High temperature and high pressure shale well wall stability evaluation device

A technology of high temperature and high pressure, evaluation device, applied in wellbore/well components, earthwork drilling and other directions, can solve the problem of not being able to fully reflect the influence of wellbore instability, and achieve improved simplicity and accuracy, simple structure , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

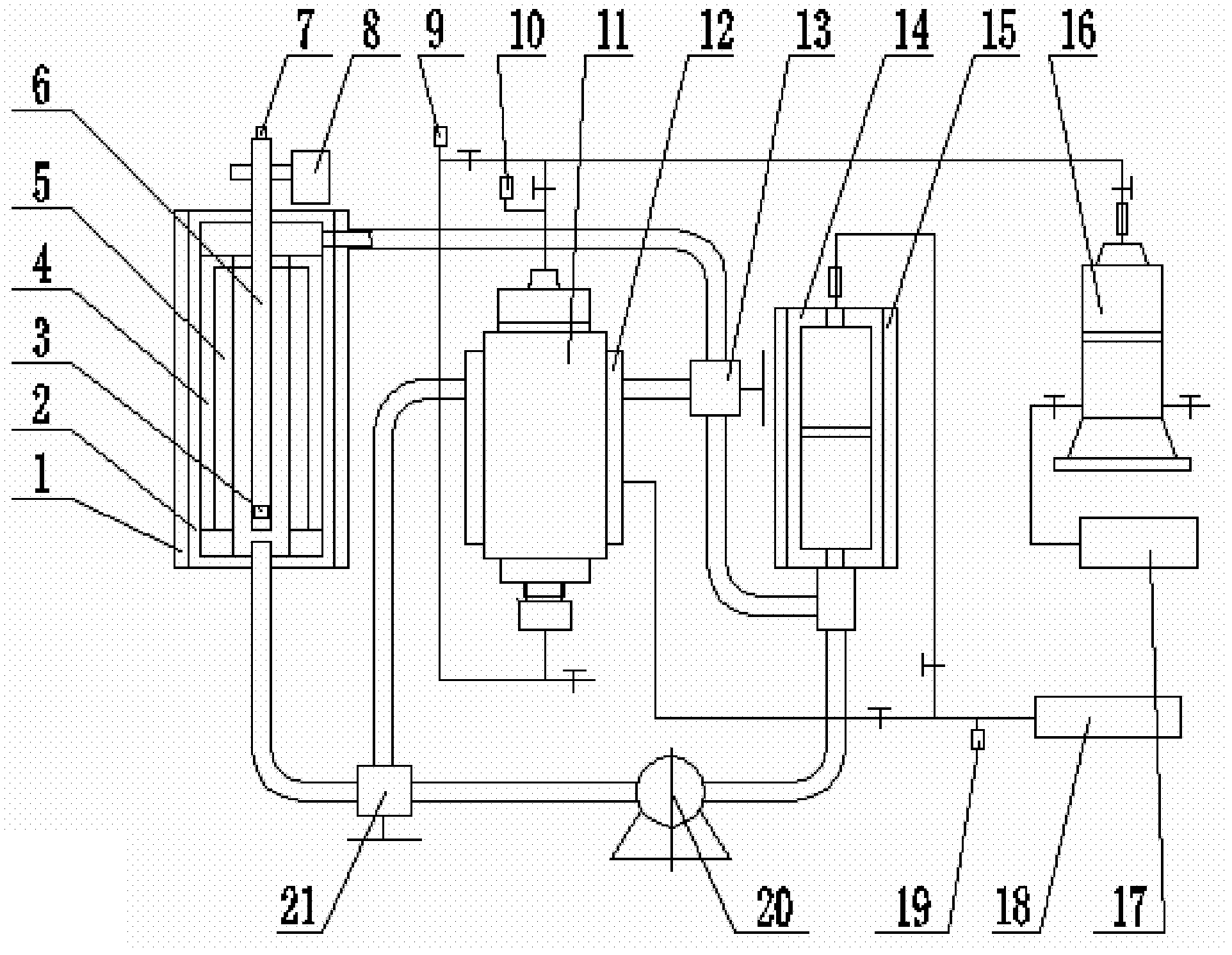

[0016] The present invention consists of a well wall simulation device, an outlet pressure sensor 9, an inlet pressure sensor 10, a triaxial pressure chamber 11, a pressure chamber heater 12, a liquid outlet reversing valve 13, a mud container 14, a mud container heater 15, a piston container 16, Advection pump 17, electric metering pump 18, confining pressure sensor 19, mud pump 20, liquid inlet reversing valve 21, and data acquisition and processing system.

[0017] The well wall simulation device is composed of a well wall heater 1, a well wall outer cylinder 2, an ultrasonic probe 3, a well wall inner cylinder 4, a simulated well wall 5, an ultrasonic probe rod 6, a data acquisition connector 7, and a rotary lifter 8 A well wall heater 1 is installed outside the well wall outer cylinder 2; a well wall inner cylinder 3 is installed in the well wall outer cylinder 2; a simulated well wall 5 is installed in the well wall inner cylinder 3; There is an inlet of drilling circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com