharge valve blocks, each having a bottom portion removably coupled to the top portion of the liner block.

Owner:EC TOOL & SUPPLY

Reverse circulation clean out system for low pressure gas wells

ActiveUS7090018B2Avoid damageEasy to produceDrilling rodsConstructionsEngineeringMechanical engineering

The present invention provides an apparatus and a method for removing undesirable material from a well bore in a hydrocarbon formation with minimum damage to the formation. The apparatus comprises a concentric tubing string, said concentric tubing string further comprising an inner tube means having an inner annulus therethrough and an outer tube means forming an outer annulus between said outer tube means and said inner tube means, means for introducing into said well bore a pressurized clean out medium through one of the said inner annulus and outer annulus, and means for removing said material and clean out medium through the other of the said inner annulus and said outer annulus to the surface of said well bore. In a preferred embodiment, the introducing means comprises a discharge compressor or mud pump and the removing means comprises a suctioning compressor.

Owner:PRESSSOL

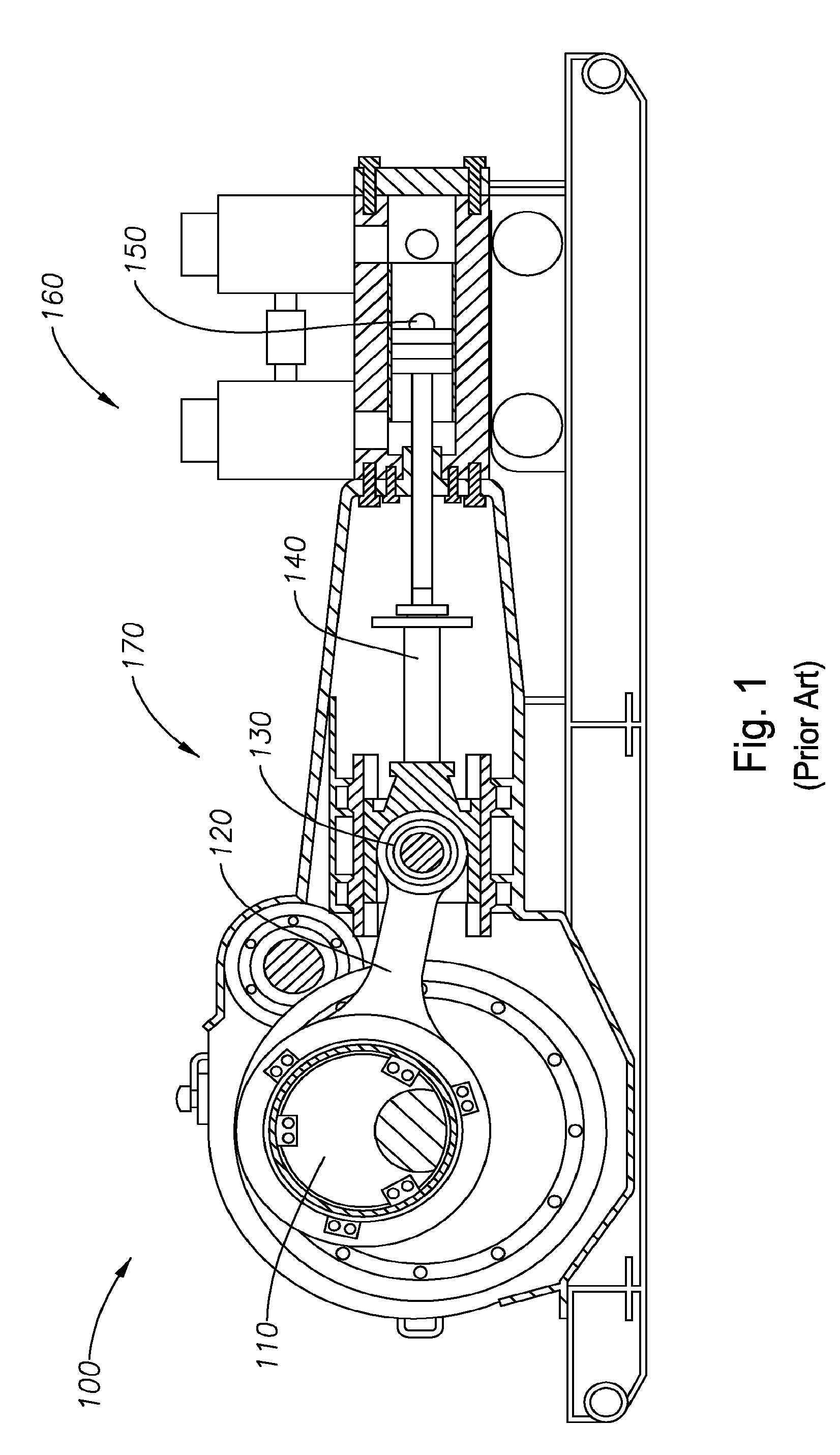

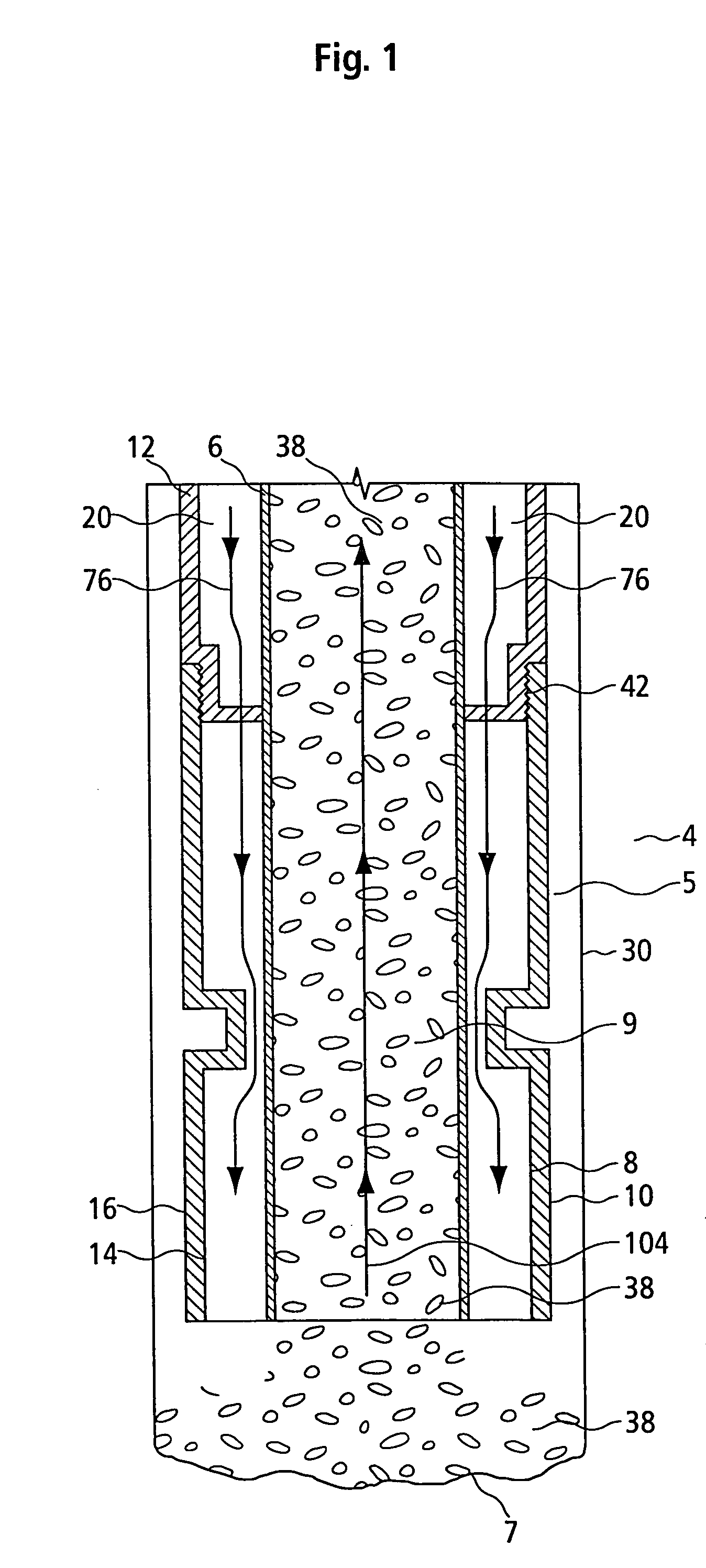

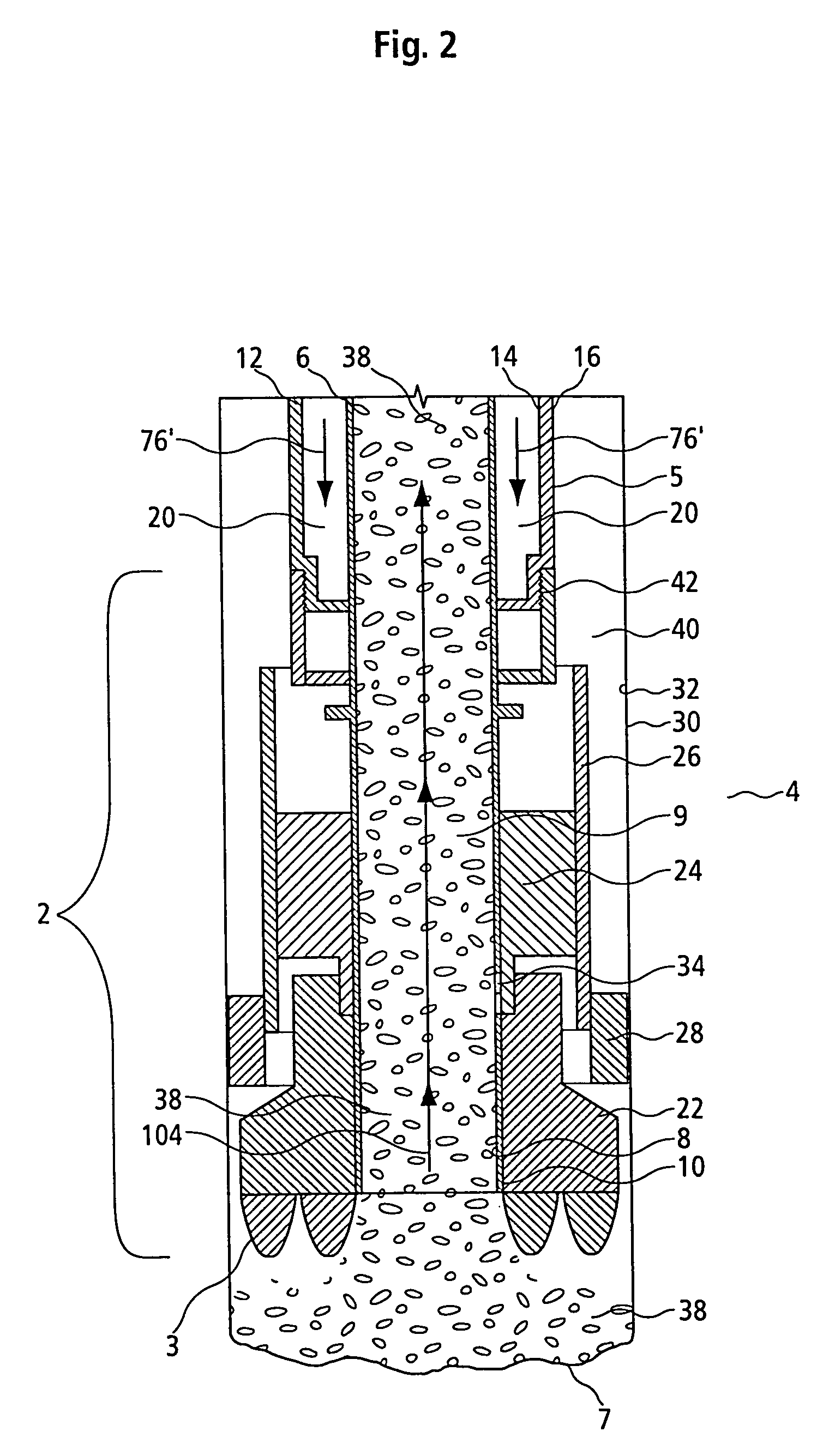

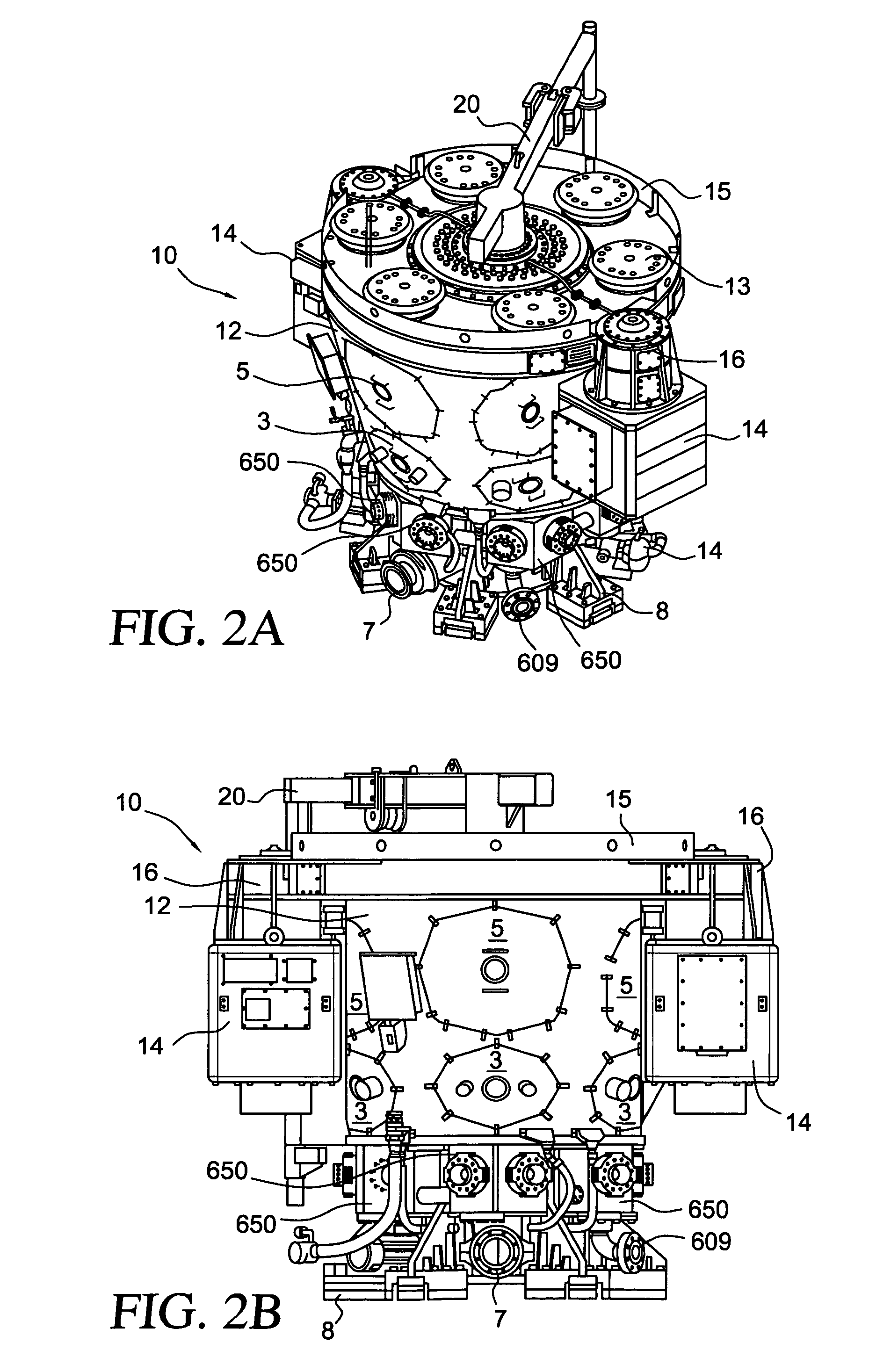

Mud pump systems for wellbore operations

InactiveUS20100098568A1Easy to moveOperating means/releasing devices for valvesConstructionsWell drillingSubject matter

A system for pumping a drilling fluid mixture, the system, in certain aspects, having a pump apparatus, the pumping apparatus having a body with an inlet and an outlet, a suction valve and a discharge valve in the body for selectively controlling flow through the body, or each valve having a curved valve seat and a valve member with a curved seating surface, the valve member selectively movable to seat against the curved valve seat to prevent the flow of the drilling fluid mixture past the valve seat; and, in one aspect, a seal in the curved valve seat against which the valve member is also sealable. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

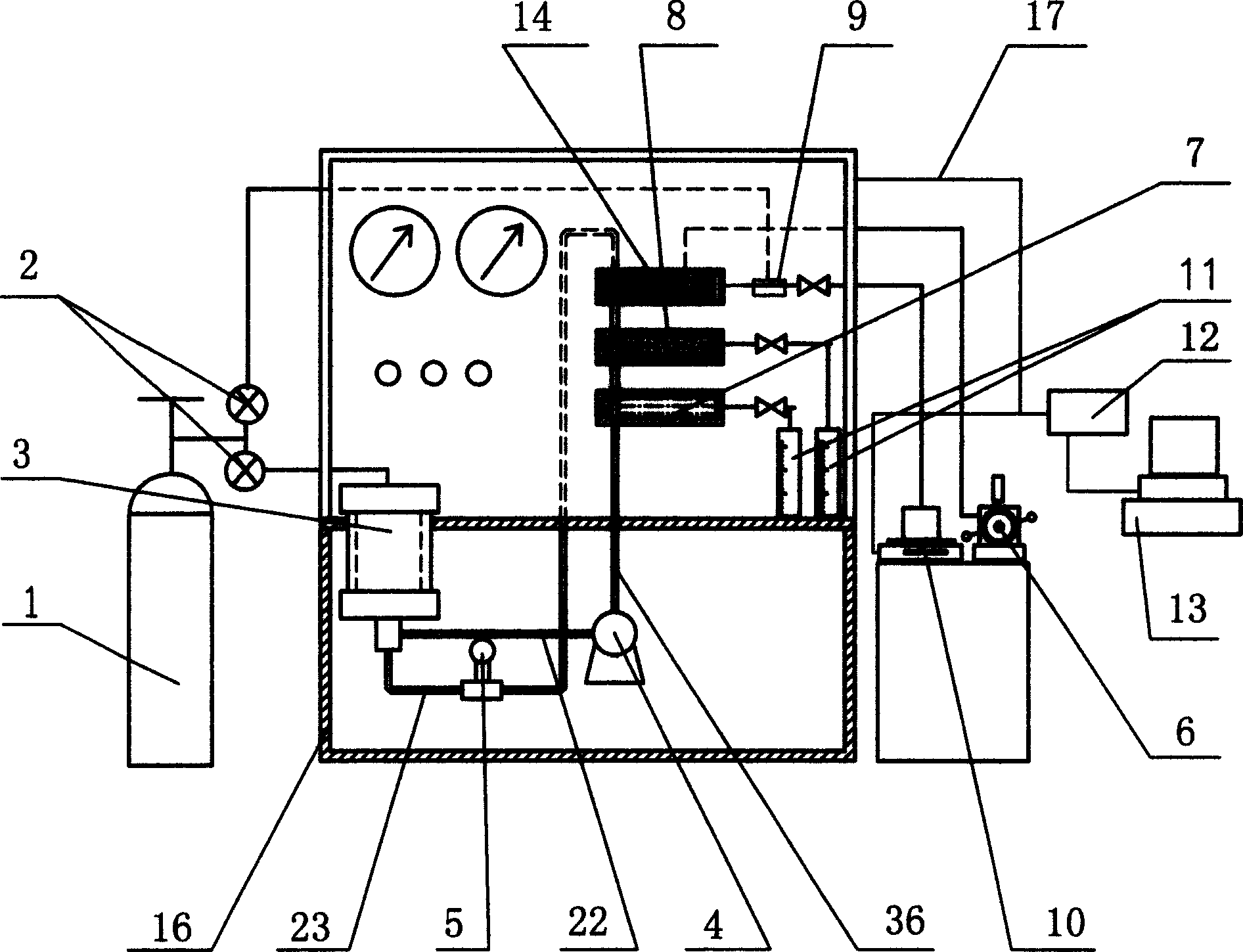

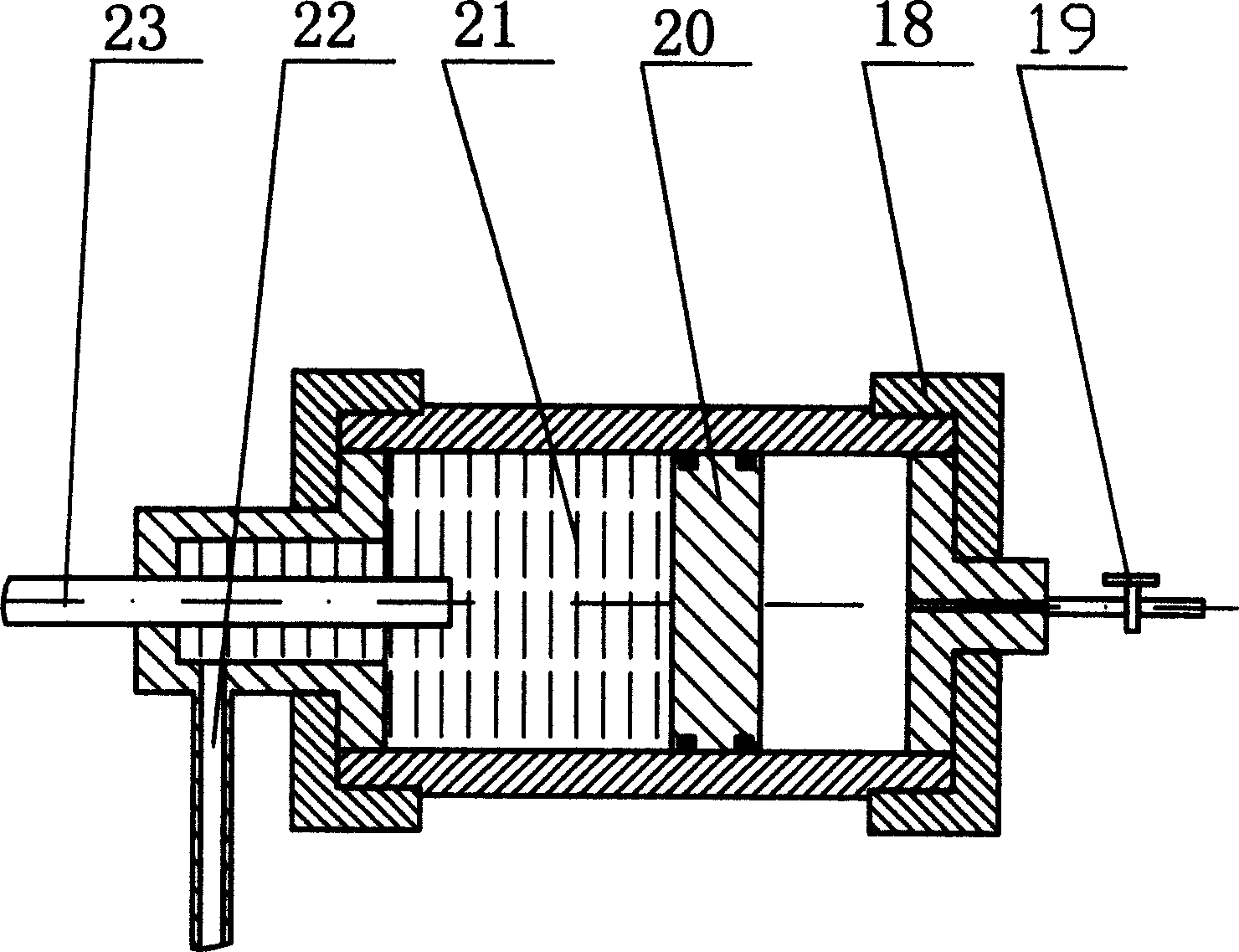

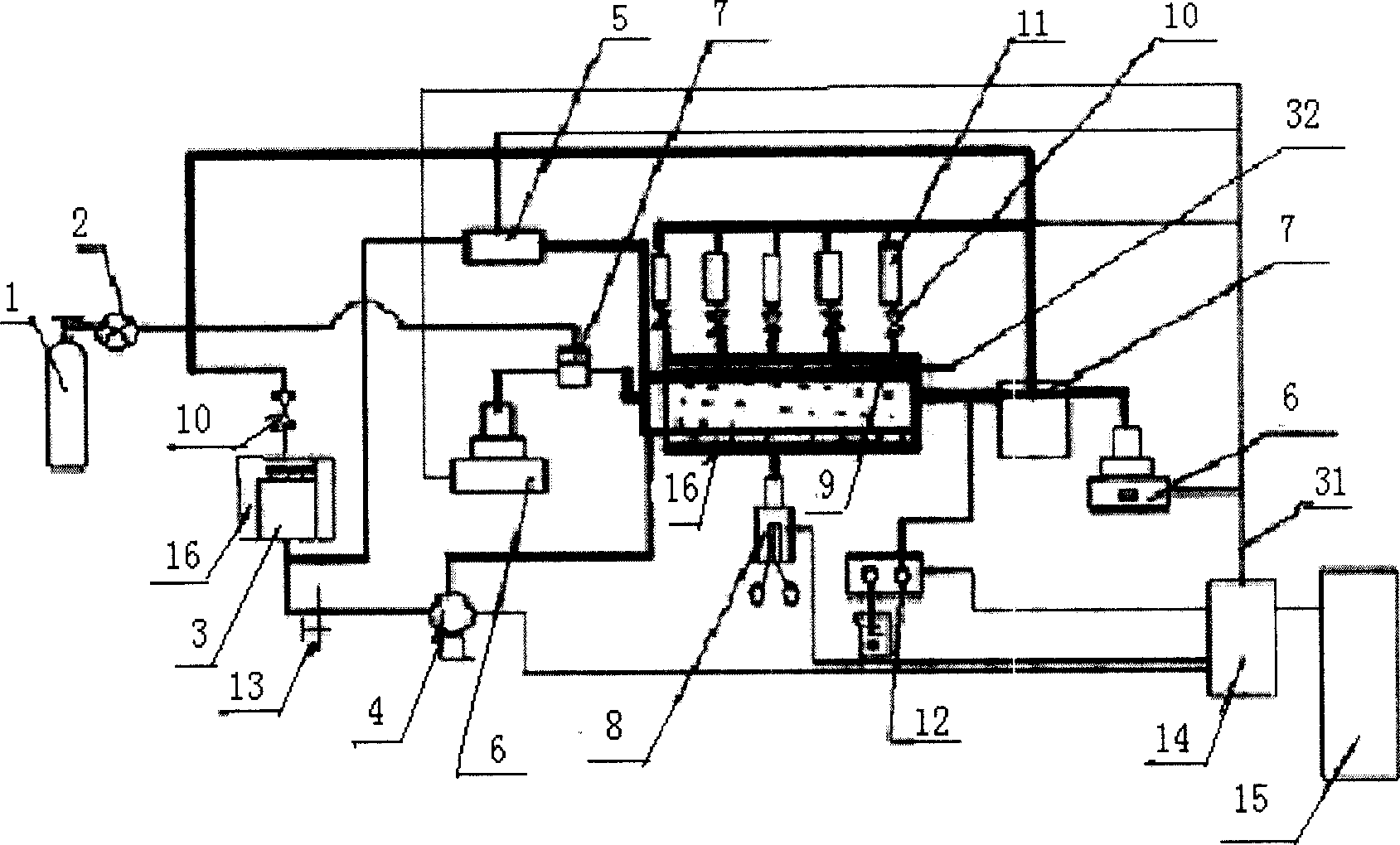

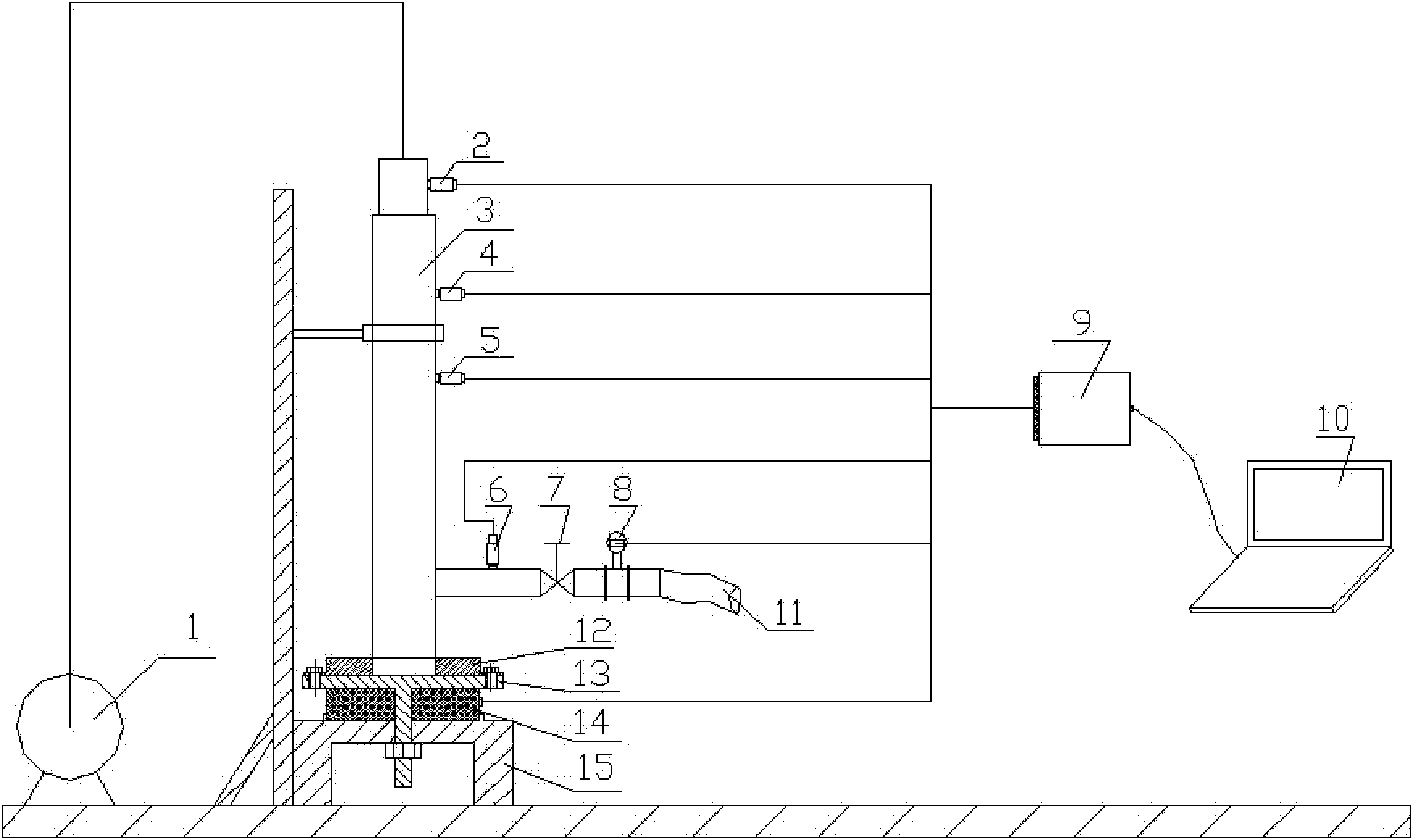

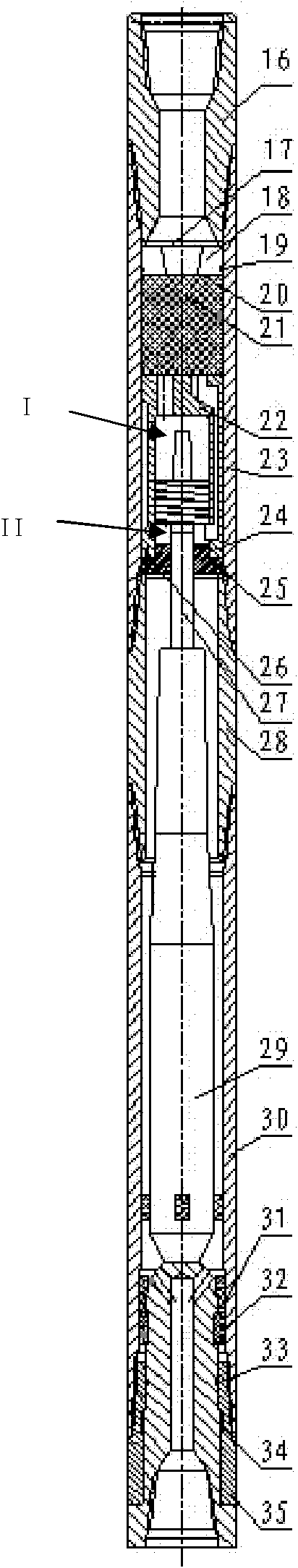

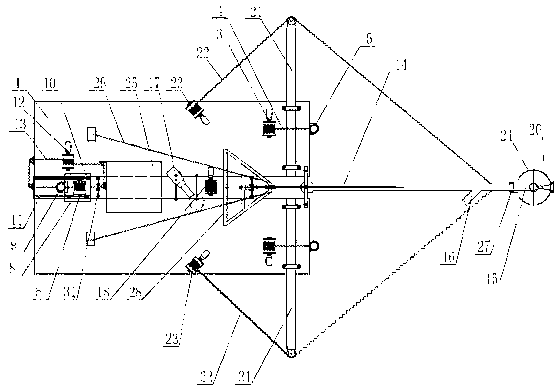

Performance testing device and testing method for petroleum drilling impact device

InactiveCN103048074AEasy to testApparatus for force/torque/work measurementForce methodCavity pressure

The invention discloses a performance testing device and a method for a petroleum drilling impact device. The testing device comprises a to-be-tested impact device, which comprises a mud pump, a sensor and a data processing unit; wherein the mud pump is connected with the liquid entrance end of the to-be-tested impact device, and by the adoption of an impact force method, the sensor is used for directly determining the impact force and the impact frequency of the to-be-tested impact device of a different model. According to the performance testing device, a mode combining the sensor and data converter is adopted, a impact force method is adopted, and the impact force and the impact frequency of the to-be-tested impact device of a different model can be directly measured; a pressure sensor can also be used for measuring the drilling liquid entrance pressure, the exit pressure, and the upper cavity pressure and the lower cavity pressure of a cylinder body, and a flow sensor is used for measuring the exit flow of the impact device. By measuring the pressure difference of a cylinder body upper cavity and a cylinder lower cavity, impact power and an impact end speed are calculated. The testing method has the advantages of accuracy, rapidness and convenience.

Owner:CHINA PETROLEUM & CHEM CORP +1

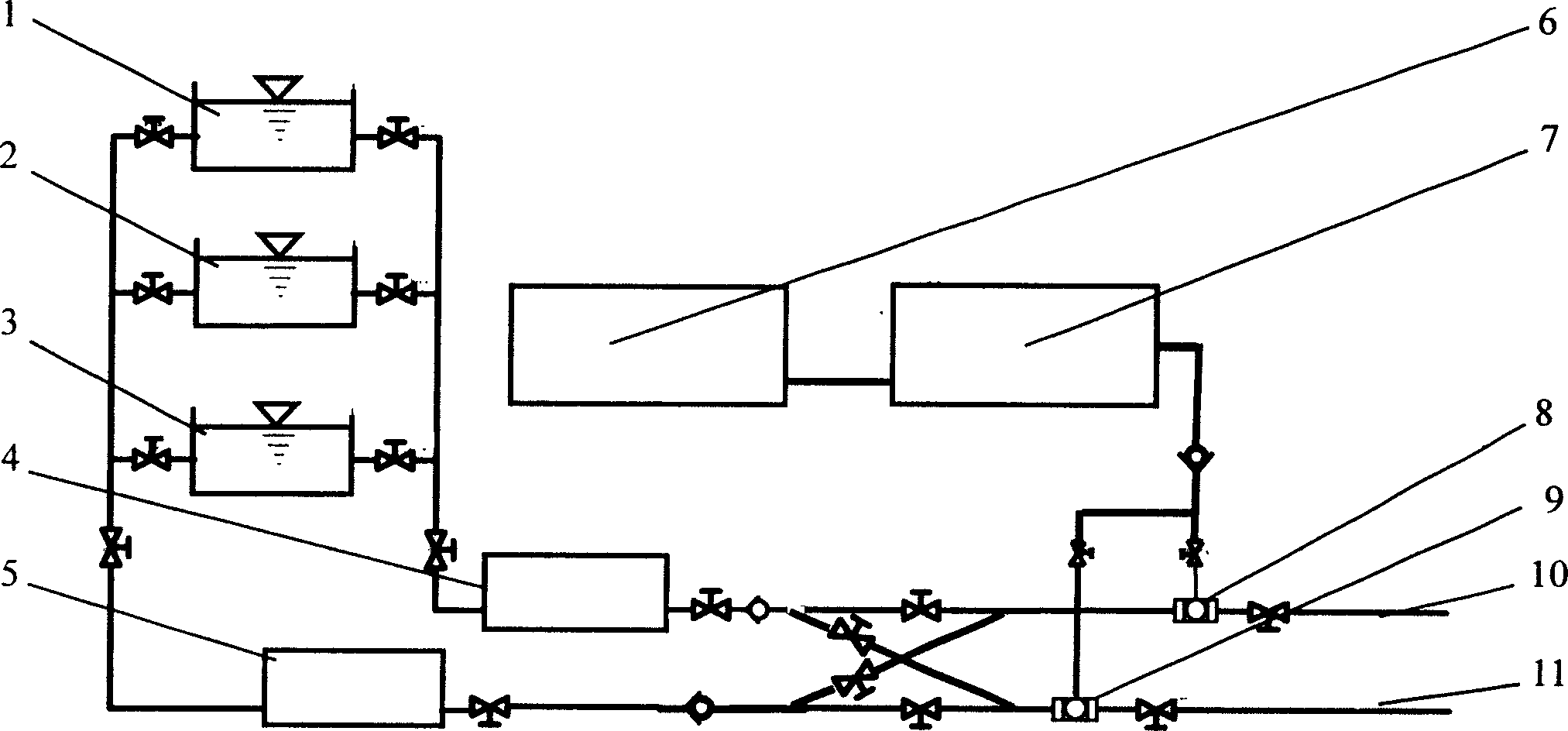

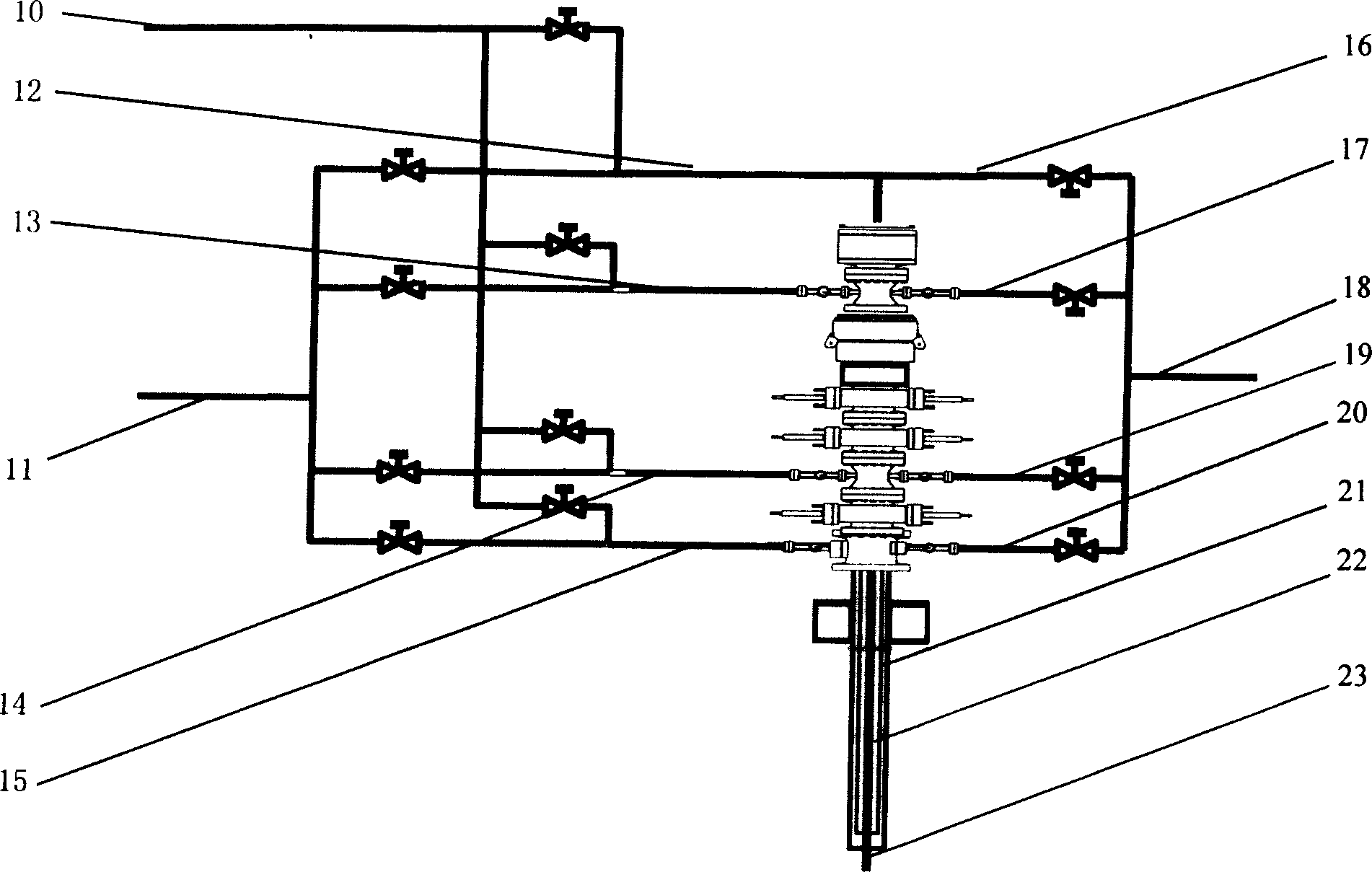

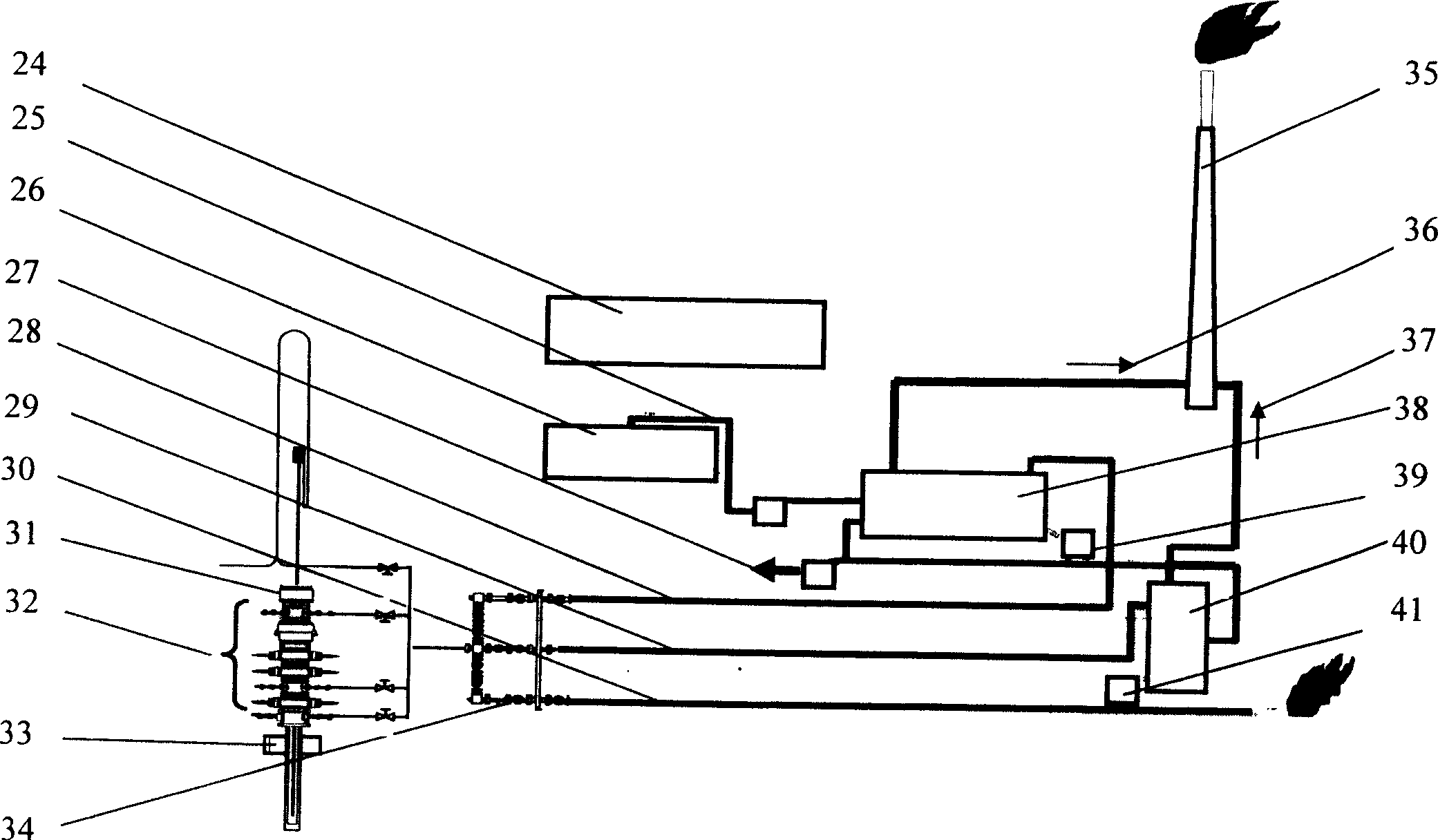

Continuous circulation system for oil and gas well and usage thereof

The invention relates to continuous circulation system that is constituted by multifunction injection system, in well circulation system and ground returning system. The injection system includes drilling fluid that has three densities, two or three mud pumps, and high pressure gas injection device. By the method of injecting two drilling fluids that have different density and fast mixing, or injecting high pressure gas, the in-well liquid column pressure would be adjusted fast and flexibly. The in-well circulation system includes double tube well structure and in-well drilling column, and supplies three flowing channels as the returning channel or injecting channel. The ground returning system includes well head control combination, casing head and gas-liquid-solid separating device. The continuous circulation system is constituted by eight purposes and improves the safety of the well.

Owner:SOUTHWEST PETROLEUM UNIV

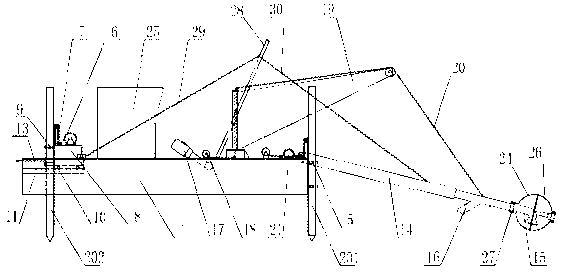

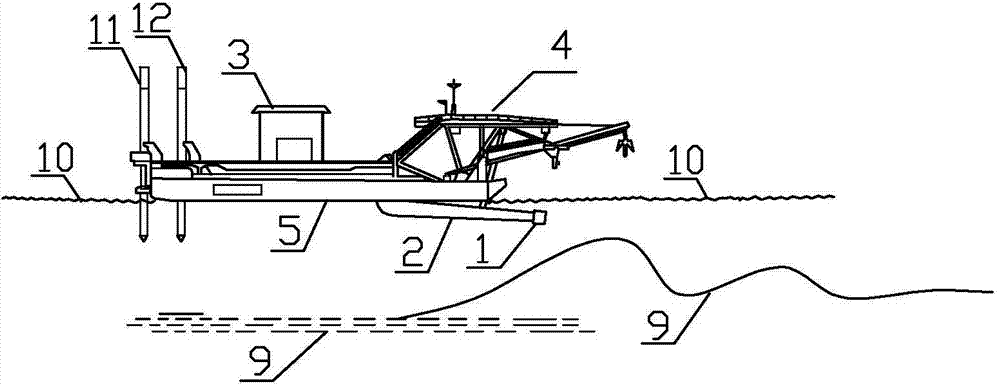

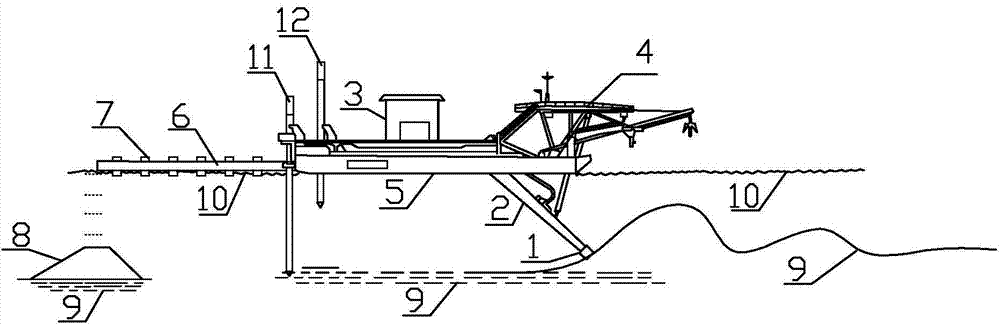

Biological dredging platform and method

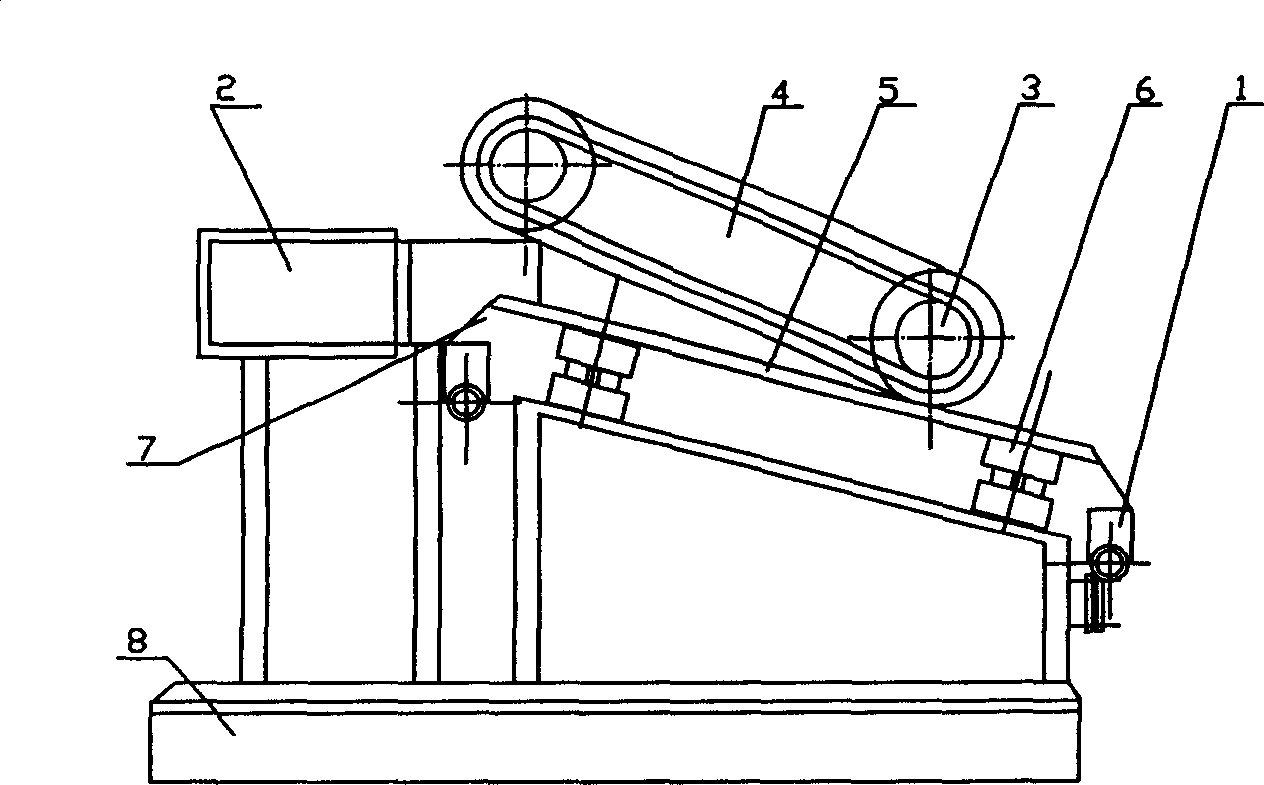

ActiveCN103015479APrecise positioningIncrease the dredging work areaMechanical machines/dredgersEngineeringWinch

The invention relates to a biological dredging platform which comprises a ship body, a positioning pile, a driving cabin and a dredging device. The positioning pile comprises a front pile and a rear pile which are controlled by a corresponding electric winch and a steel rope to lift. The ship body is provided with a moveable trolley which drives the rear pile to move step by step. The dredging device is hinged on the front side of the ship body. A mud outlet of the dredging device is connected with a mud pump through a pipeline. The dredging device is controlled by the electric winch IV and the steel rope IV to lift. The platform further comprises side arms on both sides of the ship body. One end of the steel rope V is fixedly arranged on the dredging device while the other end of the steel rope V is connected with the electric winch V through a crown block on the side arm. The electric winch V and the steel rope V control the dredging device to swing. The biological dredging method provided by the invention mainly comprises the steps of: positioning; fan-shaped dredging operation; moving step by step; positioning; and fan-shaped dredging operation in a circulating manner. According to the invention, the dredging platform moves step by step, is precisely positioned and dredges continuously in a fan shape. The dredging process is environment-friendly and the dredging efficiency is high.

Owner:中国船舶重工集团公司第七〇二研究所

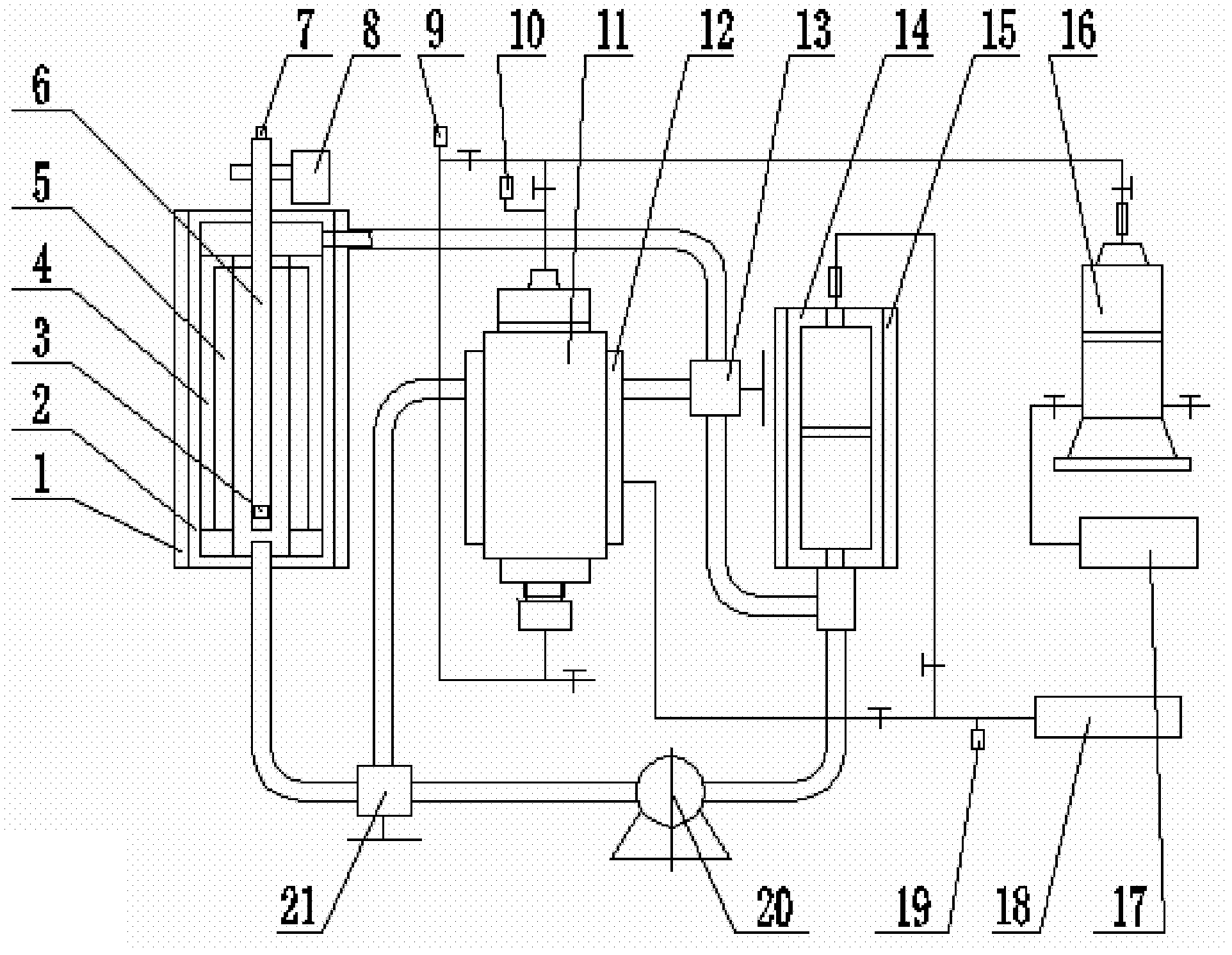

High temperature and high pressure shale well wall stability evaluation device

InactiveCN103161455AGood repeatabilitySimple structureBorehole/well accessoriesInstabilityData acquisition

The invention relates to a high temperature and high pressure shale well wall stability evaluation device and belongs to the technical field of evaluation devices of test of hydrocarbon reservoir protection in the process of petroleum exploration and development. The high temperature and high pressure shale well wall stability evaluation device is characterized by comprising a well wall analog device, a triaxial cell (11), a mud container (14), a piston container (16), a constant-flux pump (17), an electric metering pump (18), a mud pump (20) and a data collection processing system. The high temperature and high pressure shale well wall stability evaluation device can carry out drilling fluid washing damage test on an analog well wall on the condition that temperature, pressure and circulating fluid flow are simulated. An imaging method is used for simulating degrees of hole enlargement, hole shrinkage and collapse after the well wall is eroded by external liquid, microwaves are used for measuring the degrees, and therefore the washing degrees of the well wall and wall building situation can be observed and recorded in real time. A new method for comprehensively evaluating influence of the drilling fluid and completion fluid on instability and collapse degree of the well wall is provided. Besides, the high temperature and high pressure shale well wall stability evaluation device has the advantages of being good in repeatability, simple in structure, convenient to operate, stable in performance and the like.

Owner:YANGTZE UNIVERSITY

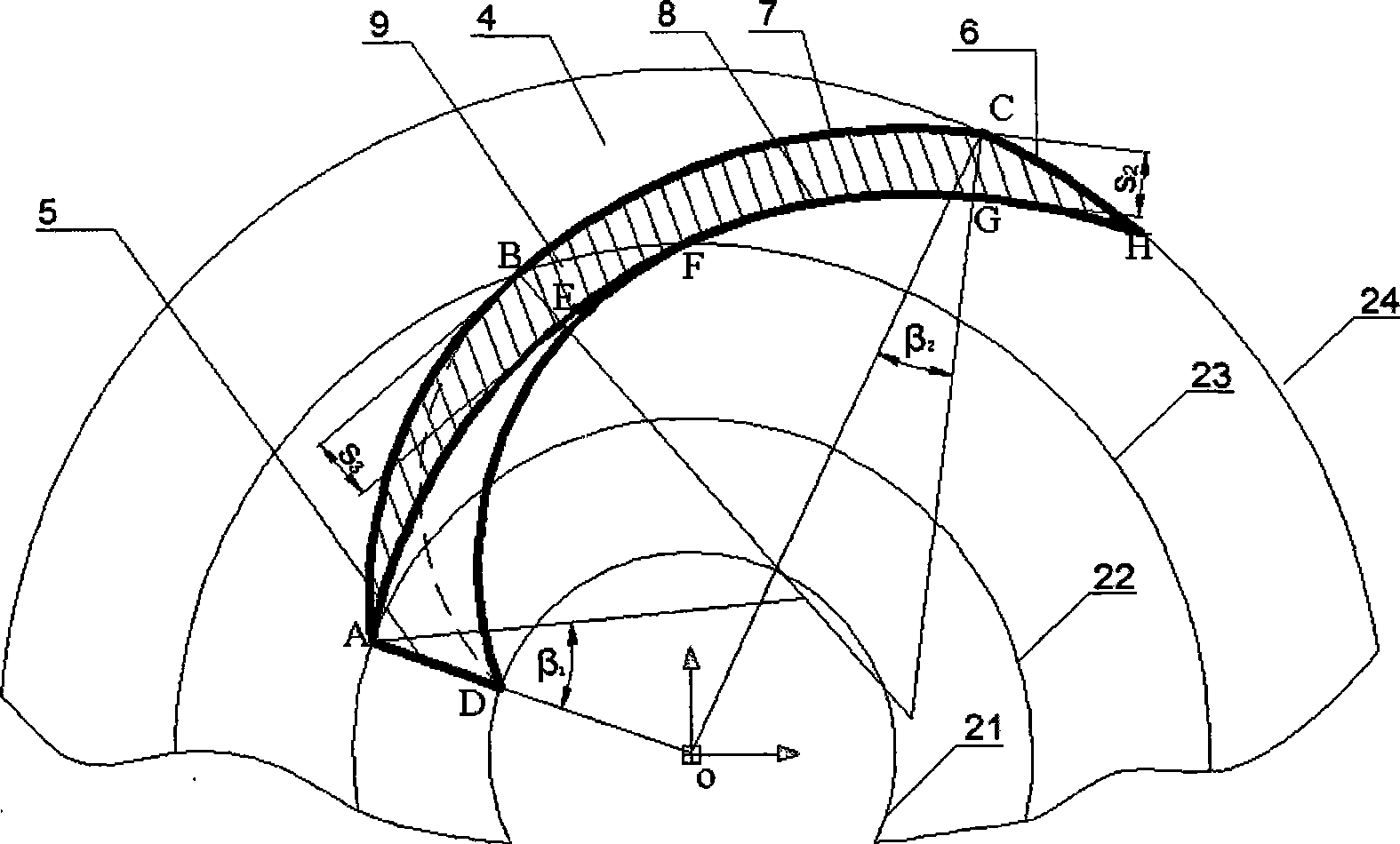

Design method of two phase flow pump impeller

InactiveCN101368574AAdhere to flow characteristicsThe angle of attack of the water flow changes evenlySpecific fluid pumpsPump componentsImpellerFriction loss

The invention discloses the design method of a two-phase flow pump; the two-phase flow pump comprises a slurry pump, a mud pump, a diving slurry pump, a diving mud pump and a diving two-phase pump; the impeller includes a main impeller and an auxiliary impeller; the main impeller mainly comprises a main vane, an auxiliary vane, a front cover plate and a back cover plate; the impeller is mainly arranged on an impeller shaft; the main vane is inclined to the front cover plate and the back cover plate through the vane inlet segment; the vane outlet segment is vertical to the front cover plate and the back cover plate to form a semi-twisted vane; the vane contour line on the impeller front cover plate has smooth transition to the vane contour line on the impeller back cover plate to form the surface of the semi-twisted vane. The auxiliary vane of the impeller and the auxiliary impeller construct a dynamic sealing device. Based on the semi-twisted vane in the invention, the water power loss and the friction loss are smaller than that of the cylindrical vane; the vibration and noise of the pump are reduced; the pump efficiency is improved; the service life of the impeller is prolonged; meanwhile, the operation of the pump become more stable.

Owner:许洪元

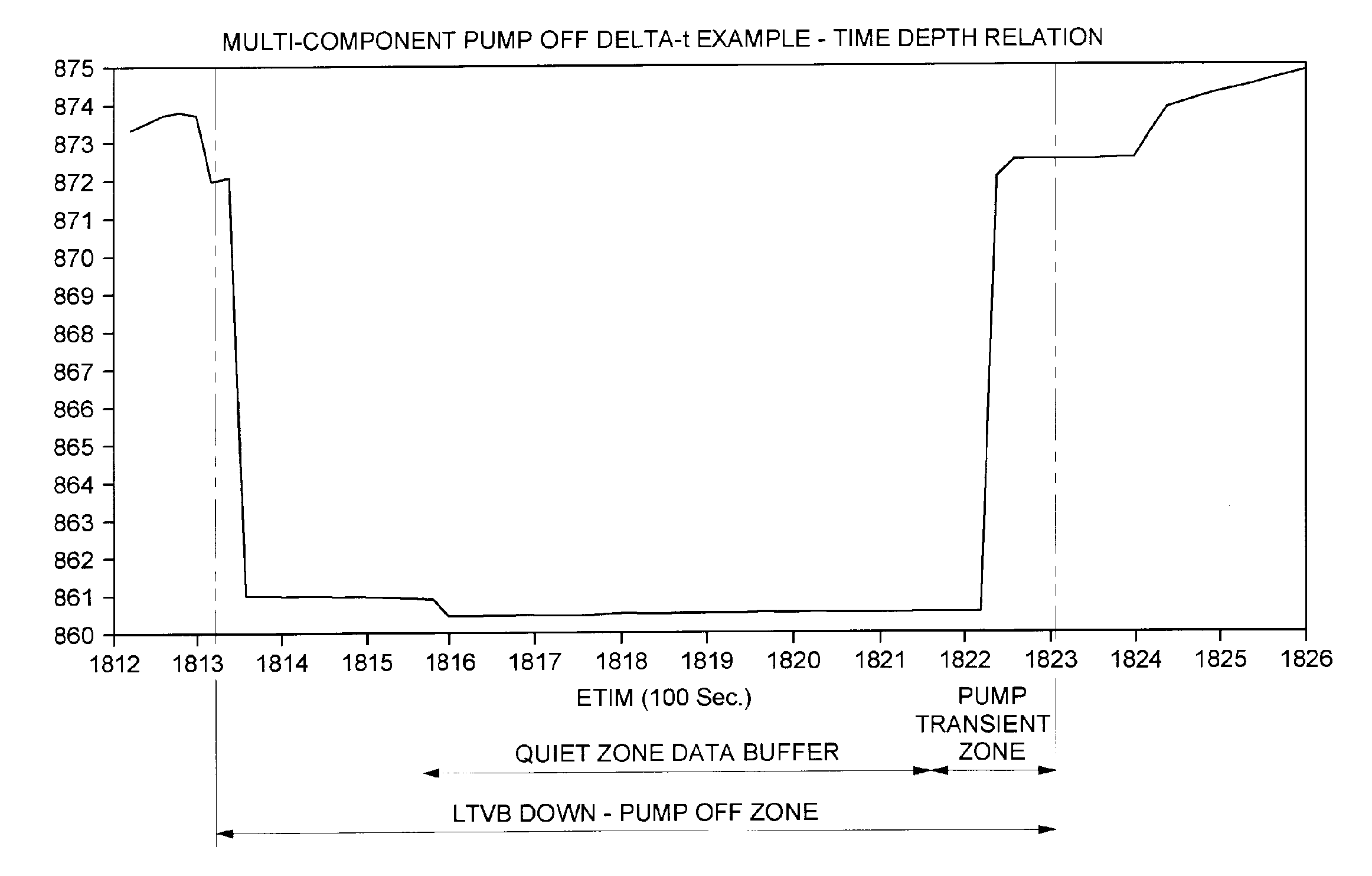

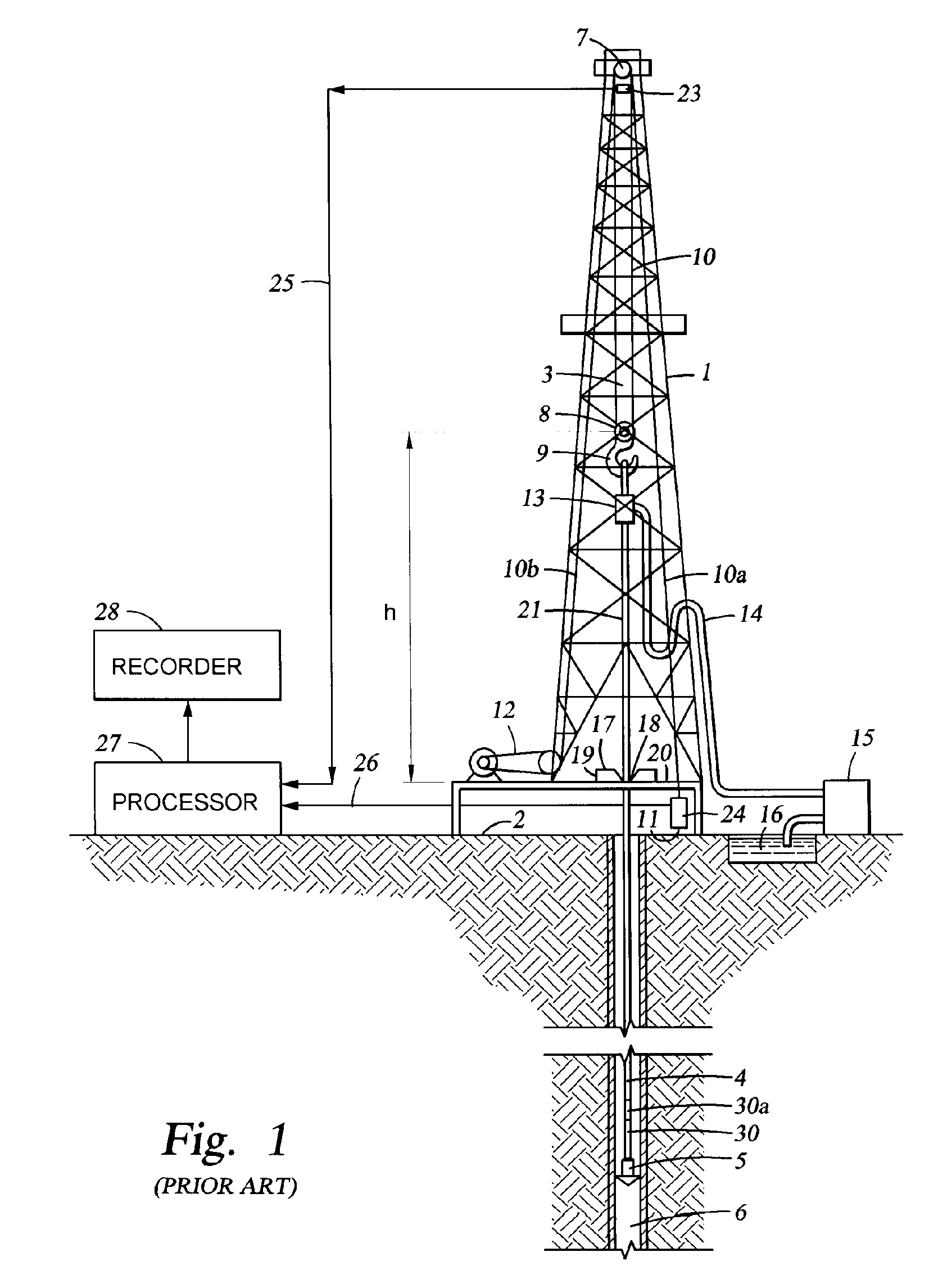

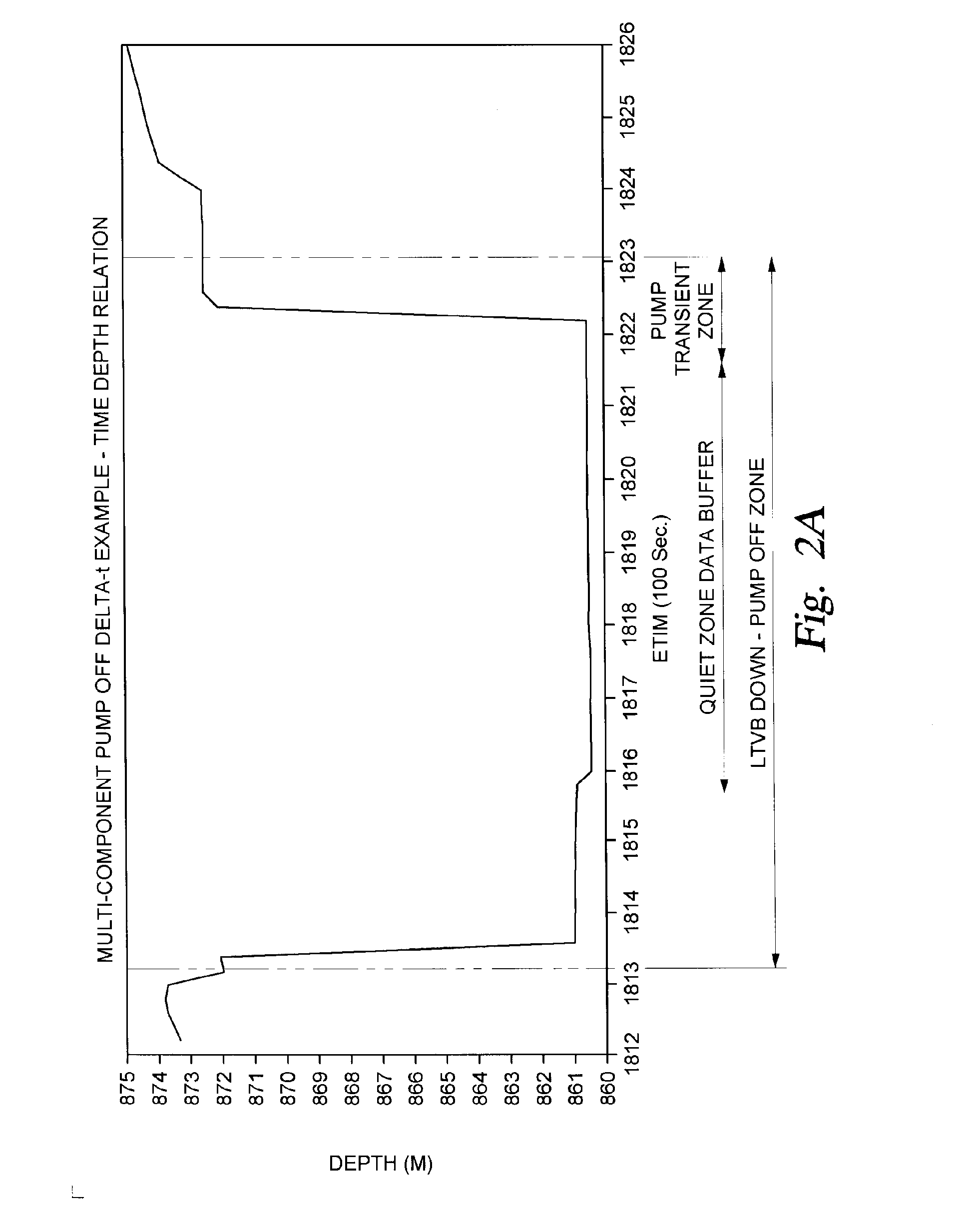

Pump off measurements for quality control and wellbore stability prediction

ActiveUS20060235618A1Benefiting environmentHigh-quality dataElectric/magnetic detection for well-loggingSeismology for water-loggingWell loggingQuality control

A method for obtaining high-quality well logging data acquired during a drilling operation includes acquiring well logging data during a pump-off period when a mud pump is turned off; and extracting a subset of data from the acquired well logging data, wherein the subset of data corresponds to a quiet period within the pump-off period, wherein the quiet period is substantially free of interference from turning the mud pump on or off.

Owner:SCHLUMBERGER TECH CORP

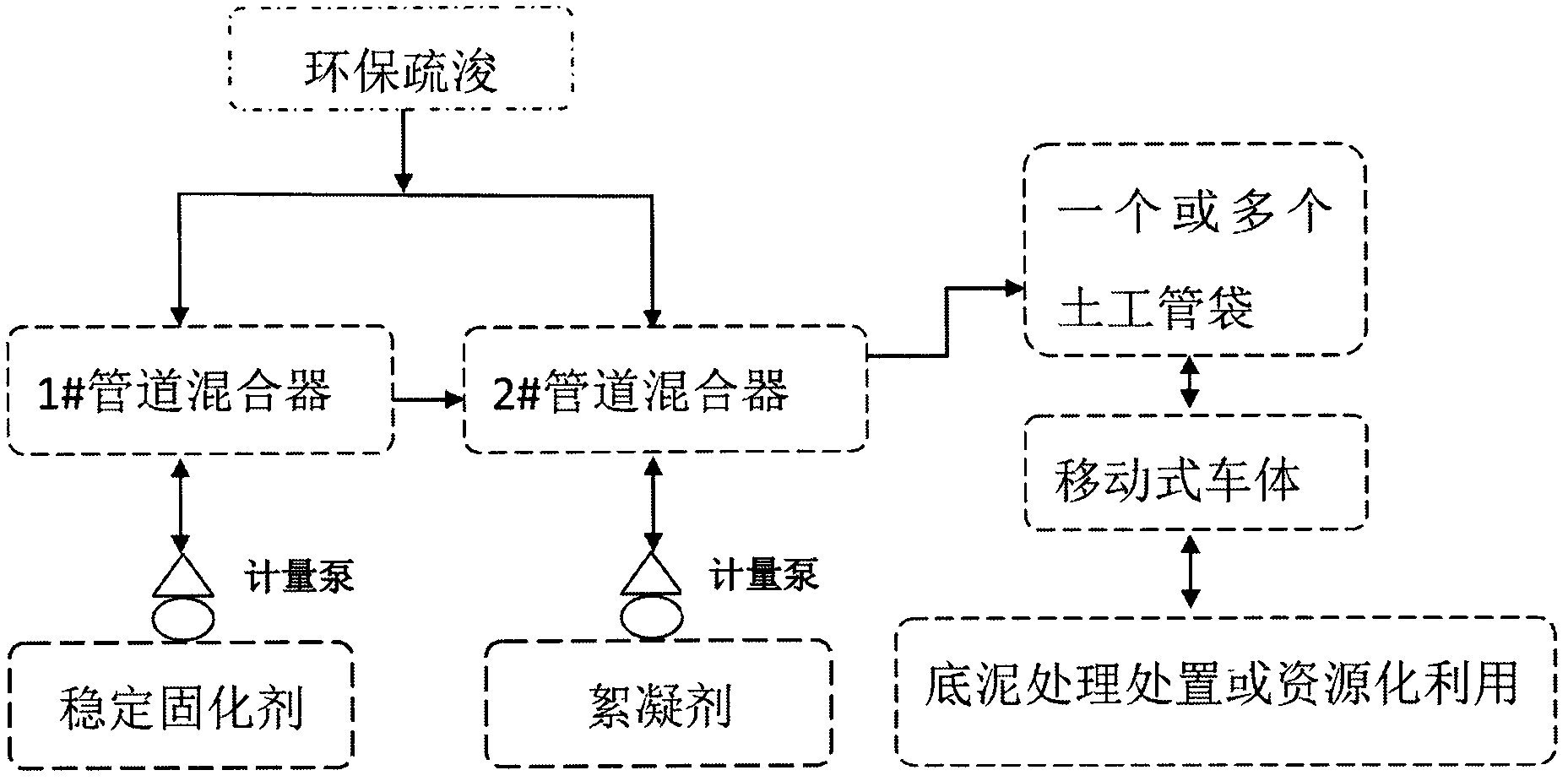

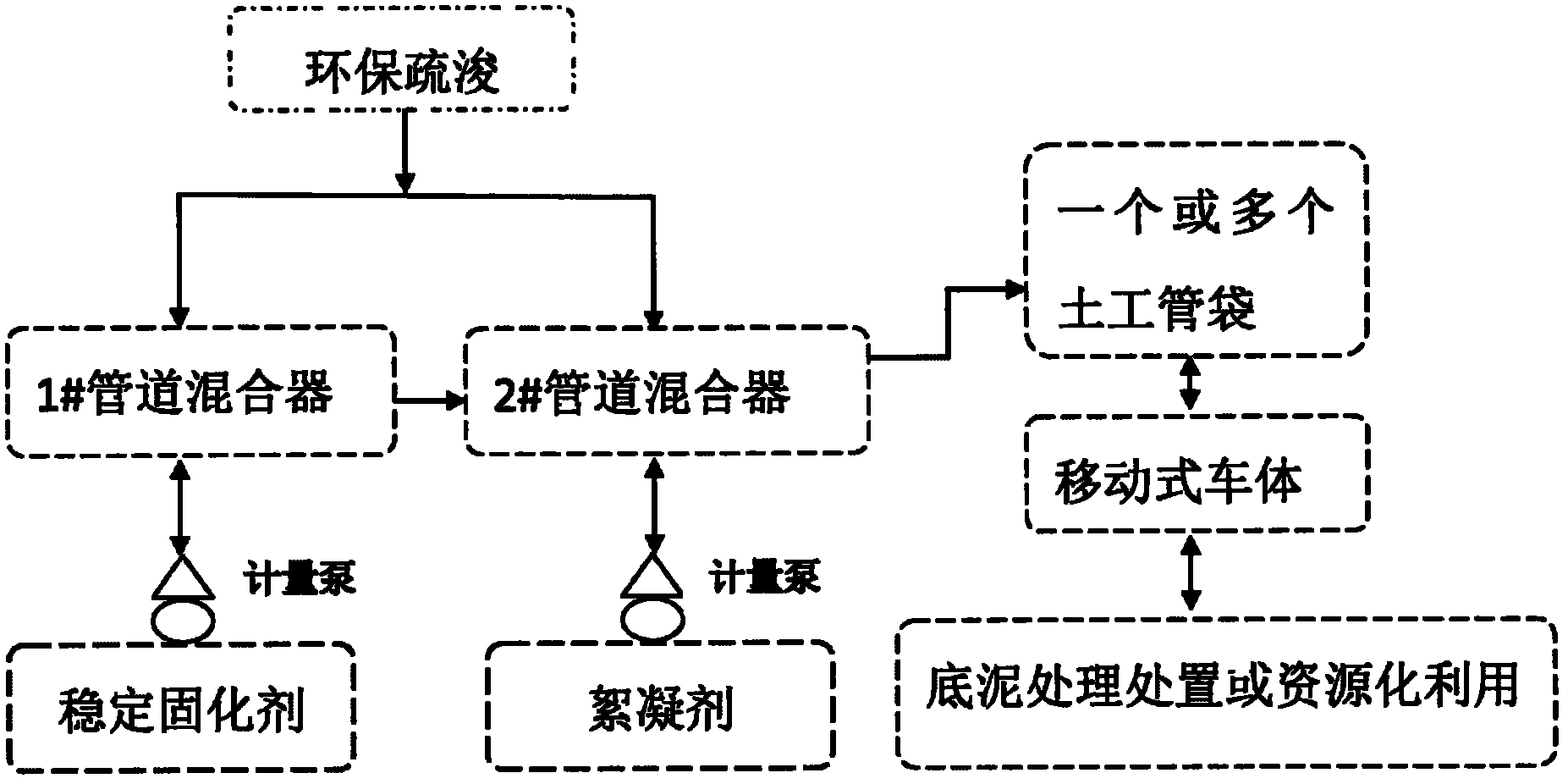

Mobile contaminated bottom mud bag pocket dewatering and volume reduction treatment method

InactiveCN102583950ASolve the problem of land occupationWill not cause secondary pollutionSludge treatment by de-watering/drying/thickeningSludgeResource utilization

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

Construction method for carrying out sea reclamation with sand in shallow sea area through cutter suction dredger

ActiveCN104846787ASave resourcesAvoid damageMechanical machines/dredgersClimate change adaptationOcean bottomEcological environment

Disclosed is a construction method for carrying out sea reclamation with sand in a shallow sea area through a cutter suction dredger. The cutter suction dredger comprises a cutter suction head, a suction pipe, a power system and a ship body. The cutter suction dredger adopts a mechanical reamer of the cutter suction head to ream the underwater sand soil layer through the power system, and then mechanically excavates and sucks soil through a mud pump of the power system. The sucked sand soil is conveyed to the destination through a pipeline conveying mode, and the construction method for carrying out sea reclamation with sand in a shallow sea area is realized through water separation and sand sedimentation. The construction method includes the steps that A, machines are arranged in place; B, a sand blasting guide pipe is laid; C, soil is sucked in a cutting mode and excavated; D, soil sediments to make land. The sand sedimentting on the seafloor serves as the filling materials of a sea reclamation structure. Cutting of coastal line resources is effectively reduced. The original ecologic environment of the sea is protected to the maximum extent. The work procedures of slurry excavation, conveying, discharging, processing and the like are finished at a time, so that the construction efficiency is improved.

Owner:广西建工第五建筑工程集团有限公司

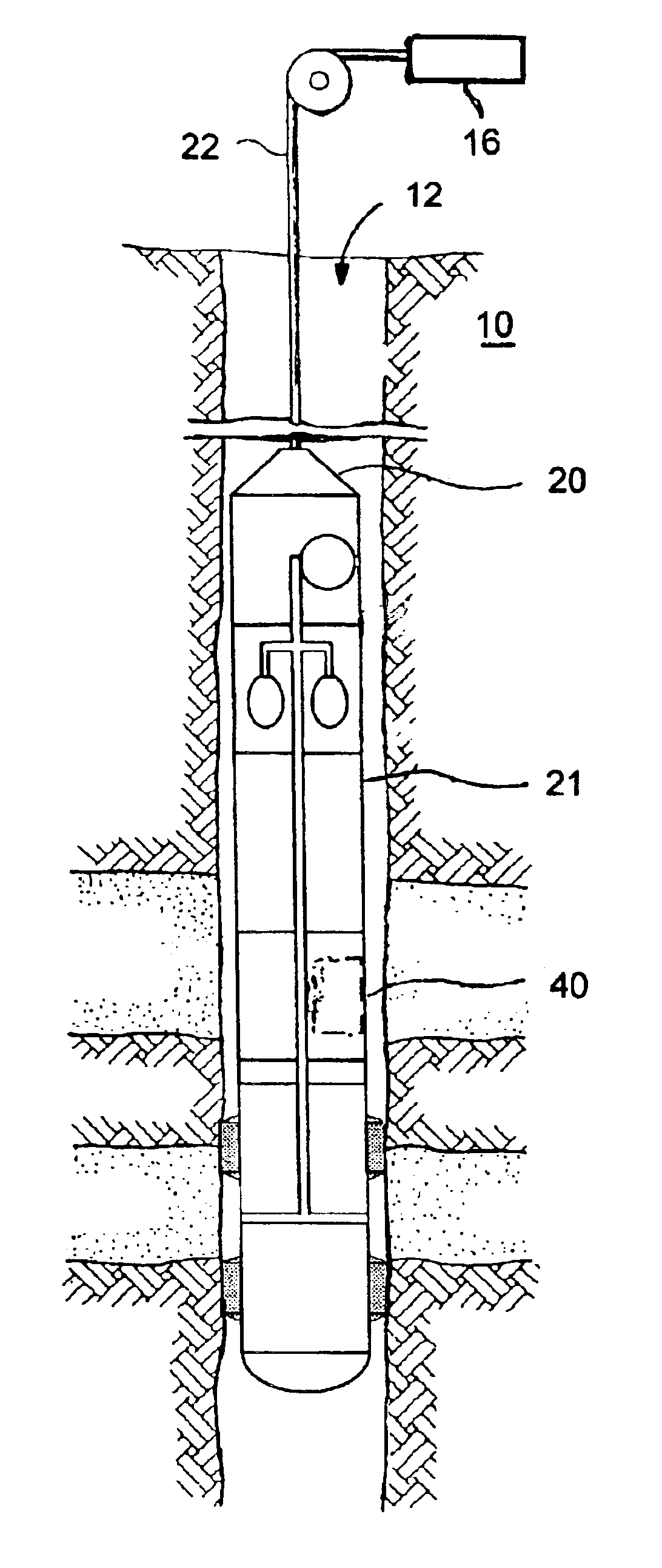

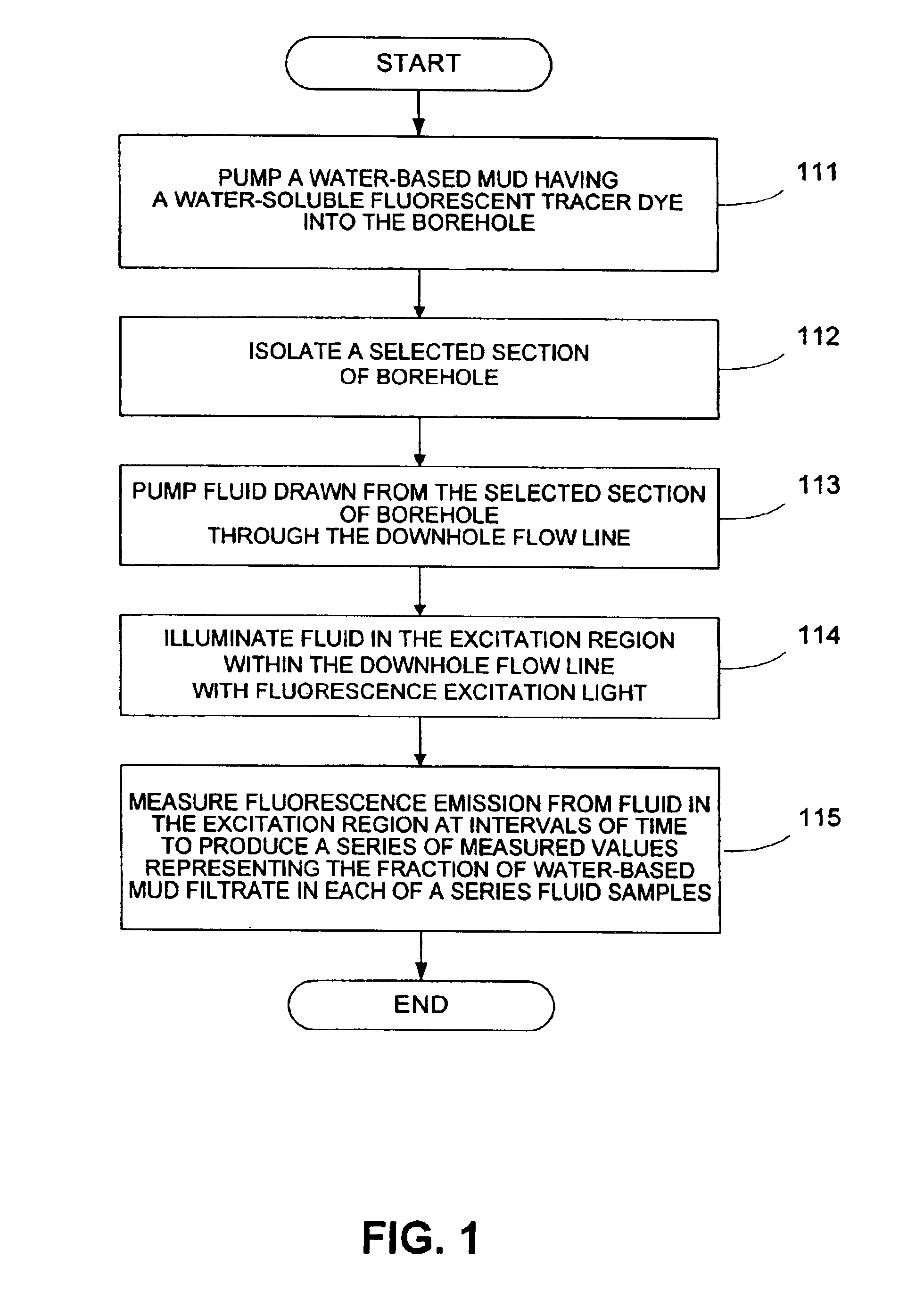

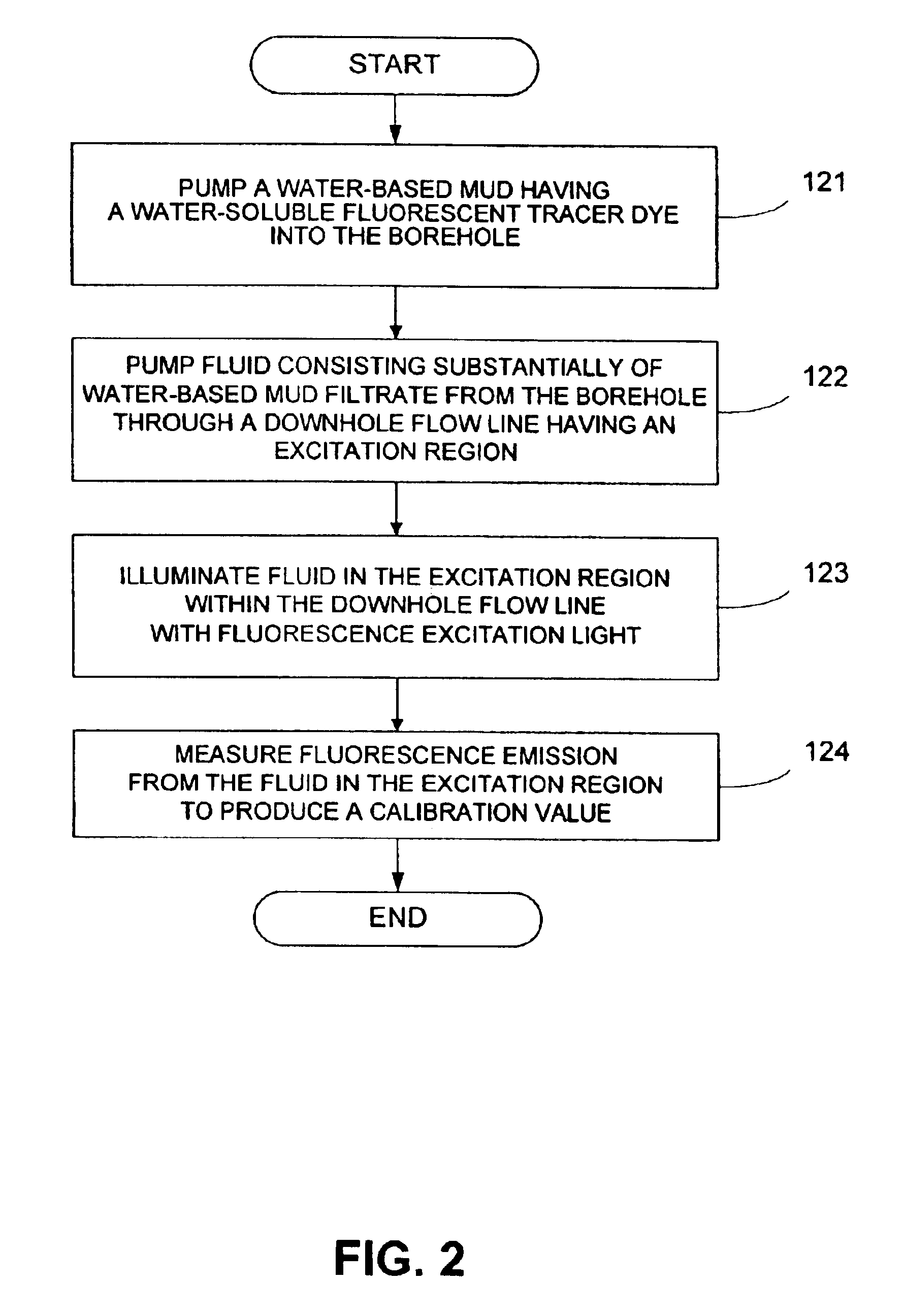

Assessing downhole WBM-contaminated connate water

Water-based mud filtrate concentration in a downhole fluid sample drawn from the borehole of an oil well is assessed. To measure water-based mud filtrate concentration, a water-based mud having a water-soluble fluorescent dye tracer is pumped into the borehole; sample fluid from a selected downhole location is pumped through a downhole flow line having a window; sample fluid flowing in an excitation region of the downhole flow line is illuminated through the window with fluorescence excitation light; and fluorescence emission from the excitation region is measured to produce a measured value. The measured value represents the fraction of water-based mud filtrate in the sample fluid. A calibration value is determined representing 100% water-based mud filtrate. A method for validating a sample of connate water as having an acceptably low WBM filtrate contamination tests for validation downhole, in real time. Each measured value of the series of measured values is compared with a predetermined fraction of a calibration value. Samples that are validated may be captured and brought to the surface for analysis. A method using the time series data and a predetermined fraction of the calibration value calculates a predicted flushing time to completion.

Owner:SCHLUMBERGER TECH CORP

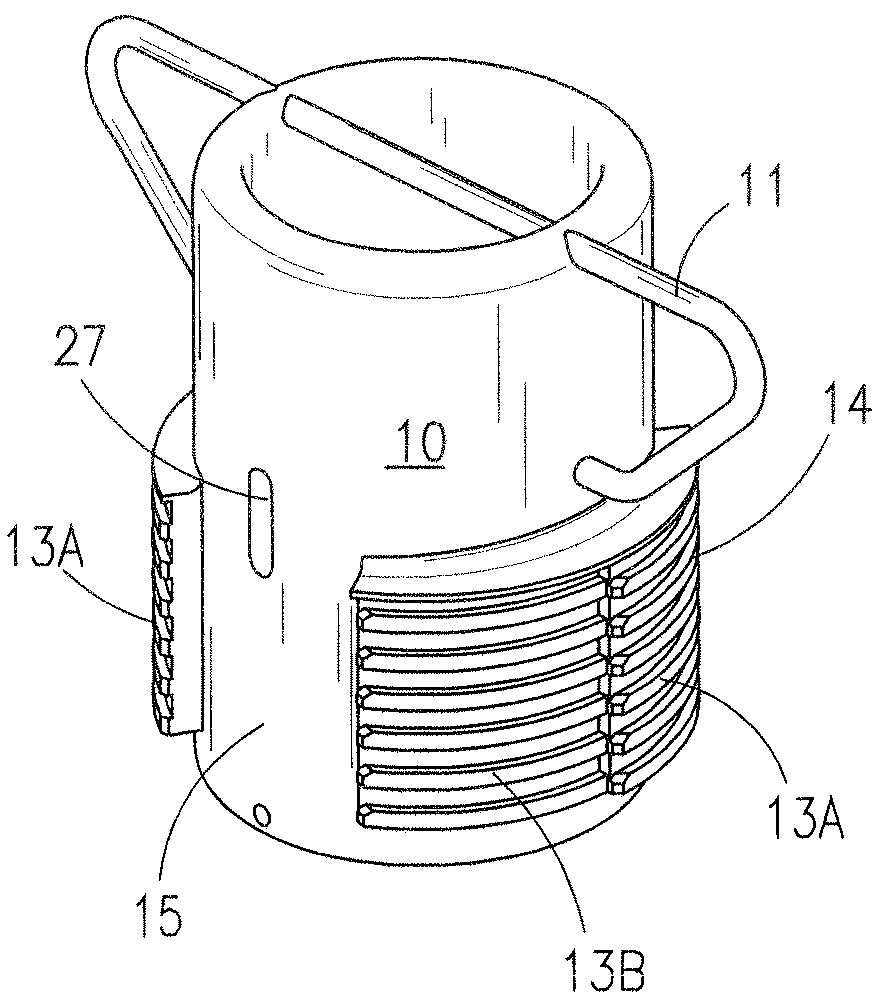

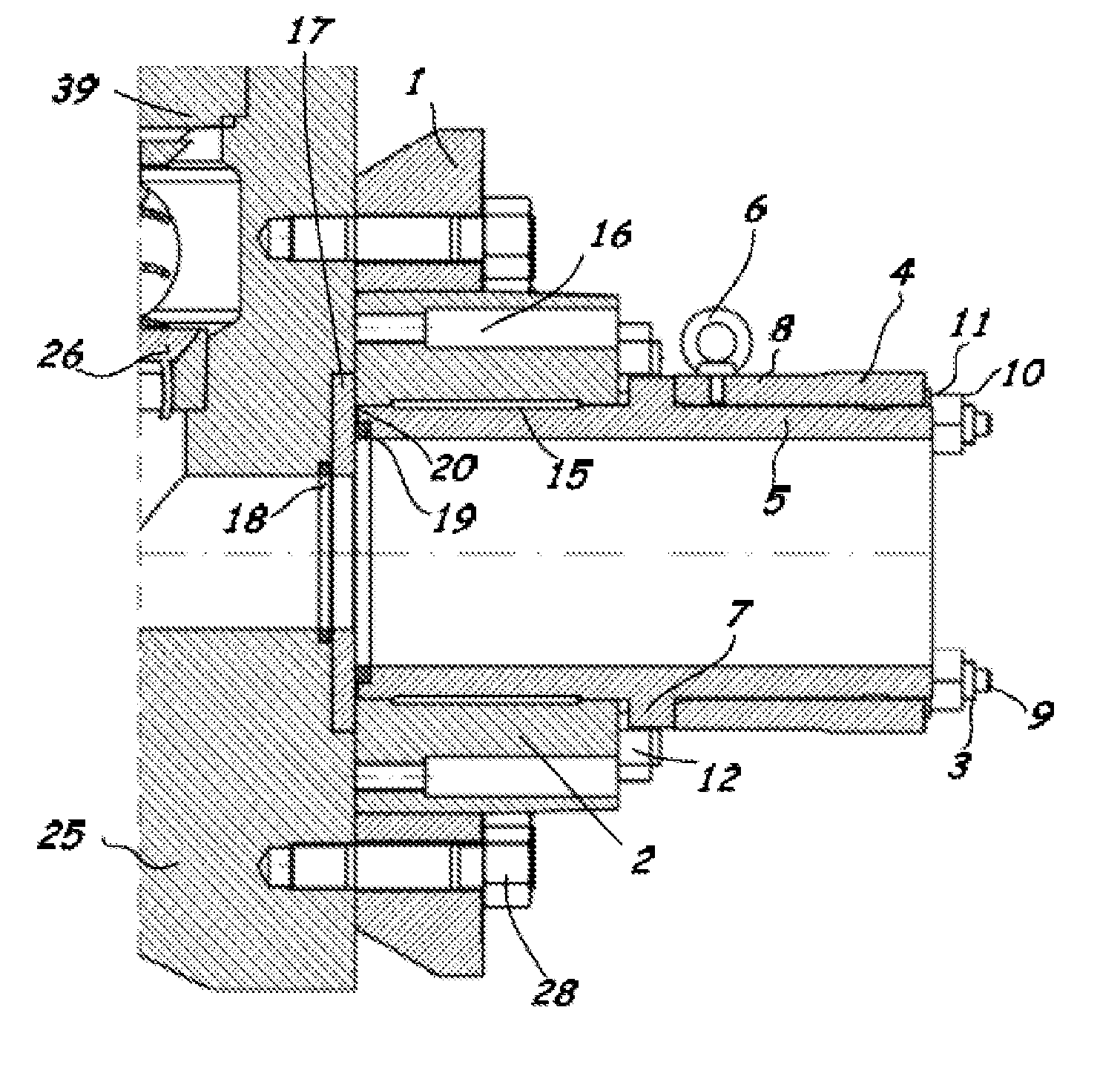

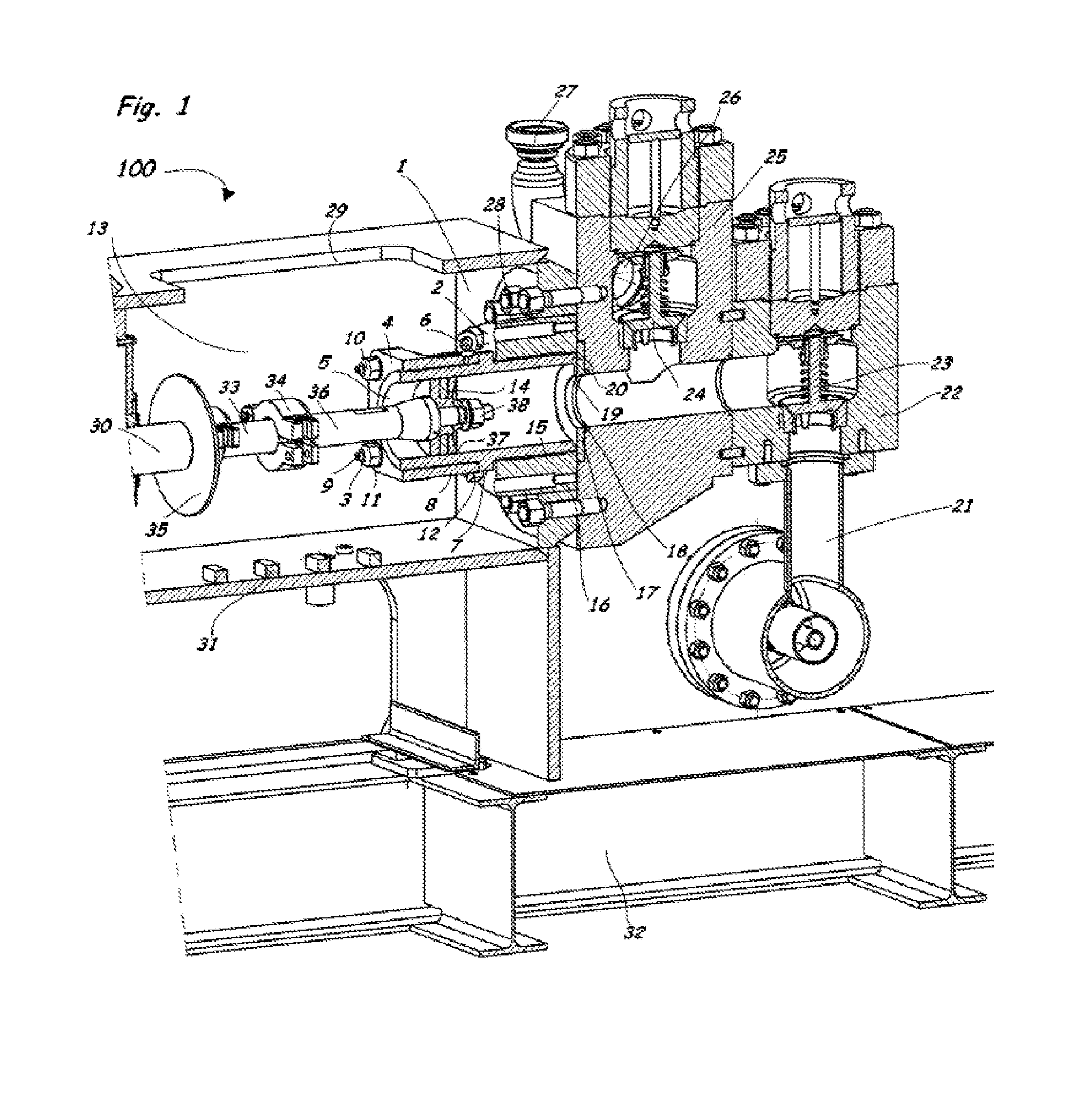

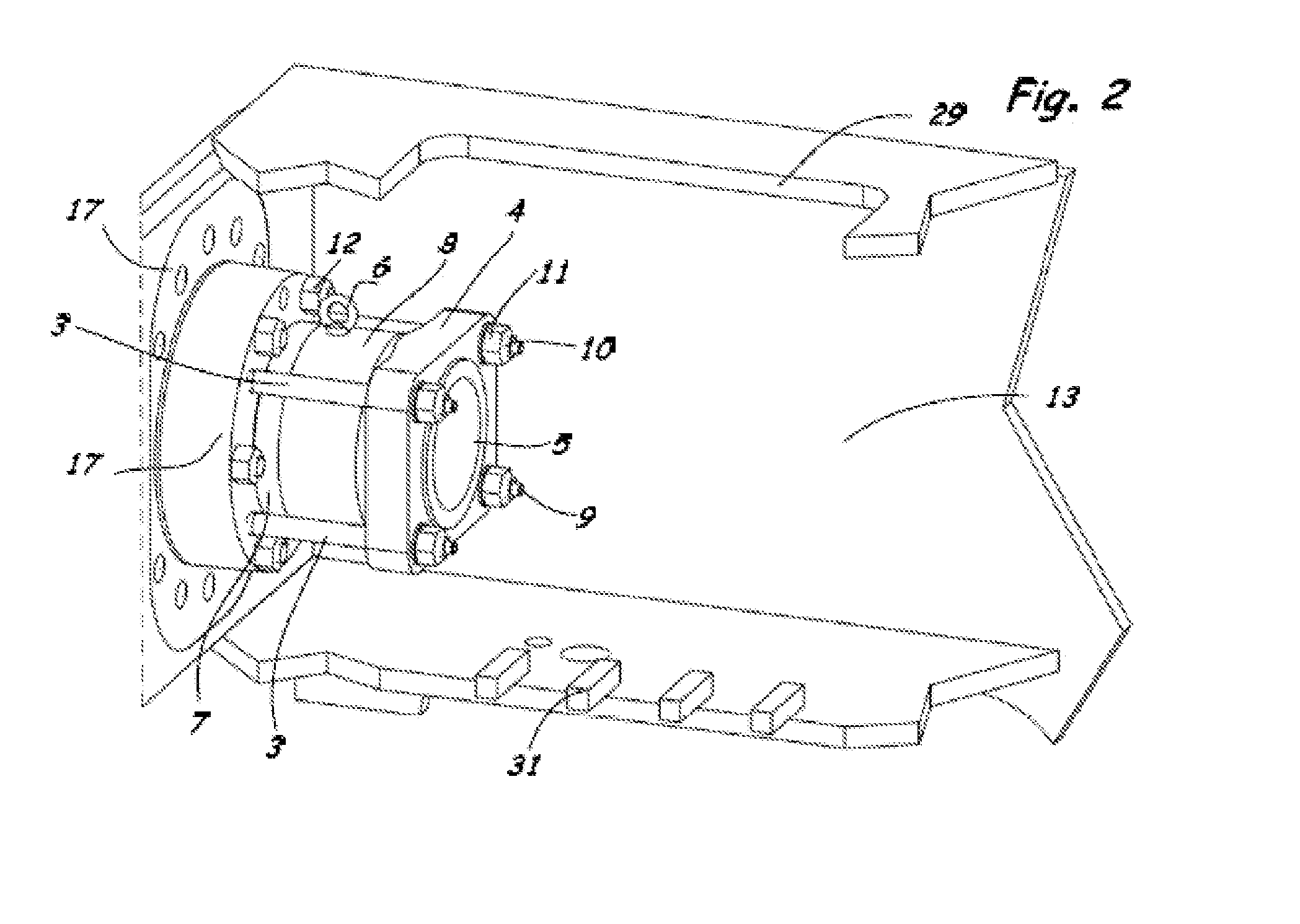

Clamping device for cylinder sleeves and use thereof, and mud pump having a clamping

ActiveUS20110236238A1Inexpensive and easy to useUniform and defined contact forceSleeve/socket jointsPositive displacement pump componentsOil and natural gasMechanical engineering

Clamping device for cylinder sleeves of a pump system, and a piston pump or plunger pump for conveying drilling fluid during drilling of boreholes, particularly in the field of oil and natural gas production, and its use. Pump system includes a pump unit and a driving rotary drive unit. Clamping device for cylinder sleeve of a piston pump or plunger pump includes a cylinder sleeve receptacle, a clamping element provided at the pump, and cylinder sleeve or a portion of the cylinder sleeve provided between the clamping element and the cylinder sleeve receptacle, Clamping element and cylinder sleeve receptacle are connected by a connecting apparatus.

Owner:BENTEC DRILLING & OILFIELD SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com